Page 1

Operator Manual

Guide de l’opérateur

Betriebsanleitung

UL25, UL32 & UL40

SERIAL NO. 21373 to Current

WARNING

All personnel shall carefully read, understand and follow all safety rules,

operating instructions, and National Safety Instructions/Requirements

before operating or performing maintenance on any UpRight Aerial Work

Platform.

The first section of this Operator Manual is the English language version.

AVERTISSEMENT

Tout le personnel doit lire attentivement, bien comprendre et suivre toutes

les règles de sécurité, le mode d’emploi et les règles nationales de

sécurité avant d’entretenir ou d’utiliser une plate-forme élévatrice

UpRight.

La deuxième section du guide de l’opérateur est la version française.

WARNUNG

Alle Bediener müssen die Sicherheitsregeln, Betriebsanleitungen sowie

geltenden Sicherheitsanweisungen/-anforderungen gründlich durchlesen,

verstehen und befolgen, bevor sie an irgendeiner UpRightHocharbeitsbühne Wartungsarbeiten ausführen oder diese in Betrieb

nehmen.

Der dritte Abschnitt dieser Betriebsanleitung ist deutschsprachig.

P/N 068017-021

Page 2

UL25,UL32&UL40

Serial Numbers 21373 – Current

E

NGLISH

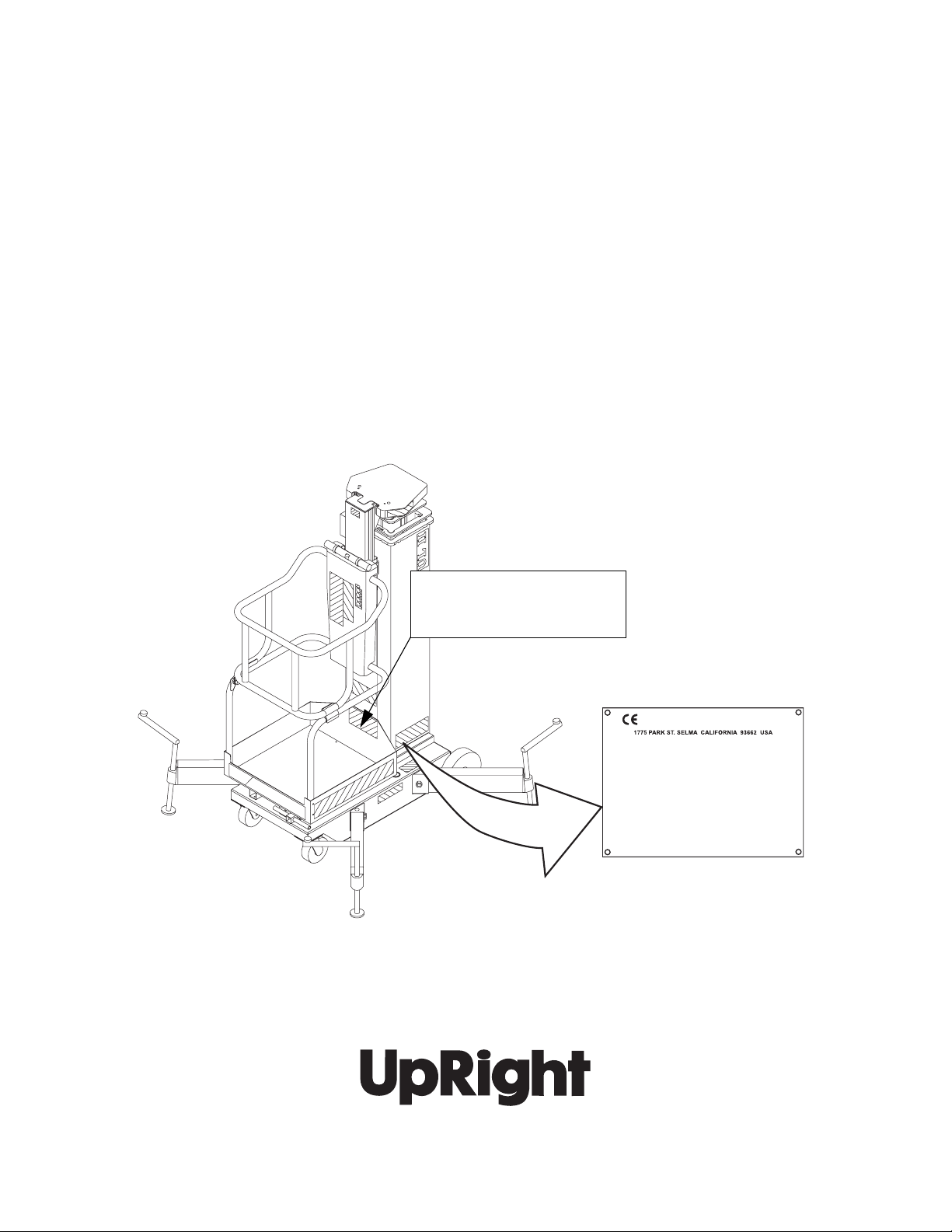

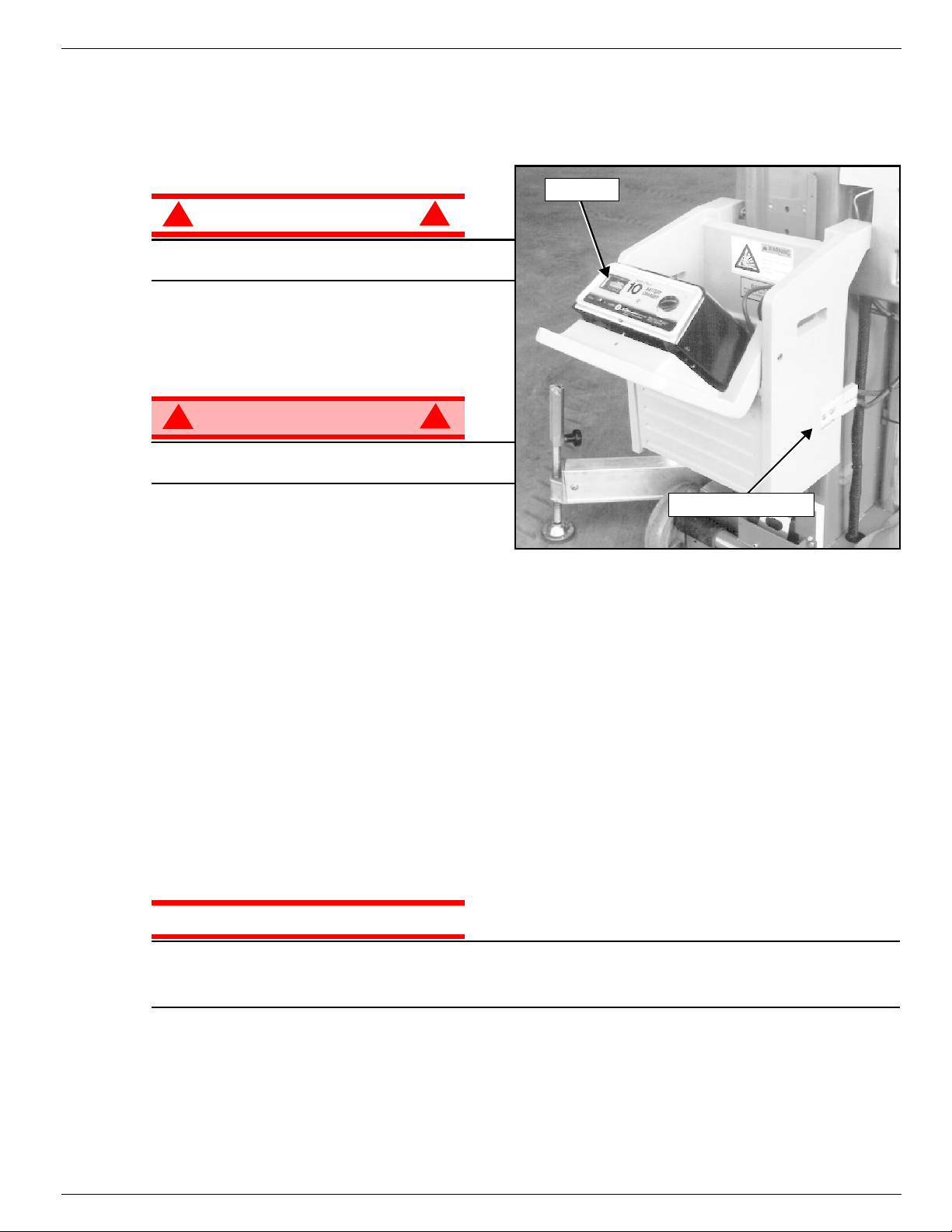

When contacting UpRight for service or parts information, be sure to include the MODEL and SERIAL NUMBERS from the

equipment nameplate. Should the nameplate be missing, the SERIAL NUMBER is also stamped on the chassis tube on the

rightsideofthemast.

F

RENCH

Lors des communications avec UpRight pour des informations au sujet de l’entretient ou des pièces, ne pas oublier

d’inclure les NUMÉROS DE MODÈLE et de SÉRIE inscrits sur la plaque signalétique. Si la plaque signalétique manque, le

NUMÉRO DE SÉRIE est également estampé sur le châssis, du côté droit du mât.

G

ERMAN

Stellen Sie sicher, dass Sie die MODELL- und SERIENNUMMERN auf dem Gerätetypenschild angeben, wenn Sie sich mit

UpRight bezüglich Wartungs- oder Ersatzteilinformationen in Verbindung setzten. Sollte das Typenschild fehlen, finden Sie

die SERIENNUMMER auch auf dem Fahrwerk auf der rechten Maststeite eingestanzt.

UpRight, Inc.

1775 Park Street

Selma, California 93662

TEL: 559/891-5200

FAX: 559/891-9012

PARTS: 1-888-UR-PARTS

PARTS FAX: 559/896-9244

Stamped Serial Number

Estampille de numéro de série

Eingestanzte Seriennummer

Call Toll Free in U.S.A.

1-800-926-LIFT

UpRight Inc.

Model______________ Serial number:___________

Machine weight _______kg Mfg. date:_________

Maximum wheel load:________

Maximum allowable incline of machine when elevated:_____deg.

Occupants and equipment must not exceed the rated maximum

load:_____kg Maximum platform occupant s:_____

Maximum allowable sIde force on platform:_____N

Maximum platformheight:______m

Maximum platform reach:______m

Maximum allowable wind speed: ______m/s=Beaufort scale_ ____

Maximum hydraulic system pressure:_____bar

Maximum system voltage: _______Vdc

This machine is manufactured to comply with

Machinery directive 89-392/CEE

CAUTION: CONSULT OPERATOR'S MANUAL BEFORE USE.

061205-003

UpRight International

Support Centre

61-63 Hong Kong Straat

3047 BR Rotterdam

Netherlands

TEL: +31-10-238-0000

FAX: +31-10-238-0001

Parts Tel: +31-10-490-8090

Parts Fax: +31-10-490-8099

Page 3

OPERATION MANUAL

WARNING

All personnel shall carefully read, understand and follow all safety rules and operating

instructions before operating or performing maintenance on any UpRight aerial work platform.

Safety Rules

Safety Rules

Safety RulesSafety Rules

Electrocution

Electrocution

ElectrocutionElectrocution

Hazard

Hazard

HazardHazard

Tip Over Hazard

Tip Over Hazard Collision Hazard

Tip Over HazardTip Over Hazard

Collision Hazard Fall Hazard

Collision HazardCollision Hazard

Fall Hazard

Fall HazardFall Hazard

THIS MACHINE IS

NOT INSULATED!

THIS MACHINE IS FOR INDOOR USE ONLY! Do not use out of doors.

USE OF THE AERIAL WORK PLATFORM: This aerial work platform is intended to lift persons and his tools as well as the material

used for the job. It is designed for repair and assembly jobs and assignments at overhead workplaces (ceilings, cranes, roof structures,

buildings etc.). All other uses of the aerial work platform are prohibited!

THIS AERIAL WORK PLATFORM IS NOT INSULATED! For this reason it is imperative to keep a safe distance from live parts of electrical equipment!

Exceeding the specified permissible maximum load is prohibited! See “Special Limitations” on page 4 for details.

The use and operation of the aerial work platform as a lifting tool or a crane (lifting of loads from below upwards or from up high on

down) is prohibited!

NEVER exceed the manual force allowed for this machine. See “Special Limitations” on page 4 for details.

DISTRIBUTE all platform loads evenly on the platform.

NEVER operate the machine without first surveying the work area for surface hazards such as holes, drop-offs, bumps, curbs, or debris;

and avoiding them.

OPERATE machine only on surfaces capable of supporting wheel loads.

IN CASE OF EMERGENCY push EMERGENCY STOP switch to deactivate all powered functions.

Climbing up the railing of the platform, standing on or stepping from the platform onto buildings, steel or prefab concrete structures, etc.,

is prohibited!

Dismantling the entry gate or other railing components is prohibited! Always make certain that the entry gate is closed and securely

locked!

It is prohibited to keep the entry gate in an open position (held open with tie-straps) when the platform is raised!

To extend the height or the range by placing of ladders, scaffolds or similar devices on the platform is prohibited!

NEVER perform service on machine while platform is elevated without blocking elevating assembly.

INSPECT the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks, loose wire connections, and damaged

cables or hoses before using.

VERIFY that all labels are in place and legible before using.

NEVER use a machine that is damaged, not functioning properly, or has damaged or missing labels.

To bypass any safety equipment is prohibited and presents a danger for the persons on the aerial work platform and in its working

range.

NEVER charge batteries near sparks or open flame. Charging batteries emit explosive hydrogen gas.

Modifications to the aerial work platform are prohibited or permissible only at the approval by UpRight.

AFTER USE, secure the work platform from unauthorized use by turning keyswitches off and removing key.

NEVER elevate the

platform unless all

four (4) outriggers

have been properly

installed.

NEVER elevate the

platform without first

leveling the base.

NEVER attempt to

push the UpRight Lift

withpeopleor

materials on the

platform or with the

platform elevated.

NEVER position the

platform without first

checkingfor overhead

obstructions or other

hazards.

NEVER climb, stand,

or sit on platform

guardrails or midrail.

Page 1

Page 4

068017-021 UL25, UL32 & UL40

C

ONTENTS

Introduction..........................................................................3

General Description ...................................................................3

SpecialLimitations....................................................................4

PlatformCapacity ........................................................................... 4

Manual Force . . ............................................................................ 4

ControlsandIndicators................................................................5

OutriggerInstallation..................................................................6

SafetyInterlockTest......................................................................... 6

Pre-OperationSafetyInspection.........................................................7

SystemFunctionInspection ............................................................7

Performalltestsfromtheground............................................................ 7

Operation............................................................................8

ElevatingthePlatform .................................................................... 8

LoweringthePlatform .................................................................... 8

EmergencyLowering..................................................................8

TransportingtheWorkPlatform.........................................................9

DC Models . ............................................................................ 9

Loading................................................................................... 9

Unloading ................................................................................ 10

DC Models . ........................................................................... 10

Passage Through a Doorway ..........................................................11

Lowering ................................................................................. 11

Raising .................................................................................. 11

Maintenance ........................................................................13

BatteryMaintenance........................................................................ 13

BatteryCharging........................................................................... 13

InspectionandMaintenanceSchedule...................................................14

Daily Preventative Maintenance Checklist................................................14

Labels .............................................................................16

Specifications.......................................................................18

Page 2 Operation Manual

Page 5

Introduction 068017-021 UL25, UL32 & UL40

I

NTRODUCTION

This manual covers operation of the UL25, UL32, and UL40 Work Platforms. This manual must be

stored on the machine at all times.

G

ENERAL

D

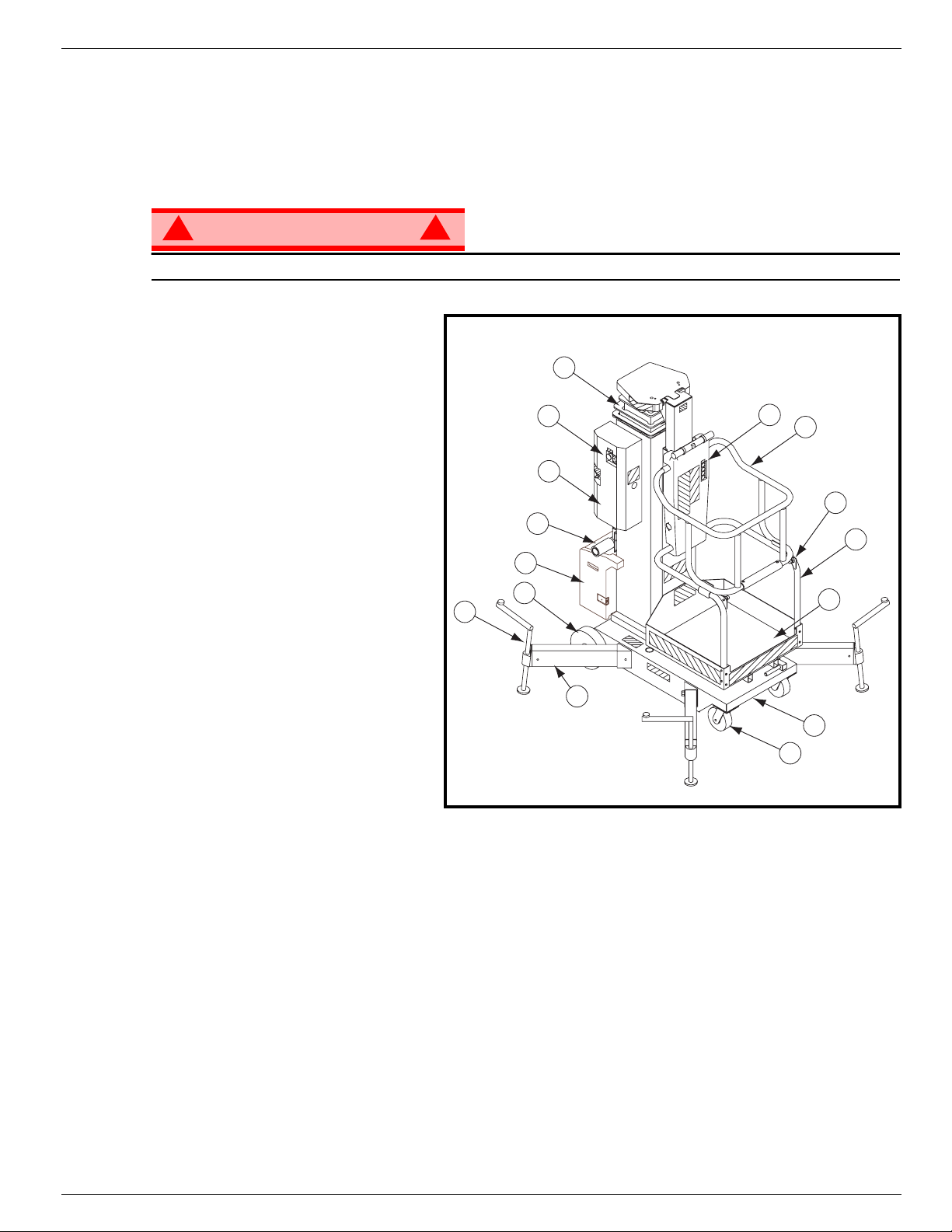

ESCRIPTION

!

WARNING

DO NOT use the maintenance platform without guardrails properly assembled and in place

1. Platform

2. Mast

3. Chassis

4. Outriggers

5. Upper Guardrail (Gate)

6. Lower Guardrail

7. Chassis Controls

8. Power Unit

• Motor

• Hydraulic Reservoir

9. Battery Box(DC Units)

•Battery

• Battery Charger

10. Casters

!

Figure 1:

2

7

8

13

9

11

12

8

Work Platform

5

14

6

1

11. Rear Wheels

12. Screw Jacks

13. Loader Assembly

14. Gate Latch Pin

4

3

10

Operation Manual Page 3

Page 6

068017-021 UL25, UL32 & UL40 Special Limitations

S

PECIAL

L

IMITATIONS

Elevating the Work Platform is limited to firm, level surfaces only.

All four (4) outriggers must be properly installed before operating the machine.

This machine is rated for indoor use only.

DANGER

! !

The elevating function shall ONLY be used when the work platform is level and on a firm surface.

P

LATFORM

The maximum platform capacity for the MACHINE is:

• UL25- 159kg(350lbs).

• UL 32 and UL 40 - 136 kg (300 lbs).

One person may occupy the platform .

DANGER

! !

C

APACITY

DO NOT exceed the maximum platform capacity or the platform occupancy limits for this machine.

M

ANUAL

Manual force is the force applied by the occupants to objects such as walls or other structures outside the

work platform.

The maximum allowable manual force is limited to 200 N (45 lbs.) of force.

DANGER

! !

DO NOT exceed the maximum amount of manual force for this machine.

F

ORCE

Page 4 Operation Manual

Page 7

Controls and Indicators 068017-021 UL25, UL32 & UL40

C

ONTROLS AND

I

NDICATORS

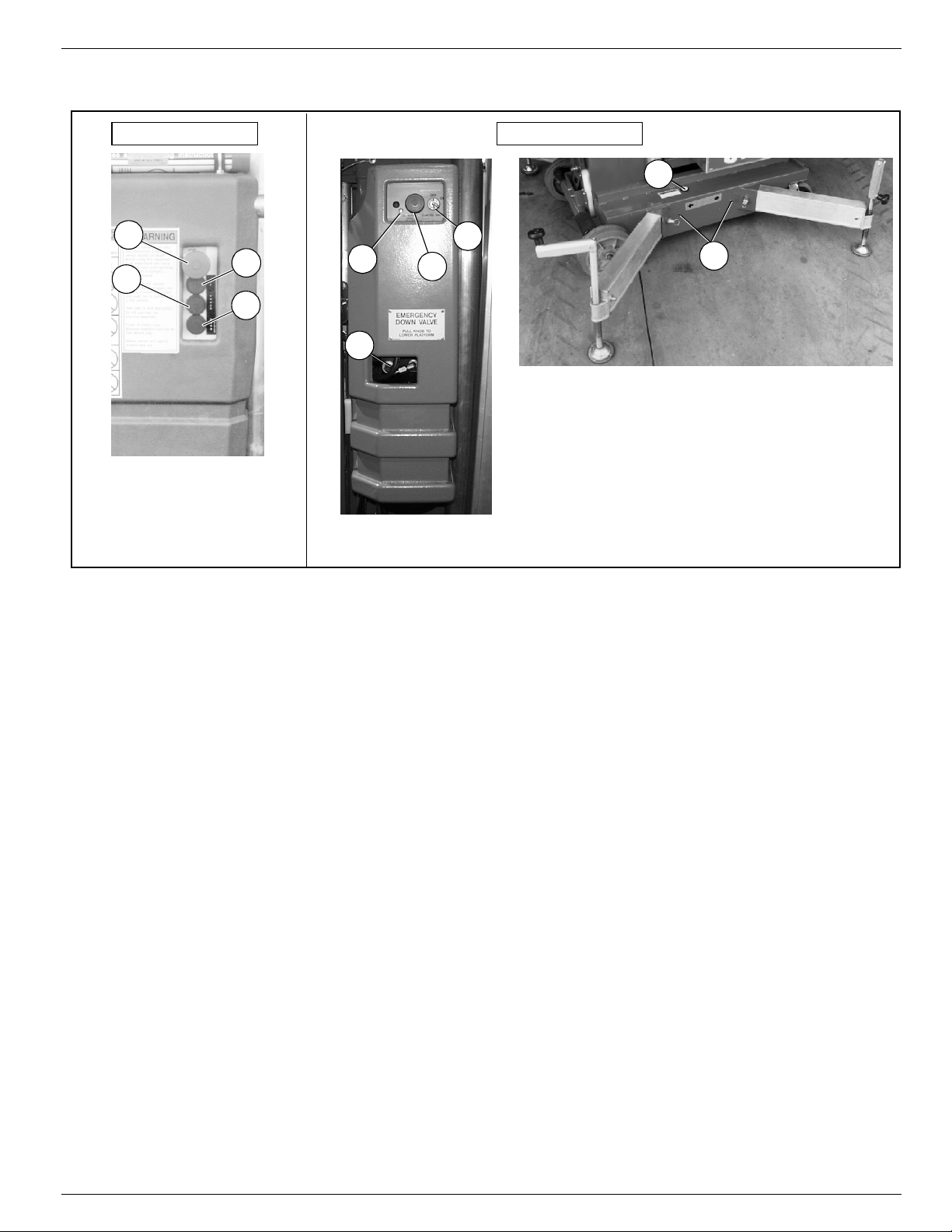

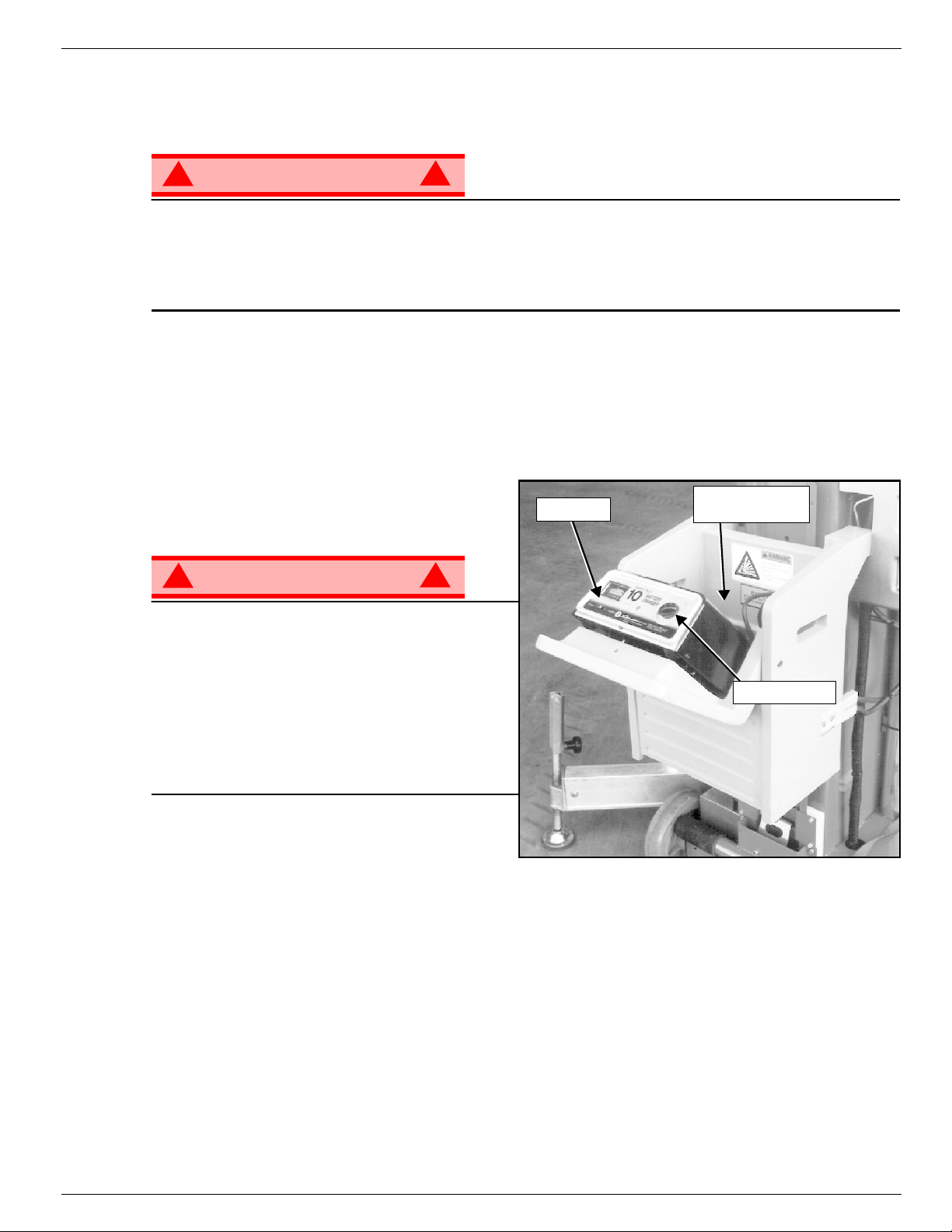

Platform Controls Chassis Controls

1

3

1

2

3

2

4

4

1 Emergency Stop Switch

2. Power On Button

3. Up Button

4. Down Button

5. Battery Charger

5

1 LED ( Indicates that

optional Emergency

Down from theplatform

battery needs replacing).

2. Emergency Stop

Switch

3. Key Switch

Figure 2:

Controls and Indicators

6

4. Emergency Lowering

Valve

5. Orbit Level

6. Outrigger Indicator

Lights

Operation Manual Page 5

Page 8

068017-021 UL25, UL32 & UL40 Outrigger Installation

O

UTRIGGER

I

NSTALLATION

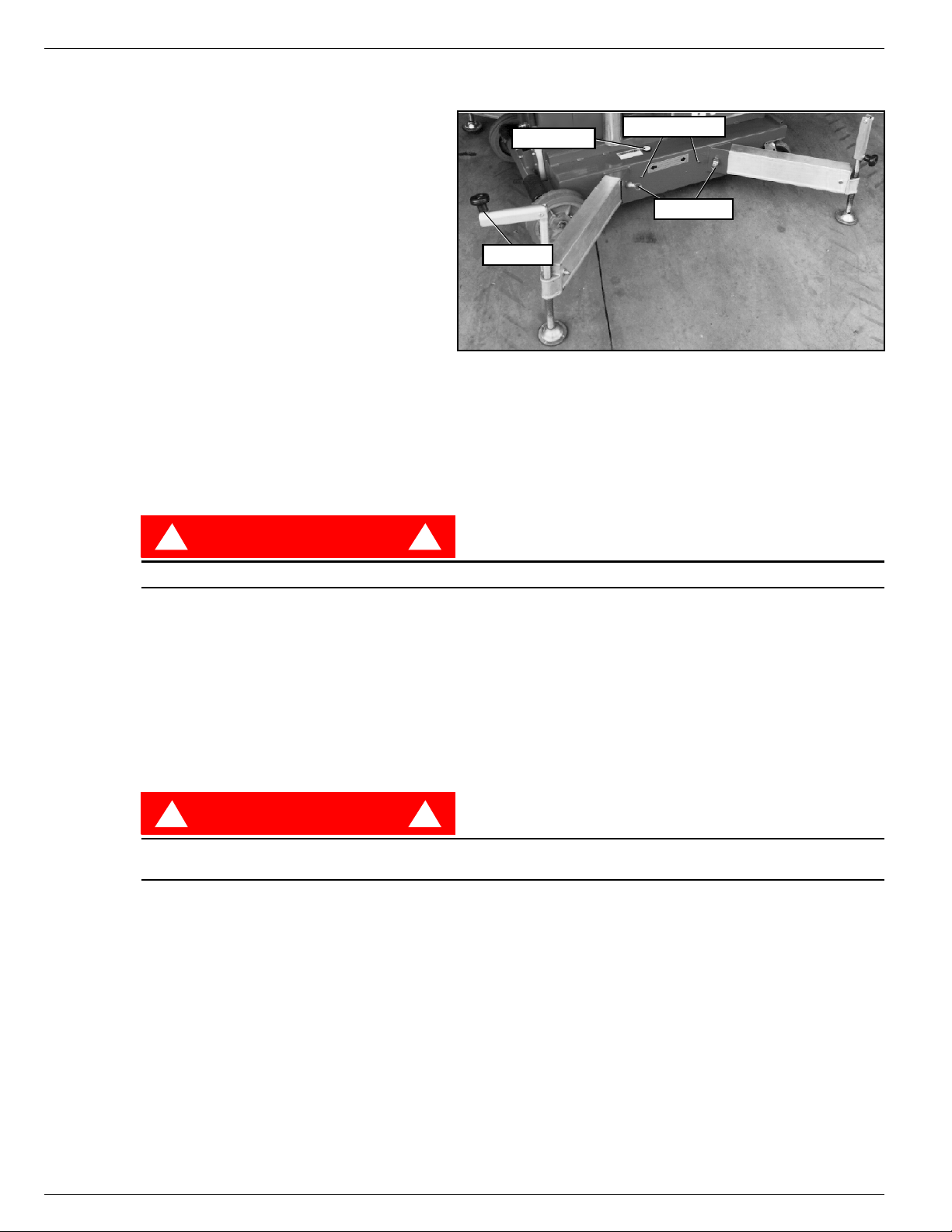

Figure 3:

1. Remove the outriggers from storage

locations on the sides of the mast.

2. Insert into the outrigger socket in the

base (Figure 1).

3. Push in until the locking pin engages

the hole in the end of the outrigger. Pull

outward on the outrigger to ensure

engagement.

4. Repeat the above steps for all other

outriggers. Make sure all four (4) locking pins are engaged.

5. Level the base, centering the bubble in

the orbit level on the base by adjusting the screwjacks (turn clockwise) at the end of each outrigger. DO

NOT release the tension (turn counterclockwise) on an outrigger to level the base.

6. All four (4) screwjack pads must be in solid contact with a firm surface and each outrigger indicator light

must be lit before the platform is elevated.

S

AFETYINTERLOCK

DANGER

! !

T

EST

Bubble Level

Screwjack

Indicator Lights

Locking Pin

Installing Outriggers

NEVER perform this test from the platform.

1. Properly install all four (4) outriggers and level the base.

2. Release the tension on one (1) outrigger by turning the screwjack counter clockwise until the indicator

light is no longer lit.

3. While standing on the ground, activate the control panel to elevate the platform. The platform should

not elevate.

4. Re-level the base.

5. Repeat steps 2, 3 and 4 until all four (4) outriggers have been tested.

DANGER

! !

DO NOT use a machine that elevates when the tension has been released on an outrigger. The

machine must be repaired before using.

Page 6 Operation Manual

Page 9

Pre-Operation Safety Inspection 068017-021 UL25, UL32 & UL40

P

RE

-O

PERATION

S

AFETYINSPECTION

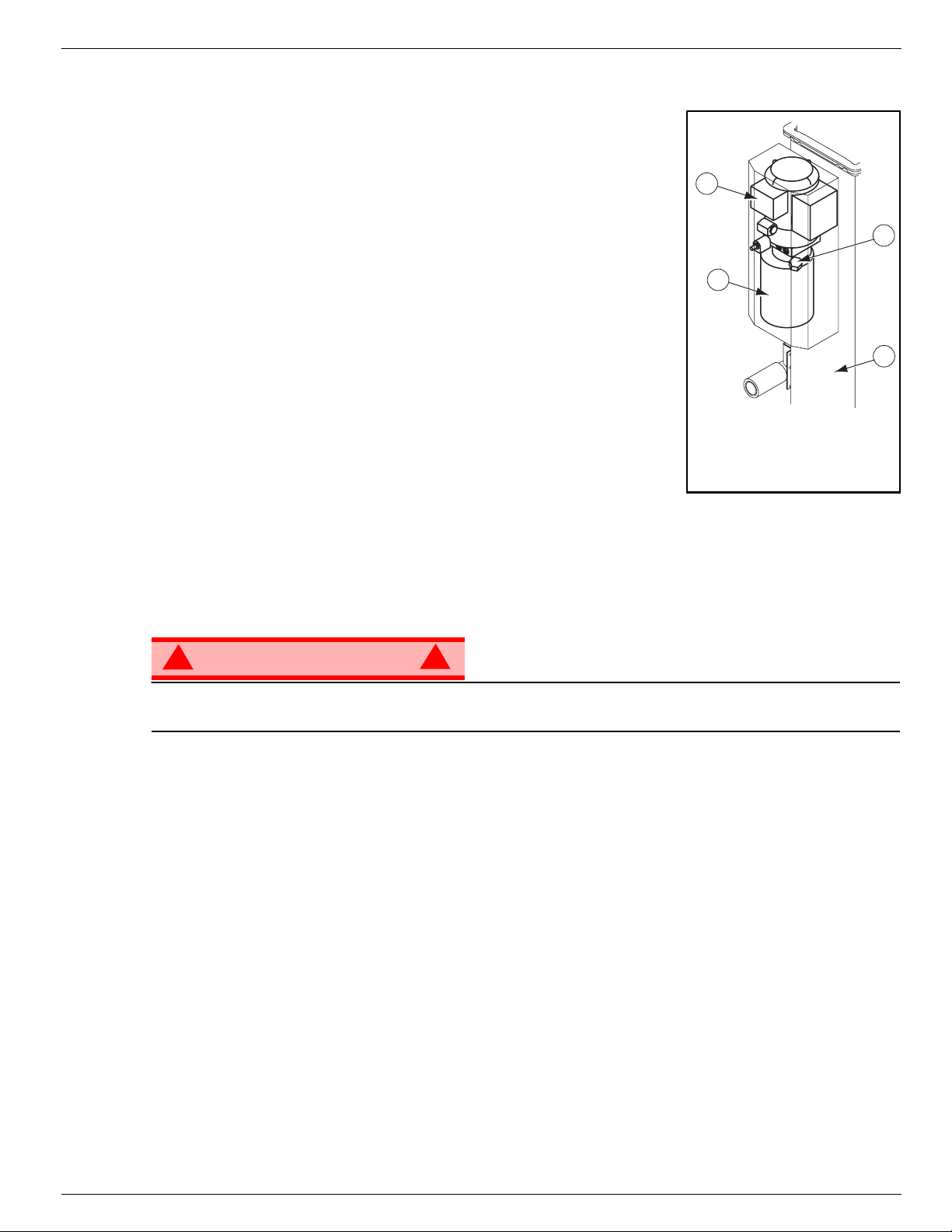

Figure 4:

NOTE: Carefully read, understand and follow all safety rules, operating

instructions, labels andNational Safety Instructions/Requirements.Perform the

following steps each day before use.

1. Check that all four (4) outriggers are properly installed.

2. Check that the base is level.

3. AC Units: connect the power unit plug to an approved extension cord.

4. DC Units: Verify that batteries are charged.

5. Perform the Safety Interlock test.

6. Check for external damage to the mast.

7. Check the level of the hydraulic fluid with the platform fully lowered:

• Remove the reservoir cap and check the fluid level on the dipstick.

• Add hydraulic fluid if necessary.

8. Check that fluid level in the batteries is correct. See “Battery Maintenance” on page 13.

9. Check that all guardrails are in place and all fasteners are properly

tightened.

10. Inspect the machine thoroughly for cracked welds and structural damage, loose or missing hardware, hydraulic leaks, damaged control cable, and loose wire connections.

3

1

1 Hydraulic Reservoir

2. Reservoir Cap/Dipstick

3. Motor (AC Shown)

4. Mast

Hydraulic Reservoir

2

4

S

YSTEM

F

UNCTION

Refer to Figure 2: “Controls and Indicators,” on page 5 for the locations of various controls and indicators.

!

WARNING

STAND CLEAR of the work platform while performing the following checks.

Check above the work platform for obstructions and electrical conductors.

NOTE: The platform will not elevate unless all four outriggers are properly installed with screwjack pads firmly in

contact with floor and each outrigger indicator lamp lit.

P

ERFORM ALL TESTS FROM THE GROUND

1. Pull the Chassis Emergency Stop Switch to the ON position.

2. Turn the Key to ON.

3. Pull the Platform Emergency Stop Switch to the ON position.

4. Push both the middle and top buttons (POWER and UP) on the Control Box at the same time to elevate

the platform. Release the buttons to stop.

5. Push both the middle and bottom buttons (POWER and DOWN) at the same time to lower the platform.

Release the buttons to stop.

6. Open the Emergency Lowering Valve to verify proper operation.

7. Push the Chassis Emergency Stop Switch to verify proper operation. All machine functions should be

disabled. Pull out the Chassis Emergency Stop Switch to resume.

8. Push the Platform Emergency Stop Switch to verify proper operation. All machine functions should be

disabled. Pull out the Platform Emergency Stop Switch to resume.

I

NSPECTION

!

Operation Manual Page 7

Page 10

068017-021 UL25, UL32 & UL40 Operation

O

PERATION

Before operating the machine, ensure that the Pre-Operation Safety Inspection has been completed and

that any deficiencies have been corrected. Never operate a damaged or malfunctioning machine. The

operator must be thoroughly trained on this machine.

NOTE: The platform will not elevate unless all four outriggers are properly installed with screwjack pads firmly in

contact with floor and each outrigger indicator lamp lit.

1. AC Units: connect the power unit plug to an approved extension cord.

2. DC Units: verify that the battery charger is turned OFF and that the extension cord is removed.

3. Pull the Chassis Emergency Stop Switch to the ON position.

4. Turn the Key to ON.

5. Enter the platform by pulling out on the locking pin and lifting up on the upper half of the cage.

6. Lower upper half of the cage after entering platform making sure locking pin is engaged.

E

LEVATING THEPLATFORM

7. Check that the area above the platform is clear before elevating the platform.

8. Pull the Platform Emergency Stop Switch to the ON position.

9. Push both the middle and top buttons (POWER and UP) on the Control Box at the same time to elevate

the platform. Release the buttons to stop.

• In the event of an emergency, push the Emergency Stop Button.

10. Visually inspect the mast assembly for cracked welds and structural damage, loose hardware, hydraulic

leaks, loose wire connections, and erratic operation. Check for missing or loose parts.

L

11. Check that the area below the platform is clear before lowering the platform.

12. Push both the middle and bottom buttons (POWER and DOWN) at the same time to lower the platform.

E

MERGENCY

NOTE: The platform will not elevate if the Emergency Lowering Valve is open.

OWERING THEPLATFORM

Release the buttons to stop.

L

OWERING

Refer to Figure 2: “Controls and Indicators,” on page 5 for the location of the Emergency Lowering Valve.

!

WARNING

If the platform should fail to lower, NEVER climb down the elevating assembly.

Stand clear of the elevating assembly while operating the Emergency Lowering Valve Knob.

Ask a person on the ground to open the Emergency Lowering Valve to lower the platform. This valve is

located through a cutout in the power unit cover on the left side of the mast.

1. Pull the knob to open the valve.

2. To close the valve, release the knob.

!

Page 8 Operation Manual

Page 11

Transporting the Work Platform 068017-021 UL25, UL32 & UL40

T

RANSPORTING THE

W

ORK

P

LATFORM

DC M

L

ODELS

Disconnect the plug from the battery box and remove the battery box from the rear of the machine.

Battery Box (DC Models Only)

!

CAUTION

The battery box is heavy, 23,6 kg (52 lbs.). Lift

properly to prevent back injury.

!

Figure 5:

Charger

OADING

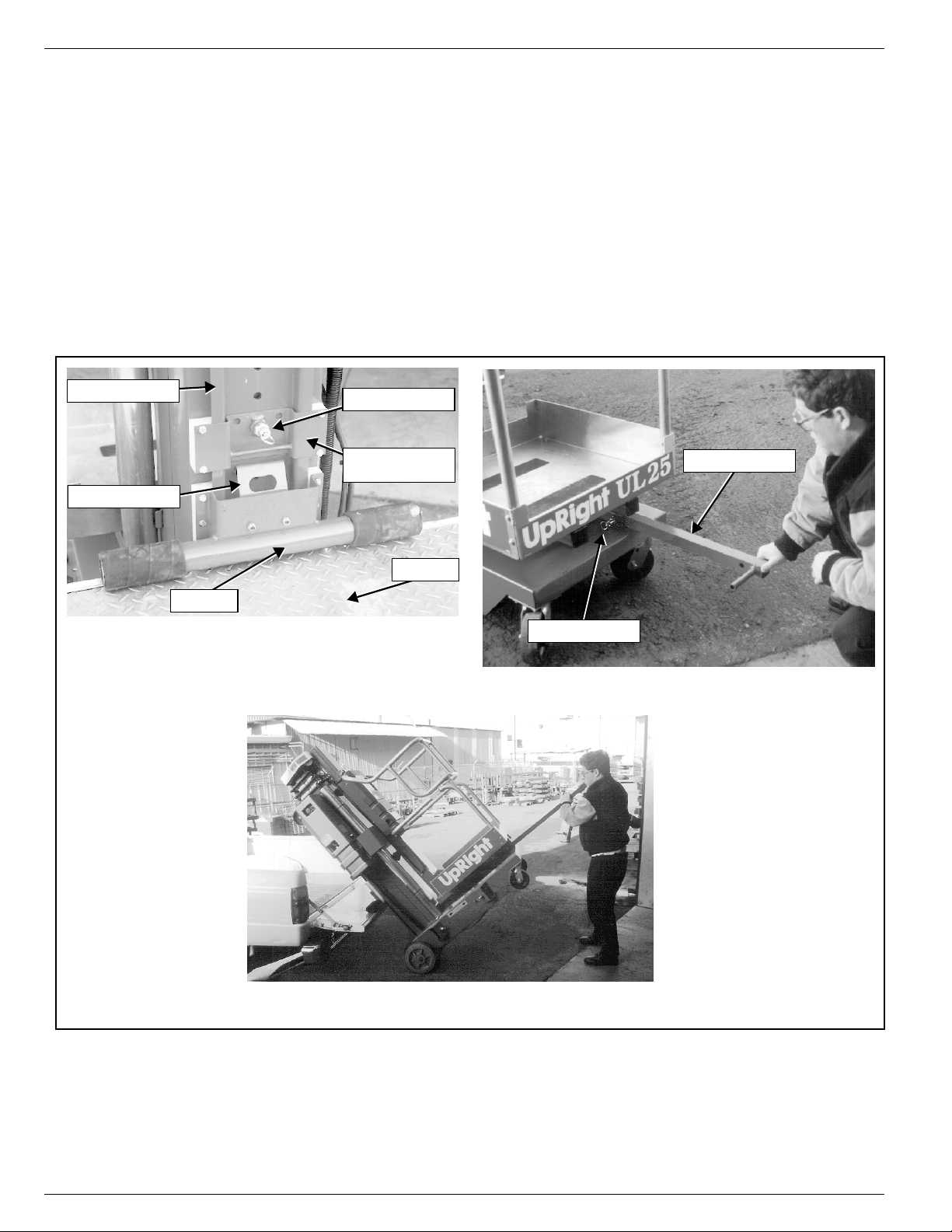

Refer to Figure 6: “Loading the UL for Transportation,” on page 10.

!

WARNING

Make sure the loader fully engages the tailgate or

vehicle bed.

1. Raise the loader support brackets and engage

the retaining pin in the top hole of the loader

channel.

2. Secure the loader to the loader support bracket with the gravity hook.

3. Position the unit so the back of the machine comes into contact with the tailgate or vehicle bed.

4. Release the gravity hook and slide the loader down until it comes into contact with the tailgate or vehicle

bed. Then reposition the loader support bracket so that the retaining pin is in the first available hole

above the loader.

5. Release the locking pin and pull the T-handle out until the locking pin engages the hole in the end of the

T-handle.

6. Lift up on the T-handle, using the loader as a pivot, until the unit rotates to a horizontal position in the

vehicle bed.

7. Push the base of the unit towards the front of the vehicle bed. The machine will slide on the loader until

the rear wheels are on the bed. The unit may then be rolled on the rear wheels and upper casters.

8. Return the T-handle to the stored position, making sure that the locking pin engages the T-handle.

9. Secure the unit with suitable tie straps using the forklift pockets located under the base of the unit, and

either the upper caster axle on the UL25 models or the tilt back frame on the UL32 and UL40 models.

!

Battery Box Plug

CAUTION

To prevent damage to the mast assembly, do not place rope or tie straps across the mast assembly when

securing the unit for transportation.

DO NOT overtighten the rope or tie straps or damage to the machine will result.

Operation Manual Page 9

Page 12

068017-021 UL25, UL32 & UL40 Transporting the Work Platform

U

NLOADING

1. Unsecure the unit.

2. Release the locking pin and pull the T-handle out until the locking pin engages the hole in the end of the

T-handle.

3. Roll the unit back until the rear wheels are off the edge of the tailgate or vehicle bed.

4. Pull downward on the T-handle, allowing the unit to slide on the loader.

• As the unit stops sliding on the loader, it will pivot on the loader to an upright position.

• Gradually counterbalance the unit’s weight by applying an upward force on the T-handle. This allows

the unit to settle gently on the wheels, avoiding undue impact on the unit.

5. Return the T-handle to the stored position, making sure that the locking pin engages the T-handle.

DC M

Loader Channel

Gravity Hook

ODELS

Replace the battery and reconnect the battery box plug, making certain it is fully engaged.

Loading the UL for Transportation

Retaining Pin

Loader

Loader in Load Position

Retaining Pin

Loader Support

Bracket

Tailgate

Figure 6:

Retaining Pin

T-Handle Positioning

Tilting the Machine Onto or Off of a Vehicle

Page 10 Operation Manual

Page 13

Passage Through a Doorway 068017-021 UL25, UL32 & UL40

P

ASSAGE

L

T

HROUGH A

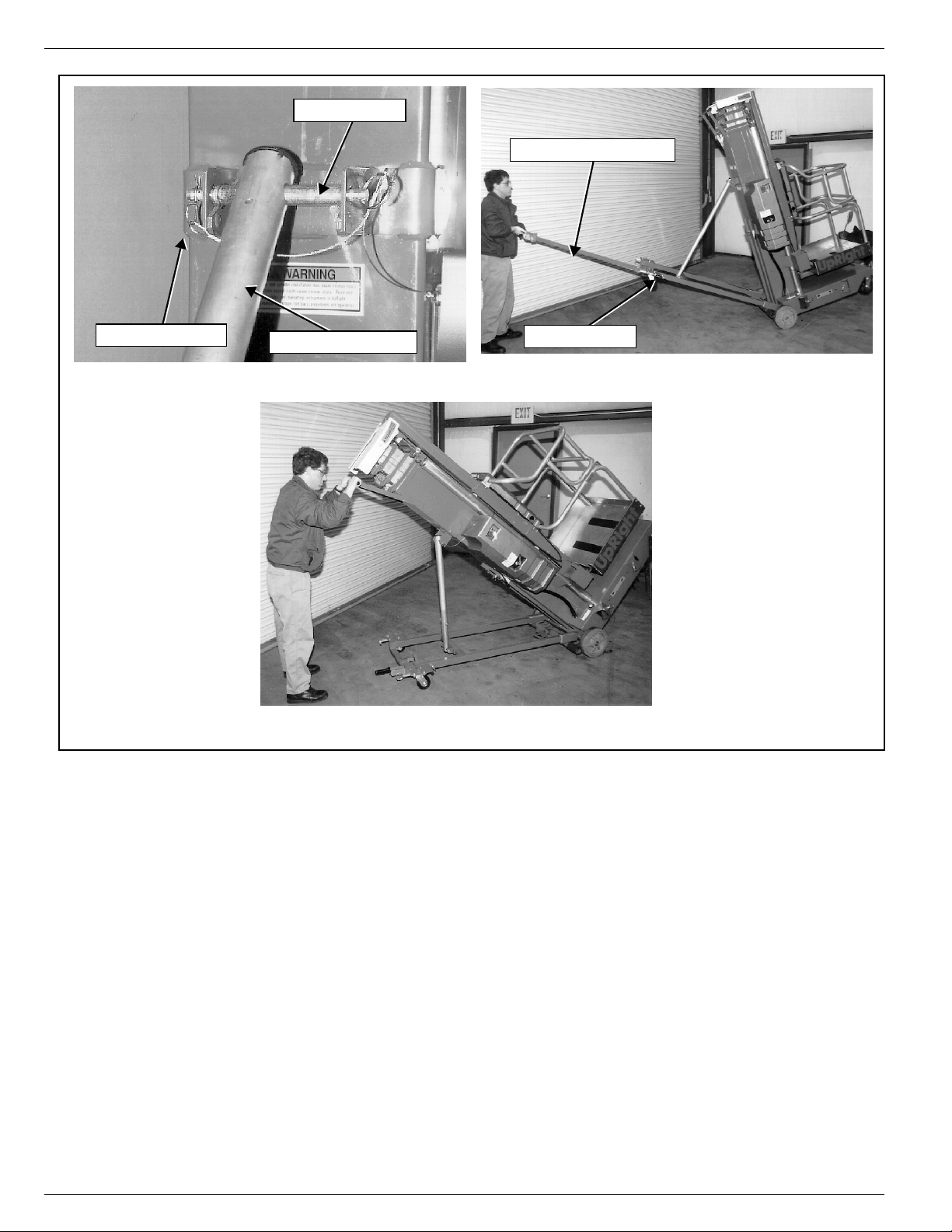

The UL32 and UL40 are equipped with a castered rear Tilt Back assembly. When the unit is tilted back

onto this support frame, the overall height is reduced to allow the unit to pass through a standard doorway.

Refer to Figure 7: “Passing Through Doorways,” on page 12.

D

OORWAY

OWERING

!

CAUTION

Before tilting the machine onto the rear Tilt Back assembly, be sure that the retaining pin is fully inserted

with the hair pin retainer installed and the cylinder assembly is fully extended.

DO NOT drop the Tilt Back frame.

Keep out from under the Tilt Back frame and machine when tilting.

1. Be sure that the area is clear of personnel and obstructions.

2. While holding the Tilt Back frame, remove the hair pin retainer and the retaining pin.

3. Lower the Tilt Back frame until the hole in the cylinder assembly align with the upper mounting bracket

pin hole. Secure the cylinder assembly to the upper mounting bracket using the retaining pin and hair pin

retainer.

4. Extend the Tilt Back Handle to the tilt/lift position by releasing the locking pin and pulling the handle out

of the Tilt Back assembly until the locking pin engages.

5. Push down on the Tilt Back Handle until the unit comes to rest on the Tilt Back frame.

• As the mast tilts back, counterbalance the machine’s weight by increasing upward force on the end of

the Tilt Back Handle. This allows the machine to gently come to rest on the Tilt Back casters.

6. Pull down on the handle on the back of the mast to compress the cylinder assembly.

7. Return the Tilt Back Handle to the storage position, making sure that the locking pin engages the handle.

R

AISING

1. Lift up on the mast handle to extend the cylinder assembly.

2. Fully engage the Tilt Back Handle until the locking pin engages.

3. Lift up on the Tilt Back Handle.

• As the mast approaches vertical, counterbalance the machine’s weight by increasing downward force

on the end of the tilt Back Handle. This allows the machine to settle gently on the front casters.

4. Return the Tilt Back handle to the storage position, making sure that the locking pin engages the handle.

5. While holding the Tilt Back frame, remove the retaining pin and raise the Tilt Back assembly to the

stowed position.

6. Secure with the retaining pin, making sure that the retaining pin is fully inserted, and that the hair pin

retainer is installed.

!

Operation Manual Page 11

Page 14

068017-021 UL25, UL32 & UL40 Passage Through a Doorway

Hair Pin Retainer

Cylinder Secured with Retaining Pin

Retaining Pin

Cylinder Assembly

Figure 7:

Tilt Back Handle

Retaining Pin

Lowering and Raising with the Tilt Back Handle

Passing Through Doorways

Compressing the Cylinder Assembly

Page 12 Operation Manual

Page 15

Maintenance 068017-021 UL25, UL32 & UL40

M

AINTENANCE

B

ATTERY

M

AINTENANCE

!

WARNING

Hazard of explosive gas mixture. Keep sparks, flame, and smoking material away from batteries.

Always wear safety glasses when working near batteries.

Battery fluid is highly corrosive. Thoroughly rinse away any spilled fluid with clean water.

Always replace batteries with UpRight batteries or manufacturer approved replacements weighing

22 kg (48 lbs.) each.

• Check the battery fluid level daily, especially if the work platform is being used in a warm, dry climate.

• If electrolyte level is lower than 10 mm (

tap water with high mineral content, as it will shorten battery life.

• Keep the terminals and tops of the batteries clean.

• Refer to the Service Manual to extend battery life and for complete service instructions.

B

ATTERY

Charge the batteries at the end of each work shift

or sooner if the batteries have been discharged.

!

WARNING

Charge the batteries in a well ventilated area.

Do not charge the batteries when the work

platform is near a source of sparks or flames.

Permanent damage to the batteries will result if

the batteries are not immediately recharged after

discharging.

Never disconnect the cables from the batteries

when the charger is operating.

Keep the charger dry.

C

HARGING

!

3

in.) above the plates add distilled water only. DO NOT use

/

8

Battery Charger

Charger

Figure 8:

Battery

(inside box)

!

Timer Knob

1. Check the battery fluid level. If the battery fluid

level is lower than 10 mm (

plates add distilled water only.

2. Verify the charger voltage switch is set to 12 volts.

3. Connect an appropriate extension cord to the charger plug. Plug the extension cord into a properly

grounded outlet of proper voltage and frequency.

4. Turn the charger timer knob to 12. The charger ammeter should indicate the charge rate.

5. When the battery is fully charged, turn the knob to OFF, do not turn the knob to HOLD. Disconnect the

extension cord.

NOTE: The battery charger circuit must be used with a GFI (Ground Fault Interrupt) outlet.

NOTE: DO NOT operate the machine while the charger is plugged in.

Operation Manual Page 13

3

in.) above the

/

8

Page 16

068017-021 UL25, UL32 & UL40 Inspection and Maintenance Schedule

I

NSPECTION AND

The Complete Inspection consists of periodic visual and operational checks, along with periodic minor

adjustments that assure proper performance. Daily inspection will prevent abnormal wear and prolong the

life of all systems. The inspection and maintenance schedule should be performed at the specified intervals. Inspection and maintenance shall be performed by personnel who are trained and familiar with

mechanical and electrical procedures.

M

AINTENANCE

S

CHEDULE

D

AILY

M

AINTENANCE

Y = Yes/Acceptable

N = No/Not Acceptable

R = Repaired/Acceptable

!

WARNING

!

Before performing preventative maintenance, familiarize yourself with the operation of the machine.

Always block the elevating assembly whenever it is necessary to perform maintenance while the

platform is elevated.

The daily preventative maintenance checklist has been designed for machine service and maintenance.

Please photocopy the Daily Preventative Maintenance Checklist and use the checklist when inspecting

the machine.

P

REVENTATIVE

T

ABLEKEY

M

AINTENANCE

C

HECKLIST

P

REVENTATIVE

Date: _______________________________________

Owner:______________________________________

Model No: ___________________________________

Serial No:____________________________________

Serviced By: _________________________________

M

AINTENANCEREPORT

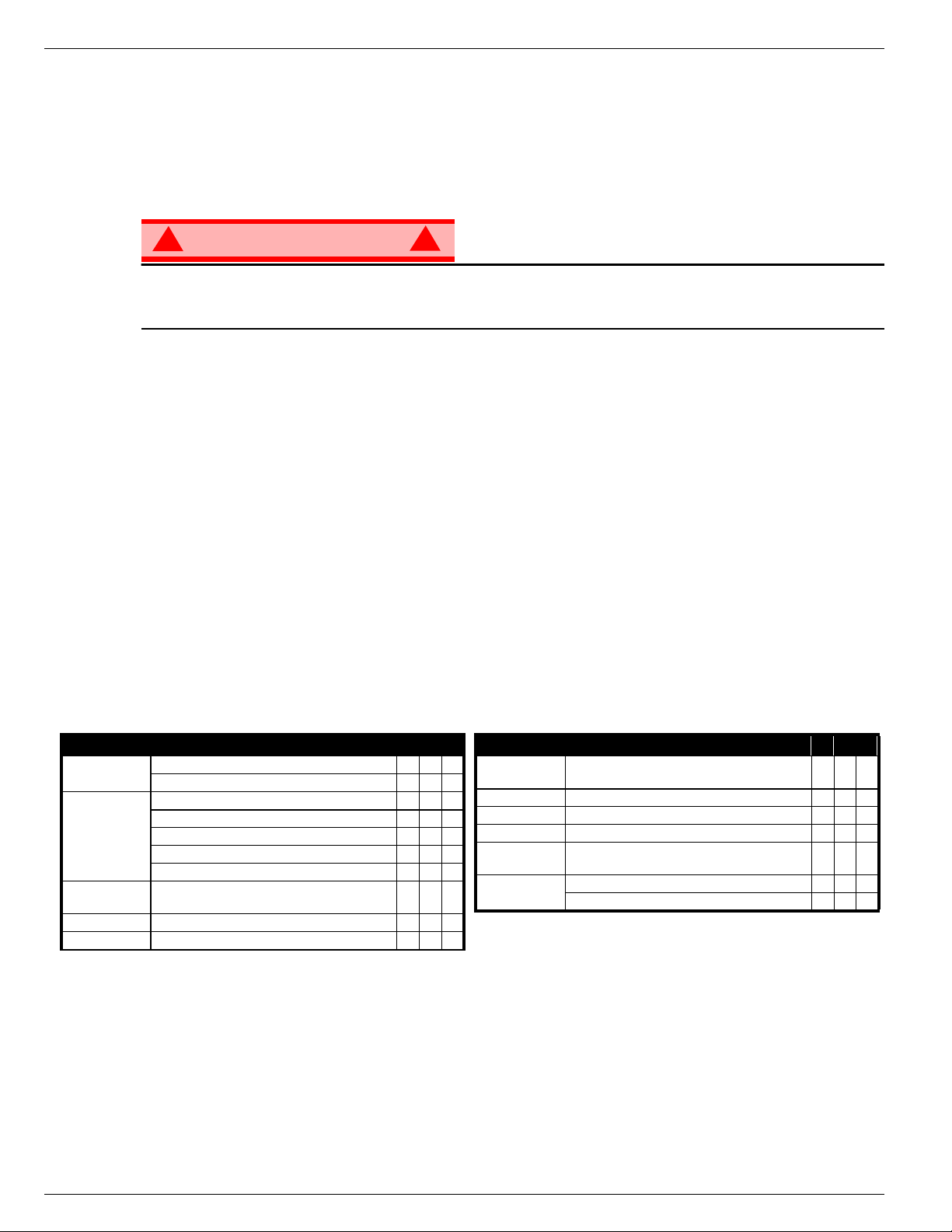

COMPONENT INSPECTION OR SERVICES Y N R

Battery

Chassis

Control Cable

Controller Check switch operation.

Mast Assembly Inspect for bends, cracks or loose rivets.

Check electrolyte level.

Check battery cable condition.

Check bubble level accuracy

Check operation of outrigger interlocks

Check casters for damage

Check hoses for pinch or rubbing points.

Check welds for cracks.

Check theexterior of the cable for pinching, binding

or wear.

COMPONEN T INSPECTION OR SERVICES Y N R

Emergency

Lowering System

Hydraulic Fluid Check fluid level.

Hydraulic Pump Check for hose fitting leaks.

Hydraulic System Check for leaks.

Labels

Cage and Deck

Operatethe emergency lowering valve andcheckfor

serviceability.

Check for peeling, missing, or unreadable labels &

replace.

Check welds for cracks.

Check condition of deck.

Page 14 Operation Manual

Page 17

Daily Preventative Maintenance Checklist 068017-021 UL25, UL32 & UL40

OTES

N

:

Operation Manual Page 15

Page 18

068017-021 UL25, UL32 & UL40 Labels

L

ABELS

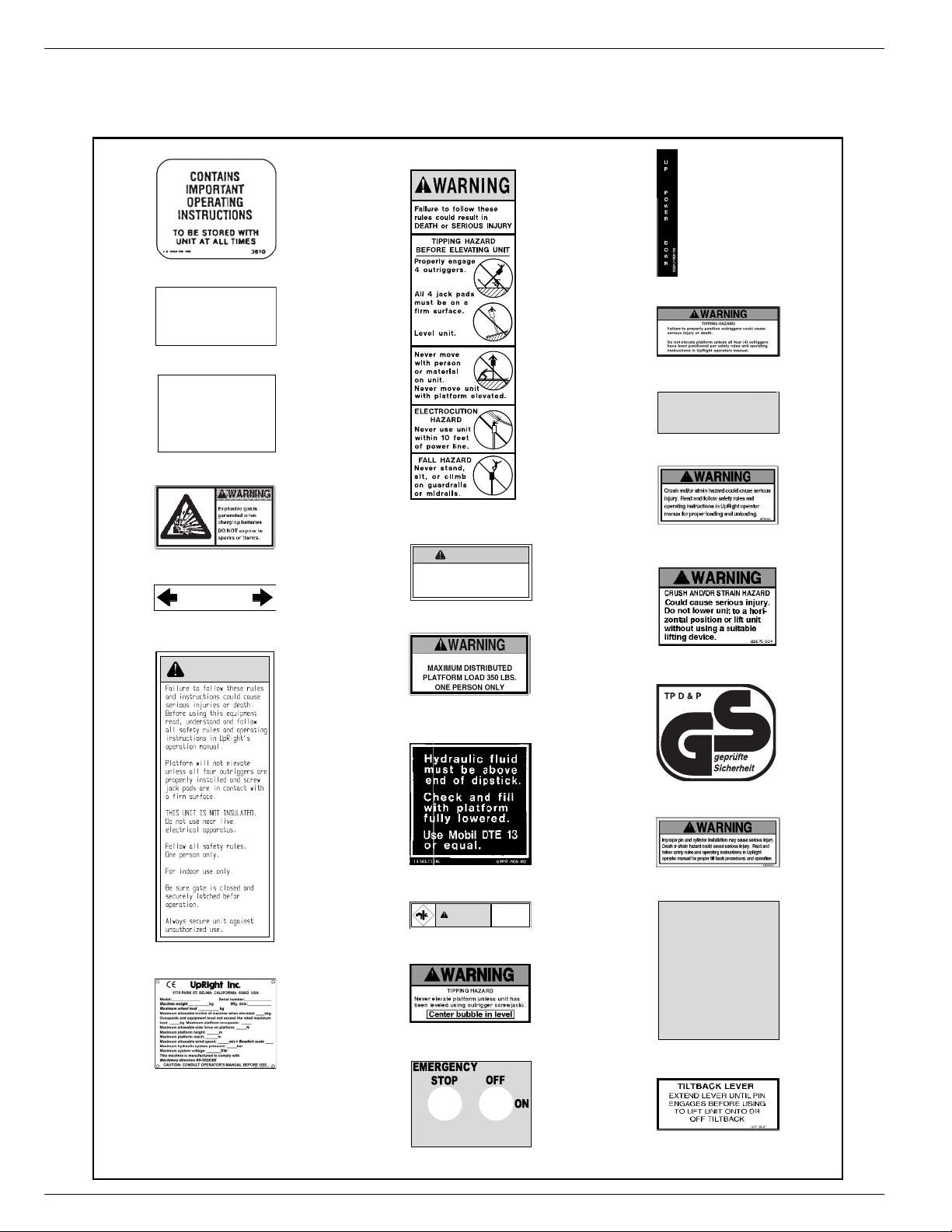

These labels shall be present and in good condition before operating the work platform. Be sure to read,

understand and follow these labels when operating the work platform.

1) 003610-000

23) 062840-000

BATTERY

MAINTAIN BATTERY FLUID

AT RECOMMENDED LEVEL

4) 005221-000 - UL40 DC ONLY

EMERGENCY

DOWNVALVE

PULL KNOB TO

LOWER PLATFORM

5) 005223-003

25) 062821-002

EMERGENCY

STOP

26) 062792-000

6) 066552-000 - UL40 DC ONLY

Insert outrigger here

until pin engages hole.

10) 062218-001

WARNING

11) 066554-003

15) 066550-010

WARNING

MAXIMUM PLATFORM

LOAD 300 LBS.

ONE PERSON ONLY.

16) 066557-009 - UL32 & 40 ONLY

16) 066557-011 - UL25 ONLY

17) 062217-000

PINCH POINT

WARNING

Keep all body

parts away.

18) 066553-002

27) 062725-002

28) 062575-001

34) 030768-002

35) 062466-002

INSERT

PIN

HERE

19) 066551-005

36) 062814-000

14) 061205-003

37) 062876-000

20) 069338-000

Page 16 Operation Manual

Page 19

Labels 068017-021 UL25, UL32 & UL40

Figure 9:

35

Safety Labels Locations

Operation Manual Page 17

Page 20

068017-021 UL25, UL32 & UL40 Specifications

S

PECIFICATIONS

ITEM UL 25 UL 32 UL 40

Platform Capacity 159 kg (350 lbs.)136kg(300 lbs.)136kg(300 lbs.)

Max. No. of occupants 1 person 1 person 1 person

Height

Working Height 9,62 m (31.6 ft.)11,75m(38.5 ft.) 14,19 m (46.6 ft.)

Max. Platform Height

Min. Platform Height 38 cm (15 in.)38cm(15 in.)38cm(15 in.)

Dimensions

Overall Weight 345 kg (760 lbs.)390kg(860 lbs.)422kg(930 lbs.)

DC Option Weight

Overall Width (outriggers extended) 1,5 m (59 in.)2,06m(81 in.)2,34m(92 in.)

Overall Length (outriggers extended) 1,42 m (56 in.)1,98m(78 in.)2,26m(89 in.)

Stowed Dimensions

Vertical Height

Width 74 cm (29 in.)74cm(29 in.)74cm(29 in.)

Depth

Diagonal Storage Height

Diagonal Storage Length N/A 2,53 m (99.5in.)2,9m(114 in.)

System Voltage

AC Electric Motor

DC Electric Power Source 1 - 12 Volt Battery, Group 27 105 Amp/Hrs., Minimum Weight 22 kg (48 lbs.)

Battery Charger

Hydraulic Tank Capacity 5,7 liter (1.5 gal.)

Maximum Hydraulic Pressure 165 bar(2400 PSI)

Hydraulic Fluid

Normal Temperature: above 0° C [32° F]

Low Temperature: below 0° C [32° F]

ExtremeTemperature: below-17° C [0° F]

Control System Push Button Lift and Lower, Red Mushroom EMERGENCY STOP Switch

Guardrails 1,1 m (43.5 in.)High

Noise Level

7,62 m (25 ft.)9,75m(32 ft.)12,19m(40 ft.)

29 kg (64 lbs.)29kg(64 lbs.)29kg(64 lbs.)

1,98 m (78 in.)2,44m(96 in.)2,84m(112 in.)

1,24 m (49 in.)1,24m(49 in.)1,24m(49 in.)

N/A 1,98 m (78 in.)1,98m(78 in.)

120 VAC 60 Hz or 220 VAC 50/60 Hz

Automatic, 120 VAC 60 Hz or 220 VAC 50 Hz

Output: 10 Amp, 12 Volts DC

ISO #46

ISO #32

ISO #15

*Specifications are subject to change without notice. Hot weather or heavy use may affect performance.

Refer to the Service Manual for complete parts and service information.

The UL25/32/40 meets or exceeds all applicable CE and GS machinery directive requirements.

Page 18 Operation Manual

Page 21

Tout le personnel doit lire attentivement et respecter toutes les consignes de sécurité avant

Risque

Risque

RisqueRisque

d’électrocution

d’électrocution

d’électrocutiond’électrocution

GUIDE DE L’OPÉRATEUR

AVERTISSEMENT

d’entretenir ou d’utiliser une plate-forme élévatrice UpRight.

Consignes de sécurité

Consignes de sécurité

Consignes de sécuritéConsignes de sécurité

Risque de collision

Risque de collision

Risque de basculement

Risque de basculement

Risque de basculementRisque de basculement

Risque de collisionRisque de collision

Risque de chute

Risque de chute

Risque de chuteRisque de chute

CETTE MACHINE

N’EST PAS ISOLÉE !

CETTE MACHINE EST CONÇUE POUR N’ÊTRE UTILISÉE QU’À L’INTÉRIEUR ! Ne pas l’utiliser à l’extérieur.

USAGEDELAPLATE-FORMEÉLÉVATRICE: Cette plate-forme élévatrice est destinée au levage de toute personne, de son outillage

et des matériaux utilisés sur le chantier. Elle est conçue pour les travaux de réparations et d’assemblage sur les points élevés (plafonds,

grues, charpentes de toit, immeubles, etc.). Tout autre usage de la plate-forme élévatrice est interdit !

CETTE PLATE-FORME ÉLÉVATRICE N’EST PAS ISOLÉE ! C’est pourquoi il est impératif de rester à distance sûre des lignes et

équipements électriques sous tension !

Il est interdit de dépasser la charge maximum admissible. Voir « Limitations particulières » à la page 22 pour plus de détails.

Il est interdit d’utiliser la plate-forme comme appareil de levage ou grue (levage des charges par le dessous ou le dessus) !

NE JAMAIS dépasser la force manuelle autorisée pour cette machine. Voir « Limitations particulières » à la page 22 pour plus de

détails.

RÉPARTIR uniformément toutes les charges placées sur la plate-forme.

NE JAMAIS utiliser la machine sans avoir d’abord vérifié si la zone de travail est exempte de dangers tels que des trous, dénivellations,

bosses, trottoirs ou débris; et les éviter.

N’UTILISER la machine que sur des surfaces pouvant supporter la charge des roues.

EN CAS D’URGENCE, appuyer sur le bouton d’ARRÊT D’URGENCE pour désactiver toutes les fonctions.

Il est interdit de monter ou de se tenir sur les garde-corps de la plate-forme et de passer de la plate-forme à un immeuble, une

structure préfabriquée, etc. !

Il est interdit de retirer le portillon ou toute autre pièce de garde-corps ! Toujours vérifier que le portillon est fermé et verrouillé !

Il est interdit de maintenir le portillon en position ouverte (par exemple au moyen d’attaches) lorsque la plate-forme est élevée !

Il est interdit d’accroître la hauteur ou la portée de la plate-forme au moyen d’échelles, échafaudages ou autres dispositifs similaires !

NE JAMAIS effectuer de travaux d’entretien sur la machine, si la plate-forme est en position élevée, sans tout d’abord bloquer le

système d’élévation.

INSPECTER minutieusement la machine en vue de soudures fissurées, de pièces de boulonnerie manquantes ou desserrées, de fuites

hydrauliques, de branchements électriques desserrés ou de câbles et flexibles endommagés avant d’utiliser la machine.

VÉRIFIER que tous les autocollants sont en place et lisibles avant d’utiliser la machine.

NE JAMAIS utiliser une machine qui est endommagée, qui ne fonctionne pas correctement ou dont les autocollants sont manquants ou

endommagés.

Il est interdit de mettre tout dispositif de sécurité hors service, ce qui mettrait en danger les personnes à bord de la plate-forme et

celles se trouvant dans la zone de travail.

NE JAMAIS charger les batteries à proximité d’étincelles ou d’une flamme vive. Lors de la charge, les batteries dégagent de

l’hydrogène, un gaz explosif.

Sauf autorisation de la part d’UpRight, toute modification de la plate-forme est interdite.

APRÈS AVOIR UTILISÉ la plate-forme élévatrice, mettre les contacteurs à clé en position d’arrêt (OFF), puis retirer la clé afin

d’empêcher l’utilisation non autorisée de la plate-forme.

NE JAMAIS

élever la plate-forme

si les quatre (4)

stabilisateurs (4) ne

sont pas correctement

installés.

NE JAMAIS

élever la plate-forme

avant d’avoir mis la

base de niveau.

NE JAMAIS

essayer de pousser la

plate-forme UpRight

si elle est occupée

par despersonnes ou

du matériel ou

si elle est élevée.

NE JAMAIS

positionner la plate-

forme avant de s’être

assuré de l’absence

d’obstacles

en hauteur

ou autres dangers.

NE JAMAIS

monter, ni se tenir

debout ou assis sur

les rampes

du garde-corps.

Page 19

Page 22

068017-021 UL25, UL32 et UL40

T

ABLE DES MATIÈRES

Introduction.........................................................................21

Descriptiongénérale .................................................................21

Limitationsparticulières ..............................................................22

Capacitédelaplate-forme ................................................................... 22

Forcemanuelle............................................................................ 22

Commandesetindicateurs............................................................23

Installationdesstabilisateurs..........................................................24

Test de verrouillage de sécurité . .............................................................. 24

Inspection de sécurité avant utilisation ..................................................25

Essaidefonctionnementdessystèmes..................................................25

Effectuertoustestsàpartirdusol.......................................................... 25

Utilisation ..........................................................................26

Élévationdelaplate-forme ............................................................... 26

Abaissementdelaplate-forme ............................................................ 26

Abaissement d’urgence ...............................................................26

Transport de la plate-forme élévatrice . ..................................................27

Modèles c.c............................................................................ 27

Chargement............................................................................... 27

Déchargement............................................................................. 28

Modèles c.c............................................................................ 28

Passagedeportes ...................................................................29

Abaissement.............................................................................. 29

Élévation................................................................................. 29

Entretien ...........................................................................31

Entretiendesbatteries ...................................................................... 31

Chargedesbatteries........................................................................ 31

Programmesd’inspectionetd’entretien.................................................32

Liste de contrôle d’entretien préventif quotidien ..........................................32

Autocollants ........................................................................34

Caractéristiques.....................................................................36

Page 20 Guidedel’opérateur

Page 23

Introduction 068017-021 UL25, UL32 et UL40

I

NTRODUCTION

Ce manuel contient les instructions d'utilisation de la plate-forme élévatrice UL25, UL32 et UL40.

Veiller à garder ce manuel sur la machine en tout temps.

D

ESCRIPTION GÉNÉRALE

!

AVERTISSEMENT

NE PAS utiliser la plate-forme sans que les garde-corps soient correctement assemblésetinstallés.

1. Plate-forme

2. Mât

3. Châssis

4. Stabilisateurs

5. Garde-corps supérieurs

(portillon)

6. Garde-corps inférieurs

7. Commandes du châssis

8. Bloc d’alimentation

• Moteur

• Réservoir hydraulique

9. Boîte à batteries (modèles c.c.)

•Batterie

• Chargeur de batterie

10. Roulettes

11. Roues arrière

12. Crics à vis

13. Chargeur

!

Figure 1 :

2

7

8

13

9

11

12

4

Plate-forme élévatrice

8

5

14

1

3

10

6

14. Axe de verrouillage de portillon

Guidedel’opérateur Page 21

Page 24

068017-021 UL25, UL32 et UL40 Limitations particulières

L

IMITATIONS PARTICULIÈRES

La plate-forme ne doit être élevée que si elle se trouve sur une surface plane et ferme.

Les quatre (4) stabilisateurs doivent être correctement installés avant d’utiliser la machine.

Cette machine est conçue pour n’être utilisée qu’à l’intérieur !

DANGER

! !

La fonction d’élévation doit être utilisée SEULEMENT lorsque la plate-forme est de niveau et placée

sur une surface plane et ferme.

C

APACITÉ DE LA PLATE-FORME

La capacité maximum de la plate-forme de la MACHINE est :

• UL25 – 159 kg (350 lb)

• UL32 et UL40 – 136 kg (300 lb)

Une personne peut occuper la plate-forme.

DANGER

! !

NE PAS dépasser la capacité de charge ou le nombre d’occupants maximum de cette machine.

F

ORCE MANUELLE

La force manuelle est la force appliquée par les occupants sur des objets tels que murs ou autres

structures extérieures à la machine.

La force manuelle maximale admissible est de 200 N (45 lb).

DANGER

! !

NE PAS dépasser la force manuelle maximale admissible pour cette machine.

Page 22 Guidedel’opérateur

Page 25

Commandes et indicateurs 068017-021 UL25, UL32 et UL40

C

OMMANDES ET INDICATEURS

Commandesdelaplate-forme

1

3

2

4

1. Bouton d’arrêt d’urgence

2. Bouton d’activation

3. Bouton de levage

4. Bouton d’abaissement

Figure 2 :

Commandes du châssis

Commandes et indicateurs

5

3

1

2

6

4

1. DEL (indique que la batterie du système d’abaissement

d’urgence en option doit être remplacée)

2. Bouton d’arrêt d’urgence

3. Contacteur à clé

4. Vanne d’abaissement d’urgence

5. Niveau d’orbite

6. Témoins de stabilisateurs

Guidedel’opérateur Page 23

Page 26

068017-021 UL25, UL32 et UL40 Installation des stabilisateurs

I

NSTALLATION DES STABILISATEURS

Figure 3 :

1. Retirer les stabilisateurs de la position

de rangement sur les côtés du mât.

2. Insérer les stabilisateur dans les

réceptacles de la base (figure 1).

3. Pousser jusqu’à ce que l’axe de

verrouillage s’engage dans le trou de

l’extrémité du stabilisateur. Tirer sur le

stabilisateur pour s’assurer que l’axe

est bien engagé.

4. Répéter l’opération ci-dessus pour les

stabilisateurs restants. S’assurer que

les quatre (4) axes de verrouillage sont

engagés.

5. Mettre la base de niveau en centrant la bulle du niveau orbital par ajustement des crics à vis (tourner

vers la droite) de l’extrémité de chaque stabilisateur. NE PAS relâcher la tension d’un stabilisateur (en

tournant la manivelle vers la gauche) pour mettre la base de niveau.

6. Chacun des quatre (4) pieds des stabiliasteurs doit s’appuyer fermement sur une surface ferme et tous

les témoins lumineux des stabilisateurs doivent être allumés avant d’élever la plate-forme.

T

ESTDEVERROUILLAGEDESÉCURITÉ

Cric à vis

Niveau à bulle

Axe de verrouillage

Installation des stabilisateurs

Témoins

DANGER

! !

NE JAMAIS effectuer ce test depuis la plate-forme.

1. Installer correctement les quatre (4) stabilisateurs et mettre la base de niveau.

2. Relâcher la tension d’un (1) des stabilisateurs en tournant la manivelle du cric à vis vers la gauche,

jusqu’à ce que le témoin lumineux s‘éteigne.

3. En se tenant debout sur le sol, actionner les commandes d’élévation de la base. La plate-forne ne

devrait pas s’élever.

4. Remettre la base de niveau.

5. Répéter les étapes 2, 3 et 4 de façon à tester chacun des quatre (4) stabilisateurs.

DANGER

! !

NE PAS utiliser une machine qui s’élève alors que la tension d’un stabilisateur àété relâchée.

La machine doit être réparée avant d’êtreremiseenservice.

Page 24 Guidedel’opérateur

Page 27

Inspection de sécurité avant utilisation 068017-021 UL25, UL32 et UL40

I

NSPECTION DE SÉCURITÉ AVANT UTILISATION

Figure 4 :

NOTA : Lire d’abord attentivement toutes les règles de sécurité, le mode d’emploi,

les autocollants et les règles nationales de sécurité. Chaque jour avant

d’utiliser la machine :

1. Vérifier que les quatre (4) stabilisateurs sont correctement installés.

2. Vérifier que la base est de niveau.

3. Modèles c.a. : Brancher la fiche du module d’alimentation sur un

cordon prolongateur approuvé.

4. Modèles c.c. : Vérifier que les batteries sont chargées.

5. Effectuer le test de verrouillage de sécurité.

6. Vérifier que le mât ne présente pas de dommages externes.

7. Vérifier le niveau de fluide hydraulique une fois la plate-forme

entièrement abaissée :

• Retirer le bouchon du réservoir et vérifier le niveau de fluide

sur la jauge.

• Faire l’appoint si nécessaire.

8. Vérifier que le niveau de fluide dans les batteries est correct.

Voir « Entretien des batteries » à la page 31.

9. Vérifier que tous les garde-corps sont en place et correctement

assujettis.

10. Inspecter soigneusement la machine en vue de soudures fissurées et de dommages structurels, pièces

de boulonnerie manquantes ou desserrées, fuites hydrauliques, câbles de commande endommagés et

branchements électriques.

3

1

1. Réservoir hydraulique

2. Bouchon du réservoir/jauge

3. Moteur (modèle c.a. illustré)

4. Mât

Réservoir hydraulique

2

4

E

SSAI DE FONCTIONNEMENT DES SYSTÈMES

Voir la figure 2 « Commandes et indicateurs » à la page 23 pour l’emplacement des divers indicateurs et

commandes.

!

AVERTISSEMENT

SE TENIR ÉLOIGNÉ de la plate-forme élévatrice lorsqu’on réalise les contrôles suivants.

Vérifier au-dessus de la plate-forme élévatrice, qu’il n’y a ni obstruction ni conducteur électrique.

NOTA : La plate-forme ne s’élèvera que si les quatre stabilisateurs sont correctement installés, les pieds des crics à

vis étant fermement appuyés sur le sol et tous les témoins de stabilisateurs allumés.

E

FFECTUER TOUS TESTS À PARTIR DU SOL

1. Tirer le bouton d’arrêt d’urgence du châssis en position ACTIVÉE.

2. Mettre la clé du commutateur en position de marche (ON).

3. Tirer le bouton d’arrêt d’urgence de la plate-forme en position ACTIVÉE.

4. Appuyer simultanément sur les boutons du milieu et du haut (ACTIVATION et LEVAGE) du boîtier de

commande pour élever la plate-forme. Relâcher les boutons pour arrêter.

5. Appuyer simultanément sur les boutons du milieu et du bas (ACTIVATION et ABAISSEMENT) du boîtier

de commande pour abaisser la plate-forme. Relâcher les boutons pour arrêter.

6. Ouvrir la vanne d’abaissement d’urgence pour en vérifier le bon fonctionnement.

7. Appuyer sur le bouton d’arrêt d’urgence du châssis pour en vérifier le bon fonctionnement. Toutes les

fonctions de la machine doivent être désactivées. Tirer le bouton d’arrêt d’urgence du châssis pour

remettre la machine en service.

8. Appuyer sur le bouton d’arrêt d’urgence de la plate-forme pour en vérifier le bon fonctionnement. Toutes

les fonctions de la machine doivent être désactivées. Tirer le bouton d’arrêt d’urgence de la plate-forme

pour remettre la machine en service.

!

Guidedel’opérateur Page 25

Page 28

068017-021 UL25, UL32 et UL40 Utilisation

U

TILISATION

Avant d’utiliser la machine, s’assurer que les inspections de sécurité avant utilisation ont été effectuées et

que tous les problèmes éventuels ont été corrigés. Ne jamais utiliser une machine endommagée ou

qui ne fonctionne pas correctement. L’opérateur doit être dûment formé sur cette machine.

NOTA : La plate-forme ne s’élèvera que si les quatre stabilisateurs sont correctement installés, les pieds des crics à

vis étant fermement appuyés sur le sol et tous les témoins de stabilisateurs allumés.

1. Modèles c.a. : Brancher la fiche du module d’alimentation sur un cordon prolongateur approuvé.

2. Modèles c.c. : Vérifier que le chargeur de batterie est ÉTEINT et que le cordon prolongateur est

débranché.

3. Tirer le bouton d’arrêt d’urgence du châssis en position ACTIVÉE.

4. Tourner le contacteur à clé en position de marche (ON).

5. Tirer sur l’axe de verrouillage et relever la moitié supérieure de la cage pour monter sur la plate-forme.

6. Abaisser la moitié supérieure de la cage en s’assurant que l’axe de verrouillage s’engage

correctement.

É

LÉVATION DE LA PLATE-FORME

7. Vérifier qu’il n’y a aucun obstacle au-dessus de la plate-forme avant de l’élever.

8. Tirer le bouton d’arrêt d’urgence de la plate-forme en position ACTIVÉE.

9. Appuyer simultanément sur les boutons du milieu et du haut (ACTIVATION et LEVAGE) du boîtier de

commande pour élever la plate-forme. Relâcher les boutons pour arrêter.

• En cas d’urgence, appuyer sur le bouton d’arrêt d’urgence.

10. Examiner le mât pour s’assurer de l’absence de soudures fissurées, dommages structurels, pièces

desserrées, fuites hydrauliques, connexions électriques desserrées et fonctionnement intermittent.

Vérifier qu’il n’y a pas de pièces desserrées ou manquantes.

A

BAISSEMENT DE LA PLATE-FORME

11. Vérifier qu’il n’y a aucun obstacle au-dessous de la plate-forme avant de l’abaisser.

12. Appuyer simultanément sur les boutons du milieu et du bas (ACTIVATION et ABAISSEMENT) du

boîtier de commande pour abaisser la plate-forme. Relâcher les boutons pour arrêter.

A

BAISSEMENT D’URGENCE

Voir la figure 2 « Commandes et indicateurs » à la page 23 pour l’emplacement de la vanne

d’abaissement d’urgence.

!

AVERTISSEMENT

Si la plate-forme ne s’abaisse pas, ne tenter EN AUCUN CAS d’en descendre par le système élévation.

Rester à l’écart du système d’élévation pendant l’utilisation de la vanne d’abaissement d’urgence.

Demander à une personne au sol d’ouvrir la vanne d’abaissement d’urgence pour abaisser la plateforme. Cette vanne est accessible par une découpe du couvercle du module d’alimentation, du côté

gauche du mât.

1. Tirer le bouton pour ouvrir la vanne.

2. Relâcher le bouton pour fermer la soupape.

NOTA : La plate-forme ne peut pas être élevée si la vanne d’abaissement d’urgence est ouverte.

!

Page 26 Guidedel’opérateur

Page 29

Transport de la plate-forme élévatrice 068017-021 UL25, UL32 et UL40

T

RANSPORT DE LA PLATE-FORME ÉLÉVATRICE

M

ODÈLES C.C

Débrancher la fiche de la boîte à batterie et retirer la boîte de l’arrière de la machine.

!

ATTENTION

La boîte à batterie est lourde, 23,6 kg (52 lb). La

soulever correctement pour éviter des problèmes

lombaires.

C

HARGEMENT

Voir la figure 6 « Chargement du modèle UL

pour le transport » à la page 28.

!

AVERTISSEMENT

S’assurer que le chargeur est complètement

engagé sur le hayon ou la plate-forme du

véhicule.

1. Relever les supports du chargeur et engager

l’axe de retenue dans le trou supérieur de la

glissière du chargeur.

2. Assujettir le chargeur sur son support avec le crochet de suspension.

3. Positionner le chargeur de manière à ce que l’arrière de la machine soit en contact avec le hayon ou la

plate-forme du véhicule.

4. Détacher le crochet de suspension et faire glisser le chargeur vers le bas jusqu’à ce qu’il soit en contact

avec le hayon ou la plate-forme du véhicule. Ensuite, repositionner le support du chargeur de manière à

ce que l’axe de retenue s’engage dans le premier trou libre au-dessus du chargeur.

5. Retirer l’axe de verrouillage et tirer la barre en T jusqu’à ce que l’axe de verrouillage s’engage dans le

trou de l’extrémité de la barre.

6. Tirer la barre en T vers le haut, en utilisant le chargeur comme pivot, jusqu’à ce que la machine bascule

en position horizontale sur la plate-forme du véhicule.

7. Tirer la base de la machine vers l’avant de la plate-forme du véhicule. La machine glisse sur le chargeur,

jusqu’à ce que ses roues arrière se trouvent sur la plate-forme du véhicule. Il est alors possible de faire

rouler la machine sur ses roues arrière et les roulettes supérieures.

8. Remettre la barre en T en position de rangement en veillant à ce que l’axe de verrouillage s’engage

dans la barre.

9. Assujettir la machine avec des sangles d’arrimage adéquates en utilisant les logements de fourches de

chariot élévateur du dessous de la base et soit de l’essieu de roulettes supérieur pour le modèle UL25

soit du bâti d’inclinaison arrière pour les modèles UL32 et UL40.

.

Figure 5 :

Chargeur

Boîte à batterie (modèles c.c. seulement)

!

!

Fichedelaboîteàbatterie

ATTENTION

Pour éviter d’endommager le mât, ne pas placer de cordes ou sangles en travers du mâtlorsdel’arrimage

de la machine pour le transport.

NE PAS trop serrer les cordes ou sangles, ce qui endommagerait la machine.

Guidedel’opérateur Page 27

Page 30

068017-021 UL25, UL32 et UL40 Transport de la plate-forme élévatrice

D

ÉCHARGEMENT

1. Détacher les sangles ou cordes d’arrimage.

2. Retirer l’axe de verrouillage et tirer la barre en T jusqu’à ce que l’axe de verrouillage s’engage dans le

trou de l’extrémité de la barre.

3. Reculer la machine jusqu’à ce que les roues arrière aient dépassé le bord du hayon ou de la plateforme du véhicule.

4. Tirer la barre en T vers le bas pour permettre à la machine de reposer sur le chargeur.

• Une fois que la machine a fini de glisser sur le chargeur, elle bascule en position verticale.

• Contrebalancer graduellement le poids du véhicule en tirant la barre en T vers le haut. Ceci permet

d’abaisser doucement la machine sur ses roues, évitant ainsi tout choc inutile.

5. Remettre la barre en T en position de rangement en veillant à ce que l’axe de verrouillage s’engage

dans la barre.

M

Glissière de

chargement

Crochet de

suspension

ODÈLES C.C

.

Remettre la batterie en place et rebrancher la fiche de la boîte à batterie en veillant à l’insérer bien à fond.

Chargement du modèle UL pour le transport

Barre en T

Axederetenue

Support du

Chargeur

Chargeur en position de chargement

Figure 6 :

chargeur

Hayon

Axederetenue

Positionnement de la barre en T

Basculement de la machine pour le chargement sur un véhicule ou le déchargement

Page 28 Guidedel’opérateur

Page 31

Passage de portes 068017-021 UL25, UL32 et UL40

P

ASSAGE DE PORTES

Les modèles UL32 et UL40 sont équipés du bâti de basculement arrière à roulettes. Lorsque la machine

est basculée en arrière sur ce support, la hauteur hors tout est réduite, ce qui permet à la machine de

traverser les portes normales.

Voir la figure 7 « Passage de portes » à la page 30.

A

BAISSEMENT

!

ATTENTION

Avant de basculer la machine en arrière sur son bâti de support, s’assurer que l’axe de retenue est inséréà

fond, que la goupille de blocage est en place et que le vérin est complètement étendu.

NE PAS laisser tomber le bâti de basculement arrière.

Se tenir à l’écart du dessous du bâti pendant le basculement en arrière de la machine

1. S’assurer que personne ni aucun obstacle se trouve sur les lieux.

2. Tout en maintenant le bâti de basculement arrière, retirer la goupille de blocage et l’axe de retenue.

3. Abaisser le bâti de basculement arrière jusqu’à ce que le trou du vérin s’aligne sur le trou d’axe du

support. Assujettir le vérin sur le support de montage supérieur à l’aide de l’axe de retenue et de la

goupille de blocage.

4. Retirer l’axe de verrouillage et tirer la barre de basculement arrière pour l’étendre en position de

basculement/levage, jusqu’à ce que l’axe de verrouillage s’engage.

5. Tirer la barre de basculement arrière vers le bas, jusqu’à ce que la machine repose contre le bâti de

basculement arrière.

• À mesure que le mât s’incline, contrebalancer le poids de la machine en augmentant la force de

poussée vers le haut sur la barre de basculement arrière. Ceci permet d’abaisser doucement la

machine sur ses roulettes de basculement arrière.

6. Tirer sur la barre de l’arrière du mât pour comprimer le vérin.

7. Remettre la barre de basculement arrière en position de rangement en veillant à ce que l’axe de

verrouillage s’engage correctement.

!

É

LÉVATION

1. Tirer la barre de mât vers le haut pour étendre le vérin.

2. Étendre complètement la barre de basculement arrière jusqu’à ce que l’axe de verrouillage s’engage.

3. Tirer la barre de basculement arrière vers le haut.

• À mesure que le mât approche de la verticale, contrebalancer le poids de la machine en augmentant

la force de poussée vers le bas sur la barre de basculement arrière. Ceci permet d’abaisser

doucement la machine sur ses roulettes.

4. Remettre la barre de basculement arrière en position de rangement en veillant à ce que l’axe de

verrouillage s’engage dans la barre.

5. Tout en maintenant le bâti de basculement arrière, retirer l’axe de retenue et redresser le bâti en position

de rangement.

6. L’assujettir au moyen de l’axe de retenue, en veillant à ce que ce dernier soit inséré à fond sans oublier

de remettre la goupille de blocage en place.

Guidedel’opérateur Page 29

Page 32

068017-021 UL25, UL32 et UL40 Passage de portes

Goupille de blocage

Vérin assujetti avec l’axederetenue

Axederetenue

Vérin

Figure 7 :

Barre de basculement arrière

Axederetenue

Abaissement et élévation avec la barre de basculement arrière

Passage de portes

Compression du vérin

Page 30 Guidedel’opérateur

Page 33

Entretien 068017-021 UL25, UL32 et UL40

E

NTRETIEN

E

NTRETIEN DES BATTERIES

!

AVERTISSEMENT

Risque d’émanations gazeuses explosives. Tenir les batteries à l’écart de toute source d’étincelles,

flammes et articles de fumeur.

Ne jamais travailler à proximité des batteries sans porter de lunettes de sécurité.

L’électrolyte (liquide de la batterie) est un liquide très corrosif. Enlever en rinçant soigneusement à l’eau

claire tout liquide renversé.

Toujours remplacer les batteries par des batteries UpRight ou de modèle agréé par le fabricant, d’un

poids de 22 kg (48 lb) chacune.

• Vérifier le niveau d’électrolyte quotidiennement surtout si la plate-forme élévatrice est utilisée en

climat chaud et sec.

• Si le niveau d’électrolyte ne recouvre pas les plaques de batterie d’au moins 10 mm (0,375 po),

ajouter de l’eau distillée seulement. NE PAS utiliser l’eau du robinet très calcaire, ce qui réduirait la

vie utile des batteries.

• Garder les bornes et le dessus de la batterie propres.

• Voir le Manuel d’entretien pour des instructions détaillées et la prolongation de la vie utile des

batteries.

C

HARGE DES BATTERIES

Charger les batteries à la fin de chaque équipe

de travail ou plus tôt si elles sont déchargées.

!

Chargeur de batterie

Batterie

Chargeur

Figure 8 :

(à l’intérieur de la boîte)

!

AVERTISSEMENT

Charger les batteries dans un endroit bien aéré.

Ne pas charger les batteries lorsque la plate-

forme élévatrice se trouve dans une zone

contenant des étincelles ou des flammes.

Les batteries seront endommagées de façon

permanente si elles ne sont pas rechargées

immédiatement aprèss’être vidées.

Ne jamais débrancher les câbles des batteries

lorsque le chargeur est en cours d’utilisation.

Garder le chargeur sec.

1. Vérifier le niveau de liquide des batteries. Si le

niveau d’électrolyte ne recouvre pas les

plaques de batterie d’au moins 10 mm (0,375 po), ajouter de l’eau distillée seulement.

2. Vérifier que la tension du chargeur est réglée sur 12 volts.

3. Brancher un cordon prolongateur adéquat sur la prise du chargeur. Brancher le cordon de rallonge sur

une prise présentant la tension et la fréquence appropriées et correctement mise à la terre.

4. Mettre le bouton du chargeur sur 12. L’ampèremètre du chargeur devrait indiquer le taux de charge.

5. Une fois la batterie complètement chargée, mettre le bouton en position d’arrêt (OFF); ne pas le mettre

en position de maintien (HOLD). Débrancher le cordon prolongateur.

!

Bouton de minuterie

NOTA : Le chargeur doit être branché sur une prise à disjoncteur différentiel.

NOTA : NE PAS utiliser la machine pendant que le chargeur est branché.

Guidedel’opérateur Page 31

Page 34

068017-021 UL25, UL32 et UL40 Programmes d’inspection et d’entretien

P

ROGRAMMES D’INSPECTION ET D’ENTRETIEN

Une inspection complète comprend les examens visuels et contrôles de fonctionnement périodiques,

ainsi que tous les réglages nécessaires au bon fonctionnement. Les inspections visuelles quotidiennes

évitent une usure anormale et prolongent la vie utile de tous les systèmes. Les opérations prescrites dans

les programmes d’inspection et d’entretien doivent être effectuées aux intervalles prescrits. Les

inspections et entretiens doivent être effectuées par un personnel compétent et familiarisé avec les

procédures mécaniques et électriques.

!

AVERTISSEMENT

!

Avant tout entretien préventif, se familiariser avec le fonctionnement de la machine.

Toujours bloquer le système d’élévation si des entretiens doivent être effectuésaveclaplate-forme

élevée.

La liste de contrôle d’entretien préventif quotidien est conçue pour les entretiens et réparations de la

machine. Faire une photocopie de la liste de contrôle d’entretien préventif quotidien et utiliser les tableaux

comme liste de contrôle lors des entretiens.

L

ISTE DE CONTRÔLE D’ENTRETIEN PRÉVENTIF QUOTIDIEN

L

ÉGENDE DU TABLEAU D’ENTRETIEN

O = Oui/acceptable

N = Non/non acceptable

R = Réparé/acceptable

R

APPORT D’ENTRETIEN PRÉVENTIF

Date :_______________________________________

Propriétaire : _________________________________

o

de modèle :________________________________

N

o

N

de série :__________________________________

Nom du technicien :____________________________

COMPOSANT VÉRIFICATION OU ENTRETIEN ÀEFFECTUER O N R

Batterie

Châssis

Câble de

commande

Commandes Vérifier le fonctionnement des commutateurs.

Mât

Vérifier le niveau d’électrolyte.

Vérifierl’état des câbles de batterie.

Vérifier l’exactitude du niveau à bulle.

Vérifier le fonctionnement des verrouillages de

stabilisateurs.

S’assurer que les roulettes ne sont pas

endommagées.

Vérifier que les tuyaux flexibles ne sont paspincés

et n’ont pas de point de frottement.

Vérifier si les soudures sont fissurées.

Vérifier l’extérieur du câble et rechercher tout

pincement, pliure ou usure.

Vérifier qu’il n’y a pas de déformations,

fissures ou rivets détachés.

COMPOSAN T VÉRIFICATION OU ENTRETIEN À EFFECTUER O N R

Système

d’abaissement

d’urgence

Fluide

hydraulique

Pompe

hydraulique

Circuit

hydraulique

Autocollants

Cage et plancher

Faire fonctionner la vanne d’abaissement d’urgence

et vérifier son bon fonctionnement.

Vérifier le niveau.

Vérifier s’il y a des fuites aux raccords.

Vérifier s’il y a des fuites.

Vérifier que lesautocollants ne sont pas décollés,

manquants ou illisibles. Remplacer au besoin.

Vérifier si les soudures sont fissurées.

Vérifier l’état du plancher.

Page 32 Guidedel’opérateur

Page 35

Liste de contrôle d’entretien préventif quotidien 068017-021 UL25, UL32 et UL40

OTES

N

:

Guidedel’opérateur Page 33

Page 36

068017-021 UL25, UL32 et UL40 Autocollants

RISQUE DE PINCEMENT

A

UTOCOLLANTS

Ces autocollants doivent être en place et en bon état pour utiliser la plate-forme. Lire, veiller à bien

comprendre et respecter les instructions des autocollants lors de l’utilisation de la plate-forme.

ATTENTION

1) 003610-300

4) 005221-300 - DC ONLY

5) 005223-303

6) 066552-300 - DC ONLY

10) 062218-301

15) 066550-310

16) 066557-311 - UL25 ONLY

20) 069338-300

23) 062840-300

ATTENTION

RISQUE DE BASCULEMENT

25) 062821-302

26) 062792-300

17) 062217-300

27) 062725-302

ATTENTION

RESTEZ A L' ECART

ATTENTION

18) 066553-302

28) 062575-301

19) 066551-305

11) 066554-303

34) 030768-002

14) 061205-303

Page 34 Guidedel’opérateur

Page 37

Autocollants 068017-021 UL25, UL32 et UL40

Figure 9 :

Emplacement des autocollants de sécurité

Guidedel’opérateur Page 35

Page 38

068017-021 UL25, UL32 et UL40 Caractéristiques

C

ARACTÉRISTIQUES

ARTICLE UL 25 UL 32 UL 40

Capacité de la plate-forme 159 kg (350 lb) 136 kg (300 lb) 136 kg (300 lb)

Nombre max. de personnes 1 personne 1 personne 1 personne

Hauteur

Hauteur de travail

Hauteur maximum de la plate-forme 7,62 m (25 pi)9,75m(32 pi) 12,19 m (40 pi)

Hauteur minimum de la plate-forme 38 cm (15 po)38cm(15 po)38cm(15 po)

Dimensions

Poids total

Poids avec option c.c.

Largeur hors tout (stabilisateurs étendus) 1,5 m (59 po)2,06m(81 po)2,34m(92 po)

Longueur hors tout (stabilisateurs étendus) 1,42 m (56 po)1,98m(78 po)2,26m(89 po)

Dimensions repliée

Hauteur 1,98 m (78 po)2,44m(96 po)2,84m(112 po)

Largeur

Profondeur

Hauteur de rangement diagonal S.O. 1,98 m (78 po)1,98m(78 po)

Longueur de rangement diagonal S.O. 2,53 m (99,5 po)2,9m(114 po)

Tension du circuit électrique

Moteur électrique c.a.

Alimentation électrique c.c.

Chargeur de batterie

Capacité du réservoir hydraulique 5,7 L (1,5 gal US)

Pression hydraulique maximum 165 bar (2400 psi)

Fluide hydraulique

Température normale : au-dessus 0 °C [32 °F]

Basse température : au-dessous 0 °C [32 °F]

Température extrême : au-dessous -17 ° C [0 °F]

Système de commande

Garde-corps 1,1 m (43,5 po)dehaut

Niveau sonore

9,62 m (31,6 pi)11,75m(38,5 pi)14,19m(46,6 pi)

345 kg (760 lb) 390 kg (860 lb) 422 kg (930 lb)

29 kg (64 lb) 29kg(64 lb) 29kg(64 lb)

74 cm (29 po)74cm(29 po)74cm(29 po)

1,24 m (49 po)1,24m(49 po)1,24m(49 po)

120 V c.a. 60 Hz ou 220 V c.a. 50/60 Hz

1 – batterie de 12 volts, groupe 27 105 A/h, poids minimum 22 kg (48 lb)

Automatique, 120 V c.a. 60 Hz ou 220 V c.a. 50 Hz

Sortie:10A,12Vc.c.

ISO no46

ISO no32

ISO no15

Appuyer sur les boutons de levage et d’abaissement et

actionner le bouton champignon rouge d’ARRÊT D’URGENCE

*Ces caractéristiques peuvent être changées sans préavis. Les performances peuvent être réduites par

temps chaud ou en cas d’utilisation intensive.

La liste des pièces et les consignes d’entretien détaillées se trouvent dans le Manuel d’entretien.

La machine est conforme ou supérieure à toutes les directives de machinerie CE et GS.

Page 36 Guidedel’opérateur

Page 39

BETRIEBSANLEITUNG

WARNUNG

Alle Bediener müssen die Sicherheitsregeln und Betriebsanleitungen gründlich durchlesen,

verstehen und befolgen, bevor sie an irgendeiner UpRight-Hocharbeitsbühne Wartungsarbeiten

ausführen oder diese in Betrieb nehmen.

Sicherheitsregeln

Sicherheitsregeln

SicherheitsregelnSicherheitsregeln

Gefahr des Umkippens

Gefahr der

Gefahr der

Gefahr derGefahr der

Tötung durch

Tötung durch

Tötung durchTötung durch

Stromschlag

Stromschlag

StromschlagStromschlag

Gefahr des Umkippens Kollisionsgefahr

Gefahr des UmkippensGefahr des Umkippens

Kollisionsgefahr Absturzgefahr

KollisionsgefahrKollisionsgefahr

Absturzgefahr

AbsturzgefahrAbsturzgefahr

Die Arbeitsbühne

hochfahren, wenn alle

DIESE

MASCHINE IST

NICHT ISOLIERT!

DIESE MASCHINE NUR IN INNENRÄUMEN BENUTZEN! Diese Maschine nicht im Freigelände einsetzen.

VERWENDUNG DER HOCHARBEITSBÜHNE: Diese Hocharbeitsbühne dient zum Heben von Personen und deren Werkzeugen sowie des für

die Arbeit benötigten Materials. Sie ist für die Ausführung von Reparatur- und Montagearbeiten an hochgelegenen Arbeitsplätzen (Decken,

Kränen, Dachkonstruktionen, Gebäuden usw.) vorgesehen. Sämtliche anderen Einsatzzwecke der Hocharbeitsbühne sind verboten!

DIESE HOCHARBEITSBÜHNE IST NICHT ISOLIERT! Aus diesem Grund ist es dringend erforderlich, von stromführenden Teilen elektrischer

Geräte einen Sicherheitsabstand einzuhalten!

Weitere Anweisungen finden Sie unter „Besondere Einschränkungen“ auf Seite 40.

Die Verwendung bzw. der Betrieb der Hocharbeitsbühne als Hebevorrichtung oder Kran (Heben oder Absenken von Lasten) ist verboten!

Weitere Anweisungen finden Sie unter „Besondere Einschränkungen“ auf Seite 40.

Alle Lasten gleichmäßig auf der Arbeitsbühne VERTEILEN.

Maschine NIEMALS in Betrieb nehmen, ohne zuvor das Arbeitsgelände auf Bodengefahren, wie z.B. Löcher, abschüssige Stellen,

Unebenheiten, Rinnsteine oder Schutt zu untersuchen und diese zu umgehen.

Maschine nur auf Standflächen BETREIBEN, deren Tragfähigkeit für die Radlasten ausreicht.

BEI NOTFÄLLEN den NOTAUSSCHALTER drücken, um alle Antriebsfunktionen zu deaktivieren.

Es ist verboten, das Geländer der Arbeitsbühne zu besteigen, auf dieser zu stehen oder von der Arbeitsbühne her Gebäude, Stahl- oder

vorgefertigte Betonbauteile zu besteigen!

Der Abbau der Tür oder anderer Teile des Geländers ist verboten! Es ist immer zu kontrollieren, ob die Tür geschlossen und sicher

verriegelt ist!

Es ist verboten, die Tür offen zu lassen (mit Befestigungsbändern offen zu halten), wenn die Arbeitsbühne angehoben wird!

Es ist verboten, die Höhe bzw. Reichweite der Arbeitsbühne durch Aufstellen von Leitern, Gerüsten oder ähnlichen Gegenständen

zu vergrößern!

An der Maschine NIEMALS Wartungsarbeiten durchführen, wenn die Arbeitsbühne hochgefahren ist, ohne das Hubgestell zu blockieren.

Maschine vor Benutzung gründlich auf gerissene Schweißnähte, lose oder fehlende Metallteile, Hydrauliklecks, lose Kabelanschlüsse und

beschädigte Kabel oder Schläuche ÜBERPRÜFEN.

Vor Benutzung SICHERSTELLEN, dass alle Schilder angebracht und gut lesbar sind.

Maschine NIEMALS in Betrieb nehmen, wenn diese beschädigt ist, nicht einwandfrei funktioniert oder deren Schilder beschädigt

sind oder fehlen.

Die Außerkraftsetzung von Sicherheitseinrichtungen ist verboten und stellt für die auf der Hocharbeitsbühne und in ihrer Reichweite

befindlichen Personen eine Gefahr dar.

Beim Laden von Batterien wird explosives Wasserstoffgas freigesetzt.

Modifikationen der Hocharbeitsbühne sind verboten bzw. nur mit Genehmigung von UpRight zulässig.

Arbeitsbühne NACH GEBRAUCH vor unbefugter Benutzung sichern, indem die Schlüsselschalter ausgeschaltet werden und der Schlüssel

abgezogen wird.

vier (4) Hilfstützen

vorschriftsmäßig

montiert sind.

NUR

Arbeitsbühne

NIEMALS

Fahrwerk auszurichten.

hochfahren,

ohne vorher das

NIEMALS

Hebebühne betätigen,

die UpRight-

wenn sich Personen

oder Material auf

der Arbeitsbühne

befinden oder diese

ausgefahren ist.

Arbeitsbühne

NIEMALS

fahren, ohne vorher

sicherzustellen, dass

oberhalb der Maschine

keine Hindernisse oder

sonstigen Gefahren

in Position

bestehen.

NIEMALS

Schutzgeländer oder

dessen mittlere

Schiene steigen,

darauf stehen oder

auf das