Page 1

tekmarNet®4 Thermostat 538

Installation & Operation Manual

D538

12/11

Zoning

Replaces:08/10

1 of 24 © 2011

D 538 - 12/11

The tekmarNet®4 Thermostat 538

provides operation for:

One Stage Heat•

Introduction

Features

Zone Synchronization

Zone Post Purge

Intelligent setback (Timer 033)

Scenes (Away override)

Auto Heating Cycle

tekmarNet® 4 communication

compatible

Requires 4 wires

Pulse Width Modulation

CSA C US Approved for use in

USA and Canada

Outdoor temperature display

Air Group member

Backlight

Freeze Protection

Equipment Exercising

Floor warming (Slab Sensor 079)

1 Auxiliary sensor input

Room Temperature Limiting

Supports Radiant Floor Cooling

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Page 2

2 of 24© 2011 D 538 - 12/11

Congratulations on the purchase of your new tekmar thermostat.

This manual will step through the complete installation, programming and sequence

of operation for this control. At the back, there are tips for control and system

troubleshooting.

Getting Started

Preparation

tekmar or jeweller screwdriver

Phillips head screwdriver

•

•

Wire Stripper•

Tool s Re qui red

------------------------------------------------------

------------------------------------------------------

Materials Required

--------------------------------------------------

--------------------------------------------------

2, #6 x 1” Wood Screws

18 AWG LVT Solid Wire

(Low Voltage Connections)

•

•

Optional Adapter Plate 007 (for

installation on 2” x 4” gang box)

•

Installation

Table of Contents

Getting Started ..............................2

Installation .........................................2

Caution ..........................................2

Preparation ....................................2

Removing The Thermostat Base ...3

Mounting The Thermostat Base ....3

Thermostat Wiring .........................4

Testing the Thermostat Wiring ......4

Mounting the Thermostat ..............5

Cleaning the Thermostat ...............6

Switch Settings ..................................6

User Interface ....................................7

Display...........................................7

Button Operation ...........................7

Symbols Description .....................7

Settings ....................................8-14

Sequence of Operation .................... 15

Heating Operation ....................... 15

Air Group Operation .................... 16

Floor Cooling ...............................16

Schedules ................................... 17

Scenes (System Override) .......... 17

Troubleshooting ...............................18

Error Messages ......................18-21

Frequently Asked Questions .......22

Job Record ..................................23

Technical Data .............................23

Limited Warranty and Product

Return Procedure ........................24

Caution

Improper installation and operation of this control could result in damage to the

equipment and possibly even personal injury or death. It is your responsibility

to ensure that this control is safely installed according to all applicable codes and

standards. This electronic control is not intended for use as a primary limit control.

Other controls that are intended and certified as safety limits must be placed into

the control circuit.

Page 3

3 of 24 © 2011 D 538 - 12/11

Choose the placement of the thermostats early in the construction process to

enable proper wiring during rough-in.

Consider the following:

Interior Wall.

Keep dry. Avoid potential leakage onto the control.

Relative Humidity max 92% up to 104°F (40°C), 50% RH above 104°F (40°C).

Non-condensing environment.

No exposure to extreme temperatures beyond 32-122°F (0-50°C).

No draft, direct sun, or other cause for inaccurate temperature readings.

Away from equipment, appliances, or other sources of electrical interference.

Easy access for wiring, viewing, and adjusting the display screen.

Approximately 5 feet (1.5 m) off the finished floor.

The maximum length of wire is 500 feet (150 m).

Strip wire to 3/8” (10 mm) for all terminal connections.

Use standard 4 conductor, 18 AWG wire.

•

•

•

•

•

•

•

•

•

•

•

Installation Location

-------------------------------------------------

-------------------------------------------------

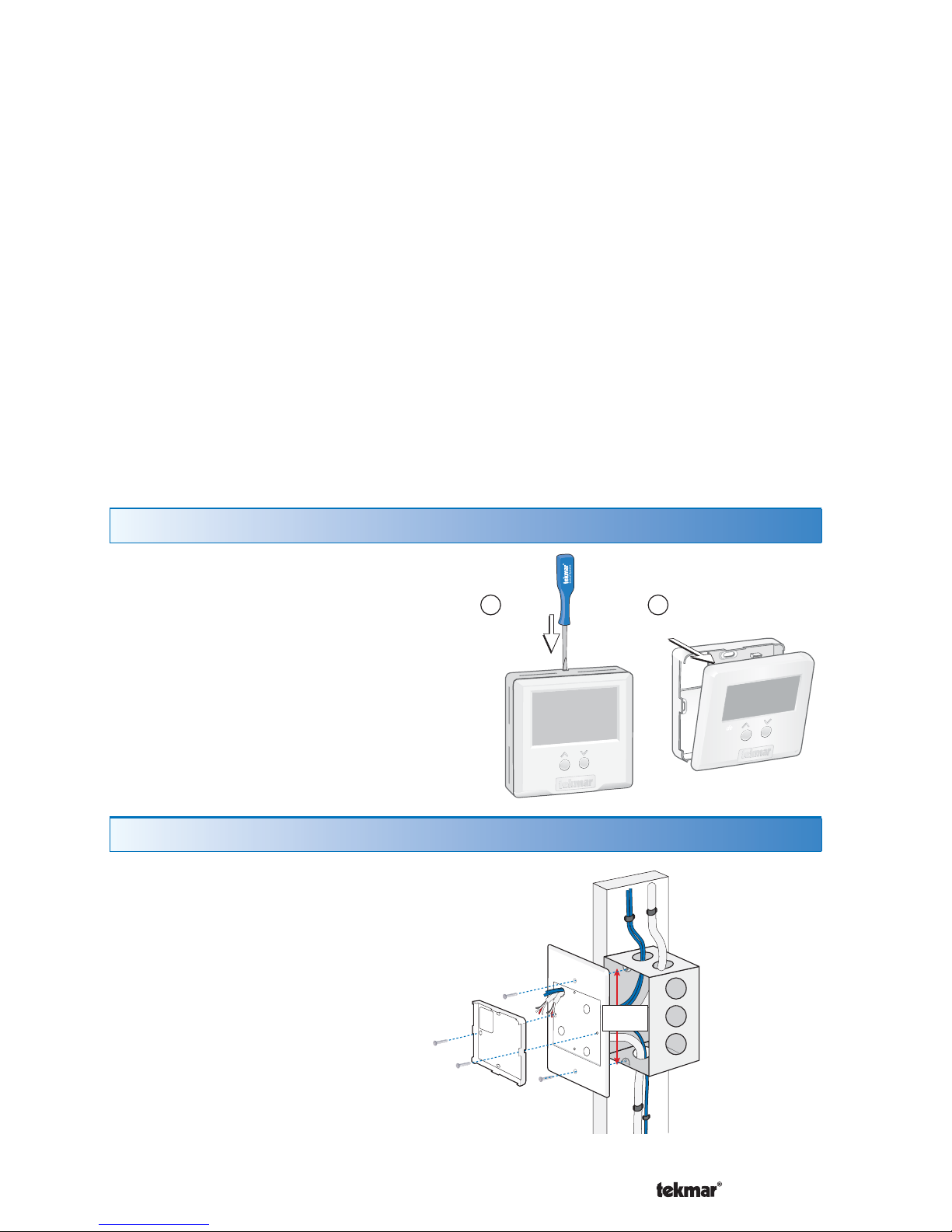

Removing The Thermostat Base

Push

tab

1

Remove thermostat

from base

2

To remove the thermostat base:

Place a small slot screwdriver or similar

tool into the slot located on the top of

the thermostat.

While pushing down against the plastic

tab, pull the thermostat away from the

thermostat’s base.

•

•

Mounting The Thermostat Base

Stud

Switch

Box

Thermostat

Base

007 Adaptor

Plate

3

1

/4”

(83 mm)

If a single gang switch box is used,

an Adaptor Plate 007 is required to

mount the thermostat to the box.

Fasten the base of the

thermostat to the adaptor plate.

Feed the wiring through the

openings in the back of the

adaptor plate and thermostat.

Use the upper and lower screw

holes to fasten the adaptor plate

to the box.

•

•

•

Mounted on switch box

Page 4

4 of 24© 2011 D 538 - 12/11

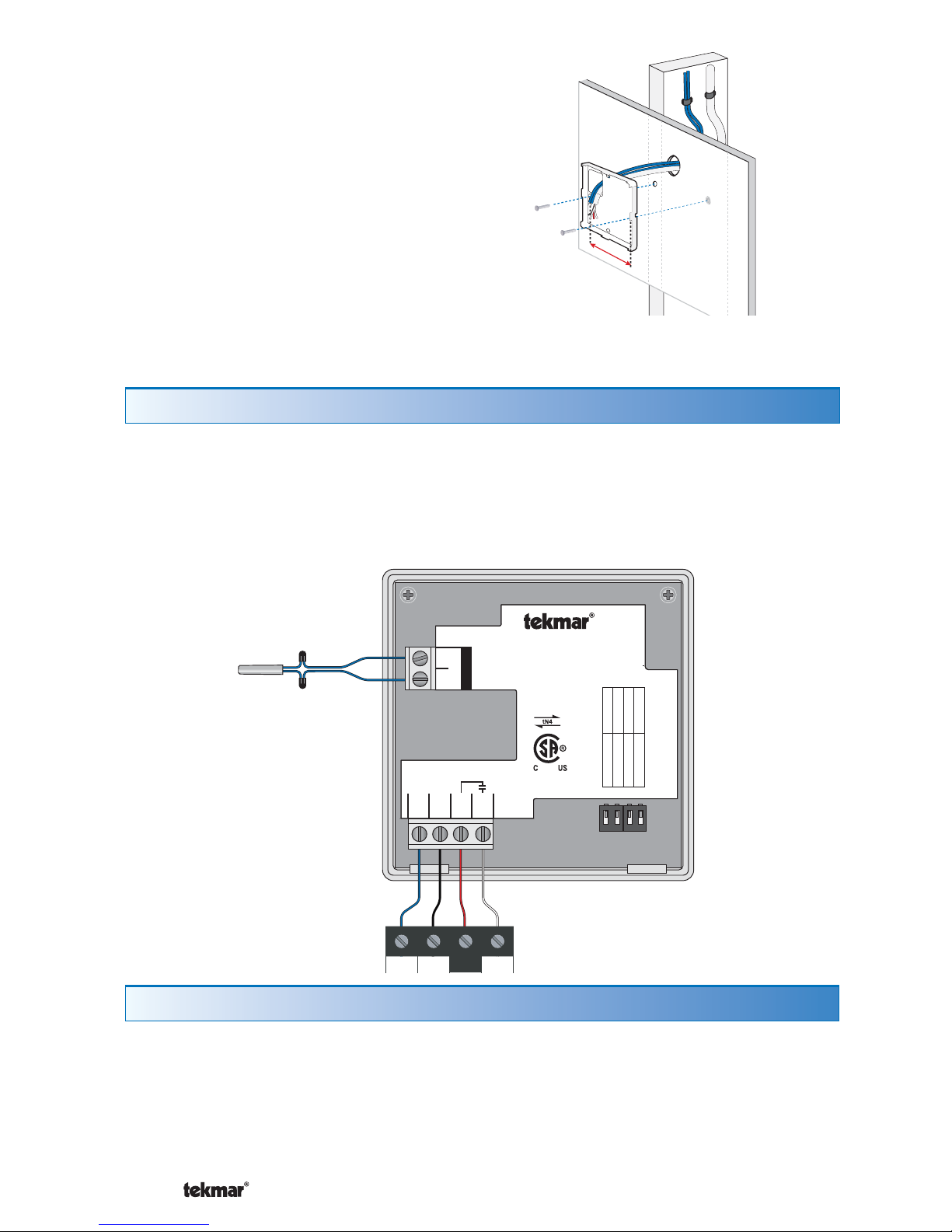

If a switch box was not used, mount the

thermostat directly to the wall.

Feed the wiring through the openings in

the back of the thermostat.

Use screws in the screw holes to fasten the

thermostat to the wall. At least one of the

screws should enter a wall stud or similar

rigid material.

•

•

Stud

2

3

/8”

(60 mm)

screwhole

2

3

/8”

(60 mm)

screwhole

Thermostat

Base

Wall

Mounted on wallboard

Thermostat Wiring

The thermostat operates a single heating system zone.

Connect tN4, C, R, and W terminals on the thermostat to the tN4, C, R, and W

terminals on the tN4 Wiring Center or Zone Manager.

Connect the optional auxiliary sensor wires to the sensor terminals 5 and 6.

12 34

tN4 Wiring Center

or

tN4 Zone Manager

Slab Sensor 072, 073, 079

OR

Outdoor Sensor 070

OR

Indoor Sensor 076, 077, 084

tN4 C W

R

1234

tNt 538

538

One Stage Heat

Mmm YYYY

Lot # 12345

Meets Class B:

Canadian ICES

FCC Part 15

Power: 24 V ±10% 50/60 Hz 1.8 VA

56 VA fully loaded

Relay: 24 V (ac) 2 A

1001- 03

tN41C2R3W

4

65

Sensor

Switch Settings:

For instructions see brochure

Use at least 75°C conductors

Setback

Scene

Lock

Not used

ON

Not used

Unlock

Off

Off

No Power

Testing the Thermostat Wiring

Testing th e Power

---------------------------------------------------

---------------------------------------------------

1. Remove the front cover from the thermostat.

2. Use an electrical test meter to measure (ac) voltage between the R and C

terminals. The reading should be 24 V (ac) +/– 10%.

3. Install the front cover.

Page 5

5 of 24 © 2011 D 538 - 12/11

Mounting the Thermostat

To place the thermostat back on the

mounting base:

Place thermostat bottom tabs on

matching mounting base notches.

Pivot top of the thermostat

towards wall, ensuring wires clear

obstructions.

The top clasp makes a clicking

sound when properly closed.

•

•

•

Pivot

Tab

Testing the Heat Relay

-----------------------------------------------

-----------------------------------------------

1. Remove the front cover from the thermostat.

2. Press the button and set the heating temperature below the current room

temperature. There should be no H1 symbol on the display.

3. Set the electrical test meter to continuity.

4. Place probes between R (3) and W (4). There should be no continuity. If there

is continuity then there may be a wiring fault or the relay may be faulty.

5. Press the button and set the heating temperature above the current room

temperature. Make sure the display does not show “WWSD”. The “H1” symbol

should appear on the display.

6. There should be continuity between the R (3) and W (4) terminals.

Testing th e tek marNet®4 Bus

-----------------------------------------

-----------------------------------------

The symbol is shown on the display when communication is present. If the

thermostat is connected in a network and the communication is missing, there may

be an open or short circuit on the tN4 and C bus wires.

1. Remove the front cover from the thermostat.

2. To test for short circuits:

Disconnect the tN4 bus wires on one end.

Install wire nuts on each wire to ensure the wire ends are not touching.

Disconnect the tN4 bus wires on the other end.

Measure for continuity using an electrical meter.

If continuity is present, there is a short circuit fault along the wires. It is

recommended to replace the tN4 bus wires.

3. To test for open circuits:

Disconnect the tN4 bus wires on one end and connect them together.

Disconnect the tN4 bus wires on the other end.

Use an electrical meter to measure for continuity.

If there is no continuity, there is an open circuit fault along the wires. It is

recommended to replace the tN4 bus wires.

•

•

•

•

•

•

•

•

•

Page 6

6 of 24© 2011 D 538 - 12/11

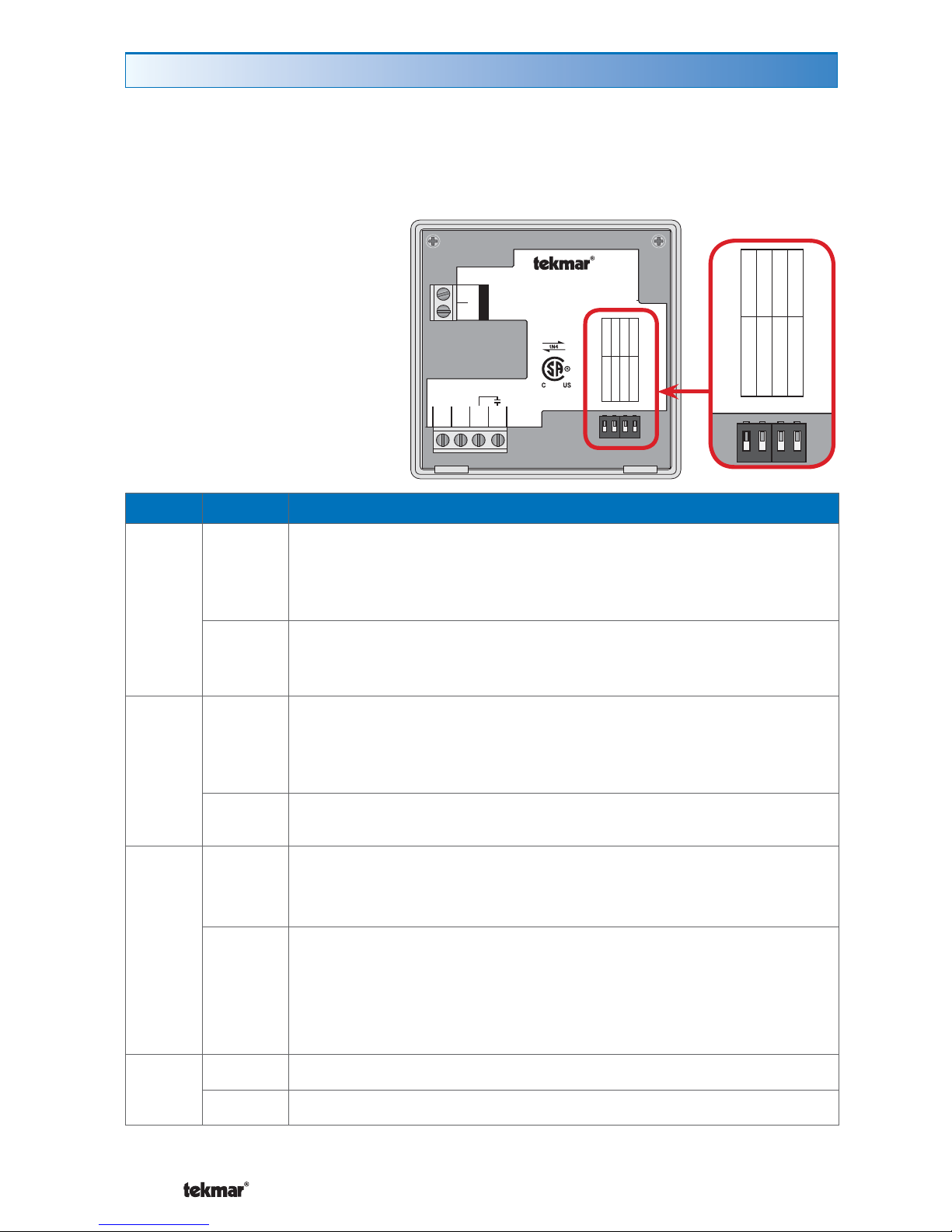

Switch Settings

Switches are set to “On”

position from the factory, and

do not require changing for

most applications.

12 34

1234

tNt 538

538

One Stage Heat

Mmm YYYY

Lot # 12345

Meets Class B:

Canadian ICES

FCC Part 15

Power: 24 V ±10% 50/60 Hz 1.8 VA

56 VA fully loaded

Relay: 24 V (ac) 2 A

1001-03

tN41C2R3W

4

65

Sensor

Switch Settings:

For instructions see brochure

Use at least 75°C conductors

Setback

Scene

Lock

Not used

ON

Not used

Unlock

Off

Off

No Power

12 34

1234

Mmm YYY

L t # 1234

Meets Class B:

Canadian ICES

2 A

Switch Settings:

Setback

Scene

Lock

Not used

ON

Not used

Unlock

Off

Off

Switch

Position

Action

1

ON

SETBACK

The thermostat follows a programmable setback schedule

as a schedule member if available. Requires the installation

of a Timer 033 to use this feature.

OFF

OFF

The thermostat does not follow a programmable setback

schedule.

2

ON

SCENE

The thermostat responds to changes in the scene (system

wide manual overrides). Requires the installation of a User

Switch 479 to use this feature.

OFF

OFF

The thermostat does not respond to scenes.

3

ON

LOCK ACCESS LEVEL

Locked to ‘User’ access level. Set to Lock when installation

completed.

OFF

UNLOCK ACCESS LEVEL

Unlock to allow ‘User’ and “Installer’ access level. Set to

Unlock during installation process.

tekmarNet® reset control must also be set to Unlocked

(Installer access level).

4

ON

Not used

OFF

Not used

The thermostats’s exterior can be cleaned using a damp cloth. Moisten the cloth

with water and wring out prior to wiping the control. Do not use solvents or cleaning

solutions.

Cleaning the Thermostat

Page 7

7 of 24 © 2011 D 538 - 12/11

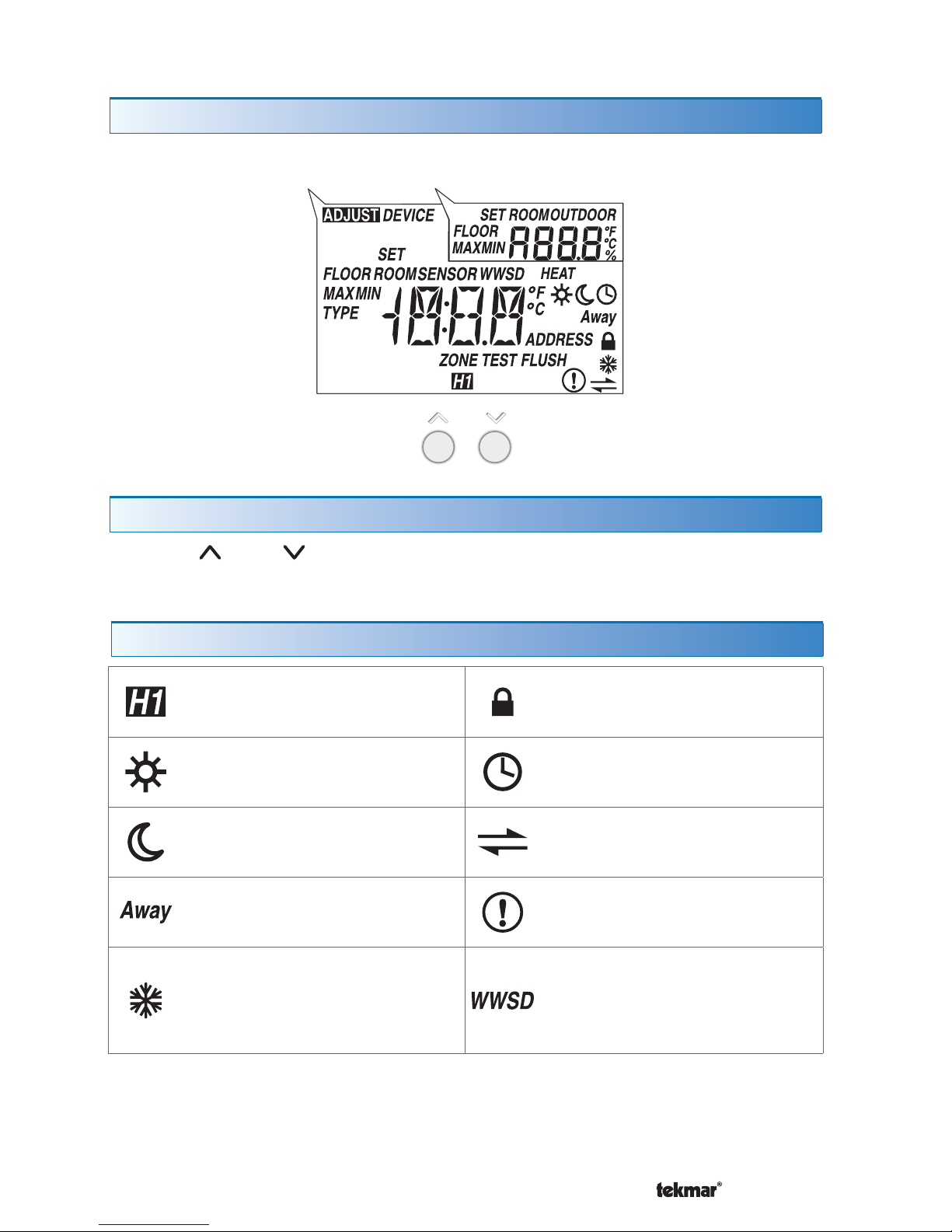

SECONDARY DISPLAYMAIN DISPLAY

HEAT

Heat is turned on.

SUN

Operating at the occupied

(day) temperature.

MOON

Operating at the unoccupied

(night) temperature.

AWAY

Operating at the Away scene

temperature.

AIR GROUP

The air group is cooling.

Heating can start once the

cooling is finished.

LOCK

Locked to ‘User’ access level.

CLOCK

Operating on a

programmable schedule.

tekmarNet

®

Communication is present.

WARNING SYMBOL

Indicates an error is present.

WARM WEATHER SHUT

DOWN

The heating system has been

shut off for the summer.

Display

Symbols Description

User Interface

Button Operation

Press the or the button to select the room temperature.

Page 8

8 of 24© 2011 D 538 - 12/11

Settings (1 of 7)

Display Range Access Description Set to

40 to 95°F

(4.5 to 35.0°C)

Default = 70°F

(21.0°C)

Installer

User

SET ROOM HEAT

Set the room heating temperature while in the

event.

40 to 95°F

(4.5 to 35.0°C)

Default = 65°F

(18.5°C)

Installer

User

SET ROOM HEAT

Set the room heating temperature while in the

event.

40 to 95°F

(4.5 to 35.0°C)

Default = 62°F

(16.5°C)

Installer

SET ROOM HEAT AWAY

Set the room heating temperature while in the Away

scene.

Continued on next page.

• Press and hold down both the and buttons for 2 seconds to change from one step to the next.

• Release both buttons once the step has been reached.

• Press the or the button to change the setting, if available.

• Press and hold down both the

and buttons for 2 seconds to go to the next step, OR

• After 10 seconds of no button activity, the display goes back to normal operation.

• Note: Set switch setting #3 and tekmarNet

®

system control to Unlock to change Access level to Installer.

Press

+

Together

Page 9

9 of 24 © 2011 D 538 - 12/11

Settings (2 of 7)

Display Range Access Description Set to

40 to 122°F

(4.5 to 50.0°C)

Default = 72°F

(22.0°C)

Installer

User

SET FLOOR HEAT

Set the floor heating temperature while in the

event.

Available when:

A slab sensor is installed on the auxiliary sensor

input AND Sensor setting in the Adjust menu is set

to Floor AND Room Sensor setting in the Adjust

menu is set to Off.

•

40 to 122°F

(4.5 to 50.0°C)

Default = 65°F

(18.5°C)

Installer

User

SET FLOOR HEAT

Set the floor heating temperature while in the

event.

Available when:

A slab sensor is installed on the auxiliary sensor

input AND Sensor setting in the Adjust menu is set

to Floor AND Room Sensor setting in the Adjust

menu is set to Off.

•

Off, 30 sec, On,

On +

Default = 30 sec

Installer

User

BACKLIGHT

Select the backlight operation.

Off = Permanently Off

30 = Temporary on for 30 seconds

On = Permanently On

On + = On during and off during

Continued on next page.

Page 10

10 of 24© 2011 D 538 - 12/11

Display Range Access Description Set to

°F or °C

Default = °F

Installer

User

TEMPERATURE UNITS

Press the or the button to change from °F to

°C and vice versa.

Device Type with

Software Version,

Address

Installer

User

DEVICE TYPE

Display alternates between the Device Type (large

number) with Software Version (upper right corner)

and the thermostat address.

40 to 95°F

(4.5 to 35.0°C)

Default = 85°F

(29.5°C)

Installer

MAXIMUM SET ROOM HEAT

Set the maximum room heating limit while in the

event.

40 to 95°F

(4.5 to 35.0°C)

Default = 85°F

(29.5°C)

Installer

MAXIMUM SET ROOM HEAT

Set the maximum room heating limit while in the

event.

40 to 95°F

(4.5 to 35.0°C)

Default = 45°F

(7.0°C)

Installer

MINIMUM SET ROOM HEAT

Set the minimum room heating limit.

Settings (3 of 7)

Continued on next page.

Page 11

11 of 24 © 2011 D 538 - 12/11

Display Range Access Description Set to

Off, 40 to 122°F

(Off, 4.5 to

50.0°C)

Default = 72°F

(22.0°C)

Installer

User

SET FLOOR MINIMUM

Set the floor minimum temperature while in the event.

The floor minimum heats the floor even when the room

temperature is satisfied.

The measured floor temperature is shown in the upper

right hand corner of the display.

Available when:

Room Sensor setting in the Adjust menu is set to

On AND

A slab sensor is installed on the auxiliary sensor

input AND

Sensor setting in the Adjust menu is set to Floor.

•

•

•

Off, 40 to 122°F

(Off, 4.5 to

50.0°C)

Default = Off

Installer

User

SET FLOOR MINIMUM

Set the floor minimum temperature while in the event.

The floor minimum heats the floor even when the room

temperature is satisfied.

The measured floor temperature is shown in the upper

right hand corner of the display.

Available when:

Room Sensor setting in the Adjust menu is set to

On AND

A slab sensor is installed on the auxiliary sensor

input AND

Sensor setting in the Adjust menu is set to Floor.

•

•

•

Settings (4 of 7)

Continued on next page.

Page 12

12 of 24© 2011 D 538 - 12/11

Display Range Access Description Set to

40 to 122°F, Off

(4.5 to 50.0°C,

Off)

Default = 85°F

(29.5°C)

Installer

FLOOR MAXIMUM

Set the floor maximum temperature in order to protect

the floor covering.

Available when:

Room Sensor setting in the Adjust menu is set to

On AND

A slab sensor is installed on the auxiliary sensor

input AND

Sensor setting in the Adjust menu is set to Floor.

•

•

•

1, 2, 3, 4

Default = 1

Installer

SCHEDULE

Thermostat can follow schedule master 1, 2, 3, or 4.

Available when:

Switch setting 1 is set to Setback (On Position).•

H1

H1

ADJUST

ADJUST

SUPPLY

OFF or On

Default = On

Installer

HEAT SUPPLY PUMP

During heating, select whether or not the system supply

pump should turn on or be off to allow a zone group

pump per manifold.

Available when:

A reset control is present on the tekmarNet

®

system.•

Settings (5 of 7)

Continued on next page.

Page 13

13 of 24 © 2011 D 538 - 12/11

Display Range Access Description Set to

H1

H1

ADJUST

ADJUST

SUPPLY

OFF or On

Default = OFF

Installer

HEAT SUPPLY PUMP DELAY

During heating, select whether or not the system supply

pump should be delayed by 3 minutes before coming

on (for thermal motor or wax actuator).

Available when:

A reset control is present on the tekmarNet

®

system.•

Auto,

SYn(Synchronize)

Default =

Sychronize

Installer

HEAT CYCLES PER HOUR

Select either Auto cycle or Synchronize with other

thermostats on the tekmarNet

®

system.

Choose Synchronize when zone heated using a boiler.

Choose Auto when zone is non-hydronic heating.

Available when:

No reset control on the tekmarNet

®

system.•

ADJUST

ADJUST

OFF, 1 to 16 Installer

AIR GROUP

Select if this thermostat should be an air group member.

Select off if the thermsotat is not an air group member.

Select 1 though 16 to select the air group number.

Available when:

The thermostat is connected to other thermostats

using tekmarNet

®

.

•

On or Off

Default = On

Installer

ROOM SENSOR

Select whether the built-in air temperature sensor is

on or off.

Available when:

A floor sensor or room sensor is installed on the

auxiliary sensor input.

Settings (6 of 7)

Continued on next page.

Page 14

14 o f 24© 2011 D 538 - 12/11

Display Range Access Description Set to

Off, Room,

Outdoor, Floor,

Floor dSP

Installer

AUXILIARY SENSOR

Select the type of auxiliary sensor.

Off = no auxiliary sensor, Room = Indoor Sensor,

Outdoor = Outdoor Sensor, Floor = Slab Sensor, Floor

dSP = Floor sensor reading in upper number field.

Available when:

Auxiliary sensor automatically detected.

01 to 24

(no reset control),

b:01 to b:24

(reset control - boiler),

1:01 to 1:24

(reset control - mixing)

Installer

tekmarNet

®

ADDRESS

The address is shown in the large number field. “Auto” is

shown in the upper number field when using automatic

addressing.

Press the or the button to manually select

an address.

The address can be returned to automatic “Auto”

addressing when address set above 24.

FLOOR

ADJUST

ADJUST

COOL

OFF or On

Default = OFF

Installer

FLOOR COOLING

Select if the thermostat should operate the heating relay

W for radiant floor cooling.

Available when:

Connected to a tekmarNet

®

heat pump or chiller

system control.

•

None

Installer

User

ESCAPE

Press the or the button to return to normal

operation.

Settings (7 of 7)

Page 15

15 of 24 © 2011 D 538 - 12/11

Heating Operation

Section A

Sequence of Operation

When using only a room temperature sensor, the thermostat operates the heating

system to maintain the Set Room Heat temperature.

When using only a floor temperature sensor, the thermostat operates the heating

system to maintain the Set Floor Heat temperature. In this case, the thermostat

does not try to control the air temperature. This is ideal for bathrooms and some

kitchen applications where the customer wants their feet to feel warm on the floor.

This is also ideal for garages so that the heating system is not affected by the

opening of the garage door in cold outdoor weather.

When using both a room temperature sensor and a floor temperature sensor, the

thermostat always maintains the Floor Minimum temperature, even when the air

temperature is satisfied. When the air temperature is below the Set Room Heat

temperature, the thermostat operates the heating system to maintain the Set Room

Heat temperature. The floor is never heated above the Floor Maximum setting in

order to protect the floor covering.

The H1 symbol is shown on the display when the thermostat is heating. The heat

can cycle on and off within +/- 1.5°F (1°C) of the Set Room Heat temperature.

Freeze Protection

----------------------------------------------------

----------------------------------------------------

The thermostat operates the heat whenever the room or floor temperature falls

below 40°F (4.5°C).

Exercising

----------------------------------------------------------

----------------------------------------------------------

When connected to a tekmarNet® reset control, the thermostat exercises the heat

relay for 10 seconds every 3 days. Exercising helps prevent zone valves or zone

pumps from failing due to precipitate buildup. During exercising, the thermostat

shows “TEST” on the display.

Flushing

------------------------------------------------------------

------------------------------------------------------------

The flushing feature is for open-loop systems that use a domestic hot water tank

as a heat source. Flushing ensures that fresh potable water is circulated through

the system once each day. If the thermostat is connected to a tekmarNet® reset

control with the Flushing feature turned on, the thermostat display will display the

“FLUSH” icon for the duration of the flushing operation.

Hydronic System Supply Pump

---------------------------------------

---------------------------------------

When connected to a tekmarNet® system control, the thermostat’s Heat Supply

Pump setting affects how the primary pump or mix pump on the system control

operates. When connected to the boiler bus, the boiler system or primary pump is

operated. When connected to the mix bus, the mix system pump is operated.

If the thermostat operates a motorized or thermal motor zone valve, the Heat Supply

Pump setting should be set to On.

Page 16

16 of 24© 2011 D 538 - 12/11

If the thermostat operates a thermal motor (wax actuator) zone valve, set the Heat

Supply Pump Delay setting to On. This provides a three minute delay to allow the

zone valve to open before the primary or mix pump is turned on.

In special applications with multiple zoning manifolds, the Heat Supply Pump setting

can be set to Off. This allows a Zone Group Pump located on the Zone Manager,

or Wiring Center to operate the pump for the manifold.

DHW Tank Priority

---------------------------------------------------

---------------------------------------------------

When a tekmarNet® reset control is heating an indirect Domestic Hot Water (DHW)

tank, the thermostat may shut off the heating zones to allow the DHW tank to recover

quickly. This is determined by the DHW priority of the tekmarNet® reset control.

Warm Weather Shut Down

--------------------------------------------

--------------------------------------------

When the outdoor air temperature exceeds the Warm Weather Shut Down (WWSD)

setting on the tekmarNet® reset control, the heating system is shut off.

Air Group Operation

Section B

In order to prevent heating and cooling at the same time, this thermostat can operate

together with other thermostats on a tekmarNet® system to form an air group.

In an air group, one thermostat is assigned as the air group master. The air group

master operates the cooling equipment for the group. This thermostat can be set

to be a member of the air group.

When operating as an air group, the air temperature readings of all the air group

member thermostats are communicated to the air group master and a temperature

average is determined.

When the air group master is in cooling

operation, the air group member thermostats

do not operate the heating system for air

heating.

If the Set Room Heat temperature is adjusted

while the air group is cooling, the snowflake

icon is flashed to alert the user that the cooling

is presently on. Once the cooling shuts off,

the heating can start operation.

Air Group

Master

MemberMember

tekmarNet Communication

Floor Cooling

Section C

The thermostat has the option to support radiant floor cooling when connected to a

heat pump control using tekmarNet® communication. The floor cooling setting must

be set to On and the heating system must be in Warm Weather Shut Down (WWSD).

When the heat pump system control operates in cooling mode, all thermostats set for

floor cooling on the tekmarNet® bus all activate the first stage heating contact (H1)

at the same time to allow chilled water into the system. The thermostat continues

to operate the cooling until either the room temperature reaches the Set Heat

temperature plus 3°F (Set Heat+1.5°C) or reaches a minimum temperature of 74°F.

If only a floor sensor is installed, the floor cooling setpoint is 67°F (19.5°C).

Page 17

17 of 24 © 2011 D 538 - 12/11

Schedules

Section D

Lowering the room temperature setting reduces the amount of fuel required to heat

the building resulting in energy savings.

This thermostat can follow a programmable schedule in order to automatically lower

the room temperature setting. A schedule master such as a Timer 033 is required

in order to gain programmable schedule functionality.

When operating on a programmable schedule, a

symbol is shown, as well as a

or a . The or indicates the current operating temperature.

If a symbol does not appear, there is no schedule available.

Display Action

Occupied temperature. No schedule.

Unoccupied temperature. No schedule.

Programmable schedule at

occupied

temperature.

Programmable schedule at

unoccupied

temperature.

Scene Display Room Temperature Setting

1

or or

Follows programmable schedule or

operates at the occupied temperature.

2

Away

Away temperature.

3

Unoccupied temperature.

Scenes (System Override)

Section E

When a programmable schedule is selected, there is a time delay for the temperature

to change from the temperature to the temperature.

The thermostat uses Optimum Start to predict the heat up and cool off rate of

the room. The optimum start feature allows the room to reach the set room

temperature by the time set in the programmable schedule. This applies for both

heating and cooling.

Scenes provide an easy way to save energy while away on vacation, or override a

pre-set schedule when plans change. tekmarNet® devices such as a User Switch

479 provide scene adjustment.

This thermostat responds to the following scenes:

While in the Away scene, the room temperature cannot be changed using the or

buttons. Change the scene from Away to or to change the temperature.

Page 18

18 of 24© 2011 D 538 - 12/11

Troubleshooting

Error Messages (1 of 4)

Error Message Description

CONTROL ERROR

The thermostat was unable to correctly read settings from memory and has reloaded the factory

default settings. The thermostat does not operate the heating, cooling, or the fan while this error

message is present.

Error clears once all adjust menu settings in the Installer access level (unlocked) have been

checked. Set thermostat’s switch setting #3 to unlock and unlock the tekmarNet

®

system control.

Then press and hold and buttons together for 2 seconds to enter the adjust menu. Continue

until all settings have been reviewed.

BUS ERROR

The tekmarNet

®

4 communication bus has either an open or a short circuit. The result is that there

are no communications. Check for loose wires. Check for short circuits between the tN4 and C

wires on the House Control, Wiring Center, or Zone Manager. Check for correct polarity between

the C and R wires.

Error clears automatically once wiring fault has been corrected.

If the thermostat is intentionally removed from the tekmarNet

®

4 bus, press the and buttons

together to clear the error message.

DEVICE LIMIT

The number of devices on the tekmarNet

®

bus has exceeded 24. Devices include tekmarNet

®

Thermostats and Setpoint Controls. The device count must be lowered to 24 or less. If possible,

move devices to other tekmarNet

®

buses.

Error clears automatically once the number of devices on the tekmarNet

®

bus is at 24 or lower.

Page 19

19 of 24 © 2011 D 538 - 12/11

Error Messages (2 of 4)

Error Message Description

ADDRESS ERROR

This thermostat and another device have been manually given the same tekmarNet

®

address.

Error clears automatically once this thermostat is given a new manually set address or if the

thermostat is set to automatic addressing.

ROOM SENSOR SHORT CIRCUIT

The built-in air temperature sensor has a short circuit fault. Do not confuse this error with the auxiliary

room sensor short circuit error.

This error cannot be field repaired.

Contact your wholesaler or tekmar sales representative for details on repair procedures.

ROOM SENSOR OPEN CIRCUIT

The built-in air temperature sensor has an open circuit fault. Do not confuse this error with the

auxiliary room sensor short circuit error.

This error cannot be field repaired.

Contact

your wholesaler or tekmar sales representative for details on repair procedures.

AIR GROUP MEMBER ERROR

The thermostat has been selected to join an air group as a member, yet there is no air group master

thermostat.

Error clears once the thermostat detects an air group master or the air group is set to OFF.

Page 20

20 of 24© 2011 D 538 - 12/11

Error Message Description

FLOOR SENSOR SHORT CIRCUIT

The auxiliary floor sensor has a short circuit. Check for damaged wires. Locate and repair the

problem as described in the Data Brochure D072 or D 079.

Error clears once the floor sensor fault is corrected.

FLOOR SENSOR OPEN CIRCUIT

The auxiliary floor sensor has an open circuit. Check for loose or damaged wires. Locate and repair

the problem as described in the Data Brochure D072 or D 079.

Error clears once the floor sensor fault is corrected.

If the floor sensor was intentionally removed, locate the Room Sensor setting in the Adjust menu

and set to On. Power the thermostat down and up to clear the error.

OUTDOOR SENSOR SHORT CIRCUIT

The auxiliary outdoor sensor has a short circuit. Check for damaged wires. Locate and repair the

problem as described in the Data Brochure D 070.

Error clears after the outdoor sensor fault is corrected.

OUTDOOR SENSOR OPEN CIRCUIT

The auxiliary outdoor sensor has an open circuit. Check for loose or damaged wires. Locate and

repair the problem as described in the Data Brochure D 070.

Error clears once the outdoor sensor fault is corrected.

If the outdoor sensor was intentionally removed, power the thermostat down and up to clear the

error.

Error Messages (3 of 4)

Page 21

21 of 24 © 2011 D 538 - 12/11

Error Message Description

AUXILIARY ROOM SENSOR SHORT CIRCUIT

The auxiliary room sensor has a short circuit. Check for damaged wires. Locate and repair the

problem as described in the Data Brochure D 076, D077, or D084.

Error clears after the auxiliary room sensor fault is corrected.

AUXILIARY ROOM SENSOR OPEN CIRCUIT

The auxiliary room sensor has an open circuit. Check for loose or damaged wires. Locate and repair

the problem as described in the Data Brochure D 076, D077, or D084.

Error clears once the auxiliary room sensor fault is corrected.

If the auxiliary room sensor was intentionally removed, power the thermostat down and up to clear

the error.

Error Messages (4 of 4)

Page 22

22 of 24© 2011 D 538 - 12/11

Symptom Look for... Corrective Action

No Heat

H1 Symbol

H1 symbol indicates heat is on. Check if

zone valve or zone pump is operating.

Flashing

WWSD

Increase WWSD setting on tekmarNet®

reset control.

Flashing Away Change User Switch to Normal scene 1.

Heat on before

scheduled time

Optimum start “learns” the heat up and

cool off rate of the room and starts the

heating or cooling early so that the room is

comfortable at the scheduled time.

Pressing

button does

not increase

temperature

Flashing Max

Installer can increase the Maximum Set

Room Heat.

Flashing Floor

Max

Floor temperature has reached the Floor

Maximum setting. If the floor is not heated,

then the floor sensor may be faulty and

require replacement.

Pressing

button does

not decrease

temperature

Flashing Min

Installer can decrease the Minimum Set

Room Heat.

Floor Min

Floor minimum takes priority over the air

heating temperature. Recommend turning

down the floor minimum temperature

setting.

Frequently Asked Questions

Page 23

23 of 24 © 2011 D 538 - 12/11

Technical Data

tekmarNet®4 Thermostat 538; One Stage Heat

Packaged weight 0.8 lb. (380 g)

Enclosure White PVC plastic, NEMA Type 1

Dimensions 2-7/8” H x 2-7/8” W x 13/16” D (73 x 73 x 21 mm)

Approvals CSA C US, meets Class B: ICES and FCC Part 15

Ambient conditions Indoor use only, 32 to 122°F (0 to 50°C).

RH max 92% to 104°F (40°C), and 50% above 104°F

(40°C)

Altitude <9840 feet (3000 m), Installation Category II,

Pollution Degree 2

Power supply

24 V (ac) ± 10% 50/60 Hz, 1.8 VA Standby, 56 VA fully

loaded, NEC / CEC Class 2

W Relay 24 V (ac) 2 A

Sensors: NTC thermistor, 10 kΩ @ 77°F (25°C ± 0.2°C) ß = 3892

– Optional tekmar type # 070, 072, 073, 076, 077, 079, 084

Job Record

Jobsite Location ________________________________________________

Thermostat Location _____________________________________________

Item Setting Item Setting

Set Room Heat

Set Floor Min

Set Room Heat Set Floor Max

Set Room Heat Away Schedule Member

Set Floor Heat

Heat Supply Pump

Set Floor Heat Heat Supply Pump Delay

Backlight Heat Cycles Per Hour

Units Air Group

Max Set Room Heat

Room Sensor

Max Set Room Heat Sensor

Min Set Room Heat tekmarNet® Address

Set Floor Min

Floor Cooling

Page 24

tekmar Control Systems Ltd., Canada

tekmar Control Systems, Inc., U.S.A.

Head Office: 5100 Silver Star Road

Vernon, B.C. Canada V1B 3K4

(250) 545-7749 Fax. (250) 545- 0650

Web Site: www.tekmarcontrols.com

Product design, software and literature

are Copyright © 2011 by:

tekmar Control Systems Ltd. and tekmar

Control Systems, Inc.

All specifications are subject

to change without notice

24 of 24 D 538 - 12/11.

Limited Warranty The liability of tekmar under this warranty is limited. The Purchaser, by taking receipt

of any tekmar product (“Product”), acknowledges the terms of the Limited Warranty in effect at the time

of such Product sale and acknowledges that it has read and understands same.

The tekmar Limited Warranty to the Purchaser on the Products sold hereunder is a manufacturer’s passthrough warranty which the Purchaser is authorized to pass through to its customers. Under the Limited

Warranty, each tekmar Product is warranted against defects in workmanship and materials if the Product

is installed and used in compliance with tekmar’s instructions, ordinary wear and tear excepted. The passthrough warranty period is for a period of twenty-four (24) months from the production date if the Product is

not installed during that period, or twelve (12) months from the documented date of installation if installed

within twenty-four (24) months from the production date.

The liability of tekmar under the Limited Warranty shall be limited to, at tekmar’s sole discretion: the cost of parts

and labor provided by tekmar to repair defects in materials and / or workmanship of the defective product; or to

the exchange of the defective product for a warranty replacement product; or to the granting of credit limited to

the original cost of the defective product, and such repair, exchange or credit shall be the sole remedy available

from tekmar, and, without limiting the foregoing in any way, tekmar is not responsible, in contract, tort or strict

product liability, for any other losses, costs, expenses, inconveniences, or damages, whether direct, indirect,

special, secondary, incidental or consequential, arising from ownership or use of the product, or from defects in

workmanship or materials, including any liability for fundamental breach of contract.

The pass-through Limited Warranty applies only to those defective Products returned to tekmar during the warranty period. This Limited Warranty does not cover the cost of the parts or labor to remove or transport the defective Product, or to reinstall the repaired or replacement Product, all such costs and expenses being subject to

Purchaser’s agreement and warranty with its customers.

Any representations or warranties about the Products made by Purchaser to its customers which are different

from or in excess of the tekmar Limited Warranty are the Purchaser’s sole responsibility and obligation. Purchaser

shall indemnify and hold tekmar harmless from and against any and all claims, liabilities and damages of any

kind or nature which arise out of or are related to any such representations or warranties by Purchaser to its

customers.

The pass-through Limited Warranty does not apply if the returned Product has been damaged by negligence by

persons other than tekmar, accident, fire, Act of God, abuse or misuse; or has been damaged by modifications,

alterations or attachments made subsequent to purchase which have not been authorized by tekmar; or if the

Product was not installed in compliance with tekmar’s instructions and / or the local codes and ordinances; or if

due to defective installation of the Product; or if the Product was not used in compliance with tekmar’s instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, WHICH THE GOVERNING

LAW ALLOWS PARTIES TO CONTRACTUALLY EXCLUDE, INCLUDING, WITHOUT LIMITATION, IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, DURABILITY OR DESCRIPTION OF THE PRODUCT, ITS NON-INFRINGEMENT OF ANY RELEVANT PATENTS OR TRADEMARKS, AND

ITS CO M PLIANCE WIT H OR N O N -VIOLATI O N OF A NY APPLICA BLE ENVIRONMENTAL , HEALTH O R SAFETY

LEGISLATION; THE TERM OF ANY OTHER WARRANTY NOT HEREBY CONTRACTUALLY EXCLUDED IS LIMITED SUCH THAT IT SHALL NOT EXTEND BEYOND TWENTY-FOUR (24) MONTHS FROM THE PRODUCTION

DATE, TO THE EXTENT THAT SUCH LIMITATION IS ALLOWED BY THE GOVERNING LAW.

Product Warranty Return Procedure All Products that are believed to have defects in workmanship or materials must be returned, together with a written description of the defect, to the tekmar Representative assigned to

the territory in which such Product is located. If tekmar receives an inquiry from someone other than a tekmar

Representative, including an inquiry from Purchaser (if not a tekmar Representative) or Purchaser’s customers,

regarding a potential warranty claim, tekmar’s sole obligation shall be to provide the address and other contact

information regarding the appropriate Representative.

Limited Warranty and Product Return Procedure

Loading...

Loading...