X26-32

Operator Manual

This first section of the Operator manual is the English language version.

Betriebsanleitung

Im zweiten Abschnitt dieser Betriebsanleitung finden Sie die Deutsche Version.

Manuel Utilisateur

èLa troisième section de ce manuel est la version en langue Française.

Manual del Usuario

El apartado cuarto de este manual del usuario corresponde a la versión en Español.

Manuale d’Uso

La quinta sezione di questo manuale d'uso è la versione in lingua Italiana.

(EN) Manual part number 504165-002.

(DE) Bestellnummer 504165-002.

WARNING

The X32 Machine has been re-assessed to ensure

compliance to the Machinery Directive (2006/42/EC).

The Machine rating has been changed from:

Windspeed rating of 12.5 m/s (Beaufort 6)

To

Windspeed rating of 7 m/s (Beaufort 4)

Please attach to the front cover of

your X32 manual

510329-000

(FR) Manuel Pièce numéro 504165-002.

(ES) El número de referencia para el manual es el 504165-002.

(IT) Manuale Ricambi Numero 504165-002.

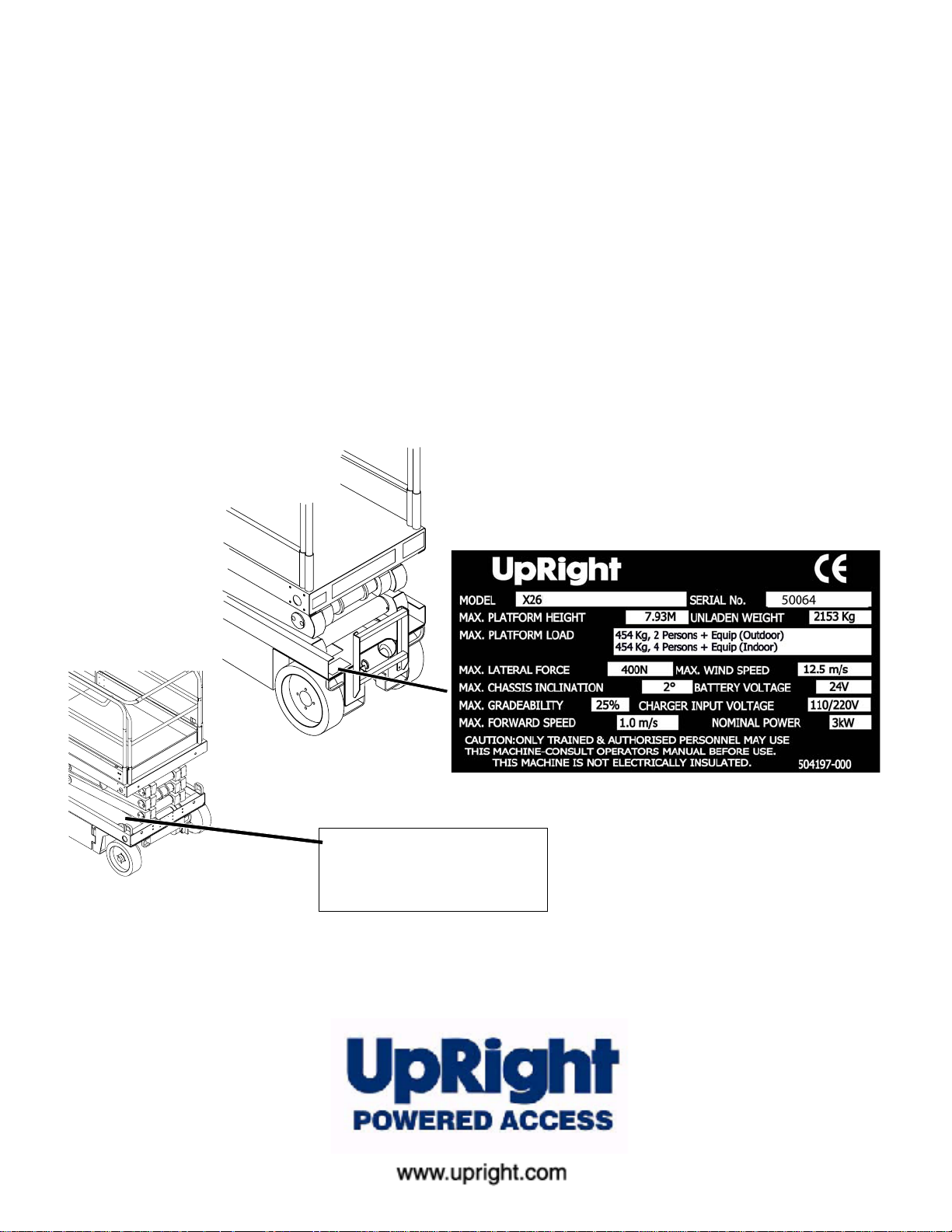

X 26-32

X26 Serial Numbers 50906 – 53099

X32 Serial Numbers 50322 – 53099

ENGLISH

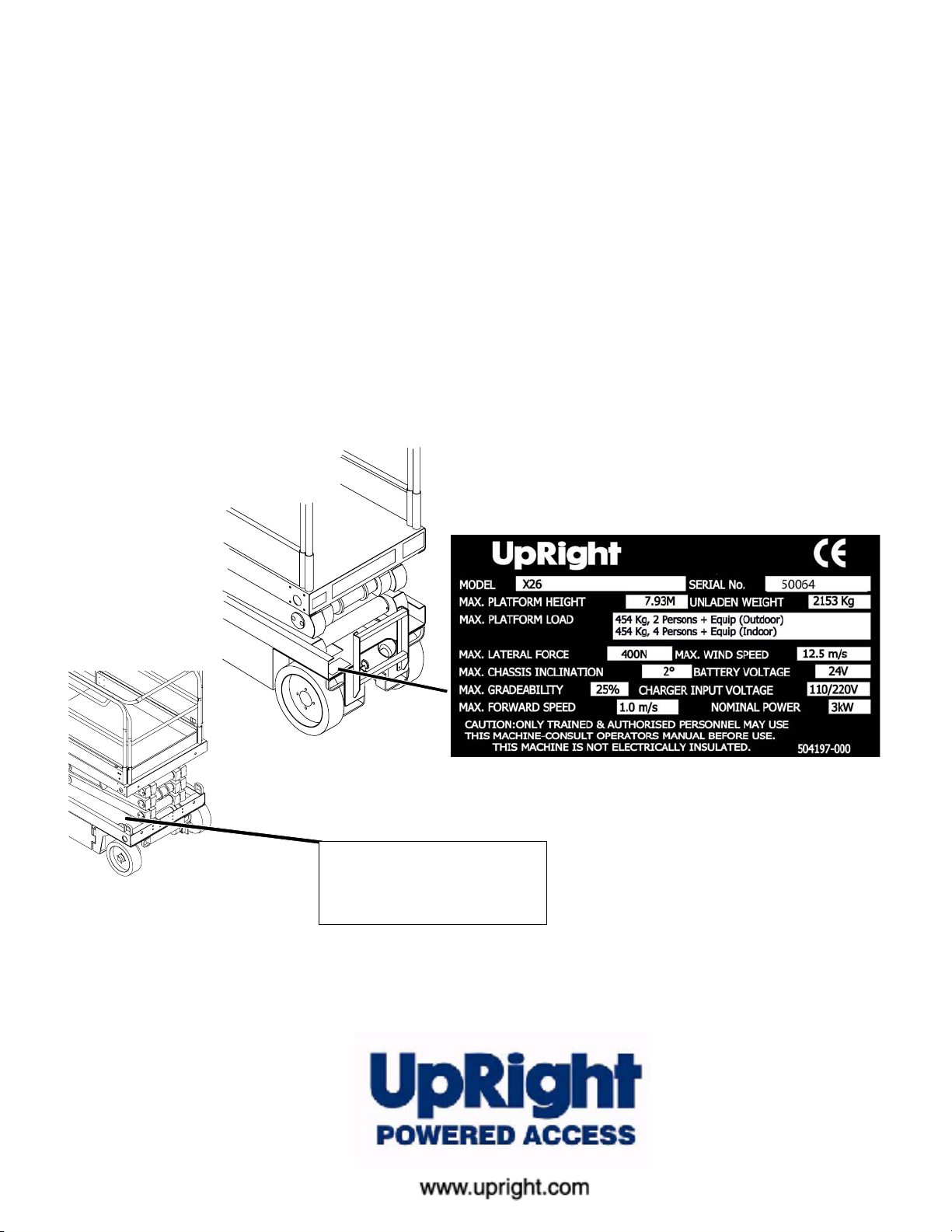

When contacting Upright for service or parts information, be sure to include the MODEL and SERIAL NUMBERS from the

equipment nameplate. Should the nameplate be missing, the SERIAL NUMBER is also stamped on top of the chassis

above the front axle pivot.

Stamped Serial Number

Estampille de numéro de série

Eingestanzte Seriennummer

OPERATION MANUAL

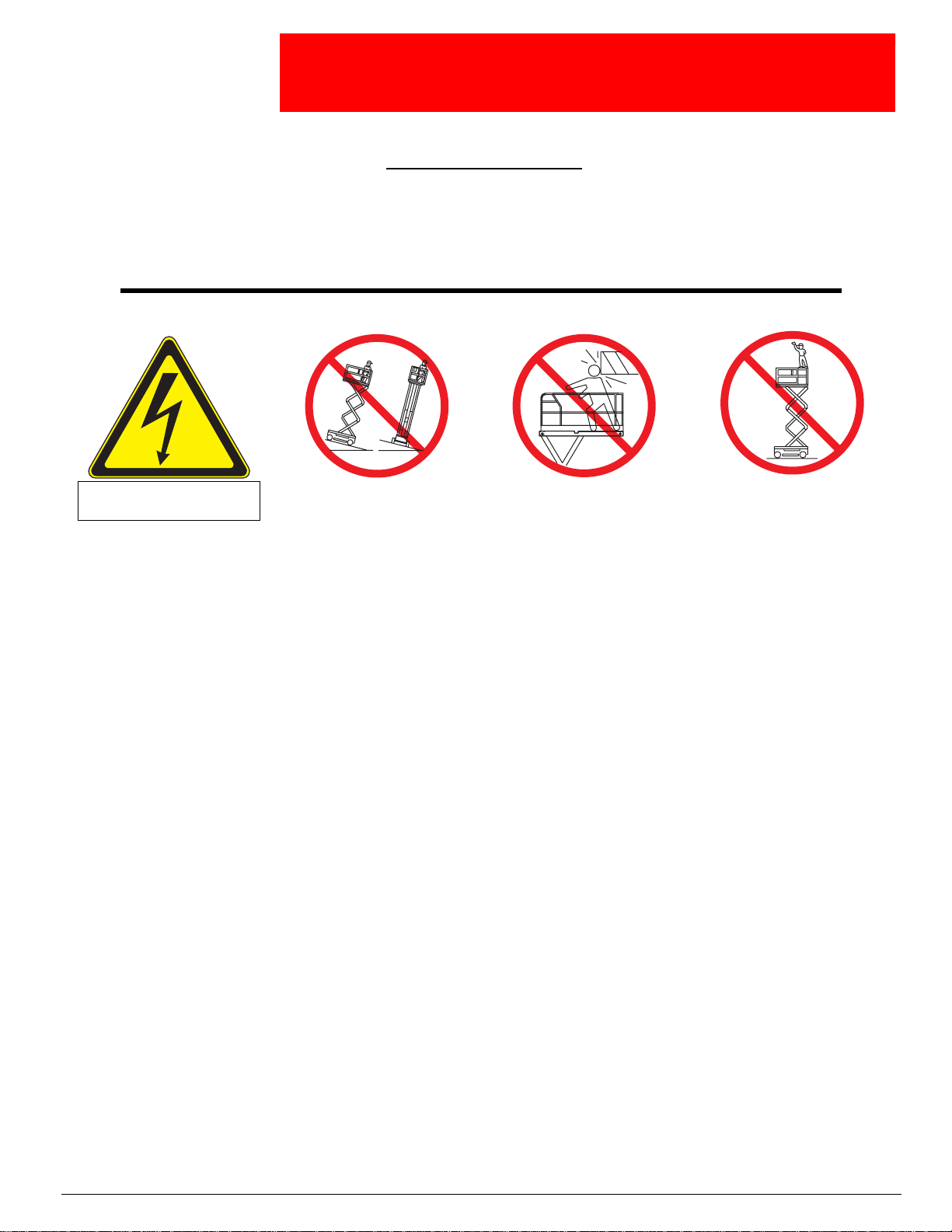

WARNING

All personnel shall carefully read, understand and follow all safety rules and operating

instructions before operating or performing maintenance on any UpRight aerial w ork platform.

Safety Rules

Electrocution Hazard Tip Over Hazard Collision Hazard

THIS MACHINE IS NOT

INSULATED!

USE OF THE AERIAL WORK PLATFORM: This aerial work platform is intended to lift persons and his tools as well as the material

used for the job. It is designed for repair and assemb ly jobs and assignments at overhead workplaces (ceilings, cranes, roof structures,

buildings etc.). All other uses of the aerial work platform are prohibited!

THIS AERIAL WORK PLATFORM IS NOT INSULATED! For this reason it is imperative to keep a safe distance from live parts of electrical equipment!

Exceeding the specified permissible maximum load is prohibited! See “Special Limitations” on page 4 for details.

The use and operation of the aerial work platform as a lifting tool or a crane (lifting of loads from below upwards or from up high on

down) is prohibited!

NEVER exceed the manual force allowed for this machine. See “Special Limitations” on page 4 for details.

DISTRIBUTE all platform loads evenly on the platform.

NEVER operate the machine without first surveying the work area for surface hazards such as holes, drop-offs, bumps, curbs, or debris;

and avoiding them.

OPERATE machine only on surfaces capable of supporting wheel loads.

NEVER operate the machine when wind speeds exceed this machine’s wind rating. See “Beaufort Scale” on page 4 for details.

IN CASE OF EMERGENCY push EMERGENCY STOP switch to deactivate all powered functions.

IF ALARM SOUNDS while platform is elevated, STOP, carefully lower platform. Move machine to a firm, level surface.

Climbing up the railing of the platform, standing on or stepping from the platform onto buildings, steel or prefab concrete structures, etc.,

is prohibited!

Dismantling the swing gate or other railing components is prohibited! Always make certain that the swing gate is closed and securely

locked!

It is prohibited to keep the swing gate in an open position (held open with tie-straps) when the platform is raised!

To extend the height or the range by placing of ladders, scaffolds or similar devices on the platform is prohibited!

NEVER perform service on machine while platform is elevated without blocking elevating assembly.

INSPECT the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks, loose wire connections, and damaged

cables or hoses before using.

VERIFY that all labels are in place and legible before using.

NEVER use a machine that is damaged, not functioning properly, or has damaged or missing labels.

To bypass an y safety equipment is prohibited and presents a danger for the persons on the aerial work platform and in its working

range.

NEVER charge batteries near sparks or open flame. Charging batteries emit explosive hydrogen gas.

Modifications to the aerial work platform are prohibited or permissible only at the approval by UpRight.

AFTER USE, secure the work platform from unauthorized use by turning both keyswitches off and removing key.

The driving of MEWPs on the public highways is subject to regulations made under the Road Traffic Acts.

NEVER elevate the platform or drive

the machine while elevated unless the

machine is on a firm, level surface.

NEVER position the platform

without first checking for overhead

obstructions or other hazards.

Fall Hazard

NEVER climb, stand, or sit on

platform guardrails or midrail.

Page 1

504165-002

C

ONTENTS

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Special Limitations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Platform Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Manual Force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Beaufort Scale. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Lift Overload Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Pre-Operation Safety Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

System Function Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Platform Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Travel With the Platform Lowered. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Steering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Elevating the Platform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Travel With the Platform Elevated. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Lowering the Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Emergency Lowering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

X26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

X32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Lower the Guardrails, X26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Lowering Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Raising Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fold Down guardrails, X32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Fold Down Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Erection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Towing or Winching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Parking Brake Release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

After Use Each Day. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Hour Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Transporting the Work Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Preparation for Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Lifting By Crane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

By Forklift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Driving or Winching onto a Truck or Trailer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Blocking The Elevating Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Scissor Brace Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Scissor Brace Stowage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Battery Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Battery Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Inspection and Maintenance Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Daily Preventative Maintenance Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

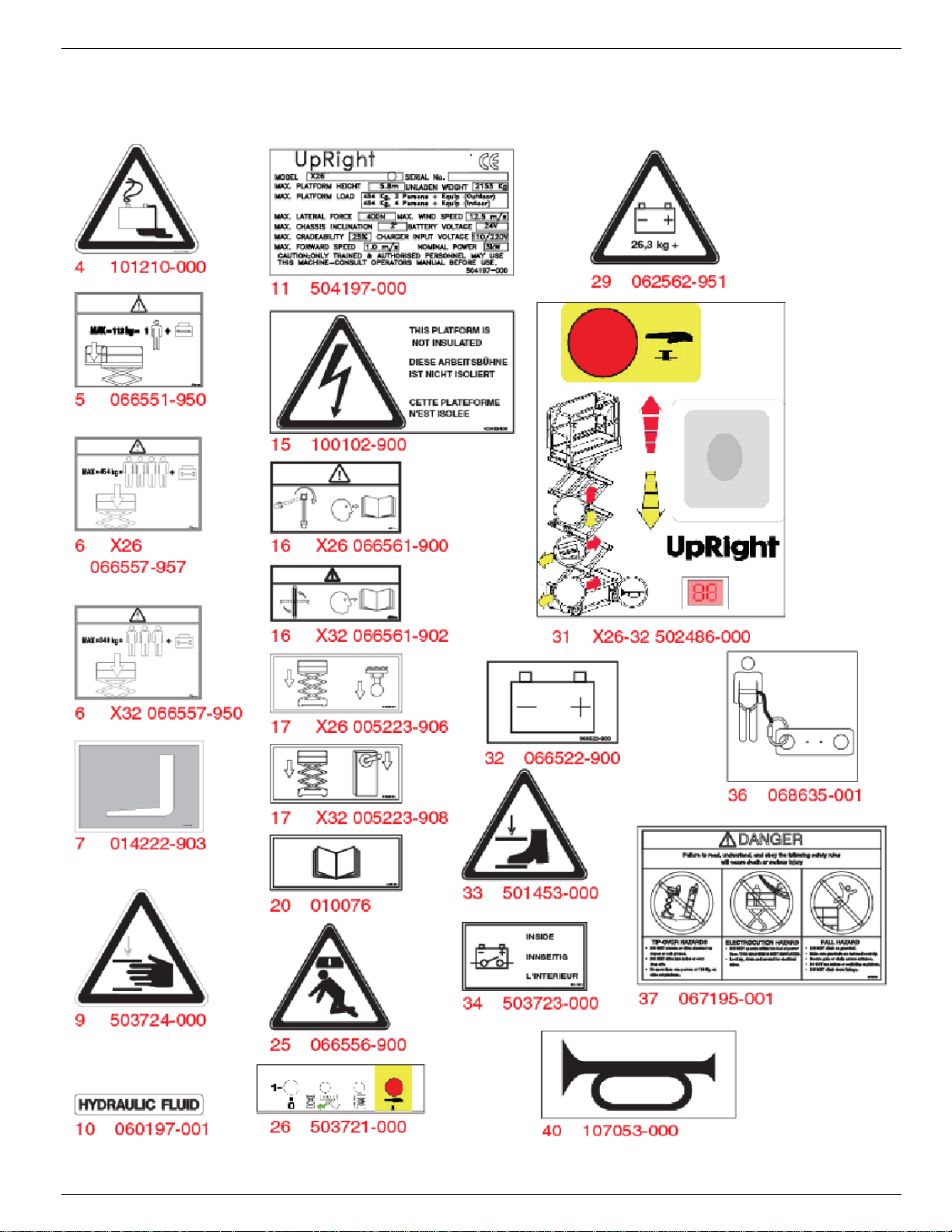

Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Page 2 Operation Manual

Introduction 504165-002

I

NTRODUCTION

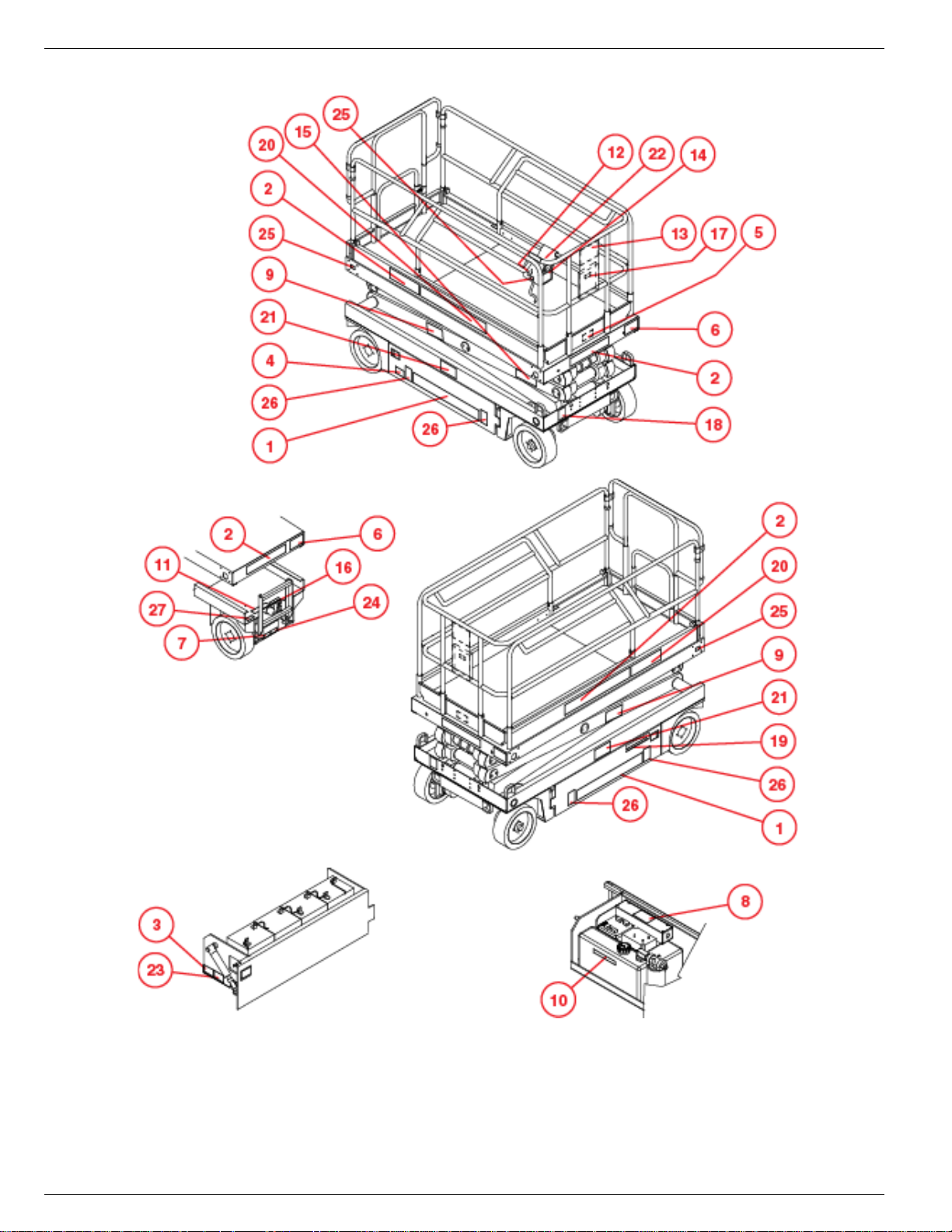

This manual covers operation of the X 26-32 Self-Propelled Work Platforms.

This manual must be stored o n the machine at all times.

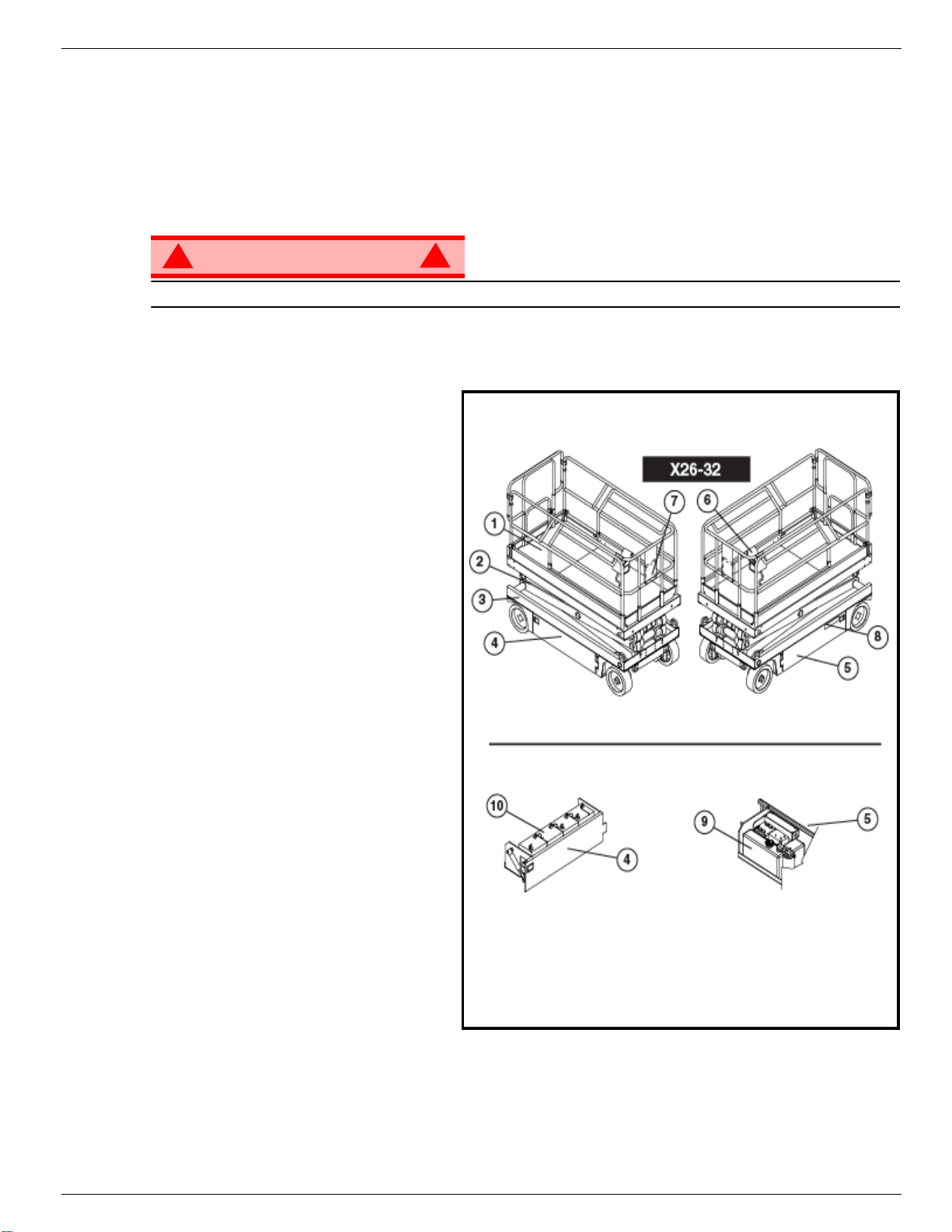

G

ENERAL

D

ESCRIPTION

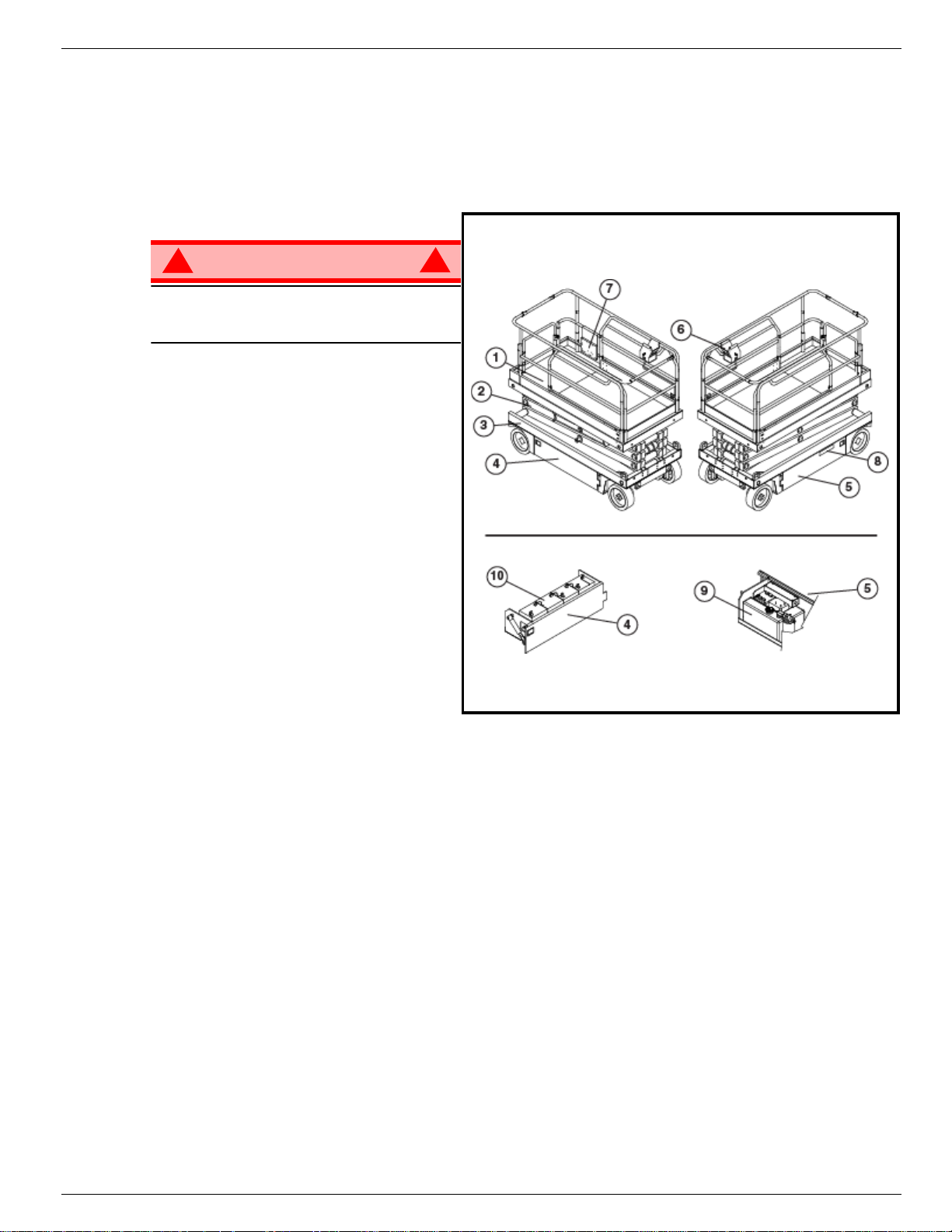

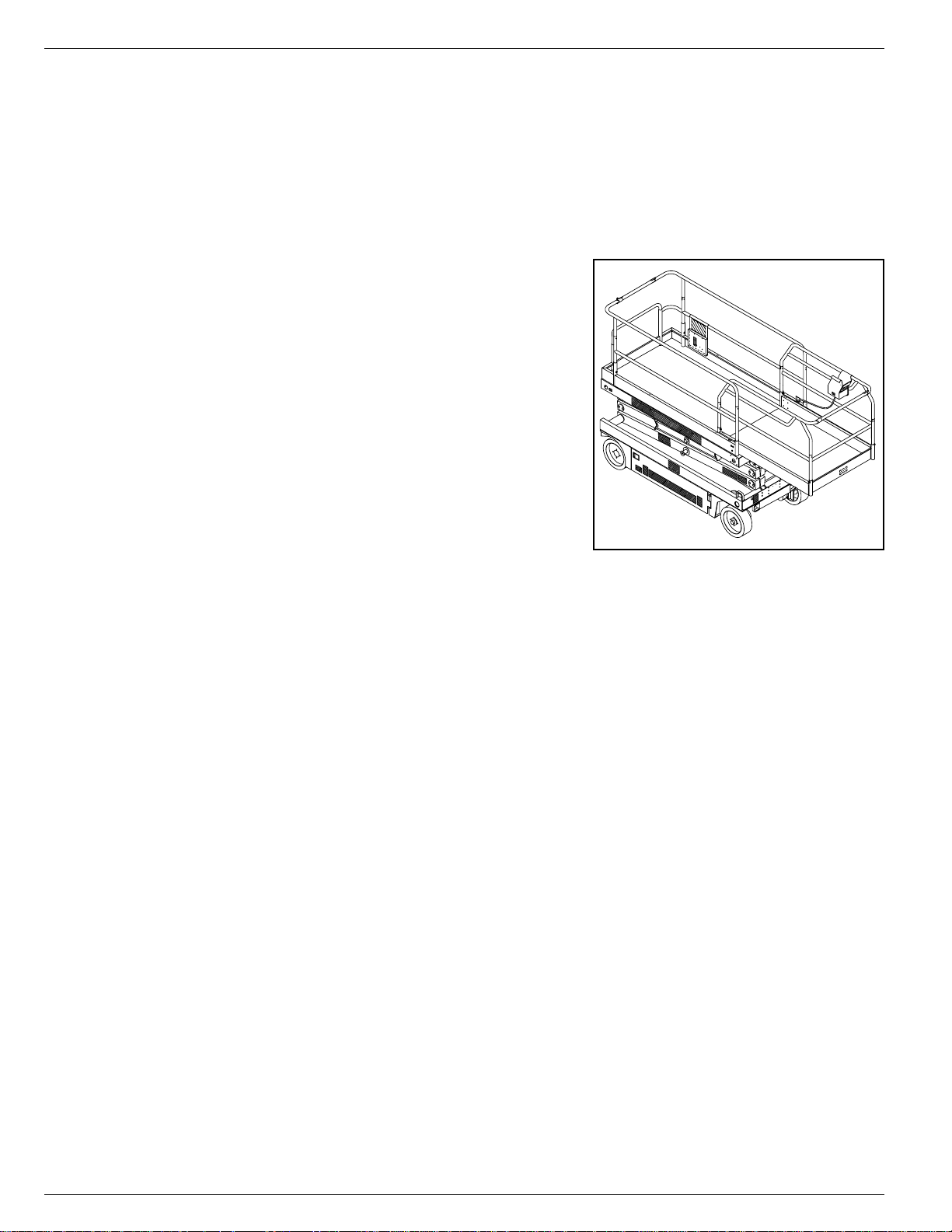

Figure 1: X 26-32

!

WARNING

DO NOT use the maintenance platform

without guardrails properly assembled

and in place

1. Platform

2. Elevating Assembly

3. Chassis

4. Power Module

5. Control Module

6. Platform Controls

7. Manual Case

8. Chassis Controls

9. Hydraulic Fluid Reservoir

10. Batteries

!

Operation Manual Page 3

504165-002 Special Limitations

S

PECIAL

L

IMITATIONS

Travel with the platform raised is limited to creep speed range.

Elevating the Work Platform is limited to firm, level surfaces only.

DANGER

! !

The elev ating function shall ONLY be used when the work platform is level and on a firm surface.

The work platform is NOT intended to be driven over uneven, rough, or soft terrain.

P

LATFORM

The maximum capacity for the MACHINE, including occupants is determined by model and options, and

is listed in “Decals” on page 18.

DANGER

! !

DO NOT exceed the maximum platform capacity or the platform occupancy limits for this machine.

M

ANUAL

Manual force is t he force applied by the occu pants to objects such a s w alls or other structures outside the

work platform.

F

C

ORCE

APACITY

The maximum allowable manual force is limited to 200 N ( 45 lb s.) of force per occupant, with a ma xim u m

of 400 N (90 lbs.) for two or more occupants.

DANGER

! !

DO NOT exceed the maximum amount of manual force for this machine.

B

EAUFORT

Never op erate the machine when wind speeds exceed 25 km/h (15 mph) [Beaufort scale 4].

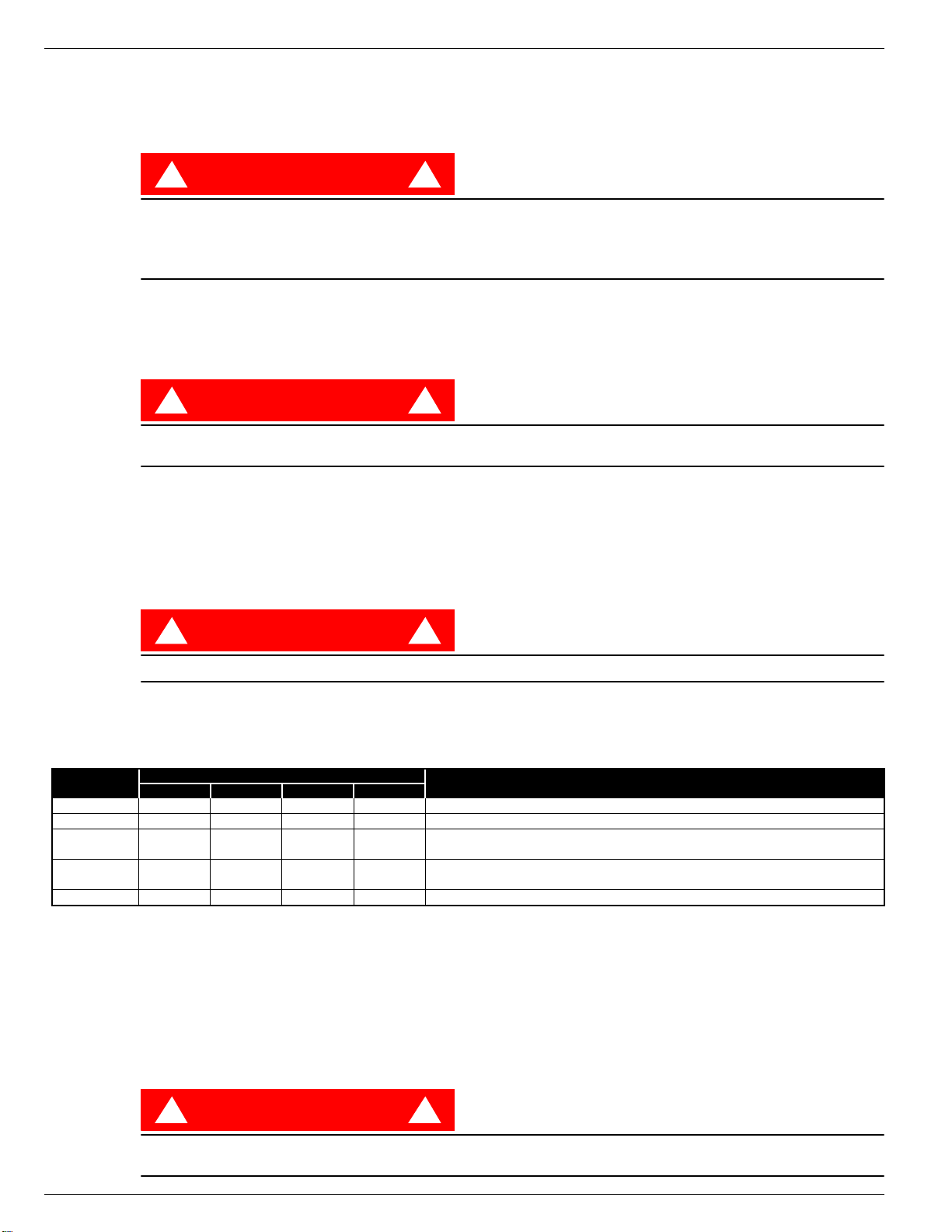

BEAUFORT

RATING

3 3,4~5,4 12,25~19,4 11.5~17.75 7.5~12.0 Papers and thin branches move, flags wave.

4 5,4~8,0 19,4~28,8 17.75~26.25 12.0~18 Dust is raised, paper whirls up, and small branches sway.

5 8,0~10,8 28,8~38,9 26.25~35.5 18~24.25 Shrubs with leaves start swaying. Wave crests are apparent in ponds or swamps.

6 10,8~13,9 38,9~50,0 35.5~45.5 24.5~31 Tree branches move. Power lines whistle. It is difficult to open an umbrella.

7 13,9~17,2 50,0~61,9 45.5~56.5 31.~38.5 Whole trees sway. It is difficult to walk against the wind.

m/s km/h ft/s mph

L

IFT

O

If a load equivalent to 90% of safe working load is lifted a fault code “03” will be displayed on the digital

display on the platform control box. If a load which is greater than the safe working load is present in the

basket all machine functions will cease to operate and an acoustic warning will sound. In order to return to

normal operation a load equal to or less than the saf e w orking load must be present in the bask e t and the

power must be re-cycled, power can be re-cycled by pushing the emergency stop button and releasing it

again.

S

WIND SPEED

VERLOAD

CALE

A

GROUND CONDITIONS

LARM

DANGER

! !

Never operate the machine with a platform load greater than the rated capacity.

Page 4 Operation Manual

Controls and Indicators 504165-002

C

ONTROLS

AND

I

NDICATORS

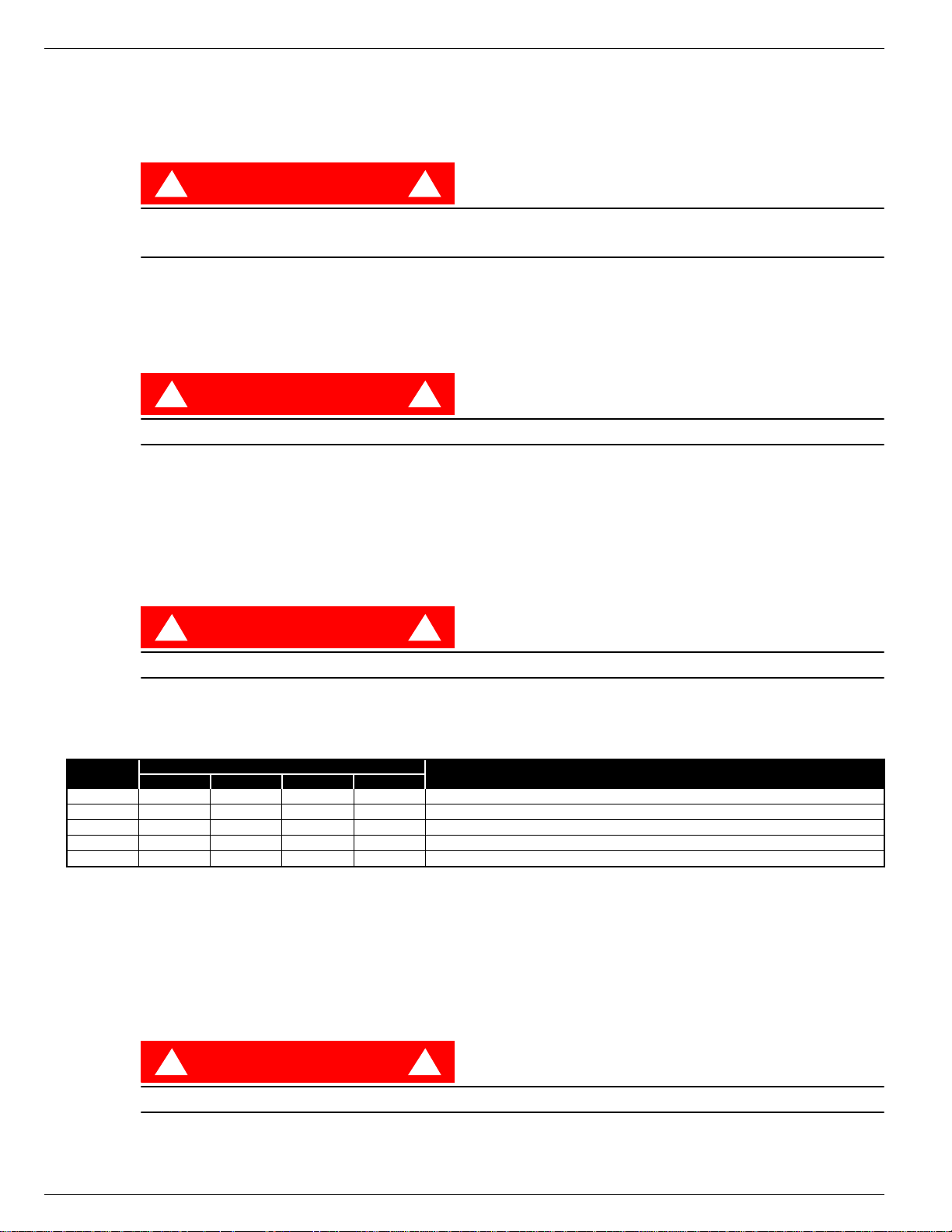

Figure 2: Controls and Indicators

Platform Controls

4

6

3

1

1Drive Selectors

2. Horn Button

3. Lift/Lower Button

4. Emergency Stop Button

5. Display

6. Joystick

Chassis Controls

2

1

234

5

1. Keyswitch

2. Enable Button

3. Toggle Switch (Up & Down)

4. Emergency Stop Switch

Operation Manual Page 5

504165-002 Pre-Operation Safety Inspection

P

RE

-O

PERATION

NOTE: Carefully read, understand and follow all safety rules, operating instructions, labels and National Safety

Instructions/Requirements. Perform the following steps each day before use.

1. Open modules and inspect for damage, fluid leaks or missing parts.

2. Check the lev el of the h ydrau lic fluid with

the platform fully lowered. The hydraulic

reservoir is located in the Control Module Door. The fluid level must be

between the MIN and MAX lines. Add

hydraulic fluid if necessary.

3. Check that fluid level in the batteries is

correct.

4. Verify that batteries are charged.

5. Check that A.C. extension cord has

been disconnected from the plug in the

rear of the machine.

6. Check that all guardrails are in place

and all fasteners are properly tightened.

7. Inspect the machine thoroughly for

cracked welds and structural damage,

loose or missing hardware, hydraulic

leaks, damaged control cable, loose wire connections and wheel bolts.

S

AFETY

I

NSPECTION

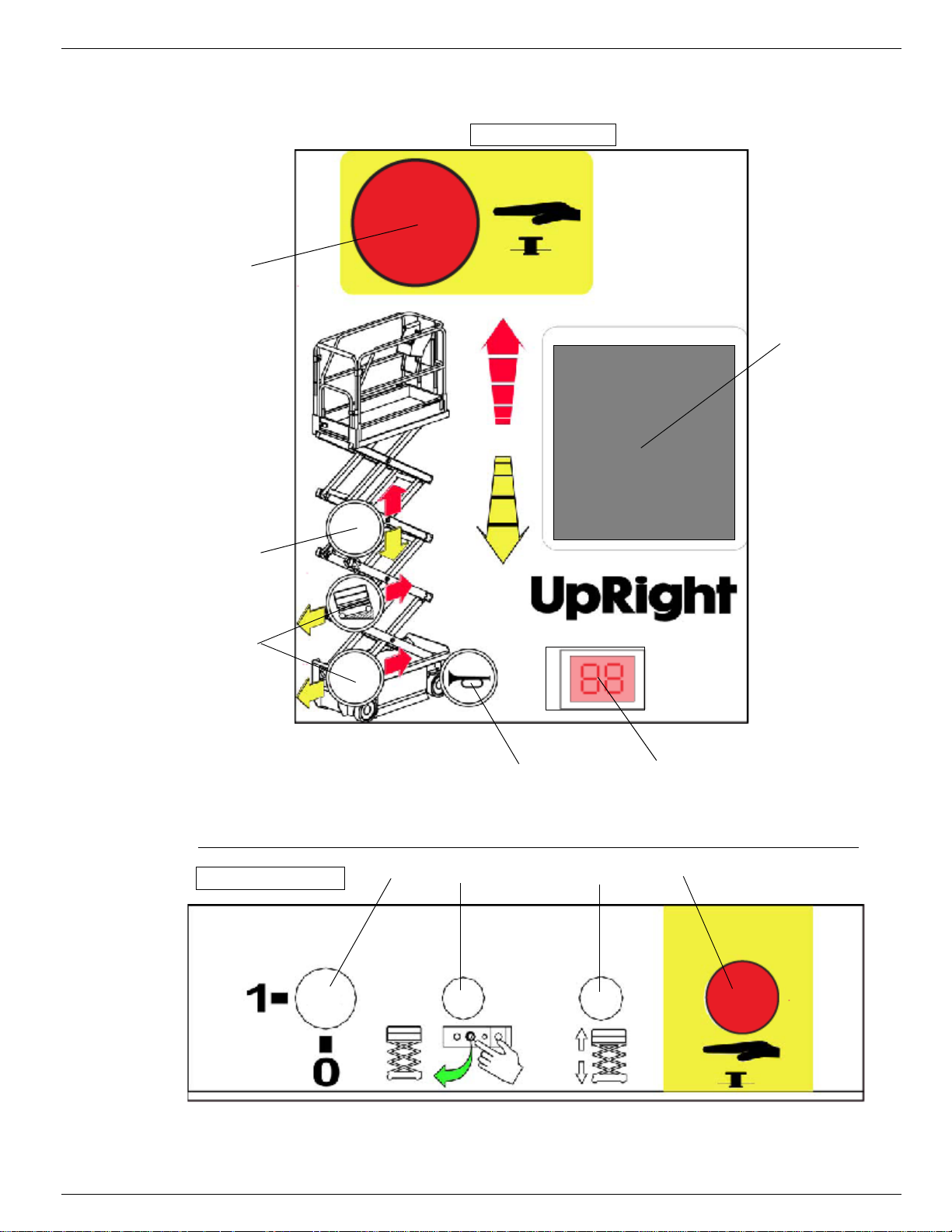

Figure 3: Hydraulic Tank

Page 6 Operation Manual

System Function Inspection 504165-002

S

YSTEM

F

UNCTION

Refer to Figure 2 for the locations of various controls and indicators.

I

NSPECTION

!

WARNING

STAND CLEAR of the work platform while performing the following checks.

Before operat ing the work platform, survey the work area for surface hazards such as holes, drop-offs,

bumps and debris.

Check in ALL directions, including above the work platform, for obstructions and electrical cond u cto rs.

Protect the control console cable from possible damage while performing checks.

1. Move the machine, if necessary, to an unobstructed area to allow for full elevation.

2. Pull Chassis Emergency Stop Switch to the ON position.

3. Pull Platform Emergency Stop Switch to the ON position.

4. Turn and hold the Chassis Key Switch to the ON position. Push the Chassis Lift/Lo w e r Switch to th e UP

position and raise the platf orm approximately 2,1 m (7 feet). BLOCK THE ELEVATING ASSEMBLY AS

DESCRIBED ON PAGE 9.

5. Visually inspect the elevating assembly, lift cylinder, cables, and hoses for cracked welds and structural

damage, loose hardware, hydraulic leaks, loose wire connections, and erratic operation. Check for missing or loose parts.

6. V erify that the Depression Mechanism Supports hav e rotated into position under t he machine . REMOVE

THE SCISSOR BRACE AS DESCRIBED ON page 13.

7. Push the Chassis Lift/Lower Switch to the UP position and fully elevate the platform.

8. Partially lower the platform by pushing Chassis Lift/Lower Switch to LOWER, and check for proper operation of the audible lowering alarm.

9. Open the Emergency Lowering Valve (see Figure 5) by pulling the knob out to check for proper operation. When the platform is low ered, release the knob.

10. Push the Chassis Emergency Stop Switch to check for proper operation. All machine functions should

be disabled. Pull out the Chassis Emergency Stop Switch to resume.

11. Check that the route is clear of obstacles (persons, obstructions, holes, and drop-offs, bumps and

debris), is level, and is capable of supporting the wheel loads.

12. Mount the platform and properly close the entrance.

13. Mount the platform and select DRIVE mode.

!

NOTE: Use both HI and LOW drive (if applicable) when performing the following step.

14. While engaging the Interlock Switch, move the Control Handle to FORWARD, then REVERSE, to check

for speed control.

15. Push the Steering Switch RIGHT, then LEFT, to check for steering control.

16. Select LIFT mode. Grasp the Control Handle, engaging the Interlock Switch, and push it forward to

check platform lift controls. Raise the platform to full elevation.

17. Pull back on the Control Handle. The platform should descend and the audible lowering alarm should

sound.

18. Push the Platform Emergency Stop Switch to check for proper operation. All machine functions should

be disabled. Pull out the Platform Emergency Stop Switch to resume.

Operation Manual Page 7

504165-002

O

PERATION

Before operating t he wo rk platform, ensure that the Pre-Operation Safety Inspection has been comple ted

and that any deficiencies ha v e been cor rected. Ne ver opera te a dama ged or malfunctioning mac hine.

The operator must be thoroughly tr ained on this machine.

P

LATFORM

1. Mount the platform and properly close the entrance.

2. Depress the foot lever located at the rear of the platform

extension. Push the platform extension forward until the

pin engages the front stop.

3. To retract the platform extension, depress the foot lever

and pull the platform extension toward the rear of the

machine until the pin engages the rear stop.

T

RAVEL

OWERED

L

1. Check that the route is clear of ob stacles (persons,

obstructions, holes, drop-off s, b umps , and debris), is le v el,

and is capable of supporting the wheel loads.

2. V erify that the Chassis K e y Switch is turned to ON and the

Chassis Emergency Stop Switch is ON (pulled out).

3. Mount the platform and properly close the entrance.

4. Check clearances above, below, and to the sides of platform.

5. Pull the Platform Emergency Stop Switch out to the ON position.

6. Select DRIVE mode.

W

E

XTENSION

ITH THE

P

LATFORM

Figure 4: Platform Extension

NOTE: Choose between standard drive and extra torque depending on the gradient.

7. Engage the Interlock Switch and move the Control Handle to FORWARD or REVERSE to travel in the

desired direction. The speed of the machine will vary depending on how far from centre the Control

Handle is moved.

S

TEERING

1. Turn the Drive/Lift Switch to DRIVE.

2. While engaging the Interlock Switch, push the Steering Switch to RIGHT or LEFT to tu rn the wheels in

the desired direction. Observe the tire s while manoeuvring the work platform to ensure proper direction.

NOTE: Steering is not self-centring. Wheels must be returned to the straight ahead position by operating the Steering

Switch.

E

LEVATING

1. Select a firm, level surface.

2. Select LIFT mode.

3. While engaging the Interlock Switch, push the Control Handle forward.

4. If the machine is not level the tilt alarm will sound and the machine will not lift or drive. If the tilt alarm

sounds the platform must be lowered and the machine moved to a firm level surface before

attempting to re-elevate the platform.

NOTE: Depression Mechanism supports will deploy automatically as the platform elevates and will retract after the

platform has been lowered completely and has been driven.

THE

P

LATFORM

Page 8 Operation Manual

Operation 504165-002

T

RAVEL

NOTE: The machine will travel at reduced speed when the platform is elevated.

1. Check that the route is clear of obsta cles (persons , obstructions, ho les, drop- offs, b umps , and debris), is

level, and is capable of supporting the wheel loads.

2. Check clearances above, below, and to the sides of platform.

3. Select DRIVe mode.

4. Engage the Interlock Switch and move the Control Handle to FORWARD or REVERSE to travel in the

desired direction. The speed of the machine will vary depending on how far from centre the Control Handle is moved.

5. If the machine is not level the tilt alarm will sound and the machine will not lift or drive. If the tilt alarm

sounds the platform must be lowered and the machine moved to a firm, level surface before

attempting to re-elevate the platform.

L

OWERING

1. Select LIFT mode.

2. Check around the base of the platform to ensure that no one is in contact with the machine. Engage the

Interlock Switch and pull back on the Control Handle to lower the platform.

3. The platform will stop when it reaches the PPE cutout height. Inspect around the machine to ensure no

one is in contact with the machine. After a four-second time delay, lower the platform as in step 2.

W

ITH THE

THE

P

P

LATFORM

LATFORM

E

LEVATED

E

MERGENCY

!

WARNING

If the platform should fail to lower, NEVER climb

down the elevating assembly.

Stand clear of the elev ating assembly while oper ating

the Emergency Lowering Valve Knob.

L

OWERING

!

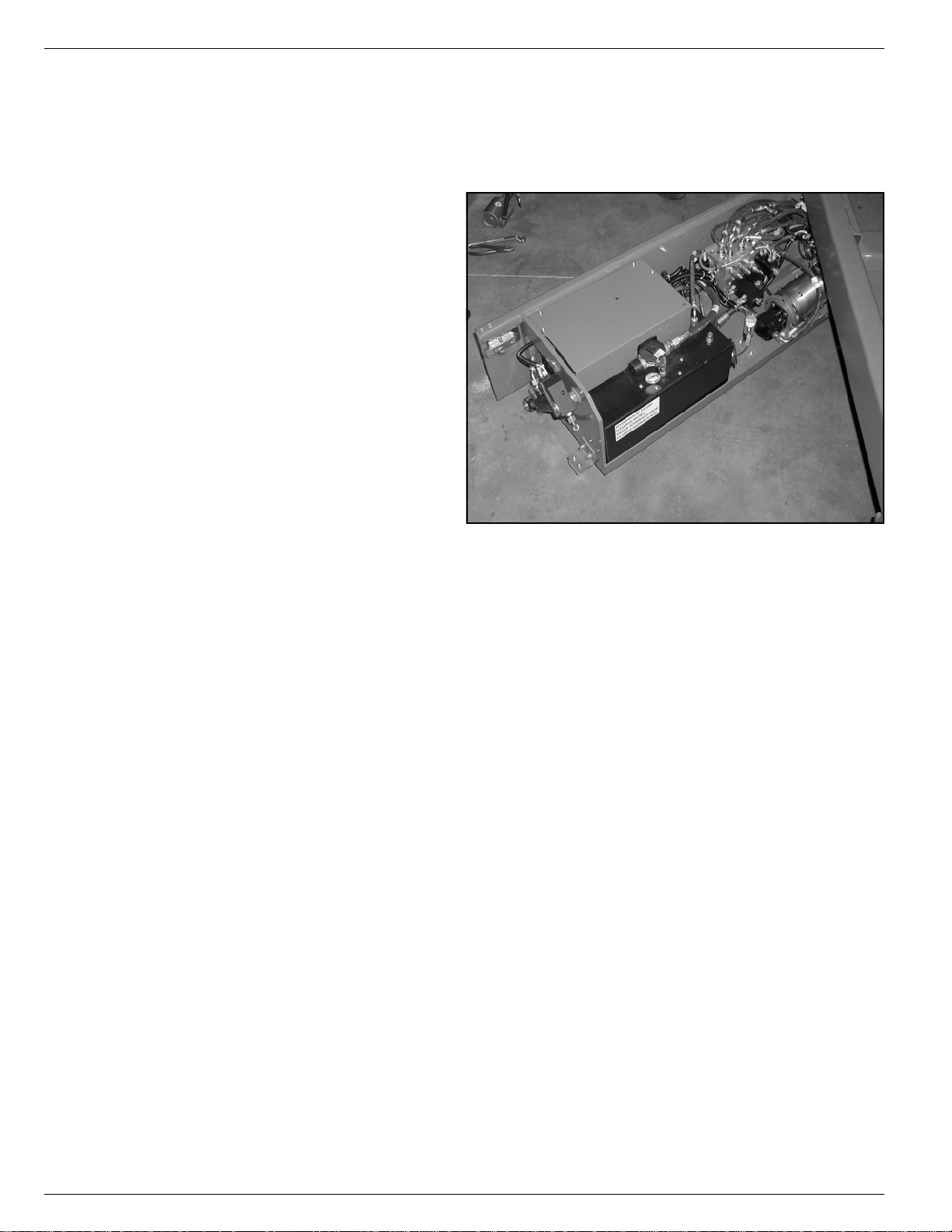

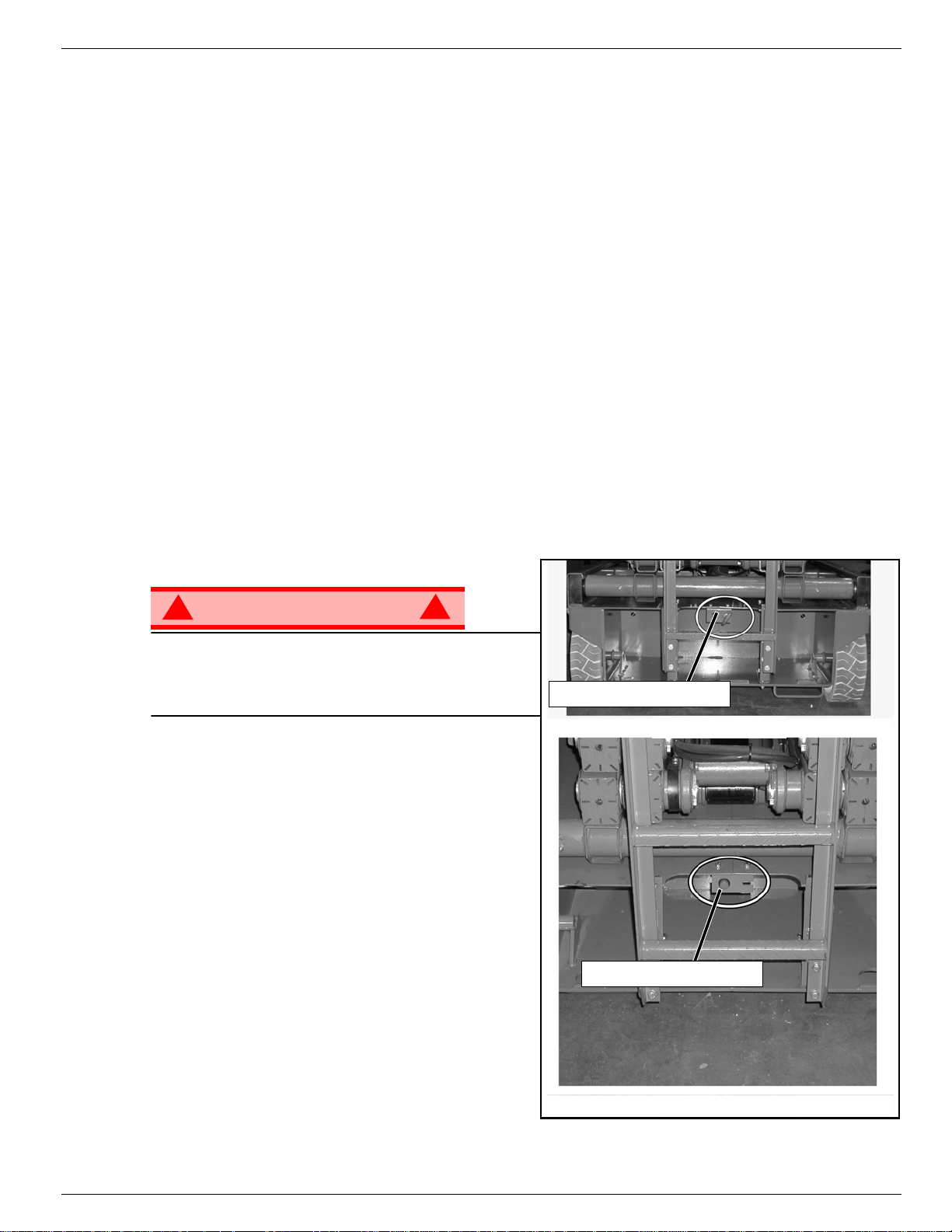

X26

The Emergency Lowering Valve for the X26 is

located at the rear of the machine, above the

charger.

1. Open the Emergency Lowering Valve by pulling

and holding the knob.

2. To close, release the knob. The platform will not

elevate if the Emergency Lowering Valve is open.

X32

The emergency lowering control s witch is located at

the rear of the machine.

Figure 5: Emergency Lowering Valve

Emergency Lowering Knob

X 26

Emergency Lowering Button

1. Open the emergency lowering valve by pushing

down on the toggle switch and holding it.

2. Once the platform is fully lowered, release the

toggle switch to close the valve. The platform will

not elev ate if the Emergency Lowering Valve is

open.

Operation Manual Page 9

X 32

504165-002 Operation

L

OWER

This procedure applies only to the X26 model for the purpose of passing through a standard double doorway. Guardrails must be returned to proper position before using the machine.

L

OWERING PROCEDURE

1. Ensure that the slide-out deck extension is fully retracted and the dec k pin is loc k e d. Place the Platform

Controls on the floor of the platform.

2. Remove and retain the set screws from the side guardrails and the slide-out deck guardrails.

3. Lower the slide-out deck guardrail completely.

4. Lower the rear guardrail until it rests on the stop screws.

5. Lower the side guardrails completely.

6. Raise the rear guardrail until the retaining pins engage. Remove and retain the stop screws and nuts

from the rear guardrail.

7. Pull the two retaining pins and lower the rear guardrail completely.

R

AISING PROCEDURE

1. Raise the rear guardrail until the retaining pins engage.

2. Install the stop screws and nuts on the rear guardrail and torque to 42 N-m (31 ft. lbs).

3. Pull the two retaining pins and lower the rear guardrail until it rests on the stop screws.

4. Raise the side guardrails until the tops are level with the rear guardrail.

• Install the set screws

5. Raise the slide-out deck guardrail until the top is level with the side guardrails.

• Install the set screws

6. Hang the controller on the slide-out deck guardrail.

7. Torque all set screws to 42 N-m (31 ft. lbs).

THE

G

UARDRAILS

, X26

!

WARNING

Before operating machine, guardrails must be securely fastened in their proper position.

F

OLD

F

OLD

1. Unhook the controller from the side guardrail and place it on the floor of the platform.

2. Pull the retaining pin on the front guardrail and rotate inwards.

3. Pull the retaining pin on the rear guardrail and rotate inwards.

4. Starting with the slide-out deck guardrails and then the outer guardrails, lift up on each guardrail and

E

RECTION PROCEDURE

1. Starting with the outer guardrails and then the slide-out de ck guardr ails , raise each guardrail and d rop it

2. Rotate the front and rear upper guardrails outward and secure them to the opposite side guardrails,

3. Hang the controller on the side guardrail.

D

OWN GUARDRAILS

This procedure applies only to the X32 model for the purpose of passing through a standard double doorway. Guardrails must be returned to proper position before using the machine.

D

OWN PROCEDURE

fold inward.

down, securing it in the vertical position.

using the retaining pins.

!

, X32

Page 10 Operation Manual

Towing or Winching 504165-002

T

OWING

OR

W

INCHING

Perform the following only when the machine will not operate under its own power and it is necessary to

move the machine or when winching onto a transport vehicle (see “Transporting the Work Platform” on

page 11).

CAUTION

DO NOT tow or winch the machine faster than 0,3 m/s (1 ft./s). Faster speeds will damage drive

components and void the warranty.

!

WARNING

Never tow faster than 0,3 m/sec. (1 ft./sec.).

Never op erate the work platform with the parking brakes released. Serious injury or damage could

result.

A

FTER

1. Ensure that the platform is fully lowered.

2. Park the machine on a firm level surface, preferably under cover, secure against vandals, children and

3. Turn the Chassis Key Switch to OFF and remove the key to prevent unauthorized operation.

H

OUR

To access the hour meter function perform the following steps.

1. Climb into the basket (with the machine powered up)

2. Push the platform emergency stop button.

3. Hold down the following buttons, Jib and Upper Boom Lift.

4. While holding the buttons twist the emergency stop button to return power to the machine.

5. “hr” will now be displayed on the read-out, Pressing the right turn button will scroll through the accumulated hours two digits at a time. F o r e xample , if pressing the right turn button once displa ys “20”, pressing it

a 2nd time displays “58”, and pressing it a 3rd time displays “hr”, the elapsed time of operation is 2058

hours.

U

SE

E

ACH

unauthorized operation.

M

ETER

D

!

AY

T

RANSPORTING

P

REPARATION

1. Fully lower the platform.

2. Disconnect the battery negative (-) lead from the battery terminal.

3. Band the controller to the front guardrail.

4. Band the elevating linkage to the frame.

Operation Manual Page 11

THE

W

FOR

ORK

S

P

LATFORM

HIPMENT

504165-002 Transporting the Work Platform

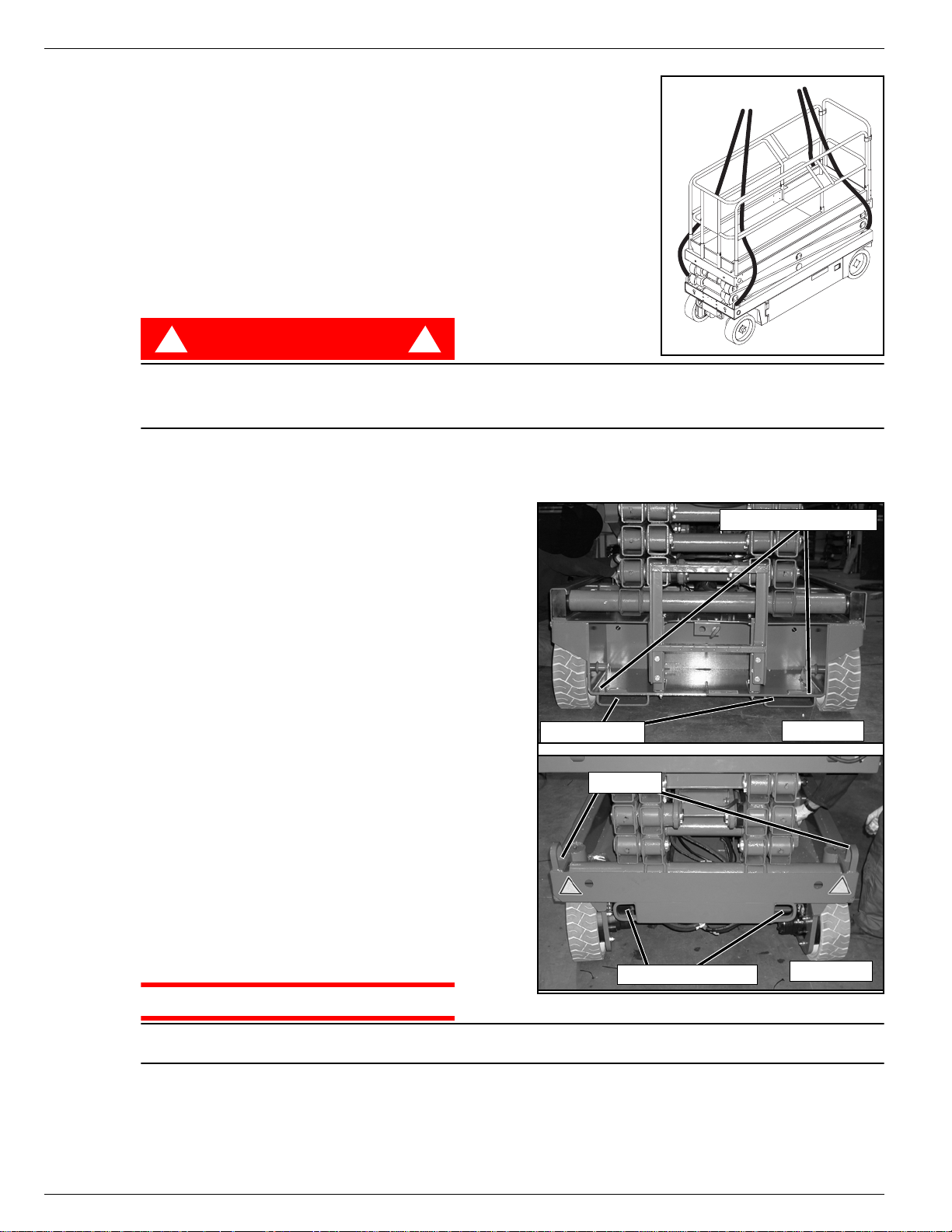

Figure 6: Secure Crane Straps

L

IFTING

1. Secure straps to chassis tie down/lifting lugs only.

2. Place the platform onto the transport vehicle in transport position.

3. Chock the wheels.

4. Secure the work platform to the transport vehicle with chains or

straps of adequate load capacity attached to the cha ssis tie down/lifting lugs.

BY C

RANE

BY F

Forklifting is for transport only.

See specifications for weight of work platform and be certain that forklift is of adequate capacity to lift

the work platform.

D

A

T

NOTE: Do not winch faster than 0,3 m/s (1 ft/s).

1. Move the machine onto the truck or trailer;

2. Secure the work platform to the transport vehicle

ORKLIFT

DANGER

! !

Forklift from the rear of the machine using the forklift pockets provided. If necessary, the machine ma y be

forklifted from the side by lifting under the Chassis Modules.

Figure 7: Transporting the Work Platform

RIVING OR

RUCK

A. To Drive the machine onto the transport vehicle:

a. Move the work platform up the ramp and into

transport position.

b. Set the wheels straight and turn off the machine.

c. Chock the wheels.

B. To Winch the machine onto the transport vehi-

cle:

a. Move the work platform up to the ramp.

b. Attach the winch cable to the tie down/lifting

lugs.

c. Release the parking brakes (refer to “Towing or

Winching” on page 11).

d. Winch the platform into transport position

e. Chock the wheels.

with chains or straps of adequate load capacity

attached to the chassis tie down/lifting lugs.

W

INCHING

OR

T

RAILER

ONTO

Forklift Pockets

Lift Lugs

Rear Tie Down/Lift Lugs

REAR

Front Tie Down Lugs

FRONT

CAUTION

Over tightening of the chains or straps attached to the Tie Down/Lifting Lugs may result in damage to

work platform.

Page 12 Operation Manual

Maintenance 504165-002

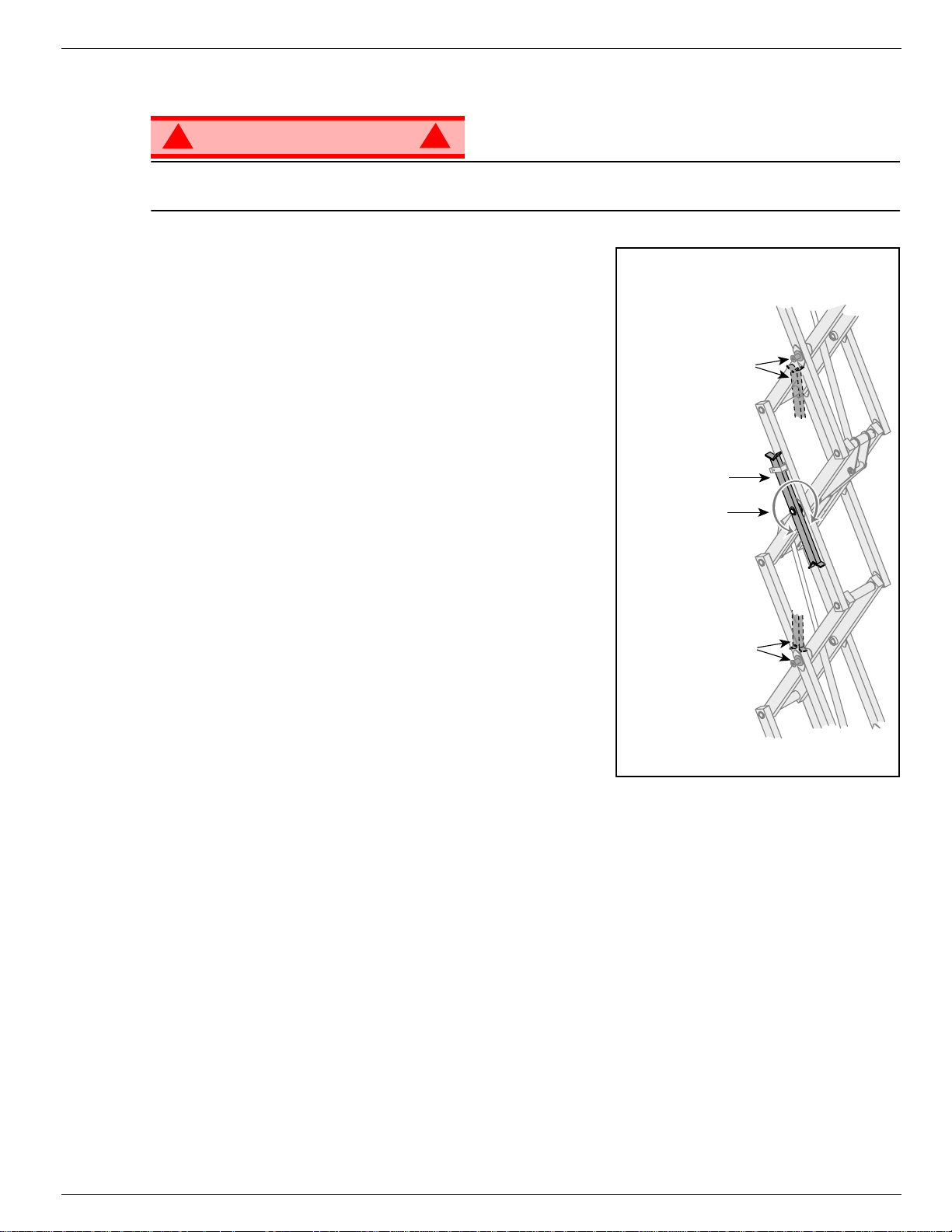

M

AINTENANCE

!

WARNING

Never pe rform service while the platform is elevated without first blocking the elevating assembly.

DO NOT stand in the elevating assembly area while deploying or storing the brace.

B

LOCKING

SSEMBLY

A

S

CISSOR BRACE INSTALLATION

1. Park the work platform on a firm, level surface.

2. Pull Chassis EMERGENCY STOP Switch to the ON position.

3. Pull Platform EMERGENCY STOP Switch to the ON position.

4. Turn and hold the Chassis Key Switch to CHASSIS.

5. Push the Chassis Lift/Lower Switch to LIFT to elevate the

platform until the Scissor Brace can be rotated to the vertical

position.

6. X26 – From the rear of the machine, lift the Scissor Brace

from its stowed position. Rotate upward and outward, then

down until it is hanging vertically below its attachment point.

7. X32 – From the left side of the machine, pull the locking pin

securing the brace. Rotate the Scissor Brace counter clockwise until it is in the vertical position.

8. Lower the platform by pushing the Chassis Lift/Lower Switch

to LOWER and grad ually lower the platform until the Scissor

Brace is supporting the platform.

T

HE

E

LEVATING

!

Figure 8: Scissor Brace

Pin Rests on Brace

when in Blocking

Position

Scissor Brace in

Rest Position

Brace Rotates to

Blocking Position

Brace Rests on Pin

when in Blocking

Position

S

CISSOR BRACE

1. Using the Chassis Controls, gradually elevate the platform

until the Scissor Brace is clear.

2. X26 – Rotate the Scissor Brace outward and upward over its mounting point until it rests in the stowed

position.

3. X32 – Rotate the Scissor Brace clockwise until the locking pin engages.

4. Lower the platform by pushing the Chassis Lift/Lower Switch to LOWER to completely lower the platform.

S

TOWAGE

Operation Manual Page 13

504165-002 Maintenance

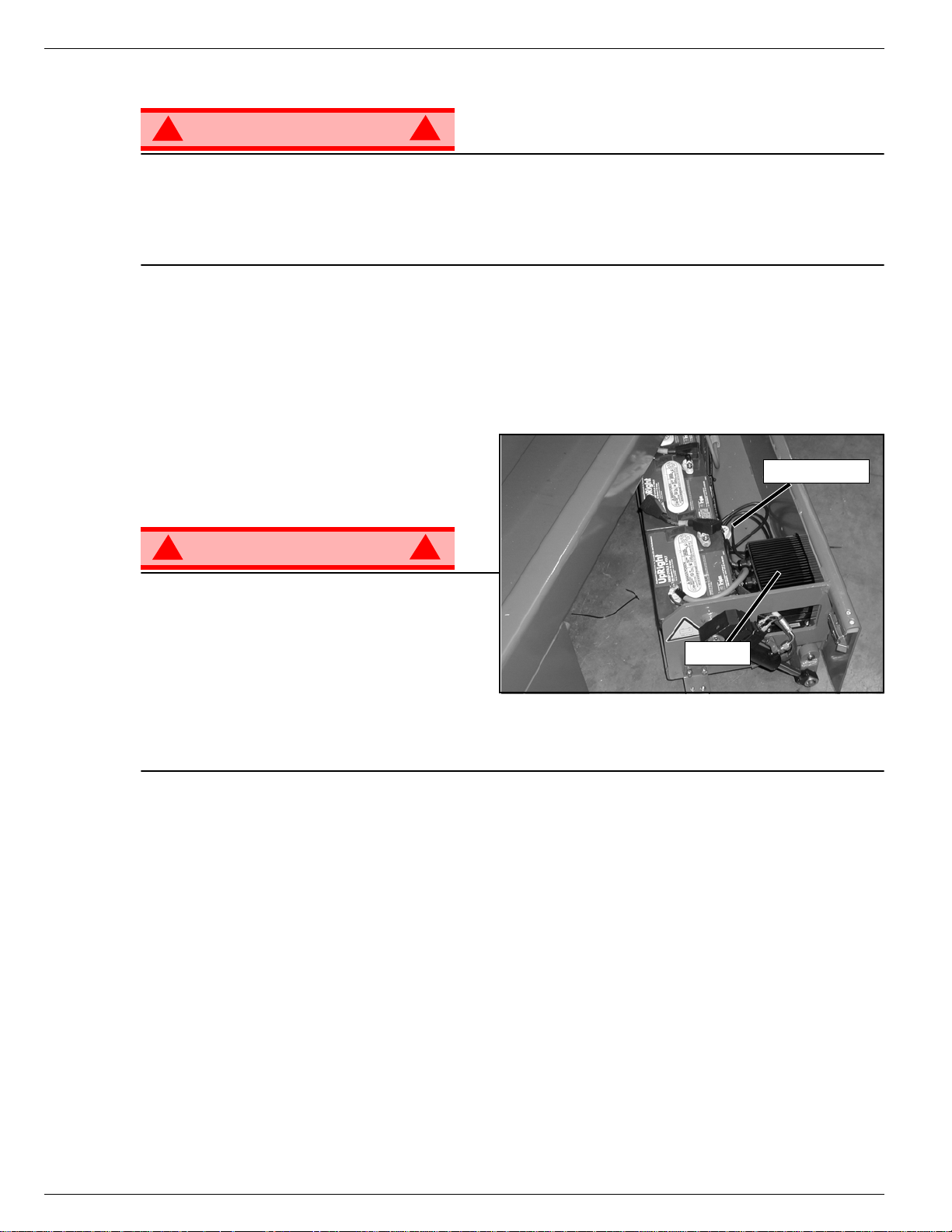

B

ATTERY

M

AINTENANCE

!

WARNING

Hazard of explosive gas mixture. Keep sparks, flame, and smoking material away from batteries.

Always wear safety glasses when working near batteries.

Battery fluid is highly corrosive. Thoroughly rinse away any spilled fluid with clean water.

Always replace batteries with UpRight batteries or manufacturer approved replacements weighing

26,3 kg (58 lbs.) each.

• Check the battery fluid lev el daily, especially if the work platform is being used in a warm, dry climate.

• If electrolyte level is lower than 10 mm

tap water with high mineral content, as it will shorten battery life.

• Keep the terminals and tops of the batteries clean.

• Refer to the Service Manual to extend battery life and for complete service instructions.

B

ATTERY CHARGING

Charge the batteries at the end of each work

shift or sooner if the batteries have been discharged.

!

WARNING

Charge the batteries in a well ventilated area.

Do not charge the batteries when the work

platform is near a source of sparks or flames.

Permanent damage to the batteries will result if

the batteries are not immediately recharged

after discharging.

Never leave the battery charger operating for more than two days.

Never disconnect the cables from the batteries when the charger is oper ating.

Keep the charger dry.

!

3

(

/

in.) above the plates add distilled water only. DO NOT use

8

Figure 9: Battery Charger

Charger Plug

!

Charger

3

(

/

1. Check the battery fluid level. If the battery fluid level is lower than 10 mm

distilled water only.

2. Connect an appropriate extension cord to ch arger outlet plug in Left Module Door. Plug the extension

cord into a properly grounded outlet of proper voltage and frequency.

3. The charger turns on automatically after a short delay. The LED charge indicator will illuminate. After

completion of the charge cycle the LED will blink, indicating that the charger is in a continuing maintenance mode. DO NO T leave the charger plugged in for more than 48 hours, as permanent damage to

the batteries may occur.

NOTE: The battery charger circuit must be used with a GFI (Ground Fault Interrupt) outlet.

NOTE: DO NOT operate the machine while the charger is plugged in.

Page 14 Operation Manual

in.) above the plates add

8

Inspection and Maintenance Schedule 504165-002

I

NSPECTION

The Complete Inspection consists of periodic visual and operational checks, along with periodic minor

adjustments that assure proper performance. Daily inspection will prevent abnormal wear and prolong the

life of all systems. The inspection and maintenance schedule should be performed at the specified intervals. Inspection and maintenance shall be performed by personnel who are trained and familiar with

mechanical and electrical proced u re s.

AND

M

AINTENANCE

S

CHEDULE

D

AILY

M

AINTENANCE

Y = Yes/Acceptable

N = No/Not Acceptable

R = Repaired/Acceptable

!

WARNING

Before performing preventative maintenance, familiarize yourself with the operation of the machine.

Always block the elevating assembly whenever it is necessary to perform maintenance while the

platform is elevated.

The daily preventative maintenance chec klist has been designed for machine service and maintenance.

Please photocopy this page and use the checklist when inspecting the machine.

P

REVENTATIVE

T

ABLE KEY

M

!

AINTENANCE

P

Date:_______________________________________

Owner: _____________________________________

Model No:___________________________________

Serial No: ___________________________________

C

HECKLIST

REVENTATIVE MAINTENANCE

R

EPORT

COMPONENT INSPECTION OR SERVICES Y N R

Battery

Chassis

Control Cable

Controller Check switch operation.

Drive Motors Check for operation and leaks.

Elevating

Assembly

Emergency

Lowering System

Entire Unit Check for and repair collision damage.

Check electrolyte level.

Check battery cable condition.

Check hoses for pinch or rubbing points.

Check welds for cracks.

Check the exterior of the cable for pinching,

binding or wear.

Inspect for structural cracks.

Operate the emergency lowering valve and check

for serviceability.

Serviced By:_________________________ ________

COMPONENT INSPECTION OR SERVICES Y N R

Hydraulic Fluid Check fluid level.

Hydraulic Pump Check for hose fitting leaks.

Hydraulic System Check for leaks.

Labels

Platform Deck

and Rails

Platform Deck

and Rails

Tyres and Wheels Check for damage.

Check for peeling, missing, or unreadable labels

& replace.

Check welds for cracks.

Check condition of deck.

Operation Manual Page 15

504165-002 Daily Preventative Maintenance Checklist

N

OTES

:

Page 16 Operation Manual

Decals 504165-002

D

ECALS

These labels shall be present and in good condition before operating the work platform. Be sure to read,

understand and follow these labels when operating the work platform.

Operation Manual Page 17

504165-002 Decals

D

ECALS

Page 18 Operation Manual

Specifications 504165-002

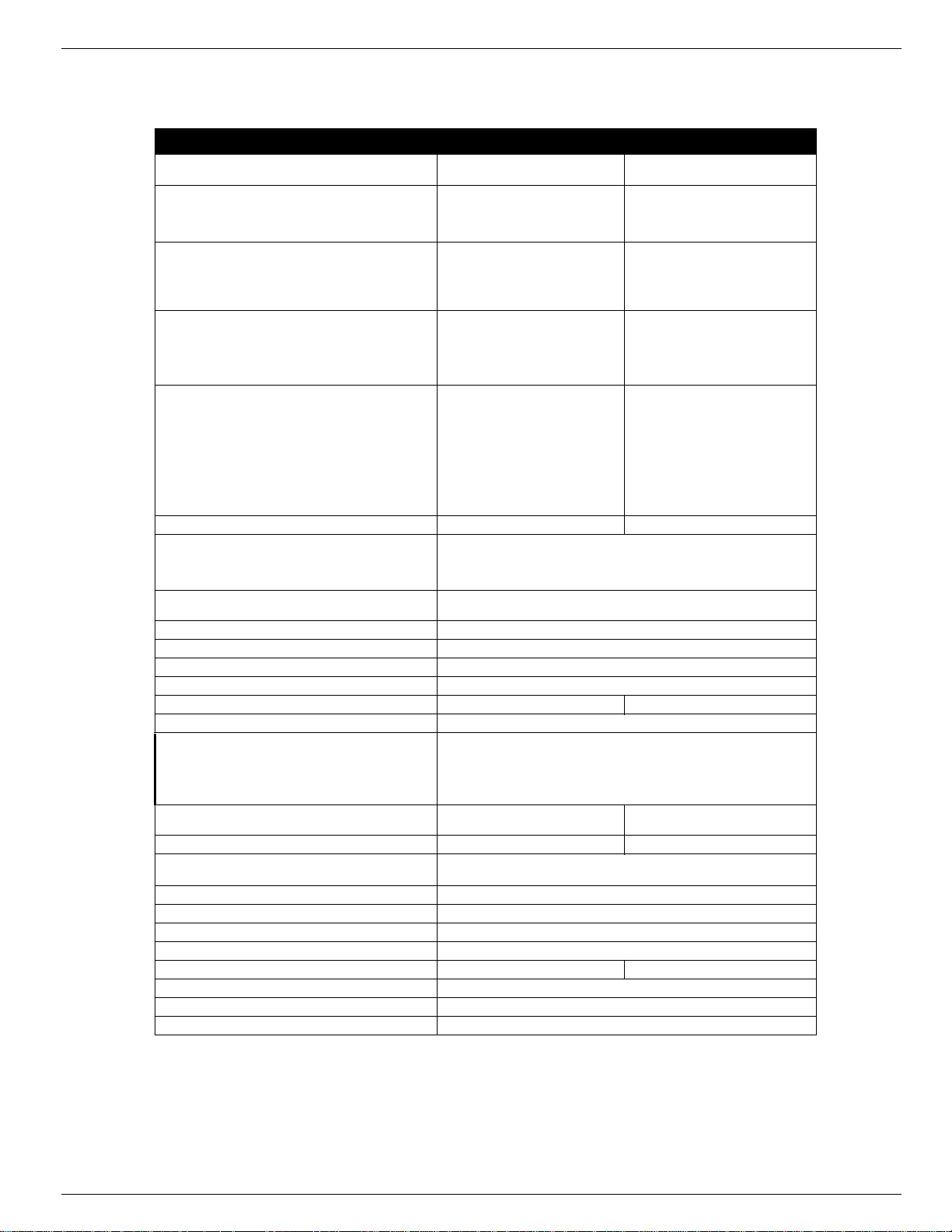

S

PECIFICATIONS

ITEM X26 X32

Platform Size w/ Extension

Max. Platform Capacity

Standard 454 kg [1000 lb] 340 kg [750 lbs.]

on Extension 113 kg [250 lb] 113 kg [250 lbs.]

Max. No. of occupants

Standard (total) 4 personas

on Extension 1 persona 1 person

Height

Working Height 9,93 m [32,58 pies] 11.6 m [38.1 ft.]

Max. Platform Height 7,93 m [26 pies] 9.75 m [32 ft.]

Min. Platform Height 1,09 m [43 pulg.] 1.22 m [48 in.]

Dimensions

Weight 2153 kg [4747 lb] 2486 kg [5481 lbs.]

Overall Width 1,22 m [48 pulg.] 1.22 m [48 in.]

Overall Height 2,19 m [83,5 pulg.] 2.32 m [88.5 in.]

Overall Height, Rails Lowered 1,98 m [78 pulg.] 1.88 m [74 in.]

Overall Length, Extension In 2,35 m [92,5 pulg.] 2.35 m [92.5 in.]

Overall Length, Extension Out 3,26 m [128,5 pulg.] 3.26 m [128.5 in.]

Drivable Height 7,93 m [26 pies] 9.75 m [32 ft.]

Drive Speed

Platform Lowered 0 to 3,2 km/h [0 to 2.0 mph]

Platform Raised 0 to 1 km/h [0 to 0.62 mph]

Energy Source

Motor 24 Volt 4 Horse Power DC Electric Motor

System Voltage 24 Volt DC

Battery Charger 25 A, 110/220 V AC

Battery Duty Cycle 25% for 8 Hours

Hydraulic Tank Capacity 15 L [4 US Gallons] 19 L [5 US Gallons]

Maximum Hydraulic Pressure 207 bar [3000 psi]

Hydraulic Fluid

Normal Temperature (>32° F [0° C])

Low Temperature (<32° F [0° C])

Extreme Temperature (<0° F [-17° C])

Lift System

Lift Speed Raise, 45 sec./Lower 40 sec. Raise, 65 sec./Lower 40 sec.

Control System

Drive System Dual Front Wheel Hydraulic Motors

Tires 381 mm [15 in.] Diameter Solid Rubber, non-marking

Parking Brake Dual Spring Applied, Hydraulic Release

Turning Radius 203 mm [8 in.] Inside

Maximum Gradeability 12° [22%] 12° [22%]

Wheel Base 1.9 m [74.75 in.]

Guardrails 1.02 m [40 in.] High

Noise Level

Proportional Control Handle with Interlock Switch, Rotary Drive/Lift Switch,

1,17 m x 2,21 m

[44,25 pulg. x 87 pulg.]

2 personas en el exterior

24 Volt Battery Pack (4-220 A Hour, 6 Volt Batteries, min. wt. 28.12 kg

[62 lbs.] each)

ISO #46

ISO #32

ISO #15

One Single Stage

Lift Cylinder

and Red Mushroom EMERGENCY STOP Switch

1.17 m x 2.21 m

[44 in. x 87 in.]

3 people

Two Single Stage

Lift Cylinders

*Specifications are subject to change without notice. Hot weather or he avy use may affect performance.

Refer to the Service Manual for complete parts and service information.

This machine meets or exceeds all applicable CE and GS machinery directive requirements.

Operation Manual Page 19

504165-002 Specifications

Page 20 Operation Manual

X 26-32

X26 Seriennummern 50906 – 53099

X32 Seriennummern 50322 – 53099

DEUTSCH

Stellen Sie sicher, dass Sie die MODELL- und SERIENNUMMERN auf dem Gerätetypenschild angeben, wenn Sie sich

mit UpRight bezüglich Wartungs- oder Ersatzteilinformationen in Verbindung setzen. Sollte das Typenschild fehlen, finden

Sie die SERIENNUMMER auch auf dem Fahrwerk über der vorderen Schwenkachse.

Stamped Serial Number

Estampille de numéro de série

Eingestanzte Seriennummer

BETRIEBSANLEITUNG

S

WARNUNG

Alle Bediener müssen die Sicherheitsregeln und Betriebsanleitungen gründlich durchlesen,

verstehen und befolgen, bevor sie an irgendeiner UpRight-Hocharbeitsbühne Wartungsarbeiten

ausführen oder die Arbeitsbühne in Betrieb nehmen.

Sicherheitsregeln

Elektroschockgefahr Kippgefahr Kollisionsgefahr

DIESE MASCHINE IST NICHT

ISOLIERT!

EINSATZ DER HOCHARBEITSBÜHNE: Diese Hocharbeitsbühne dient dazu, Personen und Werkzeuge sowie die für die jeweilige Arbeit

erforderlichen Materialien zu transportieren. Sie wurde speziell für Reparatur- und Montagearbeiten sowie für Einsatzbereiche konzipiert, die

sich oberhalb der Mitarbeiter befinden, sodass die Mitarbeit er nach oben gerichtet arbeiten müssen (z. B. Decken, Kräne, Dachstrukturen,

Gebäude etc.). Jede andere Verwendung der Hocharbeitsbühne ist strikt verboten!

DIESE HOCHARBEITSBÜHNE IST NICHT ISOLIERT! Aus diesem Grund muss zwingend ein Sicherheitsabstand zu allen leitfähigen Teilen

der elektrischen Ausrüstung eingehalten werden!

Die angegebene zulässige Höchstlast darf nic ht überschritten w erd en!Nä here Informationen hierzu finden Sie im Abschnitt “Beschränkungen”

auf Seite 4.

Es ist strikt verboten, die Hocharbeitsbühne als Hubwerkzeug ode r Kran einzusetzen (d. h. um Lasten von unten nach oben oder von oben

nach unten zu befördern).

Die für diese Maschine zuläss i ge m anu el le Kraf t NIEMALS überschreiten.Nähere Informationen hierzu finden Sie im Abschnitt

“Beschränkungen” auf Seite 4.

Lasten immer gleichmäßig auf der Plattform VERTEILEN.

Vor Inbetriebnahme der Maschine IMMER ZUERST die Aufstellfläche im Arbeitsbereich auf Gefahren wie Bodenlöcher, ausgelaufene

Flüssigkeiten, Bodenerhebungen, Kanten oder Schutt untersuchen und diese umgehen bzw. beseitigen.

Maschine nur auf Oberflächen IN BETRIEB NEHMEN, die die zulässigen Radlasten aufnehmen k önnen.

Maschine NIEMALS in Betrieb nehmen, wenn die tatsächliche Windgeschwindigkeit höher ist als die Windgeschwindigkeit, für die die

Maschine ausgelegt ist. Nähere Informationen hierzu finden Sie im Abschnitt “Beaufort-Skala” auf Seite 4.

IM NOTFALL NOT-AUS-Schalter drücken, um alle strombetriebenen Funktionen zu deaktivieren.

WENN EIN ALARM ERTÖNT, während die Plattform ausgefahren wird, Plattform ANHALTEN und vorsichtig einfahren (absenken). Maschine

auf feste, ebene Oberfläche fahren.

Auf das Schutzgeländer der Plat tform zu klettern, auf Gebäuden, Stahl- oder vorgef ertigten Betonstrukturen zu stehen oder von der Plattform

aus darauf zu klettern etc. ist verboten!

Das Schwingtor oder andere Komponenten des Schutzgeländers zu demontieren ist verboten! Vergewissern Sie sich immer, dass das

Schwingtor geschlossen und sicher verriegelt ist!

Es ist verboten, das Schwingtor geöffnet zu halten (z. B. mit Befestigungsgurten), wenn die Arbeitsplattform ausgefahren wird!

Die Höhe oder Reichweite der Plattform durch Anbringen von Leitern, Gerüsten oder ähnlichen Vorrichtungen zu vergrößern

IMMER ZUERST die Hubvorrichtung blockieren, bevor bei ausgefahrener Plattform Wartungs- oder Instandhaltungsarbeiten an der Maschine

durchgeführt werden.

Maschine vor jedem Gebrauch sorgfältig auf Risse an Schweißstellen, lose oder fehlende Beschläge, Leckagen in der Hydr aulikvorrichtung,

gelöste Kabelverbindungen und beschädigte Kabel oder Schläuche UNTERSUCHEN.

Vor Gebrauch SICHERSTELLEN, dass alle Bezeichn ungsschilder ordnungsgemäß angebracht und vollständig lesbar sind.

NIEMALS eine Maschine benutzen, die beschädigt ist, nicht ordnungsgemäß funktioniert oder deren Bezeichnungsschilder Beschädigungen

aufweisen oder sogar ganz fehlen.

Sicherheitseinrichtungen zu umgehen ist verboten und stellt eine Gef ahr für alle Personen dar , die sich auf der Hocharbeit sbüh ne und in deren

Arbeitsbereich befinden.

Batterien NIEMALS in der Nähe von Funkenquellen oder offenen Flammen aufladen. Beim Auflad en von Batterien wird explosives

Wasserstoffgas freigesetzt.

Änderungen an der Hocharbeitsbühne sind verboten bzw. nur mit ausdrücklicher Genehmigung von

NACH GEBRAUCH ist die Hocharbeit sb ühne gegen unbefug ten Gebr auch durch Dritte zu s ichern. Hierzu müs sen bei de Schlü sselschal ter auf

“Aus” gestellt und die Schlüssel abgezogen werden.

NIEMALS die Plattform ausfahren

oder die Maschine mit ausgefahrener

Plattform fortbewegen, wenn sich die

Maschine nicht auf einer festen,

ebenen Fläche befindet.

Plattform NIEMALS in Position

bringen, ohne vorher sicherzustellen,

dass der Bereich über der Plattform

frei von Hindernissen und anderen

Gefahren ist.

UpRight zulässig.

des Plattformgeländers klettern

und auch nicht darauf stehen

turzgefahr

NIEMALS auf das obere

oder mittlere Gestänge

oder sitzen.

ist verboten

!

Seite 1

504165-002

I

NHALT

Einführung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Allgemeine Beschreibung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Beschränkungen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Tragfähigkeit der Plattform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Manuelle Kraft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Beaufort-Skala. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Überlastalarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Bedienelemente und Anzeigen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Sicherheitsprüfung vor Inbetriebnahme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Überprüfung der Systemfunktionen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Bedienung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Plattformverlängerung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Fahren mit eingefahrener Plattform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Lenken. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Ausfahren der Plattform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Fahren mit ausgefahrener Plattform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Einfahren der Plattform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Notfallabsenkung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

X26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

X32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Absenken des Schutzgeländers, X26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Absenken. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Anheben. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Einklappen des Schutzgeländers, X32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Einklappen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Ausklappen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Schleppen oder Anheben . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Lösen der Parkbremse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Nach dem täglichen Gebrauch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Betriebsstundenzähler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Transport der Arbeitsbühne . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Vorbereitung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Anheben per Kran. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Per Gabelstapler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Fahren oder Heben auf einen LKW oder Anhänger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Instandhaltung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Blockieren der Hubvorrichtung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Installation der Scherenverstrebung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Verstauen der Scherenverstrebung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Instandhaltung der Batterie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Aufladen der Batterien . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Inspektions- und Instandhaltungsplan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Checkliste der täglichen präventiven Instandhaltungsmaßnahmen. . . . . . . . . . . . . . . . . . . . . . . . . . .16

Bezeichnungsschilder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Technische Daten. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Seite 2 Betriebsanleitung

Einführung 504165-002

E

INFÜHRUNG

Dieses Handbuch beschreibt Einsatz und Bedienung der selbstfahrenden Arbeitsbühnen der X 26-32.

Das Handbuch muss immer bei der Maschine aufbewahrt werden.

A

LLGEMEINE

B

ESCHREIBUNG

WARNUNG

!

Hocharbeitsbühne NICHT ohne korrekt montiertes und angebrachtes Schutzgeländer verwenden.

1. Plattform

2. Hubvorrichtung

3. Fahrwerk

4. Leistungsmodul

5. Steuermodul

6. Plattform-Bedienelemente

7. Handbuchfach

8. Fahrwerk-Bedienelemente

9. Behälter für Hydraulikflüssigkeit

10. Batterien

!

Abbildung 1: X 26-32

Betriebsanleitung Seite 3

504165-002 Beschränkungen

B

ESCHRÄNKUNGEN

Bei ausgefahrener Plattform kann die Maschine nur im Schleichgang gefahren werden.

Die Arbeitsplattform kann nur auf festen, ebenen Oberflächen ausgefahren werden.

GEFAHR

! !

Die Hubfunktion darf NUR verwendet werden, wenn die Hocharbeitsbühne nivelliert ist und auf einer

festen Oberfläche steht.

Die Hocharbeitsbühne ist NICHT dafür ausgelegt, auf unebenem, grobem oder weichem Gelände

gefahren zu werden.

T

RAGFÄHIGKEIT

Die maximale Tragfähigkeit der MASCHINE, einschließlich P ersonen , hängt vom Modell und verschiedenen

Optionen ab; Sie finden eine entsprechende Liste im Abschnitt “” auf Seite 19.

GEFAHR

! !

Maximale Tragf ähigk eit der Plattf orm oder maximal zulässige P ersonenzah l für diese Maschine NICHT

überschreiten.

DER

P

LATTFORM

M

ANUELLE

Unter manueller Kraft versteht man die Kraft, die die Personen auf der Plattform auf Objekte wie Wände

oder andere Strukturen außerhalb der Arbeits plattform ausüben.

Die maximal zulässige manuelle Kraft ist auf 200 N (45 lbs.) pro Person beschränkt, d. h. maximal 400 N

(90 lbs.), wenn sich zwei oder mehr Personen auf der Plattform befinden.

GEFAHR

! !

Die für diese Maschine maximal zulässige manuelle Kraft NICHT überschreiten.

B

EAUFORT

Niemals die Maschine in Betrieb nehmen, wenn die Windgeschwindigkeit mehr als 25 km/h (15 mph)

[Beaufort-Skala 4] beträgt.

BEAUFORT-WERT

3 3,4~5,4 12,25~19,4 11.5~17.75 7.5~12.0 Papier und dünne Zweige bewegen sich, Fahnen wehen.

4 5,4~8,0 19,4~28,8 17.75~26.25 12.0~18 Staub und Papier wird aufgewirbelt und kleine Zweige schaukeln.

5 8,0~10,8 28,8~38,9 26.25~35.5 18~24.25

6 10,8~13,9 38,9~50,0 35.5~45.5 24.5~31

7 13,9~17,2 50,0~61,9 45.5~56.5 31.~38.5 Ganze Bäume schwanken. Es ist schwierig, gegen den Wind zu gehen.

m/s km/h ft/s mph

Ü

BERLASTALARM

Wenn eine Last angehoben wird, die 90 % der Nennlast ausmacht, erscheint im digitalen Display des

Bedienpultes an der Plattform der Fehlercode “03”. Befindet sich im Fahrkorb eine Last, die höher als die

Nennlast ist, werden alle Maschinenfunktionen blockiert und eine akustische Warnung ertönt. Damit der

normale Betrieb wieder aufgenommen werden kann, muss die Last im Fahrkorb verringert werden,

sodass sie gleich oder niedriger als die Nennlast ist, und die Stromzufuhr zur Maschine muss aus- und

wieder eingeschaltet werden. Das Aus- und wieder Einschalten der Stromversorgung kann durch

Drücken und anschließendes Lösen des Not-Aus-Tasters erfolgen.

WINDGESCHWINDIGKEIT

K

-S

RAFT

KALA

BODEN-/UMGEBUNGSBEDINGUNGEN

Sträucher mit Blättern beginnen zu schaukeln. In Teichen, Sümpfen oder anderen Gewässern

erscheinen Wellenkämme.

Zweige und Äste von Bäumen bewegen sich. Stromleitungen pfeifen. Regenschirme können nur mit

Mühe geöffnet werden.

GEFAHR

! !

Niemals die Maschine in Betrieb nehmen, wenn sich auf der Arbeitsplattform eine Last befindet, die

die angegebene Tragfähigkeit überschreitet.

Seite 4 Betriebsanleitung

Loading...

Loading...