Page 1

Drive Technology \ Drive Automation \ System Integratio n \ Services

Manual

Controllers

DHE21B / DHF21B / DHR21B (standard)

DHE41B / DHF41B / DHR41B (advanced)

Edition 03/2010 16897226 / EN

Page 2

SEW-EURODRIVE—Driving the world

Page 3

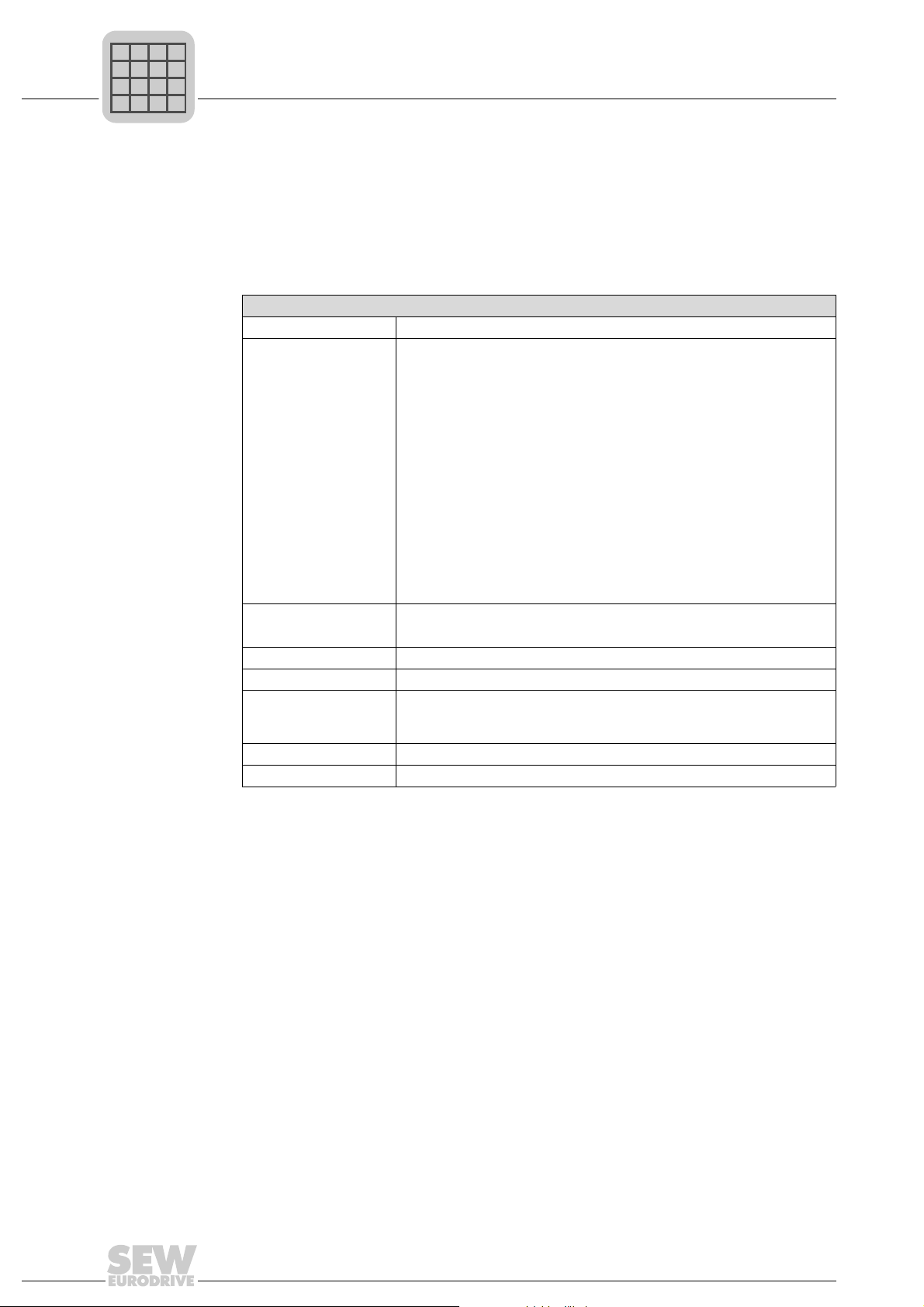

Contents

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Contents

1 General Information............................................................................................ 6

1.1 How to use the documentation ................................................................... 6

1.2 Structure of the safety notes......................................... ... ........................... 6

1.2.1 Meaning of the signal words.......... ... ... .... ... ... ... ........................... 6

1.2.2 Structure of section safety notes ................................................. 6

1.2.3 Structure of embedded safety notes . ... .... ...... ... .... ... ... ... ... .... ... ... . 6

1.3 Right to claim under warranty ..................................................................... 7

1.4 Exclusion of liability..................................................................................... 7

1.5 Copyright..................................................................................................... 7

2 Safety Notes ........................................................................................................ 8

2.1 Other applicable documentation................................................................. 8

2.2 Bus systems................................................................................................ 8

2.3 Safety functions .......................................................................................... 8

2.4 Hoist applications........................................................................................ 8

2.5 Disposal ...................................................................................................... 9

3 Introduction ....................................................................................................... 10

3.1 General information ................................... ... ... ... .... ... ... ... .... ... ... ... ... .... ..... 10

3.1.1 Content of this manual............................................................... 10

3.1.2 Additional documentation .......................................................... 10

3.2 Overview of controllers ............................................................................. 11

3.2.1 Freely programmable motion and logic co nt ro ller

(MOVI-PLC

3.2.2 Configurable application controller (CCU)................................. 11

3.3 Controller DH.21B/41B ............................................................................. 12

3.3.1 Features..................................................................................... 12

3.3.2 Device types............................ ... ... ... ... ...................................... 12

3.3.3 Overview of communication interfaces...................................... 12

3.3.4 Engineering................................................................................ 13

3.3.5 System buses CAN 1, CAN 2 and Ethernet 1 ........................... 14

3.3.6 RS485 interfaces COM1 and COM2 ......................................... 14

3.3.7 Ethernet 2 .................................................................................. 14

3.3.8 Binary inputs and outputs.............................. ... .... ... .................. 14

3.3.9 Diagnostic LEDs........................................................................ 14

®

)............................................................................. 11

4 Assembly and Installation Notes..................................................................... 15

4.1 Installation options of DH.21B/41B ........................................................... 15

4.2 Installing the DH.21B/41B option in MOVIDRIVE

®

MDX61B.................... 15

4.2.1 Before you start ......................................................................... 15

4.2.2 Basic procedure for installing or removing an option card in

MOVIDRIVE

4.3 Installing the DH.21B/41B option in MOVIDRIVE

4.4 Installing the DH.21B/41B option in the MOVIAXIS

4.4.1 Functional description of terminals X5a / X5b

(MOVIAXIS

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

®

MDX61B................................................. ... .... ... .. 16

®

MDX61B.................... 17

®

master module....... 17

®

master module).................................................... 17

3

Page 4

Contents

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

4.5 Installing the DH.21B/41B option in MOVITRAC® B / stand-alone unit .... 19

4.5.1 Description of terminals and LEDs ............................................ 19

4.5.2 RS485 interface COM1 connection (connector X24)................. 19

4.5.3 Connecting CAN 1 system bus/voltage supply (X26)................ 20

4.5.4 LED when installing in MOVITRAC

4.6 Shielding and routing bus cables.............................................................. 22

4.7 Installing the DH.21B/41B option.............................................................. 23

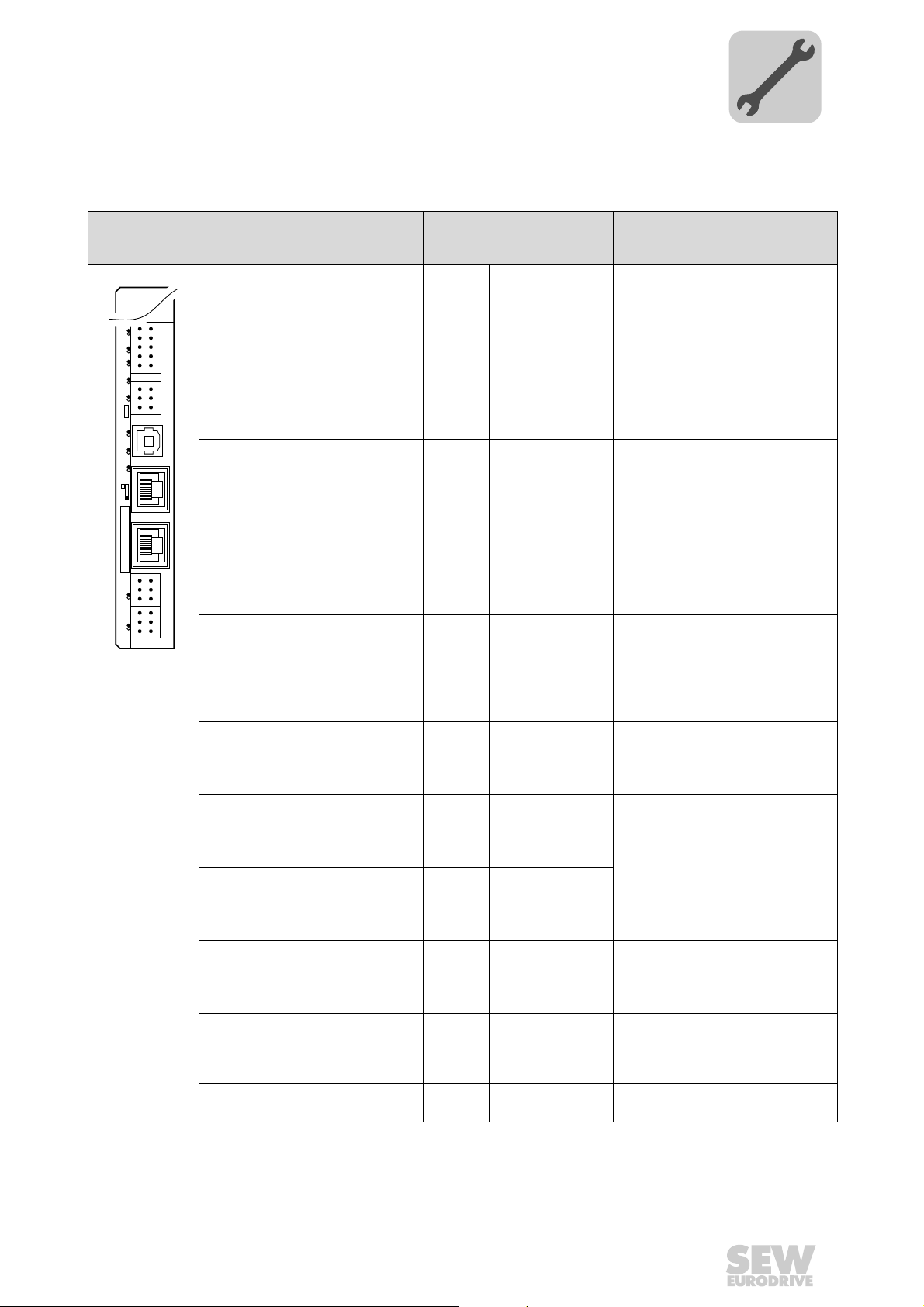

4.7.1 Functional description of terminals, DIP switches and LEDs.....23

4.7.2 Connecting binary inputs and outputs (X31 terminal)................ 24

4.7.3 Connnection to system bus CAN 2 (X32) / CAN 1 (X33)........... 25

4.7.4 RS485 interface connection (X34)............................................. 26

4.7.5 System bus Ethernet 1 connection (X36).................................. 27

4.7.6 Ethernet 2 interface connection (X37)....................................... 27

4.7.7 LEDs of the DH.21B/41B option................................................ 27

4.7.8 DIP switch S1 ........................................................................... 29

4.7.9 SD memory card types OMH41B-T. and OMC41B-T................ 30

4.8 Installing the DHF21B/41B option............................................................. 32

4.8.1 Functional description of terminals, DIP switches and LEDs.....32

4.8.2 Connecting PROFIBUS (X30P)................................................. 33

4.8.3 LEDs in PROFIBUS mode......................................................... 34

4.8.4 Connecting DeviceNet (X30D)................................................... 35

4.8.5 LEDs in DeviceNet mode........................................................... 36

4.8.6 Connecting SEW safety bus (X38)............................................ 38

4.9 Installing the DHR21B/41B option ............................................................ 39

4.9.1 Functional description of the terminals, DIP switches

and LEDs.......... ... ... .... ...................................... .... ... ... ... ... .... ..... 39

4.9.2 Connecting the DHR21B/41B controller to the

Ethernet network........................................................................ 40

4.9.3 Setting DIP switches 20 and 21................................................. 40

4.9.4 The integrated Ethernet switch.................................................. 41

4.9.5 TCP / IP addressing and subnets.............................................. 42

4.9.6 LEDs in PROFINET mode......................................................... 44

4.9.7 Setting IP address parameters via DCP.................................... 45

4.9.8 LEDs in EtherNet/IP and Modbus/TCP mode............................ 46

4.9.9 Setting IP address parameters.................................................. 47

4.10 Engineering interfaces of the DH.21B/41B option .................................... 49

5 Project Planning and Startup with MOVITOOLS

5.1 About MOVITOOLS

5.1.1 Tasks......................................................................................... 50

5.1.2 Establishing communication with other units............................. 50

5.1.3 Executing functions with the units.............................................. 50

5.2 First steps ................................................................................................. 50

5.2.1 Starting the software and creating a project.............................. 50

5.2.2 Establishing communication and scanning the network............ 51

®

MotionStudio.......................................................... 50

®

/stand-alone unit............... 21

®

MotionStudio... ... ... .... ... .. 50

4

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

Page 5

Contents

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

5.3 Connection mode................... .... ... ... ... .... ... ...................................... .... ... .. 52

5.3.1 Overview.................................................................................... 52

5.3.2 Selecting the communication mode (online or offline)............... 53

5.4 Communication via USB........................................................................... 54

5.4.1 Connecting the unit with the PC via USB .................................. 54

5.4.2 Installing the driver..................................................................... 55

5.4.3 Configuring USB communication............................................... 56

5.4.4 USB communication parameters............................................... 57

5.5 Communication via Ethernet..................................................................... 58

5.5.1 Direct communication.................... ... ... .... ... ... ... .... ..................... 58

5.5.2 Address Editor............................ ... ... ... .... ... ............................... 59

5.5.3 Configuring the communication channel via Ethernet ............... 62

5.5.4 Setting communication parameters for SMLP........................... 64

5.5.5 Communication parameters for SMLP.................................. ... .. 65

5.5.6 Communication ports used............ ... ... .... ... ... ... .... ... ... ... ... .... ... .. 65

5.6 Executing functions with the units............................................................. 66

5.6.1 Parameterizing units...... ... ... ....................................... ... ... .... ... .. 66

5.6.2 Reading or changing unit parameters........................................ 66

5.6.3 Starting up units (online)............................................................ 67

5.7 Configuration and startup of the drives..................................................... 68

5.8 Configuration and startup in the PLC Editor ............................................. 68

5.9 Replacing the unit...................... ... ... ... .... ... ... ....................................... ... .. 68

6 Error Diagnostics.............................................................................................. 69

6.1 Diagnostic procedure CAN 1/CAN 2 system bus...................................... 69

7 Technical Data and Dimension Drawings....................................................... 70

7.1 General technical data..................................................... .... ... ... ... ... .... ..... 70

7.2 DHE21B/41B option............................ .... ... ... ... ... .... ... ... ....... ... ... ... ... .... ... .. 71

7.3 DHF21B/41B option.................................................................................. 73

7.4 DHR21B/41B option.................................................................................. 74

7.5 Stand-alone unit........................................................................................ 74

7.6 Dimension drawings for stand-alone unit DH.21B/41B/UOH..B ............... 75

7.6.1 Dimension drawing for DHE21B/41B / UOH11B....................... 75

7.6.2 Dimension drawing for DHF/DHR21B/41B / UOH21B............... 76

Index................................................................................................................... 77

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

5

Page 6

1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

General Information

How to use the documentation

1 General Information

Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

1.1 How to use the documentation

The manual is part of the product and contains important information on operation and

service. The manual is written for all employees who assemble, install, startup, and

service the product.

The manual must be accessible and legible. Make sure that persons responsible for the

system and its operation, as well as persons who work independently on the unit, have

read through the manual carefully and understood it. If you ar e unclear about any of the

information in this documentation, or if you require further information, contact SEWEURODRIVE.

1.2 Structure of the safety notes

1.2.1 Meaning of the signal words

The following table shows the grading and meaning of the signal words for safety notes,

notes on potential risks of damage to propert y, an d ot he r no te s.

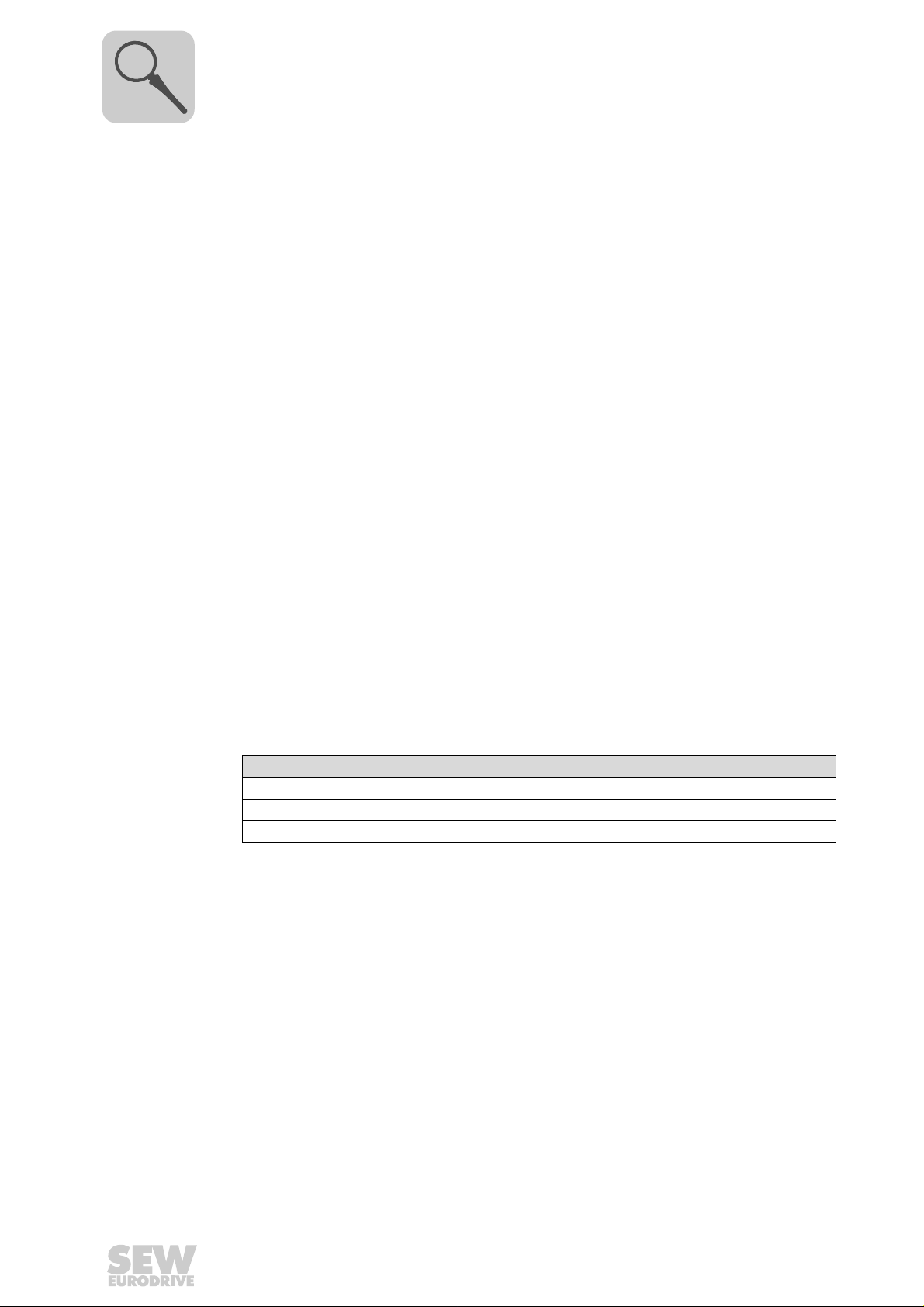

Signal word Meaning Consequences if disregarded

DANGER Imminent danger Severe or fatal injuries

WARNING Possible dangerous situation Severe or fatal injuries

CAUTION Possible dangerous situation Minor injuries

NOTICE Possible damage to property Damage to the drive system or its

INFORMATION Useful information or tip: Simplifies the

handling of the drive system.

environment

1.2.2 Structure of section safety notes

Section safety notes do not apply to a specific action, but to several actions pertaining

to one subject. The used symbols indicate either a general or a specific hazard.

This is the formal structure of a section safety note:

SIGNAL WORD

Type and source of danger.

Possible consequence(s) if disregarded.

• Measure(s) to prevent the danger.

1.2.3 Structure of embedded safety notes

Embedded safety notes are directly integrated in the instructions just before the

description of the dangerous action.

This is the formal structure of an embedded safety note:

• SIGNAL WORD Nature and source of hazard.

Possible consequence(s) if disregarded.

– Measure(s) to prevent the danger.

6

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

Page 7

1.3 Right to claim under warranty

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

A requirement of fault-free operation and fulfillment of any rights to claim under limited

warranty is that you adhere to the information in the documentation. Therefore, read the

manual before you start operating the device.

Make sure that the manual is available to persons responsible for the plant and its

operation as well as to persons wh o work independently on the device. You must also

ensure that the documentation is legible.

1.4 Exclusion of liability

You must observe this documentation and the documentation of the co nnected devices

from SEW-EURODRIVE to ensure safe operation and to achieve the specified product

characteristics and performance requirements. SEW-EURODRIVE assumes no liability

for injury to persons or damage to equipment or property resulting from no n-observance

of these operating instructions. In such cases, any liability for defects is excluded.

General Information

Right to claim under warranty

1

1.5 Copyright

© 2009 – SEW-EURODRIVE. All rights reserved.

Copyright law prohibits the unauthorized duplication, modification, distribution, and use

of this document, in whole or in part.

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

7

Page 8

2

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety Notes

Other applicable documentation

2 Safety Notes

2.1 Other applicable documentation

• Read through this document carefully before you commence inst allation and st artup

of the DH.21B/41B options.

The following publications and documents apply to the connected units:

• Operating instructions for the units (such as for MOVIDRIVE

MOVIAXIS

• Only electrical specialists are allowed to perform installation and startup observing

the relevant accident prevention regulations and the operating instructions of the

connected units (such units are, for example, MOVIDRIVE

MOVITRAC

• For units with functional safety, also observe the corresponding manual "Functional

Safety" or "Safe Disconnection – Conditions".

• You must adhere to the information in the documentation as a prerequisite to faultfree operation and fulfillment of warranty claims.

®

)

®

B, MOVIAXIS®).

®

B, MOVITRAC® B,

®

MDX60B/61B,

2.2 Bus systems

The DH.21B and DH.41B options support various bus systems. A bus system makes it

possible to adapt frequency inverters to the particulars of the machinery within wide

limits. As with all bus systems, there is a danger of invisible, external (as far as the

inverter is concerned) modifications to the parameters which give rise to changes in the

unit behavior. This may result in unexpected, though not uncontrolled, syste m behavior.

2.3 Safety functions

MOVIDRIVE® MDX60B/61B and MOVITRAC® B inverters may not perform any safety

functions without higher-level safety systems. Use higher-level safety systems to ensure

protection of equipment and personnel. For safety applications, en sure that the information in the following publications is observed: "Safe Disconnection for MOVIDRIVE

MDX60B/61B / MOVITRAC® B".

2.4 Hoist applications

MOVIDRIVE® MDX60B/61B, MOVITRAC® B and MOVIAXIS® must not be used as a

safety device in hoist applications.

Use monitoring systems or mechanical protection devices as safety equipment to avoid

possible damage to property or injury to people.

®

8

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

Page 9

2.5 Disposal

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety Notes

Disposal

Observe the applicable national regulations.

Dispose of the following materials separately in accordance with the country-specific

regulations in force, as:

• Electronics scrap

• Plastic

• Sheet metal

• Copper

2

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

9

Page 10

3

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Introduction

General information

3 Introduction

3.1 General information

3.1.1 Content of this manua l

3.1.2 Additional documentation

This user manual describes the following:

• How to install the DH.21B/41B options in MOVIDRIVE

®

MDX61B

• Interfaces and LEDs of the DH.21B/41B options

• How to install the DH.21B/41B options in MOVIDRIVE

MOVITRAC

®

B inverters, in MOVIAXIS® servo inverters, and in stand-alone

®

MDX61B and

housings

• Engineering access to the DH.21B/41B options

• Project planning and startup of DH.21B/41B options

To be able to configure and start up the DH.21B/41B options simp ly and effectively, you

should also order the following publications in addition to this manual:

• "DHF21B/41B Controller PROFIBUS DP-V1 and DeviceNet Fieldbus Interfaces"

manual

• "DHR21B/41B Controller PROFINET IO, EtherNet/IP, Modbus TCP/IP Fieldbus

Interfaces" manual

•MOVIDRIVE

•MOVITRAC

•MOVIAXIS

®

MDX60/61B system manual

®

B system manual

®

system folder

When used as freely programmable motion and logic controller with SD card OMH41B:

•"MOVI-PLC

The "MOVI-PLC

®

Programming in the PLC Editor" system manual

®

Programming in the PLC Editor" system manual contains

instructions for IEC 61131-3 compliant programming.

• "MPLCMotion_MDX and MPLCMotion_MX Libraries for MOVI-PLC

• "MPLCMotion_MC07 and MPLCMotio n_M M Libr ar ies for MO VI- P L C

®

" manual

®

" manual

The library relevant manuals describe the motion libraries for controlling

MOVIDRIVE

®

MDX60B/61B, MOVIAXIS®, MOVITRAC®B, and MOVIMOT

inverters.

When used as configurable application controller with SD card OMC41B:

• Manuals for the respective application modules

®

10

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

Page 11

Overview of controllers

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

3.2 Overview of controllers

3.2.1 Freely programmable motion and logic controller (MOVI-PLC®)

The controller can be operated as freely programmable motion and logic controller

MOVI-PLC

programmable motion and logic controllers. It allows drive solutions, logic processes

and sequence controls to be automated simply and efficiently using IEC 61131-3

compliant programming languages.

•MOVI-PLC

SEW inverters and offers a simple upgrade to a more powerful MOVI-PLC

due to the fact that all possible programs can be executed.

•MOVI-PLC

advanced, etc.) and modular software concept s (libraries for numerous applications).

•MOVI-PLC

synchronous operation) and the control of demanding app lications (such as material

handling).

®

when using SD cards of the type OMH41B. MOVI-PLC® is a series of

®

is a universal solution because it is able to control the entire portfo lio of

®

is scalable due to several different hardware platforms (standard,

®

is powerful due to extensive technologies (such as electronic cam,

Introduction

®

version

3

Performance class

MOVI-PLC

standard

Performance class

MOVI-PLC

advanced

3.2.2 Configurable application controller (CCU)

CCU standard

performance class

®

®

• DH.21B controllers enable coordinated single axis movements and integration of

external inputs/outputs as we ll as Drive Operator Panels (DOP). The DH.21B.. option

is therefore suitable for use as a module controller or stand-alone controller for

machines of medium complexity.

• The DH.41B controller is characterized by a great variety of interfaces and a higher

performance level, which allows complex calculations and interpolated movements,

for example. The DH.41B option is therefore suitable for the automation of cells and

machines. The integrated Ethernet interface enables direct connection of the

DH.41B controller to the control level.

The controller can be used as configurable application controller (CCU) by using SD

cards of the type OMC41B. Only standardized application modules created by

SEW-EURODRIVE can be executed. The application modules can be sta rted up quickly

and conveniently by graphical configuration. A defined process data interface provides

this functionality to a higher-level controller. A process data monitor with control mode

is available to support the startup procedure.

The "CCU standard" performance class is intended for application mod ules with singleaxis functionality and medium response times. A maximum of 16 axes can be connected

to a configurable application controller. The following application modules are available

and can be started up using the AxisConfigurator tool.

• Speed specification

• Cam positioning

• Bus positioning with 6 process data

• Single-axis universal module

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

11

Page 12

3

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Introduction

Controller DH.21B/41B

Performance class

CCU advanced

The "CCU advanced" performance class is intended for application modules with singleaxis and multi-axis functionality and fast response times. The following application

modules are available:

• Single-axis functionality:

– Speed specification

– Cam positioning

– Bus positioning 6 process data

– Single-axis universal module

• Multi-axis functionality:

– SyncCrane

– Energy-efficient SRU

3.3 Controller DH.21B/41B

3.3.1 Features

Two types of DH.21B/41B controllers are available:

•As option card DH.21B/41B for MOVIDRIVE

DHE21B/41B) and for MOVIAXIS

®

®

servo inverters

B and MOVITRAC®B inverters (only

•In stand-alone housing DH.21B/41B UOH.1B prepared for installation on a

mounting rail.

3.3.2 Device types

Three types of DH.21B/41B controllers are available, which differ in the fieldbus interfaces:

DH.21B/41B type Fieldbus interfaces

DHE21B/41B Ethernet TCP/IP, UDP

DHF21B/41B Ethernet TCP/IP, UDP, PROFIBUS DP-V1, DeviceNet

DHR21B/41B Ethernet TCP/IP, UDP, PROFINET, EtherNet/IP, ModbusTCP/IP

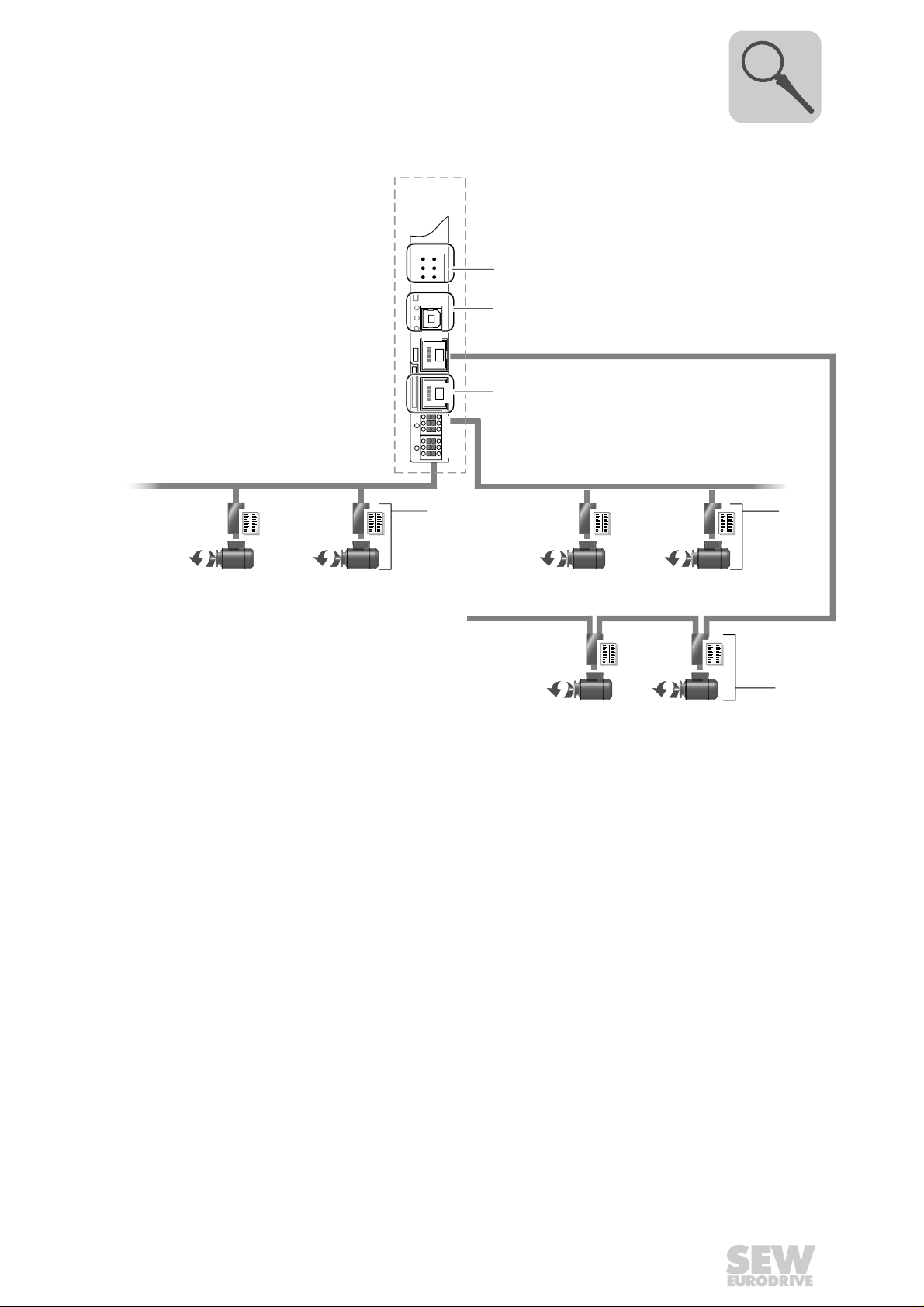

3.3.3 Overview of communication interfaces

The DH.21B/41B option is equipped with numerous communication interfaces.

The two system bus interfaces CAN 1 and CAN 2 are primarily used for co nnecting and

controlling several inverters and for integrating decentralized I/O modules.

You can operate this machine module on a higher-level controller using the integrated

fieldbus interface.

An operator terminal (e.g. DOP11B) or a MOVIMOT

frequency inverter is connected to the RS485 interfaces.

SEW drives and SEW I/O modules with EtherCAT interface ca n be connected to the

PLUS®

SBUS

system bus interface.

®

gearmotor with integrated

12

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

Page 13

Introduction

SBUS (CAN2)

SBUS (CAN1)

EtherCAT

SBUS

PLUS*

DH.41B

[3]

XM

X32X33

[2]

X37

X36

X35

[2]

[1]

[1]

X34

[4]

2

4

6

1

3

5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Controller DH.21B/41B

3

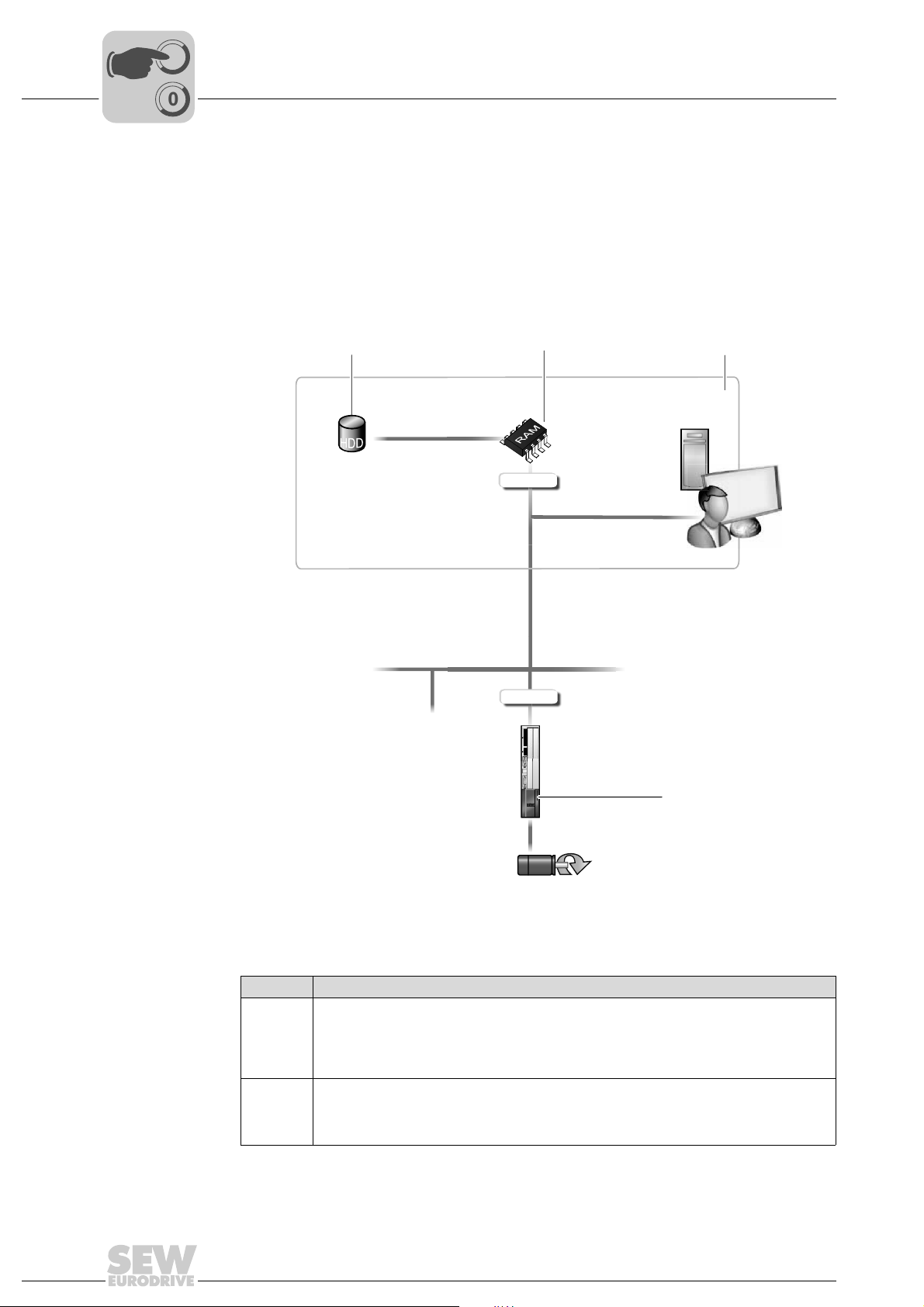

3.3.4 Engineering

2384673547

[1] Engineering interface USB (X35) and Ethernet 2 (X37)

[2] SEW inverter with SBus interface (X32/X33)

[3] SEW inverter with EtherCAT interface (X36)

[4] 2 × RS485 interfaces (X34)

Engineering of the DH.21B/41B option includes the following activities:

• Configuration

• Parameterization

• Programming (only MOVI-PLC

These activities are carried out using the MOVITOOLS

software. The software has a number of useful features for startup an d diagnostics of all

SEW-EURODRIVE units. The DH.21B/41B option is connected with the engineering PC

®

)

®

MotionStudio engineering

via

• Ethernet communication interface (X37)

• USB interface (X35)

• Engineering channels of the fieldbus system used

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

13

Page 14

3

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

3.3.5 System buses CAN 1, CAN 2 and Ethernet 1

3.3.6 RS485 interfaces COM1 and COM2

Introduction

Controller DH.21B/41B

You can use the DH.21B/41B option to control a machine module by connecting se veral

inverters via the system bus. The DH.21B/41B option controls all drives within the

machine module and in this way takes load off the higher-leve l controller (e.g. machine/

system PLC). You can connect a total of maximum 16 units to the DH.21B option, and

a total of maximum 64 units to the DH.41B option via system buses CAN 1, CAN 2,

and Ethernet 1:

®

•MOVITRAC

•MOVIDRIVE

•MOVIAXIS

• Gearmotor with integrated frequency inverter MOVIMOT

DeviceNet MFD... required)

• I/O coupler (OCC11B/OCE11B)

Connect one of the following devices each to the RS485 interfaces COM1 or COM2:

B frequency inverter

®

MDX60B/61B drive inverter

®

servo inverter

®

(Fieldbus interface

• DOP11B operator terminal

• MOVIMOT

3.3.7 Ethernet 2

You can implement the following functions and connections using the Ethernet 2

communication interface:

• Connection of a DOP11B operator terminal

• PC visualization (e.g. OPC interface)

• Connection to master level

3.3.8 Binary inputs and outputs

Binary inputs and outputs enable you to switch actuators (e.g. valves) and evaluate

binary input signals (e.g. sensors).

3.3.9 Diagnostic LEDs

The LEDs of the DH.21B/41B options indicate the following states:

• Voltage supply of the binary inputs and outputs

• General state of the DH.21B/41B options

®

gearmotor with integrated frequency inverter

• State of the control program

• State of the fieldbus interface (DHF/DHR)

• State of the Ethernet interface

• State of both CAN interfaces

You can connect operator terminals to perform diagnostics. It is recommended to

connect an operator terminal to the communication interface Ethernet 2.

14

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

Page 15

Assembly and Installation Notes

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installation options of DH.21B/41B

4 Assembly and Installation Notes

4.1 Installation options of DH.21B/41B

Observe the following installation instructions:

INFORMATION

• You can insert the DH.21B/41B option in the MOVIDRIVE®MDX61B inverter. Do

not insert it in the MOVIDRIVE

• Option cards can only be installed or remove d for M OVIDRIVE

to 6.

• The installation or removal of option cards for MOVIDRIVE

inverters must only be carried out by SEW-EURODRIVE engineers.

• The installation or removal of the DH.21B/41B option in MOVIAXIS

installation of the stand-alone housing DH.21B41B/UOH..B must only be carried

out by SEW-EURODRIVE engineers.

4.2 Installing the DH.21B/41B option in MOVIDRIVE®MDX61B

®

MDX60B inverter.

®

MDX61B sizes 1

®

MDX61B size 0

®

as well as the

4

• You must insert the DHE21B/DHE41B option into the fieldbus slot of

• Y ou must inser t the DHF21B/DHR21B and DHF41B/DHR41B opti ons into the expan-

4.2.1 Before you start

Read the following notes before installing or removing DH.21B/41B options:

• Disconnect the inverter from power. Switch off the DC 24 V and the line voltage.

• Before touching the DH.21B/41B option, take appropriate measures (discharge

• Before installing the DH.21B/41B option, remove the keypad and the front cover.

• After installing the DH.21B/41B option, replace the front cover and the keypad.

• Keep the DH.21B/41B option in its original packaging until immediately before you

• Hold the DH.21B/41B option only by its edges. Do not touch any of the components.

• Never place the DH.21B/41B option on a conductive surface.

®

MOVIDRIVE

DHE21B/41B option into the expansion slot.

sion slot of MOVIDRIVE

size 0.

strap, conductive shoes, etc.) to protect it from electrostatic charge.

are ready to install it.

MDX61B. If the fieldbus slot is not available, you can plug the

®

MDX61B. It cannot be installed in MOVIDRIVE® MDX61B

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

15

Page 16

4

1.

4.

3.

2.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Assembly and Installation Notes

Installing the DH.21B/41B option in MOVIDRIVE®MDX61B

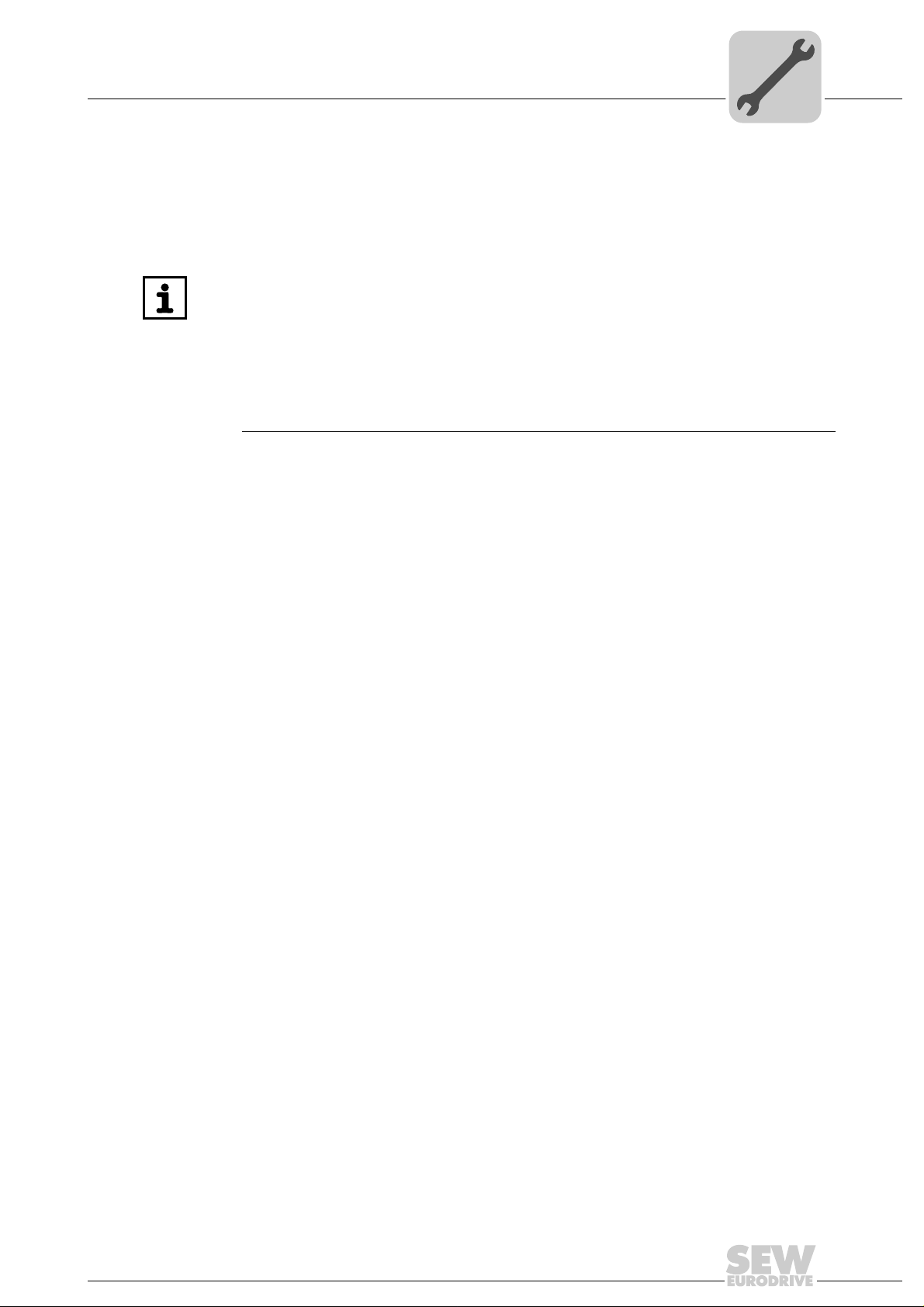

4.2.2 Basic procedure for installing or removing an option card in MOVIDRIVE® MDX61B

2102036363

1. Remove the retaining screws holding the card retaining bra cket. Pull the card retain-

ing bracket out evenly from the slot (do not twist!).

2. Remove the retaining screws of the black cover plate on the card retaining bracket.

Remove the black cover plate.

16

3. Position the option card onto the retaining bracket so th at the retaining screws fit into

the corresponding bores on the card retaining bracket.

4. Insert the retaining bracket with the installed option card into the slot, pressing

slightly so it is seated properly. Secure the option card retaining bracket with the

retaining screws.

5. Follow the instructions in reverse order when removing the option card.

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

Page 17

Assembly and Installation Notes

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installing the DH.21B/41B option in MOVIDRIVE®MDX61B

4.3 Installing the DH.21B/41B option in MOVIDRIVE®MDX61B

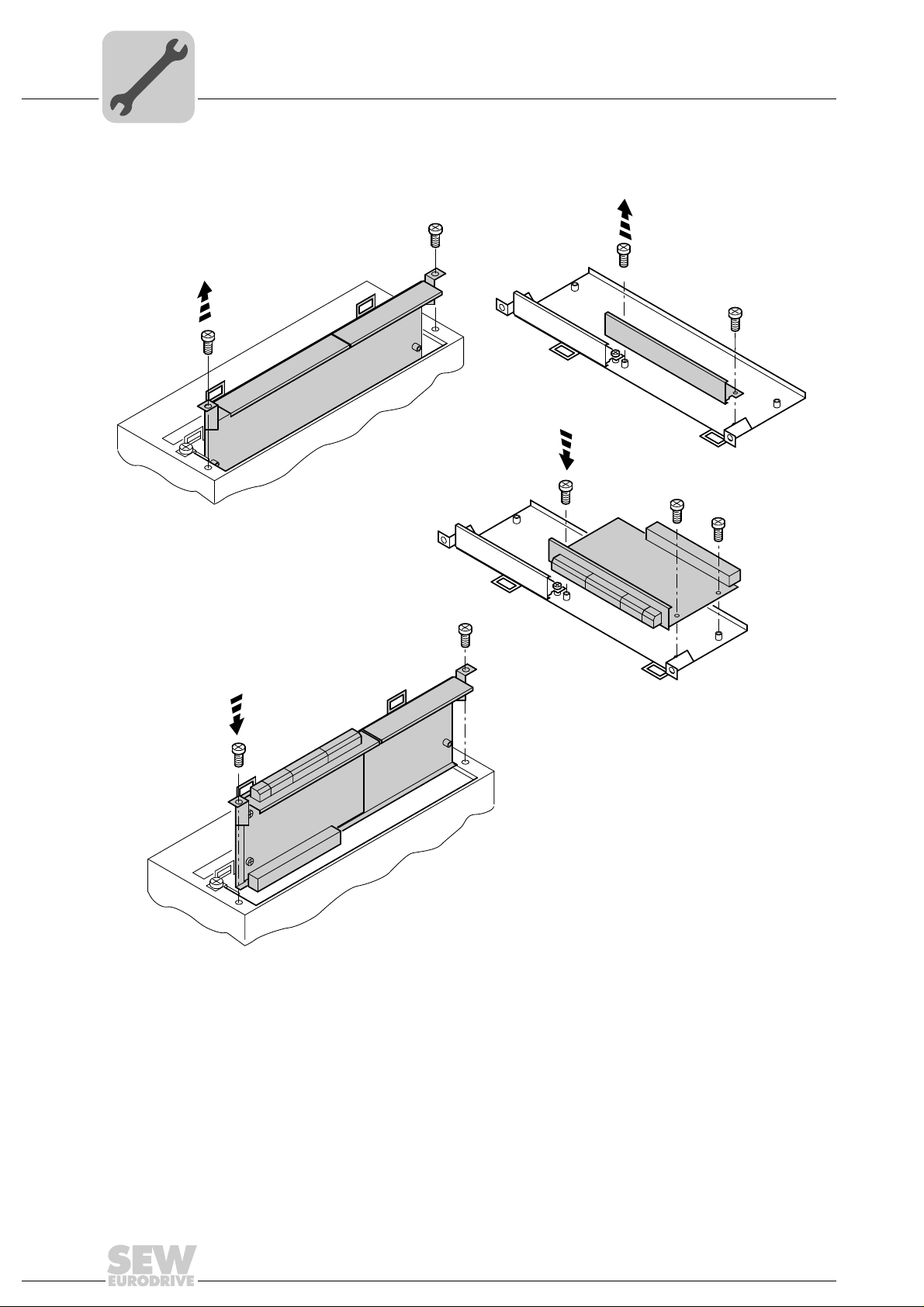

INFORMATION

The DH.21B/41B option is installed as described in the "Installation options of DH.21B/

41B" chapter. The DH.21B/41B option is powered via MOVIDRIVE

separate voltage supply is only required for the binary inputs and outputs (connector

X31). For wiring the system bus, connect the X33 plug (CAN 1) or X32 (CAN 2) of the

DH.21B/41B option with X12 of MOVIDRIVE

®

MDX61B.

4.4 Installing the DH.21B/41B option in the MOVIAXIS® master module

INFORMATION

The DH.21B/41B option is installed as described in the "Installation options of DH.21B/

41B" chapter. For wiring the system bus, connect connector X33 (CAN 1) or X32

(CAN 2) of the DH.21B/41B option with X9 (signal bus of the MOVIAXIS

module or of a MOVIAXIS

axis module). The MOVIAXIS® master module provides additional connections that

are described in the following section.

®

axis module), or with X12 (CAN 2 bus of a MOVIAXIS

®

MDX61B. A

®

supply

4

®

4.4.1 Functional description of terminals X5a / X5b (MOVIAXIS® master module)

MOVIAXIS® master

module MXM

1

X5b

2

3

4

1

X5a

2

3

4

2107418379

• The terminals X5a and X5b are connected in parallel. In this way, the voltage supply

of the MOVIAXIS

Designation Terminal Function

X5b connector X5b:1

X5b:2

X5b:3

X5b:4

Terminal X5a X5a:1

X5a:2

X5a:3

X5a:4

®

master module can be provided from the right to X5b or from

DC 24 V

DGND

DC 24 V

BGND

DC 24 V

DGND

DC 24 V

BGND

Voltage supply for control electronics

E

Reference potential for control electronics

Voltage supply for brake

B

Reference potential for brake connection

Voltage supply for control electronics

E

Reference potential for control electronics

Voltage supply for brake

B

Reference potential for brake connection

below to X5a. With connection to X5a, further modules can be connected via X5b

(e.g. supply module, axis module). The voltage supply for the brake (X5a/b:3,4) is fed

through the MOVIAXIS

• The DH.21B/41B option can be supplied from the MOVIAXIS

®

master module.

®

supply (MXS) or from an external voltage source. To do so, connect X5 between the

individual units.

• If the DH.21B/41B option is connected with DC 24 V from the MOVIAXIS

mode power supply, the functioning of the DH.21B/41B option is maintained after

disconnection from the power supply. This is the case if the DC link voltage is

maintained or an external DC 24 V supply is present from the MOVIAXIS

mode power supply.

switched-mode power

®

switched-

®

switched-

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

17

Page 18

4

MOVIAXIS®

master module MXM

2

X5b

1

DC 24V

E

DGND

3

DC 24V

B

4 BGND

DC 24 V for

brake power supply

DC 24 V supply

for control electronics

+-+-

X16

-

+

External DC 24 V

X5a

2

1

3

4

X5a

2

1

3

4

X5b

2

1

3

4

MOVIAXIS®

switched-mode

power supply MXS

X35

X36

X37

2

4

6

1

3

5

X34

Version

DHE41B

1

2

3

1

342

1

2

3

1

2

3

1

2

3

X32X33

2

4

6

1

3

5

8107

9

X31

T1

S1

L1 L2 L3 L5XM L6 L7 L8 L9L4 L10

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

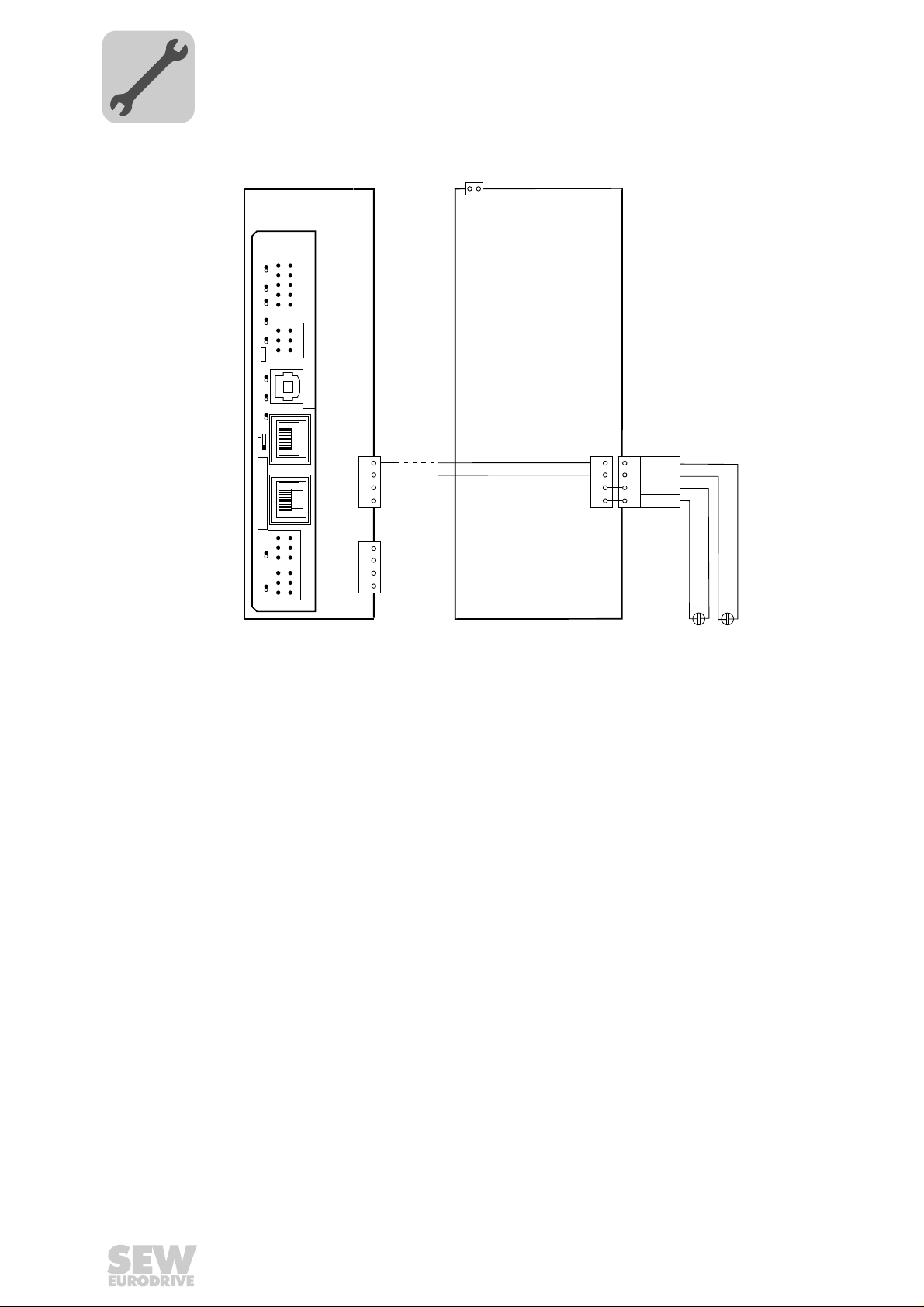

Wiring diagram

Assembly and Installation Notes

Installing the DH.21B/41B option in the MOVIAXIS® master module

2107421323

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

18

Page 19

Assembly and Installation Notes

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installing the DH.21B/41B option in MOVITRAC® B / stand-alone unit

4.5 Installing the DH.21B/41B option in MOVITRAC® B / stand-alone unit

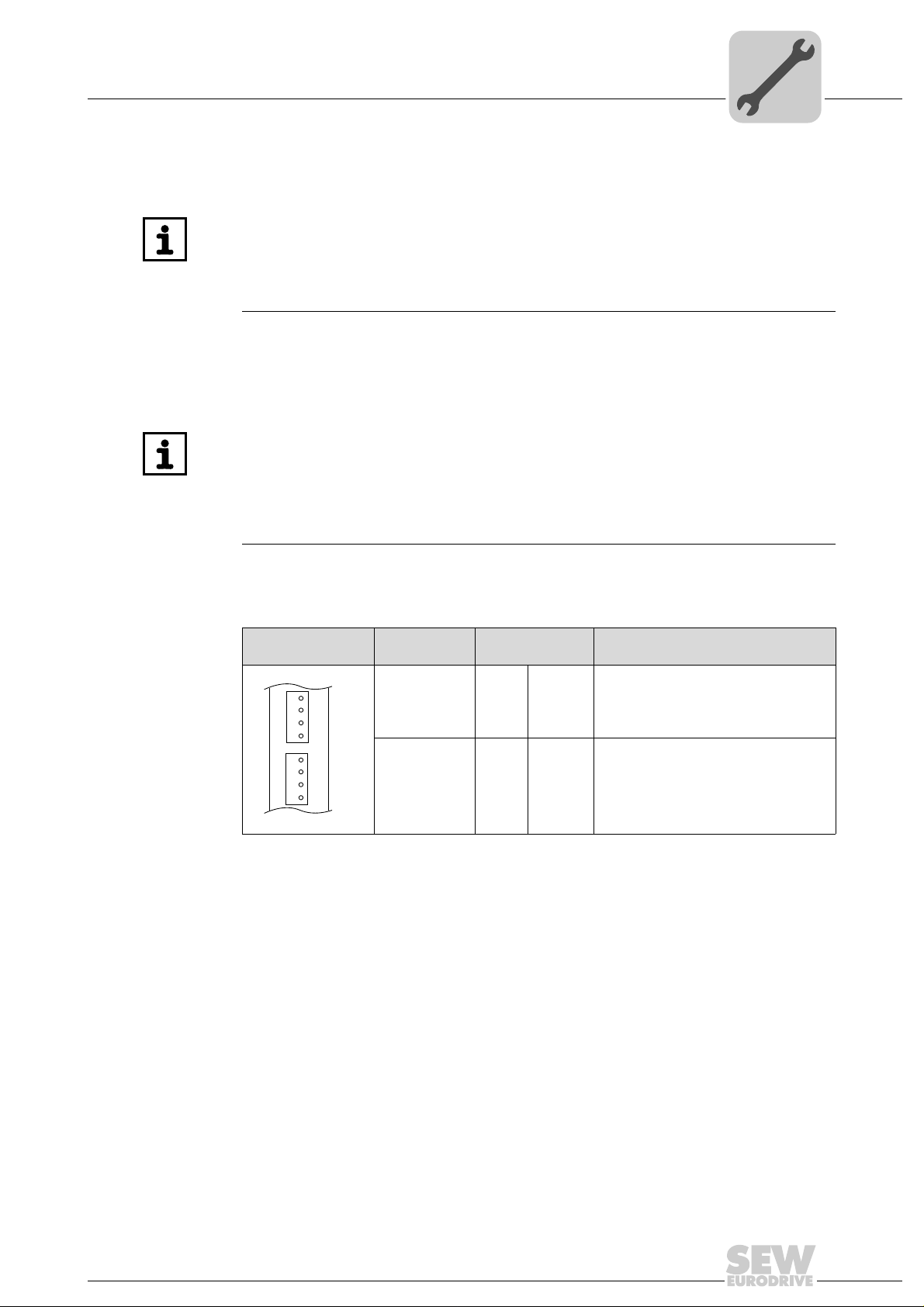

INFORMATION

The DH.21B/41B option is installed as described in the "Installation options of DH.21B/

41B" chapter. The option card slot MOVITRAC

additional connections for the DH.21B/41B option. These connections are described

below.

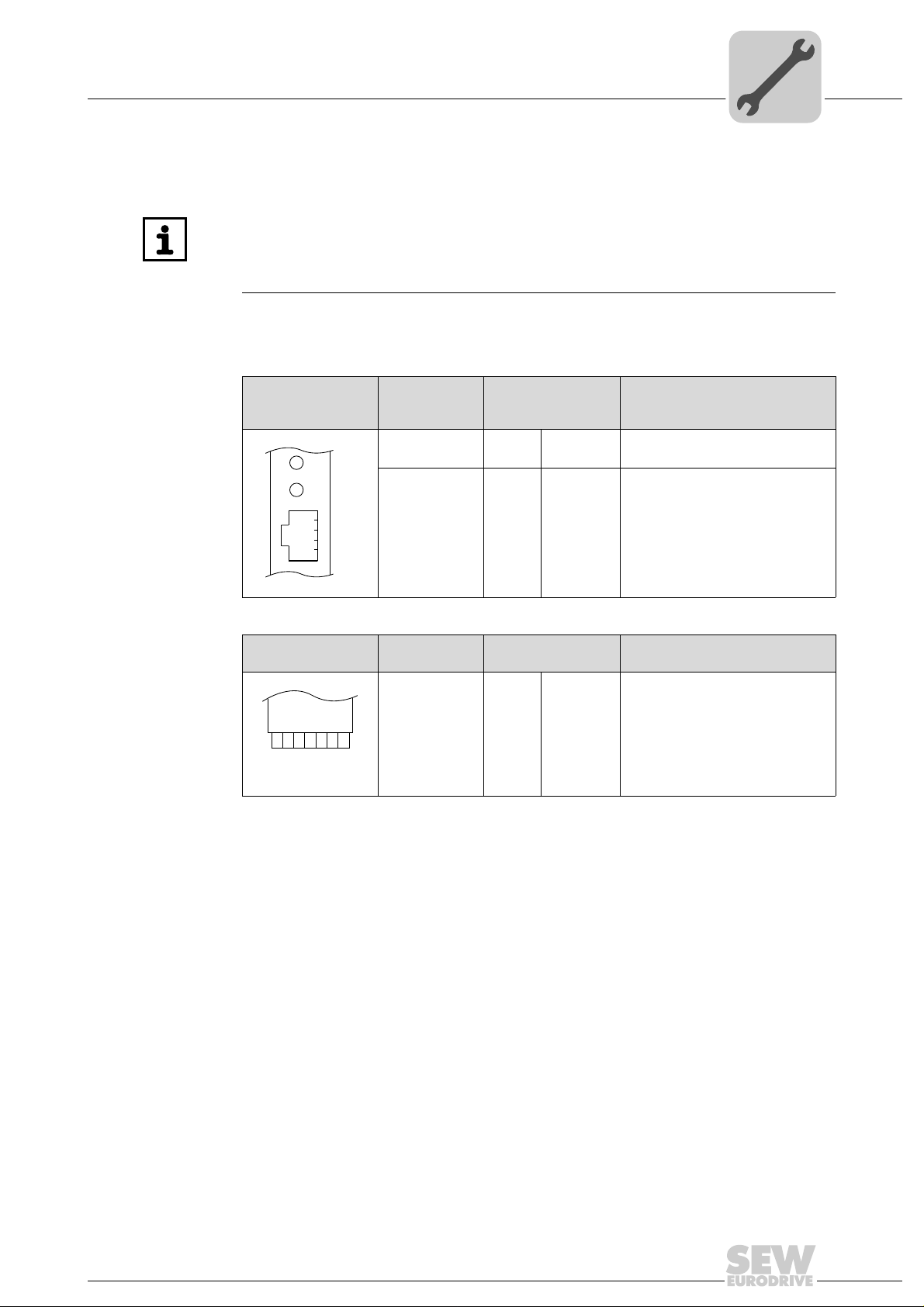

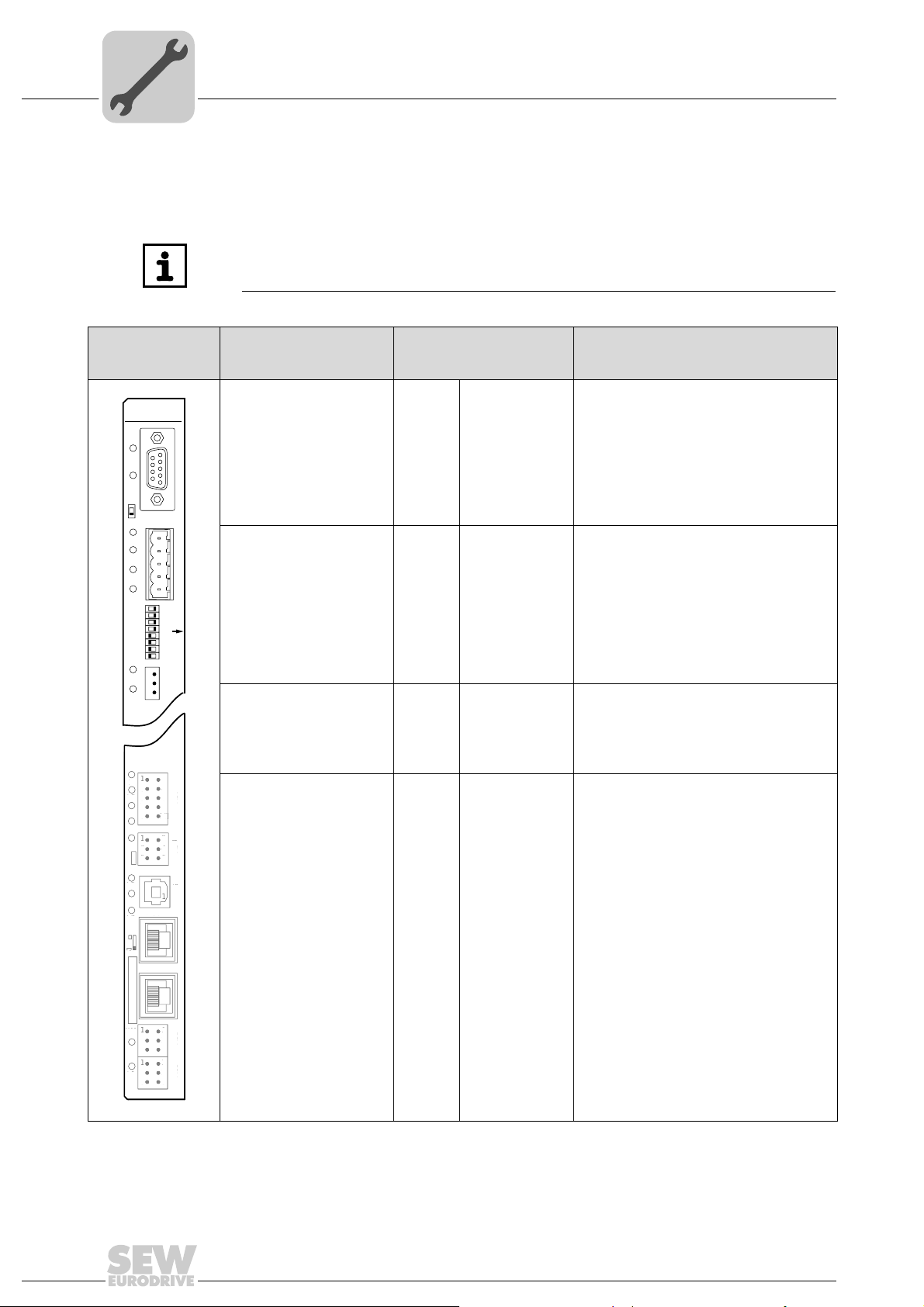

4.5.1 Description of terminals and LEDs

®

B and the stand-alone unit provide

4

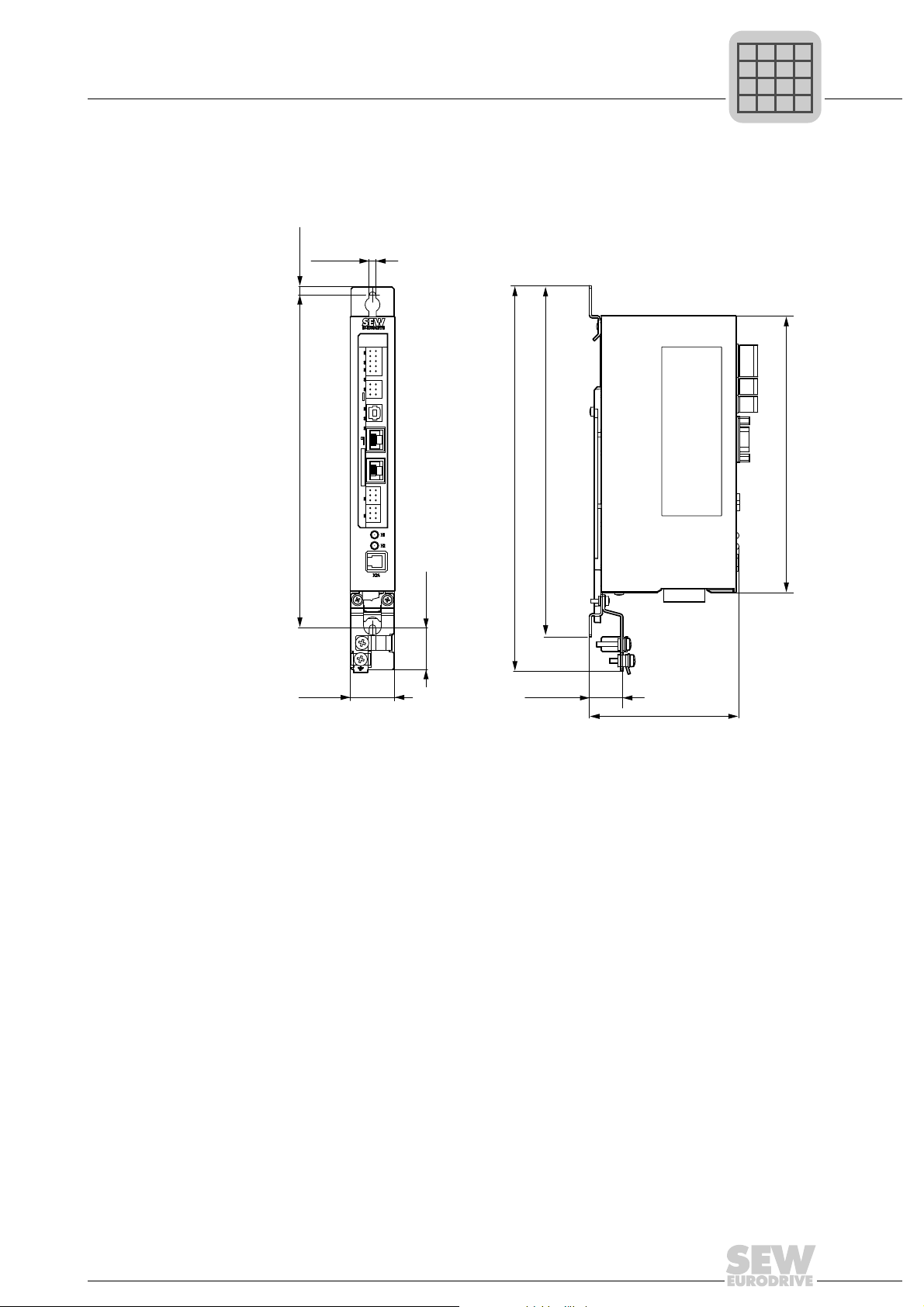

Front view

MOVITRAC

stand-alone unit

Side view

Stand-alone unit

®

2108468363

X26

2345671

2108496651

B/

H1

H2

X24

Designation

LED H1

X24 connector:

RS485 COM 1

(RJ10 socket)

Designation Terminal Function

X26 connector:

CAN 1 and

voltage supply

(plug-in

terminal)

LED

Terminal

H2

X24:4

X24:3

X24:2

X24:1

X26:1

X26:2

X26:3

X26:4

X26:5

X26:6

X26:7

4.5.2 RS485 interface COM1 connection (connector X24)

The connectors X24 and X34:1/3/5 are connected in parallel. You can connect a

DOP11B operator terminal at X24. If X24 is unassigned, you can connect an operator

terminal or a gearmotor with integrated MOVIMOT

DGND

RS–

RS+

5V

CAN 1H

CAN 1L

DGND

Reserved

Reserved

DGND

DC 24 V

®

Function

Reserved

Reserved

Reference potential COM 1

Signal RS485–

Signal RS485+

Voltage output DC +5 V

System bus CAN 1 high

System bus CAN 1 low

Reference potential control/CAN1

-

Reference potential control/CAN1

Voltage supply for controller

frequency inveter to X34:1/3/5.

For more information, refer to "RS485 interface connection (X34) ".

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

19

Page 20

4

X45

X46

1

23456HL ⊥

FSC11B

MOVITRAC® B

S1

OFF

ON

7

S2

X44

X26

1234567

X24

H1

H2

X12

1

2

3

4

5

6

7

8

24V IO

DC 24V

-

+

9

GND

=

120W

X35

X36

X37

2

4

6

1

3

5

X34

DHE41B

1

2

3

1

342

1

2

3

1

2

3

1

2

3

X32X33

2

4

6

1

3

5

8107

9

X31

T1

S1

L1 L2 L3 L5XM L6 L7 L8 L9L4 L10

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Assembly and Installation Notes

Installing the DH.21B/41B option in MOVITRAC® B / stand-alone unit

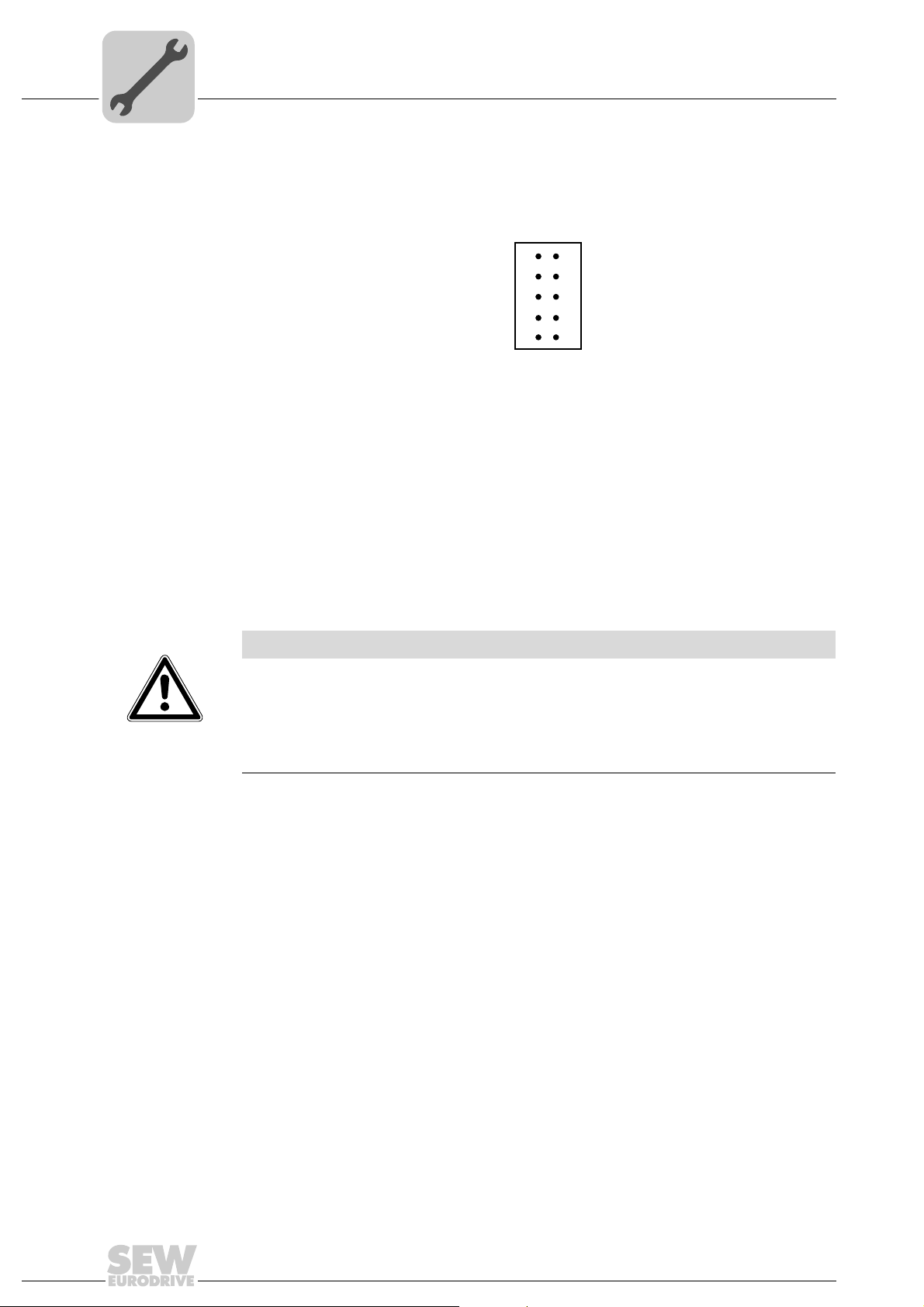

4.5.3 Connecting CAN 1 system bus/voltage supply (X26)

X26:1/2/3 and connector X33 are connected in parallel. The DH.21B/41B option in the

compact controller is supplied with voltage via X26:6/7.

The DHE21B/41B option can be supplied with the required voltage by MOVITRAC

To do so, connect X26:3 (6)/7 with X46:3 (6)/7 or with X12:9/8. If MOVITRAC

supplies the DHE21B/41B option with DC 24 V, then the functions of the DHE21B/41B

option are also ensured after disconnection from the supply system. This requires an

external DC 24 V supply to X12:8/9 of MOVITRAC

®

B.

®

B

®

B.

2108499339

20

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

Page 21

Assembly and Installation Notes

X26

1

23456

7

SEW drive

Compact controller

DC +24 V

GND

X24

H1

H2

SC11 System bus +, CAN high

SC12 System bus -, CAN low

GND, CAN GND

120W

X35

X36

X37

2

4

6

1

3

5

X34

DHE41B

1

2

3

1

342

1

2

3

1

2

3

1

2

3

X32X33

2

4

6

1

3

5

8107

9

X31

T1

S1

L1 L2 L3 L5XM L6 L7 L8 L9L4 L10

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installing the DH.21B/41B option in MOVITRAC® B / stand-alone unit

4

4.5.4 LED when installed in MOVITRAC®/stand-alone unit

LED H1, H2 LEDs H1 and H2 are reserved.

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

2108502027

21

Page 22

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Assembly and Installation Notes

Shielding and routing bus cables

4.6 Shielding and routing bus cables

Only use shielded cables and connection elements that also meet the requirements of

category 5, class 2 in compliance with IEC 11801 edition 2.0.

Correct shielding of the bus cable atte nuates electrical interference that can occur in

industrial environments. The following measures ensure the best possible shielding:

• Manually tighten the mounting screws on the connectors, modules, and equipotential

bonding conductors.

• Use only connectors with a metal housing or metallized housing.

• Connect the shielding in the connector over a wide surface area.

• Apply the shielding of the bus cable on both ends.

• Route signal and bus cables in separate cable ducts. Do not route them parallel to

power cables (motor leads).

• Use metallic, grounded cable racks in industrial environments.

• Route the signal cable and the corresponding equipotential bonding close to each

other using the shortest possible route.

• Avoid using plug connectors to extend bus cables.

• Route the bus cables closely along existing grounding surfaces.

NOTICE

In case of fluctuations in the ground potential, a compensating current may flow via the

bilaterally connected shield that is also connected to the protective earth (PE). In such

a case, make sure you supply adequate equipotential bonding in accordance with

relevant VDE regulations.

22

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

Page 23

Assembly and Installation Notes

X35

X36

X37

2

4

6

1

3

5

X34

1

2

3

1

342

1

2

3

1

2

3

1

2

3

X32X33

2

4

6

1

3

5

8107

9

X31

T1

S1

L1 L2 L3 L5XM L6 L7 L8 L9L4 L10

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

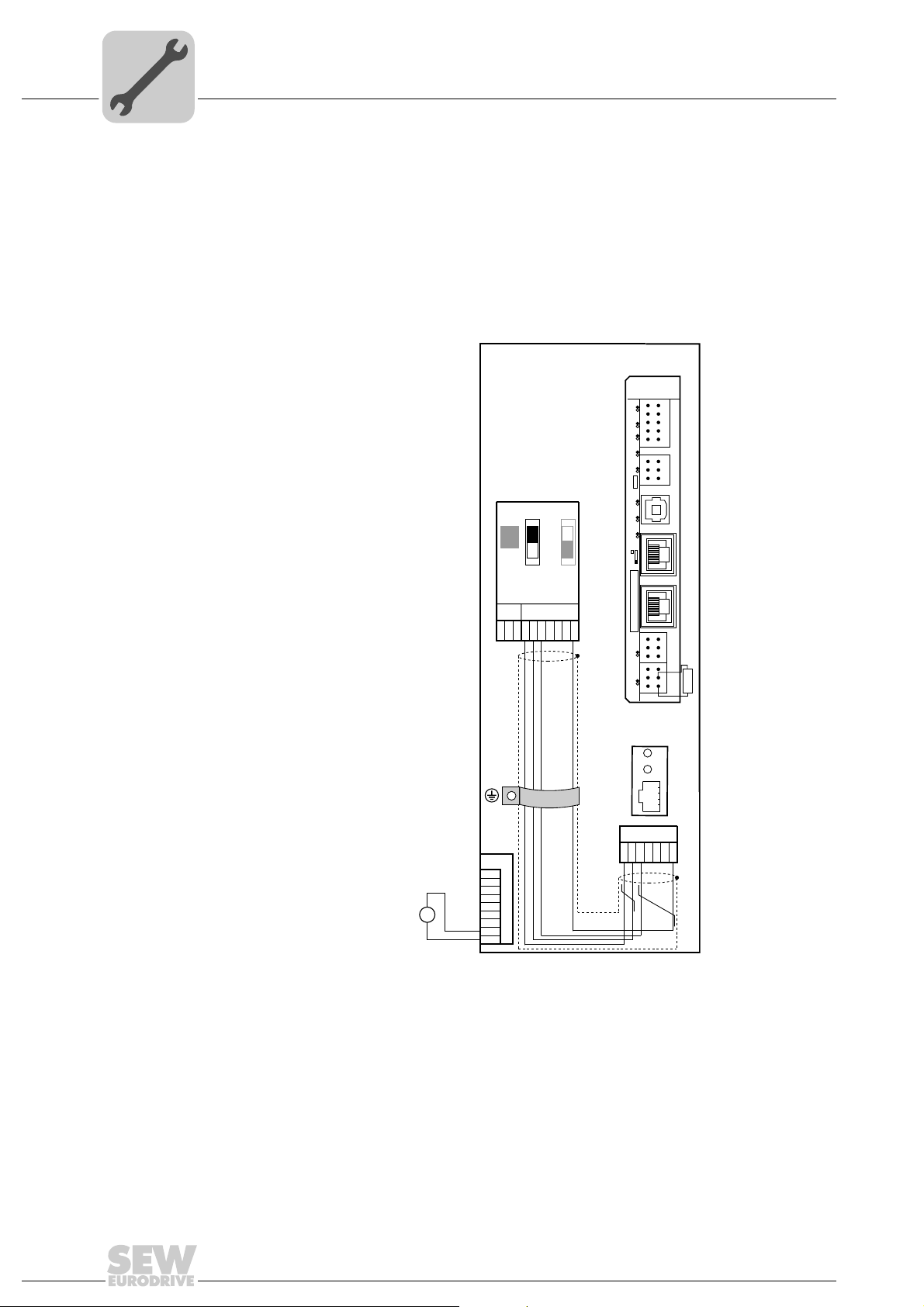

Installing the DH.21B/41B option

4.7 Installing the DH.21B/41B option

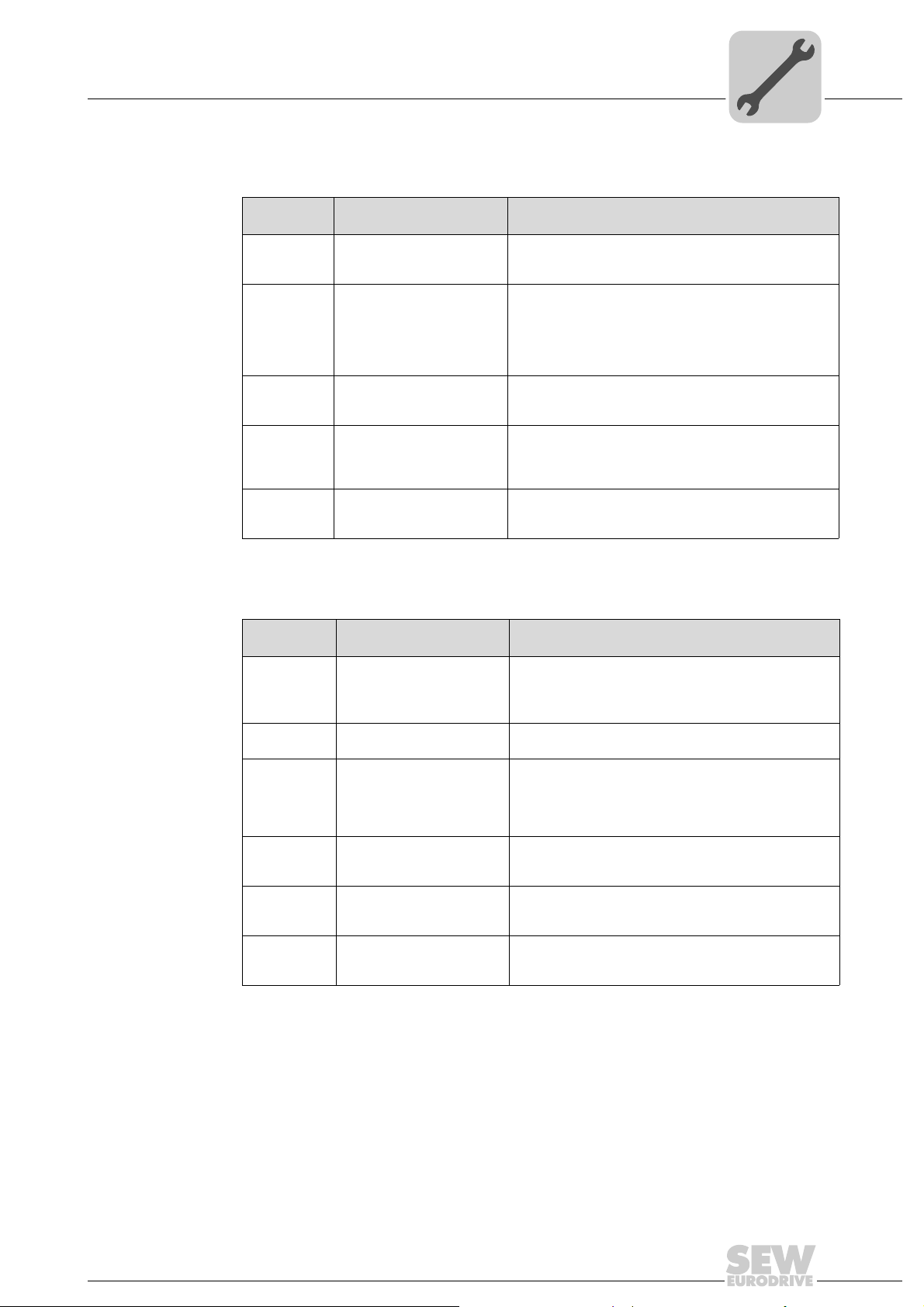

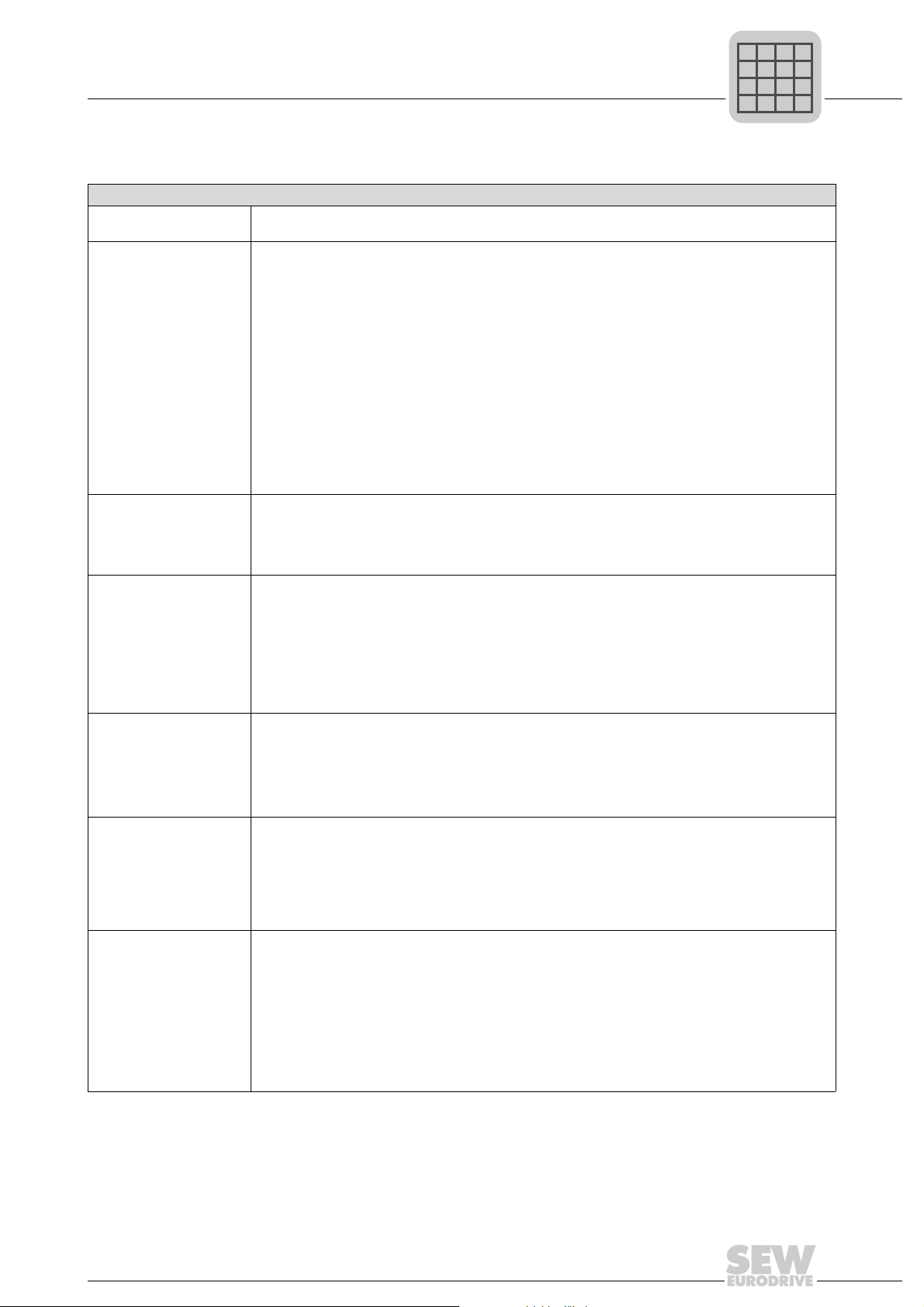

4.7.1 Functional description of terminals, DIP switches and LEDs

4

Front view

DH.21B/41B

option

2102456075

LED

Designation

DIP switch

Terminal

LED LED 10

LED 9

LED 8

LED 7

LED 6

LED 5

LED 4

LED 3

LED 2

LED 1

Terminal X31:

Binary inputs and outputs

(plug-in terminals)

X31:1

X31:2

X31:3

X31:4

X31:5

X31:6

X31:7

X31:8

X31:9

X31:10

Terminal X34:

RS485 interfaces COM1, COM2

(plug-in terminals)

X34:1

X34:2

X34:3

X34:4

X34:5

X34:6

X35 terminal:

USB connection

X35:1

X35:2

X35:3

X35:4

X36 terminal:

X36

Ethernet 1 connection

System bus (RJ45 socket)

24 V / I/O OK

DIO0/1

DIO2/3

DIO4/5

DIO6/7

User LED

PLC state

IEC progr. state

CAN 2 state

CAN 1 state

+24 V input

BZG 24 V

DIO 0

DIO 1

DIO 2

DIO 3

DIO 4

DIO 5

DIO 6

DIO 7

RS+

RS+ insulated

RS–

RS– insulated

DGND

GND insulated

USB +5 V

USB–

USB+

DGND

Function

State of voltage supply I/O

State of input or output DIO 0/1

State of input or output DIO 2/3

State of input or output DIO 4/5

State of input or output DIO 6/7

Freely programmable

State of control firmware

State of control program

State of CAN 2 system bus

State of CAN 1 system bus

Voltage input DC +24 V

Reference potential for binary signals

Binary input or output (DIO 0)

Binary input or output (DIO 1)

Binary input or output (DIO 2)

Binary input or output (DIO 3)

Binary input or output (DIO 4)

Binary input or output (DIO 5)

Binary input or output (DIO 6)

Binary input or output (DIO 7)

Signal RS485+ (COM 1)

Signal RS485+ insulated (COM 2)

Signal RS485– (COM 1)

Signal RS485– insulated (COM 2)

Reference potential (COM 1)

Reference potential (COM 2)

Standard USB-B assignment

X37 terminal:

X37

Standard Ethernet assignment

Ethernet 2 connection

(RJ45 socket)

X32 terminal:

CAN 2 system bus

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

(electrically isolated)

(plug-in terminals)

X33 terminals:

C

AN 1 system bus

(plug-in terminals)

DIP switch S1

X32:1

X32:2

X32:3

X33:

X33:2

X33:3

1

BZG_CAN 2

CAN 2H

CAN 2L

DGND

CAN 1H

CAN 1L

Up

Down

Reference potential for system bus

CAN 2

System bus CAN 2 high

System bus CAN 2 low

Reference potential for system bus

CAN 1

System bus CAN 1 high

System bus CAN 1 low

Default IP address (192.168.10.4)

IP parameter from SD memory card

23

Page 24

4

X31

1

3

5

7

9

2

4

6

8

10

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Assembly and Installation Notes

Installing the DH.21B/41B option

4.7.2 Connecting binary inputs and outputs (X31 terminal)

Terminal X31 provides eight binary inputs or outputs (e.g. for controlling external

actuators/sensors).

Binary inputs • The binary inputs are electrically isolated by optocouplers.

• The permitted input voltages are defined according to IEC 61131.

+13 V – +30 V = "1" = contact closed

–3 V – +5 V = "0" = contact open

2102458763

Binary outputs • The binary outputs are electrically isolated by optocouplers.

• The binary outputs are short-circuit proof but not interference-voltage-proof.

• The maximum permitted output current is 150 mA per binary output. All eight bi nary

outputs can be operated simultaneo usly with this current.

NOTICE

The supply voltage must be present on X31:1/2 when using binary inputs and outputs.

The DH.21B/41B option might be damaged. In this case, the specified function of the

binary inputs and outputs is no longer ensured.

If the supply voltage is switched off, you must switch off all ot he r vo lta ges at X31:1 to

10, e.g. DC 24 V of switches and sensors at the binary inputs.

• To prevent dangerous voltage peaks from occurring, do not connect inductive loads

to the supply voltage or the binary inputs or outputs without free running diodes.

Cable specification • Only connect cables with a minimum core cross section of 0.25 mm

a maximum core cross section of 1 mm

sleeves is possible in accordance with IEC 60999.

• Choose the type and core cross section of the connected cable in dependency of the

required cable length and the load expected from your application.

For more information on binary inputs or outputs, refer to the "Technical Data" chapter.

2

(AWG18). Clamping without conductor end

2

(AWG23) and

24

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

Page 25

Assembly and Installation Notes

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installing the DH.21B/41B option

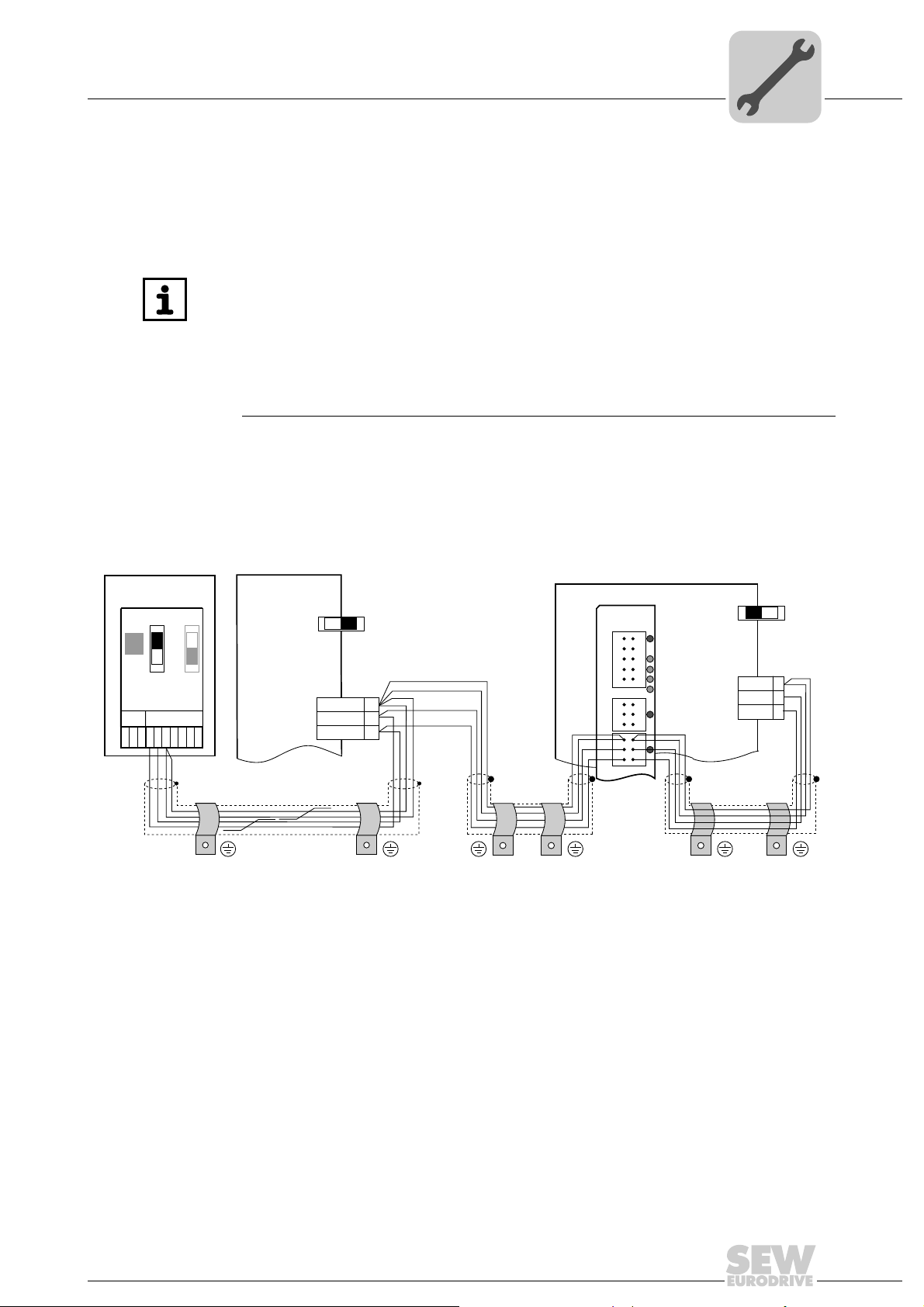

4.7.3 Connnection to system bus CAN 2 (X32) / CAN 1 (X33)

You can connect a maximum of 16 units to the DH21B option and a maximum of 64 units

to the DH.41B option on the CAN 2 or CAN 1 system bus. The system bus supports the

address range 0 to 63.

INFORMATION

• The CAN 2 system bus is electrically isolated. We therefore recommend to use

the CAN 2 ( X32) interface for connecting field devices (e .g . CANop en inpu ts and

outputs).

• The CAN 1 system bus is not electrically isolated. We therefore recommend to

use the CAN 1(X33) interface to connect inverters via the system bus in the

control cabinet.

• A system CAN connection is required for communication between

MOVIDRIVE

The CAN system bus supports transmission systems compliant with ISO 11898. The

"Serial Communication" manual contains detailed information on the system bus. This

manual can be ordered from SEW-EURODRIVE.

®

MDX61B and the integrated controller.

4

Wiring diagram for CAN 1 system bus

MOVITRAC® B

S1

ON

OFF

X44

FSC11B

X46

X45

23456HL ⊥

1

S2

7

MDX60B/61B

X12

ON OFF

DGND

SC11

SC12

S12

1

2

3

MDX61B

DHE41B

X31X32X33

1

2

3

1

2

3

ON OFF

X12:

DGND

1

2

3

1

2

3

SC11

SC12

S12

1

2

3

2102461835

Cable specification • Use a 2 × 2-core twisted and shielded copper cable (data transmission cable with

braided copper shield). Clamping without conductor end sleeves is possible in

accordance with IEC 60999. The cable must meet the following specifications:

2

– Cable cross section 0.2 mm

– 1.0 mm2 (AWG24–AWG18)

– Cable resistance 120 Ω at 1 MHz

– Capacita nce per unit length ≤ 40 pF/m at 1 kHz

Suitable cables include CAN bus or DeviceNet cables.

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

25

Page 26

4

X34

1

3

5

2

4

6

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Assembly and Installation Notes

Installing the DH.21B/41B option

Cable length • The permitted total cable length depends on the baud r ate setting of the system bus:

– 125 kBaud → 500 m

– 250 kBaud → 250 m

– 500 kBaud → 100 m

– 1000 kBaud → 40 m

Terminating

resistor

• Switch-on the system bus terminating resistor at the start an d end of the CAN system

bus connection (MOVIDRIVE

S1 = ON). For all other devices, switch off the terminating resistor (MOVIDRIVE

DIP switch S12 = OFF; MOVITRAC

DH.21B/DH.41B option is located at the end of the CAN 2 system bus, you have to

connect a terminating resistor of 120 Ω between pins X32:2 and X32:3 (for CAN 1:

terminating resistor between pins X33:2 and X33:3).

NOTICE

•There must not be any potential displacement between the units connected via

CAN 2 system bus.

•There must not be any potential displacement between the units connected via

CAN 1 system bus.

• Take suitable measures to avoid potential displacement, such as connecting the

unit ground connectors using a separate cable.

4.7.4 RS485 interface connection (X34)

NOTICE

• There must not be any potential displacement between the units connected via

RS485. Take suitable measures to avoid potential displacement, such as

connecting the unit ground connectors using a separate ca ble.

• Dynamic terminating resistors are installed. Do not connect any external

terminating resistors.

®

B, DIP switch S12 = ON; MOVITRAC® B, DIP switch

®

B, DIP switch S1 = OFF). For example, if the

®

B,

You can connect one of the following units to each of the RS485 interfaces COM1/2

(terminal X34).

• DOP11B operator terminal

• MOVIMOT

®

gearmotor with integrated frequency inverter

INFORMATION

For more information on how to connect the DOP11B operator terminal, refer to the

sections "Installation" and "Pin assignment" in the DOP11B operator terminal manual.

26

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

2102464523

Page 27

4.7.5 System bus Ethernet 1 connection (X36)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

The Ethernet 1 interface (X36) serves as system bus master of the fast SBUS

system bus.

4.7.6 Ethernet 2 interface connection (X37)

You can connect an engineering PC to the Ethernet 2 interface (X37).

Assembly and Installation Notes

Installing the DH.21B/41B option

4

Plus®

2

1

4

3

6

5

8107

X31

9

2

1

4

3

X34

6

5

X35

T1

342

1

X36

S1

X37

1

1

2

2

X32X33

3

3

1

1

2

2

3

3

L1 L2 L3 L5XM L6 L7 L8 L9L4 L10

Using the Ethernet 2 interface, the DH.21B/41B option can also exchange data with

another controller via UDP/TCP.

4.7.7 LEDs of the DH.21B/41B option

The DH.21B/41B option comes equipped with 10 LEDs (L1 through L10) that indicate

the present state of the option and its interfaces.

PC COM

2102467211

LED L1

(CAN 1 state)

LED L1 indicates the state of the CAN 1 system bus.

State of the L1 LED Diagnostics Remedy

Orange The CAN 1 system bus is being

Green The CAN 1 system bus is being

Flashing green

(0.5 Hz)

Flashing green

(1 Hz)

Red The CAN 1 system bus is off

Flashing red

(1 Hz)

initialized.

initialized.

The CAN 1 system bus is currently in

-

SCOM suspend mode.

The CAN 1 system bus is currently in

SCOM On mode.

1. Check and correct the cabling of the

(BUS-OFF).

CAN 1 system bus.

2. Check and correct the baud rate set

for the CAN 1 system bus.

3. Check and correct the terminating

resistors of the CAN 1 system bus.

Warning on the CAN 1 system bus. 1. Check and correct the cabling of the

CAN 1 system bus.

2. Check and correct the baud rate set

for the CAN 1 system bus.

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

27

Page 28

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Assembly and Installation Notes

Installing the DH.21B/41B option

LED L2

(CAN 2 state)

LED L3

(IEC program

state)

LED L2 indicates the state of the CAN 2 system bus.

State of the L2 LED Diagnostics Remedy

Orange The CAN 2 system bus is being

Green The CAN 2 system bus is being

Flashing green

(0.5 Hz)

Flashing green

(1 Hz)

Red The CAN 2 system bus is off

Flashing red

(1 Hz)

initialized.

initialized.

The CAN 2 system bus is currently in

SCOM suspend mode.

The CAN 2 system bus is currently in

SCOM On mode.

(BUS-OFF).

Warning on the CAN 2 system bus. 1. Check and correct the cabling of the

-

-

-

-

1. Check and correct the cabling of the

CAN 2 system bus.

2. Check and correct the baud rate set

for the CAN 2 system bus.

3. Check and correct the terminating

resistors of the CAN 2 system bus.

CAN 2 system bus.

2. Check and correct the baud rate set

for the CAN 2 system bus.

LED L3 indicates the state of the IEC-61131 control program.

State of L3 Diagnostics Remedy

Green IEC program is running. -

Off No program is loaded. Load the program into the controller.

Flashing orange

(1 Hz)

Program has stopped. Bootloader update required (see chapter "SD

memory card type OMH41B-T".)

LED L4

(controller state)

LED L4 indicates the firmware state of the DH.2 1 B/4 1B op tio n .

State of the L4 LED Diagnostics Remedy

Flashing green

(1 Hz)

Red • No SD card inserted.

Flashing orange

(1 Hz)

The firmware of option DH.21B/41B is

working properly.

• File system of the SD card is

corrupt.

Program has stopped. Bootloader update required (see chapter

LED L5 (User) LED L5 is freely programmable in the IEC program.

-

"SD memory card types OMH41B-T. and

OMC41B-T.")

28

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

Page 29

Assembly and Installation Notes

X31

1

3

5

7

9

2

4

6

8

10

L6

L7

L8

L9

mn

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installing the DH.21B/41B option

4

LEDs L6, L7, L8,

L9 (DIO n/m)

LED L10

(24V/ I/OOK)

LEDs L6, L7, L8, L9 indicate the state of the binary inputs and outputs (X31:3 X31:10) n or m (e.g. DIO2/3).

2102564619

State of L6, L7, L8,

L9 LEDs

Off No voltage present.

Green Voltage at terminal n.

Red Voltage at terminal m.

Orange Voltage at terminals n and m.

Diagnostics Remedy

-

LEDL10 indicates the state of the voltage supply for binary inputs and outputs.

State of the L10 LED Diagnostics Remedy

Green Voltage supply for the binary inputs

and outputs is OK.

Off No voltage supply is present at the

binary inputs and outputs.

Orange Voltage supply is present at the binary

inputs and outputs. However, one of

the following faults has occurred:

• Overload on one or more binary

inputs or outputs

• Overtemperature of the output

driver

• Short circuit in at least one of the

binary inputs or outputs

-

1. Switch off the inverter in which the

DH.21B/41B option is installed.

2. Check and correct the cabling of the

binary inputs/outputs according to

the electrical wiring diagram.

3. Check the current consumption of

the connected actuators (max.

current → "Technical Data" chapter).

4. Switch on the inverter in which the

DH.21B/41B option is installed.

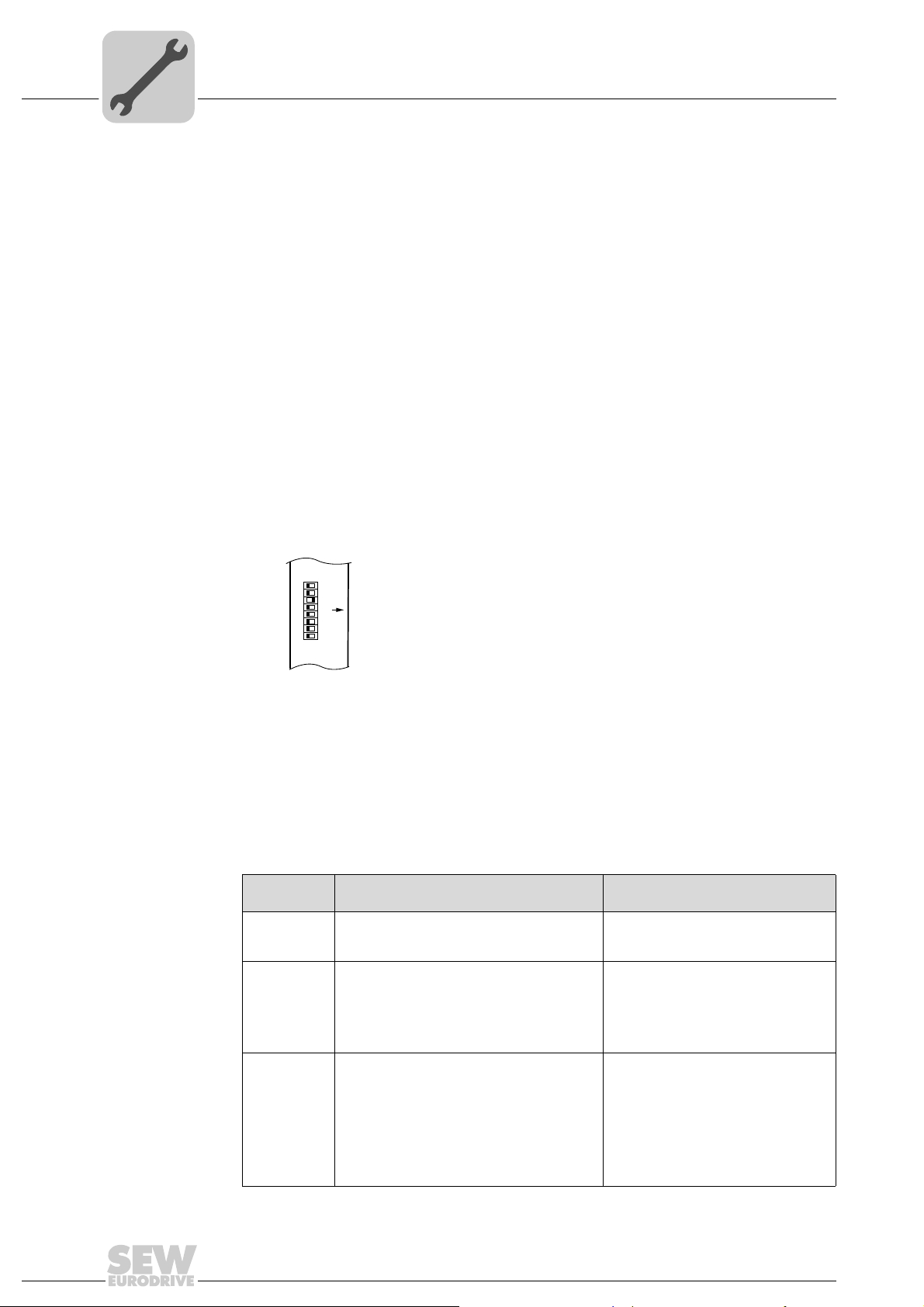

4.7.8 DIP switch S1

You can use DIP switch S1 to set a default IP address for the Ethernet 2 connection

(X37). This IP address will be applied with the next boot process.

S1 switch setting Meaning

Up IP parameter:

• IP address: 192.168.10.4

• Subnet mask: 255.255.255.0

• Standard gateway: 1.0.0.0

Down Addresses entered in the configuration file (see chapter "Functional

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

description of terminals, DIP switches and LEDs")

29

Page 30

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Assembly and Installation Notes

Installing the DH.21B/41B option

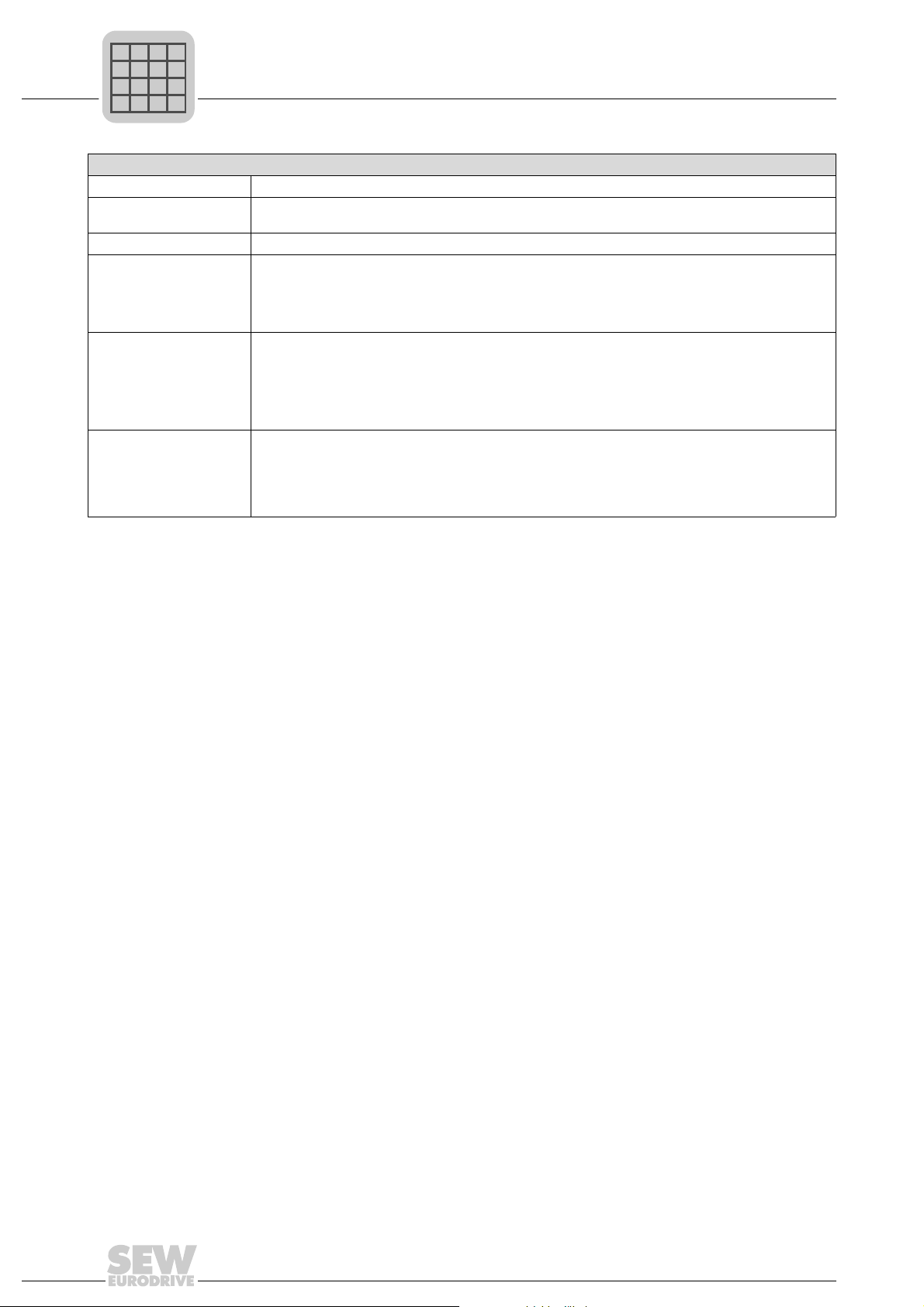

4.7.9 SD memory card types OMH41B-T. and OMC41B-T.

The SD memory card is required for operating the DH.21B/41B option. It stores the

firmware, the IEC program and user data (e.g. recipes). You can use the memory card

for data backup and automatic parameterization in the event o f an axis replacement.

The SD memory card is available in 26 variants (T0 – T25). The different variants let you

execute different technology functions. The technology level can be changed by

changing the SD memory card.

OMH41B-T. type With the SD memory card type OMH41B -T., the DH.21B/41B opti on is used as freely

programmable controller. The SD memory card OMH41B-T. is inserted in the DH.21B/

41B option. If the delivery also includes a compact controller, a MOVIAXIS

module or an inverter with installed DH.2 1B/41B option, then the SD memory card is

already installed in the DH.21B/41B option.

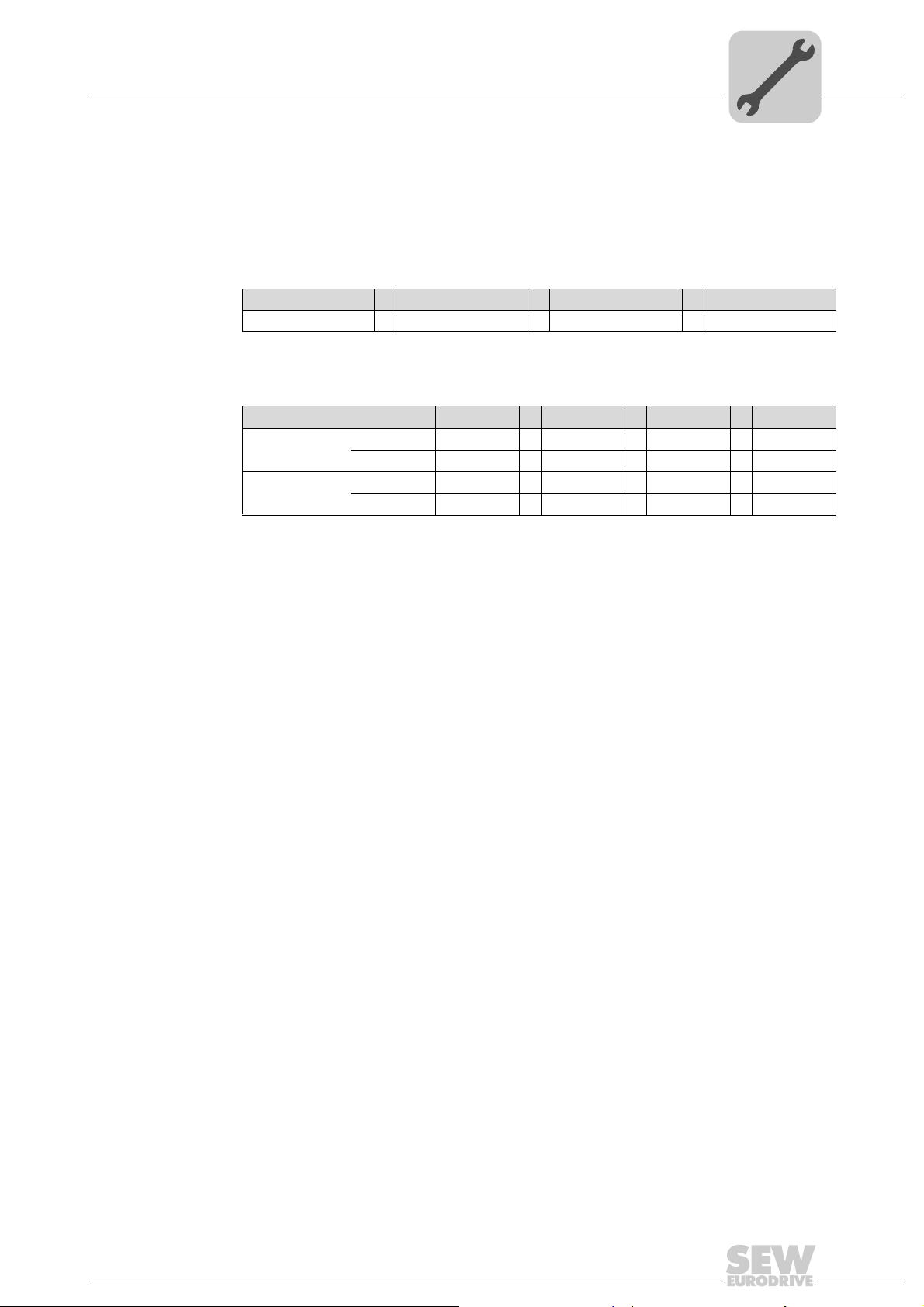

SD memory card OMH41B-T.

Technology

levels

T0 – T25

T0 1821 204 2 • Speed control management

T1 1821 205 0 Additional technology functions for T0:

T2 1821 206 9

T3 1821 967 5

T4 1821 968 3

T5 1821 969 1

T6 1821 970 5

T7 1821 971 3

T8 1821 972 1

T9 1821 974 8

T10 1821 975 6

T11 1822 860 7

T12 1822 861 6

T13 1822 862 3

T14 1822 863 1

T15 1822 865 8

T16 1822 866 6

T17 1822 867 4

T18 1822 868 2

T19 1822 869 0

T20 1822 870 4

T21 1822 871 2

T22 1822 872 0

T23 1822 873 9

T24 1822 874 7

T25 1822 875 5

Part number Description

• Positioning, e.g. with the MPLCMotion_MDX library

• Electronic cam

• Electronic gear unit

• Cam controller

A certain number of technology points is consumed depending on the

functionality used.

Refer to the relevant documentation for information on how many

technology points are required.

®

master

30

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

Page 31

Assembly and Installation Notes

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installing the DH.21B/41B option

Type OMC41B-T. The SD memory card OMC41B-T.. lets you use the DH.21B/41B option as configurable

application controller (CCU). A certain technology level is required for this purpose

depending on the application module used. Refer to the documentation of the

application module for information on the required technology level.

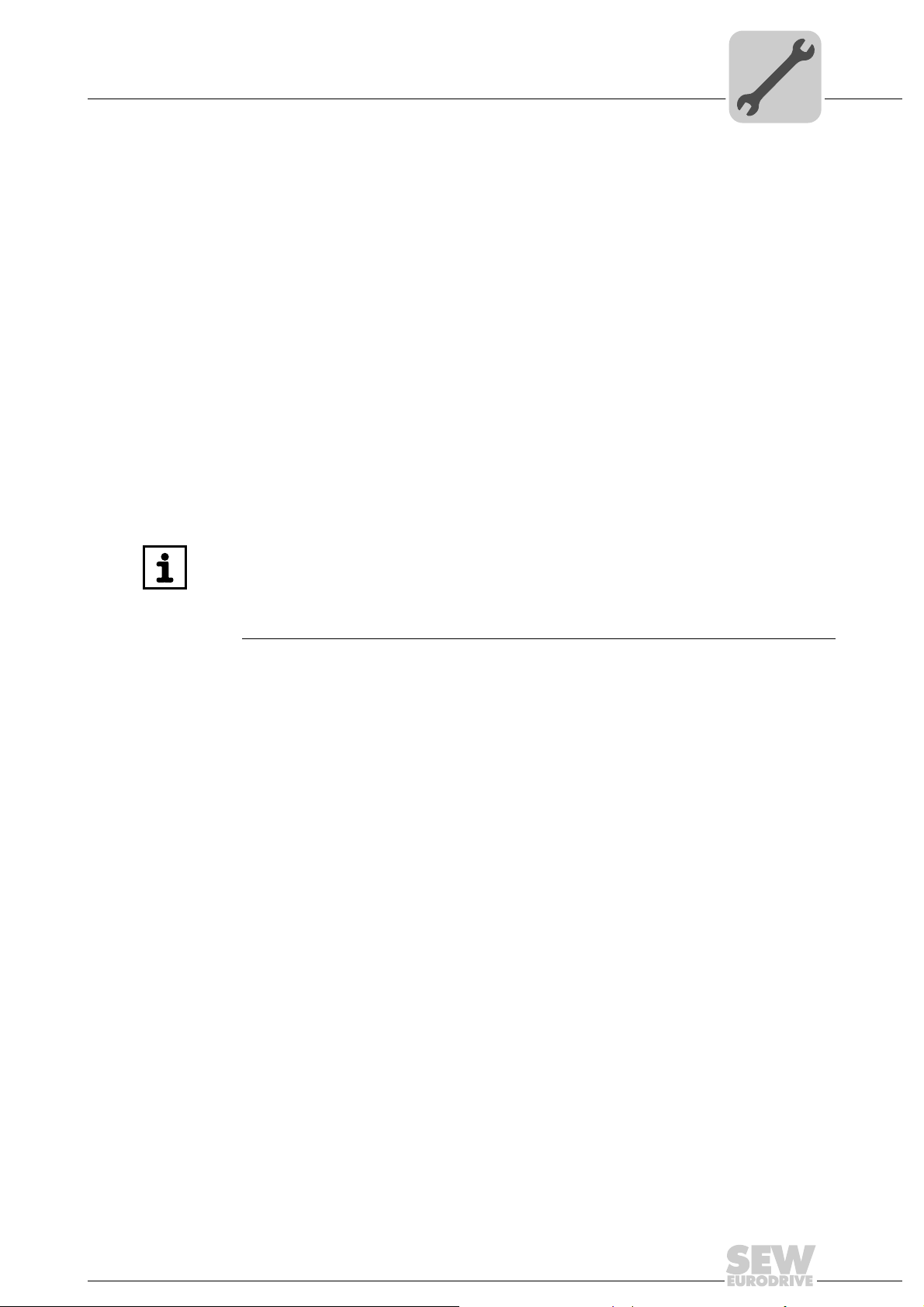

SD memory card OMC41B-T.

Technology

levels

T0 – T25

T0 1822 876 3 Single-axis applications:

T1 1822 877 1 Technology functions:

T2 1822 879 8 Multi-axis application modules:

T3 1822 880 1

T4 1822 882 8

T5 1822 883 6

T6 1822 884 4

T7 1822 885 2

T8 1822 886 0

T9 1822 887 9

T10 1822 888 7

T11 1822 889 6

T12 1822 890 9

T13 1822 891 7

T14 1822 892 5

T15 1822 893 3

T16 1822 894 1

T17 1822 896 8

T18 1822 897 6

T19 1822 898 4

T20 1822 899 2

T21 1822 901 8

T22 1822 902 6

T23 1822 903 4

T24 1822 904 2

T25 1822 905 9

Part number Description

• Velocity specification

• Bus positioning

• Universal module, etc.

• Cam positioning

• Synchronous operation, etc.

• Energy-efficient SRU

• Sync crane, etc.

A certain number of technology points is consumed depending on the

functionality used.

Refer to the relevant documentation for information on how many

technology points are required.

4

Bootloader update A bootloader update is required when LEDs L3 and L4 flash orange at a frequency of

1 Hz after power-on. Proceed as follows:

• Do not switch off the power supply during the process.

• Press the reset button T1 on the front of the DH.21B/41B o ption for 3 seconds. When

the bootloader update starts, only LED 4 is flashing.

• The bootloader update has been successful when L4 flashes green.

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

31

Page 32

4

2

2

2

2

0

1

2

3

2

2

2

4

5

6

2

7

1

2

3

X38

L18

X30P

1

5

X30D

S2

L16

L15

L14

L13

L12

L11

L17

ON

2

4

6

X34

X35

X36

X37

XM

1

3

5

1

2

3

1

2

3

1

2

3

1

2

3

X32X33

2

4

6

1

3

5

8107

9

X31

S1

342

1

L10

L9

L8

L7

T1

L6

L5

L4

L3

L2

L1

2

6

X36

X37

1

3

2

3

1

2

3

313

635

10

7

9

3

L

L9

8

L

T

6

L5

3

L1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Assembly and Installation Notes

Installing the DHF21B/41B option

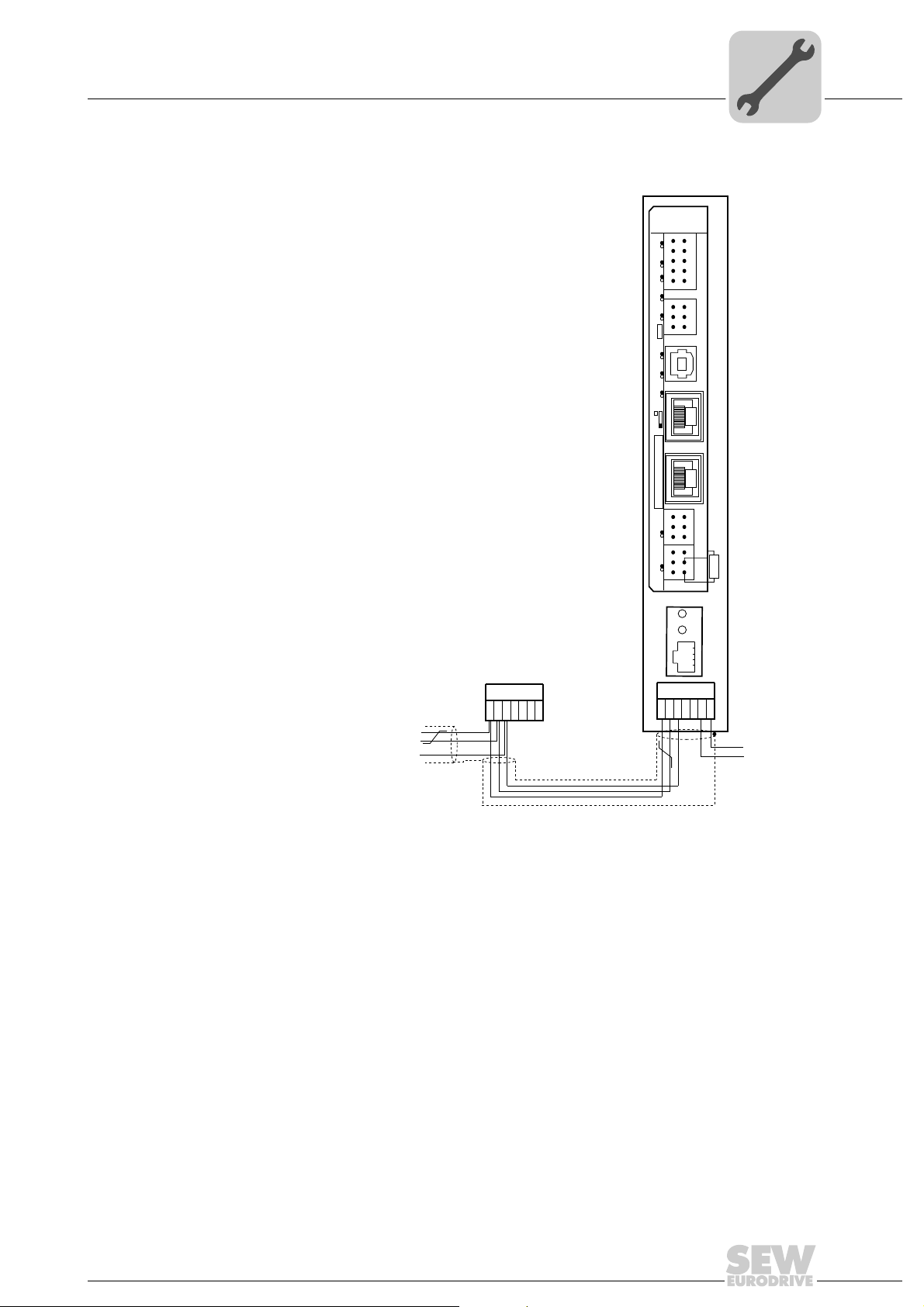

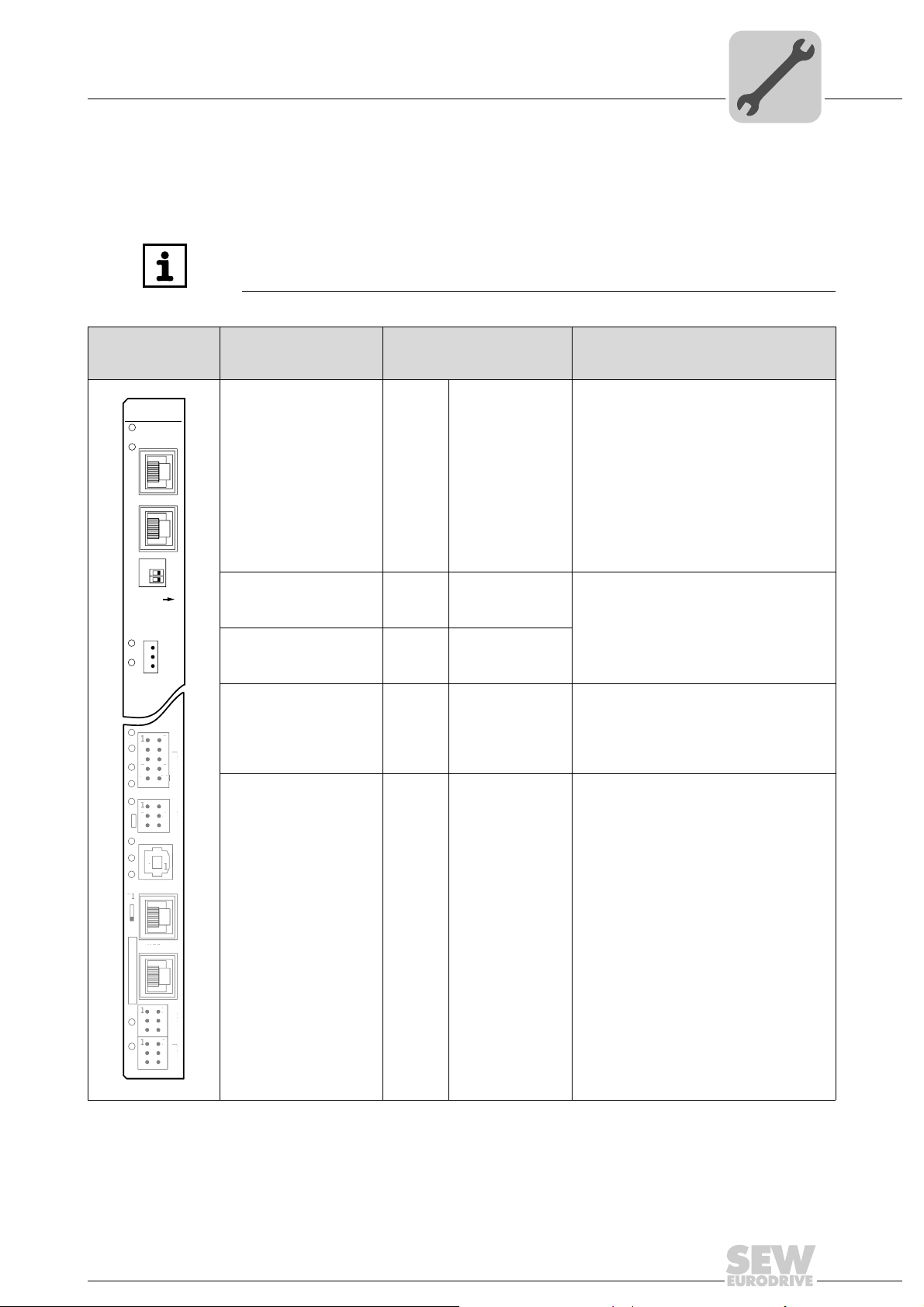

4.8 Installing the DHF21B/41B option

4.8.1 Functional description of terminals, DIP switches and LEDs

INFORMATION

The connections, which are identical for all the DH.21B/41B options, are described in

the "Installing the DH.21B/41B option" chapter.

Front view

DHF21B/41B option

Designation

LED LED 18

X30P terminal:

PROFIBUS

(Sub-D9)

X30D terminal:

DeviceNet

(plug-in terminals)

10

8

L

7

L

L4

L

4

5

1

5

DIP switch S2

Switching between

PROFIBUS and DeviceNet

LED

DIP switch

Terminal

Run PROFIBUS

LED 17

LED 16

LED 15

LED 14

LED 13

LED 12

LED 11

X30P:9

X30P:8

X30P:7

X30P:6

X30P:5

X30P:4

X30P:3

X30P:2

X30P:1

X30D:1

X30D:2

X30D:3

X30D:4

X30D:5

Fault PROFIBUS

Mod/Net

Polled I/O

Bit strobe I/O

BUSOFF

-

GND (M5V)

RxD/TxD-N

N.C.

VP (P5V/100 mA)

GND (M5V)

CNTR-P

RxD/TxD-P

N.C.

N.C.

V–

CAN_L

DRAIN

CAN_H

V+

S2 Up

Down

Function

PROFIBUS communication state

PROFIBUS bus electronics state

The two-color LEDs 13 – 16 indicate the

current state of the fieldbus interface and the

DeviceNet system

Reserved

Reserved

Reference potential for PROFIBUS

Signal receive transmit negative

Terminal unassigned

DC +5 V potential for bus terminator

Reference potential for PROFIBUS

PROFIBUS control signal for repeater

Signal receive transmit positive

Terminal unassigned

Terminal unassigned

0V24

CAN_L

DRAIN

CAN_H

24 V

Fieldbus interface PROFIBUS (X30P) active

Fieldbus interface DeviceNet (X30D) active

32

1

1

2103268363

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

Page 33

Assembly and Installation Notes

RxD/TxD-P

3

1

5

9

6

8

4

5

6

9

VP (P5V/100mA)

DGND (M5V)

DGND (M5V)

CNTR-P

RxD/TxD-N

[3]

[1]

[2]

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installing the DHF21B/41B option

4

Front view

DHF21B/41B option

Designation

For PROFIBUS mode: DIP

switch for setting the

PROFIBUS station address

For operation via

DeviceNet:

DIP switch for setting the

MAC-ID and baud rate

X38 terminal:

SEW safety bus

(plug-in terminals)

Reset button T1 T1 Reset

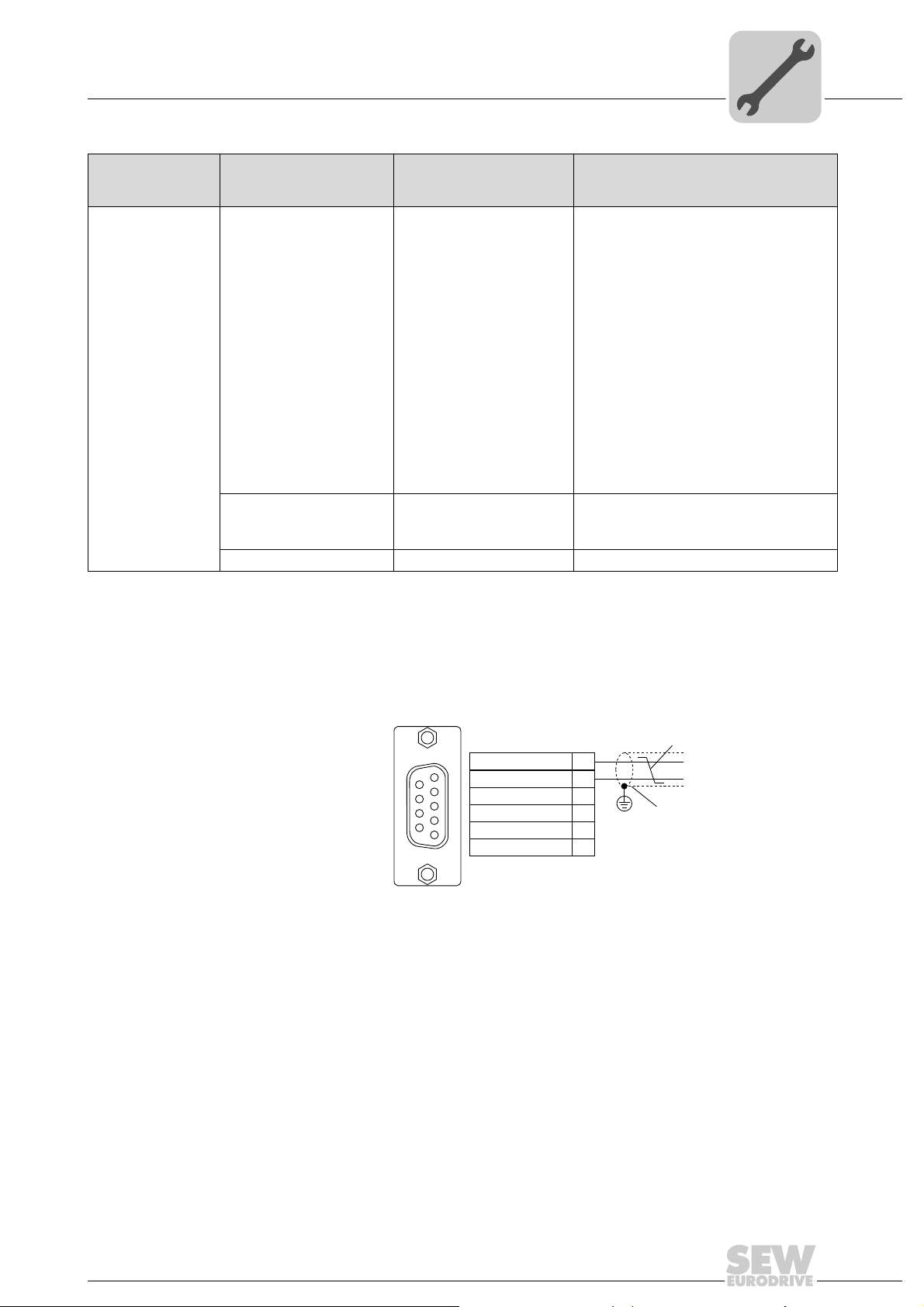

4.8.2 Connecting PROFIBUS (X30P)

Connection to the PROFIBUS system is made using a 9-pin D-sub conn ector according

to IEC 61158. The T-bus connection must be made using a connector with the

corresponding configuration. The following figure shows the PROFIBUS connector that

is connected to X30P of the DHF21B/41B option.

LED

DIP switch

Terminal

0

2

1

2

2

2

3

2

4

2

5

2

6

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

X38:1

X38:2

X38:3

Function

Significance: 1

Significance: 2

Significance: 4

Significance: 8

Significance: 16

Significance: 32

Significance: 64

DIP switches 20–25 are used to set the MAC

ID (Media Access Control Identifier). The

MAC ID represents the node address

(address range 0 – 63)

Setting the baud rate

Setting the baud rate

Reserved

Reserved

Reserved

[1] 9-pin D-sub connector

[2] Signal line, twisted

[3] Conductive connection over a large area between plug housing and shield

Connecting the

DHF21B/41B

controller to

PROFIBUS

The DHF21B/41B option is usually connected to the PROFIBUS system using a

shielded twisted-pair cable. Observe the maximum supported transmission rate when

selecting the bus connector.

The twisted-pair cable is connected to the PROFIBUS connector at pin 3 (RxD/TxD-P)

and pin 8 (RxD/TxD-N). Communication takes place using these two pins. The RS485

signals RxD/TxD-P and RxD/TxD-N must all be connected to the same contacts in all

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

PROFIBUS stations. Else, the bus components cannot communicate via the bus

medium.

2103273483

33

Page 34

4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Assembly and Installation Notes

Installing the DHF21B/41B option

The PROFIBUS interface sends a TTL control signal for a repeater or fiber optic adapter

(reference = pin 9) via pin 4 (CNTR-P).

Baud rates greater

than 1.5 MBaud

Operating the DHF21B/41B option with baud rates > 1.5 MBaud is only possible with

special 12 MBaud PROFIBUS connectors.

Bus termination You need not equip the DHF21B/41B option with bus terminating resistors. This m eans

the PROFIBUS system can be put into operation more easily and the number of error

sources during installation is reduced.

When the DHF21B/41B option is located at the start or end of a PROFIBUS segment

and when there is only one PROFIBUS cable connected to the DHF21B/41B op tion, you

must use a plug with an integrated bus terminating resistor.

Switch on the bus terminating resistors for this PROFIBUS connector.

0

Setting the station

address

To set the PROFIBUS station address, use DIP switches 2

option.

– 26 on the DHF21B/41B

The DHF21B/41B option supports address range 0 – 125.

The default setting for the station address is 4:

DHF41B

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

ON

0

2

→ Significance: 1 × 0 = 0

1

2

→ Significance: 2 × 0 = 0

2

→ Significance: 4 × 1 = 4

2

3

→ Significance: 8 × 0 = 0

2

4

2

→ Significance: 16 × 0 = 0

5

→ Significance: 32 × 0 = 0

2

6

2

→ Significance: 64 × 0 = 0

Any change made to the PROFIBUS station address duri ng ongoing operatio n does not

take effect immediately. You have to switch the compact controller or the inverter in

which DHF21B/41B option is installed on and off again for the changes to take effect

(power +24 V off/on).

4.8.3 LEDs in PROFIBUS mode

LED L17

(PROFIBUS fault)

LED L17 (PROFIBUS fault) indicates that communication via the PROFIBUS interface

is working properly.

State of the

L17 LED

Off • The DHF21B/41B option exchanges data

Red • Connection to the DP master has failed.

Flashing red

(1 Hz)

2103383051

Diagnostics Remedy

with the PROFIBUS-DP master (data

exchange state).

• The DHF21B/41B option does not detect

the PROFIBUS baud rate.

• Bus interruption.

• PROFIBUS-DP master not in operation.

• The DHF21B/41B option does not detect

the baud rate. However, the DP master

does not address the DHF21B/41B option.

• The DHF21B/41B option was either not

configured in the DP master or it was

configured incorrectly.

-

• Check the PROFIBUS connection of

• Check project planning of the

• Check all the cables in the

• Check and correct the PROFIBUS

• Check and correct the configuration

• Use the GSD file SEW_6007.GSD

the unit.

PROFIBUS DP master.

PROFIBUS network.

station address set in the DHF21B/

41B option and in the configuration

software of the DP master.

of the DP master.

with the designation MOVI-PLC for

configuration.

34

Manual – Controllers DHE/DHF/DHR21B (standard) and DHE/DHF/DHR41B (advanced)

Page 35

Assembly and Installation Notes

DFD11B

1

2

3

4

5

DHF41B

X30D

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Installing the DHF21B/41B option

4

LED L18

(Run PROFIBUS)

LED L18 (Run PROFIBUS) indicates that the PROFIBUS electronics (hardware) is

working properly.

State of the

L18 LED

Green • PROFIBUS hardware OK. -

Flashing

green

(1 Hz)

Diagnostics Remedy

• The PROFIBUS station address set on

the DIP switches exceeds 125. If the

PROFIBUS station address is set to a

value higher than 125, the DHF21B/41B

option will use PROFIBUS station

address 4.

1. Check and correct the PROFIBUS

station address set on the DIP

switches.

2. Switch on all inverters again. The

modified PROFIBUS address will

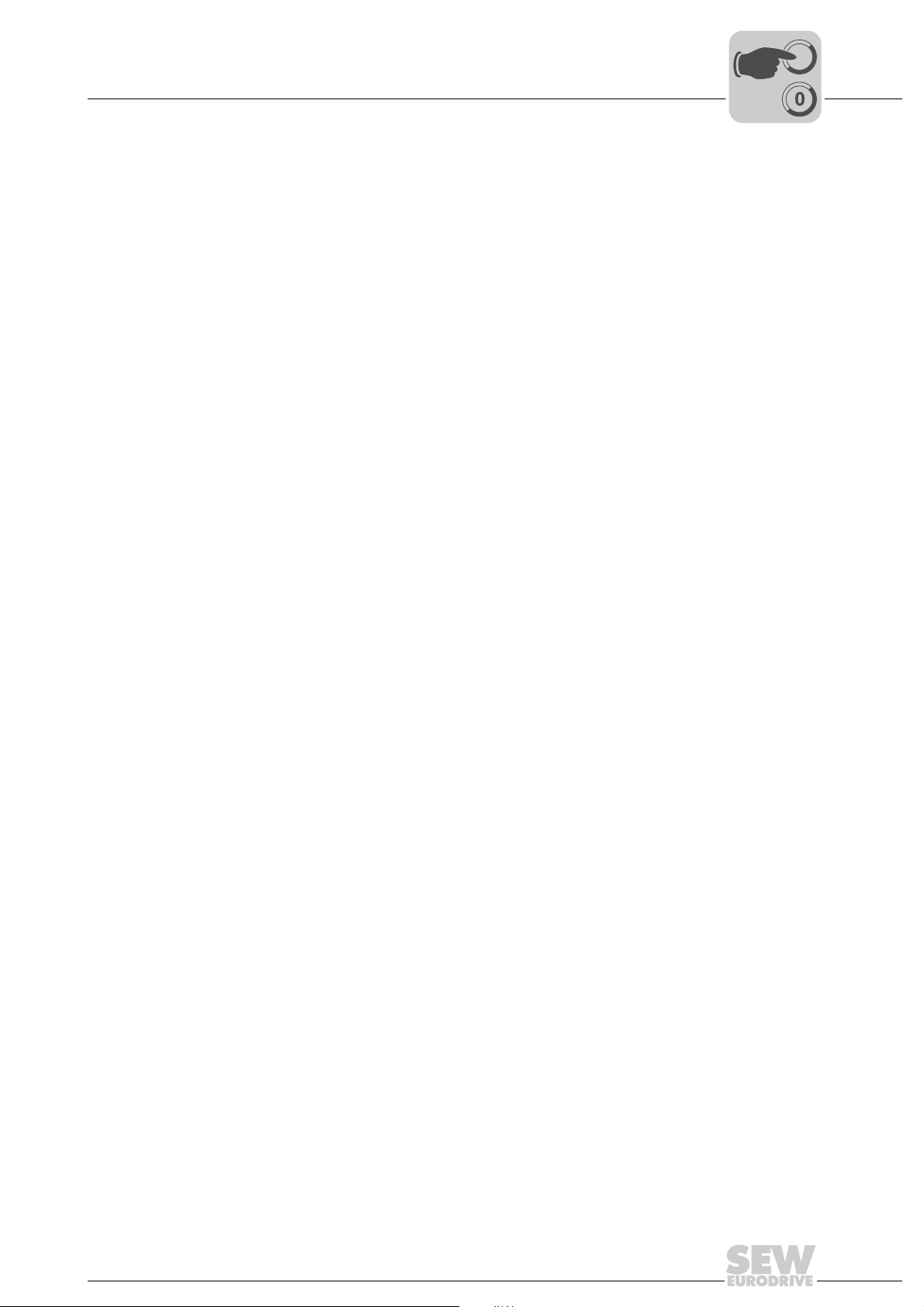

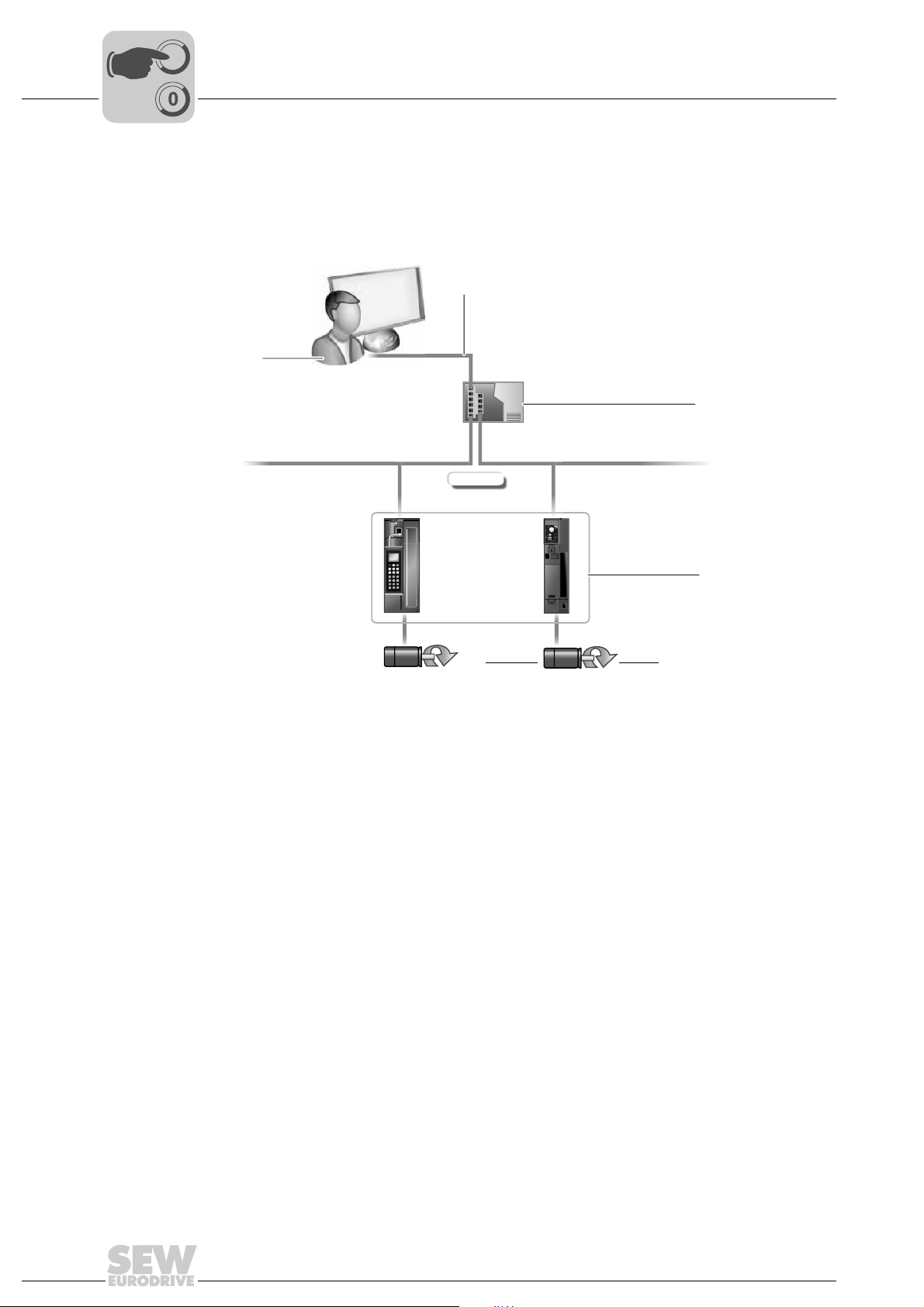

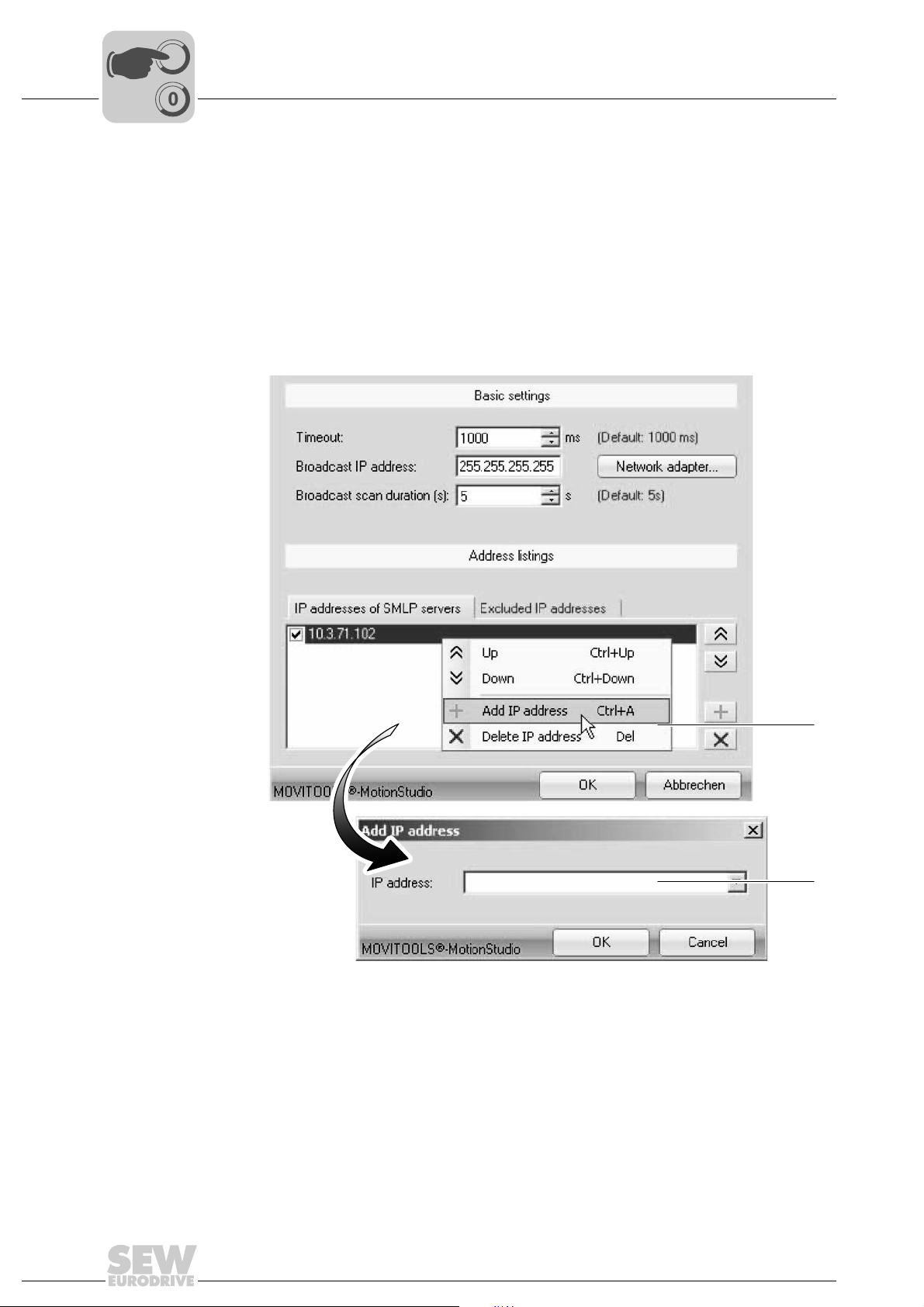

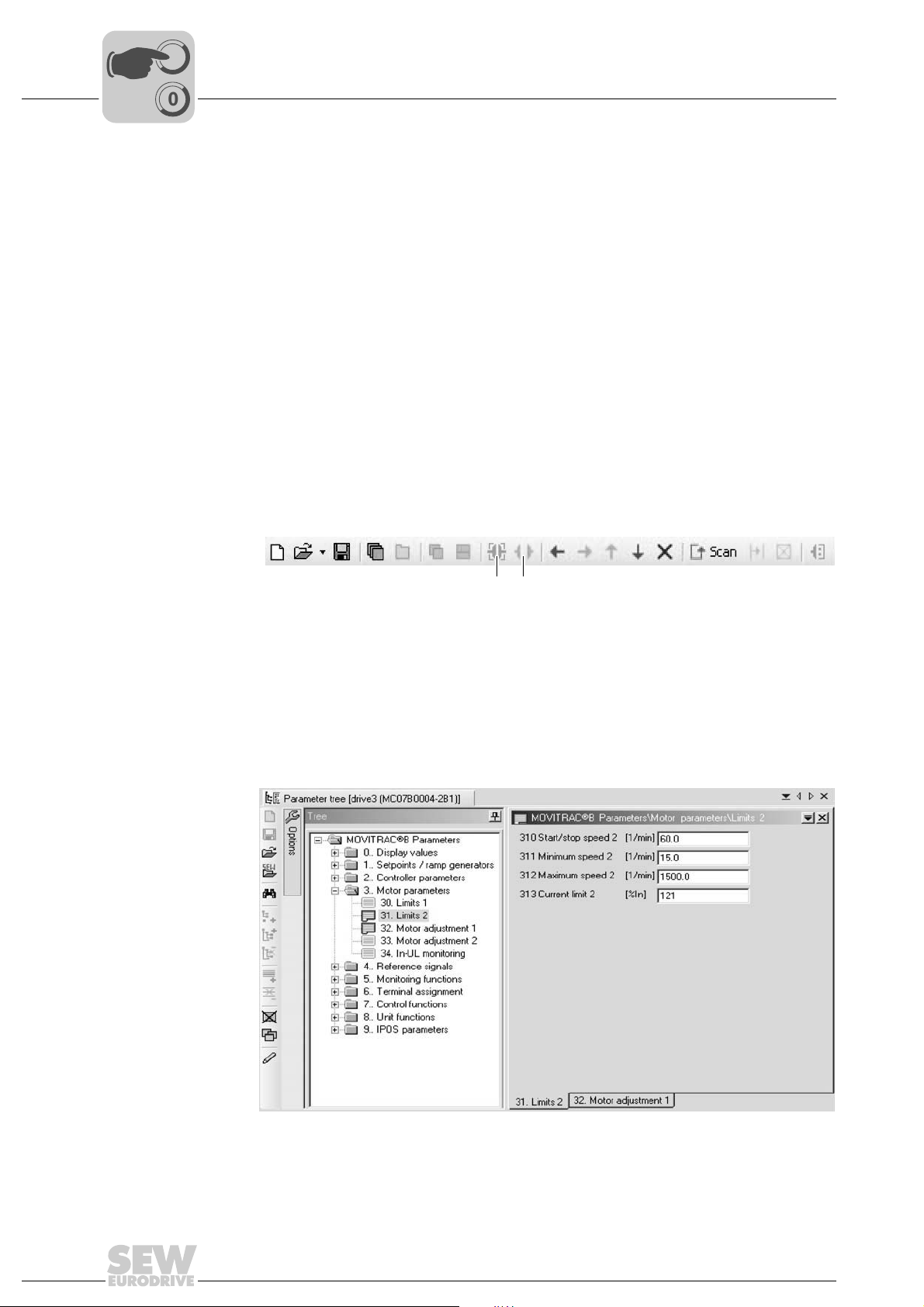

only take effect after a restart.