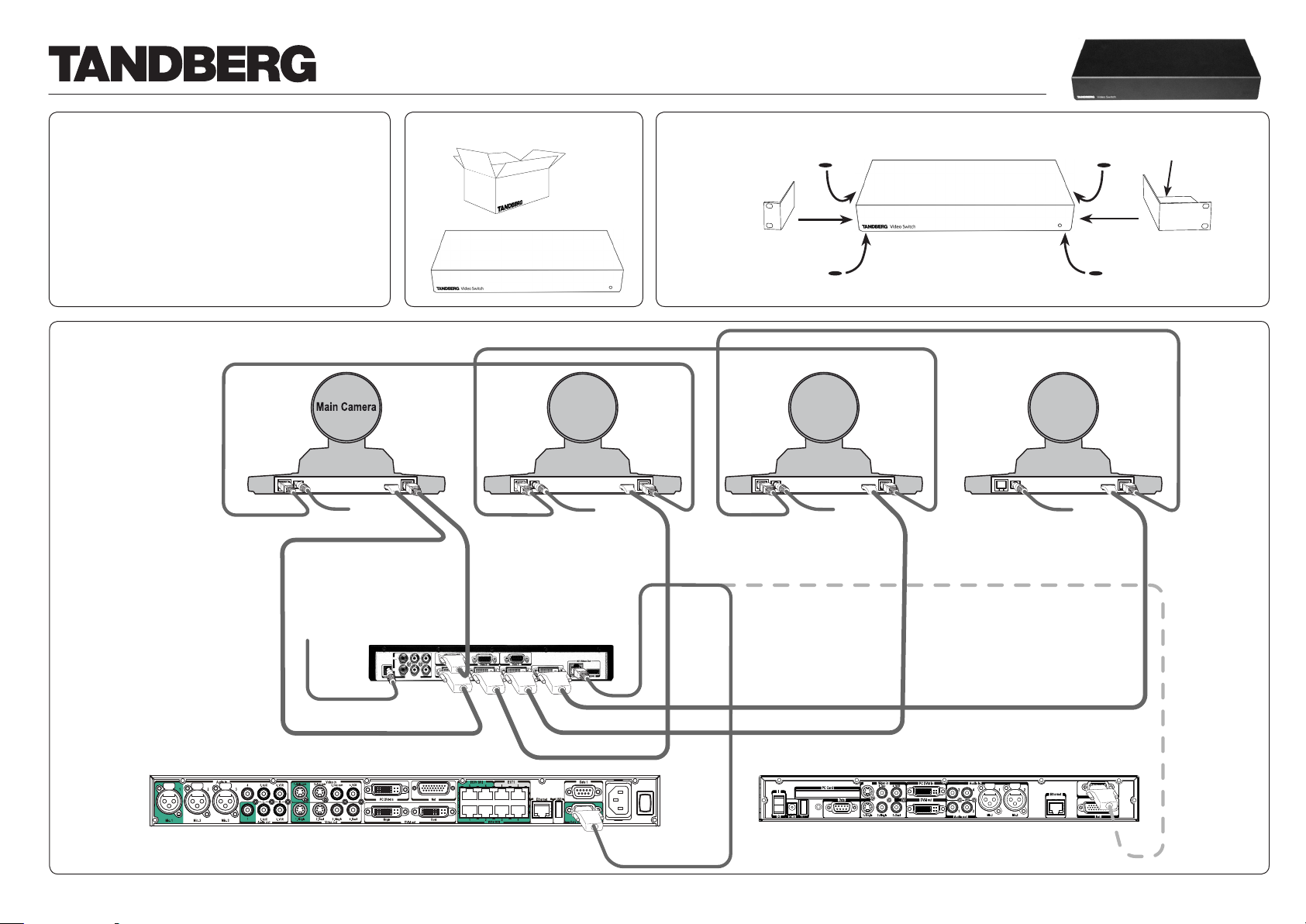

Connecting the Video Switch

Audio out

Data

Net

PC Card

1. Single 2. Single

Video out

Video in

3. Dual

2. Aux

3. Doc 4. VCR

VCR

Ethernet

PC DVI-I in

DVI-I out

1

2

4

Audio in

1

Mic.1

2

Mic.2

3

USBUSB

DC in

I

O

Camera

The Video Switch set contains:

1 Video Switch Unit

4 Rubber Feet

1 HD Camera cable (1 m) for 6000MXP Codec

1 HD Camera cable (1 m) for 3000MXP Codec

1 Power supply kit incl. cables for Video Switch

1 Power supply kit incl. cables for existing camera

1 Rack ear set (left and right)

1 Control cable (6.5 m) for Video Switch to Precision HD camera

1 HDMI cable (6.5 m) for Video Switch to precision HD camera

1 TRC4 TANDBERG Remote Control

Please report any discrepancies immediately.

Connecting up to four

TANDBERG Precision

3

HD cameras:

RJ11 – RJ45

Connect TANDBERG Video Switch

power supply here.

Connect camera power supply

here.

The Codec must be equipped with

software version F6.1 or higher to

support the use of the Video Switch.

1

Unpack the unit.

Camera 2 Camera 3 Camera 4

RJ11 – RJ45

DB 9–RJ 45

Primary chain

TANDBERG Video Switch

Mount the rack ears

and/or rubber feet

2

and mount it in the

rack, if applicable.

RJ11 – RJ45

Put the Video Switch power

supply here when rack

mounting.

Rubber feet

(rubber pads)

RJ 45 – DB 9

DVI – HDMI

TANDBERG 6000 MXP Codec

DVI – HDMI

DB 9 – RJ 45

DVI – HDMI

TANDBERG 3000 MXP Codec

116467.05Page 1 of 6

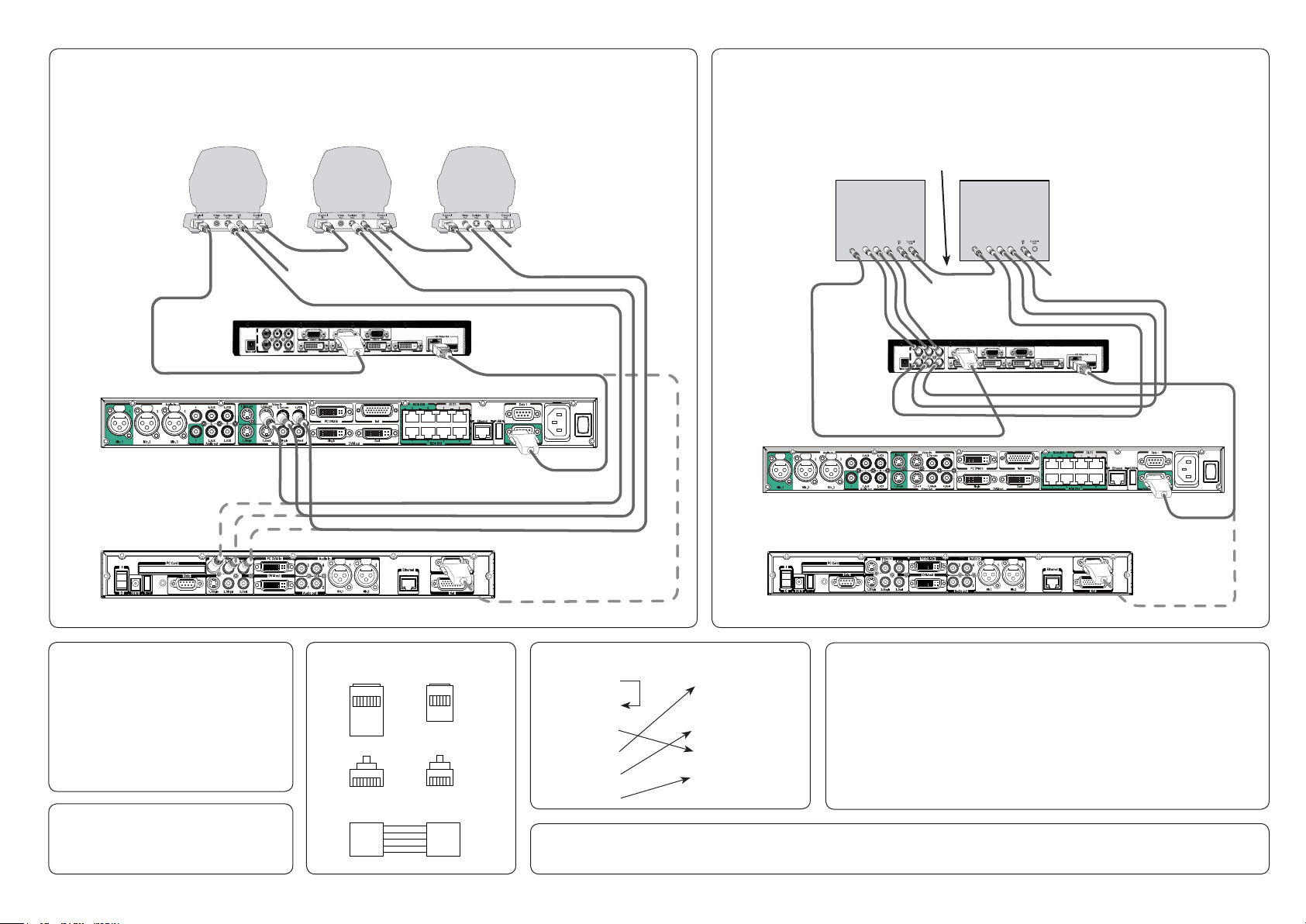

This diagram shows the additional connections needed to expand from using up to four TANDBERG

RJ45

Top

RJ45

Front

1

8

1

8

RJ11

Top

RJ11

Front

18

16

RJ45 RJ11

1

2

3

6

7

2

1

3

4

5

Audio out

Data

Net

PC Card

1. Single 2. Single

Video ou t

Video in

3. Dual

2. Aux

3. Doc 4. VCR

VCR

Ethernet

PC DVI-I in

DVI-I out

1

2

4

Audio in

1

Mic.1

2

Mic.2

3

USBUSB

DC in

I

O

Camera

Control

in

Control

in

Audio out

Data

Net

PC Card

1. Single 2. Single

Video ou t

Video in

3. Dual

2. Aux

3. Doc 4. VCR

VCR

Ethernet

PC DVI-I in

DVI-I out

1

2

4

Audio in

1

Mic.1

2

Mic.2

3

USBUSB

DC in

I

O

Camera

Precision HD cameras (see overleaf) to also include up to three TANDBERG WAVE II cameras

4

(i.e. up to seven cameras in total). Connect Video Switch power supply as shown overleaf.

Note!

Start by connecting

the Precision HD

Camera 1 Camera 2 Camera 3

cameras as shown

overleaf. The

connection shown

here comes in

addition to the one

overleaf!

RJ 11 – RJ45 RJ 11 – RJ45

RCA – RCA

RCA – RCA

S-video – S-video

Connect WAVE

camera power

supply here.

This diagram shows the connections needed to use a maximum of two analog sources

equipped with component video outputs. Connection diagram uses Sony EVI-

5

HD1 cameras as example. System supports 1280X720p50, 1280X720p59,94, and

1280X720p60 only. For full VISCA control Sony EV1-HDI cameras or true compatibles

must be used. Other units may or may not be par tly or fully controllable. Connect Video

Switch power supply as shown overleaf.

Mini DIN – Mini DIN

Connect camera power

supply here.

RCA – RCA

Camera 1 Camera 2

RCA – RCA

The Codec must be equipped with

software version F6.1 or higher to

support the use of the Video Switch.

To upgrade the software of the Precision HD

camera, connect the camera directly to the

main camera socket of the Codec (the socket

that other wise is used when connecting the

Video Switch to the Codec).

Power the units and the upgrade will start

automatically. The status will be shown on the

video system’s monitor.

RJ45–DB9 pinout is described in the

TANDBERG MXP Reference User Guide

for System Integrators, which came with

your TANDBERG Codec.

Page 2 of 6

RJ 45 – DB 9

Secondary chain

TANDBERG 3000 MXP Codec

RJ 45 – DB 9

DB 9– Mini DIN

RJ 45 – DB 9

TANDBERG 6000 MXP Codec

The Codec must be equipped with

TANDBERG 6000 MXP Codec

software version F6.1 or higher to

support the use of the Video Switch.

TANDBERG 3000 MXP Codec

TANDBERG RJ 45 – RJ 11

SONY Mini DIN Precision HD RJ 11

1 DTR 1 GND

2 DSR 2 Not Used

3 TXD 3 TXD

4 GND 4 RXD

5 RXD 5 GND

You may combine TANDBERG HD Precision cameras with analog

sources equipped with component video outputs. Just add them to the

chain of cameras in the diagram shown overleaf, but make sure the

added sources appear after the TANDBERG HD Precision cameras in

the chain (i.e. after camera 4 in the diagram overleaf).

Consequently, up to four TANDBERG HD Precision cameras may be

combined with up to two analog component video sources and up to

three TANDBERG WAVE II cameras, bringing the maximum number of

video sources (which in many cases will be all cameras) up to nine!

6 GND 6 GND

SONY Part Numbers: DB9–Mini DIN cable

SONY part number RC893

Mini DIN–Mini DIN chain cable

SONY part number RC815

116467.05

Installation of the Video Switch

The Codec must be equipped with software version

F6.1 or higher to support the use of the Video Switch.

Basic Functionality

Physical inputs refer to explicit codec input and explicit switch input.

These can only be controlled from the command interface. xconfiguration

MainVideoSource, vidin and xconfiguration Switch Source always control

the inputs directly.

Example: To select physical input 3 on the codec, use xconfiguration

MainVideoSource: 3, as usual. To see inputs on the switch, select codec

input 1 with xconfiguration MainVideoSource: 1, and select switch input

with xconfiguration Switch Source <1..6>.

Logical inputs are used when accessing inputs from the menu, remote

control and FECC. There are five input buttons on the top of the TRC4

remote control, and these can be remapped to any switch input you

wish. The same five buttons are visible in the Presentation/Main Video

menu, and these will be remapped in the same manner. If the switch

is connected with no special configuration, selecting “main cam” in the

menu will give the current input on the switch.

Example: There are two cameras connected to the switch, which we

want to access from the menu and remote using the “main cam” and

“aux” buttons:

xconfiguration Switch LogicalInput 1 Mode: On

xconfiguration Switch LogicalInput 1 Map: 1

xconfiguration Switch LogicalInput 2 Mode: On

xconfiguration Switch LogicalInput 2 Map: 2

You can rename the inputs using the standard xconfiguration Video

Inputs Source <1..6> Name or vidname:

xconfiguration Video Inputs Source 1 Name: “HD Camera 1”

xconfiguration Video Inputs Source 2 Name: “HD Camera 2”

Note: If you select a switch input that has no mapping from the command

interface, it will be called Switch-<1..6>. If you select a codec input that

has been remapped to the switch from the command interface, it will be

called Codec-<1..5>.

to chain more cameras than 4 in the secondary chain. This will also be

possible when the switch is not connected.

xconfiguration MainVideoSource/DuoVideoSource <1..6>

Will not be changed. 1 will mean current input on the switch.

xconfiguration switch source: <1..6>

Specify which input source to use on the switch. This will only cause a

visible change if MainVideoSource is 1.

xconfiguration switch config primar y: <on/off>

Default is on. If off, the codec will only do a basic setup of the primary

chain and report what kind of cameras are connected. The codec will not

set up brightness, whitebalance, gamma etc. for each camera. Turn it off

if an external control system handles all the configuration.

xconfiguration switch config secondary: <on/off>

Default is on. If off, the codec will only do a basic setup of the secondary

chain and report what kind of cameras are connected. The codec will not

set up brightness, whitebalance, gamma etc. for each camera. Turn it off

if an external control system handles all the configuration.

xConfiguration Switch LogicalInput [1..5] Mode: <On/Off>

xConfiguration Switch LogicalInput [1..5] Map: <1..6>

Default is LogicalInput [1..5] Mode: Off.

Main cam1.

Aux2.

Doc cam3.

VCR4.

PC5.

Remaps the source buttons on top of the extended remote control.

Will also remap inputs selected from the menu, and change FECC

accordingly. If mode for a key is on, the table entry will be used to specify

which input on the switch to activate.

xcommand CameraUpgrade <1..13> <filename>

Upgrade camera or switch with new software. The software must be put

on either /tmp or /user. Camera software files are named s01692.pkg.

Switch software files are named s51200.pkg. Currently only upgrading of

the first camera/switch is supported.

New Statuses

xstatus switch

Information about software version and ID will be given by xstatus

camera 1. xstatus switch will give information about sync status for the

active input, the format, and sync status for all DVI-D inputs.

xstatus switch

*s Switch (connected=True):

Input: 1

Format: 1280X720p60

Sync: True

Sync 1: True

Sync 2: True

Sync 3: False

Sync 4: False

Active input may differ from what is given in the xconfiguration Switch

Source setting. This is because an external control system may also

change the input.

Command Interface – Configurations

Important: All camera configurations will get new ranges, 1..13 instead

of 1..4. These will behave as follows if a switch is connected:

1 will be the switch.

2..7 will be cameras connected to secondar y chain (chain originating

from Data port 2 of the switch).

8..13 will be cameras connected to the primary chain (chain originating

from Data port 1 of the switch).

Since the switch is the first entry in both chains, there is a max of 6

cameras per chain. This numbering scheme will be as compatible as

possible with existing camera support. We open up for the possibility

Command Interface – New Commands

Important: All camera commands will get new ranges, 1..13 instead of

1..4. This will work as specified in the section above.

The new commands below are also useful if there is no switch

connected.

xcommand CameraReconfigure

Reconfigures all cameras connected to the switch or codec. This may be

useful if you connect new cameras without turning the power off, since

the switch does not autodetect such changes.

116467.05Page 3 of 6

Communicating with the Video Switch

Communicating Using VISCA

Note! This section applies only to users wanting to

control the switch directly from an external control

system connected to Data port 3 on the switch.

The following describes how to communicate

with the TANDBERG Video Switch using the

VISCA protocol. For details about the protocol

implementation, refer to the System Integrators

Guide – Interfacing to the TANDBERG Wave 2

Camera.

VISCA Interface Basics

The TANDBERG Video Switch (TVS) uses a RS-232

control interface that resembles the Sony VISCA

protocol.

TVS is configured in exactly the same way as a

VISCA camera. TVS will always be located first in

the camera chain(s).

The main jobs of the VISCA interface in the T VS are:

Select which video source to use•

Route VISCA messages to the connected •

cameras

Control picture resolutions sent to the codec•

Cameras chained to the switch will start with id 2.

The codec will automatically recognize this and map

the cameras accordingly.

VISCA Serial Ports

The switch has a total of 4 serial ports that

communicate using the VISCA protocol.

Port 0, on the THSI interface, is always •

connected to the codec.

Port 1 is the primary VISCA chain for cameras •

connected to the Switch.

Port 2 is the secondary VISCA chain for the •

cameras that normally are connected to codec

video inputs 2-5. See the section on Enhanced

VISCA below.

Port 3 is intended for external control systems, •

and works in the same way as port 0, but with

some limitations on available commands. It

is comparable to running the daisy port on a

TANDBERG Precision HD Camera in dualvisca

mode.

This article covers the use of port 3 as the control

port for the switch. You may use port 0 if you do

not intend to use the THSI interface, but only use

HDMI out.

Enhanced VISCA

Since the switch has two possible camera chains,

all normally formatted commands will be sent to

the primary chain. To access the secondary chain,

you must first turn Enhanced VISCA on with the

SW_eVisca command.

Commands going to the secondary chain must be

prefixed with FE 01. Replies from the secondary

chain will also be prefixed with FE 01. You will only

receive push messages from the secondary chain if

Enhanced VISCA is turned on.

Important: Since the switch can receive VISCA from

either the codec or an external control system, and

since there are two possible camera chains, there

are limitations on how commands are issued and

answered:

Only one command can be processed at a time•

Sending a new command when you receive an •

ACK from a Sony camera is not allowed. ACK

messages will be thrown away by the switch

Reply will always go to the source that issued the •

command.

Sony push messages will be sent to both •

sources.

If this is not expected behaviour, an external control

system may, of course, be setw to control all

connected cameras directly via VISCA.

VISCA Messages

Commands that are prefixed with SW_ are new for

the switch. The CAM_ prefix is used for commands

that are copied from TANDBERG Precision HD

Camera, or are standard VISCA messages.

VISCA Standard Commands

Command Set Command Packet Comments

CAM_IF_Clear 8x 01 00 01 ff Clear command buffer. Stop any current

operation in progress.

CAM_ Address_Set 8x 30 0p ff p = address for this device. If x=8

(broadcast), increase p with 1 before

sending to chain.

CAM_Command_Cancel 8x 2p ff p = Socket ID. Not supported in TVS

CAM_Power 8x 01 04 00 0p ff p = 2: Power on. p = 3: Power off.

VISCA Standard Inquiries

Command Command Packet Comments

IF_DeviceType_Inq 8x 09 00 02 ff y0 50 gg gg hh hh jj jj kk f f

gggg = Vendor ID

hhhh = Model ID

jjjj = ROM Revision

kk = Max sockets

(No support for this in the TANDBERG

Video Switch. Ignore it.)

CAM_Power_Inq 8x 09 04 00 ff y0 50 0p f f

p = 2: Power on.

p = 3: Power off.

VISCA Standard Push Messages

Command Command Packet Comments

CAM_Network_Change x0 38 ff This indicates that cameras have been

added to or removed from the camera

chain.

To avoid issues with (some) Sony

cameras, the control system or

codec should delay 9 seconds before

reconfiguring the chain.

116467.05Page 4 of 6

Configuration Commands

Messages starting with 8x-01-40-<00..1f> are configuration commands.

Inquiries

Messages starting with 8x- 09...

Command Command Packet Comments

SW_Port_0_Cfg 8x 01 40 00 ... ff Currently not in use.

SW_Port_1_Cfg 8x 01 40 01 ... ff Currently not in use.

SW_Port_2_Cfg 8x 01 40 02 0p ff p=0: Disable this port

p=1: Enable this port as a secondary

VISCA chain port for cameras usually

connected to codec input 2-5 (default).

p=2: Use this port as a debug port.

SW_Port_3_Cfg 8x 01 40 03 0p ff p=0: Disable this port

p=1: Enable this port as a dual visca port

(default).

p=2: Use this port as a debug port.

SW_Port_x_Push_Cfg 8x 01 40 04 0p 0q 0r ff Configure which push messages to send

for given por t.

p=0/3: Configure port 0 or 3.

qr bit 0: Enable/disable SW_Input_Push.

qr bit 1: Enable/disable SW_Sync_Push.

qr bit 2: Enable/disable Enhanced VISCA.

qr = 00 is default for both ports.

Switch control commands

Messages starting with 8x-01-40-<20..3f> are switch control commands.

Command Set Command Packet Comments

SW_Input_Set 8x 01 40 20 0p ff Sets which input to use.

p=0..5

This will generate a SW_Input_Push on

the THSI Visca por t if issued from the

dual visca port and vice versa.

Command set Command Packet Reply and comments

CAM_ID_Inq 8x 09 04 22 FF Reply: 90 50 zz xx 00 yy FF

zz xx = switch rev, zz=0x40 for TVS

yy = firmware rev

CAM_SWID_Inq 8x 09 04 23 ff Reply: x0 50 [1-125 bytes SWID] ff.

SW_Input_Inq 8x 09 40 20 ff Reply 90 50 0p ff

p=Active input, 0..5

SW_Sync_Inq 8x 09 40 e0 0p ff Input: p=Input 0..5

Reply: 90 50 0p ff

p=2: Input has sync

p=3: No sync on input

SW_InputFormat_ Inq 8x 09 40 e1 ff Reply: 90 50 0p 0q f f

pq = Format for active input.

0 = 720p60

1 = 720p59.94

2 = 720p50

Push Messages

Command set Push Message Comments

SW_Input_Push x0 01 40 20 0p ff The input has been changed.

p = the new input source

SW_Sync_Push x0 01 40 e0 0p 0q ff Sync state has changed on an input.

This one will also be sent if the format is

changed, so if sync is on, send a SW_

Format_Inq.

p = source 0..5

q = state: 2 = sync, 3 = no sync

Misc.

Command Command Packet Comments

CAM_Boot 8x 01 42 ff Reboot the switch. This will also reset

serial speed to 9600.

www.tandberg.com

116467.05Page 5 of 6

A 㑻ໄᯢ( A Class product declaration)

ᴀѻકЎ A 㑻 ITEˈ݊Փ⫼䇈ᯢ,䫁⠠ㄝᰒ㨫ԡ㕂ЁᏆࣙབϟݙ

ᆍⱘໄᯢ(We declare here that the subject product is A Class ITE

product, and the following statement is clearly marked in the user

manual and nameplate ˖

ໄ ᯢ

ℸЎ A 㑻ѻકˈ ⫳⌏ ⦃๗Ёˈ䆹ѻક ৃ㛑Ӯ䗴៤᮴㒓 ⬉ᑆᡄ DŽ䖭

⾡ᚙމϟˈ ৃ㛑䳔 㽕⫼᠋ᇍ݊ᑆᡄ 䞛পߛ ᅲৃ㸠ⱘᮑDŽ

WARNING:

This is a class A product. In a domestic environment this product may

cause radio interference in which case the user may be required to take

adequate measures.

ໄ

ᯢ᠔ԡ㕂 Position of the Declaration˖

݀ৌ Company Name˖

TANDBERG Telecom AS

ㅒᄫ/Ⲫゴ Signature/ Stamp˖

Disclaimer

The information in this d ocument is fur nished for informational pur poses only, is subject to

change withou t prior notice, and should not be constr ued as a commitm ent by TANDBERG.

TANDBERG reser ves th e right to amend any of the information given in this document in

order to t ake account of new developments.

Every effor t has been mad e to supply complete and accurate information, however, TANDBERG assumes no responsibilit y or liability for any errors or inaccuracies that may appear

in this document, nor for any infringements of patents or other rights of t hird parties resulting from its use. No license is granted under any patents or p atent rights of TANDBERG.

For your p rotec tion please read these safet y instr uctions completely before you con nect the equipment to the power source. Carefully observe all warnings, pre cautions and

instructions both on the apparatus and in these operating instructio ns.

Retain this manual for future reference.

Water and Moisture

Do not operate the apparatus under or near water – for •

example near a bathtub, kitchen sink, or laundry tub, in a wet

basement, near a swimming pool or in other areas with high

humidity.

Do not touch the product with wet hands.•

Cleaning

Unplug the apparatus from communication lines, mains •

power-outlet or any power source before cleaning or

polishing. Do not use liquid cleaners or aerosol cleaners. Use

a lint-free cloth lightly moistened with water for cleaning the

exterior of the apparatus.

Unplug the apparatus from communication lines before •

cleaning or polishing. Do not use liquid cleaners or aerosol

cleaners. Use a lint-free cloth lightly moistened with water for

cleaning the exterior of the apparatus.

Ventilation

Do not block any of the ventilation openings of the apparatus. •

Never cover the slots and openings with a cloth or other

material. Never install the apparatus near heat sources

such as radiators, heat registers, stoves, or other apparatus

(including amplifiers) that produce heat.

Do not place the product in direct sunlight or close to a •

surface directly heated by the sun.

Lightning

Never use this apparatus, or connect/disconnect communication

cables or power cables during lightning storms.

Dust

Do not operate the apparatus in areas with high concentration of

dust.

Vibration

Do not operate the apparatus in areas with vibration or place it

on an unstable sur face.

attempt to connect mains power, or any other power source,

before consulting service personnel.

The plug connecting the power cord to the product power •

supply ser ves as the main disconnect device for this

equipment. The power cord must always be easily accessible.

Route the power cord so as to avoid it being walked on or •

pinched by items placed upon or against it. Pay particular

attention to the plugs, receptacles and the point where the

cord exits from the apparatus.

Do not tug the power cord.•

If the provided plug does not fit into your outlet, consult an •

electrician.

Never install cables, or any peripherals, without first •

unplugging the device from it’s power source.

Always use the power supply (AC–DC adapter) provided with •

this product.

Replace only with power supply (AC–DC adapter) specified •

by TANDBERG.

Never connect the attached power supply (AC –DC adapter) to •

other products.

Servicing

Do not attempt to service the apparatus yourself as opening •

or removing covers may expose you to dangerous voltages or

other hazards, and will void the warranty. Refer all servicing to

qualified service personnel.

Unplug the apparatus from its power source and refer •

servicing to qualified personnel under the following conditions:

If the power cord or plug is damaged or frayed. •

If liquid has been spilled into the apparatus.•

If objects have fallen into the apparatus. •

If the apparatus has been exposed to rain or moisture •

If the apparatus has been subjected to excessive shock by •

being dropped.

If the cabinet has been damaged.•

If the apparatus seems to be overheated. •

If the apparatus emits smoke or abnormal odor.•

If the apparatus fails to operate in accordance with the •

operating instructions.

Power Connection and Hazardous Voltage

The product may have hazardous voltage inside. Never •

attempt to open this product, or any peripherals connected to

the product, where this action requires a tool.

This product should always be powered from an earthed •

power outlet.

Never connect attached power supply cord to other products.•

In case any par ts of the product has visual damage never •

Accessories

Use only accessories specified by the manufacturer, or sold with

the apparatus.

Communication Lines

Do not use communication equipment to repor t a gas leak in the

vicinit y of the leak.

116467.05Page 6 of 6

Loading...

Loading...