Page 1

“DRV830x-HC-C2-KIT” How to Run Guide

Version 1.0 August 2011 - TIDU396

This Guide explains the steps needed to run the DRV830x-HC-C2-KIT with the software supplied

through controlSUITE. This guide pertains to either the DRV8301-HC-EVM or the DRV8302-HCEVM. The software is located at:

controlSUITE\developement_kits\DRV830x-HC-C2-KITv*\

The following projects are currently available for the kit:

- Fixed/Floating point projects based on Piccolo (TMS320F2803x or TMS320F2806x, using v3.1

DMCLib)

• PM_Sensorless: Sensorless Field Oriented Control of Permanent Magnet Motor

• BLDC_Int: Sensorless Trapezoidal Control of BLDC Motors based on BEMF Integration

The document assumes the user has read the Kit’s Hardware Reference Guide and understood all

the safety measures that need to be taken. The guide is found under

controlSUITE\developement_kits\DRV830x-HC-C2-KITv*\~Docs\

C2000 Systems and Applications Team

WARNING

This EVM is meant to be operated in a lab environment only and is not

nsidered by TI to be a finished end-product fit for general consumer use.

co

This EVM must be used only by qualified engineers and technicians familiar

with risks associated with handling high voltage electrical and

mechanical components, systems and subsystems.

This equipment operates at voltages and currents that can result in electrical

shock, fire hazard and/or personal injury if not properly handled or applied. Equipment must

be used with necessary caution and appropriate safeguards must be employed to avoid

personal injury or property damage.

It is the user’s responsibility to confirm that the voltages are identified and understood, prior

to energizing the board and or simulation. When energized, the EVM or components

connected to the EVM should not be touched.

Page 2

Hardware Configuration

To experiment with digital motor control the following hardware components are needed:

DRV830x-HC-EVM

TMS320F28035 controlCARD;

PMSM or BLDC Motor

PC with Code Composer Studio (CCSv4) installed

Additional instruments such as oscilloscope, digital multi-meter, current sensing probe and function

generator.

A high voltage DC power supply (Up to 60V DC)

The experimental setup and connection are illustrated in the following section. Refer to the Hardware

Guide and DRV830x-HC-EVM schematic file for detailed configuration of each component and

connection of the system in detail.

Note: Keep all the power supplies to zero unless directed to energize.

There are two main power domains on the DRV830x-HC-EVM platform:

1) Controller Power Domain which provides the 5V and 3.3V for the microcontroller, the logic and

the sensing circuit present on the board.

2) DC Bus Power is the high voltage line that provides the voltage to the DRV830x chip to generate

the power to the motor. The DC Bus is provided by an external DC power supply connected to the

PVDD and GND terminals. (Max 60V DC)

Page 3

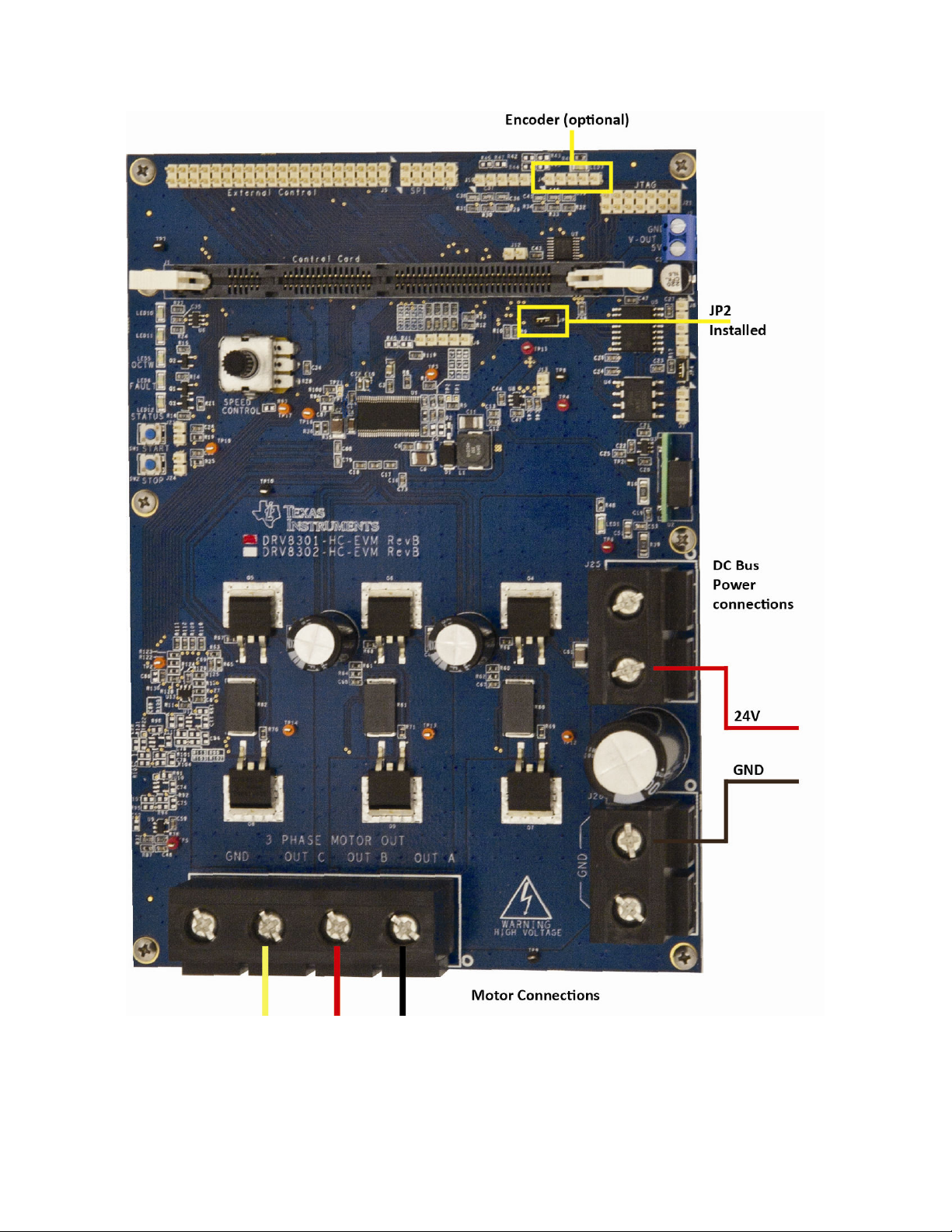

Motor Control Experiment HW Setup Instructions

Unpack the DIMM style controlCARD and verify that the DIP switch settings match Figure 1.

Figure 1 controlCARD DIP Switch Settings

1. Place the controlCARD in the connector slot of J1. Push vertically down using even pressure from

both ends of the card until the clips snap and lock. (to remove the card simply spread open the

retaining clip with thumbs)

2. Connect a USB cable to J1 on the controlCARD. This will enable isolated JTAG emulation to the

C2000 device. LD4 on the controlCARD should turn on.

3. Connect a 8-60V DC power supply to the PVDD and GND terminals of the DRV830x-HC-EVM.

Now LED1 and LED3 should turn on. Notice the control card LED would light up as well indicating

the control card is receiving power from the board.

4. Note that the motor should be connected to the OUT A, OUT B and OUT C terminals after you

finish with the first incremental build step.

Page 4

Figure 2 Hardware Setup for PM_Sensorless Experiment

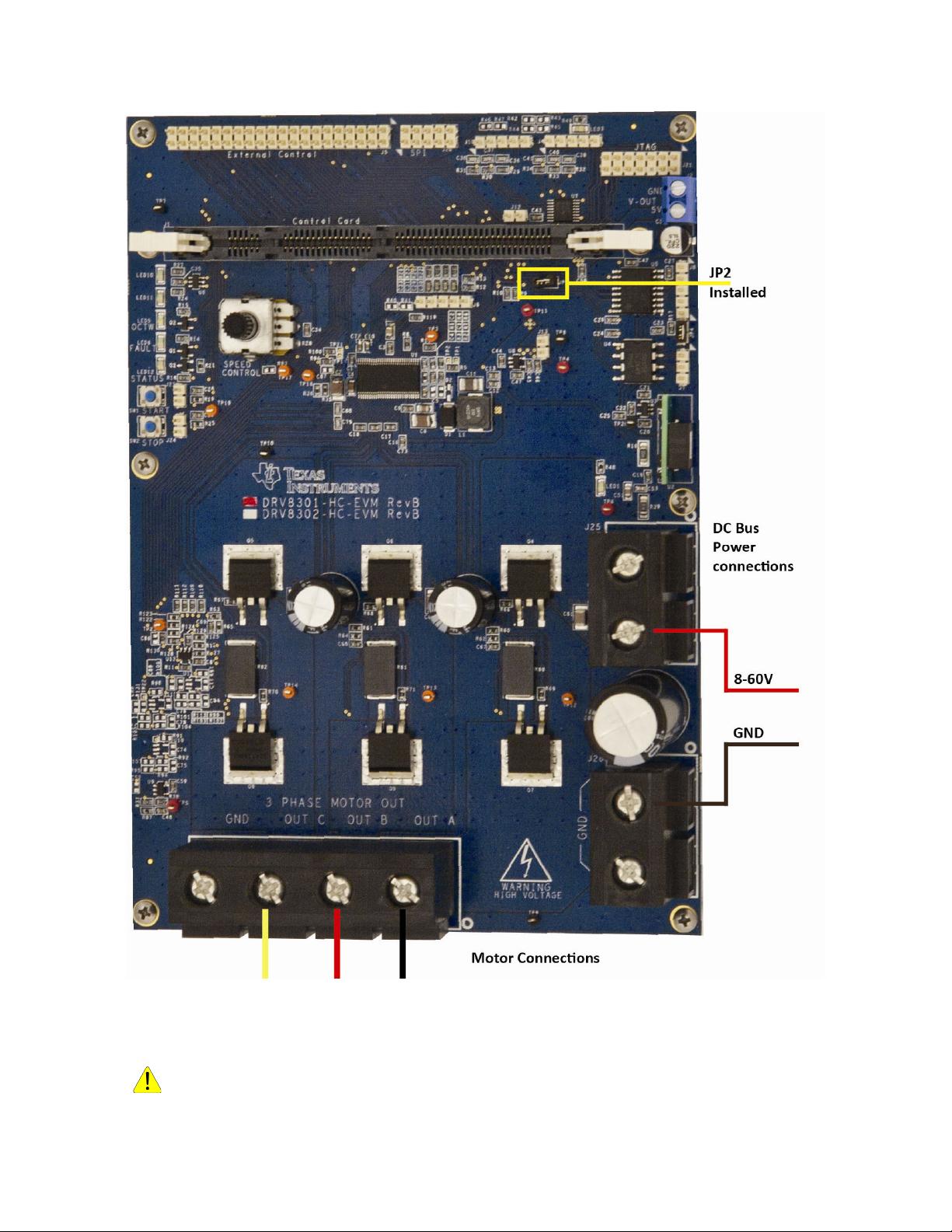

Page 5

Figure 3 Hardware Setup for BLDC_Sensored and BLDC_Sensorless Experiments

WARNING: DC bus Capacitors would remain charged for a long time after the supply is

isconnected. Use caution!

d

Page 6

Software Setup for DRV8301-HC-C2-KIT Projects

Installing Code Composer and controlSUITE

1. If not already installed, please install Code Composer v4.x from the DVD included with the kit.

2. Go to http://www.ti.com/controlsuite

“DRV830x-HC-C2-KIT” software and allow the installer to also download all automatically

checked software.

Setup Code Composer Studio to Work with the DRV830x-HC-C2-KIT

3. Open “Code Composer Studio v4”.

4. Once Code Composer Studio opens, the workspace launcher may appear that would ask to

select a workspace location,: (please note workspace is a location on the hard drive where

all the user settings for the IDE i.e. which projects are open, what configuration is selected

etc. are saved, this can be anywhere on the disk, the location mentioned below is just for

reference. Also note that if this is not your first-time running Code Composer this dialog may

not appear)

Click the “Browse…” button

Create the path below by making new folders as necessary.

“C:\Documents and Settings\My Documents\ CCSv4_workspaces\DRV830x-HC-

EVM_workspace”

and run the controlSUITE installer. Select to install the

Uncheck the box that says “Use this as the default and do not ask again”.

Click “OK”

Figure 4 Workspace Launcher

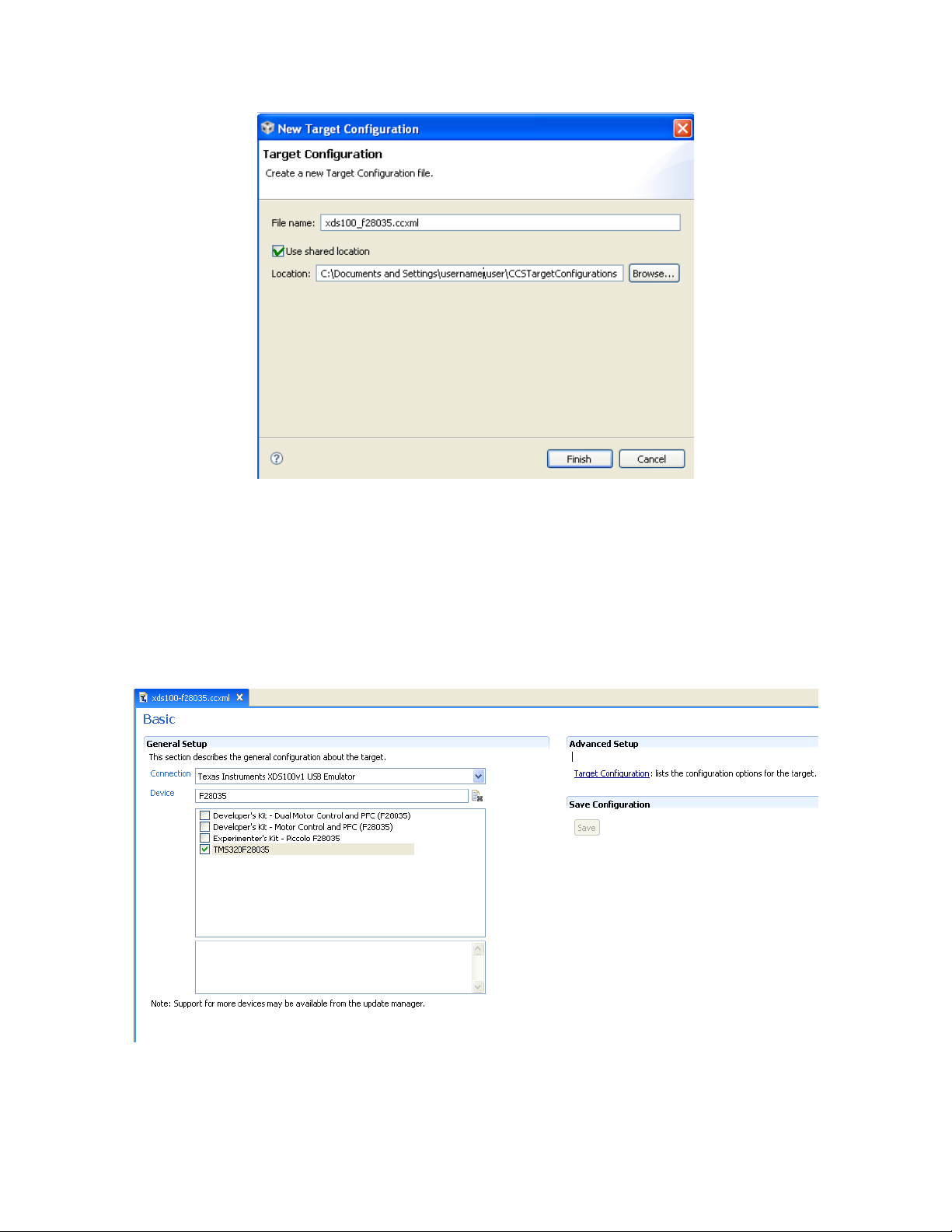

5. Next we will configure Code Composer to know which MCU it will be connecting to. Click

“Target -> New Target Configuration…”. Name the new configuration xds100-f28035.ccxml

or any other name depending on the target device. Make sure that the “Use shared location”

checkbox is checked and then click Finish.

Page 7

Figure 5 Creating a target configuration

6. This should open up a new tab as seen in Figure 6. Select and enter the options as shown:

Connection – Texas Instruments XDS100v1 USB Emulator

Device – TMS320F28035

Click Save

Close the xds100-f28035.ccxml tab

Figure 6 Configuring a new target

Page 8

7. Assuming this is your first time using Code Composer, the configuration is now set as the

default target configuration for Code Composer. Please check this by going to“View->Target

Configurations”. In the “User Defined” section, right-click on the xds100-F28035.ccxml file

and select “Set as Default”. This tab also allows you to reuse existing target configurations

and link them to specific projects.

8. Add all the motor control projects into your current workspace by clicking “Project->Import

Existing CCS/CCE Eclipse Project”.

Select the root directory of the DRV830x-HC-C2-KIT. This will be:

“controlSUITE\development_kits\DRV830x-HC-C2-KITv*\”

Figure 7 Adding all DRV830x-HC-C2-KIT projects to your workspace

Click Finish, this would copy all the projects relevant for the kit into the workspace. If you

want only a particular project to be copied uncheck the box next to the other project

names.

Page 9

Configuring a Project

9. Expand the file structure of the project you would like to run from the C/C++ Projects tab.

Right-click on this project’s name and select “Set as Active Project”.

10. Assuming this is your first time using Code Composer, the xds100-F28035 should have been

set as the default target configuration. Do verify this by viewing the xds100-f28035.ccxml file

in the expanded project structure and a [Active/Default] written next to it. By going to “View->

Target Configurations” you may edit existing target configurations or change the default or

active configuration. You can also link a target configuration to a project in the workspace by

right clicking on the Target configuration name and selecting Link to Project.

11. Each project has multiple build configurations to support different target MCUs or different

DRV83xx base boards. You will need to select the build configuration that matches your

hardware setup. As an example Figure 8 shows selection of the DRV8301-HC-EVM with a

2803x MCU. Right-click on an individual project and select Active Build Configuration->

F

DRV8301_F2803x_RAM configuration.

Figure 8 Selecting the DRV8301_F2803x_RAM configuration

Build and Load the Project

12. The TI motor control software is provided with incremental builds where different components

/ macro blocks of the system are pieced together one by one to form the entire system. This

helps in step by step debug and understanding of the system. From the C/C++ Project tab

open the file [Project-Name]-Settings.h and make sure that BUILDLEVEL is set to LEVEL1

and save this file. After we test build 1, this variable will need to be redefined to move on to

build 2, and so on until all builds are complete.

Page 10

13. Open and inspect [Project-Name] -DevInit_F2803x.c by double clicking on the filename in the

project window. Confirm that GPIO00 to GPIO05 are configured to be PWM outputs.

14. Open the [Project-Name].c file and go to the function MainISR(). Locate the following piece of

code in incremental build 1 and confirm that the Datalog buffers are pointing to the right

variables. These Datalog buffers are large arrays that contain value-triggered data that can

then be displayed to a graph. Note that in other incremental builds different variables may be

put into this buffer to be graphed. Following is an example where the datalog are pointed to

the PID module.

DlogCh1 = (int16)_IQtoIQ15(pid1_i.Ref);

DlogCh2 = (int16)_IQtoIQ15(pid1_i.Fdb);

DlogCh3 = (int16)_IQtoIQ15(pid2_i.Ref);

DlogCh4 = (int16)_IQtoIQ15(pid2_i.Fdb);

15. Now Right Click on the Project Name and click on “Rebuild Project” and watch the Console

window. Any errors in the project will be displayed in the Console window.

16. On successful completion of the build click the

of the screen. The IDE will now automatically connect to the target, load the output file into

the device and change to the Debug perspective.

17. Click “Tools->Debugger Options->Generic Debugger Options”. You can enable the debugger

to reset the processor each time it reloads program by checking “Reset the target on program

load or restart” and click “Remember My Settings” to make this setting permanent.

18. Now click on the “Enable silicon real-time mode” button and “Enable polite real-time

mode” button . This will allow the user to edit and view variables in real-time. Do not reset

the CPU without disabling these realtime options!

19. A message box may appear. If so, select YES to enable debug events. This will set bit 1

(DGBM bit) of status register 1 (ST1) to a “0”. The DGBM is the debug enable mask bit.

When the DGBM bit is set to “0”, memory and register values can be passed to the host

processor for updating the debugger windows.

“Debug” button, located in the top-left side

Page 11

Setup Watch Window & Graphs

Click: View Watch on the menu bar to open a watch window to view the variables being used in

the project. Add variables to the watch window as shown below. By right-clicking on the variable it is

possible to change the number format of the variable. Refer to the project specific document to know

what variables need to be added to the watch window. You can select the appropriate Q format for

the variable you want to watch. Figure 9 below shows a typical watch window.

Within each project folder is a CCS Java Script file that can automatically populate a watch window

with some default variables. Select View->Scripting Console to open the Java Scripting Console.

Next, in the Scripting Console window, click the open folder and browse to the project folder.

controlSUITE\developement_kits\DRV830x-HC-C2-KITv*\<project directory>

Select the AddWatchWindowVars_F280xx.js file that corresponds to your target MCU.

Figure 9 Configuring the Watch Window for) fixed point devices

20. Click on the Continuous Refresh button in the watch window. This enables the window to

run with real-time mode. By clicking the down arrow in this watch window, you may select

“Customize Continuous Refresh Interval” and edit the refresh rate of the watch window. Note

that choosing too fast an interval may affect performance.

21. The datalog buffers point to different system variables depending on the build level. They

provide a means to visually inspect the variables and judge system performance. Open and

setup time graph windows to plot the data log buffers as shown below. Alternatively, the user

can import graph configurations files in the project folder; however, these files are not

supported by all CCS4 versions. In order to import them, Click: Tools -> Graph ->

DualTime… and select import and browse to the following location

controlSUITE\developement_kits\DRV830x-HC-C2-KITv*.*\<project directory> and select

Graph1.graphProp, the Graph Properties window should now look like the Figure 10. Hit OK,

is should add the Graphs to your debug perspective. Click on Continuous Refresh button

th

on the top left corner of the graph tab.

Page 12

Note: If a second graph window is used, you could import Graph2.prop, the start Addresses

for this should be DLOG_4CH_buff3 and DLOG_4CH_buff4.

Note: The default dlog.prescaler is set to 5 which will allow the dlog function to only log one

out of every five samples.

Figure 10 Graph window settings

Run the Code

22. Run the code by pressing Run Button in the Debug Tab.

23. The project should now run, and the values in the graphs and watch window should keep on

updating. Below are some screen captures of typical CCS perspective while using this

project, You may want to resize the windows according to your preference.

24. Once complete, reset the processor (Target->Reset->Reset CPU) and then terminate

the debug session by clicking (Target->Terminate All). This will halt the program and

disconnect Code Composer from the MCU.

Page 13

Project Files

Project Files

Motor Control Code

Motor Control Code

C/C++

C/C++

Perspective

Perspective

CCS v4 C/C++

Perspective

Debug

Debug

View

View

Window

Window

view CPU’s

view CPU’s

being

being

Debugged

Debugged

currently

currently

Console window to display

Console window to display

Build progress / Errors

Build progress / Errors

Disassembly window

Disassembly window

Shows location in code

Shows location in code

when stepping through debugger

when stepping through debugger

Set Real Time mode

Set Real Time mode

Summary of all the Build

Summary of all the Build

Errors and warnings go here

Errors and warnings go here

Debug

Debug

Perspective

Perspective

Real-time

Real-time

variable

variable

Watch

Watch

Window

Window

CCSv4 Debug

Perspective

Real-time

Real-time

Graph

Graph

Window

Window

Page 14

Next Steps

25. It is not necessary to terminate the debug session each time the user changes or runs the

code again. Instead the following procedure can be followed. After rebuilding the project,

(Target->Reset->Reset CPU) , (Target->Reset->Restart ) , and enable realtime options.

Once complete, disable realtime options, and reset CPU. Terminate the project if the target

device or the configuration is changed (Ram to Flash or Flash to Ram), and before shutting

down CCS.

26. Customize the project to meet your motor. Change the motor parameters which can be found

in [motorproject].h. Feel free to also change the PWM switching frequency (ISR frequency)

and the base Q-value to balance accuracy and CPU bandwidth.

27. Now the user can open the lab manual found in : controlSUITE\development_kits\DRV830xHC-C2-KITv*\[Project-Name]\~Docs and start experiments.

Page 15

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2015, Texas Instruments Incorporated

Loading...

Loading...