System Sensor M500CH User Manual

INSTALLATION AND MAINTENANCE INSTRUCTIONS

M500M Monitor Module and |

|

A Division of Pittway |

M500CH Control Module |

|

3825 Ohio Avenue, St. Charles, Illinois 60174 |

|

1-800-SENSOR2, FAX: 630-377-6495 |

|

Before Installing |

|

must be placed into the barrier and attached to the junc- |

This information is included as a quick reference installation |

|

tion box (Figure 2A). The power-limited wiring must be |

guide. Refer to the control panel installation manual for detailed |

|

placed into the isolated quadrant of the module barrier |

system information. If the modules will be installed in an existing |

|

(Figure 2B). |

operational system, inform the operator and local authority that |

1. |

Install module wiring in accordance with the job drawings and |

the system will be temporarily out of service. Disconnect power |

|

appropriate wiring diagrams (Figures 3 - 9). |

to the control panel before installing the modules. |

2. |

Set the address on the module per job drawings. |

NOTICE: This manual should be left with the owner/user of this |

3. Secure module to electrical box (supplied by installer), as |

|

equipment. |

|

shown in Figure 2A. |

General Description |

Magnet Test |

|

M500M Monitor Modules provide a two-wire, or fault-tolerant, |

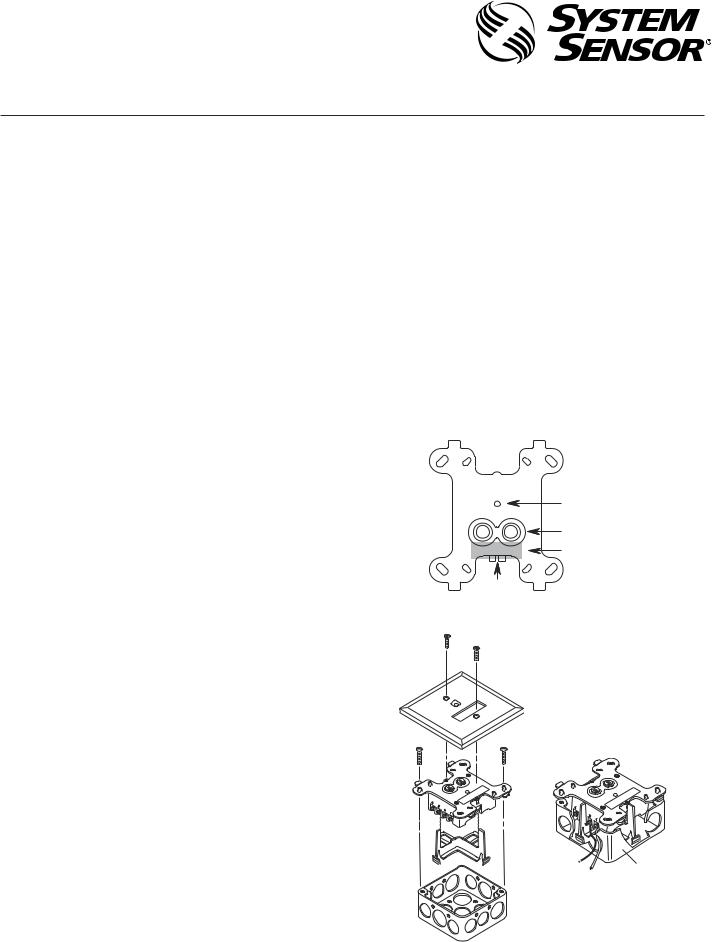

The monitor and control modules can be tested with a test mag- |

|

initiating circuit for normally open contact fire alarm and supervi- |

net available from System Sensor (M02-04-01, see Figure 1). The |

|

sory devices, or either normally open or normally closed security |

magnet test checks the module electronics and connections to the |

|

devices. The LED indicator can be latched on or returned to the |

control panel. Interfaced initiating and indicating devices must be |

|

normal mode by code command from the panel. Convenient rota- |

tested independently. |

|

ry decade switches are used to set the address of each module. |

|

|

M500CH Control Modules allow a compatible control panel to |

|

|

switch discrete contacts by code command. The control module |

Figure 1. Monitor and control module controls and indicators: |

|

has a status LED that can be latched on or returned to the normal |

||

mode by code command from the panel. Rotary decade switches |

|

|

are used to set the address of each module. |

|

|

The control module offers two modes of switching operation. |

|

|

As shipped, the module is configured for switching an external |

|

|

power source to notification appliances. The external power |

|

|

|

|

|

source can be a DC power supply or an audio amplifier (up to |

|

|

|

|

|

70.7 Vrms). In this mode, the module reports supervision status |

|

|

|

|

|

of the connected loads to the control panel. Load circuit status is |

|

|

|

|

|

reported as a NORMAL, OPEN, or SHORTED circuit. Two pairs of |

|

C0554-00 |

output termination points are available for fault-tolerant wiring. |

|

|

|

|

|

The second mode of switching operation allows the panel to con- |

|

|

trol one Form-C (SPDT) set of contacts. Circuit connections to the |

Figure 2A. Module mounting with barrier: |

|

contacts are not supervised by the module. This mode is enabled |

|

|

by breaking two external tabs on the module. |

|

|

Compatibility Requirements |

|

|

To insure proper operation, these modules shall be connected to |

|

|

listed compatible system control panels only. |

|

|

|

|

Figure 2B: |

Mounting M500M and M500CH Devices |

|

|

M500M and M500CH modules mount directly to 4″ square electri- |

|

|

cal boxes as shown in Figure 2A. The box must have a minimum |

|

|

depth of 21⁄8″. |

|

|

Wiring |

|

|

NOTE: All wiring must conform to applicable local codes, ordi- |

|

|

nances and regulations. When using control modules in |

|

|

nonpower limited applications, the System Sensor CB500 |

|

ISOLATED |

|

QUADRANT |

|

Module Barrier must be used to meet UL requirements

for the separation of power-limited and nonpower-lim-

C0485-00

ited terminals and wiring. The barrier must be inserted in a 4″x4″x21⁄8″ junction box, and the control module

C0494-00

M500-05-00 |

1 |

I56-314-14 |

M500M Monitor Module Wiring Diagrams

Figure 3. Typical 2-wire initiating circuit configuration, NFPA Style A or B:

|

|

|

|

|

|

|

|

||

|

|

|||

|

|

|

||

|

|

|

||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|||

|

|

|

||

|

|

|

||

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C0573-00 |

|

|

|

|

|

Figure 4. Typical fault tolerant initiating circuit configuration, NFPA Style D:

|

|

|

|

|

|

|

|||

|

|

|

||

|

|

|||

|

|

|||

|

|

|

||

|

|

|

|

|

|

|

|

||

|

|

|

||

|

|

|

||

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||

|

C0574-00

|

|

|

|

|

|

|

|

|

M500CH Control Module Wiring Diagrams |

|

|

|

|

|

|

|

|

Figure 5. Typical indicating circuit configuration, NFPA Style W: |

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|||

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|||

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|||

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

C0575-00 |

|

|

||

|

M500-05-00 |

2 |

I56-314-14 |

Loading...

Loading...