OPERATION & SERVICE MANUAL

VC1100 Series

MDB-120 Controller

67196-2 Software

120 Volts, 60 HZ

230 Volts, 50 HZ

Seaga Manufacturing, Inc. 700 Seaga Drive, Freeport IL 61032 USA

Phone: 815-297-9500 Fax: 815-297-1700

www.vendtronics.com www.seagamfg.com

A Member of the

Family of Companies.

DE720 Rev E

Table of Contents

SECTION 1 – SPECIFICATIONS

Physical characteristics

Environment

Health safety protection

Electrical and Refrigeration Characteristics

4

4

4

4

Location

Power supply connection

Vending

Health and Safety Range

Temperature Settings

Defrost Delay

Refrigeration System

Condensing unit

Evaporator

Temperature Display

Refrigeration Control system

Defrost System

System Control

Door Switch monitoring

Idle Condition

Coin Acceptance

First Bill Acceptance

Additional Bill Acceptance

DEX / UCS Data Retrieval

Vending Selection

SECTION 2 - INSTALLATION

SECTION 3 – INITIAL SETUP

SECTION 4 – OPERATION

5

5

6

6

6

6

7

7

7

7

8

8

8

9

9

9

9

10

10

11-12

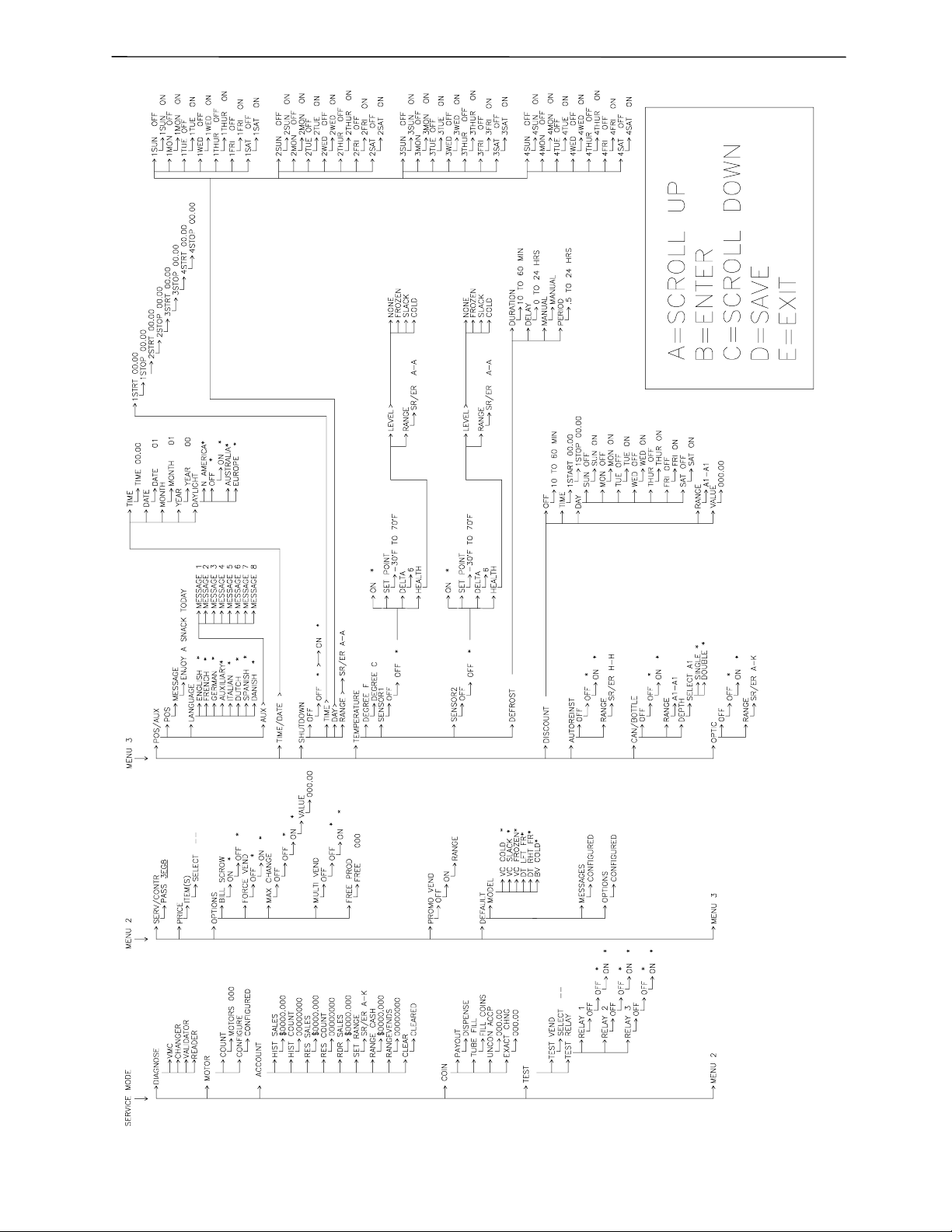

SECTION 5 – PROGRAMMING

The Service Mode of Operation

Flow Chart

Diagnose

Error Codes

Motor

Count

Config

Account

Hist Sales

Hist Count

Res Sales

Res Count

Rdr Sales

Set Range

DE720 Rev. E

13

14

15

16-17

18

18

18

18

18

18

18

18

19

19

1 VC1100

Range Cash

Range Vends

Clear

Coin

Payout

Tube Fill

Uncon Accp

Exact Change

Test

Test Vend

Test Relay

Serv / Contr

Price

Items

Options

Bill Escrow

Force Vend

Max Change

Value

Multi Vend

Free Prod

Promo Vend

Default

Model

Messages

Options

POS / AUX

POS

Language

AUX

Time / Date

Shutdown

Temperature

Degree

Sensor 1

Sensor 2

Set Point

Delta

Health

Defrost

Discount

Autoreinstate

Can / Bottle

Optic

Table of Contents

SECTION 5 – PROGRAMMING

Menu 2

Menu 3

19

19

19

20

20

20

20

21

22

22

23

24

25

25

26

26

26

26

26

27

27

28

29

29-31

31

32

33

33

34

34

35

36-37

37

37

37

37

38

38

39

40-41

42-43

44

45

46

DE720 Rev. E

2 VC1100

Table of Contents

SECTION 6 WIRING DIAGRAMS

Refrigeration Interface Diagram

High Voltage Ladder Diagram 115 Vac

High Voltage Ladder Diagram 220-240 Vac

Low Voltage Schematic

Power Panel Wire Locations 115Vac

Power Panel Wire Locations 220-240Vac

Dual Coil Tray Wiring

Dual Tray, 3 Column

Standard Tray 3 Column

Tray Options

Instructions for converting a 6 Column Tray to a 5 Column Tray

Condensing Unit

Evaporator

Trim

Service Door

Freezer Door and Product Door

VC1100 Cabinet

Electrical Panel

Cable Assemblies

SECTION 7 PARTS

SECTION 8 MAINTENANCE

SECTION 8 TROUBLESHOOTING

APPENDIX 1 MESSAGES

APPENDIX 2 DEX / UCS RECORD SUBSET

47

48

49

50

51

52

53

54

55

56

57

58

58

59

60-61

62-63

64-65

66-67

67

68

69-70

71-72

73

DE720 Rev. E

3 VC1100

SECTION 1 SPECIFICATIONS

PHYSICAL CHARACTERISTICS

• Height: 72 in. / 183 cm.

• Width: 41 in. / 104 cm.

• Depth: 32 1/8 in. / 82 cm.

• Weight: 650 lb

• Construction: Heavy Gauge Steel

• Finish: Powder Coated Paint

• Number of Trays: 5

• Maximum Selections: 30 / 45

• Maximum Capacity: 240 / 450

• Available coil sizes: 4,5,6,7,8,10,12,16

ENVIRONMENT

• Operating Ambient Temperature: 50°F to 100°F

• Location Environment: Indoors only

HEALTH AND SAFETY PROTECTION (Vending of products is disabled)

• Activation Temperature:

Frozen Foods: +0°F or higher if more than 15 minutes

Slack Frozen: +15°F or higher if more than 15 minutes

Refrigerated: +41°F or higher if more than 15 minutes

None None

ELECTRICAL AND REFRIGERATION REQUIREMENTS

Power Requirements 110 / 120 Vac, 60Hz

Amperage Rating 16

Control Transformer ½ Amp fuse

Lamp Transformer 2 Amp fuse

Compressor 3/4 hp Hermetic

Refrigerant Charge 1 lb 10 oz R-404A

Evaporator Forced air, Elec. Defrost

DE720 Rev. E

4 VC1100

SECTION 2 INSTALLATION

LOCATION

Upon receipt of the unit, inspect for any shipping damage and report directly to the

carrier. A damage report will be necessary before contacting the factory. Allow the unit to set at

room temperature for at least 24 hrs. before operation. The unit should be stored or transported

vertical at all times. When relocating the unit, it should not be tipped at extreme angles. If the

unit is relocated, it is strongly recommended that a similar 24 hr. non-operating period be

observed. If the unit was in an operating mode prior to relocation, the inside of the refrigerated

compartment should be allowed to rise to room temperature and completely dry out before

placing back into service.

The back of the unit must be located at least 6 inches from any obstruction to ensure

proper airflow in the compressor area. The system requires air to be induced from underneath the

base of the unit, through the air filter and condensing coil, and expelled out the back of the

vending machine.

POWER SUPPLY CONNECTION

CAUTION: DO NOT USE AN EXTENSION CORD

The 110 / 120 Vac unit requires an independent 20-amp earth grounded circuit.

To insure safe operation of the VC1100, the power supply must be a properly grounded

and a polarized outlet must be used. Before plugging the VC1100 into the outlet, test the outlet to

confirm it will meet the VC1100 power requirements. If the power requirements are not met,

contact a Licensed Electrician and have any necessary corrections made. After connecting to the

wall outlet, open the Service Panel and turn the main power switch on. The display on the front

panel should become active after approximately 20 seconds.

DE720 Rev. E

5 VC1100

SECTION 3 INITIAL SETUP

Upon placement of the machine on location, the following programming should be setup

to insure proper operation of the VC1100. Please verify the unit has reached the desired

temperature settings before loading product.

The temperature may be viewed at any time by pressing the “0” button on the keypad.

VENDING

Vending operations, such as, setting prices, changing the message on the front display,

handling bills, coins, credit, making change, and operating vend motors should be tested before

loading product into the machine.

(Refer to Section 5 for programming instructions)

HEALTH AND SAFETY RANGE

The function of this system is to provide additional user protection by disabling vending

operations, “PLEASE CALL SERVICE” will be displayed if the air temperature inside the

refrigerated space rises above the selected setting for a preset period of time.

Proper Health and Safety settings must be set for proper operation.

Frozen Foods: +0°F or higher if more than 15 minutes

Slack Frozen: +15°F or higher if more than 15 minutes

Refrigerated: +41°F or higher if more than 15 minutes

None: None:

A magnetic switch is located at the top of the glass door that will provide an additional 60

minutes whenever the service door is opened, an additional 15 minutes will also be provided

whenever a defrost cycle occurs.

TEMPERATURE SETTINGS

Temperature settings can be programmed for Degrees Fahrenheit or Degrees Celsius. The

Set Point can be programmed to maintain a desired temperature. A minimum 6°F / 14°C delta is

recommended to prevent short cycling and extend the life of the Compressor.

The temperature may be viewed at any time by pressing the “0” button on the keypad.

DEFROST DELAY

This option is only necessary if the customer would like the machine to defrost at a

specific time. This option allows the user to set the starting point for the first defrost cycle. When

a power loss to the Control Board has occurred, 12 hours of operation will be resumed from the

moment power was restored, before defrosting.

DE720 Rev. E

6 VC1100

SECTION 4 OPERATION

REFRIGERATION SYSTEM

The system is comprised of an Evaporator, Condensing Unit, and Electronic Control

System. The refrigeration system will shut down whenever the glass door is opened. The System

Control Board regulates all refrigeration functions; the temperatures can be adjusted by entering

the service mode and inputting the desired set point and delta temperature settings. In the event

of a Control Board failure, the Refrigeration system will run continuously, and will not cycle off

until the Control Board is repaired or replaced.

The Evaporator removes heat from the air in a refrigerated space and transfers the heat to

the liquid Refrigerant. The liquid Refrigerant evaporates and is pumped out by the Compressor

through the larger diameter tubing. The Compressor pumps the low-pressure vapor into the

Condensing Coil where it gets rid of the heat and condenses into a high-pressure liquid. The

high-pressure liquid travels through the smaller diameter tubing to the T.E.V. (Thermostatic

Expansion Valve). The T.E.V. controls the amount of refrigerant supplied to the Evaporator, and

the cycle is repeated.

The temperature can be viewed at any time by pressing the “0” symbol on the keypad.

CONDENSING UNIT

The VC1100 uses a 3/4 hp Tecumseh Condensing Unit. It is located on the base of the

cabinet and can be accessed from the back of the unit. It consists of a Compressor, Condensing

Coil, Fan, Liquid Receiver, Starting Relay, Start Capacitor, Run capacitor, and a Thermal

Overload Protection Device. Two service ports are provided for a Qualified Service Technician

to diagnose and repair the Refrigeration System.

EVAPORATOR

The VC1100 uses a low Temperature, Forced Air, and Electric Defrost Evaporator. Each

consists of an Evaporating Coil, Thermostatic Expansion Valve, Evaporator Fan, ¼ ton TEV,

and a Heating Element. They are located inside each of the refrigerated spaces at the top

WARNING:

UNAUTHORIZED ADJUSTMENT OF THE THERMOSTATIC

EXPANSION VALVE WILL VOID THE WARRANTY!

TEMPERATURE DISPLAY

The temperature sensor readings can be displayed by pressing “0” in the sales mode of

operation.

DE720 Rev. E

7 VC1100

SECTION 4 OPERATION

REFRIGERATION CONTROL SYSTEM

The following sequence describes a typical Refrigeration Control cycle.

Upon initial power up, both compartments will begin to cool down.

1. The air temperature inside the refrigerated space cools down to the Cut-Out setting.

2. The Control Board receives a signal form the Temperature Sensor.

3. The Control Board energizes a 24Vdc Refrigeration Relay and opens the Normally Closed

Contacts.

4. The Compressor shuts off, Evaporator Fans continue to run.

5. The system remains off until the air temperature inside the refrigerated space warms up to the

Cut-In setting.

6. The Control Board receives a signal From the Temperature Sensor.

7. The Control Board de-energizes the Refrigeration Relay and closes the Normally Closed

Contacts.

8. The Compressor starts up and the cycle is repeated until the unit goes into defrost.

DEFROST SYSTEM

The Control Board controls the timing of the defrost cycle. The Control Board will

simultaneously energize a Defrost Relay, and the Refrigeration relays. When the Defrost Relay is

energized, the Normally Closed Contacts open and shut off the Compressor and Evaporator fans,

the Normally Open Contacts close and turn the Defrost Heaters on. The electric defrost is

automatic and will be initiated every 12 hours. The on time will be approximately 21 minutes.

During this period the compressor and evaporator fans are turned off. Whenever power to the

Control Board is removed, the Refrigeration will run for a full 12 hrs. before a defrost period

begins. The Defrost Start Time, duration, and period can be programmed from within the service

mode of operation.

SYSTEM CONTROL

The MDB-120 Selection System Control Board controls the message on the front

Display, Bill Acceptor, Coin Changer, Accumulation and Display of Escrow, Issuing Change

Payments, Keypad Selection, Vending of product, Price Settings, Health Safety, and

Refrigeration Control Functions.

The Sales Mode is the normal mode of operation. The controller will always default to

the sales mode under the absence of other inputs.

DE720 Rev. E

8 VC1100

SECTION 4 OPERATION

DOOR SWITCH MONITORING

Both of the door switches will be monitored at all times, if an open to close transition is

detected then all health safety related errors, timers, and sold out errors will be reset.

If either glass door is opened the refrigeration system will be switched off. If this open state

exceeds 30 minutes then a DOOR OPEN ERROR message will be continuously scrolled

across the display and the refrigeration system will be reactivated.

To protect the compressor from encountering overpressure situations due to opening and closing

the door repetitively, the controller will not re-activate the refrigeration system for a period of 90

seconds from the initial opening of the glass door.

IDLE CONDITION

The controller will monitor all present MDB peripherals for customer input while waiting

for a keypad generated interruption. If no action is taken, then the programmable Point of Sales

message will be scrolled on the display; provided there are sufficient coins in the coin changer.

If an adequate quantity is not detected, the “PLEASE INSERT EXACT MONEY” message will

be displayed. When credit has been established, the amount of credit will be displayed, otherwise

the controller will continue as above until a vend sequence is initiated or a Coin Return request is

made. If a Coin Return request is received and the Force Vend feature is disabled, the deposited

credit will be returned in a “like coin” fashion.

COIN ACCEPTANCE

The controller will allow acceptance of all coins as long as the accumulated credit is

equal to or less than the maximum price of any selection in the current configuration. When

Multivend is active then this maximum value increases to 3 times the highest priced selection in

the machine. Coin acceptance will be disabled during all vends, while coins are being paid out,

and while in the service mode of operation, and if card reader credit is established.

FIRST BILL ACCEPTANCE

The first bill will be accepted if the quarter tube is above the low indicator or if the dime

and nickel tubes are both above the low indicators. When accumulated credit is greater than or

equal to the maximum price, additional bill acceptance will be prevented. When multivend is

active then this maximum value increases to 3 times the highest priced selection in the machine.

If the bill acceptor offers escrow and acceptance is disabled because of the maximum price, the

last bill inserted will be kept in the escrow position, otherwise the bill will go straight into the

bill stacker. If the bill acceptor does not offer escrow, or bill escrow is disabled, the bill will go

straight to the bill stacker. The bill will be accepted if the coin tubes total cash amount is

greater than or equal to the established credit plus the additional bill value. If credit is

established from a card reader, no bills will be accepted.

DE720 Rev. E

9 VC1100

SECTION 4 OPERATION

ADDITIONAL BILL ACCEPTANCE

Additional bills will be accepted if the dime and quarter tubes are both above the low

indicators. If the accumulated credit is greater than or equal to the maximum price, additional bill

acceptance will be disabled. When multivend is active then this maximum value increases to 3

times the highest priced selection in the machine. If the bill acceptor offers escrow, and

acceptance is disabled because of the maximum price, the last bill inserted will be kept in the

escrow position. If the bill acceptor does not offer escrow, or bill escrow is disabled, the bill will

go straight to the bill stacker and the bill acceptor will be disabled after the second bill has been

sent to the stacker.

DEX / UCS Data Retrieval

DEX / UCS data retrieval is only allowed in the sales mode of operation. The retrieval

device initializes the data retrieval after it has been properly connected to the DEX port. Refer to

page 73 for the available DEX fields.

DE720 Rev. E

10 VC1100

SECTION 4 OPERATION

VENDING SELECTION

The controller responds to keypad selections from two possible sources. One source is

the 120 Select controller's own keypad and the other source is a selection received from an MDB

USD peripheral by the 120 Select Controller.

Following reception of any keypad selection, the controller will then calculate a checksum of the

MIS and pricing information. The resulting checksum will then be compared to the previous

checksum calculated when the controller last changed a MIS or price location.

If the two checksums are different, the vend will not be allowed. This same checksum error will

cause the controller to return any deposited credit in a "like coin" fashion.

If the two check sums are identical, then the selection's character, number, and price will be

displayed while additional checks on the selection are made in the following order.

1) Passes Health and Safety rules

2) Item is not in Shutdown range of the 'Timed Shut Down Intervals' feature

3) Item is in the configuration and it does not contain a bad motor

4) Deposited credit is greater than or equal to the price of the selection

If the selection fails any of these checks then the vending attempt will be aborted. The

controller will continue to display the selection's character, number, and price for a period of 1

second. This is followed with three beeps from the speaker along with the one-time scroll of a

failure dependent message.

• If the item failed the shutdown check then this scrolled message will be "VENDING

OPERATION TO RESUME AT hh.mm”. The deposited money will be automatically

returned to the customer.

• If check #4 failed then this message will be "PLEASE INSERT MORE MONEY".

• For the other failures, "MAKE ALTERNATE SELECTION" will be the message. The

credit or the point of sales message (if no credit has been established) will be displayed

again following the message.

If the selection has passed all of the previous checks, the controller will determine if the

exact amount of change can be paid to the customer.

The vending sequence will be halted if the controller determines that exact change can

not be returned. The controller will return the deposited credit in "like coin" fashion. The

controller will issue three beep tones along with one scroll of the PLEASE INSERT EXACT

MONEY" message and then return to the idle condition of the sales mode. If a Promotional item

(in response to purchase of another item) failed to vend, the vend is considered good. The failed

motor is flagged and displayed in service mode.

If all previous checks have passed then a vend of the selection will be attempted.

DE720 Rev. E

11 VC1100

SECTION 4 OPERATION

A successful vend results in a display of the amount of change while it is returned using a

"least coins" algorithm. If the correct change is returned, the "THANK YOU" message will be

displayed for 0.8 seconds, followed by the idle condition of the sales mode. If for some reason

the exact amount of change cannot be returned, as much as possible will be paid out and the

remaining amount will be retained as credit toward another vend. An item price of $0.00 is

allowed as a valid vend while in the sales mode of operation.

When a vend fails, the controller will beep three times while the "MAKE ALTERNATE

SELECTION" message is scrolled one time. This will be followed by the amount of accumulated

credit. When the force vend feature is enabled, faulty vends will result in an override of the

force vend feature. Force vend will stay overridden until the customer has attempted to escrow

the credit or vended another product.

For those failed vend attempts of motors connected to the 120 Select controller, if the

motor is not allowed to complete a full cycle, or if after twelve seconds the motor has not yet

returned to a home position, the vend will be considered a failure.

A bad motor is defined as:

1) A motor location requiring more than 12 seconds before detecting a home position signal

2) An electrically open motor circuit at the time the controller first attempts to vend the

motor.

If a configured motor not in the autoreinstate range has been detected as being bad due to

the detection of an open circuit, that motor can not be vended until it is cleared by performing a

successful free vend from within the service mode of operation.

When the optics mode is enabled and autoreinstate is inactive for the particular selection

but the optical sensor detects no product. In this case, the controller will flag the item with a

sold out error (VMC 9) in addition to a long vend error (VMC 2). The controller will also

prevent further attempts to vend the particular selection until the selection's sold out error status

is cleared.

DE720 Rev. E

12 VC1100

SECTION 5 PROGRAMMING

THE SERVICE MODE OF OPERATIONS

To enter the Service Mode press the red button located on the controller board. The

controller automatically returns to the sales mode if no input from the keypad is received in

approximately 25 seconds, or if the button is pressed a second time within this period. If credit

exists upon entering the service mode, it will be restored when the sales mode is re-established.

At the time of initial entry into and final exit from the service mode, the controller will

briefly power all currently configured motors to determine if an open circuit condition exists.

Any configured motor that exhibits an open circuit during this process will be immediately

removed from the vending machine configuration. This means that a motor previously tagged

bad in the sales mode due to an open circuit condition, and presently found to have an open

circuit condition upon entry to the service mode, will not be flagged as bad in the diagnostics

service mode menu.

For the remainder of the programming section the following commands will be used in place of

keypad buttons

5 keypad buttons will be used to navigate the service menu

A = SCROLL UP

B = ENTER

C = SCROLL DOWN

D = SAVE

E = EXIT / CANCEL

DE720 Rev. E

A 1 2

B 3

C 5

D 7

E 9

4

6

8

0

F G H

J K L

13 VC1100

SECTION 5 PROGRAMMING

DE720 Rev. E

14 VC1100

SECTION 5 PROGRAMMING

DIAGNOSE

The Diagnostics menu item displays the current status of the controller and peripherals.

Pressing “ENTER” after the user has navigated to the menu item labeled DIAGNOSE starts

this function. Upon entry the status of the controller and each of the peripherals will be checked.

The order of checking is the Vending Machine Controller, the Changer, the bill Validator, and

the card reader. The display will show in that order "VMC", "CHANGER", "VALIDATOR",

and "READER". If no problems are encountered with the individual device then the name of the

device will be followed by "OK". If problems are encountered then the device name will be

followed by an error code.

In the case of the Vending Machine Controller, it's possible that a sequence of error codes

could follow the "VMC" display if multiple errors are found with that device. The diagnostics

for the VMC will include an error code if any motor in the configuration has been flagged as

bad. In addition, the error code for the bad motor will indicate why.

A definition of all possible error codes is shown in the table below. This function may

be exited at any time by pressing the "CANCEL" button.

ERROR CODE ERROR DESCRIPTION

VMC 1

VMC 2

VMC 4 NOVRAM checksum error. The display would read "VMC 4"

VMC 5

VMC 6

VMC 7 The door is still open after 30 minutes "VMC 7".

VMC 8 Eyes on the activated optical sensor are blocked.

VMC 9

CHANGER 3

VALIDATOR 7

READER 8

Too little motor current (under 20mA).

For an example, the display will show "VMC A1 1"

Too much time to complete vend (12 seconds).

For an example, the display will show "VMC C2 2"

Health & safety error on temperature sensor 1.

The display would read "VMC 5".

Health & safety error on temperature sensor 2.

The display would read "VMC 6".

Selection was not detected by optical sensor and, as such, is

considered sold out. ).

For an example, the display will show "VMC A1 9"

Loss of changer communications or no changer.

The display would show "CHANGER 3".

Loss of bill validator communications or no bill validator.

The display would read "VALIDATOR 7"

Loss of card reader communications or no card reader.

The display would read "READER 8"

DE720 Rev. E

15 VC1100

SECTION 5 PROGRAMMING

ERROR CODES

Enter the service mode by pressing the red button on the controller, a beep will be issued

to recognize the transition and “DIAGNOSE” will be displayed until a function key is pressed.

Press the letter “B” to enter the diagnostics menu. The diagnostics routine will present various

error codes relating to the nature of a fault condition

VMC 1

If any previously configured selection motor has become disconnected, the Control Board

will display VMC 1 after entering the Diagnostics Mode. A successful Test Vend of the selection

will clear this Error.

VMC 2

If any selection becomes jammed, turns too slow, or the home switch on the motor does

detect the home position, the Control Board will display a VMC 2. A successful Test Vend of the

selection will clear this Error.

VMC 4

A NOVRAM checksum error indicates that "some" configuration information has

changed erroneously. Configuration information consists of prices and all option settings

including health safety and temperature settings. When the error occurs, the controller does not

know what information changed, just that "some" information changed. It could be a single

location or all locations. Your customer must go in and manually check all settings to insure the

controller will function, as they want it to. This error will be cleared upon exiting the Service

Mode of Operation. Power surges are the most likely cause of a VMC 4 message

VMC 5

A VMC 5 Error indicates that Sensor 1 air temperature in the refrigerated space has risen

above the Health and Safety setting selected by the user. All vending functions within a selected

range of rows will be disabled and “MAKE ALTERNATE SELECTION” will be displayed. If

all rows are designated in the range, “PLEASE CALL SERVICE “will be displayed. This Error

will be cleared upon exiting the Service Mode of operation.

• Frozen Foods: +0°F or higher if more than 15 minutes

• Slack Frozen: +15°F or higher if more than 15 minutes

• Cold: +41°F or higher if more than 15 minutes

• None: None

VMC 6

A VMC 6 Error indicates that Sensor 2 air temperature has risen above the Health and

Safety setting; The VC1100 does not utilize a 2-sensor mode of operation and must be disabled.

DE720 Rev. E

16 VC1100

SECTION 5 PROGRAMMING

VMC 7

A VMC 7 error indicates that the reset switch at the top of the glass door has remained

open for more than 30 minutes. This error will be cleared upon exiting the service mode of

operations.

VMC 8

A VMC 8 error indicates that the optical sensor is blocked, the lens is dirty, faulty sensor,

or the connector on header P8 is disconnected. This error cannot be cleared until the problem is

resolved.

VMC 9

A VMC 9 error indicates that the optical sensor did not detect product. These errors will

be automatically cleared by either opening and closing the glass door or exiting the service

mode.

CHANGER 3

If the Coin Changer becomes disconnected from the Control Board, (i.e. Broken wire,

Faulty Control Board, or Faulty Coin Changer) CHANGER 3 will be displayed. This Error

cannot be cleared until the source of the problem is repaired. If the VC1100 uses a Debit Card

Reader without a Coin Changer or Bill Acceptor, CHANGER 3 will always be present and

cannot be cleared, this is normal

VALIDATOR 7

If the Bill Validator becomes disconnected from the Control Board, (i.e. Broken wire,

Faulty Control Board, or Faulty Bill Validator) VALIDATOR 7 will be displayed. This Error

cannot be cleared until the source of the problem is repaired. If the VC1100 uses a Debit Card

Reader without a Coin Changer or Bill Acceptor, VALIDATOR 7 will always be present and

cannot be cleared, this is normal

READER 8

If the Card Reader becomes disconnected from the Control Board, (i.e. Broken wire,

Faulty Control Board, or Card Reader) READER 8 will be displayed. This Error cannot be

cleared until the source of the problem is repaired. If the VC1100 does not use a Debit Card

Reader, READER 8 will always be present and cannot be cleared, this is normal

DE720 Rev. E

17 VC1100

SECTION 5 PROGRAMMING

MOTOR

This menu provides motor count and configuration options. Pressing the "ENTER" button

after the user has navigated to the menu item labeled MOTOR will enter this menu. To exit this

menu, the "CANCEL" button should be pressed.

COUNT

This function counts and displays the total number of functioning motors. Pressing

"ENTER" after the user has navigated to the menu item labeled COUNT starts it. The

controller will test each motor drive in the current configuration to determine if a valid

motor is connected at that instant. The message COUNT and the number of motors

responding will then be displayed. To exit this function, press the "CANCEL" button.

CONFIG

This function is used to remove undesired motor selections from the configuration.

Pressing “ENTER” after the user has navigated to the menu item labeled CONFIG

starts it. The controller will reconfigure to the currently functioning motors and display

CONFIGURED. This is the only means of removing motors from the configuration.

To exit this function, press the "CANCEL" button.

ACCOUNT

This menu provides functions for displaying the stored accountability. Pressing the

“ENTER” button after the user has navigated to the menu item labeled ACCOUNT will enter

this menu. To exit this menu or any of the functions within this menu, the "CANCEL" button

should be pressed. Pressing the “ENTER” button may enter all the following accounting

functions.

HIST SALES

Display value of all paid sales since initialization (VA101), which will rollover after

$99,999.95.

HIST COUNT

Display total number of products vended since initialization (sum of PA201 fields),

which will roll over after 79,999,920

RES SALES

Display value of all paid sales since the last reset (VA103), which will rollover after

$9,999.95.

RES COUNT

Displays total number of products vended since the last reset (sum of PA203 fields),

which will roll over after 79,999,920.

DE720 Rev. E

18 VC1100

SECTION 5 PROGRAMMING

RDR SALES

Display value of total card reader sales since initialization (no corresponding DEX

field), which will rollover after $9,999.95

SET RANGE

This allows the user to set a range of rows that will be tracked for accounting

purposes. Once in this menu item, the user will see a display similar to SR/ER A-L.

The user sets the first row in the range by selecting any letter (from "A" through "L").

The last row in the range may then be selected by entering any letter that is greater than

or equal to the first row in the range ("A" through "L"). Once the 2 letters in the range

are entered, the setting may be saved by pressing the "SAVE" button or canceled by

pressing the "CANCEL" button. Pressing either of these buttons forces exit from this

submenu and returns control to the previous menu level.

RANGE CASH

Display value of all paid sales over the range defined in SET RANGE submenu

since the last reset (sum of PA204 fields in the defined range).

RANGEVENDS

Display total number of products vended over the range defined in SET RANGE

submenu since the last reset (sum of PA203 fields in the defined range).

CLEAR

This function allows the user to set all re-settable fields to 0.Upon entry into the

function, those re-settable items are cleared and the display shows CLEARED.

DE720 Rev. E

19 VC1100

SECTION 5 PROGRAMMING

COIN

This function is provided for manually filling and dispensing coins from the changer. In

addition, there are several functions for controlling credit acceptance and the display of messages

related to credit status. Pressing the “ENTER” button after the user has navigated to the menu

item labeled COIN enters this menu. To exit this menu or any of the functions within this

menu, the "CANCEL" button should be pressed. Pressing the “ENTER” button will enter all the

following coin functions.

PAYOUT

This function allows for the dispensing of coins from the inventory tubes. Upon entry

into this function the controller will display DISPENSE and wait for the user to press

one of the following numbers. The corresponding coins will continue to be paid out until

the number is released.

1 = Most significant coin

2 = Next significant coin

3 = Next significant coin

4 = Least significant coin

TUBE FILL

Upon entry into this function, the controller will first display FILL COINS.

After a short delay, the controller will change the display to show zero credit. At this

point, the operator may begin entering coins into the changer. As coins are entered the

display will note the total value of the coins entered. After returning to sales mode the

credit will be zero. This feature will be inhibited in the service mode If a credit exist from

the sales mode before entering service mode.

UNCON ACCP

The Unconditional Acceptance option forces the controller to accept any bill or

coin less than a specified value regardless of whether the changer can return an

equivalent value of credit. All coins or bills equal to or less than this specified value will

be accepted.

Upon entry to this function a five-digit number representing the current

unconditional acceptance value appears. A value up to 5 digits may now be entered using

the numeric keys. This value may be saved at any time by pressing the SAVE key. The

maximum settable value for Unconditional Acceptance is equal to the largest

denomination of currency or coin accepted by the changer or validator. If the

operator attempts to save a value that exceeds this amount, a warning message will

appear and the displayed setting will revert to this maximum value. To exit this mode,

before entering a value, press CANCEL or exit the service mode.

DE720 Rev. E

20 VC1100

SECTION 5 PROGRAMMING

EXACT CHNG

The Exact Change option forces the controller to display the message PLEASE

INSERT EXACT MONEY if a specified value of credit and every value, in

increments of the least coin tube value, less than this value cannot be paid back.

Upon entry to this function a five-digit number representing the exact change value

appears. A value of up to 5 digits may now be entered using the numeric keys. This value

may be saved at any time by pressing the SAVE key.

• When the highest vend price is greater than the unconditional acceptance value, then

the maximum settable value for exact change will be 3 times the highest vend price.

• When the highest vend price is less than the unconditional acceptance value then the

maximum settable value for exact change is 3 times the unconditional acceptance

value.

• If the operator attempts to save a value that exceeds this amount, a warning message

will appear and the displayed setting will revert to this maximum value.

• The minimum value for exact change is the unconditional accept value. If the

operator attempts to save a value less than this amount, a warning message will

appear and the displayed setting will revert to this minimum value.

To exit this mode before entering a value, press CANCEL or exit the service mode.

DE720 Rev. E

21 VC1100

SECTION 5 PROGRAMMING

TEST

This menu provides functions that allow the operator to test motors and/or relay output

control lines. Pressing the "ENTER" button after the user has navigated to the menu item labeled

TEST will enter this menu. To exit this menu or any of the functions within this menu, the

"CANCEL" button should be pressed.

TEST VEND

This menu provides functions that allow the operator to test vend either individual

motors or a range of motors. Pressing the "ENTER" button after the user has navigated to

the menu item labeled TEST VEND will enter this menu. Upon entry to the function,

the display will read SELECT --.

To test vend a single motor the user should enter the desired selection's letter

followed by its number. To test vend a range of motors the user should enter the letter of

the first row to vend followed by the letter of the last row to vend. After entering the

selection(s), if the operator is satisfied then the "SAVE" button should be pressed to

initiate a vend attempt on the selected motor(s). If the operator is not satisfied with the

selection or if he/she wants to exit the menu then the "CANCEL" button should be

pressed and control will pass back to the higher level where TEST VEND will be

displayed once again.

When the vend process is initiated, the display will show the particular selection

followed by the price of the selection as a vend is attempted. When the vend attempt has

completed and the selection corresponded to a single selection or the last selection in a

range of selections, control will pass back to the selection display, SELECT --.

• If for any reason, a vend attempt on a particular motor fails then the controller will

signal this by beeping 3 times.

• If optical sensor is enabled, the controller will wait for 3 seconds to verify product, if

no product was detected then the controller will beep three times before attempting

the next selection in the sequence.

• During the process of test vending a range of selections, the operator may press and

hold the "CANCEL" button to cancel the process and return control to the selection

display, SELECT --.

• A successful test vend on a motor clears all errors associated with that selection.

DE720 Rev. E

22 VC1100

Loading...

Loading...