Page 1

Application

AV-607-1 and AV-609-11 linkages are designed to connect

single or dual Schneider Electric spring return and nonspring return SmartX Actuators to 1-1/2” to 6” VB-9xxx and

2-1/2” to 6” VB-8xx3 globe valves.

Features

• Allows mounting of single or dual Schneider Electric

SmartX Actuators

• AV-607-1 is compatible with Schneider Electric (Siebe,

Barber-Colman, INVENSYS) 2-1/2” to 5” VB-8xx3, 1-1/2”

to 4” VB-931x, and discontinued 1-1/2” to 4” VB-92xx

valves and Schneider Electric SmartX actuators

• AV-609-1 is compatible with Schneider Electric (Siebe,

Barber-Colman, INVENSYS) 6” VB-8xx3, 5” and 6” VB931x, and discontinued 5” and 6” VB-92xx valves and

Schneider Electric SmartX Actuators

2

2

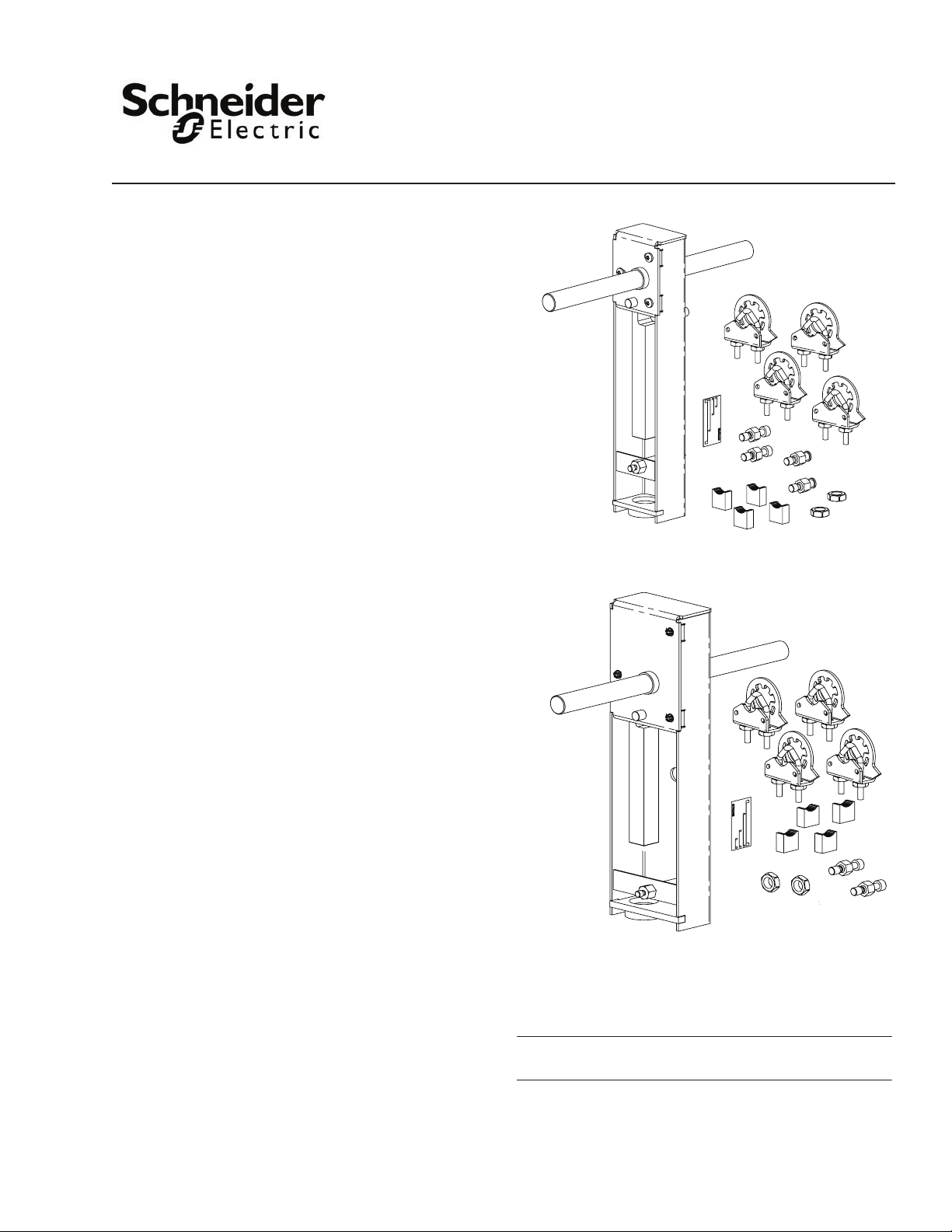

AV-607-1

AV-609-1

SmartX Actuator Linkages

for 1-1/2” to 6” Globe Valves

General Instructions

AV-607-1

• Maintenance-free construction

• Corrosion protected heavy-duty steel rack and pinion

construction and metal housing

• Precision rack self aligns with the valve stem

AV-609-1

1

AV-607-1 and AV-609-1 replace AV-607 and AV-609 respectively

2

Check the appropriate valve selection guide for close-offs for your ap plication,

Schneider Electric

F- 27479 -3 April 2014

Note: Do not install a 300 lb-in MX41-634-x actuator on the

AV-607-1 linkage as equipment damage may occur.

Page 2

Applicable Literature

Clamps (4)

AV-609-1 Stabilizer

Factory assembled to linkage

AV-607-1 Stabilizer

Factory assembled to linkage

Anti-Rotation Spacer

Factory assembled to linkage

Spacer

Clamp

Blocks (4)*

Stem Nuts (2)

NYBA-206

Anti-Rotation Stud for

MX41-6153 (2) For AV-607-1 Only

NYBA-161

Anti-Rotation Stud

for Mx4x-707x and MX4x-715x (2)

Factory assembled to linkage

NYBA-148 Anti-Rotation Stud

for Mx4x40-717x and

Mx41-6343 (2)

* Clamp blocks are only required for the MX41-634x and Mx40-717x actuators.

•

EN-205 Water System Guidelines, F-26080

• AV-608 Linkage Adapter Kit General Instructions, F-27253

• MA40-704x, MA4x-707x, MA4x-715x Schneider Electric SmartX Spring Return Two-Position Actuators General

Instructions, F-26642

• MA40-717x Schneider Electric SmartX Series Spring Return Two-Position Actuators General Instructions, F-26742

• MF4x-7xx3 Schneider Electric SmartX Series Spring Return Floating Actuator General Instructions, F-26644

• MF40-7173 Schneider Electric SmartX Series Spring Return Floating Actuator General Instructions, F-26749

• MF41-6153,/MS41-6153 Series Non-Spring Return Rotary Electronic Damper Actuator General Instructions, F-27215

• MS4x-7xx3 Schneider Electric SmartX Series Spring Return Proportional Actuator General Instructions, F-26645

• MS40-717x Schneider Electric SmartX Series Spring Return Proportional Actuator General Instructions, F-26748

• Mx41-6xxx-220/-230 and MX4x-7xxx-220/-230 Actuator/Linkage Assemblies for 2-1/2” to 6” Globe Valves General

Instructions, F-27160

• Vx-7000 Series and Vx-9000 Series Mx4x-6xxx and Mx4x-7xxx Series Linked Globe Valve Assemblies with Schneider

Electric SmartX Actuators Selection Guide, F-26752

• VB-8xx3 Series Balanced Plug Valve Selection Guide, F-27199

Accessories

•

PKG-1171 Replacement Hardware kit (to replace lost hardware; see Figure-1)

2

Figure-1 Replacement Hardware

Inspection

Inspect package for damage. If damaged, notify carrier immediately. If undamaged, open the package and inspect for obvious

damage. Return damaged products.

Inspect the hardware package included with the linkage to make sure all required clamps (4), clamp blocks (4), stem lock nuts (2),

and anti-rotation studs (six, two factory assembled to linkage) are included. See Figure-1. Not all parts will be needed for every

installation.

Requirements

•

Training: Installer must be a qualied, experienced technician.

• Tools (not provided):

– Appropriate wrenches for anti-rotation studs, stem extensions, packing nuts, and bracket nuts

– 10 mm socket wrench (for shaft clamp nuts on Mx40-717x, Mx41-707x, Mx41-715x)

– 1/2” nut driver and 1/2” open end wrench (for all except Mx41-634x, Mx40-717x)

– Measuring scale graduated in 1/32” increments

– Torque wrench, range to include 90 to 120 lb-in. (7.5 to 10 lb-ft, 10 to 14 N-m)

– Pipe wrenches, two

– 11/16” open-end wrench for jam nuts, two

– Vise grip or pliers

– Appropriate power supply (see the applicable actuator General Instructions sheet for power requirements)

Warning: Electrical shock hazard! Contact with live circuits can result in severe injury or death.

• Disconnect the power supply (line power) at the breaker or fuse before and during installation to prevent

Schneider Electric

F- 27479 -3 April 2014

electric shock and equipment damage.

• Make all connections in accordance with the wiring diagram and in accordance with national and local

electrical codes. Use copper conductors only.

Failure to observe these warnings can result in severe injury or death and can damage the equipment.

Page 3

3

General Installation

Schneider Electric globe valve rack and pinion linkages are provided as complete assemblies. The following pages contain

instructions for installing the AV-607-1 and AV-609-1 linkages. Either a single actuator or dual actuators may be installed using these

instructions.

Note: When installing dual actuators:

• Both actuators must be the same model.

• Actuators must be mounted and adjusted so as to rotate and spring return (if applicable) in the same direction. Refer to the

mounting instructions and Table- through Table-x.

• Refer to the applicable actuator literature for actuator wiring information.

• Only use the actuator and linkage combinations that are shown on Table 1. Linkage or valve damage could result if a in

correct combination is applied.

• Do not attempt to use the actuator manual override feature with two actuators clamped to the same shaft. Damage and

improper operation can occur. Using manual override to set individual actuator preload before installation on the linkage is

permissable.

Mounting Actuator and Linkage to Valve Body

Process Overview

This mounting procedure consists of two sections:

• Section A. Mounting Linkage to Valve

– A1. Select and install anti-rotation studs.

– A2. VB-9xxx and VB-8xx3 (2-way and 3-way) valves and appropriate actuator types, follow the instructions in this section

to assemble the linkage to the valve

• Section B. Actuator Mounting and Setup

In this section, choose the subsection that is appropriate for the specic actuator type and valve type, to mount the actuator

and adjust the linkage:

– B1. Spring Return Actuators with Manual Override 2-Way Valves and 3-Way Valves (Normal Position — Valve Stem Up)

– B2. Spring Return Actuators with Manual Override 2-Way Valves and 3-Way Valves (Normal Position — Valve Stem Down)

– B3. Non-Spring Return Actuator with Manual Override VB-8213 and VB-921x 2-Way Valves (Valve Stem Up, Open) VB-

8223 and VB-922x 2-Way Valves (Valve Stem Up, Closed) VB-8303 and VB-931x 3-Way Valves (Valve Stem Up, Port A

Closed)

– B4. Spring Return Actuators without Manual Override VB-8223, VB-922x 2-Way Valves (Normal Position — Valve Stem

Up, Closed) VB-8303, VB-931x 3-Way Valves (Normal Position — Valve Stem Up, Port A Closed)

– B5. Spring-Return Actuators without Manual Override VB-8213, VB-921x 2-Way Valves (Normal Position — Valve Stem

Down, Closed) VB-8303, VB-931x 3-Way Valves (Normal Position — Valve Stem Down, Port B Closed)

The linkage is assembled to the valve according to Section A. Refer to Table-1, below, to determine the remainder of the assembly

path for a specic actuator and valve.

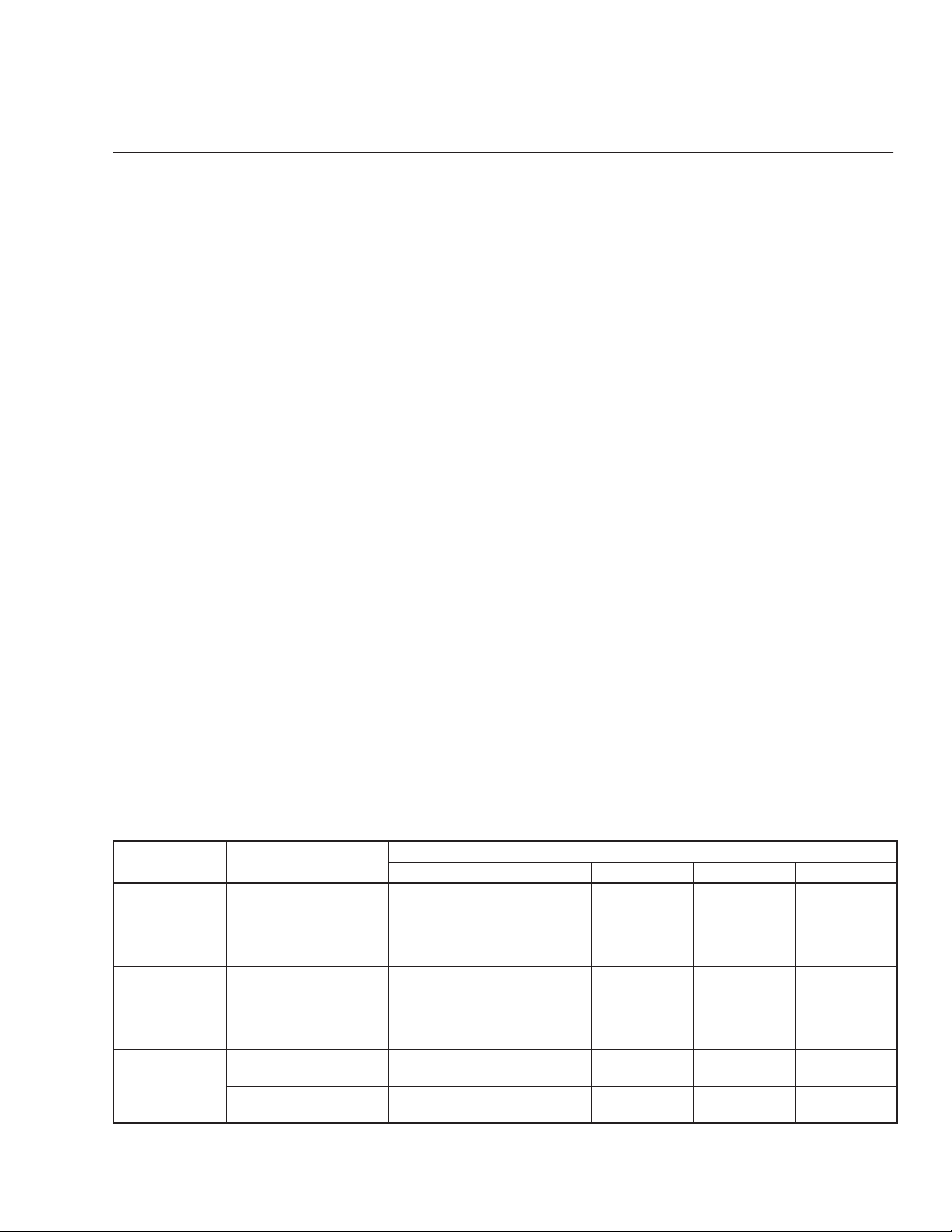

Table-1 Procedure for Mounting Actuator and Linkage to Valve Body.

Actuator Type Valve Type

Spring Return

Actuators with

Manual Override

Mx41-707x

Mx41-715x

Non-Spring Return

Actuators with

Manual Override

Mx41-6153

Mx41-634x

Spring Return

Actuators without

Manual Override

Mx40-717x

Schneider Electric

F- 27479 -3 April 2014

2-Way and 3-Way, Normal

Position Valve Stem Up

2-Way and 3-Way, Normal

Position Valve Stem Down

2-Way and 3-Way, Normal

Position Valve Stem Up

2-Way and 3-Way, Normal

Position Valve Stem Down

2-Way and 3-Way, Normal

Position Valve Stem Up

2-Way and 3-Way, Normal

Position Valve Stem Down

Subsection B1 Subsection B2 Subsection B3 Subsection B4 Subsection B5

X

X

a

Section B

X

X

X

X

Page 4

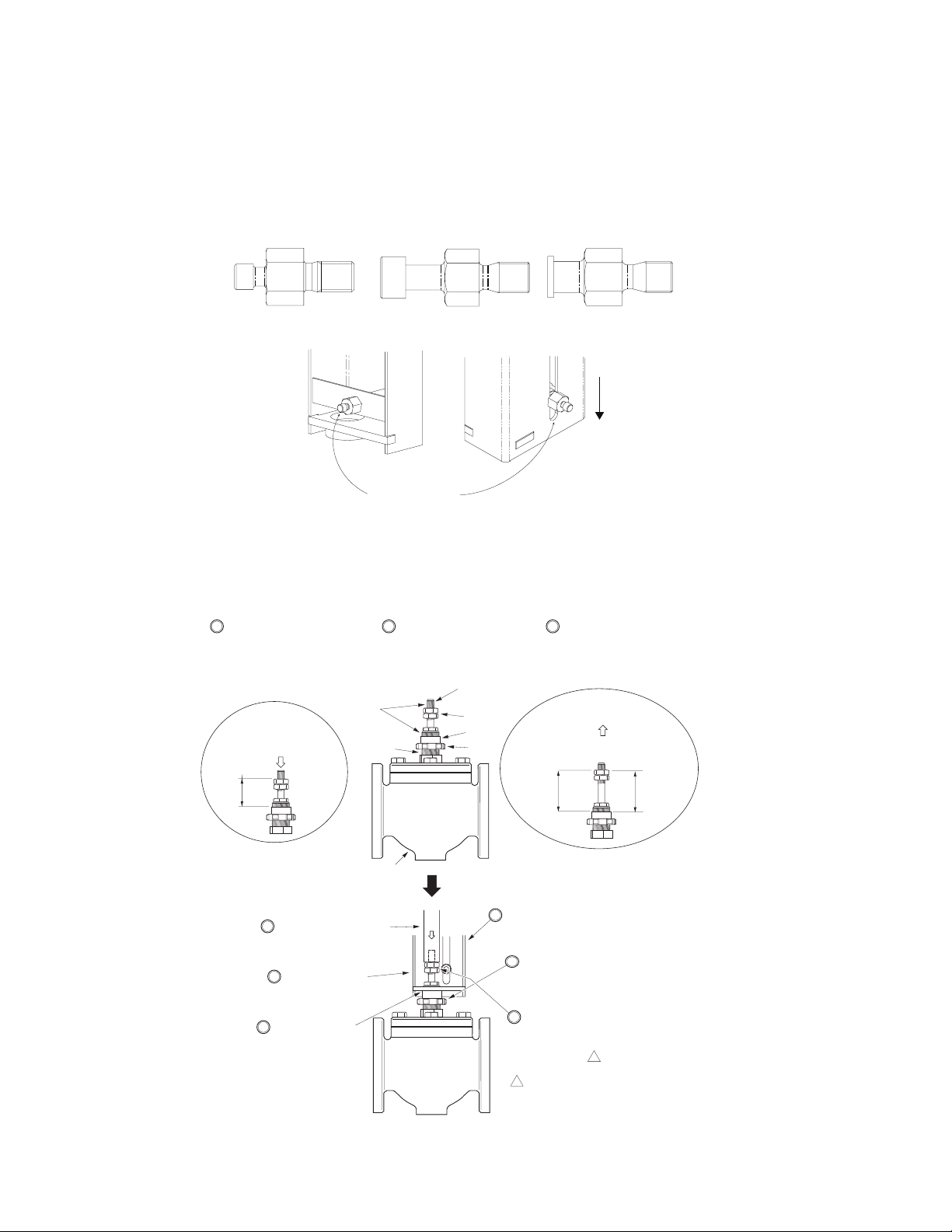

Typical Valve Body

(2-Way shown)

1 Thread the spanner nut onto the

bonnet, and then place the spacer

(provided with the AV-607-1 and

AV-609-1) on top of the spanner nut.

2 Thread the two jam nuts (provided

with the AV-607-1 and AV-609-1) onto

the valve stem. Adjust the spanner

nut and jam nuts to the height shown.

3 Tighten the two jam

nuts against each

other, using two 11/16"

open-end wrenches.

Spacer

3 threads

visible,

minimum

1 thread visible

minimum

2-19/32" ± 1/32"

(with stem up)

3-19/32" ± 1/32"

(with stem up)

VB-8223 2-Way,

Stem Up Closed &

VB-8303 3-Way

1-11/16" ± 1/32"

(with stem down)

2-1/2" to 6"

VB-8213 2-Way

VB-921x 2-Way,

Stem Up Open

Spanner

Nut

Jam Nuts (2)

Valve Stem

4 Rotate the pinion shaft CW to fully

lower the rack, and then position

the linkage over the valve stem.

5 Turn the entire linkage to

partially thread the rack

onto the valve stem.

7 Orient the linkage on the

valve as desired by rotating

the linkage up to one turn

6 Thread the entire linkage

onto the bonnet until it

contacts the spacer.

8 Tighten the spanner nut against

the spacer.

9 Tighten the jam nuts against the

rack, using an 11/16" open-end

wrench on the lower jam nut.

Note: The valve stem will rotate

with the jam nuts.

2-1/2" to 5"

for VB-8000 Series

2-1/2" to 4”

for VB-9000 Series

6" Valves

for VB-8000 Series

5” and 6”

for VB-9000 Series

1

1 To allow easier rotation of the jam

nuts and valve stem, unseat the

valve stem by rotating the pinion

shaft slightly CW or CCW.

NYBA-161 for Mx4x-707x, MX4x-715x

(Factory assembled to linkage)

NYBA-148 for Mx40-717x, Mx41-6343

A

V-601-1 Only

NYBA-206 for Mx41-6153

AV-607-1 Only

Anti-Rotation Studs (2)

(one each side)

Figure-2 Anti-Rotation Studs

Section A. Mounting Linkage to Valve

A1. Select and Install Anti-Rotation Studs.

Based on the actuator(s) being used, select the appropriate anti-rotation studs using Figure-.

Two NYBA-161 anti-rotation studs (for Mx4x-707x and Mx4x-715x actuators) are shipped factory assembled to each side of

the linkage. If NYBA-148 or NYBA-206 are required, remove the two factory-installed anti-rotation studs one at a time and

replace them with the required studs. Hand tighten the stud in the linkage frame slot and slide down to provide clearance for

actuator installation (see Figure-2 below).

4

A2. Mounting Linkage to Valve — VB-9xxx, VB-8xxx, and Appropriate1 Actuator Models

1. Assemble the linkage to the valve, according to Figure-3.

2. Continue the assembly process according to the following section, “Section B. Actuator Mounting and Setup.”

1

See Table-1 on page 3

Schneider Electric

F- 27479 -3 April 2014

Figure-3 Assembling Linkage to Valve

Page 5

L

R

L

LOCK

3 Align the actuator with the

linkage.

4 Slide anti-rotation stud(s) NYBA-161

half way into the slot on the bottom of

the actuator, and then tighten the the

anti-rotation stud.

8 Wire the actuator in accordance with the job

wiring diagrams and the wiring information

contained in the applicable actuator General

Instructions (see "Applicable Literature").

OPENCLOSED

9 Optional: Affix the Open and Closed

labels to the angle of rotation indicator, in

positions to match the actual valve stroke.

NYBA-161

Anti-Rotation Stud

Note: The manual override disengages when the actuator is

powered. The manual override may also be manually

disengaged using the supplied hex wrench. To do this,

turn, then release, the hex wrench approximately 5° CW,

to "jog" the mechanism and release the manual override

preset. Note that 1 to 1-1/2 turns of the manual override

crank is approximately 10°.

1 Normal Position - Valve Stem Up

VB-8213 & VB-921x 2-Way, Stem Up Open

Set the actuator preload to an indicator reading

of 80° (i.e. 10° from the end of stroke).

VB-8223 & VB-922x 2-Way, Stem Up Closed

VB-8303 & VB-931x 3-Way, Port A Closed

Set the actuator preload to an indicator reading

of 5°.

Remove anti-rotation stud if assembled on

linkage.

5 Make sure the actuator is in

full contact with the plastic

stand-offs on the linkage.

6 Ensure the valve is in the closed position (see Table-6;

port A closed for 3-way). Use a 10 mm wrench or socket to

tighten the two nuts equally on the shaft clamp, 8 to 10

lb-ft (11 to 14 N-m).

1

1

1 The Mx41-707x and Mx41-715x actuators feature a manual override

mechanism that may be used to reposition the actuator’s output shaft.

Both actuators have 95° of stroke (from indicator reading -5° to 90°).

80°

5°

R

L

LOCK

7 Refer to the applicable table in "Setting

Actuator/Valve Action" and, using a

screwdriver, turn the L/R selector to

choose "direct acting" or "reverse acting."

Slide the actuator, "L" side

facing out, onto the linkage's

pinion shaft.

2

Caution: Do not use manual override if using dual actuators!

Section B. Actuator Mounting and Setup

To mount the actuator and set up the assembly, refer to the subsection that applies to the specic actuator type and valve type.

B1. Spring Return Actuators with Manual Override 2-Way Valves and 3-Way Valves (Normal Position — Valve Stem Up)

Mx41-707x (VB-9xxx only with AV-607-1) and Mx41-715x (AV-607-1 and AV-609-1)

a. Install the actuator (or actuators if using dual actuators) onto the linkage and valve, and set up the assembly,

according to Table-3 on page 10 or Table-3 on page 11

Note: If using dual actuators, make sure both rotate and spring return in the same direction. Do not use manual override on

installed actuators if using dual actuators. See “General Installation” on page 3.

5

b. Refer to the appropriate actuator General Instructions sheet for actuator wiring and application information (see

“Applicable Literature” on page 2). For valve body installation and application information, refer to the appropriate valve

body General Instructions sheet.

c. Power the actuator(s) and check the system’s operation for heating or cooling output, in response to the control

Figure-4 Mounting Mx41-707x or M41-715x and Setting Up Actuator/Linkage/Valve

signal. See “Setting Actuator/Valve Action” on page 10.

Schneider Electric

F- 27479 -3 April 2014

Page 6

B2. Spring Return Actuators with Manual Override 2-Way Valves and 3-Way Valves (Normal Position — Valve Stem Down)

R

R

L

LOCK

3 Align the actuator with the

linkage.

4 Slide anti-rotation stud(s) NYBA-161

half way into the slot on the bottom of

the actuator, and then tighten the nut

on the anti-rotation stud.

8 Wire the actuator in accordance with the job

wiring diagrams and the wiring information

contained in the applicable actuator General

Instructions (see "Applicable Literature").

NYBA-161

Anti-Rotation Stud

5 Make sure the actuator is in full contact with the

plastic stand-offs on the linkage.

6 Ensure the valve is in the closed position (see Table-6;

port A closed for 3-way). Use a 10 mm wrench or

socket to tighten the two nuts equally on the shaft

clamp, 8 to 10 lb-ft (11 to 14 N-m).

1 The Mx41-707x and Mx41-715x actuators feature a manual override

mechanism that may be used to reposition the actuator’s output shaft.

Both actuators have 95° of stroke (from indicator reading -5° to 90°).

1 Normal Position - Valve Stem Down

VB-8213 & VB-921x 2-Way, Stem Up Open

Set the actuator preload to an indicator reading

of 5°.

VB-8223 & VB-922x 2-Way, Stem Up Closed

VB-8303 & VB-931x 3-Way, Port B Closed

Set the actuator preload to an indicator reading

of 80° (i.e. 10° from the end of stroke).

1

1

80°

5°

OPENCLOSED

9 Optional: Affix the Open and Closed

labels to the angle of rotation indicator, in

positions to match the actual valve stroke.

Note: The manual override disengages when the

actuator is powered.

The manual override may

also be manually disengaged using the supplied

hex wrench. To do this, turn, then release, the

hex wrench approximately 5° CW, to "jog" the

mechanism and release the manual override

preset. Note that 1 to 1-1/2 turns of the manual

override crank is approximately 10°.

R

L

LOCK

7 Refer to the applicable table in "Setting

Actuator/Valve Action" and, using a

screwdriver, turn the L/R selector to

choose "direct acting" or "reverse acting."

Slide the actuator, "R" side facing

out, onto the linkage's pinion

shaft. Relocate the actuator

clamp to the outboard side if

necessary.

2

Caution: Do not use manual override if using dual actuators!

Mx41-707x (VB-9xxx only with AV-607-1) and Mx41-715x (AV-607-1 and AV-609-1)

a. Install the actuator (or actuators if using dual actuators) onto the linkage and valve, and set up the assembly,

according to Table-2 on page 10 or Table-3 on page 11.

Note: If using dual actuators, make sure both rotate and spring return in the same direction. Do not use manual override on

installed actuators if using dual actuators. See “General Installation” on page 3.

6

Figure-5 Mounting Mx41-707x or M41-715x and Setting Up Actuator/Linkage/Valve

b. Refer to the appropriate actuator General Instructions sheet for actuator wiring and application information (see

“Applicable Literature” on page 2). For valve body installation and application information, refer to the appropriate valve

body General Instructions sheet.

c. Power the actuator(s) and check the system’s operation for heating or cooling output, in response to the control

signal. See “Setting Actuator/Valve Action” on page 10.

Schneider Electric

F- 27479 -3 April 2014

Page 7

B3. Non-Spring Return Actuator with Manual Override

2 Slide the actuator onto the

linkage's pinion shaft.

Mx41-6343 Series - Install

with the "L" side facing out.

Optional: Affix the Open and

Closed labels to the indicator

in the appropriate positions.

OPENCLOSED

6 Verify that the actuator is in full contact with the

plastic stand-offs on the linkage. Once the

valve is in the closed position, proceed as

follows:

Mx41-6153 Series

Using a 10 mm wrench or socket, tighten the

shaft clamp nut 7.5 to 9 lb-ft (10 to 12 N-m). Do

not over-tighten.

Mx41-6343 Series

Using a 1/2" wrench or socket, tighten the shaft

4 Slide the anti-rotation stud half

way into the slot on the bottom of

the actuator, and then tighten the

nut on the anti-rotation stud.

3 Align the actuator with

the linkage.

1 Rotate the linkage's pinion shaft to

the valve closed position:

• Stem Up Closed VB-922x Series

and VB-931x Series Valves Rotate the pinion shaft CCW to

retract the linkage rack to the up

position.

•

Stem Up Open VB-921x Series

Rotate the pinion shaft CW to

extend the linkage rack to the down

position.

Stem Up

Closed

(shown)

Stem Up

Open

Shaft Clamp Nut

5 Position the actuator's output shaft as

follows:

Mx41-6153 Series

a. Press and hold down the manual

override button.

b. Position the actuator output shaft, 10°

stem up open or 10° stem up closed

(note that each increment is 5°).

c. When finished, release the manual

override button.

Mx41-6343 Series

a. Using the supplied hex wrench,

position the actuator's output shaft at

10° stem up open or 10° stem up

closed (note that each increment is 5°)

Manual

Override

Button

NYBA-206

Anti-Rotation Stud for

Mx41-6153

NYBA-148

Anti-Rotation Stud for

Mx41-6343

Mx41-6153 Series

Stem Up

Closed

Stem Up

Open

L

10°

10°

1

1 Mx41-6343 Series - Position

the output shaft as shown:

VB-8213 and VB-921x 2-Way Valves (Valve Stem Up, Open)

VB-8223 and VB-922x 2-Way Valves (Valve Stem Up, Closed)

VB-8303 and VB-931x 3-Way Valves (Valve Stem Up, Port A Closed)

Mx41-6153 Series (VB-9xxx only) Actuator with AV-607-1 Linkage, Mx41-634x Actuator with AV-609-1 Linkage Only

a. Install the actuator (or actuators if using dual Mx41-6153 actuators) onto the linkage and valve, and set up the

assembly, according to Figure-7 on page 8 and Table-4 on page 11 or Table-5 on page 12.

Note: If using dual actuators, make sure both rotate in the same direction. Do not use manual override on installed actuators if

using dual actuators. See “General Installation” on page 3.

7

Schneider Electric

Figure-6 Mounting Mx41-6153 Series or Mx41-634x Series Actuator and Setting Up Actuator/Linkage/Valve

b. Refer to the appropriate actuator General Instructions sheet for actuator wiring and application information (see

“Applicable Literature” on page 2). For valve body installation and application information, refer to the appropriate valve

body General Instructions sheet.

c. Power the actuator(s) and check the system’s operation for heating or cooling output, in response to the control

signal. See “Setting Actuator/Valve Action” on page 10.

F- 27479 -3 April 2014

Page 8

B4. Spring Return Actuators without Manual Override

3 Tip:

•

MA40-717x Two-Position - When power is applied to L1, L2 (Red / Black

24V) (White / Black 120v) (Lt Blue / Brown 240v) the actuator will travel CW

(As viewed from the L side).

• MF40-7173 Floating Control - The Yellow/Black lead drives the actuator

CCW and the Blue lead drives the actuator CW (as viewed from the "L"

side). The Red lead is 24 hot and the Black is 24 Ground. Making the Red

lead to the Blue lead will drive the actuator CW.

• MS40-717x Proportional Control - Apply 10Vdc to the Gray (COM) and

Yellow/Black (+) Leads, and then apply power to( L1 and L2) (Brown / Light

Blue 240v) (Black / White 120v) or (Red / Black 24v) to drive the actuator

CW (As viewed from the L Side).

1 Mx40-717x actuators are

shipped at the zero position,

without preload.

3

6 Apply power to rotate the actuator body CCW into alignment with

the linkage, and then slide the anti-rotation stud (NYBA-148)

halfway into the slot on the bottom of the actuator. Tighten the

nut on the anti-rotation stud.

Caution: Take care not to pinch your fingers or hand between

the actuator and the linkage, when powering the actuator into

alignment.

Caution: When setting the valve preload, power must be used to

position the actuator. Do not manually force the actuator into the

mounting position. If forced, damage to the pinion shaft or

improper close-off may occur.

OPENCLOSED

7 Optional: Affix the Open and Closed labels to the

indicator, in positions to match the actual valve stroke.

2 Tip: A 1-5/8" open-end wrench

(TOOL-37) can be used to

measure the amount of rotation

(measured between opposite

sides of the slot).

3 Align the actuator with the

linkage, then rotate it 10° CW. Note

that 1-3/8" movement at the

anti-rotation slot (measured at the

slot's centerline) is sufficiently equal to

4 Make sure the actuator is in full

contact with the plastic

stand-offs on the linkage, and

that the valve is in the full up

position.

2 Slide the actuator, "L"

side facing out, onto the linkage's

pinion shaft. Make sure clamp

blocks are inserted between

pinion shaft and each clamp.

1 2

L

1-3/8"

1 Rotate the linkage's pinion shaft

CCW, to retract the rack (stem up).

1-5/8" Open-End

Wrench

2

1-5/8"

TOOL-37

5 With clamp blocks in place, hold the actuator at

the 10° position. Use a 1/2" wrench or socket to

tighten the two nuts equally on each shaft

clamp, 4 to 6 lb-ft (5 to 8 N-m).

NYBA-148

Anti-Rotation Stud for

Mx40-717x

!

Clamp blocks (one for each

clamp; see steps 2 and 5)

10

0

VB-8223, VB-922x 2-Way Valves (Normal Position — Valve Stem Up, Closed)

VB-8303, VB-931x 3-Way Valves (Normal Position — Valve Stem Up, Port A Closed)

Mx40-717x (AV-607-1 and AV-609-1)

a. Install the actuator (or actuators if using dual actuators) onto the linkage and valve, and set up the assembly,

according to Table-3 on page 11. Use the two clamps supplied with the linkage.

Note: If using dual actuators, make sure both rotate and spring return in the same direction.

8

Schneider Electric

F- 27479 -3 April 2014

b. Refer to the appropriate actuator General Instructions sheet for actuator wiring and application information (see

“Applicable Literature” on page 2). For valve body installation and application information, refer to the appropriate valve

body General Instructions sheet.

c. Power the actuator(s) and check the system’s operation for heating or cooling output, in response to the control

signal. See “Setting Actuator/Valve Action” on page 10.

Figure-7 Mounting Mx40-717x and Setting Up Actuator/Linkage/Valve

Page 9

B5. Spring-Return Actuators without Manual Override

1 2

OPENCLOSED

7 Optional: Affix the Open and Closed labels to the

indicator, in positions to match the actual valve stroke.

4 Make sure the actuator is in full

contact with the plastic

stand-offs on the linkage, and

that the valve is in the full down

Slide the actuator, "R" side facing

out, onto the linkage's pinion shaft.

Make sure clamp blocks are

inserted between pinion shaft and

each clamp.

1 Rotate the linkage's pinion

shaft CW, to extend the rack

(stem down).

3

6 Apply power to rotate actuator body CW into alignment with the

linkage, and then slide the anti-rotation stud (NYBA-148) halfway

into the slot on the bottom of the actuator. Tighten the nut on the

anti-rotation stud.

Caution: Take care not to pinch your fingers or hand between

the actuator and the linkage, when powering the actuator into

alignment.

Caution: When setting the valve preload, power must be used to

position the actuator. Do not manually force the actuator into the

mounting position. If forced, damage to the pinion shaft or

improper close-off may occur.

2 Tip: A 1-5/8" open-end wrench

(TOOL-37) can be used to

measure the amount of rotation

(measured between opposite

sides of the slot).

3 Align the actuator with the linkage,

then rotate it 10° CCW. Note that

1-3/8" movement at the

anti-rotation slot (measured at the

slot's centerline) is sufficiently

equal to 10°.

R

1-3/8"

1-5/8"

1-5/8" Open-End

Wrench

2

2

TOOL-37

NYBA-148

Anti-Rotation Stud for

Mx40-717x

1 Mx40-717x actuators are

shipped at the zero position,

without preload.

3 Tip:

• MA40-717x Two-Position - When power is applied to L1, L2 (Red / Black

24V) (White / Black 120v) (Lt Blue / Brown 240v) the actuator will travel

CWW (As viewed from the "R" side).

• MF40-717x Floating Control - the Yellow/Black lead drives the actuator CW

and the Blue lead drives the actuator CCW (as viewed from the "R" side).

The Red lead is 24 hot and the Black is 24 Ground. Making the Red lead to

the Blue lead will drive the actuator CCW.

•

MS40-717x Proportional Control - Apply 10Vdc to the Gray (COM) and

Yellow/Black (+) Leads, and then apply power to L1 and L2 (Brown / Light

Blue 240v) (Black/ White 120v) or (Red / Black 24v) to drive the actuator

full CCW (As viewed from the "R" Side).

Clamp block (one for each

clamp; see steps 2 and 5)

5 With clamp blocks in place, hold the actuator

at the 10° position. Use a 1/2" wrench or

socket to tighten the two nuts equally on each

shaft clamp, 4 to 6 lb-ft (5 to 8 N-m).

2

!

10°

VB-8213, VB-921x 2-Way Valves (Normal Position — Valve Stem Down, Closed)

VB-8303, VB-931x 3-Way Valves (Normal Position — Valve Stem Down, Port B Closed)

Mx40-717x (AV-607-1 and AV-609-1)

a. Install the actuator (or actuators if using dual actuators) onto the linkage and valve, and set up the assembly,

according to and Table-3 on page 11. Use the two clamps supplied with the linkage.

Note: If using dual actuators, make sure both rotate and spring return in the same direction.

9

Schneider Electric

F- 27479 -3 April 2014

b. Refer to the appropriate actuator General Instructions sheet for actuator wiring and application information (see

“Applicable Literature” on page 2). For valve body installation and application information, refer to the appropriate valve

body General Instructions sheet.

c. Power the actuator(s) and check the system’s operation for heating or cooling output, in response to the control

signal. See “Setting Actuator/Valve Action” on page 10.

Figure-8 Mounting Mx40-717x and Setting Up Actuator/Linkage/Valve

Page 10

Setting Actuator/Valve Action

Set the actuator/valve action according to Table-2, Table-3, Table-4, or Table-6.

These tables may also be used to check the action of the completed actuator/linkage/valve assembly.

Table-2 Mx41-707x Mx41-715x Series Spring Return Actuators.

a

Primary

Valve

Part

Number

Actuator

Facing

Side

L L R R CW CCW Down Closes CCW CW

VB-921x

VB-8213

L R R L CCW CW Up Opens CCW CW

R L L R CW CCW Down Closes CW CCW

R R L L CCW CW Up Opens CW CCW

L L R R CW CCW Down Opens CCW CW

VB-922x

VB-8223

L R R L CCW CW Up Closes CCW CW

R L L R CW CCW Down Opens CW CCW

R R L L CCW CW Up Closes CW CCW

L L R R CW CCW Down

L R R L CCW CW Up

VB-931x

R L L R CW CCW Down

R R L L CCW CW Up

L L R R CW CCW Down

L R R L CCW CW Up

VB-8303

R L L R CW CCW Down

R R L L CCW CW Up

a

Primary actuator is mounted on side of linkage with rack not visible

b

Secondary actuator is mounted on side of linkage with rack visible.

c

As viewed facing actuator.

Switch

Setting

Secondaryb

Actuator

Facing

Side

Switch

Setting

Primary

Actuator

Rotation

Control Signal Increase Spring Return

Secondary

Actuator

c

Rotation

Valve Stem

Moves

c

Valve Action

“A” Opens

“B” Closes

“A” Closes

“B” Opens

“A” Opens

“B” Closes

“A” Closes

“B” Opens

“A” Opens

“B” Closes

“A” Closes

“B” Opens

“A” Opens

“B” Closes

“A” Closes

“B” Opens

Primary

Actuator

Rotation

CCW CW

CCW CW

CW CCW

CW CCW

CCW CW

CCW CW

CW CCW

CW CCW

Secondary

Actuator

c

Rotation

Valve

Normal

c

Position

Open

(Stem Up)

Closed

(Stem Down)

Closed

(Stem Up)

Open

(Stem Down)

“A” Closed

“B” Open

(Stem Up)

“A” Open

“B” Closed

(Stem Down)

“A” Closed

“B” Open

(Stem Up)

“A” Open

“B” Closed

(Stem Down)

10

Schneider Electric

F- 27479 -3 April 2014

Page 11

Table- 3 MA40-717x Spring Return Actuators.

a

Valve Part

Number

Primary

Actuator

Facing

Secondary

Actuator

Side

VB-921x

VB-8213

VB-922x

VB-8223

L R CW CCW Down Closes CCW CW Open (Stem Up)

R L CCW CW Up Opens CW CCW Closed (Stem Down)

L R CW CCW Down Opens CCW CW Closed (Stem Up)

R L CCW CW Up Closes CW CCW Open (Stem Down)

L R CW CCW Down

VB-931x

R L CCW CW Up

L R CW CCW Down

VB-8303

R L CCW CW Up

a

Primary actuator is mounted on side of linkage with rack not visible

b

Secondary actuator is mounted on side of linkage with rack visible.

c

As viewed facing actuator.

Facing

Side

b

Primary

Actuator

Rotation

Control Signal Increase Spring Return

Secondary

Actuator

c

Rotation

11

Valve

Stem

c

Moves

Valve

Action

“A” Opens

“B” Closes

“A” Opens

“B” Closes

“A” Opens

“B” Closes

“A” Closes

“B” Opens

Primary

Actuator

Rotation

Secondary

c

Rotation

CCW CW

CW CCW

CCW CW

CW CCW

Actuator

Valve

c

Normal

Position

“B” Open, “A” Closed

(Stem Up)

“A” Open, “B” Closed

(Stem Down)

“B” Open, “A” Closed

(Stem Up)

“A” Open, “B” Closed

(Stem Down)

Table-4 MF41-6153 Floating, MS41-6153 Proportional Non-Spring Return Actuators (AV-607-1 Only)

Control Signal Increase

Secondaryc

Actuator

CCW

CW

CCW

CW

CCW

CW

CCW

CW

b

e

d

e

d

e

d

e

d

Rotation

Valve

Stem

Valve Action

Moves

Down Closes

Up Opens

Down Opens

Up Closes

Down “A” Opens, “B” Closes

Up “A” Closes, “A” Opens

Down “A” Opens, “B” Closes

Up “A” Closes, “A” Opens

Valve Part

Number

VB-921x

VB-8213

VB-922x

VB-8223

VB-931x

VB-8303

a

Primary actuator is mounted on side of linkage with rack not visible

b

Secondary actuator is mounted on side of linkage with rack visible.

c

As viewed facing actuator. MF models: control signal applied to Wire 6 (Y1).

d

MF models: control signal applied to Wire 6 (Y1). MS models: DIP switch set to “CW”.

e

MF models: control signal applied to Witre 7 (Y2). MS models: DIP switch set to “CCW”.

Primary

Actuator

Rotation

CW

CCW

CW

CCW

CW

CCW

CW

CCW

a

b

d

e

d

e

d

e

d

e

Schneider Electric

F- 27479 -3 April 2014

Page 12

Table-5 Mx41-6343 Floating and Mx41-634x Proportional Non-Spring Return Actuator (AV-609-1 Only)

a

Valve Part

Number

Primary

Actuator

Facing

Secondary

Actuator

Side

VB-921x

VB-8213

VB-922x

VB-8223

VB-931x

VB-8303

a

Primary actuator is mounted on side of linkage with rack not visible

b

Secondary actuator is mounted on side of linkage with rack visible.

c

As viewed facing actuator.

L R CW CCW Down Closes

R L CCW CW Up Opens

L R CW CCW Down Opens

R L CCW CW Up Closes

L R CW CCW Down “A” Opens, “B” Close

R L CCW CW Up “A” Closes, “B” Opens

L R CW CCW Down “A” Opens, “B” Closes

R L CCW CW Up “A” Closes, “B” Opens

Facing

Side

b

Primary

Actuator

Rotation

c

Control Signal Increase

Secondary

Actuator

c

Rotation

Valve

Stem

Moves

Valve Action

Valve Body Action

Table-6 Valve Body Action

Valve Body

Part Number

Description

VB-8213 Two-way stem up open Open Closed

VB-8223 Two-way stem up closed Closed Open

VB-8303 Three-way diverting / mixing

a

Port A Closed

Port B Open

VB-921x Two-way stem up open Open Closed

VB-922x Two-way stem up closed Closed Open

VB-931x Three-way mixing

a

AB port is the common port on 3-way valves

a

Port A Closed

Port B Open

Valve Action

Stem Up Stem Down

a

a

Port A Open

Port B Closed

Port A Open

Port B Closed

a

a

Schneider Electric

F- 27479 -3 April 2014

© 2014 Schneider Electric. All rights reserved.

Loading...

Loading...