Schneider Electric atv71lift Programming manual [EN]

2354235 11/2008

Altivar LIFT

Variable speed drive

for synchronous and asynchronous lift motors

Programming Manual

(Software V5.4)

11/2011

BBV19478

www.schneider-electric.com

Table of contents

Before you begin _____________________________________________________________________________________________ 4

Documentation structure _______________________________________________________________________________________ 5

Software enhancements _______________________________________________________________________________________ 6

Presentation_________________________________________________________________________________________________ 7

Standard EN81-1 certification ___________________________________________________________________________________ 8

Vocabulary__________________________________________________________________________________________________ 9

Setup procedure_____________________________________________________________________________________________ 10

Factory configuration _________________________________________________________________________________________ 11

Setup - Preliminary recommendations ____________________________________________________________________________ 12

Graphic terminal_____________________________________________________________________________________________ 14

Description of the terminal_______________________________________________________________________________ 14

Description of the graphic screen__________________________________________________________________________ 15

First power-up - [5. LANGUAGE] menu_____________________________________________________________________ 18

Subsequent power ups _________________________________________________________________________________ 19

Programming: Example of accessing a parameter ____________________________________________________________ 20

Quick navigation_______________________________________________________________________________________ 21

Integrated display terminal_____________________________________________________________________________________ 24

Functions of the display and the keys ______________________________________________________________________ 24

Accessing menus _____________________________________________________________________________________ 25

Accessing menu parameters _____________________________________________________________________________ 26

[2. ACCESS LEVEL] (LAC-)____________________________________________________________________________________ 27

Structure of the parameter tables________________________________________________________________________________ 30

Interdependence of parameter values____________________________________________________________________________ 31

Finding a parameter in this document ____________________________________________________________________________ 32

[1.1 LIFT] (LIF-) _____________________________________________________________________________________________ 33

[International unit] (SIU)________________________________________________________________________________ 119

[1.2 MONITORING] (SUP-) ___________________________________________________________________________________ 124

[1.3 SETTINGS] (SEt-)____________________________________________________________________________________ ___ 133

[1.4 MOTOR CONTROL] (drC-)________________________________________________________________________________ 145

[1.5 INPUTS / OUTPUTS CFG] (I-O-) ___________________________________________________________________________ 173

[1.6 COMMAND] (CtL-) ______________________________________________________________________________________ 203

[1.7 APPLICATION FUNCT.] (FUn-) ____________________________________________________________________________ 216

[1.8 FAULT MANAGEMENT] (FLt-)_____________________________________________________________________________ 269

[1.9 COMMUNICATION] (COM-)_______________________________________________________________________________ 291

[1.10 DIAGNOSTICS] _______________________________________________________________________________________ 295

[1.11 IDENTIFICATION]______________________________________________________________________________________ 298

[1.12 FACTORY SETTINGS] (FCS-)____________________________________________________________________________ 299

[1.13 USER MENU] (USr-)____________________________________________________________________________________ 302

[1.14 CONTROL. INSIDE CARD] (PLC-)_________________________________________________________________________ 303

[3 OPEN/SAVE AS] _________________________________________________________________________________________ 304

[4. PASSWORD] (COd-) _____________________________________________________________________________________ 306

[6 MONITORING CONFIG.]___________________________________________________________________________________ 308

[7 DISPLAY CONFIG.]_______________________________________________________________________________________ 312

[MULTIPOINT SCREEN] _____________________________________________________________________________________ 317

Maintenance_______________________________________________________________________________________________ 318

Diagnostics and Troubleshooting_______________________________________________________________________________ 319

User settings tables _________________________________________________________________________________________ 325

Index of functions___________________________________________________________________________________________ 327

Index of parameter codes ____________________________________________________________________________________ 328

BBV19478 11/2011 3

Before you begin

Read and understand these instructions bef ore performing any procedure using this drive.

DANGER

HAZARDOUS ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

• Read and understand the Installation Manual before inst alling or operating the ATV LIFT drive. Installation,

adjustment, repair, and maintenance must be performed by qualified personnel.

• The user is responsible for compliance with all international and national electrical standards in force concerning

protective grounding of all equipment.

• Many parts in this variable speed drive, including printed wiring boards, operate at line voltage. DO NOT TOUCH.

Use only electrically insulated tools.

• DO NOT touch unshielded components or terminal strip screw connections with volta ge present.

• DO NOT short across terminals PA/+ and PC/- or across the DC bus capacitors.

• Install and close all the covers before applying power or starting and stopping the drive.

• Before servicing the variable speed drive

- Disconnect all power.

- Place a “DO NOT TURN ON” label on the variable speed drive disconnect.

- Lock the disconnect in the open position.

• Disconnect all power including external control power that may be present before servicing the drive. WAIT

15 MINUTES to allow the DC bus capacitors to discharge. Then follow the DC bus voltage measuremen t procedure

given in the Installation Manual to verify that the DC voltage is less than 42 Vdc. The drive LEDs are not accurate

indicators of the absence of DC bus voltage.

Failure to follow these instructions will result in death or serious injury.

CAUTION

DAMAGED EQUIPMENT

Do not operate or install any drive that appears damaged.

Failure to follow this instruction can result in injury and/or equipment damage.

4 BBV19478 11/2011

Documentation structure

The following Altivar LIFT technical doc uments are available on www.schneider-electric.com

Installation manual

This describes how to assemble and connect the drive.

Programming Manual

This describes the functions, parameters and use of the drive terminal (integrated display terminal and graphic display terminal).

The communication functions are not described in this manual, but in the manual for the bus or network used.

Communication parameters manual

This manual describes:

• The drive parameters with specific information for use via a bus or communication network.

• The operating modes specific to communication (state chart).

• The interaction between communication and local control.

Manuals for Modbus®, CANopen®, Ethernet™, Profibus®, INTERBUS, Uni-Telway

®

and Modbus

Plus, etc.

These manuals describe the assembly, connection to the bus or network, signaling, diagnostics, and configuration of the communicationspecific parameters via the integrated display terminal or the graphic display terminal.

They also describe the communication services of the protocols.

BBV19478 11/2011 5

Software enhancements

Since the Altivar LIFT was first launched, it has benefited from the addition of several new functions. The software version has been

updated to V5.4.

Although this documentation relates to version V5.4, it can still be used with earlier versions.

Enhancements made to version V5.4 in comparison to V5.3

New parameters and functions

Menu [1.1 LIFT] (LIF-)

• New parameter [Preset speed selec] (PSEn) (see page 42)

• New parameter [Stop type ISP] (SttL) (see page 97

• New parameter [Delay Thermal fault] (dth) (see page 106

• New parameter [International unit] (SIU) page 119

• New parameters for the rescue mode : (see page 101)

- [Opt. rescue mode] (OrM): Optimized rescue mode.

- [Acc. time rescue] (rACC): Acceleration time during rescue.

- [Resc max cur r e nt ] (rCLI): Current limitation during rescue.

- [Calc. rescue power] (PMC): This is the power needed by the drive only during evacuation.

- [Cust. rescue speed] (OrSP): Maximum optimized rescue speed,

• New methods of assigning logic output (see page 43

- [Rescue dir.] (Opt): Optimized direction for rescue mode.

- [Rdy to run] (rdYr): The drive is ready to start or already started.

• New methods of assigning [Encoder usage] (EnU)

- [Slip Comp.] (COr):The encoder provides speed feedback for speed correction and monitoring. (s ee page 46

• New methods of assigning [Thermal alarm stop] (SAt) (see page 106

- [No] (nO): Function inactive

- [Th. mot drv] (tH): Defered stop on drive thermal alarm or motor thermal alarm

- [PTC] (PtC): Defered stop on PTC alarm

- [ALL] (ALL): Defered stop on drive thermal alarm, motor thermal alarm or PTC alarm

• New factory setting for [Dis. operat opt code] (dOtd) (see page 137

- [Freewheel] (nSt) to [Ramp stop] (rMp)

)

)

[OUTPUTS] (OUt-))

)

)

)

Menu [1.7 APPLICATION FUNCT.] (FUn-)

• New parameter [Stop type ISP] (SttL). (see page 264)

• New parameters for the rescue mode: (see page 265

- [Opt. rescue mode] (OrM): Optimized rescue mode.

- [Acc. time rescue] (rACC): Acceleration time during rescue.

- [Resc max cur r e nt ] (rCLI): Current limitation during rescue.

- [Calc. rescue power] (PMC): This is the power needed by the drive only during evacuation.

- [Cust. rescue speed] (OrSP): Maximum optimized rescue speed,

• New parameter [Delay Thermal fault] (dth) (see page 278

)

)

6 BBV19478 11/2011

Presentation

WARNING

LOSS OF CONTROL

The speed loop implemented in the ATV LIFT is specifically adapted to lift applications.

It must only be used in a lift application.

Failure to follow these instructions can result in injury and/or equipment damage.

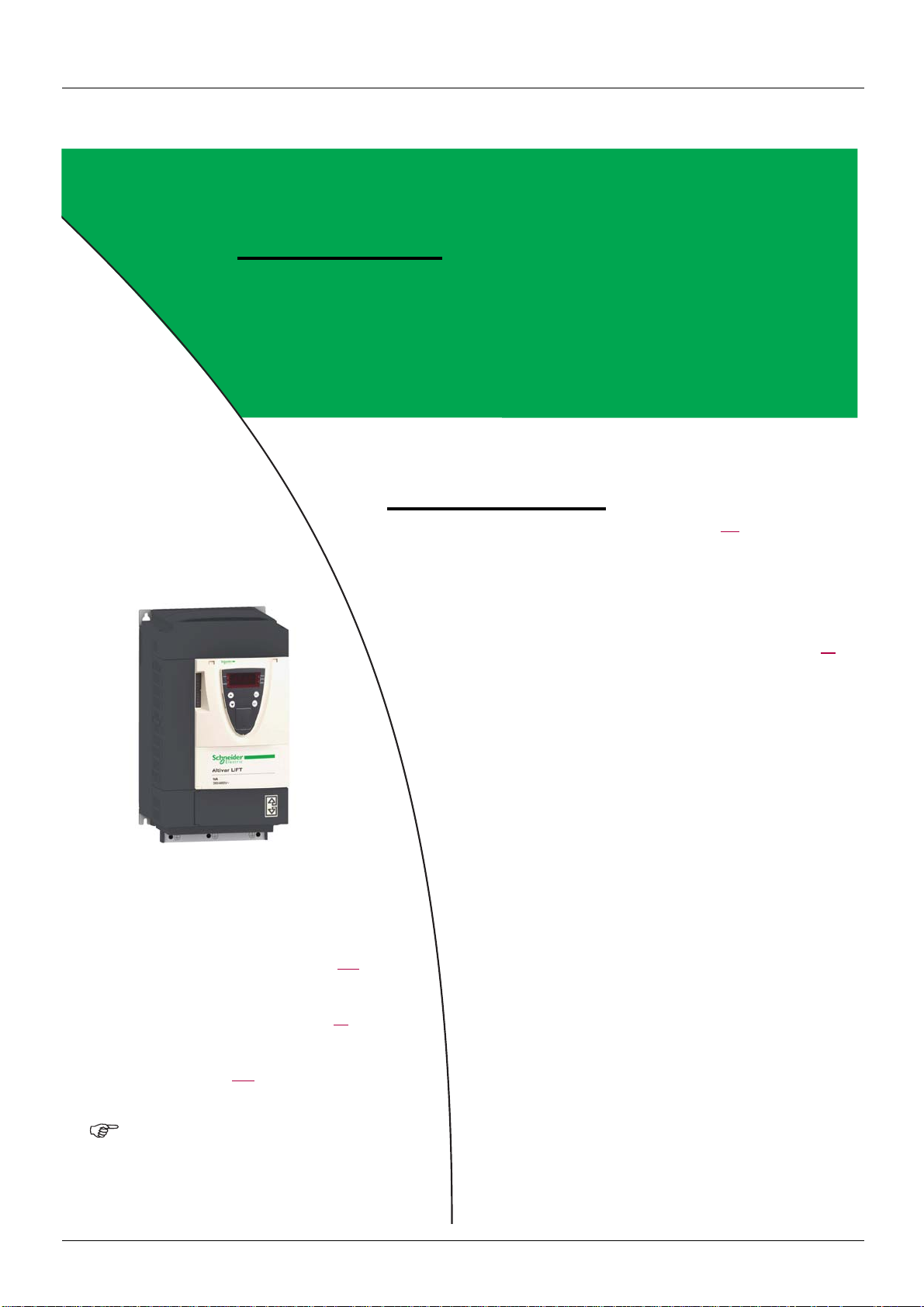

ATV LIFT has been specially developed for lift applications and therefore meets the requirements of lift installers:

• Quick, simple drive setup via a dedicated LIFT menu.

• Drive performance that offers optimum comfort.

• Integrated LIFT functions: special lift ra mp, i nspect ion fun cti on, rol lba ck mana gemen t, optimi zat i on of "h alf f loors ", UPS eva cuation,

etc.

ATV LIFT can only be used with lifts.

The following options are compatibles with ATV LIFT from a minimum version:

- graphic display terminal from the version V1.1IE24,

- universal encoder interface card (VW3A3409) from the version V1.2IE01.

ATV LIFT selection has been simplified: the sizing of the ATV LIFT is done with the nominal current

of the motor. This new policy adapts ATV LIFT references with synchronous motors. Maximum transient current has changed.

It was 1.5 In with ATV71L and is now 1.36 In with ATV LIFT.

When migrating a lift application from ATV71L to ATV LIFT, you have to check that the drive does not

reach [current Limitation] (CLI) state during acceleration or deceleration.

In case of current limitation, adapt the drive parameters if necessary:

- Increase [Acceleration time] (ACt)

- Decrease [Lift Leveling time] (LLt)

To improve the comfort in the lift, you have also the possibility to use the notch filter function.

• The previous ATV71L references not listed are no longer available. You have to take the higher power rating drive for substitution.

• Commercial reference construction: ATV71LDxxyyZ where:

- xx : Maximum continuous current at 380 Vac for N4 products and 230 Vac for M3 products.

- yy : Three phase supply voltage M3 = 230V & N4 = 380V.

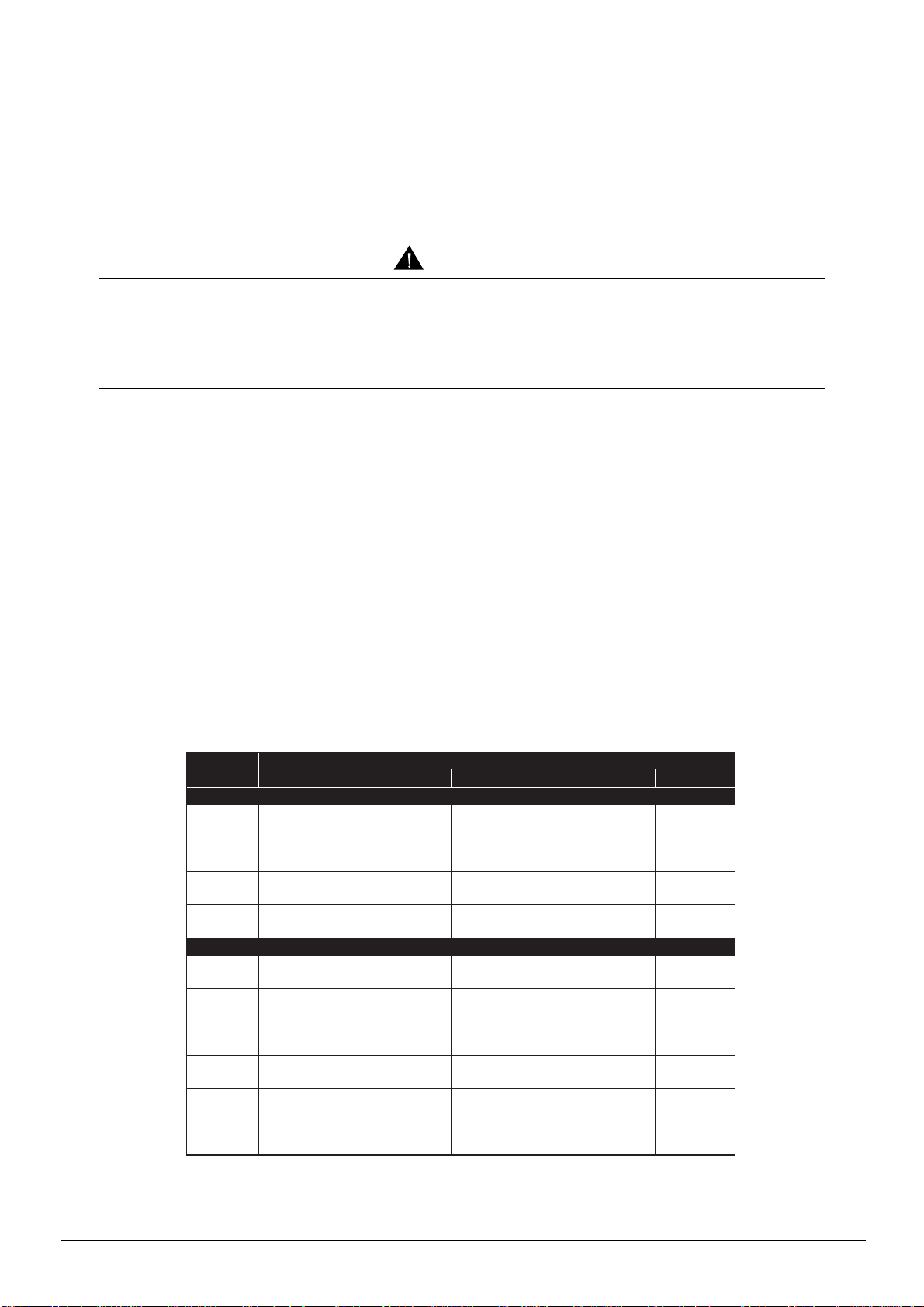

Current

Rating

27A 5,5kW

ATV71LU55M3Z ATV71LD27M3Z

Power

Rating

3-phase supply voltage : 200...240V

33A 7,5kW ATV71LU75M3Z ATV71LD33M3Z

54A 11kW ATV71LD11M3XZ ATV71LD54M3Z

66A 15kW

ATV71LD15M3XZ ATV71LD66M3Z

Catalog part number Mechanical Size

ATV71L

ATV LIFT

ATV71L

175*295*161 230*400*187

210*295*187 230*400*187

230*400*187 240*420*210

230*400*187 240*420*210

ATV LIFT

3-phase supply voltage : 380...480V

10A 4kW ATV71LU40N4Z ATV71LD10N4Z

155*260*161 175*295*161

14A 5,5kW ATV71LU55N4Z ATV71LD14N4Z

17A 7,5kW ATV71LU75N4Z ATV71LD17N4Z

27A 11kW ATV71LD11N4Z ATV71LD27N4Z

33A 15kW ATV71LD15N4Z ATV71LD33N4Z

48A 22kW ATV71LD22N4Z ATV71LD48N4Z

175*295*161 175*295*161

175*295*161 210*295*187

210*295*187 230*400*187

230*400*187 230*400*187

240*420*210 240*550*230

Note: the transfer from the graphic display terminal to the drive is possible from ATV71L to ATV LIFT.

The transfer from ATV LIFT to ATV71 L is not possible.

See [3 OPEN/SAVE AS] page 304

BBV19478 11/2011 7

for a complete description of configuration transfer.

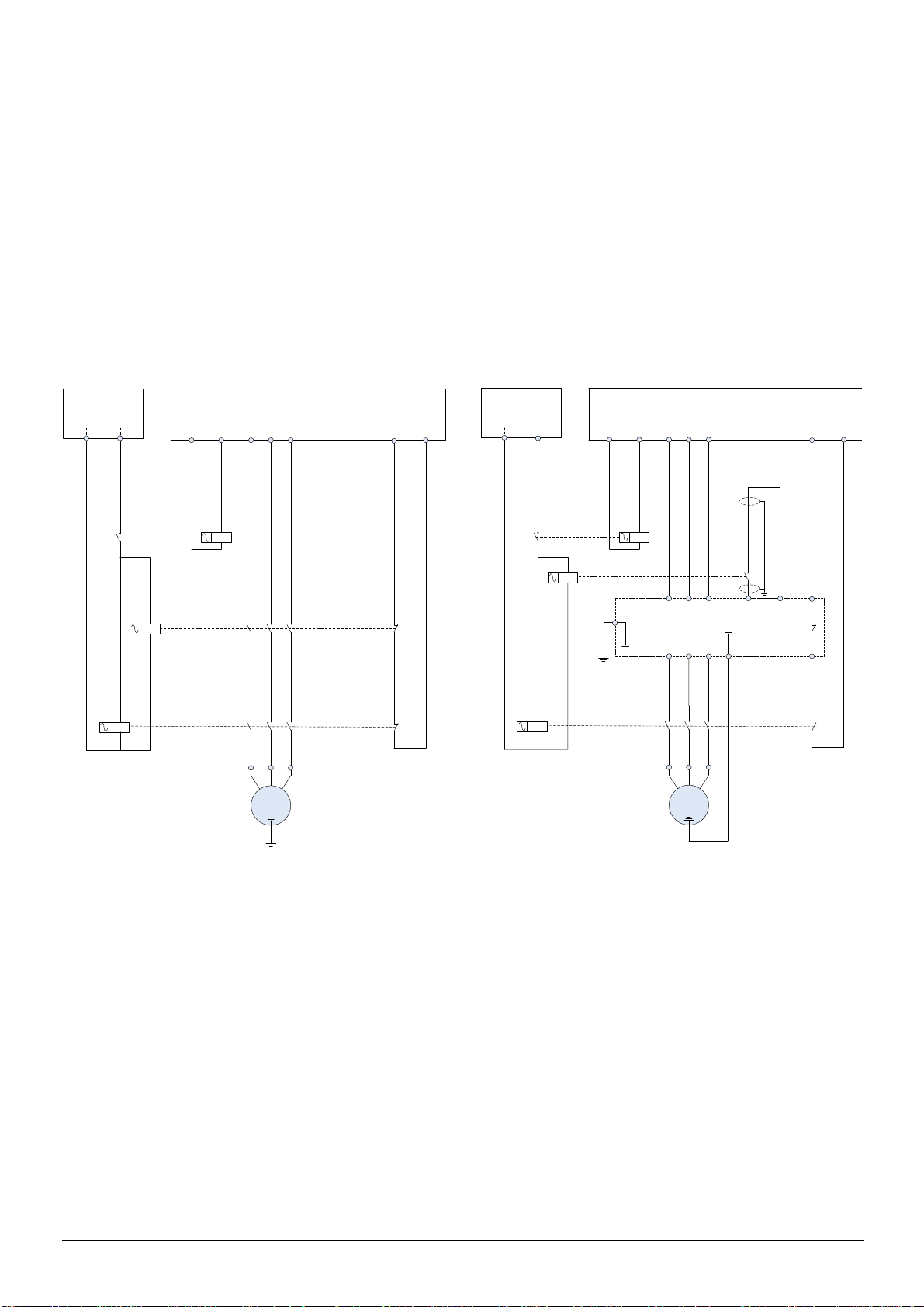

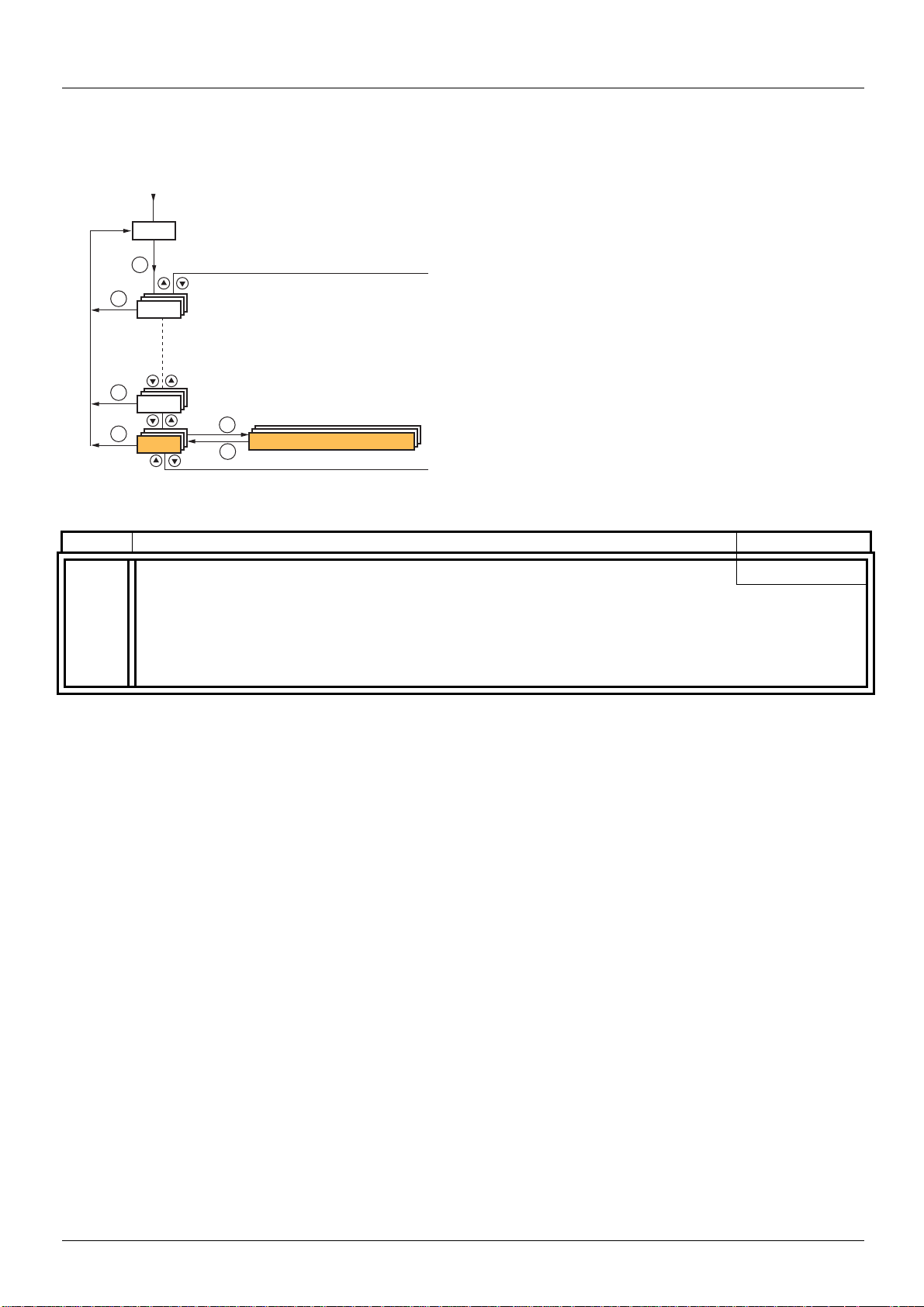

Standard EN81-1 certification

Safety Chain

Circuit

Contr ol devi ce

Command

LIFT COMMAND CONTROL CARD

Moni tori ng device

Feedbac k

K01

K01

K1

K2

K1

K2

K1

K2

UV W

UV W

M

3 ~

M

3 ~

Contr ol devi ce

Command

Safety Chain

Circuit

LIFT COMMAND CONTROL CARD

Moni tori ng device

Feedbac k

K01

K01

K1

K1

K2K2

K2

R1C

R1B

L1 L2 L3 PWR +24

R1 = RDY

ATV LIFT

U1

V1

W1

RdY or rdYr

EUROPEAN STANDARD EN 81-1 (Ref. No. EN 81-1:1998 E)

The ATV LIFT drive is now compliant with European Standard EN81-1 12.7.3 b) 2) and 3)

12 Lift machine

12.7 Stopping the machine and checking its stopped condition

12.7.3 A.C. or D.C. motor supplied and controlled by static elements

b) a system consisting of :

1) a contactor interrupting the current at all poles.

The coil of the contactor shall be released at least befo re each change in direc tion. If the cont actor does not release, any f urther movement

of the lift shall be prevented, and

2) a control device blocking the flow of energy in the static elements, and

3) a monitoring device to verify the blocking of the flow of energy each time the lift is stationary.

If, during a normal stopping period, the blocking of the flow of energy by the static elements is not effective, the monitoring device shall

cause the contactor to release and any further movement of the lift shall be prevented.

The ATV LIFT is in place of the power contactor K1.

- The contactor interrupting the current at all poles is K2

- The control device blocking the flow of energy in the static elements is the drive ATV LIFT trough Power Removal safety function input

- The monitoring device to verify the blocking of the flow of energy each time the lif t is stationary is the output drive relay R1 and the auxiliary

contact of K2 contactor.

8 BBV19478 11/2011

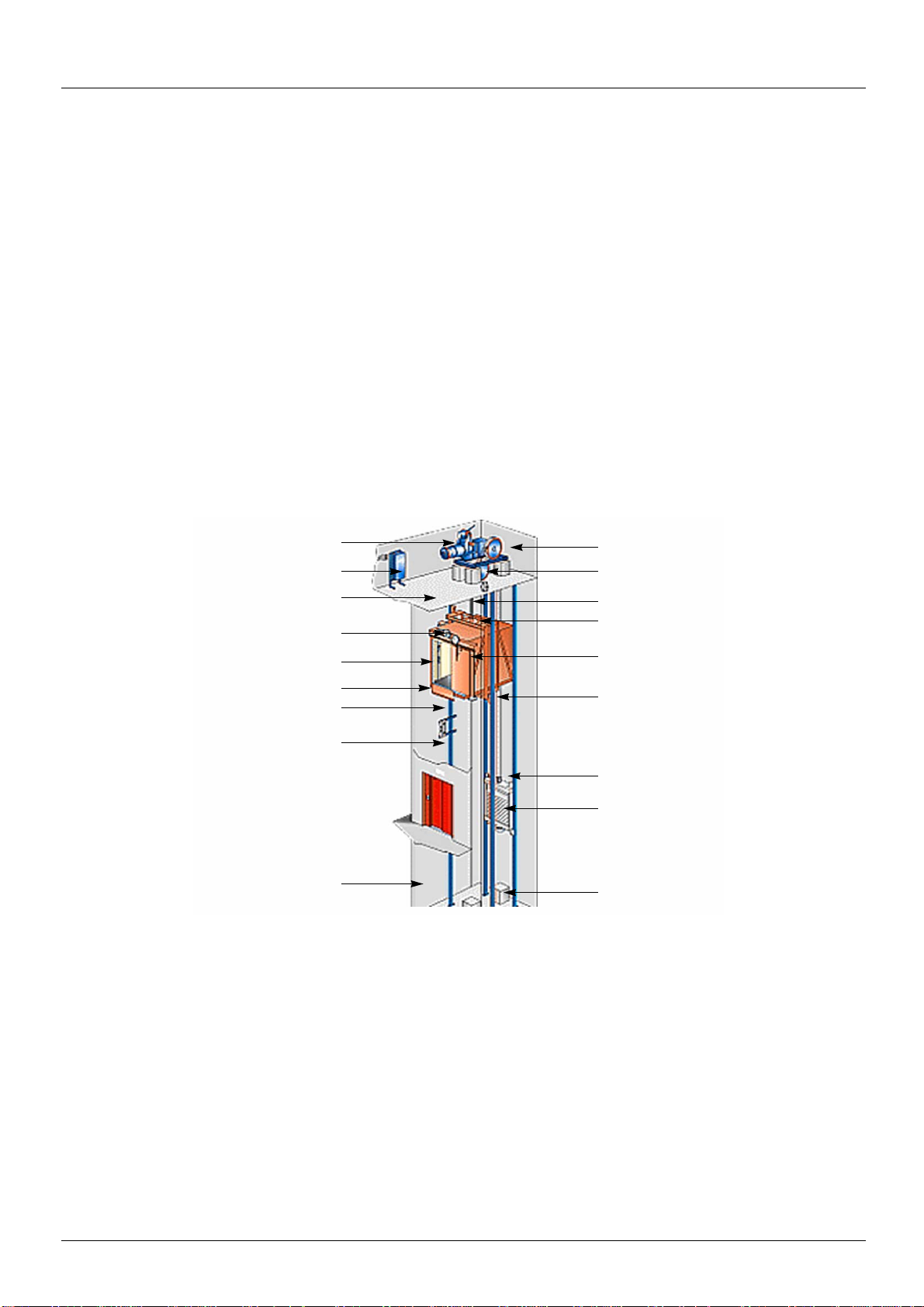

Vocabulary

machine

control panel

machine room

opening/closing system

lift car control panel

base

shaft

guide rails

well

sheave

overspeed detection

traction cables

inspection box on lift car roof

automatic lift car door

safety catch

counterweight guide

counterweight

buffers

Lift command

Electronic card integrating the lift application intelligence: call management, step displays.

The lift command card monitors the slowdown and stop indicators and controls the drive.

Slowdown indicator

Sensor placed at a precise distance (slowdown length) above and below each step.

When the car passes in front of this sensor, the lift command card removes the high speed command (travel speed) and commands a low

speed (lift leveling speed).

Stop indicator

Sensor placed at a precise distance (stop length) above and below each step.

When the car passes in front of this sensor, the lift command card removes t he run command. The car shoul d then st op comfo rtably within

the [Stop length] (StL).

Rollback

Movement of the car when the brake is released. In gearless appli cations where the i nertia at the motor is l arge, the brake rel ease must be

specially controlled to cancel this rollback (using an external weight sensor or the rollback management function).

Jerk

Jerk is a measurement of variations in acceleration. It is often related to comfort (comfort is improved as the jerk is reduced).

BBV19478 11/2011 9

Setup procedure

INSTALLATION

v 1 Consult the Installation Manual

PROGRAMMING

Procedure applicable if the factory configuration, page 11, and use of the

[1.1 LIFT] (LIF-) menu only are sufficient for the application.

b 2 Power up without run command

v If you are using a separate control power

supply, follow the instructions on page

12.

b 3 Select the language, if the drive

has a graphic display terminal

b 4 Configure the menu

[1.1 LIFT] (LIF-)

Tips:

• Before you start programming, complete

the user setting tables, page

325.

• Perform an auto-tuning operation to

optimize performance, page

54.

• If you get lost, return to the factory

settings, page

301.

.

Note: Check that the wiring of the

drive is compatible with its

configuration.

b 5 Start

10 BBV19478 11/2011

Factory configuration

Drive factory settings

The Altivar LIFT is factory-set for the most common operating conditions:

• Motor frequency: 50 Hz

• Normal stop mode on deceleration lift ramp

• Stop mode in the event of a trip: Freewheel

• Deceleration ramp with leveling speed step.

• Motor thermal current = rated drive current

• Standstill injection braking current = 0.7 x rated drive current, for 0.5 seconds

• No automatic starts after a trip

• Switching frequency 8 kHz.

• Logic inputs:

- LI1: forward, LI2: reverse (2 operating directions), 2-wire control on transition

- LI3: Inactive (not assigned)

- LI4: Lift speed

- LI5: Inspection mode

- LI6: Not assigned

• Analog inputs:

- AI1: Speed reference 0 +10 V

- AI2: 0-20 mA, inactive (not assigned)

• Relay R1: no

• Relay R2: Brake control

• Analog output AO1: dO1 (logic output)

If the above values are compatible with the application, the drive can be used without changing the settings.

Option card factory settings

The option card inputs/outputs are not factory-set.

BBV19478 11/2011 11

Setup - Preliminary recommendations

DANGER

UNINTENDED EQUIPMENT OPERATION

• Before turning on and configuring the Altivar LIFT, check that the PWR (POWER REMOVAL) input is deactivated

(at state 0) in order to prevent unintended operation.

• Before turning on the drive, or when exiting the configuration menus, check that the inputs assigned to the run

command are deactivated (at state 0) since they can cause the motor to start immediately.

Failure to follow these instructions will result in death or serious injury.

CAUTION

INCOMPATIBLE LINE VOLTAGE

Before turning on and configuring the drive, ensure that the li ne voltage is compatible with the sup ply voltage range shown

on the drive nameplate. The drive may be damaged if the line voltage is not compatible.

Failure to follow these instructions can result in equipment damage.

CAUTION

• Avoid operating the contactor frequently (premature ageing of the filter capacitors).

• Cycle times < 60 s can result in damage to the precharge resistor.

Failure to follow these instructions can result in equipment damage.

DANGER

UNINTENDED EQUIPMENT OPERATION

• Check that changes made to the settings during operation do not present any danger.

• We recommend stopping the drive before making any changes.

Failure to follow these instructions will result in death or serious injury.

Turning on and configuring the drive

Separate control section power supply

When the drive control section is powered independently of the power section (P24 and 0V terminals), whenever an option card is added

or replaced, only the power section must be supplied with power next time the drive is powered up.

By default the new card would not be recogni zed and i t would b e i mpos sib le to co nfi gure it, thereb y ca usi ng the dri ve to l ock i n fault mode.

Power switching via line contactor

User adjustment and extension of functions

• The display unit and buttons can be used to modify the settings and to extend the functions described in the following pages.

• Return to factory settings is made easy by the [1.12 FACTORY SETTINGS] (FCS-) menu, see page 299

• There are three types of parameter:

- Display: Values displayed by the drive

- Adjustment: Can be changed during operation or when stopped

- Configuration: Can only be modified when stopped and no braking is taking place. Can be displayed during operation.

.

12 BBV19478 11/2011

Setup - Preliminary recommendations

CAUTION

RISK OF DAMAGE TO THE EQUIPMENT

Motor thermal protection will not be provide d by the drive if th e motor current i s less t han 0.2 ti mes the rated drive current.

Provide an alternative means of thermal protection.

Failure to follow these instructions can result in equipment damage.

WARNING

LOSS OF CONTROL

• Identify the precise values of [Nominal car speed] (CSP) and payload [Capacity of the lift] (LCA).

• Check the [Nominal car speed] (CSP) by cal culat ion (See menu [1.1 LIFT] (LIF-), submenu [LIFT DATA] (LdA-)) or

by measurement.

If the values of [Nominal car speed] (CSP) or [Lift capacity] (LCA) are incorrect, the stop lengths ([Deceleration length]

(dEL) and [Stop length] (StL) will not be adhered to.

The speed loop preset will not be adapted to the application (risk of instability and lift car slipping).

Failure to follow these instructions will result in death or serious injury.

Starting

Important:

• In factory settings mode, the motor can only be supplied wit h power once the “forward”, “reverse” an d “DC injection st op” commands

have been reset:

- On power-up or a manual detected fault reset or after a stop command.

If they have not been reset, the drive will display "nSt" but will not start.

• If the automatic restart function has been configured ([Automatic restart] (Atr) parameter in the [1.8-FAULT MANAGEMENT] (FLt-)

menu, see page 273

Test on a low power motor or without a motor

• In factory settings mode, [Output Phase Loss] (OPL) detection page 276 is active (OPL = YES). To check the drive in a test or

maintenance environment without having to switch to a moto r with the same rating as the drive (part icularly useful in the case of high

power drives), deactivate [Output Phase Loss] (OPL = nO).

), these commands are taken into account without a reset being necessary.

Use of the LIFT menu

BBV19478 11/2011 13

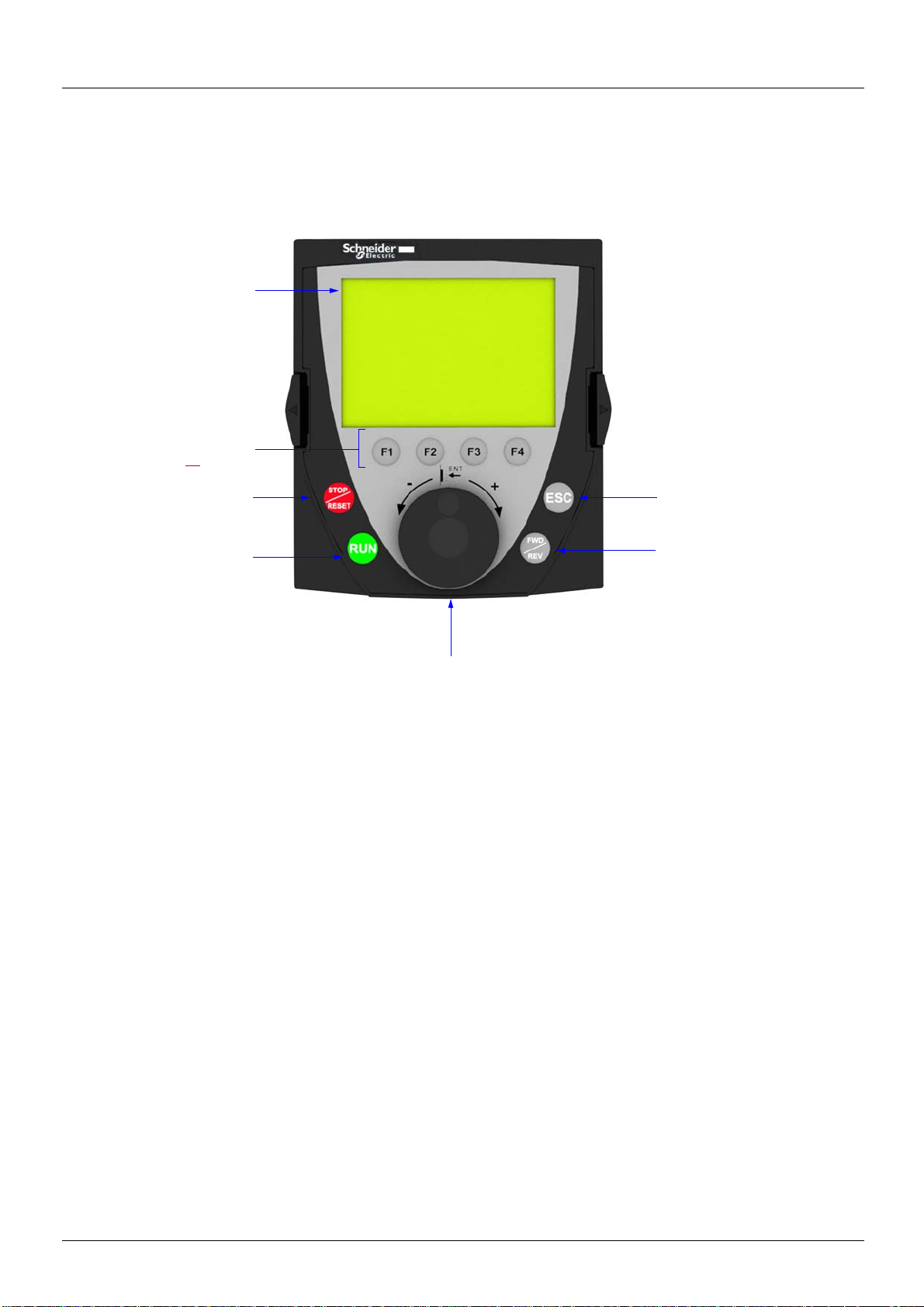

Graphic terminal

1 Graphic display

2 Function keys

F1, F2, F3, F4,

see page 15

.

3 STOP/RESET

button

4 RUN button

5 Navigation button:

• Press (ENT): - To save the current value

- To enter the selected menu or parameter

• Turn CW/

CCW:

- To increment or decrement a value

- To go to the next or previous line

- To increase or decrease the reference if control via

the display terminal is activated

7 ESC key: Aborts a value, a

parameter or a menu to return

to the previous selection

6 Button for reversing the directi on

of rotation of the motor

The graphic terminal is optional. The graphic termin al is removabl e and can be loc ated remotel y (on the door o f an enclosure, for example)

using the cables and accessories available as options (see catalog).

Description of the terminal

Note: Buttons 3, 4, 5 and 6 can be used to control the drive directly, if control via the display t erminal is activated.

14 BBV19478 11/2011

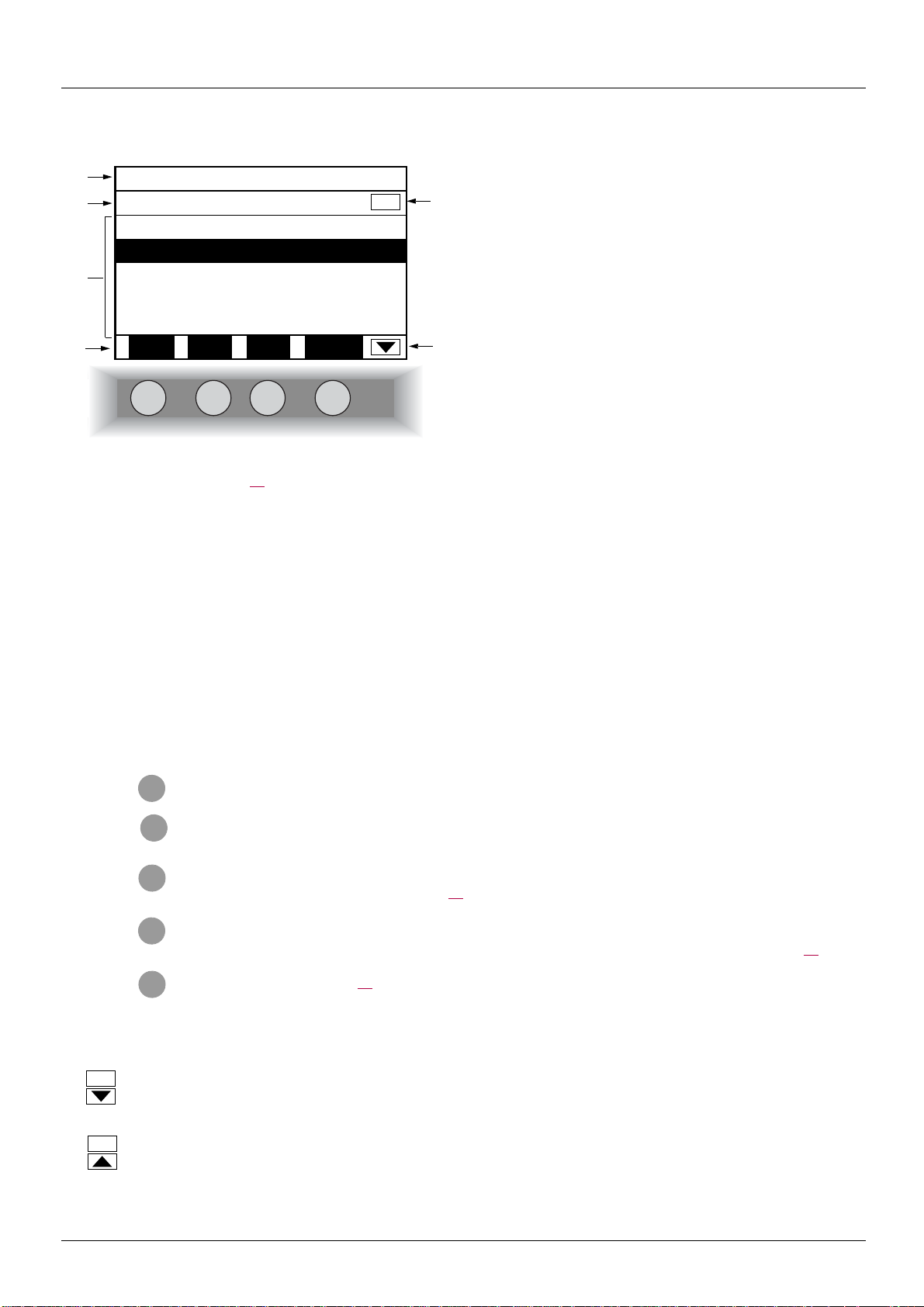

Graphic terminal

F1 F2 F3 F4

RDY Term +0.00Hz 0A

1 DRIVE MENU

1.1 LIFT

1.2 MONITORING

1.3 SETTINGS

1.4 MOTOR CONTROL

1.5 INPUTS / OUTPUTS CFG

Code << >> Quick

1

2

3

4

6

5

• Code F1

•HELP F1

• << F2

• >> F3

• Quick F4

Description of the graphic screen

1. Display line. Its content can be configured; the factory settings show:

• The drive state (see page 16

• The active control channel:

- Term: Terminals

- HMI: Graphic terminal

- MDB: Integrated Modbus

- CAN: Integrated CANopen

- NET: Communication card

- APP: Controller Inside card

• Frequency reference

• Current in the motor

)

2. Menu line. Indicates the name of the current menu or submenu.

3. Menus, submenus, parameters, values, bar charts, etc., are displayed in drop-down window format on a maximum of 5 lines.

The line or value selected by the navigation button is displayed in reverse video.

4. Section displaying the functions assigned to the F1 to F4 keys and aligned with them, for example:

The function keys are dynamic and contextual.

Other functions (application functions) can be assigned to these keys via the [1.6 COMMAND] menu.

5. Indicates that there are no more levels below this display window.

Indicates that there are more levels below this display window.

6. Indicates that this display window does not scroll further up.

Indicates that there are more levels above this display window.

: Displays the code of the selected parameter, i.e., the code corresponding to the 7-segment display.

: Contextual help

: Navigate horizontally to the left, or go to previous menu/submenu or, for a value, go to the next digit up, displayed

in reverse video (see the example on page 17

: Navigate horizontally to the right or go to next menu/submenu (going to the [2 ACCESS LEVEL] menu in this

example) or, for a value, go to the next digit down, displayed in reverse video (see the example on page 17

: Quick navigation, see page 21.

).

).

BBV19478 11/2011 15

Graphic terminal

Drive state codes:

- ACC: Acceleration

- CLI: Current limita ti on

- CTL: Controlled stop on input phase loss

- DCB: DC injection braking in progress

-DEC: Deceleration

- FLU: Motor fluxing in progress

-FST: Fast stop

- NLP: No line power (no line supply on L1, L2, L3)

- NST: Freewheel stop

- OBR: Auto-adapted deceleration

- PRA: Power Removal function active (drive locked)

- RDY: Drive ready

- RUN: Drive running

- SOC: Controlled output cut in progress

- TUN: Auto-tuning in progress

- USA: Undervoltage alarm

- ASA: Measurement of the phase-shift angle in progress

16 BBV19478 11/2011

Graphic terminal

RDY Term +0.00Hz 0A

5 LANGUAGE

English

Français

Deutsch

Español

Italiano

<< >> Quick

Chinese

Russian

Turkish

PARAMETER SELECTION

1.3 SETTINGS

Ramp increment

Acceleration

Deceleration

Acceleration 2

Deceleration 2

Edit

RDY Term +0.00Hz 0A

Acceleration

9.51 s

Min = 0.01 Max = 99.99

<< >> Quick

>>

RDY Term +0.00Hz 0A

Acceleration

9.51 s

Min = 0.01 Max = 99.99

<< >> Quick

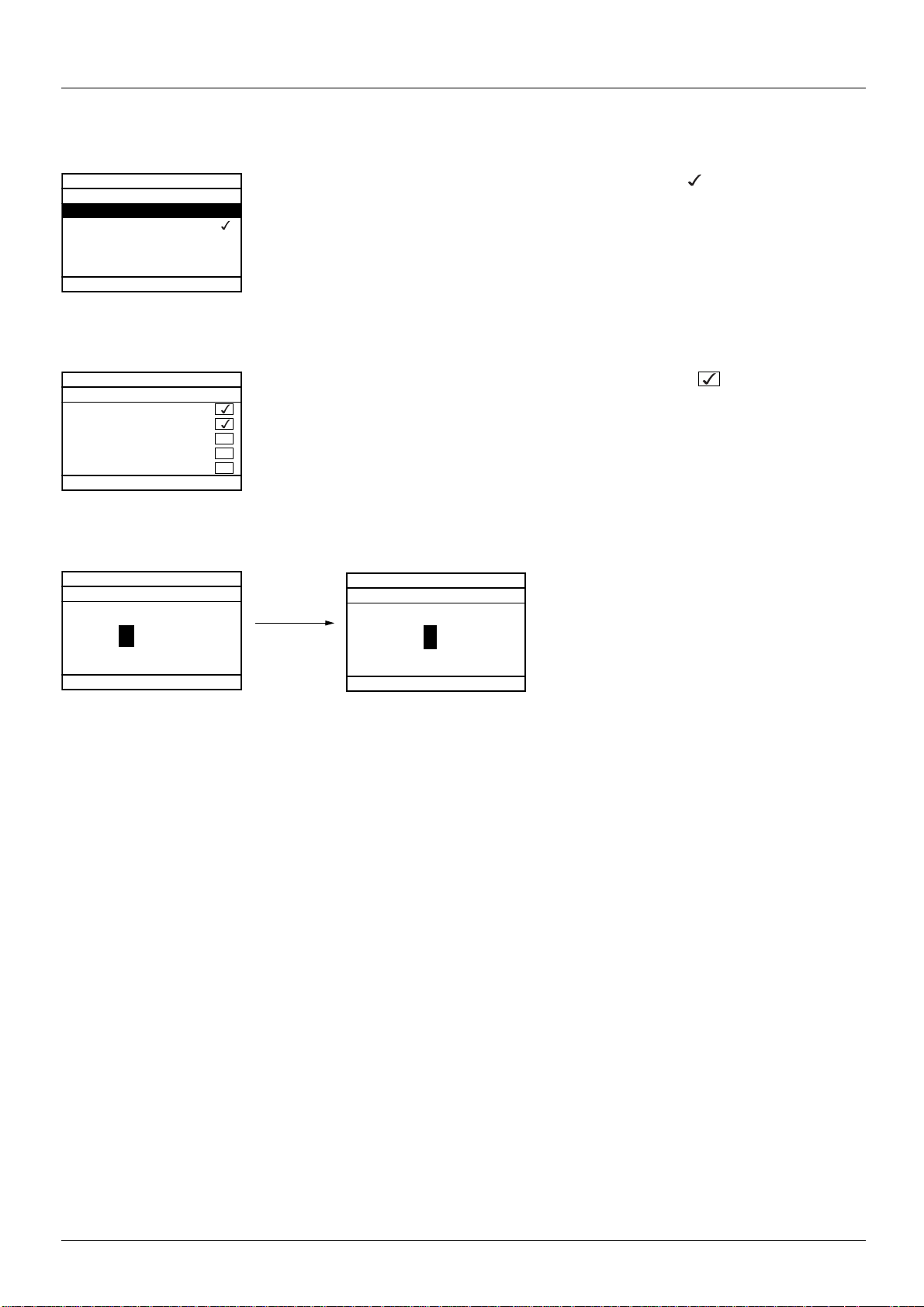

Example configuration windows:

When only one selection is possible, the selection made is indicated by .

E.g. Only one language can be chosen.

When multiple selection is possible, the selections made are indi cated by .

E.g. A number of parameters can be chosen to form the [USER MENU].

Example configuration window for one value:

The << and >> arrows (keys F2 and F3) are used to select the digit to be modified, and the navigation button is rotated to increase or

decrease this number.

BBV19478 11/2011 17

Graphic terminal

ATV71LD10N4Z

10A 380/480V

Config. n°1

5 LANGUAGE

English

Français

Deutsch

Español

Italiano

Chinese

Russian

Turkish

RDY Term 0.00m/s 0.0A

2 ACCESS LEVEL

Basic

Standard

Advanced

Expert

RDY Term 0.00 m/s 0.0 A

1.1 LIFT

International unit

LIFT CONFIGURATION

LIFT OPTIMIZATION

LIFT FUNCTIONS

MONITORING

Code << >> Quick

RDY Term 0.00 m/s 0.0 A

MAIN MENU

1 DRIVE MENU

2 ACCESS LEVEL

3 OPEN / SAVE AS

4 PASSWORD

5 LANGUAGE

Code Quick

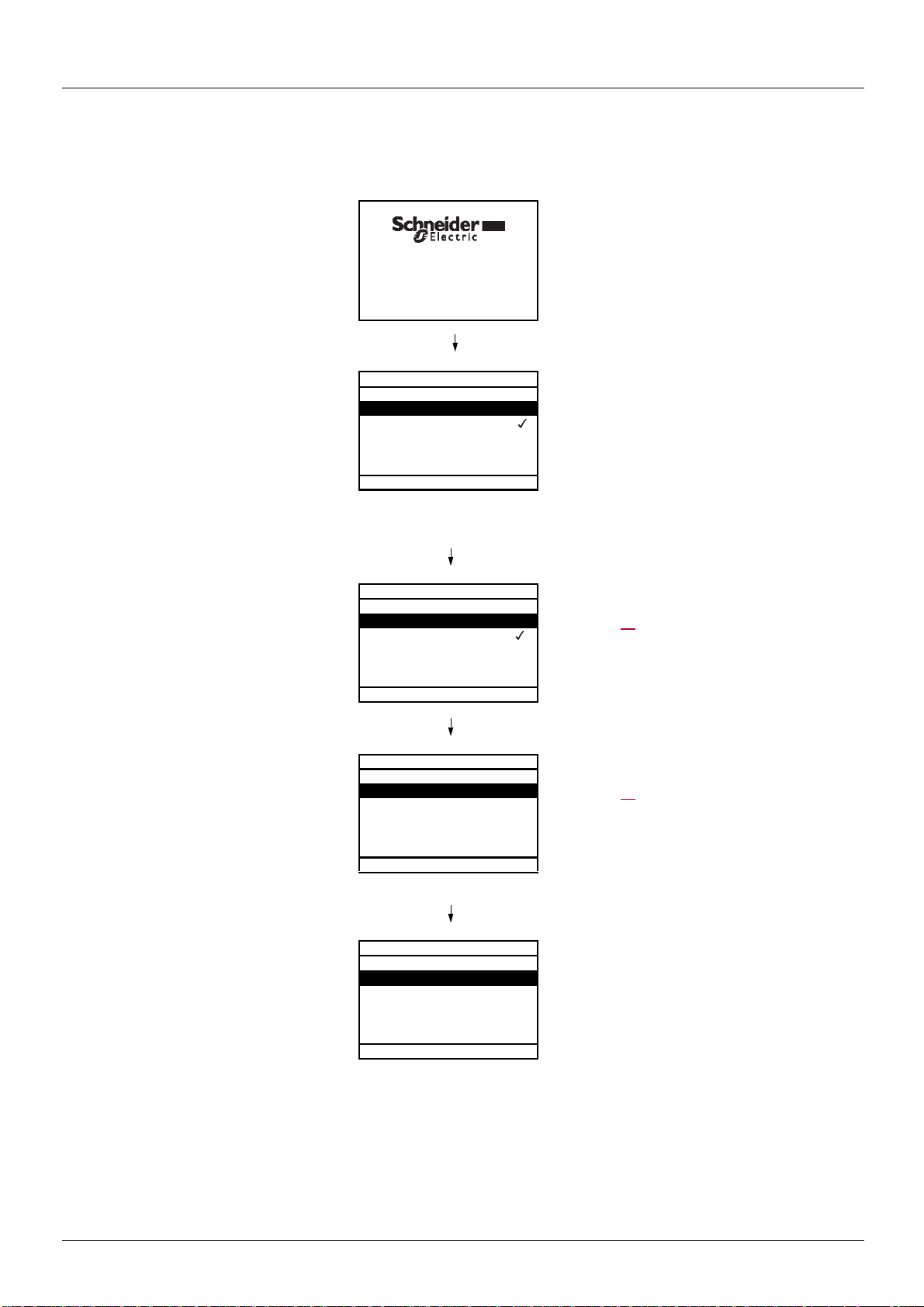

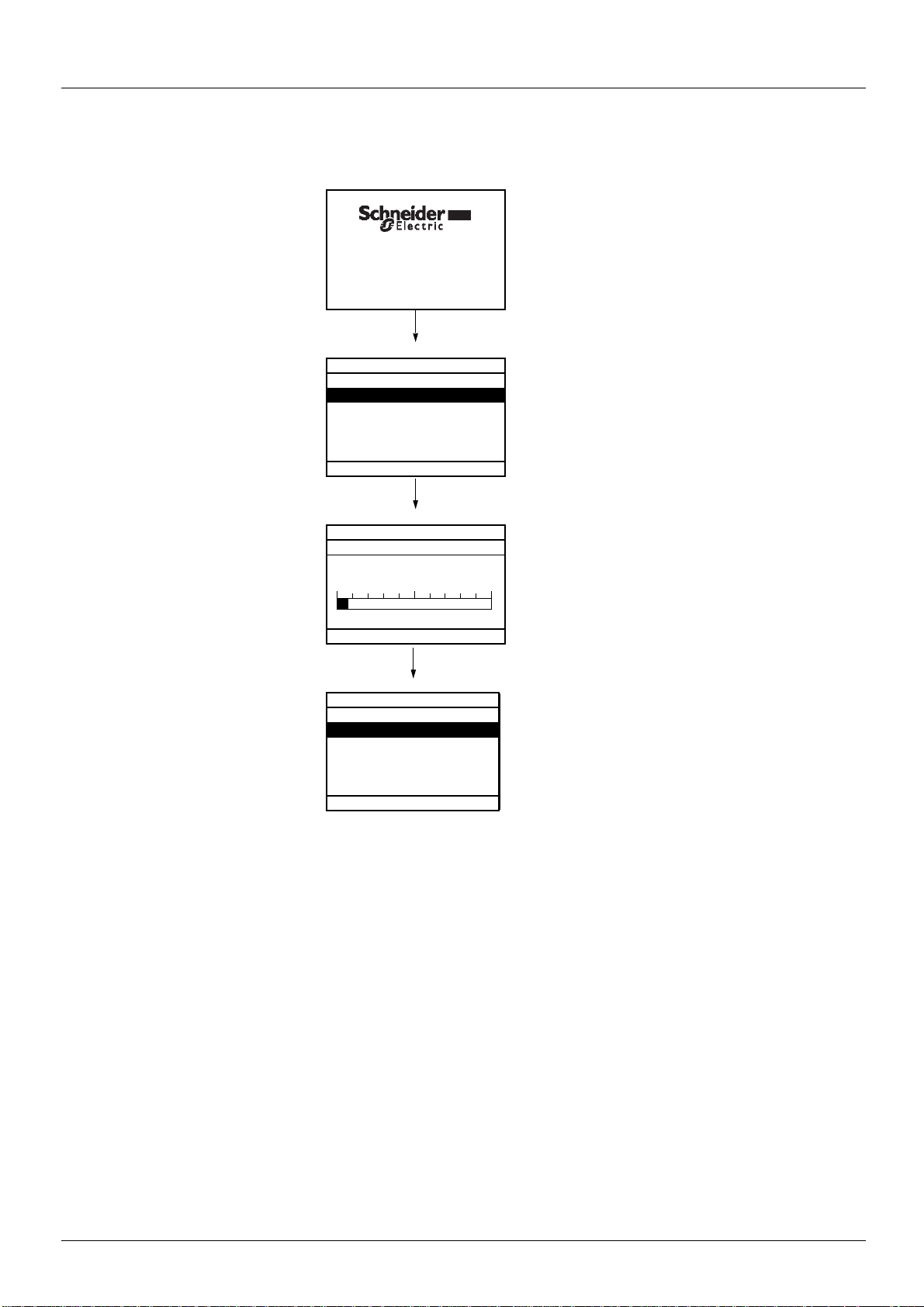

First power-up - [5. LANGUAGE] menu

The first time the drive is powered up, the user will automatically be guided through the menus as far as the [1.1. LIFT] submenu.

The parameters in this submenu must be configured and auto-tuning performed before the motor is started up.

Display for 3 seconds following power-up

3 seconds

Automatically switches to [5 LANGUAGE]

menu 3 seconds later.

Select the language and press ENT.

Switches to [2 ACCESS LEVEL] menu

(see page 27

)

Select the access level and press ENT.

Switches to [1.1 LIFT]

(see page 23

)

ESC

ESC

Press ESC twice to return to [MAIN MENU]

18 BBV19478 11/2011

Graphic terminal

3 seconds

10 seconds

ENT or ESC

ATV71LD10N4Z

10A 380/480V

Config. n°1

RDY Term 0.00 m/s 0.0 A

1.1 LIFT

LIFT CONFIGURATION

LIFT OPTIMIZATION

LIFT FUNCTIONS

MONITORING

International unit

Code << >> Quick

RDY Term 2.00 m/s 0.0 A

Elevator Speed

Min=0.00 Max=327.67

Quick

RDY Term 0.00 m/s 0.0 A

MAIN MENU

1 DRIVE MENU

2 ACCESS LEVEL

3 OPEN / SAVE AS

4 PASSWORD

5 LANGUAGE

Code Quick

2.00 m/s

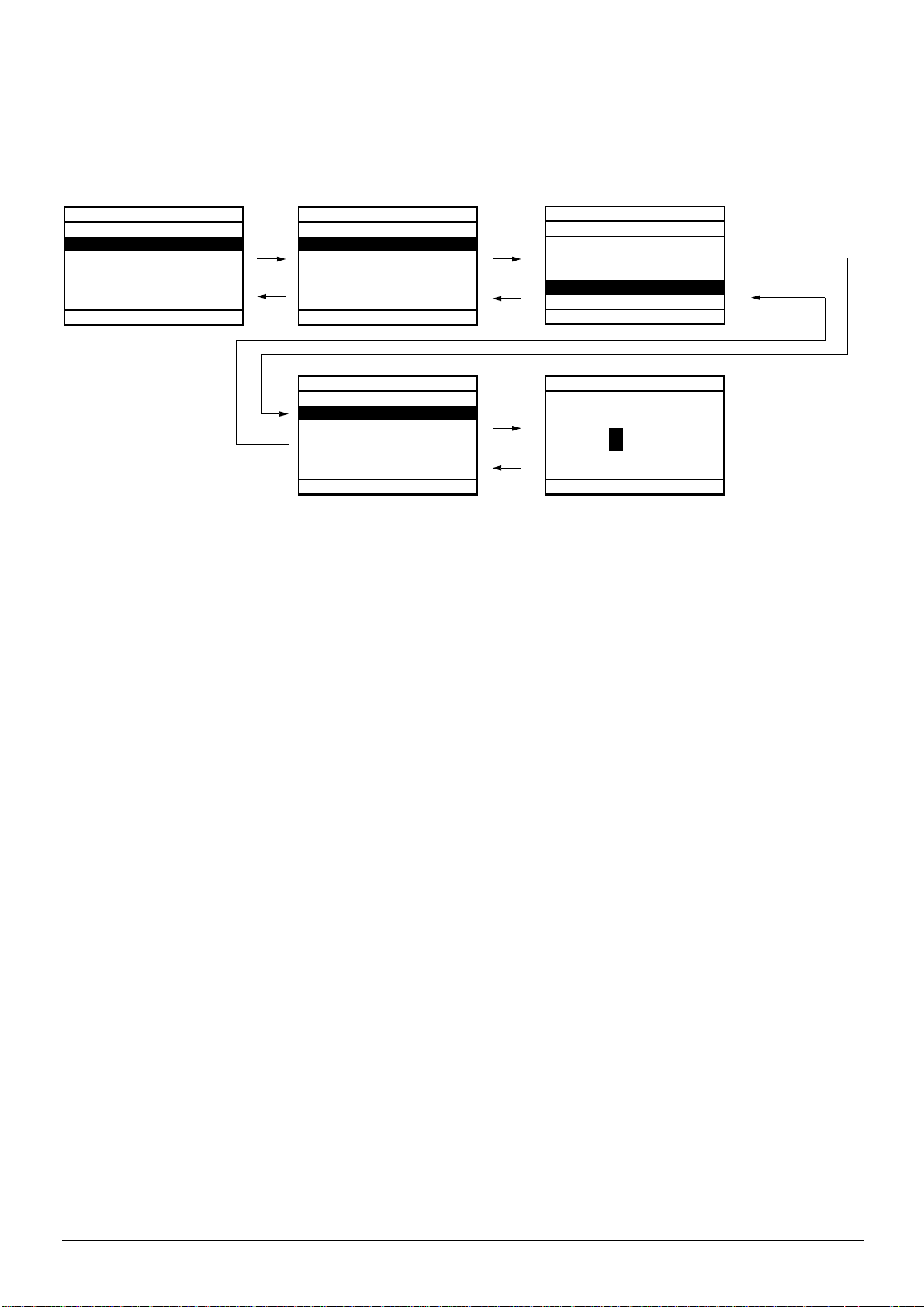

Subsequent power ups

Switches to [1.1. LIFT] 3 seconds later.

If no operator inputs are made, switches to "Display"

automatically 10 seconds later (the display will vary

depending on the selected configuration).

Users can return to [MAIN MENU] by pressing

ENT or ESC.

BBV19478 11/2011 19

Graphic terminal

RDY Term +0.00Hz 0A

1 DRIVE MENU

1.1 LIFT

1.2 MONITORING

1.3 SETTINGS

1.4 MOTOR CONTROL

1.5 INPUTS / OUTPUTS CFG

Code << >> Quick

ENT

ESC

RDY Term +0.00Hz 0A

1.1 LIFT

LIFT CONFIGURATION

LIFT OPTIMIZATION

LIFT FUNCTIONS

MONITORING

International unit

Code << >> Quick

ENT

ENT or

ESC

RDY Term +0.00Hz 0A

LIFT CONFIGURATION

I/O ASSIGNMENT

ENCODER DATA

MOTOR DATA

LIFT DATA

Code << >> Quick

ENT

ENT or

ESC

RDY Term +0.00Hz 0A

LIFT DATA

Nominal car speed 1.00 m/s

Capacity of the lift 400 kg

Car weight Auto

Counterweight Auto

Max. Acceleration 0.5 m/s²

Code << >> Quick

ENT

ENT or

ESC

RDY Term +0.00Hz 0A

Nominal car speed

1.50 m/s

Min = 0.01 Max = 10.00

<< >> Quick

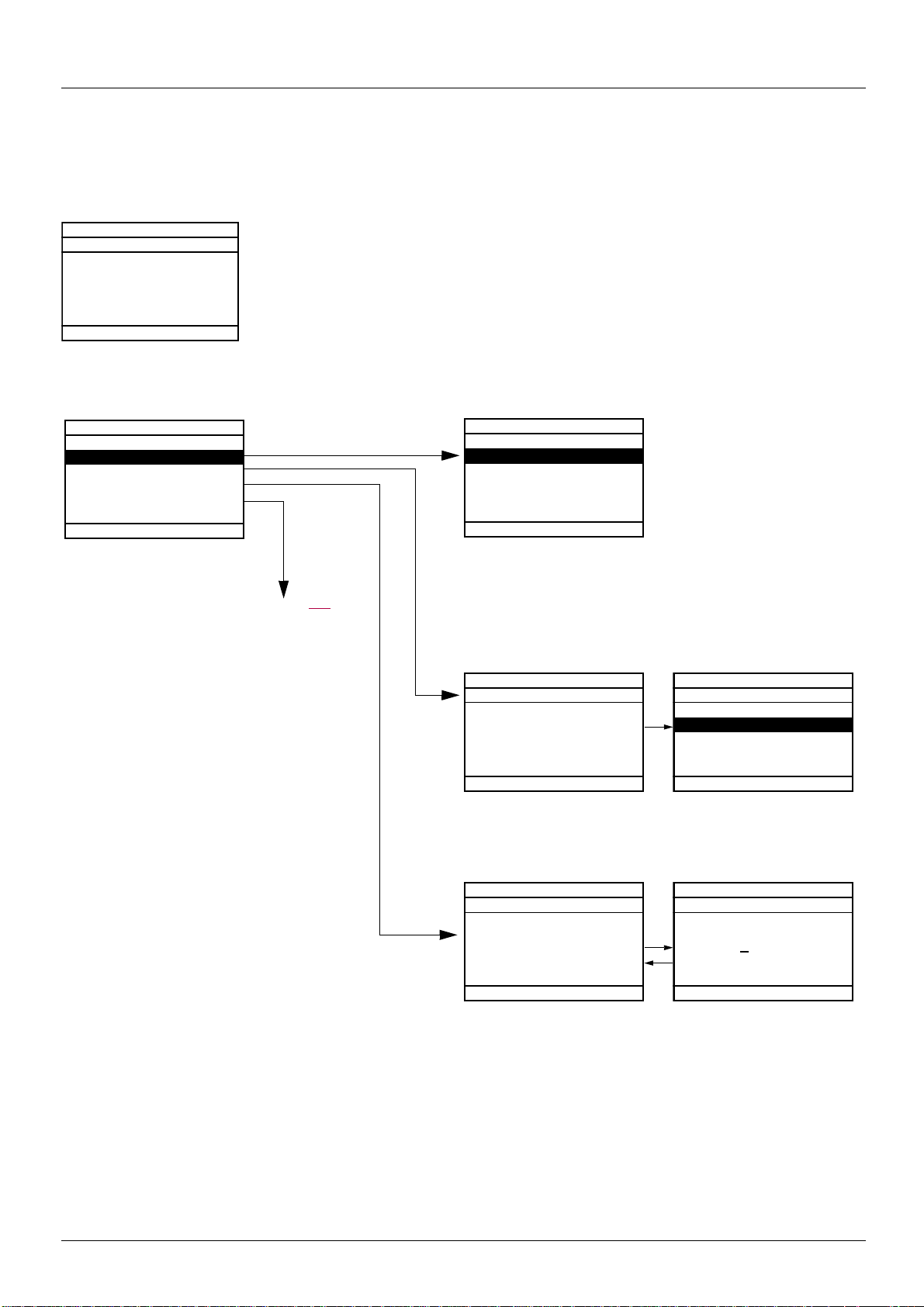

Programming: Example of accessing a parameter

Accessing the nominal car speed

Note:

• To select a parameter:

- Turn the navigation button to scroll vertically.

• To modify a parameter:

- Use the << and >> keys (F2 and F3) to scroll horizontally and select the digit to be modified (the selected di git chan ges to white

on a black background).

- Turn the navigation button to modify the digit.

• To cancel the modification:

-Press ESC.

• To save the modification:

- Press the navigation button (ENT).

20 BBV19478 11/2011

Graphic terminal

RDY Term +0.00Hz 0A

1.4 MOTOR CONTROL

Standard mot. freq: 50Hz IEC

Motor control type: SVC U

Max frequency: 60 Hz

Output Ph rotation: ABC

Sinus filter: no

Code << >> Quick

ENT

RDY Term +0.00Hz 0A

QUICK NAVIGATION

RETURN TO MAIN MENU

DIRECT ACCESS TO...

10 LAST MODIFICATIONS

GOTO MULTIPOINT SCREEN

Code

See page 317

RDY Term +0.00Hz 0A

MAIN MENU

1 DRIVE MENU

2 ACCESS LEVEL

3 OPEN / SAVE AS

4 PASSWORD

5 LANGUAGE

Code Quick

RDY Term +0.00Hz 0A

DIRECT ACCESS TO...

1.3

SETTINGS

<< >>

ENT

RDY Term +0.00Hz 0A

1.3 SETTINGS

Ramp increment: 01

Acceleration 9.51 s

Deceleration: 9.67 s

Acceleration 2: 12.58 s

Deceleration 2 : 13.45 s

Code << >> Quick

RDY Term +0.00Hz 0A

10 LAST MODIFICATIONS

Acceleration: 10 s

ENA prop.gain: 1.2

Rated mot. current: 15 A

Preset speed 4: 20 Hz

Preset speed 5: 30 Hz

Code

ESC

ENT

RDY Term +0.00Hz 0A

Rated mot. current

15.0 A

<< >>

Quick navigation

If the "Quick" function is displayed above the F4 key, you can gain quick access to a parameter from any screen.

E.g.

Press F4 to access the Quick screen, which contains

4 selection options.

• [HOME]: Return to [MAIN MENU].

• [DIRECT ACCESS TO...] : Opens the direct access window, which

will contain the text "1". The function keys << and >> (F2 and F3)

can be used to select each of the numbers and the navigation

button to increment or decrement the numbers: 1.3 in the example

below.

• [10 LAST MODIFICATIONS]: Opens a window in which the last

10 parameters modified can be accessed directly.

BBV19478 11/2011 21

Graphic terminal

RDY Term +0.00Hz 0A

MAIN MENU

1 DRIVE MENU

2 ACCESS LEVEL

3 OPEN / SAVE AS

4 PASSWORD

5 LANGUAGE

Code Quick

6 MONITORING CONFIG.

7 DISPLAY CONFIG.

8 International unit

RDY Term +0.00Hz 0A

1 DRIVE MENU

1.1 LIFT

1.2 MONITORING

1.3 SETTINGS

1.4 MOTOR CONTROL

1.5 INPUTS / OUTPUTS CFG

Code << >> Quick

1.6 COMMAND

1.7 APPLICATION FUNCT.

1.8 FAULT MANAGEMENT

1.9 COMMUNICATION

1.10 DIAGNOSTICS

1.11 IDENTIFICATION

1.12 FACTORY SETTINGS

1.13 USER MENU

1.14 CONTROL. INSIDE CARD

[MAIN MENU] - Menu mapping

Content of [MAIN MENU] menus

[1 DRIVE MENU] See next page

[2 ACCESS LEVEL] Defines which menus can be accessed (level of complexity)

[3 OPEN / SAVE AS] Can be used to save and retrieve drive configuration files

[4 PASSWORD] Provides password protection for the configuration

[5 LANGUAGE] Language selection

[6 MONITORING CONFIG.] Customization of information displayed on the graphic display terminal during operation

[7 DISPLAY CONFIG.] • Customization of parameters

• Creation of a customized user menu

• Customization of the visibility and protection mechanisms for menus and parameters

[8 International unit] • Provides the possibility to work with metric units or with imperial units for lift parameters.

See page 119.

22 BBV19478 11/2011

Graphic terminal

[1 DRIVE MENU]

RDY Term +0.00Hz 0A

1.1 LIFT

1.2 MONITORING

1.3 SETTINGS

1.4 MOTOR CONTROL

1.5 INPUTS / OUTPUTS CFG

1.6 COMMAND

1.7 APPLICATION FUNCT.

1.8 FAULT MANAGEMENT

1.9 COMMUNICATION

1.10 DIAGNOSTICS

1.11 IDENTIFICATION

1.12 FACTORY SETTINGS

1.13 USER MENU

1.14 CONTROL. INSIDE CARD

Content of [1. DRIVE MENU] menus:

[1.1 LIFT]: Lift menu

[1.2 MONITORING]: Visualization of current, motor and input/output values

[1.3 SETTINGS]: Accesses the adjustment parameters, which can be modified during operation

[1.4 MOTOR CONTROL ]: Moto r parameters (motor nameplate, auto-tuning, switching frequency, control algorithms, etc.)

[1.5 INPUTS / OUTPUTS CFG]: I/O configuration (scaling, filtering, 2-wire control, 3-wire control, etc.)

[1.6 COMMAND]: Configuration of command and reference channels (graphic displ ay t erminal , t erminals , bu s, e tc.)

[1.7 APPLICATION FUNCT.] : Configuration of application functions (e.g., preset speeds, PID, brake control , etc. )

[1.8 FAULT MANAGEMENT]: Configuration of fault management

[1.9 COMMUNICATION]: Communication parameters (fieldbus)

[1.10 DIAGNOSTICS]: Motor/drive diagnostics

[1.11 IDENTIFICATION]: Identifies the drive and internal options

[1.12 FACTORY SETTINGS]: Access to configuration files and return to factory settings

[1.13 USER MENU]: Specific menu set up by t he user in the [7. DISPLAY CONFIG.] menu

[1.14 CONTROL. INSIDE CARD]: Configuration of optional Controller Inside card

1 DRIVE MENU

Code << >> Quick

BBV19478 11/2011 23

Integrated display terminal

• Four 7-segment

displays

• Enters a menu or a

parameter, or saves the

displayed parameter or

value

• Exits a menu or parameter,

or aborts the displayed

value to return to the

previous value in the

memory

• Goes to the next menu

or parameter, or

decreases the

displayed value

• 2 CANopen status LEDs

• 2 Modbus status LEDs

• Returns to the previous

menu or parameter, or

increases the

displayed value

Note:

Altivar LIFT features an integrated display terminal with a 7-segment 4-digit di splay. The graphic displ ay terminal described on the p revious

pages can also be connected to this drive as an option.

Functions of the display and the keys

• Pressing or does not store the selection.

• Press and hold down (>2 s) or to scroll through the data quickly.

Save and store the selection: ENT

The display flashes when a value is stored.

Normal display, with no detected fault present and no startup:

- 43.0: Display of the parameter selected in the SUP menu (default selection: Lift speed).

- CLI: Current limita ti on.

- CtL: Controlled st op on in pu t phase loss.

- dCb: DC injection braking in progress.

- FLU: Motor fluxing in progress.

- FSt: Fast stop.

- nLP: No line power (no line supply on L1, L2, L3).

- nSt: Freewheel stop.

- Obr: Auto-adapted deceleration.

- PrA: Power Removal function active (drive locked).

- rdY: Drive ready.

- SOC: Controlled output cut in progress.

- tUn: Auto-tuning in progress.

- USA: Undervoltage alarm.

- ASA: Measurement of the phase-shift angle in progress.

The display flashes to indicate the presence of a detected fault.

24 BBV19478 11/2011

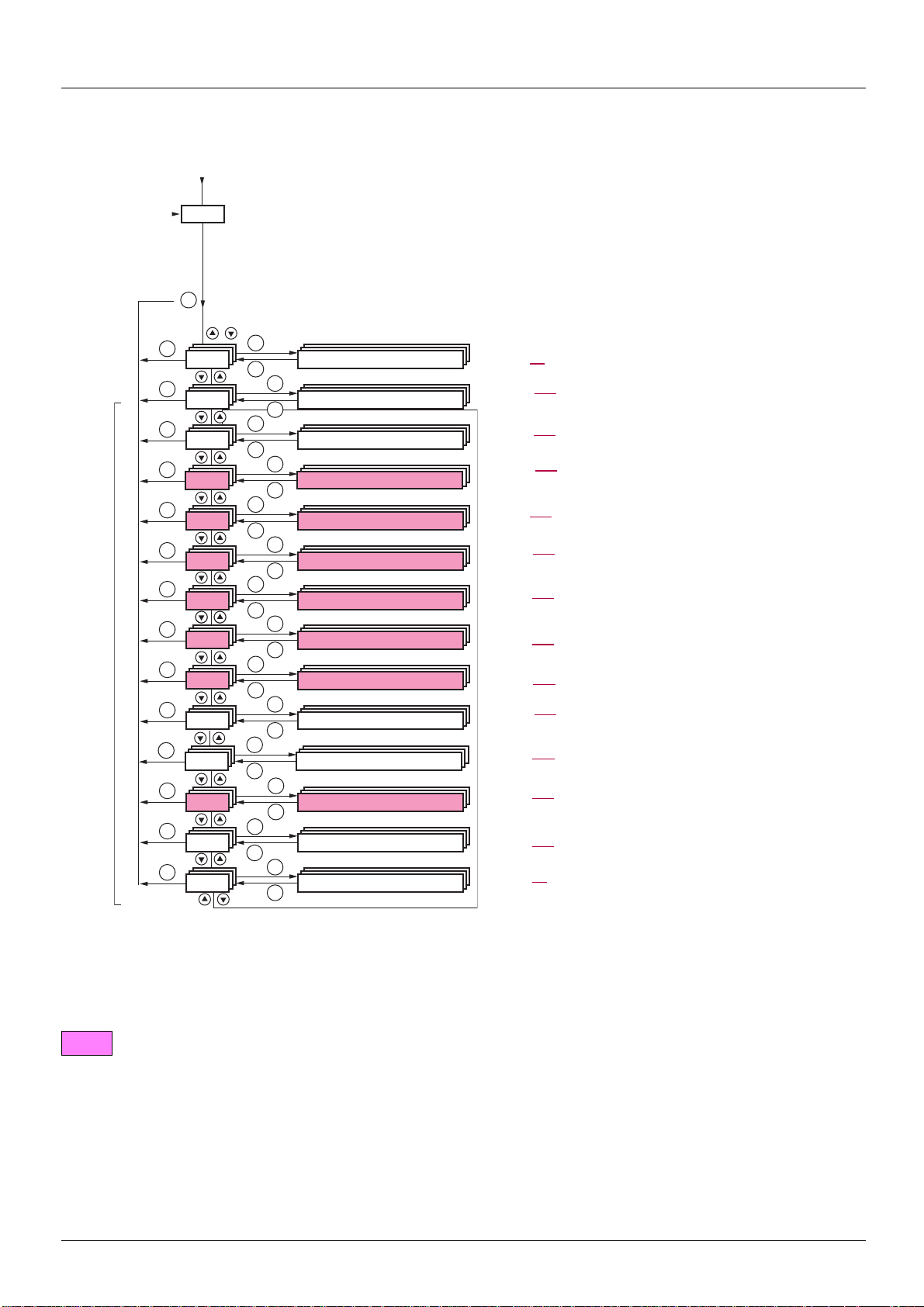

Integrated display terminal

XXX

CtL-

FUn-

LIF-

I-O-

SEt-

SUP-

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ENT

ENT

ESC

ENT

ESC

ENT

ESC

ENT

ESC

ENT

ESC

ENT

ESC

ENT

ESC

FCS-

LAC-

CON-

FLt-

ESC

ESC

ESC

ESC

ENT

ESC

ENT

ESC

ENT

ESC

ENT

ESC

ENT

ESC

PLC-

ESC

ENT

ESC

drC-

COd-

USr-

ESC

ENT

ESC

Displays the state of the drive

SETTINGS

APPLICATION FUNCT.

INPUTS / OUTPUTS CFG

FAULT MANAGEMENT

LIFT

Menus

MONITORING

MOTOR CONTROL

COMMAND

Turn on

FACTORY SETTINGS

PASSWORD

ACCESS LEVEL

COMMUNICATION

(page 133) Adjustment parameters, can be modified during

operation

(page 216

) Configuration of application functions (e.g., preset

speeds, brake control, etc.)

(page 173

) I/O configuration (scaling, filtering, 2-wire control,

3-wire control, etc.)

(page 268

) Configuration of fault management

(page 33

) Lift menu

(page 124

) Visualization of current, motor and input/output

values

(page 145

) Motor parameters (motor nameplate, auto-tuning,

switching frequency, control algorithms, etc.)

(page 203

) Configuration of command and reference channels

(graphic display terminal, terminals, bus, etc.)

(page 299

) Access to configuration files and return to factory

settings

(page 306

)

(page 27

)

(page 291

) Communication parameters (fieldbus)

(page 302

) Specific menu, set up by the user using the graphic

display terminal.

USER MENU

CONTROL. INSIDE CARD

(page 303

) Menu for the Controller Inside card, if present.

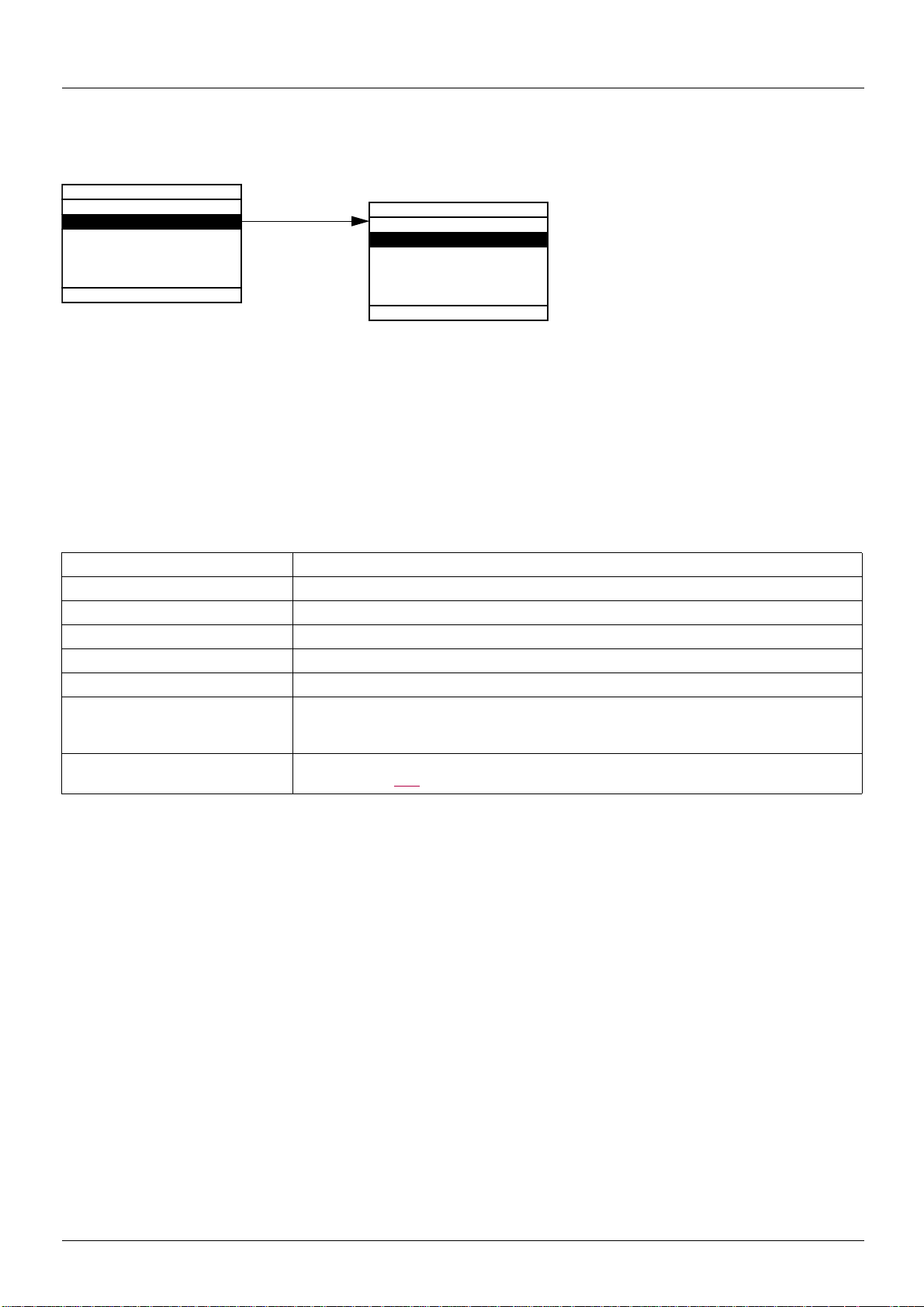

Accessing menus

A dash appears after menu and submenu codes to differentiate them from parameter codes.

Examples: FUn- menu, ACC parameter.

BBV19478 11/2011 25

The grayed-out menus may not be accessible depending on the control access (LAC) configuration.

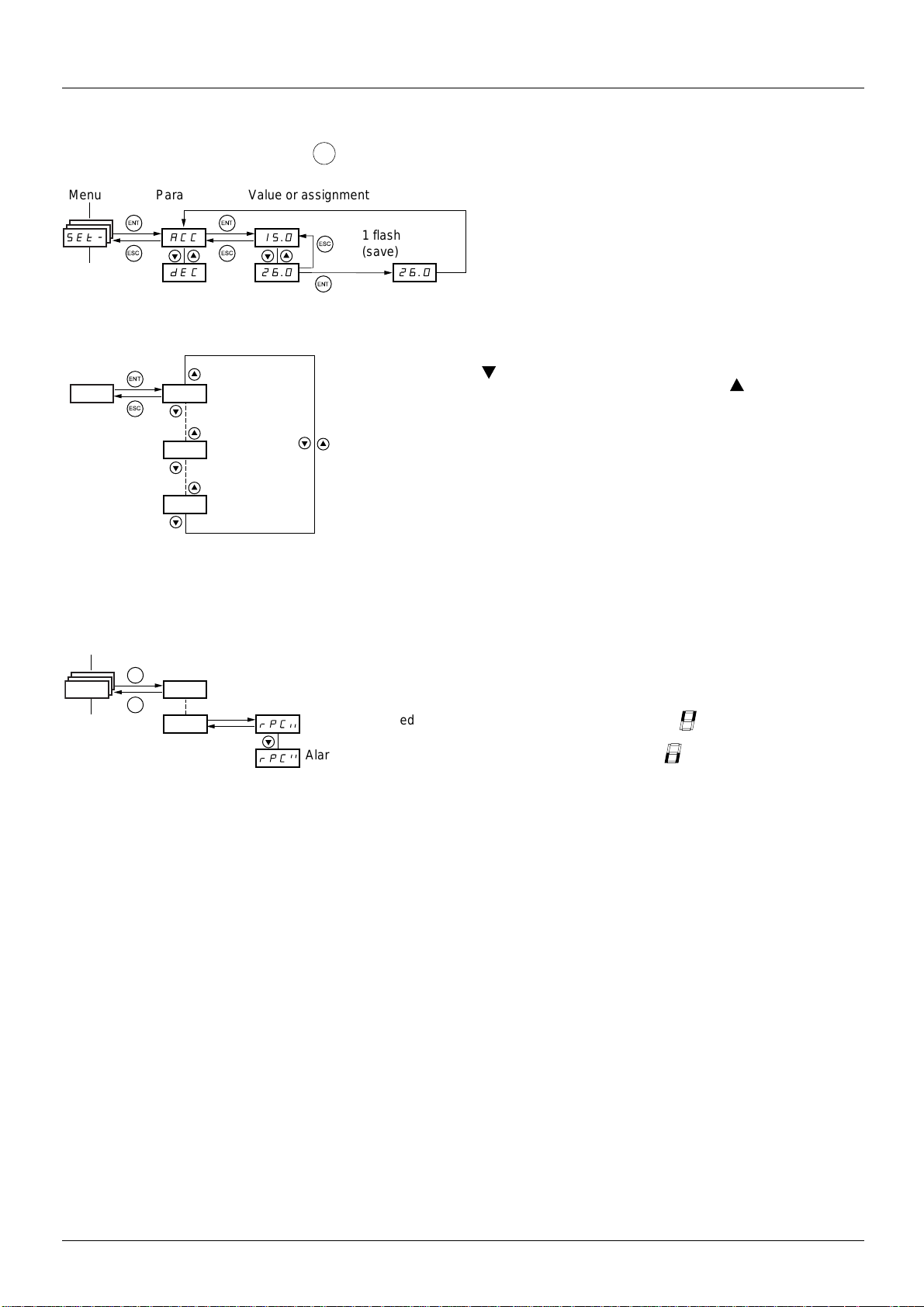

Integrated display terminal

ENT

ACC 15.0

ENT

ESC

ENT

ESC

26.0 26.0

ESC

dEC

ENT

SEt-

Menu Value or assignment

1 flash

(save)

Parameter

(Next parameter)

ENT

ESC

1

st

n

th

last

Menu

ENT

ESC

I-O-

Alarm not selected

Alarm selected

Accessing menu parameters

Save and store the displayed selection:

The display flashes when a value is stored.

All the menus are "drop-down" type menus, which means that after the last pa rameter, if

you continue to press , you will return to the fi rst p arameter and, conver sely, you c an

switch from the first parameter to the last parameter by pressing .

Selection of multiple assignments for one parameter

E.g. List of group 1 alarms in [INPUTS / OUTPUTS CFG] (I-O-)

menu

A number of alarms can be selected by "checking" them as

follows.

The digit on the right indicates: selected,

not selected.

The same principle is used for all multiple select ions.

26 BBV19478 11/2011

[2. ACCESS LEVEL] (LAC-)

RDY Term +0.00Hz 0A

2 ACCESS LEVEL

Basic

Standard

Advanced

Expert

<< >> Quick

RDY Term +0.00Hz 0A

MAIN MENU

1 DRIVE MENU

2 ACCESS LEVEL

3 OPEN / SAVE AS

4 PASSWORD

5 LANGUAGE

Code << >> Quick

8 International unit

RDY Term +0.00Hz 0A

1. DRIVE MENU

1.1 LIFT

1.2 MONITORING

1.3 SETTINGS

1.11 IDENTIFICATION

1.12 FACTORY SETTINGS

Code << >> Quick

1.13 USER MENU

RDY Term +0.00Hz 0A

MAIN MENU

1 DRIVE MENU

2 ACCESS LEVEL

3 OPEN / SAVE AS

4 PASSWORD

5 LANGUAGE

Code Quick

6 MONITORING CONFIG.

8 International unit

RDY Term +0.00Hz 0A

1 DRIVE MENU

1.1 LIFT

1.2 MONITORING

1.3 SETTINGS

1.4 MOTOR CONTROL

1.5 INPUTS / OUTPUTS CFG

Code << >> Quick

1.6 COMMAND

1.7 APPLICATION FUNCT.

1.8 FAULT MANAGEMENT

1.9 COMMUNICATION

1.10 DIAGNOSTICS

1.11 IDENTIFICATION

1.12 FACTORY SETTINGS

1.13 USER MENU

1.14 CONTROL. INSIDE CARD

RDY Term +0.00Hz 0A

MAIN MENU

1 DRIVE MENU

2 ACCESS LEVEL

3 OPEN / SAVE AS

4 PASSWORD

5 LANGUAGE

Code Quick

6 MONITORING CONFIG.

7 DISPLAY CONFIG.

8 International unit

RDY Term +0.00Hz 0A

MAIN MENU

1 DRIVE MENU

2 ACCESS LEVEL

3 OPEN / SAVE AS

4 PASSWORD

5 LANGUAGE

Code Quick

6 MONITORING CONFIG.

7 DISPLAY CONFIG.

8 International unit

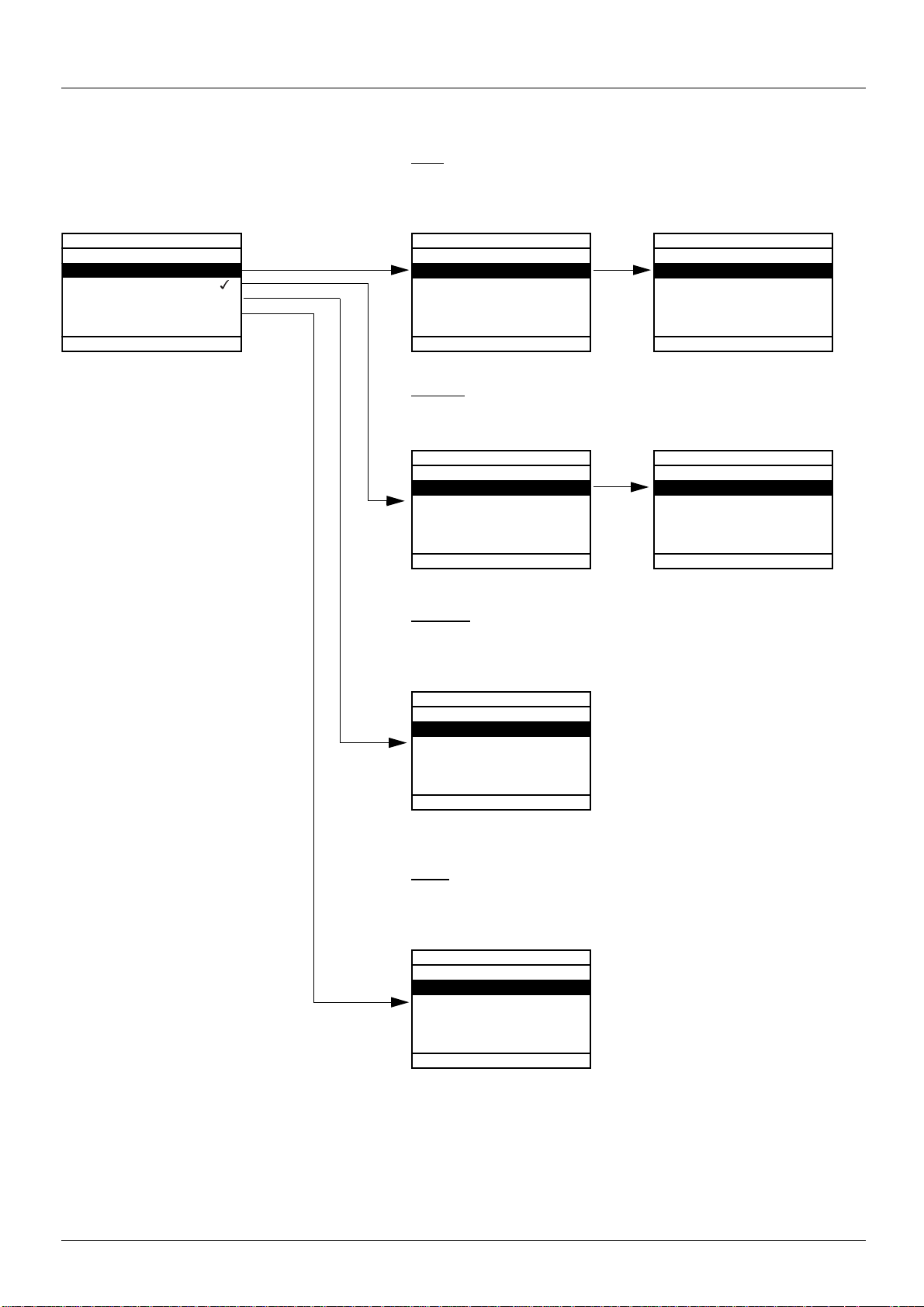

With graphic display terminal

Basic

Access to 5 menus only, and access to 6 submenus only in the

[1. DRIVE MENU] menu.

A single function can be assigned to each input.

Standard

This is the factory-set level. Access to all menus.

A single function can be assigned to each input.

BBV19478 11/2011 27

Advanced

Access to all menus and submenus.

Several functions can be assigned to

each input.

Expert

Access to all menus and submenus as for [Advanced] level, and access to

additional parameters.

Several functions can be assigned to each input.

[2. ACCESS LEVEL] (LAC-)

XXX

LIF-

ESC

ESC

ENT

LAC-

ESC

ENT

ESC

COd-

Displays the state of the drive

Turn on

With integrated display terminal:

ACCESS LEVEL

Code Name/Description Factory setting

LAC-

bAS

• bAS: Limited access to SIM, SUP, SEt, FCS, USr, COd and LAC menus. A single f unction can be assigned to each

Std

input.

Std

AdU

Epr

• Std: Access to all menus on the integrated display terminal. A single fun ction can be assigned to each input.

• AdU: Access to all menus on the integrated display terminal. Several functions can be assigned to each input.

• EPr: Access to all menus on the integrated display te rminal and access to additional p arameters. Several functions

can be assigned to each input.

28 BBV19478 11/2011

[2. ACCESS LEVEL] (LAC-)

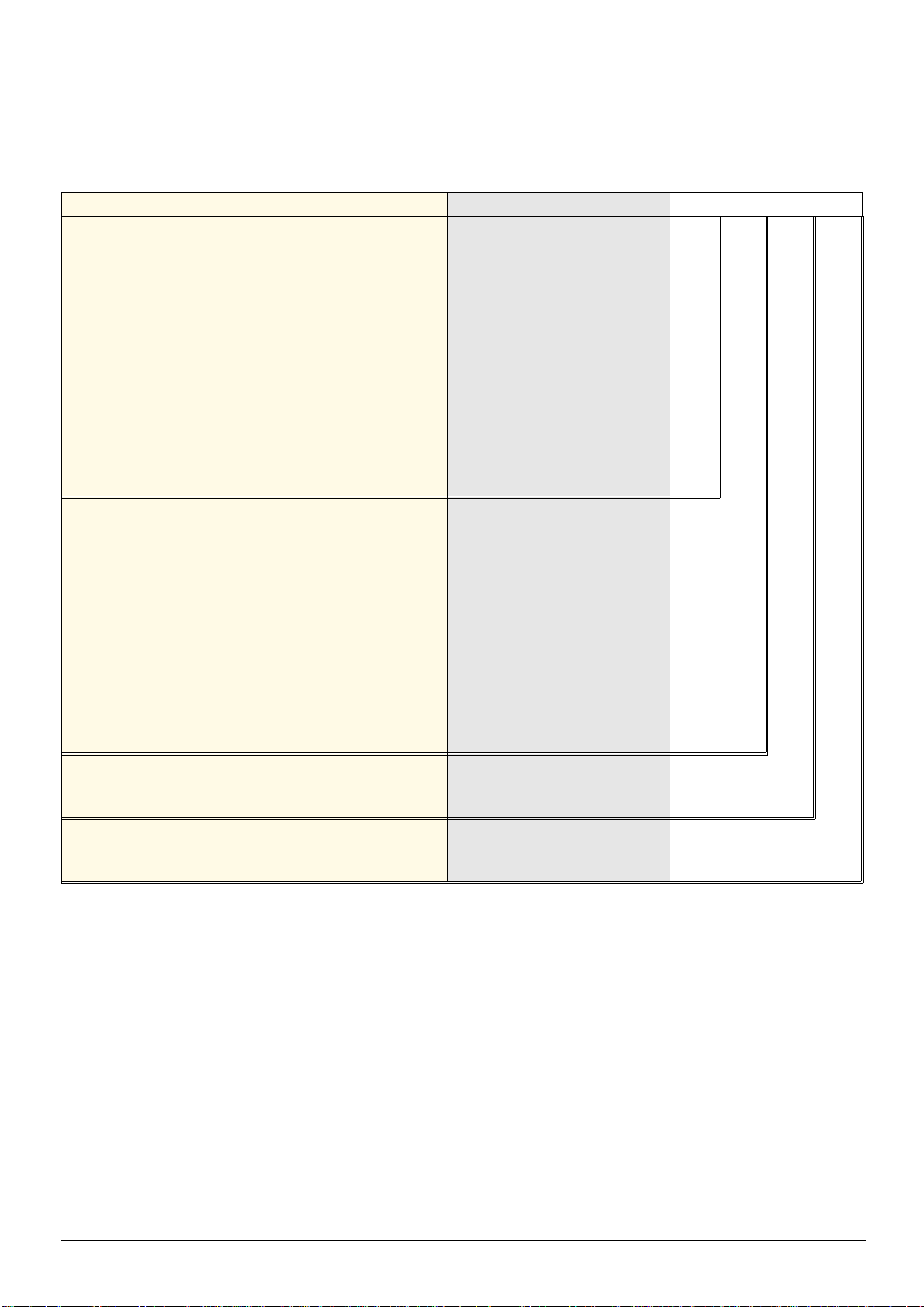

Comparison of the menus that can be accessed on the graphic display terminal/integrated display terminal

Graphic terminal Integrated Display Terminal Access Level

[2 ACCESS LEVEL] LAC- (Access level)

[3 OPEN/SAVE AS] [4 PASSWORD] COd- (Password)

[5 LANGUAGE] [1 DRIVE MENU] [1.1 LIFT] LIF- (Lift)

[1.2 MONITORING] SUP-(Monitoring)

[1.3 SETTINGS] SEt- (Settings)

[1.11 IDENTIFICATION] [1.12 FACTORY SETTINGS] FCS- (Factory settings)

[1.13 USER MENU] USr- (User menu)

A single function can be assigned to each input. A single function can be assigned to

each input.

[1.4 MOTOR CONTROL] drC- (Motor control)

[1.5 INPUTS / OUTPUTS CFG] I-O- (I/O configuration)

[1.6 COMMAND] CtL- (Command)

[1.7 APPLICATION FUNCT.] FUn- (Application functions)

[1.8 FAULT MANAGEMENT] FLt- (Fault management)

[1.9 COMMUNICATION] COM- (Communication)

[1.10 DIAGNOSTICS] [1.14 CONTROL. INSIDE CARD] (1) PLC- (Controller Inside card) (1)

[6 MONITORING CONFIG.] -

A single function can be assigned to each input. A single function can be assigned to

each input.

[7 DISPLAY CONFIG.] -

Several functions can be assigned to each input. Several functions can be assigned

to each input.

Expert parameters Expert parameters

Several functions can be assigned to each input. Several functions can be assigned

to each input.

Basic bAS

Standard Std (factory setting)

Advanced AdU

Expert EPr

(1)Can be accessed if the Controller Inside card is present.

BBV19478 11/2011 29

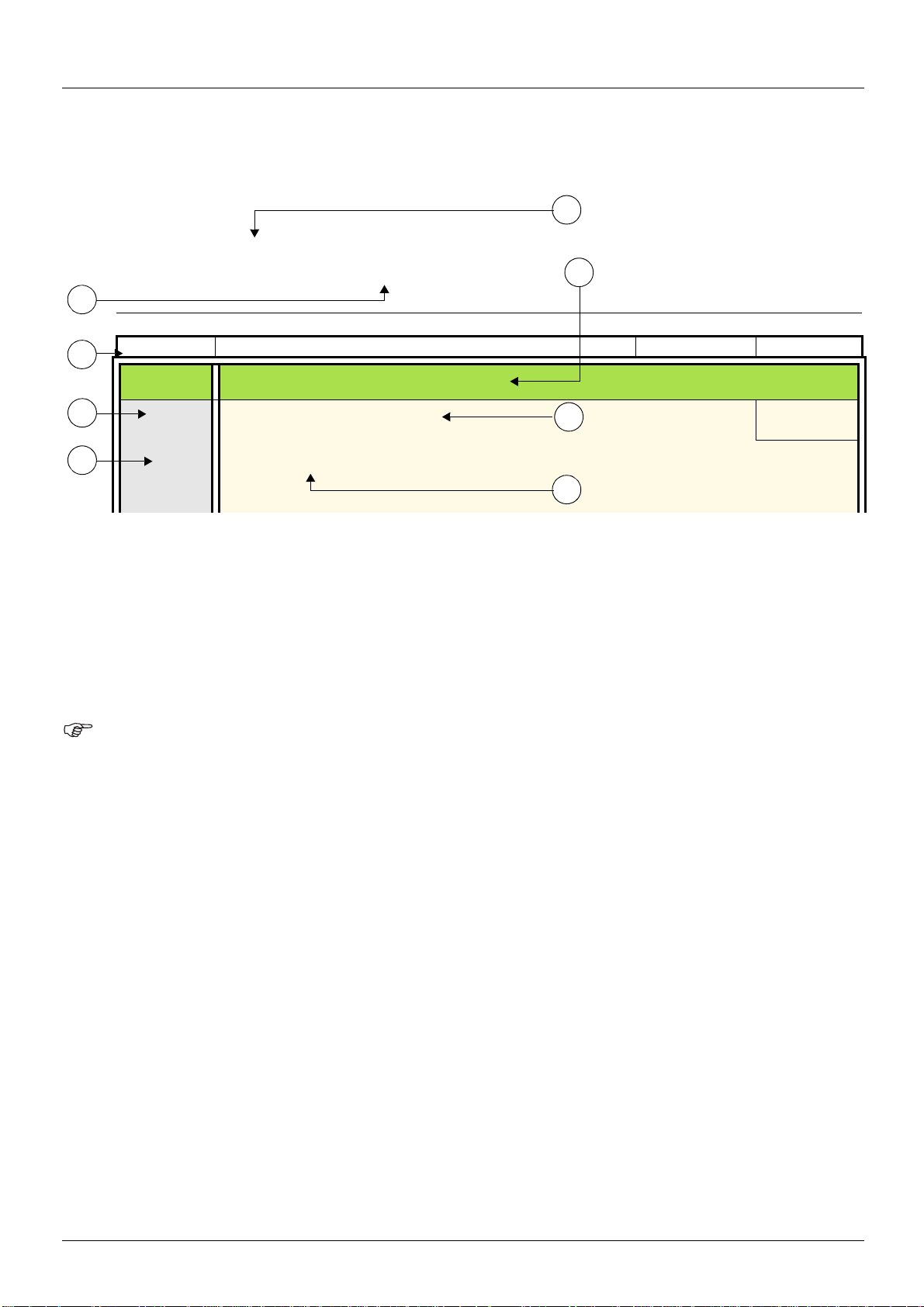

Structure of the parameter tables

5

2

3

1

4

6

8

7

1. Name of menu on 4-digit 7-segment display.

2. Submenu code on 4-digit 7-segment display.

3. Parameter code on 4-digit 7-segment display.

4. Parameter value on 4-digit 7-segment display.

5. Name of menu on graphic display terminal.

6. Name of submenu on graphic display terminal.

7. Name of parameter on graphic display terminal

8. Value of parameter on graphic display terminal

The parameter tables in the descriptio ns of the various menus can be used wit h both the graphi c display terminal an d the integrated display

terminal. They therefore contain information for these two terminals in accordance with the description below.

E.g.

[1.7 APPLICATION FUNCT.] (FUn-)

Code Name/Description Adjustment range: Factory setting

rEF-

rCb

Fr1

Fr1b

Note:

• The text in square brackets [ ] indicates what you will see on the graphic display terminal.

[REFERENCE SWITCH.]

M [Ref 1B switching]

v [ch1 active] (Fr1): No switching, [Ref.1 channel] (Fr1) active

v [ch1B active] (Fr1b): No switching, [Ref.1B channel] (Fr1b) active

[ch1 active]

(Fr1)

30 BBV19478 11/2011

Loading...

Loading...