Page 1

HCD-SBT100/SBT100B/

SBT300W/SBT300WB

SERVICE MANUAL

Ver. 1.0 2013.06

Note:

Be sure to keep your PC used for service and

checking of this unit always updated with the

latest version of your anti-virus software.

In case a virus affected unit was found during

service, contact your Service Headquarters.

• HCD-SBT100 is the compact disc receiver in CMT-SBT100.

• HCD-SBT100B is the compact disc receiver in CMT-SBT100B.

• HCD-SBT300W is the compact disc receiver in CMT-SBT300W.

• HCD-SBT300WB is the compact disc receiver in CMT-SBT300WB.

Amplier section (North American model)

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL HARMONIC

DISTORTION:

(The United States model only)

With 6 ohm loads, both channels driven, from

120 - 10,000 Hz; rated 20 watts per channel

minimum RMS power, with no more than 0.7%

total harmonic distortion from 250 milliwatts to

rated output.

Power output (rated): 20 watts + 20 watts

(at 6 ohms, 1 kHz, 1% THD)

RMS power output (reference): 25 watts + 25 watts

(per channel at 6 ohms, 1 kHz)

Amplier section (Other models)

Power output (rated):

HCD-SBT100/SBT100B:

20 watts + 20 watts (at 6 ohms, 1 kHz, 1% THD)

HCD-SBT300W/SBT300WB:

25 watts + 25 watts (at 6 ohms, 1 k Hz, 1% THD)

RMS power output (reference):

HCD-SBT100/SBT100B:

25 watts + 25 watts (per channel a t 6 ohms,

1kHz)

HCD-SBT300W/SBT300WB:

50 watts + 50 watts (per channel at 6 ohms,

1kHz)

Inputs/Outputs

AUDIO IN:

AUDIO IN (external input) jack:

Stereo mini jack, sensitivity 700 mV,

impedance 47 kilohms

(headphone) jack:

Stereo mini jack, 8 ohms o r more

USB:

Supported bit rate:

MP3 (MPEG 1 Audio Layer-3): 32 kbps - 3 20

kbps, VBR

WMA: 48 kbps - 192 kbps, VBR

AAC: 48 kbps -320 kbps

Sampling frequencies:

MP3 (MPEG 1 Audio Layer-3): 32/44.1/48 kHz

WMA: 44.1 kHz

AAC: 44.1 kHz

USB port:

Type A, 5 V DC 2.1 A

CD-DA/MP3 player section

System:

Compact disc and digital audio system

Laser Diode Properties:

Emission Duration: Continuous

Laser Output*: Less than 44.6 μW

* This output is the value measurement at a

distance of 200mm from the objective lens

surface on the Optical Pick-up Block with 7mm

aperture.

Frequency response:

50 Hz – 20 kHz

Signal-to-noise ratio:

More than 90 dB

Dynamic range:

More than 90 dB

Tuner section

AM tuner section

(HCD-SBT100/SBT300 W only):

Tuning range:

European models:

531 kHz – 1,602 kHz (with 9 kHz tuning

interval)

Other models:

530 kHz – 1,710 kHz (with 10 kHz tuning

interval)

531 kHz – 1,710 kHz (with 9 kHz tuning

interval)

Antenna:

AM loop antenna

Intermediate frequency:

400 kHz

FM tuner section:

FM stereo, FM superheterodyne tuner

North American model:

Tuning range:

87.5 MHz – 108.0 MHz (100 kHz step)

Other models:

Tuning range:

87.5 MHz – 108.0 MHz (50 kHz step)

Antenna:

FM lead antenna

DAB/DAB+ tuner section

(HCD-SBT100B/SBT300W B only):

FM stereo, DAB/FM superheterodyne tuner

Frequency range:

Band-III:

174.928 (5A) MHz – 239.200 (13F) MHz*

* For details, see “DAB/DAB+ frequency table”

below.

Antenna:

DAB/FM lead antenna:

The DAB/DAB+ services are available only in

countries/regions that support DAB/DAB+

services.

Photo: HCD-SBT300WB

SPECIFICATIONS

DAB/DAB+ frequency table (Band-III):

Frequency Label

174.928 MHz 5A

176.640 MHz 5B

178.352 MHz 5C

180.064 MHz 5D

181.936 MHz 6A

183.648 MHz 6B

185.360 MHz 6C

187.072 MHz 6D

188.928 MHz 7A

190.640 MHz 7B

192.352 MHz 7C

194.064 MHz 7D

195.936 MHz 8A

197.648 MHz 8B

199.360 MHz 8C

201.072 MHz 8D

202.928 MHz 9A

204.640 MHz 9B

206.352 MHz 9C

208.064 MHz 9D

209.936 MHz 10A

211.648 MHz 10B

213.360 MHz 10C

215.072 MHz 10D

216.928 MHz 11A

218.640 MHz 11B

220.352 MHz 11C

222.064 MHz 11D

223.936 MHz 12A

225.648 MHz 12B

227.360 MHz 12C

229.072 MHz 12D

230.784 MHz 13A

232.496 MHz 13B

234.208 MHz 13C

235.776 MHz 13D

237.488 MHz 13E

239.200 MHz 13F

* Frequencies are displa yed to two decimal

places on this system.

US Model

Canadian Model

HCD-SBT100

AEP Model

HCD-SBT100/SBT100B/

SBT300W/SBT300WB

UK Model

HCD-SBT100B/SBT300WB

Australian Model

HCD-SBT100/SBT300W/SBT300WB

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM90-DVBU202

Optical Pick-up Block Name CMS-S76RFS7G

BLUETOOTH section

Communication system:

BLUETOOTH Standard version 3.0

Output:

BLUETOOTH Standard Pow er Class 2

Maximum communication range:

Line of sight approx. 10 m

Frequency band:

2.4 GHz band (2.4000 GHz - 2.4835 GHz)

Modulation method:

FHSS

Compatible BLUETOOTH proles*2:

A2DP (Advanced Audio Distribution Prole)

AVRCP (Audio Video Remote Control Prole)

Supported content protection method

SCMS-T method

Transmission bandwidth

20 Hz – 20,000 Hz (with 44.1 kHz sampling)

1

*

The actual range will vary depending on factors

such as obstacles between devices, magnetic

fields around a microwave oven, static

electricity, reception sensitivity, antenna’s

performance, operating system, software

application, etc.

2

*

BLUETOOTH standard profiles indicate the

purpose of BLUETOOTH communication

between devices.

Network section

(HCD-SBT300/SBT300WB only)

LAN port:

RJ-45

10BASE-T/100BASE-TX

(The communication speed may vary

depending on the communication

environment. This system does not

guarantee the communication speed and

quality of 10BASE-T/100BASE-TX.)

*1

Wireless LAN:

Compatible standards:

IEEE 802.11 b/g (WEP 64 bit, WEP 128 bit)

Frequency band 2.4 GHz band (2.4000 GHz -

2.4835 GHz)

Available channels ch1 to ch13

WPA/WPA2-PSK (AES)

WPA/WPA2-PSK (TKIP)

General

Power requirements:

North American model:

AC 120 V, 60 Hz

Other models:

AC 220 V - 240 V, 50 Hz/60 Hz

Power consumption:

35 watts (HCD-SBT100/SBT100B)

36 watts (HCD-SBT300W/SBT300WB)

Dimensions (W/H/D) (incl. projecting parts,

excluding speakers):

Approx. 290 mm × 106 mm × 221 mm

Mass (excluding speakers):

Approx. 2.7 kg

Design and specications are subject to

change without notice.

Standby power consumption: 0.5 W

COMPACT DISC RECEIVER

9-893-759-01

2013F33-1

2013.06

©

Sony Corporation

Published by Sony Techno Create Corporation

Page 2

HCD-SBT100/SBT100B/SBT300W/SBT300WB

Trademarks, etc.

s Windows, the Windows logo, and Windows

Media are either registered trademarks or

trademarks of Microsoft Corporation in the

United States and/or other countries.

s This product is protected by certain intellectual

property rights of Microsoft Corporation. Use or

distribution of such technology outside of this

product is prohibited without a license from

Microsoft or an authorized Microsoft subsidiary.

s AirPlay, the AirPlay logo, iPad, iPhone, iPod,

iPod classic, iPod nano, and iPod touch are

trademarks of Apple Inc., registered in the U.S.

and other countries.

s “ ” is a mark of the Wi-Fi Alliance.

s Wi-Fi®, Wi-Fi Protected Access® and Wi-Fi

Alliance® are registered marks of the Wi-Fi

Alliance.

s Wi-Fi CERTIFIED™, WPA™, WPA2™ and Wi-Fi

Protected Setup™ are marks of the Wi-Fi

Alliance.

s DLNA™, the DLNA Logo and DLNA CERTIFIED™

are trademarks, service marks, or certification

marks of the Digital Living Network Alliance.

s MPEG Layer-3 audio coding technology and

patents licensed from Fraunhofer IIS and

Thomson.

s The BLUETOOTH® word mark and logos are

registered trademarks owned by BLUETOOTH

SIG, Inc. and any use of such marks by Sony

Corporation is under license. Other trademarks

and trade names are those of their respective

owners.

s The N Mark is a trademark or registered

trademark of NFC Forum, Inc. in the United

States and in other countries.

s Android is a trademark of Google Inc.

s “Xperia” and “Xperia Tablet” are trademarks of

Sony Mobile Communications AB.

s The system names and product names indicated

in this manual are generally the trademarks or

registered trademarks of the manufacturer.

™ and ® marks are omitted in this manual.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

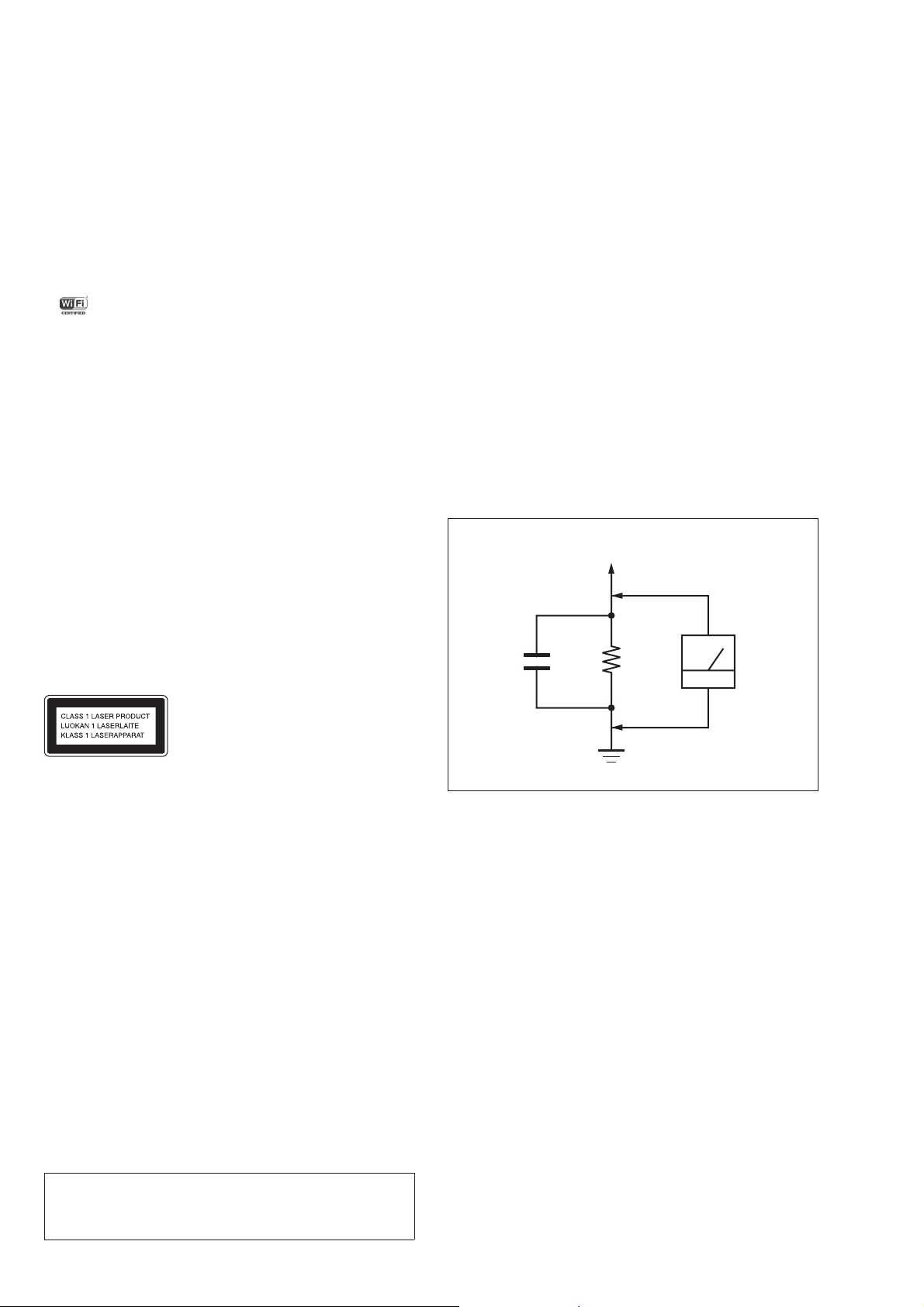

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples

of a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2 V AC range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

AC

1.5 kΩ0.15 μF

voltmeter

(0.75 V)

This appliance is classied as a

CLASS 1 LASER product. This

marking is located on the rear

exterior.

NOTES ON CHIP COMPONENT REPLACEMENT

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specifi ed herein may result in hazardous radia-

tion exposure.

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE 0 SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE

PAR DES PIÈCES SONY DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU DANS LES SUPPLÉMENTS

PUBLIÉS PAR SONY.

2

Page 3

HCD-SBT100/SBT100B/SBT300W/SBT300WB

TABLE OF CONTENTS

1. SERVICING NOTES ............................................. 4

2. DISASSEMBLY

2-1. Disassembly Flow ........................................................... 8

2-2. Case Block ...................................................................... 9

2-3. Plate (CD) Ornament Block ............................................ 9

2-4. Flexible Flat Cable (19P) (FFC6)

(HCD-SBT300W/SBT300WB) ...................................... 10

2-5. Tape (Sub Material) ........................................................ 11

2-6. Panel (Front) Block-1 ..................................................... 12

2-7. Panel (Front) Block-2 ..................................................... 13

2-8. Panel (Back) Block ......................................................... 13

2-9. NET Board Block (HCD-SBT300W/SBT300WB) ........ 14

2-10. WiFi Module (WIFI1), NET Board

(HCD-SBT300W/SBT300WB) ...................................... 14

2-11. 2.4GHz Antenna (ANT1), Holder (Antenna)

(HCD-SBT300W/SBT300WB) ...................................... 15

2-12. Chassis (Main) Block-1 .................................................. 16

2-13. Chassis (Main) Block-2 .................................................. 17

2-14. TUNER Board (HCD-SBT100/SBT300W) ................... 18

2-15. Module (DAB Tuner) (DAB1), DAB Board

(HCD-SBT100B/SBT300WB) ....................................... 18

2-16. MAIN Board ................................................................... 19

2-17. Power Cord (AC1) .......................................................... 19

2-18. POWER Board ................................................................ 20

2-19. CD Mechanism Deck Block ........................................... 21

2-20. FFC Holder ..................................................................... 21

2-21. Optical Pick-up (CMS-S76RFS7G) (OP1) ..................... 22

3. TEST MODE ............................................................ 23

4. ELECTRICAL CHECKS ...................................... 25

5. DIAGRAMS

5-1. Block Diagram - CD Section - ........................................ 27

5-2. Block Diagram - AUDIO Section - ................................. 28

5-3. Block Diagram

- PANEL/POWER SUPPLY Section - ............................ 29

5-4. Schematic Diagram - MAIN Section (1/7) - ................... 31

5-5. Schematic Diagram - MAIN Section (2/7) - ................... 32

5-6. Schematic Diagram - MAIN Section (3/7) - ................... 33

5-7. Schematic Diagram - MAIN Section (4/7) - ................... 34

5-8. Schematic Diagram - MAIN Section (5/7) - ................... 35

5-9. Schematic Diagram - MAIN Section (6/7) - ................... 36

5-10. Schematic Diagram - MAIN Section (7/7) - ................... 37

5-11. Printed Wiring Boards - MAIN Section (1/2) - .............. 38

5-12. Printed Wiring Board - MAIN Section (2/2) - ................ 39

5-13. Printed Wiring Boards - USB/HP/RELAY Boards - ....... 40

5-14. Schematic Diagram - USB/HP/RELAY Boards - ........... 41

5-15. Printed Wiring Board

- NET Board (HCD-SBT300W/SBT300WB) - .............. 42

5-16. Schematic Diagram

- NET Board (HCD-SBT300W/SBT300WB) - .............. 43

5-17. Printed Wiring Board - FL Board - ................................. 44

5-18. Schematic Diagram - FL Board - .................................... 45

5-19. Printed Wiring Boards - KEY/ILLUMI Boards - ........... 46

5-20. Schematic Diagram - KEY/ILLUMI Boards - ............... 47

5-21. Schematic Diagram - POWER Board - .......................... 48

5-22. Printed Wiring Board - POWER Board - ........................ 49

6. EXPLODED VIEWS

6-1. Case Section .................................................................... 65

6-2. Base (CD) Section .......................................................... 66

6-3. FL Board Section ............................................................ 67

6-4. Panel (Front) Section ...................................................... 68

6-5. Panel (Back) Section ....................................................... 69

6-6. MAIN Board Section ...................................................... 70

6-7. Chassis Section ............................................................... 71

6-8. CD Mechanism Deck Section (CDM90-DVBU202) ..... 72

7. ELECTRICAL PARTS LIST .............................. 73

3

Page 4

HCD-SBT100/SBT100B/SBT300W/SBT300WB

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated by

the charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The fl exible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc refl ective surface by the objective lens in the optical

pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to fl ow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

CHECKING THE OPERATION AFTER REPAIR

After repair completion, connect the “iPod” etc. corresponding to

this unit, and check the operation of playback (HCD-SBT300W/

SBT300WB only), charge, etc.

NOTE OF PERFORMING THE OPERATION CHECK IN

THE STATE THAT HEAT SINK WAS REMOVED

When performing the operation check in the state that this unit was

disassembled, it is possible to perform the operation check in the

state that heat sink was removed. But perform the operation check

in the volume state as low as possible.

TEST DISCS

Use following TEST DISC (for CD) when this unit confi rms the

operation and checks it.

Part No. Description

3-702-101-01 DISC (YEDS-18), TEST

4-225-203-01 DISC (PATD-012), TEST

RELEASING THE DISC TRAY LOCK

The disc tray lock function for the antitheft of sample disc in the

shop is equipped.

Releasing Procedure:

1. Press the [

] button to turn the power on.

?/1

2. Press the [FUNCTION] button to turn the CD function.

3. Press two buttons of the [x] and [Z] simultaneously for fi ve

seconds.

4. The message “UNLOCKED” is displayed on the fl uorescent

indicator tube and the disc tray is unlocked.

Note: When “LOCKED” is displayed, the disc tray lock is not released by

turning power on/off with the [

?/1

] button.

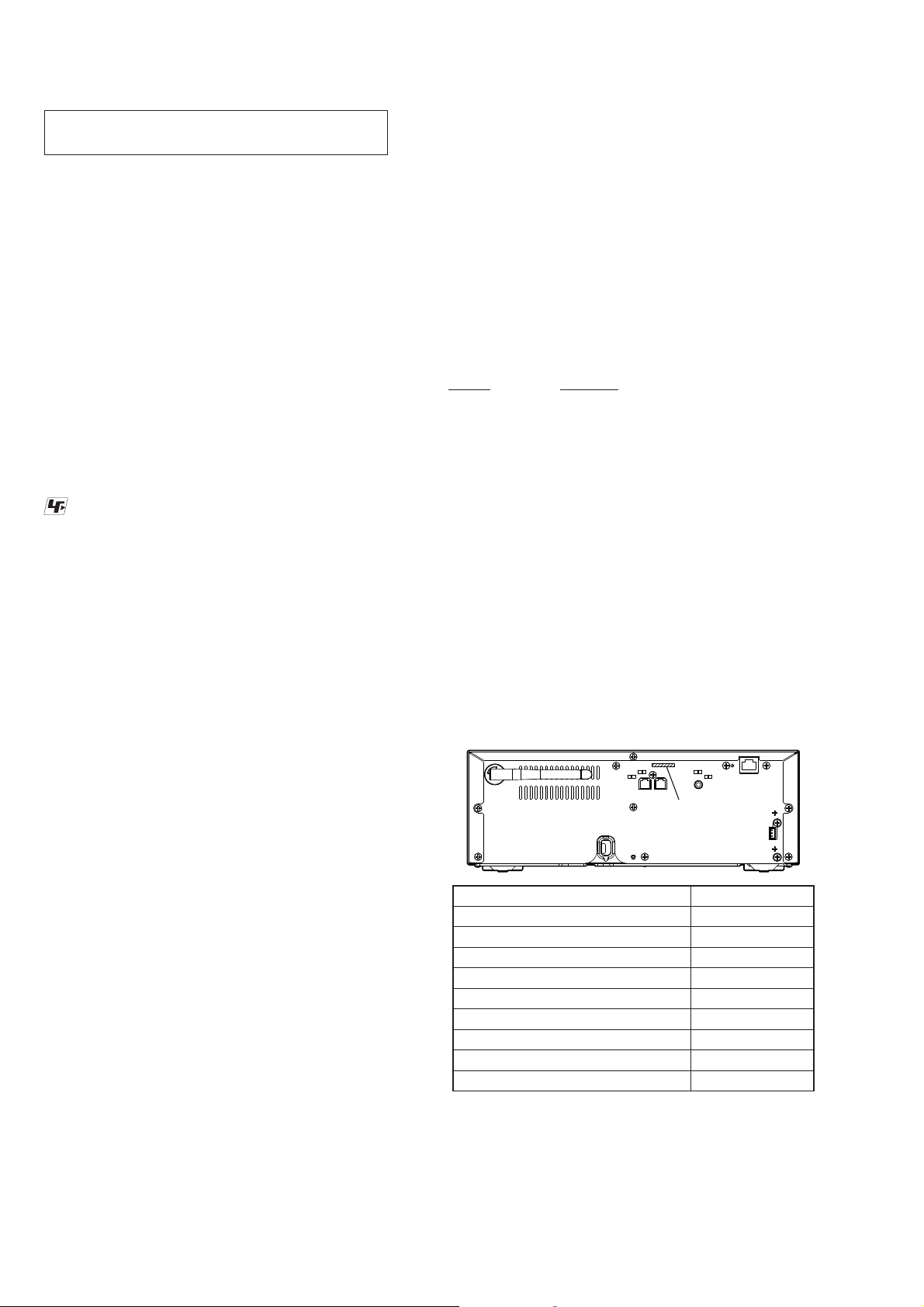

MODEL IDENTIFICATION

Distinguish by Part No. on the rear side of a main unit.

– Rear Panel –

NOTE OF REPLACING THE TUNER BOARD

When the TUNER board is defective, exchange the complete

mounted board.

NOTE OF REPLACING THE DAB BOARD

When the DAB board is defective, exchange the complete mounted board.

NOTE OF REPLACING THE MS-476 BOARD

When the MS-476 board is defective, exchange the CDM90 ASSY

(Ref. No. CDM1).

NOTE OF REPLACING THE IC501, IC502, IC504, IC702,

IC841, IC851, IC902, IC903 AND IC904 ON THE MAIN

BOARD

IC501, IC502, IC504, IC702, IC841, IC851, IC902, IC903 and

IC904 on the MAIN board cannot exchange with single. When

these parts are damaged, exchange the complete mounted board.

NOTE OF REPLACING THE IC5003 ON THE NET BOARD

IC5003 on the NET board cannot exchange with single. When this

part is damaged, exchange the complete mounted board.

NOTE OF REPLACING THE IC5008 ON THE USB BOARD

IC5008 on the USB board cannot exchange with single. When this

part is damaged, exchange the complete mounted board.

Model Part No.

HCD-SBT100: AEP model

HCD-SBT100: US model

HCD-SBT100: Canadian model

HCD-SBT100: Australian model

HCD-SBT100B: AEP and UK models

HCD-SBT300W: AEP model

HCD-SBT300W: Australian model

HCD-SBT300WB: AEP and UK models

HCD-SBT300WB: Australian model

PART No.

4-462-108-0[]

4-462-108-1[]

4-462-108-2[]

4-462-108-3[]

4-462-108-7[]

4-463-724-0[]

4-463-724-1[]

4-463-724-2[]

4-463-724-4[]

4

Page 5

HCD-SBT100/SBT100B/SBT300W/SBT300WB

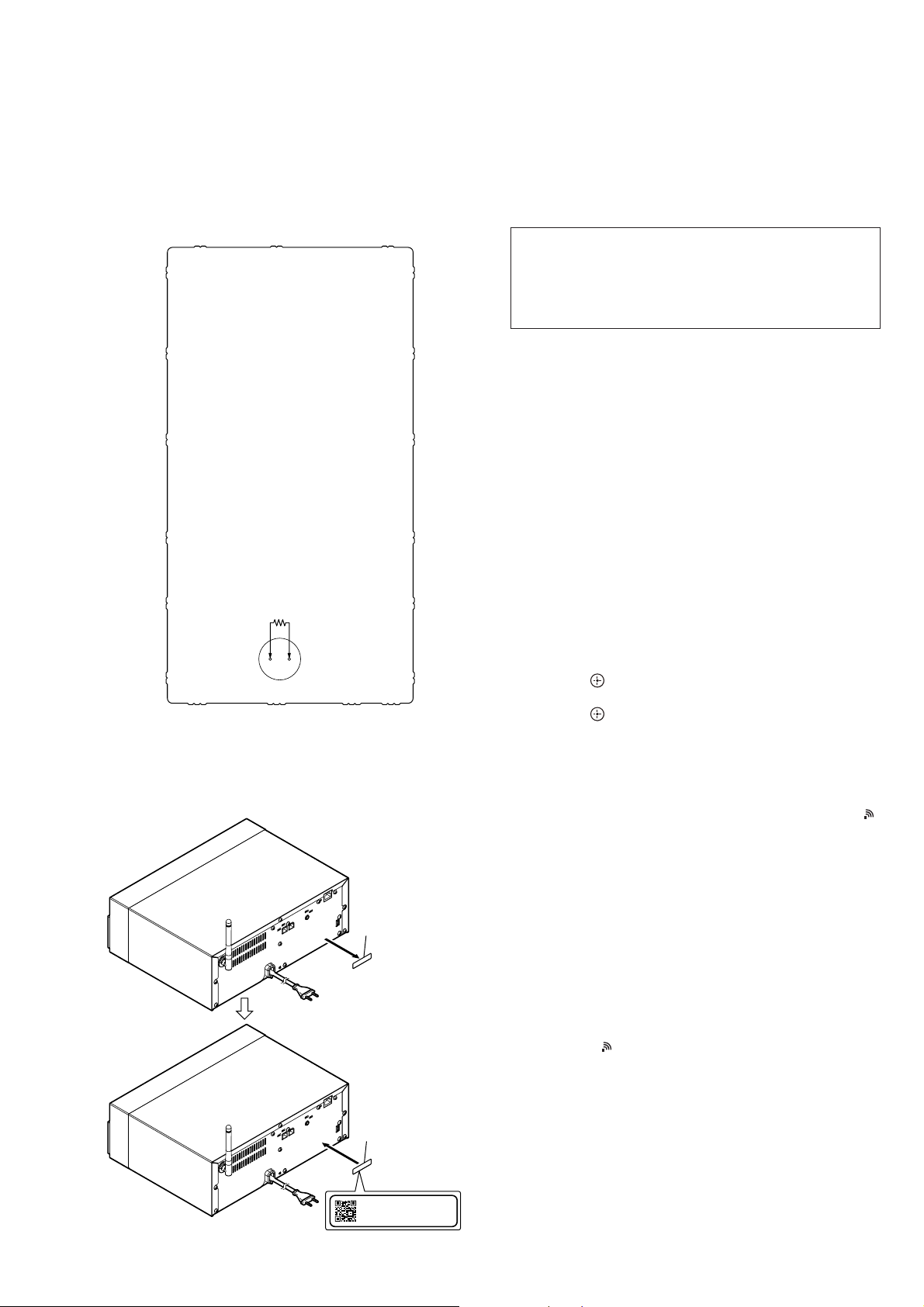

CAPACITOR ELECTRICAL DISCHARGE PROCESSING

When checking the board, the electrical discharge is necessary for

the electric shock prevention.

Connect the resistor to both ends of respective capacitors.

• POWER board

C967

– POWER Board (Conductor Side) –

NOTE OF REPLACING THE WiFi MODULE (Ref. No.

WIFI1) (HCD-SBT300W/SBT300WB only)

When replacing the WiFi module (Ref. No. WIFI1), MAC address

is changed. Print the following explanation, cut it, and hand over

it to the customer with the unit, when returning the unit that the

repair is completed to the customer.

MAC address of this unit has been changed by this repair. The

customer who uses the MAC address fi ltering function of con-

nected access point equipment please set it again. MAC address

is possible to confi rm it on the Sony Network Device Setting

screen. Please refer to “Network connections” on the operating

instructions for details.

CHECKING METHOD OF NETWORK CONNECTION

(HCD-SBT300W/SBT300WB only)

It is necessary to check the network connection, when replacing

the complete MAIN board, complete NET board, IC101 on the

MAIN board or WiFi module (Ref. No. WIFI1). Check the connection of wireless and wired LAN, according to the following

method.

1. Checking Method of Wireless LAN Connection

Necessary Equipment:

• Access point supporting WPS

800 Ω/2 W

C967

PROCESSING OF REPLACING THE WiFi MODULE

(Ref. No. WIFI1) (HCD-SBT300W/SBT300WB only)

When replacing the WiFi module (Ref. No. WIFI1), peel the device ID label stuck on the rear side of a main unit, and stick on the

new device ID label (refer to the following fi gure) enclosed with

the new WiFi module (Ref. No. WIFI1)

1 Peel the device

ID label.

Procedure:

1. Press the [

] button to turn the power on.

?/1

2. Press the [OPTIONS] button on the remote commander to the

display the setting menu on the fl uorescent indicator tube.

3. Press the [V]/[v] buttons on the remote commander to select

“WPS”.

4. Press the [ ] button on the remote commander.

(“OK” fl ashes on the fl uorescent indicator tube)

5. Press the [ ] button on the remote commander.

(“WPS” fl ashes on the fl uorescent indicator tube)

6. Press the [WPS] button on the access point.

7. When wireless LAN connection is started, “CONNECT”

fl ashes on the fl uorescent indicator tube.

8. When wireless LAN connection is completed, “COMPLETE”

appears for a moment on the fl uorescent indicator tube, then “

”

appears on the fl uorescent indicator tube.

9. Press the [

Note: Refer to the instruction manual about details of the setting method.

] button to turn the power off.

?/1

2. Checking method of wired LAN connection

Necessary Equipment:

• Router

• Network (LAN) cable

Procedure:

1. Connect the main unit to the router with the LAN cable.

2. Press the [

] button to turn the power on.

?/1

3. Check that “ ” appears on the fl uorescent indicator tube.

4. Press the [

Note: Refer to the instruction manual about details of the setting method.

] button to turn the power off.

?/1

– Rear view –

2 Stick on the new

device ID label.

Device ID: XXXXXXXXXXXXX

MAC Address: XX-XX-XX-XX-XX-XX

5

Page 6

HCD-SBT100/SBT100B/SBT300W/SBT300WB

HOW TO OPEN THE TRAY WHEN POWER SWITCH TURN OFF

Note 1: After the case is removed, this work is done.

Note 2: Please prepare the thin wire (clip etc. processed to the length of 8 cm or more).

hole

– Side view –

Insert the clip etc. processed to the

length of 8 cm or more in the hole

on the side of the chassis and push.

HP board

CD mechanism deck

8 cm or more

tray

Push after it inserts it

Note:

in these three holes well.

– Top view –

NET BOARD, WiFi MODULE SERVICE POSITION

WiFi module (WIFI1)

NET board

2 Draw out the tray.

1 Insert the clip etc. in the hole

of the chassis, and push the

lever in the direction of the

arrow.

6

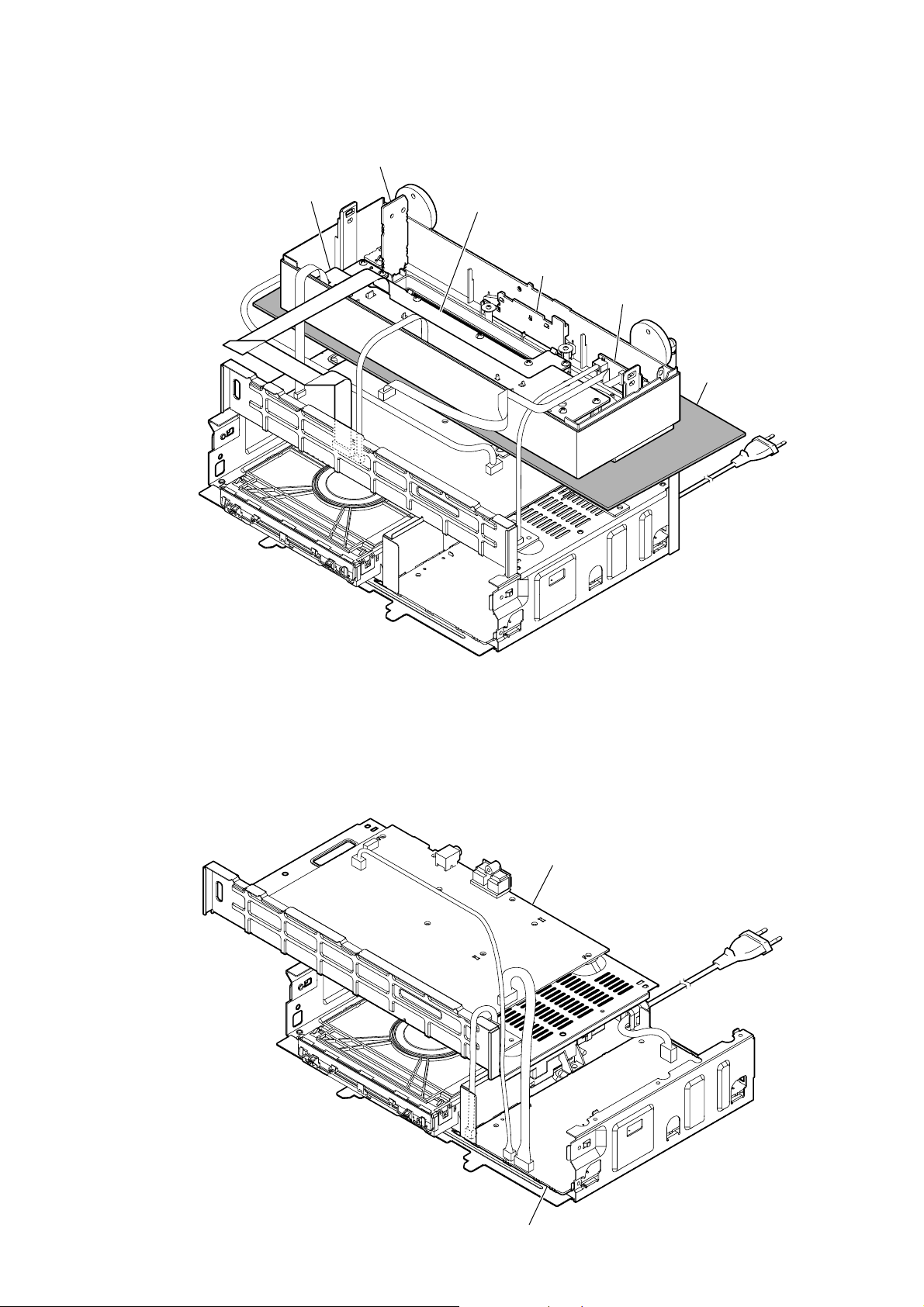

Page 7

FL, HP, KEY BOARDS SERVICE POSITION

HP board

HCD-SBT100/SBT100B/SBT300W/SBT300WB

FL board

KEY board

ILLUMI board

USB board

insulating sheet

MAIN, POWER BOARDS SERVICE POSITION

MAIN board

POWER board

7

Page 8

HCD-SBT100/SBT100B/SBT300W/SBT300WB

SECTION 2

DISASSEMBLY

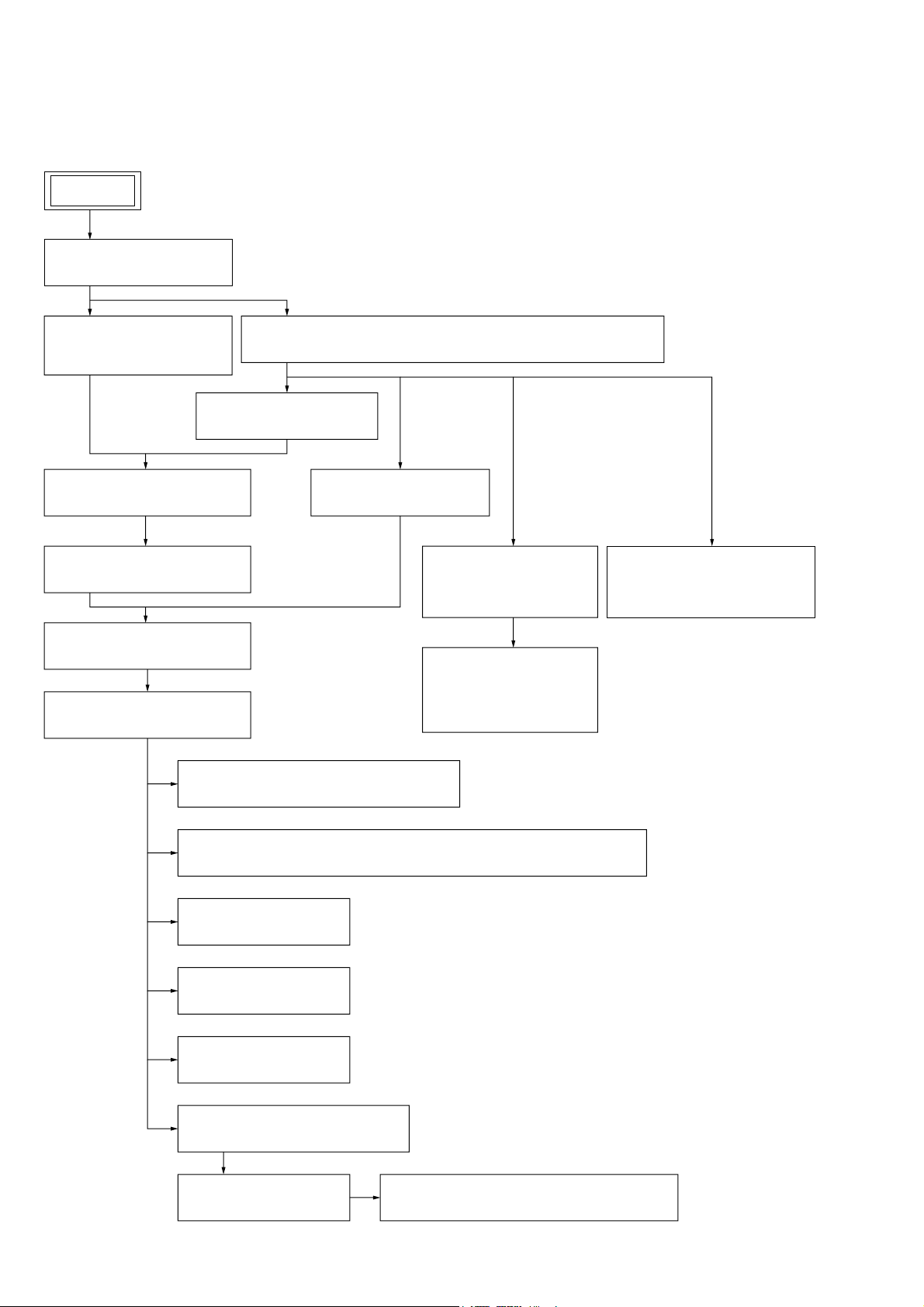

• This set can be disassembled in the order shown below.

2-1. DISASSEMBLY FLOW

SET

2-2. CASE BLOCK

(Page 9)

2-3. PLATE (CD) ORNAMENT

BLOCK

(Page 9)

2-5. TAPE (SUB MATERIAL)

(Page 11)

2-6. PANEL (FRONT) BLOCK-1

(Page 12)

2-7. PANEL (FRONT) BLOCK-2

(Page 13)

2-12. CHASSIS (MAIN) BLOCK-1

(Page 16)

2-13. CHASSIS (MAIN) BLOCK-2

(Page 17)

2-14. TUNER BOARD (HCD-SBT100/SBT300W)

(Page 18)

2-4. FLEXIBLE FLAT CABLE (19P) (FFC6) (HCD-SBT300W/SBT300WB)

(Page 10)

2-8. PANEL (BACK) BLOCK

(Page 13)

2-9. NET BOARD BLOCK

(HCD-SBT300W/

SBT300WB)

(Page 14)

2-10. WiFi MODULE (WIFI1),

NET BOARD

(HCD-SBT300W/

SBT300WB)

(Page 14)

2-11. 2.4GHz ANTENNA (ANT1),

HOLDER (ANTENNA)

(HCD-SBT300W/SBT300WB)

(Page 15)

2-15. MODULE (DAB TUNER) (DAB1), DAB BOARD (HCD-SBT100B/SBT300WB)

(Page 18)

2-16. MAIN BOARD

(Page 19)

2-17. POWER CORD (AC1)

(Page 19)

2-18. POWER BOARD

(Page 20)

2-19. CD MECHANISM DECK BLOCK

(Page 21)

2-20. FFC HOLDER

(Page 21)

2-21. OPTICAL PICK-UP (CMS-S76RFS7G) (OP1)

(Page 22)

8

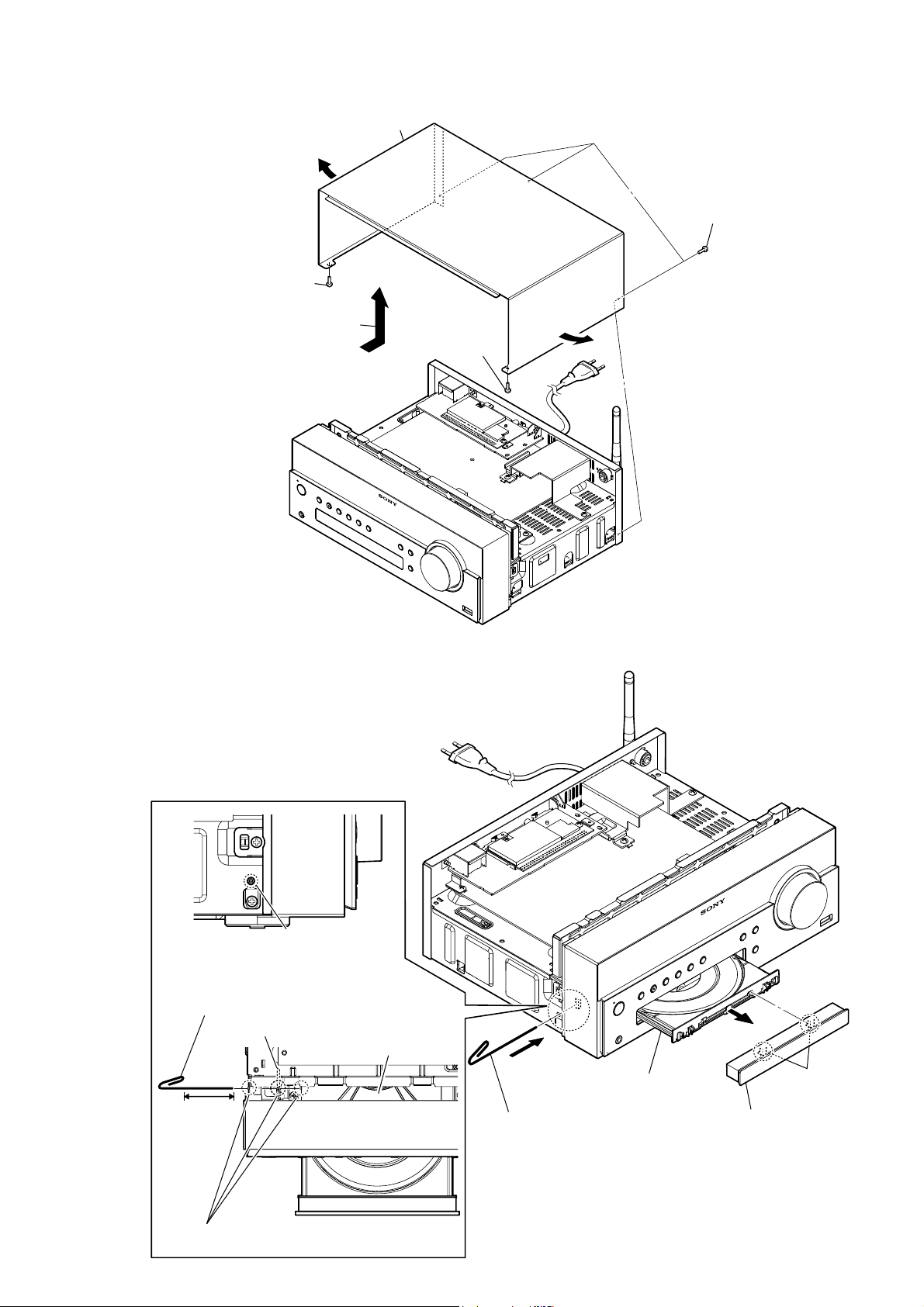

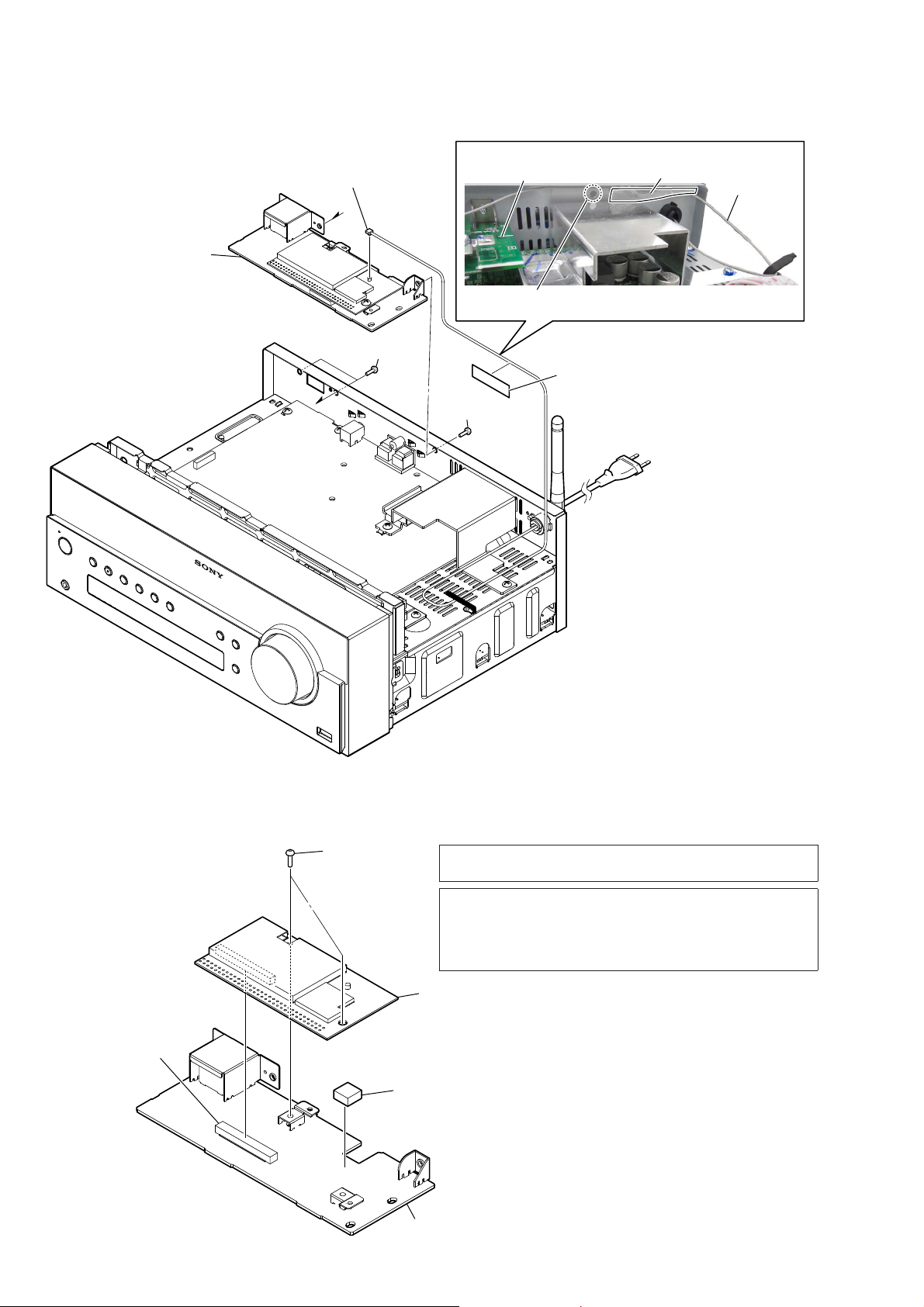

Page 9

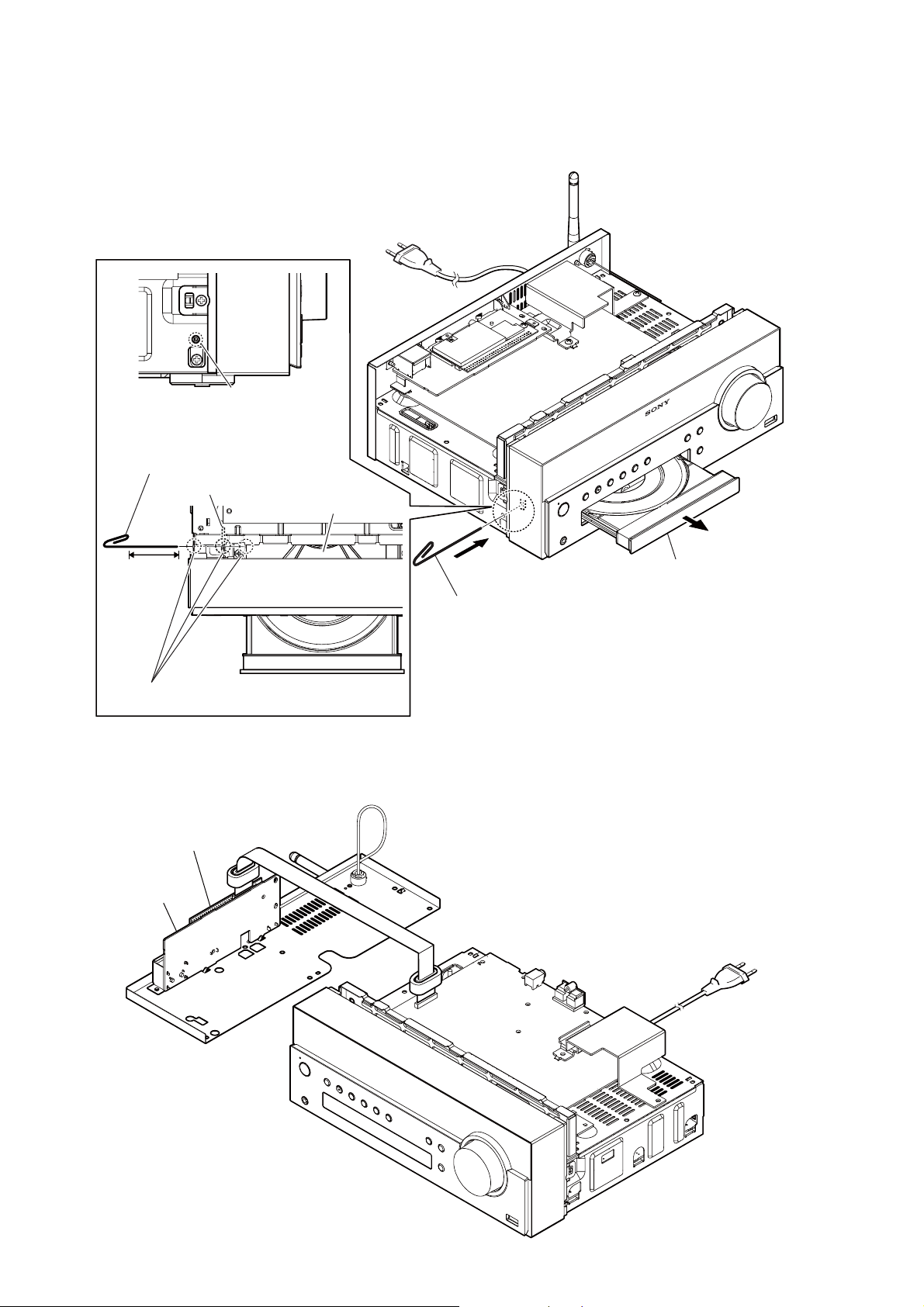

Note: Follow the disassembly procedure in the numerical order given.

2-2. CASE BLOCK

4 case block

2

1 screw (BVTP S3 u 6)

HCD-SBT100/SBT100B/SBT300W/SBT300WB

1 three screws

(BVTP S3 u 6)

3 Remove the case block in the

direction of an arrow.

2-3. PLATE (CD) ORNAMENT BLOCK

1 screw

(BVTP S3 u 6)

2

hole

– Side view –

Insert the clip etc. processed to the

length of 8 cm or more in the hole

on the side of the chassis and push.

HP board

8 cm or more

Push after it inserts it

Note:

in these three holes well.

CD mechanism deck

tray

– Top view –

2 Draw out the tray.

1 Insert the clip etc. in the hole

of the chassis, and push the

lever in the direction of the

arrow.

3 two claws

4 plate (CD) ornament

block

9

Page 10

HCD-SBT100/SBT100B/SBT300W/SBT300WB

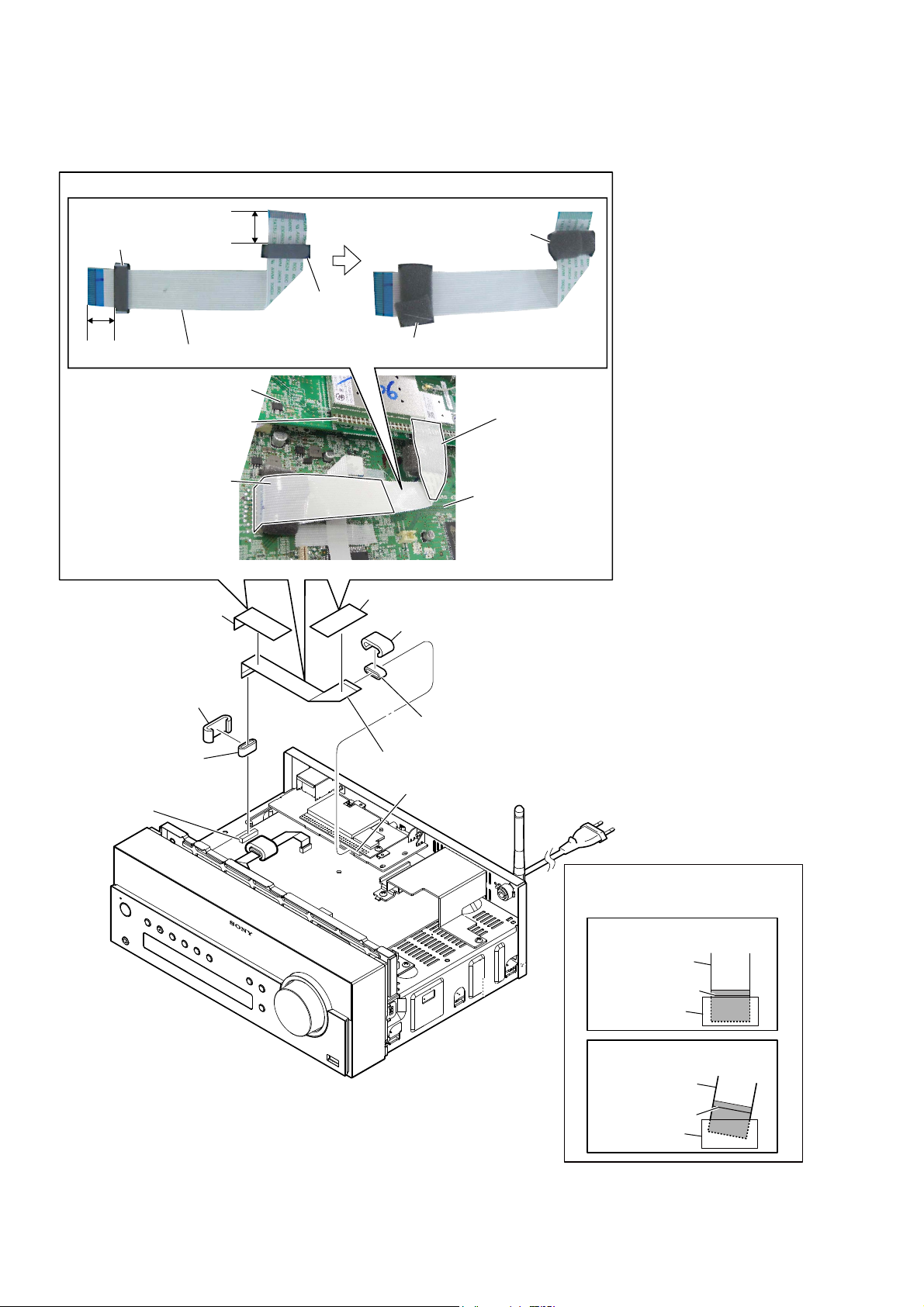

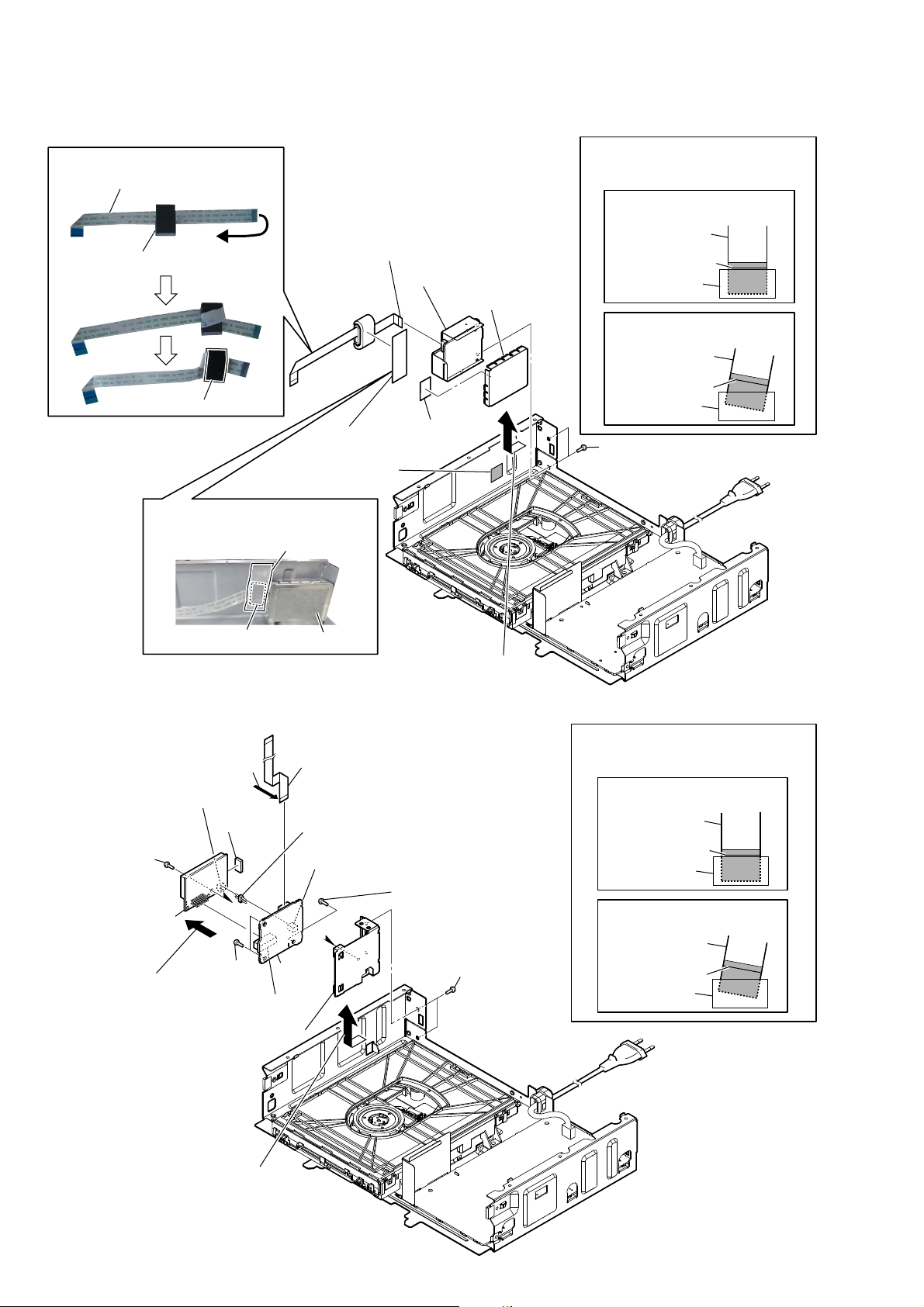

2-4. FLEXIBLE FLAT CABLE (19P) (FFC6) (HCD-SBT300W/SBT300WB)

)OH[LEOHIODWFDEOH3))&VHWWLQJ

ferrite core (FC3)

15 to 20 mm

1 tape

(sub material)

15 to 20 mm

ferrite

core

(FC4)

flexible flat cable (19P) (FFC6)

NET board

WiFi module

tape

(sub material)

cushion (S)

1 tape

(sub material)

cushion (S)

4

cushion (S)

tape

(sub material)

MAIN board

4

5 ferrite core

(FC3)

3 connector

(CN408)

cushion (S)

6 ferrite core

flexible flat cable (19P) (FFC6)

7

2 connector

(CN5010)

(FC4)

When installing the flexible flat cable,

Note:

ensure the colored line.

No slanting after insertion.

Inserting is straight to the interior.

flexible flat cable

flexible flat cable

colored line

OK

colored line

connector

NG

Inserting is slant.

connector

10

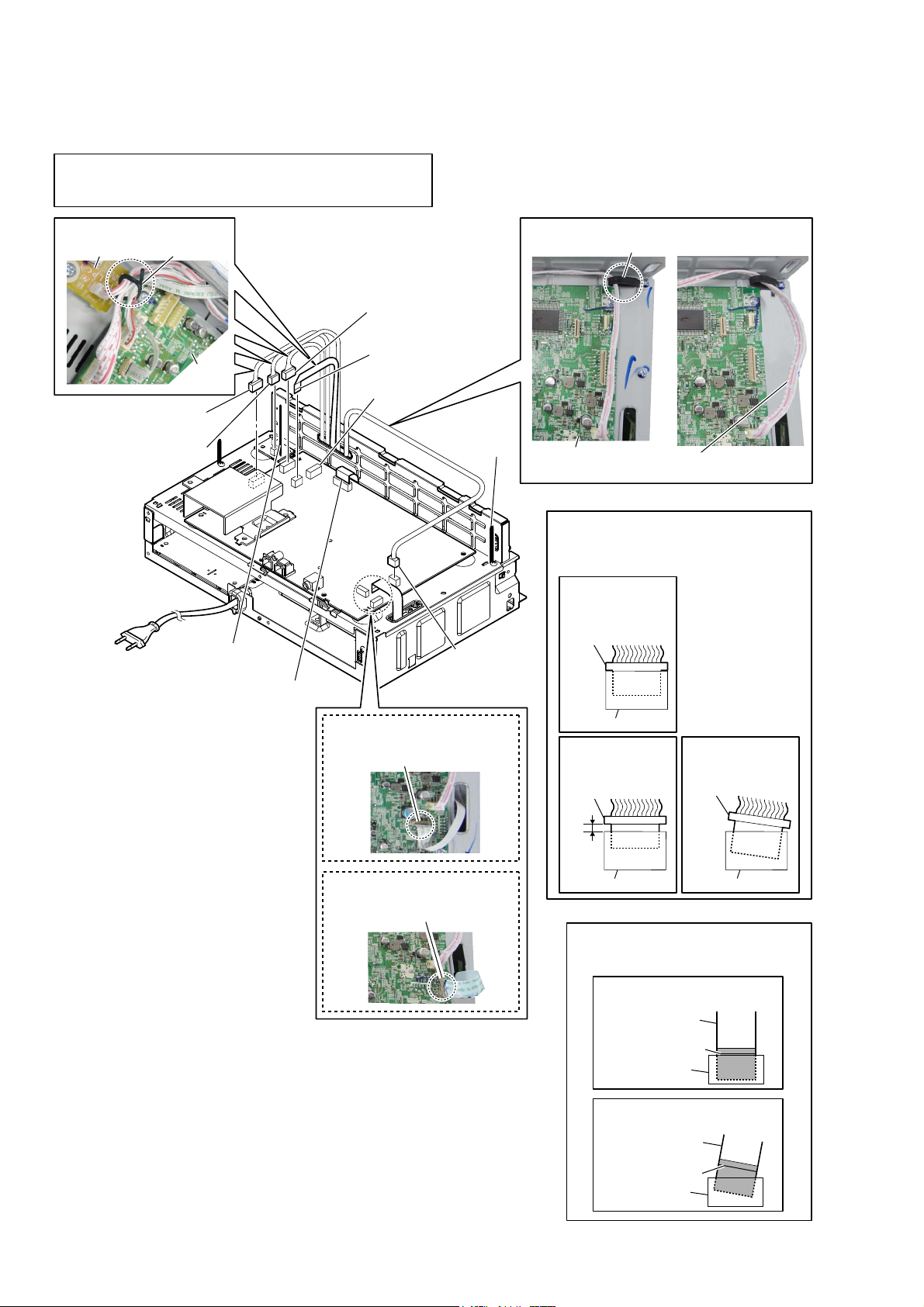

Page 11

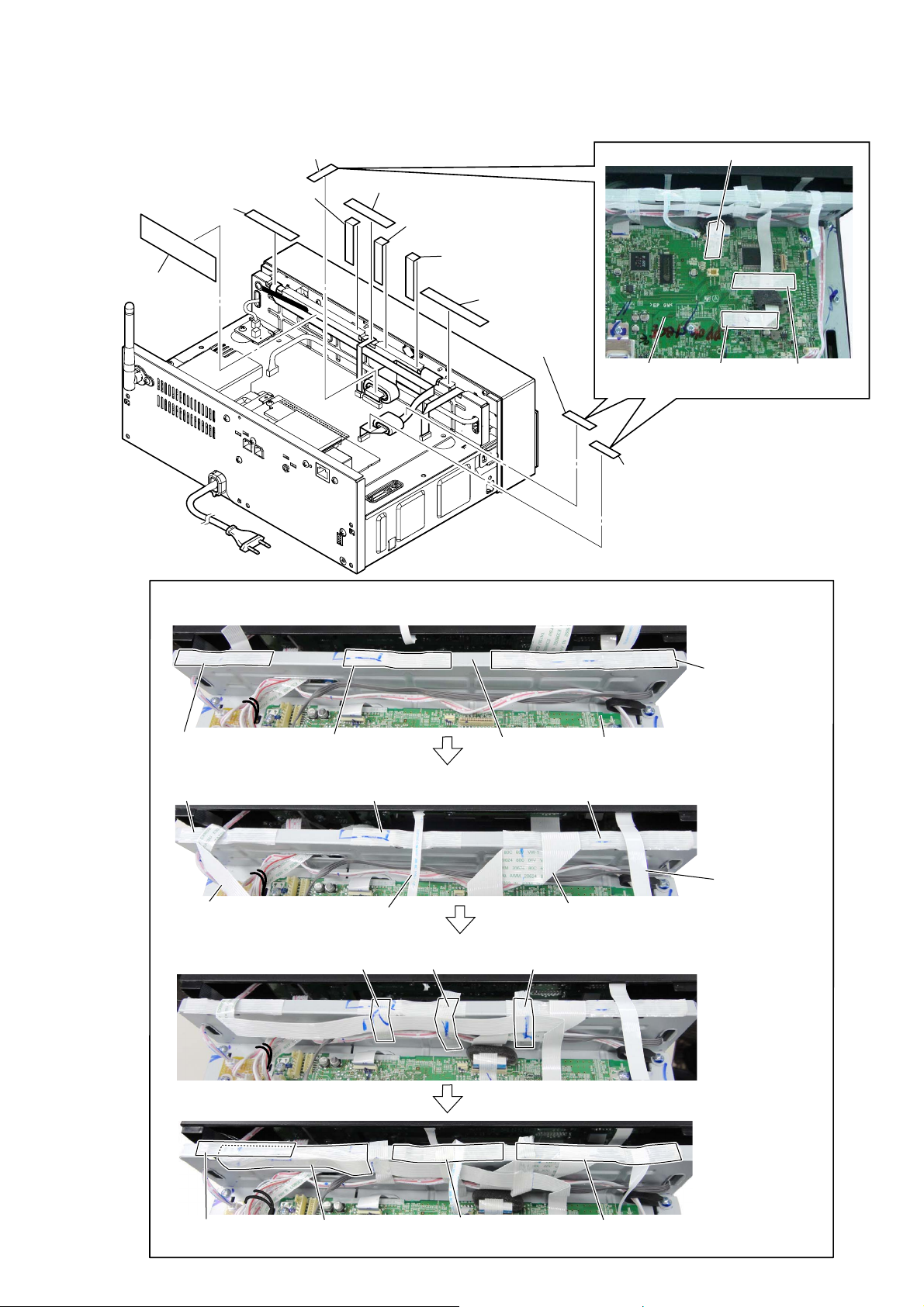

2-5. TAPE (SUB MATERIAL)

1 tape

(sub material)

HCD-SBT100/SBT100B/SBT300W/SBT300WB

:LUHVHWWLQJ

tape (sub material)

5 tape

(sub material)

6 tape

(sub material)

:LUHVHWWLQJ

1 Check that three tapes are pasted to the chassis (main).

3 tape

(sub material)

4 tape

(sub material)

3 tape

(sub material)

3 tape

(sub material)

–5HDUYLHZ–

2 tape

(sub material)

1 tape

(sub material)

MAIN board

1 tape

(sub material)

tape

(sub material)

tape

(sub material)

tape (sub material)tape (sub material)

2 Place the cable of each on top of tapes (sub material).

tape (sub material)

flexible flat cable (9P)

3 Paste three tapes (sub material).

tape (sub material)

4 Paste five tapes (sub material).

tape (sub material) tape (sub material)

flexible flat cable (8P)

tape (sub material) tape (sub material)

chassis (main)

MAIN board

flexible flat cable (17P)

tape

(sub material)

flexible flat cable

(14P)

tape

(sub material)

tape

(sub material)

tape

(sub material)

tape

(sub material)

11

Page 12

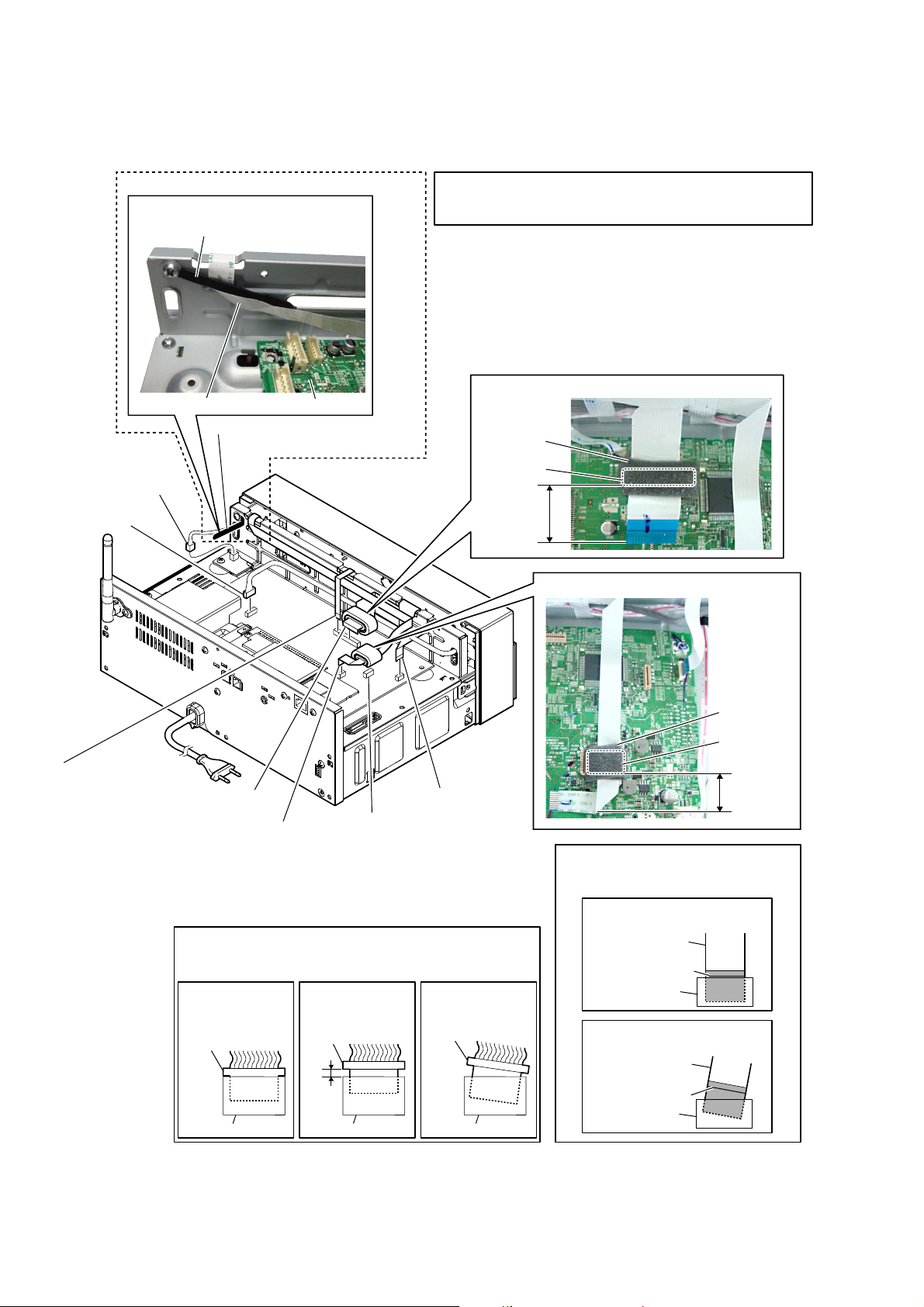

HCD-SBT100/SBT100B/SBT300W/SBT300WB

2-6. PANEL (FRONT) BLOCK-1

86&DQDGLDQ

)OH[LEOHIODWFDEOH3VHWWLQJ

coating clip

flexible flat cable (9P) MAIN board

7 Remove the flexible flat cable (9P)

from the coating clip.

6 connector

(CN906)

5 connector

(CN3001)

Note 1:

Do not insert to the wrong connector absolutely.

There is a possibility that the unit may be damaged if the wrong.

CN106 and CN340 are quantity of pins of the same.

)HUULWHFRUH)&VHWWLQJ

cushion (S)

ferrite core

(FC1)

20 to 25 mm

1 flexible flat cable (8P)

(CN404)

4 flexible flat cable (17P)

(CN506)

2 flexible flat cable (14P)

(CN407)

3 flexible flat cable (9P)

(CN340)

When you install the connector, please install them correctly.

Note 2:

There is a possibility that this machine damages when not

correctly installing it.

Insert is straight

to the interior.

connector

CN106

–5HDUYLHZ–

NGOK NG

Insert is shallow

connector

Insert is incline

connector

)HUULWHFRUH)&VHWWLQJ

When installing the flexible flat cable,

Note 3:

ensure the colored line.

No slanting after insertion.

Inserting is straight to the interior.

flexible flat cable

flexible flat cable

OK

colored line

connector

NG

Inserting is slant.

cushion (S)

ferrite core

(FC2)

15 to 20 mm

12

connector

colored line

connector

connector connector

Page 13

2-7. PANEL (FRONT) BLOCK-2

2 two screws

(BV3)

4 Draw out the wire.

1 screw

(BVTP S3 u 6)

HCD-SBT100/SBT100B/SBT300W/SBT300WB

:LUHVHWWLQJ

5 panel (front) block

Arrange the wire so as not to overlap

Note:

with the screw hole of HP board.

1 screw

(BVTP S3 u 6)

– Rear view –

2-8. PANEL (BACK) BLOCK

6%7:6%7:%

:LUHVHWWLQJ

coating clip

antenna wire

4 Draw out

the wire.

3 Remove the panel (front) block

in the direction of an arrow.

1 Remove the antenna wire

from the coating clip.

1 screw

(BVTP S3 u 6)

2 two screws (BV3)

– Left view –

2 three screws

(BVTP3 u 8)

–5HDUYLHZ–

3 panel (back) block

2 two screws

(BVTP3 u 8)

13

Page 14

HCD-SBT100/SBT100B/SBT300W/SBT300WB

2-9. NET BOARD BLOCK (HCD-SBT300W/SBT300WB)

5 NET board block

1 antenna connector

(CON2)

A

3 two screws

(BVTT3 u 6)

A

:LUHVHWWLQJ

NET board

Note:

with the screw hole of panel (rear).

4 screw

(BVTP3 u 8)

tape

(sub material)

antenna wire

Arrange the antenna wire so as not to overlap

2 tape

(sub material)

2-10. WiFi MODULE (WIFI1), NET BOARD (HCD-SBT300W/SBT300WB)

1 two screws

(BVTT3 u 6)

2 connector

(CN5002)

4 cushion

(poron T5.5)

Note 1: When the complete NET board is replaced, refer to “CHECK-

ING METHOD OF NETWORK CONNECTION” on page 5.

Note 2: When the WiFi module (Ref. No. WIFI1) is replaced, refer to

“PROCESSING OF REPLACING THE WiFi MODULE (Ref.

No. WIFI1)”, “NOTE OF REPLACING THE WiFi MODULE

(Ref. No. WIFI1)” and “CHECKING METHOD OF NETWORK CONNECTION” on page 5.

3 WiFi module (WIFI1)

5 NET board

14

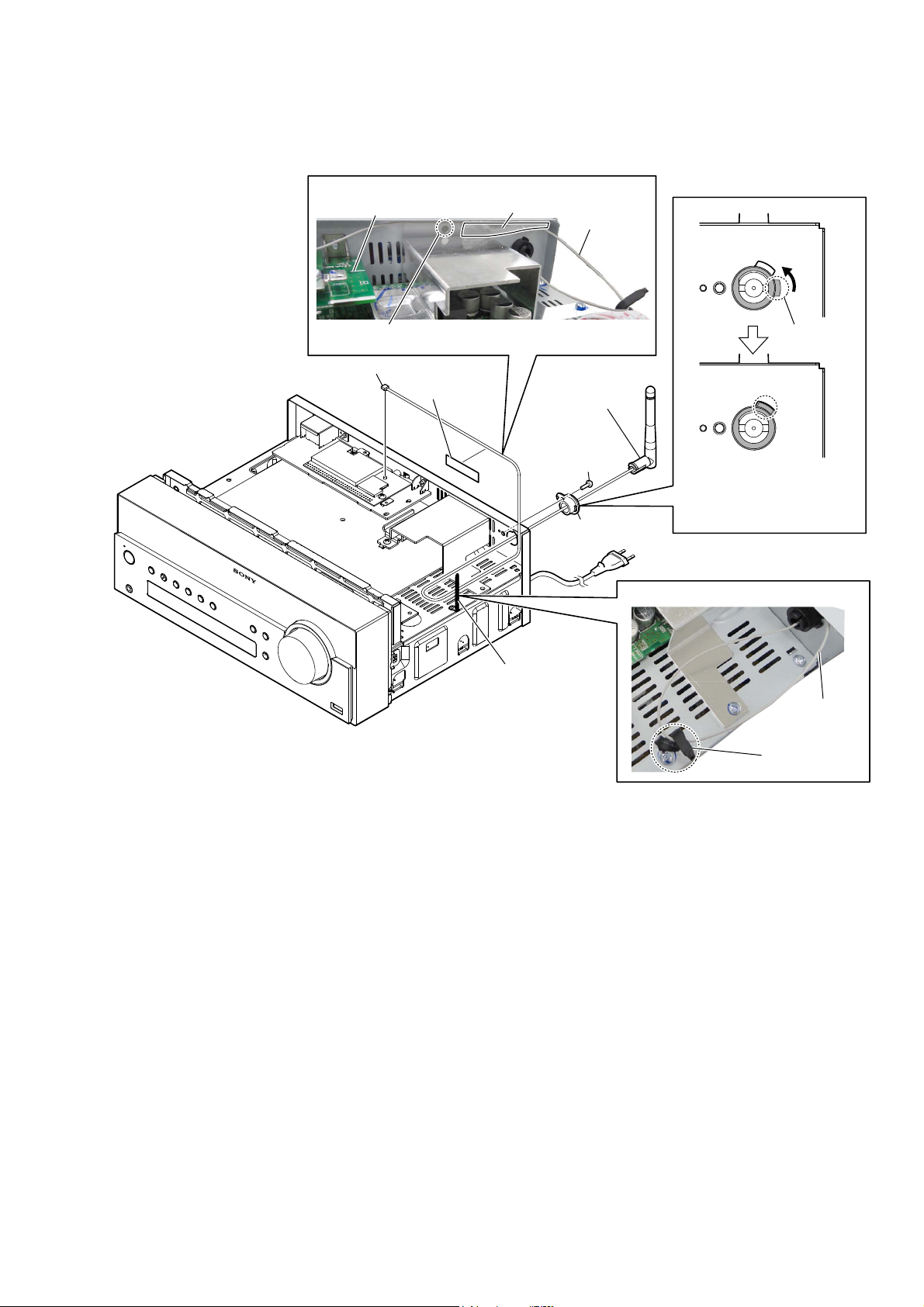

Page 15

HCD-SBT100/SBT100B/SBT300W/SBT300WB

2-11. 2.4GHz ANTENNA (ANT1), HOLDER (ANTENNA) (HCD-SBT300W/SBT300WB)

:LUHVHWWLQJ

NET board

Arrange the antenna wire so as not to overlap

Note:

with the screw hole of panel (rear).

1 antenna connector

(CON2)

2 tape

(sub material)

tape

(sub material)

4 2.4GHz antenna

(ANT1)

5 screw

(BVTP3 u 8)

7 holder

(antenna)

antenna wire

claw

6 Rotate the claw of holder

(antenna) in the direction of

an arrow, align the hole of

panel (rear).

:LUHVHWWLQJ

3 Remove the antenna

wire from the

coating clip.

antenna wire

coating clip

15

Page 16

HCD-SBT100/SBT100B/SBT300W/SBT300WB

2-12. CHASSIS (MAIN) BLOCK-1

CN3002 and CN507 are quantity of pins of the same.

Note 1:

Do not insert to the wrong connector absolutely.

There is a possibility that the unit may be damaged if the wrong.

WireVeWWiQJ

RELAY board

–5eDrYieZ–

Do not remove this connector (CN501)

Note 2:

at this point.

It is necessary to process electrostatic

measures of optical pick-up.

lead pin

MAIN

board

4 connector

(CN3002)

5 connector

(CN905)

1 Remove wires from

the lead pin.

3 connector

(CN831)

2 flexible flat cable (5P)

(CN502)

CN507

6 Remove the

wire from the

coating clip.

(SBT100/SBT300W)

8 flexible flat cable (9P)

(CN251)

7 connector

(CN304)

WireVeWWiQJ

MAIN board

Note 4:

install them correctly.

There is a possibility that this machine

damages when not correctly installing it.

Insert is straight

to the interior.

connector

Insert is shallow

connector

coating clip

OK

Wire must not be extends

Note 3:

from the edge of the chassis.

When you install the connector, please

OK

connector

NG

NG

NG

Insert is incline

connector

16

(SBT100B/SBT300WB)

8 flexible flat cable (9P)

(CN104)

connector connector

When installing the flexible flat cable,

Note 5:

ensure the colored line.

No slanting after insertion.

Inserting is straight to the interior.

flexible flat cable

flexible flat cable

colored line

OK

colored line

connector

NG

Inserting is slant.

connector

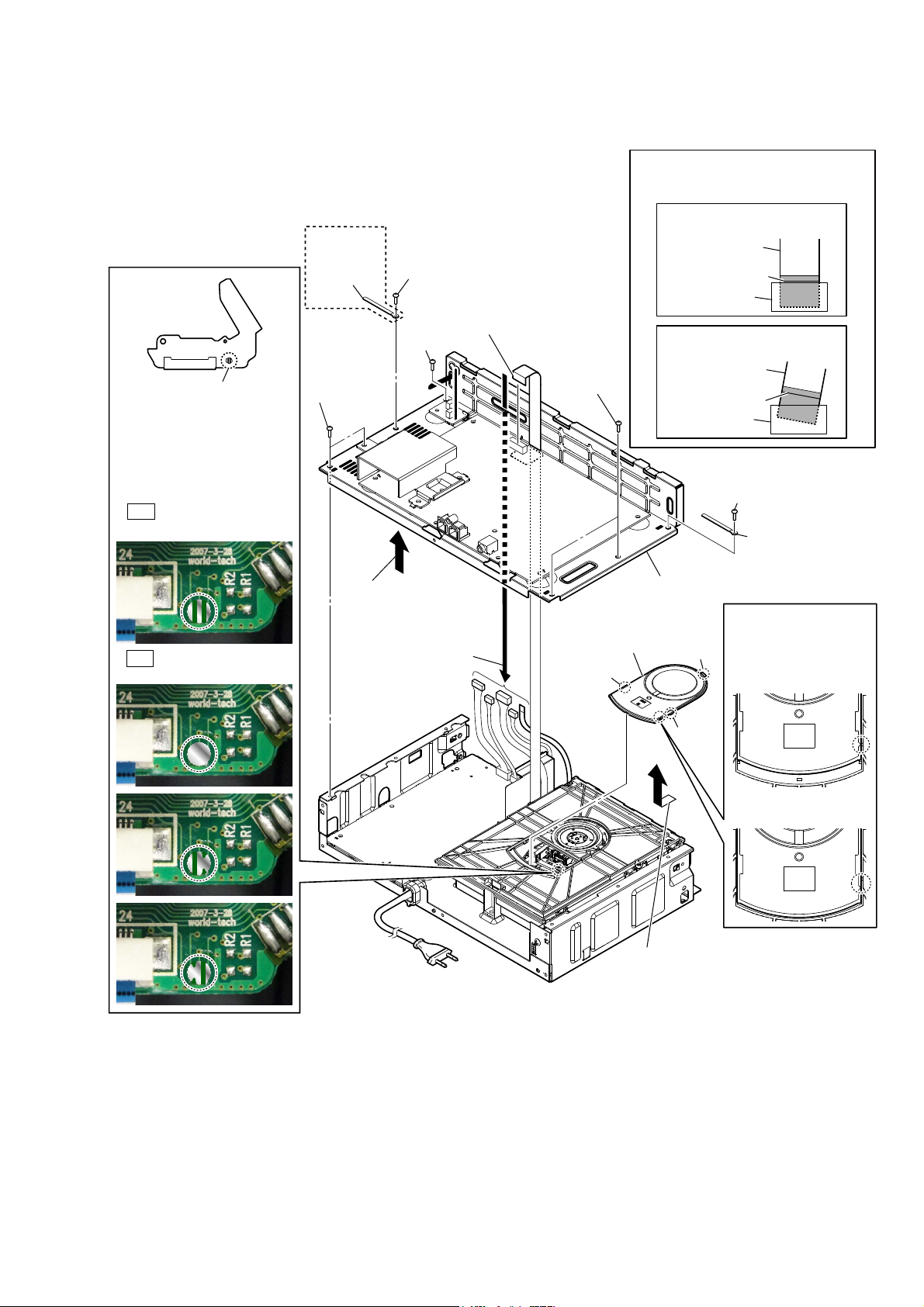

Page 17

HCD-SBT100/SBT100B/SBT300W/SBT300WB

2-13. CHASSIS (MAIN) BLOCK-2

Note 1: Before disconnecting flexible flat cable (24P) (CN501), solder the short-land.

(SBT300W/

SBT300WB)

2 screw

(BV3)

2 screw

(BV3)

9 flexible flat cable (24P)

(CN501)

Solder the short-land.

8

Note 2: When assembling the

chassis (main) block,

remove the solder of

short-land after connecting

flexible flat cable (24P)

(CN501).

OK

Solder is removed cleanly.

3 coating

clip

2 two screw

(BV3)

2 two screws

(BV3)

When installing the flexible flat cable,

Note 3:

ensure the colored line.

No slanting after insertion.

Inserting is straight to the interior.

flexible flat cable

flexible flat cable

OK

colored line

connector

NG

Inserting is slant.

colored line

connector

2 screw

(BV3)

3 coating clip

NG

Solder is not removed.

4 Remove the

chassis (main) block

in the direction

of an arrow.

1 Draw out

wires.

– Rear view –

7 chuck cap

6 claw

0 chassis (main) block

Note 4:

the chuck cap,

6 claw

6 claw

5 Remove the chuck cap

in the direction

of an arrow.

align the triangle

marks.

When installing

OK

NG

17

Page 18

HCD-SBT100/SBT100B/SBT300W/SBT300WB

2-14. TUNER BOARD (HCD-SBT100/SBT300W)

)OH[LEOHIODWFDEOH3))&VHWWLQJ

flexible flat cable (9P) (FFC3)

5 flexible flat cable (9P)

ferrite core (FC5)

cushion

(CN101)

1 tape

(sub material)

2 Peeled from the

adhesive (BT).

8 TUNER board

7 sheet (tuner)

6 shield (lower)

When installing the flexible flat cable,

Note:

ensure the colored line.

No slanting after insertion.

Inserting is straight to the interior.

flexible flat cable

flexible flat cable

3 two screws

(BVTP3 u 8)

OK

colored line

connector

NG

Inserting is slant.

colored line

connector

:LUHVHWWLQJ

tape

(sub material)

ferrite core (FC5)

TUNER board

4 Remove the TUNER board block

in the direction of an arrow.

2-15. MODULE (DAB TUNER) (DAB1), DAB BOARD (HCD-SBT100B/SBT300WB)

When installing the flexible flat cable,

Note 2:

ensure the colored line.

No slanting after insertion.

Inserting is straight to the interior.

flexible flat cable

flexible flat cable

9 Remove the two solders.

4 screw

(BVTP3 u 8)

qa module

(DAB tuner)

(DAB1)

7 Remove the module

(DAB tuner) block

in the direction

of an arrow.

conductor side

8 gasket

B

qs two screws

(BVTP3 u 8)

5 connector

(CN4001)

qd bracket DAB

flexible flat cable (9P) (CN4004)

3

Note 1:

do not mistake the insertion direction.

qf DAB

board

When installing the flexible flat cable (9P),

0 pin header 2P

(CN01)

6 connector

(CN4003)

qs screw

(BVTP3 u 8)

B

1 two screws

(BVTP3 u 8)

OK

colored line

connector

NG

Inserting is slant.

colored line

connector

18

2 Remove the DAB board

block in the direction

of an arrow.

Page 19

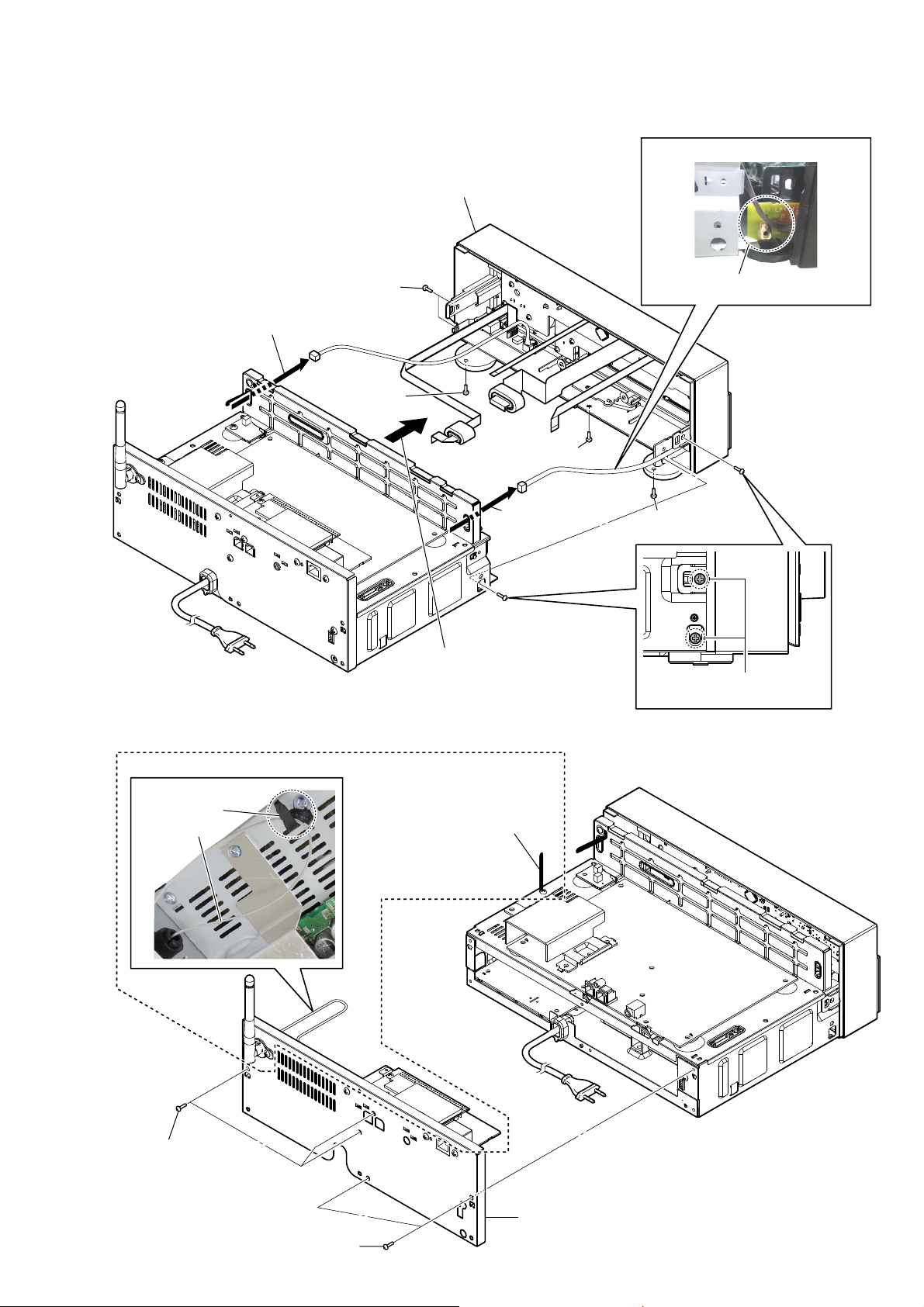

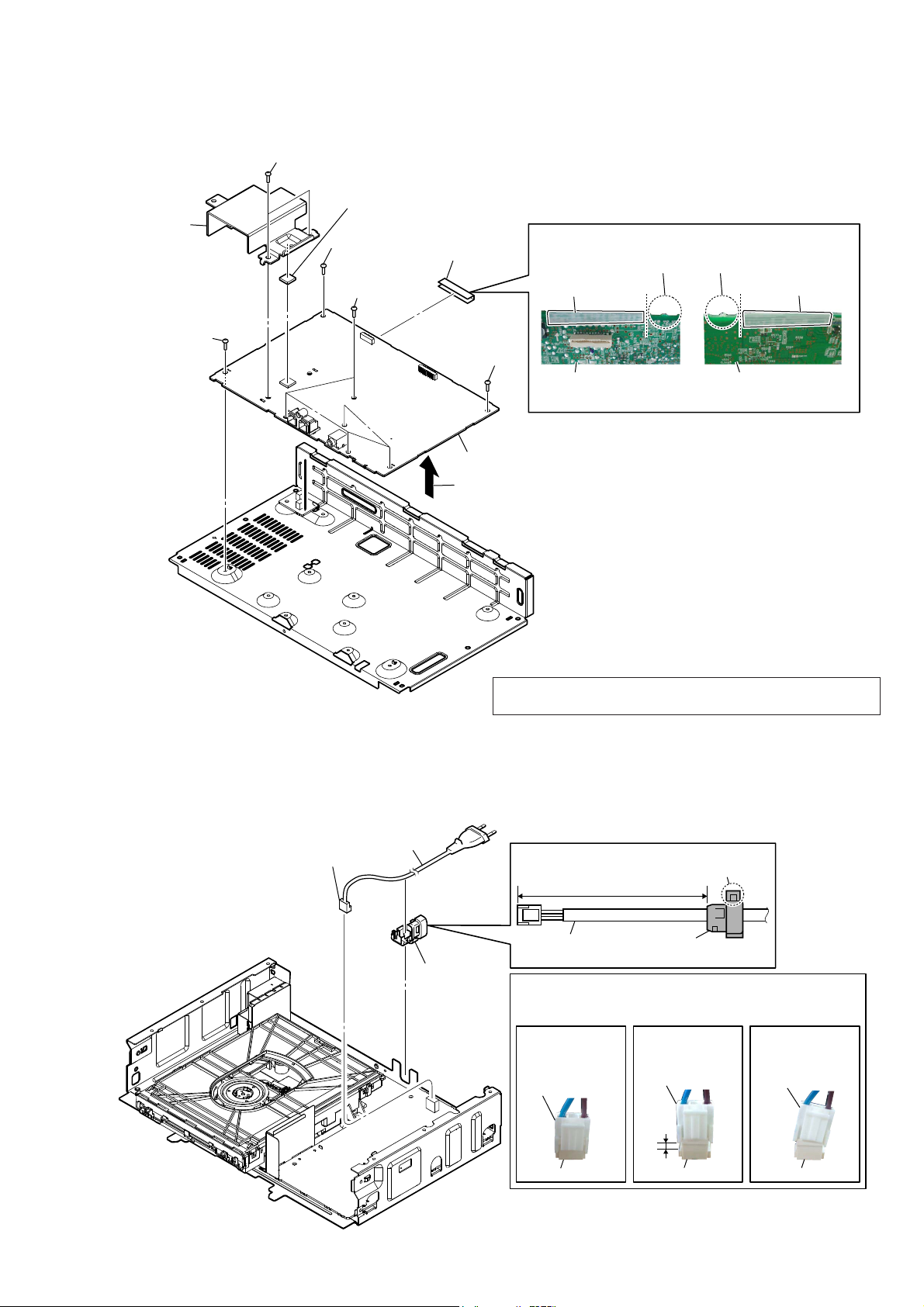

2-16. MAIN BOARD

2 heatsink

(AMP)

4 screw

(BVTP3 u 8)

1 two screws

(BVTP3 u 8)

4 screw

(BVTP3 u 8)

4 five screws

(BVTP3 u 8)

3 radiation sheet

6 tape

(sub material)

4 screw

(BVTP3 u 8)

HCD-SBT100/SBT100B/SBT300W/SBT300WB

Tape VXE materiaO VettiQJ

7 MAIN board

tape

(sub material)

MAIN board

– Top view –– Bottom view –

ditch

ditch

MAIN board

tape

(sub material)

– Rear view –

2-17. POWER CORD (AC1)

1 power cord connector

(CN901)

5 Remove the MAIN board block

in the direction of an arrow.

Note: When the complete MAIN board is replaced, refer to “CHECKING

METHOD OF NETWORK CONNECTION” on page 5.

3 power cord

(AC1)

&RUGEXVKVHWWLQJ

claw

70 to 75 mm

2 cord bush

(2104)

power cord

When you install the connector, please install them correctly.

Note:

There is a possibility that this machine damages when not

correctly installing it.

Insert is straight

to the interior.

connector

connector

cord bush

(2104)

NGOK NG

Insert is shallow

connector

connector

Insert is incline

connector

connector

19

Page 20

HCD-SBT100/SBT100B/SBT300W/SBT300WB

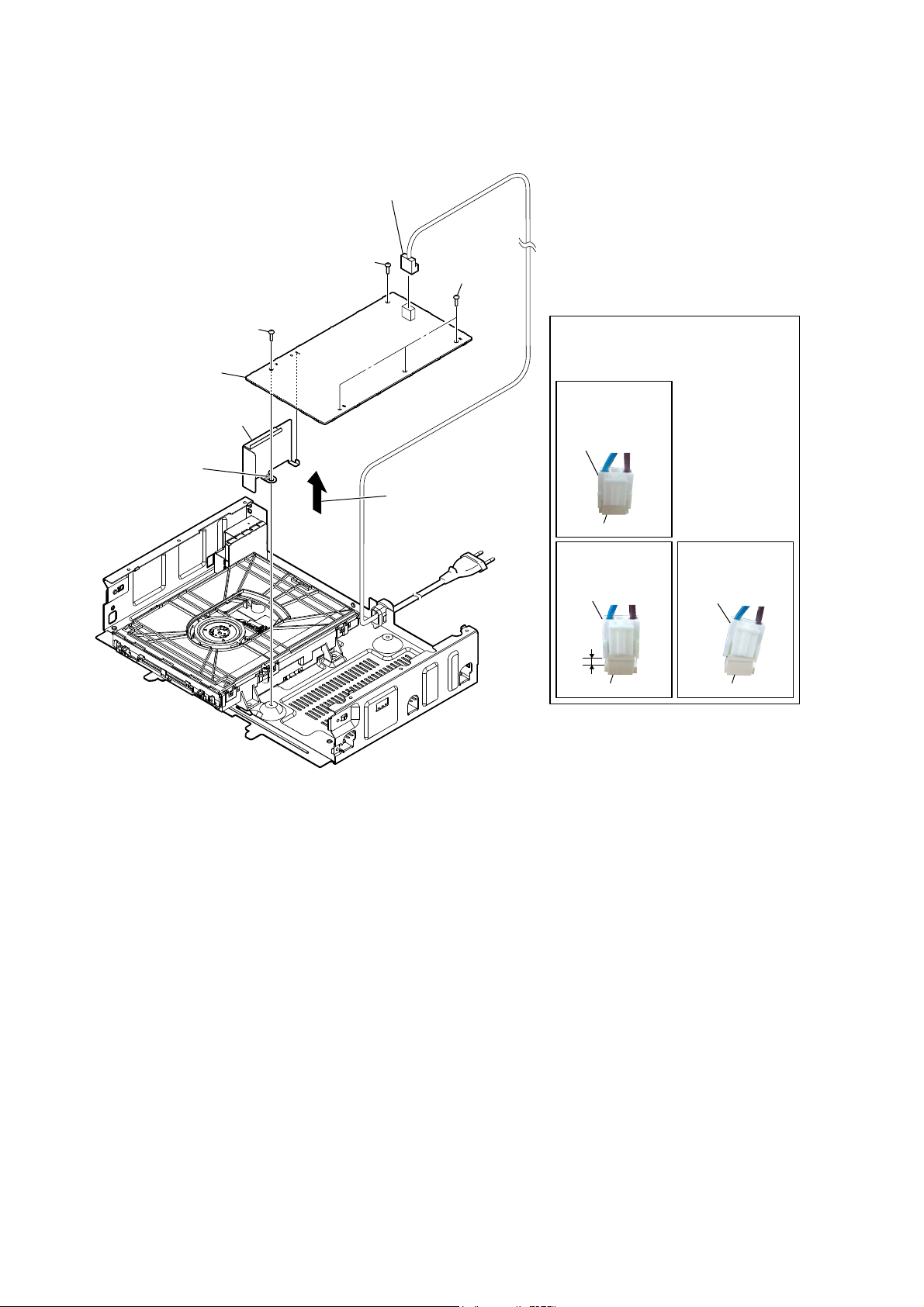

2-18. POWER BOARD

1 power cord connector

(CN901)

2 screw

(BV3)

2 three screws

(BV3)

2 screw

(BV3)

6 POWER board

5 sheet (PS UL) (US, Canadian)/

sheet (PS) (AEP, UK, Australian)

4 Peel off the

adhesive sheet.

3 Remove the

POWER board block

in the direction of

an arrow.

When you install the connector, please

Note:

install them correctly.

There is a possibility that this machine

damages when not correctly installing it.

OK

Insert is straight

to the interior.

connector

connector

NG

Insert is shallow

connector

connector

NG

Insert is incline

connector

connector

20

Page 21

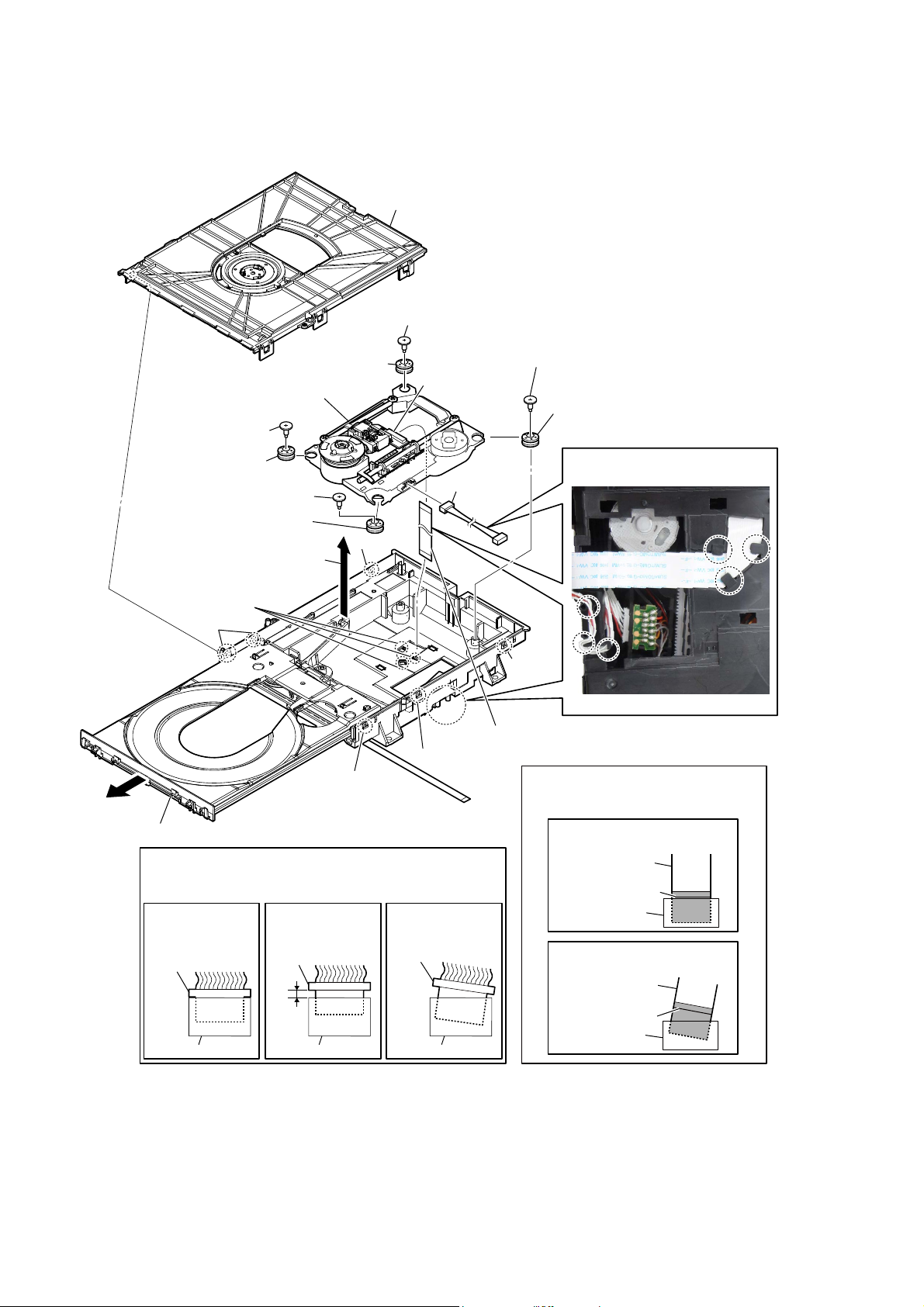

2-19. CD MECHANISM DECK BLOCK

HCD-SBT100/SBT100B/SBT300W/SBT300WB

1 two screws

(BV3)

2 CD mechanism deck block

1 two screws

(BV3)

2-20. FFC HOLDER

1 tape

(sub material)

4

Note:

check that installed firmly

two bosses and claw.

2 Remove the

FFC holder

in the direction

of an arrow.

boss

boss

–&'PHFKDQLVPGHFNEORFNERWWRPYLHZ–

claw

FFC holder

When installing the FFC holder,

3 Draw out the

flexible flat

cable (24P).

1 tape

(sub material)

:LUHVHWWLQJ

FFC holder

1 tape

(sub material)

tape

(sub material)

1 tape

(sub material)

tape

(sub material)

tape

(sub material)

tape

(sub material)

21

Page 22

HCD-SBT100/SBT100B/SBT300W/SBT300WB

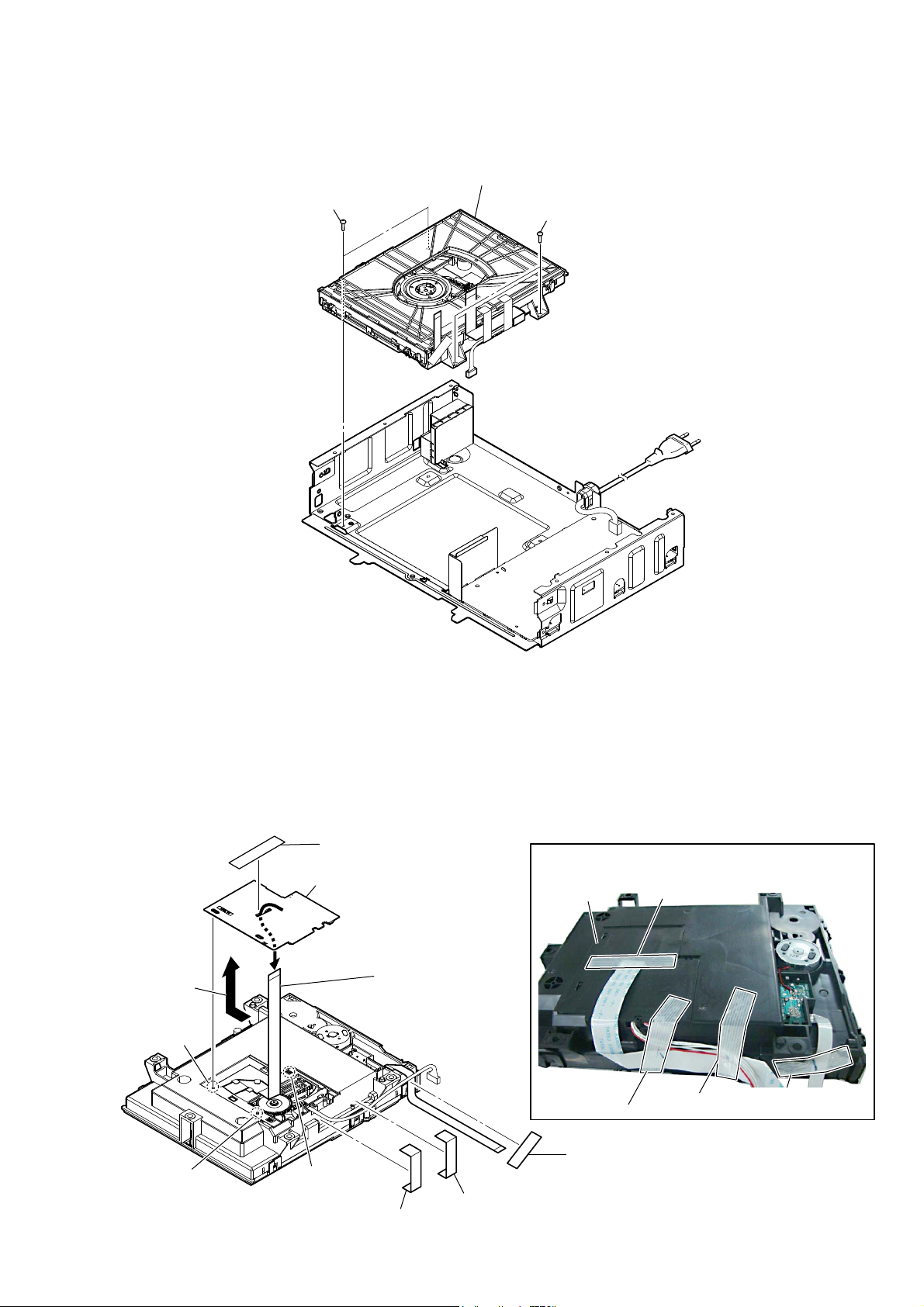

2-21. OPTICAL PICK-UP (CMS-S76RFS7G) (OP1)

chuck holder block

2

5 insulator

screw

5 insulator

screw

0 insulator

5 insulator screw

Remove the

6

in the direction of an arrow.

3 Draw out the tray.

Note 1:

There is a possibility that this machine damages when not

correctly installing it.

Insert is straight

to the interior.

connector

optical pick-up

three

4

claws

two

1

claws

When you install the connector, please install them correctly.

qa optical pick-up

(CMS-S76RFS7G)

(OP1)

0 insulator

connector

0 insulator

block

claw

1

NGOK NG

Insert is shallow

1

claw

connector

7 connector

9 connector

claw

1

Insert is incline

5 insulator screw

0 insulator

WireVHWWLQJ

claw

1

–BRWWRPYLHZ–

8 flexible flat cable (24P)

(FFC1)

When installing the flexible flat cable,

Note 2:

ensure the colored line.

No slanting after insertion.

Inserting is straight to the interior.

flexible flat cable

flexible flat cable

OK

colored line

connector

NG

Inserting is slant.

22

connector

colored line

connector

connector connector

Page 23

HCD-SBT100/SBT100B/SBT300W/SBT300WB

SECTION 3

TEST MODE

COLD RESET

It can clears all data including preset data stored in the memory to

initial conditions. Execute this mode when returning the this unit

to the customer.

Procedure:

1. Press the [?/1] button to turn the power on.

2. Press two buttons of the [x] and [?/1] simultaneously for three

seconds.

3. The message “RESET” (HCD-SBT100/SBT100B) or “ALL

RESET” (HCD-SBT300W/SBT300WB) is displayed on the

fl uorescent indicator tube, then becomes the standby state.

AUTO STANDBY TEST

It can confi rm the auto standby function operates normally.

The auto standby function operates in 60 seconds in this mode.

(Usually, it takes 30 minutes)

Procedure:

1. Press the [?/1] button to turn the power on.

2. Press the [FUNCTION] button to turn except “FM”, “AM”

and “DAB”.

3. Press two buttons of the [BASS BOOST] and [FUNCTION]

simultaneously for three seconds.

4. It enters the auto standby test mode, and the following screen

is displayed on the fl uorescent indicator tube.

(In this mode, “STEREO” continues blinking on the fl uores-

cent indicator tube)

Screen display

STEREO

COMMON TEST

It can confi rm the MAX/MIN of volume.

Procedure:

1. Press the [?/1] button to turn the power on.

2. Press two buttons of the [BASS BOOST] and [u] simultane-

ously for three seconds.

3. It enters the common test mode, the message “AUDIO IN” is

displayed on the fl uorescent indicator tube.

(In this mode, “cPLAY” and “SLEEP” continues blinking on

the liquid crystal display)

4. When rotating the [VOLUME] knob, the message is changed

with VOLUME MIN ↔ VOLUME 23 ↔ VOLUME MAX on

the fl uorescent indicator tube.

Releasing method:

Press the [?/1] button to turn the power off.

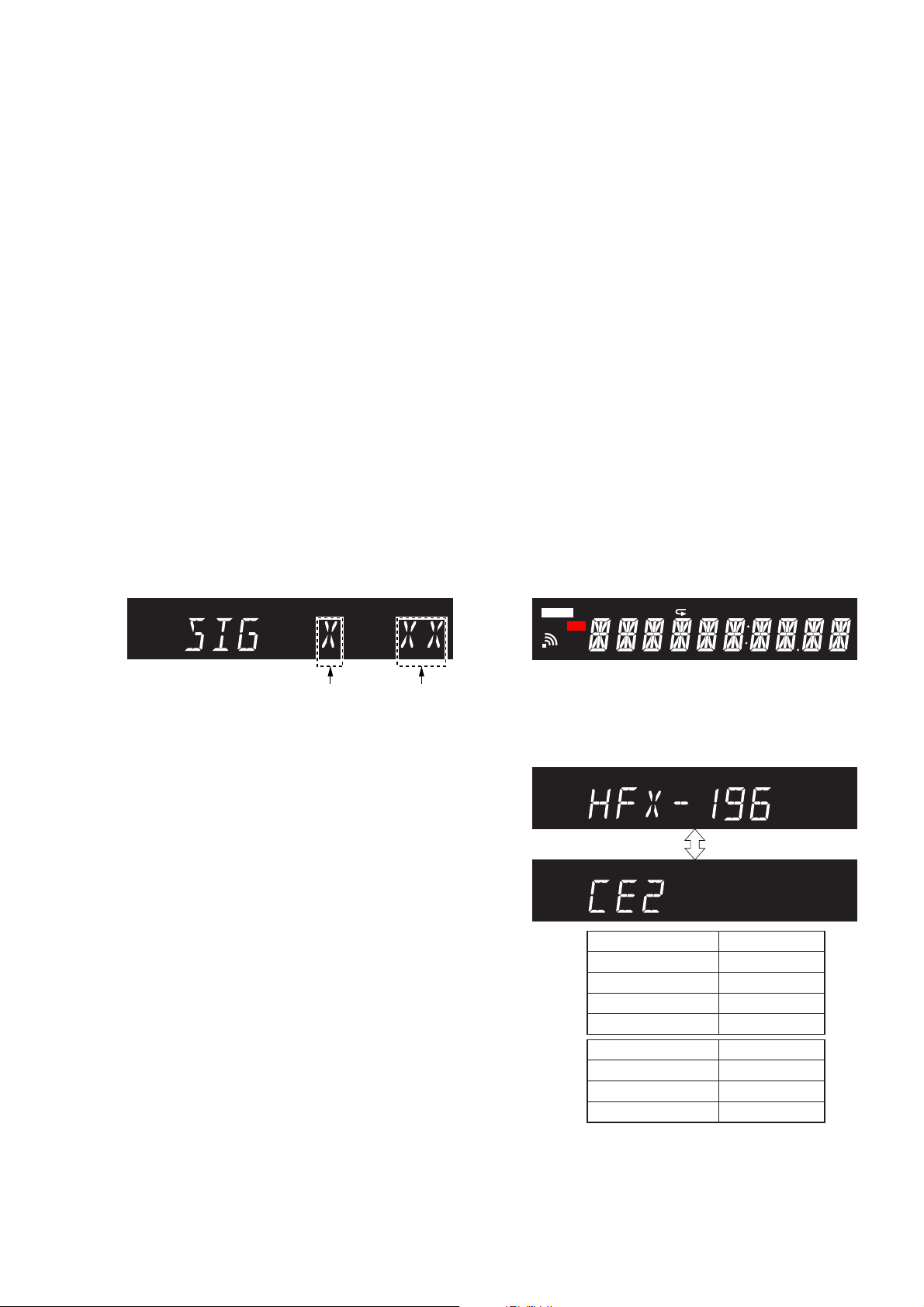

PANEL TEST

It can confi rm the fl uorescent indicator tube, LEDs, model name,

destination, software version and button.

Procedure:

1. Press the [?/1] button to turn the power on.

2. Press two buttons of the [FUNCTION] and [. TUNE −]

simultaneously for three seconds.

3. It enters the panel test mode, and all segments on the fl uores-

cent indicator tube and all LEDs light up.

Screen display

UPDATE

NX

FLDR SHUF PGM

REC

1

cPLAY cREC

SLEEPSTEREO

Signal level

(0 or 1)

Countdown

timer

(60 to 0)

5. In the case of the following states, the countdown timer decreases. This unit will become standby states if the countdown

timer decreases to “0”.

• Operation is not performed.

• The signal level is lower than threshold.

Releasing method:

Press two buttons of the [BASS BOOST] and [FUNCTION] simultaneously for three seconds.

4. When pressing the [> TUNE +] button, the model name and

destination are displayed on the fl uorescent indicator tube al-

ternately.

(In this mode, “STEREO” continues blinking on the fl uores-

cent indicator tube)

Screen display

STEREO

STEREO

Model Name

HCD-SBT100

HCD-SBT100B

HCD-SBT300W

HCD-SBT300WB

Destination Display

US and Canadian

AEP and UK

Australian

Display

HFX-193

HFX-194

HFX-195

HFX-196

NA

CE2

AU

23

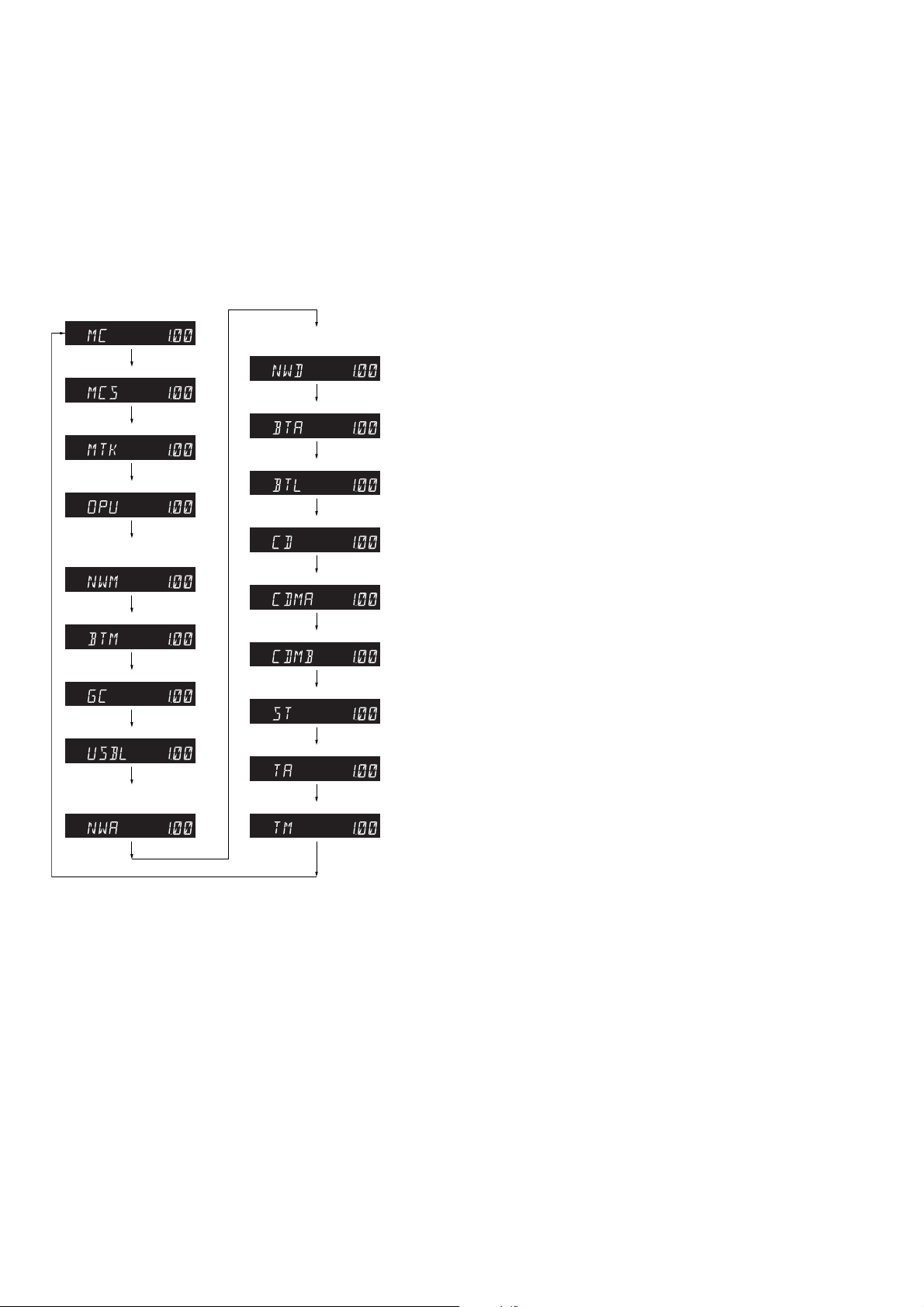

Page 24

HCD-SBT100/SBT100B/SBT300W/SBT300WB

5. When pressing the [

> TUNE +] button again, the MC ver-

sion is displayed on the fl uorescent indicator tube.

6. Each time [

> TUNE +] button is pressed, tthe display

changes MCS version → MTK version → OPU version →

NWM version (HCD-SBT300W/SBT300WB only) → BTM

version → GC version → USBL version → NWA version

(HCD-SBT300W/SBT300WB only) → NWD version (HCDSBT300W/SBT300WB only) → BTA version → BTL version

→ CD version → CDMA version → CDMB version → ST

version → TA version → TM version this order, and returns to

the MC version display.

MC version

MCS version

MTK version

OPU version

NWM version (HCDSBT300W/SBT300WB only)

BTM version

GC version

USBL version

NWA version (HCDSBT300W/SBT300WB only)

STEREO

STEREO

STEREO

STEREO

STEREO

STEREO

STEREO

STEREO

STEREO

NWD version (HCDSBT300W/SBT300WB only)

BTA version

BTL version

CD version

CDMA version

CDMB version

ST version

TA version

TM version

STEREO

STEREO

STEREO

STEREO

STEREO

STEREO

STEREO

STEREO

STEREO

(Displayed values in the above fi gure are example)

DISC TRAY LOCK MODE

It can be unable to take sample disc out of disc tray in the shop.

Procedure:

1. Press the [?/1] button to turn the power on.

2. Press the [FUNCTION] button to turn the CD function.

3. Press the [Z] button to open the disc tray and set the CD.

4. Press the [Z] button to close the disc tray.

5. Press two buttons of the [x] and [Z] simultaneously for fi ve

seconds.

6. The message “LOCKED” is displayed on the fl uorescent indi-

cator tube and the disc tray is locked.

(Even if pressing the [Z] button, the message “LOCKED”

is displayed on the liquid crystal display and the disc tray is

locked)

Releasing method:

1. Press two buttons of the [x] and [Z] simultaneously for fi ve

seconds.

2. The message “UNLOCKED” is displayed on the fl uorescent

indicator tube and the disc tray is unlocked.

AM STEP CHANGE

(Except AEP and UK models)

It can change AM step interval into 9 kHz or 10 kHz.

Procedure:

1. Press the [

] button to turn the power on.

?/1

2. Press the [FUNCTION] button to turn the AM function.

3. Press the [

4. Press two buttons of the [FUNCTION] and [

] button to turn the power off.

?/1

] simultane-

?/1

ously.

5. The message “STEP 9” or “STEP 10” is displayed on the

fl uorescent indicator tube, and AM step interval changed.

CHECK VERSION DISPLAY

It can confi rm the MC, CD and NW version.

Procedure:

1. Press the [

] button to turn the power on.

?/1

2. Press two buttons of the [x] and [BASS BOOST] simultaneously for three seconds.

3. It enters the check version display mode, the MC version is

displayed on the fl uorescent indicator tube.

4. Each time [> TUNE +] button is pressed, the display changes CD version → NW version (HCD-SBT300W/SBT300WB

only) this order, and release from check version display mode.

7. When pressing the [x] button while the each version is dis-

played, year, month and day of the software creation is displayed. When pressing the [x] button again, the display returns to the each version display.

8. When pressing the [. TUNE −] button, “K 0 V0” is dis-

played on the fl uorescent indicator tube.

9. Each time a button is pressed, “K 0” value increases. However,

once a button is pressed, it is no longer taken into account.

When pressing the all buttons, display becomes “K10”.

10. “V0” value increases “V2”, “V4”, “V6” “V8”, “V0” if turn

the [VOLUME] knob clockwise, or it decreases “V8”, “V6”,

“V4”, “V2”, “V0” if turn the knob counterclockwise.

Releasing method:

Press two buttons of the [FUNCTION] and [. TUNE −] simultaneously for three seconds.

24

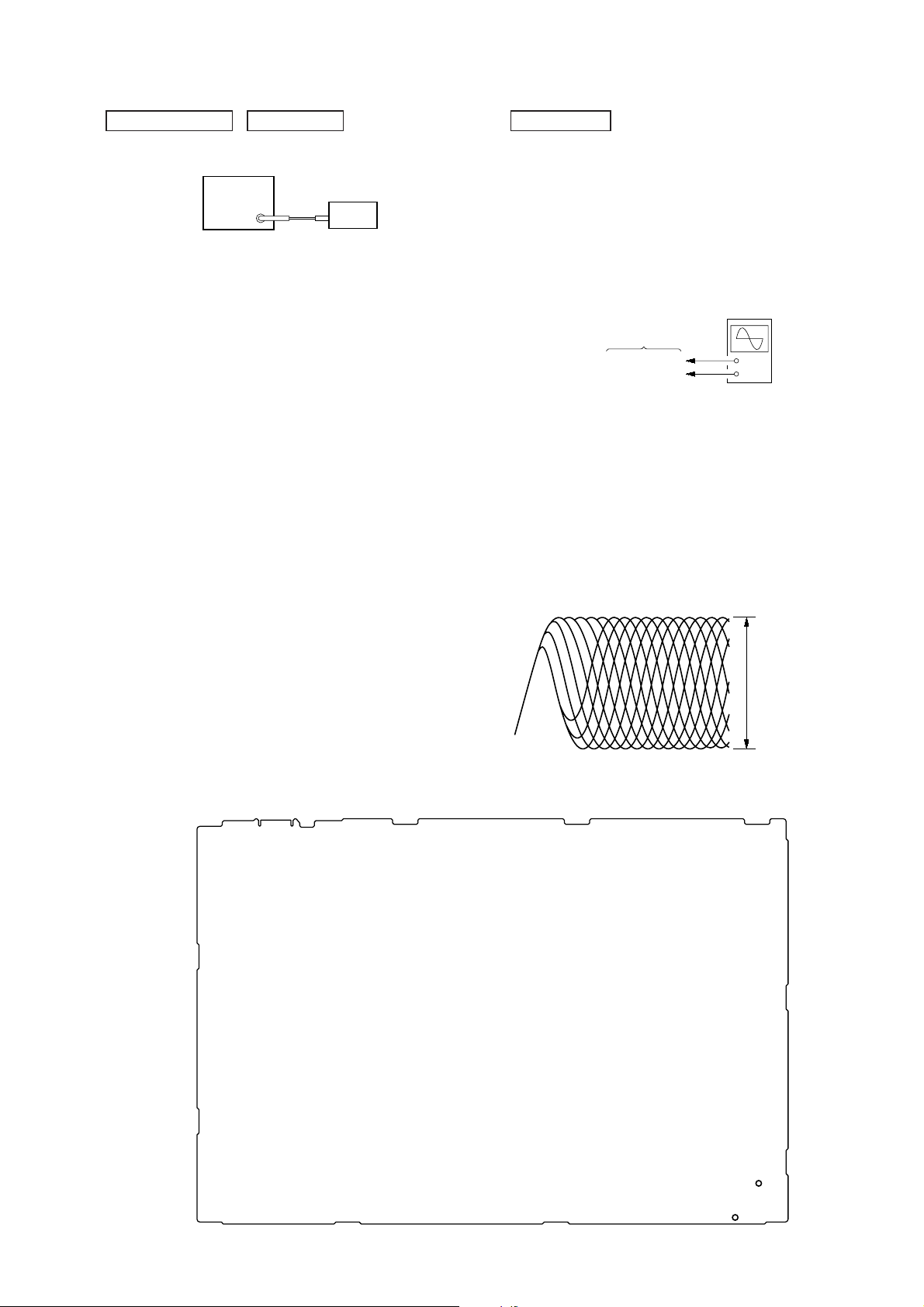

Page 25

HCD-SBT100/SBT100B/SBT300W/SBT300WB

SECTION 4

ELECTRICAL CHECKS

TUNER SECTION

0 dB = 1 μV

FM AUTO STOP CHECK

signal

generator

unit

Procedure:

1. Press the [?/1] button to turn the power on.

2. Input the following signal from signal generator to FM antenna

input directly.

Carrier frequency : A = 87.5 MHz, B = 98 MHz, C = 108 MHz

Deviation : 75 kHz

Modulation : 1 kHz

ANT input : 35 dBu (EMF)

Note: Use 75 ohm coaxial cable to connect signal generator and the unit.

You cannot use video cable for checking.

Use signal generator whose output impedance is 75 ohm.

3. Press the [FUNCTION] button to turn the FM tuner function

and scan the input FM signal with automatic scanning.

4. Confi rm that input frequency of A, B and C detected and auto-

matic scanning stops.

When the station signal is received in good condition, automatic

scanning stops.

CD SECTION

Note:

1. CD block is basically constructed to operate without adjustment.

2. Use HLX-A1 disc (Part No. J-2501-307-A) unless otherwise indicated.

3. Use an oscilloscope with more than 10 MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent when the

signal level is low than specifi ed value with the following check.

RF SIGNAL CHECK

oscilloscope

(DC range)

MAIN board

CL576 (RF)

CL573 (GND)

+

–

Procedure:

1. Connect the oscilloscope to CL576 (RF) and CL573 (GND) on

the MAIN board.

2. Press the [

] button to turn the power on.

?/1

3. Press the [FUNCTION] button to turn the CD function.

4. Press the [Z] button to open the disc tray and set the disc

(HLX-A1).

5. Press the [Z] button to close the disc tray.

6. Press the [u] button to playback.

7. Confi rm that oscilloscope waveform is as shown in the fi gure

below. (eye pattern)

A good eye pattern means that the diamond shape (◊) in the

center of the waveform can be clearly distinguished.

Connection Location:

– MAIN Board (Component Side) –

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

level: 1.05 ± 0.45 Vp-p

CL573

(GND)

CL576

(RF)

25

Page 26

HCD-SBT100/SBT100B/SBT300W/SBT300WB

MEMO

26

Page 27

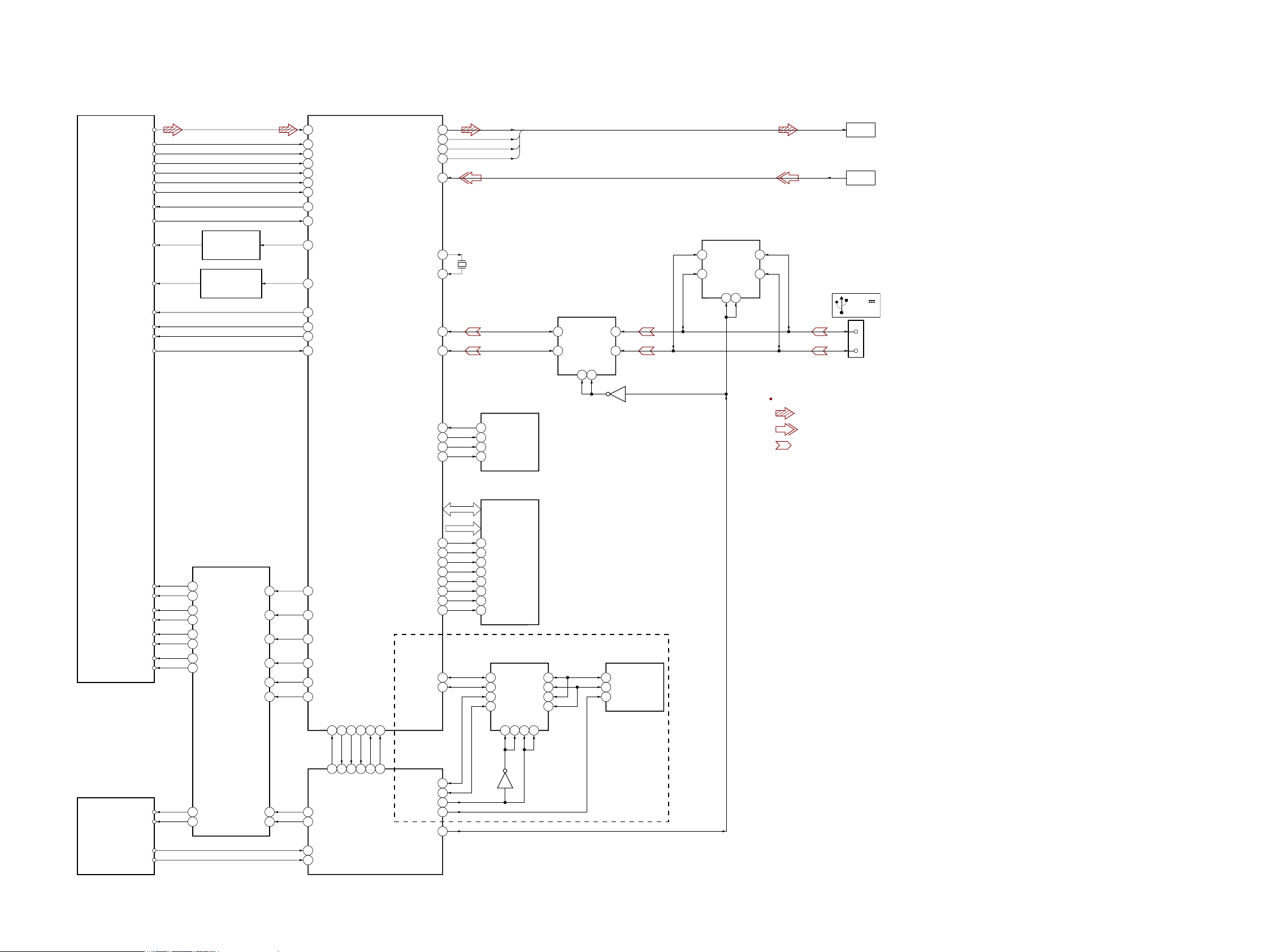

5-1. BLOCK DIAGRAM - CD Section -

OPTICAL PICK-UP BLOCK

(CMS-S76RFS7G)

RF

VOA/A

VOB/B

VOC/C

VOD/D

VOE/E+G

VOF/F+H

VC

PD

LD (780)

LD (650)

MSW

VR (780)

VR (650)

LIMIT

AUTOMATIC POWER

CONTROL (FOR CD)

Q891

AUTOMATIC POWER

CONTROL (FOR DVD)

Q881

SECTION 5

DIAGRAMS

RF AMP, SERVO/AUDIO PROCESSOR

123 R F I P

1 RF_C

128 R F _ B

127 R F _ A

2 RF_D

4 RF_F

3 RF_E

10 V20

13 MDI1

14 LDO1

15 LDO2

23 MSW

19 CD_VR

20 DVD_VR

44 LIMITSW

IC501

HCD-SBT100/SBT100B/SBT300W/SBT300WB

ASDATA0, ABCK,

ALRCK, ACLK

SIGNAL PATH

: CD PLAY

: AUDIO IN

: USB

ADIN

>001B

>002B

CN5004

DC 5V

2.1A MAX

3

2

(Page 28)

(Page 28)

D+

D–

X501

27MHz

ASDATA0

ABCK

ALRCK

ACLK

SERIAL FLASH

2

SO

5

SI

6

SCK33SF_CK

1

_CS30SF_CS#

IC502

USB DATA SWITCH

IC309

6B2

3B1

OE17OE2

1

Q303

USB CHARGER

SWITCH

IC308

6B2

3B1

5A2

2A1

5A2

2A1

OE17OE2

1

118ASDATA0

113ABCK

117ALRCK

112ACLK

106ADIN

8XTALO

7XTALI

25USB_DP

24USB_DM

31SF_DO

32SF_DI

MS-476 BOARD

SP+

SP–

SL+

SL–

TRK+

TRK–

FCS+

FCS–

LOAD+

LOAD–

FOCUS/TRACKING COIL DRIVE,

SPINDLE/SLED/LOADING MOTOR DRIVE

11 VOSL+

12 VOSL–

17 VOLD+

18 VOLD–

16 VOTK–

15 VOTK+

14 VOFC+

13 VOFC–

10 VOTR+

9VOTR–

IC851

4VINSL+

23VINLD

26VINTK

1VINFC

28MUTE

27BIAS

6FWD

7RVS

17 DMO

18 FMO

21 TRO

22 FOO

45 MUTE

11 VREFO

40

1

92 CDM FWD

93 CDM RVS

IFSDI

IFSDO

IFSCK

35

34

100

2

MTK DIN

MTK DOUT

IFCS#

42

41

95

94

MTK CS

MTK CLK

IFBSY

PRST#

38

3

MTK BUSY

MTK RESET

RD0 – RD15

RA0 – RA11 A0 – A11

85BA0

86BA1

82CAS#

83RAS#

47SDA 21O/I

48SCL

24CP IIC SDA

22CP IIC CLK

44CP SELECT

23CP IIC RESET

52USB CHARGE

DQ0 – DQ15

20

BA0

21

BA1

38

CLK72RCLK

16

WE80RWE#

17

CAS

18

RAS

15

LDQM61DQM0

39

UDQM70DQM1

DATA/CLOCK SIGNAL

1

11

4

8

Q202

SD-RAM

IC504

SWITCH

IC202

1I/O

4I/O

2I/O

3I/O

131C124C52C6

MFI

IC506

13

I2C_SDA

12

104O/I

32O/I

93O/I

3C

I2C_SCL

4

RESET

(SBT300W/SBT300WB)

LOAD_END_SW

UNLOAD_END_SW

HCD-SBT100/SBT100B/SBT300W/SBT300WB

91 CDM LOAD END SW

90 CDM UNLOAD END SW

SYSTEM CONTROLLER

IC101 (1/3)

2727

Page 28

HCD-SBT100/SBT100B/SBT300W/SBT300WB

5-2. BLOCK DIAGRAM - AUDIO Section -

ASDATA0, ABCK,

>001B

(Page 27)

>002B

(Page 27)

ALRCK, ACLK

J5001

AUDIO IN

ADIN

BT1

Bluetooth MODULE

PCM_OUT

PCM_CLK

PCM_SYNC

BT-TX

BT-RX

BT-RTS

BT-CTS

BT-RST

ASDATA0

ABCK

ALRCK

ACLK

ABCK

ALRCK

A/D CONVERTER

IC721

13

VINL

14

VINR

8

BCK

7

LRCK

6

SCKI

DOUT

DIGITAL AUDIO SELECTOR

IC741

61C0

51C1

41C2

31C3

9

CLOCK SIGNAL SELECTOR

61C0

51C1

41C2

31C3

10 2C0

11 2C1

12 2C2

13 2C3

A

14

IC742

A14B

71Y

B

2

71Y

92Y

2

SAMPLE RATE CONVERTER

IC761

4SDIN

5BCKI

6 LRCKI

2 RCKI

10

IFMT0

13

23SDOUT

25BCKO

24LRCKO

RST

X762

12.288MHz

11

SDIN1

22

SCLKOUT1

19

LRCK

4XTALO

3XTALI

32

AUDIO DSP

IC762

RESETDSP RESET

GPIOTAS INT

SDIN4DSP MUTE

8

14

SCL1DSP IIC CLK

16

SDA1DSP IIC SDA

15

27SDOUT1

23SCLKOUT2

21MCLKO

X3001

49.152MHz

CLOCK

BUFFER

IC3004

STREAM PROCESSOR

IC3005

31

DATA

30

BCK

29

LRCK

36

XFSIIN

48

XFSOIN

SCDT22SCSHIFT23SCLATCH18NSPMUTE19SOFTMUTE27INIT20PGMUTE

21

DIGITAL POWER AMP

IC3007

11OUTL1

9OUTL2

6OUTR1

4OUTR2

4

5

10

11

INPUT_A

INPUT_B

INPUT_C

INPUT_D

2

OUT_A

OUT_B

OUT_C

OUT_D

/RESET17OTW215/SD

52, 5344, 4536, 3728, 29

DC DETECT

Q3007

DC DETECT

Q3006

DC DETECT

Q3005

+

L

–

+

R

–

SPKPROTECT

TB3001

SPEAKERS

>003B

(Page 29)

45HPOUTL1

43HPOUTL2

41HPOUTR1

39HPOUTR2

MIX

AMP

IC3002

MUTING

Q3002

MUTING

CONTROL SWITCH

Q3003, 3004

J302

i

(SBT100/SBT300W) (SBT100/SBT100B)

TUNER BOARD

FM/AM

ANTENNA

DAB BOARD & MODULE (DAB TUNER)

DAB/FM

ANTENNA

(SBT100B/SBT300WB)

(SBT300W/SBT300WB)

CN5009

ETHERNET

CONNECTOR

LAN

8

7

4

3

IISD

BCK

LRCK

DA

CK

CE

RDSI

IIS-DATA

IIS-SCK (BCK)

IIS-SFR (LRCK)

DAB-TXD

DAB-RXD

DAB 1.2V-ON

DAB 3.3V-ON

WIFI MODULE

ANT1

ETH_RX+

ETH_RX−

ETH_TX+

ETH_TX−

WAVE

SHAPER

IC751, 752

(SBT100B/SBT300WB)

WIFI1

AV2 DATA0

ADA_BCK

ADA_LRCK

PDOUT0

21A

31B

52A

62B

11 3A

10 3B

(SBT300W/SBT300WB)

D-SEL C

1

41Y

72Y

93Y

DATA/CLOCK SIGNAL

SELECTOR

IC743

63 EXT-D SEL C

31

TUNER SDA/DAB TxD-OUT

32

TUNER SCL/DAB RxD-IN

34 TUNER POWER/DAB POWER-1.2V

33

RDS INT/DAB POWER-3.3V

6

BCO SPI DINSPI_OUT

5

BCO SPI DOUTSPI_DIN

7 BCO SPI CLKSPI_CLK

25

BCO SPI CSSPI_NCS0

27 BCO SPI REQPDOUT1

21 BCO SPI READYA22

19 BCO WOL INNWAIT

45

BCO RESETNRESET_MOD

40

38

BT RTS

BT RESET

37

35

BT CTS

36

BT RxD-IN

BT TxD-OUT

66

65

EXT-D SEL-A

EXT-D SEL-B

X101

5MHz

13

Xout

X102

32.768kHz

76

67

75

78

15

10

11

Xin

Xcout

Xcin

77

SYSTEM CONTROLLER

IC101 (2/3)

82

83

84

SMASTER DATA

SMASTER SHIFT

SMASTER LATCH

85

81

NSP MUTE

80

SOFT MUTE

PG_MUTE

86

SMASTER INIT

79

DAMP_RESET

59

HP MUTE

58

HP DETECT

SIGNAL PATH

: AUDIO

: TUNER

: CD PLAY

: AUDIO IN

: Bluetooth

: LAN

: WIRELESS LAN

HCD-SBT100/SBT100B/SBT300W/SBT300WB

2828

Page 29

5-3. BLOCK DIAGRAM - PANEL/POWER SUPPLY Section -

FLUORESCENT

D3201

BLUETOOTH

PARING

ND5001

INDICATOR

TUBE

GRID DRIVE

Q5002

LED DRIVE

Q5001

REMOTE CONTROL

RECEIVER

IC5002

FLUORESCENT INDICATOR TUBE DRIVER,

GR1 – GR10

32 GR11

1LED1

LED DRIVER

IC5001

4

SIRCS

7SG1 – SG16 DIN

54 DP DI

8CLK

55 DP CL

9STB

56 DP CE

12RESET

70SYSTEM PROTECT

RESET

IC102

PROTECT DETECT

Q911

D914

PROTECT DETECT

Q910

D912

EVER-3.3V

+1.8V

+3.3V

RF+1.2V

DVDD3.3V

B+ SWITCH

Q912, 913

+1.8V REGULATOR

IC3003

+1.2V REGULATOR

IC561

+3.3V REGULATOR

IC3001

+3.3V REGULATOR

IC503

+3.3V REGULATOR

IC905

HCD-SBT100/SBT100B/SBT300W/SBT300WB

D3101

STANDBY

D3001, 3005

EFFECT

INDICATOR

(BLUE)

D3003

EFFECT

INDICATOR

(WHITE)

>003B

(Page 28)

SYSPROTECT

LED DRIVE

Q3101

LED DRIVE

Q304

LED DRIVE

Q302

S3101

I / 1

S3202 – 3206

(FRONT PANEL KEYS)

S3103 – 3106

(FRONT PANEL KEYS)

S5001

VOLUME

ROTARY

ENCODER

NFC1

NFC

(RC-S801/A)

NFC DATA

NFC SPICLK

NFC IRQ

NFC SW

NFC SEL

NFC RFDET

57 STANDBY LED

26 ILLUM LED BL

28 ILLUM LED WT

74 KEY WAKE UP

68 KEY1

SYSTEM CONTROLLER

IC101 (3/3)

69 KEY2

71

VOLUME-JOG

89 NFC DATA

46 NFC SPICLK

87 NFC IRQ

41 NFC SW

88 NFC SEL

18 NFC RFDET

DSP+3.3V

FE_+3.3V

-COM+3.3V

USB+3.3V

D251

D103

39BT POWER

D908

20AC-CUT

D917

D5011

30BCO 3.3V-ON

D104

D909

D915

D5013

43USB-POWER

42USB-OC

72POWER ON

53SMASTER POWER

(SBT100: US, CND)

PROTECTOR

Q251

+5V

PROTECTOR

Q104

(SBT100: US, CND)

BT+3.3V

EVER-5V

NW1.2V

NW3.3V

(SBT100: US, CND)

PROTECTOR

Q105

FE_5.2V

USB+5.2V

USB VBUS

TO

FLUORESCENT

INDICATOR TUBE

FL-22V

D5002, 5003

VBUS SWITCH

IC5005

RECT

DC/DC CONVERTER

IC702

DC/DC CONVERTER

IC841

+3.3V REGULATOR

IC103

+3.3V REGULATOR

IC105

+1.2V REGULATOR

IC5003

T5001

DC/DC CONVERTER

TRANSFORMER

+3.3V REGULATOR

B+ SWITCH

Q5004, 5005

OSC

Q5003

B+ SWITCH

Q908, 909

IC107

DC/DC

CONVERTER

IC904

DC/DC

CONVERTER

IC5008

DC/DC CONVERTER

IC903

VOLTAGE DETECT

IC901

(SBT300W/SBT300WB)

DC/DC CONVERTER

IC902

PVDD_25V

+12V

D904

F3001

F3002

+12V

REGULATOR

IC3006

F931

F932

RECT

D967

RECT

D968

RECT

D995

SUNT

REGULATOR

IC932

T901

POWER

TRANSFORMER

ISOLATOR

PH930

D940

D934

RECT

D902

REGULATOR

Q930

TH901

Abbreviation

: Canadian modelCND

POWER CONTROL

3Vcc/OVP

6BD

1D

5FB/OLP

LINE FILTER

LF901, 902

IC930

F901

AC1

(AC IN)

HCD-SBT100/SBT100B/SBT300W/SBT300WB

2929

Page 30

HCD-SBT100/SBT100B/SBT300W/SBT300WB

d

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

For Printed Wiring Boards.

Note:

• X : Parts extracted from the component side.

• Y : Parts extracted from the conductor side.

• f : Internal component.

• : Pattern from the side which enables seeing.

(The other layers’ patterns are not indicated.)

Caution:

Pattern face side:

(Conductor Side)

Parts face side:

(Component Side)

Caution:

Pattern face side:

(SIDE B)

Parts face side:

(SIDE A)

• Indication of transistor.

C

Q

B

E

• Abbreviation

AUS : Australian model

CND : Canadian model

Note: When the complete MAIN board or complete NET

board is replaced, refer to “CHECKING METHOD OF

NETWORK CONNECTION” on page 5.

Parts on the pattern face side seen

from the pattern face are indicated.

Parts on the parts face side seen from

the parts face are indicated.

Parts on the pattern face side seen

from the pattern face are indicated.

Parts on the parts face side seen from

the parts face are indicated.

These are omitted.

For Schematic Diagrams.

Note:

• All capacitors are in μF unless otherwise noted. (p: pF) 50

WV or less are not indicated except for electrolytics and

tantalums.

• All resistors are in Ω and 1/4 W or less unless otherwise

specifi ed.

• f : Internal component.

• C : Panel designation.

Note:

The components identifi ed by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part

number specifi ed.

• A : B+ Line.

• B : B– Line.

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : TUNER

( ) : CD PLAY

[ ] : USB

‹‹ ›› : Bluetooth

* : Impossible to measure

• Voltages are taken with VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production

tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production

tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : AUDIO

f : TUNER

J : CD PLAY

L : AUDIO IN

E : USB

a : Bluetooth

d : LAN

G : WIRELESS LAN

• Abbreviation

AUS : Australian model

CND : Canadian model

Note: When the complete MAIN board or complete NET

board is replaced, refer to “CHECKING METHOD OF

NETWORK CONNECTION” on page 5.

Note:

Les composants identifi és

par une marque 0 sont

critiques pour la sécurité.

Ne les remplacer que par

une pièce portant le numéro spécifi é.

• Circuit Boards Location

module (DAB tuner) (DAB1)

(SBT100B/SBT300WB)

Bluetooth module

(BT1)

KEY board

HP board

NFC

(RC-S801/A) (NFC1)

FL board

TUNER board (SBT100/SBT300W)

DAB board (SBT100B/SBT300WB)

ILLUMI board

MS-476 board

USB board

NET board (SBT300W/SBT300WB)

WiFi module (WIFI1)

(SBT300W/SBT300WB)

MAIN boar

POWER board

RELAY board

HCD-SBT100/SBT100B/SBT300W/SBT300WB

3030

Page 31

HCD-SBT100/SBT100B/SBT300W/SBT300WB

5-4. SCHEMATIC DIAGRAM - MAIN Section (1/7) -

52

GND (LD)

LD (650)

LD (780)

VR (650)

VR (780)

VOE/E+G

GND (PDIC)

VOF/F+H

FE_OPO

FE_OP–

FE_LD_DVD

FE_CD_LDD

FE_DVD_LDD

FE_VREFO

FE_FCS–

FE_FCS+

FE_LD_CD

FE_TRK+

FE_TRK–

FE_DMO

FE_FMO

FE_TRO

FE_FOO

FE_3.3V

FE_DVD_IOP

FE_LIMIT

FE_MUTE

RFMON

DVD_IOP

(CHASSIS)

LOAD–

LOAD+

CN501

1

2

3

NC

4

NC

5

PD

6

7

8

9

NC

10

11

VCC

12

VC

13

14

15

VOB/B

16

VOA/A

17

RF

18

VOD/D

19

VOC/C

20

TRK–

21

TRK+

22

FCS+

23

FCS–

24

FE_5V

VCTL

CN502

1LOAD–

2LOAD+

3LOAD_END_SW

4SW_COMMON

5UNLOAD_END_SW

CN507

6

5

4

+3.3V

3

GND

2

RXD

1

TXD

D–

D+

MAIN BOARD (1/7)

24P

JL531

JL532

JL533

JL534

JL535

JL536

JL537

JL538

JL539

JL540

JL541

JL542

JL543

JL544

JL545

JL546

JL547

JL548

JL549

JL550

JL551

JL552

JL553

JL554

CL577

5P

JL585

JL584

JL583

JL582

JL581

6P

CL576 (RF)

CL575

CL574

CL573 (GND)

CL572

CL571

R557

ET501

E

0

R540

0

C561

R570

10k

C575

0.001

R578

10k

100R566

C580

0.1

R575

C541

100

0.1

R577

4.7k

R565

100

FE_VOE

SL576

C542

0.1

FE_VOF

FE_VOB

FE_VOA

FE_VOD

FE_VOC

C576

0.001

FE_DMO

FE_FMO

FE_TRO

FE_FOO

R573

0

1

R543

2.2k

R544

3.3k

R549

47k

R550

47k

C569

1000p

C570

1000p

C572

1000p

C573

1000p

R556

100

R574

100k

R5461kR545

A

B

C

FFC1

OP1

OPTICAL

PICK-UP

BLOCK

D

(CMS-S76RFS7G)

(1/2)

(LO:DVD.HI:CD) MSW

E

F

G

(Page 32)

>101S

MAIN

BOARD

(2/7)

H

I

FFC2

MS-476

BOARD

K

L

(NC)

M

(Page 33)

N

>102S

MAIN

BOARD

(3/7)

• See page 50 for Waveforms. • See page 52 for IC Block Diagrams. • See page 60 for IC Pin Function Description.

15612J173

C525

1

C522

47

10V

C521

0.1

RB509

47

RB505

47

R536 100

0R535

C519

0.01

C518

0.01

C517

0.01

R533

47

MFI

IC506

1

NC

(3.3)

2

MODE1

3

NC

(3.1)

4

RESET

(3.3)

5

VCC

NCNCNCNCNC

6789

R596

4.7k

1k

3.3

3.3

6NC

7NC

8Vin

IC561

+1.2V REGULATOR

IC561

MM1701CHBE

C583

10

C582

0.001

C532

0.001

C533

10

FE_DMO

FE_FMO

FE_TRO

FE_FOO

0.3

4Cn5Cont

3GND

2NC

1.2

1Vo

C504

12p

C505

12p

R508

0

R510

5.1k

C510

0.01

C571

0.1

7

C563

0.01

R503

2

100k

X501

27MHz

1

1

R504

330

15kR505

0R506

IC502

SERIAL FLASH

W25Q16CVSSIG-R

(

)

1_CS

(1.5)

2SO

(3.3) (

3_W

4GND 5SI

8

C567

FB563

0.1

R561

C562

IC502

C565

1k

1

C503

0.1

C501

0.1

FE_VOC

FE_VOB

R562

0

R502

10

0

R501

12

FE_VOA

FE_VOD

FE_VOF

FE_VOE

R572

0

(3.3)

8VCC

(3.3)

7_HOLD

)

6SCK

(0.2)

C534

C544

470p

470p

R581

R518

R519

10k

3.3k

3.3k

9 20

C530

0.01

CL533

10

C531

1

4

5

(2.1)

(2.1)

(1.7)

(1.8)

(1.1)

(0.9)

(1.2)

120121122123

124125126127128

OP–

OPO

RFIP

RFIN

RF_B

RF_A

(2.1)

1

RF_C

(2.1)

2

RF_D

(2.3)

3

RF_E

(2.3)

4

RF_F

(1.1)

5

AVDD12_2

(3.3)

6

AVDD33_1

(0.6)

7

XTALI

(0.6)

8

XTALO

9

AGND33

(2)

10

V20

(1.4)

11

VREF0

(0)

12

REXT

(0.2)

13

MDI1

(2.4)

14

LDO1

(3.2)

15

LDO2

(3.3)

16

AVDD33_2

(1.8)

17

DMO

(1.3)

18

FMO

(0)

19

CD_VR

(0.2)

20

DVD_VR

(1.3)

21

TRO

(1.5)

22

FOO

(3.2)

23

MSW

(0)

24

USB_DM

(0)

25

USB_DP

(3.3)

26

VDD33_USB

27

VSS33_USB

(0.7)

28

PAD_V RT

(1.2)

29

VDD12_USB

)

(

30

SF_CS#

(1.5)

31

SF_DO

(0.2)

32

SF_DI

SF_CK

33 34 35 36 37

)

(

R512

R511

0

R571

0

(3.2)

0

R520

4.7k

R515

R516

R517

100

100

CL593

CL594

AGND12

AVDD12_1

IFSCK

IFSDORXTX

PRST#NCIFSDI

38 39 40 41 42 434445 464748 495051 52 53 54 55 56 57 58 59 60 61 62 63 64

(0.1)

(3.3)

(3.3)

(3.3)

(3.2)

CL543

R525

100

R522 100

R521 100

R526 100

R523

100

11 14 16 19

CL560

CL557

CL556

R551

R552

100

23

(3.3)

(2.4)

R554

100

(3.3)

ADACVDD2

IFBSY

(3.1)

R527 100

CL561