Page 1

Diesel

Gasoline

Battery Electric

Bi-Energy Options

Part Number: 13618-1

January 2018 (Rev C)

OPERATION

MANUAL

Serial Number NZ110108 and after

MMHP14AT

MHP13AT

Page 2

Electrocution Hazard Warning

DANGER

THE MHP14AT / MHP13AT AERIAL WORK PLATFORM, IN STANDARD

CONFIGURATION, IS NOT ELECTRICALLY INSULATED

If the platform, scissor arms assembly or any other conductive part of the machine contacts a high voltage

electrical conductor the result can be SERIOUS INJURY or DEATH for persons on or near the machine.

GO NO CLOSER THAN THE MINIMUM SAFE APPROACH DISTANCES

(M.S.A.D) - SEE BELOW)

Be sure to allow for sag and sway in the wires and the work platform.

If the machine comes in contact with a live electrical conductor, the entire machine can be charged.

If that happens, you should remain on the machine and not contact any other structure or object within

reach. That includes the ground, adjacent buildings, poles, and any other object not part of the machine.

Such contact could make your body a conductor to the other object creating an electrical shock hazard

resulting in SERIOUS INJURY or DEATH.

DO NOT attempt to enter or leave the machine until you are sure the electricity has been turned off.

If the machine is in contact with a live conductor, the platform operator MUST warn others on the ground

in the vicinity of the machine to STAY AWAY from the machine, since their bodies can also form a path for

electricity to ground thus creating an electrical shock hazard with possible ELECTROCUTION and DEATH.

DO NOT attempt to operate the machine ground controls when the platform, scissor arms assembly or any

other conducting part of the machine is in contact with electrical wires or if there is an immediate danger of

such contact.

Regard all conductors as energised.

Personnel working on or near the machine must be continuously aware of electrical hazards, recognizing

that SERIOUS INJURY or DEATH can result if contact with an electrical wire does occur.

IMPORTANT - M.S.A.D.

It is the operators responsibility to ensure M.S.A.D., (Subject to local regulations and laws),

are known and adhered to.

Page 2

Rev C

MHP14AT & MHP13AT

Electrical Hazard

Page 3

Page 3

Rev C

MHP14AT & MHP13AT

The most important chapter in this manual is the

safety chapter - Chapter 1. Take time now to study

it closely.

The information in chapter 1 might save your life,

prevent serious injury or damage of property to the

MHP14AT / MHP13AT.

This introduction also contains important information

concerning the responsibilities of the owner of the

machine.

Standard MHP14AT / MHP13AT

The standard MHP14AT / MHP13AT includes

the following features:

• Independently operated heavy duty hydraulic

stabilisers

• Manual stabilisers

• 540 slew

• Heavy duty tow coupling

• Heavy duty jockey wheel

• Hour meter

• Hydraulic disc brakes

• Steel platform - 2 person capacity

• High strength steel boom and base construction

• Beam axle with 15” rims

• Honda petrol engine

• 600V AC rated wire to platform

• Stabiliser/boom interlocks

• Stabiliser lift points

• Gravity gates

• LED taillights

• Height restrictor in upper cylinder to keep platform at 10.9m maximum height (MHP13AT only)

• 235 R15 x 75 tyres

• Platform overload protection

Options

The following options are available for the MHP14AT

/ MHP13AT:

• Automatic stabilisers

• Custom colours

• Platform work lights

• Air line to platform

• Flashing light

• Spare wheel

• 10.9 height lock out kit

• 240V / 110V outlet in platform

• Battery isolate switch

• Platform foot switch

• Alternative power options

Diesel engine

24V DC power

240V power

110V power

• Bi-energy options

Petrol / 24V

Petrol / 240V

Diesel / 24V

Diesel / 240V

24V / 240V

• Platform rotator

Operation Manual

This manual provides information for sale and

proper operation of the aerial platform. Read and

understand the information in this Operator’s manual

before operating this machine on a job site.

Additional copies of this manual may be ordered from

Snorkel. Supply the model and manual part number

from the front cover to assure the correct manual will

be supplied.

All information in this manual is based on the latest

product information at the time of publication. Snorkel

reserves the right to make product changes at any

time without obligation.

Photographs

Photographs are taken to represent the machine

and its component parts as clearly as possible.

However, there may be minor differences between

the photographs and your machine. This represents

individual customer preferences and Snorkels on

going commitment to product development.

Safety Alerts

A safety alert symbol is used throughout this manual

to indicate danger, warning and caution instructions.

Follow these instructions to reduce the likelihood of

personal injury, property damage or damage to the

machine.

The terms danger, warning and caution indicate

varying degrees of personal injury or property damage that can result if the instruction is not followed.

DANGER

Denotes an Imminently hazardous situation

which if not avoided, will result in serious injury

or death.

Introduction

Page 4

WARNING

Denotes a potentially hazardous situation which

if not avoided, could result in serious injury or

death.

CAUTION

Denotes a potentially hazardous situation which

if not avoided, may result in minor or moderate

injury.

It may also be used to alert against unsafe practices or action which may result in damage to the

machine.

IMPORTANT

Denotes important informations pertaining to

settings, capacities, conditions, which could,

if ignored lead to machine damage or future

hazardous situations. It is also used to alert the

reader to pay careful attention to a particular

passage of text in the manual.

Notes:

Notes are used to provide special information or

helpful hints to assist in aerial platform operation, but

do not indicate a hazardous situation.

Operation

The MHP aerial platform has built in safety features

and has been factory tested for compliance with

Snorkel specifi cations and industry standards. How-

ever, any personnel lifting device can be potentially

dangerous in the hands of untrained or careless operators.

Training is vitally important and must be performed

under the direction of a qualifi ed person. You

must display profi ciency in knowledge and actual

operation of the machine before using it on a job site.

Before operation of the machine you must read and

understand the operating instructions in this manual

as well as the decals, warnings and instructions on

the machine itself.

Before operating the machine you must be authorised

by the person in charge to do so and the operation of

the machine must be within the scope of the machine

specifi cations.

WARNING

The potential for an accident increases when the

aerial platform is operated by personnel who are

not trained and authorised. Death or serious

injury can result from such accidents.

Read and understand the information in this

manual and on the placards and decals on the

machine before operating the MHP on the job.

Maintenance

Every Person who maintains, inspects, tests or repairs these machines, and every person supervising

any of these functions, must be properly trained and

qualifi ed to do so.

The Operators Manual provides a Pre-operational

inspection procedure that will help you keep your

MHP in good operating condition.

Do not perform other maintenance unless you are a

trained mechanic, qualifi ed to work on the MHP. Call

qualifi ed maintenance personnel if you fi nd problems

or malfunctions.

Do not modify this machine without written approval from the Engineering Department of Snorkel.

Modifi cation may void the warranty, adversely affect

stability, or affect the operational characteristics of

the MHP.

Responsibilities of parties

IMPORTANT

It is imperative that all owners and users of the

MHP read, understand and conform to all applicable regulations.

Ultimate compliance to OSHA regulations is the

responsibility of the user and their employer.

IMPORTANT

ANSI Standard A92.6 clearly identifi es require-

ments of all parties who might be involved with

Self-Propelled Elevating Work Platforms.

Australian / NZ Standard 2550-10 also identifi es

the requirements of all parties who might be

involved with Boom-Supported Elevated Work

Platforms.

Note

It is the responsibility of the owner to ensure that the

person operating the machine is provided with all the

relevant information relating to standards and codes

of practice applicable in their region.

Page 4

Rev C

MHP14AT & MHP13AT

Introduction

Page 5

In Summary

• Only trained and authorised operators should be

permitted to operate the equipment.

• All manufacturers operating instructions and

safety rules and all employers safety rules and all

OSHA and other government safety rules should

be strictly adhered to.

• Repairs and adjustments should be made only by

qualifi ed and trained maintenance personnel.

• No modifi cation should be made to the equip-

ment without prior written consent of the Snorkel

Engineering Department.

• Make a pre-start inspection of the MHP at the

beginning of each shift. A malfunctioning machine

must not be used.

• Make an inspection of the workplace to locate

possible hazards before operating the MHP.

Product Warranty

For full terms of your warranty policy please refer to

the Repair Parts Manual, or check with your Snorkel

distributor, or check the Snorkel website.

Additional Information

For additional information, contact your local dealer

or Snorkel at:

Snorkel New Zealand

PO Box 1041

Levin 5510

New Zealand

Page 5

Rev C

MHP14AT & MHP13AT

Introduction

Page 6

Page 6

Rev C

MHP14AT & MHP13AT

Page 7

Page 7

Rev C

MHP14AT & MHP13AT

Table of Contents

Electrical Hazard

Electrical Hazard Warning . . . . . . . . . . . . . . . . . . . . 2

Introduction

Standard MHP14AT / MHP13AT . . . . . . . . . . . . . . . 3

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operation Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Photographs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Responsibility Of Parties . . . . . . . . . . . . . . . . . . . . . . 4

In Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Product Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Additional Information . . . . . . . . . . . . . . . . . . . . . . . . 5

1. Safety

Safe Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Electrocution Hazards . . . . . . . . . . . . . . . . . . . . . . 1-1

Pre-Start Inspection . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Work Place Inspection and Practices . . . . . . . . . . 1-1

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Tipover and Falling Hazards . . . . . . . . . . . . . . . . . 1-2

General Safety Precautions . . . . . . . . . . . . . . . . . 1-3

Hydraulic System Precautions . . . . . . . . . . . . . . . 1-3

Fire prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Engine and Fuel Handling Precautions . . . . . . . . . 1-3

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Height Restriction . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Height Restriction on MHP13A T . . . . . . . . . . . . . . 1-4

10.9 Meter Restriction Kit . . . . . . . . . . . . . . . . . . . 1-4

Safety Decals and Placards . . . . . . . . . . . . . . . . . 1-4

2. Safety Devices

Safety Device Information . . . . . . . . . . . . . . . . . . . 2-1

Emergency Stop Switches . . . . . . . . . . . . . . . . . . 2-1

At ground control box . . . . . . . . . . . . . . . . . . . . 2-1

At platform control box . . . . . . . . . . . . . . . . . . . 2-1

Other Safety Devices . . . . . . . . . . . . . . . . . . . . . . 2-1

Lanyard anchor points . . . . . . . . . . . . . . . . . . . 2-1

Gravity gates . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Guardrails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Height restriction on MHP13AT . . . . . . . . . . . . 2-2

10.9m height restriction kit (option) . . . . . . . . . . 2-2

Enable switch . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Enable switch - foot (option) . . . . . . . . . . . . . . . 2-3

Platform Overload Protection . . . . . . . . . . . . . . . . 2-3

Bubble level . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

RCD/ELCB AC outlet (option) . . . . . . . . . . . . . . 2-4

Stabiliser Boom Interlock Test . . . . . . . . . . . . . . . . 2-4

Flashing light (option) . . . . . . . . . . . . . . . . . . . . 2-4

3. Specifi cations

General Specifi cations . . . . . . . . . . . . . . . . . . . . . 3-1

Specifi cations MHP14AT . . . . . . . . . . . . . . . . . . . 3-1

Specifi cations MHP13AT . . . . . . . . . . . . . . . . . . . 3-2

Engine Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Working Envelope . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

4. Gauges

Hourmeter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Level Bubble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Hydraulic Oil Level . . . . . . . . . . . . . . . . . . . . . . . . 4-1

5. Shut-Offs and Circuit Breakers

RCD/ELCB Outlet (Option) . . . . . . . . . . . . . . . . . . 5-1

Stabilisers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Electrical Circuit Protection . . . . . . . . . . . . . . . . . . 5-1

6. Controls

Controls Description . . . . . . . . . . . . . . . . . . . . . . . 6-1

Controls and control decal locations . . . . . . . . . 6-1

Ground Control Box . . . . . . . . . . . . . . . . . . . . . . . 6-2

Lower controls / indicators . . . . . . . . . . . . . . . . 6-2

Platform Control Box . . . . . . . . . . . . . . . . . . . . . . . 6-3

Upper controls / indicators . . . . . . . . . . . . . . . . 6-3

Stabiliser Controls Manual . . . . . . . . . . . . . . . . . . 6-4

Self Leveling Stabilisers (Option) . . . . . . . . . . . . . 6-5

7. Pre-Operational Inspection

Pre-Operational Inspection Table . . . . . . . . . . . . . 7-1

Stabiliser / Boom Interlock Test . . . . . . . . . . . . . . 7-2

Engine Fuel Level . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Fuel Tank Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Fuel Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Engine Oil Level . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Operators Manual . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Wiring Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Battery Terminals . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Battery Fluid Level . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Hydraulic Oil Level . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Hydraulic Oil Leaks . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Bolts and Fasteners . . . . . . . . . . . . . . . . . . . . . . . 7-5

Wheels and T yres . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Tyre Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Structural Damage and Welds . . . . . . . . . . . . . . . 7-6

Lanyard Anchor Points . . . . . . . . . . . . . . . . . . . . . 7-6

Platform Gravity Gates . . . . . . . . . . . . . . . . . . . . . 7-6

Platform Guardrails . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Platform Access Step . . . . . . . . . . . . . . . . . . . . . . 7-6

Flashing Light (Option) . . . . . . . . . . . . . . . . . . . . . 7-7

Ground Control Switches . . . . . . . . . . . . . . . . . . . 7-7

Emergency Lower . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Ground station . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Upper control box . . . . . . . . . . . . . . . . . . . . . . . 7-7

Page 8

Page 8

Rev C

MHP14AT & MHP13AT

Table of Contents

Platform Control Switches . . . . . . . . . . . . . . . . . . . 7-8

AC Outlet RCD/ELCB (Option) . . . . . . . . . . . . . . . 7-8

Placards and Decals . . . . . . . . . . . . . . . . . . . . . . . 7-8

Placards and Decals . . . . . . . . . . . . . . . . . . . . . . . 7-8

Standard placards and decals . . . . . . . . . . . . . 7-8

Decal list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Decal inspection drawing . . . . . . . . . . . . . . . . 7-11

8. Operation

Operating Procedures . . . . . . . . . . . . . . . . . . . . . . 8-1

Control Stations . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Emergency Stopping . . . . . . . . . . . . . . . . . . . . . . 8-1

Emergency Stopping . . . . . . . . . . . . . . . . . . . . . . 8-1

Operation Considerations . . . . . . . . . . . . . . . . . . . 8-1

Stabiliser Operation . . . . . . . . . . . . . . . . . . . . . . . 8-1

Using the manual stabiliser valves . . . . . . . . . . 8-2

Raising the manually operated stabilisers . . . . 8-2

Self Leveling Stabilisers (Option) . . . . . . . . . . . . . 8-3

Setting the stabilisers manually . . . . . . . . . . . . 8-3

Unlocking The Boom . . . . . . . . . . . . . . . . . . . . . . . 8-3

Starting From The Ground Control Box . . . . . . . . 8-3

Starting From The Platform Control Box . . . . . . . 8-4

Moving The Platform . . . . . . . . . . . . . . . . . . . . . . 8-5

From ground control box . . . . . . . . . . . . . . . . . 8-5

From platform control box . . . . . . . . . . . . . . . . . 8-5

Securing For The Day . . . . . . . . . . . . . . . . . . . . . 8-6

9. Emergency Operation

Emergency Operation Procedures . . . . . . . . . . . . 9-1

Emergency Operation Procedures . . . . . . . . . . . . 9-1

Operation from platform control box . . . . . . . . . 9-1

Ground control station settings . . . . . . . . . . . . . 9-1

Operation from ground control position . . . . . . . 9-2

10. Stowing and Transporting

Stowing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

The correct stowing position is shown here . . 10-1

Transporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Trailering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Securing to a transport vehicle . . . . . . . . . . . . 10-1

Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

11. Options

Bi-Energy , Petrol/Diesel 24V DC . . . . . . . . . . . . . 11-1

DC motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1-1

DC motor operation . . . . . . . . . . . . . . . . . . . . . 1 1-1

DC motor battery switch . . . . . . . . . . . . . . . . . 11-1

Setting the manual stabilisers . . . . . . . . . . . . . 1 1-1

Setting the automatic stabilisers . . . . . . . . . . . 1 1-1

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1-2

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Battery charger . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Batteries - general maintenance . . . . . . . . . . . 1 1-3

Batteries - charging . . . . . . . . . . . . . . . . . . . . . 1 1-3

Bi-Energy , Petrol/Diesel / 240V AC . . . . . . . . . . . 11-3

AC motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

AC motor operation . . . . . . . . . . . . . . . . . . . . . 11-3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

Bi-Energy, hydraulic oil tank . . . . . . . . . . . . . . 1 1-4

Other Options . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

Air Lines To Platform . . . . . . . . . . . . . . . . . . . . . . 11-4

Work Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

Flashing Light . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

Battery Isolate Switch . . . . . . . . . . . . . . . . . . . . . 1 1-4

Alternative Power Options . . . . . . . . . . . . . . . . . .1 1-4

RCD/ELCB AC Outlet . . . . . . . . . . . . . . . . . . . . . 11-4

Self Leveling Stabiliser . . . . . . . . . . . . . . . . . . . . 11-5

Spare Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1-5

Platform Foot Switch . . . . . . . . . . . . . . . . . . . . . . 1 1-5

Platform Rotator . . . . . . . . . . . . . . . . . . . . . . . . . 11-5

10.9 Meter Height Restriction Kit . . . . . . . . . . . . 11-6

12. Fire Fighting and Chemical Control

Hazardous Components . . . . . . . . . . . . . . . . . . . 12-1

Antifreeze . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

Battery lead / acid . . . . . . . . . . . . . . . . . . . . . . 12-1

Diesel fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

Foam in tyres . . . . . . . . . . . . . . . . . . . . . . . . . . 12-2

Gasoline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-2

Hydraulic oil . . . . . . . . . . . . . . . . . . . . . . . . . . 12-3

Liquefi ed petroleum gas . . . . . . . . . . . . . . . . . 12-3

Motor oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-3

13. Operators Troubleshooting

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

Operator troubleshooting chart . . . . . . . . . . . . 13-1

Appendix A. Glossary

Page 9

Note

Whilst some of the safety rules and guidelines that

follow may not apply specifi cally to this machine (e.g.

references to driving) they are included as part of an

overall safety strategy relating to the use of elevating

work platforms.

Work Place Inspection and Practices

Do not use the MHP as a ground for welding. Ground

to the work piece.

Before the MHP is used, and during use, check the

area in which the MHP is to be used for possible hazards such as, but not limited to:

• Drop offs or holes

• Side slopes

• Bumps and fl oor obstructions

• Debris

• Overhead obstructions & electrical conductors

• Hazardous locations

• Inadequate surface and support to withstand all

load forces imposed by the aerial platform in all

operating confi gurations

• Wind and weather conditions

• Presence of unauthorised persons

• Other possible unsafe conditions

Before the MHP is used, determine the hazard

classifi cation of any particular atmosphere or location

according to ANSI/NFPA 505-1987.

Any MHP operated in a hazardous location must be

approved and of the type required by ANSI/NFPA

505-1987.

While operating the MHP a recommended safety

practice is to have trained and qualifi ed personnel in

the immediate work area of the machine to:

• Help in case of an emergency

• Operate emergency controls as required

• Watch for loss of control by platform operator

• Warn the operator of any obstructions or hazards

that may not be obvious to them

• Watch for soft terrain, sloping surfaces, drop offs,

etc, where stability could be jeopardized

• Watch for bystanders and never allow anyone to

be under, or to reach through the booms while

operating the aerial platform.

Safe Operation

Knowledge of the information in this manual, and

proper training, provide a basis for safely operating

the MHP. Know the location of all the controls and

how they operate to act quickly and responsibly in an

emergency.

Safety devices reduce the likelihood of an accident.

Never disable, modify or ignore any safety device.

Safety alerts in this manual indicate situations where

accidents may occur.

If any malfunction, hazard or potentially unsafe

condition relating to capacity, intended use or safe

operation is suspected, stop the operation of the

MHP and seek assistance.

The operator bears ultimate responsibility for following all manufacturers instructions and warnings,

regulations and safety rules of their employer and/or

any country or regional law.

Electrocution Hazards

The MHP is an all metal boom aerial work platform

and is not electrically insulated. Do not operate it

near electrical conductors. Regard all conductors

as being energised. Do not operate outside during a

thunderstorm.

Pre-start Inspection

At the start of each work shift, the MHP shall be given

a visual inspection and function test. See the Daily

Inspection and Maintenance chapter 7 in this manual

for a list of items to inspect and test.

WARNING

DO NOT operate the MHP unless you are trained

and authorised, understand the operation characteristics of the machine and have inspected

and tested all functions to be sure they are in

proper working order.

WARNING

NEVER use an MHP that has a known fault or is

malfunctioning in any way until the machine has

been repaired by a qualifi ed technician.

Operating a machine in faulty condition could

result in death or serious injury.

Page 1-1

Rev C

MHP14AT & MHP13AT

1. Safety

Page 10

Use three points of support when getting on or off the

platform (two hands and one foot or a similar set of

points). Keep the platform clean.

Maintain a fi rm footing on the platform fl oor. Operate

the controls slowly and deliberately to avoid jerky and

erratic operation. Always stop the controls in neutral

before going in the opposite direction.

Do not dismount while the platform is in motion or

jump off the machine. Do not start until all personnel

are clearly away from the machine.

Do not start until all personnel are clearly away from

the machine.

Never cover the fl oor grating or otherwise obstruct

your view below. Make sure the area below the platform is free of personnel before lowering.

Tipover and Falling Hazards

Operate the machine only on a fi rm, fl at level surface

capable of withstanding all load forces imposed by

the MHP in all operating conditions.

DANGER

The machine can tip over if it does become

unstable. Death or serious injury can result from

a tip over accident. Do not drive or position the

MHP platform for elevated use near any dropoffs, hole, slope, soft or uneven ground, or other

tip-over hazard.

Do not operate the machine from a position on trucks,

trailers, railway cars, fl oating vessels, scaffolds or

similar equipment unless the application is approved

in writing by Snorkel.

Care shall be taken to prevent rope, electrical cords

and hoses etc from becoming entangled in the

aerial platform. If the platform or elevating assembly

becomes caught, snagged or otherwise prevented

from normal motion by an adjacent structure or other

obstacle such that control reversal does not free

the platform, remove all personnel from the platform

before attempts are made to free the platform using

ground controls.

No person shall access or egress from the platform

in the elevated position (except in an emergency) unless the requirements of AS2550.10 have been met.

For full requirements refer directly to AS2550.10.

DANGER

Pinch points may exist between moving components. Death or Serious injury can result from becoming trapped between components, buildings,

structures or other obstacles. Make sure there is

suffi cient clearance around the machine before

moving the chassis, booms or platform. Allow

suffi cient room and time to stop movement to

avoid contact with structures or other hazards.

Keep ground personnel from under the platform when

the platform is raised.

Secure all accessories, containers, tools and

other materials in the platform to prevent them from

accidentally falling or being kicked off the platform.

Always look in the direction of travel. Drive with care

and at speeds compatible with the workplace conditions. Use caution when driving over rough ground,

on slopes, and when turning.

Do not engage in any form of horse play or stunt

driving while operating the MHP and do not permit

riders on the machine any place other than on the

platform.

Remove all loose objects stored in or on the machine,

particularly in the platform. Remove all objects which

do not belong in or on the machine.

Never steady the platform by positioning it against

another platform.

Do not operate an MHP that is damaged or not

functioning properly. Do not use the MHP until the

machine has been repaired by a qualifi ed mainte-

nance person.

Do not operate an MHP that does not have all its decals and placards attached and legible.

Watch for bystanders and never allow any one to

be under, or to reach through, the machine and its

equipment while operating.

Use the recommended transport device when

loading the machine.

Operation

If you encounter any suspected malfunction of the

aerial platform, or any hazard or potentially unsafe

condition relating to capacity, intended use, or safe

operation, cease operation immediately and seek

assistance from management.

Page 1-2

Rev C

MHP14AT & MHP13AT

1. Safety

Page 11

Do not attempt repairs to hydraulic systems unless

you are trained. Refer to experienced repair personnel for help.

Fire Prevention

Never operate your MHP near a fl ame or spark.

Hydraulic oil and gasoline are fl ammable and can

explode.

Note

This machine is equipped with an internal combustion engine (in its standard confi guration) and should

not be used on or near any unimproved forest covered, brush covered or grass covered land unless

the engines exhaust system is equipped with a spark

arrester meeting applicable laws. If a spark arrester

is used, it should be maintained in effective working

order by the operator.

Engine and Fuel Handling Precautions

WARNING

Engine exhaust contains carbon monoxide, a

poisonous gas that is invisible and odourless.

Breathing engine exhaust fumes can cause death

or serious illness. Do not run the engine in an

enclosed area or indoors without adequate ventilation.

Only refuel your MHP outdoors in a clear area void of

gas fumes or spilled gas.

Never remove the fuel cap or refuel a gasoline engine

while the engine is running or hot. ALWAYS allow the

engine to cool before refueling. Never allow fuel to

spill on hot machine components.

DANGER

DO NOT smoke or permit open fl ames while

fueling or near fueling operations.

Maintain control of the fuel fi lter nozzle when fi lling

the tank

CAUTION

ENSURE you use an approved fuel container with

appropriate fuel fi lter nozzle.

Do not exceed the restricted platform capacity as indicated on the capacity placard at the entrance to the

platform. Do not carry loads from any point outside of

the platform.

Make sure that all protective guards, cowlings and

doors are in place and secure. Be sure the guard rail

system, including the gate, is in place and secure.

Do not climb on the guardrails or use ladders, planks

or other devices to extend or increase your work

position from the platform.

Do not use the machine as a crane, hoist or jack, or

for any other purpose other than to position personnel, their tools and materials.

Do not operate the machine in winds, or wind gusts of

28 mph, 45 km/h 12.5 m/s or more.

DANGER

Do not add banners, fl ags, screens or shelters

etc to areas of the MHP that are exposed to wind

forces as this will increase the wind loading and

effect stability.

General Safety Precautions

Do not modify the MHP in any way.

When parts or components are replaced, they shall

be identical or equivalent to original Snorkel parts or

components.

Do not override any of the safety features of the MHP.

Hydraulic System Precautions

The hydraulic system contains hoses with hydraulic

fl uid under pressure.

DANGER

Hydraulic fl uid escaping under pressure can

have enough force to inject fl uid into the fl esh.

Serious infection or reaction can result if medical treatment is not given immediately. In case

of emergency by escaping hydraulic fl uid, seek

medical attention at once.

DO NOT place your hand or any part of your body in

front of escaping hydraulic fl uid. Use a piece of card-

board or wood to search for hydraulic leaks.

Page 1-3

Rev C

MHP14AT & MHP13AT

1. Safety

Page 12

This is to allow the unit to be operated by unlicensed

operators in accordance with Australian Legislation.

WARNING

An Australian operator MUST hold a WP certifi cate of Competency in order to operate the

machine in excess of 11m.

Height Restriction on MHP13AT

The MHP13AT (in standard mode) is fi tted with a re-

strictor in the upper hydraulic lift cylinder to keep the

platform to a maximum height of 10.9m.

10.9 Meter Restriction Kit

Machines that are built for the Australian market may

be fi tted with a 10.9m restriction kit.

This kit which can be fi tted to the MHP14AT is fi tted

to restrict the maximum height to the platform fl oor at

10.9m from the ground.

Note

See the Options chapter page 6 for details

concerning this kit.

Safety Decals and Placards

There are a number of safety decals and placards on

the MHP. Their locations and descriptions are shown

in this section on the following pages. Take time to

study them.

CAUTION

Be sure that all the safety decals and placards on

the MHP are legible. Clean or replace them if you

cannot read the words or see the pictures. Clean

with soap & water and a soft cloth. Do not use

solvents.

Note

From time to time certain Snorkel decals may be

deleted, altered or replaced, or new decals may be

added in line with new safety regulations or machine

specifi cation changes.

If you are unsure or want to check a particular decal

or its placement on the machine contact your nearest

Snorkel dealer or the Snorkel website.

Do not fi ll the fuel tank to capacity. Allow room for

expansion.

If gasoline is spilled, clean up spilled fuel immediately, push/tow the MHP away from the area of the

spill and avoid creating any source of ignition until the

spilled fuel has evaporated.

Tighten the fuel tank cap securely. if the cap is lost,

replace it with an appropriate cap from Snorkel. Use

of a non-approved cap without proper venting may

result in pressurization of the tank.

Never use fuel for cleaning purposes.

For diesel engines, use the correct fuel grade for the

operating season.

Batteries

Charge batteries in a well ventilated area free of

fl ame, sparks or other hazards that might cause fi re

or explosion.

WARNING

Batteries give off hydrogen and oxygen that can

combine explosively. Death or serious injury can

result from a chemical explosion. Do not smoke

or permit open fl ames or sparks when checking

batteries.

Battery acid can damage the skin and eyes.

Serious infection or reaction can result if medical treatment is not given immediately. Wear face

and eye protection when working near batteries.

CAUTION

If acid contacts your eyes, fl ush immediately with

clear water and get medical attention. If acid contacts your skin, wash off immediately with clear

water.

Height Restriction

IMPORTANT

The height restrictor fi tted to the standard MH-

P13AT, is not the same device as the 10.9m

restriction kit, although both of these devices

achieve the same result of restricting the maximum height of the platform to 10.9m from the

ground.

Page 1-4

Rev C

MHP14AT & MHP13AT

1. Safety

Page 13

Page 1-5

Rev C

MHP14AT & MHP13AT

1. Safety

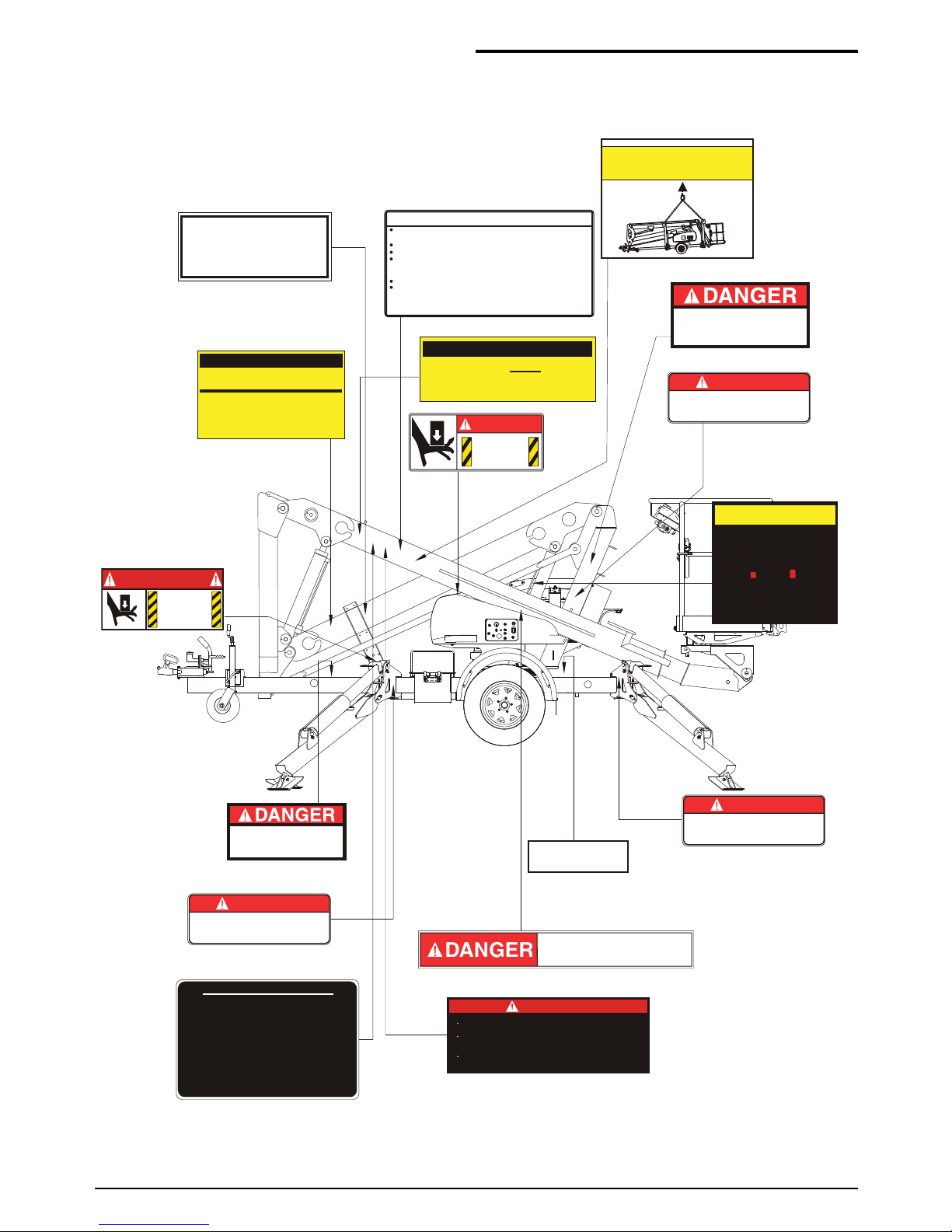

FIT BOOM CRADLE LOCK PIN

FOR TRAVELLING.

1772-002K

OPERATORS CHECKLIST

INSPECT AND/OR TEST THE FOLLOWING DAILY

OR AT THE BEGINNING OF EACH SHIFT

1. OPERATING AND EMERGENCY CONTROLS.

5. CABLES AND WIRING HARNESS.

6. LOOSE OR MISSING PARTS.

7. TYRES AND WHEELS.

8. PLACARDS, WARNINGS, CONTROL MARKINGS

AND OPERATING MANUAL(S).

9. GUARDRAIL SYSTEM.

10.OIL LEVELS.

11.BATTERY FLUID LEVEL.

4. HOSES, FITTINGS AND VALVES FOR LEAKS.

3. PERSONAL PROTECTIVE DEVICES.

2. SAFETY DEVICES.

300699

DANGER

DO NOT ALTER OR DISABLE

LIMIT SWITCHES, SAFETY

SWITCHES, OR INTERLOCKS.

451986

DANGER

DO NOT ALTER OR DISABLE

LIMIT SWITCHES, SAFETY

SWITCHES, OR INTERLOCKS.

451986

300699

13205

12545

7856-45

13111

0150602

12617

0150602

013-0025

13183

1772-002-K

451986

13276

451986

302559

MACHINE MUST BE

REMOVED FROM TOWING

VEHICLE BEFORE OPERATING

13183

WARNING

THIS MACHINE IS FITTED WITH A

10.9 METRE RESTRICTION KIT

13205

WARNING

SELECTION / OPERATION OF A

BOOM LENGTH IN EXCESS OF 11M

REQUIRES THE OPERATOR TO

HOLD A WP CERTIFICATE OF

COMPETENCY

STABILISER OPERATION

AUTOMATIC MODE

12545

Press and hold the auto level switch. The machine will auto level.

The lift enable light will illuminate once the auto level cycle is complete.

MANUAL MODE

Each stabiliser can be raised and lowered individually by using the manual switches provided.

The stabilisers will only function when the booms are stowed. Once the booms are raised the

stabilisers will not operate.

NOTE:

To stow the stabilisers press and hold the auto stow switch. The stabilisers will then all

raise to the stowed position.

SELECT STABILISER MODE ON THE BOOM / STABILISER SWITCH AT THE LOWER CONTROL STATION

The lift enable light will illuminate when the machine is level.

KEEP CLEAR OF DESCENDING BOOM

DEATH OR SERIOUS INJURY CAN

OCCUR FROM DESCENDING BOOM

0150602

KEEP CLEAR OF DESCENDING BOOM

DEATH OR SERIOUS INJURY CAN

OCCUR FROM DESCENDING BOOM

0150602

DANGER

302559

PINCH POINT

Keep hands

clear.

DANGER

13111

PINCH

POINT

Keep hands

clear

WARNING

013-0025

Death or serious injury could occur from tipover.

All outriggers must be extended onto firm level surface

before elevating or before entering platform.

Do not exceed platform capacity.

TYRE PRESSURE

45psi 310kPa COLD

7856-45

DANGER

DO NOT ALTER OR DISABLE

LIMIT SWITCHES, SAFETY

SWITCHES, OR INTERLOCKS.

451986

451986

0072531

ELECTROCUTION HAZARD

This machine is not electrically insulated.

0072531

(On top of cover)

(Mounted on cylinder cover

at base of cylinder adjacent

to valve)

APPROVED OVERHEAD LIFT METHOD FOR MHP TRAILERS

CHAIN SLING, 4 LEGS AT 2.5M/LEG (Minimum 8mm grade 80 Lifting rated)

12617

ENSURE STABILISERS ARE FULLY RAISED

FITA SHACKLE TO EACH FOOT PLATE

(16mm Hi-Load (green pin) Bow Shackles)

CONNECT SLING LEGS WITH CLOSED HOOKS

1.

2.

3.

4.

ENSURE THE JOCKEYWHEEL IS STOWED

ENSURE THAT THE BOOM SECURING PINS ARE FITTED

5.

6.

STAY CLEAR OF STRUCTURE

DURING BOOM DESCENT

Push the red button in and

turn it counter-clockwise

o

180 to open valve and

lower the boom

13276

Emergency Lowering

Procedure

Emergency Lowering

Procedure

o

Push button and turn clockwise 180

to close valve for normal operation

Closed

Open

Page 14

Page 1-6

Rev C

MHP14AT & MHP13AT

1. Safety

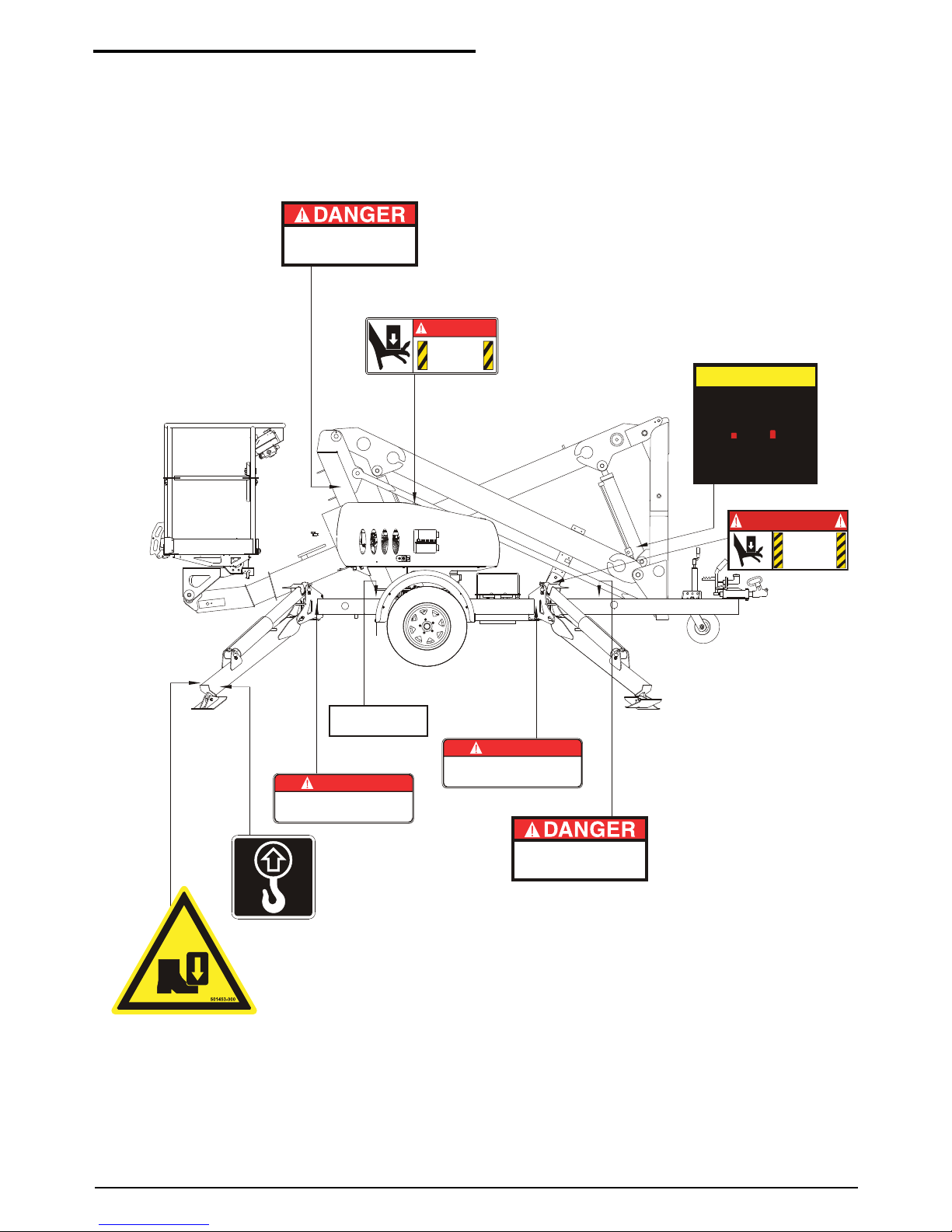

DANGER

DO NOT ALTER OR DISABLE

LIMIT SWITCHES, SAFETY

SWITCHES, OR INTERLOCKS.

451986

7856-45

13111

13276

0150602

0150602

451986

0080650

X4 all four

stabiliser legs

302559

KEEP CLEAR OF DESCENDING BOOM

DEATH OR SERIOUS INJURY CAN

OCCUR FROM DESCENDING BOOM

0150602

KEEP CLEAR OF DESCENDING BOOM

DEATH OR SERIOUS INJURY CAN

OCCUR FROM DESCENDING BOOM

0150602

DANGER

PINCH POINT

Keep hands

clear.

302559

DANGER

13111

PINCH

POINT

Keep hands

clear

TYRE PRESSURE

45psi 310kPa COLD

7856-45

(On top of cover)

STAY CLEAR OF STRUCTURE

DURING BOOM DESCENT

Push the red button in and

turn it counter-clockwise

o

180 to open valve and

lower the boom

13276

Emergency Lowering

Procedure

Emergency Lowering

Procedure

o

Push button and turn clockwise 180

to close valve for normal operation

Closed

Open

DANGER

DO NOT ALTER OR DISABLE

LIMIT SWITCHES, SAFETY

SWITCHES, OR INTERLOCKS.

451986

451986

0080650

ALL 4 STABILISERS

501453-000

Page 15

Page 1-7

Rev C

MHP14AT & MHP13AT

1. Safety

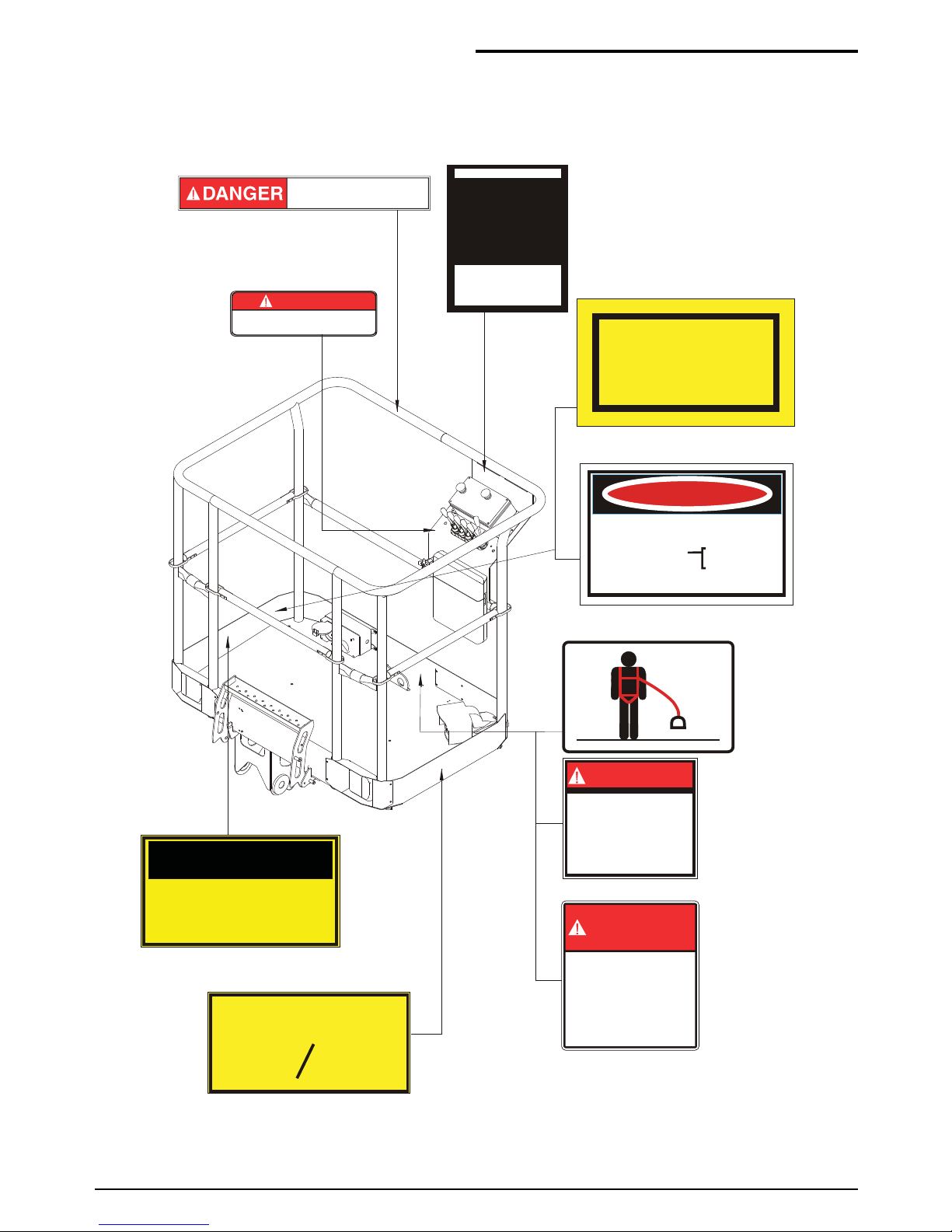

WARNING

KEEP LINESCLEAR POWEROF

Unless the Electrical Supply Authority has advised

in writing otherwise;

the clearance between any live overhead

power line and any part of this machine or

load carried is required by law to be

AT LEAST 4 METRES

This is a requirement of regulation 93 of the

Electrical Supply Regulations 1984

in the interests of safe working.

DANGER

BEWARE OF ELECTRICAL HAZARDS

REGULATION 133A OF THE

CONSTRUCTION SAFETY ACT 1912 REQUIRES

(a) Minimum approach of an appliance

(b) Inspection of the work site for

(c) Constant vigilance and an observer required

to live electrical apparatus.

electrical hazards before

commencing to use the appliance.

whilst working or travelling the appliance

in the vicinity of live electrical apparatus.

3m. for voltages up to 132,000

6m. for voltages above 132,000

and up to 330,000

8m. for voltages above 330,000

(New Zealand Only)

(Australia Only)

99228-1

CAUTION

EACH PERSON ON THE PLATFORM

MUST WEAR A FULL SAFETY HARNESS

WITH LEG STRAPS

AND ENERGY ABSORBING LANYARD

ATTACHED TO AN APPROVED ANCHOR

POINT IN THE PLATFORM

DANGER

MAXIMUM ALLOWABLE

WIND SPEED 12.5m/sec

45198-7

99228-1

1843

12423-215

9428

45198-7

0150448

0150448

RATED LOAD

475

LB

12423-215

215

KG

13030

DANGER

ELECTROCUTION

HAZARD

THIS MACHINE IS NOT

ELECTRICALLY INSULATED

13030

0072531

ELECTROCUTION HAZARD

This machine is not electrically insulated.

0072531

Inside

YOU MUST NOT OPERATE THIS DEVICE UNLESS:

AN UNTRAINED OPERATOR SUBJECTS HIMSELF AND OTHERS TO

DEATH OR SERIOUS INJURY.

0323897

1.

2.

YOU HAVE BEEN TRAINED IN THE SAFE OPERATION OF THIS

DEVICE AND HHHH

YOU KNOW AND FOLLOW THE SAFETY AND OPERATING

RECOMMENDATIONS CONTAINED IN THE MANUFACTURER'S

MANUALS, YOUR EMPLOYER'S WORK RULES, AND APPLICABLEGOVERNMENTAL REGULATIONS. HHHHHHHH

DANGER

0323897

13373

1.

2.

TO LOWER PLATFORM, OPERATE

‘ENABLE’ SWITCH & ‘EMERGENCY

LOWER’ SWITCH TOGETHER.

TO SLEW BOOM WHILE LOWERING,

OPERATE ‘UPPER OR LOWER BOOM

UP, ENABLE, EMERGENCY LOWER

AND SLEW’ SWITCHES TOGETHER.

3.

TO TELE IN WHILE LOWERING,

OPERATE ‘UPPER OR LOWER BOOM

UP, ENABLE, EMERGENCY LOWER

AND TELE IN’ SWITCHES TOGETHER.

DURING STEPS 2 & 3 EITHER UPPER

OR LOWER UP SWITCHES CAN BE

USED TO MAKE THE FUNCTION

OPERATE, HOWEVER THIS MUST BE

DONE BEFORE THE BOOMS ARE

FULLY LOWERED

EMERGENCY LOWER

13373

Page 16

Page 1-8

Rev C

MHP14AT & MHP13AT

1. Safety

Page 17

Page 2-1

Rev C

MHP14AT & MHP13AT

At platform control box

Figure 2.2 - Emergency Stop Switch at

Platform Control Box

Press the red EMERGENCY STOP button in, at any

time, under any conditions, and the entire machine

stops, and nothing moves. This switch must be out

(on) for anything on the MHP to work. Pull the switch

and it will pop out (on).

Note

The ground control box is designed to override

the platform control box. If the platform control box

EMERGENCY STOP switch is in (off) the ground

control box can still be used to start and operate the

machine.

Other Safety Devices

Lanyard anchor points

Figure 2.3 - Lanyard Anchor Points

All personnel on the platform should attach their

safety harness lanyards to one of the lanyard anchor

points.

The lanyard anchor points are located at the rear of

the platform fl oor.

Safety Device Information

For emergency operation controls and procedures,

see the “Emergency Operation” chapter 9, in this

manual.

The Devices listed in this chapter are safety devices.

They are on the MHP to increase safety in the workplace for both the operator and other people near the

MHP.

CAUTION

DO NOT bypass, disable, modify , or ignore any of

these devices. Check them carefully at the start

of each work shift to see that they are in working

order (see “Pre-Operational Inspection” chapter

7). If any is found to be defective, remove the

MHP from service immediately until a qualifi ed

service technician can make repairs.

Emergency Stop Switches

At ground control box

Figure 2.1 - Emergency Stop Switch at

Ground Control Box

Press the red EMERGENCY STOP button in, at any

time, under any conditions, and the entire machine

stops, and nothing moves. This switch must be out

(on) for anything on the MHP to work. Pull the switch

and it will pop out (on).

2. Safety Devices

Page 18

Page 2-2

Rev C

MHP14AT & MHP13AT

2. Safety Devices

Note - Height Restriction Kit

See the Options chapter page 6 for details

concerning this kit.

Enable switch

The enable switch must be operated in conjunction

with the boom/platform moving function you select.

The purpose of this switch is to prevent the platform

from moving if somebody or something accidentally

pushes one of the boom/platform moving controls.

There are enable switches fi tted to both the upper

and lower control boxes.

Figure 2.6 - Enable Switch, Upper Control Box

Figure 2.7 - Enable Switch, Lower Control Box

Gravity gates

Figure 2.4 - Gravity Gates

The gravity gates are the places in the platform

guardrail system where you should enter and leave

the platform. Raise the gate where you wish to enter

and step under it onto the platform. Once you have

entered the platform and attached your safety harness lanyard to an anchor point, check to see that the

gravity gate has fallen back into place.

Guardrails

Figure 2.5 - Guardrails

The guardrails help protect you from falling off the

platform. Be sure the guard rails are properly installed

and that the gravity gate is in place.

Height restriction on the MHP13AT

The MHP13AT (in standard mode) is fi tted with a

restrictor in the upper hydraulic lift cylinder to keep

the platform to a maximum height of 10.9m.

10.9m height restriction kit (option)

This kit may be fi tted to machines manufactured for

the Australian market.

It is fi tted to restrict the maximum height to the plat-

form fl oor to 10.9m from the ground. This is to allow

the unit to be operated by unlicensed operators in

accordance with Australian Legislation.

Page 19

Page 2-3

Rev C

MHP14AT & MHP13AT

2. Safety Devices

Figure 2.9 - Overload Indicator,

Lower Control Box

Figure 2.10 - Overload Indicator,

Upper Control Box

Bubble level

Figure 2.11 - Bubble Level

A bubble level is located on the trailer side rail, beside

the outrigger controls. Watch the bubble level while

you set the stabilisers. Lower the stabilisers one at a

time, just enough to center the bubble in the middle

piece of the gauge. When the bubble is centered the

platform is level and can be safely raised.

Enable switch (foot) - Optional

Figure 2.8 - Enable Switch (Foot)

The foot switch performs the same function as the

standard enable switch described above. Stepping

on the foot switch is an action that must be performed,

at the same time as another action, to make the

booms/platform move.

Note

If you have the optional foot switch fi tted the enable

switches on the upper control box and ground control

box will still function.

Platform Overload Protection

As soon as either boom is raised out of the travel cradle (a boom stowed switch changes state) the overload protection system becomes active.

• If 90% of rated capacity is reached in the platform

the overload light will illuminate.

This is a warning to the operator that the platform is

reaching rated capacity.

Normal function will remain and the machine can

continue to be used.

• If 100% of rated capacity is reached in the platform, the overload light will continue to illuminate

and an alarm will sound.

This is a warning to the operator that rated capacity

has been reached and the platform load must be reduced.

Normal function will remain to allow the platform to

be positioned to remove some load from the platform.

• If 110% of rated capacity is reached in the platform the overload light will continue to illuminate

and an alarm will continue to sound and all functions will be disabled.

The operator must remove load from the platform.

Normal function will resume once the platform load

has been reduced below 110% for at least two (2)

seconds.

Page 20

Page 2-4

Rev C

MHP14AT & MHP13AT

2. Safety Devices

RCD/ELCB AC outlet (Option)

Figure 2.12 - RCD/ELCB AC Outlet,

Vertical Mounting

The RCD (Residual Current Device) is located at the

base and will protect against short circuits to earth.

When there is a short circuit the RCD will shut down

the 230V AC power to the platform outlet.

To reset the outlet disconnect the power tool lead

from the platform control box and reset the RCD at

the base. If the problem persists call a trained service

technician.

Stabiliser/Boom Interlock Test

All machines in the Snorkel ‘MHP’ Series of Trailer

Mounted Elevated Work Platforms are fi tted with a

very important safety feature, a ‘Stabiliser/Boom

Interlock’ system that prevents the booms being elevated to an unsafe position unless all four stabilisers

have been correctly set and have made fi rm contact

with the ground.

IMPORTANT

The correct operation of the Stabiliser/Boom

Interlock is critical to ensure that the MHP is

operated safely and without risk.

Detailed instructions on how to carry out a test to

ensure that this function is working correctly are

provided at the beginning of the Pre-Operational Inspection chapter in this manual.

Flashing light (Option)

The fl ashing light alerts people that the booms /

platform of the MHP are moving. The light fl ashes

at about one fl ash per second any time the Master

Key switch is on. There is no On/Off switch for the

fl ashing light, it cannot be turned off while the MHP

is running.

Page 21

Page 3-1

Rev C

MHP14AT & MHP13AT

The Snorkel MHP14AT / MHP13AT are boom supported elevating work platforms built to conform to

Australian Standard AS1418-10 Elevating Work Platforms.

Note

For further details regarding lubricants, maintenance schedules and service please refer to the Maintenance

and Repair Parts Manual for this machine.

General Specifi cations

Specifi cations MHP14AT

SPECIFICATIONS MHP14AT

Nominal working height

13.5m 44.3'

Maximum height to basket floor

11.5m 37.7'

Maximum outreach

6.4m 21.0'

Maximum width of base

Stabilisers retracted

Stabilisers extended

1.6m

3.6m

5.2'

11.8'

Safe working load (unrestricted)

215kg 474lbs

Platform size

1.15 x 0.70m 3.8' x 2.3'

Construction

Steel Steel

Travelling height

2m 6.6'

Overall length

4.7m 15.4'

Maximum towing speed

80km/h 50mph

Turntable rotation

540

o

Non continuous

Trailer tongue weight (approximately)

Less than 100kg Less than 225lbs

Maximum rated axle capacity

2000kg 4409lbs

Insulation rating

Nil

(on standard models)

Weight

1460kg (Petrol model) 3218lbs (Petrol model)

Allowable manual force

400N

Maximum permitted chassis inclination

1

O/1O

Maximum load on stabilisers

978kg 2156lb

3. Specifi cations

Page 22

3. Specifi cations

Page 3-2

Rev C

MHP14AT & MHP13AT

SPECIFICATIONS MHP13AT

Nominal working height

12.9m 42.3'

Maximum height to basket floor

10.9m 35.8'

Maximum outreach

6.4m 21.0'

Maximum width of base

Stabilisers retracted

Stabilisers extended

1.6m

3.6m

5.2'

11.8'

Safe working load (unrestricted)

215kg 474lbs

Platform size

1.15 x 0.70m 3.8' x 2.3'

Construction

Steel Steel

Travelling height

2m 6.6'

Overall length

4.7m 15.4'

Maximum towing speed

80km/h 50mph

Turntable rotation

540

o

Non continuous

Trailer tongue weight (approximately)

Less than 100kg Less than 225lbs

Maximum rated axle capacity

2000kg 4409lbs

Insulation rating

Nil

(on standard models)

Weight

1460kg (Petrol model) 3218lbs (Petrol model)

Allowable manual force

400N

Maximum permitted chassis inclination

1

O/1O

Maximum load on stabilisers

978kg 2156lb

Specifi cations MHP13AT

Recommended hydraulic oil

Shell Tellus 32 or Castrol AWS 32 or similar.

Page 23

3. Specifi cations

Page 3-3

Rev C

MHP14AT & MHP13AT

Engine Data

Engine Make Honda (gas o line)

Model GX 160

Engine type 4-stroke, over head valve, 1 cylinder

Displacement 163 cm3 (9.9 cu-in)

Bore x Stroke 68 x 45 mm (2.7 x 1.8 in)

Max. output 4 kW/4,000 rpm

Max. torque 1.1 kg-m (8.0 ft-lb)/ 2500 rpm

Fuel gasoline

Fuel Grade automotive gasoline (unleaded or low leaded preferred)

Fuel consumption 230 g/PSh

Cooling system Forced air

Ignition system Transistor magneto

PTO shaft

rotation

Counterclockwise

Oil Capacity 0.60 litres (0.60 US qt, 0.53 Imp qt)

Oil Grade SAE 10W-30

Page 24

3. Specifi cations

Page 3-4

Rev C

MHP14AT & MHP13AT

01234 1234567

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

10.9 Restricted

Working Curve

Dimensions in metres

Working Envelope - MHP14AT, MHP13AT

Page 25

3. Specifi cations

Page 3-5

Rev C

MHP14AT & MHP13AT

Lower

boom

Lower Lift

Cylinder

Upper Lift

Cylinder

Telescoping

Boom

Floating

Turret

Upper boom

To w

coupling

Draw bar

Outriggers (4)

Trailer

Outrigger

controls

Ground

controls

Platform

controls

Platform

Nomenclature

Right side view of machine

Booms identifi cation

Page 26

Oil tank

Outriggers

Hand

brake

Jockey

Wheel

Engine

Left side view of the machine

Page 3-6

Rev C

MHP14AT & MHP13AT

3. Specifi cations

Page 27

Page 4-1

Rev C

MHP14AT & MHP13AT

Hydraulic Oil Level

Figure 4.3 - Hydraulic Oil Level

The hydraulic oil level gauge is attached to the side

of the hydraulic tank. Read it only when the booms

are fully lowered and the stabilisers are raised in the

travel position.

The hydraulic oil level should be between the two (2)

marks on the decal.

If necessary, add hydraulic oil at the fi ller cap. See

the ‘Specifi cations’ chapter 3, for type and grade of

hydraulic oil.

Hourmeter

Figure 4.1 - Hourmeter

The hourmeter is basically an electric clock. It

accumulates time when the master key switch is

turned on. The hour meter cannot be reset. An MHP

qualifi ed service technician can use it to tell when it is

time for the periodic maintenance listed in the maintenance manual.

Level Bubble

Figure 4.2 - Level Bubble

A level bubble is mounted on the trailer base. Watch

the bubble while you set the stabilisers. Lower the

stabilisers, front ones fi rst, one (1) at a time just

enough to center the bubble in the middle on top of

the gauge. When the bubble is central the platform is

level and the platform can be safely raised.

4. Gauges

Page 28

4. Gauges

Page 4-2

Rev C

MHP14AT & MHP13AT

Page 29

5. Shut-offs and Circuit Breakers

Electrical Circuit Protection

There is only one (1) fuse, on a standard MHP, that is

accessable to the operator. Its purpose is to protect

the electrical circuits from electrical overloads. When

the fuse blows replace it with an identically rated fuse.

If the fuse blows a second time, take the MHP out of

service and refer to a qualifi ed trained service tech-

nician for repair.

RCD/ELCB Outlet (Option)

Figure 5.1 - RCD/ELCB Outlet

The RCD (Residual Current Device) is located at the

base and will protect against short circuits to earth.

When there is a short circuit the RCD will shut down

the 230V AC power to the platform outlet.

To reset the outlet disconnect the power tool lead

from the platform box and reset the RCD at the base.

If the problem persists call a trained service technician.

Stabilisers

Figure 5.2 - Stabilisers

The MHP booms cannot be raised unless the stabilisers are set and the lift enable light on the lower

control box is lit. Once the booms are raised from the

stowed position the stabilisers become disabled until

the booms are stowed in the travel position.

Page 5-1

Rev C

MHP14AT & MHP13AT

Page 30

5. Shut-offs and Circuit Breakers

Page 5-2

Rev C

MHP14AT & MHP13AT

Page 31

Controls Description

This chapter explains what each control does.

This chapter does not explain how to use the controls

to produce useful work, refer to the “Operation” chapter 8 for that after you have read this chapter.

Controls and control decal locations

For optional equipment controls, see the “Options”

chapter 11.

See the “Emergency Operation” chapter 9-1 for the

location of the emergency bleed down control and for

correct emergency bleed down procedures.

The main operating functions of an MHP can be

controlled from the ground control box or from the

platform control box.

6. Controls

Page 6-1

Rev C

MHP14AT & MHP13AT

Page 32

2. Platform / Base Selector: Must be in the base

position for the ground control box to work. The

switch must be in the platform position for the

platform control box to work.

Note

This switch also acts as the ‘master key switch’. Turning this key to the central position and removing the

key will effectively disable all operations.

3. Choke / Cold start: Hold the switch down while

you start an engine that is at ambient air temperature (a ‘cold’ engine). This will choke the engine.

4. Start switch: Press and hold this switch down to

operate the starter motor for the MHP.

5. Boom Speed: This control determines how fast

the booms move. Set it to slow (turtle) until you

are very familiar with the way the machine works

or if the platform is working in dangerous or

cramped surroundings.

6. Stabiliser / Boom Selector Switch: Must be in Stabiliser position (down) for the stabilisers to work.

Once the stabilisers are down and set the switch

must be placed in the boom (up) position for the

booms to work.

Control Switches 7 through 11 are the platform moving switches. Each is a three (3) position, momentary

contact, normally off switch.

7. Lower Boom: Up raises the lower boom. Down

lowers the lower boom.

8. Upper Boom: Up raises the upper boom. Down

lowers the upper boom

9. Tele Boom: Left retracts the telescoping boom.

Right extends the telescoping boom.

10. Level Basket: Left tilts the basket forwards. Right

tilts the basket backwards.

11. Slew: Left rotates the entire turntable and boom

to the left. Right rotates the entire turntable and

boom to the right.

12. Enable Switch: The enable switch must be

pressed down in conjunction with the booms /

platform moving function you select. The purpose

of this switch is to prevent the platform / booms

from moving if something or someone accidentally pushes one of the boom / platforms moving

controls. The boom / platform moving switches

will not operate unless the enable switch is held

down at the same time.

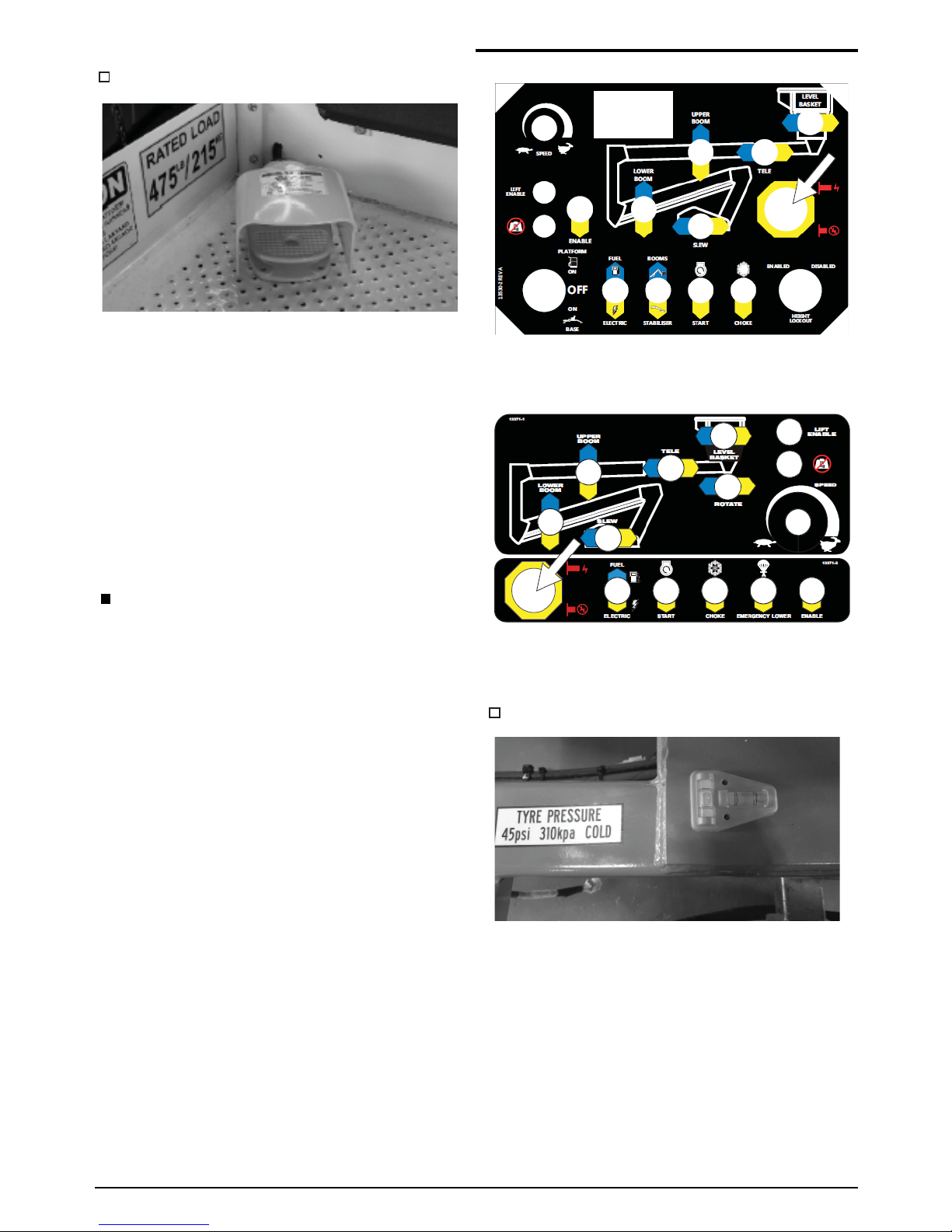

Ground Control Box

Controls for operating the MHP from the ground controls are located on the right side of the column.

Lower controls / indicators

• Emergency stop switch

• Platform / base selector switch

• Choke

• Master key switch

• Boom speed rheostat

• Stabiliser / boom selector switch

• Lower boom switch

• Upper boom switch

• Tele boom switch

• Level basket switch

• Slew switch

• Enable switch

• Lift enable indicator

• 10.9m height lockout switch (Option)

• Fuel / electric selector switch (Option)

• Overload protection indicator

• Emergency lower valve

Figure 6.2 - Lower Control Box Controls

1. Emergency Stop: Press the red emergency stop

button in at any time under any conditions, and

the entire machine stops, and nothing moves.

This switch must be out (on) for anything on the

MHP to work. Pull the switch and it will pop out

(on).

Page 6-2

Rev C

MHP14AT & MHP13AT

6. Controls

Page 33

13. Lift Enable Indicator: The platform can only be

raised when this light is lit. When this light is lit

the platform will not raise because the stabilisers

are not properly set.

14. Height Lockout Switch (option); This switch (when

fi tted) limits the maximum height of the boom to

10.9 meters (see options chapter page 6).

15. Fuel / Electric Selector Switch (Option): This

switch (when fi tted) allows switching between

different motive sources. (See options chapter).

16. Emergency Lower Controls: Allows the platform

to be lowered in the event of an emergency (see

Chapter 9 Emergency Operation) for details of

emergency lowering procedures.

Figure 6.3 - Ground Controls, Emergency

Bleed Down Control Valve, Lower Boom

Figure 6.4 - Ground Controls, Emergency

Bleed Down Control Valve, Upper Boom

Page 6-3

Rev C

MHP14AT & MHP13AT

6. Controls

Platform Control Box

Controls for operating the MHP from the platform

(upper controls) are located on the platform control

box, with the exception of the foot switch (option)

which is on the platform fl oor and the manual basket

rotator which is mounted on the front of the basket.

Upper controls / indicators

• Emergency stop switch

• Choke

• Start switch

• Boom speed rheostat

• Emergency lower switch

• Lower boom switch

• Upper boom switch

• Tele boom switch

• Level basket switch

• Slew switch

• Enable switch

• Enable foot switch (option)

• Lift enable indicator

• Fuel / electric selector switch (option)

• Overload indicator

• Rotate switch (option)

Figure 6.5 - Upper Control Box Controls

1. Emergency Stop: Press the red emergency stop

button in at any time under any conditions, and

the entire machine stops, and nothing moves. The

switch must be out (on) to start or run the MHP

from the platform control box. Pull the switch and

it will pop out (on). Press the switch in (off) if the

platform is to stay in one position for a long time.

That will turn the engine off and save fuel.

2. Choke / Cold Start: Hold the switch down while

you start an engine that is at ambient air temperature (a ‘cold’ engine). This will choke the engine.

3. Start: Press and hold the switch down to operate

the starter motor for the MHP.

Page 34

4. Boom Speed: This control determines how fast

the booms move. Set it to slow (turtle) until you

are very familiar with the way the machine works

or if the platform is working in dangerous or

cramped surroundings.

5. Emergency Lower Controls: If the engine stops

and cannot be restarted, or some other emergency prevents the platform being lowered in the

normal way, operate the emergency lower switch

and the enable switch together and this will cause

the upper and lower booms to descend. To slew

during the emergency lower operate the emergency lower, enable, upper or lower boom up and

slew switches together. See chapter 9 ‘Emergency Operation’ for details of emergency lowering

procedures from the platform. Items 6 through

10 are the platform moving switches. Each is a

three (3) position, momentary contact, normally

off switch.

6. Lower Boom: Up raises the lower boom. Down

lowers the lower boom.

7. Upper Boom: Up raises the upper boom. Down

lowers the upper boom.

8. Tele Boom: Left retracts the telescoping boom.

Right extends the telescoping boom.

9. Level Basket: Left tilts the basket forwards/ Right

tilts the basket backwards.

10. Slew: Left rotates the entire turntable and boom

to the left. Right rotates the entire turntable to the

right.

1 1. Enable: the enable switch must be pressed down

in conjunction with the boom/platform moving

function you select. The purpose of this switch

is to prevent the platform/booms from moving if

something or someone accidentally pushes one

of the moving controls. The booms/platform moving switches will not operate unless the enable

switch is held down at the same time.

12. Enable Foot Switch (Option): The foot switch

performs the same function as the standard

enable switch described above. Stepping on the

foot switch is an action that must be performed,

at the same time as one of the boom/platform

moving switches is operated.

Figure 6.6 - Upper Controls - Foot Switch

Note

If you have the optional ‘foot switch’ this is an ‘and’

option and the enable switches on the lower & upper

control boxes will still function.

13. Lift Enable Indicator: The platform can only be

raised when the light is lit. When the light is not lit

the platform will not raise because the outriggers

are not properly set.

14. Fuel / Electric Selector Switch (Option): This

switch (when fi tted) allows switching between

different motive sources (see options chapter).

16. Rotator Switch (Option): Left rotates the platform

to the left. Right rotates the platform to the right.

Stabiliser Controls (Manual)

Figure 6.7 - Stabiliser Controls (Manual)

Boom / Stabiliser Switch: Ensure the boom / stabiliser switch on the lower control box is set to stabiliser

(see item 6 on page 2 of this chapter).

6. Controls

Page 6-4

Rev C

MHP14AT & MHP13AT

Page 35

Figure 6.8 - Decal Stabiliser Controls (Manual)

Note

Ensure that the front stabilisers are lowered fi rst to

prevent damage to the jockey wheel.

Figure 6.9 - Stabiliser Controls (Manual)

• Valve Levers: Operate the valve levers to activate

the stabilisers and level the machine.

• Bubble Level: Use the bubble level to level the

machine.

Figure 6.10 - Bubble Level

Self Leveling Stabilisers (Option)

Figure 6.11 - Self Leveling Stabiliser Controls

1. Auto Level / Stow Switch: Select either auto level

or auto stow, to raise or lower the stabilisers automatically.

2. Manual Stabiliser Switches: Operate the manual switches to manually raise or lower individual

stabilisers.

3. Leg Indicator Lights: Illuminate when the legs are

in contact with the ground.

4. Lift Enable Light: This is a duplicate of the lift enable light on the lower control box. The platform

can only be raised when this light is lit. When the

light is not lit the platform will not raise because

the stabilisers are not set properly.

Note

Ensure that the front stabilisers are lowered fi rst to

prevent damage to the jockey wheel.

Activate the rear stabilisers and level the machine

using the level bubble adjacent to the control levers.

IMPORTANT

Information on controls for non-standard features (options) are shown in the options chapter.

WARNING

Pinch points may exist between moving components. Death or serious injury can result from

becoming trapped between components, buildings, structures or other obstacles. Make sure all

personnel stand clear while operating the MHP.

6. Controls

Page 6-5

Rev C

MHP14AT & MHP13AT

Page 36

6. Controls

Page 6-6

Rev C

MHP14AT & MHP13AT

Page 37

7. Pre-Operational Inspection

Page 7-1

Rev C

MHP14AT & MHP13AT

At the start of each work day (or 8 hour shift) an MHP

qualifi ed operator must perform the Pre-Operational

Inspection as listed in the table below.

The purpose of the Pre-Operational Inspection is to

keep the MHP in proper working condition and to detect signs of malfunction at the earliest possible time.

This chapter shows how to perform the inspection and maintenance required for each item in the

Pre-Operational Inspection table.

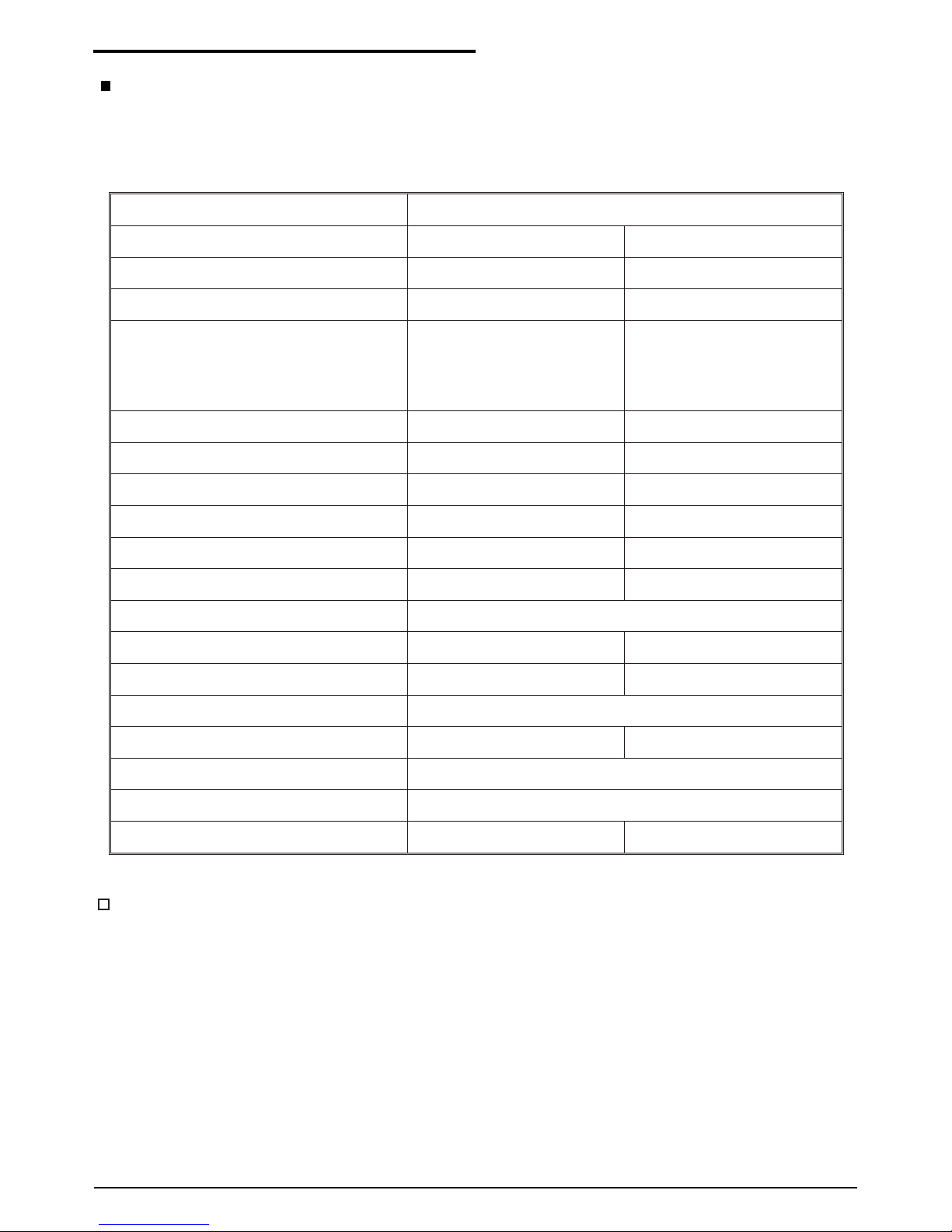

Pre-Operational Inspection Table

The MHP should be in the stowed position and the

master key switch set to off before you begin this

inspection.

Defective parts and/or equipment malfunctions jeopardize the safety of the operator and other personnel,

and can cause damage to the machines.

WARNING

Do not operate an MHP that is known to be

damaged or malfunctioning. Repair all equipment

damage or malfunctions, before placing the MHP

into service.

Page 38

Page 7-2

Rev C

MHP14AT & MHP13AT

Stabiliser / Boom Interlock Test

All machines in the Snorkel MHP Series of Trailer

Mounted Elevating Work Platforms are fi tted with a

very important safety feature, a ‘Stabiliser / Boom

Interlock’ system that prevents the booms being elevated to an unsafe position unless all four stabilisers

have been correctly set and have made fi rm contact

with the ground.

This same safety feature also prevents the Stabilisers

being operated while either or both booms are

elevated.

The correct operation of the Stabiliser/Boom Interlock

is critical to ensure that the MHP is operated safely

and without risk.

DANGER

To ensure the interlock system is functioning

correctly , before operating the MHP the following

test MUST BE CARRIED OUT PRIOR TO OPERATION EACH DAY, in conjunction with all other

relevant daily Pre-Operational checks.

1. Position the machine on a fi rm level surface.

Chock the wheels as required, engage the

parking brake, and remove the machine from the

towing vehicle.

2. From the base controls, start the engine and

allow it to warm up. Remove the travel pins from

both the upper and lower booms (as applicable

to the model). Move the Stabiliser/Boom selector

switch to ‘Boom’.

3. Attempt to raise the Upper Boom; it must not rise

out of the boom rest at all. Repeat this step for

the Lower Boom. It must not rise at all either. If

the booms will rise from the boom rest, proceed

to Step 5.

DANGER

4. If either boom rises from the boom rest and continues to rise higher than approximately 400mm,

stop the engine immediately!

Using the Emergency Lowering valve, lower the

Boom into the boom rest, remove the machine

from service and affi x a Danger Tag warning

others that the machine is not to be used.

In the fi rst instance contact the owner of who will then

contact the Snorkel branch or authorised agent to inspect, repair and test the machine before allowing it

to be placed back into service.

5. Follow the correct procedure in the Operators

manual for setting up the machine on the Stabilisers.

6. When the stabilisers are correctly set, the green

Enable Lamp is lit and the machine is level, move

the Stabiliser / Boom selector switch to ‘Boom’.

7. From the base controls, raise the Upper Boom

(no more than) approximately 400mm from the

boom rest.

IMPORTANT

Move the Stabiliser / Boom selector switch to the

‘Stabiliser’ position.

8. Using the stabiliser controls, operate one (1) of

the Stabiliser control switches or levers (any one).

There must be no corresponding movement of

the stabiliser for the switch or lever used. If the

stabiliser does not move, lower the Upper Boom

back into the boom rest, and repeat steps 7 and 8

for the Lower Boom.

9. If there is no corresponding movement of the