Page 1

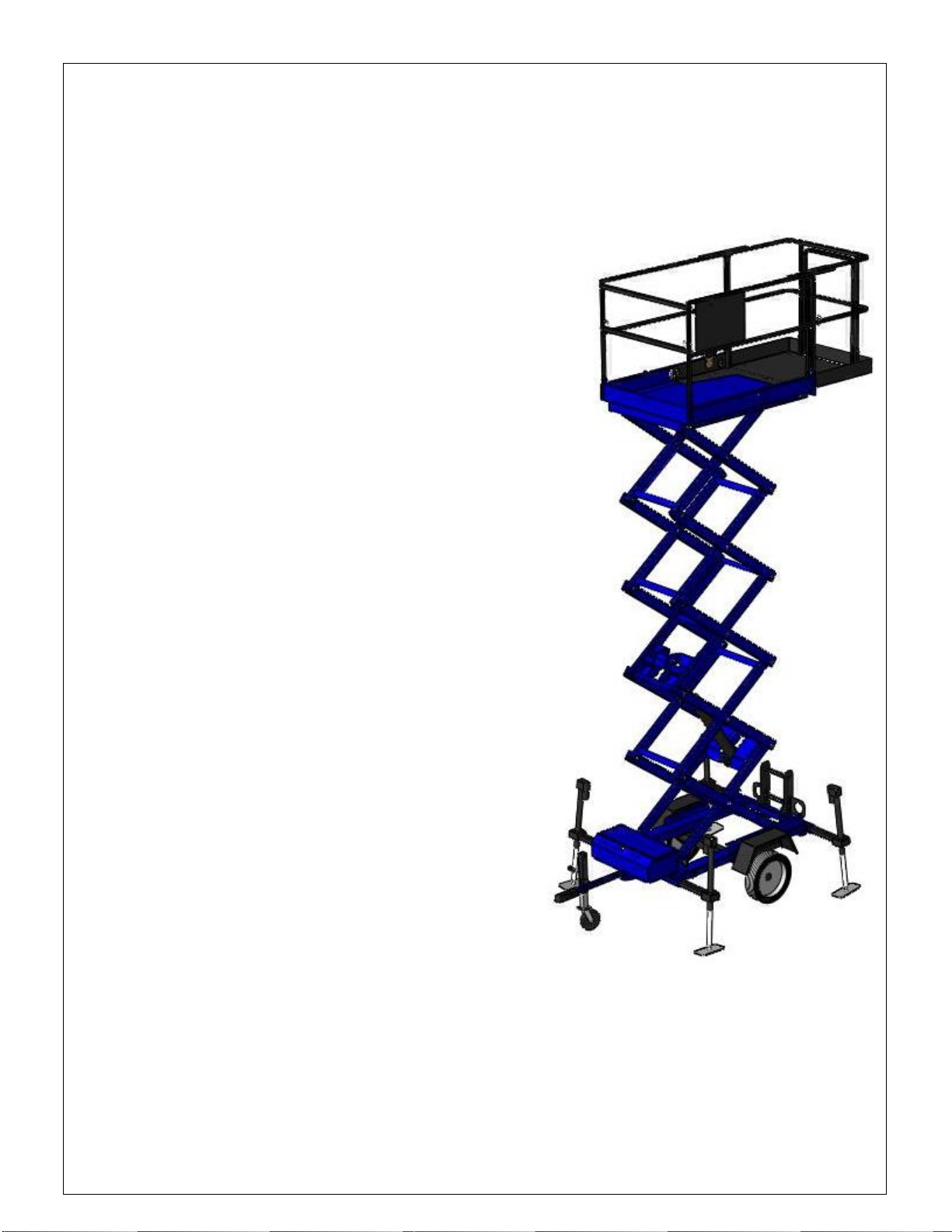

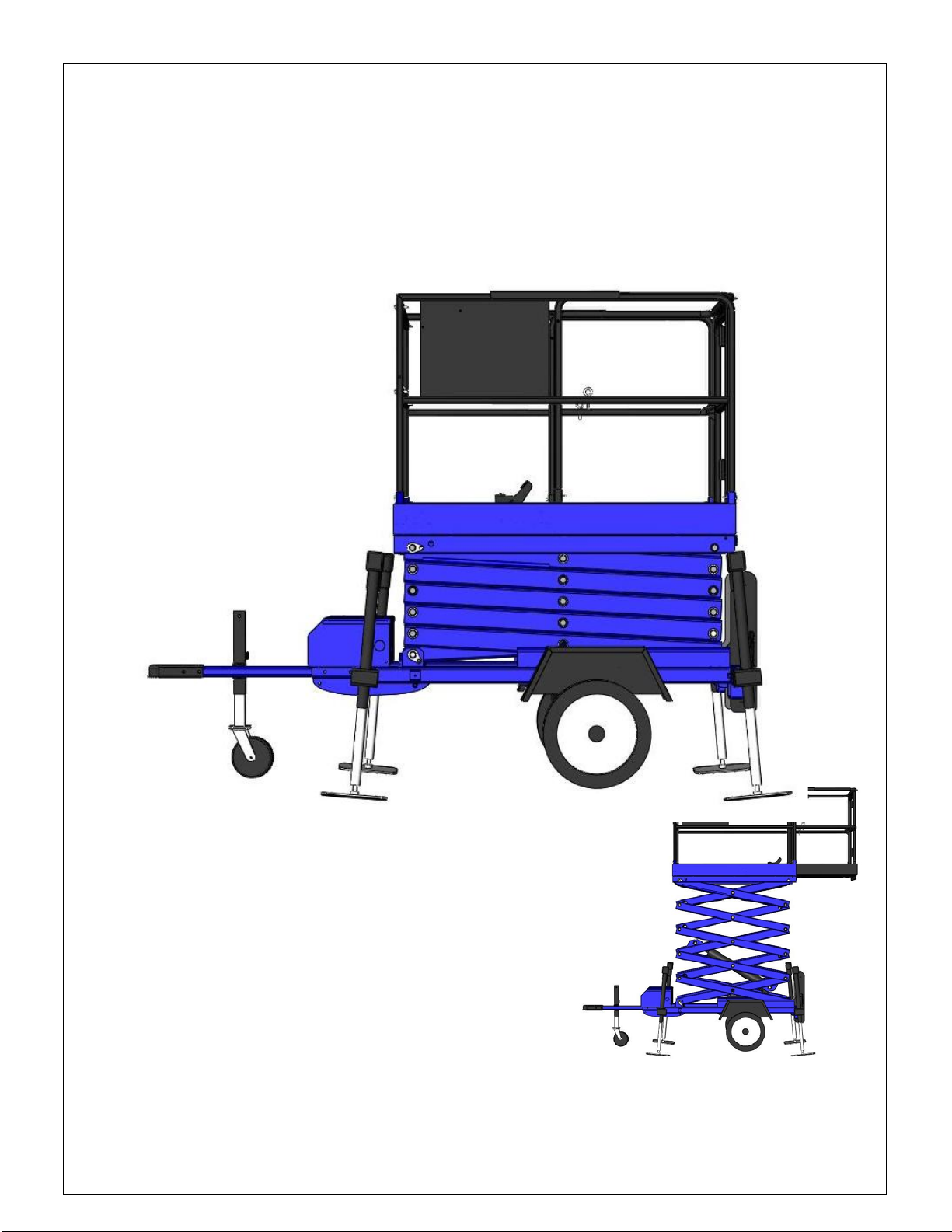

XT24AL

Scissors Lift

Operator Manual

(Maintenance, and Operations)

(EN) Manual part number 510028-000 for serial numbers 10000 to current.

December 08

Page 2

Page 3

EC DECLARATION OF CONFORMITY

FOR MACHINERY

MACHINERY:

Powered Aerial Platform known as:

Type: Upright XT24AL

Serial Number:

The machine specified above conforms to the following provisions:

Machinery directive 98/37/EC (using document EC Community Legislation on Machinery and taking

guidance from EN280:2001 + Amendment A1:2004)

E. C. Type Examination Certificate No:

Note: Modification of the specified unit renders this declaration invalid

XT24AL

Page 4

OPERATION MANUAL

WARNING

All personnel shall carefully read, understand and follow all safety rules and operating

instructions before operating or performing maintenance on any UpRight aerial work platform.

Safety Rules

Electrocution Hazard Tip Over Hazard Collision Hazard

THIS MACHINE IS NOT

INSULATED!

USE OF THE AERIAL WORK PLATFORM: This aerial work platform is intended to lift persons and his tools as well as the material

used for the job. It is designed for repair and assembly jobs and assignments at overhead workplaces (ceilings, cranes, roof structures,

buildings etc.). All other uses of the aerial work platform are prohibited!

THIS AERIAL WORK PLATFORM IS NOT INSULATED! For this reason it is imperative to keep a safe distance from live parts of electrical equipment!

Exceeding the specified permissible maximum load is prohibited! See “Special Limitations” on page 4 for details.

The use and operation of the aerial work platform as a lifting tool or a crane (lifting of loads from below upwards or from up high on

down) is prohibited!

NEVER exceed the manual force allowed for this machine. See “Special Limitations” on page 4 for details.

DISTRIBUTE all platform loads evenly on the platform.

NEVER operate the machine without first surveying the work area for surface hazards such as holes, drop-offs, bumps, curbs, or debris;

and avoiding them.

OPERATE machine only on surfaces capable of supporting wheel loads.

NEVER operate the machine when wind speeds exceed this machine’s wind rating. See “Beaufort Scale” on page 4 for details.

IN CASE OF EMERGENCY push EMERGENCY STOP switch to deactivate all powered functions.

IF ALARM SOUNDS while platform is elevated, STOP, carefully lower platform. Move machine to a firm, level surface.

Climbing up the railing of the platform, standing on or stepping from the platform onto buildings, steel or prefab concrete structures, etc.,

is prohibited!

Dismantling the swing gate or other railing components is prohibited! Always make certain that the swing gate is closed and securely

locked!

It is prohibited to keep the swing gate in an open position (held open with tie-straps) when the platform is raised!

To extend the height or the range by placing of ladders, scaffolds or similar devices on the platform is prohibited!

NEVER perform service on machine while platform is elevated without blocking elevating assembly.

INSPECT the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks, loose wire connections, and damaged

cables or hoses before using.

VERIFY that all labels are in place and legible before using.

NEVER use a machine that is damaged, not functioning properly, or has damaged or missing labels.

To bypass any safety equipment is prohibited and presents a danger for the persons on the aerial work platform and in its working

range.

NEVER charge batteries near sparks or open flame. Charging batteries emit explosive hydrogen gas.

Modifications to the aerial work platform are prohibited or permissible only at the approval by UpRight.

AFTER USE, secure the work platform from unauthorized use by turning both keyswitches off and removing key.

The driving of MEWPs on the public highways is subject to regulations made under the Road Traffic Acts.

NEVER elevate the platform or drive

the machine while elevated unless the

machine is on a firm, level surface.

NEVER position the platform

without first checking for overhead

obstructions or other hazards.

Fall Hazard

NEVER climb, stand, or sit on

platform guardrails or midrail.

Page 5

Page 6

TABLE OF CONTENTS:

IMPORTANT .................................................10

SAFETY ISSUES ............................................10

DO NOT O PERATE UNLESS YOU: .......................................................................................................................... 10

BATTERY SAFETY ............................................................................................................................... .............. 10

ELECTROCUTION HAZARDS ......................................................................................................................... 11

DAMAGED MACHINE HAZARDS ................................................................................................................... 11

BODILY INJURY HAZARD .............................................................................................................................. 11

TOWING CAUTIONS/WARNING ................................................................................................................ 11

CRUSHING HAZARDS ...................................................................................................................................... 13

OUTRIGGER/LEVELING WARNINGS .......................................................................................................... 13

SAFETY RULES REGARDING PLATFORM USE .......................................................................................... 14

OPERATIONS ................................................15

TOWING PROCEDURE ...................................................................................................................................... 15

PLATFORM........................................................................................................................................................... 16

OUTRIGGER USE ............................................................................................................................................... 17

ELECTRIC OUTRIGGER MANUAL OVER RIDE .......................................................................................... 17

OPERATION OF SCISSORS LIFT .........................17

CONTROLS: ............................................................................................................................... .......................... 17

CONTROL FROM GROUND LEVEL ................................................................................................................ 18

CONTROL THE SCISSORS LIFT FROM THE PLATFORM. ..................................................................... 19

MACHINE CONTROLS WITH OPTION “AUTO-LEVEL” AT

GROUND LEVEL..............................................21

DIAGRAM OF AUTO LEVEL AND VARIABLE HEIGHT ...22

NOTE: On European machines the enable button is moved to the left 3 slots .............................................................. 23

LEVELING PROCEDURE.................................................................................................................................... 23

PROBLEMS WITH MACHINE LEVELING .................................................................................................................. 23

MACHINE CONTROLS WITH OPTION “VARIABLE

HEIGHT” AT GROUND LEVEL ..............................26

ALARMS AND ALARM LIGHTS ..................................................................................................................... 26

- 7 - 8002/13/1

Page 7

MAINTENANCE AND TROUBLE SHOOTING .............27

OUTRIGGER SWITCHES ADJUSTMENT PROCEDURE: ..27

PRECONDITIONS FOR ADJUSTING SWITCHES:.................................................................................................... 28

PROCEDURE FOR PRESSURE SWITCH: ...................................................................................................... 28

PROCEDURE FOR THE PROXIMITY SWITCH: .......................................................................................................... 28

TESTING: ............................................................................................................................................................ 29

HYDRAULIC FLUID LEVEL/TYPE AND MAINTENANCE..29

ROUTINE MAINTENANCE MANUAL ......................29

HYDRAULICS – ATF MERCON/DEXRON III HYDRAULIC OIL ............................................................................ 30

SCISSORS STACK................................................................................................................................................... 30

BATTERY ................................................................................................................................................................. 30

SCISSORS LIFT ARM WEAR PADS........................................................................................................................ 31

ELECTRICAL WIRING............................................................................................................................................. 31

HYDRAULIC TANK CAP VENTING SYSTEM ........................................................................................................... 31

BLEEDING AIR FROM THE HYDRAULIC SYSTEM- SYSTEM “LOCK”........................................................................ 32

TIRES AND WHEELS .............................................................................................................................................. 32

OTHER LUBRICATION ............................................................................................................................................ 33

LEVEL SENSOR- AUDIBLE ALARM .......................................................................................................................... 33

DOCUMENT OF RESPONSIBILITY ........................33

DEFINITIONS:....................................................................................................................................................... 33

DEALER RESPONSIBILITIES: ................................................................................................................................34

RESPONSIBILITIES OF OWNERS:......................................................................................................................... 35

RESPONSIBILITIES OF USERS:............................................................................................................................. 37

RESPONSIBILITIES OF OPERATORS:.................................................................................................................... 42

RESPONSIBILITIES OF LEASERS:......................................................................................................................... 45

RESPONSIBILITIES OF LESSEES: ......................................................................................................................... 45

MAINTENANCE SECTION:.................................47

INSPECTION: ...............................................47

HYDRAULICS – ATF (AUTOMATIC TRANSMISSION

FLUID) MERCON/DEXRON III.............................47

SCISSORS STACK...........................................47

BATTERY .....................................................47

SCISSORS LIFT ARM WEAR PADS........................48

1/31/2008 - 8 -

Page 8

ELECTRICAL WIRING.......................................48

HYDRAULIC TANK CAP VENTING SYSTEM ..............49

BLEEDING AIR FROM THE HYDRAULIC SYSTEM-

SYSTEM “LOCK” .............................................49

TIRES AND WHEELS .......................................50

OTHER LUBRICATION ......................................50

ALARMS (A HORN IN CONTROL BOX AND A RED LIGHT

ON PLATFORM)..............................................50

Outrigger proximity and pressure switches- Audible/Visual alarm.................................................................... 50

Level sensor- Audible/Visual alarm.................................................................................................................... 50

1/31/2008 - 9 -

Page 9

IMPORTANT

Read, understand and obey these safety rules and operation instructions before operating this

machine.

Only trained and authorized personnel shall be permitted to operate this machine.

This manual should be considered a permanent part of your machine and should remain with the

machine at all times.

If you have any questions, call UPRIGHT.

SAFETY ISSUES

Failure to obey the instructions and safety rules in this manual may result in death or serious injury.

Do Not Operate Unless You:

1. Learn and practice the principles of safe machine operation contained in this operator‛s

manual

2. Avoid hazardous situations

3. Know and understand the safety rules before operating the machine

4. Always perform a pre-operation inspection

5. Always perform function tests prior to use

6. Inspect the workplace

7. Only use the machine as it was intended

8. Read, understand and obey

a. Manufacturer‛s instructions and safety rules - safety and operator‛s manuals and decals

b. Employer‛s safety rules and worksite regulations

c. Applicable governmental regulations

9. Are properly trained to operate the machine safely

10. The batteries are charged

BATTERY SAFETY

1. Do not operate the machine with low charge on the batteries.

2. Batteries contain acid. Always wear protective clothing and eyewear when working with

batteries.

3. Avoid spilling or contacting battery acid. Neutralize battery acid spills with baking soda and

water.

4. Do not expose the batteries or the charger to water and/or rain during charging.

5. Keep sparks, flames, and lighted tobacco away from batteries. Batteries emit an explosive

gas, especially during charging.

- 01 - 8002/13/1

Page 10

6. Do not contact the battery terminals or the cable clamps with tools that may cause sparks.

7. Do not use any battery charger greater than nominal 24 Volts to charge the batteries.

8. Avoid electrical shock from contact with battery terminals. Remove all rings, watches and

other jewelry.

ELECTROCUTION HAZARDS

1. This machine is not electrically insulated and will not provide protection from contact with

or proximity to electrical current.

2. Maintain safe distances from electrical power lines and apparatuses in accordance with

applicable governmental regulations.

3. Allow for platform movement, electrical line sway or sag and beware of strong or gusty

winds.

4. Keep away from the machine if it contacts energized power lines. Personnel on the ground

or in the platform must not touch or operate the machine until energized power lines are

shut off.

5. Do not operate the machine during lightning or storms.

6. Do not use the machine as a ground for welding both for operator protection and for

equipment damage.

DAMAGED MACHINE HAZARDS

1. Do not use a damaged or malfunctioning machine.

2. Conduct a thorough pre-operation inspection of the machine and test all functions before

each work shift. Immediately tag and remove from service any damaged or malfunctioning

machine.

3. Be sure all maintenance has been performed as specified in this manual.

4. Be sure the Service Manual is complete, legible and in the storage container located on the

platform.

BODILY INJURY HAZARD

Do not operate the machine with a hydraulic leak. High pressure hydraulic leaks can

penetrate, cut and/or burn skin.

Do not leave a wrench on the electric outrigger over-ride nut located on top of the electric

outriggers.

TOWING CAUTIONS/WARNING

1. Caution should be taken when towing to avoid high speeds and short turns. Unit may tip over

and this could result in death or serious injury.

1/31/2008 - 11 -

Page 11

2. Remove all cargo from the scissors lift before towing. Failure to do this could result in

death or serious injury.

3. Do not operate unit in high speed winds, death or serious injury could occur.

4. Tow only with outriggers in transport position

5. Tow only with extension deck retracted and

pinned

6. Tow only with the deck lowered in transport

position

7. All tires must be properly inflated. Find the

recommended cold tire pressures on the tire

sidewall or trailer decal which is located inside

of the bottom control box. Do not over inflate

the tires. Tire pressures go up during driving.

Checking the tire pressure when the tires are

warm will give you an inaccurate pressure

reading.

8. Increase the distance between your vehicle and

the vehicle in front of you to twice the normal

following distance when towing a trailer. Allow

more following distance in adverse weather.

9. Slow down for downgrades and shift your

transmission into a lower gear.

10. Slow down for curves, hazardous road

conditions, freeway exits, and when driving in

adverse weather. Remember that your PLE Lift

may have a center of gravity that is higher than

the vehicle that is pulling it.

11. When passing other vehicles, be sure to leave

enough room for the extra length of the trailer.

You will need to go farther beyond the past

vehicle before you can return to your lane.

12. When turning with a trailer, avoid jerky or

sudden movements.

13. Heavy winds, excessive speed, load shifting or

passing vehicles can cause the trailer to sway

while driving. If this occurs, do not brake, do not speed up, and do not turn the steering

wheel. Turning the steering wheel or applying the brakes can cause the vehicle and trailer

to jackknife. Let up on the gas pedal and keep the steering wheel straight.

14. If the vehicle and/or trailer inadvertently travel off the paved road, hold the steering

wheel firmly and let up on the gas pedal. Do not apply the brakes. Do not turn sharply.

1/31/2008 - 12 -

Page 12

Slow down to less than 25 mph or 40 km/h. Gradually turn the steering wheel to get back

on the road. Proceed with caution when entering traffic.

15. Always drive slowly when backing a trailer.

16. Keep your hand on the bottom of the steering wheel. Move your hand to the left to turn

the trailer to the left. Move your hand to the right to turn the trailer to the right. Your

PLE Lift has a short wheel base so small moves of the steering wheel have large effects on

the trailer.

17. Be aware of limited sight distance and blind spots when operating.

18. It is recommended that operators wear an approved hard hat when operating the machine.

19. Check the work area for overhead obstructions or other possible hazards.

20. Be aware of crushing hazard when grasping the platform guardrail.

21. Do not operate a machine in the path of any crane or moving overhead machinery unless the

controls of the crane have been locked out and/or precautions have been taken to prevent

any potential collision.

22. Do not lower the platform unless the area below is clear of personnel and obstructions

CRUSHING HAZARDS

1. Keep hands and limbs out of the scissors.

2. Use common sense and planning when operating the machine with the controller from the

ground.

3. Maintain safe distances between the operator, the machine and fixed objects.

OUTRIGGER/LEVELING WARNINGS

1. Do not stand on unit (other than the platform) or attempt to move unit when it is in an

elevated position. Death or serious injury may occur

2. Do not use without outriggers deployed. Death or serious injury may occur

3. Do not operate without outriggers pinned in place. Death or serious injury may occur

4. Do not elevate if machine is not level or on ground that is not firm. Death or serious injury

may occur

5. Do not ride on unit while being towed. Death or serious injury may occur

6. Do not operate unit in winds that exceed 12.5 mps/28 mph. Death or serious injury may

occur

7. Do not exceed weight capacity of 226 kg/500 pounds total weight. If unit is equipped with

the extension deck, 113kg/250 pounds on main deck 113 kg/250 pounds on extension deck.

No more than 2 people on the deck. Death or serious injury may occur

8. Do not stand on handrails. Death or serious injury may occur

9. Do not make contact with electrical wires and electrical fields. Death or serious injury may

occur

1/31/2008 - 13 -

Page 13

10. Do not use without all four outriggers deployed. Death or serious injury may occur

11. Do not operate without all four outriggers pinned in place. Death or serious injury may

occur.

12. Do not elevate this machine if the machine is not leveled in both axis (front to back and side

to side. Death or serious injury may occur.

SAFETY RULES REGARDING PLATFORM USE

1. Do not place or attach fixed or overhanging loads to any part of this machine.

2. Do not place ladders or scaffolds in the platform or against any part of this machine.

3. Be sure all tires are in good condition, lug nuts are properly tightened and cotter pins are

properly installed.

4. Do not use the machine as a crane.

5. Do not contact adjacent structures with the platform.

6. Do not alter or disable the limit switches.

7. Do not operate the machine in strong or gusty winds. Do not increase the surface area of

the platform or the load. Increasing the area exposed to the wind will decrease machine

stability.

8. Do not use the platform controls to free a platform that is caught, snagged or otherwise

prevented from normal motion by an adjacent structure. All personnel must be removed

from the platform before attempting to free the platform using the ground controls

9. Do not push off or pull toward any object outside of the platform.

10. Do not alter or disable machine components that in any way affect safety and stability.

11. Do not modify or alter an aerial work platform. Mounting attachments for holding tools or

other materials onto the platform, toe boards or guardrail systems can increase the weight

in the platform and the surface area of the platform or the load.

12. Do not replace items critical to machine stability with items of different weight or

specification.

13. Do not tie the platform to adjacent structures.

14. Do not place loads outside the platform perimeter.

15. Do not sit on, stand on, or climb on the platform guardrails. Maintain a firm footing on the

platform floor at all times.

16. Do not climb down from the platform when raised.

1/31/2008 - 14 -

Page 14

17. Do not operate the machine unless

the guardrails are properly installed

and the entry is secured for

operation. Attach the platform

entry chain before operating or if

the platform is equipped with a gate,

close and latch the gate before

operating.

18. Do not lower the platform unless the

area below is clear of personnel and

obstructions.

19. Do not attempt to level or operate

with the scissors lift connected to

the towing vehicle.

20. Be sure that the platform extension

in retracted all the way in before

exiting the platform.

OPERATIONS

TOWING PROCEDURE

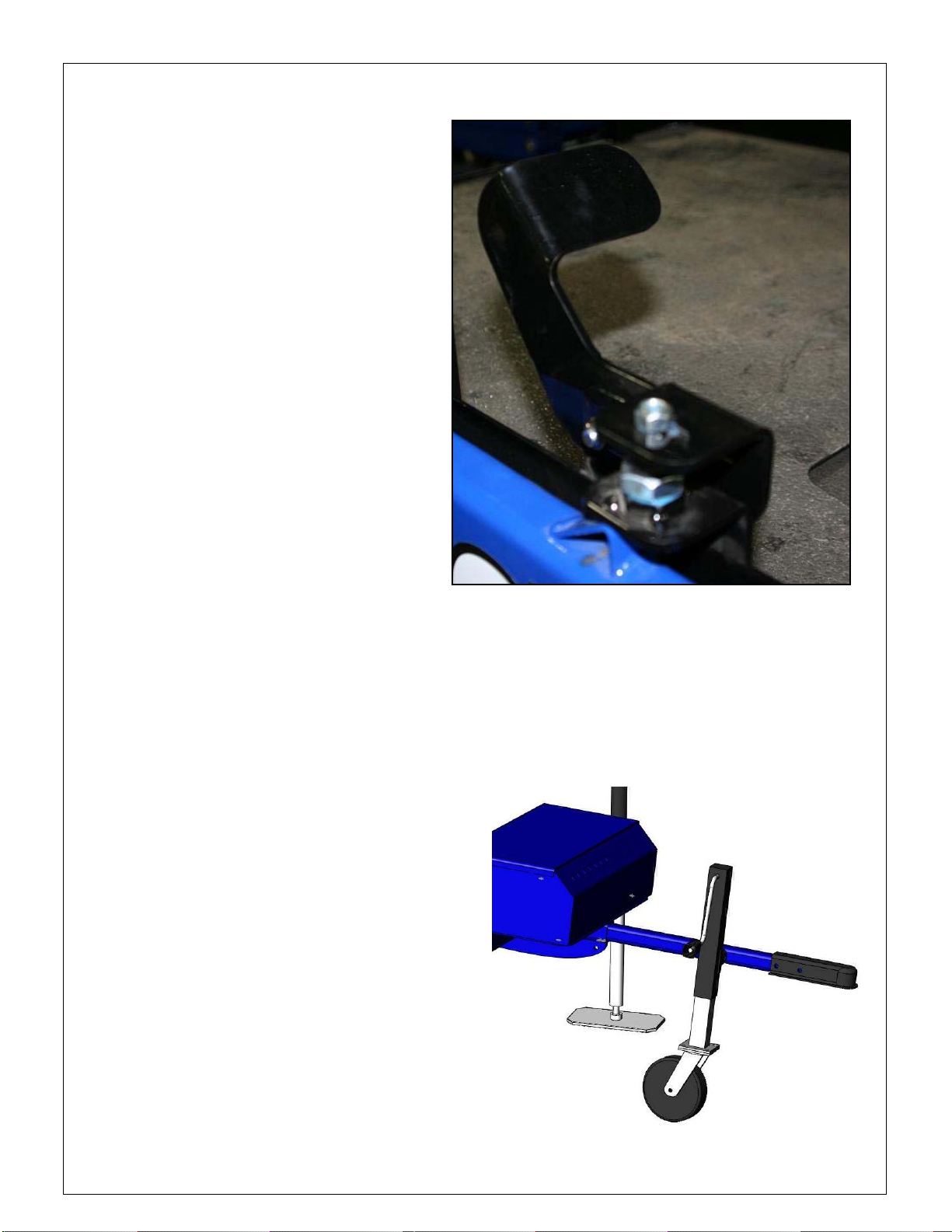

1. Requires 2 inch (5 cm) ball and coupler

hitch.

2. Attach the trailer chains to the towing

unit, put one chain over another under the

tongue

3. Unit can be towed by any large or small

vehicle, including ATV or golf cart for use

at various locations

1/31/2008 - 15 -

Page 15

4. Your UPRIGHT scissors lift is designed to be towed at highway speeds according to the laws in

your state/country.

PLATFORM

1. Platform size is 48” (1220 mm) x 64” (1625 mm) [48”

(1220 mm) x 94” (2390 mm) with deck extended],

which allows room for a worker and his equipment.

2. Platform weight capability is 500 lb (227 kg).

3. Maximum capacity is two people in the platform or

500 lb (227 kg) total weight.

4. If unit has extension deck, weight capacity is 250 lb

(114 kg) main deck, 250 lb (114 kg) on the extension deck. Do not exceed the maximum

platform capacity or the maximum capacity of the platform extension.

- 61 - 8002/13/1

Page 16

OUTRIGGER USE

1. All four outriggers are to be deployed and pinned when unit is in use.

2. The machine will not operate unless outriggers are deployed, the machine is level and the

outrigger pads are in contact with a firm surface.

3. Machines are fitted with outrigger proximity and pressure switches.

4. Outrigger proximity and pressure switch sensitivity is adjustable. Only qualified

technicians are authorized to make these adjustments. The machine will not operate if

these switches are not in proper adjustment or if they are disabled.

5. Outriggers are to be fully retracted, slid into transport position and pinned for transport.

Please refer to transport pictures in “towing procedure” section of this manual.

Transport Position

ELECTRIC OUTRIGGER MANUAL OVER RIDE

1. The electrical outriggers have a mechanical over-ride. To operate remove the top plastic

cap and turn the 3/8” nut on top.

2. Use only a 3/8” wrench on this hex nut.

3. DO NOT LEAVE THE WRENCH ON THIS NUT UNDER NORMAL OPERATIONS, THAT IS,

WHEN THE MOTOR IS POWERED. THE WRENCH COULD SPIN AND HURT SOMEONE!

OPERATION OF SCISSORS LIFT

1. DO NOT operate the machine with a low charge on the batteries, as indicated by the low

battery light on front of control box.

2. The scissors lift must be on firm ground.

3. The ground slope must not exceed 5 degrees.

4. Select the lift to operate in the ground position. Ensure the scissors lift is operating as

expected. If the scissors lift does not work as expected do not use.

5. Ensure people are clear of the machine, in particular the scissors mechanism has potential

pinch points, see warnings.

CONTROLS:

The lift is equipped with a PLC (Programmable Logic Controller) that controls the operation

of the scissors lift and is located in the main control box in front of the scissors lift. Servicing of

these components should be performed only by trained technicians.

1/31/2008 - 17 -

Page 17

The control panel

CONTROL FROM GROUND LEVEL

The controls are located in the front of the main control box located in the front of the

machine. (See diagram on page 21)

1. To operate the platform from the ground controls, turn key switch to the

ground position.

2. Push the push to enable button while simultaneously twisting the raise/lower

platform button.

3. On the far left is the emergency stop button. To stop machine operation push button in. For

operation this button must be pulled out. (The platform controls also has an emergency stop

button, which must be out for the controls to work.)

4. The next from the left-most button is the enable button.

5. The third control from the left is the outrigger retract button. This red button is operational

if:

a. The platform is all the way down

1/31/2008 - 18 -

Page 18

b. The Emergency stop buttons are not pushed

c. The key switch is on ground control

d. The legs are in the extended position

e. If the PLC is without power for an extended period of time, the button must be held in for

20-30 seconds to override the system. Push and hold the button in until all the legs are fully

retracted. The outriggers are fitted with clutches it will not damage the outrigger legs to

operate with the clutch active. The clutch will ‘click’ when they are engaged.

6. The next green button to the right is the ‘auto level’ switch.

7. Selector switch. This keyed switch is a three position switch. If the switch is in the middle

position the power to the controls is shut off. If the switch is in the left or counter-clock-wise

position the controls are active at platform level. If the switch is in the right position or the

clock-wise position then the controls are active at the ground position.

8. The next control is the up-down selector switch. This switch is active when the far enable

button is pushed. These two controls must be operated together.

9. On the lower left corner of the control box is an emergency lowering handle. Pull (don’t jerk)

this handle to lower the platform in an emergency situation.

CONTROL THE SCISSORS LIFT FROM THE PLATFORM.

The control box on the platform is as pictured. The pre-conditions, the leveling, and the

appropriate selection of the controls on the front of the main control box are assumed. The three

position selector switch located in front of the main box must be rotated to the left or platform

position. The key may be removed by the operator to ensure the personnel on the platform retain

control of the machine.

1/31/2008 - 19 -

Page 19

1. The top control button is the emergency stop. To operate the

machine this button must be out.

2. The next control is a red alarm light. This light is active at the

same time as the alarm horn, which is located inside the main box.

3. The next two switches are the up-down and the push-to-enable

buttons. The push-to-enable button must be pushed to enable the

up-down button. These buttons control the raise/lower functions

of the platform.

4. Climb onto the platform in the back of the lift

5. Close the gate or latch the chain

6. From the platform push the “push-to-enable button”, simultaneously

twist the raise/lower platform button.

1/31/2008 - 20 -

Page 20

Machine controls with option “auto-level” at

ground level

1. Emergency stop button. To stop operation in emergency the button should be pushed in. For

operation this button must be pulled out. (The platform controls also has an emergency stop

button, which must be out for the controls to work.)

2. Selector switch. This keyed switch is a three position switch. If the switch is in the middle

position the power to the controls are shut off. If the switch is in the right or clock-wise

position the controls are active at ground level. If the switch is in the left position or the

counter-clock-wise position, the controls are active on the platform.

3. The raise-lower selector switch. This switch is only active when the enable button is pushed.

These two controls must be operated together. When the enable button is pushed, the up-down

selector controls the platform raise and lower function.

4. The ‘level machine’ button. This button is for auto-level. All the preconditions and set up are

pre-conditions for this button to work. The outriggers, however, must be positioned and the

legs pinned. The machine will ‘auto-level’. That is if the legs are positioned and pinned properly,

the operator must push this green button marked “Level Machine” and the legs will extend and

1/31/2008 - 21 -

Page 21

the machine will level automatically. If the machine does level, several things could cause the

p

g

problem. (See the section “Problems with Machine Leveling.” Page 22)

Diagram of Auto Level and Variable Height

Retract Legs

and Override

Button

Platform and

Ground Key

Raise and

Lower

Controls

Variable

Height

Emergency

Sto

Alarm

Light

Platform

Overload

Low

Volta

e

Emergency

Lowering

1/31/2008 - 22 -

Level

Machine

Button

Push to

Enable

Button

Outrigger

Lights

Down Light

Page 22

NOTE: On European machines the enable button is moved to the left 3 slots

LEVELING PROCEDURE

1. This unit is designed for leveling with the scissors lift disconnected from the towing vehicle

2. This unit is designed to be used with the outriggers deployed and pinned at all times when

not in the trailer configuration

3. Inspect the ground where the jacks will contact. If the ground is soft, move the unit to

firmer ground

4. With the control switch on the control box in either the ground position, push the green

button marked ‘LEVEL MACHINE’

Problems with Machine Leveling

The scissors lift will level itself, unless there is a problem.

Problems could include the following.

1. Dead battery,

1/31/2008 - 23 -

Page 23

2. The slope the machine is on is over five degrees,

3. Either of the two emergency stop buttons is pushed

(one of the emergency stop buttons is on the platform).

4. Failed or out of adjustment of outrigger switches.

5. The ground is soft and the machine settles as the outriggers are

extending.

6. The ground is too rough or un-level such that the legs (or leg) have

reached the extent of their travel. If this condition occurs the operator

rectify the condition before trying again. The machine will not level

of more than five degrees.

7. Failed or out of adjustment of scissors stack position switch.

8. If the machine is mal-functioning. The machine should not

be used until the malfunction is remedied.

1/31/2008 - 24 -

Page 24

1/31/2008 - 25 -

Page 25

Machine controls with option “variable height”

at ground level

Your TP 7000 or TP 9000 can be equipped with a variable height selector option. Activation

of this feature is achieved by turning the selector switch to the “variable height position.” Variable

height selection gives you the option to operate the machine with the outriggers in the “in” or at

their narrowest position. This feature still requires that the outriggers “sense” pressure. The unit

will not operate if the outrigger pads are not firmly on the ground. With the selector turned to the

“variable height” position, you may safely operate the lift to a height of twelve (12) feet. The

machine will automatically stop rising at the twelve foot level. It is important to note: Your TP

7000 or TP 9000 will only rise to its full height with all four (4) of the outriggers in the fully

deployed (extended) position.

ALARMS AND ALARM LIGHTS

•

•

•

•

•

•

1. DOWN ALARM

1/31/2008 - 26 -

Page 26

2. When the platform is being lowered the alarm horn is activated. The purpose for this is to

warn personnel to stand clear of the scissors lift.

3. OUT OF LEVEL ALARM

4. If the alarm light is flashing ½ second on and ½ second off the out of level alarm is on. With

‘OUT OF LEVEL ALARM’ active the scissors lift is not level. See leveling procedure.

5. PLATFORM OVERLOADED

6. If ‘OVERLOADED’ LED is lit the weight rating for the load has been exceeded. The

operator should lower the loading to below the maximum rating. The lift will not operate in

over-loaded condition if it has the optional overload sensing device.

7. LEG POSITION

8. There are four outrigger position indicating lights. These lights must be on to operate the

machine. Exception, the scissors lift may be equipped with the variable height option. These

machines will have a switch on the control box that allows operation at a lower height if on.

The machine is stable to this lower height with the outrigger legs in. If the machine is not

equipped with the green indicator light for variable height the switch will be off, the alarm

light will be lit and the alarm horn will sound. In this state the operator will not be able to

lift the platform.

9. LOW VOLTAGE ALARM

10. If the battery has a low charge the low battery light will be lit. The alarm light will

be lit and the horn will sound. The batteries must be charged before continuing operation of

the lift.

DO NOT OPERATE THE MACHINE WITH LOW

CHARGE ON THE BATTERIES.

MAINTENANCE AND TROUBLE SHOOTING

OUTRIGGER SWITCHES ADJUSTMENT PROCEDURE:

1/31/2008 - 27 -

Page 27

The above drawings show the outrigger switches. The photo on the left shows the

“proximity” switch. The photo on the right is the ‘end’ view of the outrigger switch housing. In this

picture the right side of the housing shows the “pressure” switch and the left side shows the

proximity switch. The outrigger pin must be in place before the proper adjustment of the switches

can be made.

Caution: when inserting the outrigger legs care is needed. Do not force the outrigger leg

into position. The leg must be started in at an angle so as to get past the switches. Then the

outrigger leg can be slid into place. If the legs are forced in the legs will break the switches and

they will have to be replaced.

Preconditions for adjusting switches:

1. The scissors lift should be resting on the tires/wheels, not the outriggers.

2. The outriggers should be in position for lifting. That is the outriggers should be extended

into position so that they are ready to be put in use.

3. The pin holding the outriggers must be inserted so as to position the outrigger properly

(extended).

PROCEDURE FOR PRESSURE SWITCH:

1. Lift the outrigger leg so that it is not resting on the frame and is lifted high enough so that

it is in the same position with regard to the frame as it would be if the outrigger was

holding up the frame.

2. Loosen the adjustments screws so that the pressure switch can be moved.

3. Move the switch up then down.

4. While moving it down a slight click can be heard – that click is the switch opening.

5. Slowly lift the switch until a click is heard a second time. This click is the switch closing.

The switch should be moved only slightly so that the opening and closing of the switch will

happen when the outrigger leg is lifted or lowered.

6. Tighten that switch. This switch should now be calibrated.

Procedure for the proximity switch:

1. The proximity switch handle or leg should be directly over the detent in the outrigger leg.

2. Loosen the proximity switch screws.

3. Lift the leg

4. Lift the switch and then lower it until a click can be detected.

5. Raise the switch until the click can be detected the switch should be lifted slightly.

6. Tighten the proximity switch screws.

1/31/2008 - 28 -

Page 28

7. Test the switch by removing the outrigger retention pin, move the outrigger in and out while

the outrigger leg is held with slight upward pressure. The proximity switch should open and

close as the outrigger leg is moved in and out.

8. Extend the outrigger leg and replace the retention pin.

9. The proximity switch should be calibrated.

TESTING:

1. Ensure everything is properly adjusted by lowering the outrigger leg so as to slightly lift

the corner of the scissors jack. With a continuity tester check to see if there is continuity

across the contacts of the switches. If there is not continuity then the procedure must be

redone.

2. Next lift the outrigger leg so that there is no pressure on the leg. There should no longer

be continuity across the contacts on the pressure switch.

3. Pull the outrigger retention pin

4. Move the outrigger leg in about 5 cm.

5. Lower the outrigger leg until there is upward pressure.

6. test continuity across the proximity switch, there should be no continuity,

The outrigger should now be ready for use.

HYDRAULIC FLUID LEVEL/TYPE AND MAINTENANCE

1. Use ATF Mercon/Dexron-III fluid to refill unit

2. Check snap rings on scissors sections before each use. Replace any missing, broken or loose

nuts and bolts

3. Check and refill hydraulic fluid before each use. Fluid level should be 5 cm below top of fill

tube.

4. Check the tire pressure, hydraulic hose and electrical wires for abrasions and cuts before

each use. Replace damaged items.

5. Inspect outriggers and pins for damage and cracks before each use and once a year check

and grease wheel bearings

ROUTINE MAINTENANCE MANUAL

1. Inspect machine for any metal fatigue or wear. Do not use if any cracked welds are found.

Cease operation and contact UPRIGHT. if any defects are found. Refer to UPRIGHT

pre-delivery and inspection report for additional information

- 92 - 8002/13/1

Page 29

2. Check pinned connections on outriggers. The outrigger retaining pins are to be removed and

each outrigger is to be pulled out of its transport position. Replace the outrigger in a

vertical position so that the outrigger pad faces down. Replace the security pin from where

it was removed with the outrigger in its extended position. Always replace the spring loaded

security pin in each outrigger pin.

3. The outrigger is held in place with a hitch-type pin and a hairpin clip. Do not use if the pin

or clip is missing. Replace before use.

4. Check to see that the deck gate chain is in place. Do not use machine if the chain is missing.

Hydraulics – ATF Mercon/Dexron III Hydraulic Oil

1. Check hoses for any leaks or wear.

2. Check oil level in the reservoir. Oil level should be 2” below the top of fill tube when the

lift is fully lowered. Total oil capacity is 3 gallons. Do not overfill as this will result in fluid

discharge from the tank vent plug.

3. Vent plug on cylinder should be free of external debris. Do not use lift if vent plug on

cylinder is missing. Replace vent plug with factory supplied plug before use.

Scissors Stack

1. Check scissors stack connections for wear.

2. A washer and external snap ring hold stack sections in place. Do not operate lift if snap ring

or washer is missing. Replace before use.

3. Scissors stack sections require no lubrication

Battery

Proper battery condition is essential to good machine performance and operational safety.

Improper fluid levels or damaged cables and connections can result in component damage and

hazardous conditions.

1. Put on protective clothing and eyewear.

2. Be sure that the battery cable connections are free of corrosion.

1/31/2008 - 30 -

Page 30

3. Be sure that the battery retaining fasteners and cable connections are tight.

4. Inspect the battery charger plug and pigtail for damage or excessive insulation wear.

Replace as required.

5. Connect the battery charger to a properly grounded AC power supply.

6. You can expect a minimum of 35 to 75 complete up and down cycles from your UPRIGHT Lift.

7. Eight hours are required to completely recharge your machine with the onboard automatic

charger

Scissors Lift Arm Wear Pads

Maintaining the scissor arm wear pads is essential to safe machine operation. Continued use

of worn out wear pads may result in component damage and unsafe operating conditions. Apply a thin

layer of dry film lubricant to the area of the chassis where the scissor arm wear pads make

contact.

Electrical Wiring

Maintaining electrical wiring in good condition is essential to safe operation and good

machine performance. Failure to find and replace burnt, chafed, corroded or pinched wires could

result in unsafe operating conditions and may cause component damage.

WARNING: Electrocution hazard. Contact with hot or live circuits could result in

death or serious injury. Remove all rings, watches and other jewelry.

1. Inspect the underside of the chassis for damaged or missing wires.

2. Inspect the following areas for burnt, chafed, corroded and loose wires:

a. Ground control box

b. Scissors arms

c. Platform controls

WARNING: Crushing hazard. Keep hands clear of the safety arm when lowering

the platform.

Inspect the center chassis area and scissor arms for burnt, chafed and pinched cables.

1. Scissor arms

2. Power to platform controls

3. Power to platform wiring

Hydraulic Tank Cap Venting System

A free-breathing hydraulic tank cap is essential for good machine performance and service

life. A dirty or clogged cap may cause the machine to perform poorly. Extremely dirty conditions

may require that the cap be inspected more often.

1. Remove the breather cap from the hydraulic tank

2. Check for proper venting.

- 13 - 8002/13/1

Page 31

RESULT: If the air does not pass through the cap, clean or replace the cap.

NOTICE: When checking for positive tank cap venting, air should pass freely

through the cap.

Using a mild solvent, carefully wash the cap venting system. Dry the venting system by

using low-pressure compressed air. Repeat vent check.

Install the breather cap onto the hydraulic tank.

The hydraulic tank is a vent-type tank. The breather cap has an internal air filter that can

become clogged or, or over time, can deteriorate. If the breather cap is faulty or improperly

installed, impurities can enter the hydraulic system, which may cause component damage.

Extremely dirty conditions may require that the cap be inspected more often.

1. Remove and discard the hydraulic tank breather cap

2. Install a new cap onto the tank.

Bleeding air from the hydraulic system- System “lock”

It may be necessary to “bleed” air from the hydraulic system after service has been

performed. If the system is not free of air, the safety system will activate and the “velocity

fuse” in the manifold will “lock” the machine. This lock can be over-ridden by pulling the manual

release at the same time as you raise the machine.

Please follow the following procedure:

1. Locate the hydraulic return line (located at the top of pump)

2. Remove line and place this line in a container.

3. Pull (don’t jerk) manual release (emergency lowering valve located at the back of machine)

and have an assistance raise machine at the same time until oil comes out of the hose.

(Usually takes about two seconds) be careful as air and oil will exit the system with some

velocity.

4. Release manual release and raise lift. It will be necessary to add oil to the system when the

lift platform reaches ten feet of elevation.

5. Extend the platform until it hits the cylinder stop (twenty-four feet) and reconnect the

hydraulic return line.

6. Lower unit and cycle system.

Tires and Wheels

Maintaining the tires and wheels in good condition is essential to safe operation and

good performance. Tire and/or wheel failure could result in a machine tip-over. Component

damage may also result if problems are not discovered and repaired in a timely fashion.

1. Check the tire surface and sidewalls for cuts, cracks, punctures and unusual wear.

2. Check each wheel for damage, bends, or cracks.

1/31/2008 - 32 -

Page 32

Other lubrication

Grease zerks are provided on both the top and bottom ends of the main hydraulic cylinder.

Lift the machine and place the safety prop in position in order to grease these fittings.

Level sensor- Audible alarm

The level sensor is designed to give an audible signal at out of level attitudes of 2 degrees

front to back and 2 degrees side to side. The level sensor is pre-set at the factory and it is leveled

with the frame of the machine using three bracket bolts with spring tension on them. Always level

the machine to the frame using both the indication level on the sensor and a four foot contractor’s

level.

DOCUMENT OF RESPONSIBILITY

Definitions:

Aerial Platform - a manually propelled device that has an adjustable position platform, supported

from ground level by a structure

Authorized Personnel (authorized person) -personnel approved or assigned to perform a specific

type of duty or duties at a specific location or locations at a work site

Base - the relevant contact points of the aerial platform that form the stability fulcrum (e.g.,

wheels, casters, outriggers, stabilizers)

Chassis - the integral part of the aerial platform that provides mobility and support for the

elevating assembly

Configuration - all positions in which an aerial platform or any part thereof can be placed within its

intended operating limits

Dealer - a person or entity who buys from a manufacturer or distributor and who generally sells,

rents, and services aerial platforms

Delivery - transfer of care, control, and custody of the aerial platform from one person or entity to

another person or entity

Elevating Assembly - the mechanisms used to position the platform relative to the aerial platform

chassis

Guardrail System - a vertical barrier intended to prevent personnel from falling to lower levels

Hazardous Location - any location that contains, or has the potential to contain an explosive or

flammable atmosphere

Instability - a condition in which the sum of the moments that tend to overturn the aerial platform

exceeds the sum of the moments tending to resist overturning

Insulated Platform - a platform designed and tested to meet the specific electrical insulation

ratings consistent with the manufacturer's identification plate

1/31/2008 - 33 -

Page 33

Interlock - A control or mechanism that, under specified conditions, automatically allows or

prevents the operation of another control or mechanism

Manufacturer - A person or entity, who makes, builds, or produces an aerial platform

Modification, Modified - to make a change(s) to an aerial platform that affects the operation,

stability, safety factors, rated load, or safety of the aerial platform in any way

Operator - A qualified person who controls the movement of an aerial platform

Outriggers - Devices that increase the stability of the aerial platform and that are capable of

lifting and leveling the aerial platform

Owner - A person or entity that has possession of an aerial platform by virtue of proof of purchase

Platform - The portion of an aerial platform intended to be occupied by personnel with their

necessary tools and materials

Platform Height - The vertical distance measured from the floor of the platform to the surface

upon which the machine is being supported

Qualified Person - a person who by reason of knowledge, experience, or training is familiar with the

operation to be performed and the hazards involved

Rated Work Load - the designed carrying capacity of the aerial platform as specified by the

manufacturer

Shall - The word "shall" is to understood as mandatory

Stability - A condition in which the sum of the moments that tend to overturn the aerial platform is

less than the sum of the moments tending to resist overturning

User - A person(s) or entity that utilizes or puts into operation an aerial platform

Dealer Responsibilities:

Sound principles of safety, training, inspection, maintenance, applications, and operation

consistent with all data available regarding the parameters of intended use and expected

environment shall be applied in the training of operators, in maintenance, application, and operation

of the aerial platform with due consideration of the knowledge that the unit will be carrying

personnel.

Dealers shall keep and maintain a copy of the operation and maintenance manual stored in

the manual tube of the machine. A copy of the operations manual shall be provided upon each rental

or lease delivery.

Aerial platforms shall be inspected, serviced, and adjusted to manufacturer’s requirements

prior to each delivery by sale, lease or rental. A pre-inspection checklist is provided within each

operations and maintenance manual.

Before adjustments and repairs are started on an aerial platform, the following precautions

shall be taken as applicable:

1. All controls in the "off" position and all operating features secured from inadvertent motion

by brakes, blocks or other means.

2. Power plant stopped and starting means rendered inoperative.

1/31/2008 - 34 -

Page 34

3. Platform lowered to the full down position, if possible, or otherwise secured by locking or

cribbing to prevent dropping.

4. Hydraulic oil pressure relieved from all hydraulic circuits before loosening or removing

hydraulic components.

5. Safety props or latches installed where applicable as described by the manufacturer.

When parts or components are replaced, they shall be identical or equivalent to original

aerial platform parts or components.

Whenever a dealer directs or authorizes an individual to operate an aerial platform, the

dealer shall ensure that the individual has been trained under the direction of a qualified person in

accordance with the manufacturer's operating and maintenance manual.

Manufacturer's operating instruction and required training on the proper use and operation

of the aerial platform shall be provided upon each delivery, by sale, lease, or rental.

When a dealer operates an aerial platform in sales demonstrations or for other beneficial

use, the dealer shall assume the responsibilities of users and the operating personnel shall assume

the responsibilities of operators.

The dealer is responsible for obtaining the proper information from the manufacturer and

providing that information to the owner or user involving questions related to all aspects of the

aerial platform.

Dealers shall retain the following records for at least 3 years:

1. Name and address of the purchaser of each aerial platform by serial number and the date

of delivery.

2. Records of the person(s) trained upon each delivery of an aerial platform

3. Records of the pre-delivery preparation performed prior to each delivery

Modifications or alterations of aerial platforms shall be made only with prior written

permission of the manufacturer.

The dealer shall comply with safety-related bulletins as received from the manufacturer.

Responsibilities of Owners:

Sound principles of safety, training, inspection, maintenance, application, and operation

consistent with all data available regarding the parameters of intended use and expected

environment shall be applied in the performance of the responsibilities of owners with due

consideration of knowledge that the unit will be carrying personnel.

Owners shall keep and maintain a copy of the operation and maintenance manual stored in

the manual tube of the machine. A copy of the operations manual shall be provided upon each rental

or lease delivery. These manual(s) are considered an integral part of the aerial platform and are

vital to communicate necessary safety information to users and operators.

The owner of an aerial platform shall arrange that the maintenance specified in the

standard is properly performed on a timely basis. The owner shall establish a preventive

maintenance program in accordance with the manufacturer's recommendations and based on the

1/31/2008 - 35 -

Page 35

environment and severity of use of the aerial platform. The owner shall arrange that frequent and

annual inspections are performed. All malfunctions and problems noted shall be corrected before

the aerial platform is returned to service.

1. The owner of an aerial platform shall cause a frequent inspection to be performed on an

aerial platform:

2. That has been in service for 3 months.

3. That has been out of service for a period longer than 3 months.

4. The inspection shall be made by a person qualified as a mechanic on the specific make and

model of the aerial platform.

5. The inspection shall include all items specified by the manufacturer for a frequent

inspection and shall include, but not be limited to, the following:

6. All functions and their controls for speed(s), smoothness, and limits of motion.

7. Emergency lowering means.

8. All chain and cable mechanisms for adjustment and worn or damaged parts.

9. All emergency and safety devices

10. Lubrication of all moving parts, inspection of filter element(s), hydraulic oil, engine oil, and

coolant, as specified by the manufacturer.

11. Visual inspection of structural components and other critical components, such as fasteners,

pins, shafts, and locking devices.

12. Placards, warnings, and control markings.

13. Items specified by the manufacturer.

14. Correction of all malfunctions and problems identified and further inspection.

The owner of an aerial platform shall cause an annual inspection to be performed on the

aerial platform no later than 13 months from the date of the prior annual inspection. The

inspection shall be made by a person qualified as a mechanic on the specific make and model of the

aerial platform. The inspection shall include all items specified by the manufacturer for an annual

inspection as listed in the operations and maintenance manual.

Before adjustments and repairs are started on an aerial platform, the following precautions

shall be applicable:

1. All controls in the "off" position and all operating features from inadvertent motion by

brakes, blocks, or other means.

2. Power source disconnected/stopped and starting means rendered inoperative

3. Platform lowered to the full down position, if possible, or otherwise secured by blocking or

cribbing to prevent dropping

4. Hydraulic oil pressure relieved from all hydraulic circuits before loosening or removing

hydraulic components

1/31/2008 - 36 -

Page 36

5. Safety props or latches installed where applicable as described by the manufacturer

When parts or components are replaced, they shall be identical or equivalent to original

aerial platform parts or components.

The owners shall train their maintenance personnel in inspection and maintenance of the

aerial platform and with the manufacturer's recommendations.

An owner who directs or authorized an individual to operate an aerial platform shall ensure

that the individual has been trained in accordance with the manufacturer's operating manual before

operating the aerial platform. Manufacturer's operating instruction and required training on the

proper use and operation of the aerial platform shall be provided upon each delivery, by sale, lease,

or rental.

When the owner operates an aerial platform, the owner shall have the responsibilities of

users of this standard, and the operating personnel shall have responsibilities of Operators as

listed in this Document of Responsibility.

If an owner is unable to answer a user's or operator's questions relating to capacity,

intended use, maintenance, repair, inspection, or operation of the aerial platform, the owner shall

obtain the proper information from the dealer or manufacturer and provide that information to the

user or operator.

The owner shall retain the following records for at least three years:

1. Name and address of the purchaser of each aerial platform by serial number and date of

delivery

2. Records of the person(s) trained upon each delivery of an aerial platform

3. Written records of the frequent and annual inspections performed by the owner. The

record shall include deficiencies found, corrective action, and identification of the person(s)

performing the inspection and repairs

4. Records of the pre-delivery preparation performed prior to each delivery

The owner shall not modify or concur in modification or alteration to the aerial platform

without the modifications being approved and certified in writing by the manufacturer.

The owner shall comply with safety-related bulletins as received from the manufacturer or

dealer.

Responsibilities of Users:

The information in this standard must be supplemented by good job management, safety

control, and the application of sound principles of safety, training, inspection, maintenance,

application and operation consistent with all data available regarding the parameters of intended

use and expected environment. Since the user has direct control over the application and operation

of aerial platforms, conformance with good safety practices in this area is the responsibility of the

user and the operating personnel, including the operator. Decisions on the use and operation of the

aerial platform must always be made with due consideration for the fact that the machine will be

carrying personnel whose safety is dependent on those decisions.

1/31/2008 - 37 -

Page 37

Users shall keep and maintain a copy of the operation and maintenance manual stored in the

manual tube of the machine. These manual(s) are considered an integral part of the aerial platform

and are vital to communicate necessary safety information to users and operators.

Users shall inspect and maintain the aerial platform as required to ensure proper operation.

The frequency of inspection and maintenance shall be determined by the manufacturer's

recommendation and be compatible with operating conditions and the severity of the operating

environment. Aerial platforms that are not in proper operating condition shall be immediately

removed from service until repaired. Repairs shall be made by qualified personnel and the repairs

shall be in conformance with the manufacturer's recommendations.

An inspection as outlined in the Operations and Maintenance Manual shall be conducted.

An annual inspection shall be performed on the aerial platform no later than 13 months from

the date of the prior annual inspection. The inspection shall be made by a person qualified as a

mechanic on the specific make and model of the aerial platform. The inspection shall include all

items specified by the manufacturer for an annual inspection as listed in the Operations and

Maintenance Manual.

Before each day or at the beginning of each shift, the aerial platform shall be given a visual

inspection and functional test including but not limited to the following:

1. Operating and emergency controls

2. Safety devices

3. Personal protective devices, including fall protection

4. Air, hydraulic and fuel system leaks

5. Cables and wiring harness

6. Loose or missing parts

7. Tires and wheels

8. Placards, warnings and control markings

9. Outriggers, stabilizers, and other structures

10. Guardrail system

11. Items specified by the manufacturer

Before adjustments and repairs are started on an aerial platform, the following precautions shall be

applicable:

1. All controls in the "off" position and all operating features from inadvertent motion by

brakes, blocks, or other means.

2. Power source disconnected/stopped and starting means rendered inoperative

3. Platform lowered to the full down position, if possible, or otherwise secured by blocking or

cribbing to prevent dropping

4. Hydraulic oil pressure relieved from all hydraulic circuits before loosening or removing

hydraulic components

1/31/2008 - 38 -

Page 38

5. Safety props or latches installed where applicable as described by the manufacturer

When parts or components are replaced, they shall be identical or equivalent to original

aerial platform parts or components.

The user shall train their maintenance personnel in inspection and maintenance of the aerial

platform and with the manufacturer's recommendations.

Whenever a user directs or authorizes an individual to operate an aerial platform, the user

shall ensure that the individual has been trained in accordance with the manufacturer's operating

and maintenance manual, the user's work instructions, and the requirements listed in Users

Responsibilities of this standard before operating the aerial platform.

The user shall be responsible for the operator being trained on the model of the aerial

platform to be operated. Such training shall be in an area free of obstructions, under the direction

of a qualified person for a time sufficient to determine that the trainee displays proficiency in

knowledge and actual operation of the aerial platform. Only properly trained and authorized

personnel shall be permitted to operate the aerial platform.

A record of the trainee's aerial platform instruction shall be maintained by the user for at

least 3 years.

Before authorizing an operator to operate an aerial platform, the user shall ensure that the

operator has:

1. Been instructed by a qualified person in the intended purpose and function of each control

2. Read and understood the manufacturer's operating instructions and user's safety rules, or

been trained by a qualified person on the contents of the manufacturer's operating

instructions and user's safety rules

3. Understood by reading or by having a qualified person explain all decals, warnings, and

instructions displayed on the aerial platform

4. Determine that the purpose for which the aerial platform is to be used is within the scope

of the intended applications defined by the manufacturer

5. Been provided with approved fall protection devices and other safety gear for all personnel

of the platform

6. Before the aerial platform is used and during use, the user shall check the area in which the

aerial platform is to be used for possible hazards such as, but not limited to:

7. Drop-offs or holes

8. Bumps and floor obstructions

9. Debris

10. Overhead obstructions and high voltage conductors

11. Hazardous locations

12. Inadequate surface and support to withstand all load forces imposed by the aerial platform

in all operating configurations

13. Wind and weather conditions

1/31/2008 - 39 -

Page 39

14. Other possible unsafe conditions

15. Presence of unauthorized persons

The aerial platform shall be used in accordance with this Document of Responsibility and

the Operations and Maintenance Manual. The user shall direct the operator to ensure the following

before each elevation of the platform:

6. That the aerial platform is operated on a surface within the limits specified by the

manufacturer

7. That the outriggers, stabilizers, extendable axles, or other stabilizing methods are used as

required by the manufacturer

8. That the guardrails are installed and access gates or openings are closed per

manufacturer's instructions

9. That the load and its distribution on the platform and any platform extension are in

accordance with the manufacturer's rated capacity for that specific configuration

10. That there is adequate clearance from overhead obstructions

11. That the minimum safe approach distances to energized power lines and parts, as listed are

maintained.

12. That the precautions that are listed in this document are followed during operation of the

aerial platform

IT SHALL BE THE RESPONSIBILITY OF THE USER TO DETERMINE THE HAZARD

CLASSIFICATION OF ANY PARTICULAR ATMOSPHERE OR LOCATION.

The user shall direct his operating personnel and supervise the work to ensure operation is

in compliance with the requirements of the following statements of warning and instruction.

Personnel Footing - Personnel shall maintain a firm footing on the platform floor while

working thereon. Use of planks, ladders, or any other device on the aerial platform for achieving

additional height or reach shall be prohibited.

Other Moving Equipment - When other moving equipment or vehicles are present, special

precaution shall be taken to comply with local ordinances or safety standards established for the

workplace. Warnings such as, but not limited to, flags, roped-off areas, flashing lights, and

barricades shall be used.

Reporting Problems or Malfunctions - The operator shall immediately report to the

supervisor any problems or malfunctions that become evident during operation. Any problems or

malfunctions that affect the safety or operations shall be repaired prior to continued use of the

aerial platform.

Altering Safety Devices - Altering or disabling of interlocks or other safety devices shall

be prohibited.

Entanglement - Care shall be taken to prevent rope, electric cords, hoses, etc., from

becoming entangled in the aerial platform.

- 04 - 8002/13/1

Page 40

Capacity Limitation - Aerial platform rated capacities shall not be exceeded when loads are

transferred to the platform at any height.

Work Area - The operator shall ensure that the area surrounding the aerial platform is

clear of personnel and equipment before lowering the platform.

Battery Charging - Batteries shall be charged in a well-ventilated area free of flame,

sparks, or other hazards that may cause fire or explosion.

Platform Positioning - The aerial platform shall not be positioned against another object to

steady the platform.

Misuse as a Crane - The aerial platform shall not be used as a crane.

Operating Areas - The aerial platform shall not be operated from a position on trucks,

trailers, railway cars, floating vessels, scaffolds, or similar equipment, unless the application is

approved in writing by the manufacturer.

Travel Conditions - Under all travel conditions, the operator shall limit travel speed

according to conditions of ground surface, congestion, visibility, slope, location of personnel, and

other factors causing hazards of collision or injury to personnel.

Unauthorized Use - Means shall be used to protect against use by unauthorized person(s).

Operation of the Aerial Platform - If a user is also the operator of an aerial platform, the

user shall have the responsibilities of operators specified in Responsibilities of Operators section

of this standard as well as Responsibilities of Users as specified in this Document of Responsibility.

Assistance to Operator - If a user is unable to answer any operator's questions relating to

rated capacity, intended use, maintenance, condition, or safety of operation of the aerial platform,

the user shall obtain the proper information from the dealer, owner, or manufacturer and provide

that information to the operator before use of the aerial platform in the application of concern.

Shutdown of Aerial Platform - The user shall authorize and direct the operating personnel

to cease operation of the aerial platform in case of any suspected malfunctions of the aerial

platform, or any hazard or potentially unsafe condition that may be encountered, and to request

further information as to safe operation from the owner, dealer, or manufacturer before further

operation of the aerial platform.

Record Retention - The user shall retain the following records for at least 3 years:

1. Records of the operator(s) trained on each model of an aerial platform.

2. Written records of the frequent and annual inspections shall be kept by the user when

performing the inspections. The records shall include the date of inspection, any

deficiencies found, the corrective action recommended and identification of the person(s)

performing the repair.

3. Written records of all repairs accomplished on the aerial platform, including the date of any

such repair, a description of the work accomplished, and the identification of the person(s)

performing the repair.

Modifications - A user shall not modify or concur in modification of an aerial platform

without the specific written approval of the manufacturer of the aerial platform.

1/31/2008 - 41 -

Page 41

Manufacturer's Safety Bulletins - The user shall comply with safety-related bulletins as

received from the manufacturer, dealer, or owner.

Responsibilities of Operators:

The information in this standard must be supplemented by good job management, safety

control, and the application of sound principles of safety, training, inspection, maintenance,

application and operation consistent with all data available regarding the parameters of intended

use and expected environment. Since the user has direct control over the application and operation

of aerial platforms, conformance with good safety practices in this area is the responsibility of the

user and the operating personnel, including the operator. Decisions on the use and operation of the

aerial platform must always be made with due consideration for the fact that the machine will be

carrying personnel whose safety is dependent on those decisions.

The operator shall be aware that the operating and safety manuals, including the manual

that defines the responsibilities of dealers, owners, leasers, lessees, users and operators are

stored on the aerial platform and the location where they are stored. The operator shall be

familiar with the manuals stored on the aerial platform and consult them when questions arise with

respect to the aerial platform.

Before each day or at the beginning of each shift, the aerial platform shall be given a visual

inspection and functional test including but not limited to the following:

1. Operating and emergency controls

2. Safety devices

3. Personal protective devices, including fall protection

4. Air, hydraulic and fuel system leaks

5. Cables and wiring harness

6. Loose or missing parts

7. Tires and wheels

8. Placards, warnings and control markings

9. Outriggers, stabilizers, and other structures

10. Guardrail system

11. Items specified by the manufacturer

Any problems or malfunctions that affect the safety of operations shall be repaired prior

to the use of the aerial platform.

The operator shall have been trained either on the same model of aerial platform or one

having operating characteristics and controls consistent with the one to be used during actual work

site operation. The operator trainee shall operate the aerial platform in an area free of

obstruction under the direction of the qualified person for a time sufficient to determine that the

trainee displays proficiency in knowledge and actual operation of the aerial platform. Only properly

trained and authorized personnel shall be permitted to operate the aerial platform.

Before being authorized to operate the aerial platform, the operator shall have:

1/31/2008 - 42 -

Page 42

1. Been instructed by a qualified person in the intended purpose and function of each of the

controls.

2. Read and understood the manufacturers/owners operating instruction and safety rules, or

been trained by a qualified person on the contents of the manufacturers/owner's operating

instructions and safety rules.

3. Understood by reading or by having a qualified person explain all decals, warnings, and

instructions displayed on the aerial platform.

Before the aerial platform is used and during use, the user shall check the area in which the aerial

platform is to be used for possible hazards such as, but not limited to:

1. Drop-offs or holes

2. Bumps and floor obstructions

3. Debris

4. Overhead obstructions and high voltage conductors

5. Hazardous locations

6. Inadequate surface and support to withstand all load forces imposed by the aerial platform

in all operating configurations

7. Wind and weather conditions

8. Other possible unsafe conditions

9. Presence of unauthorized persons

The aerial platform shall be used in accordance with this Document of Responsibility and the

Operations and Maintenance Manual. The user shall direct the operator to ensure the following

before each elevation of the platform:

1. That the aerial platform is operated on a surface within the limits specified by the

manufacturer