Page 1

q

SERVICE MANUAL

MODEL

CONTENTS

CODE : 00Z

XEA102USME

ELECTRONIC

CASH REGISTER

XE-A102

SRV KEY

PRINTER

(U and V version)

: Not necessary

: M-31

CHAPTER 1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

CHAPTER 2. OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

CHAPTER 3. MASTER RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

CHAPTER 4. HARDWARE DESCRIPTION. . . . . . . . . . . . . . . . . . . . 5

CHAPTER 5. TEST FUNCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

CHAPTER 6. SERVICE PRECAUTION . . . . . . . . . . . . . . . . . . . . . . 10

CHAPTER 7. CIRCUIT DIAGRAM AND PWB LAYOUT . . . . . . . . . 11

PARTS GUIDE

Parts mark ed w ith "!" are important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

This document has been pub lished to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

Page 2

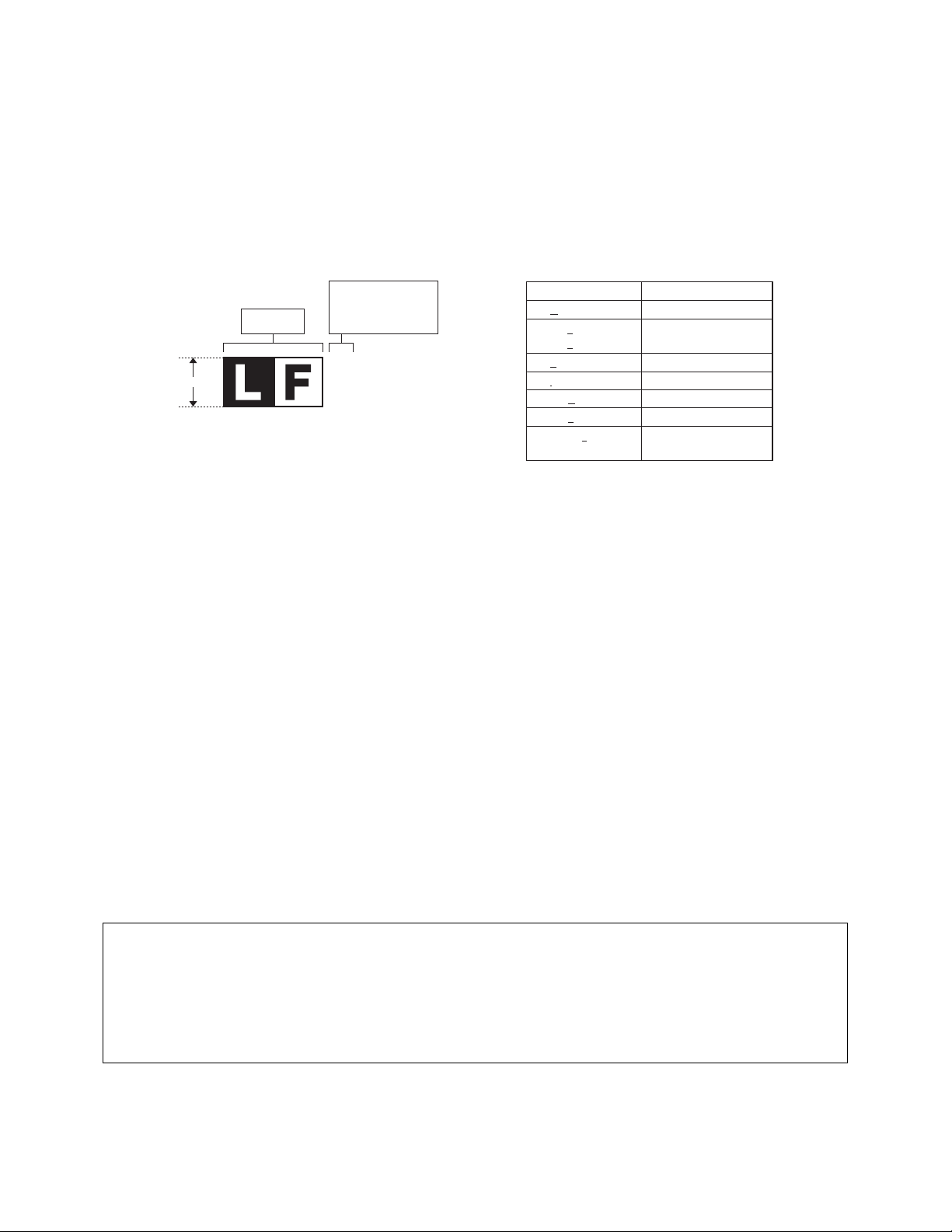

LEAD-FREE SOLDER

The PWB’s of this model employs lead-free solder. The “LF” marks indicated on the PWB’s and the Service Manual mean “Lead-Free” solder.

The alphabet following the LF mark shows the kind of lead-free solder.

Example:

<Solder composition code of lead-free solder>

Solder composition

Sn-Ag-Cu

Sn-Ag-Bi

Sn-Ag-Bi-Cu

Sn-Zn-Bi

Sn-In-Ag-Bi

Sn-Cu-Ni

Sn-Ag-Sb

Bi-Sn-Ag-P

Bi-Sn-Ag

5mm

Lead-Free

Solder composition

code (Refer to the

table at the right.)

a

(1) NOTE FOR THE USE OF LEAD-FREE SOLDER THREAD

When repairing a lead-free solder PWB, use lead-free solder thread. Never use conventional lead solder thread, which may cause a

breakdown or an accident.

Since the melting point of lead-free solder thread is about 40°C higher than that of conventional lead solder thread, the use of the exclusive-use soldering iron is recommendable.

Solder composition code

a

b

z

i

n

s

p

(2) NOTE FOR SOLDERING WORK

Since the melting point of lead-free solder is about 220°C, which is about 40°C higher t han that of conventional lead solder, and its soldering capacity is inferior to conventional one, it is apt to keep the soldering iron in contact with the PWB for longer time. This may cause land

separation or may exceed the heat-resistive temperature of components. Use enough care to separate the soldering iron from the PWB

when completion of soldering is confirmed.

Since lead-free solder includes a greater quantity of tin, the iron tip may corrode easily. Turn ON/OFF the soldering iron power frequently.

If different-kind solder remains on the soldering iron tip, it is melted together with lead-free solder. To avoid this, clean the soldering iron tip

after completion of soldering work.

If the soldering iron tip is discolored black during soldering work, clean and file the tip with steel wool or a fine filer.

CAUTIONS

THERE IS A RISK OF EXPLOSION IF THE BATTERY

IS REPLACED BY AN INCORRECT TYPE.

PROPERLY DISPOSE OF USED BATTERIES ACCORDING

TO THE INSTRUCTIONS.

XE-A102 LEAD-FREE SOLDER

– 2 –

Page 3

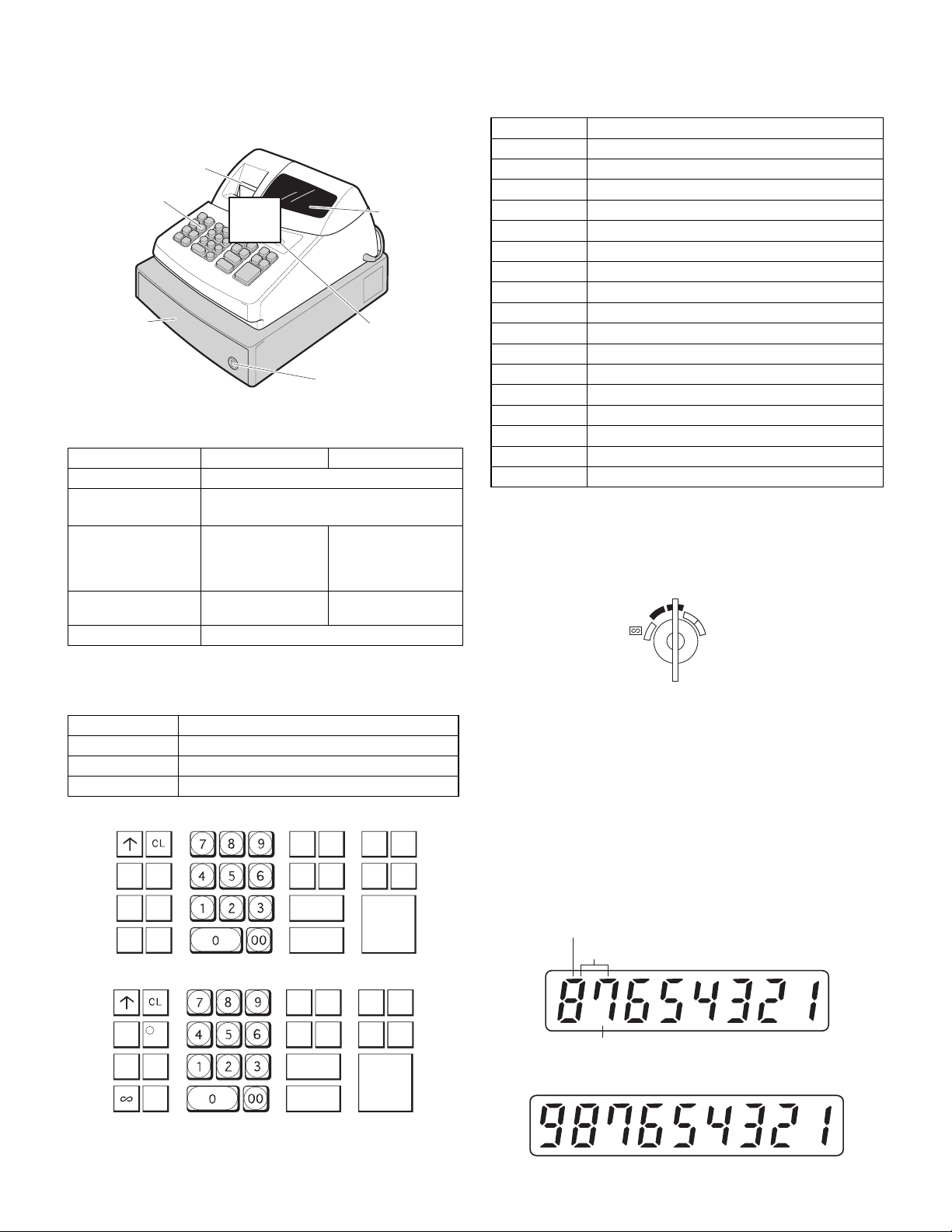

CHAPTER 1. SPECIFICATIONS

1. APPEARANCE

Front vie w

Printer cove

Keyboard

r

Display

P

Drawer

Drawer lock

2. RATING

UV

Weight Approx 5.0kg

External dimension

(Including the drawer)

Power source AC 120V (10%) 60Hz AC 220-230V (

Power consumption Stand-by 4W

Working temperature 0~40°C (32 to 104°F)

330 (W) x 363 (D) x 234 (H) mm

13 (W) x 14.3 (D) x 9.2 (H) inches

Operating 12.5W

Mode switch

50/10Hz

AC 230-240V (

50Hz

Stand-by 6.3W

Operating 13W

10%)

m

10%)

m

2) KEY LIST

Keytop Description

0-9,00 Numeric keys

CL Clear key

@/TM Multiplication & Time display key

2

Paper feed key

Tax 1 Shift/RA Tax 1 shift and Received on account key

Tax2 Shift/PO Tax 2 shift and Paid out key

% Percent key

ESC Error escape key

VOID Void key

CLK# Clerk code Entry key

PLU PLU code entry key

SHIFT Department shift key

#/SBTL Non-add code & Tax Included subtotal key

CHK Check key

CH Charge key

CA/AT/NS Cash Sale/ Amount Tender and No Sale key

Dept1-8 Department key

4. MODE SWITCH

1) LAYOUT

• Rotary SW

REG

q

X/Flash

Z/PGM

3. KEYBOARD

1) KEYBOARD LAYOUT

Type Normal keyboard

Key position STD/MAX 30

Key pitch 19 (W) x 19 (H) mm

Key layout Fixed type

[U version]

TAX1

@/TM

SHIFT

/RA

TAX2

%

SHIFT

/PO

VOID

ESC

[V version]

x /

TAX

/RA

TM

%

/PO

ESC

SHIFT PLU

7

3

4

2

1

SHIFT PLU

7

3

4

2

1

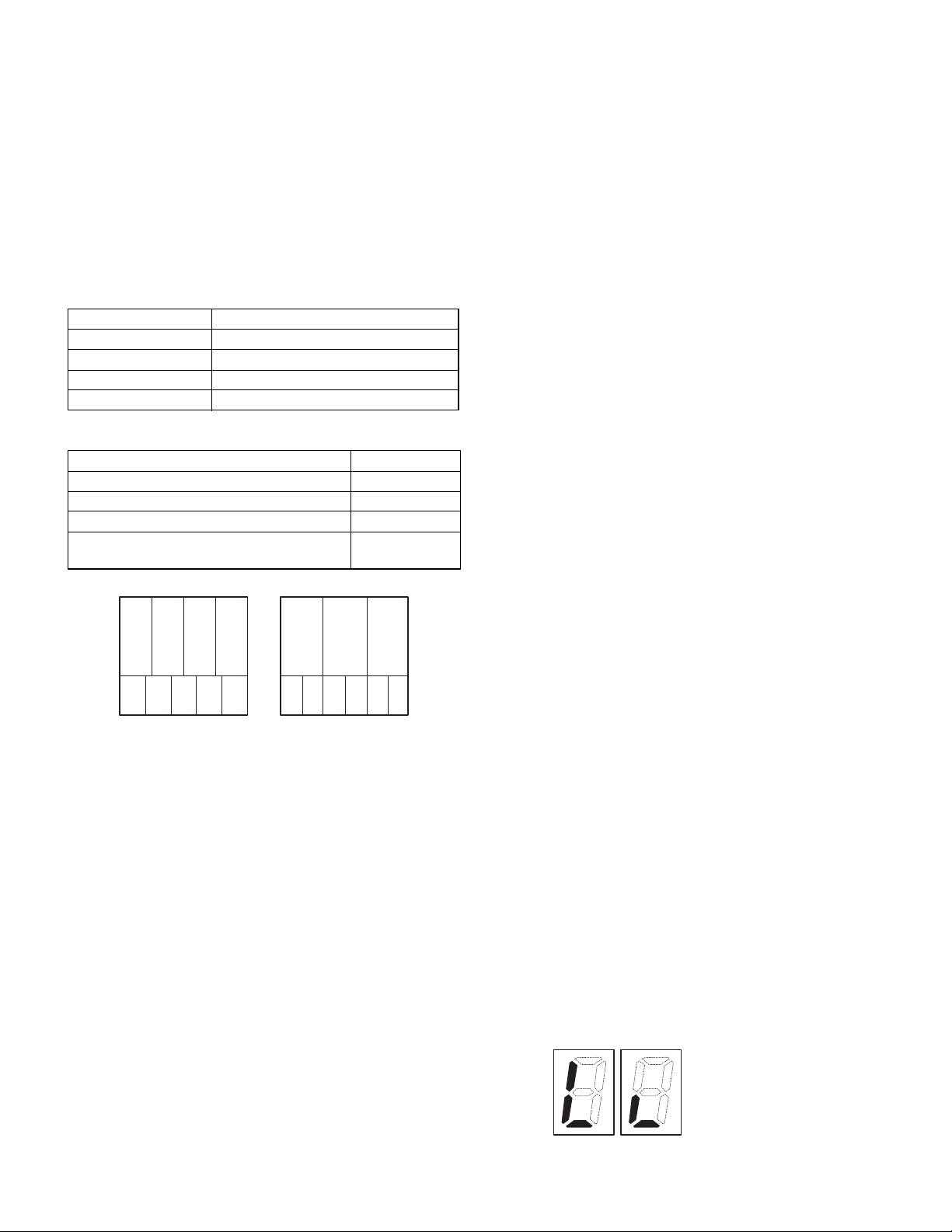

5. DISPLAY

1) OPERATOR DISPLAY

Display device: LED numeric display

Number of lines: 1 line

Number of positions: 8 positions numeric display (U)

CHK CLK#

8

#/

CH

SBTL

6

CA/AT/NS

5

EX

CR

8

#/

ST

CH

6

TL/AT/NS

5

Color of display: Yellow Green

Character size: Numeric 14.20 (H) x 7.80 (W) mm

(Layout)

Department code

[V version]

9 positions numeric display (V)

PLU code

Repeat

XE-A102 SPECIFICATIONS

– 1 –

Page 4

2) DISPLAY CONTENTS

Departments/PLU Code:

The department code or PLU code entered appears on the left. For

example, if the key for department 1 is pressed, "1" would appear in

the extreme left position.

Repeat:

Indicates the number of times the same department key is pressed. If

an entry is repeated more than ten times, only the first digit is displayed (12 displays as "2").

(E) Error:

This symbol appears, accompanied by a warning beep, when an

error is made. If this occurs during a transaction because of an excessive digit entry, simply press [CL] and re-enter correctly.

(P) Program:

This symbol remains on the display when the cash register is being

programmed in the Z/PGM mode.

(F) Finalization:

This symbol appears when a transaction is finalized by pressing

[CA/AT/NS], [CH] or [CHK].

(o) Subtotal:

This symbol appears when [#/SBTL] is pressed and the cash register

computes the subtotal and also when the amount tendered is less

than the total sale amount.

(C) Change:

This symbol appears whenever the change due amount is displayed.

(L) Low battery:

This symbol appears when the power of the installed batteries is

low or you need to replace the batteries with new ones.

(see the "Maintenance" section for explanation.)

(

) No battery:

L

This symbol appears when no batteries are installed. (see "Maintenance" and "Getting Started" sections for explanation.)

In addition, the following appear when appropriate:

• The minus sign (-) can appear in positions 2 to 8.

• The decimal point appears in positions 1 to 3.

• When entry of the secret code is necessary, "---" appears in

positions 1 to 4.

6. PRINTER

1) PRINTER

• Model name : M-31

• No. of stations : 1

• Printing system : Print wheel selective type

• Printing capacity : max. 13 characters

• Character size : 1.6mm (W) x 2.8mm (H)

• Print pitch : Column distance 2.1mm (numeric to

• Print speed : Approximate 1.4 lines/s (6 digits/line)

• Paper feed speed : Approximate 4.3 lines/s

• Reliability : MCBF 0.3 million lines

numeric), 2.6mm (numeric to symbol)

Row distance 4.6mm

XE-A102 SPECIFICATIONS

2) PAPER

• Paper roll dimension : 57.5mm ± 0.5mm

• Paper quality : Bond paper (paper thickness: 0.06 to

0.085mm paper weight: 47 to 64g/m

3) INKING

Ink supply system : Ink roll

From : Roller

Specification : Material - rubber

Ink roll type : 1 million characters

Print color : purple

4) LOGO STAMP (NONE)

5) CUTTER

• Manual cutter

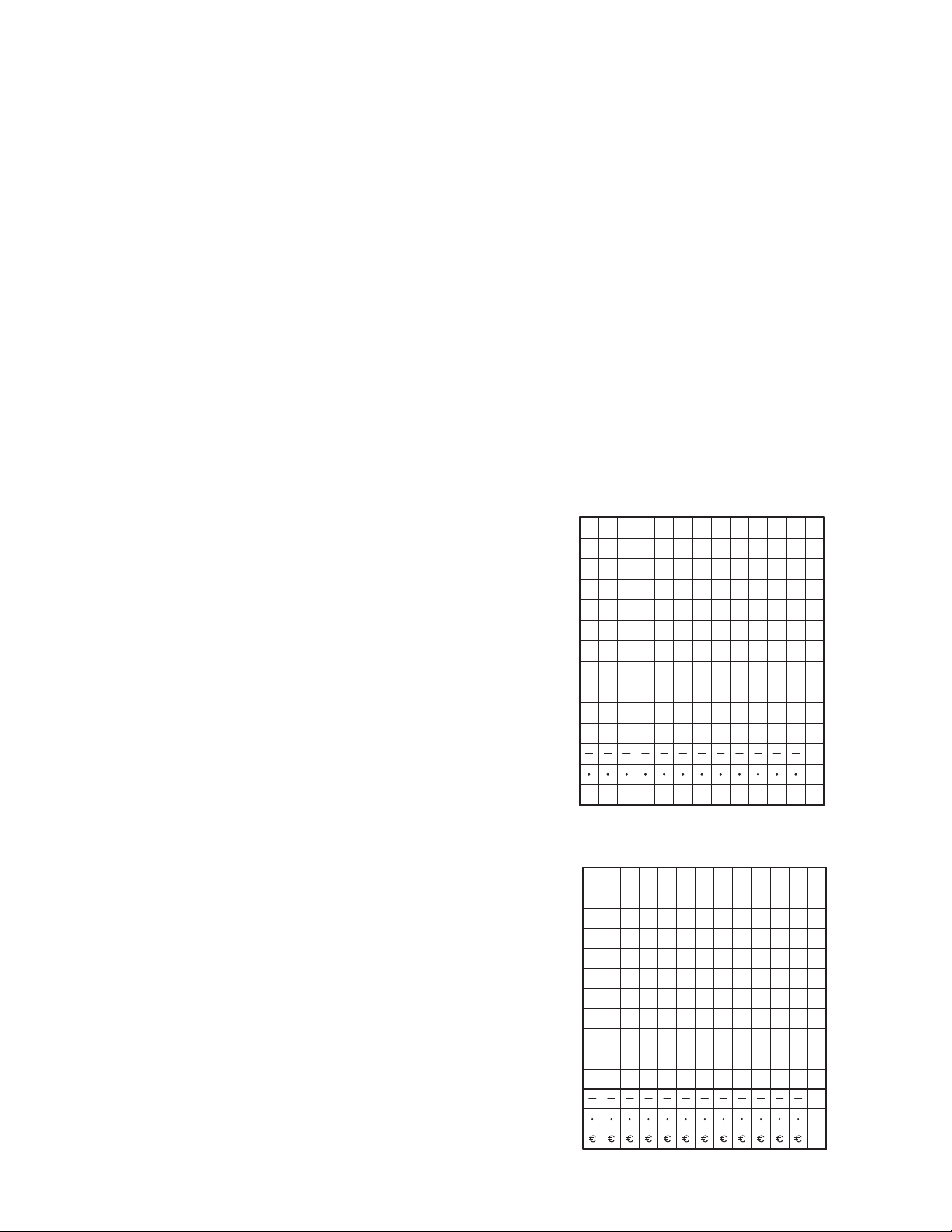

6) PRINTING WHEEL LAYOUT

[U version]

123456789101112

0

0

0

0

0

0

0

0

0

0

1

1

1

2

2

2

3

3

3

4

4

4

5

5

5

6

6

6

7

7

7

8

8

8

9

9

9

#

#

#

0

0

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

– 2 –

[V version]

0

1

1

1

1

1

1

1

1

2

2

2

2

2

2

2

2

3

3

3

3

3

3

3

3

4

4

4

4

4

4

4

4

5

5

5

5

5

5

5

5

6

6

6

6

6

6

6

6

7

7

7

7

7

7

7

7

8

8

8

8

8

8

8

8

9

9

9

9

9

9

9

9

10

11

12

#

#

#

#

#

#

13

123456789101112

0

0

0

0

0

1

1

1

1

1

2

2

2

2

2

3

3

3

3

3

4

4

4

4

4

5

5

5

5

5

6

6

6

6

6

7

7

7

7

7

8

8

8

8

8

9

9

9

9

9

10

11

12

13

#

0

0

0

1

1

1

2

2

2

3

3

3

4

4

4

5

5

5

6

6

6

7

7

7

8

8

8

9

9

9

2

)

13

0

0

X

1

1

Z

2

2

RA

3

3

PO

4

4

VD

5

5

%

6

6

@

7

7

ST

8

8

TX

9

9

CA

CH

CK

#

#

CG

13

X

0

0

0

Z

1

1

1

RA

2

2

2

PO

3

3

3

VD

4

4

4

%

5

5

5

@

6

6

6

ST

7

7

7

TX

8

8

8

CA

9

9

9

CH

CK

CG

Page 5

7. DRAWER

[OUTLINE]

• Standard equipment : Yes (1)

• Max. number of drawers : 1

• The drawer consists of :

(1) Drawer box (outer case) and drawer

(2) Money case

(3) Coin case

(4) Lock (attached to the drawer)

[SPECIFICATION]

1) DRAWER BOX AND DRAWER

Material Plastic

Bell

Release lever Standard equipment: situated at the bottom

Drawer open sensor

-

-

2) MONEY CASE

Separation from the drawer Disallowed

Separation of the bill compartments from the coin Allowed

compartments

Bill separator

Number of compartments 4B/5C (U)

Layout:

-

-

3B/5C (V)

2) LOW BATTERY

Low battery indication will appear on the left side of display when the

battery voltage is low.

CASE 1: When sitting idle or after completion of transaction.The

machine can indicate the low battery condition (Always)

CASE 2: Low battery indication will not appear during key operations,

but will appear after power up of the cash register.

[Display sample]

" 0.00 " : Battery is OK .

"L 0.00" : Low battery (You have to change the batteries.)

After finalization

"F 12.34": Battery is OK.

"L 12.34": Low battery ("L" indicate instead of "F".)

3) NO BATTERY

If the user forgets to replace the battery and the battery voltage falls

below a certain level, or if a power failure occurs with no batteries

installed, the memory contents cannot be retained. The CPU judges it

as no battery and performs the master reset . In this case, all the settings and registrations are cleared. If, however, the power is continuously supplied to the AC cord, the memory contents are retained.

Low battery : Batteries are installed, but the voltage is low. Memory

back up can be done.

No battery : Batteries are not installed or the voltage is extremely low.

The master reset is executed when a power failure

occurs, when the batteries are not properly changed.

4B/5C (u) 3B/6C (v)

3) LOCK (LOCK KEY : LKGIM7331BHZZ)

• Location of the lock: Front

• Method of locking and unlocking:

• To lock, insert the drawer lock key into the lock and turn it 90 degrees

counter clockwise. To unlock, insert the drawer lock key and turn it 90

degrees clockwise.

• Key No: SK1-1

8. BATTERY

1) MEMORY BACK UP BATTERY

For memory back up, the dry battery ULM-3 (3 ) are needed.

1. Memory holding time:

Approx. 1 year after New dry batteries are installed.

2. Battery exchange method:

When the low battery symbol "L" lights up, replace the bat teries (3

AA) replaced by the following method;

1) Power on the ECR.

2) Mode switch turn to "REG" mode.

3) Remove the OLD dry batteries (3 pieces).

4) The nobattery symbol "L" light up.

5) Insert the NEW dry batteries (3 pieces).

6) Confirm the low battery symbol "L" and nobattery symbol "L" is

off.

XE-A102 SPECIFICATIONS

Low battery & No battery indication will appear at the most left position

of display when the battery voltage is low.

CASE 1: When any numeric entry & item entry is not done or just after

finalization. The machine can indicate the battery condition.

(Always)

CASE 2:W hen numer ic entry or item entry is done.

Battery condition does not appear.

Except when power is restored after power failure, the

Low battery & No battery indication will appear on the

display only when the battery voltage is low.

And the indication will disappear after any key entry.

[Display sample]

" 0.00" : Battery is OK.

"L 0.00" : Low battery

"L 0.00" : No battery

After finalization

"F 12.34": Battery is OK.

"L 12.34": Low battery ("L" indicate instead of "F".)

12.34": No battery ("L" indicate instead of "F".)

L

"

L L

– 3 –

Page 6

CHAPTER 2. OPTIONS

1. OPTIONS (NONE)

2. SERVICE OPTIONS (NONE)

3. SUPPLIES

NO NAME PARTS CODE PRICE RANK DESCRIPTION

1 ROLL PAPER

2 INK ROLLER

DPAPR1025CSZZ

NROLR1022CC05

AS 5 ROLLS/PACK

AF

4 SPECIAL SERVICE TOOLS (NONE)

CHAPTER 3. MASTER RESET

Master reset:

Clears all the memory and initializes each preset parameter.

The master reset should be perfor med by usi ng the foll owi ng procedu re.

1. Turn off the power (Power OFF). (See Note 1.)

2. Remove the memory back up battery from ECR.

3. Turn the mode switch to any position other than Power OFF.

4. Turn on the power (Power ON). (See Note 2.)

When the master rest is completed, the buzzer sounds three times.

5. Install the memory back up batteries back into the ECR.

The master reset can also be accomplished in the following case.

(See Note 3.)

Note 1) Power OFF:

Means disconnecting the AC power supply to the

machine. (Specifically, unplugging the machine.)

Note 2) Power ON:

Means connecting the AC power to the machine. (Specifically, plugging in the machine.)

Note 3) In case a power failure occurs when the machine has no

battery installed, the master reset operation is automatically performed after the power has been restored.

XE-A102 OPTIONS

– 4 –

Page 7

CHAPTER 4. HARDWARE DESCRIPTION

1. OUTLINE

• CPU : uPD780023A (ROM 24KB, RAM 1024B)

• KEY BOARD : 30key including PF key

• MODE SW : 5position slide SW

• DISPLAY

: 7seg.+DP x 8digit LED (YELLOW GREEN) FRONT only

• DRAWER : 1ch, no open sensor

• BUZZER : 1beep, piezo buzzer

• PRINTER : M-31(no EURO SYMBOL) (U)

M-31V (V)

2. BLOCK DIAGRAM

6V

AC

Printer

M-31

D

RAWER

POWER

SUPPLY

5V

MAIN

4.19MHz

CPU

uPD780023A

BUZZER

For Clock

32.768kHz

ST1-〜ST4-,ST5

A1〜G1,DP1,A2 G2~,DP2

KST1〜KST8

KR1〜KR6

Battery

5V

FRONT display :8digit

8. 8. 8. 8. 8. 8. 8.

8.

KEY

BOARD

&

MODE SW

2) KEYBOARD AND MODE SW

MODE SW, KEY MATRIX is follows.

Note: A lthough the XE-A102 has 30 keys, the keyboard circuit is

*

actually 32 keys (+) the PF key.

REG

2

27

3

Rotary SW

28

X/

F

4

X/Flash

5

Z

3 4

11 12

21

30

SW1

/PGM

5 6

13 14

KST2

KR1

KST3

KST4

22

31 7

15 16

24 25

1

2

3

4

POWER

OFF

(u)

VOID

1

(v)

26 1 2

8 9 10

17 18 19

32

3. DISCRIPTION

1) DISPLAY

ST4-ST5- (v) ST3- ST2- ST1-

(Output Timing of STROBE signal)

1ms

30~100us

Display

strobe

ST1-

ST2-

ST3-

ST4-

5

KST5

MODE SW

KR2 KR6 KR5 KR4 KR3

KCN2

6 7 13 25

1 2 8 14

11 12 19 9

17 18 3 23

28 24 20 10

30 26 21 4

32 22 15 5

29 31 27 16

D13 1SS133 KST1

1

D14 1SS133 KST2

2

D15 1SS133 KST3

3

D16 1SS133 KST4

4

D17 1SS133 KST5

5

D18 1SS133 KST6

6

D19 1SS133 KST7

7

D20 1SS133 KST8

8

9

KEYBOARD

3) BUZZER

The BUZZER is driven by the P75/BUZ signal of the CPU.

Frequency : 4.095kHz

KST1

XE-A102 HARDWARE DESCRIPTION

– 5 –

Page 8

4) REWIND MOTOR

When the rewind motor is driven by the signal of the CPU.

PRINTER

MOTOR

REWIND

MOTOR

10ms

5ms

15ms

5) DRAWER

DRAWER OPEN signal :Output high signal between 50ms

6) DETECTING "LOW VOLTAGE"

• Values obtained by AD conversion and averaging

Register value: 138 (

2.7V) or less

L

139 - 154 (

2.7V - 3.0V)3 Low voltage

L

more than 154

No voltage

3

OK

3

7) DESTINATION DETECTION PORT

U and V version

P66 L

XE-A102 HARDWARE DESCRIPTION

– 6 –

Page 9

4. CPU PORT TABLE

No. PIN Name Signal Name Description Output/Input Initial state When STBY

1 P50/A8 RWND REWIND MOTOR O L O/L

2 P51/A9 DR To DRAWER O L O/L

3 P52/A10 SA2 DISPLAY SEGMENT O L O/L

4 P53/A11 SB2 DISPLAY SEGMENT O L O/L

5 P54/A12 SC2 DISPLAY SEGMENT O L O/L

6 P55/A13 SD2 DISPLAY SEGMENT O L O/L

7 P56/A14 SE2 DISPLAY SEGMENT O L O/L

8 P57/A15 SF2 DISPLAY SEGMENT O L O/L

9 Vss0 GND

10 Vdd0 VDD

11 P30 ST1- DISPLAY STROBE N-Ch O.D. O H I

12 P31 ST2- DISPLAY STROBE N-Ch O.D. O H I

13 P32 ST3- DISPLAY STROBE N-Ch O.D. O H I

14 P33 ST4- DISPLAY STROBE N-Ch O.D. O H I

15 P34/SI31 ST5 DISPLAY STROBE (H ACTIVE) O L O/L

16 P35/SO31 NU (GND via 56k) I I

17 P36/SCK31- NU (GND via 56k) I I

18 P20/SI30 SA1 DISPLAY SEGMENT O L O/L

19 P21/SO30 SB1 DISPLAY SEGMENT O L O/L

20 P22/SCK30- SC1 DISPLAY SEGMENT O L O/L

21 P23/RXD0 SD1 DISPLAY SEGMENT O L O/L

22 P24/TXD0 SE1 DISPLAY SEGMENT O L O/L

23 P25/ASCK0 SF1 DISPLAY SEGMENT O L O/L

24 Vdd1 VDD

25 Avss GND

26 P17/ANI7 VBAT BATTERY voltage I I

27 P16/ANI6 NU RESERVE FOR KEY RETURN I I

28 P15/ANI5 KR6 KEY RETURN I I

29 P14/ANI4 KR5 KEY RETURN I I

30 P13/ANI3 KR4 KEY RETURN I I

31 P12/ANI2 KR3 KEY RETURN I I

32 P11/ANI1 KR2 KEY RETURN I I

33 P10/ANI0 KR1 KEY RETURN I I

34 Avref VCC

35 Avdd VDD

36 RESET- RESET37 XT2 XT2 32.768Khz Xtal

38 XT1 XT1 32.768Khz Xtal

39 IC/VPP GND

40 X2 X2 SYSTEM CLOCK

41 X1 X1 SYSTEM CLOCK

42 Vss1 GND

43 P00/INTP0 /POF POWER OFF I I

44 P01/INTP1 T From PRINTER I I

45 P02/INTP2 t From PRINTER I I

46 P03/INTP3/ADTRG R Fr om PRINTER I I

47 P70/TI00/TO0 SG1 DISPLAY SEGMENT O L O/L

48 P71/TI01 SDP1 DISPLAY SEGMENT O L O/L

49 P72/TI50/TO50 SG2 DISPLAY SEGMENT O L O/L

50 P73/TI51/TO51 SDP2 DISPLAY SEGMENT O L O/L

51

P74/PCL

52 P75/BUZ BUZ BUZZER O L O/L

53 P64/RD- MTR To PRINTER O L O/L

54 P65/WR- TRG To PRINTER O L O/L

55 P66/WAIT- MSL1 MODEL SELECT1 I I

56 P67/ASTB MSL2 MODEL SELECT2 I I

57 P40/AD0 KST1 KEY STROBE O L O/L

58 P41/AD1 KST2 KEY STROBE O L O/L

59 P42/AD2 KST3 KEY STROBE O L O/L

60 P43/AD3 KST4 KEY STROBE O L O/L

61 P44/AD4 KST5 KEY STROBE O L O/L

62 P45/AD5 KST6 KEY STROBE O L O/L

63 P46/AD6 KST7 KEY STROBE O L O/L

64 P47/AD7 KST8 KEY STROBE O L O/L

NU O L O/L

XE-A102 HARDWARE DESCRIPTION

– 7 –

Page 10

CHAPTER 5. TEST FUNCTION

1) To execute the diag test, set the mode switch to Z/PGM. Enter the

desired JOB code, and press the PO (paid out) key.

2) The test message is printed by the printer.

3) Test contents and key operations.

NO. Test contents Key operations

1 Mode switch test 1

2 Key test 2

3 Display buzzer test 3

4Drawer test 4

5 Printer test 5

6 CPU version NO. print 6

7 Battery level test 7

8 Time display test 8

9 Destination display 9

3

3

3

3

3

3

3

3

3

[PO]

[PO]

[PO]

[PO]

[PO]

[PO]

[PO]

[PO]

[PO]

1. MODE SWITCH TEST

1) KEY OPERATION

PO1

2) TEST PROCEDURE

Change over the mode switch as follows. If the mode switch data in the

proper sequence is not read with the above operation, an error is

printed.

To cancel this test mode, set the mode switch to any a position other

than Z/PGM to Z/PGM. In this case, the completion print is performed.

During the test , the display indicates hard codes which correspond to

the switch positions.

3) MODE SWITCH OPERATION

Mode:

Display: (01)(02)

Z/PGM

(04)

Completion print 01

Error print - - - 01

X/FLASH

(03)

OFFREG VOID

2. KEY TEST

1) KEY OPERATION

PO2

2) TEST PROCEDURE

Perform the keyboard check with the sum check data of the key code.

Enter the sum check data of each model in the four digits preceding the

diag number 02, and compare the data with the key position code which

is added until the CA/AT/NS key is pressed.

If the data coincides with the code, the completion print is performed.

If not, the error print is performed.

Completion print 02

Error print - - -02

XXXX Sum data

3. DISPLAY BUZZER TEST

1) KEY OPERATION

PO3

2) TEST PROCEDURE

Check the continuous buzzer sound and the display state.

Display state:

8. 7. 6. 5. 4. 3. 2. 1.

The decimal point will shift from the lower digit to the upper, step by

step (500mSEC). To cancel the test mode, press any key, and the

buzzer will stop and the completion print is performed.

Completion print 03

4. DRAWER TEST

1) KEY OPERATION

PO4

2) TEST PROCEDURE

The drawer opens with the above key operation. Check that the drawer

is open. Press any key to terminate the test.

XE-A102 TEST FUNCTION

– 8 –

Completion print 04

Page 11

5. PRINTER TEST

8. TIME DISPLAY TEST

1) KEY OPERATION

PO5

2) TEST PROCEDURE

With the above key operation , the print test pattern is repeatedly

printed.

Pressing any key will terminate the test after the completion of one

cycle print. (The receipt is issued at the end.)

1) KEY OPERATION

PO8

2) TEST PROCEDURE

7

8

Display

Hour

To terminate the test and print the date and time, press any key.

Print

XXXX XXXXXX

X

X

Year Month Date Hour M

54 2136

Minute

Turn on and off(0.5s)

inute

Second

0 8

Second

9. DESTINATION DISPLAY

1) KEY OPERATION

PO9

6. CPU VERSION NO. PRINT

1) KEY OPERATION

PO6

2) DESCRIPTION

The CPU version No. are printed with above key operation.

(Print example)

0102 CPU version NO.

06

This test is terminated when printing is completed.

7. BATTERY VOLTAGE SENSOR TEST

1) KEY OPERATION

PO7

2)TEST PROCEDURE

Display the destination code as follows.

U and A version V version Japan

Display 0 1 3

Display X (X:0)

To terminate the test, press any key.

Completion print 09

2) TEST PROCEDURE

Displays A/D conversion port read value.

0155 or greater : Normal

0154 or smaller : Low battery display

0138 or smaller : No battery display and MRS is done when power on.

To terminate the test, press any key.

Completion print 07

XE-A102 TEST FUNCTION

– 9 –

Page 12

CHAPTER 6. SERVICE PRECAUTION

1. PRINTER

Since there are no service parts for this m odel printer, only the printer

unit is supplied. Therefore, the printer component parts are not supplied

and no service document is issued.

For troubleshooting of the printer, refer to the table below:

Printer life: 300 thousand lines (XE-A102: M-31)

*

Ink roll life: 1 million characters

Phenomena Check point/possible cause Repair

• The printer motor is locked and the buzzer

sounds intermittently.

• The printer does not work properly

• Defective print (Lack on the upper/ lower or

left/right side)

• Thin print • Check if the ink roll life is reached. • Replace the ink roll.

• Uneven pitch of print paper feed • Check if the roll paper size is proper. • Use roll paper as specified below;

• Check if the printer cable is disconnected. • Check and repair the printer cable.

• Check if the printer life is reached. • Replace the printer.

• Check if any foreign material is attached to

the printing type wheel or the gear section.

• Check if the printing type is worn down. • Replace the printer.

• Check if any foreign material is attached to

the printing type wheel.

• Check if the ink roll is properly installed. • Install the ink roll properly.

• Check if the printing type wheel is worn down. • Replace the printer.

• Check if a load is applied to the roll paper

during paper feeding. This may result from a

foreign materials attached to the roll paper.

• Remove the foreign material. (After removing

the foreign material, set the mode switch to

"REG" and press "CL" key.)

• Remove the foreign material. (After removing

the foreign material, set the mode switch to

"REG" and press "CL" key.)

Paper width : 57.5 ±0.5mm

Outside diameter : ϕ80mm or less

Inside diameter of paper tube: ϕ12mm or less

Paper thickness : 0.06~0.085mm

• Remove any foreign material.

XE-A102 SERVICE PRECAUTION

– 10 –

Page 13

D

1/1

C

VDD

VCC

+6V

VO

VBAT

C26

47uF/16V

+

C6

+

47uF/16V

8

K

68

1N414

R3

R2

1M

D9

0

C5

0.1uF

MYLAR

22

R1

0

10

8

R70

2

1

CN2

1N4148

1N414

D7

3

220

VOUT

TO

VIN

IC1

LM7806

1

D6

1N4002

D5

1N4002

5V

F1

T1.25AL/12

D8

GND

D3

D1

T1.0A 250V

2521P0200T

BATTERY CN

C4

100uF/25V

+

2

C3

330uF/25V

+

C2

3300uF/25V

+

D4

×4

1N4002

D2

MYLAR

C1

0.033uF

1

2

CN1

1P0202T

306

TR OUTPUT CN

1

2

4

t

TRANSFORMER

132

P

2

D30

+6V

/ST1

/ST2

/ST3

1N400

JUMPER

Q9

KTA1271YAT/

13

14

R61

6.8K

0

A

R60

33

D568GW

LED1

Q8

KTA1271YAT/P

13

14

R59

6.8K

0

A

R58

33

W

LED2

D568G

P

Q7

KTA1271YAT/

13

14

R57

6.8K

0

A

W

33

R56

LED3

D568G

P

Q6

KTA1271YAT/

13

14

R55

6.8K

0

R54

33

/ST4

V C TW ONLY

ST5

A

LED4

D568GW

8

P

3

Q5

R53

6.8K

0

LED5

33

S568GWA

KTA1271YAT/

Q4

2SC1815GR

R52

4.7K

R51

R50

11

aabcdeefggdpdp

10

8

cb

6

5

12

7

9

16

15

3

2

df

1

18

17

4

11

aabcdeefggdpdp

10

8

cb

6

5

12

7

9

16

15

3

df

2

1

18

17

4

11

aabcdeefggdpdp

10

8

cb

6

5

12

7

9

16

15

3

2

df

1

18

17

4

11

aabcdeefggdpdp

10

8

cb

6

5

12

7

9

16

15

3

2

df

1

18

17

4

7

adefgdp

6

4

cb

2

1

9

10

5

110

110

110

110

R37

R36

R35

K

12

R34

181716151413121110

181716151413121110

123456789

IC4

KID65083AP(DIP)

123456789

2

SB2SA

SD2

VCC

VO

*CAUTION*

110

110

C

110

110

110

110

.

ND

N

G

IC5

R42

R43

R41

R40

R39

R38

IC4

9 PIN :

10 PIN :

181716151413121110

181716151413121110

123456789

IC5

KID65083AP(DIP)

123456789

1

2

SA

SB1

SF2

SG

DP2

SE2SC2

XXXXX

R24

O

R23

X

R22

OOOOO

R21

A3XEA102U

UAV4V6V7

VCC

110

110

110

110

R44

R46

R47

R45

SF1

SD1

SE1

SC1

O

X

A3XEA102A

110

110

R49

R48

1

DP1

SG

K

R5

56

ZD1

HZ7B3-TA-E

O

O

X

X

A3XEA102V6

A3XEA102V4

R22

R21

47K

POWER CORD

D101N4148

X

X

O

O

X

O

A3XEA102V7

A1XEA127

J

K

R23 47

47K

R6

100K

MULTI

0.1uF

C7

R4

5.6K

X

O

X

O

A1ERA132

J

X: NOT MOUNT

R24 47K

/POF

O: 47K ohm

MTR

TRG

KST[1:8]

KST1

KST2

KST3

KST4

KST5

KST6

KST7

KST8

VDD

/ST[1:5]

876 5 4321

CHAPTER 7. CIRCUIT DIAGRAM AND PWB LAYOUT

MAIN CIRCUIT

1. CIRCUIT

BZ

0

R25 47

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

C27

BUZZER

/POF

T

t

R

484746454443424140393837363534

X1

TO 0

VSS1

INPT1

INPT0

P71/TI01

P72/TI50/TO50

P02/INTP2

P73/TI51/TO51

P74/PCL

P75/BUZ

P03/INTP3/ADTRG

P64/-RD

P65/-WR

P66/-WAIT

P67/ASTB

P40/AD0

P41/AD1

IC2

P42/AD2

P43/AN3

P44/AD4

P45/AD5

P46/AD6

P47/AD7

P50/A8

P51/A9

P52/A10

P53/A11

P54/A12

P55/A13

P56/A14

P57/A15

123456789

0.1uF

SE2

SB2

DR

SD2

SF2

SC2

RWND

SA2

R27 1M

IC

X2

XT1

XT2

uP D780023A (Q FP64)

VSS0

VDD0

P30

P31

10111213141516

1

2

/ST

/ST

/RESET

3

/ST

B

6

23

32

14

5

4

21

30

(3)

(4)

Z/PGM

X/FLASH

345

REG(5)

TOP VIEW

12

OFF(2)

(1)

VOID

POWER

Trigger(-)

Trigger(+)

1234567

PRINT HEADER

+6V

IC3

z

J6

X2

4.19MH

2

P11/AN11

P12/AN12

P13/AN13

P14/AN14

P15/AN15

P16/AN16

P17/AN17

AVSS

VDD1

P25/ASCK0

P24/TXD0

P23/RXD0

P22/-SCL30

P21/SO30

P20/SI30

P36/-SCK31

K

R12

56

7mm

SP1

SHORT PIN

K

C12

R26

330

X1

32.768KHz

DP2

SG2

DP1

SG1

KR1

KR2

32

KR3

31

KR4

30

KR5

29

KR6

28

27

26

25

24

23

SF1

22

SE1

SD1

21

20

SC1

19

SB1

18

SA1

17

56K

56K

R13

R14

S[1:16]

1

3

VCC

33

AVDD

AVREF

/RESET

P10/AN10

P32

P33

P34/SI31

P35/SO31

4

ST5

/ST

3

2

1

ROTARY SW(XE-A102)

26

223116

M

mon

m

Motor(-)

Motor(+)

co

Timing signal

Timing sub-signal

Reset signa l

8

1234567

8

(FOR:PRINTER)

1234567

8

52011-0810

P/H CON

PRINTER PCB

CON3A

HOLE ONLY

FLAT CABLE

HOLE ONLY

CON3

765

8

O1

O2

NC2

VCC

1K

1K

1K

NC1I1I2

GND

LB1268(DIP)

123

4

TRG

MTR

R29

R30

R28

T

R

t

K

K

K

10

10

10

R33

R31

R32

C13

22P

VCC

C11

P

18

C10

0.1uF

R9

4.7K

C9

R11

1K

+

22uF/50V

Q3

R10

2.7K

2SC1815GR

8

D12

1N414

VBAT

VO

F2

T400mA/250V

F3

9

1P0300T

-8

123

CN3

(FOR:DRAWER)

254

2

Q1

D21

2SD2170 SOT

1N400

R7

1K

MULTI

10uF

+

D22

1N4148

C8

R62

47K

RWND

12

20

11

19

10

9

181327

8

17

7

15

V

M-31 OR M-42

C14

0.1uF

C15

0.1uF

C16

0.1uF

0.1uF

MULTI

MYLAR

VO

0V

(F3:JUMPER)

T1.0AL/25

D11

+

JUMPER

C30

29

28

KEY SHEET

25

24

REG(2)

X/FLASH(3)

Z/PGM(4)

VOID(1)

1

SW

12345

HOLE ONLY

10

LEAD WIRE

HB05010

123

4

5

SW_CON

C21

100P

P

C20

100

P

C19

100

C18

100P

P

C17

100

47K

R20

K

R19

47

R18

47K

47K

R17

K

47

R16

R15

47K

MG1

-

+

1P0200T

1

2

CN4

MOTOR CN

252

1

2

1N4002

9

8

Q2

-

R8

1k

2SD2170 SOT

D23

R63

MODE SW

ROTARY SWITCH PCB

4

MOTOR F-75

KST3

KST4

KST5

KST2

A

18

10

27

29

31

SW

SW26

SW

9

15

32

22

SW17

SW25

SW

8

24

21

30

26

SW16

SW

SW

28

24

20

SW15

SW23

SW7

6

3

18

17

SW14

SW22

SW

12

11

19

SW13

SW21

SW5

4

2

8

1

SW

SW12

SW20

3

7

6

13

SW

SW11

SW19

KH1

KH2

C25

3300P

0P

C24

330

C23

3300P

C22

3300P

0P

C29

330

KV1

KV2

KV3

KV4

FEED

KCN1

123456789

KV8

34

16

SW

KV7

5

SW33

KV6

32

4

SW

KV5

10

SW31

KV4

23

SW30

KV3

9

SW29

KV2

14

SW28

KV1

25

SW27

KH4

KH3

KH[1:4]

KH3

KH1

KH4

KH2

FEED

5P

KCN2

12345

1253-

KV5

KV7

KV6

KV8

1253-9P

76 54321

1N4148

1N4148

1N4148

1N4148

1N4148

1N4148

1N4148

1N4148

D20

D13

D14

D15

D16

D17

D18

D19

8

KST5

KST4

KST8

KST6

KST1

KST2

KST7

KST3

D

C

B

A

XE-A102 CIRCUIT DIAGRAM AND PWB LAYOUT

– 11 –

Page 14

2. PWB LAYOUT

A side

B side

XE-A102 CIRCUIT DIAGRAM AND PWB LAYOUT

– 12 –

Page 15

3. DISPLAY LAYOUT

A side

B side

XE-A102 CIRCUIT DIAGRAM AND PWB LAYOUT

– 13 –

Page 16

q

COPYRIGHT2005 BY SHARP CORPORATION

All rights reserved.

Printed in Japan.

No part of this publication may be reproduced,

stored in a retrieval system, or transmitted.

In any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise,

without prior written permission of the publisher.

SHARP CORPORATION

Information and Communication Systems Group

Products Quality Assurance Depa rtment

Yamatokoriyama, Nara 639-1186, Japan

2005 May Printed in Japan

t

Loading...

Loading...