Page 1

BUILDING

THE

A6M2

ZERO

Product Support

(Do Not Remove From Department)

TOP FLITE MODELS, INC

Page 2

CONGRATULATIONS'

You now own the most accurate

R/C

Stand-Off Scale kit ever

produced

We

at Top Flite hope that you will find this model the most

pleasant to build, inspiring to look at and exciting to fly that you

have ever constructed

It

is honest to point out, however, that while this model is

no

more difficult - in fact is simpler than most comparable kits to

make,

R/C

scale models generally are not for the newcomer to

this hobby Previous modeling experience and careful attention to

craftsmanship are necessary Even the "old hand" will do well to

study and follow the instructions and guidance given in this booklet.

It is-our aim to have you say "This is the finest model I have ever

built".

TOP FLITE MODELS. INC

CONSTRUCTION OF THE A6M2 ZERO

BEFORE YOU START, READ THIS

The assembly sequence of your Top Rite

ZERO

has been care-

fully developed to help assure the correct alignment of your model

Utilize the check-off blocks as you build this will allow assembly

of your model in minimum time

Before beginning an assembly step, read the instructions to fami-

liarize yourself with the parts to be used Find the parts mentioned and double check them for proper identification and size with

the plans Do not separate parts from the die cut sheets until you

need them There are machined parts in the kit which are not

identified such as the leading edges, wing tips, etc These parts

can be easily identified by checking the parts against the plan.

We are sometimes asked which glues are best for model construction The answer to this depends upon the particular job This is

our normal recommendation For all hardwood to hardwood or

hardwood-to balsa joints, use white

wood

glue

"Titebond"

is

especially good, as it dries faster than other white glues and is very

strong For balsa-to-balsa joints, regular balsa-wood cements are

ample for the job, although white glue can be used here too.

Whichever type you use, remember that excess glue is no substitute for a well fitting joint Use a minimum of glue at all times,

and wipe off excess glue that squeezes out of joints before it sets

hard, when set it is difficult to remove, but if not removed it

could spoil the covering job.

IMPORTANT NOTE TO BUILDER

Every model built from a kit is different, reflecting the level of

skill as well as the favored building techniques of the modeler

ultimately thus, each model is essentially the individual creation

of

that builder.

Changes and variations take place in building so that while Top

Flite supplies most essential building materials, the end product

is the creation of the builder

Therefore, Top Flite assumes no responsibility for the performance of the model, nor does Top Flite assume any responsiblity

of any nature whatsoever for the loss of, or property damage

resulting from the operation of this model when it is completed

1

USE COMMON SENSE

When you have completed this model, you will have invested

considerable time, money and skill Protect this investment by,

1. Re-checking all critical building points (center of gravity,

hingeing of control surfaces, strength of stress areas, etc ).

2. Correctly installing the radio gear

3. Test and re-test the radio, all moving surfaces, landing gear

(if retracts), condition of batteries, etc.,

BEFORE EACH

FLIGHT!

4. OBSERVE ACADEMY OF MODEL AERONAUTICS SAFETY

CODE, particularly those rules governing RADIO CONTROLLED FLIGHT DO NOT FLY WITHOUT BEING FULLY

INSURED

WARNING!!

A radio controlled model is not a "TOY" Care and caution

must be taken in properly building the model as well as in

the installation and use of the radio controlled device It is

important to follow all directions as to construction of this

kit as well as installation and use of the engine, propellers

and radio gear The advice and assistance of a well experienced builder and pilot is highly recommended Don't

take chances Improper building, operation or flying of

model could result in serious bodily injury to others, your-

self, or property damage

CONSTRUCTION

SEQUENCE

Follow each step in order and put check marks in

the blocks as you complete each phase described.

The fuselage plans come in two sheets The smaller

must be cut along the dotted line and glued (or taped)

to the larger plan at the dotted lines Before you do

any building of this kit, we suggest you spend a few

hours reading and studying this book and the plans.

When you are ready, tape or tack the fuselage plans on a

flat

work

surface

Cover

the

working

area

of

the

plan

with

MonoKote backing or waxed paper

Page 3

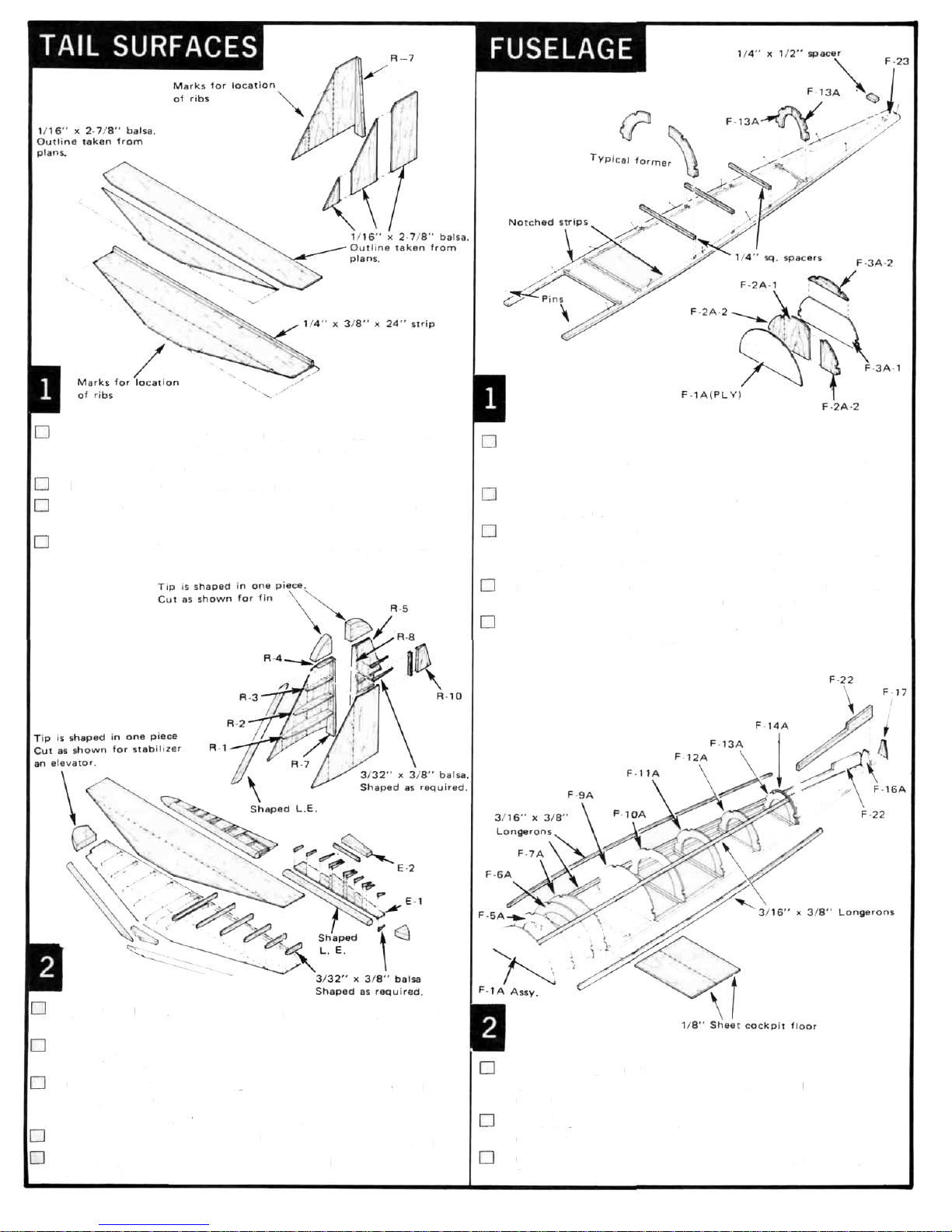

Trace pattern of Fin sheeting (3 pieces on each side) from

plans onto 1/16" x 2-7/8" balsa. Cut out and glue together

as shown above. Make two.

Do same thing with Stabilizer. Make two.

Pin Fin sheeting over plan. Glue

R-7

in place. Mark location

of ribs with soft pencil.

Pin Stabilizer sheeting over plan. Glue

1/4" x 3/8" x 24"

in place. Mark location of ribs with soft pencil.

Glue R-1.

R-2. R-3

& R-4 ribs in place. Apply glue only up

to 1/4" from front of rib.

Glue top sheeting in place. Again apply glue only up to 1/4"

from front of rib.

Glue shaped leading edge to ribs only. When dry, glue plank-

ing to leading edge on both sides. Be sure that the planking

forms to the shape of the leading edge.

Construct rudder as shown in illustration above and the plans.

Make stabilizer and elevators using same procedures as is

described

above._______

Glue

F-2A-2's to F-2A-1 and F-3A-2 to F-3A-1.

Epoxy

F-1A(PLY),

F-2A ASSEMBLY and F-3A ASSEMBLY

all

together.

Glue former halves

F-5A thru F-16A

together, using plans

to measure correct width.

Pin notched strips (sometimes referred to as "crutch strips")

down over plans, locate from inner line as the outer edge

of the strip will be trimmed off later on.

Measure, cut and glue 1/4" SQUARE spacers in place. Glue

1/4" x 1/2" SPACER and

F-23

in place at rear.

Glue formers F-5A thru F-14A in place.

Be sure formers

are perpendicular to notched strips.

Glue two

F-22's

in place so they are 1/16" from outer edge

of notched strip. Glue F-16A to F-22's and notched strip.

Glue F-17 in place.

Glue two pieces of

1/8" SHEET together and cut to fit for

cockpit floor.

Glue four

3/16" x 3/8" LONGERONS

into notches in

formers.

Page 4

Cut notch in rear center of stabilizer for clearance for elev.

control horn movement (see plan).

Epoxy elevator control horn to stabilizer at BRASS TUBING

ONLY!

Epoxy stabilizer to fuselage. Check alignment in all directions.

Cut hole in stab planking for fin leading edge and epoxy fin

place. Check alignment in all directions.

Drill holes for control horns in rudder and both elevators.

and then "Vee" notch. Make openings for plastic hinges.

Attach rudder control horn to rudder with epoxy. Attach

rudder to fin and epoxy brass tubing (only) to rear of fin.

Attach elevators to stabilizer.

Glue

R-9

in place. Fit

5/8" x 1-3/8" FILLET BLOCKS to

each side of rudder. Shape as required.

Fuselage can be removed from plans.

Carefully position wing saddle assembly in position on in-

verted fuselage half and glue.

Epoxy former F-4B to front of wing saddle, to notched

strips and to motor mounts. Epoxy F-1B Firewall assembly

over motor mounts and to F-1A assembly. Make sure firewalls are flush and true in both planes. Epoxy motor mount

support blocks in place.

Make and glue all remaining formers

(F-10B thru F-16B) i

n

position on notched strips. Glue 3/16" x 3/8"

LONGERONS

in place[F-1B assembly to F-4B and F-10B to F-15B(or

F-16B)].

Bend TAIL WHEEL WIRE as shown on plans. Over the

straight end, assemble a collar, the nylon tailwheel bracket,

F-20(PLY)(after drilling hole) and another collar.

Make two supports for F-20(PLY) from scrap 1/8" balsa and

glue into position. Cut the 3/8" x 5/8" x 3-1/2" long balsa

block into two pieces to fit in between F-16B and F-17.

Glue the pieces in place and rouqh to shape only.

Laminate F-1B(PLY),

F-2B and F-3B

firewall as described

for F-1A assembly. Set aside to dry.

Epoxy F-19(PLY) doublers to insides of F-18 pieces.

Glue formers

F-5B. F-6B. F-7B, F-8B and P-9B

into the slots

in the two F-18 pieces.

Epoxy 1/2" x 1-1/8" MOTOR MOUNTS to the insides of

F-18's and F-5B and F-6B as shown. Motor mounts are to

extend out 4-3/8" from ends of F-18's.

Cut 3/8" x 1-1/8" x 1-1/2" long maple block in half to make

two pieces 3/8" x 3/4" x 1-1/8". Epoxy these pieces into

the cut-outs in the F-19(PLY)'s.

Trim and glue a

1/8" x 7/8" x 30" STRIP

to each side of

fuselage between the notched strip and first longeron.

Fit and glue a 1/8"

x 2-7/8"(or 3") x 30" SHEET

between

next two longerons, on each side. Wood can be formed to

compund

shape

by

wetting

outside

only.

Hold

in

place

with

pins, tape and/or rubber bands while glue is drying.

Finish top with 1/8" x 3-3/4" (or 4") x 24"

SHEET.

Leave

opening at cockpit area. (F-7A to F-9A).

All seams should be in the approximate center of each long-

eron. Allsheeting is done on a "Fit and try" basis.

3

Page 5

Install elevator and rudder servos. Make and rudder pushrods.

Check all control surfaces for free and proper operation. Safety

all clevises now as they are hard to get at once the fuselage is

entirely sheeted.

Glue 1/8" x 7/8" x 42"

BALSA

to each side as shown.

Fit, form and glue 1/8" x 2-7/8"(or 3") x 42" SHEET next to

7/8" wide pieces.

Pit, form and glue

1/8" x 3-3/4"(or 4") x 24" SHEET

in last

opening.

When shells are dry, trim carefully around wing opening. Plank

(cross grain) openings from over formers F-4B thru F-10B with

1/16" balsa sheet.

Glue

1-1/8" x 2-1/2" x 2-3/4" TAIL BLOCK

in position.

Carve and sand to shape. Sand entire fuselage, cutting down

raised

edges

of notched

strip

until

flush

with

sheeting

For access to interior of fuselage, cut out formers

F-5B, F-6B,

F-7B, F-8B and F-9B from between F-18 pieces.

Tape 4 pieces

of 3/32" x 2-7/8" x 30"

Balsa

and

two

pieces

of

3/32" x 2-7/8" x 15" BALSA

together as shown above. Make

two sets.

Turn them over, open up slightly, and apply glue to joints. Lay

on flat surface, with weights, until dry.

Cut a triangular piece, as shown shaded above, off of each

piece and SAVE.

Make two more sets, using the triangle, three 3/32" x 2-7/8" x

30" and two 3/32" x 2-7/8" x 15" for each set.

Cover wing plan with MonoKote backing. Pin one assembled

over outline on plan.

Glue ribs W—3 thru W—11 to spar, pinning thru feet of ribs,

checking to be sure ribs are perpendicular.

Glue

W—22

to

front

of

each

rib

and

pin.

Glue

7/16" THICK x 28" LONG TAPERED

piece to back of

ribs and pin.

Glue upper spar in position in rib notches.

When wing is dry, take DIHEDRAL GUIDE as shown above,

mark lines and cut off spars, W—22 and trailing edge. Unpin

from plan.

Build opposite wing panel in exactly same manner.

Glue

W-3B(PLY)

and

W-3C(PLY) to W-3 RIBS.

Make one

left hand and one right hand.

Glue W-5B(PLY) and W-5C(PLY) to W-5 RIBS. Make one

left hand and one right hand.

Cut four pieces of 1/4" x 1/2"

BALSA

strips to 12-9/16"

long. Taper one end of each piece as shown.

Glue these strips to 1/4" x 1/2" x 30" SPARS, 15-1/8" from

one end of each strip as shown. Leave excess length on spar

to aid in pinning down. Make four sets.

4

Page 6

Glue

W-2C

in place on W-2B rib. Cut out one W-1B to same

length

as

W-2C

as

shown

above

(both

W—1A'S

if

flap

servo

is to be used).

Epoxy

1/4" x 3/8" SERVO RAILS

in place using servo as guide

for spacing. Install servo(s).

Make

CONTROL WIRES

as shown above (ball link connectors

are recommended at servo end).

Glue

W-8B

in place on W-8 rib. Glue

W-9B

in place.

Mount

BELLCRANK ASSEMBLY(see

plans) to

W-12(PLY)

and epoxy this assembly on W—8B and W—9B.

Plank top of wing panel that is still pinned down.

Remove wing from bench and pin down opposite wing panel.

Repeat planking procedure on this panel. Unpin and remove

all rib feet.

Epoxy

L.G. KEY BLOCKS

to W-3 ribs. Epoxy

GROOVED

L.G. BLOCK in rib notches. Locate from plans. Drill 7/32"

dia. hole to line up with groove in key block

Locate and cut openings for control wires and main L.G.

wires, in wing planking. Plank both bottom wing panels.

Glue WING TIP blocks together and saw to outline. Glue

wing tips to wings, and shape.

Shape leading edges per plan. Sand wing all over.

Hinge

ailerons

permanently

to

wing. If

flaps

are

to

be

operating, hinge them permanently, otherwise cement them in

place. Connectcontrols to ailerons (and flaps).

Glue

W-21

to center of 3/4" face of 3/8" x 3/4"

STRIP.

Mark location of each rib from the plans. Cut 3/32" x 3/8"

BALSA

to length for each rib, and glue them in place top

and bottom. When dry, taper ribs with sandpaper block or

razor plane. Make two ailerons.

Bevel front of leading edge as shown. Install three

NYLON

HINGES.

See plans for instructions.

Glue W—28(PLY)'s in place top and bottom. Location of

W-28(PLY)'s determine L.H. or R.H. aileron. Make one each.

Install NYLON HORNS with #2-56 x

1/2" R.H.M.S.

Leave last wing panel built pinned to work table. Join wing

halves together using

W-16(PLY) JOINERS and

slow drying

epoxy. Block up opposite wing panel for correct dihedral.

Epoxy

W-17(PLY)'s

to W-16(PLY)'s.

Crack W-13(PLY) and W-14(PLY) in center to conform to

angle of leading edge. Epoxy in place as shown.

Shape

17/32" x 1-3/16" x 7"

BALSA

BLOCK

to

conform

to

shape of trailing edge. Epoxy in place. Epoxy W—18(PLY) to

this block.

Glue

two

W-1A's

and

two

W-1B's

together.

Epoxy

them

in

place in wing as shown.

Assemble

HARDWOOD BLOCK,

W-2D's,W-19's and W-3D's

as shown above. Filler wedges are made from scrap balsa.

5

Page 7

Again the decision to use landing gear retracts must be made before

construction begins Construction provisions have been built into

the model for retracts There is room in the center of the wing,

foreward of the main spars, for a servo (mechanical retracts) or a

servo and valve (pneumatic retracts) The air supply tank (pneum

system) is located in the fuselage Be sure the tank(s) and air lines

DO NOT INTERFERE with the pushrod operation The model

can be balanced with the wheels up or down as the fore and aft CG

remains the same

This plane is designed to have operating flaps if desired The flaps

will have to be hinged and control horn added, instead of fastened

solid as shown on plans Provisions have been made in the wing

for the additional servo The decision to have operating flaps must

be made before the wing construction is started

Drill 1 /4" dia x 1 3/4" deep hole in leading edge in center of

wing Install

1/4" DIA x 2" LONG DOWEL

with epoxy

Dowel should stick out at least 1/4" Sand slight radius on

end of dowel

Epoxy face of

F—21

(PLY) and slip over dowel with epoxy

away from wing Do not get epoxy on dowel Put the wing

with F—21 (PLY) in place on the fuselage and align carefully

Temporarily fasten it down This will correctly locate the

F-2KPLY) on the fuselage

When the epoxy has set and while the wing is still fastened

down, drill two 1/8" DIA holes thru wing and thru fuselage

blocks See plans for location dimensions

Glue F-10C to wing only(not to fuselage) Glue

F—9C

on

wing See plan for location Make two cross pieces from scrap

1/8" stock Sheet over this area with 1/8" soft sheeting

Remove

wing

Tap

fuselage

holes

with

#8-32

self

tapping

screw

furnished

Drill

wing holes

out

to

11/64"

DIA

for

screw clearance Cut notches in planking for screw head

clearance

Drill holes in firewall at proper locations for throttle and

mixture controls and fuel line Install engine— 60 to 90 recommended Attach fuel line Install throttle and fuel mixture

control cables Check for free movement

Install the radio equipment (receiver, battery, servos, etc ) as

per the manufacturers instructions

Make cut outs in

FRONT COWL

for exhaust, glow plug, etc

Cement to rear cowl and sand lightly with 400 grit paper

prior to painting

Attach

W-26(PLY) L.G DOORS

to main landing gear wire

as shown on plans , Install main wheels and tail wheel

Cover the model (except cowl) with colored

MonoKote,

or

or cover the model with

CHROME MONOKOTE,

paint as per

color desired and then scribe panel outlines

Paint cockpit with flat black Install pilot (not furnished) Trim

and install vacuum formed gun ports and canopy See plans for

adhesives to use Apply markings furnished

Check radio carefully, including range check per manufacturers

instructions Check Center of Gravity Do not deviate from

position shown on plans If you are not a proficient R/C pilot,

get the help of one

See

warning

on

page 1 Save

your

plane-

avoid grief

Temporarily center the REAR COWL on fuselage so that the

mounting holes are at 45° to the vertical and horizontal center

lines

of

the

fuselage

Mark location

of

holes

with

soft pencil

Remove cowl and drill

1/8" DIA

holes thru at marks

Drill a 3/16" dia hole in the center of each F 23(PLY)

piece

Press a #4—40

blind

nut

firmly

in

each

one

Fasten

the

rear

cowl in place

with

four

#4-40 x

3/4"

R H M S Use the F 21 (PLY) with blind nut inside the

fuselaqe

With wing bolted in place, form and fit wing fillets

W-23,

W-24 and W-27 All fillets on each side of the wing must

be done at the same time for proper fitting W 23's are

fixed to the wing while W 24 and W 27 are fixed to the

fuselage Smooth joints with Dap

6

Page 8

For a 16-page catalog plus a free MONOKOTE™

sample and prop chart, send request

plus 50 cents to Top Flite

© Top Flite Models, Inc. 1981 150308'

Loading...

Loading...