TANDBERG SLR

AUTOLOADER

SERVICE AND REPAIR MANUAL

TANDBERG DATA ASA

P.O. Box 134 Kjelsås

N-0411 OSLO, NORWAY

Phone + 47 22 18 90 90

Telefax + 47 22 18 95 50

© Tandberg Data ASA

43 20 72 – 03

December

Part No.

2003

Related publications available from our Marketing Department:

Part No. Title

43 21 77 – 03 Tandberg SLR Autoloader Installation and User Manual

43 20 73 – 03 Tandberg SLR Autoloader SCSI Interface Manual

43 20 74 – 01 Tandberg SLR Autoloader Product Verification Report

43 04 44 - 11

43 07 43 - 13

Tandberg SLR 7-140 Tape Drive Product Reference Manual

Tandberg SLR 7-140 Tape Drive Programmers Reference Manual

This publication may describe designs for which patents are granted or pending. By

publishing this information, Tandberg Data ASA conveys no license under any patent or any

other rights.

Every effort has been made to avoid errors in text and diagrams. However, Tandberg Data

ASA assumes no responsibility for any errors which may appear in this publication.

It is the policy of Tandberg Data ASA to improve products as new techniques and

components become available. Tandberg Data ASA therefore reserves the right to change

specifications at any time.

We would appreciate any comments on this publication.

Table of Contents

Chapter 1 – Introduction..............................................................1

Models.......................................................................................2

Capacity................................................................................2

Data Transfer Rates.............................................................2

Media Compatibility..............................................................3

Product Description...................................................................3

Front Panel...........................................................................4

Control Panel........................................................................4

LCD Display .........................................................................5

Control Buttons.....................................................................5

LED Indicators......................................................................5

Front Panel Door..................................................................6

Tape Cartridge Magazine.....................................................7

Bar Code Reader..................................................................9

Calibrating the Bar Code Reader.......................................11

Rear Panel..........................................................................12

Embedded Diagnostics.......................................................14

Chapter 2 – Installation .............................................................16

Removing the Locking Pin ......................................................17

Reinstalling the Locking Pin................... .................................18

Installation Procedure..............................................................18

Mounting Tabletop Units.....................................................19

Mounting Rack Units..........................................................19

Cabling and Interface Connections.........................................21

Power Cable.......................................................................21

Interfaces............................................................................22

Interface Cable Specifications............................................23

Interface Cable and Terminator Installation.......................23

Software Installation................................................................25

Chapter 3 – Operation................................................................26

System Power-Up....................................................................26

Selecting the Control Panel Display Modes............................27

The SLR Autoloader Menu Map.........................................27

Navigating Through the Menu Map....................................28

Entering the Menu Mode....................................................28

Exiting the Menu Mode.......................................................28

System Data Menu.............................................................28

Setup Menu........................................................................32

Utilities Menu......................................................................34

Autoloader Operation Modes...................................................35

Random Mode....................................................................35

Sequential Mode.................................................................35

Setting the Write-Protect Switch..............................................37

Cartridge Handling...................................................................38

Inserting Cartridges into the Magazine..............................38

Loading a Cartridge into the Drive.....................................38

Magazine Handling .................................................................40

Inserting a Magazine into the Unit......................................40

Removing the Magazine ....................................................40

Chapter 4 – Configuration..........................................................42

Setup Options..........................................................................42

Autoloader Options.............................................................42

SCSI Options......................................................................45

Utilities Options........................................................................46

Maintenance Submenu ......................................................46

Diagnostics Submenu.........................................................46

Security Submenu..............................................................47

Changing a Configuration Option............................................48

Entering Characters from the Control Panel...........................49

Tandberg SLR Autoloader Service and Repair Manual i

Tandberg Data Table of Contents

Default Setup Options..............................................................50

Setting a Password .................................................................51

Chapter 5 – Maintenance........................................... ................53

Using the Cleaning Cartridge..................................................53

Installing a Cleaning Cartridge...........................................53

Running an Installed Cleaning Cartridge...........................54

Removing the Cleaning Cartridge......................................54

Installing Firmware Upgrades..................................................55

Firmware upload via SCSI..................................................55

Firmware upgrade via the serial port..................................56

Possible Upgrade Problems...............................................56

Chapter 6 – Troubleshooting.....................................................57

The Fault Screen.....................................................................57

Error Codes........................................................................58

Chapter 7 – Parts Removal and

Replacement................................................................................65

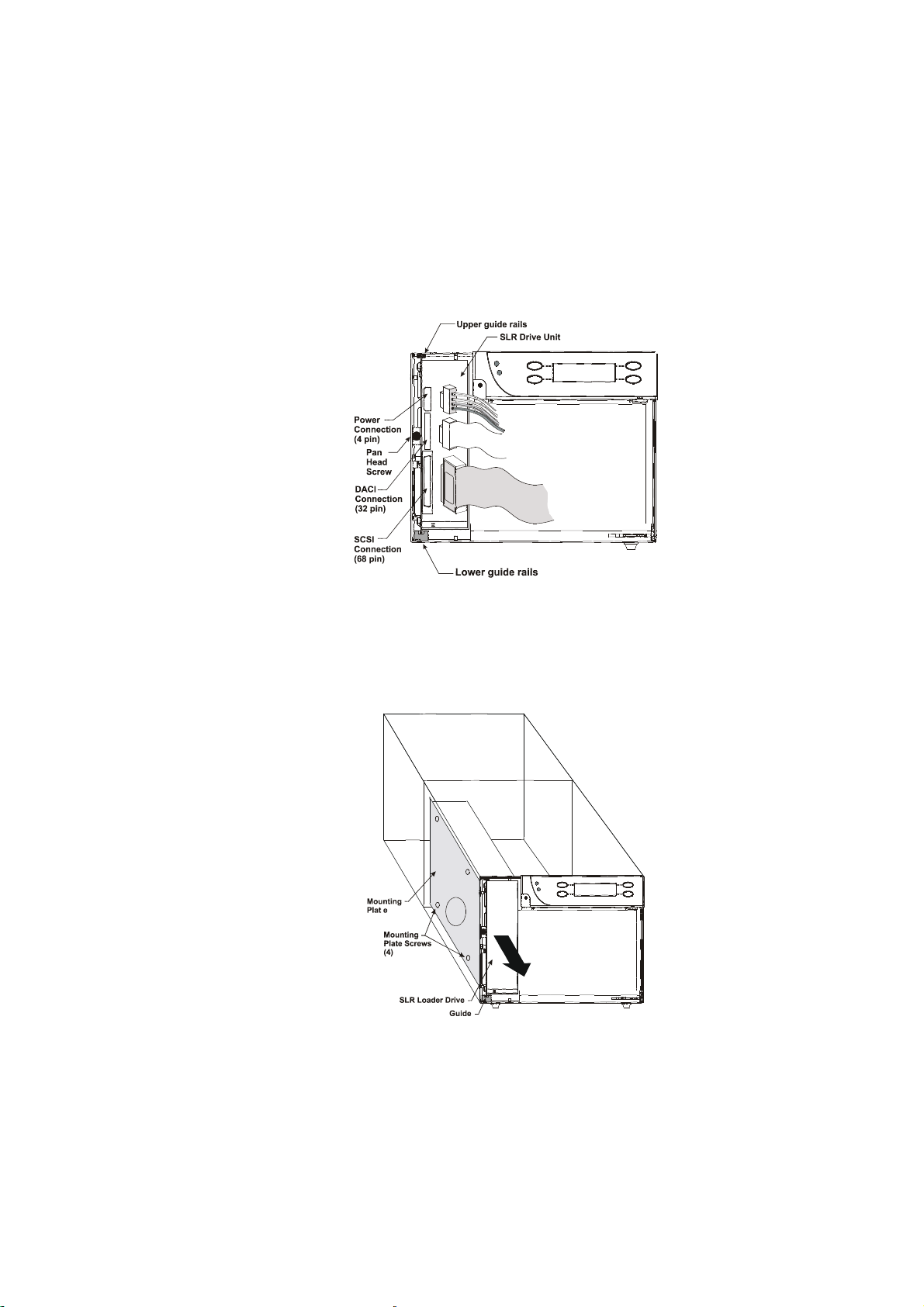

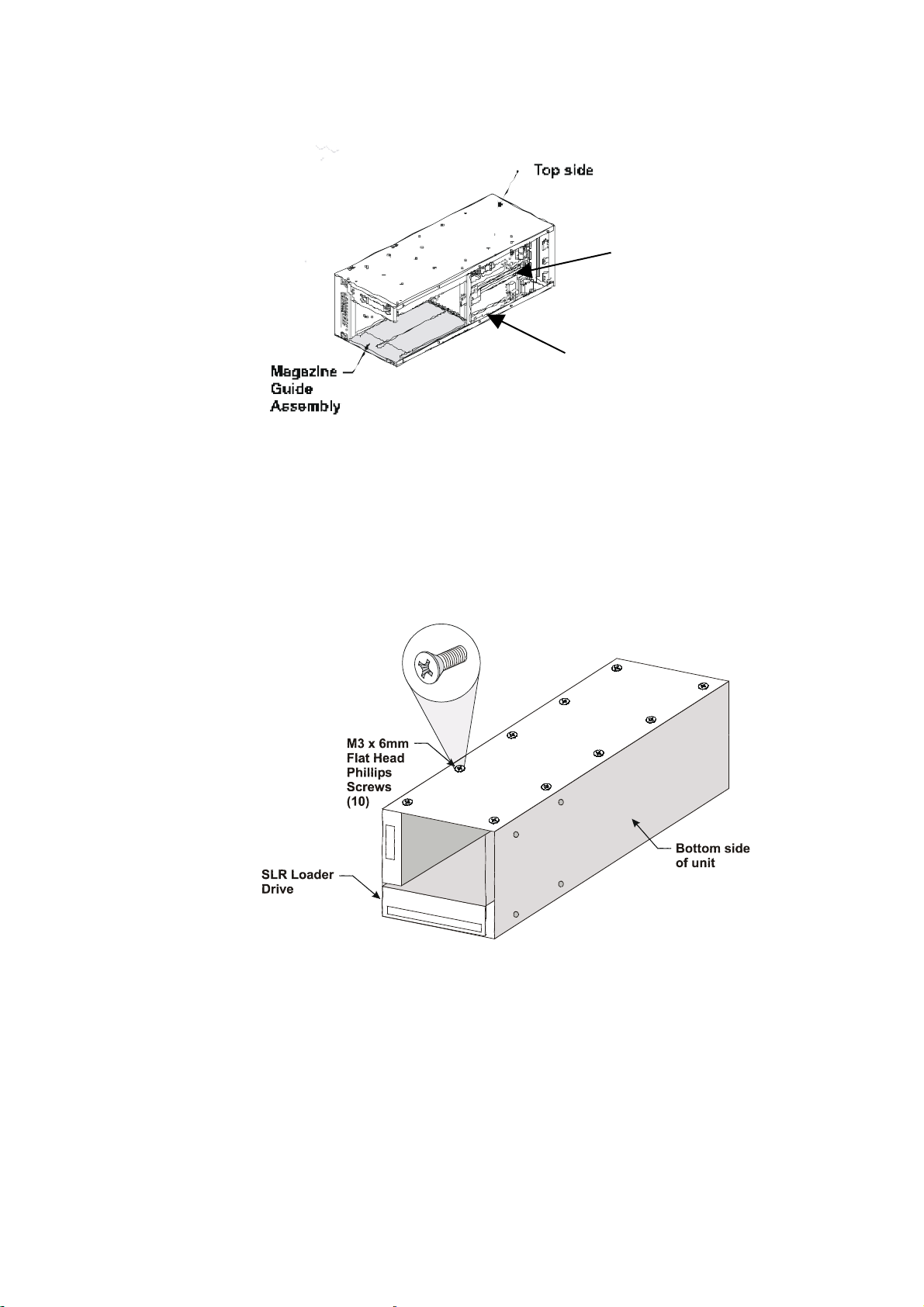

The Drive.................................................................................66

To remove the drive............................................................66

To replace the drive............................................................68

The Robot Shuttle Assembly...................................................70

Cleaning the Bar Code Reader..........................................70

Re-assembly after bar code reader cleaning.....................72

To remove the robot shuttle assembly...............................73

To replace the robot shuttle assembly...............................76

Appendix A – Specifications.....................................................81

Appendix B – Spares/Accessories ..........................................85

Appendix C – Emergency Magazine Removal ........................87

ii Tandberg SLR Autoloader Service and Repait Manual

Chapter 1 – Introduction

Tandberg Data’s SLR Autoloader is a compact tape cartridge loader designed for

secure, reliable unattended system backup. Based on advanced Scalable Linear

Recording (SLR) technology, the SLR Autoloader occupies only one half of the

shelf space in a standard 19” rack yet delivers impressive storage capacity through

its eight standard SLR data cartridges.

The tapedrive models SLR140, SLR100, SLR75 and SLR60 introduces Variable

Rate Randomizer (VR2) technology. VR2is an advanced data encoding method.

VR2improves code rate efficiency to more than 99% and can potentially double the

capacity and performance of a drive.

The entire system is under host control via an industry standard SCSI interface. Its

tape handling robotics are both rugged and simple for utmost reliability. The unit

requires no preventive maintenance beyond cleaning the tape drive.

The key features of the SLR Autoloader include:

• Removable 8-cartridge magazine

• Integrated Bar Code Reader standard

• Locking front door under system control

• Low Voltage Differential (LVD) / Single-Ended (SE) Interface

• Auto Clean Mode

• On-board Diagnostics.

*** IMPORTANT ***

Review the READ ME FIRST caution at the beginning of

Chap. 2 before you power up the unit for the first time.

Tandberg SLR Autoloader Service and Repair Manual 1

Tandberg Data Chapter 1 - Introduction

Models

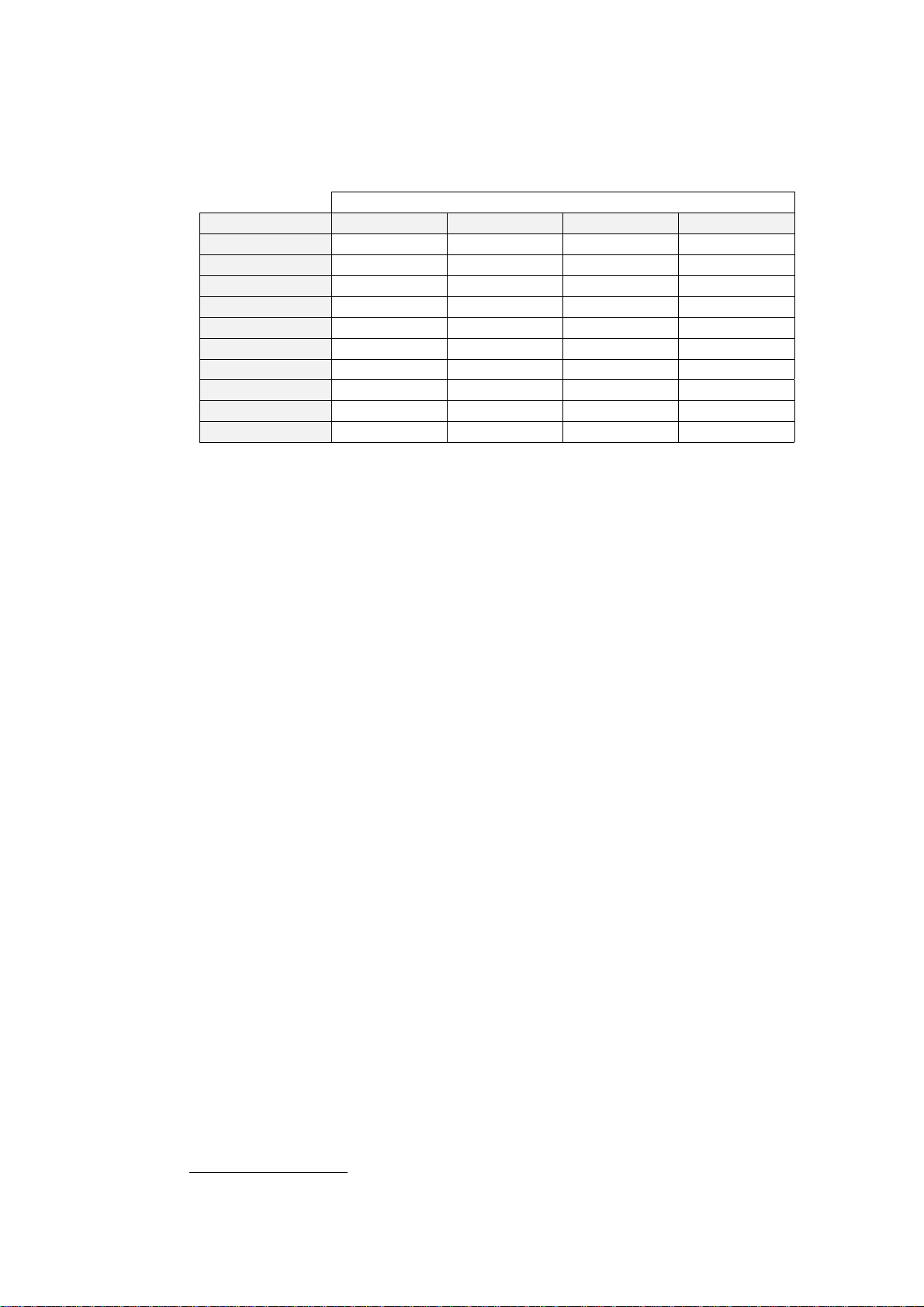

There are tree models of the SLR Autoloader. The model number for each is

identical except for the last two/three digits which represent the maximum

compressed data capacity gigabytes (GB) for each cartridge used in a particular

model. See Tables 1-1 and 1-2 below.

For additional specification information, refer to Appendix A.

Capacity

SLR Autoloader Model

Tandberg 1108 SLR 60

Tandberg 1108 SLR 75 38 GB 75 GB 304 GB 600 GB

Tandberg 1108 SLR 100 50 GB 100 GB 400 GB 800 GB

Tandberg 1108 SLR 140 70 GB 140 GB 560 GB 1,12 TB

Cartridge

Capacity

(Native)

1

30 GB 60 GB 240 GB 480 GB

Cartridge

Capacity

(Comp 2:1)

Magazine

Capacity

(Native)

Magazine

Capacity

(Comp 2:1)

Table 1-1 Data Storage Capacity

Data Transfer Rates

SLR Model Maximum Sustained

Tandberg 1108 SLR 60

Tandberg 1108 SLR 75

Tandberg 1108 SLR 100

Tandberg 1108 SLR 140

1

Rate, Native

4.0 MB/s

14.4 GB/hr

4.0 MB/s

14,4 GB/hr

5.0 MB/s

18 GB/hr

6.0 MB/s

21,6 GB/hr

Maximum Sustained

Rate, Compressed

8.0 MB/s

28.8 GB/hr

8.0 MB/s

28,8 GB/hr

10.0 MB/s

36.0 GB/hr

12.0 MB/s

43,2 GB/hr

Table 1-2 Data Transfer Rates

Note: The rates for compressed data are the native rates multiplied by the

compression factor, which depends on file content, but averages approximately 2:1.

Note: GB/hour rates are maximum and may vary due to the specific characteristics

of the data.

1

End of Life 2003

2 Tandberg SLR Autoloader Service and Repair Manual

Media Compatibility

The SLR140, SLR100, SLR75 and SLR60 Autoloader models can perform the

following operations with the indicated media

Drives

Tape type

SLRtape140

SLRtape100

SLRtape75

SLRtape60

SLRtape50

SLRtape40

SLRtape7

SLRTape32

SLRtape24

SLR5

2

Table 1-3 Media compatibility

SLR140 SLR100 SLR75 SLR60

R/W - - R/W R/W - R/W R/W R/W R/W R/W R/W R/W

R/W R/W R/W R/W

R/W R/W R/W R/W

RRRR

-RRR

-RRR

--RR

Product Description

The SLR Autoloader family of products includes several features designed to

increase the ease of use and utility of the product. This includes a removable 8cartridge magazine for easy management of data sets or archival storage. Menudriven operator control panel interface with backlit LCD providing easy control of

configuration and diagnostic modes. Autoselecting AC input power for worldwide

application. Interface support for Ultra2 SCSI (LVD) and standard FAST SCSI

single-ended systems.

2

Includes 13 and 26 GB Media

Tandberg SLR Autoloader Service and Repair Manual 3

Tandberg Data Chapter 1 - Introduction

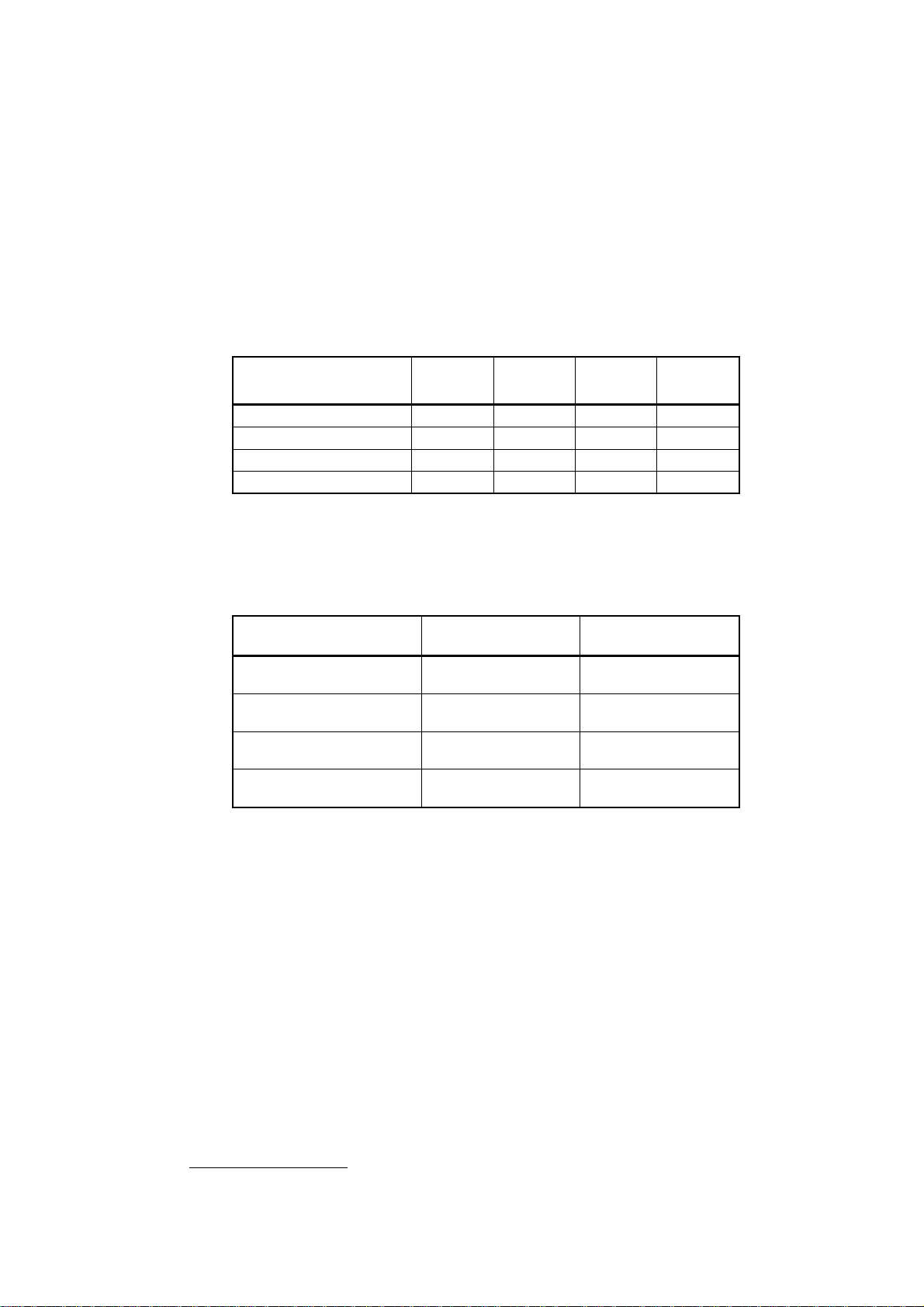

Front Panel

The Front Panel includes the User Control Panel with LCD display and Control

Buttons, LED indicators, and the Front Door Panel.

Control Panel

The control panel presents:

• A backlit green LCD matrix display

• Four control buttons

• Two LED indicators (green and red/amber).

4 Tandberg SLR Autoloader Service and Repair Manual

LCD Display

In various modes of operation, the display panel screens can show you:

• Drive and loader status

• Menu choices, and

• Error messages.

Through most of its operation, the backlit screen displays four 20-character lines of

information. This manual refers to the four text lines of the screen as line 1 through

line 4, moving from top to bottom. You can scroll some screens to greatly expand

the amount of available information. A pointer symbol (θ) indicates additional

options.

Control Buttons

The control buttons let you perform manual tape handling operations, configuration,

and diagnostics:

• The Load button (top left) lets you load tapes from the magazine to the drive.

• The Unload button (lower left) lets you unload tapes from the drive and

return them to the magazine.

• The Open Door button (lower right) releases the door latch after the

completion of any in-process action and when the loader is idle.

• The Menu button (top right) lets you enter menu mode where you can select

configuration options and perform unit diagnostics.

When you enter menu mode, the buttons are re-identified on the display screen to

indicate the different functions they perform under alternate menu levels.

LED Indicators

The green Ready indicator illuminates when the unit is powered up and standing by

to receive instructions. When you start a load, unload, or open door action, the

Ready indicator goes out. The indicator remains illuminated as you enter menu mode

and as you then access the system data. The loader will not remain in a ready state if

you access any other area of the menu mode, and the indicator will then go out.

The red or amber Fault indicator illuminates when the unit experiences a mechanical

fault in the drive or loader robotics. If such a fault occurs, refer to the Error Code

tables in Chapter 6 – Troubleshooting. If that does not clear up the fault, contact

your Technical Support Representative.

Tandberg SLR Autoloader Service and Repair Manual 5

Tandberg Data Chapter 1 - Introduction

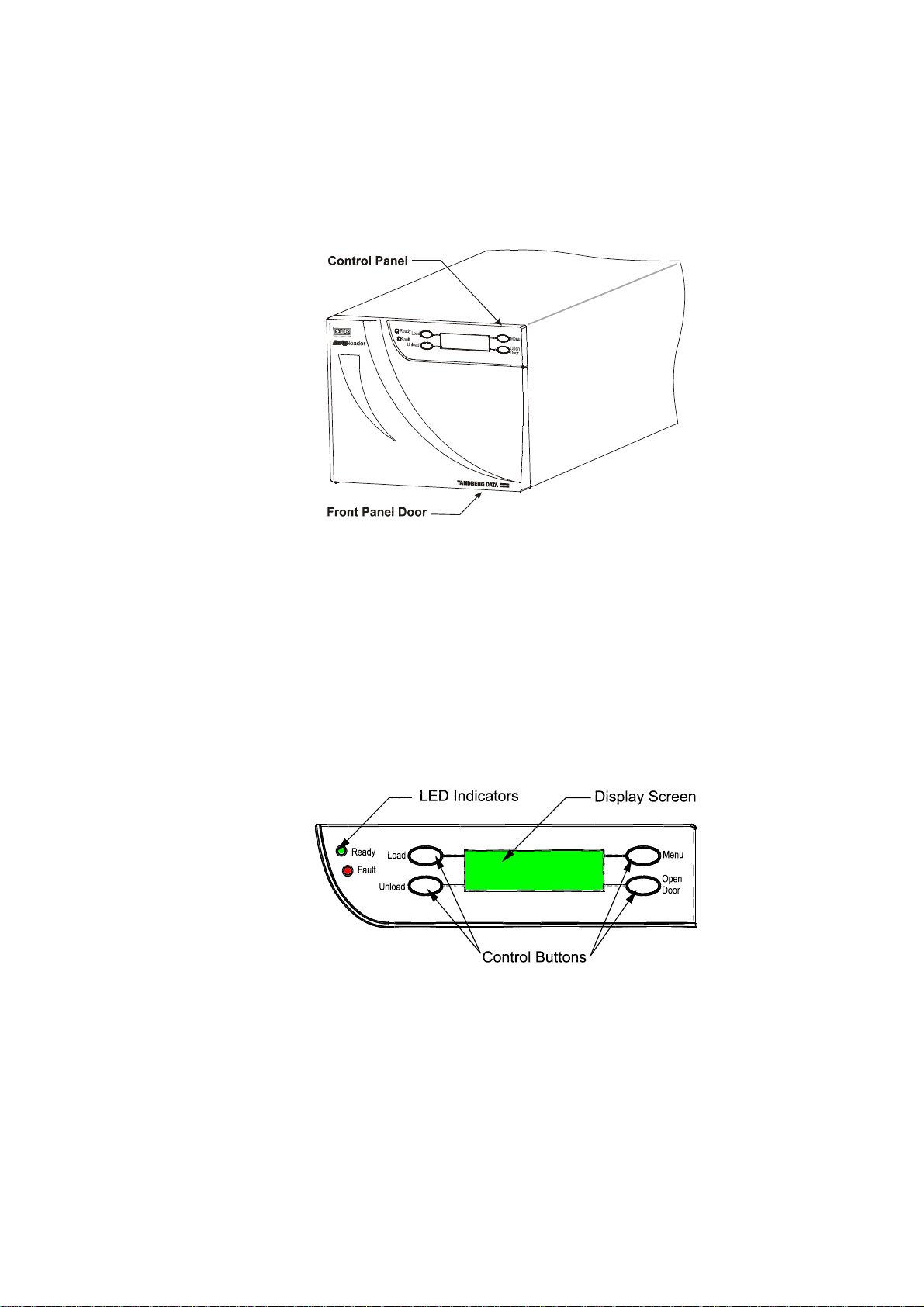

Front Panel Door

The door is opened by a control panel button, with the door latch being released by

the Autoloader robotic mechanism. In order to operate the front door AC power

must be applied. The hinged door swings open to the left, permitting access to the

tape cartridge magazine.

While the door usually remains locked during normal operations, you can open it,

even with a tape in the drive. If you try to open the door with a tape in the drive, the

unit displays a warning message. You can unlock the door or cancel the operation.

6 Tandberg SLR Autoloader Service and Repair Manual

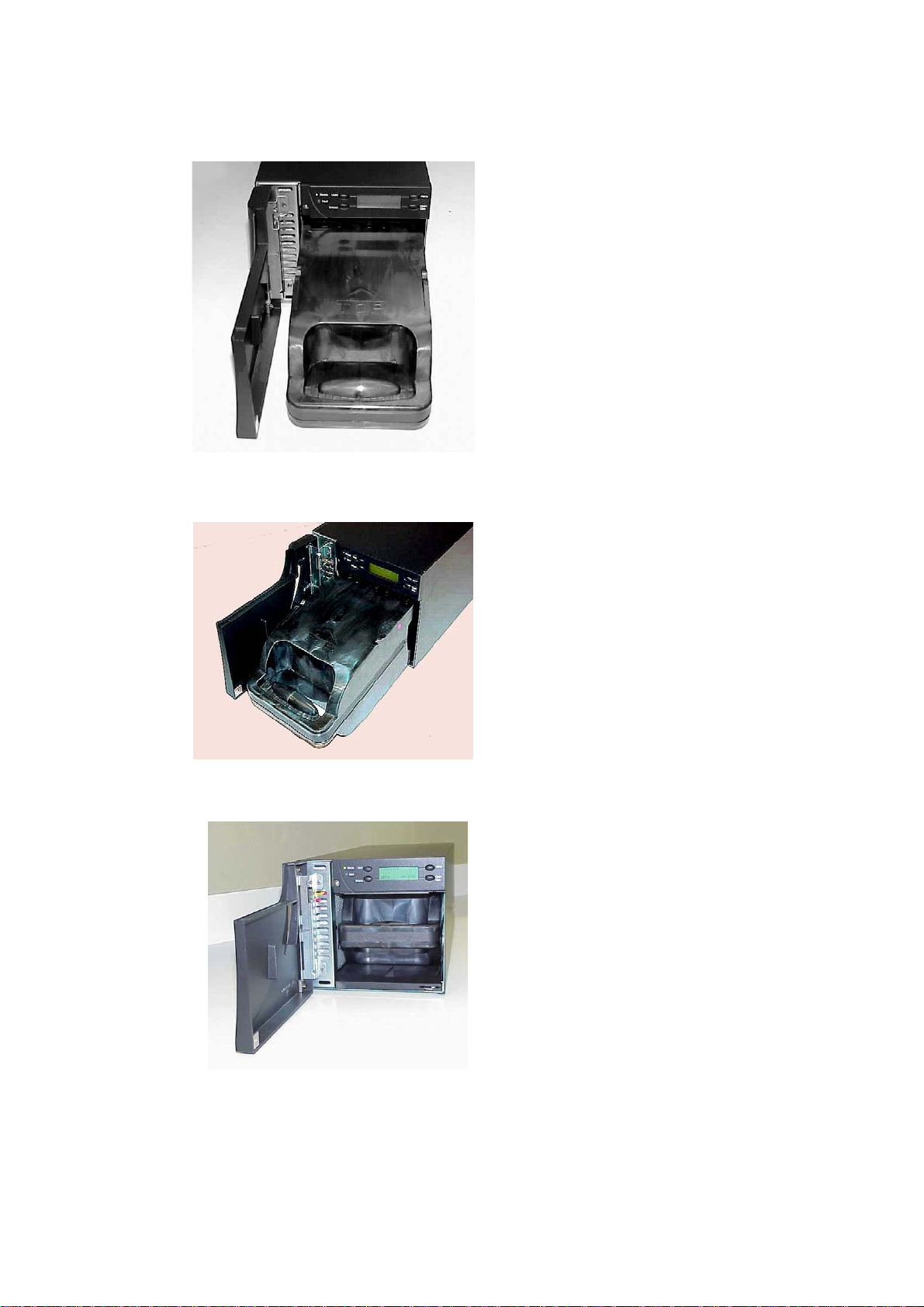

Tape Cartridge Magazine

The 8-cartridge magazine is accessible through the front panel door. The rugged

polymer magazine fits into an alignment guide, which assures precise cartridge

positioning with respect to the loader robotics.

The only correct insertion orientation for the magazine is shown in the photographic

sequence on the next page.

As the magazine moves into its loader compartment, it should move inward until it

snaps into place. (The two chassis metal detents snap into the magazine slots in its

top surface). The magazine locks into position when you close the front door panel.

Note: The SLR Autoloader is shipped with a soft vinyl dust cover for use when the

magazine is not installed in the loader unit. The cover is contained in the

Accessories Kit box and can be easily slipped over the open end of the magazine.

The SLR Autoloader magazine is shown here:

Tandberg SLR Autoloader Service and Repair Manual 7

Tandberg Data Chapter 1 - Introduction

LOADING VIEW #1

FRONT VIEW

Proper alignment of magazine prior

to loading it into its bay in the SLR

Autoloader.

LOADING VIEW #2

DIAGONAL SIDE VIEW

Better view of the front end of the

magazine entering its bay of SLR

Autoloader.

LOADING VIEW #3

FRONT VIEW

View of magazine properly locked

into detent position.

8 Tandberg SLR Autoloader Service and Repair Manual

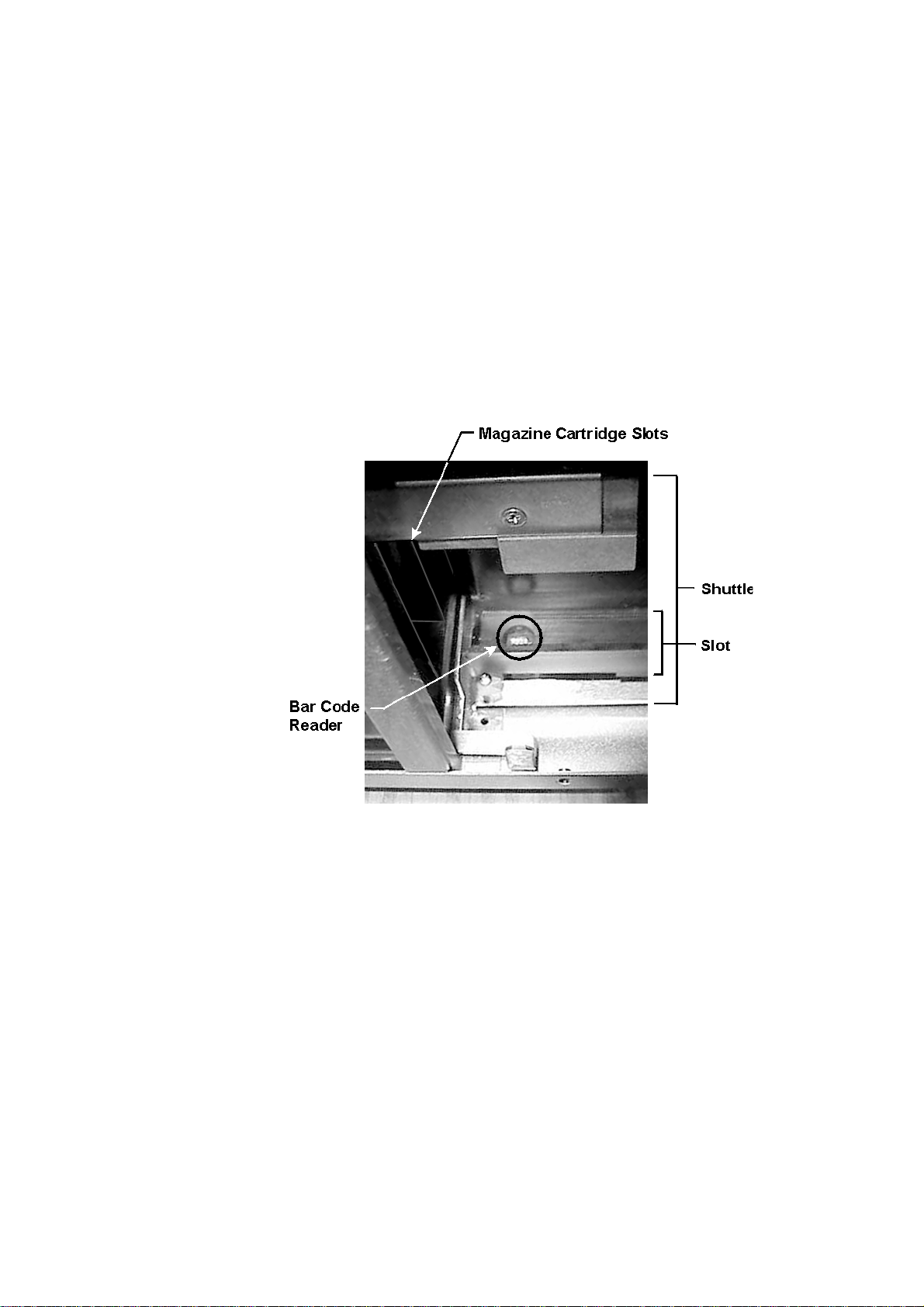

Bar Code Reader

An integrated bar code reader is installed as standard equipment in the SLR

Autoloader. It is an integral part of the robot shuttle assembly and moves with it.

At power up, the loader automatically pulls each cartridge into the robot shuttle to

scan the bar code, and replaces it in the magazine. If the magazine is full, then it

takes approximately 150 seconds (in addition to the normal inventory / calibration

time) to scan all cartridges, since one cartridge can be scanned in 9 seconds, then

returned in equal time to its slot.

Usually hidden by the metal chassis, the bar code reader is located at the leading

edge of the shuttle slot as shown in the following illustration:

Tandberg SLR Autoloader Service and Repair Manual 9

Tandberg Data Chapter 1 - Introduction

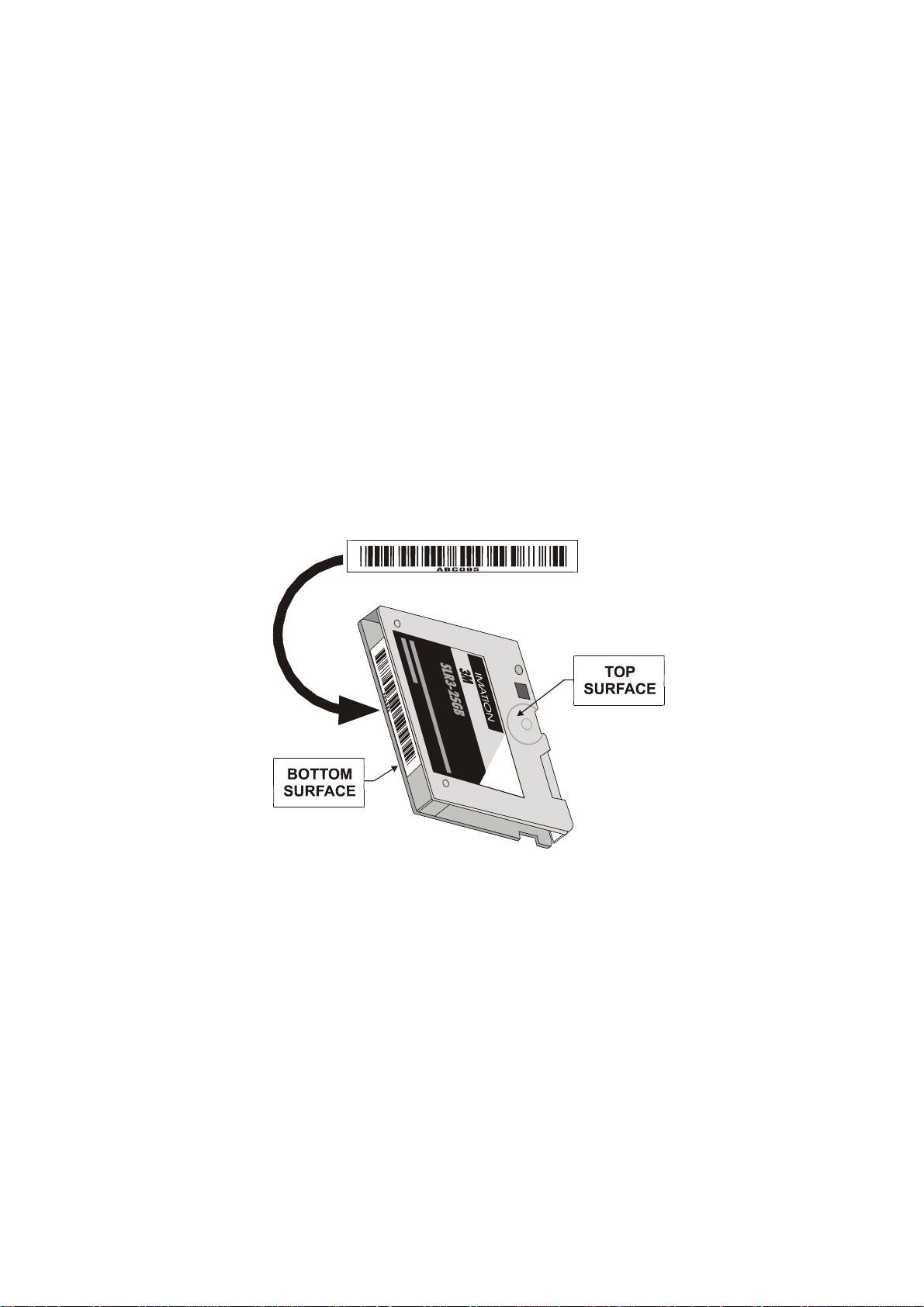

Bar Code Label

The bar code label is encoded with a Code 3 of 9 standard bar code format.

The label for all cartridges consists of six alphanumeric characters: three alpha

characters and three numeric characters. The cleaning cartridge uses CLN as the

alpha characters. For example:

Data cartridge ABC000

DEF123

Cleaning cartridge CLN000

CLN123

Note: You should enable the Enable Check Char option for the most reliable bar

code reader function.

Position the label centrally on the cartridge spine with the six alphanumeric

characters aligned with the cartridge’s base plate.

Ordering Bar Code Labels

You should order additional bar code labels directly from Tandberg Data. Tandberg

bar code labels are made of a mirror-like substrate with special reflectivity, bar

widths, and other characteristics.

Caution: Do not substitute any other bar code labels. They will be unreadable.

See Appendix B – Spares/Accessories for part number information.

10 Tandberg SLR Autoloader Service and Repair Manual

Calibrating the Bar Code Reader

To calibrate the bar code reader, do the following:

1. Insert a cartridge in Slot 2 of the SLR Autoloader. Make sure the cartridge has a

bar code label that is:

• Tandberg approved for SLR Autoloader

• Clean

• Properly positioned on the cartridge.

2. Power up the Autoloader.

3. Press and hold down the

Menu button while you press and release the Load

button.

4. Continue holding down the

Menu button until the READY light turns off. This

will take abt. 10 seconds.

5. From the DIAGNOSTICS menu, scroll down to and select Barcode Calibration.

The SLR Autoloader fetches the cartridge from Slot 2 and moves the cartridge

back and forth across the bar code reader sensor.

It displays the upper and lower values as it progresses through the calibration

and then displays one of the following:

• If the calibration passes

PASSED

• If the calibration fails or is aborted ABORTED

• If there is no cartridge in Slot 2 NO CARTRIDGE IN SLOT 2

6. If there is no cartridge in Slot 2, exit the DIAGNOSTICS MENU, open the door,

place a cartridge in Slot 2, reinsert the magazine and start the procedure again

from Step 3.

Tandberg SLR Autoloader Service and Repair Manual 11

Tandberg Data Chapter 1 - Introduction

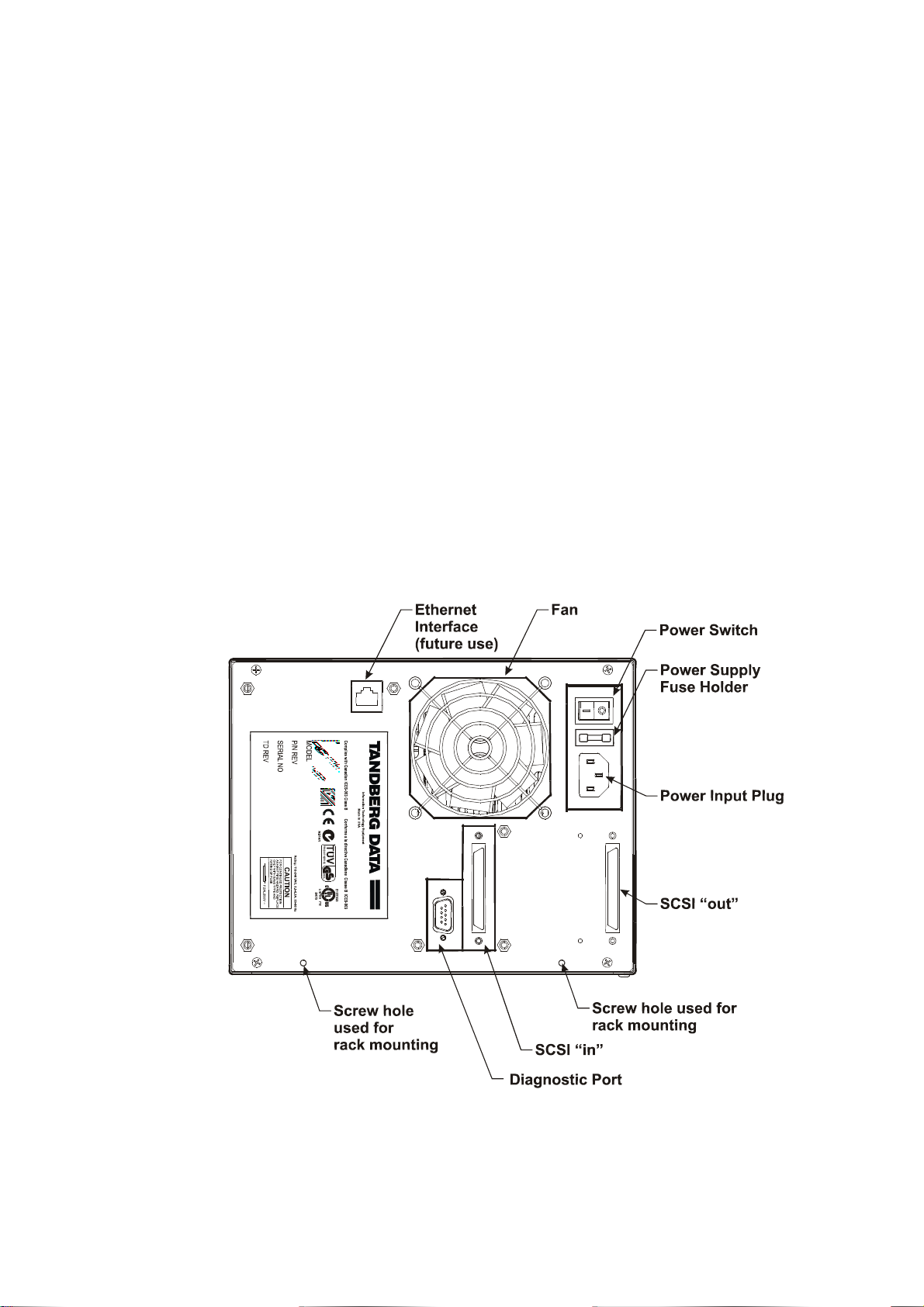

Rear Panel

The rear panel includes eight mechanical devices that relate to bus communication,

firmware upgrading and troubleshooting, device cooling, and line power. Bus

communication between the SCSI Bus connector and the Host adapter occurs

through SCSI Bus connectors (see SCSI In and SCSI Out). The Diagnostic Port

provides sequence information, diagnostic test results and firmware updates. Line

power is supplied and monitored after its circuit is opened by the Power Input Plug,

Power Supply Fuse (in its holder) and the Power Switch. The Product Information

Label includes Model and Serial numbers and cautionary information.

Note: The two empty screw holes on the bottom of the panel are intended for use

only if you mount the unit in a rack. If you have ordered the rack mount conversion

kit, the appropriate fasteners used in this location are provided.

Integrated Cooling Fan

The rear panel contains a single forced-air cooling fan, which draws air inward

through the front of the unit and expels it out the back. The fan prevents overheating

of the drive and robotics electronics, the motors, and the power supply.

Since there is no air filter to clean on a regular basis, you should inspect

occasionally for lint or dust buildup and vacuum the area if necessary.

12 Tandberg SLR Autoloader Service and Repair Manual

Power Switch

The power switch is located on the upper right corner of the rear panel. It is a twoposition rocker switch that controls the supply of AC power to the unit:

• To turn the power ON, depress the switch on the 1 side. The LCD display

illuminates.

• To turn the power OFF, depress the switch on the 0 side.

Power Supply

The auto ranging power supply will adjust to the operating voltage range supplied

through the power cable. The nominal range is 110–240 VAC. The power supply is

capable of operating at 50 or 60 Hz without modification. AC power from a properly

grounded outlet is supplied through a line power cable shipped with the SLR

Autoloader.

For more information on line power cables, see the Power Cable section of Chapter

2 – Installation.

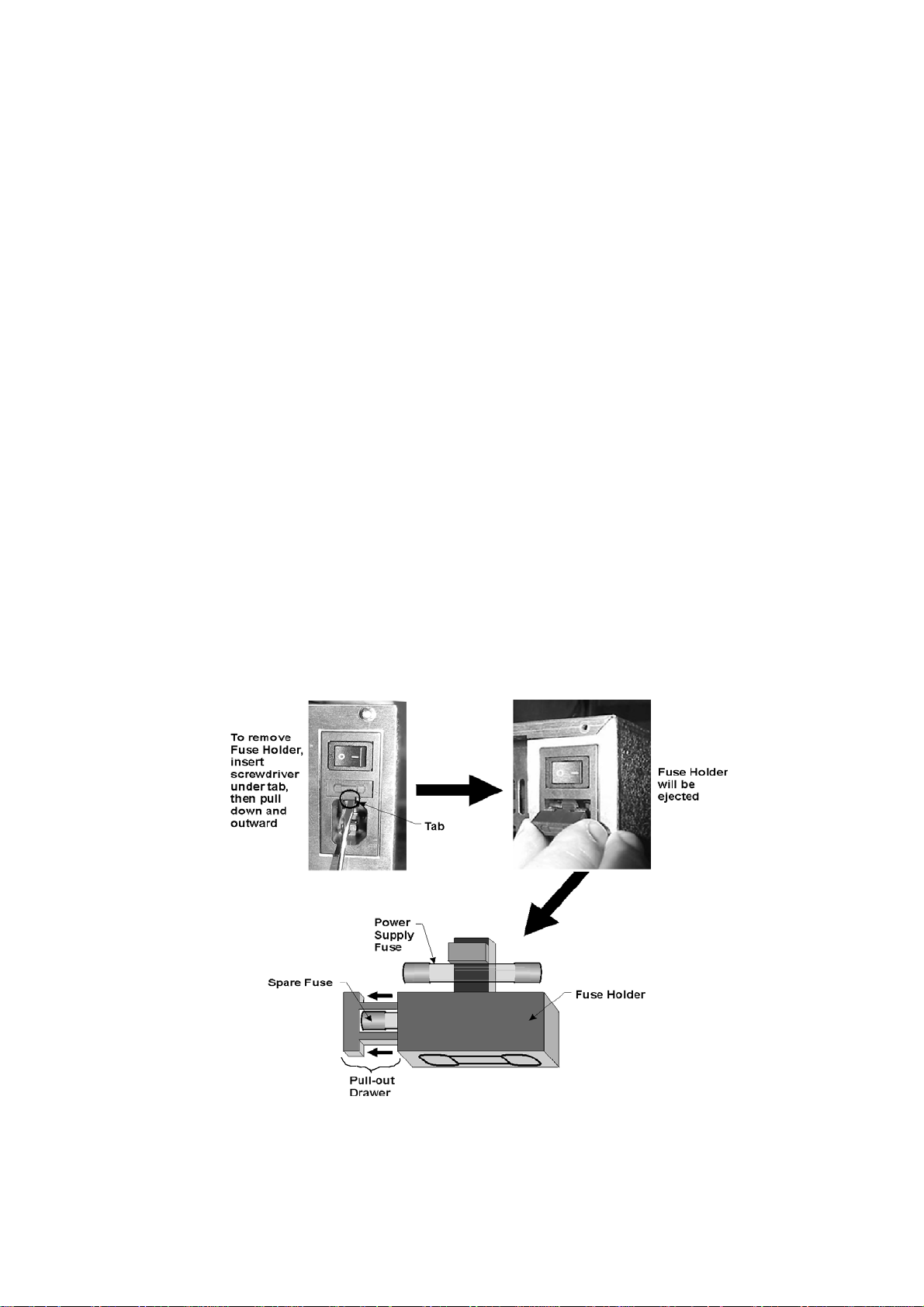

Power Supply Fuse Holder

The power supply fuse holder is located below the power switch as indicated by the

outline diagram on its surface. The procedure for accessing power fuse (and its

spare) is shown below.

Note: Before replacing the fuse, set the Main power switch to OFF and remove the

power cord.

Tandberg SLR Autoloader Service and Repair Manual 13

Tandberg Data Chapter 1 - Introduction

SCSI Interface Connectors

The SCSI Interface connectors link the internal SCSI bus devices (SCSI drive and

robotic controllers) to the external host adapter. The bi-directional SCSI bus

transfers the SCSI commands and data. To provide this function, there are two 68pin, high density, shielded D-type SCSI Connectors which connect to shielded SCSI

Type P cables. The pair of connectors allows for daisy chaining more than one SLR

Autoloader to a host adapter or other SCSI-compatible device. When only one SCSI

connector is used, the second connector must be terminated using the supplied

LVD/SE dual mode terminator.

Ethernet Port

The Ethernet port is reserved for future use.

Diagnostic Port

The Diagnostic port (RS-232) is used to upload fault analysis data by the service

technician after a fault condition occurs. It is also used to update the firmware in the

controller card’s flash memory.

Embedded Diagnostics

• The SLR Autoloader includes three levels of diagnostics:

• The Power-On Self Test (POST) — Performs several verification and

memory tests when you power on the unit.

• User Diagnostics — Lets you change setup options. Select from front panel.

• Tech Support Diagnostics — Used by Technical Support Engineers to

diagnose faults and service the unit.

14 Tandberg SLR Autoloader Service and Repair Manual

This Page Intentionally Left Blank

Tandberg SLR Autoloader Service and Repair Manual 15

Chapter 2 – Installation

*** READ ME FIRST ***

Tandberg Data has installed a locking pin as a precautionary safety mechanism to

prevent damage to the SLR Autoloader during shipment from the factory. Inserted

from underneath the loader floor, the pin prohibits any lateral movement of the

shuttle assembly by locking it down.

CAUTION!

You must remove

the Shuttle Locking Pin

before powering up the unit

or it will not operate.

See the procedure on the following pages.

Carefully unpack the unit from the shipping container. Save the container and

packing materials in case you need to return the unit to Tandberg Data for repairs.

Review the contents of the shipping container to be sure that all parts were included

in the shipment. A complete package for the SLR Autoloader consists of the

following items:

• A factory-assembled SLR Autoloader unit (black or gray metal box)

containing one cartridge magazine.

Note: The SLR Autoloader contains no cartridges prior to shipment.

• An Accessory Kit Box containing:

⎯1 The Tandberg Recource CD containing this manual.

⎯1 Warranty/Registration Card

⎯2 Line Power Cords: one for USA, one for European power outlets

⎯1 Data Cartridge

⎯1 Cleaning Cartridge

⎯1 SCSI Interface Cable

⎯1 68-pin LVD/SE Terminator.

⎯1 Magazine Dust Cover

Note: If you haven’t done so, remove the locking pin from the SLR Autoloader.

Tandberg SLR Autoloader Service and Repair Manual 16

Tandberg Data Chapter 2 - Installation

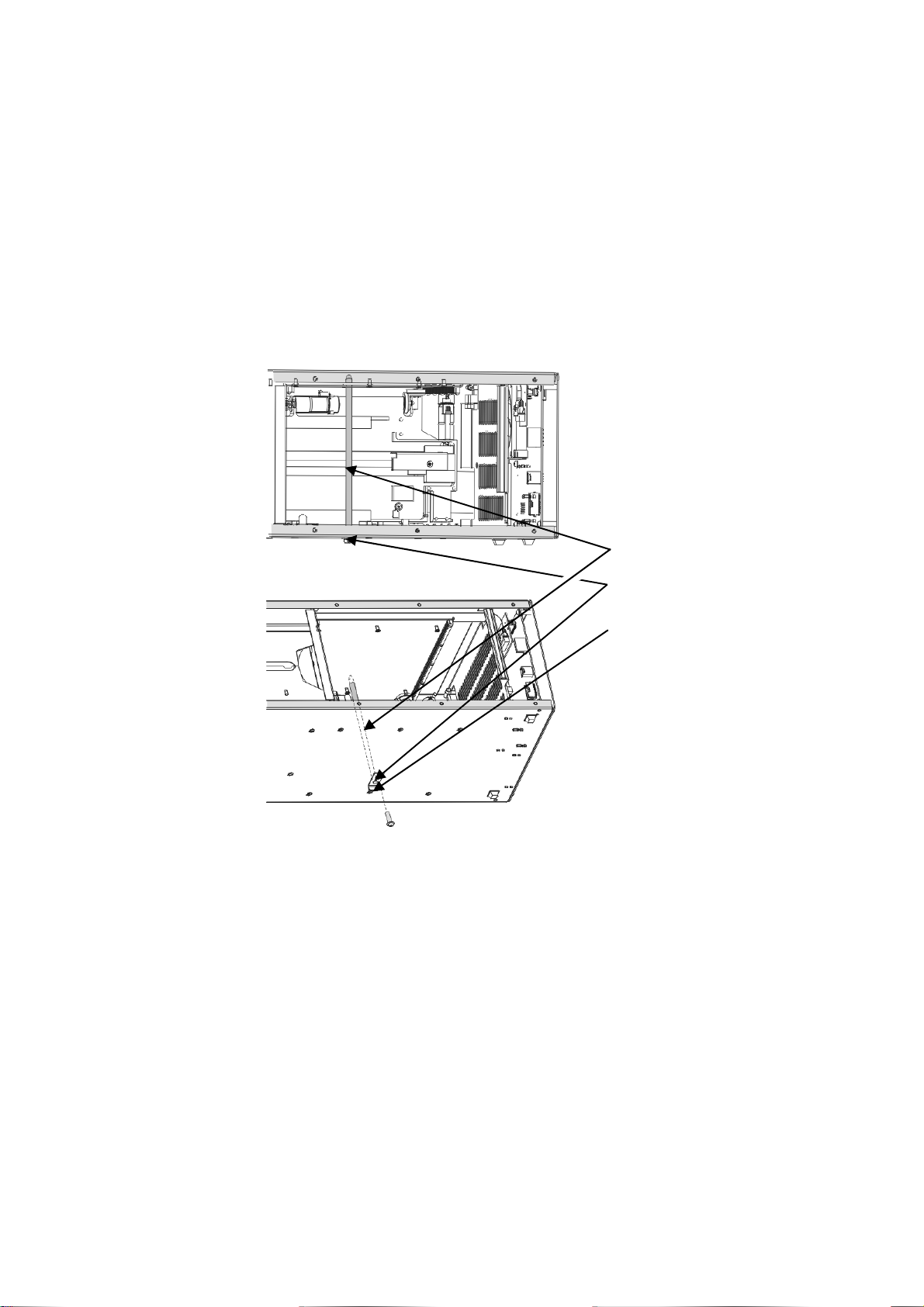

Removing the Locking Pin

To remove the locking pin (also called lockdown mechanism), do the following:

1. Make sure that the power cord is disconnected from line power.

2. Place the unit on a table at waist height.

3. Position the unit so that the front panel door is facing toward you.

4. Rotate the unit onto its left side so that the bottom of the unit faces right and

its rear chassis end points away from you.

5. Remove the screw from the locking pin as shown in the following

illustration:

Right Side View with

Chassis Panel

Removed

Locking Pin (Installed)

6. Pull the locking pin out slowly. It should come out easily. If it doesn’t,

Screw

Metal Tab on Loc k in g P in

Right S ide View, R otated 45

Upward with Chassis Panel

Removed

°

remove the magazine and investigate the internal shuttle area through the

front panel door with a flashlight. (See Appendix C for instructions on

opening the door without power.) Make sure that the pin is not bent. If it is,

contact Tandberg Data for instructions on removing the pin or returning the

unit to Tandberg Data for repair or replacement.

7. Save the locking pin (6.6” / 16.8 cm) and its screw (M3x8 Phillips panhead)

in case you must return the unit to Tandberg Data. These two parts must be

installed when shipping the unit back to Tandberg Data.

Tandberg SLR Autoloader Service and Repair Manual 17

Reinstalling the Locking Pin

Note: The locking pin must be reinstalled to prevent damage to the

cartridge shuttle mechanism during transportation.

1. Make sure that the power cord is disconnected from line power.

2. Make sure the shuttle is parked in the home position.

(See the description of the Utilities menu on page xx)

3. Place the unit on a table at waist height.

4. Position the unit so that the front panel door is facing toward you.

5. Rotate the unit onto its left side so that the bottom of the unit faces right and

its rear chassis end points away from you.

6. Remove the magazine to have a better view of the internal shuttle area.

7. Push the locking pin in slowly through the hole on the bottom (now facing

right) through to the hole in the metal rack plate on the top side (facing left).

If you have trouble with this, put your hand inside the shuttle area to guide

the pin.

8. Insert and tighten the screw (M3x8 Phillips panhead).

Installation Procedure

After removing the locking pin and confirming that all package items are present in

the shipment, proceed with the installation procedure.

1. Mounting—Proper placement of a tabletop unit or mechanical installation

into a 19” rack.

2. Cabling—Connecting the unit to AC power and to the host interface and

terminating the buses properly.

3. Software Installation.

Tandberg SLR Autoloader Service and Repair Manual 18

Tandberg Data Chapter 2 - Installation

Mounting Tabletop Units

Tabletop units require no mechanical assembly. Place the unit on a desk, table,

server top, or other stable, horizontal surface with at least 2-inch (5 cm) clearance

behind it to allow free flow of cooling air from the fan.

CAUTION: Make sure the Autoloader stays in a horizontal position while

operating. Do not operate it on its side.

Mounting Rack Units

The compact size of the SLR Autoloader permits the mounting of up to two units in

a single shelf of a standard 19” rack. Both units attach to a rack chassis. The units

are secured to the rack chassis by rear brackets and fastened in place by two

machine screws. The chassis and both units fit within a 4U rack height.

Note: Before mounting the SLR Autoloader(s), you must order a separate hardware

kit for converting the unit(s) from a tabletop to a rack mounted one.

Rackmount Installation Process

1. Add the rack chassis to the rack frame.

2. Fasten one or two SLR Autoloader chassis to the installed rack chassis.

Tandberg SLR Autoloader Service and Repair Manual 19

Installation of SLR Autoloader Rack Chassis into Rack

1. Attach the left support bracket to the left rear rail surface side using two 1032x1/2” screws and two 10-32 nut plates.

2. Attach the right support bracket to the right rear rail surface side using two 1032x1/2 screws and two 10-32 nut plates.

3. Attach the front chassis to the inside surface of the front rack rail using four 1032x1/2 screws (two for each side).

4. Attach the left and right bracket(s) to the outside rear chassis surface using four

10-32x1/2 screws and four10-32 hex nuts (two screws and two hex nuts on each

side).

5. Attach left endcap to outside surface of left front rail by snapping a ball stud into

a retaining clip located on the front chassis mounting flange.

6. Repeat Step 5 for the right endcap.

The rack chassis is now ready to mount the SLR Autoloader unit(s).

Installation of SLR Autoloader(s)

To install a single SLR Autoloader:

1. Attach to either the left or right side: the front filler panel to the chassis using

two screws (M3 x 6mm).

2. Prepare the unit before installation:

• Remove the four screws and four rubber feet from the bottom panel of the

unit

• Remove the SLR Autoloader chassis cover by sliding it rearward.

3. Insert the prepared SLR Autoloader unit into the rack chassis until it is stopped

by the rear-mounting bracket.

4. Secure the unit to this bracket using two screws (M3 x 8 mm).

To install two SLR Autoloaders:

1. Prepare both units as described in Step 2 for installing a single unit.

2. Insert both units into the chassis until they are stopped by the rear mounting

brackets.

3. Secure each unit to its mounting bracket using two screws (M3 x 8mm).

Tandberg SLR Autoloader Service and Repair Manual 20

Tandberg Data Chapter 2 - Installation

Cabling and Interface Connections

Before the SLR Autoloader can be powered up or communicate with the host device

or user applications, the following connections must be made (see the diagram of the

rear panel’s connectors on the next page):

• AC line power

• Select and connect the proper line power cable (from the pair of power

cables sent in the Accessory Kit shipped with the SLR Autoloader) between

the Power Input Plug (see the illustration below) and your line power outlet.

• SCSI bus connection to the host (68 pin LVD or SE).

• Connect the SCSI Cable between the SCSI Out connector of the Host

Adapter to the SCSI In connector of the SLR Autoloader. If the SLR

Autoloader is not being daisy-chained to another device, then connect the

supplied LVD/SE Terminator to the SCSI Out connector.

Power Cable

The power cable is a standard grounding AC cable, which plugs a 3-wire connector

into the rear panel and the other end has a country-specific connector plug that fits

into a reliably grounded AC outlet.

Tandberg SLR Autoloader Service and Repair Manual 21

There are two types of power cables supplied with the SLR Autoloader. They differ

in their cable connectors and length. Each cable has a different terminal ending for

connecting to local line power. The cable length of the USA version is 6.5 feet (2.0

m); the European one is 2.5 m.

To maintain product safety compliance, select the power cord with a suitable

electrical rating that is approved for the country where the product is used. In the

USA, use a UL listed cord; in Canada, a CSA certified cord; and in Europe, use a

Harmonized cord marked <HAR> or a nationally certified cord.

Note: After connecting the SLR Autoloader to your AC source, it is a good practice

to do a test power up of the unit before connecting to the host computer. This will

verify proper initialization and electrical behavior and isolate unexpected conditions

to the host interface. The affirmation that the system is operating properly is the

appearance of the cartridge map on the display panel, along with the green Ready

LED being lit. (See the beginning of Chapter 3 – Operation for an example of a

cartridge map on the display panel.) Power down the unit before connecting to the

host.

Interfaces

The SLR Autoloader is supplied with both single-ended Fast/Wide and LVD Ultra 2

SCSI interfaces. The unit configures automatically to either interface.

The Fast/Wide SCSI interface uses high-density 68-pin connectors. Fast/Wide SCSI

cables and terminators are secured to the connectors by jackscrews.

The drive and the robotics are separate SCSI devices. They require unique SCSI

address because they are daisy-chained on the same bus. The SCSI addresses of the

robotics and drive may be set from the control panel.

In order to connect the unit to a host computer system, the host system must have a

compatible SCSI controller and the appropriate driver software. Call your Technical

Support representative if you have any questions about installing for specific host

systems.

Tandberg SLR Autoloader Service and Repair Manual 22

Tandberg Data Chapter 2 - Installation

Interface Cable Specifications

The SLR Autoloader is a high-performance system. To avoid degradation of

performance, any additional or replacement cables you use should likewise be of the

highest quality. The detailed requirements for SCSI cables are set forth in ANSI

X3.131-1994. All SCSI cables used with the SLR Autoloader should meet the

following requirements:

• Shielded or double-shielded, as required to meet EMI specifications

• Nominal characteristic impedance is 90 single-ended and 132 ohms

differential

• Cables of different impedance should not be used together

• Maximum cable lengths as follows:

SE/Fast/Wide Bus LVD Fast Ultra 2 Bus

To Host

34.4 ft

10.46 m

Total

39.4 ft

12 m

5 ft

1.54 m

To Host Total Internal

4.8 ft

1.46 m

9.8 ft

3 m

5 ft

1.54 m

Note: This equipment has been tested for electromagnetic emissions and immunity

using good quality shielded cables. The use of unshielded cables, poor quality

cables or other variances from good practice may result in non-compliance with

national and international rules and degraded performance.

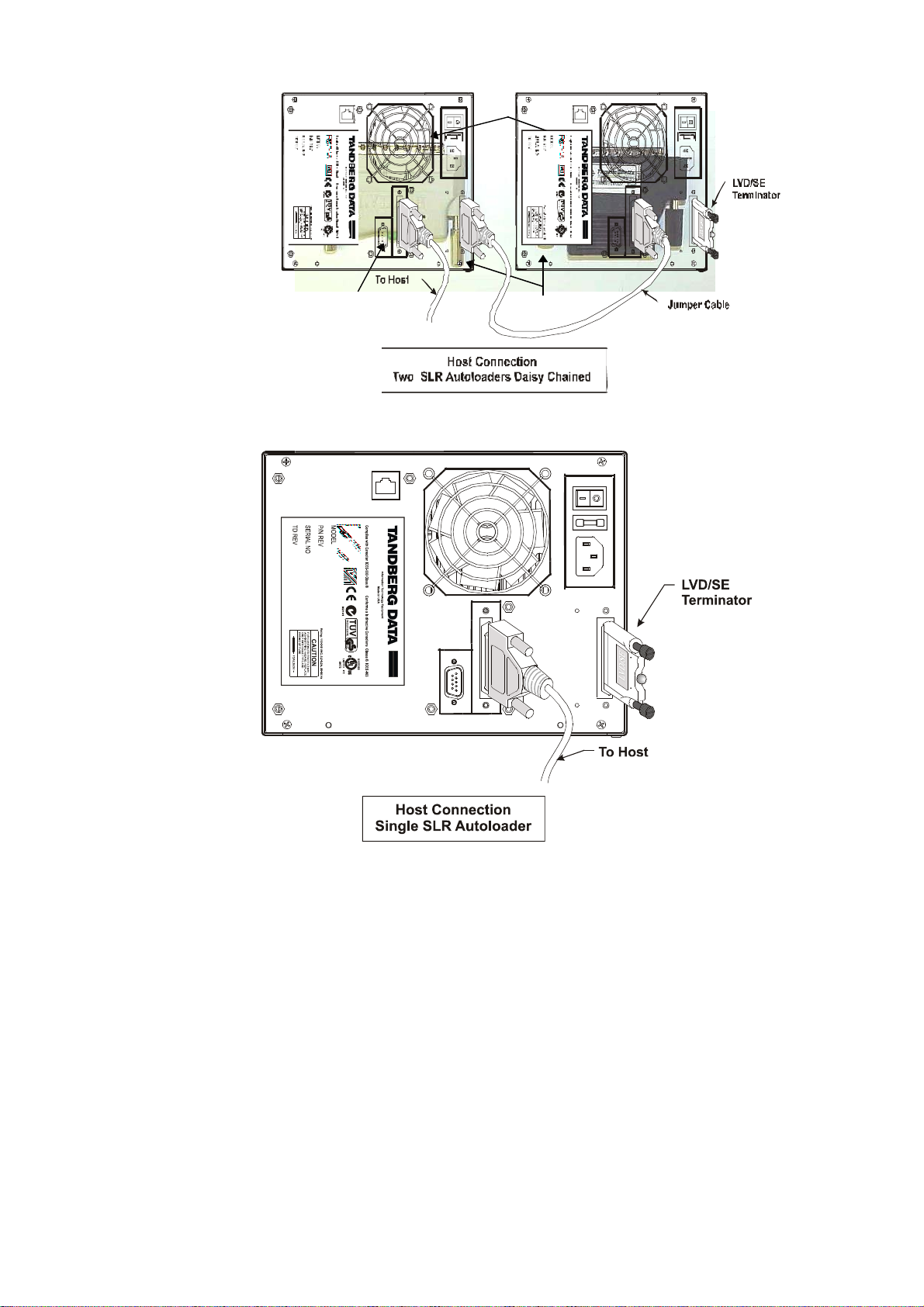

Interface Cable and Terminator Installation

An LVD/SE terminator is supplied with your unit, packaged in the accessory kit

bag.

This terminator must be installed onto the device used at either end of a SCSI bus,

such as the first or last device along a daisy-chain, or as a single SCSI peripheral.

Usually, the host computer’s SCSI interface is at one end of the bus and terminated,

so the question is whether the SLR Autoloader or another device is the last device

on the bus.

On the rear panel of the unit, the incoming SCSI bus is connected to the left SCSI

connector and the terminator or the outgoing SCSI bus is connected to the right

SCSI connector (see the illustration on the next page).

To properly cable the drive, do the following:

1. Make sure the unit and the host computer are powered down.

2. Make sure that your host system has appropriate SCSI interface card or cards

and software drivers installed. The interface card should use Fast/Wide or

Ultra/Wide SCSI, single-ended or low voltage differential (LVD). All models of

the SLR Autoloader are equipped with a LVD/SE Wide SCSI interface. Be sure

to use the same type of SCSI hardware consistently throughout your

configuration.

3. Use only the SCSI terminator supplied with the SLR Autoloader. It should be

one of two available models — either with or without an LED indicator light.

See the following illustration.

Tandberg SLR Autoloader Service and Repair Manual 23

68-Pin High Density Male Connector

LED Light

Thumb Screw Pole

4. If the SLR Autoloader is the only SCSI device you want to connect to the

interface card, connect the cable from the interface card to the incoming SCSI

connector, attach the terminator to the outgoing SCSI connector, then skip to

step 6.

5. If you have two or more additional SCSI devices to connect to the interface card,

your SLR Autoloader must be connected in daisy-chain fashion. That means

that the cable from the interface card must be connected to the incoming SCSI

connector of the first SCSI device, the cable from the outgoing connector of the

first device must be connected to the incoming connector of the second SCSI

device, and so on. You can connect them in any order. The terminator must be

attached to the outgoing SCSI connector of the last device in the chain.

6. Make sure that each cable you use meets the specifications listed earlier in this

chapter.

Tandberg SLR Autoloader Service and Repair Manual 24

Tandberg Data Chapter 2 - Installation

7. Be sure not to exceed the maximum bus length of the entire SCSI bus. The

internal SCSI bus length for the SLR Autoloader is 5.0 feet (1.54 m) including

all cabling and trace lengths. Refer to the manuals for the other SCSI devices to

determine their internal SCSI bus lengths.

Software Installation

The SLR Autoloader comes completely equipped with all necessary on-board

firmware pre-installed at the factory.

You must install and set up the host software necessary to communicate with the

SLR Autoloader that is obtained from a third-party vendor. Set up this software so

that the communication protocol properly transmits between the host adapter and the

SCSI devices of the SLR Autoloader.

Tandberg SLR Autoloader Service and Repair Manual 25

Chapter 3 – Operation

L

System Power-Up

With mechanical installation and electrical connection complete, turn on the AC

power switch. At power-up, for the first three seconds, the unit performs a sequence

of diagnostic tests called Power-On Self Tests (POST). These include: a ROM CRC

check, a RAM test, and a CPU test. As the tests are completed, the control panel

displays a sign-on message and the robotics firmware version number.

After successful completion of the POST sequence, the system performs a series of

initialization functions. The first row of text, Line 1, shows the function currently in

process.

When the unit completes initialization functions, the Default screen appears:

A ‘C’ indicates cleaning

Line 1

ine 4

Idle

Map: 1__456_8 AC

slot occupied when

cleaning is enabled If

enabled, map only

shows 7 slots.

An ‘A’ indicates that

Autoclean is enabled

• Line 1 shows the status of the tape loader mechanism and drive in combination.

When the loader is moving, messages describing the activity (such as Fetching,

Taking Inventory, etc.) appear here. Line 1 also reports the drive status as Active

during read/write operations or Ready when a tape cartridge has been inserted

but is not in motion. When the unit ejects a cartridge from the drive, Ejected

appears at line 1.

• Line 2 shows a cartridge map of the magazine. A number indicates a slot

occupied by a cartridge. An underscore line indicates an empty slot.

• Line 3 shows the six alphanumeric characters of bar code label on the cartridge

in the drive.

• Line 4 shows an activity bar if either the drive or loader is active. The line is

blank when both are idle. This line may alternately display a warning if a drive

cleaning has failed.

Tandberg SLR Autoloader Service and Repair Manual 26

Tandberg Data Chapter 3 - Operation

Selecting the Control Panel Display Modes

After normal startup, the Default Screen appears without operator or host

intervention. Several display modes appear on the display panel screen. To view the

Main Menu, press the Menu (top right) control button on the Control Panel.

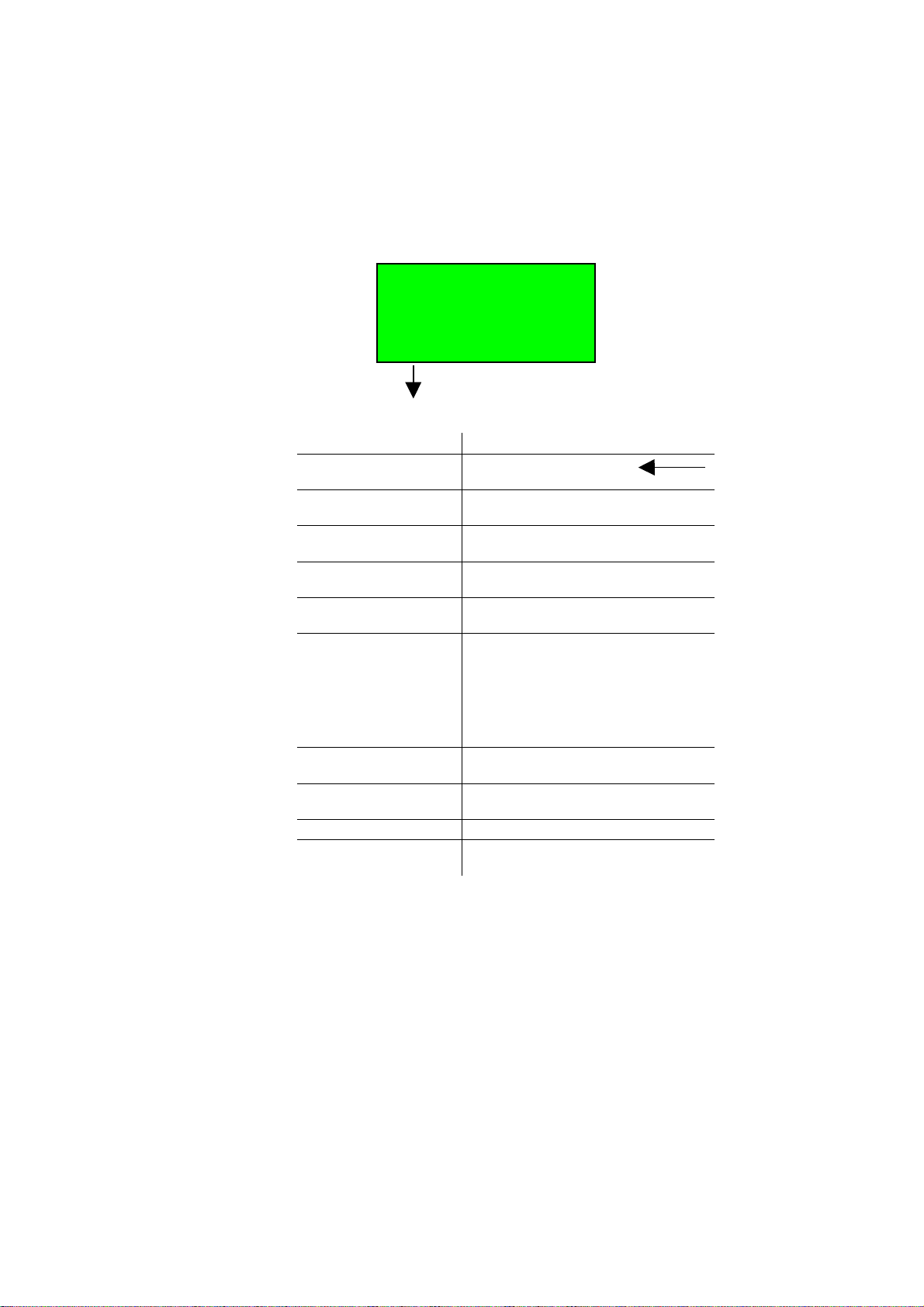

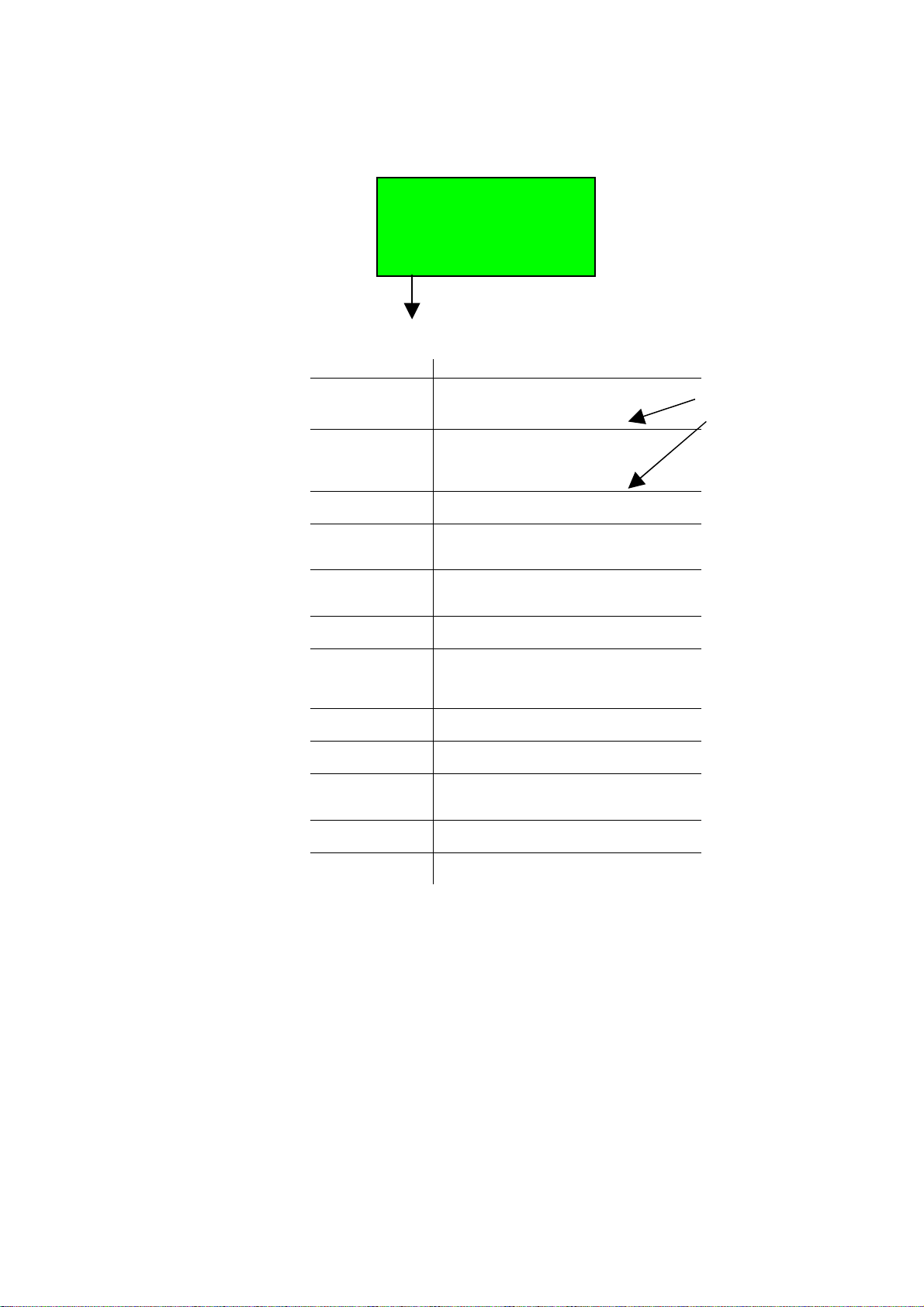

The following illustration shows the hierarchical organization of the menu tree of

the SLR Autoloader menus and menu options. The available menu options can vary

according to the specific SLR Autoloader model or firmware revision level.

The SLR Autoloader Menu Map

Takes you back to

SYSTEM DATA EXIT

the default screen

Loader Options

Unload Mode

Numbering Base

Autoclean *

Loader Mode

Sequential Mode **

Baud Rate

Enable Barcode

Enable Chk. Char. #

Serial Number

Cleaning Slot

SCSI Options

Loader SCSI Id.

Drive SCSI Id.

Loader Parity

Vendor Id.

Product Id.

Negotiating Mode

Transfer Rate

Mode Pg. 1F Length

TUR Reporting

Init Elem. Status

Unit Attn. Reporting

SCSI Mode

Cartridge Map

Drive Info

Drive Type

Firmware Id.

Serial Number

Firmware Revision

Fetch Retries

Stow Retries

Fetch Count

Time Since Clean

Power On Time

SETUP UTILITIES

AUTOLOADER

Unload Mode

Numbering Base

Auto Clean *

Loader Mode

Sequential Mode **

Baud Rate

Enable Barcode

Enable Chk. Char. #

Serial Number

Cleaning Slot

SCSI

Loader SCSI Id.

Drive SCSI Id.

Loader Parity

Vendor Id.

Product Id.

Negotiating Mode

Transfer Rate

Mode Pg. 1F Length

TUR Reporting

Init Elem. Status

Unit Attn. Reporting

SCSI Mode

* Displayed only if the Cleaning Slot is enabled.

** Displayed if selected on the Loader Mode option

# Displayed if Enable Barcode is selected

MAINTENANCE

Park

Clean Drive *

Save Configuration

Flash Loader

Download Config.

Set Defaults

Pass Thru

Reboot Module

DIAGNOSTIC

System Cycle

Cartridge Cycle

Drive Test

Barcode Reader Test

SECURITY

Set Password

Tandberg SLR Autoloader Service and Repair Manual 27

Navigating Through the Menu Map

From the Main Menu screen, you can access three submenus: System Data, Setup,

and Utilities. Access the Main Menu Screen from the Default Screen.

System Data Submen u

BACK

SELECT

AUTOLOADE R BAC K

SCSI

Setup Submenu

Main Menu Screen

SYSTEM DATA EXIT

SET UP UTILITIES

Press on the control button associated

with its menu option, either to display a

submenu or to initiate its labeled function.

Default Screen

Idle

Map : 1__3456_8 AC

MAINTENANCE BACK

DIAGNOSTIC SECURITY

Utilities Submenu

Entering the Menu Mode

While viewing the Default screen, press the upper right control button labeled Menu

to change the display to the Main Menu screen. After doing so, you will be provided

three menu options: the SYSTEM DATA menu, the SETUP menu, the UTILITIES

menu and an Exit function. To enter one of these three menus, press the nearest

control button.

Exiting the Menu Mode

If viewing the Main Menu screen, you can exit the menu mode by pressing the

upper right control button associated with the menu option labeled Exit.Otherwise,

if you are viewing one of the three menus or their submenus, then continue to press

on the control button associated with the menu option labeled

Menu screen is displayed. At this time, press

Menu control button to return the

Back until the Main

display to the Default screen.

System Data Menu

The System Data menu options contain the values assigned during device setup

through the identically-named option in the Setup menu’s Autoloader and SCSI

options. Besides the Setup menu options there are additional menu options data

stored in this menu’s fields (see The SLR Autoloader Menu Map earlier in this

chapter). The descriptions of each System Data menu option that contains a value

from the Setup menu options are discussed in Chapter 4 – Configuration.

Tandberg SLR Autoloader Service and Repair Manual 28

Tandberg Data Chapter 3 - Operation

Autoloader Options

The number of possible values for each Autoloader Option setting varies among the

entire Autoloader Option list. All of these values for each menu option of the

Autoloader Options menu are provided on the next page.

Autoloader Options Menu Legend:

[ ] = Example of a default setting for this menu option.

(##) = Number of selectable values for this menu option.

Unload Mode [= Implicit]

(2)

Implicit, Explicit

Numbering Base [= One Base]

(2)

One Base, Zero Base

Auto Clean* [=

Disabled] (2)

Disabled, Enabled

* Displayed only if Cleaning Slor Selected

Loader Mode [= Random]

(2)

Random, Sequential

Sequential Mode* [= Normal]

(2)

Normal, Recirculate

* Displayed if selected in Loader Mode

Baud Rate [=

115.000] (7)

2400; 9600; 19200; 38400; 57600 and 115200

Enable Barcode [= Disabled]

(2)

Disabled, Enabled

Enable Check Char* [= Enabled]

(2)

Disabled, Enabled

* Displayed only if Enable Barcode is selected

Set Serial Number [ None]*

(0)

* There is no value preset for this menu option.

Cleaning Slot [= Disable]

(2)

Disabled, Enabled

Tandberg SLR Autoloader Service and Repair Manual 29

SCSI Options

The number of possible values for each SCSI Option setting varies among the entire

SCSI Option list. Here is a list of all of them for each menu option of the SCSI

Options menu:

SCSI Options Menu Legend:

[ ] = Example of a default setting for this menu option.

(##) = Number of selectable values for this menu option.

Loader SCSI ID [= SCSI ID 4]

(16)

SCSI ID 0 to SCSI ID 15

Drive SCSI ID [= SCSI ID 5]

(16)

SCSI ID 0 to SCSI ID 15

Loader Parity [= Enabled]

(2)

Disabled, Enabled

Vendor ID [=

TANDBERG] (3)

TANDBERG, OVERLAND and Vendor Unique

Product ID [=

SLR AUTOLOADER] (3)

SLR AUTOILOADER, LXB and Vendor Unique

Negotiation Mode [= Do Not Initiate]

(2)

Do Not Initiate, Initiate

TransferRate [= Sync. 10MB/sec]

(3)

Async. Only, Sync. 5 MB/sec and Sync. 10 MB/sec

Mode Page 1F Length [= Short (0x0E)]

(2)

Short (0x0E), Long (0x12)

TUR Reporting [= Standard]

(2)

Standard, Custom

Init Element Status [= No Inventory]

(3)

Force Label Scan, Force Inventory

and No Inventory

Unit Attn. Reporting [= All]

(2)

One, All

SCSI Mode [=

SCSI-2] (2)

SCSI-2, SCSI-3

Tandberg SLR Autoloader Service and Repair Manual 30

Tandberg Data Chapter 3 - Operation

Cartridge Map

When this option is selected, the operator may schroll through a list of all 8

magazine slots and the drive. For each slot and for the drive, line 3 on the display

will indicate if the slot / drive has a cartridge or not. If the Barcode scan is enabled,

the text from the barcode label is displayed.

Drive Info

The SCSI Drive communicates its Product ID (alphanumeric string), Firmware ID

(alphanumeric string), and Serial Number (factory assigned alphanumeric string) to

the SLR Autoloader firmware. When this option is selected, the operator may

schroll through a list containing this information.

Firmware Revision

This option displays the Autoloader FW revision.

Fetch Retries

Displays for each slot and for the drive, the number of cartridge fetch retries.

Stow Retries

Displays for each slot and for the drive, the number of cartridge stow retries.

Fetch Count

Displays for each slot and for the drive, the number of cartridge fetches.

Time Since Clean

Displays the drive run time since the last successful cleaning operation were

performed.

Power On Time

Displays the Power on Time for the loader.

Tandberg SLR Autoloader Service and Repair Manual 31

Setup Menu

The Setup Menu options are described in more detail in Chapter 4 – Configuration.

The Autoloader Setup Submenu

SYSTEM DATA EXIT

SETUP UTILITIES

A

Option Settings

Unload Mode Implicit

Numbering Base One Based

AutoClean Disabled

Loader Mode Random

Sequential Mode Normal

Baud Rate 115,200

Enable Barcode Disabled

Enable Check Char Disabled

Serial Number <xxxxxxxxxx>

Cleaning Slot

UTOLOADER SUBMENU

Explicit

Zero Based

Enabled

Sequential

Recirculate

57,600

38,400

19,200

9,600

2,400

Auto

Enabled

Enabled

Disabled

Enabled

Default settings

display in italics

Displays if cleaning

slot is selected

Displays if selected

in Loader Mode

Displays if Barcode

option is enabled

Tandberg SLR Autoloader Service and Repair Manual 32

Tandberg Data Chapter 3 - Operation

The SCSI Setup Submenu

SYSTEM DATA EXIT

SETUP UTILITIES

SCSI S

Option Settings

Loader SCSI ID SCSI ID 0 to

Drive SCSI ID

Loader Parity Disabled

Product ID SLR AUTOLOADER

Vendor ID TANDBERG

Negotiation Mode Do Not Initiate

Transfer Rate Asynch Only

Mode Pg 1F Length Short (0x0E)

TUR Reporting Custom

Init Elem Status Force Label Scan

Unit Attn Report One

SCSI Mode SCSI – 2

UBMENU

SCSI ID 15

SCSI ID 4

SCSI ID 0 to

SCSI ID 15

SCSI ID 5

Enabled

LXB

Vendor Unique

OVERLAND

Vendor Unique

Initiate

Sync

5 MB/sec

Sync 10 MB/sec

Long (0x12)

Standard

Force Inventory

No Inventory

All

SCSI – 3

Default settings

display in italics

Tandberg SLR Autoloader Service and Repair Manual 33

Utilities Menu

The Utilities Menu options are described in detail in Chapter 4 – Configuration.

The Utility Menues

SYSTEM DATA EXIT

SETUP UTILITIES

AINTENANCE SUBMENU

M

Option Settings

Park Select this option

Clean Drive Select this option

Save Config Select this option

Flash Loader Select this option

Download Config Select this option

Set Defaults Select this option

Pass Thru Select this option

Reboot Module Select this option

Option Settings

System Cycle Select this option

Cartridge Cycle Select this option

Drive Test Select this option

Barcode Reader

Test

Option Settings

Set Password Password: <0000>

Select next or Exit

Select next or Exit

Select next or Exit

Select next or Exit

Select next or Exit

Select next or Exit

Select next or Exit

Select next or Exit

Select next or Exit

Select next or Exit

Select next or Exit

Select this option

Select next or Exit

Displays if cleaning

slot is selected

DIAGNOSTICS SUBMENU

Used by Technical

Support Engineers

SECURITY SUBMENU

Tandberg SLR Autoloader Service and Repair Manual 34

Tandberg Data Chapter 3 - Operation

Autoloader Operation Modes

The autoloader has two operating modes, random mode and sequential mode.

Random mode is the factory default operation mode.

Random Mode

When the loader is operating in random mode, the host computer controls the drive

and the loader robotics individualy through two separate SCSI Id’s. The host can

move cartridges around between magazine slots and between the magazine and the

drive.

Sequential Mode

The purpose of sequential mode is to emulate operator assisted backup over multiple

tapes. When one tape is full and unloaded by the host, the loader robotics will

automaticly replace it with the next cartridge in the cartridge set. This feature can

allow users with single drive backup systems to replace the drive with a loader and

automate their backup routines.

In sequential mode the loader operates with sets of cartridges. A cartridge set,

consist of all cartridges starting with the first cartridge in the magazine or the first

cartridge after an empty magazine slot. The set is ending with the last cartridge in

the magazine or with a cartridge in front of an empty magazine slot.

Example: If the magazine has cartridges in slot 1, 2 and 3 and in slots 5, 6, 7 and 8,

the magazine contains two cartridge sets separated by the empty slot 4.

A full magazine contains one set of 8 cartridges. (7 cartridges if the Cleaning slot is

enabled.)

When the loader is set in Sequential mode, the host can only control the tape drive.

The loader will respond normally to an Inquiry and a Request Sense command, but

will return a check condition on all media changer type commands. The Sense Key

will be set to 02h (Not Ready) and the Asc / Ascq will be 04h/8Eh (Logical unit Not

Ready, Sequential mode).

Chapter 4 – Configuration. describes how the loader can be set in sequential mode.

The Sequential mode has two sub modes, normal or recirculate sequential mode.

Tandberg SLR Autoloader Service and Repair Manual 35

Sequential Operation

A sequential operation is started when a cartridge from a set is loaded into the drive

using the front panel Load button. Any cartridge in a set can be selected as the first

cartridge and the sequential operation will run until the last cartridge in the set has

been unloaded from the drive. (Normal sequential mode).

In a backup situation, the host will write data to the cartridge until it is full. The

cartridge will be logically terminated and the host will Unload the cartridge. The

drive will now respond to Test Unit Ready (TUR) commands with Not Ready, No

Cartridge until a new cartridge has been loaded. The loader robotics will, when it

detects that the cartridge has been ejected, move the cartridge from the drive back to

it’s original slot. The next cartridge in the set will then be moved to the drive and

inserted. Once the cartridge is loaded, the drive will respond to a TUR command

with a ready status and the host can continue the backup operation on the new

cartridge.

A restore operation operates the same way. When a tape is read to End of Data, it is

unloaded by the host and the robotics replaces it with the next cartridge in the

sequence.

The sequential operation can be terminated prematurely with the front panel Unload

button. The cartridge in the drive will be ejected and moved back to the magazine.

Note: Before the sequential operation is terminated manually, make sure the backup

operation is completed. If not, the backup will fail and the data on the last tape will

be incorrectly terminated.

Recirculate Sequential Mode

The recirculate sequential mode operates like normal sequential mode with one

exception. When the last cartridge in the set is unloaded from the drive, the

sequential operation will not terminate. The operation will continue with the first

cartridge in the set.

This mode of operation has to be terminated manually with the Unload button on the

front panel.

Tandberg SLR Autoloader Service and Repair Manual 36

Tandberg Data Chapter 3 - Operation

Setting the Write-Protect Switch

Before loading cartridges into magazines, you should set the write-protect switch of

each cartridge to enable or disable data recording.

• To enable data recording, rotate the write-protect switch until it points to the

unlocked icon.

• To disable data recording, rotate the write-protect switch until it points to the

locked icon.

Tandberg SLR Autoloader Service and Repair Manual 37

Cartridge Handling

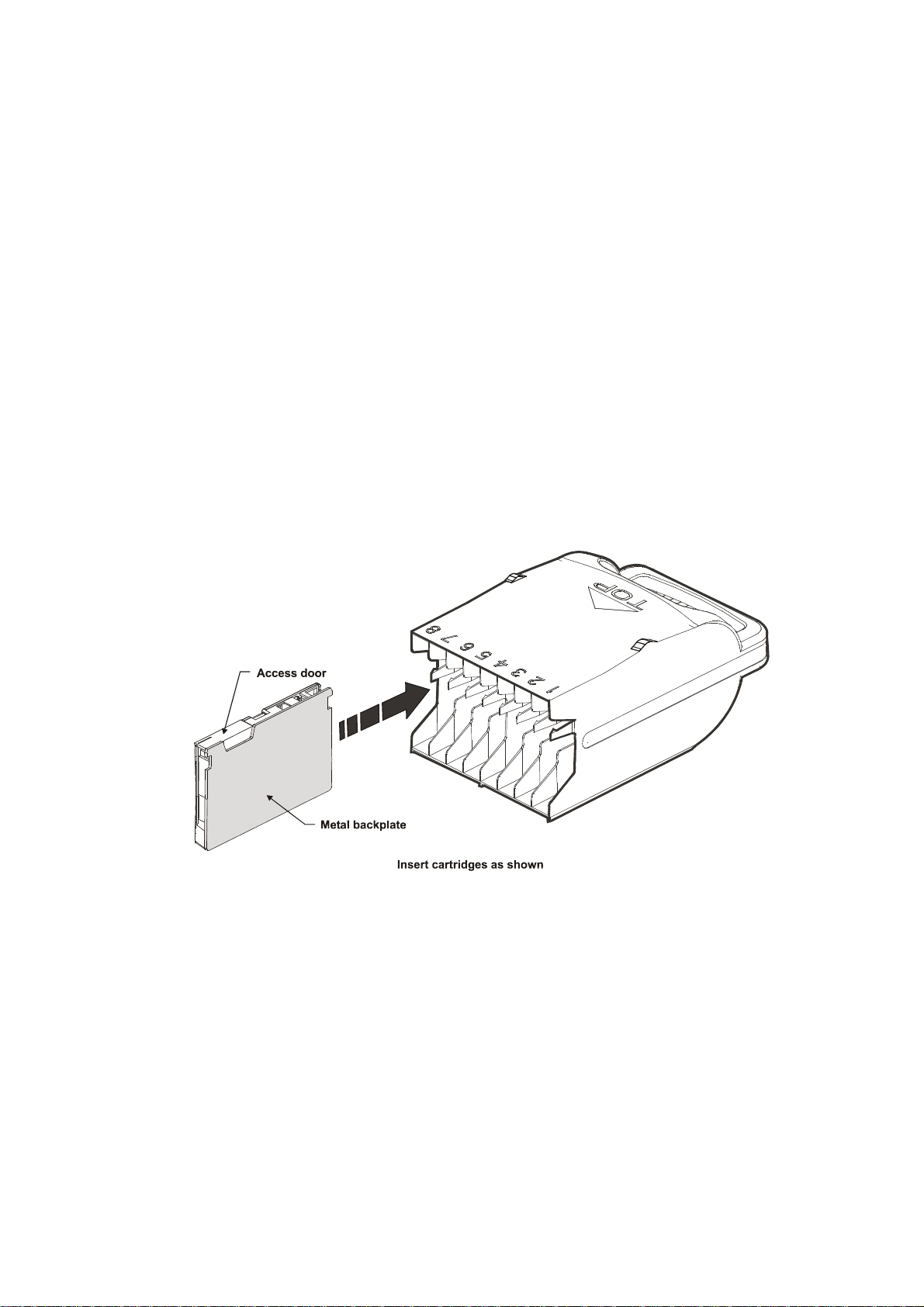

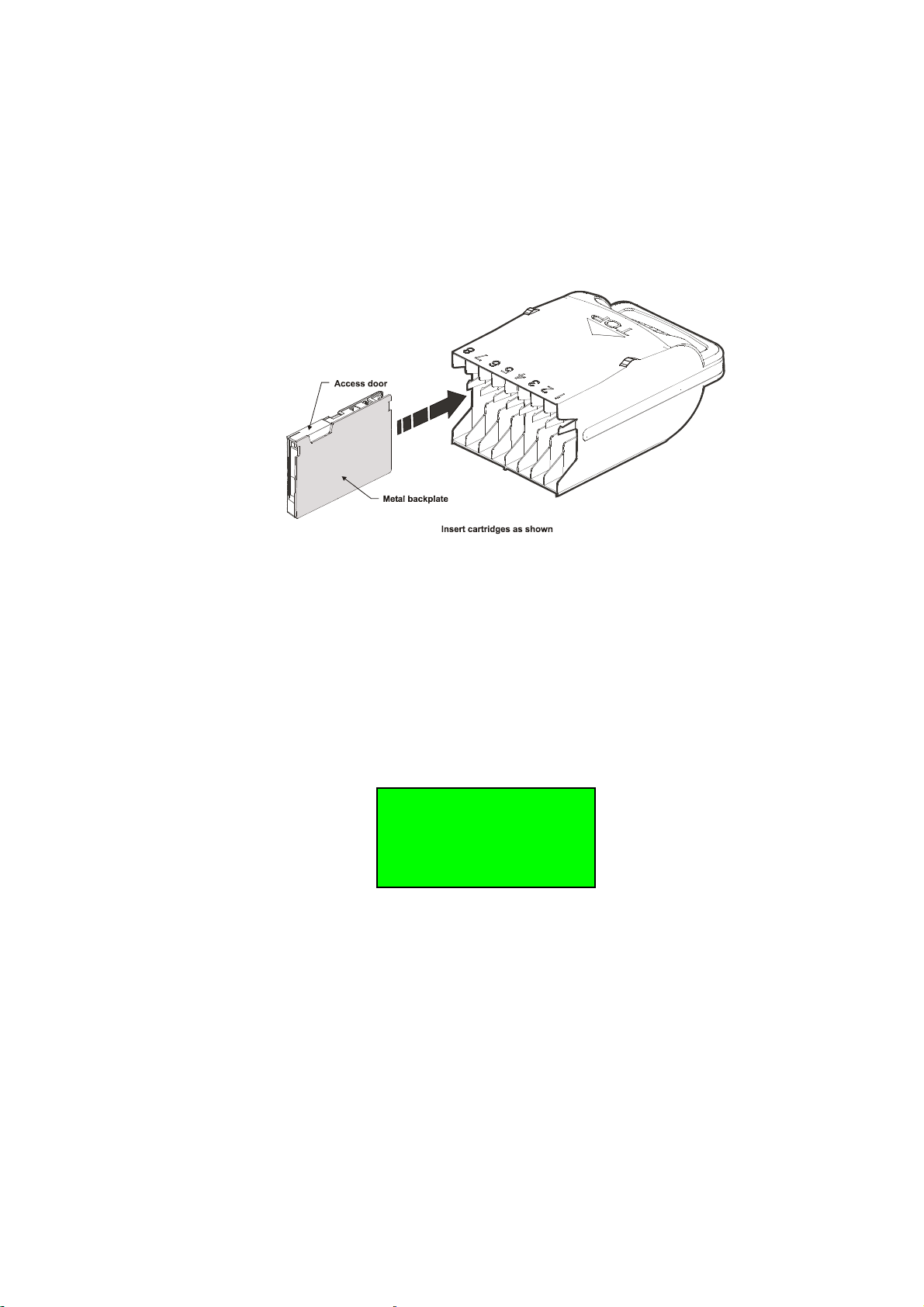

Inserting Cartridges into the Magazine

Insert cartridges so that access door is facing up and located at the magazine front.

After you insert your cartridges, position the magazine so that the cartridges face

forward and the handle is toward you. Make sure the cartridges latch.

Loading a Cartridge into the Drive

The normal operations of the unit are controlled by storage management software

resident on the host computer. When you must load or unload a specific cartridge

using the control buttons on the front panel, do the following:

To load a cartridge:

1. Press the Load button.

The screen displays a cartridge slot number on line two and the barcode label

text for the cartridge on line three:

▲ CANCEL

SLOT 1

Label = XXX111

▼ SELECT

2. Select the slot number of your choice. The system ignores empty slots. Press the

▲ button to increment and the ▼ button to decrement.

3. Press the SELECT button.

The robot shuttle removes the cartridge from the selected magazine slot and

moves it to the drive.

Tandberg SLR Autoloader Service and Repair Manual 38

Tandberg Data Chapter 3 - Operation

To unload a cartridge:

1. Press the Unload button.

The following screen appears, displaying the slot number of one of the

available, empty cartridge slots on line two:

▲ CANCEL

SLOT 1

▼ SELECT

2. Select the cartridge slot number of your choice. Press the ▲ button to increment

and the ▼ button to decrement.

3. Press the SELECT button.

The robot shuttle removes the cartridge from the drive and moves it to the

selected magazine slot.

Tandberg SLR Autoloader Service and Repair Manual 39

Magazine Handling

You must remove the magazine from the unit in order to insert or remove cartridges.

When inserting cartridges, be sure that the slot you intend to use is not already

reserved in the system map for a cartridge in a drive. The best way to avoid conflicts

is to unload the drive, either through your host computer software or by using the

Unload button on the control panel.

Note: You cannot insert or remove the magazine if the unit is password protected or

locked by host software.

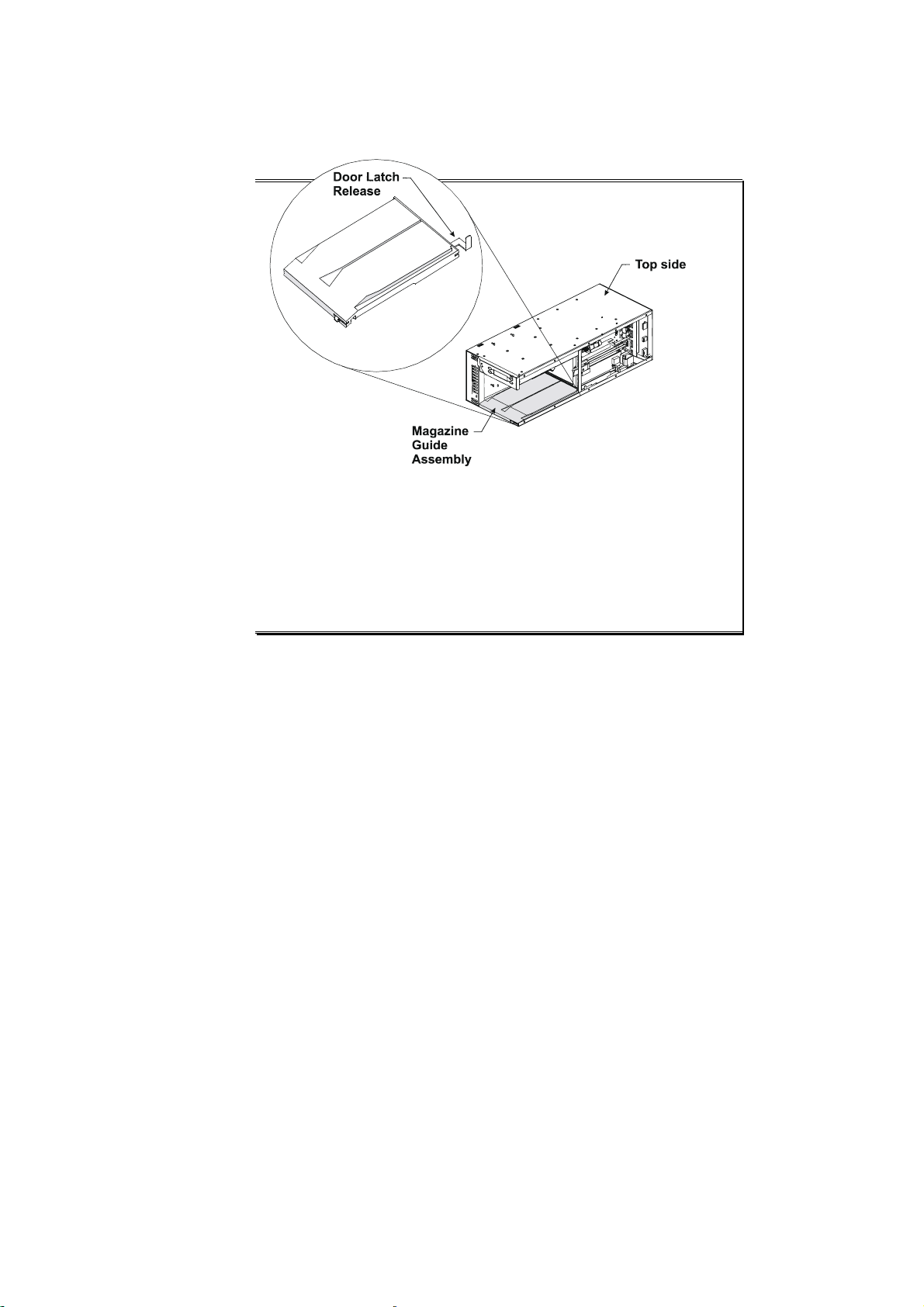

Inserting a Magazine into the Unit

If the magazine door on the front of the module is closed and locked, open it, as

follows:

1. Press the Open Door button.

The magazine door swings open.

2. Slide the magazine through the door opening, with the cartridges protruding

from the front and the molded top arrow facing up.

3. When the magazine is fully inserted, push the door closed until it locks. The

door will not close if the magazine is not fully inserted.

Removing the Magazine

Whenever the front panel door is closed, it is locked in place to prevent tampering or

accidental removal. To remove the magazine, press the Open Door button on the

control panel. After a short delay, the shuttle moves to the Door Latch Release to

activate the door latch, which opens the front panel door.

Tandberg SLR Autoloader Service and Repair Manual 40

Tandberg Data Chapter 3 - Operation

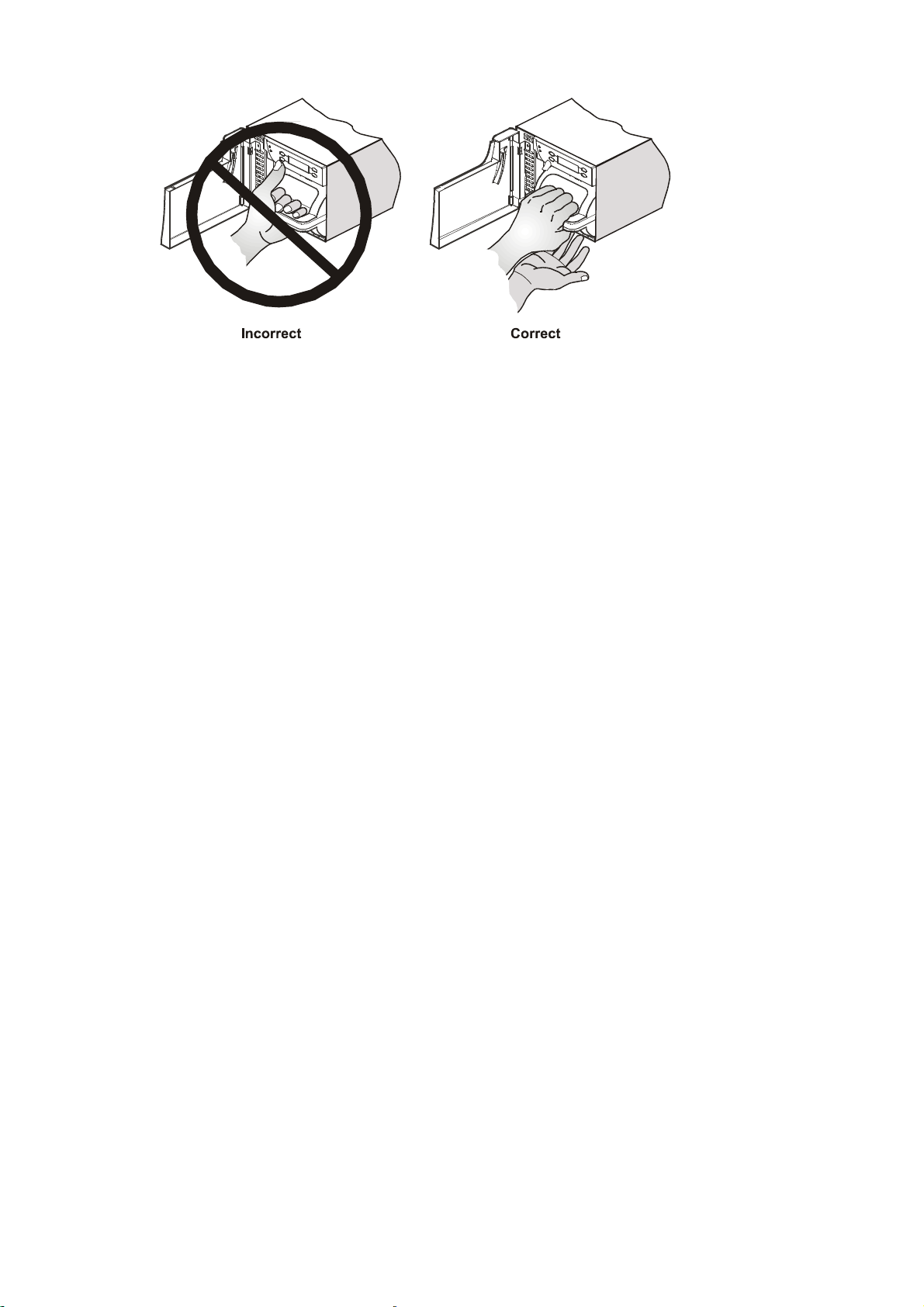

WARNING!

DO NOT push on display panel

when pulling out the magazine.

Using your thumb for leverage

can crack the display panel.

Such damage can lead to

INJURY or ELECTRICAL SHOCK.

The following illustration shows the correct way to remove the magazine from its

compartment.

Tandberg SLR Autoloader Service and Repair Manual 41

Chapter 4 – Configuration

This chapter describes:

• Setting up initial system configuration parameters with individual setup and

utility options

• Entering characters into a menu option using the Control Panel

• Protecting the system with a password.

Before using the SLR Autoloader for the first time, you must set specific

configuration parameters:

• Setup options—Setup menu under Autoloader and SCSI Options submenus

• Utility options—Utilities menu under Maintenance, Diagnostics, and Security

submenus.

Note that if any setup options are changed, the new values will immediately be

saved in Non-Volatile memory. However, some of the options will also require the

loader to be rebooted for the change to tale full effect. If any such options are

changed, the loader will automaticly reboot when exiting from the main menu.

Setup Options

Autoloader Options

Unload Mode — Determines how the loader will react to moves that require a

drive to be in the unloaded state. Setting this value to Implicit indicates that an

unload is implied, causing the loader to issue an unload command to the drive when

necessary. Explicit indicates that the host must explicitly issue an unload to the

drive before issuing a move command to the loader.

Numbering Base— Sets the base for the numbering system. One Based indicates

that all element numbering begins at 1 (Drive 1 and Slots 1 through 8). Zero Based

indicates that the elements begin at 0 (Drive 0 and Slots 0 through 7). This value

affects only the front panel display.

Tandberg SLR Autoloader Service and Repair Manual 42

Tandberg Data Chapter 4 - Configuration

Auto Clean Mode — Enables AutoClean Mode. This option does not display

unless you have selected a cleaning slot.

Loader Mode — Allows the loader to be used as either a random access device or

as a sequential loader device. When set to Random, the host has full control over the

movement of cartridges.

Tandberg SLR Autoloader Service and Repair Manual 43

Sequential Mode — Applies when the Loader Mode is set to Sequential. When

Normal is selected, sequential operation terminates after the last cartridge in the

sequence has been unloaded. A cartridge sequence ends at an empty slot or when the

cartridge in slot 8 has been unloaded. (Slot 7 if Cleaning Slot is enabled)

When Recirculate is selected, operation continues with the first cartridge in the

sequence. This option does not display unless you have selected Sequential Mode in

the Loader Mode option.

Baud Rate — Sets the trace serial port baud rate. Allowable values are:

• 2,400

• 9,600

• 19,200

• 38,400

• 57,600

• 115,200 (Default).

Enable Bar Code — Enables the bar code reader. When the reader is enabled,

the barcode of the cartridge in each occupied magazine slot and in the drive (if any)

will be scanned during the Inventory process.

Enable Check Char — Enables the check sum character to be used to verify the

correctness of each bar code label scan. Does not display unless you have enabled

the bar code reader in the Enable Bar Code option.

Cleaning Slot — If enabled, dedicates slot 8 to cleaning operations.

Note: Do not insert the cleaning cartridge in any other slot than slot 8.

Set Serial Number — The 12-character string of the assigned serial number

entered using the control panel and buttons.

Tandberg SLR Autoloader Service and Repair Manual 44

Tandberg Data Chapter 4 - Configuration

SCSI Options

Loader SCSI ID — Sets the SCSI ID of the loader. Legal values range from 0 –

15.

Drive SCSI ID — Sets the SCSI ID of the drive. Legal values range from 0 – 15.

Loader Parity — Enables/Disables the parity checking for the loader SCSI bus.

Vendor ID — Sets the SCSI Vendor ID. The default Vendor ID is “Tandberg

Data”. Other predefined Vendor ID’s can be selected by scrolling through a list of

choices or enter a unique string by selecting the <Vendor Unique> setting.

Product ID — Sets the SCSI Product ID. The default selection for this option is

SLR Autoloader. Other predefined Product IDs can be selected by scrolling through

a list, or entering a unique string after selecting the <Product Unique> setting.

Negotiation Mode — Determines if SCSI negotiation is initiated by the loader.

Allowable values are Do Not Initiate or Initiate.

Transfer Rate — Defines the SCSI burst transfer rate. Allowable values are:

• Synchronous, 10 MB/sec

• Synchronous, 5 MB/sec

• Asynchronous Only.

Mode Pg 1F Length — Defines the length of the Device Capabilities page

Parameter Length expected by a SCSI Host.

TUR Reporting — Determines how the loader should respond to a Test Unit

Ready command if in Sequential Mode. This option is available only if sequential

mode is active.

Init Elem Status — Determines how the loader should respond to an Initialize

Element Status command. The options are:

• No Inventory

• Force Inventory

• Force Label Scan.

Unit Attn Report — Determines if the loader should stack multiple Unit Attention

responses (ALL) or send only the highest priority Unit Attention response (One).

SCSI Mode — Defines the loader as SCSI-2 or SCSI-3.

Tandberg SLR Autoloader Service and Repair Manual 45

Utilities Options

Maintenance Submenu

Clean Drive — Enables running an installed cleaning cartridge. (Cleaning Slot

must also be enabled in the Setup Menu.)

Park — Enables moving the shuttle assembly to the home position. This option

must be executed before the loader is prepared for transport by insering the Locking

Pin. (See chapter 2, Installation on how to remove and install the Lockin Pin.)

Save Config — Saves all configuration modifications.

Flash Loader — Enables the loader to accept FLASH data through the serial port.

Note: Not used for firmware upgrade via SCSI.

Download Config — Downloads all configuration modifications.

Note: The use of the Save- and Download Config and the Flash Loader options

requires that the operator has access to the LibCenter utility program.

Set Defaults — Stores the default settings for all setup options in Novram.

Pass Thru — Connects drive serial port to loader serial port allowing direct pass

through. Baud rate is fixed at 19,200.

Reboot Module — Performs a soft reboot of the loader without affecting the

drive.

Diagnostics Submenu

This submenu is used by Technical Support Engineers to perform the following

diagnostic tests:

System Cycle — Cycles cartridges through random slots and the drive.

The magazine must be stocked with a minimum of two and a maximum of seven

(six if the cleaning slot is enabled) cartridges to run this test.

Drive Test — Loads a cartridge into the drive and runs a drive Standalone

Diagnostic test. The magazine must be stocked with at least one writeable cartridge

to run this test.

Cartridge Cycle — Cycles cartridges through random slots in the magazine only.

The magazine must be stocked with a minimum of one and a maximum of seven

(six if the cleaning slot is enabled) cartridges to run this test.

Tandberg SLR Autoloader Service and Repair Manual 46

Tandberg Data Chapter 4 - Configuration

Security Submenu

Set Password — Allows you to set a password that can restrict access to the

system through the front panel. If you set the password to a non-zero value, and

press the Load, Unload, or Open Door buttons, the system prompts you for the

password. If you enter the password correctly, the operation continues. If you enter

the password incorrectly, a warning message displays for three seconds and the

operation stops.

These descriptions of the setup options should have made it easier for you to select

the appropriate ones to set for your particular system. The following section will

explain how to change a Setup Option.

Tandberg SLR Autoloader Service and Repair Manual 47

Changing a Configuration Option

These configuration options (such as Setup and Utilities) allow the SLR Autoloader

to support a variety of storage management software and network platforms. The

settings for each option are stored in non-volatile memory inside the unit.

For most applications, you do not have to change the factory default settings. If you

do, follow the procedure outlined below. This section contains descriptions of each

setup option and a summary table of the default settings. If you are uncertain

whether you need to change a setting, contact your Technical Support

representative.

To change a Setup (or Utilities) option:

Note: the procedure for changing a Utilities option is identical to this procedure for

changing a Setup option except that the Utilities menu and its options are accessed

instead of the Setup menu.

1. From the Main menu screen, press the Setup button.

The Setup screen appears, displaying button functions that let you select Loader

or SCSI options or go back to the main menu:

AUTOLOADER BACK

SCSI

2. Press the AUTOLOADER or SCSI button.

A screen similar to the following appears, showing the first item in a list of

Loader or SCSI options:

CANCEL

U n lo a d M o d e

▼ ACCEPT

3. Press the ▼ button to scroll through the list to the option you want.

Each time you press the button, the next option in the list appears on the screen.

As you scroll past the first option, a ▲ button appears in the top left corner. Its

associated button lets you move backwards through the list.

Tandberg SLR Autoloader Service and Repair Manual 48

Tandberg Data Chapter 4 - Configuration

4. From the option you want, press the SELECT button. ▲

A sc reen sim ilar to the follow ing a pp ears, sho w ing the c urren t

value for the selected option:

▲ CANCEL

U n lo a d M o d e

= Im p lic it

▼ ACCEPT

5. Press the ▼ or ▲ button to scroll through the available values.

6. When you’ve displayed the option you want, press the ACCEPT button.

7. Press the CANCEL button to choose another option.

Entering Characters from the Control Panel

To enter characters into any menu option, do the following:

3. Select the appropriate menu option as described in Chapters 3 and 4.

4. Press the SELECT button to display the field data entry screen.

5. In this screen, two opposite facing arrows (▲,▼) are assigned to the left control

panel buttons and a right arrow (►) is assigned to the upper right control button.

When the up and down button is pressed, each button will scroll differently

through the ASCII character set assigned to each character position depending

on where the cursor is currently positioned.

6. Starting with the default cursor position for entering characters, press the ▲

button to move through the character set starting with symbols > numbers (0–9)

> more symbols > alphabet from A to Z. To reverse the scrolling through the

assigned character set, press the ▼ button.

7. To store the selected character, press the ► button on the control panel. This

moves the cursor one character space to the right.

8. Repeat Steps 3 and 4 of this procedure until you have entered all characters.

9. When you have entered the last character, press the DONE button.

The display changes and asks whether to “Save String?”

10. If you made no errors while entering the character string, press the YES button.

If you made an error, press the NO button.

11. Press the appropriate control panel button for your next selection or press BACK

twice to return to the main Menu Screen.

Tandberg SLR Autoloader Service and Repair Manual 49

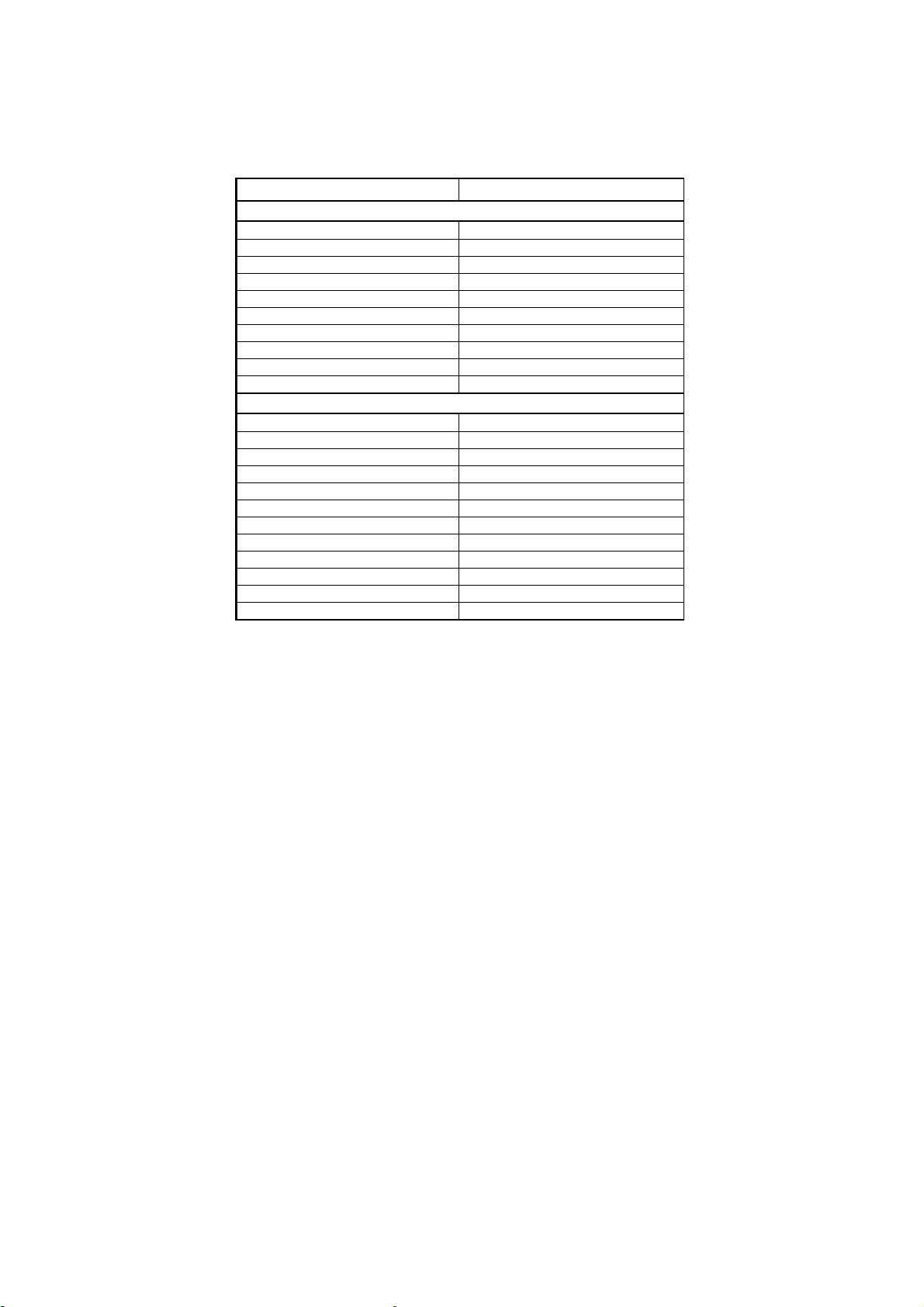

Default Setup Options

Setup Option Default

Autoloader

Unload Mode Implicit

Numbering Base One Based

Auto Clean Disabled

Loader Mode Random

Sequential Mode Normal

Baud Rate 115,200

Enable Bar Code Disabled

Enable Check Char Enabled

Cleaning Slot Disabled

Set Serial Number _ _ _ _ _ _ _ _ _ _ _ _ (12 spaces)

SCSI

Loader SCSI Bus ID 4

Drive SCSI Bus ID 5

Loader Parity Enabled

Vendor ID TANDBERG

Product ID SLR AUTOLOADER

Negotiation Mode Do Not Initiate

Transfer Rate 10 Mbytes/second Synchronous

Mode Page 1F Length Short (0X0E)

TUR Reporting Standard

Init Elem Status No Inventory

Unit Attn Report All

SCSI Mode SCSI-2

Tandberg SLR Autoloader Service and Repair Manual 50

Tandberg Data Chapter 4 - Configuration

Setting a Password

You can restrict access to the system by setting a password in the Setup options.

When these access codes are set, the Load, Unload, or Open Door buttons will cause

an entry prompt to appear on the screen. The password also restricts access to the

Utilities and Setup menues. The System Data menu has no access restrictions.

When you enter your password correctly, the operation proceeds as normal.

Incorrect entry causes a warning message to appear for 3 seconds before the

operation is terminated.

To set a password:

1. Press the Menu button.

The Main Menu screen appears.

2. Select the UTILITIES menu.

The Utilities menu screen appears.

3. Select the SECURITY menu.

4. Select Set Password.

The password screen appears:

▲ CANCEL

Password: 0

000

► ACCEPT

5. Set the password using the associated control panel buttons:

▲ Increments the number above the cursor (0–9).

► Moves the cursor one character to the right. If the cursor is in

the last position, it reverts back to the first position.

CANCEL Aborts the password operation.

ACCEPT Sets the currently displayed password.

To disable a password:

To disable the password function, set its value to zero.

WARNING: If you set a password, make sure you do not forget it. If you do, it can

only be cleared with assistance from Tandberg Data technical support or by a

qualified service technician.

Tandberg SLR Autoloader Service and Repair Manual 51

This Page Intentionally Left Blank

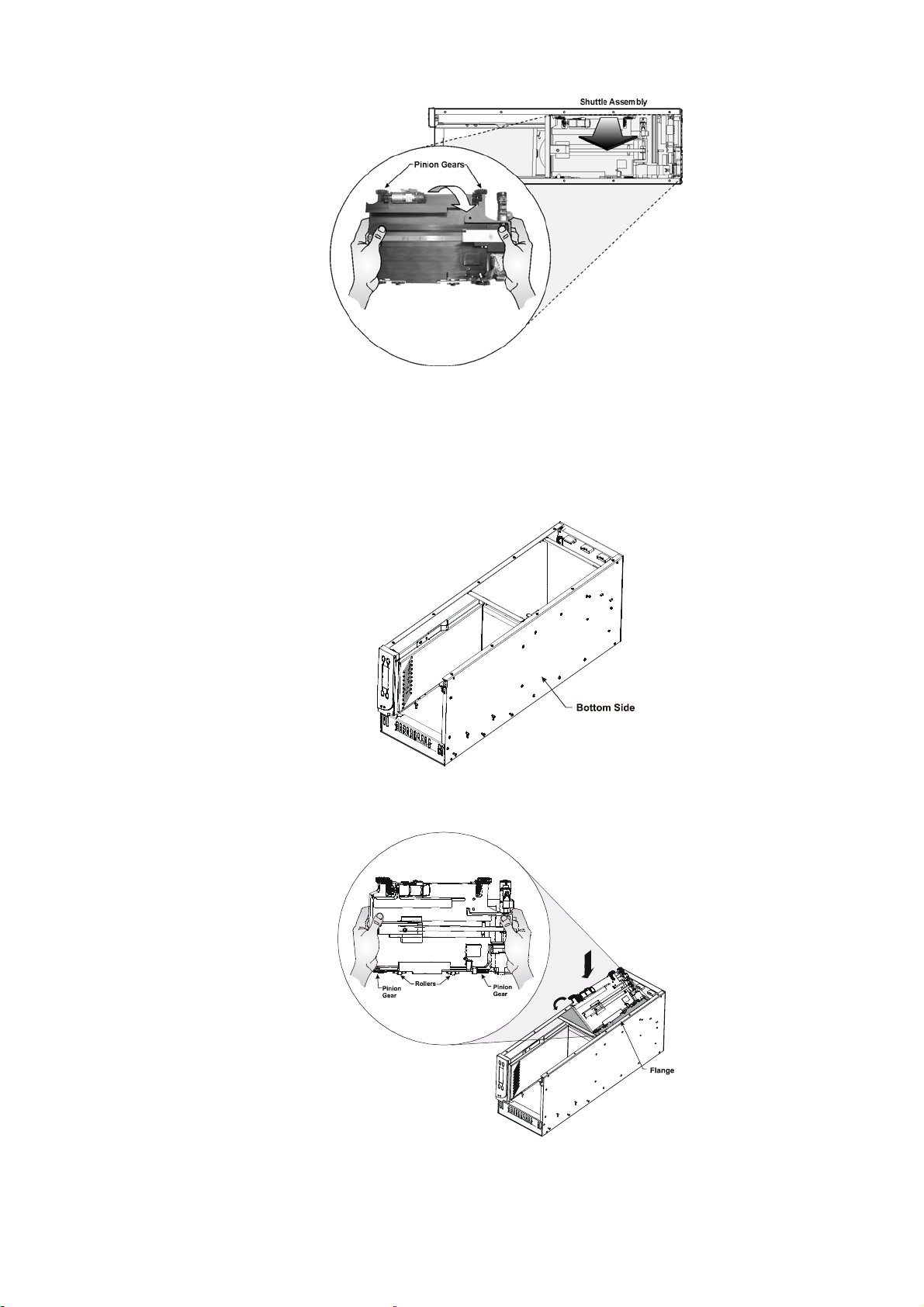

Tandberg SLR Autoloader Service and Repair Manual 52