Page 1

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428/TRV428E

RMT-833

SERVICE MANUAL

US Model

Ver 1.1 2005.06

Revision History

Revision History

How to use

How to use

Acrobat Reader

Acrobat Reader

M2100/M2101 MECHANISM

North European Model

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428E

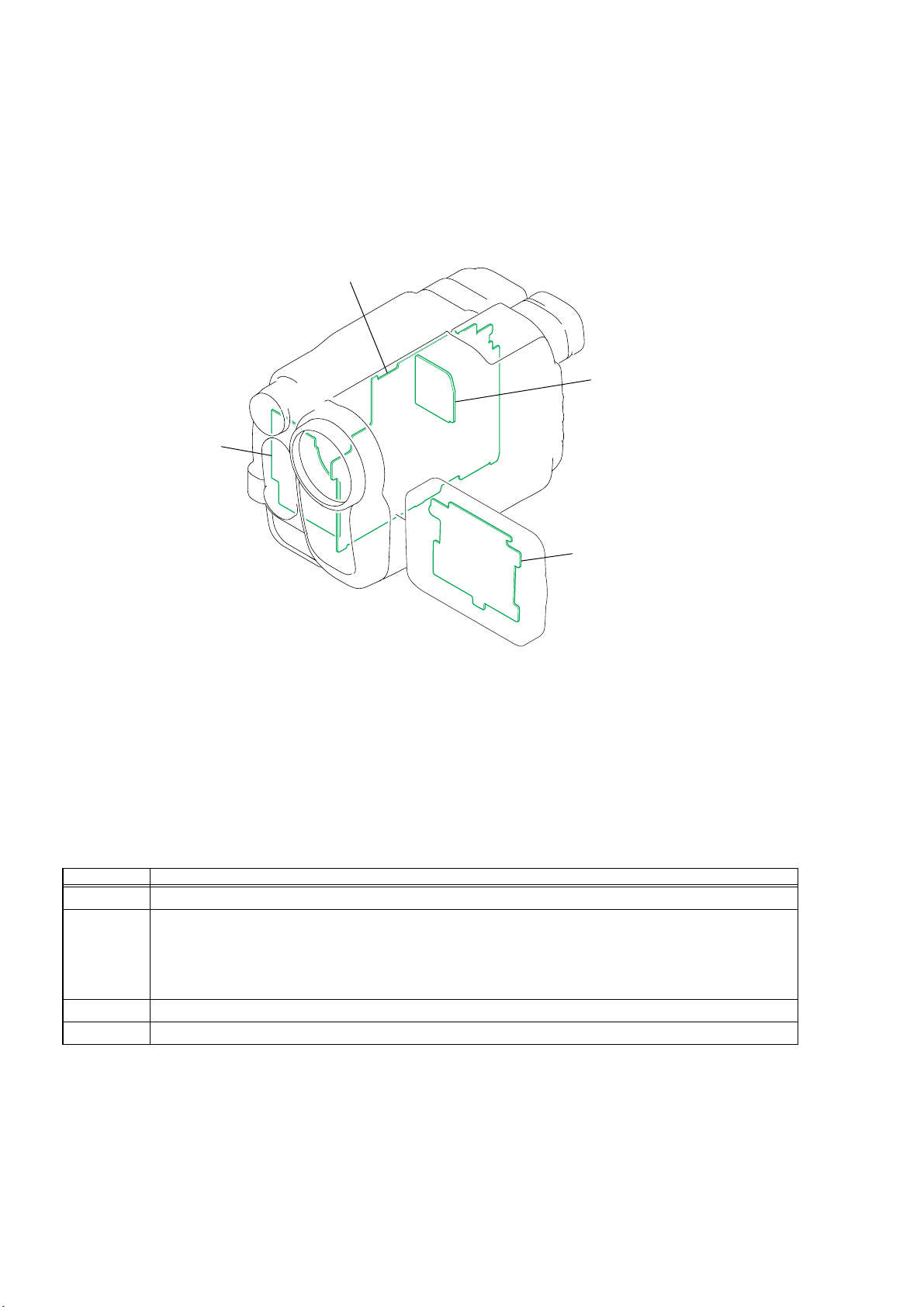

Photo: CCD-TRV328

Canadian Model

CCD-TRV128/TRV328

AEP Model

East European Model

CCD-TRV228E/TRV428E

UK Model

CCD-TRV228E

E Model

Australian Model

Hong Kong Model

CCD-TRV428E

Argentine Model

Brazilian Model

CCD-TRV128

Tourist Model

CCD-TRV428/TRV428E

Link

Link

SPECIFICATIONS

SPECIFICATIONS

SERVICE NOTE

SERVICE NOTE

DISASSEMBLY

DISASSEMBLY

NTSC MODEL: CCD-TRV128/TRV228/TRV328/TRV428

PAL MODEL: CCD-TRV228E/TRV428E

•For ADJUSTMENTS (SECTION 6), refer to SERVICE MANUAL, ADJ (987629051.pdf).

• INSTRUCTION MANUAL is shown at the end of this document.

•For MECHANISM ADJUSTMENTS, refer to the “8mm Video MECHANICAL ADJUSTMENT MANUAL IX

M2000 MECHANISM ” (9-929-861-11).

• Reference No. search on printed wiring boards is available.

•Table for differences of function of each model.

•TO TAKE OUT A CASSETTE WHEN NOT EJECT (FORCE EJECT)

•When the machine needs to be repaired, make sure to follow the items of “LCD TYPE CHECK”.

• HELP: Sheet attachment positions and procedures of processing the flexible boards/harnesses are shown.

BLOCK DIAGRAMS

BLOCK DIAGRAMS

FRAME SCHEMATIC DIAGRAMS

FRAME SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

PRINTED WIRING BOARDS

PRINTED WIRING BOARDS

REPAIR PARTS LIST

REPAIR PARTS LIST

VIDEO CAMERA RECORDER

Page 2

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428/TRV428E

S

SPECIFICATIONS

TM

SERIE

Video camera recorder

System

Video recording system

2 rotary heads, Helical scanning FM system

Audio recording system

Rotary heads, FM system

Video signal

CCD-TRV228E/428E:

PAL color, CCIR standards

CCD-TRV128/228/328/428:

NTSC color, EIA standards

Usable cassette

8 mm video format cassette

Tape speed

CCD-TRV228E/428E:

SP: Approx. 20.05 mm/s

LP: Approx. 10.06 mm/s

CCD-TRV128/228/328/428:

SP: Approx. 14.35 mm/s

LP: Approx. 7.19 mm/s

Recording/playback time (using 90 min. Hi8/

Digital8 video cassette)

CCD-TRV228E/428E:

SP: 1 h 30 min

LP: 3 h

Recording/playback time (using 120 min. Hi8/

Digital8 video cassette)

CCD-TRV128/228/328/428:

SP: 2 h

LP: 4 h

Fast forward/rewind time

(CCD-TRV228E/428E: using 90 min. Hi8/

Digital8 video cassette)

(CCD-TRV128/228/328/428: using 120 min.

Hi8/Digital8 video cassette)

Approx. 5 min

Viewfinder

Electric viewfinder (monochrome )

Image device

CCD-TRV228E/428E:

3.0 mm (1/6 type) CCD (Charge Coupled

Device)

Gross: Approx. 380 000 pixels

Effective: Approx. 230 000 pixels

CCD-TRV128/228/328/428:

3.0 mm (1/6 type) CCD (Charge Coupled

Device)

Gross: Approx. 320 000 pixels

Effective: Approx. 200 000 pixels

Lens

Combined power zoom lens

Filter diameter: 37 mm (1 1/2 in.)

20 × (Optical), 990 × (Digital)

F=1.6 - 2.4

Focal length

2.5 - 50 mm (1/8 - 2 in.)

When converted to a 35 mm still camera

42 - 840 mm (1 11/16 - 33 1/8 in.)

Color temperature

Auto

Minimum illumination

1 lx (lux) (F 1.6)

0 lx (lux) (in the NightShot plus mode)*

*Objects unable to be seen due to the dark can be

shot with infrared lighting.

Input/Output connectors

S video output

4-pin mini DIN

Luminance signal: 1 Vp-p, 75 Ω (ohms),

unbalanced

CCD-TRV228E/428E:

Chrominance signal: 0.3 Vp-p , 75 Ω (ohms),

unbalanced

CCD-TRV128/228/328/428:

Chrominance signal: 0.286 Vp-p, 75 Ω

(ohms), unbalanced

Audio/Video output

AV MINIJACK

Video signal: 1 Vp-p, 75 Ω (ohms),

unbalanced, sync negative

Audio signal: 327 mV (at output impedance

more than 47 kΩ (kilohms)), Output

impedance with less than 2.2 kΩ (kilohms)

Monaural minijack (ø 3.5 mm)

RFU DC OUT

Mini-minijack (ø 2.5 mm), DC5V

LCD screen

Picture

6.2 cm (2.5 type)

Total dot number

123 200 (560 × 220)

General

Power requirements

DC 7.2 V (battery pack)

DC 8.4 V (AC Adaptor)

Average power consumption (when using the

battery pack)

During camera recording using the viewfinder

1.8 W

During camera recording using the LCD

2.7 W

Operating temperature

0°C to 40°C (32°F to 104°F)

Storage temperature

-20°C to + 60°C (-4°F to + 140°F)

Dimensions (approx.)

85 × 98 × 151 mm (3 3/8 × 3 7/8 × 6 in.) (w/h/

d)

Mass (Approx.)

780 g (1 lb 11 oz) main unit only

890 g (1 lb 15 oz) including the

NP-FM30 rechargeable battery pack, Hi8/

Digital8 cassette, lens cap, and shoulder strap

Supplied accessories

AC Adaptor (1)

Power cord (1)

Lens cap (1)

Shoulder strap (1)

Wireless Remote Commander (1)

RMT-833: (CCD-TRV228/228E/428/428E)

A/V connecting cable (1)

Rechargeable battery pack NP-FM30 (1)

21-pin adaptor (1): (AEP, UK, EE, NE)

Camera Operations Guide (This manual) (1)

See page 5-23.

AC Adaptor AC-L15A/L15B

Power requirements

AC 100 - 240 V, 50/60 Hz

Current consumption

0.35 - 0.18 A

Power consumption

18 W

Output voltage

DC 8.4 V, 1.5 A

Operating temperature

0°C to 40°C (32°F to 104°F)

Storage temperature

-20°C to + 60°C (-4°F to + 140°F)

Dimensions (approx.)

56 × 31 × 100 mm (2 1/4 × 1 1/4 × 4 in.) (w/h/

d) excluding the projecting parts

Mass (approx.)

190 g (6.7 oz) excluding the mains lead

Rechargeable battery pack (NP-FM30)

Maximum output voltage

DC 8.4 V

Output voltage

DC 7.2 V

Capacity

5.0 Wh (700 mAh)

Dimensions (approx.)

38.2 × 20.5 × 55.6 mm

(1 9/16 × 13/16 × 2 1/4 in.) (w/h/d)

Mass (approx.)

65 g (2.3 oz)

Operating temperature

0°C to 40°C (32°F to 104°F)

Type

Lithium ion

Design and specifications are subj e ct to change

without notice.

— 2 —

Page 3

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428/TRV428E

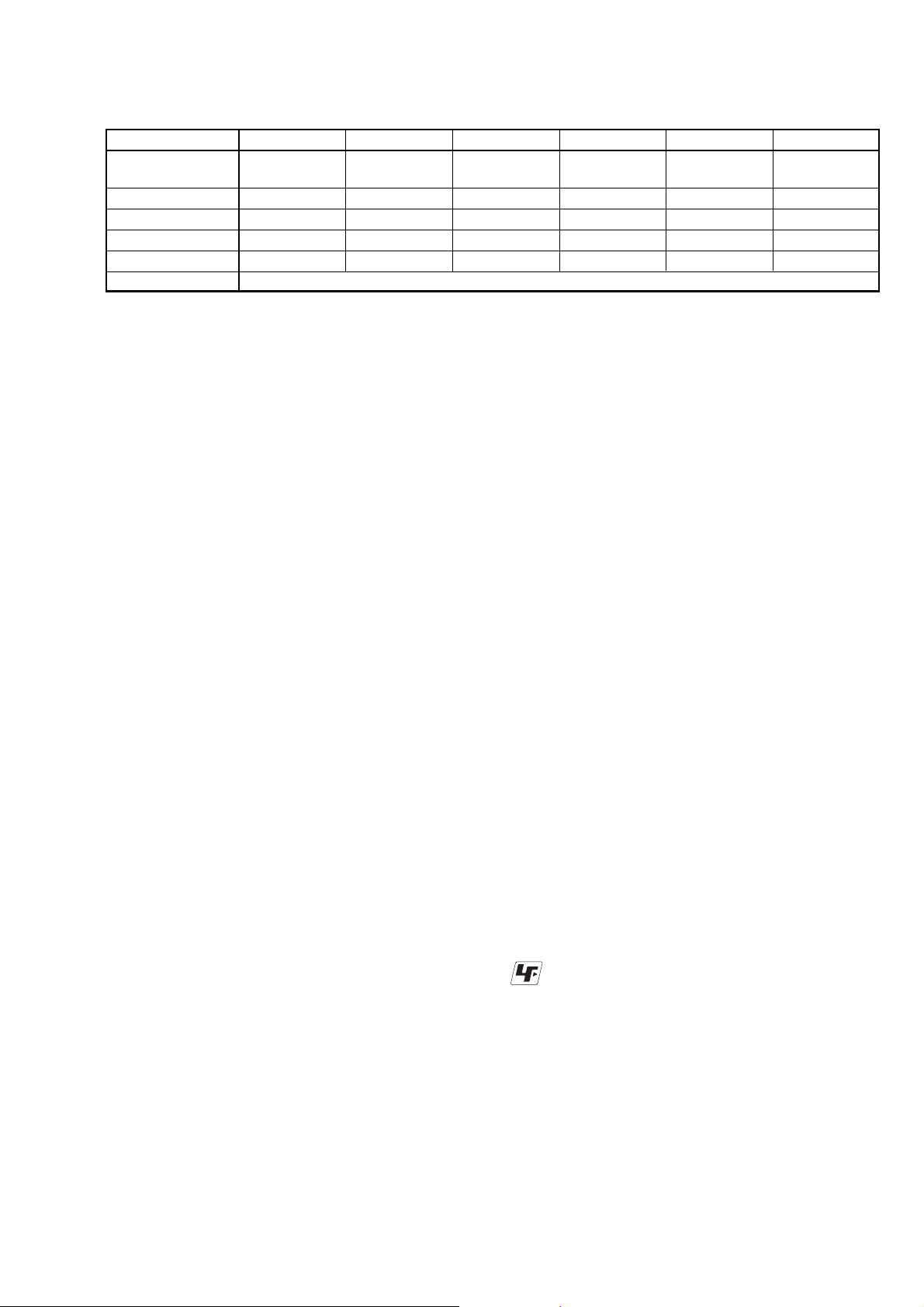

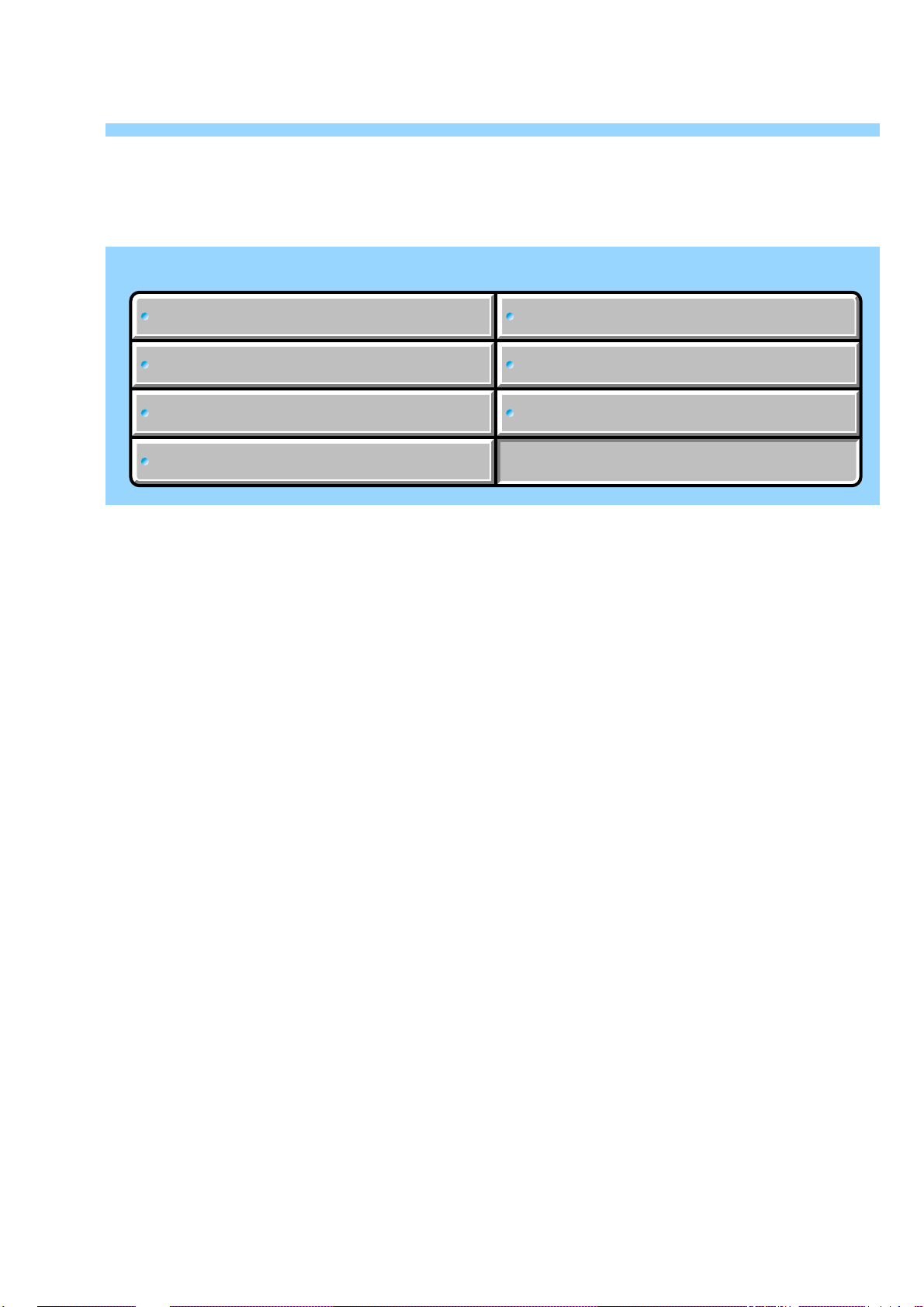

Table for differences of function

Model CCD-TRV128 CCD-TRV228 CCD-TRV228E CCD-TRV328 CCD-TRV428 CCD-TRV428E

Destination

US, CND, E,

AR, BR NE, E E, AUS, HK, JE

E

Remote commander ✕ aa✕ aa

Color system NTSC NTSC PAL NTSC NTSC PAL

Mechanism deck M2100 M2100 M2101 M2100 M2100 M2101

SteadyShot ✕✕✕aaa

LCD type Please refer to page 1-3 to discriminate the type of LCD (TYPE C or TYPE S).

AEP, UK, EE,

US, CND, E JE

AEP, EE, NE,

•Abbreviation

AR : Argentine model

AUS: Australian model

BR : Brazilian model

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY .

CND: Canadian model

EE : East European model

HK : Hong Kong model

JE : Tour ist model

NE : North European model

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair . Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky , less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

— 3 —

Page 4

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428/TRV428E

TABLE OF CONTENTS

Section Title Page Section Title Page

1. SERVICE NOTE

1-1. Note for Repair ································································1-1

1-2. Power Supply During Repairs·········································1-1

1-3. To Take Out a Cassette when not Eject (Force Eject) ·····1-2

1-4. LCD Type Check ·····························································1-3

1-5. Self-diagnosis Function ···················································1-4

1-5-1.Self-diagnosis Function ···················································1-4

1-5-2.Self-diagnosis Display·····················································1-4

1-5-3.Service Mode Display ·····················································1-4

1-5-4.Self-diagnosis Code Table ···············································1-5

2. DISASSEMBLY

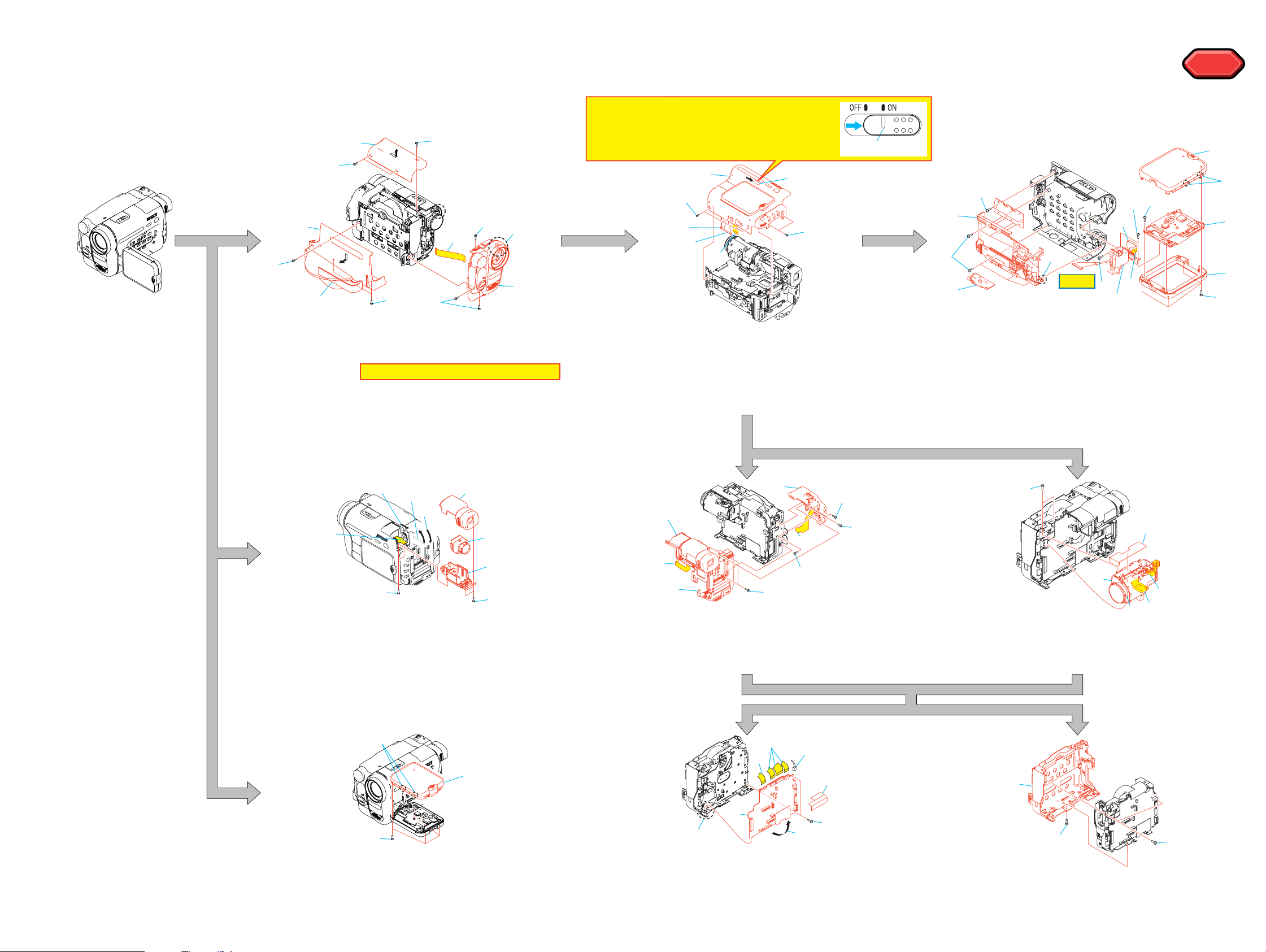

2-1. Flow Chart ·······································································2-1

2-2. Mechanism Deck Service Position··································2-3

2-3. LCD Service Position ······················································2-5

2-4. Circuit Boards Location ··················································2-6

2-5. Flexible Boards Location ················································2-7

3. BLOCK DIAGRAMS

3-1. Overall Block Diagram (1/5)···········································3-1

3-2. Overall Block Diagram (2/5)···········································3-3

3-3. Overall Block Diagram (3/5)···········································3-5

3-4. Overall Block Diagram (4/5)···········································3-7

3-5. Overall Block Diagram (5/5)···········································3-9

3-6. Power Block Diagram (1/2)··········································· 3-11

3-7. Power Block Diagram (2/2)··········································· 3-13

5. REPAIR PARTS LIST

5-1. Exploded Views ····························································5-2

5-1-1. Ov erall Assembly·························································· 5-2

5-1-2. Front Panel Block ························································· 5-3

5-1-3. Lens Block ····································································5-4

5-1-4. LCD Block···································································· 5-5

5-1-5. Cabinet R Block····························································5-6

5-1-6. EVF Block ···································································· 5-7

5-1-7. Battery Panel Block ······················································5-8

5-1-8. MD Frame Block ··························································5-9

5-1-9. Cassette Compartment Assembly, Drum Assembly ···5-10

5-1-10. LS Chassis Block Assembly ·······································5-11

5-1-11. Mechanical Chassis Block Assembly-1 ······················5-12

5-1-12. Mechanical Chassis Block Assembly-2 ······················5-13

5-2. Electrical Parts List ·····················································5-14

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. Frame Schematic Diagram ··············································4-1

4-2. Schematic Diagrams························································4-5

CD-465 (CCD IMAGER)················································4-7

VC-341 (1/10)

(A/D CONVERTER, TIMING GENERATOR)··············4-9

VC-341 (2/10)

(CAMERA/VTR PROCESS, LENS CONTROL) ········4-11

VC-341 (3/10) (LENS DRIVE) ···································· 4-13

VC-341 (4/10) (REC/PB AMP) ····································4-15

VC-341 (5/10) (SERVO) ···············································4-17

VC-341 (6/10) (CAMERA/MECHA CONTROL) ······· 4-19

VC-341 (7/10) (HI CONTROL)····································4-21

VC-341 (8/10) (AUDIO, VIDEO)································· 4-23

VC-341 (9/10) (DC CONTROL) ··································4-25

VC-341 (10/10) (STEADYSHOT, CONNECTOR)······ 4-27

PD-204 (LCD DRIVER, BACKLIGHT DRIVE)·········4-29

SI-039 (STEADYSHOT, JACK) ···································4-31

FP-792 FLEXIBLE ·······················································4-31

FP-228, FP-299, FP-300, FP-301, FP-302, FP-802

FLEXIBLE ···································································· 4-33

SS-5100, PR-5100 (CONTROL KEY BLOCK)··········· 4-34

CF-5100 (CONTROL KEY BLOCK)···························4-35

4-3. Printed Wiring Boards ···················································4-39

CD-465 ·········································································· 4-41

VC-341 ·········································································· 4-43

PD-204···········································································4-47

SI-039, FP-792 FLEXIBLE ·········································· 4-49

FP-228, FP-299, FP-300, FP-301, FP-302, FP-802

FLEXIBLE ···································································· 4-51

4-4. Mounted Parts Location ················································4-53

— 4 —

Page 5

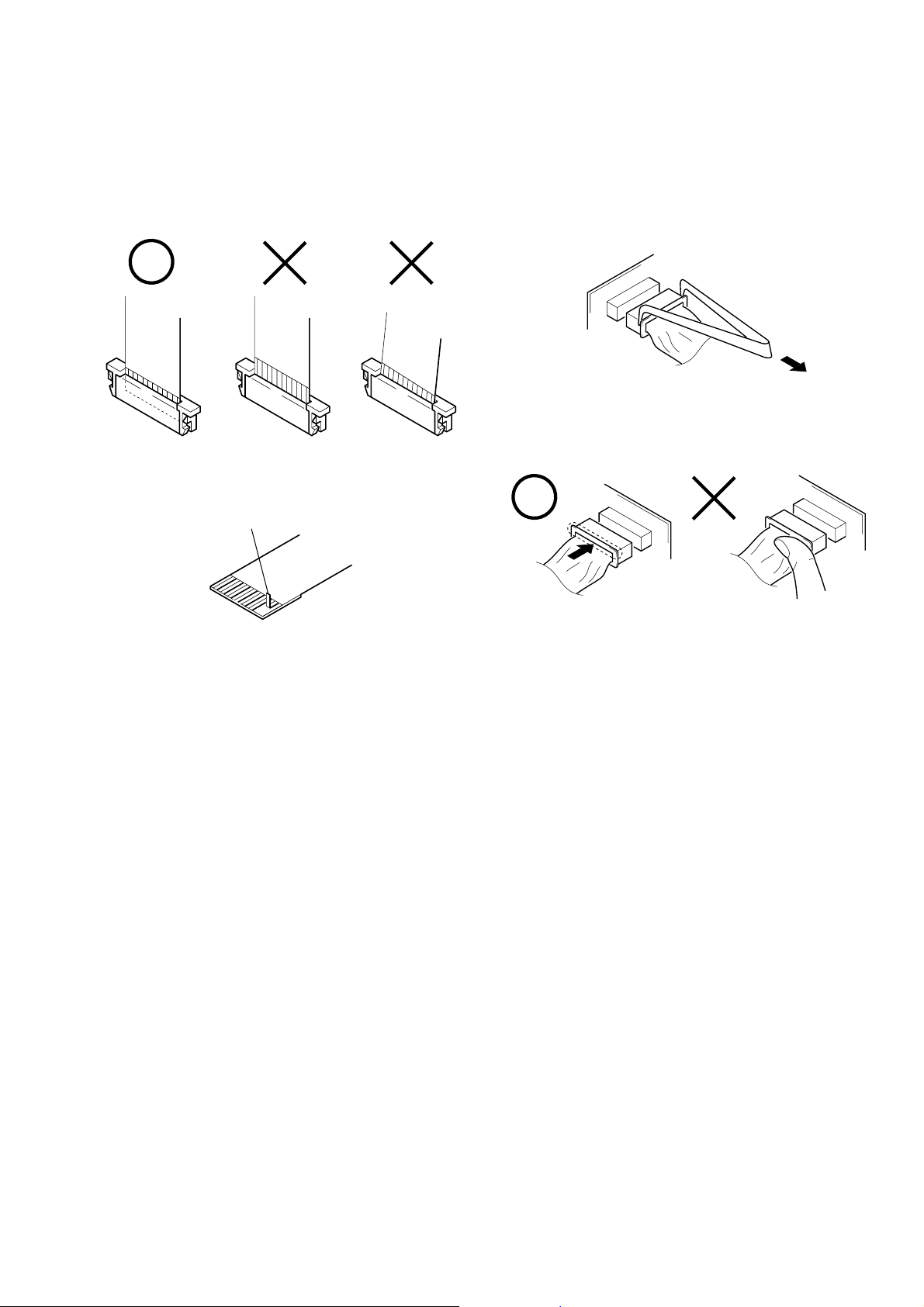

1-1. NOTE FOR REPAIR

When installing a connector, don’t press down at wire of connector.

It is possible that a wire is snapped.

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428/TRV428E

SECTION 1

SERVICE NOTE

Make sure that the flat cable and flexible board are not cracked of

bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

Cut and remove the part of gilt

which comes off at the point.

(Be careful or some

pieces of gilt may be left inside)

When remove a connector, don’t pull at wire of connector.

It is possible that a wire is snapped.

1-2. POWER SUPPLY DURING REPAIRS

In this unit, about 10 seconds after power is supplied to the battery terminal using the regulated po wer supply (8.4V), the power is shut of f so

that the unit cannot operate.

The following method is available to prevent this.

Method 1.

Use the AC power adaptor (AC-L10, AC-VQ800 etc.).

1-1

Page 6

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428/TRV428E

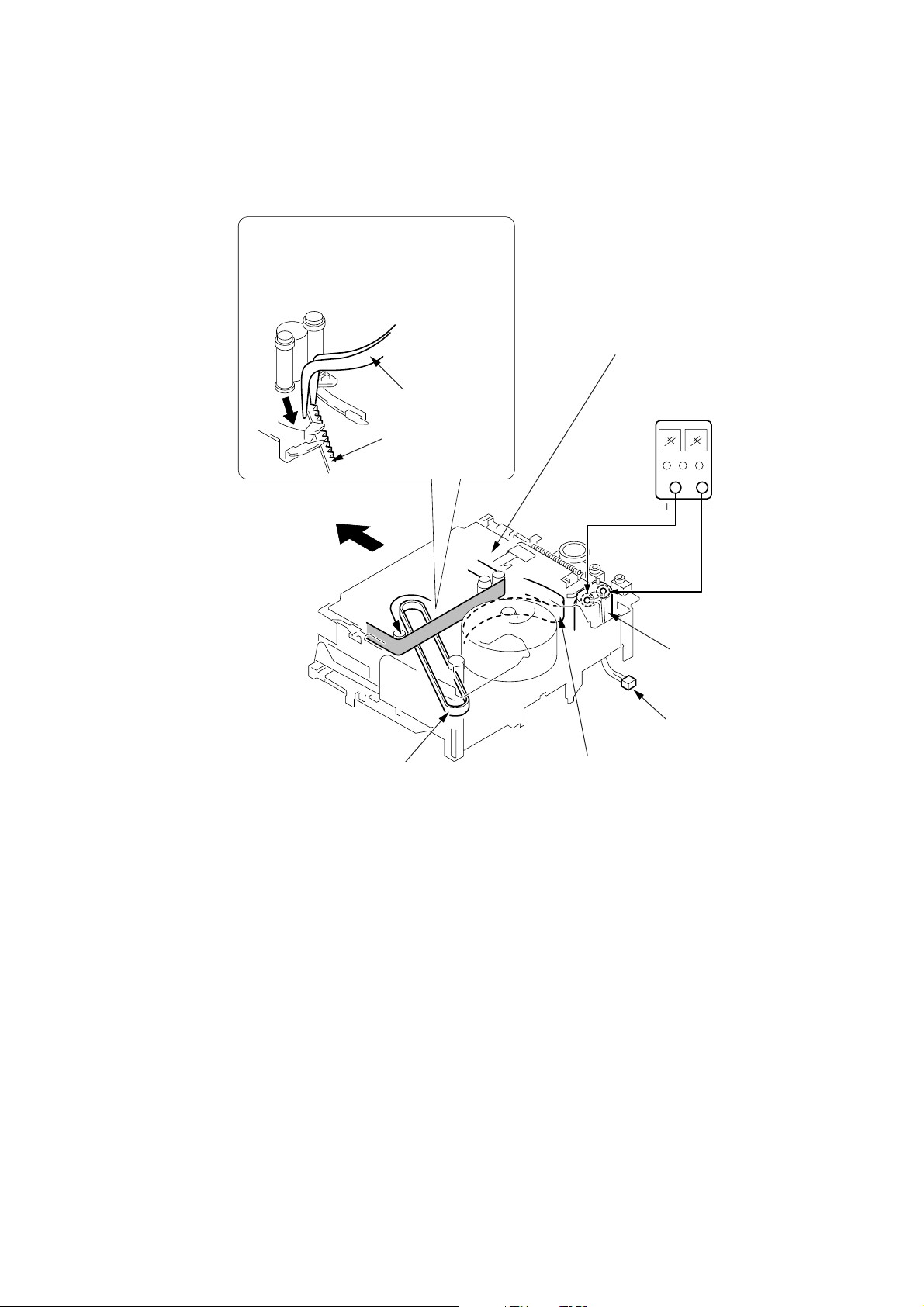

1-3. TO TAKE OUT A CASSETTE WHEN NOT EJECT (FORCE EJECT)

1 Refer to “SECTION 2. DISASSEMBLY” to remove the mechanism deck block.

2 Disconnect CN401 (2P) of VC-341 board.

3 Add +5V from the DC POWER SUPPLY and unload with a pressing the cassette compartment.

4 Pull the timing belt in the direction of

arrow A with a pincette while pressing

the cassette compartment (take care

not to damage) to adjust the bending

of a tape.

Press the cassette compartment not to

rise the cassette compartment

5 Let go your hold the cassette

compartment and rise the cassette

compartment to take out a cassette.

A

Timing belt

A

Timing belt

Pincette

[DC power supply]

(+5V)

Loading motor

Disconnect CN401

of VC-341 board.

Adjust the bending of a tape

1-2

Page 7

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428/TRV428E

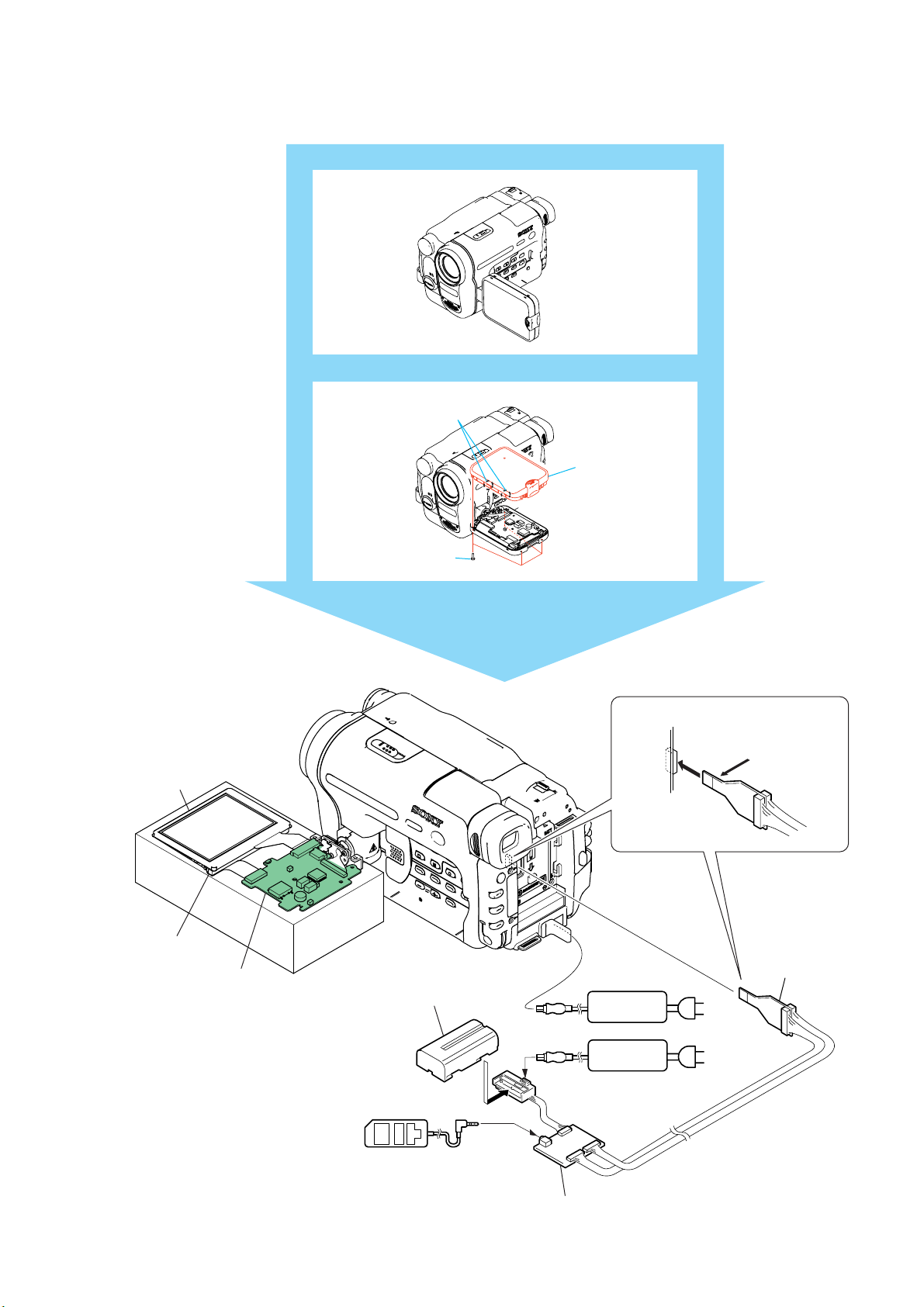

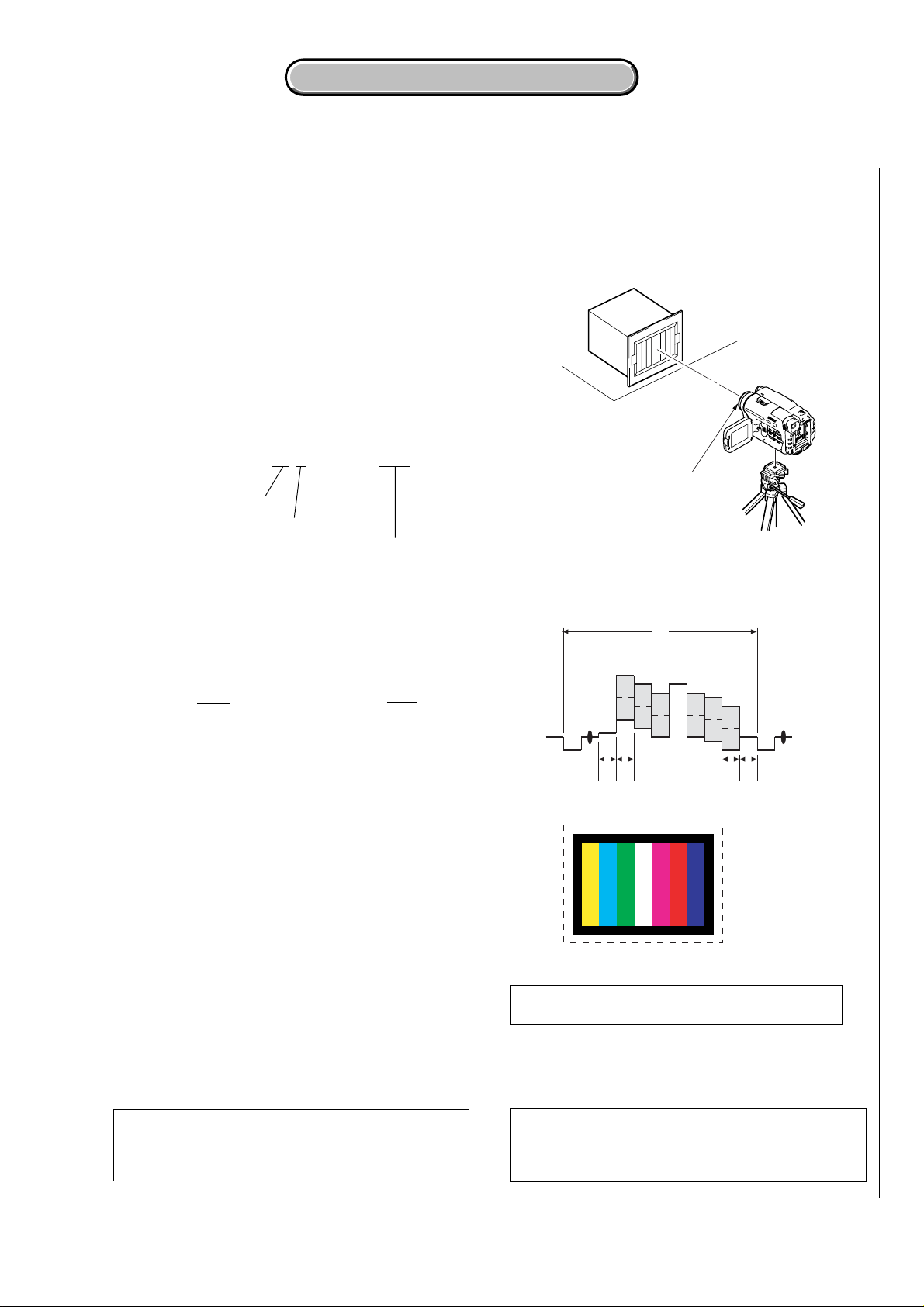

1-4. LCD TYPE CHECK

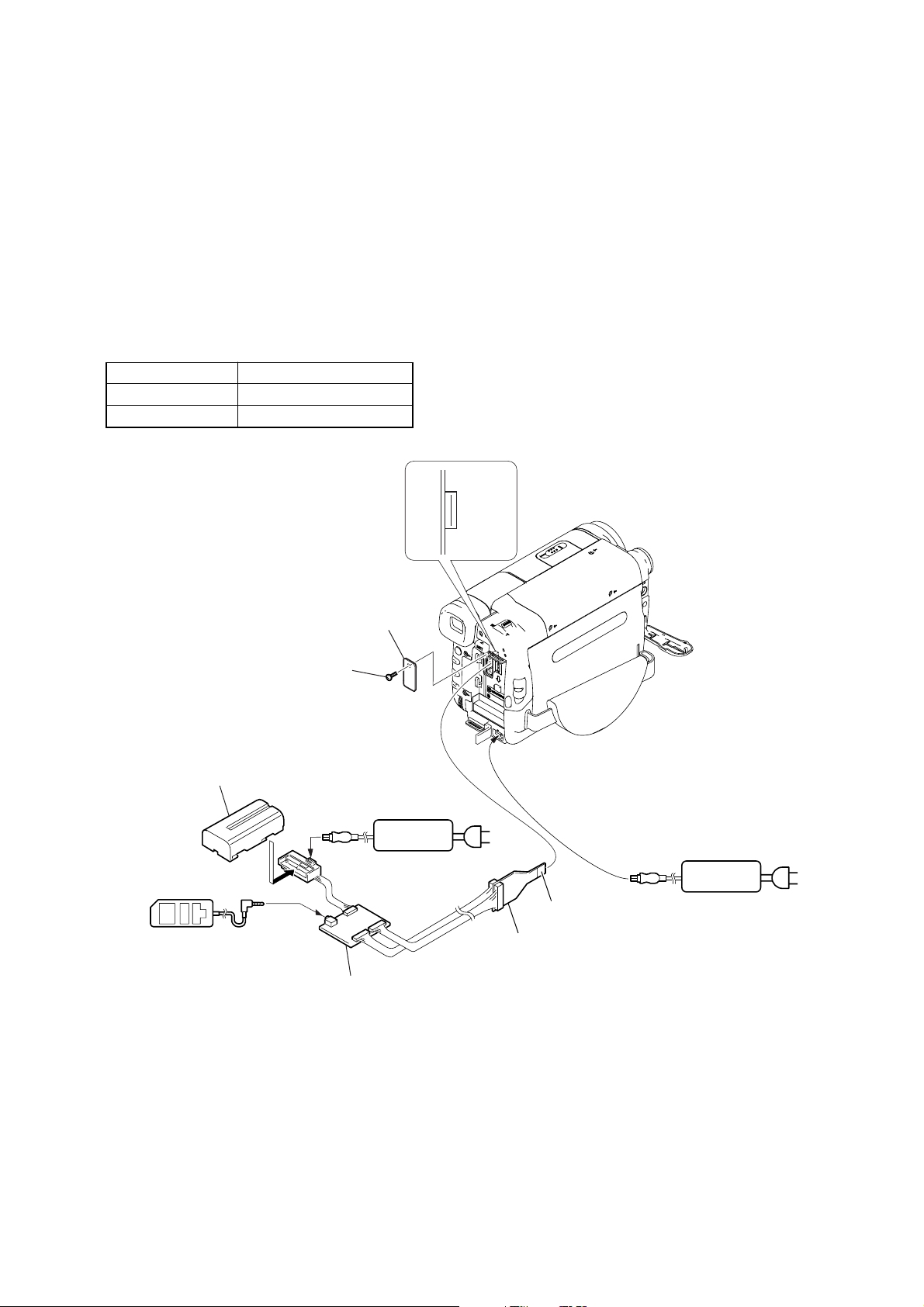

The LCD type can be checked with data value by connecting the adjustment remote commander.

Note: About PD-204 board and LCD module, discriminate LCD type on the machine, and replace the same type.

Preparations:

1) Connect the equipment for adjustments according to Fig. 1.

2) Connect the adjustment remote commander to VC-341 board CN007 via I/F unit for LANC control (J-6082-521-A) and CPC jig connector

(J-6082-539-A).

To operate the adjustment remote commander, connect the A C po wer adaptor to the DC IN jack of I/F unit for LANC control, or connect

the L series Info-LITHIUM battery to the battery terminal of I/F unit for LANC control.

Checking method:

1) Select page: 3, address: CC.

2) By checking the data value of display data, the type of LCD can be discriminated.

Data LCD type

64 to 67 TYPE C

40 to 43 TYPE S

CN007

1

Screw (M2)

L serices Info

LITHIUM battery (7.2Vdc)

LANC jack

Adjustment

remote commander (RM-95)

CPC lid

AC adaptor

16

AC IN

Conductor side

CPC jig connector

(J-6082-539-A)

AC adaptor

AC IN

I/F unit for LANC control

(J-6082-521-A)

1-3

Page 8

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428/TRV428E

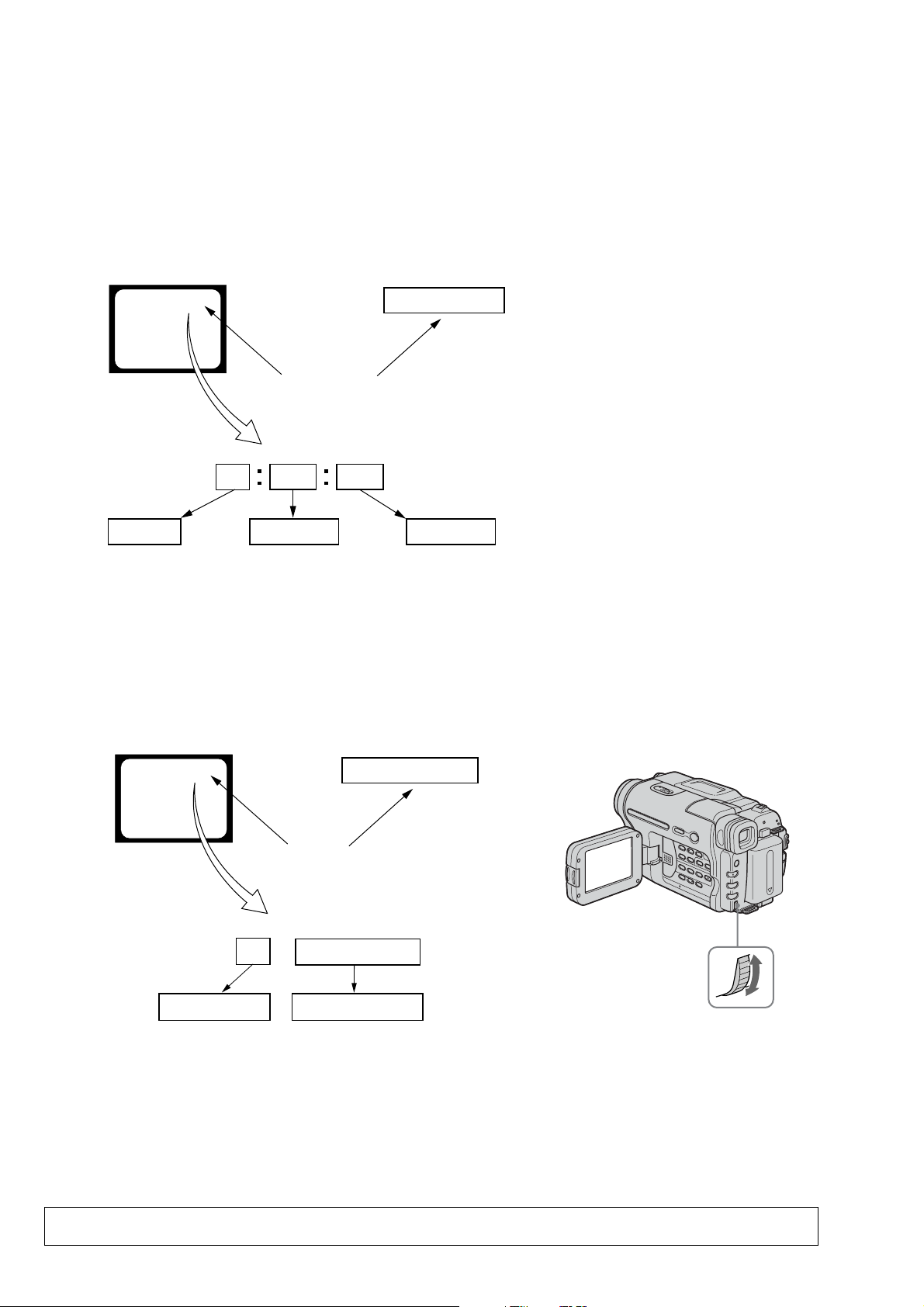

1-5. SELF-DIAGNOSIS FUNCTION

1-5-1. Self-diagnosis Function

When problems occur while the unit is operating, the self-diagnosis

function starts working, and displays on the viewfinder or Display

window what to do. This function consists of two display; selfdiagnosis display and service mode display.

Details of the self-diagnosis functions are provided in the Instruction

manual.

Viewfinder Display window

C : 3 1 : 1 1

Repaired by:

C : Corrected by customer

H : Corrected by dealer

E : Corrected by service

engineer

Blinks at 3.2Hz

C

Indicates the appropriate

step to be taken.

E.g.

31 ....Reload the tape.

32 ....Turn on power again.

3 1

Block

C : 3 1 : 11

1 1

Refer to “1-5-4. Self-diagnosis Code Table”.

1-5-2. Self-diagnosis Display

When problems occur while the unit is operating, the counter of the

viewfinder or Display window shows a 4-digit display consisting

of an alphabet and numbers, which blinks at 3.2 Hz. This 5-character

display indicates the “repaired by:”, “block” in which the problem

occurred, and “detailed code” of the problem.

Detailed Code

1-5-3. Service Mode Display

The service mode display shows up to six self-diagnosis codes shown in the past.

1. Display Method

While pressing the “STOP” key, set the switch from OFF to “ON”, and continue pressing the “STOP” key for 5 seconds continuously. The

service mode will be displayed, and the counter will show the backup No. and the 5-character self-diagnosis codes.

Viewfinder

[3] C : 3 1 : 1 1

[3]

Backup No.

Order of previous errors

Lights up

C : 3 1 : 1 1

Self-diagnosis Codes

Display window

3 C : 3 1 : 11

Control Dial

2. Switching of Backup No.

By rotating the control dial, past self-diagnosis codes will be shown in order. The backup No. in the [] indicates the order in which the

problem occurred. (If the number of problems which occurred is less than 6, only the number of problems which occurred will be shown.)

[1] : Occurred first time [3] : Occurred third time [5] : Occurred fifth time

[2] : Occurred second time [4] : Occurred fourth time [6] : Occurred the last time

3. End of Display

Turning OFF the power supply will end the service mode display.

Note: The “self-diagnosis display” data will not be erased (reset), when the lithium battery (CONTROL KEY BLOCK (CF-

5100): BT001) is removed.

1-4

Page 9

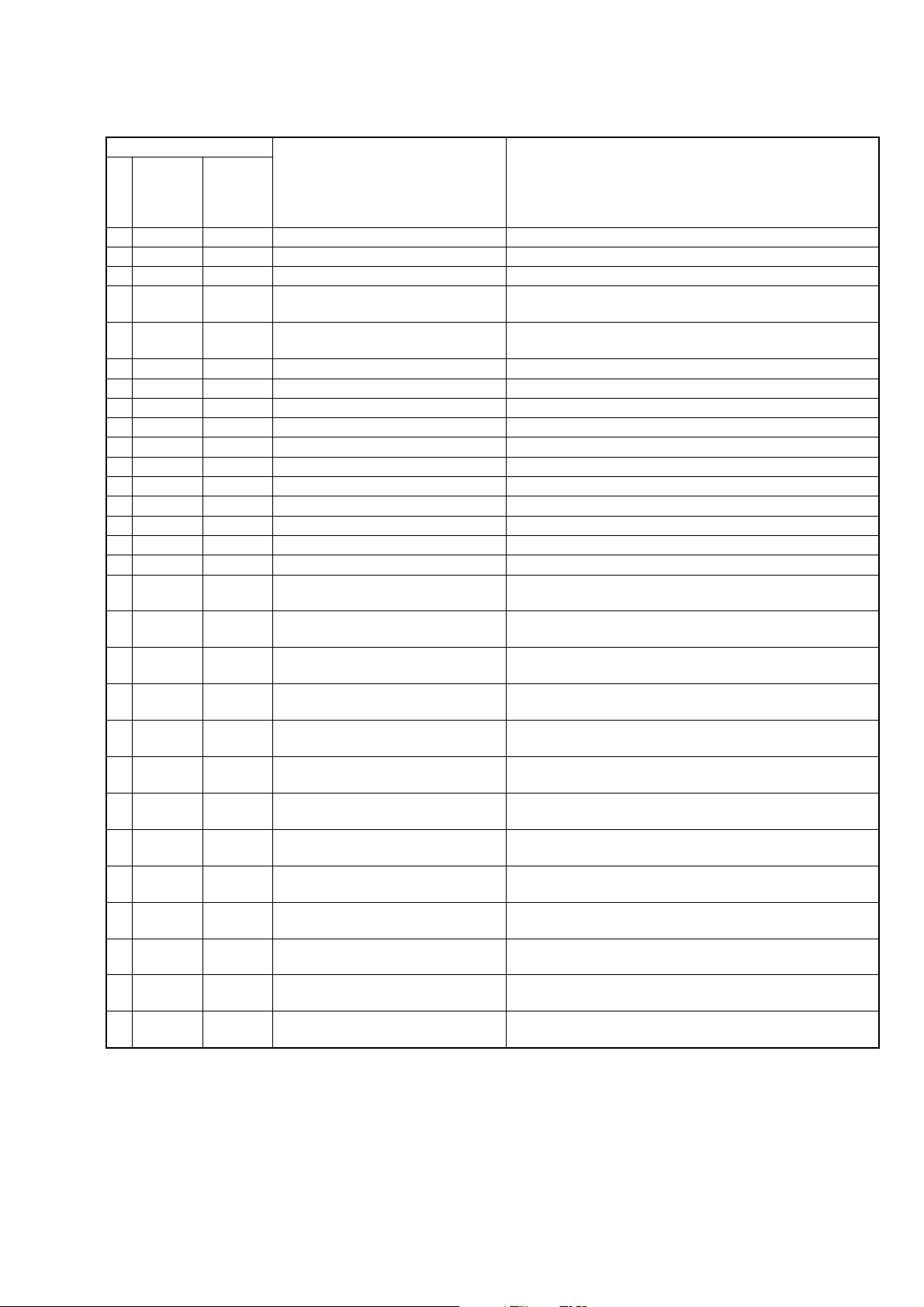

1-5-4. Self-diagnosis Code Table

Self-diagnosis Code

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428/TRV428E

Repaired by:

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

Block

Function

04

21

22

31

31

31

31

31

31

31

31

31

31

31

31

31

32

32

32

32

32

32

32

32

32

32

32

32

32

Detailed

Code

00

00

00

10

11

20

21

22

23

30

31

40

41

42

43

44

10

11

20

21

22

23

30

31

40

41

42

43

44

Symptom/State

Non-standard battery is used.

Condensation.

Video head is dirty.

LOAD direction. Loading does not

complete within specified time

UNLOAD direction. Loading does not

complete within specified time

T reel side tape slacking when unloading

S reel

side tape slacking when unloading

T reel fault.

S reel fault.

FG fault when starting capstan.

FG fault during normal capstan operations.

FG fault when starting drum.

PG fault when starting drum.

FG fault during normal drum operations.

PG fault during normal drum operations.

Phase fault during normal drum operations.

LOAD direction loading motor time-

out.

UNLOAD direction loading motor

time-out.

T reel side tape slacking when

unloading.

S reel side tape slacking when

unloading.

T reel fault.

S reel fault.

FG fault when starting capstan.

FG fault during normal capstan

operations.

FG fault when starting drum.

PG fault when starting drum.

FG fault during normal drum

operations.

PG fault during normal drum

operations.

Phase fault during normal drum

operations.

Correction

Use the InfoLITHIUM battery.

Remove the cassette, and insert it again after one hour.

Clean with the optional cleaning cassette.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

.

Load the tape again, and perform operations from the beginning.

.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Load the tape again, and perform operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

Remove the battery or power cable, connect, and perform

operations from the beginning.

1-5

Page 10

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428/TRV428E

Self-diagnosis Code

Block

Function

Repaired by:

E

61

E

61

E

62

E

62

*1: STEADYSHOT model (CCD-TRV328/TRV428/TRV428E)

Detailed

Code

00

10

00

01

Symptom/State

Difficult to adjust focus

(Cannot initialize focus.)

Zoom operations fault

(Cannot initialize zoom lens.)

Steadyshot function does not work well.

(With pitch angular velocity sensor output

stopped.)

Steadyshot function does not work well.

(With yaw angular velocity sensor output

stopped.)

Correction

Inspect the lens block focus reset sensor (Pin qs of CN201 of VC-

341 board) when focusing is performed when the control dial is

rotated in the focus manual mode and the focus motor drive circuit

(IC201 of VC-341 board) when the focusing is not performed.

Inspect the lens block zoom reset sensor (Pin qg of CN201 of VC341 board) when zooming is performed when the zoom switch is

operated and the zoom motor drive circuit (IC201 of VC-341 board)

when zooming is not performed.

Inspect pitch angular velocity sensor (SE752 of SI-039 board)

peripheral circuits. *1

Inspect yaw angular velocity sensor (SE751 of SI-039 board)

peripheral circuits. *1

1-6E

Page 11

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428/TRV428E

SECTION 2

DISASSEMBLY

2-1. FLOW CHART

The following flow chart shows the disassembly procedure.

1

5

4

3

1 Lock ace

2 Cabi (upper)

3 Grip belt

4 Lock ace

5 Cabi (L)

x3

x3

2

4

6 Lock ace

1

6

9

6

x3

7 Claw

8 Front panel

Note: Flexible board is connected.

9 FP-795: CN755, CN009

7

8

Note: When you remove Cabinet (R) Block,

or when you assembly, please slide

NS knob to the position of "ON".

3

1

6

5

4

1 Lock ace

x6

2

1

2 NS knob to the position of "ON".

3 Cabi (R)

4 VC-341: CN005

5 VC-341: CN002

6 VC-341: CN008

NS knob

3

2

5

1

1 Tripod Screw

2 Tapping P2

3 Tapping P2

4 Claw

5 CF-5100

6 Tapping P2

7 Claw

8 P Cabi (C)

x2

4

q;

9

qd

HELP

9 Tapping P2

x2

q; Tapping P2

x6

qa P Cabi (M)

qg

qs

qh

x2

x1

qs PD-204: CN6005

qd PD-204: CN6001

qf PD-204, LCD901, ND901

x4

qg Tapping P2

x4

qh Hinge assy

HELP

HELP

8

7

qf

qa

6

4

7

2

1 Lift up the EVF.

2 Tapping P2

x4

3 Down the EVF.

4 EVF block

2

1

3

5

8

6

2

5 EVF Cabi (upper)

6 EVF Cabi (lower)

7 FP-797: LCD902

8 EVF lens

3

4

1

2

1 VC-341: CN004

2 VC-341: CN053

3 Lock ace

x3

4 EVF/Battely panel block

7

8

5

6

3

7

5 VC-341: CN006

6 Tapping P2

7 Lock ace

8 SS-5100

2

3

1

3

x1

x1

4

6

1 VC-341: CN151

2 VC-341: CN201

3 Lens sheet

2

3

1

2

5

4 Lock ace

x2

5 Boss

6 Lens LSV-820A

1

1 Tapping P2

2 Claw

x2

3 P Cabi (C)

2-1 2-2

x4

8

5

1 VF blind sheet

2 VC-341: CN402, CN403, CN481

3 VC-341: CN401

4 Screw (M1.7)

x2

4

6

5 Claw

6 Open the VC-341.

7 VC-341: CN404

8 VC-341

1

1 Screw (M1.7)

2 CS frame

1

x3

Page 12

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428/TRV428E

2-2. MECHANISM DECK SERVICE POSITION

Connection to Check the Mechanism deck

To check the mechanism deck, set the Camera or VTR to the "Forced power ON" mode. (Or, connect the control key

block (SS-5100) to the CN006 of VC-341 board and set the power switch to the "CAMERA" or "PLAY/edit" position.)

Operate the Camera functions of the zoom and focus, the VTR function using the adjustment remote commander

(with the HOLD switch set in the OFF position).

4

5

3

1

2

4

6

1

9

6

7

8

2

1

1

Setting the "Forced Camera Power ON" mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: D, address: 10, set data: 02 and

press the PAUSE button of the adjustment remote

commander.

Setting the "Forced VTR Power ON" mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: D, address: 10, set data: 02 and

press the PAUSE button of the adjustment remote

commander.

How to move up the cassette

compartment manually

Press the cassette compartment

in the direction of the arrow A

to move it up in the direction of

the arrow B.

Lens block

A

B

Exiting the "Forced Power ON" mode

1) Select page: 0, address: 01, and set data: 01.

2) Select page: D, address: 10, data: 00, and press the PAUSE

button of the adjustment remote commander.

3) Select page: 0, address: 01, and set data: 00.

Mechanism deck

1

4

2

1

6

5

3

4

3

8

2

5

6

1

7

3

4

5

8

7

6

2

5

6

3

3

2

1

1

4

Front panel block

Cabinet R block

EVF block/

Battery panel block assembly

AC IN

AC adaptor

VC-341 board

Info lithium battery

(L series)

CPC jig connector

(J-6082-539-A)

Contacting

surface

Adjustment remote

commander (RM-95)

I/F unit for LANC control

(J-6082-521-A)

Eject switch

Control key block

(SS-5100)

When exiting the "Forced Power ON" mode, connect the control

key block (SS-5100) to the CN006 of VC-341 board. Or, when

ejecting the cassette, connect the control key block (SS-5100) to

the CN006 of VC-341 board. and press the Eject switch.

2-3 2-4

Page 13

2-3. LCD SERVICE POSITION

AC adaptor

AC IN

AC adaptor

I/F unit for LANC control

(J-6082-521-A)

CPC jig connector

(J-6082-539-A)

CPC jig connector

L serices Info

LITHIUM battery (7.2Vdc)

LCD panel

PD-204 board

Back light unit

Adjustment

remote commander (RM-95)

Conductor side

CN007

1

16

LANC jack

AC IN

2

1

3

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428/TRV428E

2-5

Page 14

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428/TRV428E

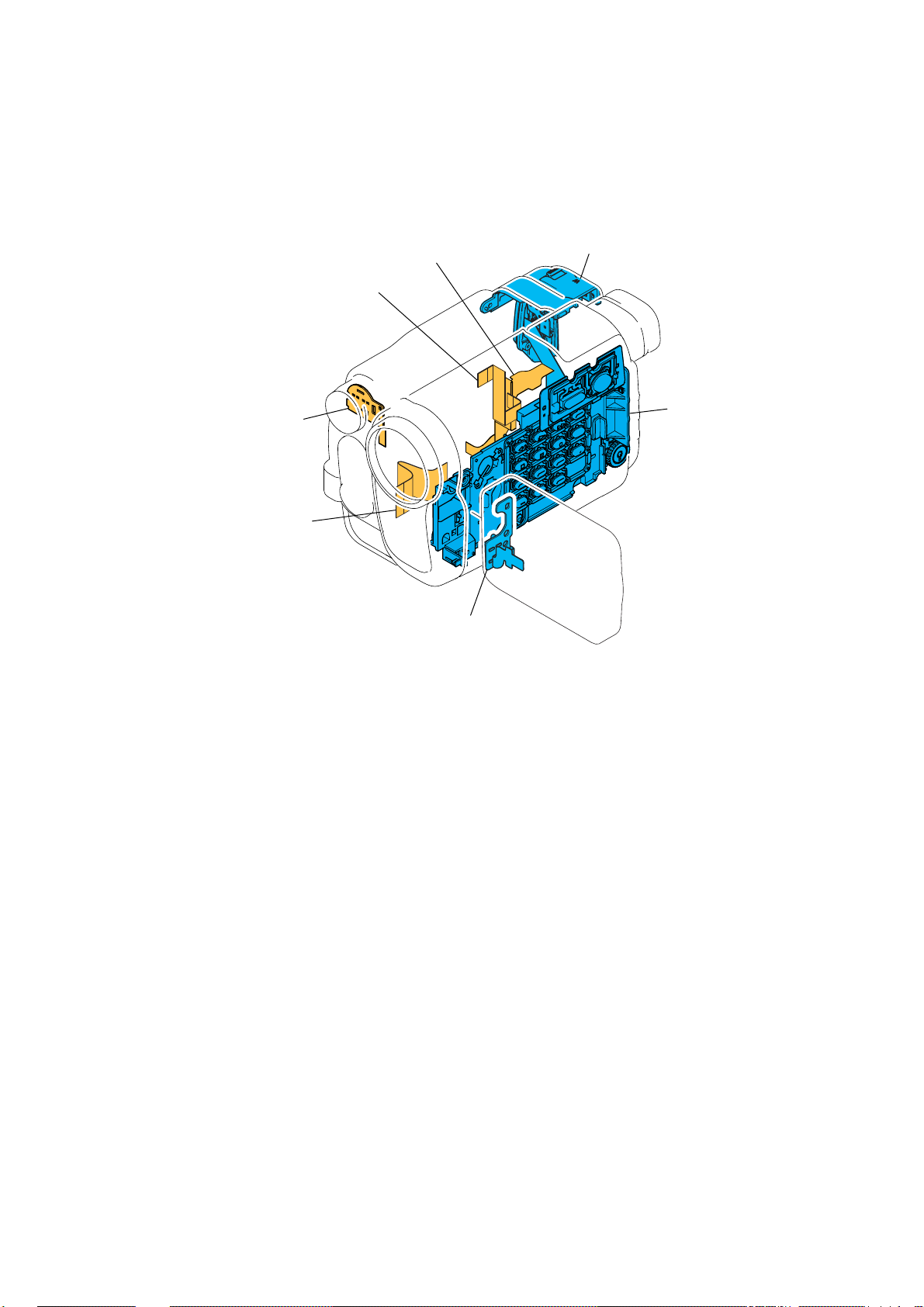

2-4. CIRCUIT BOARDS LOCATION

VC-341

SI-039

CD-465

PD-204

Board Name Function

CD-465 CCD IMAGER

VC-341 A/D CONVERTER, TIMING GENERATOR, CAMERA/VTR PROCESS,

LENS CONTROL, LENS DRIVE, REC/PB AMP, SERVO,

CAMERA/MECHA CONTROL, HI CONTROL, AUDIO, VIDEO, DC CONTROL,

STEADYSHOT, CONNECTOR

PD-204 LCD DRIVE, BACKLIGHT DRIVE

SI-039 STEADYSHOT, JACK

2-6

Page 15

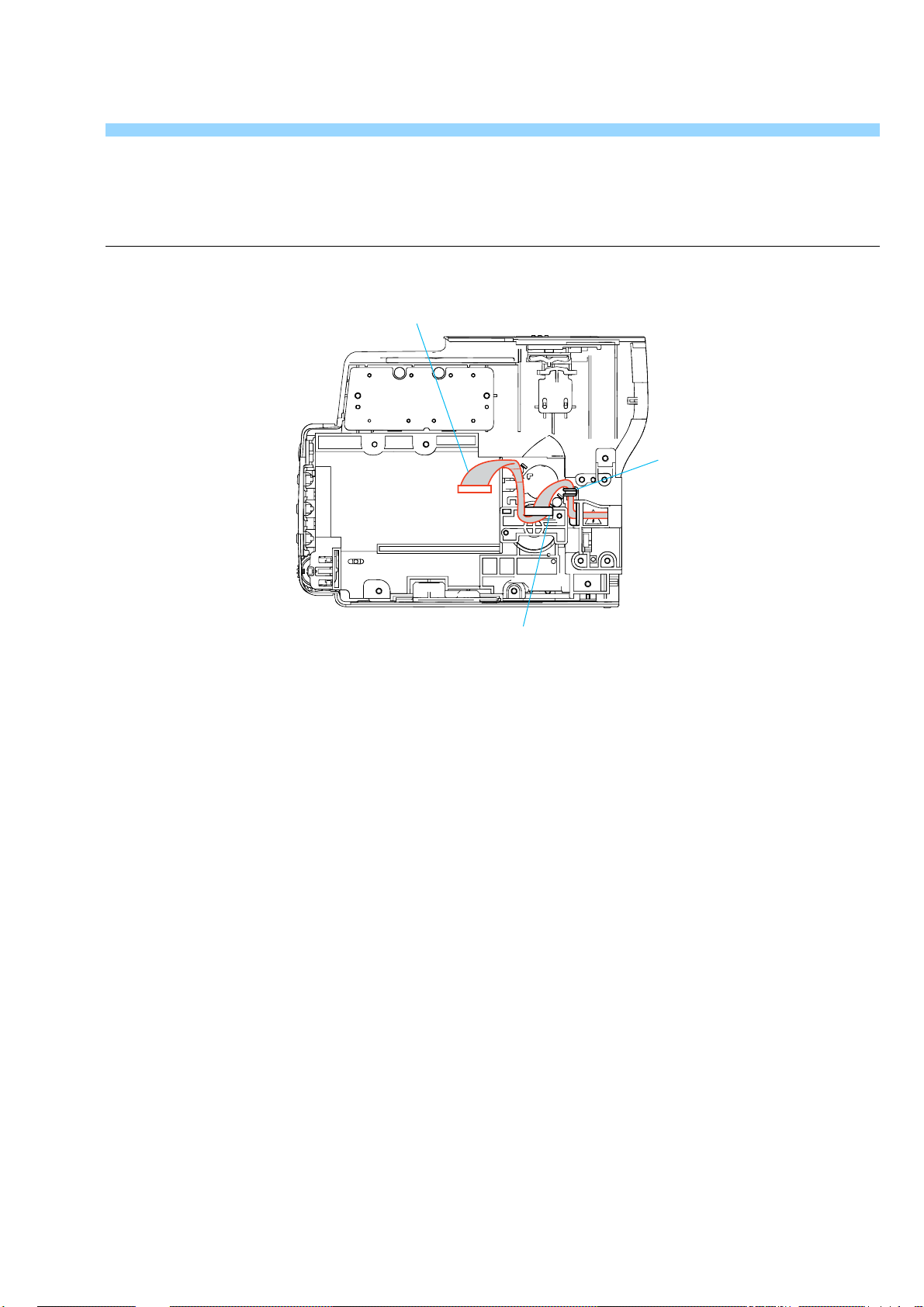

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428/TRV428E

2-5. FLEXIBLE BOARDS LOCATION

FP-792

FP-795

FFC-005

FP-797

PR-5100

SS-5100

CF-5100

2-7E

Page 16

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428/TRV428E

HELP

Sheet attachment positions and procedures of processing the flexible boards/harnesses are shown.

Harness (PD-124)

Claw

Claw

Note: Close the LCD panel, when you work.

HELP

Page 17

Link

Link

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428/TRV428E

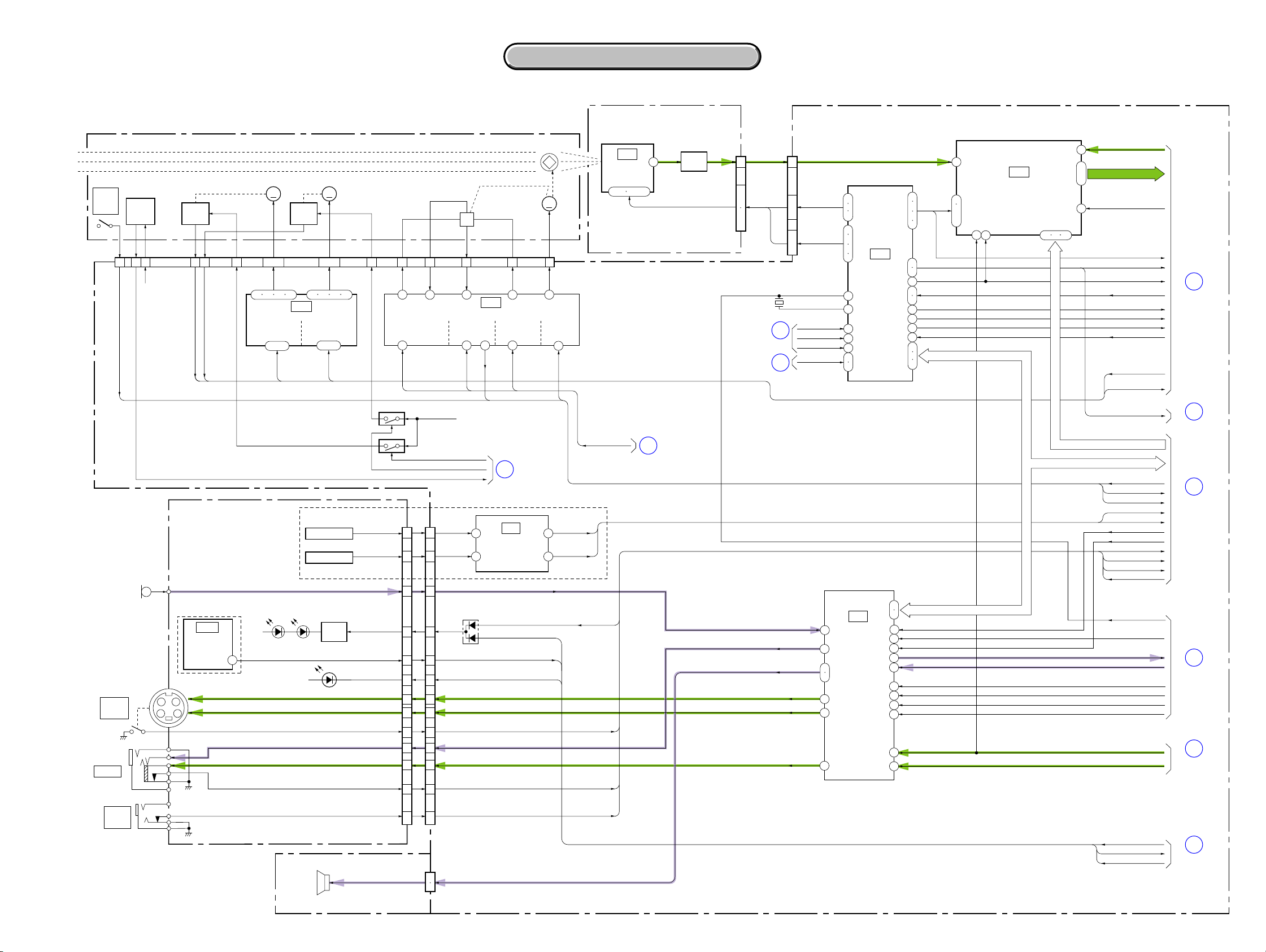

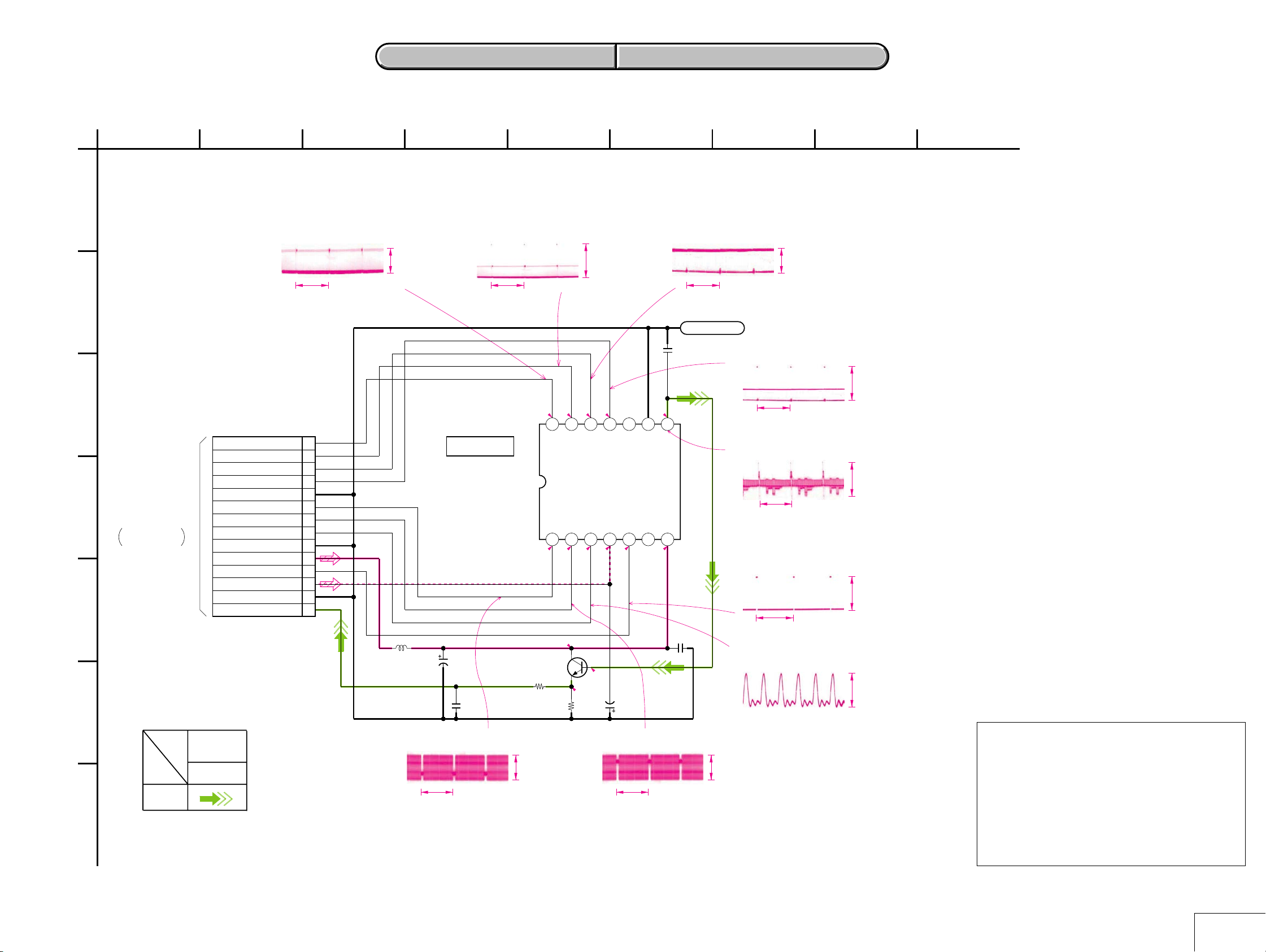

3. BLOCK DIAGRAMS

OVERALL BLOCK DIAGRAM (1/5)

OVERALL BLOCK DIAGRAM (1/5)

OVERALL BLOCK DIAGRAM (2/5)

OVERALL BLOCK DIAGRAM (2/5)

OVERALL BLOCK DIAGRAM (3/5)

OVERALL BLOCK DIAGRAM (3/5)

OVERALL BLOCK DIAGRAM (4/5)

OVERALL BLOCK DIAGRAM (4/5)

OVERALL BLOCK DIAGRAM (5/5)

OVERALL BLOCK DIAGRAM (5/5)

POWER BLOCK DIAGRAM (1/2)

POWER BLOCK DIAGRAM (1/2)

POWER BLOCK DIAGRAM (2/2)

POWER BLOCK DIAGRAM (2/2)

Page 18

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428/TRV428E

SECTION 3

BLOCK DIAGRAMS

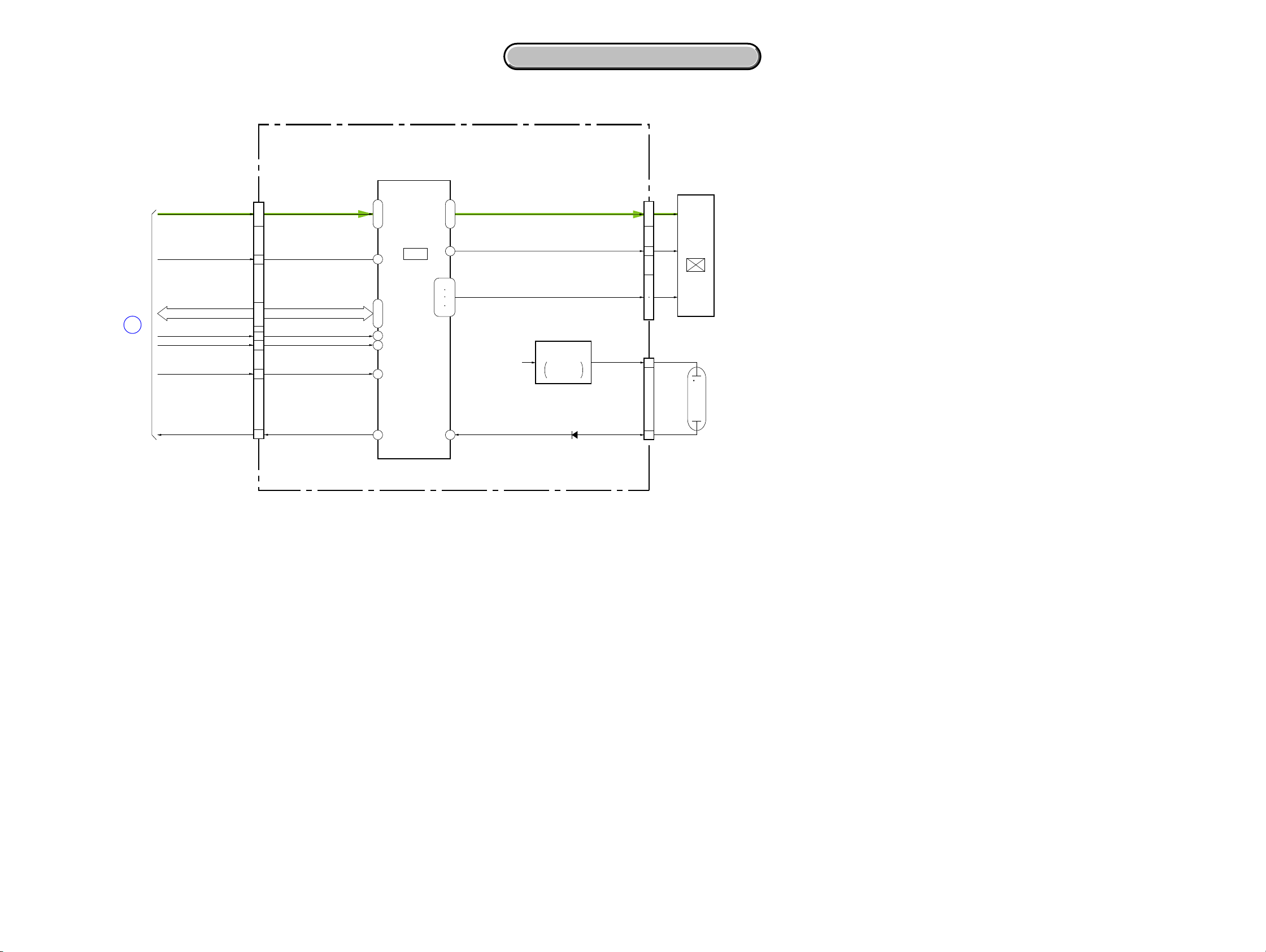

3-1. O VERALL BLOCK DIAGRAM (1/5)

LENS BLOCK

ZOOM MOTOR

NIGHT

SHOT

PLUS

CN201

LENS

TEMP

SENSOR

5 15 12 21 19

17 18

TEMP

IR SWITCHXNS SW

D 2.8V

ZOOM

SENSOR

FC SENSE OUT

ZM SENSE OUT

ZM RST

FC RST

ZM SENSE VCC

MM MM

10 – 7

5717 19 24

ZOOM

MOTOR

DRIVE

13 – 16

FOCUS

SENSOR

ZOOM

A,B,XA,XB

IC201

(3/10)

EN1

DIR1A

DIR1B

FOCUS MOTOR

1 – 4

FOCUS

MOTOR

DRIVE

9 – 12

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

CD-465 BOARD VC-341 BOARD (1/4)

CN951 CN151

Q951

BUFFER

V1-V4,RG,H1,H2

28.636363MHz : TRV128/TRV228/TRV328/TRV428

1

7

ı

9

11

ı

14

28.375MHz : TRV228E/TRV428E

OVERALL (3/5)

(PAGE 3-5)

OVERALL (3/5)

(PAGE 3-5)

X151

2

17

14

6

ı

8

1

ı

4

CCD OUT

RG, H1, H2

V1 – V4

XCS IC 301

XRST VTR

CAM DD ON

CK CONT 1, 2

FOCUS

A,B,XA,XB

21 23

EN0

DIR0A

DIR0B

1316

FC SENSE VCC

IRIS

BIAS(+)

1

HALL

BIAS

HALL

REF

2322

IRIS

HALL(+)

2

HALL

OFFSET

H

5

HALL

AMP

6

IRIS

HALL(-)

(3/10)

IC202

73

HALL

IRIS

IRIS

METER

IC951

CCD

IMAGER

1 – 4 12 – 14

7

MM

20

IRIS

BIAS(-)

14

HALL

GAIN

12

HALL

AD

GAIN

IRIS DRIVE(-)

8

IRIS

DRIVE

10

IRIS PWM

22

21

18

25

26

28

31

4

5

39

40

42

47

46

IC151

TIMING

GENERATOR

(1/10)

CLPDM,

PBLK,

1

XSHP,

2

XSHD

15

16

11

12

9

44

45

34

41

48

36

35

38

37

30

19

21

ı

23

34

16

VC SO, VC SI, XVC SCK

IC152

S/H, AGC,

A/D CONVERTER

(1/10)

46 4847

36

2

11

20

ı

PB C RF

AD1-AD10

CLP1

PBLK

MCK, CL

ADCK

AHD, AVD

XSG1

XV1

V STOP

EN0, DIR0A,B,

EN1, DIR1A,B,

FC RST, ZM RST

ID

1

OVERALL (2/5)

(PAGE 3-3)

MIC901

MICROPHONE

J751

S VIDEO

OUT

J752

A/V OUT

J753

RFU DC

OUT

SI-039 BOARD (1/2)

LND755

TRV228/TRV228E/

TRV428/TRV428E

IC751

REMOTE

COMMANDER

RECEIVER

1

S Y I/O

S C I/O

XS JACK IN

CN755 (1/2)

SIRCS PWM/

IR DRV EN

XSIRCS SIG

XF TALLY LED

AUDIO L I/O

VIDEO I/O

AV JACK IN

DCOUT JACK IN DCOUT JACK IN

D753, 754

(IR EMITTER)

D759

(TALLY)

SE752

PITCH SENSOR

SE751

YAW SENSOR

Q751

LED

DRIVE

CONTROL KEY BLOCK (CF-5100) (1/2)

SP901

SPEAKER

05

Q202 (1/2)

LIA 1

LIA 2

Q202 (2/2)

26

24

27

15

18

20 11

9

5

7

13

11

14

ZM RST LED

LENS TEMP AD

CN009 (1/2)

5

7

4

16

13

22

26

24

18

20

17

301

CN008

1

2

D 2.8V

FC RST LED

D001

SP (+), (–)

IRIS PWM

XNS SW

HALL AD,

PITCH AD

YAW AD

XCS AU

BEEP

AV JACK IN

XS JACK IN

IR ON

FRQ TUNE

RF SWP

REC AFM

PB RF

A FADE

1.5M DEV

AU BPF

FSC

IC 301 Y OUT

IC 301 C OUT

SIRCS PWM

SIRCS SIG

XF TALLY LED

CL

HALL OFFSET,

HALL GAIN,

HALL REF

OVERALL (3/5)

4

(PAGE 3-5)

TRV328/TRV428/TRV428E

IC271

8

STEADY

SHOT

(10/10)

12

SIRCS PWM

XF TALLY LED

INT MIC

SIRCS SIG

2

18

PITCH AD

YAW A D

IR_ON

XS JACK IN

AV JACK IN

OVERALL (2/5)

3

(PAGE 3-4)

INT MIC

AUDIO L I/O

SP+,–

S Y I/O

S C I/O

VIDEO I/O

58

56

49

51

21

17

19

IC801

AUDIO/VIDEO

PROCESS

(8/10)

24

25

26

27

46

33

31

9

10

11

28

13

15

CS CH, CH SO, CH SCK

VC SO, VC SI, XVC SCK

DCOUT JACK IN

VC SO, XVC SCK

16

OVERALL (3/5)

(PAGE 3-6)

5

OVERALL (3/5)

(PAGE 3-5)

6

OVERALL (2/5)

(PAGE 3-4)

7

OVERALL (2/5)

(PAGE 3-3)

8

OVERALL (4/5)

(PAGE 3-8)

A : VIDEO SIGNAL

A : AUDIO SIGNAL

3-1 3-2

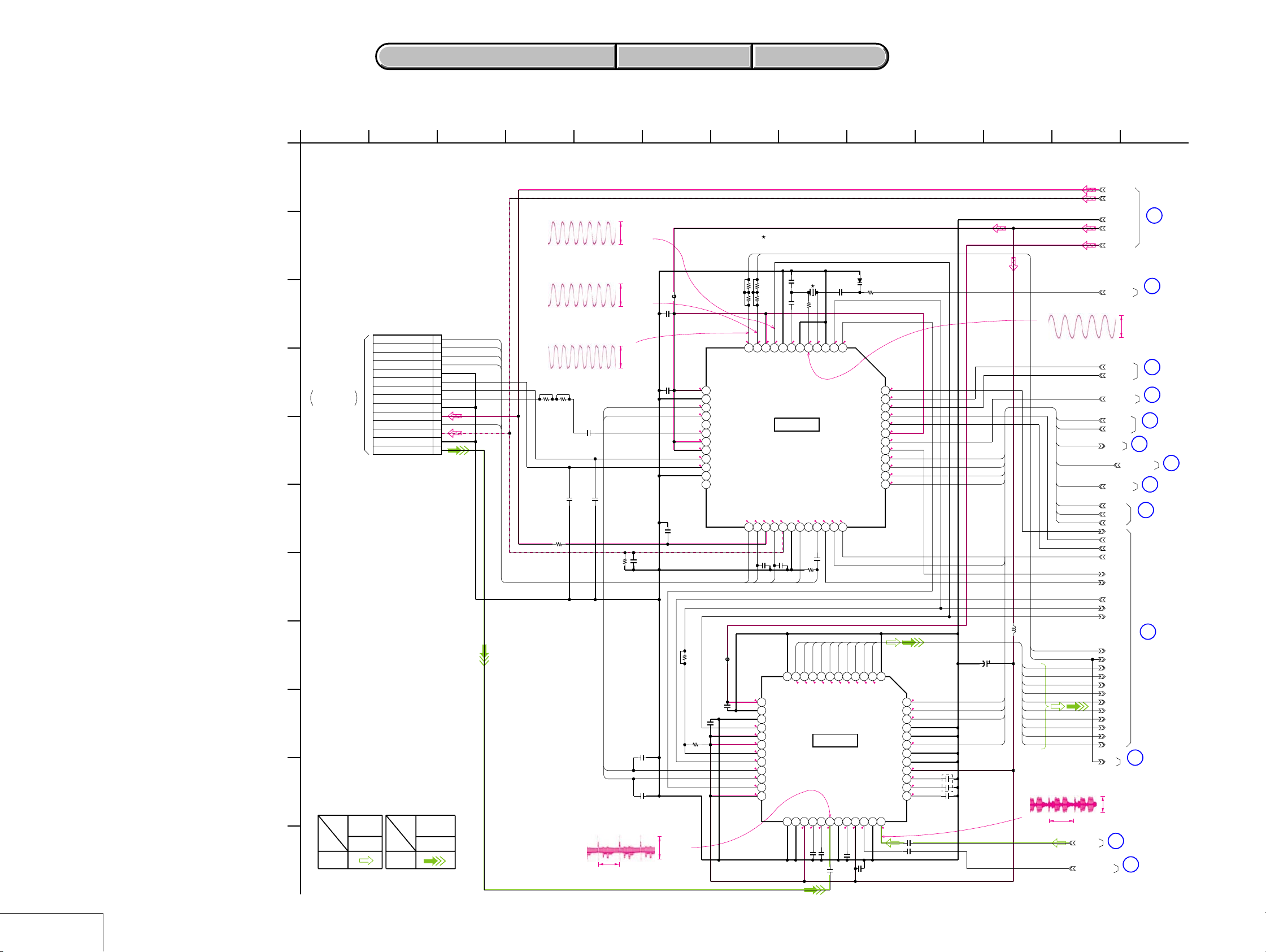

Page 19

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428/TRV428E

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

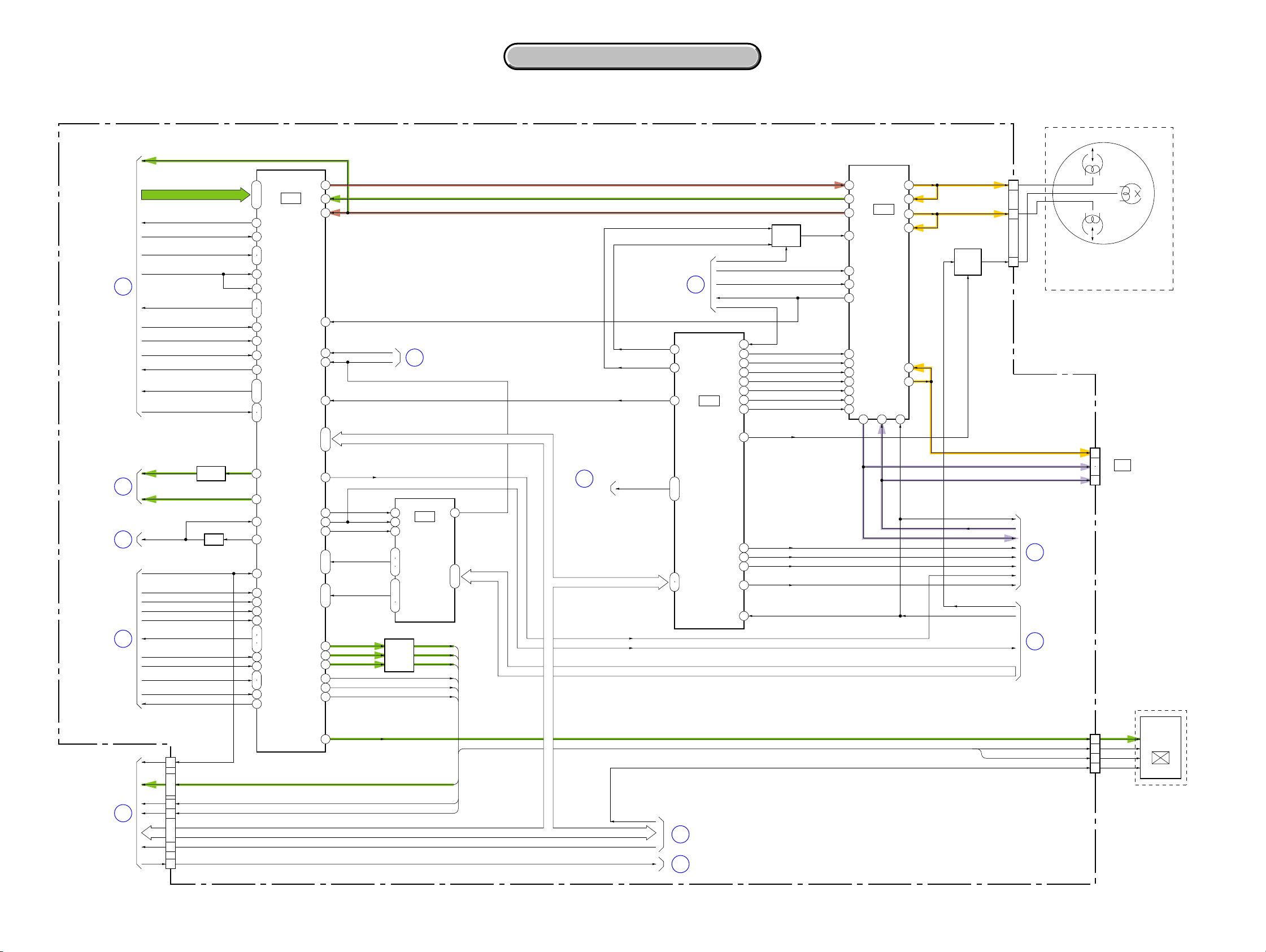

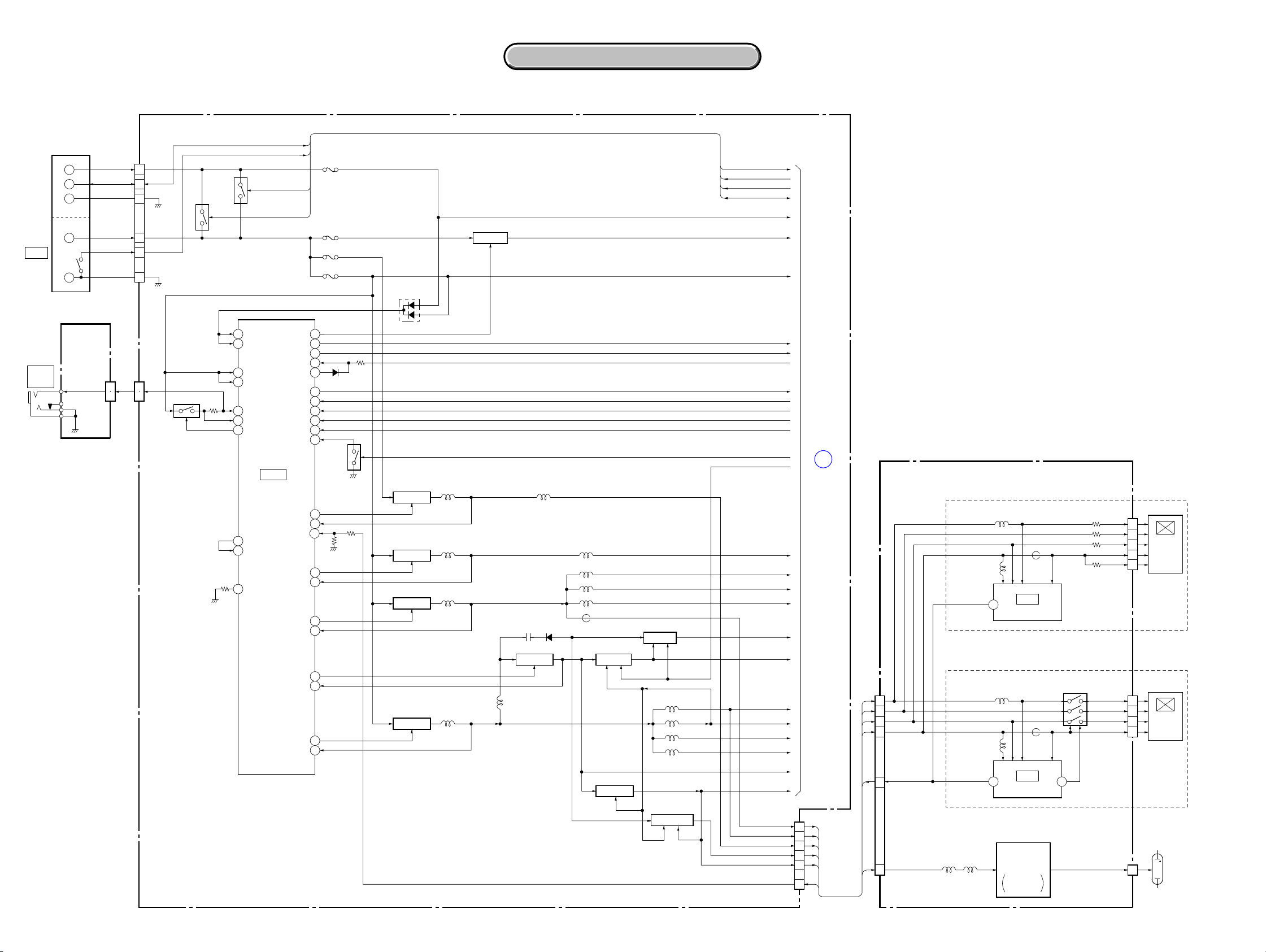

3-2. OVERALL BLOCK DIAGRAM (2/5)

VC-341 BOARD (2/4)

PB C RF

187

ı

196

183

172

81

164

185

198

169

170

166

168

171

167

148

ı

153

161

162

4

213

67

53

58

83

84

86

87

89

93

94

88

85

101

100

157

158

IC301

CAMERA/VTR

PROCESS, ATF,

LENS CONTROL

(2/10)

OVERALL (1/5)

(PAGE 3-2)

OVERALL (1/5)

(PAGE 3-2)

OVERALL (3/5)

(PAGE 3-5)

OVERALL (3/5)

(PAGE 3-5)

1

7

9

10

AD1 – AD10

CLP1

PBLK

MCK, CL

ADCK

AHD, AVD

XSG1

XV1

ID

V STOP

EN0, DIR0A, B,

EN1, DIR1A, B

FC RST, ZM RST

IC 301 Y OUT

IC 301 C OUT

AFC F0

LCD HOLD

JOG VD

X1/2 SWP

XSG V RST

ATF SAMPLE

MECHA FLD, MECHA HD,

MECHA VD

SYS V

SWP DIR

CK CONT1, 2

XTBC V RST

TBC VD

Q306

BUFFER

Q304

VCO

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

7

51

49

77

98

99

66

95

ı

97

79

146

144

179

180

ı

182

174

ı

177

14

17

24

75

74

76

DOP

AFC F0 ADJ

FSC

PANEL R

PANEL G

PANEL B

PANEL HD

PANEL VD

PANEL SYNC

REC RF

RF AGC OUT

PB C RF

XCS IC 301

XRST VTR

VC SO, VC SI, XVC SCK

VI HD

24 4

VI VDO

23

CGCK

OSD P ON,

OSD R ON,

OSD L ON

COLOR 1

COLOR 4

8

19

17

15

ı

22

ı

20

18

Q302

BUFFER

OVERALL (3/5)

11

IC302

CHARACTER

GENERATOR

(2/10)

PANEL R

PANEL G

PANEL B

(PAGE 3-5)

1

ı

3

XRST VTR

OVERALL (1/5)

(PAGE 3-1)

XCS OSD, OSD SO, XOSD SCK

3

XRF AGC OFF

RF AGC CONT

AFC F0 ADJ

HALL OFFSET,

HALL GAIN,

HALL REF

VC SO, XVC SCK

FSC

VI VDO

OVERALL (3/5)

(PAGE 3-5)

6

25

25

23

17

ı

19

27

28

AGC SLOW

BOTH REC

12

(D/A CONVERTER)

RP PB MODE

DOP

DA STRB

IC251

EVR

(4/10)

15

3

4

5

26

24

21

20

7

12

9

10

22

16

Q484, 485

SWITCH

REC Y/MT CONT

REC L CONT

MT FO

DOC DET

RP IR

REC BIAS

MT Q

XMP/ME

A FADE

1.5M DEV

AU BPF

FRQ TUNE

RF SWP

6

9

11

REC/PB AMP

10

46

13

7

3

48

15

12

8

32

19

14 1 47

IC481

(4/10)

27

28

34

33

Q481 – 483

ERASE

HEAD

OSC

38

39

XCS OSD, OSD SO, XOSD SCK

SP1X

SP2X

RF SWP

REC AFM

1.5M DEV

FRQ TUNE

RF SWP

CN481

FE (X)

PB RF

A FADE

AU BPF

FCS

XFE ON

VIVDO

VIDEO HEAD

CH

SP1

FLYING

CH

SP2

7

9

2

(FOR CHECK)

3

ERASE

CPC

EVF BLOCK

5

7

11

M2100/M2101

MECHA DECK (1/2)

M2100: TRV128/TRV228/TRV328/TRV428

M2101: TRV228E/TRV428E

CN007

(1/3)

REC RF

PB RF

BPF MONI

OVERALL (1/5)

6

(PAGE 3-2)

OVERALL (3/5)

15

(PAGE 3-5)

OVERALL (5/5)

(PAGE 3-9)

18

CN002 (1/2)

PANEL HOLD

14

7

PANEL R, PANEL G, PANEL B

ı

5

C-SYNC/XHD

9

PANEL XVD

8

11

ı

VC SO, VC SI, XVC SCK

13

XCS LCD DA

10

BL CONT

4

05

EVF G/BW Y

34

PANEL SYNC

PANEL VD

EVF DD ON

VC SO, VC SI, XVC SCK

XCS LCD

BL CONT

13

14

OVERALL (3/5)

(PAGE 3-5)

OVERALL (4/5)

(PAGE 3-8)

A : VIDEO SIGNAL

A : AUDIO SIGNAL

A : VIDEO/SERVO SIGNAL

A : VIDEO/AUDIO/SERVO SIGNAL

3-3 3-4

PANEL VD

PANEL HD

VIDEO IN

VSYNC

HSYNC

NSLEEP

CN004

LCD902

6

5

4

2

B/W

LCD UNIT

Page 20

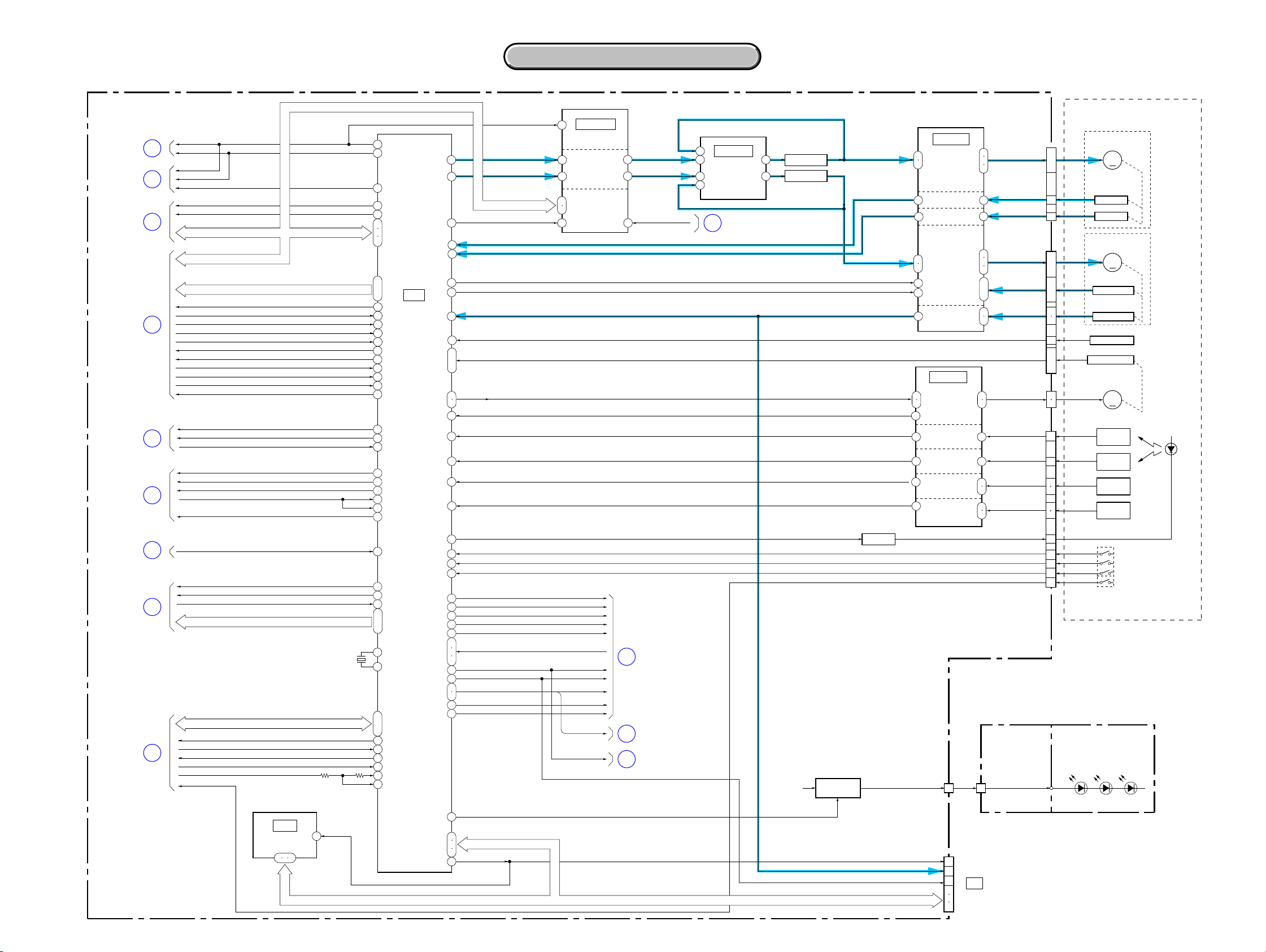

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428/TRV428E

3-3. O VERALL BLOCK DIAGRAM (3/5)

VC-341 BOARD (3/4)

OVERALL (2/5)

(PAGE 3-3)

OVERALL (1/5)

(PAGE 3-2)

OVERALL (2/5)

(PAGE 3-4)

OVERALL (1/5)

(PAGE 3-2)

OVERALL (1/5)

(PAGE 3-1)

OVERALL (2/5)

(PAGE 3-4)

OVERALL (2/5)

(PAGE 3-3)

OVERALL (2/5)

(PAGE 3-4)

OVERALL (4/5)

(PAGE 3-8)

11

13

12

15

19

XRST VTR

XCS IC 301

XRST VTR

XCS IC 301

2

CAM DD ON

EVF DD ON

XCS LCD

VC SO, VC SI, XVC SCK VC SO, VC SI, XVC SCK

VC SO, VC SI, XVC SCK

CS CH, CH SO, CH SCK

IRIS PWM

XNS SW

5

4

9

HALL AD

PITCH AD

YAW A D

XCS AU

BEEP

DCOUT JACK IN

AV JACK IN

XS JACK IN

IR ON

ZM RST LED

FC RST LED

LENS TEMP AD

AGC SLOW

BOTH REC

RP PB MODE

DOP

DA STRB

AFC F0

XFE ON

RF SWP

VIVDO

XCS OSD, OSD SO, XOSD SCK

IC701 SO, IC701 SI, IC701 SCK, XCS IC701

CUSTOM LED ON

ZOOM VR AD

DCOUT ON

OSD V

XSYS RST

XCC DOWN

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

IC401 (3/3)

34

44

41

38

36

3716

LCD HOLD

X1/2 SWP

XSG V RST

ATF SAMPLE

SWP DIR

CK CONT1, 2

XTBC V RST

CK CONT1, 2

(5/10)

LPF

SERIAL

INTERFACE

JOG VD

SYS V

TBC VD

SYS V

45

43

35

10

17

20

DRUM ERROR

CAP ERROR

CL

OVERALL (2/5)

(PAGE 3-3)

OVERALL (1/5)

(PAGE 3-2)

OVERALL (4/5)

(PAGE 3-8)

25

IC051 (1/2)

6

DRUM/CAPSTAN

9

24

16

PWM

DRIVE

(9/10)

OVERALL (1/5)

(PAGE 3-2)

SWITCHING

SWITCHING

VL 16V

Q061

Q060

TAPE LED ON

VIDEO LIGHT

DRIVE

62

61

X601

20MHz

162

109

110

128

129

130

200

111

185

186

194

127

168

169

203

117

170

159

206

133

115

208

61

76

26

75

77

78

71

ı

IC601

73

CAMERA/

93

MECHA

CONTROL

(6/10)

62

49

50

11

10

46

80

ı

82

3

1

63

ı

66

52

9

8

88

89

197

198

165

166

190

118

209

ı

211

18

17

15

20

19

119

120

201

213

212

214

163

155

157

154

156

134

173

204

181

158

95

96

179

205

VC SO, XVC SCK

DRUM FG

DRUM PG

CAP ON

CAP FWD

CAP FG

DEW AD

MODE SW A-C

LOAD

UNLOAD

LM LIM DET

TAPE END

TAPE TOP

T REEL FG

S REEL FG

TAPE LED ON

REC PROOF

ME SW

HI8 MP SW

DRUM PWM

CAP PWM

XCS IC401

MECHA FLD, MECHA HD, MECHA VD

Q001

DRUM VS

DRUM FG

DRUM PG

CAP VS

CAP FWD

CAP FG

UNLOAD

LM LIM DET

TAPE END

TAPE TOP

T REEL FG

S REEL FG

Q401

LED DRIVE

64

67

53

50

75

77

CAP ON

80

1

4

LOAD,

32

33

31

21 20

19

28

24

IC401 (1/3)

MOTOR

FG AMP

PG AMP

CAPSTAN

MOTOR

FG AMP

IC401 (2/3)

(5/10)

LOADING

MOTOR

DRIVE

TAPE END

DETECT

TAPE TOP

DETECT

T REEL

FG AMP

S REEL

FG AMP

CN009

(2/2)

(5/10)

DRUM

DRIVE

DRIVE

1 30

63

65

68

52

49

74

CAP U, V, W

76

78

10

ı

15

7

8

MODE SW A-C

LM (+) , LM (–)

69

72

TAPE END (C)

TAPE TOP (C)

18

T REEL (+) , (–)

26

27

S REEL (+) , (–)

22

23

TAPE LED (K)

REC PROOF

HI8 MP SW

XCC DOWN

SI-039 BOARD

(2/2)

CN755

(2/2)

VL+

U, V, W

HU1, 2

HV1, 2

HW1, 2

FG1, 2

DEW AD

ME SW

CN402

FG

PG

CN403

CN401

CN404

LND756

M2100/M2101 MECHA DECK (2/2)

M2100: TRV128/TRV228/TRV328/TRV428

M2101: TRV228E/TRV428E

M901

10

ı

5

3

1

14

ı

9

7

ı

2

18

16

22

21

ı

19

2

1

2

1

9

10

7

6

3

13

12

14

15

DRUM MOTOR

M

DRUM FG

DRUM PG

M902

CAPSTAN MOTOR

M

HU, HV, HW

CAPSTAN FG

DEW SENSOR

S901

MODE SWITCH

M903

LOADING MOTOR

M

Q002

TAPE END

SENSOR

Q001

TAPE TOP

SENSOR

T REEL

SENSOR

S REEL

SENSOR

S001

S002

H001

H002

REC PROOF

ME/MP

HI8 MP

C. C. LOCK

FP-792 FLEXIBLE

BOARD

D001 – 003

(VIDEO LIGHT)

D001

TAPE

LED

V LIGHT PWM

IC602

EEPROM

(6/10)

2 5 6

EEP SI, EEP SO, EEP SCK

1

XCS EEP

05

91

87

86

EEP SI, EEP SO, EEP SCK

84

XCS EEP

85

XCS EEP

CAP FG

SWP DIR

EEP SI, EEP SO, EEP SCK

CN007

(2/3)

16

4

5

15

(FOR CHECK)

14

1

CPC

A : SERVO SIGNAL

3-5 3-6

Page 21

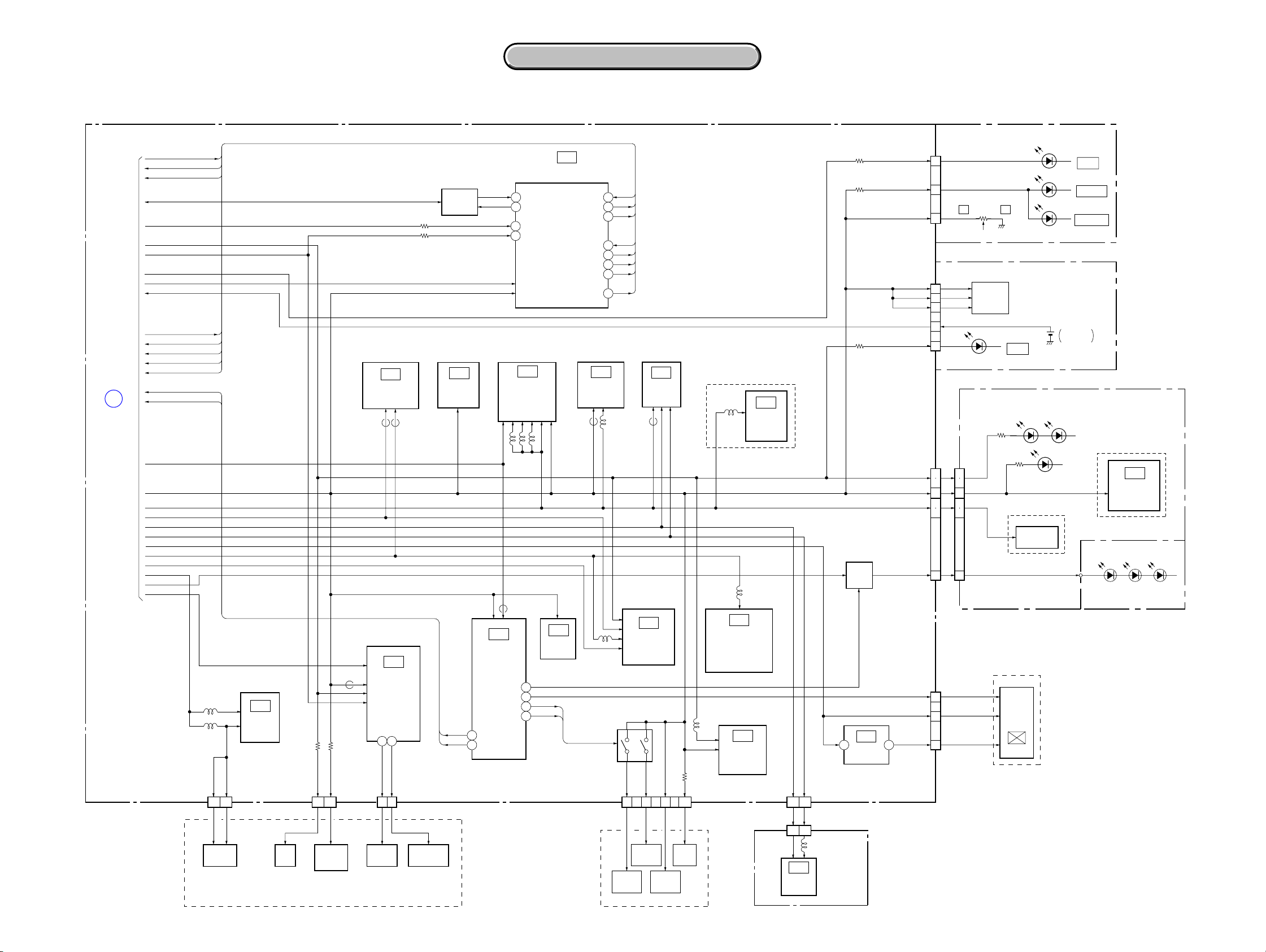

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428/TRV428E

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

3-4. O VERALL BLOCK DIAGRAM (4/5)

VC-341 BOARD (4/4)

CN007

(3/3)

12

11

13

CN002

(2/2)

20

20

CN006

1

4

3

16

6

8

9

12

CN005

19

20

5

14

18

16

6

22

Q002

LED

9

DRIVE

3

LI 3V

CN6005

1

2

PD-204 BOARD (1/2)CONTROL KEY

AD5

BLOCK (PR-5100)

S601

PANEL

REVERSE

SW

CONTROL KEY BLOCK (SS-5100)

S001

START/STOP

SW

(CHG)

S004

POWER

OFF

ON

>

MODE

D004

CHG

D002

CAMERA

D001

PLAY/EDIT

S002

EJECT SW

RV001

ZOOM VR

CONTROL KEY BLOCK (CF-5100) (2/2)

S024

SEL/PUSH

EXEC

DIAL

MENU EXEC

D002

EASY

DIAL A, B

FUNCTION

SW

S001

DISP/

BATT INFO SW

S002

RESET SW

BT001

LITHIUM

BATTERY

CPC

(FOR CHECK)

CN6001

(1/2)

XS/S SW

XPOWERSW

XMODE SW

XEJECT SW

XCHARGE LED

XCAM LED

XVTR LED

ZOOM VR

KEY AD0 – KEY AD3

CUSTOM LED ON

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

LANC IN

LANC OUT

XLANC POWER ON

KEY AD5

KEY AD7

XPOWER SW

XMODE SW

XEJECT SW

XCHARGE LED

XCAM LED

XVTR LED

ZOOM VR AD

DIAL A, B

KEY AD0 – KEY AD3

XBATT INFO SW

XRESET

X701

10MHz

X702

32.768kHz

39

40

8

29

28

52

51

67

69

1

2

4

12

11

9

79

80

59

ı

61

65

3

73

IC701

HI CONTROL

(7/10)

45

41

10

32

20

21

31

35

49

74

37

38

43

42

5

47

23

ı

26

19

Q701

BATTERY

CHARGE

DETECTOR

IC 701 SO, IC 701 SI, IC 701 SCK, XCS IC 701

SIRCS PWM

SIRCS SIG

XF TALLY LED

SYS V SYS V

HI EVER SO, HI EVER SCK

BATT IN

VTR DD ON

XCS DD

BATT/XEXT

FAST CHARGE

INIT CHARGE ON

BATT SIG

XCC DOWN

XSYS RST

OSD V

BL REG

D 1.5V

A 2.8V

D 2.8V

AU 2.8V

EP 2.8V

A 4.6V

AU 4.6V

EP 4.6V

RP 4.6V

MT 5V

VL 16V

CAM –7.5V

CAM 15V

EP 13.5V

PANEL –15.3V

EVER 3.0V

VOUT

LANC DC

D053

XRESET

VBAT

REG 3V

DC CONTROL,

27

28

44

38

26

45

39

40

14

IC051 (2/2)

RESET

(9/10)

47

IC 701 SO, IC 701 SI, IC 701 SCK, XCS IC 701

VTR UNREG

BATT UNREG

Q075

SIRCS PWM

SIRCS SIG

XF TALLY LED

BL CONT

DCOUT ON

XCC DOWN

XSYS RST

OSD V

OVERALL (1/5)

8

OVERALL (3/5)

20

OVERALL (2/5)

14

Q053, 054 Q051, 052

CHARGE

CONTROL

INIT CHARGE ON

OVERALL (3/5)

19

(PAGE 3-2)

(PAGE 3-5)

(PAGE 3-4)

FAST CHARGE

(PAGE 3-5)

BATT/XEXT

BATT SIG

CN053

BT901

4

+

–

+

S

–

DC IN

BATTERY

TERMINAL

3

2

6

5

1

ZOOM VR AD

CUSTOM LED ON

05

3-7 3-8

ZOOM VR AD

CUSTOM LED ON

Page 22

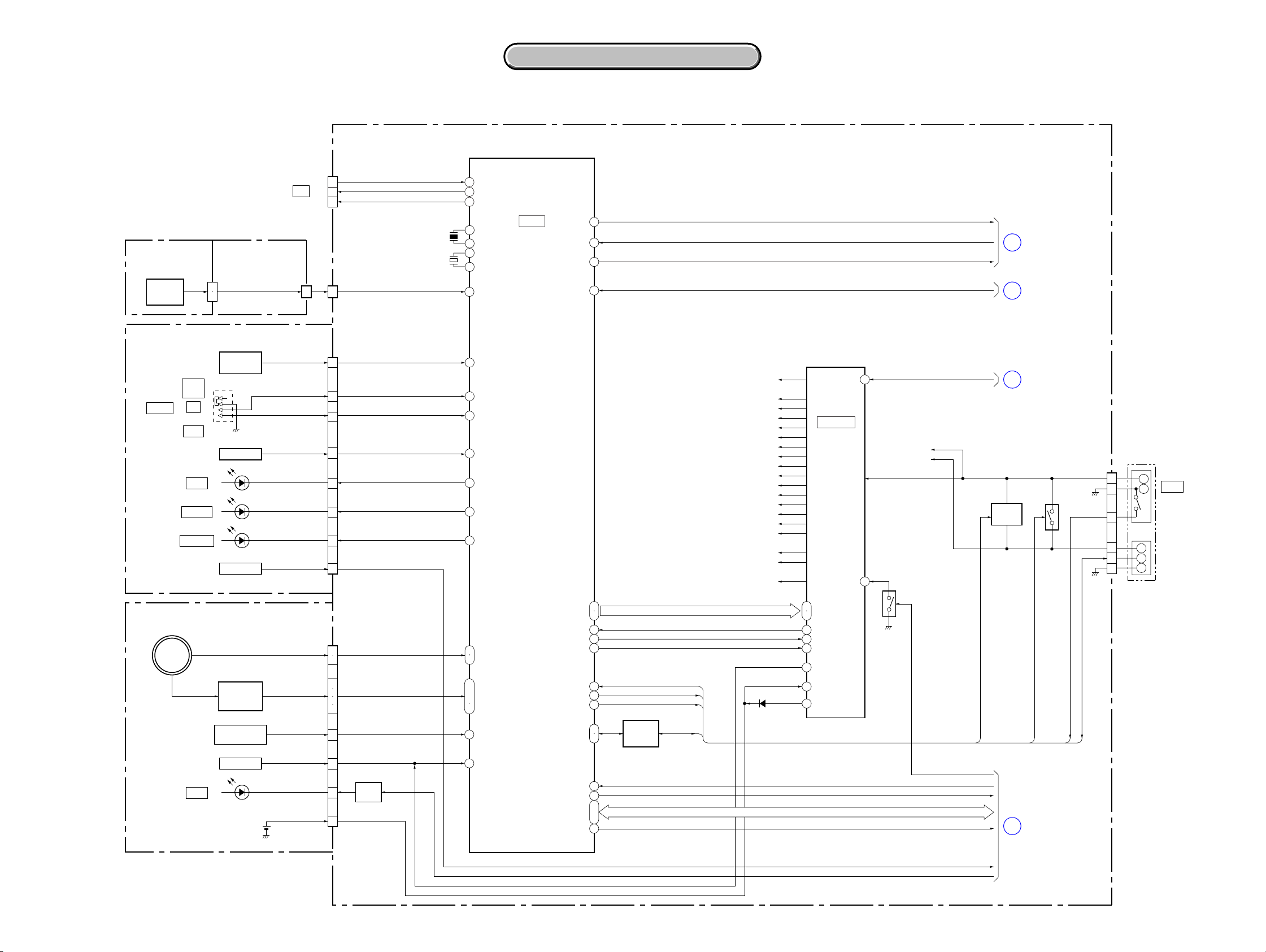

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428/TRV428E

3-5. O VERALL BLOCK DIAGRAM (5/5)

PD-204 BOARD (2/2)

CN6001

(2/2)

PANEL R, PANEL G, PANEL BPANEL R, PANEL G, PANEL B

7

ı

5

OVERALL (2/5)

(PAGE 3-3)

18

XCS LCD DA

VC SO, VC SI, XVC SCK VC SO, VC SI, XVC SCK

C-SYNC/XHD

PANEL XVD

PANEL HOLD

BL CONT BL CONT

10

11

ı

13

9

8

14

4

XCS LCD DA

C-SYNC/XHD

PANEL XVD

PANEL HOLD

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

TYPE C/S: Please refer to page 1-3

to discriminate the type of LCD.

NOTE: CN6004 Pin Name A/B

A: TYPE C MODEL

B: TYPE S MODEL

CN6004

40

ı

38

IC6001

45

46

48

43

42

28

LCD

DRIVER

ı

1

2–6

14–16

29

32–35

19

ı

21

23

N.C./SPC, GRES/EX1, GPCK/MO1, GSRT/MO2,

STBYB/PSG,RESET/EX2, VBC/CLS, STBYB/RES,

SRT/PSS1, OE/PSS2, CLR/CTR, MCLK/CLD, HCNT/SPD

T6001, Q6002

INVERTER

BL REG

BL DET

30

TRANSFORMER

BACKLIGHT

DRIBE

D6004

VR, VG, VB

VCOM

BL HIGH

BL LOW

CN6003

19

ı

21

11

5

ı

10

12

ı

18

10

3

LCD901

2.5 INCH

COLOR

LCD UNIT

ND901

BACKLIGHT

05

A : VIDEO SIGNAL

3-9 3-10

Page 23

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428/TRV428E

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

3-6. POWER BLOCK DIAGRAM (1/2)

VC-341 BOARD (1/2)

CN053

6

5

1

4

2

3

CN009

(1/2)

28

29

05

Q055

Q053, 054

CHARGE

CONTROL

Q051, 052

43

36

55

56

54

53

52

37

1

30

VIN

CDET

VCC1

VCC0

LANC DC

SENS

VCONT

VREF

DTC6

RT

INIT CHARGE ON

DC CONTROL,

DC IN

J753

RFU DC

OUT

BT901

BATTERY

TERMINAL

+

S

–

+

–

SI-039

BOARD

(1/2)

CN755

RFU DC

BATT UNREG

BATT SIG

BATT GND

ACV UNREG

BATT/XEXT

ACV GND

(1/2)

3

2

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

BATT SIG

BATT/XEXT

FAST CHARGE

REG 3V

XCTL2

IC051

RESET

(9/10)

VRO

VOUT

VBAT

DIN

CLK

CTL1

OUT2

+INE2

OUT1

OUT3

IN3

OUT7

–INE7

OUT4

IN4

F002

L052

L055

L056

L057

Q063, 065, 069

5V REG

L051

L059

D055

Q062

SWITCHING

BL REG

L058

L061

L060

L062

FB051

Q066, 073

–7.5V REG

Q064, 067, 070

+15V REG

L065

L063

L064

L066

Q071, 072

13.5V REG

Q068, 074

–15.3V REG

F003

F004

F001

VTR UNREG

VR

34

41

42

39

40

D053

CS

44

LD

26

27

28

38

47

Q075

58

21IN2

14

57

20IN1

59

22

63

2

60

23

D054

Q057

SWITCHING

Q056

SWITCHING

Q058

SWITCHING

Q059

SWITCHING

BL CONT

BATT/XEXT

FAST CHARGE

INIT CHARGE ON

BATT UNREG

VTR UNREG

EVER 3.0V

HI EVER SO

HI EVER SCK

VTR DD ON

DCOUT ON

CAM DD ON

CAM –7.5V

PANEL –15.3V

PANEL 13.5V

BATT SIG

MT 5V

V OUT

LI 3V

BATT IN

XCS DD

D 1.5V

D 2.8V

A 2.8V

AU 2.8V

CAM 15V

EP 4.6V

A 4.6V

AU 4.6V

RP 4.6V

VL 16V

EP 13.5V

CN002

PANEL 2.8V

PANEL 4.6V

BL REG

BL CONT

POWER(2/2)

(PAGE 3-13)

17

18

2

16

19

4

A

TYPE C/S: Please refer to page 1-3 to descriminate the type of LCD.

PD- 204 BOARD

TYPE C

LCD901

24

3

2.5INCH

1

COLOR

23

LCD UNIT

4

LCD901

24

3

2.5INCH

1

COLOR

23

LCD UNIT

ND901

10

BACK

LIGHT

18

16

19

17

4

2

BL REG

CN6001

PANEL 4.6V

PANEL –15.3V

PANEL 13.5V

PANEL 2.8V

BL CONT

TYPE S

PANEL 4.6V

PANEL –15.3V

PANEL 13.5V

PANEL 2.8V

BL CONT

L6002 L6003

L6004

L6001

28

L6004

L6001

FB6001

IC6001

LCD DRIVER

FB6001

IC6001

LCD DRIVER

T6001, Q6002

INVERTER

TRANSFORMER

BACKLIGHT

DRIVE

R6026

R6019

R6020

Q6004, 6005,

6008, 6009

2428

BL HIGH

R6031

CN6004

VSH

VGL

VGH

VDD

VDD

CN6004

VSH5V

VGL

VGH

VSH3V

CN6003

3-11 3-12

Page 24

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428/TRV428E

3-7. POWER BLOCK DIAGRAM (2/2)

VC-341 BOARD (2/2)

BATT/XEXT

FAST CHARGE

INIT CHARGE ON

BATT SIG

BATT UNREG

MT 5V

VTR UNREG

EVER 3.0V

VOUT VOUT

LI 3V

BATT IN

XCS DD

HI EVER SO

HI EVER SCK

VTR DD ON

DCOUT ON

A

POWER (1/2)

(PAGE 3-12)

CAM DD ON

D 1.5V

D 2.8V

A 2.8V

AU 2.8V

CAM –7.5V

CAM 15V

EP 4.6V

A 4.6V

AU 4.6V

RP 4.6V

VL 16V

EP 13.5V

L483

L481

IC481

REC/PB

AMP

(4/10)

VTR UNREG

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

IC701

HI CONTROL

L303

EEPROM

(7/10)

BATT/XEXT

FAST CHARGE

INIT CHARGE ON

BATT IN 31

XCS DD 49

HI EVER SO

HI EVER SCK 21

VTR DD ON

A/D CONVETER

FB152 FB151L151

IC602

(6/10)

IC152

S/H. AGC.

(1/10)

L801

74

37

38

20

35

Q202

IC151

TIMING

GENERATOR

(1/10)

IC801

AUDIO/VIDEO

PROCESS

(8/10)

TRV328/TRV428/TRV428E

IC271

L271

STEADY

(10/10)

CAM –7.5V

L202

IC202

IRIS DRIVE,

HALL BIAS CONTROL,

HALL GAIN CONTROL,

HALL AMP

(3/10)

L201

IC201

FOCUS/ZOOM

MOTOR DRIVE

(3/10)

SHOT

MT 5V

D 2.8V

A 2.8V

CAM 15V

EP 4.6V

MT 5V

D 2.8V

FB401

IC251

EVR

(D/A CONVERTER)

(4/10)

FB251

IC401

DRUM/

CAPSTAN/

LOADING

MOTOR DRIVE

(5/10)

VMR

VH

3 17

Q701

BATTERY

CHARGE

DETECTOR

D 2.8V

EVER 3.0V

LI 3V

IC302

CHARACTER

GENERATOR

(2/10)

FB252

D 1.5V

MT 5V

D 2.8V

A 2.8V

AU 2.8V

CAM –7.5V

CAM 15V

EP 4.6V

A 4.6V

AU 4.6V

VL UNREG VL UNREG

CAMERA/MECHA

115

162 CAM DD ON

PROCESS, ATF,

LENS CONTROL

IC601

CONTROL

(6/10)

V LIGHT PWM

DCOUT ON

43

IB SI

IB SO

42

54

BATT SENSE

55

ACV SENSE

IC301

CAMERA/VTR

(2/10)

L301

L302

FB601

91

26EVF DD ON

49ZM RST LED

50FC RST LED

EVER 3.0V

D 2.8V

MT 5V

1 4

CHARGE LED VDD

CUSTOM LED VDD

Q001

VIDEO

LIGHT

DRIVE

V LIGHT PWM

IC001

3.3V REG

(10/10)

MODE LED VDD

D 2.8V

D 2.8V

D 2.8V

D 2.8V

LI 3V

MT 5V

D 2.8V

A 2.8V

VL+

EVF DD ON

EP 4.6V

3.3V

CONTROL KEY BLOCK (SS-5100)

CN006

5

10

RV001

11

CN005

17

15

4

3

7

(ZOOM)

CONTROL KEY BLOCK (CF-5100)

FUNCTION

SWITCH

SI-039 BOARD

(2/2)

CN009

(2/2)

CN004

141517

12

9

10

1 30

NSLEEP

2

EVF 4.6V

3

1

16

19

22

21

3.3V

CN755

(2/2)

WT

D002

EASY

D753, 754

(IR EMITTER)

D759

(TALLY)

TRV328/TRV428/TRV428E

SE751, 752

YAW, PITCH

SENSOR

LND756

EVF BLOCK

LCD902

B/W

LCD

UNIT

D004

CHG

D002

CAMERA

D001

PLAY/EDIT

BT001

LITHIUM

BATTERY

TRV228/TRV228E/TRV328/

TRV428/TRV428E

COMMANDER

RECEIVER

FP-792 FLEXIBLE BOARD

D001 – 003

(VIDEO LIGHT)

IC751

REMOTE

FG VCC

17

CAPSTAN

FG

VH+

HU, HV, HW

SENSOR VCC

05

CN481

4 8

VIDEO

HEAD

TAPE

LED

D001

SP2Y

SP1Y

M2100/M2101 MECHA DECK

TAPE LED (A)

CN404 CN403

4 8 8

T REEL,

S REEL,

SENSOR

H001,002

M2100: TRV128/TRV228/TRV328/TRV428

M2101: TRV228E/TRV428E

CN201

VCC

FOCUS

SENSOR

ZOOM

SENSOR

LENS BLOCK

TEMP

18 241613

TEMP

SENSOR

IRIS DRIVE(+)

IRIS

METER

CN151

CN951

CAM –7.5V

CAM 15V

12 10

3 5

IC951

CCD

IMAGER

L951

CD-465

BOARD

ZM SENS

VCC

FC SENS

3-13 3-14E

Page 25

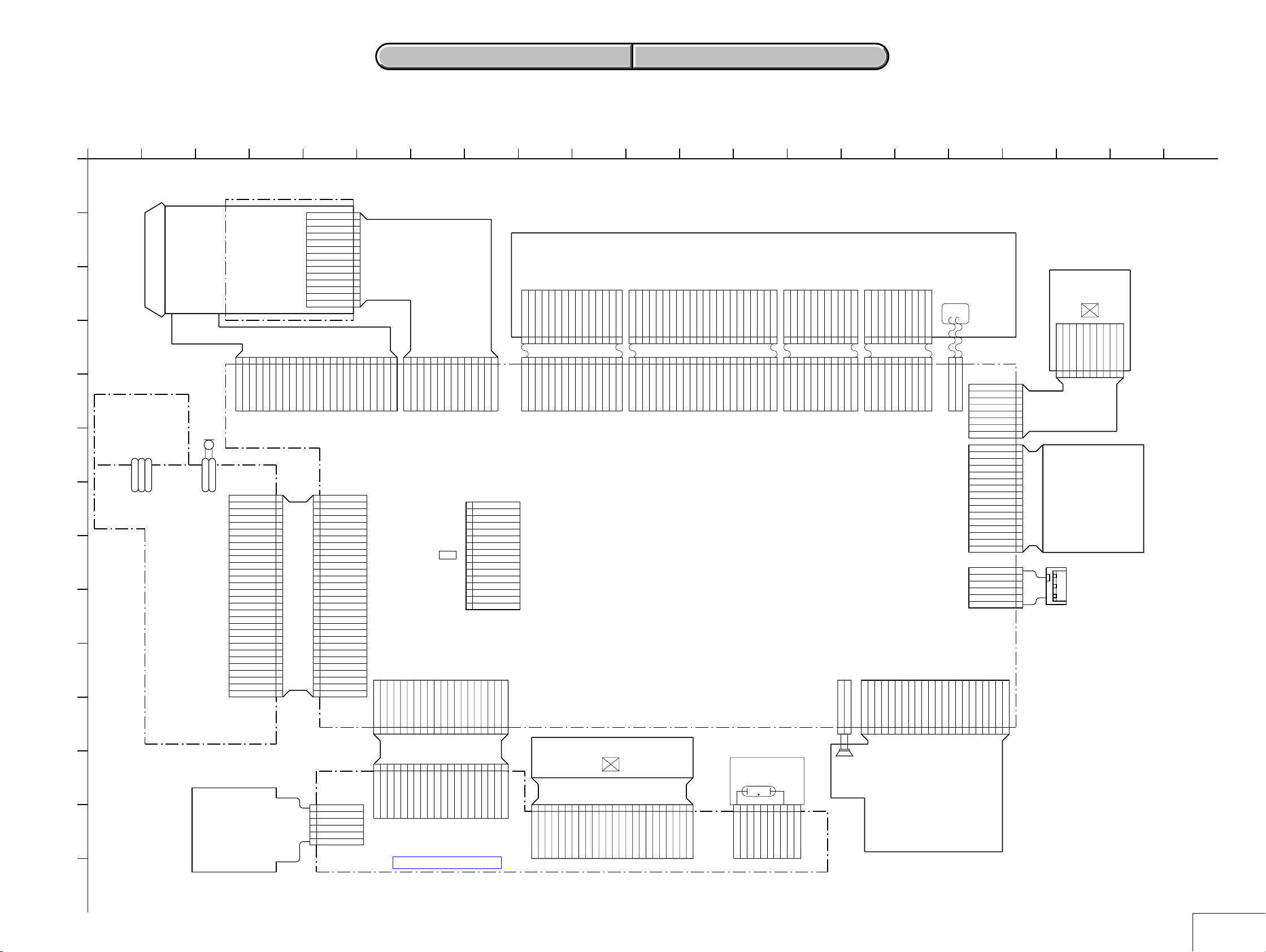

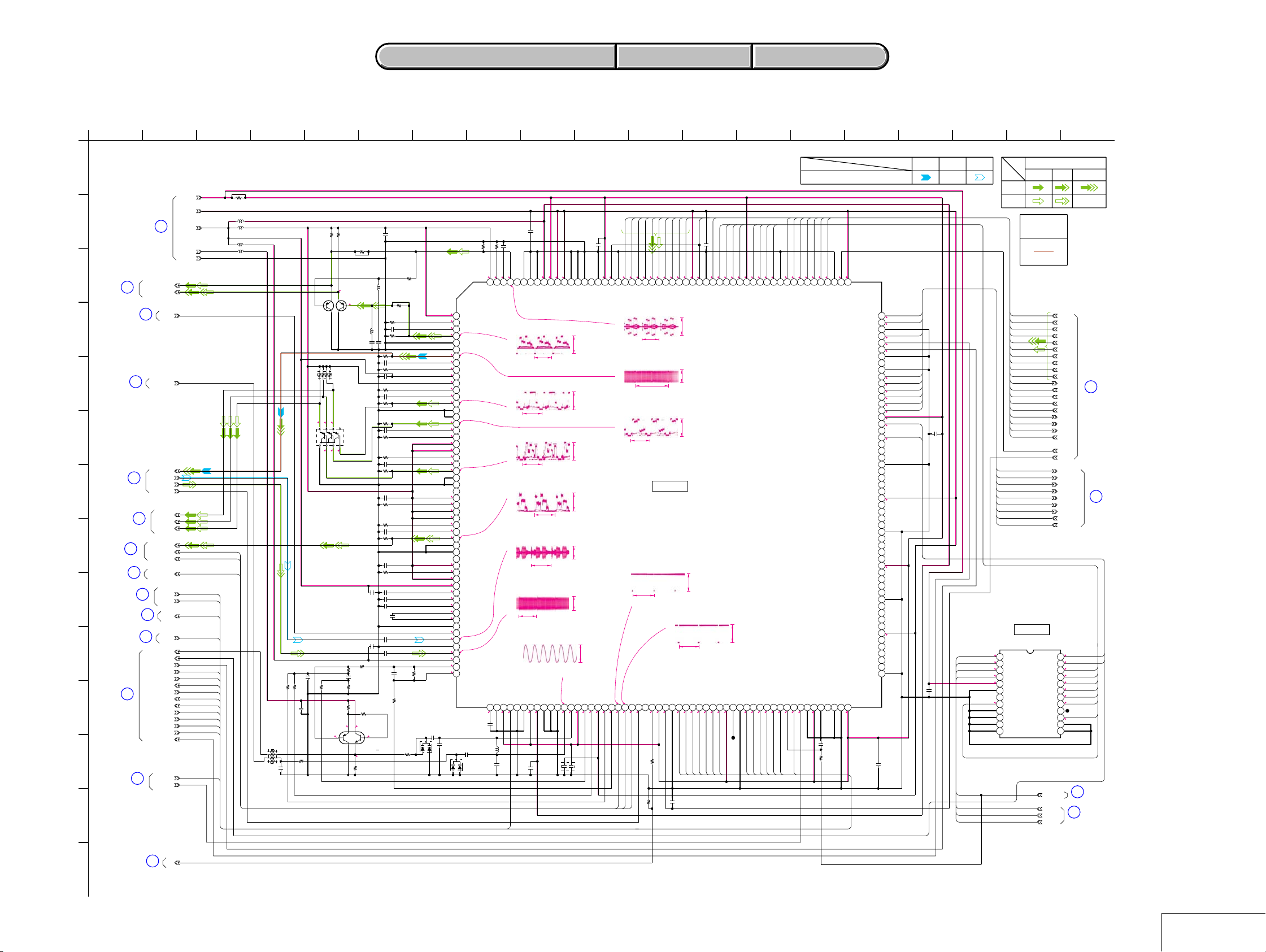

PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAMS

SECTION 4

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428/TRV428E

1

FRAME SCHEMATIC DIAGRAM

A

2 10

B

LENS

C

D

E

FP-792

F

G

H

I

FLEXIBLE

BOARD

VL+

REG_GND

REG_GND

LND759

LND756

LND760

MIC901

MICROPHONE

MIC_GND

LND754

SI-039

BOARD

J

K

L

CONTROL

M

(PR-5100)

N

05

34 1814

CD-465

BOARDBLOCK

INT_MIC

LND755

24PCN201

IRIS_HALL(+)

IRIS_DRIVE(+)

XF_TALLY_LED

SIRCS_PWM/IR_DRV_EN

DCOUT_JACK_IN

IRIS_BIAS(+)

CN755

MIC_GND

MIC_GND

INT_MIC

XSIRCS_SIG

AV_JACK_IN

AUDIO_L_I/O

REG_GND

VIDEO_I/O

REG_GND

S_Y_I/O

REG_GND

XS_JACK_IN

REG_GND

S_C_I/O

REG_GND

RFU_DC

RFU_DC

IRIS_BIAS(-)

IRIS_HALL(-)

30P

VL+

LIA1

VREF1

LIA2

VREF2

A_2.8V

A_2.8V

D_2.8V

MT_5V

MT_5V

TEMP

IRIS_DRIVE(-)

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

TEMP

KEY

BLOCK

5 12

CN951

14P

V4

14

V3

13

V2

12

V1

11

GND

10

9

H2

8

H1

7

RG

GND

LENS_DET

ZM_SENSE_VCC

ZM_SENSE_OUT

FP-795 FLEXIBLE

6

5

4

3

2

1

GND

FC_SENSE_VCC

FC_SENSE_OUT

VL+

1

MIC_GND

2

MIC_GND

3

INT_MIC

4

LIA1

5

VREF1

6

LIA2

7

VREF2

8

A_2.8V

9

A_2.8V

10

XF_TALLY_LED

11

D_2.8V

12

XSIRCS_SIG

13

MT_5V

14

MT_5V

15

SIRCS_PWM/IR_DRV_EN

16

AV_JACK_IN

17

AUDIO_L_I/O

18

REG_GND

19

VIDEO_I/O

20

REG_GND

21

S_Y_I/O

22

REG_GND

23

XS_JACK_IN

24

REG_GND

25

S_C_I/O

26

REG_GND

27

RFU_DC

28

RFU_DC

29

DCOUT_JACK_IN

30

SE_GND

SE_GND

N.C.

N.C.

PANEL_REV

PANEL_REV

CAM_15V

CAM_-7.5V

CCD_OUT

101112131415161718192021222324

ZOOM_A

30PCN009

6PCN6005

VSHT

GND

ZOOM_B

ZOOM_XB

6

5

4

3

2

1

ZOOM_XA

IR_SWITCH

IR_SWITCH

20P

CN002

20P

CN6001

FOCUS_A

FOCUS_B

AD5

AD5

FOCUS_XB

PANEL_13.5V

PANEL_13.5V

FFC-005 FLEXIBLE

FLAT CABLE

123456789

FOCUS_XA

PANEL_4.6V

PANEL_2.8V

PANEL_2.8V

PANEL_4.6V

14PCN151

CCD_OUT

PANEL_-15.3V

REG_GND

REG_GND

PANEL_-15.3V

GND

CAM_-7.5V

PANEL_HOLD

PANEL_HOLD

VSHT

VC_SI(HDO)

VC_SO

PD-124

HARNESS

VC_SO

VC_SI(HDO)

1011121314

GND

CAM_15V

CPC

(FOR CHECK)

XVC_SCK

XVC_SCK

C-SYNC/XHD

XCS_LCD_DA

9

1011121314151617181920

9

1011121314151617181920

C-SYNC/XHD

XCS_LCD_DA

PD-204

BOARD

When the machine needs to be repaired,please refer to

page 1-3 to discriminate the type of LCD(TYPE C or TYPE S).

H2RGH1

PANEL_R

PANEL_XVD

8

8

PANEL_R

PANEL_XVD

GND

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

PANEL_G

PANEL_G

16PCN007

XCS_EEP

EEP_SI

EEP_SO

XLANC_PWR_ON

LANC_IN

LANC_OUT

REG_GND

PB_RF

REG_GND

REC_RF

REG_GND

SWP_DIR

CAP_FG

BPF_MONI

PB_RF

EEP_SCK

BL_CONT

PANEL_B

PANEL_B

BL_CONT

123456789

V4

V3V1V2

SE_GND

BL_GND

BL_REG

1234567

1234567

BL_REG

BL_GND

SE_GND

9

TAPE_TOP(C)

TAPE_LED(A)

TAPE_END(C)

REG_GNDREG_GND

TAPE_LED(K)

123456789

15P

CN404

TAPE_LED(K)

TAPE_LED(A)

TAPE_TOP(C)

TAPE_END(C)

123456789

24P

VGL/VGL

VSS/GND

VGH/VGH

VDD/VGLAC

CN6004

S_REEL(-)

S_REEL(-)

N.C./SPS

SENSOR_VCC

T_REEL(+)

T_REEL(-)

HALL_COM

ME/MP

REC_PROOF

HI8_MP

C_LOCK_SW

S_REEL(+)

FP

HALL_COM

ME/MP

HI8_MP

REC_PROOF

15

C_LOCK_SW

S_REEL(+)

T_REEL(+)

SENSOR_VCC

1011121314

T_REEL(-)

VC-341 BOARD

LCD901

2.5INCH

COLOR

LCD UNIT

101112131415161718192021222324

GPCK/MO1

GSRT/MO2

STBYB/PSG

RESET/EX2

VBC/CLS

VCOM/VCOM

SRT/PSS1

STBYB/RES

GRES/EX1

11 15

M2100/M2101 MECHANISM DECK

CAP_W

CAP_W

CAP_U

22P

CN403

DEW

DEW

OE/PSS2

M-SW(A)

M-SW(B)

M-SW(A)

M-SW(B)

CLR/CTR

MCLK/CLD

CN6004 Pin Name A/BNote:

A:

TYPE C MODEL

B: TYPE S MODEL

M-SW(C)

M-SW(C)

HCNT/SPD

FG2

FG VCC

REG_GND

FG1

FG1

FG2

FG VCC

REG_GND

VB/VB

VR/VR

VG/VG

VSS/GND

CAP_U

VSH/VSH5V

VDD/VSH3V

CAP_U

CAP_U

CAP_V

FP

10111213141516171819202122

CAP_V

CAP_W

CAP_W

13 17

HV2

HW1

HU1

HV1

HU2

HU2

10

BL_HIGH

N.C

HV1

BACKLIGHT

N.C

ND901

HW2

VH-

FE(X)

123456789

11

11PCN481

VH-

HV2

HW1

HW2

FE(X)

N.C

N.C

N.C

N.C

LED

BL_LOW

CAP_V

CAP_V

VH+

VH+

HU1

10PCN6003

FE(Y)

10

FE(Y)

GND

GND

123456789

LED_GND

M2100: TRV128/TRV228/TRV328/TRV428

M2101: TRV228E/TRV428E

1916678

20

21

EVF BLOCK

LCD902

B/W

LCD

UNIT

LM

SP1X

SP1Y

GND

SP2Y

SP2X

SP2Y

SP2X

GND

GND

GND

FP

GND

SP1X

SP1Y

2PCN008

SP901

SPEAKER

GND

GND

SP(+)

SP(-)

1

2

U

123456789

10

U

10P

GND

CN402

22PCN005

REG_GND

N.C

123456789

COM

PG

FG

V

W

W

V

U

V

V

U

LI_3V

D_2.8V

FG-PG_COM

FP

W

KEY_AD0

123456789

W

FG

PG

COM

FG-PG_COM

N.C

XCUSTOM_LED_ON

BATT_INFO

REG_GND

CUSTOM_LED_VDD

XMS_LED

10111213141516171819202122

N.C

2

2P

LM(+)

CN401

MS_LED_VDD

KEY_AD1

1

LM(-)

D_2.8V

KEY_AD3

D_2.8V

XPOWER_SW

CHARGE_LED_VDD

XCHARGE_LED

MODE_LED_VDD

BATT_UNREG

KEY_AD2

DIAL_A

CN006

XS/S_SW

REG_GND

XMODE_SW

XCAM_LED

XVTR_LED

ZOOM_VR

REG_GND

XEJECT_SW

BATT_GND

BATT/XEXT

ACV_GND

ACV_UNREG

BATT_SIG

DIAL_B

N.C

D_2.8V

REG_GND

16P

N.C

N.C

XRESET

NC

NC

8PCN004

13.3V

2NSLEEP

3EVF_4.6V

4HSYNC

5VSYNC

6VIDEO_IN

7DIG_GND

8ANA_GND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

6PCN053

1

2

3

4

5

6

10

FP-797

FLEXIBLE

CONTROL

KEY

BLOCK

(SS-5100)

BT901

BATTERY

TERMINAL

3.3V3NSLEEP4EVF_4.6V5HSYNC6VSYNC7VIDEO_IN8DIG_GND9ANA_GND

1

2

CONTROL

KEY

BLOCK

(CF-5100)

4-1 4-2

FRAME

Page 26

Link

Link

CCD-TRV128/TRV228/TRV228E/TRV328/TRV428/TRV428E

4-2. SCHEMATIC DIAGRAMS

CD-465 BOARD

CD-465 BOARD

VC-341 BOARD (1/10)

VC-341 BOARD (1/10)

(A/D CONVERTER, TIMING GENERATOR)

(A/D CONVERTER, TIMING GENERATOR)

VC-341 BOARD (2/10)

VC-341 BOARD (2/10)

(CAMERA/VTR PROCESS, LENS CONTROL)

(CAMERA/VTR PROCESS, LENS CONTROL)

VC-341 BOARD (3/10)

VC-341 BOARD (3/10)

VC-341 BOARD (4/10)

VC-341 BOARD (4/10)

VC-341 BOARD (5/10)

VC-341 BOARD (5/10)

VC-341 BOARD (6/10)

VC-341 BOARD (6/10)

(CAMERA/MECHA CONTROL)

(CAMERA/MECHA CONTROL)

VC-341 BOARD (7/10)

VC-341 BOARD (7/10)

VC-341 BOARD (8/10)

VC-341 BOARD (8/10)

(CCD IMAGER)

(CCD IMAGER)

(LENS DRIVE)

(LENS DRIVE)

(REC/PB AMP)

(REC/PB AMP)

(SERVO)

(SERVO)

(HI CONTROL)

(HI CONTROL)

(AUDIO, VIDEO)

(AUDIO, VIDEO)

VC-341 BOARD (9/10)

VC-341 BOARD (9/10)

VC-341 BOARD (10/10)

VC-341 BOARD (10/10)

(STEADYSHOT, CONNECTOR)

(STEADYSHOT, CONNECTOR)

PD-204 BOARD

PD-204 BOARD

(LCD DRIVER, BACKLIGHT DRIVE)

(LCD DRIVER, BACKLIGHT DRIVE)

SI-039 BOARD

SI-039 BOARD

FP-792 FLEXIBLE BOARD

FP-792 FLEXIBLE BOARD

FP-228, FP-299, FP-300, FP-301, FP-302,

FP-228, FP-299, FP-300, FP-301, FP-302,

FP-802 FLEXIBLE BOARD

FP-802 FLEXIBLE BOARD

CONTROL KEY BLOCK

CONTROL KEY BLOCK

CONTROL KEY BLOCK

CONTROL KEY BLOCK

CONTROL KEY BLOCK

CONTROL KEY BLOCK

(STEADYSHOT, JACK)

(STEADYSHOT, JACK)

(DC CONTROL)

(DC CONTROL)

(SS-5100)

(SS-5100)

(PR-5100)

(PR-5100)

(CF-5100)

(CF-5100)

COMMON NOTE FOR SCHEMATIC DIAGRAMS

COMMON NOTE FOR SCHEMATIC DIAGRAMS