Page 1

Operator Manual

Manuel de l’utilisateur

Betriebsanleitung

Manual del Operador

LX Series

Serial No. 2747 to Current

WARNING

All personnel shall carefully read, understand and follow all safety rules and operating

instructions before performing maintenance on or operating any UpRight aerial work

platform.

Refer to page 2 for the english language version of this Operator Manual.

AVERTISSEMENT

Tout le personnel doit lire attentivement et respecter toutes les consignes de sécurité

avant d’entretenir ou d’utiliser une plate-forme de travil aérien UpRight

Réferez-vous à la page 11 pour la version en français de ce manuel de l’utilisateur.

WARNUNG

Alle Bediener müssen die Sicherheitsregelungen und die Betriebsanweisungen

gründlich durchlesen, verstehen und befolgen, bevor sie Wartungsarbeiten an irgen-

deiner UpRight Scheren-Hubbühne vornehmen oder selbige benutzen.

Siehe Seite 12 zwecks der deutschsprachigen Ausgabe dieser Betriebsanleitung.

ADVERTENCIA

Todo el personal debe leer atentamente, entender y respetar todas las reglas de segu-

ridad y las instrucciones de operación antes de efectuar trabajos de mantenimiento o

manejar cualquier plataforma aérea de trabajo UpRight.

Referirse a la página 13 para la versión en español de este manual del operador.

Page 2

English Language Section

Safety Rules

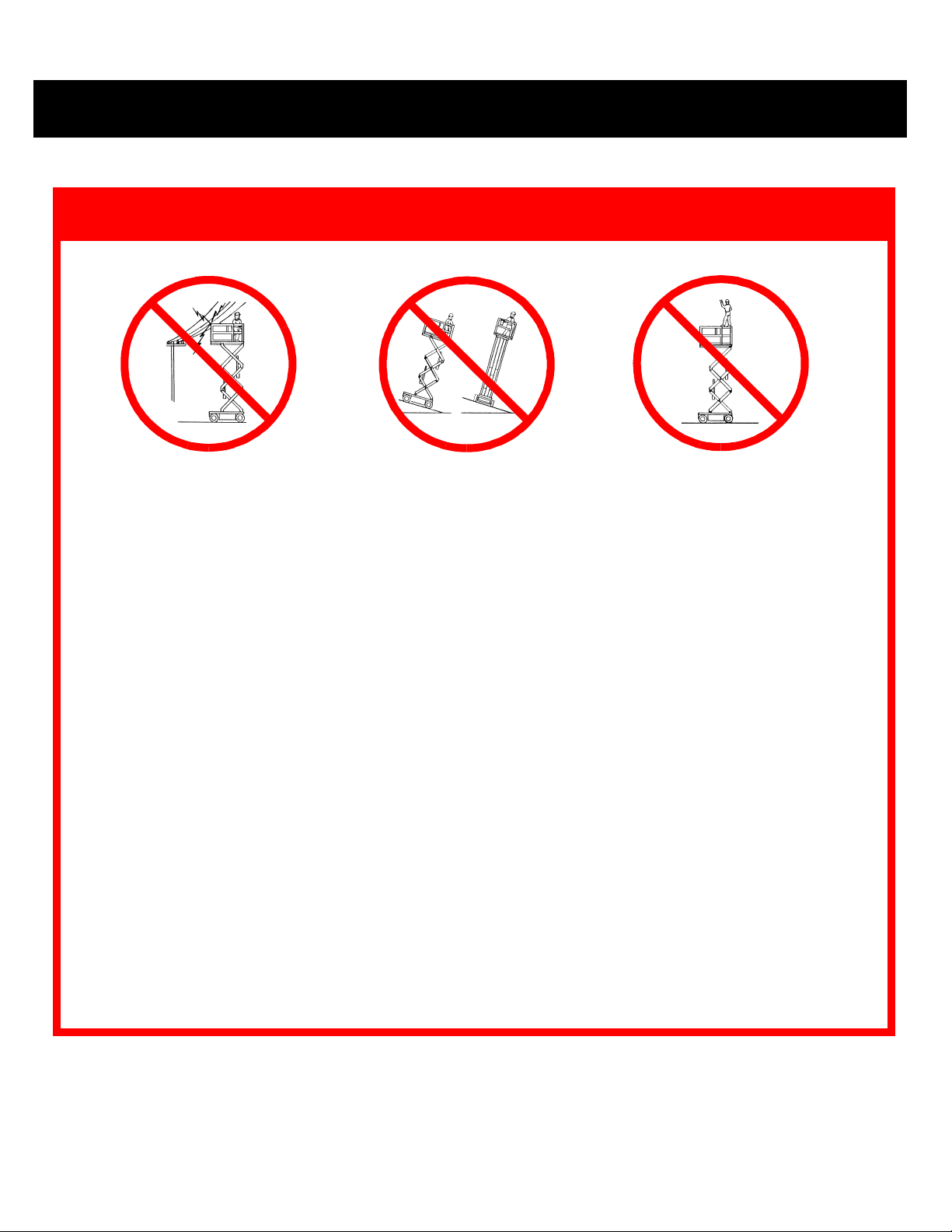

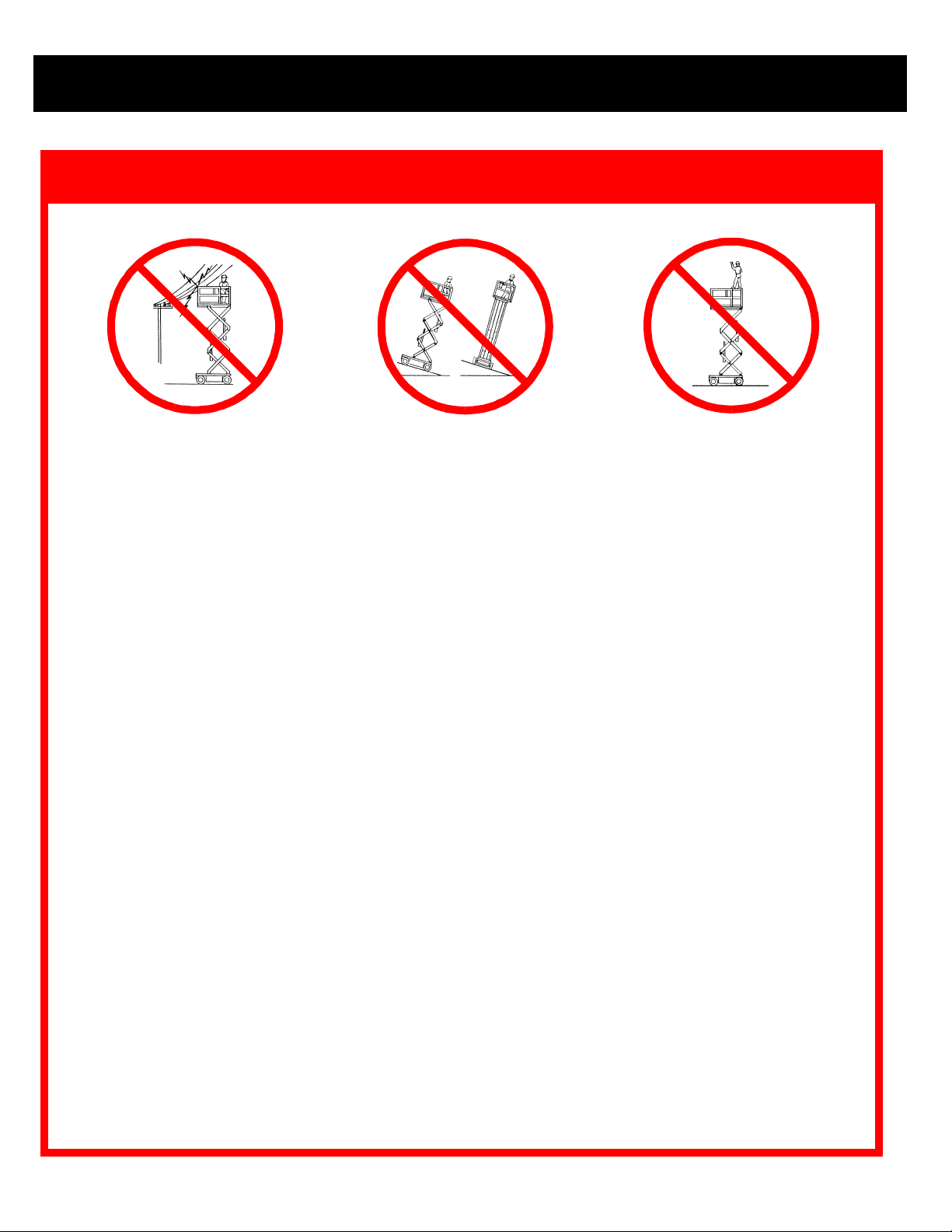

EVER

N

operate the machine within

ten feet of power lines. THIS

MACHINE IS NOT INSULATED

EVER

N

elevate or drive elevated

on uneven slopes or soft ground

.

or elevate the platform unless the

EVER

N

sit, stand or climb on

guardrail or midrail.

platform is level.

EVER

N

operate the machine without first surveying the work area for surface hazards such as holes, drop-offs,

bumps and debris.

EVER

N

S

K

N

N

M

L

D

N

N

I

operate the machine if all guardrails are not properly in place and secured with all fasteners properly torqued.

ECURE

NSPECT

and lock gate after mounting platform.

EEP

all body parts clear of outriggers when extending or retracting (outrigger equipped machines only).

EVER

use ladders or scaffolding on the platform.

EVER

attach overhanging loads or increase platform size.

AINTAIN

OOK

ISTRIBUTE

EVER

EVER

tire pressure at 50 psi (LX31/41).

up, down and around for overhead obstructions and electrical conductors.

all loads evenly on the platform. See the back cover for maximum platform load.

use damaged equipment. (Contact UpRight for instructions. See toll-free phone number on back cover.)

change operating or safety systems.

the machine thoroughly for cracked welds, loose hardware, hydraulic leaks, damaged control cable, loose

wire connections and wheel bolts.

EVER

N

N

N

climb down elevating assembly with the platform elevated.

EVER

perform service on machine while platform is elevated without blocking elevating assembly.

EVER

recharge battery near sparks or open flame; batteries that are being charged emit highly explosive hydrogen

gas.

FTER USE

A

EVER

N

secure the work platform against unauthorized use by turning key switch off and removing key.

replace any component or part with anything other than original UpRight replacement parts without the man-

ufacturer's consent.

2 43

Page 3

NTRODUCTION

I

YSTEM FUNCTION INSPECTION

S

This manual covers all models of the LX Series

Work Platforms. This manual must be stored on the

machine at all times.

PRE-O

NOTE:Carefully read, understand and follow

all safety rules, operating instructions,

labels and the Scaffold Industry Association’s MANUAL OF RESPONSIBILITIES. Perform the following steps each day before

use.

1. Open modules and inspect for damage, oil leaks or

missing parts.

2. Check the hydraulic oil level sight gauge on the hydraulic tank with the platform fully lowered. Add fluid if necessary.

3. Check that fluid level in the battery is correct (see Bat-

tery Maintenance).

4. Check the engine oil level and fuel level.

5. Check that all guardrails are in place, the slide out deck

extension is secured with the pin and all fasteners are

properly tightened.

6. Check tire pressure; 50 psi (3.4 bar)

7. Carefully inspect the entire work platform for damage

such as cracked welds or structural members, loose or

missing parts, oil leaks, damaged cables or hoses,

loose connections and tire damage.

8. Move machine, if necessary, to unobstructed area to

allow for full elevation.

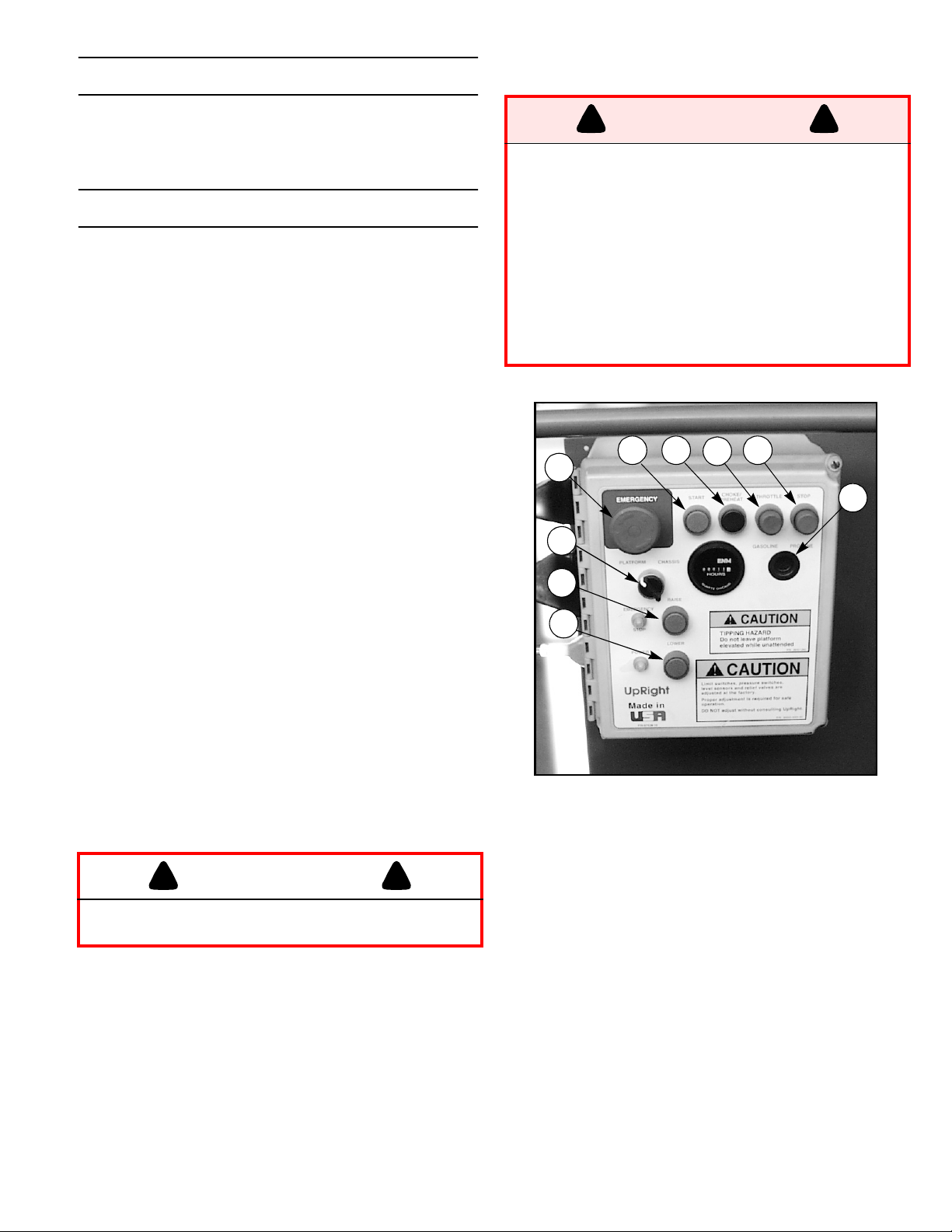

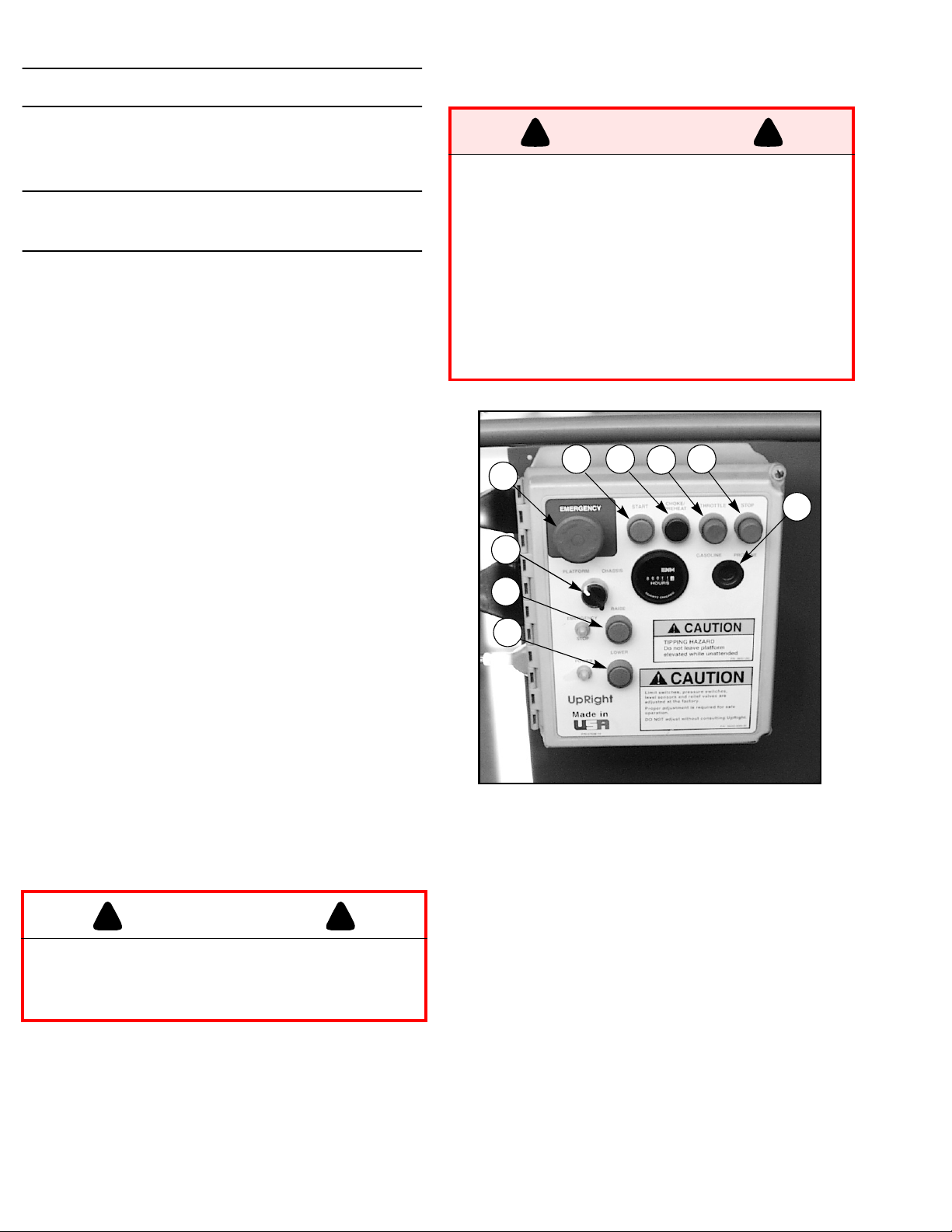

9. Place chassis and platform emergency stop switches in

the ON position (Figures 1 & 2) by pulling the buttons

out.

10. Verify platform/chassis switch is set to PLATFORM.

11. While the engine is cool check the engine coolant level.

DO NOT check coolant when engine or radiator

is hot, hot coolant can cause severe burns.

PERATION

!

CAUTION

AFETY INSPECTION

& S

!

!

WARNING

STAND CLEAR of the work platform while

performing the following checks.

Before operating the work platform survey the

work area for surface hazards such as holes,

drop-offs, bumps and debris.

Check in ALL directions, including above the

work platform, for obstructions and electrical

conductors.

Protect control console cable from possible

damage while performing checks.

5 6 8

1

2

3

4

Figure 1: Chassis Controls

1. Emergency Stop

2. Platform/Chassis

Switch

3. Raise Button

4. Lower Button

5. Start Button

1. Unhook controller from front guardrail. Firmly grasp

controller hanger in such a manner that the interlock

lever can be depressed, while performing the following

checks from the ground.

2. Turn controller key switch clockwise to ON. Turn fully

clockwise to start engine, releasing the key once the

engine starts.

7

6. Choke Button (Dual

Fuel) or Glow Plug

Button (Diesel)

7. Throttle Button

8. Stop Button

9. Fuel Selector Switch

(Dual Fuel only)

!

9

Page 4

Note: If the engine is cold, depress the glow

plug button and hold for 6 seconds to heat

the glow plugs.

1. Position drive/lift switch to DRIVE position.

2. With the speed range switch first in HIGH TORQUE and

then in HIGH SPEED depress the interlock lever and

slowly push the control lever to FORWARD then

REVERSE positions to check for speed and directional

control. The farther you push or pull the control lever

the faster the machine will travel.

3. Push steering switch RIGHT then LEFT to check for

steering control.

1

2

3

7

4

8

9

5

6

Figure 1: Controller

1. Steering Switch

2. Interlock Lever

Switch

3. Control Lever

4. Outrigger Switches

5. Emergency Stop

6. Drive/Lift Switch

7. Drive Speed/Torque

Selector Switch

8. Drive Enable Indicator

9. Key Switch

Switch

6. Depress the Interlock switch on the control handle and

position each Outrigger switch to the EXTEND position

to deploy all four Outriggers. Check the Drive Enable

indicator, it should be off.

7. Fully retract all Outriggers and check the Drive Enable

indicator, it should be on.

8. Rehook controller on front guardrail.

9. Turn the platform/chassis switch to CHASSIS.

10. Push the throttle button in. Push chassis raise button

to elevate platform while pushing the tilt sensor off of

level. The platform should only partially elevate and the

tilt alarm should sound. If the platform continues to

elevate and/or there is no alarm STOP and remove the

machine from service until it is repaired.

11. Release the tilt sensor and fully elevate platform.

12. Visually inspect the elevating assembly, lift cylinder,

cables and hoses for damage or erratic operation.

Check for missing or loose parts.

13. Lower the platform partially by pushing in on the chassis lower switch, and check operation of the audible

lowering alarm.

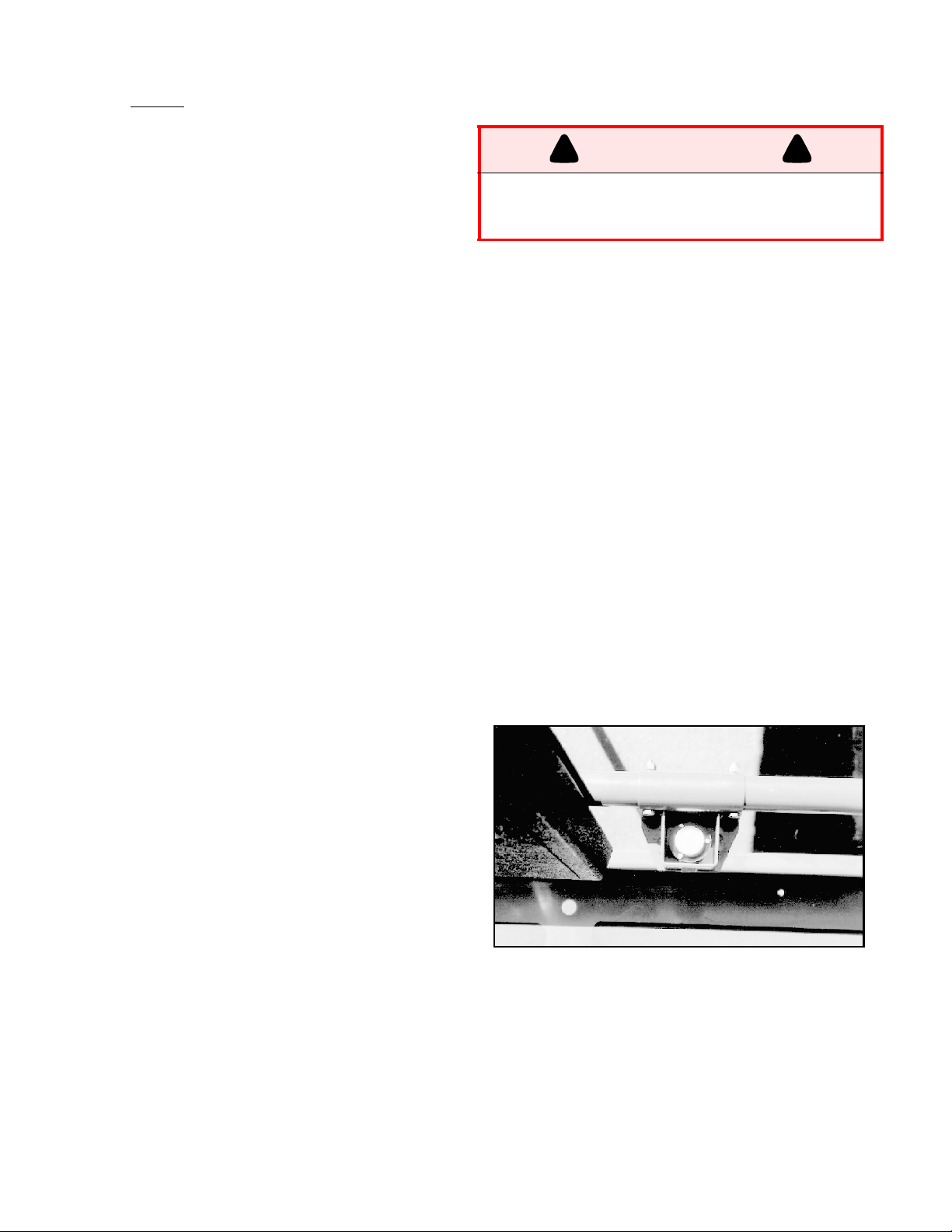

14. Open the chassis emergency lowering valve (Figure 4)

to check for proper operation by pulling and holding the

knob out. Once the platform is fully lowered, close the

valve by releasing the knob.

15. Turn the platform/chassis switch to PLATFORM.

16. Enter the platform making sure the gate is latched.

17. Position drive/lift switch to LIFT.

18. Depress the interlock lever and slowly push the control

lever to UP to raise the platform, fully actuate the control lever to check proportional lift speed. Slowly pull

control lever to DOWN position to lower platform.

Check that lowering alarm sounds.

19. Depress the interlock lever switch on the control lever

and position any Outrigger switch to the EXTEND position, Outriggers should be disabled. If an Outrigger

extends during this test STOP. Lower the platform and

remove the machine from service until it is repaired.

20. Turn controller key switch to OFF, push the emergency

stop button and dismount the platform.

21. Close and secure module covers.

4 41

Page 5

Operation

NOTE: Before operating work platform,

ensure that the pre-operation and safety

inspection has been completed, any deficiencies have been corrected and the operator has been thoroughly trained on this

machine.

RAVEL WITH PLATFORM LOWERED

T

1. Verify chassis emergency stop switch is in the ON position (turn counterclockwise), the drive enable indicator

is on, and that the platform/chassis switch is on

.

FORM

Note: If the drive enable indicator is off, verify that the platform is fully lowered and (if

so equipped) the outriggers are fully

retracted.

2. After mounting platform, close and latch gate. Check

that guardrails are in position and properly assembled

with fasteners properly torqued.

3. Check that route is clear of persons, obstructions,

holes and drop-offs and is capable of supporting the

wheel loads.

4. Check clearances above, below and to the sides of the

platform.

5. Pull controller emergency stop button out to ON position.

6. Turn controller key switch fully clockwise to start

engine, releasing the key once the engine starts.

Note: If the engine is cold, hold the glow

plug button in for 6 seconds to heat the

glow plugs.

7. Set the drive/lift speed range switch to

8. Grasp the control lever so the interlock lever is

depressed (releasing the interlock lever cuts power to

controller). Slowly push or pull the control lever to

FORWARD

tion. The farther you push or pull the control lever from

center the faster the machine will travel.

9. While moving, push the drive/lift speed range switch to

HIGH SPEED

TORQUE

areas.

or

REVERSE

for travel on level surfaces or to

for climbing grades or traveling in confined

to travel in the desired direc-

HIGH TORQUE

PLAT-

HIGH

EVELING THE PLATFORM

L

GER EQUIPPED MACHINES ONLY

!

WARNING

Never operate work platform with the parking

brakes released. Serious injury or damage

could result.

1. Look around the machine, make sure that there is nothing obstructing the outriggers, and that the surface

beneath them is suitable to support the weight of the

machine.

2. Depress the interlock lever on the control handle and

operate the outrigger switches to extend each outrigger

until it is making firm contact with the ground.

3. While observing the bubble level on the front guardrail,

(Figure 3), extend the outrigger opposite the position of

the bubble until the platform is level. For example: if the

bubble is to the front and left in the orbit, extend the

rear right outrigger. Continue to adjust until the bubble

is centered in the small circle indicating that the platform is level.

4. Outriggers must be in firm contact with the supporting

surface, observe each outrigger to verify.

TO R

1. Fully lower the platform.

2. Position each outrigger switch to

.

ETRACT THE OUTRIGGERS

the outriggers to ensure that they are fully retracted.

The drive enable indicator light will not come on until all

four outriggers are fully retracted.

UTRIG

(O

RETRACT

-

)

!

. Observe

TEERING

S

1. Push the steering switch

wheels. Observe the tires while maneuvering to insure

proper direction.

NOTE: Steering is not self-centering.

Wheels must be returned to the straight

ahead position by operating the steering

switch.

RIGHT

or

LEFT

to turn the

Figure 1: Platform Orbit Level

AISING AND LOWERING THE PLAT

R

FORM

1. Position the drive/lift switch to

2. While holding the control lever so the interlock lever is

depressed, push the control lever slowly to UP to raise

the platform. Pushing the control lever farther

increases the lift speed.

5

LIFT

.

-

Page 6

1. When the work task is completed, position the drive/lift

switch to LIFT and lower the platform by pulling back

on the control lever until the platform is fully lowered.

RAVEL WITH WORK PLATFORM ELE

T

VATED

Travel with platform elevated ONLY on firm and level

surfaces.

Note: The work platform will travel at

reduced speed when in the elevated position, and only if the front axle is parallel

with the rear axle.

1. Check that the route is clear of persons, obstructions,

holes and drop-offs, is level and capable of supporting

the wheel loads.

2. Check clearances above, below and to the sides of platform.

3. Position the drive/lift switch to the DRIVE position.

4. Push the control lever to FORWARD or REVERSE for

the desired direction of travel.

Note: Machine will not drive while elevated

above 8 meters (26 ft. 2 in.).

Note:If the machine quits driving and the tilt

alarm sounds, immediately lower the platform and move the machine to a level location before re-elevating the platform.

MERGENCY LOWERING

E

The emergency lowering control is located

at the rear of the machine at the base of the

scissor assembly (Figure 4).

1. Open the emergency lowering valve by pulling on the

knob and holding it.

2. Once the platform is fully lowered, release the knob to

close the valve.

-

FTER USE EACH DAY

A

1. Ensure that the platform is fully lowered.

2. Park the machine on level ground, preferably under

cover, secure against vandals, children or unauthorized

operation.

3. Turn the key switch to OFF and remove the key to prevent unauthorized operation.

ARKING BRAKE RELEASE

P

Perform the following only when the machine will not

operate under its own power and it is necessary to

move the machine or when winching onto a trailer to

transport.

1. Close the needle valve by turning the knob clockwise.

2. Pump the brake release pump until the parking brakes

release and the wheels can be turned.

3. The machine will now roll when pushed or pulled.

4. Be sure to open the needle valve and verify that the

parking brakes have engaged before the machine is

operated.

!

WARNING

Never operate work platform with the parking

brakes released. Serious injury or damage

could result.

(F

IGURE

!

5)

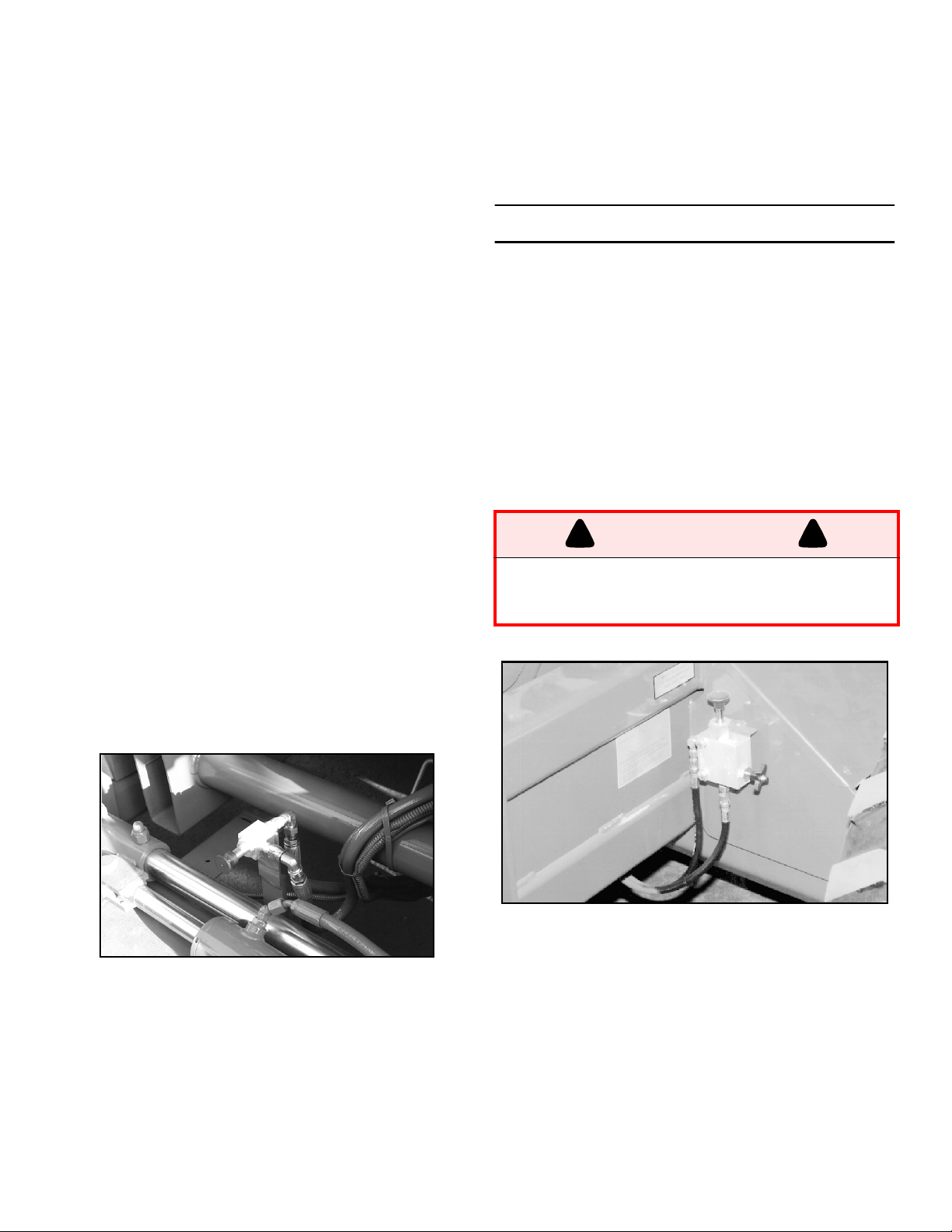

Figure 1: Emergency Lowering Valve

Figure 2: Parking Brake Release Pump

6

Page 7

OLD DOWN GUARDRAILS

F

(F

IGURE

6)

6. Before operating work platform, check that all fasteners

are in place and properly torqued.

This procedure is only for passing through doorways. Guardrails must be returned to proper position

before using the machine.

OLD DOWN PROCEDURE

F

Note:When performing the following procedures retain all fasteners.

1. Place controller on platform

2. Starting at the front of the platform, remove nuts, bolts

and washers from the top of the front guardrail. Fold

the front guardrail down onto the platform.

3. Close and latch the gate.

4. Remove nuts, bolts and washers from the top of the

rear guardrail. Fold the rear guardrail down onto the

platform being careful to keep latched at all times.

5. Remove nuts, bolts and washers from the top of the

side guardrails. Lift up and fold one side guardrail in so

it rests on the deck. Repeat with other side guardrails.

!

WARNING

Before operating machine, guardrails must be

securely fastened in their proper position.

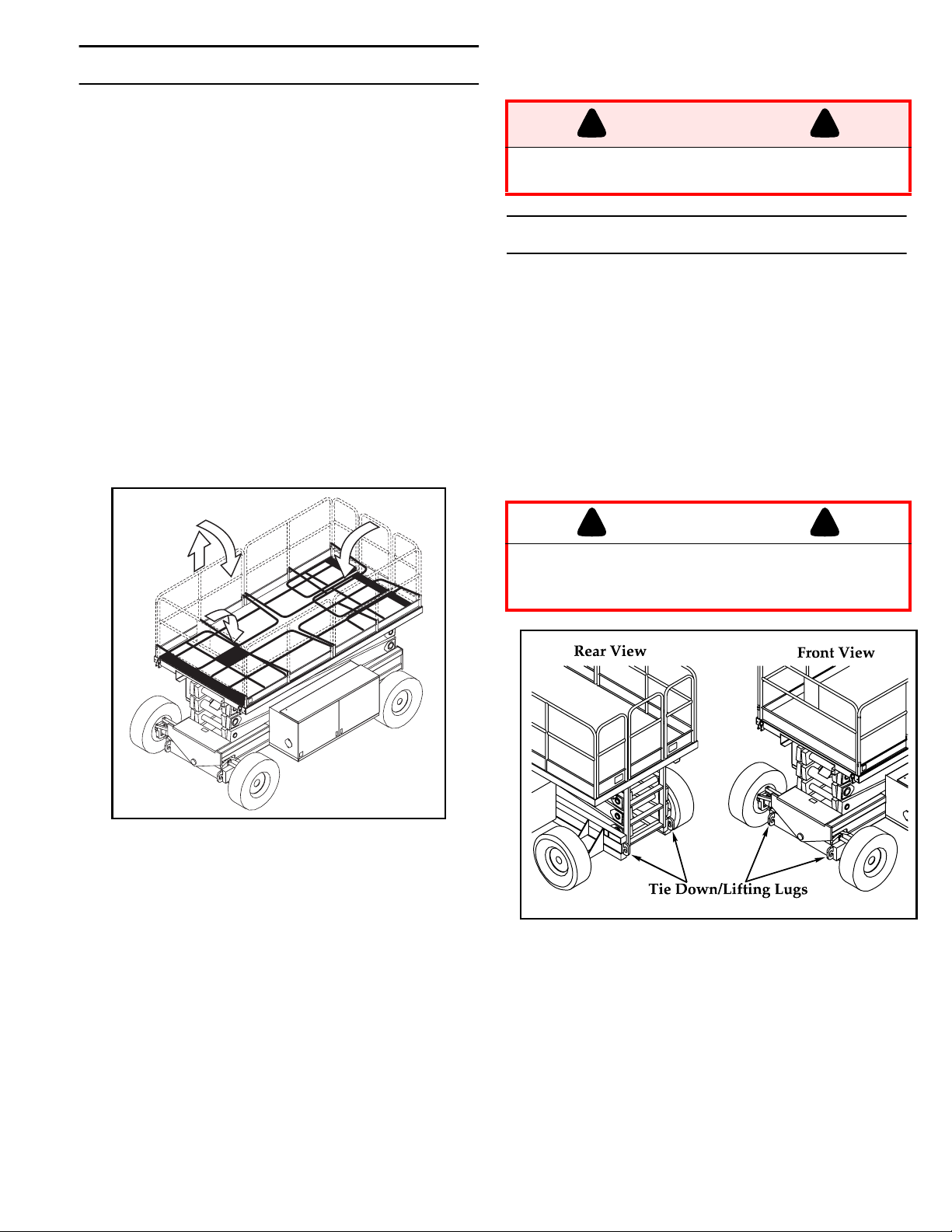

RANSPORTING WORK PLATFORM

T

BY C

1. Secure straps to chassis tie down/lifting lugs only (Fig-

BY T

1. Maneuver the work platform into transport position and

2. Secure the work platform to the transport vehicle with

RANE

ure 7).

RUCK

chock wheels.

chains or straps of adequate load capacity attached to

the chassis tie down/lifting lugs.

!

CAUTION

Overtightening of chains or straps through tie

down lugs may result in damage to work

platform.

!

!

Figure 1: Fold Down Guardrails

RECTION PROCEDURE

E

1. Raise side guardrails making sure each is pushed down

to secure the guardrail in the vertical position.

2. Install bolts, washers and nuts between the side guardrails, tighten securely.

3. Raise rear guardrail assembly, aligning holes and install

bolts, washers and nuts. Tighten securely.

4. Raise front guardrail, aligning holes and install bolts,

washer and nuts. Tighten securely.

5. Hang controller from front guardrail.

Figure 2: Transporting Work Platform

REPARATION FOR SHIPMENT

P

1. Grease all the grease fittings.

2. Fully lower the platform.

3. Disconnect the battery negative (-) lead from the battery terminal.

4. Band the controller to the front guardrail.

5. Band the elevating linkage to the frame.

Page 8

M

AINTENANCE

*

)

!

WARNING

Never perform service on the work platform in

the elevating assembly area while platform is

elevated without first blocking the elevating

assembly.

DO NOT stand in elevating assembly area

while deploying or storing brace.

B

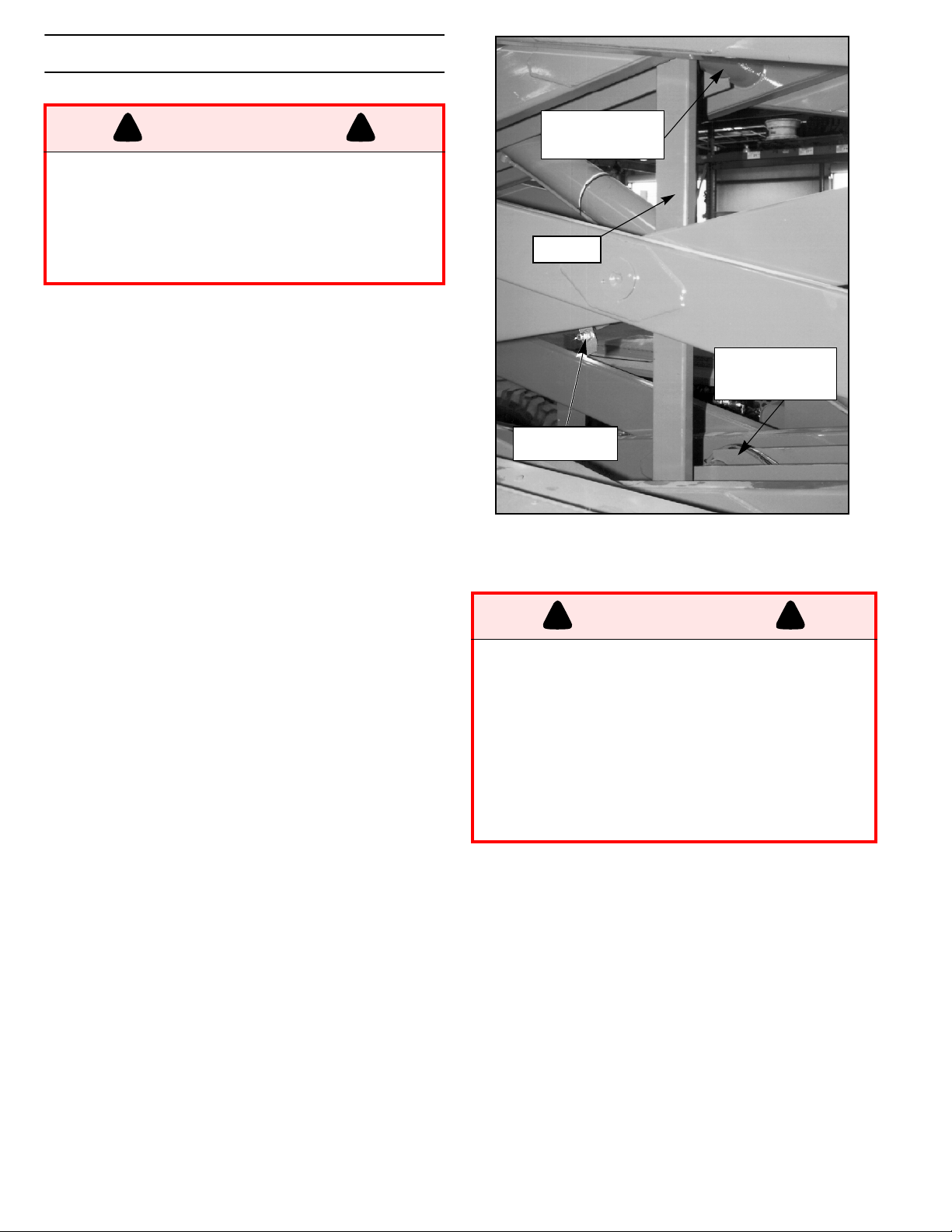

LOCKING ELEVATING ASSEMBLY

!

Brace Installation

1. Park the work platform on firm level ground.

2. Verify Platform Emergency Stop Switch is ON.

3. Turn Chassis Key Switch to CHASSIS.

4. Start the engine using chassis controls.

5. Push the throttle button in, the button will stay in and

the engine speed will increase. Using the raise button,

elevate platform until the scissors brace can be rotated

to the vertical position.

6. From the left side of the machine, disengage the locking

pin securing the brace. Rotate the scissor brace counterclockwise until it is vertical and between the two

scissor center pivots.

7. Push lower button and gradually lower platform until

brace is supporting the platform.

8. Disengage throttle by pushing throttle button in again,

the button will retract and the engine will come to idle

speed.

Brace Removal

1. Using chassis controls, gradually raise platform until

the scissors brace clears the two scissor center pivots.

2. Rotate scissors brace clockwise until the locking pin

engages.

3. Push lower button to completely lower platform.

4. Make sure the throttle button is disengaged and platform/chassis switch is on PLATFORM.

Upper Scissor

Center Pivot

Brace

Lower Scissor

Center Pivot

Locking Pin

Figure 1: Blocking Elevating Assembly

B

ATTERY MAINTENANCE

!

WARNING

Hazard of explosive gas mixture. Keep sparks,

flame, and smoking material away from battery.

Always wear safety glasses when working with

batteries.

Battery fluid is highly corrosive. Thoroughly

rinse away any spilled fluid with clean water.

Always replace batteries with UpRight batteries

or manufacturer approved replacements

weighing 62 lbs. each.

Check battery fluid level daily, especially if work platform is being used in a warm, dry climate.

If electrolyte level is lower than 3/8 in. (10 mm)

above plates, add distilled water ONLY. Do not use of

tap water with high mineral content, it will shorten

battery life.

The battery and cables should be inspected regularly for signs of cracks in the case, electrolyte leakage and corrosion of the terminals. Inspect cables

for worn spots or breaks in the insulation and for broken cable terminals.

Refer to the Service Manual to extend battery life

and for complete service instructions.

!

8

Page 9

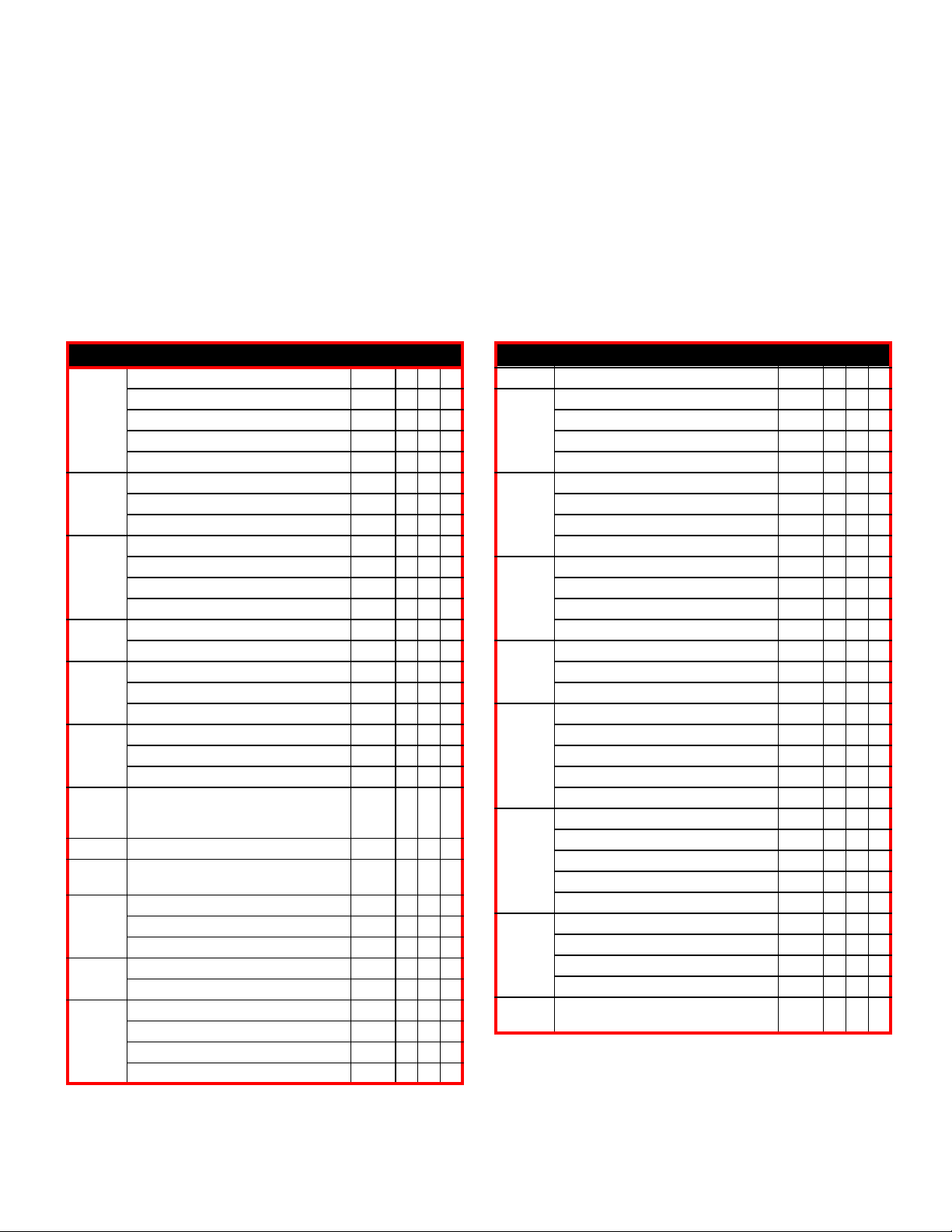

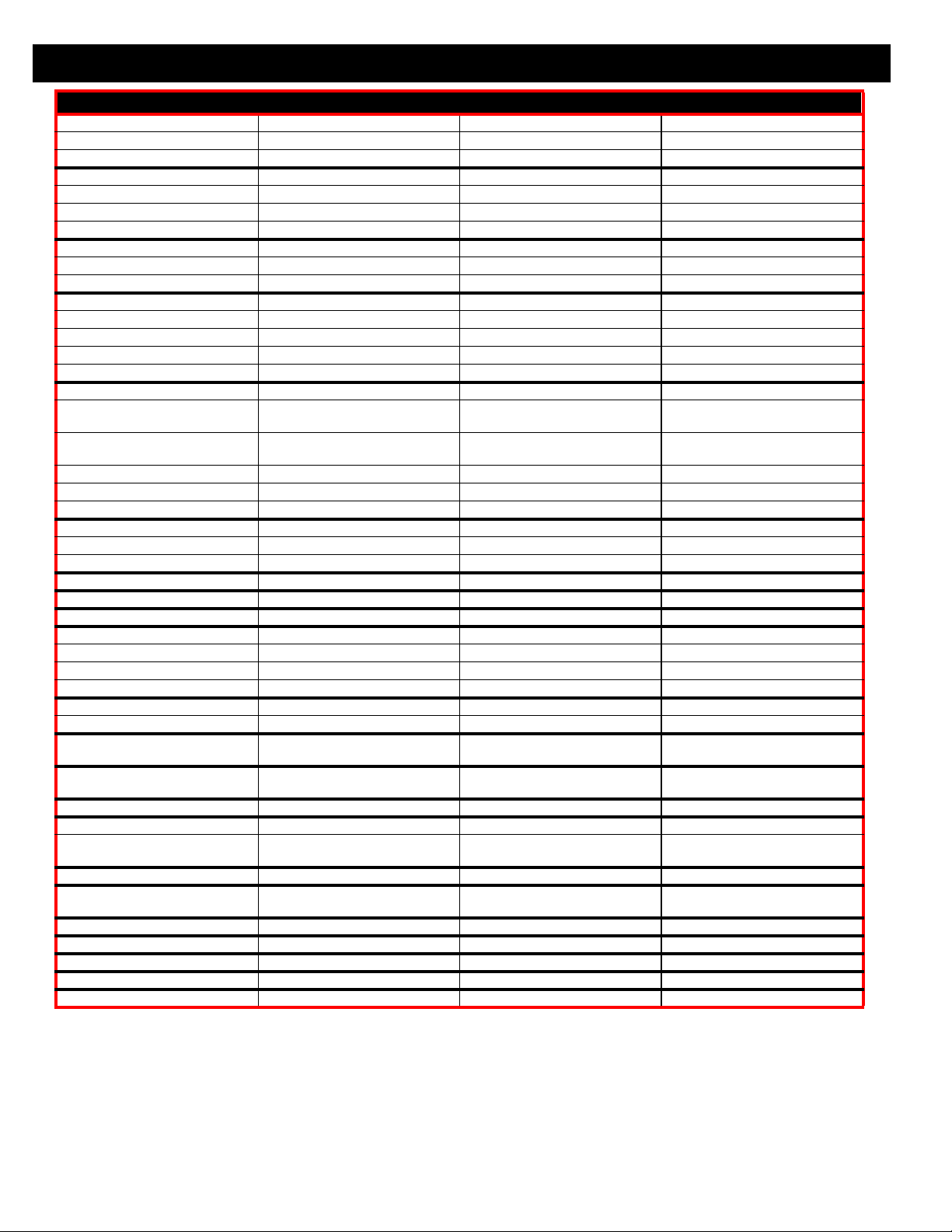

Preventative Maintenance Table Key

Interval

Daily=each shift or every day

50h/30d=every 50 hours or 30 days

250h/6m=every 250 hours or 6 months

1000h/2y=every 1000 hours or 2 years

Y=Yes/Acceptable

N=No/Not Acceptable

R=Repaired/Acceptable

Preventative Maintenance Report

Date: ___________________________________

Owner: _________________________________

Model No: _______________________________

Serial No: _______________________________

Serviced By: _____________________________

Service Interval: __________________________

Table 1: Preventative Maintenance Checklist

COMPONENT INSPECTION OR SERVICES INTE RVAL Y N R

Check electrolyte level 6m

Check specific gravity 6m

Ba ttery

Engine Oil

and F ilter

Engine F uel

System

Engine

Coolant

Hydraulic Oil

Hydraulic

System

Emergency

Hydraulic

System

Controller Check switch operation Da ily

Control

Platform

Deck and

Hydraulic

Clean exterior 6m

Check battery cable condition Daily

Clean terminals 6m

Check level a nd condition Daily

Check for leaks Daily

Change oil filter 100h

Check fuel level Daily

Check for leaks Daily

Replace fuel filter 6m

Check air cleaner Daily

Check coolant level (with engine cold) Daily

Replace coolant 3m

Check oil le vel Daily

Change filter 6m

Drain and replace oil 2y

Check for leaks Daily

Check hose connections 30d

Check hoses for exterior wear 30d

Operate the emergency lowering valve and check

for serviceability

Check the e xterior of the cable for pinching, binding

Cable

or wear

Check fasteners for proper torque Daily

Check welds for cracks Da ily

Rails

Check condition of deck Daily

Check for damage Daily

Tires

Check lug nuts (torque to 150 ft. lbs. [203 Nm]) 30d

Wipe clean 30d

Check for leaks at mating surfaces 30d

Pump

Check for hose fitting leaks Daily

Check mounting bolts for proper torque 30d

Daily

Daily

Table 1: Preventative Maintenance Checklist

(Continued)

COMPONENT INSPECTION OR SERVICES INTE RVAL Y N R

Drive Motors Check for operation and le aks Daily

Check for leaks Daily

Torque Hubs

Steering

System

Elevating

Assembly

Chassis

Lift Cylinder

Cylinder

Entire Unit

Labels

Check oil level 250h/6m

Change Oil after break-in 50h/30d

Change Oil 1000h/2y

Check hardware & fittings for proper torque 6m

Grease pivot pins 30d

Oil king pins 30d

Check steering cylinder for leaks 30d

Inspect for structural cracks Daily

Check pivot points for wear 30d

Check mounting pin pivot bolts for proper torque 30d

Check elevating arms for bending 6m

Check hoses for pinch or rubbing points Daily

Check component mounting for proper torque 6m

Check welds for cracks Daily

Check the cylinder rod for wear 30d

Check mounting pin pivot bolts for proper torque 30d

Check seals for leaks 30d

Inspect pivot points for wear 30d

Check fittings for proper torque 30d

Check the cylinder rod for wear 30d

Check mounting pin pivot bolts for proper torque 30d

Axle

Check seals for leaks 30d

Inspect pivot points for wear 30d

Check fittings for proper torque 30d

Check for and repair collision damage Daily

Check fasteners for proper torque 3m

Check for corrosion-remove a nd repaint 6m

Lubricate 30d

Check for peeling, missing, or unreadable labels &

rep lace

Daily

9

Page 10

PECIFICATIONS

*S

ITEM LX31 LX41 LX50

Platform Size (Inside toeboards)

Standard 3,64 m x 1,78 m [143.38 in x 70 in.] 3,64 m x 1,78 m [143.38 in. x 70 in.] 3,64 m x 1,78 m [143.38 in. x 70 in.]

Slide Out Deck Extended 4,56 m x 1,73 [179.38 in. x 68 in.] 4,56 in. x 1,73 m [179.38 in. x 68 in.] 4,56 m x 1,73 m [179.38 in. x 68 in.]

Max. Platform Capacity

Standard 907 kg [2,000 lbs.] 680 kg [1,500 lbs.] 454 kg [1,000 lbs.]

w/ Extension 907 kg [2,000 lbs.] 680 kg [1,500 lbs.] 454 kg [1,000 lbs.]

on Extension 227 kg [500 lbs.] 227 kg [500 lbs.] 227 kg [500 lbs.]

Max. No. of occupants

Standard 8 people 6 people 4

on Extension 2 people 2 people 2

Height

Working Height 11,4 m [37 ft.] 14,33 m [47 ft.] 17 m [56 ft.]

Max. Platform Height 9,45 m [31 ft.] 12,34 m [40 ft. 6 in.] 15,09 m [49 ft. 6 in.]

Min. Platform Height 1,43 m [56.25 in.] 1,66 m [65.25 in.] 1,93 m [76 in.]

Drivable Height 8 m [26 ft. 2 in.] 8 m [26 ft. 2 in.] 8 m [26 ft. 2 in.]

Dimensions

Weight, Standard 2WD: 4,264 kg [9,400 lbs.]

4WD: 4,368 kg [9,630 lbs.]

Weight, w/extension 2WD: 4,459 kg [9,830 lbs.]

4WD: 4,563 kg [10,060 lbs.]

Overall Width 2,29 m [90 in.] 2,29 m [90 in.] 2,29 m [90 in.]

Overall Height 2,53 m [99.75 in.] 2,76 m [108.75 in.] 2,76 m [108.75 in.]

Overall Le ngth, Standard 4,06 m [160 in.] 4,06 m [160 in.] 4,06 m [160 in.]

Surface Speed

Platform Lowered 0 to 5,0 km/h [0 to 3.1 mph] 0 to 5,0 km/h [0 to 3.1 mph] 0 to 5,0 km/h [0 to 3.1 mph]

Platform Raised 0 to 0,48 km/h [0 to 0.3 mph] 0 to 0,48 km/h [0 to 0.3 mph] 0 to 0,48 km/h [0 to 0.3 mph]

System V oltage 12 Volt DC 12 Volt DC 12 Volt DC

Hydraulic Tank Capacity 107,13 l [28.3 US Gallons] 107,13 l [28.3 US Gallons] 107,13 l [28.3 US Gallons]

Maximum Hydraulic System Pressure 206,8 bar [3000 psi] 206,8 bar [3000 psi] 206,8 bar [3000 psi]

Hydraulic Fluid

Normal use (>32° F [0° C]) ISO #46 ISO #46 ISO #46

Low Temp. Use (<32° F [0° C]) ISO #32 ISO #32 ISO #32

Extreme Temp. Use (<0° F [-17° C]) ISO #15 ISO #15 ISO #15

Lift System One Single Stage Lift Cylinder One Single Stage Lift C ylinder Two Single Stage Lift Cylinde rs

Lift Speed Raise: 40 sec. Lower: 60 sec. Raise: 45 sec. Lower: 65 sec. Raise: 45 sec. Lower: 65 sec.

Platform Leveling 8.5° (.3m [12 in.]) Side/Side, 6° (.3m [12 in.]

Fore/Aft

Power Source Diesel or Gasoline 20 HP Kubota, 3 Cylinde r,

Water Cooled

Drive Control Proportional Proportional Proportional

Control System Smooth one-hand Joystick Smooth one-hand Joystick Smooth one-hand Joystick

Horizontal Drive 2WD: 2 Whee l, Hyd. Motors

4WD: 4 Wheel, Hyd. Motors

Air Filled Tires 10-16.5 NHS 8 Ply, 3,4 bar [50psi.] 10-16.5 NHS 8 Ply, 3,4 bar [50psi.] 10-16.5 NHS 8 Ply, Foam Filled

Parking B rakes Two, Spring Applied, Hydraulic Release,

Multiple Disc

Turning Radius (inside) 1,22 m [48 in.] 1,22 m [48 in.] 1,22 m [48 in.]

Maximum G radeability: 2WD: 30% [16,7°] 4WD: 35% [19,2°] 2WD: 30% [16,7°] 4WD: 35% [19,2°] 2WD: 30% [16,7°] 4WD: 35% [19,2°]

Wheel Base 2,94 m [115.75 in.] 2,94 m [115.75 in.] 2,94 m [115.75 in.]

Gu ardrails 1.1 m [43.5 in.] high, Fold Down with gate. 1.1 m [43.5 in.] high, Fold Down with gate. 1.1 m [43.5 in.] high, Fold Down with gate.

Toeboard 152 mm [6 in.] High 152 mm [6 in.] High 152 mm [6 in.] High

*

2WD: 4,790 kg [10,560 lbs.]

4WD: 4,953 kg [10,920 lbs.]

2WD: 4,985 kg [10,990 lbs.]

4WD: 5,148 kg [11,350 lbs.]

8.5° (.3m [12 in.]) Side/Side, 6° (.3m [12 in.]

Fore/Aft

Diesel or Ga soline 20 HP Kubota, 3 Cylinde r,

Water Cooled

2WD: 2 Wheel, Hyd. Motors

4WD: 4 Wheel, Hyd. Motors

Two, Spring Applied, Hydraulic Release,

Multiple Disc

2WD: 5,498 kg [12,120 lbs.]

4WD: 5,661 kg [12,480 lbs.]

2WD: 5,693 kg [12,550 lbs.]

4WD: 5,856 kg [12,910 lbs.]

8.5° (.3m [12 in.]) Side/Side, 6° (.3m [12 in.]

Fore/Aft

Diesel or Ga soline 20 HP Kubota, 3 Cylinder,

Water Cooled

2WD: 2 Wheel, Hyd. Motors

4WD: 4 Wheel, Hyd. Motors

Two, Spring Applied, Hydraulic Release,

Multiple Disc

*Specifications subject to change without notice. Refer to the Service Manual for complete parts and service information

10

Page 11

Section française

Consignes de sécurité

NE

NE

JAMAIS

moins de 3 mètres (10 pi) de

lignes électriques. CETTE

MACHINE N’EST PAS ISOLÉE.

NE

JAMAIS

dangers tels que des trous, des dénivellations, des bosses ou des débris.

NE

JAMAIS

boulonnerie correctement serrée.

B

IEN FERMER

NE

PAS

stabilisateurs seulement.)

NE

JAMAIS

NE

JAMAIS

M

AINTENIR

V

ÉRIFIER

R

ÉPARTIR

dernière page de couverture.

NE

JAMAIS

d’appel gratuit en dernière page de couverture.)

NE

JAMAIS

V

ÉRIFIER

du circuit hydraulique, câble de commande endommagé ou connexion ou boulon de roue desserré.

NE

JAMAIS

NE

JAMAIS

le dispositif d’élévation.

NE

JAMAIS

émettent un gaz hydrogène hautement explosif.

A

PRÈS AVOIR UTILISÉ

afin d’empêcher l’utilisation de la plate-forme par toute personne non autorisée.

NE

JAMAIS

consentement du fabricant.

utiliser machine à

utiliser la machine sans avoir d’abord vérifié si la surface de la zone de travail ne présente pas de

utiliser la machine sans que tous les garde-corps soient parfaitement en place et assujettis toute la

et verrouiller le portillon après être monté sur la plate-forme.

s’approcher des stabilisateurs au moment d’élever ou d’abaisser la plate-forme. (Machines équipées de

utiliser d’échelle ni d’échafaudage sur la plate-forme.

attacher de charges suspendues ni accroître la taille de la plate-forme.

la pression des pneus à 3,4 bar (50 lb/po2)(LX 31/41).

en haut, en bas et autour qu’il n’existe aucun obstacle en hauteur ni conducteur électrique.

également toutes les charges sur la plate-forme. Voir la charge maximale pour la plate-forme en

utiliser d’équipement endommagé. (Contacter UpRight pour toutes instructions. Voir le numéro

modifier les systèmes de commande ou de sécurité.

complètement la machine avant de l’utiliser, en vue de soudure fissurée, boulonnerie desserrée, fuite

descendre sur le système d’élévation lorsque la plate-forme est élevée.

effectuer de travaux d’entretien sur la machine, si la plate-forme est élevée, sans tout d'abord bloquer

recharger la batterie près d’étincelles ou d’une flamme vive; les batteries en cours de charge

la plate-forme élévatrice, mettre le contacteur à clé en position d'arrêt (OFF), puis la retirer

utiliser de composant ou pièce de rechange autres que les articles UpRight d’origine sans le

JAMAIS

ni la déplacer en position élevée

sur des pentes inégales ou sur

terrain meuble, et n’élever la

plate-forme uniquement lorsquèlle se trouve sur une surface

horizontale

élever la plate-forme

.

N

E JAMAIS

grimper sur les rampes du gardecorps.

monter, s’asseoir ou

Page 12

I

NTRODUCTION

E

SSAI DE FONCTIONNEMENT DES SYSTÈMES

Ce manuel se rapporte à l’utilisation des modèles de

plates-formes élévatrices de travail série LX. On veillera à

le garder sur la machine en tout temps.

V

ÉRIFICATION PRÉLIMINAIRE ET

INSPECTION DE SÉCURITÉ

NOTA : Lire attentivement et veiller à bien

comprendre et à respecter toutes les règles

de sécurité, instructions d’utilisation, et autocollants, ainsi que le MANUEL DES RESPONSABILITÉS de la Scaffold Industry Association. Chaque jour avant d'utiliser la

machine :

1. Ouvrir les panneaux des modules et rechercher tout

dommage, fuite d’huile ou pièce manquante.

2. Vérifier le niveau indiqué par la jauge du réservoir

d’huile hydraulique avec la plate-forme complètement

abaissée. Faire l’appoint si nécessaire.

3. S'assurer que le niveau d’électrolyte de toutes les

batteries est correct. (Voir Entretien de la batterie).

4. Vérifier les niveaux d’huile moteur et de carburant.

5. Vérifier que les garde-corps sont en place, que

l’extension rétractable de la plate-forme est bloquée

avec l’axe et que toute la boulonnerie est

correctement serrée.

6. Vérifier la pression des pneus; elle doit être de

3,4 bar (50 lb/po

7. Vérifier à fond toute la plate-forme élévatrice pour

s’assurer qu’elle ne présente pas de dommages tels

que soudures ou organes de structure fissurés,

pièces desserrées ou manquantes, fuites d’huile,

câbles ou flexibles endommagés, connexions

desserrées ou pneus endommagés.

8. Au besoin, déplacer la machine jusqu’à un endroit

dégagé afin de pouvoir l’élever complètement.

9. Tirer les boutons d’arrêt d’urgence de la plate-forme

en position activée (ON) pour ces deux fonctions

(figures 1 et 2).

10. Vérifier que le sélecteur plate-forme/châssis est sur

la position plate-forme (PLATFORM).

11. Lorsque le moteur est froid, vérifier le niveau du

liquide de refroidissement.

!

2

).

ATTENTION

!

NE PAS vérifier le niveau de liquide de

refroidissement lorsque le moteur ou le

radiateur est chaud, car le liquide bouillant

pourrait causer des brûlures graves.

!

AVERTISSEMENT

SE TENIR ÉLOIGNÉ

lors des vérifications suivantes.

Avant d’utiliser la plate-forme, vérifier que la surface

de la zone de travail ne présente pas de dangers

tels que des trous, des dénivellations, des bosses

ou des débris.

Vérifier dans

dessus de la plate-forme élévatrice, qu’il n’y a ni

obstruction ni conducteur électrique.

Protéger le câble du pupitre de commande de tout

risque de dommage lors des vérifications.

TOUTES

5 6 8

de la plate-forme élévatrice

les directions, y compris au-

7

!

1

9

2

3

4

Figure 1 : Commandes du châssis

1. Arrêt d’urgence

2. Sélecteur de châssis/

plate-forme

3. Bouton d’élévation

4. Bouton d’abaissement

5. Bouton de démarrage

6. Bouton de starter

(carburation mixte) ou

bouton de bougie

incandescente (diesel)

7. Bouton d’accélérateur

8. Bouton d’arrêt

9. Sélecteur de

carburant (carburation

mixte seulement)

12

Page 13

1. Décrocher le boîtier de commande du garde-corps

avant. Saisir fermement le crochet de suspension du

boîtier de commande de manière à pouvoir abaisser

le levier d’enclenchement solidaire, tout en effectuant

les vérifications suivantes à partir du sol.

2. Tourner l’interrupteur à clé du boîtier de commande

en position marche (ON). Tourner la clé à fond vers la

droite pour lancer le moteur et la relâcher dès que le

moteur a démarré.

Nota : Si le moteur est froid, appuyer sur le

bouton de bougies incandescentes et le maintenir enfoncé pendant 6 secondes pour

chauffer les bougies.

3. Mettre le sélecteur de mode de fonctionnement en

position conduite (DRIVE).

4. Le sélecteur de gamme de vitesse étant d’abord

placé sur couple élevé (HIGH TORQUE) puis sur

haute vitesse (HIGH SPEED), appuyer sur le levier

de verrouillage et pousser le levier de commande sur

les positions marche avant (FORWARD) puis marche

arrière (REVERSE) pour vérifier les commandes de

vitesse et de sens de marche. La vitesse de

déplacement de la machine augmentera à mesure

que le levier de commande est éloigné du point mort.

5. Vérifier la commande de direction en poussant le

bouton de commande de direction d’abord vers la

DROITE, puis vers la GAUCHE.

1

2

3

7

4

8

9

5

6

Figure 1 : Boîtier de commande

1. Bouton de

commande de

direction

2. Levier d’enclenchement solidaire

3. Bouton de

commande de

stabilisateur

4. Commutateurs de

stabilisateurs

5. Bouton d’arrêt

d’urgence

6. Sélecteur de

conduite/levage

7. Sélecteur de vitesse/

couple

8. Témoin d’activation

de conduite

9. Interrupteur à clé

1. Appuyer sur le commutateur de verrouillage du levier

de commande et mettre le commutateur de chaque

stabilisateur en position extension (EXTEND) pour

déployer les quatre stabilisateurs. Vérifier que le

témoin de validation de conduite est éteint.

2. Rétracter complètement tous les stabilisateurs et

vérifier que le témoin de validation de conduite est

allumé.

3. Raccrocher le boîtier de commande sur le gardecorps avant.

4. Régler le sélecteur de châssis/plate-forme à la

position châssis (CHASSIS).

5. Enfoncer le bouton d’accélérateur. Appuyer sur le

bouton d’élévation du châssis pour élever la plateforme tout en poussant le détecteur d’inclinaison

hors de la position de mise de niveau. La plateforme ne devrait s’élever que partiellement et

l’alarme d’inclinaison devrait retentir. Si la plateforme continue à s’élever et/ou qu'aucune alarme ne

résonne, ARRÊTER et mettre la machine hors

service jusqu’à ce qu’elle ait été réparée.

6. Désengager le détecteur d’inclinaison et élever

complètement la plate-forme.

7. Inspecter le dispositif d’élévation, le vérin d’élévation,

les câbles et les flexibles en vue de dommages ou

fonctionnement irrégulier. Vérifier qu'aucune pièce

n’est desserrée ou manquante.

8. Abaisser partiellement la plate-forme au moyen du

bouton d'abaissement situé sur le tableau de

commande du châssis, puis vérifier le fonctionnement de l’alarme sonore d’abaissement.

9. Ouvrir la soupape d’abaissement d’urgence (figure 4)

pour en vérifier le fonctionnement. Pour ce faire tirer

et maintenir le bouton en position sortie. Une fois la

plate-forme complètement abaissée, relâcher le

bouton pour refermer la soupape.

10. Mettre le sélecteur de châssis/plate-forme en

position plate-forme (PLATFORM).

11. Monter sur la plate-forme et s’assurer que le loquet

du portillon est engagé.

12. Mettre le sélecteur de mode de fonctionnement en

position élévation (LIFT).

13. Appuyer sur le levier d’enclenchement solidaire et

amener progressivement le levier de commande en

position élévation (UP) pour élever la plate-forme. Ce

faisant, actionner le levier sur toute sa course afin de

vérifier la vitesse d’élévation proportionnelle. Amener

progressivement le levier de commande en position

d’abaissement (DOWN), pour abaisser la plate-

forme. S’assurer que l’alarme d’abaissement retentit.

14. Appuyer sur le commutateur de verrouillage du levier

de commande et mettre le commutateur de chaque

stabilisateur en position extension (EXTEND). Les

stabilisateurs devraient être désactivés. Si un

stabilisateur se déploie au cours de ce test,

ARRÊTER. Abaisser la plate-forme et la mettre hors

service jusqu’à ce qu’elle ait été réparée.

15. Mettre le commutateur à clé du boîtier de commande

en position arrêt (OFF), appuyer sur le bouton d’arrêt

d’urgence et descendre de la plate-forme.

16. Fermer et verrouiller les couvercles des modules.

13

Page 14

U

TILISATION

NOTA : Avant d’utiliser la plate-forme élévatrice, s’assurer que les vérifications préliminaires et de sécurité ont été effectuées, que

les problèmes éventuels ont été corrigés et

que l’opérateur a reçu une formation adéquate

pour l’utilisation de cette machine.

NOTA : La direction n'est pas à centrage

automatique. Les roues doivent être remises

en position droite à l'aide du bouton de commande de direction.

M

ISE DE NIVEAU DE LA PLATE-FORME

(

MACHINES ÉQUIPÉES DE STABILISATEURS

SEULEMENT

)

D

ÉPLACEMENT AVEC LA PLATE-FORME

ABAISSÉE

1. Vérifier que le bouton d’arrêt d’urgence du châssis

est en position activée (ON) (tourné vers la gauche),

que le témoin de validation de conduite est allumé et

que le sélecteur de plate-forme/châssis est sur la

position plate-forme (PLATFORM).

Nota : Si le témoin de validation de conduite

est éteint, vérifier que la plate-forme est complètement abaissée et que les stabilisateurs

(si la machine en est équipée) sont complètement rétractés.

2. Une fois sur la plate-forme, fermer et verrouiller le

portillon. Vérifier que les garde-corps sont en place

et correctement assemblés et que la boulonnerie est

correctement serrée.

3. Vérifier que le parcours est exempt de toute

personne, obstacle, trou et dénivellation, et que le

terrain peut supporter la charge des roues.

4. Vérifier les dégagements au-dessus, au-dessous et

sur les côtés de la plate-forme.

5. Tirer l’interrupteur d'arrêt d’urgence du boîtier de

commande en position activée (ON).

6. Tourner le commutateur à clé du boîtier de

commande à fond vers la droite pour lancer le moteur

et relâcher la clé dès que le moteur a démarré.

Nota : Si le moteur est froid, appuyer sur le

bouton de bougies incandescentes et le maintenir enfoncé pendant 6 secondes pour

chauffer les bougies.

7. Régler le sélecteur de plage de vitesses de levage/

conduite sur couple élevé (HIGH TORQUE).

8. Saisir le levier de commande afin de serrer le levier

d’enclenchement solidaire (lorsque le levier

d’enclenchement solidaire est relâché l’alimentation

électrique du boîtier de commande est coupée).

Pousser ou tirer lentement le levier de commande en

marche avant (FORWARD) ou marche arrière

(REVERSE) pour se déplacer dans la direction

souhaitée. Plus le levier est éloigné de la position

centrale (neutre), plus la machine se déplace

rapidement.

9. Lors du déplacement, pousser sur le sélecteur de

gamme de vitesse d’élévation/conduite sur vitesse

élevée (HIGH SPEED) pour se déplacer sur surfaces

planes, ou sur couple élevé (HIGH TORQUE) pour

gravir des côtes ou se déplacer dans des espaces

restreints.

!

AVERTISSEMENT

Ne jamais utiliser la plate-forme lorsque les freins

de stationnement sont desserrés. Ceci présenterait

des risques de blessures graves ou mortelles.

1. Regarder autour de la machine, s'assurer que rien ne

gène l'extension des stabilisateurs et que la surface

sur laquelle ils s'appuient peut supporter le poids de

la machine.

2. Appuyer sur le levier de verrouillage de la manette de

commande et actionner les commutateurs des

stabilisateurs pour les étendre, jusqu’à ce qu'ils

s’appuient fermement sur le sol.

3. Tout en observant le niveau à bulle du garde-corps

avant (figure 3), étendre le stabilisateur du côté

opposé à la position de la bulle, jusqu'à ce que la

plate-forme soit de niveau. Par exemple, si la bulle se

trouve à l’avant et sur la gauche de l’orbite, étendre le

stabilisateur arrière droit. Continuer d’ajuster les

stabilisateurs jusqu'à ce que la bulle soit centrée

dans le petit cercle indiquant que la plate-forme est

de niveau.

4. Les stabilisateurs doivent être fermement en contact

avec la surface d’appui. Vérifier que chaque

stabilisateur s’appuie fermement sur le sol.

R

ÉTRACTION DES STABILISATEURS

1. Abaisser complètement la plate-forme.

2. Mettre chaque commutateur de stabilisateur en

position de RÉTRACTION. Vérifier que tous les

stabilisateurs sont complètement rétractés. Le

témoin de validation de conduite ne s’allume que si

les quatre stabilisateurs sont complètement

rétractés.

!

D

IRECTION

1. Pousser le bouton de commande de direction vers la

DROITE ou la GAUCHE pour braquer. Observer les

roues pour s’assurer qu’elles tournent dans la bonne

direction.

Figure 1 : Niveau d’orbite de la plate-forme

14 31

Page 15

É

LÉVATION ET ABAISSEMENT DE LA

PLATE-FORME

1. Positionner le sélecteur de levage/conduite sur

levage (LIFT).

2. Tout en maintenant le levier de commande de sorte

que le levier d’enclenchement solidaire soit serré,

pousser lentement le levier de commande d’élévation

de commande vers haut (UP) pour élever la plateforme. Plus le levier est poussé vers le haut, plus

l’élévation est rapide.

3. Une fois le travail achevé, mettre le sélecteur

d’élévation/conduite en position d’élévation (LIFT) et

abaisser la plate-forme en tirant le levier de

commande en arrière jusqu’à ce que la plate-forme

soit complètement abaissée.

D

ÉPLACEMENT AVEC LA PLATE-FORME

ÉLEVÉE

Se déplacer avec la plate-forme élevée UNIQUEMENT sur

des surfaces horizontales solides.

Nota : Lorsqu’elle est élevée, la plate-forme ne

peut se déplacer qu’à vitesse réduite et seulement si les essieux avant et arrière sont parallèles.

1. Vérifier que le parcours est exempt de toute

personne, obstacle, trou et dénivellation, et que le

terrain peut supporter la charge des roues.

2. Vérifier les dégagements au-dessus, au-dessous et

sur les côtés de la plate-forme.

3. Mettre le sélecteur d’élévation/conduite en position

conduite (DRIVE).

4. Pousser le levier de commande en marche avant

(FORWARD) ou marche arrière (REVERSE) pour se

déplacer dans la direction souhaitée.

Nota : La machine ne se déplacera pas si la

plate-forme est élevée à plus de 8 mètres

(26 pi 2 po).

Nota : Si la machine s’immobilise et l’alarme

d’inclinaison résonne, abaisser immédiatement la plate-forme et conduire la machine

jusqu’à une surface plane avant d’élever à

nouveau la plate-forme.

A

BAISSEMENT D’URGENCE

La commande d’abaissement d’urgence se trouve à

l’arrière de la machine, à la base du ciseau (figure 4).

1. Ouvrir la vanne d’abaissement d’urgence en tirant le

bouton et en le maintenant dans cette position.

2. Une fois la plate-forme abaissée à fond, relâcher le

bouton pour fermer la soupape.

Figure 1 : Vanne d’abaissement d’urgence

A

PRÈS UTILISATION, TOUS LES JOURS

1. Abaisser complètement la plate-forme.

2. Garer la machine sur une surface plane, de

préférence couverte, à l’abri des vandales, et

protégée des enfants et de toute utilisation non

autorisée.

3. Tourner le commutateur à clé sur la position d’arrêt

(OFF), puis retirer la clé afin d’empêcher l’utilisation

non autorisée.

D

ESSERRAGE DU FREIN DE STATIONNEMENT

(

FIGURE

N’effectuer les opérations suivantes que si la machine est

immobilisée et qu'il est nécessaire de la déplacer, ou pour

la hisser sur une remorque à l’aide d’un treuil, pour le

transport.

1. Fermer la vanne à pointeau en tournant le bouton

vers la droite.

2. Actionner la pompe de desserrage du frein jusqu’à ce

que le frein de stationnement se desserre et que les

roues puissent être tournées.

3. La machine peut maintenant être déplacée en la

poussant ou en la remorquant.

4. S'assurer que la vanne à pointeau est ouverte et

vérifier que les freins de stationnement sont engagés

avant d'utiliser la machine.

!

AVERTISSEMENT

Ne jamais élever ou abaisser la plate-forme lorsque

les freins de stationnement sont desserrés, ce qui

pourrait résulter en des dommages ou blessures

graves.

5)

!

15

Page 16

G

ARDE-CORPS RABATTABLES (FIGURE

6)

!

AVERTISSEMENT

!

Cette procédure ne doit être utilisée que pour franchir des

portes. Remettre les garde-corps en position correcte

avant d’utiliser la machine.

R

EPLI DES GARDE-CORPS

Nota : Conserver les pièces boulonnerie lors

des procédures suivantes.

1. Placer le boîtier de commande sur la plate-forme.

2. En commençant à l’avant de la plate-forme, enlever

les écrous, boulons et rondelles en partant du haut

du garde-corps avant. Rabattre le garde-corps avant

sur la plate-forme.

3. Fermer et verrouiller le portillon.

4. Enlever les écrous, boulons et rondelles en

commençant par le haut du garde-corps arrière.

Rabattre le garde-corps arrière sur la plate-forme en

veillant à maintenir verrouillé à tout moment.

5. Enlever les écrous, boulons et rondelles à partir du

sommet des garde-corps de côtés. Soulever et

rabattre un garde-corps latéral de manière à ce qu'il

repose sur le plancher de la plate-forme. Répéter

l’opération avec les autres garde-corps latéraux.

Avant d’utiliser la machine, les garde-corps

doivent être fermement assujettis et en position

correcte.

T

RANSPORT DE LA PLATE-FORME

PAR

GRUE

1. N’attacher les sangles que dans les anneaux

d’arrimage/levage (figure 7).

PAR

CAMION

1. Mettre la plate-forme élévatrice en position de

transport et caler les roues.

2. Arrimer la plate-forme élévatrice sur le véhicule de

transport à l’aide de chaînes et sangles d’une

capacité de charge adéquate attachées aux anneaux

d’arrimage/levage du châssis.

!

ATTENTION

!

Un serrage excessif des chaînes ou des

sangles dans les anneaux d’arrimage peut

endommager la plate-forme élévatrice.

Figure 1 : Garde-corps rabattables

P

ROCÉDURE DE MISE EN PLACE

1. Relever les garde-corps latéraux en s’assurant que

chacun d’eux est bien poussé vers le bas de façon à

être maintenu fermement en position verticale.

2. Installer les boulons, rondelles et écrous entre les

garde-corps latéraux, et serrer fermement.

3. Relever le garde-corps arrière en alignant les trous et

installer les boulons, rondelles et écrous. Serrer

fermement.

4. Relever le dispositif de garde-corps avant, aligner les

trous et installer les boulons, rondelles et écrous.

Serrer fermement.

5. Suspendre le boîtier de commande au garde-corps

avant.

6. Avant d’utiliser la plate-forme élévatrice, vérifier que

toute la boulonnerie est bien en place et

correctement serrée.

Vue de derrière

Anneaux de levage/arrimage

Figure 2 : Transport de la plate-forme élévatrice

P

RÉPARATION POUR L'EXPÉDITION

1. Lubrifier tous les graisseurs.

2. Abaisser complètement la plate-forme.

3. Débrancher le câble négatif (-) de la borne de la

batterie.

4. Attacher le boîtier de commande au garde-corps

avant.

5. Attacher le mécanisme de commande d’élévation au

Vue de devant

16 29

Page 17

E

NTRETIEN

!

AVERTISSEMENT

Ne jamais travailler sur le système d’elévation de la

plate-forme élévatrice sans l’avoir d’abord bloqué.

NE PAS se tenir à proximité du système d’élévation

pendant le déploiement ou le repli de la barre de

verrouillage.

B

LOCAGE DU SYSTÈME D'ÉLÉVATION

!

Installation de la barre de verrouillage

1. Garer la plate-forme sur une surface plane et ferme.

2. Vérifier que le bouton d’arrêt d’urgence de la plateforme est en position engagé (ON).

3. Tourner le contacteur à clé sur la position châssis

CHASSIS

(

4. Démarrer le moteur au moyen des commandes du

châssis.

5. Appuyer sur le bouton d’accélérateur. Le bouton

restera enfoncé et le régime moteur augmentera. Au

moyen du bouton d’élévation, élever la plate-forme

jusqu’à ce que la barre de verrouillage puisse être

mise à la verticale.

6. Du côté gauche de la machine, désengager l’axe de

verrouillage de la barre. Tourner la barre de

verrouillage vers la gauche jusqu’à ce qu’elle soit à la

verticale, entre les deux pivots centraux du ciseau.

7. Appuyer sur le bouton d’abaissement pour faire

descendre lentement la plate-forme jusqu’à ce

qu’elle soit soutenue par la barre de verrouillage.

8. Désengager la commande d’accélération en

appuyant de nouveau sur le bouton. Celui-ci se

rétracte et le moteur retourne au ralenti.

).

Retrait de la barre de verrouillage

1. Au moyen des commandes du châssis, élever

graduellement la plate-forme jusqu’à ce que la barre

de verrouillage passe les deux pivots centraux du

ciseau.

2. Tourner la barre vers la droite jusqu’à ce que l’axe de

verrouillage s’engage.

3. Appuyer sur le bouton d’abaissement pour abaisser

complètement la plate-forme.

4. Vérifié que le bouton d’accélérateur est désengagé

et que le commutateur plate-forme/châssis est en

position plate-forme (

PLATFORM

).

Pivot central du

ciseau du haut

Barre

Pivot central du

ciseau du bas

Axe de verrouillage

Figure 1 : Blocage du système d’élévation

E

NTRETIEN DES BATTERIES

!

AVERTISSEMENT

Risque d’émanations de gaz explosifs. Tenir les

batteries à l’écart de toute source d’étincelles,

flammes et articles de fumeur.

Ne jamais travailler sur les batteries sans lunettes

de sécurité.

L’électrolyte est extrêmement corrosif. Éliminer

soigneusement tout électrolyte répandu en rinçant à

l’eau claire.

Toujours remplacer les batteries par des batteries

UpRight ou de modèle agréé par le fabricant, d’un

poids de 28 kg (62 lb).

Vérifier le niveau d’électrolyte tous les jours, particulièrement si la machine est utilisée sous les climats chauds et

secs.

Si l’électrolyte ne recouvre pas les plaques de batterie

d’au moins 10 mm (3/8 po), ajouter de l’eau distillée

SEULEMENT. L’usage de l’eau du robinet très calcaire

réduit la durée de vie des batteries.

La batterie et les câbles doivent être inspectés régulièrement pour détecter tout signe de fissures de la batterie, de

fuite d’électrolyte et de corrosion des bornes. Inspecter les

câbles en vue d’usure, de ruptures de l’isolation et bornes

de câbles cassées.

Voir le manuel d’entretien pour des instructions détaillées

et la prolongation de la vie utile des batteries.

!

17

Page 18

Légende du tableau d’entretiens préventifs

Périodicité

Quot. = chaque quart de travail ou chaque jour

50h/30j=toutes les 50 heures ou tous les mois

(30 jours)

250h/6m=toutes les 250 heures ou tous les 6 mois

1000h/2a=toutes les 1000 heures ou tous les 2 ans

O = Oui/Acceptable

N = Non/Inacceptable

R = Réparé/Acceptable

Rapport d'entretien préventif

Date : _______________________________________

Propriétaire : _______________________________________

No de modèle : ____________________________________

o

N

de série :________________________________________

Nom du technicien : ________________________________

Périodicité d’entretien : ______________________________

Tableau 1 :

ÉLÉMENT

Vérifier le niveau d’électrolyte 6m

Batterie

Huile et filtre

moteur

carburant

Liquide de

refroidisse-

hydraulique

hydraulique

hydraulique

de secours

Commandes Vérifier le fonctionnement de l’interrupteur Quot.

Câble de

commande

Plancher et

garde-corps

plate-forme

Pompe

hydraulique

Moteurs Vérifier le fonctionnement et s’assurer de l’absence

Vérifier la densité 6m

Nettoyer l’extérieur 6m

Vérifier l’état des câbles de batterie Quot.

Nettoyer les bornes 6m

Vérifier le niveau et l’état Quot.

à huile

Vérifier s’il y a des fuites Quot.

Changer le filtre à huile 100h

Vérifier le niveau de carburant Quot.

Vérifier s’il y a des fuites Quot.

Circuit

Remplacer le filtre à carburant 6m

Vérifier le filtre à air Quot.

Vérifier le niveau (moteur froid) Quot.

Remplacer le liquide de refroidissement 3m

ment

Vérifier le niveau de l’huile Quot.

Huile

Changer le filtre 6m

Vidanger et remplacer l’huile 2a

Vérifier s’il y a des fuites Quot.

Circuit

Vérifier le raccordement des tuyaux flexibles 30j

Vérifier l’usure extérieure des tuyaux flexibles 30j

Syst.

Faire fonctionner la soupape d’abaissement

d’urgence et vérifier son bon

fonctionnement

Vérifier l’extérieur du câble et rechercher tout

pincement, pliure ou usure

Vérifier le serrage des pièces de fixation Quot.

Vérifier si les soudures sont fissurées Quot.

de la

Vérifier l’état du pont Quot.

Vérifier le bon état Quot.

Pneus

Vérifier les écrous (serrer à 203 N·m [150 lb-pi]) 30j

Bien essuyer 30j

Vérifier s’il y a des fuites aux surfaces de contact 30j

Vérifier s’il y a des fuites aux raccordements Quot.

Vérifier le serrage des boulons de fixation 30j

de fuites

VÉRIFICATION OU ENTRETIEN

A EFFECTUER

Liste de contrôle des entretiens préventifs

PÉRIODICITÉ O N R

Quot.

Quot.

Quot.

ÉLÉMENT

Vérifier s’il y a des fuites Quot.

Moyeux

moteurs

Système de

direction

Dispositif

d’élévation

Châssis

Vérin de

Vérin de

Ensemble

machine

Étiquettes Vérifier que les autocollants ne sont pas

Vérifier le niveau de l’huile 250h/6m

Changer l’huile après la période de rodage 50h/30j

Vidanger l’huile 1000h/2a

Vérifier le serrage de la boulonnerie

et des raccords

Graisser les axes de pivot 30j

Huiler les axes de fusées 30j

Vérifier s’il y a des fuites au vérin de direction 30j

Vérifier si la structure présente des fissures Quot.

Vérifier l’usure des pièces aux points d’articulation 30j

Vérifier le serrage des boulons du pivot de la goupille

de fixation

Vérifier que les arbres d’élévation sont bien droits 6m

Vérifier que les tuyaux flexibles ne sont pas pincés et

n'ont pas de point de frottement

Vérifier le serrage des fixations des composants 6m

Vérifier si les soudures sont fissurées Quot.

Vérifier l’usure de la tige de vérin 30j

Vérifier le serrage des boulons du pivot de l’axe de

montage

Vérifier s’il y a des fuites aux joints 30j

levage

Vérifier l’usure des pièces aux points

d’articulation

Vérifier le serrage des raccords 30j

Vérifier l’usure de la tige de vérin 30j

Vérifier le serrage des boulons du pivot de la goupille

de fixation

l'axe

Vérifier s’il y a des fuites aux joints 30j

Vérifier l’usure des pièces aux points d’articulation 30j

Vérifier le serrage des raccords 30j

Inspecter en vue de dommages causés par une

collision et réparer

Vérifier le serrage de la boulonnerie 3m

de la

Vérifier s’il y a signe de corrosion; décaper

et repeindre

Lubrifier 30j

décollés, manquants ou illisibles

VÉRIFICATION OU ENTRETIEN

A EFFECTUER

PÉRIODICITÉ O N R

6m

30j

Quot.

30j

30j

30j

Quot.

6m

Quot.

18

Page 19

ARTICLE LX31 LX41 LX50

Taille de la plate-forme (à l'intérieur des plinthes)

Standard

Extension déployée

Capacité max. de la plate-forme

Standard

Avec extension

Sur l’extension

Nombre max. de personnes

Standard

Sur l’extension

Hauteur

Hauteur de travail

Hauteur max. de la plate-forme

Hauteur min. de la plate-forme

Hauteur max. en déplacement

Dimensions:

Poids, standard

Poids, avec extension

Largeur hors tout

Hauteur hors tout

Longueur hors tout, normale

Vitesse au sol

Plate-forme abaissée

Plate-forme élevée

Tension du circuit électrique

Capacité du réservoir hydraulique

Pression max. du circuit hydraulique

Huile hydraulique

Usage normal (>0 °C [32 °F])

Utilisation à basse temp. (<0 °C [32 °F])

Utilisation à basse temp. (<-17 °C [0 °F])

Système d’élévation

Vitesse d’élévation

Mise de niveau de la plate-forme

Moteur

Commande de déplacement

Système de commande

Déplacement horizontal

Pneus gonflés à l’air

Frein de stationnement

Rayon de braquage (intérieur)

Pente franchissable

Empattement

Garde-corps

Plinthe

*Caractéristiques

3,64 m x 1,78 m [143,38 po x 70 po] 3,64 m x 1,78 m [143,38 po x 70 po] 3,64 m x 1,78 m [143,38 po x 70 po]

4,56 m x 1,73 m [179,38 po x 68 po] 4,56 m x 1,73 m [179,38 po x 68 po] 4,56 m x 1,73 m [179,38 po x 68 po]

907 kg [2000 lb] 680 kg [1500 lb] 454 kg [1000 lb]

907 kg [2000 lb] 680 kg [1500 lb] 454 kg [1000 lb]

227 kg [500 lb] 227 kg [500 lb] 227 kg [500 lb]

8 personnes 6 personnes 4 personnes

2 personnes 2 personnes 2 personnes

11,4 m [37 pi] 14,33 m [47 pi] 17 m [56 pi]

9,45 m [31 pi] 12,34 m [40 pi 6 po] 15,09 m [49 pi 6 po]

1,43 m [56,25 pi] 1,66 m [65,25 pi] 1,93 m [76 po]

8 m [26 pi 2 po] 8 m [26 pi 2 po] 8 m [26 pi 2 po]

2X2 : 4264 kg [9400 lb]

4X4 : 4368 kg [9630 lb]

2X2 : 4459 kg [9830 lb]

4X4 : 4563 kg [10 060 lb]

2,29 m [90 po] 2,29 m [90 po] 2,29 m [90 po]

2,53 m [99,75 po] 2,76 m [108,75 po] 2,76 m [108,75 po]

4,06 m [160 po] 4,06 m [160 po] 4,06 m [160 po]

0 à 5,0 km/h [0 à 3,1 mi/h] 0 à 5,0 km/h [0 à 3,1 mi/h] 0 à 5,0 km/h [0 à 3,1 mi/h]

0 à 0,48 km/h [0 à 0,3 mi/h] 0 à 0,48 km/h [0 à 0,3 mi/h] 0 à 0,48 km/h [0 à 0,3 mi/h]

12 V CC 12 V CC 12 V CC

107,13 L [28,3 gallons US] 107,13 L [28,3 gallons US] 107,13 L [28,3 gallons US]

206,8 bar [3000 lb/po2] 206,8 bar [3000 lb/po2] 206,8 bar [3000 lb/po2]

ISO n° 46 ISO n° 46 ISO n° 46

ISO n° 32 ISO n° 32 ISO n° 32

ISO n° 15 ISO n° 15 ISO n° 15

Un vérin d’élévation à un étage Un vérin d’élévation à un étage Deux vérins d’élévation à un étage

Élévation : 40 s

Abaissement : 60 s

latérale = 8,5° (0,3 m [12 po]),

longitudinale = 6° (0,3 m [12 po])

Diesel ou essence 20 HP Kubota,

3 cylindres, refroidi par eau

Proportionnelle Proportionnelle Proportionnelle

Manche à balai muni d’un levier

d’enclenchement solidaire

2X2 : 2 roues, moteurs hyd.

4X4 : 4 roues, moteurs hyd.

8 plis NHS 10-16,5, 3,4 bar [50 lb/po2] 8 plis NHS 10-16,5, 3,4 bar [50 lb/po2]

Deux, multidisques, serrage par ressort,

desserrage hydraulique

1,22 m [48 po] 1,22 m [48 po] 1,22 m [48 po]

2X2 : 30 % [16,7°]

4X4 : 35 % [19,2°]

2,94 m [115,75 po] 2,94 m [115,75 po] 2,94 m [115,75 po]

1,1 m [43,5 po] de haut, rabattable

avec portillon

152 mm [6 po] de haut 152 mm [6 po] de haut 152 mm [6 po] de haut

2X2 : 4790 kg [10 560 lb]

4X4 : 4953 kg [10 920 lb

2X2 : 4985 kg [10 990 lb]

4X4 : 5148 kg [11 350 lb

Élévation : 45 s

Abaissement : 65 s

latérale = 8,5° (0,3 m [12 po]),

longitudinale = 6° (0,3 m [12 po])

Diesel ou essence 20 HP Kubota,

3 cylindres, refroidi par eau

Manche à balai muni d’un levier

d’enclenchement solidaire

2X2 : 2 roues, moteurs hyd.

4X4 : 4 roues, moteurs hyd.

Deux, multidisques, serrage par ressort,

desserrage hydraulique

2X2 : 30 % [16,7°]

4X4 : 35 % [19,2°]

1,1 m [43,5 po] de haut, rabattable

avec portillon

2X2 : 5498 kg [12 120 lb]

4X4 : 5661 kg [12 480 lb]

2X2 : 5693 kg [12 550 lb]

4X4 : 5856 kg [12 910 lb]

Élévation : 45 s

Abaissement : 65 s

latérale = 8,5° (0,3 m [12 po]),

longitudinale = 6° (0,3 m [12 po])

Diesel ou essence 20 HP Kubota,

3 cylindres, refroidi par eau

Manche à balai muni d’un levier

d’enclenchement solidaire

2X2 : 2 roues, moteurs hyd.

4X4 : 4 roues, moteurs hyd.

8 plis NHS 10-16,5, remplis de poly

Deux, multidisques, serrage par ressort,

desserrage hydraulique

2 roues motrices : 30 % [16,7°]

4 roues motrices : 35 % [19,2°]

1,1 m [43,5 po] de haut, rabattable

avec portillon

*Ces caractéristiques peuvent être changées sans préavis. La liste des pièces et les consignes d’entretien détaillées se trouvent

dans le Manuel d’entretien.

Page 20

Deutschsprachiger Teil

Sicherheitsregeln

Benutzen Sie die Maschine

NIEMALS im Umkreis von 3 m

(10 ft.) von Starkstromleitungen.

DIESE MASCHINE IST NICHT

ISOLIERT!

Maschine NIEMALS

abschüssige Stellen, Unebenheiten, und Abfälle zu untersuchen.

Maschine NIEMALS benutzen, solange nicht sämtliche Schutzgeländer vorschriftsmäßig angebracht und mit

allen Befestigungselementen vorschriftsmäßig festgezogen sind.

Tür nach Besteigen der Arbeitsbühne SICHERN

Alle Körperteile beim Aus- und Einfahren der Hilfsstützen von diesen FERHNALTEN (bei Maschinen mit

Hilfsstützen).

Auf der Arbeitsbühne NIEMALS Leitern oder Gerüste verwenden.

NIEMALS überhängende Lasten anbringen oder die Arbeitsbühne größenmäßig erweitern.

Reifendruck von 3,4 bar (50 psi)

Durch

oder elektrischen Leitungen vorhanden sind.

Alle Lasten gleichmäßig auf der Arbeitsbühne

der Arbeitsbühne.

NIEMALS beschädigte Geräte benutzen. (Wenden Sie sich bezüglich Anleitungen an UpRight. Die gebührenfreie Rufnummer befindet sich auf der Rückseite.)

NIEMALS irgendwelche Betriebs- oder Sicherheitseinrichtungen ändern.

Maschine gründlich auf gerissene Schweißnähte, lose Metallteile, Hydrauliklecks, beschädigte Steuerkabel, lose

Kabelanschlüsse und Radbolzen UNTERSUCHEN.

Bei angehobener Arbeitsbühne NIEMALS am Hubgestell herabklettern.

An der Maschine NIEMALS Wartungsarbeiten durchführen, wenn die Arbeitsbühne hochgefahren ist, ohne das

Hubgestell zu blockieren.

Batterie NIEMALS in der Nähe von Funken oder offenen Flammen nachladen; Batterien erzeugen beim Laden

ein hochexplosives Wasserstoffgas.

Arbeitsbühne NACH GEBRAUCH vor unbefugter Benutzung sichern, indem der Schlüsselschalter ausge-

schaltet und der Schlüssel abgezogen wird.

Komponenten und Teile

UpRight-Ersatzteile auswechseln.

in Betrieb nehmen, ohne zuvor das Arbeitsgelände auf Bodengefahren, wie z.B. Löcher,

AUFRECHTERHALTEN

SICHTPRÜFUNG nach oben, unten und im Umkreis sicherstellen, daß keine hochliegenden Hindernisse

NIEMALS ohne schriftliche Genehmigung des Herstellers gegen andere als Original-

An unebenen Steigungen oder auf

weichem Boden NIEMALS

Arbeitsbühne hochfahren oder die

Maschine verfahren, und die Arbe-

itsbühne NIEMALS hochfahren,

wenn diese nicht horizontal steht.

und verriegeln.

(LX31/41).

VERTEILEN. Siehe Rückseite bezüglich maximaler Belastung

die

NIEMALS auf dem Geländer oder

der Mittelstrebe sitzen, stehen

oder diese besteigen.

20 25

Page 21

E

INLEITUNG

S

YSTEMFUNKTIONSPRÜFUNG

Dieses Handbuch gilt für alle Arbeitsbühnenmodelle der

LX-Serie. Dieses Handbuch muß ständig an der Maschine

aufbewahrt werden.

S

ICHERHEITSINSPEKTION VOR

I

NBETRIEBNAHME

ANMERKUNG: Lesen, verstehen und befolgen

Sie sorgfältig sämtliche Sicherheitsregeln,

Betriebsanleitungen und Aufkleber sowie das

PFLICHTENHANDBUCH des Verbands der

Gerüstbauer. Führen Sie täglich vor

Inbetriebnahme die nachstehenden Schritte

durch.

1. Module öffnen und auf Beschädigung, Öllecks und

fehlende Teile prüfen.

2. Hydraulikölstand am Schauglas des Hydrauliktanks

bei völlig abgesenkter Arbeitsbühne prüfen. Bei

Bedarf Flüssigkeit nachfüllen.

3. Nachprüfen, ob der Batterieflüssigkeitsstand stimmt

(siehe Batteriewartung).

4. Füllstand von Motoröl und Kraftstoff überprüfen.

5. Nachprüfen, ob alle Schutzgeländer angebracht sind,

die Deckverlängerung durch den Bolzen gesichert ist

und alle Befestigungselemente vorschriftsmäßig

angezogen sind.

6. Reifendruck prüfen: 3,4 bar (50 psi)

7. Die gesamte Arbeitsbühne gründlich auf Schäden,

wie z.B. gerissene Schweißnähte oder Strukturteile,

lose oder fehlende Teile, Öllecks, beschädigte Kabel

und Schläuche, lose Anschlüsse und beschädigte

Reifen untersuchen.

8. Maschine, wenn erforderlich, an eine freie Stelle

bringen, die das vollständige Hochfahren ermöglicht.

9. Notaustaster des Fahrwerks und der Plattform durch

Herausziehen der Knöpfe auf Ein (ON) (Abbildung 1

und 2) stellen.

10. Sicherstellen, daß der Plattform-Fahrwerks-Schalter

auf Plattform (

11. Bei kaltem Motor den Füllstand des Motorkühlmittels

prüfen.

!

Kühlmittel NICHT bei heißem Motor oder Kühler

prüfen, da heißes Kühlmittel schwere

Verbrennungen verursachen kann.

PLATFORM

) steht.

VO RSICH T

!

!

WA RN U N G

Bei Durchführung der nachstehenden Prüfungen ist

von der Arbeitsbühne ABSTAND ZU HALTEN.

Untersuchen Sie vor Inbetriebnahme der

Arbeitsbühne den Arbeitsbereich auf FahrbahnGefahrenstellen, wie z.B. Löcher, Abhänge,

Unebenheiten und Abfall.

Prüfen Sie die GESAMTE Umgebung,

einschließlich oberhalb der Arbeitsbühne, auf

Hindernisse und elektrische Leitungen.

Schützen Sie bei den Überprüfungen das

Steuerpultkabel gegen mögliche Beschädigung.

5 6 8

7

!

1

9

2

3

4

Abbildung 1: Fahrwerks-Steuerorgane

1. Notaus

2. Plattform-/Fahrwerk-/

Schalter

3. Hochfahrknopf

4. Absenkknopf

5. Startknopf

1. Steuergerät am vorderen Schutzgeländer

aushängen. Steuergerätaufhänger so greifen, daß

sich der Sperrhebel drücken läßt, während die

nachstehenden Überprüfungen vom Boden aus

vorgenommen werden.

2. Schlüsselschalter des Steuergeräts nach rechts auf

Ein (ON) drehen. Zum Starten des Motors den

Schlüssel ganz nach rechts drehen; loslassen,

sobald der Motor anspringt.

Anmerkung: Bei kaltem Motor den

Vorglühknopf sechs Sekunden lang drücken,

um die Glühkerzen vorzuwärmen.

6. Choke-Knopf

(Zweistoffbetrieb) oder

Vorglühknopf (Diesel)

7. Drosselklappenknopf

8. Abstellknopf

9. Kraftstoff-Wählschalter

(nur bei Zweistoffbetrieb)

Page 22

1. Den Schalter Fahren / Heben (Drive/Lift) auf Fahren

(DRIVE) stellen.

2. Sperrhebel zunächst bei Gangwähl-Schalterstellung

auf hohes Drehmoment (HIGH TORQUE), und

danach auf Schneller Gang (HIGH SPEED), drücken

und den Steuerhebel langsam erst auf Vorwärts

(FORWARD), dann auf Rückwärts (REVERSE)

stellen, um die Funktion der Geschwindigkeits- und

Richtungssteuerung zu prüfen. Je weiter der

Steuerknüppel gedrückt bzw. gezogen wird, desto

schneller fährt die Maschine.

3. Den Lenkschalter auf Rechts (RIGHT), dann auf

Links (LEFT) drücken, um die Lenkfunktion zu

prüfen.

1

2

3

7

4

8

9

5

6

Abbildung 1: Steuergerät

1. Lenkungsschalter

2. Sperrhebelschalter

3. Steuerhebel

4. Hilfsstützenschalter

5. Notausschalter

6. Fahr-Hub-Schalter

7. Geschwindigkeits-/

DrehmomentWählschalter

8. Fahrfunktionsleuchte

9. Schlüsselschalter

12. Hubgestell, Hubzylinder, Kabel und Schläuche visuell

auf Beschädigungen und sprunghafte Bewegungen

untersuchen. Gerät auf fehlende oder lose Teile

untersuchen.

13. Arbeitsbühne durch Hineindrücken des Knopfes

Senken am Fahrwerk zum Teil absenken und die

Funktion der akustischen Senkwarnung prüfen.

14. Das Fahrwerk-Notsenkventil “emergency lowering”

(Abbildung 4) durch Herausziehen und Halten des

Knopfes öffnen, um die einwandfreie Funktion des

Ventils zu prüfen. Ventil nach völligem Absenken der

Arbeitsbühne durch Loslassen des Knopfes

schließen.

15. Den Schalter Arbeitsbühne / Fahrwerk auf

Arbeitsbühne (PLATFORM) stellen.

16. Plattform betreten und sicherstellen, daß die Tür

eingeklinkt ist.

17. Den Schalter Fahren / Heben auf Heben (LIFT)

stellen.

18. Sperrhebel drücken und den Steuerhebel allmählich

auf Aufwärts (UP) schieben, um die Plattform

hochzufahren; Steuerhebel ganz betätigen, um die

proportionale Hubgeschwindigkeit zu prüfen.

Steuerhebel allmählich auf Stellung Abwärts

(DOWN) ziehen, um die Plattform abzusenken.

Nachprüfen, ob die Senkwarnung ertönt.

19. Den Sperrhebelschalter am Steuerhebel drücken

und irgendeinen Hilfsstützenschalter auf Ausfahren

(EXTEND) stellen; die Hilfsstützen müssen außer

Betrieb sein. Sollte irgendeine Hilfsstütze bei diesem

Test ausfahren, STOP! Plattform absenken und

Maschine aus dem Betrieb ziehen, bis sie repariert

ist.

20. Schlüsselschalter des Steuergeräts auf Aus (OFF)

drehen, Taster Notaustaster drücken und die

Arbeitsbühne verlassen.

21. Baugruppendeckel schließen und sichern.

B

ETRIEB

6. Den Sperrschalter am Steuerhebel drücken und die

einzelnen Hilfsstützenschalter auf Ausfahren

(EXTEND) stellen, um alle vier Hilfsstützen

auszufahren. Fahrfunktionsleuchte prüfen; sie muß

aus sein.

7. Alle Hilfsstützen vollständig einfahren und die

Fahrfunktionsleuchte prüfen; sie muß an sein.

8. Steuergerät wieder am vorderen Schutzgeländer

einhängen.

9. Den Schalter Arbeitsbühne / Fahrwerk auf Fahrwerk

(CHASSIS) drehen.

10. Drosselklappenknopf hineindrücken. FahrwerksHochfahrknopf zum Hochfahren der Arbeitsbühne

drücken und gleichzeitig den Neigungssensor aus

dem Lot drücken. Die Plattform darf sich nur teilweise

heben, und die Kippwarnung muß ertönen. Falls sich

die Arbeitsbühne weiter anhebt bzw. keine Warnung

ertönt, betätigen Sie STOP und ziehen Sie die

Maschine so lange aus dem Betrieb, bis diese

repariert ist.

11. Neigungssensor loslassen und Arbeitsbühne völlig

hochfahren.

ANMERKUNG: Vor Inbetriebnahme der

Plattform ist sicherzustellen, daß die

Sicherheitsinspektion vor Inbetriebnahme

durchgeführt wurde, etwaige Mängel behoben

sind und der Bediener an dieser Maschine

gründlich ausgebildet ist.

F

AHREN MIT GESENKTER

A

RBEITSBÜHNE

1. Nachprüfen, ob der Fahrwerks-Notaustaster auf Ein

(ON) (nach links drehen) steht, die

Fahrfunktionsleuchte an ist und der Plattform-/

Fahrwerksschalter auf Plattform (PLATFORM) steht.