Sony CDP-XA20ES Service manual

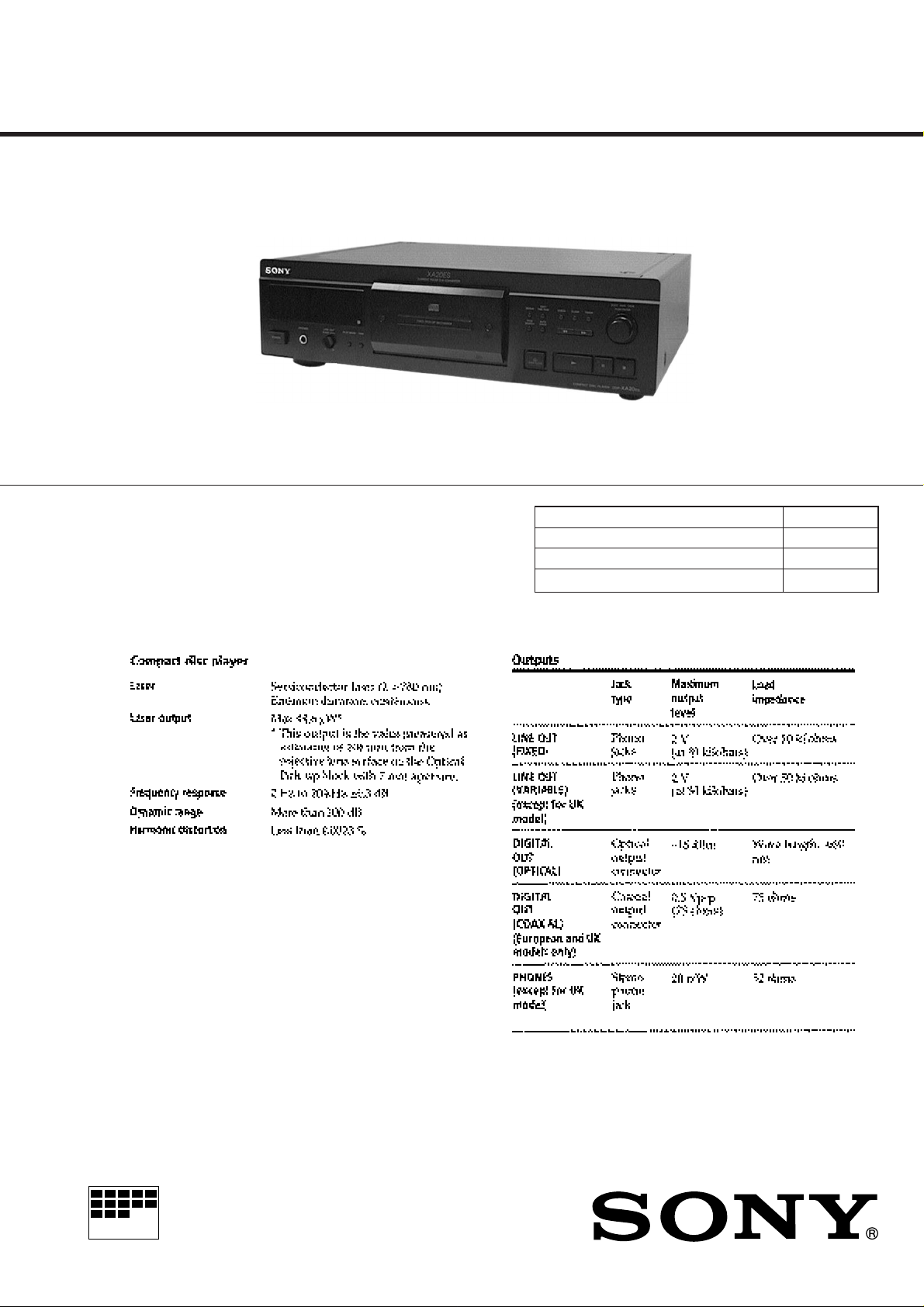

CDP-XA20ES

SERVICE MANUAL

Photo: Black

EXCEPT UK

SPECIFICATIONS

US Model

Canadian Model

AEP Model

UK Model

E Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type

Base Unit Type BU-14C

Optical Pick-up Type KSS-213B

CDM36B-14C

MICROFILM

– Continued on next page –

COMPACT DISC PLAYER

MODEL IDENTIFICATION

– BACK PANEL –

TABLE OF CONTENTS

1. SERVICING NOTES

1-1. How to Open the Disc Tray When Power Switch

Turns Off.......................................................................... 4

1-2. Preparation for Adjustment and Measurement ................ 4

2. GENERAL ................................................................... 5

3. DISASSEMBLY.......................................................... 6

4. TEST MODE

4-1. AF Mode.......................................................................... 11

4-2. ADJ Mode ....................................................................... 12

5. ELECTRICAL ADJUSTMENTS .......................... 13

6. DIAGRAMS

6-1. IC Pin Function Description ............................................ 15

6-2. Block Diagram................................................................. 21

6-3. Printed Wiring Boards –BD Section –............................. 24

6-4. Schematic Diagram — BD Section — ............................ 27

6-5. Schematic Diagram — MAIN Section — ....................... 30

6-6. Printed Wiring Boards — MAIN Section —................... 33

6-7. Schematic Diagram — POWER Section —.................... 35

6-8. Printed Wiring Boards — POWER Section — ............... 37

6-9. Printed Wiring Boards — PANEL Section —................. 39

6-10. Schematic Diagram — PANEL Section — ..................... 41

4-991-138-

AEP Model : 0

UK Model : 1

Singapore Model : 2

US Model : 3

Canadian Model : 4

7. EXPLODED VIEWS ................................................. 47

8. ELECTRICAL PARTS LIST .................................. 52

π

π

π

π

π

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE !

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

– 2 –

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objecti ve lens.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage. Check

leakage as described below.

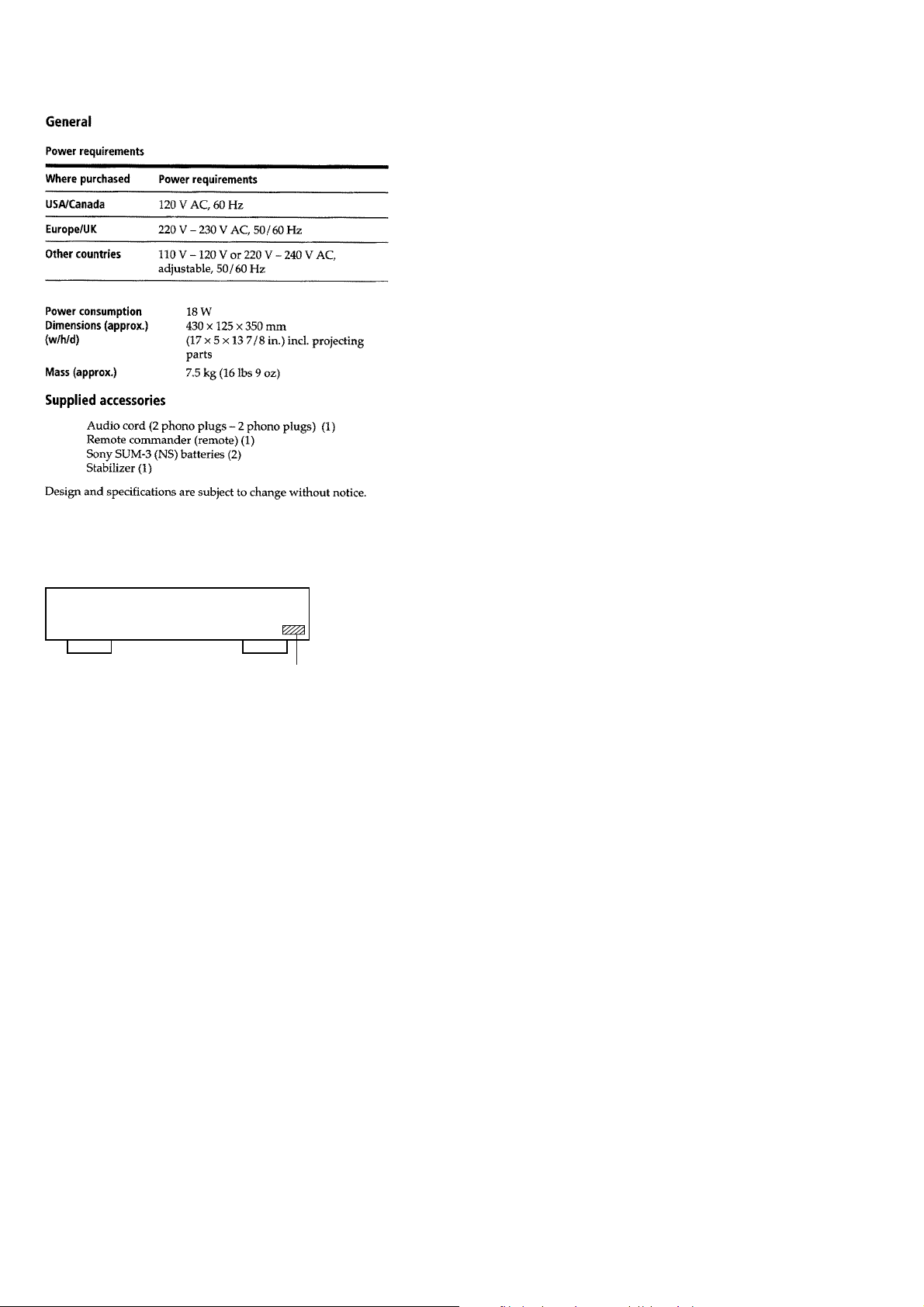

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follow the manuf acturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63Tr d are examples of a passive VOM that is suitable. Nearly all battery

operated digital multimeters that have a 2 V A C range are suitable. (See Fig. A)

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C dur-

ing repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of

procedures other than those specified herein may

result in hazardous radiation exposure.

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

To Exposed Metal

Parts on Set

AC

0.15 µF

1.5 k

Ω

Earth Ground

voltmeter

(0.75 V)

Fig. A. Using an AC voltmeter to check AC leakage.

The following caution label is located inside the unit.

– 3 –

SECTION 1

SERVICING NOTES

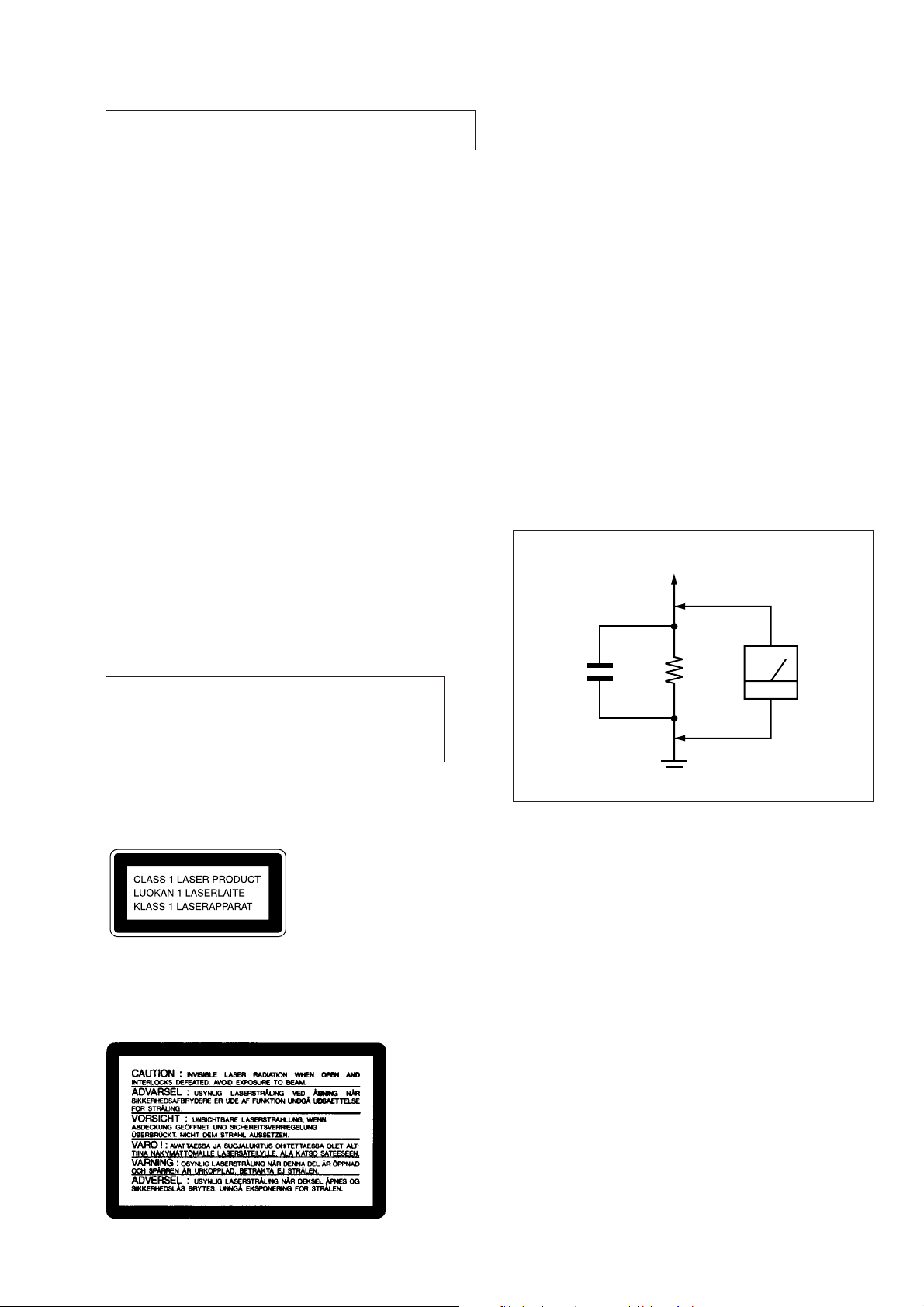

1-1. H OW T O OPEN THE DISC TRAY WHEN

POWER SWITCH TURNS OFF

1 Insert a tapering driver into the aperture of the unit bottom,

and move the limiter (LEVER) to direction of the arrow A.

2 Pull the tray to direction fo the arrow B.

tray

B

Limiter (LEVER)

A

tapering driber

*

To close the disc tray, mo v e the driv er in

the reverse direction (to IN direction).

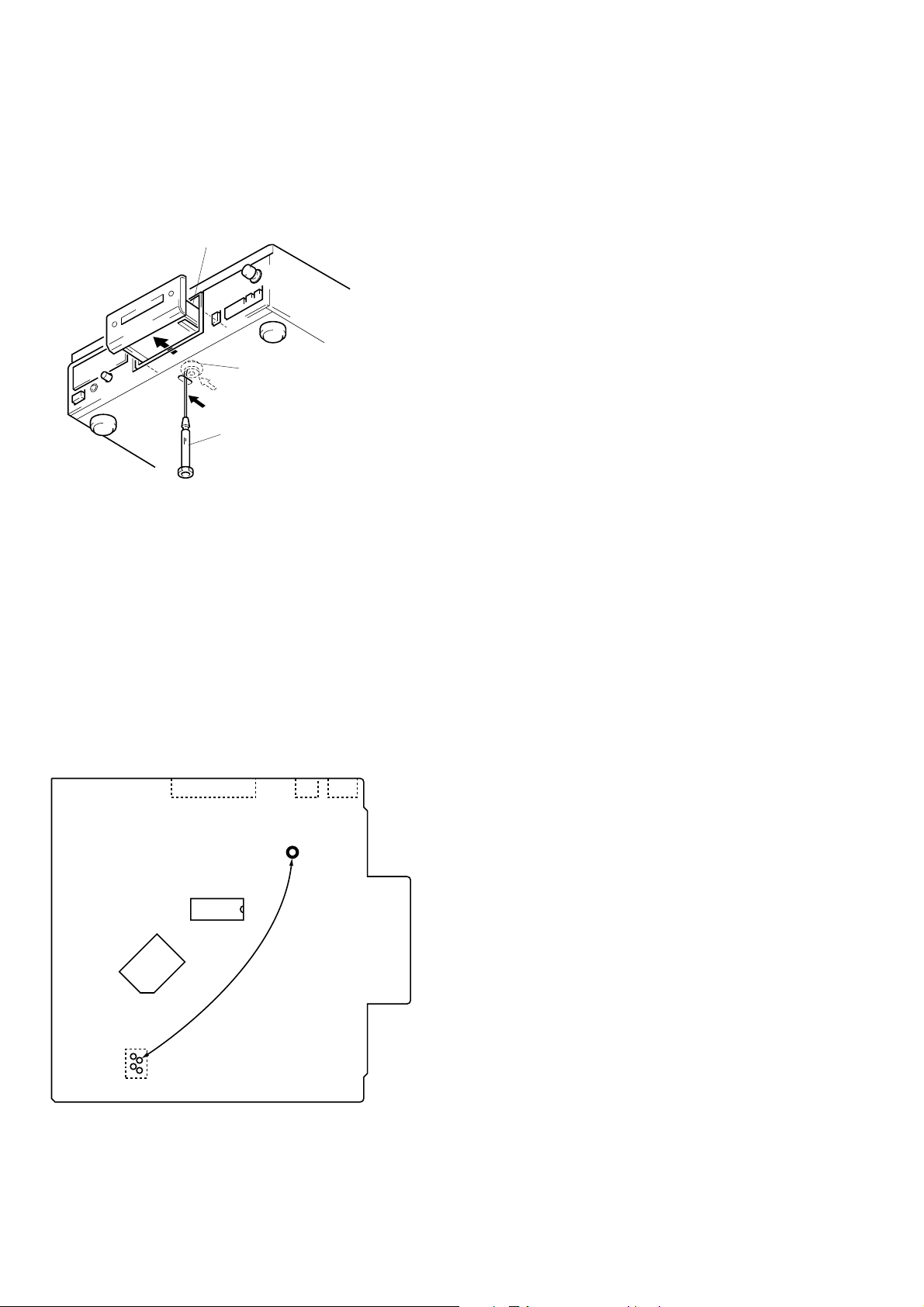

1-2. PREPARATION FOR ADJUSTMENT AND

MEASUREMENT

Perform connecting the IC361 pin 2 of BD board to the line of

+5V because this unit does not work without the stabilizer structurally.

Connecting Location:

[BD BOARD] – Side B –

CN102

CN103

CN105

TP (VCC)

IC102

IC351

IC361

1

3

2

4

– 4 –

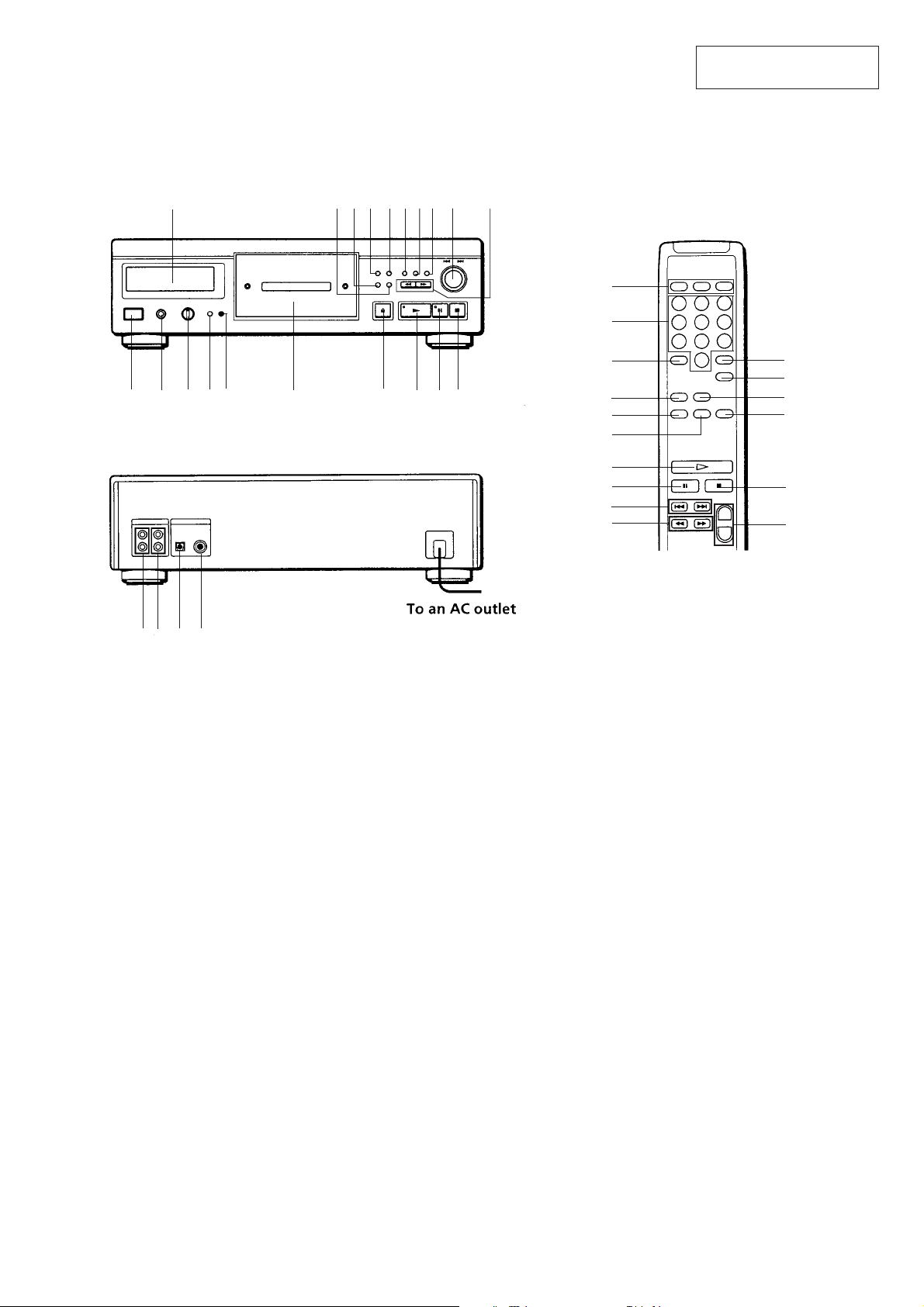

Location of Controls

SECTION 2

GENERAL

This section is extracted

from instruction manual.

• FRONT PANEL

@º

•

•

•

•

•

• REAR PANEL

• REMOTE COMMANDER

!¶ !§!∞!¢!£ !¡!™!•!ª

•

•••

•

•

••

•

••

861 23 54 7 9

•

•

0

@∞

@§

@¶

5

!¶

@ª

8

9

!¡

!™

123

456

789

•

•

10

•

•

•

•••

•

•

•

+

–

!¢

!∞

@•

!£

0

#º

@¡@™ @£ @¢

1 POWER Switch

2 PHONES jack (EXCEPT UK)

3 LINE OUT/PHONE LEVEL control (EXCEPT UK)

4 PLAY MODE button

5 TIME button

6 Disc tray

7 § OPEN/CLOSE button

8 ( (play) button

9 P (pause) button

0 p (stop) button

!¡ 0/) (manual search) buttons

!™ ≠/± ( AMS*) control

!£ FADER button

!¢ CLEAR (program clear) button

!∞ CHECK (program check) button

!§ EDIT/TIME FADE button

!¶ REPEAT button

(CLEAR REPEAT button on the remote commander)

!• PEAK SEARCH button

!ª AUTO SPACE button

@º Display

@¡ LINE OUT FIXED jack

@™ LINE OUT VARIABLE jack (EXCEPT UK)

@£ DIGITAL OUT OPTICAL jack

@¢ DIGITAL OUT COAXIAL jack (AEP, UK)

@∞ Play mode buttons

CONTINUE button

SHUFFLE button

PROGRAM button

@§ Numeric buttons

@¶ >10 (over 10) button

@• DISPLAY ON/OFF button

@ª A˜B button

#º LINE OUT LEVEL +/– buttons

* AMS is the abbreviation of Automatic Music Sensor.

– 5 –

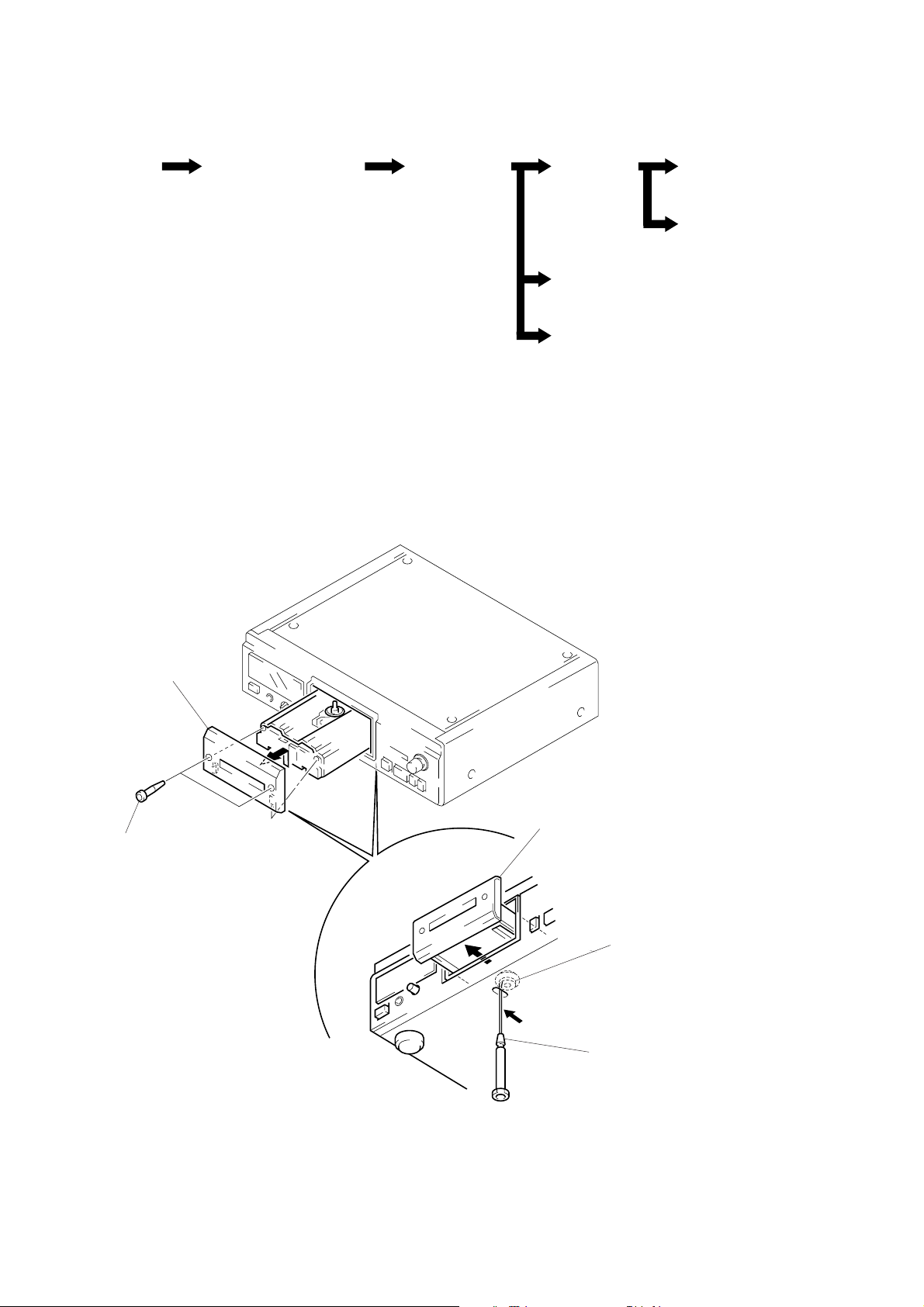

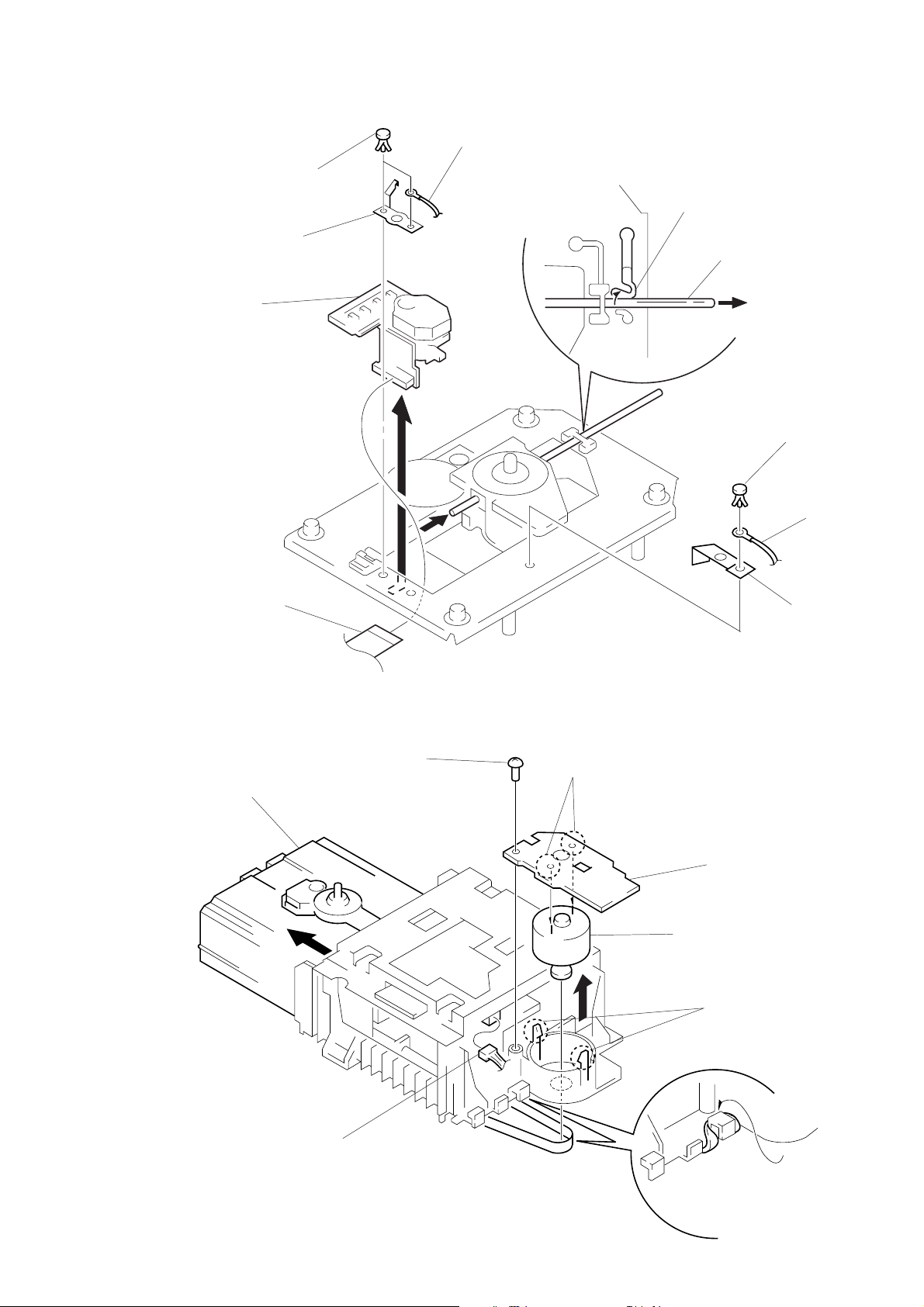

• This set can be disassembled in the order shown below.

SECTION 3

DISASSEMBLY

LOADING PANEL

SECTION

(Page 6)

Note: Follow the disassembly procedure in the numerical order given.

CASE,

FRONT PANEL SECTION

(Page 7)

MECHANISM

DECK SECTION

(Page 7)

LOADING PANEL SECTION

BASE UNIT

(Page 8)

LOADING MOTOR (M103)

(Page 9)

POWER BOARD, MAIN BOARD

(Page 10)

SLED MOTOR (M101)

(Page 8)

OPTICAL PICK-UP

(KSS-213B/S-N)

(Page 9)

4

loading panel section

3

two hexagon hole bolts

(LID)

B

2

Pull the loading panel to

direction of the arrow

A

1

B

.

limiter (LEVER)

Insert a tapering driver,

and move the limiter (LEVER)

to direction of the arrow

A

.

– 6 –

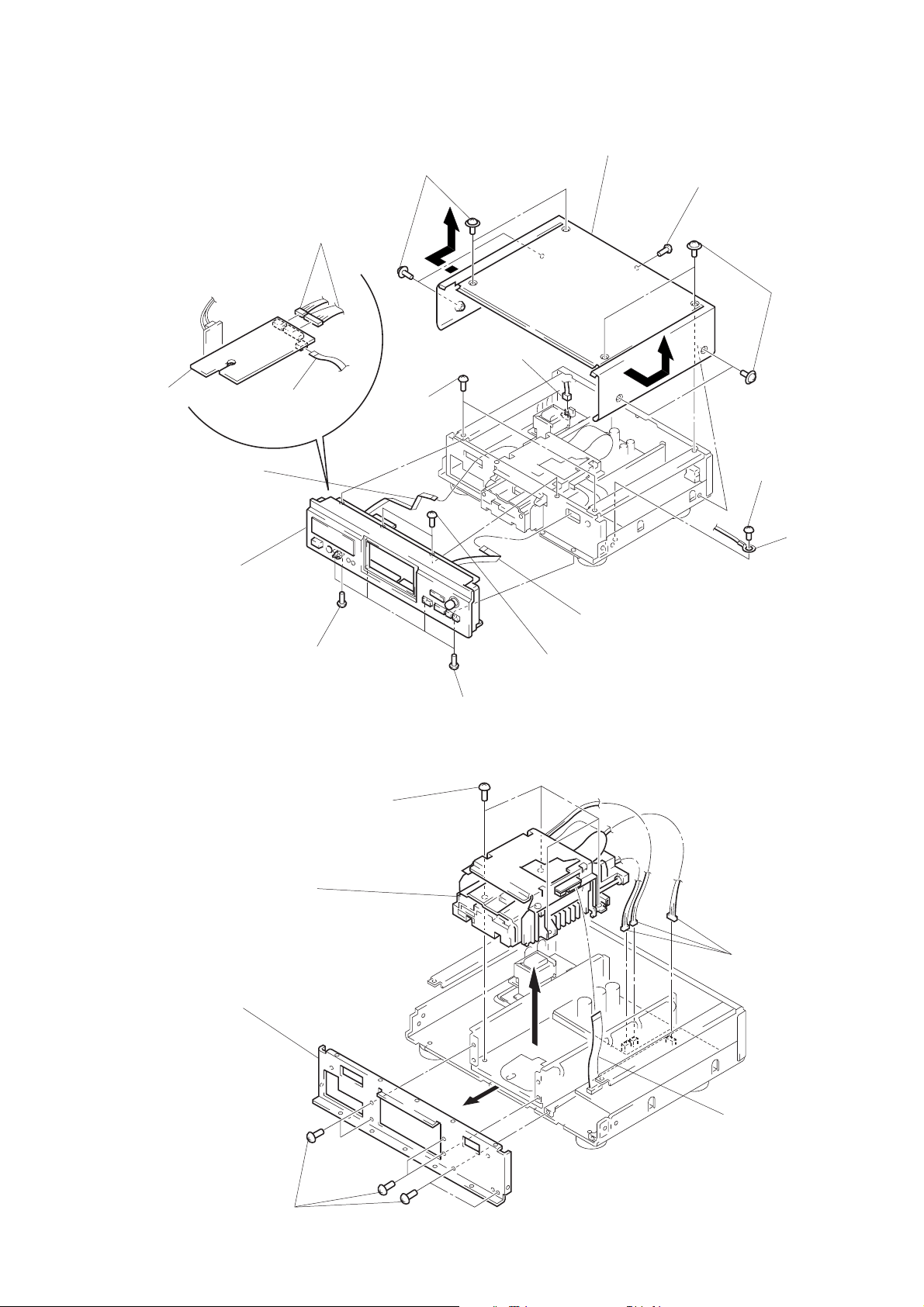

CASE, FRONT PANEL SECTION

8

two connectors

(CN471, 472)

1

four screws

(CASE 3 TP2)

4

connector

(CN992)

3

case

2

screw

(BVTT 3

×

6)

1

four screws

(CASE 3 TP2)

HP board

5

wire (flat type) (11 core)

(CN106)

!£

front panel

7

wire (flat type)

(4 core)

(CN371)

!™

screw (BV 3 × 8)

EXCEPT UK

MECHANISM DECK SECTION

5

!¡

four screws

(BVTT 3

×

two screws

(BVTT 3

!™

6)

×

6)

four screws

(BV 3

×

6)

!¡

two screws

(BVTT 3

6

wire (flat type) (7 core)

(CN107)

×

6)

9

screw

(BVTT 3

0

lug

×

6)

6

mechanism deck

(CDM36B-14C)

4

sub panel

3

six screws

(BVTT 3

1

three connectors

(CN201, 251, 903)

2

wire (flat type) (16 core)

(CN101)

×

6)

– 7 –

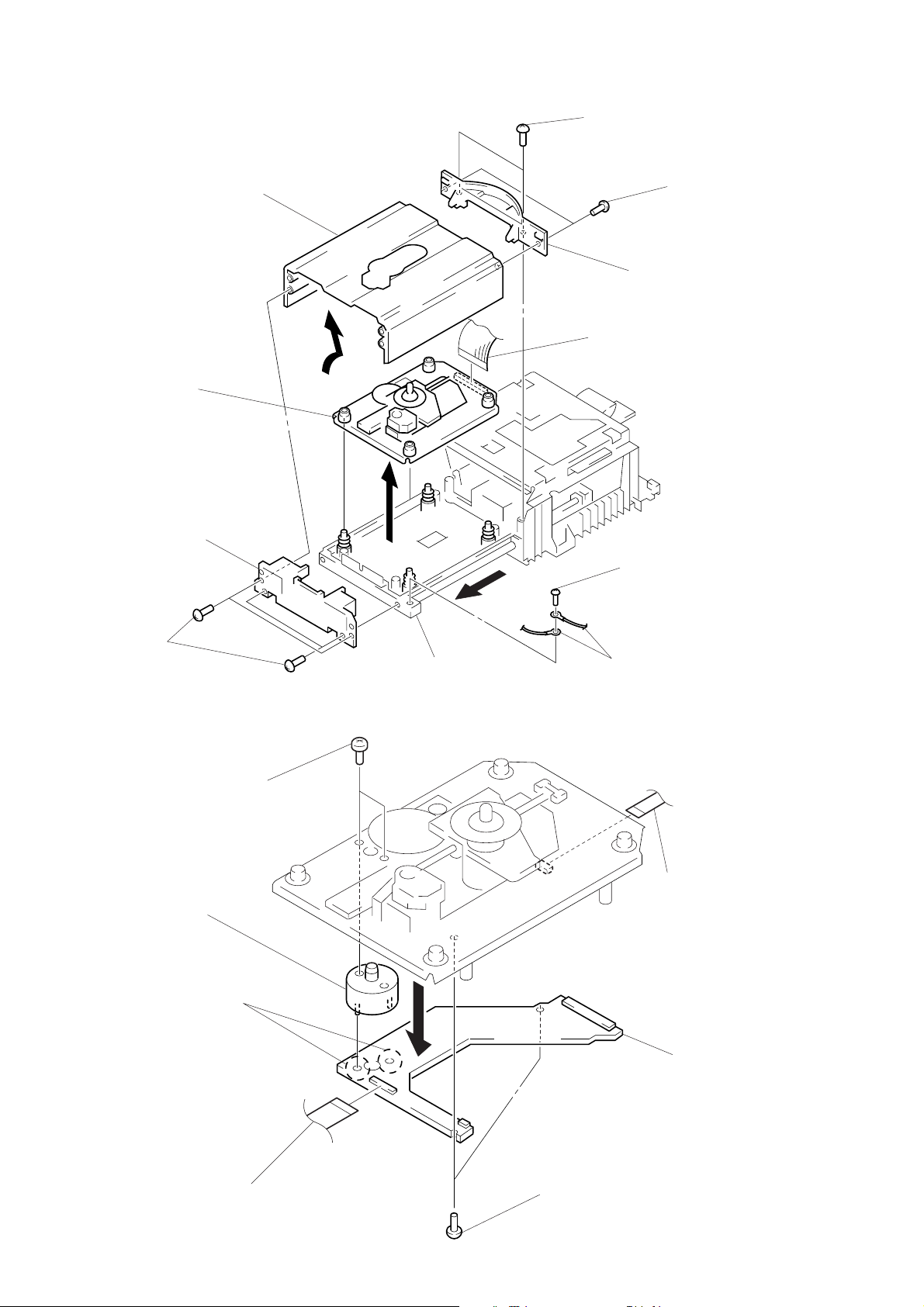

BASE UNIT

3

cover (F) (drawer)

!¡

base unit

(BU-14C)

5

panel (drawer)

4

two screws

(BVTP 3

8

×

8)

6

7

cover (R) (drawer)

wire (flat type) (21 core)

(CN104)

9

screw

(BVTP 3

two screws

(BVTP 3

×

8)

×

8)

2

four screws

(BVTP 3

×

8)

SLED MOTOR (M101)

7

sled motor

(M101)

3

Removal the two solders

of sled motor.

6

two screws

(P1.7

×

2.5)

1

pull the tray

0

two lugs

2

wire (flat type) (5 core)

(CN107)

5

sled board

1

wire (flat type) (16 core)

(CN104)

– 8 –

4

two screws

(BVTP 2.6

×

8)

OPTICAL PICK-UP (KSS-213B/S-N)

5

two nylon rivets

7

leaf spring (A) (OP)

0

Removal the optical

pick-up to direction

of the arrow

A

.

A

6

lug

8

claw

9

sled shaft

nylon rivet

2

3

lug

1

wire (flat type) (16 core)

(optical pick-up connector)

LOADING MOTOR (M103)

1

Pull the tray.

4

screw

(BVTP 3

4

leaf spring

(spindle)

7

×

8)

Remove the two

solders of loading motor.

8

loading motor

(M103)

5

6

loading motor board

two claws

2

connector

(CN103)

– 9 –

3

Hang the belt

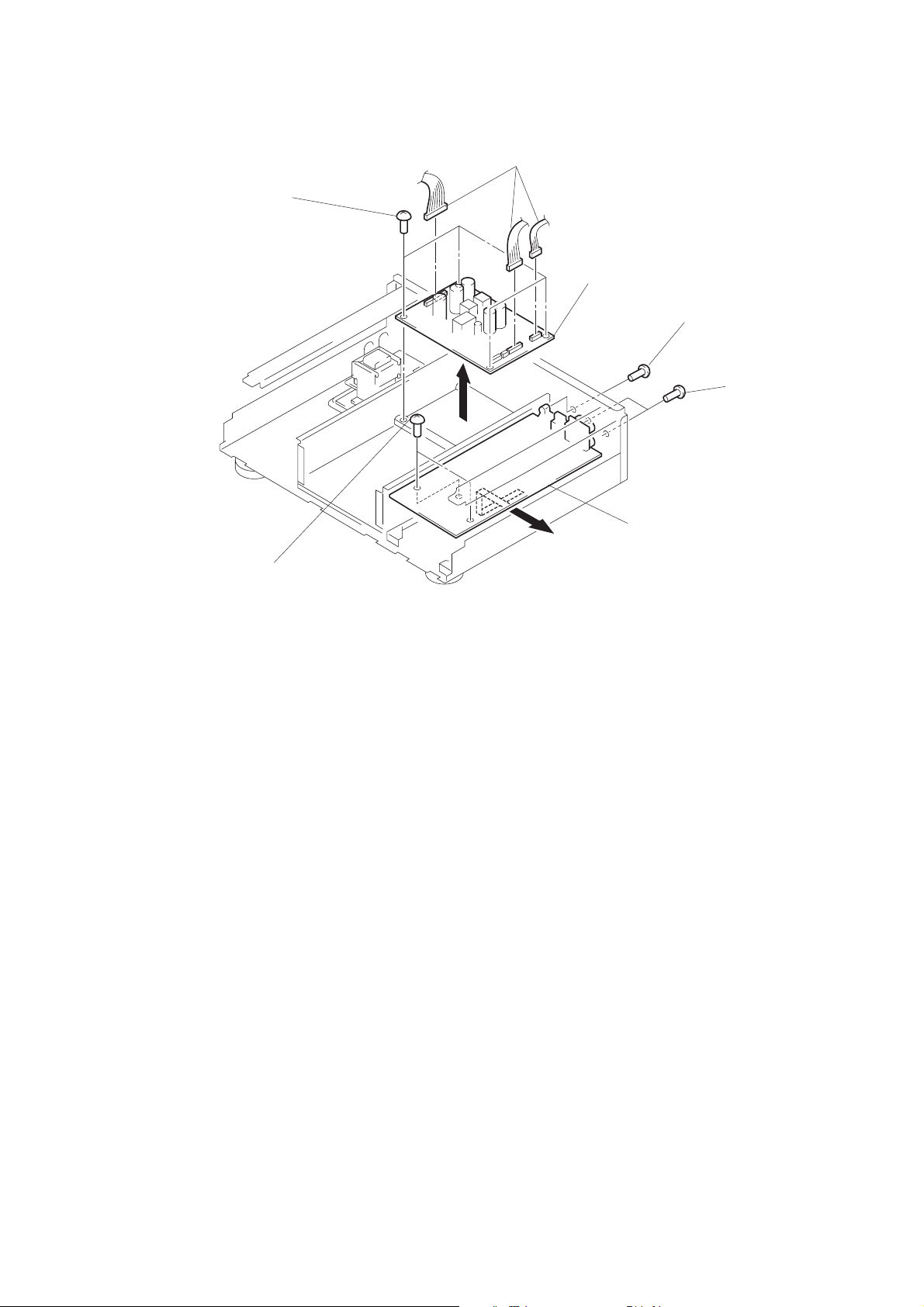

POWER BOARD, MAIN BOARD

2

four screws

(BVTT 3

1

three connectors

(CN901, 902, 951)

×

6)

3

power board

4

screw (BV/RING)

(AEP, UK)

4

two screws

(BV/RING)

6

A

Removal the main board

to direction of the arrow

A

.

5

two screws

(BVTT 3

×

6)

– 10 –

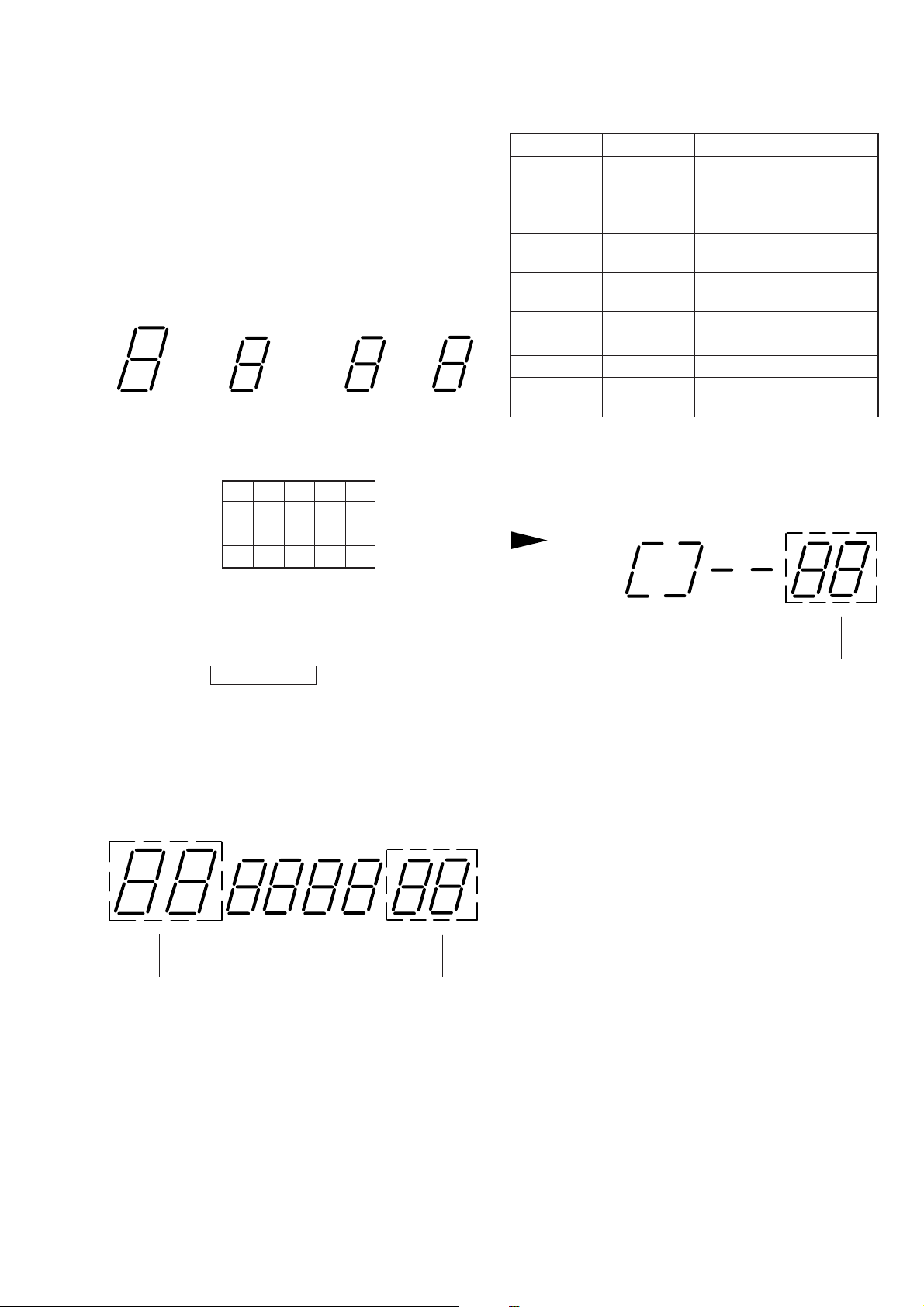

SECTION 4

TEST MODE

4-1. AF MODE

Connect the TP19 (AFADJ) on the BD board to the ground and

turn on the power supply.

The AF mode is then activated and the following check can be

made.

4-1-1. Fluorescent Indicator Tube Check

After confirming display of all on, keep pressing the following

button, and the following display is attained.

” (PLAY) button

(Display: 01)

P (PAUSE) button

24

6810

12 14

16 18 20

(Display: 02)

Table 4-1.

Button Display Button Display

TIME 09

PLAY

MODE TIME FADE

AUTO

SPACE

CHECK 19

CLEAR 20 p 33

FADER 21 ( 01

0 22 P 02

) 23

4-1-3. Remote Commander Check

All buttons are assigned with numbers respectively.

If a button is kept pressed, its button number is displayed on the

FL display tube of main unit. (Table 4-2)

10

18 REPEAT 28

PUSH

ENTER

EDIT/

PEAK

SEARCH

§ all light

OPEN/CLOSE up

24

27

29

A track number on FL display tube increases if = AMS +

knob is rotated in + direction, or decreases in = direction.

Keep pressing the §OPEN/CLOSE button, and all on display is

attained again.

4-1-2. Key Check

All buttons are assigned with numbers respectively , and when each

button is pressed, it is counted and its number is displayed. Up to

“16” can be counted.

A button pressed once is not further counted but the number is

displayed. (Table 4-1)

(

count display button number

display

(

(

button number

display

– 11 –

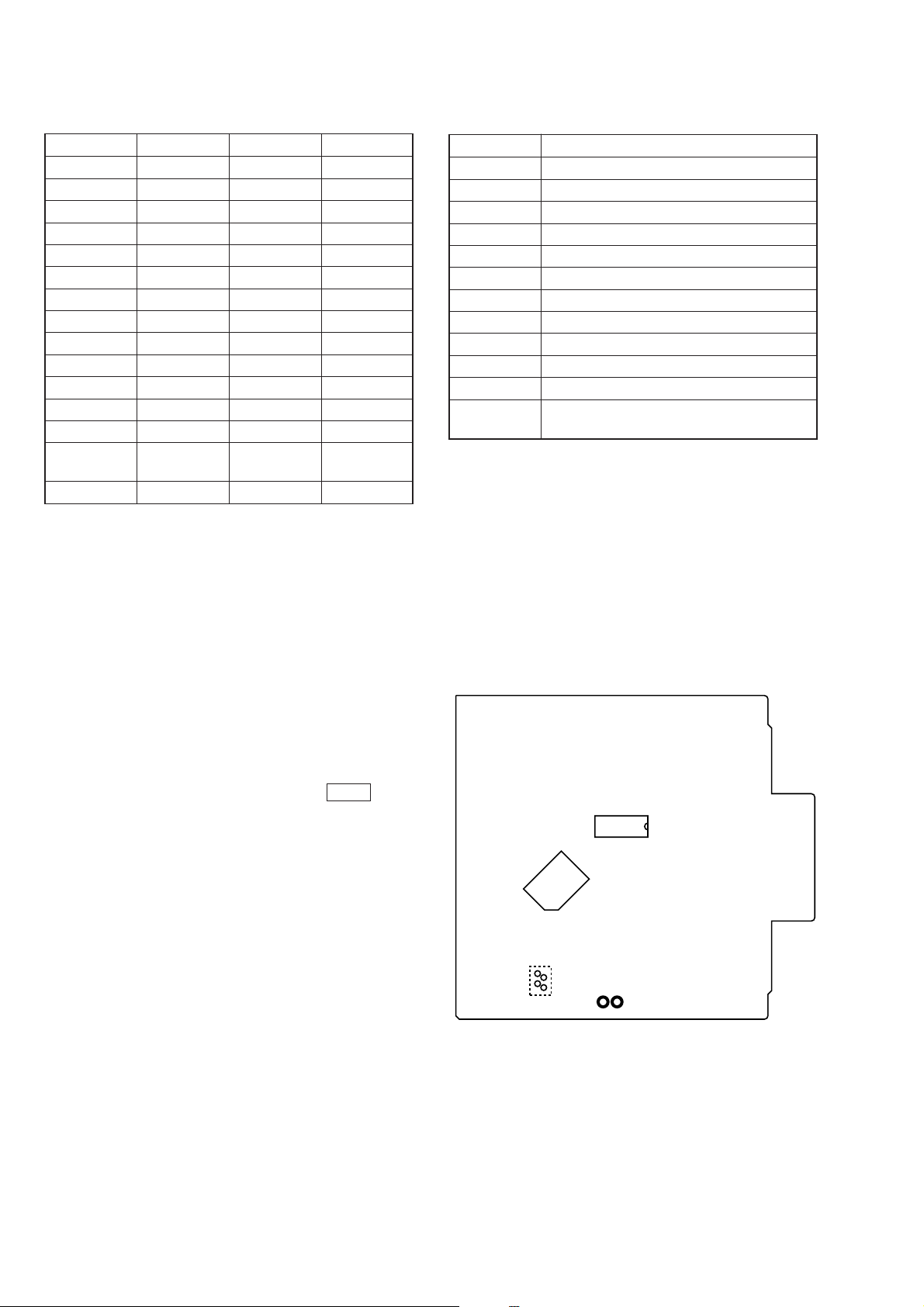

Table 4-2.

Table 4-3.

Button Display Button Display

1 00 10 32

2 01 >10 39

3 02 TIME 40

4 03 A – B 42

5 04 REPEAT 44

6 05 = 48

7 06 + 49

8 07 · 50

9 08 0 51

CHECK 13 ) 52

CLEAR 15 SHUFFLE 53

+ 18 p 56

– 19 P 57

CONTINUE 29

PROGRAM 31 FADER 95

DISPLAY

ON/OFF

86

4-2. ADJ MODE

Connect the TP18 (ADJ) on the BD board to the ground and turn

on the power supply. The ADJ mode is then activated and the

following operation is executed.

• There is no problem even if Guarded Frame Sync is low value

continuously during playing.

• Do not perform high speed search during an access.

• The gain of focus servo and spindle servo does not lo wer during

playing.

• Manual operation and measurement of the servo system are possible. (For detailed operating method, see Table 4-3. in ADJ

Mode.)

Button No. Test Mode

3 Tracking servo off

8 Tracking servo on

11 S-curve measuring mode

12 All servo off

13 Top turnblack display

14 Botton turnblack display

15 Center display

16 Optimum point display

17 Optimum jitter display

18 TE traverse display

19 VC, FE and RF display

20

* For button numbers 3, 8, 11, and 12, use them only when an

oscilloscope is connected.

Autogain display

(Focus, tracking and sled)

4-3. CLV-S MODE

The spindle servo can be operated for play in the CLV-S mode by

connecting TP18 (ADJ) and after turning on the power supply.

4-4. RELEASE THE TEST MODE

Disconnect the lead wire of test point connected in first step.

Connecting Location:

[BD BOARD] – Side B –

4-2-1. Button Operation Table in ADJ Mode

After all music numbers are displayed, press the TIME button,

and the jitter display mode is then set. The button functions are as

listed below.

Button Functions (Operate with remote commander.)

IC351

IC361

TP19 (AFADJ)

IC102

TP18 (ADJ)

– 12 –

SECTION 5

ELECTRICAL ADJUSTMENTS

Notes:

1. CD block basically constructed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (Part No.: 3-702-101-01) unless otherwise

indicated.

3. Use the oscilloscope with more than 10 MΩ impedance.

4. Clean an object lens by an applicator with neutral detergent

when the signal level is low than specified value with the following checks.

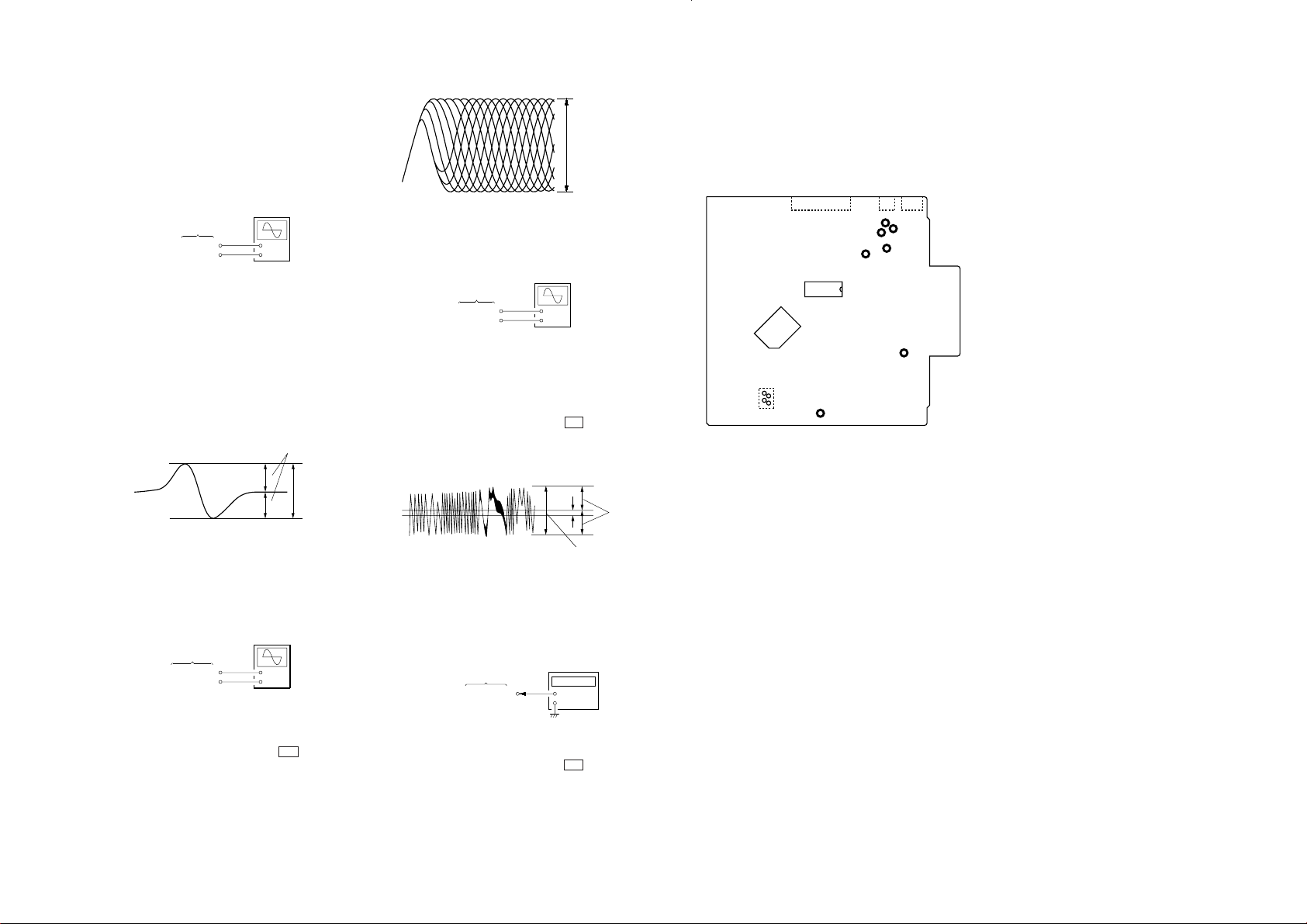

S-Curve Check

Connection:

BD board

TP2 (FE)

TP (VC)

Procedure:

1. Connect the oscilloscope to TP2 (FE) and TP (VC) on BD

board.

2. Connect the TP3 (FEI: IC101 pin @ª) and TP (VC) with lead

wire.

3. Turned power switch on.

4. Put disc (YEDS-18) in and turned power switch on again and

actuate the focus search. (actuate the focus search when disc

table is moving in and out.)

5. Confirm that the oscilloscope waveform (S-curv e) is symmetrical between A and B. And confirm peak to peak level within

3.0 ± 1.0 Vp-p.

S-curve waveform

6. After check, remove the lead wire connected in step 2.

Note: • Try to measure several times to make sure that the ratio

of A : B or B : A is more than 10 : 7.

• Take sweep time as long as possible and light up the

brightness to obtain best waveform.

RF Level Check

Connection:

BD board

TP1 (RFO)

TP (VC)

Procedure:

1. Connect the oscilloscope to TP1 (RFO) and TP (VC) on BD

board.

2. Turned power switch on. (stop mode)

3. Put disc (YEDS-18) in and press the ( button.

4. Confirm that the oscilloscope waveform is clear and check RF

signal level is correct or not.

Note: Clear RF signal waveform means that the shape “≈” can

be clearly distinguished at the center of the waveform.

oscilloscope

+

–

symmetry

A

B

oscilloscope

(AC range)

+

–

within 3.0 ± 1.0 Vp-p

RF signal waveform

When observing the eye pattern, set the oscilloscope for A C range

and raise vertical sensitivity.

E-F Balance (Traverse) Check

Connection:

BD board

TP4 (TE)

TP (VC)

Procedure:

1. Connect the TP18 (ADJ) to ground and TP5 (TEI: IC101 pin

@¶) to TP (VC)with lead wire.

2. Connect the oscilloscope to TP4 (TE) and TP (VC) on BD

board.

3. Turned power switch on.

4. Put disc (YEDS-18) in and press the ( button.

5. Confirm that the oscilloscope waveform is symmetrical on the

top and bottom in relation to A Vdc, and check this level.

Traverse waveform

×

100 is ± 20 % or less.

A/B

oscilloscope

(DC range)

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

(with the 10: 1 probe

in use)

level: 1.2 Vp-p

+

–

A

B

level: 1.3 ± 0.7 Vp-p

+0.25

–0.20

Symmetry

6. After check, remove the lead wire connected in step 1.

RF PLL Free-run Frequency Check

Connection:

BD board

TP13 (XPLCK)

Procedure:

1. Connect the frequency counter to TP13 (XPLCK).

2. Turned power switch on.

3. Put disc (YEDS-18) in and press the ( button.

4. Confirm that the reading on frequency counter is 4.3218 MHz.

frequency counter

+

–

FOCUS/TRACKING GAIN ADJUSTMENT

VR in optical block is not adjusted.

As this gain has a margin, normally a little shift of gain will not

cause a problem.

If you happened to move VR and you are not sure the original

position, set it to the mechanical center.

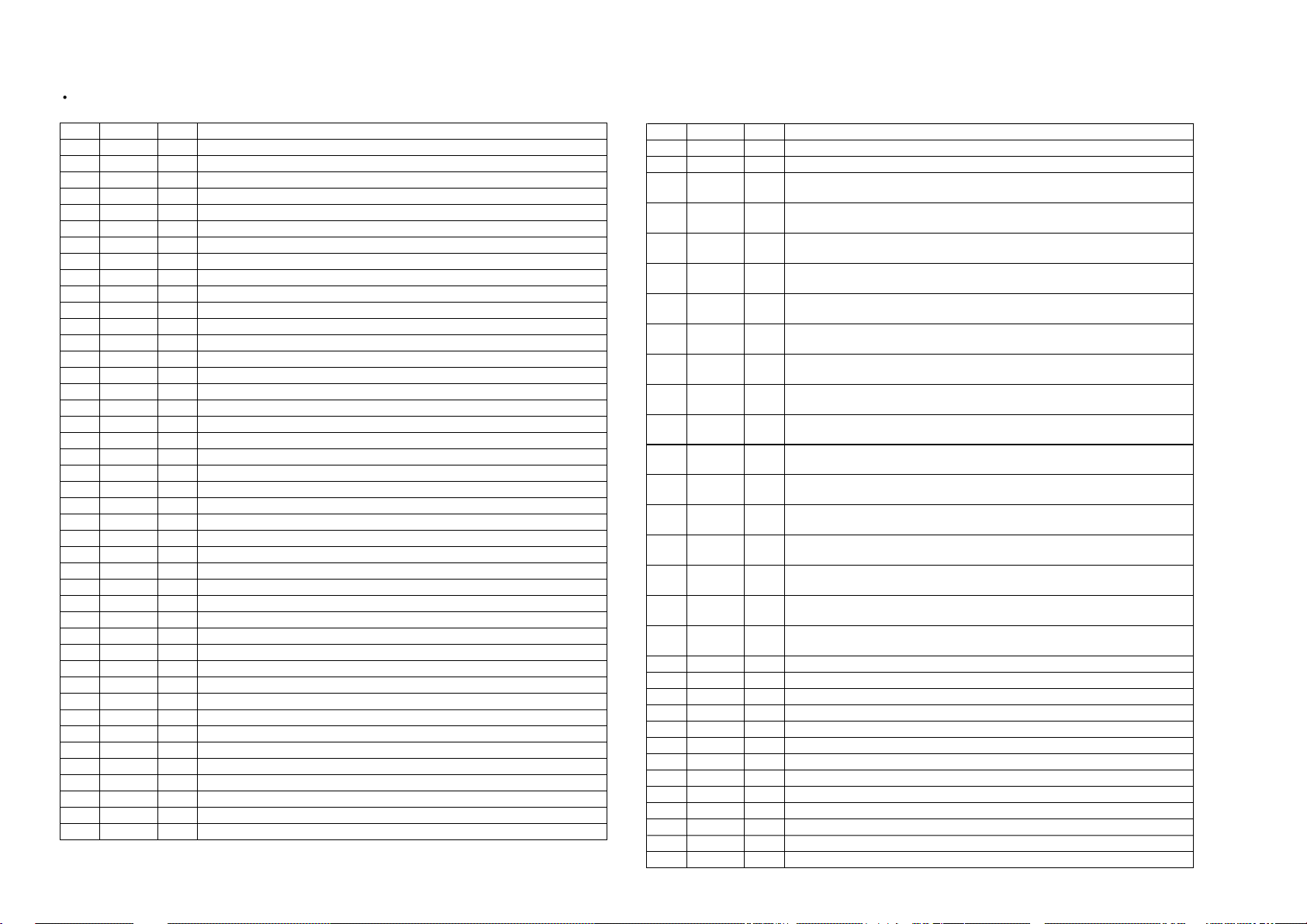

Adjustment Location:

[BD BOARD] – Side B –

CN102

TP (VC)

IC102

IC351

IC361

TP4 (TE)

TP2 (FE)

TP18 (ADJ)

CN103

CN105

TP5 (TEI)

TP1 (RFO)

TP13 (XPLCK)

– 13 –

– 14 –

SECTION 6

DIAGRAMS

6-1. IC PIN FUNCTION DESCRIPTION

BD BOARD IC101 CXD2545Q

(DIGITAL SIGNAL PROCESSOR, FOCUS/TRACKING/SLED SERVO, EFM COMPARATOR)

Pin No. Pin Name I/O Function

1 SRON O Sled servo drive PWM signal output terminal Not used (open)

2 SRDR O

3 SFON O

4 TFDR O

5 TRON O

6 TRDR O

7 TFON O

8 FFDR O

9 FRON O

10 FRDR O Focus servo drive PWM signal (–) output to the BA6297AFP (IC102)

11

FFON O Focus servo drive PWM signal output terminal Not used (open)

12

VCOO O Oscillator circuit output terminal for analog PLL of the playback EFM Not used (open)

13 VCOI I Oscillator circuit input terminal for analog PLL of the playback EFM Not used (fixed at “L”)

14 TEST I Input terminal for the test (fixed at “L”)

15 DVSS —

16 TES2 I Input terminal for the test (fixed at “L”)

17 TES3 I Input terminal for the test (fixed at “L”)

18 PDO O

19 VPCO O PLL charge-pump output terminal for the variable pitch Not used (open)

20 VCKI I Clock signal input from external VCO for the variable pitch Not used (fixed at “L”)

21

AVD2 — Power supply terminal (+5V) (analog system)

22

IGEN I Power supply terminal (+5V) (for operational amplifier)

23

AVS2 — Ground terminal (analog system)

24

ADIO O Output terminal of the operational amplifier Not used (open)

25

RFC I Input terminal for the A/D converter Not used (open)

26

RFDC I RF signal (DC level) input terminal for the digital servo process

27 TE I

28 SE I Sled error signal input from the RF amplifier in optical pick-up

29

30

31

32

33

34

35

36

37

38

39

40 AVD1 — Power supply terminal (+5V) (analog system)

41 DVDD — Power supply terminal (+5V) (digital system)

42 ASYE I Playback EFM asymmetry circuit on/off selection input terminal (fixed at “H”)

43 PSSL I Audio data output mode selection input terminal (fixed at “L”)

FE I Focus error signal input from the RF amplifier in optical pick-up

VC I Middle point voltage (+2.5V) input from the RF amplifier in optical pick-up

FILO O Filter output terminal for master clock of the playback master PLL

FILI I Filter input terminal for master clock of the playback master PLL

PCO O Phase comparison output terminal for master clock of the playback EFM master PLL

CLTV I Internal VCO control voltage input of the playback master PLL

AVS1 — Ground terminal (analog system)

RFAC I RF signal (AC level) input terminal for the EFM demodulator

BIAS I Constant current input terminal of the playback EFM asymmetry circuit

ASYI I Playback EFM asymmetry comparator voltage input terminal

ASYO O

Sled servo drive PWM signal (–) output to the BA6297AFP (IC102)

Sled servo drive PWM signal output terminal Not used (open)

Tracking servo drive PWM signal (–) output to the BA6297AFP (IC102)

Tracking servo drive PWM signal output terminal Not used (open)

Tracking servo drive PWM signal (+) output to the BA6297AFP (IC102)

Tracking servo drive PWM signal output terminal Not used (open)

Focus servo drive PWM signal (+) output to the BA6297AFP (IC102)

Focus servo drive PWM signal output terminal Not used (open)

Ground terminal (digital system)

Charge-pump output terminal for analog PLL of the playback EFM Not used (open)

Tracking error signal input from the RF amplifier in optical pick-up

Playback EFM full-swing output terminal

Pin No. Pin Name I/O Function

44 WDCK O Word clock signal (88.2 kHz) output terminal Not used (open)

45 LRCK O L/R sampling clock signal (44.1 kHz) output to the CXD8505BQ (IC302)

46 DATA O

47 BCLK O

48 64 DATA O

49 64 BCLK O

50 64 LRCK O

51 GTOP O

52 XUGF O

53 XPLCK O

54 GFS O

55 RFCK O

56 C2PO O

57 XRAOF O

58 MNT3 O

59 MNT2 O

60 MNT1 O

61 MNT0 O

62 XTAI I System clock input terminal (16 MHz)

63 XTAO O System clock output terminal (16 MHz) Not used (open)

64 XTSL I System clock selection input terminal (fixed at “L”)

65 DVSS — Ground terminal (digital system)

66 FSTI I 2/3 divider input terminal of pins ^™ (XATI) and ^£ (XTAO)

67 FSTO O 2/3 divider output terminal of pins ^™ (XATI) and ^£ (XTAO)

68 FSOF O 4.2336 MHz clock signal output terminal Not used (open)

69 C16M O 16.9344 MHz clock signal output terminal Not used (open)

70 MD2 I Digital out on/off control signal input terminal (fixed at “H”)

71 DOUT O Digital signal (for coaxial out and optical out) output terminal

72 EMPH O Emphasis control signal output terminal Not used (open)

73 WFCK O Write frame clock signal output terminal Not used (open)

74 SCOR O Sub-code sync (S0+S1) detection signal output to the system controller (IC351)

DA16 output when PSSL=“H”, 48-bit slot serial data output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Serial data output to the CXD8505BQ (IC302)

DA15 output when PSSL=“H”, 48-bit slot bit clock signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Bit clock signal (2.8224 MHz) output to the CXD8505BQ (IC302)

DA14 output when PSSL=“H”, 64-bit slot serial data output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

DA13 output when PSSL=“H”, 64-bit slot bit clock signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

DA12 output when PSSL=“H”, 64-bit slot L/R sampling clock signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

DA11 output when PSSL=“H”, GTOP signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

DA10 output when PSSL=“H”, XUGF signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

DA09 output when PSSL=“H”, XPLCK signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

DA08 output when PSSL=“H”, GFS (guard frame sync) signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

DA07 output when PSSL=“H”, RFCK (read frame clock) signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

DA06 output when PSSL=“H”, C2PO signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

DA05 output when PSSL=“H”, XRAOF (RAM over flow) signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

DA04 output when PSSL=“H”, MNT3 (monitor 3) signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

DA03 output when PSSL=“H”, MNT2 (monitor 2) signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

DA02 output when PSSL=“H”, MNT1 (monitor 1) signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

DA01 output when PSSL=“H”, MNT0 (monitor 0) signal output when PSSL=“L”

(PSSL (pin $£)=fixed at “L”) Not used (open)

– 15 –

– 16 –

Loading...

Loading...