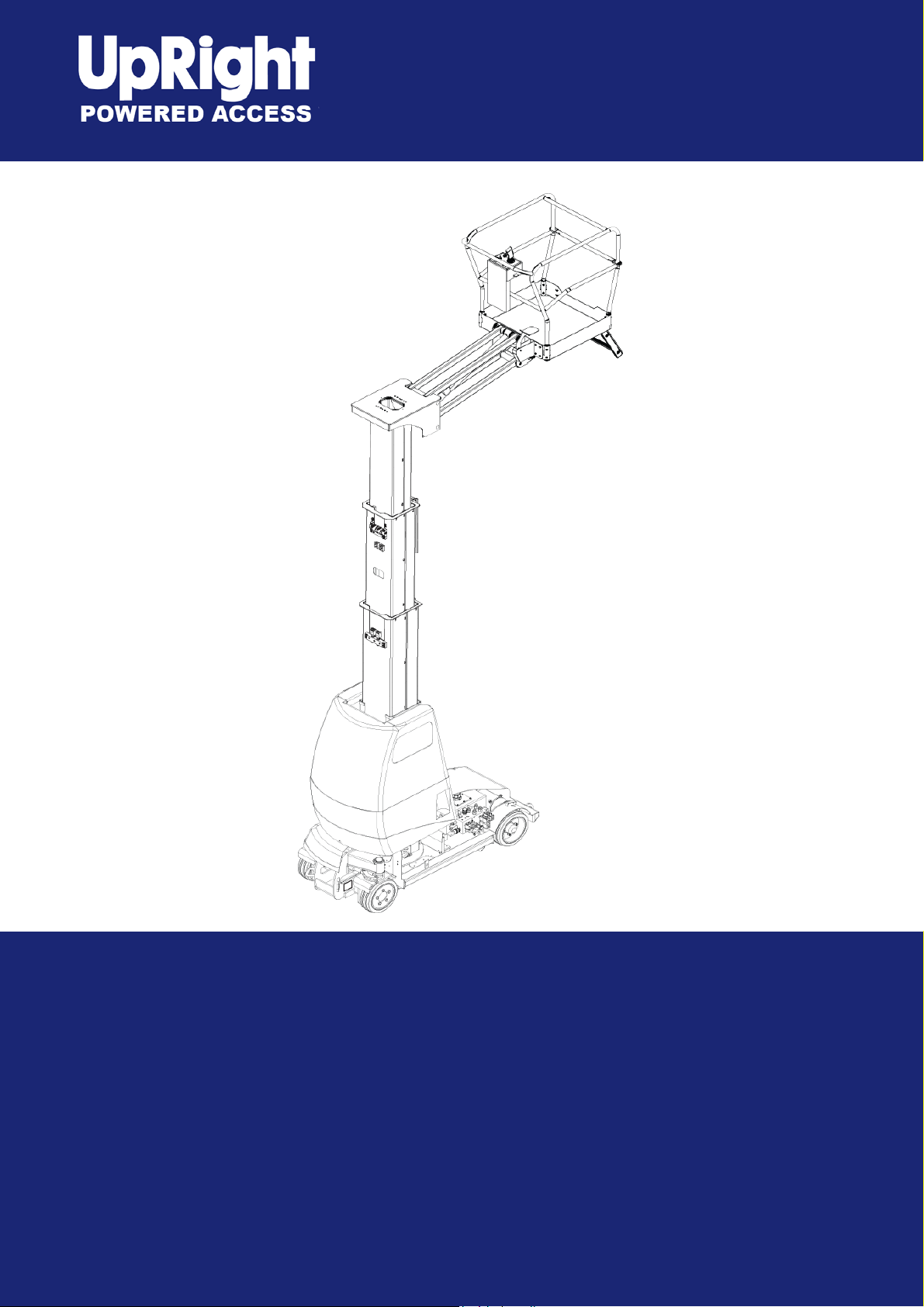

Page 1

MB20N/26

Operator Manual

This first section of the Operator manual is the English language version.

Betriebsanleitung

Im zweiten Abschnitt dieser Betriebsanleitung finden Sie die Deutsche Version.

Manuel Utilisateur

èLa troisième section de ce manuel est la version en langue Française.

Manual del Usuario

El apartado cuarto de este manual del usuario corresponde a la versión en Españo.

Manuale d’Uso

La quinta sezione di questo manuale d'uso è la versione in lingua Italiana.

(EN) Manual part number 501375-001 for serial numbers MB20N-132/MB26-

245 to current.

(DE) Bestellnummer 501375-001 ab Seriennummer MB20N-132/MB26-245

fortlaufend.

(FR) Manuel Pièce numéro 501375-001 pour numéro série MB20N-132/

MB26-245 jusqu'au numéro courant.

(ES) El número de referencia para el manual es el 501375-001 para la

números de serie del MB20N-132/MB26-245 hasta el actual.

(IT) Manuale Ricambi Numero 501375-001 per Numeri di Serie da MB20N-

132/MB26-245 all’attuale.

Feb 08

Page 2

NOTES:

Page 3

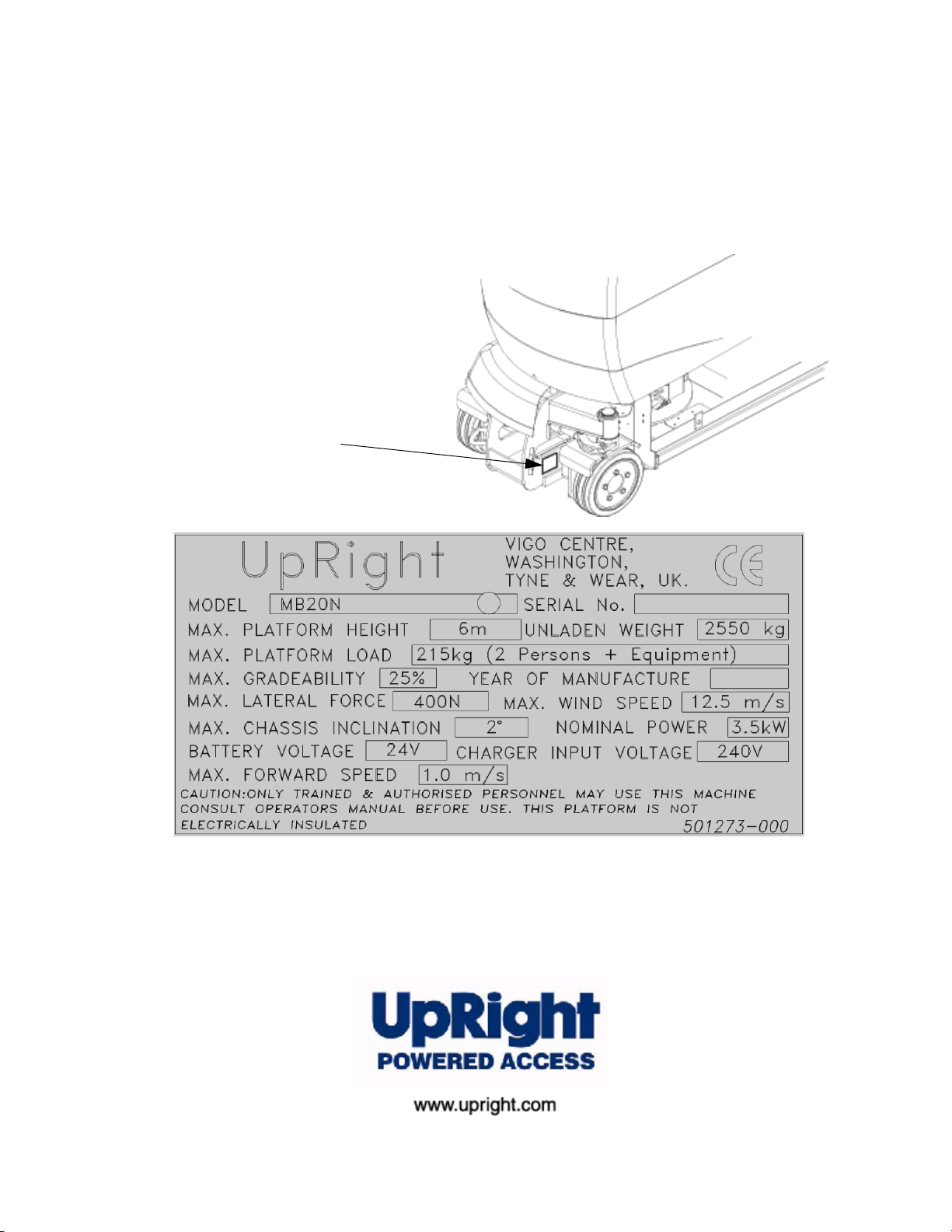

MB 20N/26

Serial Numbers MB20N 132 - Current

MB26 246 - Current

ENGLISH

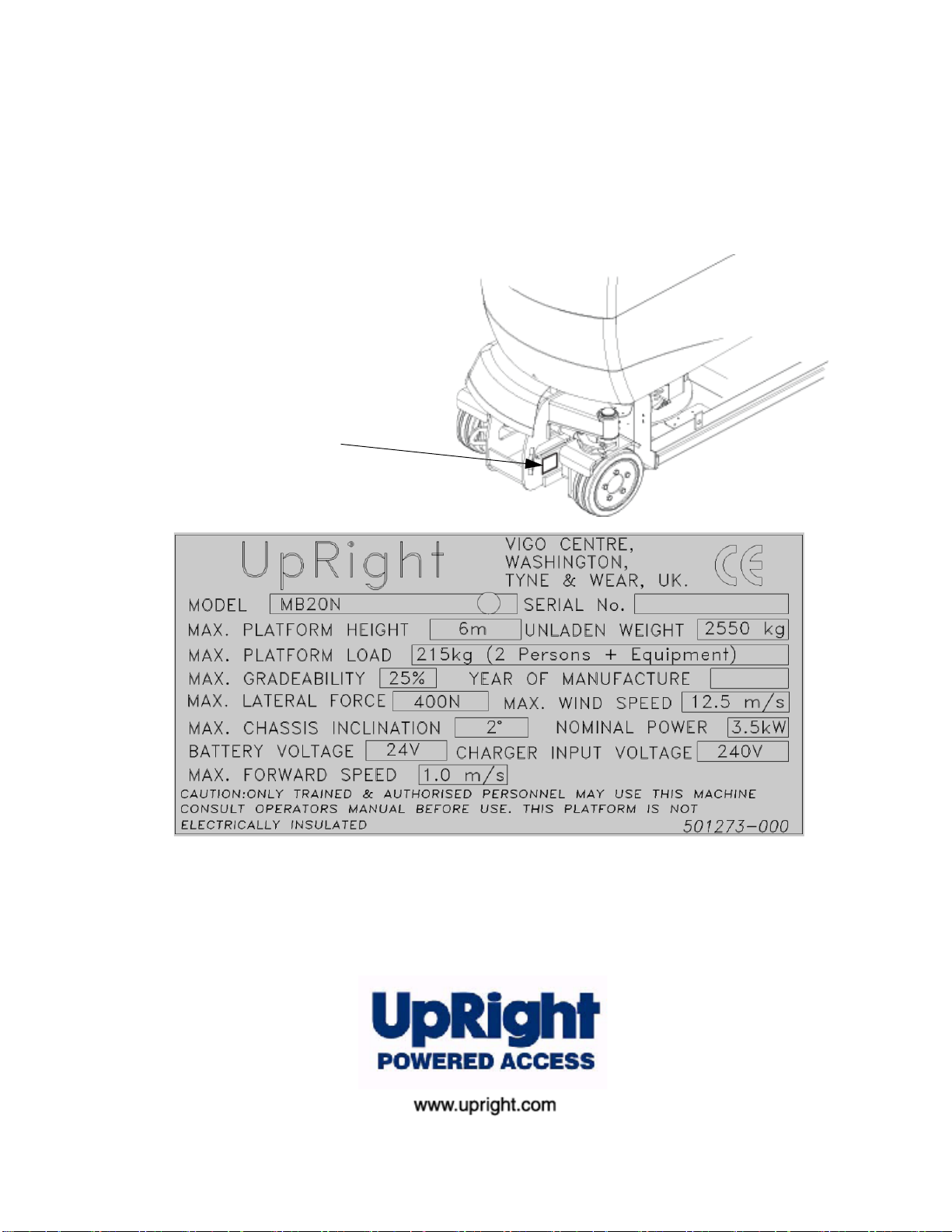

When contacting UpRight Powered Access for

service or parts information, be sure to include

the MODEL and SERIAL NUMBERS from the

equipment nameplate. Should the nameplate be

missing, the SERIAL NUMBER is also stamped

on top of the chassis above the front axle pivot.

Nameplate

The Work Platform Nameplate is located

externally at the FRONT of the chassis

When contacting UpRight for service or parts information, sure to include

the MODEL and SERIAL NUMBERS from the equipment nameplate.

The MB20N/26 work platform meets and exceeds the requirements of both:

prEn280:2001 and ANSI A92.5 (1999)

Page 4

NOTES:

Page 5

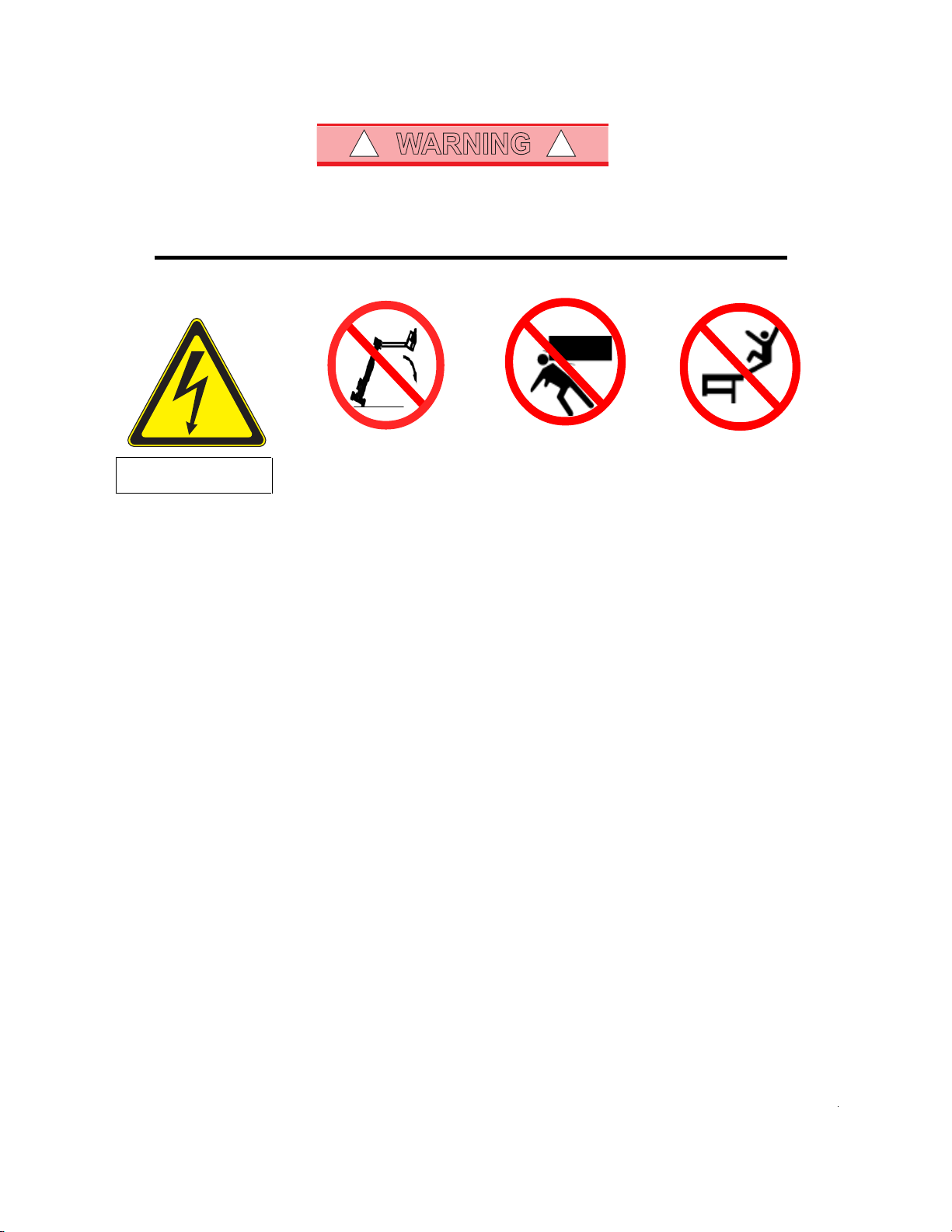

WARNING

! !

All personnel shall carefully read, understand and follow all safety rules and operating instructions

before operating or performing maintenance on any UpRight Powered Access aerial work platform.

Safety Rules

Electrocution Hazard Tip Over Hazard Collision Hazard Fall Hazard

THIS MACHINE IS NOT

INSULATED!

USE OF THE AERIAL WORK PLATFORM: This aerial work platform is intended to lift persons and his tools as well as the material used

for the job. It is designed for repair and assembly jobs and assignments at overhead workplaces (ceilings, cranes, roof structures,

buildings etc.). All other uses of the aerial work platform are prohibited!

THIS AERIAL WORK PLATFORM IS NOT INSULATED! For this reason it is imperative to keep a safe distance from live parts of

electrical equipment!

Exceeding the specified permissible maximum load is prohibited! See "Specifications - Platform Capacity" for details.

The use and operation of the aerial work platform as a lifting tool or a crane is prohibited!

NEVER exceed the manual force allowed for this machine. See “Manual Force” on page 2 for details.

DISTRIBUTE all platform loads evenly on the platform.

NEVER operate the machine without first surveying the work area for surface hazards such as holes, drop-offs, bumps, curbs, or debris;

and avoiding them.

OPERATE machine only on surfaces capable of supporting wheel loads.

NEVER operate the machine when wind speeds exceed this machine’s wind rating. See “Beaufort Scale” on page 1 for details.

NEVER attach notice boards etc. to the platform, as this will increase wind loading.

IN CASE OF EMERGENCY push EMERGENCY STOP switch to deactivate all powered functions.

IF ALARM SOUNDS while platform is elevated, STOP, carefully lower platform. Move machine to a firm, level surface.

Climbing up the railing of the platform, standing on or stepping to or from the platform onto buildings, steel or prefabricated concrete

structures, etc. is prohibited!

Dismantling the entry gate or other railing components is prohibited! Always make certain that the entry gate is closed and securely

locked!

It is prohibited to keep the entry gate in an open position when the platform is raised!

To extend the height or the range by placing of ladders, scaffolds or similar devices on the platform is prohibited!

NEVER perform service on machine while platform is elevated without blocking elevating assembly.

INSPECT the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks, loose wire connections, and damaged

cables or hoses before using.

VERIFY that all labels are in place and legible before using.

NEVER use a machine that is damaged, not functioning properly, or has damaged or missing labels.

To bypass any safety equipment is prohibited and presents a danger for the persons on the aerial work platform and in its working range.

NEVER charge batteries near sparks or open flame. Charging batteries emit explosive hydrogen gas.

Modifications to the aerial work platform are prohibited or permissible only at the approval by

AFTER USE, secure the work platform from unauthorized use by turning the keyswitch off and removing key.

The driving of MEWP’s on the public highway is subject to Regulations made under the Road Traffic Acts.

NEVER elevate the platform or drive

the machine while elevated unless

the machine is on a firm, level

surface.

NEVER position the platform

without first checking for overhead

obstructions or other hazards.

UpRight Powered Access

NEVER climb, stand, or sit on

platform guardrails or midrail.

.

Page 6

1. I

NTRODUCTION

Figure 1. Manual Storage Information 1

S

PECIAL INFORMATION

S

2. G

ENERAL

PECIAL LIMITATIONS

M

ANUAL FORCE

P

LATFORM CAPACITY

B

EAUFORT SCALE

D

ESCRIPTION

Figure 2. Work Platform 3

3. S

AFETY INSPECTION

Figure 3. Battery Fill Button & Valve 4

Figure 4. Lower Control Panel 4

Figure 5. Joystick and Tilt Sensor 6

4. O

PERATION OF THE PLATFORM CONTROLS

U

PPER CONTROL PANEL

Figure 6. Upper Control Panel 7

C

ONTROL FUNCTIONS

Table 1. Platform Controls and Indicators 8

L

OWER CONTROL PANEL

Table 2. Chassis Controls and Indicators 9

Figure 7. Lower Control Panel 9

T

YPICAL OPERATION

C

ONTROLS AND INDICATORS

E

LEVATING

T

RAVEL WITH WORK PLATFORM LOWERED

T

RAVEL WITH WORK PLATFORM ELEVATED

E

MERGENCY

E

MERGENCY

& L

S

ITUATIONS

L

OWERING (BY HAND

OWERING THE

Figure 8. Emergency Lowering - Mast Valve 12

Figure 9. Emergency Lowering - Jib Valve 12

5. T

RANSPORTATION

M

ACHINE

W

EIGHTS

Figure 10. Lifting by Forklift 13

L

IFTING BY CRANE

Figure 11. Lifting by Crane 14

T

RANSPORT BY TRUCK

Figure 12. Securing the platform 15

T

OWING

& W

INCHING VALVES

Figure 13. Valve Block-Towing Valves 16

6. A

FTER USE

& S

TORAGE

A

FTER USE EACH DAY

H

OUR

M

ETER

L

ONG-TERM STORAGE

P

RESERVATION

Figure 14. Battery Disconnect 17

B

7. S

PECIFICATIONS

ATTERIES

D

AILY

M

AINTENANCE

C

MB20N 20

C

ONTENTS

P

W

ORK PLATFORM

11

)

12

HECKLIST

Daily Maintenance Checklist 19

MB26

21

Contents

AGE NUMBER

1

1

1

1

2

2

2

3

7

7

8

9

9

10

10

11

11

13

13

14

15

15

17

17

17

17

17

18

19

Page 7

1. I

This Operation manual is designed to provide instructions and illustrations for the safe

Figure 1: Manual Storage Information

structures outside the work platform.The maximum allowable manual force is limited to

D A N G E R

!

!

W A R N I N G

!

!

C A U T I O N

!

!

D A N G E R

!

!

NTRODUCTION

Indicates an imminently hazardous situation which, if not

avoided, will result in severe injury or death.

1 INTRODUCTION

use and operation of the MB20N & MB26 Work Platform manufactured by Upright

Powered Access Ltd.

The manual MUST be stored in the

box provided in the machine cage,

AT ALL TIMES.

S

PECIAL INFORMATION

Throughout this manual the users attention is drawn to these special warning boxes:

Indicates a potentially hazardous situation which, if not avoided,

could result in severe injury or death.

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

S

PECIAL LIMITATIONS

The purpose of this machine is to provide fast and safe access to difficult to reach

areas.

Refer to the Specification section for the machines access limitations.

Travel with the platform raised is limited to creep speed range.

M

ANUAL FORCE

Manual force is the force applied by the occupants to objects such as walls or other

200 N (45 lbs.) of force per occupant, with a maximum of 400 N (90 lbs.)

DO NOT exceed the maximum manual force.

NEVER exceed the platform capacity.

Page 1

Page 8

2

DANGER

!

!

DANGER

!

!

DANGER

!

!

G

ENERAL

B

EAUFORT

R

ATING

3 3,4~5,4 12,25~19,411.5~17.75 7.5~12.0

4 5,4~8,0 19,4~28,817.75~26.25 12.0~18

5 8,0~10,8 28,8~38,9 26.25~35.5 18~24.25

6 10,8~13,9 38,9~50,0 35.5~45.5 24.5~31

7 13,9~17,2 50,0~61,9 45.5~56.5 31.~38.5

D

ESCRIPTION

P

LATFORM

The Platform is designed to travel with safe working load (SWL) including work tools to

an upper limit of 215 kg (475 lbs).

B

EAUFORT

Never operate the machine when wind speeds exceed 12.5m/s (28 m.p.h.)

[Beaufort scale 6].

M/S KM/H FT./S M.P.H

C

S

W

IND SPEED

APACITY

CALE

G

.

Papers and thin branches move.

Flags wave.

Dust is raised, paper whirls up, and small branches

sway.

Shrubs with leaves start swaying.

Wave crests are apparent in ponds or swamps.

Tree branches move.

Power lines whistle. It is difficult to open an umbrella.

Whole trees sway.

It is difficult to walk against the wind.

ROUND CONDITIONS

2. G

ENERAL

DO NOT use on soft ground or on slopes greater than 2 degrees.

The work platform is NOT intended for use on uneven or rough

terrain.

ONLY operate this machine on FIRM and LEVEL ground.

DO NOT use the lifting mechanism to raise or lower goods or persons

except within the cage and subject to the specified weight limitations.

D

ESCRIPTION

The MB20/26 are self propelled, fast acting aerial work platforms, designed to raise

two operators with hand tools to a platform floor height of 6.00m and 7.76m

respectively. The accessible height is approximately 2.00m above these figures.

The unit offers the ability to reach over obstacles but must be used on firm and level

ground at all times.

DO NOT enter the platform from any structure, rack or other platform.

Page 2

Page 9

3

Work Platform

WARNING

!

!

Elevating Assembly

S

AFETY INSPECTION

Figure 2:

Platform Controller

Safety Drop-bar

Platform

Chassis Controls

Chassis

3. S

DO NOT use the work platform without safety drop-bar in place and

with the safety harness fitted.

AFETY INSPECTION

This Safety Inspection shall be carried out by the owner immediately prior to

transporting this machine.

This Safety Inspection shall also be carried out by the user prior to use each day.

The procedure is to carry out the following 14 checks in order as follows.

1.Remove the rear chassis covers by means of the two top twist-locks and the two liftand-turn catches at the sides. The cover is removed by sliding it backwards and

upwards. Use the central handle provided.

2.Ensure that the mast and jib are fully lowered. Remove the hydraulic oil filler cap and

check that the hydraulic oil level is correct. Oil should be visible on the dip stick. Top

up as necessary using hydraulic oil Viscosity Grade ISO 46.

3.Inspect the chassis area for oil leaks, loose parts, frayed cables and hoses and

structural damage etc. Check that all cable connections to the solenoid valves are

intact.

Page 3

Page 10

3

CAUTION

!

!

S

AFETY INSPECTION

4.Open the Inspection hatches on both sides of the upper mast cover. Check that the AC

mains cable is disconnected from the battery charger. Check the electrolyte level in

each battery cell. Top up as necessary with distilled water only.

5.Use the automated battery top-up system fill the batteries to the correct electrolyte

level. This is done by opening the shut off valve and pressing the green fill button for

approximately 10 seconds, then re-closing the shut-off valve.

Batteries should be examined for cracks, acid leakage and terminal corrosion. Take

corrective action immediately if either check fails.

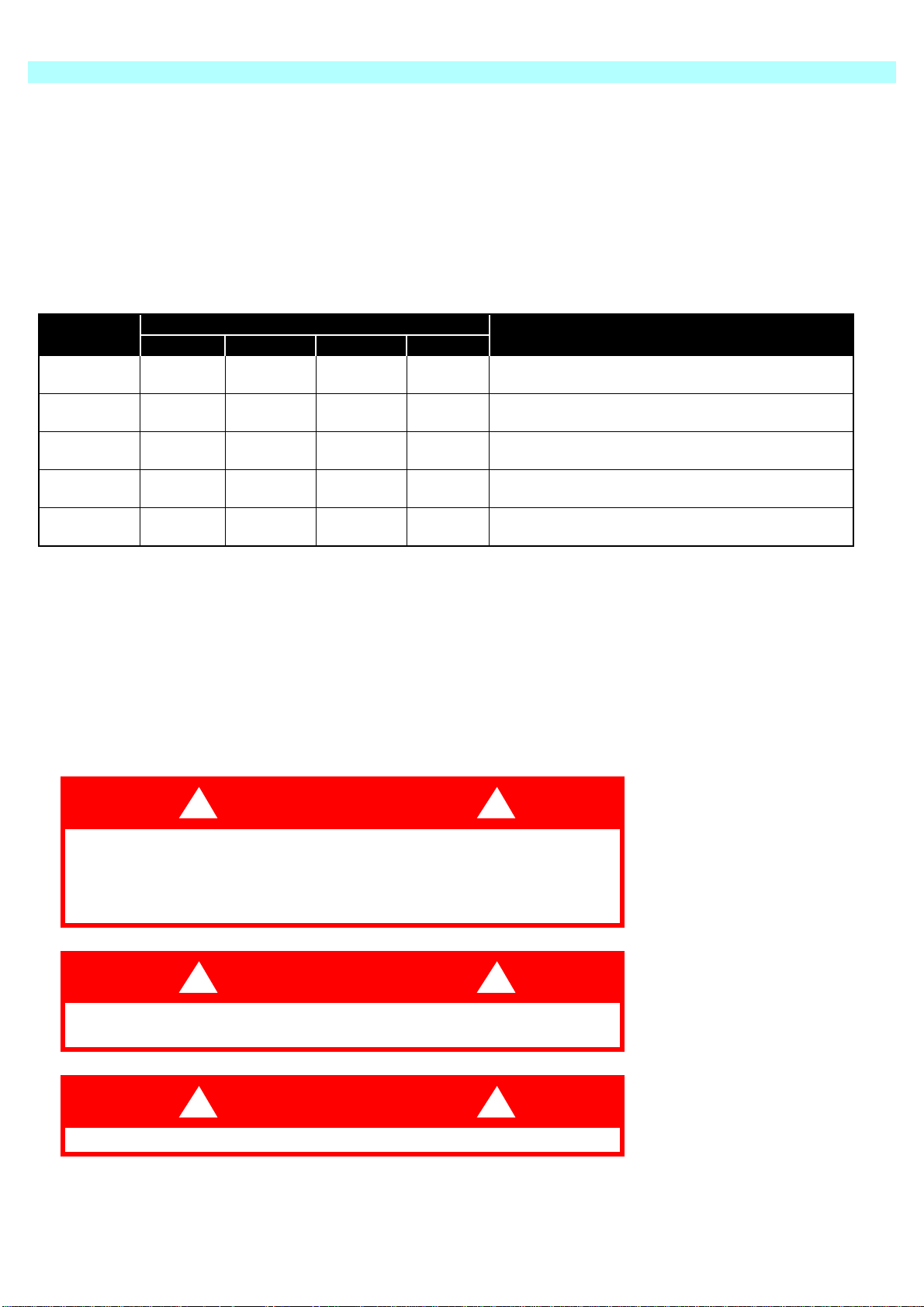

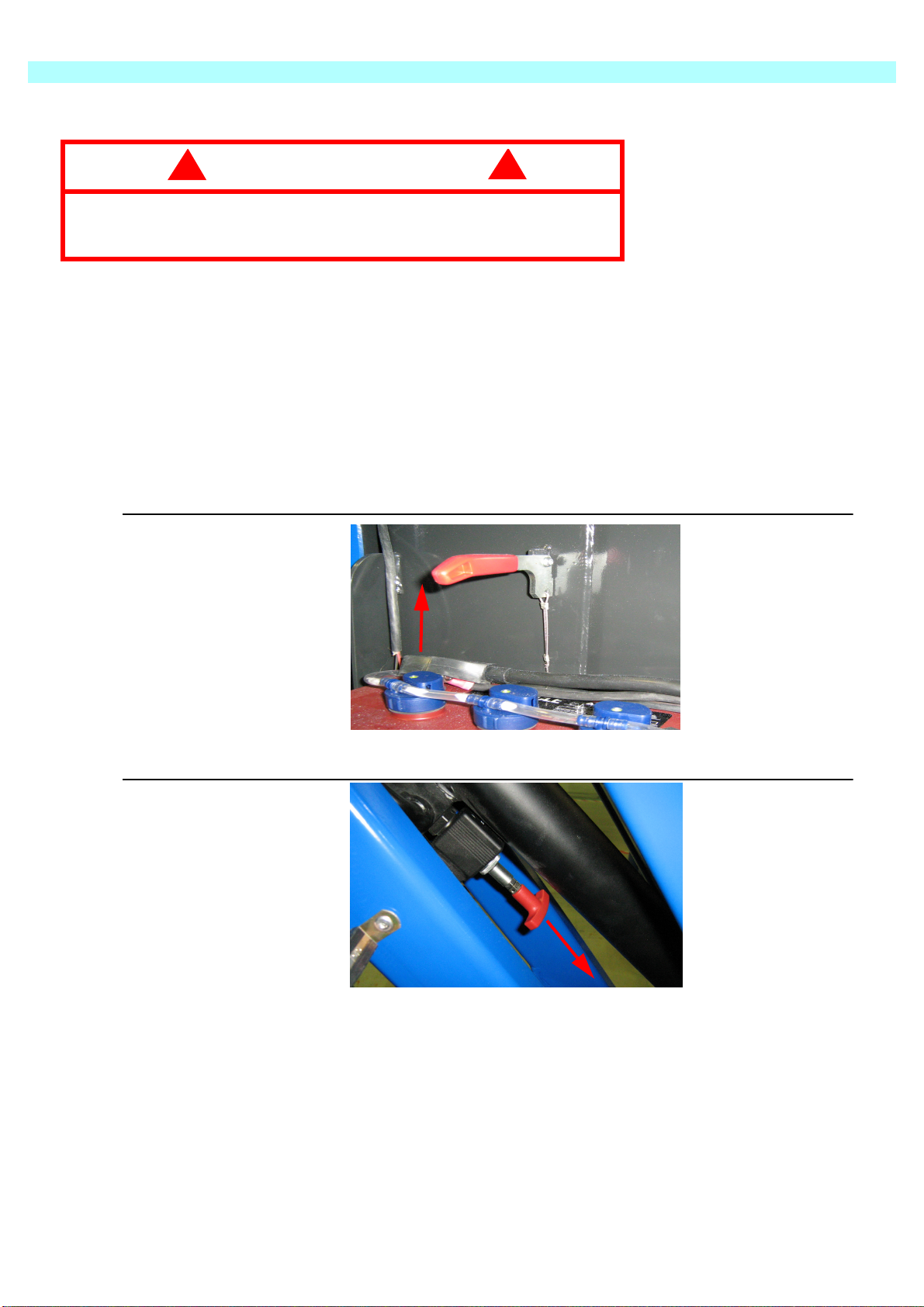

Figure 3: Battery Fill Button & Valve

Battery fill Button

Shut off Valve

In CLOSED Position

Vehicles fitted with the automated battery top-up system with shut

off valve, top up the battery cells with distilled water using the

electrolyte fill button, ensuring that the shut-off valve is open during

the fill and closed after use.

This is the only time this valve should be opened.

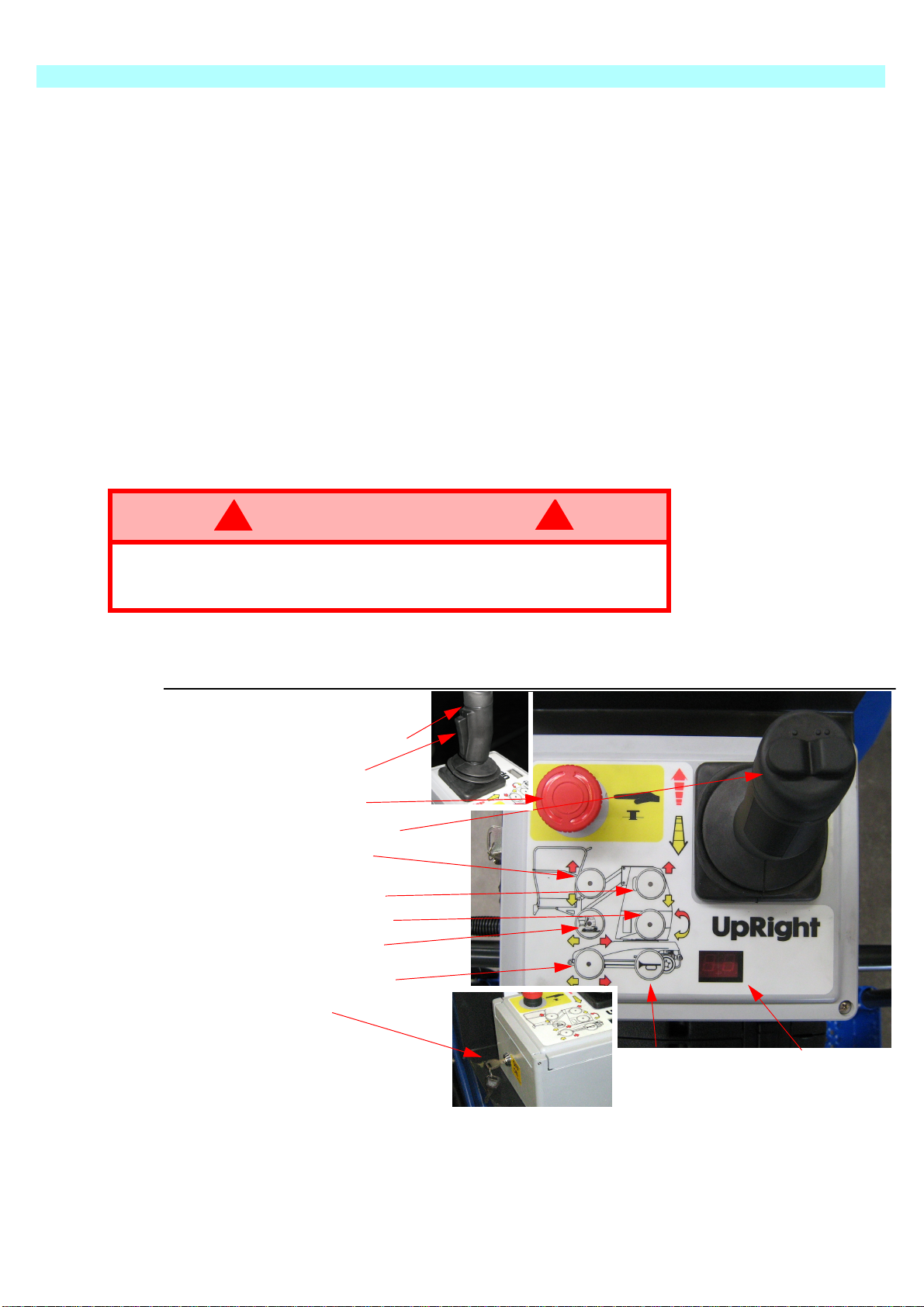

1. Enable Button

2. Analog Rocker

Figure 4: Lower Control Panel

1

2

Page 4

3. Mast Button

4. Jib Button

5. Rotate Button

6. Emergency Stop

3

4

5

6

Page 11

3

buttons on each control station are retracted; turn clockwise if necessary. Carry out the

Check jib operation by extending the jib to its fully elevated position. Check for correct

and check for correct adjustment of each lifting chain as follows. Each chain in the pair

should bear load. Use a hand held spring balance or tensiometer apply a nominal load

(approximately 10kgf.) to either chain in the pair. Apply the load about half way up the

Lowering’ decal label. Check the wear pads for damage or heavy scoring. Replace as

CAUTION

!

!

S

AFETY INSPECTION

6.Prior to operating the functions, check that the upper and lower emergency stop

following function from the Lower Control Station.

NOTE: DO NOT enter the platform at this stage.

7.

routing of the hoses and cables. Check the Emergency Lowering feature of the jib.

Ensure that when the Emergency Lowering lever/button is disengaged, the jib no

longer descends. Return the jib to its rest position using the normal Lower Control

Station.

8.Check mast chains by elevating the masts approximately 30cm above the rest

position. Check for correct routing of the energy chain. Raise the masts to full height

chain. Record the approximate deflection i.e. the offset distance from the mast.

Repeat the measurement on the adjacent chain at the same location. Chains bearing

equal load will deflect equal amounts. Carefully adjust the slack chain until the

deflections are approximately equal. Torque up the locknuts to 70 Nm.

NOTE: Apply a thin layer of grease to the lifting chains with a small paintbrush.

Over-tensioning of either lifting chain will result in unnecessary

lifting of the mast and a subsequent increase in machine stowed

height.

The function of the mast straps is to ensure that masts descend in the correct order

and more importantly, that masts cannot continue to descend if the jib or platform

meets an external obstacle. Raise the masts about 30cm. Check the external mast

clamp screws for tightness. Pull on the short length of each strap and check that they

are secure. Refer to the maintenance manual for instructions on more stringent

periodic checks on these straps.

Check the Emergency Lowering feature of the mast. The lever is located in the upper

mast over. Open the left hand battery inspection hatch and locate the ‘Emergency

necessary.

9.Elevate the jib fully. Using the Lower Control Station, turn the mast assembly through

about 90 degrees. Check the correct routing of the hoses and cables and the correct

smooth operation of the energy chain in its chassis base slide. Continue rotating

through 180 degrees in both directions. Confirm that the rotation stops are intact.

10.STANDARD PLATFORM CONTROLS Repeat the mast, jib and rotate functions from

the Upper Control Station in the platform. Check that pressing the emergency stop

button prevents subsequent operation of the joystick.

Page 5

Page 12

3

WARNING

!

!

S

AFETY INSPECTION

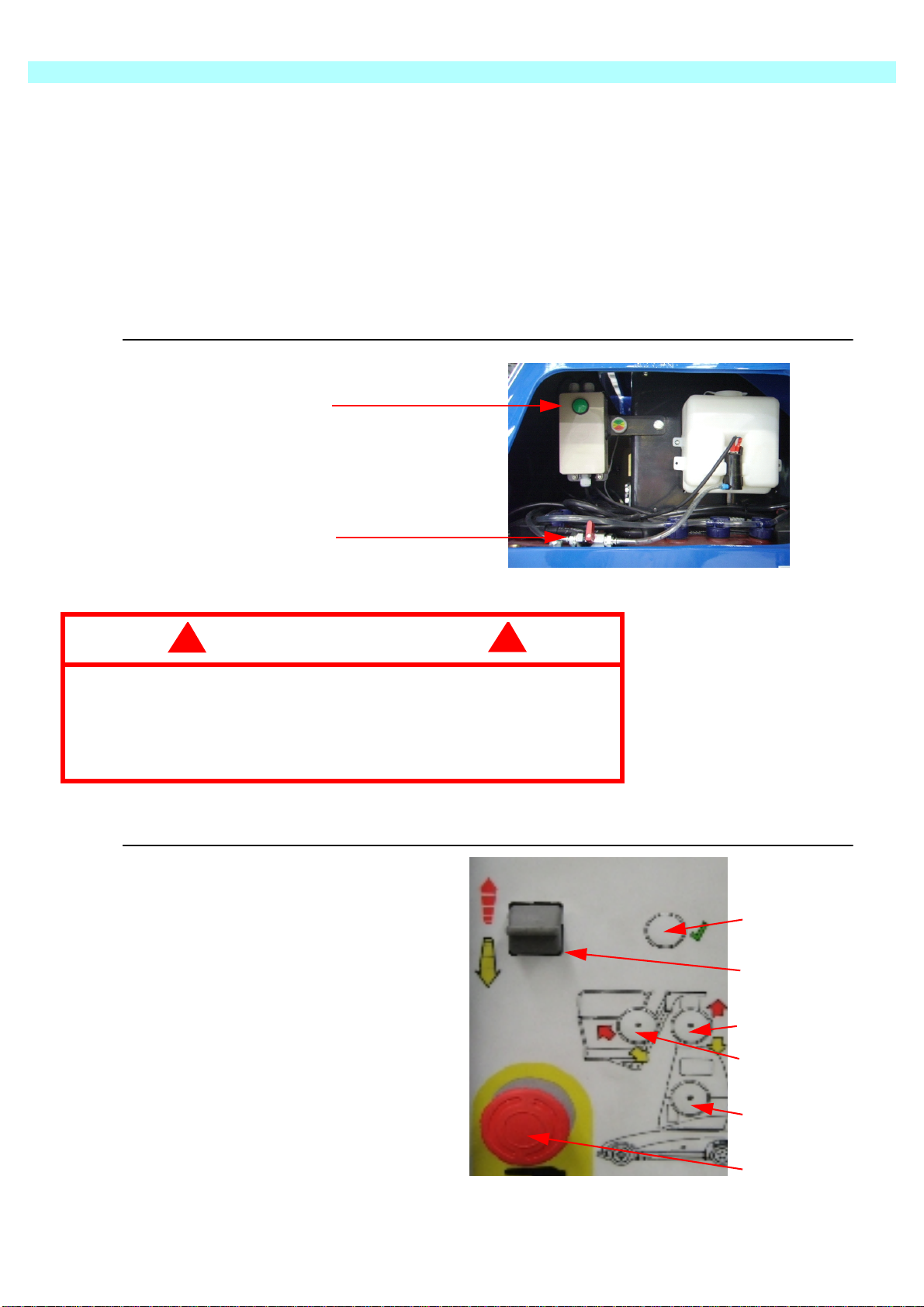

11.EMERGENCY OVER-RIDE While in the platform, ask a colleague to deflect the tilt

alarm sensor body. This sensor is located on the chassis base. The alarm will sound

and all normal function will become interrupted.

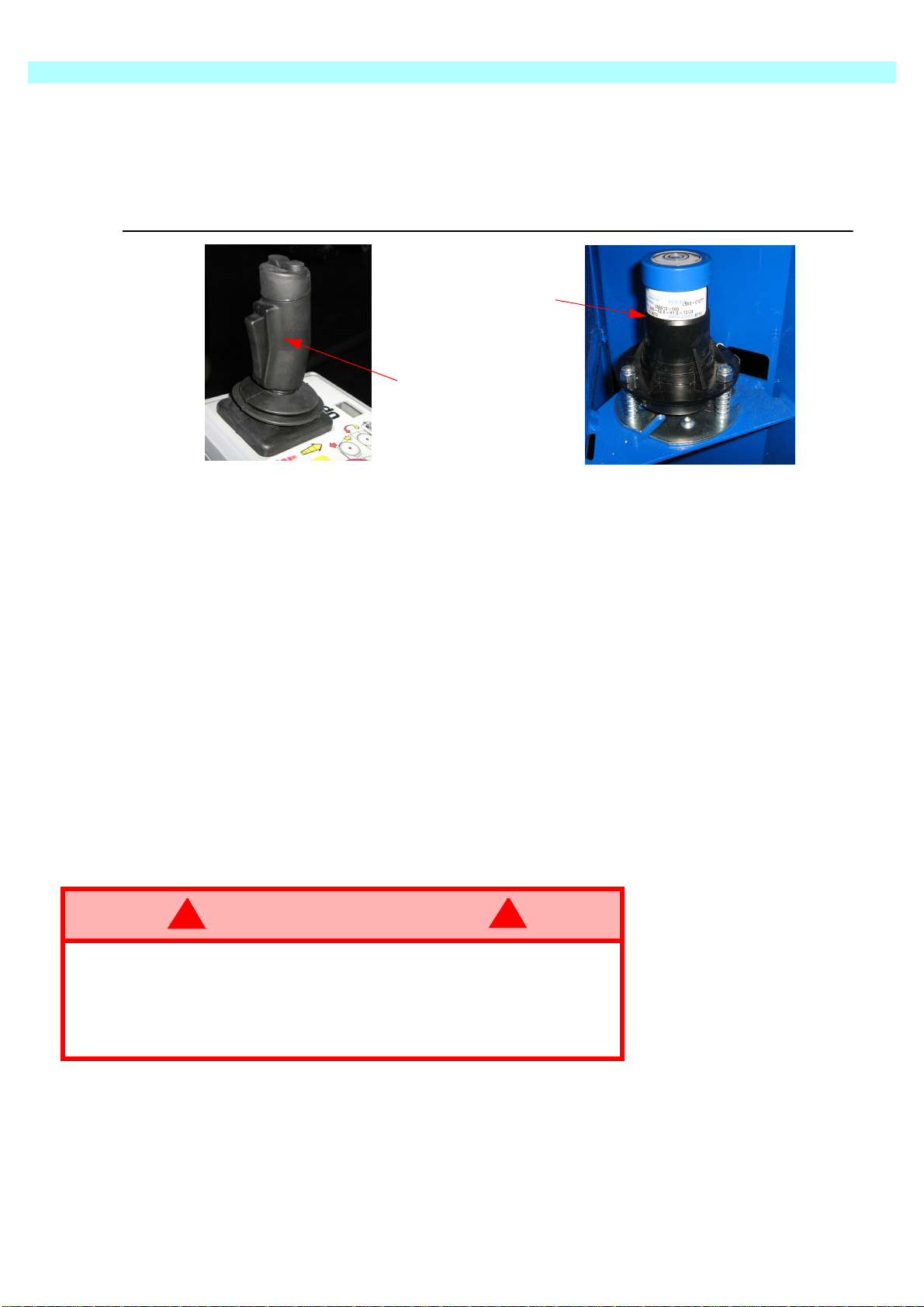

Figure 5: Joystick and Tilt Sensor

Tilt Sensor

Joystick

with Deadman Grip

12.MACHINE TRAVEL - UNELEVATED Travel functions are possible only from the

platform Upper Control Station. As with all such controls, the deadman handgrip switch

must be depressed before any function can operate.

Select Drive on the upper control panel. Pushing back and forward on the joystick

moves the machine backwards and forwards respectively.

The pothole protection will begin to retract immediately. However, full demand speed

will not be realised until the bars are fully raised. This takes about 3 seconds. Check

that the motion alarm DOES sound during travel. Check that the thumb operated

switches on the top of the joystick operates the front wheel steering.

13.MACHINE TRAVEL-ELEVATED While the masts are raised, it is possible to drive and

steer the machine at a much reduced speed. Also note that while the masts are raised,

the pothole protection bars should be fully extended and should remain extended

during slow speed motion of the machine.

The issue of reduced speed while elevated and deployment of the

pothole protection bars is crucial to the safe operation of this

machine.

The machine may not be released or operated unless these

functions operate properly.

14.FINAL PREPARATION Configure the masts and jib to the stowed position. Replace all

machine covers and secure.

NOTE: The machine is now ready for Operation or Transportation.

Page 6

Page 13

4

A safety Interlock Switch or ‘deadman button’ is incorporated into the Joystick. It must

be used to position

Upper Control Panel

WARNING

!

!

O

PERATION OF THE PLATFORM CONTROLS

4. O

PERATION OF THE

The primary (Upper) control box is permanently fitted to the front of the platform. It

features a multi-use joystick which provides proportional control for all the machines

functions. That includes, raising or lowering the mast, raising or lowering the jib,

rotating the mast assembly, and also to drive and steer the machine.

be activated at all times in order to operate any function. This feature allows for onehanded operation.

The secondary (Lower) control box is fitted to the mast cover at arm level. It features

an enable button and selector buttons to provide pre-programmed speeds for all

functions except drive and steering. This control station is used primarily for servicetype operations including pre-operation inspection. It should never

a manned or un-maned platform.

NOTE: It may be used in the event of emergency to lower the manned platform.

NEVER operate the machine from the upper controls until the

platform entrance drop-bar is in the fully lowered position and the

safety harness is fitted.

P

LATFORM

C

ONTROLS

U

PPER

1.Joystick (forward/back)

2.Deadman Grip

3.Emergency Stop

4.Steering Switch (L/R)

5.Jib Select Button

6.Mast Select Button

7.Rotate Select Button

8.Drive (Slow)

9.Drive (Fast)

10.Key Switch

C

ONTROL

P

ANEL

Figure 6:

11. Horn 12. MultiFunction Display

Page 7

Page 14

4

O

PERATION OF THE PLATFORM CONTROLS

C

ONTROL FUNCTIONS

I

TEMS

N

AMES

1 Joystick

F

UNCTION

Refer to the decal logic diagrams for correct direction of

motion.

e.g. If Drive is preselected - pushing forward moves

machine forward.

2 Deadman Grip

3 Emergency Stop

The ‘Deadman’ grip switch on the joystick must be

grasped for any function to operate.

Push this red button at any time to isolate power.

Turn clockwise to reset.

4 Steering Switch Turns the wheels left or right.

5 Jib Select Button Pre-selects the Jib function.

6 Mast Select Button Pre-selects the Mast function.

7 Rotate Select Button Per-selects the Mast Rotate function.

8 Drive (Mast Raised)

9 Drive (Mast Lowered)

Pre-selects the drive function with the mast in the raised

position and for high torque. (i.e. slow speed)

Pre-selects the drive function with the mast in the

lowered position. (i.e. maximum speed)

10 Key Switch

Activates (ON) and De-actives (OFF) all machine

functions.

11 Horn Button Use to warn bystanders or to attract attention.

12 Multi-Function Display Displays the Percentage battery life. (99=Full, 01-Empty)

Table 1: Platform Controls and Indicators

Page 8

Page 15

Lower Control Panel

I

TEMS

L

OWER

N

AMES

C

ONTROL

P

ANEL

4

O

PERATION OF THE PLATFORM CONTROLS

F

UNCTION

1 Enable Button

This button enables the Rocker Switch, and must be

held down during operation

2 Rocker Switch Activates the pre-selected operation, in either direction

3 Mast Select Button Pre-selects the Mast function.

4 Jib Select Button Pre-selects the Jib function.

5 Rotate Select Button Per-selects the Mast Rotate function.

6 Emergency Stop

Table 2: Chassis Controls and Indicators

Push this red button at any time to isolate power.

Turn clockwise to reset.

Figure 7:

1. Enable button

2. Rocker switch

3. Mast selection button

4. Jib selection button

5. Rotate selection button

6. Emergency Stop

T

YPICAL

Raising the mast.

•The Keyswitch located on the Upper Control box must be turned on.

•Select Mast by pressing the Mast button (3)

•Press and hold the enable button (1),

•Activate the Rocker Switch (2) in the direction required.

O

PERATION

1

2

3

4

5

6

Page 9

Page 16

4

WARNING

!

!

WARNING

!

!

O

PERATION OF THE PLATFORM CONTROLS

C

ONTROLS AND INDICATORS

The pre-operation safety checks should be carried out prior to operation. These checks

are detailed in the previous section. Operators who follow these guidelines will become

familiar with the controls and indicators on the machine.

This section summarises the controls and indicators in tabular form and provides more

detailed information.

DO NOT operate the machine from the upper controls until the

platform entrance drop-bar is in the fully lowered position and your

safety harness has been fitted and attached.

E

LEVATING

Before operating the MB20 Work Platform it is imperative that the pre-operation Safety

Inspection has been completed and any deficiencies have been corrected. The

operator must also be fully trained in the use of this machine.

& L

OWERING THE

W

ORK

P

LATFORM

Before beginning any operation, the following checks should be carried out.

ENSURE that no other persons are within 1 metre of the machine.

Be aware of the pothole protection bar hazard on both sides of the

machine.

LOOK up and around for obstructions before performing the lift or

drive functions.

DO NOT overload the platform.

DO NOT operate within 3 metres of any electrical power cables.

THIS WORK PLATFORM IS NOT ELECTRICALLY INSULATED.

NOTE: Chassis controls are for service use only.

1.Enter the Platform through the entrance at the rear of the MB20/26 and ensure that the

drop bar is in position. Raise and lock the entry step by means of the pedal in the

platform.

2.Before using the machine all local Safety Regulations involving helmets and restraining

devices should be observed. Safety harness lanyards, not exceeding 1 metre in length,

should be attached to anchor points in cage floor.

3.Ensure that the ‘ON/OFF Key Switch on the Upper Control Box is turned to the ‘ON’

position and both emergency stop buttons are off (twist clockwise if necessary).

4.Check the Display L.E.D. is illuminated. If not, the battery may need recharging.

5.Check if the audible alarm sounds due to un-level ground. None of the functions can

work if the machine is not level.

Page 10

Page 17

4

Climb into the Platform and check that the Keyswitch is turned to the ‘ON’ position and

Thumb-switch, on top of the Joystick, LEFT or RIGHT to turn the wheels. Observe the

Ensure that the pothole guards remain in the extended (down) position during elevated

In any emergency situation, the immediate action is to push the red “Emergency Stop”

button. This will instantly cut of all electrical power to the controls. The button must be

CAUTION

!

!

O

PERATION OF THE PLATFORM CONTROLS

T

RAVEL WITH

Refer to Tables 1 & 2 for controls and indicators.

1.Verify that both Lower and Upper Control Console Emergency Stop Button is in the

‘ON’ position (turn clockwise to reset).

2.

that the Drive Button is illuminated. Ensure that the drop bar is in position.

3.Check that the route is clear of persons, obstructions, pot holes or ledges and is

capable of supporting the wheel loads. Also, check that the clearances above, below,

and to the side of the Work Platform are sufficient.

4.To steer the MB20/26, activate the Deadman Switch while pushing the Steering

tyres while manoeuvring to ensure correct direction.

NOTE: Steering is not self-centring. The wheels must be returned to the straight ahead

position by operating the Steering Switch.

T

RAVEL WITH

W

W

ORK

ORK

P

LATFORM LOWERED

P

LATFORM

E

LEVATED

If the machine stops driving and the Tilt Alarm sounds, lower the

Platform immediately.

Using the Emergency Override functions, move the machine to a

level location before re-elevating the platform.

Travel with platform elevated ONLY on firm and level surfaces.

Refer to Tables 1 & 2 for controls and indicators.

NOTE: The Work Platform will travel at reduced speed when in the elevated position.

1.Check that the route is clear of persons, obstructions, pot holes or ledges and is

capable of supporting the wheel loads. Also, check that the clearances above, below

and to the side of the Work Platform are sufficient.

2.

travel.

E

MERGENCY

twisted in a clockwise direction in order to recommence control.

However, the switch should be reset only when it is safe to do so.

S

ITUATIONS

If the Audible warning alarm sounds, normal control functions will cease to operate.

This will be due to the following problem;

•The Tilt Sensor has been activated

NOTE: that during emergency operation, controls will operate only at a fixed, slow speed

and will not allow the raising of the Booms. The Booms can only be lowered.

Page 11

Page 18

4

CAUTION

!

!

O

PERATION OF THE PLATFORM CONTROLS

E

MERGENCY

During manual emergency lowering, extreme care must be taken

to ensure that the person carrying out the task is not struck by the

jib or platform structure.

Should the machine become inoperable when elevated request a person on the

ground to lower the platform using the emergency lowering valves. Lower the mast

structure before lowering the jib/platform structure.

Locate the red lever behind the mast cover inspection door on the left hand side of the

machine. By pushing the lever up, the mast will descend fully under gravity. Releasing

the spring-loaded lever will cease this operation immediately if required.

Lower the masts fully before lowering the jib structure.

L

OWERING (BY HAND

)

Figure 8: Emergency Lowering - Mast Valve

Figure 9: Emergency Lowering - Jib Valve

The Jib may be manually lowered by operating the manual release valve located

between the Jib Structure (Figure 9).

M

ANUAL

1.Lower the masts and jib fully before manually slewing the assembly. Press the

Emergency Stop Button to prevent inadvertent powered motion.

2.Locate the opening behind the front right drive wheel. Apply a 7/8 inch socket wrench

with extension bar to the shaft and turn to rotate the elevating assembly. (Turning the

wheel fully to one side will facilitate this operation).

R

OTATION

Page 12

Page 19

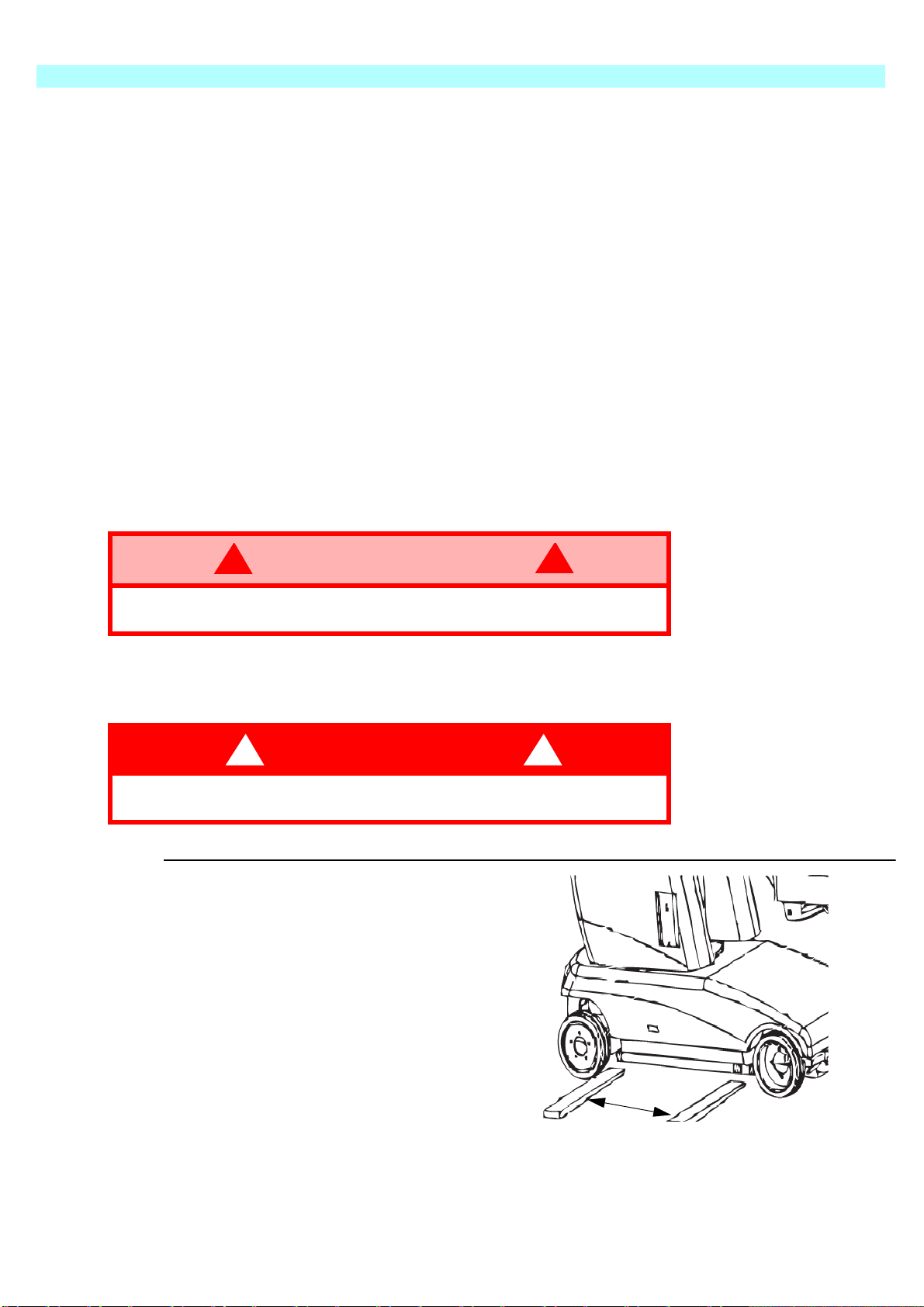

5. T

80 cm above ground and in the plane of the energy chain which is located on the back

cover to the mast. Undo the 4 bolts connecting the ballast to the mast and use a forklift

Figure 10: Lifting by Forklift

WARNING

!

!

DANGER

!

!

RANSPORTATION

5

T

RANSPORTATION

M

ACHINE

Before transporting or lifting the MB20N/26 machine be aware of its weight. It is very

important to realise that the centre of gravity of the stowed machine is approximately

of the mast.

MB20N CE Version= 2550 kg

MB20N US Version= 3000 kg (6615 lbs)

MB26 CE Version = 2650 kg

MB26 US Version = 3150 kg (6945 lbs)

In cases of particular difficulties with lifting or shipping it is possible to remove the

single block ballast from the machine. Remove the 13 screws connecting the ballast

to remove the ballast block. The ballast block weighs 850 kg on the CE version and

1300kg on the US (ANSI) version.

W

EIGHTS

This work must not be carried out without the prior written permission

of UpRight Powered Access.

L

IFTING BY FORK

Forklifting is for transport only. See machine weights and ensure

that the forklift is of adequate capacity.

Adjust the forks so that

the minimum clearance

between them is 800mm

as shown above.

Approach the machine

from either side but place

the fork as close as

possible to the front wheel

as shown.

-L

IFT

Front

800mm

Page 13

Page 20

5

CAUTION

!

!

T

RANSPORTATION

1.Never approach the MB20 from the front or rear while fork lifting.

2.Use maximum forklift tilt as soon as possible when raising the MB20/26.

3.If travelling over sloped or uneven ground it is strongly recommended to temporarily tie

the MB20 jib mount structure to the forklift mast as a safety precaution.

4.The MB20/26 may be lifted by forklift subject to the following strict procedure.

5.Ensure that the mast and jib are fully stowed and that the pothole bars are fully

retracted (raised).

L

IFTING

The MB20/26 may be lifted by an overhead hoist/crane subject to the following strict

procedure.

Raise the jib to clear the lifting straps as shown.

Use 4 separate lifting straps connected to a spreader beam. DO NOT use a lesser

number of threaded straps as these could slip and lead to instability. The

recommended minimum capacity of EACH of the 4 straps is 2 tonne and the minimum

length of each strap is 2 metres. Damage to the covers and/or cage rails can occur if a

spreader beam is not deployed during a crane lift.

BY C

RANE

Apply the straps via 1 tonne shackles to each of the 4 lifting lugs on the chassis. See

Figure 9: below.

Figure 11: Lifting by Crane

DO NOT apply lifting straps to any other part of the machine.

Page 14

Page 21

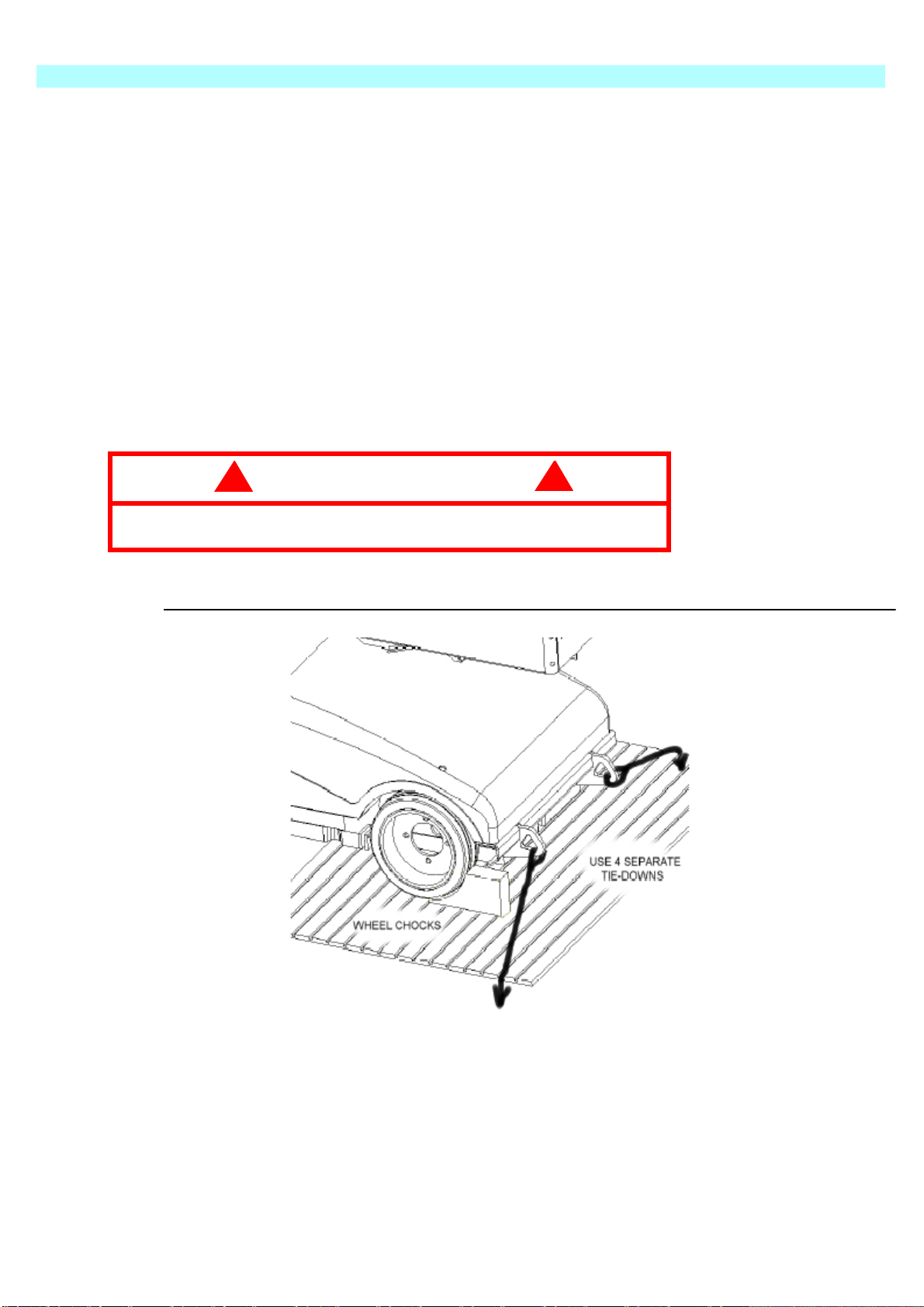

T

Because of its high gradeability, the machine can be driven under its own power on to

Figure 12: Securing the Platform

The fail-safe brakes are automatically applied when the machine comes to a stop or in

To tow the vehicle or to winch it on to a truck it is necessary to hydraulically bypass the

CAUTION

!

!

RANSPORT BY TRUCK

The MB20/26 can be carried on a suitably rated transportation vehicle or trailer.

a standard loading ramp (Up to 14 degrees).

It is recommended to reverse the machine up on to the truck thus forward travelling

down the ramp at the delivery point. Winch-assisted loading is allowable for larger

slopes, however, operate the trucks assist winch at minimum speed to avoid overpressurising the hydraulic system in the machine.

When the MB20/26 is on the truck or trailer it should then be made secure by:-

1.Chocking the wheels.

2.Securing with adequate chains or straps to the lifting lugs on the chassis.

DO NOT loop straps through the cage, ladder or jib as this could

cause permanent structural damage during transportation.

5

T

RANSPORTATION

T

OWING

the event of total power loss due to low battery or malfunction of the hydraulic drive

system.

control valves and release these brakes.

& W

INCHING

V

ALVES

Page 15

Page 22

5

WARNING

!

!

T

RANSPORTATION

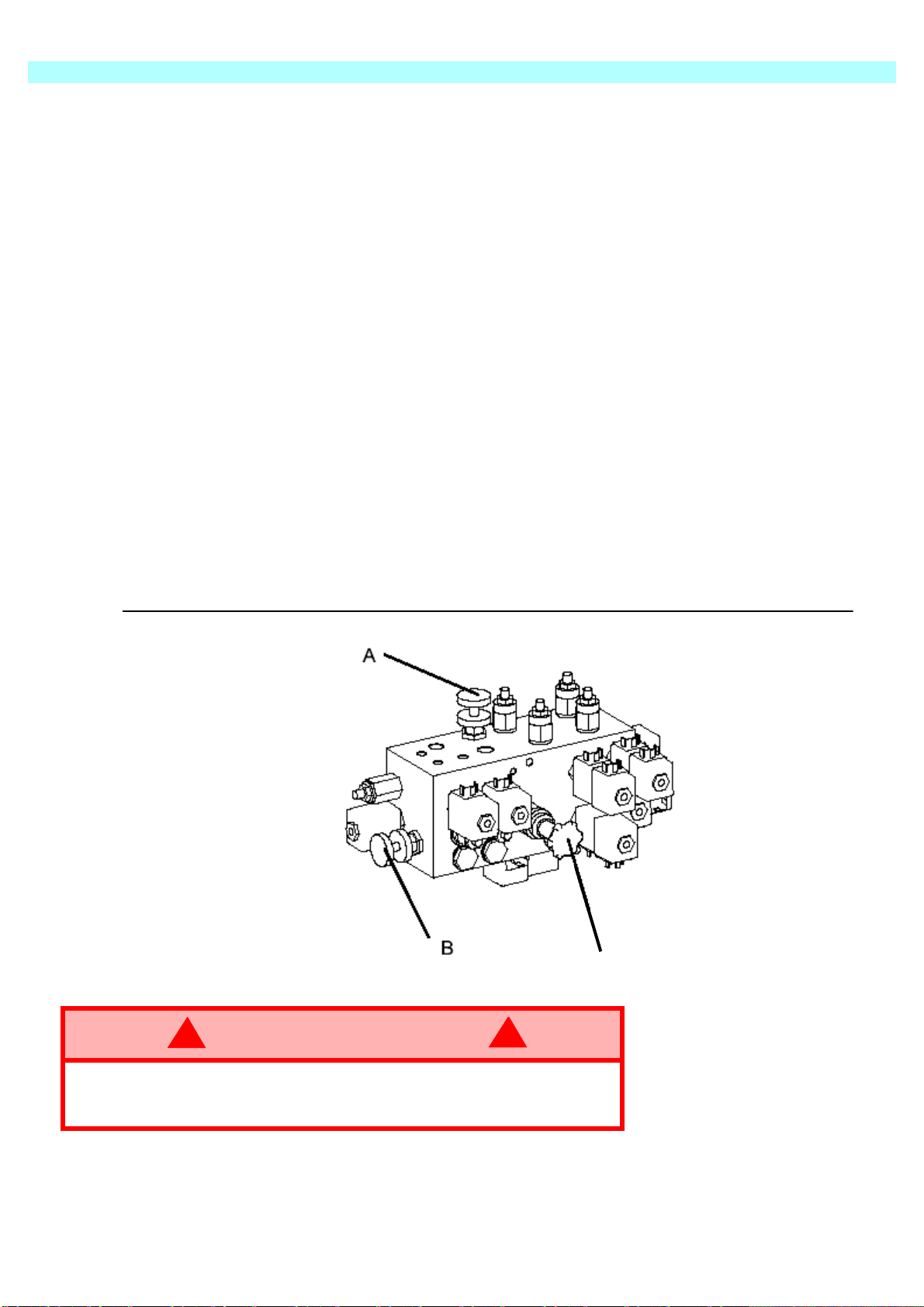

Proceed as follows:Refer to the valve block drawing Figure 13.

1.Fully lower the jib boom and the mast sections. Rotate the mast into the stowed

position.

2.Turn the Upper Control Box to the OFF position and remove the key.

3.Remove the rear GRP cover from the chassis and locate the hydraulic control valve

block.

4.The hand valve marked ‘A’ should be turned fully clockwise to close. The hand valve

marked ‘B’ should be turned fully anti-clockwise to open.

5.Operate the red handpump a number of times to develop sufficient pressure to

‘separate’ the internal brake disks. These brakes are integral with the hydraulic drive

motors.

NOTE: The machine can now be safely towed or winched.

6.On completion of towing/winching, reverse the position of the rotary hand valves ‘A’

and ‘B’. The handpump becomes inoperative when the valves are returned to their

normal position.

Figure 13: Valve Block-Towing Valves

Handpump

RISK OF SERIOUS INJURY. Releasing the brakes will cause the

machine to move uncontrollably on a slope. Damaging momentum

can be developed due to the large mass of a slow moving machine

Page 16

Page 23

6

Fill the hydraulic tank to operating level with the platform fully lowered. Fluid should be

Battery Disconnect

A

FTER USE

& S

TORAGE

6. A

FTER

U

SE

& S

A

1.Ensure that the platform (masts and jib) are fully lowered.

2.Park the machine on firm and level ground, never on a grass surface.

3.Turn the key switch to the OFF position and remove.

4.Put the batteries on charge.

H

1.Climb into the basket (with the machine powered up)

2.Push the platform emergency stop button.

3.Hold down the following buttons, Horn and Lift.

4.While holding the buttons twist the emergency stop button to return power to the

5.“hr.” will now be displayed on the read-out, Pressing the right turn button will scroll

TORAGE

FTER

OUR

To access the hour meter function perform the following steps.

machine.

through the accumulated hours two digits at a time. For example, if pressing the right

turn button once displays “20”, pressing it a 2nd time displays “58”, and pressing it a

3rd time displays “hr.”, the elapsed time of operation is 2058 hours.

U

SE EACH

M

ETER

D

AY

L

ONG

1.Clean and touch up damaged paint surfaces.

2.

3.Coat exposed portions of cylinder rods with a preservative such as multipurpose

4.Coat all exposed un-painted metal surfaces with a light oil or other preservative.

5.Cover the machine with tarpaulin if possible. If this is not available it is advisable to

-T

ERM

P

RESERVATION

visible on the tank dip stick.

grease and wrap with barrier material.

cover the mast and jib mount area as a minimum. This will prevent moisture from

entering the mast, battery and chassis areas.

S

TORAGE

Figure 14:

Battery disconnect

is located behind the

controller

Page 17

Page 24

6

WARNING

!

!

A

FTER USE

RISK OF SERIOUS INJURY. Take particular care when handling

batteries. Acid spills can cause severe burns or blindness.

DO NOT store batteries close to naked flames or close to steel

fabrication areas.

& S

TORAGE

B

ATTERIES

1.Disconnect the batteries at the quick connect plug and socket. This is located in the

chassis between the controller and the hydraulic tank.

2.Disconnect the battery leads and tape up the lead terminals to ensure insulation.

Better battery life and efficiency is achieved if the batteries are used consistently. It is

therefore recommended that the batteries are used elsewhere if the machine is to be

unused for an extended period (2 weeks or more).

Page 18

Page 25

D

WARNING

!

!

DAILY PREVENTATIVE MAINTENANCE CHECKLIST

AILY

P

REVENTATIVE

M

AINTENANCE

Daily daily preventative maintenance will prevent abnormal wear and prolong the life

of all systems. The inspection & maintenance schedule should be performed at the

specified intervals.

Inspection and maintenance shall be performed by personnel who are trained and

familiar with mechanical and electrical procedures.

Before performing preventative maintenance, familiarize yourself with

the operation of the machine.

Always block the elevating assembly whenever it is necessary to

perform maintenance while the platform is elevated.

This Daily checklist has been designed for machine service and maintenance.

Please photocopy this page and use the checklist when inspecting the machine.

C

HECKLIST

M

AINTENANCE TABLE

C

OMPONENT

B

ATTERY

C

HASSIS

C

ONTROL CABLE

C

ONTROLLER

D

RIVE MOTORS

E

LEVATING ASSEMBLY

E

MERGENCY LOWERING

S

YSTEM

E

NTIRE UNIT

H

YDRAULIC FLUID

H

YDRAULIC PUMP

H

YDRAULIC SYSTEM

L

ABELS

P

LATFORM DECK AND

R

AILS

T

YRES AND WHEELS

Y = Yes/Acceptable

N = No/Not Acceptable

R = Repaired/Acceptable

Check electrolyte level.

Check battery cable condition.

Check hoses for pinch or rubbing points.

Check welds for cracks.

Check the exterior of the cable for pinching, binding or wear.

Check switch operation.

Check for operation and leaks.

Inspect for structural cracks.

Operate the emergency lowering valve & check for serviceability.

Check for and repair collision damage.

Check fluid level.

Check for hose fitting leaks.

Check for leaks.

Check for peeling, missing, or unreadable labels & replace.

Check welds for cracks.

Check for damage.

P

K

EY

I

NSPECTION OR SERVICE

REVENTATIVE MAINTENANCE

Date:_______________________________________

Owner:_____________________________________

Model No:___________________________________

Serial No:___________________________________

Serviced By:_________________________________

R

EPORT

Y N R

Table 1: Daily Maintenance Checklist

Page 19

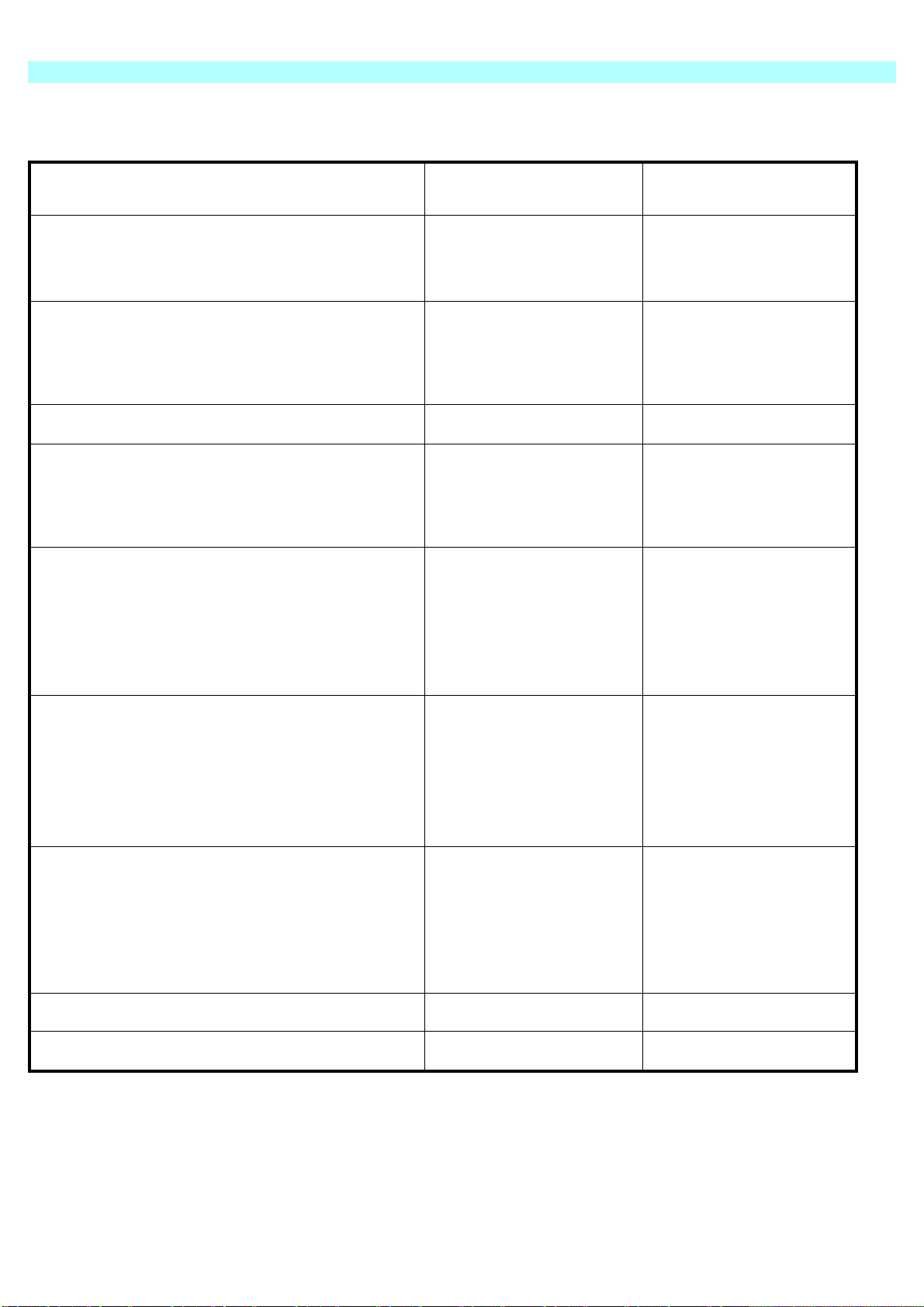

Page 26

S

PECIFICATIONS

S

PECIFICATIONS

MB20

P

ARAMETER

Duty Cycle

Platform Size

Maximum Platform Capacity

Maximum No. of Persons

Heights:

Maximum Platform Height

Maximum Working Height

Platform Height at Maximum Outreach

Maximum Working Outreach

Stowed Dimensions:

Length

Width

Height

Chassis Ground Clearance

Wheelbase x Wheel Gauge

Rotation

Gross Vehicle Weight

Maximum Drive Speed - Stowed

Maximum Drive Speed - Elevated

Maximum Gradeability

Outside Turning Radius

N

MB20N EU V

45%over 8 hour cycle

780mm x 745mm

215kg.

6.00m

8.00m

5.04m

2.64M 8.66ft.

2.222m

0.815m

1.990m

90mm

1465mm x 708mm

360deg non-continuous

2570kg.

3.03 km/h

0.70km/h

1.85m

ERSION

2

25%

MB20N US V

35%over 8 hour cycle

31in. x 29in.

425lbs.

19.69ft.

26.25ft.

16.54ft.

7.97ft.

3.54in.

4.81ft. x 2.32ft.

360 deg non-continuous

6674lbs.

1.9mph.

0.43mph

6.10ft.

ERSION

2

32in.

6.50ft

25%

Electrical:

Power Source

System Voltage

Battery Charger

Control System

Hydraulic System:

System Relief Setting

Hydraulic Oil Type

Hydraulic Tank Capacity

Brakes

Wheel & Tyres 13.5in. x 4.0

Noise Pressure Level

4 x 6V @ 375Ah Battery

24 Volt DC

24V x 30A, 220V 50Hz AC

Single Joystick, Function

Selector, DC Motor Controller

220bar

ISO VG46

20 litres

Spring applied hydraulically

released

solid, Non-Marking

68dB (A) at Control Station 68dB (A) at Control Station

4 x 6V @ 375Ah Battery

24 Volt DC

24V x 30A, 110V 60Hz AC

Single Joystick, Function

Selector, DC Motor Controller

3190psi

ISO VG46

5.3 gallons (U.S.)

Spring applied hydraulically

released

13.5in. x 4.0

solid, Non-Marking

Page 20

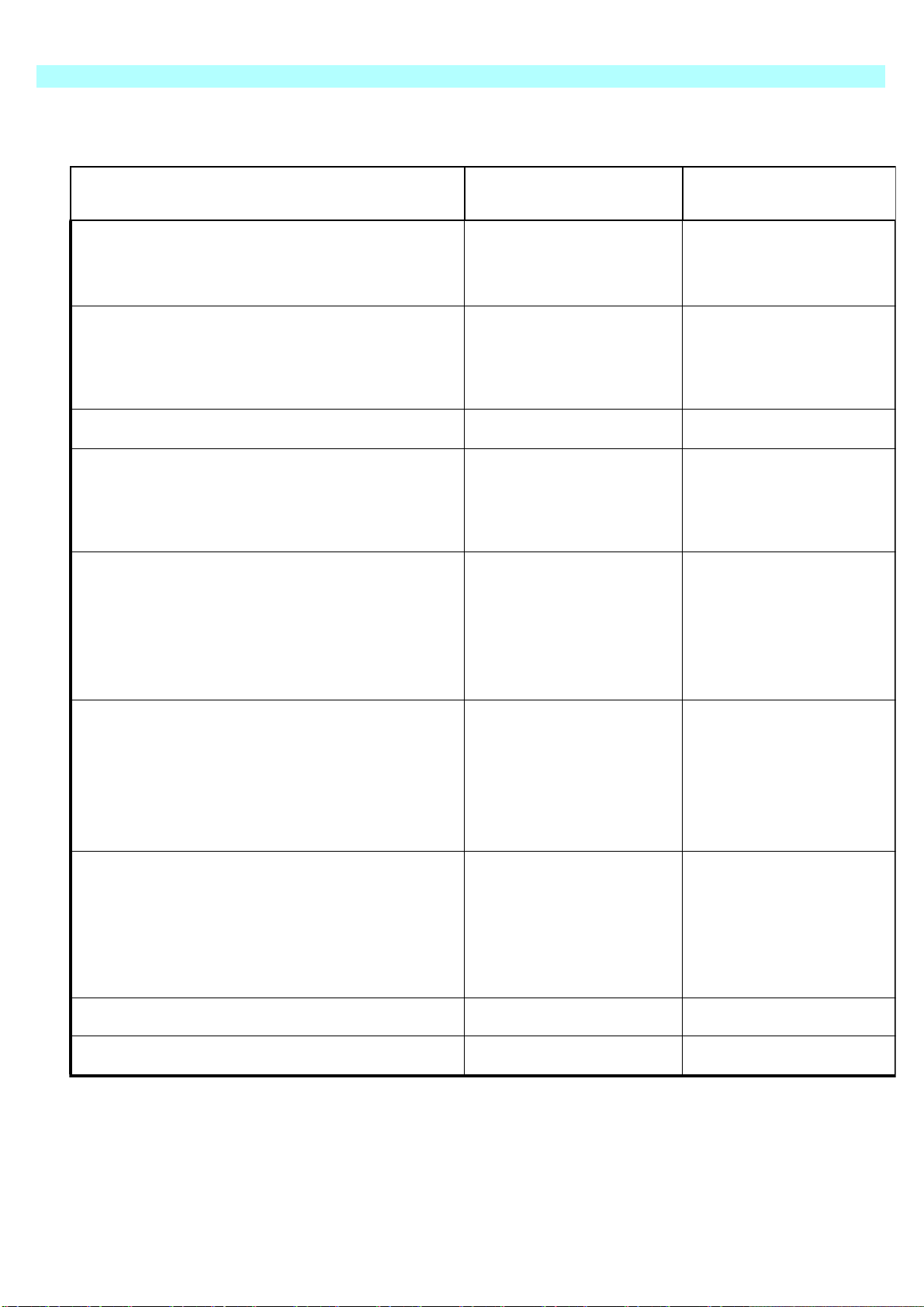

Page 27

S

PECIFICATIONS

MB26

P

ARAMETER

MB26 EU V

ERSION

S

PECIFICATIONS

MB26 US V

ERSION

Duty Cycle

Platform Size

Maximum Platform Capacity

Maximum No. of Persons

Heights:

Maximum Platform Height

Maximum Working Height

Platform Height at Maximum Outreach

Maximum Working Outreach

Stowed Dimensions:

Length

Width

Height

Chassis Ground Clearance

Wheelbase x Wheel Gauge

Rotation

Gross Vehicle Weight

Maximum Drive Speed - Stowed

Maximum Drive Speed - Elevated

Maximum Gradeability

Outside Turning Radius

45%over 8 hour cycle

780mm x 745mm

215kg.

2

7.79m

9.79m

6.51m

3m 10ft.

2.825m

0.990m

1.990m

90mm

1465mm x 890mm

360deg non-continuous

2672kg.

3.03 km/h

0.70km/h

25%

2.10m

35%over 8 hour cycle

31in. x 29in.

425lbs.

2

26.00ft.

32.00ft.

21.36ft.

9.3ft.

39in.

6.54ft.

3.54in.

4.81ft. x 2.93ft.

360 deg non-continuous

7012lbs.

1.9mph.

0.43mph

25%

6.90ft.

Electrical:

Power Source

System Voltage

Battery Charger

Control System

Hydraulic System:

System Relief Setting

Hydraulic Oil Type

Hydraulic Tank Capacity

Brakes

Wheel & Tyres 13.5in x 4.0

Noise Pressure Level

4 x 6V @ 375Ah Battery

24 Volt DC

24V x 30A, 220V 50Hz AC

Single Joystick, Function

Selector, DC Motor Controller

220bar

ISO VG46

18 litres

Spring applied hydraulically

released

solid, Non-Marking

68dB (A) at Control Station 68dB (A) at Control Station

4 x 6V @ 375Ah Battery

24 Volt DC

24V x 30A, 110V 60Hz AC

Single Joystick, Function

Selector, DC Motor Controller

3190psi

ISO VG46

4.7 gallons (U.S.)

Spring applied hydraulically

released

13.5in x 4.0

solid, Non-Marking

Page 21

Page 28

Notizen:

Page 29

MB 20N/26

Seriennummern MB20N 132 - aktuelles Modell

MB26 246 - aktuelles Modell

DEUTSCH

Wenn Sie bei UpRight Powered Access Serviceoder Teileinformationen anfordern, halten Sie

die MODELL- und SERIENNUMMERN vom

Typenschild der Maschine bereit. Falls das

Typenschild fehlen sollte, ist die

SERIENNUMMER auch auf dem Chassis über

dem vorderen Achsschenkel eingeprägt.

Typenschild

Das Typenschild der Arbeitsplattform

befindet sich außen an der VORDERSEITE

des Chassis

Wenn Sie bei UpRight Powered Access Service- oder Teileinformationen anfordern,

halten Sie die MODELL- und SERIENNUMMERN vom Typenschild der Maschine bereit.

Die Arbeitsplattform MB20N/26 erfüllt bzw. übertrifft die Anforderungen folgender Normen:

prEn280:2001 und ANSI A92.5 (1999)

Page 30

Notizen:

Page 31

S

! !

WARNUNG

Alle Bediener müssen die Sicherheitsregeln und Betriebsanleitungen gründlich durchlesen,

verstehen und befolgen, bevor sie an irgendeiner UpRight-Hocharbeitsbühne Wartungsarbeiten

ausführen oder die Arbeitsbühne in Betrieb nehmen.

Sicherheitsregeln

Elektroschockgefahr Kippgefahr Kollisionsgefahr

DIESE MASCHINE IST NICHT

ISOLIERT!

EINSATZ DER HOCHARBEITSBÜHNE: Diese Hocharbeitsbühne dient dazu, Personen und Werkzeuge sowie die für die jeweilige Arbeit

erforderlichen Materialien zu transportieren. Sie wurde speziell für Reparatur- und Montagearbeiten sowie für Einsatzbereiche k

die sich oberhalb der Mitarbeiter befinden, sodass die Mitarbeiter nach oben gerichtet arbeiten müssen (z. B. Decken, Kräne,

Dachstrukturen, Gebäude etc.). Jede andere Verwendung der Hocharbeitsbühne ist strikt verboten!

DIESE HOCHARBEITSBÜHNE IST NICHT ISOLIERT! Aus diesem Grund muss zwingend ein Sicherheitsabstand zu allen leitfähigen

Teilen der elektrischen Ausrüstung eingehalten werden!

Die angegebene zulässige Höchstlast darf nicht überschritten werden!Nähere Informationen hierzu finden Sie im Abschnitt

“Beschränkungen” auf Seite 4.

Es ist strikt verboten, die Hocharbeitsbühne als Hubwerkzeug oder Kran einzusetzen (d. h. um Lasten von unten nach oben oder von

oben nach unten zu befördern).

Die für diese Maschine zulässige manuelle Kraft NIEMALS überschreiten.Nähere Informationen hierzu finden Sie im Abschnitt

“Beschränkungen” auf Seite 4.

Lasten immer gleichmäßig auf der Plattform VERTEILEN.

Vor Inbetriebnahme der Maschine IMMER ZUERST die Aufstellfläche im Arbeitsbereich auf Gefahren wie Bodenlöcher, ausgelaufene

Flüssigkeiten, Bodenerhebungen, Kanten oder Schutt untersuchen und diese umgehen bzw. beseitigen.

Maschine nur auf Oberflächen IN BETRIEB NEHMEN, die die zulässigen Radlasten aufnehmen können.

Maschine NIEMALS in Betrieb nehmen, wenn die tatsächliche Windgeschwindigkeit höher ist als die Windgeschwindigkeit, für die die

Maschine ausgelegt ist. Nähere Informationen hierzu finden Sie im Abschnitt “Beaufort-Skala” auf Seite 4.

IM NOTFALL NOT-AUS-Schalter drücken, um alle strombetriebenen Funktionen zu deaktivieren.

WENN EIN ALARM ERTÖNT, während die Plattform ausgefahren wird, Plattform ANHALTEN und vorsichtig einfahren (absenken).

Maschine auf feste, ebene Oberfläche fahren.

Auf das Schutzgeländer der Plattform zu klettern, auf Gebäuden, Stahl- oder vorgefertigten Betonstrukturen zu stehen oder von der

Plattform aus darauf zu klettern etc. ist verboten!

Das Schwingtor oder andere Komponenten des Schutzgeländers zu demontieren ist verboten! Vergewissern Sie sich immer, dass das

Schwingtor geschlossen und sicher verriegelt ist!

Es ist verboten, das Schwingtor geöffnet zu halten (z. B. mit Befestigungsgurten), wenn die Arbeitsplattform ausgefahren wird!

Die Höhe oder Reichweite der Plattform durch Anbringen von Leitern, Gerüsten oder ähnlichen Vorrichtungen zu vergrößern ist

verboten!

IMMER ZUERST die Hubvorrichtung blockieren, bevor bei ausgefahrener Plattform Wartungs- oder Instandhaltungsarbeiten an der

Maschine durchgeführt werden.

Maschine vor jedem Gebrauch sorgfältig auf Risse an Schweißstellen, lose oder fehlende Beschläge, Leckagen in der

Hydraulikvorrichtung, gelöste Kabelverbindungen und beschädigte Kabel oder Schläuche UNTERSUCHEN.

Vor Gebrauch SICHERSTELLEN, dass alle Bezeichnungsschilder ordnungsgemäß angebracht und vollständig lesbar sind.

NIEMALS eine Maschine benutzen, die beschädigt ist, nicht ordnungsgemäß funktioniert oder deren Bezeichnungsschilder

Beschädigungen aufweisen oder sogar ganz fehlen.

Sicherheitseinrichtungen zu umgehen ist verboten und stellt eine Gefahr für alle Personen dar, die sich auf der Hocharbeitsbühne und in

deren Arbeitsbereich befinden.

Batterien NIEMALS in der Nähe von Funkenquellen oder offenen Flammen aufladen. Beim Aufladen von Batterien wird explosives

Wasserstoffgas freigesetzt.

Änderungen an der Hocharbeitsbühne sind verboten bzw. nur mit ausdrücklicher Genehmigung von

NACH GEBRAUCH ist die Hocharbeitsbühne gegen unbefugten Gebrauch durch Dritte zu sichern. Hierzu müssen beide

Schlüsselschalter auf “Aus” gestellt und die Schlüssel abgezogen werden.

NIEMALS die Plattform ausfahren

oder die Maschine mit

ausgefahrener Plattform

fortbewegen, wenn sich die

Maschine nicht auf einer festen,

ebenen Fläche befindet.

Plattform NIEMALS in Position

bringen, ohne vorher

sicherzustellen, dass der Bereich

über der Plattform frei von

Hindernissen und anderen

Gefahren ist.

UpRight zulässig.

turzgefahr

NIEMALS auf das obere oder

mittlere Gestänge des

Plattformgeländers klettern

und auch nicht darauf stehen

oder sitzen.

onzipiert,

Page 32

I

NHALT

1. E

INFÜHRUNG

Abbildung 1. Informationen zum Aufbewahren

der Betriebsanleitung 1

S

2. A

LLGEMEINE

PEZIELLE INFORMATIONEN

B

ESONDERE EINSCHRÄNKUNGEN

M

ANUELLE

P

LATTFORMKAPAZITÄT

B

EAUFORT-SKALA

B

ESCHREIBUNG

K

RAFT

Abbildung 2. Arbeitsplattform 3

3. S

ICHERHEITSPRÜFUNG

Abbildung 3. Fülltaste und Ventil für Batterie 4

Abbildung 4. Untere Bedienkonsole 4

Abbildung 5. Joystick und Neigungssensor 6

4. B

ETÄTIGUNG DER BEDIENELEMENTE

O

BERE BEDIENKONSOLE

DER PLATTFORM

Abbildung 6. Obere Bedienkonsole 7

S

TEUERFUNKTIONEN

Tabelle 1. Bedienelemente und Anzeigen der Plattform

U

NTERE BEDIENKONSOLE

Tabelle 2. Bedienelemente und Anzeigen am Chassis 9

Abbildung 7. Untere Bedienkonsole 9

T

YPISCHER BETRIEB

B

EDIENELEMENTE

A

NHEBEN UND ABSENKEN DER ARBEITSPLATTFORM

F

AHREN MIT ABGESENKTER ARBEITSPLATTFORM

F

AHREN MIT ANGEHOBENER

N

OTFÄLLE

A

BSENKUNG IM NOTFALL (VON HAND

UND ANZEIGEN

A

RBEITSPLATTFORM

Abbildung 8. Absenkung im Notfall (Mastventil) 12

Abbildung 9. Absenkung im Notfall (Auslegerventil) 12

5. T

RANSPORT

M

ASCHINENGEWICHTE

Abbildung 10. Anheben mit einem Gabelstapler 13

A

NHEBEN MIT EINEM KRAN

Abbildung 11. Anheben mit einem Kran 14

T

RANSPORT MIT EINEM LASTWAGEN

Abbildung 12. Sichern der Plattform 15

S

CHLEPP- UND

W

INDENVENTILE

Abbildung 13. Schleppventile am Ventilblock 16

6. A

RBEITEN NACH DEM BETRIEB UND VOR DER LAGERUNG

N

ACH DEM TÄGLICHEN GEBRAUCH

B

ETRIEBSSTUNDENZÄHLER

L

ANGZEITLAGERUNG

K

ONSERVIERUNG

Abbildung 14. Abklemmen der Batterie 17

B

ATTERIEN

C

HECKLISTE FÜR TÄGLICHE WARTUNGSARBEITEN

Tabelle 1. Checkliste für tägliche Wartungsarbeiten 19

7. T

ECHNISCHE DATEN

MB20N 20

MB26

21

11

)

12

S

Contents

EITE

1

1

1

1

2

2

2

3

7

7

8

8

9

9

10

10

11

11

13

13

14

15

15

17

17

17

17

17

18

19

Page 33

1 Einführung

1. E

INFÜHRUNG

Diese Betriebsanleitung enthält Anweisungen und Bilder zur sicheren Verwendung

und Bedienung der Arbeitsplattformen MB20N und MB26 von Upright Powered

Access Ltd.

Abbildung 1: Informationen zum Aufbewahren der Betriebsanleitung

Die Betriebsanleitung MUSS

IMMER in dem dafür

vorgesehenen Fach im

Maschinenkäfig aufbewahrt

werden.

S

PEZIELLE

In diesem Handbuch sollen die folgenden speziellen Rahmen die Aufmerksamkeit des

Benutzers auf sich ziehen:

GEFAHR

! !

Weist auf eine unmittelbare, gefährliche Situation hin, die, falls

sie nicht vermieden wird, zu schweren Verletzungen oder zum

Tod führen kann.

I

NFORMATIONEN

!

WARNUNG

Weist auf eine mögliche, gefährliche Situation hin, die, falls sie

nicht vermieden wird, zu schweren Verletzungen oder zum Tod

führen könnte.

!

VORSICHT

Weist auf eine mögliche, gefährliche Situation hin, die, falls sie

nicht vermieden wird, zu leichten oder mittleren Verletzungen

führen kann.

B

ESONDERE

Zweck dieser Maschine ist es, schnellen und sicheren Zugriff auf Bereiche zu

ermöglichen, die nur schwer zugänglich sind.

Informationen zu den Zugriffsbeschränkungen der Maschine finden Sie im Abschnitt

"Technische Daten".

Bei angehobener Plattform kann die Maschine nur mit sehr geringer Geschwindigkeit

bewegt werden.

M

ANUELLE

Unter manueller Kraft versteht man die Kraft, die von den Insassen auf Objekte wie

Wände oder andere Strukturen außerhalb der Arbeitsplattform angewandt wird. Die

maximale manuelle Kraft ist auf 200 N pro Insasse begrenzt und darf insgesamt

maximal 400 N betragen.

E

INSCHRÄNKUNGEN

K

RAFT

!

!

GEFAHR

! !

Überschreiten Sie NICHT die maximale manuelle Kraft.

Überschreiten Sie NIEMALS die Plattformkapazität.

Seite 1

Page 34

2

A

LLGEMEINE BESCHREIBUNG

P

LATTFORMKAPAZITÄT

Die Plattform ist dafür ausgelegt, sich mit einer sicheren Arbeitslast

Arbeitswerkzeugen bis zu einem maximalen Gewicht von

B

EAUFORT

Setzen Sie die Maschine niemals bei Windgeschwindigkeiten von über 12,5 m ein

[Beaufort-Skala 6].

W

B

EAUFORT

INSTUFUNG

E

-

M/S KM/H FT./S M.P.H

3 3,4~5,4 12,25~19,4 11,5~17,75 7,5~12,0

4 5,4~8,0 19,4~28,8 17,75~26,25 12,0~18

5 8,0~10,8 28,8~38,9 26,25~35,5 18~24,25

6 10,8~13,9 38,9~50,0 35,5~45,5 24,5~31

7 13,9~17,2 50,0~61,9 45,5~56,5 31,0~38,5

INDGESCHWINDIGKEIT

-S

KALA

(SAL)

einschließlich

215 kg

B

.

Papier und dünne Äste bewegen sich.

Fahnen bewegen sich im Wind.

Staub und Papier werden aufgewirbelt, kleine Äste

wiegen sich hin und her.

Laubsträucher beginnen, sich hin und her zu bewegen.

In Teichen oder Sümpfen werden Wellenkämme sichtbar.

Äste in Bäumen bewegen sich.

Stromleitungen pfeifen. Ein Regenschirm lässt sich nur

noch schwer öffnen.

Ganze Bäume wiegen sich hin und her.

Es ist schwierig, gegen den Wind zu laufen.

ODENBEDINGUNGEN

zu bewegen.

2. A

LLGEMEINE

Verwenden Sie die Einheit NICHT auf weichem Untergrund oder an

Steigungen mit über 2 Grad Gefälle.

Die Arbeitsplattform ist NICHT für die Verwendung auf unebenem

oder rauem Gelände vorgesehen.

Bedienen Sie diese Maschine NUR auf FESTEM und EBENEM

Untergrund.

Wenn Sie mit dem Hebemechanismus Gegenstände oder Personen

anheben, MÜSSEN sich diese im Käfig befinden. Die angegebene

Gewichtsbeschränkung darf nicht überschritten werden.

B

ESCHREIBUNG

Bei den MB20/26 handelt es sich um schnell bewegliche Arbeitsplattformen mit

eigenem Antrieb, mit denen zwei Bediener mit Handwerkzeugen auf eine

Plattformhöhe von 6,00 m bzw. 7,76 m angehoben werden können. Die maximale

Zugriffshöhe liegt bei etwa 2,00 m über diesen Angaben.

Die Einheit ermöglicht es, Hindernisse zu überwinden, muss jedoch beim Einsatz stets

auf festem und ebenen Untergrund stehen.

GEFAHR

! !

GEFAHR

! !

Seite 2

GEFAHR

! !

Steigen Sie NICHT von einer anderen Konstruktion, einem Gerüst

oder einer anderen Plattform auf die Plattform.

Page 35

Hubeinheit

3

S

ICHERHEITSPRÜFUNG

Abbildung 2: Arbeitsplattform

Steuerung

der Plattform

Sicherungsstange

Plattform

Bedienelemente

für das Chassis

Chassis

3. S

!

WARNUNG

Verwenden Sie die Arbeitsplattform NICHT ohne installierte

Sicherungsstange. Auch das Sicherheitsgeschirr muss stets

angelegt sein.

ICHERHEITSPRÜFUNG

Diese Sicherheitsprüfung kann vom Eigentümer unmittelbar vor dem Transport dieser

Maschine durchgeführt werden.

Diese Sicherheitsprüfung kann vom Benutzer auch täglich vor Benutzung der

Maschine durchgeführt werden.

Für die Prüfung müssen die folgenden 14 Schritte in der angegebenen Reihenfolge

ausgeführt werden.

1. Entfernen Sie die hinteren Chassisabdeckungen, indem Sie die beiden oberen

Verriegelungszapfen und die beiden Hebe-Dreh-Verschlüsse an den Seiten lösen. Die

Abdeckung lässt sich durch Schieben nach hinten und oben entfernen. Verwenden Sie

hierfür den zentral angebrachten Griff.

2. Vergewissern Sie sich, dass Mast und Ausleger ganz eingefahren sind. Nehmen Sie

die Abdeckung des Öleinfüllstutzens ab, und überprüfen Sie den Hydraulikölstand. Auf

dem Ölmessstab muss Öl sichtbar sein. Füllen Sie gegebenenfalls Hydrauliköl mit

dem Viskositätsgrad ISO 46 nach.

!

3. Überprüfen Sie den Chassisbereich auf Öllecks, lose Teile, durchgescheuerte Kabel

und Schläuche sowie strukturelle Schäden. Achten Sie außerdem darauf, dass alle

Kabelanschlüsse zu den Magnetventilen intakt sind.

Seite 3

Page 36

3

S

ICHERHEITSPRÜFUNG

Absperrventil

In GESCHLOSSENER

Position

4. Öffnen Sie die Inspektionsluken auf beiden Seiten der oberen Mastabdeckung.

Vergewissern Sie sich, dass das Netzanschlusskabel nicht am Batterieladegerät

angeschlossen ist. Überprüfen Sie den Elektrolytstand in allen Batteriezellen. Füllen

Sie gegebenenfalls destilliertes Wasser nach.

5. Verwenden Sie das automatische Batterieauffüllsystem, um den erforderlichen

Elektrolytstand wiederherzustellen. Öffnen Sie hierfür das Absperrventil, und drücken

Sie etwa 10 Sekunden lang auf die grüne Fülltaste. Schließen Sie anschließend das

Absperrventil.

Die Batterien müssen auf Risse, austretende Säure und korrodierte Klemmen

überprüft werden. Beheben Sie eventuell festgestellte Schäden sofort.

Abbildung 3: Fülltaste und Ventil für Batterie

Fülltaste für Batterie

!

VORSICHT

!

Füllen Sie die Batteriezellen bei Fahrzeugen, die mit einem

automatischen Batteriefüllsystem mit Absperrventil ausgestattet

sind, mit Hilfe der Elektrolytfülltaste mit destilliertem Wasser auf.

Achten Sie dabei darauf, dass das Absperrventil während der

Befüllung geöffnet ist, und schließen Sie es nach dem Auffüllen

wieder.

Das Ventil darf nur zu diesem Zweck geöffnet werden.

1. Aktivierungsschalter

2. Analoger Wippschalter

3. Mastschalter

4. Auslegerschalter

Abbildung 4: Untere Bedienkonsole

1

2

3

4

Seite 4

5. Drehschalter

6. Not-Aus-Schalter

5

6

Page 37

3

S

ICHERHEITSPRÜFUNG

6. Überprüfen Sie vor dem Aktivieren der Funktionen, dass die oberen und unteren

Not-Aus-Schalter an allen Bedienstationen zurückgezogen sind. Drehen Sie diese

gegebenenfalls im Uhrzeigersinn. Aktivieren Sie die folgenden Funktionen von der

unteren Bedienstation aus.

HINWEIS: Betreten Sie in dieser Phase NICHT die Plattform.

7. Überprüfen Sie die Auslegerfunktion, indem Sie den Ausleger ganz nach oben fahren.

Vergewissern Sie sich, dass alle Schläuche und Kabel richtig verlegt sind. Überprüfen

Sie die Notabsenkfunktion des Auslegers. Vergewissern Sie sich, dass sich der

Ausleger bei gelöstem Notabsenkhebel/bei gelöstem Notabsenkschalter nicht weiter

nach unten bewegt. Bringen Sie den Ausleger über die normale untere Bedienstation

wieder in seine Ausgangsposition.

8. Überprüfen Sie die Mastketten, indem Sie die Masten etwa 30 cm über ihre

Ausgangsposition bringen. Vergewissern Sie sich, dass die Energiekette richtig verlegt

ist. Fahren Sie die Masten bis zur maximalen Höhe aus, und prüfen Sie, ob alle

Hubketten richtig ausgerichtet sind. Gehen Sie dazu wie folgt vor: Jedes Kettenpaar

muss belastet sein. Verwenden Sie eine Handfederwaage oder ein Tensiometer, und

wenden Sie eine nominale Last (etwa 10 kg) auf beide Ketten des Kettenpaars an.

Wenden Sie die Last etwa in der Mitte der Kette an. Notieren Sie die ungefähre

Durchbiegung, d. h. den Versatzabstand vom Mast. Wiederholen Sie die Messung an

der benachbarten Kette an derselben Stelle. Gleich belastete Ketten weisen dieselbe

Durchbiegung auf. Stellen Sie die losere Kette so ein, dass die Durchbiegungen in

etwa gleich sind. Ziehen Sie die Sicherungsmuttern mit 70 Nm fest.

HINWEIS: Tragen Sie mit einem kleinen Pinsel eine dünne Fettschicht auf die Hubketten

auf.

!

VORSICHT

Eine Überspannung einer der Hubketten führt zu einer unnötigen

Anhebung des Masts, wodurch die Maschine im eingefahrenen

Zustand eine größere Höhe aufweist.

Die Mastriemen sollen zum einen sicherstellen, dass sich die Masten in der richtigen

Reihenfolge absenken. Viel wichtiger ist jedoch, dass sie dafür sorgen, dass sich die

Masten nicht weiter absenken können, wenn Ausleger oder Plattform auf ein externes

Hindernis treffen. Heben Sie die Masten etwa 30 cm an. Überprüfen Sie die äußeren

Mastklemmschrauben auf festen Sitz. Ziehen Sie am kürzeren Teil der Riemen, und

überprüfen Sie, ob diese sicher sitzen. Anweisungen zur regelmäßigen, genaueren

Überprüfung dieser Riemen finden Sie im Wartungshandbuch.

Überprüfen Sie die Notabsenkfunktion des Masts. Der Hebel befindet sich am oberen

Mastende. Öffnen Sie die linke Batterieprüfluke, und suchen Sie das Etikett mit der

Aufschrift "Emergency Lowering" (Notabsenkung). Überprüfen Sie die Abriebpolster

auf Beschädigungen oder starke Abnutzung. Ersetzen Sie diese bei Bedarf.

9. Heben Sie den Ausleger vollständig an. Drehen Sie die gesamte Masteinheit mit Hilfe

der unteren Bedienstation um etwa 90 Grad. Überprüfen Sie, ob die Schläuche und

Kabel richtig verlegt sind und ob die Energiekette in der Schiene der Chassisbasis

problemlos läuft. Drehen Sie den Mast weiter um 180 Grad in beide Richtungen.

Vergewissern Sie sich, dass die Drehanschläge intakt sind.

!

10. STANDARDBEDIENELEMENTE FÜR DIE PLATTFORM Wiederholen Sie die Mast-,

Ausleger- und Drehfunktionen von der oberen Bedienstation der Plattform. Überprüfen

Sie, ob nach dem Drücken des Not-Aus-Schalters der Joystick funktionslos wird.

Seite 5

Page 38

3

S

ICHERHEITSPRÜFUNG

11. NOTFALLÜBERSTEUERUNG Bitten Sie einen Kollegen, während Sie auf der

Plattform stehen, den Neigungsalarmsensor zu kippen. Dieser Sensor befindet sich in

der Chassisbasis. Der Alarm ertönt, und alle normalen Funktionen werden

unterbrochen.

Abbildung 5: Joystick und Neigungssensor

Neigungssensor

Joystick

mit Totmanngriff

12. MASCHINENBEWEGUNG – OHNE ANGEHOBENE PLATTFORM

Die Bewegungsfunktionen können nur von der oberen Bedienstation der Plattform aus

aktiviert werden. Wie bei solchen Bedienelementen üblich, muss zunächst der

Totmannschalter gedrückt werden, bevor sich die Funktionen aktivieren lassen.

Wählen Sie in der oberen Bedienkonsole die Option "Drive" (Antrieb) aus. Durch

Drücken des Joysticks nach vorne oder hinten bewegt sich die Maschine in Vorwärtsoder Rückwärtsrichtung.

Die Kippschutzbalken werden sofort eingefahren. Die maximale Geschwindigkeit kann

erst erreicht werden, wenn die Balken ganz angehoben sind. Dies dauert etwa 3

Sekunden. Überprüfen Sie, dass der Bewegungsalarm ERTÖNT, während die

Maschine bewegt wird. Stellen Sie sicher, dass die mit dem Daumen betätigten

Schalter oben am Joystick die Vorderräder lenken.

13. MASCHINENBEWEGUNG – BEI ANGEHOBENER PLATTFORM Mit angehobenen

Masten kann die Maschine mit wesentlich geringerer Geschwindigkeit gefahren und

gelenkt werden. Beachten Sie auch, dass bei angehobenen Masten die

Kippschutzbalken vollständig ausgefahren sein müssen – selbst dann, wenn die

Maschine mit langsamer Geschwindigkeit bewegt wird.

!

WARNUNG

Diese Geschwindigkeitsverringerung bei angehobenen Masten

und das Ausfahren der Kippschutzbalken ist ein wesentlicher

Bestandteil der Sicherheitsfunktionen dieser Maschine.

Die Maschine darf nicht betätigt werden, wenn diese Funktionen

nicht einwandfrei ausgeführt werden können.

!

Seite 6

14. LETZTE VORBEREITUNGEN Fahren Sie die Masten und den Ausleger ein. Bringen

Sie alle Maschinenabdeckungen wieder an, und befestigen Sie diese.

HINWEIS: Die Maschine kann jetzt betrieben oder transportiert werden.

Page 39

4

B

ETÄTIGUNG DER BEDIENELEMENTE

DER PLATTFORM

4. B

ETÄTIGUNG

DER

B

EDIENELEMENTE

Das primäre (obere) Bedienfeld ist an der Vorderseite der Plattform befestigt. Es ist mit

einem Multifunktions-Joystick ausgestattet, der eine proportionale Betätigung aller

Maschinenfunktionen ermöglicht. Hierzu gehören das Anheben oder Absenken des

Masts, das Anheben oder Absenken des Auslegers, das Drehen der Masteinheit

sowie das Fahren und Lenken der Maschine.

Der Joystick ist mit einem Sicherheitsverriegelungsschalter oder "Totmannschalter"

ausgestattet. Dieser muss stets aktiviert werden, um eine Funktion auszuführen.

Diese Funktion ermöglicht die Bedienung mit einer Hand.

Das sekundäre (untere) Bedienfeld ist an der Mastabdeckung auf Armhöhe

angebracht. Es ist mit einem Aktivierungsschalter und Wahlschaltern ausgestattet, die

vorprogrammierte Geschwindigkeiten für alle Funktionen zur Verfügung stellen, mit

Ausnahme von Fahren und Lenken. Diese Bedienstation wird vor allem für den

Wartungsbetrieb verwendet. Hierzu zählt auch die Überprüfung vor der

Inbetriebnahme. Sie darf niemals zum Positionieren einer bemannten oder

unbemannten Plattform verwendet werden.

HINWEIS: Sie kann im Notfall zum Absenken der bemannten Plattform verwendet

werden.

DER

P

LATTFORM

!

WARNUNG

Bedienen Sie die Maschine NUR über die oberen Bedienelemente,

wenn die Sicherungsstange am Eingang der Plattform vollständig

abgesenkt und das Sicherheitsgeschirr angelegt ist.

O

BERE

1. Joystick (vorwärts/rückwärts)

2. Totmanngriff

3. Not-Aus-Schalter

4. Lenkschalter (L/R)

5. Wahlschalter Ausleger

6. Wahlschalter Mast

7. Wahlschalter Drehen

8. Antrieb (langsam)

B

EDIENKONSOLE

!

Abbildung 6: Obere Bedienkonsole

9. Antrieb (schnell)

10. Schlüsselschalter

11. Hupe 12. MultifunktionsDisplay

Seite 7

Page 40

4

B

ETÄTIGUNG DER BEDIENELEMENTE DER PLATTFORM

S

TEUERFUNKTIONEN

E

LEMENT

B

EZEICHNUNG

1Joystick

F

UNKTION

Die richtige Bewegungsrichtung entnehmen Sie bitte den

aufgeklebten Logikdiagrammen.

Bei Auswahl von "Drive" (Antrieb) bewegt sich die

Maschine beispielsweise in Vorwärtsrichtung, wenn der

Joystick nach vorne gedrückt wird.

2 Totmanngriff

Der "Totmannschalter" am Joystick muss festgehalten

werden, damit sich die Funktionen aktivieren lassen.

Drücken Sie diesen roten Schalter jederzeit, wenn Sie die

3 Not-Aus-Schalter

Stromversorgung unterbrechen möchten.

Drehen Sie ihn im Uhrzeigersinn, um ihn zurückzusetzen.

4 Lenkschalter Dreht die Räder nach links oder rechts.

5 Wahlschalter Ausleger Dient zur Vorauswahl der Auslegerfunktion.

6 Wahlschalter Mast Dient zur Vorauswahl der Mastfunktion.

7 Wahlschalter Drehen Dient zur Vorauswahl der Drehfunktion.

Dient zur Vorauswahl der Fahrfunktion mit angehobenem

8 Antrieb (Mast angehoben)

Mast und mit hohem Drehmoment (d. h. niedrige

Geschwindigkeit)

9 Antrieb (Mast abgesenkt)

10 Schlüsselschalter

11 Hupe

12 Multifunktions-Display

Tabelle 1: Bedienelemente und Anzeigen der Plattform

Seite 8

Dient zur Vorauswahl der Fahrfunktion mit abgesenktem

Mast (d. h. maximale Geschwindigkeit)

Aktiviert (ON) und deaktiviert (OFF) alle

Maschinenfunktionen.

Dient zum Warnen anderer Personen oder dazu, deren

Aufmerksamkeit zu wecken.

Zeigt die Batterielebensdauer in Prozent an. (99=Voll,

01=Leer)

Page 41

U

NTERE

E

LEMENT

B

EZEICHNUNG

1 Aktivierungsschalter

4

B

B

EDIENKONSOLE

ETÄTIGUNG DER BEDIENELEMENTE

F

UNKTION

DER PLATTFORM

Mit diesem Schalter wird der Wippschalter aktiviert.

Dieser muss während des Betriebs gedrückt gehalten

werden.

2 Wippschalter

Aktiviert die vorab ausgewählte Funktion in eine der

beiden Richtungen.

3 Wahlschalter Mast Dient zur Vorauswahl der Mastfunktion.

4 Wahlschalter Ausleger Dient zur Vorauswahl der Auslegerfunktion.

5 Wahlschalter Drehen Dient zur Vorauswahl der Drehfunktion.

Drücken Sie diesen roten Schalter jederzeit, wenn Sie

6 Not-Aus-Schalter

die Stromversorgung unterbrechen möchten.

Drehen Sie ihn im Uhrzeigersinn, um ihn

zurückzusetzen.

Tabelle 2: Bedienelemente und Anzeigen am Chassis

Abbildung 7: Untere Bedienkonsole

1. Aktivierungsschalter

2. Wippschalter

3. Wahlschalter Mast

4. Wahlschalter Ausleger

5. Wahlschalter Drehen

6. Not-Aus-Schalter

T

YPISCHER

Anheben des Masts.

• Der Schlüsselschalter im oberen Bedienfeld muss eingeschaltet sein.

• Wählen Sie den Mastschalter (3) aus.

• Halten Sie den Aktivierungsschalter gedrückt (1).

• Aktivieren Sie den Wippschalter (2) in der gewünschten Richtung.

B

ETRIEB

1

2

3

4

5

6

Seite 9

Page 42

4

B

ETÄTIGUNG DER BEDIENELEMENTE DER PLATTFORM

B

EDIENELEMENTE

Die Sicherheitsprüfungen vor der Inbetriebnahme müssen vorgenommen werden,

bevor die Maschine verwendet wird. Diese Prüfungen sind im vorherigen Abschnitt

näher beschrieben. Bediener, die diesen Richtlinien folgen, können sich gleichzeitig

mit den Bedienelementen und Anzeigen der Maschine vertraut machen.

In diesem Abschnitt sind die Bedienelemente und Anzeigen in Tabellenform aufgeführt

und werden anschließend ausführlicher erläutert.

UND

A

NZEIGEN

!

WARNUNG

Bedienen Sie die Maschine NUR über die oberen Bedienelemente,

wenn die Sicherungsstange am Eingang der Plattform vollständig

abgesenkt und das Sicherheitsgeschirr angelegt und befestigt ist.

A

NHEBEN UND

Vor der Inbetriebnahme der Arbeitsplattform MB20 muss die Sicherheitsprüfung vor

der Inbetriebnahme durchgeführt werden. Alle eventuellen Mängel sind zu beheben.

Darüber hinaus muss der Bediener vor der Verwendung dieser Maschine umfassend

geschult werden.

Vor dem Aktivieren der Funktionen muss Folgendes überprüft werden.

!

WARNUNG

VERGEWISSERN Sie sich, dass sich im Umkreis von 1 Meter um

die Maschine keine anderen Personen befinden. Beachten Sie die

Gefahr, die von den Kippschutzbalken auf beiden Seiten der

Maschine ausgeht.

SUCHEN Sie über der und um die Maschine nach Hindernissen,

bevor Sie die Hebe- oder Antriebsfunktionen aktivieren.

A

BSENKEN DER

!

A

RBEITSPLATTFORM

!

Überladen Sie die Plattform NICHT.

Halten Sie mit der Maschine von Stromkabeln einen ABSTAND

von 3 Metern ein.

DIESE ARBEITSPLATTFORM VERFÜGT ÜBER KEINE

ELEKTRISCHE ISOLIERUNG.

HINWEIS: Die Bedienelemente am Chassis sind allein für Wartungszwecke vorgesehen.

1. Betreten Sie die Plattform durch den Eingang auf der Rückseite der MB20/26, und

vergewissern Sie sich, dass die Sicherungsstange in Position ist. Heben Sie mit Hilfe

des Pedals in der Plattform die Einstiegsleiter an, und verriegeln Sie diese.

2. Bevor Sie die Maschine in Betrieb nehmen, müssen alle lokal geltenden

Sicherheitsrichtlinien hinsichtlich Helmen und Stabilisierungseinrichtungen beachtet

werden. Die Leinen des Sicherheitsgeschirrs dürfen maximal 1 Meter lang sein und

müssen an den Verankerungen am Käfigboden befestigt werden.

3. Vergewissern Sie sich, dass sich der Schlüsselschalter (ON/OFF) im oberen

Bedienfeld in der Position ON (EIN) befindet, und dass beide Not-Aus-Schalter

deaktiviert sind (gegebenenfalls im Uhrzeigersinn drehen).

4. Überprüfen Sie, ob die LED des Displays leuchtet. Falls nicht, muss eventuell die

Batterie geladen werden.

5. Achten Sie darauf, ob ein Alarmsignal aufgrund eines unebenen Untergrunds ertönt.

Keine der Funktionen kann ausgeführt werden, wenn die Maschine nicht eben steht.

Seite 10

Page 43

4

B

ETÄTIGUNG DER BEDIENELEMENTE

F

AHREN MIT ABGESENKTER

Informationen zu den Bedienelementen und Anzeigen entnehmen Sie bitte den

Tabellen 1 und 2.

1. Überprüfen Sie, ob sich die Not-Aus-Schalter der unteren und oberen Bedienkonsolen

in der Position ON (EIN) befinden (drehen Sie die Schalter im Uhrzeigersinn, um sie

zurückzusetzen).

2. Steigen Sie auf die Plattform, und überprüfen Sie, ob sich der Schlüsselschalter in der

Position ON befindet, und ob der Antriebsschalter beleuchtet ist. Vergewissern Sie

sich, dass sich die Sicherungsstange in der richtigen Position befindet.

3. Überprüfen Sie, dass sich auf dem zu fahrenden Weg keine Personen, Hindernisse,

Schlaglöcher oder Vorsprünge befinden und dass der Untergrund das Gewicht der

Maschine trägt. Überprüfen Sie außerdem, dass die oben genannten Abstände über,

unter und seitlich der Plattform ausreichen.

4. Aktivieren Sie zum Lenken der MB20/26 den Totmannschalter, während Sie zum

Lenken links oder rechts auf den Daumenschalter drücken, der sich oben auf dem