Page 1

OPERATOR'S

MANUAL

Model C709 & C717

Heat Treatment

Soft Serve Freezers

Original Operating Instructions

062080-M

2/4/05 (Original Publication)

(Updated 9/2/14)

Page 2

Complete this page for quick reference when service is required:

Taylor Distributor:

Address:

Phone:

Fax:

E-mail:

Service:

Parts:

Date of Installation:

Information found on the data label:

Model Number:

Serial Number:

Electrical Specs: Voltage Cycle

Phase

Maximum Fuse Size: A

Minimum Wire Ampacity: A

E 2005 Carrier Commercial Refrigeration, Inc.

062080-M

Any unauthorized reproduction, disclosure, or distribution of copies by any person of any portion of this work may

be a violation of Copyright Law of the United States of America and other countries, could result in the awarding

of Statutory Damages of up to $250,000 (17 USC 504) for infringement, and may result in further civil and criminal

penalties. All rights reserved.

Taylor Company

a division of Carrier Commercial Refrigeration, Inc.

750 N. Blackhawk Blvd.

Rockton, IL 61072

Page 3

Table of Contents

Section 1 To th e Installer 1............................................

Installer Safety 1........................................................

Site Preparation 1.......................................................

Air Cooled Units 1.......................................................

Water Connections (Water Cooled Units Only) 2............................

Electrical Connections 2.................................................

Beater Rotation 3.......................................................

Refrigerant 3...........................................................

Section 2 To the Operator 4...........................................

Section 3 Safety 5....................................................

Section 4 Operator Parts Id entification 7...............................

Model C709 7..........................................................

Model C709 Single Spout Door and Beater Assembly 8......................

Model C717 9..........................................................

Model C717 Three Spout Door and Beater Assembly 11......................

Feed T ube Assembly 12..................................................

Accessories 13..........................................................

Brushes 14..............................................................

Section 5 Important: To the Operator 15.................................

Symbol Definitions 16....................................................

Operating Screen Descriptions 18..........................................

Freezer Locks 20........................................................

Manager's Menu 22......................................................

Section 6 Operating Procedures 31.....................................

Assembly 31............................................................

Freezer Door Assembly 32................................................

Sanitizing 37............................................................

Priming 39..............................................................

Daily Closing Procedures 40..............................................

Daily Opening Procedures 41..............................................

Manual Brush Cleaning 42................................................

Table of Contents Models C709 & C717

Page 4

Table of Contents - Page 2

Draining Product From T he Freezing Cylinder 43............................

Rinsing 43..............................................................

Hopper Cleaning 44......................................................

Disassembly 44..........................................................

Brush Cleaning 45.......................................................

Section 7 Important: Operator Checklist 46..............................

During Brush Cleaning and Sanitizing 46....................................

Troubleshooting Bacterial Count 46........................................

Regular Maintenance Checks 46...........................................

Winter Storage 47........................................................

Section 8 Troubleshooting Guide 48....................................

Section 9 Parts Replacement Schedule 52...............................

Section 10 Limited Warranty on Equipment 53............................

Section 11 Limited Warranty on Parts 55.................................

Wiring Diagrams 58......................................................

Note: Continuing research results in steady improvements; therefore, information

in this manual is subject to change without notice.

Note: Only instructions originating from the factory or its authorized translation

representative(s) are considered to be the original set of in structions.

E 2005 Carrier Commercial Refrigeration, Inc. (Original Publication)

(Updated September, 2014)

062080-M

Any unauthorized reproduction, disclosure, or distribution of copies by any person of any portion of this

work may be a violation of Copyright Law of the United States of America and other countries, could result

in the awarding of Statutory Damages of up to $250,000 (17 USC 504) for infringement, and may result

in further civil and criminal penalties.

All rights reserved.

Taylor Company

a division of Carrier Commercial Refrigeration, Inc.

750 N. Blackhawk Blvd.

Rockton, IL 61072

Models C709 & C717 Table of Contents

Page 5

Section 1 To the Installer

The following information has been included in the

manual as safety and regulatory guidelines. For

complete installation instructions, please see the

Installation Checklist.

Installer Safety

In all areas of the world, equipment should

be installed in accordance with existing local codes.

Please contact your local authorities if you have any

questions.

Care should be taken to ensure that all basic safety

practices are followed during the installation and

servicing activities related to the installation and

service of Taylor equipment.

S Only authorized Taylor service personnel

should perform installation and repairs on

the equipment.

S Authorized service personnel should consult

OSHA Standard 29CFRI910.147 or the

applicable code of the local area for the

industry standards on lockout/tagout

procedures before beginning any installation

or repairs.

S Authorized service personnel must ensure

that the proper PPE is available and worn

when required during installation and

service.

S Authorized service personnel must remove

all metal jewelry, rings, and watches before

working on electrical equipment.

Site Preparation

Review the area where the unit will be installed

before uncrating the unit. Make sure all possible

hazards to the user or equipment have been

addressed.

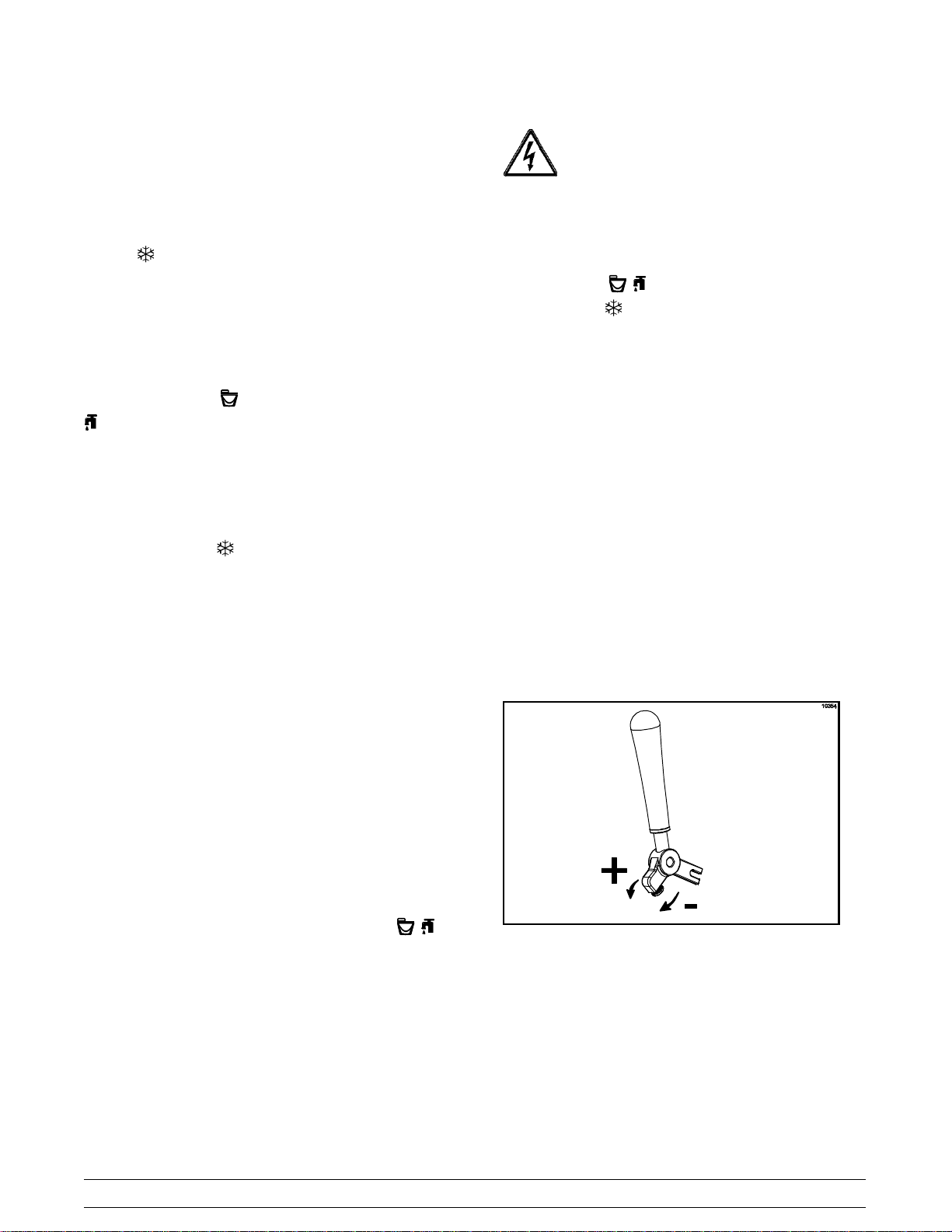

For Indoor Use Only: This unit is designed to

operate indoors, under normal ambient

temperatures of 70_-75_F(21_-24_C). The freezer

has successfully performed in high ambient

temperatures of 104_(40_C) at reduced capacities.

This unit must NOT beinstalledinanarea

where a water jet or hose can be used. NEVER use

a water jet or hose to rinse or clean the unit. Failure

to follow this instruction may result in electrocution.

This unit must be installed on a level surface

to avoid the hazard of tipping. Extreme care should

be taken in moving this equipment for any reason.

Two or more persons are required to safely move

this unit. Failure to comply may result in personal

injury or equipment damage.

Uncrate the unit and inspect it for damage. Report

any damage to your Taylor Distributor.

This piece of equipment is made in the USA and has

USA sizes of hardware. All metric conversions are

approximate and vary in size.

The main power supply(s) to the freezer

must be disconnected prior to performing any

repairs. Failure to follow this instruction may result in

personal injury or death from electrical shock or

hazardous moving parts as well as poor

performance or damage to the equipment.

Note:Allrepairsmustbeperformedbyan

authorized Taylor Service Technician.

This unit has many sharp edges that can

cause severe injuries.

Models C709 & C717 To the Installer

Air Cooled Units

DO NOT obstruct air intake and discharge openings:

C709: A minimum of 6” (152 mm) airspace isrequired

on both sides and 0” on the rear.

C717: A minimum of 3” (76 mm) air space is required

around all sides. Install the deflector provided to

prevent recirculation of warm air.

This will allow for adequate air flow across the

condenser. Failure to allow adequate clearance can

reduce the refrigeration capacity of the freezer and

possibly cause permanent damage to the

compressor.

131121

1

Page 6

Water Connections

(Water Cooled Units Only)

An adequate cold water supply must be provided

with a hand shut-off valve. On the underside of the

base pan or on the right side, two 3/8” I.P.S. water

connections for inlet and outlet are provided for easy

hook-up. 1/2” inside diameter water lines should be

connected to the machine. (Flexible lines are

recommended, if local codes permit.) Depending on

local water conditions, it may be advisable to install

a water strainer to prevent foreign substances from

clogging the automatic water valve. There will be

only one water “in” and one water “out” connection.

DO NOT install a hand shut-off valve on the water

“out” line! Water should always flow in this order:

first, through the automatic water valve; second,

through the condenser; and third, through the outlet

fitting to an opentrapdrain.

inside of the electrical box for proper power

connections.

CAUTION: THIS EQUIPMENT MUST BE

PROPERLY GROUNDED! FAILURE TO DO SO

CAN RESULT IN SEVERE PERSONAL INJURY

FROM ELECTRICAL SHOCK!

This unit is provided with an equipotential

grounding lug that is to be properly attached to the

rear of the frame by the authorized installer. The

installation location is marked by the equipotential

bonding symbol (5021 of IEC 60417-1) on both the

removable panel and the equipment's frame.

A back flow prevention device is

required on the incoming water connection side.

Please refer to the applicable National, State, and

local codes for determining the proper configuration.

Electrical Connections

In the United States, this equipment is intended to

be installed in accordance with the National

Electrical Code (NEC), ANSI/NFPA 70-1987. The

purpose of the NEC code is the practical

safeguarding of persons and property from hazards

arising from the use of electricity. This code contains

provisions considered necessary for safety.

Compliance therewith and proper maintenance will

result in an installation essentially free from hazard!

In all other areas of the world, equipment should be

installed in accordance with the existing local codes.

Please contact your local authorities.

FOLLOW YOUR LOCAL ELECTRICAL CODES!

Each unit requires one power supply for each data

label on the unit. Check the data label(s) on the

freezer for branch circuit overcurrent protection or

fuse, circuit ampacity, and other electrical

specifications. Refer to the wiring diagram provided

S Stationary appliances which are not

equipped with a power cord and a plug or

another device to disconnect the appliance

from the power source must have an all-pole

disconnecting device with a contact gap of

at least 3 mm installed in the external

installation.

S Appliances that are permanently connected

to fixed wiring and for which leakage

currents may exceed 10 mA, particularly

when disconnected or not used for long

periods, or during initial installation, shall

have protective devices such as a GFI, to

protect against the leakage of current,

installed by the authorized personnel to the

local codes.

S Supply cords used with this unit shall be

oil-resistant, sheathed flexible cable not

lighter than ordinary polychloroprene or

other equivalent synthetic

elastomer-sheathed cord (Code designation

60245 IEC 57) installed with the proper cord

anchorage to relieve conductors from strain,

including twisting, at the terminals and

protect the insulation of the conductors from

abrasion.

If the supply cord is damaged, it must be

replaced by the manufacturer, its service

agent, or similarly qualified person, in order

to avoid a hazard.

130225

2

Models C709 & C717To the Installer

Page 7

Beater Rotation

Beater rotation must be clockwise as viewed

looking into the freezing cylinder.

Note: The following procedures should be

performed by a trained service technician.

To correct rotation on a three-phase unit,

interchange any two incoming power supply lines at

freezer main terminal block only.

To correct rotation on a single-phase unit, change

the leads inside the beater motor. (Follow diagram

printed on motor.)

Electrical connections are made directly to the

terminal block provided behind the lower front panel.

Refrigerant

In consideration of our environment, Taylor

proudly uses only earth friendly HFC refrigerants.

The HFC refrigerant used in this unit is R404A. This

refrigerant is generally considered non-toxic and

non-flammable, with an Ozone Depleting Potential

(ODP) of zero (0).

However, any gas under pressure is potentially

hazardous and must be handled with caution.

NEVER fill any refrigerant cylinder completely with

liquid. Filling the cylinder to approximately 80% will

allow for normal expansion.

Refrigerant liquid sprayed onto the skin may

cause serious damage to tissue. Keep eyes and skin

protected. If refrigerant burns should occur, flush

immediately with cold water. If burns are severe,

apply ice packs and contact a physician

immediately.

Taylor reminds technicians to be cautious of

government laws regarding refrigerant recovery,

recycling, and reclaiming systems. If you have any

questions regarding these laws, please contact the

factory Service Department.

WARNING: R404A refrigerant used in

conjunction with polyolester oils is extremely

moisture absorbent. When opening a refrigeration

system, the maximum time the system is open must

not exceed 15 minutes. Cap all open tubing to

prevent humid air or water from being absorbed by

the oil.

Use only R404A refrigerant that conforms

to the AHRI standard 700 specification. The use of

any other refrigerant may expose users and

operators to unexpected safety hazards.

130819

Models C709 & C717 To the Installer

3

Page 8

Section 2 To the Operator

Your freezer has been carefully engineered and

manufactured to give you dependable operation.

When properly operated and cared for, it will

produce a consistent, quality product. Like all

mechanical products, cleaning and maintenance will

be required. A minimum amount of care and

attention is necessary if the operating procedures

outlined in this manual are followed closely.

This Operator's Manual should be read

before operating or performing any maintenance on

your equipment.

Your Taylor freezer will NOT eventually compensate

for and correct any errors during the set-up or filling

operations. Thus, the initial assembly and priming

procedures are of extreme importance. It is strongly

recommended that personnel responsible for the

equipment's operation, both assembly and

disassembly, go through these procedures together

in order to be properly trained and to make sure that

no confusion exists.

In the event you should require technical assistance,

please contact your local authorized Taylor

Distributor.

Note: Your Taylor warranty is valid only if the parts

are authorized Taylor parts, purchased from the

local authorized Taylor Distributor, and only if all

required service work is provided by an authorized

Taylor service technician. Taylor reserves the right

to deny warranty claims on units or parts if

non-Taylor approved parts or incorrect refrigerant

were installed in the unit, system modifications were

performed beyond factory recommendations, or it is

determined that the failure was caused by abuse,

misuse, neglect, or failure to follow all operating

instructions. For full details of your Taylor Warranty,

please see the Limited Warranty section in this

manual.

Note: Constant research results in steady

improvements; therefore, information in this

manual is subject to change without notice.

If the crossed out wheeled bin symbol is

affixed to this product, it signifies that this product is

compliant with the EU Directive as well as other

similar legislation in effect after August 13, 2005.

Therefore, it must be collected separately after its

use is completed, and cannot be disposed as

unsorted municipal waste. The user is responsible

for returning the product to the appropriate collection

facility, as specified by your local code.

For additional information regarding applicable local

laws, please contact the municipal facility and/or

local distributor.

Compressor Warranty Disclaimer

The refrigeration compressor(s) on this unit are

warranted for the term stated in the Limited

Warranty section in this manual. However, due to

the Montreal Protocol and the U.S. Clean Air Act

Amendments of 1990, many new refrigerants are

being tested and developed, thus seeking their way

into the service industry. Some of these new

refrigerants are being advertised as drop-in

replacements for numerous applications. It should

be noted that in the event of ordinary service to this

unit's refrigeration system, only the refrigerant

specified on the affixed data label should be

used. The unauthorized use of alternate refrigerants

will void your Taylor compressor warranty. It is the

unit owner's responsibility to make this fact known to

any technician he employs.

It should also be noted that Taylor does not warrant

the refrigerant used in its equipment. For example, if

the refrigerant is lost during the course of ordinary

service to this machine, Taylor has no obligation to

either supply or provide its replacement either at

billable or unbillable terms. Taylor does have the

obligation to recommend a suitable replacement if

the original refrigerant is banned, obsoleted, or no

longer available during the five year warranty of the

compressor.

Taylor will continue to monitor the industry and test

new alternates as they are being developed. Should

a new alternate prove, through our testing, that it

would be accepted as a drop-in replacement, then

the above disclaimer would become null and void.

To find out the current status of an alternate

refrigerant as it relates to your compressor warranty,

call the local Taylor Distributor or the Taylor Factory.

Be prepared to provide the Model/Serial Number of

the unit in question.

131121

4

Models C709 & C717To the Operator

Page 9

Section 3 Safety

We, at Taylor Company, are concerned about the

safety of the operator when he or she comes in

contact with the freezer and its parts. Taylor has

gone to extreme efforts to design and manufacture

built-in safety features to protect both you and the

service technician. As an example, warning labels

have been attached to the freezer to further point

out safety precautions to the operator.

IMPORTANT - Failure to adhere to the

following safety precautions may result in

severe personal injury or death. Failure to

comply with these warnings may damage the

machine and its components. Component

damage will result in part replacement expense

and service repair expense.

DO NOT operate the freezer without

reading this Operator Manual. Failure to follow this

instruction may result in equipment damage, poor

freezer performance, health hazards, or personal

injury.

This appliance is to be used only by trained

personnel. It is not intended for use by children or

people with reduced physical, sensory, or mental

capabilities, or lack of experience and knowledge,

unless given supervision or instruction concerning

the use of the appliance by a person responsible for

their safety. Children should be supervised to ensure

that they do not play with the appliance.

This unit is provided with an equipotential

grounding lug that is to be properly attached to the

rear of the frame by the authorized installer. The

installation location is marked by the equipotential

bonding symbol (5021 of IEC 60417-1) on both the

removable panel and the equipment's frame.

the freezer. Failure to follow these instructions may

result in serious electrical shock.

DO NOT use a water jet to clean or rinse

S DO NOT operate the freezer unless it is

properly grounded.

S DO NOT operate the freezer with larger

fuses than specified on the data label.

S All repairs must be performed by an

authorized Taylor service technician.

S The main power supplies to the machine

must be disconnected prior to performing

any repairs.

S For Cord Connected Units: Only Taylor

authorized service technicians or licensed

electricians may install a plug or

replacement cord on these units.

S Stationary appliances which are not

equipped with a power cord and a plug or

another device to disconnect the appliance

from the power source must have an all-pole

disconnecting device with a contact gap of

at least 3 mm installed in the external

installation.

S Appliances that are permanently connected

to fixed wiring and for which leakage

currents may exceed 10 mA, particularly

when disconnected or not used for long

periods, or during initial installation, shall

have protective devices such as a GFI, to

protect against the leakage of current,

installed by the authorized personnel to the

local codes.

130128

Models C709 & C717 Safety

5

Page 10

S Supply cords used with this unit shall be

oil-resistant, sheathed flexible cable not

lighter than ordinary polychloroprene or

other equivalent synthetic

elastomer-sheathed cord (Code designation

60245 IEC 57) installed with the proper cord

anchorage to relieve conductors from strain,

including twisting, at the terminals and

protect the insulation of the conductors from

abrasion.

If the supply cord is damaged, it must be

replaced by the manufacturer, its service

agent, or similarly qualified person, in order

to avoid a hazard.

Failure to follow these instructions may result in

electrocution. Contact your local authorized Taylor

Distributor for service.

S DO NOT allow untrained personnel to

operate this machine.

S DO NOT operate the freezer unless all

service panels and access doors are

restrained with screws.

S DO NOT remove any internal operating

parts (example: freezer door, beater,

scraper blades, etc.) unless all control

switches are in the OFF position.

Failure to follow these instructions may result in

severe personal injury from hazardous moving parts.

This unit has many sharp edges that can

cause severe injuries.

S DO NOT put objects or fingers in the door

spout. This may contaminate the product

and cause severe personal injury from blade

contact.

S USE EXTREME CAUTION when removing

the beater asssembly. The scraper blades

are very sharp.

S CAUTION-SHARP EDGES: Two people are

required to handle the cup/cone dispenser.

Protective gloves must be worn and the

mounting holes must NOT be used to lift or

hold the dispenser. Failure to follow this

instruction can result in personal injury to

fingers or equipment damage.

Access to the service area of the unit is

restricted to persons having knowledge and practical

experience with the appliance, in particular as far as

safety and hygiene are concerned.

This freezer must be placed on a level

surface. Failure to comply may result in personal

injury or equipment damage.

Cleaning and sanitizing schedules are

governed by your state or local regulatory agencies

and must be followed accordingly. Please refer to

the cleaning section of this manual for the proper

procedure to clean this unit.

DO NOT run the unit without product. Failure to

follow this instruction can result in damage to the

unit.

This machine is designed to maintain

product temperature under 41°F (5°C). Any product

being added to this machine must be below 41°F

(5°C). Failure to follow this instruction may result in

health hazards and poor freezer performance.

DO NOT run the machine without product. Failure to

follow this instruction can result in damage to the

machine.

DO NOT obstruct air intake and discharge openings:

C709: A minimum of 6” (152 mm) air space is

required on both sides and 0” on the rear.

C717: A minimum of 3” (76 mm) air space is

required around all sides. Install the deflector

provided to prevent recirculation of warm air.

Failure to follow these instructions may cause poor

freezer performance and damage to the machine.

For Indoor Use Only: This unit is designed to

operate indoors, under normal ambient

temperatures of 70° - 75°F (21° - 24°C). The freezer

has successfully performed in high ambient

temperatures of 104°(40°C) at reduced capacities.

NOISE LEVEL: Airborne noise emission does not

exceed 78 dB(A) when measured at a distance of

1.0 meter from the surface of the machine and at a

height of 1.6 meters from the floor.

130228

6

Models C709 & C717Safety

Page 11

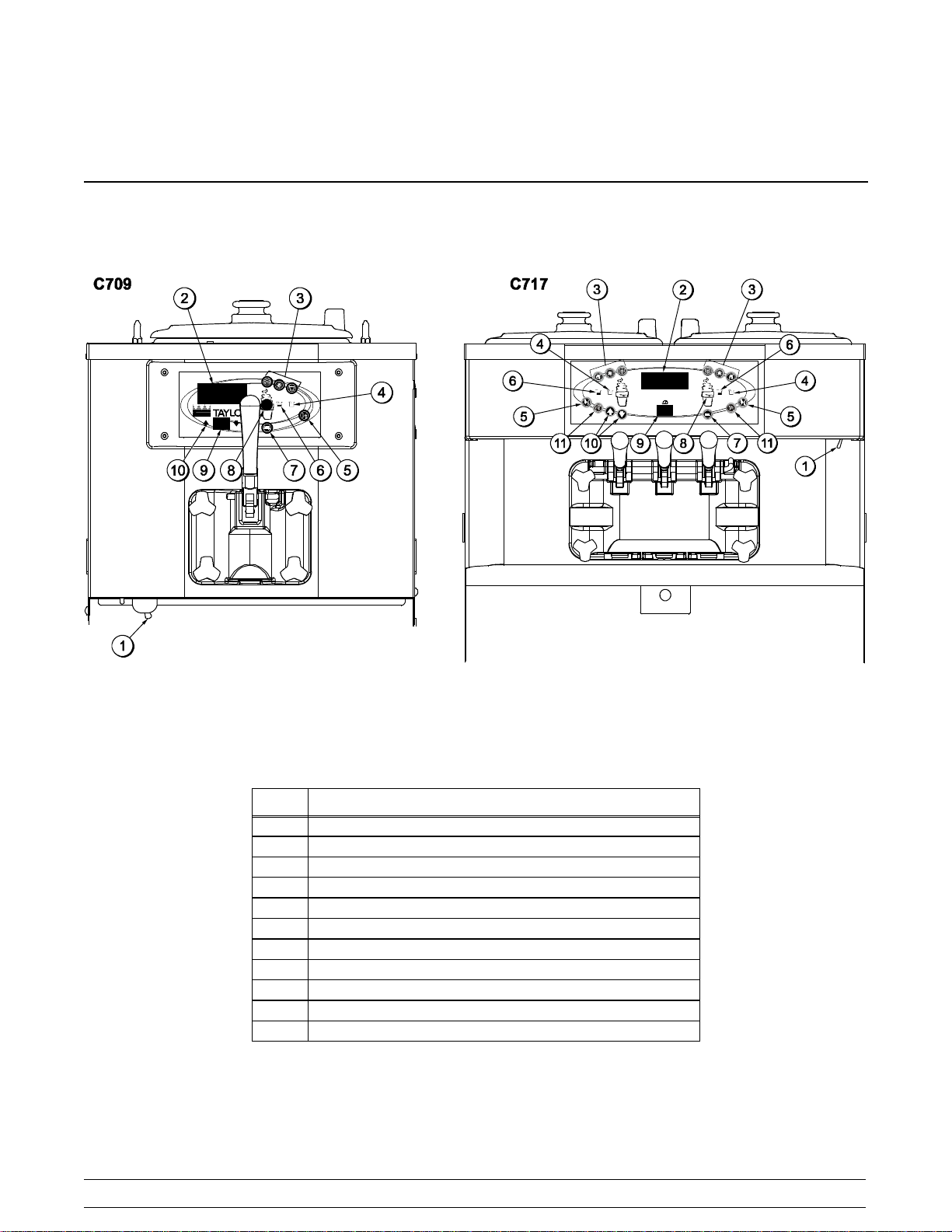

Section 4 Operator Parts Identification

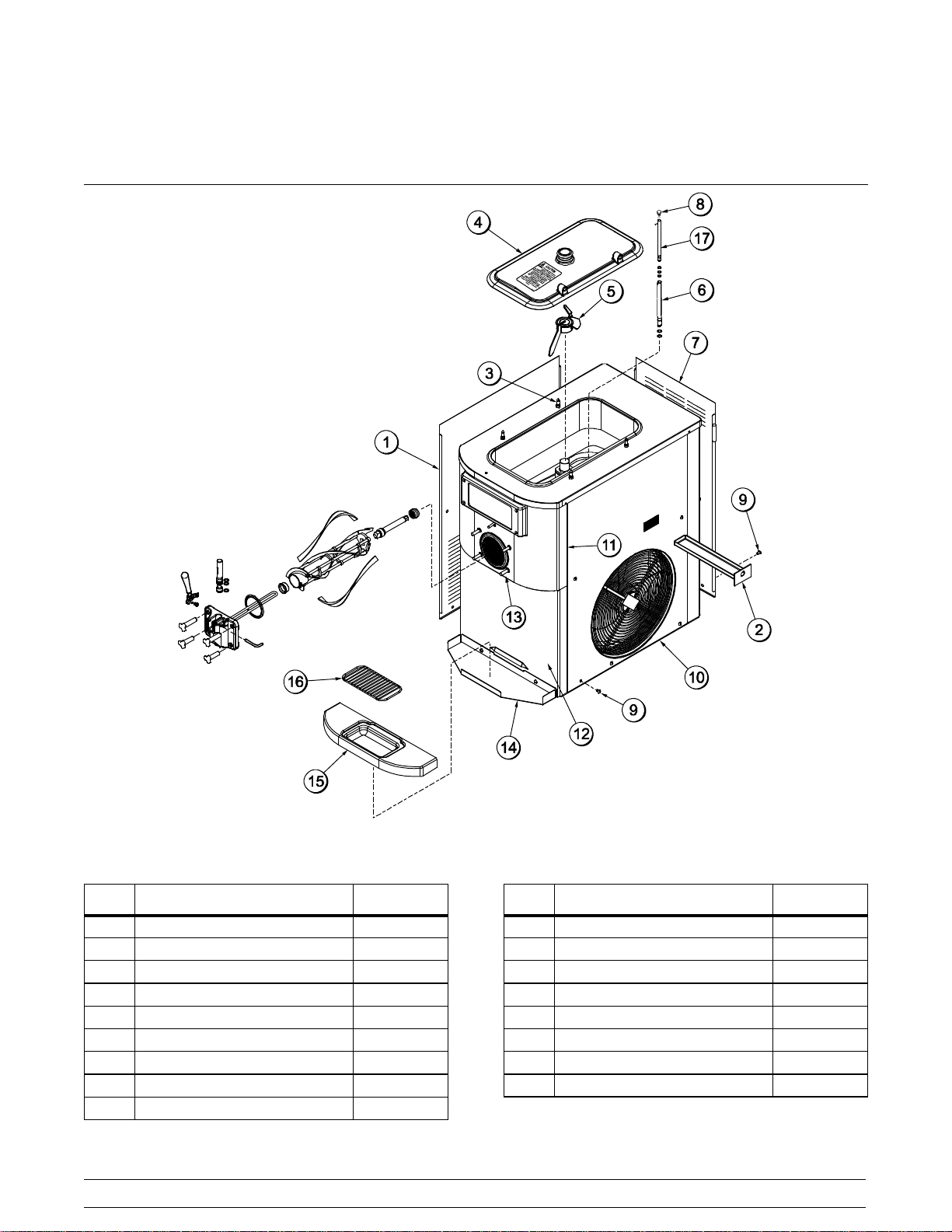

Model C709

Figure 1

ITEM DESCRIPTION PART NO.

1 PANEL-SIDE-LEFT 056963-SP1

2 PAN-DRIP 11-5/8 LONG 027503

3 PIN-RETAINING-HOPPER CVR 043934

4 KIT A.-COVER-HOPPER X65368

5 BLADE A.-AGITATOR X56591

6 TUBE A.-FEED-OUTER-HT X34641

7 PANEL-REAR 056077-SP1

8 ORIFICE 022465-100

9 SCREW-1/4-20X3/8 RHM-SS 011694

Models C709 & C717 Operator Parts Identification

ITEM DESCRIPTION PART NO.

10 PANEL A-SIDE-RIGHT X57871

11 PANEL A.-FRONT-UPPER X59423

12 PANEL A.-FRONT-LOWER X58955

13 STUD-NOSE CONE 055987

14 SHELF-TRAY-DRIP 056076

15 TRAY-DRIP 056858

16 SHIELD-SPLASH 049203

17 TUBE A.-FEED-SC-INNER X32824-2

100324

7

Page 12

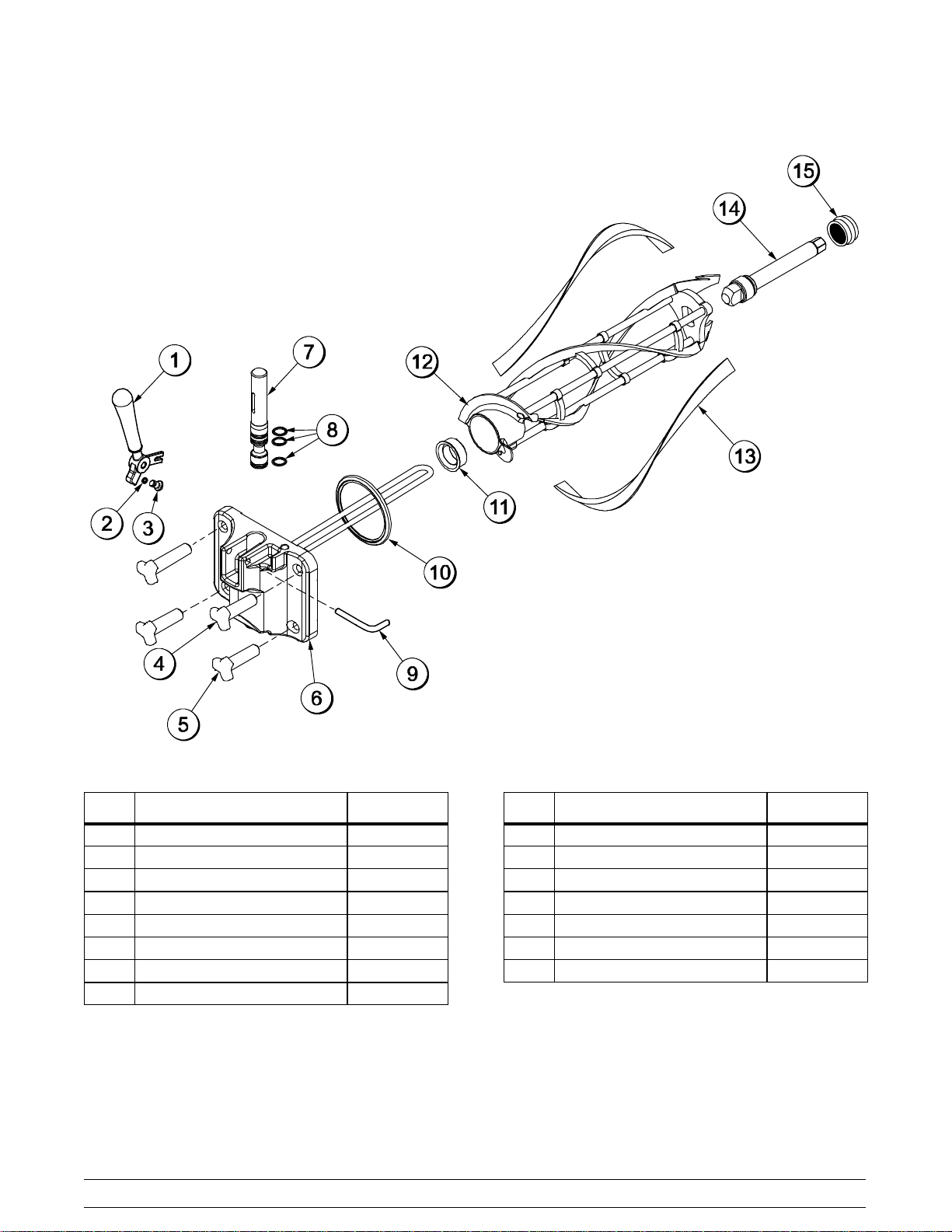

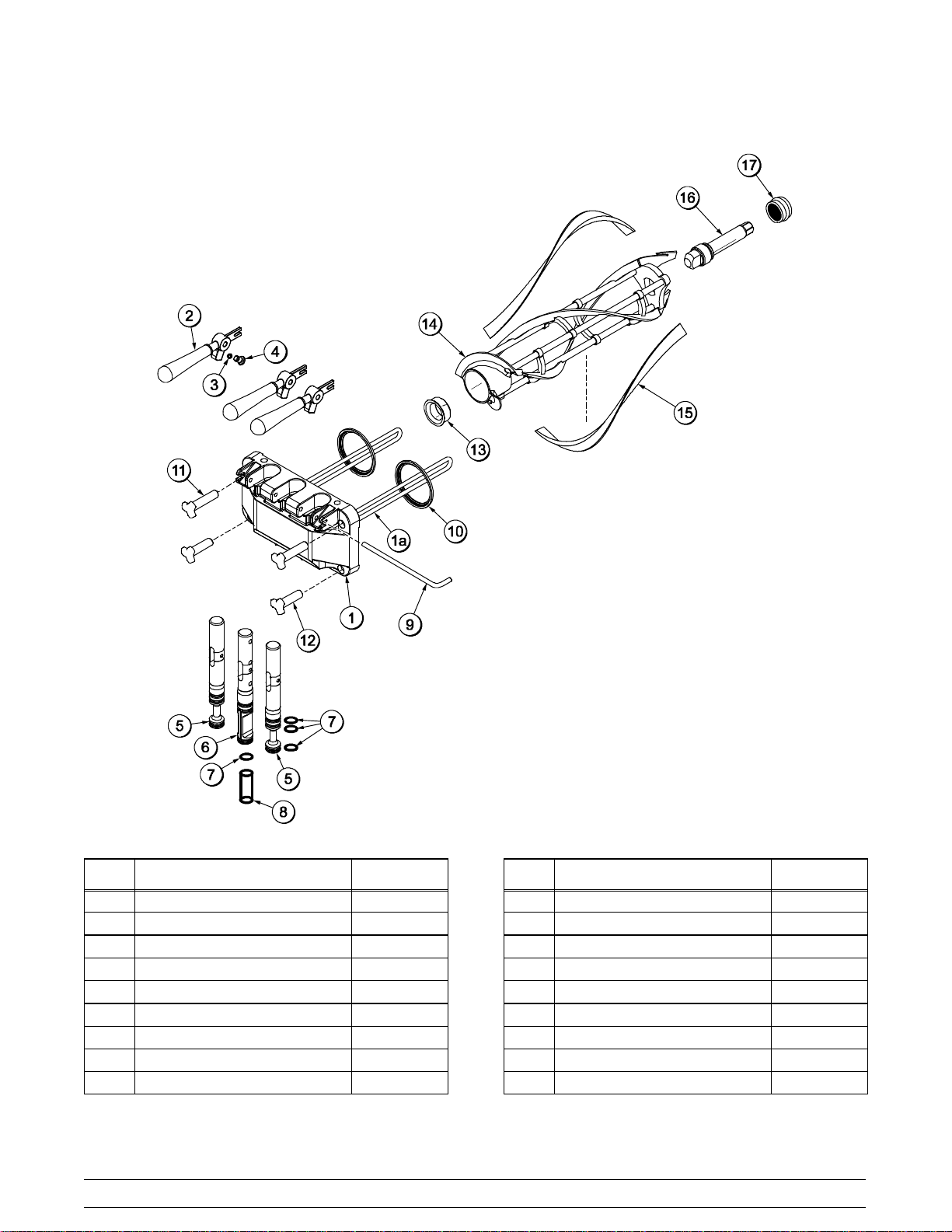

Model C709 Single Spout Door and Beater Assembly

ITEM DESCRIPTION PART NO.

1 HANDLE A.-DRAW-WELDED X56246

2 O-RING-1/4 OD X .070W 50 015872

3 SCREW-ADJUSTMT-5/16-24 056332

4 NUT-STUD BLACK 3.250” 058765

5 NUT-STUD BLACK 2.563“ 058764

6 DOOR A.-W/BAFFLE X57332-SER

7 VALVE A.-DRAW X55820

8 O-RING-DRAW VALVE-S.S. 014402

Figure 2

8

ITEM DESCRIPTION PART NO.

9 PIN-HANDLE-SS 055819

10 GASKET-DOOR HT 4”-DBL 048926

11 BEARING-FRONT 050216

12 BEATER A.-3.4 QT HELICORE X31761

13 BLADE-SCRAPER-PLASTIC 035174

14 SHAFT-BEATER 056078

15 SEAL-DRIVE SHAFT 032560

Models C709 & C717Operator Parts Identification

Page 13

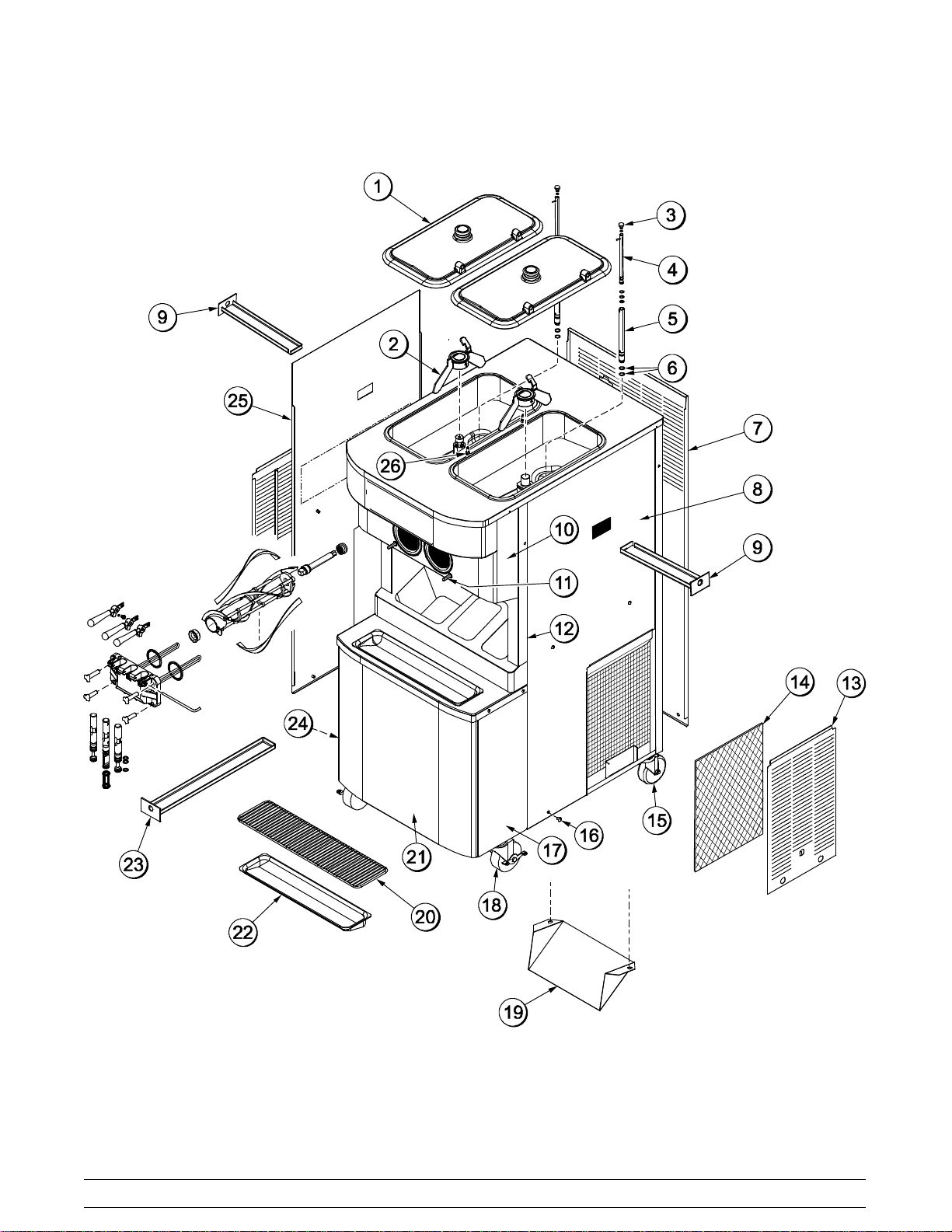

Model C717

Figure 3

130129

Models C709 & C717 Operator Parts Identification

9

Page 14

Model C717 Exploded View Parts Identification

ITEM DESCRIPTION PART NO.

1 COVER-HOPPER 053809-1

2 BLADE A.-AGITATOR X56591

3 ORIFICE 022465-100

4 TUBE A.-FEED-SC-INNER-3/16 X32824-3

5 TUBE A.-FEED-OUTER-HT X34641

6 O-RING-.643 OD X .077 W 018572

7 PANEL-REAR 059917

8 PANEL-SIDE*RIGHT 059907

9 PAN-DRIP 12.5 059736

10 PANEL A.-FRONT (MIDDLE) X63879

11 PANEL A.-FRONT (UPPER) X59836

12 STUD-NOSE CONE 055987

13 FILTER-AIR-POLY-FLO 052779-11

ITEM DESCRIPTION PART NO.

14 PANEL A.-FILTER-LOUVERED X59928

15 CASTER-4” SWV 3/4-10 STEM 044106

16 SCREW-1/4-20X 3/8 RHM-SS 011694

17 PANEL-CORNER-FRONT R. 063087

18 CASTER-4” SWV 3/4-10 STEM

W/BRAKE

19 DEFLECTOR-BLOWER 059929

20 SHIELD-SPLASH-WIRE-19-3/4L 033813

21 PANEL A.-FRONT LOWER X59854-SER

22 TRAY-DRIP-19-5/8 L X 4-7/8 033812

23 PAN-DRIP 19-1/2 LONG 035034

24 PANEL-CORNER-FRONT-LEFT 063088

25 PANEL-SIDE-LEFT 059906

26 PIN-RETAINING-HOPPER CVR 043934

046437

130128

10

Models C709 & C717Operator Parts Identification

Page 15

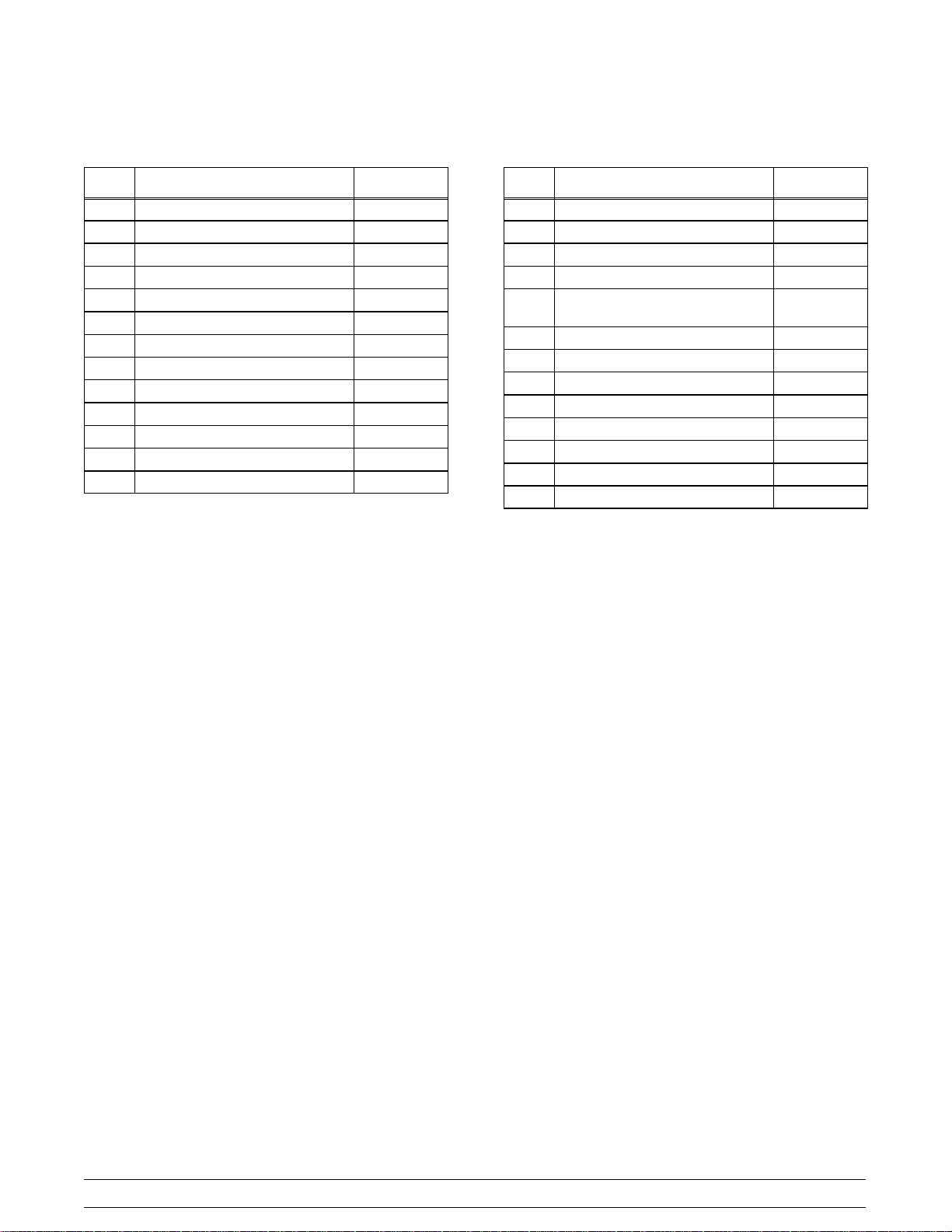

Model C717 Three Spout Door and Beater Assembly

Figure 4

ITEM DESCRIPTION PART NO.

1 DOOR A.-3SPT*HT*LG BAF X59923-SER

1a BAFFLE A.-LONG 4 IN W/RAD X50882

2 HANDLE A.-DRAW-WELDED X56421-1

3 O-RING-1/4 OD X .070W 50 015872

4 SCREW-ADJUSTMENT-5/16-24 056332

5 VALVE A.-DRAW-L&R X59888

6 VALVE A.-DRAW-CENTER X59890

7 O-RING-7/8 OD X .103W 014402

8 SEAL-DRAW VALVE 034698

Models C709 & C717 Operator Parts Identification

ITEM DESCRIPTION PART NO.

9 PIN-HANDLE-TWIN 059894

10 GASKET-DOOR HT 4"-DOUBLE 048926

11 NUT-STUD BLACK 3.250 LONG 058765

12 NUT-STUD BLACK 2.563 LONG 058764

13 BEARING-FRONT 050216

14 BEATER A.-3.4QT-HELICORE X31761

15 BLADE-SCRAPER-PLASTIC 035174

16 SHAFT-BEATER 032564

17 SEAL-DRIVE SHAFT 032560

140121

11

Page 16

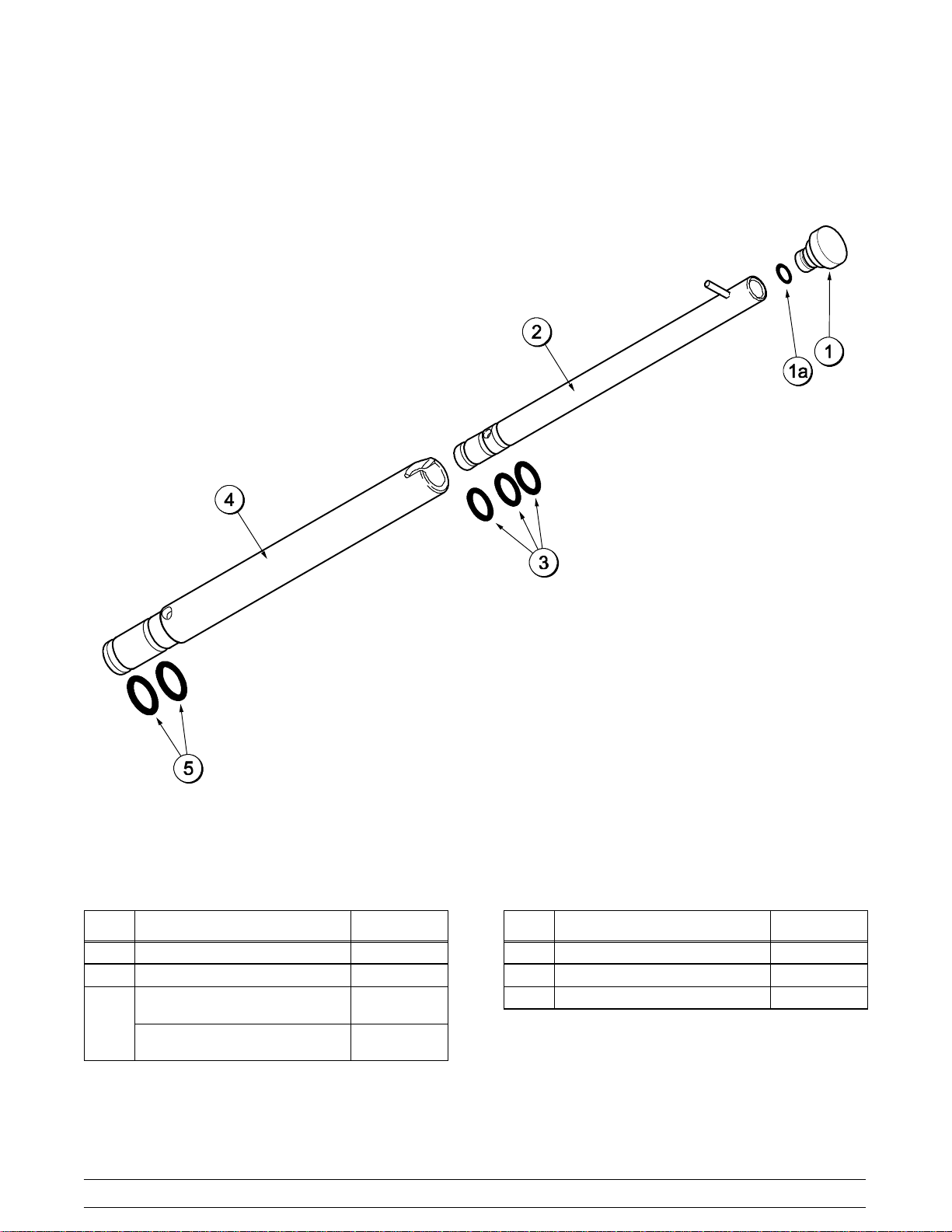

Feed Tube Assembly

ITEM DESCRIPTION PART NO.

1 AIR ORIFICE 022465-100

1a O-RING 016137

TUBE A.-FEED-SC-INNER

2

(C709)

TUBE A.-FEED-SC-INNER

(C717)

X32824-2

X32824-3

Figure 5

12

ITEM DESCRIPTION PART NO.

3 O-RING - .291 ID x .080 W 018550

4 TUBEA.-FEED-OUTER-HT X34641

5 O-RING- .643 OD x .077 W 018572

Models C709 & C717Operator Parts Identification

Page 17

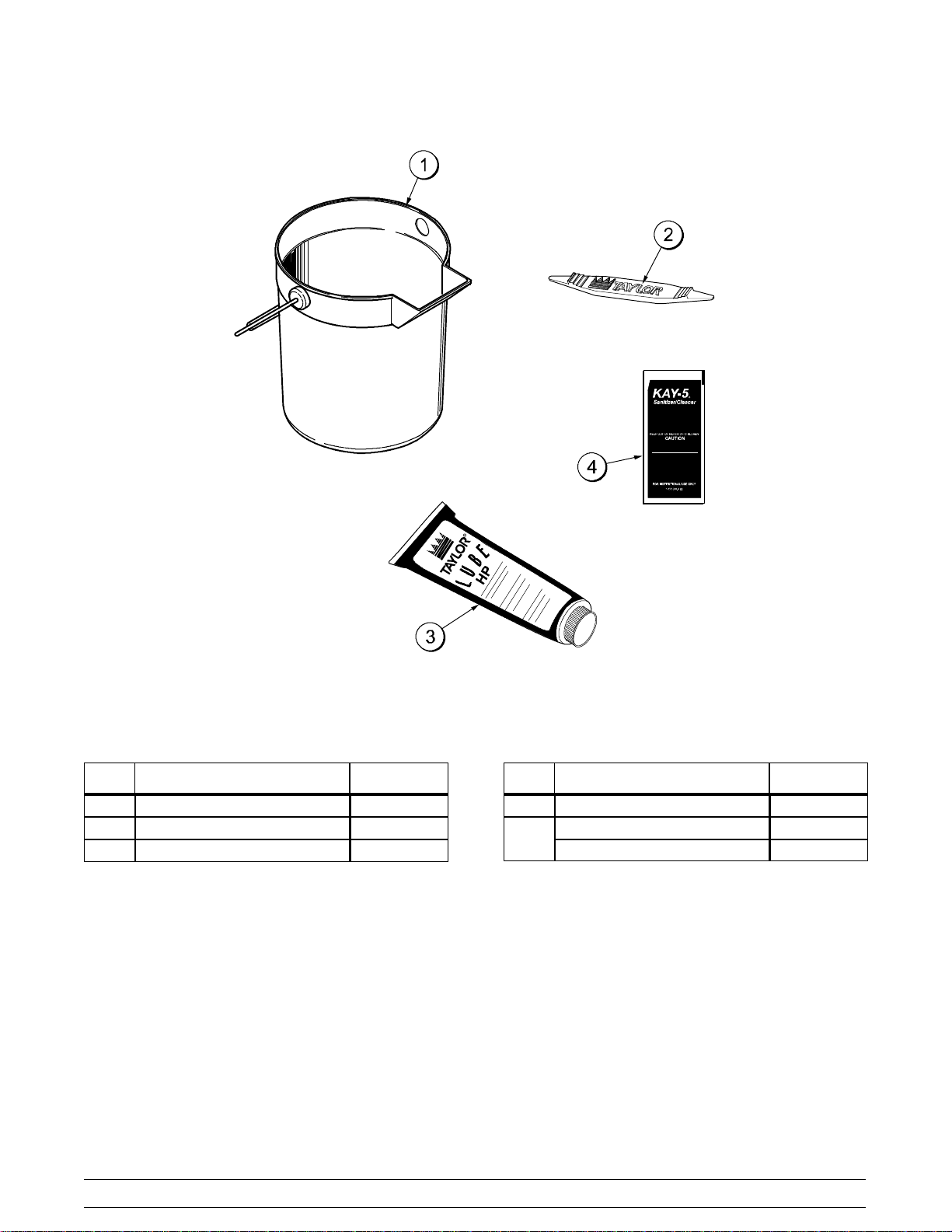

Accessories

ITEM DESCRIPTION PART NO.

1 PAIL-10 QT. 013163

2 TOOL-O-RING REMOVAL 048260-WHT

3 LUBRICANT-TAYLOR HI-PERF 048232

Figure 6

ITEM DESCRIPTION PART NO.

*4 SANITIZER KAY-5 25 PACKS SEE NOTE

KIT A.-TUNE-UP (C709) X49463-92

**5

KIT A.-TUNE-UP (C717) X49463-79

*Note: A sample container of sanitizer is sent with the

unit. For reorders,orderKay-5partno. 041082 (200

packs) or Stera Sheen part no. 055492 (100 2 oz.

packs).

**NotShown

140718

Models C709 & C717 Operator Parts Identification

13

Page 18

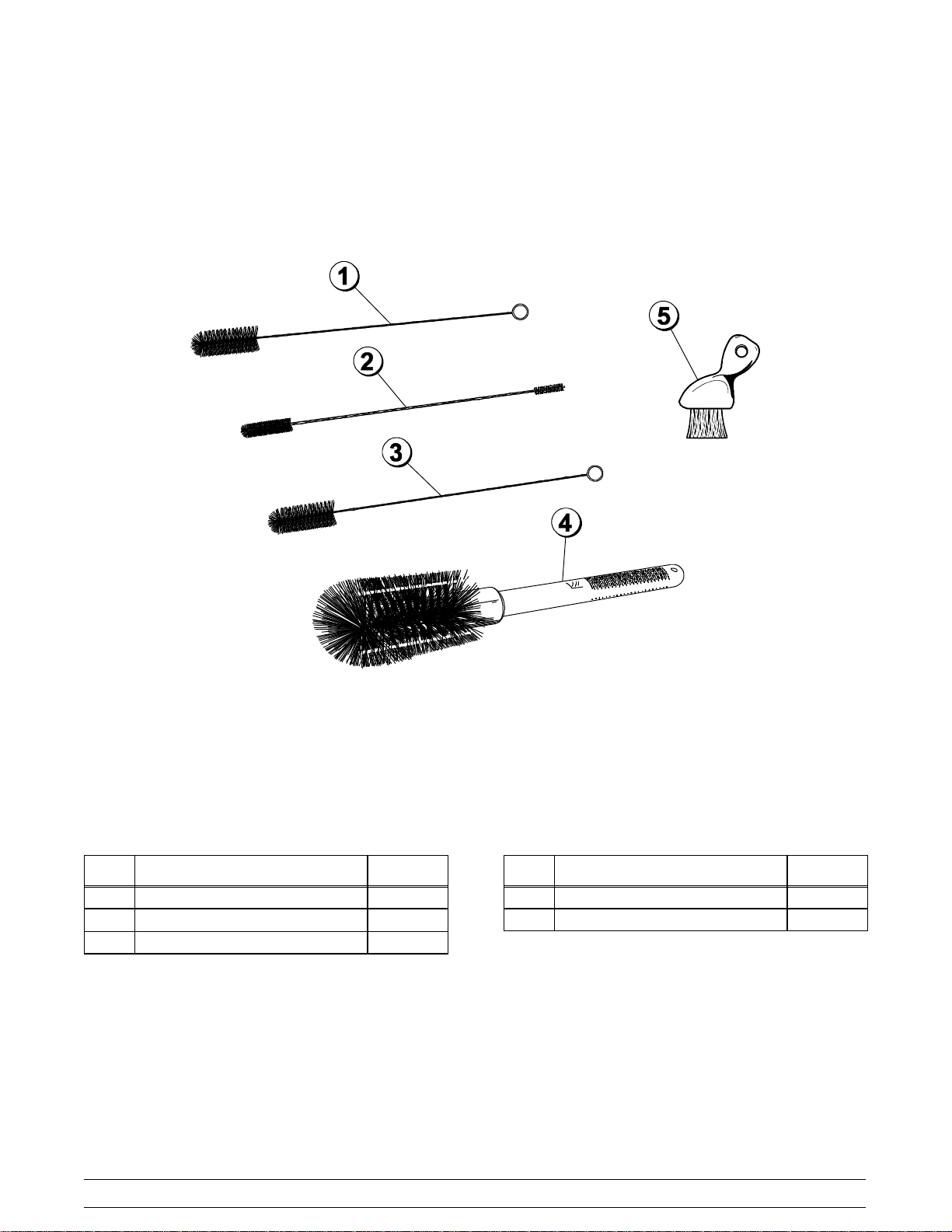

Brushes

ITEM DESCRIPTION PART NO.

1 BRUSH-REAR BRG 1” D X 2” L 013071

2 BRUSH-DOUBLE ENDED 013072

3 BRUSH-DRAW VALVE 1”OD X 2 013073

Figure 7

14

ITEM DESCRIPTION PART NO.

4 BRUSH-MIX PUMP BODY 3” X 7” 023316

5 BRUSH-END-DOOR-SPOUT-SS 039719

Models C709 & C717Operator Parts Identification

Page 19

Section 5 Important: To the Operator

Figure 8

ITEM DESCRIPTION

1 POWER SWITCH

2 LIQUID CRYSTAL DISPLAY

3 KEYPADS

4 MIX OUT INDICATOR

5 STANDBY KEY

6 MIX LOW INDICATOR

7 SELECT KEY

8 SERVICE MENU KEY

9 BRUSH CLEAN COUNTER

10 ARROW KEYS

11 TOPPING HEATER KEY

130228

Models C709 & C717 Important: To the Operator

15

Page 20

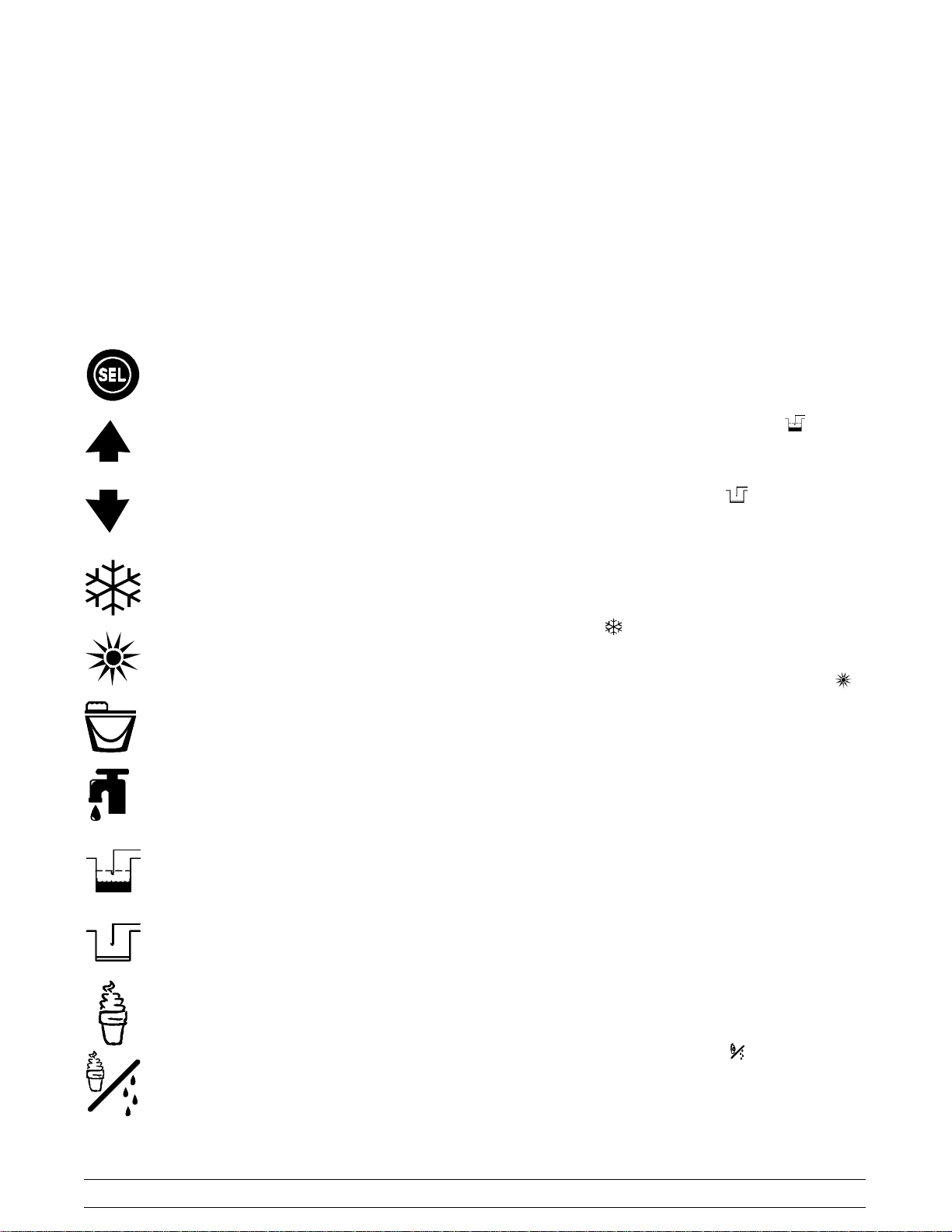

Symbol Definitions

To better communicate in the International arena,

symbols have replaced words on many of our

operator switches, function, and fault indicators.

Your Taylor equipment is designed with these

International symbols.

The following chart identifies the symbol definitions.

= SELECT

Power Switch

When placed in the ON position, the power switch

allows control panel operation.

Fluorescent Display

The fluorescent display is located on the front

control panel. During normal operation the display is

blank. The display is used to show menu options

and notifies the operator if a fault is detected. On

International models, the display will indicate the

temperature of the mix in the hopper.

Indicator Lights

= UP ARROW

= DOWN ARROW

=AUTO

= HEAT CYCLE

= WASH (Model C709)

= WASH (Model C717)

=MIXLOW

= MIX OUT

MIX LOW - When the MIX LOW symbol is

illuminated, the mix hopper has a low supply of mix

and should be refilled as soon as possible.

MIX OUT - When the MIX OUT

illuminated, the mix hopper has been almost

completely exhausted and has an insufficient supply

of mix to operate the freezer. At this time, the AUTO

mode is locked out and the freezer will be placed in

the STANDBY mode. To initiate the refrigeration

system, add mix to the mix hopper and touch the

AUTO symbol

begin operation.

HEAT MODE - When the HEAT MODE symbol

is illuminated, the freezer is in the process of a heat

cycle.

BRUSH CLEAN COUNTER - When the BRUSH

CLEAN COUNTER display has counted down to “1”,

the machine must be disassembled and brush

cleaned within 24 hours.

. The freezer will automatically

symbol is

Standby Symbol

The Standby feature maintains product

temperatures in both the hopper and the freezing

cylinder below 40°F (4.4°C). This feature is useful

during long “No Sale” periods to prevent overbeating

and product breakdown.

130228

= MENU DISPLAY

= STANDBY

To activate STANDBY, enter the Manager Menu

access code (see pageNO TAG.) Remove the air

orifice and turn the inner feed tube so the pin rests

on top of the outer feed tube. When STANDBY is

selected, the STANDBY symbol

indicating the Standby feature has been activated. In

the STANDBY mode, the WASH and AUTO

functions are automatically cancelled.

16

illuminates,

Models C709 & C717Important: To the Operator

Page 21

IMPORTANT: Make sure the level of mix in the

hopper is below the mix delivery hole in the feed

tube. Failure to follow this instruction may result in

lower product quality when normal operation is

resumed.

To resume normal operation, press the AUTO

symbol

the freezing cylinder will be at serving viscosity. At

this time, turn the inner feed tube so the pin fits into

the groove of the outer feed tube. Install the air

orifice.

. When the unit cycles off, the product in

Wash Symbol

The WASH symbol (Model C709) or

(Model C717) will illuminate when it is touched.

This indicates beater motor operation. The

STANDBY or AUTO modes must be cancelled first

to activate the Wash mode.

Auto Symbol

The AUTO symbol will illuminate when it is

touched. This indicates that the refrigeration system

has been activated. In the AUTO mode, the WASH

or STANDBY functions are automatically cancelled.

Note: An indicating light and an audible tone will

sound whenever a mode of operation has been

selected. To cancel any function, touch the key

again. The light and the mode of operation will shut

off.

WARNING: Do not use metal objects to

press the reset button. Failure to comply may

result in severe personal injury or death.

If the beater motor is turning properly, touch the

WASH symbol

AUTO symbol

freezer shuts down again, contact your authorized

service technician.

/ to cancel the cycle. Touch the

to resume normal operation. If the

Adjustable Draw Handle

These units feature an adjustable draw handle(s) to

provide the best portion control, giving a better,

consistent quality to your product and controlling

costs. The draw handle(s) should be adjusted to

provide a flow rate of 5 to 7-1/2 oz. (142 to 213 g.)

of product by weight per 10 seconds. To INCREASE

the flow rate, turn the screw CLOCKWISE, and

COUNTERCLOCKWISE to DECREASE the flow

rate.

Reset Mechanism

The C709 reset button is located in the service panel

on the left side of the machine. The C717 reset

buttons are located in the rear panel of the machine.

Reset button(s) protect the beater motor(s) from an

overload condition. Should an overload occur, the

reset mechanism will trip. To properly reset the

freezer, place the power switch in the OFF position.

Press the reset button firmly. Turn the power switch

to the ON position. Touch the WASH symbol

and observe the freezer's performance.

Note: To clear the fault, refer to page NO TAG.

Models C709 & C717 Important: To the Operator

/

Figure 9

130819

17

Page 22

Operating Screen Descriptions

The fluorescent display located in the center of the

control panel is normally blank during the daily

operation of the machine. The display is activated

when the SEL symbol or the Manager's Menu is

selected. The display screen will also alert the

operator of specific faults detected by the control.

Note: The displays illustrated in this section are

those seen on the Models C709. The Model C717

displays may vary slightly.

System Data

System data is protected separately from the rest of

the data in memory. System data includes variables

that change frequently such as the mode the

machine is in, lockout status, serving counters, fault

codes, and others. While System Data is being

checked the following screen is displayed.

Initializing

System Data

Power Up Memory (Initializin g)

The seven segment display should display “00”

during the initializing sequence.

When the machine is powered, the control system

will initialize to perform a system check. The screen

will display “INITIALIZING”. There will be four types

of data the system will check: LANGUAGE,

SYSTEM DATA, CONFIG DATA, and LOCKOUT

DATA.

Language Initialization

The UVC platform supports multiple languages by

keeping specific strings in battery backed RAM.

After power-up or a CPU reset, the strings are

tested to see if the language strings are present and

not corrupted. If the strings are present and not

corrupted, initialization continues. Otherwise, the

operator is prompted to select a language. While

language strings are being checked for integrity, the

following screen is displayed.

Initializing

Language

If the System Data is corrupted, the machine is set

to OFF, the serving counters are set to zero, and the

faults are cleared. A “SYSTEM CRC ERR” fault is

set and displayed on the VFD. An acknowledgement

(SEL key) is required.

Configuration Data

Configuration data is separate from the rest of the

data in the memory. Configuration data is

information entered through operator and service

menus. While Configuration Data is being checked

the following screen is displayed.

Initializing

Config Data

If Configuration data is corrupted, all user and

service settings are set to defaults. A “CONFIG

CRC ERR” fault is set and displayed on the VFD.

The system will continue to operate in its previous

mode but according to default settings.

Lockout Data

Note: If there is a language initialization fault, the

machine will force a language selection prior to the

initializing sequence. The standard menu LED's

should light, as if it were in a menu. If a language

has been selected, the unit is powered down, the

machine should not ask for a language unless there

is another language initialization fault. English is the

factory default setting.

Lockout data is protected separately from the rest of

the data in the memory. While the Lockout Data is

being checked, the following screen is displayed.

Initializing

Lockout Data

18

Models C709 & C717Important: To the Operator

Page 23

If Lockout Data is corrupted, all lockout history data

is cleared. A “LOCKOUT CRC ERR” fault is

displayed.

After the memory integrity has been tested, the

Safety Timeout screen will be displayed.

Heat Cycle Data

Heat cycle data is checked separately from the rest

of the data in memory. Each individual Heat Cycle

Data record is monitored for corruption individually.

At the start of a heat cycle, the next Heat Cycle data

record is cleared and data for the heat cycle is

writtentoit.ThecurrentHeatCycleDatais

displayed as the first heat cycle record in the HEAT

CYCLE DATA menu option.

The heat cycle data records are checked for integrity

when the record is accessed, presently only through

the HEAT CYCLE DATA menu option.

(For additional Heat Cycle Data information,

see page 28.)

Power Switch ON

When the power switch is placed in the ON position,

the control panel touch keys become operative. The

fluorescent display will be either blank or indicate

that the unit has been cleaned.

UNIT CLEANED

International M odels Only:

Once the system has initialized, the number of days

until brush cleaning is required is indicated on the

control panel. The SAFETY TIMEOUT screen will

be displayed with the alarm on for 60 seconds or

until any control symbol is touched.

SAFETY TIMEOUT

ANY KEY ABORTS

Power Switch OFF

After the safety timeout has been completed and the

power switch is OFF, the following screen is

displayed.

POWER SWITCH OFF

-=-=-=-=-=UNIT CLEANED

Some International models will continuously display

the temperature of the mix hopper when the power

switch is in the ON position.

HOPPER 21.0

UNIT CLEANED

If the control is set for international configuration, the

following screen will appear when the heat symbol is

touched.

ARE YOU SURE

>Yes

No

Models C709 & C717 Important: To the Operator

19

Page 24

Use the up or down arrow symbol to move the

cursor to “YES”. Touch the SEL symbol to

immediately start a heat cycle.

Note: The machine must be in AUTO or STANDBY

and have sufficient mix in the hopper before the

machine can successfully enter the HEAT mode of

operation.

Heat Cycle

The HEAT symbol on the control panel is illuminated

throughout the heat treatment cycle. Two warning

messages will be displayed on the screen. “DO NOT

DRAW” will be displayed when the mix temperature

is below 130°F (54.4°C).

DO NOT DRAW

When the temperature of the mix is above 130°F

(54.4°C) the screen will display a message

indicating that HOT PRODUCT is in the machine.

When the entire heat cycle has been completed, the

HEAT symbol will no longer be illuminated. The

machine will enter the STANDBY mode (STANDBY

symbol illuminates). The machine can be placed in

AUTO or left in STANDBY.

To comply with health codes, heat treatment system

freezers must complete a heat treatment cycle daily

and must be disassembled and brush cleaned

according to the frequency specified by your

Federal, State, or local regulatory agencies. Please

consult your governing Food Code to determine the

maximum number of days allowed between brush

clean cycles.

Brush cleaning is the normal disassembly and

cleaning procedure found in the Operator Manual.

Failure to follow these guidelines will cause the

control to lock the freezer out of the AUTO mode.

If the Heat Treatment Cycle fails, the screen will

display a failure message and return the freezer to

the STANDBY mode.

Always comply with local guidelines for the

maximum number of days allowed between brush

clean cycles.

Freezer Locks

HOT PRODUCT

DO NOT attempt to draw product or

disassemble the unit during the HEAT cycle. The

product is hot and under extreme pressure.

In the HEAT cycle, the mix temperature in the

hopper and freezing cylinder must be raised to

151°F (66.1°C) within 90 minutes.

When the heating phase is complete, the freezer

goes into the holding phase of the cycle. The holding

phase will keep the temperature above 151°F

(66.1°C) for a minimum of 35 minutes.

The final phase of the heat treatment cycle is the

cooling phase. The freezer must cool the mix below

41°F (5°C) within 90 minutes for UVC3 units or 120

minutes for UVC4 units.

There are two types of freezer lock conditions that

can occur: Hard Lock or Soft Lock. A Hard Lock

requires the machine be disassembled and brush

cleaned. A Soft Lock can be corrected by either

disassembling and brush cleaning the machine, or

by starting another heat treatment cycle.

Hardlock

There are two causes of a hard lock failure. The

freezer will hardlock if either the Brush Clean Timer

has elapsed or if a Thermistor Failure (Freezing

Cylinder or Hopper) occurred during a Heat cycle.

1. The following screen will be displayed if a Brush

Clean Cycle Time has occurred.

BRUSH CLEAN TIMEOUT

FREEZER LOCKED

CLEANING REQ'D

> WASH TO BRUSH CLEAN

140303

20

Models C709 & C717Important: To the Operator

Page 25

Touching the SEL symbol will display the following

screen.

FREEZER LOCKED

2. The following screen will display if there has

been a thermistor failure (freezing cylinder or

hopper) during the heat treatment process.

SYSTEM FAULT

FREEZER LOCKED

SERVICE REQ'D

> WASH TO BRUSH CLEAN

Touching the SEL symbol will indicate which

thermistor caused the Hard Lock.

Soft Lock

If a heat treatment cycle has not been initiated within

the last 24 hours, a soft lock failure will occur. A soft

lock allows the operator to correct the cause of the

soft lock. The operator has the option of either

starting another heat cycle or brush cleaning the

machine. When a soft lock occurs, the machine will

go into the STANDBY mode. The following message

is displayed on the screen. The reason for the soft

lock is indicated on the second line.

NO HEAT CYCLE START

REASON

> HEAT FOR HEAT CYCLE

WASH TO BRUSH CLEAN

If the reason for the soft lock has been corrected,

selecting HEAT CYCLE initiates a Heat Cycle

immediately. Selecting BRUSH CLEAN when the

previous message is displayed will hard lock the

machine and brush cleaning will be necessary.

HOPPER THERM BAD

FREEZER LOCKED

If the machine has hard locked and an attempt is

made to enter AUTO, the machine will enter the

STANDBY mode and display the following message.

FREEZER LOCKED

To restore the message that identified the reason for

the hard lock, turn the power switch OFF for five

seconds and then return the power switch to the ON

position. The original message with the reason for

the Hard Lock will be displayed.

The FREEZER LOCKED message will remain on

the display until the brush clean requirements are

fulfilled. The freezer must be disassembled in order

to activate the five minute timer on the display

screen. Once the timer counts down to zero, the

lockout is cleared.

Following are the variable messages for soft lock

failures that appear on the second line of the screen.

POWER SWITCH OFF

Power switch was in the

OFF position.

MIX OUT PRESENT There was a mix out

condition present.

AUTO OR STANDBY

OFF

The machine was not in

the AUTO or STANDBY

mode.

NO HEAT CYCLE

TRIED

A heat treatment cycle

was not attemptedin

the last 24 hours.

(AUTO HEAT TIME

was advanced or a

power loss was experienced at the time the

cycle was to occur.)

If the following screen appears, a soft lock has

occurred during the heat treatment cycle.

HEAT TREAT FAILURE

FREEZER LOCKED

> HEAT FOR HEAT CYCLE

WASH TO BRUSH CLEAN

Models C709 & C717 Important: To the Operator

21

Page 26

A soft lock can also occur any time during operation

when the hopper or freezing cylinder temperature

rises above 59°F (15°C), the temperature rises and

remains above 45°F(7°C) for more than one hour, or

the temperature rises and remains above 41°F(5°C)

for more than four hours.

To restore the message that identified the reason for

the soft lock, turn the power switch OFF for five

seconds, and then return the power switch to the

ON position. The original message with the reason

for the soft lock will be displayed.

If a PRODUCT OVER TEMPERATURE condition

occurs during operation, the following screen will

appear.

PRODUCT OVER TEMP

> HEAT FOR HEAT CYCLE

WASH TO BRUSH CLEAN

When one of these messages appears, automatic

freezer operation cannot take place until the freezer

is disassembled and brush cleaned, or has

completed a heat treatment cycle.

Once the freezer is unlocked by starting a heat

treatment cycle the HEAT symbol will illuminate and

the following message will be displayed on the

screen.

HEAT TREAT FAILURE

REASON

> HEAT FOR HEAT CYCLE

WASH TO BRUSH CLEAN

Note: A record of Heat Cycle Data and Lock Out

History can be found in the Manager's Menu.

Manager's Menu

The Manager's Menu is used to enter the operator

function displays. To access the Menu, touch the

center of the CONE symbol on the control panel.

The arrow symbols, the SEL symbol and the CONE

symbol will be lit when the ACCESS CODE screen

is displayed.

DO NOT DRAW

If BRUSH CLEAN is selected to clear the lockout by

brush cleaning the machine, the FREEZER

LOCKED message will remain on the display until

the brush clean requirements are fulfilled. The

freezer must be disassembled in order to activate

the five minute timer on the display screen. Once

the timer counts down to zero, the lockout is

cleared.

FREEZER LOCKED

130228

Figure 10

In the Menu program, the arrow symbols and the

SEL symbol will function as menu keys.

S UP ARROW - increases the value above the

cursor and is used to scroll upward in text

displays.

S DOWN ARROW - decreases the value

above the cursor and is used to scroll

downward in text displays.

S SEL - advances the cursor position to the

right and is used to select menu options.

22

Models C709 & C717Important: To the Operator

Page 27

There is a two minute time-out in effect during the

Manager's Menu. While in the Manager's Menu, if no

activity occurs within a two minute period, the

display will exit to the Main Menu. There is one

exception to this time-out, and that is the Current

Conditions Display.

Manager Menu Options

Touch the ARROW symbols to move up or down

through the Menu. Select a Menu option by touching

the SEL symbol. Exit the Menu program by selecting

EXIT FROM MENU or touch the CONE symbol.

Note: The machine will continue operation in the

mode it was in whenthe Menu was selected. However,

the control keys will not be lit and are non- functional

when the Manager’s Menu is displayed. The control

keys are functional in the Manager’s Menu when the

CURRENT CONDITIONS screen is displayed. (See

CURRENT CONDITIONS on page 30.)

Entering Access Code

With the ACCESS CODE screen on the display, use

the SEL symbol to set the first code number in the

cursor position. When the correct number is

selected, touch the SEL symbol to move the cursor

to the next number position.

ENTER ACCESS CODE

83 0 9

__

Continue to enter the proper access code numbers

(8309) until all four numbers are displayed, then

touch the SEL symbol. The Manager's Menu list will

display on the screen, provided the correct access

code is entered.

If an incorrect number is entered for the access

code, the display will exit the Menu program when

the SEL symbol is touched.

The following menu options are listed in the

Manager's Menu.

EXIT FROM MENU

SERVINGS COUNTER

SET CLOCK

AUTO HEAT TIME

AUTO START TIME

STANDBY MODE

MIX LEVEL AUDIBLE

F AULT DESCRIPTION

FAULT HISTORY

LOCKOUT HISTORY

HEAT CYCLE SUMMARY

HEAT CYCLE DATA

SYSTEM INFORMATION

CURRENT CONDITIONS

NET SERVICE PIN

Exit From Menu

Selecting “EXIT FROM MENU” will exit the

Manager's Menu and the return the control panel

symbols to normal operation.

Servings Counter

The SERVINGS COUNTER screen is used to check

or reset the number of servings dispensed from the

machine. The SERVINGS COUNTER will

automatically reset to zero when the machine is

brush cleaned.

SERVINGS COUNTER

Draws 0

> Next

Figure 11

140131

Models C709 & C717 Important: To the Operator

23

Page 28

Reset the SERVINGS COUNTER by touching the

SEL symbol to advance to the next screen. Touch

the UP arrow symbol to move the arrow (>) to YES

and touch the SEL symbol. The servings counter will

reset to zero and exit back to the Manager's Menu.

RESET COUNTERS

ARE YOU SURE ?

>Yes

No

Set Clock

The SET CLOCK option allows the Manager to

adjust the control clock date and time. The date and

time may only be changed after the freezer has

been manually cleaned but before it has been

placed in the AUTO or STANDBY mode. The

following message will be displayed if the SET

CLOCK option is selected when the machine is not

in a brush clean state.

SET CLOCK

12:01 6/10/2010

NO CHANGES ALLOWED

Press Any Key

To change the date or time, select the SET CLOCK

option in the menu. Touch the UP arrow symbol to

advance the arrow from Exit to Change, then touch

the SEL symbol to select the Change option.

Enter the correct month, day, and year. Then touch

the SEL symbol to advance to the DAYLIGHT

SAVING TIME (DST) screen.

DAYLIGHT SAVING TIME

ENABLED

> Enable

Disable

Pressing the UP or DOWN arrow symbols will move

the arrow to “Enable” or “Disable”. Pressing the SEL

symbol next to “Disable” selects that option and

returns to the Manager Menu. Pressing the SEL

symbol next to “Enable” selects that option and

displays the second screen.

MAR Second Sunday

NOV First Sunday

Change

>Exit

If the correct Sunday for the time change is not

displayed, then “Change” should be selected.

Pressing the SEL symbol with the arrow next to

“Change” displays the third screen. Press the UP or

DOWN symbol to move the arrow to the appropriate

month for the start of DST.

SET CLOCK

12:01 6/10/2010

Change

>Exit

Change the time by touching the UP arrow with the

cursor under the hour position. Move the cursor to

the minutes position by touching the SEL symbol.

Once the correct minutes are entered, touch the

SEL symbol to advance the cursor to the month.

SET CLOCK

:01 6/10/2010

12

>Exit

140131

DST START MONTH

>MAR

APR

MAY

Pressing the SEL symbol with the arrow next to the

appropriate month will display the following screen.

DST START WEEK

> Second Sunday

Third Sunday

Fourth Sunday

24

Models C709 & C717Important: To the Operator

Page 29

Pressing the UP or DOWN symbol will move the

arrow to the appropriate week for the start of DST.

Pressing the SEL symbol next to the appropriate

week will display the following screen. Press the UP

or DOWN symbol to move the arrow to the

appropriate month for the end of DST.

DST END MONTH

>NOV

DEC

Touch the arrow symbols to increase or decrease

the hour to the desired setting. Then move the

cursor to the minutes position by touching the SEL

symbol. Adjust the setting for minutes. Then touch

the SEL symbol to save the setting and return to the

AUTO HEAT TIME screen. Touch the SEL symbol

to exit the screen and return to the Menu.

Auto Start Time

Pressing the SEL symbol next to the appropriate

month will display the following screen. Press the

UP or DOWN symbol to move the arrow to the

appropriate week for the end of DST.

DST END WEEK

> First Sunday

Second Sunday

Third Sunday

Pressing the SEL symbol with the arrow by the

appropriate week will select that setting and return to

the Manager Menu.

Auto Heat Time

The AUTO HEAT TIME screen allows the Manager

to set the time of day in which the heat treatment

cycle will start.

AUTO HEAT TIME

00:00

Change

>Exit

The AUTO START TIME option allows the Manager

to set the time of day at which the machine

automatically enters the AUTO mode from the

STANDBY mode. The machine must be in the

STANDBY mode without a freezer lock condition in

order to AUTO start at the programmable time. The

AUTO START TIME can also be Disabled and

require starting the AUTO mode manually.

AUTO START TIME

DISABLED

Enable

> Disable

Enable the AUTO START TIME by touching the UP

arrow symbol to move the arrow up to “Enable”.

Touch the SEL symbol to advance to the next

screen.

AUTO START TIME

00:00

Change

>Exit

To set the AUTO HEAT TIME, touch the UP arrow

symbol to move the arrow to “Change”. Then touch

the SEL symbol. The screen will display the time

with the cursor under the hour position.

AUTO HEAT TIME

:00

00

Models C709 & C717 Important: To the Operator

Program the AUTO START TIME by touching the

UP arrow symbol to move the arrow to “Change”.

Touch the SEL symbol to advance to the next

screen.

AUTO START TIME

:00

00

25

Page 30

Use the arrow symbols to program the AUTO

START TIME by increasing or decreasing the hour

setting above the cursor. Touch the SEL symbol to

advance the cursor and program the minutes

setting. Touch the SEL symbol to return to the

previous screen with the new time setting displayed.

Touch the SEL symbol to exit the screen and return

to the Menu.

Standby Mode

Fault Description

The Fault Description screen will indicate if there is a

fault with the freezer and where the fault occurred.

When no faults are detected, the following screen

will be displayed.

FAULT DESCRIPTION

NO FAULT FOUND

The STANDBY option is used to manually place the

machine in the standby mode during long, no draw

periods. Select the STANDBY screen from the

Manager's Menu. Touch the SEL symbol to activate

Standby. Standby may also be entered by touching

the STANDBY key when not in the Manager's Menu.

Discontinue Standby operation by exiting the

Manager's Menu and select the AUTO mode.

STANDBY MODE

Yes

No

>Exit

Mix Level Audible

The MIX LEVEL AUDIBLE option, when enabled,

will alert the operator with an audible tone when

there is Mix Low or Mix Out condition. The following

screen is displayed upon selecting this option.

Touch the SEL symbol to display the next fault

found or return to the Manager Menu if no other

faults exist. Touching the SEL symbol any time

faults are displayed will clear the faults, if corrected,

upon returning to the Menu screen.

Listed below are the variable messages which will

appear, along with an explanation for the corrective

action.

NO FAULT FOUND - There was no fault found in

the freezer. Nothing will appear on the screen after

this variable message appears.

BEATER OVERLOAD - Place the power switch in

the OFF position. Wait 5 minutes for the machine to

cool. Press the beater reset button firmly. Place the

power switch in the ON position and restart in

AUTO.

COMPRESSOR HPCO - Place the power switch in

the OFF position. Wait 5 minutes for the machine to

cool. Place the power switch in the ON position and

restart in AUTO.

HOPPER THERMISTOR FAIL* - Place the power

switch in the OFF position. Call service technician.

MIX LEVEL AUDIBLE

ENABLED

> Enable

Disable

Disable the audible tone feature by touching the

DOWN arrow symbol to move the arrow to

“Disable”. Touch the SEL symbol to save the new

setting and return to the Menu. The control panel

icons for Mix Low and Mix Out will illuminate as the

mix level drops in the hopper, but the audible tone

will be disabled.

BARREL THERMISTOR FAIL* - Place the power

switch in the OFF position. Call service technician.

*Note: Three codes have been set up to assist in

diagnosing bad thermistor probes. If a probe has

shorted (resistance less than 1 ohm), “SHRT” will

display for its respective machine location. If the

probe is open (resistance above 1 megohm),

“OPEN” will display. If the actual probe environment

exceeds 200°F (93°C), the respective screen display

location will read “OVER”, indicating the temperature

is “out of range”.

COMP ON TOO LONG - The compressor run time

exceeded the 11 minute timer.

26

Models C709 & C717Important: To the Operator

Page 31

Fault History

The FAULT HISTORY will display up to 100 faults

that have occurred. The most recent fault is

displayed on screen 1. The date, time, and fault

description is displayed on each screen.

FAULT HISTORY 1

00/00/00 00:00

REASON

>Exit

Lockout History

The LOCKOUT HISTORY screen displays a history

of the last 100 soft locks, hard locks, brush clean

dates, or aborted heat cycles. Page numbers are

indicated in the upper right hand corner. Page 1

always contains the most recent failure.

Faults Occurring Entering a Heat Treatment

Cycle

POWER SWITCH OFF - The power switch is OFF.

AUTO OR STBY OFF - The control was not in the

AUTO or STANDBY mode.

MIX OUT FAILURE - A Mix Out condition was

present.

NO HEAT CYCLE TRIED - The Auto Heat Time

was set to attempt a heat cycle more than 24 hours

after the last successful heat cycle.

Faults Occurring While in Heat Mode

HEAT MODE FAILURE - The maximum allowable

heat mode time exceeded 90 minutes.

COOL MODE FAILURE - The maximum allowable

cool mode time exceeded 90 minutes for UVC3 units

or 120 minutes for UVC4 units.

TOTAL TIME FAILURE - The maximum allowable

total heat treatment time exceeded 4 hours.

BRUSH CLEAN TIMEOUT - The total days in

operation exceeded the brush clean cycle setting.

LOCKOUT HISTORY 1

00/00/00 00:00

REASON

>Exit

The second line of the screen displays the date and

time a failure occurs. The third line indicates the

reason for a failure, or will indicate if a successful

brush cleaning has occurred. Some failures occur

with multiple reasons. When this occurs, a page will

be generated for each reason.

Use the arrow symbols to advance forward or move

backward to view each screen. Listed below are the

variable messages that may appear.

POWER SWITCH OFF - The power switch was

turned OFF during the heat cycle.

POWERFAILINH/C-A power failure occurred

during the heat treatment cycle.

MIX LOW FAILURE - The mix level in the hopper is

too low for a successful heat cycle.

BEATER OVLD H/C - The overload tripped for the

beater motor.

BRL THERM FAIL - The thermistor sensor for the

freezing cylinder failed.

HOPPER THERM FAIL - The thermistor sensor for

the hopper failed.

HPCO H/C - The high pressure switch opened

during the heat treatment cycle.

140303

Models C709 & C717 Important: To the Operator

27

Page 32

Faults Occurring While in AUTO Mode

(L/R) HPR>41F (5C) AFTER 4 HR - The mix

temperature in the hopper was above 41°F (5°C)

more than four hours.

Heat Cycle Summary

The HEAT CYCLE SUMMARY screen displays the

hours since the last heat cycle, the hours since the

product temperature was above 150_F (65.6_C),

and the number of heat cycles completed since the

last brush clean date.

(L/R) BRL>41F (5C) AFTER 4 HR - The mix

temperature in the freezing cylinder (barrel) was

above 41°F (5°C) more than four hours.

(L/R) HPR>41F (5C) AFTER PF - The mix

temperature in the hopper was above 41°F (5°C)

more than four hours following a power failure.

(L/R) BRL>41F (5C) AFTER PF - The mix

temperature in the freezing cylinder (barrel) was

above 41°F (5°C) more than four hours following a

power failure.

(L/R) HPR>45F (7C) AFTER 1 HR - The mix

temperature in the left or right hopper was above

45°F (7°C) more than one hour.

(L/R) BRL>45F (7C) AFTER 1 HR - The mix

temperature in the left or right freezing cylinder

(barrel) was above 45°F (7°C) more than one hour.

(L/R) HPR>59F (15C) - The mix temperature in the

hopper exceeded 59°F (15°C).

(L/R) BRL>59F (15C) - The mix temperature in the

freezing cylinder (barrel) exceeded 59°F (15°C).

HEAT CYCLE SUMMARY

HRS SINCE HC 0

HRS SINCE 150 0

HC SINCE BC 0

Heat Cycle Data

The HEAT CYCLE DATA screen contains a record

of up to 366 heat treatment cycles. The most recent

heat cycle data will be shown first.

Each heat cycle record has three screens. The first

screen displays the month and day of the heat cycle,

the start time and end time, and the fault description.

The bottom line displays the record number and

indicates if a power failure occurred during the heat

cycle (POWER FAILURE IN HC).

HEAT TREAT CYCLE

01/01 02:00 05:14

NO FAULT F OUND

1

Touch the UP arrow symbol to advance forward

through the data pages. Touch the DOWN arrow

symbol to reverse the page direction.

Hopper and barrel temperature records for each side

of the freezer are displayed in the second and third

screens. The second screen shows the left side (L)

side of the freezer.

051025

28

Models C709 & C717Important: To the Operator

Page 33

The third screen shows the right side (R) of the

freezer.

Listed below are variable failure code messages

which could appear on line 2.

The top line of these screens shows the hopper (H)

and barrel (B) temperatures recorded at the end of

the Heat Treat Cycle and indicates the side (L or R)

of the freezer.

The remaining lines indicate the following:

HEAT = Total time for the hopper (h) and barrel (b)

to reach 150.9°F (66.1°C).

OVER = Total time the hopper (h) and barrel (b)

temperature was above 150°F (65.6°C).

COOL = Total time the hopper (h) and barrel (b)

temperature was above 41°F (5°C) during the COOL

phase.

PEAK = Highest temperature reading for the hopper

(h) and barrel (b) during the Heat Treatment Cycle.

H: 40.9 B:26.3 L

HEAT OVER COOL PEAK

1:12 0:49 h 1:19 161.0

0:46 1:11 b 0:15 169.7

H: 38.0 B:23.7 R

HEAT OVER COOL PEAK

1:09 0:52 h 1:11 161.2

0:66 1:00 b 0:11 169.9

The HEAT time indicates the amount of time taken

in each zone to reach 150.9°F (66.1°C). Each zone

must remain above 150°F (65.6°C) for a minimum of

35 minutes.

Touch the UP arrow symbol to advance to the next

page or the DOWN arrow symbol to view the

previous page. A Heat Cycle Failure message will

display on the first screen if a failure occurred.

HT HEAT TIME FAILURE

Mix temperature did not rise above 151_F

(66.1_C) in less than 90 minutes.

CL COOL MODE FAILURE

Mix temperature in the hopper and freezing

cylinder did not fall below 41_F(5_C) in less

than 90 minutes for UVC3 units or 120

minutes for UVC4 units.

TT TOTAL TIME FAILURE

The heat treatment cycle must be completed

in no more than 4 hours.

ML MIX LOW FAILURE

The Heat Phase or Cool Phase time was

exceeded and a mix low condition was

present.

MO MIX OUT FAILURE

A mix out condition was detected at the start

or during the heat cycle.

BO BEATER OLVD IN HC

A beater overload occurred during the heat

cycle.

HO HPCO IN HEAT CYCLE

A high pressure cut-out condition occurred

during the heat cycle.

PF POWER FAILURE IN HC

A power failure caused the Heat Phase,

Cool Phase, or Total Cycle Time to exceed

the maximum allowed time. If a power failure

occurs, but the heat treatment cycle does

not fail, an asterisk(*) will appear on the third

line of the display.

OP OPERATOR INTERRUPT

Indicates the heat cycle was aborted in the

OPERATOR INTERRUPT option in the

Service Menu.

PS POWER SWITCH OFF

The power switch was placed into the OFF

position during the heat cycle.

TH THERMISTOR FAILURE

A thermistor probe has failed.

PD PRODUCT DOOR OFF

A product door is not in place or is loose.

140303

Models C709 & C717 Important: To the Operator

29

Page 34

System Information

Current Conditions

The SYSTEM INFORMATION is displayed on three

separate screens. The first screen contains the

control and software version installed in the

machine.

SOFTWARE VERSION

C709 CONTROL UVC

VERSION X.XX

> Next

Touch the SEL symbol to advance to the next

system information screen containing the software

language version.

Language

V3.00 English

> Next

Touch the SEL symbol to advance to the third

system information screen containing the model bill

of material and machine serial number. Touching the

SEL symbol again will return to the Menu list.

The CURRENT CONDITIONS screen provides the

viscosity readings for the product when the machine

is running, and the hopper and the freezing cylinder

temperatures for the machine.

VISC 0.0

HOPPER 41.0

BARREL 41.0

CURRENT CONDITIONS is the only Menu screen

that will return the control panel keys to normal

operation. The Menu symbols will not be lit when

this option is selected but the panel touch keys are

fully functional. Exit the CURRENT CONDITIONS

screen and return to the Menu by touching the SEL

symbol.

Net Service Pin

The NET SERVICE PIN screen allows the manager

or service technician to initialize a network

connection for networking kitchens.

NET SERVICE PIN

ARE YOU SURE?

Yes

>No

120227

B.O.M. C70927C000

S/N M0000000

> Next

Pressing the UP or DOWN key will move the arrow

to “Yes” or “No”. Pressing the SEL key with the

arrow next to either option selects that option and

returns to the Menu screen.

30

Models C709 & C717Important: To the Operator

Page 35

Section 6 Operating Procedures

The C709 machine stores mix in a hopper. It has a

3.4 quart (3.2 liter) capacity freezing cylinder with a

single spout door.

The C717 machine stores mix in two hoppers. It has

two 3.4 quart (3.2 liter) capacity freezing cylinders

with a three spout door.

We begin our instructions at the point where we

enter the store in the morning and find the parts

disassembled and laid out to air dry from the

previous night's cleaning.

These opening procedures will show you how to

assemble these parts into the freezer, sanitize them,

and prime the freezer with fresh mix in preparation

to serve your first portion.

If you are disassembling the machine for the first

time or need information to get to this starting point

in our instructions, turn to page 44, “Disassembly”,

and start there.

Note: To ensure the mix does not leak out of the

back of the freezing cylinder, the middle section of

the boot seal should be convex or extend out from

the seal. If the middle section of the boot seal is

concave or extending into the middle of the seal,

turn the seal inside out.

Figure 12

Assembly

Note: When lubricating parts, use an approved food

grade lubricant (example: Taylor Lube).

MAKE SURE POWER SWITCH IS IN THE

“OFF” POSITION! Failure to follow this instruction

may result in severe personal injury from hazardous

moving parts.

Step 1

Before installing the beater drive shaft, lubricate the

groove on the beater drive shaft. Slide the beater

drive shaft boot seal over the small end of the beater

drive shaft and engage into the groove on the shaft.

Heavily lubricate the inside portion of the boot seal

and also lubricate the flat end of the boot seal that

comes in contact with the rear shell bearing. Apply

an even coat of lubricant to the shaft. DO NOT

lubricate the hex end.

Step 2

Insert the beater drive shaft through the rear shell

bearing in the freezing cylinder and engage the hex

end firmly into the drive coupling.

Figure 13

Models C709 & C717 Operating Procedures

31

Page 36

Step 3

Take one of the scraper blades and slip it under the

hook at the front of the beater. Wrap the blade

around the beater following the helix and pushing

the blade down onto the helix as you wrap. At the

back end of the beater, slip the blade under the

hook. Repeat this step for the second scraper

blade.

Figure 14

Step 5

Slide the beater the remainder of the way into the

freezing cylinder and over the end of the drive shaft.

The beater should fit snugly, but not so tightly that

the beater cannot be turned slightly to engage the

drive shaft. If the beater slides in too easily with little

or no resistance, there will not be enough force

against the beater to hold the blades in place.

Repeat these steps for the other side of the

C717.

Freezer Door Assembly

The assembly of the C709 freezer door is different

from the C717 freezer door. Please follow the

appropriate instructions for your machine.

USE EXTREME CAUTION when handling

the beater assembly. The scraper blades are very

sharp and may cause injury.

Step 4