Page 1

Operator Manual

LX31/41/50

SERIAL NO. 4022 to Current

WARNING

All personnel shall carefully read, understand and follow all safety rules,

operating instructions, and the Scaffold Industry Association’s

MANUAL OF RESPONSIBILITIES of ANSI A92.6-1999 before performing

maintenance on or operating any UpRight Aerial Work Platform.

067903-004R1

Page 2

LX31/41/50

Gasoline, Dual Fuel, and Diesel Models

Serial Numbers 4022 - Current

When contacting UpRight for service or parts information, be sure to include the MODEL and SERIAL NUMBERS

from the equipment nameplate. Should the nameplate be missing, the SERIAL NUMBER is also stamped on top of

the chassis above the left front axle pivot.

UpRight, Inc.

801 South Pine Street

Madera, California 93637

TEL: 559-662-3900

FAX: 559-673-6184

PA R T S : 1 - 8 8 8- UR -PA R TS

PARTS FAX: 1-800-669-9884

Call Toll Free in U.S.A.

1-800-926-LIFT

UpRight

Unit S1, Park West Industrial Park

Friel Avenue

Nangor Road

Dublin 12, Ireland

TEL: +353 1 620 9300

FAX: +353 1 620 9301

Page 3

PERATOR

O

M

ANUAL

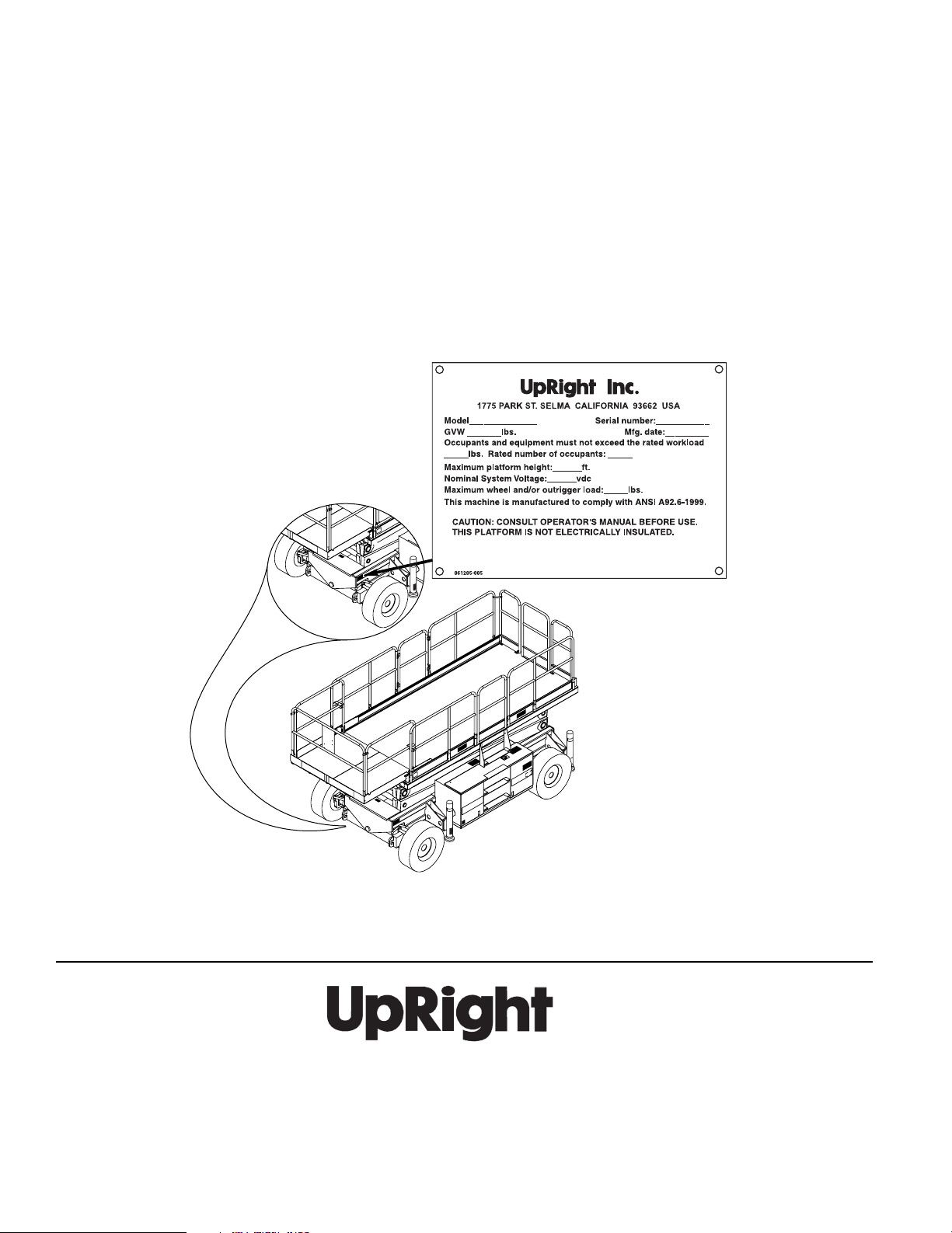

WARNING

All personnel shall carefully read, understand and follow all safety rules, operating

instructions, and the Scaffold Industry Association’s MANUAL OF

RESPONSIBILITIES (ANSI A92.6) before performing maintenance on or operating

any UpRight Aerial Work Platform.

Safety Rules

Electrocution Hazard

Electrocution Hazard Tip Over Hazard

Electrocution HazardElectrocution Hazard

Tip Over Hazard Collision Hazard

Tip Over HazardTip Over Hazard

Collision Hazard Fall Hazard

Collision HazardCollision Hazard

Fall Hazard

Fall HazardFall Hazard

NEVER operate the machine within ten

(10) feet of power lines.

THIS MACHINE IS NOT INSULATED.

•

NEVER

•

NEVER

•

NEVER

curbs, or debris.

•

ALWAYS

•

NEVER

•

NEVER

•

LOOK

•

DISTRIBUTE

•

NEVER

•

NEVER

•

INSPECT

hoses, loose wire connections, and wheel bolts.

•

NEVER

•

IF ALARM SOUNDS

surface.

•

IN CASE OF EMERGENCY

•

NEVER

•

NEVER

•

NEVER

turer’s written consent.

•

VERIFY

•

NEVER

•

AFTER USE

exceed the maximum platform load. See “Specifications” on page 20.

operate the machine if all guardrails are not properly in place and secured with all fasteners properly torqued.

operate the machine without first surveying the work area for surface hazards such as holes, drop-offs, bumps,

close and secure the entrance after entering the platform.

use ladders or scaffolding on the platform.

attach overhanging loads or increase platform size.

up, down and around for overhead obstructions and electrical conductors.

all platform loads evenly on the platform.

use damaged equipment. (Contact UpRight for instructions. See toll free phone number on inside back cover.)

change operating or safety systems.

the machine thoroughly for cracked welds, loose or missing hardware, hydraulic leaks, damaged cables or

climb down elevating assembly when the platform is elevated.

while the platform is elevated, STOP, carefully lower the platform. Move the machine to a firm, level

perform service on the machine while the platform is elevated without blocking the elevating assembly.

recharge batteries near sparks or open flame; batteries that are being charged emit explosive hydrogen gas.

replace any component or part with anything other than original UpRight replacement parts without the manufac-

that all labels are in place and legible before using.

tow the machine. Transport by truck or trailer only.

, secure the work platform against unauthorized use by turning the key switch off and removing the key.

NEVER operate the boom or drive with

the platform elevated unless on firm,

push the Emergency Stop button to cut power to all machine functions.

level surface.

NEVER position the platform without

first checking for overhead obstructions

or other hazards.

NEVER climb, stand or sit on the

platform guardrails or midrail.

California Proposition 65 Warning

Gasoline and diesel engine exhaust and some of their constituents are known to the State of California to

cause cancer, birth defects, and other reproductive harm.

Battery Posts, terminals and related accessories contain lead compounds, chemicals known to the State of

California to cause cancer and reproductive harm. Wash hands after handling.

Page 1

Page 4

067903-004R1 LX Series Work Platform

C

ONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Pre-Operation & Safety Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

System Function Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Switching Fuels (Dual Fuel Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Travel with Platform Lowered. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Travel with Work Platform Elevated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Raising and Lowering the Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Emergency Lowering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Serial # 4022 to 4274 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

LX31 and LX41, Serial # 4275 to Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

LX50, Serial # 4275 to Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Leveling the Platform

(Outrigger equipped machines only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Outrigger Switches and Indicator Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

To Level the Platform (Extend the Outriggers) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

To Retract the Outriggers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Towing or Winching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Parking Brake Release. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

After Use Each Day . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Fold Down Guardrails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Fold Down Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Erection Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Transporting Work Platform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Preparation for Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Lifting By Crane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Driving or Winching onto a Truck or Trailer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Blocking Elevating Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Brace Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Brace Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Hydraulic Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Battery Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Diesel or Gasoline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Propane (LP Gas) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Daily Preventative Maintenance Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Page 2 Operator Manual

Page 5

Introduction 067903-004R1 LX Series Work Platform

WARNING

!

!

I

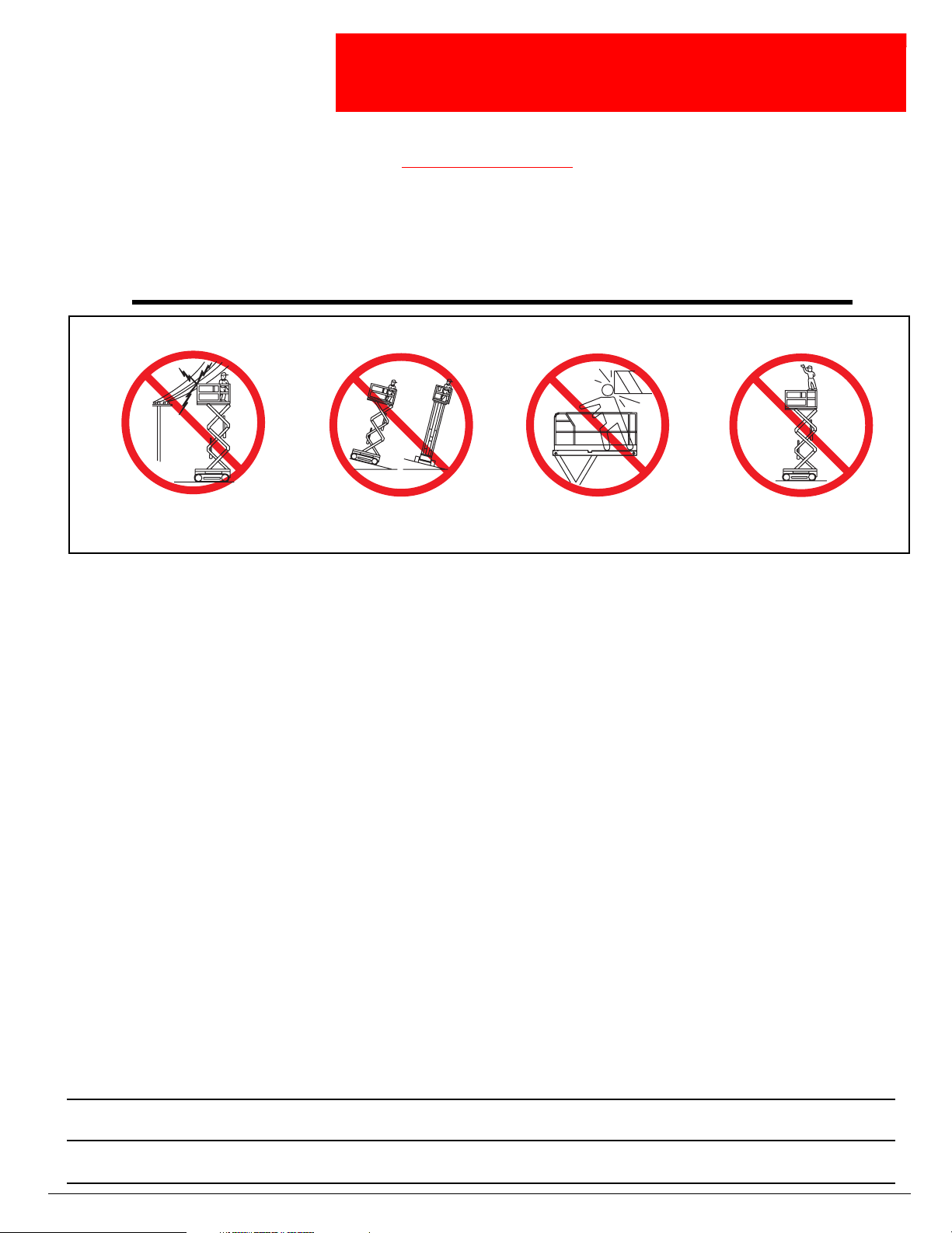

NTRODUCTION

G

ENERAL

This manual covers the operation of the LX31, LX41 and LX50 Internal Combustion Work Platforms.

manual must be stored on the machine at all times.

D

ESCRIPTION

Figure 2:

1. Platform

LX Series Work Platform

3

The platform has a reinforced steel floor,

guardrails with midrail, toeboards and an

entrance gate at the rear and left side of the

platform. The guardrails can be folded down

for access through doors or for shipment.

2. Slide-out Deck

9

DO NOT

without guardrails properly assembled and in

place

use the maintenance platform

7

3. Platform Controls

1

The platform controls contain the controls to

operate the machine. It should be hung on

the front, left, or right guardrail.

4. Manual Case

5. Elevating Assembly

9

This

4

2

The platform is raised and lowered by the

elevating assembly;

• LX31 - a three section scissor assembly

powered by one single-stage lift cylinder.

• LX - a four section scissor assembly

powered by one single-stage lift cylinder.

• LX50 - a five section scissor assembly

powered by two single-stage lift cylinders.

6. Control Module

The control module contains the fuel tank,

hydraulic valve manifold, horn/alarms, battery, and chassis control panel.

7. Power Module

The power module contains the engine, the hydraulic pump, the hydraulic reservoir.

8. Chassis

The chassis is a structural frame that supports all the components of the Work Platform.

9. Outriggers (optional)

2

8

6

5

9

9

Operator Manual Page 3

Page 6

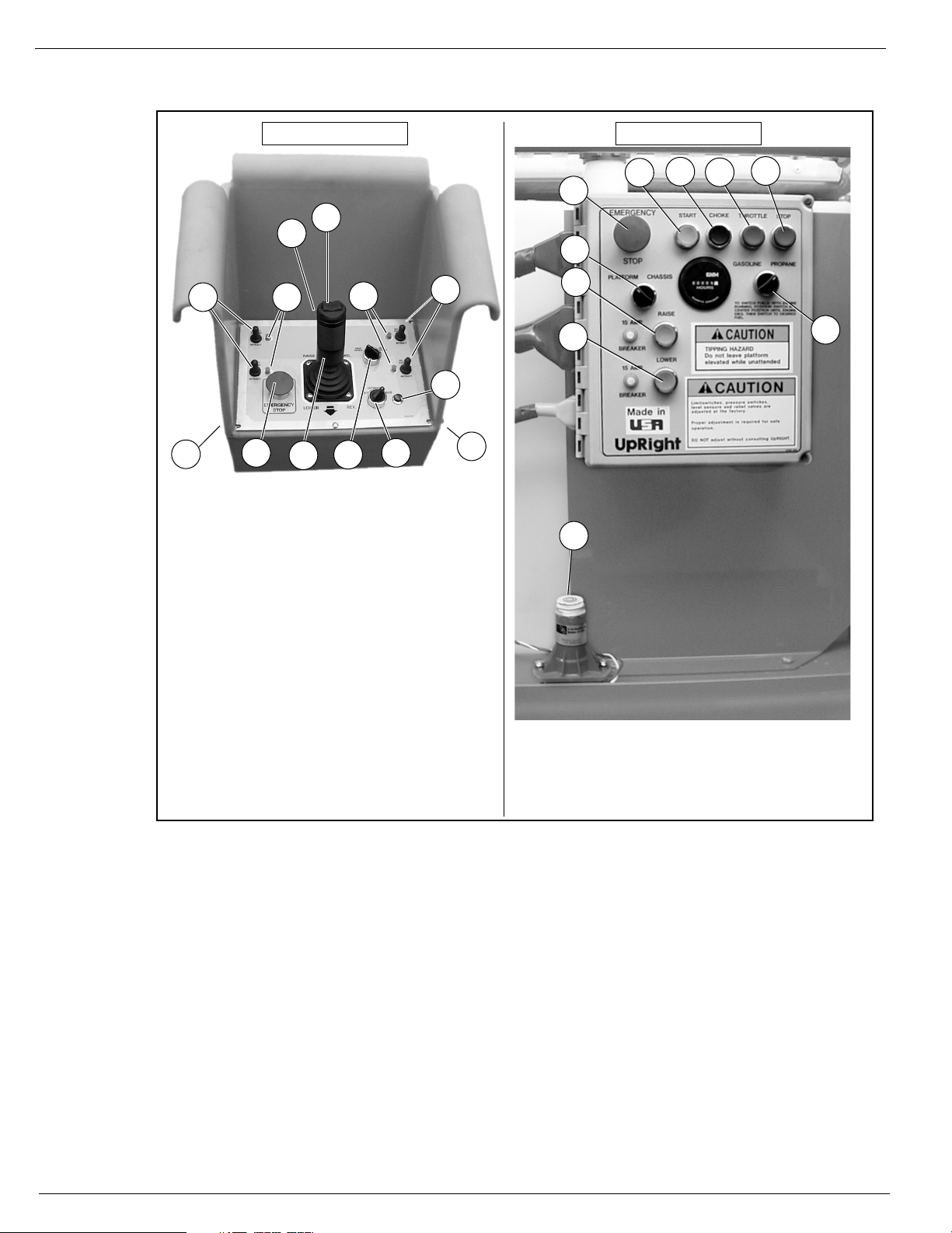

067903-004R1 LX Series Work Platform Controls and Indicators

4*

2

1

3

7**

9

10

8

Outrigger Options

* Outrigger Switches and Outrigger Lights are installed on

outrigger equipped machines only.

** Outrigger selection is available on outrigger equipped

machines only.

5*

5*

4*

1 Steering Switch

2. Interlock Lever Switch

3. Control Lever

4. Outrigger Switches

5. Outrigger Indicator Lights

6. Emergency Stop Switch

7. Lift/Drive Switch

8. Drive Speed/Torque Selector Switch

9. Drive Enable Indicator

10. Key Switch

11. • Choke Button (dual fuel)

• Glow Plug Button (diesel)

6

11

1 Emergency Stop

2. Platform/Chassis Switch

3. Raise Button

4. Lower Button

5. Start Button

6. Glow Plug Button

7. Throttle Button

8. Stop Button

9. Level Sensor

10. Fuel Selector Switch

7

1

2

3

4

5

6

8

9

Platform Controls Chassis Controls

10

C

ONTROLS

AND

I

NDICATORS

Figure 3:

Controls and Indicators

Page 4 Operator Manual

Page 7

Pre-Operation & Safety Inspection 067903-004R1 LX Series Work Platform

WARNING

!

!

CAUTION

!

!

WARNING

!

!

P

RE

-O

PERATION

NOTE:

Carefully read, understand and follow all safety rules, operating instructions, labels and the Scaffold Industry

Association’s MANUAL OF RESPONSIBILITIES. Perform the following steps each day before use.

1. Open modules and inspect for damage, oil leaks or missing parts.

2. Check the hydraulic oil level sight gauge on the hydraulic tank with the platform fully lowered. Add fluid if

necessary.

3. Check that fluid level in the battery is correct (see “Battery Maintenance” on page 15).

4. Check the engine oil level and fuel level.

5. Check that all guardrails are in place, the slide-out deck extension is secured with the pin, and all fasteners are properly tightened.

6. Check tire pressure: LX31 and LX41 - 3,4 bar (

7. Carefully inspect the entire work platform for damage such as cracked welds in structural members,

loose or missing parts, oil leaks, damaged cables or hoses, loose connections and tire damage.

8. Carefully inspect the limit switches for signs of tampering.

9. Dual Fuel Models: set the dual fuel selector to the desired position. Set to the center position to purge

the system when switching fuels. If the machine is to be operated on propane, open the supply valve on

the tank

& S

AFETY

I

NSPECTION

). The LX50 is equipped with poly-filled tires.

50 psi

NOTE:

When using LP gas, use clean, water-free liquid petroleum gas, preferably from a bulk storage tank. Follow the

instructions located on the power module tray for filling the tank.

If you smell propane, close the supply valve on the tank immediately until you have located and

corrected the leak.

10. While the engine is cool, check the engine coolant level.

DO NOT check coolant when engine or radiator is hot; hot coolant can cause severe burns.

S

YSTEM

STAND CLEAR

Before operating the work platform, survey the work area for surface hazards such as holes, drop-offs,

bumps and debris.

Check in

Protect control console cable from possible damage while performing checks.

F

UNCTION

of the work platform while performing the following checks.

directions, including above the work platform, for obstructions and electrical conductors.

ALL

I

NSPECTION

1. Move the machine, if necessary, to an unobstructed area to allow for full elevation.

2. Place chassis and platform emergency stop switches in the ON position (Figure 3, Page 4) by pulling the

3. Verify that the platform/chassis switch is set to PLATFORM (Figure 3, Page 4).

4. Unhook the controller from the front guardrail. Firmly grasp the controller hanger in such a manner that

5. Turn the controller key switch clockwise to ON. Turn fully clockwise to start the engine, releasing the key

Operator Manual Page 5

buttons out.

the interlock lever switch can be depressed, while performing the following checks from the ground.

once the engine starts.

Page 8

067903-004R1 LX Series Work Platform Pre-Operation & Safety Inspection

NOTE:

If the engine is cold:

- on dual fuel models, hold the choke button in while starting the engine;

- on diesel models, depress the glow plug button and hold for 6 seconds to heat the glow plugs.

6. Position the Lift/Drive switch to the DRIVE position. The drive enable light should be ON.

7. With the speed range switch first in HIGH TORQUE and then in HIGH SPEED, depress the interlock

lever switch and slowly push the control lever to FORWARD then REVERSE positions to check for

speed and directional control. The farther you push or pull the control lever, the faster the machine will

travel.

8. Push steering switch RIGHT then LEFT to check for steering control.

9. Optional Outrigger Equipped Machines:

a. With the Lift/Outrigger/Drive switch in DRIVE, depress the interlock lever switch on the control lever

and position each Outrigger switch to the EXTEND position.

• Outriggers should be disabled. If an outrigger extends during this test

machine from service until it is repaired.

b. Turn the Drive/Outrigger/Lift switch to OUTRIGGER.

c. Depress the interlock lever switch on the control lever and position each Outrigger switch to the

EXTEND position to deploy all four (4) outriggers.

• Check the outrigger indicator lights; they should be ON.

NOTE:

When the platform is elevated 1 m (3 ft.) or higher the outrigger function should be disabled.

d. Depress the interlock lever switch on the control lever and position each Outrigger switch to the

RETRACT position.

• Partially retract all four (4) outriggers. The outrigger indicator lights should FLASH.

• Fully retract all four (4) outriggers. The outrigger indicator lights should be OFF.

10. Rehook the controller on the front guardrail.

11. Open the Control Module covers to gain access to the chassis controls and tilt sensor.

12. Turn the Platform/Chassis switch to CHASSIS.

13. Push the throttle button in. Push the Raise button to elevate platform while pushing the tilt sensor off of

level. The platform should only partially elevate and the tilt alarm should sound. If the platform continues to elevate and/or there is no alarm,

14. Release the tilt sensor and fully elevate the platform.

15. Visually inspect the elevating assembly, lift cylinder, cables and hoses for damage or erratic operation.

Check for missing or loose parts.

16. Lower the platform partially by pushing in on the Lower button, and check operation of the audible lowering alarm.

17. Open the chassis emergency lowering valve to check for proper operation by pulling and holding the

knob out (refer to “Emergency Lowering” on page 9). Once the platform is fully lowered, close the valve

by releasing the knob.

18. Turn the Platform/Chassis switch to PLATFORM.

19. Close and secure the module covers.

20. Enter the platform making sure the gate is latched.

21. Position the Lift/Drive switch to LIFT.

22. Depress the interlock lever switch and slowly push the control lever to UP to raise the platform; fully

actuate the control lever to check proportional lift speed. Slowly pull the control lever to the DOWN position to lower the platform. Check that the lowering alarm sounds.

23. Optional Outrigger Equipped Machines:

a. With the Lift/Outrigger/Drive switch in LIFT, depress the interlock lever switch on the control lever and

position any outrigger switch to the EXTEND position.

• Outriggers should be disabled. If an outrigger extends during this test,

and remove the machine from service until it is repaired.

24. Turn the controller key switch to OFF, push the Emergency Stop button, and dismount the platform.

and remove the machine from service until it is repaired.

STOP

. Remove the

STOP

. Lower the platform

STOP

Page 6 Operator Manual

Page 9

Operation 067903-004R1 LX Series Work Platform

WARNING

!

!

O

PERATION

NOTE:

Before

operating the work platform, ensure that the pre-operation and safety inspection has been completed,

any deficiencies have been corrected, and the operator has been thoroughly trained on this machine.

Never operate the work platform with the parking brakes released. Serious injury or damage could

result.

S

WITCHING

1. With the engine running, turn the fuel selector switch (Figure 3: “Controls and Indicators,” on page 4) to

the center position.

2. After the engine has quit running, select the appropriate fuel supply.

3. Restart the engine.

F

UELS

(D

UAL

F

UEL

O

NLY

)

T

RAVEL

1. Verify the following:

• the chassis Emergency Stop button is in the ON position (pull out)

• the drive enable indicator is ON

• the Platform/Chassis switch is on PLATFORM.

NOTE:

If the drive enable indicator is OFF, verify that the platform is fully lowered and (if so equipped) the outriggers

are fully retracted.

2. After mounting the platform, close and latch the gate. Check that the guardrails are in position and properly assembled, with the fasteners properly torqued.

3. Check that the route is clear of persons, obstructions, holes and drop-offs, and is capable of supporting

the wheel loads.

4. Check clearances above, below and to the sides of the platform.

5. Pull the controller Emergency Stop button out to the ON position.

6. Turn the controller key switch fully clockwise to start the engine, releasing the key once the engine

starts.

NOTE:

If the engine is cold, on dual fuel models, depress and hold the choke button in while starting the engine. On

diesel models, hold the glow plug button in for 6 seconds to heat the glow plugs.

7. Set the Lift/Drive switch to DRIVE.

8. Set the speed range switch to HIGH TORQUE.

9. Grasp the control lever so that the interlock lever switch is depressed (releasing the interlock lever switch

cuts power to controller). Slowly push or pull the control lever to FORWARD or REVERSE to travel in the

desired direction. The farther you push or pull the control lever from center, the faster the machine will

travel.

10. While moving, push the speed range switch to HIGH SPEED for travel on level surfaces or to HIGH

TORQUE for climbing grades or traveling in confined areas.

WITH

P

LATFORM

L

OWERED

Operator Manual Page 7

Page 10

067903-004R1 LX Series Work Platform Operation

T

RAVEL

Travel with the platform elevated

NOTE:

The work platform will travel at reduced speed when in the elevated position, and only if the front axle is

parallel with the rear axle.

1. Check that the route is clear of persons, obstructions, holes and drop-offs, is level and capable of supporting the wheel loads.

2. Check clearances above, below and to the sides of the platform.

3. Position the Lift/Drive switch to the DRIVE position.

4. Push the control lever to FORWARD or REVERSE for the desired direction of travel.

5. If the machine quits driving and the tilt alarm sounds, immediately lower the platform and move the

machine to a level location before re-elevating the platform.

S

TEERING

Push the steering switch

insure proper direction.

NOTE:

Steering is not self-centering. Wheels must be returned to the straight ahead position by operating the steering

switch.

WITH

W

ORK

RIGHT

P

LATFORM

on firm and level surfaces.

ONLY

or

to turn the wheels. Observe the tires while maneuvering to

LEFT

E

LEVATED

R

AISING

The machine must be on a firm, level surface, capable of supporting the weight of the machine. On

machines equipped with optional outriggers, use the outriggers to level the machine (refer to “Leveling the

Platform (Outrigger equipped machines only)” on page 10.

1. Position the Lift/Drive switch to LIFT.

2. While holding the control lever so the interlock lever switch is depressed, push the control lever slowly

to UP to raise the platform. Pushing the control lever farther increases the lift speed.

3. When the work task is completed, position the Lift/Drive switch to LIFT, and lower the platform by pulling

back on the control lever until the platform is fully lowered.

AND

L

OWERING

THE

P

LATFORM

Page 8 Operator Manual

Page 11

Operation 067903-004R1 LX Series Work Platform

E

MERGENCY

S

ERIAL

The Emergency Lowering

Control is located at the rear

of the machine at the base of

the elevating assembly.

1. Open the Emergency Low-

2. Once the platform is fully

# 4022

ering Valve by pulling on

the knob and holding it.

lowered, release the knob

to close the valve.

L

OWERING

TO

4274

Figure 4:

LX31

1. Open the Emergency Lowering Valve by

2. Once the platform is fully lowered,

LX50, S

1. Open the Emergency Lowering Valve by

2. Once the platform is fully lowered,

AND

LX41, S

The Emergency Lowering Control Knob is

located at the rear of the machine at the

base of the elevating assembly.

pulling on the knob and holding it.

release the knob to close the valve.

ERIAL

The Emergency Lowering Control Switch is

located at the rear of the machine at the

base of the elevating assembly.

pusshing down on the toggle switch and

holding it.

release the toggle switch to close the

valve.

# 4275

ERIAL

# 4275

TO CURRENT

TO CURRENT

Figure 5:

Emergency Lowering Knob, LX31 and LX41

Figure 6:

Emergency Lowering switch, LX50

Operator Manual Page 9

Page 12

067903-004R1 LX Series Work Platform Operation

L

EVELING

(O

UTRIGGER

THE

P

LATFORM

EQUIPPED

MACHINES

ONLY

)

!

WARNING

When using outriggers, all four (4) outriggers must be in firm contact with the supporting surface.

O

UTRIGGER SWITCHES AND INDICATOR

For each outrigger, there is an outrigger switch and an outrigger indicator light (refer to Figure 3, Page 4).

Each outrigger switch will raise and lower one outrigger.

Each outrigger indicator light will indicate the position of one outrigger.

• When the indicator light is OFF - the outrigger is fully retracted.

• When the indicator light is FLASHING - the outrigger is partially extended.

• When the indicator light is ON - the outrigger is in firm contact with the supporting surface.

TO L

EVEL THE PLATFORM

1. Make sure that the extension deck is retracted before operating the

outriggers.

2. Look around the machine; make sure that there is nothing obstructing the outriggers, and that the surface beneath them is suitable to

support the weight of the machine.

3. Position the Lift/Outrigger/Drive switch set to OUTRIGGER.

4. Depress the interlock lever switch on the control lever, and operate

the outrigger switches to extend each outrigger until it is making firm

contact with the supporting surface.

• Pushing the control lever forward will increase the speed of the

extending outriggers.

5. While observing the bubble level on the guardrail, extend the outrigger opposite the position of the bubble until the platform is level. For example: if the bubble is to the front and left in the orbit, extend the

rear right outrigger. Continue to adjust until the bubble is centered in the small circle indicating that the

platform is level.

6. Confirm that all four (4) outriggers are in firm contact with the supporting surface. The outriggers are in

contact with the supporting surface when the indicator lights are ON.

!

(E

XTEND THE

L

IGHTS

O

UTRIGGERS

)

Figure 7:

Platform Orbit Bubble Level

TO R

Page 10 Operator Manual

ETRACT THE

1. Fully lower the platform.

2. Position the Lift/Outrigger/Drive switch set to OUTRIGGER.

3. Depress the interlock lever switch on the control lever, and position each outrigger switch to RETRACT.

• The outrigger indicator lights will be OFF when the outriggers are fully retracted.

• The drive enable indicator light will not come on until all four outriggers are fully retracted..

O

UTRIGGERS

Page 13

Towing or Winching 067903-004R1 LX Series Work Platform

CAUTION

WARNING

!

!

T

OWING

OR

W

INCHING

Perform the following only when the machine will not operate under its own power and it is necessary to

move the machine or when winching onto a transport vehicle (see “Transporting Work Platform” on

page 13).

DO NOT tow or winch the machine faster than 0,3 m/s (

components and void the warranty.

P

ARKING

Never operate the work platform with the parking brakes

released. Serious injury or damage could result.

Never release the brakes if the machine is on a slope.

Chock the wheels before releasing the parking brakes.

Hook the machine to a towing vehicle before releasing

the parking brakes.

1. Close the needle valve by turning the knob clockwise.

2. Pump the brake release pump until the parking brakes release and the wheels can be turned.

3. The machine will now roll when pushed or pulled.

4. Be sure to open the needle valve and verify that the parking brakes have engaged before the machine is

operated.

B

RAKE

R

ELEASE

). Faster speeds will damage drive

1 ft./s

Figure 8:

Parking Brake Release Pump

A

FTER

Operator Manual Page 11

U

1. Ensure that the platform is fully lowered.

2. Park the machine on level ground, preferably under cover, secure against vandals, children or unautho-

3. Turn the key switch to OFF and remove the key to prevent unauthorized operation.

SE

E

ACH

rized operation.

D

AY

Page 14

067903-004R1 LX Series Work Platform Fold Down Guardrails

F

OLD

D

OWN

This procedure is only for passing through doorways. Guardrails must be returned to proper position

before using the machine.

G

UARDRAILS

Figure 9:

Fold Down Guardrails

F

OLD

P

NOTE:

1. Place the controller on the plat-

2. Starting at the slide-out deck:

3. Go to the rear of the platform:

4. Unlatch the side gate so the left side guardrails can be folded down in two separate pieces. Also

5. Fold the rear half of the side guardrails onto the deck:

6. Fold the front half of the side guardrails onto the deck:

7. Lift up and fold down the front slideout deck guardrail.

D

OWN

ROCEDURE

When performing the following

procedures, retain all fasteners.

form.

A

• remove nuts, bolts and washers

from the top front corners of

guardrails (A)

• remove the nuts, bolts and washers from the slide-out deck side

guardrail midrails (B)

• remove nuts, bolts and washers

located at the top of the sockets

that hold the slide-out deck side

guardrails to the deck (C)

• fold the side guardrails down onto

the slide-out deck platform

• leave the end rail up and slide the

deck all the way in.

• close and latch the rear gate

• remove the nuts, bolts, washers, and corner brackets from the top of the rear guardrail

• fold the rear guardrail down onto the platform, being careful to keep the gate latched.

remove the nuts, bolts and washers opposite the gate latch on the right side guardrail so it too can be

separated into two pieces (E).

• lift up and fold down so the guardrails rest on the deck, on top of the rear guardrail.

• lift up and fold down so the guardrails rest on the slideout deck, with the guardrail posts resting in the

cutouts on the slideout deck toeboard (F).

B

C

F

D

E

E

RECTION

1. Raise the front guardrail, making sure it is pushed down to secure the guardrail in the vertical position.

2. Raise the side guardrails, making sure each is pushed down to secure the guardrail in the vertical position; align holes and install bolts, washers and nuts. Tighten securely.

3. Raise one of the slide-out deck side guardrail assemblies; align holes and install bolts, washers and

nuts. Tighten securely. Repeat this procedure for the other slide-out deck side guardrails.

4. Raise the rear guardrail, and install the corner brackets, nuts, bolts and washers.

5. Hang the controller from the front guardrail.

6. Before operating work platform check that all fasteners are in place and properly torqued.

!

WARNING

Before operating the machine, guardrails must be securely fastened in their erected position.

Page 12 Operator Manual

P

ROCEDURE

!

Page 15

Transporting Work Platform 067903-004R1 LX Series Work Platform

CAUTION

T

RANSPORTING

P

REPARATION

1. Fully lower the platform.

2. Disconnect the battery negative (-) lead from the battery terminal.

3. Band the controller to the front guardrail.

4. Band the elevating linkage to the frame.

L

IFTING

1. Secure straps to chassis tie down/lifting lugs

only.

2. Place the platform onto the transport vehicle

in transport position.

3. Chock the wheels.

4. Secure the work platform to the transport

vehicle with chains or straps of adequate

load capacity attached to the chassis tie

down/lifting lugs.

W

BY C

ORK

RANE

FOR

P

LATFORM

S

HIPMENT

Figure 10:

Transporting Work Platform

D

RIVING

NOTE:

Do not winch faster than 0,3 m/s (1 ft/s).

1. Move the machine onto the truck or trailer;

A. To

a. Move the work platform up the ramp and into transport position.

b. Set the wheels straight and turn off the machine.

c. Chock the wheels.

B. To

a. Move the work platform up to the ramp.

b. Attach the winch cable to the tie down/lifting lugs.

c. Release the parking brakes (refer to “Parking Brake Release” on page 11).

d. Winch the platform into transport position

e. Chock the wheels.

NOTE:

Engage the parking brakes after transporting.

2. Secure the work platform to the transport vehicle with chains or straps of adequate load capacity

attached to the chassis tie down/lifting lugs.

OR

W

INCHING

the machine onto the transport vehicle:

Drive

Winch

the machine onto the transport vehicle:

ONTO

A T

RUCK

OR

T

RAILER

Overtightening of chains or straps through tie down/lifting lugs may result in damage to the work

platform.

Operator Manual Page 13

Page 16

067903-004R1 LX Series Work Platform Maintenance

Brace

Upper Scissor

Center Pivot

Locking Pin

Lower Scissor

Center Pivot

M

AINTENANCE

Figure 11:

!

WARNING

Never perform service on the work platform in the elevating

assembly area while the platform is elevated without first blocking

the elevating assembly.

DO NOT

storing brace.

B

LOCKING

B

RACE INSTALLATION

1. Park the work platform on firm, level ground.

2. Verify that the platform Emergency Stop button is ON.

3. Turn the Platform/Chassis switch to CHASSIS.

4. Start the engine, using the chassis controls.

5. Push the Throttle button in. The button will stay in and the engine speed will increase. Using the Raise

6. From the left side of the machine, disengage the locking pin securing the brace. Rotate the scissor

7. Push the Lower button and gradually lower the platform until the brace is supporting the platform.

8. Disengage the throttle by pushing the Throttle button in again. The button will retract and the engine will

stand in elevating assembly area while deploying or

E

LEVATING

button, elevate the platform until the scissor brace can be rotated to the vertical position.

brace counterclockwise until it is vertical and between the two scissor center pivots.

come to idle speed.

!

A

SSEMBLY

Blocking Elevating Assembly

B

RACE

1. Using the chassis controls, gradually raise the platform until the scissor brace clears the two scissor

2. Rotate the scissor brace clockwise until the locking pin engages.

3. Push the Lower button to completely lower the platform.

4. Make sure the Throttle button is disengaged and Platform/Chassis switch is on PLATFORM.

R

EMOVAL

center pivots.

Page 14 Operator Manual

Page 17

Maintenance 067903-004R1 LX Series Work Platform

WARNING

!

!

2

1

1 Fluid Sight Gauge

2. Filler Cap

H

YDRAULIC

The hydraulic fluid tank is located in the Power Module.

NOTE:

Never add oil if the platform is elevated.

1. Make sure that the platform is fully lowered.

2. Check fluid level by observing the oil sight gauge

3. Remove the filler cap to fill with the appropriate fluid.

B

ATTERY

F

M

AINTENANCE

LUID

Figure 12:

Figure 13:

Hydraulic Oil Tank

Battery Location

Hazard of explosive gas mixture. Keep sparks, flame, and smoking

material away from battery.

Always wear safety glasses when working with batteries.

Battery posts, terminals and related accessories contain lead and

lead compounds, chemicals known to the State of California to

cause cancer and reproductive harm.

Battery fluid is highly corrosive. Thoroughly rinse away any spilled

fluid with clean water.

Always replace batteries with UpRight batteries or manufacturer

approved replacements.

Check battery fluid level daily, especially if the work platform is

being used in a warm, dry climate.

If the electrolyte level is lower than 10 mm (

add distilled water ONLY. Do not use tap water with high mineral

content; it will shorten battery life.

The battery and cables should be inspected regularly for signs of cracks in the case, electrolyte leakage

and corrosion of the terminals. Inspect the cables for worn spots or breaks in the insulation and for broken

cable terminals.

Refer to the Service Manual to extend battery life and for complete service instructions.

Wash hands after handling.

) above plates,

3/8 in.

Operator Manual Page 15

Page 18

067903-004R1 LX Series Work Platform Maintenance

Propane (LP Gas)

Diesel or Gasoline

E

NGINE

Engine

1

C

OOLANT

The coolant recovery tank is mounted

on the inside of the door of the power

module.

1. Remove the cap on the coolant

recovery tank.

2. Add coolant to the “FULL” mark.

Figure 14:

3

NOTE:

Never remove the radiator cap when

the engine is hot.

O

IL

The engine

when you check and replenish the

engine oil. Refer to the Service Manual

to change the oil filter.

1. Remove the oil dipstick and check

the level indicator marks.

2. If the level is low, remove the oil filler cap.

3. Replenish with the proper engine oil (refer to the engine service manual that came with the machine).

!

CAUTION

DO NOT check coolant when engine or radiator is hot; hot coolant can cause severe burns.

F

UEL

must not be running

1 Radiator Cap

2. Coolant Recovery Tank

3. Oil Filler Cap

4. Oil Dipstick

!

4

2

Figure 15:

Fuel Supply

D

IESEL OR GASOLINE

IMPORTANT: Fill with the correct fuel! Observe the

label near the fuel tank. It will say “Gasoline Only”

or “Diesel Only”.

The fuel tank for gasoline or diesel machines is

located in the Control Module, behind the chassis controls. The tank is translucent. Check the

fuel level by observing the level of the liquid

through the tank.

P

ROPANE

Page 16 Operator Manual

The propane tank (dual fuel machines) is located in the Control Module to the left of the ladder, in front of

the battery.

(LP G

AS

)

Page 19

Preventative Maintenance 067903-004R1 LX Series Work Platform

WARNING

!

!

P

REVENTATIVE

M

AINTENANCE

The complete inspection consists of periodic visual and operational checks, along with periodic minor

adjustments to assure proper performance. Daily inspection will prevent abnormal wear and prolong the

life of all systems. The inspection and maintenance schedule is to be performed at regular intervals.

Inspection and maintenance shall be performed by personnel who are trained and familiar with mechanical

and electrical procedures.

Before performing preventative maintenance, familiarize yourself with the operation of the machine.

Always block the elevating assembly whenever it is necessary to enter the scissor assembly to perform

maintenance while the platform is elevated.

The preventative maintenance table has been designed for machine service and maintenance repair.

Please photocopy the Daily Preventative Maintenance Check List and use the table as a checklist when

inspecting the machine for service.

D

M

AINTENANCE

AILY

P

REVENTATIVE

T

ABLE KEY

M

AINTENANCE

M

AINTENANCE

C

HECK

R

EPORT

L

IST

\

Y=Yes/Acceptable

N=No/Not Acceptable

R=Repaired/Acceptable

COMPONENT INSPECTION OR SERVICES Y N R

Battery Check electrolyte level

Chassis

Control Cable

Controller Check switch operation

Drive Motors Check for operation and leaks

Elevating Assembly Inspect for structural cracks

Emergency Lowering

System

Entire Unit Check for and repair collision damage

Hydraulic fluid Check fluid level

Hydraulic Pump Check for hose fitting leaks

Hydraulic System Check for leaks

Check hoses for pinch or rubbing points

Check welds for cracks

Check the exterior of the cable for pinching,

binding or wear

Operate the emergency lowering valve and

check for serviceability

Date: _______________________________________

Owner: _____________________________________

Model No: ___________________________________

Serial No: ___________________________________

Serviced By: _________________________________

COMPONENT INSPECTION OR SERVICES Y N R

Labels

Platform Deck and

Rails

Tires and Wheels Check for damage

Engine Oil and Filter

Engine Fuel System

Engine Coolant Check coolant level (with engine cold)

Torque Hubs Check for leaks

Outriggers Check for operation and leaks

Check for peeling, missing, or unreadable

labels & replace

Check welds for cracks

Check condition of deck

Check level and condition

Check for leaks

Check fuel level

Check for leaks

Check air cleaner

Operator Manual Page 17

Page 20

067903-004R1 LX Series Work Platform Labels

L

ABELS

These labels shall be present and in good condition before operating the work platform. Be sure to read,

understand and follow these labels when operating the work platform.

OUTRIGGER

OPTION

PLATFORM CONTROLS

POWER MODULE

CONTROL MODULE

POWER MODULE

REAR

CONTROL

MODULE

FRONT

Page 18 Operator Manual

Page 21

Labels 067903-004R1 LX Series Work Platform

2

010076-001

063423-000

21

060197-000

4

067480-000

5

061205-005

6

061220-002

8

064166-000

13

13

067480-001

(Outrigger Units)

22

22

23

WARNING

TIPPING HAZARD

Check tire pressure daily.

Pressure must be

maintained at 50 P.S.I.

LX31/LX41:

066562-000

LX50:

066562-003

061515-000

38

066561-001

066558-000

40

066558-002

40

LX50 S/N 4275

to current

9

066552-000

10

064189-001

11

067642-003

(Outrigger Units:

067642-009)

066550-009

14

START CIRCUIT PROTECTION

If engine stops cranking while

starting, let machine sit for

10-15 minutes before re-starting

067478-000

15

TIPPING HAZARD

If horn sounds continuously

lower platform and relevel.

066551-003

16

067822-000

17

030624-024

17

027898-000

25

LX31: 101250-009

26

LX41: 101250-008

26

LX50: 101250-003

26

066556-000

41

(Outrigger Units)

LX31: 101252-013

42

LX41: 101252-014

42

LX50: 101252-015

42

067481-001 - Diesel

12

067481-000 - Dual Fuel

066554-000

19

067822-001

3434

43

066556-001

(Outrigger Units)

Operator Manual Page 19

Page 22

067903-004R1 LX Series Work Platform Specifications

S

PECIFICATIONS

Specifications subject to change without notice. Refer to the Service Manual for service information. Refer

to the Parts Manual for illustrated parts breakdown. Hot weather or heavy use may reduce performance.

Meets or exceeds all applicable requirements of OSHA and ANSI A92.6-1999.

ITEM LX31 LX41 LX50

Platform Size (Inside toeboards)

Standard

slide-out Deck Extended

Max. Platform Capacity

Standard

Dual Deck

on Extension

Max. No. of occupants

Standard

Dual Deck

Height

Working Height

Max. Platform Height

Min. Platform Height

Drivable Height, Standard

Drivable Height, Dual Deck

Dimensions

Weight, Standard 2WD:

Weight, Dual Deck 2WD:

Overall Width

Overall Height, guardrails up

Overall Height, guardrails lowered

Overall Length, deck in

Overall Length, deck extended

Surface Speed

Platform Lowered

Platform Raised

System Voltage

Hydraulic Tank Capacity

Maximum Hydraulic System Pressure

Hydraulic Fluid

Normal Temperature (>32° F [0° C])

Low Temperature (<32° F [0° C])

Extreme Temperature (<0° F [-17° C])

Lift System

Lift Speed

Power Source

Drive Control

Control System

Horizontal Drive

Tires

Tire Air Pressure

Parking Brakes

Turning Radius (inside)

Maximum Gradeability:

Wheel Base

Ground Clearance

Guardrails

Toeboard

3,97 m x 1,73 m [

4,8 m x 1,73 [

907 kg [

794 kg [

227 kg [

156 in x 68 in.

190 in. x 68 in.

2,000 lbs.

1750 lbs.

500 lbs.

] 3,97 m x 1,73 m [

] 4,8 m x 1,73 [

] 680 kg [

] 567 kg [

] 227 kg [

156 in x 68 in.

190 in. x 68 in.

1,500 lbs.

1,250 lbs.

500 lbs.

] 3,97 m x 1,73 m [

] 4,8 m x 1,73 [

] 454 kg [

] 340 kg [

] 227 kg [

5 people 5 people 4 people

4 people 3 people

4WD:

4WD:

11,4 m [

9,45 m [

1,43 m [

9,4 m [

4282 kg [

4404 kg [

4613 kg [

4736 kg [

2,29 m [

2,53 m [

1,64 m [

4,06 m [

4,88 m [

0 to 5,0 km/h [

0 to 0,48 km/h [

] 14,33 m [

37 ft.

] 12,34 m [

31 ft.

] 1,66 m [

56.3 in.

] 12,3 m [

31 ft.

9,440 lbs.

9,710 lbs.

10,170 lbs.

10,440 lbs.

]

]

]

]

] 2,29 m [

90 in.

] 2,77 m [

99.8 in.

] 1,87 m [

64.5 in.

] 4,06 m [

160 in.

] 4,88 m [

192 in.

0 to 3.1 mph

0 to 0.5 mph

] 0 to 5,0 km/h [

] 0 to 0,48 km/h [

4994 kg [

5117kg [

5325 kg [

5448 kg [

] 17 m [

47 ft.

40 ft. 6 in.

40 ft. 6 in.

11,010 lbs.

11,280 lbs.

11,740 lbs.

12,010 lbs.

] 15,09 m [

] 1,93 m [

65.3 in.

] 12,34 m [

]

]

]

]

] 2,29 m [

90 in.

]3 m [

109 in.

] 2,1 m [

73.5 in.

] 4,06 m [

160 in.

] 4,88 m [

192 in.

0 to 3.1 mph

0 to 0.5 mph

GAS: 5756 kg [

GAS: 5879 kg [

GAS: 6087 kg [

GAS: 6210 kg [

12,690 lbs.

12,960 lbs.

13,420 lbs.

13,690 lbs.

] 0 to 5,0 km/h [

] 0 to 0,48 km/h [

12 Volt DC 12 Volt DC 12 Volt DC

107,13 l [

206,8 bar [

28.3 US Gallons

3000 psi

] 107,13 l [

28.3 US Gallons

] 206,8 bar [

] 107,13 l [

] 206,8 bar [

3000 psi

ISO #46 ISO #46 ISO #46

ISO #32 ISO #32 ISO #32

ISO #15 ISO #15 ISO #15

One Single Stage Lift Cylinder One Single Stage Lift Cylinder Two Single Stage Lift Cylinders

Raise: 40 sec. Lower: 52 sec. Raise: 45 sec. Lower: 60 sec. Raise: 80 sec. Lower: 112 sec.

Diesel or Gasoline 20 HP Kubota,

3 Cylinder, Water Cooled

Diesel or Gasoline 20 HP Kubota,

3 Cylinder, Water Cooled

Diesel or Gasoline 20 HP Kubota, 3 Cylinder, Water Cooled

Proportional Proportional Proportional

Smooth one-hand Joystick Smooth one-hand Joystick Smooth one-hand Joystick

2WD:

4WD:

2 Wheel, Hyd. Motors

4 Wheel, Hyd. Motors

2 Wheel, Hyd. Motors

4 Wheel, Hyd. Motors

2 Wheel, Hyd. Motors

4 Wheel, Hyd. Motors

10-16.5 NHS 8 Ply 10-16.5 NHS 8 Ply 10-16.5 NHS 8 Ply

2WD:

4WD:

2WD:

4WD:

3,4 bar [

Dual Disc, Spring Applied,

Hydraulic Release

1,22 m [

17° [

19° [

2,9 m [

2,95 m [

0,24 m [

1.1 m [

43.5 in.

Fold Down with gate.

152 mm [

]3,4 bar [

50psi.

50psi.

Dual Disc, Spring Applied,

Hydraulic Release

] 1,22 m [

48 in.

]

30%

]

35%

]

114.5 in.

]

116 in.

]0,24 m [

9.5 in.

] high,

1.1 m [

17° [

19° [

2,9 m [

2,95 m [

43.5 in.

48 in.

30%

35%

114.5 in.

116 in.

9.5 in.

Fold Down with gate.

] High 152 mm [

6 in.

6 in.

]NA

Dual Disc, Spring Applied, Hydraulic Release

] 1,22 m [

]

]

]

]

2,9 m [

2,95 m [

] 0,24 m [

] high,

1.1 m [

Fold Down with gate.

] High 152 mm [

156 in x 68 in.

190 in. x 68 in.

1,000 lbs.

750 lbs.

500 lbs.

56 ft.

49 ft. 6 in.

76 in.

49 ft. 6 in.

12,2 m [

40 ft.

] DIES: 5788 kg [

] DIES: 5910 kg [

] DIES: 6119 kg [

] DIES:6241 kg [

90 in.

118.3 in.

82.5 in.

160 in.

192 in.

0 to 3.1 mph

0 to 0.5 mph

28.3 US Gallons

3000 psi

48 in.

13,5° [

24%

13,5° [

24%

114.5 in.

116 in.

9.5 in.

43.5 in.

6 in.

]

]

]

]

]

]

]

]

]

]

12,760 lbs.

13,030 lbs.

13,490 lbs.

13,760 lbs.

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

] high,

] High

]

]

]

]

Page 20 Operator Manual

Page 23

Call Toll Free in U.S.A.

1-800-926-LIFT

Page 24

USA

TEL: (1) 800-926-5438 or (1) 559-662-3900

FAX: (1) 559-673-6184

Parts FAX: (1) 800-669-9884

801 South Pine Street

Madera, California 93637

http://www.upright.com

E

UROPE

TEL: +353 1 620 9300

FAX: +353 1 620 9301

Unit S1, Park West Industrial Park

Friel Avenue

Nangor Road

Dublin 12, Ireland

L

OCAL DISTRIBUTOR

:

067903-004R1

06-02

Loading...

Loading...