Page 1

INSTRUCTION MANUAL

Top Flite Models Champaign, IL

Ph: (217) 398-8970, Ext. 5

Fax: (217) 398-7721

airsupport@top-flite.com

WARRANTY

Top Flite® Model Manufacturing Co. guarantees this kit to be free from defects in both material and workmanship at the date of purchase. This warranty does

not cover any component parts damaged by use or modification. In no case shall Top Flite’s liability exceed the original cost of the purchased kit. Further,

Top Flite reserves the right to change or modify this warranty without notice.

In that Top Flite has no control over the final assembly or material used for final assembly, no liability shall be assumed nor accepted for any damage resulting

from the use by the user of the final user-assembled product. By the act of using the user-assembled product, the user accepts all resulting liability.

If the buyer is not prepared to accept the liability associated with the use of this product, the buyer is advised to return this kit immediately in new

and unused condition to the place of purchase.

To make a warranty claim send

the defective part or item to

Hobby Services at this address:

Include a letter stating your name, return shipping address, as much contact information as possible (daytime telephone number, fax number, e-mail address), a

detailed description of the problem and a photocopy of the purchase receipt. Upon receipt of the package the problem will be evaluated as quickly as possible.

READ THROUGH THIS MANUAL BEFORE STARTING CONSTRUCTION. IT CONTAINS IMPORTANT INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

Entire Contents © 2014 Hobbico, Inc. TOPA1956

Hobby Services

3002 N. Apollo Dr. Suite 1

Champaign IL 61822 USA

Page 2

INTRODUCTION

Top Flite is very proud to bring you the giant scale Zero.

The Zero became one of the most important fi ghters of

World War II. You will enjoy using this scale accessory

to add to the overall look and enjoyment of your Zero.

Mail parts orders Hobby Services

and payments by 3002 N Apollo Drive, Suite 1

personal check to: Champaign IL 61822

Be certain to specify the order number exactly as listed

in the Replacement Parts List. Payment by credit card

or personal check only; no C.O.D.

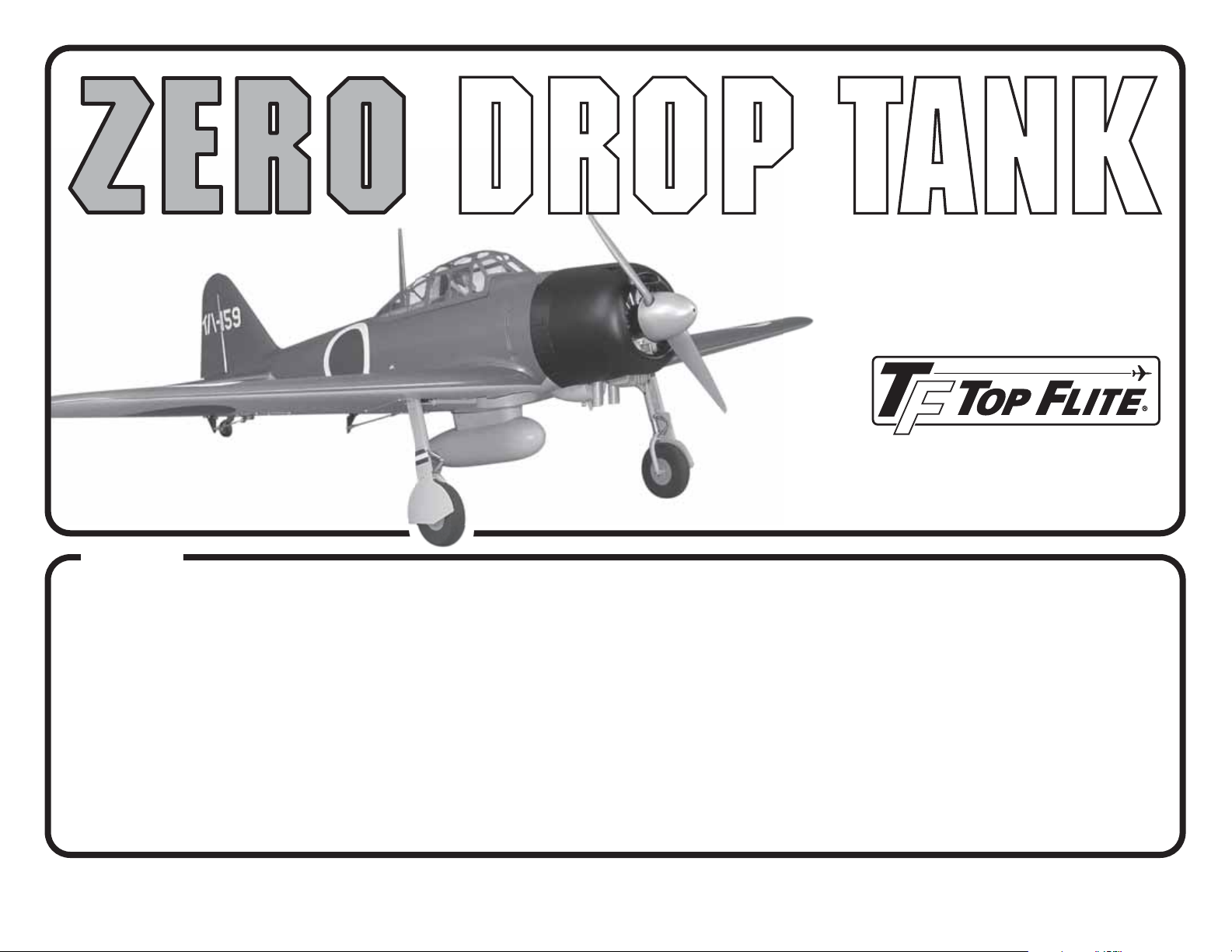

KIT CONTENTS

REQUIRED FOR COMPLETION

❍ 1- Futaba S3102 Servo 50 oz. in. of torque

(FUTM0034)

❍ ½ oz. Medium Pro CA+ (GPMR6009)

ORDERING REPLACEMENT PARTS

Replacement parts for the Top Flite Giant Scale Zero

ARF are available using the order numbers in the

Replacement Parts List that follows. The fastest, most

economical service can be provided by your hobby

dealer or mail-order company.

To locate a hobby dealer, visit the Top Flite web

site at www.top-flite.com. Select “ Where to Buy” in

the menu across the top of the page and follow the

instructions provided to locate a U.S., Canadian or

International dealer.

Parts may also be ordered directly from Hobby Services

by calling (217) 398-0007, or via facsimile at (217) 398-

7721, but full retail prices and shipping and handling

charges will apply. Illinois and Nevada residents will

also be charged sales tax. If ordering via fax, include

a Visa® or MasterCard® number and expiration date

for payment.

If additional assistance is required for any reason

contact Product Support:

by e-mail at or by telephone at

productsupport@top-fl ite.com (217) 398-8970

REPLACEMENT PARTS LIST

TOPA1956 . . Giant Zero Drop Tank

Complete Parts Set

TOPA1949 . . Giant Zero Drop Tank Release Set

TOPA1948 . . Giant Zero Drop Tank Set

ASSEMBLE THE

DROP TANK MOUNT

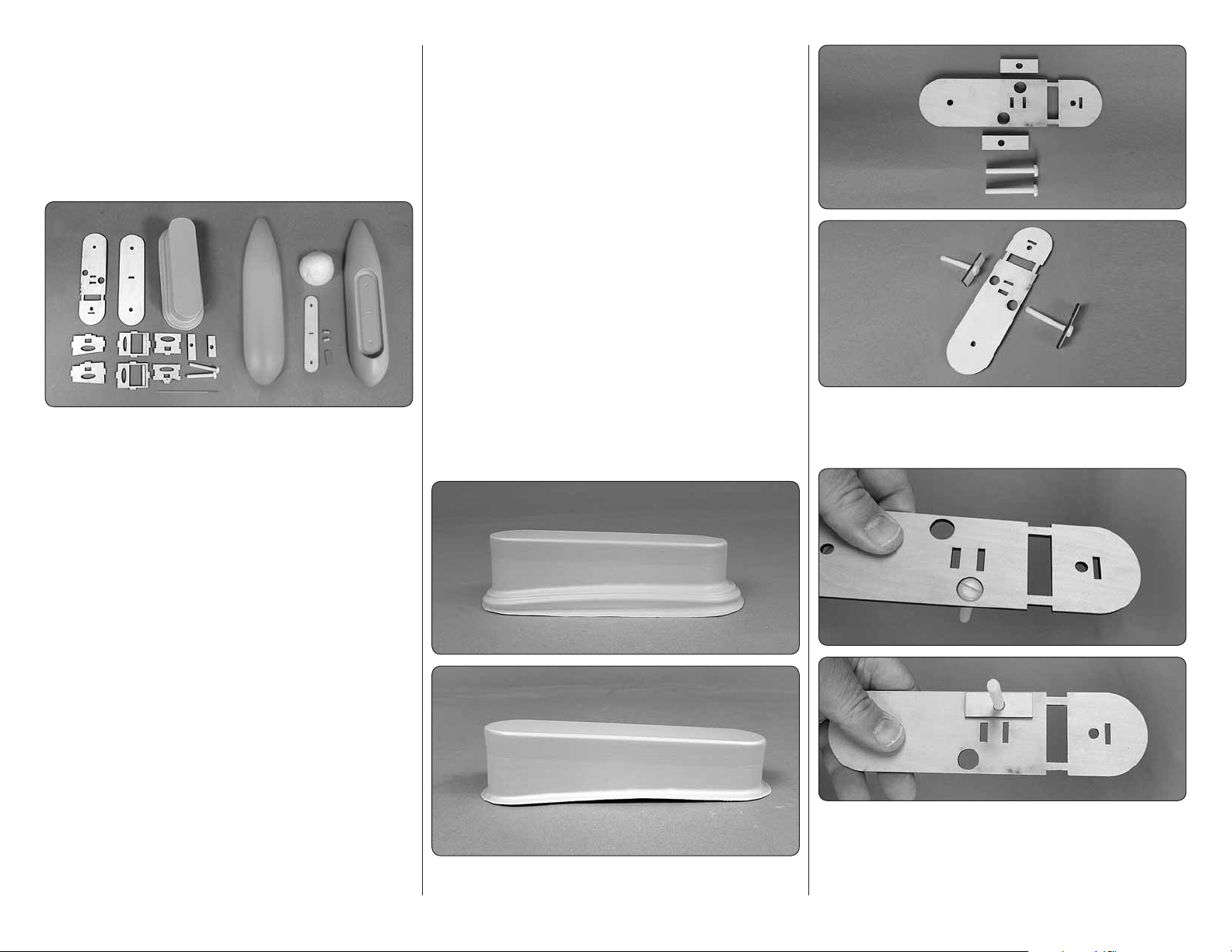

1. Locate the ABS drop tank mount. Cut it as shown.

❏

2

2. Locate the plywood former, plywood mounting

❏

screw doublers and 1/4- 20 2" [ 51 mm] ny lon mountin g

screws. Insert the screws into the doublers.

3. IMPORTANT! When assembling the parts that

❏

follow, pay close attention to the photos. Make sure you

assemble the parts exactly as shown. Place one of the

doublers and screws in place on the former. Center

Page 3

the head of the screw in the hole and then glue the

doubler to the former. Repeat this for the other screw

and doubler.

4. Once assembled the former should look like

❏

these photos.

5. Determine the size of the servo you will use for

❏

your dro p tank rele ase. For our s er vo we ne e d ed to cut

the servo tray on the laser cut lines in the tray. This can

be easily done with a sharp hobby knife. Glue the two

parts of the servo tray together.

3

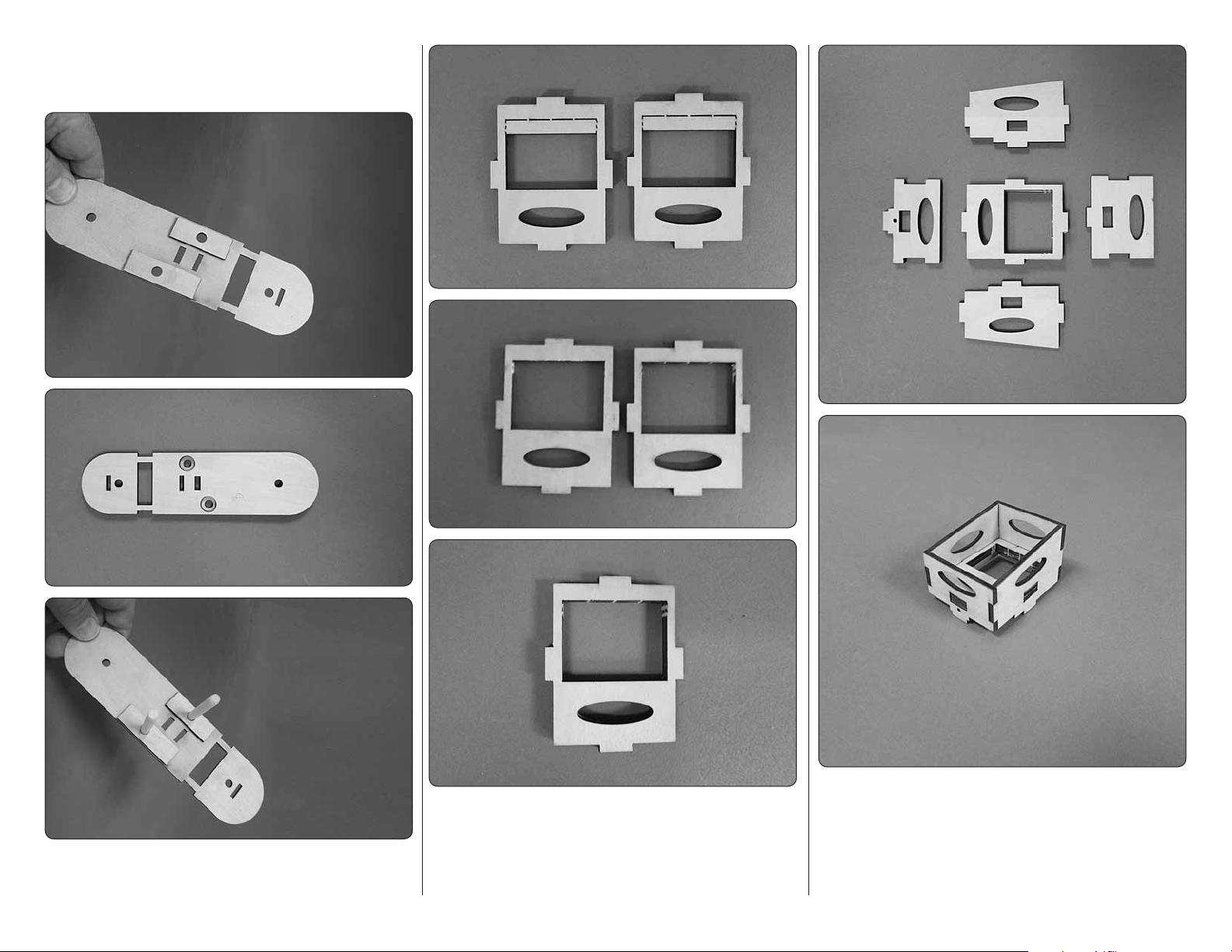

6. Locate all of the plywood parts shown and glue

❏

the parts together forming the servo box. Once again,

pay close attention to the photos to make sure you

assemble the box exactly as shown.

Page 4

Release Pin

Template

7. If you are using the servo we used, Futaba S3102,

❏

the instructions for the release pin that follows will

be correct for this servo. You may need to adjust the

overall length of the pin for your servo choice. From a

2-56 6" threaded wire, bend and cut the release pin

as shown in the sketch.

8. This photo shows the former in the orientation it

❏

will be when it will be glued into the mount. Use the

former as your guide and cut the holes into the ABS

plastic mount as shown. Refer to the photos in the next

step for a reference of what to cut.

9. Glue the former into the bottom of the plastic mount.

❏

For better adhesion, roughen the plastic with some 220

grit sandpaper before gluing the parts together.

10. Install the servo with the screws that came with

❏

the servo. Center the servo and install the servo arm.

4

11. Using a 5/64" [ 2 mm] drill open up the outer

❏

hole in the servo arm. Install the release pin into the

servo horn.

12. Install the servo box into the plywood former

❏

without any glue. Drill two 1/16" [1.6 mm] holes

through the ABS plastic mount into the plywood servo

box. Do thi s on both s i d es of the m ount. Af ter installing

the screws, remove the screws and the mount. Apply

a couple of drops of thin CA glue in the holes. After

the glue has hardened, reinstall the servo box and

the screws.

Page 5

ASSEMBLE THE DROP TANK

1. Locate the parts shown here. Glue the two plywood

❏

plates together. Use the two wood dowels to align the

two plates when gluing them together. Do not glue the

wood dowels to the plates

3. Glue the dowels into the holes as shown.

❏

5. For the next step it will be extremely helpful if you

❏

can either use a servo driver to move the servo arm

during this installation or put a long servo extension on

the servo and plug it into your receiver, allowing you

to use your radio to move the servo arm. Locate the

hard fi ber drop tank retainer. Test fi t it onto the release

pin. The fi ber drop tank retainer should fi t loose on the

release pin. If it is too tight open the hole with a drill bit.

2. Locate the top half of the drop tank. Cut the two

❏

holes and the center slot from the part. These holes

will match with the plywood parts you glued together.

4. Test fi t the plywood assembly into the top half

❏

of the drop tank. Once you are satisfi ed with the fi t,

glue the plate inside of the drop tank. Use some 220

grit sandpaper to roughen the plastic, giving the best

adhesion between the plastic and plywood.

5

Page 6

6. With the fi ber drop tank retainer in place on the

❏

release pin, slide the top half of the drop tank onto the

retainer. When positioning the tank on the retainer be

sure the alignment pins in the drop tank are installed

into the pod. Once you are satisfi ed with the positioning

of the pod, apply a drop of CA glue to tack glue the

retainer to the drop tank. Once the glue hardens operate

the servo several times to make sure the release pin

consistently slides freely into and out of the retainer.

7. When you are satisfi ed with the position of the

❏

retainer, locate two 3/8" 3/8" 9/16" [101014 mm ]

hardwood blo c ks and glue them to t he retain er and th e

plywood former.

8. After the glue has hardened, double check to be

❏

sure the release pin still moves freely in the retainer.

9. Locate the foam drop t ank inser t an d glue it to the

❏

front of the top half of the drop tank.

10. Once the glue has hardened on the foam insert

❏

glue the two halves of the drop tank together, taping the

two halves together while the glue dries. We found that

using white aliphatic glue like RC Z56 glue works well

because it has a long working time, cleans up easily

with water and dries clear.

6

Page 7

11. On the bottom of the wing, under the covering,

❏

you will fi nd two pre-installed blind nuts and an access

hole to feed the servo lead through the wing and into

the fuselage. Cut the covering from these holes.

and rear of the pod. Position the holes you drill so that

you drill into the root rib of the wing. Install and then

remove a #2 3/ 8" screw an d # 2 fl at washer i nto eac h

of the holes you drilled. Remove the pod from the wing.

Apply a couple of drops of thin CA glue into the four

holes to harden the threads.

13. Install a 12" [ 305 mm] servo extension onto the

❏

servo. Secure it with tape, heat shrink tubing or some

other method to secure the leads. Feed the servo

through the wing and reinstall the pod to the wing.

12. Install the pod to the wing with two 1/4 -20 2"

❏

nylon bolts. Don’t worry about feeding the servo lead

into the wing. Make sure you have the pod centered

on the wing. Drill two 1/16" [1.6 mm] holes into the front

7

14. Install the drop tank to the pod.

❏

Page 8

Loading...

Loading...