Page 1

WARRANTY.....Top Flite

®

Models guarantees this kit to be free from defects in both material and workmanship at the date of purchase.This warranty

does not cover any component parts damaged by use or modification.In no case shall Top Flite’s liability exceed the original cost of the purchased kit. Further, T op Flite

reserves the right to change or modify this warranty without notice. In that Top Flite has no control over the final assembly or material used for final assembly, no liability shall

be assumed nor accepted for any damage resulting from the use by the user of the final user-assembled product. By the act of using the user-assembled product, the user

accepts all resulting liability .If the buyer is not prepared to accept the liability associated with the use of this pr oduct,the buyer is advised to return this kit immediately

in new and unused condition to the place of purchase.

Top Flite Models Champaign, IL Telephone (217) 398-8970, Ext. 5 airsupport@top-flite.com

READ THROUGH THIS INSTRUCTION BOOK FIRST. IT CONTAINS IMPORTANT INSTRUCTIONS AND WARNINGS CONCERNING THE ASSEMBLY AND USE OF THIS MODEL.

TOPZ9300 for TOPA1005 V1.0

Entire Contents © Copyright 2003

Wingspan: 50.5 in [1,285mm]

Wing Area: 500 sq in [32.2 dm2]

Weight: 42 – 50 oz [1,190 – 1,420g]

Wing Loading: 12 – 14 oz/sq ft

[37 – 43 g/dm

2

]

Length: 38.5 in [980mm] (tip of rudder

to tip of spinner)

Engine: .35 – .46 cu in [5.5 – 7.5cc]

2-stroke glow

Page 2

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . 2

IMPORTANT SAFETY PRECAUTIONS . . . . . . . . . 2

ENGINE & LINE RECOMMENDATIONS . . . . . . . . . 3

ADDITIONAL ITEMS REQUIRED. . . . . . . . . . . . . . 3

Hardware & Accessories. . . . . . . . . . . . . . . . . 3

Adhesives & Building Supplies . . . . . . . . . . . . 3

Optional Supplies & Tools . . . . . . . . . . . . . . . . 4

Covering Tools . . . . . . . . . . . . . . . . . . . . . . . . 4

KIT INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . . 4

ORDERING REPLACEMENT PARTS. . . . . . . . . . . 4

KIT CONTENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . 5

IMPORTANT BUILDING NOTES . . . . . . . . . . . . . . 6

ASSEMBLE THE WING . . . . . . . . . . . . . . . . . . . . . 6

Hinge the Flaps . . . . . . . . . . . . . . . . . . . . . . . 6

Make the Flap Pushrod. . . . . . . . . . . . . . . . . . 7

Join the Flaps to the Wing . . . . . . . . . . . . . . . 8

Finish the Wing. . . . . . . . . . . . . . . . . . . . . . . . 9

ASSEMBLE THE FUSELAGE . . . . . . . . . . . . . . . 10

Prepare the Stab . . . . . . . . . . . . . . . . . . . . . 10

Make the Elevator Pushrod . . . . . . . . . . . . . . 12

Mount the Fuel Tank . . . . . . . . . . . . . . . . . . . 12

Join the Wing & Stab to the Fuselage . . . . . . 13

Join the Fin & Tail Wheel. . . . . . . . . . . . . . . . 13

Mount the Main Landing Gear . . . . . . . . . . . . 14

Mount the Engine . . . . . . . . . . . . . . . . . . . . . 14

Mount the Cowl. . . . . . . . . . . . . . . . . . . . . . . 15

FINAL DETAILS . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Mount the Canopy . . . . . . . . . . . . . . . . . . . . 17

Apply the Decals. . . . . . . . . . . . . . . . . . . . . . 17

GET THE MODEL READY TO FLY . . . . . . . . . . . . 17

Balance the Model (C.G.) . . . . . . . . . . . . . . . 17

Wing Tip Weight . . . . . . . . . . . . . . . . . . . . . . 18

PREFLIGHT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Balance the Propellers . . . . . . . . . . . . . . . . . 18

Engine Check. . . . . . . . . . . . . . . . . . . . . . . . 18

Control Check. . . . . . . . . . . . . . . . . . . . . . . . 19

ENGINE SAFETY PRECAUTIONS. . . . . . . . . . . . 19

AMA SAFETY CODE (excerpt) . . . . . . . . . . . . . . 19

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Control Line . . . . . . . . . . . . . . . . . . . . . . . . . 19

CHECK LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

FLYING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Flying Precautions . . . . . . . . . . . . . . . . . . . . 20

Preflight . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Takeoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Landing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

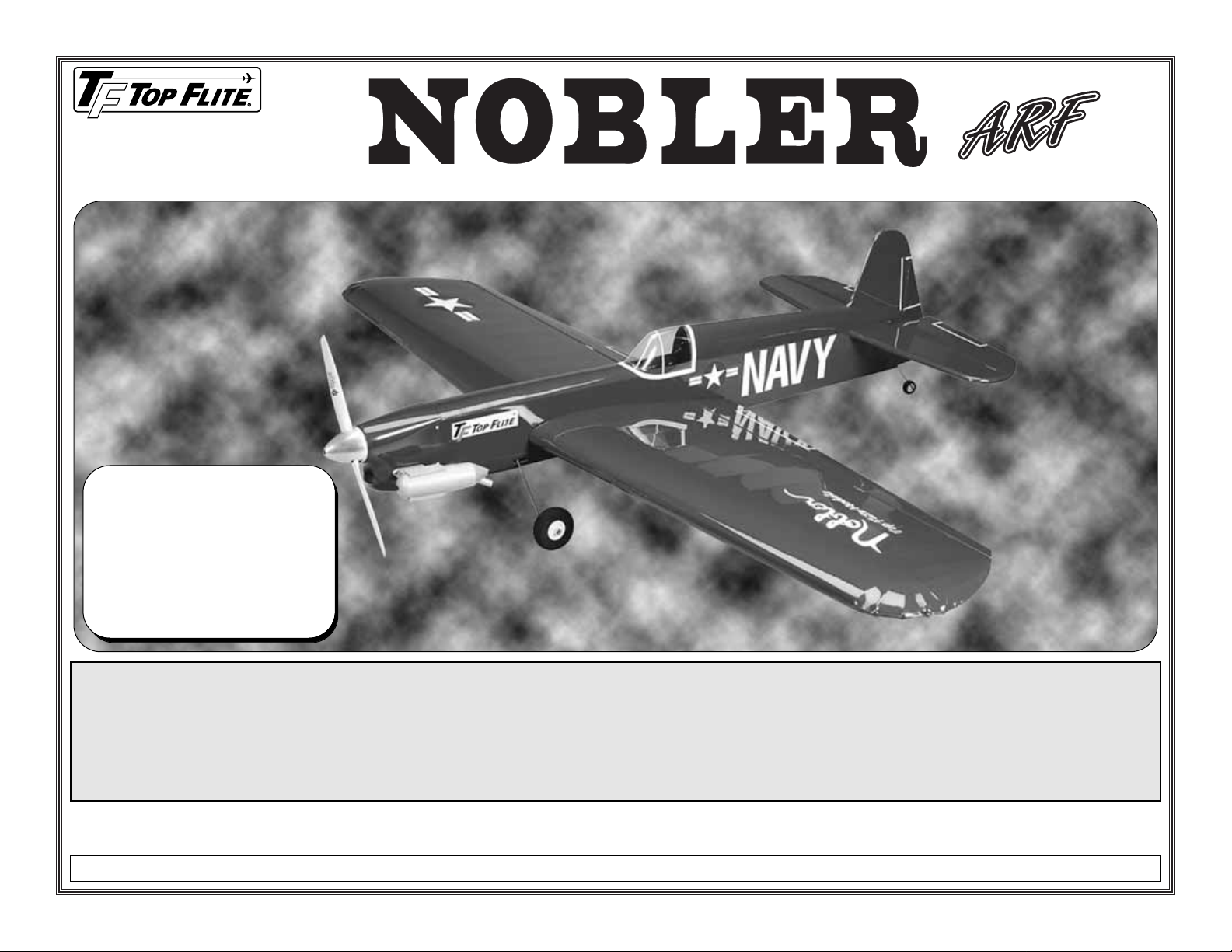

INTRODUCTION

Congratulations and thank you for purchasing the

Top Flite Control Line Nobler ARF. Originally

designed and flown by the legendary George

Aldrich in the 1950’s, the Nobler is now recognized

as one of the most popular and successful control

line stunt models of all time. While studying the

Nobler’s histor y, it was revealed just how much of a

control line legend the late Mr. Aldrich is. Much of

the fun, success and satisfaction control line pilots

enjoy today can be directly attributed to Mr. Aldrich

and his Nobler. And now, Top Flite merges the past

with the present by bringing this old-time favorite

back to life–only in ARF form. Reincarnated from

original Top Flite plans, the Nobler ARF is a perfect

way to get into beginner stunt flying without the

initial time and money commitment required for

today’s kit-built stunters. And if you plan to just

dabble in control line, the Nobler ARF has the

perfect blend of maneuverability and stability to get

you into the air with minimal assistance from an

experienced flyer.

Note: The Top Flite Nobler ARF pictured on the kit

box cover features a Great Planes 1-3/4" [45mm]

aluminum spinner (not included). However, serious

stunt pilots who wish to reduce the model’s overall

weight should use a lightweight plastic spinner, thus

reducing the amount of tail-weight that would be

required to offset an aluminum spinner.

1.Your Top Flite Nobler ARF should not be considered

a toy, but rather a working model that functions like a

full-size airplane. Because of its performance

capabilities, the Nobler ARF, if not assembled and

operated correctly, could possibly cause injury to

yourself or spectators and damage to property.

2. You must assemble the model according to the

instructions.Do not alter or modify the model, as doing

so may result in an unsafe or unflyable model. In a few

cases the instructions may differ slightly from the

photos. In those instances the written instructions

should be considered as correct.

3. You must take time to build straight, true

and strong.

4. You must use lines that are in first-class condition,

and a correctly sized engine and components

throughout the building process.

5. You must correctly install all pushrods and other

components so that the model operates correctly on the

ground and in the air.

6. You must check the operation of the model before

every flight to insure that all equipment is operating and

that the model has remained structurally sound.

7. If you are not already an experienced control line

pilot, you should fly the model only with the help of a

competent, experienced control line pilot.

8.While this kit has been flight tested to exceed normal

use, if the plane will be used for extremely high stress

flying, such as racing, the modeler is responsible for

taking steps to reinforce the high stress points.

PRO TECT YOUR MODEL,

YOURSELF & OTHERS

FOLLO W THESE IMPORT ANT

SAFETY PRECAUTIONS

- 2 -

Page 3

9. WARNING: The cowl included in this kit is made of

fiberglass, the fibers of which may cause eye, skin and

respiratory tract irritation. Ne v er blo w into an y fiberglass

part to remove fiberglass dust, as the dust will blow

back into your eyes. Always wear safety goggles, a

particle mask and rubber gloves when grinding, drilling

and sanding any fiberglass part and thoroughly vacuum

the part and work area afterward.

Remember: Take your time and follow the

instructions to end up with a well-built model that is

straight and true.

If you have not flown a control line stunt model before,

we recommend that you get the assistance of an

experienced pilot in your club for your first flights. If

you’re not a member of a club, your local hobby shop

has information about clubs in your area whose

membership includes experienced pilots.

In addition to joining a control line club, we strongly

recommend you join the AMA (Academy of Model

Aeronautics). AMA membership is required to fly at

AMA sanctioned clubs.Among other benefits, the AMA

provides insurance to its members who fly at

sanctioned sites and events. Additionally, training

programs and instructors are available at AMA club

sites to help you get started the right way. Contact the

AMA at the following address or toll-free phone number:

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie, IN 47302-9252

Tele. (800) 435-9262

Fax (765) 741-0057

Or via the Internet at: http://www.modelaircraft.org

ENGINE & LINE

RECOMMENDATIONS

ADDITIONAL ITEMS REQUIRED

Hardware & Accessories

In addition to the engine, lines, handle and

connectors previously listed, following is the list of

hardware and accessories required to finish the Top

Flite Control Line Nobler ARF. Order numbers are

provided in parentheses.

❏ 3' [900mm] Standard silicone fuel tubing

(GPMQ4131)

❏ Aluminum fuel line plug (GPMQ4166)

❏ 1-3/4" [45mm] White spinner (GPMQ4505)

-or-

❏ 1-3/4" [45mm] Aluminum spinner (GPMQ4551)

and appropriate adapter (GPMQ4581 for O.S.

MAX LA and other engines with 1/4-28

crankshaft thread)

❏ 1/4" [6mm] White striping tape (GPMQ1610)

❏ 1/16" [2mm] White striping tape (GPMQ1580)

Adhesives & Building Supplies

In addition to common hobby tools and household

tools, this is the “short list” of the most important

items required to build the Top Flite Nobler ARF.

Great Planes®Pro™CA and Epoxy glue are

recommended.

❏ 1/2 oz. [15g] Thin Pro CA (GPMR6001)

❏ Pro 30-minute epoxy (GPMR6047)

❏Threadlocker™thread-locking cement

(GPMR6060)

❏ Silver solder w/flux (GPMR8070)

❏ RTV silicone (for mounting fuel tank)

❏ #1 Hobby knife (HCAR0105)

❏ #11 blades (5-pack HCAR0211, or 100-pack

HCAR0311)

❏ Drill bits: 1/16" [1.6mm], 3/32" [2.4mm], 1/8"

[3.2mm], 9/64" [3.6mm]

❏ 1/8" [3.2mm] K&S brass tube or 1/8" [3.2mm] dril l

❏ Small metal file

❏ Rotary tool such as Dremel®with cutting/grinding

assortment (for cutting holes in fiberglass cowl)

❏ Stick-on segmented lead weights (GPMQ4485)

❏Top Flite Panel Line Pen (TOPQ2510)

❏ Sandpaper assortment

A .35-.46 cu in [5.5-7.5cc] two-stroke glow

engine is recommended for the Top Flite Nobler

ARF. Our test models performed superbly with

the O.S.®MAX .40 LA-S and a Top Flite 11 x 4

Power Point®wood prop. This combination

provided good line-tension and lap times on 60'

lines. A .46 engine could be used as well, but

expect faster speeds with this setup. For most

engines, .015" [.38mm] multi-strand lines are

recommended, but .018" [.46mm] multi-strand

lines are recommended if flying with a .46

engine.

#132 U156 .015" x 60' [.38mm x 18m] lines

(SULP2632)

#135 U186 .018" x 60' [.46mm x 18m] lines

(SULP2635)

#136 U187 .018" x 70' [.46 x 21.3m] lines

(SULP2639)

#166 IJ1 Standard handle (SULP2866)

#148 80 lb. [36kg] test line connectors

(SULP2948–pkg. of 2)

Note: We , as the kit manuf acturer, provide you with

a top quality, thoroughly tested kit and instructions,

but ultimately the quality and flyability of your

finished model depends on how you build it;

therefore, we cannot in any way guarantee the

performance of your completed model, and no

representations are expressed or implied as to the

performance or safety of your completed model.

- 3 -

Page 4

Optional Supplies & Tools

These are some of the items used while building the

Nobler that are not absolutely necessary, but are

mentioned in the manual.

❏ 2 oz. [57g] Spray CA activator (GPMR6035)

❏ 4 oz. [113g] Aerosol CA activator (GPMR634)

❏ CA applicator tips (HCAR3780)

❏ CA debonder (GPMR6039)

❏ Epoxy brushes (6, GPMR8060)

❏ Mixing sticks (50, GPMR8055)

❏ Mixing cups (GPMR8056)

❏ Builder’s Triangle Set (HCAR0480)

❏ Curved-tip canopy scissors for trimming plastic

parts (HCAR0667)

❏ Milled fiberglass (GPMR6165)

❏ Denatured alcohol (for epoxy clean up)

❏ K & S #801 Kevlar®thread (for stab alignment,

K+SR4575)

❏ Hobby Heat™micro torch (HCAR0750)

❏ Dead Center™Engine Mount Hole Locator

(GPMR8130)

❏ CG Machine™(GPMR2400)

❏ Precision Magnetic Prop Balancer™(TOPQ5700)

❏ Prop Reamer (GPMQ5005)

Covering T ools

❏ 21st Century®(COVR2700) or Top Flite

MonoKote®sealing iron (TOPR2100)

❏ 21st Century (COVR2702) or Top Flite Hot Sock

™

iron cover (TOPR2175)

Note: The stabilizer and wing incidences and engine

thrust angles have been factory-built into this model.

However, some technically-minded modelers may

wish to check these measurements anyway. To view

this information, visit the web site at

www.top-

flite.com

and click on “Technical Data.” Due to

manufacturing tolerances which will have little or no

effect on the way the model will fly, there may be

slight deviations between your model and the

published values.

KIT INSPECTION

Before starting to build, take an inv entory of this kit to

make sure it is complete, and inspect the parts to

make sure they are of acceptable quality. If any parts

are missing or are not of acceptable quality, or if you

need assistance with assembly, contact Product

Support. When reporting defective or missing parts,

use the part names exactly as they are written in the

Kit Contents list on page 5.

Great Planes Product Support

3002 N Apollo Drive Suite 1

Champaign, IL 61822

Telephone: (217) 398-8970

Fax:(217) 398-7721

E-mail:

airsupport@top-flite.com

ORDERING REPLACEMENT PARTS

Top Flite offers replacement parts for all of its

models. However, due to the nature of the Nobler

ARF and the fact that it is essentially a “one-piece”

model, fuselage and wing kits are not offered

separately. The only replacement parts offered are

the cowl (TOPA1300) and canopy (TOPA1301).

Replacement parts are not available from Product

Support, but can be purchased from hobby shops or

mail order/Internet order firms. Hardware items

(screws, nuts, bolts) are also available from these

outlets. If you need assistance locating a dealer to

purchase parts, visit www.greatplanes.com and

click on “Where to Buy.” If this kit is missing parts,

contact Product Support.

Note: Full-size plans are not available for the

Nobler ARF.

The Top Flite Control Line Nobler ARF is factory

covered with Top Flite MonoKote Sapphire blue

film (6' [1.8m] roll–TOPQ0226). Should repairs

ever be required, MonoKote can be patched with

additional MonoKote purchased separately.

MonoKote is packaged in six-foot rolls, but some

hobby shops also sell it by the foot. If only a

small piece of MonoKote is needed for a minor

patch, perhaps a fellow modeler would give you

some. MonoKote is applied with a model

airplane covering iron, but in an emergency a

regular iron could be used. A roll of MonoKote

includes full instructions for application.

- 4 -

Page 5

- 5 -

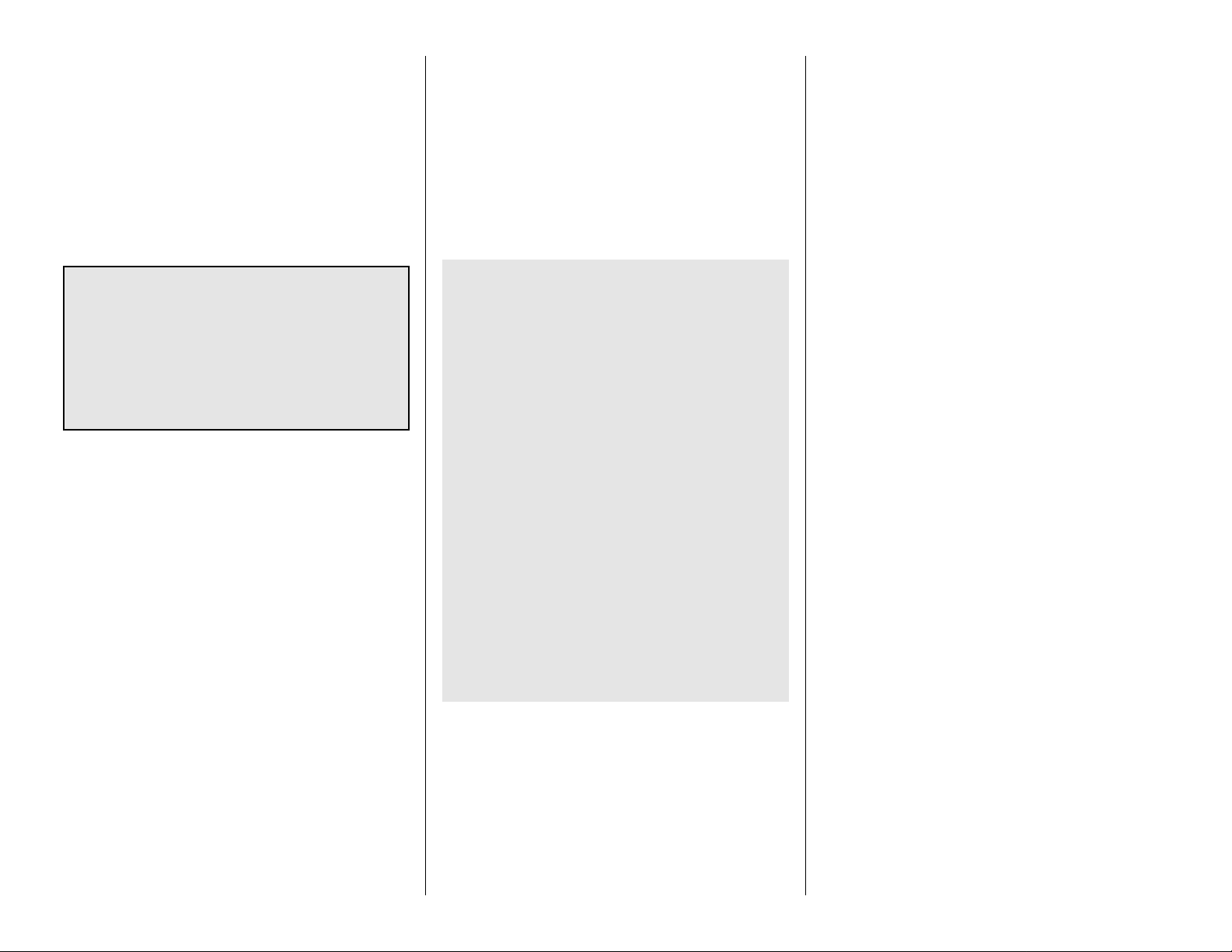

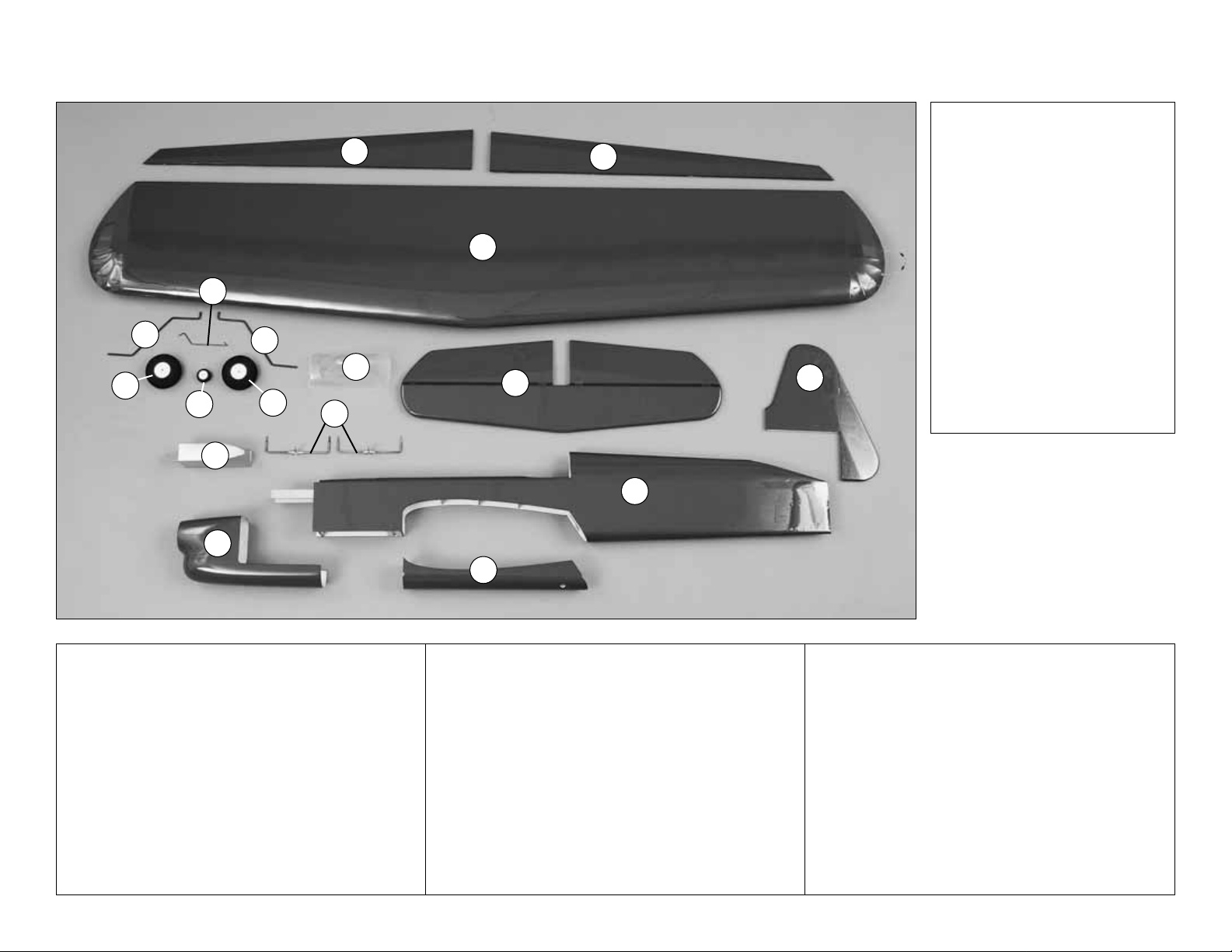

PARTS PHOTOGRAPHED

1. Flaps

2. Wing

3. Hor izontal Stabilizer with

Elevators

4. Fuselage

5. Belly Pan

6. Ver tical Stabilizer (Fin) with

Rudder

7. Fiberglass Cowl

8. Canopy

9. Main Landing Gear (2)

10. 2-1/2" [65mm] Main Wheels (2)

11. Tail Gear Wire

12. Tail Wheel

13. Fuel Tank

14. Joiner Wires (2)

PARTS NOT PHOTOGRAPHED

(2) 4-40 x 17-1/2" [445mm] Pushrods

(2) 4-40 Threaded Metal Clevises

(1) Non-threaded Metal Clevis

(2) 4-40 x 1-1/2" [38mm] Phillips Head Screws

(wing mounting)

(4) 4-40 x 1" [25mm] Socket Head Cap Screws

(engine mounting)

(6) 4-40 Blind Nuts (2-wing mounting, 4-engine

mounting)

(6) #4 Flat Washers (2-wing mounting, 4-engine

mounting)

(4) #4 Lock Washers (engine mounting)

(2) 4-40 Nuts (for pushrods)

(4) 1/8" [3mm] Wheel Collars (main wheels)

(1) 3/32" [2mm] Wheel Collar (tail wheel)

(5) 6-32 Set Screws (wheel collars)

(4) #2 x 1/2" [13mm] Screws (landing gear straps)

(6) #2 x 1/4" [6mm] Screws (cowl)

(2) Nylon Straps (main landing gear)

(14) Hinges

(3) Silicone Clevis Retainers

(1) Bellcrank w/leadouts (factory installed)

(1) 1/4" x 1/2" x 5" [6 x 12 x 130mm] Balsa Stick

(fuel tank mounting)

(1) 1" x 1-1/2" [26 x 38mm] Plywood Wing Bolt Plate

(1) Decal Sheet.

KIT CONTENTS

1

2

3

4

5

7

8

9

13

12

9

6

1

10

10

11

14

Page 6

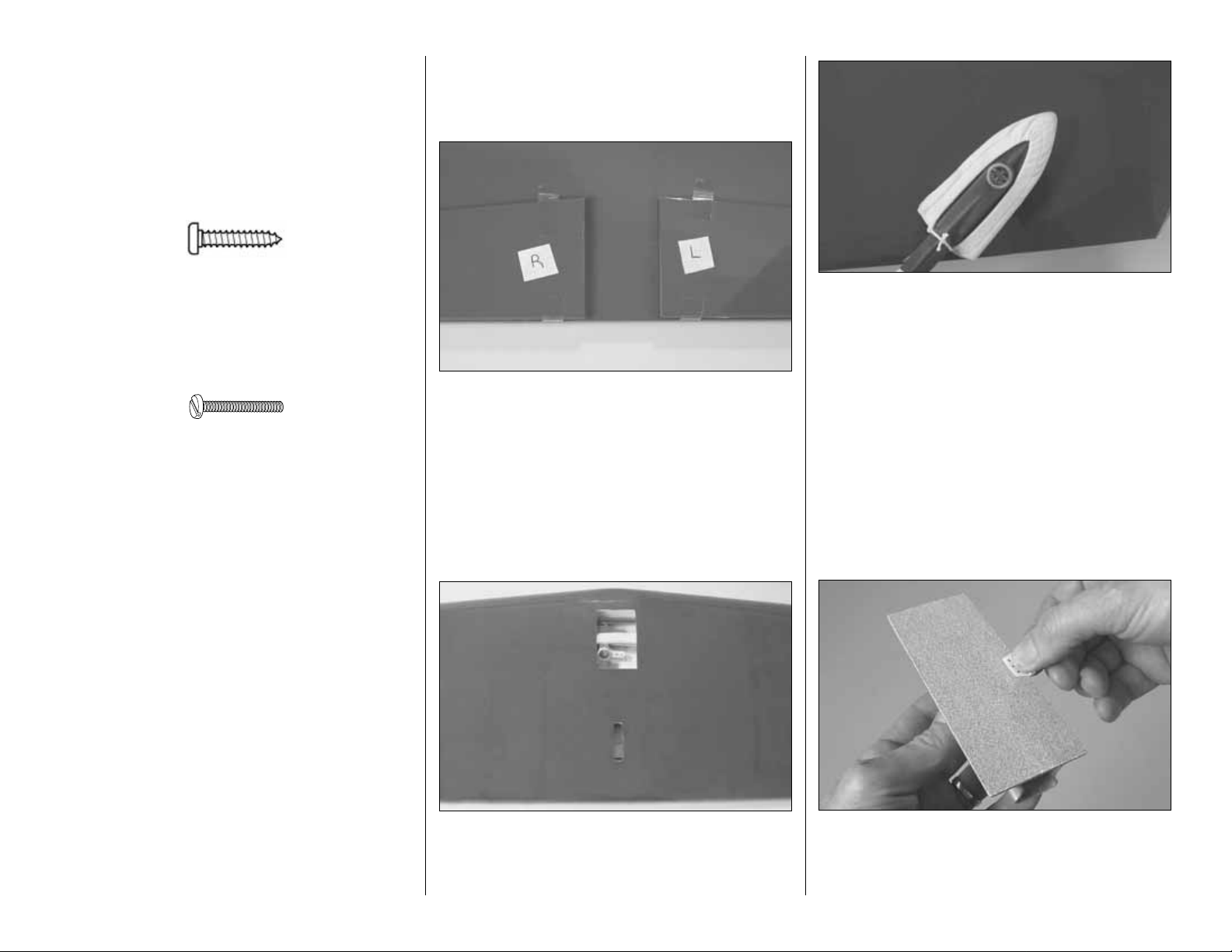

IMPORTANT BUILDING NOTES

•

There are two types of screws used in this kit:

Sheet metal screws are designated by a number

and a length.

For example #6 x 3/4" long [19mm]

This is a number six screw that is 3/4" [19mm] long.

Machine screws are designated by a number,

threads per inch, and a length.

For example 4-40 x 3/4" long [19mm]

This is a number four screw that is 3/4" [19.1mm]

long with forty threads per inch

.

•

When you see the term

test fit

in the instructions,

it means that you should first position the part on

the assembly without using any glue, then

slightly modify or

custom fit

the part as necessar y

for the best fit.

•

Whenever the term

glue

is written you should rely

upon your experience to decide what type of glue

to use. When a specific type of adhesive works

best for that step, the instructions will tell y ou what

glue is recommended.

•

Whenever just

epoxy

is specified, you may use

either

30-minute (or 45-minute) epoxy

or

6-minute

epoxy. When 30-minute epoxy is specified, it is

highly recommended that you use only 30-minut e

(or 45-minute) epoxy because you will need the

working time and/or the additional strength.

•

Photos and sketches are placed before the

step they refer to .Frequently y ou can study photos in

following steps to get another view of the same parts.

ASSEMBLE THE WING

Hinge the Flaps

❏ 1. Mark the flaps as “right” and “left” before

removing them from the wing (the right flap is about

3/4" [20mm] shorter than the left flap).

❏ 2. Separate the flaps from the wing by peeling off

the tape.Any glue left from the tape can be removed

with naphtha lighter fluid or denatured alcohol.

❏3.Cut and remove the covering from the top of the

wing over the bellcrank opening and the pushrod

exit. Also cut the covering from the opening in the

bottom of the wing directly under the bellcrank screw .

❏ 4. Use a covering iron with a covering sock to

remove any wrinkles in the covering on the wing and

flaps. The best way is to glide the iron over the

covering until the wrinkles disappear, and then go

over the area again pushing down to bond the

covering to the wood. If the wrinkles don’t go away,

the balsa in that area may be bending inward. If this

is happening, do not press down on the iron in that

area. Simply let the heat of the iron shrink the

covering.If the wrinkles momentarily disappear, then

immediately reappear, the iron may be too hot, thus

causing air bubbles. Lower the temperature of the

iron or use a sharp #11 blade to puncture several

holes in the covering, then reheat. The suggested

iron temperature is around 360 degrees F.

❏ 5. Using a bar sander or a sanding block with

medium-grit sandpaper, remove any raised molding

imperfections and roughen the gluing surface of all

the hinges so glue will adhere.

- 6 -

Page 7

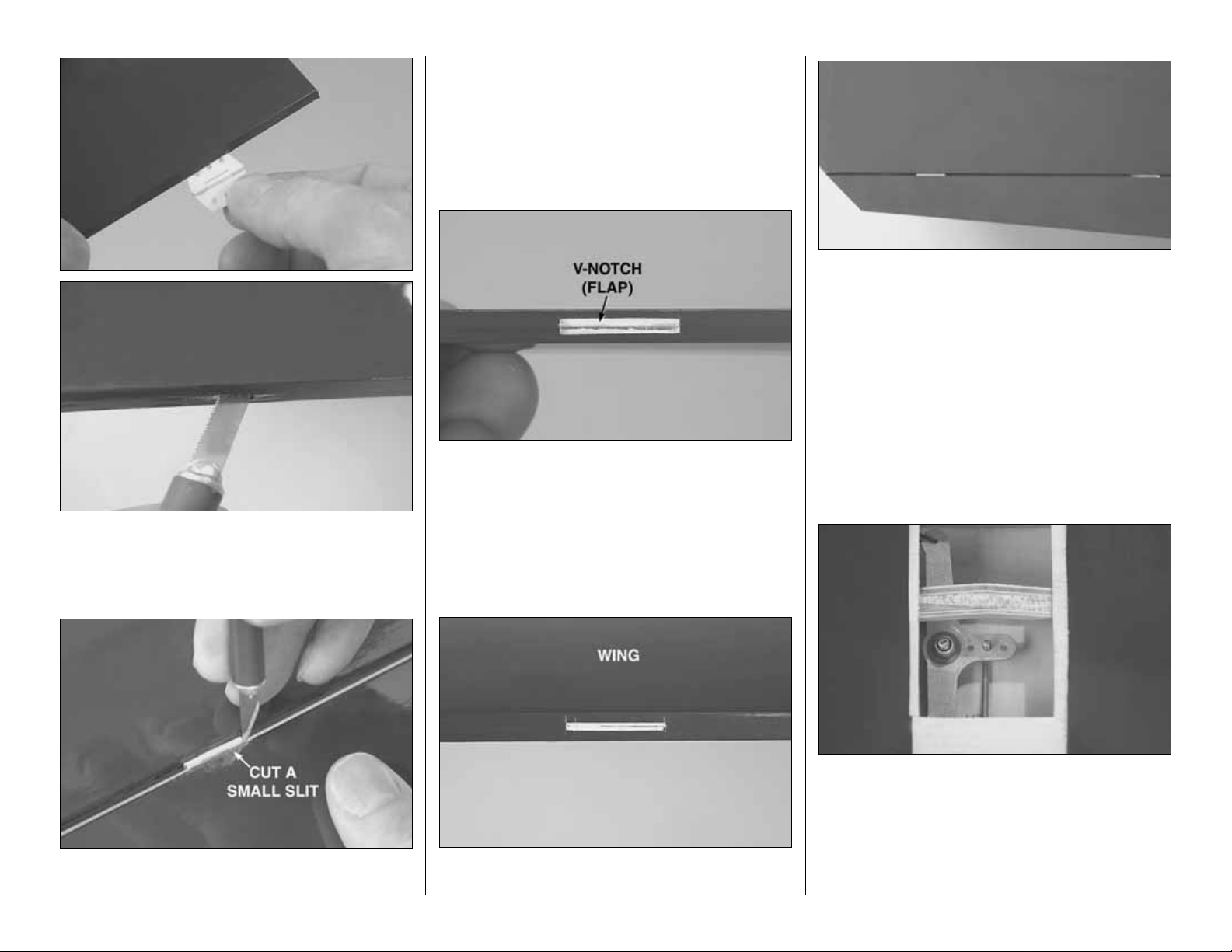

❏ 6. Test fit the hinges in the hinge slots in the wing

and flaps. If necessary, use a hobby knife or a small

razor saw blade to enlarge any hinge slots that are

too tight.

❏ 7. Without using any glue temporarily join both

flaps to the wing with eight hinges. Use a #11 hobby

blade to cut a small slit in the wing and flap on both

sides of all the hinges.These slits will mark the ends

of the hinge slots.

❏8.Remove the flaps from the wing and tak e out the

hinges.Cut a small “V-notch”between the slits cut in

the flaps only to accommodate the pin portion of the

hinges.This will allow the flaps to fit close to the

wing.

❏ 9. Cut a small str ip of covering between the slits

you cut over each hinge slot in the wing.

❏ 10. Without using any glue temporarily rejoin the

flaps to the wing with the hinges. There should be

little or no hinge gap and the flaps should move up

and down freely. Make adjustments where necessary

to close the hinge gaps.

Make the Flap Pushrod

❏1.Bend and cut the flap pushrod as shown in the

full-size drawing on the back cover page from a 4-40

x 17-1/2" [445mm] threaded one-end pushrod.

Thread a 4-40 nut followed by a clevis onto the

pushrod.

❏2.Use a 7mm socket wrench or needle nose pliers

to loosen, but do not remove , the 4mm nut on the top

of the wing that secures the bellcrank.Guide the flap

pushrod through the exit slot in the top of the wing.

Then lift the bellcrank and fit the pushrod up through

the middle hole. Tighten the nut. Make sure the

pushrod and bellcrank operate freely.

- 7 -

Page 8

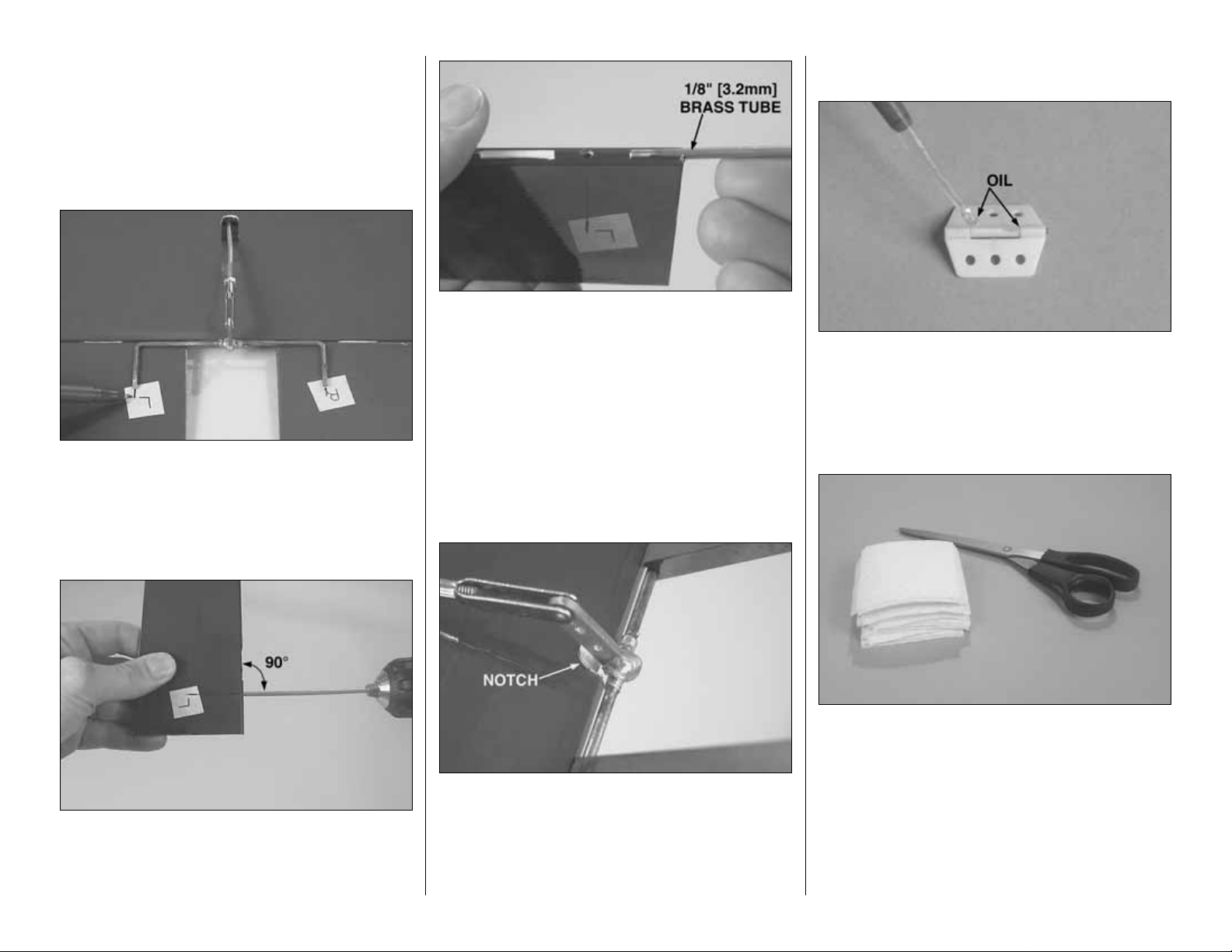

❏ 3. Test fit one of the metal clevises in the holes in

both control hornson both joiner wires. If the clevis

pins don’t go in, enlarge the holes in the joiner wires

with a 1/16" [1.6mm] drill. Clean the joiner

wires with

denatured alcohol, and then thoroughly

roughen them

with coarse sandpaper so epoxy will adhere.

❏ 4. Temporarily connect the clevis on the flap

pushrod to the top hole in the control horn on one of

the joiner wires. Position the joiner wire so the

pushrod is centered in the exit slot in the wing.Then

mark the location of the joiner wire onto the flaps.

❏ 5. Use a 1/8" [3.2mm] brass tube shar pened on

the end or a 1/8" [3.2mm] drill to drill holes into the

flaps in alignment with the marks that note the

location of the joiner wire.

❏ 6. Use a 1/8" [3.2mm] brass tube shar pened on

the end or a hobby knife to cut g rooves in the leading

edge of the flaps to accommodate the wire.

❏ 7. Test fit both flaps to the joiner wire. View the

trailing edges of the flaps from the end of the wing.

See if the flaps are parallel with each other (have the

same “up” and “down”). If necessary, “tweak” the

joiner wire to align the flaps.

❏ 8.Test fit the flaps to the wing with the joiner wire.

Cut a half-round notch in the trailing edge of the wing

to accommodate the solder joint and the control horn

during maximum flap deflection. Make certain

nothing interferes with full, smooth flap movement.

Make adjustments where necessary.

Join the Flaps to the Wing

❏ 1. Remove the flaps, hinges and joiner wire from

the wing. Carefully apply a small dab of petroleum

jelly or small drop of oil to the pivot points on the

hinges to keep epoxy from getting into the hinge joint

and jamming up the hinges.

❏ 2. Lay two or three paper towels on top of each

other.Cut the stack into small squares by cutting the

stack into four, equal-width strips. Cut the strips into

four equal squares. These paper towel squares will

come in handy throughout the building project (and

save you from wasting whole paper towels!).

One flap at a time will be glued to the wing…

- 8 -

Page 9

❏ 3. Mix a small batch of 30-minute epoxy. Use a

thin, metal ruler or something similar to force epoxy

into the hinge slots in one of the flaps and in the

hinge slots in the matching half of the wing. Proceed

immediately to the next step.

❏4.One at a time, lightly coat the top and bottom of

one half of four hinges with epoxy, then insert the

coated end of the hinges into the flap. Working

carefully not to get any epoxy into the hinge pins, use

small scraps of balsa or something similar to wipe off

excess epoxy as it is forced back out of the hinge

slots. Proceed immediately to the next step.

❏5.Use a piece of wire or a toothpick to apply epoxy

in the hole and groove in the flap for the joiner wire.

Coat the matching half of the control horn with epoxy,

and then insert it into the flap. Coat the other side of

hinges protruding from the flap with epoxy, and then

join the flap to the wing with the joiner wire. Wipe

away excess epoxy as it squeezes out.

❏ 6. Without using any glue, temporarily join the

other flap to the wing and the joiner wire. This will

align the joiner wire while the epoxy on the other side

is hardening. Do not disturb the wing until the epoxy

hardens.

❏ 7. After the epoxy on the first flap has hardened,

glue the other flap to the wing the same way. Allow

the epoxy on both flaps to fully harden for at least a

few hours before moving them. After the epoxy has

hardened, “break” the flaps free by rapidly moving

them up and down several times. Use a hobby knife

to pick any bits of epoxy from the hinge pins.

❏8.Adjust the clevis on the flap pushrod so the flaps

will be centered when the bellcrank is neutral. Slip a

silicone clevis retainer over the clevis, then connect

the clevis to the top hole in the control horn. Slip the

retainer over the clevis, and then tighten the 4-40 nut.

Finish the Wing

❏1.Cut the covering from the hole in the front of the

wing and glue in the wing dowel.

❏2. Cut the covering from the top and bottom of the

wing over the holes near the trailing edge for the

wing bolts.

Note: The Nobler includes bolts for mounting the

wing to the fuselage.However , the wing bolts are

intended for alignment and assembly only. Later,

the wing will be permanently glued to the

fuselage. If considering modifying your Nobler to

make the wing removable, keep in mind that

disengaging the elevator pushrod from the flap

control horn in order to remove the wing would

be cumbersome. Further, the Nobler has not

been flight tested with a removable wing.

- 9 -

Page 10

❏ 3. Remove the belly pan from the bottom of the

fuselage. Temporarily bolt the wing to the fuselage

with two 4-40 x 1-1/2" [38mm] screws and #4

washers. Trim the balsa cross brace as necessary

to accommodate the solder joint holding the control

horn to the flap joiner wire.

❏4.Place the belly pan on the bottom of the wing in

alignment with the fuselage. Tape the belly pan into

position. Use a fine-point felt-tip pen to mark the

outline of the belly pan onto the bottom of the wing.

Mark the fuselage sides on the top of the wing.

❏ 5. Remove the belly pan and wing. Use a shar p,

new knife blade or a heated soldering iron to cut the

covering from the wing 1/16" [2mm] inside the lines.

If using a knife, use a light touch and great care not

to cut into the sheeting under the covering or the

wing will be weakened. Using a soldering iron is

preferred because it melts through the covering

without cutting into the wood.Move the soldering iron

fast enough to melt through the covering without

burning the wood. After cutting the covering use

denatured alcohol and a tissue to clean the ink lines

from the covering.Then, peel off the covering.

❏ 6. Center the 1" x 1-1/2" [26 x 38mm] plywood

wing bolt plate over the holes on the bottom of the

wing. Glue the plate into position. Using the holes in

the top of the wing as a guide, drill 9/64" [3.6mm] (or

1/8" [3.2mm]) holes through the plate. Bolt the wing

onto the fuselage.

ASSEMBLE THE FUSELAGE

Prepare the Stab

❏ 1. Examine the stab and elevators and determine

which side looks best.Use a felt-tip pen to write “top”

on the side that looks best.

❏2. Separate the elevators from the stab by peeling

off the tape. Use a pin to poke three or four holes

along one side of all the “ribs” in the bottom of the

stab and elevators. These holes will allow expanded

air to escape while tightening the covering.

❏ 3. Use a covering iron to tighten the covering on

the stab and elevators.

❏4.The same as was done with the wing and flaps,

prepare the elevators and stab for the hinges by

enlarging the slots if necessary , test fitting the hinges

and cutting “V” notches in the elevators to

accommodate the hinge pins. Also prepare the

elevators for the joiner wire. Trim the trailing edge of

the stab as necessary to accommodate the solder

joint on the joiner wire. “Tweak” the joiner wire as

necessary to align the elevators with each other.

Refer to this photo for the following

two steps.

- 10 -

Page 11

❏ 5. Cut the covering from the fuselage over the

slots for the stab and fin.

❏ 6. Slide the stab into position. For now, center the

stab in the fuselage as best as you can by “eye.”

Stand approximately ten feet behind the model and

view the alignment of the stab and wing.If the stab is

not parallel with the wing, place a small weight on the

“high side” of the stab to bring it into alignment. If

weight is not enough, remove the stab from the

fuselage

and lightly trim or sand the stab saddle as necessary

until you can get the stab to align with the wing.

❏ 7. Now that the stab is level with the wing, center

the trailing edge of the stab in the fuselage by

measuring from both tips to the fuselage. Make sure

“X” = “X”on both sides of the stab as indicated in the

photo. Stick pins into the stab near the trailing edge

on both sides of the fuselage. This will keep the

trailing edge of the stab centered.

❏ 8. Insert a pin through the top, center of the

fuselage over the firewall. Tie a loop in one end of a

36" [1m] piece of non-elastic string such as

monofilament

or Ke vlar

line (K+SR4575).Slip the loop in the string over

the

T-pin.

❏ 9. Fold a piece of masking tape over the string

near the other end and draw an arrow on it.Slide the

tape along the string and align the arrow with one

end of the stab as shown in the photo. Swing the

string over to the other end of the stab and hold it in

the same position. Keeping the trailing edge of the

stab centered from side-to-side, move the stab tips

forward or back as necessary until the arrow aligns

with both ends of the stab.

❏10.The same as w as done for the wing, use a fine-

point felt-tip pen to mark the outline of the fuselage

all the way around both sides of the stab. Then, cut

and remove the covering from the center-section.

❏ 11. Cut the covering from the wing saddle 1/16"

[1mm] from the fuselage sides.

- 11 -

Page 12

Make the Elevator Pushrod

❏ 1. Make the elevator pushrod by cutting a 4-40 x

17-1/2" [445mm] threaded one-end pushrod to a

length of 13" [330mm]. Read the following

Hot Tip

about soldering. Then, solder a clevis onto the

un-threaded end of the pushrod (this will be the aft

end of the pushrod).

❏ 2. Thread a 4-40 nut and a clevis onto the

threaded end of the pushrod (this will be the front of

the pushrod and is the end that connects to the

control horn on the flap joiner wire). Slip a silicone

clevis retainer over both clevises on the pushrod.

❏ 3. Fit the elevator control horn into the slot in the

fuselage for the stabilizer. Then, guide the pushrod

down through the fuselage.Connect the clevis on the

pushrod to the middle hole in the flap control horn.

❏ 4. Bolt the wing to the fuselage. Working through

the cockpit, use hemostats or needle-nose pliers to

connect the clevis on the elevator pushrod to the

middle hole in the flap control horn.

❏5.Slide the stabilizer into the fuselage.Temporarily

join the elevators to the stab and joiner wire with the

hinges. Make certain the stab is pushed all the way

forward. The elevators must be centered when the

flaps are centered. If necessary, adjust the clevis on

the front of the elevator pushrod to center the

elevators with the flaps. This can be done by

disconnecting the clevis on the front of the pushrod,

removing the stab, and then feeding the pushrod

forward to access the clevis. Screw the clevis in or

out as necessary to lengthen or shorten the pushrod.

❏ 6. While the stab is in position and the pushrod is

connected, operate the flaps and elevators by pulling

on the leadouts.Make any adjustments necessary to

achieve smooth control movement. (When the

elevators move up, the flaps should move down.)

It’s best to install the fuel tank bef ore

permanently

mounting the wing, so let’s do that first.

Mount the Fuel Tank

❏ 1. Use epoxy thinned with denatured alcohol,

epoxy or fuelproof paint to fuelproof the fuel tank

compartment and the main landing gear rail.

This is what a properly soldered clevis looks like;

shiny solder with good flow, no blobs, flux

removed.

4. Immediately after the solder has solidified, but

while it is still hot, carefully use a cloth to quickly

wipe off the flux before it hardens. Important:

After the joint cools, coat with oil to prevent rust.

Note: Do not use the acid flux that comes with

silver solder for electrical soldering.

HOW T O SOLDER

1. Use denatured alcohol or other solvent to

thoroughly clean the pushrod. Use coarse

sandpaper to roughen the end of the pushrod

where it is to be soldered.

2. Apply a few drops of soldering flux to the end

of the pushrod, and then use a soldering iron or

a torch to heat it.“Tin” the heated area with silver

solder (GPMR8070) by applying the solder to

the end.The heat of the pushrod should melt the

solder–not the flame of the torch or soldering

iron–thus allowing the solder to flow. The end of

the wire should be coated with solder all the way

around.

3.Place the clevis on the end of the pushrod.Add

another drop of flux. Then, simultaneously heat

the clevis and pushrod.Slide the clevis the rest of

the way onto the pushrod as the solder melts.

Apply another small amount of solder while the

pushrod and clevis are still hot. The same as

before, the heat of the parts being soldered

should melt the solder, thus allowing it to flow.

Allow the joint to cool naturally without disturbing.

Avoid excess blobs, but make certain the joint is

thoroughly soldered.The solder should be shiny,

not rough.If necessary, reheat the joint and allow

to cool.

- 12 -

Page 13

❏2.Add a bead of RTV silicone to the bottom of the

engine mount rails where the fuel tank will contact

them, and then install the tank. Be certain the

narrower “wedge” portion of the tank faces the

outside of the circle (the right wing tip).

❏ 3. Cut two fuel tank rails from the 1/4" x 1/2" x 5"

[6 x 12 x 130mm] balsa stick to fit between the

fuselage sides below the tank. Apply a bead of RTV

silicone to the bottom of the rails. Glue them into the

fuselage securely, holding the tank in place.

…Now back to the wing.

Join the Wing & Stab to the Fuselage

❏ 1. Disconnect the elevator pushrod from the flap

and remove the wing and stab from the fuselage.

Now that the final length of the elevator pushrod has

been determined, tighten the 4-40 nut to the clevis

on the front of the pushrod.

❏ 2. Paint the cockpit and add any other details at

this time. The cockpit in the prototype was simply

painted black.

❏3.Mix up a batch of 30-minute epoxy. Apply epoxy

to the wing saddle on both sides of the fuselage and

to the wing where it contacts the fuselage. Install the

wing and bolt it into position. Use small balsa sticks

and/or your paper towel squares to wipe up excess

epoxy. Be cer tain none of the epoxy enters the flap

linkage. Allow the epoxy to fully harden before

proceeding.

❏ 4. Reconnect the elevator pushrod to the flap

control

horn (middle hole). Apply 30-minute epoxy to the

stab and fuselage where they join. Then, slide the

stabilizer into position.Use your paper towel squares

dampened with denatured alcohol to clean off any

excess epoxy.Then, confirm the stab alignment using

the

pin-and-string and by viewing the model from the

rear.

❏ 5. The same as was done with the flaps, apply a

few drops of oil or a dab of petroleum jelly to the

hinge pins on the elevator hinges. Use 30-minute

epoxy to permanently join one of the elevators to the

stab and the joiner wire with the hinges.Temporarily

join the other elevator to the other side of the stab.

Use a couple of rubber bands to close the hinge gap

by holding the elevator to the stab and clamp the

elevators together to k eep them aligned with each

other.

❏ 6. After the epoxy from the previous step has

hardened permanently, join the other elevator.

Join the Fin & Tail Wheel

❏

1. Mount the tail wheel to the prebent tail gear

wire with a small wheel collar and a 6-32 set screw.

Use Threadloc k er on the set scre w bef ore installing it

into the collar.

❏ 2. Cut the covering on the end of the fuselage

down the center.Peel bac k the cov ering, but don’t cut

any off.

❏ 3. Dr ill a 1/16" [1.6mm] hole and cut a groove in

the end of the fuselage for the tail gear wire.

❏ 4. Clean the tail gear wire with denatured alcohol

or other solvent. Roughen the wire so glue will

adhere. Glue the wire in the end of the fuselage with

30-minute epoxy.

Refer to this photo for the following

four steps.

Refer to this photo for the following

two steps.

- 13 -

Page 14

❏ 5. Using the same technique you used when

marking, cutting and removing the covering from the

wing and stabilizer, cut and remove the covering

from the fin where it will be glued to the fuselage.

❏ 6. Test fit the fin to be certain it fits well. Make

adjustments where necessary.

❏ 7. Glue the fin into position with 30-minute epoxy.

Use a builder’s triangle to make certain the fin is

perpendicular to the stabilizer.If necessary, masking

tape could be used to pull the fin to one side or the

other of the stab.Wipe away excess epoxy before it

hardens.

Mount the Main Landing Gear

❏

1. Use a small metal file to grind a flat spot near

the end of both prebent main landing gear wires.

❏2.Mount the wheels to the landing gear with a 1/8"

[3mm] wheel collar fastened by a 6-32 set screw on

both sides. Add a drop of oil to both sides of the

wheels so they spin freely.

❏3.Install the main landing gear wires in the landing

gear rail.Using the screw holes in the nylon straps as

a guide, drill 1/16" [1.6mm] holes through the landing

gear rail. Then, mount the gear with the straps and

four #2 x 1/2" [13mm] screws.

❏4.Use epoxy to glue the belly pan to the bottom of

the wing and fuselage.

Mount the Engine

❏1.Position the engine on the mounting rails so the

front of the drive washer (or the backplate of your

spinner) will be 3-5/8" to 3-3/4" [92 to 95mm] from

the firewall.With some engines (such as the O.S..40

LA) it may be necessary to slightly trim the lower,

inner edges of the mounting rails to accommodate

the engine. Note: The remote needle valve was

temporarily removed from the engine to facilitate

mounting and cowl installation.

❏2.Use a Great Planes Dead Center

™

Hole Locator

or a wire sharpened on the end to mark the engine

mounting rails for the mounting screws.

- 14 -

Page 15

❏ 3. Remove the engine. Drill 1/8" [3.2mm] holes at

the marks. Mount the engine to the mount with four

4-40 x 1" [25mm] SHCS (socket head cap screws),

#4 flat washers and lock washers and 4-40 b lind

nuts.

Mount the Cowl

❏

1.Use a high-speed rotary tool with a cutting bit to

cut slots in the aft end of the cowl to accommodate

the landing gear wires. Also cut an air inlet and air

exit hole. The exit hole may be combined with the

glow plug access hole.

❏ 2. Place the cowl on the fuselage and mount the

spinner and propeller.Align the cowl with the spinner.

There should be approximately 3/32" [2mm] between

the spinner and the cowl.

❏3.Holding the cowl in position, drill a 1/16"

[1.6mm]

hole through the cowl and fuselage for one of the

cowl mounting screws. The hole should be about

5/16" [8mm] from the aft edge of the cowl, placing it

about 1/4" behind the front edge of the fuselage side.

Screw in a #2 x 1/4" [6mm] screw just enough to hold

the cowl, but do not tighten the screw.

❏4.One at a time while holding the cowl in position,

drill a 1/16" [1.6mm] hole and insert a screw at the

remaining three marks. Also drill a hole through both

sides of the cowl and fuselage approximately 3/4"

[20mm] forward of the landing gear.

❏5.Remove the cowl.Enlarge the holes in the cowl

only with a 3/32" [2.4mm] drill. Test fit the cowl and

mount it to the fuselage with six #2 x 1/4" [6mm]

screws.

❏ 6. Remove the cowl screws and cowl. Add a

couple of drops of thin CA to the screw holes–don’t

add too much CA, or you will seal the holes.

❏7. Cut the holes in the cowl for the muffler screws.

This can be done by using a pencil to mark the

heads of the screws on the inside of the cowl, and

then removing the cowl and cutting the holes.

- 15 -

Page 16

❏ 8. Cut the hole for the muffler.Start by making the

hole small, and then enlarge it until the muffler can

be mounted.

❏ 9. Mount the needle valve and cut an access hole

for it in the cowl.Note: On the model featured in this

manual, the needle valve was mounted inverted. If

mounting the needle sideways (as the engine is

provided from the factory), a slot must be cut in the

cowl to accommodate the needle valve body.

❏ 10. Connect the fuel lines. The fuel tank included

with this kit uses a three-line system.As shown in the

sketch to the left, one line is the fuel pickup which

goes to the carburetor (or to the remote needle as in

the case of the O.S.LA engines).The other line goes

to the muffler for pressure (when the tank is full, fuel

will overflow through this line indicating that the tank

is full). The third line is used for filling the tank.This

line should be accessible from outside the fuselage

and is to be closed after fueling. A Great Planes

aluminum fuel line plug (GPMQ4166) was used to

close the fueling line. After the tank has been filled,

the fueling line can be tucked back inside the cowl.

- 16 -

Page 17

FINAL DETAILS

Mount the Canopy

❏ 1. Be certain that the flaps are centered when the

elevators are centered. Also be cer tain that all the

pushrods are connected and that the flaps and

elevator are operating smoothly. Make any

adjustments necessary.

❏ 2. Use scissors to cut out the canopy on the

molded-in cutlines. Start by cutting approximately

1/8" [3mm] from the lines. Then, do a final cut right

on the lines.

❏ 3. Mount the canopy to the fuselage with 1/4"

[6mm] white striping tape. Use 1/16" [2mm] white

striping tape to add the panel lines.

❏ 4. While you’ve got the 1/16" [2mm] striping tape

out, add the flap, elevator and rudder trim tab lines

as well.

Apply the Decals

1. Use scissors or a sharp hobby knife to cut the

decals from the decal sheet. Where possible, round

the corners so they are less likely to peel up during

cleaning and handling.

2. Be certain the model is clean. Prepare a dishpan

or small bucket with a mixture of liquid dish soap and

warm water–about 1/2 teaspoon of soap per gallon

of water.Submerse one of the decals in the solution

and peel off the paper backing. Note: Even though

the decals have a “sticky-back” and are not the water

transfer type, submersing them in soap & water

allows accurate positioning and reduces air bubbles

underneath.

3. Position the decal on the model where desired.

Holding the decal down, use a paper towel to wipe

away most of the water.

4. Use a piece of soft balsa or something similar to

squeegee remaining water from under the decal.

Apply the rest of the decals the same way.

GET THE MODEL READY TO FLY

Balance the Model (C.G.)

At this stage the model should be completely readyto-fly with all of the components installed including

the engine, muffler, propeller, spinner, landing gear

and wheels.

❏1.If using a Great Planes C.G.Machine to balance

the model, set the rulers to 2-1/2" [65mm]. If not

using a C.G. Machine, use a fine-point felt-tip pen or

More than any other factor, the C.G. (balance

point) can have the greatest effect on how a

model flies, and may determine whether or not

your first flight will be successful.If you value this

model and wish to enjoy it for many flights, DO

NOT OVERLOOK THISIMPORTANTPROCEDURE.

A model that is not properly balanced will be

unstable and possibly unflyable.

Do not permanently mount the canopy. If

adjustments are ever required to the pushrods,

the canopy may be removed to do so.

- 17 -

Page 18

1/8" wide tape to accurately mark the recommended

C.G. (center of gravity, or “balance point”) on the

bottom of the wing 2-1/2" [65mm] back from the

leading edge on both sides of the belly pan.

❏ 2. Place the model on a Great Planes CG

Machine, or lift it at the balance point you marked on

both sides of the fuselage. Note whether the nose or

tail drops. If the tail drops, the model is “tail heavy”

and weight must be added to the nose to balance.If,

however, the nose drops (as will likely be the case),

weight must be added to the tail to balance.

❏ 3. Add nose or tail weight to balance the model. If

nose weight is required it may be added by using a

“spinner weight” (GPMQ4645 for the 1 oz. [30g]

weight, or GPMQ4646 for the 2 oz. [55g] weight) or

Great Planes (GPMQ4485) “stick-on” lead which

may be added to the firewall (don’t attach weight to

the cowl–it is not intended to support weight). If tail

weight is required it may be placed on the right side

of the fuselage (opposite the muffler) under the

stabilizer. After the final amount of tail weight has

been determined (from several test flights) the

covering

may be cut from the lightening hole in the back of the

fuselage and the lead permanently glued inside.

Note: Do not rely upon the adhesive on the back of

the lead weight to permanently hold it in place. Over

time, fuel and exhaust residue may soften the

adhesive and cause the weight to fall off. Use #2

sheet metal screws, RTV silicone or epoxy to

permanently hold the weight in place.

❏ 4. IMPORTANT: If you found it necessary to add

any weight, recheck the C.G. after the weight has

been installed.

Wing Tip Weight

To begin, add 1 oz. [30g] of lead weight to the right

wing tip. This can be temporarily attached to the

bottom of the wing with the self-adhesive foam tape

attached to the weight. After the final amount of

weight required has been determined (after test

flying), it can be permanently attached inside the

wing tip with epoxy.

PREFLIGHT

Balance the Propellers

Carefully balance your propeller and spare

propellers before you fly. An unbalanced prop can be

the single most significant cause of vibration that can

damage your model. Not only will engine mounting

screws and bolts loosen, possibly with disastrous

effect, but vibration can also cause your fuel to foam,

which will, in turn, cause your engine to run hot or

quit.

We use a Top Flite Precision Magnetic Prop

Balancer™(TOPQ5700) in the workshop and keep a

Great Planes Fingertip Prop Balancer (GPMQ5000)

in our flight box.

Engine Check

If the engine is new,follow the engine manufacturer’ s

instructions to break-in the engine. After break-in,

confirm that the engine runs reliably and smoothly

and maintains full power–indefinitely. After you run

the engine on the model, inspect the model closely

to make sure all screws remained tight, the hinges

are secure and the prop is secure.

This is where the Nobler should balance for the

first flights–especially for sport flying and

beginning aerobatics. After the first few flights,

experienced modelers may wish to experiment

by shifting the C.G.

forward up to

1/4" [5mm]

or by

shifting the C.G. back, up to

1/4" [5mm] to

change

the flying

characteristics. If the C.G.is moved too

far forward (nose-heavy) response is slow and

the model becomes too difficult to flare for

landing. If the C.G. is moved too far aft (tailheavy) the model becomes too unstable and

over-responsive to control inputs. In any case,

start at the recommended balance point.

- 18 -

Page 19

Control Check

With the lines connected to the leadouts and your

assistant holding the model, operate the controls to

make sure they move smoothly. If any binding or

hesitation is detected, inspect the model and

eliminate the problem.

ENGINE SAFETY PRECAUTIONS

Keep all engine fuel in a safe place, away from high

heat, sparks or flames, as fuel is very flammable.Do

not smoke near the engine or fuel; and remember

that engine exhaust gives off a great deal of deadly

carbon monoxide.Therefore, do not run the engine

in a closed room or garage.

Get help from an experienced pilot when learning to

operate engines.

Use safety glasses when starting or running engines.

Do not run the engine in an area of loose gravel or

sand; the propeller may throw such material in your

face or eyes.

Keep your face and body as well as all spectators

away from the plane of rotation of the propeller as

you start and run the engine.

Keep these items aw a y from the prop:loose clothing,

shirt sleeves, ties, scarfs, long hair or loose objects

such as pencils or screwdrivers that may fall out of

shirt or jacket pockets into the prop.

Use a “chicken stick” or electric starter to star t the

engine. Do not use your fingers to flip the propeller.

Make certain the glow plug clip or connector is

secure so that it will not pop off or otherwise get into

the running propeller.

Make all engine adjustments from behind the rotating

propeller.

The engine gets hot! Do not touch it during or right

after operation. Make sure fuel lines are in good

condition so fuel will not leak onto a hot engine,

causing a fire.

To stop a glow engine, cut off the fuel supply by

closing off the fuel line or following the engine

manufacturer’ s recommendations .Do not use hands,

fingers or any other body part to try to stop the

engine.To stop a gasoline powered engine an on/off

switch should be connected to the engine coil.Do not

throw anything into the propeller of a running engine.

AMA SAFETY CODE (excerpt)

Read and abide by the following Academy of Model

Aeronautics Official Safety Code:

GENERAL

1.I will not fly my model aircraft in sanctioned events,

air shows, or model flying demonstrations until it has

been proven to be airworthy by having been

previously successfully flight tested.

3. Where established, I will abide by the safety rules

for the flying site I use, and I will not willfully and

deliberately fly my models in a careless, reckless

and/or dangerous manner.

5.I will not fly m y model unless it is identified with m y

name and address or AMA number, on or in the

model.

7. I will not operate models with pyrotechnics (any

device that explodes , b urns, or propels a projectile of

any kind).

8.I will not consume alcoholic beverages prior to, nor

during, participation in any model operations.

9.Children under 6 y ears old are only allowed on the

flight line as a pilot or while under flight instruction.

CONTROL LINE

1. I will subject my complete control system

(including safety thong, where applicable) to an

inspection and pull test prior to flying. Pull test will be

in accordance with the current Competition

Regulations for applicable model category. Models

not fitting a specific category as detailed shall use

those pull test requirements for Control Line

Precision Aerobatics.

2.I will assure that m y flying area is safely clear of all

utility wires or poles.

3.I will assure that m y flying area is safely clear of all

non-essential participants and spectators before

permitting my engine to be started.

4. I will not fly a model closer than 50 feet [15m] to

any electrical power line.

CHECK LIST

❏ 1. Make sure areas exposed to fuel or exhaust

residue have been fuelproofed (such as the

fuel tank compartment, the landing gear rail,

the back of the firewall and the front of the

wing belly pan).

❏ 2. Check the C .G.according to the

measurements

and procedure provided in the manual.

❏ 3.

Use thread-locking compound on the set

screws

in the wheel collars that hold on the wheels.

During the last few moments of preparation your

mind may be elsewhere anticipating the

excitement of the first flight.Because of this, you

may be more likely to overlook certain checks

and procedures that should be performed before

the model is flown.To help avoid this, a check list

is provided to make sure these important areas

are not overlooked. Many are covered in the

instruction manual, so where appropriate, refer

to the manual for complete instructions. Be sure

to check the items off as they are completed

(that’s why it’s called a

check list!

).

Failure to follow these safety precautions

may result in severe injury to yourself and

others.

- 19 -

Page 20

❏ 4. Add a drop of oil to the axles so the wheels will

turn freely.

❏ 5. Make sure all hinges are securely glued

in place.

❏ 6. Use thin CA to harden the holes in the

fuselage for the cowl mounting screws.

❏ 7. Confirm that the flaps and elevators operate

freely and smoothly by pulling on the leadouts.

❏ 8. Make sure the fuel lines are connected and

are not kinked.

❏ 9. Balance your propeller and spare propellers.

❏ 10. Tighten the propeller nut and spinner.

❏ 11. Place your name, address, AMA number and

telephone number on or inside your model.

❏ 12. If you wish to photograph your model, do so

before the first flight.

FLYING

Flying Precautions

Preflight

Note: The Top Flite Nobler ARF is not a beginner’s

model. It is intended for beginning to advanced stunt

pilots who have had some previous control line

experience. If you are an inexperienced pilot seek

the assistance of a knowledgeable control line pilot

who can help you with your first flights.

Beginning stunt pilots should make their first flights in

calm or low wind conditions. Stronger winds may

blow the model inward which will decrease line

tension resulting in loss of control.If the lines ever do

go slack, quickly step back to tighten the lines and

regain control. Of course, this is most likely to

happen, and should be expected, as the model

approaches the upwind half of the circle.

Place the model and starting equipment where the

wind will be behind the model when it is released for

takeoff.

For the first half-circle (during the brief period when

the pilot has the least control before the model is “up

to speed”) the wind will push the model outward to

maintain line tension.

Mark the center of the flying circle with paint, chalk or

a suitable object (such as a shop towel) so you won’t

wander.This is especially important if the flying area

is limited.

With your assistant holding the model, walk from the

model toward the handle in the center of the circle

while using your fingers to keep the lines separated.

This will ensure that the lines are not twisted and are

free to operate the controls.

Study these flying safety precautions before

flying the Nobler ARF.

1. Always inspect your equipment before each

flight. Make certain the lines, leadouts and

handle are in good condition. Make sure

there are no kinks in the lines.

2. Fly only in unobstructed areas free from

trees, shrubs and bushes, poles, stakes,

parking barriers and fences.

3. Be aware of any spectators that may wander

into the flying circle.If this is a possibility,

have

your assistant ready to perform crowd

control.

4. The model must NEVER be flown in the

vicinity of high-tension lines or any other

electrical lines.

5. Never fly when thunder storms or lightning

are present.

6. Take any precautions necessary to insure the

safety of spectators, the model and property.

7. Never touch the engine during or soon after

operation.

8. Keep clear of the rotating propeller and do

not let assistants or spectators get in the arc

of the propeller.

- 20 -

Page 21

While the pilot is holding the lines, the assistant

should walk the model once around the circle to be

certain the flight path is clear and to double-check

that

there are no obstructions that could snag the lines.

The pilot should double-check the operation of the

controls by pulling and pushing on the handle and

having the assistant signal what the controls are

doing (“up” and “down”).

Takeoff

Note: A fully cowled engine may run at a higher

temperature than an un-cowled engine. Therefore,

the fuel mixture should be richened so the engine

runs at least 200 RPM below peak speed.By running

the engine slightly rich, you will help prevent deadstick landings caused by overheating. Traditionally,

control line pilots intentionally set their engines rich

so that during vertical maneuvers, the engine will not

“over lean,” thus causing overheating. Further, full

RPM is usually not desired for stunt flying.

When both the pilot and assistant are ready, the

model may be fueled and started.Once the engine is

running and the model is ready to be released, the

assistant should point the nose of the model slightly

away from the circle .This will help keep the lines taut

for the first few feet until the model gets going.

Upon the pilot’s signal, the assistant may release the

model–never push the model forward as doing so

may result in a crash.

The pilot should be ready–especially during

takeoff–to

briefly step back to maintain line tension until the

model has gained enough air speed to achieve line

tension on its own. Allow the model to roll out and

gain enough speed to become airborne. When

enough speed has been gained the pilot may raise

his arm slightly giving “up” elevator command, thus

allowing the model to leave the ground.

Once the model has lifted, maintain a slow and

steady climb until a comfortable altitude has been

reached (usually between “ey e-lev el”and

approximately

ten feet in the air). The lines must remain taut

throughout the entire flight. If the lines ever do go

slack the pilot will not have control of the model.

During most situations the model’s factory built-in

features will allow it to maintain good line tension, but

on occasions when the wind blows the model inward

or the model becomes too slow the modeler must

anticipate or notice a decrease in “pull” and quickly

step backward to tighten the lines and regain control.

To climb, the pilot will slowly raise his arm. To

descend, the pilot will slowly lower his arm. To

maintain level flight the pilot will hold his arm

horizontally. Beginning pilots should control the

model by keeping their arm straight and bending at

the elbow with little or no wrist movement. Later,

- 21 -

Page 22

when they become more experienced, wrist

movement may be increased to increase control

response. All control inputs should be smooth.

Continue flying the model in a level attitude, getting

used to how the controls react and how the model

“feels.” Do this until the engine r uns out of fuel. With

a full tank of fuel the Nobler will fly for a little ov er f our

minutes, but actual flight time depends on several

factors, such as the engine size and brand, needle

valve setting, propeller size, fuel, atmospheric

conditions, etc.

Landing

When the engine starts to sputter and/or speed up,

this is an indication that the tank is nearly empty.

Continue to fly the model in a level attitude until the

engine finally quits.The same as any time the model

slows, the pilot should step back to keep the lines

taut and maintain control. Allow the model to

descend until it is about two feet off the ground.

When the model has lost nearly all flying speed and

is a foot or two from the ground the pilot should raise

his arm to keep the lines taut and apply full up

elevator, allowing the model to gently touch down.

After the model has come to a stop the assistant may

retrieve the model and return it to the starting area.

In doing so the lines should be kept taut so they do

not become twisted or entangled.

Clean the model using paper towels and household

cleaner to wipe off exhaust residue. Inspect the

model thoroughly, looking for loose fasteners and

signs of damage or fatigue.Also make sure the prop

has not been damaged. Perform any maintenance

necessary to prepare the model for the next flight.

At the end of the flying session any residual fuel

should be drained from the tank.

After you have become familiar with the way your

Nobler flies and you are ready to begin performing

stunts, seek the assistance of an experienced stunt

pilot before attempting to learn new maneuvers on

your own. Almost any control line stunt maneuvers

are started with the model downwind from the pilot,

i.e.wind on the pilots back. Consult the AMA Control

Line section for stunt maneuvers.

One final note about flying your model. Have a goal

or flight plan in mind for every flight. This can be

learning a new maneuver(s), improving a

maneuver(s) you already know, or lear ning how the

model behaves in certain conditions (such as when

testing different propellers or fuel). This is not

necessarily to improve your skills

(though it is never

a bad idea!)

, but more importantly so you do not

surprise yourself by impulsively attempting a

maneuver and suddenly finding that you’v e run out of

time, altitude or airspeed.Every maneuver should be

deliberate, not impulsive.For example , if y ou’ re going

to do a loop, check your altitude and mind the wind

direction.A flight plan greatly reduces the chances of

crashing your model just because of poor planning

and impulsive moves. Remember to think!

Have a ball, keep the lines taut and always fly in

a safe manner.

GOOD LUCK, GREAT FLYING, AND HAVE FUN!

O.S. Engines

®

.40 LA-S Control Line Engine with Muffler

(OSMG1440)

The O.S. 40 LA-S offers the proven power of LA

Series R/C sport engines – but is engineered for the

special requirements of control line flying, replacing

the carburetor with a venturi that keeps the engine

running at a constant speed. A remotely mounted

needle valve k eeps your hands saf ely distanced from

the spinning prop during adjustments. An O-ring

helps seal the needle against fuel and air leaks,

while heavy-duty webbing reinforces the blue-finish,

one-piece crankcase in high-stress areas. Includes

E-3030 muffler, muffler mounting screws, #A3 glow

plug, and 2-year warranty. Fuel with 10-20% nitro

and 18% oil content recommended.

- 22 -

Page 23

- 23 -

AMA STUNT MANEUVERS

Here are some of the AMA Stunt Maneuvers. Refer

to the AMA Rule Book for full descriptions.

Takeoff

Reverse Wingovers

Consecutive Inside Loops

Inverted Flight

Consecutive Outside Loops

Consecutive Inside Square Loops

Consecutive Outside Square Loops

Consecutive Inside Triangular Loops

Horizontal Eights

Page 24

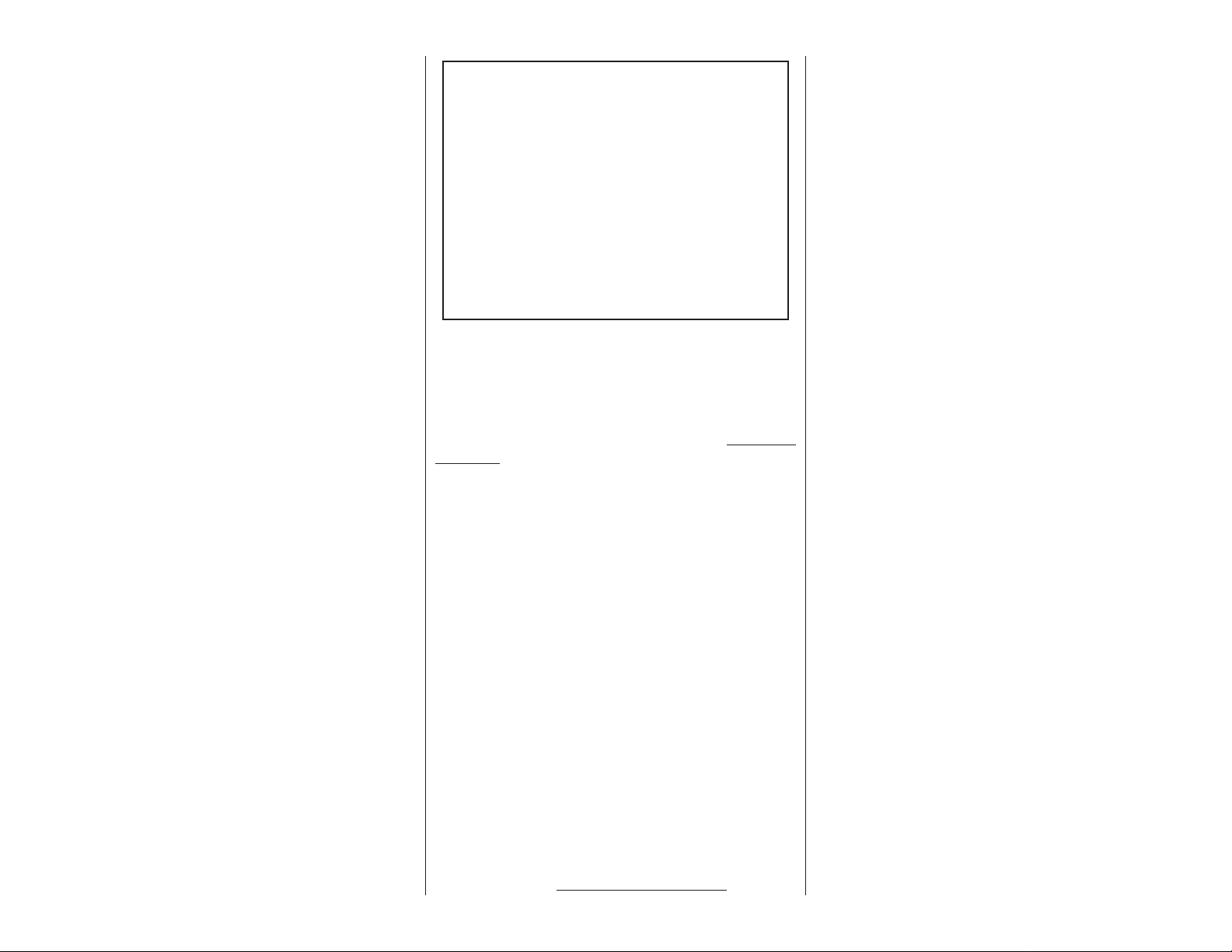

FLAP PUSHROD

TEMPLATE

FLIGHT LOG

DATE COMMENTS

Started Constr uction

Finished Construction

First Flight

First Loop

First Inverted Flight

First Wingover

Loading...

Loading...