Page 1

HCD-S3000

SERVICE MANUAL

HCD-S3000 is the tuner, deck, CD and

amplifier section in LBT-S3000.

Manufactured under license from Dolby Laboratories

Licensing Corporation.

“DOLBY” and the double-D symbol a are trademarks

of Dolby Laboratories Licensing Corporation.

U.S and foreign patents licensed from Dolby

Laboratories Licensing Corporation.

CD

SECTION

T APE

DECK

SECTION

US Model

Canadian Model

Model Name Using Similar Mechanism HCD-G2500

CD Mechanism Type 5CD DISC

Base Unit Type KSM-213ECM

Optical Pick-up Type

Model Name Using Similar Mechanism NEW

T ape Transport Mechanism Type CWL-44-RR

KSS-213ECM/C2NP

(For the U.S model)

AUDIO POWER SPECIFICATIONS:

POWER OUTPUT AND TOTAL

HARMONIC DISTORTION:

with 6 Ω loads both channels driven, from 70 –

20,000 Hz; rated 70 W per channel minimum RMS

power, with no more than 0.9% total harmonic

distortion from 250 mW to rated output.

Amplifier section

Continuous RMS power output

80W + 80W

(6 Ω at 1 kHz, 10%

THD)

Total harmonics distortion Less than 0.07%

(6 Ω at 1 kHz, 35W)

Inputs

PHONO IN (phono jack):

sensitivity 3mV,

impedance 47 kΩ

MD/VIDEO IN (phono jacks):

sensitivity 250mV,

impedance 47 kΩ

Outputs

PHONOS (stereo phono jacks):

accepts headphones of

8 W or more

MD/VIDEO OUT (phone jack):

voltage 250mV,

impedance 1 kΩ

SPEAKER: accepts impedance of

6 to 16 Ω

SPECIFICATIONS

CD player section

System Compact disc and digital

audio system

Laser Semiconductor laser

(λ = 780 nm)

Emission

duration: continuous

Laser output Max. 44.6µW*

*This output is the value

measured at a distance of

200 mm from the

objective lens surface on

the Optical Pock-up

Block with 7 mm

aperture.

Wavelength 780 – 790 nm

Frequency response 20Hz – 20kHz (±0.5 dB)

Signal-to-noise retio More than 90 dB

Dynamic range More than 90 dB

DIGITAL OUT

(Square optical connector jack, rear panel)

Wavelength 600 nm

Output Level –18 dBm

COMPACT Hi-Fi STEREO SYSTEM

Tape deck section

Recording system 4-track 2-channel stereo

Frequency response (DOLBY NR OFF)

60 – 13,000 Hz (±3 dB),

using Sony TYPE I

cassette

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tunr section

Tuning range 87.5 – 108.0 MHz

(100 kHz step)

AM tuner section

Tuning renge 530 – 1,710 kHz

(with the tuning interval

set at 10 kHz)

Antenna AM loop antenna

External antenna

terminal

Intermediate frequency 450 kHz

— Continued on next page —

MICROFILM

Page 2

SAFETY CHECK-OUT

General

Power requirements 120V AC, 60Hz

Power consumption 135W

Dimensions (w/h/d) Approx. 355 × 425 × 442 mm

(14 × 163/4 × 171/2 in) incl. projecting patrs and

controls

Mass Approx. 13.1kg (28 lb 14 oz.)

Supplied accessories: AM loop antenna (1)

Remote RM-SG7B(1)

FM wire antenna (1)

Design and specifications are subject to change without notice.

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for A C leakage. Check leakage as

described below.

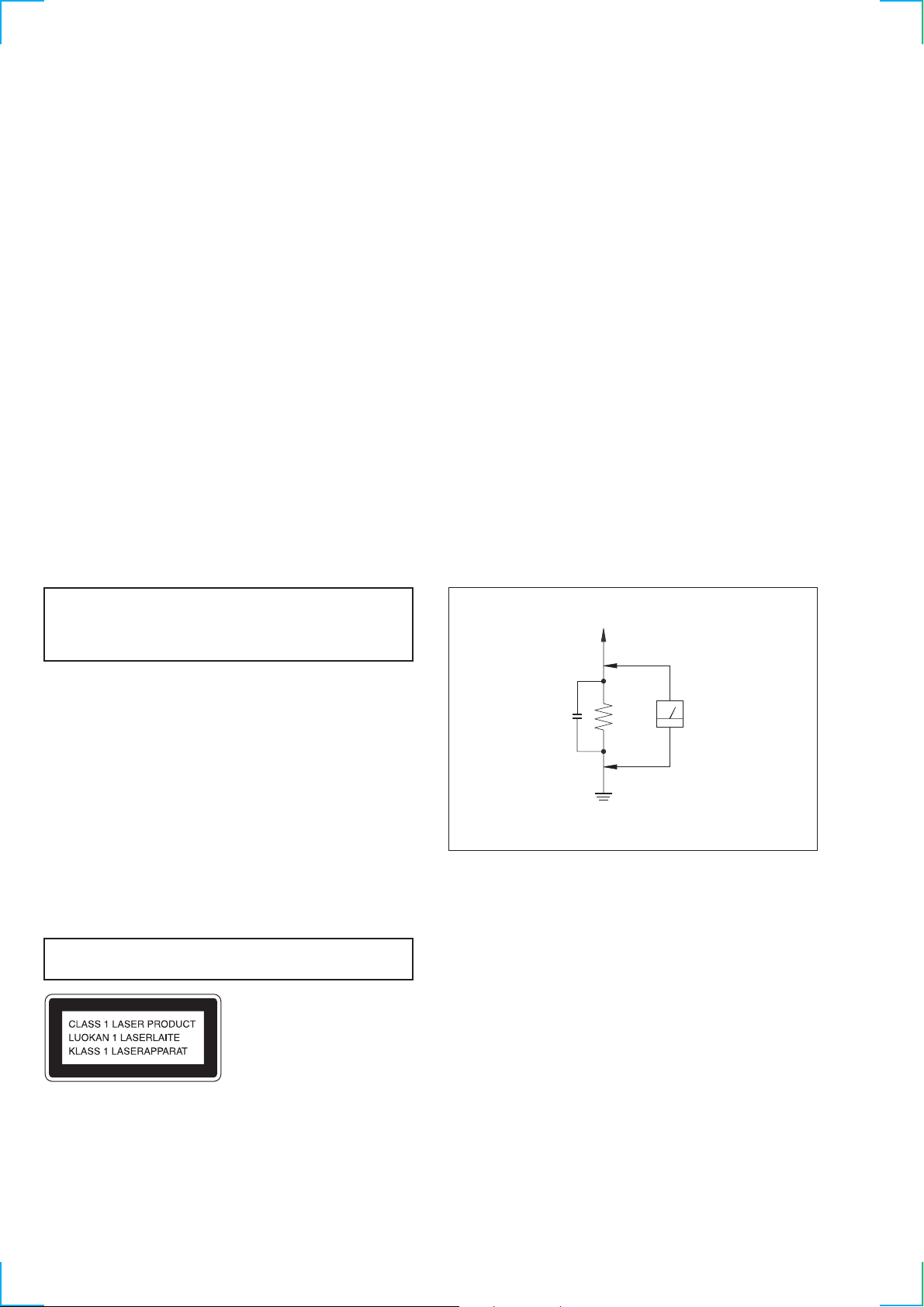

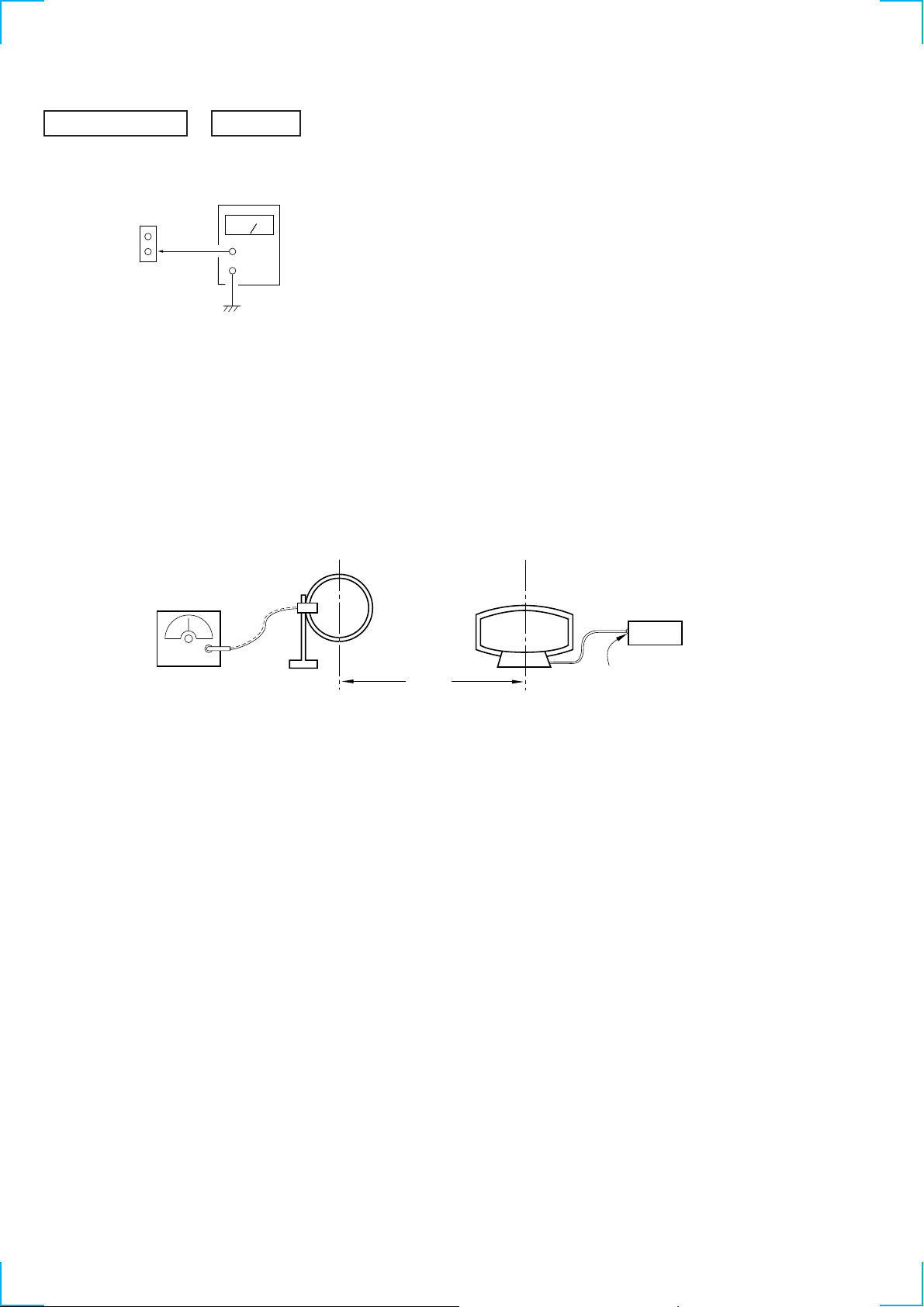

LEAKAGE

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leaka ge tester, such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC v oltmeter . The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are e xamples of

a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2V AC range are suitable. (See

Fig. A)

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

T o Exposed Metal

Parts on Set

AC

0.15

µ

F

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

1.5 k

Ω

Earth Ground

Voltmeter

(0.75 V)

This appliance is classified as a CLASS 1 LASER product. The

CLASS 1 LASER PRODUCT MARKING is located on the rear

exterior.

— 2 —

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE ! SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

Page 3

TABLE OF CONTENTS

1. GENERAL ·········································································· 4

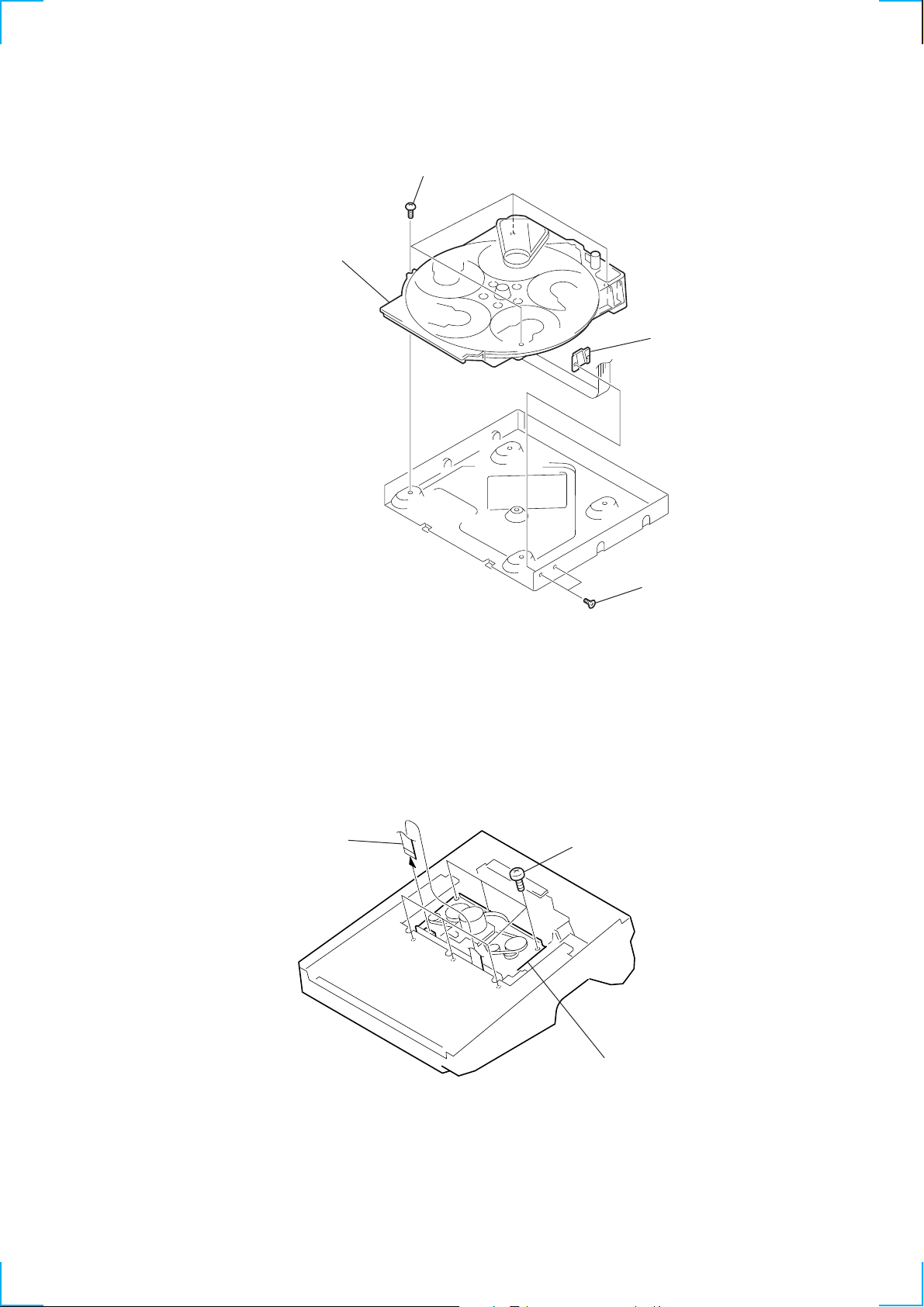

2. DISASSEMBLY

2-1. Top Cover ··········································································· 5

2-2. Front Panel Assy ································································· 5

2-3. Main Board·········································································6

2-4. Main Section······································································· 6

2-5. CD Mechanism Deck Section ············································ 7

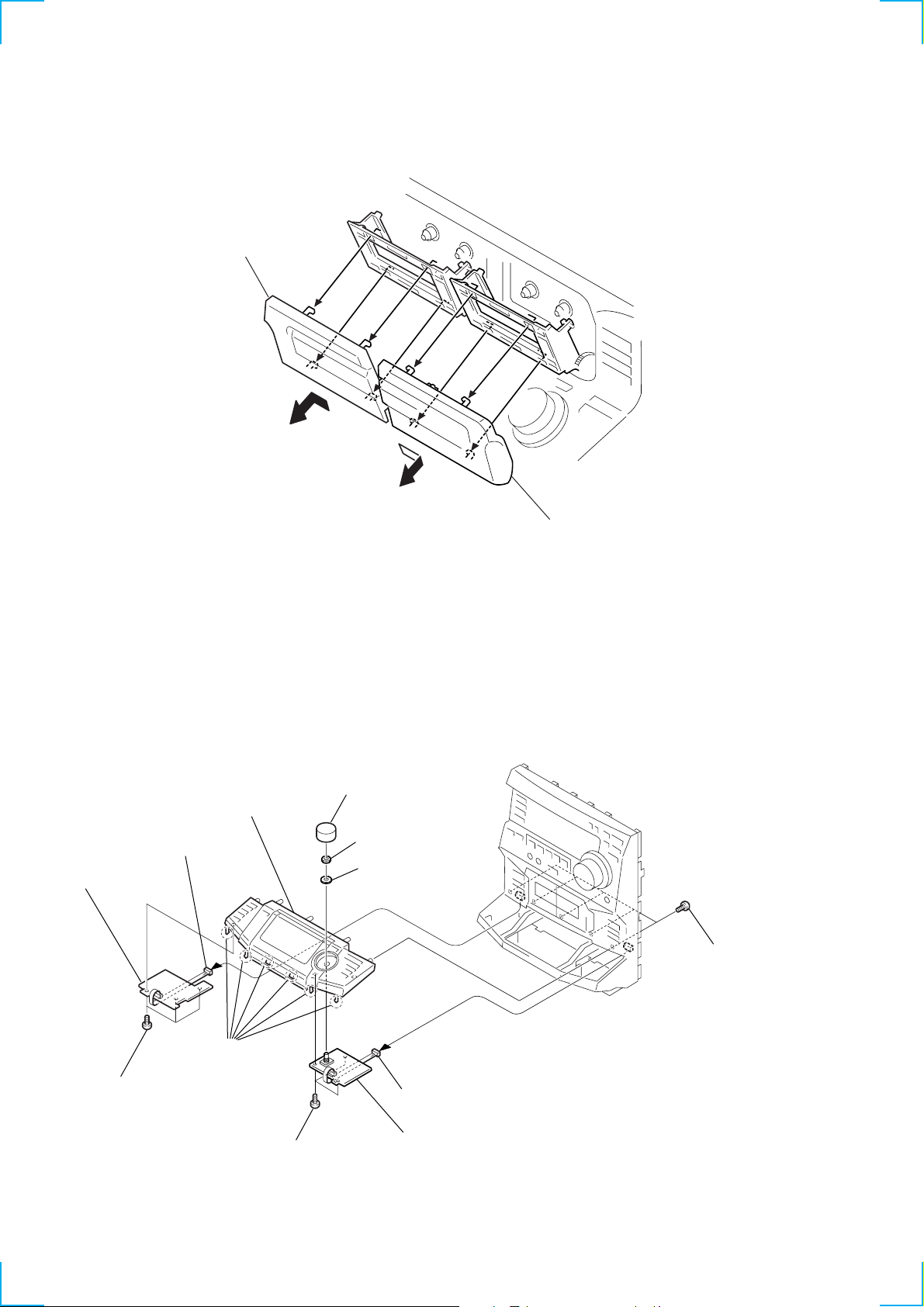

2-6. Tape Mechanism Deck Section ·········································· 7

2-7. Cassette Doors ···································································· 8

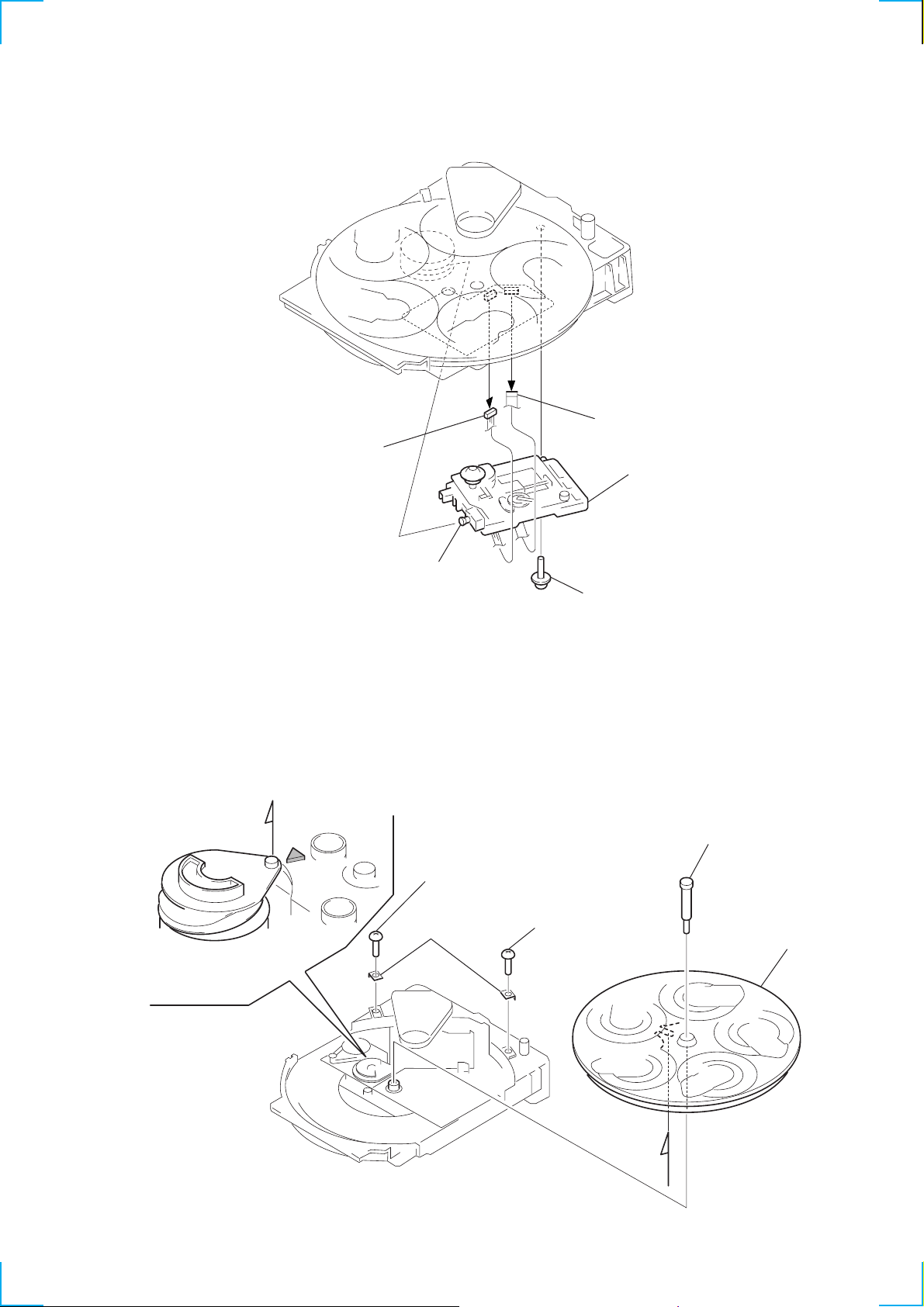

2-8. CD Chassis Assy ································································ 8

2-9. Base Unit ············································································ 9

2-10. Turn Table ··········································································· 9

3. MECHANICAL ADJUSTMENTS ····························· 10

4. ELECTRICAL ADJUSTMENTS ······························· 10

5. DIAGRAMS

5-1. Ciecuit Boards Location ··················································· 15

5-2. Block Diagrams ································································ 17

Main Section····································································· 17

Tuner/CD Section·····························································19

5-3. Printed Wiring Board Main Section ····························· 21

5-4. Schematic Diagram Main (1/3) Section ······················· 23

5-5. Schematic Diagram Main (2/3) Section ······················· 25

5-6. Schematic Diagram Main (3/3) Section ······················· 27

5-7. Printed Wiring Board Amp Section ······························ 29

5-8. Schematic Diagram Amp Section································· 31

5-9. Printed Wiring Board CD Decoder Section ·················33

5-10. Schematic Diagram CD Decoder Section ····················35

5-11. Printed Wiring Board Front Section····························· 37

5-12. Schematic Diagram Front (1/2) Section ······················· 39

5-13. Schematic Diagram Front (2/2) Section ······················· 41

5-14. IC Pin Function Description·············································43

5-15. IC Block Diagrams ··························································· 45

6. EXPLODED VIEWS

6-1. Top Cover Section ···························································· 47

6-2. CD Door Section ······························································ 48

6-3. Panel Section ···································································· 49

6-4. Main Section····································································· 50

7. ELECTRICAL PARTS LIST······································· 51

— 3 —

Page 4

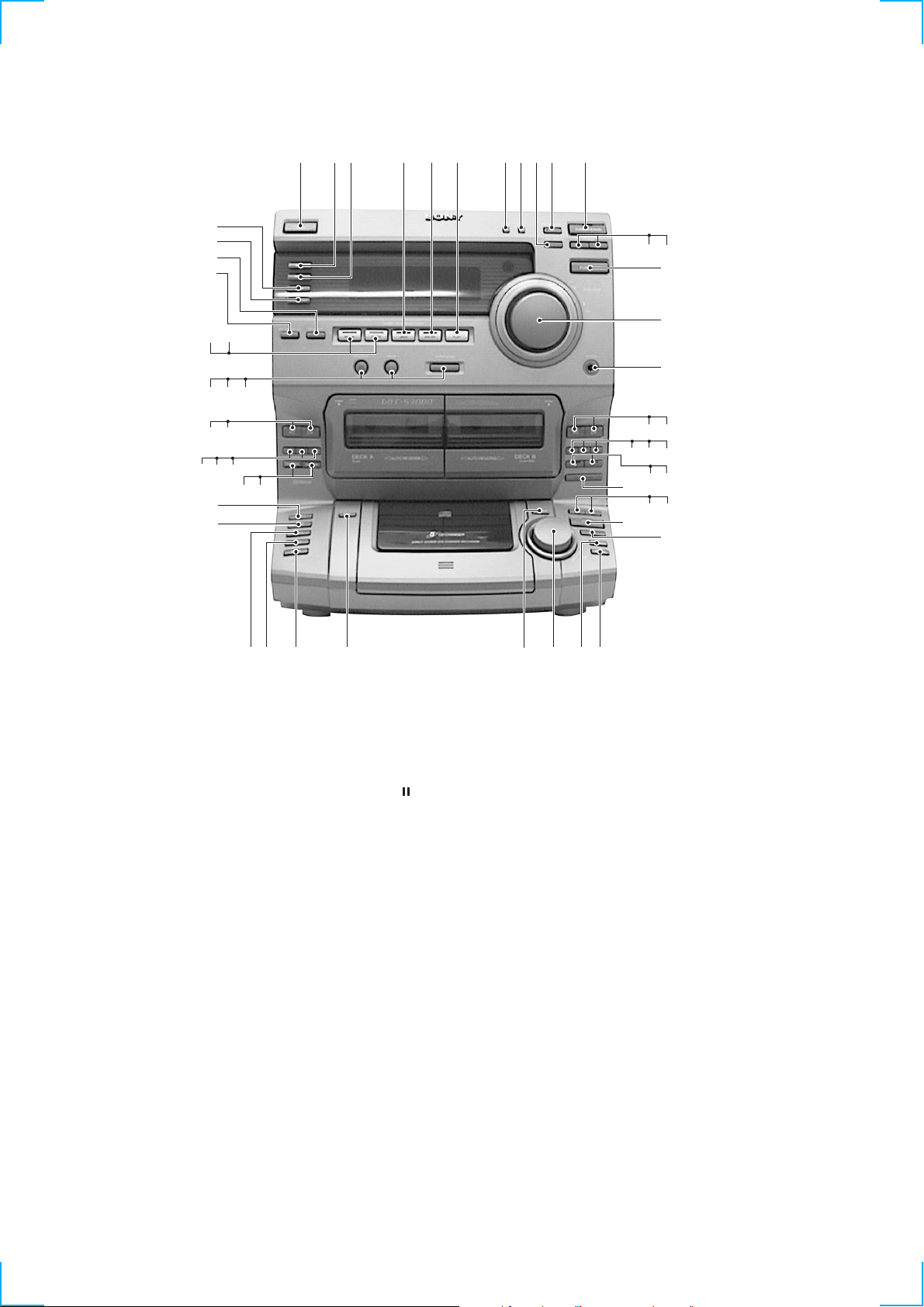

SECTION 1

GENERAL

#§

%™

%¡

$∞

$¢

#£

#™

#¶

$¶$§

$™$¡ $£

$º#ª

#•

#∞#¢

1 %¢ %£

$ª$• %º

23 54

6

!ª

@™

7

!¶

8

9

0

!¡

!£!™

!§!∞!¢

!•

@¡@º

@£

#º#¡ @¢

1 1/u (POWER) button

2 TUNING MODE button

3 STEREO/MONO button

4 TUNER MEMORY button

5 ENTER/NEXT button

6 TUNER/BAND button

7 TUNING – button

8 TUNING + button

9 FUNCTION button

!º VOLUME knob

!¡ PHONES jack

!™ ª button (DECK B)

!£ · button (DECK B)

!¢ p button (DECK B)

!∞ 0 button (DECK B)

!§ ) button (DECK B)

!¶ P button (DECK B)

!• r REC button (DECK B)

@ª

@•

!ª CD SYNCHRO button

@º 0 button (CD)

@¡ ) button (CD)

@™ fl button (CD)

@£ p button (CD)

@¢ REPEAT button

@∞ PLAY MODE button

@§ AMS knob

@¶ DISC SKIP button

@• EDIT button

@ª DISC 5 button

#º DISC 4 button

#¡ DISC 3 button

#™ DISC 2 button

#£ DISC 1 button

#¢ DIRECTION button

#∞ DOLBY NR button

#§ p button (DECK A)

@¶

@§

@∞

#¶ 0 button (DECK A)

#• ) button (DECK A)

#ª ª button (DECK A)

$º · button (DECK A)

$¡ GROOVE button

$™ DBFB button

$£ SURROUND button

$¢ SPECTRUM ANALYZER button

$∞ DISPLAY/DEMO button

$§ ROCK button

$¶ POPS button

$• JAZZ button

$ª SALSA button

%º FLAT button

%¡ t /CLOCK SET button

%™ SLEEP button

%£ REC button

%¢ DAILY button

— 4 —

Page 5

SECTION 2

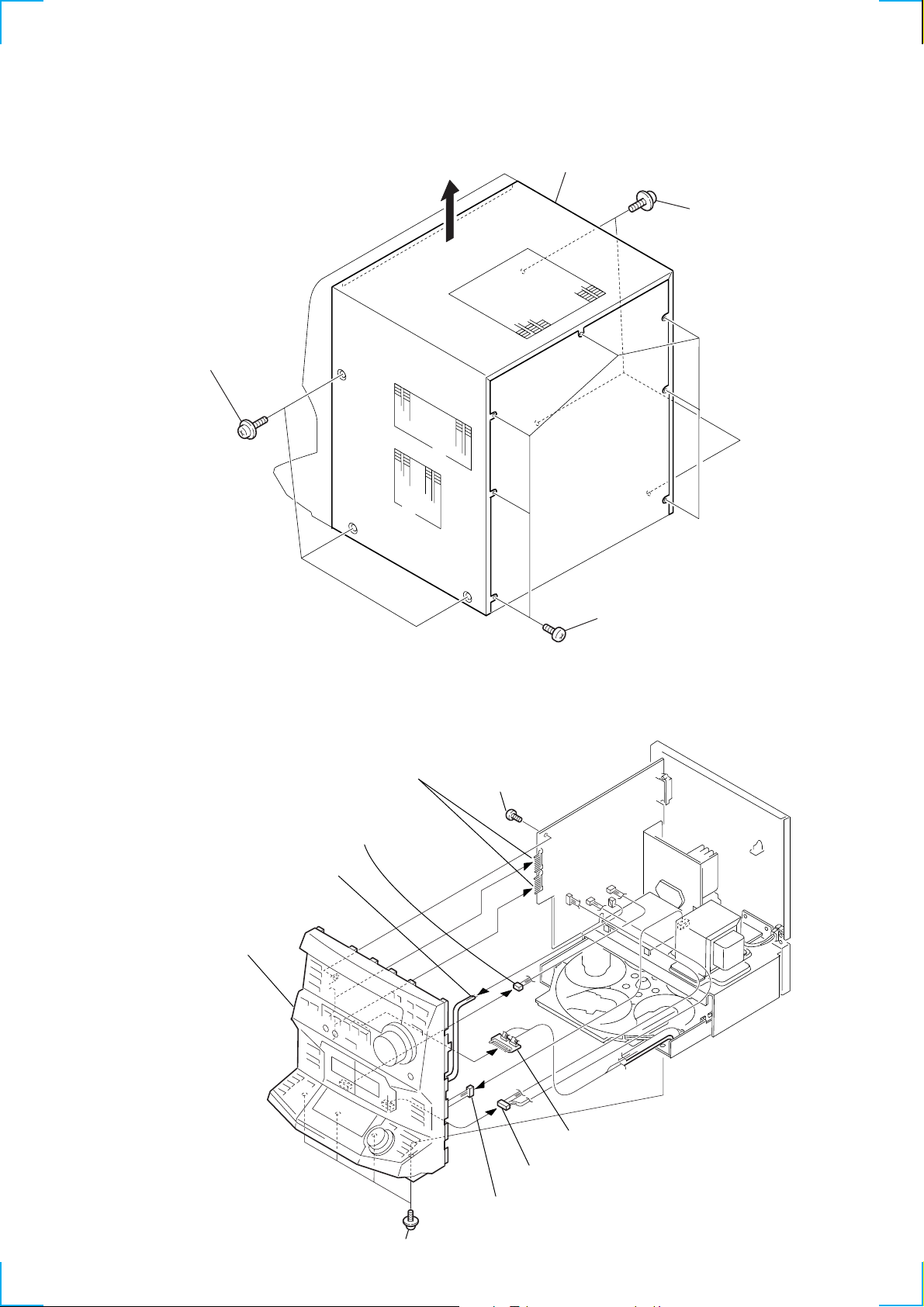

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

2-1. TOP COVER

1

Three screws

3

Top cover

1

Three screws

2-2. FRONT PANEL ASSY

9

Front panel assy

8

Board to board connector

(CN602)

(CN601)

1

Connector

2

Harness

(CN302)

(to deck A)

7

Screw

2

Seven screws

6

Four screws

5

Connector

(CN702)

— 5 —

3

Connector board

(CN11)

4

Connector

(to deck B)

Page 6

2-3. MAIN BOARD

!™

!¡

Two screws

Main board

!º

Connector

(CN701)

9

Connector

(CN301)

8

Rear panel

1

Four screws

2

Three screws

3

Screw

5

Four screws

6

Three screws

7

Three screws

4

Photo Socket board

2-4. MAIN SECTION

6

Two screws

1

Connector

(CN301)

7

Main section

2

Screw

5

Two screws

4

Three screws

3

Photo Socket board

— 6 —

Page 7

2-5. CD MECHANISM DECK SECTION

4

CD mechanism

deck section

3

Four screws

2

Holder, wire

2-6. TAPE MECHANISM DECK

1

Flexible flat cable

(to connector 16pin

on tape mechanism deck)

2

Six screws

1

T wo screws

— 7 —

3

Tape mechanism deck

Page 8

2-7. CASSETTE DOORS

)

Cassette door (L)

(Note: Four claws are used.)

Cassette door (R)

(Note: Four claws are used.

2-8. CD CHASSIS ASSY

!™

2

Connector

(CN606)

!¡

CD key board

4

six claws

!º

Three screws

CD chassis assy

Remove the

8

5

AMS knob

6

7

Three screws

Nut

Washer

1

(CN603)

Connector

9

AMS board

3

Five screws

— 8 —

Page 9

2-9. BASE UNIT

t

e

1

Connector

(CN02)

2

Connector

(CN01)

5

Base uni

2-10. TURN T ABLE

Note:

When the disc table is installed, adjust the positions of

roller can and mark ” as shown in the figure, then set

to the groove of disc table.

A

4

Boss

1

Screw

2

Bracket (BU)

1

Screw

3

Yoke bracket

3

Step screw

4

Turn tabl

A

— 9 —

Page 10

SECTION 3

MECHANICAL ADJUSTMENTS

SECTION 4

ELECTRICAL ADJUSTMENTS

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback head pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head

demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

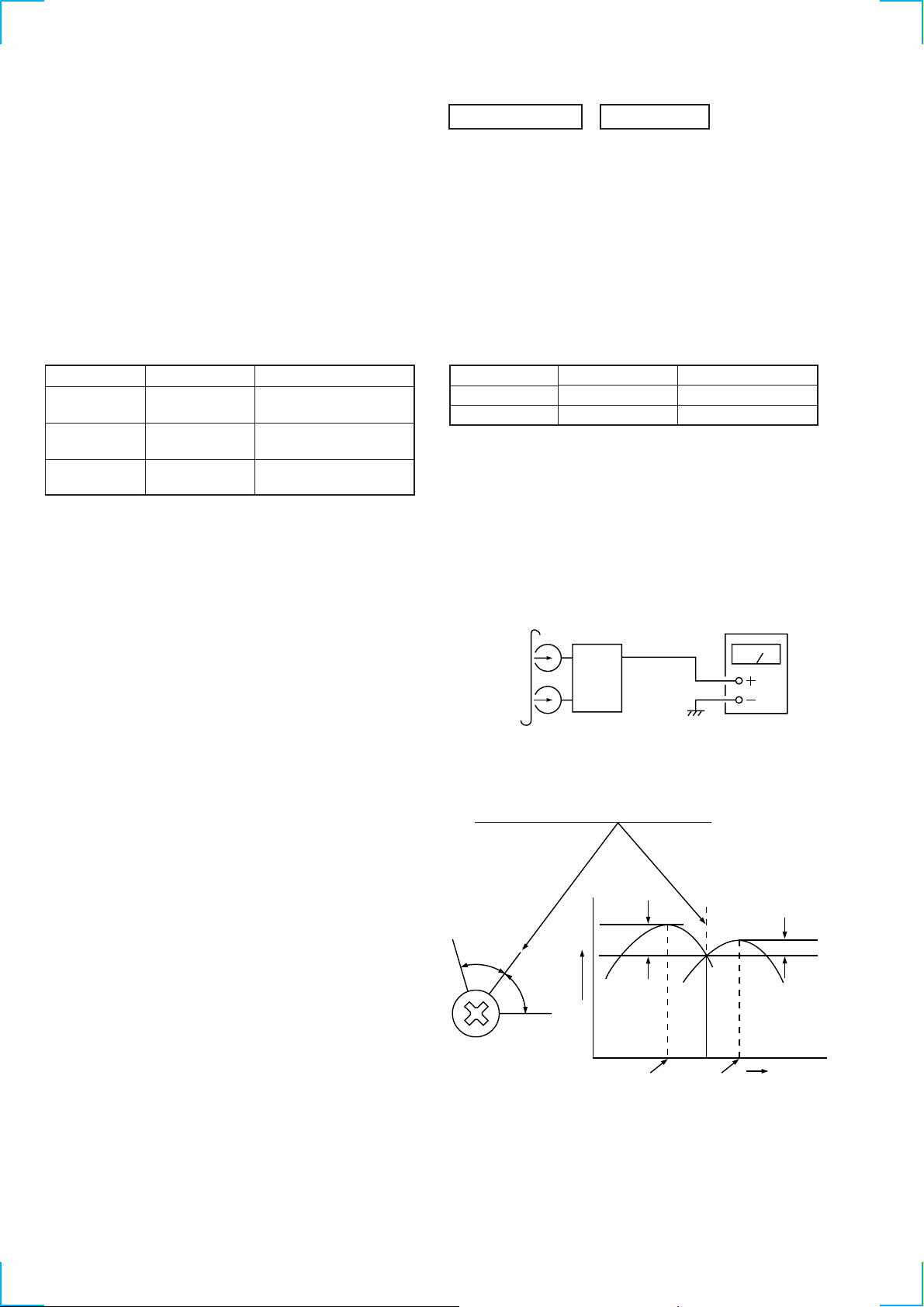

Torque Measurement

Torque

FWD

FWD

back tension

FF/REW

Torque meter

CQ-102C

CQ-102C

CQ-201B

Meter reading

40 to 70 g • cm

(0.56 - 0.97 oz • inch)

1 to 5 g • cm

(0.01 - 0.07 oz • inch)

55 to 140 g • cm

(0.76 - 1.94 oz • inch)

DECK SECTION 0 dB=0.775V

1. Demagnetize the record/playback head with a head

demagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjusted.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

5. The adjustments should be performed in the order gi ven in this

service manual. (As a general rule, playback circuit adjustment

should be completed before performing recording circuit

adjustment.)

6. The adjustments should be performed for both L-CH and RCH.

Tape

P-4-A100

WS-48B

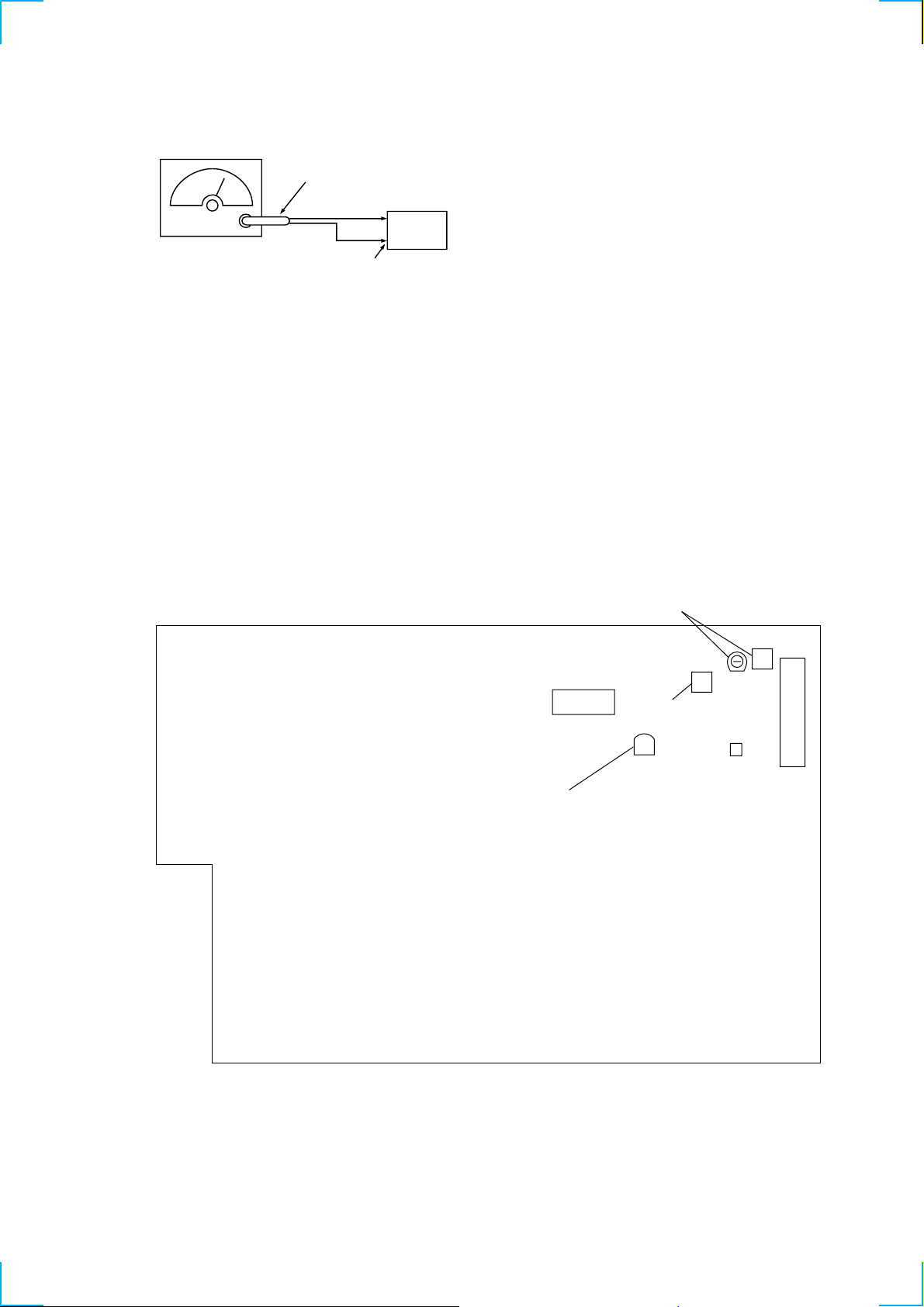

Record/Playback Head Azimuth Adjustment

(Deck A, Deck B)

Note: Perform this adjustments for both decks.

Procedure:

1. Mode : Playback

Signal

10 kHz, –10 dB

3 kHz, 0 dB

Used for

Azimuth Adjustment

Tape Speed Adjustment

test tape

P-4-A100

(10kHz, –10dB)

2. T urn the adjustment scre w and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw

so that outputs match within 2 dB of peak.

L-CH

peak

screw

position

output

level

R-CH

peak

SPEAKER

terminal (JK703)

set

within

2dB

L-CH

peak

R-CH

peak

level meter

within 2dB

screw

position

— 10 —

Page 11

e

r

3. Mode: Playback Tape Speed Adjustment (Deck A)

test tape

P-4-A100

(10kHz, –10dB)

in phase 45˚ 90˚ 135˚ 180˚

SPEAKER

terminal (JK703)

(L-CH)

L

R

SPEAKER

terminal (JK703)

(R-CH)

Waveform of oscilloscope

good wrong

oscilloscop

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

Procedure:

1. Mode: Playback

test tape

WS-48B

(3kHz, 0dB)

set

SPEAKER

terminal (JK703)

frequency counte

+

–

2. Adjust the SFR601 so that the frequency counter reads 3,000

Hz ± 90Hz.

Adjustment Location: FRONT board

Sample Value of Wow and flutter

W. RMS (JIS) within 0.3%

(test tape: WS-48B)

Adjustment Location: FRONT board

[FRONT BOARD] — Component side —

Adjustment Location:

Remove the cassette lid before adjustment (See page 8)

Adjustment screws

PB head (deckA)

or REC/PB head (deck B)

SFR601

IC603

TAPE SPEED

CN603

— 11 —

Page 12

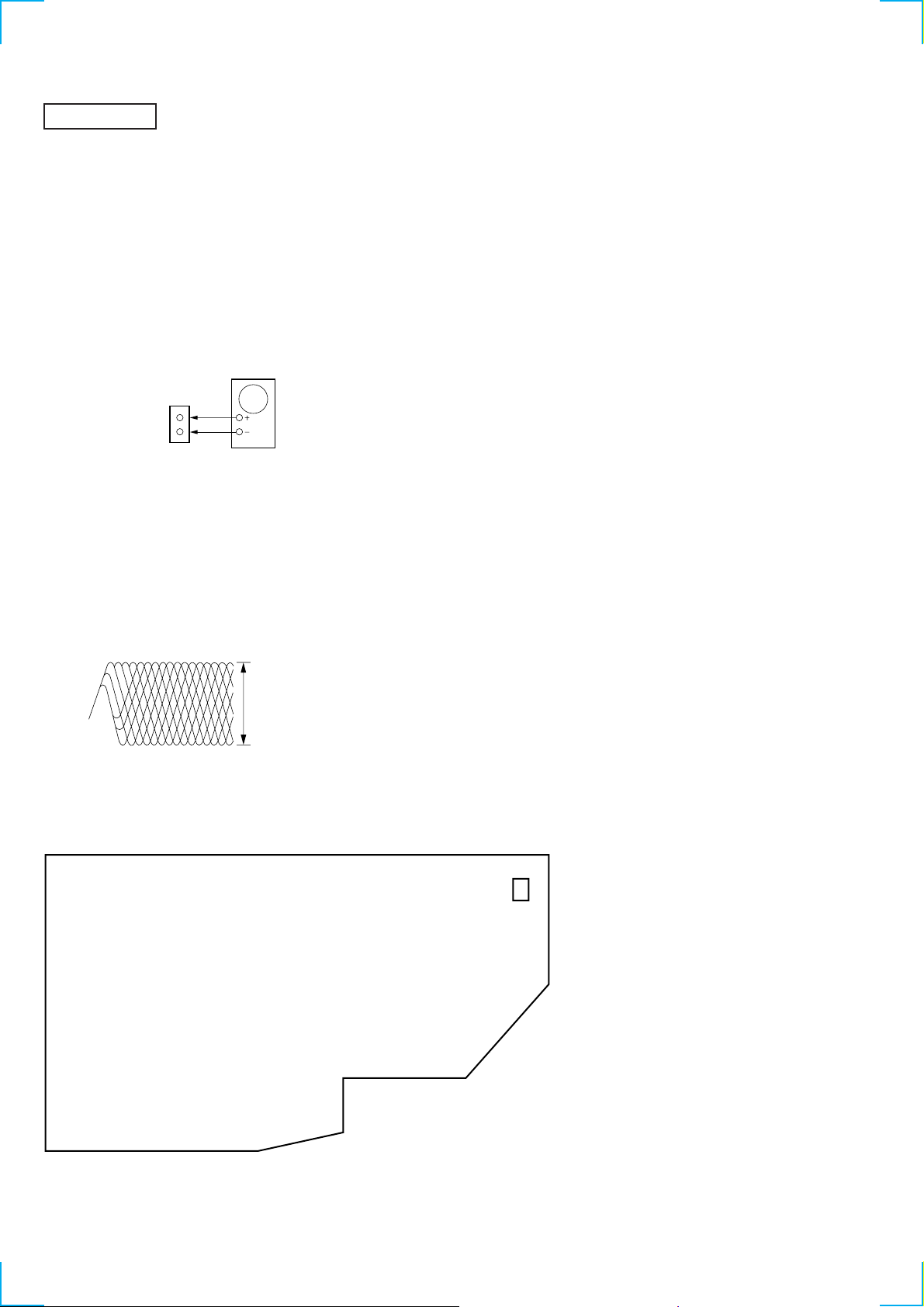

TUNER SECTION 0 dB=1µV

r

AM T uning Volta ge Adjustment

Main board

TP1

G

VT

DC voltmete

+

–

Procedure:

1. Set the reception frequency of the unit to 530 kHz.

2. Adjust L105 for 1.2 ± 0.05 V reading on the DC voltmeter.

3. Set the reception frequency of the unit to 1,710 kHz.

4. Conf irm that the voltage reading on the DC voltmeter is within

8.0 ± 0.5 V.

Adjustment Location: MAIN board (See page 13)

AM T racking Adjustment

loop antenna

AM RF SSG

loop antenna

(Supplied accessories)

set

30% amplitude

modulation by

400 Hz signal

Field strength dB (

Procedure:

1. Tune the set to 600 kHz.

2. Set the output of AM RF SSG so that the input level of the set

will become 60 dB (µV/m).

3. Adjust L104 so that when the wa v eform on the oscilloscope is

maximum, no noise appears.

4. Tune the set to 1,400 kHz.

60 cm

µ

V/m) =SSG output level dB (µV/m) –26 dB.

AM ANTENNA

terminal (TM1)

5. Adjust TC102 so that when the waveform on the oscilloscope

is maximum, no noise appears.

• Repeat the procedures in each adjustment several times, and the

tracking adjustment should be finally done by the trimmer

capacitors.

Adjustment Location: MAIN board (See page 13)

— 12 —

Page 13

FM Tuned Level Adjustment

FM RF SSG

Ω

coaxial

75

set

Carrier frequency : 98 MHz

Modulation : AUDIO 1 kHz, 75 kHz

deviation (100%)

Output level : 28 dB (at 75 W open)

FM ANTENNA terminal

(JK101)

Procedure:

1. Supply a 28 dB 98 MHz signal from the ANTENNA terminal.

2. Tune the set to 98 MHz.

3. Adjust SFR101 to the point (moment) when the TUNED

indicator will change from going off to going on.

Adjustment Location: MAIN board

Adjustment Location

[MAIN BOARD] — Component side —

IC102

FM T uned Level

AM T rac king

L105

TC102

AM T uning Voltage

SFR101

L104

TP1

JK101

— 13 —

Page 14

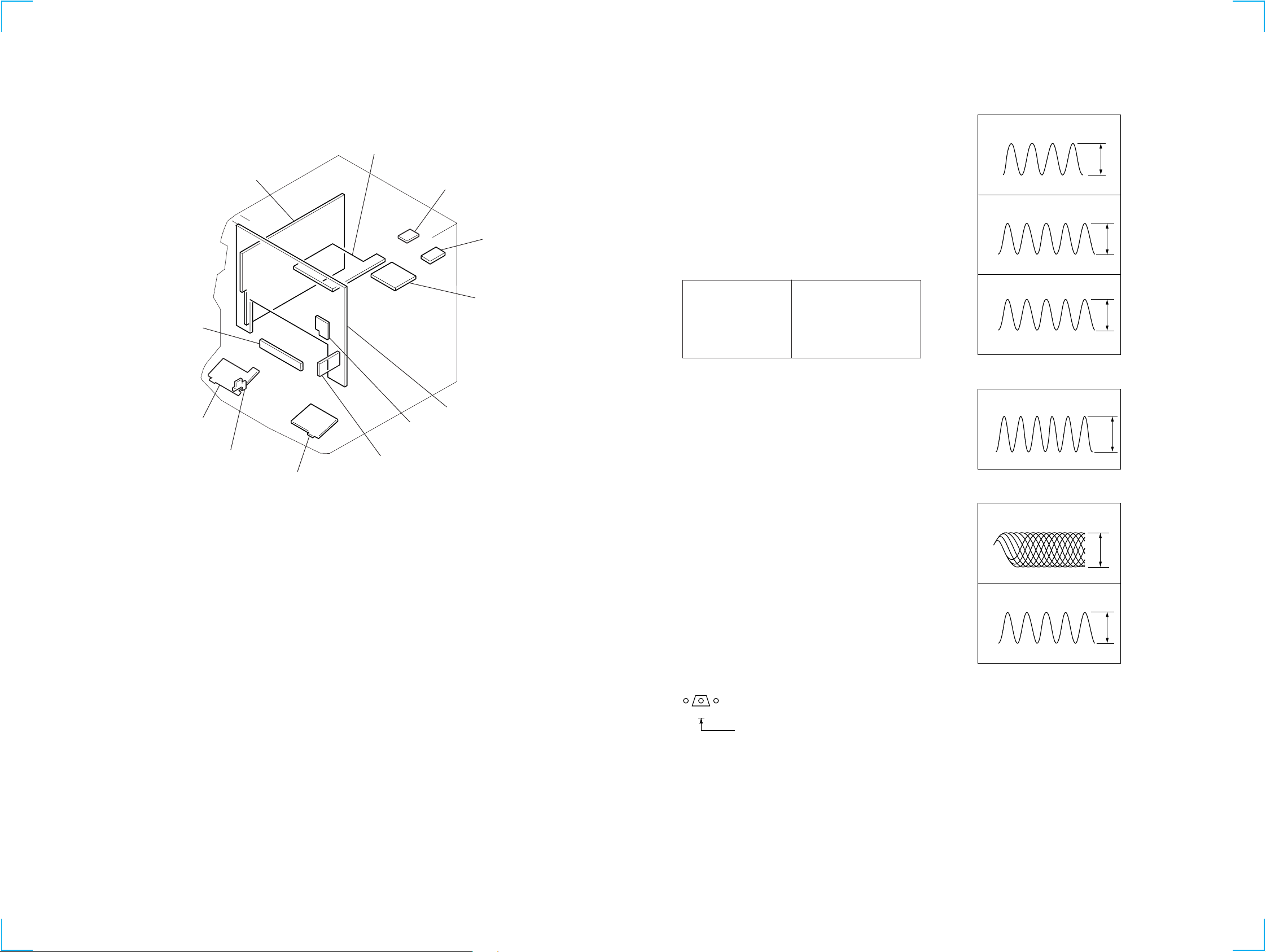

CD SECTION

V

Note:

1. CD Block is basically constructed to operate without

adjustment. Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specified value with the

following checks.

5. Adjust the focus bias adjustment when optical pick-up block is

replaced.

RF Level Check

CD DECODER

board

TP01

RF

VC

oscilloscope

Procedure :

1. Connect oscilloscope to test point TP01 on CD DECODER

board.

2. Turned Power switch on.

3. Put disc (YEDS-18) in and playback.

4. Confirm that oscilloscope waveform is clear and check RF

signal level is correct or not.

Note: Clear RF signal waveform means that the shape “◊” can be

clearly distinguished at the center of the waveform.

VOLT/DIV: 200 m

TIME/DIV: 500 nS

level: 1.0 Vp-p

+0.3

–0.2

Adjustment Location:

[CD DECODER BOARD] — Component side —

TP01

(VC)

— 14 —

Page 15

SECTION 5

DIAGRAMS

HCD-S3000

5-1. CIRCUIT BOARDS LOCATION

MAIN board

LED board

CD KEY board

CD SW board

AMS board

POWER (AMP) board

PHOTO SOCKET board

VR board

H/P board

POWER SUPPLY board

FRONT board

REM board

THIS NOTE IS COMMON FOR PRINTED WIRING

BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this necessary note is printed in each

block.)

For schematic diagrams.

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• % : indicates tolerance.

¢

•

• 2 : nonflammable resistor.

• 1 : fusible resistor.

• C : panel designation.

• U : B+ Line.

• V : B– Line.

• H : adjustment for repair.

• Voltages and waveforms are dc with respect to ground

• Voltages are taken with a VOM (Input impedance 10 M Ω).

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

: internal component.

Note:

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part

number specified.

under no-signal (detuned) conditions.

Voltage variations may be noted due to normal produc-

tion tolerances.

F : FM

f : AM

E : PB (DECK A)

d : PB (DECK B)

G : REC (DECK B)

J : CD

g : MD/VIDEO

i : PHONO

For printed wiring boards.

Note:

• X : parts extracted from the component side.

®

•

•

• b : Pattern from the side which enables seeing.

• Indication of transistor.

: Through hole.

¢

: internal component.

4

W or less unless otherwise

Note:

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

• Wavef orm

MAIN BOARD

IC103 @™

1

7.2 MHz

L809 5

5

111.7 kHz

L809 6

6

111.0 kHz

FRONT BOARD

IC601 !§

2

6 MHz

CD DECODE BOARD

IC01 #£

3

IC02 &¡

4

16.9345 MHz

3.6 Vp-p

32 Vp-p

96 Vp-p

3.8 Vp-p

1.3 Vp-p

5.0 Vp-p

Q

B

CE

This is omitted.

— 15 — — 16 —

Page 16

HCD-S3000

5-2. BLOCK DIAGRAM

MAIN SECTION

CD L

B

CD

SECTION

(PAGE 20)

JK201

L

PHONO

MD/VIDEO

IN

TAPE A

HP901

PB

HEAD

TAPE B

HRP901

REC/PB

HEAD

HE901

ERASE

HEAD

SECTION

(PAGE 20)

SECTION

(PAGE 20)

A

TUNER

C

CD

R

L

R

TU L

ST IND

TU MUTE

DO1

DATA IN

SCOR

SCOR

SENS1

SQSO

SENS2

XLAT

SQCK

DATA

CNIN

FOK

LOCK

CLK

STB

R CH

R CH

R CHR CH

R CH

Q803,805

PLAY/REC

CONTROL

Q823

PLAY/REC

CONTROL

DRIVE

D803

DI

CE

SFR8079SFR807

Q801

PLAY/REC

CONTROL

D802

CE

IC202

CLK

CLK

JK201

L

T100

R

SPEAKER

JK703

MD/VIDEO OUT

JK701

PHONES

AC

IN

IC203

8

9

6

10

12

Q201

AMP

IC607

IC606

PHOTO A

PHOTO B

A MODE SW

B MODE SW

Q607

SOL A

SOL B

Q204

MUTE

11

SELECTOR

IC201

Q305

SURROUND

CONTROL

Q306

IC301

IC302

Q301

Q303

2

L1 (CD)

9

8

7

3

M+12V

Q610,613

M+12V

SWITCH

4PLAY

Q612,615

SOL A

5

DRIVE

Q611,614

SOL B

6

DRIVE

3REC A

4REC B

5

6

11

12

13A HALF

14B HALF

IC604

12

13

4

5

8

6

10

12

L4 (AUX)

L3 (TAPE)

L2 (TUNER)

L (REC)

DATA CLK

13 14

1

3

9

11

MECHA

BLOCK

VR

11

Q709

MUTE

POWER AMP

IC701

14 7

Q713

MUTE

SWITCH

+12V

IC701 B+

IC701 B-

-30V

-5.6V

CD +7.5V

+12V

(TUNER)

+12V

(BIAS)

+12V

(CASSETTE)

D+12V

(MOTOR)

+5.6V

µCON B+

VCC

Q707

MUTE

D601

D602

Q308

-5.6V

REG

Q711

Q703

-27V

REG

Q702

+7.5V

REG

Q309

SITCHING

Q310

+5.6V

REG

Q708

Q701

+12V

REG

1

2

D715

IC702

SPEAKER

RELAY

DRIVE

4

Q704 705

AC OFF

DET

Q207

Q209

Q210

MUTE

EQ AMP

IC801

6

PB OUT

5

SFR801

7

L805

BIAS

TRAP

L609

BIAS OSC

Q816,817

BIAS

OSC

Q829,830

BIAS

+12V

DI

BIAS

SWITCH

2

Q807

SW

A/B

SFR803

3

D804

Q825,826

MUTE

CONT

+12V

DI

CLK

10

14

13

Q833

LED DRIVE

IC603

1

2

3

PB/REC AMP

IC802

REC AMP

VALC

8 1

4

11

14

.

16

.

17

11

12

D807

Q809

LED610-615

DOLBY AMP

IC803

14

16

Q811

BUFFER

LED DRIVE

IC602

CLK

3

DI

2

4

9

12

SFR805

Q813

D808

REC

MUTE

DOLBY OUT

16

LED601-603

LED605-608

7

9

.

11

14

Q608,609

5

LED

DRIVE

6

5

LED516

Q822

11

IC303

Q831

Q815

Q832

PB

AMS

MUTE

MUTE

D811

Q205

CLK

BUS REGISTER

13

REC MUTE

7

TAPE PLAY

14

PLAY MUTE

11

A/B

12

BIAS

10

Q'S

1

STB

DI

2

SI

CLK

3

CLK

SHIFT REGISTER

CLK

2

CK

1

S/L

9

QH

R CH

R CH

+12V

RL701

6

D705-708

RECT

D701

RECT

AC5.4V

AC5.4V

4

6

FLD601

FLUORESCENT

5

DBFB H/L

DBFB ON/OFF

G1 G16

45 3019 23

1

POWER OUT

2

SYSTEM MUTE

• RCH is omitted

• Signal Path

: PB (DECK A)

: PB (DECK B)

: REC (DECK A)

: FM

: CD

: MD

91

100

98

100

93

CE

STB

SCLK

SCLK

SDATA OUT

16

95

94

96

11

27

99

9

73

SDATA IN

MD MUTE

FM ST IND

A

CD ENCODER

88

LATCH

CD ENCODER A

83

84

VR602

CD ENCODER B

B

S653

DOOR SW

79

CD DOOR

SYSTEM CONTROLLER/

FLD DRIVER

IC601

UP SW

77

S06

UP SW

78

TABLE

SENSOR

SENS01

TABLE SENSOR

86

80

26

10

S/L

VACS

DATA IN

SPEANA H/L

K0 K4

KEY

MATRIX

S601-651

Q601

DOWN DET

7 8 85

MD/VIDEO

POWER DOWN

13

POWER

MD (HI)

DATA

REMOTE

29

RM601

2

REMOTE

CONTROL

RECEIVER

3

VCCVCC

74

AMS

RESET

12

Q602

RESET

SWITCH

25

SPEANA 224SPEANA 1

SURROUND OUT

P1 P21

.

47 50 52 68

INDICATOR TUBE

87

76

28

FOK

CNIN

LOCK

16

X601

6MHz

75

XLAT

DATA97SQCK

SQSO

SCOR

SENS1

SENS2

VR DOWN

X217X1

VR UP

81

82

A

B

VR601

VOLUME

— 17 — — 18 —

Page 17

HCD-S3000

TUNER/CD SECTION

FM

75Ω

JK101

ANTENNA

AM

L104

AM ANT

AGC

FM

FM

DET

AM

DET

20

IF

SMET

FM/AM MPX

IC102

AM

OSCAMMIX

TU LED

ST MONO

12

6

AM/FM

IF BUFF

AM

IF

FM DET

ST IND

IF BUFF

MUTE

L

CF103

450kHz

13

R

14

R CH

Q117

MUTE

DECODER

CF104

8

10.7MHz

4

T102

AM IFT

2

7

10

TU L

ST IND

TU MUTE

DO 1

A

MAIN

SECTION

(PAGE 17)

• RCH is omitted

• SIGNAL PATH

:FM

:AM

:CD

FM FRONT END

FE101

8

RF

D107

1

MIX

3

OSC

OSC

4

VT

TUB+

TP1

+12V

VT

Q108

AM RF

AMP

Q114

CF101

10.7MHz

G

X201

7.2MHz

Q101

RF IF

AMP

IF

CF102

10.7MHz

TP2

G

L105

MW OSC

SFR101

FM

B+

TUNED

LEVEL

PLL

IC103

FM

PD1

FM B+

XO

XI

SD SPEED

SD IN

FM ST

IF IN

CLK

AM

15

10

11

12

DO

DI

CE

16

18

7

22

1

FM IF

1

MPX

16

AM OUT

19

OSC

23

AFC

22

AM RF

21

OSC/FMSD

24

9

DO

6

DI

4

CLK

5

CE

3

16

OPTICAL PICK-UP

BLOCK

DETECTOR

7

8

4

1

2

5

6

10

LD

PD

FOCUS

COIL

TRACKING

COIL

GND

VR

SPINDOL

VC

A

C

B

D

E

F

LD

PD

F+

F

T+

T

M102

SLED

MOTOR

M101

MOTOR

TABLE

MOTOR

Q09

MUTE

PH01

DIGITAL

OUT

SCOR

SENS1

SQSO

XLAT

SQCK

DATA

SENS2

LOCK

CNIN

FOK

DI

CLK

CE

DATA IN

STB

CD L

B

MAIN

SECTION

(PAGE 17)

C

MAIN

SECTION

(PAGE 17)

PWM

PWM

15

SPOA

D OUT

XTA1

XTA0

L MUTE

53

NL

67

NR

74

R-CH

70

X701

16.9344MHz

71

Q11,13

2

MUTE

SWITCH

CD RF/SERVO

PROSSESOR

VCC

VC

51

PD1

38

PD2

39

E

42

F

Q01

APC

F/T COIL

SL/SP MOTOR

T.T/TRAY MOTOR

DRIVER

IC03

15

F+

F IN

TABLE

IC05

T IN

SL IN

SP IN

27

25

6

23

IN1

9

IN2

1

16

F

17

T+

18

T

SL+

12

M

SL

11

SP+

14

M

SP

13

MOTOR DRIVE

OUT1

7

M

OUT2

3

41

LD

36

APC

PD

PD

37

16

IC01 (1/2)

RF

AMP

FE

AMP

FOCUS PHASE

COMPENSATION

FEO TAO

6

IC701 (2/2)

14

+5.6V

VCC

COMAND

SERIAL/

PARALLEL

CONVERTER

DECODER

+5V SW

Q03

TRACKING PHASE

COMPENSATION

13

D06

DISC NO

RFO

33

FOK

27

C OUT

IIL

TTL

TTL

IIL

REG

Q04

SENS1

SENS2

DATA

XLT

CLK

XRST

LOCK

Q702

LED

DRIVER

24

25

26

22

21

20

23

19

SHIFT REGISTER

B+

6

12

13

12

12

XRST

LED CONT

MIN1

MIN2

LED CONT

IC04

MUTE

CLOK

DATA

STB

4

3

2

1

RF

35

FOK

18

CIN

11

SE

10

DAT

12

XLT

13

CLK

14

79

XRST

MDP

21

CD DIGITAL

SIGNAL PROCESSOR

IC02

CLV

SERVO

DIGITAL

CLV

EFM

DEMO.

D/A

I/F

SUB CODE

PROSSESOR

CPU I/F

CLOCK

DATA

7 9 4 5 6 6257

SQCK

SQSO

XLAT

8

SENS

SCOR

SERIAL

MUTE

I/F

CLOCK

GEN.

STOP

SWITCH

— 19 — — 20 —

Page 18

HCD-S3000

• Semiconductor Location

Ref. No. Location

D07 J-11

D08 J-10

D09 J-9

D10 J-8

D101 C-2

D102 C-2

D103 A-2

D104 A-2

D107 B-3

D109 C-5

D110 B-8

D111 A-8

D301 E-4

D302 D-10

D303 I-4

D304 B-11

D305 D-3

D306 E-7

D307 A-9

D308 A-9

D309 C-11

D310 C-11

D802 I-9

D803 I-9

D804 F-8

D805 C-11

D806 D-11

D807 E-7

D808 E-7

D811 I-10

D812 F-12

IC102 B-6

IC103 D-3

IC201 E-4

IC202 H-3

IC203 F-3

IC301 F-4

IC302 H-4

IC303 B-9

IC801 G-8

IC802 F-8

IC803 G-6

Q101 B-5

Q108 A-3

Q114 C-3

Ref. No. Location

Q116 B-7

Q117 A-7

Q201 D-9

Q202 E-7

Q203 C-9

Q204 D-8

Q205 C-10

Q206 H-8

Q207 E-3

Q208 E-3

Q209 E-3

Q210 D-3

Q301 H-4

Q302 G-5

Q303 H-4

Q304 G-5

Q305 G-4

Q306 D-10

Q308 I-4

Q309 I-4

Q310 A-10

Q801 F-10

Q802 G-9

Q803 G-10

Q804 G-10

Q805 G-10

Q806 G-10

Q807 F-8

Q808 G-7

Q809 H-9

Q810 F-6

Q811 G-7

Q812 F-6

Q813 H-7

Q814 F-6

Q815 H-6

Q816 I-10

Q817 I-10

Q822 E-6

Q825 G-10

Q826 F-10

Q829 E-11

Q830 E-11

Q831 D-11

Q832 D-11

Q833 F-12

5-3. PRINTED WIRING BOARD MAIN SECTION

12

3456789101112

MAIN BOARD

A

ANTENNA

AM

B

FM

C

D

E

F

JK201

OUT

MD/VIDEO

G

IN

PHONO IN

H

I

J

JK101

RL

RL

RL

16

C250

C204

C206

C216

D104

D103

C165

C185

R251

D102

D101

C186

R252

R208

Q208

C218

C201

R206

L104

C113

FE101

Q114

S

R117

G

D

Q210

S

E

B

B

R255

E

Q209

C219

8

7

R256

C213

R222

R224

C203

R223

R209

C217

C202

C208

R202

C252

R204

R210

R220

GND301

TC102

L114

C155

R135

GD

12 22

11

C197

C199

C152

R260

R229

R254

R253

C221

R225

IC203

C222

R227

R217

R221

C205

R207

R205

R203

C209

R211

C207

R201

5

IC202

R212

C210

D107

C148

D305

R228

14

C211

8

14

C212

R214

C337

C255

GDS

C150

R115

C143

IC103

C196

B

E

1

R262

R261

C220

R218

C251

C215

C114

L108

C179

458

R133

D301

Q207

C223

R310

C214

Q305

R215

R213

R219

C327

R267

R352

R216

R356

R357

C248

B

E

C338

C116

R114

R113

R134

R268

C311

R309

C321

B

E

Q108

1

C144

1

R354

C322

D303

• Refer to page 15 for Circuit Boards Location.

R118

C121

C163

C120

CF102

R124

SFR101

C240

C235

C241

R304

C304

C310

R312

R326

R914

R332

C324 C325

1

6

R327

AMP BOARD

T102

R123

C128

C137

C239

C302

C908

CN807

C907

R915

CN701

(Page 29)

CF103

C126

C127

1

IC102

C188

C164

R175

C151

C135

C138

R180

R263

R264

R266

R259

R265

B

Q812

E

C236

R868

B

C892

Q814

E

R866

C862

R862

R874

R880

R864

18

1

3

R865

C893

R861

B

R877

R863

E

Q815

CN401

12

C

TO

C117

C108

R104

C187

TP1

R132

R714

C246

R355

28

R244

C312

C346

R311

SD

G

R324

1

C317

R323

R313

C313

Q309

C335 C336

Q308

C159

X101

C195

C244

R308

R351

C309

C320

R321

C315

R155

R147

C158

IC201

C301

R314

C314

R322

IC302

R317

R315

C334

R347

C194

C249

L105

CF101

C162

R107

B

C177

R106

L113

R112

R105

C156

C157

C260

C226

C242

15

1

C247

R243

R306

1

R301

C307

R307

C316

R305

B

E

Q304

R320

R318

R316

C318

4

C319

58

C323

Q301

B

E

R325

B

E

R246

R319

Q303

R248

R245

R247

R350

CD DECODER

BOARD

CN03

(Page 34)

Q101

D109L106

R140

14

R245

C308

C306

4

IC301

58

C305

B

E

R331

D

TO

R151

R118

R144

E

R139

C243

R302

C302

R303

Q302

CN301

C115

C154

R173

R891

R887

C894

C857

R876

IC803

R878

R875

C146

R119

R121

C870

C858

C860

C868

CF104

12

1324

B

R892

R850

R854

C866

R869

C861

R136

E

SFR806

C122

R137

C123

C189

C129

R258

C876

Q822

C825

Q810

B

E

R870

R872 R860

R884

C864

916

C859

R882

SFR805

C869

1

R120

C125

C149

R825

R856

C854

B

Q811

E

R881

C161

C160

C131

C232

C867

R888

R846

R855

C863

C865

R871

C853

R328

C130

R334

R858

R859

R853

R857

C895

C855

C800A

E

R126

R128

C328

R845

R873

B

E

C891

Q117

R127R129

C257

C124

R236

D306

C830

C832

L802

R883

B

C133

C132

B

C230

E

D808

SFR804

R851

Q813

R867

R131

R116

R156

R172

C198

C140

R157

B

E

Q116

C139

C256

R232

Q204

B

R234

R250

C228

Q202

R238

C834

R848

C827

C234

R831

R836

C856

D807

R826

C851

Q807

B

R825

E

SFR803

C822

B

E

Q808

C824

2

1

C831

L801

C819

C806

R818

C820

C803

R824

CN302

R828

CN801

B

E

R527

LED BOARD

CN302

1

2

D111

R130

C142

D110

C141

R329

R333

C231

C238

E

R239

R233

R330

L804

C828

C836

C838

R842

18

IC802

C829

R830

R829

C837

C826

R819

D804

C821

C825

13

Q206

C823

C816

C804

C817

R821

1

C901

C902

SFR802

R817

R905

C815

IC801

R816

R820

C812

R812

R810

R800A

GND302

Q203

B

C329

C229

R235

C848

R849

R838

R840

916

C835

R841

C896

SFR801

R822

C818

C814

B

E

Q809

C333

E

Q201

B

E

R237

R823

C813

8

916

C897

C809

R811

R344

R249

C833

R844

R837

R839

C811

C808

C877

D307

D308

C347

L803

R847

C849

C839

R827

CN808

R809

R893

C805

14

IC303

R339

C227

C345

C233

C840

R834

C847

C842

C845

C807

R805

R806

C801

B

Q802

C802

E

1

2

CN803

C887

1

2

E

R807

R897

D802

D803

R337

C330

58

R242

R241

R231

Q306

R353

G

D

S

R843

C883

R814R832

C846

L805

B

R801

Q801

E

BB

E

E

Q805Q803

B

B

E

E

Q806

Q804

R804

R802

R898

C882

Q823

C880

B

B

E

C875

R808

R338

R143

R833

R835

1

2

Q817

R142

R240

C841

R815

C884

2

1

R895

R141

C922

3

1

5

1

SFR807

CN811

C885

L809

C888

C881

L808

R896

B

E

R899

Q816

R138

L301

R346

R926

CN809

L806

R803

CN812

CN802

Q310

C237

C906

D302

B

E

B

E

C886

C921

R894

B

E

Q205

S

D

G

B

C903

R906

Q825

SFR808

R890

R901

D811

1-674-636-

(4144268510)

D10 D09 D08 D07

R448

1-674-637-(CASSETTE BOX BACK LIGHT)

(4144268520)

C343

D304

R889

Q832

R923

R919

Q826

R907

R345

C342

C340

D310

R921

E

R922

R920

B

R917

Q829

Q830

R912

C339

D805

R918

Q831

E

R916

R911

E

C341

D309

E

C904

R925

B

R913

B

11

(11)

11

(11)

R924

D806

E

1

2

3

4

5

C905

C350

C925

R931

D812

R930

B

Q833

1

2

1

2

3

L302

CN602

16

1

16

1

CN601

X

FRONT BOARD

FRONT BOARD

HRP901

RECORD/

PLAYBACK

HEAD

B DECK

HE901

ERASE

HEAD

A DECK

HP901

PLAYBACK

HEAD

A

TO

CN602

(Page 38)

B

TO

CN601

(Page 38)

— 21 — — 22 —

Page 19

HCD-S3000

5-4. SCHEMATIC DIAGRAM MAIN (1/3) SECTION

• Refer to page 16 for Waveform. • Refer to page 45 for IC Block Diagrams.

— 23 — — 24 —

Page 20

HCD-S3000

5-5. SCHEMATIC DIAGRAM MAIN (2/3) SECTION

• Refer to page 16 for Waveform. • Refer to page 21 for Printed Wiring Board.

— 25 — — 26 —

Page 21

HCD-S3000

5-6. SCHEMATIC DIAGRAM MAIN (3/3) SECTION

• Refer to page 21 for Printed Wiring Board. • Refer to page 45 for IC Block Diagrams.

— 27 — — 28 —

Page 22

HCD-S3000

5-7. PRINTED WIRING BOARD AMP SECTION

• Semiconductor

Location

Ref. No. Location

D701 H-3

D702 E-7

D703 I-6

D704 E-7

D705 H-1

D706 H-2

D707 H-1

D708 H-2

D709 H-1

D710 G-4

D712 G-7

D713 F-7

D714 F-2

D715 G-7

D716 G-3

D717 F-2

D718 H-6

D719 G-2

IC701 E-3

IC702 G-7

Q701 C-6

Q702 D-7

Q703 I-7

Q704 G-2

Q705 G-2

Q706 E-2

Q707 E-2

Q708 G-7

Q709 F-3

Q710 F-6

Q711 G-6

Q712 G-7

Q713 G-5

A

B

C

D

E

F

12

JK703

SPEAKER

C722

CN702

R

C721

R736

5

1

L

R735

R723

R739

D714

R764

C733

G

R749

D705

D707

D708

D709

H

D709

I

Z

16

C747

C749

F701

GND

C750

1

C748

AC6

AC5

J

• Refer to page 15 for Circuit Boards Location.

345678910111213

JK701

PHONES

A

AMP BOARD

R766

D719

R748

Q704

CN703

A5.4V

Q706

R765

R762

C762

S

D

G

A5.4V

Q707

RL701

E

Q705

Z

7

AC3

AC4

R724

D717

R763

R747

C751

GND

BE

B

C759

C763

D701

IC701

R725

R703

D716

C701

R726

C746

C745

R705

R701

E

Q709

B

C743

15 2 1

C703 C713

R751

R707R709

C705

C706

R719

C741

C744

R740

C707

15

CN702

1-674-641-

(4146269620)

R708

C714

R710

C711

D

D710

C742

H/P BOARD

11

(11)

R711

S

G

R714

R720

R750

Q713

R753

R754

12

R752

1

CN701

C709

C708

R704

TR BOARD

BE

Q701

CN704

C710

C719

C737

C736

R706

R722

C718

C764

D703

C

R712

R743

11

(11)

1-674-642-

R742

CN704

C702

C704

R702

E

Q710

B

R731

C725

E

R713

R721

C717

Q711

B

R716

E

Q712

B

R761

D715

D718

R760

C734

Q703

B

E

1-674-640-

TO MAIN BOARD

CN401

(Page 21)

BE

C755

C752

D702

C754

C756

R715

D712

R734

C735

D713

IC702

B

R727

GND

Q702

C740C753

R744

C739

R732

C724

1

8

C723

(4146269610)

C758

D704

C738

R730

C727

C728

C726

R733

Q708

E

R728

R729

C757

11

(11)

AC6

AC5

AC5.4V

AC5.4V

AC3

GND

AC4

AC IN

T001

POWER

TRANSFORMER

POWER SUPPLY BOARD

AC2

BRN

F702

P1

P6

RED

P6

P7

P3

P4

AC1

BLU

P7

WHT

P5

P2

GND2

P8

R001

1-674-638-

(4144268530)

11

(11)

— 29 — — 30 —

Page 23

HCD-S3000

5-8. SCHEMATIC DIAGRAM AMP SECTION

• Refer to page 46 for IC Block Diagram.

2.0A 250V

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

— 31 — — 32 —

Les composants identifiés par

une marque ! sont cr itiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

Page 24

HCD-S3000

5-9. PRINTED WIRING BOARD CD DECORD SECTION

12

A

CD DECODER BOARD

B

C

D

• Refer to page 15 for Circuit Boards Location.

3456789101112

E

B

E

B

16

15

2

1

16

3

1

9

7

CONNECTOR BOARD

1

1

1

E

1

2

B

B

B

B

B

E

B

E

B

E

E

E

E

DISC NO LED BOARD

CN06

1

2

(DISC NO LED)

E

TO FRONT BOARD

CN11 (Page 38)

D06

221

11

(11)

(4146266850)

11

(11)

(4146266840)

E

OPTICAL PICK-UP

KSS-213ECM/C2NP

F

MOTOR (6P) (C) BOARD

G

+

M101

SPINDLE

MOTOR

H

I

16

M

_

BLOCK

9

1

B

E

46 3

E

B

111

11

(11)

PHOTO SOCKET BOARD

PH01

CD DIGITAL

3

1

(4146266860)

OUTOUT

(OPTICAL)

11

(11)

(4146266810)

TO MAIN BOARD

D

CN301

_

1

(Page 21)

SENSOR BOARD

MOTOR BOARD

S05

LIMIT

+

M102

SLED

MOTOR

CN03

M

_

_

1-639-678-

6

MO1

M

_

11

(TABLE MOTOR)

C43

CN08

1

4

S06

11

(11)

(4146266830)

13

CN05

R47

SENSO1

3

4

5

1

2

(4146266820)

11

(11)

— 33 — — 34 —

Page 25

HCD-S3000

5-10. SCHEMATIC DIAGRAM CD DECORD SECTION

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

Les composants identifiés par

une marque ! sont cr itiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

CM/C2NP

• Refer to page 16 for Waveforms.

— 35 — — 36 —

Page 26

HCD-S3000

5-11. PRINTED WIRING BOARD FRONT SECTION

12

• Semiconductor

Location

Ref. No. Location

A

REM BOARD

D601 C-11

D602 C-11

D603 D-10

D604 D-12

D605 C-11

D606 B-9

D608 B-8

D609 B-8

D612 B-9

D613 E-6

D614 B-9

D615 A-10

D616 B-10

D617 B-11

D618 A-12

D619 A-12

D620 B-12

D621 F-4

D622 E-5

D624 E-6

D723 B-9

D730 A-10

D731 B-9

LED601 A-5

LED602 A-3

LED603 F-10

LED605 E-8

LED606 E-9

LED607 E-10

LED608 E-11

LED610 I-3

LED611 I-4

LED612 H-4

LED613 H-3

LED614 H-12

LED615 H-12

LED616 I-5

IC601 D-8

IC602 F-8

IC603 G-3

IC604 B-11

IC606 E-4

IC607 E-6

B

C

VR601

VOLUME

D

E

F

G

RM601

C666

CN604

1-674-633-

(4146268940)

VR BOARD

RV601

CN605

113

11

3

(11)

1-674-631-

(416268920)

11

(11)

• Refer to page 15 for Circuit Boards Location.

345678910111213

FRONT BOARD

LED602

S632

TUNER

/BAND

R629

S612

TUNING +

S622

FUNCTION

R736

R682

R702

C629

C630

C632

R687

R688

R691

18

1019

C631

R690

LED613 LED612

R647

R646

S613

TUNING –

16

R733

R726

R734

R727

R683

R684

IC603

R689

S631

ENTER/NEXT

1

IC606

89

R610

C633

R685

D621

C634

R763

S

D

Q609

G

LED601

R693

R694

S630

TUNER MEMORY

C659

C658

R732

R731

R729

R728

R749

SFR601

S

R762

D

Q608

G

AMS BOARD CD KEY BOARD

STEREO/MONO

R649

1

3

CN605

S619

R648

R737

S633

TUNING MODE

R615

R612

1

C673

R747

15

R678

IC607

16

R756

R748

16

R735

R772

R606

C662

C621

D624

R730

Q615

C664

3

CN604

R676

C665

C663

89

C623

C660

C661

1

R746

R757

R773

E

BBB

D622

EEB

B

R725

R739

Q612

Q614

CN607

1

2

E

Q611

C624

R738

TO TAPE

MECHANISM

R611

RA603 RA605 RA604

110

2

3

C627 C628

C672

R750

R745

R681

CN11

16

R741

Q610

E

E

R771

B

R635

D613

Q613

R761

R770

80

81

100

1

R697

R698

S618

R634

FLAT

10 18

S621

SURROUND

CONNECTOR BOARD

E

CN11

(Page 34)

IC601

S617

R699

SALSA

IC602

TO

1

D609

R606

D608

R636

R637

D612

D606

RA602

31

30

19

2820 30

C613

C609

R700

C636

C637

C638

C639

C648

R714

R715

C650

C611

C649

R717

R616

R703

D616

C605

C610

LED607LED605

S615

POPS

R701

E

B

R706

D615

Q607

R601

C625

R758

C643

C644

D723

D731D614

R675

R709

FLD601

36 40 505051515455

X601

C614

LED606

S616

R632

JAZZ

R633

C635

S620

DBFB

C647

8

R707

R704

R618

C607

L601

Q601

R614

R631

TP601

EE

Q603

R695

GROOVE

D730

R713

IC604

R718

E

D603

C602

S614

ROCK

BB

R607

Q604

LED603

S634

R617

RA601

C603

R602

R608

R711

C646

14

C651

B

R613

17

R764

C618

R710

C645

C608

C606

R604

LED608

C601

R705

C668

D605

C604

C616

C640

C654

D602

D601

R630

D617

R722

C671

B

R679

E

S628

DISPLAY

/DEMO

D619

C653

C655

D618

R719

R723

R721

D620

R724

R639

S627

SLEEP

R603

R605

D604

Q602

R654

LED615 LED614

A DECKB DECK

S623

S625

DAILY

R640

S626

REC

R641

R642

S624

/CLOCK SET

16

1

R644

C620

16

C619

1

R692

R623

C670

CN602CN601

C622

C626

R643

S629

C612

R645

C669

ANALYZER

SPECTRUM

R615

A

B

TO

MAIN BOARD

CN602

(Page 22)

TO

MAIN BOARD

CN601

(Page 22)

Q601 D-11

Q602 D-12

Q603 E-10

Q604 E-10

Q607 B-10

Q608 G-4

Q609 G-4

Q610 F-7

Q611 F-5

Q612 F-6

Q613 F-6

Q614 E-6

Q615 F-6

H

I

J

S648

LED616

S645

S646

S650

PLAY MODE

S651

REPEAT

R668

S649

R667

R663

R666

R664

R662

16

R665

VR602

CN603

(4146268960)

S647

DISC SKIP

AMS

1-674-635-

CD SW BOARD

(DOOR SW)

S653

11

(11)

1-674-632-

(4146268930)

CN608

2

1

(11)

11

S644

EDIT

R658R659

R651

R660R661

R652

1

CN608

2

CN606

1

3

1-674-634-

(4146268950)

16

S606

S609 S608S610

LED610

S637

REC

C667

S638

CD SYNCHRO

R624

R628

CN603

S607

R627

R625

R626

LED611

S611

16

R756

R751

R752

— 37 — — 38 —

S639

DISC 1

S640

DISC 2

S641

DISC 3

S642

DISC 4

S643

DISC 5

11

(11)

S601 S602

R653

S636

DOLBY NR

CN606

3

DIRECTION

1-674-630-

1

(4146268910)

R619

R620

R622

R621

S635

S603S605S604

11

(11)

Page 27

HCD-S3000

5-12. SCHEMATIC DIAGRAM FRONT (1/2) SECTION

• Refer to page 16 for Waveform. • Refer to page 43 for IC Pin Function Description. • Refer to page 46 for IC Block Diagrams.

— 39 — — 40 —

Page 28

HCD-S3000

5-13. SCHEMATIC DIAGRAM FRONT (2/2) SECTION

• Refer to page 37 for Printed Wiring Board.

— 41 — — 42 —

Page 29

5-14. IC PIN FUNCTION DESCRIPTION

IC601 LC866540A-5K40 SYSTEM CONTROL (FRONT board)

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

Pin Name

POWER OUT

S.MUT

TU.MUT OUT

SURROUND OUT

DBFB HI/LOW

DBFB ON/OFF

MD/VIDEO

MD(HI)

MD MUTE

SPEANA H/L

SENS 1

RESET

POWER DOWN IN

VDD

VSS

X1

X2

VDD1

K0

K1

K2

K3

K4

SPEANA IN 1

SPEANA IN 2

VACS IN

CXD2588Q SCOR

COUNT

REMOTE IN

16G

15G

14G

13G

12G

11G

10G

9G

8G

7G

6G

5G

4G

3G

2G

1G

VDD

P1 S0

P2 S1

P3 S2

P4 S3

I/O

O

Power on/off output

O

System mute output (ON at H)

O

Tuner mute output (ON at H)

O

Surround output (ON at H)

O

DBFB normal output (ON at H)

O

DBFB high output (ON at H)

O

MD/VIDEO output

O

MD(HI) output

O

Function mute(Line out mute)

O

Spectrum analyzer 1,2/3,4

I

CXD2589Q SCOR input

—

Reset

I

Power down in(AC on at H,AC off at H)

—

FLD VDD

—

Ground

—

X’tal oscillator 6MHz

—

X’tal oscillator 6MHz

—

System VDD 1

I

Key input 0

I

Key input 1

I

Key input 2

I

Key input 3

I

Key input 4

I

Spectrum analyzer 1

I

Spectrum analyzer 2

I

Vacs in

I

CXD2588Q SCOR input

I

CXD2588Q COUNT input

I

Remote in

O

FLD digital output 16

O

FLD digital output 15

O

FLD digital output 14

O

FLD digital output 13

O

FLD digital output 12

O

FLD digital output 11

O

FLD digital output 10

O

FLD digital output 9

O

FLD digital output 8

O

FLD digital output 7

O

FLD digital output 6

O

FLD digital output 5

O

FLD digital output 4

O

FLD digital output 3

O

FLD digital output 2

O

FLD digital output 1

—

FLD VDD

O

FLD segment output 1

O

FLD segment output 2

O

FLD segment output 3

O

FLD segment output 4

Description

— 43 —

Page 30

Pin No.

51

52

53

54

55

56

57

58

59

60

61

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

Pin Name

P4 S3

P5 S4

P6 S5

P7 S6

P8 S7

P9 S8

P10 S9

P11 S10

P12 S11

P13 S12

P14 S13

P15-P21

P22

P23

MODE

VDD

FM ST IN

AMS IN

CXD 2589Q SENS2

FOK

UP SW

TABLE SENSOR

CD DOOR SW

DATA IN

VR+

VRCD ENCORDER IN A

CD ENCORDER IN B

S-DATA

S/L

CXA1992 LOCK

BU2114 LATCH

VSS2

VDD2

HC4094 STB

CDP 2589 CLOK

7218 STB

CXD2589Q XLAT

CXD2589Q DATA

SQSO

SQCK

DAT A

DI

CLK

I/O

O

FLD segment output 4

O

FLD segment output 5

O

FLD segment output 6

O

FLD segment output 7

O

FLD segment output 8

O

FLD segment output 9

O

FLD segment output 10

O

FLD segment output 11

O

FLD segment output 12

O

FLD segment output 13

I

FLD segment output 14

I

FLD segment output 15-21

I

FLD segment output 22

I

FLD segment output 23

I

Destination selector switch input

—

VDD

I

FM stereo indicator input

I

AMS input

I

CXD 2589Q SENS input

I

CXD 2589Q FOK input

I

Changer mechanism UP switch input

I

Table sensor switch input

I

CD door switch input

I

HC 165 data in

I

VR encoder(+) input

I

VR encoder(-) input

I

CD encoder input A

I

CD encoder input B

O

M62433 S.DATA

O

HC165 S/L

O

CXA1992 LOCK output

O

BU2114 LATCH output

—

System Vss 2

—

System VDD 2

O

HC4094 STB output

O

CDP 2589 clock output

O

7218 standby output

O

CXD2589Q XLAT output

O

CXD2589Q DATA output

O

SQSO output

O

SQCK output

O

Serial data output

I

Serial data input

O

Clock output

Description

— 44 —

Page 31

5-15. IC BLOCK DIAGRAMS

MAIN BOARD

IC103 LC72131M

XOUT

1

XIN

VSS

1920

18

REFERENCE

CCB

INTERFACE

2

3

DI

CE

AOUT

DIVIDER

4

5

CL

17

DO

AIN

PD

16

PHASE

DETECTOR

CHARGE PUMP

UNLOCK

DETECTOR

SWALLOW COUNTER

1/16, 1/17 4BITS

12BITS

PROGRAMMABLE

DRIVER

DATA SHIFT REGISTER LATCH

9

6

8

7

BO2

BO1

BO3

BO4

10

POWER

IO1

15

ON

RESET

VDD

AMIN

IO2

FMIN

14

1/2

13

12

UNIVERSAL

COUNTER

IFIN

11

IC202 M5218AL

+

–

V–

2 3 6

1

4

5

IC203 MC14066BF

+

–

V+

8

7

CONTROL IN

CONTROL IN

IN/OUT

OUT/IN

OUT/IN

IN/OUT

1

2

3

4

5

6

7

SS

V

V

DD

14

CONTROL IN

13

12 CONTROL IN

IN/OUT

11

10 OUT/IN

OUT/IN

9

8

IN/OUT

— 45 —

Page 32

FRONT BOARD

IC602 BU2092F-E2

CONTROL

CIRCUIT

2 3

1

VSS

DATA

CLOCK

IC606 SN74HC161

VCC

RIPPLE

CARRY

OUTPUT

CLEAR

QA

VDDOEQ11

12 BIT

SHIFT

REGISTER

12 BIT

STORAGE

REGISTER

4

LCK

QB QC QD ENABLE

1718

Q10Q9Q8Q7Q6

OUTPUT

BUFFER

(OPEN DRAIN)

5 6 7 8 9

Q0

IC603 BU2114F

18

Q5

1016 15 14 13 12 11

SIN

1

CK

2

3

LATCH

SOUT

4

5

EN

Q4

Q3

Q2

Q1

91016 15 14 13 12 11

T

LOAD

RST

GND

GND

6

7

8

ENABLE

SHIFT

REGISTER

LATCH

VDD

17

O1

16

O2

15

O3

14

O4

13

O5

12

O6

O7

11

10

O8

9

GND

CK

2 3

1

AMP BOARD

ABCD

5 6 7 8

4

IC702 MPC1237HA

OVER LOAD DET

OFFSET DET

LATCH/

AUTORESET

ENABLE

P

GND

AC OFF

DET

CC

ON

F/F

V

MUTE

1 2 3 4 5 6 7 8

— 46 —

V

CC

Page 33

NOTE:

• The mechanical parts with no reference number

in the exploded views are not supplied.

6-1. TOP COVER SECTION

SECTION 6

EXPLODED VIEWS

• Hardware (# mark) list and accessories and

packing materials are given in the last of this

parts list.

The components identified by mark ! or

dotted line with mark ! are critical for safety .

Replace only with part number specified.

Les composants identifiés par une marque

! sont critiques pour la sécurité.

Ne les remplacer que par une pièce portant

le numéro spécifié.

#4

#1

1

#2

#2

2

#3

#3

#2

#1

included CD decoder board

#4

#3

#3

#4

#4

#4

Main section

#1

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

1 4-221-012-01 COVER, TOP 2 4-221-013-01 PANEL, REAR

Front panel section

— 47 —

Page 34

6-2. CD DOOR SECTION

68

67

#5

66

70

#6

61

62

59

60

57

58

63

#6

#5

56

55

#6

65

not supplied

64

53

54

69

#7

51

52

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

51 4-221-007-01 BUTTON, CD PLAY

52 4-221-008-01 LENS, CD PLAY BUTTON

53 4-221-006-01 BUTTON, CD SKIP

54 1-674-635-11 AMS BOARD

55 4-221-011-01 SPRING (R), CD DOOR

56 4-211-920-01 DAMPER (PG-5), GEAR

57 1-674-632-11 CD SW BOARD

58 4-221-128-01 LOCK

59 4-221-010-01 SPRING (L), CD DOOR

60 1-674-634-11 CD KEY BOARD

61 4-221-004-01 BUTTON, CD DISC

62 4-221-005-01 BUTTON, CD EDIT

63 4-220-995-01 PANEL, CD FRONT

64 4-221-002-01 RING, AMS

65 4-221-003-01 KNOB, AMS

66 4-220-996-01 WINDOW, CD DOOR

67 4-221-009-01 HOOK, CD DOOR

68 4-221-001-01 DOOR, CD

69 4-211-914-01 LENS, CD DOOR

70 1-674-637-11 LED BOARD

— 48 —

Page 35

d

6-3. PANEL SECTION

119

120

118

117

114

113

115

116

109

121

122

123

126

124

125

126

#7

127

141

132

102

#7

128

103

104

#7

129

142

130

143

#4

131

134

138

140

#7

144

Not supplied

139

#7

#7

135 136

137

144

145

Not supplie

#7

#7

133

#7

106

105

111

112

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

101 4-221-028-01 BUTTON (R), CASS

102 4-221-034-01 LENS (A), CASS BUTTON (R)

103 4-221-035-01 LENS (B), CASS BUTTON (R)

104 4-221-036-01 LENS (C), CASS BUTTON (R)

105 4-221-037-01 LENS (D), CASS BUTTON (R)

106 4-221-014-01 PANEL, FRONT

107 4-221-000-01 RING, VR

108 4-221-026-01 KNOB, VOLUME

109 4-221-016-01 HOLDER (R), CASS DOOR

110 4-220-989-01 SPRING (R), CASS

111 4-221-020-01 DOOR (R), CASS

112 4-220-998-01 WINDOW (R), CASS DOOR

113 4-220-997-01 WINDOW (L), CASS DOOR

114 4-221-017-01 DOOR (L), CASS

115 4-220-988-01 SPRING (L), CASS

116 4-221-015-01 HOLDER (L), CASS DOOR

117 4-220-999-01 WINDOW, DISPLAY

118 4-221-027-01 BUTTON (L), CASS

119 4-221-033-01 LENS (B), CASS BUTTON (L)

120 4-221-032-01 LENS (A), CASS BUTTON (L)

110

108

107

not

supplied

101

123 4-220-987-01 PLATE, DISPLAY

124 1-772-164-11 DECK, MECH

125 4-221-024-01 BUTTON, MODE

126 4-220-992-01 DAMPER (GRAY), GEAR

127 4-221-038-01 LENS, ROCK BUTTON

128 4-221-039-01 LENS, POP BUTTON

129 4-220-985-01 LENS, JAZZ BUTTON

130 4-220-986-01 LENS, SALSA BUTTON

131 1-674-633-11 REM BOARD

132 3-306-734-01 SCREW (M3 × 12), TAPPING

133 A-4426-110-A FRONT BOARD, COMPLETE

134 1-674-633-11 VR BOARD

135 1-783-579-11 WIRE (FLAT TYPE) (16 CORE)

136 4-221-031-01 LENS, GROOVE BUTTON

137 4-221-025-01 BUTTON, SURROUND

138 4-221-030-01 LENS, ENTER BUTTON

139 4-221-029-01 LENS, TUNER BUTTON

140 4-221-022-01 BUTTON, TUNER

141 1-674-641-11 H/P BOARD

142 4-220-990-01 HOLDER, EJECT

142

121 4-221-021-01 BUTTON, POWER

122 4-221-023-01 BUTTON, CLOCK

143 4-220-994-01 SPRING (R), PUSHING

144 4-220-991-01 LEVER, EJECT

145 4-220-993-01 SPRING (L), PUSHING

— 49 —

Page 36

6-4. MAIN SECTION

#4

T001

#9

152

not supplied

#4

#11

#4

#3

#7

153

#4

not supplied

155

#10

not supplied

#4

154

#4

151

#3

#3 #3

156

#4

CD section

not supplied

not supplied

not supplied

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

! 151 1-783-531-51 CORD, POWER

152 A-4426-118-A MAIN BOARD, COMPLETE

153 A-4426-123-A POWER (AMP) BOARD, COMPLETE

154 1-674-638-11 POWER SUPPLY BOARD

— 50 —

155 1-674-642-11 TR BOARD

* 156 3-703-244-00 BUSHING (2104), CORD

! T001 1-433-921-11 TRANSFORMER, POWER

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

Les composants identifiés par

une marque ! sont cr itiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

Page 37

SECTION 7

ELECTRICAL PARTS LIST

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts

specified in the diagrams or the components

used on the set.

• -XX, -X mean standardized parts, so they

may have some difference from the original

one.

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when

ordering these items.

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

1-674-635-11 AMS BOARD

*********

< LED >

LED616 8-719-304-83 LED SEL2410G (CD, ^)

< RESISTOR >

R663 1-247-835-11 CARBON 1.5K 5% 1/4W

R664 1-247-839-11 CARBON 2.2K 5% 1/4W

R665 1-247-843-11 CARBON 3.3K 5% 1/4W

R666 1-247-847-11 CARBON 4.7K 5% 1/4W

R667 1-249-428-11 CARBON 8.2K 5% 1/4W

R668 1-249-431-11 CARBON 15K 5% 1/4W

• CAPACITORS:

uF: µF

• RESISTORS

All resistors are in ohms.

METAL: metal-film resistor

METAL OXIDE: Metal Oxide-film resistor

F: nonflammable

• COILS

uH: µH

• Abbreviation

CND : Canadian

When indicating parts by reference number,

please include the board name.

A-4426-110-A FRONT BOARD, COMPLETE

C601 1-126-960-11 ELECT 1uF 20% 50V

C602 1-126-933-11 ELECT 100uF 20% 16V

C603 1-126-916-11 ELECT 1000uF 20% 6.3V

C604 1-161-494-00 CERAMIC 0.022uF 25V

C605 1-104-664-11 ELECT 47uF 20% 10V

C606 1-164-159-11 CERAMIC 0.1uF 50V

C607 1-126-961-11 ELECT 2.2uF 20% 50V

C608 1-126-958-11 ELECT 0.33uF 20% 50V

C609 1-164-159-11 CERAMIC 0.1uF 50V

C610 1-126-964-11 ELECT 10uF 20% 50V

AMS CD KEY FRONT

• SEMICONDUCTORS

In each case, u: µ, for example:

uA...: µA... , uPA... , µPA... ,

uPB... , µPB... , uPC... , µPC... ,

uPD..., µPD...

The components identified by mark ! or

dotted line with mark ! are critical for safety .

Replace only with part number specified.

Les composants identifiés par une marque

! sont critiques pour la sécurité.

Ne les remplacer que par une pièce portant

le numéro spécifié.

*********************

< CAPACITOR >

< SWITCH >

S645 1-762-875-11 SWITCH, KEYBOARD (CD, ^)

S646 1-762-875-11 SWITCH, KEYBOARD (CD, p)

S647 1-762-875-11 SWITCH, KEYBOARD (DISK SKIP)

S648 1-762-875-11 SWITCH, KEYBOARD (CD, ))

S649 1-762-875-11 SWITCH, KEYBOARD (CD, 0)