Page 1

DRV830x Rev D. Hardware Quick Start Guide

Version 1.0.5 Motor Solutions

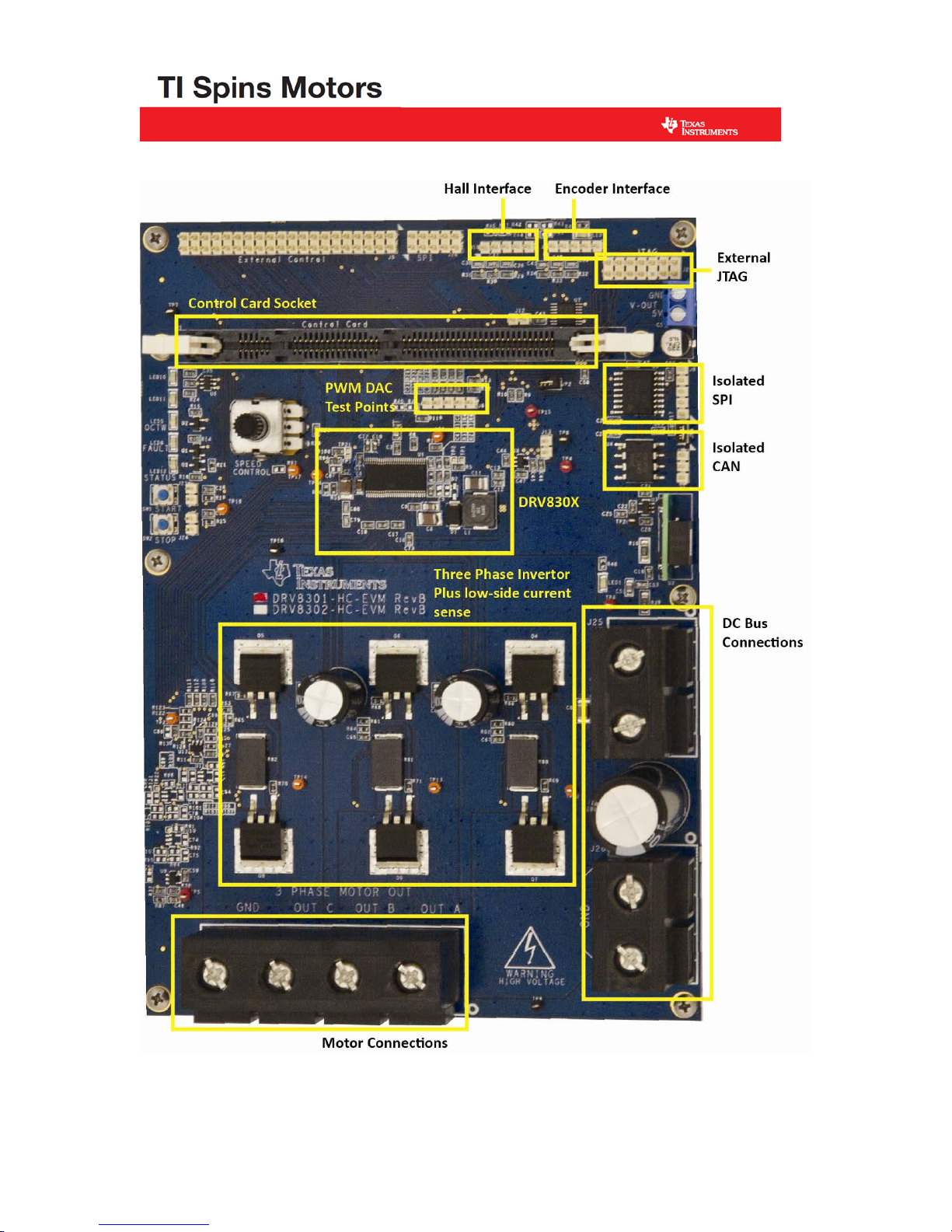

Fig 1: DRV830x EVM with controlCARD

Abstract

The Low Voltage, High C urrent Motor Drive EV M (DRV8301, F igure 1), provides a gr eat way to

learn and experiment with digital control of sub 60 volt three-phase motors to increase efficienc y

of operation. The bo ard is available in two conf igurations, the DRV8301 or the DRV8302. This

document goes over the typical kit contents and hardw are details, and explains t he functions and

locations of jumpers and connectors present on the board. This document supersedes all the

documents available for the kit.

1

Page 2

Version: 1.0.5

Revision History:

1.0.5 April 23, 2014 Fixed page 18-20 co mm ent s rega r di ng A DC

and IQ CURRENT, VOLTAGE, and pole settings

1.04 January 29, 2014 Changed page 8 regarding GPIO to Enable Pin

connection with TMDSCN C D 28027F

1.03 July 11, 2013 Updated for TMDSCNCD28027F support. See

specific instruction s o n Page 8.

Added section on Optimizing Sense Circuitry

1.0.2 March 21, 2013 Added Revision History

1.0.1 February 26,

2013

First release

2

Page 3

WARNING

This EVM is meant to be operated in a lab environment only and is not

considered by TI to be a finished end-product fit for gene ral consu mer u se

This EVM must be used only by qualified engineers and technicians familiar

with risks associated with handling high voltage electrical and

mechanical components, systems and subsystems.

This equipment operates at voltages and currents that can result in electrical shock, fire

hazard and/or personal injury if not properly handled or applied. Equipment must be used

with necessary caution and appropriate safeguards employed to avoid personal injury or

property damage.

It is the user’s responsibility to confirm that the voltages and isolation requirements are

identified and understood, prior to energizing the board and or simulation. When

energized, the EVM or components connected to the EVM should not be touched.

3

Page 4

Table of Contents

Getting Familiar with the Kit .......................................................................................................... 5

Kit Contents .............................................................................................................................................................................. 5

Board Features: ........................................................................................................................................................................ 5

Warning: about low switching frequencies on the DRV830x .................................................................................................... 5

Hardware Overview ........................................................................................................................ 6

Macro Blocks ............................................................................................................................................................................ 6

Powering the Board ......................................................................................................................... 8

Hardware Resource Mapping .......................................................................................................... 9

Resource Allocation .................................................................................................................................................................. 9

Jumpers and Connectors ........................................................................................................................................................ 11

Optimizing Sense Circuitry ........................................................................................................... 16

Overview ................................................................................................................................................................................. 16

Shunt Current Feedback ......................................................................................................................................................... 17

Phase Voltage Feedback ........................................................................................................................................................ 18

Phase Voltage Filter Feedback ............................................................................................................................................... 20

SCHEMATIC DISCLAIMER AND WARNINGS ...................................................................... 22

4

Page 5

Getting Familiar with the Kit

Kit Contents

The DRV830x EVM is usually available packaged as a full solution kit:

• MCU controlCARD

• DRV830x EVM board with slot for the controlCARD

• USB Cable

• USB/DVD with CCStudio IDE, GUI, documentation, and link to project software

distribution

• Some versions ship with a tabl etop 24V 2.5A power supply and 24V M otor with built-in

Hall Sensors and Encoder

The DRV830x EVM board can accept m any of the TI MCU controlCARDs, but we r ecommend

using the versions that ship with the kits that include the JTAG emulator, USB to serial, and

isolation on the controlCARD. It is recommended to always check for any updates to the GUI

executable and MCU program.

Board Features

:

The board has the following features

• Three-Phase Pow er Stage, DRV830x capable of driving 3-phase brushless DC motors

and Permanent Magnet Synchronous Motors.

o 60V DC max input voltage

o 60A peak output current per phase

o Up to 200khz driver switching frequency

o Integrated 1A buck converter to provide logic and analog power

o Dual integrated current sense amplifiers

• Isolated CAN and SPI communication (will only work if MCU supports and SW is

enabled)

• JTAG connector for external emulators

• Quadrature Encoder Interfa ce and Hall Sensor Interface availab le for speed and pos ition

measurement (only if MCU supports and SW is enabled)

• High precision low-side cur rent sensing using integrated curr ent sense amplifiers in the

DRV830x (2-ch) or optional external 3-ch (Starting with DRV8301 RevD)

• Over current protection on the inverter stage by DRV830x

• Hardware Developer’s Package that includes schematics and bill of materials

• Closed-loop digital control with feedback using the MCU’s on-chip PWM and ADC

peripherals

Warning: about low switching frequencies on the DRV830x

When the DRV830x runs at a low switching frequency (e.g. less than 20 kHz with 100 nF

bootstrap capacitor), the bootstrap capacitor voltage might not be able to maintain a proper

5

Page 6

voltage level for the high-side gate driver. A bootstrap capacitor under voltage protection circuit

(BST_UVP) will start under this circumstance to prevent the potential failure of the high-side

MOSFET. In this circumstance, both the FAULT and OTW pins should pull low and the device

should self-protect itself. The motor’s inductance and the inverter’s bootstrap cap ac itance will

allow the DRV830x to run efficiently until approximately 10 kHz (with margin). Setting the PWM

switching frequency below 10 kHz may cause issues on the inverter output and is not

recommended. Please reference the datasheet.

Hardware Overview

The example projects made available wit h th e kit may be done with a s up pl ied 24V power suppl y,

but many of the examples will work with an externally supplied laboratory power supply of a

different voltage or current limit. The DRV830x EVM has all the power and control blocks that

constitute a typical m otor drive system for a three-phase system : Communications + Control +

Feedback + Feedforward + Drive

Macro Blocks

The motor control board is separated into function al groups that enable a com plete motor drive

system, these are ref erred to as m acro blocks . Following is a list of the mac ro blocks pr esent on

the board and their functions:

• controlCARD socket – Socket for a controlCARD (preferably using built-in em ulation) .

• DC Bus Connection

o “PVDD/GND” Terminals – Connect an external 8-60V DC lab supply here

making sure to observe correct polarity..

• DRV830x – This module includes either the DRV8301 or DRV8302 Three Phase Pre-

Driver as well as all of the necessary external passive components.

• Current Sense – Low-side shunt current sensing on each half-bridge.

• Quadrature Encoder Connections – Connections are available for an optional shaft

encoder to interface to the MCU’s QEP peripheral.

• Hall Effect Sensor Connections – Connections are available for optional Hall Effect

Sensors.

Fig 2, illustrates the position of these macro blocks on the board. The use of a macro block

approach, for different po wer stages enables easy debug an d testing of one stage at a time. All

the PWM’s and ADC signals which are the actuation and sense signals have designated test

points on the board , which makes it eas y for an application d eveloper to try out new algorithms

and strategies.

6

Page 7

Fig2: DRV830x-EVM Board Macros

7

Page 8

Powering the Board

The board is separated int o two power domains*, the low volt age Controller Power domain that

powers the controller and t he logic circuit present on the board, and the medium voltage power

delivery line that is used to carry the medium voltage and current like the DC power for the

Inverter also referred to as DC Bus.

1) Controller Power comprises of the 5 V and 3.3V that t he board uses to power the controller

and the logic and sensi ng circuit present o n the board. This power is regulat ed from the DC bus

by the DRV830x integrated buck converter.

2) DC Bus Power is the medium voltage line – up to 60V - that provides the voltage to the

inverter stage to generate 3 phases to control the motor

Note: Do not apply power to board before you have verified these settings!

The kit ships with the control card inserted and the jumper and switch settings pre done

for connecting with the GUI. However the user must ensure that these settings are valid

on the board.

1. Make sure nothing is connected to the board, and no power is being supplied to

the board.

2. Insert the controlCARD into the connector if not already populated.

Special Notes Regarding controlCARD Use

• Make sure switches are set properly on the controlCARD according to the

appropriate qsg_hw_cncd280xxx.pdf

• Special notes for using controlCARDs with this motor drive board

o When using TMDSCNCD28027F

Connect pin 2 of J12 (GPIO-29) to pin 6 of J5 (EN_GATE).

Note, for all MotorWare versions up to _11 this was pin1 of

J11. Changed in _12 due to pin conflict.

3. Make sure the following jumpers & connector settings are valid i.e.

a. JP2 is installed

4. Connect your PC to the kit

a. controlCARDs with on-card XDS100 USB-JTAG:

i. connect USB cable from computer to USB connector on control

card

b. controlCARDs without on-card USB -JTAG

i. connect USB cable from comput er to external emulator, and

emulator to 14-pin JTAG header (J21)

5. Connect the motor you want to spin to the “MOTOR” terminal block as shown

below. The order is not important unless a rotor sensor is used. If ground is

available with your motor it should also be used.

8

Page 9

6. Connect an 8-60V DC power supply to the PVDD and GND terminals.

Fig3: DRV830x-HC-EVM Motor Connections

Hardware Resource Mapping

Resource Allocation

J1

Pin no.

GPIO Signal Name

Function

(DRV8301/DRV8302)

23 GPIO-00 PWM_AH DRV830x Phase AH PW M input

73 GPIO-01 PWM_AL DRV830x Phase AL PW M input

24 GPIO-02 PWM_BL DRV830x Phase BH PW M input

74 GPIO-03 PWM_BL DRV830x Phase BL PW M input

25 GPIO-04 PWM_CH DRV830x Phase CH PWM input

75 GPIO-05 PWM_CL DRV830x Phase CL PWM input

26 GPIO-06 DAC_PWM4 PWM DAC

76 GPIO-07 STOP Push button input

28 GPIO-08 DAC_PWM3 PWM DAC

78 GPIO-09 START Push button input

29 GPIO-10 DAC_PWM1 PWM DAC

79 GPIO-11 DAC_PWM2 PWM DAC

33 GPIO-12 LED-1 User LED

9

Page 10

83 GPIO-13 OCTWn Over-temperatur e warnin g

84 GPIO-14 FAULTn Over-current fault

34 GPIO-15 LED-2 User LED

38 GPIO-16 SPI-SIMO Isolated SPI Interface

88 GPIO-17 SPI-SOMI Isolated SPI Interface

39 GPIO-18 SPI-CLK Isolated SPI Interface

89 GPIO-19 SPI-STE Isolated SPI Interface

40 GPIO-20 QEPA Encoder A

90 GPIO-21 QEPB Encoder B

41 GPIO-22 STATUS User LED

91 GPIO-23 QEPI Encoder Index

35 GPIO-24 SDI SPI Data In/M_DC

85 GPIO-25 SDO SPI Data Out/GAIN

36 GPIO-26 SCLK SPI ClockDC_ADJ

86 GPIO-27 /SCS /SCS/M_PWM

44 GPIO-30 CAN-RX Isolated CAN Interface

94 GPIO-31 CAN-TX Isolated CAN Interface

30 GPIO-40 CAP1 Hall Input 1

80 GPIO-41 CAP2 Hall Input 2

31 GPIO-42 CAP3 Hall Input 3

81

59 ADC-A1 IA-FB Current sense phase A

61 ADC-A2 I-TOTAL DC Bus current sense

63 ADC-A3 IC-FB Current sense phase C

GPIO-43 DC-CAL

Short DC current sense amplifier

inputs to ground, calibrate offset

67 ADC-A5 IC-FB Current sense phase C

10

Page 11

71 ADC-A7 ADC-Vhb2 Phase Voltage sense B

7 ADC-B0 TSI Tach/Pot input

9 ADC-B1 IB-FB Current sense phase B

11 ADC-B2 VDCBUS DC Bus voltage sense

13 ADC-B3 IA-FB Current sense phase A

15 ADC-B4 ADC-Vhb3 Phase Voltage sense C

17 ADC-B5 IB-FB Current sense phase B

21 ADC-B7 ADC-Vhb1 Phase Voltage sense A

Table 1: Signal mapping to the controlCARD DIMM slot

Jumpers and Connectors

The Tables below show the various connections available on the board.

Connector Reference # of Pins Name

J2 2 HEADER2x1

J4 5 HEADER5x1

J5 40 HEADER20x2

J6 5 HEADER5x1

J7 3 HEADER3x1

J8 5 HEADER5x1

J10 5 HEADER5x1

TERM BLOCK HEADER

J11 4

J12 2 HEADER2x1

J13 2 HEADER2x1

J20 10 HEADER5x2

4x1

J21 14 HEADER7x2

11

Page 12

J23 2 HEADER2x1

J24 2 HEADER2x1

TERM BLOCK HEADER

J25 2

J26 2

Table 2: List of Connecto rs

2X1

TERM BLOCK HEADER

2X2

12

Page 13

13

J2 (User Power Access) J8 (User SPI)

Pin # Signal

1 VCC_5V 1 iSD-O 1 VCC_3.3V 1 TMS

2 GND 2 iCLK-O 2 GND 2 TRSTn

3 iSD-I 3 TDI

J4 (Optional Encoder)

Pin # Signal

1 E1A 1 NC 6 NC

2 E1B

3 E1C

4 VCC_5V 1 E2A 4 NC 9 TCK

5 GND 2 E2B 5 SDO 10 GND

3 E2C 6 NC 11 TCK

Pin # Signal

4 iGPIO

5 IGND

J10 (HALL Sensor)

Pin # Signal

J13 (User Power Access) J21 (External JTAG)

Pin # Signal

J20 (DRV8301 SPI))

Pin # Signal

2 GND 7 TDO

3 NC 8 GND

Pin # Signal

4 GND

5 VCC_3.3V

J6 (PWM DAC)

Pin # Signal

1 DAC1 9 /SCS 14 EMU1

2 DAC2

3 DAC3

4 DAC4 1 Phase A

5 GND 2 Phase B

3 Phase C 1 START 2 PVDD

J7 (CAN)

Pin # Signal

4 GND 2 GND

1 CAN-H

2 CAN-L

3 IGND 1 GPIO-28 1 STOP 2 GND

4 VCC_5V 7 SCLK 12 GND

5 GND 8 SDI 13 EMU0

J11 (Motor)

Pin # Signal

J12 (GPIO/SCI)

Pin # Signal

10 GND

J23 (Push Button)

Pin # Signal

J24 (Push Button)

Pin # Signal

J25 (Power Input)

Pin # Signal

1 PVDD

J26 (Power Input)

Pin # Signal

1 GND

2 GPIO-29 2 GND

Page 14

14

Tables3-17 Individual Connector Pinouts

J5 (External Controller Ac ces s )

Pin # Signal Pin # Signal

1 VCC_5V 2 VCC_5V

3 GND 4 GND

5 STATUS 6 EN_GATE

7 QEPA 8 QEPI

9 FAULTn 10 QEPB

11 CAP3 12 OCTWn

13 DC_CAL 14 CAP1

15 DAC_PWM1 16 CAP2

17 DAC_PWM3 18 DAC_PWM2

19 GND 20 GND

21 DACE_PWM4 22 PWM_CL

23 PWM_AL 24 PWM_BL

25 PWM_AH 26 PWM_CH

27 GND 28 PWM_BH

29 ADC-Vhb1 30 GND

31 ADC-Vhb2 32 ADC-Vhb3

33 IC-FB 34 VDCBUS

35 I_TOTAL 36 IB-FB

37 IA-FB 38 TSI

39 GND 40 GND

Table 18: J5 Pinout

Page 15

15

Test Points

Test Point Net Connection

TP1 VCC_5V JP2 VCC_5V to controlCARD

TP2 VCC_5V_R5 JP4 CAN termination

TP3 PWRGD

TP4 VCC_3.3V

TP5 REF_1.65V

TP6 PVDD

TP7 GND

TP8 GND

TP9 GND

TP10 GND

TP11 VCC_5V

Jumpers

Reference Function

TP12 SH_A

TP13 SH_B

TP14 SH_C

TP15 S02

TP16 IB-FB

TP17 IA-FB

TP18 U10_1

TP19 IC-FB

TP20 IGND

TP21 S01

TP22 U11_1

TP23 I-TOTAL

Table 20: Testpoints and Jumpers

Page 16

16

Optimizing Sense Circuitry

Overview

Proper resolution of motor signals is critical to the performance of any control system, but especially those

with software observers attempting to replace the precision of an absolute encoder. Because the

DRV83xx are built to work at over 50 Vdc-bus, the resolution of the voltage sensing is not as precise as

you would like for motors < 48V. And in the case of the DRV8301 which measures 41.25A, the current

resolution may also be unacceptable. This section describes how to update both the hardware and

corresponding software to maximize resolution and performance.

Steps to follow

1. Determine MAXIMUM phase current, adjust current gain to 3.3V ADC

2. Set MAX voltage at +30% margin of motor voltage, adjust voltage gain to 3.3V ADC

3. Configure software to hardware changes

Page 17

17

Shunt Current Feedback

=

1.65

=

3.3 1.65

10 0.01

= 16.5

= 16.5 = 16.5 k with = 1 k

= 1.65 +

Select resistor values to provide Vout = 3.3V for maximum peak-to-peak phase current

• Ex: For a maximum of 10A, consider a 0.01Ω shunt resistor

o One possible solution

Page 18

18

o Update the current hardware resistors

o

o

o

= R80, R81, R82

= R107, R95; R108,R105; R113, R103

= R92, R94; R101, R104; R99, R102

• Update your software settings in user.h; for this example of +/- 10A peak

//! \brief Defines the maximum current at the input to the AD converter

# USER_ADC_FULL_SCALE_CURRENT_A (20.0)

Insure that your IQ variable is >= 0.5 * the ADC value

# USER_IQ_FULL_SCALE_CURRENT_A (10.0)

Phase Voltage Feedback

Page 19

19

=

(

4.99 k+

)

4.99 k

15.6 = 3.3 V

(

4.99 k+

)

4.99 k

=

15.6 V 4.99 k

3.3 V

4.99 k = 18.6 k

• Ex: for a maximum of 12V, add headroom of 30% to set

o Update the voltage hardware resistors

to 15.6V

o

o = R62; R64; R65

o Update your software settings in user.h; for this example of 15.6V maximum

= R60; R61; R63

//! \brief Defines the maximum voltage at the input to the AD converter

# USER_ADC_FULL_SCALE_VOLTAGE_V (15.6)

In general an IQ value equal to your Voltage bus is effective.

During motor identification – for very small flux motors - you may need to make this value

smaller to lower the minimum flux value that can be identified, which is given by:

USER_IQ_FULL_SCALE_VOLTAGE_V / Effective Estimator Hz / 0.7

After motor identification - for larger flux motors - you may need to increase this value to

insure that the following is true:

USER_IQ_FULL_SCALE_VOLTAGE_V > USER_MOTOR_RATED_FLUX *

Maximum_Frequency_Hz (this is the maximum speed you will ever run the motor,

including deep field weakening).

# USER_IQ_FULL_SCALE_VOLTAGE_V (12.0)

Page 20

20

Phase Voltage Filter Feedback

_

=

=

_

= 400 =

1

2

18.6k 4.99 k

18.6k+ 4.99 k

C

v

• See 5.2.4 of the User’s Guide

• The voltage filter pole is needed by the FAST estimator to allow an accurate detection of the

voltage feedback. The filter should be low enough to filter out the PWM signals, and at the same

time allow a high speed voltage feedback signal to pass through the filter

• This pole should be designed to fall between

200 Hz <= Pole <= USER_IQ_FULL_SCALE_FREQ_Hz / 4 [hard upper limit]

o Higher poles are more sensitive to capacitor error and drift, so please recognize

the trade-offs in using a higher pole, especially for high frequency motors

• Example

o 4 pole pairs; 5 kRPM

Hz = RPM * Poles / 120 = 5000 * 8 / 120 = 333 Hz

Select 400 Hz (> 333 Hz)

o With our previous

=101

o

• Update the hardware capacitors

C

= C67; C68; C69

o

• Update your software settings in user.h

=4.99 kΩ ;

= =18.6 kΩ

Page 21

21

//! \brief Defines the analog voltage filter pole location, Hz

# USER_VOLTAGE_FILTER_POLE_Hz (400.0)

Page 22

22

SCHEMATIC DISCLAIMER AND WARNINGS

TI provides the DRV830x EVM schemati c drawi ngs to hel p users dev elop DRV30x & TI MCU

based reference design products. Application safety, safety of th e Medi um Voltage DMC kit

and design integrity of such reference designs are solely responsibility of the user. Any

reference d esign s generated off these schematics must take into account necessary product

safety design requirements, including interface components and load motors in order to

avoid user risks including potential for fire hazard, electrical shock hazard and personal

injury, including considerations for anticipated agency certification compliance

requirements.

Such product safety design criteria shall include but not be limited to critical circuit

creepages and clearances, component selection, ratings compatibility of controlled motor

loads, and required protective means (ie output fusing) depending on the specific loads

being controlled.

TI accepts no responsibility for design integrity of any reference designs based on supplied

schematic drawings and the schematics are strictly for development purposes.

EVALUATION BOAR D/KIT IMPORTANT NOTICE

Texas Instruments (TI) provides the enclos ed product(s) under the following conditions:

This evaluation board/kit is intended for use for ENGINEERING DEVELOPMENT,

DEMONSTRATION, OR EVALU ATION PURPOSES ONLY and is not considered by TI to

be a finished end-product fit for general consumer use. Persons handling the product(s)

must have electronics training and observe good engineering practice standards. As such,

the goods being provided are not intended to be complete in terms of required design-,

marketing-, and/or manufacturing-related protective considerations, including product

safety and environmental measures typically found in end products that incorporate such

semiconductor c omponents or circuit boards. This evaluation board/kit does not fall within

the scope of the European Union directives regarding electromagnetic compatibility,

restricted substances (RoHS), recycling (WEEE), FCC, CE or UL, and therefore may not meet

the technical requirements of these directives or other related directives.

Should this evaluation board/kit not meet the specifications indicated in the User’s Guide,

the board/ki t may be returned within 30 days from th e date of delivery for a full refund.

THE FOREGOING WARRANTY IS THE EXCLUSIVE WARRANTY MADE BY SELLER TO BUYER

AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY,

INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR

PURPOSE.

The user assumes al l responsibility and liability for proper and safe handling of the goods.

Further, the user indemnifies TI from all claims arising from the handling or use of the

goods. Due to the open construction of the product, it is the user’s responsibility to take any

and all appropriate precautions with regard to electrostatic discharge.

EXCEPT TO THE EXTEN T OF THE INDE MNITY S ET FORTH AB OVE, NE ITHER PARTY S HALL BE

LIABLE TO THE OTHER FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES.

TI currentl y deals with a vari ety of customers for products, an d therefore our a rrangement

with the user is not exclusive.

Page 23

23

TI assumes no liability for applications assistance, customer product design,

software performance, or infringement of patents or services described herein.

Please read the U ser’s Guide and, specifi cally, the Warnings and R estrictions notice in th e

User’s Guide prior to handling the product. This notice contains important safety information

about temperatures and voltages. For additional information on TI’s environmental and/or

safety programs, please contac t the TI appl ication engineer or visit www.ti.com/esh.

No license is granted under any patent right or other intellectual property right of TI

covering or relating to any machine, process, or combination in which such TI products or

services might be or are used.

Mailing Address:

Texas Instrum en t s

Post Office Box 655303

Dallas, Texas 75265

Copyright © 2012, Texas Instrum en t s Incorporat ed

FCC Warning

This evaluation board/kit is intended for use for ENGINEERING DEVELOPMENT,

DEMONSTRATION, OR EVALUATION PURPOSES ONLY and is not considered by TI to

be a finished end-product f it for general consumer us e. It generat es, uses, and can radiat e

radio frequency energy and has not been tested for compliance with the limits of computing

devices pursuant to part 15 of FCC rules, which are designed to provide reasonable

protection against radio frequency interference. Operation of this equipment in other

environment s may caus e interfer ence with radio commun icati ons, in whi ch case the user at

his own expen se wil l b e requi red t o take whatever mea su res m ay be r equ ired to cor rect th i s

interference.

Page 24

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2015, Texas Instruments Incorporated

Loading...

Loading...