Seaga RUBINO-200 Installation Manual

Hot beverage vending Machine

RUBINO 200

RUBINO 200 T.T.T.

Model:

ESPRESSO

TYPE: SG200E

i

WARNING: This instruction manual is intended exclusively for specialized personnel.

TION AND MAINTENANCETION AND MAINTENANCE

TION AND MAINTENANCETION AND MAINTENANCE

TION AND MAINTENANCE

OPERAOPERA

OPERAOPERA

OPERA

English

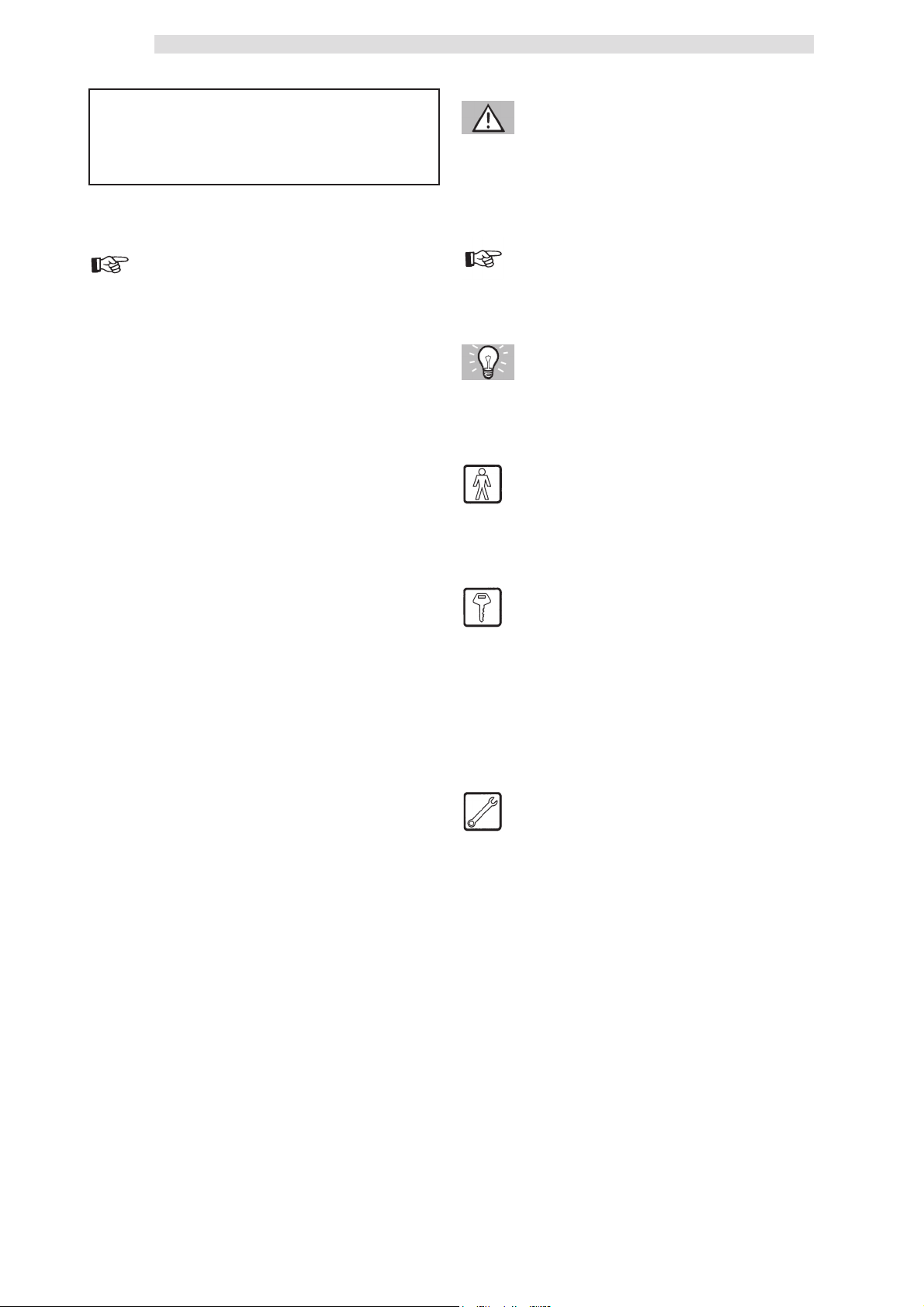

MAIN PARTS

13

12

11

10

RUBINO 200

5

316

2

4

RUBINO 200 T.T.T.

7

5

8

9

316

2

4

1 Brew group and coffee grinder

2 Brewing hopper group

3 Sugar and stirrer dispensing group

4 CPU card

5 Cup dispenser

6 Payment system area

7 POWER card

2

8 Water circuit equipped with air-break

device

9 Pump

10 Tray socket

11 Data plate

12 Data plate showing the minimum and

maximum water pressure

13 Water mains connection

TABLE OF CONTENTS

1 - INTRODUCTION TO THE

MANUAL ............................. 4

1.1 Foreword ............................................ 4

1.2 Symbols used.................................... 4

1.3 General instructions.......................... 5

1.4 Operator requirements ....................... 7

2 - TECHNICAL SPECIFICATIONS 7

3 - SAFETY STANDARDS ............. 8

3.1 Foreword ............................................ 8

3.2 General safety rules ........................... 8

4 - HANDLING AND STORAGE .. 9

English

7 - PAYMENT SYSTEM

INSTALLATION .................... 24

7.1 Payment system installation on the

machine ............................................ 24

7.2 Payment system installation on the

cabinet............................................... 25

8 - PROGRAMMING AND

MAINTENANCE MENU ........ 26

8.1 Description of programming and

maintenance phase keys 27

8.2 Programming menu 27

8.2.1 Entering the programming menu 27

8.2.2 Structure of the programming menu 35

8.2.3 Functions of the programming menu 3 5

8.3 Maintenance menu 46

8.3.1 Access to the maintenance menu 4 6

8.3.2 Description of maintenance menu

messages 48

8.4 Software updating

(machine re-programming) 51

9 -

MAINTENANCE AND

INACTIVITY .........................

52

4.1 Handling and transport ...................... 9

4.2 Storage ............................................ 9

4.3 Packaging ........................................ 10

5 - GENERAL TECHNICAL

DESCRIPTION ..................... 10

5.1 Permitted use .................................... 10

5.2 Versions and Models.......................... 10

5.3 Basic operating concepts...................10

6 - INSTALLATION .................... 13

6.1 Positioning ......................................... 13

6.2 Receipt .............................................. 14

6.3 Unpacking.......................................... 15

6.4 Water mains connection .................... 16

6.5 Electric mains connection.................. 16

6.6 Machine start-up ................................ 17

6.7 Installation ......................................... 18

6.7.1 Cleaning and filling of resin-based

water softener .................................... 18

6.7.2 Water circuit filling ............................. 19

6.7.3 Cleaning the parts in contact with

foodstuff ............................................. 20

6.8 Product loading .................................. 21

6.8.1 Container loading ............................... 21

6.8.2 Label insertion ................................... 22

6.8.3 Cup loading........................................ 22

6.8.4 Stirrer loading..................................... 23

9.1 Cleaning and loading .......................... 5 2

9.1.1 Daily cleaning .................................... 52

9.1.2 Weekly cleaning ................................ 54

9.1.3 Product loading .................................. 55

9.2 Maintenance ...................................... 55

9.2.1 Scheduled and unscheduled

maintenance ...................................... 56

9.2.2 Brew group maintenance.................... 56

9.3 Adjustments ...................................... 57

9.3.1 Dose and grinding adjustment ............ 57

9.4 Cup releasing device cleaning and .....

adjustment ......................................... 58

9.5 Resin regeneration - where the water .

softner is provided .............................. 60

10 - INACTIVITY......................... 61

11 - DISMANTLING.................... 61

12 - TROUBLESHOOTING GUIDE

FOR THE MOST COMMON

FAILURES OR ERRORS ........ 62

13 - VISUAL SIGNALS (LEDs) ..... 66

14 - INSTRUCTIONS FOR

END-OF-LIFE DISPOSAL

TREATMENT ........................ 69

3

English

1 - INTRODUCTION TO

THE MANUAL

1.1 Foreword

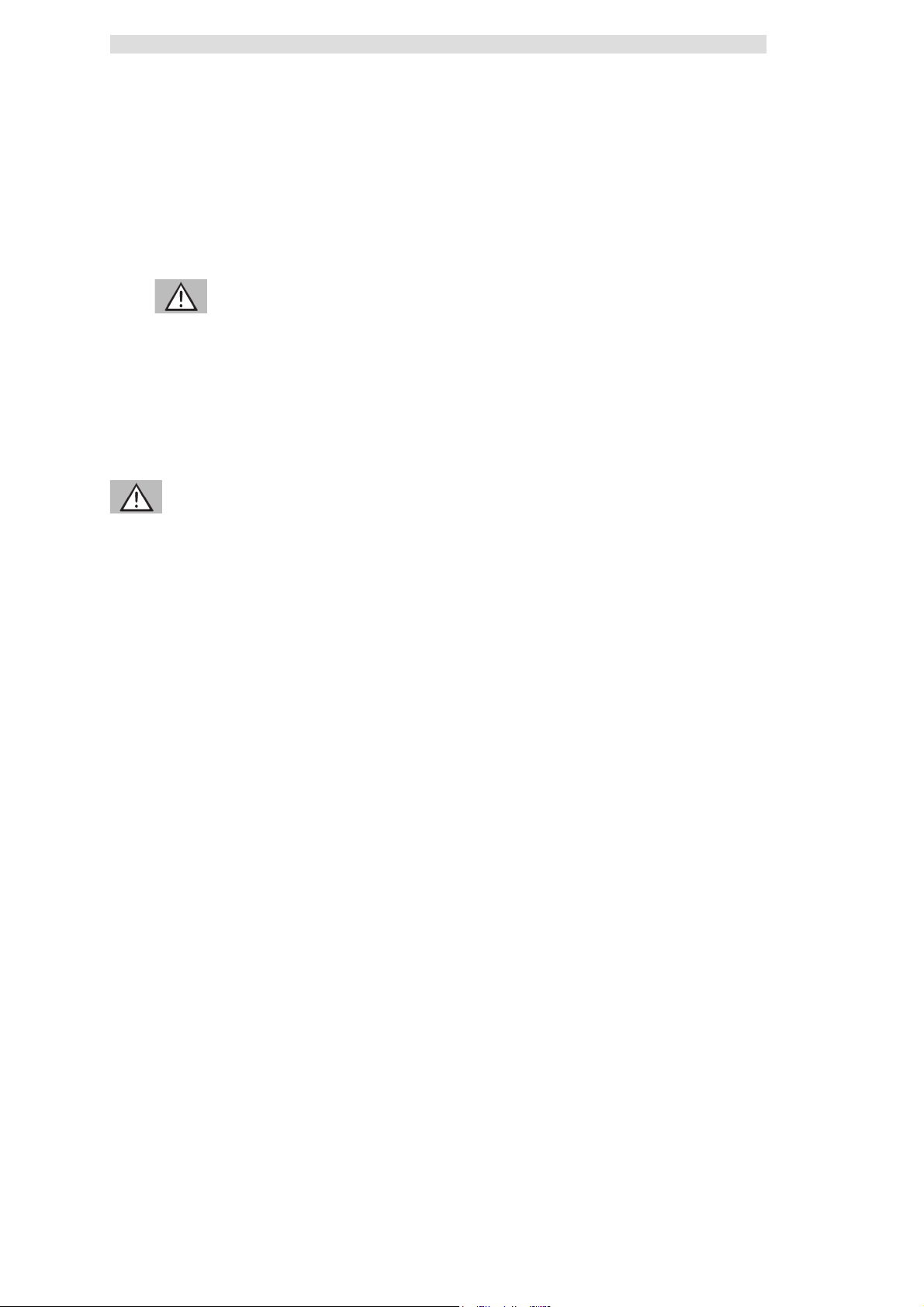

Important

This publication is an integral part of the machine

and should be read carefully in order to use it in

a correct way. Complying with safety

requirements is also essential

This manual contains the technical information

necessary to carry out the procedures of use,

cleaning, installation and maintenance of the

vending machine mod. RUBINO 200 correctly.

Always consult this publication before carrying

out any operation.

Manufacturer: Saeco International Group

Via Panigali, 39 - 40041 Gaggio Montano (BO).

Warning

This symbol indicates dangerous situations for

the users, supply operators and maintenance

technicians dealing with either the vending

machine or the product to be dispensed.

Important

This symbol indicates operations that keep the

machine in good working conditions, if properly

carried out.

Recommended solutions

This symbol indicates the procedures that make

the programming and/or maintenance

operations quicker.

User

This symbol indicates the machine user, who is

not authorized to clean or service the vending

machine.

This manual should be kept with care and go

with the machine throughout its operational life,

also in case of changes of ownership.

If this manual should be lost or worn out, it is

possible to require another copy to the

Manufacturer or to an Authorized Service Centre.

In this event, please indicate the data on the plate

located on the back of the machine.

All the images in this manual refer to the RUBINO

200 model.

The data that refers to a single model is

indicated.

1.2 Symbols used

A number of symbols are used in this manual to

classify situations according to their degree of

danger, and that require technicians with dif ferent

skills.

Supply operator

It is used to indicate operations to be exclusively

carried out by personnel in charge of machine

supplying and cleaning.

Maintenance is exclusive task of the

maintenance technician, and cannot be

performed by the supply operator.

Maintenance technician

This symbol is used to indicate operations to be

only performed by specialized maintenance

personnel.

The maintenance technician is the only person

authorized to keep the MAIN SWITCH

ACTIVATION KEY, which allows disabling the

safety system.

The symbol is integrated with a message

suggesting operating procedures or behaviours

and providing useful information concerning the

machine performance.

4

: Read

This symbol indicates that the user should read

the instruction manual carefully before operating

the machine.

English

• It is the buyer’s responsibility to ascertain that

the machine operators have been trained and

informed of all the indications and

specifications contained in the documentation

supplied. Even so, the operator should be

aware of the potential risks that exist while

operating the automatic vending machine.

1.3 General instructions

::

: Warning

::

Before using the vending machine, read this

manual carefully. A good knowledge of the

information and instructions contained in this

document is essential for a correct use of the

vending machine, in compliance with essential

safety requirements.

Warning

L’addetto al rifornimento non deve per alcun

motivo accedere a quelle parti del distributore

automatico le cui protezioni sono bloccate da

mezzi che richiedano un utensile per essere

liberati.

For no reason whatsoever should the personnel

in charge of the machine reach those parts of

the machine that are protected by guards

requiring special instruments for their removal.

Some maintenance operations (to be carried out

solely by specialised technicians) expressly

require that certain safety devices be switched

off.

• Operating reliability and the efficiency of the

machine performance are guaranteed only if

original spare parts are used.

• The user will be held entirely responsible for

any modifications made on the machine. All

the operations necessary to keep the

machine in good working order, before and

during use, are user’s duty.

• Altering and tampering with the machine

without prior consent of the manufacturer, will

release the latter from any liability for any

damage or injury resulting from, or connected

to the above modifications.

• This manual reflects the state of the art of

the automatic vending machine at the

moment of the issue on the market. Possible

modifications, improvements or adjustments

that are made to machines that are

subsequently marketed, do not oblige the

Saeco International Group either to intervene

on the previously supplied machine or

consider it and the relevant manual to be

defective or inadequate.

knowledge and absolute respect, from a

technical point of view, of the safety standards

and warnings contained in this manual, are

fundamental for installing, using and servicing

the machine under reduced risk conditions.

• Vending machine operator is only allowed for

interventions under his own responsibility and

specialization.

The user should have a good knowledge of

all mechanisms of the machine, as far as he

is concerned.

5

English

• However, the Saeco International Group,

whenever necessary and for valid reasons is

entitled to update existing manuals and send

to his customers all updating sheets that have

to be kept with the original manual. Any

technical problems that may arise can easily

be solved by consulting this manual. For

further information, contact the dealer where

the machine was purchased, or one of the

authorized service centres.

When calling, please, provide the following

information:

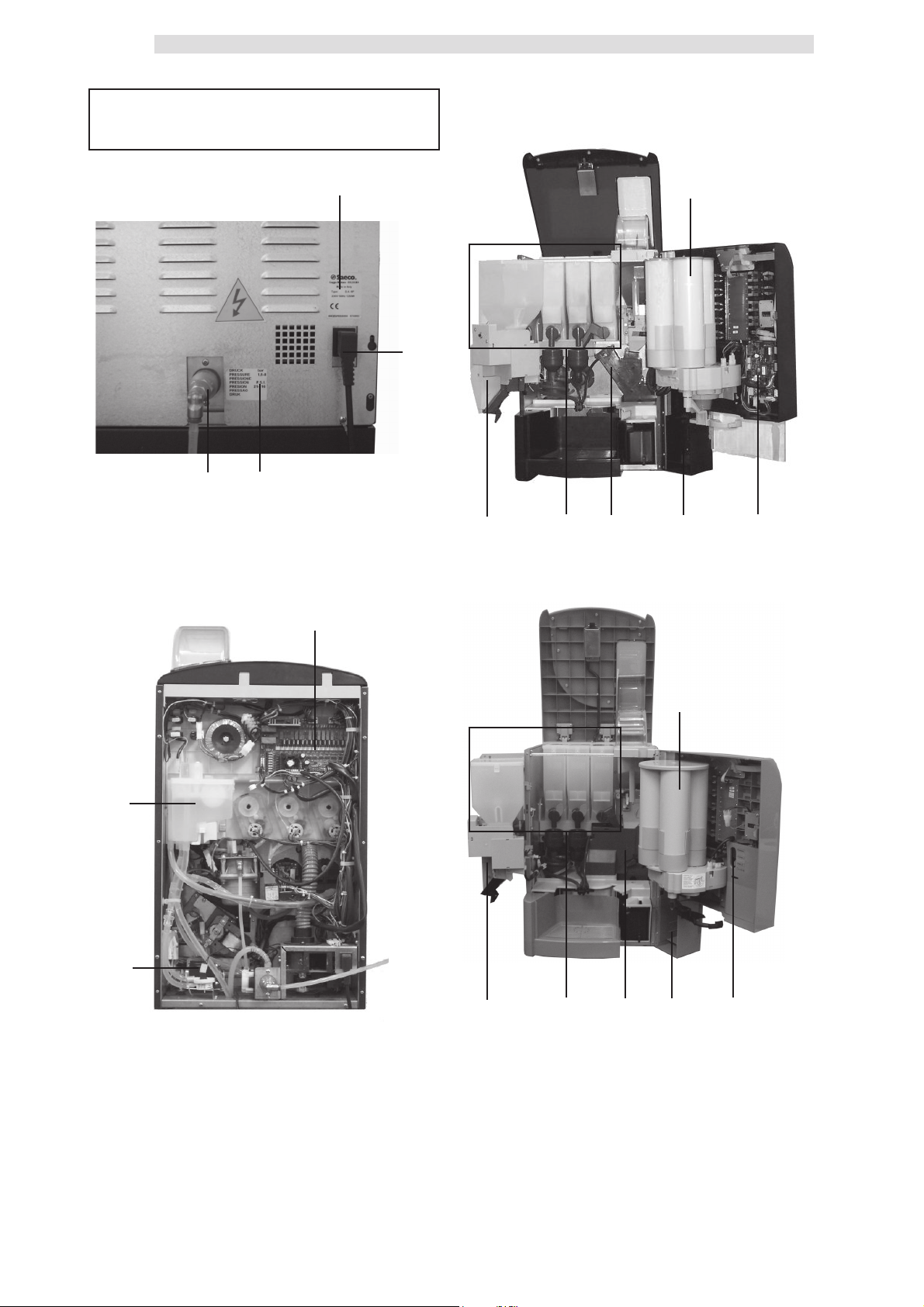

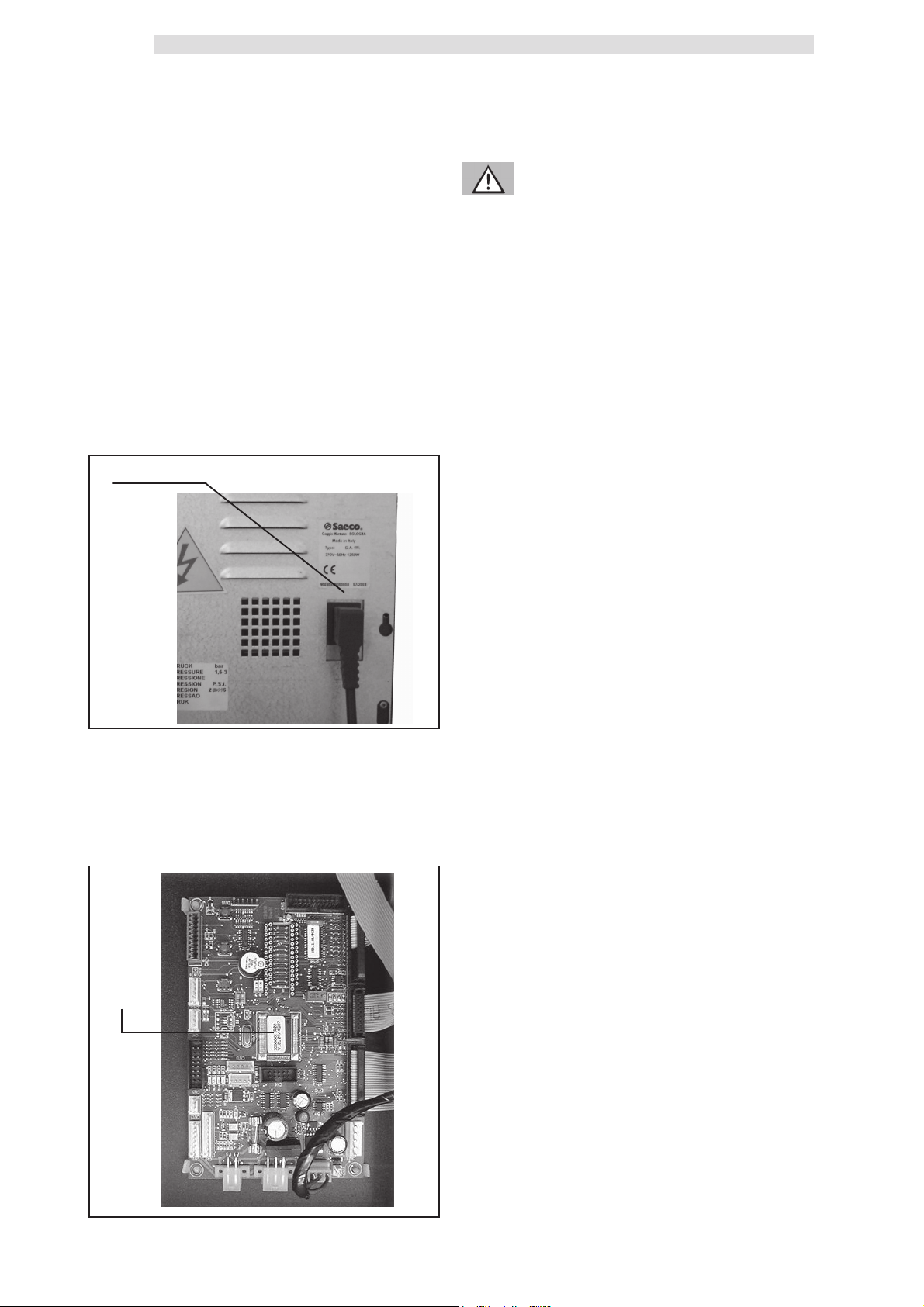

- the data written on the data plate located on

the rear side of the vending machine (fig. 1)

Data Plate

- The card code and version, to be found on

the component side of the CPU card (ref.’2’,

fig. 2).

Warning

It is absolutely forbidden to tamper with or modify

the data plate.

The Saeco International Group declines all

responsibility for injuries to people or damage to

things resulting from:

- incorrect installation

- inappropriate electrical and/or water

connection

- inadequate cleaning and maintenance

- unauthorized modification

- improper use of the vending machine

- non-original spare parts

• The Saeco International Group will not be

obliged in any case to indemnify any damage

caused as a result of the forced inactivity of

the machine due to failure.

fig. 1

- The program version in the microprocessor

(see adhesive label on the component

mounted on the CPU card) (ref.’1’, fig. 2).

”1”

• Installation and maintenance must be only

carried out by qualified technicians.

• Use only specific foodstuffs suitable for

vending machines.

• The automatic vending machine is not

suitable for outside installation. The machine

must be installed in dry places, with

temperatures not below 1°C and it must not

be installed in places where cleaning is made

with water hoses (e.g. large kitchens, etc.).

• If at the time of installation, the usage

conditions are different from those

established or are subject to change over

time, please contact the manufacturer

immediately before using the machine.

Furthermore, always act in compliance with

national or local standards.

fig. 2

6

1.4 Operators requirements

To guarantee safety, three different machine

users are to be distinguished, each having

specific characteristics:

User

Access to the inside of the machine is forbidden

to the user.

Supply operator

The safekeeping of the access key to the inside

of the machine is entrusted to the Supply

operator by the Maintenance T echnician. He has

the task of supplying the products, external

cleaning, activating and stopping the machine.

Warning

English

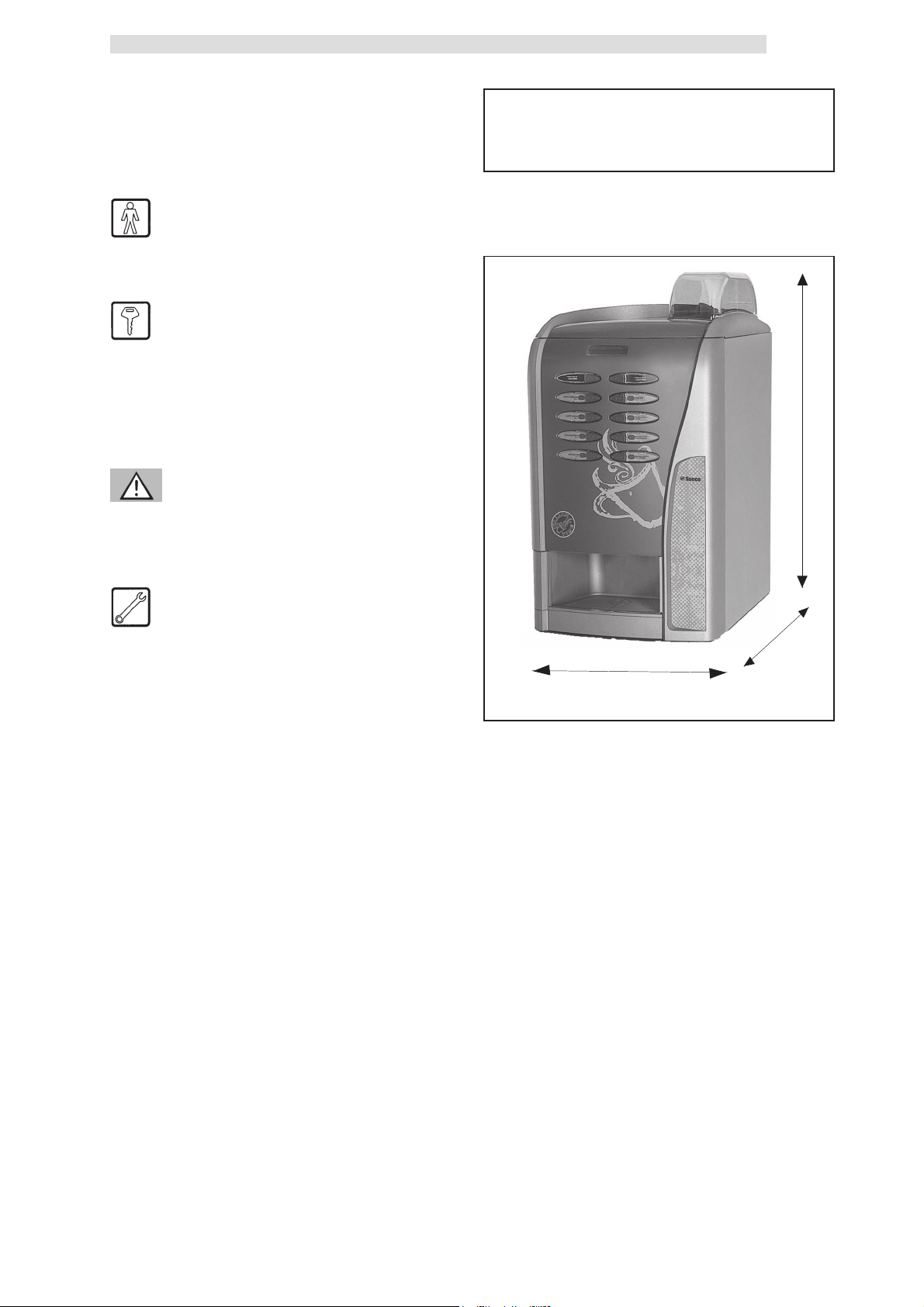

2 - TECHNICAL

SPECIFICATIONS

Weight 40 Kg

Overall dimensions See fig. 3

759.5

The Supply Operator is not authorized to carry

out operations that are indicated as competence

of the Maintenance technician in this publication.

Maintenance technician

Is the only person authorized to carry out and

start programming procedures for adjusting,

setting up and upkeep the machine.

537.8

410

fig. 3

Power consumption see Data plate

(fig. 1)

Mains voltage: see Data plate

(fig. 1)

Electric voltage frequency. see Data plate

(fig. 1)

Power cord length 1,600 mm

Connection to water mains 3/8 gas type

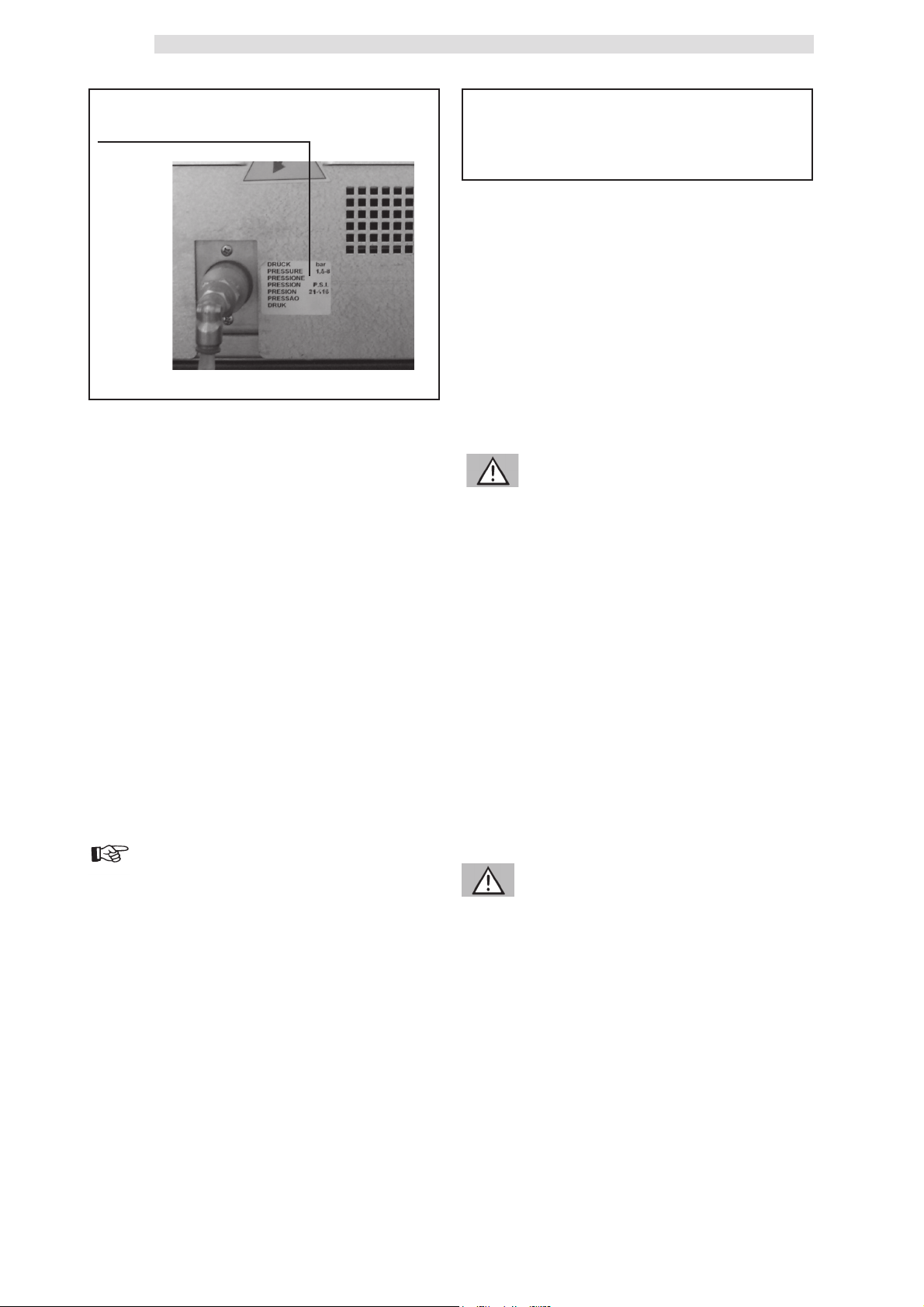

Water system pressure: from 1.5 up to 8

bar (fig. 4)

A-Weighted sound

pressure level: lower than 70 db

7

English

Data plate showing the minimum

and maximum water pressure

fig. 4

CUP DISPENSER

suitable for cups with 70-71 mm dia. and for cups

with 73 mm dia. through an adequate release

ring.

BOILER HEATING ELEMENTS

armoured types:

from 1,000 Watt for coffee boiler

CONTAINER CAPACITY

Coffee beans 2.0 Kg

Instant coffee 0.6 Kg (instead of tea)

Granular milk 0.85 Kg

Chocolate 1.7 Kg (or 2.6)

Tea 2.0 Kg

Sugar 2.0 Kg

Cups 195

Stirrers 185

Important

3 - SAFETY

STANDARDS

3.1 Foreword

In compliance with the Machine Directive 98/37/

EEC, Low Tension Directive 73/23/EEC and CE

Marking Directive 93/68/EEC, the Saeco

International Group has drawn up a technical file

on RUBINO 200 vending machine at its plants,

acknowledging during the design phase the

regulations listed in the Declaration of Conformity

inside any vending machine.

3.2 General safety rules

- Before using the vending machine, read this

- Installation and maintenance must only be

- For no reason whatsoever shall the operator

- Good knowledge and absolute respect, from

Warning

manual carefully .

carried out by qualified technicians.

reach those parts of the machine that are

protected by guards requiring special

instruments for removal.

a technical point of view, of the safety

standards and danger warnings contained in

this manual, are imperative for installing,

using, servicing and maintaining the machine

in minimum minimum risk conditions.

Warning

To guarantee the correct functioning and

durability of the vending machine, follow the

indications below:

- room temperature: from +1°C to +40°C

- maximum humidity: 90% (without

condensation water)

8

Always disconnect the POWER CABLE before

servicing or cleaning the machine.

Under no circumstances neither service the

machine, nor remove safety guards before hot

parts have cooled down!

- Operating reliability and the efficiency of the

machine performance are only guaranteed if

original spare parts are used.

- The automatic vending machine is not

suitable for outside installation. The machine

must be installed in dry places, with

temperatures never below 1°C and it must

not be installed in places where cleaning is

made with water hoses (e.g. large kitchens,

etc).

- In order to guarantee the performance of the

machine, always keep the automatic vending

machine in perfect cleaning conditions.

- The Saeco International Group declines all

responsibility for injuries to people or damage

to things as a consequence of:

- Use individual protection devices during

installation, testing and maintenance.

• incorrect installation

• inappropriate electrical and/or water

connection

• inadequate cleaning and maintenance

• unauthorized modification

• improper use of the vending machine

• non-original spare parts

Important

English

4- HANDLING AND

STORAGE

4.1 Handling and transport

The transport of the vending machine should be

carried out by skilled personnel.

The vending machine is delivered on a pallet;

for handling purposes use a fork lift truck and

move it slowly in order to avoid any possible

overturning or dangerous oscillations.

Important

Avoid:

- lifting the vending machine with ropes or

presses;

- dragging the vending machine

- turning over or laying down the vending

machine during transport

- shaking the vending machine

Avoid the machine:

- being bumped into

- being overloaded with other parcels

- being exposed to rain, frost or heat sources

- being kept in damp places

It is forbidden to:

- Tamper with or cut off the safety systems

installed on the vending machine;

- Use water jets to clean the machine.

Furthermore, always act in compliance with

national or local standards.

Warning

In case of failure or malfunctioning, contact

exclusively qualified CUSTOMER SERVICE

CENTER repairmen.

4.2 Storage

In the event of storage, avoid any stacking of

several machines, keep them in a vertical

position, in dry places with temperatures not

below 1°C.

9

English

4.3 Packaging

The vending machine is protected by cardboard

angles, by a transparent polypropylene film and

it is supplied in a box. The vending machine will

be delivered in a package, so as to ensure

protection against any mechanical and

environmental agent.

Labels are applied on the packaging, indicating:

- handle with care

- do not overturn

- protect from rain

- do not stack

- protect from heat sources

- not shock resistant

- machine type and serial number

Important

Once the transport is over, the p ackaging should

be undamaged, which means it should not:

- show any crushed parts, sign of shocks,

buckling or breaking

5- GENERAL

TECHNICAL

DESCRIPTION

5.1 Permitted use

The vending machine is to be used exclusively

for the dispensing of beverages, prepared by

mixing foodstuffs with water (by brewing, as to

coffee).

To this purpose, use products that the

manufacturer has declared as being suitable for

vending in open containers. Beverages are

brewed in suitable plastic cups, which the

machine dispenses automatically. The stirrer

used for mixing sugar is automatically dispensed.

Beverage should be drunk at once and under no

circumstances can they be kept for subsequent

consumption.

5.2 Versions and models

Warning:

- show wet parts or signs that could lead to

suppose its exposure to rain, frost or heat

- show signs of tampering

This manual refers to the top-of-the -range

model: it is therefore possible to find descriptions

or explanations not relating to the machine you

have.

5.3 Basic operating concepts

During normal operation, the vending machine

is in standby mode. By introducing the amount

corresponding to the price displayed and by

pressing the key relevant to the desired

beverage, you will start the dispensing cycle. This

one basically consists of:

BEVERAGE SELECTION

The machine can dispense 8 beverages. A

beverage can be selected according to the

following conditions:

• the vending machine has reached the set

temperature after start-up. Otherwise, once

a key is pressed, the display shows the

message ‘ PLEASE WAIT’.

10

English

• the available credit is sufficient or the vending

machine has been set in free mode. If this is

not the case, the display shows the message

‘INSERT ...’;

• there is no error condition that prevents

beverage brewing. If it is not the case the

display shows the error message

‘BEVERAGE... OUT OF SERVICE’ alternated

to a ‘NOT A V AILABLE’ message;

• the selected beverage has been enabled. If

this is not the case, the message ‘NOT

A V AILABLE’ will be displayed;

• the selected beverage is not prevented.

Otherwise, before pressing the key, the

message ‘BEVERAGE ...’ alternated to a

‘NOT AV AILABLE’ message is displayed. After

pressing the key, the display shows ‘NOT

A VAILABLE’;

During hot beverage brewing:

- payment systems are disabled;

- the first line on the display shows the

programmable dispensing message (default

message is: ‘WAIT FOR PRODUCT’).

• The same motor draws the cup under the

sugar dispenser – there it stops for 2

seconds. In this way dispensing is enabled

and, where it is set or required, a stirrer is

dispensed. Finally, it sets the cup under the

beverage brewing nozzles.

• The stirrer dispensing is controlled through a

solenoid which actuates the stirrer ejector.

The stirrer is then dropped into the cup by

means of the proper chute.

When selecting a beverage, sugar is dosed

through a motor that activates the sugar hopper

screw.

INSTANT BEVERAGE BREWING

This process takes place after dispensing of cup,

sugar and stirrer.

According to the type of beverage selected and

machine model, the following processes are

activated.

• If present, the motor mixer starts.

Beverage selection

If the vending machine has not been

programmed to freely dispense beverages insert

the required credit

Press the key corresponding to the beverage

requested. After beverage dispensing, the

message ‘REMOVE CUP’ is displayed. T ake the

beverage from the dispensing outlet.

Warning

Not to burn your hand, wait for the signal ‘REMOVE CUP’- before introducing your hand.

Do not open the dispensing outlet door while the

VM is brewing.

In case of failures or product missing during the

brewing phase, the display indicates the causes.

CUP, SUGAR AND STIRRER

DISPENSING

This is the first operation that the vending

machine activates (except for ‘without cup’

dispensing selection):

• the instant product solenoid valve (ref.’1' fig.5),

located on the coffee boiler , starts and allows

to fill the mixer with the preset amount of

water. The pump (ref.’2' fig.5) is then activated

and the preset amount of water dispensed,

under the control of an appropriate electronic

device (volumetric meter) (ref.’3' fig.5).

”1”

”2”

fig. 5

”3”

• the cup bracket motor is activated and moves

under the cup chute. At the same time, it

operates the cup scrolls to separate the first

cup and let it drop into the special support

fork.

• the gear motor of the instant product activates

the screw, dispensing the desired amount of

product into the mixer.

• once the pre-set amount of water and product

is dispensed, the mixer is disconnected.

11

English

ESPRESSO COFFEE BREWING

This process takes place only after the

dispensing of cup, sugar and stirrer.

• the grinder (ref.1 fig.6) is activated until the

quantity of coffee set on the dosing unit (ref.2

fig.6) is reached

• the activation of the dosing unit solenoid (ref.

‘3’ fig. 6) causes the door to open and, as a

consequence, the coffee is dispensed into the

cup.

”1”

”2

fig. 6

• the unit rotation gear motor activates, thus

moving the unit to the brewing position. The

coffee tablet is pressed simultaneously.

• the pump brewing the set quantity of water

activates, under the control of an appropriate

electronic device (volumetric meter) (ref. ‘3’

fig. 5).

• the brew group gear motor is restarted, and

goes back to the rest position. During this

movement the coffee tablet is ejected.

The grinder and dosing unit activation sequence

can take place in reverse order , according to the

program selected (see programming menu).

FRESH BREW WITH PRE-GROUND

COFFEE

- unlike the figure of the expresso coffee

brewing, the fresh brew coffee cycle with

preground coffee does neither imply the

activation of the coffee grinder nor of the doser

soleoid. The gearmotor of the pre-ground

coffee, contained in the third instant product

container, activates the screw conveyor so

”3”

as to dispense the preset amount of product

into the brewing cup through the appropriate

channel.

- The group rotation gearmotor, which moves

the group in an advance brewing position as

regards to the one reached during the

expresso coffee brewing, is activated. As a

result, the compression of the coffee tablet

is lower so as to obtain a beverage which is

noticeably less full-bodied as regards to

expresso coffee.

- The cycle ends as described above in the two

final phases of the expresso coffee brewing.

FRESH BREW WITH COFFEE BEANS

- As for the expresso coffee brewing, the

brewing cup is filled through the activation of

the coffee grinder and, then, of the doser

solenoid.

- The group rotation gearmotor, which moves

the group in an advance brewing position as

regards to the one reached during the

expresso coffee brewing, is activated. As a

result, the compression of the coffee tablet

is lower so as to obtain a beverage which is

noticeably less full-bodied as regards to

expresso coffee.

- The cycle ends as described above in the two

final phases of the expresso coffee brewing.

EXPRESSO WITH PRE-GROUND COFFEE

- As shown for the brewing of fresh brew coffee

with pre-ground coffee, the expresso coffee

cycle with pre-ground coffee does neither

imply the activation of the coffee grinder nor

of the doser soleoid. The gearmotor of the

pre-ground coffee, contained in the third

instant product container , activates the screw

conveyor so as to dispense the preset

amount of product into the brewing cup

through the appropriate channel.

- the group rotation gearmotor, which moves

the group to the brewing position and

simultaneously compresses the coffee tablet,

is activated.

- the pump is activated and dispenses the

preset quantity of water under the control of

an appropriate electronic device (volumetric

counter) (ref. ”3” fig. 5).

The Brew Group gearmotor is activated again,

and goes back to the rest position. During

this movement the coffee tablet is ejected.

12

66

- -

6

- INSTALLATION

66

- -

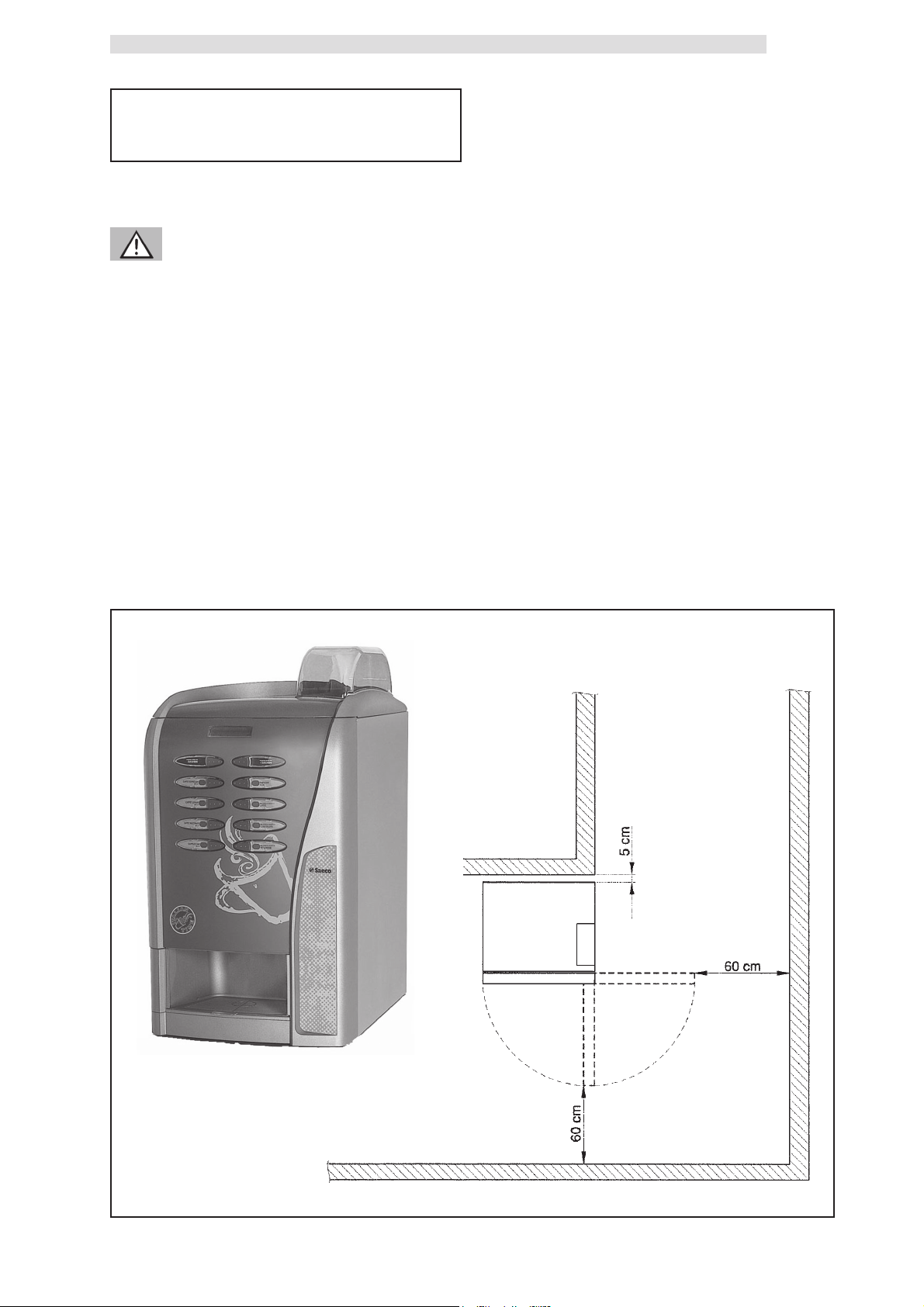

6.1 Positioning

Warning

The vending machine cannot be installed in

external areas, avoid placing it in areas where

the temperature is less than 1°C or more than

40°C and in particularly humid or dusty areas

and it should not be installed in places subject

to explosion or fire hazards, or where cleaning

is done with water jets.

- If positioned near a wall, there must be a

minimum distance of at least 5 cm from the

wall (fig. 7), so as to allow regular ventilation.

Under no circumstances cover the vending

machine with cloths or similar.

English

fig.7

13

English

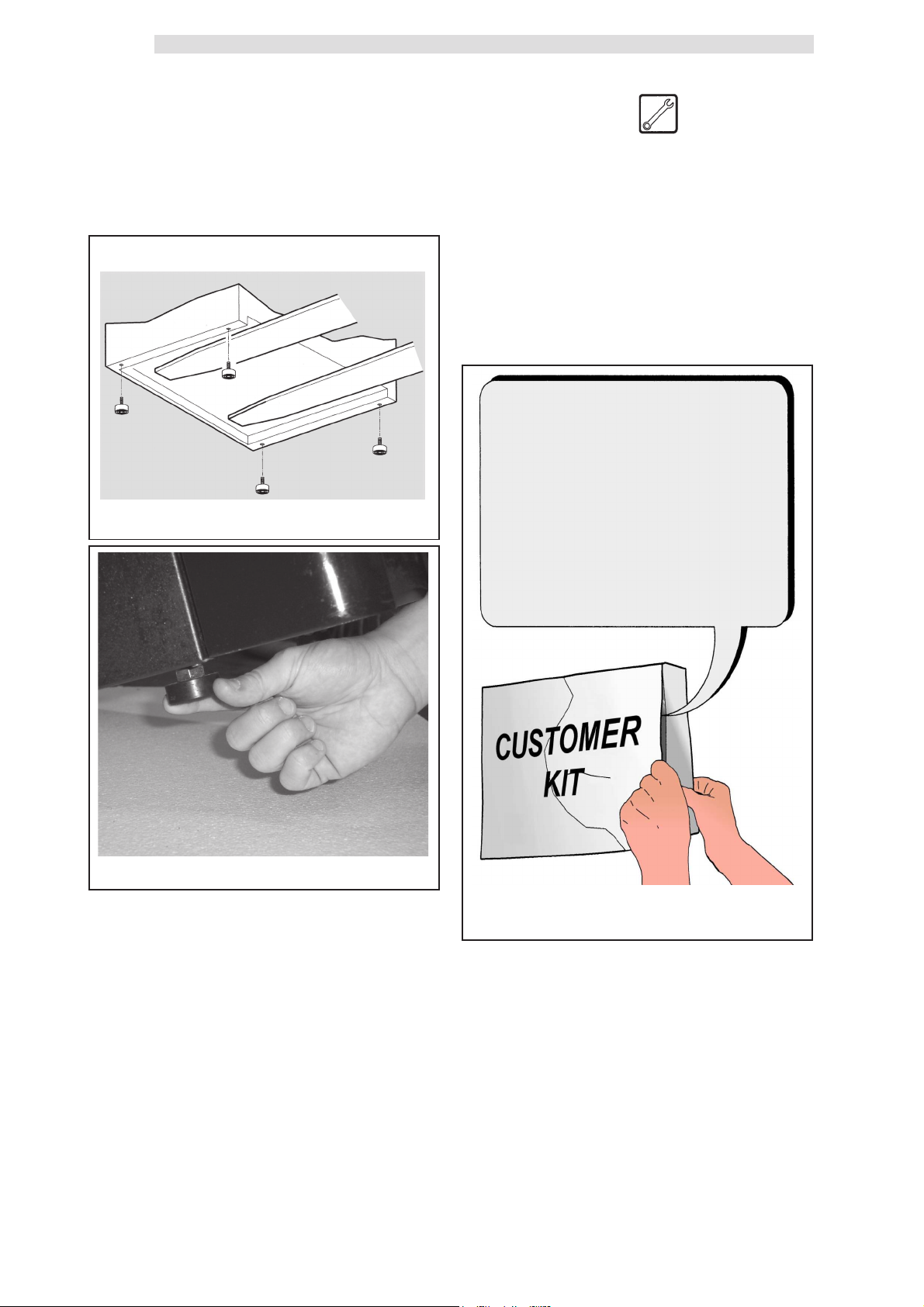

- When positioning the vending machine, check

its levelling by means of the adjustable feet

already fitted under the vending housing (fig.

8) or under the cabinet (fig. 9) Make sure that

the vending machine does not have an

inclination exceeding 2 degrees.

fig.8

6.2 Receipt

Upon receipt of the automatic vending machine,

it is necessary to check it has not suffered

damage during transport. If damage of any kind

is noticed, immediately place a claim with the

forwarder.

An envelope is supplied with the vending

machine, called ‘CUSTOMER KIT’. It contains

the objects shown in Fig. 10.

- Instruction manual.

- Powder tank plates and prices in

euro.

- Push-button panel selection plates.

- Instruction plates.

- Wiring and hydraulic diagram.

- Power cord.

- Safety switch key

(Technical engineer).

- Declaration of conformity

fig. 9

The Saeco International Group declines all

responsibility for troubles due to the failure in

observing the assembly rules.

If installation takes place in safety evacuation

corridors, make sure that the machine with the

door open assure sufficient space for people to

pass by (fig. 7).

In order to avoid the floor from getting dirty as a

result of accidental spillage of products, place a

sufficiently wide protection to cover the working

area under the vending machine.

14

fig. 10

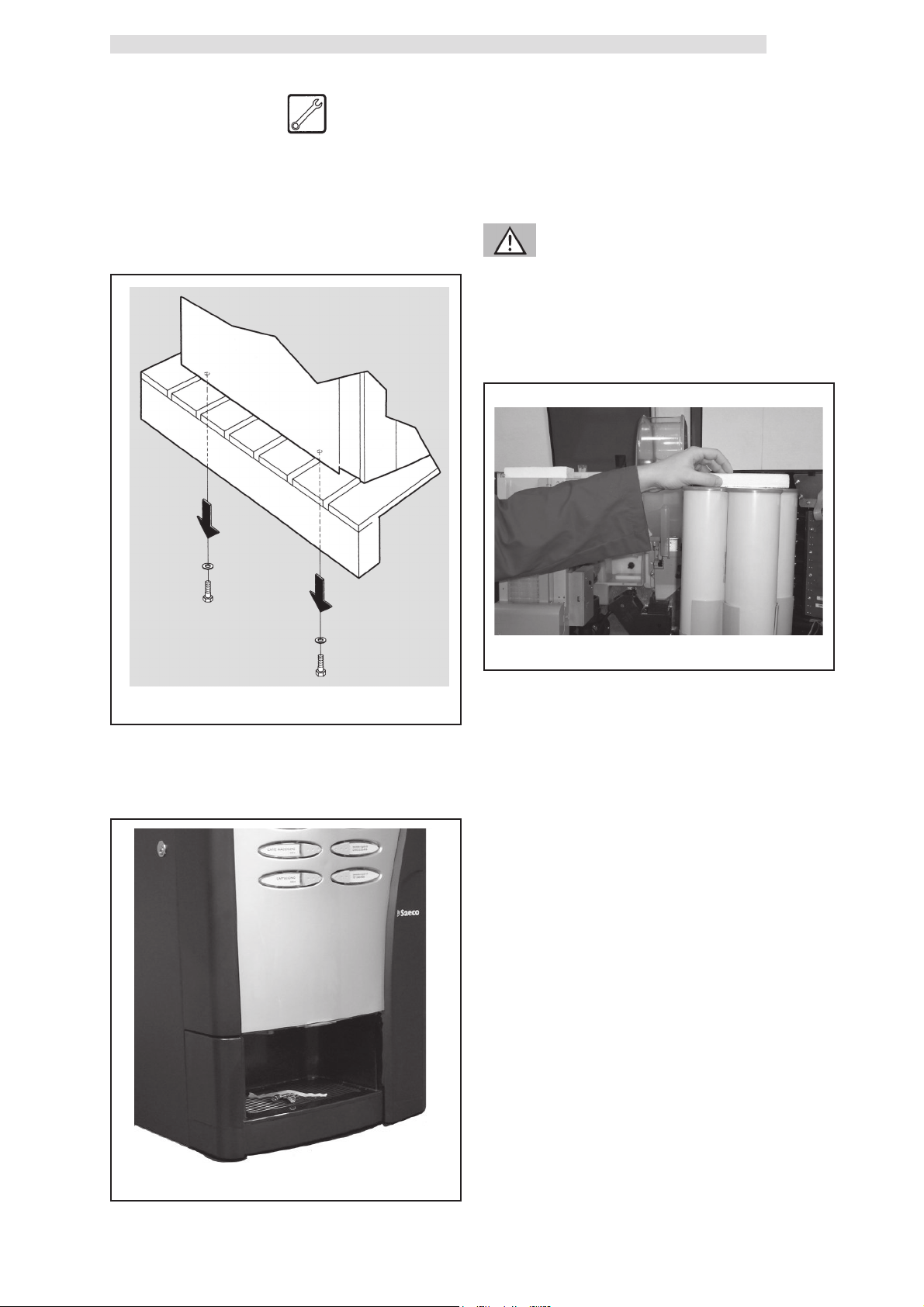

6.3 Unpacking

English

Open the door of the vending machine and

remove the adhesive tape from the components

concerned.

- Free the vending machine from the package.

- Remove the vending machine from the

transport pallet. Unloose its fastening screws

(fig. 1 1).

- Remove polystyrene securing internal

components (fig. 13)

Warning:

The packing material must not be accessible to

unauthorized people, as it is a potential source

of danger. For the disposal please contact

qualified companies.

fig.1 1

- Remove the key from the beverage

dispensing outlet (fig. 12).

fig.13

fig.12

15

English

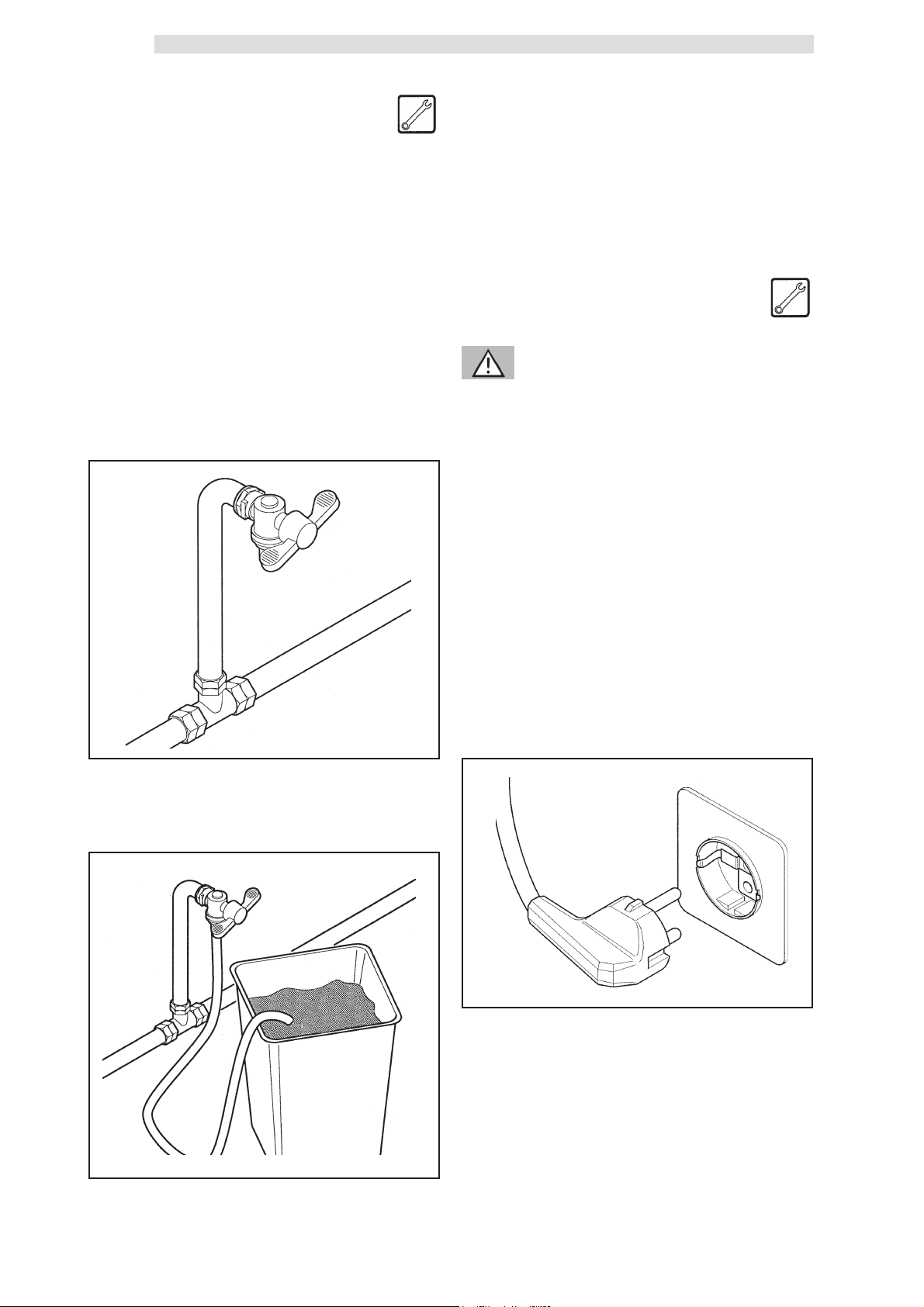

6.4 Water system connection

Before connecting the vending machine to the

water mains, make sure that the water is:

- connect the tap to the vending machine, using

a copper or nylon hose, suitable for foodstuff

and resistant to the supply pressure. Should

a flexible hose be used, it is necessary to

assemble the reinforcement bearing inside,

supplied with the machine.

- drinkable, if necessary by means of a test

laboratory certification

- has a pressure ranging between 1.5 and 8

bar, otherwise use a pump or a water

pressure reducer accordingly.

- if not already fitted, install a tap in an

accessible position, so as to separate the

equipment from the water mains, should it

be necessary (fig. 14).

- Use a 3/8 gas-type connection.

6.5 Power supply connection

Warning

The Maintenance T echnician, who is responsible

for the vending machine installation, must

ensure that:

- the electric system complies with current

regulations on safety;

- the mains voltage corresponds to that

indicated on the data plate.

If in doubt, do not proceed with the installation

but ask skilled personnel, qualified to carry out

these tasks, to carefully check the system.

fig.14

- let some water flow out of the tap in order to

eliminate possible traces of impurities and dirt

(fig.15).

fig.15

- The machine is equipped with power cord

(fig.16)

fig.16

16

English

- The sockets that are not compatible with the

plug of the machine should be replaced.

- The use of extensions, adapters and/or

multiple plugs is forbidden (fig 17).

fig.17

6.6 Machine start-up

The machine is equipped with a safety switch located on its top cover (fig. 18) which

disconnects the utilities whenever the door is

opened (see wiring diagram).

Therefore, open the door or unplug the

installation in case of need.

Safety switch

Warning

During the setting-up phase, before powering up

the machine, make sure you have connected it

to the hydraulic system and opened the water

tap.

Warning

The safety switch remains live (ref. ‘1’, fig. 18)

- For some operations, it is however necessary

to operate with the door open but the vending

machine connected to the mains.

Skilled technicians may operate in this way, by

inserting the special plastic key, supplied with

the machine, into the switch located on the

machine top cover, turning it of 90° (fig. 18).

Warning

The opening and possible machine start with door

open must only be performed by authorized and

technically qualified personnel. Do not leave the

machine unattended while it is open.

Give the key to qualified and authorized personnel

only.

Whenever the machine is switched on a test

cycle is performed in order to verify the correct

position of the moving parts and the presence of

water and other products.

fig.18

17

English

6.7 Installation

IMPORTANT: When switched on, the machine

automatically fills the water circuit and the related

boilers. For a correct automatic installation in

case of a water softener system being used, it

is necessary that the latter is completely filled

with water and properly relieved of any air

bubbles.

6.7.1 Cleaning and filling of resinbased water softener

IMPORTANT: Before installing the water

softener in the machine and using it, clean the

resins and fill the water softener . Then install the

water softener already filled with water and

cleaned.

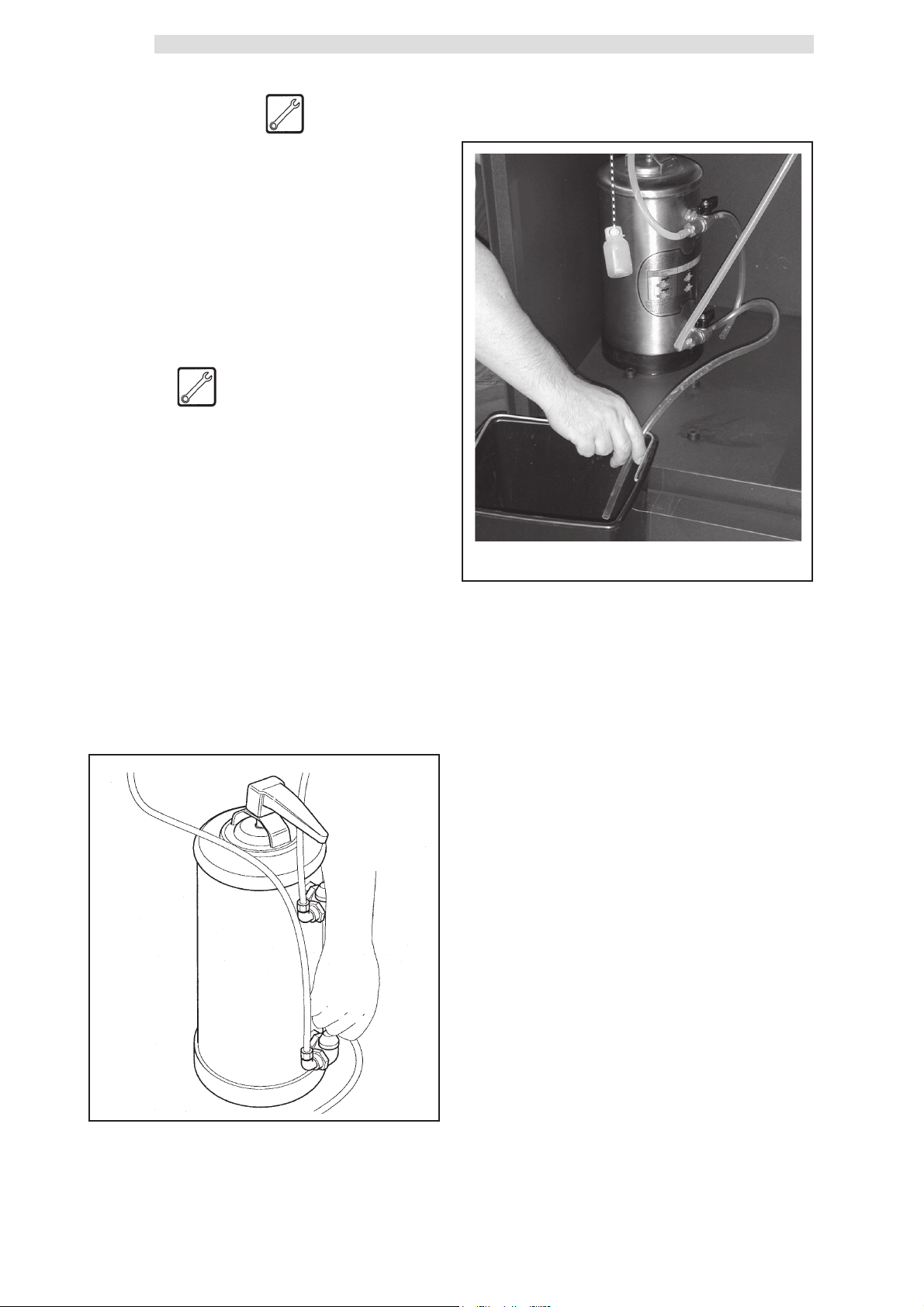

- fill up the water softener and let the water flow

out of the drain hose until it is clear (fig.20).

In order to fill in the water softener before installing

it on the machine, stick to the following

instructions:

- Insert the hose of the bottom tap into a drain

container suitable for this purpose.

- open the bottom tap (fig. 19) and the upper

plug of the water softener so as to remove

the air bubble.

fig.20

- close upper plug and turn off the bottom tap

fig.19

18

6.7.2 Water circuit filling

The machine automatically activates the pump

and starts filling the espresso coffee boiler.

English

During the setting-up phase:

- the coffee boiler and the water tank are filled

up

IMPORTANT:

Before powering the machine, thus starting the

automatic installation:

1. Make sure that the water softener is filled with

water and the air bubbles removed.

2. Load the reachable columns of the cup holder.

NOTE:

If the filling of the boiler is not successful, the

machine cannot be set into service. A failure

message will be shown on the display . Should it

be the case, eliminate the cause and reset the

error recorded (section 8 ‘Programming and

maintenance menu’), then repeat the automatic

installation, switching the machine on once again.

After a testing phase on start-up, the machine

automatically fills the water circuit of the tray

equipped with a float and of the brew group boiler.

During this stage, the heating element of the

boiler remains automatically off. If the machine

detects that the boiler is already filled, it passes

to the heating stage.

- once the water circuit is filled, the heating

phase starts up, thus switching on

automatically the boiler heating element.

Recommended solutions

When the boiler is completely filled, wash the

mixer repeatedly in order to remove possible

residues from the hydraulic circuits. NB: see

section 8 - Programming and Maintenance

menu, in order to start test or cleaning brewing.

- After performing these operations, wait a few

minutes for the machine to reach service

temperature and make beverages available.

The sequence of operations will be:

- insert the special key in the machine cover

switch

- on start-up of the machine, the filling of the

tray equipped with a float starts automatically ,

while the machine carries out the automatic

testing phase.

During testing, the following components start

up in the given order:

- the brew group, so as to reach the correct

start-up position

- the cup holder, so as to load the first cup

column into the releasing device.

19

English

6.7.3 Cleaning the parts in contact

with foodstuffs

Clean all the parts of the vending machine which

are in contact with foodstuffs.

- wash your hands carefully.

- prepare a chlorine-based anti-bacterial

cleaning solution - they can be purchased at

chemists - following the concentrations given

on the product instruction label.

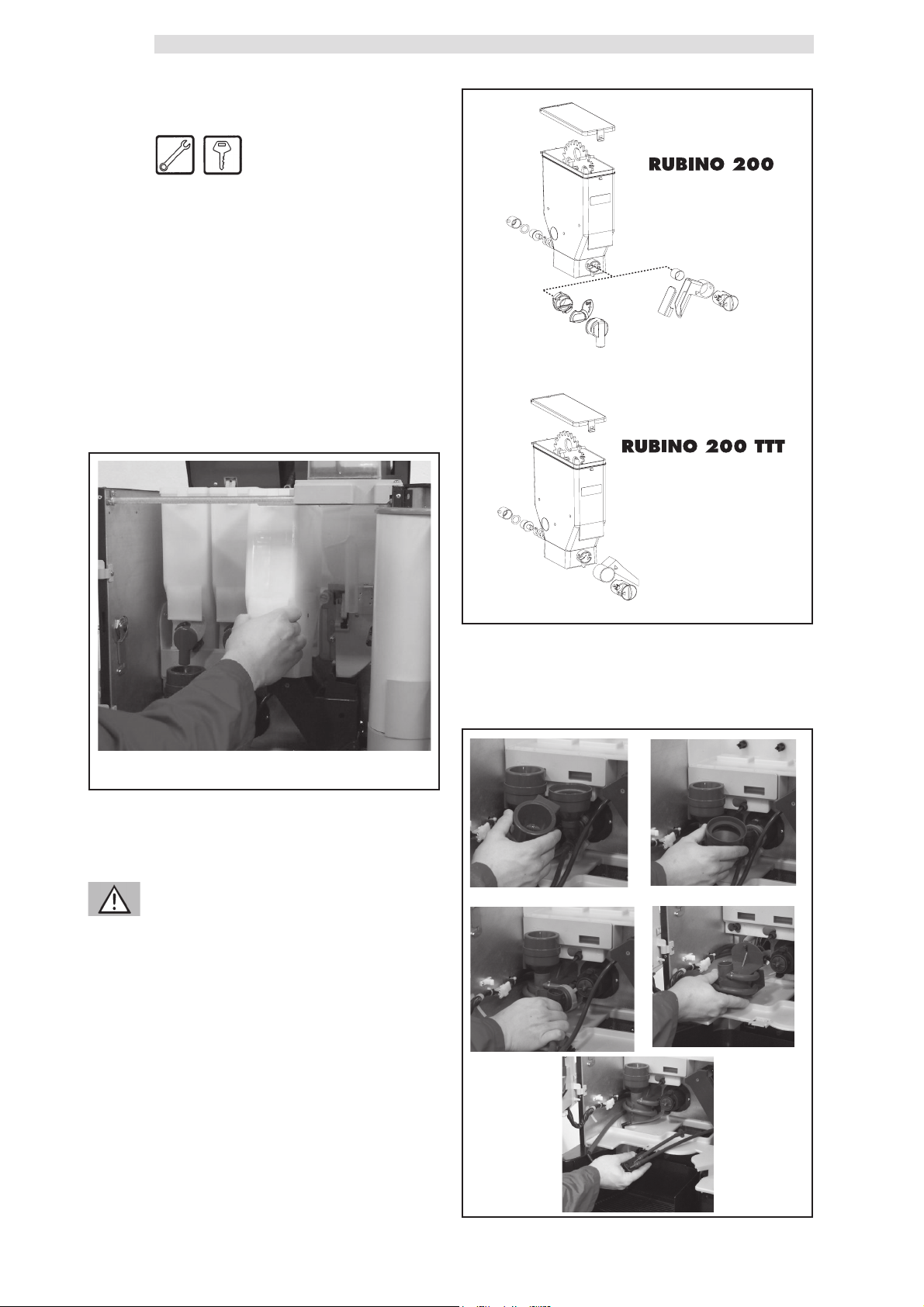

- remove all the product containers from the

vending machine (fig. 21).

fig.21

- remove their covers, bushes and conveyors

(fig. 22). Plunge all parts into the solution,

apart from the steel spiral conveyor.

Important

Do not plunge the spiral conveyor into the

chlorine-based solution; clean it with washing up

detergent and rinse carefully .

fig.22

- remove all the powder conveyors, water

funnels, mixer chambers and fans, silicone

hoses and plunge them into the solution

(fig.23).

20

fig.23

- clean also the mixer bases with a cloth

soaked in the solution (fig.24)

English

fig.25

- lift the container cover and fill with the product.

fig.24

- leave all parts in the solution for the time

specified on the packaging

- take all parts off, rinse and wipe carefully , then

reassemble them into the vending machine.

Warning

For safety’s sake, carry out several automatic

washings so as to remove possible residues.

6.8 Product loading

6.8.1 Container loading

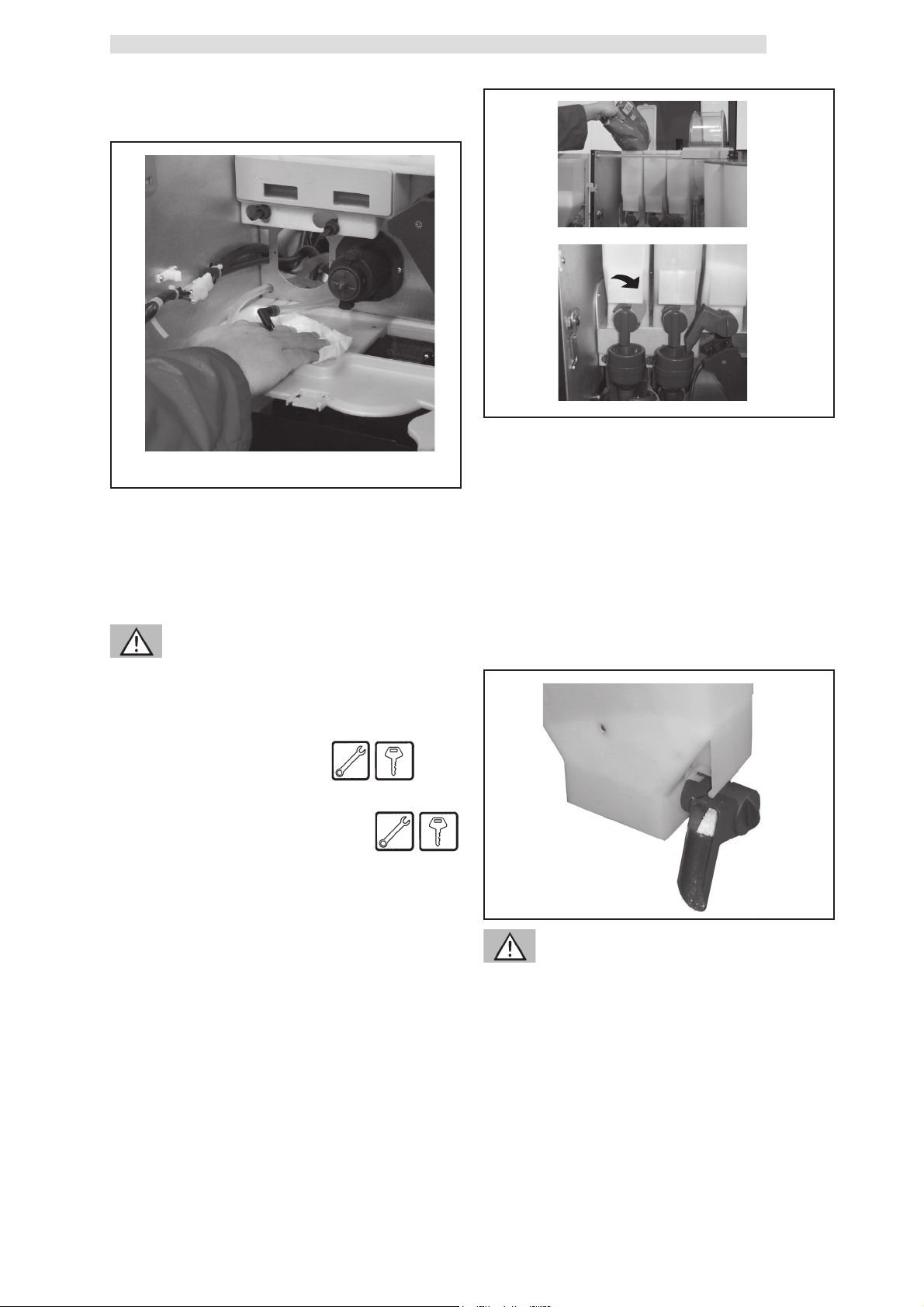

- product containers can be loaded without

removing them; however, should it be

necessary to remove them, make sure the

sliding panel on the product outlet is closed

(fig.25). In particular , it is necessary to close

the panel located on the hopper before

removing the coffee bean container.

NB:containers can also be loaded without

removing them from their supports

- make sure there is no lump, avoid pressing

the product and using too much of it, so as to

prevent it from ageing. It is advisable to fill the

containers with the exact amount of product

necessary for the estimated consumption

between two consecutive refillings.

Check each container capacity in the

TECHNICAL SPECIFICA TIONS section.

fig.26

Warning

- For correct operation of the swivelling

conveyor follow the indications below: before

starting up, brew the product 3 - 4 times so

as to have the duct full (fig.26)

- After filling up the sugar container , make sure

the bracket is properly repositioned - the jack

on the side is supposed to click.

21

English

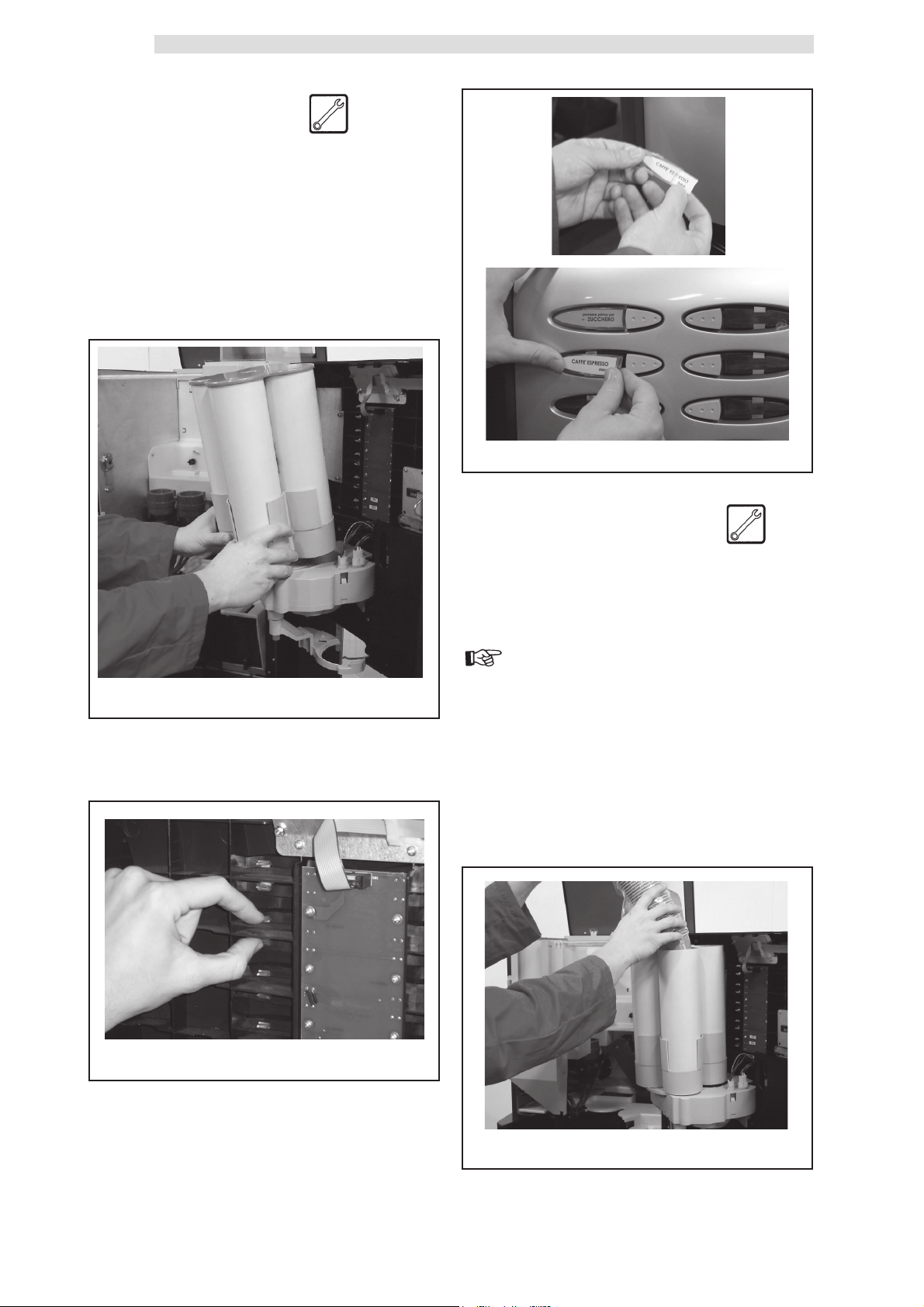

6.8.2 Label insertion

- Selection labels are to be placed in the proper

seat, under the transparent plastic plates,

following the order set in the Programming

and Maintenance Menu.

Perform the operation as follows:

- remove the cup holder (fig. 27)

fig.29/30

- reassemble the cup holder

fig.27

- release the transparent plates from the

internal side of the door by pressing the

retaining tabs (fig.28)

6.8.3 Cup loading

Use only cups suitable for automatic distribution,

having 70-71 mm diameter, without pressing

them while loading.

Important

DO NOT A TTEMPT T O TURN

THE COULUMN MANUALL Y .

During installation, with the cup dispenser empty ,

proceed as follows:

- before powering up the vending machine, load

the most easy-to-reach columns (fig. 31).

fig.28

- insert product plates on the external side of

the door in the desired order (fig. 29)

- apply the transparent plates by snapping

them (fig.30)

22

fig.31

Loading...

Loading...