Page 1

Operator Manual

Guide de l’opérateur

Betriebsanleitung

LX Series

SERIAL NO. 4275 to Current

WARNING

All personnel shall carefully read, understand and follow all safety rules,

operating instructions, and National Safety Instructions/Requirements

before operating or performing maintenance on any UpRight Aerial Work

Platform.

The first section of this Operator Manual is the English language version.

AVERTISSEMENT

Tout le personnel doit lire attentivement, bien comprendre et suivre toutes

les règles de sécurité, le mode d’emploi et les règles nationales de sécurité avant d’entretenir ou d’utiliser une plate-forme élévatrice UpRight.

La deuxième section du guide de l’opérateur est la version française.

WARNUNG

Alle Bediener müssen die Sicherheitsregeln, Betriebsanleitungen sowie

geltenden Sicherheitsanweisungen/-anforderungen gründlich durchlesen,

verstehen und befolgen, bevor sie an irgendeiner UpRight-Hocharbeitsbühne Wartungsarbeiten ausführen oder diese in Betrieb nehmen.

Der dritte Abschnitt dieser Betriebsanleitung ist deutschsprachig.

P/N 067903-025

Page 2

LX Series

Serial Numbers 4275 – Current

NGLISH

E

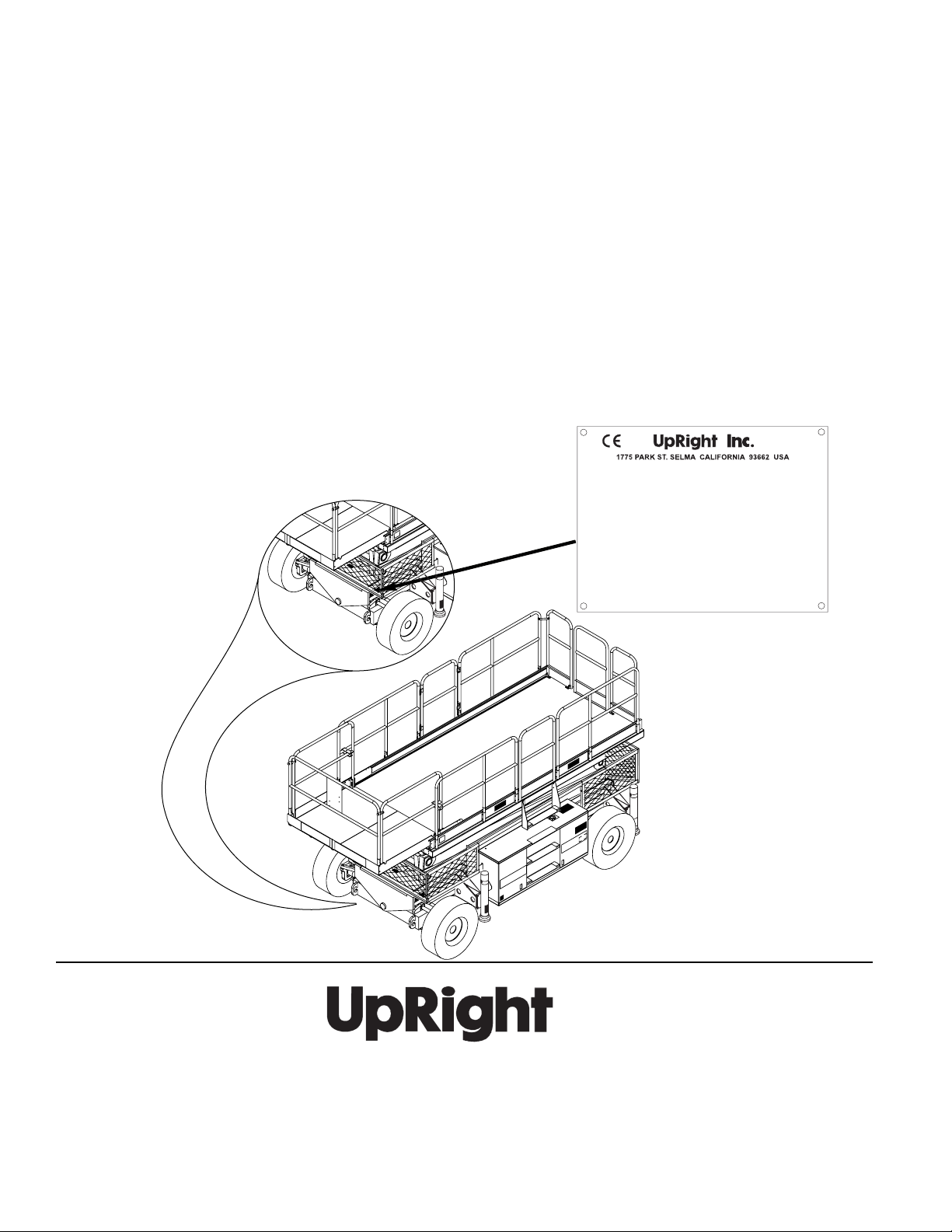

When contacting UpRight for service or parts information, be sure to include the MODEL and SERIAL NUMBERS from the

equipment nameplate. Should the nameplate be missing, the SERIAL NUMBER is also stamped on top of the chassis

above the front axle pivot.

RANÇAIS

F

Lors des communications avec UpRight pour des informations au sujet de l’entretient ou des pièces, ne pas oublier

d’inclure les NUMÉROS DE MODÈLE et de SÉRIE inscrits sur la plaque signalétique. Si la plaque signalétique manque, le

NUMÉRO DE SÉRIE est également estampé sur le dessus du châssis, au-dessus de l’axe pivot avant.

EUTSCH

D

Stellen Sie sicher, dass Sie die MODELL- und SERIENNUMMERN auf dem Gerätetypenschild angeben, wenn Sie sich mit

UpRight bezüglich Wartungs- oder Ersatzteilinformationen in Verbindung setzten. Sollte das Typenschild fehlen, finden Sie

die SERIENNUMMER auch auf dem Fahrwerk über der vorderen Schwenkachse.

Model______________ Serial number:____ _______

Machine weight _______kg Mfg. date:_________

Maximum wheel load:________

Maximum allowable incline of machine when elevated:_ ____deg.

Occupants and equipment must not exceed the rated maximum

load:_____kg Maximum platform occupa nts: _ ____

Maximum allowable sIde force on platform:_____N

Maximum platform height:______m

Maximum platform reach:______m

Maximum allowable wind speed: ______m/s=Beaufor t scale_____

Maximum hydraulic system pressure:___ __bar

Maximum system voltag e: _______Vdc

This machine is manufactured to co mply with

Machinery directive 89-392/CEE

CAUTION: CONSULT OPERAT OR'S MANUAL BEFORE USE.

061205-003

UpRight, Inc.

801 South Pine Street

Madera, California 93637

TEL: 559-662-3900

FAX: 559-673-6184

PARTS: 1-888-UR-PARTS

PARTS FAX: 1-800-669-9884

Call Toll Free in U.S.A.

1-800-926-LIFT

UpRight

Unit S1, Park West Industrial Park

Friel Avenue

Nangor Road

Dublin 12, Ireland

TEL: +353 1 620 9300

FAX: +353 1 620 9301

Page 3

PERATOR

O

M

ANUAL

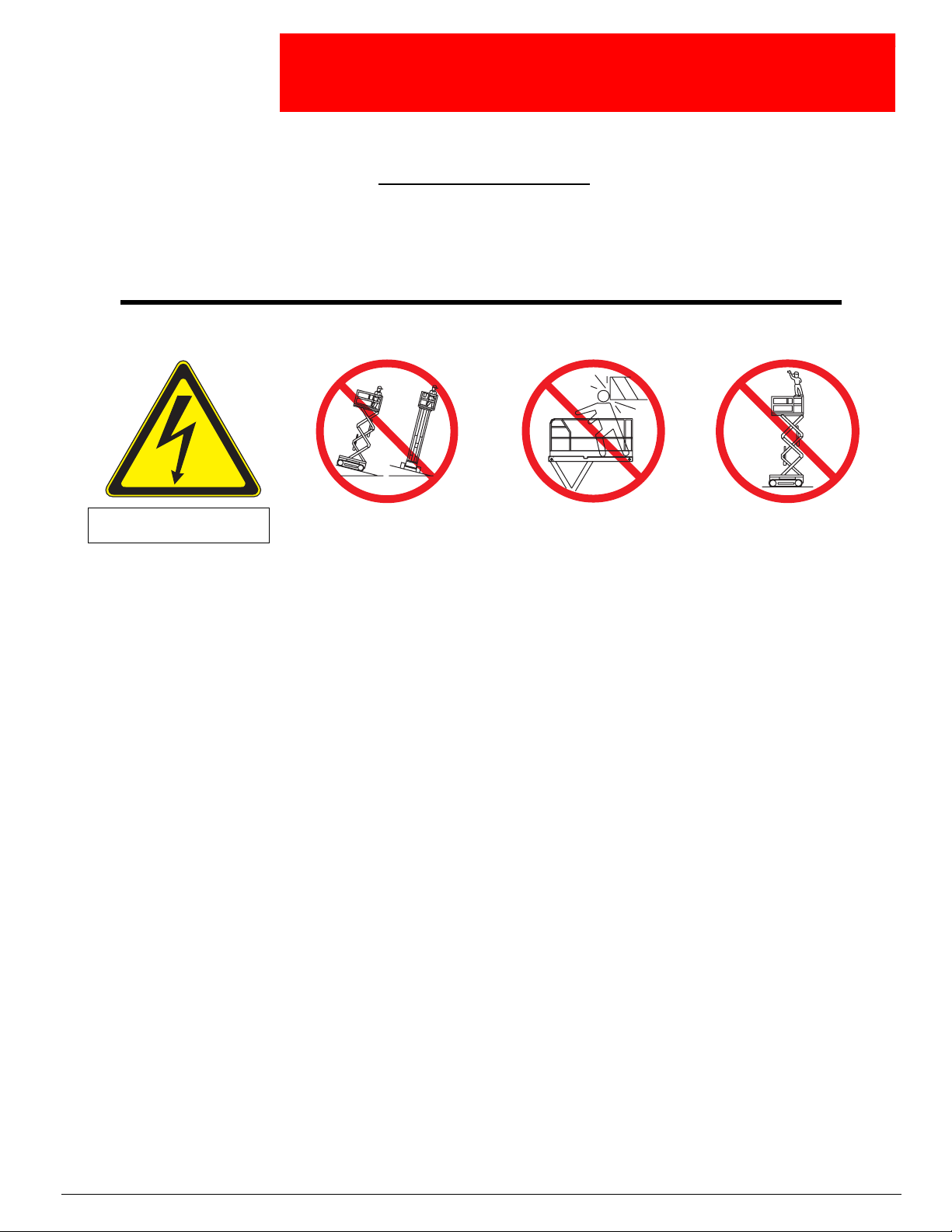

WARNING

All personnel shall carefully read, understand and follow all safety rules and operating

instructions before operating or performing maintenance on any UpRight aerial work platform.

Safety Rules

Safety Rules

Safety RulesSafety Rules

Electrocution Hazard

Electrocution Hazard Tip Over Hazard

Electrocution HazardElectrocution Hazard

THIS MACHINE IS NOT

INSULATED!

NEVER

the machine while elevated unless the

Tip Over Hazard Collision Hazard

Tip Over HazardTip Over Hazard

elevate the platform or drive

machine is on a firm, level surface.

Collision Hazard Fall Hazard

Collision HazardCollision Hazard

NEVER

without first checking for overhead

obstructions or other hazards.

position the platform

Fall Hazard

Fall HazardFall Hazard

climb, stand or sit on

NEVER

platform guardrails or midrail.

USE OF THE AERIAL WORK PLATFORM

used for the job. It is designed for repair and assembly jobs and assignments at overhead workplaces (ceilings, cranes, roof structures,

buildings etc.). All other uses of the aerial work platform are prohibited!

THIS AERIAL WORK PLATFORM IS NOT INSULATED!

trical equipment!

Exceeding the specified permissible maximum load

The use and operation of the aerial work platform as a lifting tool or a crane (lifting of loads from below upwards or from up high on

down)

is prohibited!

NEVER

DISTRIBUTE

NEVER

and avoiding them.

OPERATE

NEVER

IN CASE OF EMERGENCY

IF ALARM SOUNDS

Climbing up the railing of the platform, standing on or stepping from the platform onto buildings, steel or prefab concrete structures, etc.,

is prohibited!

Dismantling the swing gate or other railing components

locked!

It is prohibited

To extend the height or the range by placing of ladders, scaffolds or similar devices on the platform

NEVER

INSPECT

cables or hoses before using.

VERIFY

NEVER

To bypass any safety equipment

range.

NEVER

Modifications to the aerial work platform

AFTER USE

exceed the manual force allowed for this machine. See “Special Limitations” on page 4 for details.

all platform loads evenly on the platform.

operate the machine without first surveying the work area for surface hazards such as holes, drop-offs, bumps, curbs, or debris;

machine only on surfaces capable of supporting wheel loads.

operate the machine when wind speeds exceed this machine’s wind rating. See “Beaufort Scale” on page 4 for details.

push EMERGENCY STOP switch to deactivate all powered functions.

while platform is elevated, STOP, carefully lower platform. Move machine to a firm, level surface.

to keep the swing gate in an open position (held open with tie-straps) when the platform is raised!

perform service on machine while platform is elevated without blocking elevating assembly.

the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks, loose wire connections, and damaged

that all labels are in place and legible before using.

use a machine that is damaged, not functioning properly, or has damaged or missing labels.

is prohibited

charge batteries near sparks or open flame. Charging batteries emit explosive hydrogen gas.

, secure the work platform from unauthorized use by turning both keyswitches off and removing key.

: This aerial work platform is intended to lift persons and his tools as well as the material

For this reason it is imperative to keep a safe distance from live parts of elec-

is prohibited!

is prohibited!

and presents a danger for the persons on the aerial work platform and in its working

are prohibited

or permissible only at the approval by UpRight.

See “Special Limitations” on page 4 for details.

Always make certain that the swing gate is closed and securely

is prohibited!

Page 1

Page 4

067903-025 LX31/LX41/LX50

C

ONTENTS

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Special Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

All Models:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Platform Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Manual Force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Beaufort Scale. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Lift Overload Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Pre-Operation & Safety Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

System Function Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Travel with Platform Lowered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Travel with Work Platform Elevated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Steering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Raising and Lowering the Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Leveling the Platform

(Outrigger equipped machines only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Outrigger Switches and Indicator Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

To Level the Platform (Extend the Outriggers). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

To Retract the Outriggers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Emergency Lowering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

LX31 and LX41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

LX50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Towing or Winching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Parking Brake Release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

After Use Each Day. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Fold Down Guardrails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Fold Down Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Erection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Transporting the Work Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Preparation for Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Lifting By Crane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Driving or Winching onto a Truck or Trailer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Blocking the Elevating Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Brace Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Brace Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Hydraulic Fluid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Battery Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Coolant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Preventative Maintenance Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Daily Preventative Maintenance Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Maintenance Table Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Maintenance Report. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Page 2 Operator Manual

Page 5

Introduction 067903-025 LX31/LX41/LX50

WARNING

!

!

I

NTRODUCTION

G

ENERAL

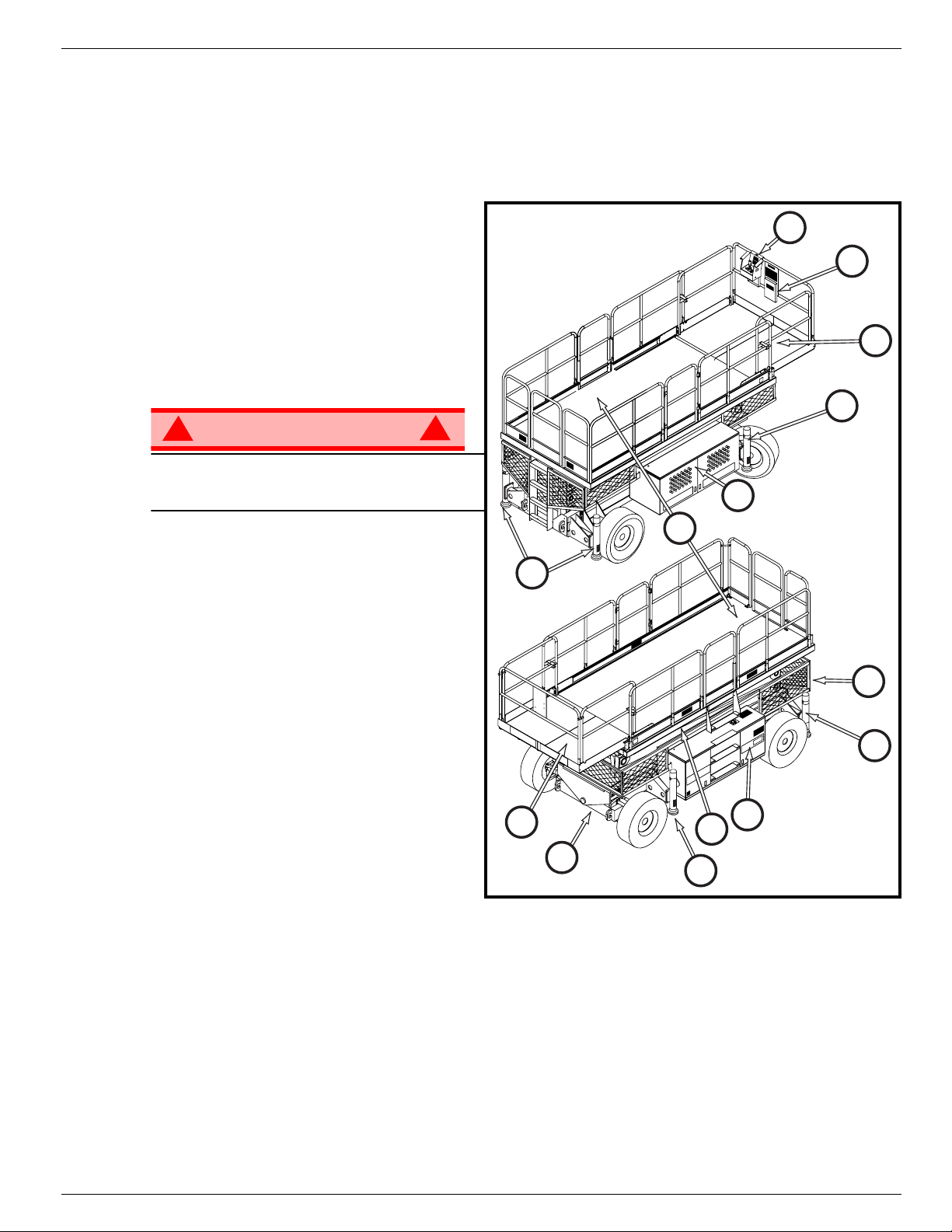

This manual covers the operation of the LX 31, LX 41 and LX50 Internal Combustion Work Platform.

amnual must be stored on the machine at all times.

D

ESCRIPTION

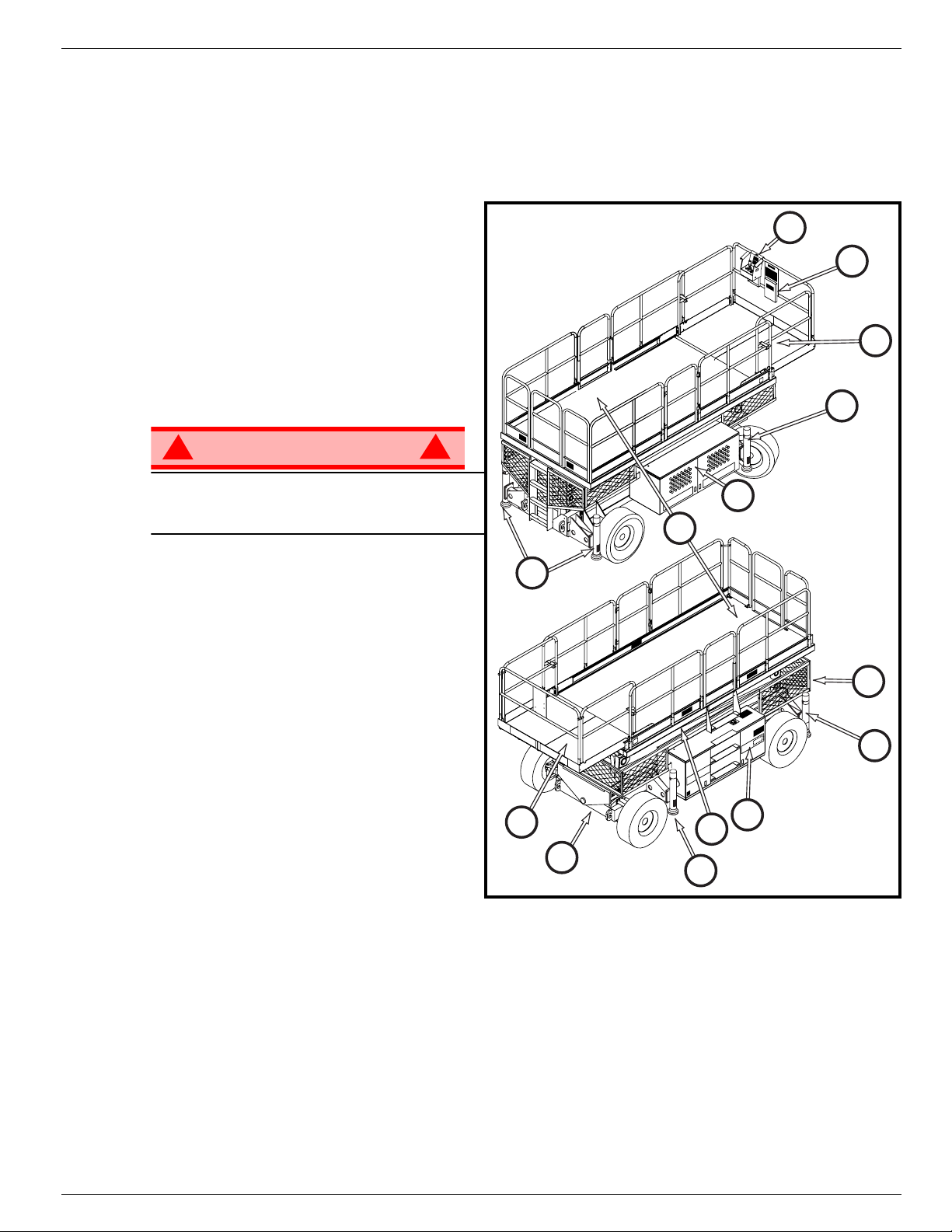

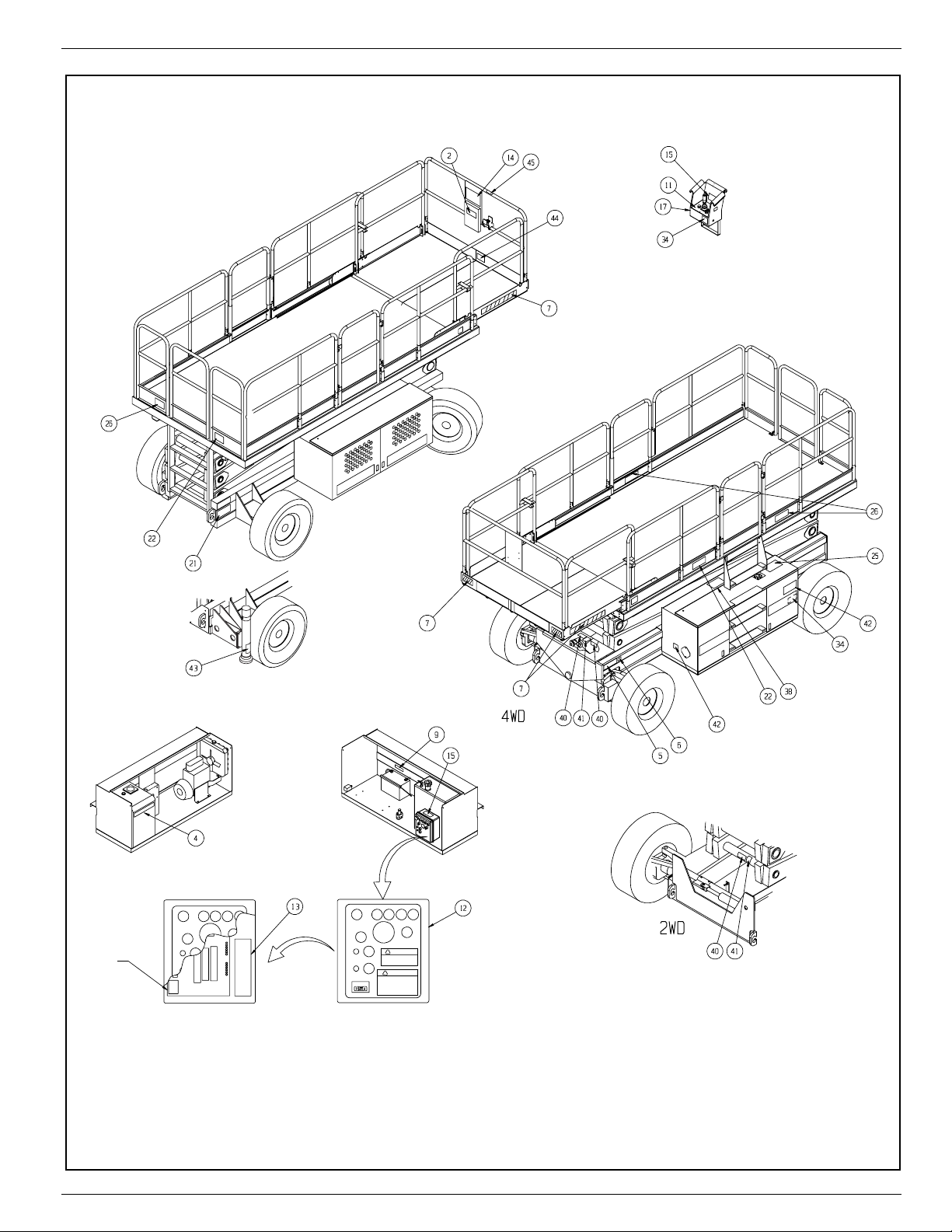

Figure 1:

1. Platform

LX Series Work Platform

3

The platform has a reinforced steel floor,

guardrails with midrail, toeboards and an

entrance gate at the rear and both sides of

the platform. The guardrails can be folded

down for access through doors or for shipment.

2. Slide-out Deck

10

DO NOT use the maintenance platform

without guardrails properly assembled and in

place

3. Platform Controls

1

8

This

4

2

The platform controls contain the controls to

operate the machine. It should be hung on

the front, left, or right guardrail.

4. Manual Case

5. Elevating Assembly

The platform is raised and lowered by the

elevating assembly; a five section scissor

assembly powered by two single-stage lift

cylinders.

6. Scissor Guard

7. Control Module

The control module contains the fuel tank,

hydraulic valve manifold, horn/alarms, battery, and chassis control panel.

8. Power Module

The power module contains the engine, the hydraulic pump, the hydraulic reservoir.

9. Chassis

The chassis is a structural frame that supports all the components of the Work Platform.

10. Outriggers (optional)

10

2

7

5

9

10

6

10

Operator Manual Page 3

Page 6

067903-025 LX31/LX41/LX50 Special Limitations

DANGER

! !

DANGER

! !

DANGER

! !

DANGER

! !

S

PECIAL

L

IMITATIONS

A

LL

M

ODELS

Travel with the platform raised is limited to a creep speed range.

Elevating of the Work Platform is limited to firm, level surfaces only.

The elevating function shall ONLY be used when the work platform is level and on a firm surface.

The work platform is NOT intended to be driven over uneven, rough, or soft terrain.

P

LATFORM

The maximum capacity for the MACHINE, including occupants is determined by model and options, and

is listed in “Specifications” on page 22.

DO NOT exceed the maximum platform capacity or the platform occupancy limits for this machine.

:

C

APACITY

M

ANUAL

Manual force is the force applied by the occupants to objects such as walls or other structures outside the

work platform.

The maximum allowable manual force is limited to 200 N (45 lbs.) of force per occupant, with a maximum

of 400 N (90 lbs.) for two or more occupants.

DO NOT exceed the maximum amount of manual force for this machine.

B

EAUFORT

Never operate the machine when wind speeds exceed 45 km/h (28 mph) [Beaufort scale 6].

BEAUFORT

RATING

3 3,4~5,4 12,25~19,4 11.5~17.75 7.5~12.0 Papers and thin branches move, flags wave.

4 5,4~8,0 19,4~28,8 17.75~26.25 12.0~18 Dust is raised, paper whirls up, and small branches sway.

5 8,0~10,8 28,8~38,9 26.25~35.5 18~24.25 Shrubs with leaves start swaying. Wave crests are apparent in ponds or swamps.

6 10,8~13,9 38,9~50,0 35.5~45.5 24.5~31 Tree branches move. Power lines whistle. It is difficult to open an umbrella.

7 13,9~17,2 50,0~61,9 45.5~56.5 31.~38.5 Whole trees sway. It is difficult to walk against the wind.

m/s km/h ft/s mph

L

IFT

O

All models include a feature that alerts the operator when the platform load is exceeded. If the alarm

sounds during the lift function, lower the platform and reduce the platform load.

F

ORCE

S

WIND SPEED

VERLOAD

CALE

A

GROUND CONDITIONS

LARM

Never operate the machine with a platform load greater than the rated capacity.

Page 4 Operator Manual

Page 7

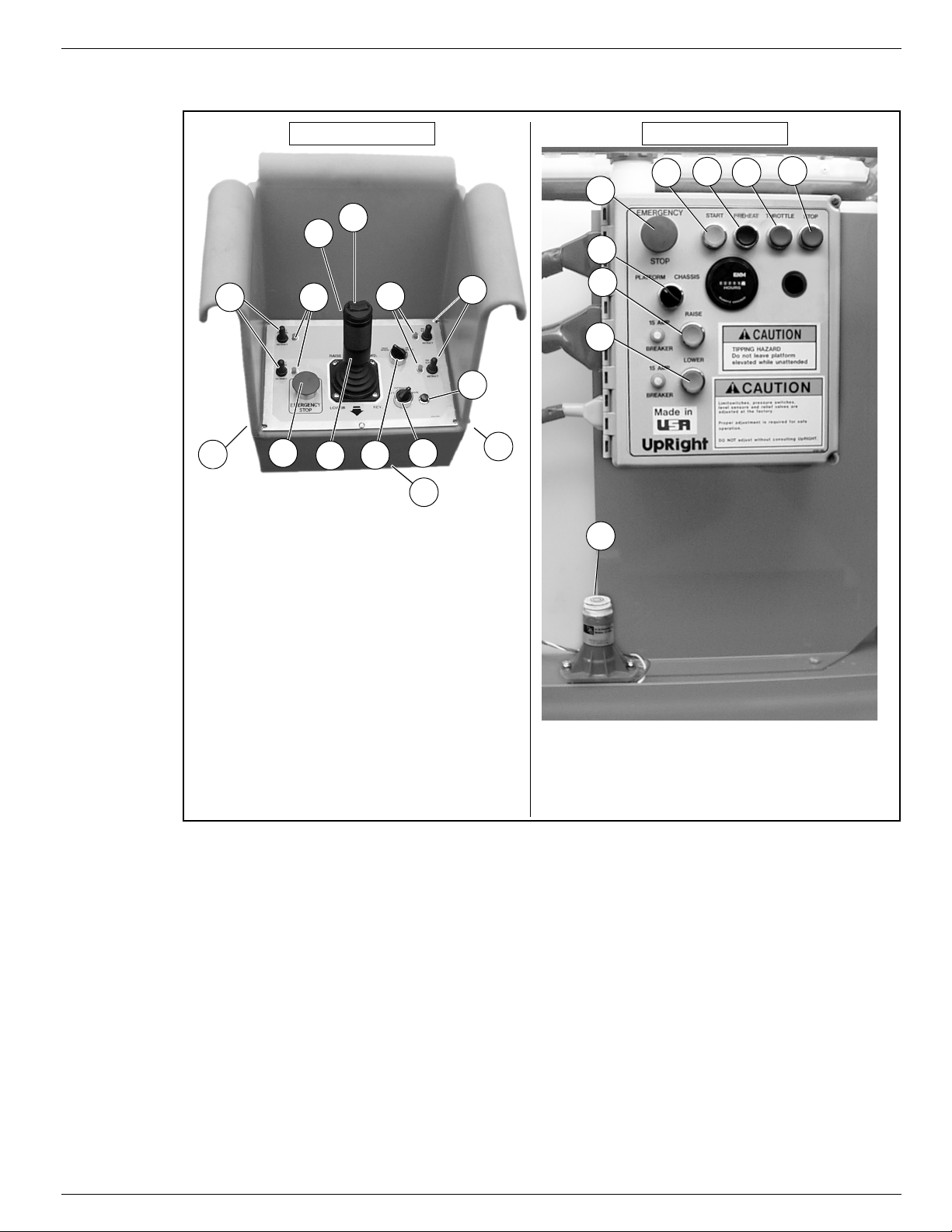

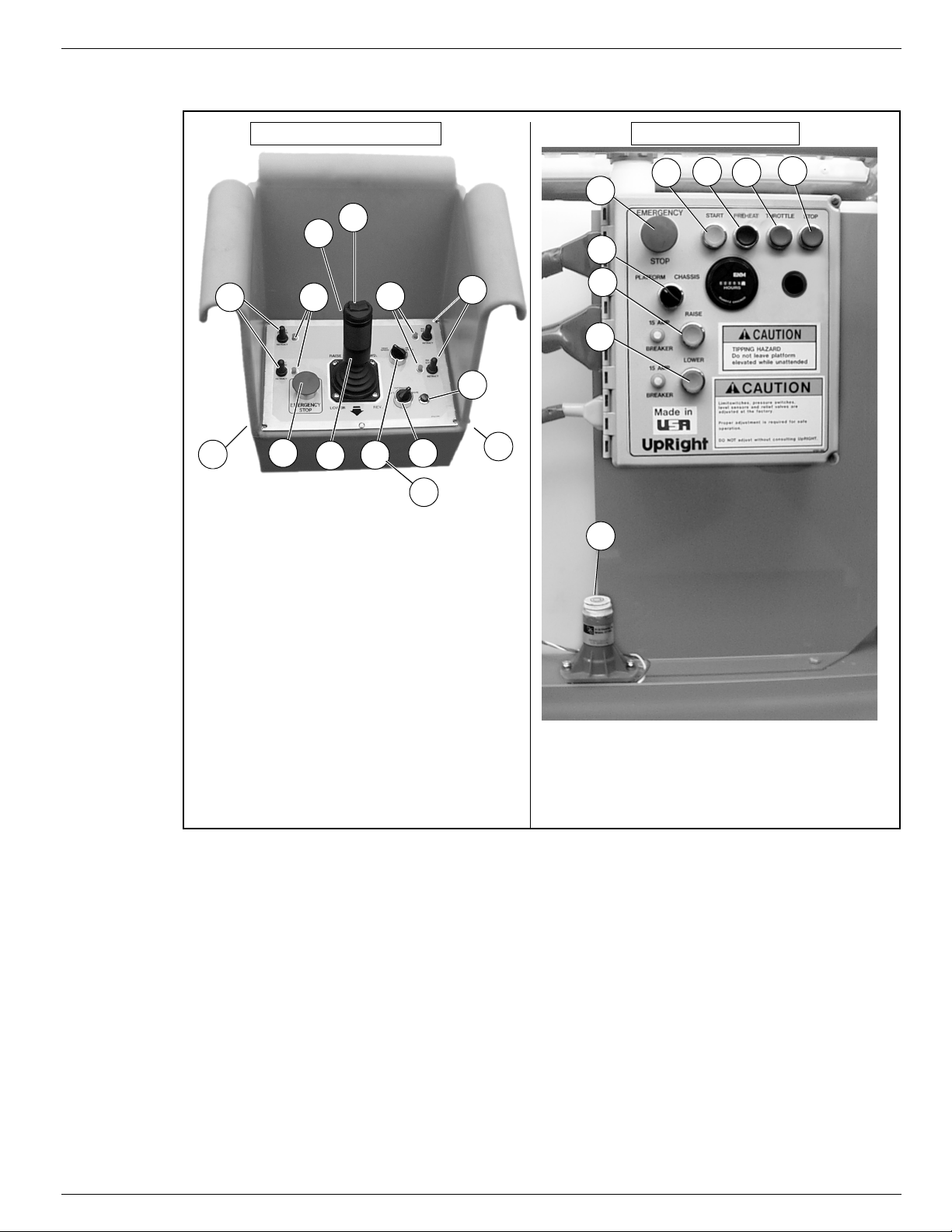

Controls and Indicators 067903-025 LX31/LX41/LX50

4*

2

1

3

7**

9

10

8

Outrigger Options

* Outrigger Switches and Outrigger Lights are installed on

outrigger equipped machines only.

** Outrigger selection is available on outrigger equipped

machines only.

5*

5*

4*

1 Steering Switch

2. Interlock Lever Switch

3. Control Lever

4. Outrigger Switches

5. Outrigger Indicator Lights

6. Emergency Stop Switch

7. Lift/Drive Switch

8. Drive Speed/Torque Selector Switch

9. Drive Enable Indicator

10. Key Switch

11. Glow Plug Button

12. Horn Button

6

11

1Emergency Stop

2. Platform/Chassis Switch

3. Raise Button

4. Lower Button

5. Start Button

6. Glow Plug Button

7. Throttle Button

8. Stop Button

9. Level Sensor

7

1

2

3

4

5

6

8

9

Platform Controls Chassis Controls

12

C

ONTROLS

AND

I

NDICATORS

Figure 2:

Controls and Indicators

Operator Manual Page 5

Page 8

067903-025 LX31/LX41/LX50 Pre-Operation & Safety Inspection

CAUTION

!

!

WARNING

!

!

P

RE

-O

PERATION

Carefully read, understand and follow all safety rules, operating instructions, labels and National Safety

NOTE:

Instructions/Requirements. Perform the following steps each day before use.

1. Open modules and inspect for damage, fluid leaks or missing parts.

2. Check the hydraulic fluid level sight gauge on the hydraulic tank with the platform fully lowered. Add

fluid if necessary.

3. Check that fluid level in the battery is correct (see “Battery Maintenance” on page 16).

4. Check the engine oil level and fuel level.

5. Check that all guardrails are in place, the slide-out deck extension is secured with the pin, and all fasteners are properly tightened.

6. Check tire pressure: 3,4 bar (

7. Carefully inspect the entire work platform for damage such as cracked welds or structural members,

loose or missing parts, fluid leaks, damaged cables or hoses, loose connections and tire damage.

8. While the engine is cool, check the engine coolant level.

& S

AFETY

50 psi

I

NSPECTION

).

S

YSTEM

DO NOT check coolant when engine or radiator is hot; hot coolant can cause severe burns.

F

UNCTION

STAND CLEAR of the work platform while performing the following checks.

Before operating the work platform, survey the work area for surface hazards such as holes, drop-offs,

bumps and debris.

Check in ALL directions, including above the work platform, for obstructions and electrical conductors.

Protect control console cable from possible damage while performing checks.

1. Move the machine, if necessary, to an unobstructed area to allow for full elevation.

2. Place chassis and platform emergency stop switches in the ON position (Figure 2) by pulling the buttons out.

3. Verify that the Platform/Chassis switch is set to PLATFORM.

4. Turn the Platform Controls key switch clockwise to ON. Turn fully clockwise to start the engine, releasing the key once the engine starts.

If the engine is cold, depress the glow plug button and hold for 6 seconds to heat the glow plugs.

NOTE:

I

NSPECTION

5. Position the Lift/Drive switch to the DRIVE position. The drive enable light should be ON.

6. With the speed range switch first in HIGH TORQUE and then in HIGH SPEED, depress the interlock

lever switch and slowly push the control lever to FORWARD then REVERSE positions to check for

speed and directional control. The farther you push or pull the control lever, the faster the machine will

travel.

7. Depress the interlock lever switch and push the steering switch RIGHT then LEFT to check for steering

control.

Page 6 Operator Manual

Page 9

System Function Inspection 067903-025 LX31/LX41/LX50

8. Optional Outrigger Equipped Machines:

a. With the Lift/Outrigger/Drive switch in DRIVE, depress the interlock lever switch on the control lever

and position each Outrigger switch to the EXTEND position.

• Outriggers should be disabled. If an outrigger extends during this test

from service until it is repaired.

b. Turn the Drive/Outrigger/Lift switch to OUTRIGGER.

c. Depress the interlock lever switch on the control lever and position each Outrigger switch to the

EXTEND position to deploy all four (4) outriggers.

• Check the outrigger indicator lights; they should be ON.

d. Depress the Interlock Lever switch on the control lever and position each Outrigger switch to the

RETRACT position.

• Partially retract all four (4) outriggers. The outrigger indicator lights should FLASH.

• Fully retract all four (4) outriggers. The outrigger indicator lights should be OFF.

9. Open the Control Module covers to gain access to the chassis controls and level sensor.

10. Turn the Platform/Chassis switch to CHASSIS.

11. Push the throttle button in. Push the Raise button to elevate platform while pushing the level sensor off

of level. The platform should only partially elevate and the tilt alarm should sound. If the platform continues to elevate and/or there is no alarm,

12. Release the level sensor and fully elevate the platform.

13. Visually inspect the elevating assembly, lift cylinder, cables and hoses for damage or erratic operation.

Check for missing or loose parts.

14. Lower the platform partially by pushing in on the Lower button, and check operation of the audible lowering alarm.

15. Open the chassis emergency lowering valve to check for proper operation (refer to “Emergency Lowering” on page 11). Once the platform is fully lowered, close the valve by releasing the knob.

16. Turn the Platform/Chassis switch to PLATFORM.

17. Close and secure the module covers.

18. Enter the platform making sure the gate is latched.

19. Position the Lift/Drive switch to LIFT.

20. Depress the interlock lever switch and slowly push the control lever to UP to raise the platform; fully actuate the control lever to check proportional lift speed. Slowly pull the control lever to the DOWN position to

lower the platform. Check that the lowering alarm sounds.

21. Optional Outrigger Equipped Machines:

a. With the Lift/Outrigger/Drive switch in LIFT, depress the interlock lever switch on the control lever and

position any outrigger switch to the EXTEND position.

• Outriggers should be disabled. If an outrigger extends during this test,

and remove the machine from service until it is repaired.

22. Turn the controller key switch to OFF, push the Emergency Stop button, and dismount the platform.

and remove the machine from service until it is repaired.

STOP

. Remove the machine

STOP

. Lower the platform

STOP

Operator Manual Page 7

Page 10

067903-025 LX31/LX41/LX50 Operation

WARNING

!

!

O

PERATION

Before

NOTE:

any deficiencies have been corrected, and the operator has been thoroughly trained on this machine.

Never operate the work platform with the parking brakes released. Serious injury or damage could

result.

T

RAVEL

1. Verify the following:

• the chassis Emergency Stop button is in the ON position (pull out)

• the drive enable indicator is ON

• the Platform/Chassis switch is on PLATFORM.

NOTE:

are fully retracted.

operating the work platform, ensure that the pre-operation and safety inspection has been completed,

WITH

If the drive enable indicator is OFF, verify that the platform is fully lowered and (if so equipped) the outriggers

P

LATFORM

L

OWERED

2. After mounting the platform, close and latch the gate. Check that the guardrails are in position and

properly assembled, with the fasteners properly torqued.

3. Check that the route is clear of persons, obstructions, holes and drop-offs, and is capable of supporting

the wheel loads.

4. Check clearances above, below and to the sides of the platform.

5. Pull the controller Emergency Stop button out to the ON position.

6. Turn the controller key switch fully clockwise to start the engine, releasing the key once the engine

starts.

If the engine is cold, hold the glow plug button in for 6 seconds to heat the glow plugs.

NOTE:

7. Set the Lift/Drive switch to DRIVE.

8. Set the speed range switch to HIGH TORQUE.

9. Grasp the control lever so that the interlock lever switch is depressed (releasing the interlock lever

switch cuts power to controller). Slowly push or pull the control lever to FORWARD or REVERSE to

travel in the desired direction. The farther you push or pull the control lever from center, the faster the

machine will travel.

10. While moving, push the speed range switch to HIGH SPEED for travel on level surfaces or to HIGH

TORQUE for climbing grades or traveling in confined areas.

Page 8 Operator Manual

Page 11

Operation 067903-025 LX31/LX41/LX50

T

RAVEL

Travel with the platform elevated

The work platform will travel at reduced speed when in the elevated position, and only if the front axle is

NOTE:

parallel with the rear axle.

1. Check that the route is clear of persons, obstructions, holes and drop-offs, is level and capable of supporting the wheel loads.

2. Check clearances above, below and to the sides of the platform.

3. Position the Lift/Drive switch to the DRIVE position.

4. Push the control lever to FORWARD or REVERSE for the desired direction of travel.

5. If the machine quits driving and the tilt alarm sounds, immediately lower the platform and move the

machine to a level location before re-elevating the platform.

S

TEERING

Push the steering switch

insure proper direction.

WITH

W

ORK

RIGHT

P

LATFORM

on firm and level surfaces.

ONLY

or

to turn the wheels. Observe the tires while maneuvering to

LEFT

E

LEVATED

Steering is not self-centering. Wheels must be returned to the straight ahead position by operating the steering

NOTE:

switch.

R

AISING AND

The machine must be on a firm, level surface, capable of supporting the weight of the machine. On

machines equipped with optional outriggers, use the outriggers to level the machine (refer to “Leveling the

Platform (Outrigger equipped machines only)” on page 10.

1. Position the Lift/Drive switch to LIFT.

2. While holding the control lever so the interlock lever switch is depressed, push the control lever slowly to

UP to raise the platform. Pushing the control lever farther increases the lift speed.

3. When the work task is completed, position the Lift/Drive switch to LIFT, and lower the platform by pulling

back on the control lever until the platform is fully lowered.

L

OWERING

THE

P

LATFORM

Operator Manual Page 9

Page 12

067903-025 LX31/LX41/LX50 Operation

WARNING

!

!

L

EVELING

(O

UTRIGGER

When using outriggers, all four (4) outriggers must be in firm contact with the supporting surface.

THE

P

LATFORM

EQUIPPED

MACHINES

ONLY

)

UTRIGGER SWITCHES AND INDICATOR

O

For each outrigger, there is an outrigger switch and an outrigger indicator light (refer to Figure 2).

Each outrigger switch will raise and lower one outrigger.

Each outrigger indicator light will indicate the position of one outrigger.

• When the indicator light is OFF - the outrigger is fully retracted.

• When the indicator light is FLASHING - the outrigger is partially extended.

• When the indicator light is ON - the outrigger is in firm contact with the supporting surface.

EVEL THE PLATFORM

TO L

1. Make sure that the extension deck is retracted before operating the outriggers.

2. Look around the machine; make sure that there is nothing obstructing the

outriggers, and that the surface beneath them is suitable to support the

weight of the machine.

3. Position the Lift/Outrigger/Drive switch set to OUTRIGGER.

4. Depress the interlock lever switch on the control lever, and operate the

outrigger switches to extend each outrigger until it is making firm contact

with the supporting surface.

5. While observing the bubble level on the guardrail, extend the outrigger

opposite the position of the bubble until the platform is level. For example:

if the bubble is to the front and left in the orbit, extend the rear right outrigger. Continue to adjust until

the bubble is centered in the small circle indicating that the platform is level.

6. Confirm that all four (4) outriggers are in firm contact with the supporting surface. The outriggers are in

contact with the supporting surface when the indicator lights are ON.

XTEND THE

(E

IGHTS

L

UTRIGGERS

O

)

Figure 3:

Platform Orbit Bubble Level

TO R

Page 10 Operator Manual

ETRACT THE OUTRIGGERS

1. Fully lower the platform.

2. Position the Lift/Outrigger/Drive switch set to OUTRIGGER.

3. Depress the interlock lever switch on the control lever, and position each outrigger switch to RETRACT.

• The outrigger indicator lights will be OFF when the outriggers are fully retracted.

• The drive enable indicator light will not come on until all four outriggers are fully retracted.

Page 13

Operation 067903-025 LX31/LX41/LX50

E

MERGENCY

L

OWERING

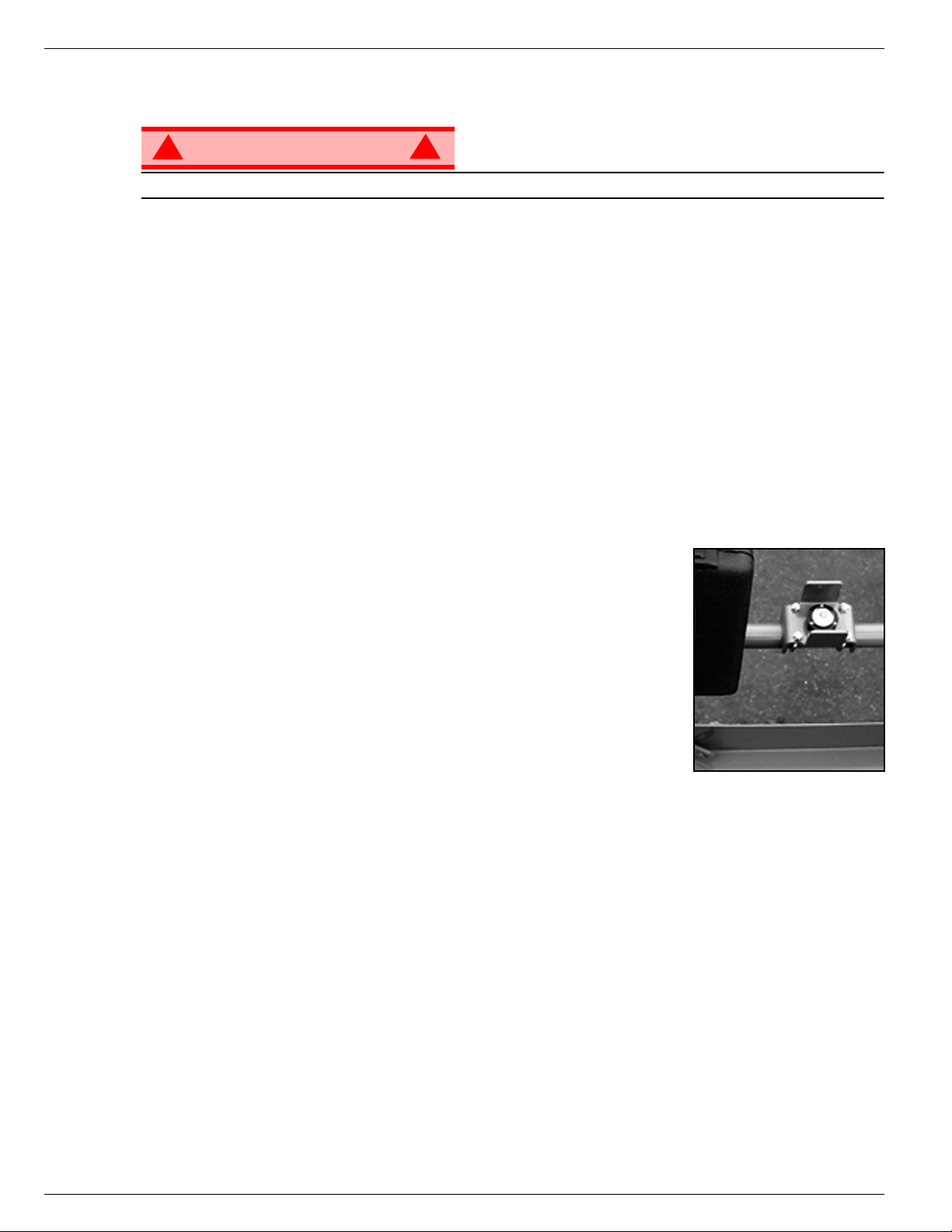

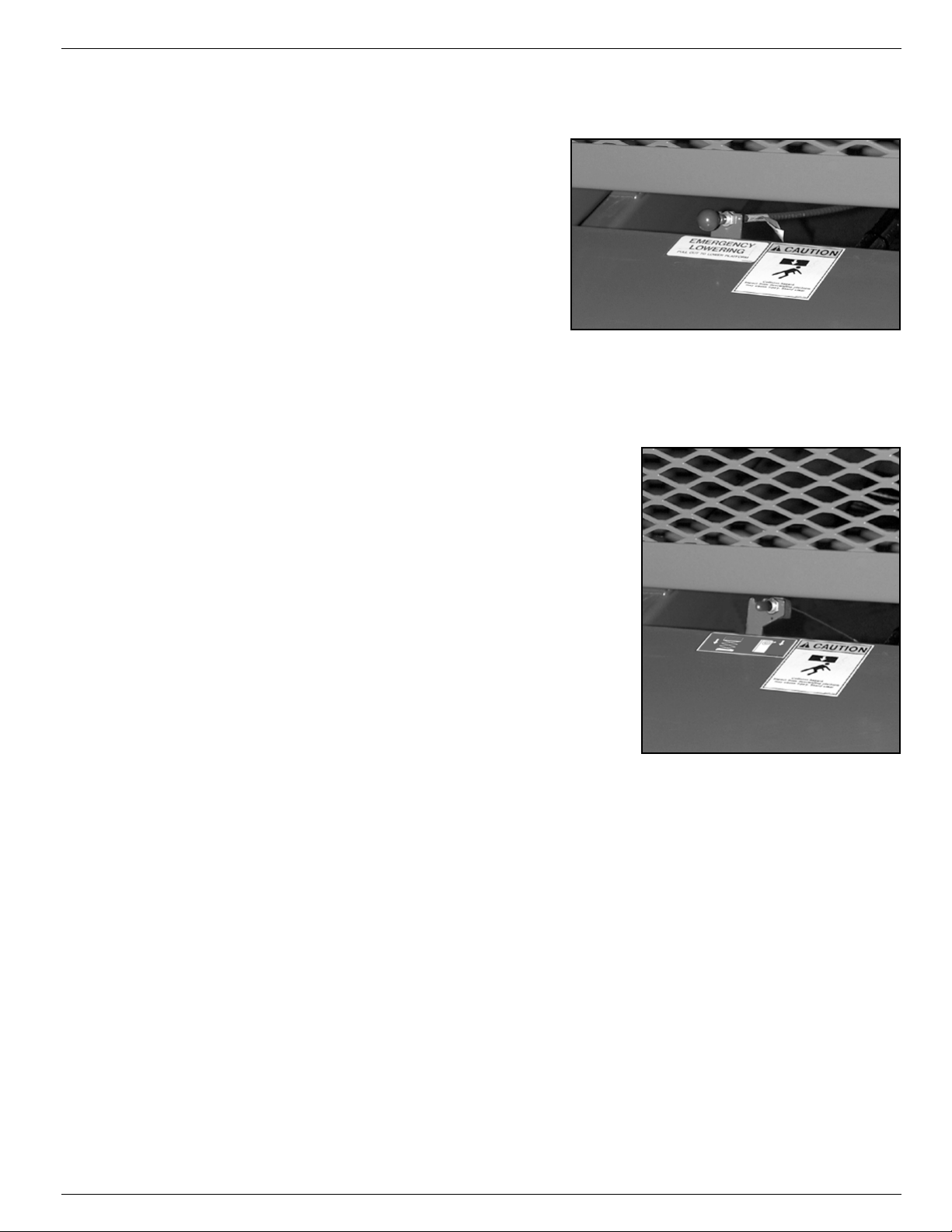

LX31

1. Open the emergency lowering valve by pulling on the

2. Once the platform is fully lowered, release the knob to

AND

LX41

The emergency lowering control knob is located at the

rear of the machine at the base of the scissor assembly.

knob and holding it.

close the valve.

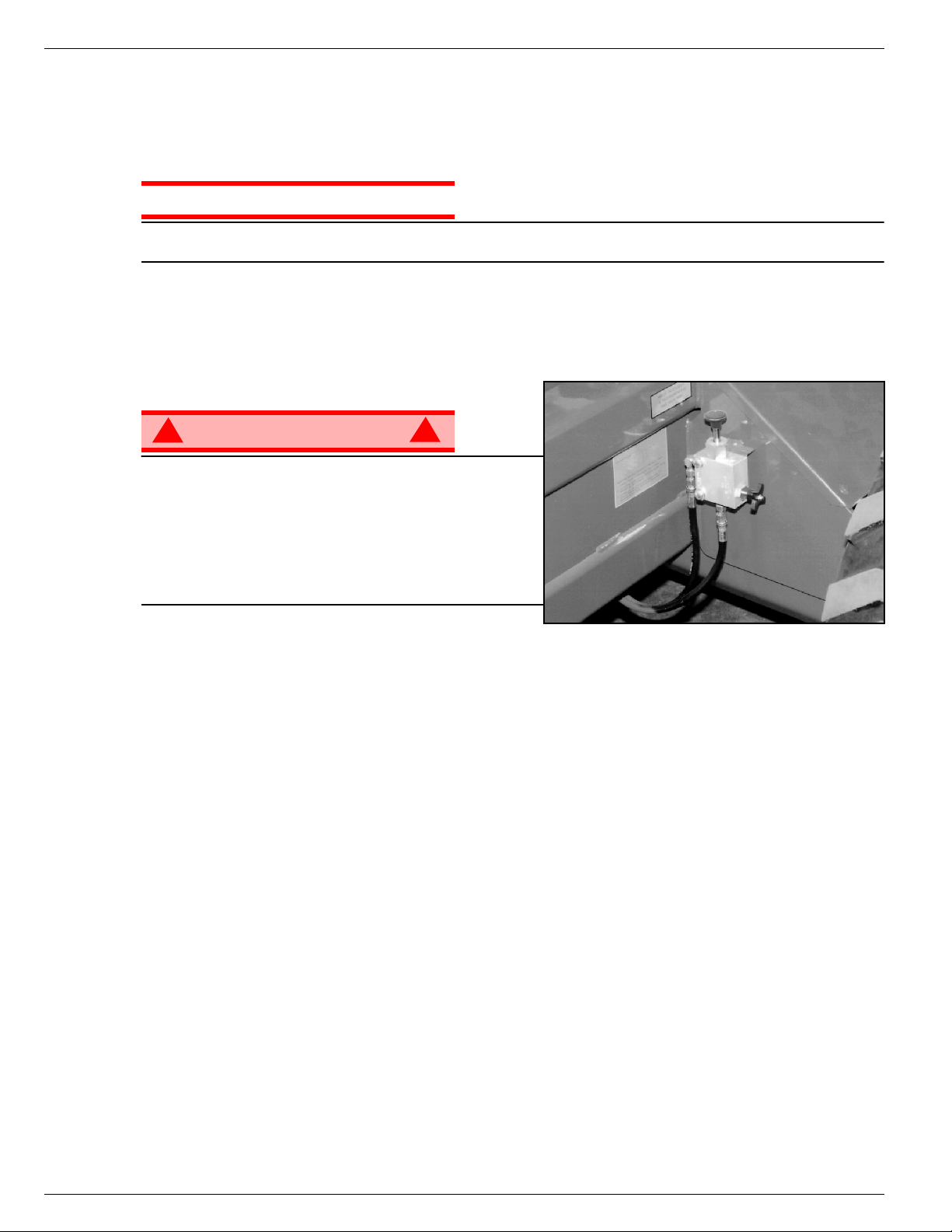

LX50

The emergency lowering control switch is located at the rear of the

machine at the base of the scissor assembly.

1. Open the emergency lowering valve by pushing down on the toggle switch and holding it.

2. Once the platform is fully lowered, release the toggle switch to

close the valve.

Figure 4:

Emergency Lowering Valve, LX31 and LX41

Figure 5:

Emergency Lowering, LX50

Operator Manual Page 11

Page 14

067903-025 LX31/LX41/LX50 Towing or Winching

CAUTION

WARNING

!

!

T

OWING

OR

W

INCHING

Perform the following only when the machine will not operate under its own power and it is necessary to

move the machine or when winching onto a transport vehicle (see “Transporting the Work Platform” on

page 14).

DO NOT tow or winch the machine faster than 0,3 m/s (1 ft./s). Faster speeds will damage drive

components and void the warranty.

P

ARKING

Never operate the work platform with the parking

brakes released. Serious injury or damage could

result.

Never release the brakes if the machine is on a slope.

Chock the wheels before releasing the parking brakes.

Hook the machine to a towing vehicle before releasing

the parking brakes.

B

RAKE

R

ELEASE

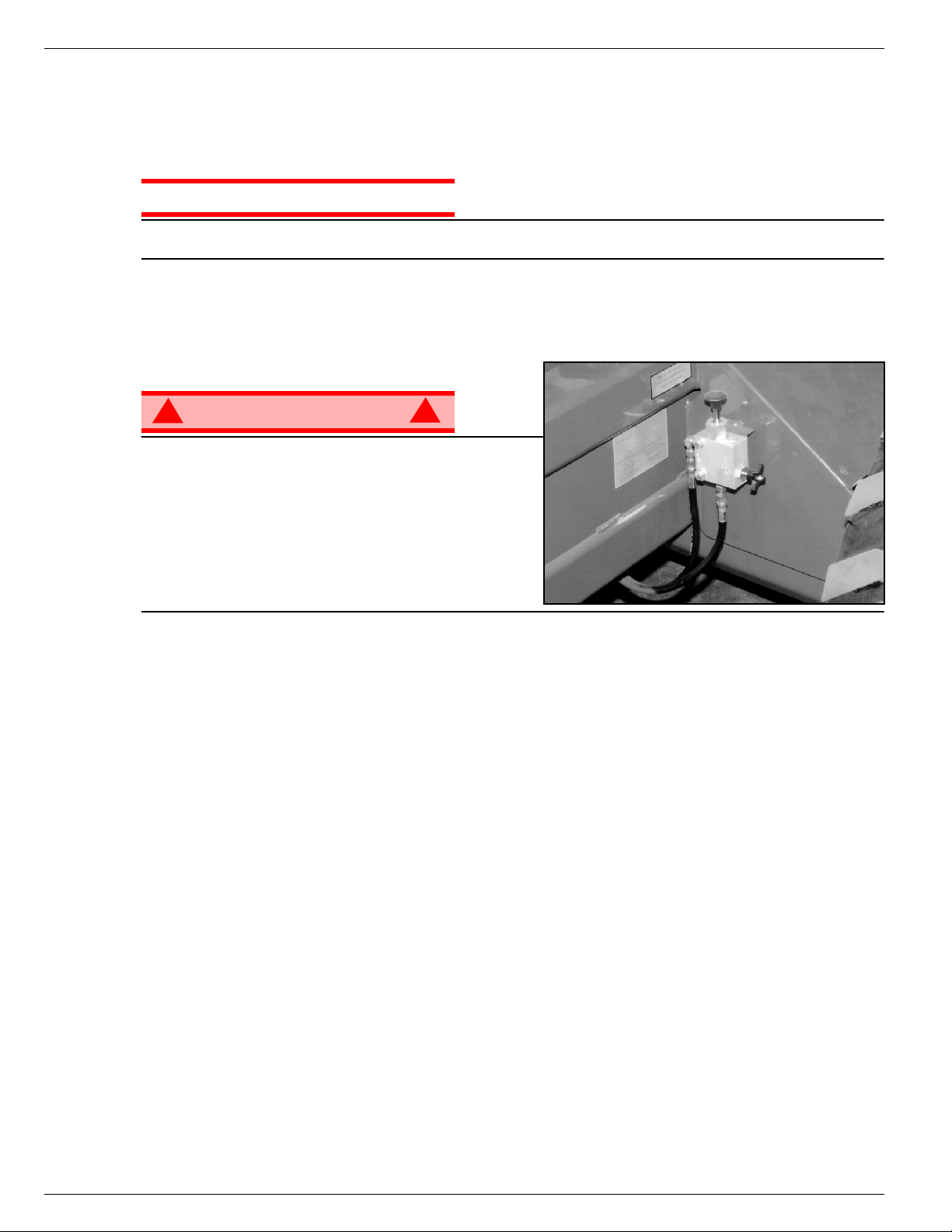

Figure 6:

Parking Brake Release Pump

A

FTER

1. Close the needle valve by turning the knob clockwise.

2. Pump the brake release pump until the parking brakes release and the wheels can be turned.

3. The machine will now roll when pushed or pulled.

4. Be sure to open the needle valve and verify that the parking brakes have engaged before the machine

is operated.

U

SE

E

ACH

1. Ensure that the platform is fully lowered.

2. Park the machine on level ground, preferably under cover, secure against vandals, children or unauthorized operation.

3. Turn the key switch to OFF and remove the key to prevent unauthorized operation.

D

AY

Page 12 Operator Manual

Page 15

Fold Down Guardrails 067903-025 LX31/LX41/LX50

WARNING

!

!

F

OLD

D

OWN

This procedure is only for passing through doorways. Guardrails must be returned to proper position

before using the machine.

G

UARDRAILS

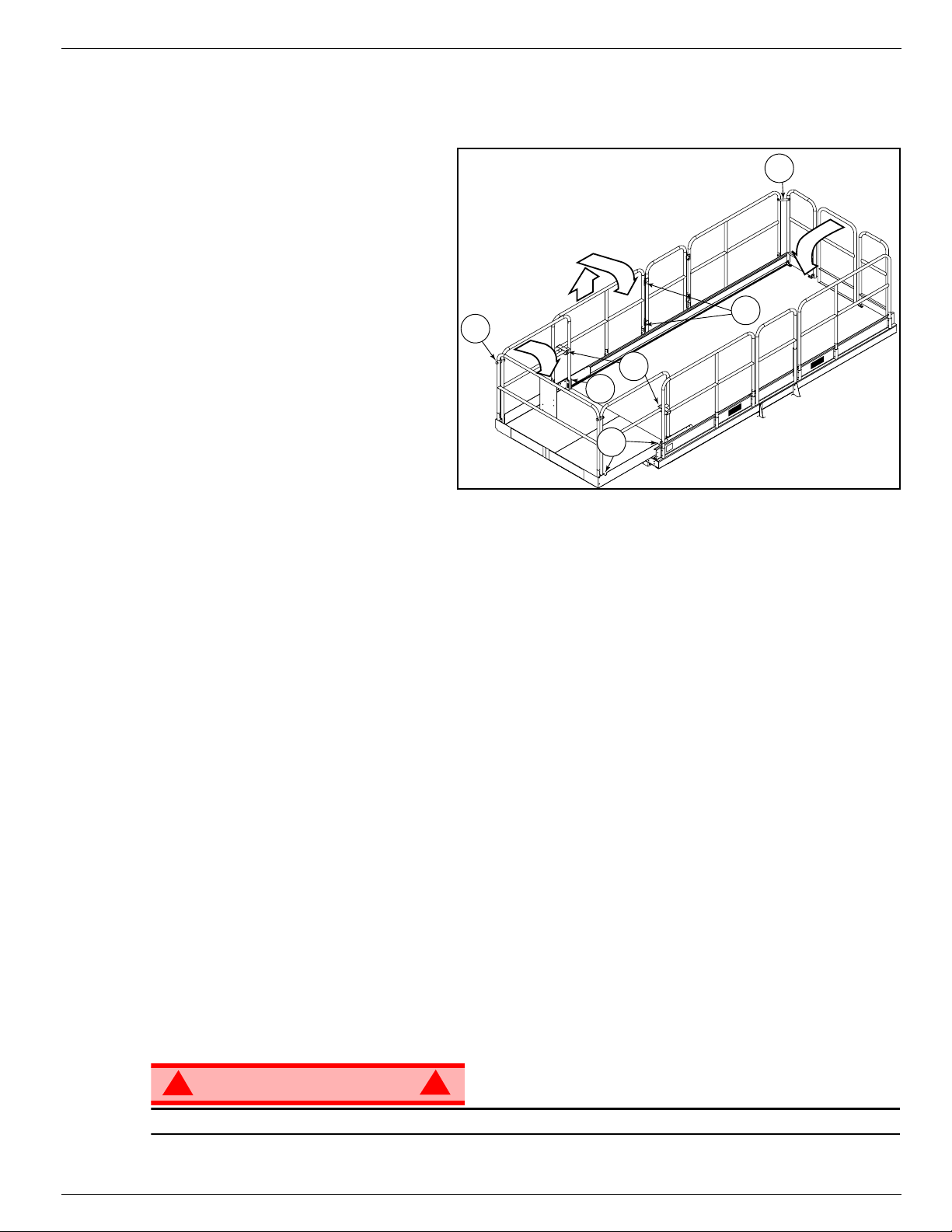

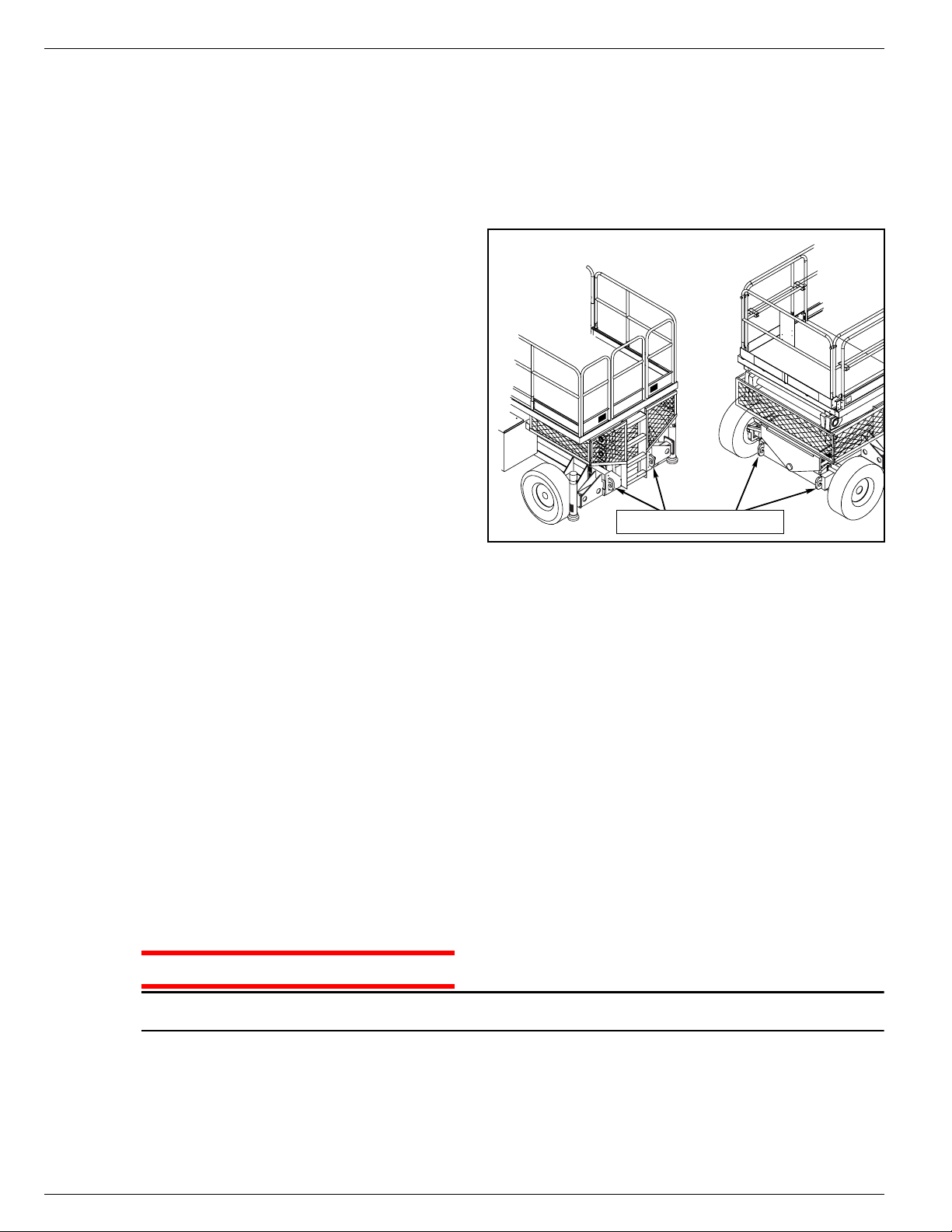

Figure 7:

Fold Down Guardrails

F

OLD

P

NOTE:

1. Place the controller on the platform.

2. Starting at the slide-out deck:

3. Go to the rear of the platform:

4. Unlatch the side gate so the left side guardrails can be folded down in two separate pieces. Also remove

5. Fold the rear half of the side guardrails onto the deck:

6. Fold the front half of the side guardrails onto the deck:

7. Lift up and fold down the front slide-out deck guardrail.

D

OWN

ROCEDURE

When performing the following

procedures, retain all fasteners.

• remove nuts, bolts and washers

from the top front corners of guardrails (A)

• remove the nuts, bolts and washers

from the slide-out deck side guardrail mid-rails (B)

• remove nuts, bolts and washers

located at the top of the sockets that

hold the slide-out deck side guardrails to the deck (C)

• fold the side guardrails down onto

the slide-out deck platform

• leave the end rail up and slide the deck all the way in.

• close and latch the rear gate

• remove the nuts, bolts, washers, and corner brackets from the top of the rear guardrail

• fold the rear guardrail down onto the platform, being careful to keep the gate latched.

the nuts, bolts and washers opposite the gate latch on the right side guardrail so it too can be separated

into two pieces (E).

• lift up and fold down so the guardrails rest on the deck, on top of the rear guardrail.

• lift up and fold down so the guardrails rest on the slide-out deck, with the guardrail posts resting in the

cutouts on the slide-out deck toeboard (F).

A

B

C

F

D

E

E

RECTION

1. Raise the front guardrail, making sure it is pushed down to secure the guardrail in the vertical position.

2. Raise the side guardrails, making sure each is pushed down to secure the guardrail in the vertical position; align holes and install bolts, washers and nuts. Tighten securely.

3. Raise one of the slide-out deck side guardrail assemblies; align holes and install bolts, washers and

nuts. Tighten securely. Repeat this procedure for the other slide-out deck side guardrails.

4. Raise the rear guardrail, and install the corner brackets, nuts, bolts and washers.

5. Hang the controller from the front guardrail.

6. Before operating work platform check that all fasteners are in place and properly torqued.

Before operating machine, guardrails must be securely fastened in their proper position.

Operator Manual Page 13

P

ROCEDURE

Page 16

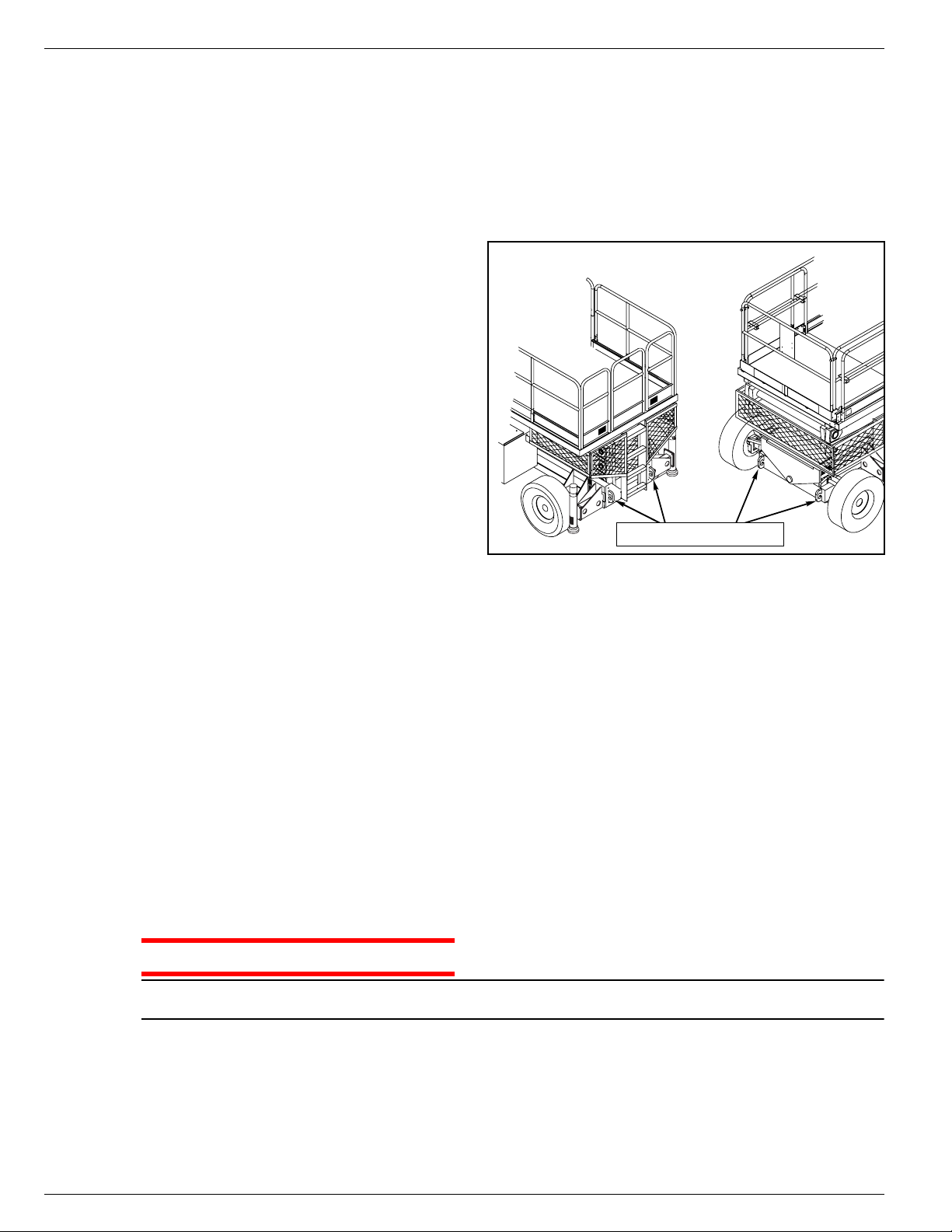

067903-025 LX31/LX41/LX50 Transporting the Work Platform

CAUTION

T

RANSPORTING

P

REPARATION

1. Fully lower the platform.

2. Disconnect the battery negative (-) lead from the battery terminal.

3. Band the controller to the front guardrail.

4. Band the elevating linkage to the frame.

L

IFTING

1. Secure straps to chassis tie down/lifting

2. Place the platform onto the transport vehi-

3. Chock the wheels.

4. Secure the work platform to the transport

lugs only.

cle in transport position.

vehicle with chains or straps of adequate

load capacity attached to the chassis tie

down/lifting lugs.

THE

BY C

W

FOR

RANE

ORK

P

S

HIPMENT

LATFORM

Rear View

Figure 8:

Front View

Transporting Work Platform

Tie Downs/Lifting Lugs

D

RIVING OR

Do not winch faster than 0,3 m/s

NOTE:

1. Move the machine onto the truck or trailer;

A. To

B. To

2. Secure the work platform to the transport vehicle with chains or straps of adequate load capacity

Drive

a. Move the work platform up the ramp and into transport position.

b. Set the wheels straight and turn off the machine.

c. Chock the wheels.

Winch

a. Move the work platform up to the ramp.

b. Attach the winch cable to the tie down/lifting lugs.

c. Release the parking brakes (refer to “Towing or Winching” on page 12).

d. Winch the platform into transport position

e. Chock the wheels.

attached to the chassis tie down/lifting lugs.

W

INCHING

the machine onto the transport vehicle:

the machine onto the transport vehicle:

(1 ft/s)

ONTO

.

A T

RUCK

OR

T

RAILER

Overtightening of chains or straps through tie down/lifting lugs may result in damage to the work

platform.

Page 14 Operator Manual

Page 17

Maintenance 067903-025 LX31/LX41/LX50

WARNING

!

!

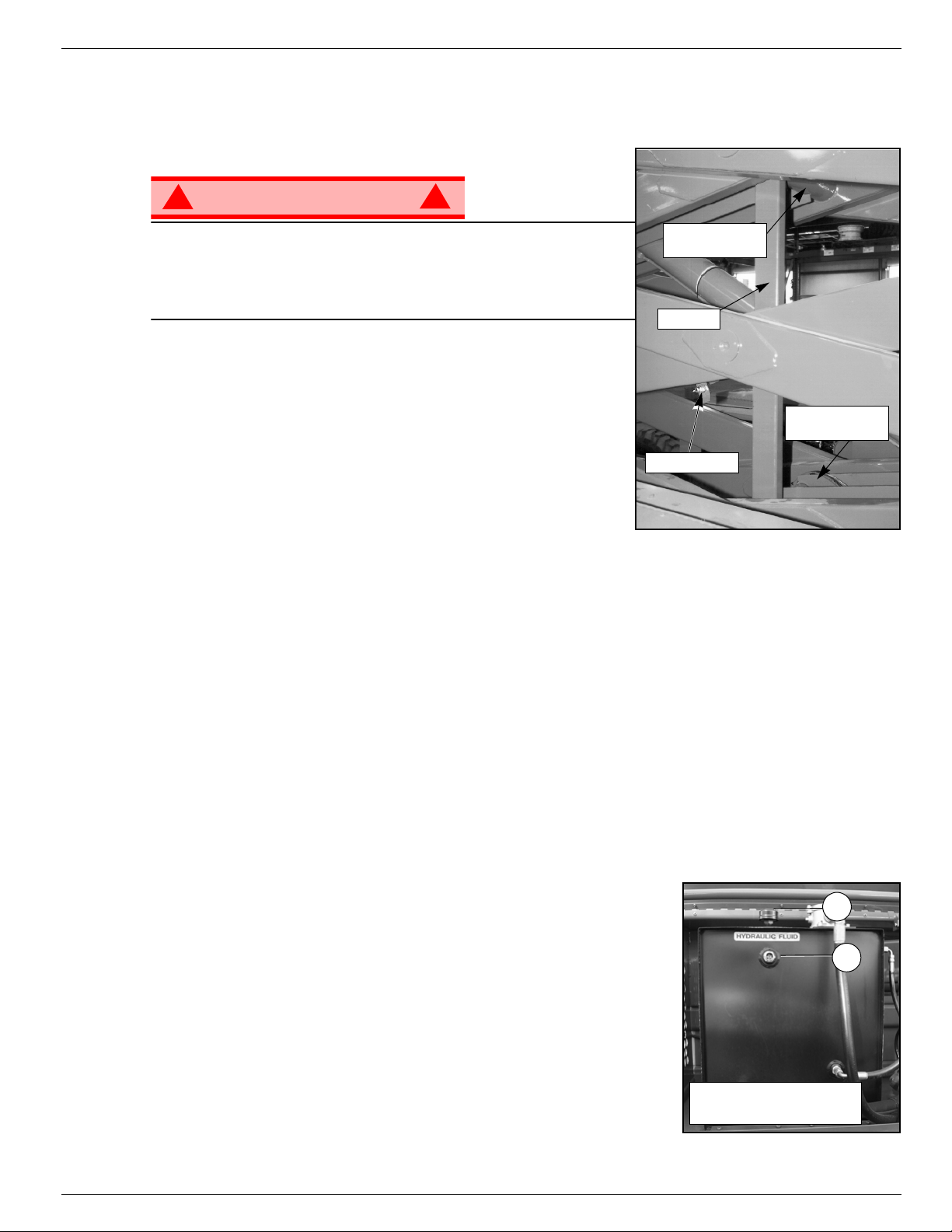

Lower Scissor

Center Pivot

Upper Scissor

Center Pivot

Brace

Locking Pin

2

1

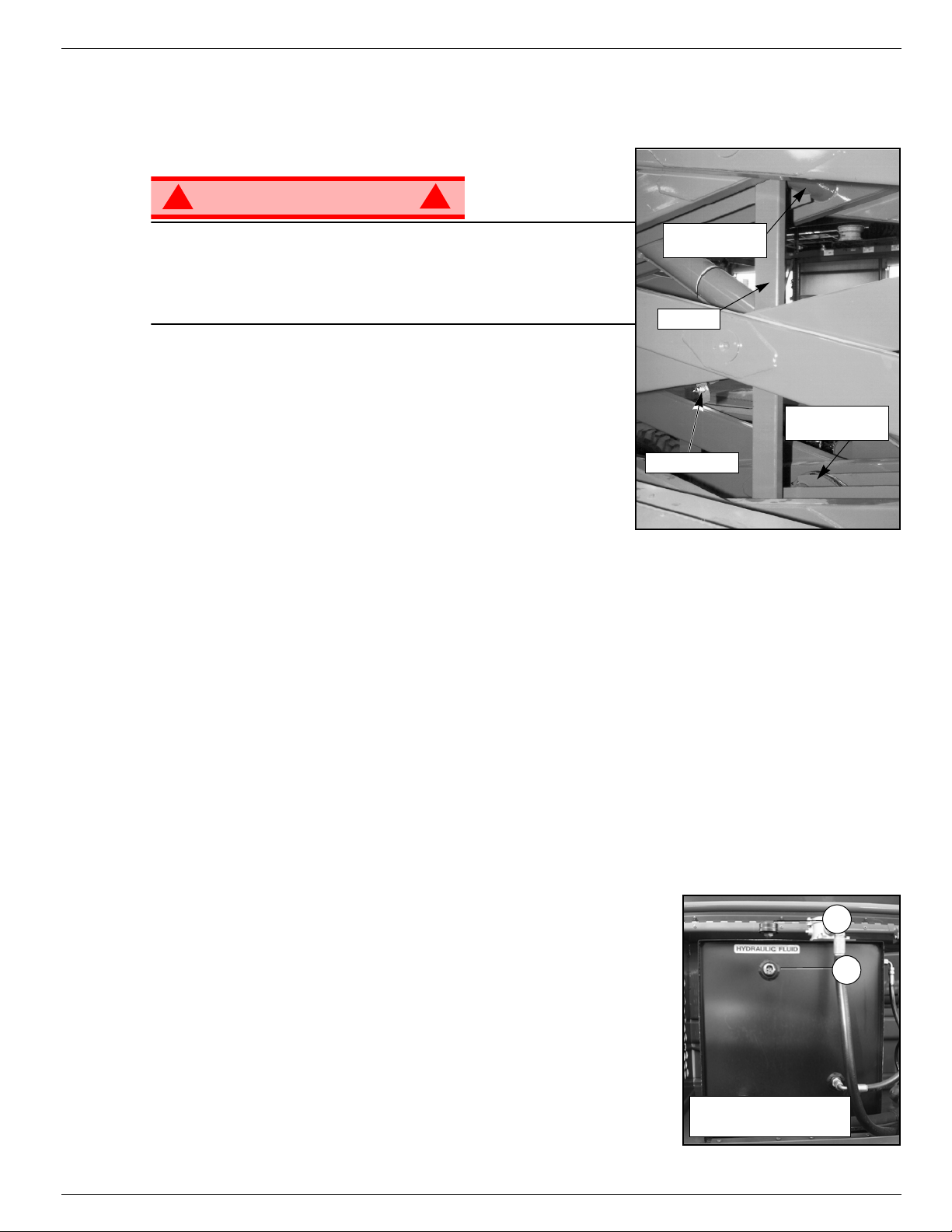

1. Fluid Sight Gauge

2. Filler Cap

M

AINTENANCE

B

LOCKING

Never perform service on the work platform in the elevating

assembly area while the platform is elevated without first blocking

the elevating assembly.

DO NOT stand in elevating assembly area while deploying or

storing brace.

RACE INSTALLATION

B

1. Park the work platform on firm, level ground.

2. Verify that the platform Emergency Stop button is ON.

3. Turn the Platform/Chassis switch to CHASSIS.

4. Start the engine, using the chassis controls.

5. Push the Throttle button in. The button will stay in and the

engine speed will increase. Using the Raise button, elevate the

platform until the scissor brace can be rotated to the vertical

position.

6. From the left side of the machine, disengage the locking pin securing the brace. Rotate the scissor brace

counterclockwise until it is vertical and between the two scissor center pivots.

7. Push the Lower button and gradually lower the platform until the brace is supporting the platform.

8. Disengage the throttle by pushing the Throttle button in again. The button will retract and the engine will

come to idle speed.

THE

E

LEVATING

A

SSEMBLY

Figure 9:

Blocking Elevating Assembly

RACE

B

1. Using the chassis controls, gradually raise the platform until the scissor brace clears the two scissor center pivots.

2. Rotate the scissor brace clockwise until the locking pin engages.

3. Push the Lower button to completely lower the platform.

4. Make sure the Throttle button is disengaged and Platform/Chassis switch is on PLATFORM.

H

YDRAULIC

The hydraulic fluid tank is located in the Power Module.

Never add fluid if the platform is elevated.

NOTE:

1. Make sure that the platform is fully lowered.

2. Check fluid level by observing the fluid sight gauge

3. Remove the filler cap to fill with the appropriate fluid.

EMOVAL

R

F

LUID

Figure 10:

Hydraulic Fluid Tank

Operator Manual Page 15

Page 18

067903-025 LX31/LX41/LX50 Maintenance

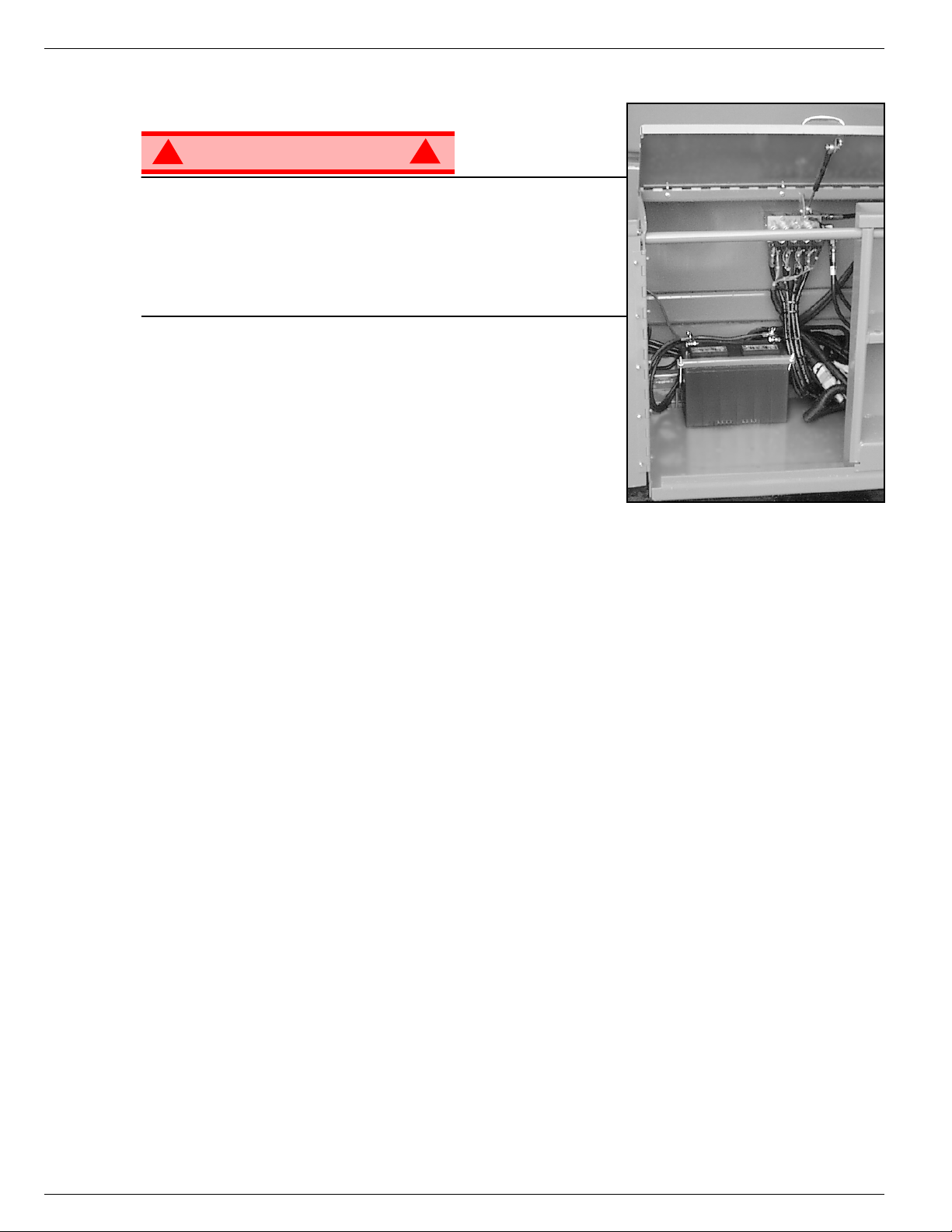

WARNING

!

!

B

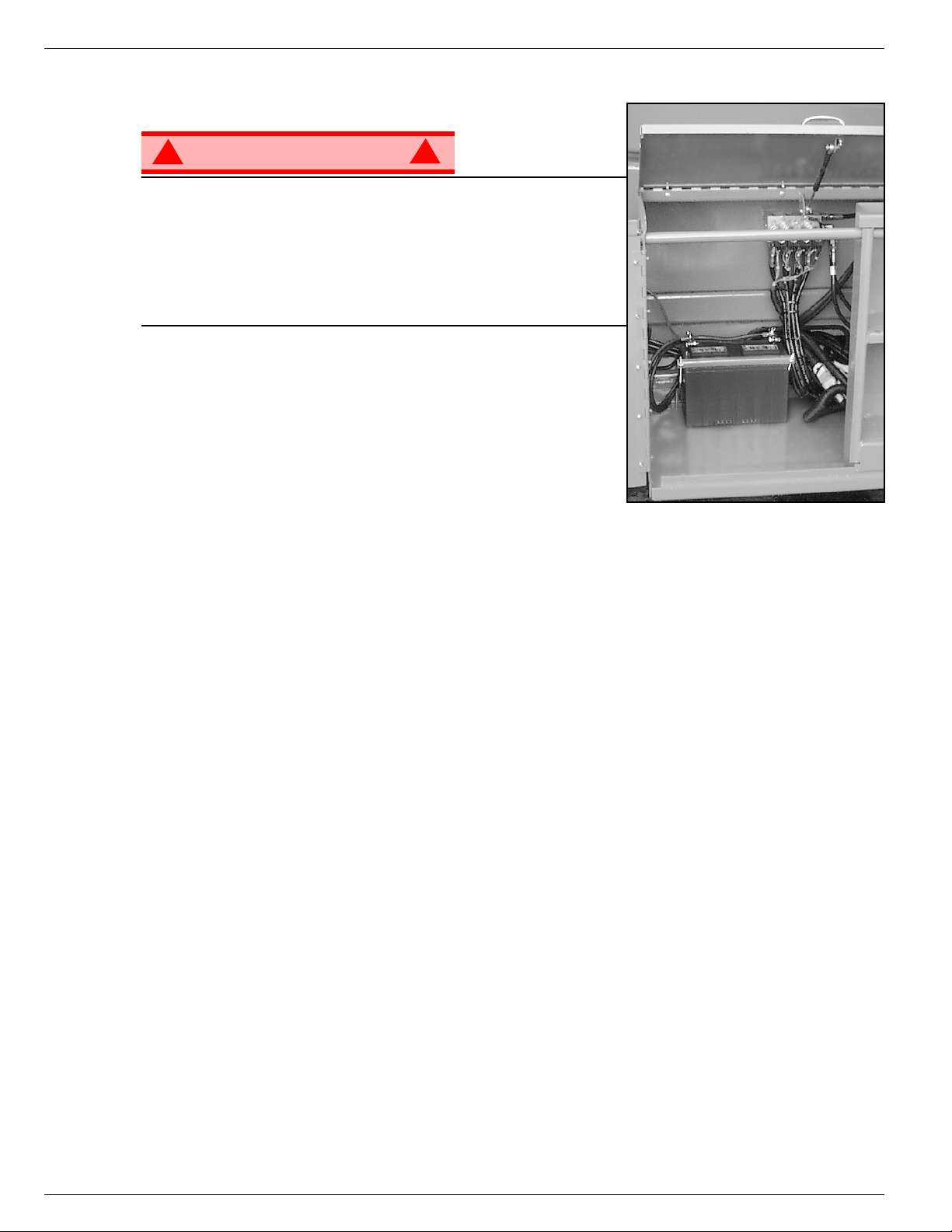

ATTERY

Hazard of explosive gas mixture. Keep sparks, flame, and smoking

material away from battery.

Always wear safety glasses when working with batteries.

Battery fluid is highly corrosive. Thoroughly rinse away any spilled

fluid with clean water.

Always replace batteries with UpRight batteries or manufacturer

approved replacements.

Check battery fluid level weekly, especially if the work platform is

being used in a warm, dry climate.

M

AINTENANCE

Figure 11:

Battery Location

If the electrolyte level is lower than 10 mm (

add distilled water ONLY. Do not use tap water with high mineral

content; it will shorten battery life.

The battery and cables should be inspected regularly for signs of

cracks in the case, electrolyte leakage and corrosion of the terminals. Inspect the cables for worn spots or breaks in the insulation

and for broken cable terminals.

Refer to the Service Manual to extend battery life and for complete service instructions.

) above plates,

3/8 in.

Page 16 Operator Manual

Page 19

Maintenance 067903-025 LX31/LX41/LX50

CAUTION

!

!

E

NGINE

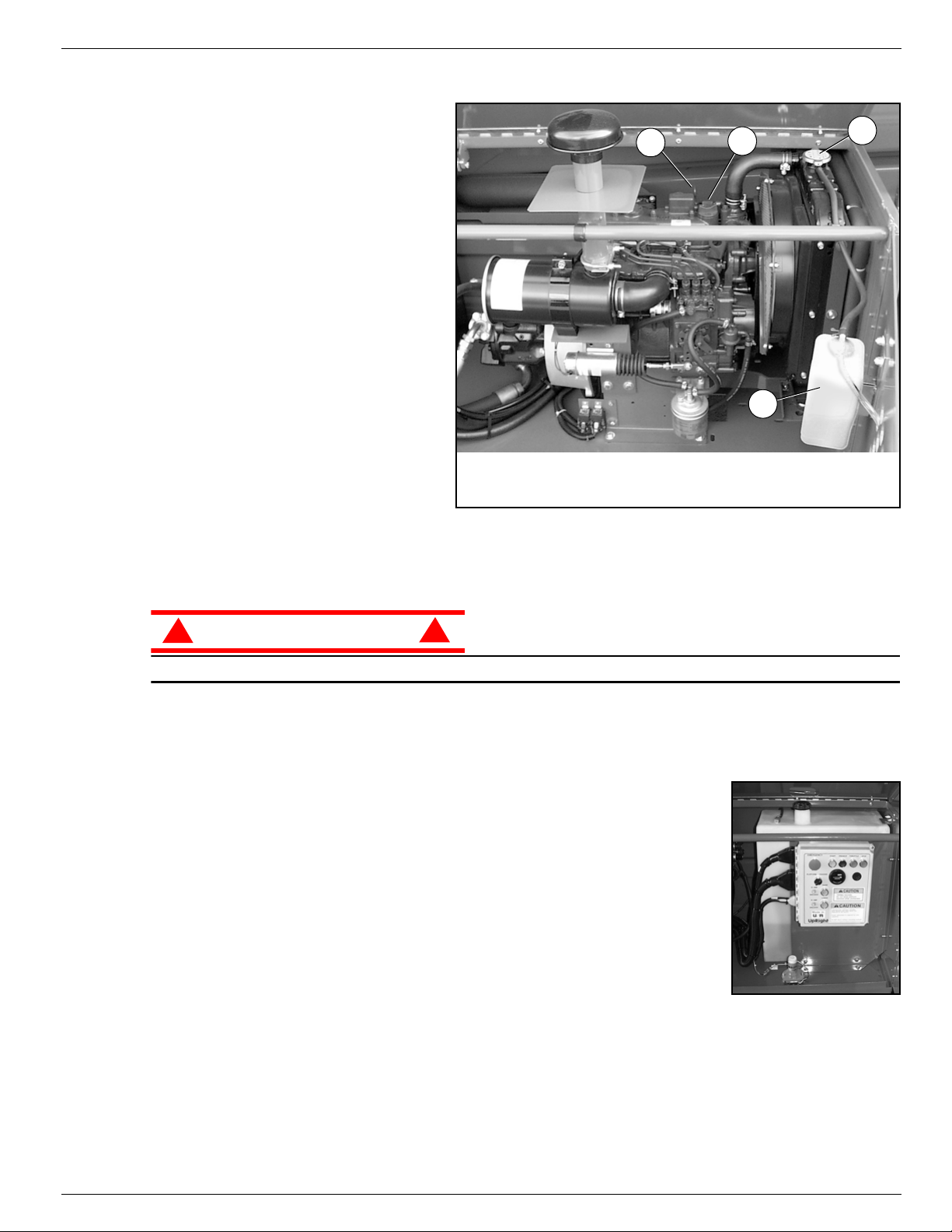

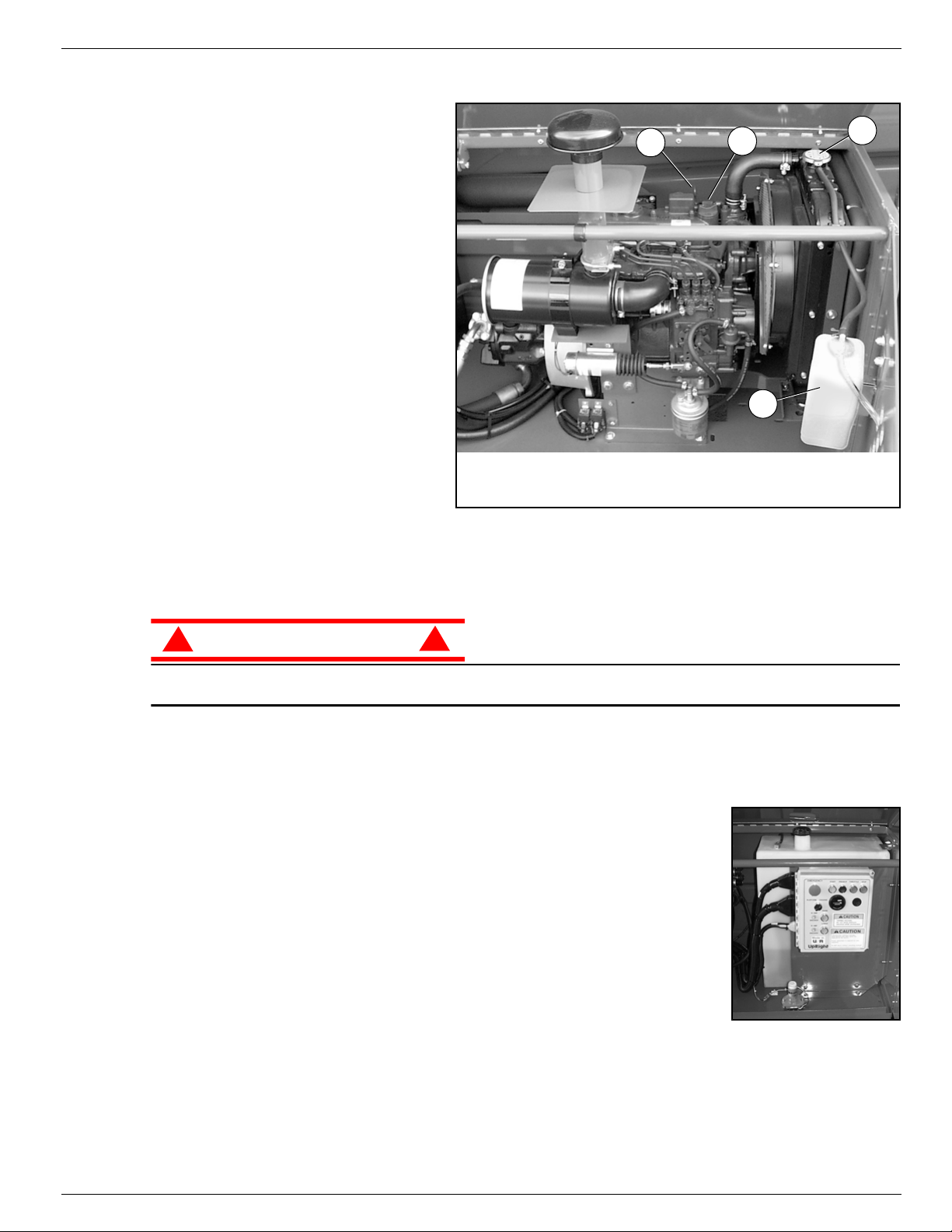

Figure 12:

OOLANT

C

The coolant recovery tank is mounted

on the inside of the door of the power

module.

1. Remove the cap on the coolant

recovery tank.

2. Add coolant to the “FULL” mark.

Never remove the radiator cap when the

NOTE:

engine is hot.

IL

O

The engine

you check and replenish the engine oil.

Refer to the Service Manual to change

the oil filter.

1. Remove the oil dipstick and check the

level indicator marks.

2. If the level is low, remove the oil filler cap.

3. Replenish with the proper engine oil (refer to the engine service manual that came with the machine).

must not be running

when

1 Radiator Cap

2. Coolant Recovery Tank

4

3

2

3. Oil Filler Cap

4. Oil Dipstick

Engine

1

DO NOT check coolant when engine or radiator is hot; hot coolant can cause severe burns.

UEL

F

The fuel tank for is located in the Control Module, behind the chassis controls.

The tank is translucent. Check the fuel level by observing the level of the liquid

through the tank.

Figure 13:

Fuel Supply

Operator Manual Page 17

Page 20

067903-025 LX31/LX41/LX50 Preventative Maintenance Schedule

WARNING

!

!

P

REVENTATIVE

M

AINTENANCE

S

CHEDULE

The complete inspection consists of periodic visual and operational checks, along with periodic minor

adjustments to assure proper performance. Daily inspection will prevent abnormal wear and prolong the

life of all systems. The inspection and maintenance schedule is to be performed at regular intervals.

Inspection and maintenance shall be performed by personnel who are trained and familiar with mechanical and electrical procedures.

Before performing preventative maintenance, familiarize yourself with the operation of the machine.

Always block the elevating assembly whenever it is necessary to enter the scissor assembly to perform

maintenance while the platform is elevated (see page 15).

The daily preventative maintenance table has been designed for machine service and maintenance

repair. Please photocopy the Daily Preventative Maintenance Check List and use the table as a checklist

when inspecting the machine for service.

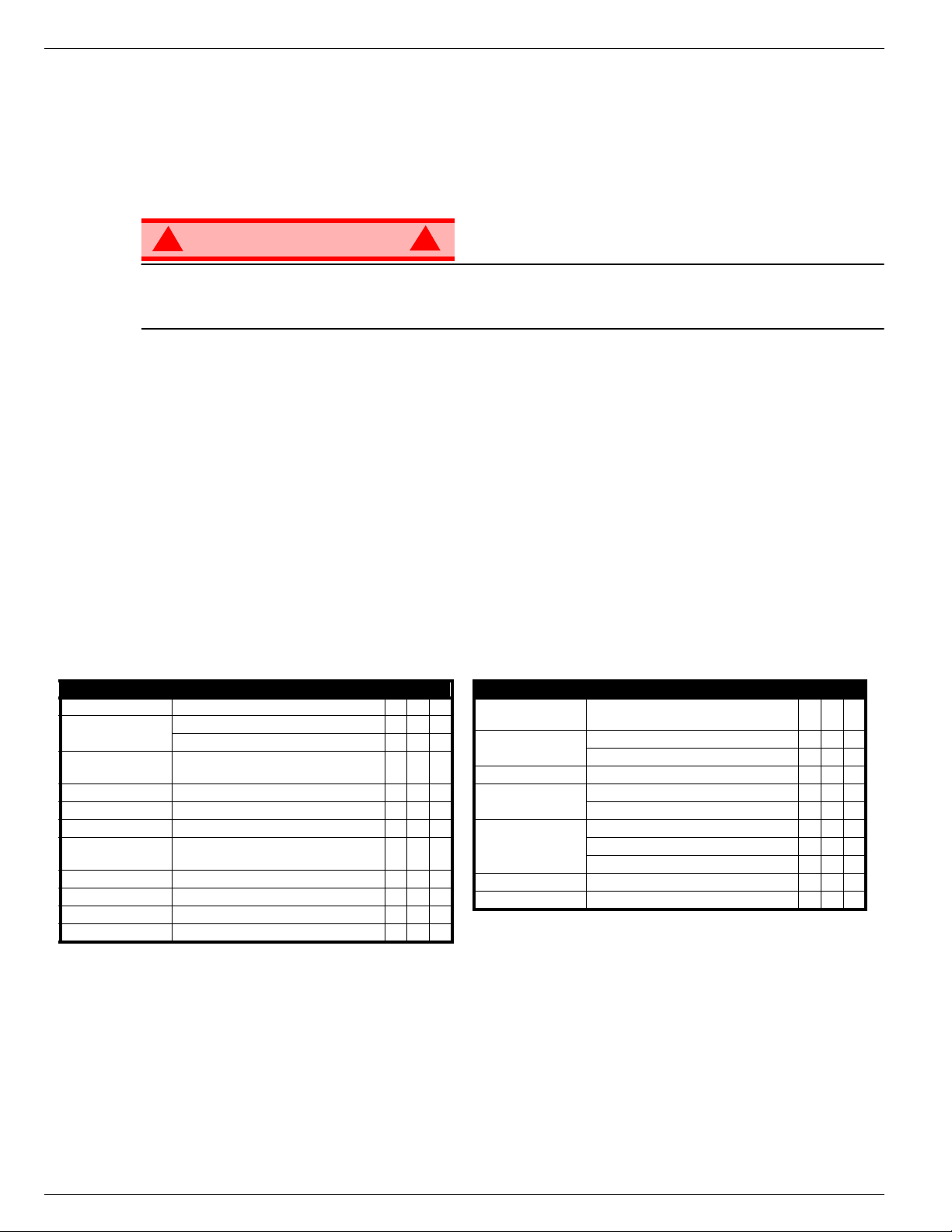

D

AINTENANCE

M

AILY

P

REVENTATIVE

ABLE KEY

T

M

AINTENANCE

AINTENANCE

M

C

R

HECK

EPORT

L

IST

\

Y = Yes/Acceptable

N = No/Not Acceptable

R = Repaired/Acceptable

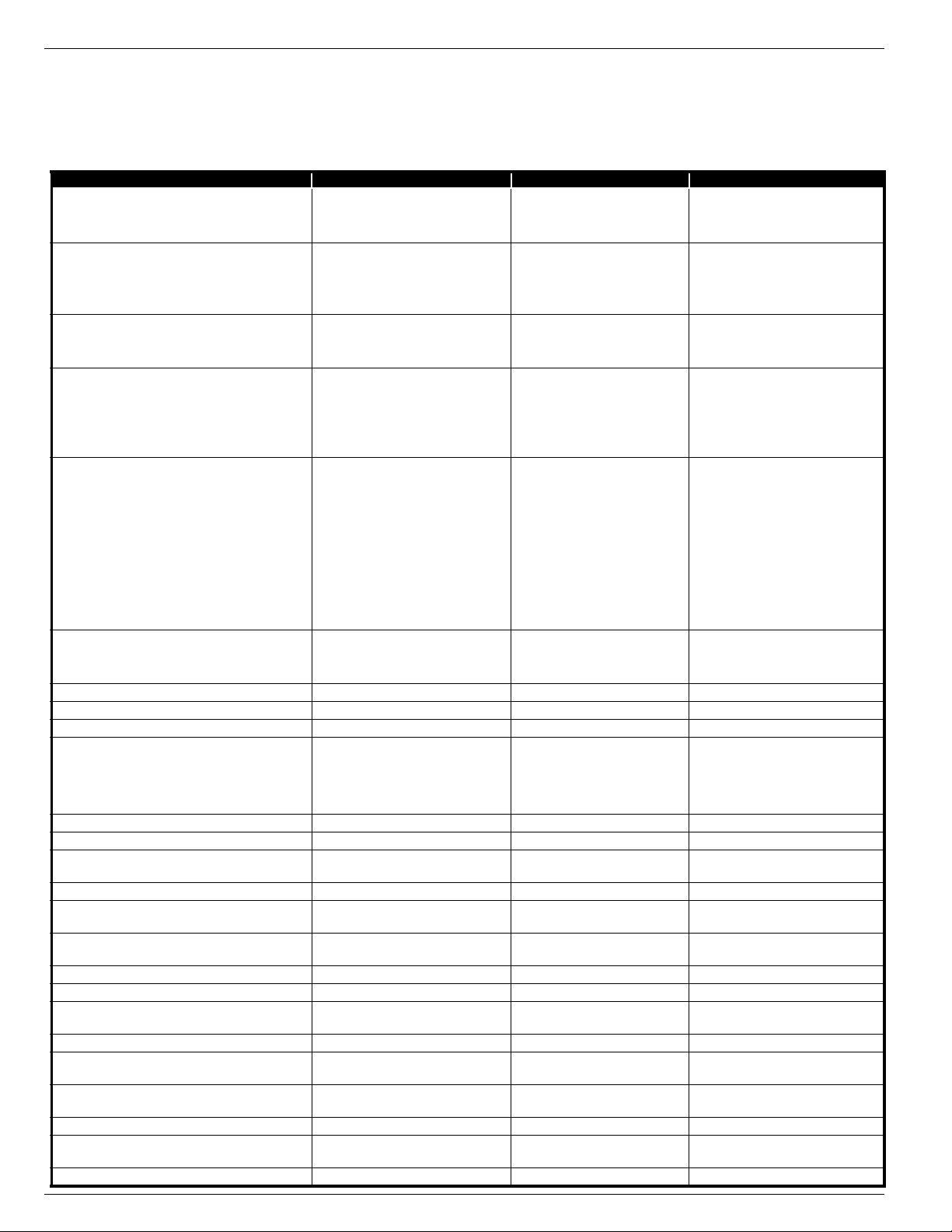

COMPONENT INSPECTION OR SERVICES Y N R

Battery Check electrolyte level

Chassis

Control Cable

Controller Check switch operation

Drive Motors Check for operation and leaks

Elevating Assembly Inspect for structural cracks

Emergency Lowering

System

Entire Unit Check for and repair collision damage

Hydraulic fluid Check fluid level

Hydraulic Pump Check for hose fitting leaks

Hydraulic System Check for leaks

Check hoses for pinch or rubbing points

Check welds for cracks

Check the exterior of the cable for pinching,

binding or wear

Operate the emergency lowering valve and

check for serviceability

Date: _______________________________________

Owner: _____________________________________

Model No: ___________________________________

Serial No: ___________________________________

Serviced By: _________________________________

COMPONENT INSPECTION OR SERVICES Y N R

Labels

Platform Deck and

Rails

Tires and Wheels Check for damage

Engine Oil and Filter

Engine Fuel System

Engine Coolant Check coolant level (with engine cold)

Torque Hubs Check for leaks

Check for peeling, missing, or unreadable

labels & replace

Check welds for cracks

Check condition of deck

Check level and condition

Check for leaks

Check fuel level

Check for leaks

Check air cleaner

Page 18 Operator Manual

Page 21

Preventative Maintenance Schedule 067903-025 LX31/LX41/LX50

NNNN

OOOOTTTTEEEESSSS

::::

Operator Manual Page 19

Page 22

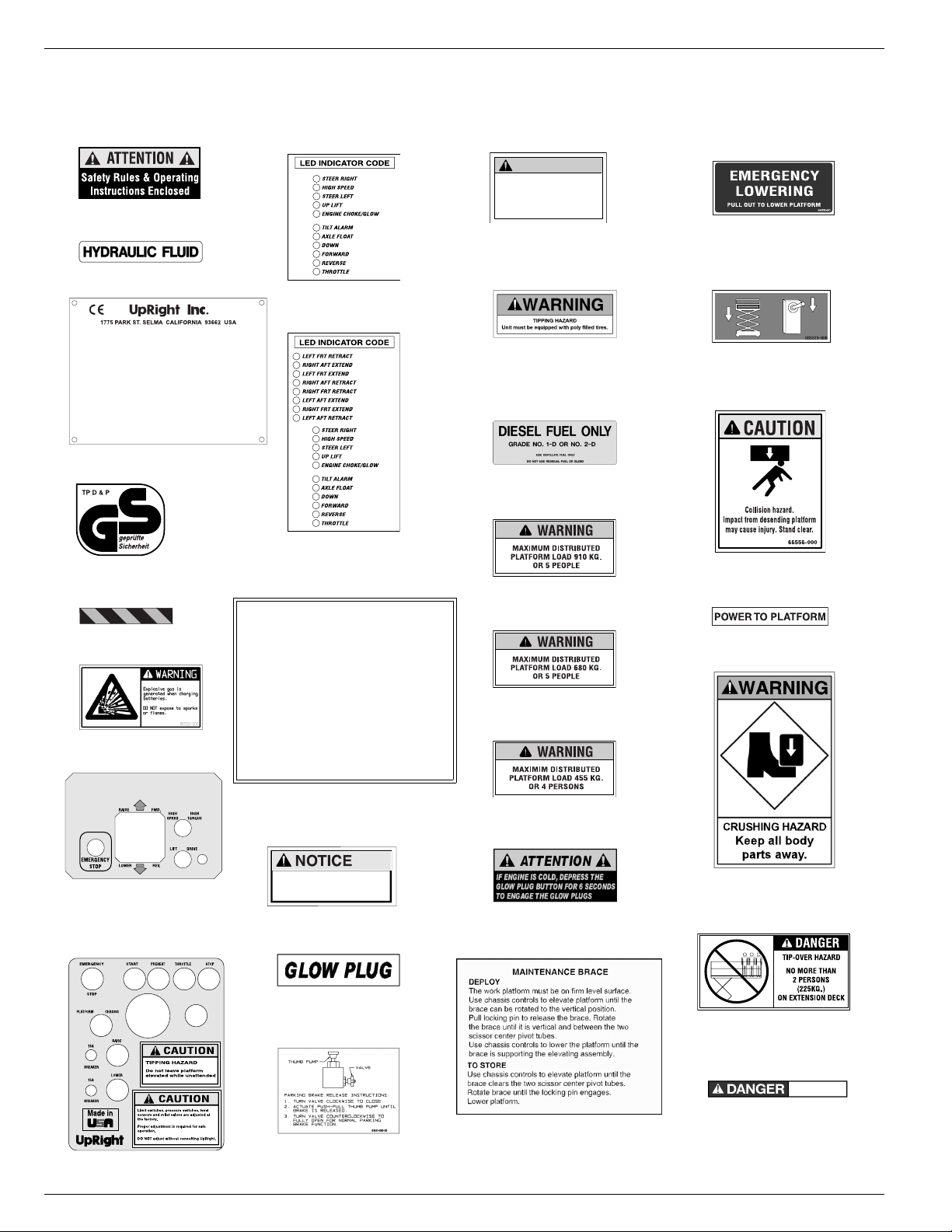

067903-025 LX31/LX41/LX50 Labels

L

ABELS

These labels shall be present and in good condition before operating the work platform. Be sure to read,

understand and follow these labels when operating the work platform.

WARNING

TIPPING HAZARD

Check tire pressure daily.

Pressure must be

2

010076-001

060197-000

4

Model______________ Serial number:___________

Machine weight _______kg Mfg. date:_________

Maximum wheel load:________

Maximum allowable incline of machine when elevated:_____de g.

Occupants and equipment must not exceed the rated maximum

load:_____kg Maximum platform occupants: _____

Maximum allowable sIde force on platform:_____N

Maximum platform height:______m

Maximum platform reach:______m

Maximum allowable wind speed: ______m/s=Beaufort scale_____

Maximum hydraulic system pressure:_____bar

Maximum system voltage: _______Vdc

This machine is manufactured to comply with

Machinery directive 89-392/CEE

CAUTION: CONSULT OPERATOR'S MANUAL BEFORE USE.

5

061205-003

061205-003

067480-000

13

maintained at 50 P.S.I.

LX31/LX41:

22

066562-000

LX50:

22

066562-003

LX31/LX41:

40

066558-001

LX50:

40

005223-908

6

030768-002

7

064936-099

9

066552-000

11

067642-011

(Outrigger Units:

067642-004)

13

067480-001

(Outrigger Units)

USE OF THE AERIAL WORK PLATFORM: This aerial work platform is intended to lift persons and

their tools as well as the material used for the job. IT IS designed for repair and assembly jobs and

assignments at overhead workplaces (ceilings, cranes, roof structures, buildings etc.). All other uses

of the aerial work platform ARE PROHIBITED!

THIS AERIAL WORK PLATFORM IS NOT INSULATED! For this reason it is imperative to keep a safe

distance from live parts of electrical equipment!

ALL occupants must wear an approved fall restraint properly attached to a designated platform

anchorage point. Attach only one fall restraint to each anchorage point.

Exceeding the specified permissible maximum load on the platform IS PROHIBITED!

The use and operation of the aerial work platform as a lifting tool or a crane (lifting of loads from

below upwards or from up high on down) IS PROHIBITED!

NEVER exceed 400 N of side force.

DISTRIBUTE all platform loads evenly on the platform.

NEVER operate the machine without first surveying the work area for surface hazards such as

holes, drop-offs, bumps, curbs, or debris; and avoiding them.

OPERATE machine only on surfaces capable of supporting wheel loads.

NEVER operate the machine when wind speeds exceed 28mph (12.5m/sec.=Beaufort scale 6).

IN CASE OF EMERGENCY push emergency stop button to deactivate all powered functions.

Climbing up the railing of the platform, standing on or stepping from the platform onto buildings, steel

or prefab concrete structures, etc., IS PROHIBITED!

Dismantling the swing gate or the liftable bar or other railing components IS PROHIBITED! Always make

certain that the swing gate or the liftable bar is closed and securely locked! IT IS PROHIBITED to keep

the swing gate or the liftable bar in an open position (e.g. held open with tie-straps) when the platform

is raised!

To extend the height or the range by placing of ladders, scaffolds or similar devices on the platform

IS PROHIBITED!

INSPECT the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks,loose wire

connections, and damaged cables or hoses before using.

VERIFY that all labels are in place and legible before using.

NEVER use a machine that is damaged, not functioning properly, or has damaged or missing labels.

IF ALARM SOUNDS while platform is elevated, STOP, carefully lower platform. Move machine to a firm,

level surface.

To bypass any safety equipment IS PROHIBITED and presents a danger for the persons on the aerial work

platform and in its working range.

NEVER charge batteries near sparks of open flame. Charging batteries emit explosive hydrogen gas.

067195-001

14

START CIRCUIT PROTECTION

If engine stops cranking while

starting, let machine sit for

10-15 minutes before re-starting

067478-000

15

027898-000

25

LX31: 066557-060

26

LX41: 066557-057

26

26

LX50: 066557-054

067822-001

3434

066556-000

41

068639-000

42

43

066556-001

(Outrigger Units)

067822-000

17

066551-051

44

TIPPING HAZARD

If horn sounds continuously

lower platform and relevel.

066551-003

45

38

067481-001

12

063423-000

21

066561-001

(Outrigger Units)

Page 20 Operator Manual

Page 23

Labels 067903-025 LX31/LX41/LX50

Rear

Figure 14:

Safety Labels Locations

Platform Controls

Power Module

Control Module

Front

Inside

Inside

Chassis Controls

Operator Manual Page 21

Page 24

067903-025 LX31/LX41/LX50 Specifications

S

PECIFICATIONS

Specifications subject to change without notice. Refer to the Service Manual for service and repair information. Refer to the Parts Manual for illustrated parts breakdown. Hot weather or heavy use may reduce

performance. Meets or exceeds all applicable national safety requirements

ITEM LX31 LX41 LX50

Platform Size (Inside toeboards)

Standard

Slide-out Deck Extended

Max. Platform Capacity

Standard

With Rear Deck Option

On Extension

Max. No. of occupants

Standard

With Rear Deck Option

Height

Working Height

Max. Platform Height

Min. Platform Height

Drivable Height

Dimensions

Weight, Standard 2WD:

Weight, Dual Deck 2WD:

Overall Width

Overall Height, guardrails up

Overall Height, guardrails lowered

Overall Length, deck in

Overall Length, deck extended

Surface Speed

Platform Lowered

Platform Raised

System Voltage

Hydraulic Tank Capacity

Maximum Hydraulic System Pressure

Hydraulic Fluid

Normal Temperature: above 0° C [32° F]

Low Temperature: below 0° C [32° F]

Extreme Temperature: below -17° C [0° F]

Lift System

Lift Speed

Power Source

Drive Control

Control System

Horizontal Drive

Tires

Tire Air Pressure

Parking Brakes

Turning Radius (inside)

Maximum Gradeability:

Wheel Base

Ground Clearance

Guardrails

4WD:

4WD:

2WD:

4WD:

2WD:

4WD:

2WD:

4WD:

Noise Level

3,96 m x 1,73 m [

4,83 m x 1,73 [

907 kg [

794 kg [

11,45 m [

4314 kg [

4436 kg [

4645 kg [

4767 kg [

0 to 5,0 km/h [

0 to 0,48 km/h [

107 liters [

207 bar [

One Single Stage Lift Cylinder One Single Stage Lift Cylinder Two Single Stage Lift Cylinders

Raise: 40 sec. Lower: 52 sec. Raise: 45 sec. Lower: 60 sec. Raise: 80 sec. Lower: 112 sec.

Diesel 20 HP Kubota, 3 Cylinder,

Smooth one-hand Joystick Smooth one-hand Joystick Smooth one-hand Joystick

2 Wheel, Hyd. Motors

4 Wheel, Hyd. Motors

10-16.5 NHS 8 Ply 10-16.5 NHS 8 Ply 10-16.5 NHS 8 Ply Poly Filled

Dual Disc, Spring Applied,

1.1 m [

Fold Down with gate.

227 kg [

156 in x 68 in.

190 in. x 68 in.

2,000 lbs.

] 680 kg [

1750 lbs.

] 567 kg [

500 lbs.

] 227 kg [

] 3,96 m x 1,73 m [

] 4,83 m x 1,73 [

156 in x 68 in.

190 in. x 68 in.

1,500 lbs.

1,250 lbs.

500 lbs.

] 3,96 m x 1,73 m [

] 4,83 m x 1,73 [

] 454 kg [

] 341 kg [

] 227 kg [

5 people 5 people 4 people

5 people 4 people 3 people

9,45 m [

1,43 m [

26 ft. 3 in.

8 m [

2,29 m [

2,53 m [

1,64 m [

4,02 m [

4,89 m [

37 ft. 6 in.

56.3 in.

] 14,34 m [

31 ft.

] 12,34 m [

]1,66 m [

] 8 m [

9,511 lbs.

9,780 lbs.

10,241 lbs.

10,440 lbs.

]

5026 kg [

]

]

]

90 in.

]2,29 m [

99.8 in.

] 2,76 m [

64.5 in.

]1,87 m [

160 in.

] 4,02 m [

192 in.

] 4,89 m [

0 to 3.1 mph

0 to 0.5 mph

] 0 to 5,0 km/h [

] 0 to 0,48 km/h [

5357 kg [

5479 kg [

5148kg [

47 ft. 3 in.

40 ft. 6 in.

26 ft. 3 in.

11,080 lbs.

11,349 lbs.

11,810 lbs.

12,079 lbs.

] 17,1 m [

]15,1 m [

65.3 in.

] 1,9 m [

] 8 m [

]

]

]

]

90 in.

] 2,29 m [

109 in.

]3 m [

73.5 in.

] 2,1 m [

160 in.

] 4,02 m [

192 in.

] 4,89 m [

0 to 3.1 mph

0 to 0.5 mph

] 0 to 5,0 km/h [

] 0 to 0,48 km/h [

26 ft. 3 in.

6242 kg [

6364 kg [

6460 kg [

6583 kg [

118.3 in.

12 Volt DC 12 Volt DC 12 Volt DC

28.3 US Gallons

3000 psi

] 207 bar [

] 107 liters [

28.3 US Gallons

3000 psi

] 207 bar [

] 107 liters [

28.3 US Gallons

ISO #46 ISO #46 ISO #46

ISO #32 ISO #32 ISO #32

ISO #15 ISO #15 ISO #15

Water Cooled

Diesel 20 HP Kubota, 3 Cylinder,

Water Cooled

Diesel or HP Kubota, 3 Cylinder, Water Cooled

Proportional Proportional Proportional

50psi.

3,4 bar [

Hydraulic Release

48 in.

1,22 m [

30%

17° [

]

35%

19° [

]

114.5 in.

2,9 m [

116 in.

2,95 m [

9.5 in.

0,24 m [

43.5 in.

] high,

2 Wheel, Hyd. Motors

4 Wheel, Hyd. Motors

]3,4 bar [

50psi.

]NA

Dual Disc, Spring Applied,

Hydraulic Release

17° [

19° [

2,9 m [

2,95 m [

48 in.

30%

35%

114.5 in.

116 in.

9.5 in.

43.5 in.

] 1,22 m [

]

]

]

]

] 0,24 m [

] high,

]1,22 m [

]

]

] 0,24 m [

1.1 m [

Fold Down with gate.

Dual Disc, Spring Applied, Hydraulic Release

2 Wheel, Hyd. Motors

4 Wheel, Hyd. Motors

13,5° [

13,5° [

2,9 m [

2,95 m [

43.5 in.

1.1 m [

Fold Down with gate.

156 in x 68 in.

190 in. x 68 in.

1,000 lbs.

49 ft. 6 in.

750 lbs.

500 lbs.

56 ft.

76 in.

]

]

]

]

]

]

]

13,761 lbs.

14,030 lbs.

14,242 lbs.

14,513 lbs.

90 in.

]

]

]

]

]

]

82.5 in.

]

160 in.

]

192 in.

]

0 to 3.1 mph

0 to 0.5 mph

3000 psi

]

48 in.

]

24%

]

24%

]

114.5 in.

]

116 in.

]

9.5 in.

]

] high,

]

]

]

]

]

Page 22 Operator Manual

Page 25

Tout le personnel doit lire attentivement et respecter toutes les consignes de sécurité avant

Consignes de sécurité

Consignes de sécurité

Consignes de sécuritéConsignes de sécurité

Risque d’électrocution

Risque d’électrocution

Risque d’électrocutionRisque d’électrocution

UIDE DE L’OPÉRATEUR

G

AVERTISSEMENT

d’entretenir ou d’utiliser une plate-forme élévatrice UpRight.

Risque de basculement

Risque de basculement Risque de collision

Risque de basculementRisque de basculement

Risque de collision Risque de chute

Risque de collisionRisque de collision

Risque de chute

Risque de chuteRisque de chute

CETTE MACHINE

N’EST PAS ISOLÉE !

USAGE DE LA PLATE-FORME ÉLÉVAT RI CE

matériaux utilisés sur le chantier. Elle est conçue pour les travaux de réparations et d’assemblage sur les points élevés (plafonds, grues,

charpentes de toit, immeubles, etc.). Tout autre usage de la plate-forme élévatrice est interdit !

CETTE PLATE-FORME ÉLÉVATRICE N’EST PAS ISOLÉE !

équipements électriques sous tension !

Il est interdit

Il est interdit

NE JAMAIS

RÉPA RT I R

NE JAMAIS

bosses, trottoirs ou débris; et les éviter.

N’UTILISER

NE JAMAIS

pour plus de détails.

EN CAS D’URGENCE

SI L’ALARME RETENTIT

une surface plane et ferme.

Il est interdit

préfabriquée, etc. !

Il est interdit

Il est interdit

Il est interdit

NE JAMAIS

d’élévation.

INSPECTER

hydrauliques, de branchements électriques desserrés ou de câbles et flexibles endommagés avant d’utiliser la machine.

VÉRIFIER

NE JAMAIS

endommagés.

Il est interdit

trouvant dans la zone de travail.

NE JAMAIS

gaz explosif.

Sauf autorisation de la part d’UpRight, toute modification de la plate-forme

APRÈS AVOIR UTILISÉ

l’utilisation non autorisée de la plate-forme.

de dépasser la charge maximum admissible. Voir « Limitations particulières » à la page 26 pour plus de détails.

d’utiliser la plate-forme comme appareil de levage ou grue (levage des charges par le dessous ou le dessus) !

dépasser la force manuelle autorisée pour cette machine. Voir « Limitations particulières » à la page 26 pour plus de détails.

uniformément toutes les charges placées sur la plate-forme.

utiliser la machine sans avoir d’abord vérifié si la zone de travail est exempte de dangers tels que des trous, dénivellations,

la machine que sur des surfaces pouvant supporter la charge des roues.

utiliser la machine lorsque la vitesse du vent dépasse les spécifications pour la machine. Voir« Échelle de Beaufort » à la page 26

, appuyer sur le bouton d’ARRÊT D’URGENCE pour désactiver toutes les fonctions.

lorsque la plate-forme est élevée, ARRÊTER, abaisser la plate-forme avec précaution. Conduire la machine jusqu’à

de monter ou de se tenir sur les garde-corps de la plate-forme et de passer de la plate-forme à un immeuble, une structure

de retirer le portillon pivotant ou toute autre pièce de garde-corps ! Toujours vérifier que le portillon est fermé et verrouillé !

de maintenir le portillon pivotant en position ouverte (par exemple au moyen d’attaches) lorsque la plate-forme est élevée !

d’accroître la hauteur ou la portée de la plate-forme au moyen d’échelles, échafaudages ou autres dispositifs similaires !

effectuer de travaux d’entretien sur la machine, si la plate-forme est en position élevée, sans tout d’abord bloquer le dispositif

minutieusement la machine en vue de soudures fissurées, de pièces de boulonnerie manquantes ou desserrées, de fuites

que tous les autocollants sont en place et lisibles avant d’utiliser la machine.

utiliser une machine qui est endommagée, qui ne fonctionne pas correctement ou dont les autocollants sont manquants ou

de mettre tout dispositif de sécurité hors service, ce qui mettrait en danger les personnes à bord de la plate-forme et celles se

charger les batteries à proximité d’étincelles ou d’une flamme vive. Lors de la charge, les batteries dégagent de l’hydrogène, un

la plate-forme élévatrice, mettre les deux contacteurs à clé en position d’arrêt (off), puis retirer la clé afin d’empêcher

NE JAMAIS

conduire la machine avec la plate-forme

élevée si la machine ne se trouve pas sur

élever la plate-forme ou

une surface plane et ferme.

: Cette plate-forme élévatrice est destinée au levage de toute personne, de son outillage et des

C’est pourquoi il est impératif de rester à distance sûre des lignes et

NE JAMAIS

avant de s’être assuré de l’absence

est interdite

positionner la plate-forme

d’obstacles en hauteur

ou autres dangers.

.

NE JAMAIS

debout ou assis sur les rampes

monter, ni se tenir

du garde-corps.

Page 1

Page 26

067903-025 LX31/LX41/LX50

T

ABLE

DES MATIÈRES

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Description générale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Limitations particulières . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Tous les modèles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Capacité de la plate-forme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Force manuelle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Échelle de Beaufort. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Alarme de surcharge de levage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Commandes et indicateurs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Inspection de sécurité avant utilisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Essai de fonctionnement des systèmes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Utilisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Déplacement avec la plate-forme abaissée . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Déplacement avec la plate-forme élevée . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Élévation et abaissement de la plate-forme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Mise de niveau de la plate-forme

(machines équipées de stabilisateurs seulement) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Commutateurs et témoins de stabilisateurs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Mise de niveau de la plate-forme (extension des stabilisateurs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Rétraction des stabilisateurs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Abaissement d’urgence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

LX31 et LX41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

LX50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Remorquage ou treuillage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Desserrage de frein de stationnement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Après utilisation, tous les jours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Garde-corps rabattables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Repli des

garde-corps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Procédure de mise en place . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Transport de la plate-forme élévatrice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Préparation pour l’expédition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Levage par grue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Conduite ou treuillage sur un camion ou

une remorque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Entretien . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Blocage du système d’élévation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Installation de la barre de blocage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Retrait de la barre de blocage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Fluide hydraulique. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Entretien des batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Moteur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Liquide de refroidissement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Huile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Carburant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Programme d’entretien préventif . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Liste de contrôle d’entretien préventif quotidien . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Légende du tableau d’entretien . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Rapport d’entretien. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Autocollants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Caractéristiques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Page 2 Guide de l’opérateur

Page 27

Introduction 067903-025 LX31/LX41/LX50

AVERTISSEMENT

!

!

I

NTRODUCTION

Ce manuel porte sur le fonctionnement des plates-formes à moteur à combustion LX31, LX41 et LX50.

Veiller à le garder sur la machine en tout temps.

D

ESCRIPTION

GÉNÉRALE

1. Plate-forme

La plate-forme est dotée d’un plancher en

acier renforcé, de garde-corps avec rail

intermédiaire, de plinthes et de portillons,

l’un à l’arrière et de chaque côté de la plateforme. Les garde-corps peuvent être

rabattus pour le franchissement de portes

ou l’expédition.

2. Extension coulissante

NE PAS utiliser la plate-forme sans que les

garde-corps soient correctement assemblés

et installés.

3. Commandes de la plate-forme

La plate-forme est équipée des commandes

de fonctionnement de la machine. Cette

commande doit être suspendue sur le

garde-corps avant, gauche ou arrière.

10

Figure 15 :

1

Plate-forme élévatrice série LX

3

4

2

10

8

4. Coffret du manuel

5. Dispositif d’élévation

La plate-forme est élevée et abaissée par

un mécanisme constitué d’un ciseau en cinq

sections contrôlé par deux vérins.

6. Garde de ciseaux

7. Module de commande

Le module de commande contient le

réservoir de carburant, le collecteur de

vannes hydrauliques, l’avertisseur et les

alarmes sonores et le panneau de

commande du châssis.

8. Module de puissance

Le module de puissance contient le moteur, la pompe hydraulique et le réservoir hydraulique.

9. Châssis

Le châssis est un cadre structurel qui supporte tous les composants de la plate-forme.

10. Stabilisateurs (en option)

2

9

10

7

5

6

10

Guide de l’opérateur Page 3

Page 28

067903-025 LX31/LX41/LX50 Limitations particulières

DANGER

! !

DANGER

! !

DANGER

! !

DANGER

! !

L

IMITATIONS

T

OUS LES MODÈLES

La fonction d’élévation doit être utilisée SEULEMENT lorsque la plate-forme est de niveau et placée sur

une surface plane et ferme.

La plate-forme élévatrice n’est PAS conçue pour être conduite sur terrain inégal, accidenté ou meuble.

C

Le déplacement avec la plate-forme élevée est limité à la gamme de vitesses rampantes.

La plate-forme ne doit être élevée que si elle se trouve sur une surface plane et ferme.

APACITÉ

La capacité maximum de la MACHINE, occupants inclus, est déterminée par le modèle et les options et

indiquée dans la section « Caractéristiques » à la page 44.

PARTICULIÈRES

DE LA PLATE

-

FORME

NE PAS dépasser la capacité de charge ou le nombre d’occupants maximum de cette machine.

F

ORCE

La force manuelle est la force appliquée par les occupants sur des objets tels que murs ou autres

structures extérieures à la machine.

La force manuelle maximale admissible est de 200 N (45 lb) par occupant, avec un maximum de 400 N

(90 lb) pour deux occupants ou plus.

NE PAS dépasser la force manuelle maximale admissible pour cette machine.

É

CHELLE

Ne jamais utiliser la machine par vents soufflant à plus de 45 km/h (28 mi/h) (force 6 de l’échelle de

Beaufort).

FORCE

BEAUFORT

3 3,4~5,4 12,25~19,4 11,5~17,75 7,5~12,0 Les papiers et branchettes bougent, les drapeaux flottent.

4 5,4~8,0 19,4~28,8 17,75~26,25 12,0~18,0 La poussière est soulevée, les papiers volent et les petites branches ploient.

5 8,0~10,8 28,8~38,9 26,25~35,5 18,0~24,25