Page 1

5 Commonwealth Ave

Woburn, MA 01801

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

testo 300 Smoke Edition / testo 300 Pro - Combustion Analyzer

Instruction manual

Page 2

Page 3

Contents

Contents

1 About this document ................................................................................... 7

1.1 Symbols ................................................................................................. 7

1.2 Warning notices ...................................................................................... 7

2 Safety and disposal ..................................................................................... 8

3 Product-specific safety instructions .......................................................... 8

4 Authorizations and certification ................................................................. 8

5 Specifications ............................................................................................... 9

6 Product description ................................................................................... 10

6.1 Front view ............................................................................................. 10

6.2 Rear view ............................................................................................. 11

6.3 Connections ......................................................................................... 11

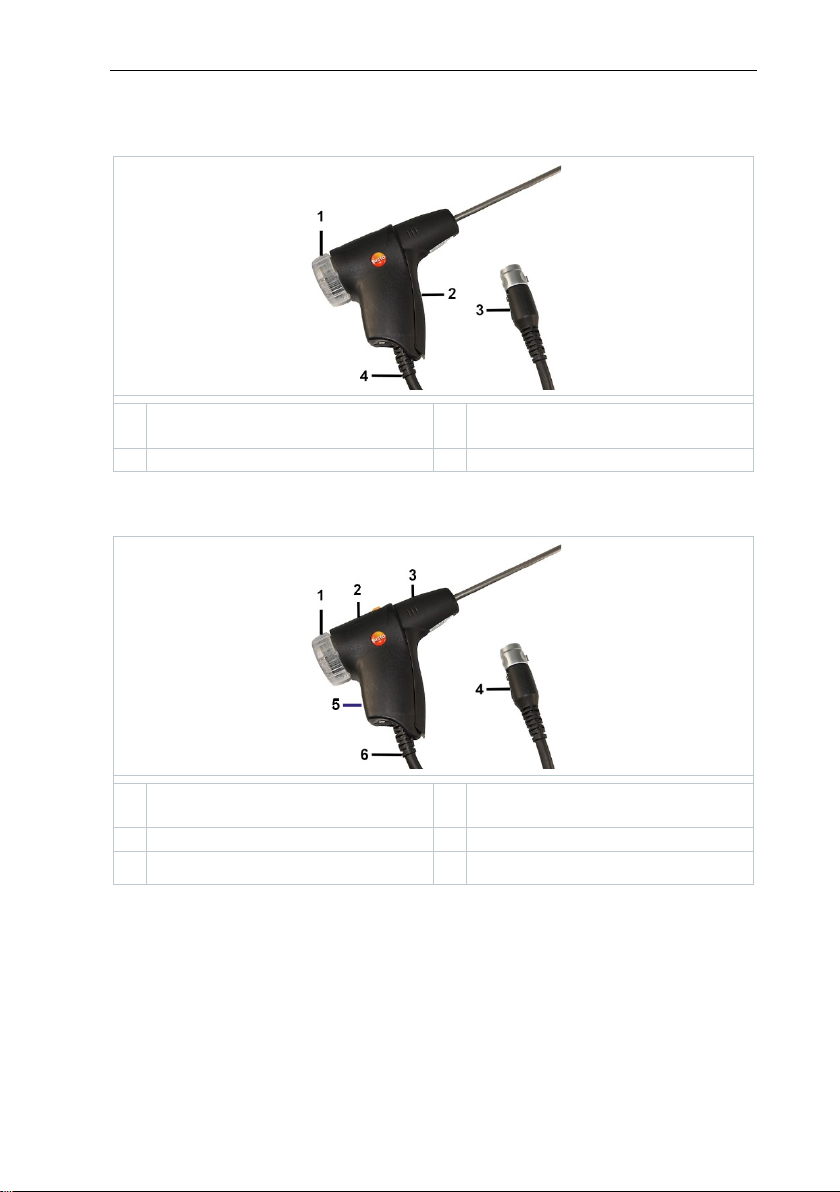

6.4 Compact flue gas probe ....................................................................... 12

6.5 Modular flue gas probe ......................................................................... 12

7 First steps ................................................................................................... 13

7.1 Commissioning ..................................................................................... 13

7.2 Power supply / Battery ......................................................................... 13

7.2.1 Charge battery ....................................................................... 13

7.2.2 Power Supply (AC) operation ................................................ 14

7.3 Touchscreen operating concept ........................................................... 14

7.4 Keypad ................................................................................................. 15

7.5 Switch instrument on and off ................................................................ 16

7.6 Connect probes .................................................................................... 17

8 Using the product ...................................................................................... 18

8.1 User interface ....................................................................................... 18

8.1.1 Main measurement display - List ........................................... 19

8.1.2 Main measurement display - Graphics .................................. 20

8.1.3 Main measurement display - Hot Spot ................................... 21

8.2 Overview of main menu ( ) ............................................................. 22

8.2.1 Customer / Measuring site (point) .......................................... 23

8.2.2 Tests ...................................................................................... 26

8.2.3 Saved reports ........................................................................ 27

8.2.4 Gas path check ...................................................................... 29

Page 4

Contents

8.2.5 Device settings ...................................................................... 29

8.2.5.1 Country version and language ............................. 29

8.2.5.2 Wi-Fi ..................................................................... 31

8.2.5.3 Date/Time ............................................................. 32

8.2.5.4 My company address ........................................... 34

8.2.5.5 Bluetooth .............................................................. 35

8.2.5.6 Hotspot ................................................................. 35

8.2.5.7 Display Brightness ............................................... 35

8.2.5.8 CO/NO sensor protect .......................................... 36

8.2.5.9 O2 Reference ....................................................... 36

8.2.5.10 Alarm limits ........................................................... 36

8.2.6 Sensor Diagnosis .................................................................. 37

8.2.7 Error List ............................................................................... 37

8.2.8 Device Information ................................................................ 37

8.2.9 Server Information................................................................. 37

8.2.10 E-mail .................................................................................... 37

8.2.11 My Apps ................................................................................ 39

8.2.12 Help ....................................................................................... 40

8.2.12.1 Please register your testo 300 .............................. 40

8.2.12.2 Tutorial ................................................................. 40

8.2.12.3 Setup Wizard ........................................................ 40

8.2.12.4 Update via USB .................................................... 41

9 Performing the measurement ................................................................... 42

9.1 Prepare for measurement .................................................................... 42

9.2 Zeroing phases .................................................................................... 42

9.3 Carry out gas path check ..................................................................... 43

9.4 Use of flue gas probe ........................................................................... 43

9.5 Overview of measurement types ( ) ............................................ 44

9.6 Overview of options ( ) ................................................................. 45

9.6.1 Configure measurement displa y ........................................... 46

9.6.2 Flue Gas Analysis ................................................................. 48

9.6.3 Draft-Measurement ............................................................... 49

9.6.4 CO Air free ............................................................................ 50

Page 5

Contents

9.6.5 Smoke Number ...................................................................... 50

9.6.6 Differential pressure ............................................................... 51

9.6.7 Differential temperature ......................................................... 51

9.6.8 O2 air (EU regulation) ............................................................ 52

9.6.9 Clock Meter ........................................................................... 52

9.6.10 Oil flow calculation ................................................................. 53

9.6.11 CO Ambient ........................................................................... 53

9.6.12 Pipe Commissioning (EU regulation) ..................................... 54

9.6.13 Pressure Drop test (EU regulation) ........................................ 55

9.6.14 Pretest (EU regulation) .......................................................... 57

9.7 Overview of tests ( ) ...................................................................... 58

9.7.1 Print values ............................................................................ 58

9.7.2 Save ...................................................................................... 59

9.7.3 Finish test .............................................................................. 59

10 Maintenance ............................................................................................... 62

10.1 Service ................................................................................................. 62

10.2 Calibration ............................................................................................ 62

10.3 Check instrument status ....................................................................... 62

10.3.1 Sensor diagnosis ................................................................... 62

10.3.2 Error list ................................................................................. 62

10.4 Clean the measuring instrument .......................................................... 63

10.5 Drain condensate trap .......................................................................... 63

10.6 Open the measuring instrument ........................................................... 65

10.7 Replace sensors ................................................................................... 66

10.7.1 Replace O2 sensor ................................................................ 67

10.7.2 Change CO, CO H2 and NO sensor ...................................... 68

10.8 Clean modular flue gas probe .............................................................. 69

10.9 Replace the probe module ................................................................... 69

10.10 Check/replace particle filter ............................................................... 69

10.11 Replace thermocouple ...................................................................... 71

11 Techni cal data ............................................................................................ 72

11.1 Contact and support ............................................................................. 73

Page 6

Page 7

1 About this document

Note: basic or additional information

…

Result of an action

Requirement

Risk of death!

Indicates possible serious injury.

Indicates possible minor injury .

CAUTION

Indicates possible damage to equipment.

1 About this document

• The instruction manual is an integral part on the instrument.

• Keep this documentation to hand so that you can refer to it when necessary.

• Please read this instruction manual carefully and familiarize yoursel f with the

product before use.

• Hand this instruction manual on to any other users of the product.

• Pay attention to the safety instructions and warning advice in order to

prevent injury and damage to the produc t.

1.1 Symbols

Display Explanation

1

Action: several steps, the sequence must be followed.

2

1.2 Warning notices

Always pay attention to any information marked with the following warning

notices along with warning pict ograms. Implement the specified precautionary

measures!

DANGER

WARNING

CAUTION

7

Page 8

2 Safety and disposal

-

Dangerous mixture of gases

Danger of explosion!

-

-

2 Safety and disposal

Take the testo information document into account (accompanies the product).

3 Product-specific safety instructions

CAUTION

The condensate may be acidic.

Risk of burns to the hands!

Wear acid-resistant safety gloves, glasses and overalls to empty the

condensate.

• Make sure that the condensate has been fully emptied out of the condensate

trap before the measuring instrument i s stored for a long time.

• Before disposing of the product, the condensate trap must be emptied and

the condensate in the crude gas tube dis posed of in a suitable container.

• When testing a gas pipe, pay attent ion to the following:

WARNING

Make sure there are no leaks between the sampling point and the measuring

instrument.

Do not smoke or use open flames during the measurement.

4 Authorizations and certification

Please find the current country approvals in the Approval and Certification

document which is enclosed with the product.

8

Page 9

5 Specifications

5 Specifications

The testo 300 is a measuring instrument for flue gas analysis on applications,

such as

• residential, commercial and industrial applications (oil, gas, wood, coal)

• low-temperature and condensing boilers

• boilers, furnaces and gas heaters.

Using the instrument, these system s can be adjusted and checked for

applicable limit values.

The instrument has been verified as a sh ort-term measuring instrument and

should not be used as a safety (alarm) device.

The following tasks can also be performed using the instrument:

• Checking the O

ensure optimum operation.

• Draft measurement.

• Measuring the gas flow pressure in gas heaters.

• Measuring and optimizing the f low and return temperatures of heating

systems.

• Measuring the CO concentration in the am bient air.

A NO

filter for the CO sensor can be order ed as a spare part to replace a used

x

filter.

, CO and CO2, NO, NOx values in combustion plants to

2

9

Page 10

6 Product description

1

USB interface/

power connection

4

User interface

2

Gas outlet

5

Condensate trap

3

On/Off button

6

Connections

6 Product description

6.1 Front view

10

Page 11

6.2 Rear view

1

Attachment point for carrying

strap

2

Magnets

1

Probe connections for additional

probes

3

Flue gas socket

2

Integrated ambient air probe

4

Differential pressure

measurement connection

There must be no more than one extens ion lead (0554 1202)

6 Product description

6.3 Connections

connected between flue gas socket and flue gas probe.

11

Page 12

6 Product description

window and particle filter

instrument

2

Probe handle

4

Connection cable

Removable filter chamber with

window and particle filter

Connector plug for measuring

instrument

2

Lock release

5

Probe handle

6.4 Compact flue gas probe

1 Removable filter chamber with

6.5 Modular flue gas probe

1

3 Connector plug for measuring

4

3 Probe module 6 Connection cable

12

Page 13

7 First steps

, the measuring instrument is automatically powered via the

Storage conditions for the ener gy storage unit:

1

Connect the instrument plug of the power supply to the power supply

2

Connect the power plug of the power supply to an outlet.

If the battery has discharged completely, the charging time at room

7 First steps

7.1 Commissioning

Take the information in the testo information document (included with the

product) into account for this.

7.2 Power supply / Battery

The measuring instrument is supplied with a rechargeable battery.

Fully charge the battery before use.

If plugged in

power supply.

Only charge the battery at an ambient temperature of 32 to 95°F.

• Ambient temperature from 50 to 68°F

• Charge level of 50 to 80%

7.2.1 Charge battery

socket on the measuring instrument.

The charging process starts. LED i n

the condensate trap flashes red.

The charging process stops

automatically when battery is fully

charged. LED in the condensate trap

has a continuous red light.

temperature is approx. 5-6 hrs.

13

Page 14

7 First steps

1

Connect the instrument plug of the power supply to the power supply

2

Connect the power plug of the power supply to an outlet.

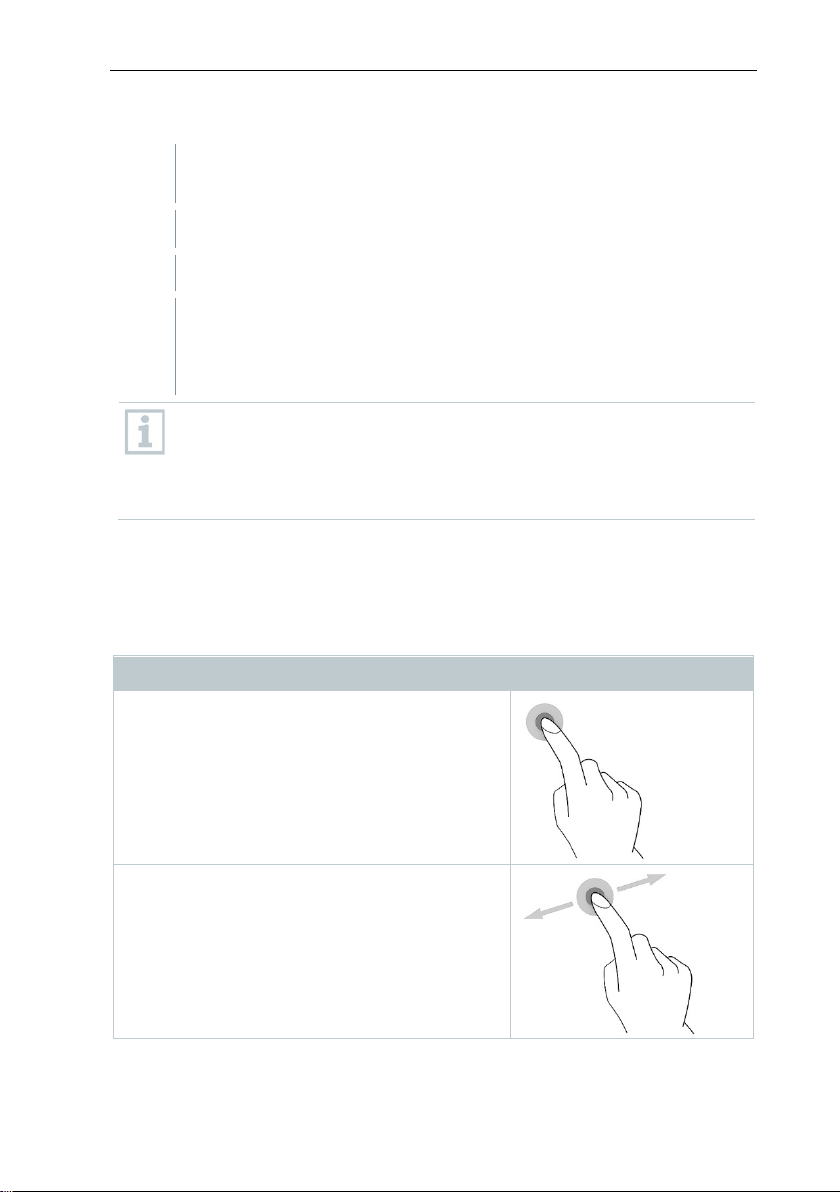

Tapping

Swiping

7.2.2 Power Supply (AC) operation

socket on the measuring instrument.

The measuring instrument is po wered vi a the power supply.

If the instrument is turned off and a power plug is inserted, the

charging process will start autom atically. Switching the measuring

instrument on stops the charging of t he battery and the measuring

instrument is powered via the power supply.

For longer measurements involving AC operation, Testo recommends

using a combustion air temperat ure probe with connection cable. Selfheating of the instrument during AC operation may influence the

combustion air temperature measurement using a mini ambient air

probe.

7.3 Touchscreen operating concept

Familiarize yourself with the touchscreen operating concept before yo u us e the

measuring instrument.

Actions are mostly performed by:

Description

To open applications, select menu symbols,

press buttons on the display or enter characters

with the keypad, in each case tap thes e with a

finger.

Swipe to the right or left on the display to show

further views, e.g. to switch from the list view to

the graphic view.

14

Page 15

7 First steps

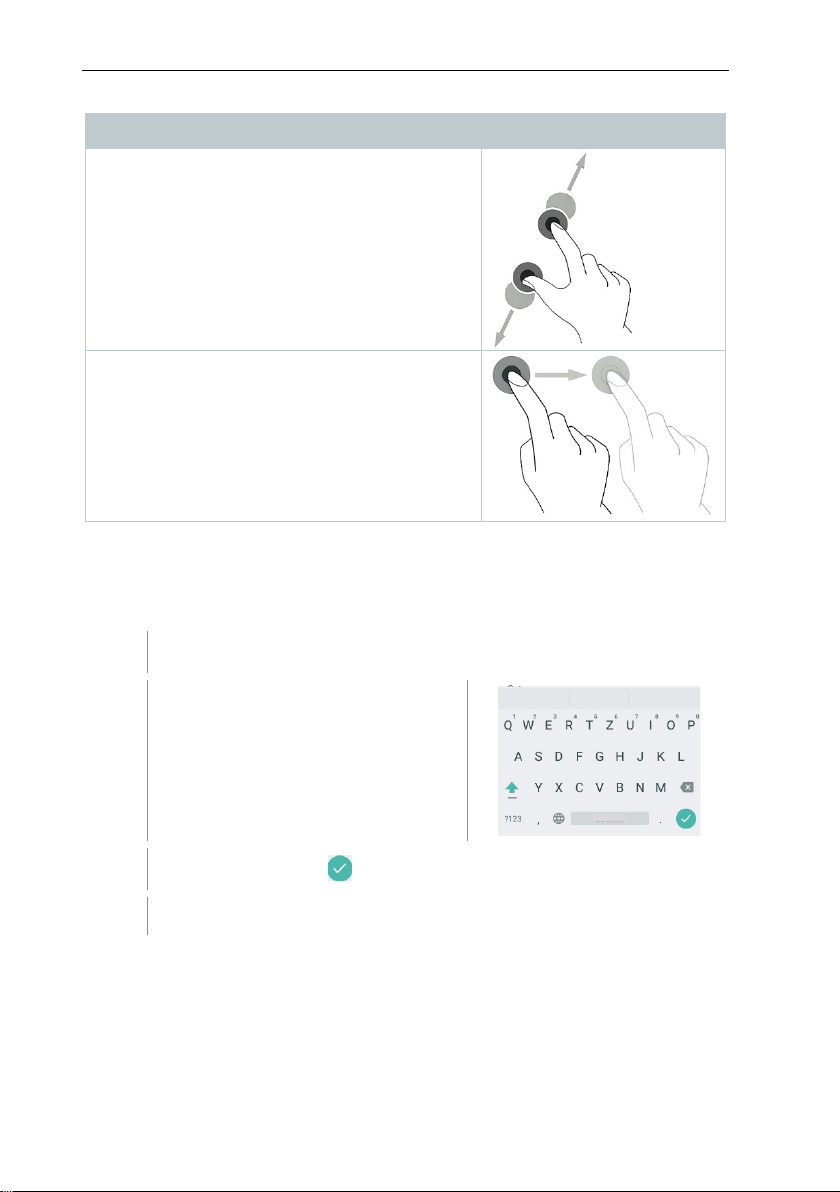

Zooming

1

Enter value: tap the required value

2

Confirm entry: Press .

3

Description

To make a section of the display larger or

smaller, touch the display with two fingers and

move them apart or together.

Dragging

You can move an element by touching it,

holding it and dragging it to the requi r ed

position.

Example: Changing the display sequ ence of the

measurement parameters.

7.4 Keypad

Some functions require values ( figures, numerical value, unit, charact ers) to be

entered. The values are entered via a k eypad.

Input field is enabled (flashing cur sor)

on the display (figures, numerical

value, unit, characters).

Repeat steps as required.

15

Page 16

7 First steps

Instrument

Press the button for

Instrument is turned on.

The tutorial demonstrates the general operation and the most important

button is pressed again.

Instrument

Press the button for

Selection: [OK] Instrument is turned off

with [Cancel].

Unsaved readings are lost when the measuring instrument is turned off.

7.5 Switch instrument on and off

Current

status

off

Instrument

on

on

Action Function

a long time (> 3 s)

When the measuring instrument is st arted for the first time, the setup

wizard guides you through the following setting parameters step by

step:

- Country version (basis of calculations)

- Language

- Wi-Fi

- Date and Time

- Own company address

- E-mail account*

- Product registration

A tutorial can be started after the setup wizard.

functions of the measuring instrument using examples.

Press the button

briefly (< 1 s)

a long time (> 1 s)

Instrument is turned to standb y mode.

The instrument is re-activated when the

or cancel the instrument being turned off

*Note: If you don’t have your Email server information available you can skip

this step.

16

Page 17

7.6 Connect probes

Instrument is turned on.

1

There must be no more than one extension line (0554 1201) between

Instrument is turned on.

1

Insert the connector plug of the

Flue gas probes

Insert the connector plug into the fl ue

gas socket and lock it in place by

turning it slightly clockwise (ba yonet

lock).

measuring instrument and flue gas probe.

Temperature adapter

7 First steps

probe into the probe socket.

System recognizes the probe (info is displayed).

When an external “ext.” probe is used, the display will show “ext.”.

17

Page 18

8 Using the product

1 Measurement types

2

3 Main menu

4

Fuels

5 Select Customer/Measuring site

Select reading display type:

•

•

•

7

Stop measurement

8 Using the product

8.1 User interface

Status bar

Open

6

8

9

18

List

Graphics

Hot Spot

Edit measurement data

Start measurement

Pause measurement

Options

selection list

Page 19

Further symbols on the user interface (without numbering)

One level back

One level back

Refresh measurement

One level back

Cancel process

Print values

Save report

8 Using the product

8.1.1 Main measurement display - List

The measurement units and the number and order of the measurement

parameters displayed in the Main me as urement display – List, can be changed,

Save and send report

see section Configure measurement display.

Only those parameters shown in the reading display appear in the saved

measurement and on the report printouts.

The settings only apply to the measurement type currently enabled.

19

Page 20

8 Using the product

1

Call up function: Graphics

2

Tap on to open selection list for measurement parameters/units.

3

Select desired measurement data / units.

8.1.2 Main measurement display - Graphics

In the Main measurement display - Graphics, the reading progression can be

displayed as a line diagram.

A maximum of 4 measurement parameters can be set at any one time. Only

those measurement parameters c an be displayed that are available in the Main

measurement display - Graphics.

The measurement parameters can be adjusted if necessary:

Measurement view is enabled.

Selection is accepted automatically.

20

Page 21

8 Using the product

1

Call up function: Hot Spot

2

3

Perform zeroing.

4

Align the flue gas probe in the flue so

8.1.3 Main measurement display - Hot Spot

Search for hot spot:

Measurement view is enabled.

Start search:

that the probe tip is in the hot spot

(area of the highest flue gas

temperature Max Tstack).

- Grey value/grey pointer: Displ ay

of current flue gas temperature

- Orange value/orange pointer:

Display of maximum flue gas

temperature

- Reset values/pointer:

The measurement starts automatical ly after zeroing.

21

Page 22

8 Using the product

Create, edit and delete customer and system

information.

possible).

Saved reports

Call up and delete measurement repor t.

Gas path check

For flawless operation of the measuring

recommended.

Device Settings

Settings

- Alarm limits

Sensor Diagnosis

Overview of the sensors installed and their

condition.

Error List

Show error reports

8.2 Overview of main menu ( )

Main menu Description

Customer / Measuring site

Tests Call up, delete and send measurements that

have been performed (various formats

22

instrument, regular tightness testing of

measurement systems (measuring

instrument + flue gas probe) is

- Country version and language

- Wi-Fi

- Date & Time

- My company address

- Bluetooth®

- Hotspot

- Display brightness

- CO sensor protect

- NO2 addition

- O2 reference

Page 23

Main menu Description

Device information

Information

Server information

Information about the available server

E-Mail

Set up e-mail account and the e-mail

account can be displayed.

My App s

- File manager

Help

Aids

- Update via USB

1

- Device name

- Serial number

- Last service date

- Free memory

- Operating hours

- Operating hours since last service

- Software version

- Firmware version

- Firmware date

Additional applications

- Alarm clock

- E-Mail

- Gallery

- Browser

- Calendar

- Pocket calculator

- QuickSupport

8 Using the product

8.2.1 Customer / Measuring site (point)

Create, edit and copy Customer / Meas ur i ng site information.

Customer / Measuring site can be deleted.

Call up function: | Customer / Measuring site

Customer / Measuring site menu is displayed.

- Device Registration

- Tutorial

- Setup Wizard

- Help Online

- Testo Website

23

Page 24

8 Using the product

View/edit existing data about

Customer / Measuring site

Create new Customer / Measuring

site

1

Tap Search operating field.

2

Enter search test using the text edit or.

Via the search text, only the Customer / Measuring site is

3

1

Tap + New Customer / Measuring sit e .

2

Tap the required input field.

3

Enter the information via the keypad.

The following functions are availa ble:

1 Search 3

2

Search

Text cursor flashes.

displayed that contains characteristics of the search text.

Confirm search result: press .

Create new customer

Customer input screen is opened.

Keypad appears.

24

Page 25

4

Confirm each input with .

5

Save.

To be able to select a customer, at least one measuring site must be

A customer is created.

1

Tap Measuring site button.

2

Tap + New measuring site operating f i eld.

3

Enter data.

input field is a required field and must be

4

5

Save.

1

Tap customer.

2

Input fields can be edited.

The Customer/Company Name input field i s a required field and must

be filled in.

Customer is created.

created and selected!

Create new measuring site

Measuring site parameters menu is opened.

The Name of measuring site

filled in.

Confirm each input with .

An additional button (>) appears in some input fields.

These buttons contain a selection of parameters which are adopted in

the input field by tapping on them.

8 Using the product

Edit customer

Customer input screen is opened.

25

Page 26

8 Using the product

Customer input screen is open.

1

Tap Measuring site button.

2

Select Measuring site.

3

Edit data.

4

Save.

1

2

Select customer.

3

Open measuring site.

4

Measurements for the selected

Edit measuring site

8.2.2 Tests

Call up function: | Tests

Tests menu is displayed.

customer / measuring site can be

viewed and deleted .

More options for selected

measurement :

Print readings

Save report

Save and send report

The following information can be sel ec ted / added to create a report.

26

Page 27

Category Description

Format and print

Sweeps in Germany).

Comments and pictures

Select measurements

are identified with .

5

Back to the measurement menu: tap .

1

1

Tap required report.

Select output format(s):

- CSV (comma separated text file, e.g. for

Microsoft

- PDF

- ZIV 2.00 (XML file, complying wit h the

regulations of the Guild of Master Chimney

®

Excel)

8 Using the product

Customer data

Enter / add contact details.

Enter comments and Add (opens the Gallery).

Pictures are only included when output is in PDF

format.

All saved measurements are displa yed in one of

the following time categories, depending on the

creation date: Today, Yesterday or Older.

The measurements selected to creat e the report

Signature

Sign report.

Back to the main menu: tap

or

8.2.3 Saved reports

The measurement reports that have been created are stored under Saved

reports. These can be brought up again, sent or deleted.

Call up function: | Saved reports.

The OI File Manager folder is opened, and the av ailable reports are

Open report

displayed.

Report is displayed as a PDF.

27

Page 28

8 Using the product

1

Touch required report for >2 sec.

2

If necessary, mark more reports b y tappi ng.

3

1

Touch report for >2 sec.

2

If necessary, mark more reports by tapping

3

4

Tap Send.

5

Send report by e-mail.

1

2

Tap Settings.

3

Disable in ascending order under sort settings.

Delete report(s)

Report is marked.

Delete report(s): tap .

Send report(s)

Report is marked.

Tap symbol.

Sort report(s)

Tap symbol.

The latest reports are displayed first.

28

Page 29

8 Using the product

1

2

Place the black sealing cap on the tip of the flue gas probe.

gas paths are not leaking, and the measurement is ended.

3

4

1

8.2.4 Gas path check

Regular tightness testing of measur ement systems (measuring instrument + flue

gas probe) is recommended.

Call up function: | Gas path check

8.2.5 Device settings

8.2.5.1 Country version and language

Set up your measuring instrument count ry-specifically.

The country version configurat i on affects the measurement parameters, fuel s ,

fuel parameters and the bases of and for mulas for calculations that are enabled.

The country version configurat i on affects the user interface languages that can

be enabled.

Gas path check starts automatically.

The pump flow is displayed. If the fl ow rate is less than 0.02 l/min, the

Remove the sealing cap from the prob e tip.

Back to the main menu: tap .

Call up function: | Device Settings | Country and Language

29

Page 30

8 Using the product

1

Tap Country version (basis of calculations) selection field.

2

Select country version.

3

Tap Next.

Country & language settings menu

1

Tap Language selection field.

2

The instrument is reconfigured to the selected language.

1

Set country version

Set language

The available country versions ar e di s played.

The query Change country version? is displayed.

Configuration of the country version can be ended by

cancelling. The display goes b ac k to Device Settings.

The selected country version is conf igured (this may take a few

minutes). The Device Settings menu is then displayed.

Restart the measuring instrument to complete its configuration.

The available languages for the selected country version are

displayed.

Select Language and tap .

Back to the main menu: tap and .

30

Page 31

8 Using the product

1

2

Tap Wi-Fi selection field.

3

Enable Wi-Fi: tap Off button or move grey point to t he r i ght.

4

Select Wi-Fi router or Wi-Fi hotspot.

5

Tap Connect.

6

It may be necessary to enter the password for the selected Wi-Fi.

further options. Save entry.

Saved networks

Advanced

is disabled in standby mode and enabled aga in once you quit

8.2.5.2 Wi-Fi

A radio link, such as a Wi-Fi, is not needed for performing

measurements.

Set up a connection to a Wi-Fi router or a Wi-Fi hotspot. The connection allows

sending of measurement reports b y e-mail.

Call up function: | Device Settings | Wi-Fi.

Further entries via button

Instrument switches to On. The point changes to green.

Display of all available Wi-Fi routers or Wi-Fi hotspots in t he vicinity.

Connection is set up and shown by Connected.

Category Description

Add network Enter network name using the keypad,

set security standard and if necessary enter

Display of saved networks.

Refresh

Updating the display of available networks.

Further Wi-Fi settings are displayed.

The Wi-Fi

standby mode. The enabling process may take a few seconds.

31

Page 32

8 Using the product

1

2

8.2.5.3 Date/Time

You can set the date, time and time zone in the Date/Time menu. You can

choose between the 24 hr or AM/PM formats for the time.

If the Wi-Fi has already been enabled, the Date/Time pr ovided by the

network is automatically set.

Call up function: | Device

Settings | Date/Time.

Various setting options are displa yed. Depending on your

requirements, you can

• Enable ( ) / disable( ) selection fiel ds by tapping

• Open other selection fields

• Enter parameters using the keypad

• Set 24 hr or AM/PM format: 24 hr ( ) / AM/PM ( )

Back to the Device Settings menu: Tap | | .

32

Page 33

Set Date/Time manually

1

Tap Date/Time.

2

Tap Autom. Date/Time.

3

Select Off.

4

Tap Set Date.

5

Select date via the calendar and confirm with OK.

8 Using the product

Autom. Date/Time is disabled. The pop-up window closes

automatically.

33

Page 34

8 Using the product

6

Tap Set Time.

7

Tap hour and set.

8

Tap minute, set and confirm with OK.

9

1

Tap Time Zone.

2

Tap Autom. Time Zone and disable ( ).

3

Tap Select time zone.

1

Select desired time zone.

2

1

Call up function: | Device Settings | My company address

2

Tap the required input field.

3

Enter the information via the keypad.

4

5

Back to the Device Settings menu: tap .

Back to the Device Settings menu: tap | | .

Set time zone manually

Back to the Device Settings menu: tap | | .

8.2.5.4 My company address

Enter own company address. This information will be shown on the reports.

Contact information input screen is opened.

Keypad appears.

Confirm each input with ✓.

34

Page 35

8 Using the product

1

Call up function: | Device Settings | Bluetooth®

2

Enable/disable Bluetooth by tapping the selection fie ld.

3

Back to the Device Settings menu: Tap .

2

3

Back to the Device Settings menu: tap .

1

Tap Hotspot settings.

2

Select Wi-Fi Hotspot.

3

Tap Set up Wi-Fi Hotspot.

4

Edit network name and password.

5

Tap Save.

6

Back to the Device Settings menu: tap .

2

Adjust the display brightness using the slide control.

3

Back to the Device Settings menu: tap .

8.2.5.5 Bluetooth

Enable Bluetooth to print out or trans m i t measurement data.

8.2.5.6 Hotspot

Enable a hotspot to be able to transmit readings to software / industry software.

The interface must also be available in the software / industry software.

Call up function: | Device Settings | Hotspot

1

By tapping the selection field, enable ( )/disable ( ) Hotspot.

Edit hotspot name and password

8.2.5.7 Display Brightness

Call up function: | Device Settings | Display brightness

1

35

Page 36

8 Using the product

1

Call up function: | Device Settings | Sensor Protection

2

Enter the alarm limit value via the keyp ad.

3

1

Call up function: | Device settings | O2 Reference

2

Enter the value via the keypad.

3

4

Tap [OK].

1

Call up function: | Device Settings | Alarm limits

2

Tap directly on the value in the relevant input field.

8.2.5.8 CO/NO sensor protect

Limit values can be set to protect t he C O/NO sensors against overload. Sensor

protect is enabled if these are exceeded:

• Fresh air dilution if exceeded (onl y for instruments with the "Dilution" opti on)

• Shutdown if exceeded again

When dilution is enabled, the CO and C O undiluted values are

displayed in a blue font. A “*” is shown on the printout after the name of

both values to indicate dilution .

CO input screen: Set Sensor Setting is opened.

Confirm input with .

The limit values must be set to 0 ppm to disable sensor protect.

8.2.5.9 O2 Reference

The O2 reference value can be set.

O2 Reference input screen is opened.

Confirm input with .

8.2.5.10 Alarm limits

Alarm limits can be set for the CO Ambient measurement type. An audible

alarm signal is triggered when the alar m l imit is reached.

36

Alarm limits input screen is opened.

Page 37

8 Using the product

3

Enter the value via the keypad.

4

5

Tap [OK].

1

Call up function: | Sensor Diagnosis

1

Call up function: | Error List

1

Call up function: | Device Information

1

Call up function: | Server Information

1

Call up function: | E-Mail

2

Enter e-mail address.

3

Enter password.

4

Set account options, such as s ynchr onization interval

Confirm each input with ✓.

Keypad appears.

8.2.6 Sensor Diagnosis

Overview of the sensors fitted and t heir condition.

8.2.7 Error List

Call up error reports.

8.2.8 Device Information

Call up device information.

8.2.9 Server Information

Information about the available server.

8.2.10 E-mail

Set up e-mail account

An e-mail account must be set up in order to be able to send reports as

e-mails. A Wi-Fi connection must be available to set the ac c ount up.

37

Page 38

8 Using the product

5

Entry of account name (optional) a nd name which appears with the

sent e-mails.

If the system does not accept the e-mail address and password

1.

E-Mail.

2.

Enter e-mail address.

3.

Select Manual set-up.

Personal account type (IMAP)

6.

Enter/change server, port and secur ity type.

your account provider or on the Int er net.

7.

[Next]

your account provider or on the Int er net.

9.

[Next]

10.

Set account options, such as synchr onization interval.

11.

[Next]

with the sent e-mails.

13.

[Next]

The inbox of the e-mail account is opened.

combination, but you are certain it i s correct, check the following

possible solutions:

• Open e-mail client, e.g. gmail, on a PC and check e-mail reception.

The provider may have sent a security e-mail which has to be

confirmed before the e-mail account on the testo 300 is accepted.

• Enable IMAP account

To do this, call up your e-mail account on the PC. You will find the

setting for the common e-mail providers, e.g. yahoo, under settings

- POP/IMAP. Account-specific information about the enabl i ng of the

IMAP account is supplied by the relevant provider. Find out about

this from the relevant provider or on the Internet.

• Manual set-up of the e-mail account

Call up function: |

4. Select

5. Enter password.

(recommended).

This information is e-mail account specific and is supplied

by your e-mail account provider. Find out about this from

8. Enter/change smtp ser ver, port and security type.

This information is e-mail account specific and is supplied

by your e-mail account provider. Find out about this from

12. Entry of account name (optional) and name which appears

The inbox of the e-mail account is opened.

38

Page 39

Call up e-mail account

1

Call up function: | E-Mail

2

3

Enter the e-mail address via the keyp ad.

4

Fill in subject and create text.

mail using the paper

5

1

Call up function: | My Apps

Inbox menu is opened.

Create e-mail: tap .

Compose menu and the keypad is opened.

If required, additional files can be attached to the eclip symbol.

Send e-mail: tap .

E-mail is sent.

8.2.11 My Apps

Additional applications

8 Using the product

Available Apps are displayed.

Symbol Name

Alarm clock

Gallery

Browser

Calendar

Calculator

Quick Support

39

Page 40

8 Using the product

1

Call up function: | Help | Please register your testo 300

1

Call up function: | Help | Tutorial

1

Call up function: | Help | Setup Wizard

2

The following settings can be made:

Country version and language

8.2.5.2

Wi-Fi

8.2.5.2

Contact information

8.2.5.4 (Own company address)

E-Mail

8.2.10

3

Next >

4

If necessary, tap start tutorial or end setup.

8.2.12 Help

8.2.12.1 Please register your testo 300

Testo would like to offer you the best p ossible customer service. Register your

instrument so that, when you call, our employees in Customer Service have all

the information they need available at all times, so that they can quickly provide

you with further assistance.

Register at: https://testo.com/register

You will find the information you need for registration on the sticker on the back

of the instrument.

Follow the instructions on the dis play.

Registration gives you the foll owing advantages:

• 1 year's additional warranty for free

• Always get the latest information from testo

8.2.12.2 Tutorial

The tutorial provides you with an over view of and an introduction to the

operation and functions of the instr ument.

8.2.12.3 Setup Wizard

Function Section

Time 8.2.5.3

Registration 8.2.11.1 (Device Registration)

Setup is complete.

40

Page 41

8 Using the product

1

Call up function: | Help | Update via USB

2

Confirm info with OK.

3

Insert the connecting cable (0449 0 134) into the USB port on the

measuring instrument, then connec t it to the PC.

4

Copy the new instrument software file (t300.zip) to the identified

Length of the copying process: approx. 10 – 15 minutes

5

Disconnect the connecting cable from the measuring instrument.

Once the instrument software has been updated (duration approx. 1.5

use again.

8.2.12.4 Update via USB

You will find the current instrument software (firmware) on the Testo home page

www.testo.com under the product -specific downloads.

Firmware update is started.

Your PC identifies the measuring instrument as a removable medium.

removable medium.

hrs), the measuring instrument will automatically reboot and is ready for

41

Page 42

9 Performing the measurement

1

Check the condensate trap fill level and if necessary empty trap, see

2

Check the particle filter of the flue gas probe for contamination and

testo 300 without option of probe zeroing in the flue gas:

zeroing phase

(30 sec).

>

testo 300 without option of probe zeroing in the flue gas:

(depressurized, not closed).

9 Performing the measurement

9.1 Prepare for measurement

Section 10.5 Empty condensate trap.

replace it in good time. If necessary, see Section 10.10 Check/replace

particle filter.

9.2 Zeroing phases

Measuring the combustion air temperature (Tamb)

If no external combustion air temperature probe is connected, the combustion

air temperature is measured via t he integrated temperature probe.

Gas zeroing

The gas sensors are automatically zeroed after the instrument is turned on.

The flue gas probe must be in fresh air during the zeroing phase (30

sec)!

testo 300 with option of probe zeroing in the flue gas:

The flue gas probe can be in the flue gas duct during the

Start zeroing of the gas sensors manually: | Zeroing Gas Sensors

Draft/pressure zeroing

The pressure sensors are zeroed whe n a pressure measuring function is called

up.

The flue gas probe must be in fresh air during the zeroing phase! The

instrument must not be pressurize d dur ing zeroing!

testo 300 with option of probe zeroing in the flue gas:

The flue gas probe can be in the flue gas duct during the zeroing

phase. The pressure socket of the i ns trument must be free

42

Page 43

9 Performing the measurement

Regularly check the measurement system (measuring instrument + flue

>

>

The thermocouple of the flue gas

>

The thermocouple must be freely

The tip of the probe is in the hot spot of the flue gas.

1

Select Hot Spot.

2

Start hot spot search: tap .

3

Perform zeroing. Please follow the instructions.

9.3 Carry out gas path check

gas probe) for leaks.

Too high an O2 value may be an indicator of a leaking measurement system.

| Gas path check.

9.4 Use of flue gas probe

Check thermocouple before use

probe must not be touching the probe

cage.

Bend the thermocouple back if

necessary.

Align flue gas probe

exposed to the flue gas flow.

Align the probe by turning it as

required.

Search for hot spot

43

Page 44

9 Performing the measurement

4

Align the flue gas probe in the flue

Orange value/orange pointer: Dis play of maximum flue gas temperature

>

Reset values/pointer: .

5

Measurement types

Flue Gas Analysis

Draft

CO Air free

Smoke Number

Differential pressure

gas duct so that the probe tip is in

the hot spot (area of the highest f lue

gas temperature Max Tstack).

9.5 Overview of measurement types ( )

Grey value/grey pointer: Displ ay of current flue gas temperature

End hot spot search: tap .

44

Page 45

9 Performing the measurement

Measurement types

Differential temperature

O2 Air

Clock Meter

Oil flow calculation

CO Ambient

Pipe Commissioning

Pressure Drop test

Pretest

Options

Description

Config. Measurem. display

Add, delete ( ), measurement parameters,

Unit).

Zeroing Gas Sensors

Manually zeroing gas sensors.

9.6 Overview of options ( )

display sequences ( ) and edit units (c li c k on

Menu is only available for measurements

with gas sensors.

45

Page 46

9 Performing the measurement

1

Call up function: | Options | Config. measurem. Display

2

Measurement parameter

- Accept changes: tap Confirm.

Tstack

Flue gas temperature

9.6.1 Configure measurement display

Edit Display menu is opened.

- Add: tap Add to open selection list of measurement parameters.

- Delete: tap on .

- Edit unit: tap on the measurement parameter you want to edit. Tap

- Change position in the list: Press and hold and drag to the

Selection list (example: Country version USA)

The overview of measurement parameter s (available selection depends on the

chosen measurement type, fuel set and the sensors available in the measuring

instrument):

Display Measurement parameter

Tamb Combustion air temperature

Tinst. Instrument temperature

Pump Pump performance

O2 Oxygen

on the required measurement unit in the selection list that has been

opened.

required position.

46

Page 47

9 Performing the measurement

Display Measurement parameter

CO2 Carbon dioxide

Eff net Efficiency without consideration of the heat value range

Eff Efficiency with consideration of the calorific value range

CO Carbon monoxide

Draft Flue draft

CO AF Undiluted carbon monoxide

cCO Corrected CO for environmental regulation

ExAir Excess Air

CO amb Ambient carbon monoxide

ΔT Differential temperature

Dew Pt Flue gas dewpoint temperature

Δp Differential pressure

NO Nitrogen monoxide

NOx Nitrogen oxides

O2ref Oxygen reference

Smoke 1

Smoke 2

Smoke 3

Smoke

number Ø

Only those measurement parameters and units that are enabled in the

reading display appear in the readi ng display, in the saved

measurement tests and on the report printouts.

The settings only apply to the measurement type currently enabled.

47

Page 48

9 Performing the measurement

1

2

measurement parameter is enabled in the reading display, a

9.6.2 Flue Gas Analysis

To maintain the measuring accuracy of the instrument, the correct fuel

must be selected or configured.

Tap (Fuels)

> Select fuel.

To achieve usable measurement results, the test time of a flue gas

measurement should be at least 3 mi nutes and the measuring

instrument should display stable readings.

If a separate CO Air free measurement has not yet been performed,

this value is calculated using the readings from the flue gas probe and

continuously updated.

Call up function: | Flue Gas Analysis

Start measurement: Tap .

Zeroing takes place.

Readings are displayed.

If the Draft

draft measurement is automatically started in parallel to the flue gas

measurement. In the List measurement data view, the parallel draft

measurement can be stopped/restar ted. This draft measurement is

performed separately to a measurement of the Draft measurement

type.

48

Page 49

For the draft measurement, the minus connection for differential

3

4

A flue gas probe must be connected.

1

2

3

pressure measurement must be free ( am bient pressure, not closed).

Tap on the draft reading display or next to it.

End measurement: tap .

9.6.3 Draft-Measurement

Call up function: | Draft-Measurement

9 Performing the measurement

The minus connection for differential pressure measurements must be

clear (ambient pressure, not closed).

Start measurement: tap .

Zeroing takes place. Please follow the instructions.

Reading is displayed.

End measurement: tap .

49

Page 50

9 Performing the measurement

A multi-hole probe (0554 5762) must be connected.

1

2

3

The Smoke Number and Oil depos. parameters are only available for

1

2

Tap required value.

3

Enter value.

4

5

9.6.4 CO Air free

Call up function: | CO Air free

Start measurement: tap .

Reading is displayed.

End measurement: tap .

9.6.5 Smoke Number

oil fuels. The values calculated by a smoke tester can be entered.

Edit values

All values that can be modified have a dotted underlining.

Call up function: | Smoke Number

Keypad appears.

Confirm entry: tap ✓.

Reset readings: tap .

50

Page 51

9 Performing the measurement

The gas pressure kit (0554 1203) must be connected.

For an instrument with no dilution option: The minus connection for

1

2

Tap Differential pressure.

3

4

The differential temperature kit (0554 1208) or two external temperature

1

2

3

9.6.6 Differential pressure

WARNING

Dangerous mixture of gases!

Danger of explosion!

- Make sure there are no leaks between the sampling point and the

measuring instrument.

- Do not smoke or use naked flames during the measurement.

differential pressure measurem ent must be depressurized at the start of

the measurement (ambient pressur e, instrument not connected to

system being checked), since the pres s ure sensor is zeroed.

Call up function: | Differential pressure

Start measurement: tap .

Zeroing the pressure sensor.

Reading is displayed.

End measurement: tap .

9.6.7 Differential temperature

probes must be connected.

Call up function: | Differential temperature

Start measurement: tap .

The readings and the calculated diff erential temperature ΔT (T1 - T2)

are displayed.

End measurement: tap .

51

Page 52

9 Performing the measurement

An O2 dual wall clearance probe (0632 1260) m ust be connected.

1

2

4

1

2

Set the gas amount to watch for at the gas meter.

3

Set the heating value of the burnt gas.

4

5

9.6.8 O2 air (EU regulation)

Call up function: | O2 air

Start measurement: tap .

Reading is displayed.

End measurement: tap .

9.6.9 Clock Meter

The function is only available if the chosen fuel is a gas.

The gas burner capacity is calculate d by means of the gas amount consumed.

To this end, a gas amount is input, and its consumption read out at the gas

meter.

Call up function: | Clock Meter

Start measurement: tap .

The test time is displayed.

When the set gas amount is reached: tap .

The calculated gas flow and the gas bur ner capacity (in BTU/h) are

displayed.

Edit values

All values that can be modified have a dotted underlining.

52

Page 53

9 Performing the measurement

1

2

Set oil flow rate of the oil nozzle and oil pressure.

• Cigarette smoke influences the measurement by more than 50 ppm.

An ambient CO probe (0632 1272) must be connected.

1

2

3

9.6.10 Oil flow calculation

The function is only available if the chosen fuel is an oil.

This function is used to calculate the capacity of the burner from the set oil

pressure and the oil flow rate of the oil nozzle.

Call up function: | Oil flow calculation

The calculated oil burner energy is dis played (in BTU/h).

Edit values

All values that can be modified have a dotted underlining.

9.6.11 CO Ambient

The breath of a smoker influences the measurement by about 5

ppm.

• When using an ambient CO probe, note that:

The direction of flow of the gas influences the accuracy of

measurement. Frontal flow onto t he sensor leads to higher

readings. The best measurement r es ul ts are achieved when the

probe is moved gently backwards and f orwards.

• When using the ambient CO probe and the flue gas probe, note

that:

The probe must be in the fresh air (CO-free) during the zeroing

phase.

Call up function: | CO Ambient

Start measurement: tap .

Reading is displayed.

End measurement: tap .

53

Page 54

9 Performing the measurement

- Pipe volume > 200 l: Adjustment time 60 min, test time 30 min.

>

Connect the connector plug of the hose pressure connection kit (0554

The pressure socket of the instrument must be free (depressurized, not

Pressure zeroing has been performed.

1

2

Set parameters or enter values.

3

Pressurize the system.

4

9.6.12 Pipe Commissioning (EU regulation)

The pipe commissioning (using air or inert gas such as CO2 or N2) is a tightness

test for pipes, including fitting s , but without gas appliances and the relevant

regulating and safety devices. T he pipe commissioning is performed after a load

test has been successfully complet ed on newly laid gas pipes, or after

renovation of existing gas pipes, and is used for the acceptance of these pipes.

It shows up even the smallest leaks in gas pipes.

According to DVGW TRGI 2008 and ÖVG W G10, the stabilization time

and test time depend on the pipe volume.

- Pipe volume < 100 l: Adjustment time 10 min, test time 10 min.

- Pipe volume > 100 l to < 200 l: Adjustm ent time 30 min, test time

20 min.

1203) to the pressure test kit (0554 1213). Insert the pressure adapter

into the flue gas socket and lock b y sli ghtly turning it clockwise (bayonet

fitting).

Performing the measurement

closed).

Call up function: | Pipe Commissioning

All values that can be modified have a dotted underlining.

Once the pressure has built up, a stabilization time specified by DVGWTRGI 2008 should be observed to ensure that any possible pressure

fluctuations are not recorded in t he measurement as well. The relevant

standard provides more detailed inf ormation.

Start stabilization time: tap . If applicable, follow instructions.

Reading is displayed.

54

Page 55

9 Performing the measurement

5

The measuring value result can be assessed.

6

Conclude measurement: tap Next.

7

>

Insert the connector plug of the hose pressure connection kit (0554

The pressure socket of the instrument must be free (depressurized, not

1

Stabilization time is finished.

End stabilization time early: tap .

Measuring time starts.

The readings are automatically saved and displayed after the

measurement has been completed.

If applicable, repeat measurement : tap .

9.6.13 Pressure Drop test (EU regulation)

This measurement is performed to test the serviceability of an existing g as pipe

system (in contrast to the load test and pipe commissioning) and is used to

check the actual condition of the pipes . The pipe system may be in operation or

disused.

Adhere to DVGW-TRGI 2008, worksheet G624!

Absolute pressure (parameter of the measuring location) must be

entered to obtain correct readings. If this is not known, it is advisable to

use the value 966 hPa (corresponds to 1013 hPa barom. 400 m above

sea level).

1203) into the flue gas socket and loc k it in place by turning it slightly

clockwise (bayonet fitting).

Performing the measurement

closed).

Pressure zeroing has been performed.

Call up function: | Pressure Drop test

55

Page 56

9 Performing the measurement

2

Set parameters or enter values.

Three circle diameters and three pipe lengths can be entered, which

calculated by adding these three part ial volumes.

3

Pressurize the system.

4

5

6

The measuring value result can be asses sed.

7

Conclude measurement: tap Next.

8

All values that can be modified have a dotted underlining.

are then used to calculate three parti al volumes. The pipe volume is

Start stabilization time: tap . If applicable, follow instructions.

Reading is displayed.

Stabilization time is finished.

End stabilization time early: tap .

End measurement: tap .

Measuring time starts.

The readings are automatically saved and displayed after the

measurement has been completed.

If applicable, repeat measurement : tap .

56

Page 57

9.6.14 Pretest (EU regulation)

>

Insert the connector plug of the hose connection kit (0554 1203) into

The pressure socket of the instrument must be free (depressurized, not

Pressure zeroing has been performed.

1

2

Set parameters or enter values.

3

4

The measuring value result can be assessed.

5

Conclude measurement: tap Next.

6

the flue gas socket and lock it in place by turning it slightly clockwise

(bayonet fitting).

Performing the measurement

closed).

Call up function: | Pretest

All values that can be modified have a dotted underlining.

Start stabilization time: tap . If applicable, follow instructions.

Reading is displayed.

Stabilization time is finished.

9 Performing the measurement

End stabilization time early: tap .

Measuring time starts.

The readings are automatically saved and displayed after the

measurement has been completed.

If applicable, repeat measurement : tap .

57

Page 58

9 Performing the measurement

Tests

Feature

Print values

Print out measuring values via Bluet ooth®.

values can be retrieved in the main me nu.

Finish test

Create, save and send measurement repor t,

Saved reports can be retrieved in the main menu.

9.7 Overview of tests ( )

Save Save measuring values, including selec ted

customers / measuring sites. Saved m easuring

including

- Own company data

- Format and print

- Customer data

- Comments and pictures

- Select measurements

- Signature

9.7.1 Print values

The current readings are printed via a Bluetooth® printer (accessories: Testo

printer 0554 0621).

Carry out print text settings

Print text settings can be performed and the reading printout can be

supplemented with individual cr eator information (header: company addr ess;

footer: name of technician), se e S ec tion 8.2.5.4 My company address.

58

Page 59

9 Performing the measurement

The printer is turned on and within wireless rang e.

1

2

Tap Print values.

1

2

Tap Save.

1

Print current readings

Tap .

Tests menu is opened.

The test is created and sent to the printer.

The test is printed.

9.7.2 Save

The measurement data from the last measurement performed of each

measurement type are saved on the measuring instrument.

Measurements that have been performed can be saved to back up the

measurement data and for the subsequent creation of a report:

Tap .

Tests menu is opened.

The measurement test is saved.

Only saved readings can be further processed at a later stage for a

report.

The readings are automatically saved for the following measurement

types:

• Pipe Commissioning

• Pressure Drop test

• Pretest

9.7.3 Finish test

Tap .

Tests menu is opened.

59

Page 60

9 Performing the measurement

2

Tap Finish test.

3

Enter/select log data:

Format and print

Germany’).

Customer data

Enter contact details

Comments and pictures

Enter comments and add pictures.

Select measurements

.

Signature

Tap Sign Report and sign.

Abort, Reset and Save

Options for Tests are opened.

Category Description

Select output format(s):

- CSV (comma separated text file,

e.g. for Microsoft

- PDF

- ZIV (XML file, complying with the

regulations of the ‘Federal

Association of Chimney Sweeps in

All saved measurements are displa yed

in one of the following time categories,

depending on the creation date:

Today, Yesterday or Older.

The measurements selected to creat e

the report are identified with .

Recently saved measurements for

these customers are automatically

identified.

To display saved readings to check

them:

.

To delete individual measurement:

.

To delete all measurements of a tim e

category:

Tap next to the time category

name.

To select/deselect a measurement for

the report:

®

Excel),

60

Options:

Page 61

4

Print values: tap .

Save and send report: tap .

To save readings: tap .

9 Performing the measurement

61

Page 62

10 Maintenance

10 Maintenance

10.1 Service

Testo recommends an annual check of the testo 300 which can be

performed by a service center authorized by Test o. Please contac t

Fr d

10.2 Calibration

10.3 Check instrument status

10.3.1 Sensor diagnosis

The status of the sensors can be displaye d.

To replace expended sensors, see Section "Replace sensors".

Call up function: | Sensor Diagnosis

10.3.2 Error list

Instrument errors that have not yet been cleared can be displayed.

Call up function: | Error list

Testo at http://www.testo.com for more information.

The measuring instrument is supplied with a calibration protocol as

standard. Testo recommends calibration of the measuring instrument

once every 12 months. This can be performed by Tes to or another

certified service center. Ple ase contact Testo at http://www.testo.com

for more information.

Sensor diagnosis is displayed.

A sensor can recover. It is therefore possibl e for the sensor status

display to change from not OK to OK.

Error list is displayed if there are errors present.

62

Page 63

10 Maintenance

>

If the housing of the measuring instrum ent is dirty, clean it with a damp

10.4 Clean the measuring instrument

cloth.

Use distilled water, or alternat ively mild solvents, such as isopropanol,

to clean the flue gas analyzer.

CAUTION

Improper use of isopropanol!

Irritation of the eyes and sensitive mucous membranes! Fumes have a

slight narcotic effect!

- If using isopropanol, please refer to the instruc tion leaflet for the product.

- When using it, please ensure that there is adequate ventilation.

ATTENTION

Leaking solvents and degreasers!

Damage to the instrument and senso rs!

- Do not store solvents and degreasers, such as isopropanol, in the case.

ATTENTION

Strong or harsh alcohol or brake cleaner!

Damage to the instrument!

- Do not use any strong or harsh alcohol or brake cleaner .

10.5 Drain condensate trap

The fill level of the condensate trap can be read from the markings. Hold the

instrument horizontally or vertically to check the fill level.

63

Page 64

10 Maintenance

1

2

Let the condensate drain out.

3

- Wipe off any drops still on the condensate outlet with a cloth and close

CAUTION

Weak mix of acids in the condensate!

Minor injuries!

- Avoid skin contact.

- Make sure that the condensate does not run over the housing.

CAUTION

Condensate entering the gas path!

Damage to sensors and flue gas pump!

- Do not empty condensate trap while the flue gas pump is in operation.

Open the condensate outlet on the

condensate trap.

the condensate outlet.

The condensate outlet must be completely closed, otherwise incorrect

measurements could occur due to infil tration of external air.

64

Page 65

10 Maintenance

The measuring instrument must not be connected to a mains socket via

1

2

Using a torx screwdriver (size T 10),

ATTENTION

3

Unlock the operating module in the

4

Remove the operating module.

10.6 Open the measuring instrument

Only open the measuring instrument when this is required for maintenance

purposes (replacing gas sensor s ).

the mains unit. The measuring instrument must be turned off.

When opening/assembling the instrument, take care not to lose any

screws that have been removed. It is advisable to place a cloth on the

work surface.

Place the instrument on its front so that the back is facing upwards.

remove both housing screws on the

top of the instrument.

The instrument may be damaged by incorrect removal of the housing

screws!

- Only remove the two housing screws on the top of the inst rument. The

other four screws must be left as the y are.

direction of the arrow.

65

Page 66

10 Maintenance

5

Place the instrument on its front again.

6

Remove the remaining four screws on the back of the instrument.

7

Lift off the back of the instrument.

Perform in reverse order to assembl e. Please note:

- Make sure that hoses and lines do not get jammed.

2

CO sensor type

When retrofitting a sensor, the associated measurement parameter/unit

Assembly

- Lay hoses and lines in the guides intended for this purpose.

10.7 Replace sensors

A slot bridge (0192 1552) must be inser ted in slots which are not

equipped with a sensor. Used sensors must be disposed of according

Available slots:

to local regulations!

1 NO sensor type 3 O2 sensor type

66

must be enabled in the reading displa y.

Page 67

Measuring instrument is open, see Section Open measuring

instrument.

1

Unlock retaining bracket and open

2

Remove faulty sensor from the slot.

3

Insert new sensor in the slot.

4

5

Close the measuring instrument.

10.7.1 Replace O2 sensor

out.

Make sure that the socket on the

sensor circuit board is correctly

connected to the contact plug.

10 Maintenance

Close the retaining bracket with an au di ble "click".

After replacing an O2 sensor, wait for an acclimatization time of 15 min

to elapse before using the instrument.

When replacing an O2 sensor and when there is an interruption of the

power supply for more than 10 hours, we recommend an

acclimatization time of 1 hour for c ompliance with measuring accuracy.

67

Page 68

10 Maintenance

Measuring instrument is open, s ee S ec tion Open measuring

instrument.

1

Remove faulty sensor and hose

2

Remove hose connections from the

3

4

Fit new sensor into the slot and at the s ame time fit the hose

5

10.7.2 Change CO, CO H2 and NO sensor

connections from the slot.

faulty sensor/bridge.

For NO sensor: Remove auxiliary circuit board.

Do not remove the auxiliary circuit board of the NO sensor until

immediately before installation. Do not leave the sensor without

auxiliary circuit board for long er than 15 minutes.

Fit the hose connections onto the new sensor.

connections onto the gas path connections.

Make sure that the socket on the sensor circuit board is

correctly connected to the contac t plug.

Close the measuring instrument.

68

Page 69

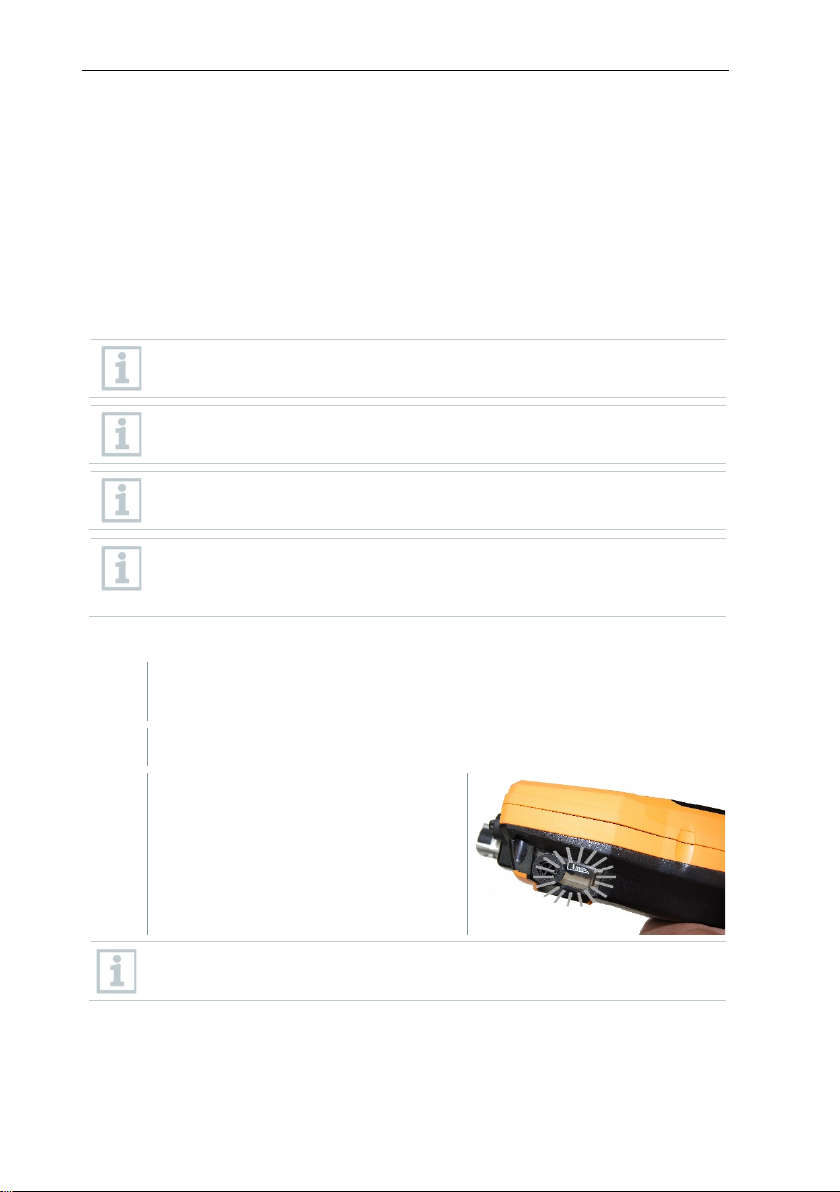

10.8 Clean modular flue gas probe

Disconnect flue gas probe from t he measuring instrument.

1

Release probe catch by pressing the ke y on the probe handle and

2

Blow compressed air through flue gas

3

Fit probe module onto the probe hand l e and click into place.

Disconnect the flue gas probe from the measuring instrument.

1

Press the key on the top of the probe

2

Fit new probe module and click into place.

remove probe module.

ducts of the probe module and probe

handle (see illustration).

Do not use a

brush!

10.9 Replace the probe module

handle and remove the probe module.

10 Maintenance

10.10 Check/replace particle filter

Check particle filter

• Particle filters of the modular flue gas probe must be checked regularly for

contamination: check visually by looking through the window of the filter

chamber.

• If there is visible contamination or inadequate pump flow, replace the filter.

69

Page 70

10 Maintenance

1

Open filter chamber: turn slightl y

2

3

4

Attach the filter chamber and lock it:

Replace particle filter

The filter chamber may contain condensate. This is not a malfunction

and will not cause incorrect readings.

counter-clockwise.

Remove filter chamber.

Remove filter plate and replace it

with a new one (0554 3385).

turn slightly clockwise.

70

Page 71

10.11 Replace thermocouple

1

Release probe catch by pressing the ke y on the probe handle and

2

Remove thermocouple plug-in head

and pull thermocouple out of the probe

3

Insert new thermocouple into the pro be shaft until the plug-in head

4

Fit probe module onto the probe handle and click into place.

remove probe module.

from the socket using a screwdriver

shaft.

clicks into place.

10 Maintenance

71

Page 72

11 Technical data

Temperature measuring instrument

-40 to +2192°F

Draft measurement

-4.01 to +16.06 inH2O

Pressure measurement

-40.15 to 80.29 inH2O

O2 measurement

0 to 21 vol.%

CO measurement

0 to 4000 ppm

Option: CO measurement

(H2-compensated)

0 to 8000 ppm

extension

Option: CO measurement

0 to 30000 ppm

NO measurement

0 to 3000 ppm

Efficiency testing (Eta)

0 to 120%

Flue gas losses

0 to 99.9%

CO2 determination (calculation from O2)

Display range 0 to CO

2 max.

Ambient CO measurement (internal/ flue

gas probe)

0 to 2000 ppm

CO probe)

load

Lifetime CO-sensor

up to 72 months, depending on the

load

Lifetime NO-sensor

up to 72 months, depending on the

load

Storage temperature

-4 to +122°F

Operating temperature

23 to +113°F

Charging temperature

32 to +113°F

Energy storage unit

3.6 V/3.5 Ah

Mains unit

5 V / 1 A

Humidity application range

15 to 90% RH, non-condensing

11 Technical data

Feature Value

Option: CO measurement with activated

0 to 15000 ppm

fresh air dilution/measuring range

(H2-compensated) with activated fresh

air dilution/measuring range e xt ension

Ambient CO measurement (external with

0 to 500 ppm

Lifetime O2-sensor up to 72 months, depending on the

General technical data

Feature Value

72

Page 73

11 Technical data

Power supply

Energy storage unit, USB mains

unit

Energy storage unit service life

10 hrs

Lifetime energy storage

> 1000 charging cycles

Protection class

IP 40

Memory

1 million measuring values

5.0" touch display,

HD 1280x720 pixels

Weight

Approx. 800 g

W: 3.86 inch

TÜV-tested according to 1st German

Federal Immission Control Ordinance

(BImSchV) EN 50379, Parts 1-3

Feature Value

Display

Dimensions L: 9.6 inch (including probe

connection)

H: 2.3 inch

Certification

11.1 Contact and support

If you have any questions or need further information, please contact your

dealer or Testo Customer Service. For contact details, please visit

www.testo.com/service-contact.

73

Page 74

Page 75

Page 76

0970 3010 en-US 01

Loading...

Loading...