SU Series: DIN Rail Snap-Mount Sockets

a

Cab

ts

8

8

31

32

.5

35.3

S

g

g

e

Clamp

➀➁➂

➃➄➅

➀➁➄➅

➁➂➃➄

Screwd

s

C

al

Coil

e

s

e

s

s

3

3

865

910

0

9

568

3

3

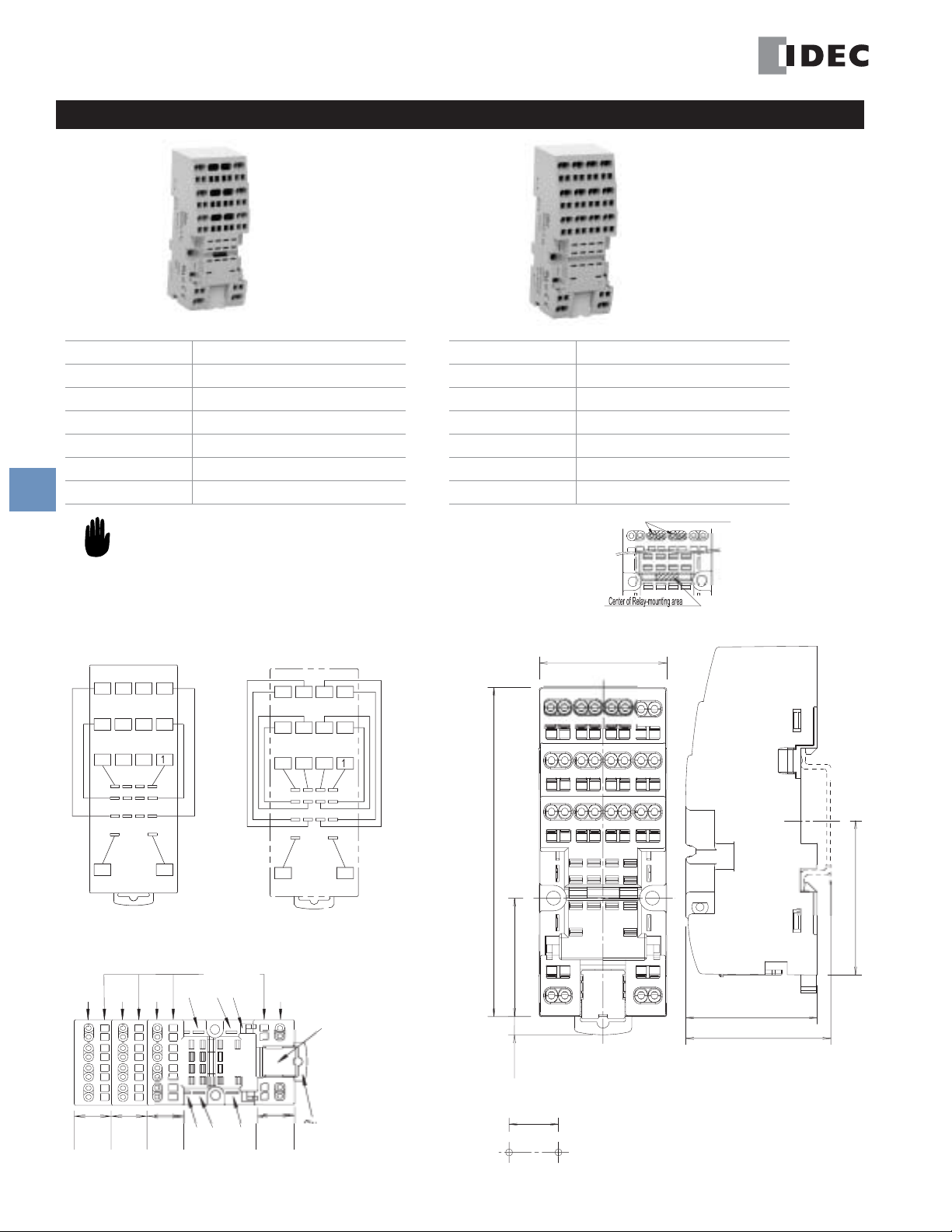

SU Series: DIN Rail Snap-Mount Sockets

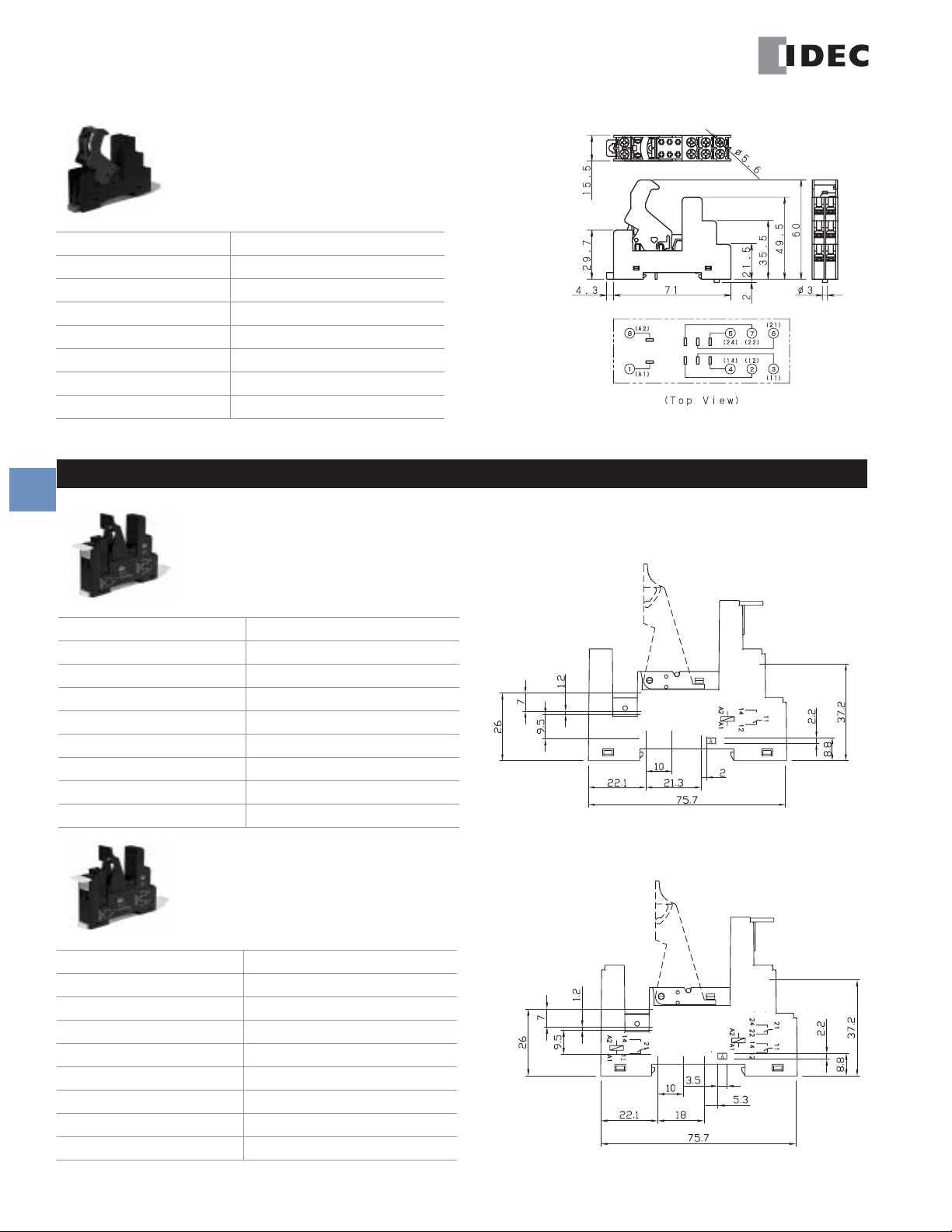

SU2S-11L SU4S-11L

F

Style

Terminal

Wire Size

Electrical Rating

Compatible Relay

Compatible Timer

Hold-Down Clip

1. On the SU2S, wires or ferrules cannot be connected to terminals 2, 3,

6, 7, 10 or 11 because neither springs nor conductive brackets are

installed in these terminals.

2. For socket mounting accessories, see page F-29.

8-blade DIN-mount/surface mount

Spring clamp terminals

24-16 AWG

10A

RU2, RM2

GT5Y-2

SFA-101 (top latch), SFA-202 (side latch)

Style

Terminal

Wire Size

Electrical Rating

Compatible Relay

Compatible Timer

Hold-Down Clip

Inside the

14-blade DIN-mount/surface mount

Spring clamp terminals

24-16 AWG

6A (using RU4), 10A (using RU2)

RY4S, RY42S, RU4, RU42S, RY2KS, RM2S

GT5Y

SFA-101 (top latch), SFA-202 (side latch)

Inside the Cable Port

le Por

Sockets

Terminal Arrangement (top view) Dimensions

SU2S-11L

Parts

Wire

Ports

Wire

Ports

Wir

Port

1

river Port

SU4S-11L

Wir

Port

Markin

1

1

Plat

Sprin

slots for SFA-101:

Center of Relay-mounting are

.

2

7

F-6

C

TerminalNOTerminal

N

Termin

Terminal

pring slots for SFA-202:

Panel Cutout for Surface Mounting

All dimensions are in mm.

Sockets SU Series: DIN Rail Snap-Mount

9 to 10mm

5

5

(

)

8.0

9

0

8.0

M

e

d

g

surface

of

r

M

e

p

9

0

r

t

.

sec

Screwd

s

Correct

ect

ect

ect

(

)

Marking Plate

Note: For installation of optional jumper,

see the instruction sheet provided

pjp

pjp

ith the j

.

plate ribs

r

r

y

g

e

s

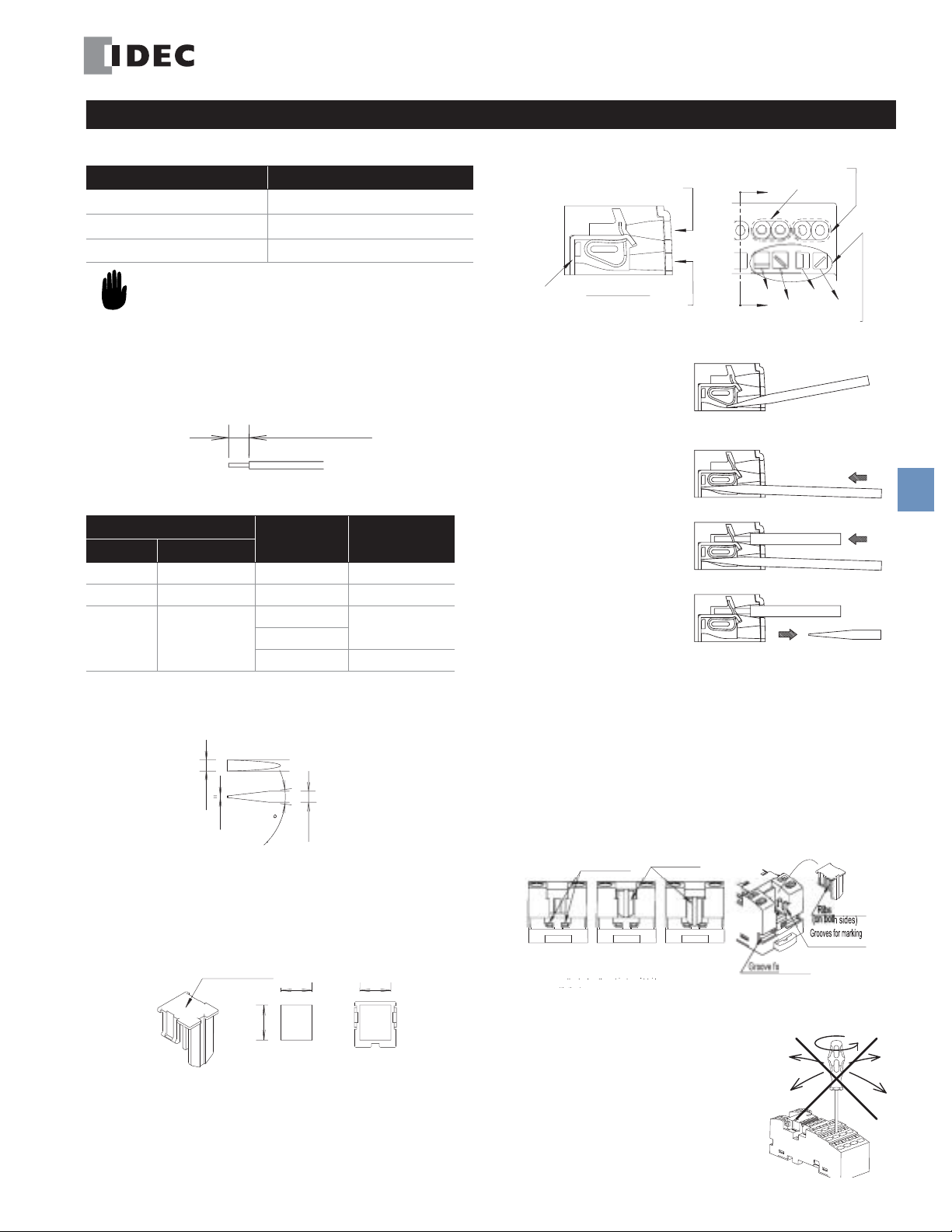

SU Series: General Instructions

Applicable Wires

Wire Size

Stranded wire

Solid wire

Wire insulation diameter

1. Strip the wire insulation 9 to 10mm from the end.

2. In applications using ferrules for stranded wires, choose

the ferrule listed in table below. Make sure that an insulation sheath is applied when using the ferrules. When using

stranded wires without ferrules, make sure that the core

wires have not been loosened.

3. Two cable ports are provided for each terminal.

0.2 to 1.25 mm2 or AWG24 to 16

0.2 to 1.5 mm2 or AWG24 to 16

ø3.15mm maximum

Applicable Ferrules

Applicable Wire (stranded)

2

mm

0.2 24 A10.25-12BU Phoenix Contact

_22 A10.34-8TQ Phoenix Contact

0.5 20

AWG

Type Manufacturer

A10.5-8WH

A10.5-10WH

TE0.5 Nichifu Co. Ltd

Phoenix Contact

Wiring Instructions

Wire Por

Stoppe

A - B

river Port

1. Insert the optional screwdriver

(BC1S-SDO) or an applicable

screwdriver into the squareshaped port as shown on the right,

until the screwdriver tip touches

the bottom of the spring.

2. Push in the screwdriver until it

touches the bottom of the port.

The wire port is now open, and the

screwdriver is held in place. The

screwdriver will not come off even

if you release your hand.

3. While the screwdriver is

retained in the port, insert the wire

or ferrule into the round-shaped

wire port. Each wire port can

accommodate one wire or ferrule.

When connecting two wires to one

terminal, use the adjoining port of

the same terminal.

4. Pull out the screwdriver. The

connection is now complete.

Wire Ports for Terminal

Wire Ports for Terminal 1

Incorr

Incorr

Note: Two cable ports are provided for each terminal

Direction of Screwdriver Ti

Incorr

F

Sockets

For wiring, use the optional screwdriver (BC1S-SDO) or the

following applicable screwdriver.

Dimensions in mm

2.

.4

2.

Marking Instructions

Write markings on the SU sockets using an oil-based marker, or glue printed

mylar on the marking surface. The size of the printed mylar can be 8 x 9mm

maximum.

arking Surfac

.

Position of printe

mylar on the markin

arking Plat

Maximum size

printed myla

Safety Precautions

Installing the Marking Plate

Because of its removable structure, the marking plate may have fallen from

the socket or become loose in delivery. Make sure that the marking plate is

securely installed before starting operation. The marking plate protects the

conductive portion of the socket, located under the marking plate, by preventing metal fragments or pieces of wire from dropping inside. Should any such

fragments enter the socket, they may cause fire hazard, damage, or malfunction.

Jumper Port

No marking plat

w

umper

Loose fittin

Installed securel

on both sides

Jumpe

Inserting Screwdriver into the Wire Ports

F-7

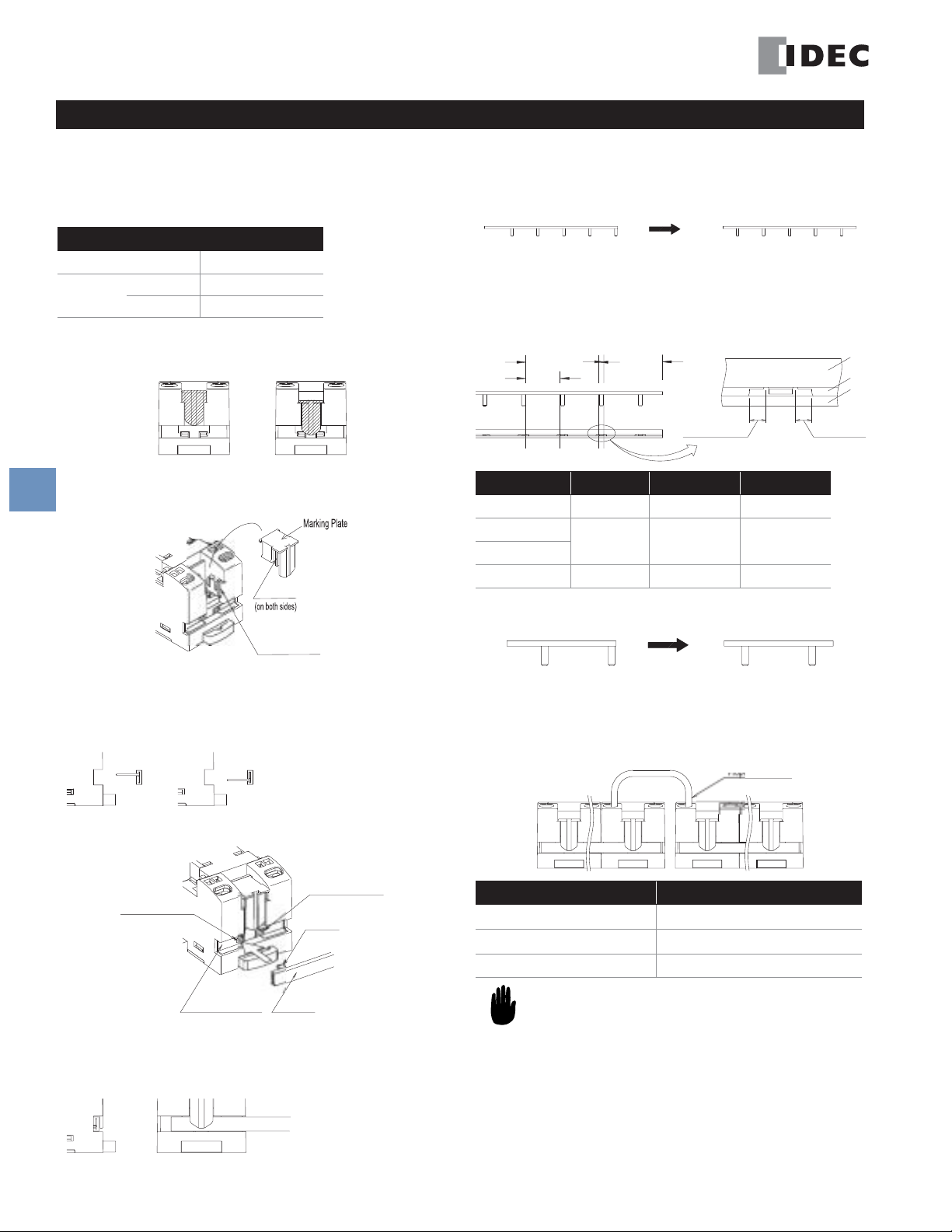

SU Series: DIN Rail Snap-Mount Sockets

y

g

bs

(

)

Grooves for marking

plate ribs

C

t

ect

on

r

ade

t

3

t

4

C

l

D

Shea

p

a

D

C

Proper wire

SU Series: SU9Z-J5 Jumper Installation Instructions

SU9Z-J5 Jumper for SU2S-11L and SU4S-11L

The SU9Z-J5 is used to install five sockets. When installing less than five

sockets cut the jumper according to the instructions listed to the right.

The SU9Z-J5 jumper is for coil terminals only.

SU9Z-95 Jumper

Rated Current

Material

Conductor Nickel-plated brass

Sheath ABS resin

3A

Installation

Loosen the marking plate on the socket.

A: Loose fittin

B: Installed securel

F

Sockets

Ri

Installing Two, Three or Four SU Sockets on the SU9Z-J5

Jumper

As shown below, slide the jumper in the sheath so that the jumper aligns with

the center of the sheath.

Jumper on centerJumper off center

With the sheath properly installed on the jumper, cut the sheath and

jumper at the points shown below, using cutting pliers. Referring to the

drawing on the right, make sure that the sheath and jumper are cut

within the cutting area. Dispose of unused portions according to local

waste disposal requirements.

She

Jum

Cutting Area

Cutting Area in Detai

Cutting Area

Qty Cutting Area Discard

2 Sockets

2 Sockets

3 Sockets

4 Sockets

2 A, C Y

1 A, B X

1D Z

After cutting the jumper and sheath, slide the jumper as shown below, so that

the ends of the jumper ar e not exposed.

on both sides

Alignment

Making sure that the SU9Z-J5 jumper is correctly aligned, insert the blades

into the ports in the groove of the SU sockets.

Incorr

Insertion Directi

Jumper por

for terminal 1

Jumper GrooveJumpe

orrec

Jumper por

for terminal 1

Bl

Install Jumper Securely

Press down the marking plate to secure the jumper. The jumper installation is

now complete.

Jumper Wiring to Six or More SU Sockets

To jumper wire six or more SU sockets, connect five sockets using whole

jumpers and the remaining sockets using a cut jumper. Then connect the two

terminals on adjoining sockets using an applicable wire (see table below).

Wire Size

Stranded wire

Solid wire

AWG

1. Use a wire with cable insulation diameter of ø3.15mm

maximum.

2. Strip the cable insulation 9 to 10mm from the end.

0.2 to 1.25 mm

0.2 to 1.5 mm

24 to 16

2

2

Safety Precautions

Turn off the power to the SU9Z-J5 jumper before starting installation,

removal, wiring, maintenance, or inspection of the jumper. Failure to turn

power off may cause an electrical shock or fire hazard.

To avoid a short circuit due to incorrect wiring, confirm which terminals are

connected to the jumper before beginning wiring.

F-8

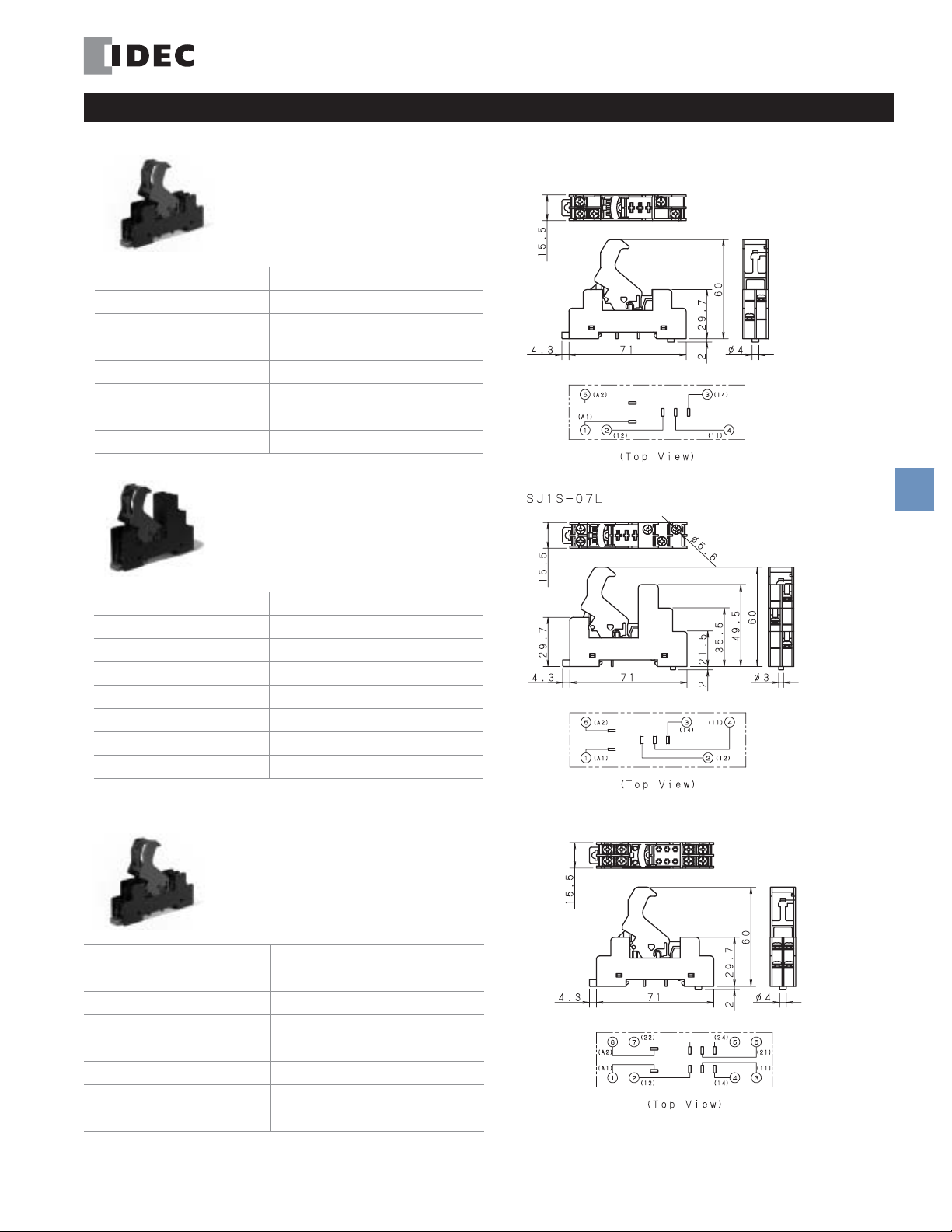

Sockets SJ Series: DIN Rail Snap-Mount

SJ1S-05B

Style

Terminal/Torque

Wire Size

Electrical Rating

Compatible Relay

Compatible Timer

Hold-Down Spring

Replacement Locking Lever

SJ Series: General Information

5 -blade snap mount/surface mount

0.6 - 1.0N•m (Maximum 1.2N•m)

Maximum up to 2 - #14 AWG

250V, 12A

RJ1S

N/A

N/A

SJ9Z-C

F

Sockets

SJ1S-07L Fingersafe

Style

Terminal/Torque

Wire Size

Electrical Rating

Compatible Relay

Compatible Timer

Hold-Down Spring

Replacement Locking Lever

SJ2S-05B

Style

Terminal/Torque

Wire Size

Electrical Rating

Compatible Relay

Compatible Timer

Hold-Down Spring

Replacement Locking Lever

5-blade, snap mount/surface mount

0.6 - 1.0N•m (Maximum 1.2N•m)

Maximum up to 2 - #14 AWG

250V, 12A

RJ1S

N/A

N/A

SJ9Z-C

8-blade, snap mount/surface mount

0.6 - 1.0N•m (Maximum 1.2N•m)

Maximum up to 2 - #14 AWG

250V, 8A

RJ2S

N/A

N/A

SJ9Z-C

All dimensions are in mm.

F-9

SJ/SQ Series: DIN Rail Snap-Mount Sockets

SJ2S-07L Fingersafe

Style

Terminal/Torque

Wire Size

Electrical Rating

Compatible Relay

Compatible Timer

Hold-Down Spring

Replacement Locking Lever

8-blade snap mount/surface mount

0.6 - 1.0N•m (Maximum 1.2N•m)

Maximum up to 2 - #14 AWG

250V, 8A

RJ2S

N/A

N/A

SJ9Z-C

SQ Series: General Information

F

All dimensions are in mm.

Sockets

SQ1V-07B Fingersafe

Style

Terminal/Torque

Wire Size

Electrical Rating

Compatible Relay

Replacement Locking Lever

Replacement Marking Plate

Plug-in LED/Diode (6-24VDC)

Plug-in LED/RC (120/240VAC)

SQ2V-07B Fingersafe

Style

Terminal/Torque

Wire Size

Electrical Rating

Compatible Relay

Replacement Locking Lever

Replacement Marking Plate

Plug-in LED/Diode (6-24VDC)

Plug-in LED/RC (120/240VAC)

5-pin, snap mount/surface mount

1.0N•m Maximum

Maximum up to 2 - #14 AWG

300V, 12A

RQ1V-CM

SQ9Z-C

SQ9Z-P

SQ9Z-LD

SQ9Z-LR

8-pin, snap mount/surface mount

1.0N•m Maximum

Maximum up to 2 - #14 AWG

300V, 8A

RQ2V, RQ1V-CH

SQ9Z-C

SQ9Z-P

SQ9Z-LD

SQ9Z-LR

All dimensions are in mm.

F-10

Sockets SR Series: DIN Rail Snap-Mount

SR Series: DIN Rail Snap-Mount Sockets

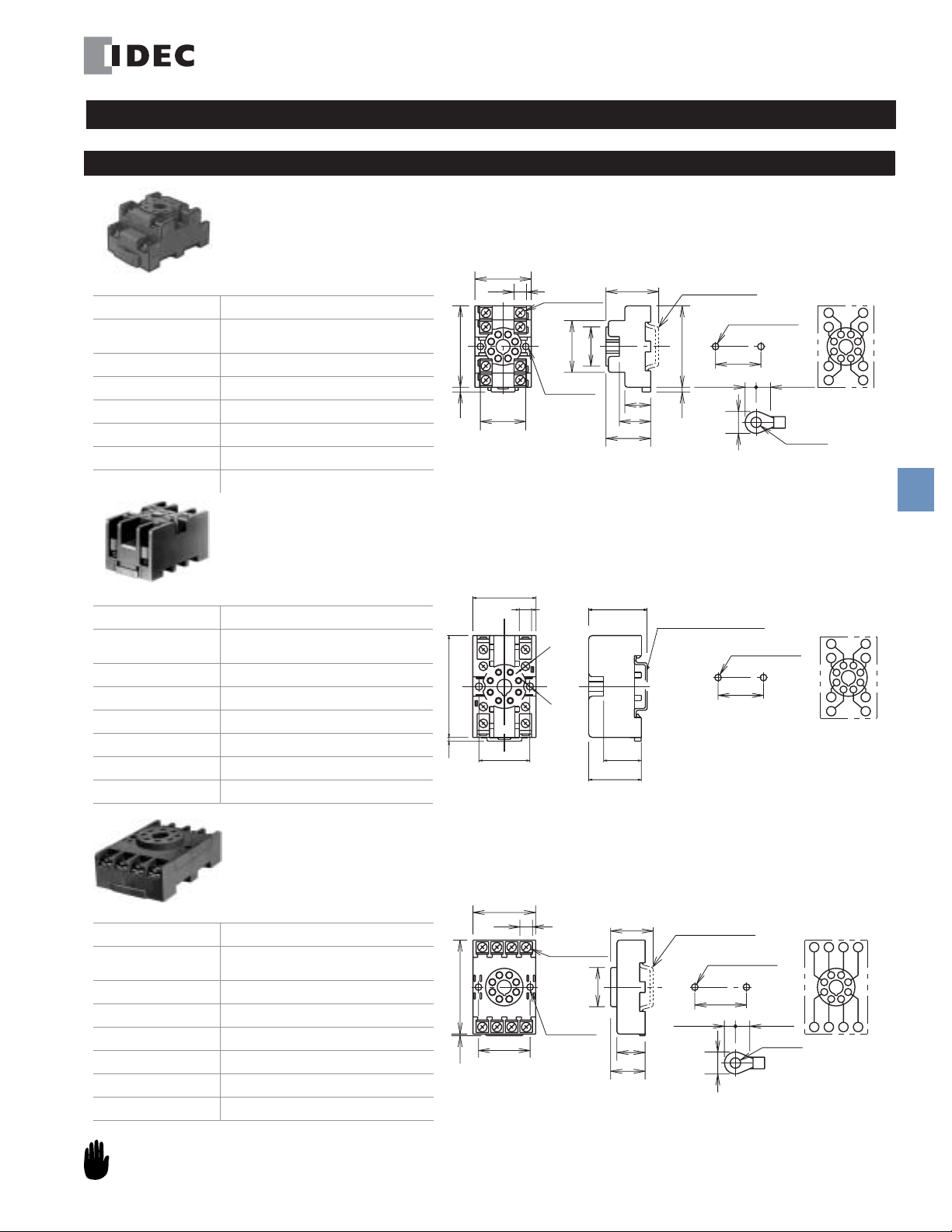

SR2P Sockets

SR2P-05

Style

Terminal/Torque

Wire Size

Electrical Rating

Compatible Relay

Compatible Timer

Hold-Down Spring

Hold-Down Clip

SR2P-05C Fingersafe

Style

Terminal/Torque

Wire Size

Electrical Rating

Compatible Relay

Compatible Timer

Hold-Down Spring

Hold-Down Clip

8-pin octal, snap-mount/surface mount

M3.5 screws with captive wire clamp

(9 - 11.5 in•lbs)

Maximum up to 2–#12AWG

300V, 10A

RR2P

RTE-P1, GT3 (8-pin), GT5P, GE1A

SR2B-02F1 (for RR2P)

SFA-203 (for timers only, except GE1A)

8-pin octal, snap-mount/surface mount

M3.5 screws with captive wire clamp,

fingersafe (9 - 11.5 in•lbs)

Maximum up to 2–#12AWG

300V, 10A

RR2P

RTE-P1, GT3 (8-pin), GT5P, GE1A

SR2B-02F1 (for RR2P)

SFA-203 (for timers only, except GE1A)

Screw

33

ø25

32 when

using BAA

16.5

20

28.5

DIN Rail (BAA)

2-ø4.2 Mounting Hole

(M4 screw hole)

523

29

4.4max. 5min.

7.9max.

ø3.6min.

Terminal

Arrangement

4

5

6

3

2

7

1

8

(

TOP VIEW

)

36

8

523

29

M3.5

ø4.2

Mounting

Hole

F

Sockets

4.2

33.5 when

using BAA

DIN Rail (BAA)

5

21.5

30

2-ø4.2 Mounting Hole

(M4 screw hole)

29

(cannot use ring terminal)

Terminal

Arrangement

4

5

6

3

2

7

1

8

(

TOP VIEW

)

36

7

54

6

3

7

2

8

1

2.2 58

29

SR2P-06

Style

Terminal/Torque

Wire Size

Electrical Rating

Compatible Relay

Compatible Timer

Hold-Down Spring

Hold-Down Clip

1. For socket mounting accessories, see page F-29.

2. For hold-down clip/spring selections, see page F-4.

8-pin octal, snap-mount/surface mount

M3.5 screws with captive wire clamp

(9 - 11.5 in•lbs)

Maximum up to 2–#12AWG

300V, 10A

RR2P

RTE-P1, GT3 (8-pin), GT5P, GE1A

SR2B-02F1 (for RR2P)

SFA-202 (for timers only, except GE1A)

40

8

33

160

M3.5

Screw

ø4.2

Mounting

Hole

25.5 when

using BAA

ø25

22

ø3.6min.

Terminal

Arrangement

6543

(

TOP VIEW

2187

)

DIN Rail (BAA)

2-ø4.2 Mounting Hole

(M4 screw hole)

33

4.9max. 5min.

18

7.9max.

All dimensions are in mm.

F-11

Loading...

Loading...