Page 1

Operator Manual

UL20

UL20

SERIAL NUMBERS 17745 TO CURRENT

WARNING

All personnel shall carefully read, understand and follow all safety rules, operating

instructions and the Scaffold Industry Association's MANUAL OF RESPONSIBILITIES

before performing maintenance on or operating any UpRight aerial work platform.

SAFETY RULES

Safety Rules and Operating Instructions

NEVER elevate

platform unless all

four (4) outriggers

have been properly

installed. All

outrigger screwjack

pads must be in solid

contact with a firm

surface before the

platform is elevated.

NEVER operate the machine

within ten feet of power lines.

THIS MACHINE IS NOT

INSULATED.

NEVER use ladders, planks or other devices to increase the height of the platform.

NEVER attach overhanging loads to the platform or increase the platform size.

NEVER elevate the platform if it contains more than one person or more than the rated load (see specifica-

tions on back page).

LOOK up, down and around for overhead obstructions and electrical conductors.

NEVER change operating or safety systems.

NEVER use outriggers from one model on another model.

CLOSE and secure cage mid rail after entering platform.

Safety Rules and Operating Instructions

INSPECT the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks, damaged

control or power cables and loose wire connections.

NEVER use the machine as a freight or personnel elevator.

NEVER recharge battery near sparks or open flame; batteries that are being charged emit highly explosive

hydrogen gas.

AFTER USE secure the work platform against unauthorized use by turning key switch off and removing key.

NEVER replace any component or part with anything other than original UpRight replacement parts

without the manufacturer's consent.

NEVER sit, climb, or stand on the

platform guardrails or midrail.

1

NEVER elevate platform without

first leveling the base.

NEVER attempt to

move the UpRight

Lift with people or

materials on the

platform or with

the platform

elevated.

Page 2

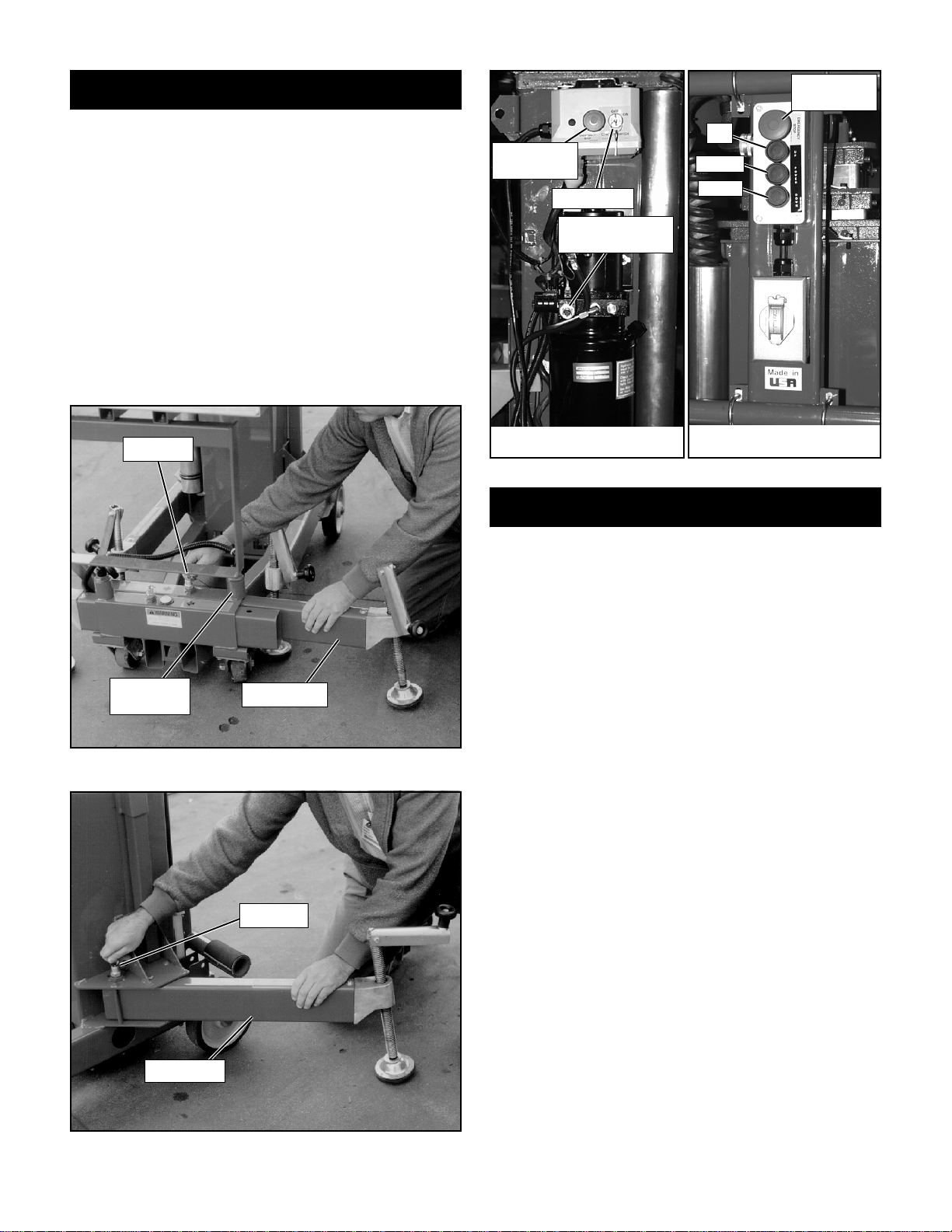

Outrigger Installation

Emergency

Stop Button

1. Pull each front outrigger out until lockpin

engages (Figure 1A).

2. Rotate each rear outrigger out towards rear of

machine and push in place until lockpin engages (Figure 1B).

3. Level the base, centering the bubble in the orbit

level, using screwjacks at the end of each

outrigger. Do not release tension on an outrigger by turning screwjacks counter clockwise to

level the base.

4. All four (4) screwjack pads must be in solid

contact with a firm surface. Each interlock

switch must be engaged before the platform

will elevate.

Lockpin

Interlock

Switch

Outrigger

Figure 1A: Installing front outriggers

Lockpin

Up

Emergency

Stop Button

Lowering Valve

Key

Switch

Emergency

Power

Down

Platform ControlsBase Controls

Figure 2: Controls

Operation

Before operating UL Lift insure that: the operator has

been thoroughly trained on this machine, the operator has read, fully understands and follows this

Operator Manual and the Scaffold Industry

Association's MANUAL OF RESPONSIBILITIES, the

unit has been properly set up with all four (4) outriggers properly installed and the base leveled, and the

machine has passed the Safety Interlock Test.

Note: Platform will not elevate unless all four

outriggers are properly positioned with screwjack

pads firmly in contact with floor and each outrigger indicator lamp lit.

1. Check for external damage to the mast.

2. For AC units connect power unit plug to extension cord (12 ga.) (1.5 mm²) conductor minimum

and 50 ft. (15 m) in length maximum).

Connect extension cord to properly grounded

outlet of proper voltage and frequency.

NOTE: AC units are protected by a 15 amp circuit

breaker. If breaker trips, push button in to reset

breaker (Figure 3).

Outrigger

Figure 1B: Installing rear outriggers

2

Page 3

AC Circuit

Breaker

Figure 3: AC Base Controls

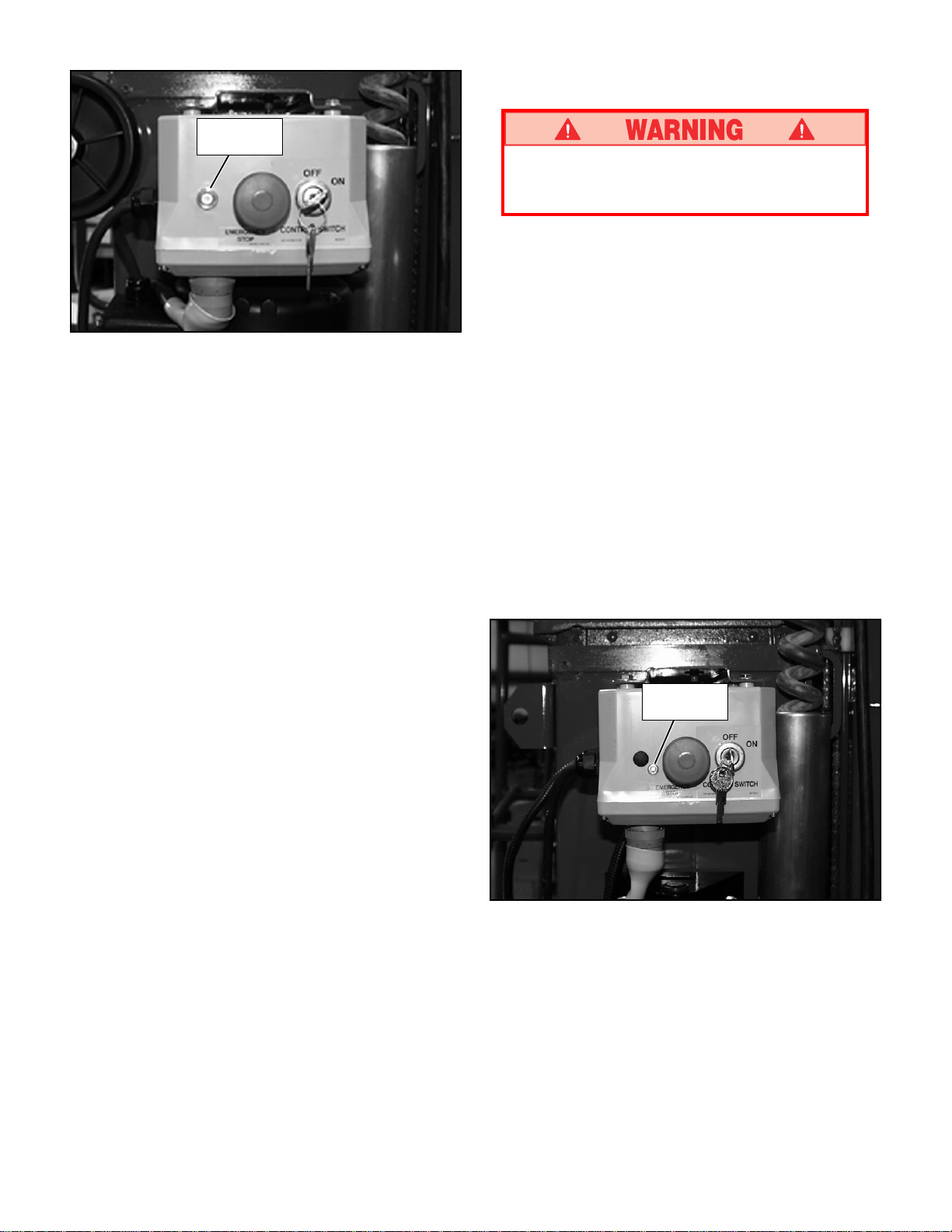

3. Turn Key to ON. Key Switch is located on the

left side of the mast (Figure 2).

4. Pull out on Lower Emergency Stop Button,

located on the left side of the mast (Figure 2), to

turn switch ON. In the event of an emergency

push the button in to cut power to all controls.

5. Enter the platform by lifting up on the cage mid

rail.

6. Lower cage mid rail after entering platform.

7. Check that the area above the platform is clear

before elevating the platform.

8. Pull out on Emergency Stop Button, located on

platform control panel (Figure 2). In the event of

an emergency push the button in to cut power to

all controls.

9. Push both the middle and top buttons (POWER

and UP), on the platform control panel (Figure

2), at the same time to elevate the platform.

Release the buttons to stop.

10.Check that the area below the platform is clear

before lowering the platform.

11.Push both the middle and bottom buttons

(POWER and DOWN) at the same time to lower

the platform. Release the buttons to stop.

12.After use, secure unit from unauthorized use by

turning Key Switch to OFF and remove key.

EMERGENCY LOWERING

If the platform should fail to lower, NEVER

climb down the mast.

Ask a person on the ground to open the Emergency Lowering Valve to lower the platform. This

valve is located on the left side of the mast (Figure

2).

1. Pull the knob out and turn

Emergency Lowering Valve.

2. To close the Emergency Lowering Valve, turn

the auxiliary platform lowering knob until it

snaps back in.

Once the platform is fully lowered, be certain that the

Emergency Lowering Valve is closed again. The

platform will not elevate if the Emergency Lowering

Valve is open.

NOTE: Optional auxiliary platform lowering

circuit allows operator to lower platform when

power source is interrupted. A warning light on

base control box shines when batteries for auxiliary platform lowering circuit are low (Figure 4).

Batteries are located inside base control box.

Warning

Light

Figure 4: Warning light shines when batteries

for optional auxiliary platform lowering

circuit are low.

1

/4 turn to open the

AFTER USE EACH DAY

1. Ensure that the platform is fully lowered.

2. Park the machine on level ground, preferably

under cover.

3. Secure against vandals, children or unauthorized operation by turning the Key Switch to

OFF and remove the key.

3

Page 4

Safety Interlock Test

NEVER perform this test from the platform.

BATTERY CHARGING (Figure 5)

Charge batteries at end of each work shift or

sooner if batteries have been discharged.

1. Properly set all four (4) outriggers and level base.

2. Release the tension on one (1) outrigger by turning the screwjack counterclockwise.

3. While standing on the ground activate the control

panel to elevate the platform. Platform should not

elevate.

4. Re-level the base with all four (4) outriggers then

repeat step 2 with another outrigger.

5. Repeat steps 2 , 3 & 4 until all four (4) outriggers

have been tested.

DO NOT use a machine that elevates when the

tension has been released on an outrigger.

Machine must be repaired before using.

Battery Maintenance

Hazard of explosive gas mixture. Keep

sparks, flame and smoking materials away

from battery.

Always wear safety glasses when working

with batteries.

Battery fluid is highly corrosive. Rinse

away any spilled fluid thoroughly with

clean water.

Always replace battery with UpRight battery

or manufacturer approved replacement

weighing at least 76 lbs. (34.5 kg) each.

Check battery fluid level daily, especially if

work platform is being used in a warm, dry

climate.

Charge battery in a well ventilated area.

Do not charge battery when the work

platform is in an area containing sparks or

flames.

Permanent damage to battery will result if

not immediately recharged after discharging.

Keep charger dry.

1. Check battery fluid level. If electrolyte level is

lower than 3/8 in. (10 mm) above plates add

distilled water only.

2. Verify charger voltage switch is set to 12 volts.

3. Connect extension cord (12 ga. (1.5 mm²) conductor minimum and 50 ft. (15 m) in length

maximum) to charger plug.

Connect extension cord to properly grounded

outlet of proper voltage and frequency.

4. Set charger control to "conventional" setting.

Charger ammeter should indicate charge rate.

5. When battery is fully charged, charger automatically turns itself off. Disconnect extension

cord.

Charger

Charging Control

3

If electrolyte level is less than

plates add distilled water only. DO NOT use tap

water with high mineral content, it will shorten

battery life.

Keep terminals and tops of batteries clean.

Refer to the Service Manual to extend battery life

and for complete service instructions.

/8 in. (10 mm) above

Battery Box Plug

Figure 5: Battery Box (DC Models only)

4

Page 5

Loaders

DC MODELS

Disconnect the plug from the battery box and

remove the battery box from the rear of the machine (Figure 5).

The battery box is heavy, 76 lbs. (34.5 kg),

lift properly (or have someone help you) to

prevent back injury.

7. Push the base of the unit towards the front of

the vehicle bed. The machine will slide on the

loader until the rear wheels are on the bed. The

unit may then be rolled on the rear wheels and

upper wheels.

8. Return the loading handle to the stored position.

9. Secure the unit with suitable strength rope or

tie straps.

Make sure loader fully engages tailgate or

vehicle bed.

LOADING

1. Raise the loader support bracket and engage the

retaining pin in the top hole of the loader

channel (Figure 7).

2. Secure the loader to the loader support bracket

with the gravity hook (Figure 7).

3. Position the unit so the back of the machine

comes in contact with the vehicle bed or tailgate.

4. Release the retaining pin and slide the loader

down until it comes into contact with the

vehicle bed or tailgate (Figure 7). Reposition the

loader support bracket so the retaining pin is in

the first available hole above the loader.

5. Remove loading handle from storage position

on left side of mast. Secure loading handle in

loading position in base of unit using clevis pin.

(Figure 6).

6. Lift up on the loading handle, using the loader

as a pivot until the unit rotates to a horizontal

position in the vehicle bed (Figure 8).

Clevis Pin

Loading Handle

Loading Handle

Storage Position

Figure 6: Installing loading handle

To prevent damage to the mast assembly,

do not place rope or tie straps across the

mast assembly when securing the unit for

transportation.

DO NOT overtighten the rope or tie straps,

damage to the machine will result.

Loader Channel

Retaining Pin

Gravity Hook

5

Loader Support

Bracket

Tailgate

Loader

Figure 7: Loader in load position

Page 6

Figure 8: Tilting machine onto or off of a vehicle

UNLOADING

1. Unsecure the unit.

2. Remove loading handle from its storage position on left side of mast. Secure handle in base

of unit using clevis pin (Figure 6).

3. Roll the unit back until the rear wheels are off

the edge of the tailgate or vehicle bed.

4. Pull downward on the loading handle, allowing

the unit to slide on the loader. As the unit stops

sliding on the loader, it will pivot on the loader

to an upright position. Gradually counterbalance the unit’s weight by applying an upward

force on the loading handle. This allows the

unit to settle gently on the wheels, avoiding

undue impact on the unit.

5. Return the loading handle to its storage position.

DC Models

Reinstall the battery box and reconnect the plug

making certain it is fully engaged.

Figure 9: Pushing machine into transport position

Passage Through A Doorway

When completely lowered, UL20 will pass through

a standard doorway without tilting back.

6

Page 7

66550-010

1-REQUIRED

66554-002

1-REQUIRED

62821-000

1-REQUIRED

66553-002

2-REQUIRED

62725-002

1-REQUIRED

61205-000

1-REQUIRED

62792-000

2-REQUIRED

62322-000

1-REQUIRED

62840-000

1-REQUIRED

5223-003

1-REQUIRED

62217-000

1-REQUIRED

62612-000

1-REQUIRED

66557-011

1-REQUIRED

62726-000

2-REQUIRED

66551-005

2-REQUIRED

05221-000

66552-000

1-REQUIRED

D.C. UNITS ONLY

1-REQUIRED

D.C. UNITS ONLY

For machines equipped with options consult Service Manual.

66551-005

2-REQUIRED

Note: Labels can be ordered by using Part Number located by each label.

UL LIFT LABEL INSTALLATION: THESE LABELS SHALL BE PRESENT AND IN GOOD

CONDITION BEFORE OPERATING THE WORK PLATFORM. BE SURE TO READ,

UNDERSTAND AND FOLLOW THESE LABELS WHEN OPERATING THE WORK PLATFORM.

7

Page 8

Specifications*

Working Height (A)

Platform Height (Max) (B)

Platform Height (Lowered) (C)

Platform Capacity

H

A

B

C

G

E

Platform Dimensions (l x w)

Unit Dimensions (G x H)

Outriggers Extended (l x w)

Unit Dimensions (D) (E) (F)

Outriggers Stowed (w x h x l)

Net Weight

A.C. Model with outriggers

Net Weight

D.C. Model with outriggers

*Specifications subject to change without notice.

25 ft. 6 in. (7.8 m)

19 ft. 6 in. (5.9 m)

34-1/2 in. (0.87 m)

350 lbs. (159 kg)

22 in. x 26 in.

(0.56 m x 0.66 m)

55 in. x 53 in.

(1.4 m x 1.35 m)

29 in. x 78 in. x 45 in.

(0.74 m x 1.98 m x 1.14 m)

646 lbs.

293 kg

698 lbs.

317 kg

Safety Rules and Operating Instructions

Meets or exceeds all applicable requirements of

D

F

OSHA and ANSI A92.3-1990.

ROUTINE SERVICE

Use the following table as a guide for routine maintenance, refer to Service and Parts Manual for complete

service instructions.

SERVICE OPERATION INTERVAL

DAILY OR OR OR

Check bubble level accuracy X

Check operation of outrigger interlocks X

Check battery fluid level and charge battery (D.C. models only) X

Check for peeling, faded or missing labels & replace X

Check condition of control cable X

Inspect mast assembly for bends, cracks or loose rivets X

Check chassis and platform emergency stop switch operation X

Check emergency lowering valve operation X

Check casters for damage X

Check hydraulic fluid level X

Check cage and cage support fasteners for proper torque X

Inspect and adjust sequence straps slack X

Lubricate lift chains and sheaves X

Change hydraulic fluid (ISO #46) X

MONTHLY 3 MONTHS YEARLY

50 HRS. 125 HRS. 500 HRS.

Safety Rules and Operating Instructions

FOR MORE INFORMATION

Distributor:

TEL: 1-800-926-5438 or 559-662-3900

FAX: 559-673-6184

PARTSFAX: 1-800-669-9884

801 S. Pine St., Madera, CA 93637

http://www.upright.com

8

067997-000

12-02

Loading...

Loading...