System Sensor 1451 User Manual

INSTALLATION AND MAINTENANCE INSTRUCTIONS

1451 Plug-in Ionization

Smoke Detector

3825 Ohio Avenue, St. Charles, Illinois 60174 1-800-SENSOR2, FAX: 630-377-6495 www.systemsensor.com

Specifications |

|

Size |

|

Height: |

2.4 inches (6.1 cm) |

Diameter: |

4.0 inches (10.1 cm) |

Weight: |

0.6 lb. (277 g) |

Operating Temperature Range: |

0°C to +49°C (32°F to 120°F) |

Operating Humidity Range: |

10% to 93% Relative Humidity Non-condensing |

Latching Alarm: |

Reset by momentary power interruption. |

|

|

Before installing

Please thoroughly read the System Sensor manual A051003, Applications Guide for System Smoke Detectors, which provides detailed information on detector spacing, placement, zoning, wiring, and special applications. Copies of this manual are available at no charge from System Sensor. (For installation in Canada refer to CAN/ULC-S524, Standard for the Installation of Fire Alarm Systems, and CEC Part 1, Sec. 32.)

NOTICE: This manual should be left with the owner/user of this equipment.

NOTICE: Model 1451 is a direct replacement for Honeywell model TC805C1000

IMPORTANT: This sensor must be tested and maintained regularly following NFPA 72 requirements. This sensor should be cleaned at least once a year.

General Description

Model 1451 dual chamber ionization detectors utilize state- of-the-art, unipolar sensing chambers. These detectors are designed to provide open area protection, and to be used with compatible UL-listed control panels only. The capability of plugging these detectors into a variety of special bases makes them more versatile than equivalent directwired models.

Two LEDs on each detector light to provide a local 360° visible alarm indication. Remote LED annunciator capability is available as an optional accessory. These detectors also have the latching alarm feature. The alarm can be reset only by a momentary power interruption. For testing, these detectors have an internal magnetically activated reed switch.

Model 1451 has been approved for marine use in dry locations by Underwriters Laboratory, Inc. The detector is to be used in dry interior locations only.

Spacing

Spacing of 30 ft. on a smooth ceiling as per NFPA 72E. Where conditions or response requirements vary, other spacing may apply.

Base Selection And Wiring Guide

Refer to the installation instructions for the plug-in detector bases for wiring instructions. System Sensor has available a variety of detector bases for this smoke detector, including 2-wire applications with and without relays and/or current limiting resistors, 4-wire and 120VAC applications. (Note: the 120VAC detector base is not available in Canada.)

All bases are provided with screw terminals for power, ground, remote annunciator connections, and relay contact connections, if applicable. The electrical ratings for each detector-base combination are also included in the base installation instructions.

Installation

NOTE: All wiring must conform to applicable local codes, ordinances, and regulations.

NOTE: Verify that all detector bases are installed, that the initiating-device circuits have been tested, and that the wiring is correct.

WARNING

WARNING

Remove power from initiating-device circuits before installing detectors.

D400-01-01 |

1 |

I56-0278-008R |

1.Install Detectors:

a.Place the detector into the detector base.

b.Turn the detector clockwise until the detector drops into place.

c.Continue turning detector clockwise to lock it in place.

2.Tamper-proof Feature

The detector bases include a feature that, when activated, prevents removal of the detector without the use of a tool. See the installation instruction manual of the detector base for details in using this feature.

3.After all detectors have been installed, apply power to the control unit.

4.Test the detector as described under TESTING.

5.Reset the detector at the system control panel.

6.Notify the proper authorities that the system is in operation.

CAUTION

CAUTION

Dust covers can be used to help limit dust entry to the detector, but they are not a substitute for removing the detector during building construction. Remove any dust covers before placing system in service.

CAUTION

CAUTION

Smoke detectors are not to be used with detector guards unless the combination has been evaluated and found suitable for that purpose.

Testing

Before testing, notify the proper authorities that the smoke detector system is undergoing maintenance and will temporarily be out of service. Disable the zone or system undergoing maintenance to prevent unwanted alarms.

Detectors must be tested after installation and periodic maintenance. The 1451 may be tested as follows:

Before testing the detector, look for the presence of the flashing LEDs. If they do not flash, either power has been lost to the detector (check the wiring), or it is defective (return for repair).

A.Test Magnet (System Sensor Model No. M02-04-00)

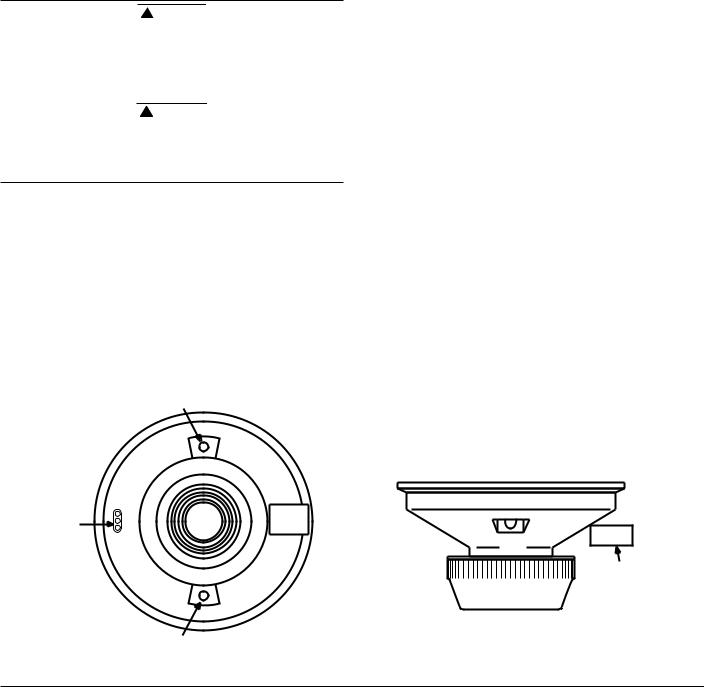

1.Place the magnet against the cover opposite the test module socket. (See Figure 1.)

2.The LEDs on the detector should latch on within 30 seconds.

3.Reset the detector at the system control panel.

B.Test Module (System Sensor Model No. MOD400R)

The MOD400 or MOD400R is used with a digital or analog voltmeter to check the detector sensitivity as described in the test module’s manual.

C.Aerosol Generator (Gemini 501)

Set the generator to represent 4%/ft. to 5%/ft. obscuration as described in the Gemini 501 manual. Using the bowl shaped applicator, apply aerosol until unit alarms.

Notify the proper authorities that the system is back on line.

Detectors that fail these tests should be cleaned as described under MAINTENANCE and retested. If the detectors still fail these tests they should be returned for repair.

Figure 1. Bottom and side views showing test magnet position:

LED

TEST MODULE

SOCKET

LED

TEST

MAGNET

PAINTED

SURFACE

TEST

MAGNET

S0137-00

D400-01-01 |

2 |

I56-0278-008R |

Loading...

Loading...