Page 1

ModiconM340

35012676 10/2019

Modicon M340

Processors

Setup Manual

Original instructions

10/2019

35012676.14

www.schneider-electric.com

Page 2

The information provided in this documentation contains general descriptions and/or technical

characteristics of the performance of the products contained herein. This documentation is not

intended as a substitute for and is not to be used for determining suitability or reliability of these

products for specific user applications. It is the duty of any such user or integrator to perform the

appropriate and complete risk analysis, evaluation and testing of the products with respect to the

relevant specific application or use thereof. Neither Schneider Electric nor any of its affiliates or

subsidiaries shall be responsible or liable for misuse of the information contained herein. If you

have any suggestions for improvements or amendments or have found errors in this publication,

please notify us.

You agree not to reproduce, other than for your own personal, noncommercial use, all or part of

this document on any medium whatsoever without permission of Schneider Electric, given in

writing. You also agree not to establish any hypertext links to this document or its content.

Schneider Electric does not grant any right or license for the personal and noncommercial use of

the document or its content, except for a non-exclusive license to consult it on an "as is" basis, at

your own risk. All other rights are reserved.

All pertinent state, regional, and local safety regulations must be observed when installing and

using this product. For reasons of safety and to help ensure compliance with documented system

data, only the manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant

instructions must be followed.

Failure to use Schneider Electric software or approved software with our hardware products may

result in injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2019 Schneider Electric. All rights reserved.

2 35012676 10/2019

Page 3

Table of Contents

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Part I Modicon M340 PLCs . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 1 Introduction to Modicon M340 PLC Stations . . . . . . . . . 13

Modicon M340 PLC Station. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 General Introduction to PLC Station Components . . . . . 15

General Introduction to Processors . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Introduction to Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Introduction to Power Supply Modules . . . . . . . . . . . . . . . . .

General Introduction to Rack Extender Module. . . . . . . . . . . . . . . . . .

General Introduction to Input/Output Modules. . . . . . . . . . . . . . . . . . .

General Introduction to Counting Modules . . . . . . . . . . . . . . . . . . . . .

General Introduction to Communication . . . . . . . . . . . . . . . . . . . . . . .

Grounding of Installed Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modicon M340H (Hardened) Processors, Modules and Equipment . .

Chapter 3 General Introduction to PLC Networks . . . . . . . . . . . . . . 31

General Introduction to the Modbus Protocol . . . . . . . . . . . . . . . . . . .

General Introduction to an Ethernet Network . . . . . . . . . . . . . . . . . . .

General Introduction to the CANopen Field Bus . . . . . . . . . . . . . . . . .

Chapter 4 Operating Standards and Conditions . . . . . . . . . . . . . . . 35

Standards and Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part II BMX P34 xxxx Processors . . . . . . . . . . . . . . . . . . . .

Chapter 5 Introduction to BMX P34 xxxx Processors . . . . . . . . . . . 39

General Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Description of BMX P34 xxxx Processors. . . . . . . . . . . . . . .

USB Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modbus Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CANopen Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ethernet Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BMX P34 xxxxx Processors Catalog . . . . . . . . . . . . . . . . . . . . . . . . . .

Real-Time Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11

13

16

17

18

19

20

23

25

26

28

32

33

34

35

37

40

43

45

46

48

50

53

54

35012676 10/2019 3

Page 4

Chapter 6 General Characteristics of the BMX P34 xxxx Processors 57

Electrical Characteristics of the BMX P34 xxxxx Processors. . . . . . . .

General Characteristics of the BMX P34 1000 Processor . . . . . . . . . .

General Characteristics of the BMX P34 2000 Processor . . . . . . . . . .

General Characteristics of the BMX P34 2010/20102 Processors . . .

General Characteristics of the BMX P34 2020 Processor . . . . . . . . . .

General Characteristics of the BMX P34 2030/20302 Processor . . . .

Characteristics of the BMX P34 xxxxx Processor Memory . . . . . . . . .

58

60

62

64

66

68

70

Chapter 7 Installation of BMX P34 xxxx Processors . . . . . . . . . . . . . 73

Fitting of Processors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Cards for BMX P34 xxxxx Processors . . . . . . . . . . . . . . . . . .

74

76

Chapter 8 BMX P34 xxxx Processors Diagnostics . . . . . . . . . . . . . . 85

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Searching for Errors Using the Processor Status LEDs. . . . . . . . . . . .

Blocking Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Non-Blocking Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Processor or System Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

86

91

92

94

96

Chapter 9 Processor Performance . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Execution of Tasks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAST Task Cycle Time: Introduction. . . . . . . . . . . . . . . . . . . . . . . . . .

MAST Task Cycle Time: Program Processing. . . . . . . . . . . . . . . . . . .

MAST Task Cycle Time: Internal Processing on Input and Output . . .

MAST Task Cycle Time Calculation. . . . . . . . . . . . . . . . . . . . . . . . . . .

FAST Task Cycle Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Event Response Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

98

102

103

104

107

108

109

111

4 35012676 10/2019

Page 5

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device

before trying to install, operate, service, or maintain it. The following special messages may appear

throughout this documentation or on the equipment to warn of potential hazards or to call attention

to information that clarifies or simplifies a procedure.

35012676 10/2019 5

Page 6

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained only by qualified

personnel. No responsibility is assumed by Schneider Electric for any consequences arising out of

the use of this material.

A qualified person is one who has skills and knowledge related to the construction and operation

of electrical equipment and its installation, and has received safety training to recognize and avoid

the hazards involved.

BEFORE YOU BEGIN

Do not use this product on machinery lacking effective point-of-operation guarding. Lack of

effective point-of-operation guarding on a machine can result in serious injury to the operator of

that machine.

UNGUARDED EQUIPMENT

Do not use this software and related automation equipment on equipment which does not have

point-of-operation protection.

Do not reach into machinery during operation.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

This automation equipment and related software is used to control a variety of industrial processes.

The type or model of automation equipment suitable for each application will vary depending on

factors such as the control function required, degree of protection required, production methods,

unusual conditions, government regulations, etc. In some applications, more than one processor

may be required, as when backup redundancy is needed.

Only you, the user, machine builder or system integrator can be aware of all the conditions and

factors present during setup, operation, and maintenance of the machine and, therefore, can

determine the automation equipment and the related safeties and interlocks which can be properly

used. When selecting automation and control equipment and related software for a particular

application, you should refer to the applicable local and national standards and regulations. The

National Safety Council's Accident Prevention Manual (nationally recognized in the United States

of America) also provides much useful information.

In some applications, such as packaging machinery, additional operator protection such as pointof-operation guarding must be provided. This is necessary if the operator's hands and other parts

of the body are free to enter the pinch points or other hazardous areas and serious injury can occur.

Software products alone cannot protect an operator from injury. For this reason the software

cannot be substituted for or take the place of point-of-operation protection.

WARNING

6 35012676 10/2019

Page 7

Ensure that appropriate safeties and mechanical/electrical interlocks related to point-of-operation

protection have been installed and are operational before placing the equipment into service. All

interlocks and safeties related to point-of-operation protection must be coordinated with the related

automation equipment and software programming.

NOTE: Coordination of safeties and mechanical/electrical interlocks for point-of-operation

protection is outside the scope of the Function Block Library, System User Guide, or other

implementation referenced in this documentation.

START-UP AND TEST

Before using electrical control and automation equipment for regular operation after installation,

the system should be given a start-up test by qualified personnel to verify correct operation of the

equipment. It is important that arrangements for such a check be made and that enough time is

allowed to perform complete and satisfactory testing.

EQUIPMENT OPERATION HAZARD

Verify that all installation and set up procedures have been completed.

Before operational tests are performed, remove all blocks or other temporary holding means

used for shipment from all component devices.

Remove tools, meters, and debris from equipment.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Follow all start-up tests recommended in the equipment documentation. Store all equipment

documentation for future references.

Software testing must be done in both simulated and real environments.

Verify that the completed system is free from all short circuits and temporary grounds that are not

installed according to local regulations (according to the National Electrical Code in the U.S.A, for

instance). If high-potential voltage testing is necessary, follow recommendations in equipment

documentation to prevent accidental equipment damage.

Before energizing equipment:

Remove tools, meters, and debris from equipment.

Close the equipment enclosure door.

Remove all temporary grounds from incoming power lines.

Perform all start-up tests recommended by the manufacturer.

WARNING

35012676 10/2019 7

Page 8

OPERATION AND ADJUSTMENTS

The following precautions are from the NEMA Standards Publication ICS 7.1-1995 (English

version prevails):

Regardless of the care exercised in the design and manufacture of equipment or in the selection

and ratings of components, there are hazards that can be encountered if such equipment is

improperly operated.

It is sometimes possible to misadjust the equipment and thus produce unsatisfactory or unsafe

operation. Always use the manufacturer’s instructions as a guide for functional adjustments.

Personnel who have access to these adjustments should be familiar with the equipment

manufacturer’s instructions and the machinery used with the electrical equipment.

Only those operational adjustments actually required by the operator should be accessible to

the operator. Access to other controls should be restricted to prevent unauthorized changes in

operating characteristics.

8 35012676 10/2019

Page 9

About the Book

At a Glance

Document Scope

This manual describes the hardware installation of the Modicon M340 PLCs and installation of their

main accessories.

This document is also valid for the Modicon M340H PLCs and their accessories.

Validity Note

This documentation is valid for EcoStruxure™ Control Expert 14.1 or later.

You need Modicon M340 firmware 2.4 or later.

The technical characteristics of the devices described in the present document also appear online.

To access the information online:

Step Action

1 Go to the Schneider Electric home page

2 In the Search box type the reference of a product or the name of a product range.

3 If you entered a reference, go to the Product Datasheets search results and click on the

4 If more than one reference appears in the Products search results, click on the reference that

5 Depending on the size of your screen, you may need to scroll down to see the datasheet.

6 To save or print a datasheet as a .pdf file, click Download XXX product datasheet.

www.schneider-electric.com

Do not include blank spaces in the reference or product range.

To get information on grouping similar modules, use asterisks (

reference that interests you.

If you entered the name of a product range, go to the Product Ranges search results and click

on the product range that interests you.

interests you.

.

*

).

The characteristics that are presented in the present document should be the same as those

characteristics that appear online. In line with our policy of constant improvement, we may revise

content over time to improve clarity and accuracy. If you see a difference between the document

and online information, use the online information as your reference.

35012676 10/2019 9

Page 10

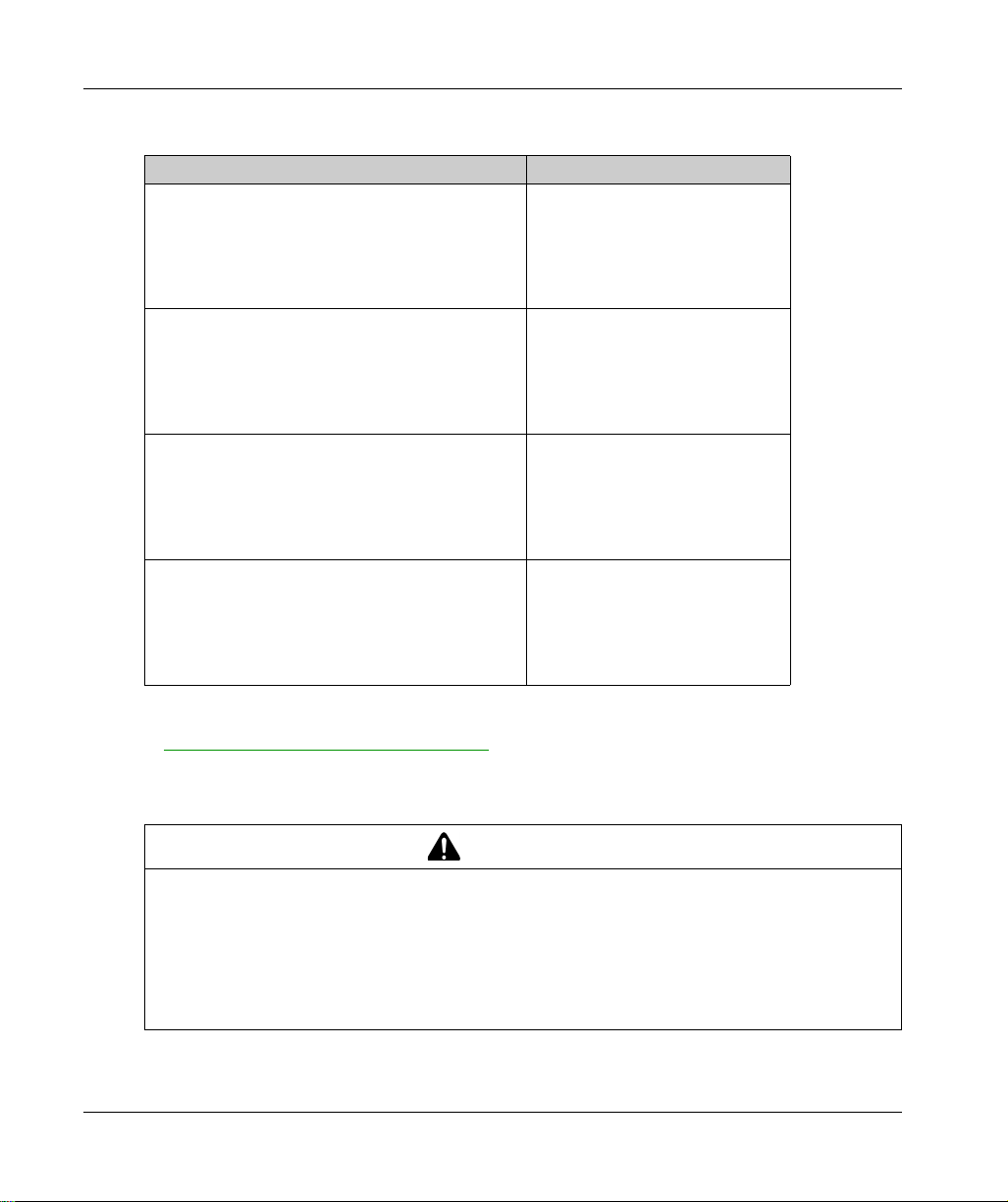

Related Documents

Title of documentation Reference number

Modicon M580, M340, and X80 I/O Platforms,

Standards and Certifications

Modicon X80 Racks and Power Supplies, Hardware,

Reference Manual

EcoStruxure™ Control Expert, Program Languages

and Structure, Reference Manual

EcoStruxure™ Control Expert, Operating Modes 33003101 (English),

EIO0000002726 (English),

EIO0000002727 (French),

EIO0000002728 (German),

EIO0000002730 (Italian),

EIO0000002729 (Spanish),

EIO0000002731 (Chinese)

EIO0000002626 (English),

EIO0000002627 (French),

EIO0000002628 (German),

EIO0000002630 (Italian),

EIO0000002629 (Spanish),

EIO0000002631 (Chinese)

35006144 (English),

35006145 (French),

35006146 (German),

35013361 (Italian),

35006147 (Spanish),

35013362 (Chinese)

33003102 (French),

33003103 (German),

33003104 (Spanish),

33003696 (Italian),

33003697 (Chinese)

You can download these technical publications and other technical information from our website

www.schneider-electric.com/en/download

at

.

Product Related Information

WARNING

UNINTENDED EQUIPMENT OPERATION

The application of this product requires expertise in the design and programming of control

systems. Only persons with such expertise should be allowed to program, install, alter, and apply

this product.

Follow all local and national safety codes and standards.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

10 35012676 10/2019

Page 11

ModiconM340

ModiconM340 PLCs

35012676 10/2019

ModiconM340 PLCs

Part I

Modicon M340 PLCs

Subject of this Part

This part provides a general overview of the Modicon M340 PLC configurations and the various

sub-assemblies, as well as the networks and field buses used.

What Is in This Part?

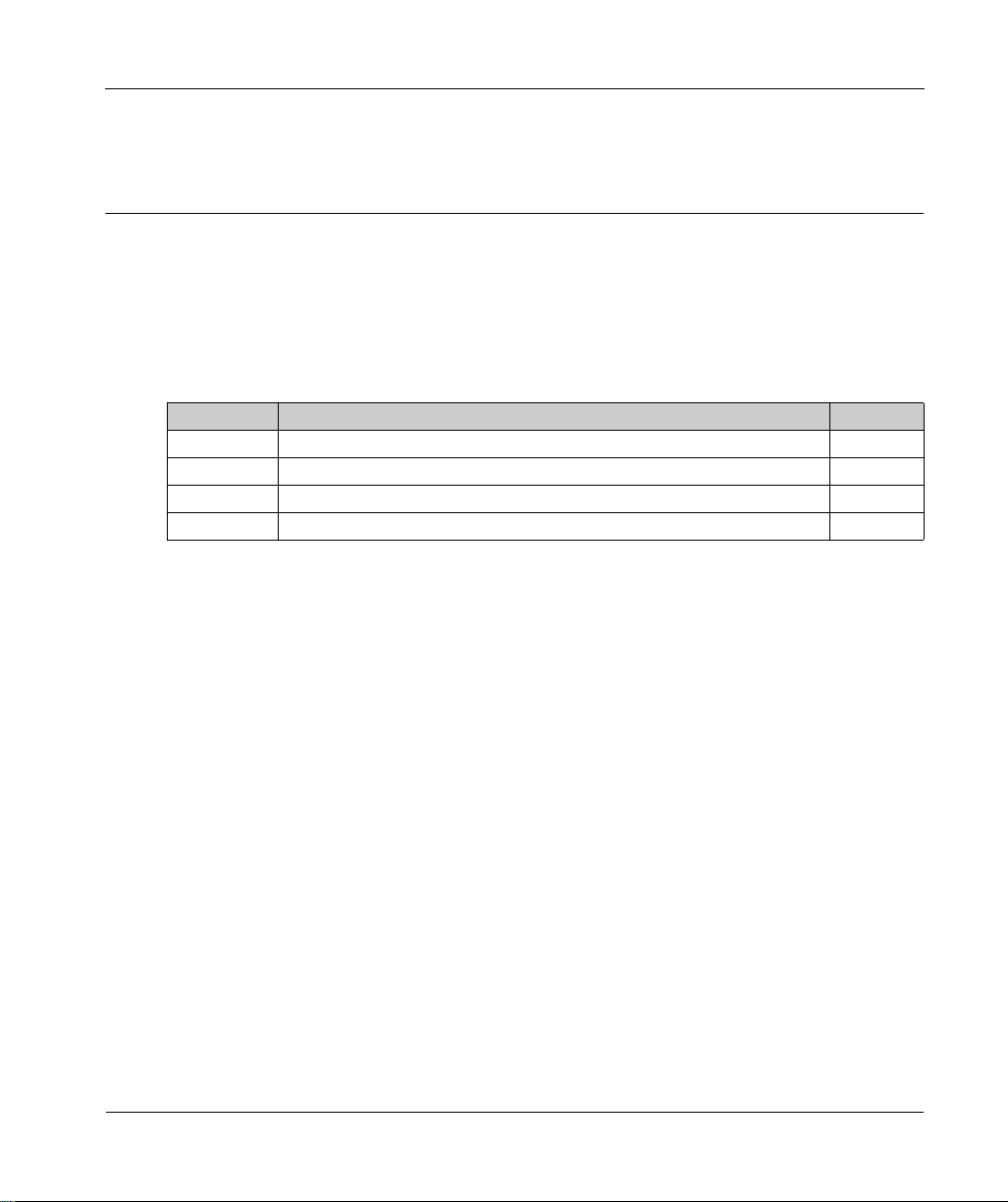

This part contains the following chapters:

Chapter Chapter Name Page

1 Introduction to Modicon M340 PLC Stations 13

2 General Introduction to PLC Station Components 15

3 General Introduction to PLC Networks 31

4 Operating Standards and Conditions 35

35012676 10/2019 11

Page 12

Modicon M340 PLCs

12

35012676 10/2019

Page 13

ModiconM340

Introduction to ModiconM340 PLC Stations

35012676 10/2019

Introduction to ModiconM340 PLC Stations

Chapter 1

Introduction to Modicon M340 PLC Stations

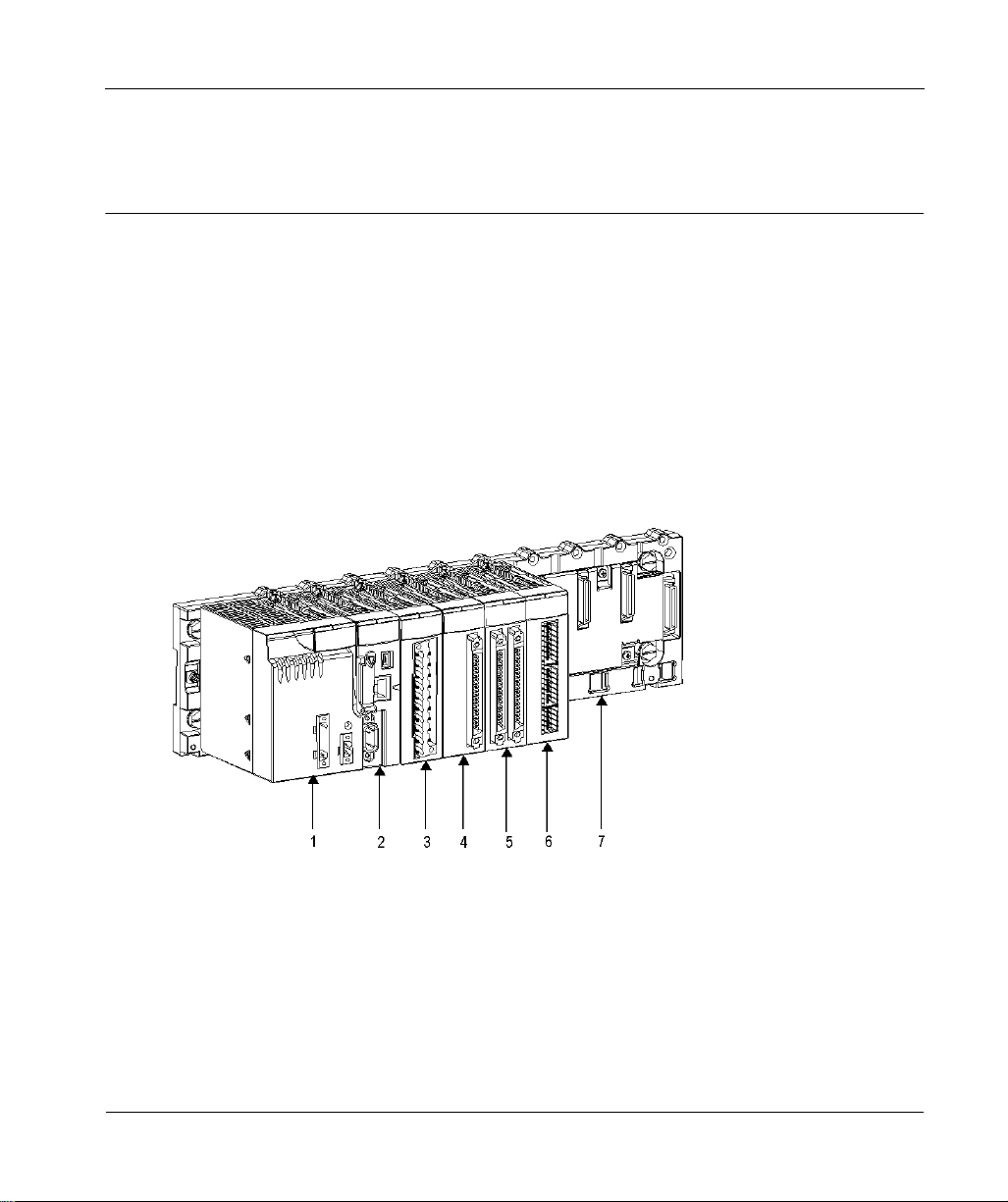

Modicon M340 PLC Station

General

Modicon M340 automated platform processors manage the entire PLC station, which is made up

of discrete I/O modules, analog I/O modules, counting modules, discrete I/O modules, analog I/O

modules, other expert modules, and communication modules. These are distributed across one or

more racks connected on the local bus. Each rack must include a power supply module; the main

rack supports the CPU.

Illustration

The following diagram shows a configuration example for the Modicon M340 PLC with one rack:

35012676 10/2019 13

Page 14

Introduction to Modicon M340 PLC Stations

Number Table

The following table describes the numbered components of the PLC station above.

Number Description

1 Power supply module

2 Processor

3 20-pin terminal block I/O module

4 40-pin single connector I/O module

5 40-pin 2-connector I/O module

6 Counting module

7 8-slot rack

14

35012676 10/2019

Page 15

ModiconM340

General Introduction to PLC station components

35012676 10/2019

General Introduction to PLC Station C omponents

Chapter 2

General Introduction to PLC Station Components

Subject of this Section

This section provides a general overview of the various components of which a PLC station may

consist.

What Is in This Chapter?

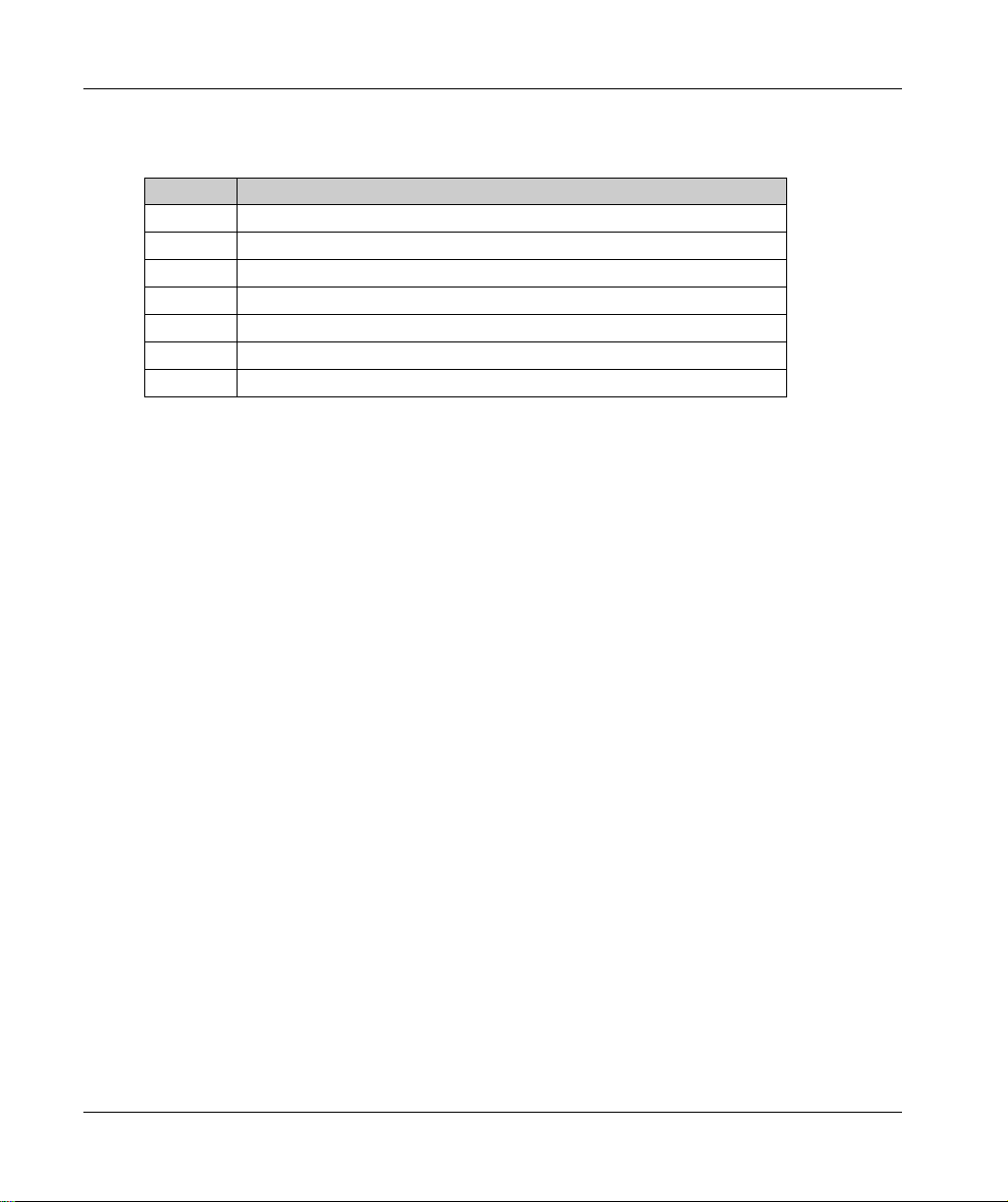

This chapter contains the following topics:

General Introduction to Processors 16

General Introduction to Racks 17

General Introduction to Power Supply Modules 18

General Introduction to Rack Extender Module 19

General Introduction to Input/Output Modules 20

General Introduction to Counting Modules 23

General Introduction to Communication 25

Grounding of Installed Modules 26

Modicon M340H (Hardened) Processors, Modules and Equipment 28

Topic Page

35012676 10/2019 15

Page 16

General Introduction to PLC station components

General Introduction to Processors

General

Each PLC station is equipped with a processor, chosen according to the following characteristics:

processing power (number of inputs/outputs managed)

memory capacity

communication ports

For further information, please refer to

Introduction to BMX P34 xxxx Processors, page 39

).

16

35012676 10/2019

Page 17

General Introduction to Racks

General

There are various sizes of racks. The following list presents the quantity of slots available for the

CPU and modules for each rack reference:

4 slots: BMXXBP0400(H) or BMEXBP0400(H)

6 slots: BMXXBP0600(H)

8 slots: BMXXBP0800(H) or BMEXBP0800(H)

12 slots: BMXXBP1200(H) or BMEXBP1200(H)

racks with redundant power supplies:

6 slots: BMEXBP0602(H)

10 slots: BMEXBP1002(H)

Each rack includes one extra slot that is reserved for the power supply module, and one slot on the

right is reserved for the BMXXBE1000 rack extender module.

For further information, refer to the chapter

Racks and Power Supplies, Hardware Reference Manual)

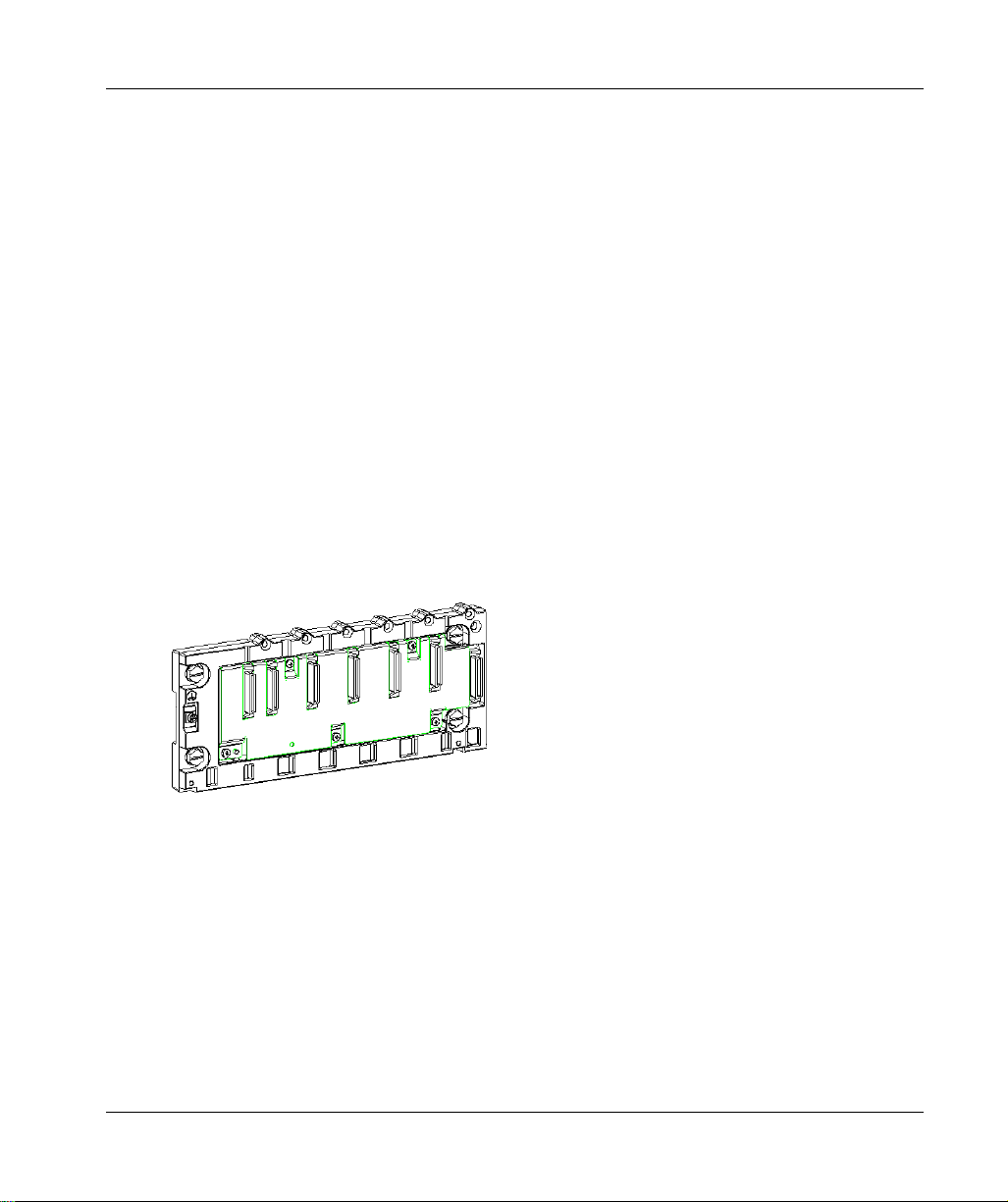

Representation of the Racks

The following diagram shows the BMXXPB0400 rack:

General Introduction to PLC station components

Modicon X80 Racks Description (see Modicon X80,

.

35012676 10/2019 17

Page 18

General Introduction to PLC station components

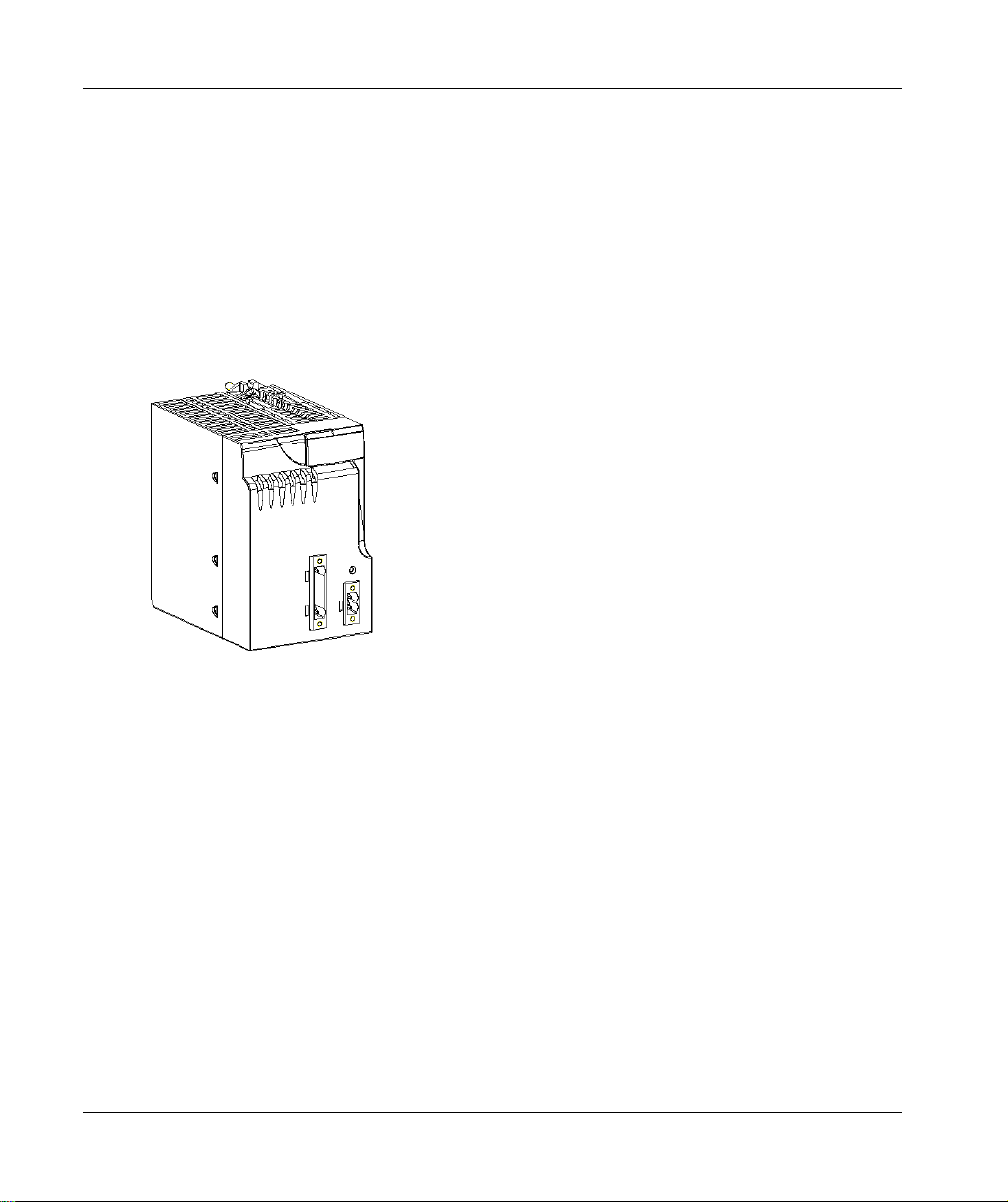

General Introduction to Power Supply Modules

General

Each rack requires one power supply module defined according to the distributed network

(alternating or direct current) and the power necessary at rack level.

For further information, refer to the chapter

(see Modicon X80, Racks and Power Supplies, Hardware Reference Manual)

Illustration

The following illustration shows a BMXCPS•••• power supply module:

Modicon X80 Power Supply Modules Description

.

18

35012676 10/2019

Page 19

General Introduction to Rack Extender Module

General

This module allows connecting a maximum of 4 chained racks, depending on the CPU, distributed

along a maximum length of 30 meters.

For further information, refer to chapter

Racks and Power Supplies, Hardware Reference Manual)

Illustration

Illustration of the BMXXBE1000 rack extender module:

BMXXBE1000 Rack Extender Module (see Modicon X80,

General Introduction to PLC station components

.

35012676 10/2019 19

Page 20

General Introduction to PLC station components

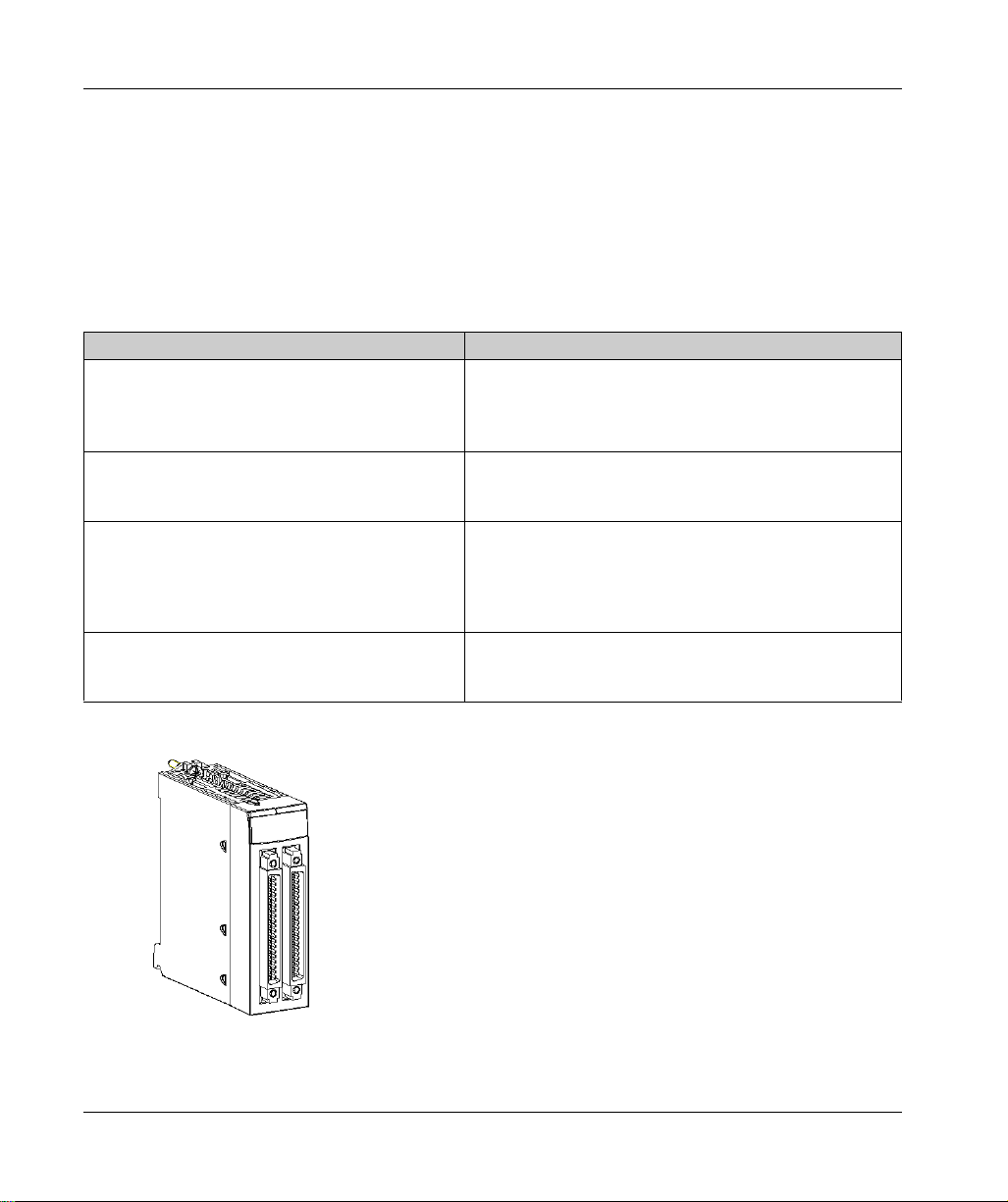

General Introduction to Input/Output Modules

General

The Modicon M340 range includes discrete and analog input/output modules.

Discrete Input/Output

A wide range of discrete input/output modules enables you to select the module best suited to your

needs. The characteristics of these modules differ as follows:

Characteristics Description

Modularity

Type of Inputs

Type of Outputs

Type of Connector

8 channels

16 channels

32 channels

64 channels

Modules with direct current inputs (24 VCC and 48 VCC)

Modules with alternating current inputs (24 VCA, 48 VCA

and 120 VCA)

Modules with relay outputs

Modules with direct current static outputs (24 VCC / 0.1 A

- 0.5 A - 3 A)

Modules with alternating current static outputs (24 VCC /

240 VAC / 3 A)

20-pin terminal blocks

40-pin connectors allowing connection to sensors and pre-

actuators by means of the TELEFAST 2 prewiring system

20

The following illustration shows a discrete input/output modules with 40-pin connectors:

35012676 10/2019

Page 21

The following illustration shows a discrete input/output module with a 20-pin terminal block:

Analog Inputs/Outputs

A wide range of analog input/output modules enables you to select the module best suited to your

needs. The characteristics of these modules differ as follows:

Characteristics Description

Modularity

Performance and Range of Signals Offered

Type of Connector

General Introduction to PLC station components

2 channels

4 channels

Voltage/current

Thermocouple

Thermowell

20-pin terminal blocks

40-pin connectors allowing connection to

sensors and pre-actuators by means of

the TELEFAST 2 prewiring system

35012676 10/2019 21

Page 22

General Introduction to PLC station components

The following illustration shows an analog input/output module with one 40-pin connector:

The following illustration shows an analog input/output module with 20-pin terminal block:

22

35012676 10/2019

Page 23

General Introduction to Counting Modules

General

The PLCs in the Modicon M340 range offer counting functions (downcounting, counting,

counting/downcounting) by utilizing the application-specific counting modules.

Two counting modules are offered:

BMX EHC 0200 module with two counting channels and a maximum acquisition frequency of

60 kHz

BMX EHC 0800 module with eight counting channels and a maximum acquisition frequency of

10 kHz

Illustration

The following illustration shows a BMX EHC 0200 counting module:

General Introduction to PLC station components

35012676 10/2019 23

Page 24

General Introduction to PLC station components

The following illustration shows a BMX EHC 0800 counting module:

24

35012676 10/2019

Page 25

General Introduction to Communication

General

PLCs from the Modicon M340 range can be used in different communication modes:

USB

Serial

Ethernet

CANopen

AS-Interface

General Introduction to PLC station components

35012676 10/2019 25

Page 26

General Introduction to PLC station components

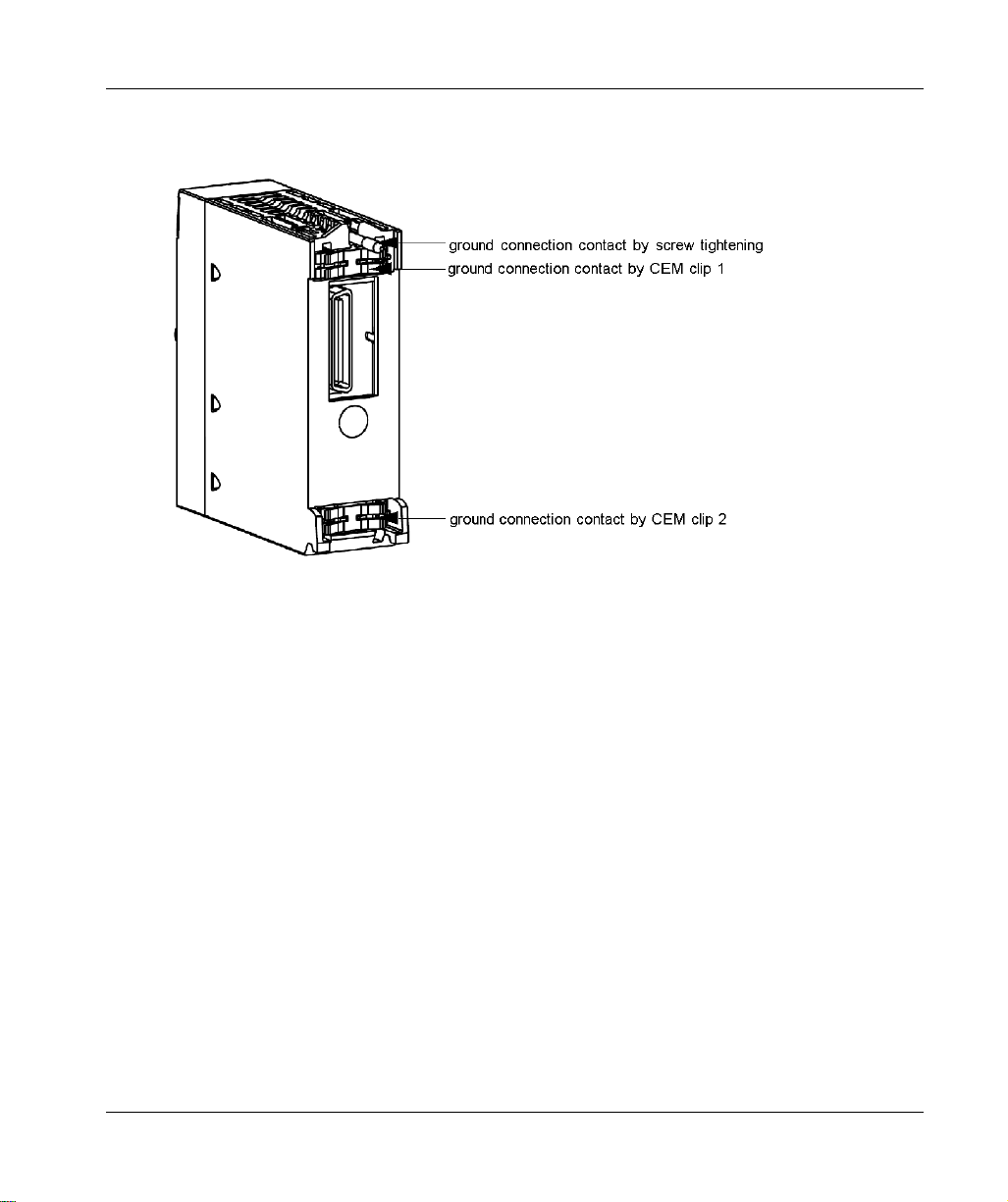

Grounding of Installed Modules

General

The grounding of Modicon M340 modules is crucial to avoid electric shock.

Grounding Processors and Power Supplies

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Ensure ground connection contacts are present and not bent out of shape. If they are, do not use

the module and contact your Schneider Electric representative.

Failure to follow these instructions will result in death or serious injury.

UNINTENDED EQUIPMENT OPERATION

Tighten the clamping screws of the modules. A break in the circuit could lead to an unexpected

behavior of the system.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

DANGER

WARNING

26

35012676 10/2019

Page 27

General Introduction to PLC station components

All Modicon M340 modules are equipped with ground connection contacts at the rear for grounding

purposes:

These contacts connect the grounding bus of the modules to the grounding bus of the rack.

35012676 10/2019 27

Page 28

General Introduction to PLC station components

Modicon M340H (Hardened) Processors, Modules and Equipment

At a Glance

Hardened equipment can operate in extended temperature ranges and harsher environments

compared to standard M340 equipment.

NOTE: For more information, refer to chapter

(see Modicon M580, M340, and X80 I/O Platforms, Standards and Certifications)

“H” Equipment

The follow equipment are available in Hardened versions:

CPUs:

BMX P34 2020H

BMX P34 2030 2H

Power Supplies:

BMX CPS 3020H

BMX CPS 3500H

BMX CPS 4002H

Backplanes:

BMX XBP 0400H

BMX XBP 0600H

BMX XBP 0800H

BMX XBP 1200H

BME XBP 0400H

BME XBP 0800H

BME XBP 1200H

BME XBP 0602H

BME XBP 1002H

Backplane Extension:

BMX XBE 1000H

Counting Modules:

BMX ECH 0200H

BMX ECH 0800H

Analog Input Modules:

BMX ART 0414H

BMX ART 0814H

BMX AMI 0810H

Analog Output Modules:

BMX AMO 0210H

BMX AMO 0410H

Installation in More Severe Environments

.

28

35012676 10/2019

Page 29

Analog Input/Output Module:

BMX AMM 0600H

TELEFAST Wiring Accessories

ABE7 CPA 0410H

ABE7 CPA 0412H

Digital Input modules:

BMX DDI 1602H

BMX DDI 1603H

Digital Input/Output modules:

BMX DAI 1602H

BMX DAI 1603H

BMX DAI 1604H

BMX DAI 1614H

BMX DAI 1615H

BMX DDM 16022H

BMX DDM 16025H

Digital Output modules:

BMX DAO 1605H

BMX DAO 1615H

BMX DDO 1602H

BMX DDO 1612H

BMX DRA 0805H

BMX DRA 0815H

BMX DRA 1605H

BMX DRC 0805H

Synchronous Serial Interface (SSI) Modules:

BMX EAE 0300H

General Introduction to PLC station components

35012676 10/2019 29

Page 30

General Introduction to PLC station components

30

35012676 10/2019

Page 31

ModiconM340

General Introduction to PLC Network s

35012676 10/2019

General Introduction to PLC Network s

Chapter 3

General Introduction to PLC Networks

Subject of this Section

This section provides a general overview of PLC networks.

What Is in This Chapter?

This chapter contains the following topics:

General Introduction to the Modbus Protocol 32

General Introduction to an Ethernet Network 33

General Introduction to the CANopen Field Bus 34

Topic Page

35012676 10/2019 31

Page 32

General Introduction to PLC Networks

General Introduction to the Modbus Protocol

General

The Modbus protocol creates a hierarchical structure (one master and several slaves).

The master manages all exchanges according to two types of dialog:

the master exchanges with a slave and awaits the response

the master exchanges with all slaves without awaiting a response (broadcast queries).

Illustration

The following illustration shows a Modbus network:

32

35012676 10/2019

Page 33

General Introduction to an Ethernet Network

General

Ethernet communication essentially targets applications of:

coordination between PLCs

local or centralized monitoring

communication with the production management information system

communication with remote inputs/outputs

Acting as an agent, Ethernet communication also supports management of the network monitoring

standard SNMP.

Illustration

The following illustration shows an Ethernet network:

General Introduction to PLC Networks

35012676 10/2019 33

Page 34

General Introduction to PLC Networks

General Introduction to the CANopen Field Bus

General

The CANopen structure consists of:

a bus master

slave devices, also called nodes

Bus operation is point to point. At any time, each device can send a request on the bus and the

affected devices answer.

Bus request priority is calculated by an identifier in each message.

Illustration

The following example illustrates a CANopen field bus architecture:

34

35012676 10/2019

Page 35

ModiconM340

Operating Standards an d Conditions

35012676 10/2019

Operating Standards an d Conditions

Chapter 4

Operating Standards and Conditions

Standards and Certifications

Download

Click the link that corresponds to your preferred language to download standards and certifications

(PDF format) that apply to the modules in this product line:

Title Languages

Modicon M580, M340, and X80 I/O Platforms,

Standards and Certifications

English:

French:

German:

Italian:

Spanish:

Chinese:

EIO0000002730

EIO0000002726

EIO0000002727

EIO0000002728

EIO0000002729

EIO0000002731

35012676 10/2019 35

Page 36

Operating Standards and Conditions

36

35012676 10/2019

Page 37

ModiconM340

BMXP34 •••• Processors

35012676 10/2019

BMXP34 xxxx Processors

Part II

BMX P34 xxxx Processors

Subject of this Part

This part describes the BMX P34 •••• processors and their installation.

What Is in This Part?

This part contains the following chapters:

Chapter Chapter Name Page

5 Introduction to BMX P34 xxxx Processors 39

6 General Characteristics of the BMX P34 xxxx Processors 57

7 Installation of BMX P34 xxxx Processors 73

8 BMX P34 xxxx Processors Diagnostics 85

9 Processor Performance 97

35012676 10/2019 37

Page 38

BMX P34 •••• Processors

38

35012676 10/2019

Page 39

ModiconM340

Introduction to BMX P34 xxxx Processors

35012676 10/2019

Introduction to BMX P34 xxxx Processors

Chapter 5

Introduction to BMX P34 xxxx Processors

Subject of this Section

This section describes the BMX P34 •••• processors.

What Is in This Chapter?

This chapter contains the following topics:

General Introduction 40

Physical Description of BMX P34 xxxx Processors 43

USB Link 45

Modbus Link 46

CANopen Link 48

Ethernet Link 50

BMX P34 xxxxx Processors Catalog 53

Real-Time Clock 54

Topic Page

35012676 10/2019 39

Page 40

Introduction to BMX P34 xxxx Processors

General Introduction

Introduction

A wide range of BMX P34 ••••• processors, with increasing performance and capability, are

available to respond to various needs.

General

BMX P34 ••••• processors can be installed onto Modicon X80 racks.

Functions

BMX P34 ••••• processors manage the entire PLC station, which includes the following elements:

discrete input/output modules

analog input/output modules

other expert modules

communication modules.

40

35012676 10/2019

Page 41

Illustration

The figure below shows a processor-managed architecture:

Introduction to BMX P34 xxxx Processors

The following table gives the numbered components of the configuration above.

Number Designation

1 Power supply module

2 Processor

3 20-pin terminal block module

4 40-pin single connector module

5 40-pin twin connector module

6 Counting module

7Rack

35012676 10/2019 41

Page 42

Introduction to BMX P34 xxxx Processors

Processor product references

The following diagram shows the location of the product references on the side of the processor:

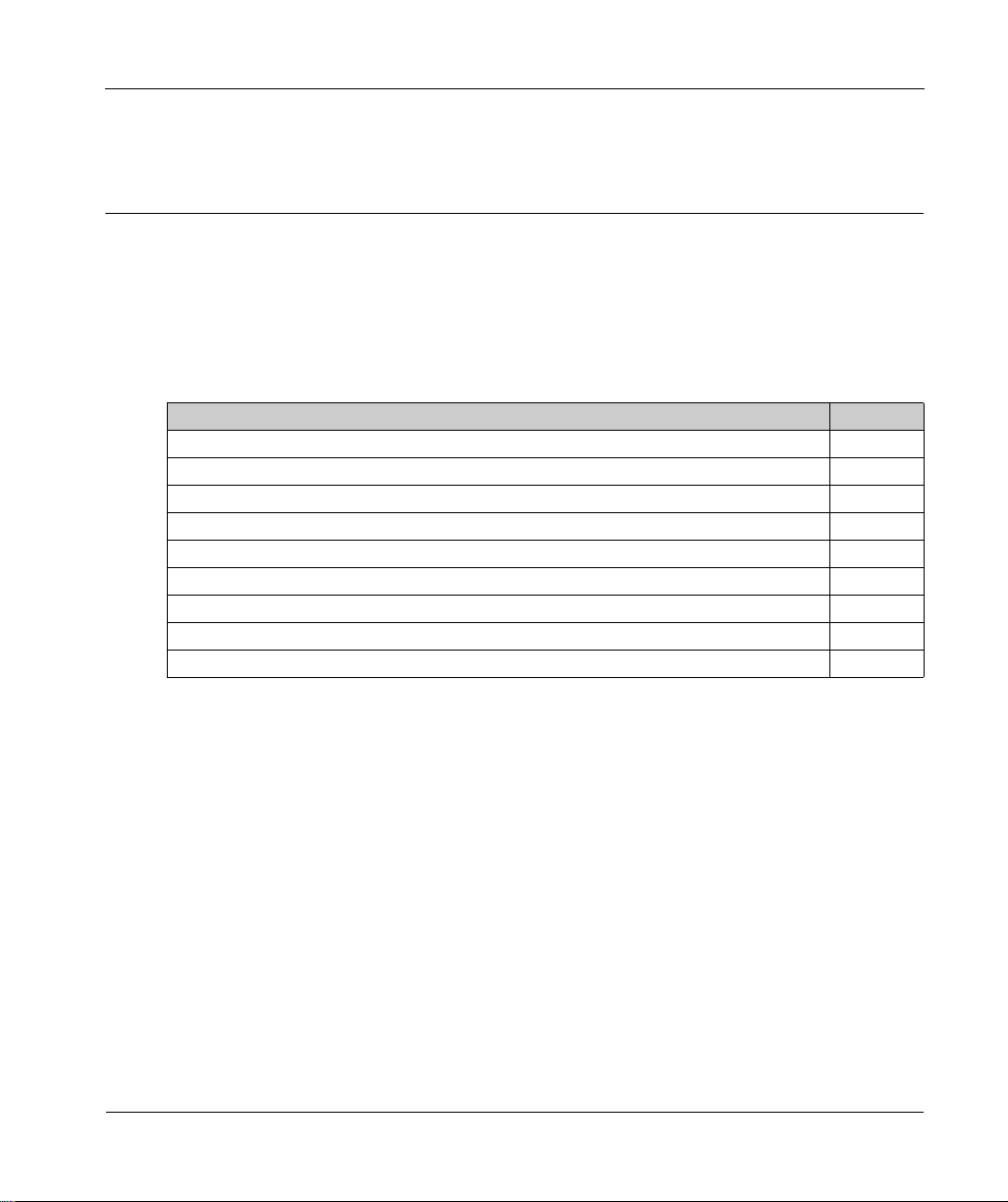

Main Characteristics of the BMX P34 ••••• Processors

The following table shows the main characteristics of the BMX P34 ••••• processors.

Processor Global maximum

number of

discrete

inputs/outputs

BMX P34 1000 512 128 2048 Kb X - -

BMX P34 2000 1024 256 4096 Kb X - -

BMX P34 2010/20

102

BMX P34 2020 1024 256 4096 Kb X - X

BMX P34 2030/20

302

Key

X Available

- Not available

42

1024 256 4096 Kb X X -

1024 256 4096 Kb - X X

Global

maximum

number of

analog

inputs/outputs

Maximum

memory size

Modbus

Connection

Integrated

CANopen

Master

Connection

Integrated

Ethernet

Connection

35012676 10/2019

Page 43

Physical Description of BMX P34 xxxx Processors

General

The BMX P34 •••• processors differ according to the various components they include.

Illustration

The following diagrams identify the various components of a BMX P34 •••• processor:

Introduction to BMX P34 xxxx Processors

35012676 10/2019 43

Page 44

Introduction to BMX P34 xxxx Processors

Description

The following table shows the components of a BMX P34 •••• processor.

Number Function

1 Display panel

2 USB port

3 Memory card protection port

4 Serial port

5 Serial port identification ring (black)

6 Ethernet port

7 Ethernet port identification ring (green)

8 CANopen port

44

35012676 10/2019

Page 45

USB Link

General

All processors have a USB link.

Description

Two connection cables are available to connect a human-machine interface to the processor USB

port:

BMX XCA USB 018, 1.8 m (5.91 ft) in length

BMX XCA USB 045, 4.5 m (14.76 ft) in length

Both of these cables are fitted with a connector at each end:

Type A USB: connects to the console

Type mini B USB: connects to the processor

In fixed assembly with an XBT type console connected to the processor via the USB port, you are

advised to connect the USB cable to the shielding connection kit

Power Supplies, Hardware Reference Manual)

NOTE: When using the M340, it is strongly recommended to use a USB 2.0 shielded cable

following the USB international standard. The cables BMX XCA USB 018 and BMX XCA USB 045

are designed for this type of use and avoid unexpected behavior of the PLC. Those cables are

shielded and tested against electrical noises.

Introduction to BMX P34 xxxx Processors

(see Modicon X80, Racks and

.

35012676 10/2019 45

Page 46

Introduction to BMX P34 xxxx Processors

Modbus Link

General

The following processors have a built-in communication channel dedicated to serial

communication, and support communication via a Modbus link:

BMX P34 1000,

BMX P34 2000,

BMX P34 2010/20102,

BMX P34 2020.

Introduction to the Serial Port

The following table describes the characteristics of the serial communication channels:.

Characteristic Description

Channel number Channel 0

Protocols supported

Connection RJ45 female connector

Physical link

Modbus protocol (ASCII and RTU)

Character Mode protocol

RS 485 non-insulated serial link

RS 232 non-insulated serial link

46

The following illustration shows the RJ45 serial port:

35012676 10/2019

Page 47

Introduction to BMX P34 xxxx Processors

The following table shows the pin assignment of the serial port for the BMX P34 xxxxx processors:

The RJ45 connector has eight pins. The pins used differ according to the physical link used.

The pins used by the RS 232 serial link are as follows:

Pin 1: RXD signal

Pin 2: TXD signal

Pin 3: RTS signal

Pin 6: CTS signal

The pins used by the RS 485 serial link are as follows:

Pin 4: D1 signal

Pin 5: D0 signal

Pins 7 and 8 are dedicated to the power supply of the man-machine interface via the serial link:

Pin 7: 5 VDC/190 mA network power supply

Pin 8: common of the network power supply (0 V)

NOTE: The RS 232 4-wire, RS 485 2-wire, and RS 485 2-wire and power supply cables all use the

same RJ45 male connector.

35012676 10/2019 47

Page 48

Introduction to BMX P34 xxxx Processors

CANopen Link

Introduction

The following processors have a built-in communication channel dedicated to CANopen

communication,and support communication via CANopen link:

BMX P34 2010/20102,

BMX P34 2030/20302.

Introduction to the CANopen Port

The following illustration shows the position of the BMX P34 2030 processor’s CANopen port:

48

35012676 10/2019

Page 49

CANopen Connectors

The CANopen port of the processor module is fitted with a SUB-D9 connection.

The following illustration shows the processor CANopen port and the pins labels:

The following table shows the pin assignment of the CANopen link.

Pin Signal Description

1- Reserved

2 CAN_L CAN_L bus line (low dominant)

3 CAN_GND CAN ground

4- Reserved

5 Reserved Optional CAN protection

6 (GND) Optional ground

7 CAN_H CAN_H bus line (high dominant)

8- Reserved

9 Reserved Positive external CAN power supply

Introduction to BMX P34 xxxx Processors

(dedicated to the power supply of optocouplers and

transmitters/receivers)

Optional

NOTE: CAN_SHLD and CAN_V+ are not installed on the Modicon M340 range processors. These

are reserved connections.

35012676 10/2019 49

Page 50

Introduction to BMX P34 xxxx Processors

Ethernet Link

General

The following processors have a built-in communication channel dedicated to Ethernet

communication, with 2 rotary switches which enable easy selection of the IP address processor.

BMX P34 2020,

BMX P34 2030/20302.

NOTE: These processors have only one IP address.

Introduction to the Ethernet Port

The following illustration shows the processor of the RJ45 Ethernet port:

The following illustration shows the pin assignment of the Ethernet port:

Introduction to the MAC address

The MAC address is located on the front panel of the processor below the processor display panel.

50

35012676 10/2019

Page 51

Introduction to the Rotary Switches

This processor operates as a single node on an Ethernet and possibly other networks. The module

must have a unique IP address. The 2 rotary switches on the back of the module provide a simple

way to select an IP address:

NOTE: Set the arrow firmly into the desired position. If you do not feel the switch click into place,

the value of the switch may be incorrect or undetermined.

Each rotary switch position that you can use to set a valid IP address is marked on the module.

The following information summarizes the valid address settings:

device name: for a switch-set device name, select a numeric value from 00 to 159. You can use

both switches:

On the upper switch (TENS digit), the available settings are 0 to 15

On the lower switch (ONES digit), the available settings are 0 to 9.

For example, a BMX P34 2020 processor with the switch setting in the above figure is assigned

the DHCP device name BMX_2020_123.

The selection on the lower switch of any non-numeric parameter (BOOTP, STORED, CLEAR

IP, DISABLED) makes the setting on the upper switch inconsequential.

BOOTP: To get an IP address from a BOOTP server, select either of the two BOOTP positions

on the bottom switch.

STORED: The device uses the application’s configured (stored) parameters.

CLEAR IP: The device uses the default IP parameters.

DISABLED: The device does not respond to communications.

The functionality of the rotary switch when used in conjunction with the IP Configuration tab

(see Modicon M340 for Ethernet, Communications Modules and Processors, User Manual)

discussed throughout the IP Address chapter

Modules and Processors, User Manual)

Introduction to BMX P34 xxxx Processors

is

(see Modicon M340 for Ethernet, Communications

.

35012676 10/2019 51

Page 52

Introduction to BMX P34 xxxx Processors

Switch Labels

To assist you in setting the rotary switches to their proper positions, a label is affixed to the right

side of the module. The switch settings are described in this table:

Upper Switch

0 to 9: Tens value for the device name

(0, 10, 20 . . . 90)

10(A) to 15(F): Tens value for the

device name (100, 110, 120 . . . 150)

Lower Switch

0 to 9: Ones value for the device name

(0, 1, 2...9)

Bootp: Set the switch to A or B to

receive an IP address from a BOOTP

server.

Stored: Set the switch to C or D to use

the application’s configured (stored)

parameters.

Clear IP: Set the switch to E to use the

default IP parameters.

Disabled: Set the switch to F to disable

communications.

52

35012676 10/2019

Page 53

BMX P34 xxxxx Processors Catalog

Introduction

The choice of BMX P34 xxxxx processor is made, primarily, according to its characteristics and

possibilities.

BMX P34 xxxxx Processors Catalog

The following table describes the important maximum characteristics of the BMX P34 xxxxx

processors.

Introduction to BMX P34 xxxx Processors

Characteristic BMX P34 1000 BMX P34 2000 BMX P34 2010

/20102

Maximum

Number of

channels

Maximum

Number of

modules

Memory

size

Legend 1 The AS-i field bus requires at least PLC Operating System V2.10.

Discrete rack

inputs/outputs

Analog

inputs/outputs

Expert

channels

(counting, PTO,

MPS, NOM,

etc.)

Embedded

Serial port

Embedded

Ethernet port

Embedded

CANopen port

Network

communication

(TCP/IP)

AS-i fieldbus

communication

User

application

512 1024 1024 1024 1024

128 256 256 256 256

20 36 36 36 36

1111-

---11

--1-1

23333

1

24444

2048 Kb 4096 Kb 4096 Kb 4096 Kb 4096 Kb

BMX P34 2020 BMX P34 2030

/20302

35012676 10/2019 53

Page 54

Introduction to BMX P34 xxxx Processors

Real-Time Clock

Introduction

Each BMX P34 xxxxx processor has a real-time clock which manages:

The current date and time

The date and time of the last application shut-down

When power of the processor is turned off, the real-time clock continues counting during four

weeks. This duration is guarantied for a temperature below 45°C (113°F). At a higher temperature

this duration is reduced. No maintenance is requested for a real-time clock back up.

Current Date and Time

The processor updates the current date and time in the system words %SW49...%SW53 and %SW70.

This data is in BCD (Binary Coded Decimal).

System Word Most Significant Byte Least Significant Byte

%SW49

%SW50

%SW51

%SW52

%SW53

%SW70

00 Days of the week in the range of values

Seconds (0 - 59) 00

Hours (0 - 23) Minutes (0 - 59)

Month (1 - 12) Days of the month (1 - 31)

Century (0 - 99) Year (0 - 99)

1 - 7 (1 for Monday and 7 for Sunday)

Week (1 - 52)

Accessing the Date and Time

You can access the date and time as follows:

through the processor debug screen.

with the program:

Reading system words: %SW49 - %SW53 if the system bit %S50 is at 0,

immediate update: writing system words %SW50 to %SW53 if the system bit %S50 is at 1,

incremental update: writing the system word %SW59. With this word the date and time can be

set field by field from the current value (if the system bit %S59 is at 1), or an overall

increment/decrement can be done.

The following table shows the function performed by each bit in the word %SW59.

Bit Range Function

0 Increments the day of the week

1 Increments the seconds

2 Increments the minutes

3 Increments the hours

54

35012676 10/2019

Page 55

Bit Range Function

4 Increments the days

5 Increments the months

6 Increments the years

7 Increments the centuries

8 Decrements the day of the week

9 Decrements the seconds

10 Decrements the minutes

11 Decrements the hours

12 Decrements the days

13 Decrements the months

14 Decrements the years

15 Decrements the centuries

NOTE: The function is performed when the corresponding bit %S59 is at 1.

NOTE: The processor does not automatically manage Daylight Savings Time.

Date and Time of the Last Application Shutdown

The date and time of the last application shutdown are in BCD in the system words %SW54 - %SW58.

Introduction to BMX P34 xxxx Processors

System Word Most Significant Byte Least Significant Byte

%SW54

%SW55

%SW56

%SW57

%SW58

Seconds (0 to 59) 00

Hours (0 to 23) Minutes (0 to 59)

Month (1 to 12) Days of the month (1 to 31)

Century (0 to 99) Year (0 to 99)

Day of the week (1 to 7) Reason for the last application shutdown

The reason for the last application shutdown can be accessed by reading the least significant byte

of the system word %SW58 (value in BCD) which can have the following values.

Word value %SW58 Meaning

1 Application switched to STOP mode.

2 Application stopped by watchdog.

4 Power loss or memory card lock operation.

5 Stop on hardware fault.

6 Stop on software fault (HALT instruction, SFC errors,

35012676 10/2019 55

application CRC check fail, undefined system function call,

etc). Details on the software fault type are stored in %SW125.

Page 56

Introduction to BMX P34 xxxx Processors

56

35012676 10/2019

Page 57

ModiconM340

General Characteristics of the BMXP34 •••• Processors

35012676 10/2019

General Characteristics of the BMXP34 xxxx Processors

Chapter 6

General Characteristics of the BMX P34 xxxx Processors

Subject of this Section

This section describes the general characteristics of the BMX P34 •••• processors used during

installation.

What Is in This Chapter?

This chapter contains the following topics:

Electrical Characteristics of the BMX P34 xxxxx Processors 58

General Characteristics of the BMX P34 1000 Processor 60

General Characteristics of the BMX P34 2000 Processor 62

General Characteristics of the BMX P34 2010/20102 Processors 64

General Characteristics of the BMX P34 2020 Processor 66

General Characteristics of the BMX P34 2030/20302 Processor 68

Characteristics of the BMX P34 xxxxx Processor Memory 70

Topic Page

35012676 10/2019 57

Page 58

General Characteristics of the BMX P34 •••• Processors

Electrical Characteristics of the BMX P34 xxxxx Processors

General

The processors can support certain devices which do not have their own power supply. It is,

therefore, necessary to take the power consumption of these devices into account when

establishing the overall power consumption breakdown.

Processor Power Consumption

The following table shows the power consumption for all the BMX P34 xxxxx processors with no

connected devices.

Processor Average Consumption

BMX P34 1000 72 mA

BMX P34 2000 72 mA

BMX P34 2010/20102 90 mA

BMX P34 2020 95 mA

BMX P34 2030/20302 135 mA

NOTE: The processor power consumption values are measured at the 24 V_BAC output of the

power supply module, which is the only power supply output used by the processors.

NOTE: When a device consumes power on the processor serial port connection, its power needs

to be added to the power consumed by the processor. The power supplied by the serial port is

5 VCC/190 mA.

58

NOTICE

IMPROPER POWER SUPPLY

Only use network power-supplied devices tested by Schneider Electric.

Failure to follow these instructions can result in equipment damage.

NOTE: It is possible to use network power-supplied devices not tested by Schneider Electric.

However, their operation is not guaranteed. For further information, please contact your Schneider

sales office.

35012676 10/2019

Page 59

Processor Dissipated Power

The following table shows the average dissipated power for all the BMX P34 xxxxx processors with

no connected devices.

Processor Average Dissipated Power

BMX P34 1000 1.7 W

BMX P34 2000 1.7 W

BMX P34 2010/20102 2.2 W

BMX P34 2020 2.3 W

BMX P34 2030/20302 3.2 W

General Characteristics of the BMX P34 •••• Processors

35012676 10/2019 59

Page 60

General Characteristics of the BMX P34 •••• Processors

General Characteristics of the BMX P34 1000 Processor

General

The characteristics of the BMX P34 1000 processor are presented below.

Ruggedized Version

The BMX P34 1000H (hardened) equipment is the ruggedized version of the BMX P34 1000

(standard) equipment. It can be used at extended temperatures and in harsh chemical

environments.

For more information, refer to chapter

M580, M340, and X80 I/O Platforms, Standards and Certifications)

Altitude Operating Conditions

The characteristics apply to the modules BMX P34 1000, and BMX P34 1000H for use at altitude

up to 2000 m (6560 ft). When the modules operate above 2000 m (6560 ft), apply additional

derating.

For detailed information, refer to chapter

M340, and X80 I/O Platforms, Standards and Certifications)

Installation in More Severe Environments (see Modicon

Operating and Storage Conditions (see Modicon M580,

.

.

60

35012676 10/2019

Page 61

BMX P34 1000 Processor Characteristics

The following table shows the general characteristics of the BMX P34 1000 processor.

Characteristic Available

Operating Temperature BMX P34 1000 0...+60 °C (+32...+140 °F)

BMX P34 1000H -25...+70 °C (-13...+158 °F)

Functions Maximum

Savable Application Data Memory Capacity 128 Kb

Application

Structure

Application Code

Execution Speed

Execution Time One basic Boolean instruction 0.18 μs (theoretical)

number of

Maximum

number of

modules

Savable real-time clock Yes

MAST task 1

FAST task 1

Event processing 32

Internal

RAM

One basic digital instruction 0.25 μs (theoretical)

One floating point instruction 1.74 μs (theoretical)

Discrete rack inputs/outputs 512

Analog rack inputs/outputs 128

Expert channels 20

Ethernet channels 2

AS-I Field Bus 2

Simultaneous communication EF 8

USB 1

Embedded Serial Modbus link port 1

Embedded CANopen master port -

Embedded Ethernet port -

100% Boolean 5.4 Kins/ms (1)

65% Boolean + 35% digital 4.2 Kins/ms (1)

General Characteristics of the BMX P34 •••• Processors

(1) Kins: 1024 instructions (list), theoretical

35012676 10/2019 61

Page 62

General Characteristics of the BMX P34 •••• Processors

General Characteristics of the BMX P34 2000 Processor

General

The characteristics of the BMX P34 2000 processor are presented below.

Altitude Operating Conditions

The characteristics apply to the module BMX P34 2000 for use at altitude up to 2000 m (6560 ft).

When the module operates above 2000 m (6560 ft), apply additional derating.

For detailed information, refer to chapter

M340, and X80 I/O Platforms, Standards and Certifications)

Operating and Storage Conditions (see Modicon M580,

.

62

35012676 10/2019

Page 63

BMX P34 2000 Processor Characteristics

The following table shows the general characteristics of the BMX P34 2000 processor.

Characteristic Available

Operating Temperature 0...+60 °C (+32...+140 °F)

Functions Maximum

number of

Maximum

number of

modules

Savable real-time clock Yes

Savable Application Data Memory Capacity 256 Kb

Application

Structure

Application Code

Execution Speed

Execution Time One basic Boolean instruction 0.12 μs

MAST task 1

FAST task 1

Event processing 64

Internal

RAM

One basic digital instruction 0.17 μs

One floating point instruction 1.16 μs

Discrete rack inputs/outputs 1024

Analog rack inputs/outputs 256

Counting channels 36

Ethernet channels 2

AS-i Field Bus 4

Simultaneous communication EF 16

USB 1

Embedded Serial Modbus link port 1

Embedded CANopen master port -

Embedded Ethernet port -

100% Boolean 8.1 Kins/ms (1)

65% Boolean + 35% digital 6.4 Kins/ms (1)

General Characteristics of the BMX P34 •••• Processors

(1) Kins: 1024 instructions (list)

35012676 10/2019 63

Page 64

General Characteristics of the BMX P34 •••• Processors

General Characteristics of the BMX P34 2010/20102 Processors

Altitude Operating Conditions

The characteristics apply to the modules BMX P34 2010, and BMX P34 20102 for use at altitude

up to 2000 m (6560 ft). When the modules operate above 2000 m (6560 ft), apply additional

derating.

For detailed information, refer to chapter

M340, and X80 I/O Platforms, Standards and Certifications)

Operating and Storage Conditions (see Modicon M580,

.

64

35012676 10/2019

Page 65

BMX P34 2010/20102 Processors Characteristics

The following table shows the general characteristics of the BMX P34 2010/20102 processors.

Characteristic Available

Operating Temperature 0...+60 °C (+32...+140 °F)

Functions Maximum

number of

Maximum

number of

modules

Savable real-time clock Yes

Savable Application Data Memory Capacity 256 Kb

Application

Structure

Application Code

Execution Speed

Execution Time One basic Boolean instruction 0.12 μs

MAST task 1

FAST task 1

Event processing 64

Internal

RAM

One basic digital instruction 0.17 μs

One floating point instruction 1.16 μs

Discrete rack inputs/outputs 1024

Analog rack inputs/outputs 256

Expert channels 36

Ethernet channels 2

AS-i field Bus BMX P34 2010: 0

Simultaneous communication EF 16

USB 1

Embedded Serial Modbus link port 1

Embedded CANopen master port 1

Embedded Ethernet port -

100% Boolean 8.1 Kins/ms (1)

65% Boolean + 35% digital 6.4 Kins/ms (1)

General Characteristics of the BMX P34 •••• Processors

BMX P34 20102: 4

(1) Kins: 1024 instructions (list)

NOTE: Expert mode function is available for BMX P34 20102 processors.

35012676 10/2019 65

Page 66

General Characteristics of the BMX P34 •••• Processors

General Characteristics of the BMX P34 2020 Processor

General

The characteristics of the BMX P34 2020 processor are presented below.

Ruggedized Version

The BMX P34 2020H (hardened) equipment is the ruggedized version of the BMX P34 2020

(standard) equipment. It can be used at extended temperatures and in harsh chemical

environments.

For more information, refer to chapter

M580, M340, and X80 I/O Platforms, Standards and Certifications)

Altitude Operating Conditions

The characteristics apply to the modules BMX P34 2020, and BMX P34 2020H for use at altitude

up to 2000 m (6560 ft). When the modules operate above 2000 m (6560 ft), apply additional

derating.

For detailed information, refer to chapter

M340, and X80 I/O Platforms, Standards and Certifications)

Installation in More Severe Environments (see Modicon

Operating and Storage Conditions (see Modicon M580,

.

.

66

35012676 10/2019

Page 67

BMX P34 2020 Processor Characteristics

The following table shows the general characteristics of the BMX P34 2020 processor.

Characteristic Available

Operating Temperature BMX P34 2020 0...+60 °C (+32...+140 °F)

BMX P34 2020H -25...+70 °C (-13...+158 °F)

Functions Maximum

Savable Application Data Memory Capacity 256 Kb

Application

Structure

Application Code

Execution Speed

Execution Time One basic Boolean instruction 0.12 μs

number of

Maximum

number of

modules

Savable real-time clock Yes

MAST task 1

FAST task 1

Event processing 64

Internal

RAM

One basic digital instruction 0.17 μs

One floating point instruction 1.16 μs

Discrete rack inputs/outputs 1024

Analog rack inputs/outputs 256

Expert channels 36

Ethernet channels 3

AS-i Field Bus 4

Simultaneous communication EF 16

USB 1

Embedded Serial Modbus link port 1

Embedded CANopen master port -

Embedded Ethernet port 1

100% Boolean 8.1 Kins/ms (1)

65% Boolean + 35% digital 6.4 Kins/ms (1)

General Characteristics of the BMX P34 •••• Processors

(1) Kins: 1024 instructions (list)

35012676 10/2019 67

Page 68

General Characteristics of the BMX P34 •••• Processors

General Characteristics of the BMX P34 2030/20302 Processor

Ruggedized Version

The BMX P34 20302H (hardened) equipment is the ruggedized version of the BMX P34 20302

(standard) equipment. It can be used at extended temperatures and in harsh chemical

environments.

For more information, refer to chapter

M580, M340, and X80 I/O Platforms, Standards and Certifications)

Altitude Operating Conditions

The characteristics apply to the modules BMX P34 2030, BMX P34 20302, and BMX P34 20302H

for use at altitude up to 2000 m (6560 ft). When the modules operate above 2000 m (6560 ft), apply

additional derating.

For detailed information, refer to chapter

M340, and X80 I/O Platforms, Standards and Certifications)

Installation in More Severe Environments (see Modicon

.

Operating and Storage Conditions (see Modicon M580,

.

68

35012676 10/2019

Page 69

BMX P34 2030/20302 Processor Characteristics

The following table shows the general characteristics of the BMX P34 2030/20302 processor.

Characteristic Available

Operating Temperature BMX P34 2030/20302 0...+60 °C (+32...+140 °F)

BMX P34 20302H -25...+70 °C (-13...+158 °F)

Functions Maximum

Savable Application Data Memory Capacity 256 Kb

Application

Structure

Application Code

Execution Speed

Execution Time One basic Boolean instruction 0.12 μs

number of

Maximum

number of

modules

Savable real-time clock Yes

MAST task 1

FAST task 1

Event processing 64

Internal

RAM

One basic digital instruction 0.17 μs

One floating point instruction 1.16 μs

Discrete rack inputs/outputs 1024

Analog rack inputs/outputs 256

Expert channels 36

Ethernet channels 3

AS-i Field Bus BMX P34 2030: 0

Simultaneous communication EF 16

USB 1

Embedded Serial Modbus link port -

Embedded CANopen master port 1

Embedded Ethernet port 1

100% Boolean 8.1 Kins/ms (1)

65% Boolean + 35% digital 6.4 Kins/ms (1)

General Characteristics of the BMX P34 •••• Processors

BMX P34 20302: 4

(1) Kins: 1024 instructions (list)

NOTE: Expert mode function is available for BMX P34 20302 processors.

35012676 10/2019 69

Page 70

General Characteristics of the BMX P34 •••• Processors

Characteristics of the BMX P34 xxxxx Processor Memory

Introduction

The following pages present the main characteristics of the BMX P34 ••••• processor memory.

Size of Located Data

The following table shows maximum size of located data according to the type of processor:

Type of

Objects

Internal bits

Input/Output

bits

System bits

Internal words

Constant

words

System words

Address Maximum Size for

the BMX P34 1000

Processor

%Mi

%Ir.m.c

%Qr.m.c

%Si

%MWi

%KWi

%SWi

16250 256 32634 512

(1) (1) (1) (1)

128 128 128 128

32464 512 32464 1024

32760 128 32760 256

168 168 168 168

(1) Depends on the equipment configuration declared (input/output modules).

Size of unlocated Data

Unlocated data is as follows:

Elementary Data Types (EDT)

Derived Data Types (DDT)

DFB and EFB function block data.

Size of Located and Unlocated Data

The total size of located and unlocated data is limited to:

128 kilobytes for the BMX P34 1000 processor.

256 kilobytes for the BMX P34 20x0x processors

Default Size for the

BMX P34 1000

Processor

Maximum Size for

the BMX P34 20x0x

Processors

Default Size for the

BMX P34 20x0x

Processors

70

35012676 10/2019

Page 71

Size of Located Data in Case of State RAM

The following table shows maximum and default size of located data in case of State RAM

configuration according to the type of processor.

General Characteristics of the BMX P34 •••• Processors

Type of

Objects

output bits

and internal

bits

input bits and

internal bits

input words

and internal

words

output words

and internal

words

Address BMX P34 1000 V2.40 Processor BMX P34 2000, 20102, 2020, 20302

Processors (all V2.40)

Maximum Size Default Size Maximum Size Default Size

%M (0x)

%I (1x)

%IW (3x)

%MW (4x)

32765 752 65530 1504

32765 752 65530 1504

32765 256 65530 512

32765 256 65530 512

NOTE: To use State RAM configuration you need Modicon M340 firmware 2.4 or later.

NOTE: When changing the processor type from a BMX P34 2xxx to a BMX P34 1000, remove the

unavailable features (DFBs, EFBs...) in the sections and in the data editor too (Purge Unused FB

Instances, Purge Unused Types, Purge Unused Private Data Instance if needed). Otherwise the

application can't be built.

35012676 10/2019 71

Page 72

General Characteristics of the BMX P34 •••• Processors

72

35012676 10/2019

Page 73

ModiconM340

Installation of BMX P34 •••• Processor s

35012676 10/2019

Installation of BMX P34 xxxx Process ors

Chapter 7

Installation of BMX P34 xxxx Processors

Subject of this Section

This section deals with the installation of BMX P34 •••• processors and memory extension cards.

What Is in This Chapter?

This chapter contains the following topics:

Fitting of Processors 74

Memory Cards for BMX P34 xxxxx Processors 76

Topic Page

35012676 10/2019 73

Page 74

Installation of BMX P34 •••• Processors

Fitting of Processors

At a Glance

BMX P34 xxxxx processors are powered by the rack bus.

Fitting operations (installation, assembly, and disassembly) are described below.

Installation Precautions

A BMX P34 xxxxx processor is always installed on the rack in slot marked 00.

Before installing a module, you must take off the protective cap from the module connector located

on the rack.

HAZARD OF ELECTRIC SHOCK

Disconnect all power sources before installing the processor.

Failure to follow these instructions will result in death or serious injury.

Installation

The following illustration shows a BMX P34 2010 processor mounted on a BMX XBP 0800 rack:

DANGER

74

The following table describes the different elements which make up the assembly below.

Number Description

1 Processor

2 Standard rack

35012676 10/2019

Page 75

Installation of BMX P34 •••• Processors

Installing the Processor on the Rack

The following table presents the procedure for installing a processor on a rack.

Step Action Illustration

WARNING

UNEXPECTED EQUIPMENT OPERATION

Ensure that the correct memory card is installed before plugging a new processor on the rack. An

incorrect card could lead to unexpected system behavior.

Refer to %SW97 to check the status of the card.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

1 Verify that power is OFF and make

sure that the memory card is correct.

2 Position the locating pins situated at

the rear of the module (on the bottom

part) in the corresponding slots in the

rack.

Note: Before positioning the pins,

make sure that you have removed the

protective cover.

3 Swivel the module towards the top of

the rack so that the module sits flush

with the back of the rack. It is now set

in position.

The following illustration describes steps 1 and 2:

4 Tighten the mounting screw to ensure

that the module is held in place on the

rack.

Tightening torque: 0.4...1.5 N•m

(0.30...1.10 lbf-ft).

35012676 10/2019 75

The following illustration describes step 3:

Page 76

Installation of BMX P34 •••• Processors

Memory Cards for BMX P34 xxxxx Processors

General

All BMX P34 •••• processors require a memory card.

Memory Card Slot

The following illustration shows the memory card slot on a BMX P34 •••• processor with a

protective cover in place:

76

WARNING

UNEXPECTED EQUIPMENT OPERATION

Ensure that the protective cover is closed when the processor is running to maintain enclosure

environmental ratings.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

35012676 10/2019

Page 77

Memory Card Description

Only Schneider memory cards are compatible with BMX P34 •••• processors.

Schneider memory cards use Flash technology and do not require a battery. These cards can

support about 100,000 write/delete cycles (typical).

Three models of memory card are available:

The BMX RMS 008MP card, used to save application and Web pages.

The BMX RMS 008MPF card, used to save applications and Web pages as well as to store user

files created by the application with the file management function blocks (or files transferred

through FTP). The available size for user files in the file system partition is 8 MB (Data Storage

area).

The BMX RMS 128MPF card, used to save applications and Web pages as well as to store user

files created by the application with the file management function blocks (or files transferred

through FTP). The available size for user files in the file system partition is 128 MB (Data

Storage area).

NOTE: The web pages are Schneider Electric pages and cannot be modified.

NOTE: The BMX RMS 008MP card is supplied with each processor, the other ones must be

ordered separately.

Memory Card Characteristics

The following table shows the main characteristics of the memory cards.

Memory Card Reference Application Storage Data Storage

BMX RMS 008MP Yes No

BMX RMS 008MPF Yes 8 MB

BMX RMS 128MPF Yes 128 MB

Installation of BMX P34 •••• Processors

NOTE: The size shown above for the Data Storage area is the maximum recommended size for

user files, although file storage is still possible until the global file system partition is full. The risk

of going over this recommended maximum is that sufficient free space may not be available for a

firmware upgrade, in this case it would be necessary to delete some user files.

35012676 10/2019 77

Page 78

Installation of BMX P34 •••• Processors

The compatibility of the two memory cards is as follows:

BMX RMS 008MP card compatible with all processors.

BMX RMS 008MPF and BMX RMS 128MPF cards compatible with the following processors:

BMX P34 2000,

BMX P34 2010,

BMX P34 20102,

BMX P34 2020,

BMX P34 2030,

BMX P34 20302.

NOTE: The memory card is formatted for use with Schneider Electric products. Do not attempt to

use or format the card in any other tool. Doing so will prevent program and data transfer usage in

a Modicon M340 PLC.

NOTE: For further information about the memory structure of the memory cards, see the Memory

Structure of Modicon M340 PLCs

Structure, Reference Manual)

NOTE: For further information about Ethernet services provided by memory cards, see the

Modicon M340 Memory cards

Processors, User Manual)

Memory Card Access LED

A memory card access LED is included on all Modicon M340 processors. This LED informs the

user of the memory card’s status for its removal.

The following illustration shows the physical location of the memory card access LED:

(see EcoStruxure™ Control Expert, Program Languages and

page.

(see Modicon M340 for Ethernet, Communications Modules and

page in the Ethernet Communication part.

78

35012676 10/2019

Page 79

This LED is green and has several different states:

On: the card is recognized and the processor has access to it,

Flashing: the LED goes off each time the processor accesses it and comes on again at the end

of access,

Off: the card may be removed as the processor has no access to it.

NOTE: A rising edge on the bit %S65 finishes the current actions, disables access to the card, then

switches off the CARDAC LED. As soon as this LED is off, the card can be removed.

NOTE: The memory card access LED is only visible if the cover is open.

NOTE: The red CARDERR LED shows that either the memory card is in error or the memorized

application is different from the one processed by the processor. It is located near the top of the

processor front panel.

LED States on Power Cycle

The following table presents the different states of the PLC, memory card access LED and

CARDERR LED on a power cycle or a PLC reset.

Installation of BMX P34 •••• Processors

PLC/memory card

behavior

No memory card - No configuration OFF ON

Memory card not OK - No configuration OFF ON

Memory card without

project

Memory card with a

non-compatible project

Memory card with a

compatible project

Memory card with a

compatible project

- No configuration ON ON

- No configuration ON ON

Error detected

when the restore

project from

memory card to

the PLC RAM

No Error when the

restore project

from memory card

to the PLC RAM

PLC state Memory

card access

LED

No configuration Flashing

during

transfer

Finally ON

Flashing

during

transfer

Finally ON

CARDERR

LED

ON

ON durring

transfer

Finally OFF

35012676 10/2019 79

Page 80

Installation of BMX P34 •••• Processors

Memory Card Insertion Procedure

The following illustration shows the procedure for inserting a memory card into a BMX P34 ••••

processor.

Step Description Illustration

WARNING

UNEXPECTED EQUIPMENT OPERATION

Ensure that the correct memory card is installed before plugging a new processor on the rack. An

incorrect card could lead to unexpected system behavior.

Refer to %SW97 to check the status of the card.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

1 Open the processor’s protective cover by

pulling the cover towards you.

Opening the cover:

2 Insert the memory card into its slot by

pushing it right in.

Result: The card should now be clipped

into its slot.

Note: Insertion of the memory card does

not force an application restore.

3 Close the memory card protective cover.

80

Inserting the memory card:

35012676 10/2019

Page 81

Memory Card Removal Procedure

Before removing a memory card, a rising edge on bit %S65 has to be generated to ensure the

information consistency. When the CARDAC LED is off, then it is possible to extract the card.

There is a risk of inconsistency or loss of data if the extraction is done without the management of

the bit %S65. The following illustration shows the procedure for removing a memory card from a

BMX P34 •••• processor.

Step Description Illustration

1 Open the processor’s protective cover by

pulling the cover towards you.

Opening the cover:

Installation of BMX P34 •••• Processors

2 Push the memory card in its slot.

Result: The card should unclip from its slot.

3 Remove the card from its slot.

Note: The CARDERR LED is on when the

memory card is removed from the

processor.

4 Close the protective cover.

35012676 10/2019 81

Pushing the memory card in its slot:

Removing the memory card:

Page 82

Installation of BMX P34 •••• Processors

Update an Application

Before removing a memory card, a rising edge on bit %S65 has to be generated to ensure the