Sony CCD-TRV21E, CCD-TRV21, CCD-TRV21PK, B Mechanism Operation Manual

Video8

B MECHANISM

OPERATION

MANUAL

A18

m MECHANISMDECK

CONTENTS

1. Main parts layout diagram ....................................................................... 4

2. Operation of main parts ............................................................................ 5

3. Operation of each part .............................................................................. 6

3-1. Driving of LS chassis ......................................................................................... 6

3-2. Driving of pinch roller ....................................................................................... 8

3-3. Driving of tension regulator and TG1 ............................................................ 10

3-4. Driving of S reel and S ratchet ....................................................................... 12

3-5. Driving of T ratchet and T soft gear .............................................................. 14

4. Operation in each mode .......................................................................... 17

4-1. Cassette IN =====:=_ STOP ............................................................................. 17

4-2.

4-3.

4-4.

4-5.

4-6.

4-7.

4-8.

4-9.

STOP _ PB ............................................................................................ 23

STOP =:=:===_ REC ......................................................................................... 27

STOP ====:==_ FF ............................................................................................ 31

STOP =====_ REWIND ................................................................................ 35

PB ===:==_ CUE .............................................................................................. 38

PB ==:===_ REVIEW ...................................................................................... 40

PB _ PAUSE ......................................................................................... 42

STOP ===:=:=_ EJECT .................................................................................... 45

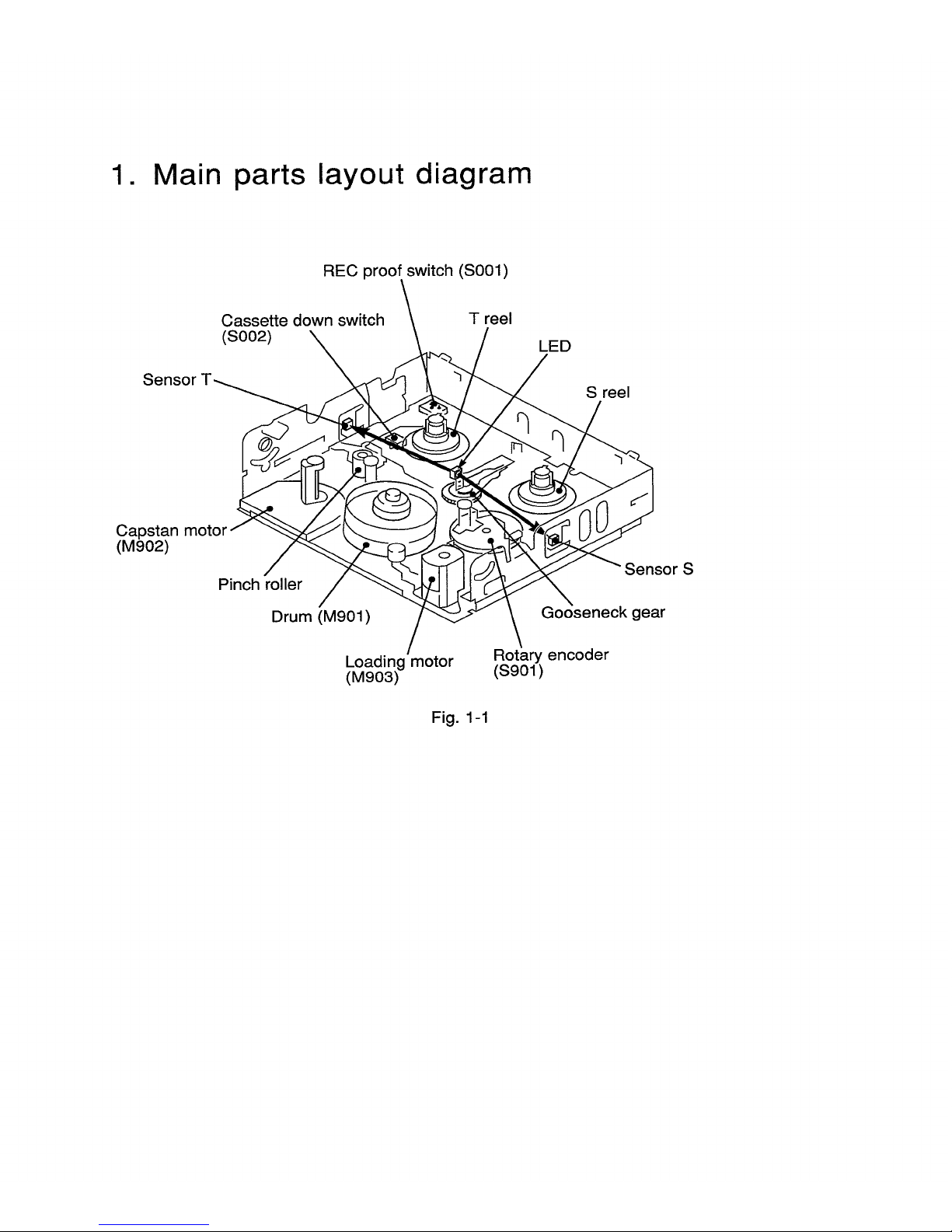

1. Main parts layout diagram

REC proof switch (S001)

Sensor

Cassette down switch

(S002)

T reel

LED

S reel

Capstan motor

(M902)

Pinch roller

Drum (M901)

Loading motor

(M903)

Sensor S

Gooseneck gear

Rotary encoder

(S901)

Fig. 1-1

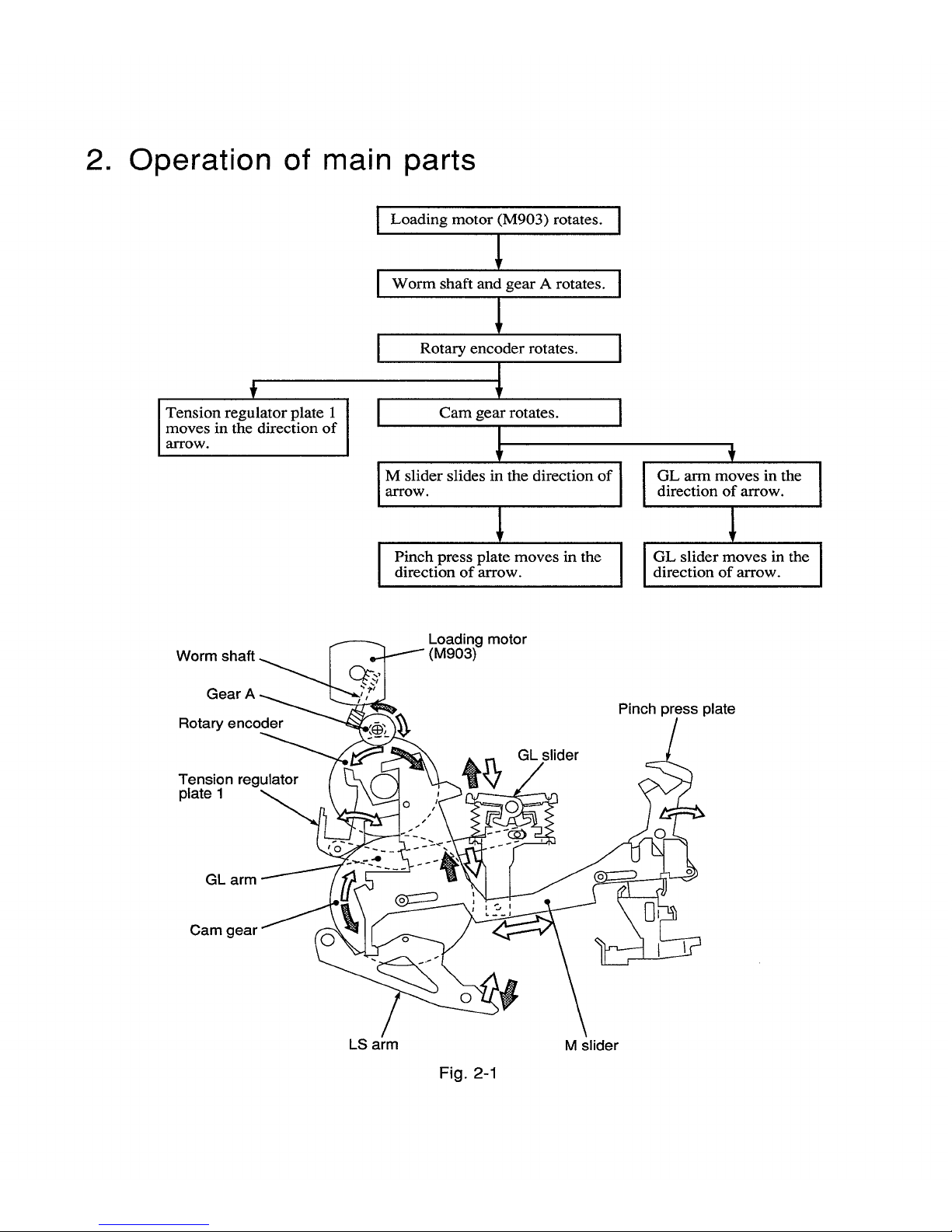

2. Operation of main parts

Tension regulator plate 1

moves in the direction of

arrow.

Loading motor (M903) rotates. ]

[ Worm shaft and gear A rotates. [

[ Rotary encoder rotates. [

[ Cam gear rotates. [

M slider slides in the direction of [

arrow.

Pinch press plate moves in the ]

direction of arrow.

f

I L arm moves in the [

direction of arrow.

direction of arrow.

Worm

Loading motor

Gear

Rotary encoder

Tension regulator

plate 1

GL slider

Pinch press plate

GL arm

Cam gear

LS arm

Fig. 2-1

M slider

3. Operation of each part

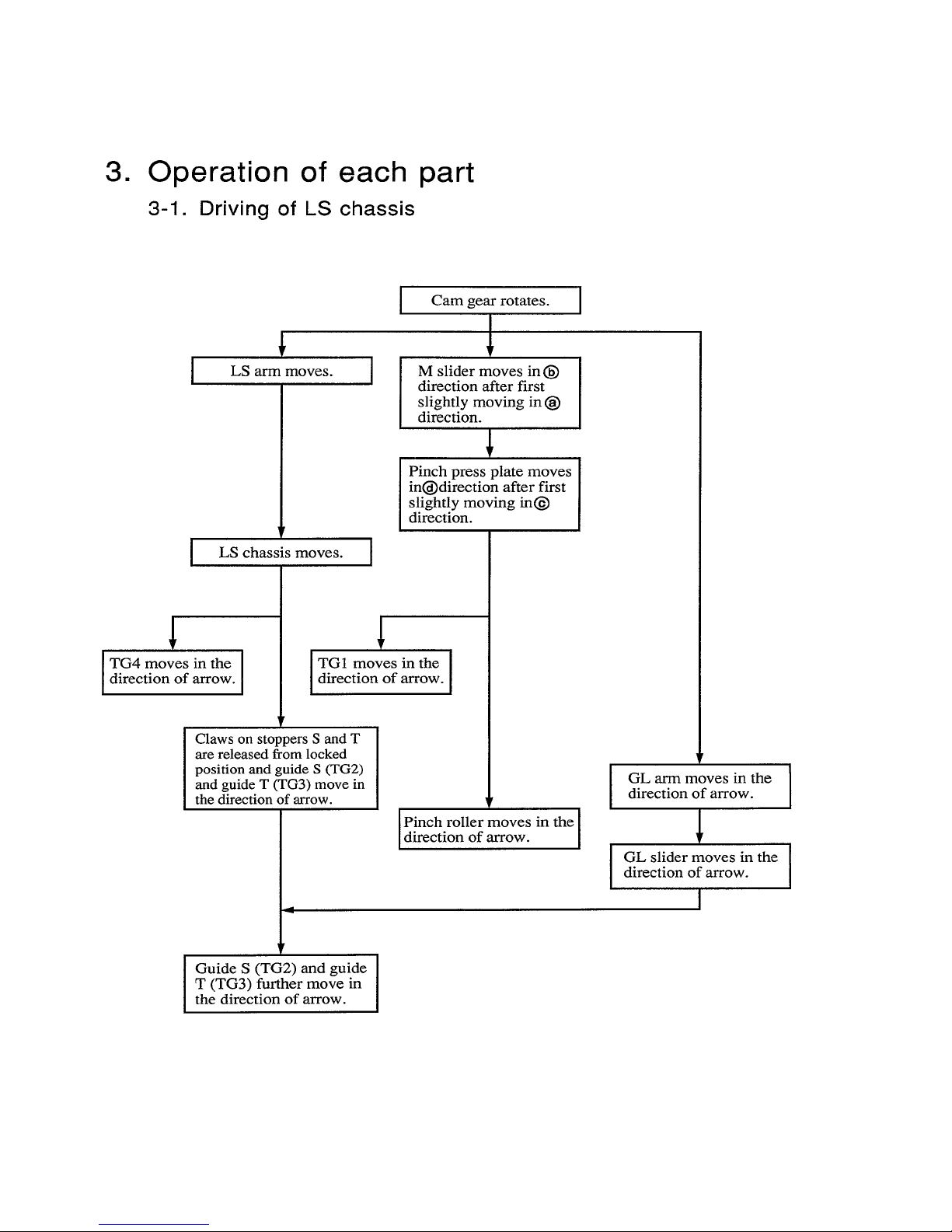

3-1. Driving of LS chassis

1

I

i

TG4 moves in the |

direction of arrow.

J

LS arm moves.

r

LS chassis moves.

Cam gear rotates.

!

I M slider in

®moves

direction after first

slightly moving in O

direction.

Pinch press plate moves

inOdirection after first

slightly moving int_)

direction.

I

I

TG1 moves m the |

I

direction of arrow.

1

Claws on stoppers S and T

are released from locked

position and guide S (TG2)

and guide T (TG3) move in

the direction of arrow.

Pinch roller moves in theJ

direction of arrow.

GL arm moves in the

direction of arrow.

!

GL slider moves in the

direction of arrow.

I

I

Guide S (TG2) and guide

T (TG3) further move in

the direction of arrow.

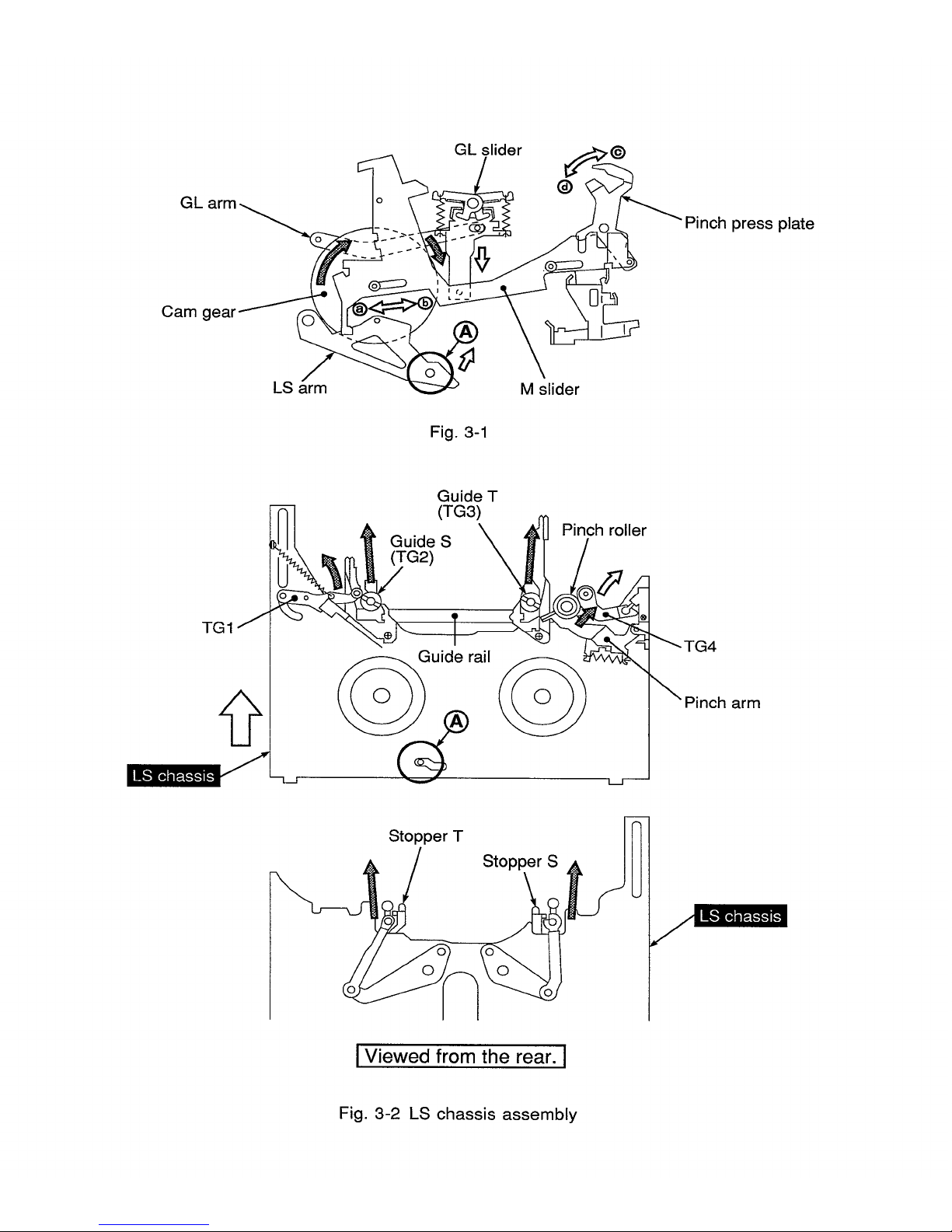

GL arm

GL slider

@

•Pinch press plate

Cam gea=

LS arm

M slider

Fig. 3-1

TG1

Guide T

(TG3)

Guide S

(TG2)

uide rail

Pinch roller

arm

Stopper T

Stopper S

IViewed from the rear. I

Fig. 3-2 LS chassis assembly

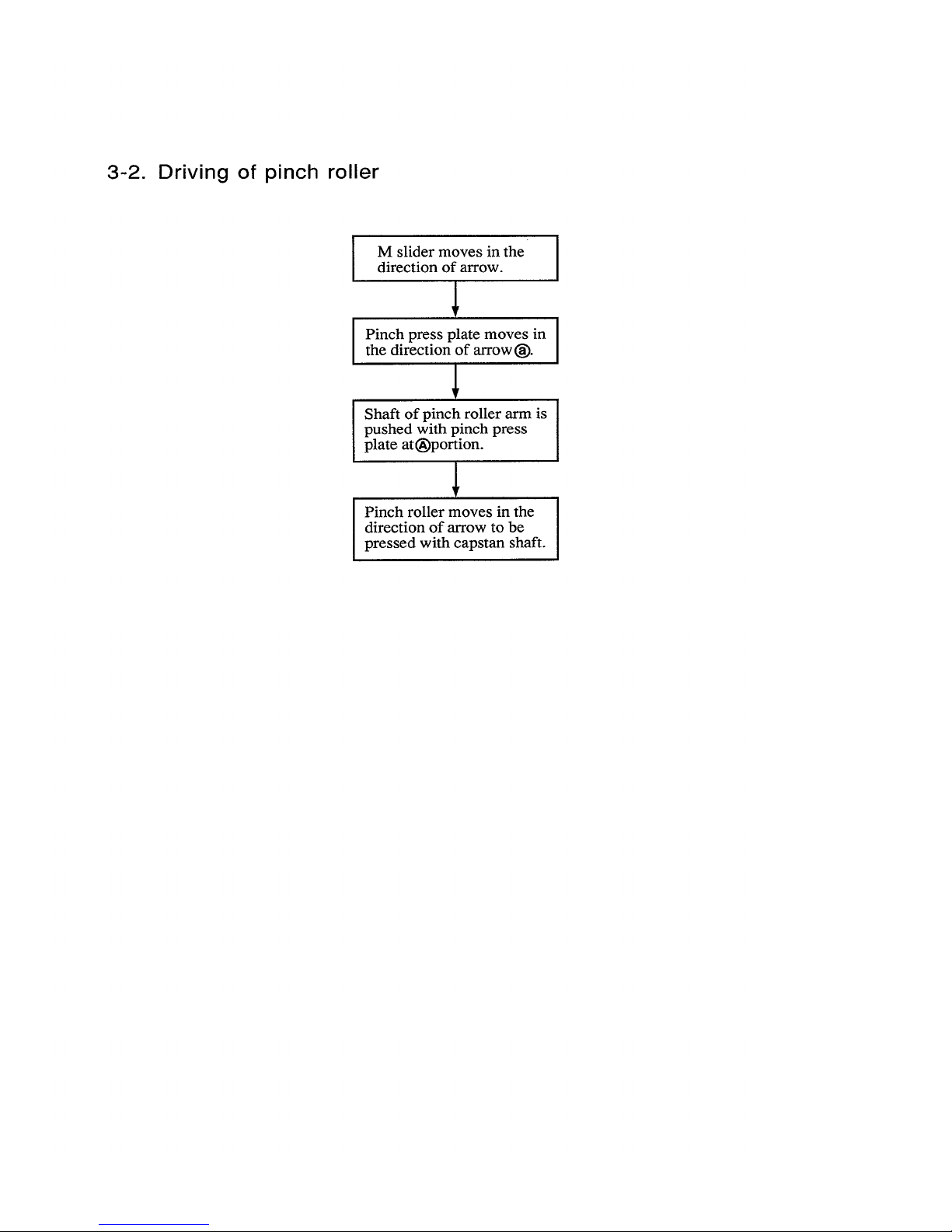

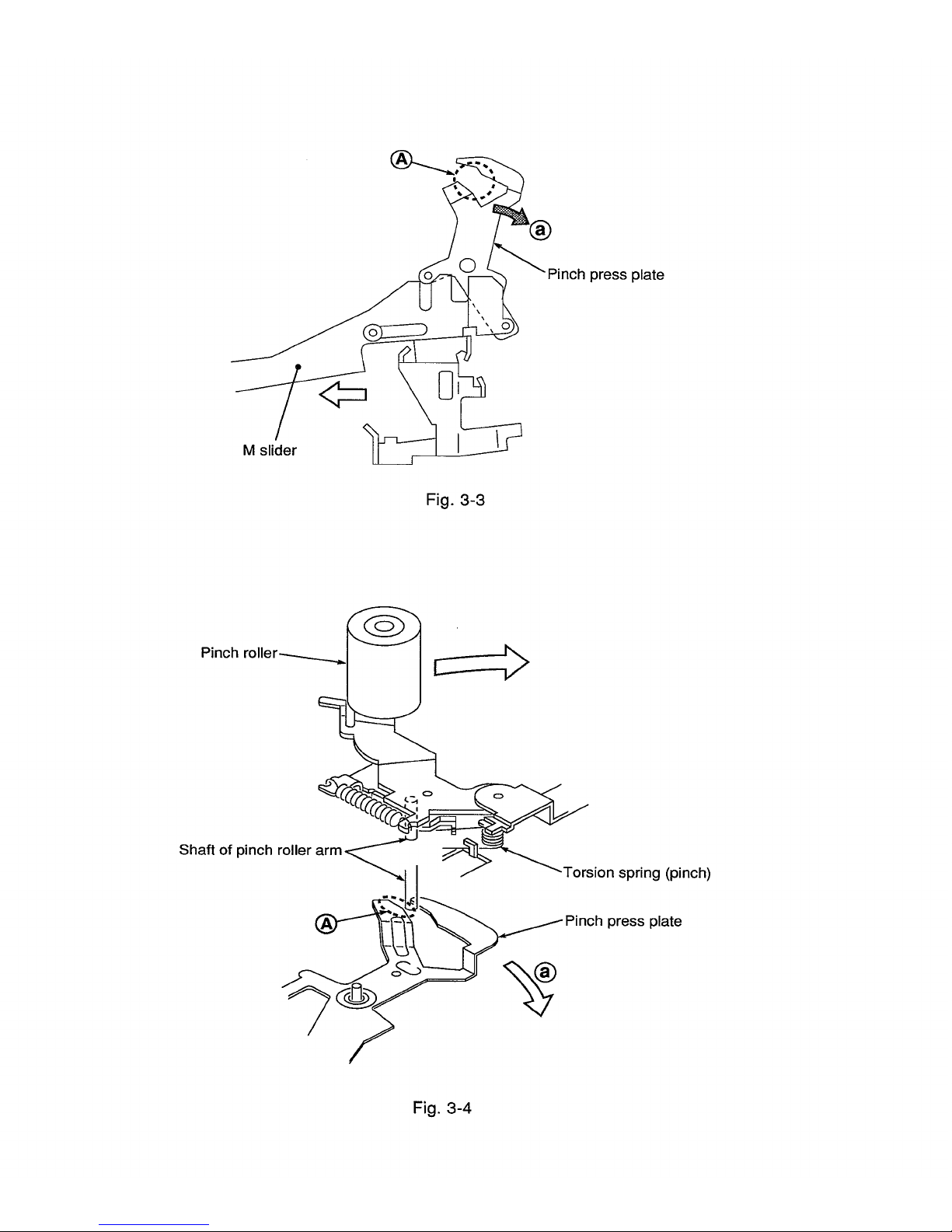

3-2. Driving of pinch roller

M slider moves in the

direction of arrow.

!

Pinch press plate moves in

the direction of arrow (_).

,!

Shaft of pinch roller arm is

pushed with pinch press

plate at!_)portion.

Pinch roller moves in the

direction of arrow to be

pressed with capstan shaft.

I

I

Pinch press plate

M slider

Fig. 3-3

Shaft of pinch roller

"-Torsion spring (pinch)

press plate

Fig. 3-4

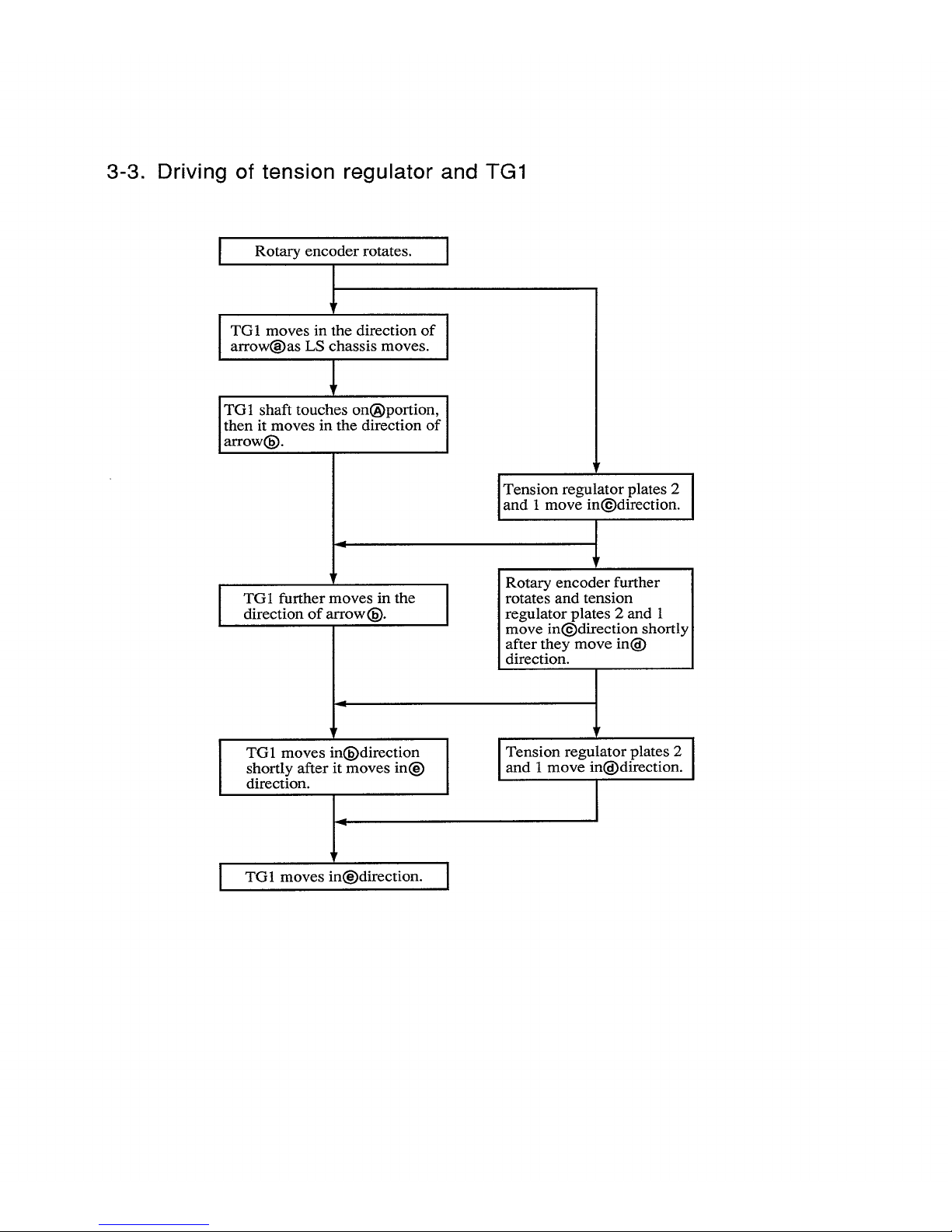

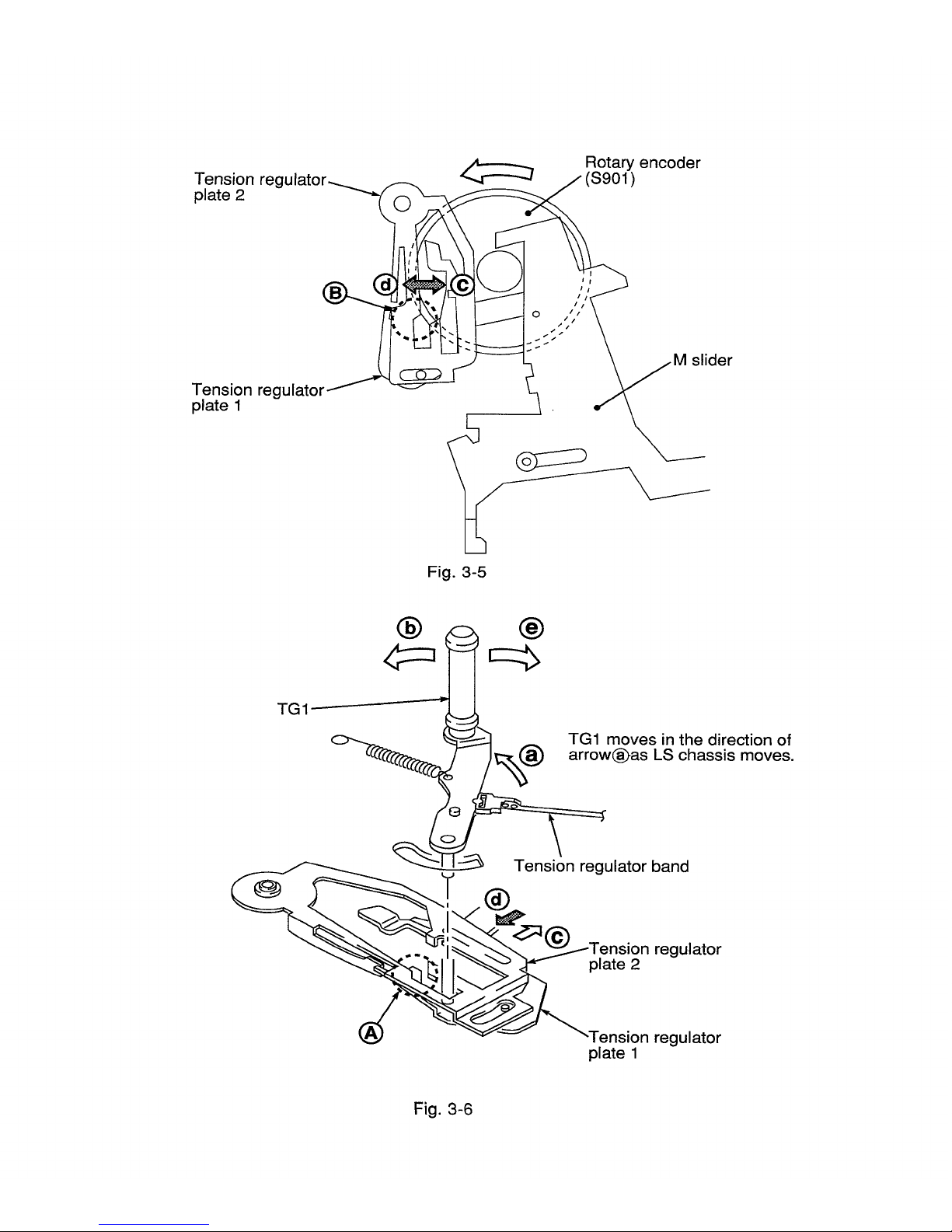

3-3. Driving of tension regulator and TG1

Rotary encoder rotates. [

|

TG1 moves in the direction of I

arrowf_)as LS chassis moves.

I

TG1 shaft touches on!_)portion, I

then it moves in the direction of

1

arrow_.

I

!

TG1 further moves in the [

direction of arrow(fi).

I

!

TG1 moves in(_)direction I

shortly after it moves int_)

I

direction.

!"

TG1 moves inl_)direction. I

Tension regulator plates 2

I

and 1 move in@direction, i

|

!

Rotary encoder further ]

rotates and tension [

regulator plates 2 and 1 [

move in(_)direction shortly I

after they move in(_ ]

direction. [

!

I Tension regulator plates 2 I

and 1 move inl_)direction.

I

Tension reg

plate 2

Rotary encoder

(S901)

Tension regulator

plate 1

O

slider

Fig. 3-5

TG1 _1_(_ TG1 moves in the direction of

arrow(_as LS chassis moves.

Tension regulator band

regulator

plate 2

®

"-Tension regulator

plate 1

Fig. 3-6

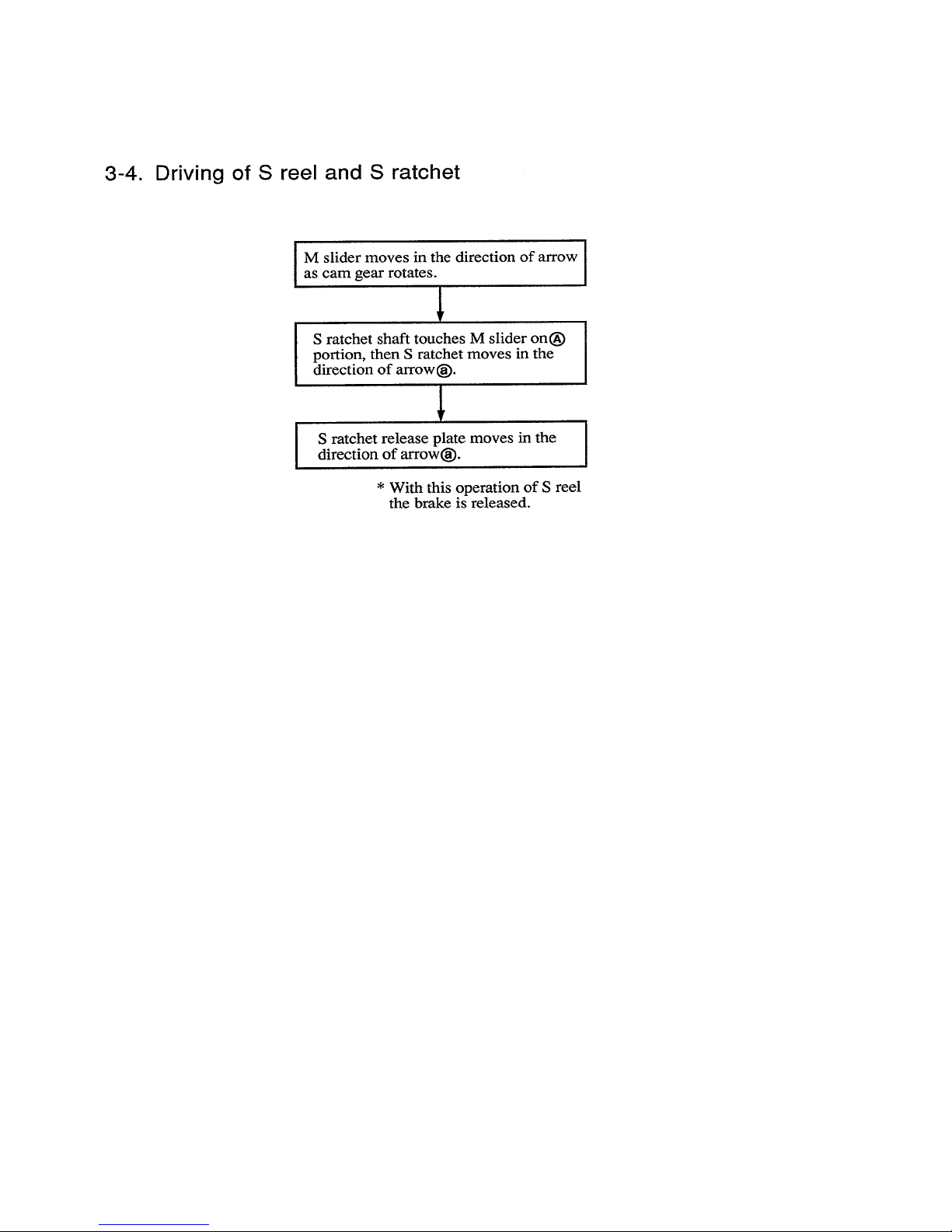

3-4. Driving of S reel and S ratchet

I M slider moves in the direction of arrow [

I

as cam gear rotates.

I

,L

1

S ratchet shaft touches M slider onl_

portion, then S ratchet moves in the

direction of arrowl_).

S ratchet release plate moves in the

direction of arrowt_).

* With this operation of S reel

the brake is released.

Loading...

Loading...