Page 1

Operator Manual

This first section of the Operator manual is the English language version.

(EN) Manual part number 508401-003-EN for serial numbers 10131 to current.

June 08 ( Rev C )

VERSION II

X27RT / X33RT

X27BE / X33BE

Diesel

Bi-Energy 24V DC

Page 2

Page 3

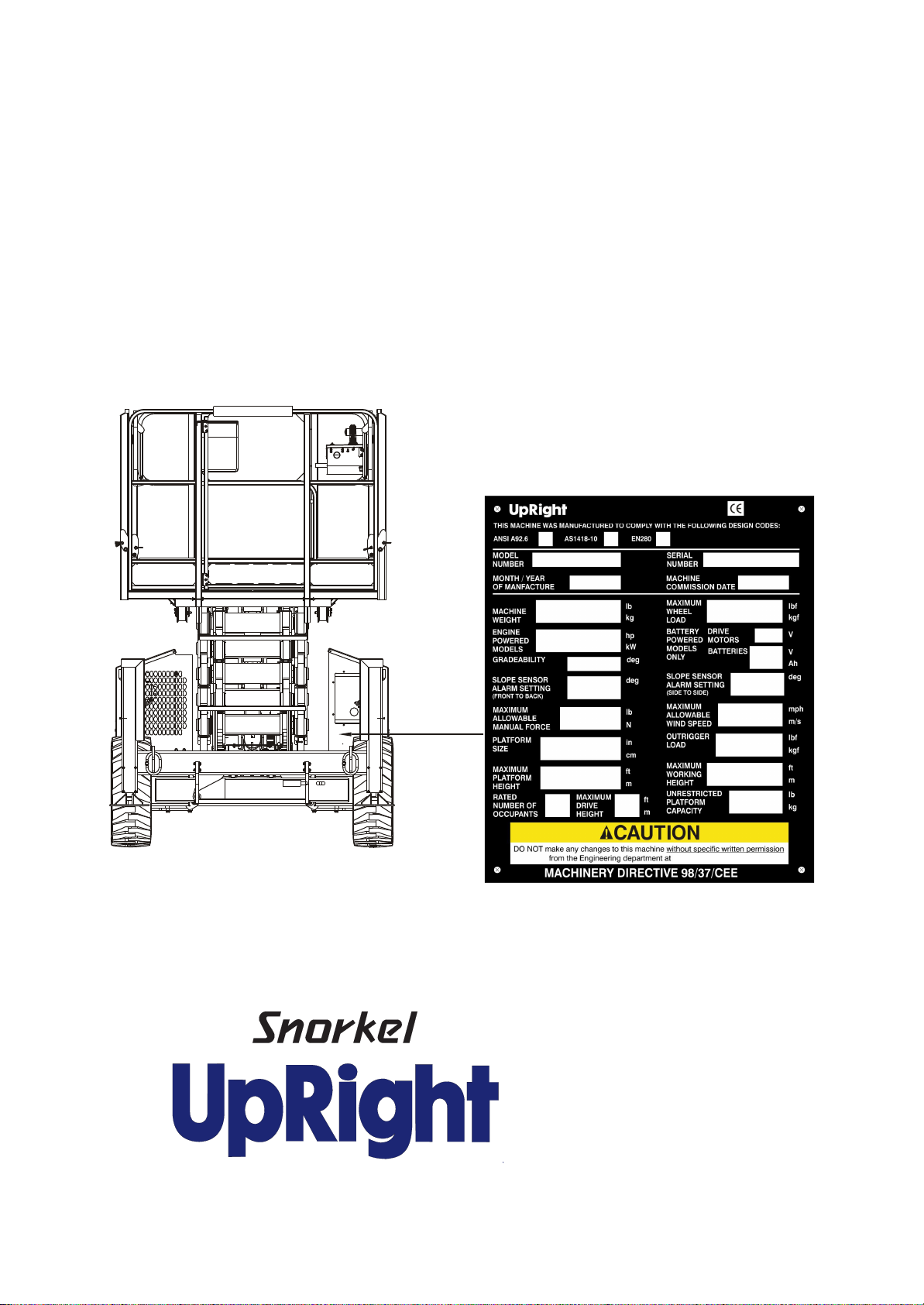

X-27-33-RT

o

o

o

Tanfield Engineering Systems Ltd.

Vigo Centre, Washington, Tyne and Wear, UK.

Upright.

508764-001

Serial Numbers 10131 - Current

Please note:

The Upright X-27-33-RT/BE is also sold as the Snorkel SR Series in some regions.

Therefore any reference to the Snorkel SR Series also applies to the UpRight X-27-33-RT/BE .

ENGLISH

When contacting UpRight for service or parts information, be sure to include the MODEL and SE RIAL

NUMBERS from the equipment nameplate.

UNLOADED

UpRight Powered Access HQ

Vigo Centre

POWERED ACCESS

www.upright.com

Birtley Road

Washington

Tyne & Wear

NE38 9DA

Tel: +44 (0) 845 1550 057

Fax: +44 (0) 845 1557 756

Page 4

Page 5

OPERATION MANUAL

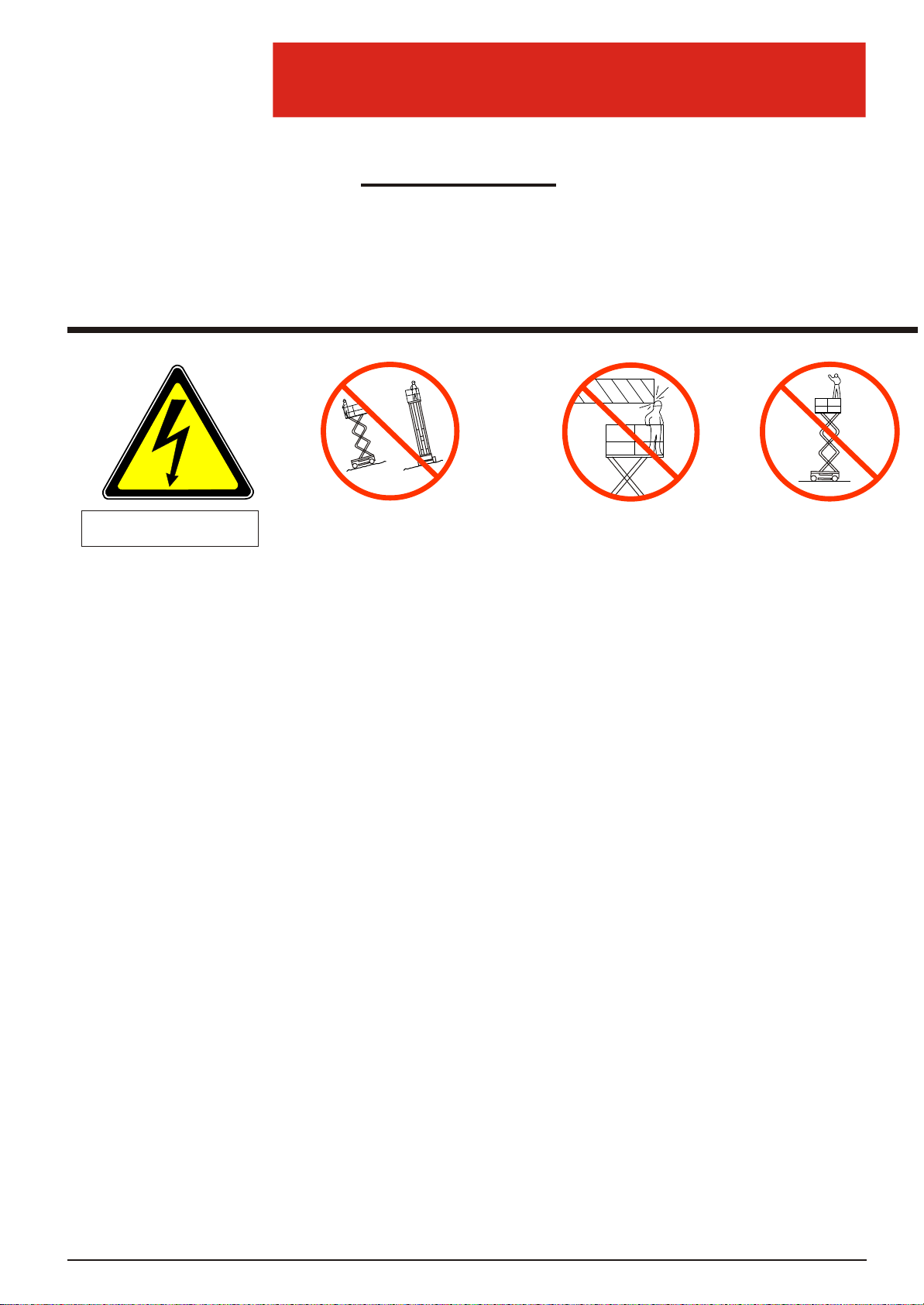

Electrocution Hazard

Tip Over Hazard

Collision Hazard

Fall Hazard

This machine is not

insulated

NEVER elevate the platform or drive

the machine while elevated unless

the machine is on a firm, level surface

NEVER position the platform

without first checking for overhead

obstructions or other hazards

NEVER climb, stand or sit on

platform guardrails or midrail

WARNING

All per son nel shall care fully read, un der stand and fol low all safety rules and op er at ing

in struc tions be fore op er at ing or per form ing main te nance on any Up Right ae rial work plat form.

Safety Rules

USE OF THE AERIAL WORK PLATFORM: This ae rial work plat form is in tended to lift peo ple and their tools as well as the ma te rial

used for the job. It is de signed for re pair and as sem bly jobs and as sign ments at over head workplaces (ceil ings, cranes, roof struc tures, build ings etc.). All other uses of the ae rial work plat form are pro hib ited!

THIS AERIAL WORK PLATFORM IS NOT INSULATED! For this rea son it is im per a tive to keep a safe dis tance from live parts of

elec tri cal equip ment!

Ex ceed ing the spec i fied per mis si ble max i mum load is pro hib ited! See "Spe cial Lim i ta tions" on page 4 for de tails.

The use and op er a tion of the ae rial work plat form as a lift ing tool or a crane (lift ing of loads from be low up wards or from up high on

down) is pro hib ited!

NEVER ex ceed the man ual force al lowed for this ma chine. See "Spe cial Lim i ta tions" on page 4 for de tails.

DISTRIBUTE all plat form loads evenly on the plat form.

NEVER op er ate the ma chine with out first sur vey ing the work area for sur face haz ards such as holes, drop-offs, bumps, curbs, or de -

bris; and avoid ing them.

OPERATE ma chine only on sur faces ca pa ble of sup port ing wheel loads.

NEVER op er ate the ma chine when wind speeds ex ceed this ma chine's wind rat ing. See "Beau fort Scale" on page 4 for de tails.

IN CASE OF EMERGENCY push EMERGENCY STOP switch to de ac ti vate all pow ered func tions.

IF ALARM SOUNDS while the plat form is el e vated, STOP, care fully lower the plat form. Move ma chine to a firm level sur face.

Climb ing up the rail ing of the plat form, stand ing on or step ping from the plat form onto build ings, steel or pre fab con crete struc tures,

etc., is pro hib ited!

Dis man tling the swing gate or other rail ing com po nents is pro hib ited! Al ways make cer tain that the swing gate is closed and se curely locked!

It is pro hib ited to keep the swing gate in an open po si tion (held open with tie straps) when the plat form is raised!

To ex tend the height or range by plac ing lad ders, scaf folds or sim i lar de vices on the plat form is pro hib ited!

NEVER per form ser vice on the ma chine while the plat form is el e vated with out block ing the el e vat ing as sem bly.

INSPECT the ma chine thor oughly for cracked welds, loose or miss ing hard ware, hy drau lic leaks, loose wire con nec tions, and dam -

aged ca bles or hoses be fore us ing.

VERIFY that all la bels are in place and leg i ble be fore us ing.

NEVER use a ma chine that is dam aged, not func tion ing prop erly, or has dam aged or miss ing la bels.

To by pass any safety equip ment is pro hib ited and pres ents a dan ger for the per sons on the ae rial work plat form and in its work ing

range.

NEVER charge bat ter ies near sparks or open flame. Charg ing bat ter ies emit ex plo sive hy dro gen gas.

Mod i fi ca tions to the ae rial work plat form are pro hib ited or per mis si ble only at the ap proval by UpRight.

AFTER USE, se cure the work plat form from un au tho rized use by turn ing the keyswitch off and re mov ing the key.

Operation Manual Page I

Page 6

Page 7

Introduction

DANGER

WARNING

CAUTION

IMPORTANT

The most im por tant chap ter in this man ual is the

safety chap ter - Chap ter 1. Take time, now, to study

it closely.

The in for ma tion in Chap ter 1, might save your life,

pre vent se ri ous in jury, or dam age to prop erty or the

X33RT / X27RT.

This in tro duc tion also con tains im por tant in for ma tion con cern ing the re spon si bil i ties of the owner of

the ma chine.

■

Standard X33RT / X27RT Version 2

The stan dard X33RT / X27RT in cludes the fol low ing fea tures:

●

Fully proportional one handed joy stick

control

●

Reliable diesel engine

●

Large 1200mm multi position extension deck

●

35% gradeability

●

4 wheel drive

●

Hour meter

●

Temperature & ammeter gauges

●

Easy access side trays for engine &

hydraulics

●

Lockable hinged covers

●

Independently operated hydraulic stabilisers

with auto level

●

Swinging gate

●

Independent articulating rear axles

●

Forklift pockets

●

Lifting lugs and tie down rings

●

Flashing light

Ad di tional cop ies of this man ual may be or dered

from Snor kel. Sup ply the model and man ual part

num ber from the front cover to as sure that the cor rect man ual will be supplied.

All in for ma tion in this man ual is based on the lat est

prod uct in for ma tion at the time of pub li ca tion. Snor kel re serves the right to make prod uct changes at

any time with out obligation.

■

Photographs

Pho to graphs are taken to rep re sent the ma chine

and its com po nent parts as clearly as pos si ble.

How ever, there may be mi nor dif fer ences be tween

the pho to graphs and your ma chine. This rep re sents in di vid ual cus tomer pref er ences and Snor kel's on-go ing committment to prod uct

de vel op ment.

■

Safety Alerts

A safety alert sym bol is used through out this man ual to in di cate dan ger, warn ing and cau tion in struc tions. Fol low these in struc tions to re duce the

like li hood of per sonal in jury, prop erty dam age or

dam age to the machine.

The terms dan ger, warn ing, and cau tion in di cate

vary ing de grees of per sonal in jury or prop erty dam age that can re sult if the in struc tion is not followed.

Denotes an imminently hazardous situation

which, if not avoided, will result in death or

serious injury.

■

Options

The fol low ing op tions are avail able for the X33RT

/ X27RT:

●

No stabilisers

●

Non-marking tyres

●

110/240V power to platform

●

RCD/ELCB Outlet

●

Alternative power options

❍

Gasoline engine

❍

LPG engine

❍

Combination LPG/Gasoline engine

❍

Bi-Energy 24V DC / Diesel engine

■

Operation Manual

This man ual pro vides in for ma tion for safe and

proper op er a tion of the ae rial plat form. Read and

un der stand the in for ma tion in this Op er a tor’s man -

Denotes a potentially hazardous situation

which, if not avoided, could result in death or

serious injury.

Denotes a potentially hazardous situation

which, if not avoided, may result in minor or

moderate injury.

It may also be used to alert against unsafe

practices or action which may result in

damage to the RT.

Denotes important information pertaining to

settings, capacities, conditions, which

could, if ignored lead to machine damage or

future hazardous situations.

ual be fore op er at ing this ma chine on a job site.

SR3370 & SR2770 – 13184A Rev A page - iii

Page 8

Introduction

WARNING

IMPORTANT

IMPORTANT

It is also used to alert the reader to pay

careful attention to a particular passage of

text in the manual.

Notes

Notes are used to provide special information or

helpful hints to assist in aerial platform operation,

but do not indicate a hazardous situation.

■

Operation

The RT ae rial plat form has built in safety fea tures

and has been fac tory tested for com pli ance with

Snor kel spec i fi ca tions and in dus try stan dards.

How ever, any per son nel lift ing de vice can be po ten tially dan ger ous in the hands of un trained or

careless operators.

Train ing is vi tally im por tant and must be per formed

un der the di rec tion of a QUALIFIED per son. You

must dis play pro fi ciency in knowl edge and ac tual

op er a tion of the RT be fore us ing it on a job site.

Be fore op er a tion of the RT you must read and un der stand the op er at ing in struc tions in this man ual

as well as the de cals, warn ings, and in struc tions on

the ma chine it self.

Be fore op er at ing the RT you must be

AUTHORIZED by the per son in charge to do so

and the op er a tion of the RT must be within the

scope of the ma chine spec i fi ca tions.

Do not mod ify this ma chine with out writ ten ap proval from the En gi neer ing De part ment of Snor kel. Mod i fi ca tion may void the war ranty, ad versely

af fect sta bil ity, or af fect the op er a tional char ac ter is tics of the RT.

■

Responsibilities of parties

It is imperative that all owners and users of the RT

read, understand, and conform to all applicable

regulations. Ultimate compliance to OSHA

regulations is the responsibility of the user and their

employer.

It is imperative that all owners and users of

the RT read, understand, and conform to all

applicable regulations.

Ultimate compliance to OSHA regulations is the

responsibility of the user and their employer.

ANSI Standard A92.6 clearly identifies

requirements of all parties who might be

involved with Self-Propelled Elevating Work

Platforms. EN280:2001(E)

AUSTRALIAN / NZ STANDARD 2550-10 also

identifies the requirements of all parties who

might be involved with Boom-Supported

Elevating Work Platforms.

The potential for an accident increases when

the aerial platform is operated by personnel

who are not trained and authorised. Death or

serious injury can result from such

accidents.

Read and understand the information in this

manual and on the placards and decals on

the machine before operating the RT on the

job site.

■

Maintenance

Ev ery per son who main tains, in spects, tests, or re pairs these ma chines, and ev ery per son su per vis ing any of these func tions, must be prop erly trained

and qual i fied to do so.

This Op er a tors Man ual pro vides a daily in spec tion

pro ce dure that will help you keep your RT in good

op er at ing con di tion.

Do not per form other main te nance un less you are a

trained me chanic, qual i fied to work on the RT. Call

qual i fied main te nance per son nel if you find prob lems or mal func tions.

Note - Standards

It is the responsibility of the owner to ensure that

the person operating the X33RT / X27RT is

provided with all the relevant information relating

to standards and codes of practice applicable in

their region.

❑ In summary

●

Only trained and authorised operators should

be permitted to operate the equipment.

●

All manufacturers operating instructions and

safety rules and all employers safety rules

and all OSHA and other government safety

rules should be strictly adhered to.

●

Repairs and adjustments should be made

only by qualified and trained maintenance

personnel.

●

No modification should be made to the

equipment without prior written consent of

the UpRight Engineering Department.

●

Make a pre-start inspection of the RT at the

beginning of each shift. A malfunctioning

machine must not be used.

page - iv Rev A SR3370 & SR2770 – 13184A

Page 9

●

Make an inspection of the work place to

locate possible hazards before operating the

RT.

■

Additional information

For ad di tional in for ma tion, con tact your lo cal

dealer or UpRight at:

UpRight Power Access HQ

Vigo Centre,

Birtley Road

Washington

Tyne & Wear,

NE38 9DA

Tel : +44 (0) 845 1550 057

Fax : +44 (0) 845 1557 756

Introduction

SR3370 & SR2770 – 13184A Rev A page - v

Page 10

Table of Contents

Electrical Hazard

Electrical Hazard Warning . . . . . . . . . . . . . . . . . . i

Introduction

Standard X33RT / X27RT Version 2 . . . . . . . iii

Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Operation Manual. . . . . . . . . . . . . . . . . . . . . . . . iii

Photographs. . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Safety Alerts. . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Responsibilities of parties . . . . . . . . . . . . . . . . . iv

Additional information . . . . . . . . . . . . . . . . . . . . . v

1. Safety

Safe Operation . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Electrocution Hazards . . . . . . . . . . . . . . . . . . . 1-1

Minimum safe approach distance . . . . . . . . . 1-1

Pre-start Inspection . . . . . . . . . . . . . . . . . . . . . 1-1

Work Place Inspection and Practices . . . . . . . 1-1

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Tipover and Falling Hazards . . . . . . . . . . . . . . 1-3

General Safety Precautions . . . . . . . . . . . . . . 1-3

Hydraulic System Precautions . . . . . . . . . . . . 1-3

Fire Prevention . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Engine and Fuel Handling Precautions. . . . . . 1-3

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Safety Decals and Placards . . . . . . . . . . . . . . 1-4

Safety Placards and Decals Location . . . . . . . 1-5

2. Safety Devices

Safety Device Information . . . . . . . . . . . . . . . . 2-1

Emergency Stop Switches . . . . . . . . . . . . . . . 2-1

At platform control box . . . . . . . . . . . . . . . . . 2-1

At ground control box . . . . . . . . . . . . . . . . . . 2-1

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Level sensor . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Lowering . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

High temperature . . . . . . . . . . . . . . . . . . . . . 2-2

Low oil pressure . . . . . . . . . . . . . . . . . . . . . . 2-2

Drive (reverse) . . . . . . . . . . . . . . . . . . . . . . . 2-2

Drive (forward) . . . . . . . . . . . . . . . . . . . . . . . 2-2

Guardrails . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Safety Prop . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Swinging Gate . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Safety Control . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Bubble Level . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Operator Horn . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Stabilisers (Option) . . . . . . . . . . . . . . . . . . . . . 2-3

RCD/ELCB AC Outlet (option) . . . . . . . . . . . . 2-3

Flashing Light (option). . . . . . . . . . . . . . . . . . . 2-4

Lanyard Anchor Points (option) . . . . . . . . . . . 2-4

3. Specifications

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

General Specifications, Standard Machine

X33RT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Recommended Hydraulic Oil. . . . . . . . . . . . . . 3-1

General Specifications, Standard Machine

X27RT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Engine Oil Charts . . . . . . . . . . . . . . . . . . . . . . 3-3

Engine Data. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

DF752 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

D902 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Machine Component Identification . . . . . . . . . 3-4

4. Gauges

Water. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Amps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Hydraulic Oil Level . . . . . . . . . . . . . . . . . . . . . 4-1

Hours. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Fuel Level (option). . . . . . . . . . . . . . . . . . . . . . 4-2

Bubble Level . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

5. Automatic Shut-offs and Circuit Breakers

Automatic Shut-offs . . . . . . . . . . . . . . . . . . . . 5-1

Level sensor . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Engine temperature . . . . . . . . . . . . . . . . . . . 5-1

Engine oil pressure . . . . . . . . . . . . . . . . . . . . 5-1

Platform height vs. drive speed. . . . . . . . . . . 5-1

Dynamic brakes . . . . . . . . . . . . . . . . . . . . . . 5-1

Alternator not charging . . . . . . . . . . . . . . . . . 5-1

Stabilisers . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . 5-2

Main breaker . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

RCD / ELCB outlet (option). . . . . . . . . . . . . . 5-2

6. Controls

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Hydraulic Compartment. . . . . . . . . . . . . . . . . . 6-1

Ground Control Box. . . . . . . . . . . . . . . . . . . . . 6-1

Platform Control Box . . . . . . . . . . . . . . . . . . . . 6-2

7. Daily Inspection and Maintenance

Daily Inspection and Maintenance Table . . . . 7-1

Fuel Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

(LPG - Option) . . . . . . . . . . . . . . . . . . . . . . . 7-2

Fuel Filter (diesel engines only) . . . . . . . . . . . 7-2

Fuel Leaks. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Engine Coolant . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Radiator Cap . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

SR3370 & SR2770 – 13184A

Page 11

Table of Contents

Swinging Gate ........................7-3

Wiring Harnesses and Connectors .........7-3

Battery Terminals ......................7-4

Battery Fluid Level ....................7-4

Hydraulic Oil Tank ......................7-4

Hydraulic tank cap ....................7-4

Hydraulic oil level .....................7-4

Hydraulic Oil Leaks ....................7-4

Tires and Wheels ......................7-5

Bolts and Fasteners ....................7-5

Structural Damage & Welds ..............7-6

Guardrails ............................7-6

Bubble Level ..........................7-6

Guides, rollers, and slides................7-6

Charging System.......................7-7

Ground Controls .......................7-7

Flashing Light .........................7-7

Platform Controls.......................7-7

Emergency Lowering....................7-8

RCD / ELCB (Option) ...................7-8

Safety prop ...........................7-8

Lanyard Anchorages (Option) ............7-8

Non-Slip Tread Grip ....................7-8

Wrist Support..........................7-9

Operator Manual .......................7-9

Placards and Decals ...................7-10

Standard placards and decals ..........7-10

Inspection drawing ...................7-11

8. Operation

Operating Procedures ...................8-1

Control Stations........................8-1

Emergency Stopping ....................8-1

Operation Considerations ................8-1

Fuel type .............................8-2

Operating From The Ground Control Box ...8-2

Raising the platform ...................8-3

Operating From The Platform Control Box ...8-4

Driving ..............................8-6

Raising the Platform ...................8-7

Stabilisers ............................8-7

Operating The Stabilisers Manually ........8-8

To set the stabilisers ...................8-8

To raise the stabilisers: ................8-8

Operating The Auto Level System .........8-9

Setting the stabilisers automatically .......8-9

Raising the stabilisers automatically.......8-9

Extending The Multi-Position Platform ......8-9

Pushing / Towing.......................9-2

10. Stowing and Transporting

Stowing .............................10-1

Transporting .........................10-2

Trailering ...........................10-2

Securing to a Transport Vehicle .........10-2

Towing ............................10-3

Lifting / Lashing Down.................10-3

Pushing ...........................10-3

Winching Procedure ..................10-3

11. Options

Bi-En ergy Option ......................11-1

DC motor...........................11-1

DC motor operation...................11-1

Master battery isolater switches .........11-1

Steering in DC motor mode ............11-2

Batteries ...........................11-2

Battery charger ......................11-2

Batteries - General maintenance ........11-3

Batteries - Charging ..................11-3

RCD / ELCB Outlet ....................11-3

Flashing Light ........................11-3

Lanyard Anchor Points .................11-4

Electrical Outlet .......................11-4

Non-Marking Tyres ....................11-4

Alternative Power Options...............11-4

Stabilisers ...........................11-4

12. Fire Fighting and Chemical Containment

Hazardous Components ................12-1

Antifreeze (UN 1993) .................12-1

Battery, Lead/Acid (UN 2794) ...........12-1

Diesel Fuel (NA 1993).................12-1

Foam In Tires .......................12-2

Gasoline (UN 1203) ..................12-2

Hydraulic Oil (UN 1270) ...............12-3

Liquefied Petroleum Gas (UN 1075)......12-3

Motor Oil (UN 1270) ..................12-3

13. Operator's Troubleshooting

Troubleshooting.......................13-1

Operator Troubleshooting Chart .........13-1

Appendix A. Glossary

9. Emergency Operation

Emergency Operation Procedures .........9-1

Emergency Stop .......................9-1

Emergency Bleed-Down .................9-1

page - viii SR3370 & SR2770 – 13184A

Page 12

■

Denotes prohibited zone

Caution:

- Diagrams shown are only for purposes of illustrating

M.S.A.D. Work positions, not all work positions.

DANGER

No go zone

6.4

6.4

3

3

Spotter

required

zone

Variations

in Sag

Personal

protection

barriers

Sag

FRONT VIEW SIDE VIEW

Distribution Lines Up to and Including 133kV

(Dimensions are in metres)

CLEARANCES FROM LIVE AERIAL CONDUCTORS

Safe Operation

Knowl edge of the in for ma tion in this man ual, and

proper train ing, pro vide a ba sis for safely op er at ing

the X33RT / X27RT. Know the lo ca tion of all the

con trols and how they op er ate to act quickly and re spon si bly in an emergency.

Safety de vices re duce the like li hood of an ac ci dent. Never dis able, mod ify, or ig nore any safety

de vice. Safety alerts in this man ual in di cate sit u a tions where ac ci dents may occur.

If any mal func tion, haz ard or po ten tially un safe

con di tion re lat ing to ca pac ity, in tended use, or safe

op er a tion is sus pected, stop the op er a tion of the

RT and seek assistance.

The op er a tor bears ul ti mate re spon si bil ity for fol low ing all man u fac tur ers in struc tions and warn ings, reg u la tions and safety rules of their em ployer

and/or any coun try or regional law.

1. Safety

The RT is not electrically insulated. Death or

serious injury can result from contact with,

or inadequate clearance from, an energised

conductor. Do not go closer than the

minimum safe approach distance as defined

by ANSI.

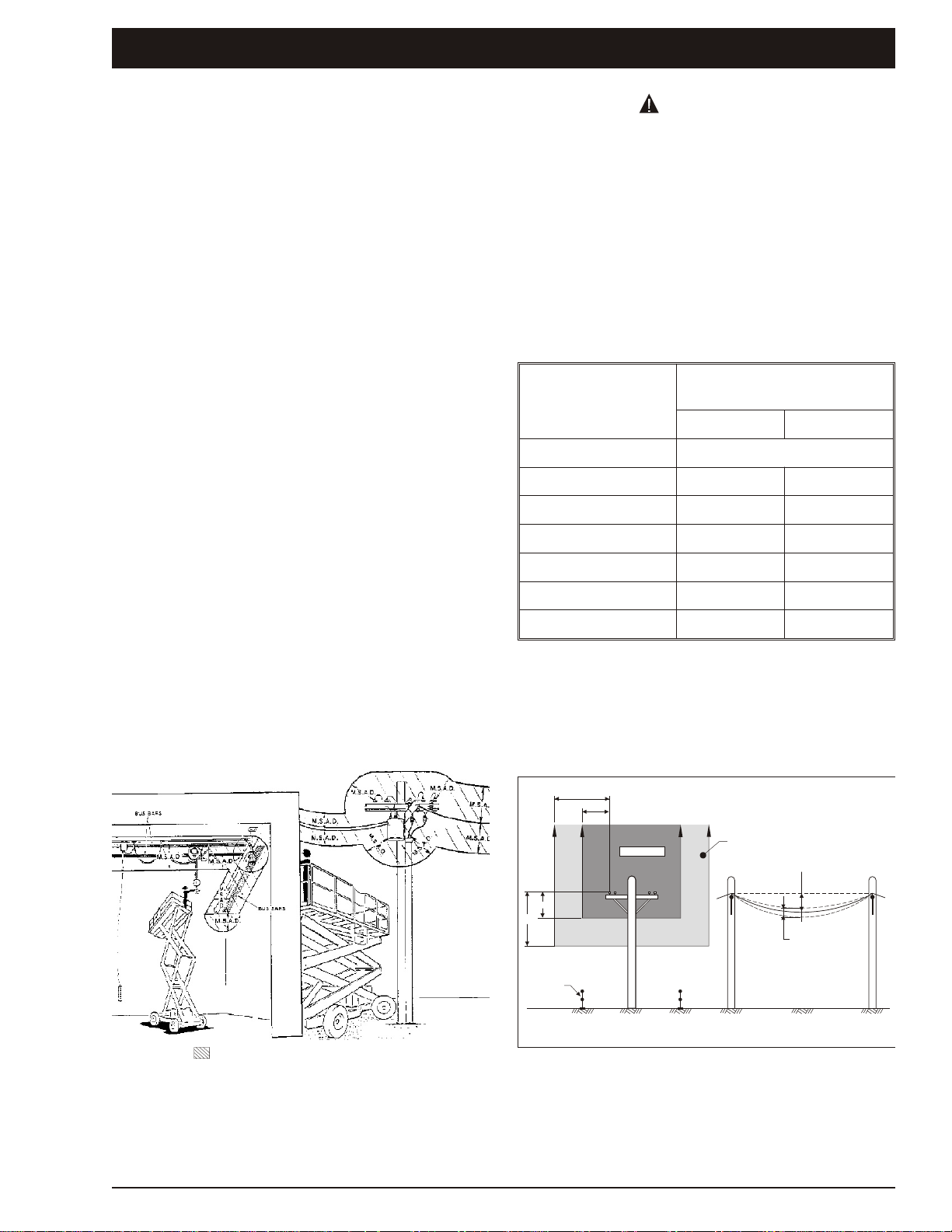

ANSI pub li ca tions de fine min i mum dis tances that

must be ob served when work ing near bus bars and

energised power lines. Fig ure 1 and Ta ble 1 are re printed cour tesy of the Scaf fold in dus try As so ci a tion, ANSI/SIA A92.5.

Voltage Range

(Phase to Phase

0 to 300V

Minimum Safe Approach

Distance

Feet Metres

Avoid Contact

■

Electrocution Hazards

The RT is an all metal ae rial work plat form and is

not elec tri cally in su lated. Do not op er ate it near

elec tri cal con duc tors. Re gard all con duc tors as be ing en er gized. Do not op er ate out side dur ing a

thunderstorm.

❑ Minimum safe approach distance

Min i mum safe ap proach dis tances to energised

power lines and their as so ci ated parts must be ob served wile op er at ing the RT.

Over 300V to 50kV

Over 50kV to 200kV

Over 200kV to 350kV

Over 350kV to 500kV

Over 500kV to 750kV

Over 750kV to 1000kV

10 3.05

15 4.60

20 6.10

25 7.62

35 10.7

45 13.72

Table 1. - Minimum Safe Approach Distance

Aus tra lian Stan dard AS 2550.10 de fines min i mum

dis tances that must be ob served when work ing

near live ae rial con duc tors up to and in clud ing

133kV (see Fig ure 2).

Figure 1. - Minimum Safe Approach Distance

SR3370 & SR2770 – 13184A Rev C page 1 - 1

Figure 2 - Minimum Safe Approach Distance

AS 2550.10

Page 13

1. Safety

DANGER

WARNING

■

Pre-start Inspection

At the start of each work shift, the X33RT /

X27RT shall be given a vi sual in spec tion and

func tion test. See the Daily In spec tion and Main te nance chap ter , in this man ual for a list of items to

in spect and test.

DO NOT operate the X33RT / X27RT unless

you are trained and authorized, understand

the operation characteristics of theX33RT /

X27RT, and have inspected and tested all

functions to be sure they are in proper

working order.

■

Work Place Inspection and Practices

Do not use the X33RT / X27RT as a ground for

weld ing. Ground to the work piece.

Be fore the X33RT / X27RT is used, and dur ing

use, check the area in which the X33RT / X27RT

is to be used for pos si ble haz ards such as, but not

lim ited to:

●

Drop-offs or holes.

●

Side slopes.

●

Bumps and floor obstructions.

●

Debris.

●

Overhead obstructions and electrical

conductors.

●

Hazardous locations.

●

Inadequate surface and support to withstand

all load forces imposed by the aerial platform

in all operating configurations.

●

Wind and weather conditions.

●

Presence of unauthorized persons.

●

Other possible unsafe conditions.

Be fore the X33RT / X27RT is used, de ter mine

the haz ard clas si fi ca tion of any par tic u lar at mo sphere or lo ca tion ac cord ing to ANSI/NFPA

505-1987.

Any X33RT / X27RT op er ated in a haz ard ous lo ca tion must be ap proved and of the type re quired

by ANSI/NFPA 505-1987.

While op er at ing the RT a rec om mended safety

prac tice is to have trained and qual i fied per son nel

in the im me di ate work area of the X33RT /

X27RT to:

●

Help in case of an emergency.

●

Operate emergency controls as required.

●

Watch for loss of control by platform

operator.

●

Warn the operator of any obstructions or

hazards that may not be obvious to them.

●

Watch for soft terrain, sloping surfaces,

drop-offs, etc., where stability could be

jeopardized.

●

Watch for bystanders and never allow

anyone to be under, or to reach through the

booms while operating the aerial platform.

Pinch points may exist between moving

components. Death or serious injury can

result from becoming trapped between

components, buildings, structures, or other

obstacles. Make sure there is sufficient

clearance around the machine before

moving the chassis, booms, or platform.

Allow sufficient room and time to stop

movement to avoid contact with structures

or other hazards.

Keep ground per son nel from un der the plat form

when the plat form is raised.

Se cure all ac ces so ries, con tain ers, tools, and

other ma te ri als in the plat form to pre vent them from

ac ci den tally fall ing or be ing kicked off the platform.

Al ways look in the di rec tion of travel. Drive with

care and at speeds com pat i ble with the work-place

con di tions. Use cau tion when driv ing over rough

ground, on slopes, and when turning.

Do not en gage in any form of horse play or stunt

driv ing while op er at ing the X33RT / X27RT.

Do not per mit rid ers on the ma chine any place other

than on the plat form.

Re move all loose ob jects stored in or on the ma chine, par tic u larly in the plat form. Re move all ob jects which do not be long in or on the machine.

Never steady the plat form by po si tion ing it against

an other plat form.

Do not op er ate an X33RT / X27RT that is dam aged or not func tion ing prop erly. Do not use the RT

un til the ma chine has been re paired by a qual i fied

main te nance person.

Do not op er ate a X33RT / X27RT that does not

have all its de cals and plac ards at tached and leg i ble.

Watch for by stand ers and never al low any one to be

un der, or to reach through, the ma chine and its

equip ment while op er at ing.

page 1 - 2 Rev C SR3370 & SR2770 – 13184A

Page 14

1. Safety

DANGER

DANGER

Use the rec om mended trans port de vice when

load ing the ma chine.

■

Operation

If you en coun ter any sus pected mal func tion of the

ae rial plat form, or any haz ard or po ten tially un safe

con di tion re lat ing to ca pac ity, in tended use, or safe

op er a tion, cease op er a tion im me di ately and seek

as sis tance from management.

Use three points of sup port when get ting on or off

the plat form (two hands and one foot or a sim i lar set

of points). Keep the plat form clean.

Main tain a firm foot ing on the plat form floor. Op er ate the con trols slowly and de lib er ately to avoid

jerky and er ratic op er a tion. Al ways stop the con trols in neu tral be fore go ing in the op po site

direction.

Do not dis mount while the plat form is in mo tion or

jump off the ma chine.

Do not start un til all per son nel are clearly away

from the ma chine.

Never cover the floor grat ing or oth er wise ob struct

your view be low. Make sure the area be low the

plat form is free of per son nel be fore low er ing.

■

Tipover and Falling Hazards

Op er ate the RT only on a firm, flat, level sur face ca pa ble of with stand ing all load forces im posed by

the X33RT / X27RT in all op er at ing con di tions.

vice versa, un less that is the saf est way to do the

job. Each sit u a tion must be judged sep a rately

tak ing the work en vi ron ment into ac count. The

fol low ing guidelines apply:

1. Where possible, place the work platform over

a roof or walking structure to do the transfer.

2. Transfer your anchorage from one structure

to another before you step across.

3. Remember, you might be departing the work

platform to a structure where fall arrest is

required.

4. Do not climb over or through the guardrails.

Use the platform entrance.

All plat form oc cu pants MUST wear and use fall re straint. At tach fall re straints to the plat form lan yard

an chor points.

Do not ex ceed the un re stricted plat form ca pac ity

as in di cated on the ca pac ity plac ard at the en trance to the plat form. Do not carry loads from any

point out side of the platform.

Make sure that all pro tec tive guards, cowl ings, and

doors are in place and se cure. Be sure the guard rail sys tem, in clud ing the gate, is in place and se cure.

Do not climb on the guard rails or use lad ders,

planks, or other de vices to ex tend or in crease your

work po si tion from the plat form.

Do not use the RT as a crane, hoist, or jack,or for

any other pur pose other than to po si tion per son nel,

their tools, and ma te ri als.

The RT can tip over if it becomes unstable.

Death or serious injury can result from a

tip-over accident. Do not drive or position

the RT platform for elevated use near any

drop-off, hole, slope, soft or uneven ground,

or other tip-over hazard.

Do not op er ate the X33RT / X27RT from a po si tion on trucks, trail ers, rail way cars, float ing ves sels, scaf folds, or sim i lar equip ment un less the

ap pli ca tion is ap proved in writ ing by Snorkel.

Care shall be taken to pre vent rope, elec tric cords,

and hoses, etc., from be com ing en tan gled in the

ae rial plat form. If the plat form or el e vat ing as sem bly be comes caught, snagged, or oth er wise pre vented from nor mal mo tion by an ad ja cent

struc ture or other ob sta cle such that con trol re ver sal does not free the plat form, re move all per son nel

from the plat form be fore at tempts are made to free

the platform using ground controls.

Un der nor mal work ing con di tions it is best not to

trans fer from the plat form to an other struc ture or

Do not op er ate the X33RT / X27RT in winds, or

wind gusts, of 28 mph, 45kph 12.5 m/s) or more

and do not add any thing to the X33RT / X27RT

that will in crease the wind load ing (ban ners, flags,

etc.).

■

General Safety Precautions

Do not mod ify the X33RT / X27RT in any way.

When parts or com po nents are re placed, they shall

be iden ti cal or equiv a lent to orig i nal Snor kel parts

or com po nents.

Do not over ride any of the safety fea tures of the

X33RT / X27RT.

■

Hydraulic System Precautions

The hy drau lic sys tem con tains hoses with hy drau lic fluid un der pres sure.

Hydraulic fluid escaping under pressure can

have enough force to inject fluid into the

SR3370 & SR2770 – 13184A Rev C page 1 - 3

Page 15

1. Safety

WARNING

CAUTION

WARNING

CAUTION

DANGER

flesh. Serious infection or reaction can

result if medical treatment is not given

immediately. In case of injury by escaping

hydraulic fluid, seek medical attention at

once.

DO NOT place your hand or any part of your body in

front of es cap ing hy drau lic fluid. Use a piece of

card board or wood to search for hy drau lic leaks.

Do not at tempt re pairs to hy drau lic sys tems un less

you are trained. Re fer to ex pe ri enced re pair per son nel for help.

■

Fire Prevention

Never op er ate your RT near a flame or spark. Hy drau lic oil and gas o line are flam ma ble and can ex plode.

■

Engine and Fuel Handling Precautions

Engine exhaust contains carbon monoxide,

a poisonous gas that is invisible and

odorless. Breathing engine exhaust fumes

can cause death or serious illness. Do not

run the engine in an enclosed area or

indoors without adequate ventilation.

Only re fuel your RT out doors in a clear area void of

gas fumes or spilled gas.

Never re move the fuel cap or re fuel a gas o line en gine while the en gine is run ning or hot. ALWAYS al low the en gine to cool be fore re fu el ing. Never al low

fuel to spill on hot ma chine components.

DO NOT smoke or permit open flames while

fueling or near fueling operations.

Main tain con trol of the fuel filler noz zle when fill ing

the tank.

Tighten the fuel tank cap se curely. If the fuel cap is

lost, re place it with an ap proved cap from Snor kel.

Use of a non-ap proved cap with out proper vent ing

may re sult in pres sur iza tion of the tank.

Never use fuel for clean ing pur poses.

For die sel en gines, use the cor rect fuel grade for

the op er at ing sea son.

■

Batteries

Charge bat ter ies in a well ven ti lated area free of

flame, sparks, or other haz ards that might cause

fire or ex plo sion.

Batteries give off hydrogen and oxygen that

can combine explosively. Death or serious

injury can result from a chemical explosion.

Do not smoke or permit open flames or

sparks when checking batteries.

Battery acid can damage the skin and eyes.

Serious infection or reaction can result if

medical treatment is not given immediately.

Wear face and eye protection when working

near batteries.

Bat ter ies con tain sul fu ric acid that can dam age

your eyes or skin on con tact. Wear a face shield,

rub ber gloves, and pro tec tive cloth ing when work ing around bat ter ies. If acid con tacts your eyes,

flush im me di ately with clear wa ter and get med i cal

at ten tion. If acid con tacts your skin, wash off im me di ately with clear water.

■

Safety Decals and Placards

There are sev eral safety de cals and plac ards on

the X33RT / X27RT. Their lo ca tions and de scrip tions are shown in this sec tion. Take time to study

them.

Be sure that all the safety decals and

ENSURE you use an approved fuel container

with appropriate fuel filler nozzle

Do not fill the fuel tank to ca pac ity. Al low room for

ex pan sion.

If gas o line is spilled, clean up spilled fuel im me di ately, push/tow the RT away from the area of the

spill and avoid cre at ing any source of ig ni tion un til

the spilled fuel has evap o rated.

page 1 - 4 Rev C SR3370 & SR2770 – 13184A

placards on the X33RT / X27RT are legible.

Clean or replace them if you cannot read the

words or see the pictures. Clean with soap &

water and a soft cloth. Do not use solvents.

You MUST replace a decal or placard if it is

damaged, missing, or cannot be read. If it is

on a part that is replaced, make sure a new

decal or placard is installed on the replaced

part. See your Snorkel dealer for new decals

and placards.

Page 16

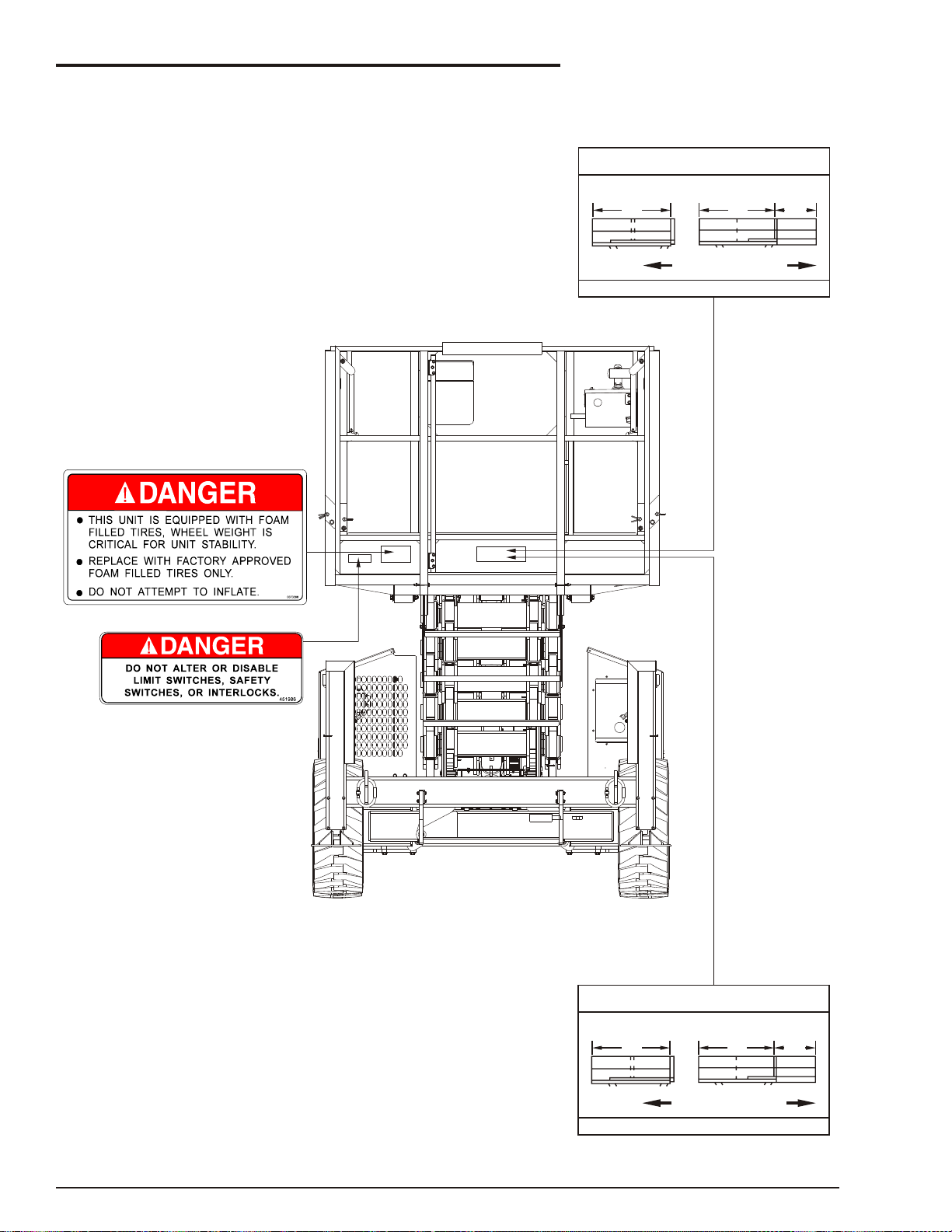

■

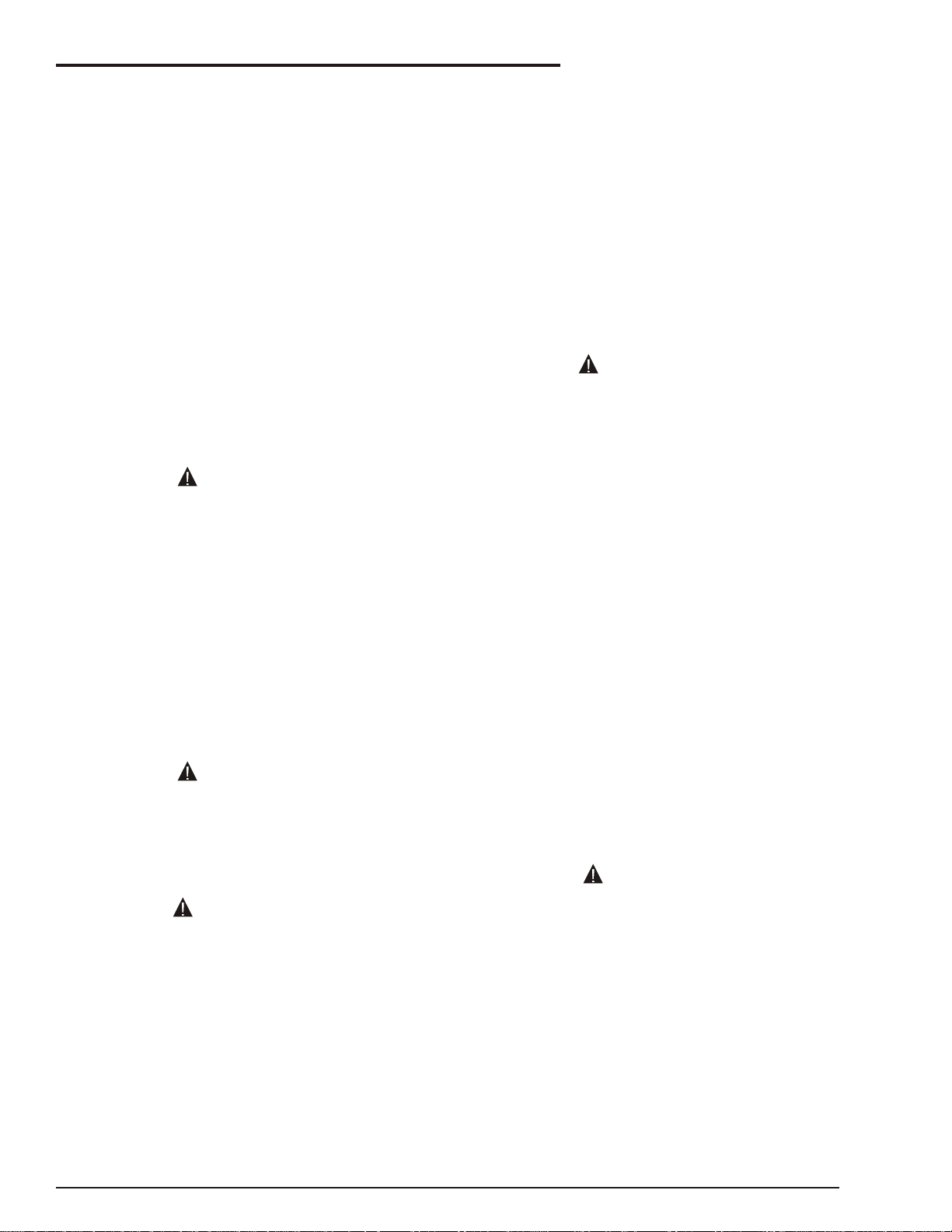

LEFT HAND SIDE OF THE RT

On Fuel Tank Inside Cabinet &

Outside Of Cabinet Door

0372061

TORQUE

·

90-100 Ft. Lbs.122-135 N m

Lug Bolts/Nuts

Check Every 30 Days

Safety Placards and Decals Location

1. Safety

SR3370 & SR2770 – 13184A Rev A page 1 - 5

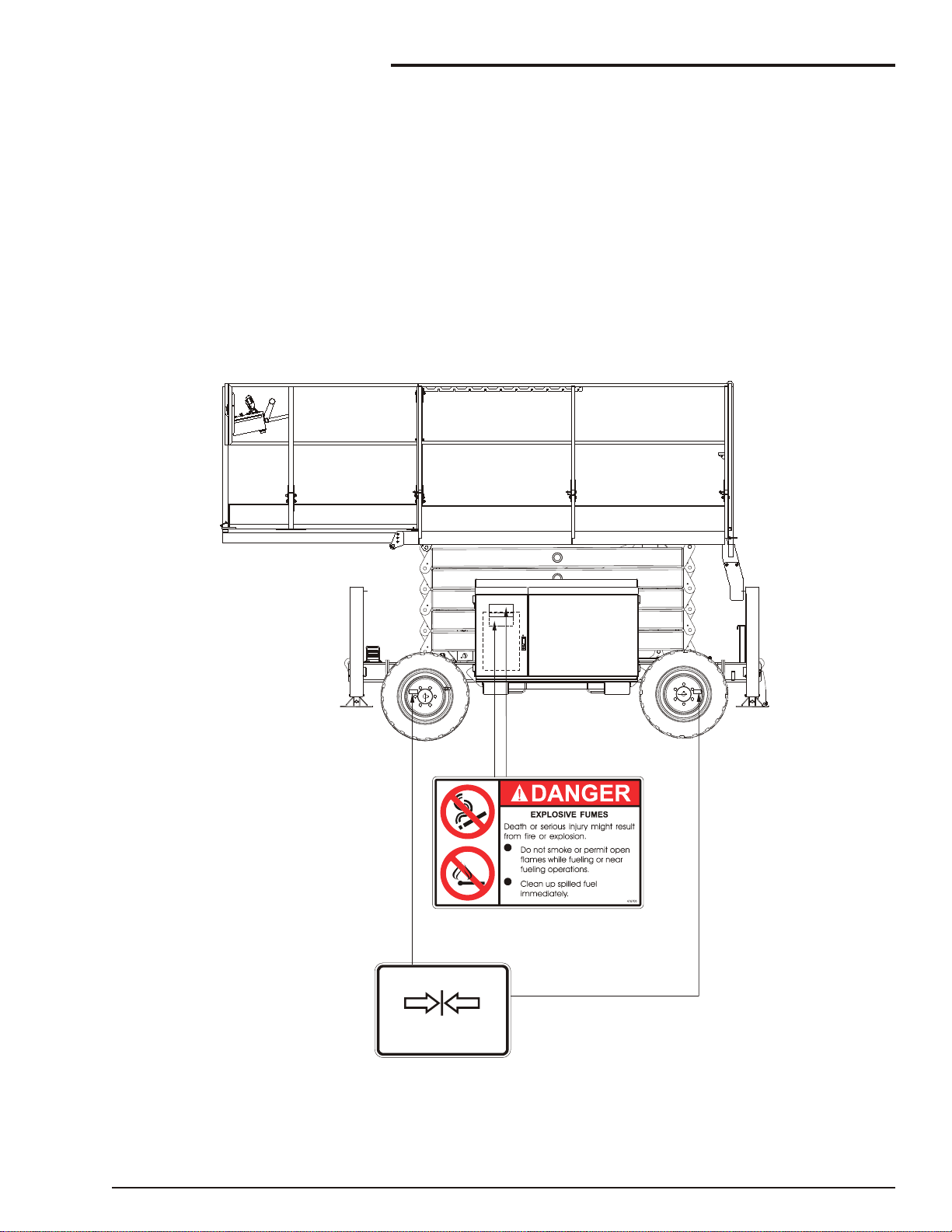

Page 17

1. Safety

RIGHT-HAND SIDE OF SR

STORAGE POSITION

PROPER POSITION FOR USE

SAFETY BAR

24”

YOU MUST NOT OPERATE THIS DEVICE UNLESS:

AN UNTRAINED OPERATOR SUBJECTS HIMSELF AND OTHERS TO

DEATH OR SERIOUS INJURY.

0323897

1.

2.

YOU HAVE BEEN TRAINED IN THE SAFE OPERATION OF THIS

DEVICE AND HHHH

YOU KNOW AND FOLLOW THE SAFETY AND OPERATING

RECOMMENDATIONS CONTAINED IN THE MANUFACTURER'S

MANUALS, YOUR EMPLOYER'S WORK RULES, AND APPLICABLE GOVERNMENTAL REGULATIONS. HHHHHHHH

DANGER

DANGER

300700

SHEARING HAZARD/CRUSHING HAZARD

Death or serious injury might result from

having body parts sheared or crushed as the

platform descends. Keep away from closing

scissor arms and keep out from under the

platform as the platform comes down.

0372061

TORQUE

·

90-100 Ft. Lbs.122-135 N m

Lug Bolts/Nuts

Check Every 30 Days

0372061

TORQUE

·

90-100 Ft. Lbs.122-135 N m

Lug Bolts/Nuts

Check Every 30 Days

EMERGENCY OPERATION

1. EMERGENCY LOWERING

In the event of total power failure pull the emergency lowering handle

mounted at the front of the chassis until the platform starts to descend.

Once the platform is lowered the handle can be released.

In order to push or tow the SR the following steps MUST be taken.

A runaway SR can cause Death or serious injury. Do not proceed

unless the SR is on a level surface or is attached to an object that can

hold the SR on a slope.

The SR Drive motors will be ruined if the SR is pushed or towed faster

than 3.2 kph (2 mph).

2. TOWING OR PUSHING THE SR

Freewheel the Drive Motors

DANGER

CAUTION

Turn the FREEWHEEL knob [A] Counterclockwise fully.

Release the Brakes

Pump the hand pump [B] 5 to 10 times or until the Brakes are

released.

To re-set the Brakes pull knob [C] until it is fully open.

To re-set the Drive Motors turn the FREEWHEEL knob [A] clockwise

until it is fully closed.

After the SR has been pushed or towed the Brakes and the Drive

Motors MUST be re-set.

A

B

C

Pull To Reset

Brakes

12816

Freewheel

Valve

Hand Pump

13193

page 1 - 6 Rev C SR3370 & SR2770 – 13184A

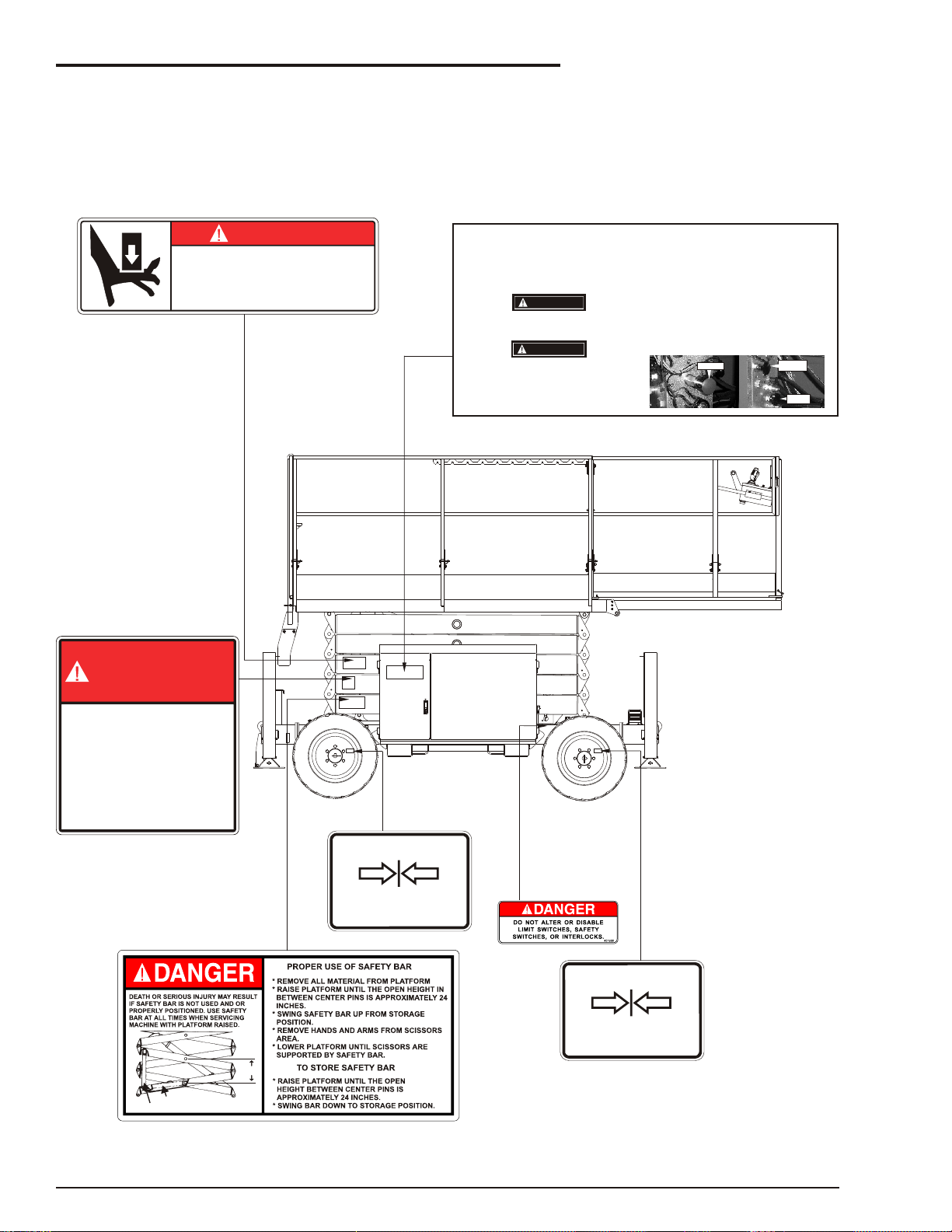

Page 18

FRONT END OF RT

DEATH OR SERIOUS INJURY CAN RESULT FROM TIPPING OVER.

TO KEEP FROM TIPPING THIS MACHINE OVER FOLLOW THESE RULES.

OTHER ACTIONS CAN ALSO CAUSE THIS MACHINE TO TIP OVER

NOTE: STUDY THE OPERATOR'S MANUAL BEFORE OPERATING THIS MACHINE.

12574

DO NOT override safety devices.

DO NOT overload the machine.

DO NOT stand or sit on guardrails.

DO NOT attach ropes or chains to guardrails.

DO NOT carry loads outside the railing or use

as a crane.

DO NOT use this machine without the railings and the

entry gate in place. You could

fall out and hurt or kill yourself.

DO NOT use this machine if it is not operating correctly,

or if any part of it is damaged,

worn, or missing. An accident

could cause injury or death.

DO NOT let an untrained or unauthorized person use this machine.

When you leave the machine unattended,

remove the key, or turn off the battery

switch on the base of the machine and lock

the battery switch in the off position.

DO NOT replace components critical to machine stability, such as

batteries and wheel equipment, with lighter

DO NOT ride platform while machine is on a truck, fork

lift or other device.

DO NOT use ladder, scaffold, or other means to

increase size or platform height.

DO NOT use with improperly inflated or damaged tires

or wheels.

DO NOT RAISE OR DRIVE AN ELEVATED

PLATFORM ON

SOFT OR UNEVEN

SURFACES

DO NOT RAISE OR DRIVE AN ELEVATED

PLATFORM ON A

SLOPE

GO NO CLOSER THAN 4 feet (1.2m)

to ANY DROP OFF

OR HOLE

4 FT/1.2M

OK

1.

3.2.

TWO-TONE ALARM MEANS TIPOVER DANGER!

LOWER PLATFORM IMMEDIATELY

TO AVOID

TIPOVER HAZARDS

USE ON

FLAT, LEVEL, AND

SOLID SURFACES

ONLY

OK

DO NOT RAISE A PLATFORM

IN WIND ABOVE 28 MPH (12.5 M/S)

4 FT/1.2M

DANGER

BEWARE OF ELECTRICAL HAZARDS

REGULATION 133A OF THE

CONSTRUCTION SAFETY ACT 1912 REQUIRES

(a) Minimum approach of an appliance

(b) Inspection of the work site for

(c) Constant vigilance and an observer required

to live electrical apparatus.

electrical hazards before

commencing to use the appliance.

whilst working or travelling the appliance

in the vicinity of live electrical apparatus.

3m. for voltages up to 132,000

6m. for voltages above 132,000

and up to 330,000

8m. for voltages above 330,000

WARNING

KEEP LINESCLEAR POWEROF

Unless the Electrical Supply Authority has advised

in writing otherwise;

the clearance between any live overhead

power line and any part of this machine or

load carried is required by law to be

AT LEAST 4 METRES

This is a requirement of regulation 93 of the

Electrical Supply Regulations 1984

in the interests of safe working.

EMERGENCY BLEED

DOWN VALVE

12753

Australia Only

New Zealand Only

ALL DECALS ON

REVERSE SIDE

On Top Of Chassis Member

1. Safety

SR3370 & SR2770 – 13184A Rev A page 1 - 7

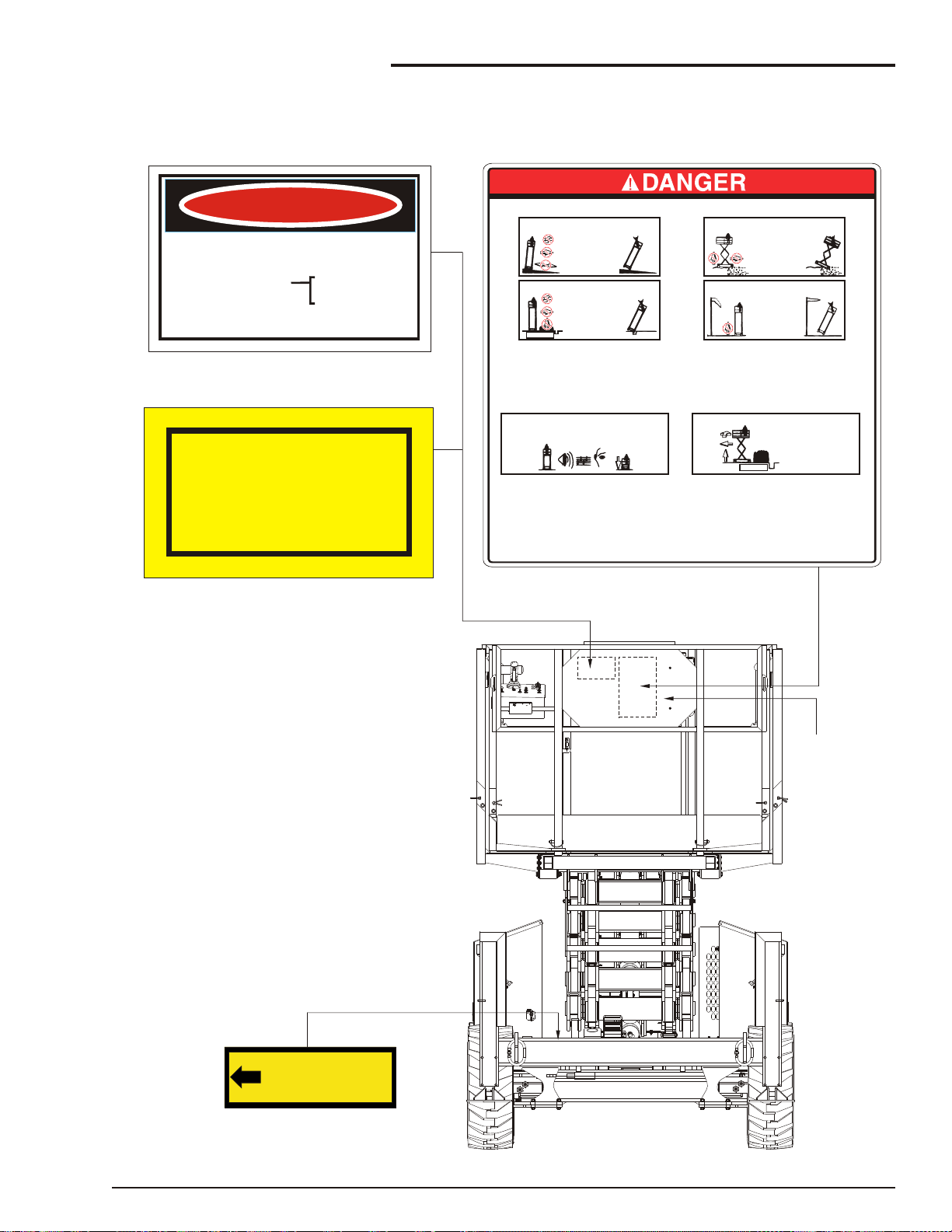

Page 19

1. Safety

REAR END OF RT

X27RT PLATFORM RATINGS

UNIFORMLY DISTRIBUTED

RATED NUMBER OF OCCUPANTS: 2 PERSONS

12699

450kg

RATED WORK LOAD

RATED WORK LOAD

MAIN

DECK

EXTENSION

DECK

MAIN

DECK

990lb

120kg

264lb

330kg

726lb

EXTENSION DECK RETRACTED

EXTENSION DECK EXTENDED

X27RT PLATFORM RATINGS

UNIFORMLY DISTRIBUTED

RATED NUMBER OF OCCUPANTS: 5 PERSONS

11346-1

580kg

RATED WORK LOAD

RATED WORK LOAD

MAIN

DECK

EXTENSION

DECK

MAIN

DECK

1280lb

120kg

264lb

460kg

1015lb

EXTENSION DECK RETRACTED

EXTENSION DECK EXTENDED

X33RT

X27RT

page 1 - 8 Rev A SR3370 & SR2770 – 13184A

Page 20

■

WARNING

Safety Device Information

For emer gency op er a tion con trols and pro ce dures

see the Emer gency Op er a tion chap ter 9, in this

manual.

The de vices listed in this chap ter are safety de vices.

They are on an RT to in crease safety in the work

place for both the op er a tor and other peo ple near

the ma chine.

Do not by-pass, disable, modify, or ignore

any of these devices. Check them carefully

at the start of each work shift to see that they

are in working order (see Daily Inspection &

Maintenance chapter 7). If any is found to be

defective, remove the RT from service

immediately until a qualified service

technician can make repairs.

■

Emergency Stop Switches

2. Safety Devices

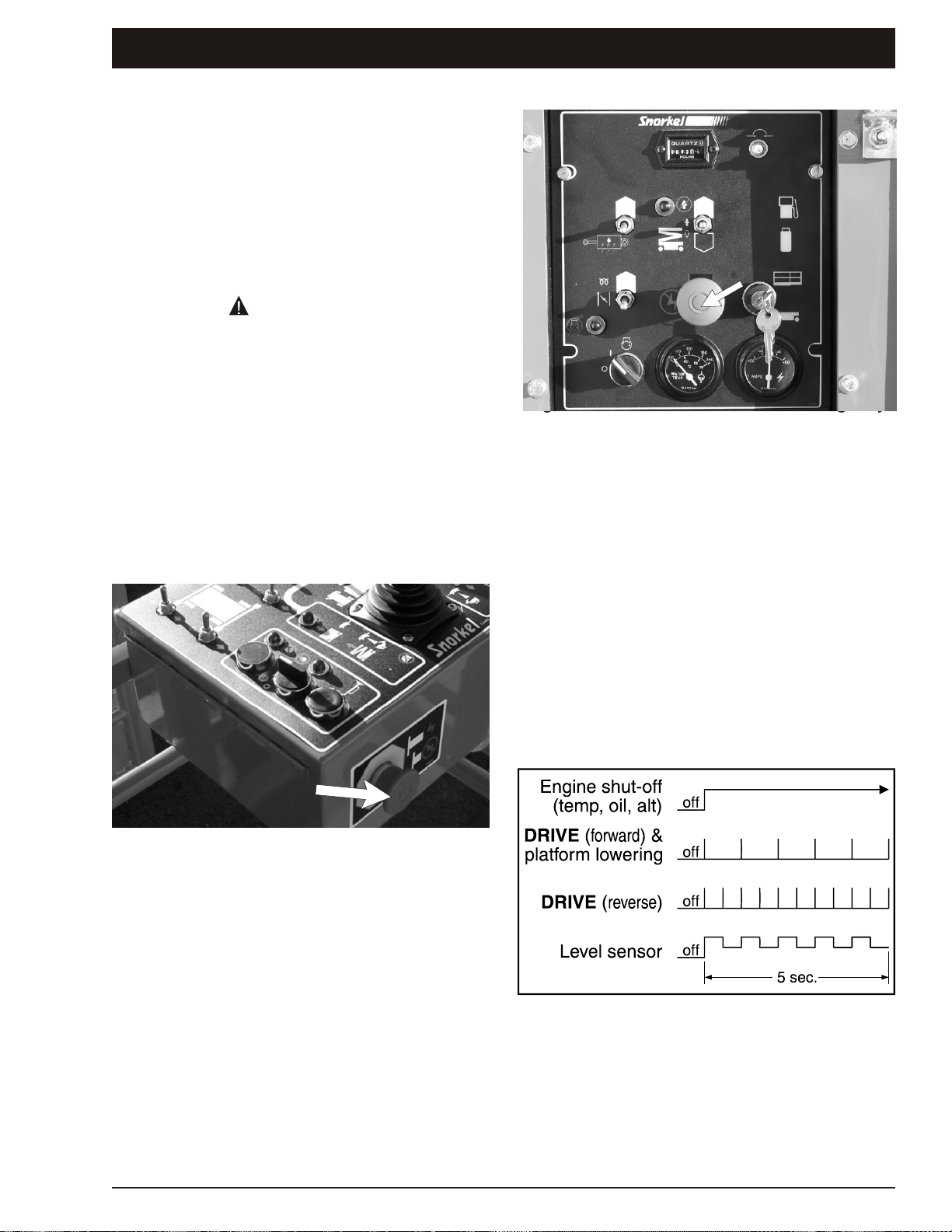

❑ At ground control box

Figure 2.2 - Ground Control Box Emergency

Stop Switch

Press the red EMERGENCY STOP switch cover

down, at any time, un der any con di tions, and the

en tire ma chine stops, the en gine turns off, and

noth ing moves. the EMERGENCY STOP switch

must be up for any thing on the RT to work.

❑ At platform control box

Figure 2.1 - Platform Control Box Emergency

Stop Switch

Press the large red EMERGENCY STOP but ton in

and the en tire ma chine stops, the en gine turns off,

and noth ing moves. This switch must be out (on) to

con trol the RT from the plat form (pull the switch

and it will pop out).

■

Alarms

There are two alarms on an RT. One is lo cated in

the plat form con trol box, the other is lo cated in the

ground con trol box.

The alarms are con nected in par al lel, they both

emit the same pat tern of sound at the same time.

The dif fer ent alarm sound pat terns are shown in

the ta ble im me di ately be low and dis cussed be low

the table.

Figure 2.3 - Alarm Sound Patterns

The high-tem per a ture, low oil-pres sure, and al ter na tor not-charg ing alarms are each a con tin u ous

tone.

SR3370 & SR2770 – 13184A Rev A page 2 - 1

Page 21

2. Safety Devices

The DRIVE (forward) and the platform-lowering

alarms beep at one beep per second. DRIVE (reverse) beeps at two beeps per second. The level

sensor alarm is a high-low warbling sound.

The LOAD SENSING alarm also emits a high-low

warbling sound, as does the alarm that sounds

when the scissor stack stops descending at 1

metre from stowed position

❑ Load sensing system

The load sensing system sounds an alarm and

illuminates a lamp to warn the operator that the

platform is overloaded.

The alarm will sound and the overload light (see

figure 2.3) will illuminate as soon as the overload

point is reached.

1

NOTE 2:

The joystick must be released and then reapplied

once the preset time period has elapsed before

the platform will continue to descend.

❑ High temperature

The high-temperature alarm warns you that the engine is overheating. When the alarm sounds you

should immediately lower the platform completely

down then turn the engine off until the condition

that caused the overheating has been corrected.

(See Automatic Shut-Offs & Circuit Breakers chapter 5 for more information.)

❑ Low oil pressure

The low pressure alarm warns you that the engine

oil pressure is near the lowerlimit for safe operation

of the engine. When the alarm sounds you should

immediately lower the platform completely down

then turn the engine off until the condition that

caused the low oil pressure has been corrected.

(See Automatic Shut-Offs & Circuit Breakers chapter 5 for more information.)

Figure 2.3 - Platform Overload Light

NOTE:

When the alarm sounds all platform movement

[drive forward / reverse and lift up / down is

prevented.

The alarm and function interlock will be active

until the load is reduced.

❑ Lowering

The lowering alarm warns people near an RT that

the platform is coming down and the scissor arm

assembly is closing.

When the plat form is ap proximately 1 metre from

the stowed po sition the plat form will stop low ering

and a warn ing alarm will sound. This alarm will con tinue to sound un til the joy stick is re leased and the

preset time pe riod has elapsed.

NOTE 1:

This is intended to prompt, and allow time for the

operator to check that no person has any

appendage in the scissor arm mechanism.

❑ Drive (reverse)

The DRIVE (reverse) alarm alerts people that the

RT is traveling backward along the ground. This

a larm beeps twice as fast as the DRIVE (forward)

❑ Drive (forward)

The DRIVE (forward) alarm alerts people that the

RT is traveling forward along the ground. This

alarm beeps half as fast as the DRIVE (reverse)

alarm.

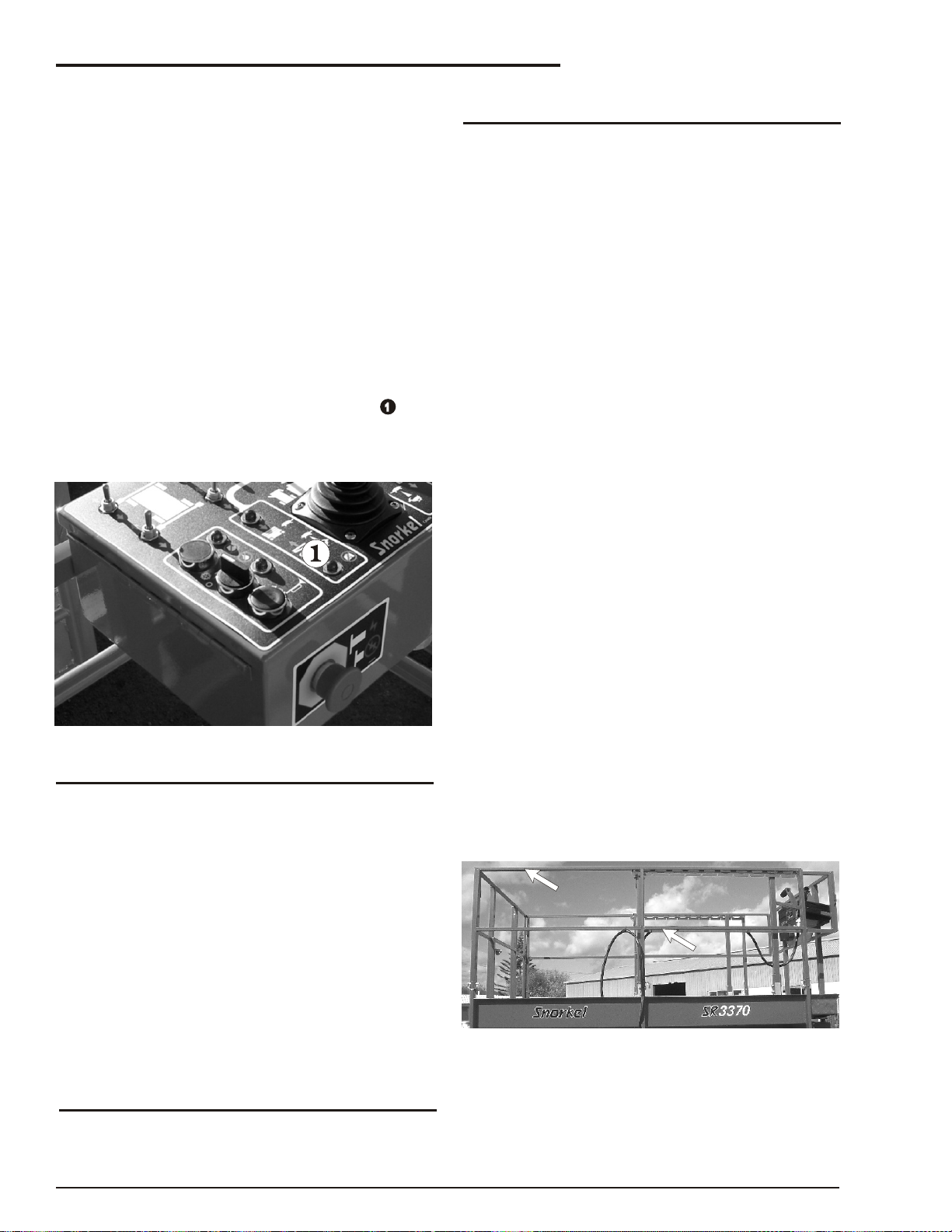

■

Guardrails

Figure 2.4 - Guardrails

The guardrails help protect you from falling off the

platform. Be sure the guardrails are properly installed and that the gate is in place.

Figure 2.6 - Swinging Gate

page 2 - 2 Rev A SR3370 & SR2770 – 13184A

Page 22

■

Safety Prop

Figure 2.5 - Safety Prop

Always raise the safety prop then lower the scis sor-arm as sembly onto the safety prop be fore

reaching into the scis sor-arm as sembly for any

reason.

■

Swinging Gate

2. Safety Devices

■

Bubble Level

Figure 2.8 - Bubble Level

See the Gauges chapter 4 for a discussion of the

elbbub level.

■

Operator Horn

Figure 2.6 - Swinging Gate

The swinging gate should be closed at all times except when someone is entering or leaving the platform.

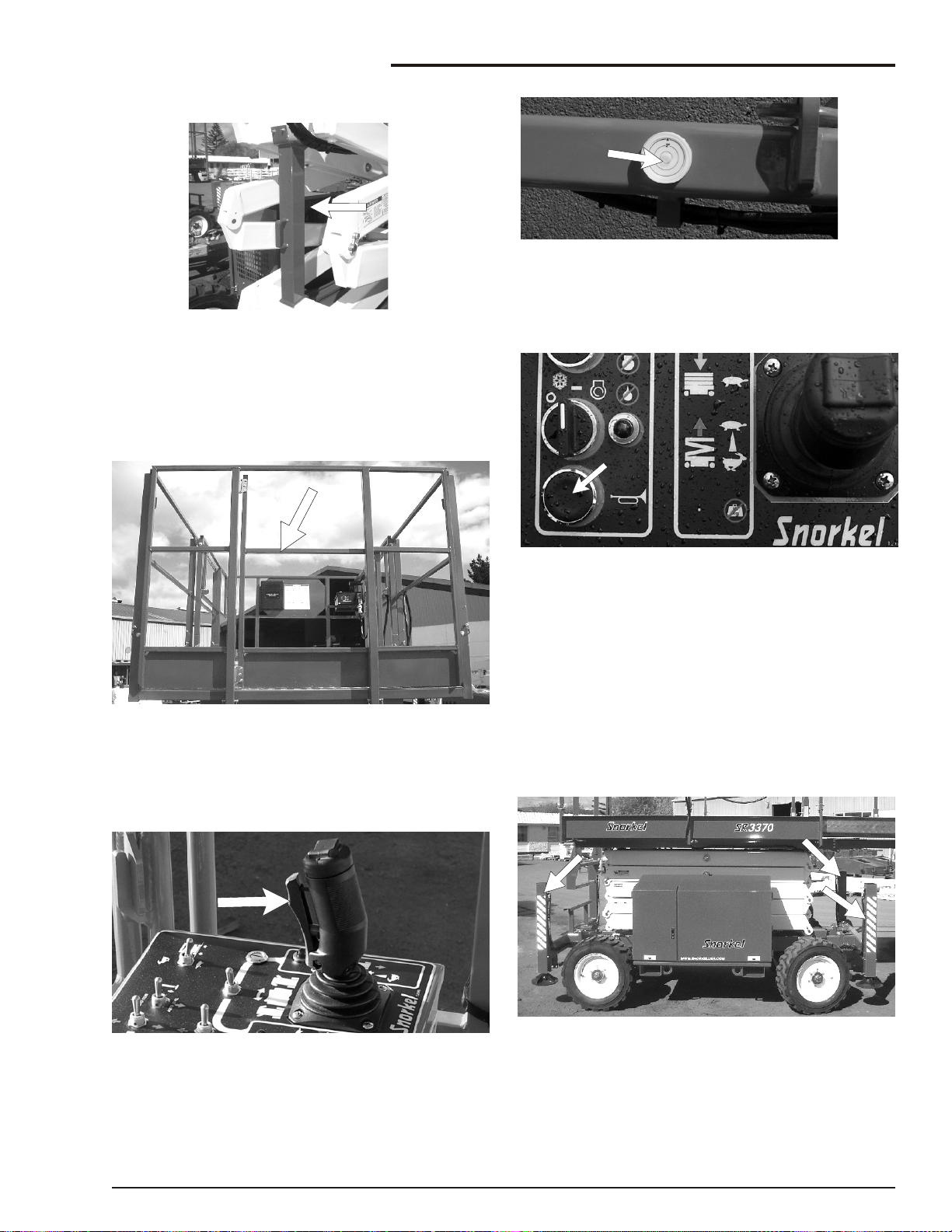

■

Safety Control

Figure 2.9 - Operator Horn

The operator horn is usedprimarily to get the attention of people on the ground when you are working

aloft. For the horn to work the following switches,

on the ground control box, must be set as indicated:

MAIN POWER........................ON

EMERGENCY STOP..............ON (up)

SELECTOR............................PLATFORM

■

Stabilisers (Option)

Figure 2.10 - Stabilisers

Figure 2.7 - Joystick Safety Control

The safety control must be squeezed and held to

activate the joystick. The safety control prevents

the joystick from moving the platform if something

accidentally pushes the joystick. Donot disable the

safety control in any way.

SR3370 & SR2770 – 13184A Rev A page 2 - 3

The stabiliser controls are on the upper left side of

the platform controlbox. The stabilisers are usedto

level the RT (for complete stabiliser operating pro-

c edures see the Operation chapter 8).

Page 23

2. Safety Devices

RCD

Power Input

Connector

Power Outlet

At Platform

NOTE

The RT must be on a firm surface capable of

w ithstanding all load forces imposed by the aerial

platform in all operation conditions before the

stabilisers are used.

■

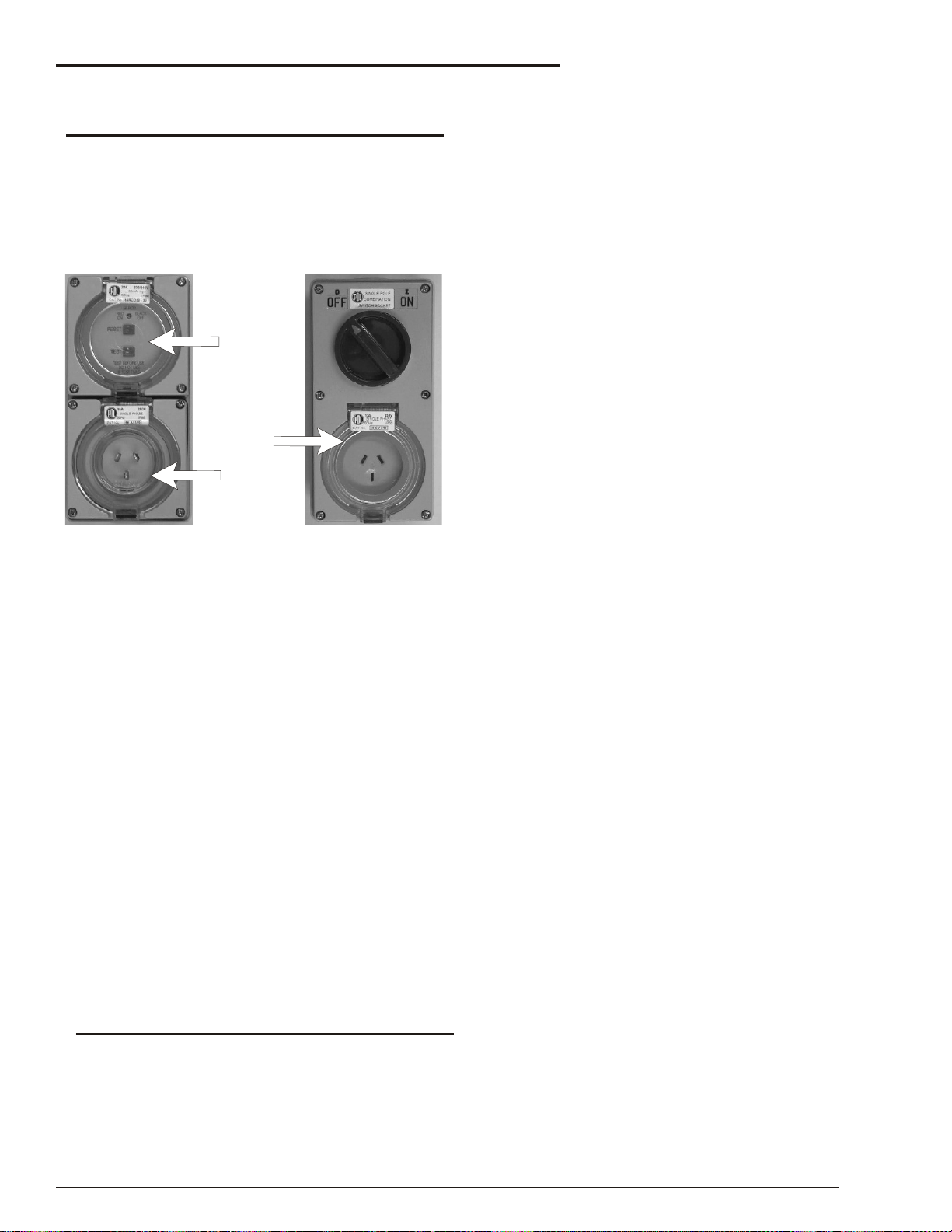

RCD/ELCB AC Outlet (option)

Figure 2.11 - RCD/ELCB AC Outlet

vice technician.

■

Flashing Light (option)

The flash ing light alerts peo ple that the RT is pres -

is run ning. There is no ON/OFF switch for the flash ing light, it can not be turned off while the RT is run ning.

■

Lanyard Anchor Points (option)

one at the front of the roll-out deck, one at the back

form.

NOTE

These anchors are not for lifting or tying down

the machine.

ta detac ol si )eciv eD tner ruC lau dis eR( DCR ehT

ot stiuc ric trohs tsniaga tcet orp lliw dna dnuorg eht

lliw DCR eht tiuc ric trohs a si ereht nehW .htrae

tuo mrof talp eht ot rewop CA v032 eht nwod tuhs loot rewop eht tcen noc sid tel tuo eht tes er oT .tel

eht ta DCR eht tes er dna xob mrof talp eht morf dael

res deniart a llac stsis rep mel borp eht fI .dnuorg -

ta sehsalf thgil ehT .gni vom si RS eht taht dna tne

enig ne RS eht emit yna dno ces rep hsalf eno tuoba

,mrof talp eht fo roolf eht no srohc na ruof era erehT

talp eht fo edis hcae no eno dna ,mrof talp eht fo -

na eht ot noit cet orp llaf ruoy hcat ta dluohs uoY -

page 2 - 4 Rev A SR3370 & SR2770 – 13184A

.ti eriuq er selur krow fi srohc

Page 24

3. Specifications

■

Specifications

The X33RT /X27RT se ries ma chines are scis sor-supported el evating work plat forms built to con form to

the fol low ing stan dards.

OSHA Paragraph 1910.67 Ti tle 29, C.F.R., Vehicle-Mounted El evating and Ro tating Work Plat forms - Labour.OSHA Para graph 1926.556 Ti tle 29, C.F.R., Aerial Lifts - Con struction.Australian Stan dard

AS1418-10(Int) 2004 Elevating Work Platforms. EN280:2001(E)

NOTE:

For further details regarding lubricants, maintenance schedules and service please refer to the

Maintenance and Repair Parts Manual for this machine.

■

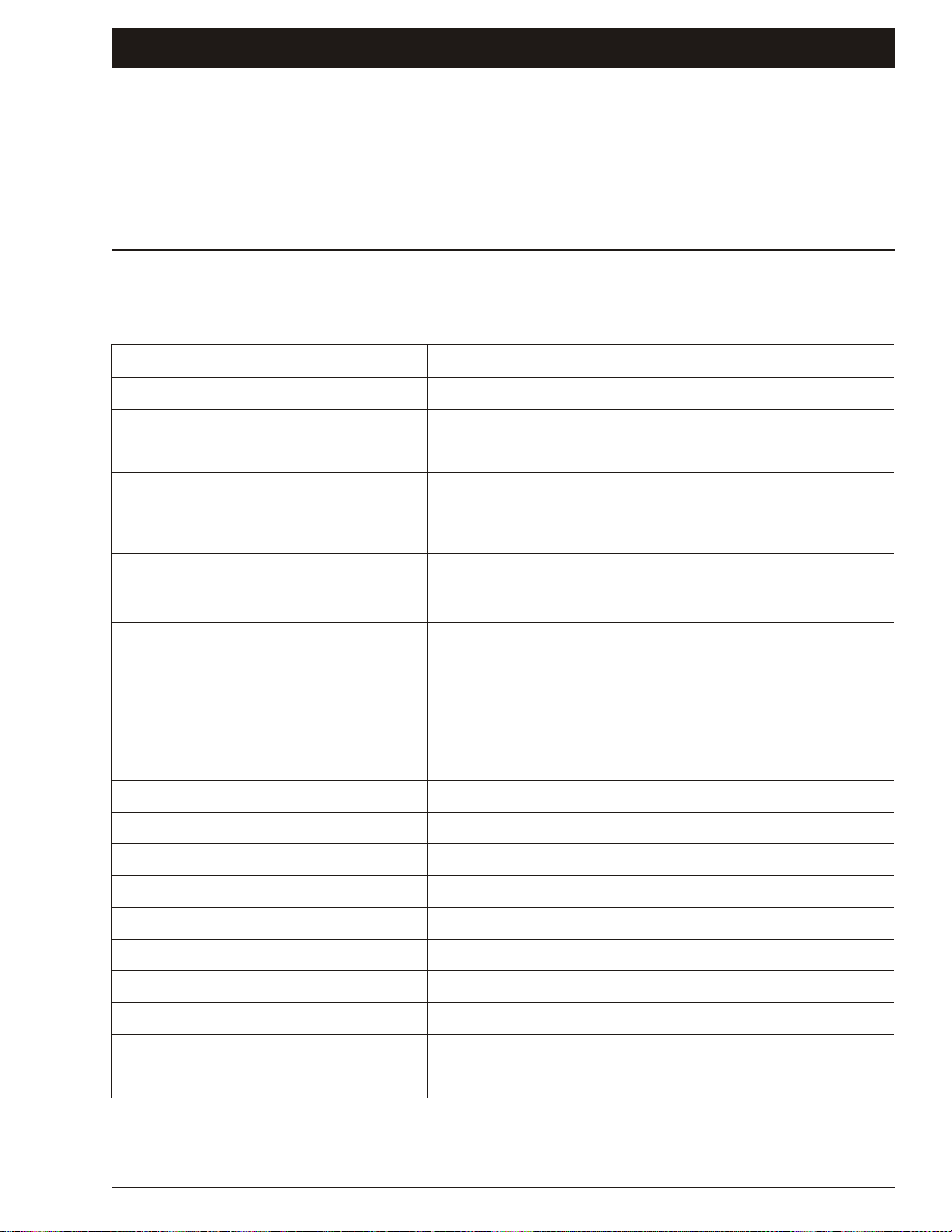

General Specifications, Standard Machine X33RT

SPECIFICATIONS X33RT

Nominal working height

Roll out deck size

Drive speed (below 2.4m)

Drive speed (above 2.4m)

Safe working load - Main deck

(Roll out deck not extended)

Safe working load - Main deck

Roll out deck extended - Roll out

deck

Platform size

Stowed height

Stowed height (hand rails folded down)

Overall length

Overall width

Gradeability

Lift time

12.12m 39' 2”

1200mm 48”

0 to 4.5kph 0 to 2.8mph

0 to 0.35kph 0 to 0.22mph

450kg 990lbs

330kg

120kg

2.73 x 1.65m 8’ 11” x 5’ 5”

2.7m 8' 10"

2.0m 6' 6"

3.36m 11’ 0”

1.77m 5' 9"

35%

50 seconds

726lbs

264lbs

Turning radius (inner)

Turning radius (outer)

Maximum wind speed (12.5m/s)

Insulation rating

Tyres - Poly filled loader lug

Overall weight

Ground clearance

Maximum sound level at platform

■

Recommended Hydraulic Oil

Shell Tellus 32 or Castrol AWS 32 or sim ilar.

SR3370 & SR2770 – 13184A Rev A page 3 - 1

2.38m 7’ 8”

4.75m 15’ 6”

45km/h 28mph

Nil

27" x 10.5" x 15"

3620kg 7964lbs

350mm 13.8”

86db

Page 25

3. Specifications

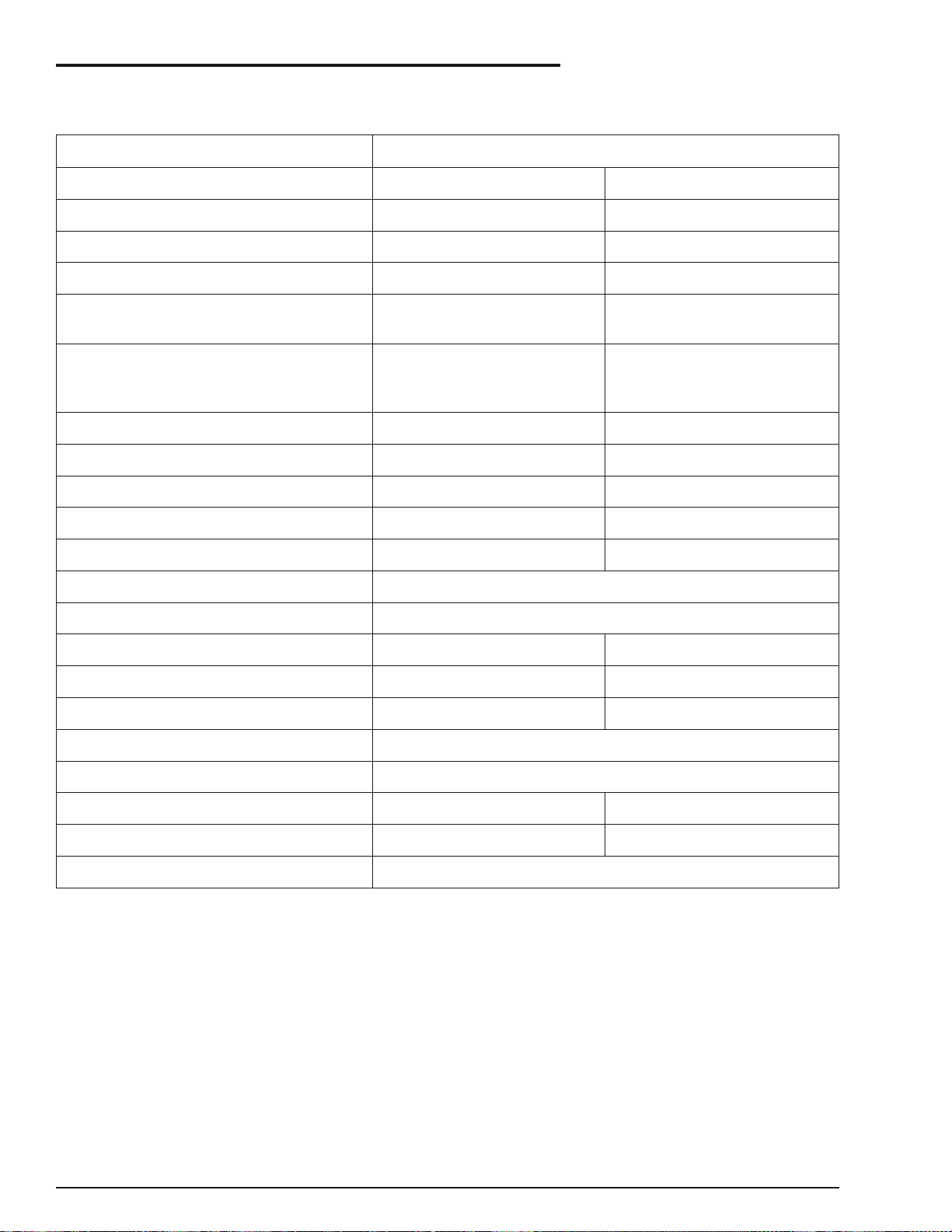

■

General Specifications, Standard Machine X27RT

SPECIFICATIONS X27RT

Nominal working height

Roll out deck size

Drive speed (below 2.4m)

Drive speed (above 2.4m)

Safe working load - Main deck

(Roll out deck not extended)

Safe working load - Main deck

Roll out deck extended - Roll out

deck

Platform size

Stowed height

Stowed height (hand rails folded down)

Overall length

Overall width

Gradeability

Lift time

10.28m 33' 9”

1200mm 48”

0 to 4.5kph 0 to 2.8mph

0 to 0.9kph 0 to 0.6mph

580kg 1280lbs

460kg

120kg

2.73 x 1.65m 8’ 11” x 5’ 5”

2.5m 8' 2"

1.7m 5' 8"

3.36m 11’ 0”

1.7m 5' 8"

35%

26 seconds

1015lbs

265lbs

Turning radius (inner)

Turning radius (outer)

Maximum wind speed (12.5m/s)

Insulation rating

Tyres - Poly filled loader lug

Overall weight

Ground clearance

Maximum sound level at platform

2.83m 9’ 3”

4.6m 15’ 1”

45km/h 28mph

Nil

27" x 10.5" x 15"

2800kg 6272lbs

350mm 13.8”

86db

page 3 - 2 Rev A SR3370 & SR2770 – 13184A

Page 26

■

Engine Data

Engine Make Kubota

Model DF752 D902

Fuel gasoline LPG Diesel

3. Specifications

Fuel grade Unleaded

85 octane

(motor method

Do not use

gasoline blended

with methyl

alcohol.

Coolant 50% water + 50% ethylene glycol

Maximum

temperature

Oil Capacity 3.7L

Oil grade API: Quality better than CD

Oil weight See chart below

■

Engine Oil Charts

110oC

HD5

Gas Processors

Association

Standard 2140

Category: special

duty propane

ASTM Grade 2-D S5000

Tier 4 Compliance:

Low Sulpher

ASTM Grade 2-D S500

Centane number >44

(For operating temp. Below 32oF (0oC)

use “winterized” number 2-D.)

❑ DF752

Ambient temperature Engine oil weight

Above 77oF (25oC) SAE30 or 10W30

32oF to 77oF

(0oC) to (25oC)

0oF to 32oF

(-17oC) to (0oC)

SR3370 & SR2770 – 13184A Rev A page 3 - 3

SAE20 or 10W30

SAE10W or 10W30

❑ D902

Ambient temperature Engine oil weight

Above 77oF (25oC) SAE30 or 10W30

10W40

32oF to 77oF

(0oC) to (25oC)

Below 32oF (0oC) SAE10W or 10W30

SAE20 or 10W30

10W40

10W40

Page 27

3. Specifications

■

Machine Component Identification

1. Base control panel

2. Serial number plate

3. Engine & fuel compartments

1. Extendable platform

2. Entry gate

3. Hydraulic compartment

4. Front end

5. Rear end

6. Guard rails

7. Steering (front) wheels

8. Rear Wheels

9. Scissor arms

10. Platform

11. Platform control box

12. Stabilisers / outriggers (Option)

page 3 - 4 Rev A SR3370 & SR2770 – 13184A

Page 28

4. Gauges

■

Water

Figure 4.1 - Water Temperature Gauge

The wa ter gauge is lo cated on the ground con trol

box. It shows the tem perature of the wa ter-antifreeze mix ture in the en gine block. The typ ical op er at ing-tem per a ture range for Kubota en gines is

180°F to 205°F (82°C to 96°C), both die sel and

gasoline. (See the Au tomatic Shut-Offs & Cir cuit

Breakers chap ter 5 for more information.)

■

Amps

●

The oil dipstick is the only way to

accurately gauge if the engine oil level is

correct.

●

Engine oil level should always be between

the lines on the dipstick - never above the

top line or below the bottom line.

Gas o line Die sel

Figure 4.3 - Oil Dipstick Levels for Gasoline

and Diesel Engines

■

Hydraulic Oil Level

Figure 4.4 - Hydraulic Oil Level

The hy draulic-oil level gauge is on the side of the

hydraulic oil tank. It shows the ac tual level of oil in -

Figure 4.2 - Ammeter Gauge

The AMPS gauge shows the elec tric cur rent from

the al ternator to the bat tery. When the en gine is

running, the nee dle in the AMPS gauge should not

be to the left of 0. Un der nor mal op erating con ditions, af ter the en gine has been run ning for a few

minutes, the AMPS gauge should read 0.

■

Engine Oil

Engine oil level is mea sured with a dip stick. Oil ca pac i ties given in the Spec i fi ca tions chap ter 3 are

approximate. True val ues will vary from ma chine to

ma chine due to slight vari a tions or mod i fi ca tions

during production.

SR3370 & SR2770 – 13184A Rev A page 4 - 1

side the tank. Read it only when the plat form is

completely down. Oth erwise, the lift cyl inders be come large res ervoirs for hy draulic oil and the oil

level in the tank will be low. The oil level should be

within ( 0.25 inches, 6.4 mm) of the line.

Page 29

4. Gauges

■

Hours

Figure 4.5 - Hour Gauge

The HOURS gauge is ba sically an elec tric clock. It

accumulates time only when the en gine is run ning.

The HOURS gauge cannot be reset. An RT-qualified ser vice tech nician uses it to tell when it is time

for the pe riodic main tenance listed in the Main tenance Manual.

■

Bubble Level

Figure 4.7 - Bubble Level

A bub ble level is lo cated on the plat form side rail,

below the plat form con trol box. Watch the bub ble

level while you set the sta bilisers man ually. Lower

the sta bilisers, one at a time, just enough to cen ter

the bub ble in the cir cle on top of the gauge. When

the bub ble is cen tered the plat form is level and can

safely be raised.

■

Fuel Level (option)

Figure 4.6 - Fuel Level Gauge

LPG tanks have two fuel gauges on top. One measures cor rectly when the tank is stand ing on end

(VERTICAL) € the other measures cor rectly when

the tank is lay ing down (HORIZONTAL)

read in frac tions-of-a-full-tank. (see Fig ure 4.6).

NOTE:

LPG fuel installations are usually fitted post

production and may vary from machine to

machine. It is the operator’s responsibility

therefore, to be aware of how the system is

installed on their individual machine and know

which gauge, (horizontal or vertical) to read.

page 4 - 2 Rev A SR3370 & SR2770 – 13184A

Page 30

5. Automatic Shut-offs and Circuit Breakers

■

Automatic Shut-offs

❑ Level sensor

When the level sen sor alarm sounds, au to matic in ter locks make it im pos si ble to drive the RT or raise

the plat form. For more com plete in for ma tion see

the Level Sen sor sub sec tion of the Safety De vices

2 chapter.

❑ Engine temperature

engine shuts off. The engine will restart with low

pressure but it will only run a few seconds before it

automatically shuts off again.

❑ Platform height vs. drive speed

When the plat form is over 1.7m (5 6") above the

ground the drive speed is lim ited to its slow est

speed and the en gine revs are also au to mat i cally

low ered.

❑ Dynamic brakes

When you drive an RT down a slope, if the RT be gins to coast (out run the drive mo tors) the hy drau lic

sys tem senses the coast ing con di tion. The hy drau lic drive mo tors then be come hy drau lic brakes and

the RT is slowed. This ac tion pre vents SRs from

speed ing down grades.

❑ Alternator not charging

Figure 5.1 - Engine Temperature Sensor

There is a tem per a ture sen sor in the en gine. It

mea sures the tem per a ture of the an ti freeze-wa ter

mix ture as the mix ture leaves the top of the ra di a tor

and en ters the top of the en gine. If the tem per a ture

reaches 210(F (99(C) an alarm sounds. If the tem per a ture con tin ues to rise, the en gine shuts off

when the tem per a ture reaches 230(F (110(C). The

en gine will not re start un til the tem per a ture drops

below 210(F (99(C).

❑ Engine oil pressure

Figure 5.3 - Alternator Output Shutdown

When the fan belt breaks, or the al ter na tor out put

falls be low a safe level for other rea sons, the en gine au to mat i cally shuts off and an alarm sounds.

As long as the RT bat tery is charged you can lower

the plat form, in the usual way, from the plat form

con trol box or the ground con trol box with out the

en gine running.

❑ Stabilisers

The RT can not be driven un less the sta bi lis ers are

com pletely up. If you have just raised the sta bi lis ers but the RT will not drive, dou ble check to be

sure all four sta bi lis ers are com pletely up.

Figure 5.2 - Engine Oil Pressure Sensor

There is an oil pressure sensor in the engine. It

measures the engine oil pressure at the oil filter. If

the pressure falls below a safe operating value the

SR3370 & SR2770 – 13184A Rev A page 5 - 1

Page 31

5. Automatic Shut-offs and Circuit Breakers

❑ Load sensing system

The load sens ing sys tem sounds an alarm to warn

the op er a tor that the plat form is over loaded.

NOTE:

When the alarm sounds all plat form move ment

[drive for ward / re verse and lift up / down is pre vented].

The alarm and func tion in ter lock will be ac tive un til

the load is reduced.

❑ Lowering

The low er ing warn ing alarm will ac ti vate and plat form de scent will stop ap prox i mately 1 metre from

the stowed po si tion. This alarm will con tinue to

sound and no fur ther plat form move ment will oc cur

un til the joy stick has been re leased for the pre set

pe riod of time.

■

Circuit Breakers

❑ Main breaker

❑ RCD / ELCB outlet (option)

Figure 5.5 - RCD/ELCB Outlet

The RCD (Re sid ual Cur rent De vice) is lo cated at

the ground and will pro tect against short cir cuits to

earth. When there is a short cir cuit the RCD will

shut down the 230v AC power to the plat form

out let.

To re set the out let dis con nect the power tool lead

from the plat form box and re set the RCD at the

ground.

Figure 5.4 - Main Circuit Breaker

There is only one cir cuit breaker, on a stan dard ,

that is ac ces si ble to the op er a tor. Its pur pose is to

pro tect the elec tri cal cir cuits from elec tri cal over loads. When the cir cuit breaker trips (pops out)

push it back in then at tempt to use the RT.

If the cir cuit breaker trips a sec ond time, take the

RT out of ser vice and re fer the prob lem to a qual i fied trained ser vice tech ni cian for repair.

If the prob lem per sists call a trained ser vice tech ni cian.

page 5 - 2 SR3370 & SR2770 – 12884A

Page 32

6. Controls

■

Controls

This chap ter ex plains what each con trol does.

This chap ter does not ex plain how to use the con trols to pro duce use ful work, re fer to the Op er a tion

chap ter 8 for that, af ter you have read this chapter.

For op tional-equip ment con trols, see the Op tions

chap ter 11 .

See the Emer gency Op er a tion chap ter 9 for the lo ca tion of the emer gency bleed down con trol and for

cor rect emer gency bleed down pro ce dures.

The main op er at ing func tions of an RT can be con trolled from the ground con trol box (1) or the plat form con trol box (2).

■

Hydraulic Compartment

Figure 6.2 - Battery Switch

1.

Battery Switch: This must be ON for the

engine to start. When the battery switch is

OFF the positive side of the RT battery is

disconnected from the electrical system.

Lock this switch OFF when the RT is left

unattended.

■

Ground Control Box

Con trols for op er at ing an RT from the ground are

lo cated on the right side of the ma chine on the rear

of the hy drau lic com part ment.

Figure 6.1.1 - Control Box Location, Ground

Position

Figure 6.1.2 - Control Box Location, Platform

Position

NOTE 1

The number of each control corresponds to

Figure 6.3.

NOTE 2

Some switches and indicators are either not

used, or may serve a different purpose

depending on the configuration of your machine.

Figure 6.3 - Ground Control Box Controls

SR3370 & SR2770 – 13184A Rev A page 6 - 1

Page 33

6. Controls

1.

Emergency Stop: Press the red

switch-cover down, at any time, under any

conditions, and the entire machine stops the engine turns off and nothing moves. This

switch must be up for anything on the

machine to work.

2.

Key Switch: This switch works like an

automobile ignition switch. Hold the key at

the start symbol (extreme clockwise position)

until the engine starts then release it to the

on position (bar symbol).Turn the key to off

(O) if the platform is to stay in one position

for a long time. That will turn the engine off

and save fuel.

3.

Choke Indicator Light: (gasoline engines

only): This light will be lit while you choke the

engine (see CHOKE below).

3.

Glow-Plug Indicator Light: (diesel engines

only): This light will be on while the glow

plugs are on. Wait, about 30 seconds for the

light to go out before you try to start a diesel.

4.

Choke: (gasoline engines only): Hold the

choke switch up anytime you start a gasoline

engine that is at ambient air temperature (a

cold engine).

4.

Glow Plug: (diesel engines only): This is a

momentary contact switch. Press it up then

release it just before you start a diesel

engine that is at ambient air temperature (a

cold engine). This action automatically

causes glow plugs to come on for 30

seconds to warm the inside top of each

cylinder, thus aiding combustion.

5.

Lift Indicator Light: The platform can be

raised only when this light is lit. When this

light is not lit the platform will not rise

because: the platform is not level, or the

stabilisers are not properly set.

6.

Platform Lift/Lower: Holding this switch up

causes the platform to rise. Pushing this

switch down causes the platform to lower.

7.

Fuel (option): Before starting a dual-fuel

engine set the FUEL switch to gasoline (up)

or LP gas (down) depending on which you

want to use. If you select LP gas, be sure to

open the valve on top the LP gas tank.

8.

Ground/Platform Selector: Must be down

for the ground control box to work. Must be

up for the platform control box to work.

Figure 6.3 Ground Control Box Controls

■

Platform Control Box

Con trols for op er at ing an RT from the plat form are

lo cated on the plat form con trol box.

NOTE

The number of each control corresponds to

Figure 6.4.

Figure 6.4 - Platform Control Box Controls

1.

Emergency Stop: Press the red button in at

any time, under any conditions, and the

entire machine stops - the engine turns off

and nothing moves. This switch must be out

(on) to start and run the RT from the platform

control box, pull the switch and it will pop out

(on). Press the switch in (off) if the platform

is to stay in one position for a long time. That

will turn the engine off and save fuel.

page 6 - 2 Rev A SR3370 & SR2770 – 13184A

Page 34

NOTE

The EMERGENCY STOP switch on the ground

control box overrides the one on the platform

control box. If the one on the ground control box

is off the RT will not start or run, it does not make

any difference whether the one on the platform

control box is on or off.

2.

Start: Turn and hold the switch to the right to

start the engine. As soon as the engine

starts, release the switch.

3.

Choke: (gasoline engines only): Press and

hold the switch in anytime you start a

gasoline engine that is at ambient air

temperature (a cold engine).

3.

Glow-Plug: (diesel engines only): This is a

momentary contact switch. Press it up then

release it just before you start a diesel

engine that is at ambient air temperature (a

cold engine). This action automatically

causes glow plugs to come on for 30

seconds to warm the inside top of each

cylinder, thus aiding combustion.

4.

Choke Indicator Light: (gasoline engines

only): This light will be lit while you choke the

engine.

4.

Glow-Plug Indicator Light: (diesel engines

only): This light will be on while the glow

plugs are on. Wait for the light to go out

before you try to start a diesel.

5.

Safety Control: The SAFETY CONTROL

must be squeezed against the JOYSTICK

CONTROLLER to activate the joystick

controller. If the safety control is not

squeezed the joystick controller is

inoperative.

6.

Joystick Controller: If the LIFT/DRIVE

SELECTOR is set to the left (lift function),

pulling the joystick controller backward

causes the platform to rise, pushing the

joystick controller forward causes the

platform to lower. If the LIFT/DRIVE

SELECTOR is set to the right (drive

function), pushing the joystick controller

forward causes the RT to move forward,

pulling the joystick controller backward

causes the RT to move backward. The

further you push or pull the controller the

faster the motion (except lowering-it occurs

at one speed only).

6. Controls

7.

Steering: The rocker switch on top of the

JOYSTICK CONTROLLER turns the front

wheels left or right depending upon which

side of the switch you press.

NOTE

The wheels do not return to straight ahead, after

a turn, the way automobile wheels do. You must

use the STEERING switch to straighten the

wheels after a turn.

8.

Lift/Drive Selector: When this switch is set

to the left the JOYSTICK CONTROLLER

becomes a lift/lower controller to raise or

lower the platform. When this switch is set to

the right the JOYSTICK CONTROLLER

becomes a drive controller to drive the RT

forward or backward. The RT will not drive

and lift at the same time.

9.

Speed: Set the switch to turtle (slow) when

you are working in close quarters or if you

are new to the machine. Setting the switch to

rabbit (fast) doubles the top speed of the RT.

10.

Lift Indicator Light: The platform can be

raised only when this light is lit. When this

light is not lit the platform will not rise

because: the platform is not level, or the

stabilisers are not properly set.

11.

Drive Indicator Light: The platform can be

driven when this light is lit. When it is not lit

the platform will not drive because with the

platform raised the base is not level or with

the platform raised the axle switches are not