Page 1

GENERAL INFORMATION

For proportional pneumatic actuator with 11 sq. in. (71 cm2)

effective area used to control damper and air valves in heating,

ventilating and air conditioning systems

FEATURES

•

Rugged cast aluminum body.

• Special linkage permits easy adjustment of stroke to suit

various applications.

• Hesitiation and non-hesitation models available.

Specfications

Housing: Die cast aluminum body.

Diaphragm: Replaceable beaded molded neoprene (Part

number PNV-002). Factory set for 1" (25 mm).

nkage: Adjustable 1/2 to 3" (13 to 76 mm). Factory set for

Li

2" (51 mm).

Nominal Damper Area: Actuator sizing should be done in

accordance with damper manu

Start point: Adjustable, Refer to Description Model Chart.

Spring: Retracts actuator crank arm on loss of air pressure.

Maximum Safe Air Pressure: 30 psig (207 kPa).

Ambient Temperature Limits:

Shipping, -40 to 160°F (-40 to 71°C).

ting, -20 to 160°F (-29 to 71°C).

Opera

Air Connec

tions: 1/8" FNPT

Mounting: In any position. Mounting bracket, linkage and

connector for 5/16" (8 mm) diameter push rod assembled to

actuator.

Air Connections: 1/8" FNPT.

Dimensions: 7-7/16" H x 5-3/4" W x 4-7/8" D

(189 x 146 x 124 mm).

ACCESSORIES

Model No. Description

AK-42309-500 Positive positioning relay.

AM-111 Crank arm for 5/16 in. diameter damper shaft.

AM-112 Crank arm for 3/8 in. diameter damper shaft.

AM-113 Crank arm for 1/2 in. diameter damper shaft.

AM-115 Crank arm for 7/16 in. diameter damper shaft.

AM-122 Linkage connector straight type.

AM-123 Damper clip.

AM-125 5/16 x 20 in. damper rod.

AM-125-048 5/16 x 48 in. damper rod.

AM-132 Ball joint connector.

AM-161-3 Damper linkage kit (AM-173 crank arm and AM-132 connector).

AM-743 Linkage kit for M-693 Series replacement.

TOOL-095-1 Pneuma ic calibration tool kit.

Maintenance Parts

PNV-002 Diaphragm.

PNV-251 High temperature diaphragm.

PND-145-104 Black, 3 to 8 psi or 5 to 10 psi spring.

PND-145-107 Blue, 8 to 13 psi or 6 to 11 psi spring.

PND-143-083

Violet, 3 to 6 psi spring.

facturer’s specifications.

MK-44X1

Pneumatic Damper Actuator

General Instructions

Table-1

Nominal Damper

Damper Type

Parallel

Blade

Opposed

de

Bla

a

MK-4421 requires 15 psi be available to actuator.

b

Damper ratings are nominal and based on standard (not low leakage)

damper at 1" W.C. static pressure and 2000 fpm (10 m/s) velocity.

Area for

Proportional

b

Control

4.4 sq. ft. 13.2 sq. ft.

5.6 sq. ft. 16.8 sq. ft.

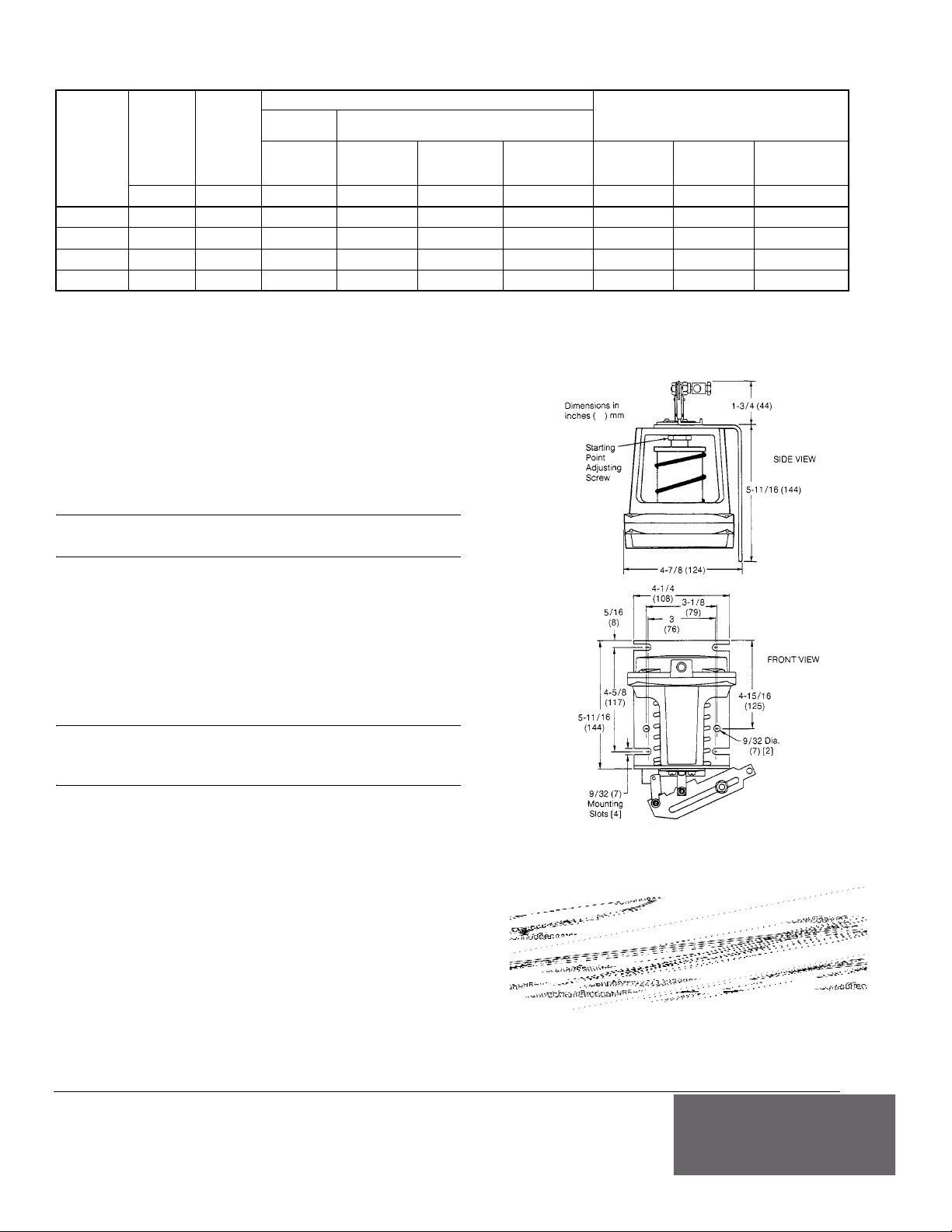

Figure-1 Relationship between Stroke and Control Air

Pressure for MK-4451 Two-Stage Actuators.

INSTALLATION

Make all connections in accordance with job piping diagram.

Use 1/4" OD copper or plastic tubing to connect the actuator

to the controller. Units have 1/8" NPT female inlet for

connection to the supply air. Actuators are mounted by

means of four screws (not included) through the mounting

bracket. See Figure 3 for mounting dimensions.

Insert the push rod in the actuator and damper connectors

and tighten

for 90° rotation. Apply air pressure and run the actuator

through the entire stroke. Readjust linkage if binding occurs

during damper shaft rotation. Readjustment may also be

necessary if damper shaft does not achieve acceptable

rotation.

the set screws. See Figure 4 for damper linkage

Nominal Damper Area for

Two-Position Control

a

MK-4421 (8-13 Spring, 20

psi Supply)

b

Printed in U.S.A. 1/10 © Copyright 2010 Schneider Electric All Rights Reserved. F-13776-6

Page 2

On Oc tobe r 1s t, 20 09, TAC became th e Bu ildings busin ess of its pare nt compan y Schne i de r El ectr ic . Thi s document ref lect s the visu al i de nt ity of Schn eid er El ec tr ic,

however t he re rem ains references to TAC as a c orp ora te brand in t he bo dy copy. As each do cumen t is upd at ed , t he bo dy copy will be c ha nged to refl ect app rop ri ate

g

Table-2

mum Force

Maxi

Return

Stroke

Based on 1 5

psi Pressure

to Actuator

1

5 psi Supply

Dual Press.

ystem

S

Part

Number

Nominal

Operating

Range

psi psi lb. lb.

Starting

sure

Pres

Adjustable

MK-4401 3-8 3 ± 1 8.25 30.25 38.5 66 7.9 7.9 7.9

MK-4411 5-10 5 ± 1 19.25 19.25 27.5 55 7.9 7.9 7.9

MK-4421 8-13 8 ± 1 35.75 2.75 11 38.5 2.6 7.9 7.9

MK-4451 3-6, 9-12 3 to 6 8.25 8.25 16.5 44 7.9 7.9 7.9

a

Force and torques based on factory set stroke and starting pressure.

b

Nominal torque for actuators is based on 1.5 psi pressure change at the actuator..

c

Adjust pressure reducing valve so that listed pressures are available at the actuator.

a

Power Stroke

15 psi Supply

ngle Press.

Si

System

c

lb.

20 psi Supply

Single or Dual

Press. System

lb. lb-in. lb-in. lb-in.

15 psi Supply

Dual Press.

c

System

Nominal Torque

Proportional Control

15 psi Supply

Single Press.

System

c

b

a

20 psi Supply

Single or Dual

Press. System

ADJUSTABLE STARTING PRESSURE

The start point is the air pressure value that causes the actuator

shaft to just begin to extend. If adjustment of starting pressure is

required, turn adjusting nut supporting the spring clockwise to

decrease and counterclockwise to increase the starting pressure,

when viewing the actuator from the shaft end (Figure 3). Each

rotation of the adjusting nut changes the starting pressure 0.04 psi

(.28 kPa).

c

Note: The stroke of the MK-4451 during the first stage of

operation is adjustable from 0 to 50% of total stroke.

DIAPHRAGM REPLACEMENT

If the actuator diaphragm should leak, it may easily be replaced:

1. Disconnect air line to the actuator.

2. Remove the screws on the top power housing, the top cover

and the old diaphragm.

3. In

sert new diaphragm over piston.

Note: Put the top power housing back in place making sure the

bead on the diaphragm is in the housing groove and the screw

holes are lined up.

4. Tighten the top power housing screws.

MAINTENANCE

This is a quality product. Regular maintenance of the total system

is recommended to assure sustained optimum performance.

Figure-2

corporate brand chan

Copyright 2010, Schneider Electric

All brand names, trademarks and registered

trademarks are the property of their respective

owners. Information contained within this

document is subject to change without notice.

F-13776-6

es.

Figure-3

Loading...

Loading...