Page 1

X40RT

Operator Manual

Page 2

Page 3

Please Note:

The UpRight X40 is sold in some regions as the

Snorkel SR4084.

Therefore any reference to the Snokel SR4084 also applies to the

UpRight X40.

UpRight Powered Access HQ

Vigo Centre

Birtley Road

Washington

Tyne & Wear

NE38 9DA

UK.

Europe

TEL: +44 (0) 845 1550 058

FAX: +44 (0) 195 2299 948

USA

TEL: +1 (785) 989 3000

FAX: +1 (785) 989 3070

www.upright.com

Page 4

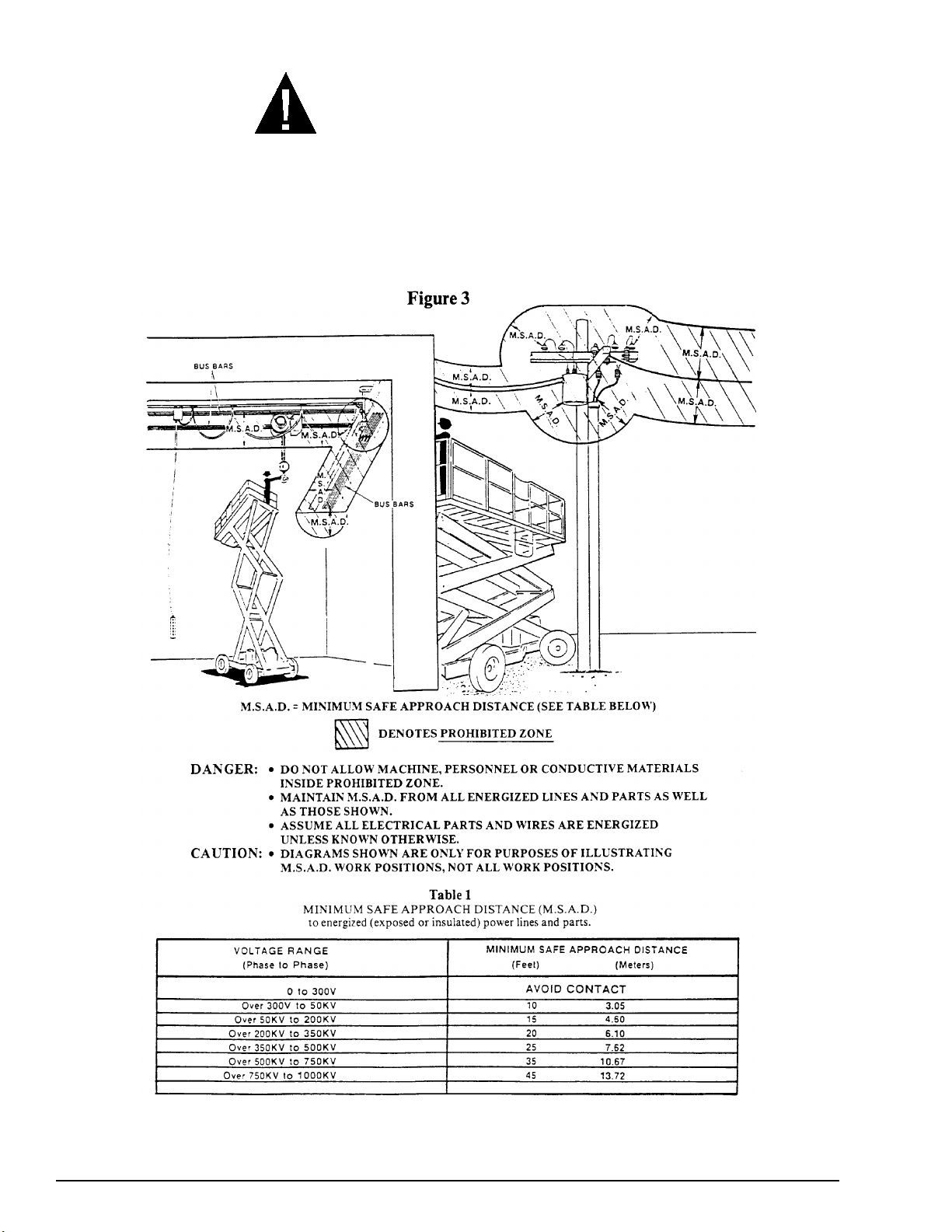

DANGER

ELECTRICAL HAZARD

An SR is an all-metal, NON-INSULATED, aerial work-platform. Do not operate it near

ELECTRICAL conductors. Regard all conductors as being energized. Use the table and

illustration below to determine safe clearance from electrical conductors. Table 1 and Figure 3

are reprinted courtesy of Scaffold Industry Association, ANSI/SIA A92.6, page 26.

P/N 569300

Page 5

DANGER

ELECTRICAL HAZARD

SR ELEVATING WORK PLATFORMS ARE NOT

ELECTRICALLY INSULATED.

If the platform, scissors arm assembly, or any other conductive part of an SR

contacts a high-voltage electrical conductor, the result can be

DEATH

or

Be sure to allow for sag and sway in the wires and the work platform.

If an SR comes in contact with a live electrical conductor, the entire machine can

be charged. If that happens, you should remain on the machine and not contact

any other structure or object within reach. That includes the ground, adjacent

buildings, poles, and any object not a part of the SR. Such contact could make

your body a conductor to the other object creating an electrical shock hazard

resulting in

SR until you are sure the electricity has been turned off.

for persons on or near the machine.

GO NO CLOSER THAN THE MINIMUM SAFE APPROACH

DISTANCES ON THE OPPOSITE PAGE.

SERIOUS INJURY

or

DEATH

. Do not attempt to enter or leave the

SERIOUS INJURY

If an SR is in contact with a live conductor, the platform operator

others on the ground in the vicinity of the SR to

since their bodies can also form a path for electricity to ground thus creating an

electrical shock hazard with possible

Do not attempt to operate SR ground controls when the platform, scissors arm

assembly, or any other conducting part of the SR is in contact with electrical

wires or if there is an immediate danger of such contact.

Regard all conductors as energized.

Personnel working on or near an SR must be continuously aware of electrical

hazards, recognizing that

an electrical wire does occur.

SERIOUS INJURY

ELECTROCUTION

STAY AWAY

DEATH

or

and

can result if contact with

MUST

from the machine,

DEATH

warn

.

P/N

569300

i

Page 6

TABLE OF CONTENTS

XX. CHAPTER TITLE

INTRODUCTION ....................................................iii

SIGNS .............................................................iii

QUALIFIED OPERATORS..............................iii

MAINTENANCE ..............................................iii

RESPONSIBILITIES OF PARTIES .................iv

ADDITIONAL INFORMATION.........................iv

1. SAFETY ............................................................. 1 - 1

SAFE OPERATION......................................... 1 - 1

Pre-start Inspection..................................... 1 - 1

Work Place Inspection and Practices ......... 1 - 1

Electrocution ............................................... 1 - 2

Tipover & Falling Hazards........................... 1 - 2

Crushing...................................................... 1 - 2

GENERAL SAFETY PRECAUTIONS.............. 1 - 3

Personnel Precautions................................ 1 - 3

Operator General Precautions .................... 1 - 3

Mounting & Dismounting Precautions......... 1 - 3

Starting and Stopping Precautions ............. 1 - 3

Operating Precautions ................................ 1 - 3

Operator Maintenance Precautions ............ 1 - 3

Fuel Handling Precautions.......................... 1 - 3

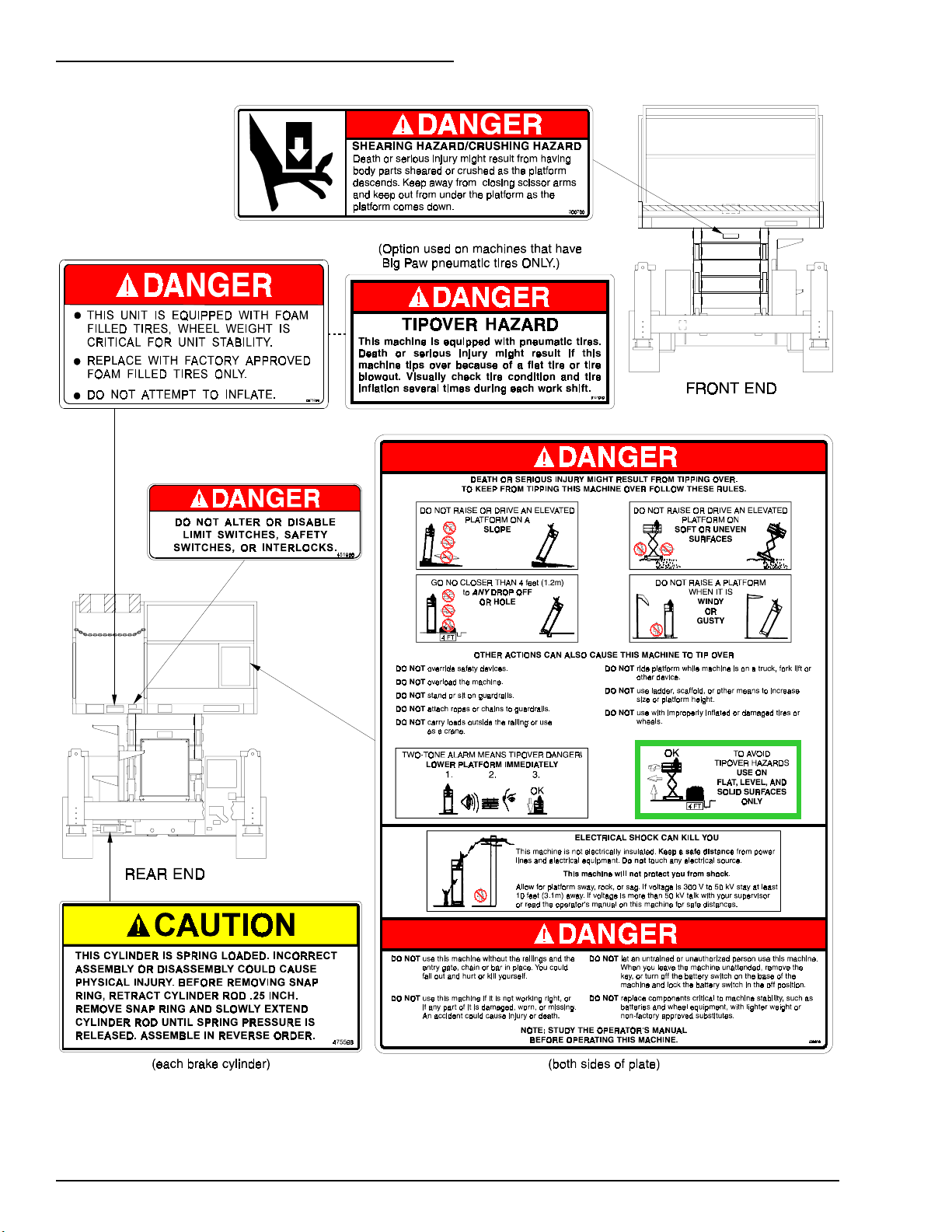

SAFETY DECALS & PLACARDS.................... 1 - 3

2. SAFETY DEVICES............................................. 2 - 1

EMERGENCY STOP SWITCHES................... 2 - 1

ALARMS.......................................................... 2 - 1

Level Sensor ............................................... 2 - 2

Lowering ..................................................... 2 - 2

High Temperature ....................................... 2 - 2

Low Oil Pressure......................................... 2 - 2

DRIVE (reverse).......................................... 2 - 2

DRIVE (forward).......................................... 2 - 2

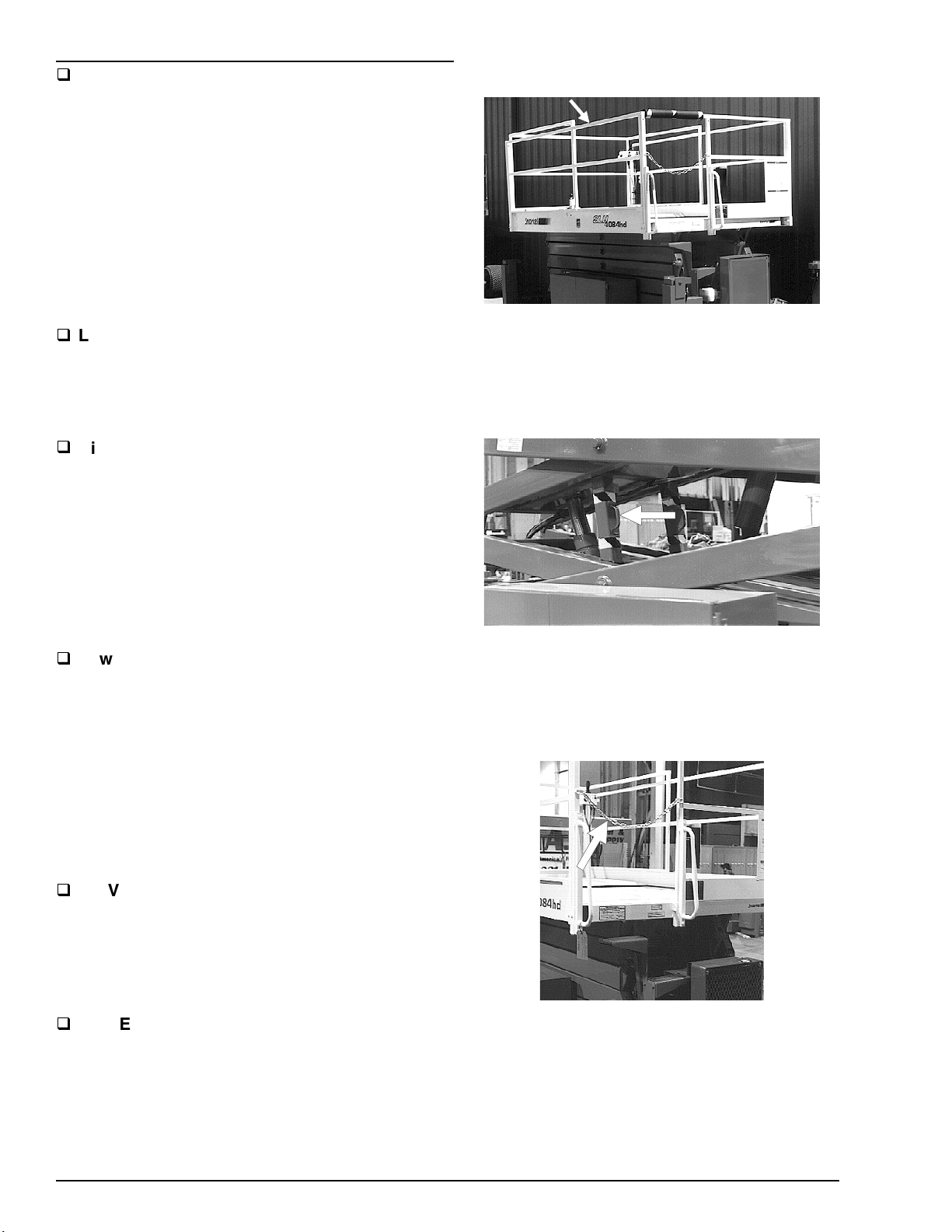

GUARDRAILS ................................................. 2 - 2

SAFETY PROP ............................................... 2 - 2

SAFETY CHAIN .............................................. 2 - 2

SWINGING GATE (option).............................. 2 - 3

SAFETY CONTROL........................................ 2 - 3

BUBBLE LEVEL (outrigger machines only) .... 2 - 3

OPERATOR HORN......................................... 2 - 3

OUTRIGGERS (option) ................................... 2 - 3

GFCI AC OUTLET (option).............................. 2 - 4

FLASHING LIGHT (option).............................. 2 - 4

LANYARD ANCHORAGE (option) .................. 2 - 4

3. SPECIFICATIONS ............................................. 3 - 1

GENERAL SPECIFICATIONS FOR

STANDARD MACHINES............................... 3 - 1

ENGINE DATA ................................................ 3 - 2

ENGINE OIL CHARTS .................................... 3 - 2

HYDRAULIC FLUID RECOMMENDED........... 3 - 2

NOMENCLATURE & SERIAL NUMBERS ......... 3 - 3

4. GAUGES............................................................ 4 - 1

WATER ........................................................... 4 - 1

AIR FILTER

AMPS .............................................................. 4 - 1

ENGINE OIL.................................................... 4 - 1

HOURS ........................................................... 4 - 2

FUEL LEVEL (option)...................................... 4 - 2

HYDRAULIC OIL LEVEL................................. 4 - 2

BUBBLE LEVEL (outrigger machines only) .... 4 - 2

COOLANT ....................................................... 4 - 2

5. AUTOMATIC SHUT-OFFS

& CIRCUIT BREAKERS .................................... 5 - 1

AUTOMATIC SHUT-OFFS.............................. 5 - 1

Level Sensor ............................................... 5 - 1

Engine Temperature ................................... 5 - 1

Engine Oil Pressure .................................... 5 - 1

Platform Height vs. Drive Speed................. 5 - 1

Parking Brakes............................................ 5 - 1

Dynamic Brakes.......................................... 5 - 1

Alternator Not Charging .............................. 5 - 2

Outriggers (option) ...................................... 5 - 2

Hydraulic Generator (option)....................... 5 - 2

.....................................................

4 - 1

CIRCUIT BREAKERS ..................................... 5 - 2

Main Breaker .............................................. 5 - 2

Hydraulic Generator Circuit Breaker (option).. 5 - 2

GFCI Outlet (option) ................................... 5 - 2

6. CONTROLS ....................................................... 6 - 1

HYDRAULIC COMPARTMENT....................... 6 - 2

BASE-CONTROL PANEL ............................... 6 - 2

PLATFORM-CONTROL BOX.......................... 6 - 4

7. OPERATION...................................................... 7 - 1

OPERATING FROM THE

BASE-CONTROL PANEL ............................ 7 - 1

Starting a Gasoline,

LP-only, or Dual-fuel Engine.................... 7 - 1

Starting a Diesel Engine ............................. 7 - 2

Raising the Platform ................................... 7 - 3

Warming the Hydraulic Oil.......................... 7 - 3

OPERATING FROM THE

PLATFORM-CONTROL BOX ...................... 7 - 4

Starting a Gasoline,

LP-only, or Dual-fuel Engine.................... 7 - 4

Starting a Diesel Engine ............................. 7 - 5

Driving......................................................... 7 - 6

Raising the Platform ................................... 7 - 7

SETTING THE OUTRIGGERS........................ 7 - 7

EXTENDING THE TWO-POSITION

PLATFORM................................................... 7 - 8

8. EMERGENCY OPERATION.............................. 8 - 1

EMERGENCY STOP ...................................... 8 - 1

EMERGENCY BLEED-DOWN........................ 8 - 1

PUSHING........................................................ 8 - 2

9. STOWING & TRANSPORTING......................... 9 - 1

STOWING....................................................... 9 - 1

TRANSPORTING............................................ 9 - 1

Trailering..................................................... 9 - 1

Securing to a Transport Vehicle ................. 9 - 3

Towing ........................................................ 9 - 3

Lifting .......................................................... 9 - 3

Pushing....................................................... 9 - 3

10. DAILY INSPECTION & MAINTENANCE......... 10 - 1

DAILY INSPECTION AND

MAINTENANCE TABLE................................ 10 - 1

PLACARDS AND DECALS

INSPECTION CHART...................................10 - 10

PLACARDS AND DECALS

INSPECTION DRAWING.............................. 10 - 11

11. TROUBLESHOOTING..................................... 11 - 1

12. OPTIONS ......................................................... 12 - 1

OPERATOR HORN.........................................12 - 1

OUTRIGGERS................................................ 12 - 1

GFCI OUTLET ................................................12 - 1

BIG PAW TIRES .............................................12 - 1

FLASHING LIGHT...........................................12 - 2

ELECTRICAL OUTLET................................... 12 - 2

SWINGING GATE........................................... 12 - 2

SPARK ARRESTOR ....................................... 12 - 3

LANYARD ANCHOR POINTS ........................12 - 3

AC GENERATOR ...........................................12 - 3

13. FIRE FIGHTING & HAZARDOUS

CHEMICAL CONTAINMENT...........................13 - 1

ANTI-FREEZE.................................................13 - 1

BATTERY, LEAD/ACID................................... 13 - 1

DIESEL FUEL .................................................13 - 1

FOAM IN TIRES..............................................13 - 1

GASOLINE...................................................... 13 - 2

HYDRAULIC OIL............................................. 13 - 2

LIQUEFIED PETROLEUM GAS .....................13 - 2

MOTOR OIL.................................................... 13 - 2

INDEX .......................................................................I - 1

WARRANTY................................. (inside back cover)

ii

P/N 569300

Page 7

X. CHAPTER NAME

INTRODUCTION

The most important chapter in this manual is “1.

SAFETY.” Take time, now, to study it closely.

The information in that chapter might save your

life or prevent serious injury.

SIGNS

T

The following two conventions are used

throughout this manual.

1. This sign

DANGER

means:

is involved

2. This sign

Attention! Become alert! Your safety

.

CAUTION

means one of two things: (1) an action, about to

be performed, is potentially hazardous and might

result in minor personal injury if not done

correctly, or (2) an action, about to be performed,

can harm the SR if not done correctly.

QUALIFIED OPERATORS

T

SR aerial platforms have built-in safety features

and have been factory tested for compliance with

Snorkel specifications and industry standards.

However, any personnel-lifting device can be

potentially dangerous in the hands of untrained

or careless operators.

Training is essential and must be performed by a

QUALIFIED person. Become proficient in

knowledge and actual operation before using the

SR on the job. You must be trained and

authorized to perform any functions of the SR.

Operation of the SR must be within the scope of

the machine specifications.

Before operating an SR you must read and

understand the operating instructions in this

manual as well as the decals, warnings, and

instructions on the machine itself.

Before operating an SR you must be

AUTHORIZED by the person in charge to do

so.

The following rules will help ensure the

safety of personnel and help prevent

needless downtime because of damaged

equipment.

1. Only TRAINED and AUTHORIZED operators

shall be permitted to operate the equipment.

2. All manufacturer’s operating instructions and

safety rules and all employers’ safety rules and

all OSHA and other government safety rules

must be strictly adhered to.

3. Repairs and adjustments shall be made only

by QUALIFIED TRAINED maintenance

personnel.

4. No modification shall be made to the

equipment without prior written consent of the

Snorkel Engineering Department.

5. You must make a prestart inspection of the SR

at the beginning of each shift. A malfunctioning

machine must not be used.

6. You must make an inspection of the work

place to locate possible hazards before operating

an SR.

DANGER

Misuse of this machine can result in DEATH

or SERIOUS INJURY.

Do not operate this equipment unless you are

TRAINED and AUTHORIZED and have read

and thoroughly understand all information

given in this Operator’s Manual and on all

DANGER and CAUTION signs on the

machine.

MAINTENANCE

T

Every person who maintains, inspects, tests, or

repairs these machines, and every person

supervising any of these functions, must be

properly trained.

This Operator’s Manual provides a daily

inspection procedure that will help you keep your

SR in good operating condition. Do not perform

other maintenance unless you are a TRAINED

mechanic, QUALIFIED to work on SR’s. Call

QUALIFIED maintenance personnel if you find

problems or malfunctions.

P/N 569300

iii

Page 8

INTRODUCTION

Information contained in this manual concerns

only current SR models, and the right is reserved

to make changes at any time without obligation.

RESPONSIBILITIES OF PARTIES

It is imperative that all owners and users of an

SR read, understand, and conform to all

applicable regulations. Ultimate compliance to

OSHA regulations is the responsibility of the

employer using the equipment.

ANSI Standard A92.6 identifies requirements of

all parties who might be involved with SelfPropelled Elevating Work Platforms.

A reprint of the “Manual of Responsibilities for

Dealers, Owners, Users, Operators, Lessors and

Lessees of ANSI/SIA A92.6-1999 Self-Propelled

Elevating Work Platforms” is available from

Snorkel dealers or from the factory upon request.

Copies are also available from:

Scaffold Industry Association, Inc.

P. O. Box 20574

Phoenix, AZ 85036-0574 USA

ADDITIONAL INFORMATION

For additional information, contact your local

dealer or write:

Snorkel International, Inc.

P.O. Box 1160

St. Joseph, MO 64502-1160 USA

1-800-255-0317

http://www.snorkelusa.com

iv

P/N 569300

Page 9

SAFE OPERATION

T

The following safety information is vitally

important for safe operation of an SR. Failure to

follow these instructions can result in personal

injury or DEATH.

Pre-start Inspection

Prior to each shift, the SR shall be given a visual

inspection and function test. (See the “DAILY

INSPECTION & MAINTENANCE” chapter in this

manual for a list of items to inspect and test.)

Do not operate an SR unless you are trained and

authorized, understand the operating

characteristics of the SR, and have inspected

and tested all functions to be sure they are in

proper working order. (See the “DAILY

INSPECTION & MAINTENANCE” chapter.)

Work Place Inspection and Practices

Do not use an SR as a ground for welding.

Ground to the work piece.

Before an SR is used, and during use, check the

area in which it is to be used for possible hazards

such as, but not limited to:

drop-offs or holes,

•

side slopes,

•

bumps and floor obstructions,

•

debris,

•

overhead obstructions and electrical

•

conductors,

hazardous locations,

•

inadequate surface and support to withstand

•

all load forces imposed by the aerial platform

in all operating configurations,

wind and weather conditions,

•

presence of unauthorized persons,

•

other possible unsafe conditions.

•

Before using the aerial platform in any hazardous

(classified) location, make certain it is approved

and of the type required by ANSI/NFPA 505 for

use in that particular location.

A recommended safety practice is to have

ground personnel, who are trained in the

operation of SR emergency controls, working in

the immediate vicinity of an elevated SR. In the

event of an emergency, they can assist the

platform operator.

1. SAFETY

1. SAFETY

1. SAFETY

When moving the platform, check the clearance

around the SR to avoid contact with structures or

other hazards. Always look in the direction of

motion.

Keep ground personnel from under the platform

when the platform is raised.

Secure all accessories, containers, tools, and

other materials in the platform to prevent them

from accidentally falling or being kicked off the

platform.

Do not engage in any form of “horseplay” or

“stunt driving” while operating an SR.

Do not permit riders on the machine anyplace

other than on the platform.

Remove all loose objects stored in or on the

machine, particularly in the platform. Remove all

objects which do not belong in or on the

machine.

When other moving equipment is in the area,

take special precautions to comply with local

regulations regarding warnings.

Never steady the platform by positioning it

against another platform.

Do not operate an SR that is not functioning

properly, or has been damaged, until the

machine has been repaired by a qualified

maintenance person.

Do not operate an SR that does not have all its

decals and placards attached and legible.

Drive the machine with care and at speeds

compatible with conditions. Use extra caution

when driving over rough ground, on slopes, and

when turning.

Know and understand the job site traffic-flow

patterns and obey the flagmen, road signs, and

signals.

Watch for bystanders and never allow anyone to

be under, or to reach through, the machine and

its equipment while operating.

P/N 569300

1 - 1

Page 10

1. SAFETY

Electrocution

SR’s are all-metal, NON-INSULATED, aerial

work-platforms. Do not operate an SR near

ELECTRICAL conductors. Regard all conductors

as being energized.

Do not operate outside during a thunderstorm.

platform before attempts are made to free the

platform using ground controls.

Do not exceed the platform capacity nor the

platform-extension capacity shown on the

capacity placards located at the entrance to the

platform and on the toeboard of the platform

extension.

Tipover & Falling Hazards

On scissor lifts, like the SR, personal fall

protection is not required by ANSI, Federal

OSHA, nor Snorkel. However, fall restraint might

be required by work regulations. If so, the user is

responsible for fitness and method of use.

The guardrail system is your fall protection. Make

sure the guardrail system is properly installed

and that all gates and fasteners are in place.

It is best not to transfer from the platform to

another structure or from the structure to the

platform, unless that is the safest way to do the

job. Judge each situation separately taking the

work environment into account. If it is necessary

to transfer from the platform to another structure

the following guidelines apply:

Where possible, place the work platform

•

next to a roof or walking structure to do

the transfer.

Transfer your anchorage from one

•

structure to another before you step

across.

Remember that you might be transferring

•

to a structure where

personal fall arrest

is required.

Do not raise the platform if the SR is on soft

ground. Raise the platform only on a firm surface

capable of withstanding all load forces imposed

by the aerial platform in all operating conditions.

Do not allow wires, cables, hoses, rope, or other

materials to trail down from the platform or be

entangled in the platform.

If you have to level an SR, that does not have

outriggers, be sure the shoring you use is strong

enough to support the weight of the SR and that

the SR wheels are chocked so that the SR

cannot be driven.

Do not jerk the controls. Move the controls slowly

and deliberately to avoid jerky and erratic

operation. Always stop the controls in the neutral,

off, position before going in the opposite

direction.

Do not use the platform for any purpose other

than to position personnel, their tools and

materials.

Do not use an SR as a crane, hoist, or jack.

Do not operate an SR in winds, or wind gusts, of

28 mph (12.5 m/s) or more.

Do not add anything to an SR that will increase

the wind loading (billboards, banners, flags, etc.).

Use the platform entrance, do not climb

•

over the guard rails.

Maintain a firm footing on the platform floor.

Climbing on the guardrails is prohibited.

Do not use ladders, planks, or other devices to

extend or increase your work position from the

platform.

Do not operate an SR from a position on trucks,

trailers, railway cars, floating vessels, scaffolds,

or similar equipment unless the application is

approved in writing by Snorkel.

If the platform or elevating assembly becomes

caught, snagged, or otherwise prevented from

normal motion by an adjacent structure, or other

obstacles, such that control reversal does not

free the platform, remove all personnel from the

1 - 2

Crushing

Always look in the direction of travel. Avoid

overhead obstructions.

Make sure the area below the platform is free of

personnel before lowering.

P/N 569300

Page 11

GENERAL SAFETY PRECAUTIONS

T

Personnel Precautions

If you encounter any suspected malfunction of

the aerial platform, or any hazard or potentially

unsafe condition relating to capacity, intended

use, or safe operation, cease operation and seek

assistance from management.

Operator General Precautions

Make sure that all protective guards, cowlings,

and doors are in place and secure.

Mounting & Dismounting Precautions

Use three points of support when getting on or

off the platform. Keep the platform clean.

Do not jump off the machine.

Do not dismount while the machine is in motion.

1. SAFETY

Do not attempt repairs unless you are trained.

Refer to manuals and experienced repair

personnel for help.

Charge batteries in a well-ventilated area free of

flame, sparks, or other hazards that might cause

fire or explosion.

Use extreme caution when removing radiator

caps. Park the machine and let it cool down

before opening a pressurized compartment.

Fuel Handling Precautions

Do not smoke or permit open flames while

fueling or near fueling operations.

Maintain control of the fuel filler nozzle when

filling the tank.

Do not fill the fuel tank to capacity. Allow room

for expansion.

Starting and Stopping Precautions

Do not start until all personnel are clearly away

from the machine.

Before leaving the operator’s station, place the

machine in the stowed position.

Remove the starter key from the

set the

the machine parked or unattended.

Do not modify an SR in any way.

Do not override any of the safety features of an

SR.

Do not exceed the side-pull forces listed on the

capacity placards located at the entrance to the

platform and on the toeboard of the platform

extension.

Limit travel speeds according to conditions. Take

into account: grade, surface, congestion,

visibility, side slope, location of personnel, and

other hazards.

Do not use your hand to search for hydraulic oil

leaks. High pressure hydraulic oil can easily cut

and penetrate your skin — a very serious injury

that requires immediate attention by a medical

specialist trained in that type of injury. Use a

piece of cardboard or wood to search for

hydraulic oil leaks.

BATTERY

Operating Precautions

Operator Maintenance Precautions

switch to OFF when leaving

KEY

switch and

Clean up spilled fuel immediately.

Tighten the fuel tank cap securely. If the fuel cap

is lost, replace it with an approved cap from

Snorkel. Use of a non-approved cap without

proper venting may result in pressurization of the

tank.

Never use fuel for cleaning purposes.

For diesel engines, use the correct fuel grade for

the operating season.

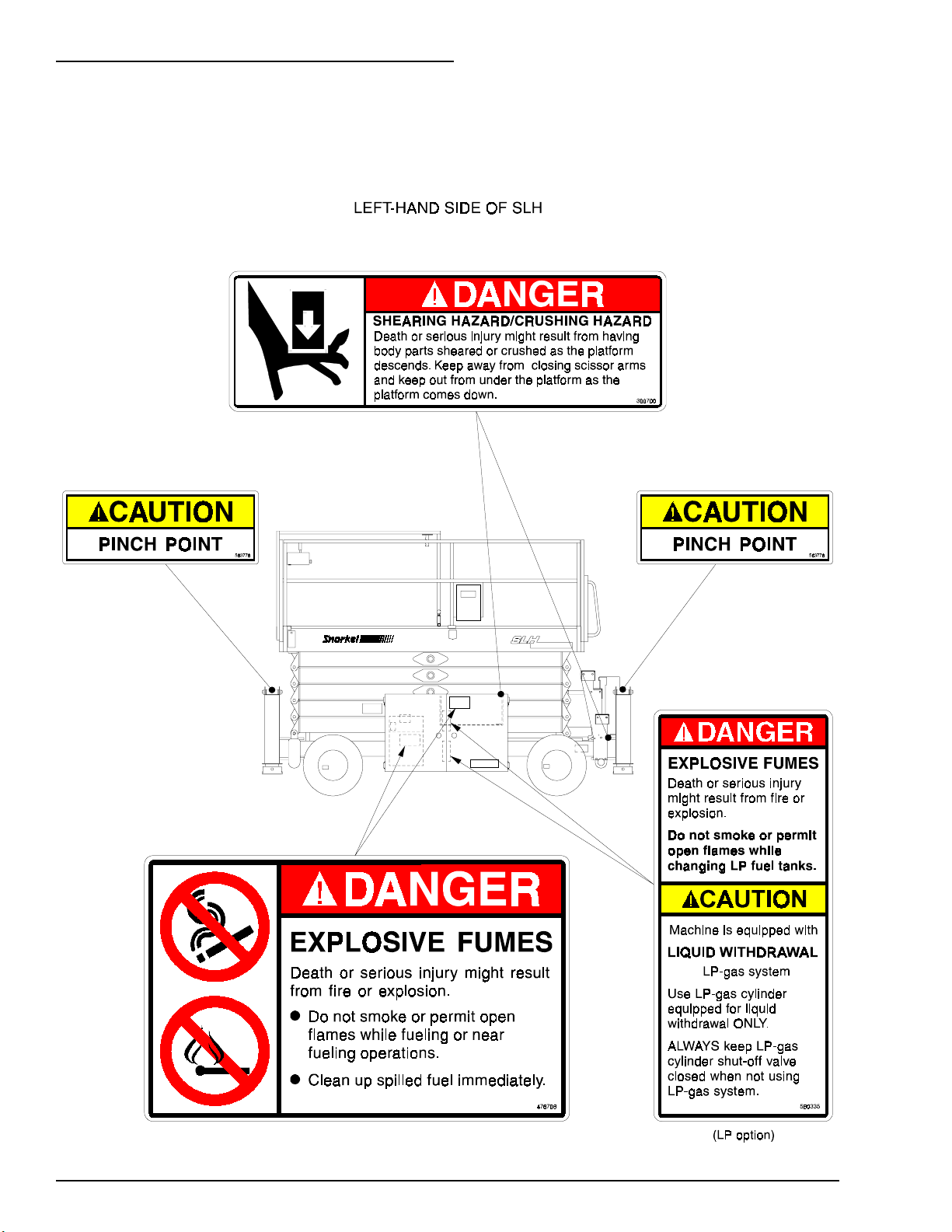

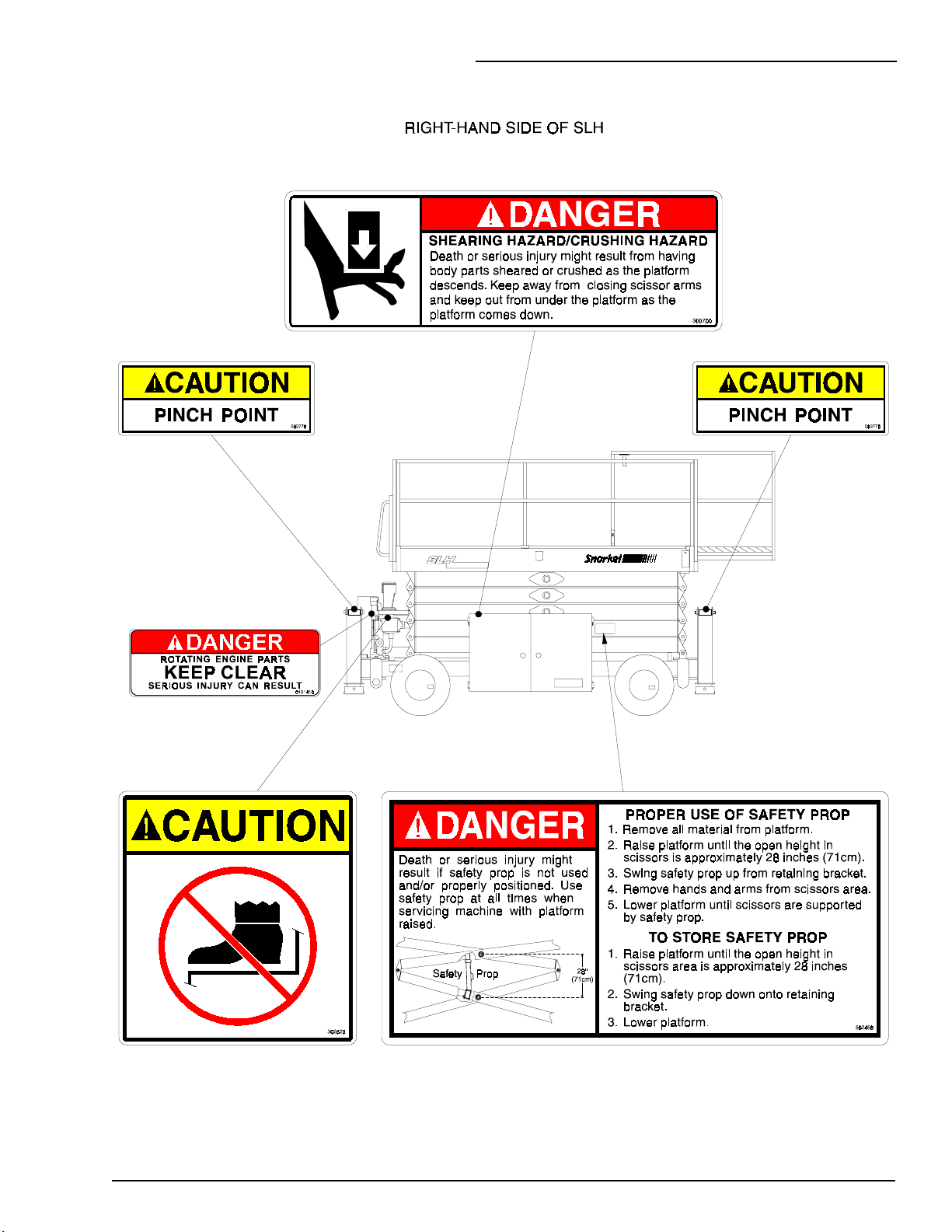

SAFETY DECALS & PLACARDS

T

There are several safety decals and placards on

an SR. Their locations and descriptions are

shown in this section. Take time to study them.

Be sure that all the safety decals and placards

on the SR are legible. Clean or replace them if

you cannot read the words or see the pictures.

Clean with soap & water and a soft cloth. Do not

use solvents.

You must replace a decal or placard if it is

damaged, missing, or cannot be read. If it is on a

part that is replaced, make sure a new decal or

placard is installed on the replaced part. See

your Snorkel dealer for new decals and placards.

Refer to the PLACARDS AND DECALS

INSPECTION CHART and DRAWING in the

“DAILY INSPECTION AND MAINTENANCE”

chapter for part numbers, location, and required

quantities of all placards and decals.

P/N 569300

1 - 3

Page 12

1. SAFETY

Refer to the PLACARDS AND DECALS INSPECTION CHART and DRAWING in the

“DAILY INSPECTION AND MAINTENANCE” chapter for part numbers, locations, and

required quantities of all placards and decals.

1 - 4

P/N 569300

Page 13

1. SAFETY

P/N 569300

1 - 5

Page 14

1. SAFETY

1 - 6

P/N 569300

Page 15

2. SAFETY DEVICES

2. SAFETY DEVICES

The devices listed in this chapter are safety

devices. They are on an SR to increase safety in

the work place for both the operator and other

people near the machine. Do not by-pass,

disable, modify, or ignore any of these devices.

Check them carefully at the start of each work

shift to see that they are in working order (see

“DAILY INSPECTION & MAINTENANCE”

chapter). If any is found to be defective, remove

the SR from service immediately until a qualified

service technician can make repairs.

EMERGENCY STOP SWITCHES

T

T

ALARMS

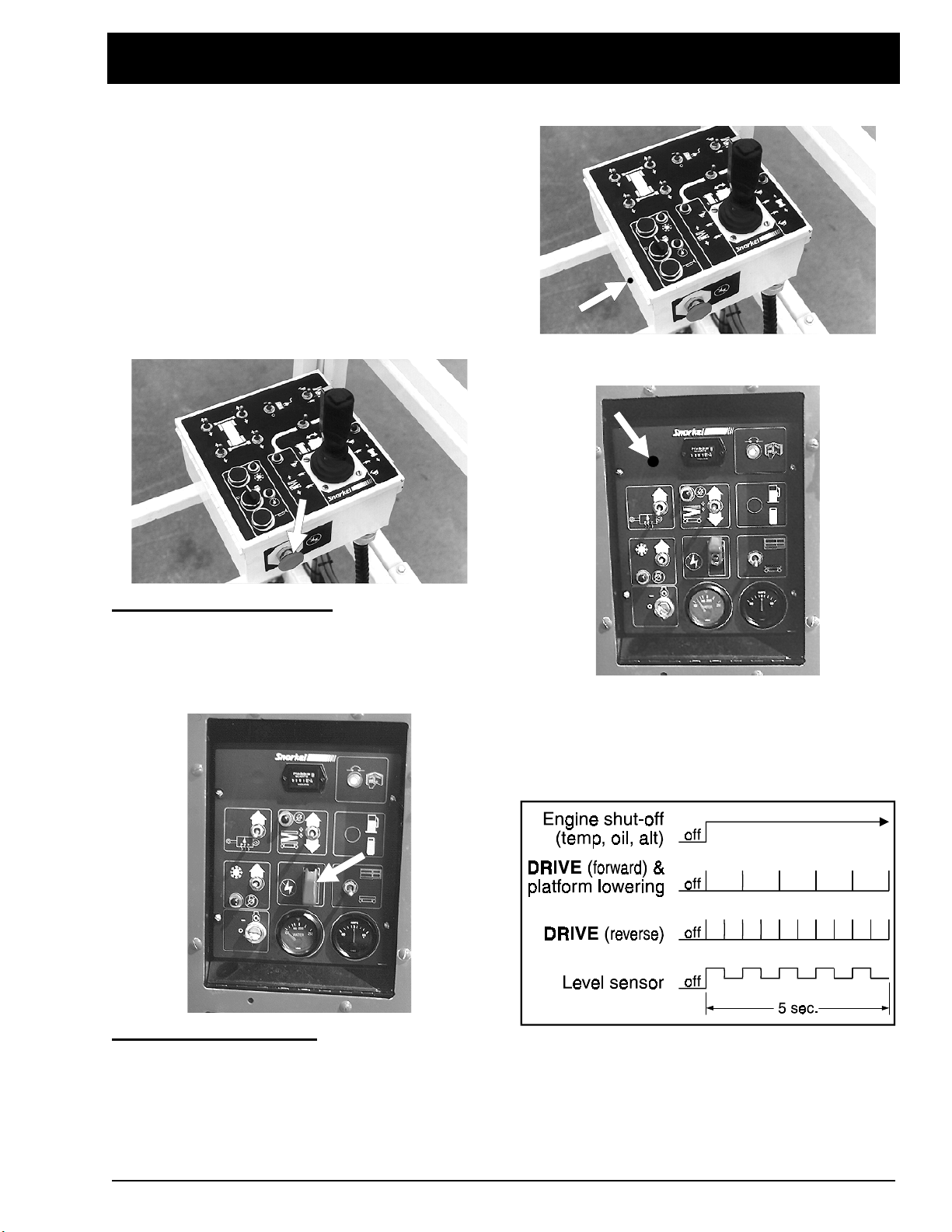

There are two alarms on an SR. One is located

in the platform-control box,

At the platform-control box:

red

EMERGENCY STOP

machine stops, the engine turns off, and nothing

moves. This switch must be out (on) to control

the SR from the platform (turn the switch

clockwise and it will pop out.

At the base-control panel:

EMERGENCY STOP

time, under any conditions, and the entire

machine stops, the engine turns off, and nothing

moves. The

up for anything on the SR to work.

EMERGENCY STOP

switch cover down, at any

Press the large

button in and the entire

Press the red

switch must be

the other is located in the base-control box. The

alarms are connected in parallel, they both emit

the same pattern of sound at the same time. The

different alarm sound patterns are shown in the

table immediately below and discussed below the

table.

The high-temperature, low oil-pressure, and

alternator not-charging alarms are each a

continuous tone. The

platform-lowering alarms beep at one beep per

second.

second. The level sensor alarm is a high-low

warbling sound.

DRIVE

DRIVE

(reverse) beeps at two beeps per

(forward) and the

P/N 569300

2 - 1

Page 16

2. SAFETY DEVICES

Level Sensor

The level sensor alarm warns the SR operator

that the SR is not level. If the tilt continues to

increase, the SR will eventually tip over. When

you hear this alarm, immediately lower the

platform completely down. When the platform is

completely down, determine and correct the

cause of the tilt before raising the platform again.

NOTE: While the alarm is sounding it is not

possible to drive the SR nor raise the

platform.

T

GUARDRAILS

Lowering

The lowering alarm warns people near an SR

that the platform is coming down and the scissor

arm assembly is closing.

High Temperature

The high-temperature alarm warns you that the

engine is overheating. When the alarm sounds

you should immediately lower the platform

completely down then turn the engine off until the

condition that caused the overheating has been

corrected. (See “AUTOMATIC SHUT-OFFS &

CIRCUIT BREAKERS” chapter for more

information.)

Low Oil Pressure

The low pressure alarm warns you that the

engine oil pressure is near the lower limit for safe

operation of the engine. When the alarm sounds

you should immediately lower the platform

completely down then turn the engine off until the

condition that caused the low oil pressure has

been corrected. (See “AUTOMATIC SHUT-OFFS

& CIRCUIT BREAKERS” chapter for more

information.)

The guardrails help protect you from falling off

the platform. Be sure the guardrails are properly

installed and that the safety chain (or gate) and

fasteners are in place.

T

SAFETY PROP

Always raise the safety prop then lower the

scissor-arm assembly onto the safety prop

before reaching into the scissor-arm assembly

for any reason.

T

SAFETY CHAIN

DRIVE (reverse)

The

DRIVE

SR is traveling backward along the ground. This

alarm beeps twice as fast as the

(forward) alarm.

DRIVE (forward)

The

DRIVE

SR is traveling forward along the ground. This

alarm beeps half as fast as the

alarm.

2 - 2

(reverse) alarm alerts people that the

DRIVE

(forward) alarm alerts people that the

DRIVE

(reverse)

The safety chain should be closed at all times

except when someone is entering or leaving the

platform.

P/N 569300

Page 17

2. SAFETY DEVICES

SWINGING GATE

T

The swinging gate should be closed at all times

except when someone is entering or leaving the

platform.

SAFETY CONTROL

T

(option)

OPERATOR HORN

T

The operator horn is used primarily to get the

attention of people on the ground when you are

working aloft. For the horn to work the following

switches, on the base-control panel, must be set

as indicated:

MAIN POWER

EMERGENCY STOP

SELECTOR

OUTRIGGERS

T

.................ON

......................PLATFORM

(option)

.......on (up)

(option)

The safety control must be squeezed and held to

activate the joystick. The safety control prevents

the joystick from moving the platform if

something accidentally pushes the joystick. Do

not disable the safety control in any way.

BUBBLE LEVEL

T

(outrigger machines

only)

See the “GAUGES” chapter for a discussion of

the bubble level.

The outrigger controls are on the upper left side

of the platform-control box.

The outriggers are used to level the SR (for

complete outrigger operating procedures see the

“OPERATION” chapter).

NOTE: The SR must be on a firm surface

capable of withstanding all load forces

imposed by the aerial platform in all operation

conditions before the outriggers are used.

P/N 569300

2 - 3

Page 18

2. SAFETY DEVICES

GFCI AC OUTLET

T

The GFCI (ground fault circuit interrupt) is

located under the platform-control box. To use

the outlet set the

NOTE: If the SR does not have the ac

generator option, connect a source of power

to the GFCI plug at the base-control panel.

The GFCI will protect against short circuits to

ground. When there is a short to ground the

GFCI will shut off power to the outlet.

To reset the outlet:

Unplug the equipment being used.

Press the

This should restore power to the outlet. If it does

not, set the

refer the problem to a trained service technician.

RESET

AC OUTLET SWITCH

(option)

AC OUTLET SWITCH

button on the GFCI outlet.

to off (O) and

to on (-).

FLASHING LIGHT

T

The flashing light alerts people that the SR is

present and that the SR is moving. The light

flashes at about one flash per second any time

the SR engine is running. There is no ON/OFF

switch for the flashing light, it cannot be turned

off while the SR is running.

LANYARD ANCHOR POINTS

T

There are four anchors on the floor of the

platform, one at the front of the roll-out deck, one

at the back of the platform, and one on each side

of the platform.

NOTE: These anchors are not for lifting or

tying down the machine.

You should attach your fall protection to the

anchors if work rules require it.

(option)

(option)

2 - 4

P/N 569300

Page 19

3. SPECIFICATIONS

3. SPECIFICATIONS

Snorkelift SR series machines are scissorsupported elevating work-platforms built to

conform to the following standards:

OSHA Paragraph 1910.67 Title 29,

C.F.R.Vehicle-Mounted Elevating and Rotating

Work Platforms - Labor.

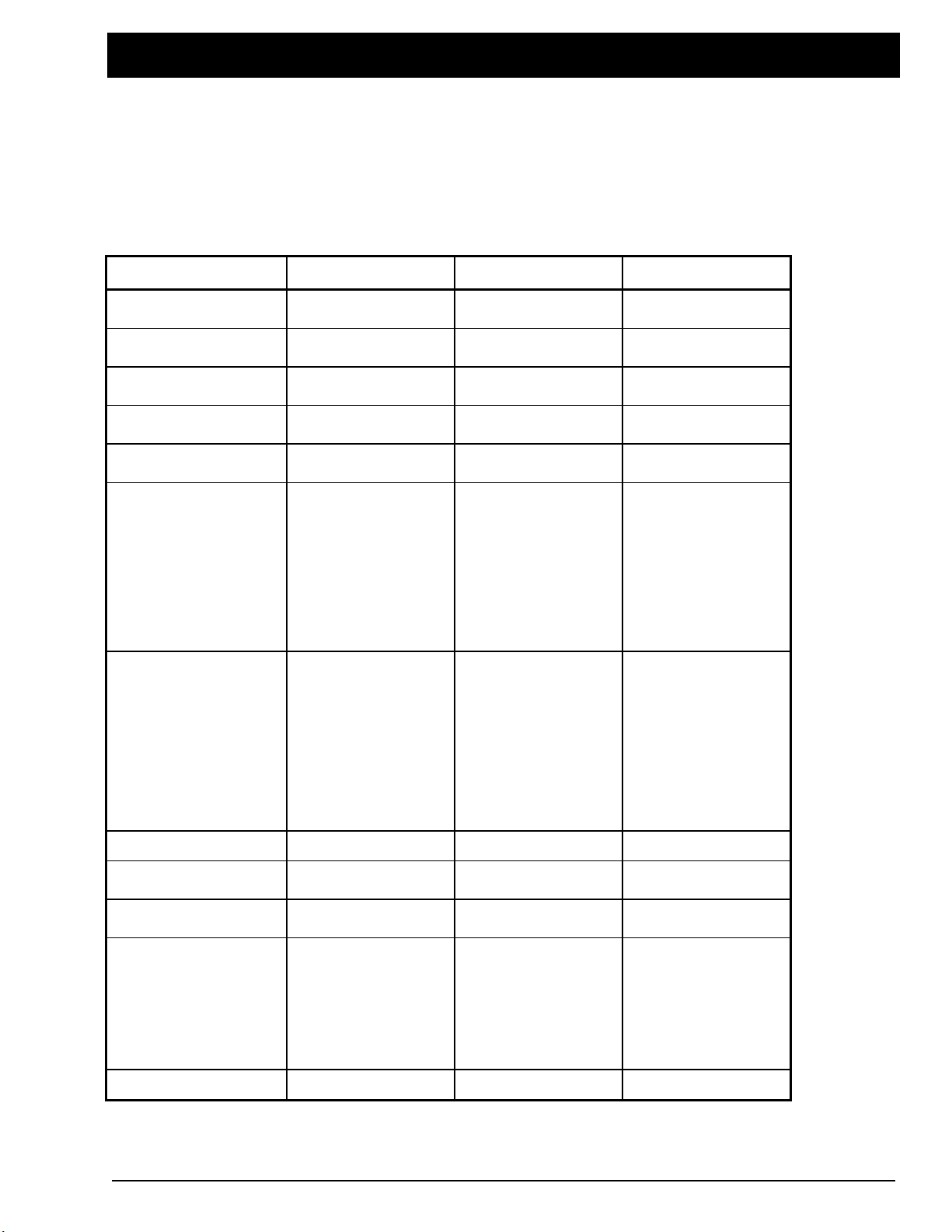

GENERAL SPECIFICATIONS FOR STANDARD MACHINES

T

OSHA Paragraph 1926.556 Title 29, C.F.R.,

Aerial Lifts - Construction. ANSI Standard A92.6,

Self-Propelled Elevating Work Platforms.

CSA Standard CAN 3-B354.3-M82, Self

Propelled Elevating Work Platforms for use as

“Off Slab” Units.

SR: SR2584 SR3284 SR4084

Weight

Max. single wheel

load

Ground pressure

(max)

Width

Length

Height:

working

6280 lbs.

(2855 kg)

3332 lbs.

1511 kg

34 psi

2.4 kg/cm

84 in.

(213 cm)

137 in.

(348 cm)

31 ft.

(9.4 m)

7650 lbs.

(3477 kg)

3560 lbs.

1615 kg

2

39 psi

2.7 kg/cm

84 in.

(213 cm)

137 in.

(348 cm)

38 ft.

(11.6 m)

2

8720 lbs.

(3964 kg)

3788 lbs.

1718 kg

45 psi

3.2 kg/cm

84 in.

(213 cm)

149 in.

(378 cm)

46 ft.

(14 m)

2

raised

lowered

Platform:

driveable ht.

size* in.

(cm)

capacity

Drive wheels

Rear axle

Tires in.

(cm)

Speed:

Max. drive

25 ft.

(7.6 m)

47 in.

(119 cm)

FULL

72x120

(183x305)

1750 lbs.

795 kg)

444

Driven

Articulated

26x12

66x30.5

2.2 mph

(1 km/h)

32 ft.

(9.8 m)

53.5 in.

(136 cm)

FULL

72x120

(183x305)

1250 lbs.

(568 kg)

Driven

Articulated

26x12

66x30.5

2.2 mph

(1 km/h)

40 ft.

(12.2 m)

60 in.

(152 cm)

32 ft.

(9.8 m)

72x120

(183x305)

750 lbs.

(341 kg)

Driven

Articulated

26x12

66x30.5

2.2 mph

(1 km/h)

Max. raise

Lower

Gradeability

22 sec

25 sec

32% 32% 30%

* Four foot (1.8 m) platform-extension retracted.

P/N 569300

30 sec

40 sec

45 sec

40 sec

3 - 1

Page 20

3. SPECIFICATIONS

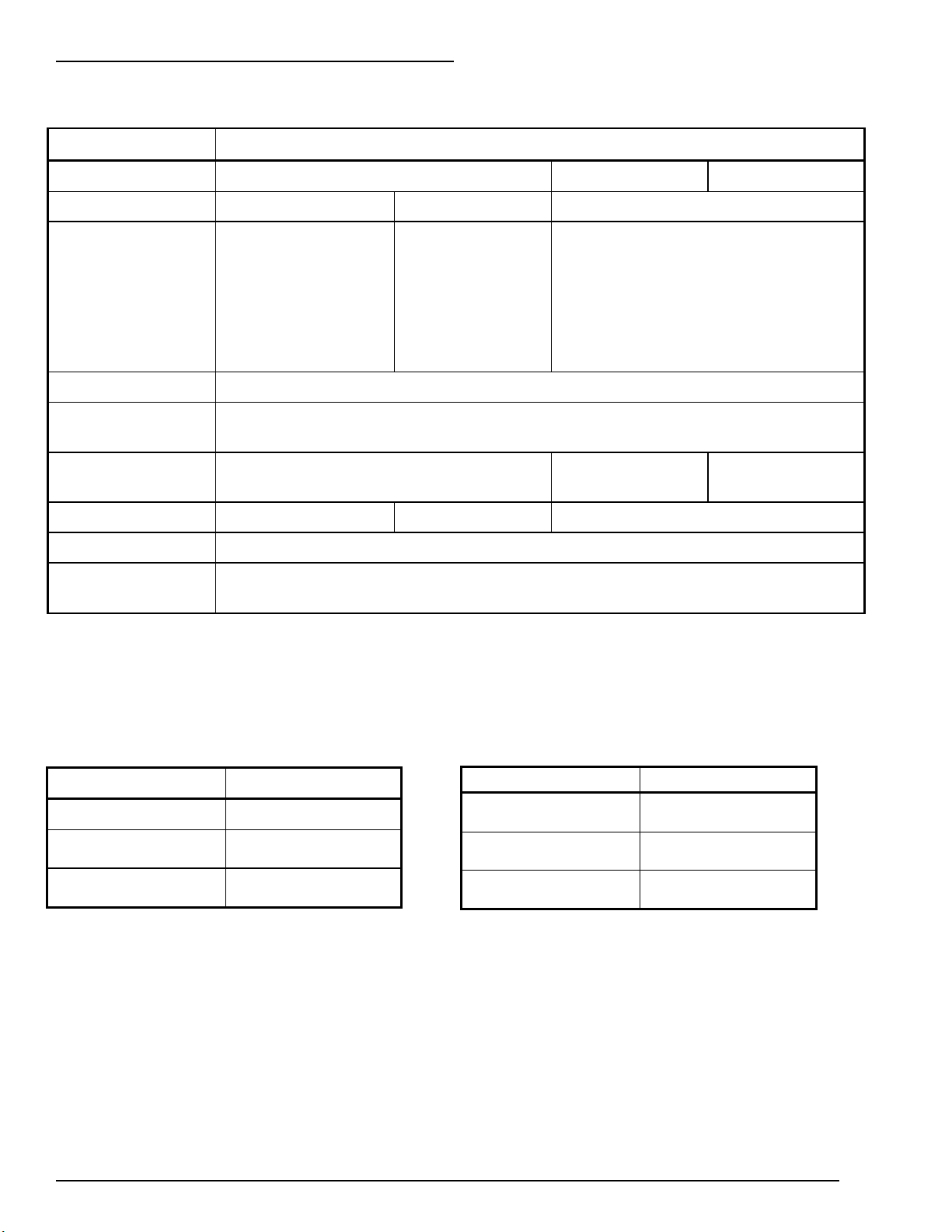

ENGINE DATA

T

ENGINE MAKE KUBOTA

MODEL WG750-G D905-B V800-B

FUEL gasoline LPG diesel no. 2-D

FUEL GRADE

COOLANT 50% water + 50% ethylene glycol

unleaded

85 octane

(motor method)

Do not use

gasoline blended

with methyl

alcohol

.

HD5

Gas Processors

Association

Standard 2140

Category: special

duty propane

ASTM no. 2-D

ASTM D975

cetane no. > 44

(For operating temp. below 32°F (0°C)

use “winterized” no. 2-D.)

OPERATING

TEMPERATURE

OIL CAPACITY 3.5 qt USA

OIL GRADE API: SF, SF/CD API:CC/CD/CE

OIL WEIGHT see chart below

RUNNING TIME

(one tank of fuel)

ENGINE OIL CHARTS

T

WG750-G

Ambient temperature

above 77°F (25°C)

32°F to 77°F

(0°C) to (25°C)

0°F to 32°F

(-17°C) to (0°C)

180°F - 205°F(82°C - 96°C)

5.2 qt USA

(3.25 liters)

A full tank of gasoline, or diesel, will last an entire eight hour shift, under normal

working conditions. It normally takes two tanks of LPG per eight hour shift.

D905-B and V800-B

Engine oil weight

SAE30 or 10W30

SAE20 or 10W30

SAE10W or 10W30

Ambient temperature

above 77°F (25°C)

32°F to 77°F

(0°C) to (25°C)

below 32°F (0°C)

(5.1 liters)

Engine oil weight

SAE30 or 10W30

10W40

SAE20 or 10W30

10W40

SAE10W or 10W30

10W40

4.2 qt USA

(4.0 liters)

HYDRAULIC FLUID RECOMMENDED

T

Above 10°F (13°C) use Mobil DTE-13M (ISO VG32)

Below 10°F (13°C) use Mobil DTE-11 (ISO VG15)

3 - 2

P/N 569300

Page 21

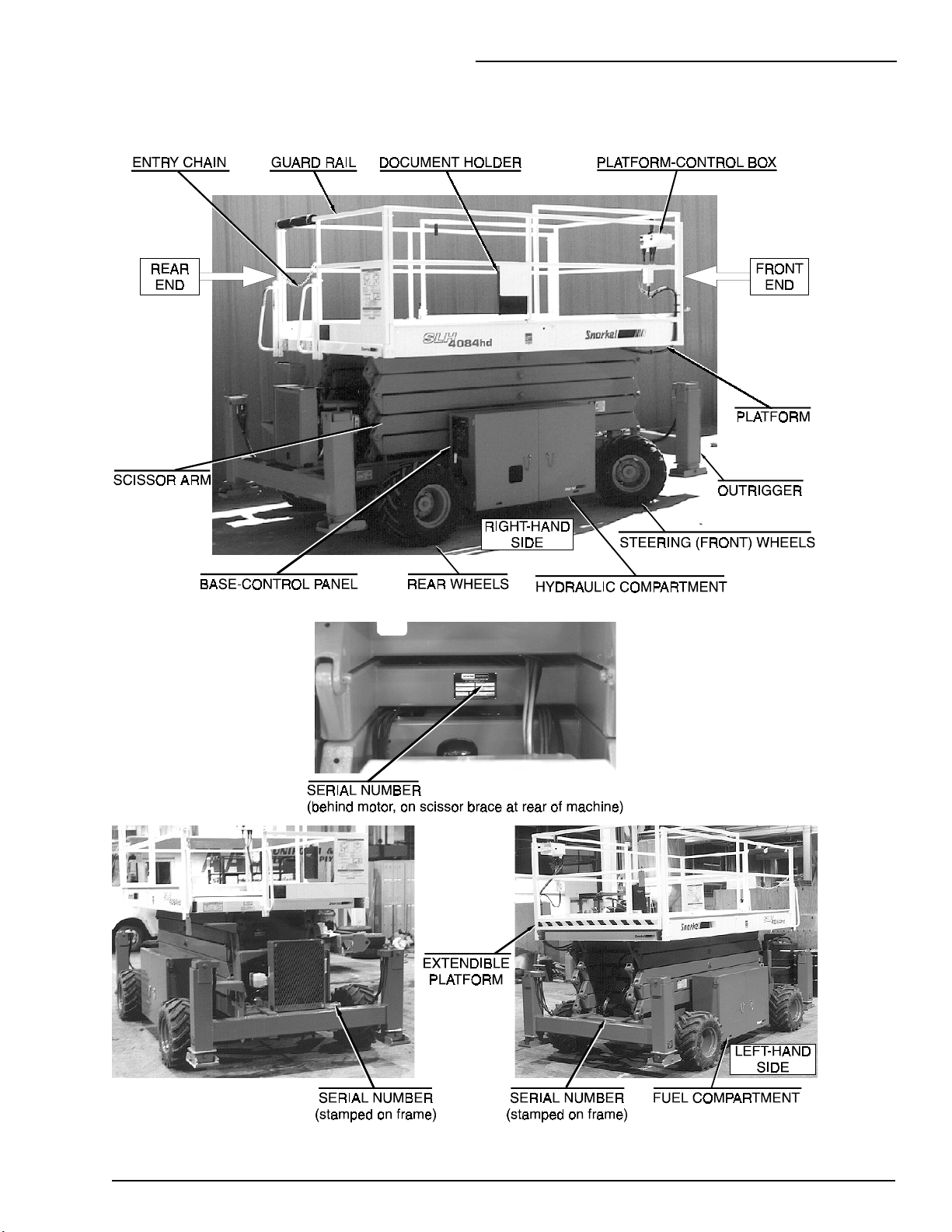

NOMENCLATURE & SERIAL-NUMBERS

)

T

3. SPECIFICATIONS

P/N 569300

3 - 3 (3 - 4 blank

3 - 3

Page 22

Page 23

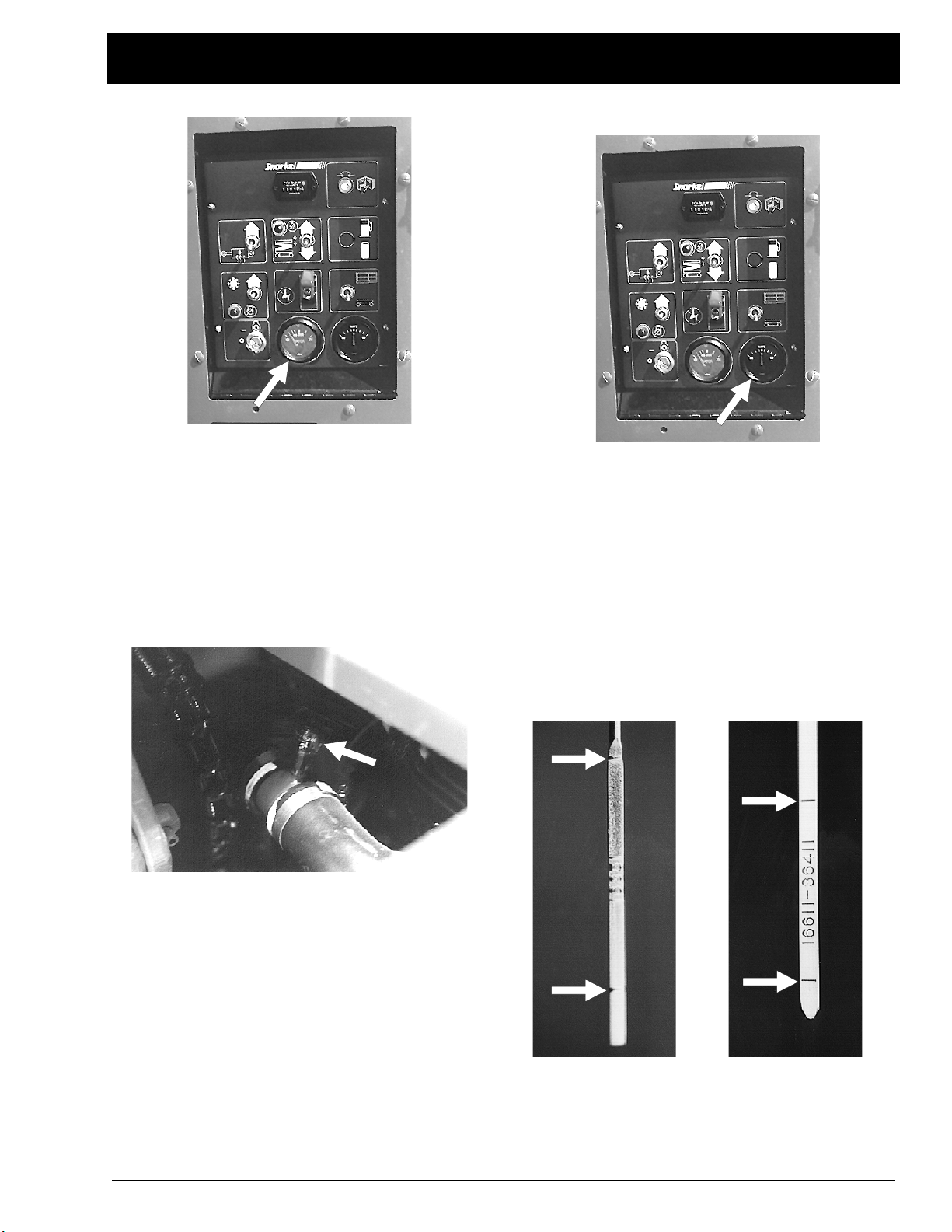

WATER

T

T

AMPS

4. GAUGES

4. GAUGES

The

WATER

control panel. It shows the temperature of the

water-antifreeze mixture in the engine block. The

typical operating-temperature range for Kubota

engines is 180°F to 205°F (82°C to 96°C), both

diesel and gasoline. (See the “AUTOMATIC

SHUT-OFFS & CIRCUIT BREAKERS “ chapter

for more information.)

T

AIR FILTER

The air filter gauge is located between the air

filter and the intake manifold. The gauge

measures the vacuum (air pressure) between the

intake manifold and the air filter. As the filter

clogs, the vacuum increases (pressure drops).

As the vacuum increases, a red indicator raises

toward the clear area of the gauge. When you

can see the indicator in the clear area of the

gauge, it’s time to change the air filter.

The indicator stays at its highest setting, it does

not go to the bottom of the gauge when the

engine is turned off or the filter changed. After

the filter is changed, press the small reset button

to reset the indicator to the bottom of the gauge.

gauge is located on the base-

The

AMPS

from the alternator to the battery. When the

engine is running, the needle in the

should not be to the left of “0.” Under normal

operating conditions, after the engine has been

running for a few minutes, the

should read “0.”

T

ENGINE OIL

GASOLINE DIESEL

Engine oil level is measured with a dipstick. Oil

capacities given in the “SPECIFICATIONS”

chapter are approximate. True values will vary

from machine to machine due to slight variations

or modifications during production. The oil

dipstick is the only way to accurately gauge if the

engine oil level is correct. Engine oil level should

gauge shows the electric current

AMPS

AMPS

gauge

gauge

P/N 569300

4 - 1

Page 24

4. GAUGES

always be between the lines on the dipstick —

never above the top line or below the bottom line.

HOURS

T

HYDRAULIC OIL LEVEL

T

The hydraulic-oil level gauge is on the side of

the hydraulic oil tank. It shows the actual level of

oil inside the tank. Read it only when the platform

is completely down. Otherwise, the lift cylinders

become large reservoirs for hydraulic oil and the

oil level in the tank will be low. The oil level

should be within ± 0.25 inches (± 6.4 mm) of the

line.

HOURS

The

It accumulates time only when the engine is

running. The

SR-qualified service technician uses it to tell

when it is time for the periodic maintenance listed

in the Maintenance Manual.

FUEL LEVEL

T

LPG tanks have two fuel gauges (1) (2) on top.

One measures correctly when the tank is

standing on end (

measures correctly when the tank is laying down

HORIZONTAL

(

tank. SR tanks are mounted horizontally.

Therefore, you should read the

scale (2).

gauge is basically an electric clock.

HOURS

gauge cannot be reset. An

(option)

VERTICAL

). Both read in fractions-of-a-full-

) the other

HORIZONTAL

BUBBLE LEVEL

T

A bubble level is located on the platform side rail,

below the platform-control box. Watch the bubble

level while you set the outriggers. Lower the

outriggers, one at a time, just enough to center

the bubble in the circle on top of the gauge.

When the bubble is centered the platform is level

and can safely be raised.

COOLANT

T

The engine coolant reservoir is on the front of the

step weldment. When the engine is at operating

temperature the coolant should be at the HOT

line. When the engine is cold there should be

about one inch (2.54 cm) of coolant in the bottom

of the reservoir.

(outrigger machines only)

4 - 2

P/N 569300

Page 25

5. AUTOMATIC SHUT-OFFS

5. AUTOMATIC SHUT-OFFS

& CIRCUIT BREAKERS

AUTOMATIC SHUT-OFFS

T

Level Sensor

When the level sensor alarm sounds, automatic

interlocks make it impossible to drive the SR or

raise the platform. For more complete

information see the “Level Sensor” subsection of

the “SAFETY DEVICES “ chapter.

Engine Temperature

the engine shuts off. The engine will restart with

low pressure but it will only run a few seconds

before it automatically shuts off again.

Platform Height vs. Drive Speed

When the platform is over seven feet (2.1 m)

above the ground the drive speed is limited to the

slowest speed and the lift speed is also limited to

the slowest speed.

Parking Brakes

There is a temperature sensor in the engine. It

measures the temperature of the antifreezewater mixture as the mixture leaves the top of

the radiator and enters the top of the engine. If

the temperature reaches 210°F (99°C) an alarm

sounds. If the temperature continues to rise, the

engine shuts off when the temperature reaches

230°F (110°C). The engine will not restart until

the temperature drops below 210°F (99°C).

Engine Oil Pressure

When the

neutral position the SR parking brakes are

automatically set. The brakes automatically

release when you move the

CONTROLLER

Dynamic Brakes

When you drive an SR down a slope, if the SR

begins to coast (outrun the drive motors) the

hydraulic system “senses” the coasting condition.

The hydraulic drive motors then become

hydraulic brakes and the SR is slowed. This

action prevents SRs from speeding down

grades.

JOYSTICK CONTROLLER

JOYSTICK

to drive.

is in the

There is an oil pressure sensor in the engine. It

measures the engine oil pressure at the oil filter.

If the pressure falls below a safe operating value

P/N 569300

5 - 1

Page 26

5. AUTOMATIC SHUT-OFFS

Alternator Not Charging

problem to a qualified trained service technician

for repair.

Hydraulic Generator Circuit Breaker

(option)

SRs that have hydraulically powered ac

generators have a circuit breaker at the

generator to protect the generator from

overloads. If the breaker trips (pops out) do the

following:

When the fan belt breaks, or the alternator

output falls below a safe level for other reasons,

the engine automatically shuts off and an alarm

sounds. As long as the SR battery is charged

you can lower the platform, in the usual way,

from the platform-control box or the base-control

panel without the engine running.

Outriggers

The SR cannot be driven unless the outriggers

are completely up. If you have just raised the

outriggers but the SR will not drive, double check

to be sure all four outriggers are completely up.

Hydraulic Generator

The SR cannot be driven nor can the platform be

raised while the 120 V ac, hydraulically powered,

generator is running (the

GENERATOR/MACHINE

GENERATOR).

(option)

(option)

switch is set to

Turn the

MACHINE.

Disconnect whatever is plugged into the ac

outlet on the platform.

After the breaker has had time to cool off,

push it back in then attempt to reuse the

generator in the normal way.

If the breaker trips a second time, refer the

problem to a qualified trained service technician.

GFCI Outlet

MACHINE/GENERATOR

(option)

switch to

T

CIRCUIT BREAKERS

Main Breaker

There is only one circuit breaker, on a standard

SR, that is accessible to the operator. Its

purpose is to protect the electrical circuits from

electrical overloads. When the circuit breaker

trips (pops out) push it back in then attempt to

use the SR. If the circuit breaker trips a second

time, take the SR out of service and refer the

5 - 2

The GFCI (ground fault circuit interrupt) will

protect against short circuits to ground. When

there is a short to ground the GFCI will shut off

power to the outlet.

To reset the outlet:

Unplug the equipment being used.

Press the

This should restore power to the outlet. If it does

not, set the

refer the problem to a trained service technician.

NOTE: The GFCI does not protect against

electrical overloads.

RESET

AC OUTLET SWITCH

button on the GFCI outlet.

to off (O) and

P/N 569300

Page 27

6. CONTROLS

6. CONTROLS

6. CONTROLS

This chapter explains what each control does.

This chapter does not explain how to use the

controls to produce useful work, refer to the

“OPERATION” chapter for that, after you have

read this chapter.

For optional-equipment controls, see the

“OPTIONS” chapter. The only optionalequipment controls discussed in this chapter are

the controls for: diesel engines, dual-fuel

engines, LP-only engines, and outriggers.

See the “EMERGENCY OPERATION” chapter

for the location of the emergency bleed down

control and for correct emergency bleed down

procedures.

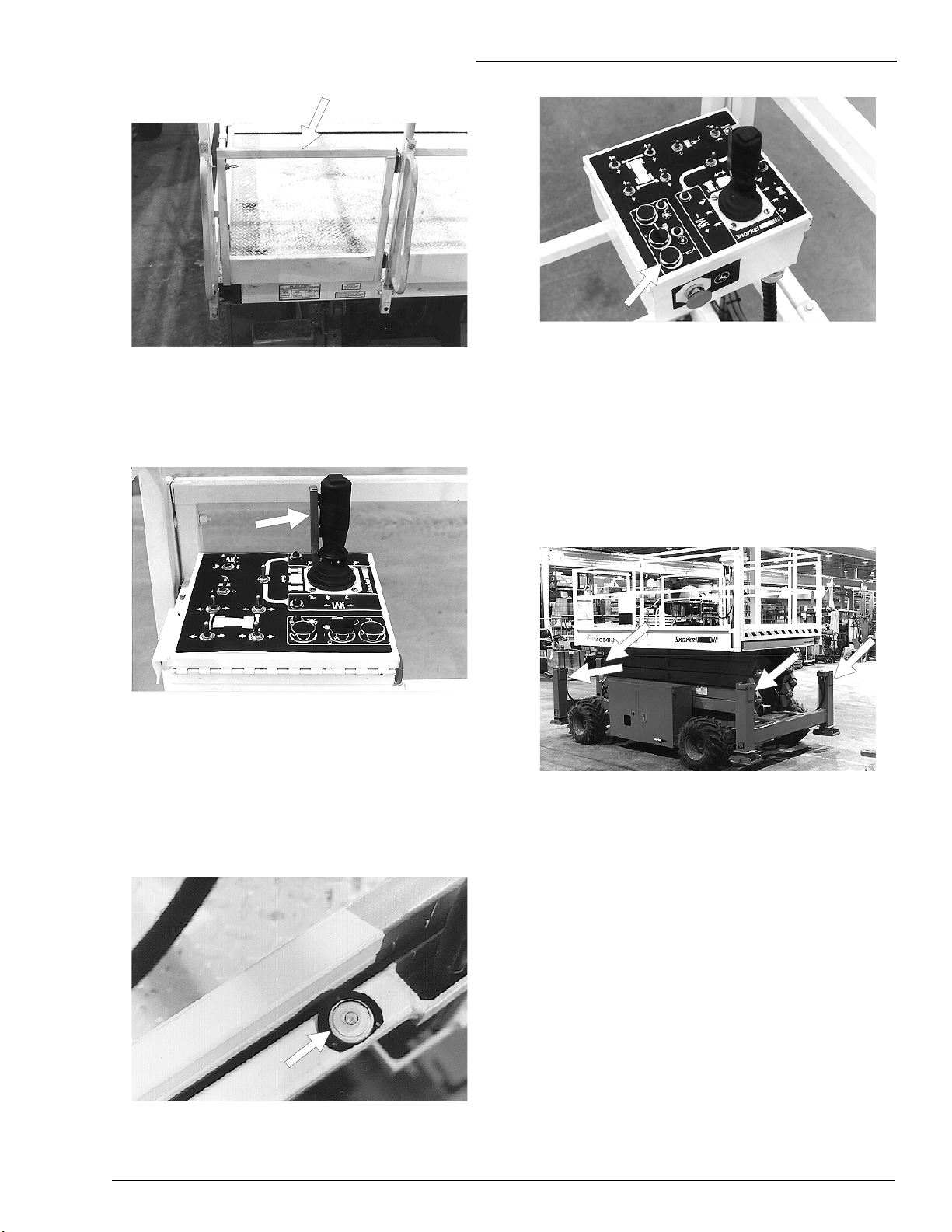

The main operating functions of an SR can be

controlled from the base-control panel (1) or the

platform-control box (2).

P/N 569300

6 - 1

Page 28

6. CONTROLS

HYDRAULIC COMPARTMENT

T

BATTERY

for the engine to start. When the BATTERY

switch is OFF the positive side of the SR battery

is disconnected from the electrical system. Lock

this switch OFF when the SR is left unattended.

: The BATTERY switch must be ON

3.

GLOW-PLUG INDICATOR LIGHT

engines only): This light will be on while the glow

plugs are on. Wait, about 10 seconds for the light

to go out before you try to start a diesel.

4.

CHOKE

choke switch up anytime you start a gasoline

engine that is at ambient air temperature (a

“cold” engine).

(gasoline engines only): Hold the

(diesel

BASE-CONTROL PANEL

T

Controls for operating an SR from the ground are

located on the right side of the machine on the

rear of the hydraulic compartment.

NOTE: The number of each control below

corresponds to the control’s call-out on the

next page.

1.

EMERGENCY STOP

cover down, at any time, under any conditions,

and the entire machine stops — the engine turns

off and nothing moves. This switch must be up

for anything on the machine to work.

2.

KEY SWITCH

automobile ignition switch. Hold the key at the

start symbol (extreme clockwise position) until

the engine starts then release it to the on

position (bar symbol).

Turn the key to off (O) if the platform is to stay in

one position for a long time. That will turn the

engine off and save fuel.

3.

CHOKE INDICATOR LIGHT

engines only): This light will be lit while you

choke the engine (see

: This switch works like an

: Press the red switch-

(gasoline

CHOKE

below).

4.

GLOW PLUG

momentary contact switch. Press it up then

release it just before you start a diesel engine

that is at ambient air temperature (a “cold”

engine). This action automatically causes glow

plugs to come on for 10 seconds to warm the

inside top of each cylinder, thus aiding

combustion.

5.

HYDRAULIC OIL WARM-UP

ambient air temperature is below 50°F (10°C)

and SR movement is sluggish because of cold

hydraulic oil, turn the warm-up switch on (up) for

5 to 10 minutes or until the hydraulic oil tank is

warm to the touch then turn the switch off

(down).

For the warm-up system to work, the engine

must be running.

While the warm-up system is on, do not attempt

to move the SR in any way.

6.

LIFT INDICATOR LIGHT

raised only when this light is lit. When this light is

not lit the platform will not rise because: the

platform is not level, the outriggers are not

properly set, or the articulating axles are not all

set.

7.

PLATFORM LIFT/LOWER

up causes the platform to rise. Pushing this

switch down causes the platform to lower.

8.

engine set the FUEL switch to gasoline (up) or

LP gas (down) depending on which you want to

use. If you select LP gas, be sure to open the

valve on top the LP gas tank.

9.

down for the base-control panel to work. Must be

up for the platform-control box to work.

(option): Before starting a dual-fuel

FUEL

BASE/PLATFORM SELECTOR

(diesel engines only): This is a

: When the

: The platform can be

: Holding this switch

: Must be

6 - 2

P/N 569300

Page 29

BASE-CONTROL PANEL

6. CONTROLS

P/N 569300

6 - 3

Page 30

6. CONTROLS

PLATFORM-CONTROL BOX

T

Controls for operating an SR from the platform

are located on the platform-control box.

NOTE: The number of each control below

corresponds to the control’s call-out on the

next page.

EMERGENCY STOP

1.

at any time, under any conditions, and the entire

machine stops — the engine turns off and

nothing moves. This switch must be out (on) to

start and run the SR from the platform-control

box, turn the switch clockwise and it will pop out

(on). Press the switch in (off) if the platform is to

stay in one position for a long time. That will turn

the engine off and save fuel.

NOTE: The EMERGENCY STOP switch on

the base-control panel overrides the one on

the platform-control box. If the one on the

base-control panel is off the SR will not start

or run, it does not make any difference

whether the one on the platform-control box is

on or off.

START

2.

the engine. As soon as the engine starts, release

the switch.

CHOKE

3.

hold the switch in anytime you start a gasoline

engine that is at ambient air temperature (a

“cold” engine).

GLOW PLUG

3.

momentary contact switch. Press it up then

release it just before you start a diesel engine

that is at ambient air temperature (a “cold”

engine). This action automatically causes glow

plugs to come on for 10 seconds to warm the

inside top of each cylinder, thus aiding

combustion.

CHOKE INDICATOR LIGHT

4.

engines only): This light will be lit while you

choke the engine.

GLOW PLUG INDICATOR LIGHT

4.

engines only): This light will be on while the glow

plugs are on. Wait for the light to go out before

you try to start a diesel.

SAFETY CONTROL

5.

must be squeezed against the JOYSTICK

CONTROLLER to activate the JOYSTICK

: Press and hold the switch in to start

(gasoline engines only): Press and

(diesel engines only): This is a

: Press the red button in

(gasoline

(diesel

The SAFETY CONTROL

CONTROLLER. If the SAFETY CONTROL is not

squeezed the JOYSTICK CONTROLLER is

inoperative.

JOYSTICK CONTROLLER

6.

SELECTOR is set to the left (lift function),

pushing the JOYSTICK CONTROLLER forward

causes the platform to rise, pulling the

JOYSTICK CONTROLLER backward causes the

platform to lower. If the LIFT/DRIVE SELECTOR

is set to the right (drive function), pushing the

JOYSTICK CONTROLLER forward causes the

SR to move forward, pulling the JOYSTICK

CONTROLLER backward causes the SR to

move backward. The further you push or pull the

controller the faster the motion (except

lowering—it occurs at one speed only).

NOTE: Squeeze the SAFETY CONTROL

anytime you use the JOYSTICK

CONTROLLER.

STEERING

7.

JOYSTICK CONTROLLER turns the front

wheels left or right depending upon which side of

the switch you press.

NOTE: The wheels do not return to straight

ahead, after a turn, the way automobile

wheels do. You must use the STEERING

switch to straighten the wheels after a turn.

LIFT/DRIVE SELECTOR

8.

set to the left the JOYSTICK CONTROLLER

becomes a lift/lower controller to raise or lower

the platform. When this switch is set to the right

the JOYSTICK CONTROLLER becomes a drive

controller to drive the SR forward or backward.

The SR will not drive and lift at the same time.

SPEED

9.

you are working in close quarters or if you are

new to the machine. Setting the switch to rabbit

(fast) doubles the top speed of the SR.

AC OUTLET SWITCH

10.

on/off switch for the 120 V ac hydraulically

powered generator. When the switch is on, the

outlet box at the platform is energized.

LIFT INDICATOR LIGHT

11.

be raised only when this light is lit. When this

light is not lit the platform will not rise because:

the platform is not level, the outriggers are not

properly set, or the articulating axles are not all

set.

OUTRIGGERS

12.

one of the outriggers. Pull a switch backward to

lower an outrigger, push it forward to raise the

outrigger.

: The rocker switch on top of the

: Set the switch to turtle (slow) when

: Each switch corresponds to

: If the LIFT/DRIVE

: When this switch is

(option): This is an

: The platform can

6 - 4

P/N 569300

Page 31

PLATFORM-CONTROL BOX

)

6. CONTROLS

P/N 569300

6 - 5 (6 - 6 blank

6 - 5

Page 32

Page 33

7. OPERATION

7. OPERATION

This chapter explains how to start and run an SR

that has either a gasoline or diesel engine.

Starting a gasoline engine that is set up to burn

LP-only or dual-fuel is also discussed in this

chapter.

To use this chapter, first decide whether you will

be starting and operating the SR from the basecontrol panel or the platform-control box. Go to

the section entitled “OPERATING FROM THE

BASE-CONTROL BOX” if you intend to start and

run the SR from the base-control panel. Go to

“OPERATING FROM THE PLATFORMCONTROL BOX” if you intend to start and run

the SR from the platform.

After you have made the “base-control / platformcontrol” decision you need to know whether the

SR has a gasoline or diesel engine. If it has a

“gasoline” engine you further need to know

whether it is set up to burn LP-only, or dual-fuel

(LP or gasoline). If it is set up to burn dual-fuel

you have to decide whether to burn gasoline or

LP. The simplest way to tell what kind of engine

set up you have is to look in the fuel

compartment on the left side of the SR -- open

both fuel compartment doors.

OPERATING FROM THE BASE-

T

CONTROL PANEL

Starting a Gasoline, LP-only, or Dual-fuel

Engine

To start a gasoline, LP-only, or dual-fuel (LP &

gasoline) engine from the base-control panel do

the following:

1

1. Set the

BATTERY

switch (1) to ON.

1. If the only fuel source you see there is a

tank labeled GASOLINE FUEL, the SR has a

gasoline engine set up to burn gasoline.

2. If the only fuel source you see is a tank

labeled DIESEL FUEL, the SR has a diesel

engine.

3. If the only fuel source you see is one or

more LP tanks, the SR has a special gasoline

engine set up to burn LP-only.

4. If you see a GASOLINE FUEL tank and

one or more LP tanks, the SR has a special

gasoline engine set up to burn either gasoline

or LP.

Once you have determined the type of engine

installed and the type of fuel you will burn you

should go to the corresponding subsection that

explains how to start that type engine. Read the

“TABLE OF CONTENTS” at the front of this

manual to see how the different sections and

subsections of this chapter are arranged.

2. Set the

(up).

3. Set the

(3) to base (down).

EMERGENCY STOP

BASE/PLATFORM SELECTOR

switch (2) to on

switch

P/N 569300

7 - 1

Page 34

7. OPERATION

Starting a Diesel Engine

To start a diesel engine from the base-control

panel do the following:

4

1

4. For LP operation

(4) on top of the LP tank (unscrew

counterclockwise until it stops).

5. For a dual-fuel engine

(9) to LP fuel (5) or gasoline fuel (6), depending

on which you want to use.

: Completely open the valve

: Set the

FUEL

switch

1. Set the

2. Set the

(up).

3. Set the

(3) to base.

BATTERY

EMERGENCY STOP

BASE/PLATFORM SELECTOR

switch (1) to ON.

switch (2) to on

switch

6. If the engine is cold, press and hold the

CHOKE

7. Turn the key (8) to start and hold it there until

the engine starts or for 20 seconds, whichever

comes first. When the engine starts, release both

the key (8) and the

switch (7) during the next step.

CHOKE

switch (7).

CAUTION

If the engine does not start in 20 seconds, turn

the key (8) to off and release the

(7) then wait 60 seconds before trying to start the

engine again.

7 - 2

CHOKE

switch

4. Turn the key (4) to on -- do not turn the key (4)

to start.

5. If the engine is at ambient temperature,

momentarily press the

This action will automatically turn the glow-plugs,

in the engine, on for 10 seconds. A light (6) will

automatically come on to indicate that the glowplugs are on.

GLOW-PLUG

switch (5).

P/N 569300

Page 35

CAUTION

If the engine does not start in 20 seconds, turn

the key (4) to off then wait 60 seconds before

trying to start the engine again with the

PLUG

6. When the light (6) goes out, turn the key (4) to

start and hold it there until the engine starts or

for 20 seconds, whichever comes first. When the

engine starts, release the key (4).

switch (5) and key (6).

Raising the Platform

GLOW-

7. OPERATION

Warming the Hydraulic Oil

When SR movement is sluggish due to low

ambient temperature -- below about 50°F (10°C)

-- do the following:

The platform,

be raised above 32 feet (9.8 m) if the outriggers

are not set. (See “SETTING THE

OUTRIGGERS” below in this chapter.

To raise the platform from the base-control

panel, do the following:

1. The engine must be running. If not, start it

from the base-control panel as described above.

on models with outriggers

, cannot

1. Start the motor from the base-control panel.

2. Set the

(1) to on (up).

3. Leave the

(1) on for 5 to 10 minutes, or until the hydraulic

oil tank feels warm to the touch, then turn the

switch off (down) and use the SR in the normal

way.

NOTE: The SR should respond more quickly

than when it was cold.

HYDRAULIC OIL WARM-UP

HYDRAULIC OIL WARM-UP

switch

switch

2. To raise the platform, press and hold the

PLATFORM LIFT/LOWER

NOTE: If the indicator light (2) is not lit, the

platform will not rise because: the chassis is

not level, the outriggers (if present) are not

properly set, or the articulating axles are not

locked. Correct the problem then continue.

3. To lower the platform, press and hold the

PLATFORM LIFT/LOWER

P/N 569300

switch (1) up.

switch (3) down.

7 - 3

Page 36

7. OPERATION

OPERATING FROM THE PLATFORM-

T

CONTROL BOX

Starting a Gasoline, LP-only, or Dual-fuel

Engine

To start a gasoline, LP-only, or dual-fuel (LP &

gasoline) engine from the platform-control box do

the following:

1

4

1. Set the

BATTERY

switch (1) to ON.

4. For LP operation

(4) on top of the LP tank (unscrew

counterclockwise until it stops).

5. For a dual-fuel engine

(5) to gasoline (6) or LP gas (7), depending on

which you want to use.

: Completely open the valve

: Set the

FUEL

switch

2. Set the

(up).

3. Set the

(3) to platform (up).

7 - 4

EMERGENCY STOP

BASE/PLATFORM SELECTOR

switch (2) to on

switch

6. Enter the platform and latch the safety chain

(8) closed.

P/N 569300

Page 37

7. OPERATION

7. Turn the

clockwise and it will pop out (on).

8. If the engine is cold, press and hold the

CHOKE

9. Turn and hold the

clockwise (to the start position) until the engine

starts or for 20 seconds, whichever comes first.

When the engine starts, release both the

switch (11) and the

EMERGENCY STOP

switch (10) during the next step.

START

CHOKE

switch (9)

switch (11)

START

switch (10).

CAUTION

If the engine does not start in 20 seconds,

release the

CHOKE

trying to start the engine again.

Starting a Diesel Engine

To start a diesel engine from the platform-control

box do the following:

START

switch (10) then wait 60 seconds before

switch (11) and release the

2. Set the

(up).

3. Set the

(3) to platform (up).

4. Turn the key (4) to on -- do not turn the key (4)

to start.

EMERGENCY STOP

BASE/PLATFORM SELECTOR

switch (2) to on

switch

1. Set the

P/N 569300

BATTERY

5. Enter the platform (5) and latch the safety

chain (6) closed.

1

switch (1) to ON.

7 - 5

Page 38

7. OPERATION

NOTE: Setting the

the travel speed. (See the

“SPECIFICATIONS” chapter for speeds of

different models.)

SPEED

to rabbit doubles

6. Turn the

clockwise and it will pop out (on).

7. If the engine is at ambient temperature,

momentarily press the

This action will automatically turn the glow-plugs,

in the engine, on for 10 seconds. A light (9) will

automatically come on to indicate that the glowplugs are on.

8. When the light (9) goes out, press and hold

the

START

for 20 seconds, whichever comes first. When the

engine starts, release the

EMERGENCY STOP

GLOW-PLUG

switch (10) until the engine starts or

START

switch (7)

switch (8).

switch (10).

CAUTION

If the engine does not start in 20 seconds,

release the

seconds before trying to start the engine again

with the

(10).

Driving

1. The engine should be running. If not, start it

from the platform-control box as described

above.

START

GLOW-PLUG

switch (10) then wait 60

(8) and

START

switches

3. Set the

drive (right).

LIFT/DRIVE SELECTOR

switch (2) to

CAUTION

The SR is about to move. If you have to make an

emergency stop, release the

CONTROLLER

EMERGENCY STOP

To make a normal stop, slowly move the

JOYSTICK CONTROLLER

neutral position then release it.

4. Squeeze and hold the

against the

5. Push the

slowly forward or pull it slowly backward,

depending on which way you want to go. The

further you move the joystick the faster the SR

moves.

6. To make a right or left turn, press and hold the

STEERING

JOYSTICK CONTROLLER

NOTE: When you release the

rocker-switch (6) the steering wheels remain

pointed in the direction you left them. They do

not return to “straight ahead” the way

automobile wheels do. You will have to press

the opposite side of the

switch (6) to return to straight line travel. In

tight spots you should stop the SR, turn the

wheels the direction you want to go, then,

after you have “aimed” the steering wheels,

squeeze the

move the

slowly forward or backward.

(3) and sharply strike the

switch (4) straight in.

JOYSTICK CONTROLLER

JOYSTICK CONTROLLER

rocker-switch (6) on top of the

SAFETY CONTROL

JOYSTICK CONTROLLER

JOYSTICK

(3) to its “centered”

SAFETY CONTROL

(3).

(3)

(3).

STEERING

STEERING

rocker-

(5) and

(3)

(5)

2. Set the

are going to be driving close to other objects or

need to move the SR very slowly for other

reasons.

7 - 6

SPEED

switch (1) to turtle (slow) if you

P/N 569300

Page 39

Raising the Platform

The platform,

be raised above 32 feet (9.8 m) if the outriggers

are not set. (See “SETTING THE

OUTRIGGERS” below in this chapter.

To raise the platform from the platform-control

box do the following:

1. The engine must be running. If not, start it

from the platform-control box as described

above.

2. Set the

(left).

on models with outriggers

LIFT/DRIVE SELECTOR

, cannot

(1) to lift

7. OPERATION

T

SETTING THE OUTRIGGERS

1. Check to see that the ground under the four

outrigger pads (1 typ.) is firm, stable, and

unobstructed.

2. Completely lower the platform (3).

NOTE: If the platform (3) is above 8 feet (2.4

m) the outriggers cannot be set or adjusted.

This safety feature prevents the SR from

being tipped over by the outriggers if the

OUTRIGGER

pushed while the platform is raised.

switches are accidentally

NOTE: If the

not lit, the platform will not go up because: the

chassis is not level, the outriggers (if present)

are not properly set, or the articulating axles

(if present) are not locked. Correct the

problem then continue.

NOTE: The platform is about to move. If you

have to make an emergency stop, release the

JOYSTICK CONTROLLER

strike the

straight in.

To make a normal stop, slowly move the

JOYSTICK CONTROLLER

neutral position then release it.

3. Squeeze and hold the

against the

4. Push the

forward to raise the platform, or backward to

lower it. The further you push the

CONTROLLER

platform rises. There is only one down speed.

LIFT INDICATOR LIGHT

(3) and sharply

EMERGENCY STOP

(3) to its “centered”

SAFETY CONTROL

JOYSTICK CONTROLLER

JOYSTICK CONTROLLER

(3) forward, the faster the

switch (4)

JOYSTICK

(2) is

(3).

(3)

(5)

3. The engine must be running and the SR set

for platform-control box (2) operation.

4. Pull and hold the

backward, one at a time, until all four outrigger

pads (1) contact the ground.

OUTRIGGER

switches (4)

P/N 569300

7 - 7

Page 40

7. OPERATION

DANGER

Death or serious injury can result if an SR

tips over. Do not use the outriggers to gain

extra working height, they are not designed

for that purpose. At least one of the

outriggers should raise the SR less than six

inches (15 cm) above the ground -- use the

other three outriggers to level the SR as

necessary.

5

6

To raise the outriggers:

1. Completely lower the platform.

2. Push and hold the

forward until all the outriggers are completely up.

NOTE: The DRIVE function will not work

unless the outriggers are completely up.

OUTRIGGER

switches (9)

7

5. Visually check the bubble level (5) to

determine which outriggers must be further

extended to level the platform (3).

NOTE: When the bubble (6) in the bubble

level is in the center of the ring (7), the

platform is level.

DANGER

If the platform is up and the ground

compresses unevenly under different

outrigger pads the SR might fall over causing

serious injury or death. Check the bubble

level (5) frequently during operation. If any

movement of the bubble (6) occurs,

completely lower the platform immediately

and readjust the outriggers to recenter the

bubble (6) in the ring (7).

6. Lower the appropriate outriggers just enough

to center the bubble (5). When the

INDICATOR LIGHT

can be safely raised.

(8) comes on, the platform

LIFT

EXTENDING THE TWO-POSITION

T

PLATFORM

The two-position extendible platform (1) can be

securely locked into two different positions. To

move it from one position to the other do the

following:

1. Stand on the non-extendible part of the

platform and face the front of the machine.

7 - 8

P/N 569300

Page 41

DANGER

)

The distribution of the RATED WORK LOAD

changes when the extendible platform is

extended. Read the decal on the toe board at

the front of the platform or at the entrance to

the platform for safe weight distribution.

7. OPERATION

4. The lock pin (6) should lock into the second

lock ramp (7).

2. Pull up and hold the lock pin (2) while you

push or pull the rails (3) just far enough to get

the lock pin (2) past the lock ramp (4).

3. Push or pull the rails (5) vigorously until the

extendible platform moves to the second

position.

P/N 569300

7 - 9 (7 - 10 blank

7 - 9

Page 42

Page 43

8. EMERGENCY OPERATION

8. EMERGENCY OPERATION

There are three forms of emergency operation

for the SR: emergency stop, emergency bleeddown, and pushing. Each is covered as a

separate section below.

EMERGENCY STOP

T

There are two

an SR.

One is located on the platform-control box.

EMERGENCY STOP

switches on

pop out (on). To reset the

switch at the base-control panel, raise the red

switch-cover and push the switch up. The SR

engine can then be restarted in the normal way.

T

EMERGENCY BLEED-DOWN

The SR platform can be lowered from the

platform-control box anytime there is electricity to

the platform-control box -- the SR engine does

have to be running. If you are working from

not

the platform and the engine dies and cannot be

restarted, do the following:

EMERGENCY STOP

One is located on the base-control panel.

Push either

time, and the entire machine stops, the engine

turns off, and nothing moves.

Functionally, the

do the same thing as turning the

switch to off. The

are designed to be easier to find and faster to

use than key switches.

To reset the

platform-control box, turn it clockwise and it will

EMERGENCY STOP

EMERGENCY STOP

EMERGENCY STOP

EMERGENCY STOP

switch, at any

switches

MAIN POWER

switches

switch at the

1. Check to be sure the

switch (1) is pulled out (on).

2. Set the

function (left).

3. Squeeze the

the

JOYSTICK CONTROLLER

platform should lower. If it does not lower, call for

help from someone on the ground.

The person on the ground should do the

following:

1. Check to be sure the

ON.

SELECTOR

SAFETY CONTROL

EMERGENCY STOP

switch (2) to the platform

(3) and pull

(4) back. The

BATTERY

switch (5) is

P/N 569300

8 - 1

Page 44

8. EMERGENCY OPERATION

2. Check to be sure the

switch (6) is on (up).

3. Check to be sure the

is on.

4. Check to be sure the

set to platform (up).

5. If the

MAIN POWER

are all set correctly, and the engine will not start

from the platform-control box, set the

SELECTOR