Texas Instruments TMS320F28069, TMS320F28068, TMS320F28065, TMS320F28064, TMS320F28067 User Manual

...Page 1

Product

Folder

Sample &

Buy

Technical

Documents

Tools &

Software

Support &

Community

TMS320F28069,TMS320F28068,TMS320F28067,TMS320F28066

TMS320F28065, TMS320F28064, TMS320F28063, TMS320F28062

TMS320F2806x Piccolo™ Microcontrollers

1 Device Overview

1.1 Features

1

• High-Efficiency 32-Bit CPU (TMS320C28x)

– 90 MHz (11.11-ns Cycle Time)

– 16 × 16 and 32 × 32 Multiply and Accumulate

(MAC) Operations

– 16 × 16 Dual MAC

– Harvard Bus Architecture

– Atomic Operations

– Fast Interrupt Response and Processing

– Unified Memory Programming Model

– Code-Efficient (in C/C++ and Assembly)

• Floating-Point Unit (FPU)

– Native Single-Precision Floating-Point

Operations

• Programmable Control Law Accelerator (CLA)

– 32-Bit Floating-Point Math Accelerator

– Executes Code Independently of the Main CPU

• Viterbi, Complex Math, CRC Unit (VCU)

– Extends C28x Instruction Set to Support

Complex Multiply, Viterbi Operations, and Cyclic

Redundency Check (CRC)

• Embedded Memory

– Up to 256KB of Flash

– Up to 100KB of RAM

– 2KB of One-Time Programmable (OTP) ROM

• 6-Channel Direct Memory Access (DMA)

• Low Device and System Cost

– Single 3.3-V Supply

– No Power Sequencing Requirement

– Integrated Power-on Reset and Brown-out

Reset

– Low-Power Operating Modes

– No Analog Support Pin

• Endianness: Little Endian

• JTAG Boundary Scan Support

– IEEE Standard 1149.1-1990 Standard Test

Access Port and Boundary Scan Architecture

• Clocking

– Two Internal Zero-Pin Oscillators

– On-Chip Crystal Oscillator/External Clock Input

– Watchdog Timer Module

– Missing Clock Detection Circuitry

• Peripheral Interrupt Expansion (PIE) Block That

Supports All Peripheral Interrupts

SPRS698F –NOVEMBER 2010–REVISED MARCH 2016

• Three 32-Bit CPU Timers

• Advanced Control Peripherals

• Up to 8 Enhanced Pulse-Width Modulator (ePWM)

Modules

– 16 PWM Channels Total (8 HRPWM-Capable)

– Independent 16-Bit Timer in Each Module

• Three Input Enhanced Capture (eCAP) Modules

• Up to 4 High-Resolution Capture (HRCAP)

Modules

• Up to 2 Enhanced Quadrature Encoder Pulse

(eQEP) Modules

• 12-Bit Analog-to-Digital Converter (ADC), Dual

Sample-and-Hold (S/H)

– Up to 3.46 MSPS

– Up to 16 Channels

• On-Chip Temperature Sensor

• 128-Bit Security Key and Lock

– Protects Secure Memory Blocks

– Prevents Reverse-Engineering of Firmware

• Serial Port Peripherals

– Two Serial Communications Interface (SCI)

[UART] Modules

– Two Serial Peripheral Interface (SPI) Modules

– One Inter-Integrated-Circuit (I2C) Bus

– One Multichannel Buffered Serial Port (McBSP)

Bus

– One Enhanced Controller Area Network (eCAN)

– Universal Serial Bus (USB) 2.0

(see Device Comparison Table for Availability)

• Full-Speed Device Mode

• Full-Speed or Low-Speed Host Mode

• Up to 54 Individually Programmable, Multiplexed

General-Purpose Input/Output (GPIO) Pins With

Input Filtering

• Advanced Emulation Features

– Analysis and Breakpoint Functions

– Real-Time Debug Through Hardware

• 2806x Packages

– 80-Pin PFP and 100-Pin PZP PowerPAD™

Thermally Enhanced Thin Quad Flatpacks

(HTQFPs)

– 80-Pin PN and 100-Pin PZ Low-Profile Quad

Flatpacks (LQFPs)

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

Page 2

TMS320F28069,TMS320F28068,TMS320F28067,TMS320F28066

TMS320F28065, TMS320F28064, TMS320F28063, TMS320F28062

SPRS698F –NOVEMBER 2010–REVISED MARCH 2016

1.2 Applications

• Switch Mode Power Supplies (SMPSs)

• Solar Micro Inverters and Converters

• Power Factor Correction (PFC)

• Smart Grid and Power Line Communications

• AC/DC Inverters

1.3 Description

The F2806x Piccolo™ family of microcontrollers (MCUs) provides the power of the C28x core and CLA

coupled with highly integrated control peripherals in low pin-count devices. This family is code-compatible

with previous C28x-based code, and also provides a high level of analog integration.

An internal voltage regulator allows for single-rail operation. Enhancements have been made to the HighResolution Pulse Width Modulator (HRPWM) module to allow for dual-edge control (frequency

modulation). Analog comparators with internal 10-bit references have been added and can be routed

directly to control the ePWM outputs. The ADC converts from 0 to 3.3-V fixed full-scale range and

supports ratio-metric V

and latency.

REFHI/VREFLO

references. The ADC interface has been optimized for low overhead

www.ti.com

Device Information

PART NUMBER PACKAGE BODY SIZE

TMS320F28069PZP HTQFP (100) 14.0 mm × 14.0 mm

TMS320F28069PFP HTQFP (80) 12.0 mm × 12.0 mm

TMS320F28069PZ LQFP (100) 14.0 mm × 14.0 mm

TMS320F28069PN LQFP (80) 12.0 mm × 12.0 mm

(1) For more information on these devices, see Section 9, Mechanical Packaging and Orderable

Information.

(1)

2

Device Overview Copyright © 2010–2016, Texas Instruments Incorporated

Product Folder Links: TMS320F28069 TMS320F28068 TMS320F28067 TMS320F28066 TMS320F28065

Submit Documentation Feedback

TMS320F28064 TMS320F28063 TMS320F28062

Page 3

CLA Bus

DMA Bus

DMA Bus

16-bit Peripheral Bus

32-bit Peripheral

Bus

Memory Bus

A7:0

B7:0

Memory Bus

Memory Bus

DMA Bus

CLA Bus

DMA Bus

GPIO Mux

AIO Mux

32-bit Peripheral Bus

ADC

0-wait

Result

Regs

ADC

COMP

+

DAC

COMP1OUT

COMP2OUT

COMP3OUT

COMP1A

COMP2A

COMP3A

COMP1B

COMP2B

COMP3B

Boot-ROM

(32K 16)

(0-wait,

Non-Secure)

´

GPIO

Mux

GPIO

Mux

TRST

TCK, TDI, TMS

TDO

XCLKIN

LPM Wakeup

3 Ext. Interrupts

X1

X2

XRS

M0 SARAM (1K 16)

(0-wait, Non-Secure)

´

M1 SARAM (1K 16)

(0-wait, Non-Secure)

´

L5 DPSARAM (8K 16)

(0-wait, Non-Secure)

DMA RAM0

´

L6 DPSARAM (8K 16)

(0-wait, Non-Secure)

DMA RAM1

´

L7 DPSARAM (8K 16)

(0-wait, Non-Secure)

DMA RAM2

´

L8 DPSARAM (8K 16)

(0-wait, Non-Secure)

DMA RAM3

´

L0 DPSARAM (2K 16)

(0-wait, Secure)

CLA Data RAM2

´

L1 DPSARAM (1K 16)

(0-wait, Secure)

CLA Data RAM0

´

L2 DPSARAM (1K 16)

(0-wait, Secure)

CLA Data RAM1

´

L3 DPSARAM (4K 16)

(0-wait, Secure)

CLA Program RAM

´

L4 SARAM (8K 16)

(0-wait, Secure)

´

Code

Security

Module

(CSM)

PSWD

OTP 1K 16

Secure

´

FLASH

128K 16

8 equal sectors

Secure

´

64K 16´

PUMP

OTP/Flash

Wrapper

32-bit Peripheral

Bus

USB-0

GPIO Mux

SCITXDx

SCIRXDx

SPISIMOx

SPISOMIx

SPICLKx

SPISTEx

SDAx

SCLx

MFSRA

MDRA

MCLKRA

MFSXA

MDXA

MCLKXA

ECAPx

EQEPxA

EQEPxB

EQEPxI

EQEPxS

HRCAPx

CANRXx

CANTXx

USB0DP

USB0DM

TZx

EPWMxA

EPWMxB

EPWMSYNCI

EPWMSYNCO

SCI-A

SCI-B

(4L FIFO)

SPI-A

SPI-B

(4L FIFO)

I2C-A

(4L FIFO)

32-bit Peripheral Bus

(CLA accessible)

ePWM1 to ePWM8

HRPWM (8ch)

McBSP-A

32-bit

Peripheral Bus

(CLA accessible)

eCAP1

eCAP2

eCAP3

eQEP1

eQEP2

32-bit Peripheral

Bus

HRCAP1

HRCAP2

HRCAP3

HRCAP4

eCAN-A

(32-mbox)

CLA +

Message

RAMs

DMA

6-ch

C28x 32-bit CPU

FPU

VCU

OSC1, OSC2,

Ext, PLLs,

LPM, WD,

CPU Timer 0,

CPU Timer 1,

CPU Timer 2,

PIE

www.ti.com

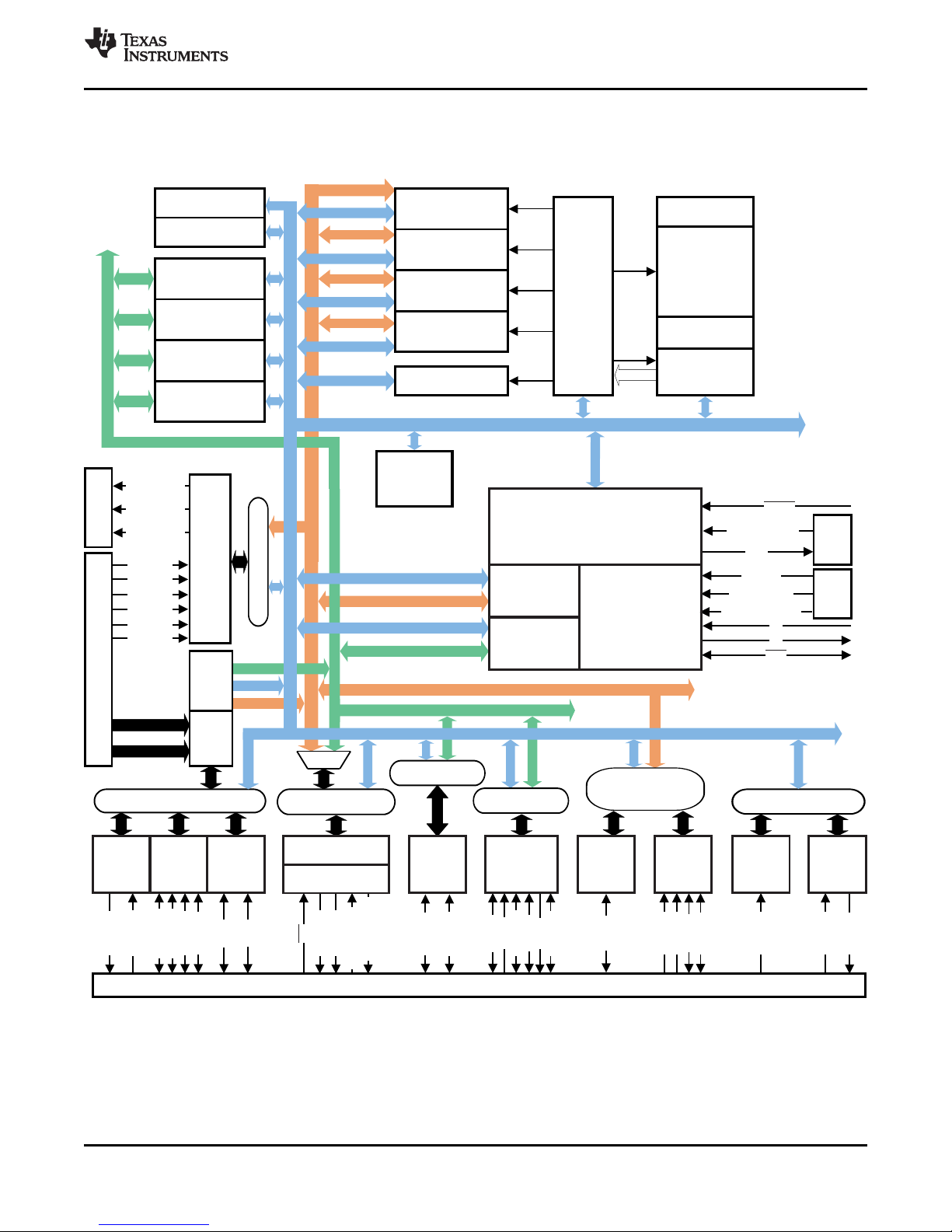

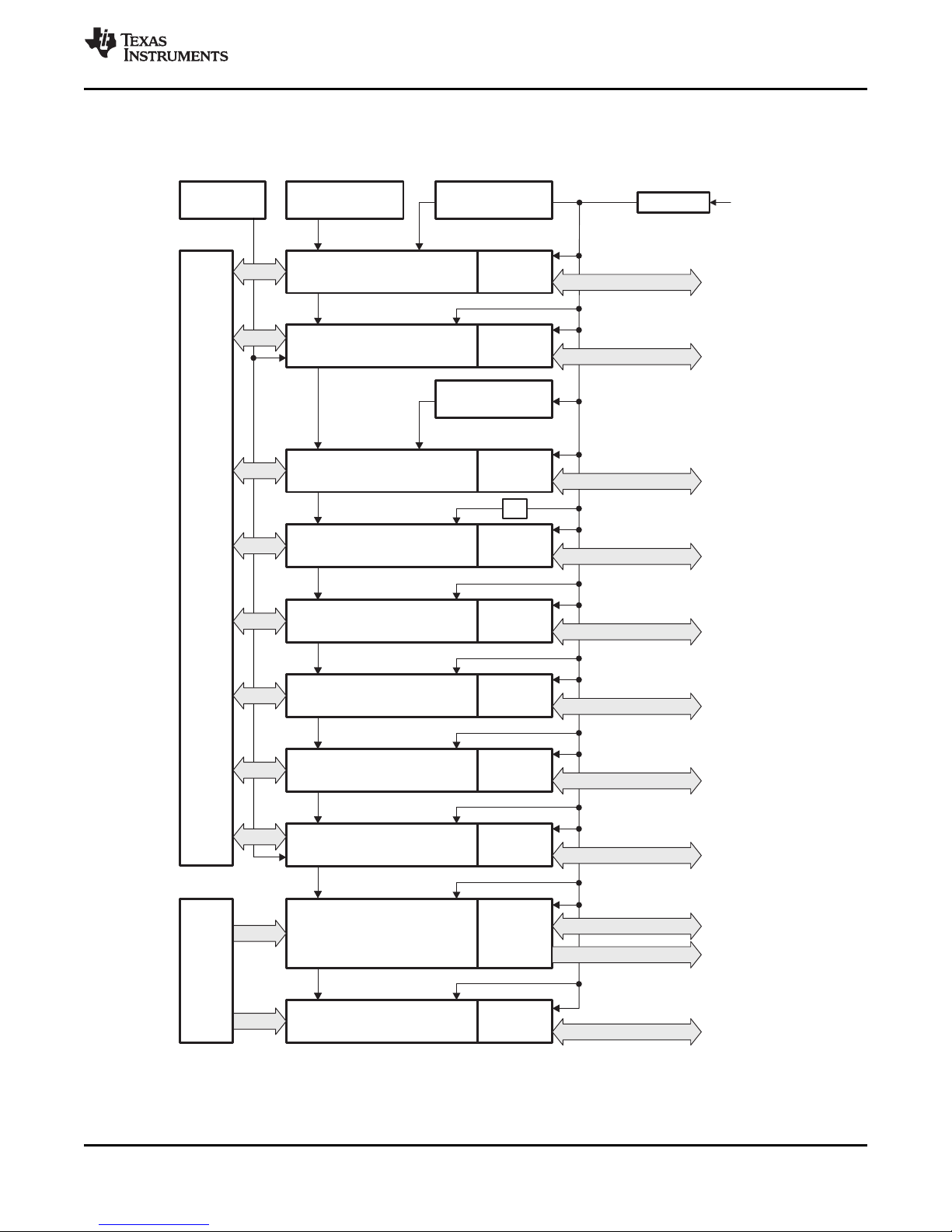

1.4 Functional Block Diagram

Figure 1-1 shows a functional block diagram of the device.

TMS320F28069,TMS320F28068,TMS320F28067,TMS320F28066

TMS320F28065, TMS320F28064, TMS320F28063, TMS320F28062

SPRS698F –NOVEMBER 2010–REVISED MARCH 2016

A. Not all peripheral pins are available at the same time due to multiplexing.

Figure 1-1. Functional Block Diagram

Product Folder Links: TMS320F28069 TMS320F28068 TMS320F28067 TMS320F28066 TMS320F28065

Submit Documentation Feedback

TMS320F28064 TMS320F28063 TMS320F28062

Device OverviewCopyright © 2010–2016, Texas Instruments Incorporated

3

Page 4

10-bit

DAC

Analog

Comparators

CMP1-Out

CMP2-Out

CMP3-Out

Trip Zone

Temp

Sensor

ADC

(DMA-

accessible)

12-bit

3.46-MSPS

Dual

Sample-

andHold

SOC-based

V

REF

CLA Core

90-MHz Floating-Point

(Accelerator)

(DMA-accessible)

10-bit

DAC

10-bit

DAC

A0

A2

A3

A4

A5

A6

A7

B0

B1

B2

B3

B4

B5

B6

B7

A1

6

eQEP 2´

HRCAP 4´

eCAP 3´

System

Vreg

Int-Osc-1

POR/BOR

Int-Osc-2

On-chip Osc

WD

PLL

CLKSEL

Timers 32-bit

Timer-0

Timer-1

Timer-2

GPIO

Control

COMMS

X1

X2

V

REFLO

V

REFHI

C28x

Core

(90-MHz)

FPU

VCU

Flash Memory

RAM

RAM

(Dual-Access)

eQEP

8

HRCAP

4

eCAP

3

4

8

2

2

6

PWM-1A

PWM-1B

PWM-2A

PWM-2B

PWM-3A

PWM-3B

PWM-4A

PWM-4B

PWM-5A

PWM-5B

PWM-6A

PWM-6B

PWM-7A

PWM-7B

PWM-8A

PWM-8B

TZ1

TZ2

TZ3

CMP1-out

CMP2-out

CMP3-out

PWM1

(DMA-accessible)

PWM5

(DMA-accessible)

PWM8

(DMA-accessible)

PWM7

(DMA-accessible)

PWM6

(DMA-accessible)

PWM4

(DMA-accessible)

PWM3

(DMA-accessible)

PWM2

(DMA-accessible)

UART 2´

SPI 2´

I C

2

CAN

McBSP

(DMA-accessible)

2

USB

(DMA-accessible)

TMS320F28069,TMS320F28068,TMS320F28067,TMS320F28066

TMS320F28065, TMS320F28064, TMS320F28063, TMS320F28062

SPRS698F –NOVEMBER 2010–REVISED MARCH 2016

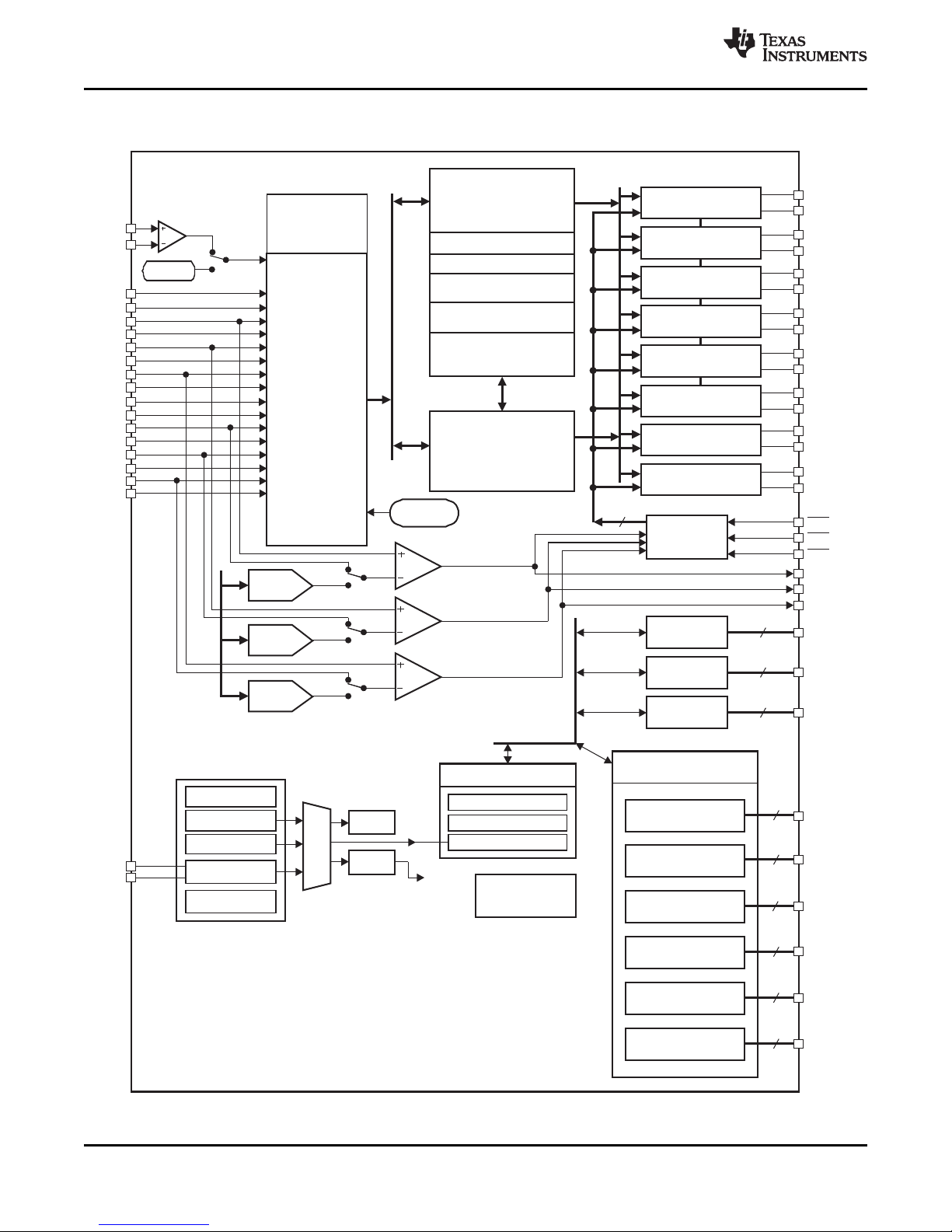

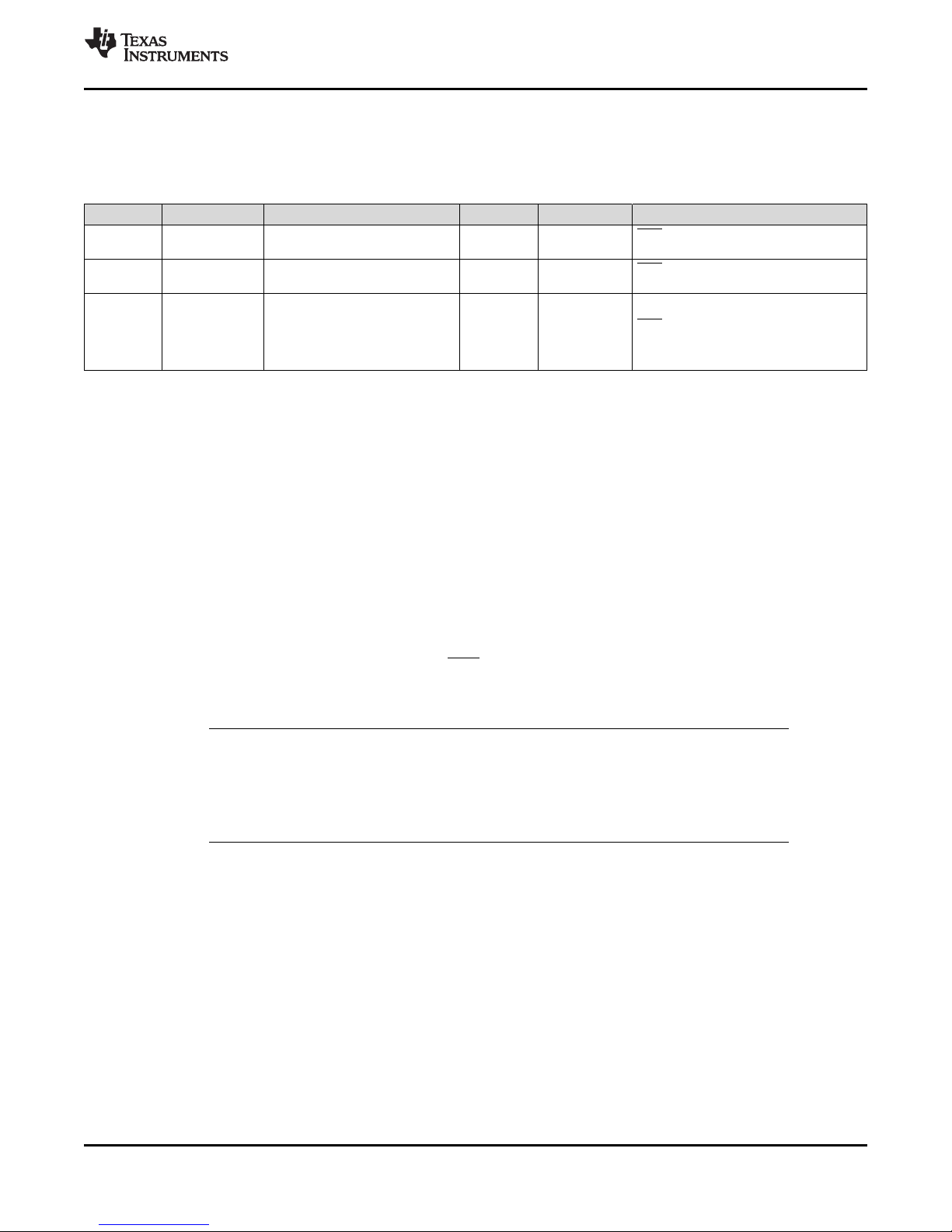

1.5 System Device Diagram

www.ti.com

4

Device Overview Copyright © 2010–2016, Texas Instruments Incorporated

Product Folder Links: TMS320F28069 TMS320F28068 TMS320F28067 TMS320F28066 TMS320F28065

Figure 1-2. Peripheral Blocks

Submit Documentation Feedback

TMS320F28064 TMS320F28063 TMS320F28062

Page 5

www.ti.com

TMS320F28069,TMS320F28068,TMS320F28067,TMS320F28066

TMS320F28065, TMS320F28064, TMS320F28063, TMS320F28062

SPRS698F –NOVEMBER 2010–REVISED MARCH 2016

Table of Contents

1 Device Overview ......................................... 1

1.1 Features .............................................. 1

1.2 Applications........................................... 2

1.3 Description............................................ 2

1.4 Functional Block Diagram ............................ 3

1.5 System Device Diagram.............................. 4

2 Revision History ......................................... 6

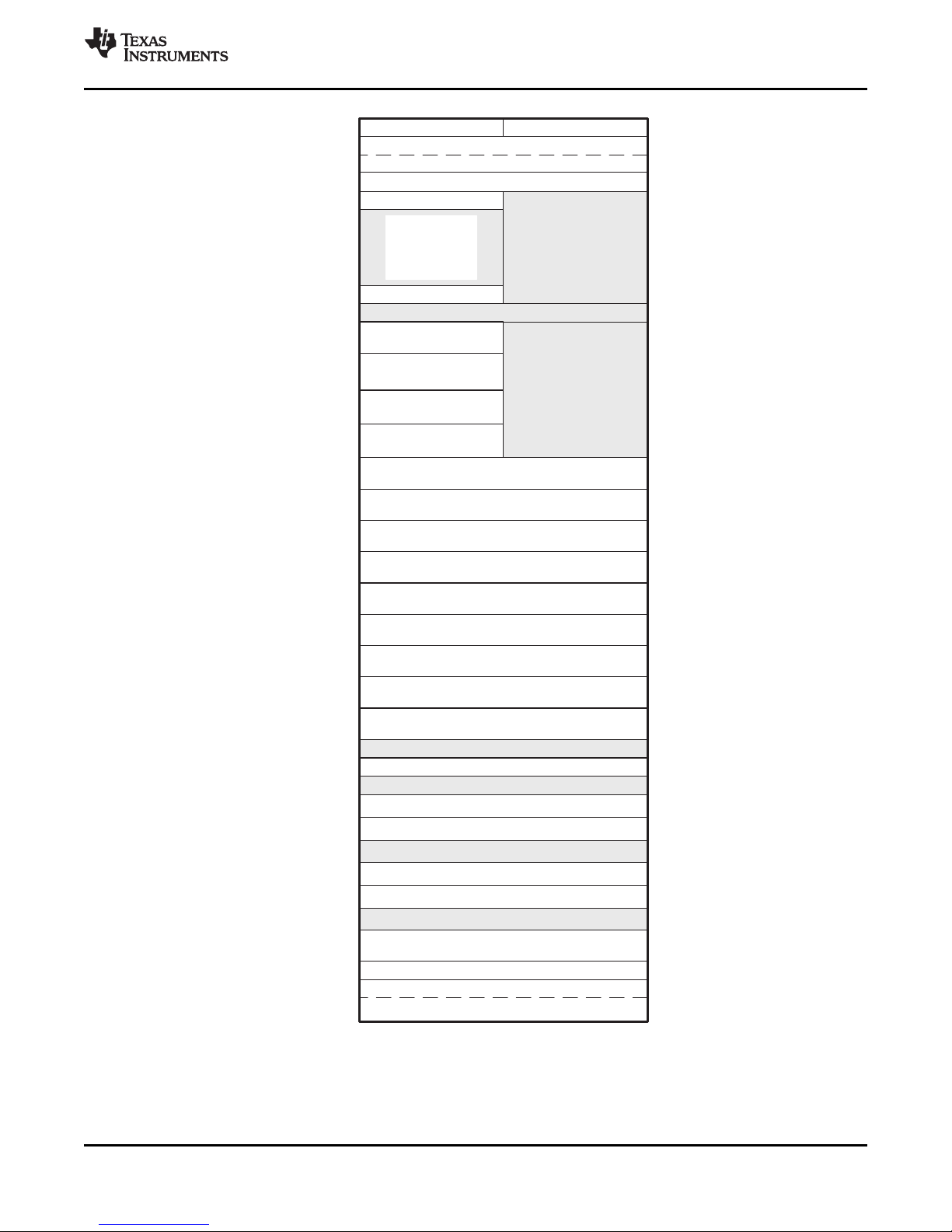

3 Device Comparison ..................................... 7

4 Terminal Configuration and Functions.............. 9

4.1 Pin Diagrams ......................................... 9

4.2 Signal Descriptions.................................. 11

5 Specifications........................................... 19

5.1 Absolute Maximum Ratings ........................ 19

5.2 ESD Ratings for TMS320F2806xU ................. 19

5.3 ESD Ratings for TMS320F2806x,

TMS320F2806xM, and TMS320F2806xF .......... 19

5.4 Recommended Operating Conditions............... 20

5.5 Electrical Characteristics............................ 20

5.6 Power Consumption Summary...................... 21

5.7 Thermal Resistance Characteristics ................ 25

5.8 Thermal Design Considerations .................... 27

5.9 Emulator Connection Without Signal Buffering for

the MCU............................................. 27

5.10 Parameter Information .............................. 28

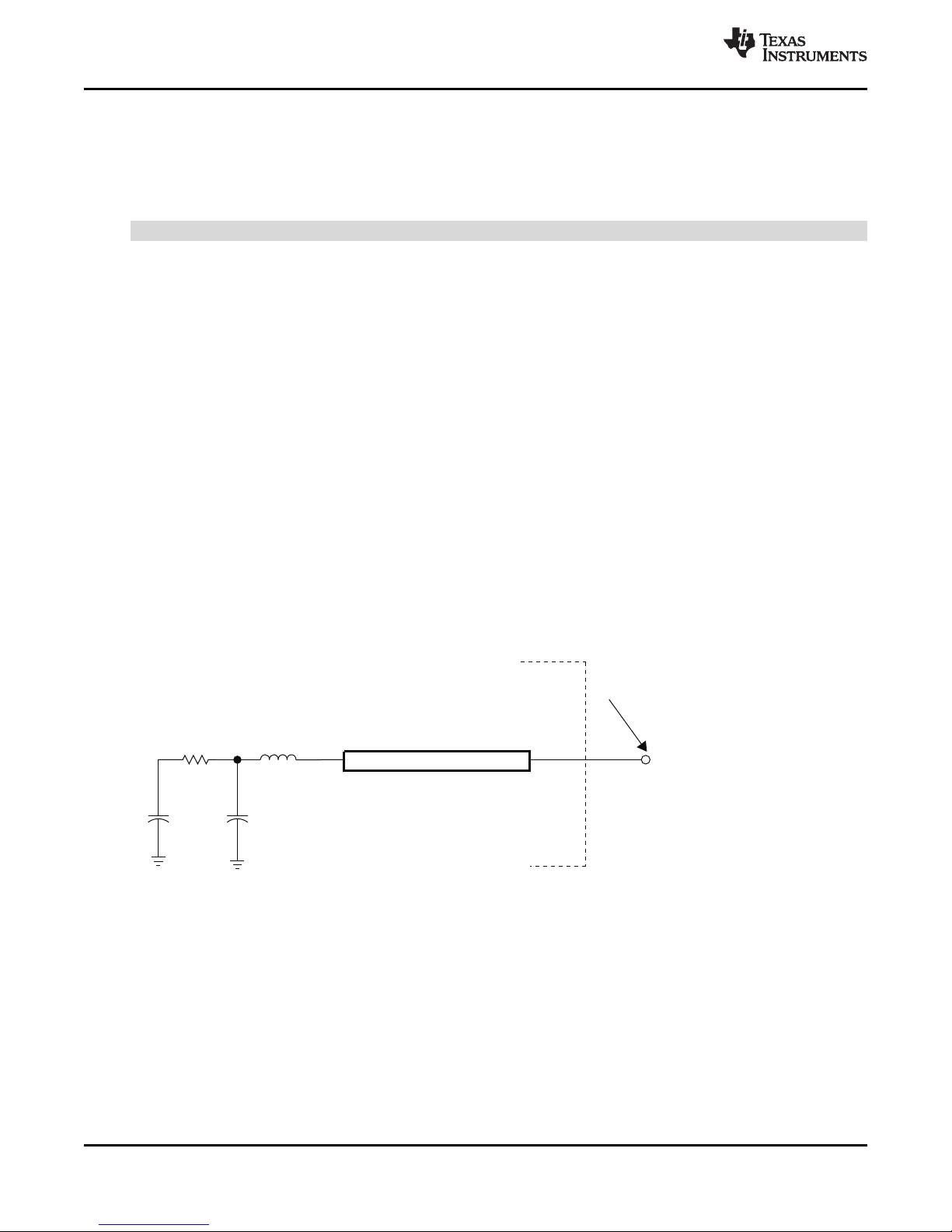

5.11 Test Load Circuit .................................... 28

5.12 Power Sequencing.................................. 29

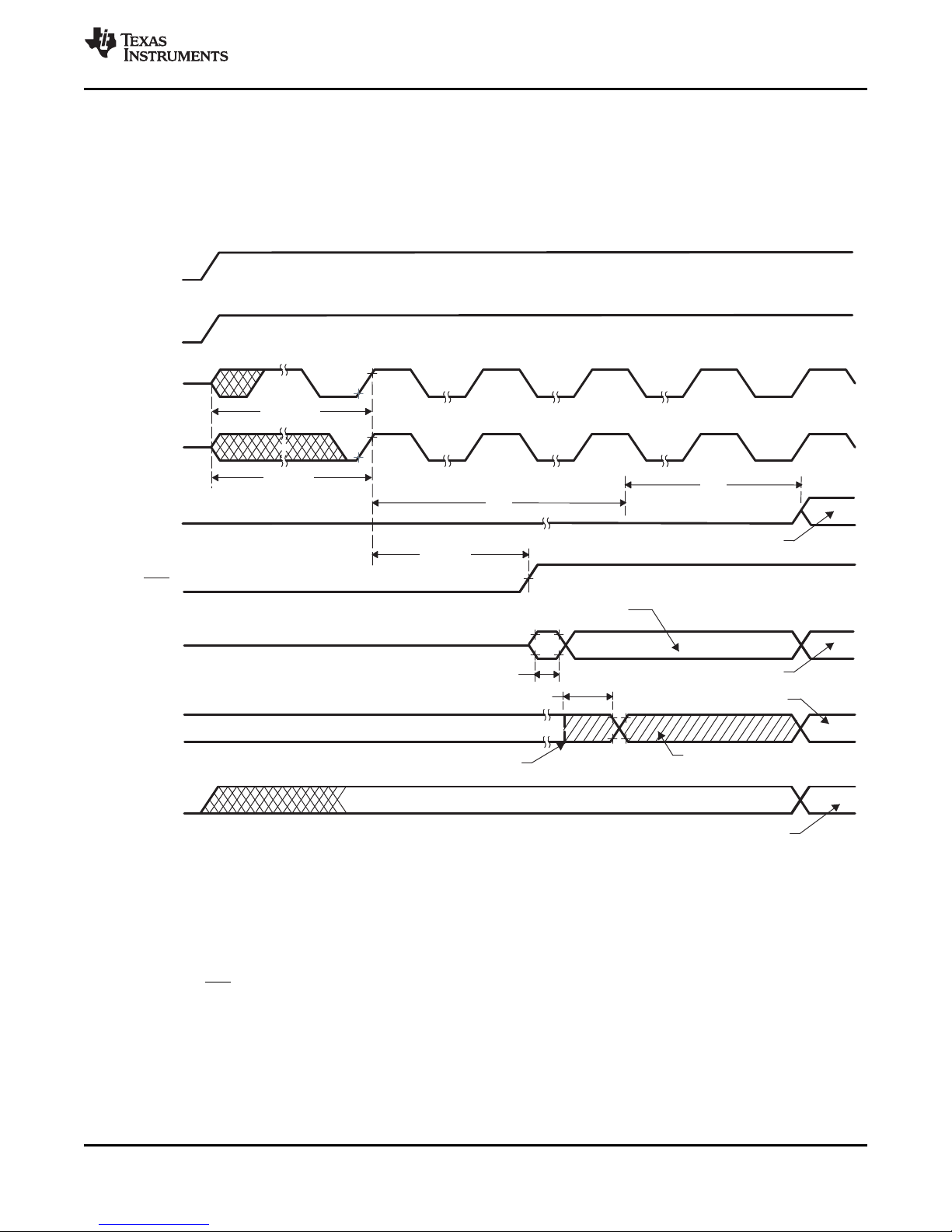

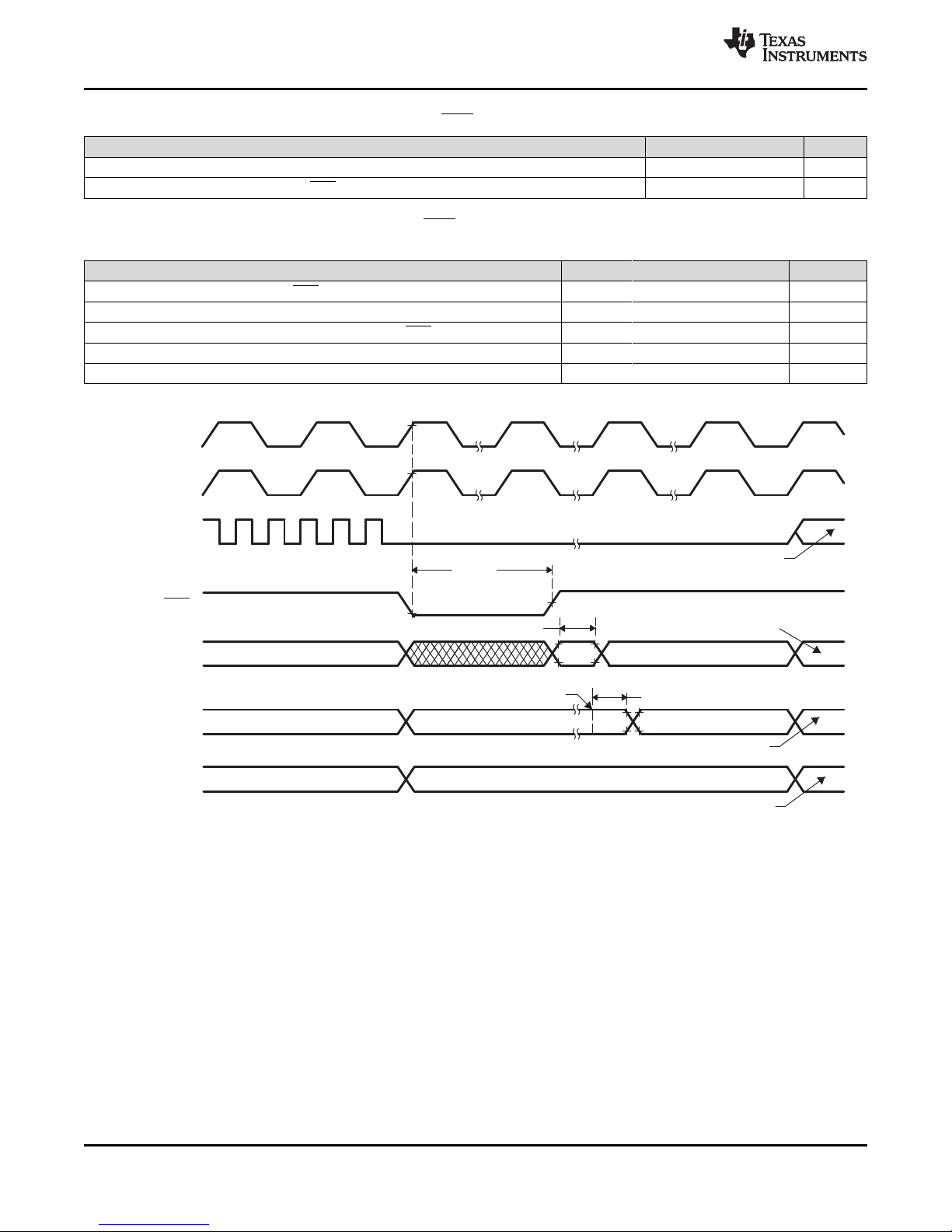

5.13 Clock Specifications................................. 32

5.14 Flash Timing ........................................ 35

6 Detailed Description................................... 37

6.1 Overview ............................................ 37

6.2 Memory Maps....................................... 47

6.3 Register Maps....................................... 58

6.4 Device Emulation Registers......................... 60

6.5 VREG, BOR, POR .................................. 62

6.6 System Control ...................................... 64

6.7 Low-power Modes Block ............................ 73

6.8 Interrupts ............................................ 74

6.9 Peripherals .......................................... 79

7 Applications, Implementation, and Layout ...... 156

7.1 TI Design or Reference Design.................... 156

7.2 Development Tools ................................ 157

7.3 Software Tools ..................................... 157

7.4 Training ............................................ 158

8 Device and Documentation Support.............. 159

8.1 Device Support..................................... 159

8.2 Documentation Support............................ 161

8.3 Related Links ...................................... 162

8.4 Community Resources............................. 162

8.5 Trademarks ........................................ 162

8.6 Electrostatic Discharge Caution ................... 162

8.7 Glossary............................................ 162

9 Mechanical Packaging and Orderable

Information............................................. 163

9.1 Packaging Information ............................. 163

Product Folder Links: TMS320F28069 TMS320F28068 TMS320F28067 TMS320F28066 TMS320F28065

Submit Documentation Feedback

TMS320F28064 TMS320F28063 TMS320F28062

Table of ContentsCopyright © 2010–2016, Texas Instruments Incorporated

5

Page 6

TMS320F28069,TMS320F28068,TMS320F28067,TMS320F28066

TMS320F28065, TMS320F28064, TMS320F28063, TMS320F28062

SPRS698F –NOVEMBER 2010–REVISED MARCH 2016

www.ti.com

2 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from July 2, 2014 to March 22, 2016 (from E Revision (July 2014) to F Revision) Page

• Global: Changed "CAN 2.0B" to "ISO11898-1 (CAN 2.0B)". .................................................................. 1

• Table 3-1 (Device Comparison): Changed the number of High-resolution ePWM Channels on the 80-Pin

PN/PFP packages from 6 to 8. ..................................................................................................... 7

• Table 3-1: Removed "Product status" row and associated footnote. ......................................................... 7

• Figure 4-1 (80-Pin PN and PFP Packages (Top View)): Added footnote about PowerPAD. .............................. 9

• Figure 4-2 (100-Pin PZ and PZP Packages (Top View)): Added footnote about PowerPAD. ........................... 10

• Section 4.2 (Signal Descriptions): Added "GPIO26–27" to NOTE. .......................................................... 11

• Table 4-1 (Signal Descriptions): Updated DESCRIPTION of X1, V

• Section 5.1 (Absolute Maximum Ratings): Added Input voltage, V

• Section 5.1: Added T

. ........................................................................................................... 19

stg

• Section 5.2 (ESD Ratings for TMS320F2806xU): Added section. ........................................................... 19

• Section 5.3 (ESD Ratings for TMS320F2806x, TMS320F2806xM, and TMS320F2806xF): Changed title from

"Handling Ratings" to "ESD Ratings for TMS320F2806x, TMS320F2806xM, and TMS320F2806xF". ................. 19

• Section 5.3: Updated footnotes. .................................................................................................. 19

• Section 5.4 (Recommended Operating Conditions): Removed footnote that read "V

maintained within approximately 0.3 V of each other". ........................................................................ 20

• Section 5.6 (Power Consumption Summary): Changed section title from "Current Consumption" to "Power

Consumption Summary". .......................................................................................................... 21

• Section 5.12 (Power Sequencing): Updated paragraph that reads "There is no power sequencing requirement

needed ...". .......................................................................................................................... 29

• Table 5-10 (XCLKOUT Switching Characteristics (PLL Bypassed or Enabled)): Added MAX value for t

• Table 5-10: Added MAX value for t

......................................................................................... 34

r(XCO)

• Table 5-15 (Flash/OTP Access Timing): Removed footnote. ................................................................. 36

• Figure 6-1 (28069 Memory Map): Added "FAST and SpinTAC Libraries" block. Changed size of Boot ROM. ........ 48

• Figure 6-2 (28068 Memory Map): Added "FAST and SpinTAC Libraries" block. Changed size of Boot ROM. ....... 49

• Figure 6-3 (28067 Memory Map): Added figure. ............................................................................... 50

• Figure 6-8 (28062 Memory Map): Added "FAST and SpinTAC Libraries" block. Changed size of Boot ROM. ........ 55

• Section 6.6.2 (Crystal Oscillator Option): Added paragraph that begins "The on-chip crystal oscillator X1 and X2

pins are 1.8-V level signals ...". ................................................................................................... 67

• Section 6.9.6.1.2 (McBSP as SPI Master or Slave Timing): Replaced "For all SPI slave modes ..." paragraphs

with "For all SPI slave modes ..." table footnotes. ............................................................................ 115

• Table 6-44 (McBSP as SPI Master or Slave Timing Requirements (CLKSTP = 10b, CLKXP = 0)): Added "For all

SPI slave modes ..." footnote. ................................................................................................... 115

• Table 6-46 (McBSP as SPI Master or Slave Timing Requirements (CLKSTP = 11b, CLKXP = 0)): Added "For all

SPI slave modes ..." footnote. ................................................................................................... 116

• Table 6-48 (McBSP as SPI Master or Slave Timing Requirements (CLKSTP = 10b, CLKXP = 1)): Added "For all

SPI slave modes ..." footnote. ................................................................................................... 117

• Table 6-50 (McBSP as SPI Master or Slave Timing Requirements (CLKSTP = 11b, CLKXP = 1)): Added "For all

SPI slave modes ..." footnote. ................................................................................................... 118

• Table 6-65 (HRCAP Registers): Added reference to footnote for HCICLR and HCIFRC. .............................. 137

• Section 7 (Applications, Implementation, and Layout): Added section. .................................................... 156

• Section 8.1.1.1 (Getting Started): Updated links. ............................................................................. 159

• Figure 8-1 (Device Nomenclature): Updated list of devices. ................................................................ 160

• Section 8.2 (Documentation Support): Added the Calculating Useful Lifetimes of Embedded Processors

Application Report (SPRABX4) to list of application reports. ............................................................... 161

• Section 8.2.1 (Receiving Notification of Document Updates): Added section. ............................................ 162

, V

REFHI

(X1). ................................................. 19

IN

REFLO

, and V

DDIO

. ............................. 11

DDIO

and V

DDA

should be

f(XCO)

........ 34

6

Revision History Copyright © 2010–2016, Texas Instruments Incorporated

Product Folder Links: TMS320F28069 TMS320F28068 TMS320F28067 TMS320F28066 TMS320F28065

Submit Documentation Feedback

TMS320F28064 TMS320F28063 TMS320F28062

Page 7

Copyright © 2010–2016, Texas Instruments Incorporated Device Comparison

Submit Documentation Feedback

Product Folder Links: TMS320F28069 TMS320F28068 TMS320F28067 TMS320F28066 TMS320F28065

TMS320F28064 TMS320F28063 TMS320F28062

7

TMS320F28069,TMS320F28068,TMS320F28067,TMS320F28066

TMS320F28065, TMS320F28064, TMS320F28063, TMS320F28062

www.ti.com

SPRS698F – NOVEMBER 2010–REVISED MARCH 2016

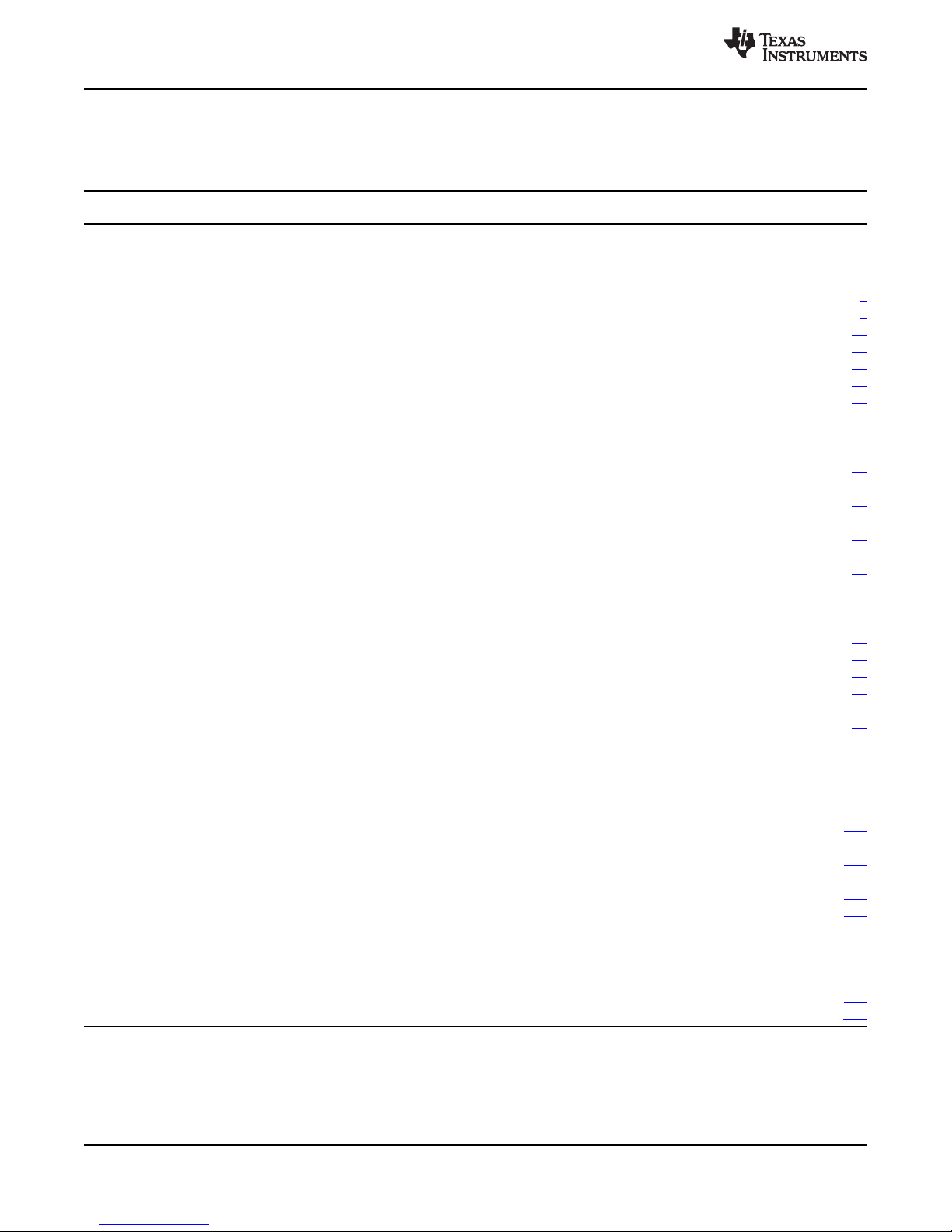

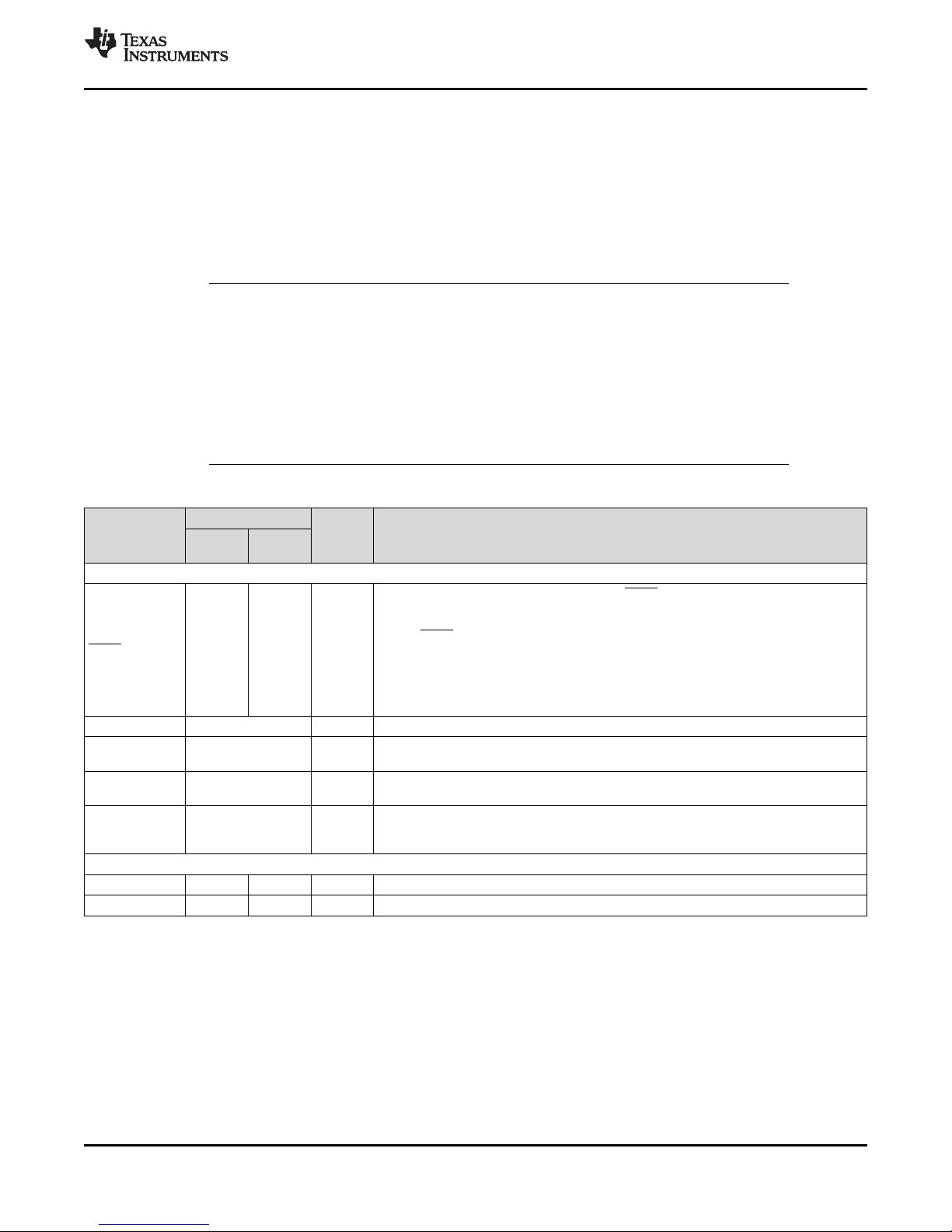

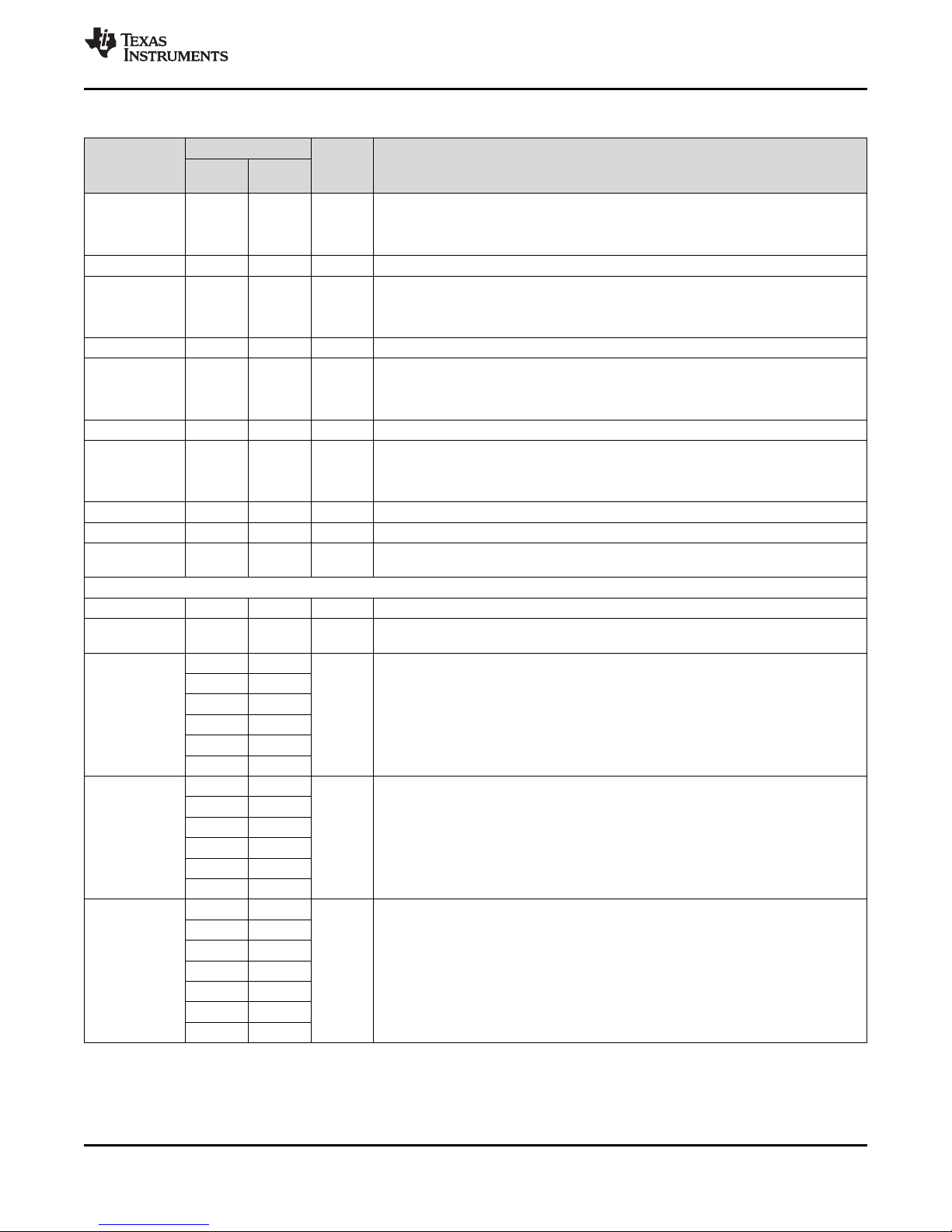

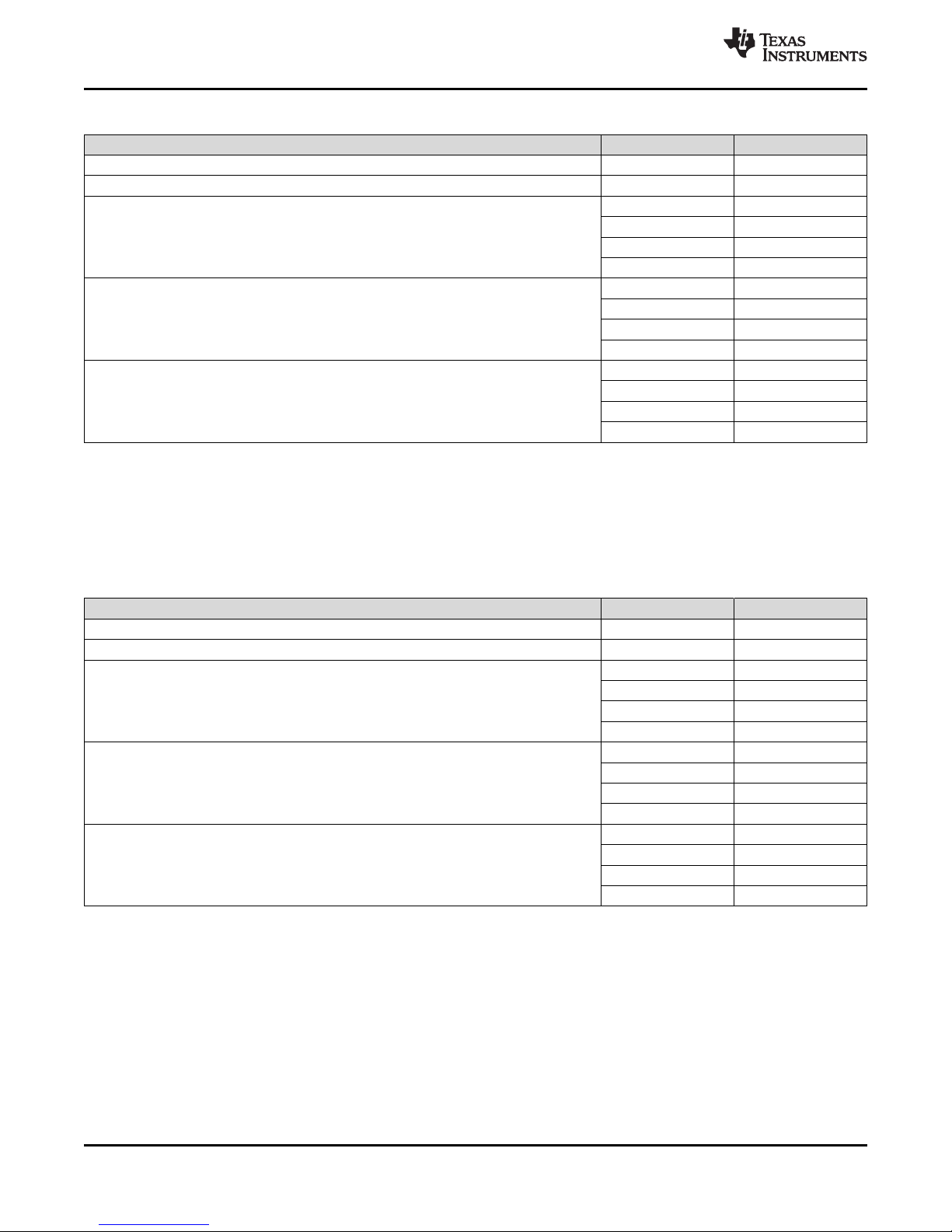

3 Device Comparison

(1) A type change represents a major functional feature difference in a peripheral module. Within a peripheral type, there may be minor differences between devices that do not affect the

basic functionality of the module. These device-specific differences are listed in the TMS320x28xx, 28xxx DSP Peripheral Reference Guide (SPRU566) and in the peripheral reference

guides.

(2) USB is present on TMS320F2806xU, TMS320F2806xM, and TMS320F2806xF devices.

(3) The "Q" temperature option is not available on the TMS320F2806xU devices.

(4) TMS320F2806xM devices are InstaSPIN-MOTION-enabled MCUs. TMS320F2806xF devices are InstaSPIN-FOC-enabled MCUs. For more information, see Section 8.2 for a list of

InstaSPIN Technical Reference Manuals.

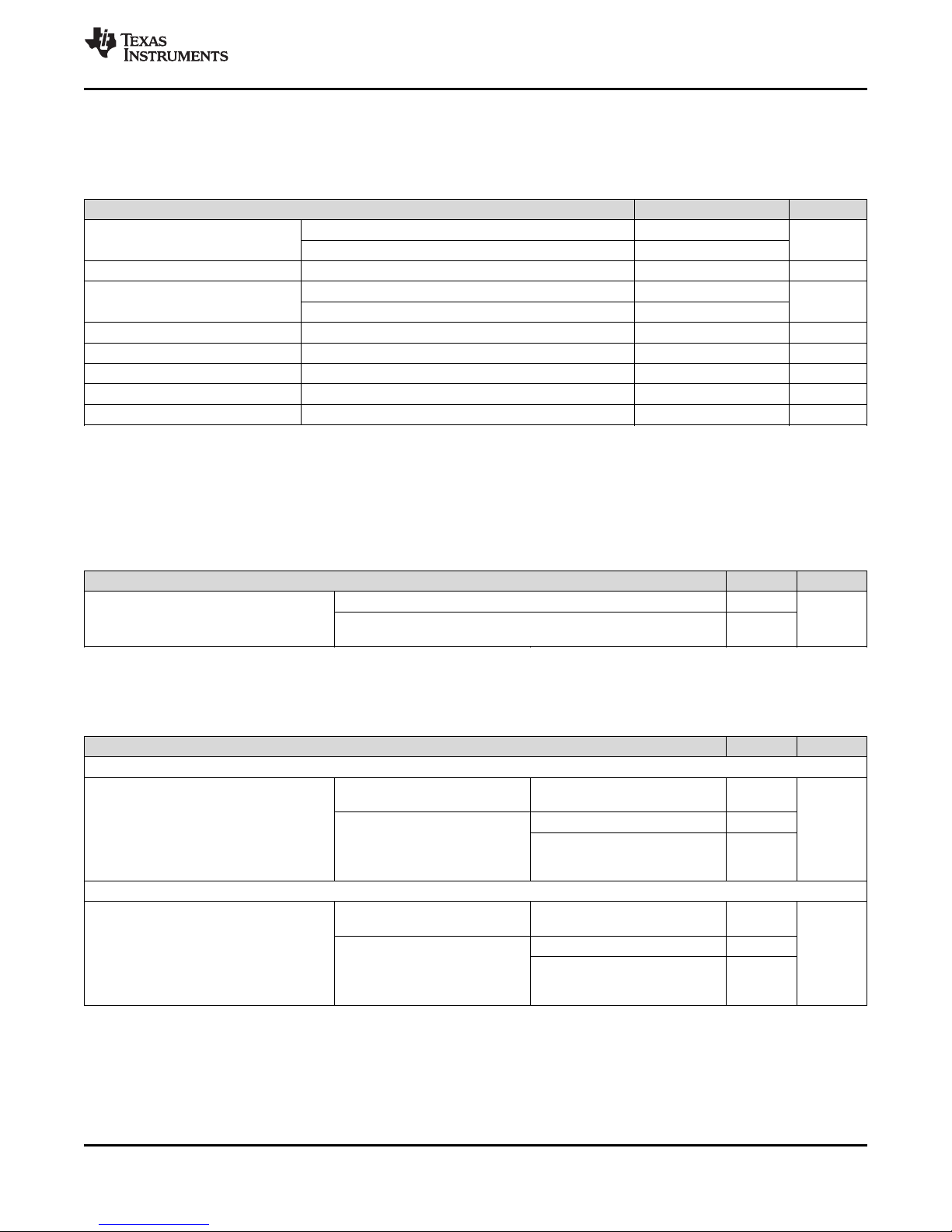

Table 3-1. Device Comparison

FEATURE TYPE

(1)

28069

28069U

(2) (3)

28069M

(2) (4)

28069F

(2) (4)

(90 MHz)

28068

28068U

(2) (3)

28068M

(2) (4)

28068F

(2) (4)

(90 MHz)

28067

28067U

(2) (3)

(90 MHz)

28066

28066U

(2) (3)

(90 MHz)

28065

28065U

(2) (3)

(90 MHz)

28064

28064U

(2) (3)

(90 MHz)

28063

28063U

(2) (3)

(90 MHz)

28062

28062U

(2) (3)

28062F

(2) (4)

(90 MHz)

Package Type

(PFP andPZP are PowerPAD HTQFPs.

PN andPZ are LQFPs.)

100-Pin

PZ

PZP

80-Pin

PN

PFP

100-Pin

PZ

PZP

80-Pin

PN

PFP

100-Pin

PZ

PZP

80-Pin

PN

PFP

100-Pin

PZ

PZP

80-Pin

PN

PFP

100-Pin

PZ

PZP

80-Pin

PN

PFP

100-Pin

PZ

PZP

80-Pin

PN

PFP

100-Pin

PZ

PZP

80-Pin

PN

PFP

100-Pin

PZ

PZP

80-Pin

PN

PFP

Instruction cycle – 11.11 ns 11.11 ns 11.11 ns 11.11 ns 11.11 ns 11.11 ns 11.11 ns 11.11 ns

Floating-Point Unit(FPU) Yes Yes Yes Yes Yes Yes Yes Yes

VCU Yes Yes No No Yes Yes No No

CLA 0 Yes No No No Yes No No No

6-Channel DMA 0 Yes Yes Yes Yes Yes Yes Yes Yes

On-chip Flash(16-bit word) – 128K 128K 128K 128K 64K 64K 64K 64K

On-chip SARAM(16-bit word) – 50K 50K 50K 34K 50K 50K 34K 26K

Code securityfor on-chip Flash, SARAM,

and OTPblocks

– Yes Yes Yes Yes Yes Yes Yes Yes

Boot ROM(32K × 16) – Yes Yes Yes Yes Yes Yes Yes Yes

One-time programmable(OTP) ROM

(16-bit word)

– 1K 1K 1K 1K 1K 1K 1K 1K

ePWM channels 1 16 14 16 14 16 14 16 14 16 14 16 14 16 14 16 14

High-resolution ePWMChannels 1 8 8 8 8 8 8 8 8

eCAP inputs 0 3 3 3 3 3 3 3 3

HRCAP 0 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1

eQEP modules 0 2 1 2 1 2 1 2 1 2 1 2 1 2 1 2 1

Watchdog timer – Yes Yes Yes Yes Yes Yes Yes Yes

12-Bit ADC

MSPS

3

3.46 3.46 3.46 3.46 3.46 3.46 3.46 3.46

Conversion Time 289 ns 289 ns 289 ns 289 ns 289 ns 289 ns 289 ns 289 ns

Channels 16 12 16 12 16 12 16 12 16 12 16 12 16 12 16 12

Temperature Sensor Yes Yes Yes Yes Yes Yes Yes Yes

Dual Sample-and-Hold Yes Yes Yes Yes Yes Yes Yes Yes

32-Bit CPUtimers – 3 3 3 3 3 3 3 3

Comparators withIntegrated DACs 0 3 3 3 3 3 3 3 3

I2C

0 1 1 1 1 1 1 1 1

Page 8

Copyright © 2010–2016, Texas Instruments IncorporatedDevice Comparison

Submit Documentation Feedback

Product Folder Links: TMS320F28069 TMS320F28068 TMS320F28067 TMS320F28066 TMS320F28065

TMS320F28064 TMS320F28063 TMS320F28062

8

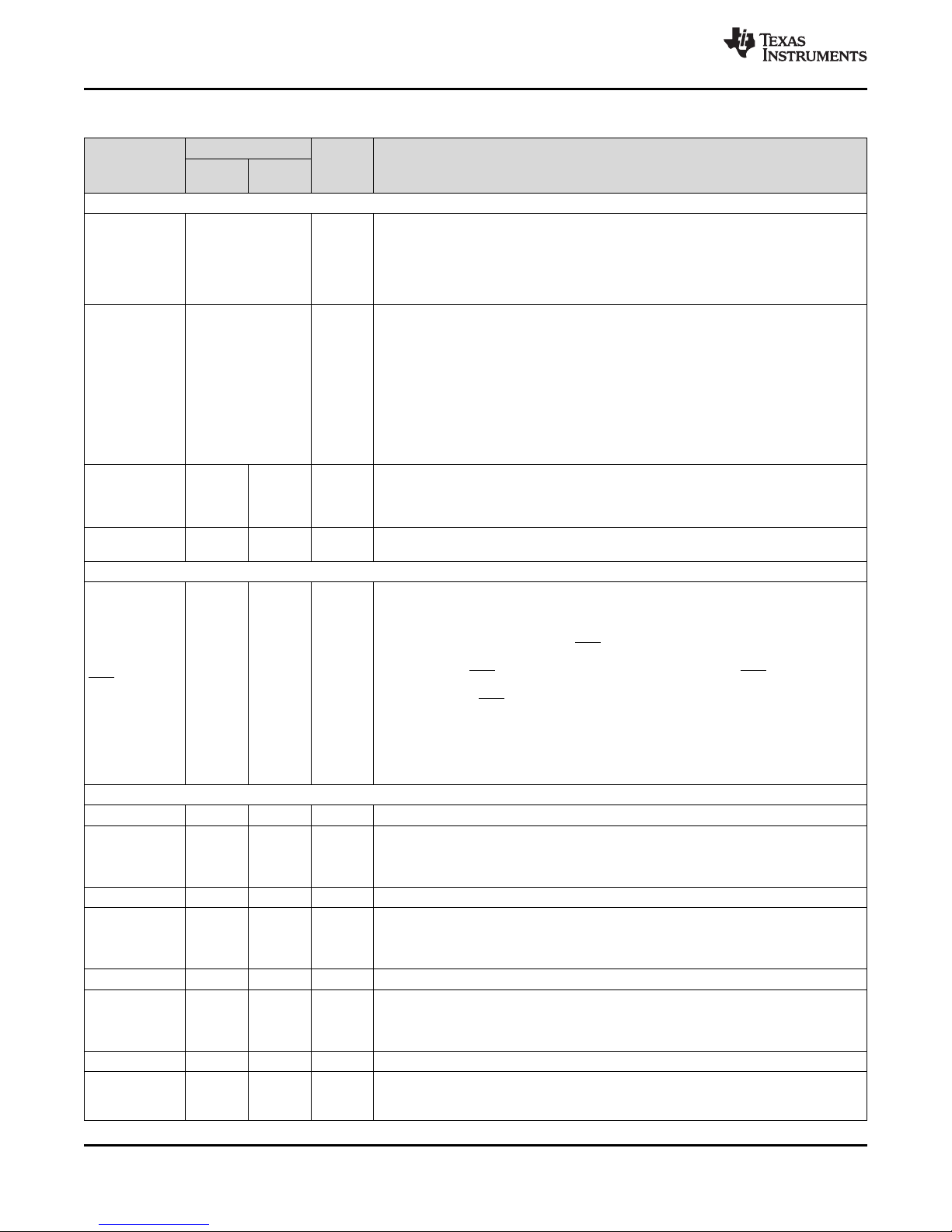

TMS320F28069,TMS320F28068,TMS320F28067,TMS320F28066

TMS320F28065, TMS320F28064, TMS320F28063, TMS320F28062

SPRS698F – NOVEMBER 2010–REVISED MARCH 2016

www.ti.com

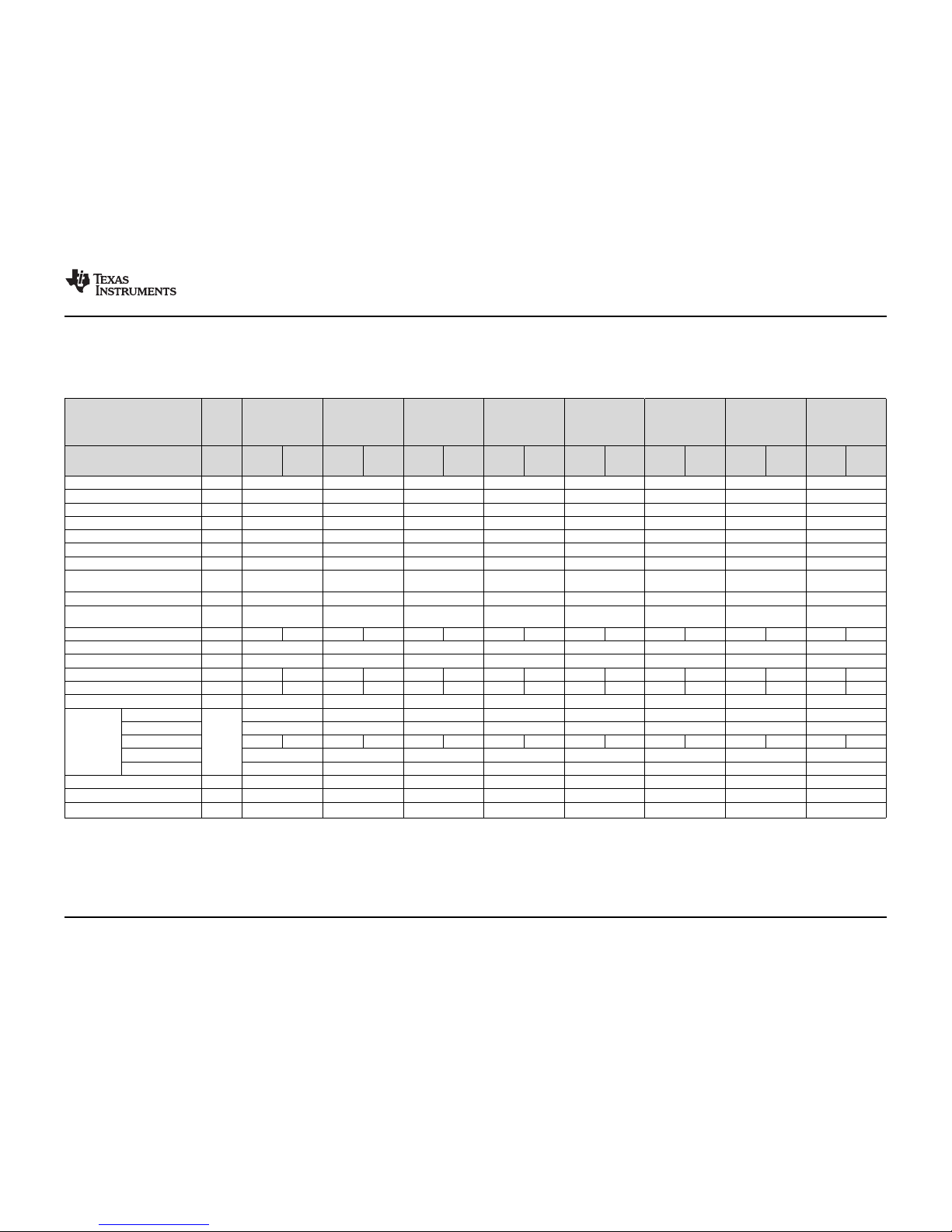

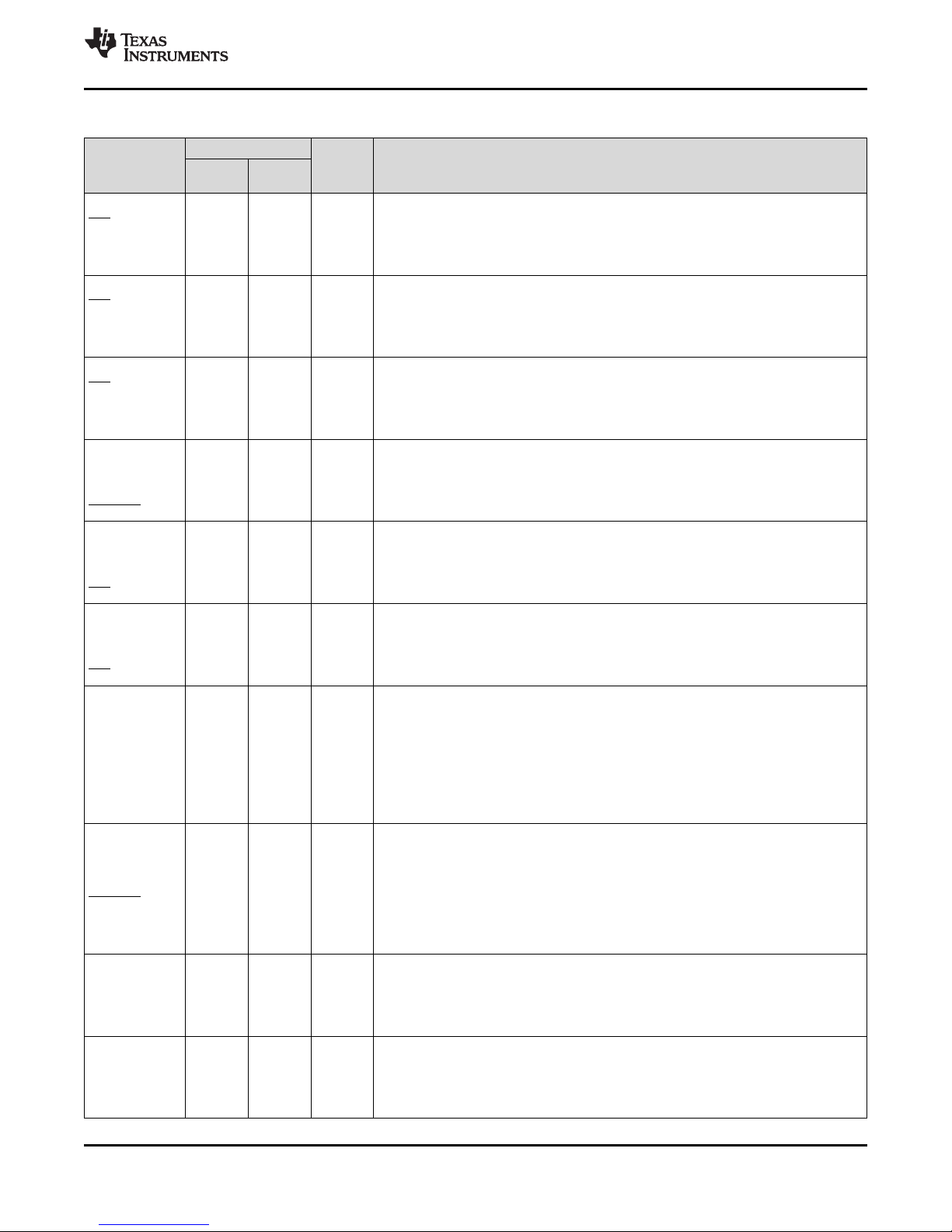

Table 3-1. Device Comparison (continued)

FEATURE TYPE

(1)

28069

28069U

(2) (3)

28069M

(2) (4)

28069F

(2) (4)

(90 MHz)

28068

28068U

(2) (3)

28068M

(2) (4)

28068F

(2) (4)

(90 MHz)

28067

28067U

(2) (3)

(90 MHz)

28066

28066U

(2) (3)

(90 MHz)

28065

28065U

(2) (3)

(90 MHz)

28064

28064U

(2) (3)

(90 MHz)

28063

28063U

(2) (3)

(90 MHz)

28062

28062U

(2) (3)

28062F

(2) (4)

(90 MHz)

Package Type

(PFP andPZP are PowerPAD HTQFPs.

PN andPZ are LQFPs.)

100-Pin

PZ

PZP

80-Pin

PN

PFP

100-Pin

PZ

PZP

80-Pin

PN

PFP

100-Pin

PZ

PZP

80-Pin

PN

PFP

100-Pin

PZ

PZP

80-Pin

PN

PFP

100-Pin

PZ

PZP

80-Pin

PN

PFP

100-Pin

PZ

PZP

80-Pin

PN

PFP

100-Pin

PZ

PZP

80-Pin

PN

PFP

100-Pin

PZ

PZP

80-Pin

PN

PFP

(5) "Q" refers to Q100 qualification for automotive applications.

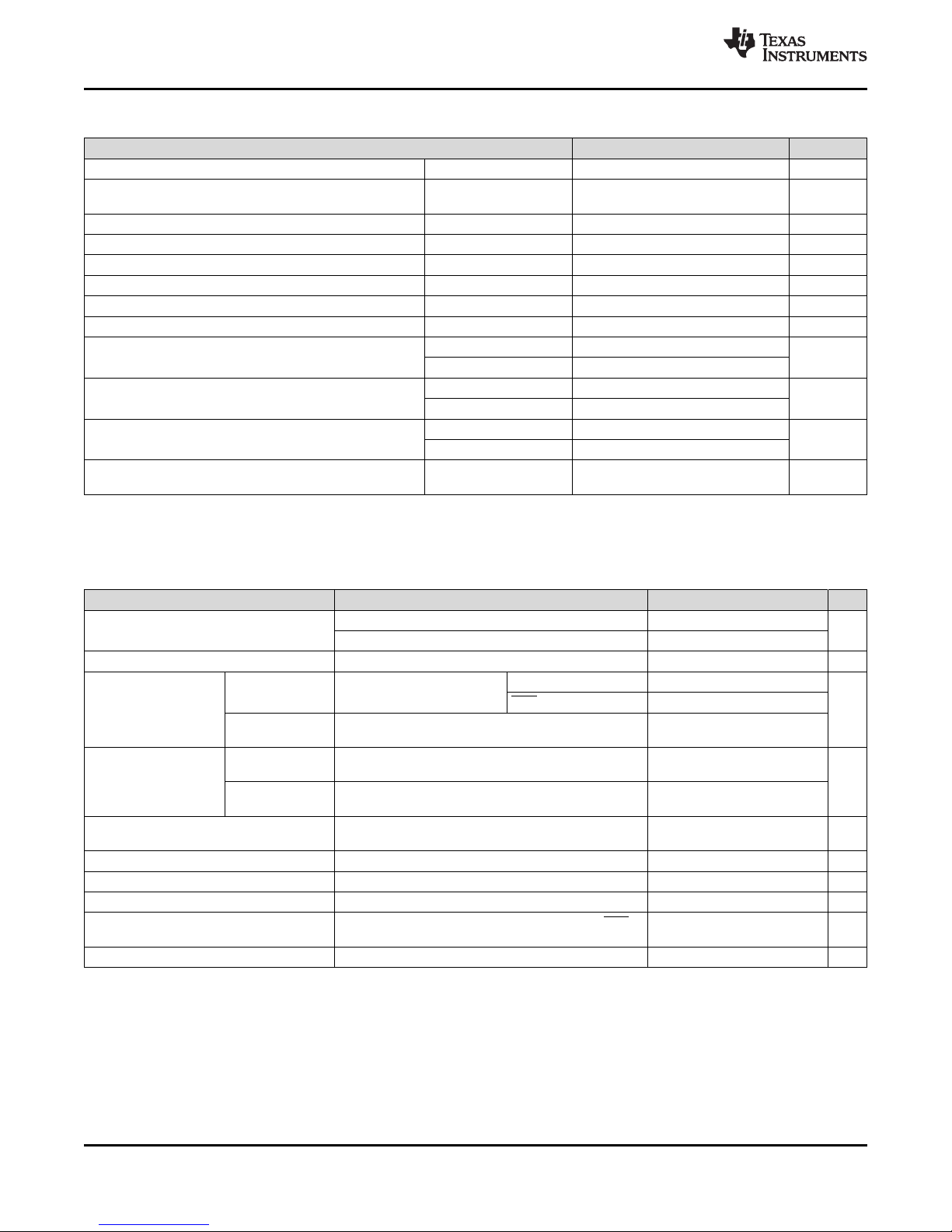

McBSP 1 1 1 1 1 1 1 1 1

eCAN 0 1 1 1 1 1 1 1 1

SPI 1 2 2 2 2 2 2 2 2

SCI 0 2 2 2 2 2 2 2 2

USB 0 1

(2)

1

(2)

1

(2)

1

(2)

1

(2)

1

(2)

1

(2)

1

(2)

2-pin Oscillator 1 1 1 1 1 1 1 1

0-pin Oscillator 2 2 2 2 2 2 2 2

I/O pins

(shared)

GPIO – 54 40 54 40 54 40 54 40 54 40 54 40 54 40 54 40

AIO – 6 6 6 6 6 6 6 6

External interrupts – 3 3 3 3 3 3 3 3

Supply voltage(nominal) – 3.3 V 3.3 V 3.3 V 3.3V 3.3 V 3.3V 3.3 V 3.3V

Temperature

options

T: –40°Cto 105°C – PZ PN PZ PN PZ PN PZ PN PZ PN PZ PN PZ PN PZ PN

S: –40°C to 125°C – PZP PFP PZP PFP PZP PFP PZP PFP PZP PFP PZP PFP PZP PFP PZP PFP

Q: –40°Cto 125°C

(3)(5)

– PZP PFP PZP PFP PZP PFP PZP PFP PZP PFP PZP PFP PZP PFP PZP PFP

Page 9

60

59

58

57

56

55

54

53

52

51

50

49

48

47

40

39

38

37

36

35

34

33

32

31

30

29

28

27

61

62

63

64

65

66

67

68

69

70

71

72

73

74

1

2

3

4

5

6

7

8

9

101112

13

14

46

45

44

43

42

41

15

16

17

18

19

20

75

76

77

78

79

80

26

25

24

23

22

21

GPIO23/EQEP1I/MFSXA/SCIRXDB

V

DD

V

DD

V

SS

V

DDIO

GPIO20/EQEP1A/MDXA/COMP1OUT

GPIO21/EQEP1B/MDRA/COMP2OUT

GPIO4/EPWM3A

GPIO5/EPWM3B/SPISIMOA/ECAP1

XRS

TRST

V

SS

V

DDIO

ADCINA6/COMP3A/AIO6

ADCINA5

ADCINA4/COMP2A/AIO4

ADCINA2/COMP1A/AIO2

ADCINA1

ADCINA0, V

REFHI

V

DDA

GPIO10/EPWM6A/ADCSOCBO

GPIO11/EPWM6B/SCIRXDB/ECAP1

GPIO36/TMS

GPIO35/TDI

GPIO37/TDO

GPIO34/COMP2OUT/COMP3OUT

GPIO38/XCLKIN/TCK

GPIO39

GPIO19/XCLKIN/ /SCIRXDB/ECAP1SPISTEA

VDDVSSV

DDIO

X1

X2

GPIO6/EPWM4A/EPWMSYNCI/EPWMSYNCO

GPIO7/EPWM4B/SCIRXDA/ECAP2

GPIO16/SPISIMOA/TZ2

GPIO8/EPWM5A/ADCSOCAO

GPIO17/SPISOMIA/TZ3

GPIO18/SPICLKA/SCITXDB/XCLKOUT

GPIO26/ECAP3/SPICLKB/USB0DP

GPIO27/HRCAP2/SPISTEB/USB0DM

V

DDIO

V

SS

V

DD

GPIO3/EPWM2B/SPISOMIA/COMP2OUT

GPIO2/EPWM2A

GPIO1/EPWM1B/COMP1OUT

GPIO0/EPWM1A

GPIO15/ECAP2/SCIRXDB/SPISTEB

VREGENZ

V

DD

V

SS

V

DDIO

GPIO13/ /SPISOMIBTZ2

GPIO14/ /SCITXDB/SPICLKBTZ3

GPIO24/ECAP1/SPISIMOB

GPIO22/EQEP1S/MCLKXA/SCITXDB

GPIO32/SDAA/EPWMSYNCI/ADCSOCAO

GPIO33/SCLA/EPWMSYNCO/ADCSOCBO

GPIO29/SCITXDA/SCLA/TZ3

GPIO12/ /SCITXDA/SPISIMOBTZ1

TEST2

V

DD3VFL

V

SS

GPIO9/EPWM5B/SCITXDB/ECAP3

GPIO28/SCIRXDA/SDAA/TZ2

GPIO30/CANRXA/EPWM7A

GPIO31/CANTXA/EPWM8A

GPIO25/ECAP2/SPISOMIB

V

DD

V

SS

V

DDIO

ADCINB6/COMP3B/AIO14

ADCINB5

ADCINB4/COMP2B/AIO12

ADCINB2/COMP1B/AIO10

ADCINB1

ADCINB0

V , V

REFLO SSA

TMS320F28069,TMS320F28068,TMS320F28067,TMS320F28066

TMS320F28065, TMS320F28064, TMS320F28063, TMS320F28062

www.ti.com

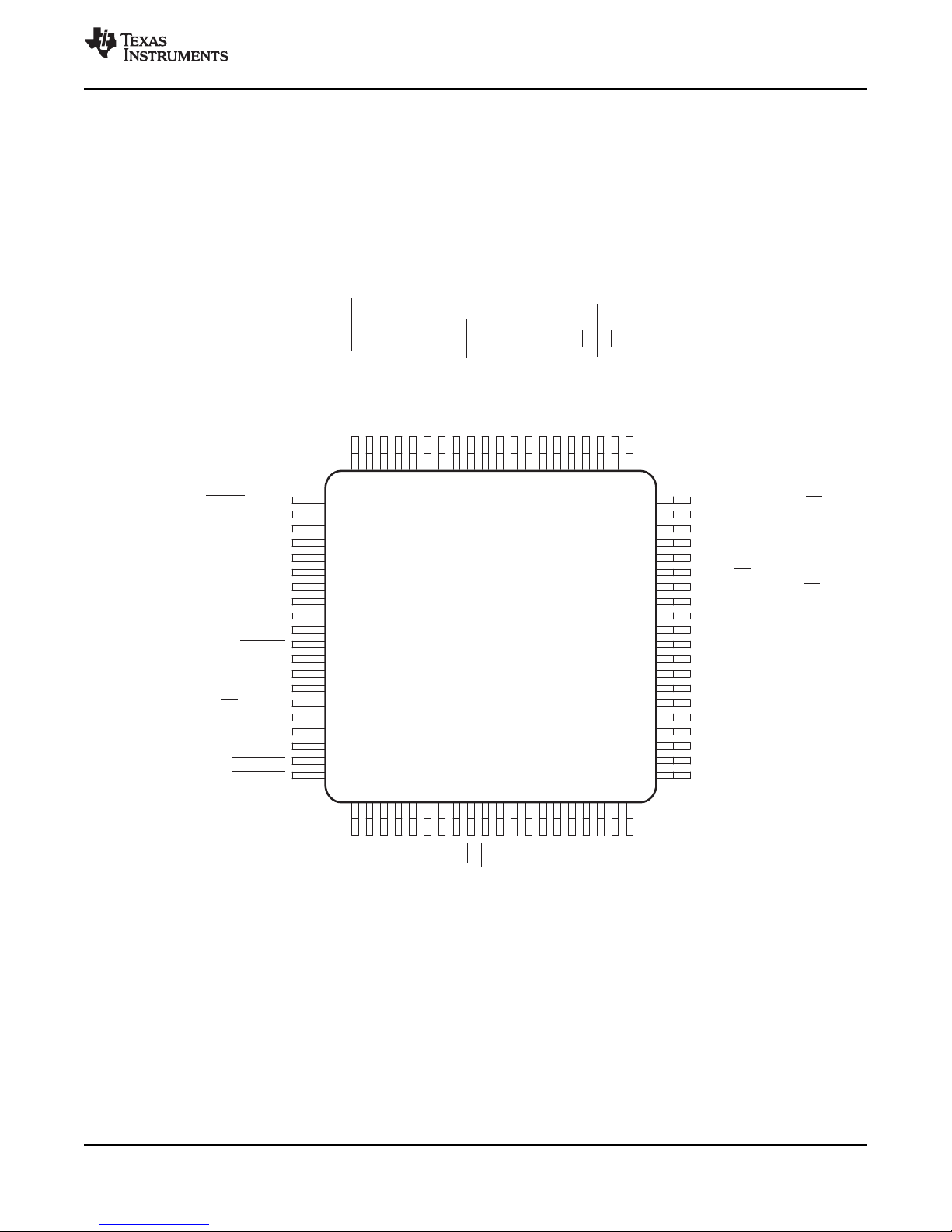

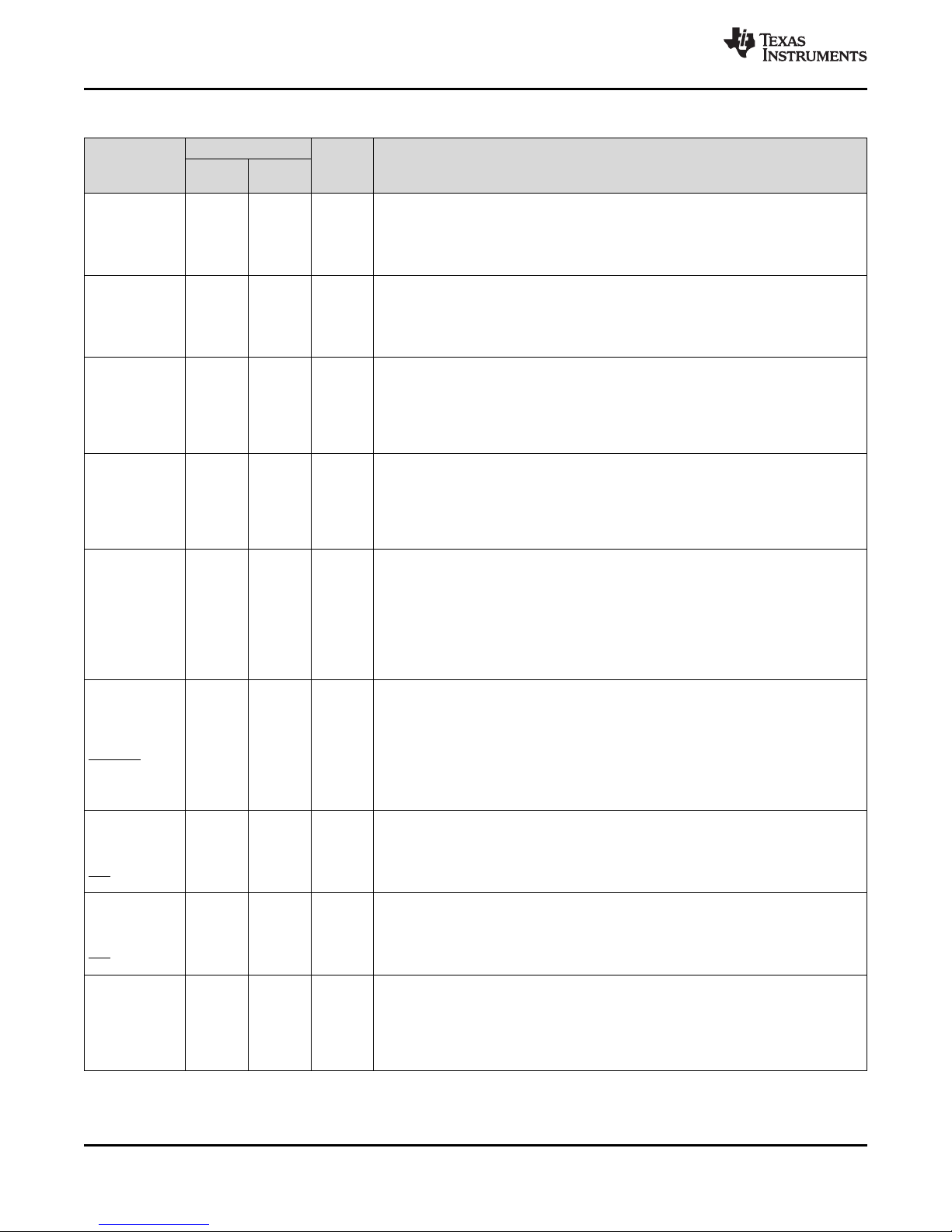

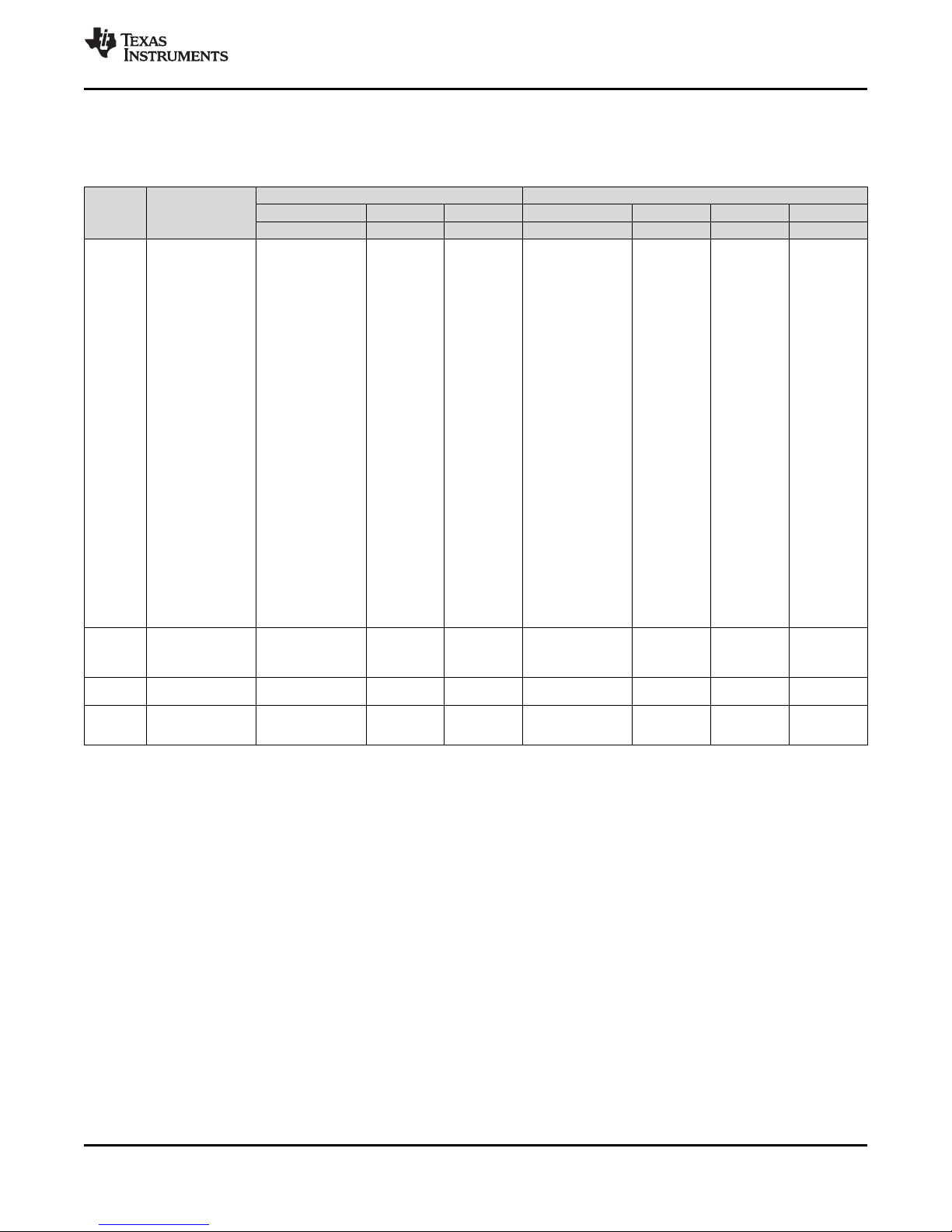

4 Terminal Configuration and Functions

4.1 Pin Diagrams

Figure 4-1 shows the pin assignments on the 80-pin PN and PFP packages. Figure 4-2 shows the pin

assignments on the 100-pin PZ and PZP packages.

SPRS698F –NOVEMBER 2010–REVISED MARCH 2016

A. Pin 19: V

exclusive to one another.

Pin 21: V

REFHI

is always connected to V

REFLO

and ADCINA0 share the same pin on the 80-pin PN and PFP devices and their use is mutually

B. The PowerPAD is not connected to the ground on the die. To facilitate effective heat dissipation, the PowerPAD must

be connected to the ground plane of the PCB. It should not be left unconnected. For more details, see the

PowerPAD™ Thermally Enhanced Package Application Report (SLMA002).

Figure 4-1. 80-Pin PN and PFP Packages (Top View)

Product Folder Links: TMS320F28069 TMS320F28068 TMS320F28067 TMS320F28066 TMS320F28065

SSA

on the 80-pin PN and PFP devices.

Submit Documentation Feedback

TMS320F28064 TMS320F28063 TMS320F28062

Terminal Configuration and FunctionsCopyright © 2010–2016, Texas Instruments Incorporated

9

Page 10

75

74

73

72

71

70

69

68

67

66

65

64

63

62

50

49

48

47

46

45

44

43

42

41

40

39

38

37

76

77

78

79

80

81

82

83

84

85

86

87

88

89

1

2

3

4

5

6

7

8

9

10

11

12

13

14

61

60

59

58

57

56

15

16

17

18

19

20

90

91

92

93

94

95

36

35

34

33

32

31

21

22

23

24

25

30

29

28

27

26

55

54

53

52

51

96

97

98

99

100

V

DD

V

DD

V

DD

V

DD

V

DD

V

DD

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

SS

V

DDIO

V

DDIO

V

DDIO

V

DDIO

V

REFHI

V

DDIO

V

DDIO

V

DD3VFL

V

SSA

TEST2

ADCINB7

ADCINB3

X1

X2

VREGENZ

V

REFLO

ADCINB6/COMP3B/AIO14

ADCINB5

ADCINB4/COMP2B/AIO12

ADCINB2/COMP1B/AIO10

ADCINB1

ADCINB0

GPIO0/EPWM1A

GPIO1/EPWM1B/COMP1OUT

GPIO2/EPWM2A

GPIO56/SPICLKA/EQEP2I/HRCAP3

GPIO57/ /EQEP2S/HRCAP4SPISTEA

GPIO58/MCLKRA/SCITXDB/EPWM7A

GPIO40/EPWM7A/SCITXDB

GPIO41/EPWM7B/SCIRXDB

GPIO3/EPWM2B/SPISOMIA/COMP2OUT

GPIO6/EPWM4A/EPWMSYNCI/EPWMSYNCO

GPIO44/MFSRA/SCIRXDB/EPWM7B

GPIO7/EPWM4B/SCIRXDA/ECAP2

GPIO8/EPWM5A/ADCSOCAO

GPIO9/EPWM5B/SCITXDB/ECAP3

GPIO10/EPWM6A/ADCSOCBO

GPIO11/EPWM6B/SCIRXDB/ECAP1

GPIO12/ /SCITXDA/SPISIMOBTZ1

GPIO13/ /SPISOMIBTZ2

GPIO14/ /SCITXDB/SPICLKBTZ3

GPIO15/ECAP2/SCIRXDB/SPISTEB

GPIO16/SPISIMOA/TZ2

GPIO17/SPISOMIA/TZ3

GPIO42/EPWM8A/ /COMP1OUTTZ1

GPIO43/EPWM8B/ /COMP2OUTTZ2

GPIO18/SPICLKA/SCITXDB/XCLKOUT

GPIO19/XCLKIN/ /SCIRXDB/ECAP1SPISTEA

GPIO22/EQEP1S/MCLKXA/SCITXDB

GPIO24/ECAP1/EQEP2A/SPISIMOB

GPIO25/ECAP2/EQEP2B/SPISOMIB

GPIO26/ECAP3/EQEP2I/SPICLKB/USB0DP

GPIO27/HRCAP2/EQEP2S/SPISTEB/USB0DM

GPIO28/SCIRXDA/SDAA/TZ2

GPIO29/SCITXDA/SCLA/TZ3

GPIO30/CANRXA/EQEP2I/EPWM7A

GPIO50/EQEP1A/MDXA/TZ1

GPIO51/EQEP1B/MDRA/TZ2

GPIO52/EQEP1S/MCLKXA/TZ3

GPIO53/EQEP1I/MFSXA

GPIO54/SPISIMOA/EQEP2A/HRCAP1

GPIO55/SPISOMIA/EQEP2B/HRCAP2

GPIO31/CANTXA/EQEP2S/EPWM8A

GPIO32/SDAA/EPWMSYNCI/ADCSOCAO

GPIO33/SCLA/EPWMSYNCO/ADCSOCBO

GPIO34/COMP2OUT/COMP3OUT

GPIO35/TDI

GPIO36/TMS

GPIO37/TDO

GPIO38/XCLKIN/TCK

GPIO39

GPIO23/EQEP1I/MFSXA/SCIRXDB

GPIO20/EQEP1A/MDXA/COMP1OUT

GPIO21/EQEP1B/MDRA/COMP2OUT

GPIO4/EPWM3A

GPIO5/EPWM3B/SPISIMOA/ECAP1

ADCINA7

ADCINA3

XRS

TRST

ADCINA6/COMP3A/AIO6

ADCINA5

ADCINA4/COMP2A/AIO4

ADCINA2/COMP1A/AIO2

ADCINA1

ADCINA0

V

DDA

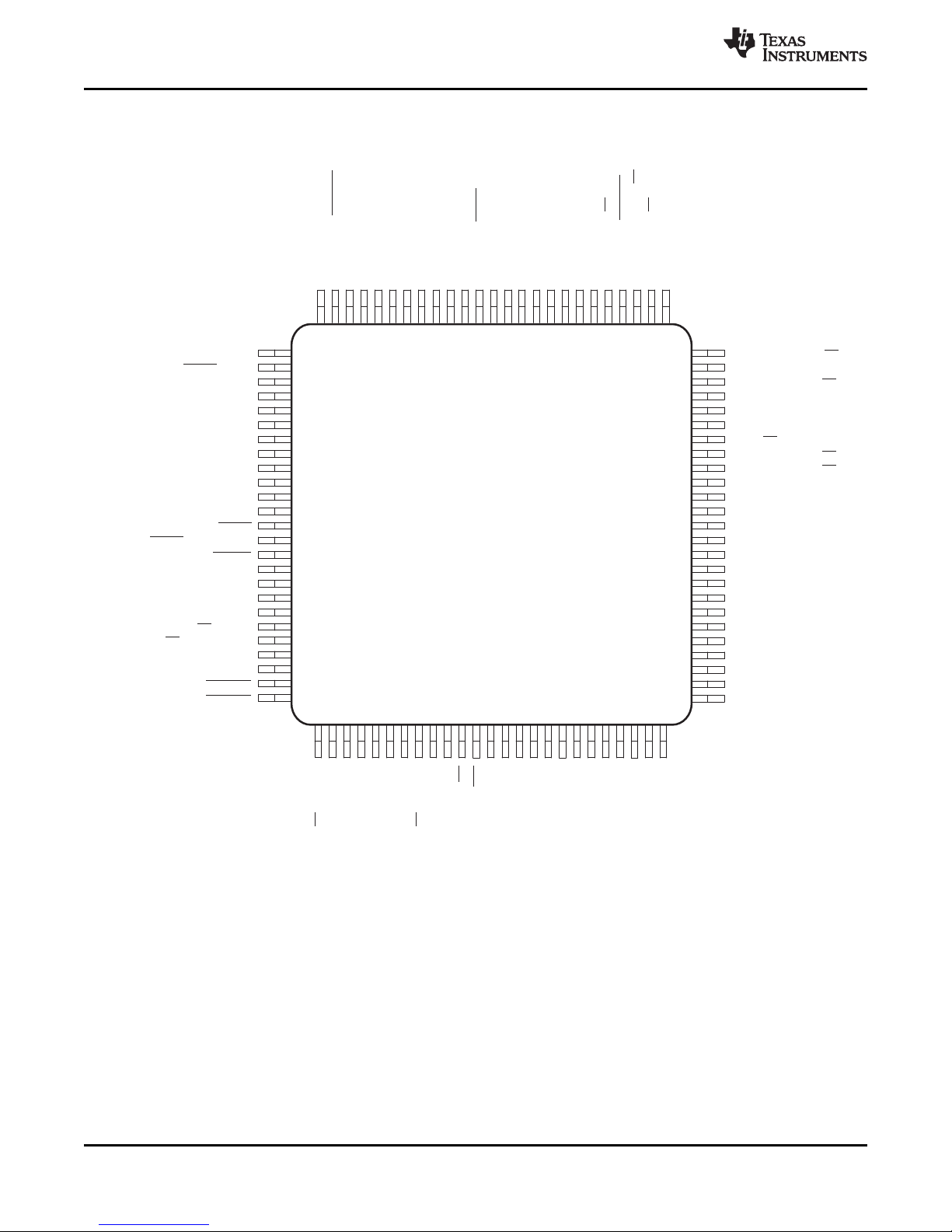

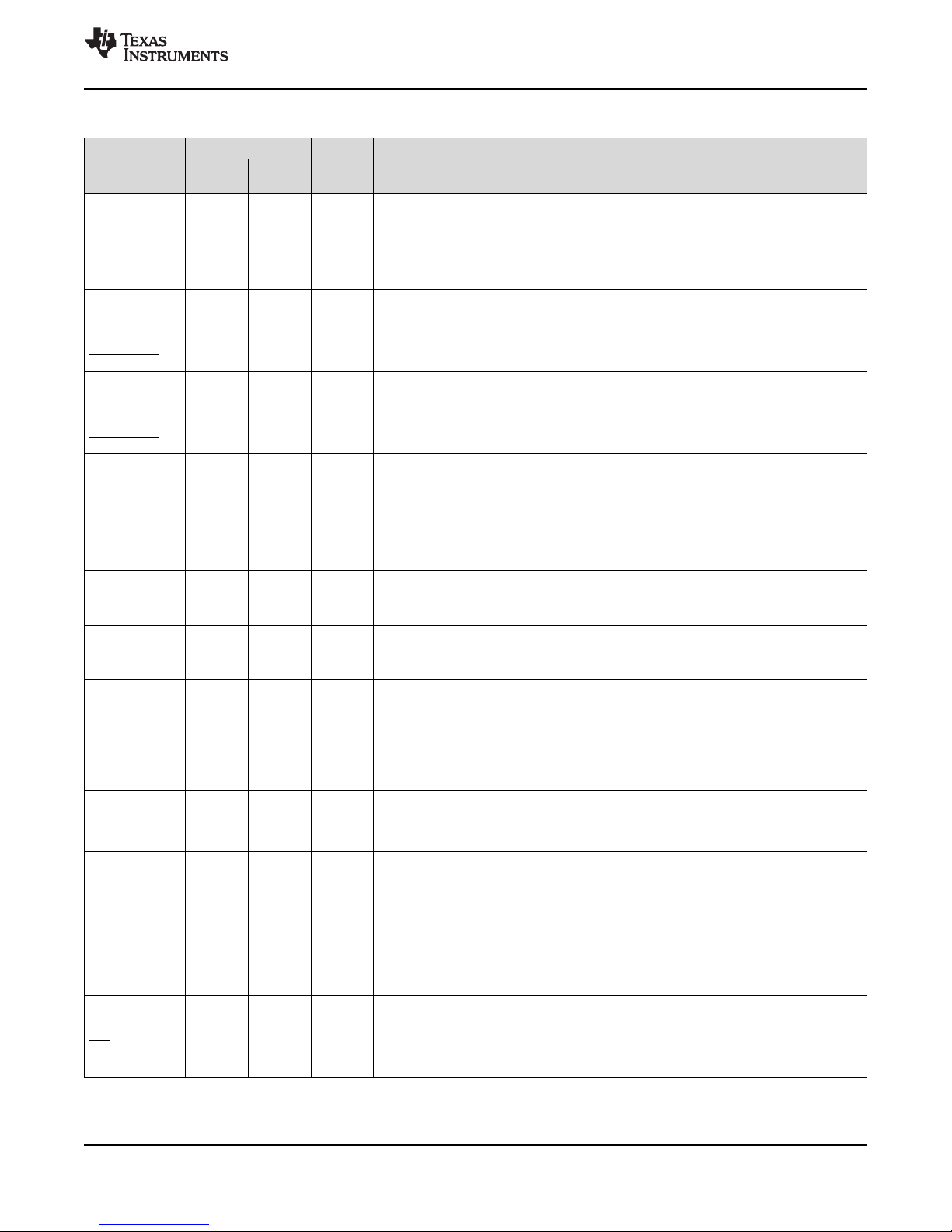

TMS320F28069,TMS320F28068,TMS320F28067,TMS320F28066

TMS320F28065, TMS320F28064, TMS320F28063, TMS320F28062

SPRS698F –NOVEMBER 2010–REVISED MARCH 2016

www.ti.com

A. The PowerPAD is not connected to the ground on the die. To facilitate effective heat dissipation, the PowerPAD must

be connected to the ground plane of the PCB. It should not be left unconnected. For more details, see the

PowerPAD™ Thermally Enhanced Package Application Report (SLMA002).

Figure 4-2. 100-Pin PZ and PZP Packages (Top View)

10

Terminal Configuration and Functions Copyright © 2010–2016, Texas Instruments Incorporated

Product Folder Links: TMS320F28069 TMS320F28068 TMS320F28067 TMS320F28066 TMS320F28065

Submit Documentation Feedback

TMS320F28064 TMS320F28063 TMS320F28062

Page 11

www.ti.com

4.2 Signal Descriptions

Table 4-1 describes the signals. With the exception of the JTAG pins, the GPIO function is the default at

reset, unless otherwise mentioned. The peripheral signals that are listed under them are alternate

functions. Some peripheral functions may not be available in all devices. See Table 3-1 for details. Inputs

are not 5-V tolerant. All GPIO pins are I/O/Z and have an internal pullup (PU), which can be selectively

enabled or disabled on a per-pin basis. This feature only applies to the GPIO pins. The pullups on the

PWM pins are not enabled at reset. The pullups on other GPIO pins are enabled upon reset. The AIO pins

do not have an internal pullup.

When the on-chip voltage regulator (VREG) is used, the GPIO19, GPIO26–27, and

GPIO34–38 pins could glitch during power up. If this is unacceptable in an application, 1.8 V

could be supplied externally. There is no power-sequencing requirement when using an

external 1.8-V supply. However, if the 3.3-V transistors in the level-shifting output buffers of

the I/O pins are powered before the 1.9-V transistors, it is possible for the output buffers to

turn on, causing a glitch to occur on the pin during power up. To avoid this behavior, power

the VDDpins before or simultaneously with the V

reached 0.7 V before the V

TMS320F28069,TMS320F28068,TMS320F28067,TMS320F28066

TMS320F28065, TMS320F28064, TMS320F28063, TMS320F28062

SPRS698F –NOVEMBER 2010–REVISED MARCH 2016

NOTE

pins, ensuring that the VDDpins have

pins reach 0.7 V.

DDIO

DDIO

Table 4-1. Signal Descriptions

PIN NO.

PIN NAME

TRST 12 10 I

TCK See GPIO38 I See GPIO38. JTAG test clock with internal pullup. (↑)

TMS See GPIO36 I

TDI See GPIO35 I

TDO See GPIO37 O/Z

V

DD3VFL

TEST2 45 36 I/O Test Pin. Reserved for TI. Must be left unconnected.

PZ

PZP

46 37 3.3-V Flash Core Power Pin. This pin should be connected to 3.3 V at all times.

PN

PFP

I/O/Z DESCRIPTION

JTAG

JTAG test reset with internal pulldown (PD). TRST, when driven high, gives the scan

system control of the operations of the device. If this signal is not connected or driven

low, the device operates in its functional mode, and the test reset signals are ignored.

NOTE: TRST is an active-high test pin and must be maintained low at all times during

normal device operation. An external pulldown resistor is required on this pin. The

value of this resistor should be based on drive strength of the debugger pods

applicable to the design. A 2.2-kΩ resistor generally offers adequate protection.

Because this is application-specific, TI recommends validating each target board for

proper operation of the debugger and the application. (↓)

See GPIO36. JTAG test-mode select (TMS) with internal pullup. This serial control

input is clocked into the TAP controller on the rising edge of TCK. (↑)

See GPIO35. JTAG test data input (TDI) with internal pullup. TDI is clocked into the

selected register (instruction or data) on a rising edge of TCK. (↑)

See GPIO37. JTAG scan out, test data output (TDO). The contents of the selected

register (instruction or data) are shifted out of TDO on the falling edge of TCK.

(8-mA drive)

FLASH

(1)

Product Folder Links: TMS320F28069 TMS320F28068 TMS320F28067 TMS320F28066 TMS320F28065

Submit Documentation Feedback

TMS320F28064 TMS320F28063 TMS320F28062

Terminal Configuration and FunctionsCopyright © 2010–2016, Texas Instruments Incorporated

11

Page 12

TMS320F28069,TMS320F28068,TMS320F28067,TMS320F28066

TMS320F28065, TMS320F28064, TMS320F28063, TMS320F28062

SPRS698F –NOVEMBER 2010–REVISED MARCH 2016

www.ti.com

Table 4-1. Signal Descriptions

PIN NO.

PIN NAME

XCLKOUT See GPIO18 O/Z

XCLKIN

X1 60 48 I

X2 59 47 O

XRS 11 9 I/OD

ADCINA7 16 – I ADC Group A, Channel 7 input

ADCINA6

COMP3A I Comparator Input 3A

AIO6 I/O Digital AIO 6

ADCINA5 18 15 I ADC Group A, Channel 5 input

ADCINA4

COMP2A I Comparator Input 2A

AIO4 I/O Digital AIO 4

ADCINA3 20 – I ADC Group A, Channel 3 input

ADCINA2

COMP1A I Comparator Input 1A

AIO2 I/O Digital AIO 2

ADCINA1 22 18 I ADC Group A, Channel 1 input

ADCINA0 23 19 I

PZ

PZP

See GPIO19 and

17 14

19 16

21 17

PN

PFP

GPIO38

I/O/Z DESCRIPTION

CLOCK

See GPIO18. Output clock derived from SYSCLKOUT. XCLKOUT is either the same

frequency, one-half the frequency, or one-fourth the frequency of SYSCLKOUT. This is

controlled by bits 1:0 (XCLKOUTDIV) in the XCLK register. At reset, XCLKOUT =

SYSCLKOUT/4. The XCLKOUT signal can be turned off by setting XCLKOUTDIV to 3.

The mux control for GPIO18 must also be set to XCLKOUT for this signal to propogate

to the pin.

See GPIO19 and GPIO38. External oscillator input. Pin source for the clock is

controlled by the XCLKINSEL bit in the XCLK register, GPIO38 is the default selection.

This pin feeds a clock from an external 3.3-V oscillator. In this case, the X1 pin, if

available, must be tied to GND and the on-chip crystal oscillator must be disabled

through bit 14 in the CLKCTL register. If a crystal or resonator is used, the XCLKIN

I

path must be disabled by bit 13 in the CLKCTL register.

NOTE: Designs that use the GPIO38/XCLKIN/TCK pin to supply an external clock for

normal device operation may need to incorporate some hooks to disable this path

during debug using the JTAG connector. This is to prevent contention with the TCK

signal, which is active during JTAG debug sessions. The zero-pin internal oscillators

may be used during this time to clock the device.

On-chip 1.8-V crystal-oscillator input. To use this oscillator, a quartz crystal or a

ceramic resonator must be connected across X1 and X2. In this case, the XCLKIN path

must be disabled by bit 13 in the CLKCTL register. If this pin is not used, it must be tied

to GND.

On-chip crystal-oscillator output. A quartz crystal or a ceramic resonator must be

connected across X1 and X2. If X2 is not used, it must be left unconnected.

RESET

Device Reset (in) and Watchdog Reset (out). Piccolo devices have a built-in power-on

reset (POR) and brown-out reset (BOR) circuitry. During a power-on or brown-out

condition, this pin is driven low by the device. An external circuit may also drive this pin

to assert a device reset. This pin is also driven low by the MCU when a watchdog reset

occurs. During watchdog reset, the XRS pin is driven low for the watchdog reset

duration of 512 OSCCLK cycles. A resistor between 2.2 kΩ and 10 kΩ should be

placed between XRS and V

noise filtering, it should be 100 nF or smaller. These values will allow the watchdog to

properly drive the XRS pin to VOLwithin 512 OSCCLK cycles when the watchdog reset

is asserted. Regardless of the source, a device reset causes the device to terminate

execution. The program counter points to the address contained at the location

0x3F FFC0. When reset is deactivated, execution begins at the location designated by

the program counter. The output buffer of this pin is an open-drain with an internal

pullup. (↑)

ADC, COMPARATOR, ANALOG I/O

I ADC Group A, Channel 6 input

I ADC Group A, Channel 4 input

I ADC Group A, Channel 2 input

ADC Group A, Channel 0 input.

NOTE: V

and their use is mutually exclusive to one another.

and ADCINA0 share the same pin on the 80-pin PN and PFP devices

REFHI

(1)

DDIO

(continued)

. If a capacitor is placed between XRS and VSSfor

12

Terminal Configuration and Functions Copyright © 2010–2016, Texas Instruments Incorporated

Product Folder Links: TMS320F28069 TMS320F28068 TMS320F28067 TMS320F28066 TMS320F28065

Submit Documentation Feedback

TMS320F28064 TMS320F28063 TMS320F28062

Page 13

www.ti.com

TMS320F28069,TMS320F28068,TMS320F28067,TMS320F28066

TMS320F28065, TMS320F28064, TMS320F28063, TMS320F28062

SPRS698F –NOVEMBER 2010–REVISED MARCH 2016

Table 4-1. Signal Descriptions

(1)

PIN NO.

PIN NAME

PZ

PZP

PN

PFP

I/O/Z DESCRIPTION

ADC External Reference High – only used when in ADC external reference mode. See

V

REFHI

24 19

Section 6.9.2.1.

NOTE: V

and their use is mutually exclusive to one another.

and ADCINA0 share the same pin on the 80-pin PN and PFP devices

REFHI

ADCINB7 35 – I ADC Group B, Channel 7 input

ADCINB6

COMP3B I Comparator Input 3B

34 27

I ADC Group B, Channel 6 input

AIO14 I/O Digital AIO 14

ADCINB5 33 26 I ADC Group B, Channel 5 input

ADCINB4

COMP2B I Comparator Input 2B

32 25

I ADC Group B, Channel 4 input

AIO12 I/O Digital AIO12

ADCINB3 31 – I ADC Group B, Channel 3 input

ADCINB2

COMP1B I Comparator Input 1B

30 24

I ADC Group B, Channel 2 input

AIO10 I/O Digital AIO 10

ADCINB1 29 23 I ADC Group B, Channel 1 input

ADCINB0 28 22 I ADC Group B, Channel 0 input

V

REFLO

27 21

ADC External Reference Low.

NOTE: V

is always connected to V

REFLO

CPU AND I/O POWER

V

DDA

V

SSA

25 20 Analog Power Pin. Tie with a 2.2-μF capacitor (typical) close to the pin.

26 21

Analog Ground Pin.

NOTE: V

is always connected to V

REFLO

3 2

14 12

V

DD

37 29

63 51

CPU and Logic Digital Power Pins. When using internal VREG, place one 1.2-µF

capacitor between each VDDpin and ground. Higher value capacitors may be used.

81 65

91 72

5 4

13 11

V

DDIO

38 30

61 49

Digital I/O and Flash Power Pin. Single supply source when VREG is enabled. Place a

2.2-uF decoupling capacitor on each pin. The exact value of the total decoupling

capacitance should be determined by the system voltage regulation solution.

79 63

93 74

4 3

15 13

36 28

V

SS

47 38

Digital Ground Pins

62 50

80 64

92 73

(continued)

on the 80-pin PN and PFP devices.

SSA

on the 80-pin PN and PFP devices.

SSA

Product Folder Links: TMS320F28069 TMS320F28068 TMS320F28067 TMS320F28066 TMS320F28065

Submit Documentation Feedback

TMS320F28064 TMS320F28063 TMS320F28062

Terminal Configuration and FunctionsCopyright © 2010–2016, Texas Instruments Incorporated

13

Page 14

TMS320F28069,TMS320F28068,TMS320F28067,TMS320F28066

TMS320F28065, TMS320F28064, TMS320F28063, TMS320F28062

SPRS698F –NOVEMBER 2010–REVISED MARCH 2016

www.ti.com

Table 4-1. Signal Descriptions

PIN NO.

PIN NAME

VREGENZ 90 71 I Internal VREG Enable/Disable. Pull low to enable VREG, pull high to disable VREG.

GPIO0

EPWM1A O Enhanced PWM1 Output A and HRPWM channel

GPIO1

EPWM1B O Enhanced PWM1 Output B

COMP1OUT O Direct output of Comparator 1

GPIO2

EPWM2A O Enhanced PWM2 Output A and HRPWM channel

GPIO3

EPWM2B O Enhanced PWM2 Output B

SPISOMIA I/O SPI-A slave out, master in

COMP2OUT O Direct output of Comparator 2

GPIO4

EPWM3A O Enhanced PWM3 output A and HRPWM channel

GPIO5

EPWM3B O Enhanced PWM3 output B

SPISIMOA I/O SPI-A slave in, master out

ECAP1 I/O Enhanced Capture input/output 1

GPIO6

EPWM4A O Enhanced PWM4 output A and HRPWM channel

EPWMSYNCI I External ePWM sync pulse input

EPWMSYNCO O External ePWM sync pulse output

GPIO7

EPWM4B O Enhanced PWM4 output B

SCIRXDA I SCI-A receive data

ECAP2 I/O Enhanced Capture input/output 2

GPIO8

EPWM5A O Enhanced PWM5 output A and HRPWM channel

Reserved – Reserved

ADCSOCAO O ADC start-of-conversion A

GPIO9

EPWM5B O Enhanced PWM5 output B

SCITXDB O SCI-B transmit data

ECAP3 I/O Enhanced Capture input/output 3

GPIO10

EPWM6A O Enhanced PWM6 output A and HRPWM channel

Reserved – Reserved

ADCSOCBO O ADC start-of-conversion B

GPIO11

EPWM6B O Enhanced PWM6 output B

SCIRXDB I SCI-B receive data

ECAP1 I/O Enhanced Capture input/output 1

PZ

PZP

87 69

86 68

84 67

83 66

9 7

10 8

58 46

57 45

54 43

49 39

74 60

73 59

PN

PFP

I/O/Z DESCRIPTION

VOLTAGE REGULATOR CONTROL SIGNAL

GPIO AND PERIPHERAL SIGNALS

I/O/Z General-purpose input/output 0

I/O/Z General-purpose input/output 1

I/O/Z General-purpose input/output 2

I/O/Z General-purpose input/output 3

I/O/Z General-purpose input/output 4

I/O/Z General-purpose input/output 5

I/O/Z General-purpose input/output 6

I/O/Z General-purpose input/output 7

I/O/Z General-purpose input/output 8

I/O/Z General-purpose input/output 9

I/O/Z General-purpose input/output 10

I/O/Z General-purpose input/output 11

(1)

(continued)

(2)

14

Terminal Configuration and Functions Copyright © 2010–2016, Texas Instruments Incorporated

Product Folder Links: TMS320F28069 TMS320F28068 TMS320F28067 TMS320F28066 TMS320F28065

Submit Documentation Feedback

TMS320F28064 TMS320F28063 TMS320F28062

Page 15

www.ti.com

TMS320F28069,TMS320F28068,TMS320F28067,TMS320F28066

TMS320F28065, TMS320F28064, TMS320F28063, TMS320F28062

SPRS698F –NOVEMBER 2010–REVISED MARCH 2016

Table 4-1. Signal Descriptions

PIN NO.

PIN NAME

GPIO12

TZ1 I Trip Zone input 1

SCITXDA O SCI-A transmit data

SPISIMOB I/O SPI-B slave in, master out

GPIO13

TZ2 I Trip Zone input 2

Reserved – Reserved

SPISOMIB I/O SPI-B slave out, master in

GPIO14

TZ3 I Trip zone input 3

SCITXDB O SCI-B transmit data

SPICLKB I/O SPI-B clock input/output

GPIO15

ECAP2 I/O Enhanced Capture input/output 2

SCIRXDB I SCI-B receive data

SPISTEB I/O SPI-B slave transmit enable input/output

GPIO16

SPISIMOA I/O SPI-A slave in, master out

Reserved – Reserved

TZ2 I Trip Zone input 2

GPIO17

SPISOMIA I/O SPI-A slave out, master in

Reserved – Reserved

TZ3 I Trip zone input 3

GPIO18

SPICLKA I/O SPI-A clock input/output

SCITXDB O SCI-B transmit data

XCLKOUT

GPIO19

XCLKIN

SPISTEA I/O SPI-A slave transmit enable input/output

SCIRXDB I SCI-B receive data

ECAP1 I/O Enhanced Capture input/output 1

GPIO20

EQEP1A I Enhanced QEP1 input A

MDXA O McBSP transmit serial data

COMP1OUT O Direct output of Comparator 1

GPIO21

EQEP1B I Enhanced QEP1 input B

MDRA I McBSP receive serial data

COMP2OUT O Direct output of Comparator 2

PZ

PZP

44 35

95 75

96 76

88 70

55 44

52 42

51 41

64 52

6 5

7 6

PN

PFP

I/O/Z DESCRIPTION

I/O/Z General-purpose input/output 12

I/O/Z General-purpose input/output 13

I/O/Z General-purpose input/output 14

I/O/Z General-purpose input/output 15

I/O/Z General-purpose input/output 16

I/O/Z General-purpose input/output 17

I/O/Z General-purpose input/output 18

Output clock derived from SYSCLKOUT. XCLKOUT is either the same frequency, one-

half the frequency, or one-fourth the frequency of SYSCLKOUT. This is controlled by

O/Z

bits 1:0 (XCLKOUTDIV) in the XCLK register. At reset, XCLKOUT = SYSCLKOUT/4.

The XCLKOUT signal can be turned off by setting XCLKOUTDIV to 3. The mux control

for GPIO18 must also be set to XCLKOUT for this signal to propogate to the pin.

I/O/Z General-purpose input/output 19

External Oscillator Input. The path from this pin to the clock block is not gated by the

I

mux function of this pin. Care must be taken not to enable this path for clocking if it is

being used for the other peripheral functions.

I/O/Z General-purpose input/output 20

I/O/Z General-purpose input/output 21

(1)

(continued)

Product Folder Links: TMS320F28069 TMS320F28068 TMS320F28067 TMS320F28066 TMS320F28065

Submit Documentation Feedback

TMS320F28064 TMS320F28063 TMS320F28062

Terminal Configuration and FunctionsCopyright © 2010–2016, Texas Instruments Incorporated

15

Page 16

TMS320F28069,TMS320F28068,TMS320F28067,TMS320F28066

TMS320F28065, TMS320F28064, TMS320F28063, TMS320F28062

SPRS698F –NOVEMBER 2010–REVISED MARCH 2016

www.ti.com

Table 4-1. Signal Descriptions

PIN NO.

PIN NAME

GPIO22

EQEP1S I/O Enhanced QEP1 strobe

MCLKXA I/O McBSP transmit clock

SCITXDB O SCI-B transmit data

GPIO23

EQEP1I I/O Enhanced QEP1 index

MFSXA I/O McBSP transmit frame synch

SCIRXDB I SCI-B receive data

GPIO24

ECAP1 I/O Enhanced Capture input/output 1

EQEP2A

SPISIMOB I/O SPI-B slave in, master out

GPIO25

ECAP2 I/O Enhanced Capture input/output 2

EQEP2B I

SPISOMIB I/O SPI-B slave out, master in

GPIO26

ECAP3 I/O Enhanced Capture input/output 3

EQEP2I I/O

SPICLKB I/O SPI-B clock input/output

USB0DP

GPIO27

HRCAP2 I High-Resolution Input Capture 2

EQEP2S I/O

SPISTEB I/O SPI-B slave transmit enable input/output

USB0DM

GPIO28

SCIRXDA I SCI-A receive data

SDAA I/OD I2C data open-drain bidirectional port

TZ2 I Trip zone input 2

GPIO29

SCITXDA O SCI-A transmit data

SCLA I/OD I2C clock open-drain bidirectional port

TZ3 I Trip zone input 3

GPIO30

CANRXA I CAN receive

EQEP2I I/O

EPWM7A O Enhanced PWM7 Output A and HRPWM channel

(3)

(3)

PZ

PZP

98 78

2 1

97 77

39 31

78 62

77 61

50 40

43 34

41 33

PN

PFP

I/O/Z DESCRIPTION

I/O/Z General-purpose input/output 22

I/O/Z General-purpose input/output 23

I/O/Z General-purpose input/output 24

Enhanced QEP2 input A.

I

NOTE: eQEP2 is only available in the PZ and PZP packages.

I/O/Z General-purpose input/output 25

Enhanced QEP2 input B.

NOTE: eQEP2 is only available in the PZ and PZP packages.

I/O/Z General-purpose input/output 26

Enhanced QEP2 index.

NOTE: eQEP2 is only available in the PZ and PZP packages.

Positive Differential half of USB signal. To enable USB functionality on this pin, set the

I/O

USBIOEN bit in the GPACTRL2 register.

I/O/Z General-purpose input/output 27

Enhanced QEP2 strobe.

NOTE: eQEP2 is only available in the PZ and PZP packages.

Negative Differential half of USB signal. To enable USB functionality on this pin, set the

I/O

USBIOEN bit in the GPACTRL2 register.

I/O/Z General-purpose input/output 28

I/O/Z General-purpose input/output 29

I/O/Z General-purpose input/output 30

Enhanced QEP2 index.

NOTE: eQEP2 is only available in the PZ and PZP packages.

(1)

(continued)

16

Terminal Configuration and Functions Copyright © 2010–2016, Texas Instruments Incorporated

Product Folder Links: TMS320F28069 TMS320F28068 TMS320F28067 TMS320F28066 TMS320F28065

Submit Documentation Feedback

TMS320F28064 TMS320F28063 TMS320F28062

Page 17

www.ti.com

TMS320F28069,TMS320F28068,TMS320F28067,TMS320F28066

TMS320F28065, TMS320F28064, TMS320F28063, TMS320F28062

SPRS698F –NOVEMBER 2010–REVISED MARCH 2016

Table 4-1. Signal Descriptions

PIN NO.

PIN NAME

GPIO31

CANTXA O CAN transmit

EQEP2S I/O

EPWM8A O Enhanced PWM8 Output A and HRPWM channel

GPIO32

SDAA I/OD I2C data open-drain bidirectional port

EPWMSYNCI I Enhanced PWM external sync pulse input

ADCSOCAO O ADC start-of-conversion A

GPIO33

SCLA I/OD I2C clock open-drain bidirectional port

EPWMSYNCO O Enhanced PWM external synch pulse output

ADCSOCBO O ADC start-of-conversion B

GPIO34

COMP2OUT O Direct output of Comparator 2

COMP3OUT O Direct output of Comparator 3

GPIO35

TDI

GPIO36

TMS

GPIO37

TDO

GPIO38

XCLKIN

TCK I JTAG test clock with internal pullup

GPIO39 66 53 I/O/Z General-purpose input/output 39

GPIO40

EPWM7A O Enhanced PWM7 output A and HRPWM channel

SCITXDB O SCI-B transmit data

GPIO41

EPWM7B O Enhanced PWM7 output B

SCIRXDB I SCI-B receive data

GPIO42

EPWM8A O Enhanced PWM8 output A and HRPWM channel

TZ1 I Trip zone input 1

COMP1OUT O Direct output of Comparator 1

GPIO43

EPWM8B O Enhanced PWM8 output B

TZ2 I Trip zone input 2

COMP2OUT O Direct output of Comparator 2

PZ

PZP

40 32

99 79

100 80

68 55

71 57

72 58

70 56

67 54

82 –

76 –

1 –

8 –

PFP

PN

I/O/Z DESCRIPTION

I/O/Z General-purpose input/output 31

Enhanced QEP2 strobe.

NOTE: eQEP2 is only available in the PZ and PZP packages.

I/O/Z General-purpose input/output 32

I/O/Z General-purpose input/output 33

I/O/Z General-purpose input/output 34

I/O/Z General-purpose input/output 35

JTAG test data input (TDI) with internal pullup. TDI is clocked into the selected register

I

(instruction or data) on a rising edge of TCK.

I/O/Z General-purpose input/output 36

JTAG test-mode select (TMS) with internal pullup. This serial control input is clocked

I

into the TAP controller on the rising edge of TCK.

I/O/Z General-purpose input/output 37

JTAG scan out, test data output (TDO). The contents of the selected register

O/Z

(instruction or data) are shifted out of TDO on the falling edge of TCK (8 mA drive).

I/O/Z General-purpose input/output 38

External Oscillator Input. The path from this pin to the clock block is not gated by the

I

mux function of this pin. Care must be taken to not enable this path for clocking if it is

being used for the other functions.

I/O/Z General-purpose input/output 40

I/O/Z General-purpose input/output 41

I/O/Z General-purpose input/output 42

I/O/Z General-purpose input/output 43

(1)

(continued)

Product Folder Links: TMS320F28069 TMS320F28068 TMS320F28067 TMS320F28066 TMS320F28065

Submit Documentation Feedback

TMS320F28064 TMS320F28063 TMS320F28062

Terminal Configuration and FunctionsCopyright © 2010–2016, Texas Instruments Incorporated

17

Page 18

TMS320F28069,TMS320F28068,TMS320F28067,TMS320F28066

TMS320F28065, TMS320F28064, TMS320F28063, TMS320F28062

SPRS698F –NOVEMBER 2010–REVISED MARCH 2016

www.ti.com

Table 4-1. Signal Descriptions

PIN NO.

PIN NAME

GPIO44

MFSRA I/O McBSP receive frame synch

SCIRXDB I SCI-B receive data

EPWM7B O Enhanced PWM7 output B

GPIO50

EQEP1A I Enhanced QEP1 input A

MDXA O McBSP transmit serial data

TZ1 I Trip zone input 1

GPIO51

EQEP1B I Enhanced QEP1 input B

MDRA I McBSP receive serial data

TZ2 I Trip zone input 2

GPIO52

EQEP1S I/O Enhanced QEP1 strobe

MCLKXA I/O McBSP transmit clock

TZ3 I Trip zone input 3

GPIO53

EQEP1I I/O Enhanced QEP1 index

MFSXA I/O McBSP transmit frame synch

GPIO54

SPISIMOA I/O SPI-A slave in, master out

EQEP2A I Enhanced QEP2 input A

HRCAP1 I High-Resolution Input Capture 1

GPIO55

SPISOMIA I/O SPI-A slave out, master in

EQEP2B I Enhanced QEP2 input B

HRCAP2 I High-Resolution Input Capture 2

GPIO56

SPICLKA I/O SPI-A clock input/output

EQEP2I I/O Enhanced QEP2 index

HRCAP3 I High-Resolution Input Capture 3

GPIO57

SPISTEA I/O SPI-A slave transmit enable input/output

EQEP2S I/O Enhanced QEP2 strobe

HRCAP4 I High-Resolution Input Capture 4

GPIO58

MCLKRA I/O McBSP receive clock

SCITXDB O SCI-B transmit data

EPWM7A O Enhanced PWM7 output A and HRPWM channel

(1) I = Input, O = Output, Z = High Impedance, OD = Open Drain, ↑ = Pullup, ↓ = Pulldown

(2) The GPIO function (shown in bold italics) is the default at reset. The peripheral signals that are listed under them are alternate functions.

For JTAG pins that have the GPIO functionality multiplexed, the input path to the GPIO block is always valid. The output path from the

GPIO block and the path to the JTAG block from a pin is enabled or disabled based on the condition of the TRST signal. See the

Systems Control and Interrupts chapter of the TMS320x2806x Piccolo Technical Reference Manual (SPRUH18).

(3) Depending on your USB application, additional pins may be required to maintain compliance with the USB 2.0 Specification. For more

information, see the Universal Serial Bus (USB) Controller chapter of the TMS320x2806x Piccolo Technical Reference Manual

(SPRUH18).

PZ

PZP

56 –

42 –

48 –

53 –

65 –

69 –

75 –

85 –

89 –

94 –

PN

PFP

I/O/Z DESCRIPTION

I/O/Z General-purpose input/output 44

I/O/Z General-purpose input/output 50

I/O/Z General-purpose input/output 51

I/O/Z General-purpose input/output 52

I/O/Z General-purpose input/output 53

I/O/Z General-purpose input/output 54

I/O/Z General-purpose input/output 55

I/O/Z General-purpose input/output 56

I/O/Z General-purpose input/output 57

I/O/Z General-purpose input/output 58

(1)

(continued)

18

Terminal Configuration and Functions Copyright © 2010–2016, Texas Instruments Incorporated

Product Folder Links: TMS320F28069 TMS320F28068 TMS320F28067 TMS320F28066 TMS320F28065

Submit Documentation Feedback

TMS320F28064 TMS320F28063 TMS320F28062

Page 19

www.ti.com

5 Specifications

TMS320F28069,TMS320F28068,TMS320F28067,TMS320F28066

TMS320F28065, TMS320F28064, TMS320F28063, TMS320F28062

SPRS698F –NOVEMBER 2010–REVISED MARCH 2016

5.1 Absolute Maximum Ratings

(1)(2)

over operating free-air temperature range (unless otherwise noted)

MIN MAX UNIT

V

(I/O and Flash) with respect to V

Supply voltage

Analog voltage V

Input voltage

Output voltage V

DDIO

VDDwith respect to V

with respect to V

DDA

VIN(3.3 V) –0.3 4.6

VIN(X1) –0.3 2.5

O

Input clamp current IIK(VIN< 0 or VIN> V

Output clamp current IOK(VO< 0 or VO> V

Junction temperature

Storage temperature

(4)

(4)

T

J

T

stg

SS

SS

SSA

(3)

)

DDIO

) –20 20 mA

DDIO

–0.3 4.6

–0.3 2.5

–0.3 4.6 V

–0.3 4.6 V

–20 20 mA

–40 150 °C

–65 150 °C

V

V

(1) Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under Section 5.4 is not implied.

Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) All voltage values are with respect to VSS, unless otherwise noted.

(3) Continuous clamp current per pin is ±2 mA.

(4) Long-term high-temperature storage or extended use at maximum temperature conditions may result in a reduction of overall device life.

For additional information, see the IC Package Thermal Metrics Application Report (SPRA953).

5.2 ESD Ratings for TMS320F2806xU

VALUE UNIT

Human-body model (HBM), per ANSI/ESDA/JEDEC JS-001

V

(ESD)

Electrostatic discharge (ESD)

Charged-device model (CDM), per JEDEC specification JESD22-

(2)

C101

(1) JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

(2) JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

(1)

±2000

±500

V

5.3 ESD Ratings for TMS320F2806x, TMS320F2806xM, and TMS320F2806xF

TMS320F2806x, TMS320F2806xM, and TMS320F2806xF in 100-pin PZ and PZP packages

V

(ESD)

TMS320F2806x, TMS320F2806xM, and TMS320F2806xF in 80-pin PN and PFP packages

V

(ESD)

(1) AEC Q100-002 indicates HBM stressing is done in accordance with the ANSI/ESDA/JEDEC JS-001 specification.

Electrostatic discharge

Electrostatic discharge

Product Folder Links: TMS320F28069 TMS320F28068 TMS320F28067 TMS320F28066 TMS320F28065

Human body model (HBM), per

AEC Q100-002

(1)

Charged device model (CDM),

per AEC Q100-011

All pins ±2000

All pins ±500

Corner pins on 100-pin PZ and

PZP:

1, 25, 26, 50, 51, 75, 76, 100

Human body model (HBM), per

AEC Q100-002

(1)

Charged device model (CDM),

per AEC Q100-011

All pins ±2000

All pins ±500

Corner pins on 80-pin PN and

PFP:

1, 20, 21, 40, 41, 60, 61, 80

Submit Documentation Feedback

TMS320F28064 TMS320F28063 TMS320F28062

VALUE UNIT

V

±750

V

±750

SpecificationsCopyright © 2010–2016, Texas Instruments Incorporated

19

Page 20

TMS320F28069,TMS320F28068,TMS320F28067,TMS320F28066

TMS320F28065, TMS320F28064, TMS320F28063, TMS320F28062

SPRS698F –NOVEMBER 2010–REVISED MARCH 2016

www.ti.com

5.4 Recommended Operating Conditions

MIN NOM MAX UNIT

Device supply voltage, I/O, V

DDIO

Device supply voltage CPU, VDD(When internal VREG is

disabled and 1.8 V is supplied externally)

Supply ground, V

Analog supply voltage, V

Analog ground, V

SS

DDA

SSA

Device clock frequency (system clock) 2 90 MHz

High-level input voltage, VIH(3.3 V) 2 V

Low-level input voltage, VIL(3.3 V) VSS– 0.3 0.8 V

High-level output source current, VOH= V

Low-level output sink current, VOL= V

Junction temperature, T

J

OL(MAX)

OH(MIN)

, I

, I

OH

OL

All GPIO/AIO pins –4

Group 2

(1)

All GPIO/AIO pins 4

Group 2

(1)

T version –40 105

S version –40 125

Ambient temperature, T

A

Q version

(Q100 qualification)

(2)

(1) Group 2 pins are as follows: GPIO16, GPIO17, GPIO18, GPIO19, GPIO28, GPIO29, GPIO36, GPIO37.

(2) The "Q" temperature option is not available on the 2806xU devices.

2.97 3.3 3.63 V

1.71 1.8 1.995

0 V

2.97 3.3 3.63 V

0 V

+ 0.3 V

DDIO

–8

mA

mA

8

–40 125

V

°C

°C

5.5 Electrical Characteristics

(1)

over recommended operating conditions (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

OH

V

OL

High-level output voltage

Low-level output voltage IOL= IOLMAX 0.4 V

Pin with pullup

I

IL

Input current

(low level)

enabled

Pin with pulldown

enabled

Pin with pullup

I

IH

Input current

(high level)

enabled

Pin with pulldown

enabled

I

OZ

C

I

Output current, pullup or

pulldown disabled

Input capacitance 2 pF

V

BOR trip point Falling V

DDIO

V

BOR hysteresis 35 mV

DDIO

Supervisor reset release delay

time

VREG VDDoutput Internal VREG on 1.9 V

(1) When the on-chip VREG is used, its output is monitored by the POR/BOR circuit, which will reset the device should the core voltage

(VDD) go out of range.

IOH= IOHMAX 2.4

IOH= 50 μA V

V

= 3.3 V, VIN= 0 V

DDIO

V

= 3.3 V, VIN= 0 V ±2

DDIO

V

= 3.3 V, VIN= V

DDIO

V

= 3.3 V, VIN= V

DDIO

VO= V

DDIO

or 0 V ±2 μA

DDIO

DDIO

DDIO

All GPIO –80 –140 –205

XRS pin –230 –300 –375

Time after BOR/POR/OVR event is removed to XRS

release

– 0.2

DDIO

28 50 80

2.50 2.78 2.96 V

400 800 μs

±2

V

μA

μA

20

Specifications Copyright © 2010–2016, Texas Instruments Incorporated

Product Folder Links: TMS320F28069 TMS320F28068 TMS320F28067 TMS320F28066 TMS320F28065

Submit Documentation Feedback

TMS320F28064 TMS320F28063 TMS320F28062

Page 21

TMS320F28069,TMS320F28068,TMS320F28067,TMS320F28066

TMS320F28065, TMS320F28064, TMS320F28063, TMS320F28062

www.ti.com

SPRS698F –NOVEMBER 2010–REVISED MARCH 2016

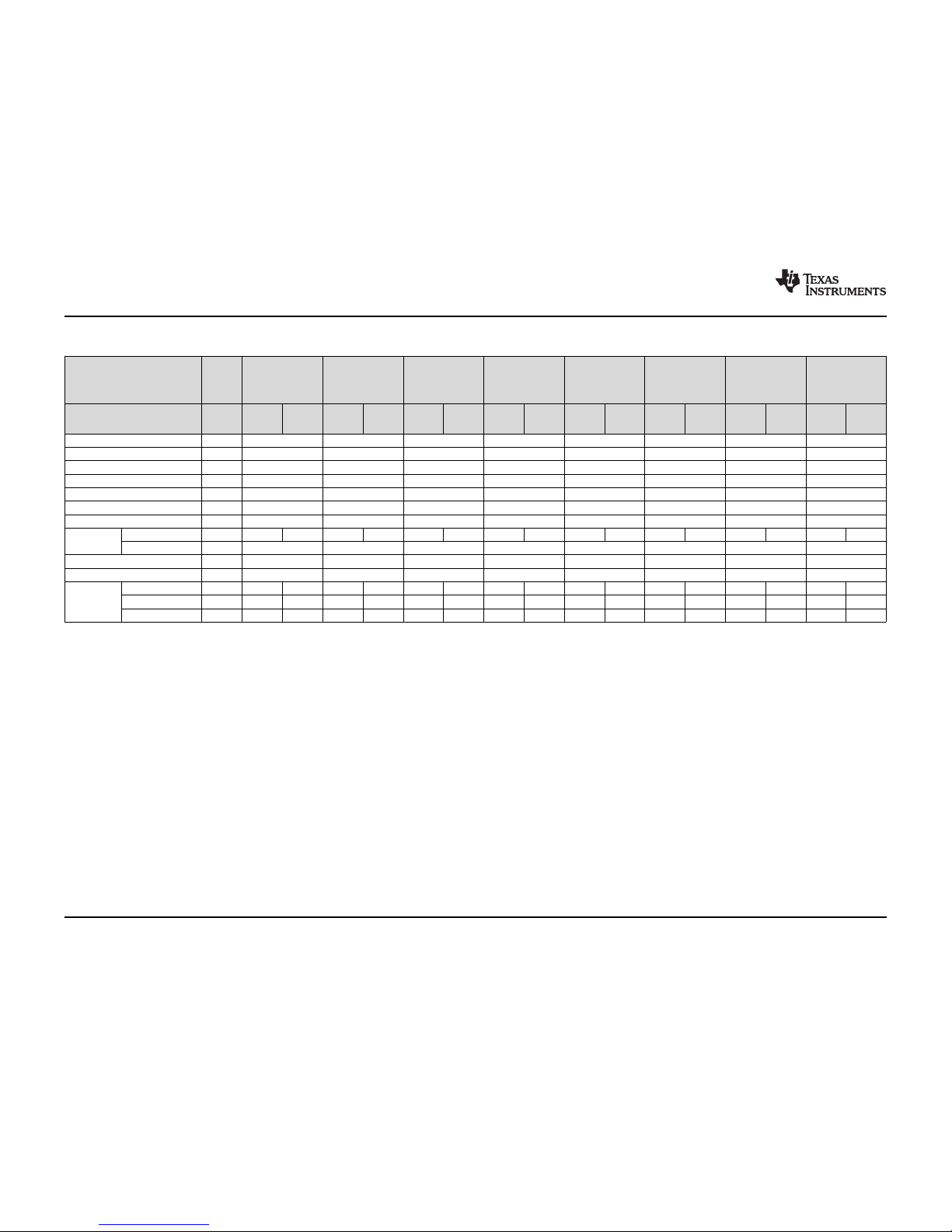

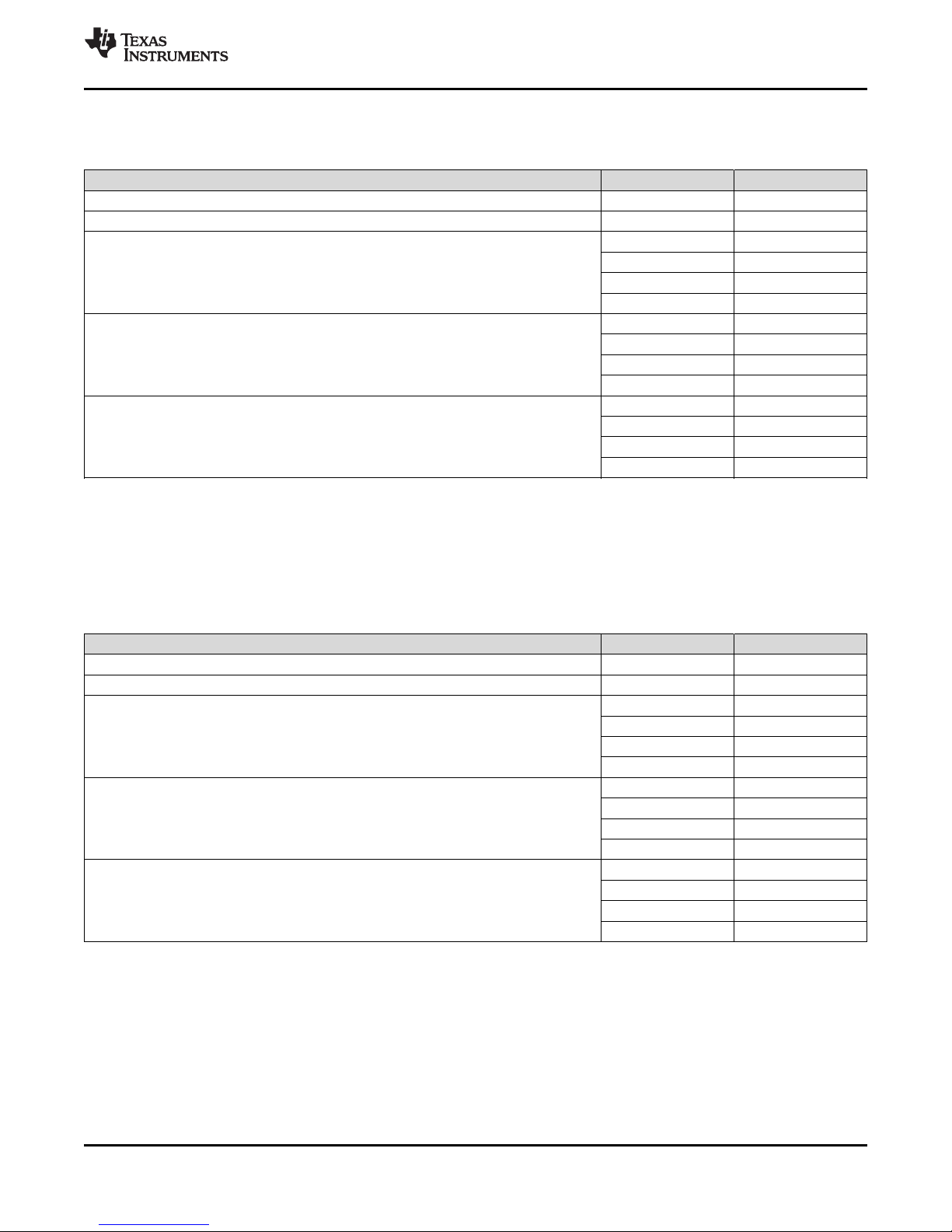

5.6 Power Consumption Summary

Table 5-1. TMS320F2806x Current Consumption at 90-MHz SYSCLKOUT

VREG ENABLED VREG DISABLED

MODE TEST CONDITIONS

The following peripheral

clocks are enabled:

• ePWM1, ePWM2,

ePWM3, ePWM4,

ePWM5, ePWM6,

ePWM7, ePWM8

• eCAP1, eCAP2,

eCAP3

• eQEP1, eQEP2

• eCAN

• CLA

• HRPWM

• SCI-A, SCI-B

Operational

(Flash)

IDLE

STANDBY

HALT

(1) I

(2) In order to realize the I

• SPI-A, SPI-B

• ADC

• I2C

• COMP1, COMP2,

COMP3

• CPU-TIMER0,

CPU-TIMER1,

CPU-TIMER2

• McBSP

• USB

All PWM pins are toggled

at 90 kHz.

All I/O pins are left

unconnected.

Code is running out of

flash with 3 wait-states.

XCLKOUT is turned off.

Flash is powered down.

XCLKOUT is turned off.

All peripheral clocks are

turned off.

Flash is powered down.

Peripheral clocks are off.

Flash is powered down.

Peripheral clocks are off.

Input clock is disabled.

current is dependent on the electrical loading on the I/O pins.

DDIO

(4) (5)

writing to the PCLKCR0 register.

185 mA

(7)

currents shown for IDLE, STANDBY, and HALT, clock to the ADC module must be turned off explicitly by

DDA

(1)

I

DDIO

(3)

TYP

22 mA 27 mA 15 µA 25 µA 5 µA 10 µA 21 mA 26 mA 120 µA 400 µA 15 µA 25 µA 5 µA 10 µA

9 mA 11 mA 15 µA 25 µA 5 µA 10 µA 8 mA 10 mA 120 µA 400 µA 15 µA 25 µA 5 µA 10 µA

75 µA 15 µA 25 µA 5 µA 10 µA 25 µA

MAX TYP

(6)

245 mA

(6)

(3) The TYP numbers are applicable over room temperature and nominal voltage.

(4) The following is done in a loop:

• Data is continuously transmitted out of SPI-A, SPI-B, SCI-A, eCAN-A, McBSP-A, and I2C ports.

• The hardware multiplier is exercised.

• Watchdog is reset.

• ADC is performing continuous conversion.

• COMP1 and COMP2 are continuously switching voltages.

• GPIO17 is toggled.

(5) CLA is continuously performing polynomial calculations.

(6) For F2806x devices that do not have CLA, subtract the IDDcurrent number for CLA (see Table 5-2) from the IDD(VREG disabled)/I

(VREG enabled) current numbers shown in Table 5-1 for operational mode.

(7) If a quartz crystal or ceramic resonator is used as the clock source, the HALT mode shuts down the on-chip crystal oscillator.

(8) To realize the IDDnumber shown for HALT mode, the following must be done:

• PLL2 must be shut down by clearing bit 2 of the PLLCTL register.

• A value of 0x00FF must be written to address 0x6822.

(2)

I

DDA

(3)

MAX TYP

16 mA 22 mA 35 mA 40 mA 165 mA

I

DD3VFL

(3)

MAX TYP

I

DD

(3)

MAX TYP

(6)

(8)

220 mA

(6)

(1)

I

DDIO

(3)

MAX TYP

15 mA 20 mA 16 mA 22 mA 35 mA 40 mA

40 µA 15 µA 25 µA 5 µA 10 µA

I

DDA

(3)

(2)

MAX TYP

I

DD3VFL

(3)

MAX

DDIO

Product Folder Links: TMS320F28069 TMS320F28068 TMS320F28067 TMS320F28066 TMS320F28065

Submit Documentation Feedback

TMS320F28064 TMS320F28063 TMS320F28062

SpecificationsCopyright © 2010–2016, Texas Instruments Incorporated

21

Page 22

TMS320F28069,TMS320F28068,TMS320F28067,TMS320F28066

TMS320F28065, TMS320F28064, TMS320F28063, TMS320F28062

SPRS698F –NOVEMBER 2010–REVISED MARCH 2016

NOTE

The peripheral - I/O multiplexing implemented in the device prevents all available peripherals

from being used at the same time. This is because more than one peripheral function may

share an I/O pin. It is, however, possible to turn on the clocks to all the peripherals at the

same time, although such a configuration is not useful. If this is done, the current drawn by

the device will be more than the numbers specified in the current consumption tables.

www.ti.com

22

Specifications Copyright © 2010–2016, Texas Instruments Incorporated

Product Folder Links: TMS320F28069 TMS320F28068 TMS320F28067 TMS320F28066 TMS320F28065

Submit Documentation Feedback

TMS320F28064 TMS320F28063 TMS320F28062

Page 23

www.ti.com

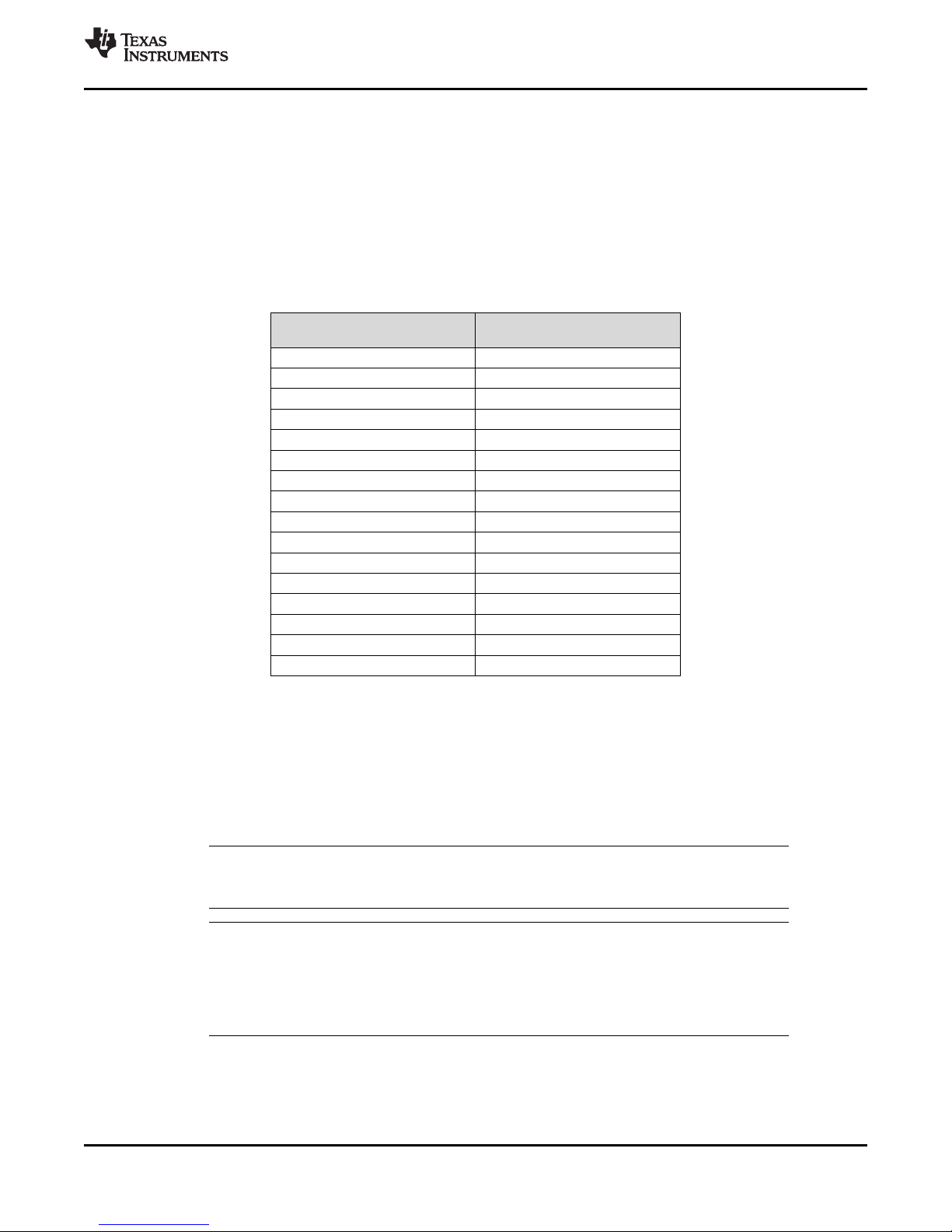

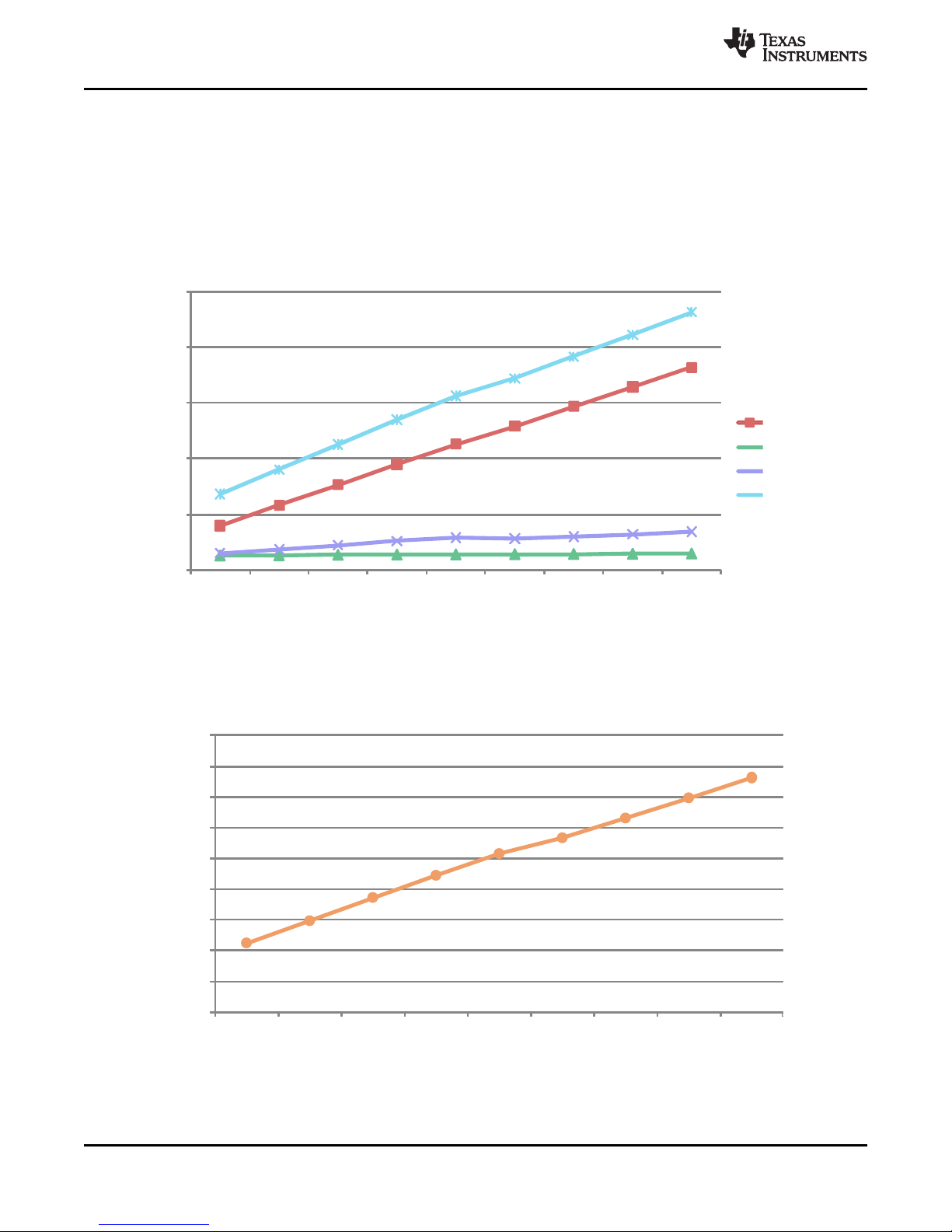

5.6.1 Reducing Current Consumption

The 2806x devices incorporate a method to reduce the device current consumption. Since each peripheral

unit has an individual clock-enable bit, significant reduction in current consumption can be achieved by

turning off the clock to any peripheral module that is not used in a given application. Furthermore, any one

of the three low-power modes could be taken advantage of to reduce the current consumption even

further. Table 5-2 indicates the typical reduction in current consumption achieved by turning off the clocks.

TMS320F28069,TMS320F28068,TMS320F28067,TMS320F28066

TMS320F28065, TMS320F28064, TMS320F28063, TMS320F28062

SPRS698F –NOVEMBER 2010–REVISED MARCH 2016

Table 5-2. Typical Current Consumption by Various

Peripherals (at 90 MHz)

PERIPHERAL

MODULE

COMP/DAC 1

CPU-TIMER 1

Internal zero-pin oscillator 0.5

(1) All peripheral clocks (except CPU Timer clock) are disabled upon

reset. Writing to or reading from peripheral registers is possible only

after the peripheral clocks are turned on.

(2) For peripherals with multiple instances, the current quoted is per

module. For example, the 2 mA value quoted for ePWM is for one

ePWM module.

(3) This number represents the current drawn by the digital portion of

the ADC module. Turning off the clock to the ADC module results in

the elimination of the current drawn by the analog portion of the ADC

(I

) as well.

DDA

(2)

ADC 2

I2C 3

ePWM 2

eCAP 2

eQEP 2

SCI 2

SPI 2

HRPWM 3

HRCAP 3

USB 12

CAN 2.5

CLA 20

McBSP 6

(1)

IDDCURRENT

REDUCTION (mA)

(3)

I

current consumption is reduced by 15 mA (typical) when XCLKOUT is turned off.

DDIO

The baseline IDDcurrent (current when the core is executing a dummy loop with no

peripherals enabled) is 40 mA, typical. To arrive at the IDDcurrent for a given application, the

current-drawn by the peripherals (enabled by that application) must be added to the baseline

IDDcurrent.

Product Folder Links: TMS320F28069 TMS320F28068 TMS320F28067 TMS320F28066 TMS320F28065

NOTE

NOTE

Submit Documentation Feedback

TMS320F28064 TMS320F28063 TMS320F28062

SpecificationsCopyright © 2010–2016, Texas Instruments Incorporated

23

Page 24

0

100

200

300

400

500

600

700

800

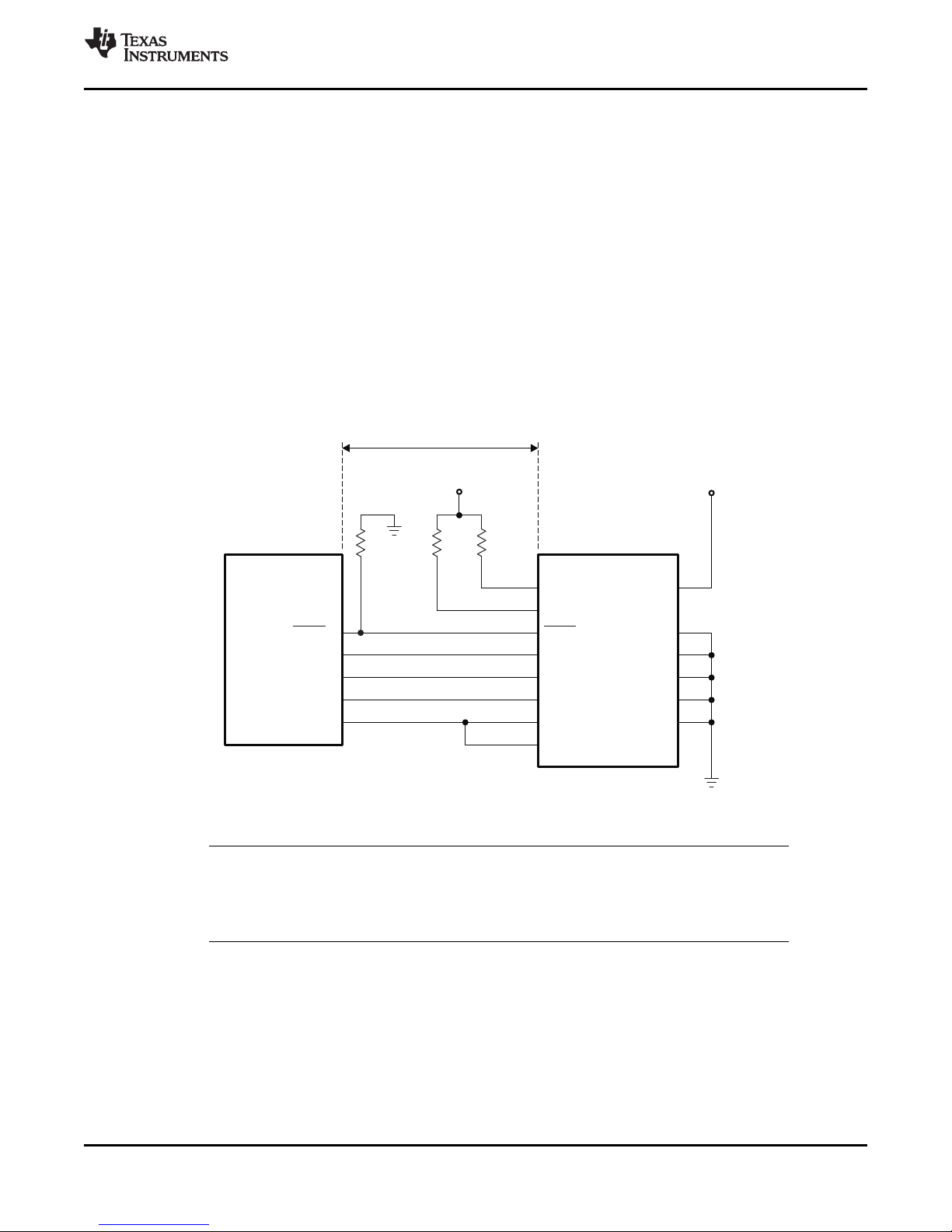

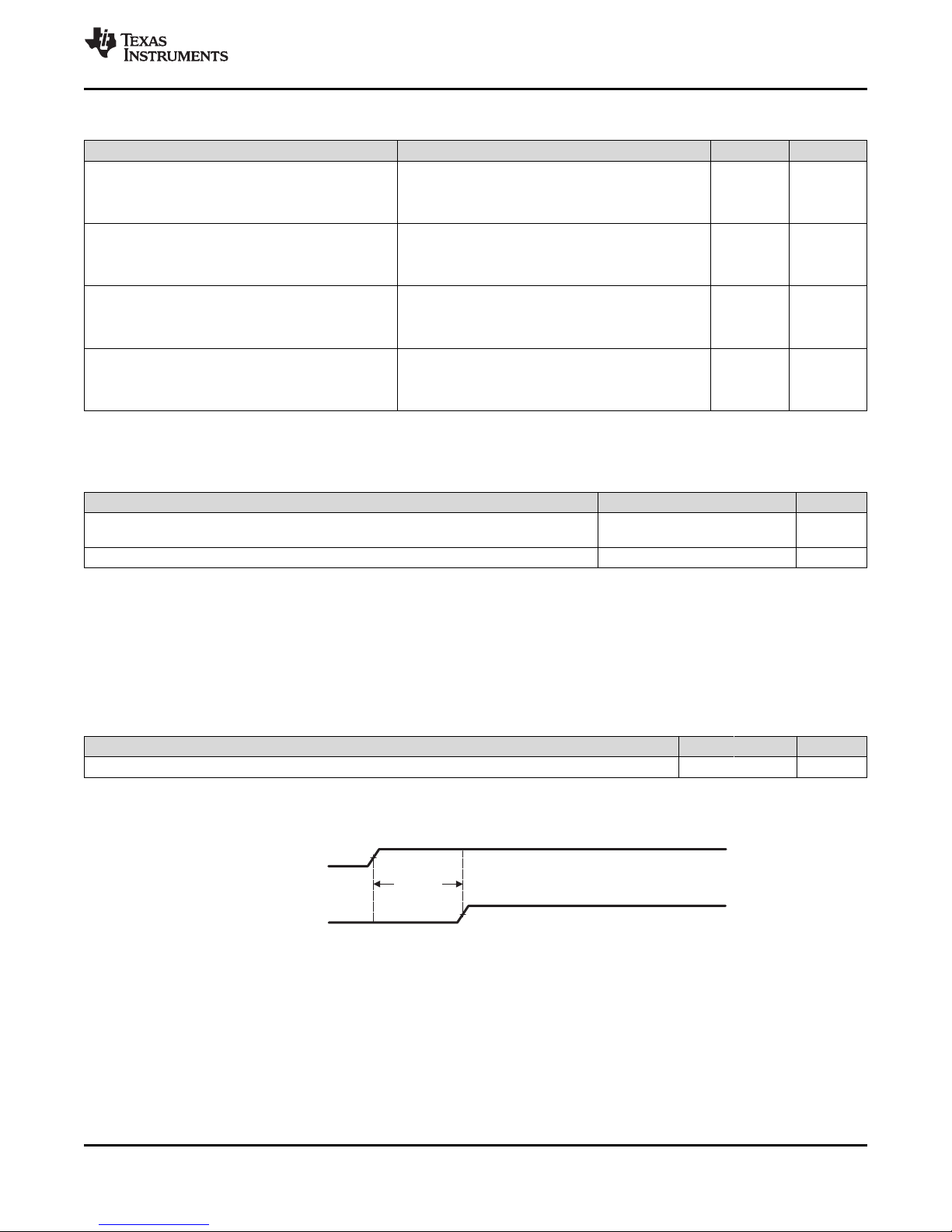

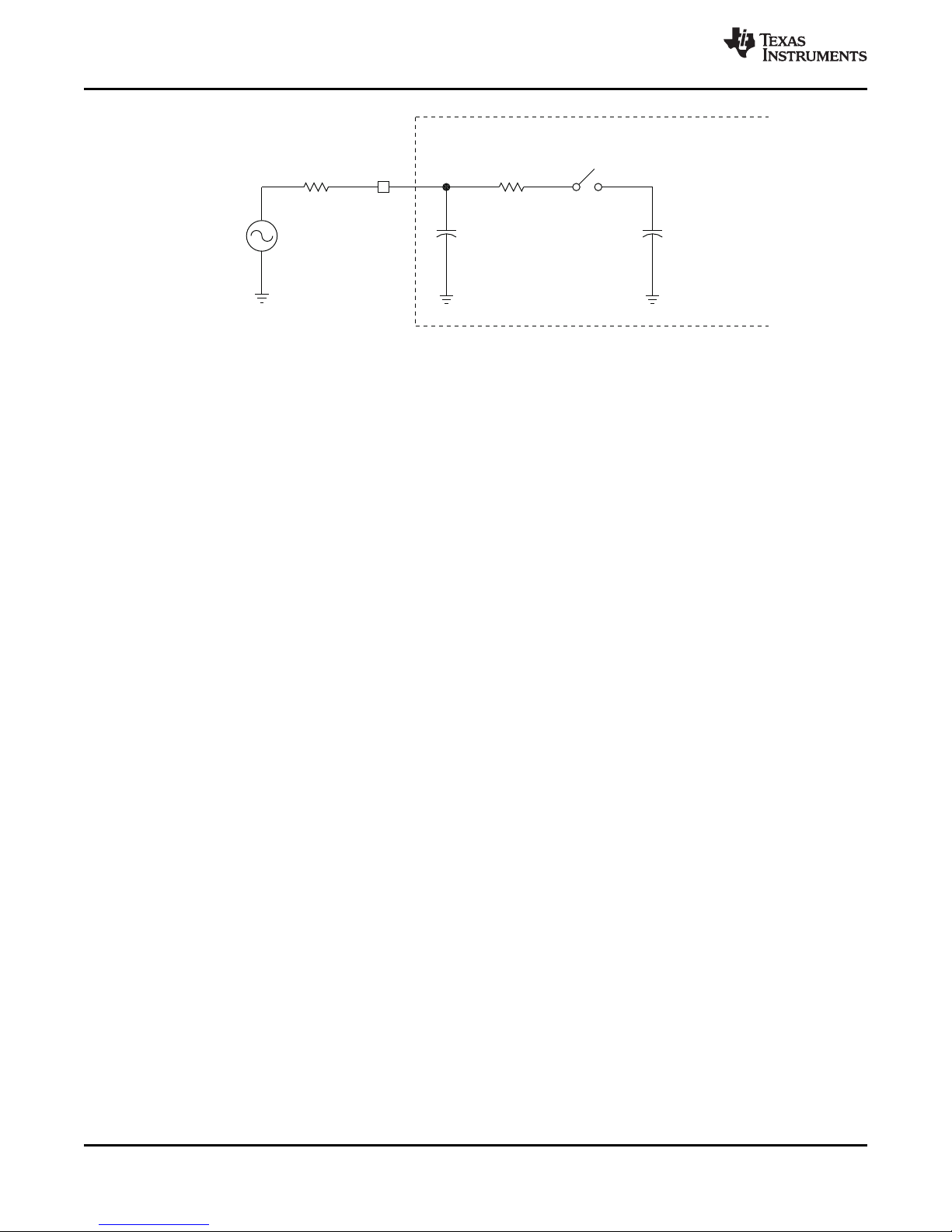

900