Page 1

MAMMOMAT 1000/3000 Nova

SP

Installation

Installation and Start-Up Instructions

from Serial No. 9000

© Siemens AG 2003

The reproduction, transmission or

use of this document or its contents

is not permitted without express

written authority. Offenders will be

liable for damages. All rights,

including rights created by patent

grant or registration of a utility

model _or_ design,_are_ reserved.

Register 3 English

Print No.: SPB7-230.033.11.05.02 Doc. Gen. Date: 05.05

Replaces: SPB7-230.033.11.04.02

Page 2

0 - 2 Revision

Chapter Page Revision

All All 05

Document revision level

The document corresponds to the version/revision level effective at the time of system delivery. Revisions to hardcopy documentation are not automatically distributed.

Please contact your local Siemens office to order current revision levels.

Disclaimer

The installation and service of equipment described herein is to be performed by qualified personnel

who are employed by Siemens or one of its affiliates or who are otherwise authorized by Siemens or

one of its affiliates to provide such services.

Assemblers and other persons who are not employed by or otherwise directly affiliated with or authorized by Siemens or one of its affiliates are directed to contact one of the local offices of Siemens or

one of its affiliates before attempting installation or service procedures.

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 2 of 8 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 3

Contents 0 - 3

Page

1 _______Prerequisites __________________________________________________ 1 - 1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

MAMMOMAT 1000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

MAMMOMAT 3000 Nova . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Meters and appliances, tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Meters and appliances required . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Tools required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Important notes on start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

Checking and recording for the area of application of the X-ray decree (§16 Germany)1 - 4

Checking and recording for the DHHS area of application . . . . . . . . . . . . . . . 1 - 5

Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

Note on delivery state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

2 _______Protective measures ____________________________________________ 2 - 1

Protective measures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

Delay times between two exposures . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

3 _______Preparatory work_______________________________________________ 3 - 1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 1

Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Unpacking the stand. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

Removing the transport safeguards . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

Removing the swivel-arm system transport safeguard . . . . . . . . . . . . . . . 3 - 3

Transport safeguard for the lifting carriage . . . . . . . . . . . . . . . . . . . . . 3 - 3

Transport safeguard for the rotary motion . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

Ball bearings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 5

Protective strips for the metal curtain . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 5

Unpacking the generator and mounting the radiation shield (optional) . . . . . . . . . 3 - 6

4 _______Installing the generator and the stand _____________________________ 4 - 1

Arranging the components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Notes on installations with separate generator and separate control console. . . . 4 - 1

Free-standing radiation shield (option) . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Removing the generator cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Installing the cable ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Installations with separate control console . . . . . . . . . . . . . . . . . . . . . 4 - 3

Laying the cable harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4

Installations with separate control console . . . . . . . . . . . . . . . . . . . . . 4 - 5

Aligning the stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 6

5 _______Cable connections______________________________________________ 5 - 1

EMC measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

Siemens AG Register 3 SPB7-230.033.11 Page 3 of 8 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 4

0 - 4 Contents

Page

EMC measures at the cable entry . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

Fitting the hose clamps and ferrite sleeves . . . . . . . . . . . . . . . . . . . . . 5 - 1

Note on separate control console and separate generator . . . . . . . . . . . . . 5 - 2

EMC measures on the bottom plate . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 3

Fitting the cables X1, X8 and X9 onto the bottom plate . . . . . . . . . . . . . . 5 - 3

Connecting the stand cable-harness . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

High-voltage connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 4

Connecting the high-voltage connector. . . . . . . . . . . . . . . . . . . . . . . . . 5 - 5

Connecting the cable harness to the generator . . . . . . . . . . . . . . . . . . . . 5 - 6

Unit control cable X1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 6

Filament cable X8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 6

Power supply cable X14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 6

AEC signal cable X10 and X11 . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 6

Rotating anode cable X9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 7

Installations with separate control console and separate generator . . . . . . . . 5 - 8

Main voltage connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 10

Connecting the incoming mains to the stand (400 V, 2-phase). . . . . . . . . . . . .5 - 11

400 V 2-phase connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 11

Connecting the mains supply to the generator (400 V, 2-phase) . . . . . . . . . . . .5 - 12

Measures for changing from 2-phase to 1-phase connection . . . . . . . . . . .5 - 13

6 ______ Mains connection and power supply_______________________________6 - 1

Checks before powering up the generator . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Measuring the line resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Checking the line voltage in the generator . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

Checking the supply voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 3

7 ______ Attaching the swivel-arm covers __________________________________7 - 1

Attaching the swivel-arm covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

Arranging the swivel-arm system . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

Connecting the cables to control-button boards and patient handles . . . . . . . 7 - 1

Attaching the side covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 2

Attaching the front cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 2

8 ______ Checking the microprocessors ___________________________________8 - 1

Microprocessors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 1

9 ______ Checks without high voltage _____________________________________9 - 1

Checks without high voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 1

10 _____ Checks with high voltage _______________________________________10 - 1

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 - 1

kV-adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 - 2

Filament . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 - 4

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 4 of 8 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 5

Contents 0 - 5

Page

Checking X-ray tube high voltage, tube current and mAs values . . . . . . . . . . . 10 - 5

Oscilloscope diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 6

11 ______Calibrating and adjusting the AEC _______________________________ 11 - 1

Checking and programming with the service PC . . . . . . . . . . . . . . . . . . . 11 - 1

Preparation of backup floppy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 3

Offset compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 4

Configuration of the AEC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 6

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 6

Object table group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 6

General conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 6

Calibration conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 6

Reference cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 6

Film . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 6

Mains voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 6

Sensitivity conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 6

Correction of the measured Optical Density (O.D.) . . . . . . . . . . . . . . . . 11 - 7

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 7

Normal developing conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 7

Incremental gamma . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 9

Overview of work routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 10

AEC Correction tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 11

DLF switch off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 11

Increase grid speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 11

Installation of AEC correction tables. . . . . . . . . . . . . . . . . . . . . . . 11 - 12

Calibrate correction tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 14

Recalibration of an object table . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 19

Sensitivity correction (fine setting). . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 20

Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 21

Copy H to D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 - 22

12 ______Dose Calculation System _______________________________________ 12 - 1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 - 1

Enable/Disable Dose Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 - 1

Configuring of Dose Calculation System . . . . . . . . . . . . . . . . . . . . . . . 12 - 2

Label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 - 2

13 ______Testing ______________________________________________________ 13 - 1

Testing the AEC-function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 - 1

AEC performance test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 - 1

Testing and adjusting OPDOSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 - 2

14 ______Further programming __________________________________________ 14 - 1

Setting the real time clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 - 1

Prerequisite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 - 1

Siemens AG Register 3 SPB7-230.033.11 Page 5 of 8 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 6

0 - 6 Contents

Page

Setting the time in the MAMMOMAT . . . . . . . . . . . . . . . . . . . . . . . . . .14 - 1

Reducing the generator power . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14 - 1

Main menu: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14 - 1

15 _____ Checking the swivel-arm system _________________________________15 - 1

Rotary motion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15 - 1

Vertical adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15 - 2

Emergency stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15 - 3

16 _____ Field light ____________________________________________________16 - 1

Checking and adjusting the field light time . . . . . . . . . . . . . . . . . . . . . . .16 - 1

Checking the field light time . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 - 1

Adjusting the field light time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 - 2

17 _____ Checking the compression device and OPCOMP ___________________ 17 - 1

Checking the compression device . . . . . . . . . . . . . . . . . . . . . . . . . . .17 - 1

Decompression button (only with separate control console) . . . . . . . . . . . .17 - 2

Checking the OPCOMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 - 3

Adapting OPCOMP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 - 3

18 _____ Checking the exposure blocking _________________________________ 18 - 1

DLF switch on. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 - 1

Reduce grid speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 - 1

Cassette loaded switch on . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 - 1

Checking the exposure blocking . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 - 2

19 _____ Checking the radiation field limitation_____________________________19 - 1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19 - 1

Measuring procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19 - 2

Evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19 - 3

Alignment radiation field/light field . . . . . . . . . . . . . . . . . . . . . . . . .19 - 3

Radiation field limitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19 - 3

20 _____ Final procedures ______________________________________________20 - 1

Service PC and measuring instruments . . . . . . . . . . . . . . . . . . . . . . . .20 - 1

Saving the configuration file . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 - 1

Reading the exposure counter . . . . . . . . . . . . . . . . . . . . . . . . . . .20 - 1

Deleting the error memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 - 1

Saving the programmed values. . . . . . . . . . . . . . . . . . . . . . . . . . .20 - 1

Removing the measuring instruments . . . . . . . . . . . . . . . . . . . . . . . . .20 - 2

Checking the protective grounding resistance . . . . . . . . . . . . . . . . . . . . .20 - 2

Mounting the cable duct covers . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 - 2

Mounting the stand covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 - 2

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 6 of 8 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 7

Contents 0 - 7

Page

MAMMOMAT stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 - 3

Fitting the MAMMOMAT cap . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 - 4

Fitting the cable outlet cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 - 4

Mounting the front cover onto the generator . . . . . . . . . . . . . . . . . . . . . 20 - 5

Final protective grounding resistance test. . . . . . . . . . . . . . . . . . . . . . . 20 - 5

Face shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 - 6

Warning label on control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 - 7

Affixing the identification labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 - 8

Reporting IVK status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 - 8

Other installation material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 - 8

Handling the Installation report . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 - 9

21 ______Bolting the stand/generator to the floor ___________________________ 21 - 1

Stand and generator with integrated radiation shield and control panel. . . . . . . . 21 - 1

Installation with separate generator . . . . . . . . . . . . . . . . . . . . . . . . 21 - 2

Free-standing radiation shield (option) . . . . . . . . . . . . . . . . . . . . . . 21 - 3

22 ______Appendix ____________________________________________________ 22 - 1

Working with the service PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 - 1

Description of the syntax used in these instructions. . . . . . . . . . . . . . . . 22 - 1

Connecting the service PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 - 2

Configuration of the service PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 - 3

Configuration of computer BIOS. . . . . . . . . . . . . . . . . . . . . . . . . . 22 - 3

Configuration of Windows® . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 - 3

Starting up and using the service PC . . . . . . . . . . . . . . . . . . . . . . . 22 - 4

Starting up and using the service PC - Dose Calculation program . . . . . . . . 22 - 5

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 - 5

Test protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 - 6

kV-adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 - 6

Filament . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 - 6

AEC performance test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 - 7

M1000 or Wing 1 M3000 Nova . . . . . . . . . . . . . . . . . . . . . . . . . . 22 - 7

Wing 2 M3000 Nova . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 - 9

OPDOSE settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 - 9

23 ______Changes to previous version ____________________________________ 23 - 1

Siemens AG Register 3 SPB7-230.033.11 Page 7 of 8 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 8

0 - 8 Contents

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 8 of 8 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 9

Prerequisites 1

General 1

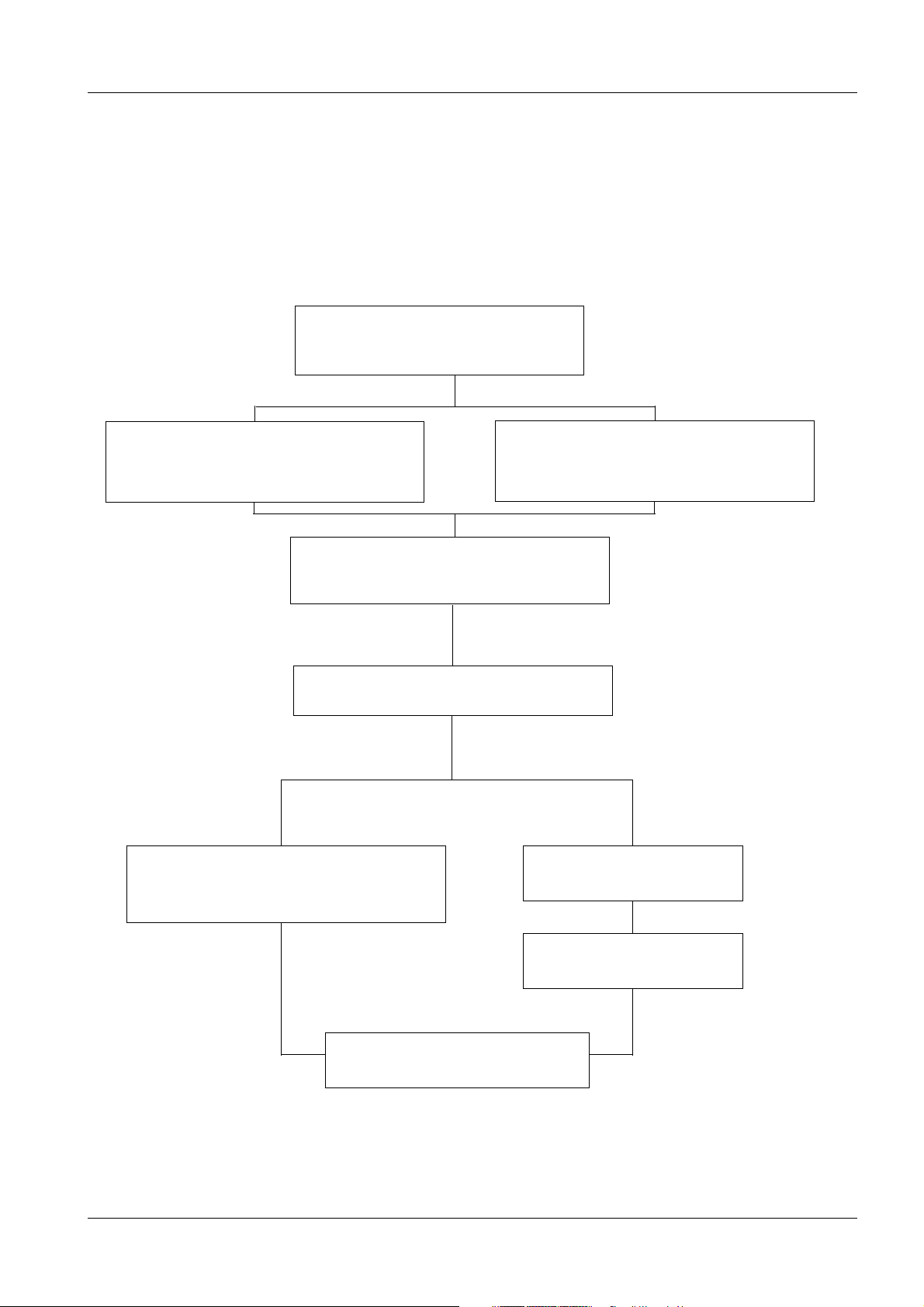

The configuration of the Mammomat installation is dependent on the customer’s choice.

Up to twelve various combinations are possible as shown below:

MAMMOMAT 1000 1

MAMMOMAT 1000 - Basic unit

1 - 1

Molybdenum anode X-ray tube

assembly with filter Mo 0.03

Fixed object-table arm

("Wing 2" no counterweight)

Dose Calculation System

Generator with integrated

control panel and radiation shield

Molybdenum anode X-ray tube

assembly with filter disc

Mo 0.03/Rh 0.025

Separate generator

Separate control console

Free-standing radiation shield

Fig. 1

Siemens AG Register 3 SPB7-230.033.11 Page 1 of 6 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 10

1 - 2 Prerequisites

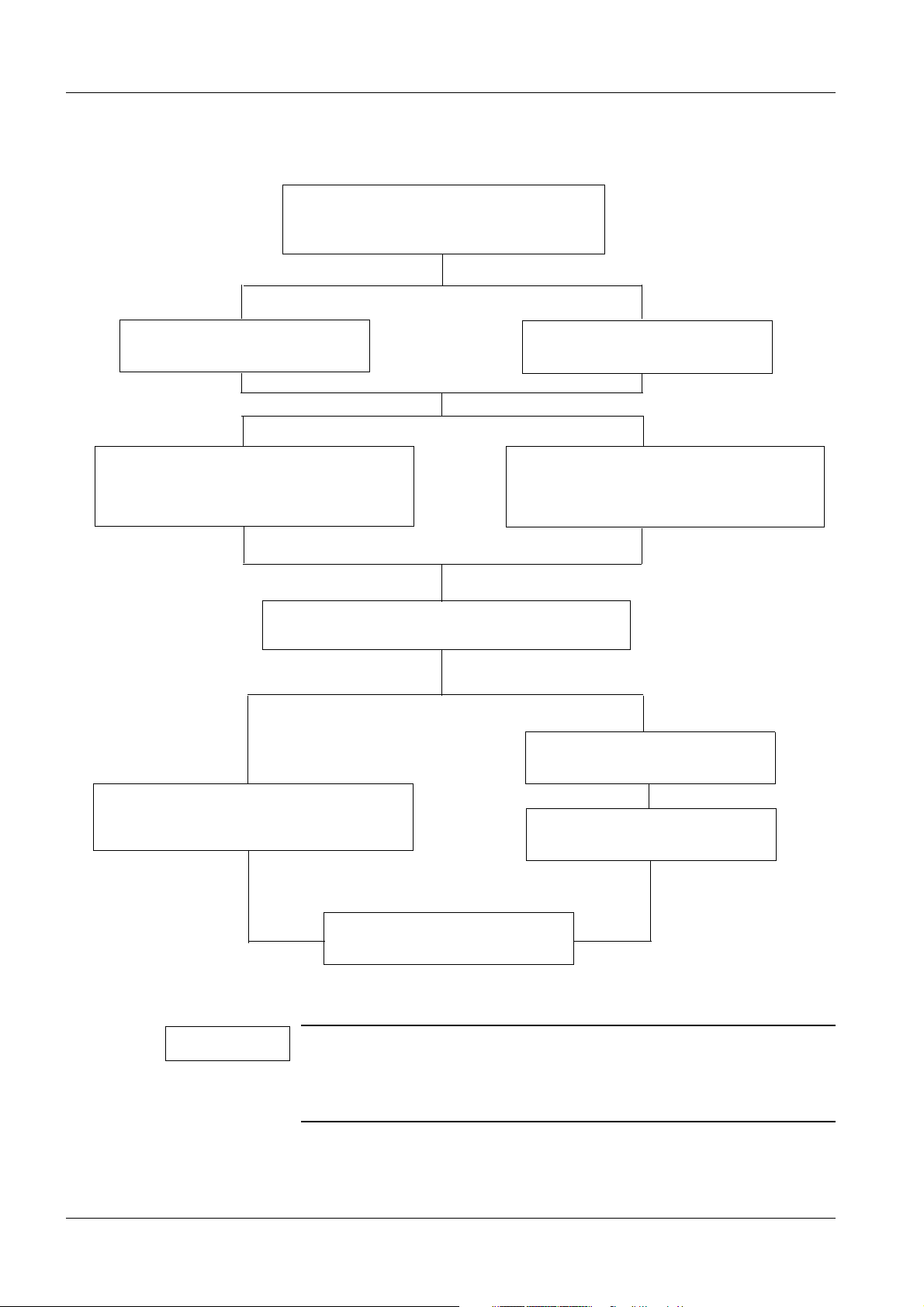

MAMMOMAT 3000 Nova 1

MAMMOMAT 3000 Nova - Basic unit

Pivoting object-table arm

("Wing 1"+ "Wing 2")

Molybdenum/tungsten anode X-ray

tube assembly with filter disc

Mo 0.03/Rh 0.025/Rh 0.050

Dose Calculation System

Fixed object-table arm

("Wing 1" + counterweight)

Molybdenum anode X-ray tube

assembly with filter disc

Mo 0.03/Rh 0.025

Separate generator

Generator with integrated

control panel and radiation shield

Separate control console

Free-standing radiation shield

Fig. 2

NOTE

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 2 of 6 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

A P40 MoW tube will be delivered irrespective of whether the customer has chosen the molybdenum/tungsten anode X-ray tube or

the molybdenum anode X-ray tube. In the last case, the tungsten

anode is deselected by the software.

Page 11

Prerequisites 1 - 3

Unless otherwise stated, these instructions describe the stand with pivoted object-table

arm and generator with integrated radiation shield and control panel.

Depending on the installation configuration, some points may be omitted.

Meters and appliances, tools 1

Meters and appliances required 1

NOTE

Calibrated instruments are required.

• Power Line Impedance Meter.

• Protective ground-wire tester.

• Oscilloscope, e.g TEKTRONIX 314.

• Digital multimeter (Fluke type 8060A, part no. 97 02 101 Y4290 or Fluke type 87, part no.

97 03 976 Y4290).

• Sensitometer.

• Densitometer e.g PDA 81.

• Service PC with connecting cable (PC-Generator), part no. 99 00 440 RE999.

• Normi 7 test body (provided by the customer) or SIB phantom Type 42 001 (PTW or

INAK).

• Centering cross, part no. 96 60 051 RE 999.

• AEC calibration plexi:

- Three plates, "2" cm (part no. 65 61 232)

- One plate, "1" cm (part no. 65 61 224)

WAR NING

The existing ground conductor in the mains cable must under no

circumstances be disconnected when operating the oscilloscope.

Life-threatening electric shock hazard exist.

For those measurements, in which any resulting ground loop may

falsify the measuring result, use the differential amplifier (difference measurement).

Tools required 1

• Standard installation tool kit.

• Torque wrench for bolting the stand/generator to the floor (optional).

• Electrical screwdriver with adjustable torque is recommended.

• Calculator

This symbol indicates exposure of X-ray radiation.

Siemens AG Register 3 SPB7-230.033.11 Page 3 of 6 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 12

1 - 4 Prerequisites

Important notes on start-up 1

The MAMMOMAT is adjusted, programmed and tested in the factory, leaving the adapta-

tion to the on-site mains voltage, adjustment of the AEC and the functional tests to be performed.

When the measurements to be made (kV, mAs, etc.) are within the tolerances stated in

these instructions, this confirms that the settings made in the factory have not changed

and the equipment is fully serviceable.

The measured values marked with in Chapter 10 "Checks with high voltage" shall be

entered in the "start-up" column in the test certificate provided.

The service PC is required only for programming according to:

• Chapter 10 "Checks with high voltage"

• Chapter 11 "Calibrating and adjusting the AEC"

• Chapter 12 "Dose Calculation System"

• Chapter 13 "Testing"

• Chapter 14 "Further programming"

• Chapter 20 "Final procedures"

Description of the service PC syntax is found in Chapter 22 "Appendix".

NOTE

If the generator is switched off with the service PC connected,

wait approximately 5 s before switching it on again.

Checking and recording for the area of application of the X-ray decree (§16 Germany)

In the area of application of the X-ray decree, an acceptance test certificate is supplied,

with most of the data filled in by the factory.

Only:

• the cut-off dose

• the resolution of the film/screen systems used

• the output values of the constancy test

must be determined by the owner of the equipment and recorded in the acceptance test

certificate. Furthermore, the front page of the acceptance test certificate must also be

completed with the operator´s data.

1

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 4 of 6 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 13

Prerequisites 1 - 5

Checking and recording for the DHHS area of application 1

In the area of application of the DHHS regulations, maintenance measurements must be

made according to the "DHHS Maintenance Instructions" SPB7-230.662.03.04.02 and the

"DHHS Supplements to the instructions for use" SPB7-230.661.02.03.02.

Sections 1

• Required labels.

• Radiation ON indicators.

• Manual termination of exposure.

• Checking the maximum adjustable mAs.

• Filters in beam limiting device (BLD).

• Reproducibility.

• kVp-accuracy.

• mAs-accuracy.

• Automatic exposure control (AEC).

• Coincidence of radiation field/image receptor.

• Alignment of light field/X-ray field.

• Illuminance of light localizer (light field).

• Shut-down of motor-driven compression movement.

The result must be recorded in "DHHS Measurement certificates"

SPB7-230.663.03.03.02.

Some of the values to be determined can be taken from the acceptance test certificate.

The radiation-field limitation is set at the factory and recorded in the acceptance test certif-

icate.

If the measurements to be made concerning the radiation-field limitation are within the tol-

erances stated in these instructions, this confirms that the settings made at the factory

have not changed.

Note on delivery state 1

The MAMMOMAT has been tested and adjusted at the factory, and should therefore be

ready for operation after completion of the installation.

The equipment is set to 400 V, 2-phase, on delivery.

Siemens AG Register 3 SPB7-230.033.11 Page 5 of 6 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 14

1 - 6 Prerequisites

This page intentionally left blank.

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 6 of 6 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 15

Protective measures 2

Protective measures 2

It is very important that any intervention in the equipment will start with disconnecting it

from the power supply with the main circuit-breaker. Before removing or inserting any of

the printed circuit board, switch of the equipment. To prevent accidental triggering of high

voltage and radiation, set the switch S2 (SS) on p.c. board D702 to "OFF" (lower position,

no triggering of the SS relay).

2 - 1

WAR NING

WAR NING

CAUTION

If the system is only switched off at the control panel or with

S2/D711, line voltage will still be present at the generator line connection, line filter Z1, Z2, transformer T1, transformer T10 and p.c.

board D711 (see wiring diagram).

Life-threatening electric shock hazard exists.

Disconnect mains cable and comply with the information on this

page.

After shut-down of the system, there may still be 380 V DC

present on the intermediate circuit.

Life-threatening electric shock hazard exists.

The voltage level will be indicated by LED V24 on PC board D710.

The voltage will drop to less than 30 V within about 3 minutes, the

LED goes out at about 30 V.

The p.c. boards contain electrostatic highly sensitive components.

If not regarded, the components could be damaged.

Use ESD-equipment, ground prior to making contact and place

the components on a conductive surface.

WAR NING

Siemens AG Register 3 SPB7-230.033.11 Page 1 of 2 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

The edges of the metal curtain of the stand are very sharp.

They may cause severe injury.

Apply the protective strips as mentioned in section "Protective

strips for the metal curtain" on page 3 - 5 after removing the covers from the stand. Remove the protective strips only when the

covers are to be mounted or when vertical adjustment of the

swivel-arm system is necessary.

Page 16

2 - 2 Protective measures

Delay times between two exposures 2

Delay times listed below must be followed in order to prevent the tube from overheating.

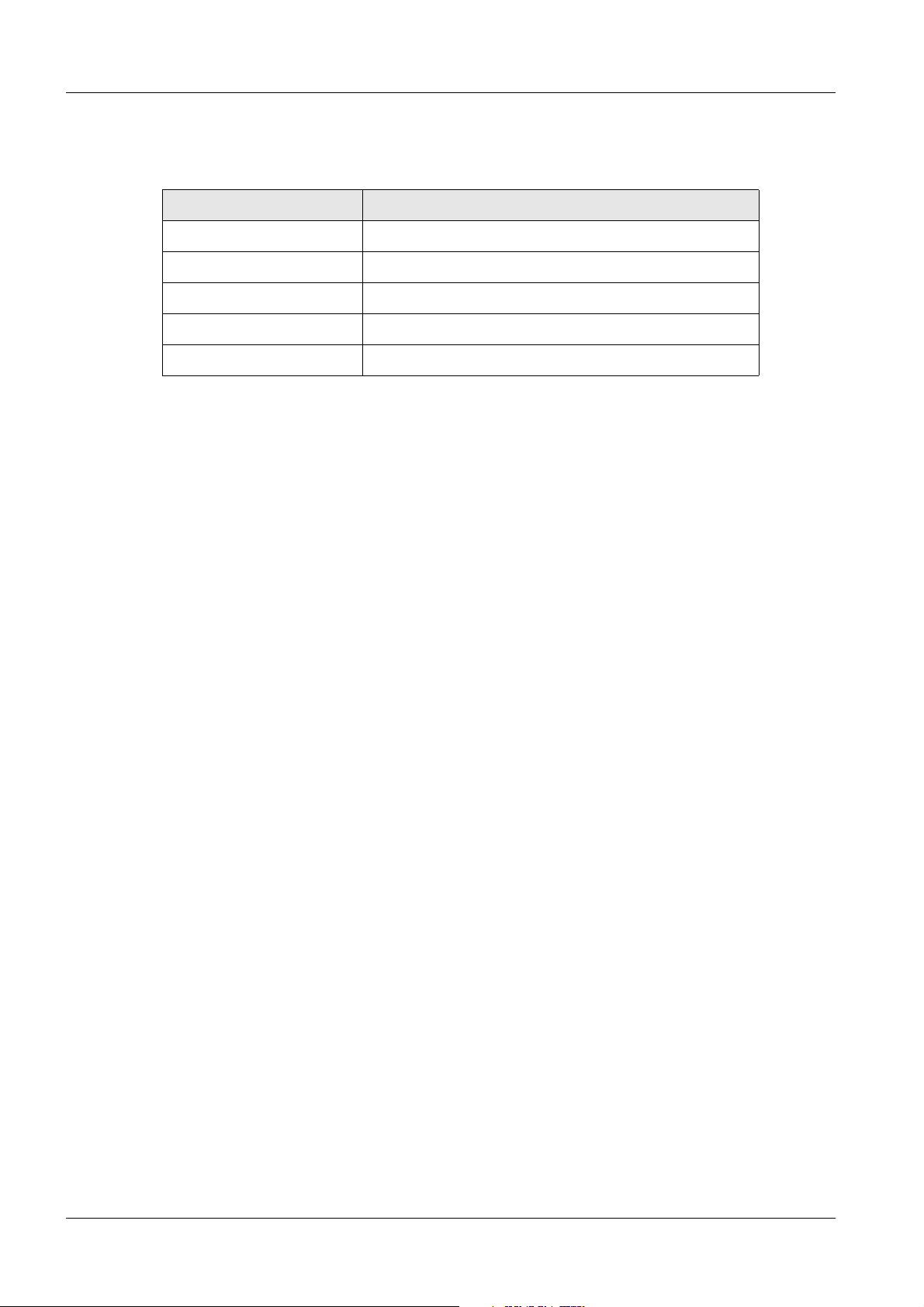

Exposure mAs value Delay time between two exposures (seconds)

max 100 min 15

max 200 min 30

max 300 min 45

max 400 min 60

max 500 min 75

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 2 of 2 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 17

Preparatory work 3

General 3

Scope of delivery 3

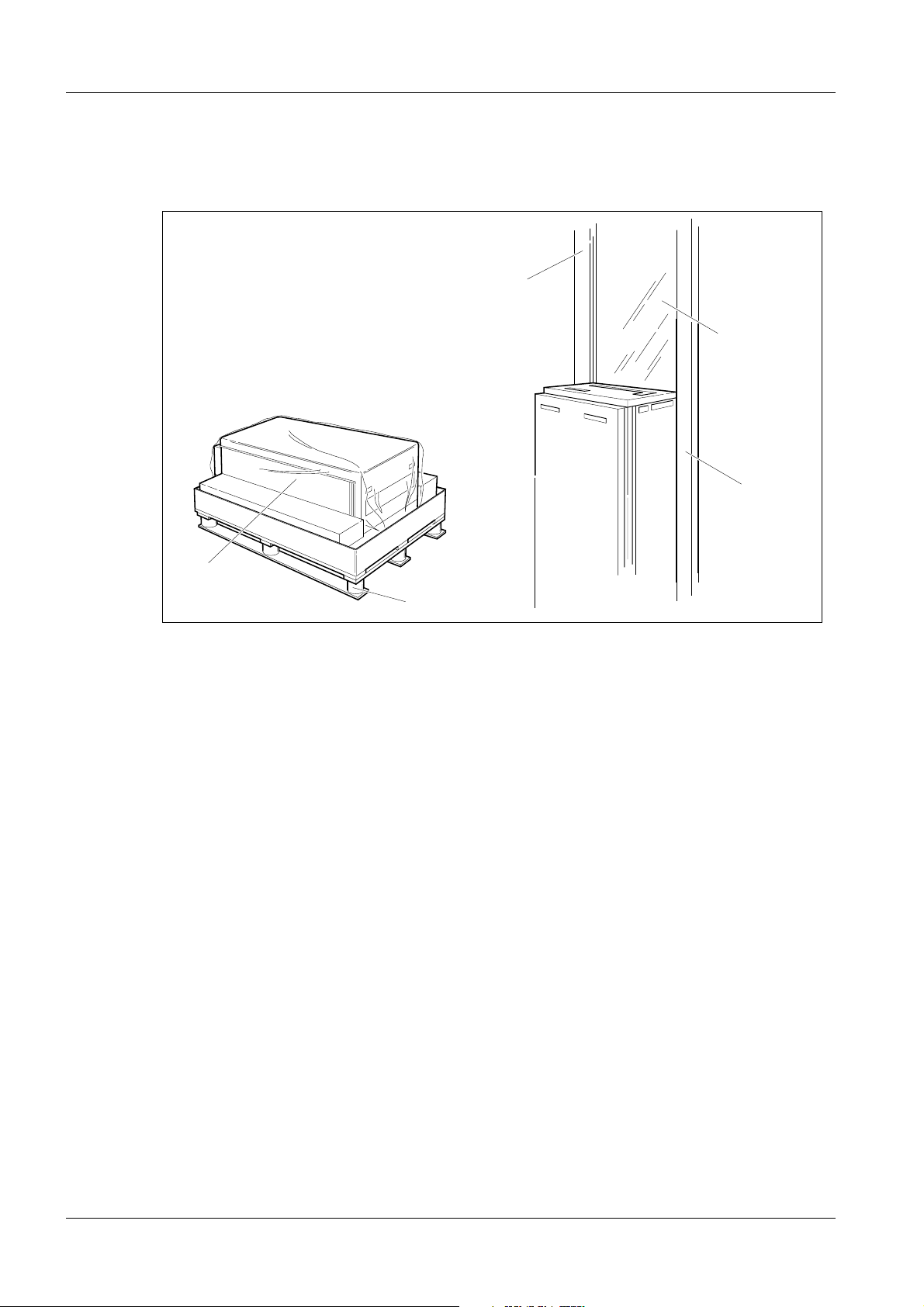

The MAMMOMAT is normally packed in one crate and one cardboard box (the number of

packages is dependent on the customer’s choice, however):

Crate (length 2140 mm, width 800 mm, height 1375 mm)

The crate contains:

• Compression plate

• Stand with X-ray tube assembly and base plate

• Object table 18 cm x 24 cm (Bucky)

• External diaphragm

• Cover panels

• Installation material

• Optional: Stanchions for the lead-glass pane (radiation shield)

3 - 1

• Cable ducts

• Technical documents

Cardboard box (lenght 1210 mm, width 820 mm, height 700 mm)

The cardboard box contains:

• Generator with high-voltage generator and base plate.

• Optional: Lead-glass pane

• Optional: Separate control console

Further accessories are packed in a separate cardboard box.

Unpacking 3

As a general rule, the directional marks on the crates should be observed during transport, storage and unpacking.

The stand crate is bolted together, while the cardboard box is secured with plastic straps.

CAUTION

The unpacking must be carfully performed.

There’s a risk for foot injuries when handling heavy parts.

Wear safety footwear.

Siemens AG Register 3 SPB7-230.033.11 Page 1 of 8 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 18

3 - 2 Preparatory work

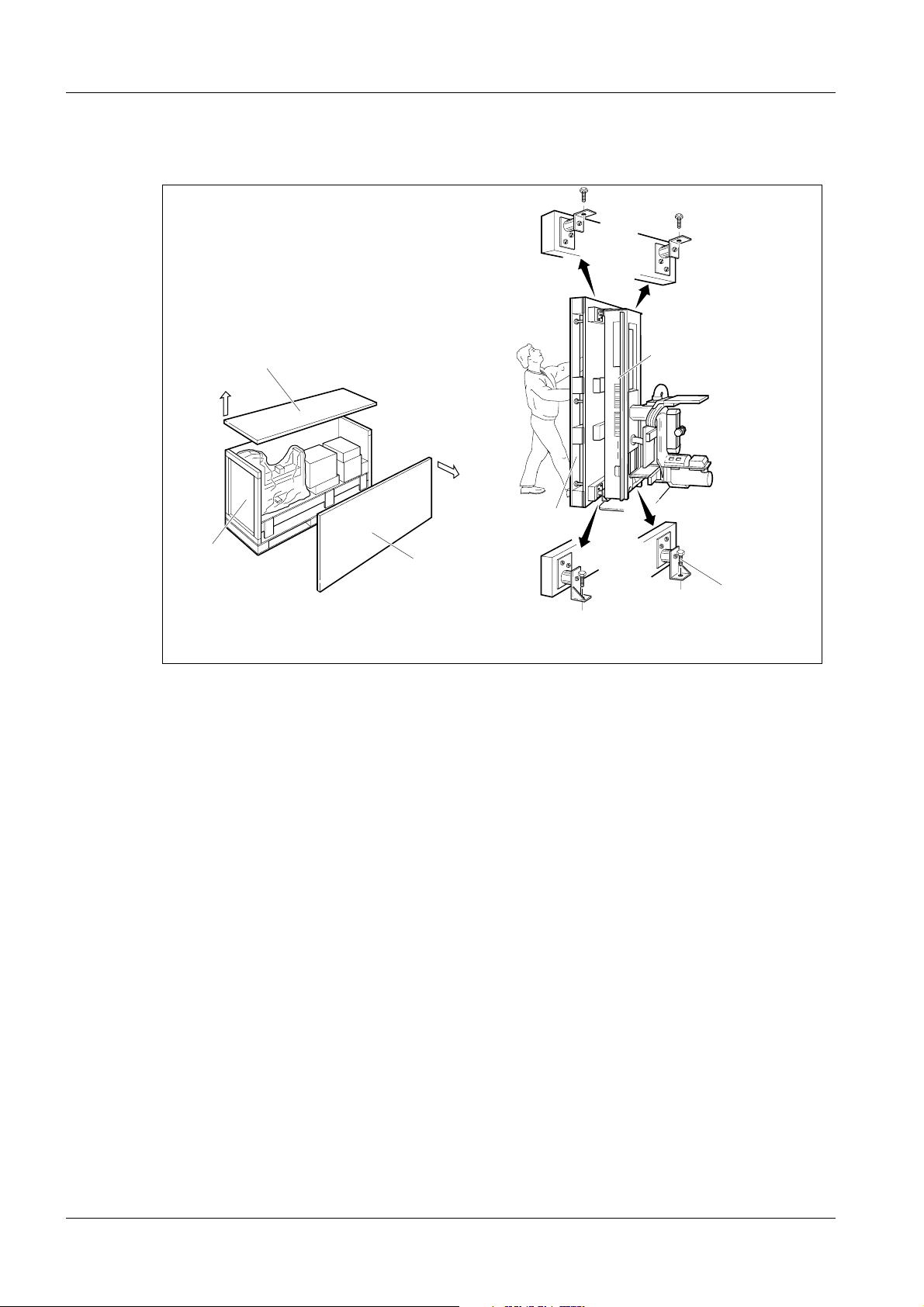

Unpacking the stand 3

1

3

Fig. 1 Unpacking the stand

1

2

5

2

4

6

Unpacking

1. Open the stand crate by removing the top (1) and then the side wall (2).

2. Take out all enclosed packages (accessories, installation material, cover panels

etc.) from the crate.

MAM00167

3. Remove the wooden supports.

4. Remove the remaining walls (3).

5. Upend the stand (4), with pallet (5) (two persons are required).

6. Loosen the four bolts (6) and remove the pallet (5).

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 2 of 8 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 19

Preparatory work 3 - 3

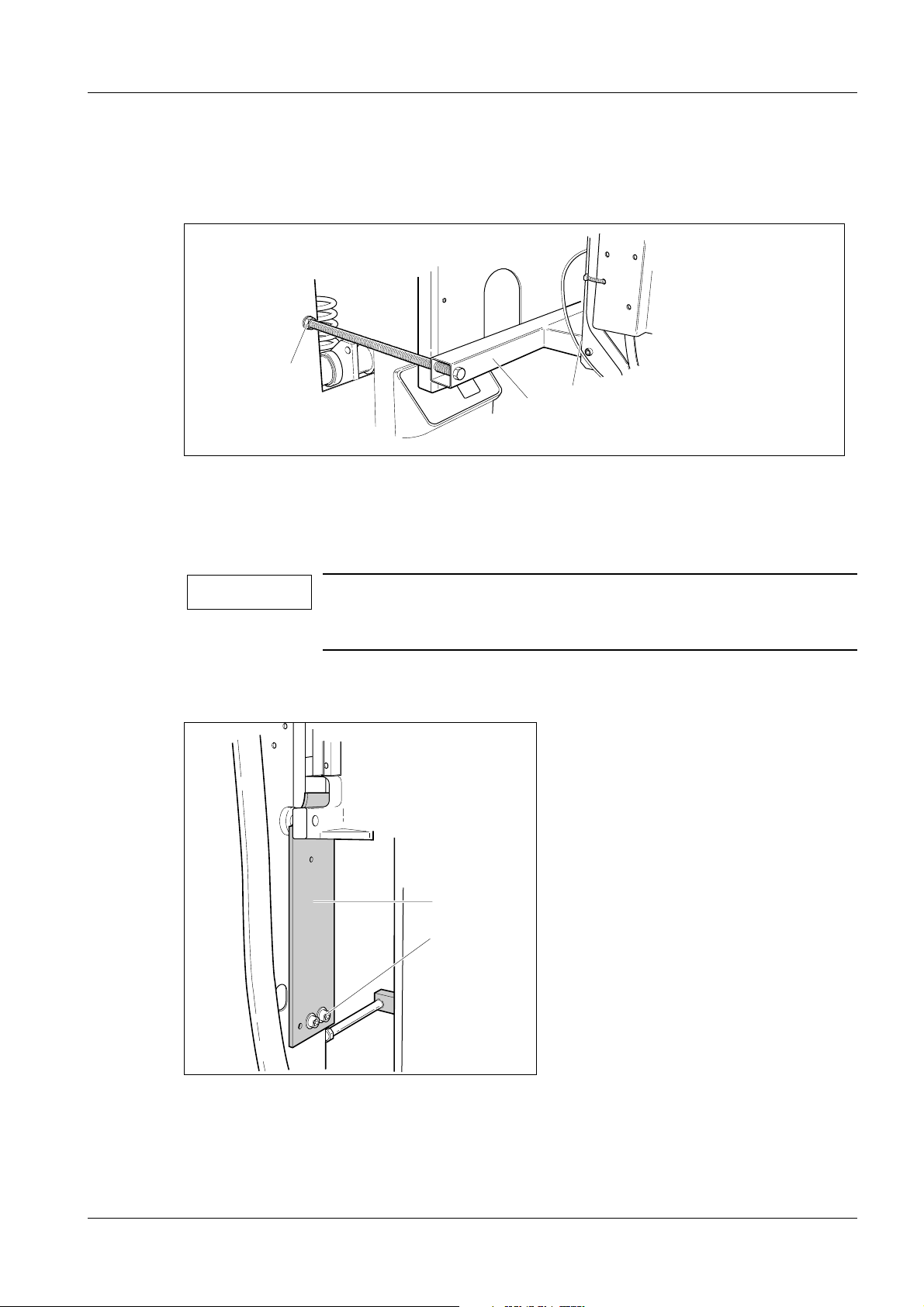

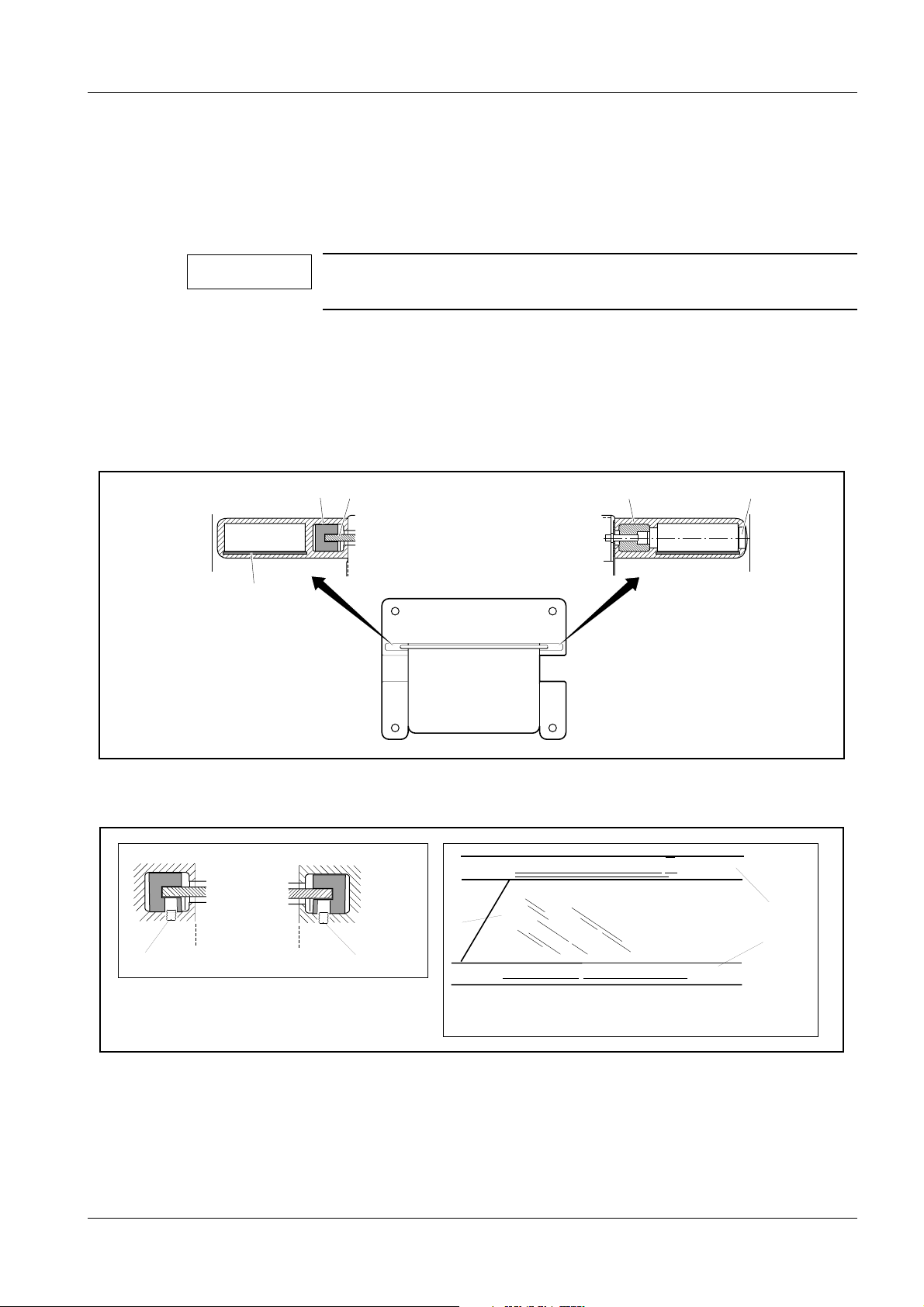

Removing the transport safeguards 3

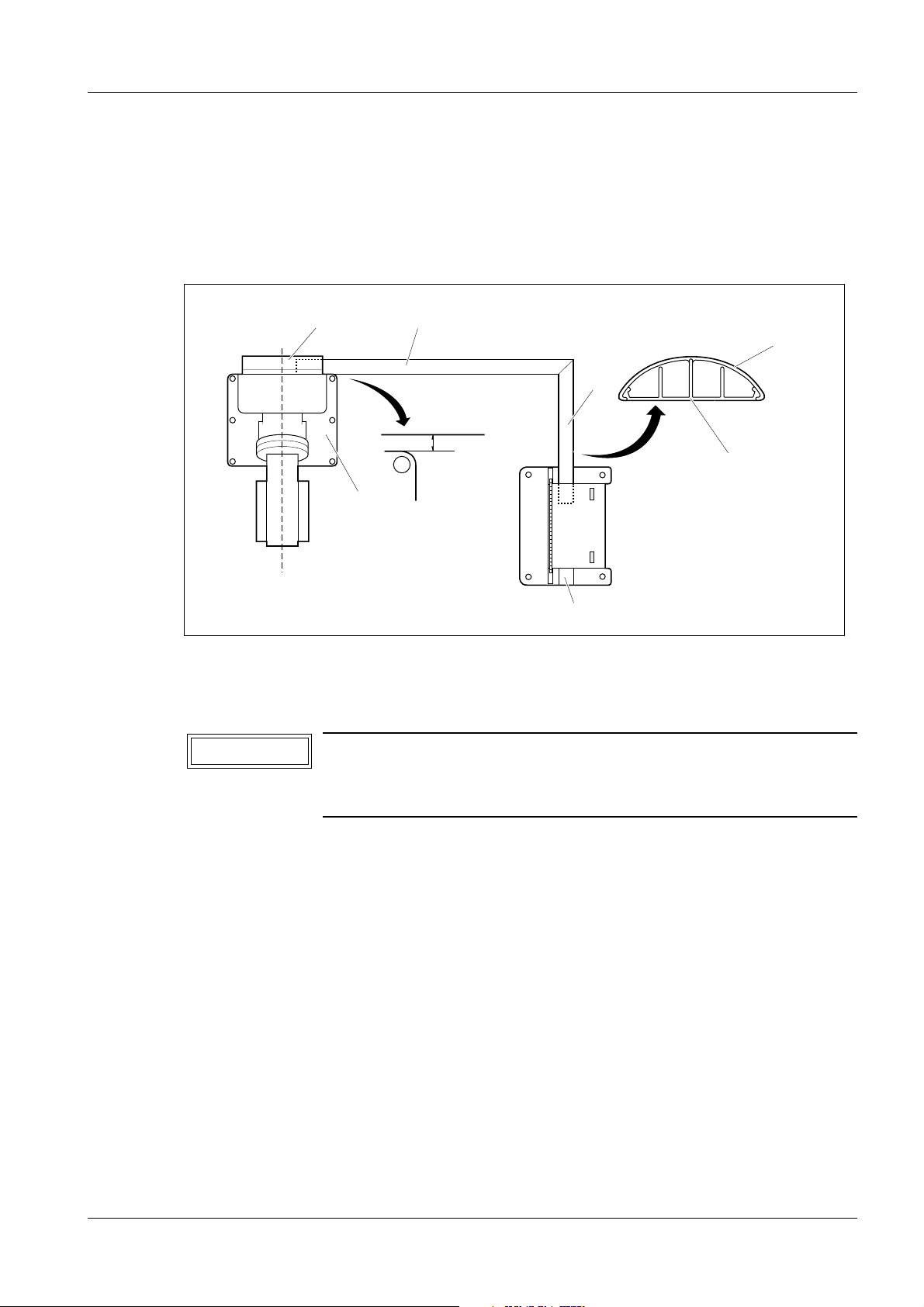

Removing the swivel-arm system transport safeguard 3

1

2

3

MAM00081

Fig. 2 Swivel-arm system transport safeguard

1. Loosen the transport safeguard nuts (1/Fig. 2) and remove the tube head screws

(2/Fig. 2).

2. Push the red transport safeguard (3/Fig. 2) inwards, away from the tube head.

NOTE

Removal of the swivel-arm system transport safeguard is done

after the equipment has been powered up, see further section

"Attaching the swivel-arm covers" on page 7 - 1.

Transport safeguard for the lifting carriage 3

2

1

MAM00082

Fig. 3 Transport safeguard for the lifting carriage

1. Loosen the two screws (1/Fig. 3) and remove the red transport safeguard (2/Fig.

3). Reinsert screws (1/Fig. 3), they might be needed for service purposes.

Siemens AG Register 3 SPB7-230.033.11 Page 3 of 8 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 20

3 - 4 Preparatory work

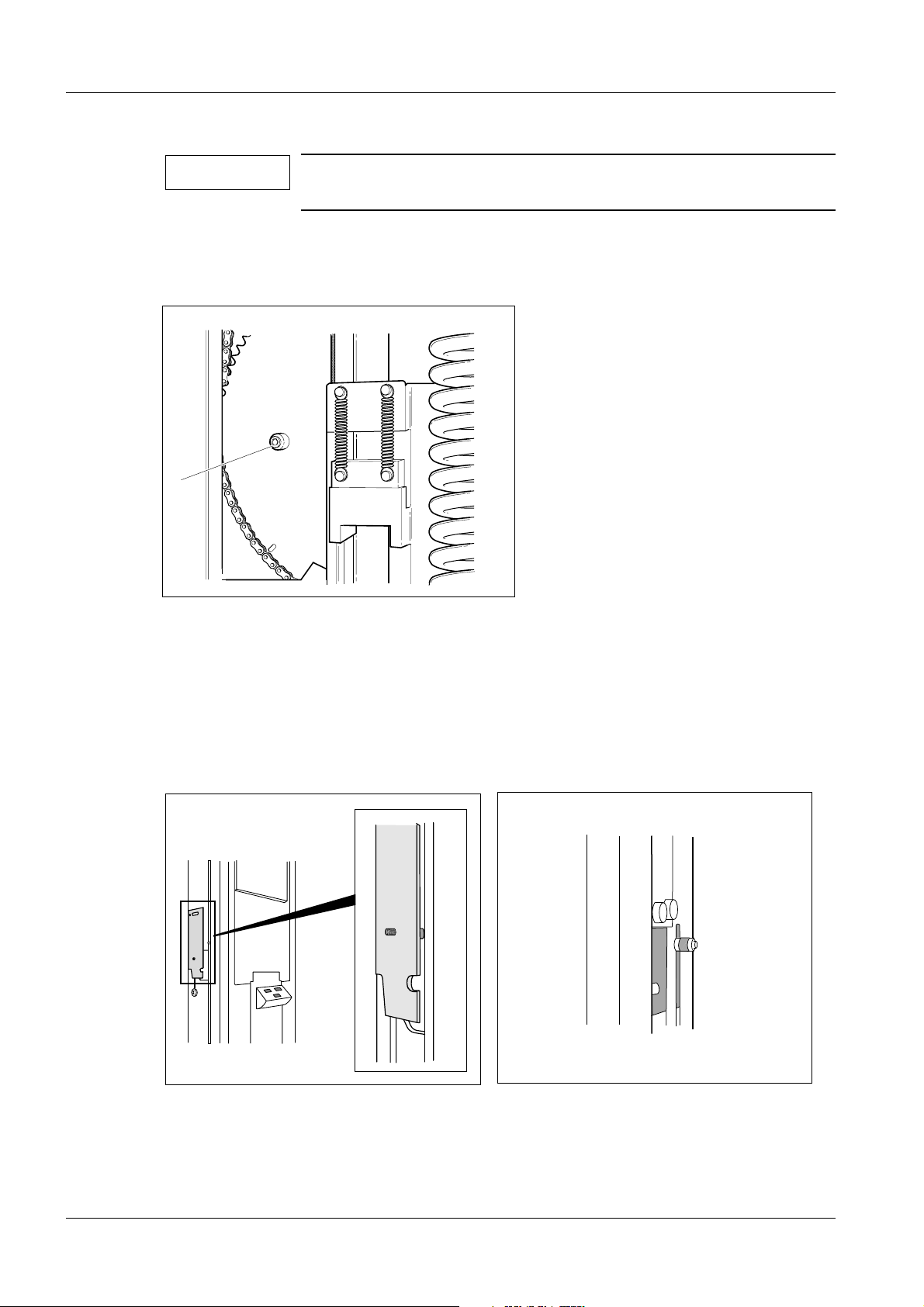

NOTE

The lifting carriage transport safeguard shall be kept for service

purposes (Fig. 5).

2. Cut and remove the cable tie securing the balancing spring during transport.

Transport safeguard for the rotary motion 3

1

MAM00083

Fig. 4 Transport safeguard for the rotary motion

1. Remove the transport safeguard screw (1/Fig. 4) with spacer to enable rotary

motion.

The screw and the spacer should be kept for the mounting of the lifting carriage

transport safeguard.

2. Mount the red lifting carriage transport safeguard with screw and spacer

(1/Fig. 4) on the left hand side of the stand, see Fig. 5. Insert the screw through the

slot from the inside of the stand, see Fig. 6

MAM00314

MAM00312

MAM00313

Fig. 5 Transport safeguard mounted on the stand Fig. 6 Screw and spacer inserted from the inside of the

stand

3. Tighten the screw. Make sure that the transport safeguard is parallell to the

stand.

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 4 of 8 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 21

Preparatory work 3 - 5

Ball bearings 3

The lifting carriage is equipped with twelve ball bearings (Fig. 7). Check that all twelve ball

bearings are in place and that they show no sign of damage.

Fig. 7 Ball bearings

Protective strips for the metal curtain 3

1

2

MAM00084

Fig. 8 Protective strips for the metal curtain

The edges of the metal curtain are very sharp and are therefore provided with protective

strips (1) on delivery. These strips must always be applied onto the edges of the metal

curtain during service and maintenance work.

CAUTION

Remove the protective strips before performing vertical adjustment of the swivel arm.

If not removed, the protective strips could be damaged.

Make sure the protective strips are removed before adjustments.

Holders (2) for storing the protective strips when not in use, are provided on both sides of

the curtain, see Fig. 8.

Siemens AG Register 3 SPB7-230.033.11 Page 5 of 8 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 22

3 - 6 Preparatory work

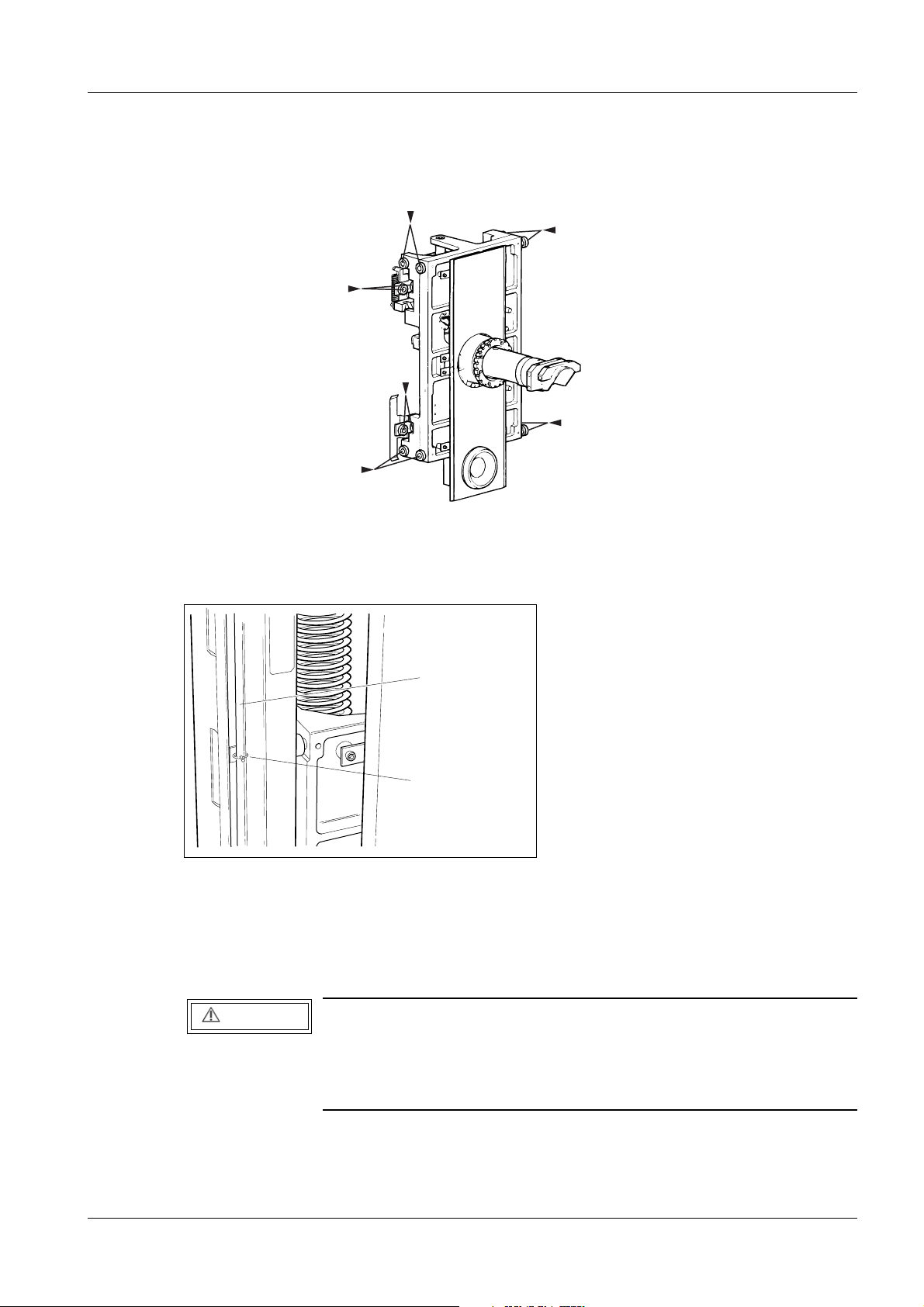

Unpacking the generator and mounting the radiation shield (optional)

1

3

3

4

3

2

MAM00085

Fig. 9 Unpacking the generator

1. Open the cardboard box by cutting the plastic straps.

2. Lift out the lead-glass and put it away in a safe place.

3. Remove the protective cover from the generator.

4. Upend the generator (1/Fig. 9) and lift it off the pallet (2/Fig. 9) (two persons are

required).

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 6 of 8 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 23

Preparatory work 3 - 7

Optional:

5. Insert sheet-metal strip (5/Fig. 10) (additional radiation protection) into both

stanchions.

6. Fit the lead-glass (4/Fig. 10) into both vibration absorbing strips (6/Fig. 10) and fix

it softly by screws (1/Fig. 10).

NOTE

The screws must be mounted before the lead-glass is inserted in

the stanchions.

7. Fit the lead-glass (2/Fig. 10) into the groove of one of the stanchions (3 /Fig. 10)

and keep it in position while mounting the other stanchion (3 /Fig. 10).

8. Mount the stanchions and lead-glass unit with 6 screws onto the generator

(3, 4 /Fig. 9) (two persons are required).

9. Cover the holes with plastic caps (7/Fig. 10).

6

5

3

74

Fig. 10

MAM00086

Fig. 10 Mounting the radiation shield

3

2

1

1

MAM00630

3

MAM00633

Siemens AG Register 3 SPB7-230.033.11 Page 7 of 8 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 24

3 - 8 Preparatory work

This page intentionally left blank.

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 8 of 8 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 25

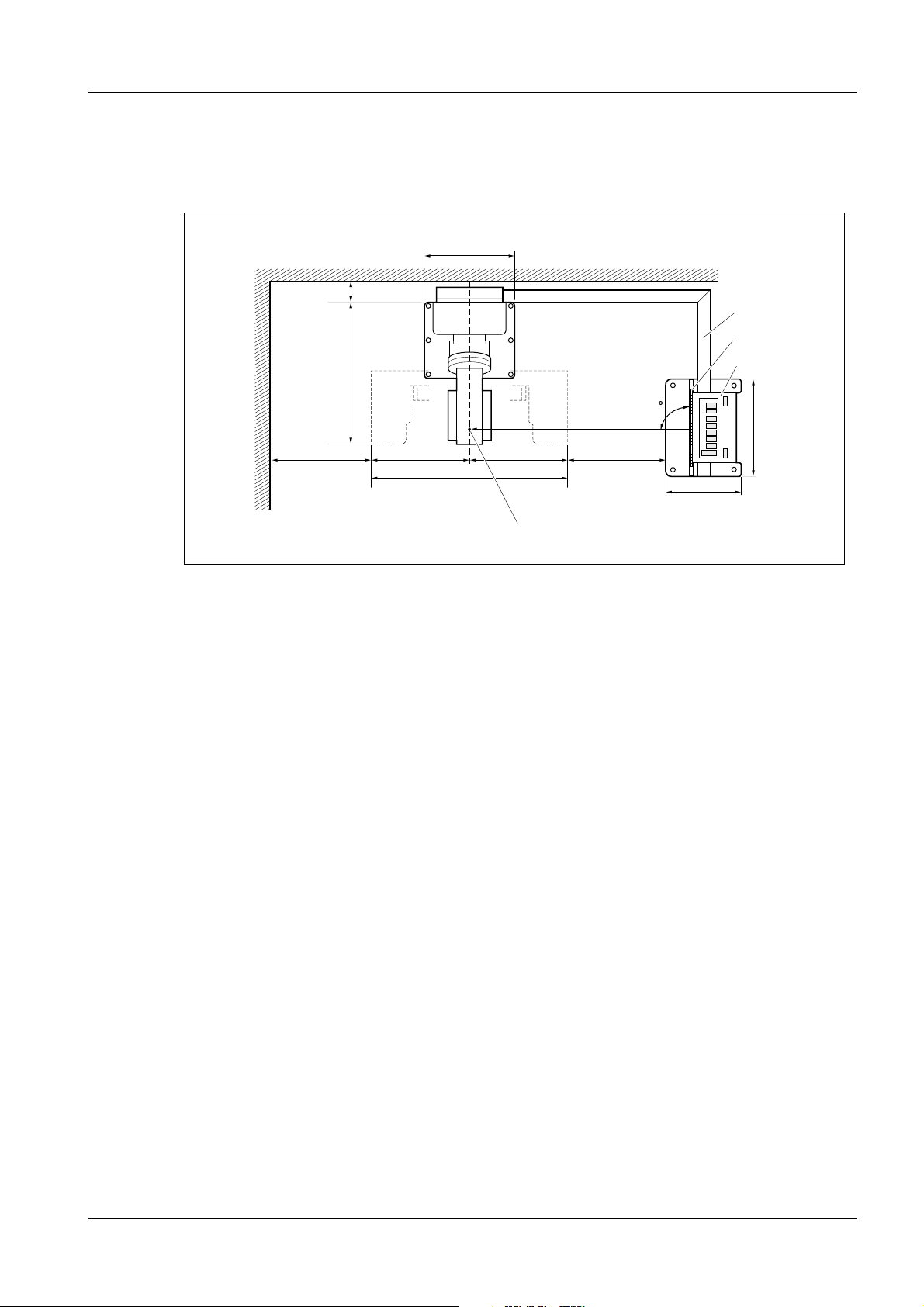

Installing the generator and the stand 4

Arranging the components 4

Position the stand and the generator in accordance with installation plan and Fig. 1 below.

640

4 - 1

700

Fig. 1 Installation, top view

180

1091

700 700

1400

4

90

700

540

1

2

3

708

MAM00503

Cable duct (1) and generator (3) with radiation shield (2) can be installed optionally to the

left or to the right of the the stand. The cables can also be laid underfloor. Maximum cable

length between stand and generator is approximately 3.5 m.

Radiation shield (2) at right angles to the swivel-arm system and centered to the focus

mark (4) on the tube-head cover according to Fig. 1.

Recommended minimum distance to wall and generator base plate respectively is

700 mm (shorter distances may be used at the customer´s desire, if in compliance with

local regulations).

For the installation of the cable duct, a minimum distance of 180 mm between wall and

stands is required.

Notes on installations with separate generator and separate control console

- The separate generator can be installed in any suitable place. The maximum distance

of 3.5 m (maximum cable length) to the stand must be maintained, however. If

separately installed, the generator must be bolted to the floor alternatively be attached

to the wall by means of wall brackets, see further Chapter 21 "Bolting the stand/

generator to the floor".

- The separate control console can be installed in a suitable place (wall-mounted or

mounted on a table, for example in an adjacent room with radiation-proof window), or

be mounted onto the free-standing radiation shield (option). The connection cable to

the generator measures 10 m.

4

Siemens AG Register 3 SPB7-230.033.11 Page 1 of 6 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 26

4 - 2 Installing the generator and the stand

Free-standing radiation shield (option) 4

For the installation of the free-standing radiation shield, please refer to separate instructions enclosed with the radiation shield.

Removing the generator cover 4

1. Pry loose the plastic strip (1) and remove the sixteen screws (2), eight on each

side.

NOTICE

Pay special attention to the contact washers (there are four contact washers on either side).

They are needed again when reassembling the front cover to

establish protective ground connection and to fulfil EMC (Electro

Magnetic Compatibility) requirements.

2. Remove the front cover (3) from the generator.

2

3

MAM00091

1

Fig. 2 Removing the generator cover

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 2 of 6 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 27

Installing the generator and the stand 4 - 3

Installing the cable ducts 4

1. Position the cable ducts (1) to the stand and the generator respectively.

2. Leave sufficient space, approx 10 mm between the cable ducts (1) and the base

plate of the stand (3) to allow for the mounting of the cable outlet cover (4).

3. Check that the cable duct (1) is slightly overlapped by the cable outlet cover (4).

4

3

Fig. 3 Installing the cable ducts (top view)

1

1

10 mm

6

7

1. Mark the outlines of the cable ducts (1) on the floor.

2. Cut the bottom of the cable ducts (6) and the cable duct cover (5) to proper length.

NOTICE

Fig. 3 shows a right-angled installation of the cable ducts.

5

MAM00089

If the generator is to be installed at an other angle to the stand,

you just have to cut the cable ducts correspondingly.

3. Fasten the bottom plate of the cable ducts (6) to the floor according to marking,

using double-sided adhesive tape.

4. At the generator, cover the cable entry not used with the enclosed cover plate (7).

Installations with separate control console 4

For the connection cable separate control console – generator, additional cable ducts are

required, unless the cables are to be laid underfloor.

Siemens AG Register 3 SPB7-230.033.11 Page 3 of 6 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 28

4 - 4 Installing the generator and the stand

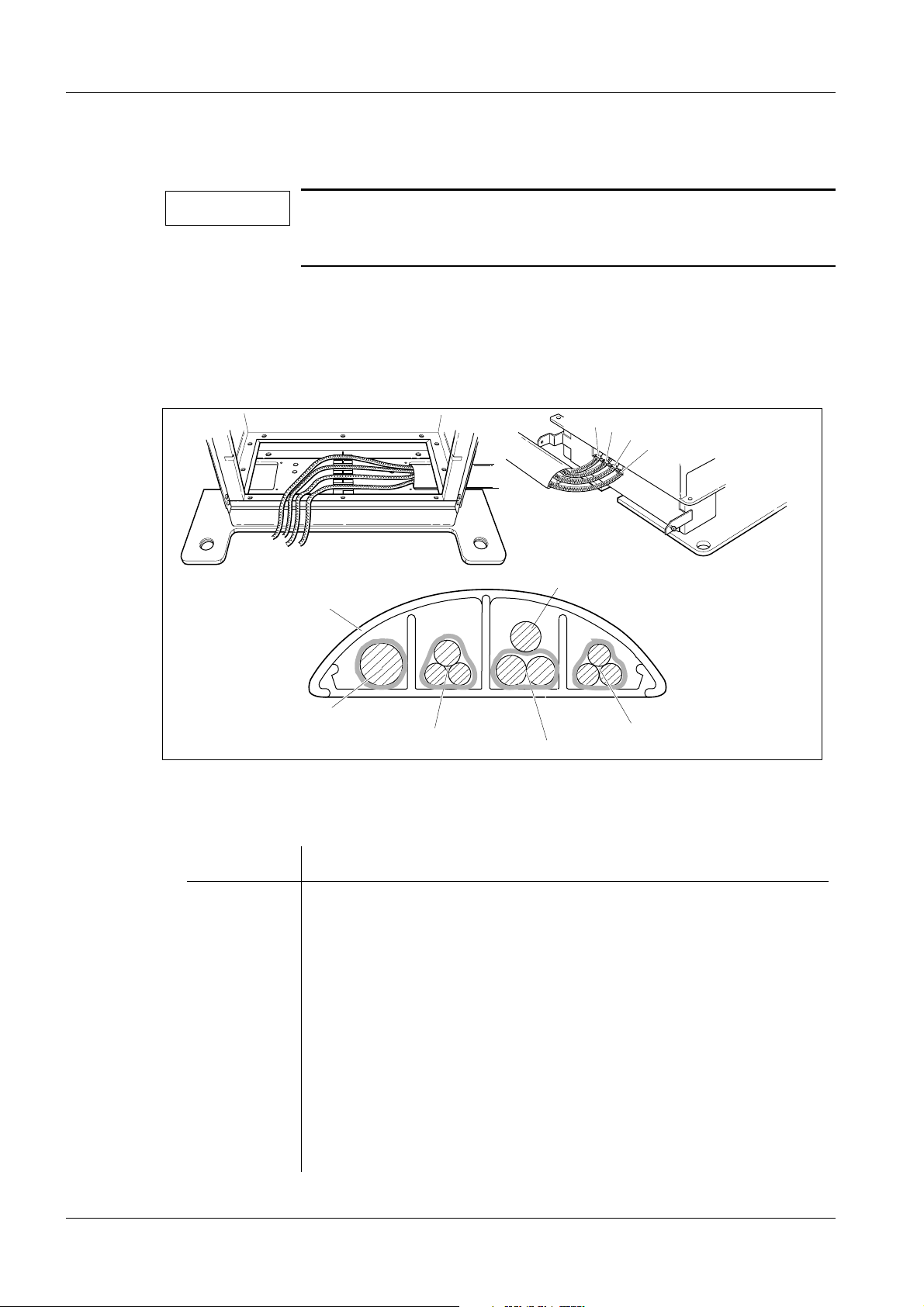

Laying the cable harness 4

NOTE

Remove the transport safeguards which consist of cable ties

(four around the cable harness and one at the end of each

shielded cable).

1. Separate the cable harness.

2. Lay the stand cable harness in the cable duct, as shown in Fig. 4, all the way to the

generator.

3. Fit the cable duct covers (6) onto the cable ducts.

1

2

3

4

MAM00092

5

6

1

2

Fig. 4 Laying the cable harness

The cable harness consists of four shielded cables, see Fig. 4.

Pos in Fig. 4 Description

1 High voltage cable H1

2 AEC signal cables X10 and X11

Unit control cable X1

Power supply cable X14

3 Anode rotation cable X9

Filament cable X8

4 Mains supply cables L1, L2

Protective ground

MAM00215

4

3

5 Decompression-button cable (only with separate control console)

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 4 of 6 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 29

Installing the generator and the stand 4 - 5

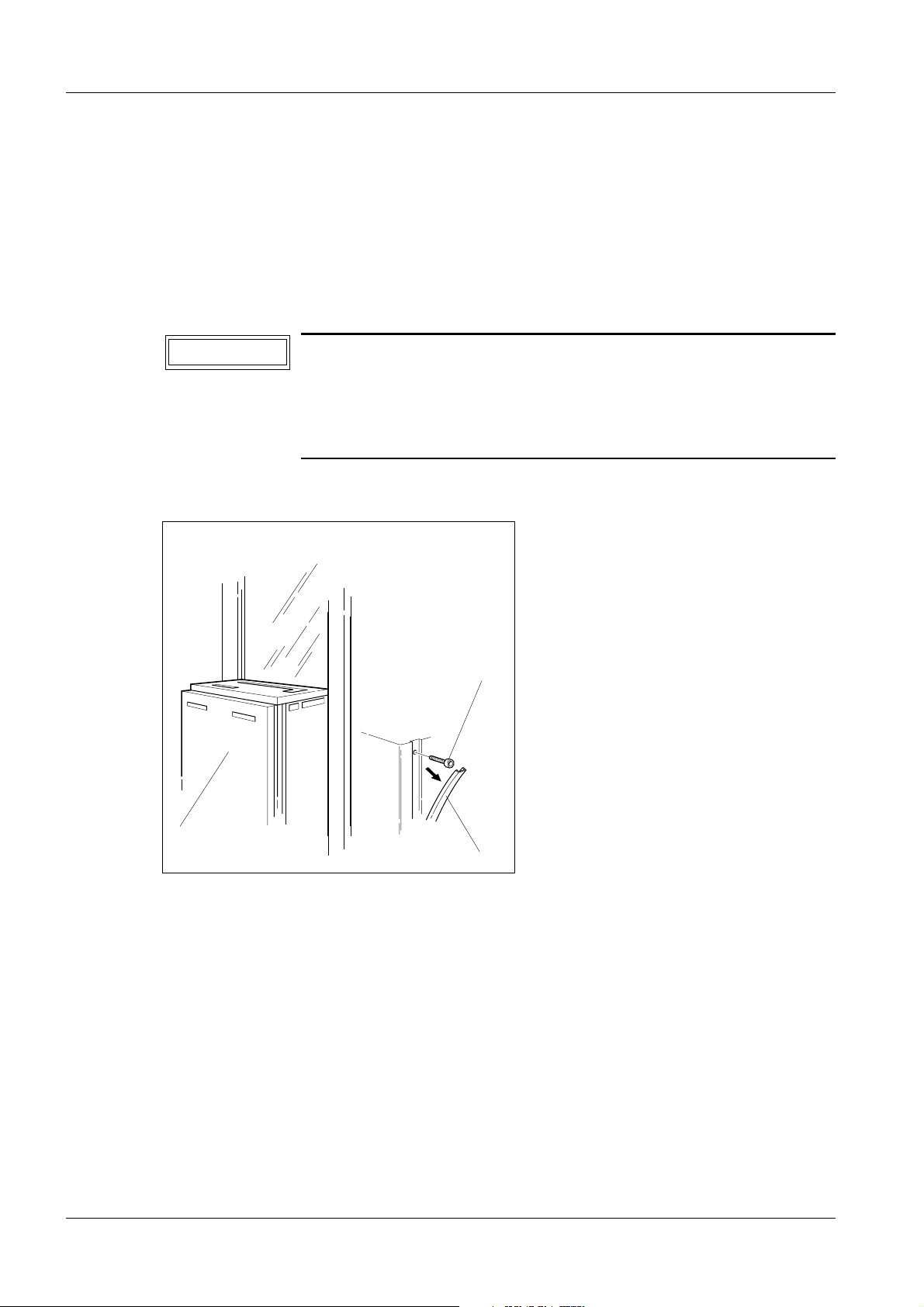

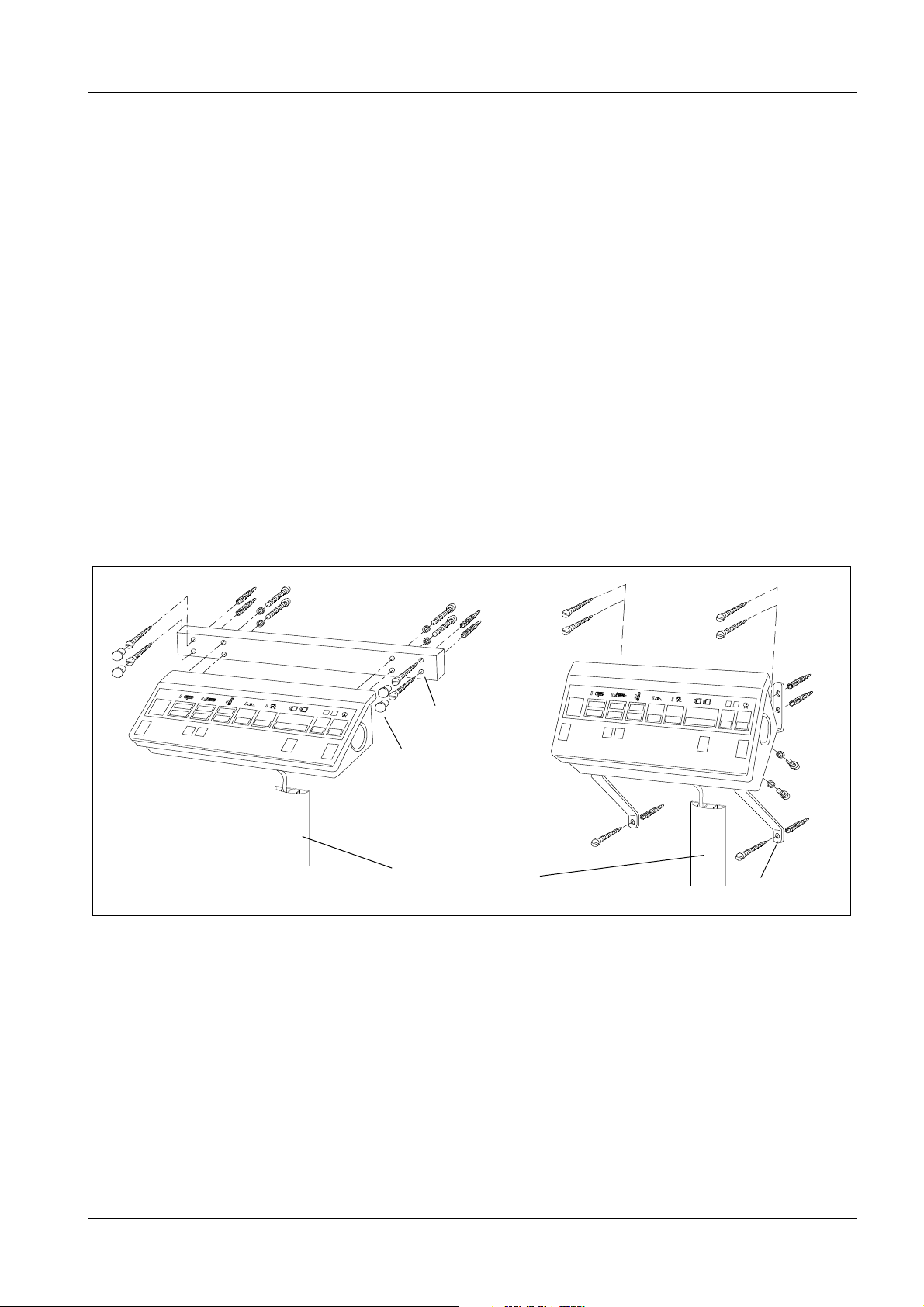

Installations with separate control console 4

Lay the connecting cable from the control console in additional cable ducts, alternatively

underfloor, to the free cable entry of the generator, see further section on page 5 - 8.

The separate control console can be wall-mounted – horizontally or vertically as shown in

Fig. 5 below – or be mounted on a table, either in the examination room or in an adjacent

room with radiation-proof window. It is important that the control console be placed so that

the operator has good view of the patient from the control console.

Ensure that the control console is attached to the wall with adequate safety margins. Dowels and screws are not supplied. Please obtain these locally and ensure that they are suitable for the material used in the wall. The separate control console has a weight of 4 kg.

There are two cable outlets on the separate control console; one at the back and one on

the underside. On delivery, the cable is led through the outlet at the back of the control

console. For wall-mounted control console, the cable shall be led through the outlet on the

underside.

If the control console is to be mounted on a table, the minimum/maximum length of the

screws penetrating into the control console must be observed, see Fig. 7 below.

The control console can also be mounted on the free-standing radiation shield (option) as

shown in Fig. 6 below, see separate instructions enclosed with the radiation shield.

MAM00168

Horizontal mounting

Fig. 5 Wall-mounted control console

∅ 6.5 mm

Plastic cap

Wall-mounted cable duct

is recommended

MAM00169

∅ 6.5 mm

Vertical mounting

Siemens AG Register 3 SPB7-230.033.11 Page 5 of 6 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 30

4 - 6 Installing the generator and the stand

MAM00171

<

min. 10 mm –

max. 30 mm

<

Tabl e t op

MAM00170

Fig. 6 Control console on free-standing radiation shield

(option)

Welded nut

M6

Fig. 7 Control console mounted on table

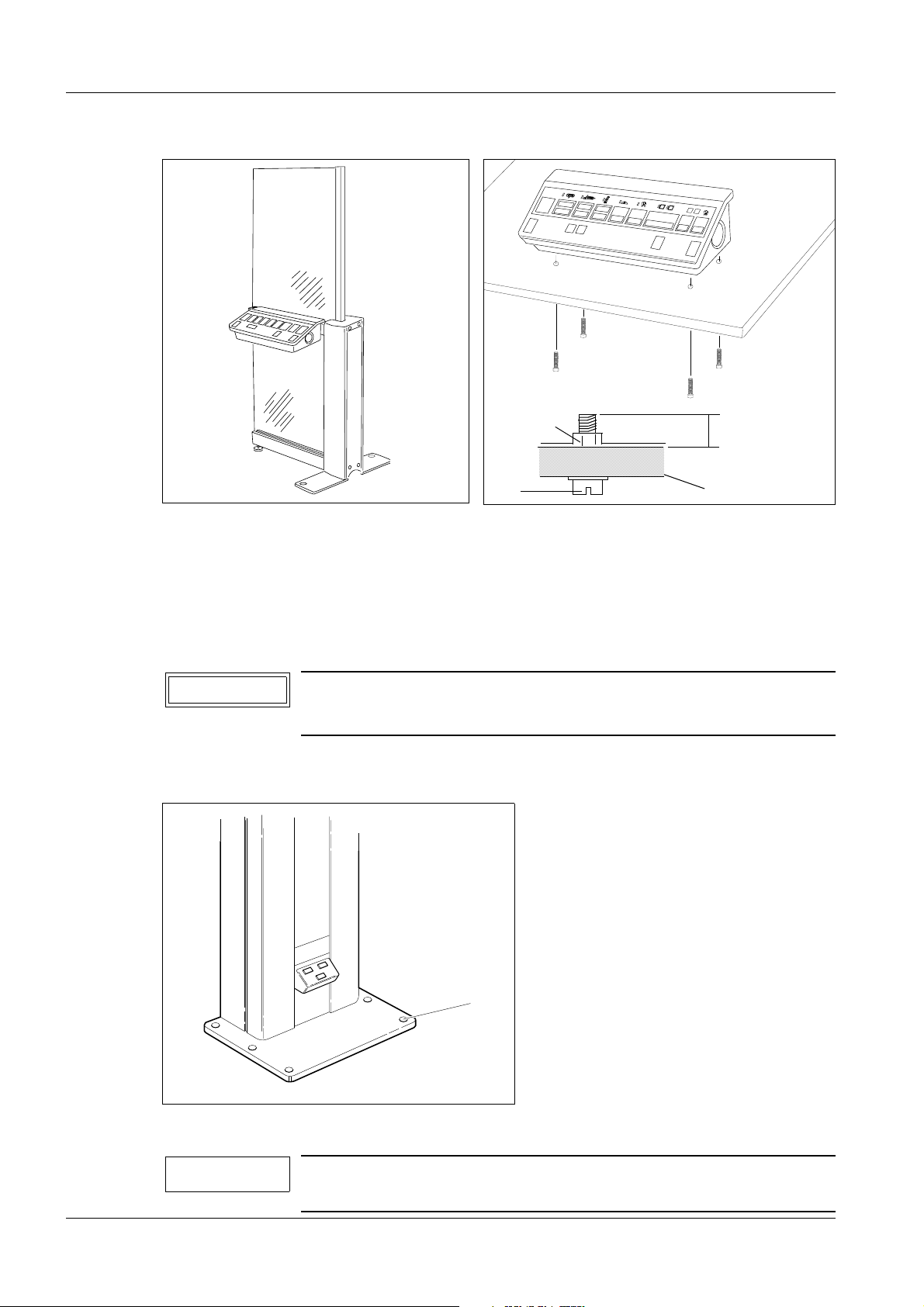

Aligning the stand 4

1. Align the stand vertically by means of the levelling screws (1/Fig. 8).

For adjustment of the levelling screws, use a ratchet spanner 1/2" with extension

(without socket).

NOTICE

2. Cover the levelling screws with the cover discs supplied.

It is important that all six screws bear against the floor.

This is to ensure optimum stability of the stand.

1

MAM00090

Fig. 8 Levelling screws

NOTE

If bolting to the floor is required, please refer to Chapter 21 "Bolting the stand/generator to the floor" on page 21 - 1.

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 6 of 6 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 31

Cable connections 5

EMC measures 5

The following measures are required to ensure electromagnetic compatibility of the equipment.

EMC measures at the cable entry 5

Fitting the hose clamps and ferrite sleeves 5

3cm

5 - 1

Fig. 1 Cables from the stand

1. Lay the cable harness from the stand to the generator and leave approximately

3 cm of the shielding at the U-bracket, see Fig. 1.

Stow away excessive cable lengths as shown in Fig. 2.

MAM00100

Siemens AG Register 3 SPB7-230.033.11 Page 1 of 14 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 32

5 - 2 Cable connections

4

Fig. 2 Ferrite sleeves and hose clamp

3

3

2

2

1

2. Provide each incoming cable with a ferrite sleeve (4), except for mains supply

cables L1 and L2 and the ground wire, which shall be laid together in one and the

same ferrite sleeve. Ferrite sleeves are included in the delivery.

MAM00098

3. Provide each cable with a hose clamp (3). Hose clamps are included in the

delivery.

4. Fold the shield braid (1) backwards over the U-bracket (2) on each cable and

secure with the hose clamp (3).

Note on separate control console and separate generator 5

If the installation includes a separate control console and separate generator, please refer

to page 5 - 8 for information on how to install the additional connection cable between the

control console and the generator.

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 2 of 14 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 33

Cable connections 5 - 3

EMC measures on the bottom plate 5

Fitting the cables X1, X8 and X9 onto the bottom plate 5

3

Fig. 3 Bottom plate

4

2

1

1. Fit the bottom plate at the bottom of the generator stand as shown in Fig. 3.

2. Carefully cut away the insulation on cables X1, X8 and X9 to lay bare the shield

braid (1).

3. Select proper clamps (2) with regard to the thickness of the cables. Cable clamps

in different sizes are provided on the bottom plate.

4. Fit the clamp (2) over the shield braid and screw tight to ensure satisfactory

contact between shield braid and clamp.

NOTE

Make sure that all excess cable lengths are placed below the bottom plate.

5. Fasten the bottom plate with four screws (3) and contact washers (4).

MAM00099

NOTE

Cable X9 shall also be clamped to the side wall of the cabinet, if

not already done, see Fig. 7 in this chapter.

NOTE

Do not remove insulation and do not ground the shields of the

AEC signal cables to X10 and X11.

Siemens AG Register 3 SPB7-230.033.11 Page 3 of 14 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 34

5 - 4 Cable connections

Connecting the stand cable-harness 5

High-voltage connector 5

3

1

2

MAM00161

Fig. 4 High-voltage connector

NOTICE

The high-voltage connector (1) is factory-adjusted for correct fit.

The high-voltage connector shall be inserted with silicone oil, silicone-rubber ring (2) and silicone-rubber disc (3). Lubricate the silicone-rubber disc and the pins with silicon oil before mounting

the disc. Make sure that there aren’t any air bubbles between the

disc and the connector.

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 4 of 14 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 35

Cable connections 5 - 5

Connecting the high-voltage connector 5

3

2

1

Fig. 5 Connecting the high-voltage connector

4

MAM00162

1. Plug in the high-voltage connector (1) at H1.

2. Tighten the sleeve nut (2) by hand.

3. Tighten the stop screws on the sleeve nut.

4. Position the high-voltage cable (3) to the right in the generator and fasten with

cable ties (4).

Siemens AG Register 3 SPB7-230.033.11 Page 5 of 14 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 36

5 - 6 Cable connections

Connecting the cable harness to the generator 5

NOTICE

EMC measures required.

They are described on page 5 - 1 in this chapter.

2

1

6

5

Fig. 6 Cable harness at the generator

F10 F20

F1

F2

F3

F4

F5

3

4

7

MAM00165

MAM00165

Unit control cable X1 5

1. Connect the unit control cable X1 to D700 X1 (1).

Filament cable X8 5

1. Connect the filament cable X8 to D700 X8 (2).

Power supply cable X14 5

1. Connect the power supply cable X14 to D711 X14 (3).

2. Strain-relieve it on the side with a cable tie (4).

AEC signal cable X10 and X11 5

NOTE

1. Connect the AEC signal cable connectors, X10 and X11, to D700 X10 (5) and X11

(6).

The AEC signal cable consists of two cables laid together as one

cable with two connectors labeled X10 and X11 at the end of the

cable.

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 6 of 14 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 37

Cable connections 5 - 7

Rotating anode cable X9 5

2

4

3

1

MAM00163

Fig. 7 Connecting X9 to the generator

1. Connect the rotating anode cable X9 to D711 X9 (1).

2. Connect the two blue free wires from connector D711 X9 (1) to capacitor C51 (2).

3. Clamp the cable to the chassis with a cable clamp (3).

NOTICE

Obtain proper grounding.

When fitting the cable clamp, ensure satisfactory contact

between shield braid (pos. 4 / Fig. 7) and chassis.

Siemens AG Register 3 SPB7-230.033.11 Page 7 of 14 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 38

5 - 8 Cable connections

MAM001 2

Installations with separate control console and separate generator 5

MAM00166

Connection cable from separate control console

Fig. 8 Connection cable from separate control console

NOTICE

Comply with EMC regulations!

The cable must be shielded from the separate control console as

described below.

1. Lay the connection cable from the separate control console in additional cable

ducts, alternatively underfloor, to the free cable entry of the generator, see Fig. 8.

2. Lay the connection cable in a free U-bracket. Fold the shield braid over the

U-bracket and secure with a hose clamp as shown in Fig. 9.

MAM00173

Fig. 9 Shielding the control console cable

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 8 of 14 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

MAM00172

Page 39

Cable connections 5 - 9

F

3. Shield the control console cable to the bottom plate of the generator as shown in

Fig. 10.

4. Provide the cables with ferrite sleeves. Cables X5 and X32 can be laid together in

one ferrite sleeve, X30 and the decompression-button cable in another sleeve

(two extra ferrite sleeves are included in the delivery). Plug together the

decompression button cables. Shield the decompression button cable to the

bottom plate, see Fig. 10. Lay the decompression button cable in the cable duct,

alter-natively underfloor, to the stand, see Fig. 4 in Chapter 4 "Installing the

generator and the stand".

X5, X32

Ground wire

Fig. 10 Cables from separate control console

X30

Decompression

button cable

5. Connect X5 and X32 to the corresponding sockets on circuit board D700, X30 to

connector T3/X30 at the side of the circuit board chassis. Connect the ground wire

to the protective ground terminal below fuse F10, see Fig. 11.

3

F4

F5

MAM00174

Protective

F10 F20

X32 X5 T3/X30

Fig. 11 Connecting the cables from the separate control console

Siemens AG Register 3 SPB7-230.033.11 Page 9 of 14 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

ground

MAM00164

Page 40

5 - 10 Cable connections

6. Shield the decompression button cable to the stand chassis as shown in Fig. 12.

Connect to terminals 2 and 3 in terminal block X803 on the inside of the stand

chassis, see Fig. 12.

Fig. 12 Connecting the decompression button cable at the stand

1

Z801

2

1

23

X880

4

X885

MAM00879

Main voltage connection 5

The equipment has been set to 400 V, 2-phase, in the factory (see test certificate).

Adjustment to the line frequency is not needed. If the mains voltage is not 400 V, 2-phase

at the installation site, a reconnection of the mains is necessary.

Should a reconnection for the mains voltage be necessary, this must be done at transformer T10 as well as p.c. board D711 (insertion or removal of fuses and labeling is specified in the wiring diagram, see Line Input page 5-3).

Change the rated voltage labels to the correct voltage (there are two labels on the generator and one on the stand). Labels are included in the installation material.

NOTE

For more details about changing mains, insertion or removal of

jumpers, fuses, labeling etc., see Wiring Diagram.

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 10 of 14 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 41

Cable connections 5 - 11

Connecting the incoming mains to the stand (400 V, 2-phase) 5

400 V 2-phase connection 5

N

L1

L2

L3

1

2

1

1

4

3

1

Fig. 13 Incoming mains cable

1. Connect the incoming mains cable (1) to X899 (2) in the stand as shown in Fig. 13

and Fig. 14.

2. Fit plastic tubes (4) on the plates.

3. Strain-relieve (3) the incoming mains cable.

TWO-PHASE

GENERATOR STAND

F10

F20

X881

Incoming mains

208, 230, 240, 277 or 400 VAC

P.EN L1L2L3

X899

MAM00097

MAM00095

Fig. 14 Incoming mains, 2-phase

Siemens AG Register 3 SPB7-230.033.11 Page 11 of 14 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 42

5 - 12 Cable connections

Connecting the mains supply to the generator (400 V, 2-phase) 5

F1

Fig. 15 Mains supply to the generator

F10 F20

F2

F3

F4

F5

2

1

3

MAM00176

1. Check that there is no wire jumper at F20 (1) and no brass plug at F5 (2).

Fuses must be inserted into fuse holders F20 and F5.

2. Connect the mains supply cables between stand and generator to fuses F10 and

F20 on the generator.

Wire marked L1 to F10 and L2/N to F20.

3. Connect the protective ground wire from the stand to the generator (3).

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 12 of 14 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 43

Cable connections 5 - 13

Measures for changing from 2-phase to 1-phase connection 5

SINGLE PHASE

GENERATOR STAND

F10

X881

Fig. 16 Incoming mains, 1-phase

Incoming mains

110, 208, 230, 240 or 277 VAC

P.EN L1L2L3

X899

MAM00096

1. Move wire marked N/L2 from X899 L2 to X899 N (stand).

2. Connect incoming phase of the power supply to L1 and the neutral conductor of

the power supply (0 V) to N and fuse F20.

3. Strain-relieve the incoming mains cable as shown in Fig. 13.

4. Short circuit F20 (1) and F5 (2) in Fig. 15 with the jumper and brass plug included

in the service bag.

CAUTION

For single-phase mains connection, make sure that the neutral

conductor of the power supply (0V) is connected to terminal N

and fuse F20.

NOTE

Connections on transformer T10 must be adapted to the actual

mains voltage, see Wiring Diagram for details.

5. Connect the mains supply cable between stand and generator to fuses F10 and

F20 on the generator. Wire marked L1 to F10 and L2/N to F20.

Siemens AG Register 3 SPB7-230.033.11 Page 13 of 14 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 44

5 - 14 Cable connections

This page intentionally left blank.

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 14 of 14 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 45

Mains connection and power supply 6

Checks before powering up the generator 6

On P.C. board D702:

1. Set switch S1(UZW) to "OFF" (lower position).

2. Set switch S2 (SS) to "OFF" (lower position).

6 - 1

ZBL

AR

KVE

BRAKE

STATUS

UZW

SS

TEST

V6

V7

V1

V2

V3

V4

V5

VH

NSE1

NSE2

DS

SS

BS

GND

X990

X967

X980

X981

X982

X983

X984

X985

S1

S2

S3

J39

X962

X964

X960

R13

R11

R43

J50

X965

X961

X963

IHREG

MAREG

X966

X968

X969

X702

MAM00106

Fig. 1 P.C. board D702

Measuring the line resistance 6

See Fig. 2.

1. Remove fuses F10 (1) and F20 (2) or, when single-phase supply, fuse F10 (1).

2. Connect line resistance meter to fuse holders F10 and F20.

3. Mains supply "ON".

4. Carry out measurement.

5. Mains supply "OFF".

Siemens AG Register 3 SPB7-230.033.11 Page 1 of 4 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 46

6 - 2 Mains connection and power supply

To achieve the full output, the resistance measured must not exceed the following values:

• 0.25 c at 110 V (1-phase)

• 0.45 c at 208 V

• 0.50 c at 230 V

• 0.60 c at 240 V

• 0.65 c at 277 V

• 0.85 c at 400 V (2-phase)

If the above values are exceeded, reduce the generator power in accordance to

Chapter 14 "Further programming" in this manual.

Checking the line voltage in the generator 6

1. If not already done, remove fuses F10 (1) and F20 (2) or, when single-phase

supply, fuse F10 (1).

4

5

6

1

2

3

Fig. 2 Line voltage in the generator

2. Mains supply "ON".

3. Measure the voltage at fuse holders F10 (1) and F20 (2).

4. Check that the mains voltage agrees with the voltage plugged on transformer T10

(3) and P.C. board D711 (4), located above line filter Z1 (5).

5. Mains supply "OFF".

MAM00177

6. Reinsert fuses F10 (1) and F20 (2).

7. Mains supply "ON" (Do not switch the system on yet).

8. Measure the voltage at transformer T1 (6) terminals 1 and 3, transformer T1 is

located under the line filter Z1 (5). There must be 195 V- 253 V between the

terminals.

9. Measure the voltage at the output of line filter Z1 it must lie within 195 V- 264 V.

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 2 of 4 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 47

Mains connection and power supply 6 - 3

Checking the supply voltages 6

The correct supply voltages +5 V, +15 V and +24 V have already been tested in the factory. Only a visual check of the function is therefore needed.

1. System "ON".

2. Check that the following orange diodes are "ON" on p.c. board D704:

V39 (+15 V)

V38 (-15 V)

V41 (+5 V)

V40 (+24 V)

Siemens AG Register 3 SPB7-230.033.11 Page 3 of 4 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 48

6 - 4 Mains connection and power supply

This page intentionally left blank.

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 4 of 4 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 49

Attaching the swivel-arm covers 7

Attaching the swivel-arm covers 7

Arranging the swivel-arm system 7

1. Install object table, no compression force (swivel-arm system still upside down).

2. Remove the protective strips from the metal curtain.

3. Run the lifting carriage upwards.

4. Put back the protective strips onto the metal curtain.

5. Rotate the swivel-arm system to 0 degrees by pressing one of the switches for

clockwise rotation on the supporting arm.

6. System and mains "OFF".

7. Remove the swivel-arm system transport safeguard, see Chapter 3

"Preparatory work".

Connecting the cables to control-button boards and patient handles 7

MAMMOMAT 1000/3000 Nova

4

2

1

3

7 - 1

2

Fig. 1 Connecting the cables

Before installing the side covers, the cables are to be connected.

1. Connect cables X807 (1) to control-button circuit boards D807 (2).

2. Connect ground wires (3) to patient handles (4).

1

4

3

MAM00108

Siemens AG Register 3 SPB7-230.033.11 Page 1 of 2 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 50

7 - 2 Attaching the swivel-arm covers

Attaching the side covers 7

Screws in different sizes are included in the delivery.

5

4

Fig. 2 Covers and sign

2

1

1. Mount the side covers (1) with six screws (2) on each side.

NOTE

Do not forget to fit the sign (3) when mounting the side covers.

Use the two longer screws.

3

MAM00700

Attaching the front cover 7

CAUTION

1. The side covers must be flush at the front. If necessary, loosen the screws and

adjust the side covers.

2. Carefully fit the front cover (4) so that both openings engage with the lugs of the

side covers.

3. Carefully swing the front cover upwards and let it snap in position over the side

covers.

CAUTION

4. Fasten the front cover to the side covers with two short screws (5).

Risk of damages.

If the covers are exposed to internal stress cracks might arise.

The following work must be carried out with caution.

The front cover must not press against the collimator.

Risk of damage.

Be careful while attaching the front cover.

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 2 of 2 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 51

Checking the microprocessors 8

Microprocessors 8

The following LED displays on the processor P.C. boards indicate whether the relevant

microprocessors are operating correctly.

1. Mains and system "ON".

The following conditions must be indicated after not more than 15 s.

8 - 1

Microprocessors for:

AEC: P.c. board D701

Master: P.c. board D702

P.C. board D711:

• V9 "ON" (line voltage on).

• V13 "OFF" (system stand-by).

• V11 "ON" (system on).

• V16 "ON" (intermediate circuit - filament).

LED displays

Must be off.

Steadily on.

Must be steadily

on or off.

Must be off.

Flashing rapidly.

MAM00649

Siemens AG Register 3 SPB7-230.033.11 Page 1 of 2 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 52

8 - 2 Checking the microprocessors

This page intentionally left blank.

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 2 of 2 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 53

Checks without high voltage 9

Checks without high voltage 9

1. System "OFF".

2. On P.C. board D702 set switch S1 (UZW) to "ON" (upper position) and switch S2

(SS) to "OFF" (lower position).

3. System "ON".

4. Insert a cassette.

5. Set 27 kV and maximum mAs on the control panel.

9 - 1

NOTE

6. Press the exposure buttons on the control panel. The rotating anode shall start up.

At the end of the time limit, the rotating anode is braked.

7. Release the exposure buttons.

8. System "OFF".

The cassette must be removed and reinserted after each

exposure to allow for the next exposure release. This is to avoid

double exposures.

Siemens AG Register 3 SPB7-230.033.11 Page 1 of 2 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 54

9 - 2 Checks without high voltage

This page intentionally left blank.

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 2 of 2 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 55

Checks with high voltage 10

Preparation 10

This section describes how to check:

• High voltage.

• Tube current.

• mAs values.

10 - 1

NOTE

kV>17

kV>50

WR_AUS

MASOLL

MAIST

IHSOLL

IHIST

UZIST

ISCHWING

KVSOLL

KVIST

0VA

KVE

KVA

ZBL

BRAKE

0VD

V39

V41

V40

Check that the high-voltage plug is plugged into H1 and properly

secured.

X706

X707

X705

X704

X713

X710

X712

X711

X708

X714

X715

X716

X717

X709

R136

X703

MAM00111

Fig. 1 P.C. board D705

1. Set switch S2 (SS) to "ON" (upper position) on P.C. board D702.

2. Remove the jumper and connect the mAs meter to mAs measuring sockets X3

and X4 on P.C. board D710.

Siemens AG Register 3 SPB7-230.033.11 Page 1 of 10 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 56

10 - 2 Checks with high voltage

3. Connect oscilloscope to P.C. board D705 as follows:

• Channel 1 to measuring point "KVIST (actual value)" (1 V= 5 kV).

• Channel 2 to measuring point "MAIST (actual value)" (1 V= 40 mA).

• Trigger at measuring point "KVE" (start with high voltage "ON"), rising edge.

• Twist the measuring leads and connect their grounding braids to measuring

point "0 VA".

4. Connect service PC to circuit board D702 using the connection cable.

5. Start the Service Program, see Chapter 22 "Appendix".

6. Check the anode menu for correct selection (tungsten anode enabled or disabled,

depending on which type of X-ray tube the customer has chosen). See Service

Program Instructions SPB7-230.114.03. ... .

NOTE

It is possible to select tungsten anode, even if the customer does

not have this option. However, the 50 µm Rh filter will then be

missing.

kV-adjustment 10

Check the kV as follows:

1. Mains voltage and system OFF.

WAR NING

2. Connect DVM between the lower ends of R72 and R73 (on the left side of the high

tension plug) on D710 circuit board.

3. Mains voltage and system ON.

4. Set 27 kV and maximum mAs on the control panel.

After shut-down of the system, there may still be 380 V DC present

on the intermediate circuit.

Life-threatening electric shock hazard exists.

The voltage level will be indicated by LED V24 on PC board D710.

The voltage will drop to less than 30 V within about 3 minutes, the

LED goes out at about 30 V.

5. Make an exposure and check that the DVM shows +2.700 V +0.010 V. Note the

values in the kV-adjustment protocol on page 22 - 6.

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 2 of 10 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 57

Checks with high voltage 10 - 3

6. If necessary, adjust R43 on D702 (Fig. 2) and make another exposure. Note the

new values in the kV-adjustment protocol.

NOTE

Decrease

kV

Potentiometer

R43

Fig. 2

Do not overload the X-ray tube by making too many exposures in a

Increase

kV

short time.

R43 does not need to be relocked with locking paint.

7. Mains and system OFF.

8. Disconnect DVM from R72 and R73.

MAM00528

Siemens AG Register 3 SPB7-230.033.11 Page 3 of 10 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 58

10 - 4 Checks with high voltage

Filament 10

1. In <Mainmenu> select <Configuration> and <Filament>.

2. Perform Learn filament for available options.

3. Note the new values in the Test protocol (Filament).

NOTE

Only settings for Mo available for M1000.

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 4 of 10 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 59

Checks with high voltage 10 - 5

Checking X-ray tube high voltage, tube current and mAs values 10

1. System "ON".

2. Set the "cassette loaded" switch to "OFF" with the Service Program:

Configuration - Miscellaneous - Cassette loaded check.

3. Trigger test exposures with the following exposure values and check the kV

values and tube current characteristic on the oscilloscope (see oscillograms).

The accuracy of the kV is &5% plus &1.5 kV during the first 5 ms of the exposure.

For mA values < 50 mA, the accuracy of the kV is &5% plus &2 kV during the first

5ms.

The tube current must rise quickly to the set value at the beginning of the exposure and run linearly during the exposure.

The accuracy of the mAs product must be &10%.

4. Replace the jumper previously removed from sockets X3 and X4 on P.C. board

D710.

Siemens AG Register 3 SPB7-230.033.11 Page 5 of 10 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 60

10 - 6 Checks with high voltage

Oscilloscope diagrams 10

• MAMMOMAT in mAs mode, see Fig. 3 - Fig. 10.

NOTE

Tube P40 MoW,

MAMMOMAT 3000 Nova

* tungsten anode 0.3

30 kV 20 mAs (P = 4.7 kW)

Checks indicated by

filter disc Mo 0.03 / Rh 0.025 (molybdenum rotating anode).

Tube P40 MoW,

MAMMOMAT 1000/3000 Nova

molybdenum anode 0.3

"

MAM00179

Fig. 3 Fig. 4

* shall be disregarded in installations with

30 kV 20 mAs (P = 3.75 kW)

"

MAM00112

30 kV 1 V/T (1 T <=> 5 kV) 30 kV 1 V/T (1 T <=> 5 kV)

158 mA 1 V/T (1 T <=> 40 mA) 125 mA 1 V/T (1 T <=> 40 mA)

127 ms 20 ms/T 160 ms 20 ms/T

NOTE

Record the measured kV and mAs value in the Test protocol, page

22 - 10.

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 6 of 10 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 61

Checks with high voltage 10 - 7

Tube P40 MoW,

MAMMOMAT 3000 Nova

* tungsten anode 0.3

35 kV 100 mAs (P = 4.7 kW)

MAM00180

Fig. 5 Fig. 6

Tube P40 MoW,

MAMMOMAT 1000/3000 Nova

molybdenum anode 0.3

35 kV 100 mAs(P = 3.75 kW)

35 kV 1 V/T (1 T <=> 5 kV) 35 kV 1 V/T (1 T <=> 5 kV)

134 mA 1 V/T (1 T <=> 40 mA) 107 mA 1 V/T (1 T <=> 40 mA)

0.75 s 0.2 s/T 0.93 s 0.2 s/T

MAM00113

25 kV 100 mAs (P = 4.7 kW)

MAM00181

Fig. 7 Fig. 8

25 kV 100 mAs(P = 3.75 kW)

25 kV 1 V/T (1 T <=>5 kV) 25 kV 1 V/T (1 T <=> 5 kV)

188 mA 2 V/T (1 T <=> 80 mA) 150 mA 2 V/T (1 T <=> 80 mA)

0.53 s 0.1 s/T 0.67 s 0.1 s/T

MAM00114

Siemens AG Register 3 SPB7-230.033.11 Page 7 of 10 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 62

10 - 8 Checks with high voltage

Tube P40 MoW,

MAMMOMAT 3000 Nova

* tungsten anode 0.15

30 kV 10 mAs (P = 0.85 kW)

Tube P40 MoW,

MAMMOMAT 1000/3000 Nova

molybdenum anode 0.15

30 kV 10 mAs (P = 0.70 kW)

"

MAM00182

Fig. 9 Fig. 10

30 kV 1 V/T (1 T <=> 5 kV) 30 kV 1 V/T (1 T <=> 5 kV)

28 mA 0.5 V/T (1 T = 20 mA) 23 mA 0.5 V/T (1 T <=> 20 mA)

>>

"

MAM00115

360 ms 50 ms/T 430 ms 100 ms/T

NOTE

NOTE

Small focus is selected by attaching a magnification table.

Record the measured kV and mAs value in the test protocol, page

22 - 10.

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 8 of 10 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 63

Checks with high voltage 10 - 9

NOTE

Tube P40 MoW,

MAMMOMAT 3000 Nova

* tungsten anode 0.3

30 kV AEC

40 mm plexiglass

Fig. 11 Fig. 12

Measurements in AEC mode shall be performed after calibrating

and adjusting the AEC.

Tube P40 MoW,

MAMMOMAT 1000/3000 Nova

molybdenum anode 0.3

(P = 4.7 kW)

40 mm plexiglass

MAM00666

30 kV

AEC

(P = 3.75 kW)

MAM00667

30 kV 1 V/T (1 T <=> 5 kV) 30 kV 1 V/T (1 T <=> 5 kV)

158 mA 1 V/T (1 T <=> 40 mA) 125 mA 1 V/T (1 T <=> 40 A)

*) 100 ms/T) *) 100 ms/T

*) total exposure time dependent on programmed sensitivity

Siemens AG Register 3 SPB7-230.033.11 Page 9 of 10 M1000/3000 Nova

Medical Solutions Rev. 05 05.05 CS PS 24 Installation and Start-Up

Page 64

10 - 10 Checks with high voltage

This page intentionally left blank.

M1000/3000 Nova Register 3 SPB7-230.033.11 Page 10 of 10 Siemens AG

Installation and Start-Up Rev. 05 05.05 CS PS 24 Medical Solutions

Page 65

Calibrating and adjusting the AEC 11

11 - 1

NOTE

Check that all object tables do not have AEC grids.

If they have AEC grids remove the grid bars according to

"Installation Instructions object tables" RXB7-120.031.06..., which

is delivered with each object table.

Checking and programming with the service PC 11

Use the service PC to check and program the AEC.

Operation of the service PC is described in Chapter 22 "Appendix".

The AEC is based on correction tables. The tables are optimized for the following film/

screen combinations.

The tolerances of the AEC are specified for incremental gamma e 5.

Table 1 Correction table identifications

Film Screen Cassette Sensitivity Mo/Mo Mo/Rh W/Rh

Kodak

Min-R 2000

Kodak

Min-R 2000

Kodak

Min-R 2000

Kodak