Page 1

DSR-40/40P

SERVICE MANUAL

Ver 1.0 1999. 03

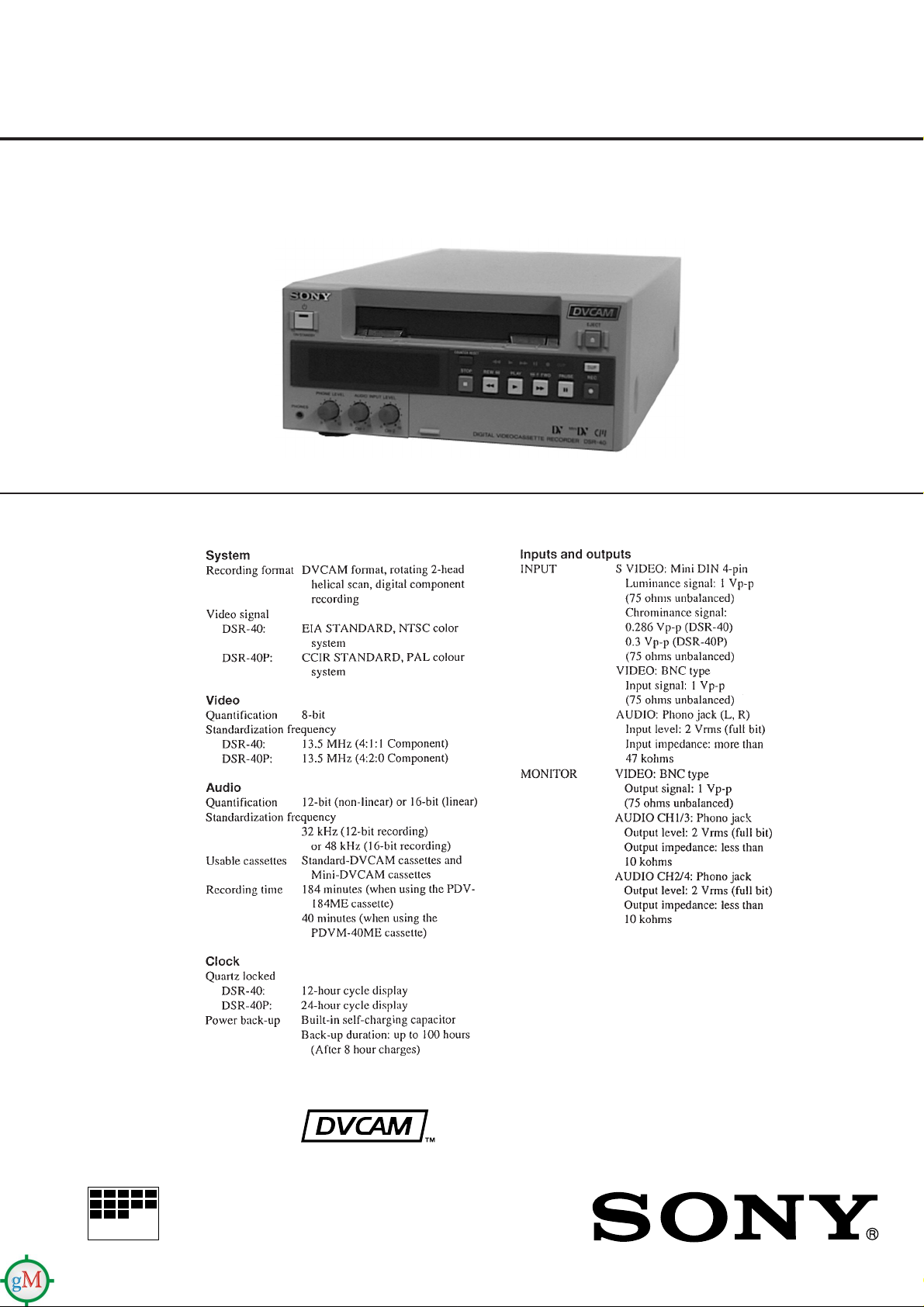

Photo: DSR-40

SPECIFICATIONS

US Model

Canadian Model

DSR-40

AEP Model

DSR-40P

MICROFILM

– Continued on next page –

DIGITAL VIDEO CASSETTE RECORDER

Page 2

http://getMANUAL.com

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE !

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

– 2 –

Page 3

SAFETY CHECK-OUT

(US Model only)

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly-soldered connections. Check the entire board surface for solder

splashes and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly transistors, that were installed during a previous repair. Point them

out to the customer and recommend their replacement.

4. Look for parts which, though functioning, show obvious signs

of deterioration. Point them out to the customer and recommend their replacement.

5. Check the line cord for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

6. Check the B+ voltage to see it is at the values specified.

7. Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

To Exposed Metal

Parts on Set

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground

and from all exposed metal parts to any exposed metal part having

a return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follow the manufacturers' instructions to use these

instruments.

2. A battery-operated A C milliammeter . The Data Precision 245

digital multimeter is suitable for this job.

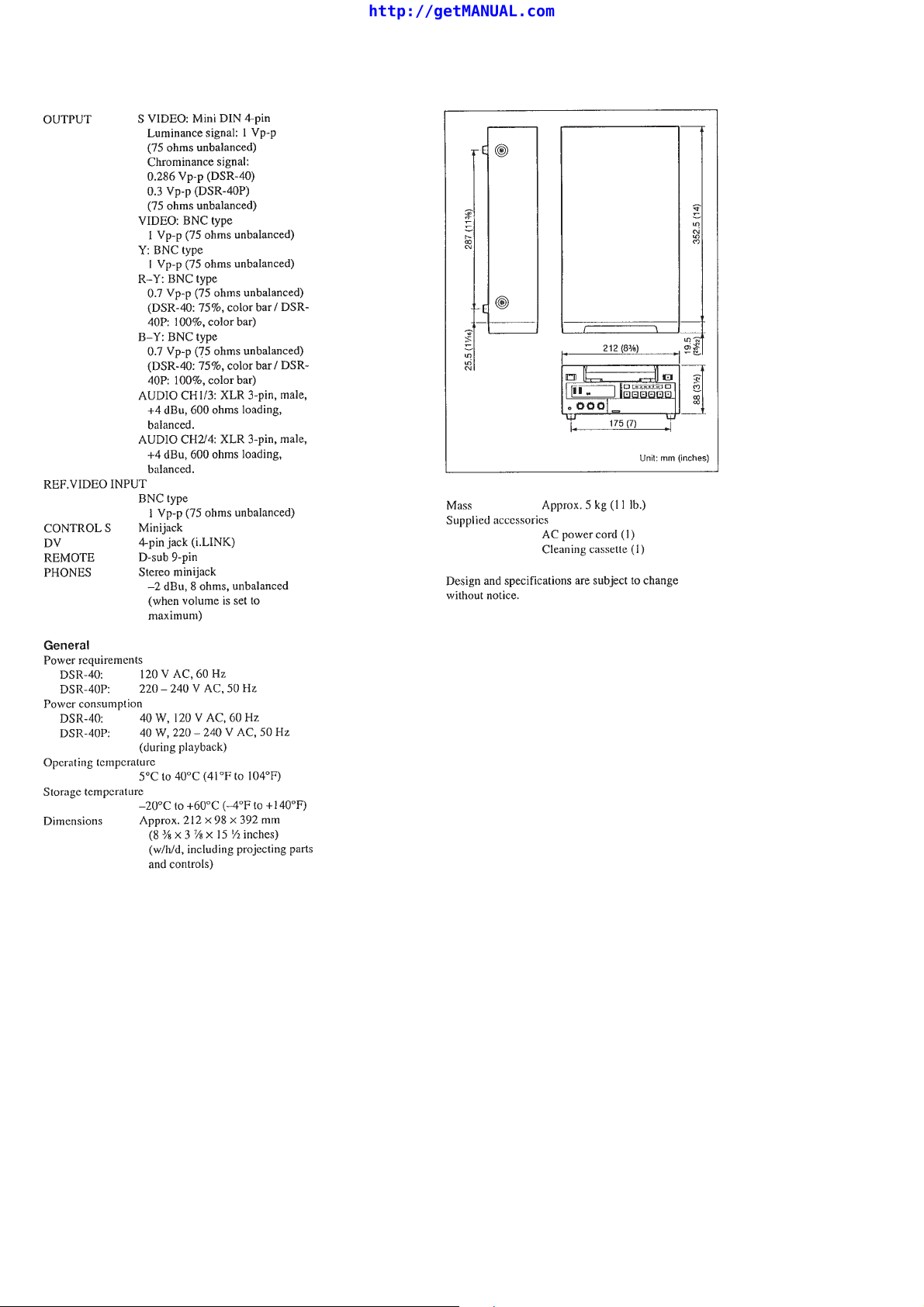

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indica-

tion is 0.75V, so analog meters must have an accurate low-

voltage scale. The Simpson 250 and Sanwa SH-63T rd are ex-

amples of a passive VOM that is suitable. Nearly all battery

operated digital multimeters that have a 2V A C range are suit-

able. (See Fig. A)

AC

0.15 µF

1.5 k

Ω

Earth Ground

Voltmeter

(0.75 V)

Fig. A Using AC voltmeter to check AC leakage

– 3 –

Page 4

SERVICE NOTE

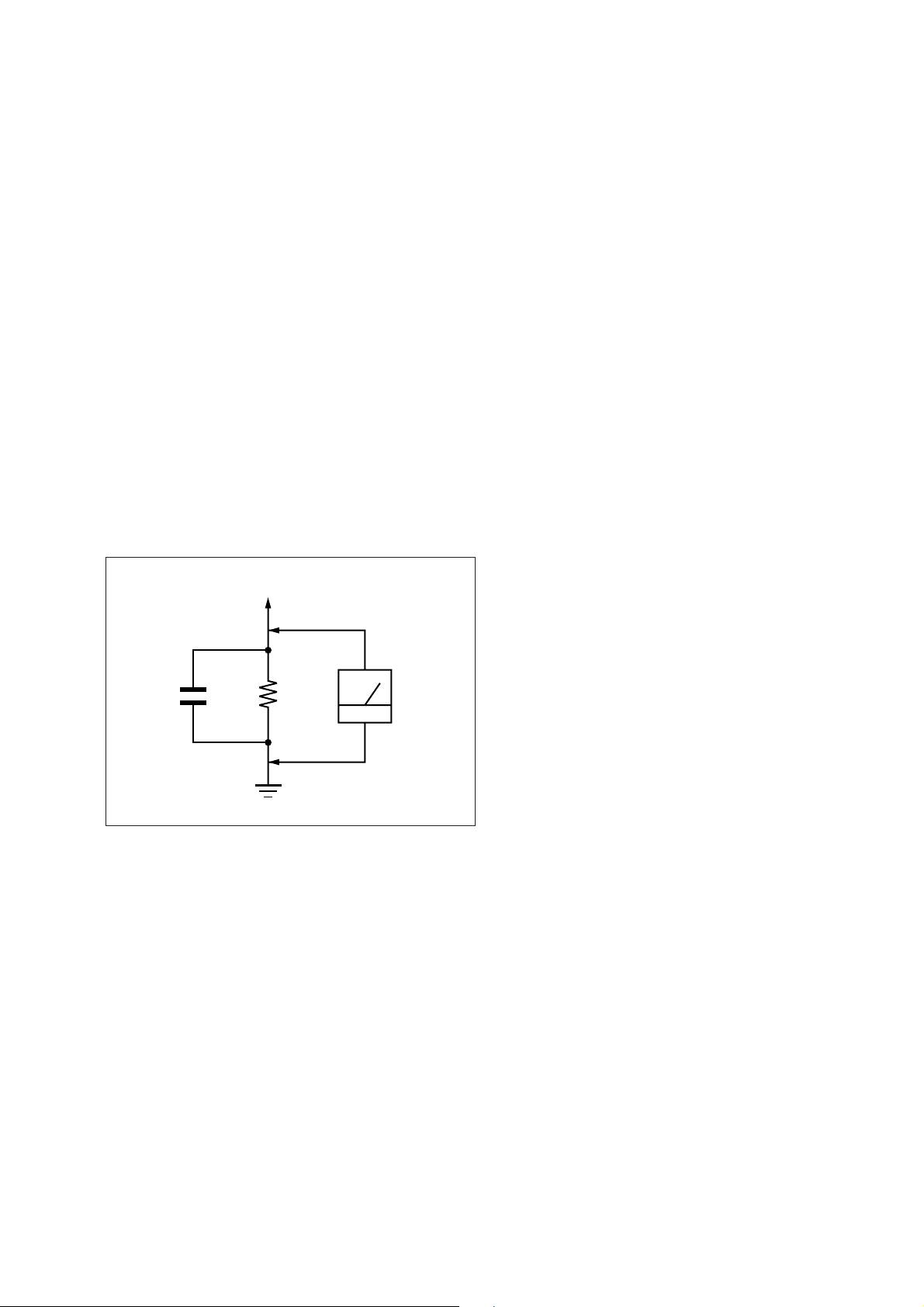

• Note for Repair

Make sure that the flat cable and flexible board are not cracked or bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

Cut and remove the part of gilt

which comes off at the point.

(Take care that there is some pieces of gilt left inside.)

– 4 –

Page 5

TABLE OF CONTENTS

Section Title Page Section Title Page

SERVICE NOTE .................................................................... 4

1. GENERAL

Features................................................................................ 1-1

Notes on Video Cassettes..................................................... 1-1

Notes on Recording /Playing................................................. 1-1

Location and Function of Parts ......................................... 1-2

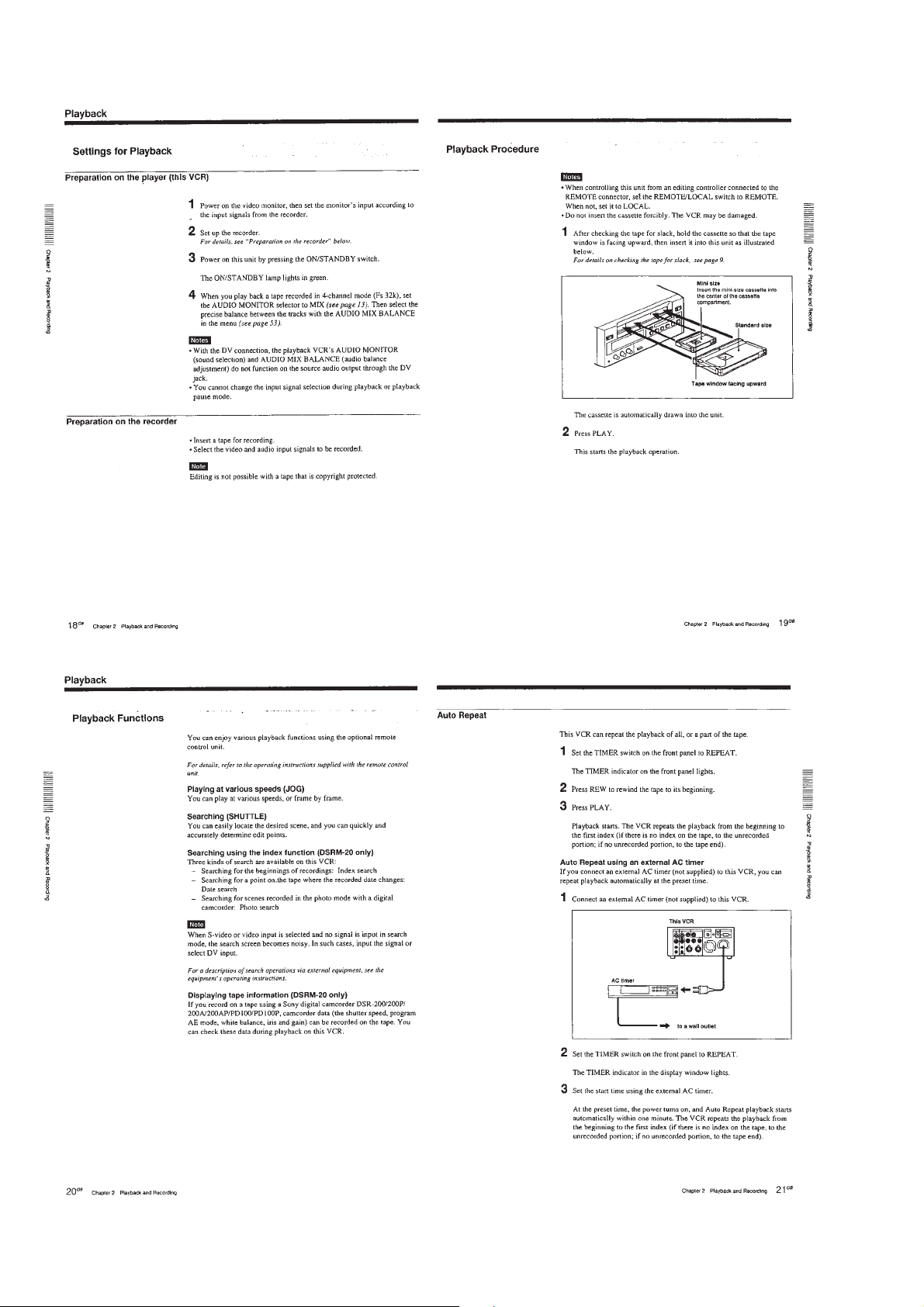

Playback ............................................................................... 1-3

Connections for Playback ..................................................... 1-3

Settings for Playback............................................................. 1-4

Playback Procedure .............................................................. 1-4

Playback Functions ............................................................... 1-4

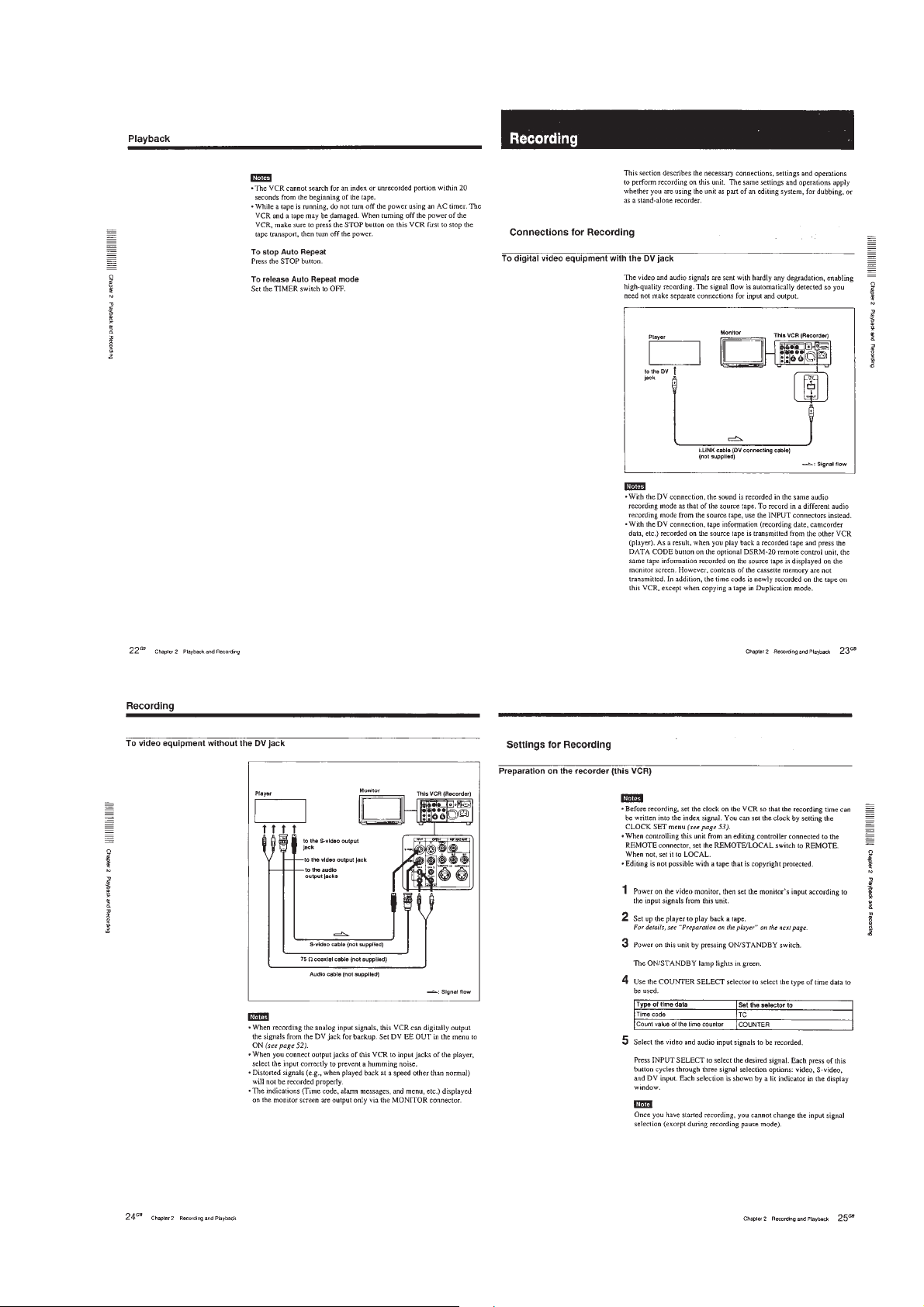

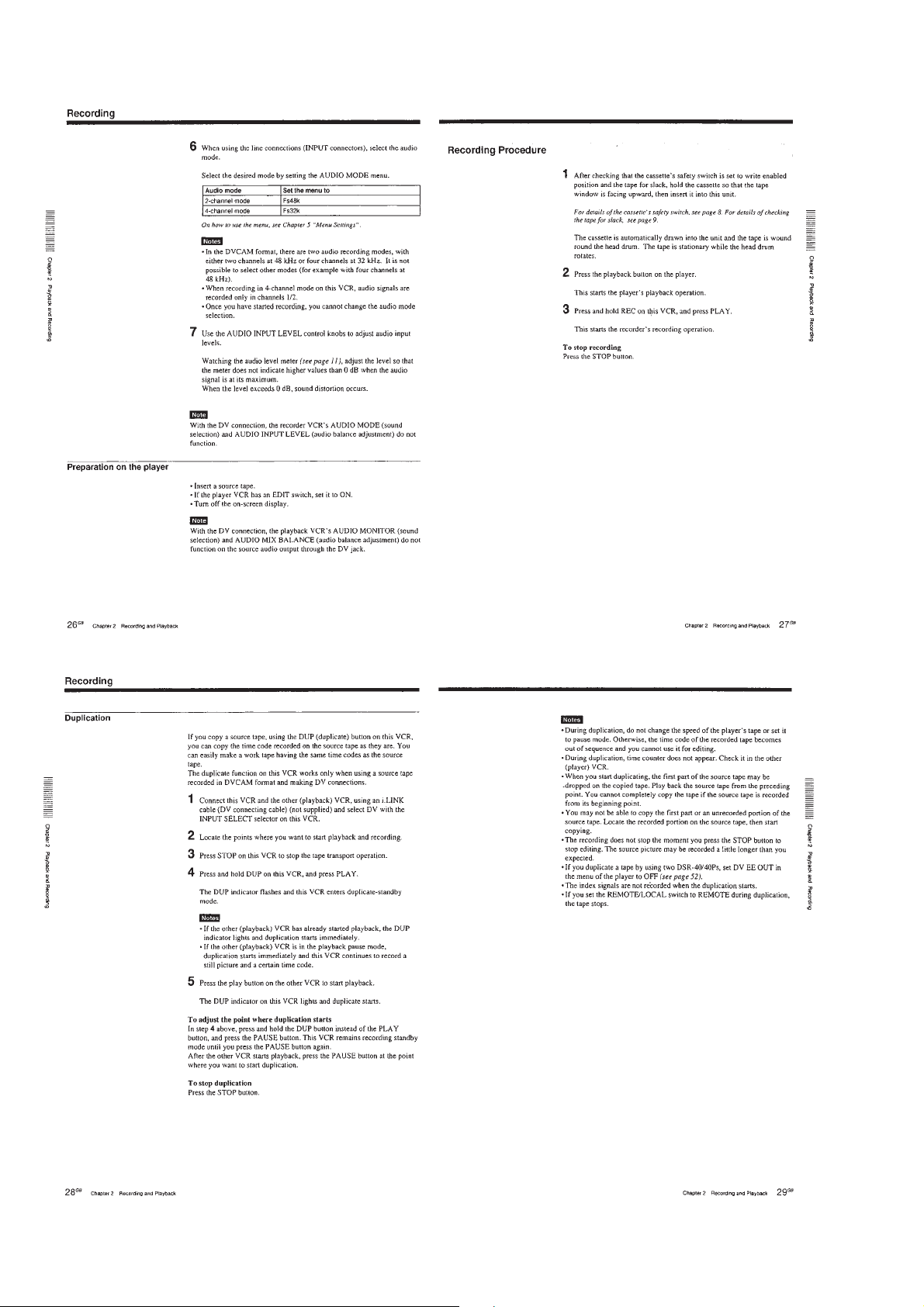

Recording ............................................................................. 1-5

Connections for Recording.................................................... 1-5

Setting for Recording............................................................. 1-5

Recording Procedure ............................................................ 1-6

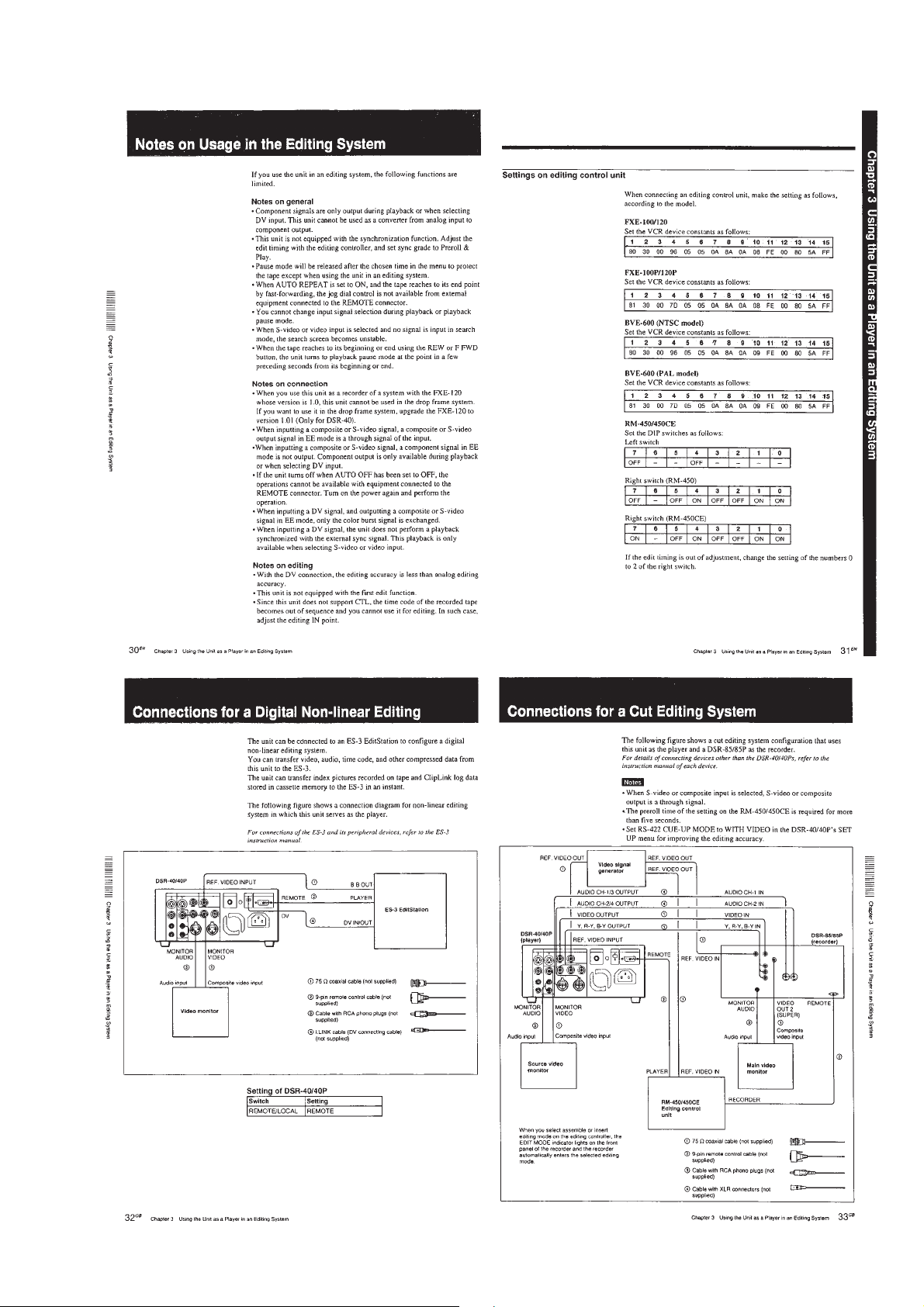

Notes on Usage in the Editing System ............................. 1-7

Connections for a Digital Non-linear Editing ................... 1-7

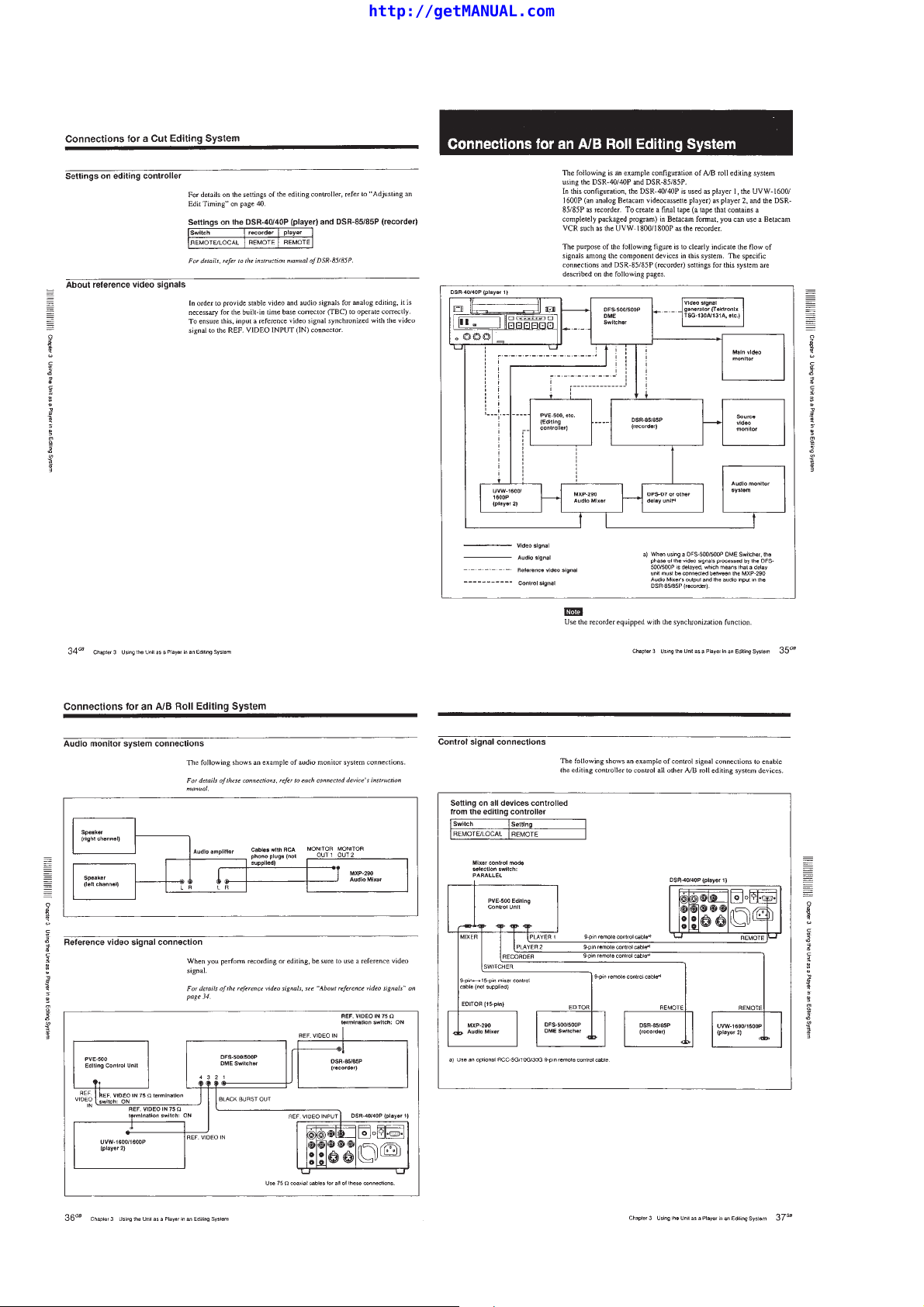

Connections for a Cut Editing System ............................. 1-7

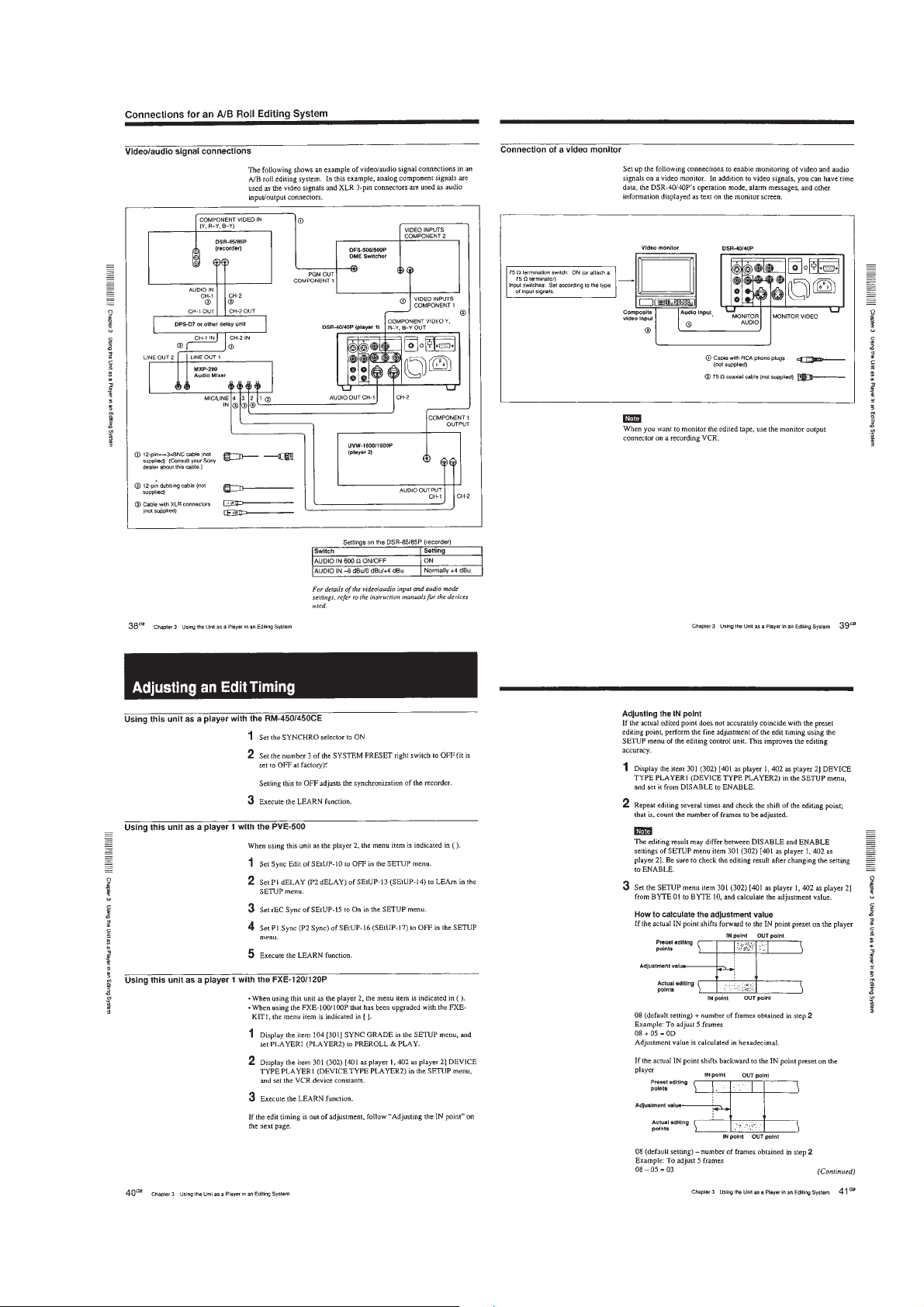

Connections for an A/B Roll Editing System................... 1-8

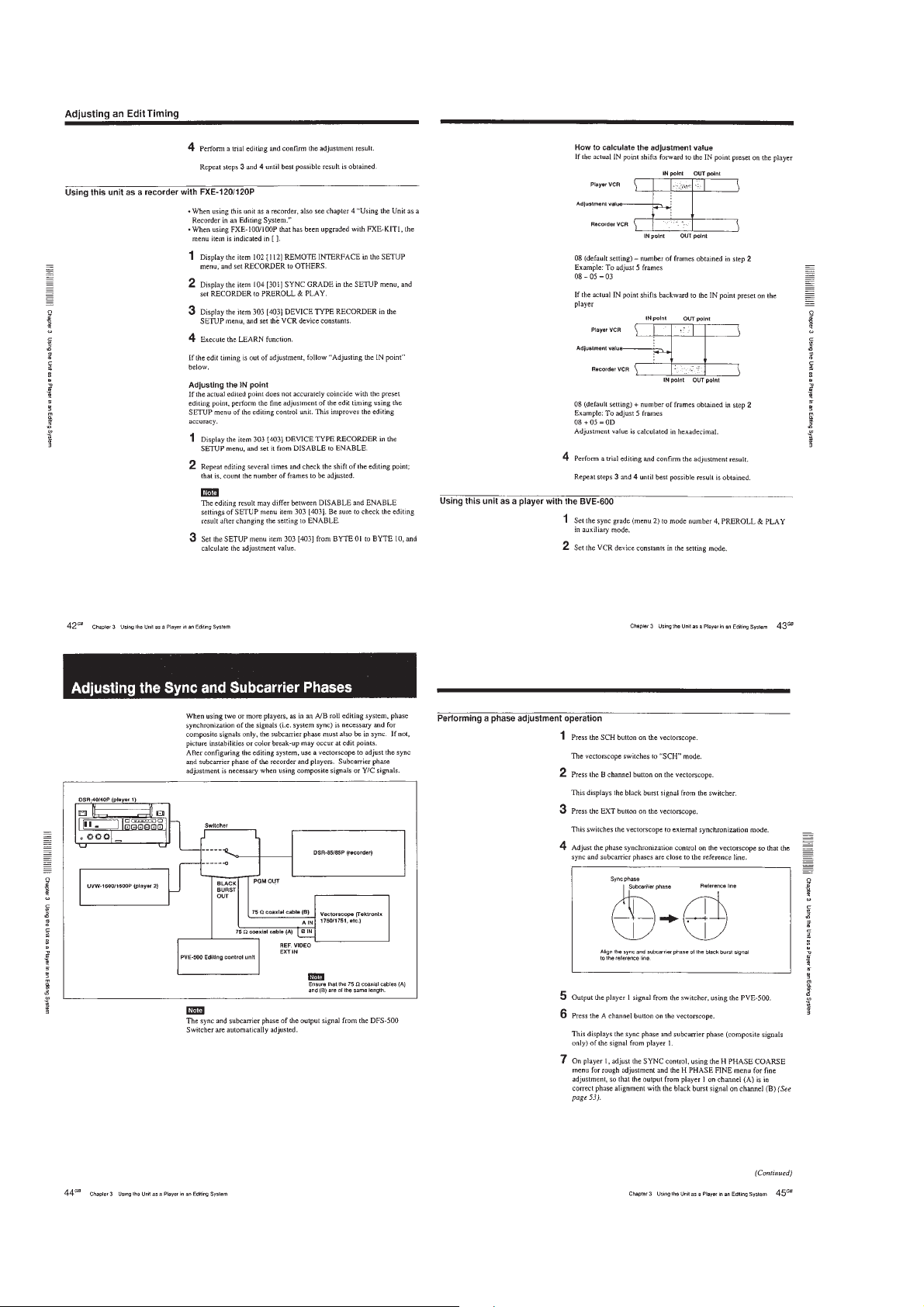

Adjusting an Edit Timing .................................................... 1-9

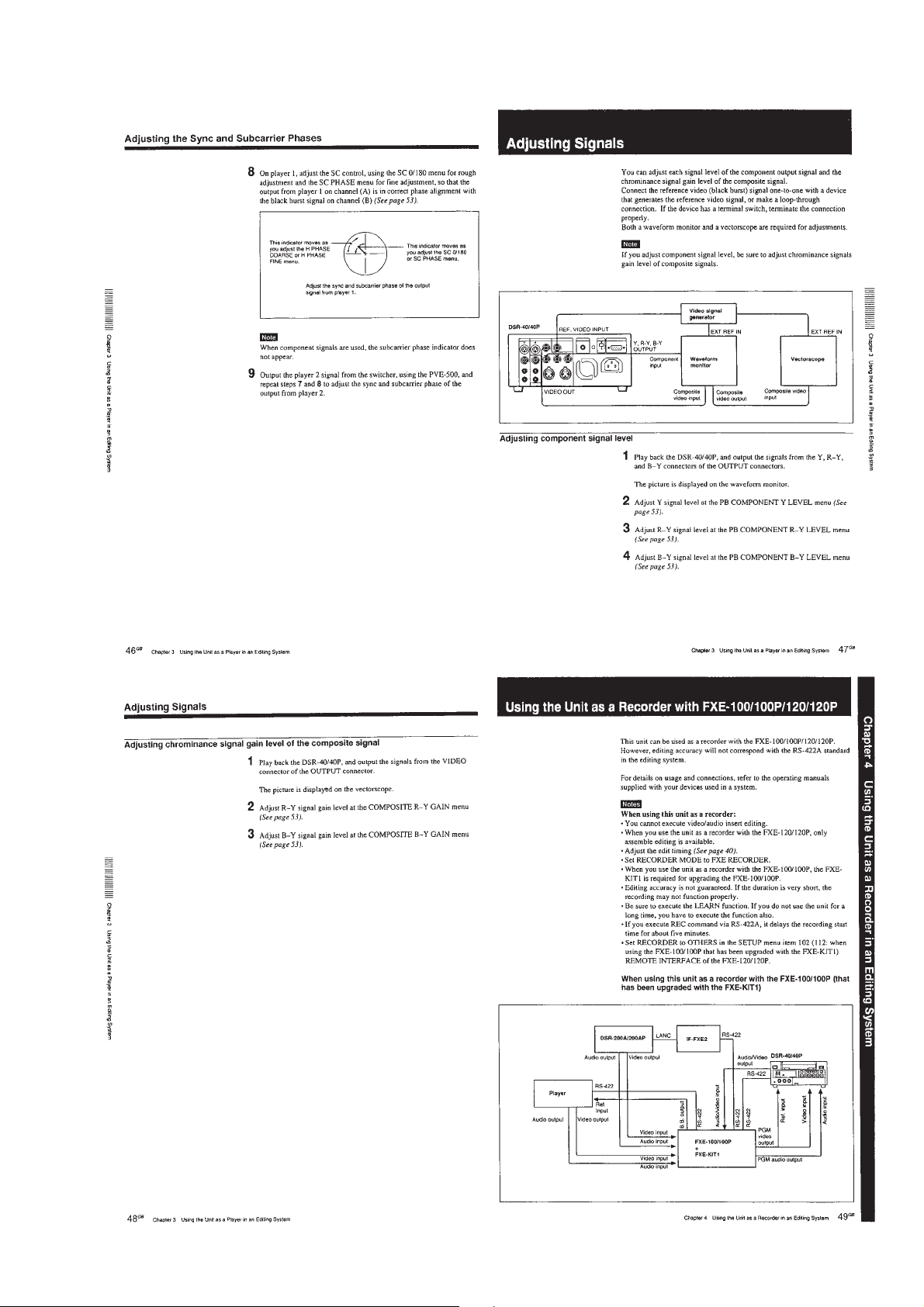

Adjusting the Sync and Subcarrier Phases ..................... 1-10

Adjusting Signals ................................................................ 1-11

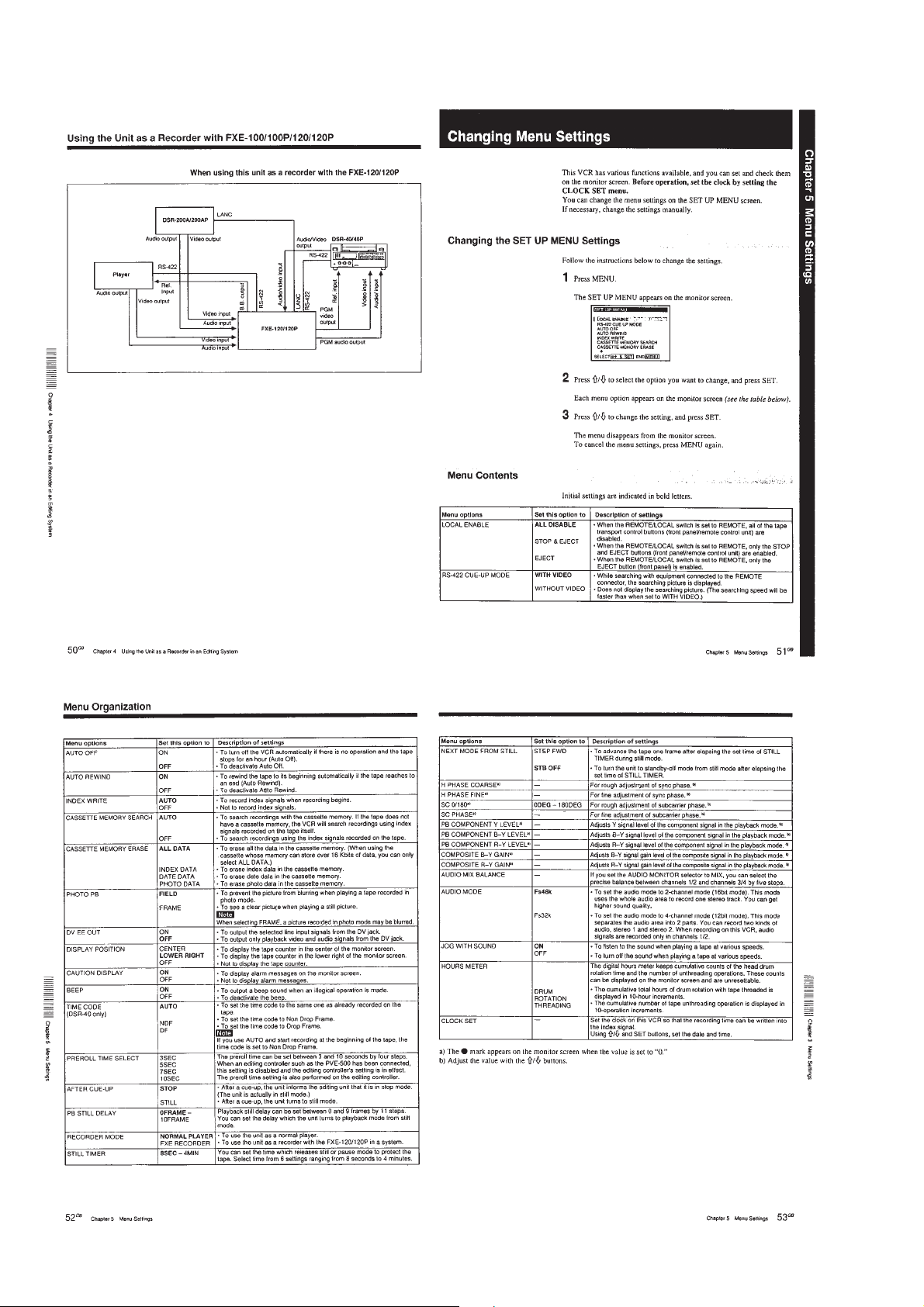

Using the Unit as a Recorder

with FXE-100/100P/120/120P .............................................. 1-11

Changing Menu Settings .................................................... 1-12

Changing the SET UP MENU Settings ................................. 1-12

Menu Contents ...................................................................... 1-12

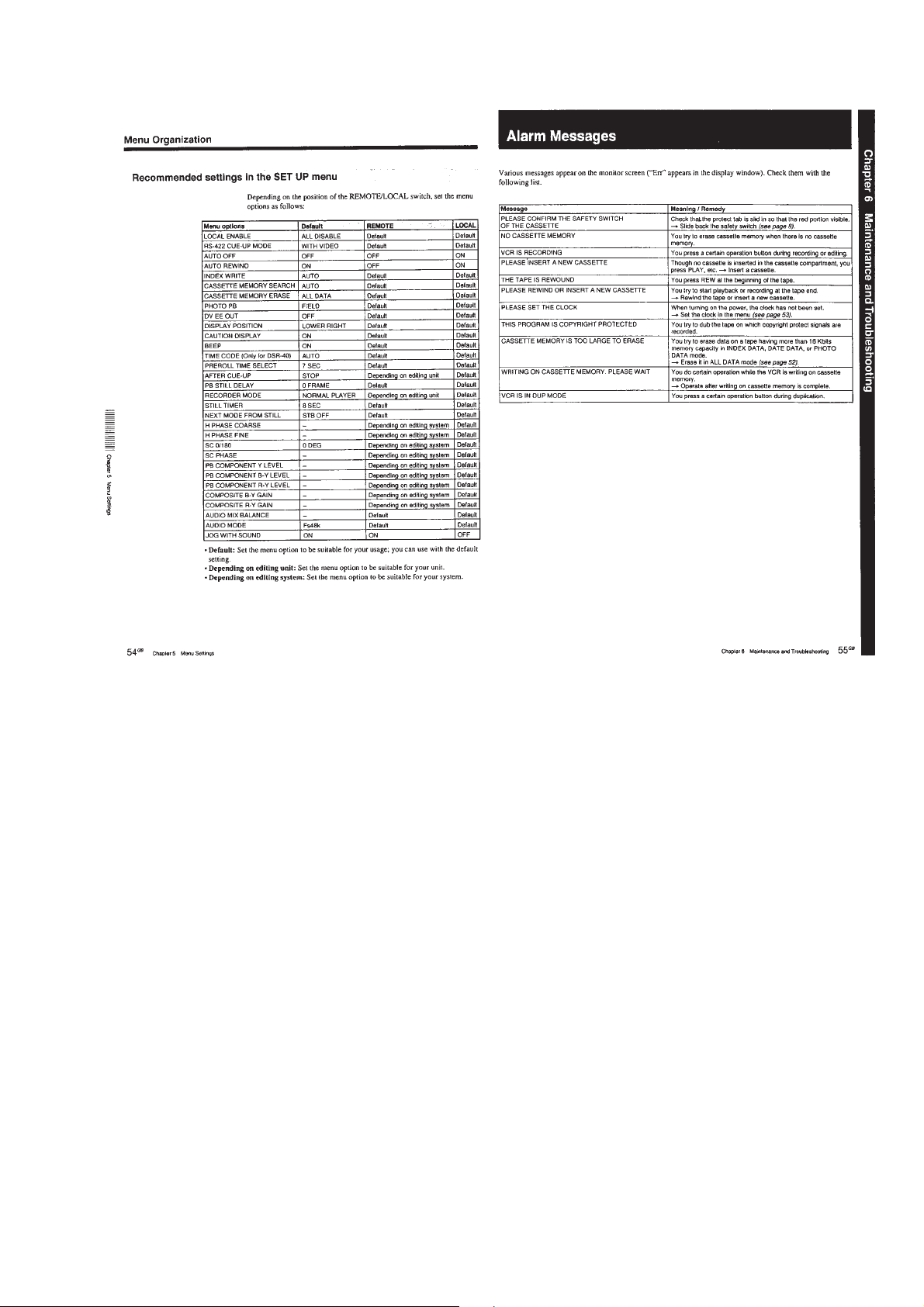

Recommended Settings in the SET UP Menu...................... 1-13

Alarm Messages .................................................................. 1-13

2. DISASSEMBLY

2-1. Removal of Upper Case .............................................. 2-1

2-2. Removal of Front Panel Assembly .............................. 2-1

2-3. Removal of VA-106 Board ........................................... 2-1

2-4. Removal of Power Block ............................................. 2-1

2-5. Removal of MD Block Assembly ................................. 2-2

2-6. Removal of CM-56 Board............................................ 2-2

2-7. Removal of JC-19 Board ............................................. 2-2

2-8. Removal of RP-228 Board .......................................... 2-2

2-9. Circuit Boards Location ............................................... 2-3

3. BLOCK DIAGRAMS

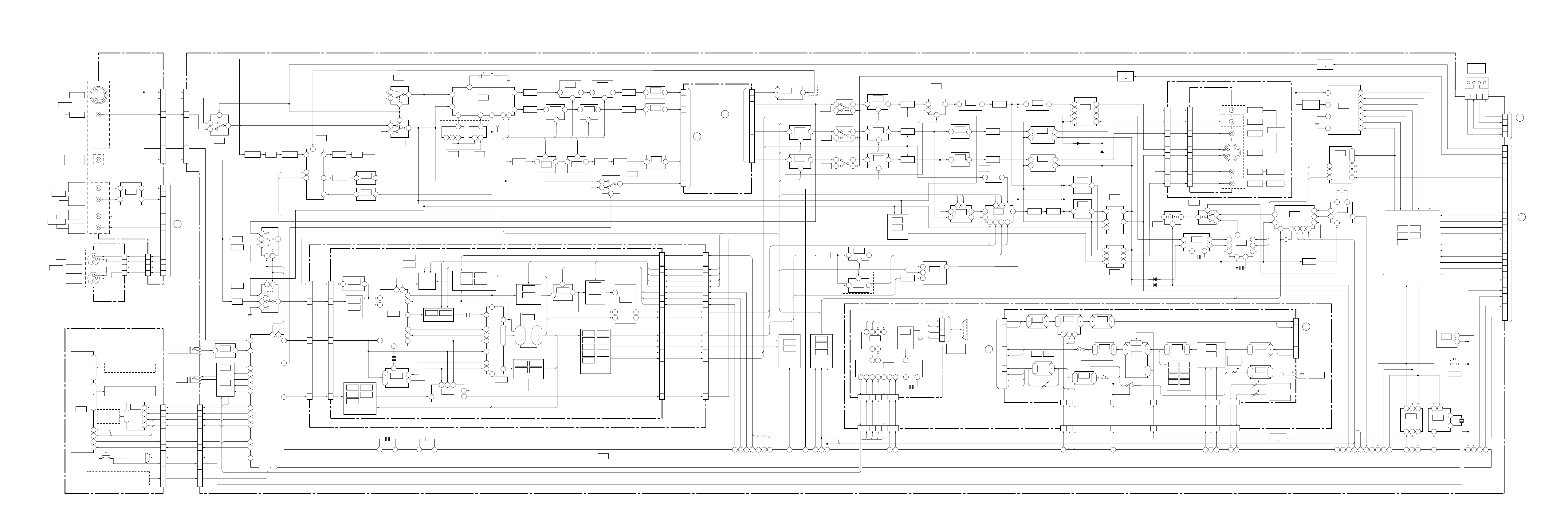

3-1. Overall Block Diagram 1.............................................. 3-1

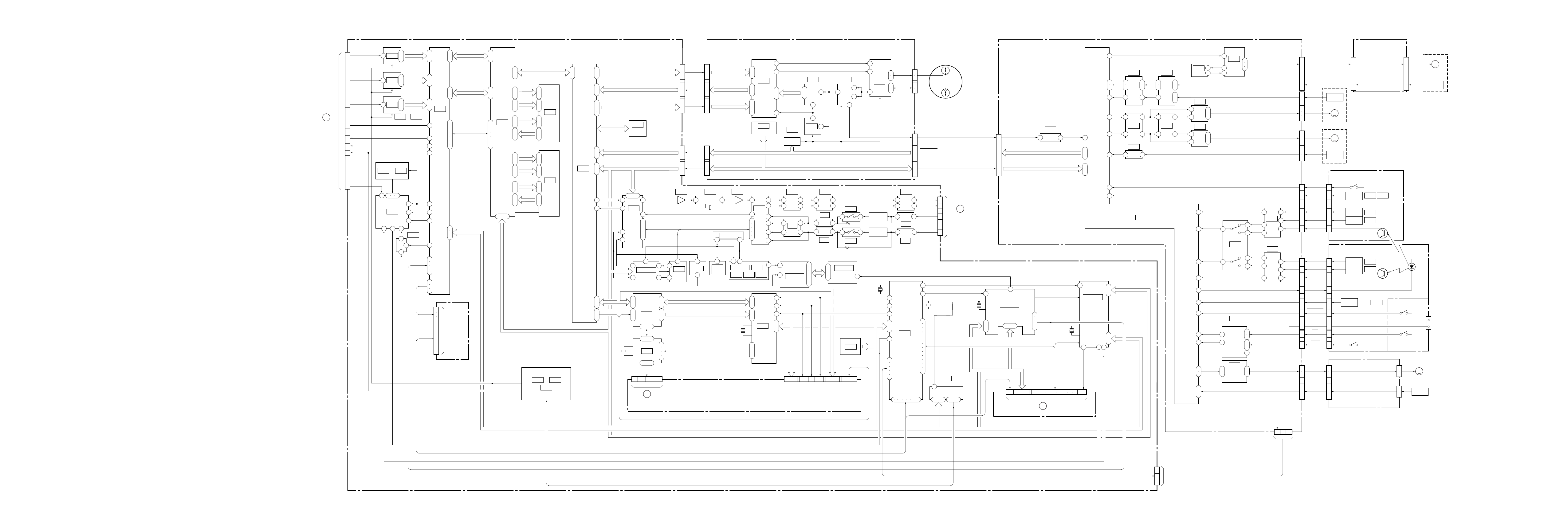

3-2. Overall Block Diagram 2.............................................. 3-7

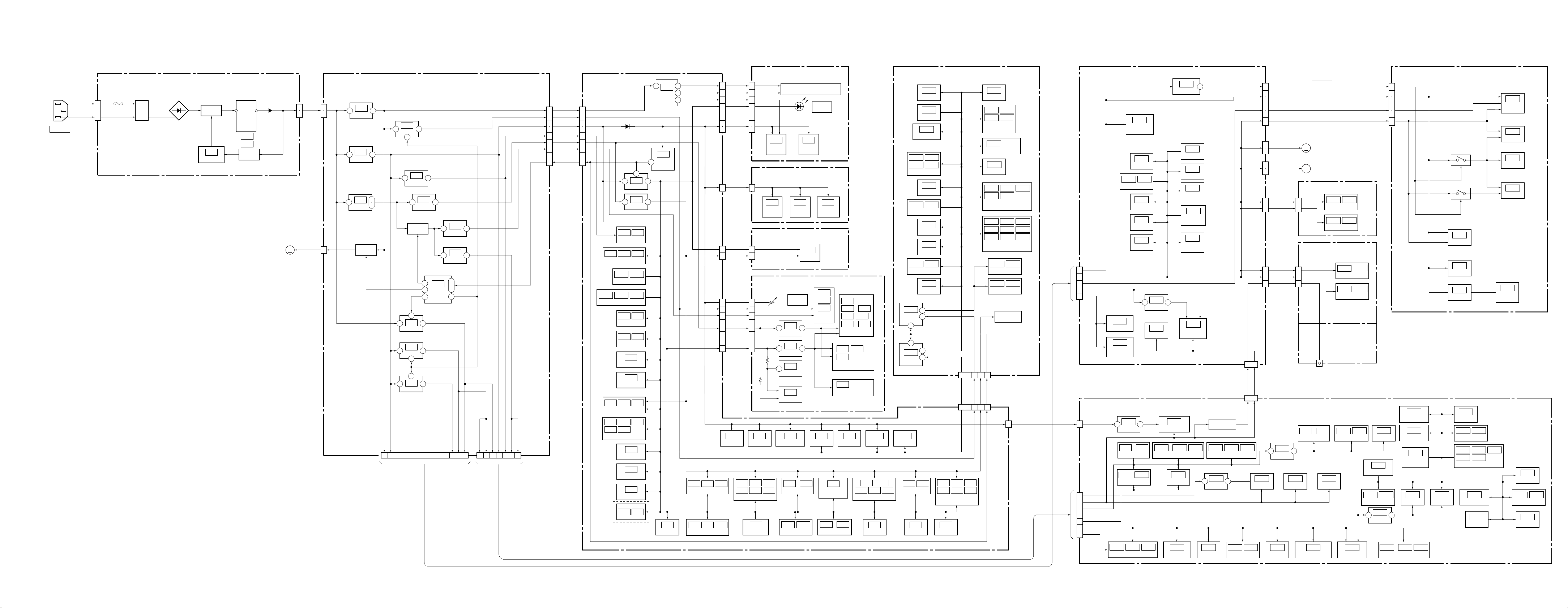

3-3. Overall Block Diagram 3.............................................. 3-11

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. Frame Schematic Diagram.......................................... 4-1

4-2. Printed Wiring Boards and Schematic Diagrams ....... 4-5

• RP-228 Printed Wiring Board ................................ 4-5

• RP-228 Schematic Diagram .................................. 4-9

• JC-19 Printed Wiring Board ................................... 4-15

• JC-19 (AD/DA CONVERTER)

Schematic Diagram ................................................ 4-19

• JC-19 (S1 AFC) Schematic Diagram..................... 4-25

• JC-19 (U1) Schematic Diagram ............................. 4-29

• JC-19 (D1) Schematic Diagram ............................. 4-34

• JC-19 (C1 SPCON) Schematic Diagram............... 4-37

• JC-19 (MODE) Schematic Diagram....................... 4-41

• JC-19 (DV IN/OUT) Schematic Diagram ............... 4-45

• JC-19 (AUDIO CORE) Schematic Diagram........... 4-50

• JC-19 (DIGITAL AUDIO) Schematic Diagram ....... 4-53

• JC-19 (AUDIO D/A, A/D CONVERTER)

Schematic Diagram ................................................ 4-58

• RE-33, CB-67 Printed Wiring Boards .................... 4-61

• RE-33, CB-67 Schematic Diagram ........................ 4-63

• VA-106 Printed Wiring Board ................................. 4-66

• VA-106 (IF) Schematic Diagram ............................ 4-71

• VA-106 (VIDEO IN) Schematic Diagram ............... 4-75

• VA-106 (VIDEO OUT) Schematic Diagram ........... 4-81

• VA-106 (UVIC, DV IN/OUT) Schematic Diagram .. 4-86

• VA-106 (MONITOR OUT) Schematic Diagram...... 4-89

• VA-106 (HI CON) Schematic Diagram................... 4-92

• VA-106 (SG SELECT, EVR) Schematic Diagram.. 4-95

• RS-80 Printed Wiring Board .................................. 4-97

• RS-80 Schematic Diagram .................................... 4-99

• FR-158 Printed Wiring Board................................. 4-103

• FR-158 Schematic Diagram................................... 4-105

• GL-10 Printed Wiring Board................................... 4-109

• GL-10 Schematic Diagram..................................... 4-111

• HP-118 Printed Wiring Board ................................ 4-116

• HP-118 Schematic Diagram .................................. 4-119

• CM-56 Printed Wiring Board .................................. 4-123

• CM-56 Schematic Diagram .................................... 4-127

• MD-63, MD-64, MD-65, FP-406

Printed Wiring Boards ............................................ 4-132

• MD-63, MD-64, MD-65, FP-406

Schematic Diagram................................................ 4-135

• U-1 Printed Wiring Board ....................................... 4-137

• U-1 Schematic Diagram ......................................... 4-138

• U-2 Printed Wiring Board ....................................... 4-141

• U-2 Schematic Diagram ......................................... 4-142

5. ADJUSTMENTS

5-1. MECHANICAL SECTION ADJUSTMENTS................ 5-1

5-1-1. Information ............................................................. 5-1

1-1. How to Search Reference Pages for Removal ........... 5-1

1-2. Phase Adjustment Mark “ PH- ” .................................. 5-1

5-1-2. Preparation for Mechanical Check,

Adjustment and Maintenance ................................ 5-2

2-1. FL Block Assembly................................................. 5-2

2-2. Cassette Positions.................................................. 5-2

2-3. Loading/Unloading ................................................. 5-3

2-4. Manual Up/Down the FL Block .............................. 5-3

2-5. Service Jigs List ..................................................... 5-4

5-1-3. Phase Adjustments ................................................ 5-6

3-1. Phase Adjustment

(Loading/Unloading Driving Section) ..................... 5-6

3-2. Phase Adjustment

(S/L Cassette Selection Section)........................... 5-8

3-3. Phase Adjustment

(Mechanism Chassis Upper Surface Parts) .......... 5-10

5-1-4. Periodic Check and Maintenance .......................... 5-12

4-1. Cleaning of Rotary Drum Assembly ...................... 5-12

4-2. Cleaning of Tape Path System............................... 5-12

4-3. Periodic Checks ..................................................... 5-13

5-1-5. Mechanism Section Checks and Replacements... 5-14

5-1. Tape Stopper, Motor FPC Assembly and

Elastic Connector ................................................... 5-14

5-2. Drum Assembly and Drum Base ........................... 5-14

5-3. LM Cover, LM Worm Wheel, LM Holder and

LM Motor Assembly ............................................... 5-15

5-4. TG3/4 Catcher Block Assembly,

Pinch Driving Gear and TC Arm Assembly ........... 5-15

5-5. Pinch Arm Assembly, Pinch Limiter and

Tension Coil Spring (Pinch) ................................... 5-16

5-6. HC Arm, HC Roller Assembly,

Pinch Retainer, Pinch Cam Gear and

TG5/6 Catcher Block Assembly............................. 5-16

5-7. RL Arm and RL Link............................................... 5-17

5-8. Gooseneck Guard and Gooseneck Arm Assembly 5-17

5-9. Tension Coil Spring (TG2), Spring Adjustor,

TG2 Spring Hook, TG2 Selection Arm and Damper

Sheet ...................................................................... 5-18

5-10. Tension Coil Spring (TG7), Spring Adjustor and

TG7 Spring Hook ................................................... 5-18

– 5 –

Page 6

Section Title Page Section Title Page

5-11. TG2 Retainer, TG2 Arm Assembly (TG2 Plate Spring

and ET Magnet), S Tension Regulator Band Assembly

and TG2 Laod Arm Assembly ................................ 5-19

5-12. TG7 Retainer, TG7 Arm Assembly (TG7 Plate Spring

and ET Magnet), T Tension Regulator Band Assembly

and TG7 Load Arm Assembly ................................ 5-20

5-13. S Reel Table Block Assembly ................................ 5-21

5-14. T Reel Holder and T Reel Table Block Assembly .. 5-22

5-15. S Reel Plate Assembly ........................................... 5-22

5-16. T Reel Plate Assembly........................................... 5-24

5-17. TG1/8 Base Assembly, S Brake and T Ratchet..... 5-25

5-18 TG3/6 Roller Assembly and TG3/6 Lock Spring.... 5-26

5-19. FL Joint Gear, TG5/6 Retainer and

Capstan Motor........................................................ 5-26

5-20. FL Selection Arm, FL Relay Gear and FL Joint Arm

Assembly ................................................................ 5-27

5-21. Rotary Switch, TC Gear and Relay Gear .............. 5-27

5-22. GL Arm Retainer and GL Arm ............................... 5-28

5-23. M Slider and M Slider Arm ..................................... 5-28

5-24 . TG7 Selection Arm, TG7 Cam Gear and

T Cam Gear............................................................ 5-28

5-25. Main Cam, TG2 SL Arm Assembly and

Tension Coil Spr ing (TG2 SL) ................................ 5-29

5-26. TG3/4 Arm Block Assembly (TG3/4 Arm Assembly,

TG3/4 Limiter Spring and TG3/4 Gear), TG3/4 Base

Block Assembly (TG3/4 Base Assembly) .............. 5-30

5-27. TG5/6 Arm Block Assembly (TG5/6 Arm Assembly,

TG5/6 Limiter Spring and TG5/6 Gear), TG5/6

Base Block Assembly (TG5/6 Base Assembly)..... 5-32

5-28. Reel Motor.............................................................. 5-34

5-29. RS Arm Assembly .................................................. 5-34

5-30. RS Gear Assembly, Mic Press Spring and

Mic Lever ................................................................ 5-34

5-31. Rack Joint Gear, Rack Holder, Mic Holder,

Rack (LC) and Rack (SC) ...................................... 5-35

5-32. Plate Link Assembly............................................... 5-36

5-33. Roller Shaft Assembly and Roller Belt................... 5-38

5-34. Lid Opener.............................................................. 5-39

5-35. C Door .................................................................... 5-40

5-36. Damper Arm and Tension Spring (DB) .................. 5-40

5-37. Gear (A), Gear (B), and C Worm ........................... 5-40

5-38. Tension Coil Spring (HS), Tension (DB), Shift Plate

Spring and C Sloat Block Assembly ...................... 5-41

5-1-6. Adjustments and Checks ....................................... 5-42

6-1. Adjustment Position ............................................... 5-42

6-2. Adjustment Order ................................................... 5-43

6-3. Adjustment and Checking Method......................... 5-44

6-3-1. Reel Table Height Adjustment................................ 5-44

6-3-2. TG2/TG7 Height Adjustment.................................. 5-45

6-3-3. FWD/RVS Position Adjustment.............................. 5-45

6-3-4. TG2/TG7 Electric Tension Regulator Adjustment.. 5-46

6-3-5. FWD/RVS Back Tension Adjustment ..................... 5-48

6-3-6. Adjustment Preparations and

RF Wavef orm Check .............................................. 5-49

6-3-7. Tracking Adjustment ............................................... 5-50

6-3-8. Tracking Check ....................................................... 5-51

6-3-9. CUE and REV Check............................................. 5-52

6-3-10. Rising Check .......................................................... 5-53

6-3-11. Tape Path Check .................................................... 5-54

5-2. SERVICE MODE ......................................................... 5-55

5-2-1. Adjusting Remote Commander.............................. 5-55

1. Used Adjustment Remote Commander................. 5-55

2. Precautions Upon Using The Adjusting Remote

Commander............................................................ 5-55

5-2-2. Data Processing..................................................... 5-56

5-2-3. Service Mode ......................................................... 5-57

1. Emergence Memory Address ................................ 5-57

1-1. EMG Code (Emergency Code) .............................. 5-57

5-3. VIDEO SECTION ADJUSTMENTS ............................ 5-58

3-1. Preparations Before Adjustment............................ 5-58

3-1-1. Equipment Used..................................................... 5-58

3-1-2. Connection of Equipment ....................................... 5-58

3-1-3. Adjusting Connectors (RP 228 Board CN775)...... 5-59

3-1-4. Checking the Input Signals .................................... 5-60

1. S Video Input .......................................................... 5-60

2. Video Input ............................................................. 5-60

3-1-5. Alignment Tapes ..................................................... 5-61

3-1-6. Input/Output Level and Impedance ....................... 5-62

3-2. Power Supply System Adjustment ......................... 5-62

1. Power Supply Voltage Check,

Power Block (U-2 Board)........................................ 5-62

2. Video/Audio Block Power Supply Voltage Check,

Power Block (U-2 Board)........................................ 5-62

3-3. System Control System Adjustment ...................... 5-63

1. Initializing the C, D, E Page Data........................... 5-63

2. Input of C Pge Initial Data...................................... 5-63

3. Input of D Pge Initial Data...................................... 5-63

4. Input of E Pge Initial Data ...................................... 5-63

5. Modification of C, D, E Page Data ......................... 5-63

6. Page C Address List .............................................. 5-64

7. Page D Address List .............................................. 5-64

8. Page E Address List............................................... 5-65

3-4. Servo System Adjustments.................................... 5-66

1. Switching Position Adjustment (CM-56 Board) ..... 5-66

2. Capstan FG Duty Adjustment (CM-56 Board)....... 5-66

3-5. Video System Adjustments .................................... 5-67

3-5-1. RP-228 Board Adjustments ................................... 5-67

1. Recording Current Adjustment (RP-228 Board).... 5-67

2. PLL fo Adjustment (RP-228 Board) ....................... 5-67

3. CLK Delay Adjustment (RP-228 Board) ................ 5-68

4. AGC Center Level Adjustment (RP-228 Board) .... 5-68

5. AEQ Adjustment (RP-228 Board) .......................... 5-69

6. PLL Capture Range Adjustment

(RP-228 Board) ...................................................... 5-70

7. IC774 41.85 MHz VCO Check (RP-228 Board) .... 5-70

3-5-2. JC-19 Board Adjustments...................................... 5-71

1. A/D Converter Reference Voltage Adjustment 1

(JC-19 Board)......................................................... 5-71

2. A/D Converter Reference Voltage Adjustment 2

(JC-19 Board)......................................................... 5-71

3. Y Signal Clamp Reference Voltage Adjustment

(JC-19 Board)......................................................... 5-71

4. CR Signal Clamp Reference Voltage Adjustment

(JC-19 Board)......................................................... 5-71

5. CB Signal Clamp Reference Voltage Adjustment

(JC-19 Board)......................................................... 5-71

6. Playback Y Signal Level Adjustment

(JC-19 Board)......................................................... 5-72

7. Playback CR Signal Level Adjustment

(JC-19 Board)......................................................... 5-72

8. Playback CB Signal Level Adjustment

(JC-19 Board)......................................................... 5-73

9. IC422 27MHz XTAL fo Adjustment (JC-19 Board) 5-73

10. AFC Preliminary Adjustment (JC-19 Board) ......... 5-73

11. AFC Picture Frame Adjustment (JC-19 Board) ..... 5-74

12. AFC Adjustment (JC-19 Board) ............................. 5-74

3-5-3. General Adjustments .............................................. 5-75

1. Playback Y/CR Delay Adjustment

(VA-106 Board)....................................................... 5-75

2. Playback Y/CB Delay Adjustment

(VA-106 Board)....................................................... 5-75

3. Playback Y Signal Level Adjustment

(VA-106 Board)....................................................... 5-76

4. Playback Y Setup Level Adjustment

(VA-106 Board)....................................................... 5-76

5. Playback CR Signal Level Adjustment

(VA-106 Board)....................................................... 5-77

6. Playback CB Signal Level Adjustment

(VA-106 Board)....................................................... 5-77

7. Playback Sync Level Adjustment

(VA-106 Board)....................................................... 5-78

8. Playback Carrier Balance Adjustment

(VA-106 Board)....................................................... 5-78

9. Playback Burst Level Adjustment

(VA-106 Board)....................................................... 5-79

– 6 –

Page 7

Section Title Page

10. Playback Composite Video Chroma

(R-Y Signal Level) Adjustment (VA-106 Board)..... 5-80

11. Playback Composite Video Chroma

(B-Y Signal Level) Adjustment (VA-106 Board)..... 5-80

12. Playback Composite Video Chroma

(R-Y Phase) Adjustment (VA-106 Board).............. 5-81

13. INT Subcarrier Frequency Adjustment

(GL-10 Board) ........................................................ 5-81

14. Decoder Freerunning Frequency Adjustment

(VA-106 Board) ....................................................... 5-81

15. Recording Y/CR Delay Adjustment

(VA-106 Board) ....................................................... 5-82

16. Recording Y/CB Delay Adjustment

(VA-106 Board) ....................................................... 5-82

17. Recording Y Signal Level Adjustment

(VA-106 Board) ....................................................... 5-83

18. Recording Chroma Decoder HUE Adjustment

(VA-106 Board) ....................................................... 5-83

19. Recording CR Signal Level Adjustment

(VA-106 Board) ....................................................... 5-84

20. Recording CB Signal Level Adjustment

(VA-106 Board) ....................................................... 5-84

21. SYNC Position Adjustment (GL-10 Board)............ 5-85

22. EXIT Subcarrier Phase Adjustment

(GL-10 Board) ........................................................ 5-85

23. Burst Position Adjustment (GL-10 Board) ............. 5-86

24. Y/C Separation Adjustment (VA-106 Board) ......... 5-86

25. OSD1 Subcarrier Adjustment (VA-106 Board) ...... 5-87

26. OSD2 Subcarrier Adjustment (VA-106 Board) ...... 5-87

3-5-4. BIST Check ............................................................ 5-88

1. Playback System Check

(JC-19, RP-228 Boards) ........................................ 5-88

2. Record System Check ........................................... 5-89

3-6. Audio System Adjustments .................................... 5-90

1. E-E Level Check..................................................... 5-90

2. Playback Level/Indicator Check ............................. 5-90

3. Recording/Playback Check (Audio Lock Mode) .... 5-91

3-7. Arrangement Diagram for Adjustment Parts.......... 5-92

6. REPAIR PARTS LIST

6-1. Exploded Views ........................................................... 6-1

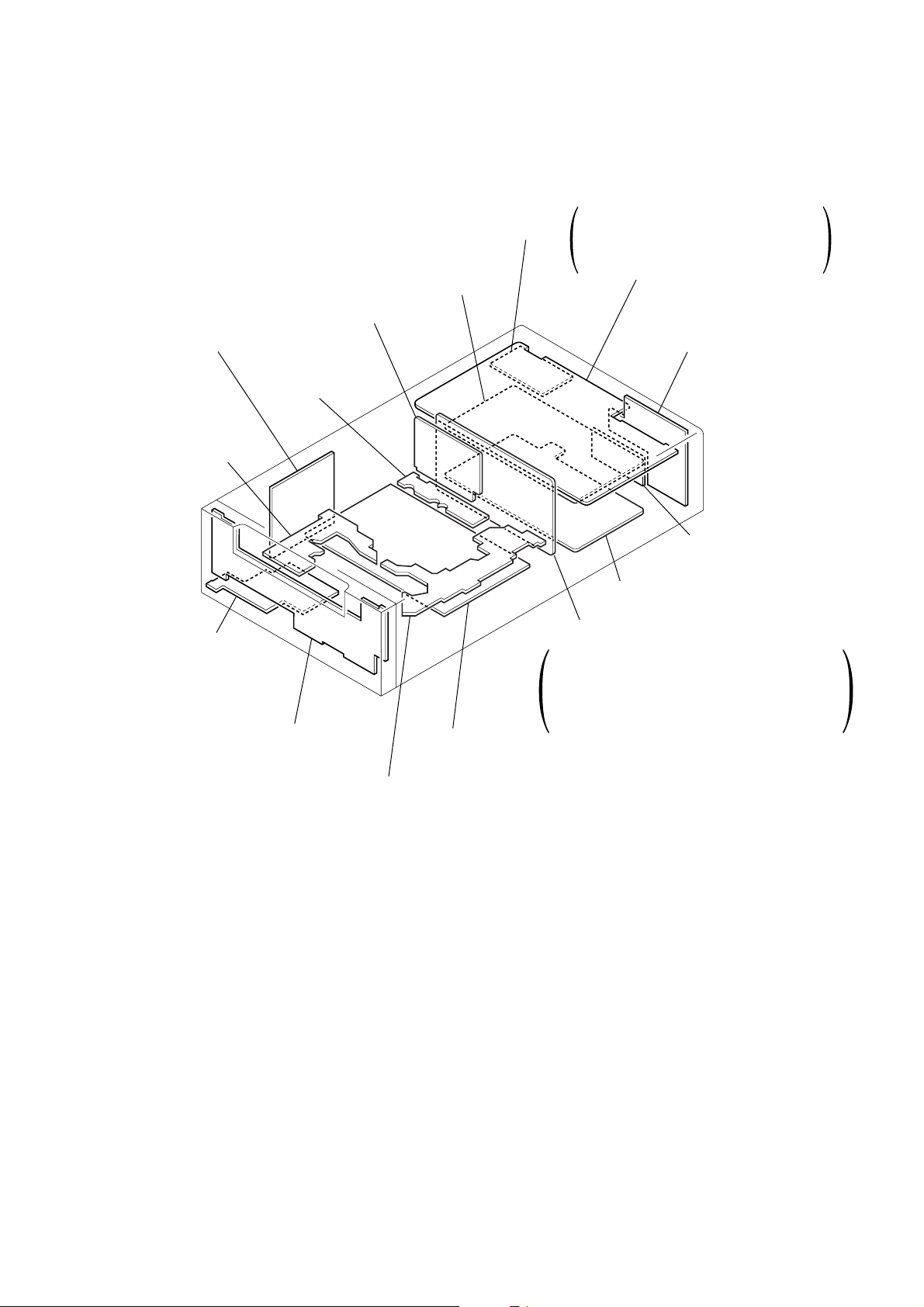

6-1-1. Overall Assembly ................................................... 6-1

6-1-2. Chassis Assembly.................................................. 6-2

6-1-3. MD Block Assembly ............................................... 6-3

6-1-4. FL Cassette Compartment Assembly.................... 6-4

6-1-5. Mechanism Chassis Assembly (1)

(Top Side View (1))................................................. 6-5

6-1-6. Mechanism Chassis Assembly (2)

(Top Side View (2))................................................. 6-6

6-1-7. Mechanism Chassis Assembly (3)

(Top Side View (3))................................................. 6-7

6-1-8. Mechanism Chassis Assembly (4)

(Bottom Side View (1)) ........................................... 6-8

6-1-9. Mechanism Chassis Assembly (5)

6-2. Electrical Parts List ..................................................... 6-10

Hardware List ........................................................................ 6-48

(Bottom Side View (2)) ........................................... 6-9

– 7 –

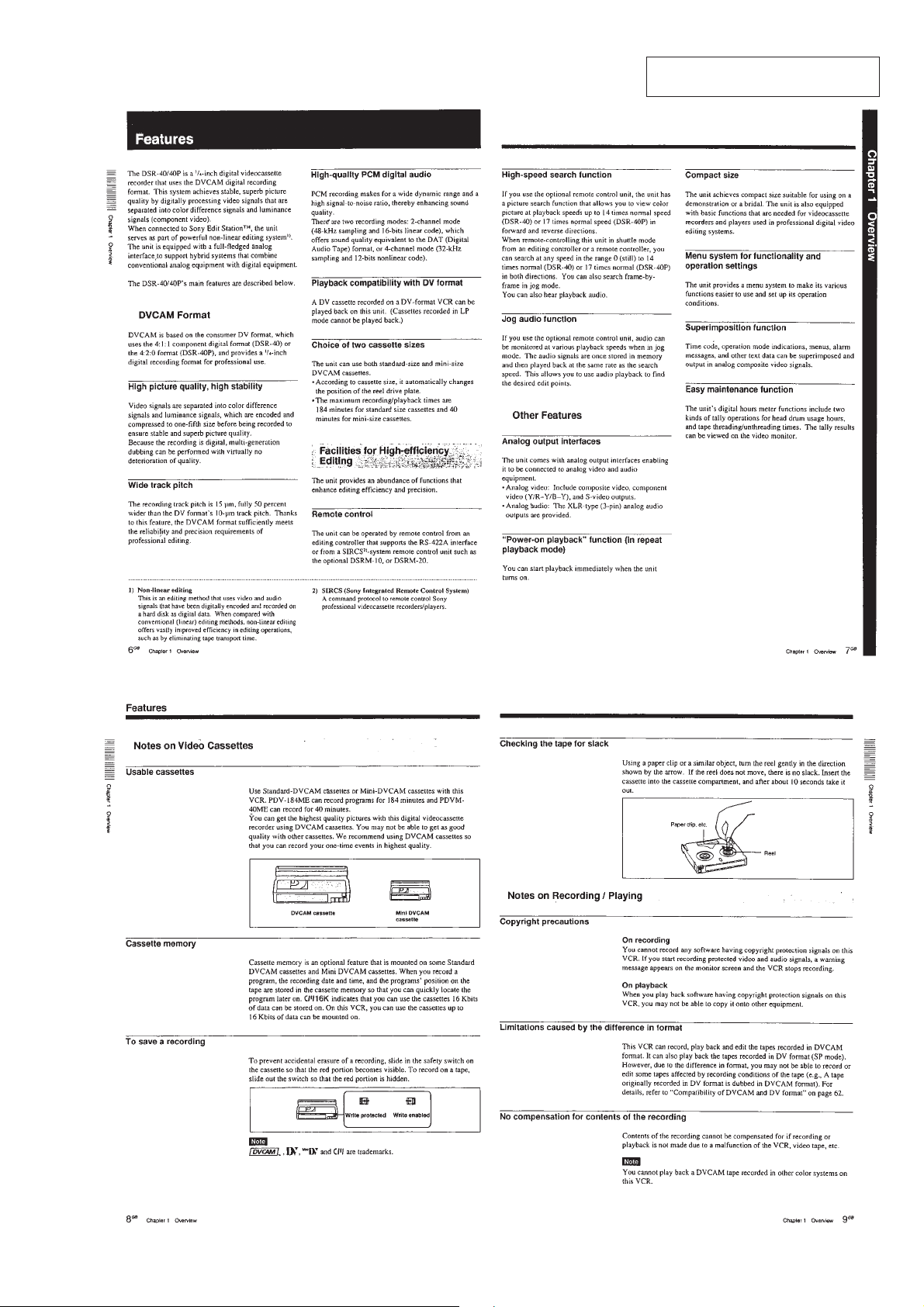

Page 8

SECTION 1

GENERAL

DSR-40/40P

This section is extracted from DSR40/40P instruction manual.

1-1

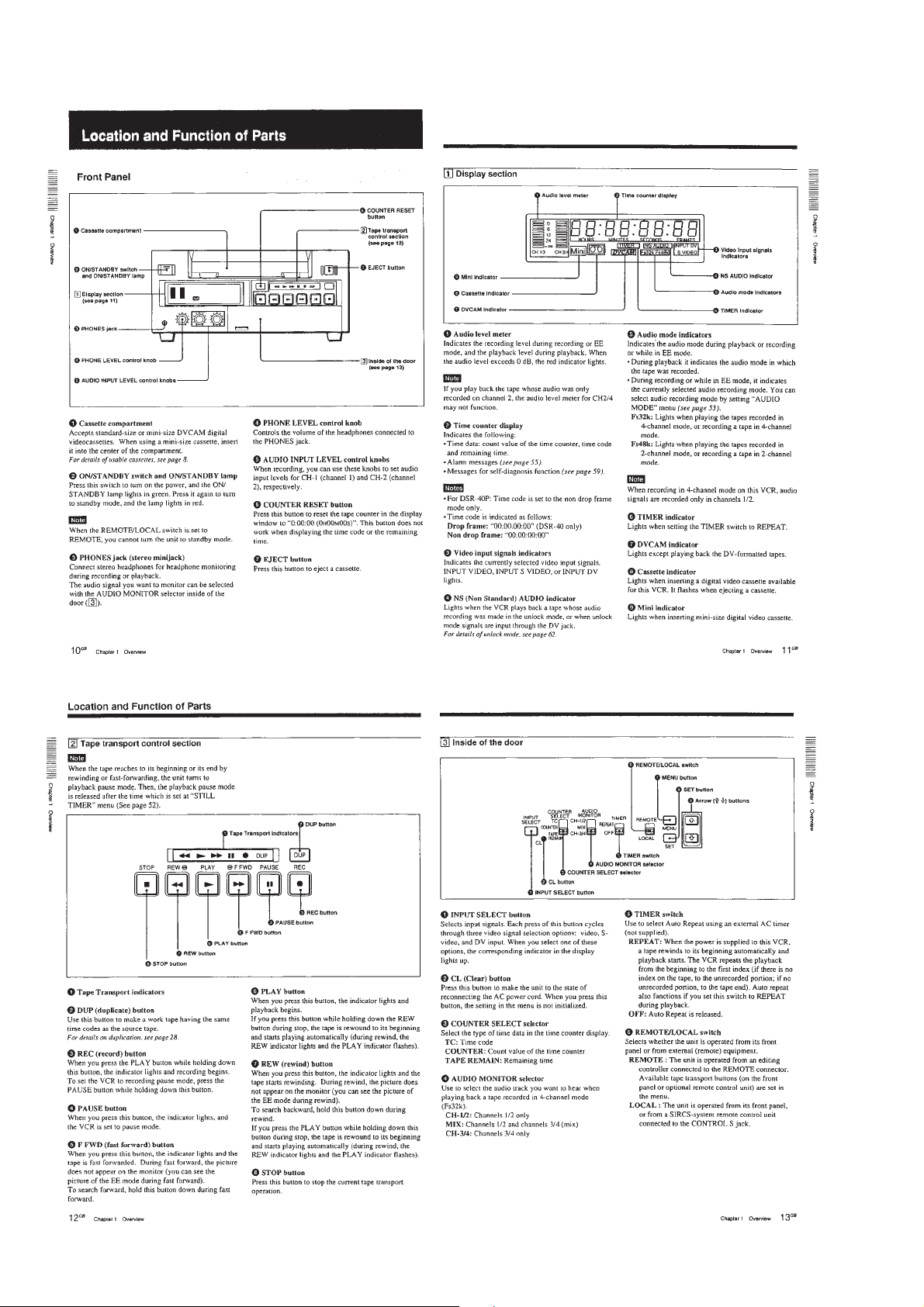

Page 9

1-2

Page 10

1-3

Page 11

1-4

Page 12

1-5

Page 13

1-6

Page 14

1-7

Page 15

http://getMANUAL.com

1-8

Page 16

1-9

Page 17

1-10

Page 18

1-11

Page 19

1-12

Page 20

1-13 E

1-13

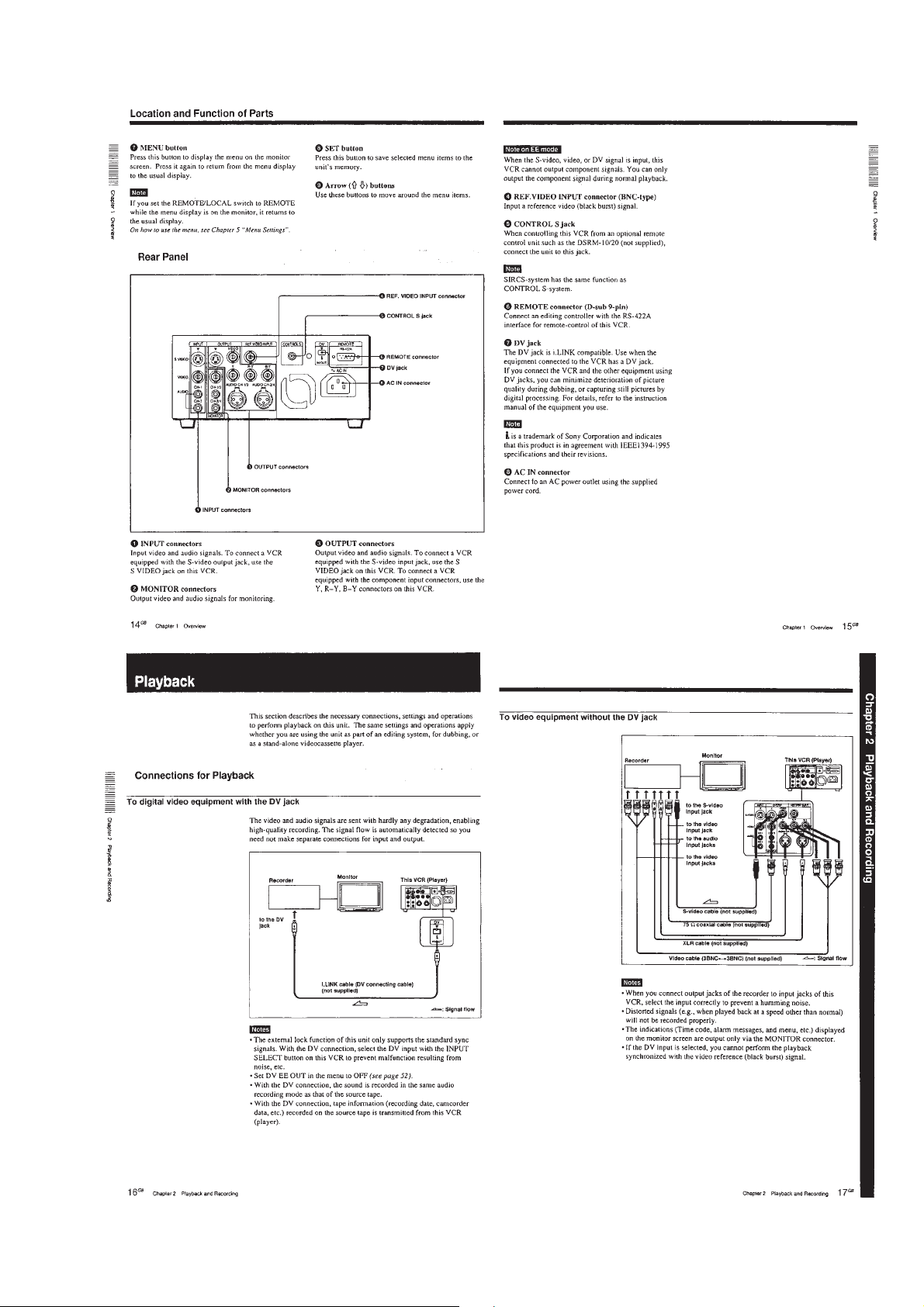

Page 21

SECTION 2

4 Two sumitite

screws (B3)

5 Power block

3 Harness

(CN13)

2 Two harnesses

(CN10, 11)

1 Harness

(CN1)

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

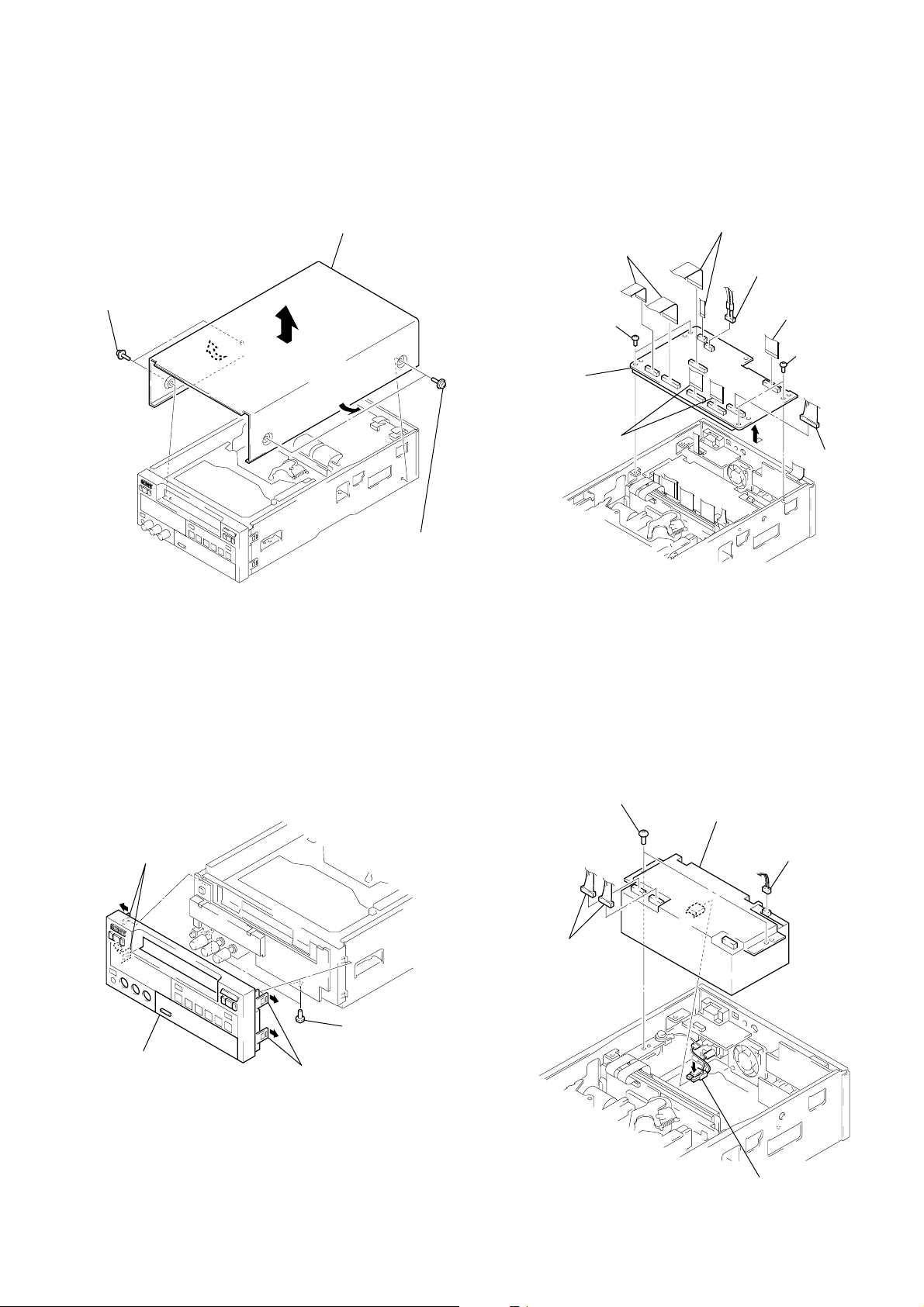

2-1. REMOVAL OF UPPER CASE 2-3. REMOVAL OF VA-106 BOARD

3 Open sides of upper case and

1 Two case screws

(M3)

remove the one in the direction

of the arrow A.

A

1 Two flat cables

(CN851, 856)

8 Two sumitite

screws (B3)

9 Remove the

VA-106 board in the

direction of the arrow.

2 Two flat cables

(CN101, 102)

3 Two flat cables

(CN001, 852)

4 Harness

(CN601)

5 Flat cable

VA-106 board

DSR-40/40P

(CN401)

7 Two sumitite

screws (B3)

6 Harness

(CN855)

2-2. REMOVAL OF FRONT PANEL

3 Two claws

2 Two case screws

(M3)

2-4. REMOVAL OF POWER BLOCK

ASSEMBLY

4 Front panel

assembly

2 Two claws

1 Two sumitite screws

(B3)

2-1

Page 22

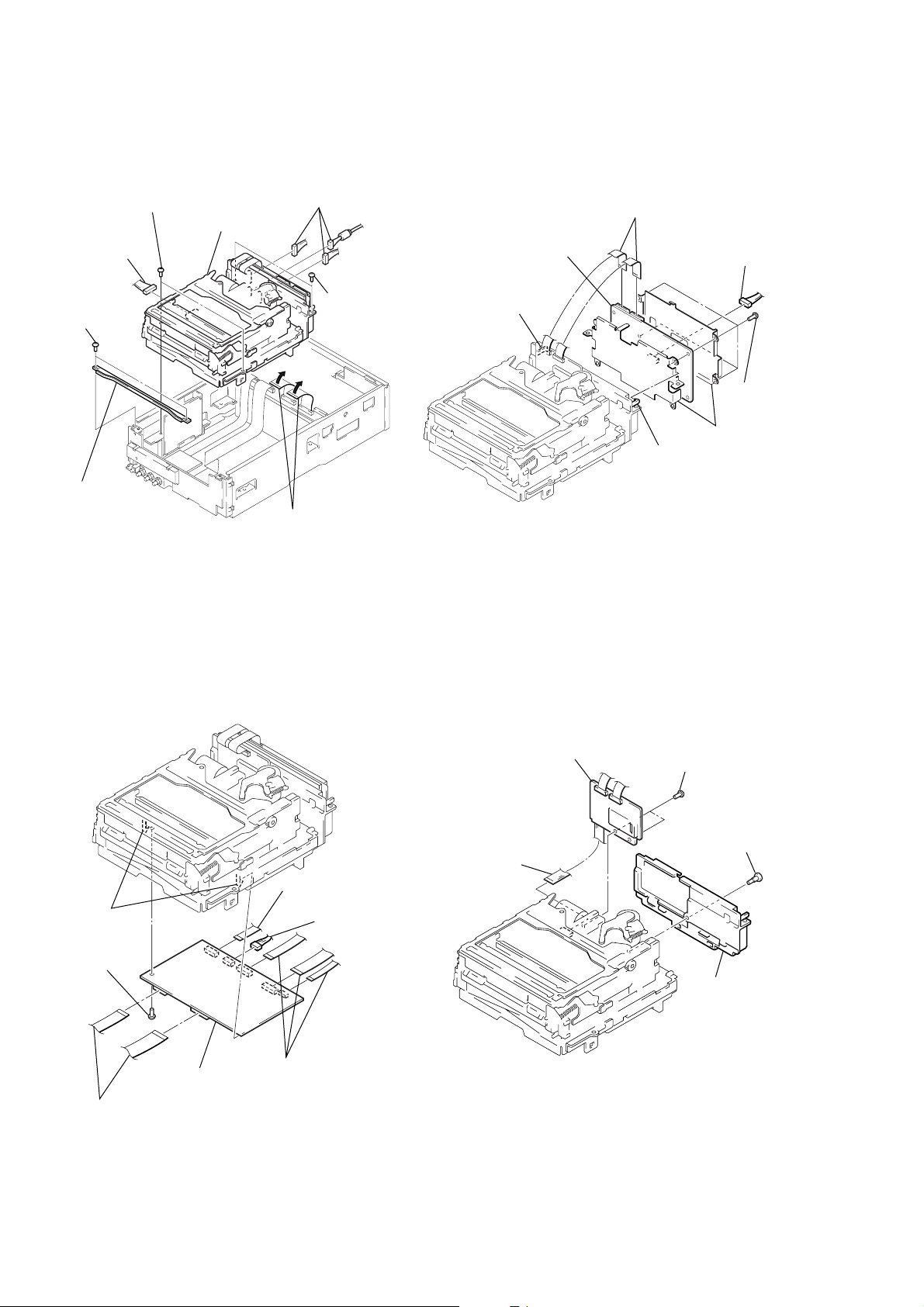

2-5. REMOVAL OF MD BLOCK ASSEMBLY 2-7. REMOVAL OF JC-19 BOARD

4 Two sumitite

screws (B3)

8 Harness

(CN004)

2 Two sumitite

screws (B3)

3 Cassette

Compartment

support

6 MD block

assembly

7 Three harnesses

(CN101, 701, 831)

5 Two sumitite

screws (B3)

1 Two flat cables

(CN103, 104)

7 JC-19 board

4 Claw

2 Two flat cable

(CN411, 412)

JC-19 board

3 Claw

1 Harness

(CN501)

5 Four screws

(P2.6 × 5)

6 Two shield

cases

2-6. REMOVAL OF CM-56 BOARD

3 Flat cable

(CN003)

6 Two claws

5 Sumitite screw

(B3)

CM-56 board

7 CM-56 board

2 Harness

1 Three flat cables

(CN005, 007, 008)

(CN002)

2-8. REMOVAL OF RP-228 BOARD

5 RP-228 board

RP-228 board

1 Flat cable

(CN003)

4 Two tapping screws

(2 × 4.5)

2 Special tapping

screw

3 JC support

4 Two flat cables

(CN001, 006)

2-2

Page 23

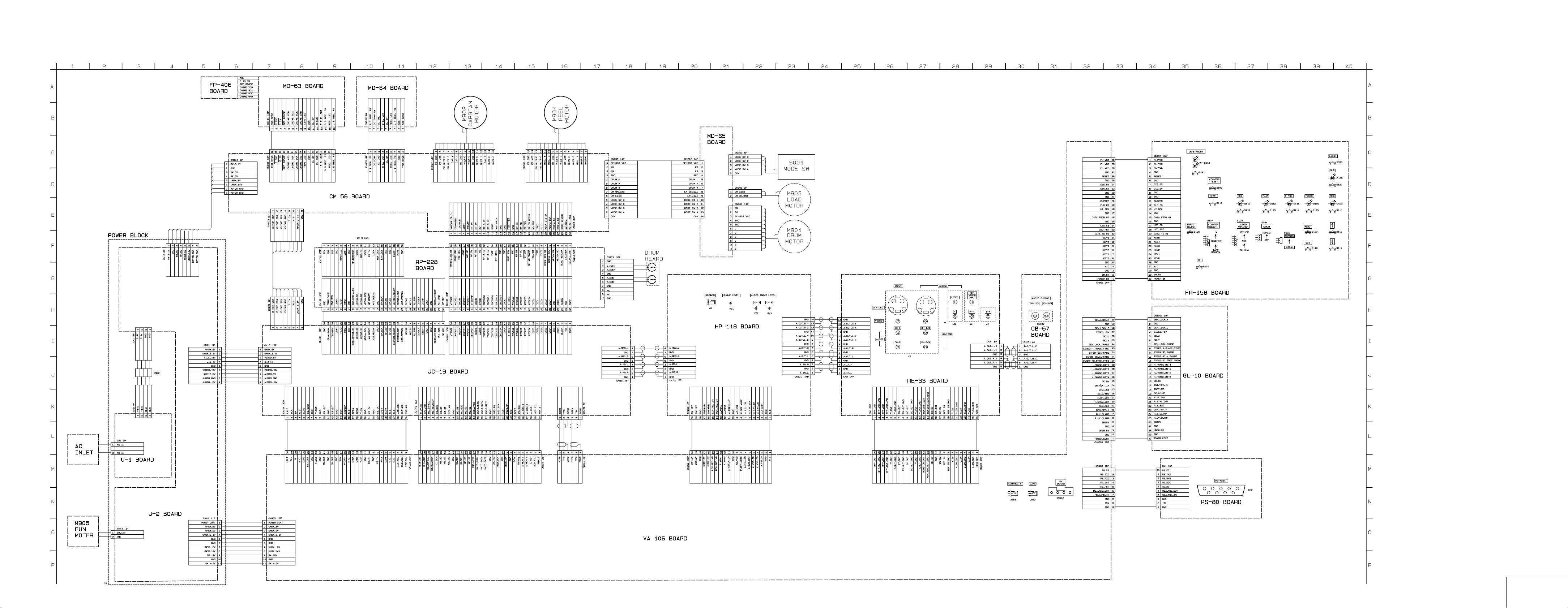

2-9. CIRCUIT BOARDS LOCATION

GL-10

(SYNC GENERATOR)

MD-65

(TAPE DETECT)

MD-63

(TAPE DETECT)

HP-118

(AUDIO)

FR-158

(DISPLAY CONTROL)

U-2

RP-228

(POWER 2)

(REC/PB AMP)

MD-64

(TAPE DETECT)

RS-80

(RS-422A IF)

VA-106

IF, VIDEO IN/OUT, UVIC,

DV IN/OUT, MONITOR OUT,

HI MICOM, RS MICOM

U-1 (POWER 1)

JC-19

AD/DA CONVERTER, S1 AFC, U1,

D1, C1 SPCON, MODE, DV IN/OUT,

AUDIO CORE, DIGITAL AUDIO,

AUDIO D/A, A/D CONVERTER

CM-56

(SERVO, SYSTEM CONTROL)

RE-33

(V/A IN/OUT)

CB-67 (AUDIO OUT)

2-3

2-3 E

Page 24

3-1. OVERALL BLOCK DIAGRAM 1

DSR-40/40P

SECTION 3

BLOCK DIAGRAMS

INPUT

MONITOR

OUTPUT

S VIDEO

INPUT

VIDEO

REF, VIDEO

INPUT

AUDIO

CH1

AUDIO

CH2

AUDIO

CH1/3

AUDIO

CH2/4

AUDIO

CH1/3

AUDIO

CH2/4

FR-158 BOARD

(SEE PAGE 4-105~107)

DRIVER

RE-33 BOARD (1/2)

(SEE PAGE 4-63~65)

J1 (1/2)

J3 (1/2)

CN102

CB-67 BOARD

(SEE PAGE 4-65)

1

ı

4

FF,REW, STOP, PLAY, DUP,

10

COUNTER RESET, PAUSE, REC

ı

13

15

ı

32

FLUORESCENT INDICATOR TUBE

35

39

ı

LED

44

IC104

FL

DUP, REC,

PAUSE, FF,

REW, PLAY

1

8

2

6

5

9

S101

FUNCTION KEY

AUDIO MONITOR, INPUT SELECT, UP,

DOWN, POWER, EJECT, TIMER,

COUNTER SELECT, SET, MENU

A OUT LX

A OUT LY

A OUT RX

A OUT RY

IC103

LED

DRIVER

BZ101

BUZZER

7

10

12

11

14

A IN L

A IN R

A OUT L

A OUT R

1

2

4

5

CN104

5

IC1

AMP

3 1

CN101 CN3

1

2

4

5

FUNCTION KEY

ND101

1

ı

6

MAIN

RESET

CN1

(1/2)

CN2

1

2

22

20

24

SDC DET

26

REF IN

18

1

3

5

7

9

10

12

13

CONTROL S

18

17

13

DATA FROM HI

15

19

12

11

5

20

ı

25

30

C-IN

5

Y-IN

7

V-IN

3

1

9

A

HP-118 BOARD

CN201

(SEE PAGE 3-3)

LANC

LED RST

LED CS

HI SCK

DATA TO HI

FLD CS

BUZZER

RESET

KEY0-5

POWER SW

VA-106 BOARD

(SEE PAGE 4-71~96)

CN401

(1/2)

3

1

S-Y/VIDEO SWITCH

CN851

13

14

18

16

12

19

20

26

1

6

ı

11

2

7

IC201

IC853

2 4

INVERTER

IC860

LANC OUT

IC855

MULTI

PLEXER

1

2

33

44

55

BUFFER CLAMP

L.P.F

IC0001

SIGNAL

SELECT

IC0002

SIGNAL

SELECT

B.P.F

33

6

3

4

25

26

29

27

30

46

47

48

18

62

L.P.F

3

1

5

4 2

4 2

5

1

3

91–96 99

Q102

3V 5V

TP201

G10

E6

23

31

10

26

IC1124

SYNC GEN

14.3MHz : DSR-40

17.7MHz : DSR-40P

IC204

VC DELAY

IC212

6

VC DELAY

G2

4

IC207

1

E5

E1, E2, E4, E6, E8

E6, E8

6

3

4

G6G5G4

1

3

3

2

IC1135

EX OR

E7

4

IC208

VC AMP

4

20

TRAP

19

TRAP

G9

C1

IC1128

IC1132

SC PHASE ADJ

IC1121

BUFFER

3

11

5

13

9

15

12

17

IC1143

IC1144IC1142

DELAY

6

VC DELAY

12

14

16

18

DL202 FL204 DL201

2

2

4

ı

6

6

8

*IC1105, IC1143 :

DSR-40 ONLY

IC1105

3

1

G1

3

IC1115

IC1126

1

IC214

VC AMP

3

5

C4

IC1133

IC1137

HD PHASE

90 SHIFT

TIMING DELAY

PULSE STRECH

IC206

VC AMP

3

5

G3

1

3

2

IC1129

IC1131IC1117

IC1134IC1120

IC1139IC1123

IC854

HI CON

5

FL203

FL205

IC217

SYNC SELECT

7

CN1001 (2/2)

4

IC1138

0/180 LALT

1

9

GL-10 BOARD

(SEE PAGE 4-111~114)

3

6

CN102

(1/2)

CR-IN

IC209

3

3

AMP

IC218

AMP

1

10

CB-IN

1

8

B

JC-19 BOARD

CN104

(SEE PAGE 3-7)

B

JC-19 BOARD

CN104

(SEE PAGE 3-7)

Y-IN

IC215

3

AMP

12

ı

15

C3

8

C1

9

C4

10

C3

11

1

16

2

18

3

19

5

6

20

21

22

24

25

23

1

12

AFCY

7

H PHASE BIT 1-4

EVER 23 H PHASE FINE

EVER 24 SC PHASE

EVER 25 SC V PHASE

EVER 22 SC FREE FREQ

SC ON

INDI EE

SC 0/180

SC U

SC V

R BF OUT

R SYNC OUT

R Y BLK

R Y CLAMP

R UV CLAMP

GEN REF Y

16

ı

19

23

22

21

20

15

13

12

26

25

11

10

9

7

6

8

CN0001

(2/2)

C3

C1

C4

C3

87 82 64 84 85 86 60 100 2 51 52 22 23 19 12 57 58 59 97 98 16 14 10 17 65 32 2483

16

23

21

19

CN102

(2/2)

XYC SEP

Y OUT

1

2

1

CR OUT

2

CB OUT

1

2

9

10

(1/2)

IC104

BUFFER

6

6

1

2

IC1115

IC1116

AND GATE

8

IC402

VC DELAY

4

B2

IC403

VC DELAY

4

B3

1

2

*DSR-40P ONLY

IC404

Y SWICH

3

IC405

R-Y SWICH

3

IC406

B-Y SWICH

FL402

B2-16, C1-4,

G1-10, O1

IC1105

IC1110

IC1114

D/A

CONVERTER

IC409

Y BLANKING

B13

B4

B5

3

7

1

614KHz

X1

8MHz

SET UP ADD

2

4

6

IC407

VC AMP

CN2

1

2

3

4

X2

IC412

4

16

INVERT AMP

IC413

3

1

AMP

IC414

3

1

AMP

B9

B8

2 6

2

7

5

7

2

8

3

REMOTE

RS-422A

IC420

VC AMP

3

5

RE-33 BOARD

(SEE PAGE 3-1)

DL401

1

IC424

INVERTER

2

B10

4

IC422

1

C ENCODE

24

5 20 3 22

1212

A

CN2

4

B11

21 17

1

3

5

7

9

10

12

13

18

CN201

A IN L

A IN R

A OUT L

A OUT R

A OUT LX

A OUT LY

A OUT RX

A OUT RY

IC418

4

INVERT AMP

IC410

2

R-Y OUT

6

DRIVER

IC408

2

B-Y OUT

6

DRIVER

FL403 B.P.F

3

IC704

5

BUFFER

IC204

AUDIO AMP

1

7

RV201

RV202

2

4

6

14

4

4

IC708

10

7

AUDIO

PROCESS

3 12 13

312

Q710

Q711

MUTE

1

7

312

546 1483 12 1311 15

A XVR CS

A XVR SO

A XVR SCK

546 1483 12 1311 15

1

2

IC415

Y OUT

DRIVER

IC421

INVERT

AMP

IC426

INVERT

AMP

8

5

IC201

BUFFER

1

1

3

5

13

7

16

10

1

7

2

6

IC715

BUFFER

IC716

BUFFER

Q201

Q202

MUTE

1

7

IC205

1

3

5

CN200

CN856

13

14

13

14

7

2

7

2

7

2

IC411

VC AMP

B6

B7

3

IC416

VC AMP

1

VC AMP

3

B14

IC428

1

VC AMP

3

B16

IC429

1

VC AMP

3

B15

1

5

3

2

5

*DSR-40P

ONLY

3

1

3

1

3

1

1

1

IC427

CLAMP

5

CLAMP DL402

5

CLAMP DL403

5

IC401

IC430

INVERT AMP

FL401

RS-80 BOARD (SEE PAGE 4-99~101)

123

4

65 7

8

IC3

INTERFACE

2 3

86 87

RS-422A CONTROL

21 20 22 23 24 26 9 87

CN1

54789106

RS TXD

RS SCK

RS RXD

RS LANC IN

RS LANC OUT

6743215

234

1

2

CN852

1

5

IC1

RS CS

RS-422

CLOCK

DRIVER

RS RST

IC2

85

IC205

S-C/C SWITCH

3

7

1

2

2

3

7

1

IC211

Y/C SEP

79

25 39

G7

33

G8

41

7

1

2

LOCK Y

30

CN0001

(1/2)

7

2

1

8081

34

45

49

28

14

24

LOCK C

INT/EXT

LOCK

PHASE

GEN

GEN

IN

GEN

FL201

31

11

CN1001

(1/2)

1

3

17

7

FL202

2

*IC1112 :

DSR-40 ONLY

B.P.F

IC202

3 1

AMP

IC210

4 1

OSC

IC1101

1

SYNC SEP

IC1102

IC1106

SC PROC

IC1104

IC1111

IC1107

IC1112

IC1108

COUNTER

SHIFT REGISTER

17

4

11

X1101

E7, E9

42

S-Y/Y SWITCH

IC1109

GEN LOCK

8

IC1103

9

11

IC203

IC1116

IC1119

HD SHIFT

FINE ADJ

15 20

18

14

1

8

10

19

9

14.3MHz : DSR-40

14.1MHz : DSR-40P

6

12

1

NOR

X851

20MHz

43

1

IC1113

SC SWITCH AMP

54

C3

55

IC216

*DSR-40P ONLY

2

C2

IC1118

1824 13

IC1141

SYNC GEN

X853

32.798KHz

10

5

25

28

1

91312

IC1122

IC1127

HD SHIFT COURSE ADJ

X1102

14.3MHz : DSR-40

17.7MHz : DSR-40P

21

229

X201

CT201

IC213

C DECODE

24 18 4 11

4

12

IC219

IC1125

IC1130

17

8

29

22

13

18

7

24

15

E9

3V 5V

IC417

C OUT DRIVER

2

6

4

2

6

4

IC419

VIDEO OUT

DRIVER

1

7

2

6

P OFF MUTE

Q103

14

13

14

13

16

14

4

9 11

IC711

AUDIO

SELECTOR

Q708, Q709

MUTE

CN401

IC654

MONITOR OUT

DRIVER

13

3

12

5

A FIL ON

Y OUT

22

R-Y OUT

24

B-Y OUT

26

SY OUT

20

SC OUT

18

MONITOR

OUT

14

V OUT

16

13 2

14

IC706

1

7

BUFFER

IC705

IC707 IC714

IC709 IC717

IC710 IC718

FILTER

RE-33 BOARD(2/2)

(SEE PAGE 4-63~65)

CN1

5

3

1

7

9

13

11

IC653

OSD SELECT

7

2 9

IC423

SYNC SEP

8

10 11

3

5

IC713

J2

J3 (2/2)

J4

J1 (2/2)

2

3 25

1

25

12

5

X401

500KMz

IC702

IC703

AUDIO

SELECTOR

A MON2

A XGAIN UP

A MON1

IC425

13

OSD1

3

98

X402

14.3MHz : DSR-40

17.7MHz : DSR-40P

B12

HP-118 BOARD

(SEE PAGE 4-119~122)

RV1

PHONE

LEVEL

RCH REC VR

LCH REC VR

Y

R-Y

B-Y

S VIDEO

VIDEO

VIDEO

22

23

24

1

7

BUFFER

5

3

HP AMP

OUTPUT

MONITOR

OUTPUT

3 65

1

2

3

IC701

3

5

IC1

6

1

L REC LEVEL

R REC LEVEL

Q101

3V 5V

IC651

OSD2

8

X651

14.3MHz : DSR-40

17.7MHz : DSR-40P

O1

CN701

A REC L

A REC R

A PB L

A PB R

RV2

RV3

Q613

SYNC SEP

X601

3.58MHz : DSR-40

4.43MHz : DSR-40P

1

2

3

12

13

2423229

123

L.P.F

8

6

C

JC-19 BOARD

CN831

(SEE PAGE 3-9)

4

2

PHONES

18

17 11

IC602

U VIC CONTROL

31

32

IC106

AND GATE

3

6

11 12

10 11

IC652

9

SYNC SEP

5 8

2

4

1

4

13

2

5

X652

500KMz

3

3

10

12

13

29

28

IC101

IC104

(2/2)

IC102

IC105

IC103

AND GATE/INVERTER

4 3 2

IC856

EEP ROM

1 6 7 5

4

35 36 37 20 21 7 31 40 63 38 39

7 6

IC858

CLOCK GEN

IC859

RESET

CN602

S851

RESET

X852

0.032MHz

2

3

8

6

DV

IN/OUT

1234

TPB

NTPB

PB/XEE

OSD SCK

OSD SO

UVIC GATE

UVIC SWIN

UVIC BUSY

XCS UVIC

MO XPFAIL

XWAKEUP

TPA

NTPA

S/XV

XCS

MO SI

MO SO

MO SCK

MO RST

XCS MO

HI SI

HI SO

HI SCK

XHI RST

MO

JOG FIL

CN601

CN101

2

3

5

6

7

6

11

12

10

14

15

16

17

18

19

20

21

23

24

25

26

29

28

27

2

D

JC-19 BOARD

CN701

(SEE PAGE 3-8)

E

JC-19 BOARD

CN103

(SEE PAGE 3-9)

3-1 3-2 3-3 3-4 3-5

Page 25

DSR-40/40P

3-2. OVERALL BLOCK DIAGRAM 2

B

VA-106 BOARD

CN102

(SEE PAGE 3-2,3)

19

21

23

8

12

10

15

24

CN104

Y-IN

CR-IN

CB-IN

Y-OUT

CB-OUT

CR-OUT

XYCSEP

AFCY

21

IC017

21

IC016

21

IC015

IC015 ~

A/D CONVERTER

~

IC209 IC214

TIMING GEN.

7

12 16 60

IC205

CLOCK GEN.

2252

46

1

8bit DATA 8bit DATA

ı

8

1

8bit DATA

ı

8

1

8bit DATA

ı

7

28

43

53

IC206

1

4

2

SGH, SCCK

CK135, SCOE

AND

IC017

TDI

TCK

TMS

64

ı

71

55

ı

62

46

ı

53

139

145

146

44

76

78

79

77

80

82

83

101

88

89

92

CN503

IC200

I/O

INTERFACE

16

18

20

10

ı

13

15

17

19

111

ı

118

122

ı

129

107

FLBKY, FLBKC

ı

CINV, REC, JSYC, JSYY

110

JFDE, JODE

120

130

131

166

103

104

106

FOR CHECK

8bit DATA

17

ı

26

5

ı

13

2

ı

4

16

26

ı

29

IC401

BLANKING

92–94

VRT, VRB

68

ı

84

158

ı

165

149

ı

157

142

ı

148

134

ı

141

124

ı

131

116

ı

120

109

ı

113

97

ı

106

DATA

ADDRESS

ADDRESS

DATA

DATA

ADDRESS

ADDRESS

DATA

CONTROL

16bit DATA

2

ı

9

12

ı

24

52

ı

64

67

ı

74

2

ı

9

16

ı

19

57

ı

60

67

ı

74

IC009

IC018

REF DC GEN.

JC-19 BOARD

(SEE PAGE 4-19~60)

IC403

V RAM

C

IC402

V RAM

Y

SP SI, SO, SCK

~

IC013

172

ı

189

DESHUFFLE

IC411

AV MIX

ECC

TBC

91

ı

95

81

ı

85

74

ı

77

80

62

ı

64

158

ı

160

193

198

34

ı

54

55

INPV, IOCE, IENPA

ı

57

IC410

4M

D RAM

MECHA SI, SO, SCK

SP SI, SO, SCK

70–72

60 11

58

IC805

A/D, D/A

14

CON V.

10

54

55

X701

24.6MHz

28

98

99

24

IC904 (1/2)

FS CON

25

82

ı

100

78

DV SIGNAL

ı

80

PROCESS

DV INTERFACE

2 3 5 6

VA-106 BOARD

(SEE PAGE 3-5)

9

LRCK, BCK, MCK, FSE1, FSE2

23

59

612835

2

ı

20

IC701

22

ı

27

59–67

REQ, CLK, D0/1

CTL0/1

7–12

1

2

IC702

43

46

33–36

TPA, TPB

NTPA, NTPB

CN701

D

CN601

CN412

18

ISCDXI 0-4

ı

22

11

AVDXI 0-4

ı

15

6

DXO 0-4

ı

10

CN411

MECHA

20

SO/SI/SCK

ı

22

SP

14

SCK/SO/SI

ı

16

IC804

MCK

30 3

IC911

AUDIO

CLK GEN.

CNA, LPS, PWR DN, XRESET

RP-228 BOARD

(SEE PAGE 4-9~12)

CN101

9

ı

13

16

ı

20

21

ı

25

CN102

9

ı

11

15

ı

17

IC801

40 36 13 26

TIMING CONT

X801

49.152MHz

IC422 (2/2)

59 66

FLTA

FLTT

2 3 11

9

D-FFS

DATA BUS

IC901

(1/2)

INDT 0–15

IC902

ADDRESS BUS

50

ı

54

IC774

59

CHANNEL

ı

CODING

63

1

ı

4

64

IC770

2

E PROM

MECHA SI, SO, SCK

SP SI, SO, SCK

IC807 IC836

A/D, D/A CON V.

IC837

14

11

12

15

16

17

AUDIO CLOCK

IC901 (2/2)

IC907 IC909

X702

6MHz

36

51

53

57

81

83

85

IC903

ı

ı

ı

IC916

IC703

DV

CONTROL

25

27

IC772

29

ı

35

37

6 7 6 7 6 7

27

2 1

6

7 6

5

3

1 2

4

5

29

28

11

12

88

22

ı

24

CN702

2

A/D

21 20

ı

CONV

8

12

23

28

EVR

IC773

PLL

2 1

7 6

7 6

10

27

63

ı

65

93

FOR CHECK

IC838

BUFF

IC831

BUFF

BUFF

IC833

IC771

BUFF

IC835

BUFF

IC421 (2/2)

SP CON

4 – 6 8 7 3 25 – 40 22 – 24

11

ı

15

41

IC775

RF EQ

IC834

3 4

13 14

IC834

IC904 (2/2)

FS CON

MO SI, SO, SCK

IC502

2

E PROM

2

27

31

IC777

42

47

REC/PB

AMP

19

EMPHASIS

EMPHASIS

53

X501

20MHz

X/Y ODD

6

7

2

X/Y EVEN

3

PB RF

IC840

BUFF

2 1

2 3

BUFF

IC831

2 3

BUFF

IC833

15

25

24

48

ı

50

IC501

MODE

78

CONTROL

5

6

27

72

73

1 2 26 30 38 61 85

CN771

5

6

2

3

CN103

20

4

ı

6

12

ı

14

X HI RST, MO XPFAIL

DRUM HEAD

PBRF

MECHA SCK,DATA FROM MECHA,DATA TO MECHA

SP SI,SP SO,SP SCK

CN831

A. PB. L

A. PB. R

A. REC. L

A. REC. R

14

19

16

22

29

32

ı

35

45

46

55

65

67

80

81

4

2

HP-118 BOARD

8

(SEE PAGE 3-4)

6

X502

32.768kHz

IC504

D/A CONV

4

19–21 10–12

CN701

OSDSO S X/V, HI SCK, HI SO, HI SI, XCS MO, MORST, PB/XEE

OSD SCK, XCS UVIC, UVIC BUSY, UVIC SWIN, UVIC GATE, XCS OSD2

CM-56 BOARD

(SEE PAGE 4-127~130)

IC005

5 32 74

ATF

33

ı

35

60

ı

62

11

25

27

17

19

CN003

ı

ı

C

59

IC421 (1/2)

SP CON

MO RST

96

X422

27MHz

6

FRAME PLL

77

ı

79

MO SI, SO, SCK

CN103

28

TRKD, FLTD

IC422 (1/2)

7–9

2 3 11 – 13 5 – 8 10 14 – 17 19 – 21 24 25 29

2

SGH, SCCK

3

CK135, SCOE

32

33

E

X421

20MHz

VA-106 BOARD

CN101

(SEE PAGE 3-5)

43

4

15

15

4

IC019

BUFFER

IC503

CAP

MOTOR

DRIVE

IC022

REEL

MOTOR

DRIVE

78

52

51

79

28

71

26

20

19

95

96

22

ı

25

IC008

57

6

56

58

44

45

49

29

72

33

ı

35

60

ı

62

18

50

5

11

12

5V~3V

LEVEL

CONV.

3 2 12

5 7 13

IC016

LPF

3 1 4

IC014

FG

1 3

AMP

IC003

MECHA CONTROL

IC011

9

1

10

6

FG, PG

AMP

13

14

10

IC012

DC/DC

7

CONV.

18

IC021

1

DRUM

3

19

1

21

21

ı

23

21

ı

23

4

15

6

11

6

8

MOTOR

DRIVE

S

L

IC017

S

L

IC002

AND

IC009

LOADING

MOTOR

DRIVE

29

31

13

IC018

1

3

5

1

2

1

5

2

12

3

15

24

COMP

2

IC006

1

2

COMP

13 10

CN008

8

DRUM U/V/W

ı

10

CN007

CN006

12

13

3

4

5

6

13

3

10

11

12

13

FG OUT

CAP

U/V/W

REEL

U/V/W

FG OUT

FG,PG

CAP

FG

M

M

REEL

FG

MD-64 BOARD

CN005

CC DOWN SW

2

S EL OUT

4

S T REEL FG

7

5

10

1

L T REEL FG

7

TOP SENS

9

CN002

8

6

9

3

1

MD-63 BOARD

CN001

CN008

S S REEL FG

3

L S REEL FG

1

16

8

4

13

11

10

14

15

6

7

2

ı

5

END SENS

TAPE LED

T EL OUT

REC PROOF

CHIME SDA

CHIME SCK

C IN

C OUT

LM LOARD

/UNLOAD

MODE SW

A-D

7

5

CN101

14

16

1

9

S ELETEN

13

4

6

7

3

2

CN202 CN203

8

9

10

ı

13

MD-65 BOARD(1/2)

(SEE PAGE 4-136)

CN202 CN201

5

ı

7

2

3

M902

CAPSTAN

MOTOR

M904

REEL

MOTOR

(SEE PAGE 4-135,136)

S002

(CC DOWN)

T ELETEN

S T REEL

L T REEL

S S REEL

L S REEL

IC005 IC006

IC003

FG

IC004

FG

Q101

TAPE END

SENSOR

(SEE PAGE 4-134,135)

IC102

FG

IC101

FG

Q102

TAPE END

SENSOR

IC103 IC105

S101

(C OUT)

MD-65 BOARD(2/2)

(SEE PAGE 4-136)

6

11

1

2

REC

PROOF

C IN

FP-406 BOARD

(SEE PAGE 4-135)

1

2

CN204

1

ı

4

U,V,W

ı

PG,FG

TAPE

LED

CN901

M

MODE

SW

DRUM

PG FG

M903

LOADING

MOTOR

M

(FOR CASSETTE MEMORY)

M901

DRUM

MOTOR

MO SI, SO, SCK

X PARSLEY MODE, X RESET, P FAIL, X LANC PWR ON, LANC P CONT, LANC OUT, LANC IN

SGH, SCCK, CK135, SCOE

Y CLP ERR, CR CLP ERR, CB CLP ERR

SP SI, SO, SCK

C IN

CHIME SDA

CHIME SCK

CN501

2

3

5

CHIME SDA

C IN

5 2 3

CN002

CHIME SCK

3-6 3-7 3-8 3-9 3-10

Page 26

3-3. OVERALL BLOCK DIAGRAM 3

DSR-40/40P

AC INLET

AC IN

F1

CN1

3.15A/250V

1

2

U-1 BOARD

(SEE PAGE 4-138~140)

FR-158 BOARD (SEE PAGE 4-105~107)

U-2 BOARD

L1

L2

D1

Q1

SWITCH

Z1

PWM

T1

POWER TRANS

Z2

Z3

PHOTO

COUPLER

M905

FAN

MOTOR

CN3

+14V

1

2

M

(SEE PAGE 4-142~144)

CN1

1

2

CN13

SW 12V

1

Z1

1 2

+14V REG

Z2

1 2

+6V REG

Z9

1

REG

Q1

12V REG

Z7

1 2

+12V REG

4

Z5

1 2

+3.1V REG

3

5

1 2

1 2

1 2

UNSW 14V

UNSW 6V

CN10 CN11

2 3

Q2, Q4

SWITCH

5

Z8

+3.1V REG

Z6

+5V REG

4

4

Z4

+5V REG

Z10

–8V REG

14

13

15

Z4

POWER

CONTROL

Z11

2 3

–12V REG

Z12

2 3

–5V REG

1

ı

4

16

RF 5V

SW 5V

SW 3.1V

VIDEO 5V

AUDIO 5V

J 3.1V

UNSW 6V

UNSW 3.1V

VIDEO –5V

AUDIO –5V

962147313456

CN12

UNSW 14V

8

9

UNSW 6V

2

3

UNSW 3.1V

4

UNSW –8V

7

SW –12V

11

POWER CONT

1

SW 12V

VA-106 BOARD

(SEE PAGE 4-71~96)

CN855

8

9

2

3

4

7

11

1

B UP 5V, D5V

2

IC862

1 3

+5V REG

IC861

2 3

–5V REG

IC103

IC101

AND/BUFFER

IC106

IC104IC102

BUFFER/AND

IC1116

IC1115

AND

D/A CONVERTER

* IC416 : DSR-40P ONLY

IC1114IC1110IC1105

IC651

IC425

OSD

IC652

IC423

SYNC SEP

IC653

OSD SELECT

IC602

UVIC CONTROL

IC416

IC411IC407

VC AMP

IC212IC207IC204

IC403IC402

VC DELAY

IC211

Y/C SEP

IC213

C DECODE

IC210

OSC

IC219IC216

*DSR-40P ONLY

2

11

IC857

DC/DC

CONV.

IC854

HI CON

IC202

L.P.F

3

4

8

CN851

CN852 CN1

CN401 CN1

CN856

IC214

IC208IC206

VC AMP

IC205

IC203IC201

VIDEO/Y/C SWITCH

30

29

28

2

23

24

9

12

10

9

19

20

17

16

EEP ROM

FL+VDD

FL–VDD

FL–VEE

SW 5V

DIG 5V

+5V

AUDIO +5V

AUDIO –5V

AD VDD

SW+12V

SW–12V

UNSW–8V

UNSW+6V

IC856

CN104

1

2

3

29

7

8

FLUORESCENT INDICATOR TUBE

IC104

FL

DRIVER

RS-80 BOARD (SEE PAGE 4-99~101)

2

IC1

RS-422A

CONTROL

RE-33 BOARD (SEE PAGE 4-63~65)

15

17

HP-118 BOARD (SEE PAGE 4-119~122)

A+4V

A–4V

IC218IC215IC209

IC222

RV2

RV3

IC862

2 3

–5V REG

IC863

1 3

+5V REG

IC864

1

REG CONT

HP AMP

IC855

MULTI PLEXER

IC427 IC429–

IC0001

SIGNAL SELECT

IC220

SYNC SELECT

9

19

20

17

16

IC859

RESET

IC221

AMP

IC217

ND101

POWER/

STANDBY

D113

IC103

LED

DRIVER

IC2

CLOCK

DRIVER

L/R REC

LEVEL

IC1

VC AMP Y BLANKING

IC0002

INTERFACE

IC1

AMP

IC860

LANC OUT

Y/R-Y/B-Y SWITCH

IC3

IC201

IC204

IC205

AUDIO

AMP

IC409

SET UP ADJ

IC404

IC701

IC704

IC707–

IC709

IC710

IC712 IC718–

BUFFER

IC702 IC703

IC711

AUDIO SELECTOR

IC708

AUDIO PROCESS

IC853

INVERTER

IC406–

IC851

SIRCS IN

IC412 IC414–

INVERT AMP

IC420

VC AMP

GL-10 BOARD (SEE PAGE 4-111~114) CM-56 BOARD (SEE PAGE 4-127~130)

IC426IC421IC418

SC PHASE ADJ

* IC1105, IC1143 :

DSR-40 ONLY

IC1105

IC1142

IC1124

IC1102

IC1136

+9V REG

2

2

IC1140

+5V REG

IC858

CLOCK GEN

IC401

YC MIX

IC422

C ENCODE

IC1138

0/180 LALT

IC1135

EX OR

IC1128

IC1143

IC1144

DELAY

IC1121

BUFFER

IC1141

SYNC GEN

IC1113

SC SWITCH

IC1109

GEN LOCK

IC1106

SC PROC

IC1101

SYNC SEP

3

1

3

1

IC430

CN1001

UNSW 6V

CN0001

IC415IC410IC408

IC419

IC417

MONITOR OUT DRIVER

IC424

INVERTER

IC654

B-Y/R-Y/Y/C/V/

IC1116

HD SHIFT

IC1122

IC1127

HD SHIFT

COURCE ADJ

IC1133

SC PHASE 90 SHIFT

IC1103

NOR

* IC1112 : DSR-40 ONLY

IC1104

IC1111

SHIFT REGISTOR

IC1115

IC1123

IC1131

TIMING DELAY

PULSE STRECH

IC1118

IC1119

3042628

SW 12V

VIDEO –5V

POWER CONT

12753

CN101

IC1125

IC1130

IC1107

IC1112

COUNTER

IC1117

IC1126

IC1134

IC1132

AMP

IC1137

AMP

Q1101, Q1102

FILTER

30

IC1108

IC1120

IC1129

IC1139

B. UP 5V

B. UP 5V

CN004

SW 3.1V

1

SW 5V

3

RF 5V

4

UNSW 6V

5

UNSW 14V

6

JC-19 BOARD

(SEE PAGE 4-19~60)

CN103

1

CN101

UNSW 6V

1

UNSW 3.1V

2

VIDEO 5V

3

J 3.1V

4

VIDEO –5V

6

AUDIO 5V

7

AUDIO –5V

9

IC012

DC/DC CONV.

IC009

LOADING

MOTOR DRIVE

2 3

IC015

A/D CONVERTER

LEVEL CONV.

IC006

COMP

FG, PG AMP

IC510

+3V REG

IC012

RF DC GEN.

IC008

5V–3V

IC001

SWITCH

IC018

IC014

FG AMP

IC011

IC005

ATF

IC017–

IC013

IC501

1 2

+5V REG

IC002

SWITCH

MODE CONTROL

IC009

IC003

MECHA CONT

IC501

IC011

–

RF DC GEN. TIMING GEN.

IC014

FG AMP

36

IC019

BUFFER

IC016

L.P.F

IC017

SWITCH

IC022

REEL MOTOR

DRIVE

IC503

CAP MOTOR

DRIVE

IC021

DRUM

MOTOR DRIVE

IC018

Q504– Q506

REG. SWITCH

IC209

IC511

3 1

+5V REG

CN002

CN501

IC210

CN003

CN007

CN006

CN005

CN001

1

CHIME VDD

1

IC214

15

9

10

6

7

8

2

10

6

14

5

6

2

6

12

7

UNSW 3.1V

7

IC504

D/A CONV.

FG/HE VCC

HE/FG VCC

EL 5V

REEL LED

REEL LED

EL 5V

CHIME VDD

IC207

1 3

+3V REG

EEP ROM

PB RF PSV

RP 3.1V

RF 5V

5V

M

M

M902

CAPSTAN MOTOR

M904

REEL MOTOR

MD-64 BOARD (SEE PAGE 4-135,136)

CN002

5

4

MD-63 BOARD

(SEE PAGE 4-134,135)

CN101

15

11

5

CN901

(FOR CASSETTE MEMORY)

IC211

IC213–

TIMING GEN

IC502

INVERTER

IC005

T ELETEN

IC003

T REEL FG

IC101

IC103

FP-406 BOARD

(SEE PAGE 4-135)

IC205

IC503

IC006

IC004

S REEL FG

S ELETEN

CLOCK GEN

IC102

IC105

IC206

IC422

FRAME PLL

IC200

I/O INTERFACE

IC403

IC402

V RAM

IC019

3 1

+2.1V REG

16

21

22

24

25

23

RP-228 BOARD (SEE PAGE 4-9~12)

CN103

IC702

DV INTERFACE

IC703

DV CONTROL

IC701

DV SIGNAL

PROCESS

IC401

BLANKING

IC411

AV MIX

Q772, 773

Q774, 775

IC771

EVR

IC770

EEP ROM

IC791

+3.1V REG

IC421

SP CON

IC807

IC903

IC909

AD/DA CONV.

IC908

AND

IC906

IC916

AUDIO CLK

IC805

IC841

COMP

IC907

IC777

REC/PB

AMP

IC775

RF EQ

IC773

IC772

A/D CONV.

IC774

CHANNEL

CODING

PLL

IC410

4M DRAM

IC901

IC904

FS CON

IC902

D-FFS

3-11 3-12

3-13

IC836

IC838

BUFFER

IC840

IC801

TIMING CONT

IC804

AND

IC914

COMP

IC915

IC802

REG CONT

IC911 IC837

AUDIO CLOCK GEN AD/DA CONV.

3-14 E

IC831

–

BUFFER

IC833

IC835

Page 27

PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAM

DSR-40/40P

SECTION 4

4-1

4-2 4-3

FRAME

4-4

Page 28

DSR-40/40P

4-2. PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

THIS NOTE IS COMMON FOR PRINTED WIRING

BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed

in each block)

For printed wiring boards:

• b : Pattern from the side which enables seeing.

(The other layers’ pattern are not indicated)

• Circled numbers refer to waveforms.

• Through hole is omitted.

• There are few cases that the part printed on diagram isn’t

mounted in this model.

• Chip parts.

Transistor Diode

5

5246

31

654

123

10

W unless otherwise noted.

22U

TA A

C

EB

For schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF : µµF

50V or less are not indicated except for electrolytics and

tantalums.

• Chip resistors are 1/

kΩ : 1000Ω, MΩ : 1000kΩ.

• Caution when replacing chip parts.

New parts must be attached after removal of chip.

Be careful not to heat the minus side of tantalum capacitor,

because it is damaged by the heat.

• Some chip part will be indicated as follows.

Example C 541

21

21

21321321

345

123

L 452

10UH

2520

3

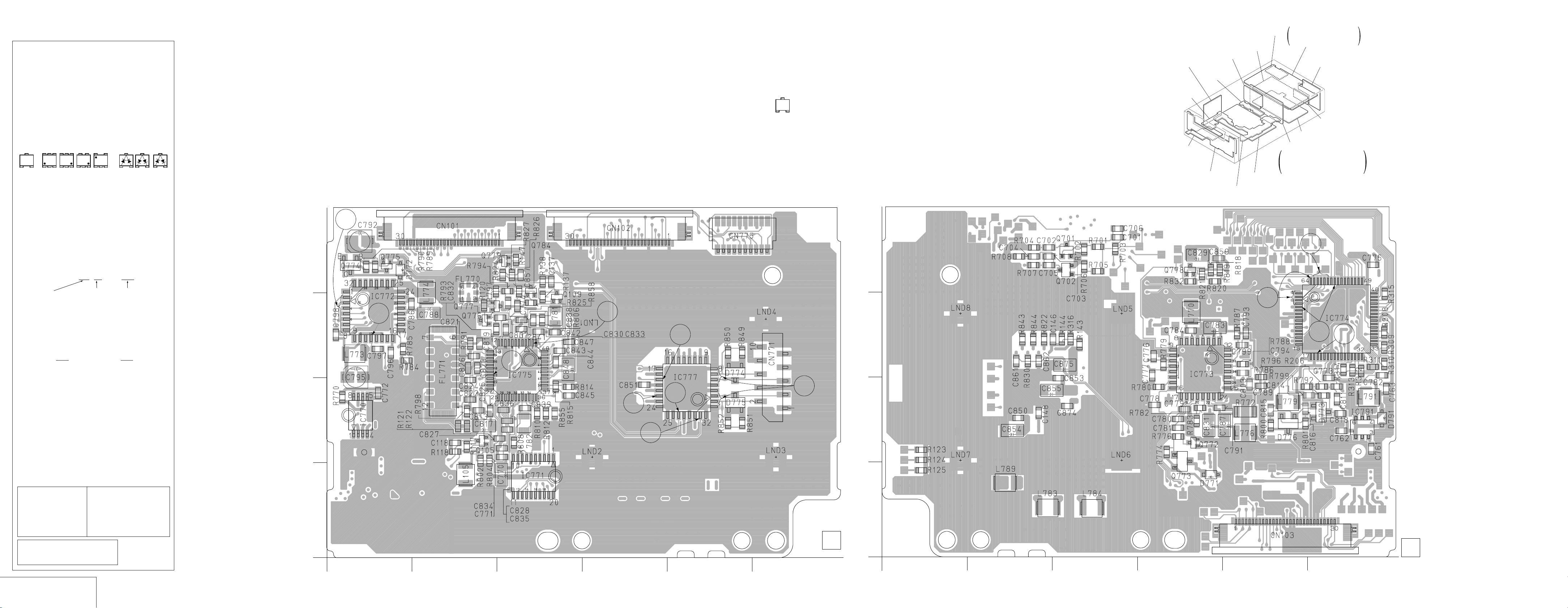

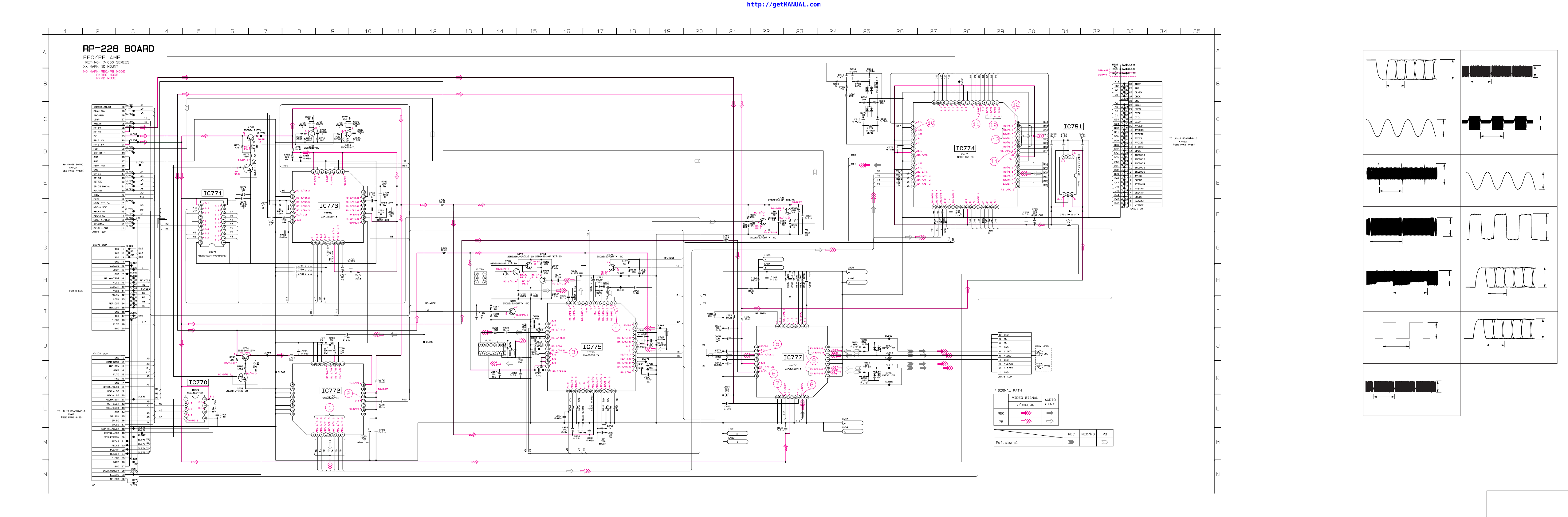

RP-228 BOARD (SIDE A)

CN101 A-2

CN102 A-4

CN771 B-6

CN775 A-5

D772 A-1

D774 B-5

D775 C-5

IC770 C-1

IC771 D-3

IC772 B-1

IC775 B-3

IC777 C-5

Q105 C-2

Q109 B-3

Q774 A-1

Q775 A-1

Q776 B-2

Q777 B-2

Q779 A-3

Q784 B-3

RP-228

1

A

RP-228 (REC/PB AMP) PRINTED WIRING BOARD

– Ref. No.: RP-228 board; 7,000 series –

BOARD (SIDE A)

• For Printed Wiring Board.

• RP-228 board is six-layer print board. However, the patterns

of layers 2 to 5 have not been included in the diagram.

• There are few cases that the part isn't mounted in this model

is printed on this diagram.

• Chip transistor

C

EB

RP-228

A

BOARD (SIDE B)

GL-10

(SYNC GENERATOR)

MD-65

(TAPE DETECT)

MD-63

(TAPE DETECT)

HP-118

(AUDIO)

FR-158

(DISPLAY CONTROL)

RP-228

(REC/PB AMP)

MD-64

(TAPE DETECT)

RS-80

(RS-422A IF)

U-2

(POWER 2)

CM-56

(SERVO, SYSTEM CONTROL)

VA-106

IF, VIDEO IN/OUT, UVIC,

DV IN/OUT, MONITOR OUT,

HI MICOM, RS MICOM

U-1 (POWER 1)

JC-19

AD/DA CONVERTER, S1 AFC, U1,

D1, C1 SPCON, MODE, DV IN/OUT,

AUDIO CORE, DIGITAL AUDIO,

AUDIO D/A, A/D CONVERTER

13

RE-33

(V/A IN/OUT)

CB-67 (AUDIO OUT)

RP-228 BOARD

(SIDE B)

CN103 D-5

D771 D-4

D773 C-6

IC773 B-4

IC774 B-6

Q701 A-3

Q702 A-3

Q772 C-4

Q773 D-4

Q778 A-4

Kinds of Temperature External

capacitor characteristics dimensions (mm)

• Constants of resistors, capasitors, ICs and etc with XX indicate that they are not used. In such cases, the unused circuits may be indicated.

• Parts with ★ differ according to the model/destination. Refer to the mount table for each function.

• All variable and adjustable resistors have characteristic curve

B, unless otherwise noted.

• Signal name

XEDIT → EDIT PB/XREC → PB/REC

• 2 : nonflammable resistor.

• 1 : fusible resistor.

• C : panel designation.

• A : B+ Line.*

• B : B– Line.*

• J : IN/OUT direction of B line (+, –).*

• C : adjustment for repair.*

• Circled numbers refer to waveforms.*

Measuring conditions voltege and waveform:

• Voltages and waveforms are measured between the measurement points and graound when color bar signal

input.They are reference v alues and reference wav eforms.*

(VOM of DC 10 M Ω input impedance is used)

• Voltage values change depending upon input impedance

of VOM used.

* Indicated by the color red.

Note:

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part

number specified.

When indicating parts by reference

number, please include the board

name.

Note:

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

B

C

D

05

2

4

5

3

9

7

6

8

1-668-406-

12

123456

B

C

D

05

12

11

10

1-668-406-

12

123456

REC/PB AMP

RP-228

4-5 4-6 4-7 4-8

Page 29

http://getMANUAL.com

RP-228 (REC/PB AMP) SCHEMATIC DIAGRAM

RP-228 BOARD

1

0.04 µsec

IC772 2 – 8 PB

2

41.8 MHz

IC772 !™ PB

3

3.4 Vp-p

2.3 Vp-p

1.6 Vp-p

DSR-40/40P

8

4.0 Vp-p

3.3 msec

IC777 #¡ REC

9

4.5 Vp-p

6.7 msec

IC777 2 3 6 7

0

4.3 Vp-p

4

5

6

7

3.3 msec

IC775 @º PB IC774 !ª REC/PB

!¡

0.5 Vp-p

3.3 msec

IC775 2 PB

!™

0.6 Vp-p

6.7 msec

IC777 !ª PB IC774 1 – 4, ^¢

!£

3.0 Vp-p

6.7 msec

IC777 @™ REC/PB IC774 %ª – ^£

0.25 µsec

0.25 µsec

41.8 MHz

3.6 Vp-p

8.38 MHz

IC774 5 REC/PB

IC774 %¶ PB

3.4 Vp-p

3.4 Vp-p

4-9 4-10 4-11

4-12

3.3 msec

IC777 @¶ REC

6.0 Vp-p

4-13

REC/PB AMP

RP-228

Page 30

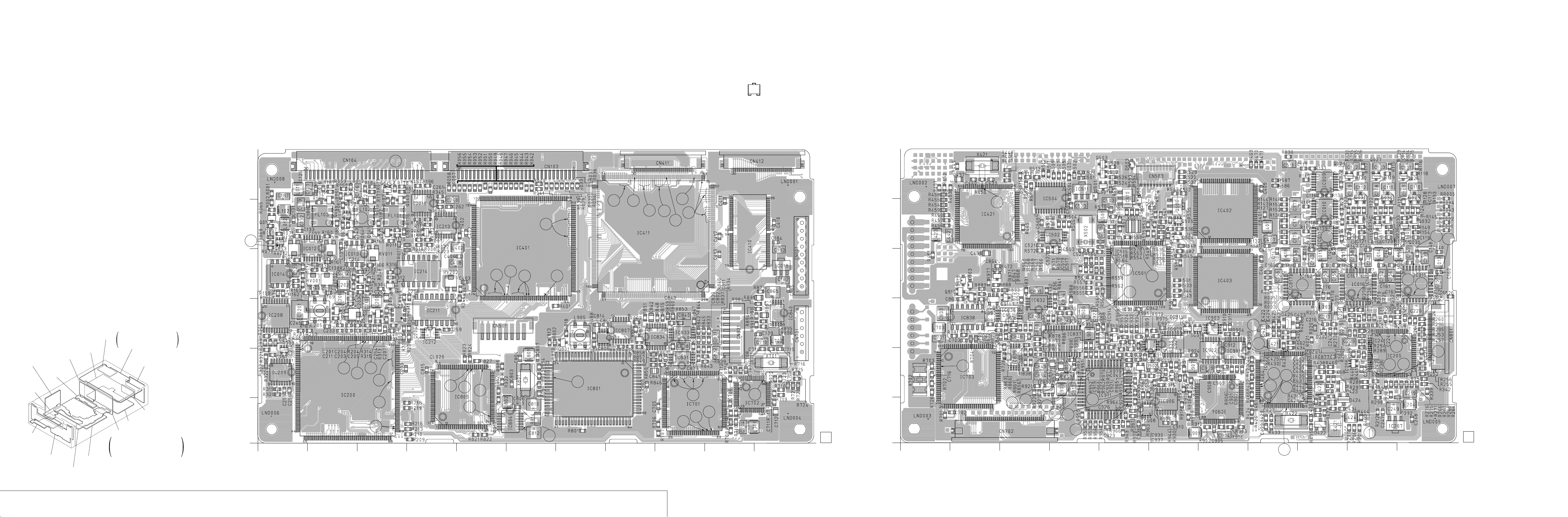

DSR-40/40P

1-668-404-

05

JC-19

BOARD (SIDE B)

A

B

C

D

E

F

1234567891011

21

41

49

43

42

64

60

59

58

57

63

62

4

5

6

7

8

10

9

17

18

19

20

21

36

34

40

39

37

38

61

35

JC-19 (AD/DA CONVERTER, S1 AFC, U1, D1, C1 SPCON, MODE, DV IN/OUT, AUDIO CORE,

JC-19 BOARD (SIDE A)

CN103 A-6

CN104 A-3

CN411 A-9

CN412 A-10

CN501 D-5

CN831 D-10

IC012 C-2

IC013 C-2

IC014 C-1

IC018 B-4

IC019 C-11

IC200 E-2

IC209 E-1

IC210 E-1

IC211 D-4

IC212 D-4

IC213 B-4

IC214 C-4

IC401 B-6

IC410 B-10

IC411 B-8

IC701 F-9

IC702 E-10

IC801 E-7

IC804 F-6

IC805 E-4

IC807 D-8

IC831 E-9

IC833 D-9

IC840 D-11

Q039 B-3

Q040 B-3

Q041 B-3

Q042 B-3

Q043 B-2

Q044 B-2

Q045 A-3

Q048 B-4

Q050 A-2

Q051 B-2

Q052 B-1

Q053 B-1

Q200 C-3

Q201 D-2

Q801 D-7

DIGITAL AUDIO, AUDIO D/A, A/D CONVERTER) PRINTED WIRING BOARD

– Ref. No.: JC-19 board; 5,000 series –

JC-19

BOARD (SIDE A)

A

B

3

1

33

32

31

2

26

C

22

23

24

25

51

50

GL-10

(SYNC GENERATOR)

MD-63

(TAPE DETECT)

HP-118

(AUDIO)

(DISPLAY CONTROL)

RP-228

(REC/PB AMP)

MD-65

(TAPE DETECT)

FR-158

MD-64

(TAPE DETECT)

RS-80

(RS-422A IF)

U-2

(POWER 2)

CM-56

(SERVO, SYSTEM CONTROL)

VA-106

IF, VIDEO IN/OUT, UVIC,

DV IN/OUT, MONITOR OUT,

HI MICOM, RS MICOM

RE-33

(V/A IN/OUT)

CB-67 (AUDIO OUT)

U-1 (POWER 1)

JC-19

AD/DA CONVERTER, S1 AFC, U1,

D1, C1 SPCON, MODE, DV IN/OUT,

AUDIO CORE, DIGITAL AUDIO,

AUDIO D/A, A/D CONVERTER

4-14 4-15

AD/DA CONVERTER, S1 AFC, U1, D1, C1 SPCON, MODE, DV IN/OUT, AUDIO CORE, DIGITAL AUDIO, AUDIO D/A, A/D CONVERTER

D

05

E

16

14

15

13

12

F

1234567891011

11

55

54

52

53

JC-19

30

29

28

44

27

47

45

46

4-16

• For Printed Wiring Board.

• JC-19 board is six-lay er print board. How ev er , the patterns of

layers 2 to 5 have not been included in the diagram.

• There are few cases that the part isn't mounted in this model

is printed on this diagram.

• Chip transistor

C

EB

48

1-668-404-

21

4-17 4-18

JC-19 BOARD (SIDE B)

CN101 B-1

CN503 A-6

CN701 D-1

D201 D-9

D421 D-8

D422 F-9

D423 E-9

D424 E-9

D425 D-8

D501 A-4

D503 A-5

D504 B-5

D901 E-6

D902 E-6

D903 C-2

D910 C-2

IC009 A-9

IC010 B-9

IC011 B-9

IC015 C-11

IC016 C-10

IC017 C-9

IC205 E-10

IC206 E-10

IC207 F-10

IC402 B-7

IC403 C-7

IC421 B-2

IC422 E-8

IC501 C-5

IC502 B-4

IC503 B-4

IC504 A-4

IC510 A-5

IC511 A-4

IC703 E-2

IC802 E-3

IC832 D-3

IC835 E-3

IC836 D-3

IC837 D-4

IC838 D-2

IC841 D-2

IC901 D-7

IC902 D-7

IC903 D-7

IC904 F-7

IC906 F-6

IC907 D-6

IC908 F-5

IC909 D-6

IC911 E-5

IC914 D-5

IC915 D-6

IC916 D-6

Q026 A-11

Q027 A-10

Q028 A-10

Q029 A-11

Q030 A-10

Q031 A-10

Q032 B-11

Q033 B-10

Q034 B-10

Q035 B-11

Q036 B-10

Q037 B-10

Q501 A-5

Q502 A-5

Q504 B-6

Q505 B-6

Q506 B-6

Q832 C-2

Q902 E-6

Q903 D-5

Q910 C-2

Q911 C-3

Page 31

JC-19 (AD/DA CONVERTER) SCHEMATIC DIAGRAM

JC-19 BOARD (1/10)

1

DSR-40/40P

6

0.54 Vp-p

H

Q045 E PB

27

0.54 Vp-p

H

Q051 2 PB

38

0.39 Vp-p

H

Q053 2 PB IC015 @¡ REC

4

2.0 Vp-p

9

H

IC016 @¡ REC

0.15 µsec

IC016 1 – 8 REC

H

0.9 Vp-p

3.6 Vp-p

0.8 Vp-p

3.6 Vp-p

H

IC017 @¡ REC

50

3.6 Vp-p

0.15 µsec

IC017 1 – 8 REC IC015 – IC017 !™ REC/PB

0.15 µsec

IC015 1 – 8 REC

3.4 Vp-p

13.5 MHz

4-19

4-20 4-21 4-22

AD/DA CONVERTER

JC-19 (1/10)

Page 32

DSR-40/40P

JC-19 BOARD (2/10)

!¡

JC-19 (S1 AFC) SCHEMATIC DIAGRAM • See page 4-14 for JC-19 printed wiring board.

!¶

3.8 Vp-p

13.5 MHz

IC200 (º (¡ REC/PB

!™ !•

3.4 Vp-p

0.15 µsec

IC200 `⁄⁄⁄ – `⁄⁄° REC/PB

!£ !ª

3.4 Vp-p

0.15 µsec

IC200 `⁄¤¤ – `⁄¤· REC/PB IC205 !• @º REC/PB

!¢ @º

1.2 Vp-p

H

IC200 `⁄‹· PB