Page 1

JANUARY 2018

01-00054+ (MB20 )/ 01-00071+(MB26)

Page 2

Page 3

MB 20/26J

ENGLISH

When contacting Snorkel for service or parts

information, be sure to include the MODEL

and SERIAL NUMBERS from the equipment

nameplate. Should the nameplate be missing, the

SERIAL NUMBER is also stamped on top of the

chassis above the front axle pivot.

Nameplate

The Work Platform Nameplate is located

externally at the FRONT of the chassis

When contacting Snorkel for service or parts information, sure to include the MODEL and SERIAL

NUMBERS from the equipment nameplate.

The MB20/26J work platform meets and exceeds the requirements of both:

En280:2001 and ANSI A92.5 (1999)

Page 4

Page 5

All personnel shall carefully read, understand and follow all safety rules and operating instructions before

operating or performing maintenance on any Snorkel aerial work platform.

Safety Rules

Electrocution Hazard Tip Over Hazard Collision Hazard Fall Hazard

THIS MACHINE IS NOT

INSULATED!

NEVER elevate the platform or drive

the machine while elevated unless the

machine is on a firm, level surface.

NEVER position the platform without

first checking for overhead obstructions

or other hazards.

NEVER climb, stand, or sit on

platform guardrails or midrail.

USE OF THE WORK PLATFORM: This aerial work platform is intended to lift persons and his tools as well as the material used for the

job. It is designed for repair and assembly jobs and assignments at overhead workplaces (ceilings, cranes, roof structures, buildings

etc.). All other uses of the aerial work platform are prohibited!

THIS WORK PLATFORM IS NOT INSULATED! For this reason it is imperative to keep a safe distance from live parts of electrical

equipment! - DO NOT get closer than the minimum distance recommended by the “National Regulations”.

Exceeding the specied permissible maximum load is prohibited! See “Specications - Platform Capacity” for details.

The use and operation of the aerial work platform as a lifting tool or a crane is prohibited!

NEVER exceed the manual force allowed for this machine. See “Manual Force” on page 2 for details.

DISTRIBUTE all platform loads evenly on the platform.

NEVER operate the machine without rst surveying the work area for surface hazards such as holes, drop-offs, bumps, curbs, or debris;

and avoiding them.

OPERATE machine only on surfaces capable of supporting wheel loads.

NEVER operate the machine when wind speeds exceed this machine’s wind rating. See “Beaufort Scale” on page 1 for details.

NEVER attach notice boards etc. to the platform, as this will increase wind loading.

IN CASE OF EMERGENCY push EMERGENCY STOP switch to deactivate all powered functions.

IF ALARM SOUNDS while platform is elevated, STOP, carefully lower platform. Move machine to a rm, level surface. Climbing up the

railing of the platform, standing on or stepping to or from the platform onto buildings, steel or prefabricated concrete structures, etc. is

prohibited!

Dismantling the entry gate or other railing components is prohibited! Always make certain that the entry gate is closed and securely

locked!

It is prohibited to keep the entry gate in an open position when the platform is raised!

To extend the height or the range by placing of ladders, scaffolds or similar devices on the platform is prohibited!

NEVER perform service on machine while platform is elevated without blocking elevating assembly.

INSPECT the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks, loose wire connections, and damaged

cables or hoses before using.

VERIFY that all labels are in place and legible before using.

NEVER use a machine that is damaged, not functioning properly, or has damaged or missing labels.

To bypass any safety equipment is prohibited and presents a danger for the persons on the aerial work platform and in its working

range.

NEVER charge batteries near sparks or open ame. Charging batteries emit explosive hydrogen gas.

Modications to the aerial work platform are prohibited or permissible only at the approval by Snorkel.

AFTER USE, secure the work platform from unauthorized use by turning the keyswitch off and removing key.

The driving of MEWP’s on the public highway is subject to Regulations made under the Road Trafc Acts.

ENVIRONMENTAL TEMPERATURE LIMITATION, The machine is primarily for use in normal ambient temperatures and conditions

ranging between 50c to -20c.

! !

WARNING

Page 6

NOTES:

Page 7

Contents

CONTENTS PAGE NUMBER

1. INTRODUCTION 1 - 1

SPECIAL INFORMATION 1 - 1

SPECIAL LIMITATIONS 1 - 1

MANUAL FORCE 2 - 1

PLATFORM CAPACITY 2 - 1

BEAUFORT SCALE 2 - 1

2. GENERAL DESCRIPTION 2 - 2

Figure 2. Work Platform 2 - 2

3. SAFETY INSPECTION 2 - 3

Figure 3. Battery Fill & Valve 2 - 3

Figure 4. Lower Control Panel 2 - 4

Figure 5. Joystick 2 - 5

4. OPERATION OF THE PLATFORM CONTROLS 2 - 6

UPPER CONTROL PANEL 2 - 7

Figure 3. Upper Control Panel 2 - 7

CONTROL FUNCTIONS 2 - 7

Table 1. Platform Controls and Indicators 2 - 7

LOWER CONTROL PANEL 2 - 9

Figure 4. Lower Control Panel 2 - 8

TYPICAL OPERATION 2 - 9

CONTROLS AND INDICATORS 2 - 9

ELEVATING & LOWERING THE WORK PLATFORM 2 - 9

TRAVEL WITH WORK PLATFORM LOWERED 2 - 10

TRAVEL WITH WORK PLATFORM ELEVATED 2 - 10

EMERGENCY SITUATIONS 2 - 11

EMERGENCY LOWERING (BY HAND) 2 - 11

Figure 8. Emergency Lowering - Mast Valve 2 - 11

Figure 9. Emergency Lowering - Jib Valve 2 - 11

5. TRANSPORTATION 2 - 12

MACHINE WEIGHTS 2 - 12

Figure 3. Lifting by Forklift 2 - 12

LIFTING BY CRANE 2 - 13

Figure 4. Lifting by Crane 2 - 13

TRANSPORT BY TRUCK 2 - 14

Figure 5. Securing the platform 2 - 14

TOWING & WINCHING VALVES 2 - 14

Figure 6. Valve Block-Towing Valves 2 - 15

6. AFTER USE & STORAGE 2 - 15

AFTER USE EACH DAY 2 - 15

HOUR METER 2 - 16

LONG-TERM STORAGE 2 - 16

PRESERVATION 2 - 16

Figure 3. Battery Disconnect 2 - 16

BATTERIES 2 - 16

DAILY MAINTENANCE CHECKLIST 2 - 17

Daily Maintenance Checklist 2 - 17

7. SPECIFICATIONS MB20J 2 - 18

MB26J 2 - 18

Page 8

1. Introduction

1 - 1

!

!

Indicates a potentially hazardous situation which, if not avoided, could

result in severe injury or death.

W A R N I N G

1. Introduction

1.1 INTRODUCTION

PURPOSE & LIMITATIONS

This Service & Parts Manual is designed to provide instructions and illustrations for the

safe operation and maintenance of the MB20J & MB26J Work Platform manufactured

by Snorkel. The purpose of this machine is to provide fast and safe access to difcult to

reach areas. The machine may only safely operated on rm level ground. Refer to the

Specication section for the machines access limitations.

DO NOT use on soft ground or on slopes greater than 2 degrees.

DO NOT use the lifting mechanism to raise or lower goods or persons except within the

cage and subject to the weight limitations.

DO NOT enter the platform from a structure, rack or other platform.

ENVIRONMENTAL TEMPERATURE LIMITATION, The machine is primarily for use in

normal ambient temperatures and conditions ranging between 50c to -20c.

SCOPE

This manual includes the procedures and responsibilities for the inspection, transportation,

safe operation, maintenance, and repair of this product. The Maintenance Section within

the Parts & Service Manual also covers preventative maintenance and troubleshooting.

SPECIAL INFORMATION

Throughout this manual the users attention is drawn to these special warning boxes:

1.2 GENERAL DESCRIPTION

The MB20/26J are self propelled, fast acting aerial work platforms, designed to raise two

operators with hand tools to a platform oor height of 6.00 m and 7.76 m respectively. The

accessible height is approximately 2.00 m above these gures. It is designed to travel with

safe working load and work tools up to an upper limit, See table on page 2-18 / 2-19.

The unit offers the ability to reach over obstacles but must be used on rm and level ground

at all times.

Indicates an imminently hazardous situation which, if not avoided, will

result in severe injury or death.

! !

D A N G E R

!

!

Indicates a potentially hazardous sit uation which, if not avoided, may

result in minor or moderate injury.

C A U T I O N

Page 9

1. Introduction

1 - 2

PLATFORM

The MB20/26J platform is large enough for two operators indoors, one outdoors and has

a free-draining perforated oor with 150 mm toeboards. Hand-rails are constructed from

Steel tubing and a safety drop-bar is provided at the entrance. Safety restraint harness

anchor points are also tted in the oor of the platform. These must be used at all times.

The main controls are tted to this platform.

PLATFORM CONTROLLER

The primary (Upper) control box is permanently tted to the front of the platform. It features

a joystick which provides proportional control for raising or lowering the mast, raising or

lowering the jib or rotating the complete mast assembly. The same joystick is also used to

drive and steer the machine.

A safety Interlock Switch or ‘deadman button’ is incorporated into the Joystick. It must be

activated at all times in order to operate any function. This feature allows for one-handed

operation. A comprehensive explanation of control functions is given in the Operators

Manual - a copy of which shall be located in the platform document wallet located just

beneath the upper control station in the platform.

The secondary (Lower) control box is tted to the mast cover at arm level. It features a

‘deadman’ enable button and selector buttons to provide pre-programmed speeds for all

functions except drive and steering. This control station is used primarily for service-type

operations including pre-operation inspection. It should never be used to position a manned

or unmanned platform. It may be used in the event of emergency, however, to lower the

manned platform.

ELEVATING ASSEMBLY

The platform is raised and lowered by a combination of a steel jib and a series of

telescoping mast sections. The main hydraulic cylinder, mounted within the masts, lifts the

2nd mast directly. The other masts are connected by a system of heavy duty plate chains

and pulleys to ensure sequential lifting.

A parallel system of heavy duty straps ensures that the masts descend in the proper

sequence and also ensure that a mast cannot be held in suspension by an obstacle during

descent.

The jib cylinder provides a lifting arc to the jib and cage assembly. All hydraulic functions

are carried out using solenoid operated control valves. Each cylinder features an integral

holding valve to prevent uncontrolled descent in the case of a hose bursting.

!

!

DO NOT use the work platform without guardrails properly

assembled and in place.

W A R N I N G

!

!

NEVER operate the machine from the upper controls until the

platform entrance drop-bar is in the fully lowered position and the

safety harness is tted.

W A R N I N G

Page 10

1. Introduction

1 - 3

ROTATION GEAR

The complete mast, jib and cage assembly can be rotated to provide a maximum outreach

of 2.6m in the case of the MB20J and 2.96m in the case of the MB26J machine. This

dimension is measured from the centreline of rotation and is carried out by means of an

integral hydraulic motor driving a Worm Drive Unit, around a Slew Gear.

DRIVE & STEER SYSTEM

An electronic controller, mounted in the chassis, is pre-programmed to adjust the upper

speed limit of each individual function. The controller limits the rotational speed of the

electronic motor and oil pump, thereby limiting the maximum oil ow rate.

The following functions are controlled and driven by the electro-hydraulic system:

• Traction Drives (Fwd & Rev) mast stowed/mast raised.

• Steering and Jib elevation.

• Mast elevation, descent and rotation.

• The Jib descent function is gravity operated and is determined by built in ow regulators.

POWER SYSTEM

The Power System (Prime Mover) incorporates four 6V batteries driving a 4KW electrohydraulic pump. The pump drives all hydraulic cylinders and the traction drive motors. A

single multi-valve control block diverts the oil pressure to the individual actuators. The oil

ow rate is limited by the pre-programmed speed setting on the motor but is determined by

the position of the joystick in the Upper Control Box.

1.3 WORKSHOP PROCEDURES

All information contained in this manual is based on the latest product information available

at the time of printing. We reserve the right to make changes at any time without notice.

No part of this publication may be reproduced, stored in retrieval system, or transmitted,

in any form by any means, electronic, mechanical, photocopying, recording, or otherwise,

without the prior written permission of the publisher. This includes text, gures, and tables.

!

!

Detailed descriptions of standard workshop procedures, safety

principles and service operations are not included. Note that this

manual does contain warnings and cautions against some specic

service methods that could cause personal injury, or could damage a

machine or make it unsafe.

Please understand that these warnings cannot cover all conceivable

ways in which service, whether or not recommended by Snorkel,

might be done, or of the possible hazardous consequences of each

conceivable way, nor could Snorkel investigate all such ways.

Anyone using service procedures or tools, whether or not

recommended by Snorkel must satisfy themselves thoroughly that

neither personal safety nor machine safety will be jeopardized. When

in doubt, contact your local distributor or Snorkel.

C A U T I O N

Page 11

2. Operation & Specications

2 - 1

2. Operation & Specications

2.1 INTRODUCTION

SPECIAL LIMITATIONS

The purpose of this machine is to provide fast and safe access to difcult to reach areas.

Refer to the Specication section for the machines access limitations.

Travel with the platform raised is limited to creep speed range.

MANUAL FORCE

Manual force is the force applied by the occupants to objects such as walls or other

structures outside the work platform.The maximum allowable manual force is limited to

200 N (45 lbs.) of force per occupant.

PLATFORM CAPACITY

The Platform is designed to travel with safe working load (SWL) including work tools to an

upper limit of 215 kg (425 lbs for ANSI MB20J)

BEAUFORT SCALE

Never operate the machine when wind speeds exceed 12.5m/s (28 m.p.h.)

[Beaufort scale 6].

BEAUFORT

RATING

WIND SPEED

GROUND CONDITIONS

M/S KM/H FT./S M.P.H.

3 3,4~5,4 12,25~19,4 11.5~17.75 7.5~12.0

Papers and thin branches move.

Flags wave.

4 5,4~8,0 19,4~28,8 17.75~26.25 12.0~18

Dust is raised, paper whirls up, and small branches

sway.

5 8,0~10,8 28,8~38,9 26.25~35.5 18~24.25

Shrubs with leaves start swaying.

Wave crests are apparent in ponds or swamps.

6 10,8~13,9 38,9~50,0 35.5~45.5 24.5~31

Tree branches move.

Power lines whistle. It is difcult to open an umbrella.

7 13,9~17,2 50,0~61,9 45.5~56.5 31.~38.5

Whole trees sway.

It is difcult to walk against the wind.

DO NOT exceed the maximum manual force.

NEVER exceed the platform capacity.

! !

D A N G E R

DO NOT use on soft ground or on slopes greater than 2 degrees.

The work platform is NOT intended for use on uneven or rough

terrain.

ONLY operate this machine on FIRM and LEVEL ground.

! !

D A N G E R

Page 12

2. Operation & Specications

2 - 2

2.2 GENERAL DESCRIPTION

The MB20/26J are self propelled, fast acting aerial work platforms, designed to raise two

operators with hand tools to a platform oor height of 6.00m and 7.76m respectively. The

accessible height is approximately 2.00m above these gures.

The unit offers the ability to reach over obstacles but must be used on rm and level

ground at all times.

DO NOT use the lifting mechanism to raise or lower goods or

persons except within the cage and subject to the specied weight

limitations.

! !

D A N G E R

DO NOT enter the platform from any structure, rack or other

platform.

! !

D A N G E R

Figure 3: Work Platform

PLATFORM

CONTROLS

SAFETY

DROP-BAR

PLATFORM

CHASSIS

CHASSIS

CONTROLS

ELEVATING

ASSEMBLY

!

!

DO NOT use the work platform without safety drop-bar in place and

with the safety harness tted.

W A R N I N G

Page 13

2. Operation & Specications

2 - 3

2.3 SAFETY INSPECTION

This Safety Inspection shall be carried out by the owner immediately prior to transporting

this machine.

This Safety Inspection shall also be carried out by the user prior to use each day.

The procedure is to carry out the following 14 checks in order as follows.

1. Remove the rear chassis covers by means of the two top twist-locks and the two lift-andturn catches at the sides. The cover is removed by sliding it backwards and upwards. Use

the central handle provided.

2. Ensure that the mast and jib are fully lowered. Remove the hydraulic oil ller cap and

check that the hydraulic oil level is correct. Oil should be visible on the dip stick. Top up as

necessary using hydraulic oil Viscosity Grade ISO 46.

3. Inspect the chassis area for oil leaks, loose parts, frayed cables and hoses and structural

damage etc. Check that all cable connections to the solenoid valves are intact.

4. Open the Inspection hatches on both sides of the upper mast cover. Check that the AC

mains cable is disconnected from the battery charger. Check the electrolyte level in each

battery cell. Top up as necessary with distilled water only.

5. Use the distilled water container supplied with the machine to ll the batteries to the correct

electrolyte level.

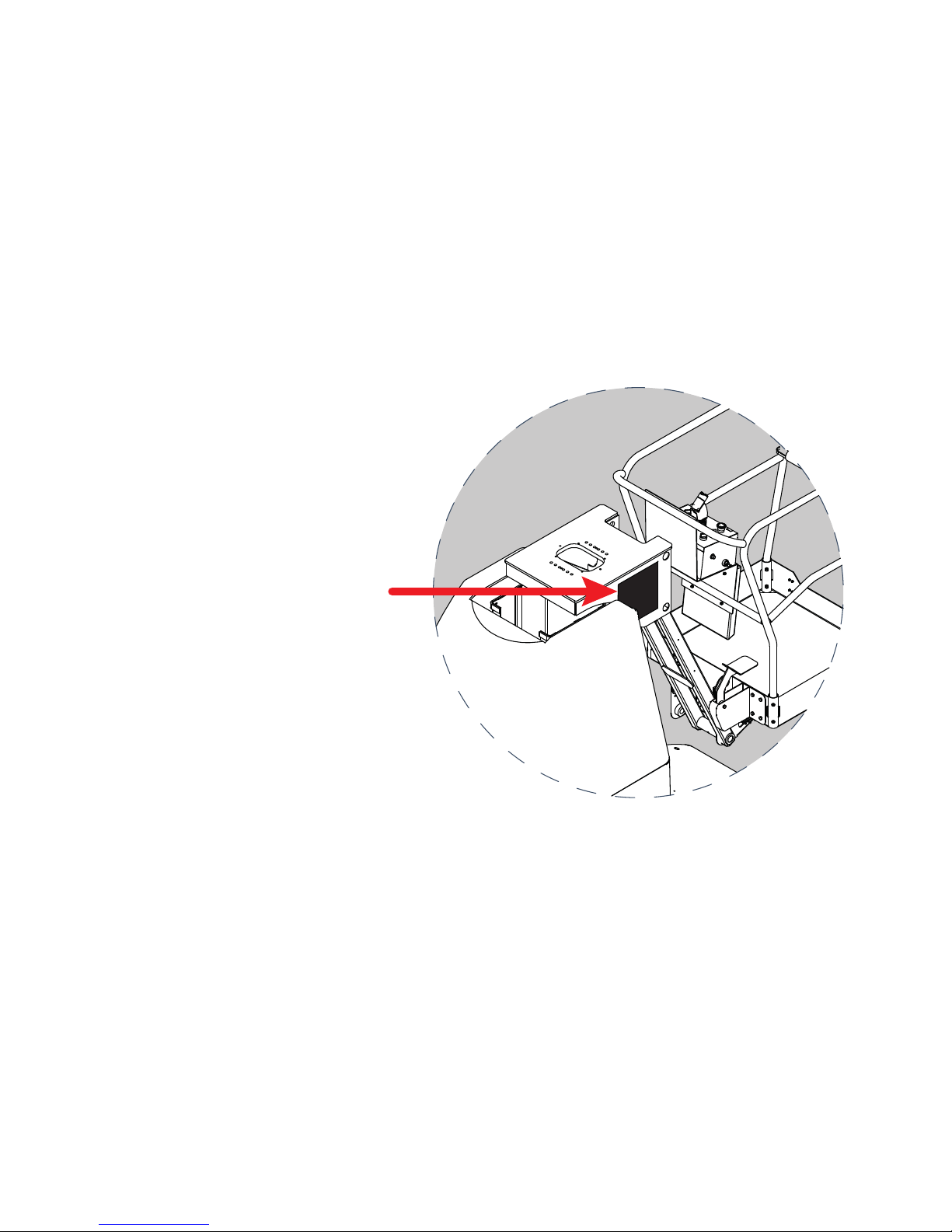

This is done by locating the battery topup valve behind the mast cover inspection door

(refer to gure 3) and connecting it to the valve tted to the distilled water container tube.

The container can now be placed on top of the mast cover. Once both valves are securely

fastened together the air release cap located on the distilled water container can be

loosened, this will allow air to enter the container and start the release of distilled water.

The red ow indicator will start spinning (Refer to Fig 3) to indicate the distilled water has

started to ow into the batteries. The ow indicator will continue to spin until all batteries

are full, to verify batteries have been lled to the correct level each battery cell has its own

indicator that will become visible through the indicator window (Refer to Fig 3).

Once the battery ll has competed the air release cap can be tightened to prevent the

ow of distilled water from the container, it is now possible to disconnect the two valves by

pressing the release button located on the female valve (Refer to Fig 3).

Batteries should be examined for cracks, acid leakage and terminal corrosion. Take

corrective action immediately if either check fails.

Figure 3: Battery Fill & Valve

Water container

Battery Topup Valve

Container tube valve

Flow indicator

Water Level indicator

Air release

Page 14

2. Operation & Specications

2 - 4

Figure 4: Lower Control Panel

1. Emergency Stop

2. KeySwitch - Platform Controls

- OFF

- Lower Controls

3. Analogue Rocker

4. Selector Switch - Jib

- Mast

- Mast Rotate

5. Enable Switch

6. Ez 230 Display

6. Prior to operating the functions, check that the upper and lower emergency stop buttons

on each control station are retracted; turn clockwise if necessary. Carry out the following

function from the Lower Control Station.

NOTE: DO NOT enter the platform at this stage.

7. Check jib operation by extending the jib to its fully elevated position. Check for correct

routing of the hoses and cables. Check the Emergency Lowering feature of the jib. Ensure

that when the Emergency Lowering lever/button is disengaged, the jib no longer descends.

Return the jib to its rest position using the normal Lower Control Station.

8. Check mast chains by elevating the masts approximately 30cm above the rest position.

Check for correct routing of the energy chain. Raise the masts to full height and check

for correct adjustment of each lifting chain as follows. Each chain in the pair should bear

load. Use a hand held spring balance or tensiometer apply a nominal load (approximately

10kgf.) to either chain in the pair. Apply the load about half way up the chain. Record the

approximate deection i.e. the offset distance from the mast. Repeat the measurement

on the adjacent chain at the same location. Chains bearing equal load will deect equal

amounts. Carefully adjust the slack chain until the deections are approximately equal.

Torque up the locknuts to 70 Nm.

NOTE: Apply a thin layer of grease to the lifting chains with a small paintbrush.

!

!

Over-tensioning of either lifting chain will result in unnecessary lifting of

the mast.

This will lead to a subsequent increase in machine stowed height.

C A U T I O N

1

6

3

2

5

4

Page 15

2. Operation & Specications

2 - 5

The function of the mast straps is to ensure that masts descend in the correct order and

more importantly, that masts cannot continue to descend if the jib or platform meets an

external obstacle. Raise the masts about 30cm. Check the external mast clamp screws for

tightness. Pull on the short length of each strap and check that they are secure. Refer to

the maintenance manual for instructions on more stringent periodic checks on these straps.

Check the Emergency Lowering feature of the mast. The lever is located in the upper mast

over. Open the left hand battery inspection hatch and locate the ‘Emergency Lowering’

decal label. Check the wear pads for damage or heavy scoring. Replace as necessary.

9. Elevate the jib fully. Using the Lower Control Station, turn the mast assembly through about

90 degrees. Check the correct routing of the hoses and cables and the correct smooth

operation of the energy chain in its chassis base slide. Continue rotating through 180

degrees in both directions. Conrm that the rotation stops are intact.

10. STANDARD PLATFORM CONTROLS Repeat the mast, jib and rotate functions from the

Upper Control Station in the platform. Check that pressing the emergency stop button

prevents subsequent operation of the joystick.

11. TILT SENSOR FUNCTION CHECK. The tilt sensor is incorporated in the EZ230 control

module. To check it’s operation while in platrom drive the machine onto a suitable ramp

to raise it’s tilt angle above 2 degrees, lift the Jib until the jib limit switch just separates, a

continuous audible alarm should sound and all functions on the machine become disabled.

Lower the jib using the emergency manual release valve located between the jib structure,

the alarm should silence and normal operation becomes enabled.

Figure 5: Joystick

12. MACHINE TRAVEL - UNELEVATED Travel functions are possible only from the platform

Upper Control Station. As with all such controls, the deadman handgrip switch must be

depressed before any function can operate.

Select Drive on the upper control panel. Pushing back and forward on the joystick moves

the machine backwards and forwards respectively.

The pothole protection will begin to retract immediately. However, full demand speed will

not be realised until the bars are fully raised. This takes about 3 seconds. Check that the

motion alarm DOES sound during travel. Check that the thumb operated switches on the

top of the joystick operates the front wheel steering.

13. MACHINE TRAVEL-ELEVATED While the masts are raised, it is possible to drive and

steer the machine at a much reduced speed. Also note that while the masts are raised, the

pothole protection bars should be fully extended and should remain extended during slow

speed motion of the machine.

Joystick with

Deadman Grip

!

!

During manual lowering extreme care must be taken to

ensure hands are not trapped in the jib structure.

C A U T I O N

Page 16

2. Operation & Specications

2 - 6

14. FINAL PREPARATION Congure the masts and jib to the stowed position. Replace all

machine covers and secure.

NOTE: The machine is now ready for Operation or Transportation.

2.4 OPERATION OF THE PLATFORM CONTROLS

The primary (Upper) control box is permanently tted to the front of the platform. It features

a multi-use joystick which provides proportional control for all the machines functions.

That includes, raising or lowering the mast, raising or lowering the jib, rotating the mast

assembly, and also to drive and steer the machine.

A safety Interlock Switch or ‘deadman button’ is incorporated into the Joystick. It must be

activated at all times in order to operate any function. This feature allows for one-handed

operation.

The secondary (Lower) control box is tted to the mast cover at arm level. It features an

enable button and selector buttons to provide pre-programmed speeds for all functions

except drive and steering. This control station is used primarily for service-type operations

including pre-operation inspection. It should never be used to position a manned or unmaned platform.

NOTE: It may be used in the event of emergency to lower the manned platform.

!

!

The issue of reduced speed while elevated and deployment of

the pothole protection bars is crucial to the safe operation of this

machine.

The machine may not be released or operated unless these functions

operate properly.

W A R N I N G

!

!

NEVER operate the machine from the upper controls until

the platform entrance drop-bar is in the fully lowered position

and the safety harness is tted.

W A R N I N G

TO TURN THE MACHINE ON

Turn the key switch on the lower controls panel to platform controls or lower controls as

required, the overload warning lamp on the platform control box will ash for 2 seconds and

the buzzer will sound twice conrming that the overload sensor has booted up.

CONTROLS AND INDICATORS

The pre-operation safety checks should be carried out prior to operation. These checks are

detailed in the previous section. Operators who follow these guidelines will become familiar

with the controls and indicators on the machine.

This section summarises the controls and indicators in tabular form and provides more

detailed information.

Page 17

2. Operation & Specications

2 - 7

UPPER CONTROL PANEL

Figure 3: Upper Control Panel

!

!

DO NOT operate the machine from the upper controls until the

platform entrance drop-bar is in the fully lowered position and your

safety harness has been tted and attached.

W A R N I N G

1. JOYSTICK

(FORWARD/BACKWARD)

10. OVERLOAD WARNING

LIGHT

3. EMERGENCY

STOP BUTTON

4. STEERING

SWITCH

5. SELECTOR

SWITCH

6. MAST SELECT

BUTTON

7. LOW/HIGH

TORQUE SELECTOR

8. HORN

2. DEADMAN

GRIP

9. LOW BATTERY

WARNING

CONTROL FUNCTIONS

Table 1: Platform Controls and Indicators

ITEMS NAMES FUNCTION

1 Joystick

Refer to the decal logic diagrams for correct direction of

motion.

e.g. If Drive is preselected - pushing forward moves

machine forward.

2 Deadman Grip

The ‘Deadman’ grip switch on the joystick must be grasped

for any function to operate.

3 Emergency Stop

Push this red button at any time to isolate power.

Turn clockwise to reset.

Page 18

2. Operation & Specications

2 - 8

ITEMS NAMES FUNCTION

4 Steering Switch Turns the wheels left or right.

5 Selector Switch Pre selects Jib, Mast or Mast Rotate function.

6 Drive / Lift Selector Pre selects either drive or lift function.

7 Low / High Torque Selector

In drive function pre-selects low torque high speed

drive or high torque low speed drive, only functions

when mast and jib are down.

8 Horn Button Use to warn bystanders or to attract attention.

9 Low battery warning lamp

Illuminates when battery charge is low and machine

automatically switches into limp mode.

10 Overload warning lamp Illuminates when load in basket exceeds SWL

Table 2: Lower controls and Indicators

LOWER CONTROL PANEL

ITEMS NAMES FUNCTION

1 Emergency Stop

Push this red button at any time to isolate power.

Turn clockwise to reset.

2 Key Switch Selects Platform controls, OFF, or lower controls.

3 Rocker Switch

Activates the Pre-Selected operation, in either

direction.

4 Selector Switch Pre-selects Jib, Mast or Mast Rotate function.

5 Enable Switch

This Switch Enables the rocker switch and must be

held up during operation.

6 Hour Meter / BCI

Displays total run time of the machine and an

indication of remaining battery capacity.

Page 19

2. Operation & Specications

2 - 9

Figure 4: Lower Control Panel

1. Emergency Stop

2. KeySwitch - Platform Controls

- OFF

- Lower Controls

3. Analogue Rocker

4. Selector Switch - Jib

- Mast

- Mast Rotate

5. Enable Switch

6. Ez 230 Display

TYPICAL OPERATION

Raising the mast.

• The Keyswitch must be turned to lower controls (2).

• Select Mast using the selector switch (4)

• Press up and hold the switch (5),

• Activate the Rocker Switch (2) in the direction required.

ELEVATING & LOWERING THE WORK PLATFORM

Before operating the MB20/26J Work Platform it is imperative that the pre-operation Safety

Inspection has been completed and any deciencies have been corrected. The operator must

also be fully trained in the use of this machine.

Before beginning any operation, the following checks should be carried out.

NOTE: Chassis controls are for service use only.

!

!

ENSURE that no other persons are within 1 metre of the machine.

Be aware of the pothole protection bar hazard on both sides of the

machine.

LOOK up and around for obstructions before performing the lift or

drive functions.

DO NOT overload the platform.

DO NOT operate near electrical power cables, keep within national

safety limits.

THIS WORK PLATFORM IS NOT ELECTRICALLY INSULATED.

W A R N I N G

1

6

3

2

5

4

Page 20

2. Operation & Specications

2 - 10

1. Ensure that the Key Switch on the Lower Control Box is turned to the Platform Controls

position and both emergency stop buttons are off (twist clockwise if necessary).

2. Check the Display B.C.I. is illuminated. If not, the battery may need recharging.

3. Enter the Platform through the entrance at the rear of the MB20/26J and ensure that the

drop bar is in position. Raise and lock the entry step.

4. Before using the machine all local Safety Regulations involving helmets and restraining

devices should be observed. Safety harness lanyards, not exceeding 1 metre in length,

should be attached to anchor points in cage oor.

5. Check if the audible alarm sounds due to un-level ground. None of the functions can

work if the machine is not level.

TRAVEL WITH WORK PLATFORM LOWERED

Refer to Tables 1 & 2 for controls and indicators.

1. Verify that both Lower and Upper Control Console Emergency Stop Button is in the ‘ON’

position (turn clockwise to reset).

2. Turn the key switch on the lower control panel to the platform controls position.

3. Climb into the Platform and select drive using the drive / lift selector toggle switch.

Ensure that the drop bar is in position.

4. Check that the route is clear of persons, obstructions, pot holes or ledges and is capable

of supporting the wheel loads. Also, check that the clearances above, below, and to the

side of the Work Platform are sufcient.

5. To steer the MB20/26J, activate the Deadman Switch while pushing the Steering

Thumb-switch, on top of the Joystick, LEFT or RIGHT to turn the wheels. Observe the

tyres while manoeuvring to ensure correct direction.

NOTE: Steering is not self-centring. The wheels must be returned to the straight ahead

position by operating the Steering Switch.

TRAVEL WITH WORK PLATFORM ELEVATED

Refer to Tables 1 & 2 for controls and indicators.

NOTE: The Work Platform will travel at reduced speed when in the elevated position.

1. Check that the route is clear of persons, obstructions, pot holes or ledges and is capable

of supporting the wheel loads. Also, check that the clearances above, below and to the

side of the Work Platform are sufcient.

2. Ensure that the pothole guards remain in the extended (down) position during elevated

travel.

!

!

If the machine stops driving and the Tilt Alarm sounds, lower the

Platform immediately.

Using the Emergency Override functions, move the machine to a

level location before re-elevating the platform.

Travel with platform elevated ONLY on rm and level surfaces.

C A U T I O N

Page 21

2. Operation & Specications

2 - 11

EMERGENCY SITUATIONS

In any emergency situation, the immediate action is to push the red “Emergency Stop” button.

This will instantly cut of all electrical power to the controls. The button must be twisted in a

clockwise direction in order to recommence control.

However, the switch should be reset only when it is safe to do so.

If the Continuous Audible warning alarm sounds, normal control functions will cease to operate.

This will be due to the following problem;

• The Tilt Sensor has been activated

EMERGENCY LOWERING (BY HAND)

!

!

During manual emergency lowering, extreme care must be taken to

ensure that the person carrying out the task is not struck by the jib or

platform structure.

C A U T I O N

Should the machine become inoperable when elevated request a person on the ground to lower

the platform using the emergency lowering valves. Lower the mast structure before lowering the

jib/platform structure.

NOTE: Lower the masts fully before lowering the jib structure.

Figure 8: Emergency Lowering - Mast Valve Figure

Locate the red lever behind the mast cover

inspection door on the left hand side of the

machine. By pushing the lever up, the mast

will descend fully under gravity. Releasing the

spring-loaded lever will cease this operation

immediately if required.

9: Emergency Lowering - Jib Valve

The Jib may be manually lowered by operating

the manual release valve located between the

Jib Structure.

MANUAL ROTATION

1. Lower the masts and jib fully before manually slewing the assembly. Press the Emergency Stop

Button to prevent inadvertent powered motion.

2. Locate the opening behind the front right drive wheel. Apply a 23 mm socket wrench with

extension bar to the shaft and turn to rotate the elevating assembly. (Turning the front wheel fully

to one side will facilitate this operation).

Page 22

2. Operation & Specications

2 - 12

2.5 TRANSPORTATION

MACHINE WEIGHTS

Before transporting or lifting the MB20/26J machine be aware of its weight. It is very

important to realise that the centre of gravity of the stowed machine is approximately

80 cm above ground and in the plane of the energy chain which is located on the back of

the mast.

MB20J CE Version = 2590 kg

MB20J US Version = 3012 kg (6640 lbs)

MB26J CE Version = 2660 kg

MB26J US Version = 3175 kg (7000 lbs)

In cases of particular difculties with lifting or shipping it is possible to remove the single

block ballast from the machine. Remove the 13 screws connecting the ballast cover to the

mast. Undo the 4 bolts connecting the ballast to the mast and use a forklift to remove the

ballast block. The ballast block weighs 600 kg on MB20J, 460 kg on MB26J ( CE version )

and 1300kg on the US (ANSI) version.

!

!

This work must not be carried out without the prior written permission

of Snorkel.

W A R N I N G

LIFTING BY FORK-LIFT

Forklifting is for transport only. See machine weights and ensure

that the forklift is of adequate capacity.

! !

D A N G E R

Figure 3: Lifting by Forklift

Adjust the forks so that the minimum

clearance between them is 800mm as

shown.

Approach the machine from either side

but place the fork as close as possible to

the front wheel as shown.

800mm

Front

Page 23

2. Operation & Specications

2 - 13

1. Never approach the MB20J from the front or rear while fork lifting.

2. Use maximum forklift tilt as soon as possible when raising the MB20/26J.

3. If travelling over sloped or uneven ground it is strongly recommended to temporarily tie the

MB20J jib mount structure to the forklift mast as a safety precaution.

4. The MB20/26J may be lifted by forklift subject to the following strict procedure.

5. Ensure that the mast and jib are fully stowed and that the pothole bars are fully retracted

(raised).

LIFTING BY CRANE

The MB20/26J may be lifted by an overhead hoist/crane subject to the following strict

procedure.

Raise the jib to clear the lifting straps as shown.

Use 4 separate lifting straps connected to a spreader beam. DO NOT use a lesser number

of threaded straps as these could slip and lead to instability. The recommended minimum

capacity of EACH of the 4 straps is 2 tonne and the minimum length of each strap is

2 metres. Damage to the covers and/or cage rails can occur if a spreader beam is not

deployed during a crane lift.

Figure 4: Lifting by Crane

Apply the straps via 2 tonne shackles

to each of the 4 lifting lugs on the

chassis.

SPREADER

BEAM CAPACITY

4 TONNE

!

!

DO NOT apply lifting straps to any other part of the machine.

C A U T I O N

Page 24

2. Operation & Specications

2 - 14

TRANSPORT BY TRUCK

The MB20/26J can be carried on a suitably rated transportation vehicle or trailer. Because

of its high gradeability, the machine can be driven under its own power on to a standard

loading ramp (Up to 14 degrees).

It is recommended to reverse the machine up on to the truck thus forward travelling down

the ramp at the delivery point. Winch-assisted loading is allowable for larger slopes,

however, operate the trucks assist winch at minimum speed to avoid over-pressurising the

hydraulic system in the machine.

When the MB20/26J is on the truck or trailer it should then be made secure by:-

1. Chocking the wheels.

2. Securing with adequate chains or straps to the lifting lugs on the chassis.

Figure 5: Securing the Platform

TOWING & WINCHING VALVES

The fail-safe brakes are automatically applied when the machine comes to a stop or in the

event of total power loss due to low battery or malfunction of the hydraulic drive system.

To tow the vehicle or to winch it on to a truck it is necessary to hydraulically bypass the

control valves and release these brakes.

Make sure the Jib is tied down securely during transport, DO NOT over tighten straps.

Straps should have adequate slack so no downward force is applied to the Jib.

!

!

DO NOT loop straps through the cage, ladder or jib as this could

cause permanent structural damage during transportation.

C A U T I O N

WHEEL CHOCKS

USE 4 SEPARATE

TIE-DOWNS

Page 25

2. Operation & Specications

2 - 15

Proceed as follows:- (Refer to the valve block drawing Figure 6.)

1. Fully lower the jib boom and the mast sections. Rotate the mast into the stowed position.

2. Turn the Upper Control Box Keyswitch to the OFF position and remove the key.

3. Remove the rear GRP cover from the chassis and locate the hydraulic control valve block.

4. The hand valve marked ‘A’ should be turned fully clockwise to close. The hand valve marked ‘B’

should be turned fully anti-clockwise to open.

5. Operate the red handpump a number of times to develop sufcient pressure to ‘separate’ the

internal brake disks. These brakes are integral with the hydraulic drive motors.

NOTE: The machine can now be safely towed or winched.

6. On completion of towing/winching, reverse the position of the rotary hand valves ‘A’ and ‘B’. The

handpump becomes inoperative when the valves are returned to their normal position.

Figure 6: Valve Block-Towing Valves

!

!

RISK OF SERIOUS INJURY. Releasing the brakes will cause the

machine to move uncontrollably on a slope. Damaging momentum can

be developed due to the large mass of a slow moving machine

W A R N I N G

2.6 AFTER USE & STORAGE

AFTER USE EACH DAY

1. Ensure that the platform (masts and jib) are fully lowered.

2. Park the machine on rm and level ground, never on a grass surface.

3. Turn the key switch to the OFF position and remove.

4. Put the batteries on charge.

BATTERY CHARGING

Before charging check that:-

1. The correct mains voltage and current is available to the charger.

The MB machine is tted with a high output charging assembly. this consists of two 24V 30A 900W

Chargers. The chargers can be linked together if the supply voltage and current are high enough

to meet the power demand. If the power supply is not good enough, a single charger can be used.

If this option is taken, it is important that charger ‘A’ is used, as it is the one linked to the remote

display for battery charge level.

2. Check that the extension cord(s) is in good condition and is no longer than 8M (26fT). 1.5mm

Sq (12 AWG) or larger cable is required. Ensure that the plug(s) is of the correct rating and is

compatible with the electrical installation into which it will be plugged.

3. The charger(s) will turn on automatically after going through a self test sequence. the remote LED

on the control Panel will indicate the status of charging.

Handpump

‘A’

LED Remote

Charge Indicator.

Page 26

2. Operation & Specications

2 - 16

LONG-TERM STORAGE

PRESERVATION

1. Clean and touch up damaged paint surfaces.

2. Fill the hydraulic tank to operating level with the platform fully lowered. Fluid should be

visible on the tank dip stick.

3. Coat exposed portions of cylinder rods with a preservative such as multipurpose grease

and wrap with barrier material.

4. Coat all exposed un-painted metal surfaces with a light oil or other preservative.

5. Cover the machine with tarpaulin if possible. If this is not available it is advisable to cover

the mast and jib mount area as a minimum. This will prevent moisture from entering the

mast, battery and chassis areas.

Figure 3: Battery Disconnect

Battery Disconnect

switch

BATTERIES

1. Disconnect the batteries at the battery disconnect switch located on the right hand side of the

chassis (refer to Figure 3).

2. Better battery life and efciency is achieved if the batteries are used consistently. It is

therefore recommended that the batteries are used elsewhere if the machine is to be unused

for an extended period (2 weeks or more).

!

!

RISK OF SERIOUS INJURY. Take particular care when handling

batteries. Acid spills can cause severe burns or blindness.

DO NOT store batteries close to naked ames or close to steel

fabrication areas.

W A R N I N G

Page 27

2. Operation & Specications

2 - 17

DAILY PREVENTATIVE MAINTENANCE CHECKLIST

Daily preventative maintenance will prevent abnormal wear and prolong the life of all

systems. The inspection & maintenance schedule should be performed at the specied

intervals.

Inspection and maintenance shall be performed by personnel who are trained and familiar

with mechanical and electrical procedures.

!

!

Before performing preventative maintenance, familiarize yourself with

the operation of the machine.

Always block the elevating assembly whenever it is necessary to perform

maintenance while the platform is elevated.

W A R N I N G

This Daily checklist has been designed for machine service and maintenance. Please

photocopy this page and use the checklist when inspecting the machine.

MAINTENANCE TABLE KEY

Y = Yes/Acceptable

N = No/Not Acceptable

R = Repaired/Acceptable

PREVENTATIVE MAINTENANCE REPORT

Date: _______________________________

Owner: _____________________________

Model No: __________________________

Serial No: ___________________________

Serviced By: _________________________

COMPONENT INSPECTION OR SERVICE Y N R

BATTERY

Check electrolyte level.

Check battery cable condition.

CHASSIS

Check hoses for pinch or rubbing points.

Check welds for cracks.

CONTROL CABLE

Check the exterior of the cable for pinching, binding or

wear.

CONTROLLER Check switch operation.

DRIVE MOTORS Check for operation and leaks.

ELEVATING ASSEMBLY Inspect for structural cracks.

EMERGENCY LOWERING

SYSTEM

Operate the emergency lowering valve & check for

serviceability.

ENTIRE UNIT Check for and repair collision damage.

HYDRAULIC FLUID Check uid level.

HYDRAULIC PUMP Check for hose tting leaks.

HYDRAULIC SYSTEM Check for leaks.

LABELS Check for peeling, missing, or unreadable labels & replace.

PLATFORM DECK AND

RAILS

Check welds for cracks.

TYRES AND WHEELS Check for damage.

Table 1: Daily Maintenance Checklist

Page 28

2. Operation & Specications

2 - 18

SPECIFICATIONS

MB20J

PARAMETER MB20J EU VERSION MB20J US VERSION

Duty Cycle 45%over 8 hour cycle 35%over 8 hour cycle

Platform Size 770mm x 730mm 30.5in. x 28.5in.

Maximum Platform Capacity 215kg. 425lbs.

Indoors 2 People 2 People

Outdoors 1 Person 2 People

Max Wind Speed 12.5 m/s 26.8 mph

Max Manual Force Per Person 200N 45lbs

Maximum Chassis Inclination 2° 2°

Heights:

Maximum Platform Height 6.10m 20.00ft.

Maximum Working Height 8.10m 26.50ft.

Platform Height at Maximum Outreach 5.04m 16.54ft.

Maximum Working Outreach 2.64m 8.66ft

Stowed Dimensions:

Length 2.430m 7.97ft

.

Width 0.810m 32in.

Height 2.013m 6.60ft

Chassis Ground Clearance 90mm 3.54in.

Wheelbase x Wheel Gauge 1465mm x 708mm 4.81ft. x 2.32ft.

Rotation 360deg non-continuous 360 deg non-continuous

Gross Vehicle Weight 2590kg. 6640lbs.

Maximum Drive Speed - Stowed 3.30 km/h 2.05mph.

Maximum Drive Speed - Elevated 0.60km/h 0.37mph

Maximum Gradeability 25% 25%

Outside Turning Radius 1.90m 6.23ft.

Electrical:

Power Source 4 x 6V @ 375Ah Battery 4 x 6V @ 375Ah Battery

System Voltage 24 Volt DC 24 Volt DC

Battery Charger ( 2 Per Machine ) 24V x 30A, Output 24V x 30A, Output

Auto Select AC input Auto Select AC input

100-240v -50/60Hz 12-6A 100-240v -50/60Hz 12-6A

Control System Single Joystick, Function

Selector, DC Motor Controller

Single Joystick, Function

Selector, DC Motor Controller

Hydraulic System:

System Relief Setting 220bar 3190psi

Hydraulic Oil Type ISO VG46 ISO VG46

Hydraulic Tank Capacity 20 litres 5.3 gallons (U.S.)

Brakes Spring applied hydraulically

released

Spring applied hydraulically

released

Wheel & Tyres 13.5in. x 4.0

solid, Non-Marking

13.5in. x 4.0

solid, Non-Marking

Wheel loading 1300kg per wheel 3466lbs per wheel

Vibration of this machine does not exceed 2.5m/sec х

2

2.5m/sec х

2

Noise Pressure Level 68dB (A) at Control Station 68dB (A) at Control Station

Page 29

2. Operation & Specications

2 - 19

SPECIFICATIONS

MB26J

PARAMETER MB26J EU VERSION MB26J US VERSION

Duty Cycle 45%over 8 hour cycle 35%over 8 hour cycle

Platform Size 770mm x 730mm 30.5in. x 28.5in.

Maximum Platform Capacity 215kg. 475lbs.

Indoors 2 People 2 People

Outdoors 1 Person 2 People

Max Wind Speed 12.5 m/s 26.8 mph

Max Manual Force Per Person 200N 45lbs

Maximum Chassis Inclination 2° 2°

Heights:

Maximum Platform Height 7.75m 25.45ft.

Maximum Working Height 9.75m 32.00ft.

Platform Height at Maximum Outreach 6.51m 21.36ft.

Maximum Working Outreach 3m 10ft.

Stowed Dimensions:

Length 2.800m 9.2ft.

Width 1.010m 40in.

Height 2.010m 6.59ft.

Chassis Ground Clearance 90mm 3.54in.

Wheelbase x Wheel Gauge 1465mm x 890mm 4.81ft. x 2.93ft.

Rotation 360deg non-continuous 360 deg non-continuous

Gross Vehicle Weight 2660kg. 7000lbs.

Maximum Drive Speed - Stowed 3.13 km/h 1.94mph.

Maximum Drive Speed - Elevated 0.60km/h 0.37mph

Maximum Gradeability 25% 25%

Outside Turning Radius 1.93m 6.33ft.

Electrical:

Power Source 4 x 6V @ 375Ah Battery 4 x 6V @ 375Ah Battery

System Voltage 24 Volt DC 24 Volt DC

Battery Charger ( 2 Per Machine ) 24V x 30A, Output 24V x 30A, Output

Auto Select AC input Auto Select AC input

100-240v -50/60Hz 12-6A 100-240v -50/60Hz 12-6A

Control System Single Joystick, Function

Selector, DC Motor Controller

Single Joystick, Function

Selector, DC Motor Controller

Hydraulic System:

System Relief Setting 220bar 3190psi

Hydraulic Oil Type ISO VG46 ISO VG46

Hydraulic Tank Capacity 18 litres 4.7 gallons (U.S.)

Brakes Spring applied hydraulically

released

Spring applied hydraulically

released

Wheels & Tyres 13.5in x 4.0

solid, Non-Marking

13.5in x 4.0

solid, Non-Marking

Wheel loading 1300kg per wheel 3566lbs per wheel

Vibration of this machine does not exceed 2.5m/sec х2 2.5m/sec х2

Noise Pressure Level 68dB (A) at Control Station 68dB (A) at Control Station

Page 30

2. Operation & Specications

2 - 20

NOTES:

Page 31

Page 32

Local Distributor / Lokaler Vertiebshändler / Distributeur local

El Distribuidor local / ll Distributore locale

EUROPE, MIDDLE EAST

AFRICA & ASIA

PHONE: +44 (0) 845 1550 057

FAX: +44 (0) 845 1557 756

NORTH & SOUTH AMERICA

PHONE: +1 785 989 3000

TOLL FREE: +1 800 225 0317

FAX: +1 785 989 3070

AUSTRALIA

PHONE: +61 2 9725 4000

FAX: +61 2 9609 3057

NEW ZEALAND

PHONE: +64 6 3689 168

FAX: +64 6 3689 164

USA

TEL: +1 (559) 443 6600

FAX: +1 (559) 268 2433

Europe

TEL: +44 (0) 845 1550 058

FAX: +44 (0) 195 2299 948

Loading...

Loading...