Page 1

TL49K

Operator Manual

This first section of the Operator manual is the English language version.

Betriebsanleitung

Im zweiten Abschnitt dieser Betriebsanleitung finden Sie die Deutsche Version.

Manuel Utilisateur

La troisième section de ce manuel est la version en langue Française.

Manual del Usuario

El apartado cuarto de este manual del usuario corresponde a la versión en Españo.

Manuale d’Uso

La quinta sezione di questo manuale d'uso è la versione in lingua Italiana.

(EN) Manual part number 508159-000 for serial numbers 8000 to current.

(DE) Bestellnummer 508159-000 ab Seriennummer 8000 fortlaufend.

(FR) Manuel Pièce numéro 508159-000 pour numéro série 8000 jusqu'au

numéro courant.

(ES) El número de referencia para el manual es el 508159-000 para la números

de serie del 8000 hasta el actual.

(IT) Manuale Ricambi Numero 508159-000 per Numeri di Serie da 8000

all’attuale.

Feb 08

Page 2

Page 3

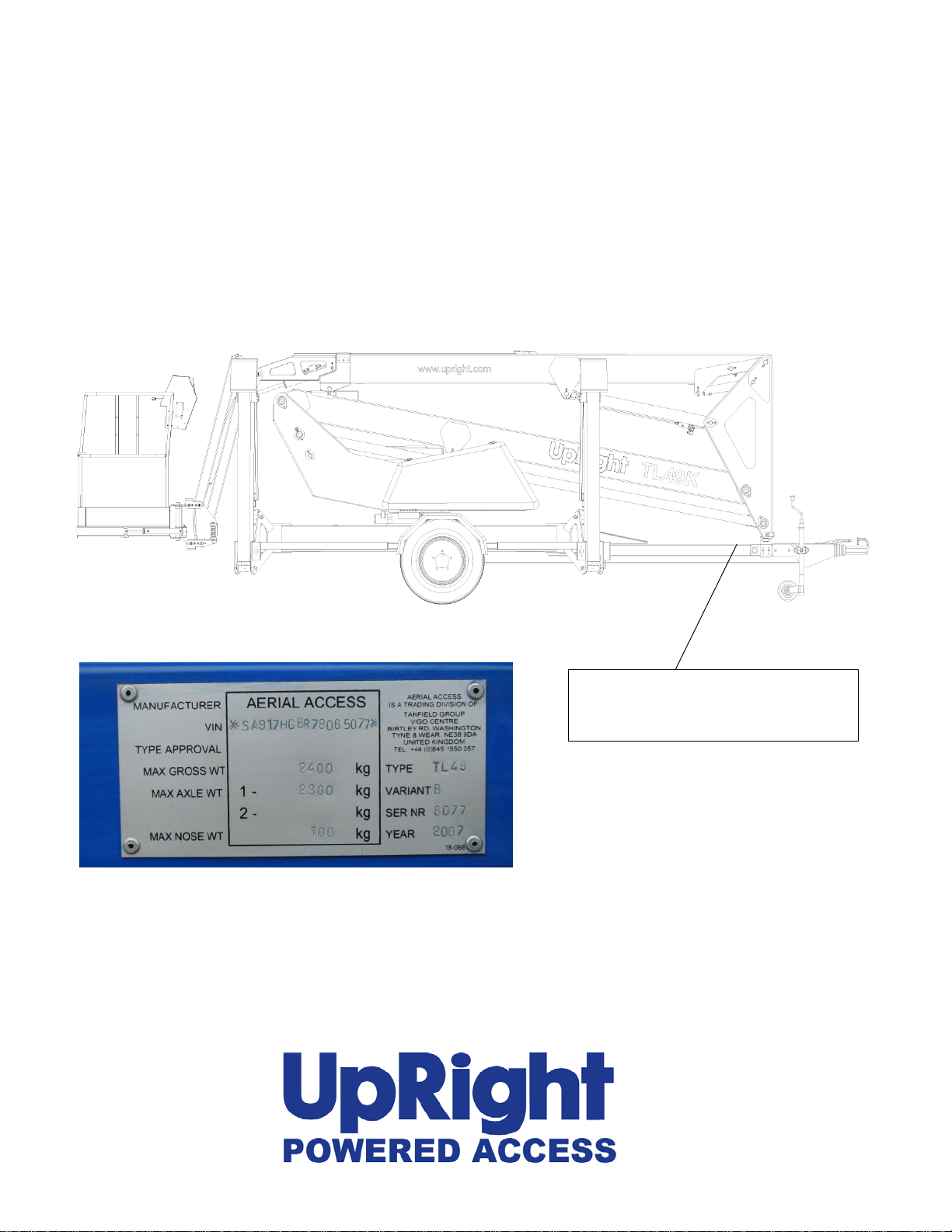

TL49K

Serial Numbers 8000 – Current

ENGLISH

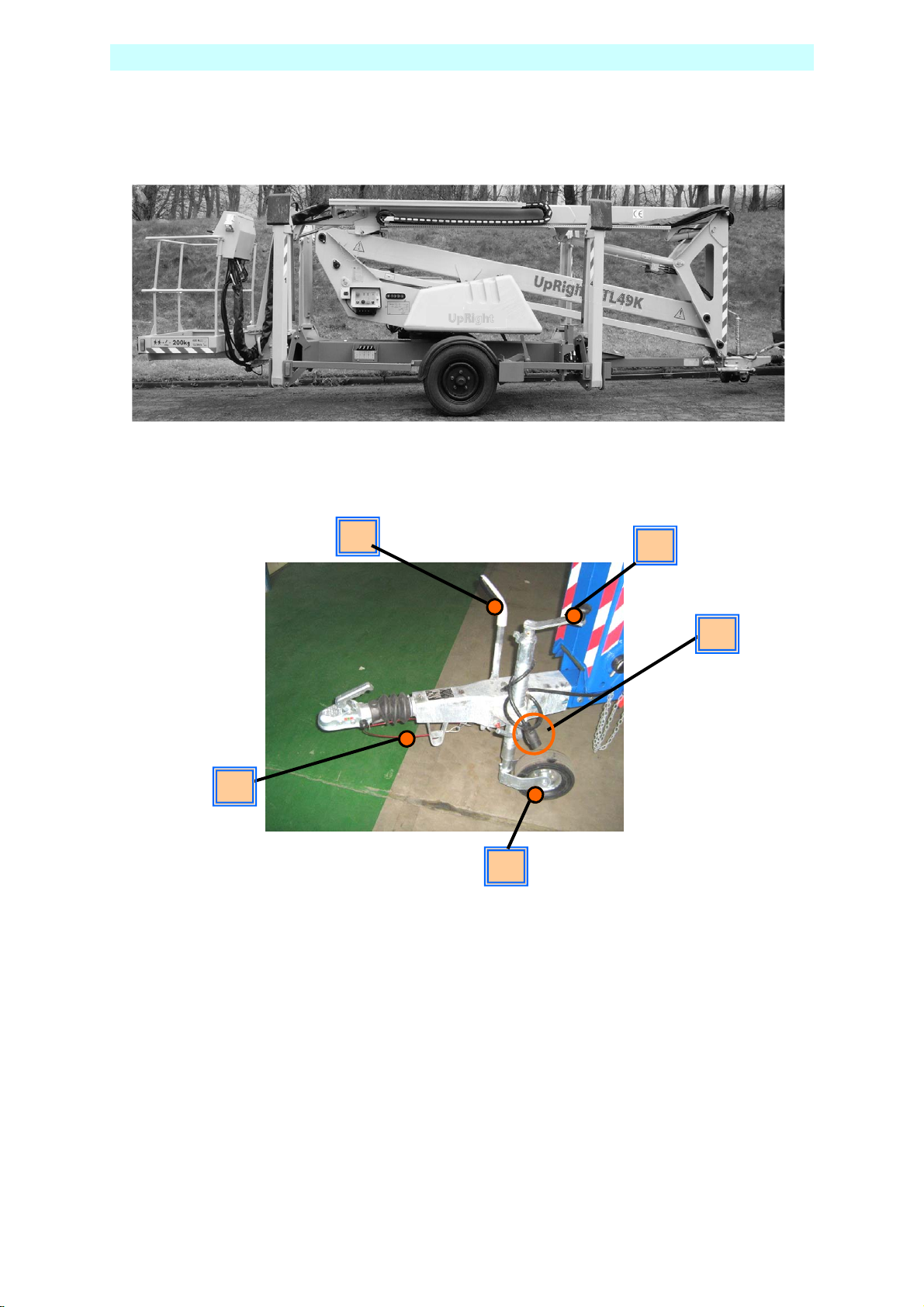

When contacting UpRight for service or parts information, be sure to include the MODEL and SERIAL NUMBERS

from the equipment nameplate. Should the nameplate be missing, the SERIAL NUMBER is also stamped on top of

the chassis bhind the toe hitch.

Serial number stamped on chassis behind the

toe hitch and above the Vehical Identification

Number Plate.

www.upright.com

Page 4

Page 5

p

,

! WARNING !

Safety Rules

All personnel shall carefully read, understand and follow all safety rules and operating in-

structions before operating or performing maintenance on any UpRight aerial work platform

Electrocution Hazard Tip Over Hazard Collision Hazard Fall Hazard

NEVER

cl imb, stan d, or s it on

latfor m gua rd ra ils or mid ra i l.

This Machine is NOT

NE VER

elevate the platform or drive

t he mach ine w hile elevat ed u nless t he

machine is on a firm

le ve l sur f ac e .

NEVER

posi tion the p latform

witho ut first che cking for overhead

obstructions or other hazards.

Insulated

USE OF THE AERIAL WORK PLATFORM: This aerial work platform is intended to lift persons and his tools as

well as the material used for the job. It is designed for repair and assembly jobs and assignments at overhead

workplaces (ceilings, cranes, roof structures, buildings etc.). All other uses of the aerial work platform are prohibited!

THIS AERIAL WORK PLATFORM IS NOT INSULATED! For this reason it is imperative to keep a safe distance

from live parts of electrical equipment!

Exceeding the specified permissible maximum load is prohibited! See “Special Limitations” for details.

The use and operation of the aerial work platform as a lifting tool or a crane (lifting of loads from below upwards or

from up high on down) is prohibited!

NEVER exceed the manual force allowed for this machine. See “Special Limitations” for details.

DISTRIBUTE all platform loads evenly on the platform.

NEVER operate the machine without first surveying the work area for surface hazards such as holes, drop-offs,

bumps, curbs, or debris; and avoiding them.

OPERATE machine only on surfaces capable of supporting wheel loads.

NEVER operate the machine when wind speeds exceed this machine’s wind rating. See “Beaufort Scale” for de-

tails.

IN CASE OF EMERGENCY push EMERGENCY STOP switch to deactivate all powered functions.

IF ALARM SOUNDS while platform is elevated, STOP, carefully lower platform. Move machine to a firm, level

surface.

Climbing up the railing of the platform, standing on or stepping from the platform onto buildings, steel or prefab

concrete structures, etc., is prohibited!

Dismantling the swing gate or other railing components is prohibited! Always make certain that the swing

gate is closed and securely locked!

It is prohibited to keep the swing gate in an open position (held open with tie-straps) when the platform is raised!

To extend the height or the range by placing of ladders, scaffolds or similar devices on the platform is prohibited!

NEVER perform service on machine while platform is elevated without blocking elevating assembly.

INSPECT the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks, loose wire con-

nections, and damaged cables or hoses before using.

VERIFY that all labels are in place and legible before using.

NEVER use a machine that is damaged, not functioning properly, or has damaged or missing labels.

To bypass any safety equipment is prohibited and presents a danger for the persons on the aerial work platform

and in its working range.

NEVER charge batteries near sparks or open flame. Charging batteries emit explosive hydrogen gas.

Modifications to the aerial work platform are prohibited or permissible only at the approval by

AFTER USE, secure the work platform from unauthorized use by turning both keyswitches off and removing key.

UpRight.

TL49K 508159-000

Page 6

CONTENTS

Page

Introduction 3

Description of Equipment 4

Technical Specification 5

Working Envelope 6

Operator Requirements 7

Warning Notices 8

. Beaufort Scale 9

Towing Instructions 10

Hand Manoeuvring (Friction Drive Option) 12

Pre-Start Checks 13

Power Supply 19

Batteries, & Power Pack 15

Setting Up 16

Extending Structure 18

. Basket Controls 18

. Ground Controls 20

Safety Harness 21

Emergency Controls

. Emergency Stops 21

. Emergency Lower (Electronically) 22

. Emergency Lower (Manually) 23

. Emergency Raise Outriggers 24

. Emergency Cage Overload 24

. Emergency Battery Isolation 25

Stowing the Machine 26

Maintenance

. Daily Checks 27

. Weekly and Monthly Checks 28

. Slew Drive and Limit Switches 29

. Trailer Lighting Diagram 30

Appendices

Petrol/Bi-fuel Option. 31

Generator Option. 32

Mains connection. 33

2 508159-000 TL49K

Page 7

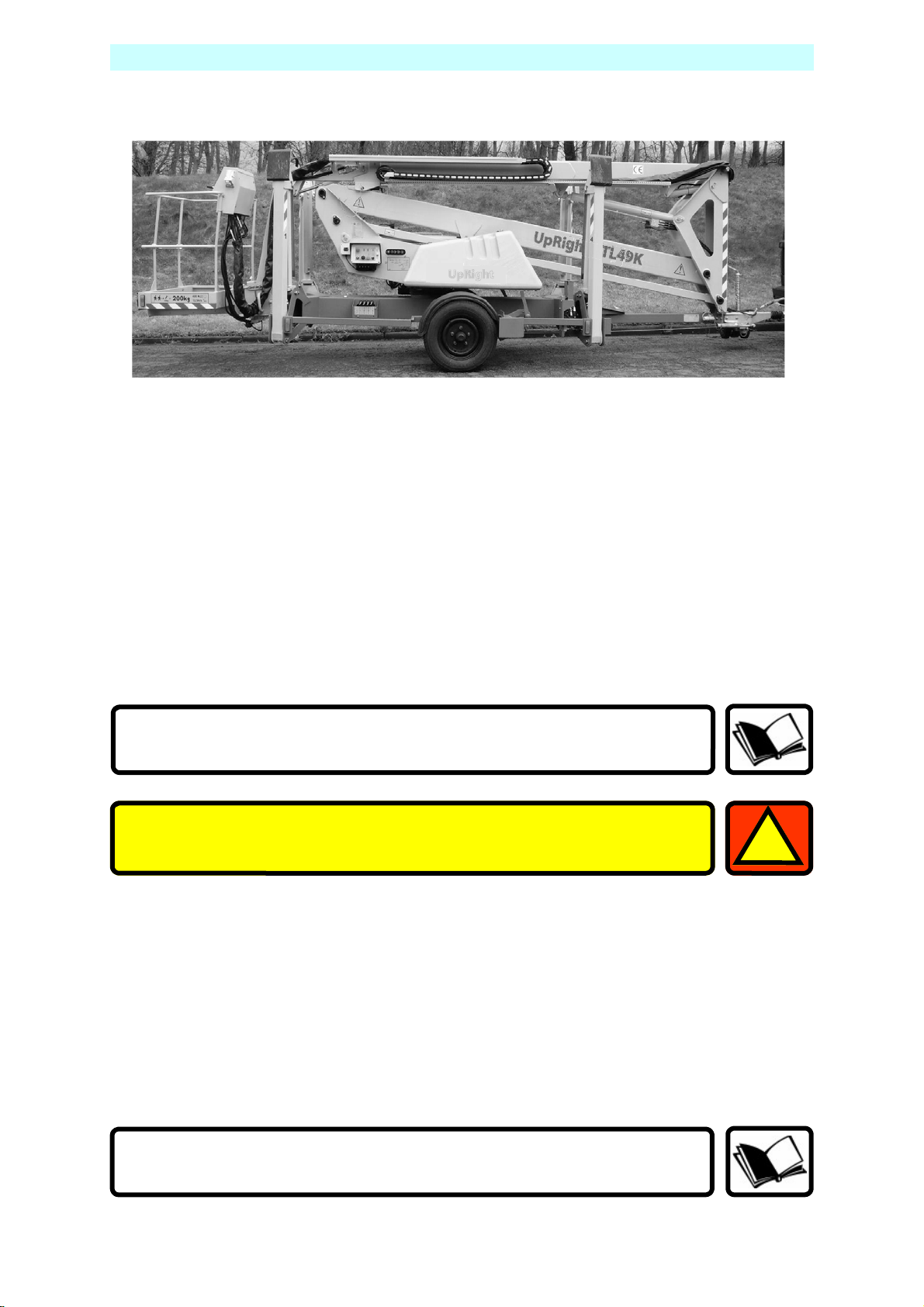

INTRODUCTION

The UpRight TL49K is a class leader, offering several features as standard that

other manufacturers only provide as optional extras.

These include powered basket rotation and fully proportional hydraulic controls, at

both basket and ground level.

The third flick boom, with 130 DEGREES working arc, guarantees access to the

most hard to reach places, while the 90 DEGREES basket rotation provides the

precision positioning that is vital for working in tight spaces.

UpRight Powered Access has a global reputation for innovation and a proud

heritage in the design and manufacture of high quality powered access equipment.

The company was founded in the UK more than 25 years ago, on the principle of

constantly improving service excellence for end users.

Every model in our growing range of versatile, trailer mounted units is a class

leader and together they have set new industry benchmarks.

Our commitment to research and design, plus 250,000sq ft of same site

fabrication, build and support capacity, mean UpRight can offer complete solutions

to meet even the most demanding access applications.

UpRight has third party accreditation to quality standard ISO 9001 and the full

range carries the CE mark, complying with or exceeding all relevant standards and

EC directives.

UpRight Powered Access is a member of the

International Powered Access Federation (IPAF).

To ensure you are fully aware of safety and operational information, the

following symbols are used throughout this manual;

This type of box contains, Points of operation to NOTE.

The information contained in this type of box contains, WARNING

!

1

text. It gives Warnings about the risk of Damage to equipment,

and possibly personnel.

The information contained in this type of box contains, DANGER

text. It gives Warnings about the risk of PERSONAL INJURY to the

operator and or others.

TL49K 508159-000 3

Page 8

DESCRIPTION OF EQUIPMENT

The UpRight TL49K is of the parallel linkage vertical boom design, mounted on a

road towable trailer. The unique, yet very simple boom configuration gives the

maximum safety and control ability combined with a robust construction to

withstand a heavy working environment

The TL49K machine is designed for two man capacity (200 kg S.W.L.).

The machine incorporates a bottom boom with tie-rod, a short vertical boom and a

top boom with a telescope section. The TL49K also has an independent

hydraulically operated flick-out boom and rotating cage for extra manoeuvrability.

The hydraulic system is of a failsafe design throughout, with built in hydraulic lock

valves on all of the rams as a precaution against hose failure. The machine is

controlled by means of proportional manual controls of the ‘direct hand’ lever

operating type. These valves are located at both the base and in the cage, as

standard.

Electrically operated emergency lowering valves are fitted as standard to allow the

machine to be lowered from the base and basket.

The hydraulically operated outriggers are fitted with load sensing interlocks, to

prevent the booms from being raised without the outriggers being extended and

under load. An interlock prevents the hydraulic outriggers being accidentally

retracted while the booms are raised. A simple system of warning lights show the

power supply is on and each of the outriggers is under load.

Performance.

Maximum Working Height 17.00 m

Maximum Working Outreach: 9.10 m

Capacity (2 man working): 200 kg

Slewing Arc: 680°

Airborne Noise Emissions (Battery): 70 dB(A)

Construction Standards.

The machine complies fully with the requirements of the following EEC Directives:

Directive 98/37/EC – the ‘Machinery Directive’.

Directive 89/336/EEC – the ‘Electromagnetic Compatibility Directive’.

Directive 73/23/EEC – the ‘Low Voltage Directive’.

EN 6020-1/1993 ‘Safety of Machinery.’

The machine is designed and tested in accordance with all relevant B.S.I and

European Standards including EN280.

4 508159-000 TL49K

Page 9

TECHNICAL SPECIFICATION

Cage Dimensions

Length 1.20m

Width 0.80m

Guard-rail Height 1.10m

Toe-board Height 0.15m

Operating Dimensions

Maximum Working Height 17.00m

Maximum Cage Height 15.00m

Maximum Outreach ( From centre of rotation ) 9.10m

Travel Dimensions

Towing Length 7.10m

Closed Width 1.75m

Closed Height 2.10m

Weight (Battery Model) 2250 kg (un-laden)

(Battery Model + Friction Drive) 2395 kg (un-laden)

(Bi-fuel Model) 2300 kg (un-laden)

Operating Parameters

Safe Working Load 200 kg

Maximum Horizontal Pull 400N

Maximum Wind Speed 12.5 ms

Rotation 680°

Cage Slew 90°

Equipment

Bottom Ram Double acting: Bore Ø 80.0 mm

Rod Ø 50.0 mm

Top Ram Double acting: Bore Ø 80.0 mm

Rod Ø 50.0 mm

Tele’ Ram Double acting: Bore Ø 65.0 mm

Rod Ø 45.0 mm

Flick Ram Double acting: Bore Ø 60.0 mm

Rod Ø 40.0 mm

Stabiliser Ram Double acting: Bore Ø 70.0 mm

Rod Ø 40.0 mm

Bottom & Top Ram Lock Valves Pilot operated over centre valves

Control Valve (Cage) Monoblock unit consisting of seven

double acting spools

Control Valve (Ground) Monoblock unit consisting of five

double acting spools

Control Valve (Stabiliser) Monoblock unit consisting of four

double acting spools

Bushes Acetol resin polymer with sintered

bronze base (DX)

Pivot Pins Stainless Steel Bright Bar

To Grade BS970 303 S31 CW, &

MecaVal 147m, Tuftride TFI-AB1

coated.

-1

TL49K 508159-000 5

Page 10

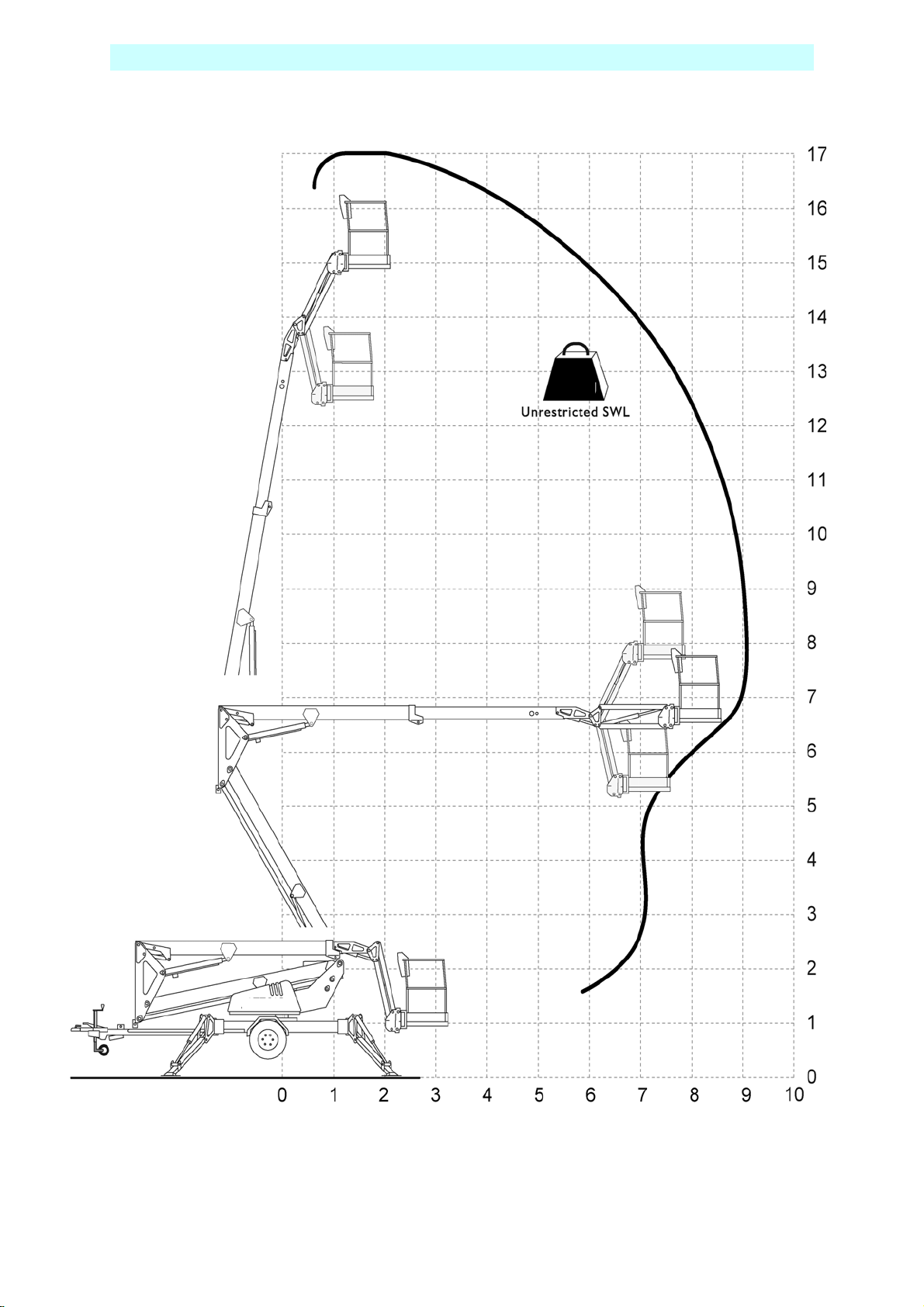

OPERATING ENVELOPE

200kg

Height and Distance in Metres.

6 508159-000 TL49K

Page 11

OPERATOR REQUIREMENTS

Please read this carefully, and ensure you have received the correct training

prior to operating this machine.

1. To operate the machine you must be medically fit and have no problems

with eyesight or hearing.

2. You must have a good head for heights.

3. Your primary concern must be the safe operation of the work platform, the

safety of the people working with you, and the safety of other persons in

your working area.

4. You must be familiar with the contents of this manual, and at no time

attempt to operate the machine beyond the recommended limits.

5. The proper care of the work platform is a major factor in ensuring the safety

of those who work with it.

6. You must not misuse the machine or ignore or interfere with the devices

that have been provided to maintain safety.

7. Operation of the machine should be restricted to personnel who have been

authorised to operate the equipment and have received proper training.

TL49K 508159-000 7

Page 12

WARNING NOTICES

1. DO NOT operate this machine unless you have been fully trained in its safe

use.

2. DO NOT operate the machine on soft, slippery or sloping ground unless

adequate precautions have been taken.

The stabilisers are designed to operate on firm level ground with a minimum

bearing strength of 50N/cm

The maximum load imposed by an outrigger is 12.5kN.

Advice should be obtained from UpRight as to the type of supports and

precautions required before attempting to operate the machine outside

these parameters.

3. DO NOT use any equipment in the basket to increase the reach or working

height of the machine, e.g. ladders.

4. DO NOT fit any additional equipment to the machine that would increase

the wind loading, e.g. notice boards.

5. DO NOT use the machine for any application that may produce special loads

or forces: the manufacturer, UpRight Powered Access, must be consulted for

approval of special applications prior to use.

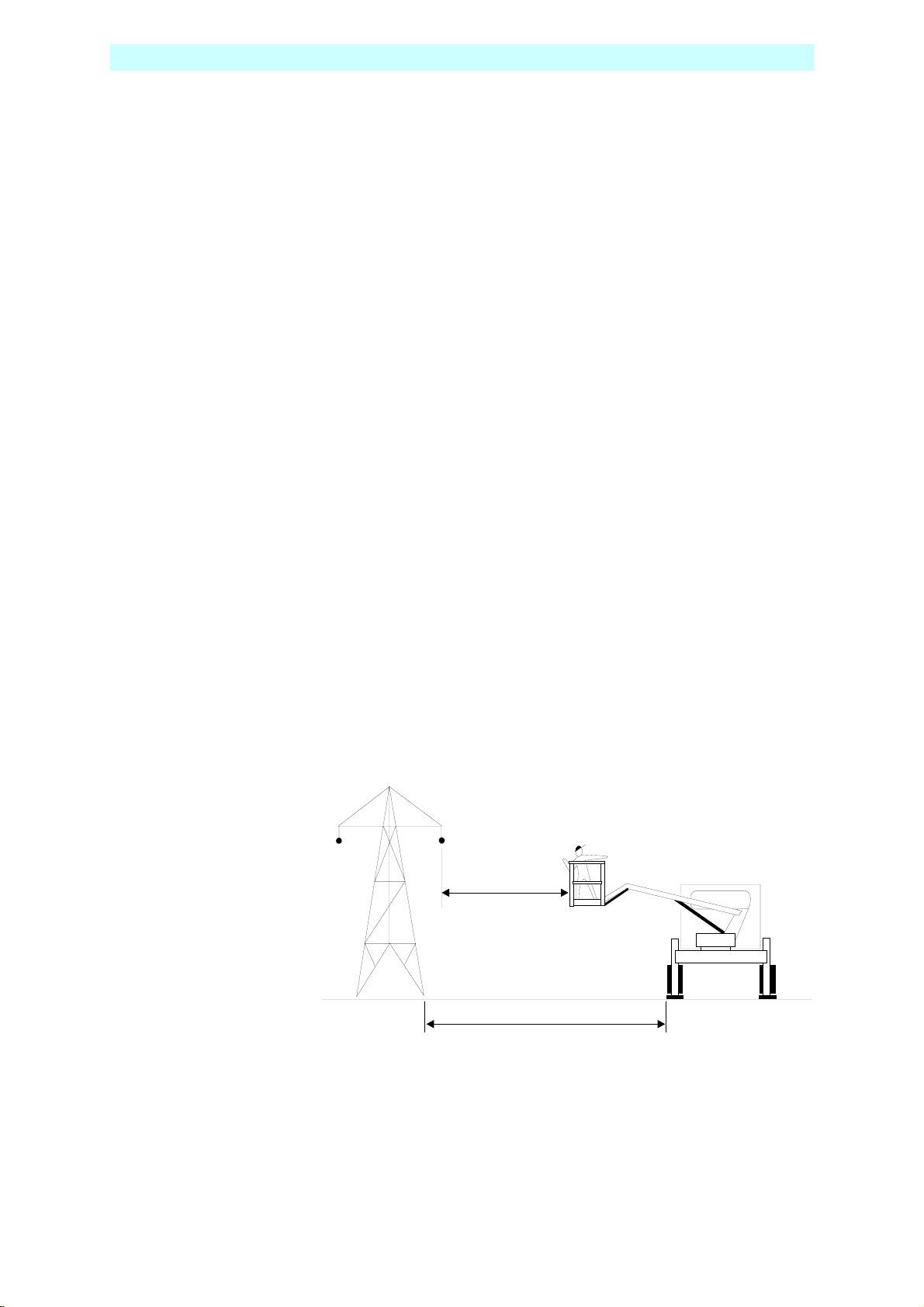

6. DO NOT use the machine close to live electrical conductors. The minimum

safe working distance for a machine working near overhead power cables is

the maximum extended length of the booms plus 15 metres, measured

with the booms pointing towards the lines, i.e. safe working distance for the

TL49K is 24 metres. It is the operator‘s responsibility to ensure that, when

working in the vicinity of live overhead high-voltage lines, the minimum safe

working distance is maintained. Erect a simple barrier tape at the safe

distance.

7. WORKING CLOSE TO POWER CABLES – if work has to be carried out at less

than the safe working distance, the operator must ensure that the

electricity supply has been switched off. Before commencing work, a

written permit to work must be obtained from the owners of the power

cables or the responsible authority.

2

.

15m

15m

24m

26m

8 508159-000 TL49K

Page 13

WARNING NOTICES

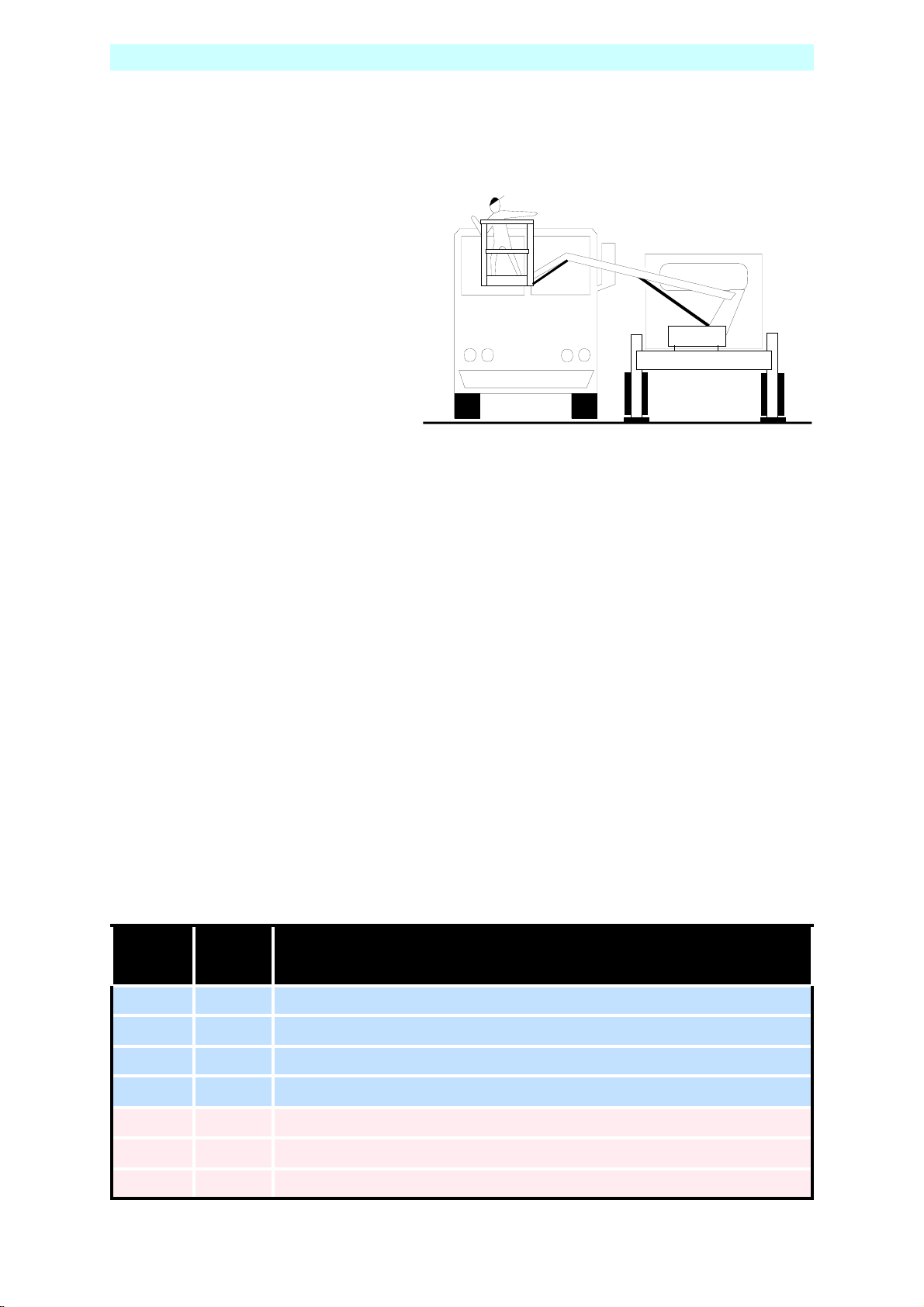

8. DO NOT operate the machine unless all four outriggers are down and in full

contact with the ground. The machine must be level and the wheels lifted

visibly clear of the surface before the booms are raised.

9. DO NOT move the machine

with the basket raised and

never allow cage or booms to

slew into the path of

oncoming vehicles.

10. DO NOT operate the machine if the wind speed exceeds 12.5 m/s. Be aware

that, when working near high buildings or structures, shielding and

funnelling effects may cause high wind forces on days when the nominal

wind speed in the open is low. Wind speed can either be measured from

the work platform with a hand held anemometer or estimated using the

Beaufort Scale.

BEAUFORT WIND SPEED SCALE

The Beaufort Scale of wi nd force is accepted internationally and is used in communicating weather

conditions. It consists of numbers 0 - 12, each representing a certain strength of velocity of wind at

10m (33ft.) above ground in t he o pen .

Approximate corrections for wind speeds at other heights are:

2m subtract 30%;

3m subtract 20%;

6m subtract 10%

15m add 10%;

30m add 25%

Beaufort

M/Sec Ground Conditions

Scale

3 3.5-5

4 6-8

5 9-10

6 11-13

7 14-17

8 18-21

9 22-24

TL49K 508159-000 9

Leaves and small twigs in constant motion; wind extends light flag.

Raises dust and loose paper; small branches are moved.

Small trees in leaf begin to sway; crested wavelets on inland waterways.

Large branches in motion; umbrellas used with difficulty.

Whole trees in motion; inconvenience felt when walking against wind.

Breaks twigs off trees; generally impedes progress.

Slight structural damage occurs (chimney pots and slates removed)

Page 14

Right

Up

g

h

h

L

4

L

4

TOWING INSTRUCTIONS

Trailer mounted machines are fitted with suspension units that may be safely

towed behind a car or van at speeds of up 50mph (80km/h) where permitted.

1. Before towing, check the capacity of the vehicle being used.

(Machine weight will increase if optional extras are fitted)

2. Ensure that the road tyres and brakes are in good, serviceable condition.

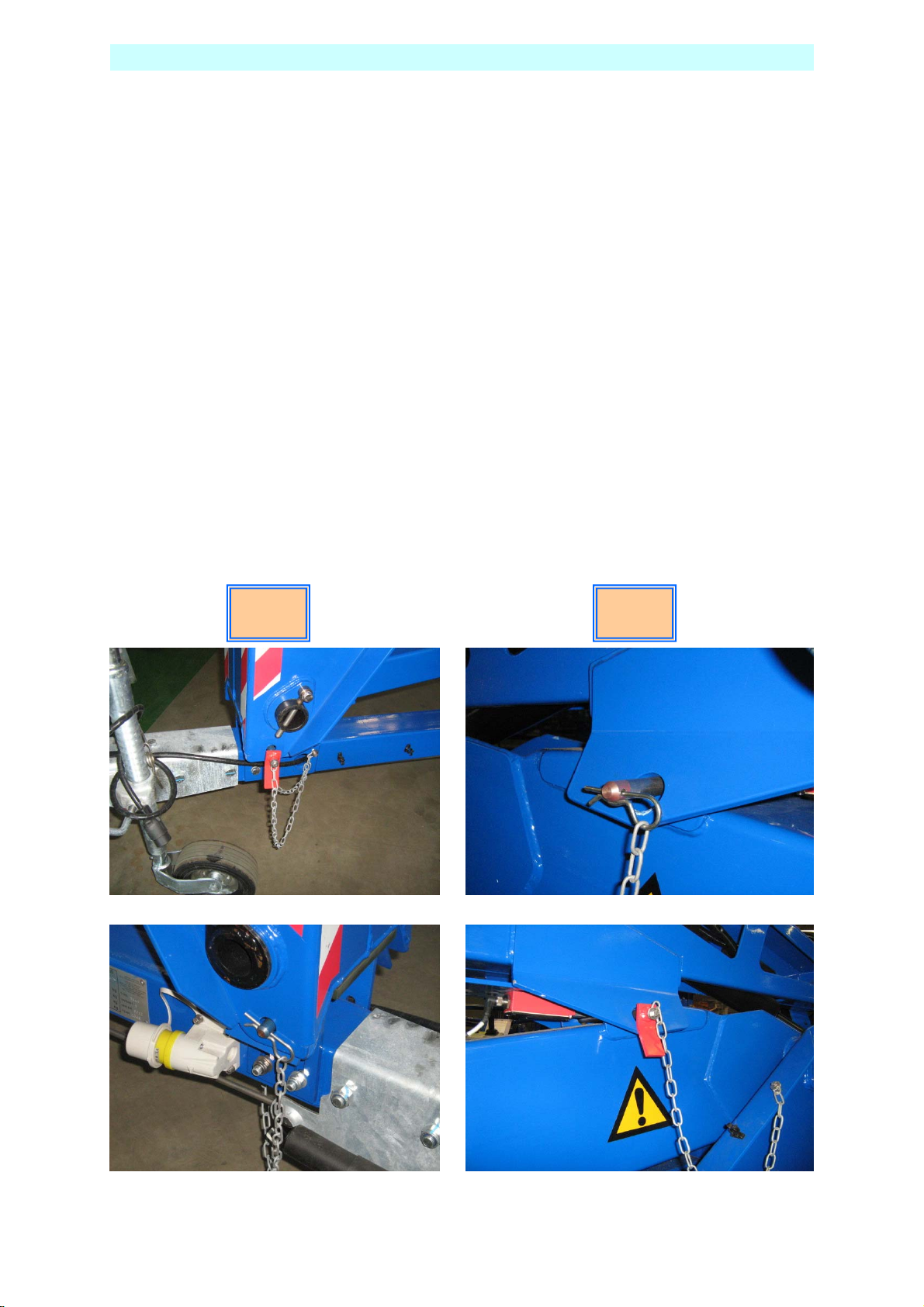

3. Ensure that all booms are fully lowered and both the transit pins are fitted

through the loops and secured with the “R” clip on the end of the chain.

10 508159-000 TL49K

Page 15

R ight

g

h

h

L

4

L

4

TOWING INSTRUCTIONS

4. Ensure that all outriggers are fully raised.

5. Use the Jockey Wheel to raise or lower the tow bar coupling to position the

machine above the 50mm ball hitch on the towing vehicle.

8

6. Apply the handbrake.

7. Lower the tow bar coupling down onto the ball hitch using the Jockey Wheel

8. Secure the breakaway cable,

(Ensure correct engagement of 50mm ball).

9. Fully raise the Jockey Wheel and lock in position.

10. Release the Handbrake.

11. Plug in the trailer lights (7 pin plug) and check that both vehicle and trailer

lights operate correctly.

6

7

11

9

TL49K 508159-000 11

Page 16

HAND MANOEUVERING (Optional)

1. Ensure that the booms are fully lowered, all outriggers are fully raised

and the machine is in a menoeverable condition.

2. Engage the the friction drive cylinders against the trailer tyres by pulling

actuating levers forward and down until they lock overcentre.

3. Ensure the power selector switch is set to Base.

4. Disengage the handbrake, and ensure that the Jockey wheel directional

locking pin is removed

5. Traction is controlled via the 2 hydraulic levers on the R/H side of the

chassis.

6. The left lever controls the left motor and the right lever the right.

Operating only the left lever forward will turn the machine right and the

right lever will turn the machine left, operate both levers together for

parallel drive.

7. When the machine is in position replace handbrake.

Ensure friction drive cylinders are disengaged prior to platform

!

12 508159-000 TL49K

operation or towing.

Page 17

R ight

g

h

h

L

4

L

4

PRE-START CHECKS

The following Pre-Start Checks should be carried out before taking the

machine to the place of work.

1. Damaged or Loose Fittings.

Visually Inspect the machine for signs of wear and tear, damage, loose or

missing parts.

2. Wheels. (For towing only)

Check tyres are at the correct pressure, TL49K = 76psi (5.25 bar).

3. Hydraulic fluid.

The hydraulic oil tank is located underneath the slew cover on the right

hand side of the machine (looking from the cage end), Ref, Fig.2, section J

With the booms and outriggers in the transport position, the hydraulic oil

level should be visible between the upper and lower marks of the

Sight Glass.

Top up with ISO Grade 22 hydraulic oil if necessary.

Do Not Overfill the Tank

Serious injury or even death may result by not carrying out the

following checks of the interlock system before the platform is

used!

4. Safety Switches.

Visually check the cage overload switch is free from damage.

Check all limit switch arms are free from damage and move easily

(outrigger switches shown in Fig.6 ).

With outriggers in transport position, it must not be possible to operate the

extending structure. With outriggers deployed, under load and top or

bottom boom raised approximately 50mm, it must not be possible to

operate the outrigger controls.

The flick boom is not interlocked with the outriggers.

1

TL49K 508159-000 13

Page 18

PRE-START CHECKS

5. Emergency Stop Switches.

Emergency stop switches must operate correctly. Check that each stops the

machine’s controls and that restarting is prevented until all stop switches

are unlatched.

6. Emergency Lower/Slew.

With the top and bottom booms raised approximately 500mm each and the

unit switched off, check:

The emergency lower switch located in the basket and ground control

stations, lowers the booms when operated.

The emergency slew, telescopic boom retraction can be operated by using

the hand pump and control lever at the ground control station.

To Reset the hydraulic system after checks;

Fully slew the Basket to the right, so that he ram is fully extended.

Fully extend the Outriggers while still maintaining Level. (check the bubble)

Using the ground controls, fully extend Top, Bottom and Telescopic Booms.

Fully extend the Flick Out Boom.

All rams must be fully extended at the same time before returning them to

their transit position.

If the Emergency Lower is used during normal operation, DO NOT

use the machine, Contact your local UpRight representative.

7. Emergency Hand Pump.

With the unit set up for working (i.e. outriggers down, under load and the

machine level with wheels clear of ground) it is possible to lower the cage

using the emergency hand pump.

8. Battery Power (Where applicable)

Check batteries are fully charged and topped up with distilled water (these

are fitted under the slew cover on both sides of the platform).

Hydrometer reading should be 1280-1320sg.

With machine level, the distilled water should cover the plates by

approximately 6mm.

9. Mains Power (Where applicable)

Check that the voltage and frequency of the power input matches that of the

motor. All extensions must be a minimum of 2.5mm², and no longer than

10m due to possible voltage drop.

10. Petrol/diesel Power (Where applicable)

Check that there is sufficient oil and fuel to complete a full working shift.

14 508159-000 TL49K

Page 19

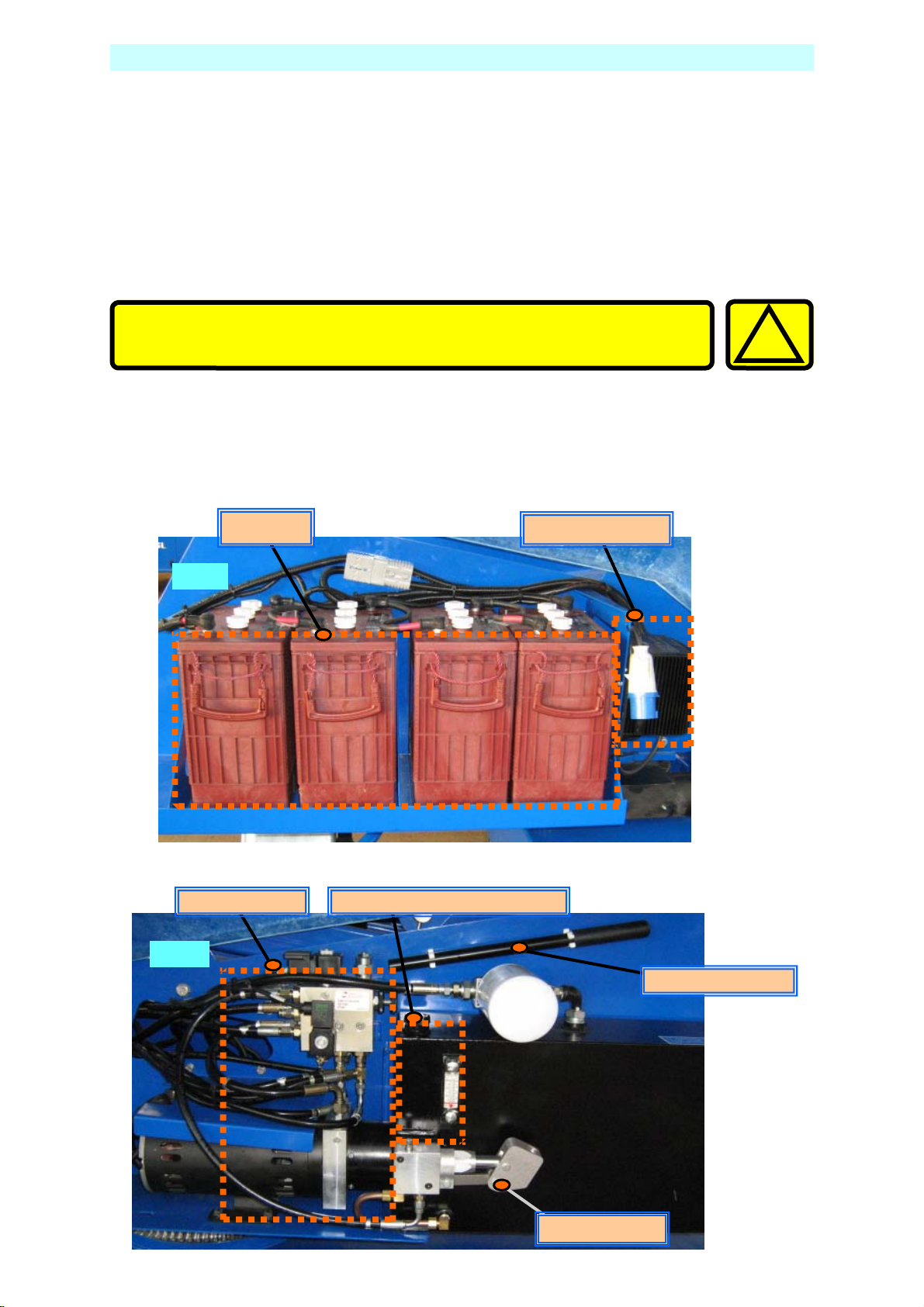

BATTERIES & POWER PACK

Battery Power, 24V DC.

Ensure batteries have been fully charged before use and that the Battery Isolating

Plug is securely connected.

Mains Power, (OPTIONAL)

Connect the mains supply, either 110V or 220/240V A.C., depending upon the

motor specification. Check the motor is running when the key is turned to the ON

position.

All extensions must be a minimum of 2.5mm², and no longer than

10m, due to possible voltage drop, which will damage the motor.

Petrol/diesel Power, (OPTIONAL)

Check the fuel and oil levels of the engine. Switch on the ignition using the key

switch on the slew mounted legend panel. Check the engine runs using the start

and stop buttons in the basket.

!

Fig. 1

Power Pack

Fig. 2

Batteries

Battery Charger

Oil Filler and Sight Glass

Pump Handle

Hand Pump

TL49K 508159-000 15

Page 20

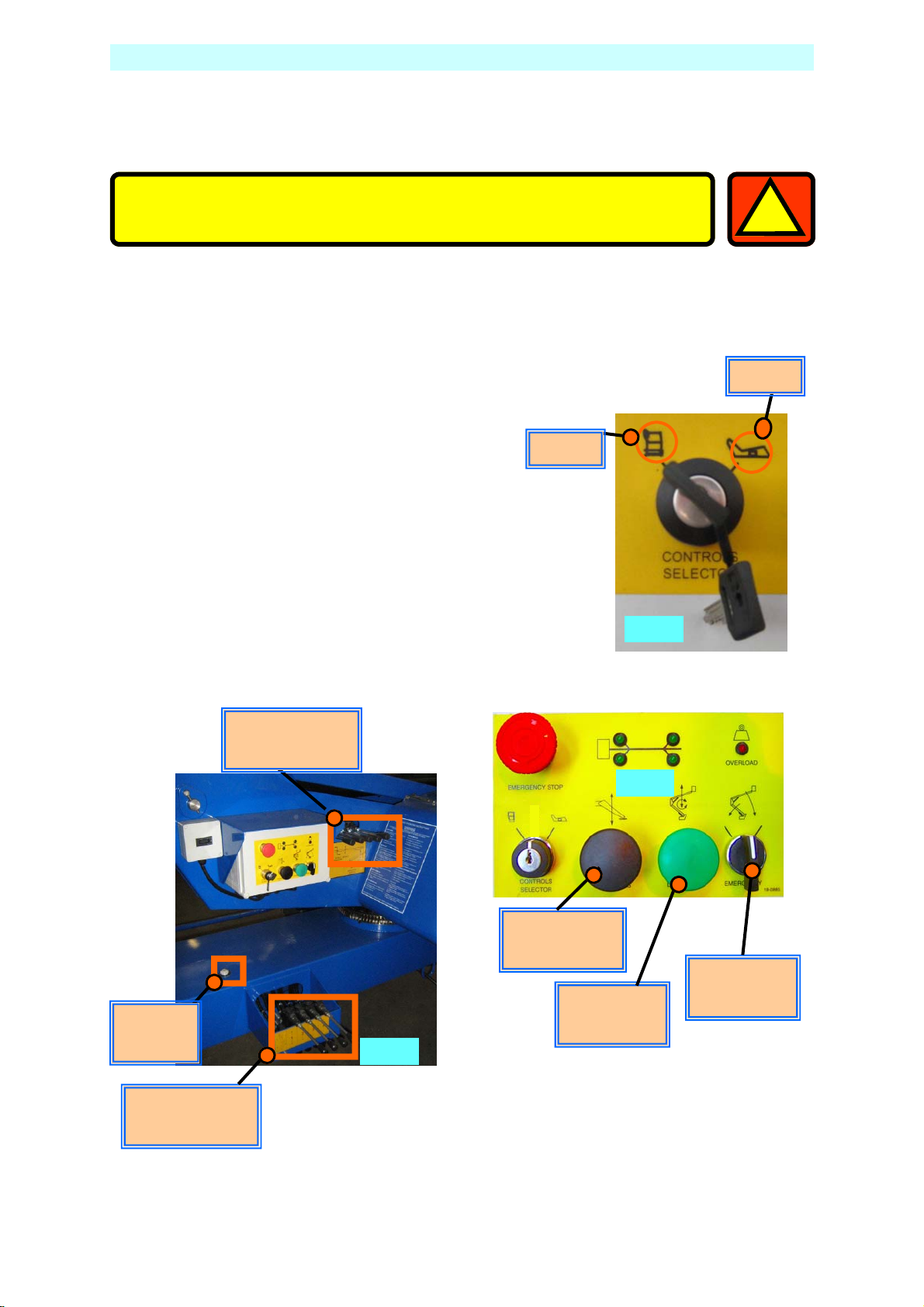

SETTING UP

1. Park the unit in an appropriate location at the workplace.

Do not attempt to set up the machine on steep slopes, ramps or

soft ground.

2. Apply the handbrake on the trailer and remove from the towing vehicle.

3. With platform key switch set to ’Ground’ (Fig 3)

lower the outriggers by keeping the

‘Outrigger Motor Run’ button (Fig 4)

pushed in, operate the appropriate

‘Outrigger control lever’ (Fig 5), until all

four are 25mm to 50mm from the

ground.

Basket

1

Ground

Level

indicator

Control Levers

Ground

Fig. 5

Motor Run

Outrigger

Motor Run

Booms

Fig. 3

Fig. 4

Emergency

Lower

Control Levers

Outriggers

16 508159-000 TL49K

Page 21

SETTING UP

4. Lower the Outriggers two at a time starting at the tow bar end (No’s 3&4) until

the jockey wheel just clears the ground.

5. Lower Outriggers 1&2 until the green LED display indicates that they are

under load. (As shown below)

Take EXTREME care NOT to ground either the Basket, or the

!

6. Repeat this sequence for Outriggers 3&4.

7. By alternating from 1&2 to 3&4, carefully inch down each pair of Outriggers

until all four Outriggers are fully deployed, and the wheels are well clear of

the ground.

8. Now, by using the Level indicator (Fig.5), raise opposite Outriggers until the

bubble and indicator ring are concentric (i.e., the bubble rests in the centre).

9. Check that each LED on the Ground Control panel is still illuminated. This

indicates that each foot is in firm contact with the supporting surface.

1

Jockey Wheel during the next step.

The unit is designed to operate on a supporting surface of

minimum bearing strength of 50N/cm

2

.

The maximum outrigger load is 12.5kN.

1

TL49K 508159-000 17

Page 22

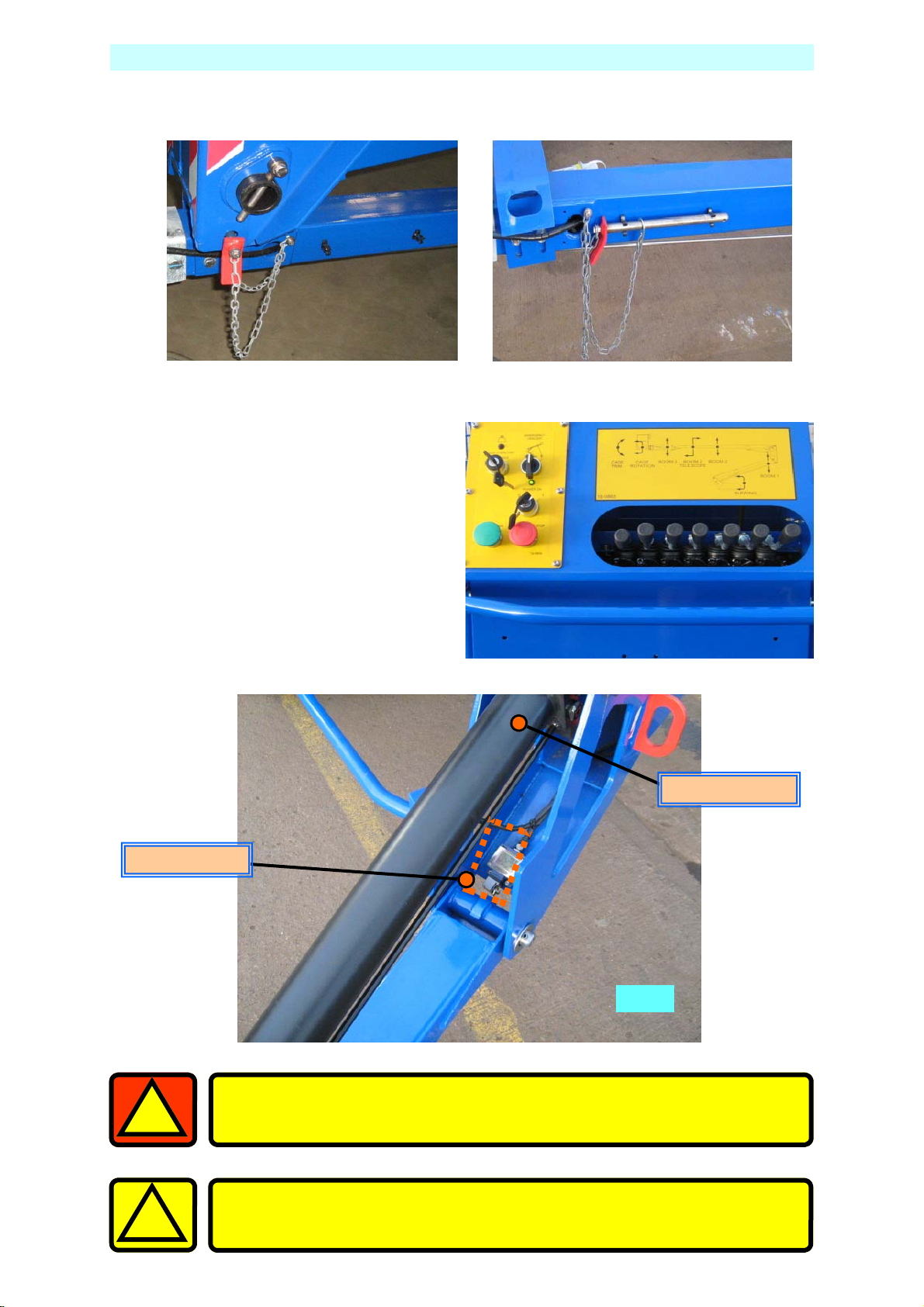

EXTENDING STRUCTURE

1. Remove and correctly stow the Transit Pins, from both the Upper and Lower

Booms.

2. At the Ground Control Station, turn the key to ‘Basket’. (See Fig. 3)

3.

Climb into the basket. Check that

all Emergency Stop Switches are

released (twist release). The platform may now be raised, lowered

or slewed in any direction by operating the control levers at the

basket, whilst depressing the motor run button (DEADMAN).

Limit Switch

Before raising, ensure there are no overhead obstructions or

1

!

power cables and the outriggers are properly extended and

secure.

Take EXTREME care when slewing both basket and turret, at low

levels.

Outrigger Ram

Fig. 6

18 508159-000 TL49K

Page 23

EXTENDING STRUCTURE

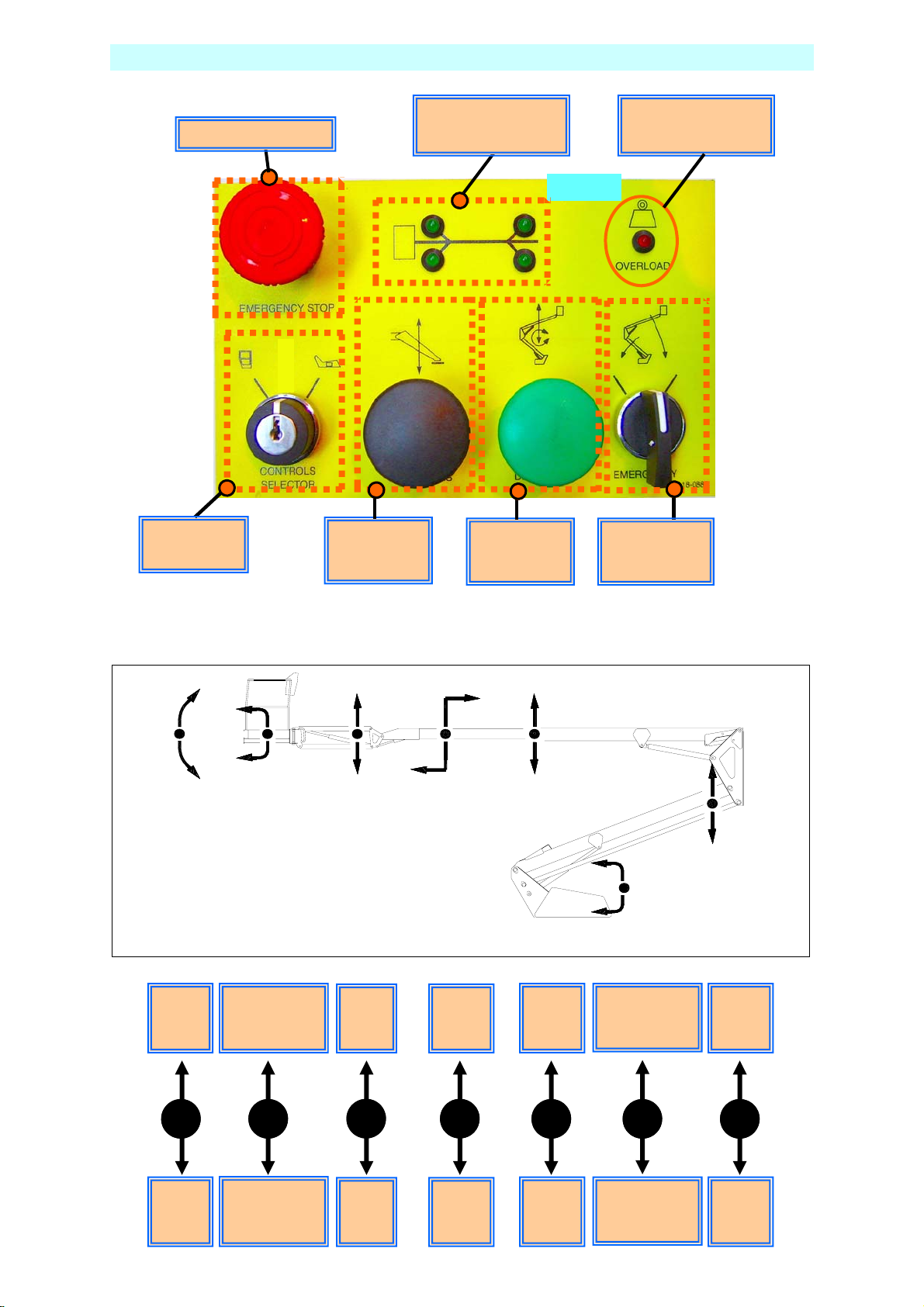

Emergency Stop

Control

Selector

Motor Run

Outriggers

Outrigger Load

Indicators

Motor Run

Booms

Basket overload

Indicator

Fig. 4a

Emergency

Lower

4. Explanation of the Basket Control Station, Directional Control Levers.

CAGE

TRIM

18-0865-02

Raise

Basket

Trim

CAGE

ROTATION

Slew

Basket

Anticlockwise

Raise

Flick

Boom

BOOM 2

TELESCOPE

Retract

Tele-

Boom

BOOM 2BOOM 3

Raise

Tele-

Boom

SLEWING

Slew

Turret

Anticlockwise

BOOM 1

Raise

Lower

Boom

Lower

Basket

Trim

Slew

Basket

Clockwise

Lower

Flick

Boom

Extend

Tele-

Boom

Lower

Tele-

Boom

Slew

Turret

Clockwise

Lower

Lower

Boom

TL49K 508159-000 19

Page 24

EXTENDING STRUCTURE

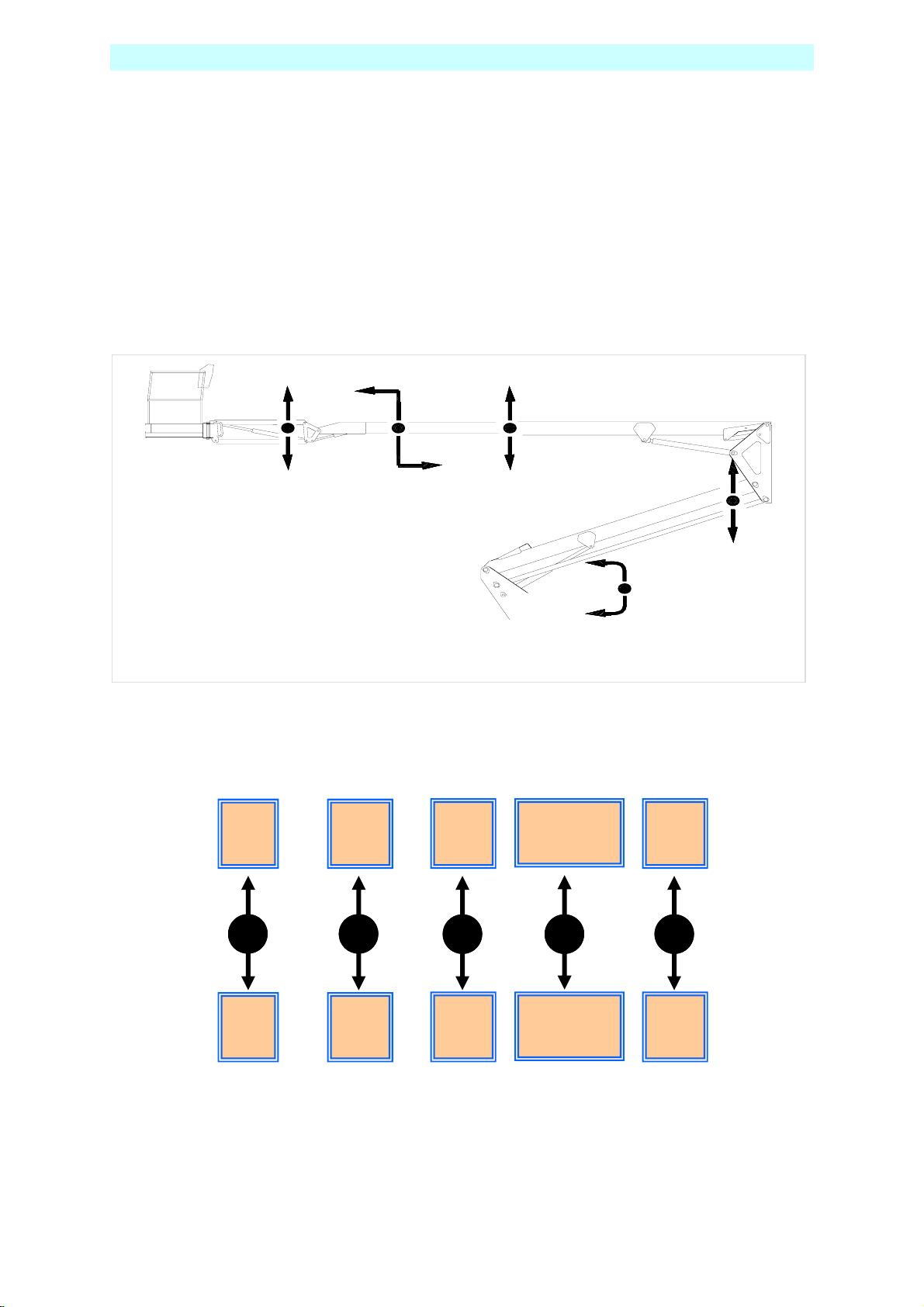

5. A duplicate set of controls (excluding Slew Basket) is mounted on the Slew

Turret under the right hand side cover, which allows the platform to be

operated from the Ground.

6. At the Ground Control Station, turn the key to ‘Ground’. (See Fig.3)

7. Explanation of the Ground Control Station, Directional Control Levers

18-0884

Raise

Flick

Boom

BOOM 2

TELESCOPE

Extend

Tele-

Boom

BOOM 2BOOM 3

Raise

Tele-

Boom

SLEW ING

Slew

Turret

Anticlockwise

BOOM 1

Raise

Lower

Boom

Lower

Flick

Boom

Retract

Tele-

Boom

Lower

Tele-

Boom

Slew

Turret

Clockwise

Lower

Lower

Boom

20 508159-000 TL49K

Page 25

g

h

h

L

4

L

49

Right

g

h

h

L

4

L

4

SAFETY

Safety Harness

1. In accordance with IPAF recommendations, UpRight recommend the use of a Full

Body Harness with an adjustable lanyard is used when operation from the basket.

2. The lanyard length should be as short as possible.

3. A permanent attachment point is provided in the basket for fixing the harness.

EMERGENCY CONTROLS

1. Emergency Stop

Emergency Stop buttons are fitted on the machine to stop the motor in an

emergency.

There are 2 Emergency Stop Buttons, one in the basket, and one on the

ground control panel.

The emergency stops are ‘Reset’ by twisting.

TL49K 508159-000 21

Page 26

Right

g

h

h

L

4

L

4

EMERGENCY CONTROLS

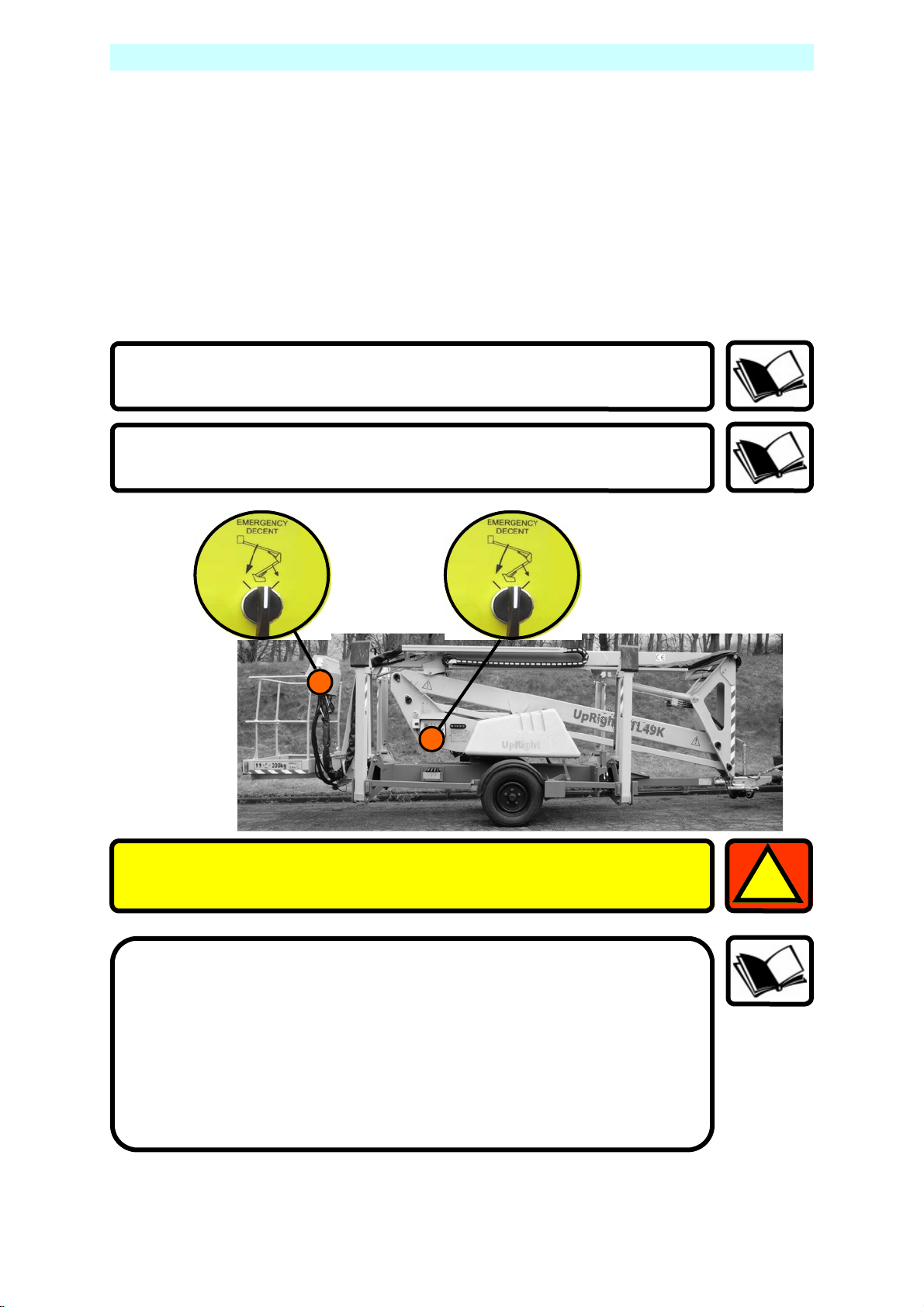

Emergency Lower.

In the event of a power failure, There are two ways of Safely lowe ring the

basket.

2. Emergency Lowering, method one

The operator or someone on the ground, can lower the booms to a safe

position by activating the Emergency lowering selector switch both ways, o n

the Basket Control Panel and the Ground Control Panel.

The Flick Boom cannot be lowered by activating the Emergency

Lowering Switch.

The Emergency lowering valve will automatically close when the

switch is released.

If the Emergency Lower is used due to a machine defect, DO NOT use

the machine, Contact your local UpRight representative.

If the Emergency Lower is used, The TOP and BOTTOM BOOMS must

be fully extended then fully lowered before work can continue.

After Emergency lowering, any further POWERED lowering could

cause an AIRLOCK in the hydraulic system.

This could cause the Hydraulic operations to Fail.

ALL BOOMS MUST BE FULLY EXTENDED/RAISED, THEN LOWERED

BEFORE WORK CAN RECOMMENCE.

1

22 508159-000 TL49K

Page 27

EMERGENCY CONTROLS

3. Emergency Lowering a, method two.

You can operate the hand pump from the ground control station cage

and operate the boom controls and slewing functions.

To operate the hand pump, insert the lever over the pump shaft, then lower

the lever to a convenient position to start pumping.

Move a control lever to the required direction of movement, and

operate the hand pump. When the machine starts to lower, continue

depressing the control lever.

Vigorous pumping is required to lower and slew the machine.

TL49K 508159-000 23

Page 28

EMERGENCY CONTROLS

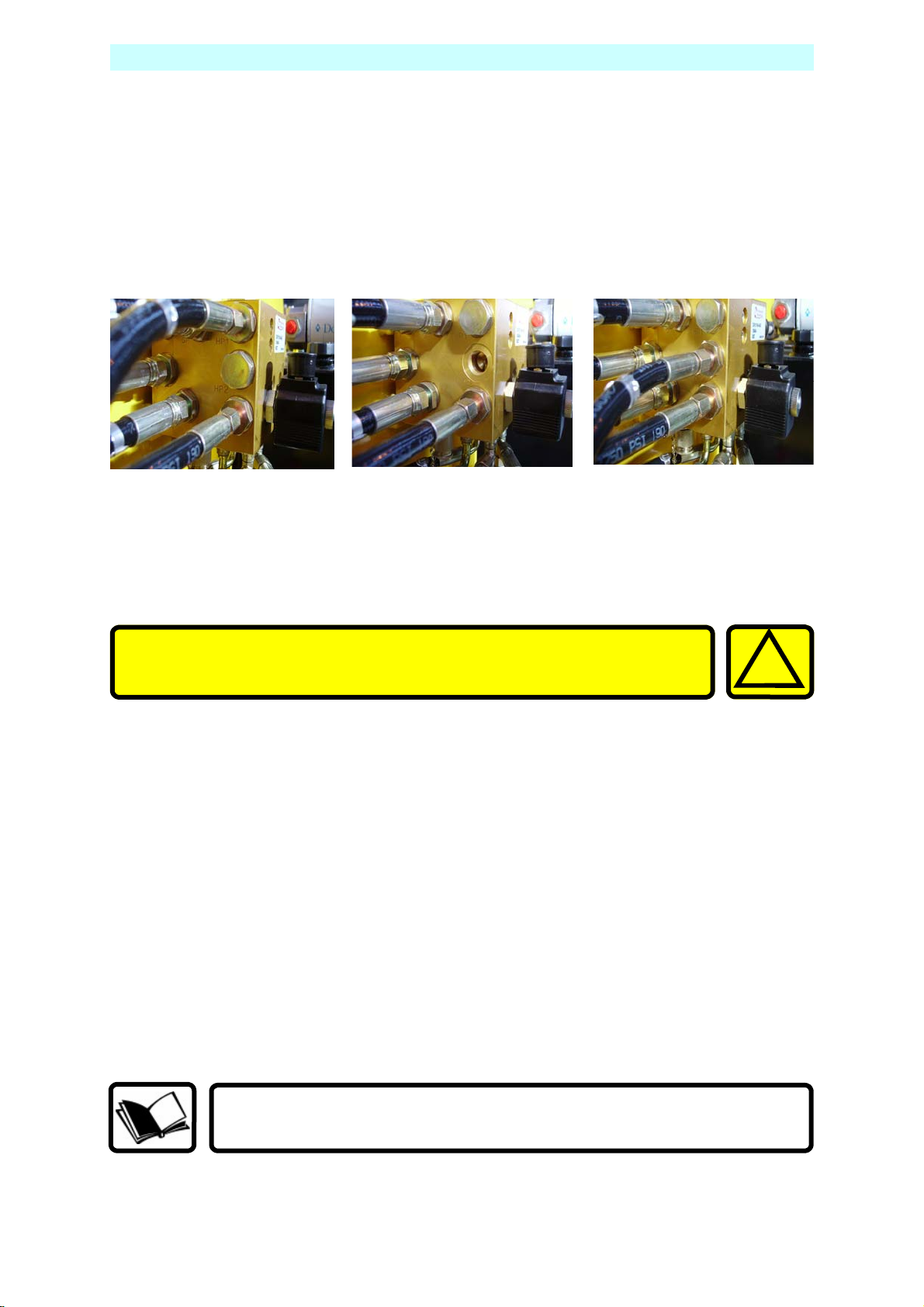

4. Emergency Procedure, Manual Raising of Outriggers.

In the event of power failure, the outriggers can be raised to their transport

position.

First the hand pump hose fitted to port HP1, must be redirected from HP1,

to port HP2, and the blanking plug from HP2 must be replaced into HP1,

using a 22mm spanner.

Once connected, move an Outrigger Control Lever in the required

direction of movement, and operate the hand pump. When the Outrigger

starts to raise, continue depressing the control lever.

Some hydraulic oil will be lost during this procedure. This will

still allow Emergency operations, but will need to be replaced

before full normal use can resumed.

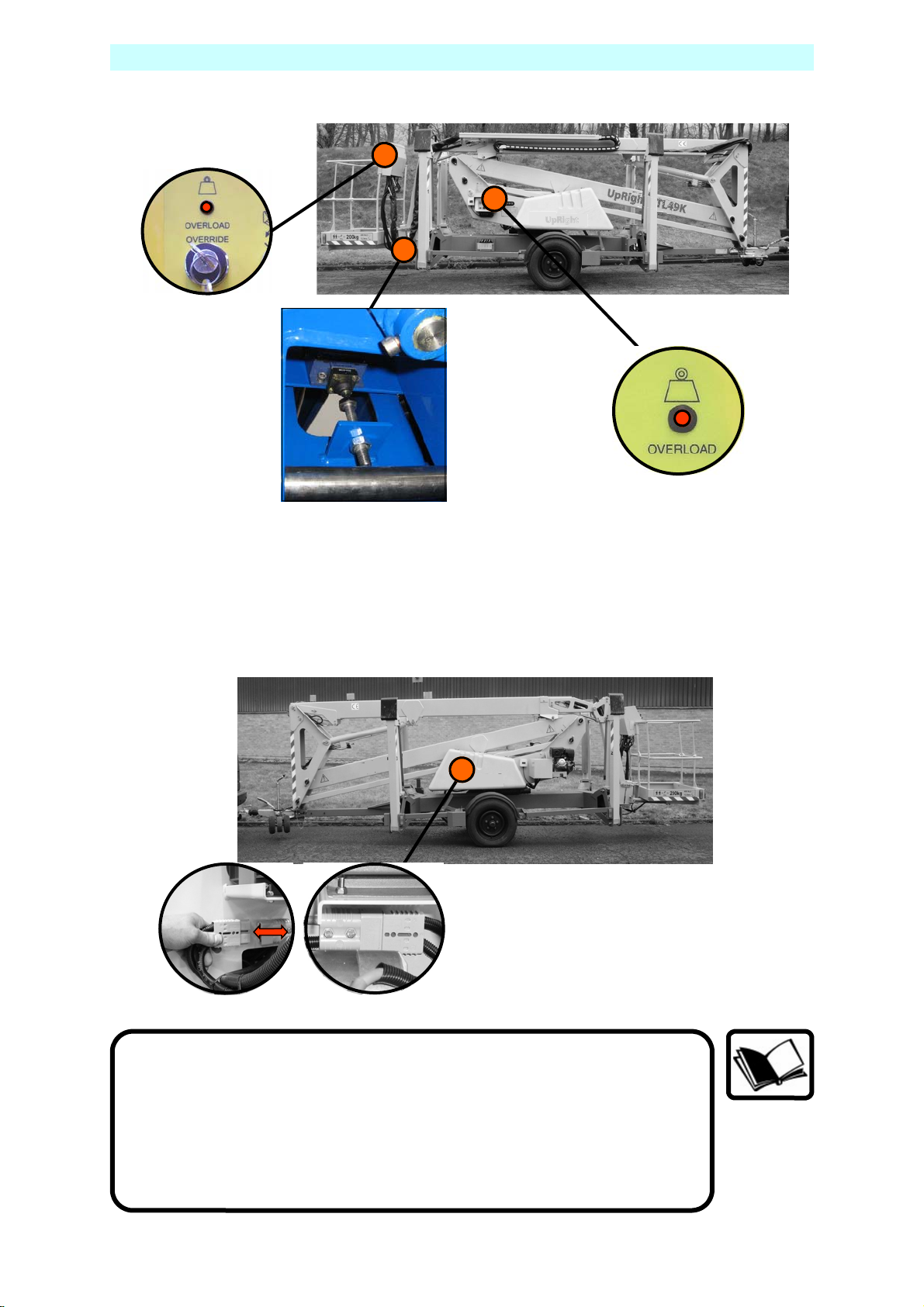

5. Cage Overload

In the event of the cage being overloaded, an audible alarm will sound and

the cage controls will cut out.

To re-start, enough load must be removed from the cage so that the

alarm stops sounding.

In cases where the overload can not be immediatley removed or the cage

has fouled, then the overload override selector switch can be used to move

the platform to a safe position so that the overload can safely removed.

!

The Key, Motor Run/Deadman and a Control Lever must be

operated at the same time to effect this action

24 508159-000 TL49K

Page 29

Right

g

h

h

L

4

L

4

EMERGENCY CONTROLS

6. Emergency Battery Isolating Plug.

Disconnecting this plug will isolate the batteries from the powerpack

and operating circuits.

Before operating this machine, it is important that both the

Operator and another responsible person on site, is aware of the

position and function of the following:

A) Emergency Stop Buttons.

B) Emergency Lowering Buttons.

C) Emergency Slew Drive Shaft.

D) Battery Isolating Plug.

TL49K 508159-000 25

Page 30

STOWING THE MACHINE

1. Fully lower all the booms.

2. Engage the Transit Pins, and lock in place using ‘R’ clip.

3. With platform keyswitch set to ‘Ground’:

Raise the outriggers by simultaneously depressing the ‘MOTOR RUN

Outrigger’ button and using the appropriate control levers, two at a time,

alternating between the cage and tow bar end until the road wheels are in

contact with the ground.

Only when the road wheels are in contact with the ground should the unit be

lowered further until the jockey wheel makes contact with the supporting

surface.

Now fully raise the outriggers until they are in the stowed position.

Switch off the platform and ensure all loose items/covers are secure before

towing the unit.

The machine is now ready for transportation.

TRANSPORT PIN LOCATIONS – SHOWN READY FOR TRANSPORT

Lower

Boom

Upper

Boom

26 508159-000 TL49K

Page 31

MAINTENANCE

The unit must have a thorough inspection carried out every 6

months in accordance with LOLER Regulations 1998 and a

Certificate of Thorough Inspection produced by a competent

person.

Always ensure the machine structure is in good, sound,

undamaged condition. Any inspection procedure is always aided

by keeping the machine clean. NB. Do not steam clean the battery

charger or electrical components.

Daily Checks.

1. Damaged or Loose Fittings.

Visually Inspect the machine for signs of wear and tear, damage, loose or

missing parts.

2. Wheels.

Check tyres are at the correct pressure, TL49K = 76psi (5.25 bar).

3. Hydraulic fluid.

The hydraulic oil tank is located underneath the slew cover on the left

hand side of the machine (looking from the cage end), Ref, Fig.2, section J.

With the booms and outriggers in the transport position, the hydraulic oil

level should be visible between the upper and lower marks of the

dipstick.

1

!

Do Not Overfill the Tank

Top up with ISO Grade 22 hydraulic oil if necessary.

4. Safety Switches.

Check all limit switch arms are free from damage and move easily

outrigger switches.

With outriggers in transport position, it must not be possible to operate the

extending structure.

With outriggers deployed, under load and top or bottom boom raised

approximately 50mm, it must NOT be possible to operate the outrigger

controls.

The flick boom is not interlocked with the outriggers.

5. Emergency Stop Switches.

Emergency stop switches must operate correctly. Check that each stops the

machine’s controls and that restarting is prevented until all stop switches

are unlatched.

TL49K 508159-000 27

Page 32

MAINTENANCE

The unit must have a thorough inspection carried out every 6

1

!

1. Apply grease to the slew gear wheel and all grease nipples.

2. From the Ground controls, Fully extend the Telescipic Boom and visually

inspect along its entire length for signs of wear and tear damage or

deformation.

3. Check battery acid level, top up with distilled water if required (maximum

6mm over plates when battery is standing level), and check mains cable

wiring.

1. Thorough inspection to be carried out by a competent person.(LOLER)

Weekly Checks.

Monthly Checks.

months in accordance with LOLER Regulations 1998 and a

Certificate of Thorough Inspection produced by a competent

person.

Always ensure the machine structure is in good, sound,

undamaged condition. Any inspection procedure is always aided

by keeping the machine clean. NB. Do not steam clean the battery

charger or electrical components.

FOR ENGINE MAINTENANCE REFER TO MANUFACTURES GUIDELINES

28 508159-000 TL49K

Page 33

MAINTENANCE

Slew Drive Gears.

The slew drive gear is designed to be largely maintenance free. However, we

recommend the gear teeth be greased on a monthly basis with a high pressure

grease. Additionally, the ring gear and gear box should be greased on a six

monthly basis. The grease nipple for the ring gear is on the top face of the slew

gear, set between the fixing bolts. It can be accessed by lifting one of the side

covers, and slewing the structure appropriately.

The ring gear should be inspected on a six monthly basis for excessive play. It is

unlikely there will be any wear if the machine is maintained correctly.

To check the gear, place a payload of approximately 80Kg in the platform. Elevate

the lower boom to approximately half way. Then gently elevate the top boom,

whilst observing the ring gear. Excessive wear will be observed by noticing more

than 0.5mm movement between the inner and outer bearing rings.

Checking Limit Switch Operation.

The limit switches require no maintenance, other than a visual inspection, on a pre

operation basis. This is an important check, to ensure the switch is not

mechanically damaged, and the roller is always in contact with the cam, when not

under load.

The switch operation can be simply checked, by observing the LED display when

deploying the stabilizers. As an outrigger foot touches the ground and becomes

loaded, the appropriate light will change to green. This indicates that the switch

contact has operated correctly.

Outriggers

under load

If the LED displays green at any other time then the machine must not be operated,

until the fault is rectified.

Grease

Nipple

Grease

Nipples

Outriggers NOT

under load

TL49K 508159-000 29

Page 34

MAINTENANCE

Pin No. Ref. Colour Function

1

2

3

4

5

6

7

L YELLOW L.H.INDICATOR

54G BLUE FOG LIGHT(S)

31 WHITE EARTH

R GREEN R.H. INDICATOR

58R BROWN R.H. TAIL, No. PLATE & MARKER LIGHTS

54 RED STOP LIGHT

58L BLACK L.H. TAIL, No. PLATE & MARKER LIGHTS

30 508159-000 TL49K

Page 35

APPENDIX Bi-Fuel Option

This machine variant is fitted with a petrol/diesel engine, with remote start

and stop

Diesel Engine

This manual does not cover the maintenance of the engine.

For engine maintenance details refer to the manufacturers handbook.

Prior to operating the engine, follow these simple guidelines;

a) ensure there is adequate fuel for the task in hand

b) check the oil level prior to starting the generator

c) Check battery electrolyte level. (Where applicable, Lead Acid batteries Only)

1. To use the engine, simply switch the fuel on, with the lever.

2. With the key, turn the ignition to start, motor on, releasing the starter when

the engine fires.

3. Or, if using the basket controls turn the key to engine and push the start

button.

4. With the engine running, It will now be possible to operate the machine

Hydraulic controls as long as there is power in the main batteries.

Petrol

Engine

TL49K 508159-000 31

Page 36

Generator option APPENDIX

This machine variant is fitted with a 2.2 kva generator, with remote start and

stop.

This manual does not cover the maintenance of the generator.

For maintenance details refer to the manufacturers handbook.

Prior to operating the generator, follow these simple guidelines;

a) ensure there is adequate fuel for the task in hand

b) warm the engine prior to switching off at the platform.

c) check the oil level prior to starting the generator

1. To use the generator, simply switch the fuel on, with the lever.

2. With the key, turn the ignition to start, motor on, releasing the starter

when the engine fires.

3. Ensure the voltage output matches the appliance intended for use.

4. Connect the flying plug.

5. With the engine running, power will automatically be supplied to the

battery charger, and the platform socket. It is possible to operate the

machine lift controls with the battery charger switched on.

32 508159-000 TL49K

Page 37

APPENDIX Mains connection

This machine variant requires a power supply from a fixed source.

Prior to operating the generator, follow these simple guidelines;

a) Ensure the power supply being attached is the correct voltage.

b) Ensure the power supply being used is being supplied via an

appropriate power extension.

1. To connect to a mains supply, simply remove the socket’s protection cap.

All extensions must be a minimum of 2.5mm², and no longer than

!

2. Connect an appropriately rated power extension.

3. Ensure the voltage output matches the appliance intended for use.

4. Ensure that the connection is secure before use.

10m, due to possible voltage drop, which will damage the motor.

Blue sockets is 240V output. Yellow sockets is 110V output.

!

TL49K 508159-000 33

Page 38

Page 39

TL49K

Seriennummern 8000 - Aktuell

Bitte geben Sie unbedingt das MODEL und die SERIENNUMMER auf dem K ennschild des Gerät es an, wenn Sie sich

wegen Service oder Teileinformationen an UpRight wenden. Sollte kein Kennschild vorhanden sein, finden Sie die

SERIENNUMMER auch auf dem Fahrgestell hinter der Anhängerkupplung eingestanzt.

Die Seriennummer ist auf dem Fahrgestell

hinter der Anhängerkupplung und über dem

Fahrgestellnummernschild eingestanzt.

www.upright.com

Page 40

Page 41

p

,

! WARNUNG !

Sicherheitsregeln

Alle Mitarbeiter müssen vor Inbetriebnahme von UpRight Hubarbeitsbühnen und der

Durchführung von Wartungsarbeiten an diesen alle Sicherheitsregeln und Bedienungsan-

weisungen sorgfältig lesen, verstehen und befolgen.

Electrocution Hazard Tip Over Hazard Collision Hazard Fall Hazard

NEVER

cl imb, s tand, or sit on

latfor m gua rd ra i ls or mid ra i l.

Dieses Gerät ist NICHT

NE VER

elevate the platform or drive

t he mach ine w hile elevat ed u nless t he

machine is on a firm

le ve l sur f ac e .

NEVER

posi tion the p latform

witho ut first checking for overhead

obstructions or other hazards.

isoliert.

VERWENDUNG DER HUBARBEITSBÜHNE: Diese Hubarbeitsbühne dient dem Anheben von Personen und

deren Werkzeugen sowie des für die Arbeit notwendigen Materials. Sie wurde für Reparatur- und Montagearbeiten

konstruiert, die über Kopf ausgeführt werden (Decken, Kräne, Dachgerüste, Gebäude usw.). Jegliche andere

Verwendung der Hubarbeitsbühne ist verboten!

DIESE HUBARBEITSBÜHNE IST NICHT ISOLIERT! Halten Sie daher unbedingt einen sicheren Abstand zu den

stromführenden Teilen der elektrischen Ausrüstung ein!

Es ist verboten, das spezifizierte zulässige Gesamtgewicht zu überschreiten! Weitere Details finden Sie unter

„Spezielle Begrenzungen“.

Die Verwendung und Bedienung der Hubarbeitsbühne als Hebezeug oder Kran (zum Heben von Lasten von unten

nach oben oder von oben nach unten) ist verboten!

Überschreiten Sie NIEMALS die für dieses

„Spezielle Begrenzungen“.

VERTEILEN Sie alle Lasten gleichmäßig auf der Plattform.

Setzen Sie das Gerät NIEMALS in Betrieb, ohne vorher den Arbeitsbereich auf Gefahren auf der Oberfläche

überprüft zu haben und vermeiden Sie diese. Dazu gehören Löcher, Abfälle, Beulen, Kanten oder Ablagerungen.

VERWENDEN Sie das

Verwenden Sie das

Weitere Details finden Sie unter „Beaufortskala“.

Drücken Sie bei NOTFÄLLEN den NOTAUSSCHALTER, um alle angeschalteten Funktionen zu deaktivieren.

WENN DER ALARM ERTÖNT während sich die Plattform angehobener Position befindet, beenden Sie die Arbeit

und senken Sie die Plattform vorsichtig. Bringen Sie das

Es ist verboten, auf das Geländer der Plattform zu steigen, auf der Plattform zu stehen oder von ihr auf Gebäude,

Stahl- oder Fertigbetonbauten usw. überzutreten!

Es ist verboten, den Schwenkrahmen oder andere Geländerkomponten abzumontieren! Stellen Sie immer

sicher, dass der Schwenkrahmen geschlossen und sicher verriegelt ist!

Es ist verboten, den Schwenkrahmen geöffnet zu lassen (offen halten mit Tie-Straps), wenn sich die Plattform in

angehobener Position befindet.

Es ist verboten, die Höhe oder Reichweite zu vergrößern, indem Leitern, Gerüste oder ähnliche Gegenstände auf

die Plattform gestellt werden.

Warten Sie das Gerät NIEMALS, während sich die Plattform in angehobener Position befindet, ohne die

hebenden Bauteile zu blockieren.

UNTERSUCHEN Sie das

fehlenden Ausstattungsteilen, hydraulischen Leckagen, lockeren Kabelverbindungen und beschädigten Kabeln

oder Schläuchen.

STELLEN SIE vor der Verwendung SICHER, dass alle Schilder vorhanden und lesbar sind.

Verwenden Sie NIEMALS ein

fehlende Beschilderung aufweist.

Es ist verboten, jegliche Sicherheitsausstattung kurzzuschließen, da es für die Person auf der Hubarbeitsbühne

sowie für die Personen in deren Arbeitsbereich eine Gefahr darstellt.

Laden Sie die Batterien NIEMALS in unmittelbarer Nähe von Funken oder offenen Flammen auf, da ladende

Batterien explosives Wasserstoffgas ausstoßen.

Es ist verboten, Veränderungen an der Hubarbeitsbühne vorzunehmen, es sei denn, sie wurden ausdrücklich

von UpRight genehmigt.

Sichern Sie die Arbeitsbühne NACH DER VERWENDUNG vor unautorisierter Verwendung, indem Sie beide

Gerät ausschließlich auf Oberflächen, die Radlasten unterstützen.

Gerät NIEMALS, wenn die Windgeschwindigkeit die Windwerte des Geräts überschreitet.

Gerät vor der Verwendung gründlich nach rissigen Schweißnähten, lockeren oder

Gerät, das beschädigt ist, nicht ordnungsgemäß arbeitet oder schadhafte oder

Gerät zulässige manuelle Kraft. Weitere Details finden sie unter

Gerät auf eine feste, ebene Oberfläche.

TL49K 508159-000

Page 42

INHALT

Seite

Einleitung 3

Ausstattungsbeschreibung 4

Technische Spezifikationen 5

Arbeitsbereich 6

Anforderungen an den Bediener 7

Warnhinweise 8

. Beaufortskala 9

Schleppanweisungen 10

Manuelles Manövrieren (Friktionsantrieb) 12

Kontrolle vor Inbetriebnahme 13

Stromversorgung 19

Batterien & Netzteil 15

Einrichtung 16

Auslegersystem 18

. Korbsteuerung 18

. Bodensteuerung 20

Sicherheitsgurt 21

Notfallsteuerung

. Notausschalter 21

. Notfall-Absenkung (Elektronisch) 22

. Notfall-Absenkung (Manuell) 23

. Notfall-Hebungsausleger 24

. Notfall-Käfigüberlast 24

. Notfall-Batterieisolierung 25

Verstauen des Geräts 26

Wartung

. Tägliche Kontrolle 27

. Wöchentliche und monatliche Kontrolle 28

. Drehantriebs– und

Begrenzungsschalter 29

. Lichtdiagramm des Anhängers 30

Anhang

Benzin-/Bi-Energy-Option. 31

Generator-Option. 32

Netzanschluss. 33

2 508159-000 TL49K

Page 43

EINLEITUNG

Die UpRight TL49K ist führend in ihrer Klasse und bietet standardmäßig

verschiedene Funktionen, die andere Hersteller nur als optionale Zusatzfunktionen

anbieten.

Dazu gehören die angetriebene Plattformrotation und die vollständig proportionale

Hydrauliksteuerung sowohl auf Korb– als auch auf Bodenebene.

Der dritte Ausschlagarm hat einen Arbeitsbereich von 130 Grad und bietet somit

Zugang auch zu schwer erreichbaren Plätzen. Der Drehbereich der Korbrotation

von 90 Grad gewährleistet währenddessen eine präzise Positionierung, welche für

die Arbeit an engen Plätzen unabdingbar ist.

UpRight Powered Access steht auf der ganzen Welt für Innovation und schaut auf

eine stolze Geschichte in der Konzipierung und Fertigung angetriebener

Zugangsmittel für höher gelegene Arbeitsplätze von höchster Qualität zurück.

Das Unternehmen wurde vor mehr als 25 Jahren in Großbritannien gegründet und

vertritt seitdem den Grundsatz, dass der Service für den Endnutzer ständig

verbessert werden muss.

Jedes Modell unserer immer größer werdenden Reihe von vielseitigen

Anhängerbühnen ist führend in seiner Klasse. Alle zusammen haben in unserer

Branche neue Maßstäbe gesetzt.

Mit Hilfe unseres Engagements für Forschung und Konstruktion sowie unseres über

23.000,00 m² großen Fertigungs-, Bau- und Supportstandorts kann UpRight

komplette Lösungen anbieten, die selbst die größten Herausforderungen in Sachen

Zugangsmittel erfüllen können.

Im gesamten Handbuch werden folgende Symbole verwendet, um auf Sicherheits- und Bedienungsinformationen hinzuweisen;

Diese Art von Kästchen beinhaltet WICHTIGE Bedienungshinweise.

Diese Art von Kästchen beinhaltet WARNHINWEISE. Hier werden

!

1

Warnungen zur Vermeidung von Schäden an der Ausstattung

und möglicherweise am Personal gegeben.

Diese Art von Kästchen beinhaltet GEFAHRENHINWEISE. Hier werden Warnungen zur Vermeidung von KÖRPERLICHEN VERLETZUNGEN von Bediener und anderem Personal gegeben.

TL49K 508159-000 3

Page 44

AUSSTATTUNGSBESCHREIBUNG

Die Upright TL49K verfügt über einen vertikalen Arm mit Parallelverbindung und ist

auf einem schleppbaren Straßenanhänger aufgesetzt. Die einzigartige und doch

einfache Auslegerkonfiguration garantiert ein Höchstmaß an Sicherheit und

Steuerungsfähigkeit. Dazu kommt die stabile Konstruktion dieses Modells, mit der

jede noch so schwere Arbeit bewältigt werden kann.

Die TL49K hat eine Plattformkapazität für zwei Personen (200 kg Traglast).

Das Gerät umfasst einen Unterarm mit Zugstange, einen kurzen vertikalen Arm

sowie einen oberen Arm mit Teleskopteil. Die TL49K verfügt außerdem über einen

eigenständigen, hydraulisch betriebenen Arm und einen rotierenden Käfig für

zusätzliche Manövrierfähigkeit.

Das hydraulische System ist eine durchweg ausfallfreie Konstruktion mit

eingebauten hydraulischen Absperrventilen an allen Rammen als

Vorsichtsmaßnahme für Schlauchausfälle. Die Bühne wird durch eine proportionale

manuelle Steuerung durch einen Hebel bedient, die als ‚direkte Hand‘ bezeichnet

wird. Diese Ventile befinden sich standardmäßig sowohl an der Basiseinheit als

auch im Korb.

Die Bühne verfügt standardmäßig über elektrisch betriebene Notfall-Absenkventile,

mit der das Gerät von der Basiseinheit und dem Korb gesenkt werden kann.

Die hydraulisch betriebenen Ausleger verfügen über Sperren mit Lasterfassung.

Damit wird verhindert, dass die Arme angehoben werden, ohne dass die Ausleger

erweitert sind und unter Last stehen. Eine Sperre verhindert, dass die hydraulischen

Ausleger versehentlich zurückgezogen werden, während sich die Arme in

angehobener Position befinden. Ein einfaches Warnlichtsystem zeigt, ob die

Stromversorgung angeschaltet ist und jeder Ausleger unter Last steht.

Leistung.

Maximale Arbeitshöhe: 17,00 m

Maximale Arbeitsreichweite: 9,10 m

Kapazität (zwei Personen): 200 kg

Turmdrehung: 680°

Lärmemission (Batterie): 70 dB(A)

Konstruktionsstandards.

Dieses Gerät stimmt vollständig mit den folgenden EWG-Richtlinien überein:

Richtlinie 98/37/EC – ‚Maschinenenrichtlinie‘.

Richtlinie 89/336/EEC – ‚Elektromagnetische Kompatibilitätsrichtlinie‘.

Richtlinie 73/23/EEC – ‚Niederspannungsrichtlinie‘.

EN 6020-1/1993 ‚Maschinensicherheit’.

Das Gerät wurde in Übereinstimmung mit allen relevanten BSI und

europäischen Standards konstruiert und getestet, einschließlich EN280.

4 508159-000 TL49K

Page 45

TECHNISCHE SPEZIFIKATIONEN

Käfigmaße

Länge 1,20 m

Breite 0,80 m

Höhe des Schutzgeländers 1,10 m

Höhe des Fußbretts 0,15 m

Kapazität

Maximale Arbeitshöhe 17,00 m

Maximale Käfighöhe 15,00 m

Maximale Reichweite (vom Drehpunkt aus) 9,10 m

Transportabmessungen

Schlepplänge 7,10 m

Breite bei geschlossenem Zustand 1,75 m

Höhe bei geschlossenem Zustand 2,10 m

Gewicht (Batterie-Modell) 2250 kg (unbelastet)

(Batterie-Modell + Friktionsgetriebe) 2395 kg (unbelastet)

(Bi-Energy-Modell) 2300 kg (unbelastet)

Betriebsparameter

Zulässige Arbeitsbelastung 200 kg

Maximaler horizontaler Zug 400 N

Maximale Windgeschwindigkeit 12,5 ms

Drehbereich 680°

Käfigdrehung 90°

Ausstattung

Bodenramme Doppelwirkend: Bohrung Ø 80,0 mm

Stange Ø 50,0 mm

Oberramme Doppelwirkend: Bohrung Ø 80,0 mm

Stange Ø 50,0 mm

Teleskopramme Doppelwirkend: Bohrung Ø 65,0 mm

Stange Ø 45,0 mm

Flick-Ramme Doppelwirkend: Bohrung Ø 60,0 mm

Stange Ø 40,0 mm

Stabilisatorramme Doppelwirkend: Bohrung Ø 70,0 mm

Stange Ø 40,0 mm

Absperrventile der Boden- & Oberramme Vorgesteuert über Mittelventile

Steuerventil (Käfig) Vollrad, bestehend aus sieben

doppelwirkenden Spulen

Steuerventil (Boden) Vollrad, bestehend aus fünf

doppelwirkenden Spulen

Steuerventil (Stabilisatoren) Vollrad, bestehend aus vier

doppelwirkenden Spulen

Buchsen Azetalharz-Polymer mit gesinteter

Bronzebasis (DX)

Lagerbolzen Polierter Edelstahlstab

Klassifiziert nach BS970 303 S31

CW & MecaVal 147 m, Tuftride TFI AB1-beschichtet.

-1

TL49K 508159-000 5

Page 46

ARBEITSBEREICH

200kg

Abmessungen in Metern.

6 508159-000 TL49K

Page 47

ANFORDERUNGEN AN DEN BEDIENER

Bitte lesen Sie die folgenden Punkte sorgfältig durch und stellen Sie sicher,

dass Sie ausreichende Trainingsmaßnahmen erhalten haben, bevor Sie dieses

Gerät bedienen.

1. Wenn Sie gesundheitlich beeinträchtigt sind oder Ihr Seh- oder Hörvermögen

eingeschränkt ist, dürfen Sie dieses Gerät nicht bedienen.

2. Sie müssen schwindelfrei sein.

3. Das sichere Arbeiten auf der Plattform, die Sicherheit Ihrer Mitarbeiter sowie

die Sicherheit der Personen im umgebenden Arbeitsbereich hat höchste

Priorität.

4. Sie müssen den Inhalt dieses Betriebshandbuchs genau kennen. Versuchen

Sie niemals das Gerät außerhalb der empfohlenen Begrenzungen zu

bedienen.

5. Die angemessene Behandlung der Arbeitsplattform ist für die Sicherheit

Ihrer Mitarbeiter unerlässlich.

6. Es ist verboten, das Gerät unsachgemäß zu verwenden oder die Geräte,

die zur Sicherheitsbewahrung dienen, zu ignorieren oder zu beeinträchtigen.

7. Das Gerät darf ausschließlich von Personal bedient werden, dass für die

Arbeit mit dieser Ausstattung autorisiert ist und ausreichend geschult

wurde.

TL49K 508159-000 7

Page 48

WARNHINWEISE

1. Bedienen Sie dieses Gerät nur, wenn Sie ein umfassendes Training zum sicheren

Umgang mit ihr erhalten haben.

2. Verwenden Sie

Untergrund, es sei denn, es wurden angemessene Vorsichtsmaßnahmen getroffen.

Die Stabilisatoren arbeiten auf festem, ebenen Untergrund mit einer minimalen

Auflagekraft von 50 N/cm².

Ein Ausleger trägt eine Maximallast von 12,5 kN.

Wenn Sie

vorher bitte an UpRight, um die entsprechenden Unterstützungs- und

Vorsichtsmaßnahmen zu erfragen.

3. Verwenden Sie im Korb NIEMALS irgendwelche Ausstattung, um die Reichweite oder

die Arbeitshöhe des Gerätes zu vergrößern, z.B. Leitern.

4. Befestigen Sie NIEMALS irgendwelche zusätzliche Ausstattung an dem Gerät, die die

Windlast erhöhen könnte, z.B. Anschlagtafeln.

5. Nutzen Sie

oder Kräfte erzeugen könnte: Sie müssen vor speziellen Anwendungen die

Genehmigung des Herstellers, UpRight Powered Access, einholen.

6. Verwenden Sie

minimale Sicherheitsabstand von Geräten zu darüber liegenden Stromkabeln ist die

maximale Länge (bei ausgefahrenem Zustand) der Arme plus 15 Meter, wobei die

Arme beim Messen in Richtung Leitung zeigen. Der Sicherheitsabstand der

TL49K beträgt beispielsweise 24 Meter. Es obliegt der Verantwortung des Bedieners,

sicherzustellen, dass bei der Arbeit in Nähe von darüber liegenden

Hochspannungsleitungen der minimale Sicherheitsabstand eingehalten wird.

Befestigen Sie ein einfaches Absperrband an der Sicherheitsabstandslinie.

7. ARBEITEN IN DER NÄHE VON STROMKABELN – sollte eine Arbeit ausgeführt

werden müssen, die ein Unterschreiten des Sicherheitsabstandes erfordert, muss

der Bediener sicher stellen, dass die Stromzufuhr abgeschaltet ist. Vor

Arbeitsbeginn muss eine schriftliche Genehmigung von den Eigentümern der

Stromkabel oder der verantwortlichen Dienststelle eingeholt werden.

das Gerät NIEMALS auf weichem, rutschigen oder abschüssigen

das Gerät außerhalb dieser Parameter nutzen wollen, wenden Sie sich

das Gerät NIEMALS für irgendeine Anwendung, die bestimmte Lasten

das Gerät NIEMALS in der Nähe von stromführenden Leitern. Der

15m

15m

24m

26m

8 508159-000 TL49K

Page 49

WARNHINWEISE

8. Setzen Sie das Gerät NIEMALS in Betrieb, wenn nicht alle Ausleger unten sind

und vollständigen Kontakt zum Boden haben. Das Gerät muss eben und die

Räder eindeutig von der Oberfläche abgehoben sein, bevor die Ausleger

angehoben werden können.

9. Bewegen Sie

NIEMALS mit angehobenem

Korb und stellen Sie immer

sicher, dass der Käfig oder die

Arme kein entgegenkommenden

Fahrzeuge behindern.

das Gerät

10. Verwenden Sie das Gerät NIEMALS, wenn die Windgeschwindigkeit mehr als 12,5 m/

s beträgt. Beachten Sie, dass bei der Arbeit in der Nähe von hohen Gebäuden und

Gebilden auch an Tagen, an denen die nominale Windgeschwindigkeit auf freiem Feld

niedrig ist, Abschirm- und Tunneleffekte hohe Windkräfte verursachen können. Die

Windgeschwindigkeit kann auf der Plattform entweder per Hand mit einem

Windmesser gemessen oder mit Hilfe der Beaufortskala geschätzt werden.

DIE BEAUFORT-WINDGESCHWINDIGKEITSSKALA

Die Beaufortskala der Windkraft ist international anerkannt und wird zur Verbreitung von

Wetterbedingungen verwendet. Sie setzt sich aus den Zahlen 0 bis 12 zusammen, wobei

jede eine bestimmte Windgeschwindigkeitsstärke bei 10 Metern über der Erde auf

dem freien Feld darstellt.

Ungefähre Werte für die Windgeschwindigkeit bei anderen Höhen:

bei 2 m minus 30 %;

bei 3 m minus 20 %;

bei 6 m minus 10 %

bei 15 m plus 10 %;

bei 30 m plus 25 %.

Beaufort-

M/Sek Bodenbedingungen

skala

3 3,5-5

4 6-8

5 9-10

6 11-13

7 14-17

8 18-21

9 22-24

TL49K 508159-000 9

Blätter und dünne Zweige bewegen sich, Wimpel werden gestreckt.

Staub und loses Papier werden vom Boden gehoben, dünne Äste bew egen sich.

Kleine Bäume beginnen sich zu bewegen; Schaumköpfe a uf den Wellen in Binnenwasserstraßen.

Große Zweige bewegen sich; das Benutzen von Regenschirmen bere itet Schwierigkeiten.

Bäume schwanken; Widerstand beim Gehen gegen den Wind.

Zweige brechen von Bäumen; erhebliche Behinderung beim Gehen.

Kleinere Schäden an Gebäuden (Schornsteinaufsätze und Schiefer werde n ge-

hoben)

Page 50

Right

g

h

h

L

4

L

4

SCHLEPPANWEISUNGEN

Auf Anhängern aufgesetzte Geräte verfügen über Federbeine, die auf sichere

Art und Weise hinter einem Auto oder einem Lastwagen bei einer

Geschwindigkeit von bis zu 80 km/h, wo erlaubt, hergezogen werden können.

1. Überprüfen Sie vor dem Schleppen, ob das verwendete Fahrzeug geeignet ist.

(Das Gewicht des Geräts nimmt zu, wenn optionale Zusatzfunktionen

angebracht werden.)

2. Stellen Sie sicher, dass sich die Reifen und Bremsen in einem guten,

brauchbaren Zustand befinden.

3. Stellen Sie sicher, dass alle Arme vollständig gesenkt sind und sich beide

Durchgangsbolzen in den Ösen befinden und mit der Klemme „R“ am Ende der Kette

gesichert sind.

10 508159-000 TL49K

Page 51

R ight

g

h

h

L

4

L

4

SCHLEPPANWEISUNGEN

4. Stellen Sie sicher, dass alle Ausleger vollständig angehoben sind.

5. Senken oder heben Sie die Kupplung der Schleppstange mit dem Deichselrad, um

das Gerät über dem 50 mm großen Kugelkopf am Schleppfahrzeug zu positionieren.

8

6. Ziehen Sie die Handbremse an.

7. Senken Sie mithilfe des Deichselrads die Kupplung der Schleppstange auf den

Kugelkopf.

8. Sichern Sie das Abreißkabel (stellen Sie die korrekte Kupplung mit dem 50

mm Ball sicher).

9. Heben Sie das Deichselrad vollständig an und rasten Sie es in dieser Position

ein.

10. Lösen Sie die Handbremse.

11. Schließen Sie die Anhängerlichter an (siebenpoliger Stecker) und überprüfen Sie, o b

sowohl die Fahrzeug- als auch Anhängerlichter ordnungsgemäß funktionieren.

6

7

11

9

TL49K 508159-000 11

Page 52

MANUELLES MANÖVRIEREN (Optional)

1. Stellen Sie sicher, dass alle Arme vollständig gesenkt und alle Ausleger angehoben sind,

und dass das Gerät manövrierfähig ist.

2. Befestigen Sie die Friktionsantriebszylinder an den Reifen des Anhängers, indem Sie die

antreibenden Hebel nach vorn und nach unten ziehen bis sie über der Mitte einrasten.

3. Stellen Sie sicher, dass der Stromauswahlschalter auf der Basiseinheit ist.

4. Lösen Sie die Handbremse und stellen Sie sicher, dass der direktionale Sperrbolzen des

Deichselrads entfernt wurde.

5. Die Zugkraft wird über zwei hydraulische Hebel an der Rundhumpseite des Fahrgestells

gesteuert

6. Der linke Hebel steuert den linken Motor und rechte Hebel den rechten.

Wenn Sie nur den linken Hebel nach vorn drücken, dreht sich das Gerät nach rechts und d e r

rechte Hebel dreht das Gerät nach links. Bedienen Sie für einen Parallelantrieb beide

Hebel gleichzeitig.

7. Wenn sich das Gerät in der richtigen Position befindet, ziehen Sie die Handbremse wieder

fest.

.

Stellen Sie sicher, dass alle Friktionsantriebszylinder gelöst sind,

!

bevor Sie die Plattform verwenden oder schleppen.

12 508159-000 TL49K

Page 53

R ight

g

h

h

L

4

L

4

KONTROLLE VOR INBETRIEBNAHME

Die folgenden Kontrollen sollten vor Inbetriebnahme des Gerätes durchgeführt

werden.

1. Beschädigtes oder lockeres Zubehör.

Untersuchen Sie das Gerät visuell auf Anzeichen von Verschleiß und

Schäden sowie lockere oder fehlende Teile.

2. Räder. (Nur für das Schleppen)

Überprüfen Sie den Reifendruck: TL49K = 76 Psi (5,25 Bar).

3. Hydraulikflüssigkeit.

Der Hydrauliköltank befindet sich unter der Drehabdeckung auf der rechten

Seite des Gerätes (vom Käfigende aus gesehen), siehe Abb.2, Abschnitt J.

Der Hydraulikölstand muss sich zwischen der oberen und unteren

Markierung des Sichtglases befinden, wenn sich die Arme und Ausleger in

Transportposition befinden.

Füllen Sie, wenn notwendig, ISO Grade 22 Hydrauliköl nach.

Überfüllen Sie den Tank nicht.

Wenn die folgenden Kontrollen des Verriegelungssystems vor

Verwendung der Plattform nicht durchgeführt werden, besteht

extreme Verletzungs- oder sogar Todesgefaht!

4. Sicherheitsschalter.

Überprüfen Sie den Überlastschalter des Käfigs visuell auf Schäden.

Überprüfen Sie, ob alle Begrenzungsschalter-Hauptzweige unbeschädigt sind

und sich einfach bewegen lassen (Auslegerschalter sehen sie in Abb. 6).

Wenn sich die Ausleger in Transportposition befinden, darf es nicht

möglich sein, die Erweiterungsteile zu bedienen. Wenn die Ausleger

ausgefahren sind, unter Last stehen oder die Ober– und Unterarme ca. 50

mm angehoben sind, darf es nicht möglich sein, die Auslegersteuerung zu

bedienen.

Der Ausschlagarm ist nicht mit den Auslegern verzahnt.

1

TL49K 508159-000 13

Page 54

KONTROLLE VOR INBETRIEBNAHME

5. Notausschalter.

Notausschalter müssen ordnungsgemäß funktionieren. Überprüfen Sie, ob

jeder von ihnen die Steuerung des Gerätes stoppt und das ein erneutes S t a r t e n

verhindert wird, bis alle Notausschalter aufgeklinkt sind.

6. Notfall-Absenkung/-Drehung.

Überprüfen Sie folgende Punkte, wenn die Ober– und Unterarme jeweils um ca.

500 mm angehoben und

Der Notfall-Absenkschalter im Korb und in der Bodenkontrollstation senkt die

Arme.

Mit der Notfall-Drehung kann das Einziehen des Teleskoparms aktiviert w e r d e n ,

indem die Handpumpe und der Steuerhebel in der Bodenkontrollstation bedient

wird.

Um das Hydrauliksystem nach den Kontrollen wieder zurückzusetzen:

Drehen Sie den Korb vollständig nach rechts, so dass die Ramme vollständig

ausgezogen ist.

Fahren Sie die Ausleger vollständig aus und halten Sie die Höhe (überprüfen Sie die

Blase).

Fahren Sie mit der Bodensteuerung Ober-, Unter– und Teleskoparme vollständig aus.

Fahren Sie den Aufschlagarm vollständig aus.

Fahren Sie alle Rammen gleichzeitig vollständig aus, bevor Sie sie in ihre

Übergangsposition zurückbringen.

das Gerät ausgeschaltet ist:

Wenn die Notfall-Absenkung während des normalen Betriebs eingesetzt wird, nutzen

Sie das Gerät nicht mehr, sondern wenden Sie sich an Ihren zuständigen UpRightVertreter.

7. Notfall-Handpumpe.

Es ist möglich, mithilfe der Handpumpe den Käfig zu senken, wenn das Gerät

arbeitsbereit ist (z.B. die Ausleger unten sind und unter Last stehen, das Gerät

gerade steht und die Räder den Boden nicht berühren).

8. Batteriebetrieb (wo möglich)

Überprüfen Sie, ob die Batterien vollständig geladen und mit destilliertem Wasser

aufgefüllt sind (diese befinden sich unter der Drehabdeckung an beiden Seiten der

Plattform).

Das Hydrometer sollte zwischen 1280 und 1320 sg anzeigen.

Wenn das Gerät gerade steht, sollte das destillierte Wasser ca. 6 mm über den

Platten stehen.

9. Hauptstrom (wo möglich)

Überprüfen Sie, ob die Spannung und die Frequenz der Stromeinspeisung der des

Motors entspricht. Alle Verlängerungen müssen mindestens 2,5 mm² betragen und

dürfen aufgrund eines möglichen Spannungsabfalls nicht länger als 10 m sein.

10. Benzin-/Dieselantrieb (wo möglich)

Stellen Sie sicher, dass das Gerät über ausreichend Öl und Kraftstoff verfügt, um die

Arbeit zu erledigen.

14 508159-000 TL49K

Page 55

BATTERIEN & NETZTEIL

Batterieantrieb, 24V DC.

Stellen Sie sicher, dass die Batterien vor der Verwendung vollständig geladen sind und der

Batterietrennschalter sicher angeschlossen ist.

Hauptstrom (OPTIONAL)

Schließen Sie die Hauptstromversorgung entweder mit 110 V oder 220/240 V Wechselstrom

(abhängig von der Motorspezifikation) an. Überprüfen Sie, ob der Motor läuft, wenn der

Schlüssel auf „ON“ steht.

Alle Verlängerungen müssen mindestens 2,5 mm² betragen und dürfen aufgrund eines möglichen Spannungsabfalls, was den Motor beschädigen würde,

nicht länger als 10 m sein.

Benzin-/

Überprüfen Sie den Kraftstoff– und Ölstand des Motors. Schalten Sie mit dem

Schlüsselschalter an der Piktogrammscheibe die Zündung an. Kontrollieren Sie mit den

Start- und Stoptasten im Korb, ob der Motor läuft

Dieselantrieb (OPTIONAL)

.

!

Abb. 1

Abb. 2

Batterien

Netzteil

Ladegerät

Ölfilter und Sichtglas

Pumpenschwengel

Handpumpe

TL49K 508159-000 15

Page 56

EINRICHTUNG

1. Parken Sie das Gerät an einem angemessenen Standort am Arbeitsplatz.

Versuchen Sie nicht, die Maschine an steilen Gefällen, Rampen

oder auf weichem Untergrund einzurichten.

2. Ziehen Sie die Handbremse des Anhängers an und entfernen Sie das Gerät vom

Schleppfahrzeug..

3. Stellen Sie den Schlüsselschalter der

Plattform auf ‚Boden‘ (Abb. 3) und sen

ken Sie die Ausleger, indem Sie den Schalt

er ‚Auslegermotor RUN‘ gedrückt halten

(Abb. 4). Bedienen Sie den entsprechenden

‚Ausleger-Steuerhebel‘ (Abb. 5) bis sich

alle vier 25 mm bis 50 mm vom Boden ent

fernt befinden.

Korb

1

Boden

Füllstands-

anzeige

Steuerhebel

Boden

Abb. 5

Motor RUN

Ausleger

Motor RUN

Arme

Abb. 3

Abb. 4

Notfall-

Absenkung

Steuerhebel

Ausleger

16 508159-000 TL49K

Page 57

EINRICHTUNG

4. Senken Sie gleichzeitig zwei der Ausleger. Beginnen Sie dabei am Ende der

Abschleppstange (Nr. 3 und 4) bis das Deichselrad den Boden frei macht.

5. Senken Sie die Ausleger 1 und 2 bis das grüne LED-Display anzeigt, dass sie

unter Last stehen (wie unten gezeigt).

Seien Sie EXTREM vorsichtig, dass während des nächsten Schritts

!

6. Wiederholen Sie diesen Abschnitt für die Ausleger 3 und 4..

7. Wenn Sie von 1 und 2 zu 3 und 4 wechseln, bewegen Sie vorsichtig jedes

Auslegerpaar millimeterweise nach unten bis alle vier Ausleger vollständig

positioniert sind und sich die Räder nicht mehr auf dem Boden befinden.

8. Heben Sie nun mithilfe des Füllstandsanzeigers (Abb. 5) die

gegenüberliegenden Ausleger an bis die Blase und der Anzeigering

konzentrisch sind (z.B. wenn sich die Blase in der Mitte befindet).

9. Überprüfen Sie, ob noch immer jede LED-Leuchte auf der

Bodensteuerungsblende leuchtet. Dies zeigt an, dass jeder Fuß festen

Kontakt zur tragenden Oberfläche hat.

1

den Korb oder das Deichselrad NICHT erden.

Das Gerät ist für tragende Oberflächen mit einer minimalen

Tragfähigkeit von 50 N/cm² geeignet.

Die maximale Auslegerlast beträgt 12,5 kN.

1

TL49K 508159-000 17

Page 58

AUSLEGERSYSTEM

1. Entfernen Sie die Übergangsbolzen von Ober– und Unterarm und bewahren

Sie sie ordnungsgemäß auf.

2. Schalten Sie in der Bodenkontrollstation den Schlüssel auf ‚Korb’ (siehe

Abb. 3).

3.

Steigen Sie in den Korb.

Überprüfen Sie, ob alle

Notausschalter frei sind (stellen

Sie auf ‚Release‘). Die Plattform

kann nun angehoben,

abgeschleppt oder in jede

Richtung gedreht werden,

während der ‚Motor RUN‘-Schalter

gedrückt wird (DEADMAN).

Begrenzungsschalter

Stellen Sie vor dem Anheben sicher, dass sich oberhalb keine Hin-

1

!

dernisse oder Stromkabel befinden und die Ausleger ordnungsgemäß ausgefahren und gesichert sind.

Seine Sie bei niedriger Höhe beim Drehen von Korb und Turm EXTREM vorsichtig.

Auslegerramme

Abb. 6

18 508159-000 TL49K

Page 59

AUSLEGERSYSTEM

Notausschalter

Wahlschal-

ter

Motor RUN

Ausleger

Auslegerlast-

Anzeige

Motor RUN

Arme

Korbüberlast-

Anzeige

Abb. 4a

Notfall-

Senkung

4. Erklärung der Korbkontrollstation, direktionale Steuerhebel.

CAGE

TRIM

18-0865-02

Heben

Korbverkleidung

CAGE

ROTATION

Drehen

Korb

Entgegen dem

Uhrzeigersinn

Heben

Aus-

schlag-

arm

BOOM 2

TELESCOPE

Einfahren

Tele-

skoparm

BOOM 2BOOM 3

SLEWING

Heben

Tele-

skoparm

Drehen

Turm

Entgegen dem

Uhrzeigersinn

BOOM 1

Heben

Unter-

arm

Senken

Korbverkleidung

Drehen

Korb

Im Uhrzeigersinn

Senken

Aus-

schlag-

arm

Aus-

fahren

Tele-

skoparm

Senken

Tele-

skoparm

Drehen

Turm

Im Uhrzeigersinn

Senken

Unter-

arm

TL49K 508159-000 19

Page 60

AUSLEGERSYSTEM

5. Auf dem Drehturm ist unter der rechten Abdeckung ein zweifaches

Steuerungsset befestigt (dieses umfasst nicht den Drehkorb), das das Steuern

der Plattform vom Boden aus ermöglicht.

6. Stellen Sie in der Bodenkontrollstation den Schlüssel auf ‚Boden‘ (siehe

Abb.3).

7. Erläuterung der Bodenkontrollstation, direktionale Steuerhebel.

18-0884

Heben

Aus-

schlag-

arm

BOOM 2

TELESCOPE

Aus-

fahren

Tele-

skoparm

BOOM 2BO O M 3

Heben

Tele-

skoparm

SLEW ING

Drehen

Turm

Entgegen dem

Uhrzeigersinn

Heben

Unter-

arm

BOOM 1

Senken

Ausschl

agarm

Boom

Einfahren

Tele-

skoparm

Senken

Tele-

skoparm

Drehen

Turm

Im Uhrzeigersinn

Senken

Unter-

arm

20 508159-000 TL49K

Page 61

g

h

h

L

4

L

49

Right

g

h

h

L

4

L

4

SICHERHEIT

Sicherheitsgurt

1. UpRight empfiehlt gemäß den Empfehlungen von IPAF bei der Arbeit im Korb das

Verwenden eines kompletten Auffanggurtes mit einem verstellbaren Fangriemen.

2. Die Länge des Fangriemens sollte so kurz wie möglich sein.

3. Im Korb befindet sich für die Befestigung des Gurtes ein fester Befestigungspunkt.

NOTFALLSTEUERUNG

1. Notausschalter

Das Gerät verfügt über Notausschalter, mit denen der Motor in Notfällen

gestoppt werden kann.

Es gibt zwei Notausschalter: einen im Korb und einen auf der

Bodenkontrollblende.

Die Notausschalter können durch Drehen zurückgesetzt werden.

TL49K 508159-000 21

Page 62

Right

g

L

4

L

4

NOTFALLSTEUERUNG

Notfall-Absenkung.

2. Notfall-Absenkung: 1. Methode

Position bringen, indem er den Wahlschalter für die Notfall-Absenkung auf der

Korbkontrollblende und der Bodenkontrollblende aktiviert.

Der Auffschlagarm kann durch die Aktivierung des NotfallAbsenkungsschalters nicht gesenkt werden.

Das Notfall-Absenkungsventil schließt sich beim Auslösen des

Schalters automatisch.

Bei Stromausfällen kann der Korb auf zwei Arten sicher gesenkt werden.

Der Bediener oder eine andere Person am Boden kann die Arme senken und in eine sichere

Wenn die Notfall-Absenkung eingesetzt wird, weil das Gerät einen Defekt aufweist, darf das Gerät NICHT weiter verwendet werden.

Wenden Sie sich in diesem Fall an Ihren UpRight-Vertreter.

Wenn die Notfall-Absenkung eingesetzt wird, müssen die OBER- und UNTERARME vollständig ausgefahren und dann gesenkt werden, bevor die Arbeit fortgesetzt werden

kann.

Jedes weitere ANGETRIEBENE Senken nach einer Notfall-Absenkung kann eine

LUFTSCHLEUSE im Hydrauliksystem verursachen.

Das könnte zum Ausfall der Hydraulik führen.

ALLE ARME MÜSSEN VOLLSTÄNDIG AUSGEFAHREN/ANGEHOBEN UND DANN GESENKT WERDEN, BEVOR DIE ARBEIT FORTGESETZT WERDEN KANN.

1

22 508159-000 TL49K

Page 63

NOTFALLSTEUERUNG

3. Notfall-Absenkung: 2. Methode.

Drehfunktionen bedienen.

senken Sie dann den Hebel in eine angemessene Position, um mit dem Pumpen zu beginnen.

die Handpumpe. Wenn das Gerät beginnt, sich zu senken, fahren Sie mit dem Drücken des

Steuerhebels fort.

Sie können vom Bodenkontrollstationskäfig aus die Handpumpe, die Armsteuerung und die