Page 1

MANUAL

Part Number 515066-200

July 2017

Serial Number UL25-01-060166 and after

Serial Number UL25-01-060167 and after

Serial Number UL32-01-060036 and after

Serial Number UL32-01-060037 and after

Serial Number UL40-01-060200 and after

Serial Number UL40-01-060201 and after

PARTS & SERVICES

Page 2

Page 3

UL25, UL32 & UL40

ENGLISH

When contacting Snorkel for service or parts information, be sure to include the model and serial

numbers from the equipment name plate. Should the name plate be missing, the serial number

is also stamped on top of the chassis above the front axle pivot.

USA Europe

TEL: +1 (559)443 6600 TEL: +44 (0) 1952 200

FAX: +1 (559)268 2433 FAX: +44 (0) 1952 229

www.snorkellifts.com

SERIAL

NUMBER

MODEL

NUMBER

NON-LOADED

MACHINE

WEIGHT

lbs

kg

MAXIMUM

WHEEL

LOAD

lbs

kg

ENGINE

POWERED

MODELS

hp

kW

BATTERY

POWERED

MODELS

V

DRIVE

MOTORS

BATTERIES

V

Ah

MONTH / YEAR

OF MANUFACTURE

MAXIMUM

PLATFORM

HEIGHT

RATED NUMBER

OF OCCUPANTS

ft

m

MAXIMUM

DRIVE

HEIGHT

ft

m

MAXIMUM

PLATFORM

LOAD

MAXIMUM

ALLOWABLE

WIND SPEED

mph

m/s

MAXIMUM

PLATFORM

REACH

ft

m

MAXIMUM

ALLOWABLE

MANUAL FORCE

(SIDE PULL)

lbs

N

Indoors

Outdoors

SLOPE SENSOR ALARM SETTING

FRONT

TO BACK

deg

SIDE

TO SIDE

deg

MAXIMUM

OUTRIGGER

LOAD

lbs

kg

MAXIMUM

GRADEABILITY

%

CHARGER

INPUT

V

ASSEMBLED IN

Axle weights wi th machine in the stowed position.

lbs

lbs

kg

kg

DRIVE AXLE

STEER AXLE

Indoors

Outdoors

CAUTION

ONLY trained and authorised personnel may operate this machine.Consult the Operation Manual before using this machine.

DO NOT make any changes to this machine, any changes made will invalidate the manufactures warranty and

may contravene legislation.

Stamped Serial

Number on Rear Axle

The serial number is available on

nameplate

Page 4

UL25, UL32 & UL40 SERVICE AND PARTS MANUAL

FOREWORD

This manual is divided into six sections namely;

SECTION 1: INTRODUCTION

General description and machine specications.

SECTION 2: OPERATION AND SPECIFICATION

Information on how to operate the work platform

and how to prepare it for operation.

SECTION 3: SERVICE AND REPAIR

Preventative maintenance and service information.

SECTION 4: TROUBLESHOOTING

Causes and solutions to typical problems.

SECTION 5: SCHEMATICS

Schematics and valve block diagrams with

description and location of components.

SECTION 6: ILLUSTRATED PARTS BREAKDOWN

Complete parts list with illustrations.

SPECIAL INFORMATION

NOTE: Provides helpful information.

!

D A N G E R

!

Indicates an imminently hazardous situation which if not avoided, will result in

death or serious injury.

!

W A R N I N G

!

Indicates a potentially hazardous situation which if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous situation which if not avoided,

may result in minor or moderate injury.

!

C A U T I O N

!

Page 5

WORKSHOP PROCEDURES

All information contained in this manual is based on the latest product information available at the

time of printing. We reserve the right to make changes at any time without notice.

No part of this publication may be reproduced, stored in retrieval system or transmitted in any

form by any means whether electronic, mechanical, photocopying, recording or otherwise with-

out the prior written permission of the publisher. This also includes text, gures and tables.

Detailed prescriptions of standard workshop procedures, safety

principles and service operations are not included.

Please note that this manual contains warnings and cautions

against some specic service methods which could cause personal

injury or could damage a machine or make it unsafe.

Please understand that these warnings cannot cover all conceivable

ways in which service, whether or not recommended by Snorkel,

might be carried out, or of the possible hazardous consequences of

each conceivable way, nor could snorkel investigate all such ways.

Anyone using service procedures or tools whether or not recom-

mended by Snorkel must satisfy themselves thoroughly that neither

personal saftey nor machine safety will be jeopardized.

!

C A U T I O N

!

Page 6

Page 7

Page 1 - 1UL25/UL32/UL40

INTRODUCTION

INTRODUCTION

PURPOSE

The purpose of this service and parts manual is to provide instructions and illustrations for

the operation and maintenance of this work platform manufactured by Snorkel.

SCOPE

The manual includes procedures for proper operation, maintenance, adjustment and repair

of this product as well as recommended maintenance schedules and troubleshooting.

GENERAL DESCRIPTION

The work platform consists of the platform, controller, elevating assembly, power module,

control module and chassis.

!

W A R N I N G

!

DO NOT use the work platform without

guardrails properly assembled and in place

PLATFORM

The platform has a reinforced steel oor, 1.1 m (43.75 inches) high guardrails with a mid rail,

152 mm (6 inches) toe boards and an entry gate at the rear of the platform.

Features of the UL25/UL32/UL40 is shown in Figure 1-1.

1. Platform

2. Mast

3. Chassis

4. Outriggers

5. Drop bar

6. Lower Guardrail

Figure 1-1: Work platform

1

2

34

5

6

Page 8

Page 1 - 2 UL25/UL32/UL40

PLATFORM CONTROLLER

The platform controller contains the controls to operate the machine. It is located at the front

of the platform. A complete explanation of control functions can be found in section 2.

ELEVATING ASSEMBLY

The platform is raised and lowered by the elevating assembly. The hydraulic pump driven

by the engine, powers the cylinders. Solenoid operated valves control raising and lowering.

CHASSIS

The chassis is a structural frame that supports all the components of the SL26/30SL work

platform.

PURPOSE OF EQUIPMENT

The objective of the work platform is to provide a quickly deployable, self propelled, variable

height work platform to elevate personnel and materials to overhead work areas.

INTRODUCTION

!

D A N G E R

!

The elevating function shall ONLY be used when the work

platform is level and on a rm surface.

Page 9

Page 2 - 1UL25/UL32/UL40

OPERATION AND SPECIFICATION

Page 10

Page 2 - 2 UL25/UL32/UL40

SAFETY RULES

WARNING

All personnel shall carefully read, understand and follow all safety rules and operating instructions before operating or

performing maintenance on any SNORKEL aerial work platform.

USE OF THE AERIAL WORK PLATFORM: This aerial work platform is intended to lift a person or persons and their tools in-

cluding material needed for a job. The work platform is designed to be used for repair and assembly jobs ONLY at overhead work

places (ceilings, cranes, roof structures, buildings, etc.).

The use and operation of the aerial work platform as a lifting tool or a crane is prohibited!

Climbing up the railing of the platform, standing on or stepping from the platform unto buildings, steel or prefab concrete structures

etc is prohibited!

NEVER use the machine if damaged, not functioning properly, has damaged or missing decals.

NEVER attach notice boards etc. to the platform as this will increase the wind loading.

INSULATION: The aerial work platform is not insulated. It is imperative to keep a safe distance from live parts or electrical

equipment. DO NOT get closer than the minimum distance recommended by the “National Regulations”.

PLATFORM CAPACITY: Exceeding the specied permissible maximum load is prohibited! Refer to platform capacity on page 24

for details.

MANUAL FORCE: NEVER exceed the manual force allowed for this machine. Refer to special limitations on page 9 for details.

LOAD DISTRIBUTION: Ensure that all loads are distributed evenly on the platform.

SURVEILLANCE: NEVER operate the machine without rst surveying the work area for surface hazards such as holes, drop-offs,

bumps, curbs or debris and avoiding them.

WHEEL LOAD: OPERATE the machine only on surfaces capable of supporting wheel load.

WIND SPEED: NEVER operate the machine when the wind speed exceeds the machine’s wind speed rating. Refer to the Beaufort

scale for details.

EMERGENCY STOP: In case of an emergency, push the EMERGENCY STOP switch to de-activate all powered functions.

ALARM: If the alarm sounds while the platform is elevated, STOP operation immediately and carefully lower the platform. Move the

machine to a rm, level surface.

SWING GATE: Dismantling the entry gate or other railing components is prohibited! Always make certain that the entry gate is

closed and securely locked.

It is prohibited to keep the entry gate in an open position when the platform is raised.

Extending the height of the platform by placing ladders, scaffolds or similar devices on the platform is prohibited!

SERVICING: NEVER perform service on machine while platform is elevated without blocking the elevating assembly. Refer to

“maintenance” for details.

INSPECT: the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks, loose wire connections and

damaged cables or hoses before usage.

DECALS: VERIFY that all labels are in place and legible before using the machine.

BATTERIES: NEVER charge batteries near sparks or open ame. Charging batteries emit explosive hydrogen gas.

STORAGE: AFTER USE, secure the work platform from unauthorised use by turning the key switch off and removing the key.

HARNESS: Harness attachment points are provided on the platform and the manufacturer recommends the usage of a fall restraint

harness especially where required by national safety regulations.

Modications to the aerial work platform are prohibited or permissible only at the approval of the manufacturer.

ENVIRONMENTAL TEMPERATURE LIMITATION: The machine is primarily for use in normal ambient temperatures and conditions

ranging between 50°C to -20°C

INDOOR USE: This machine is for indoor use only. Do not use outdoors.

ELECTROCUTION

HAZARD

TIP OVER

HAZARD

COLLISION

HAZARD

FALL

HAZARD

TRAPPING/CRUSHING

HAZARD

THIS MACHINE IS

NOT INSULATED

NEVER ELEVATE THE

PLATFORM OR DRIVE

THE MACHINE WHILE

ELEVATED UNLESS

THE MACHINE IS ON A

FIRM LEVEL SURFACE

NEVER POSITION

THE PLATFORM

WITHOUT FIRST

CHECKING FOR

OVERHEAD OB-

STRUCTIONS OR

OTHER HAZARDS

NEVER CLIMB,

STAND OR SIT

ON PLATFORM

GUARDRAILS OR

MIDRAIL

BEWARE OF CRUSH-

ING HAZARD WHEN

HOLDING HANDRAILS

WHILE THE PLATFORM

IS MOVING IN CLOSE

PROXIMITY TO OTHER

OBJECTS

NEVER ATTEMPT TO

PUSH THE SNORKEL

LIFT WITH PEOPLE

OR MATERIALS ON

THE PLATFORM OR

WITH THE PLATFORM

ELEVATED.

NEVER ELEVATE THE

PLATFORM UNLESS

ALL 4 OUTRIGGERS

HAVE BEEN PROP-

ERLY INSTALLED

PUSH

HAZARD

STABILITY

HAZARD

Page 11

Page 2 - 3UL25/UL32/UL40

Harness attachment points are provided in the platform and the manufacturer recommends the usage of a fall

restraint harness, especially where required by national safety regulations.

All harness attachment points on SNORKEL vehicles have been tested with a force of 3,650 lbs (16.3 KN)

per person.

See below examples of harness attachment points used on SNORKEL vehicles with their corrosponding rating;

Type 1.

Harness attachment point Type 1. is rated for one lanyard attachment per loop as shown in the

illustrations depending upon platform occupancy rating (see operators manual & decals).

Type 2.

Harness attachment point Type 2. is rated for two

lanyard attachments per loop as shown in the

illustrations depending upon platform occupancy rating

(see operators manual & decals).

Type 3.

Harness attachment point Type 3. is rated for one

lanyard attachment per loop as shown in the

illustrations depending upon platform occupancy rating

(see operators manual & decals).

Top View

2 lanyard

attachments

1 lanyard

attachment

1 lanyard

attachment

Top View

Front View

Type 4.

Harness attachment point Type 4. is rated for one

lanyard attachment per loop as shown in the

illustrations depending upon platform occupancy rating

(see operators manual & decals).

1 lanyard

attachment

NOTE: There can be more harness attachment points per machine than the

maximum number of occupants allowed in a platform. Refer to

the platform decal & specifications table listed in the operators

manual for the correct occupancy rating before use.

Type 1.

Top View Top View

2 lanyard

attachments

Top View

1 lanyard

attachment

Top View

1 lanyard

attachment

SAFETY NOTICE

Page 12

Page 2 - 4 UL25/UL32/UL40

NOTE:

1. To bypass any safety equipment is prohibited and presents a danger for the person/persons on

the aerial work platform and in its working range.

2. Modication to the aerial work platform is prohibited or permissible only at the approval of Snor-

kel.

3. The driving of MEWP’S on the public highway is subject to national trafc regulations.

4. It is important to ensure that the machine meets the requirements of stability during use, transportation, assembly, dismantling when out of service, testing or foreseeable breakdowns.

5. Never use a machine that is damaged or not functioning properly. Verify that all labels are in

place and legible before using.

SAFETY NOTICE

Page 13

Page 2 - 5UL25/UL32/UL40

QUA 217 Iss1 EC Declaration UL

Model Modello

Modell Verticaal model

UL32DC

Modele Malli

Modelo

Serial number Serienummer

Matricola Numero de serie UL32-01-060004

ajanumero Matricola

Holder of Technical File

Snorkel

Inhaber des technischen Dossiers Vigo centre

Titulaire du dossier technique Washington

Titular del expediente técnico Tyne and Wear

Houder van een technisch dossier NE38 9DA

Innehavaren av technichal fil England

Voer tekst in om hier te vertalen

Haltija technichal tiedosto

Titolare del fascicolo technichal

Innehaveren av technichal fil

Signed for Snorkel Jan-15

EC Declaration of Conformity of Machinery 2006/42/EC

EC-Konformitätserklärung für Maschinen 2006/42/EC

Declaration De Conformite CE pour les Machines 2006/42/EC

Declaracion De Conformidad CE Para Maquinaria 2006/42/EC

Dichiarazione Di Conformità CE Per Le Macchine 2006/42/EC

CE Conformiteitsverklaring voor Machinerie 2006/42/EC

EU Deklaration Avseende Överensstammelse För Maskinutrustning 2006/42/EC

EF-Samsvarserklaering For Maskiner 2006/42/EC

EF-Overensstemmelseserklaering for Maskiner 2006/42/EC

EU Vaatimustenmukaisuusvakuutus 2006/42/EC

Manufacturer

Snorkel

Hersteller Vigo Centre, Washington

Fabrikant Tyne and Wear, England , NE38 9DA

Produsent TEL:+44(0)845 1557 755

Tillverkare

FAX:+44

(

0)845 1557 756

Valmistaja

Fabbricante

Fabricante

Fabricant

Authorized Representative Snorkel Europe

Autorisierte Vertretung Vigo Centre, Washington

Representant autorise Tyne and Wear, England

Representante autorizado Tel: +44 (0) 845 1557 755

Mandatario FAX: +44 (0) 845 1557 756

Erkend vertegenwoordiger

Auktoriserad representant

Autorisert representant

Represenentant

Valtuutettu edustaja

Description .................................... Aerial Work Platform

Bezeichnung ................................... Arbeitsbühne

Description ...................................... Plate-forme elevatrice de personnel Descripcion

........................................................ Platforma aerea de trabajo con motor

Descrizione ..................................... Piattaforma di sollevamento motorizzata

Beschrijving..................................... Mechanisch aangedreven werkplatform

Beskrivning ..................................... Höj-och sänkbar arbetsplattform

Beskrivelse...................................... Selvgående arbetsplattform

Beskrivelse...................................... Motordrevet lofteplatform

Kuvaus ............................................ Konevoimalla toi

miva nostolava

Selvgående personarbetslift

Manufacturing Quality Manager

Datum

Fecha

Data

Dato

Paivamaara

Date

Page 14

Page 2 - 6 UL25/UL32/UL40

CONTENTS

INTRODUCTION 2-7

GENERAL DESCRIPTION 2-7

SPECIAL LIMITATIONS 2-8

PLATFORM CAPACITY 2-8

MANUAL FORCE 2-8

LIFT LEVEL SENSOR INTERLOCK 2-8

CONTROLS/PRE-OPERATION 2-9

PLATFORM CONTROLS AND INDICATORS DC 2-9

CHASSIS CONTROLS AND INDICATORS DC 2-9

PLATFORM CONTROLS AND INDICATORS AC 2-10

CHASSIS CONTROLS AND INDICATORS AC 2-10

PRE-OPERATION SAFETY INSPECTION 2-11

OUTRIGGER INTERLOCK TEST 2-12

LEVEL SENSOR INTERLOCK TEST 2-12

SYSTEM FUNCTION INSPECTION 2-13

OPERATION 2-14

OUTRIGGER INSTALLATION 2-14

PLATFORM ELEVATION 2-14

PLATFORM LOWER 2-14

BATTERY CONTROLLED LED 2-14

EMERGENCY PROCEDURE 2-15

EMERGENCY LOWERING 2-15

TRANSPORTATION 2-16

AFTER USE EACH DAY 2-16

TRANSPORTING THE WORK PLATFORM 2-16

FORKLIFT 2-16

TRUCK 2-16

DC MODELS 2-16

LOADING 2-19

UN-LOADING 2-18

PASSAGE THROUGH A DOORWAY 2-18

LOWERING 2-19

RAISING 2-19

MAINTENANCE 2-21

BATTERY MAINTENANCE 2-21

BATTERY CHARGER 2-21

HYDRAULIC FLUID 2-22

HYDRAULIC FLUID CHECK 2-22

INSPECTION AND MAINTENANCE 2-23

DAILY PREVENTATIVE MAINTENANCE SCHEDULE 2-24

SPECIFICATIONS 2-25

WASTE REMOVAL AND DISPOSAL 2-26

Page 15

Page 2 - 7UL25/UL32/UL40

INTRODUCTION

INTRODUCTION

This manual covers the operation of the UL25, UL32 and UL40 work platforms. This manual must

be stored on the machine at all times. Read, understand and follow all safety rules and operating

instructions before attempting to operate the machine.

GENERAL DESCRIPTION

!

W A R N I N G

!

DO NOT use the maintenance platform without guardrails properly

assembled and in place.

1. Platform

2. Mast

3. Chassis

4. Outriggers

5. Guardrail

6. Entry drop bar

7. Chassis controls

8. Power unit

• Motor

• Hydraulic reservoir

9. Battery box (DC units)

• Battery

• Battery charger

10. Casters

11. Rear wheels

12. Screw jacks

13. Loader assembly

14. Emergency lowering valve

2

7

5

1

3

10

11

12

4

6

8

9

13

14

Figure 2-1: UL25/UL32/UL40 work platform.

Page 16

Page 2 - 8 UL25/UL32/UL40

SPECIAL LIMITATIONS

SPECIAL LIMITATIONS

Elevating the work platform is limited to rm, level surfaces only. This machine is rated for indoor

use only. All four outriggers must be properly installed before operating the machine.

!

D A N G E R

!

The elevating function shall ONLY be used when the work platform

is levelled and on a rm surface. DO NOT attempt to move this

machine with the mast in an elevated position. The machine weighs

in excess of 760 lb (345 kg) and must only be manoeuvered on rm,

level ground.

PLATFORM CAPACITY

The platform capacity for the machine including occupants is determined by model and options.

This is listed under “specications”.

!

D A N G E R

!

DO NOT exceed the maximum platform

occupancy limits for this machine

MANUAL FORCE

Manual force is the force applied by the occupants to objects such as walls or other structures outside the work platform. The maximum allowable manual force is limited to 200N (45 lbs.) of force.

!

D A N G E R

!

DO NOT exceed the maximum amount of

manual force for this machine.

LIFT LEVEL SENSOR INTERLOCK

The platform lift function is interlocked through a level sensor system. If the chassis is tilted more

than 1.5 degrees in either direction, an alarm will sound when the power is turned on and the lift

function will not operate. When the alarm sounds, only the platform lower function will operate.

Page 17

Page 2 - 9UL25/UL32/UL40

CONTROLS/PRE-OPERATION

PLATFORM CONTROLS AND INDICATORS DC MODELS

1. Emergency stop button

2. Platform raise button

3. Enable button

4. Platform lower button

5. Battery condition indicator

Figure 2-2: Platform controls and indicator locations

CHASSIS CONTROLS AND INDICATORS DC MODELS

1. Emergency stop button

2. Diagnostics port

3. Enable button

4. Platform raise button

5. Platform lower button

6. Power indicator

7. Control selector switch

Figure 2-3: Chassis controls and indicator locations

514826-000

1

2

3

4

5

514441-001

0

1

2

3

4

6

7

5

Page 18

Page 2 - 10 UL25/UL32/UL40

CONTROLS/PRE-OPERATION

PLATFORM CONTROLS AND INDICATORS AC MODELS

1. Emergency stop button

2. Platform raise button

3. Enable button

4. Platform lower button

5. Emergency lower switch

NB: Use emergency lower switch in

conjunction with the enable button (3)

and the platform lower button (4) to lower

the platform in the event of a mains

power failure only.

Figure 2-4: Platform controls and indicator locations

CHASSIS CONTROLS AND INDICATORS AC MODELS

1. Emergency stop button

2. Diagnostic port

3. Circuit breaker (MCB)

4. Enable button

5. Platform raise button

6. Platform lower button

7. Control selector switch

Figure 2-5: Chassis controls and indicator locations

514825-000

1

2

3

4

5

514442-001

0

1

2

3

4

7

6

5

Page 19

Page 2 - 11UL25/UL32/UL40

CONTROLS/PRE-OPERATION

PRE-OPERATION SAFETY INSPECTION

NOTE: Carefully read, understand and follow all safety rules, operating instructions, labels

and National Safety Instructions/Requirements. Perform the following steps each day before use.

1. Check that all 4 outriggers are properly installed.

2. Check that the base is level.

3. AC units: Connect the power unit plug to an approved extension cord.

4. DC units: Verify that the batteries are charged.

5. Perform the safety interlock tests.

6. Check for external damage to the mast.

7. Check the level of the hydraulic uid with the platform fully lowered using the following procedures;

• Remove the reservoir cap and check the uid level on the dipstick.

• Add hydraulic uid if necessary. Oil should be visible on the end of the dipstick.

8. Check that the uid level in the batteries is correct. Refer to “Battery maintenance”.

9. Check that all guardrails are in place and all fasteners are properly tightened.

10. Inspect the machine thoroughly for cracked welds and structural damage, loose or missing

hardware, hydraulic leaks, damaged control cable and loose wire connections.

Page 20

Page 2 - 12 UL25/UL32/UL40

CONTROLS/PRE-OPERATION

OUTRIGGERS INTERLOCK TEST

!

D A N G E R

!

Never perform this test from the platform.

1. Properly install all 4 outriggers and level the base.

2. Release the tension on 1 outrigger by turning the screw jack counter clockwise until the indicator light is no longer lit.

3. While standing on the ground, activate the control panel to elevate the platform. The platform

should not elevate.

4. Re-level the base.

5. Repeat steps 2, 3 and 4 until all 4 outriggers have been tested.

6. Repeat steps 1 to 5 using the platform controls.

!

D A N G E R

!

DO NOT use a machine that elevates when the

tension has been released on an outrigger. The

machine must be repaired before using.

!

D A N G E R

!

DO NOT use a machine if any outrigger indicator light remains illumi-

nated when the related outrigger screw jack foot is clear of the ground.

The machine must be repaired before use.

LEVEL SENSOR INTERLOCK TEST

1. Properly install all 4 outriggers and ensure they all have tension applied. All 4 outrigger lights

should be on.

2. Adjust the outriggers so that the platform is tilted by more than 1.5 degrees.

3. Verify that the tilt alarm sounds and using the ground control panel, the platform should not

elevate.

4. Repeat steps 1 to 3 using the platform controls.

Page 21

Page 2 - 13UL25/UL32/UL40

SYSTEM FUNCTION INSPECTION

Refer to “Controls and indicators” for the locations of various controls and indicators.

!

W A R N I N G

!

Stand Clear of the work platform while performing the

following checks. Check above the work platforms for ob-

structions and electrical conductors.

NOTE: The platform will not elevate unless all four outriggers are properly installed with

screw jack pads rmly in contact with the oor and each outrigger indicator lamp lit. The

chassis is level to 1.0 degree or less in all directions.

Perform all tests prior to operating the machine.

1. Pull the chassis emergency stop switch to the ON position.

2. Turn the key to “ground controls”.

3. Pull the platform emergency stop switch to the ON position.

4. Push both the middle and the top buttons (enable and up) on the ground control box at the

same time to elevate the platform. Release the buttons to stop.

5. Push both the middle and the bottom buttons (enable and down) at the same time to lower the

platform. Release the buttons to stop.

6. Open the emergency lowering valve to verify proper operation.

7. Push the chassis emergency stop switch to verify proper operation. All machine functions

should be disabled. Pull out the chassis emergency stop switch to resume.

8. Turn the key to platform controls and enter the platform ensuring the drop bar gate is correctly

closed.

9. Repeat tests 4 & 5 from the platform controls.

10. Push the platform emergency stop switch to verify proper operation. All machine functions

should be disabled. Pull out the platform emergency stop switch to resume.

Page 22

Page 2 - 14 UL25/UL32/UL40

OPERATION

Before operating the work platform, ensure that the pre-operation safety inspection has been com-

pleted and that any deciencies have been corrected. Never operate a damaged or malfunctioning

machine. The operator must be thoroughly trained on this machine.

NOTE: The platform will not elevate unless all 4 outriggers are properly installed with screw

jack pads rmly in contact with the oor and each outrigger indicator lamp lit. The chassis

is level to 1.0 degrees or less in all directions.

1. AC units: Connect the power unit plug to an approved extension cord.

2. DC units: Verify that the battery charger is turned off and that the extension cord is removed.

3. Pull the chassis emergency stop switch to the ON position.

4. Turn the key to platform.

5. Enter the platform by raising the drop bar.

6. Ensure the drop bar falls freely to its lowered position.

OUTRIGGER INSTALLATION

1. Remove the outriggers from the storage locations

on the sides of the mast.

2. Insert the outriggers into the outrigger socket at the

base.

3. Ensure the locking pin engages with the hole at the

end of the outrigger. Pull the outrigger outwards to

ensure it is engaged.

4. Repeat step 3 for the rest of the outriggers. Make

sure all 4 locking pins are engaged.

5. Level the base, centring the bubble in the orbit

level on the base by adjusting the screw jacks (turn

clockwise) at the end of each outrigger. Do not

release the tension (turn counterclockwise) on an

outrigger to level the base.

6. All 4 screw jack pads must be in solid contact with

a rm surface and each outrigger indicator light must be lit before the platform is elevated.

PLATFORM ELEVATION

1. Check that the area above the platform is clear before elevating the platform.

2. Pull the platform emergency stop switch to the ON position.

3. Push both the middle and the top buttons (enable and up) on the control box at the same time

to elevate the platform. Release the buttons to stop.

• In the event of an emergency, push the emergency stop button.

4. Visually inspect the mast assembly for cracked welds and structural damage, loose hardware,

hydraulic leaks, loose wire connections and erratic operation. Check for missing or loose parts

PLATFORM LOWER

1. Check that the area below the platform is clear before lowering the platform.

2. Push both the middle and bottom buttons (enable and down) at the same time to lower the

platform. Release the buttons to stop.

BATTERY CONDITION LED

The battery condition LED illuminates to give an approximate indication of the amount of charge

left to be used as follows:

Not illuminated 100% to 40%

Slow ash 40% to 20%

Fast ash 20% to 10%

Steady on less than 10%

NOTE: To maximise battery life, always re-charge the battery after use and never store the

machine for extended periods without rst fully re-charging the battery.

Figure 2-6: Outrigger installation

components

Table 2-1: Battery condition indicators.

Screw jack

Bubble level

Indicator lights

Locking pin

Page 23

Page 2 - 15UL25/UL32/UL40

EMERGENCY LOWERING

!

W A R N I N G

!

If the platform should fail to lower, never climb down

the elevating assembly.

Stand clear of the elevating assembly while operat-

ing the emergency lowering valve knob.

The emergency lowering valve can be reached only

from the ground. When needed to be open to lower

the platform, ask for assistance from the ground. The

valve is located at the rear of the machine as shown in

Figure 9.

1. Pull the knob to open the valve.

2. To close the valve, release the knob.

NOTE: The platform will not elevate if the emergency lowering valve is open.

AC UNITS ONLY

In the event of a mains power failure, the platform can

be lowered from the platform controls by operating the

emergency lower switch, the enable button and the

platform lower button at the same time.

NOTE: This procedure should only be used in the event of an emergency.

Figure 2-7: Emergency lowering valve

location

Emergency

lowering valve

EMERGENCY PROCEDURE

Page 24

Page 2 - 16 UL25/UL32/UL40

TRANSPORTATION

AFTER USE EACH DAY

1. Ensure that the platform is fully lowered.

2. Park the machine on a rm level surface, preferably under cover. Secure against vandals, chil-

dren and unauthorized operation.

3. Turn the chassis key switch to OFF and remove the key to prevent unauthorized operation.

TRANSPORTING THE WORK PLATFORM

FORKLIFT

Forklift the aerial platform from the rear by lifting from the fork pockets shown in Figure 2-10

TRUCK

1. Manoeuvre the machine into the transport position and chock the wheels.

2. Secure the machine to the transport vehicle with chains or straps of adequate load capacity attached to the chassis lifting/tie down points.

DC MODELS

For DC models, prior to transportation, disconnect the plug from the battery box and remove the

battery box from the rear of the machine.

Figure 2-9: Fork pockets

location.

Figure 2-10: Battery box (DC

model).

Figure 2-8: Centre of gravity.

Forklift pockets

Battery

Charger

Centre of gravity

!

C A U T I O N

!

Forklifting is for transportation only. Refer to specications for weight of the machine and be certain that the

forklift is of adequate capacity to lift the machine.

!

C A U T I O N

!

The battery box is heavy (23.6kg/52 lbs). Lift

properly to avoid back injury.

Page 25

Page 2 - 17UL25/UL32/UL40

TRANSPORTATION

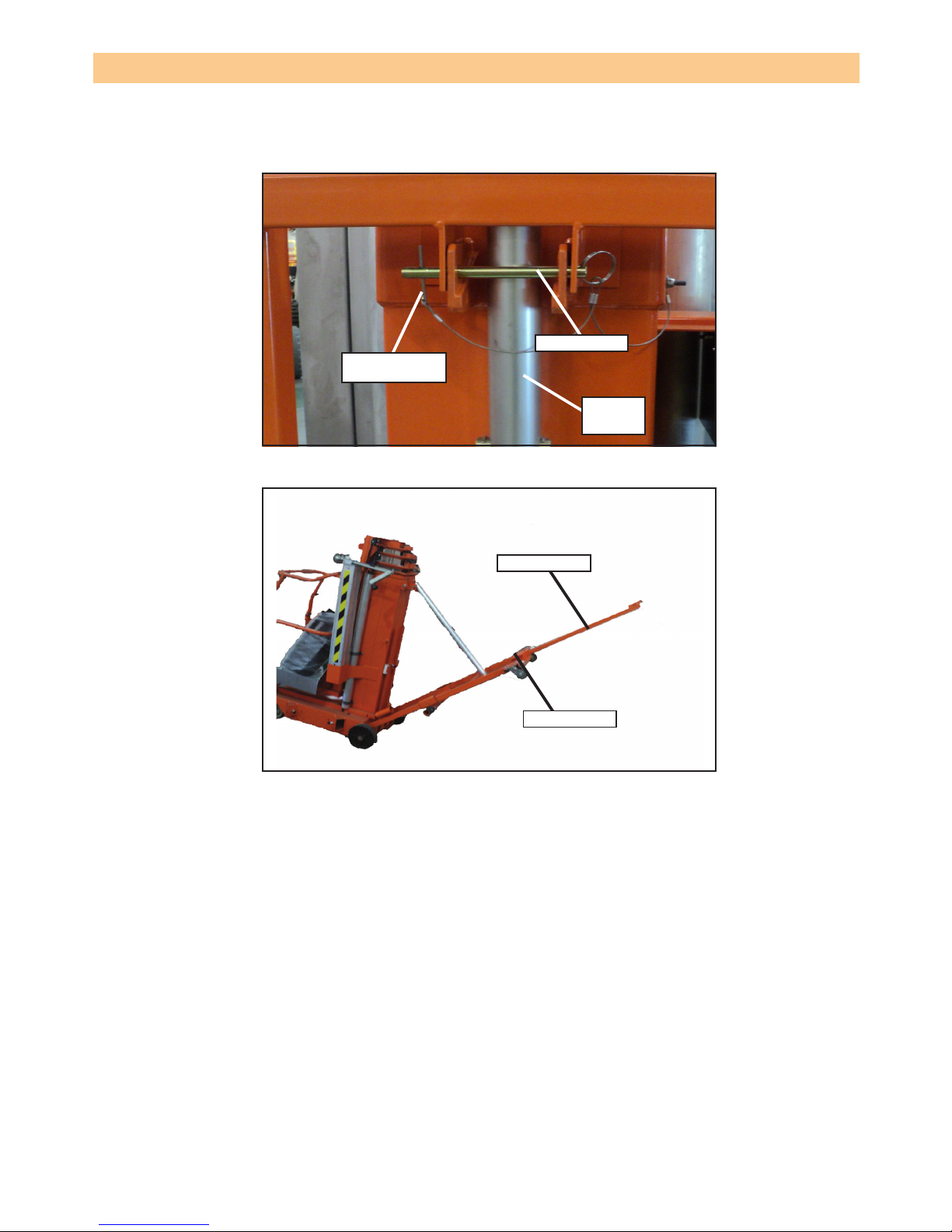

Figure 2-11: Loader in load position.

Figure 2-12: handle positioning.

Loader channel

Retaining pin

Loader

Gravity hook

Loader support

bracket

Handle bar

Handle

Retaining pin

Page 26

Page 2 - 18 UL25/UL32/UL40

TRANSPORTATION

LOADING

1. Raise the loader support brackets and engage the retaining pin in the top hole of the loader

channel.

2. Secure the loader to the loader support bracket with the gravity hook.

3. Position the unit so that the back of the machine comes into contact with the tailgate or vehicle

bed.

4. Release the gravity hook and slide the loader down until it comes into contact with the tailgate

or vehicle bed. Then, re-position the loader support bracket so that the retaining pin is in the

rst available hole above the loader.

5. Release the locking pin and pull the T-handle out until the locking pin engages the hole in the

end of the T-handle.

6. Lift up on the T-handle using the loader as a pivot until the unit rotates to a horizontal position

in the vehicle bed.

7. Push the base of the unit towards the front of the vehicle bed. The machine will slide on the

loader until the rear wheels are on the bed. The unit may then be rolled on the rear wheels and

upper casters.

8. Re-turn the T-handle to the stored position making sure that the locking pin engages the Thandle.

9. Secure the unit with suitable tie straps using the forklift pockets located under the base of the

tilt back frame.

!

C A U T I O N

!

To prevent damage to the mast assembly, do not place

rope or tie straps across the mast assembly when secur-

ing the unit for transportation.

DO NOT overtighten the rope or tie straps otherwise

damage to the machine will result.

UNLOADING

1. Unsecure the unit.

2. Release the locking pin and pull the T-handle out until the locking pin engages the hole at the

end of the T-handle.

3. Roll the unit back until the rear wheels are off the edge of the tailgate or vehicle bed.

4. Pull downward on the T-handle allowing the unit to slide on the loader.

• As the unit stops sliding on the loader, it will pivot on the loader to an upright position.

• Gradually counterbalance the unit’s weight by applying an upward force on the T-handle.

This allows the unit to settle gently on the wheels avoiding undue impact on the unit.

5. Return the T-handle to the stored position making sure that the locking pin engages the T-handle.

!

W A R N I N G

!

Ensure that the loader fully engages the

tailgate or vehicle bed.

Page 27

Page 2 - 19UL25/UL32/UL40

TRANSPORTATION

PASSAGE THROUGH A DOORWAY

The UL machine is equipped with a castered rear tilt back assembly. When the unit is tilted back

onto this support frame, the overall height is reduced to allow the unit to pass through a standard

doorway.

LOWERING

!

C A U T I O N

!

Before tilting the machine unto the rear tilt back as-

sembly, be sure that the retaining pin is fully inserted

with the hair pin retainer and the cylinder assembly is

fully extended.

DO NOT drop the tilt back frame. Keep out from under

the tilt back frame and machine when tilting.

1. Ensure that the area is clear of personnel and obstructions.

2. While holding the tilt back frame, remove the hair pin retainer and the retaining pin.

3. Lower the tilt back frame until the hole in the cylinder assembly align with the upper mounting

bracket pin hole. Secure the cylinder assembly to the upper mounting bracket using the retaining pin and hair pin retainer.

4. Extend the tilt back handle to the tilt/lift position by releasing the locking pin and pulling the

handle out of the tilt back assembly until the locking pin engages.

5. Push down on the tilt back handle until the unit comes to rest on the tilt back frame.

• As the mast tilts back, counterbalance the machine’s weight by increasing upward force

on the end of the tilt back handle. This allows the machine to gently come to rest on the tilt

back casters.

6. Pull down on the handle on the back of the mast to compress the cylinder assembly.

7. Return the tilt back handle to the storage position, making sure that the locking pin engages

the handle.

RAISING

1. Lift up on the mast handle to extend the cylinder assembly.

2. Fully engage the tilt back handle until the locking pin engages.

3. Lift up on the tilt back handle.

• As the mast approaches vertical, counterbalance the machine’s weight by increasing

downward force on the end of the tilt back handle. This allows the machine to settle gently

on the front casters.

4. Return the tilt back handle to the storage position, making sure that the locking pin engages

the handle.

5. While holding the tilt back frame, remove the retaining pin and raise the tilt back assembly to

the stowed position.

6. Secure with the retaining pin, making sure that the retaining pin is fully inserted and that the

hair pin retainer is installed.

Page 28

Page 2 - 20 UL25/UL32/UL40

TRANSPORTATION

Figure 2-13: Cylinder secured with retaining pin.

Figure 2-14: Lowering and raising with the tilt back handle.

Retaining pin

Cylinder

assembly

Hair pin retainer

Tilt back handle

Retaining pin

Page 29

Page 2 - 21UL25/UL32/UL40

MAINTENANCE

BATTERY MAINTENANCE

!

W A R N I N G

!

Hazard of explosive gas mixture. Keep sparks, ame and smoking

material away from batteries.

Always wear safety glasses when working near batteries.

Battery uid is highly corrosive. Thoroughly rinse away any spilled uid with

clean water.

Always replace the batteries with Snorkel batteries or manufacturer approved replacements weighing 22 kg (48 lbs.) each.

Use the following procedure to ensure battery maintenance.

1. Check the battery uid level daily especially if the work platform is being used in a warm, dry

climate.

2. If the electrolyte level is lower than 10 mm (3/8") above the plates, add distilled water only. Do

not use tap water due to its high mineral content since it will shorten battery life.

3. Keep the terminals and tops of the batteries clean.

4. Refer to the service manual to extend battery life and for complete service instructions.

BATTERY CHARGING

!

W A R N I N G

!

Charge the batteries in a well ventilated area. Do not charge the batteries when

the work platform is near a source of spark or ames.

Permanent damage to the batteries will result if the batteries are not

immediately recharged after discharging. Never disconnect the cables from the

batteries when the charger is operating. Keep the charger dry.

Use the following procedure to charge the batteries after use.

1. Check the battery uid level. If the battery uid level is lower than 10 mm (3/8") above the

plates, add distilled water only.

2. Verify the charger voltage switch is set to 12 volts.

3. Connect an appropriate extension cord to the charger plug. Plug the extension cord into a

properly grounded outlet of proper voltage and frequency.

NOTE: The battery charger circuit must be used with a GFI (Ground fault interrupt) outlet.

NOTE: Do not operate the machine while the charger is plugged in.

Page 30

Page 2 - 22 UL25/UL32/UL40

HYDRAULIC FLUID

The hydraulic uid reservoir is located under the power unit cover.

NOTE: Never add uid if the platform is elevated.

HYDRAULIC FLUID CHECK

1. Make sure that the platform is fully lowered.

2. Open the chassis door.

3. Check the uid level using the gauge on the dipstick.

4. To add hydraulic uid, remove the ller cap.

5. Add the appropriate hydraulic uid to raise the level to the end of the dipstick.

MAINTENANCE

Page 31

Page 2 - 23UL25/UL32/UL40

The complete inspection consists of periodic visual and operational checks along with periodic minor adjustments that assure proper performance. Daily inspection will prevent abnormal wear and

prolong the life of all systems. The inspection and maintenance schedule should be performed by

personnel who are trained and familiar with mechanical and electrical procedures.

!

W A R N I N G

!

Before performing preventative maintenance, familiarize yourself with the

operation of the machine. Always block the elevating assembly whenever it is

necessary to perform maintenance while the platform is elevated.

The daily preventative maintenance checklist has been designed for machine service and maintenance. Photocopy the checklist page and use the checklist when inspecting the machine.

INSPECTION AND MAINTENANCE

Page 32

Page 2 - 24 UL25/UL32/UL40

INSPECTION AND MAINTENANCE

Table 2-2: Daily preventative maintenance

checklist

DAILY PREVENTATIVE MAINTENANCE SCHEDULE

MAINTENANCE TABLE KEY PREVENTATIVE MAINTENANCE REPORT

Y = Yes/Acceptable Date: ______________________________

N = No/Not Acceptable Owner: _____________________________

R = Repaired/Acceptable Model #: ____________________________

Serial #: ____________________________

Serviced by: _________________________

Operator’s

Manual

Check that the operators manual is in

the manual holder and all pages are

intact and readable

Labels &

Decals

Check that labels and decals are in

place, intact and readable

Control

Cable

Check the exterior of the cable for

pinching, binding or wear.

Mast

Assembly

Inspect for bends, cracks or loose

rivets.

Battery

System

Check electrolyte level

Check battery cable condition

Check terminals are clean and connectors are tight

Check charger condition and operation

Charge batteries

Hydraulic

uid

Check oil level

Hydraulic

system

Check all ttings are tight and there are

no leaks

Drive motors Check for operation and leaks

Hydraulic

pump

Check ttings are secure and there are

no leaks

Emergency

lowering

Operate the emergency lowering valve

and check for serviceability.

Controller Check switch operation

Platform

deck and

rails

Check fasteners are in place, correctly

tightened and not damaged

Check the structure and welds for damage, deformation, corrosion and cracks

Check condition of deck (no damage,

deformation, corrosion or cracks

Check entry gate closure functions

correcly

Elevating

assembly

Inspect for external damage, dents, loose

rivets or cracks.

Check the structure and welds for damage, deformation, corrosion and cracks

Chassis Check operation of outrigger interlocks

Check castors for damage

Check hoses for pinch or rubbing points

Check welds for cracks

Lift Cylinders Check for leaks

Harness

anchor point

Check fasteners are secure

Check for damage, deformation, corrosion

and cracks

System function inspection

Conduct system function inspection (see

system function inspection pocedure)

Emergency

stops

Check that the emergency stop button on

the basket panels opertates correctly

Check that the emergency stop button

on the ground control panel operates

correctly

Alarm Check that the alarm sounds when

activated

* NOTE: Use ISO #46 during summer

and ISO #32 during winter

COMPONENT

INSPECTION OR SERVICES

Y N

R

COMPONENT

INSPECTION OR SERVICES

Y

N

R

Page 33

Page 2 - 25UL25/UL32/UL40

SPECIFICATIONS

ITEM UL25 UL32 UL40

Platform capacity 159 kg (350 lbs.) 136 kg (300 lbs.) 136 kg (300 lbs.)

Occupants 1 PERSON 1 PERSON 1 PERSON

Height

Working height 9.62 m (31.6 ft.) 11.75 m (38.5 ft.) 14.19 m (46.6 ft.)

Maximum platform height 7.62 m (25 ft.) 9.75 m (32 ft.) 12.19 m (40 ft.)

Minimum platform height 38 cm (15") 38 cm (15") 38 cm (15")

Dimensions

Overall weight 390 kg (860 lbs) 435 kg (960 lbs) 470 kg (1040 lbs)

DC option weight 29 kg (64 lbs.) 29 kg (64 lbs.) 29 kg (64 lbs.)

Overall width (outriggers extended) 2.06 m (81") 2.06 m (81") 2.95 m (116")

Overall length (outriggers extended) 1.98 m (78") 1.98 m (78") 2.84 m (112")

Stowed dimensions

Vertical height 1.98 m (78") 2.53 m (100") 2.90 m (114")

Width 74 cm (29") 74 cm (29”) 74 cm (29”)

Depth 1.24 m (49") 1.32 m (52") 1.32 m (52")

Diagonal storage height 1.94 m (76") 1.94 m (76") 2 m (79")

Diagonal storage length 2.59 m (102") 2.72 m (107") 3.05 m (120")

System voltage

AC electric motor 120 VAC 60 Hz or 220 VAC 50/60 Hz

DC electric power source 1-12 volt battery, group 27 105 Amp/hrs. minimum weight 22 kg (48 lbs.)

Battery charger Automatic, 120 VAC 60 Hz or 220 VAC 50 Hz

Output: 10 Amp, 12 volts DC

Hydraulic tank capacity 5.7 litres (1.5 gal)

Maximum hydraulic

pressure

165 bar (2400 PSI)

Hydraulic Fluid

Normal temperature: above 0° C

[32 F]

ISO #46

Low temperature: below 0° C [32 F] ISO #32

Extreme temperature: below -17° C

[ 0 F]

ISO #15

Control system Push button lift and lower, red mushroom emergency stop switch

Guardrails 1.1 m (43.5") high

Toeboard 152 mm (6") high

Maximum chassis inclination 1.0 degrees in all directions

Outrigger loading 170 kg (374 lbs.)

Vibration Whole body vibration < 0.5 m/s2, Handarm vibration < 2.5 m/s

2

Sound pressure 68 dB (A) at control station

Operating temperature range -20° C to +50° C

Table 3: UL25/32/40 Specication

NOTE: Specications are subject to change without notice. Hot weather or heavy use may affect

performance. Refer to the service manual for complete parts and service information. This machine meets or exceeds all applicable OSHA and ANSI A92.6 - 1999.

Page 34

Page 2 - 26 UL25/UL32/UL40

End of Life Waste Advice Chart :

No

Your waste can't be recycled as scrap metal.

No

Is the metal:

YesAluminum,

Copper,

Iron, Yes

Lead,

Steel, or Zinc?

No

Your waste is a HAZARDOUS WASTE Follow your

YesYes

Is your waste (not Leaking / damaged)?Is your waste (Leaking / damaged)?

No No

Yes

Yes

Is your waste?

No *Any type of oil contaminated with a hazardous chemical

Is your waste:Yes

* Motor Oil Yes* Degreasing solvents Your waste is a HAZARDOUS WASTE

Is your waste?

* Power Steering Fluid * Naptha Yes

Yes* Diesel Fuel No * Coolant from chillers/HAVC systemsNo* Transformer oil

* Gear Oil * Brake Fluid

* Hydraulic Oil * Radiator Flush

* Kerosene (#3,#4, & #6) * Deicers

Oils can NOT be disposed down the drain * Oily Water

(even if they are not hazardous waste).

No

Is your waste:

Yes* Armer cable

* Electrical Components

* Electrical circuit boards

No

Is your waste:

YesPolymer wear pads

Tyres

Hydraulic hoses

Is the waste: a Polymer, Tyre or Hose ?

Your waste is a HAZARDOUS WASTE Follow your

HAZARDOUS WASTE

Is the waste: an electrical component

or wiring ?

Is the waste: an

Your End of life waste is a HAZARDOUS WASTE

disposal of HAZARDOUS WASTE

been depoluted

IIs the waste: A used

HAZARDOUS

WASTE

Your waste should be RECYCLED following your

Is the waste: A solid metal ?

HAZARDOUS WASTE

RECYCLED according to

These are non-hazardous and can be

placed in regular trash, however, in an

friendly you may chouse to collect

RECYCLING purposes.

should be RECYCLED according to the universal

WASTE DISPOSAL AND REMOVAL

Page 35

Page 3 - 1UL25/UL32/UL40

SERVICE AND REPAIR

CONTENTS

INTRODUCTION 3-2

SPECIAL TOOLS 3-2

PREVENTATIVE MAINTENANCE 3-2

PREVENTATIVE MAINTENANCE TABLE 3-3

LUBRICATION 3-4

CASTERS 3-4

CHAINS 3-4

SCREW JACKS 3-4

HYDRAULIC OIL RESERVOIR 3-4

BATTERY MAINTENANCE 3-5

BATTERY INSPECTION AND CLEANING 3-5

BATTERY CHARGING 3-5

BATTERY CELL EQUALIZATION 3-6

SETTING SYSTEM RELIEF VALVE 3-6

MAST ASSEMBLY/DISASSEMBLY 3-7

PLATFORM ASSEMBLY REMOVAL 3-7

PLATFORM ASSEMBLY 3-12

PLATFORM SUPPORT ASSEMBLY 3-13

SEQUENCING STRAP INSTALLATION 3-13

CYLINDER ASSEMBLY 3-13

SEAL REPLACEMENT 3-13

ORIFICE VALVE CLEANING 3-15

CYLINDER REMOVAL 3-17

CYLINDER INSTALLATION 3-17

TORQUE SPECIFICATIONS 3-18

HYDRAULIC COMPONENTS 3-18

FASTENERS 3-19

Page 36

Page 3 - 2 UL25/UL32/UL40

INTRODUCTION

This section contains instructions for the maintenance of the work platform. Refer to the general

information section for information relevant to all Snorkel work platform and help in diagnosing and

repair of the machine.

The preventative maintenance table should be used at intervals specied by Snorkel or that of Local/National regulations to ensure the aerial platform is in good condition for use.

SPECIAL TOOLS

The following is a list of special tools that are required to perform certain maintenance procedures.

These tools may be purchased from local dealers.

Description Part Number

Spanner Wrench for UL 25/32/40 062521-010

Strap Wrench 062482-000

Tie Rod Tensioner ( 2 required) 062738-000

Tensioner Bracket (2 required) 062739-000

EZCal Caliberation & Diagnostic Tool 3072123

PREVENTATIVE MAINTENANCE

The complete inspection consists of periodic visual and operational checks together with all necessary adjustments to assure proper performance. Daily inspection will prevent abnormal wear and

pro-long the life of all systems. The inspection and maintenance schedule is to be performed at

regular intervals. Inspection and maintenance shall be performed by personnel who are trained

and familiar with mechanical and electrical procedures. Complete descriptions of the procedures

are stated in the table 3-2.

The preventative maintenance table has been designed to be used for machine service and maintenance repair.

SERVICE AND REPAIR

!

W A R N I N G

!

Be sure to read, understand and follow all information

stated in the operation section of this manual before

attempting to operate or perform service on any work

platform.

!

D A N G E R

!

Never perform service on the work platform in the elevating

assembly area while the platform is elevated without rst blocking

the elevating assembly. DO NOT stand in the elevating assembly

area while deploying or storing the brace.

Table 3-1: List of special maintenance tools.

!

W A R N I N G

!

Before performing preventative maintenance, it is important

to get familiar with the operation of the machine.

Never enter the area below the platform when the platform

is elevated.

Page 37

Page 3 - 3UL25/UL32/UL40

PREVENTATIVE MAINTENANCE TABLE

INTERVAL

Daily = each shift or everyday

30 d = every 30 days

3 m = every 3 months

1 y = every 1 year

Y = Yes/Acceptable

N = No/Not Acceptable

R = Repaired/Acceptable

DO NOT t replacement parts other than genuine components without express written approval

from the manufacturer.

SERVICE AND REPAIR

PREVENTATIVE MAINTENANCE REPORT

Date:

Owner:

Model #:

Serial #:

Serviced By:

Service Interval:

COMPO-

NENT

INSPECTION OR SERVICES INTER-

VAL

Y N R

Battery

System

(DC units

only)

Check electrolyte level Daily

Check specic gravity 30d

Charge batteries Daily

Check charger condition &

operation

Daily

Clean exterior 3m

Check battery cable condition Daily

Clean terminals 3m

Hydraulic

Oil

Check oil level Daily

Drain and replace oil (ISO

#46)

1y

Hydraulic

system

Check for leaks Daily

Check line connections 30d

Check hoses for exterior wear 30d

Emergency

hydraulic

System

Open the emergency lower-

ing valve and check for

serviceability

3m

Emergency

Down

Check procedure for emer-

gency down batteries

3m

A.C. Only: Replace emergen-

cy down batteries in upper

control box

1y

Controls Check condition and opera-

tion

Daily

Control

Cable

Check the exterior of the

cable for pinching, binding or

wear

Daily

Platform

deck and

rails

Check fasteners for proper

torque

Daily

Check welds for cracks Daily

Check condition of deck Daily

Check entry way closure Daily

Hydraulic

Pump

Check for tting leaks Daily

Wipe clean 30d

Check for leaks at mating

surfaces

30d

Check mounting bolts for

proper torque

30d

COMPO-

NENT

INSPECTION OR SER-

VICES

INTER-

VAL

Y N R

Elevating

Assembly

Inspect for external damage, dents loose rivets or

cracks

Daily

Check chains and

sheaves for wear

3m

Inspect and adjust se-

quence straps

30d

Chassis

Check cables for pinch

or rubbing points

Daily

Check component

mounting for proper

torque

6m

Check welds for cracks Daily

Check casters for dam-

age

Daily

Lift Cylin-

der

Check for leaks Daily

Check for proper torque 30d

Entire Unit

Perform pre-operation

inspection

Daily

Check for and repair col-

lision damage

Daily

Lubricate 3m

Check fasteners for

proper torque

3m

Check for corrosion;

remove and repaint

3m

Labels Check for peeling, miss-

ing or unreadable labels

& replace

Daily

Entire

unit

Check for and repair col-

lision damage

Daily

Check fasteners for

proper torque

3m

Check for corrosion-

remove and paint

6m

Lubricate 30d

Table 3-2: Preventative maintenance checklist

A thorough investigation should be carried out every 6 months.

NOTE: Frequency and extent of periodic examinations may depend on national regulations.

Page 38

Page 3 - 4 UL25/UL32/UL40

SERVICE AND REPAIR

LUBRICATION

Refer to gure 3-1 for the location of items that require lubrication service. Use an aerosol chain

lubricant for all components to be lubricated.

CASTERS

Using a grease gun, apply 1 or 2 shots of multi-purpose bearing grease to each zerk tting. Swivel

casters have two zerk ttings, one at the wheel bearing and one at the swivel.

CHAINS

1. Ensure that the platform is fully lowered.

2. Apply enough aerosol chain lubricant to exposed section of chain to allow lubricant to run down

chain.

SCREW JACKS

Apply a moderate amount of aerosol chain lubricant to each screw jack assembly.

HYDRAULIC OIL RESERVOIR

To change oil in the reservoir, rstly verify that the platform is fully lowered.

1. Remove the hydraulic reservoir from the pump by removing four screws and four grip plates.

2. Provide a suitable container as an ideal reservoir for a 5.7 litres (1.5 U.S. gallon) capacity and

dispose of hydraulic uid properly. Contact local oil recyclers for more information.

NOTE: Ensure the o-ring is in place on the pump when installing the hydraulic reservoir.

3. Reinstall hydraulic reservoir to pump assembly with grip plates and screws.

Figure 3-1: Locations for lubrication.

1 Chains

2 Casters

3 Rear Wheels

4 Screw Jacks

3

1

2

5&6

4

1 Motor

2 Pump

3 Reservoir

4 Breather/Dipstick

5 Capscrew (under pump)

6 Grip Plate (under pump)

Figure 3-2: Hydraulic Power Unit.

Page 39

Page 3 - 5UL25/UL32/UL40

SERVICE AND REPAIR

4. Fill hydraulic reservoir through the dipstick hole with ISO #46 hydraulic uid. The hydraulic res-

ervoir has a 5.7 litres (1.5 U.S. gallon capacity. Ensure that the oil is visible on the end of the

dipstick.

BATTERY MAINTENANCE - DC UNITS ONLY

Electrical energy for the motor is supplied by a 12 volt battery. Proper care and maintenance of the

battery and motor will ensure maximum performance from the lift.

!

W A R N I N G

!

Hazard of explosive gas mixture. Keep sparks, ames and smoking materials away

from batteries.

Always wear safety glasses when working with batteries.

Battery uid is highly corrosive. Rinse away any spilled uid thoroughly with clear

water.

BATTERY INSPECTION AND CLEANING

Check the battery uid level daily, especially if the work platform is being used in a warm, dry

climate. If required, add distilled water only. Use of tap water with high mineral content will shorten

battery life.

!

W A R N I N G

!

If the battery water level is not maintained, a full charge cannot be achieved. This

will create a low discharge rate which will damage the motor/pump unit and void the

warranty.

The battery should be inspected periodically for signs of cracks and in some cases, electrolyte

leakage and corrosion of the terminals. Inspect cables for worn spots or breaks in the insulation

and for broken cable terminals.

Clean battery that shows signs of corrosion at the terminals or onto which the electrolyte has over-

owed during charging. Use a baking soda solution to clean the battery, taking care not to get the

solution inside the cells. Rinse thoroughly with clear water. Clean battery and cable contact sur-

faces to a bright metal nish whenever a cable is removed.

BATTERY CHARGING

Charge the battery at the end of each work shift or when the battery has been discharged; which-

ever occurs rst.

!

C A U T I O N

!

Charge the battery in a well ventilated area. DO NOT charge the battery

when the lift is in an area containing sparks or ames.

Permanent damage to the battery will result if not immediately recharged

after discharging.

NEVER leave the charger operating unattended for more than two days.

NEVER disconnect cables from the battery when the charger is operating.

Keep the charger dry.

Page 40

Page 3 - 6 UL25/UL32/UL40

SERVICE AND REPAIR

When night air temperatures fall below 18°C (65°F), a battery charged in an unheated area should

be placed on charge as soon as possible after use. Under such conditions, a 4 hour charge once a

week in the early afternoon will improve the battery life. Use the following procedure to charge the

battery.

1. Check battery uid level. If the electrolyte level is lower than 10mm (3/8 inches) above the plates,

add distilled water only.

2. Verify charger voltage switch is set to 12 volts.

3. The battery charger is located at the rear of the mast. Connect an extension cord (a minimum

of 1.5mm2 [12 gauge] conductor and a maximum length of 15m [50 feet]) to the charger plug.

Connect the other end of the extension plug to a properly grounded outlet of proper voltage and

frequency.

4. Set charger control to “conventional” setting. Charger ammeter should indicate charger rate.

5. When battery is fully charged, charger automatically turns itself off. Disconnect the extension

cord.

BATTERY CELL EQUALIZATION

The specic gravity of the electrolyte in the battery cells should be equalized monthly. To do this;

• Charge batteries as outlined in battery charging.

• After the initial charge, check the electrolyte level in all cells and add distilled water as neces-

sary.

• Turn the charger on for an additional 8 hours. During this charge, the charging current will be

low (four amps) as cells are equalizing.

• After equalization, the specic gravity of all cells should be checked with a hydrometer. The

temperature corrected specic gravity in this state should be 1.260. If any corrected readings

are below 1.230, the battery should be replaced.

Do not check the specic gravity in a cell to which water has just been added. If there is not enough

electrolyte in a fully charged cell to obtain a sample for the hydrometer, add water and continue

charging for 1 to 2 hours to adequately mix the water with the electrolyte.

SETTING SYSTEM RELIEF VALVE

Check the hydraulic system pressure whenever the pump or relief valve has been serviced or replaced.

Battery

Charger

Figure 3-3: Battery Charger.

Page 41

Page 3 - 7UL25/UL32/UL40

SERVICE AND REPAIR

!

W A R N I N G

!

The hydraulic oil may be of sufcient temperature to

cause burns. Wear safety gloves and safety glasses

when handling hot oil.

1. Install the outriggers and level the unit as normal (refer to the operators manual for operating

instructions). Operate the hydraulic system for 5-10 minutes to warm up the hydraulic oil.

2. Remove the cover from the power unit assembly.

3. Place the rated safe working load for the machine (as stated under specications in the operation

section) on the platform. Do not use personnel as safe working load for this procedure.

4. Install a pressure gauge on the gauge port.

5. Remove the cap from the system relief valve (refer to gure 3-4) and turn the adjustment screw

counterclockwise, 2 full turns.

6. Operate controls to elevate the machine. Note that the machine will not raise until the relief valve

is properly adjusted.

7. Turn the system relief valve clockwise (refer to gure 3-4) until the machine begins to rise.

8. Elevate the platform fully and verify that the pressure does not exceed 165 bar (2400 PSI) at any

time during the lift cycle.

9. Replace cap on the system relief valve and reassemble cover.

Relief Valve

Gauge Port

MAST ASSEMBLY/DISASSEMBLY

Using a suitable lifting device, lower the work platform into a horizontal position (refer to gure 3-5).

If possible, place the machine unto a sturdy work table using a forklift.

!

W A R N I N G

!

Never attempt to lower the lift into a horizontal position

without the use of a suitable lifting device; bodily injury

or damage to the machine may result.

NOTE: Mark all components as they are removed to ease with re-installation in the correct

location and sequence.

PLATFORM ASSEMBLY REMOVAL

1. Extend elevating assembly far enough to expose the eight screws attaching the cage support

assembly to stage 6 by opening the emergency lowering valve and pulling on the cage guardrail.

2. Remove cover from the front of the platform assembly.

Figure 3-4: System Relief Valve.

Page 42

Page 3 - 8 UL25/UL32/UL40

SERVICE AND REPAIR

Forklift

3. Remove the cotter pins and chain retaining pins from the top front of stage 5.

4. Loosen screws from the strap retainer on the top casting of stage 5. Pull the strap free of the

retainer.

5. Remove the cage support screws, slide the cage support out of the sixth stage mast and set

aside. It should not be necessary to remove the pinch shield. Be careful not to damage the control cable.

NOTE: To remove the platform assembly from the cage support assembly, follow the steps

6-10 below.

6. Remove cable sheaves from the cage support weldment and strain reliefs from the top casting

of stage 5.

7. Loosen screws from the strap retainer on the platform assembly weldment and free strap from

the retainer.

8. Remove the 2 screws and washers holding the stop bracket located on the top of platform assembly weldment. Remove the stop bracket.

9. Slide the cage support weldment out of the top of the platform assembly weldment.

10. The slide bearings in platform assembly may now be inspected or replaced if necessary.

Use the following procedure in the sequence provided to disassemble the masts.

#6 MAST

1. Remove sequence strap retainer on the top of #4 mast.

2. Remove the allen head screws holding the top mast bearings between the #5 and #6 mast. Remove the top mast bearings.

3. Slide #6 mast out of #5 mast. As mast is removed, the bottom four mast bearings will fall out. Its

important to note their orientation for re-assembly.

4. Disconnect the chain from the top of #4 mast.

#5 MAST

1. Remove the sequence strap retainer on the top of #3 mast.

2. Remove the allen head screws holding the top mast bearings between the #4 and #5 mast. Remove the top mast bearings.

3. Slide #5 mast out of #4 mast. As the mast is removed, the bottom four mast bearings will fall out.

Its important to note their orientation for re-assembly.

4. Disconnect the chain from the top of #3 mast.

#4 MAST

1. Remove sequence strap retainer on the top of #2 mast.

2. Remove the Allen head screws holding the top mast bearings between the #3 and #4 mast. Remove the top mast bearings.

Figure 3-5: Lifting/Lowering Procedure.

Page 43

Page 3 - 9UL25/UL32/UL40

3. Slide #4 mast out of #3 mast. As mast is removed, the bottom four mast bearings will fall out;

note their orientation for re-assembly.

4. Disconnect the chain from the top of the #2 mast.

5. Remove the cylinder by following instructions provided under the section named “CYLINDER

ASSEMBLY”.

#3 MAST

1. Remove the sequence strap retainer on the top of #1 mast.

2. Remove the Allen head screws holding the top mast bearings between the #2 and #3 mast. Remove the top mast bearings.

3. Slide #3 mast out of #2 mast. As mast is removed, the bottom four mast bearings will fall out. Its

important to note their orientation for re-assembly.

#2 MAST

1. Remove the Allen head screws holding the top mast bearings between the #1 and #2 mast. Remove the top mast bearings.

2. Slide the #2 mast out of the #1 mast. As mast is removed, the bottom four mast bearings will fall

out. Its important to note their orientation for re-assembly.

SERVICE AND REPAIR

Page 44

Page 3 - 10 UL25/UL32/UL40

SERVICE AND REPAIR

Figure 3-6: Mast Assembly, Strap and Chain Detail.

Page 45

Page 3 - 11UL25/UL32/UL40

SERVICE AND REPAIR

Figure 3-7: Mast Assembly, Bearing Detail.

Page 46

Page 3 - 12 UL25/UL32/UL40

PLATFORM ASSEMBLY

NOTE: Use WD-40 lubricant as necessary to aid with re-assembly.

#2 MAST

1. Set #2 mast in place.

2. Install bottom lower bearings.

3. Install bottom upper bearings.

4. Slide #2 mast in all the way except 30-38 cm (12-15 inches).

5. Install top bearings and secure with retaining screws using loctite 242 or equivalent on the

threads.

6. Slide #2 mast in completely.

#3 MAST

1. Set #3 mast in place with the sequencing strap inside.

2. Install bottom lower bearings.

3. Install bottom upper bearings.

4. Slide #3 mast in all the way except 30-38 cm (12-15 inches).

5. Install top bearings and secure with retaining screws using loctite 242 or equivalent on the

threads.

6. Place a 25 cm (10 inches) long wood block between #3 and #2 masts, slide #3 mast down tight

against block. Pull sequencing strap completely out of the bottom assembly.

7. Install cylinder assembly by following instructions under “CYLINDER ASSEMBLY” section.

#4 MAST

1. Set #4 mast in place with the sequencing strap inside and the chains on the bottom.

2. Install bottom lower bearings.

3. Install bottom upper bearings.

4. Slide mast #4 in, making sure chains are not twisted.

5. Install top bearings and secure with retaining screws using loctite 242 or equivalent on the

threads.

6. Install chains around #3 sheave and down through #3 casting. Secure to #2 casting with new roll

pins.

7. Use a centre punch to dimple pin hole after roll pins are installed.

#5 MAST

1. Set #5 mast in place with the sequencing strap inside.

2. Install bottom lower bearings.

3. Install bottom upper bearings.

4. Slide #5 mast in, making sure chains are not twisted.

5. Install top bearings and secure with retaining screw using loctite 242 or equivalent on the threads.

6. Install chains around #4 sheaves and down through the casting. Secure to #3 casting with new

roll pins.

7. Use a center punch to dimple pin holes after all roll pins are installed.

8. Slide mast in, leaving 25 cm (10 inches) exposed.

#6 MAST

1. Set #6 mast in place with the sequencing strap inside.

2. Run the remaining sequencing strap from the platform to the assembly through the slot in the

bottom of stage #6 and up through the inside. Leave just enough slack on the outside to reach

the attachment point at the top of stage #5.

3. Install the bottom lower bearings.

4. Install the bottom upper bearings.

5. Slide #6 mast in, making sure the chains are not twisted.

6. Install the top bearings and secure with retaining screws using loctite 242 or equivalent on the

threads.

7. Install the #6 chain around the #5 sheave and through the casting secured to the #4 casting with

SERVICE AND REPAIR

Page 47

Page 3 - 13UL25/UL32/UL40

new roll pins.

8. Use a centre punch to dimple pin holes after all roll pins are installed.

9. Pull the sequencing strap attached to the bottom of mast #6 out through the bottom of the mast

assembly. Be sure not to pull the strap that is attached to the top of mast #5.

PLATFORM SUPPORT ASSEMBLY

1. Slide the cage support weldment into the top of the platform assembly weldment.

2. Install the stop bracket and retaining screws/washers.

3. Feed chains over sheave.

4. Install cable sheaves with cables to the top of the cage support weldment.

5. Feed sequencing strap from inside mast #6 over sheave and out through the slot in the top of

the cage support weldment.

6. Install cage support weldment to mast #6 using 8 screws and tighten.

7. Attach chains to #5 casting front using new cotter pins.

SEQUENCING STRAP INSTALLATION

NOTE: When installing straps, make sure they are not twisted.

1. Feed sh tape up through the bottom slot in the cage support weldment and out through the top

slot.

2. Attach strap to the sh tape and pull out through bottom slot.

3. Feed sh tape down through the opening in the front of the platform support weldment and out

through the bottom of the platform support weldment.

4. Attach strap to the sh tape and pull out through the opening. Attach the strap to the platform

support weldment, pull tightly and secure with strap clamp and screws using loctite 242 or equivalent on the threads.

5. Feed #6 strap up through the mast between fourth and fth stages with a sh tape.

6. Feed #5 strap up through the mast between third and fourth stages with a sh tape.

7. Feed #4 strap up through the mast between third and second stages with a sh tape.

8. Feed #3 strap up through the mast between rst and second stages with a sh tape.

9. Install strap #6 to #4 top casting.

10. Install strap #5 to #3 top casting.

11. Install strap #4 to #2 top casting.

12. Install strap #3 to the top of #1 mast weldment.

13. Install the strap clamps and retaining screws using loctite 242 or equivalent on the threads. Pull

straps tight while tightening retaining screws.

CYLINDER ASSEMBLY

SEAL REPLACEMENT

NOTE: The lift cylinder seal can be accessed from the bottom of the lift without removing the

cylinder assembly.

Using a suitable lifting device, lower the work platform into a horizontal position (refer to Figure 3-5).

If possible, place the machine on a sturdy work table using a forklift.

!

W A R N I N G

!

Never attempt to lower lift into a horizontal position without the

use of a suitable lifting device as this can lead to bodily injury

or damage to the machine .

1. Remove cylinder mounting plate fasteners and retaining ring.

2. Remove tie rod nuts and count the number of turns required to bring the nut ush with the tie

rod end and record for reference during installation. The tension on the tie rods maintain the left/

right positioning of the cylinder within the mast assembly. Re-installing the nuts with the proper

tension will speed up adjustment later.

3. Remove the cylinder mounting plate. Be careful not to allow the tie rods to suck back inside the

SERVICE AND REPAIR

Page 48

Page 3 - 14 UL25/UL32/UL40

mast assembly. Replace the nuts on the tie rod ends temporarily to prevent this.

4. Remove the hydraulic line from the cylinder tting and cap the cylinder tting to prevent contami-

nants from entering the cylinder.

!

C A U T I O N

!

Marring the surface of the cylinder rod will dam-

age cylinder seals and cause leakages. Use a strap

wrench to prevent rod damage.

5. Extend the cylinder rod at least 12 inches by hand. Apply heat to rod near end cap to loosen

loctite.

!

W A R N I N G

!

Wear safety glasses and heat resistant gloves when operating torch. Do not touch hot surfaces without proper

protection.

6. Using a strap wrench - 062482-000 to secure the cylinder rod, unscrew the cylinder rod end. If

necessary, thread a 9/16 x 18 bolt into end cap port to use as a lever. Remove rod end cap and

orice/bleeder tube assembly.

7. Remove the seal retainer, using the spanner wrench - 062521-010.

8. Clean all sealing surfaces with a solvent. Inspect the cylinder rod for excessive wear. Replace if

necessary.

9. Remove all seals from seal retainer, rod end cap and discard.

NOTE: Apply clean hydraulic uid to new cylinder seal, threads and all sliding surfaces prior

to assembly. If necessary, soften new seals with warm water 82°C (180° F) to aid in installation.

10. Twist the pressure seal into a ‘C’ shape and snap into a seal groove in seal retainer making sure

the lip of the seal is facing inward.

11. Using the same method, install the rod wiper into the seal retainer outer groove, making sure that

the blade of the seal is facing outward from the seal retainer.