Page 1

Altivar 61

Transition manual

Migration from ATV38 V ATV61

Page 2

This document has been designed to assist you when replacing an Altivar 38 with an Altivar 61 version V1.1 ie01 or later.

Scope of application:

- Variable-torque applications

- Replacement of Altivar 38 on three-phase 380 V 460 V ranges

The Altivar 61 and its various options or accessories can be selected on the basis of the hardware configuration used on the Altivar 38.

The fundamental expansions offered by the Altivar 61 affect features such as the number of I/O, application functions, operating

temperature, etc.

This manual also outlines assembly, installation and wiring instructions.

Migrating an Altivar 38 to an Altivar 61 software configuration is made simple by the use of the PowerSuite v2.20 software workshop.

Page 3

Table of contents

Determining catalog numbers____________________________________________________________________________________ 6

Choosing the Altivar 61 catalog number _____________________________________________________________________ 6

Selecting the power circuit options _________________________________________________________________________ 7

Mounting accessories ___________________________________________________________________________________ 8

Control circuit options ___________________________________________________________________________________ 9

Selecting I/O extension cards (VW3A58201, VW3A58202) _____________________________________________________ 10

Selecting communication channels ________________________________________________________________________ 12

Drive implementation _________________________________________________________________________________________ 14

Installation ___________________________________________________________________________________________ 14

Comparison of dimensions ______________________________________________________________________________ 17

Mounting the RFI filter __________________________________________________________________________________ 20

NEMA mounting kits ___________________________________________________________________________________ 24

Separate control card power supply _______________________________________________________________________ 26

Remote display terminal ________________________________________________________________________________ 26

Power cables _______________________________________________ __________________________________________ 27

Implementation of the Altivar 61 communication option cards __________________________________________________________ 37

General _____________________________________________________________________________________________ 37

Communication via Modbus network _______________________________________________________________________ 39

Communication via Unitelway/Modbus network and VW3 A3 303 option card _______________________________________ 42

Communication via CANopen network _____________________________________________________________________ 43

Communication via Profibus DP network ___________________________________________________________________ 45

Communication via Fipio network - VW3 A3 311 option card ____________________________________________________ 47

Communication via Interbus network _______________________________________________________________________ 49

Communication via Modbus Plus network ___________________________________________________________________ 50

Communication via DeviceNet network _____________________________________________________________________ 52

Communication via Ethernet network ______________________________________________________________________ 61

AS-i ________________________________________________________________________________________________ 70

Application-specific option cards __________________________________________________________________________ 73

3

Page 4

Implementation procedure

Migration from ATV 38 ATV 61

b 1 Identifying the existing ATV 38

Steps 3 and 4 must

be performed with

the power off.

V

v Make an inventory of your Altivar 38 installation.

b 2 Selecting the ATV 61

v Determine the Altivar 61 catalog number.

v Choose the various options required.

b 3 Mounting

v Mount the drive in accordance with the

instructions in this document, using the

substitution kit.

v Install any internal and external options.

b 4 Wiring

v Connect the motor, ensuring that its

connections correspond to the voltage.

v Connect the control.

v Connect the speed reference.

v Connect the line supply, after making sure

that the power is off.

b 5 Configuration

v Drive

v Communication cards

4

Page 5

Altivar 38 hardware identification

Before selecting the Altivar 61, the Altivar 38 hardware configuration needs to be determined carefully.

Measure the line voltage and indicate the type of power supply:

1

Line voltage:_________V Three-phase

ATV38HD16N4

Input V : 380/460V-50/60Hz

Input phase : 3

Note down the drive catalog number, which appears on the Altivar 38 nameplate:

2

ATV38______________________

Note down the catalog number of any EMC filter installed under the drive:

3

Input I : 35.4/28 A

Input fuse : Type J : 60A Max

Cu AWG 6 : 75˚C : 20lb-in/2.26 Nm

LISTED 170M

IND.CONT.EQ

Serial N . 1703001070 France - 6W 0202

VW3A584 ___________________

Note down the catalog number of any option cards installed in the Altivar 38; this can be found on the label attached to the card:

4

Motor Rating : 11 kW / 15HP

Output 3 Ph : 380/460V

Output I : 22A

Output I max. transient (1mn) : 24.2A

Output frequency : 0.1-500Hz

N998

Motor Protective Device

AIC 22000 A Protection type Classe 20

VW3A58_____________________

Note down whether the operator terminal is used:

5

VW3A58101: YES NO

Is the operator terminal connected remotely on the enclosure

door?

Note down the catalog number of the NEMA type 1 mounting kit, if used:

6

VW3A5885___________________

Note down the catalog number of the control card fan kit, if used:

7

VW3A5882___________________

Make sure you have the diagrams for the existing installation.

8

YES NO

5

Page 6

1. Determining catalog numbers

1. 1. Choosing the Altivar 61 catalog number

Required information (refer to page 5): type of use, line voltage, Altivar 38 catalog number

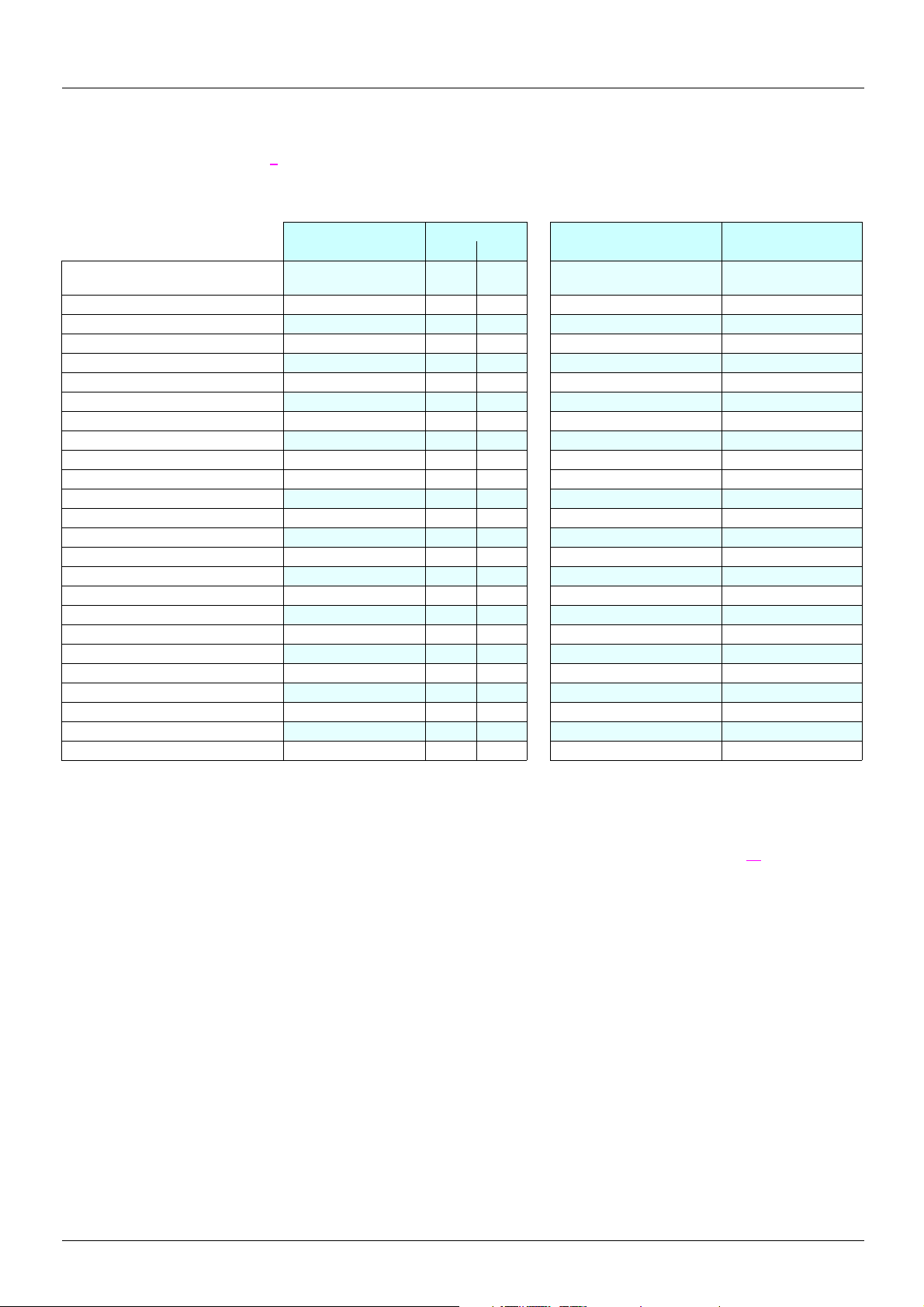

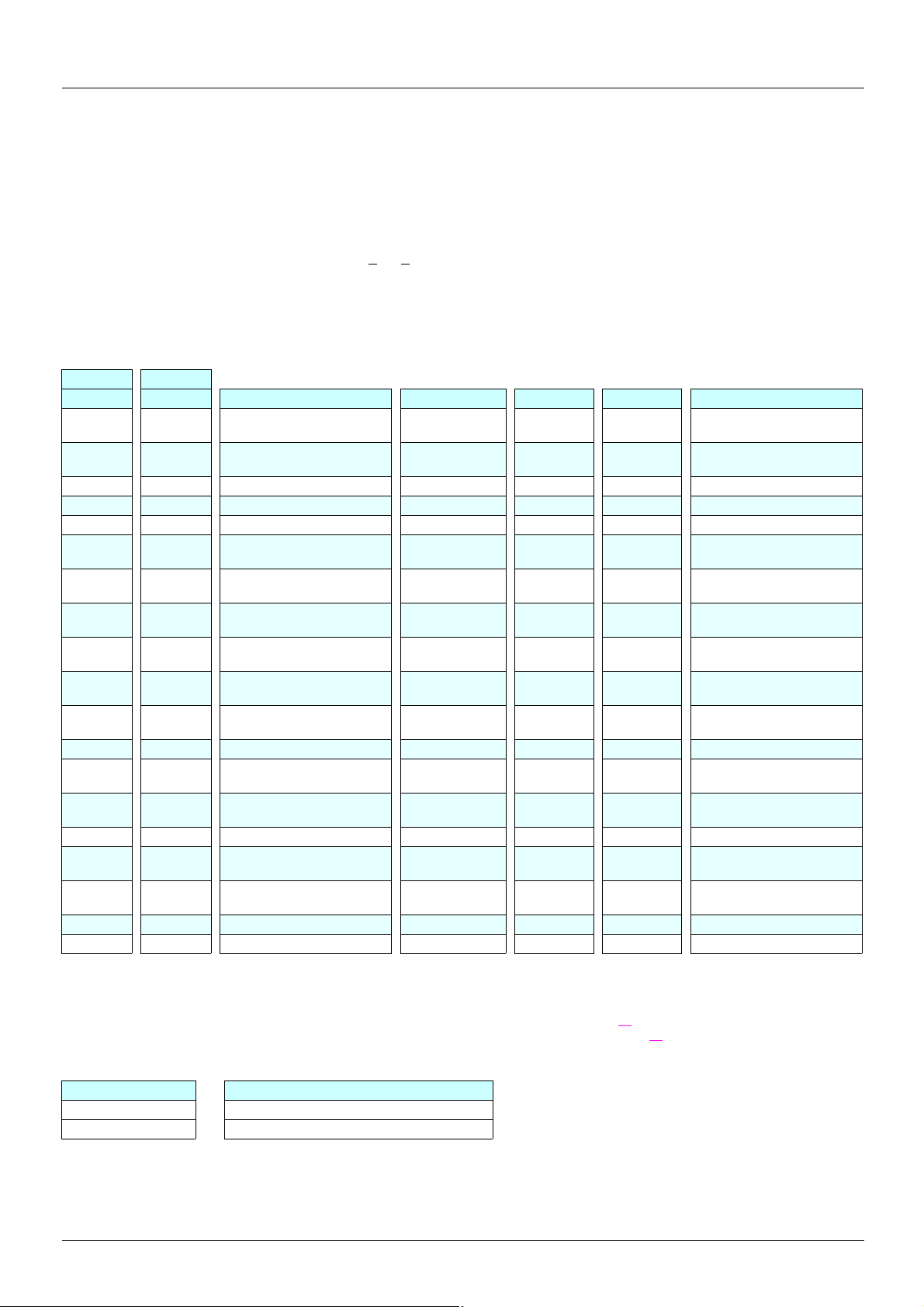

1. 1. 1. Your catalog number starts with ATV38H

Power supply

380…460 V three-phase

ATV38 catalog

number

ATV38HU18N4 0.75 1 ATV 61H075N4 (1) VW3 A9 302

ATV38HU29N4 1.5 2 ATV 61HU15N4 (1) VW3 A9 302

ATV38HU41N4 2.2 3 ATV 61HU22N4 (1) VW3 A9 304

ATV38HU54N4 3.0 - ATV 61HU30N4 (1) VW3 A9 304

ATV38HU72N4 4.0 5 ATV 61HU40N4 (1) VW3 A9 304

ATV38HU90N4 5.5 7.5 ATV 61HU55N4 (1) VW3 A9 305

ATV38HD12N4 7.5 10 ATV 61HU75N4 (1) VW3 A9 306

ATV38HD16N4 11 15 ATV 61HD11N4 (1) VW3 A9 307

ATV38HD23N4 15 20 ATV 61HD15N4 (1) VW3 A9 308

ATV38HD25N4 (X) 18.5 25 ATV 61HD18N4 (2) VW3 A9 309

ATV38HD28N4 (X) 22 30 ATV 61HD22N4 (2) VW3 A9 310

ATV38HD33N4 (X) 30 40 ATV 61HD30N4 (2) VW3 A9 312

ATV38HD46N4 (X) 37 50 ATV 61HD37N4 (2) VW3 A9 312

ATV38HD54N4 (X) 45 60 ATV 61HD45N4 (2) VW3 A9 312

ATV38HD64N4 (X) 55 75 ATV 61HD55N4 (2) VW3 A9 312

ATV38HD79N4 (X) 75 100 ATV 61HD75N4 (2) VW3 A9 312

ATV38HC10N4 (X) 90 125 ATV 61HD90N4 (2)

ATV38HC13N4 (X) 110 150 ATV 61HC11N4 (2)

ATV38HC15N4 (X) 132 200 ATV 61HC13N4 (2)

ATV38HC19N4 (X) 160 250 ATV 61HC16N4 (2)

ATV38HC23N4 (X) 200 300 ATV 61HC22N4 (2)

ATV38HC25N4 (X) 220 350 ATV 61HC22N4 (2)

ATV38HC28N4 (X) 250 400 ATV 61HC25N4 (2)

ATV38HC31N4 (X) 280 450 ATV 61HC31N4 (2)

ATV38HC33N4 (X) 315 500 ATV 61HC31N4 (2)

Power

kW HP

ATV 61 catalog number Substitution kit

Substitution kit: This kit consists of a metal support plate that makes it possible to re-use the same mounting holes as the ATV38.

(1)Drive supplied with a graphic display terminal that can be connected remotely. To order a drive without a graphic display terminal, add

the letter Z at the end of the catalog number. The drive will then be equipped with the integrated 7-segment display terminal.

(2)On ATV38 catalog numbers ending with X, the RFI filter is disconnected in the event of use on an IT system (page 27

implementation).

1. 1. 2. Your catalog number starts with ATV38ED

You must install the Altivar 61 in an enclosure and customize the control devices yourself.

6

Page 7

1. Determining catalog numbers

1. 2. Selecting the power circuit options

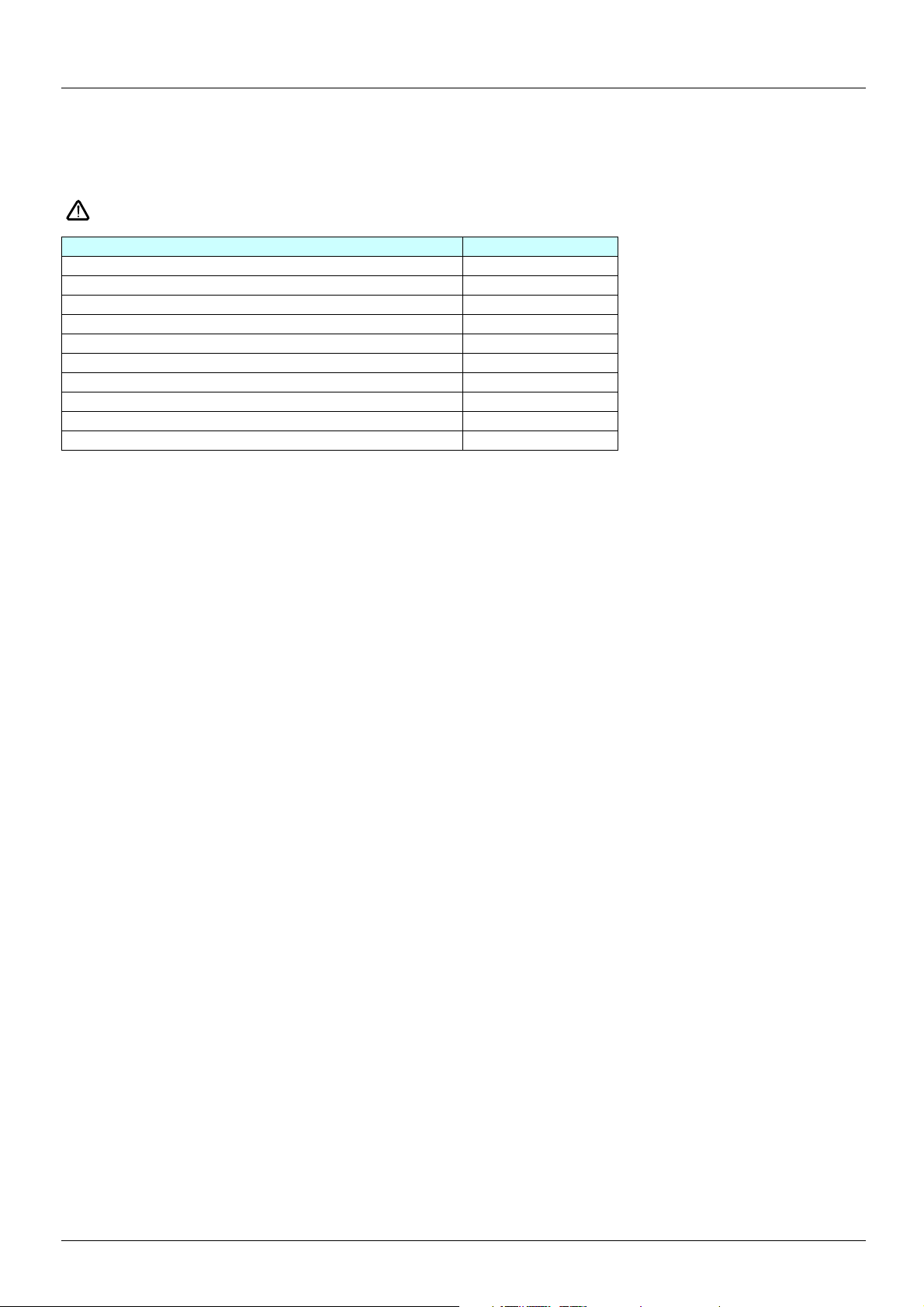

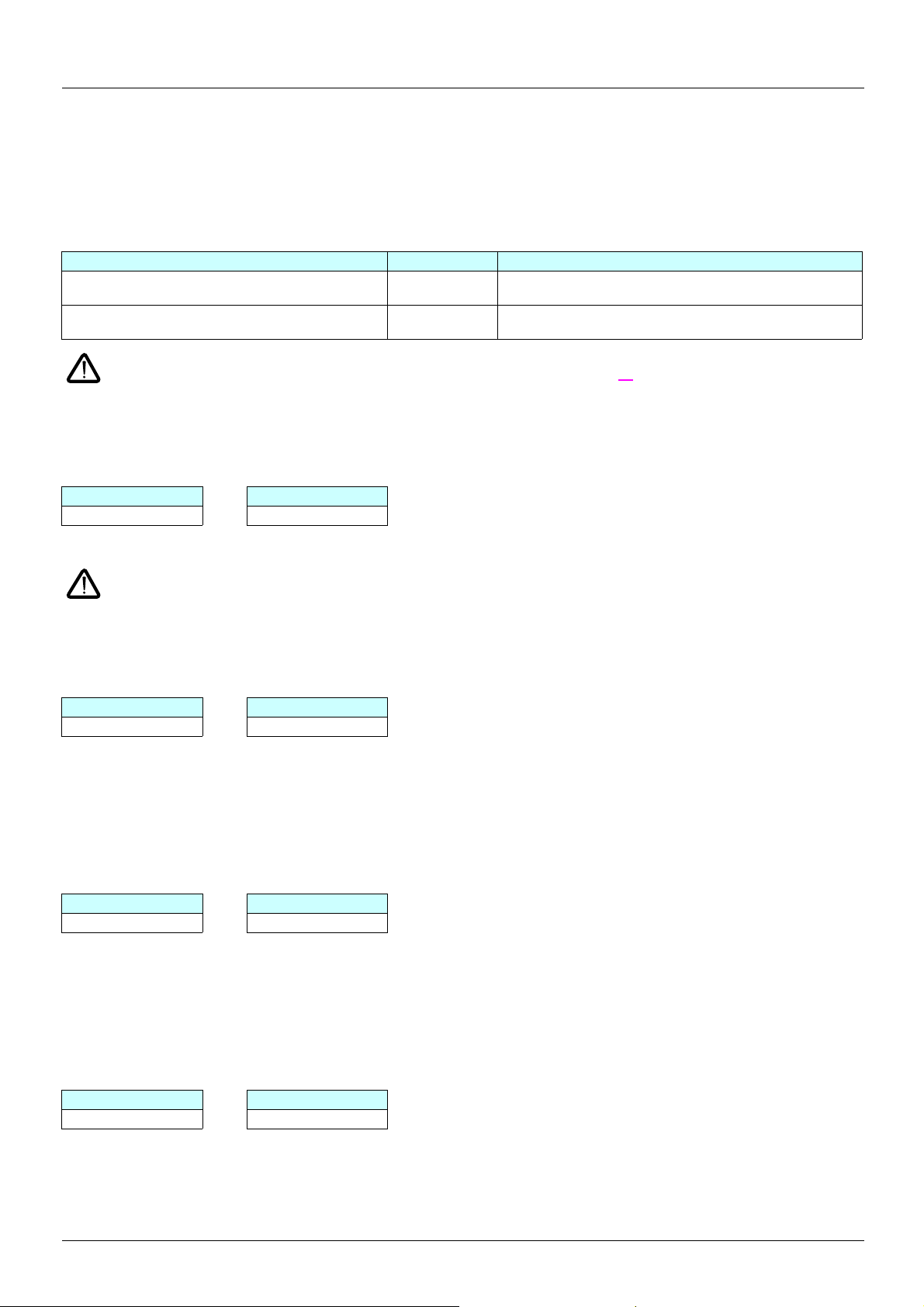

1. 2. 1. Radio interference filters (VW3A684x)

The filters previously installed on the ATV38 are not compatible with the ATV 61 and must, therefore, be replaced.

No kit for substitution (mounting) between the 2 filter ranges.

Drive catalog number Filter catalog number

ATV 61H075N4, U15N4, U22N4 VW3 A4 401

ATV 61HU30N4, U40N4 VW3 A4 402

ATV 61HU55N4, U75N4 VW3 A4 403

ATV 61HD11N4 VW3 A4 404

ATV 61HD15N4, D18N4 VW3 A4 405

ATV 61HD22N4 VW3 A4 406

ATV 61HD30N4, D37N4 VW3 A4 407

ATV 61HD45N4, D55N4, D75N4 VW3 A4 408

ATV 61HD90N4, C11N4, C13N4, C16N4 VW3 A4 410

ATV61HC22N4, C25N4, C31N4 VW3 A4 411

1. 2. 2. Line chokes

VZ1L0xxxMxx, VW3A5850x, VW3A6650x, VW3A6850x

The line chokes used with the ATV38 can be re-used with the ATV 61 and do not, therefore, need to be replaced.

1. 2. 3. Output filters (LR filters, LC filters)

VW3A584 5x, VW3A6641x, VW3A6642x

The output filters used with the ATV38 can be re-used with the ATV 61 and do not, therefore, need to be replaced.

1. 2. 4. Motor chokes

VW3A6650x, VW3A6855x

The motor chokes used with the ATV38 can be re-used with the ATV 61 and do not, therefore, need to be replaced.

1. 2. 5. Braking resistors

VW3A5870x, VW3A5873x, VW3A6670x

The braking resistors used with the ATV38 can be re-used with the ATV 61 and do not, therefore, need to be replaced.

7

Page 8

1. Determining catalog numbers

1. 3. Mounting accessories

1. 3. 1. Removable power terminal kit (VW3A5881x)

There is no equivalent to this kit for the Altivar 61.

1. 3. 2. Air exchanger kit (VW3A5880x)

There is no equivalent to this kit for the Altivar 61.

Alternative solution: Mount the power part outside the enclosure using the ATV 61 VW3 A9 5xx flange-mounting kit. This solution can be

used to reduce the heat dissipated inside the enclosure.

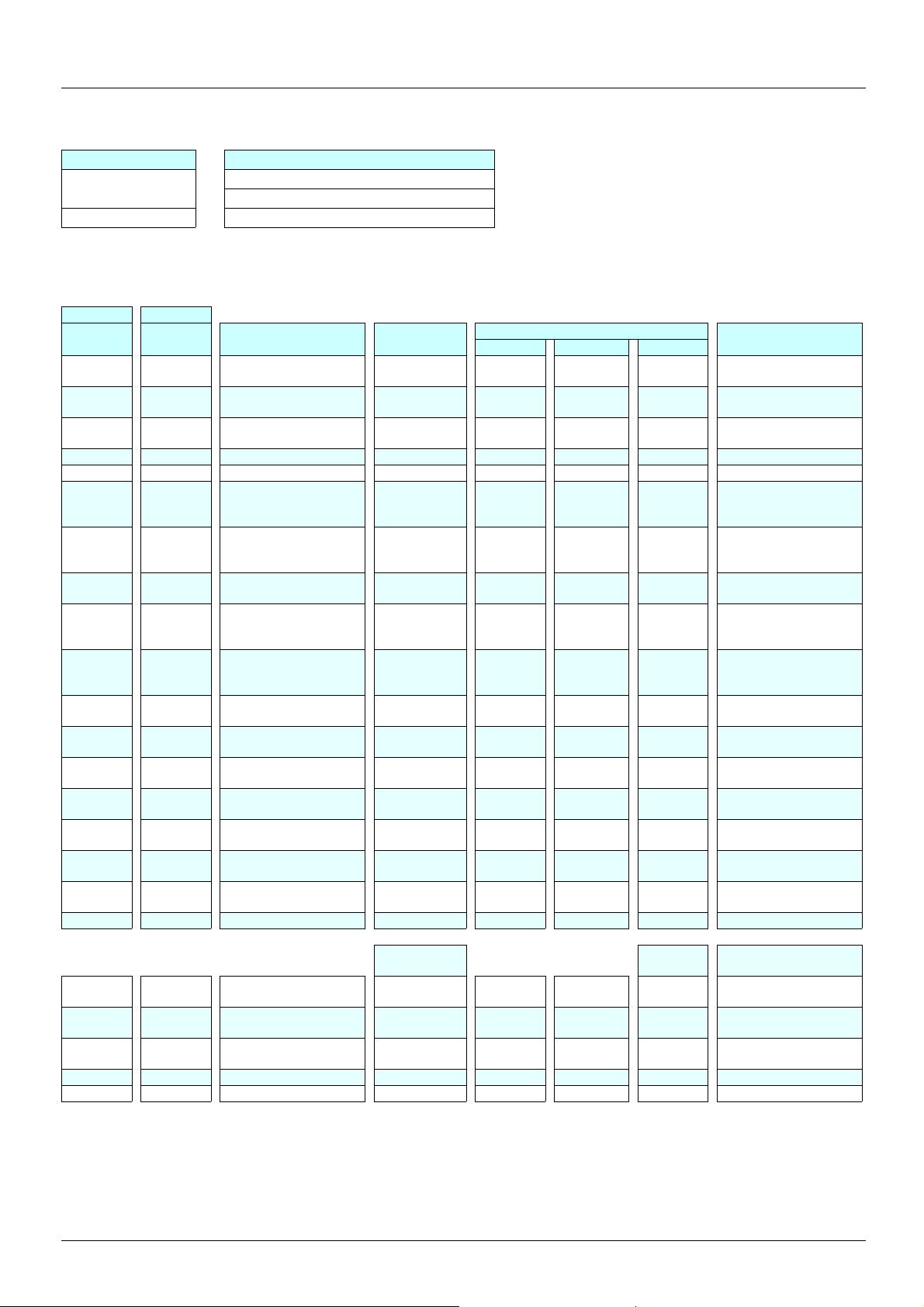

1. 3. 3. NEMA type 1 mounting kit

Required information: Altivar 61 catalog number

Catalog number selectio n gu ide:

ATV 61 catalog number NEMA kit

ATV 61H075N4 VW3 A9 201

ATV 61HU15N4 VW3 A9 201

ATV 61HU22N4 VW3 A9 201

ATV 61HU30N4 VW3 A9 202

ATV 61HU40N4 VW3 A9 202

ATV 61HU55N4 VW3 A9 203

ATV 61HU75N4 VW3 A9 203

ATV 61HD11N4 VW3 A9 204

ATV 61HD15N4 VW3 A9 205

ATV 61HD18N4 VW3 A9 205

ATV 61HD22N4 VW3 A9 206

ATV 61HD30N4 VW3 A9 207

ATV 61HD37N4 VW3 A9 207

ATV 61HD45N4 VW3 A9 209

ATV 61HD55N4 VW3 A9 209

ATV 61HD75N4 VW3 A9 209

8

Page 9

1. Determining catalog numbers

1. 4. Control circuit options

1. 4. 1. Control card fan kit (VW3A5882x)

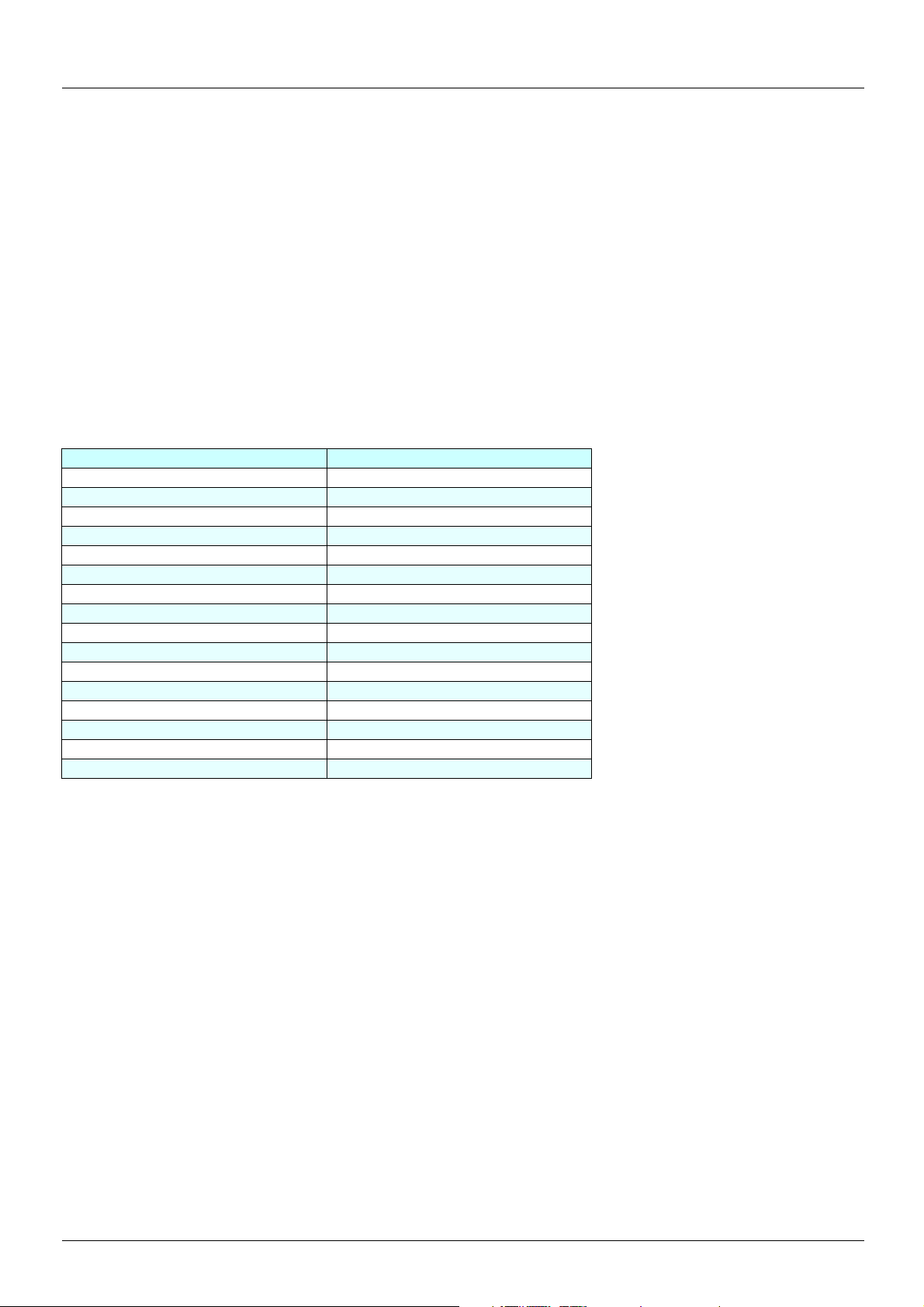

Required information: Altivar 61 catalog number

At an ambient temperature between 50°C and 60°C, the Altivar 61 has a higher operati ng capacity than the Altivar 38.

The control card fan kit is required for the following ATV 61 ratings if t he ambient temperature is between 50 and 60°C.

ATV 61 catalog number Control card fan kit

ATV 61HD22N4 VW3 A9 404

ATV 61HD30N4 VW3 A9 405

ATV 61HD37N4 VW3 A9 405

ATV 61HD45N4 VW3 A9 407

ATV 61HD55N4 VW3 A9 407

ATV 61HD75N4 VW3 A9 407

1. 4. 2. Separate control card power supply kit (VW3A5860x)

This kit serves no purpose as the ATV 61 integrates this function as standard and requires the presence of an external 24 V DC (30 W)

supply.

1. 4. 3. Remote display terminal (VW3A58103)

Remote connection of the Altivar 61 graphic display terminal on the enclosure door

IP54 version Remote mounting kit : VW3 A1 102

3-meter cable : VW3 A1 104 R30

IP65 version Remote mounting kit : VW3 A1 102

IP65 door : VW3 A1 103

3-meter cable : VW3 A1 104 R30

RJ45 female/female adapter : VW3 A1 105

This should be used in the above two instances.

Note: Order an Altivar 61 with graphic display terminal (without Z at the end of the catalog number).

Other connection cable lengths are available:

Cable 1 m VW3 A1 104 R10

5 m VW3 A1 104 R50

10 m VW3 A1 104 R100

Note: The graphic display terminal catalog number is VW3 A1 101.

9

Page 10

1. Determining catalog numbers

1. 5. Selecting I/O extension cards (VW3A58201, VW3A58202)

1. 5. 1. ATV38 and I/O option cards (VW3A58201, VW3A58202)

Required information: Connection diagram, presence of an I/O extension card

As standard the ATV 61 has more I/O than the ATV38.

• If the ATV38 is not equipped with an I/O extension card, there is no need to add a card to the Altivar 61. Ignore this section.

• If the ATV38 is equipped with an I/O extension card, it is important to know which inp uts/outputs are used as wel l as the function assigned

to AI3 (VW3A58201 card) and to encoder input A, A

The tables below can be used to ascertain what was used previously and, therefore, to find the equivalent on ATV 61 with or without an

option card.

Scenario 1: Replacing an ATV38 with or without a VW3A58201 option card:

Used: Becomes:

ATV38 ATV 61 Description VW3A58201 VW3 A3 201 VW3 A3 202 Description

R1A/R1B/

R1C

R2A/R2C R2A/R2C Programmable relay (R2)

AO 1 AO 1 0-20 mA analog output -10 -10 -10 -10 V output

COM COM Analog input common TH1+ TH2+ PTC probe

AI 1 AI 1+ 0…10 V analog input TH1- TH2- PTC probe

+10 +10

AI 2 AI 2

LI 1 LI 1

LI 2 LI 2

LI 3 LI 3

LI 4 LI 4

+24 +24 Logic input power supply LO 2 LO 4 Logic output

R1A/R1B/

R1C

LI 5

LI 6

Fault relay (R1) COM 0 V 0 V Common

1 to 10 kΩ potentiometer

power supply

Analog input

0…10 V 0..4/20 mA

24 V DC run forward logic

inputs

24 V DC programmable

logic input

24 V DC programmable

logic input

24 V DC programmable

logic input

24 V DC programmable

logic input

24 V DC programmable

logic input

, B, B (VW3A58201 card).

+24 +24 +24 Logic input power supply

LI 5 also on

control card

LI 6 also on

control card

LO LO 1 LO 3 Logi c output

LO + CLO CLO Logic output power supply

AI 3A/AI3 B

g

AO AO 2

+10 +10 V output

R3A/R3B/

R3C

LI 7 LI 11

LI 8 LI 12

LI 9 LI 13

LI10 LI 14

AI3 +/AI3 -

R4A/R4B/

R4C

Current

AI4 Programmable analog input

AO 3

FP Pulse input

Programmable relay

24 V DC programmable

logic input

24 V DC programmable

logic input

24 V DC programmable

logic input

24 V DC programmable

logic input

Programmable analog input

Programmable analog

output

Programmable analog

output

g Review of the various instances of use of the AI3 input on the VW3A58201 card:

AI3 assignment

PTC Use LI6 on ATV 61 control card in PTC mode and adjust SW2 (see page xx

Use the TH inputs on the VW3 A3 201 or VW3 A3 202 option cards (see page xx

Speed reference Two different options

ATV38 ATV 61

AI3 (0..10 V) AI1 or AI2 if available

AI3 (+/- 10 V) AI1

10

)

)

Page 11

1. Determining catalog numbers

PI feedback or summed reference: Three different options

ATV38 ATV 61

AI3 (0..10 V) AI1 or AI2 if available

AI4 on VW3 A3 202 option card

AI3 (+/- 10 V) AI1

Tachometer: Totally incompatible. Alternative solution: use an incremental encoder.

Scenario 2: Replacing an ATV38 with or without a VW3A58202 option card:

Used: Becomes:

ATV38 ATV 61 Description VW3A58202

R1A/R1B/

R1C

R2A/R2C R2A/R2C

AO 1 AO 1

COM COM Analog input common TH1+ TH2+ PTC probe

AI 1 AI 1+ 0…10 V analog input TH1- TH2- PTC probe

+10 +10

AI 2 AI 2

LI 1 LI 1

LI 2 LI 2

LI 3 LI 3

LI 4 LI 4

+24 +24

R1A/R1B/

R1C

LI 5

LI 6

Fault relay (R1) COM 0 V 0 V Common

Programmable relay

(R2)

0-20 mA

analog output

1 to 10 kΩ

potentiometer power

supply

0…10 V 0..4/20 mA

analog input

24 V DC run forward

logic inputs

24 V DC programmable

logic input

24 V DC programmable

logic input

24 V DC programmable

logic input

Logic input power

supply

24 V DC programmable

logic input

24 V DC programmable

logic input

-10 -10 -10 -10 V output

+24 +24 +24

LI 5 also on

control card

LI 6 also on

control card

LO LO 1 LO 3 Logic output

LO + CLO CLO

AO AO 2

A3 201 A3 202 A3 407

R3A/R3B/

R3C

LI 7 LI 11

LI 8 LI 12

LI 9 LI 13

LI 10 LI 14

LO 2 LO 4 Logic output

VW3... card

R4A/R4B/

R4C

Current

AI3 +/AI3 -

AI4

AO 3

FP Pulse input

Description

Programmable relay

Logic input power

programmable logic

24 V DC programmable

programmable logic

programmable logic

Logic output power

Programmable analog

Programmable analog

Programmable analog

Programmable analog

24 V DC

logic input

24 V DC

24 V DC

supply

input

input

input

supply

input

input

output

output

A A

A- A-

B B

B- B-

Examples:

- If only LI5 and LI6 are used on the VW3A58202 card

ª An option card is not needed with the ATV 61 because Li5 and Li6 are features of the standard product.

- If only the incremental encoder inputs are used on the VW3A58202 card

ª Use the VW3 A3 407 encoder card.

Incremental encoder

input

Incremental encoder

input

Incremental encoder

input

Incremental encoder

input

0 V Encoder 0 V

PES Encoder 5 V

11

Page 12

1. Determining catalog numbers

1. 6. Selecting communication channels

1. 6. 1. Communication via Modbus network

With this type of communication, there are several possible scenarios:

1) The Altivar 38 was connected via the connector port using the RS485 connection kit (VW3A58306): The connection cable should be

replaced because the ATV61 has an RJ45 type Modbus port, but the port on the ATV38 is a 9-way SUB-D.

ATV38 connected to Catalog number Description

TSXSCA50 junction box or other screw terminals VW3 A8 306 D30 Length 3 m, an RJ45 connector at one end and stripped at the

TSXSCA62 subscriber socket VW3 A8 306 Length 3 m, an RJ45 connector at one end and a 15-way

other

SUB-D connector at the other

The integrated Modbus port does not have any pulldown resistors, but d epending on the type of subscriber and the master modul e

present on the bus, it may be necessary to match these pulldown resistors (see page 39

2) The Altivar 38 was connected via the VW3A58303 card to a Unitelway or 4-wire Modbus RTU/Jbus/ASCII network.

The Altivar 61’s integrated Modbus port does not support these network services and it is, therefore, necessary to use an option card.

Card catalog number

ATV38 ATV 61

VW3A58303 VW3 A3 303

In this example, keep the existing connections.

If the VW3A58303 card was used with the 2-wire Modbus RTU protocol, connec tion on t he Alti var 61’s RJ45 port is pos sible, as

this is compatible with the presence of the graphic displa y terminal . Only the di agnosti c service (08) is restri cted to subcodes 00,

0A, 0C, 0E. Use the connection method described in Point 1.

).

1. 6. 2. Communication with Profibus bus (VW3A58307)

Card catalog number

ATV38 ATV 61

VW3A58307 VW3 A3 307

Installation and connection

For the Altivar 61, keep the existing connections.

1. 6. 3. Communication with DeviceNet bus (VW3A58309)

Card catalog number

ATV38 ATV 61

VW3A58309 VW3 A3 309

Installation and connection

For the Altivar 61, keep the existing connections.

1. 6. 4. Communication via Modbus Plus bus (VW3A58302)

Card catalog number

ATV38 ATV 61

VW3A58302 VW3 A3 302

Installation and connection

For the Altivar 61, keep the existing connections.

12

Page 13

1. Determining catalog numbers

1. 6. 5. Communication with Metasys N2 bus VW3A58354U

Card catalog number

ATV38 ATV 61

VW3A58354U VW3 A3 313

1. 6. 6. Communication with INTERBUS bus (VW3A58304(E))

Card catalog number

ATV38 ATV 61

VW3A58304 VW3 A3 304

VW3A58304E VW3 A3 304

Installation and connection

For the Altivar 61, keep the existing connections.

It is essential to use the Altivar 61 control card’s external power supply function so that the bus token can circulate continuously (see

page 26

).

1. 6. 7. Communication via Ethernet network (VW3A58310)

Card catalog number

ATV38 ATV 61

VW3A58310 VW3 A3 310

Installation and connection

For the Altivar 61, keep the existing connections.

1. 6. 8. Communication via Fipio bus VW3A58311

Card catalog number

ATV38 ATV 61

VW3A58311 VW3 A3 311

Installation and connection

If a TSX FP ACC12 connector is used to link the Altivar to the bus, keep the existing connections. However, it is necessary to alter the

position of the cable(s) when using a TSX FP ACC2 connector (see page 47

).

1. 6. 9. Communication via CANopen bus (VW3A58308)

Card catalog number

The Altivar 61 integrates the ATV38 CANopen communication card’s connection and services as standard (VW3A58308).

It is however necessary to modify the wiring.

ATV38 ATV 61

Screw terminals 9-way Sub-D

To adapt the wiring, order:

- 9-way Sub-D connector (1 per drive): VW3 CAN KCDF 180T

- 9-way Sub-D/RJ45 adapter (1 per drive): VW3 CAN A71

1. 6. 10. Communication via AS-i bus (VW3A58305)

Card catalog number

Although the AS-i communication card has not been continued in the Altivar 61 offer, there is a solution for substitution using a 4-input/

4-output module on the AS-i bus.

ATV38 ATV 61

VW3A58305 ASI 20M T4I4OS

13

Page 14

2. Drive implementation

2. 1. Installation

2. 1. 1. Using catalog numbers starting with ATV38H

The dimensions given in the following sections can be used to compare those of an Al tivar 38 equipped with an optio n card and its operator

terminal with an Altivar 61 also equipped with an opti on card and operator terminal.

These tables only include examples where the Altivar 61 takes up more space than the Altivar 38, as well as the proposed solutions.

14

Page 15

2. Drive implementation

2. 1. 1. 1. Three-phase supply 380…480 V (for catalog numbers starting with ATV38H)

Comparison of dimensions

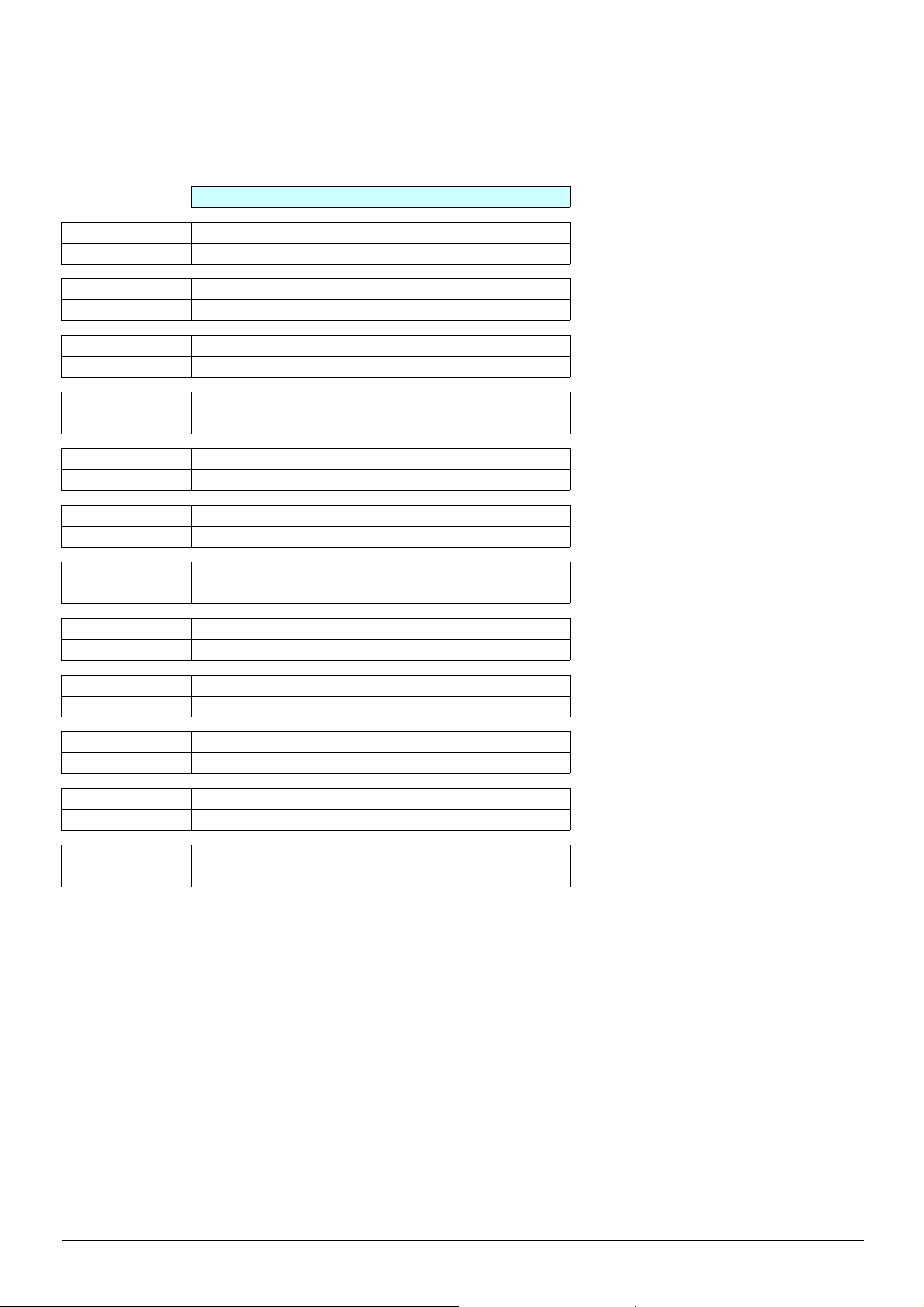

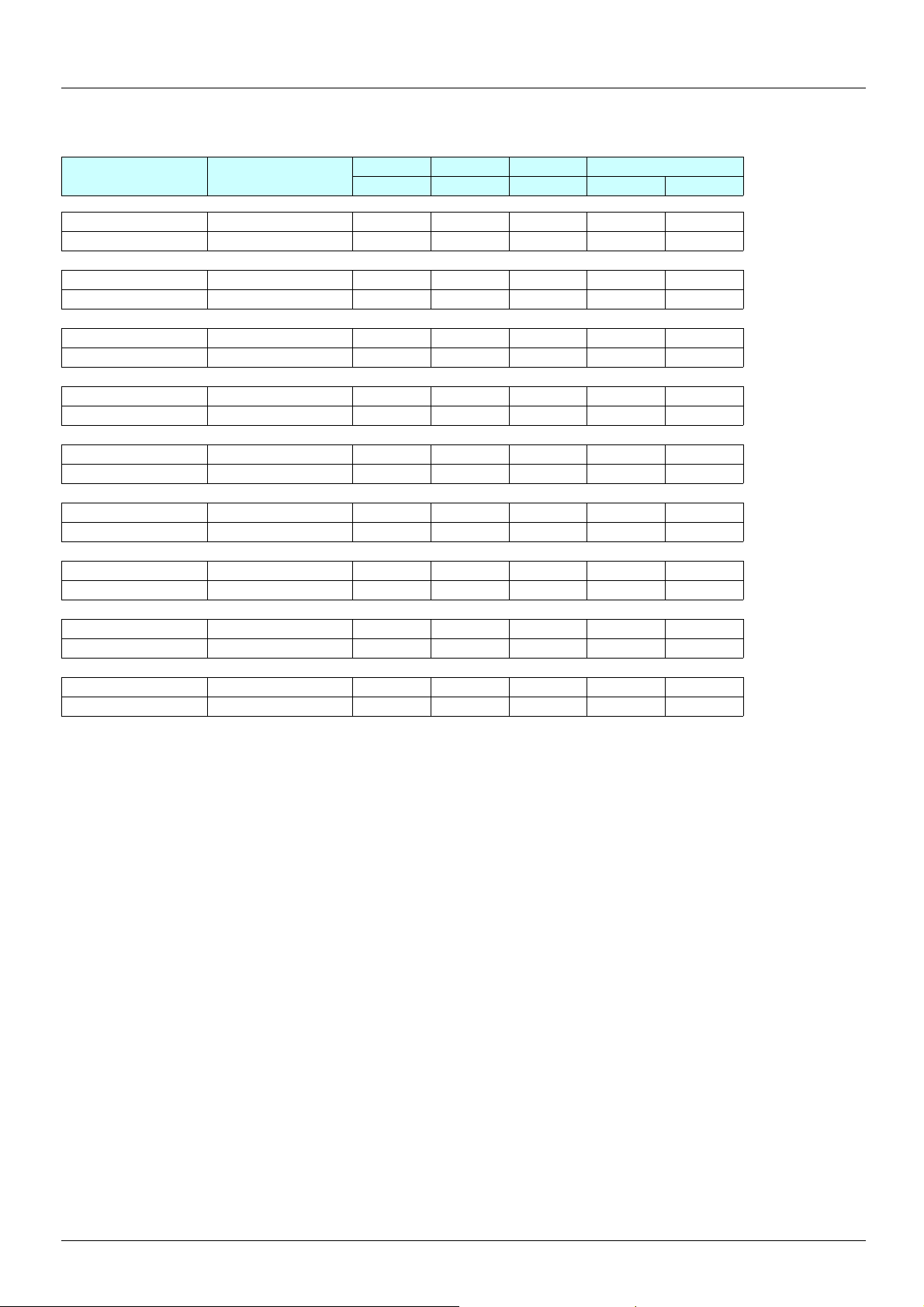

Width (1) Height (2) Depth (3)

ATV38HU18N4 150 226 184

ATV 61H075N4 130 230 195

ATV38HU29N4 150 226 184

ATV 61HU15N4 130 230 195

ATV38HU41N4 150 226 184

ATV 61HU22N4 130 230 195

ATV38HU54N4 175 285 184

ATV 61HU22N4 155 260 207

ATV38HU72N4 175 285 184

ATV 61HU40N4 155 260 207

ATV38HU90N4 175 285 184

ATV 61HU55N4 175 295 207

ATV38HD12N4 230 325 210

ATV 61HU75N4 175 295 187

ATV38HD16N4 230 325 210

ATV 61HD11N4 210 295 213

ATV38HD23N4 230 415 210

ATV 61HD15N4 230 400 213

ATV38HD28N4 (X) 240 550 283

ATV 61HD15N4 230 400 213

ATV38HD25N4 (X) 240 550 283

ATV 61HD18N4 230 400 213

ATV38HD33N4 (X) 240 550 283

ATV 61HD30N4 240 550 266

ATV38HD46N4 (X) 240 550 283

ATV 61HD37N4 240 550 266

(1) No problem if space is left between 2 drives. Width incompatible if the ATV38 drives are mounted side by side.

(2) This difference is easily made up by the space required for the drive wiring.

(3) The depth of enclosures is usually considerably greater than that of the products.

If the enclosure depth poses a problem, it is alwa ys possible to order an Alt ivar 61 wit h a Z at the end of th e catalog numbe r. Your drive wi ll

be supplied without a graphic display terminal and will, therefore , be 23 mm slimmer, e.g., ATV 61H075N4Z.

15

Page 16

2. Drive implementation

2. 1. 1. 2. Three-phase supply 380…480 V for catalog numbers starting with ATV38H.

Comparison of dimensions

Width (1) Height (2) Depth (3)

ATV38HD54N4 (X) 350 650 304

ATV 61HD45N4 320 630 290

ATV38H64N4(X) 350 650 304

ATV 61HD55N4 320 630 290

ATV38HD79N4 (X) 350 650 304

ATV 61HD75N4 320 630 290

ATV38HC10N4 (X) 370 630 360

ATV 61HD90N4 320 920 377

ATV38HC13N4 (X) 480 680 400

ATV 61HC11N4 320 920 377

ATV38HC15N4 (X) 480 680 400

ATV 61HC13N4 360 1022 377

ATV38HC19N4 (X) 480 680 400

ATV 61HC16N4 340 1190 377

ATV38HC23N4 (X) 660 950 440

ATV 61HC22N4 440 1190 377

ATV38HC25N4 (X) 660 950 440

ATV 61HC22N4 440 1190 377

ATV38HC28N4 (X) 660 950 440

ATV 61HC25N4 440 1190 377

ATV38HC31N4 (X) 660 950 440

ATV 61HC31N4 440 1190 377

ATV38HC33N4 (X) 660 950 440

ATV 61HC31N4 440 1190 377

(1) No problem if space is left between 2 drives. Width incompatible if the ATV38 drives are mounted side by side.

(2) This difference is easily made up by the space required for the drive wiring.

(3) The depth of enclosures is usually considerably greater than that of the products.

If the enclosure depth poses a problem, it is alwa ys possible to order an Alt ivar 61 wit h a Z at the end of th e catalog numbe r. Your drive wi ll

be supplied without a graphic display terminal and will, therefore , be 23 mm slimmer, e.g., ATV 61H075N4Z.

16

Page 17

2. Drive implementation

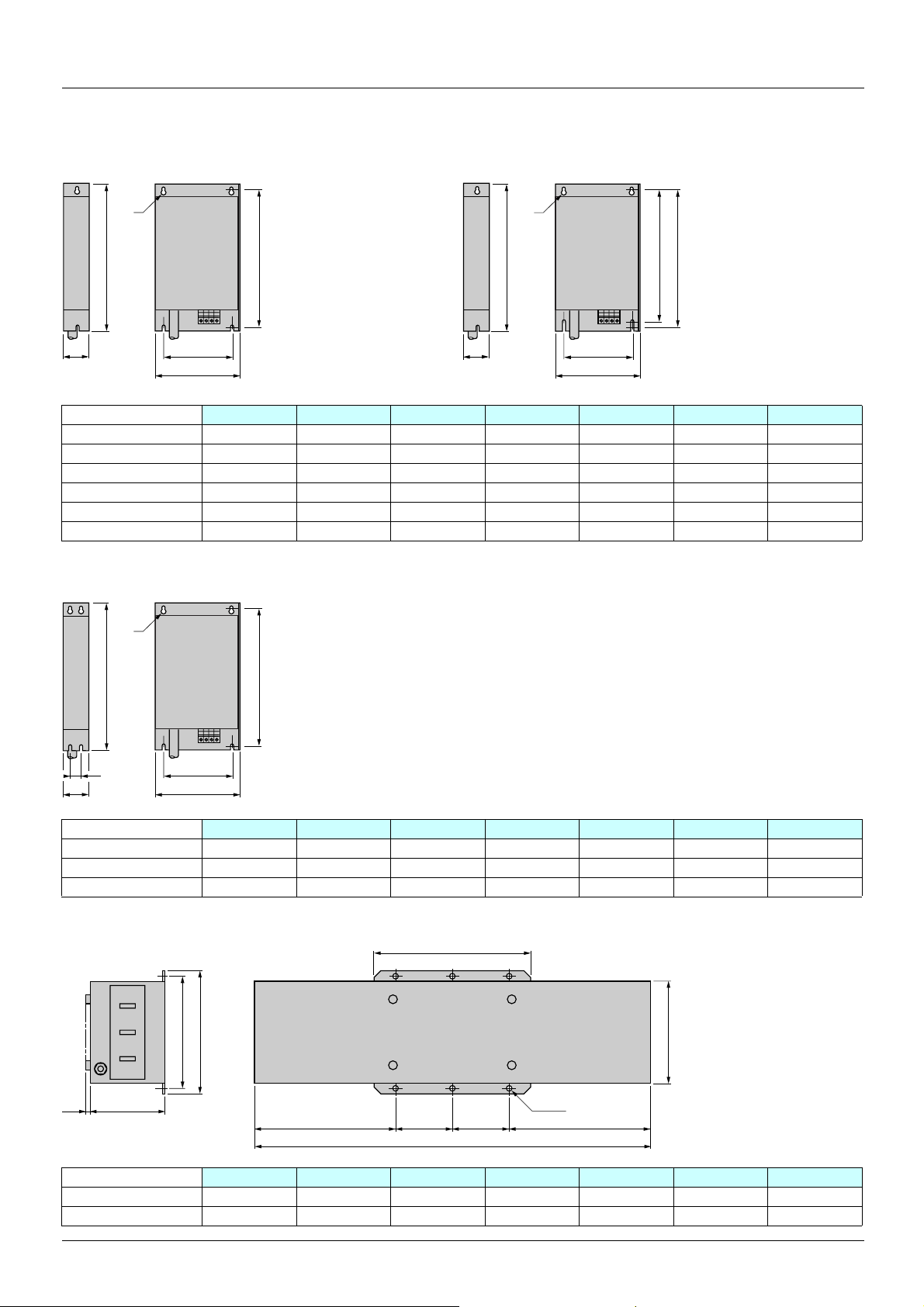

2. 2. Comparison of dimensions

2. 2. 1. Dimensions

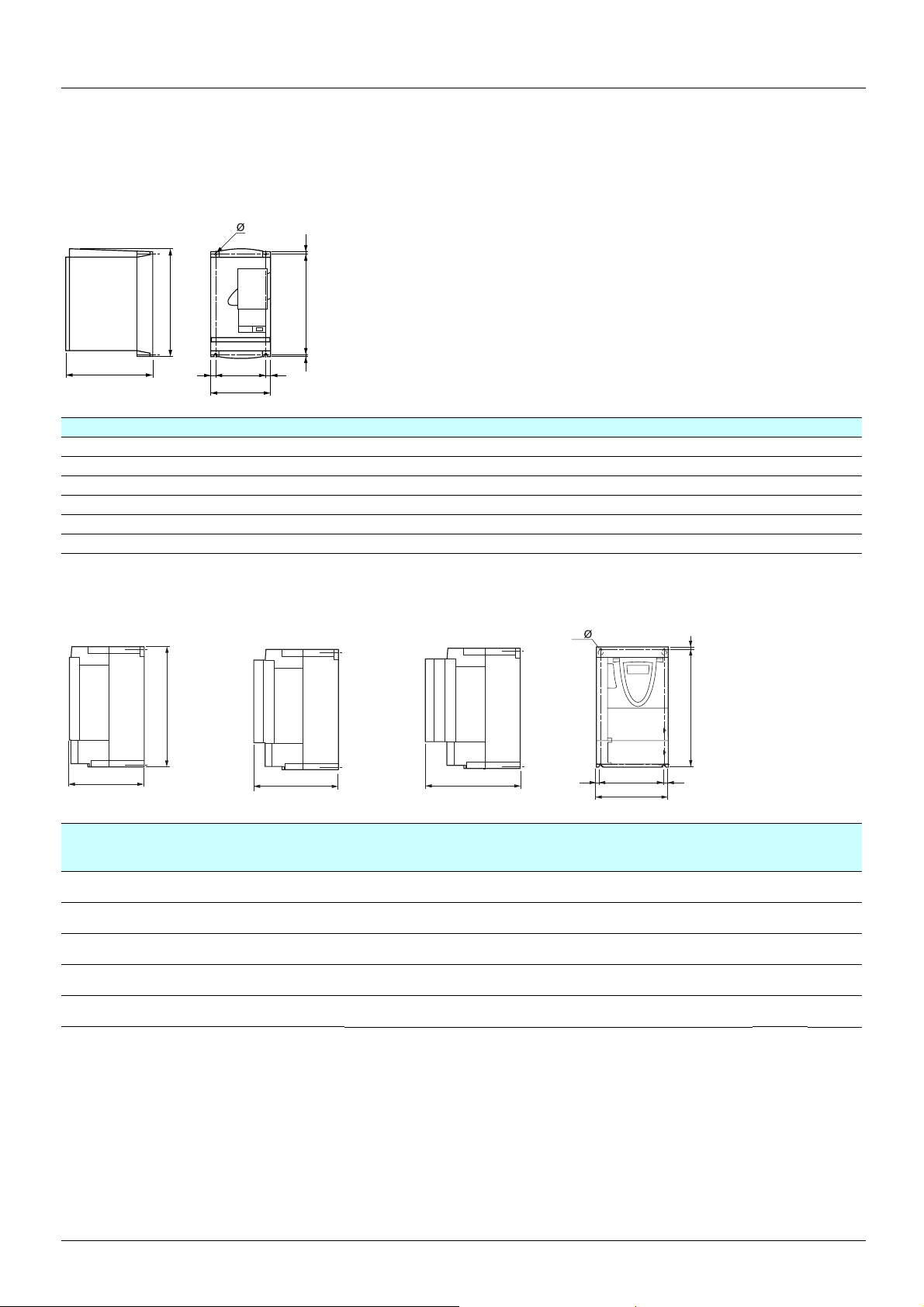

ATV38Hppp product on heatsink

=

b

=c

G=

a

=H

ATV-38H a b c G H Ø

U18N4, U29N4, U41N4 150 230 184 133 210 5

U54N4, U72N4, U90N4 175 286 184 155 270 5.5

D12N4, D16N4 230 325 210 200 310 5.5

D23N4 230 415 210 200 400 5.5

D25N4p, D28N4p, D33N4p, D46N4p 240 550 283 205 530 7

D54N4p, D64N4p, D79N4p 350 650 304 300 619 9

ATV 61H

No option card

ppp y 15 kW without graphic display terminal, with and without option cards

With 1 option card

b

c

c1

With 2 option cards

c2

4 x

=

G

a

h

H

=

ATV 61H a

mm

(in.)

075N4, U15N4,U22N4

U30N4, U40N4

U55N4, U75N4

D11N4

D15N4

130

(5.12)

155

(6.10)

175

(6.89)

210

(8.27)

230

(9.05)

b

mm

(in.)

230

(9.05)

260

(10.23)

295

(11.61)

295

(11.61)

400

(15.75)

c

mm

(in.)

149

(5.87)

161

(6.34)

161

(6.34)

187

(7.36)

187

(7.36)

c1

mm

(in.)

172

(6.77)

184

(7.25)

184

(7.25)

210

(8.27)

210

(8.27)

c2

mm

(in.)

195

(7.68)

207

(8.15)

207

(8.15)

233

(9.17)

233

(9.17)

G

mm

(in.)

113.5

(4.47)

138

(5.43)

158

(6.22)

190

(7.48)

210

(8.26)

H

mm

(in.)

220

(8.66)5(0.20)5(0.20)

249

(9.80)4(0.16)5(0.20)

283

(11.14)6(0.24)6(0.24)

283

(11.14)6(0.24)6(0.24)

386

(15.20)8(0.31)6(0.24)

h

mm

(in.)

Ø

mm

(in.)

For

screws

M4 3

M4 4

M5 5.5

M5 7

M6 9

Weight

kg

(lb.)

(6.61)

(8.82)

(12.13)

(15.43)

(19.84)

17

Page 18

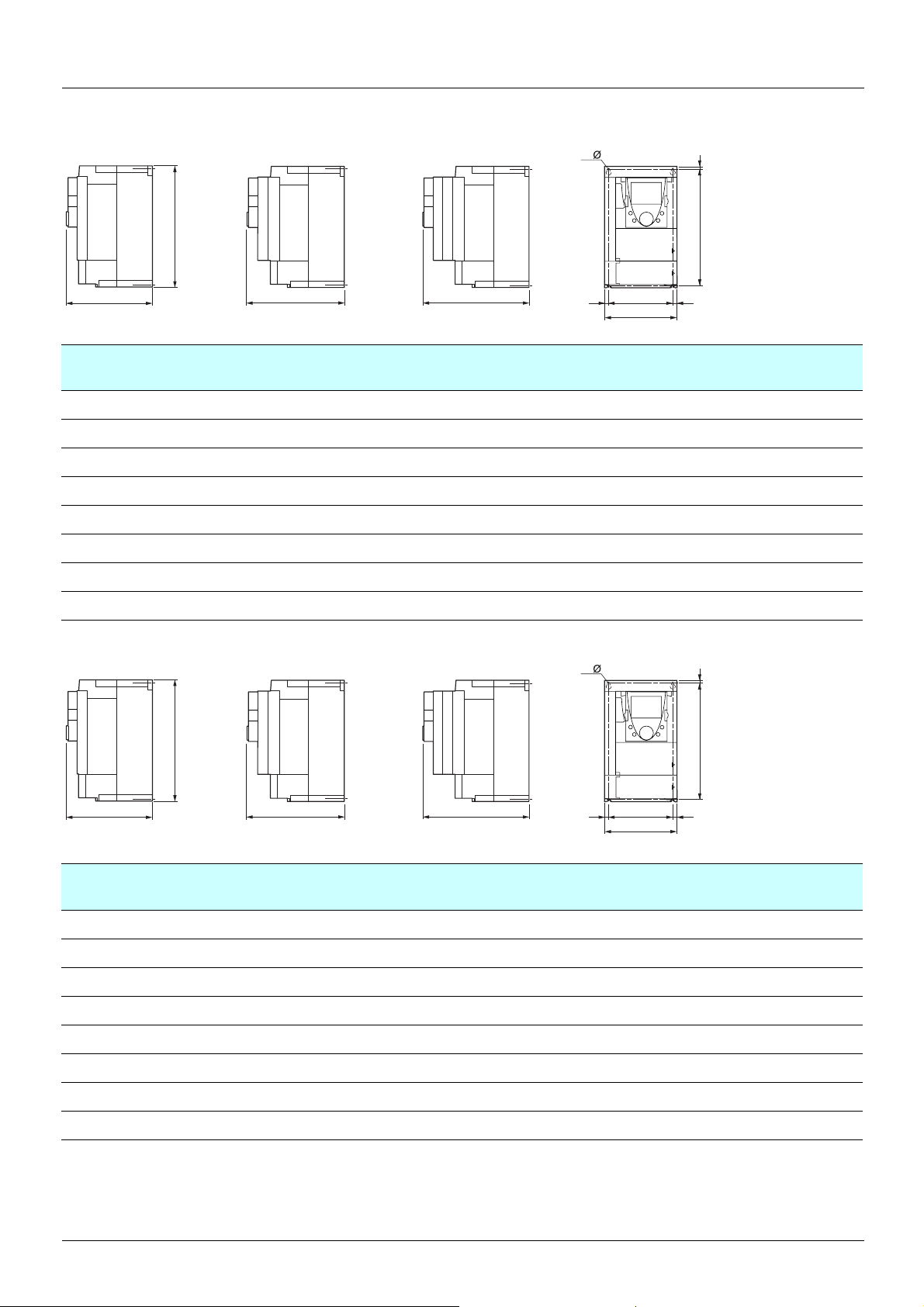

2. Drive implementation

ATV 61Hppp y 15 kW with graphic display terminal, with and without option cards

No option card

With 1 option card (1)

With 2 option cards (1)

4 x

h

b

c

ATV 61H a

075N4, U15N4,U22N4

U30N4, U40N4

U55N4, U75N4

D11N4

D15N4, D18N4

D22N4

D30N4, D37N4

D45N4, D55N4, D75N4

ATV 61H

No option card

ppp y 75 kW with graphic display terminal, with and without option cards

(5.12)

(6.10)

(6.89)

(8.27)

(9.05)

(9.45)

(9.45)

(12.60)

With 1 option card (1)

mm

(in.)

130

155

175

210

230

240

240

320

H

c1

b

mm

(in.)

230

(9.05)

260

(10.23)

295

(11.61)

295

(11.61)

400

(15.75)

420

(16.54)

550

(21.65)

630

(24.80)

c

mm

(in.)

172

(6.77)

184

(7.25)

184

(7.25)

210

(8.27)

210

(8.27)

210

(8.27)

240

(9.45)

290

(11.42)

With 2 option cards (1)

c2

c1

mm

(in.)

195

(7.68)

207

(8.15)

207

(8.15)

233

(9.17)

233

(9.17)

243

(9.57)

263

(10.35)

315

(12.40)

c2

mm

(in.)

218

(8.58)

230

(9.06)

230

(9.06)

256

(10.08)

256

(10.08)

266

(10.47)

286

(11.25)

335

(13.19)

G

==

G

mm

(in.)

113.5

(4.47)

138

(5.43)

158

(6.22)

190

(7.48)

210

(8.26)

206

(8.11)

206

(8.11)

280

(11.02)

4 x

a

H

mm

(in.)

220

(8.66)5(0.20)5(0.20)

249

(9.80)4(0.16)5(0.20)

283

(11.14)6(0.24)6(0.24)

283

(11.14)6(0.24)6(0.24)

386

(15.20)8(0.31)6(0.24)

403

(15.87)11(0.45)

531.5

(20.93)11(0.45)

604.5

(23.80)15(0.59)9(0.22)

h

mm

(in.)

h

Ø

mm

(in.)

5.5

(0.22)

5.5

(0.22)

For

screw

s

M4 3

M4 4

M5 5.5

M5 7

M6 9

M6 30

M6 37

M8 45

Weight

kg

(lb.)

(6.61)

(8.82)

(12.13)

(15.43)

(19.84)

(66.14)

(81.57)

(99.21)

b

c

ATV 61H a

mm

(in.)

075N4, U15N4,U22N4

U30N4, U40N4

U55N4, U75N4

D11N4

D15N4, D18N4

D22N4

D30N4, D37N4

D45N4, D55N4, D75N4

130

(5.12)

155

(6.10)

175

(6.89)

210

(8.27)

230

(9.05)

240

(9.45)

240

(9.45)

320

(12.60)

H

c1

b

mm

(in.)

230

(9.05)

260

(10.23)

295

(11.61)

295

(11.61)

400

(15.75)

420

(16.54)

550

(21.65)

630

(24.80)

c

mm

(in.)

172

(6.77)

184

(7.25)

184

(7.25)

210

(8.27)

210

(8.27)

210

(8.27)

240

(9.45)

290

(11.42)

c2

c1

mm

(in.)

195

(7.68)

207

(8.15)

207

(8.15)

233

(9.17)

233

(9.17)

243

(9.57)

263

(10.35)

315

(12.40)

c2

mm

(in.)

218

(8.58)

230

(9.06)

230

(9.06)

256

(10.08)

256

(10.08)

266

(10.47)

286

(11.25)

335

(13.19)

G

==

G

mm

(in.)

113.5

(4.47)

138

(5.43)

158

(6.22)

190

(7.48)

210

(8.26)

206

(8.11)

206

(8.11)

280

(11.02)

a

H

mm

(in.)

220

(8.66)5(0.20)5(0.20)

249

(9.80)4(0.16)5(0.20)

283

(11.14)6(0.24)6(0.24)

283

(11.14)6(0.24)6(0.24)

386

(15.20)8(0.31)6(0.24)

403

(15.87)11(0.45)

531.5

(20.93)11(0.45)

604.5

(23.80)15(0.59)9(0.22)

h

mm

(in.)

Ø

mm

(in.)

5.5

(0.22)

5.5

(0.22)

For

screw

s

M4 3

M4 4

M5 5.5

M5 7

M6 9

M6 30

M6 37

M8 45

Weight

kg

(lb.)

(6.61)

(8.82)

(12.13)

(15.43)

(19.84)

(66.14)

(81.57)

(99.21)

18

Page 19

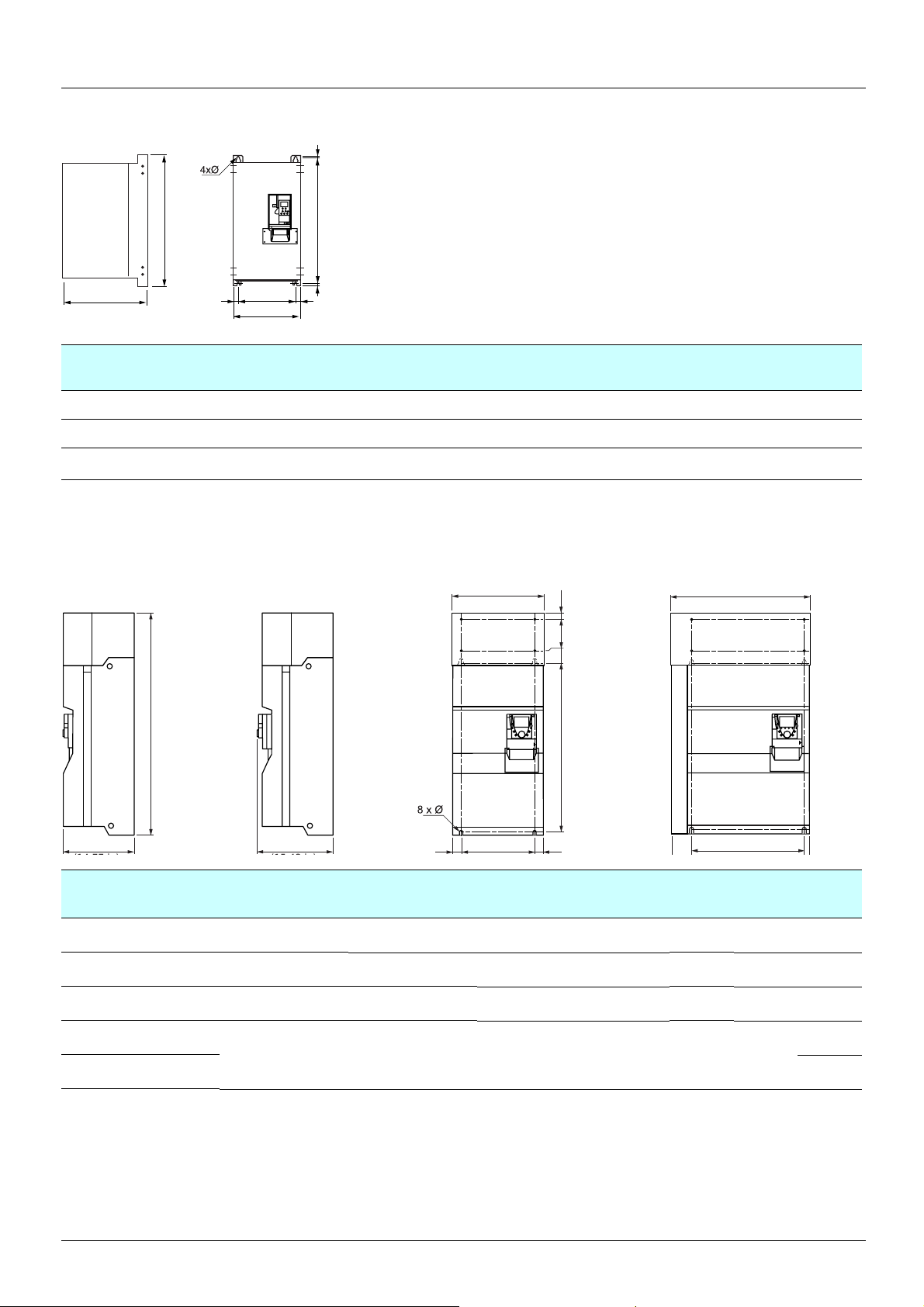

2. Drive implementation

=

ATV 38Hppp > 75 kW and y 315 kW - Product on heatsink

b

G

c

==

a

ATV 61H a

C10N4X

C13N4X, C15N4X, C19N4X

C23N4X, C25N4X, C28N4X,

C31N4X, C33N4X

ATV 61H

ppp > 75 kW and y 315 kW with graphic display terminal, with and without option cards

With 2 option cards (1)With 0 or 1 option card (1) ATV61H C25N4 to C31N4 with braking unit

(14.57)

(18.90)

(25.98)

H=

mm

(in.)

370

480

660

b

mm

(in.)

630

(24.80)

680

(26.77)

950

(37.40)

ATV61H D55M3X to D90M3X

ATV61H D90N4 to C31N4

(14.17)

(15.75)

(17.32)

a

c

mm

(in.)

360

400

440

G

mm

(in.)

317.5

(12.50)

426

(16.77)

598

(23.54)

H

mm

(in.)

609

(23.98)

652

(25.67)

920

(36.22)

670 (26.37)

Ø

mm

(in.)

12

(0.47)

12

(0.47)

15

(0.59)

b

HK1KK2

540 mm (21.26 in)

Ø

mm

(in.)

11.5

(0.45)

11.5

(0.45)

11.5

(0.45)

11.5

(0.45)

For

Weight

screws

M10 80

M10 110

M10 140

M10

kg

(lb.)

(176)

(242)

(309)

140

(309)

mm

(in.)

(14.17)

(13.39)

(17.32)

392 mm

(40.23)

(46.62)

(46.62)

b

mm

(in.)

1022

1190

1190

G

mm

(in.)

298

(11.73)

285

(11.22)

350

(13.78)

==G

H

mm

(in.)

758

(29.84)

920

(36.22)

920

(36.22)

K

mm

(in.)

K1

mm

(in.)

K2

mm

(in.)

150

(5.91)72(2.83)30(1.18)

150

(5.91)75(2.95)30(1.18)

150

(5.91)75(2.95)30(1.18)

377 mm

ATV61H a

C13N4 360

C16N4 340

C22N4 440

C25N4

595

C31N4 215

(23.43)

1190

(46.62)

540

(21.26)

920

(36.22)

150

(5.91)75(2.95)30(1.18)

(474)

19

Page 20

2. Drive implementation

2. 3. Mounting the RFI filter

The dimensions given in the following sections can be used to compare the dimensions of the Altivar 38 RFI filters with those used on the

Altivar 61.

These tables only include examples where the Altivar 61 filters take up more space than those fitted on the Altivar 38, as well as the

proposed solutions.

It is important to remember that, without ex ception, it will be necessary to adapt the mounting as the mounting di mensions are not the same.

2. 3. 0. 1. Three-phase supply 400 V for catalog numbers starting with ATV38H

Drive Filter

ATV38HU18N4 VW3A58402 150 276 60 133 260

ATV 61H075N4 VW3 A4 401 130 290 40 105 260

ATV38HU29N4 VW3A58402 150 276 60 133 260

ATV 61HU15N4 VW3 A4 401 130 290 40 105 260

ATV38HU41N4 VW3A58402 150 276 60 133 260

ATV 61HU22N4 VW3 A4 401 130 290 40 105 260

ATV38HU90N4 VW3A58403 175 340 60 153 320

ATV 61HU55N4 VW3 A4 403 175 370 60 150 355

ATV38HD23N4 VW3A58405 230 480 60 200 460

ATV 61HD15N4 VW3 A4 405 230 498.5 62 190 460

ATV38HD54N4 (X) VW3A58408 350 770 110 300 770

ATV 61HD45N4 VW3 A4 408 320 750 119 280 725

ATV38HD64N4 (X) VW3A58408 350 770 110 300 770

ATV 61HD45N4 VW3 A4 408 320 750 119 280 725

ATV38HD79N4 (X) VW3A58408 350 770 110 300 770

ATV 61HD55N4 VW3 A4 408 320 750 119 280 725

ATV38HC10N4 (X) VW3A68401 204 243 88 90 80

ATV 61HD90N4 VW3 A4 410 800 261 139 120 235

Width Height Depth Mounting

a b c G H

ATV38HC13N4 (X) VW3A68402 204 295 89 90 90

ATV 61HC11N4 VW3 A4 410 800 261 139 120 235

ATV38HC15N4 (X) VW3A68402 204 295 89 90 90

ATV 61HC13N4 VW3 A4 410 800 261 139 120 235

ATV38HC19N4 (X) VW3A68402 204 295 89 90 90

ATV 61HC16N4 VW3 A4 410 800 261 139 120 235

ATV38HC23N4 (X) VW3A68403 224 295 89 90 90

ATV 61HC22N4 VW3 A4 411 800 261 139 120 235

ATV38HC25N4 (X) VW3A68403 224 295 89 90 90

ATV 61HC22N4 VW3 A4 411 800 261 139 120 235

ATV38HC28N4 (X) VW3A68403 224 295 89 90 90

ATV 61HC25N4 VW3 A4 411 800 261 139 120 235

ATV38HC31N4 (X) VW3A68403 224 295 89 90 90

ATV 61HC31N4 VW3 A4 411 800 261 139 120 235

ATV38HC33N4 (X) VW3A68403 224 295 89 90 90

ATV 61HC31N4 VW3 A4 411 800 261 139 120 235

20

Page 21

2. Drive implementation

2. 3. 0. 2. Three-phase supply 400…460 V for catalog numbers starting with ATV38H

Drive Filter

ATV38HC10N4 (X) VW3A68415 260 386 115 235 240

ATV 61HD90N4 VW3 A4 410 800 261 139 120 235

ATV38HC13N4 (X) VW3A68435 260 386 115 235 240

ATV 61HC11N4 VW3 A4 410 800 261 139 120 235

ATV38HC15N4 (X) VW3A68435 260 386 115 235 240

ATV 61HC13N4 VW3 A4 410 800 261 139 120 235

ATV38HC19N4 (X) VW3A68435 260 386 115 235 240

ATV 61HC16N4 VW3 A4 410 800 261 139 120 235

ATV38HC23N4 (X) VW3A68465 260 386 135 235 240

ATV 61HC22N4 VW3 A4 411 800 261 139 120 235

ATV38HC25N4 (X) VW3A68465 260 386 135 235 240

ATV 61HC22N4 VW3 A4 411 800 261 139 120 235

ATV38HC28N4 (X) VW3A68465 260 386 135 235 240

ATV 61HC25N4 VW3 A4 411 800 261 139 120 235

Width Height Depth Mounting

a b c G H

ATV38HC31N4 (X) VW3A68465 260 386 135 235 240

ATV 61HC31N4 VW3 A4 411 800 261 139 120 235

ATV38HC33N4 (X) VW3A68465 260 386 135 235 240

ATV 61HC31N4 VW3 A4 411 800 261 139 120 235

21

Page 22

2. Drive implementation

2. 3. 1. Comparison of dimensions

2. 3. 1. 1. RFI filters

Ø

b

c

G

a

H

c

Ø

b

G

a

H1

H

VW3 a (mm) b (mm) c (mm) G (mm) H (mm) H1 (mm) Ø (mm)

A4 401 130 290 40 105 275 – 4.5

A4 402 155 324 50 130 309 – 4.5

A4 403 175 370 60 150 355 – 5.5

A4 404 210 380 60 190 365 – 5.5

A4 405 230 498.5 62 190 479.5 460 6.6

A4 409 230 498.5 62 190 479.5 460 6.6

Ø

H

a (mm) b (mm) c (mm) G (mm) H (mm) J (mm) Ø (mm)

c

VW3

b

GJ

a

A4 406 240 522 79 200 502.5 40 6.6

A4 407 240 650 79 200 631 40 6.6

A4 408 320 750 119 280 725 80 9

a1

b

H

c10

GG==

a

6xØ12

b1

VW3

a (mm) a1 (mm) b (mm) b1 (mm) c (mm) G (mm) H (mm)

A4 410 800 302 261 219 139 120 235

A4 411 800 302 261 219 139 120 235

22

Page 23

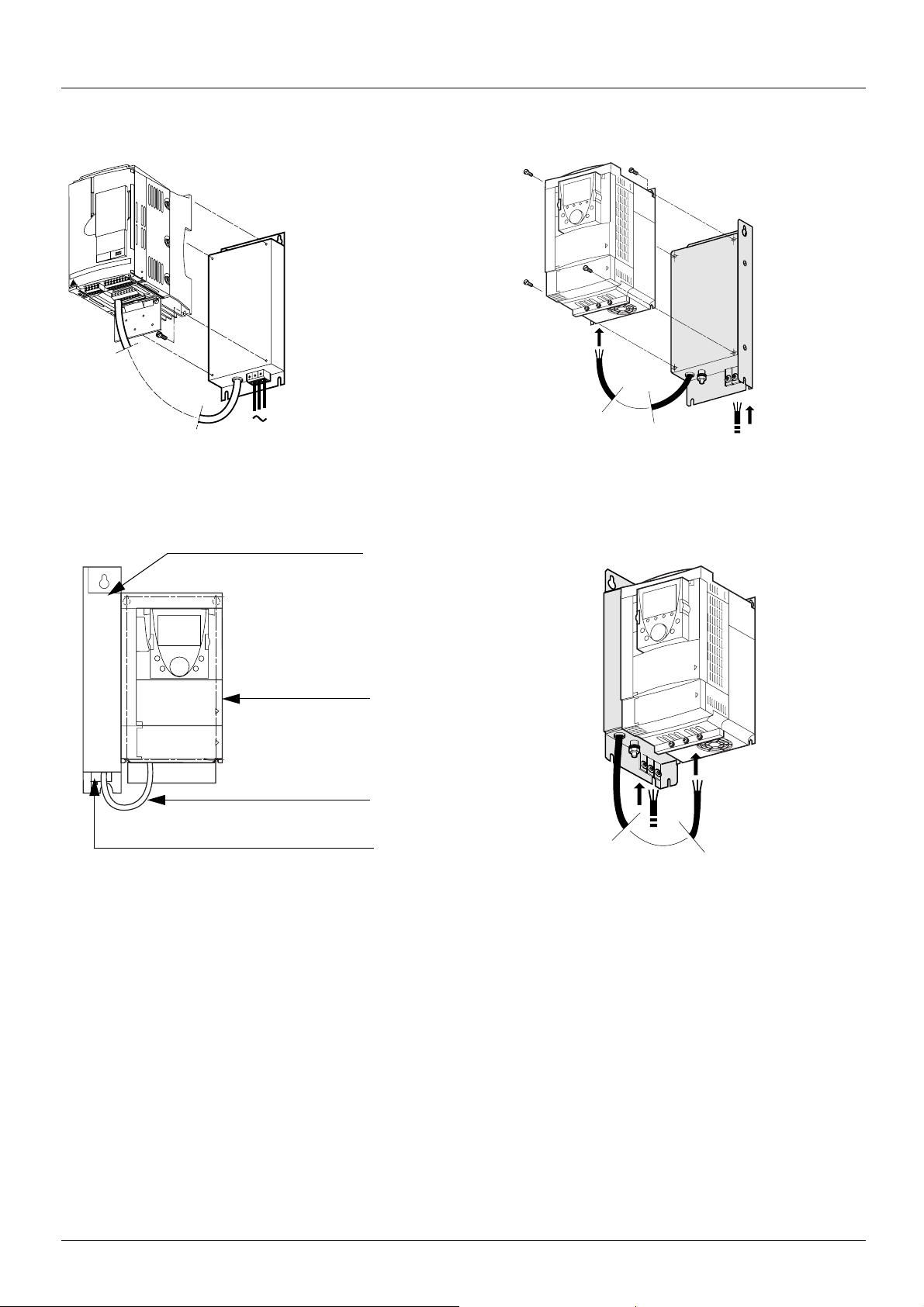

2. Drive implementation

Mounting under the drive

4 x

ATV 38

Side mounting against the ATV 61

ATV 61

Filter

Drive

Filter - Drive connection

Power connection

23

Page 24

2. Drive implementation

2. 4. NEMA mounting kits

Dimensions, in inches and (mm)

a

=

G=

=

c

bd

Kit

Kit catalog

number

=H

Product

size

Kit

Drive catalog number

ATV38Hppppp

a

(in.)b(in.)c(in.)G(in.)H(in.)Ø(in.)d(lb.)

VW3A58852 2 U18N4, U29N4, U41N4 5.91

(150)

VW3A58853 3 U54N4, U72N4, U90N4 6.89

(175)

VW3A58854 4 D12N4, D16N4 9.06

(230)

VW3A58855 5 D23N4 9.06

(203)

C

9.06

(230)

11.26

(286)

12.80

(325)

16.35

(415)

7.24

(184)

7.24

(184)

8.27

(210)

8.27

(201)

5.20

(133)

6.10

(155)

7.9

(200)

7.9

(200)

8.27

(210)

10.63

(270)

12.20

(310)

15.75

(400)

0.20

(5)

0.22

(5.5)

0.22

(5.5)

0.22

(5.5)

2.81

(71)

2.94

(75)

2.94

(75)

2.94

(75)

Kit Kit

Kit catalog

number

Product

size

Drive catalog number

ATV38Hppppp

VW3A58856 6 D25N4, D28N4, D33N4,

D46N4

VW3A58857 7 D54N4, D64N4, D79N4 13.78

24

A

(in.)B(in.)C(in.)E(in.)F(in.)G(in.)I(in.)K(in.)Ø(in.)L(lb.)

9.45

21.65

(240)

25.59

(350)

(550)

(650)

11.14

(283)

11.97

(304)

5.57

(146)

9.29

(236)

12.05

(306)

15.35

(390)

8.07

(205)

11.81

(300)

20.87

(530)

24.37

(619)

0.39

(10)

0.39

(10)

0.28

(7)

0.36

(9)

3.5

(89)

6.75

(171)

Page 25

2. Drive implementation

VW3 A9 101…105, 201…205 VW3 A9 106…108, 206…208

VW3 A9 109…116, VW3 A9 209

Kit for UL NEMA Type 1 conformity or IP 21 protection

VW3 A9 ppp

Drive

Δb

VW3 A9 xxxxx kit

c

b

a

b

a

VW3 a (in.) b (in.) VW3 a (in.) b (in.)

A9 101, 201 130 (5.12) 113 (4.45) A9 106, 206 240 (9.45) 185 (7.28)

A9 102, 202 155 (6.10) 103 (4.06) A9 107, 207 240 (9.45) 180 (7.09)

A9 103, 203 175 (6.89) 113 (4.45) A9 108, 208 32 0 (1 2. 6 0) 178 (7.01)

A9 104, 204 210 (8.27) 113 (4.45)

A9 105, 205 230 (9.06) 108 (4.25)

4xØ

b

c

G

==

a

K2

K

K1

VW3 a (in.) b (in.) c (in.) G (in.) K (in.) K1 (in.) K2 (in.) Ø (in.)

A9 109, 209 320 (12.60) 220 (8.66) 377 (14.84) 250 (9.84) 95 (3.74) 65 (2.56) 75 (2.95) 11.5 (0.45)

25

Page 26

2. Drive implementation

2. 5. Separate control card power supply

A1

ATV61Hppppp

P240V

0 V

+24 V

2. 6. Remote display terminal

Used to connect the programming terminal remotely on the fron t of the enclosure.

Fixings:

As the dimensions are not the same, the fixing holes must be modified.

ATV38 ATV 61

55,6 mm

24 mm

This type of wiring is essential when using a VW3 A3 304 Interbus-S communication option card.

115 mm (4.53 in)

104 mm (4.09 in)

52 mm

79,6 mm

4 x 3,5 mm 36 mm

115 mm (4.53 in)

100 mm (3.93 in) 5 mm (0.2 in)

4

F

3

F

2

F

1

F

P

STO

RESET

N

U

R

C

S

E

D

FW

REV

26

Page 27

2. Drive implementation

2. 7. Power cables

The layout and type of power terminals have changed:

Ring terminals must be used rather than ferrules for the ground terminals, alth ough for the power terminals the f errules used previously can

be retained if they are in good condition (a flattened ferrule will not make a good connection).

Table of correspondence for power terminals

ATV38 ATV 61

Power supply L1 R/L1

L2 S/L2

L3 T/L3

DC bus + PO

-PC/-

Braking resistor PA PA/+

PB PB

Motor output U U/T1

VV/T2

WW/T3

Connecting to the Altivar 38 Connecting to the Altivar 61

A1

L2

L3

L1

U

V

W

V1

U1

W1

M

3 a

R1A

R1B

R1C

PA

PB

Braking resistor

R2A

R2C

ATV58pppppp

A1

U1

(if used)

Disconnecting the RFI filter if using an IT system

IT system: Isolated or impedance grounded neutral.

Use a permanent insulation monitor compatible with non-linear loads, such as a

Merlin Gerin type XM200 or equivalent.

Altivar 61 drives feature built-in RFI filters. These filters can be isolated from ground for

operation on an IT system as follows:

Remove the jumper located to the left of the power terminals

Layout of the ATV38 power terminals

t L1 L2 L3

t L1 L2 L3 + -

UVWt ATV-38HD18N4 to D23N4

UVWt ATV-38HD25N4(X) to D79N4(X)

R / L1

U / T1

V1

3 a

S / L2

V / T2

M

T / L3

W / T3

W1

R1A

R1B

R1C

P0

PA / +

PB

Braking resistor

(if used)

R2A

R2C

PWR

ATV71HpppM3

PC / -

Normal

(filter connected)

IT system

(filter disconnected)

+24

t

++-t ATV-38HC10N4(X)

L1 L2 L3 U V W

L1 L2 L3 tt ATV-38H13N4(X) to C15N4(X)

+

- UVW

L1 L2 L3 tt ATV-38HC23N4(X) to C33N4(X)

-

++UVW

Do not use

27

Page 28

2. Drive implementation

Characteristics of the ATV38 power terminals

ATV 38 E rating

Maximum wire size

AWG mm

2

Tightening torque

in Nm

D05N4, D07N4, D09N4, AWG 8 6 0.75

D12N4, D16N4, D23N4 AWG 6 10 2

D25N4, D28N4 AWG 4 16 3

D33N4, D46N4 AWG 2 35 4

D54N4, D64N4, D79N4 AWG 2/0 70 10

Layout of the ATV 61 power terminals and tightening torque

For ATV 61pppppp drives

PO PA/+ PB PC/-

R/L1 S/L2 T/L3

For ATV 61pppppp drives

U/T1 V/T2 W/T3

ATV 61H Maximum wire

size

mm² AWG Nm

075N4, U15N4, U22N4

U30N4, U40N4

2,5 14

68

Tightening

torque

(lb.in)

1.2

(10.6)

1.2

(10.6)

R/L1 S/L2 T/L3

For ATV 61pppppp drives

R/L1 S/L2 T/L3

PO PA/+ PB PC/-

U/T1 V/T2 W/T3

U/T1 V/T2 W/T3

ATV 61H Maximum wire

size

mm² AWG Nm

U55N4, U75N4

D11N4

D15N4, D18N4

10 6

16 4

35 1

ATV 61H Maximum wire

size

mm² AWG Nm

D22N4, D30N4, D37N4

50 1/0

ATV 61H Maximum wire

size

mm² kcmils Nm

D45N4, D55N4, D75N4

120 350

Tightening

torque

(lb.in)

2

(17.7)

2,4

(21)

2,4

(21)

Tightening

torque

(lb.in)

6

(53)

Tightening

torque

(lb.in)

19

(168)

PO PA/+ PB PC/-

28

Page 29

2. Drive implementation

Layout of the ATV 61 power terminals and tightening torque

ATV61H D55M3X, D75M3X, D90N4, C11N4

Front view

320 (12.54)

View from above

View from below

70 (2.74) 60 (2.35)

115 (4.50)

M12

5 (0.2)

PC/-PA/+PO

M10

M8

295 (11.55)

230 (9.01)

172 (6.74)

U/T1 V/T2

R/L1

S/L2 T/L3

W/T3

PA PB

225 (8.81)

100 (3.92)

65 (2.55)

14 (0.55)

M10

85(3.33)

105(4.11)

M10

60(2.35)

50 (1.96)

Maximum terminal wire size/tightening torque

Drive terminals L1/R, L2/S, L3/T, U/T1, V/T2, W/T3 PC/-, PO, PA/+ PA, PB

2

2 x 100 mm

2 x 250 MCM/212 lb.in 2 x 250 MCM/360 lb.in 250 MCM/106 lb.in

/24 Nm 2 x 100 mm2/41Nm 60 mm2 /12 Nm

38 (1.49)57(2.23)

32 (1.25)

29

Page 30

2. Drive implementation

ATV61H D90M3X, C13N4

Front view

View from above

320 (12.54)

125 (4.90)

149(5.84)

67 (2.62)

M12

5 (0.2)

PC/-PA/+PO

View from below

Fan terminals

M10

38 (1.49)

(1)

M8

62 (2.43)

70 (2.74)

265 (10.38)

250 (9.80)

U/T1 V/T2

R/L1

S/L2 T/L3

W/T3

PA PB

328 (4.02)

260 (10.18)

200 (7.83)

155 (6.07)

27 (1.06)

55,5 (2.17)

M10

M10

34 (1.33)

58 (2.27)

60 (2.35)

79,5 (3.11)

217 (8.50)

Maximum terminal wire size/tightening torque

Drive terminals L1/R, L2/S, L3/T, U/T1, V/T2, W/T3 PC/-, PO, PA/+ PA, PB RO, SO, TO

2

2 x 100 mm

/24Nm 2 x 150 mm2/41 Nm 60 mm2 /12 Nm 5.5 mm2 /1.4 Nm

2 x 250 MCM/212 lb.in 2 x 250 MCM/360 lb.in 250 MCM/106 lb.in AWG 10/12 lb.in

(1)

137 (5.37)

(1)Power supply for the fans, compulsory if the drive is only powered by the DC bus. Do not use if the drive is powered with a 3-phase

supply by L1/R, L2/S, L3/T.

30

Page 31

2. Drive implementation

ATV61HC16N4

View from above

Front view

80 (3.13) 56 (2.19) 58 (2.28)

317 (12.43)

PA/+

View from below

115 (4.50)

M12

PC/-PO

Fan terminals

(1)

321 (12.58)

322 (12.62)

281 (11.01)

252 (9.87)

U/T1 V/T2

R/L1

S/L2 T/L3

W/T3

PA PB

252 (9.87)

99 (3.88)

80 (3.13)

76 (2.98)

18 (0.71)

43 (1.68)

72 (2.83)

80 (3.13)

M10

75 (2.94)

M10

75 (2.94)

257 (10.07)

M10

M8

68 (2.66)

38 (1.49)

Maximum terminal wire size/tightening torque

Drive terminals L1/R, L2/S, L3/T, U/T1, V/T2, W/T3 PC/-, PO, PA/+ PA, PB RO, SO, TO

2

2 x 120 mm

/24 Nm 2 x 120 mm2/41 Nm 120 mm2 /24 Nm 5.5 mm2 /1.4 Nm

2 x 250 MCM/212 lb.in 2 x 250 MCM/360 lb.in 250 MCM/212 lb.in AWG 10/12 lb.in

(1)Power supply for the fans, compulsory if the drive is only powered by the DC bus. Do not use if the drive is powered with a 3-phase

supply by L1/R, L2/S, L3/T.

(1)

31

Page 32

2. Drive implementation

ATV61HC22N4

View from above

47 (1.84)

Front view

100 (3.92) 150 (5.88)

319,50 (12.52)

PO PA/+ PC/-

View from below

319,50 (12.52)

112 (4.39)

40 (1.57)

M12

Fan terminals

(1)

68 (2.66)

286 (11.20)

321 (12.58)

270 (10.58)

251 (9.83)

U/T1 V/T2

R/L1

S/L2 T/L3

W/T3

PA PB

260 (10.18)

104 (4.07)

80 (3.13)

74 (2.90)

114 (4.47) 102 (4.00)

21 (0.82) 104 (4.07) 102 (4.00)

102 (4.00)74 (2.90)

357 (13.99)

M12

M12

M12

M8

38 (1.49)

Maximum terminal wire size/tightening torque

Drive terminals L1/R, L2/S, L3/T, U/T1, V/T2, W/T3 PC/-, PO, PA/+ PA, PB RO, SO, TO

2

2 x 150 mm

/41 Nm 2 x 150 mm2/41 Nm 120 mm2 /24 Nm 5.5 mm2 /1.4 Nm

2 x 350 MCM/360 lb.in 2 x 350 MCM/360 lb.in 250 MCM/212 lb.in AWG 10/12 lb.in

Power supply for the fans, compulsory i f t he d rive is onl y powe red b y t he DC bu s. Do no t use if t he d rive is powered wit h a 3-p h a se s upply

by L1/R, L2/S, L3/T.

32

(1)

Page 33

2. Drive implementation

ATV61H C25N4, C31N4

Front view

View from above

PO PA/+ PC/-

View from below

319,50 (12.52)

102 (4.00)

145 (5.68)

87 (3.41)

100 (3.92) 112 (4.39)

2 x M12

Fan terminals

(1)

67 (2.62)

70 (2.74)

98 (3.84)

271 (10.61)

251 (9.83)

R/L1

U/T1 V/T2

S/L2 T/L3

W/T3

322 (12.62)

36 (1.41)

43 (1.67)

113,5 (4.45) 175 (6.85)

173,5 (68.01)

130 (5.09)

M12

176,5 (69.19)

175 (6.85)175 (6.85)

M12

M12

Maximum terminal wire size/tightening torque

Drive terminals L1/R, L2/S, L3/T, U/T1, V/T2, W/T3 PC/-, PO, PA/+ RO, SO, TO

2

4 x 185 mm

/41 Nm 4 x 185 mm2/41 Nm 5.5 mm2 /1.4 Nm

3 x 350 MCM/360 lb.in 3 x 350 MCM/360 lb.in AWG 10/12 lb.in

(1)Power supply for the fans, compulsory if the drive is only powered by the DC bus. Do not use if the drive is powered with a 3-phase

supply by L1/R, L2/S, L3/T.

(1)

33

Page 34

2. Drive implementation

Control wiring and I/O characteristics

(Warning: Check the I/O assignment made by PowerSuite)

In order to ensure that the Altivar 61 works correctly, the following rules must be adhered to:

• Check that the SW1 switch on the Altivar 61 and the SW3 and SW4 switches on the option cards are in "Source" position.

SW1

SW2

R1A

R1B

P24

R1C

0V

LI1

R2A

R2C

LI2

LI3

+10

LI4

AI1+

LI5

AI1-

LI6

COM

+24

AI2

PWR

AO1

COM

RJ45

• Check that the strap is present between +24 and PWR.

Source

Sink

Int

Ext

SW3

SW4

Source

Ext

Sink

Int

VW3 A3 201

Source

Ext

Sink

Int

VW3 A3 202

+24

PWR

ATV71HpppM3

• The PTC probes connected on an ATV 61 correspond to market standards. Please note that t he values are sli ghtly diff erent. Check tha t

the trip thresholds are suitable for the temperature levels supported by the motor.

ATV38 value (kOhms) ATV 61 value (kOhms)

Probe short-circuit 0.200 < 0.05

Reset 1.5 1.8

Overheating 2 3

Probe break 20 > 100

In PTC mode, Li6 is only taken into account after a Power on.

Control and option card logic input wiring

Control card connection diagram

A1

+24

ATV71Hppppp

LI1

LI2

LI3

LI4

LI5

LI6

0V

34

Page 35

2. Drive implementation

Connection diagram for logic I/O option card (VW3 A3 201)

A1

+24

0V

R3A

R3C

LI7

R3B

LO1

LO2

VW3A3201

CLO

TH1+

TH1-

Motor

Connection diagram for extended I/O option card (VW3 A3 202)

A1

+24

0V

R4A

R4C

LI11

R4B

LO3

LO4

CLO

RP

0V

VW3A3202

AO2

AO3

AI4

COM

AI3-

AI3+

TH2+

TH2-

Source

0-20 mA

4-20 mA

X-Y mA

0 ± 10 V

or

X-Y mA

AI1 input on the ATV 61 wired as non differential 0-10 V (same as AI1 on the ATV38)

+ 10

COM

Al 1

Reference

potentiometer

X-Y mA

ATV 38

AI2

+10

AI1+

AI1-

COM

AI2

Reference

potentiometer

ATV61

LI6 wired as PTC probe

A1

ATV61Hppppp

Motor

SW2

PTC

LI6

0V

Motor

LI

35

Page 36

2. Drive implementation

Wiring the VW3 A3 401 option card encoder input when replacing an ATV38

On the Altivar 38, encoder signals A A- or B B- had to be reversed in order to avoid the motor rotating in the wrong direction. This anomaly

has been corrected on the Altivar 61 and, therefore, the wiring conforms to the signal order A A- B B-.

ATV38

A

A-

B

ATV 61

B-

A

B

A-

B-

Encoder Encoder

0 V

5 V

0 V

5 V

OR

A

A-

B

B-

A

B

A-

B-

0 V

5 V

0 V

5 V

VW3 A3 40p

A

A-

B

A

B

A-

Encoder

B-

B-

0 Vs

0 Vs

+ Vs

+ Vs

The encoder card’s connector does not have a terminal for connecting the cable shielding.

This shielding must, therefore, be connected to the power terminals; use a tag connector or an accessory: D23 FA3.

R/L1 S/L2 T/L3

PO PA/+ PB PC/-

U/T1 V/T2 W/T3

36

Page 37

3. Implementation of the Altivar 61 communication option cards

3. 1. General

Acceptance

Check that the card catalog number marked on the label is the same as that on the delivery note corresponding to the purchase order.

Remove the option card from its packaging and check that it has not been damaged in transit.

Check that the drive is turned off.

Check that there is no voltage on the DC bus: Red LED (POWER) off, wait for 3 minutes

after turning off the drive.

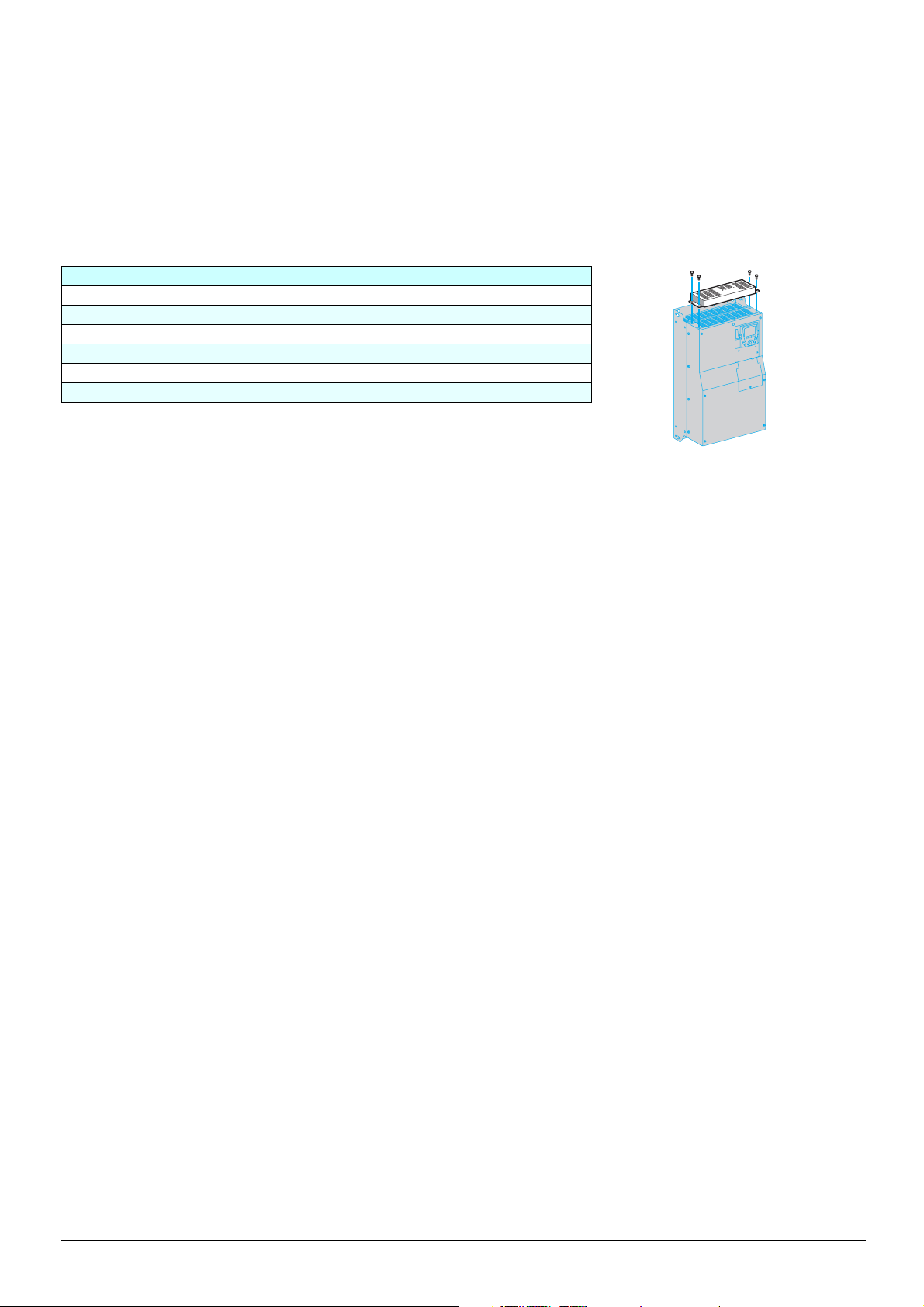

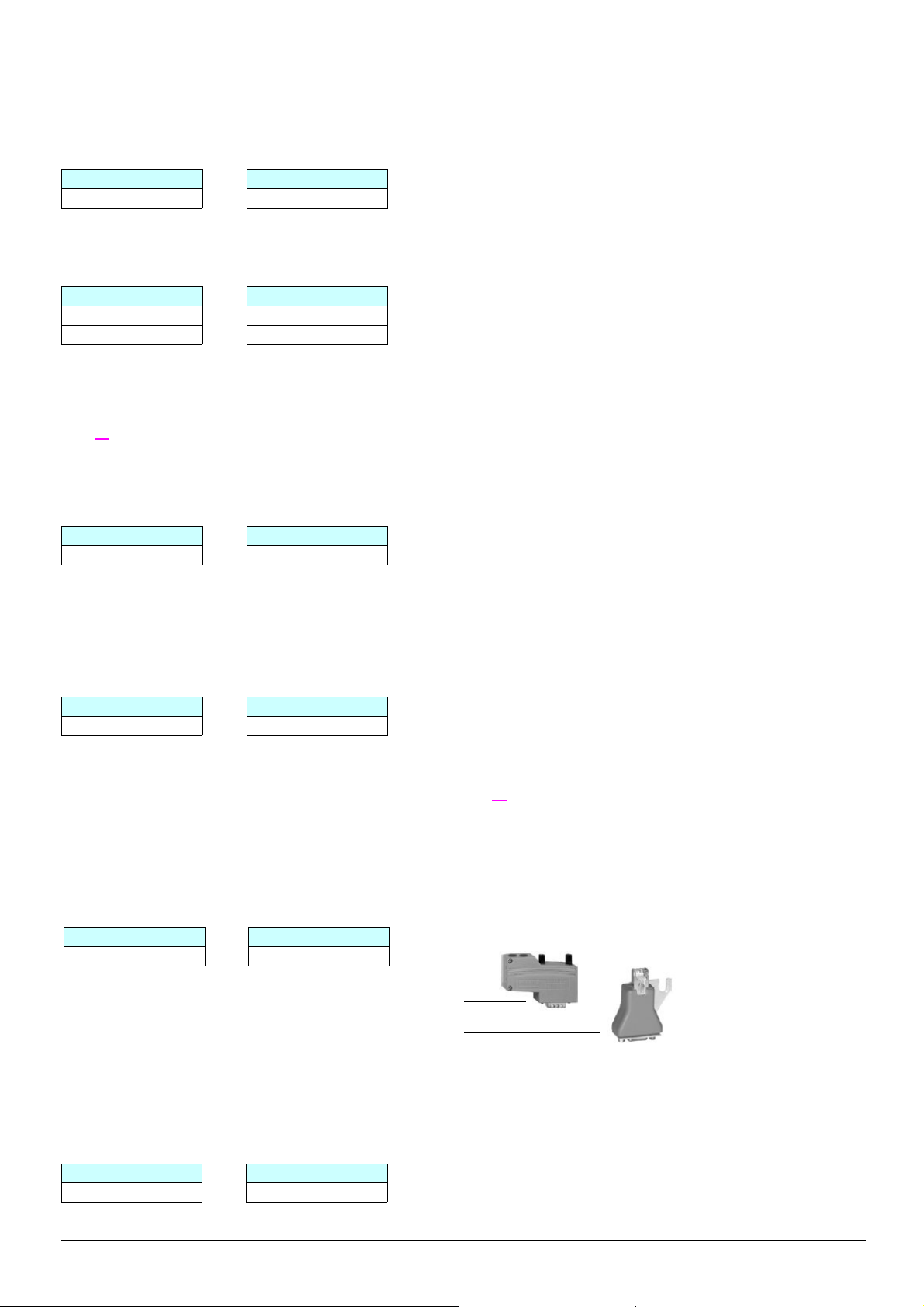

ATV 61 075N4 to D18N4 ATV 61H D22N4 to C31N4

Red LED indicating that

the DC bus is turned on.

Installing the communication option card

See Installation Manual pages 16 and 17.

When migrating an Altivar 38 installation to Altivar 61, t he PowerSui te v2.40 program must be used to configure the ATV61 in 8 serie mode

in order to ensure absolute consistency of the communication, drive and adjustment parameters between the two drive ranges.

However, for some communications options, one or more of the microswitches on the card have to be toggled manually.

The connector for connecting the option card to th e communic ation bus i s not the same on t he Altivar 61. This is n ow on the top righ t-hand

side of the drive.

You should, therefore, make sure that the cable(s) is(are) long enough to make this connection.

If necessary, you should do one of the following:

- Reconnect the wiring up and/or downstream of the drive

- Adjust the drive position

- Use an extension cable

37

Page 38

3. Implementation of the communication option cards

Option card fault

The [internal com. link] (ILF-) fault appears when the following seri ous problems occur:

- Hardware fault on the option card

- Dialog fault between the option card and the drive

[Internal link fault 1] (ILF1) diagnostic parameter can be used to obtain more detailed information about the origin of the last

The

[internal com. link] (ILF) fault:

This parameter can be accessed on the graphic display terminal onl y, in the

INFO]

(AFI-).

Value Description of parameter values Value Description of parameter values

0 No fault 8 Faulty analog input

1 Loss of internal communication with the drive 9 Faulty analog output

2 Hardware fault detected 10 Faulty logic input

3 Error in the EEPROM checksum 11 Faulty logic output

4 Faulty EEPROM 101 Unknown card

5 Faulty Flash memory 102 Exchange problem on the drive internal bus

6 Faulty RAM memory 103 Time out on the drive internal bus (500 ms)

7 Faulty NVRAM memory

• When the External Fault function is used via a communication card, the Altivar 38 would display EPF, but the Altivar 61 now displays

EPF2.

• When the Fast Stop function is used via a communication card, the Altivar 38 would display RDY, but the Altivar 61 now displays FST.

• It is essential to follow the Altivar 38 internal variables manual when the Altivar 61 is being used in 8 serie mode. If not, migration may

not proceed smoothly.

[1.10 DIAGNOSTICS] (DGt-) menu, [MORE FAULT

38

Page 39

3. Implementation of the communication option cards

3. 2. Communication via Modbus network

3. 2. 1. Calculating the polarization resistors

Mixed schematic

Slaves with 4.7 kΩ polarization can be integrated into a standard schematic. Suitable polarization resistance (Rp) must be calculated.

Schematic diagram

Master

T

R

5 V

Rp

Rp

0 V

D1

120 Ω

1 nF

D0

Common

4,7 kΩ

Slave 1

5 V

4,7 kΩ

0 V

R

T

R

T

Slave n

Type of trunk cable Shielded cable with 1 twisted pair and at least a 3rd conductor

Maximum length of bus 1000 m at 19200 bps

Maximum number of stations (without repeater) Up to 32 stations, i.e., 31 slaves (depending on Rp and the number of 4.7 kΩ resistors)

Maximum length of tap links • 20 m for a single tap link

• 40 m divided by the number of tap links on a multiple junction box

Bus polarization • One pulldown resistor at the 5 V (Rp)

• One pulldown resistor at the Common (Rp)

This polarization can be provided in the master.

The value of Rp should be validated (or determined) by calculating the eq uivalent

polarization (Re) according to the polarization of the master and slave stations.

The value of Re must be between 162 Ω and 650 Ω (recommended value: 650 Ω).

Line termination One 120 Ω 0.25 W resistor in series with a 1 nF 10 V capacitor

Common polarity Yes (Common)

• To calculate the polarization resistance (Rp), all station polarizations must be deemed to be connected in parallel.

Example

If the bus Rp polarization is 470 Ω (installed in the master) and 2 slaves have 4700 Ω polarization, the equivalent polarization is:

1/Re = 1/470 + 1/4700 + 1/4700,

i.e., Re = 1/(1/470 + 1/4700 + 1/4700)

and, therefore, Re = 390 Ω

390 Ω is greater than 162 Ω, and the schematic is correct.

For an ideal equivalent polarization (650 Ω), Rp bus polarization can be installed so that:

1/650 = 1/Rp + 1/4700 + 1/4700,

i.e., Rp = 1/(1/650 - 1/4700 - 1/4700)

and, therefore, Rp = 587 Ω.

• If the master has 470 Ω polarization, up to 18 slaves with 4.7 kΩ polarization can be connected.

39

Page 40

3. Implementation of the communication option cards

3. 2. 2. Reminder of the various connection methods:

ATV 61 RJ45 connector on TSXSCA50 or other screw terminals: Use cable VW3 A8 306 D30 (RJ45 to stripped end, 3 meters)

t

2 = 0 V - brown

3 = D_B - blue 12345 4 = D_A

5 = D_A - white/blue 5 = D_B

8........................1

ATV 61 RJ45 connector on TSXSCA62: Use cable VW3 A8 306 (RJ45 to 15-way Sub-D)

0VL 0VL D(A) D(B) 2 = 0 V

8........................1

2 = 0 V - brown 15 = 0 V

3 = D_B - blue 14 = D_A

5 = D_A - white/blue 7 = D_B

1

234

5678

1514131211109

3. 2. 2. 1. Configuring the drive

There are two possible scenarios.

Scenario 1 Using the built-in port when replacing the VW3A58303 Modbus/Unitelway option card

As the PowerSuite software workshop is not able to anticipate this scenario, the communication, address and protocol-format parameters

must be entered manually:

Configuring the address

Transfer the Altivar 38 parameters to the Altivar 61 using the integrated display terminal, the graphic display terminal or the PowerSuite

software workshop:

The configuration of the Modbus network parameters can be acce ssed via the

- COMMUNICATION]

Modbus parameter Description/Possible values Terminal display Default value

(COM-) menu.

[Modbus Address] (Add) 1 to 247

Drive Modbus disabled (0)

[Modbus baud rate] (tbr) 4800 bps

[MODBUS NETWORK] (MdI-) submenu in the [1.9

[1] (1) to [247] (247) [Off] (OFF)

[4.8 Kbps] (48)

[19200] (192)

9600 bps

19200 bps

38400 bps

[Modbus format] (tFO) 8 data bits, odd parity, 1 stop bit

8 data bits, even parity, 1 stop bit

8 data bits, no parity, 1 stop bit

8 data bits, no parity, 2 stop bits

[9.6 Kbps] (96)

[19.2 Kbps] (192)

[38.4 Kbps] (384)

[8-0-1] (8o1)

[8-E-1] (8E1)

[8-N-1] (8n1)

[8-N-2] (8n2)

[8 E 1] (8E1)

Configuring the drive control mode

Check and configure the control mode applied to t he drive in the [1.6 - COMMAND] (CtL-) menu on the graphic display terminal, the

integrated display terminal or the PowerSuite software workshop.

[Profile] (CHCF) = [8 serie] (SE8)

40

Page 41

3. Implementation of the communication option cards

Configuring communication monitoring

Since the Altivar 38’s communication monitoring time out is th e same as the default value of the Al tivar 61’s [Modbus time out] (ttO)

field (10 s), there is no point in modifying the value of thi s field.

Modification of these parameters will only take effect on the next power-up.

After transfer of the drive configuration by the PowerSuite software workshop, the

automatically assigned to

[8 serie] (SE8), thus providing access to memory mapping for the Altivar 38 compatible with the Altivar 61.

[Channel switching] (CHCF) parameter is

PLC configuration and application

The fact of opening the Altivar 61’s "ATV38 compatibility" memory zone (SE8 mode) means that no changes need to be made in the PLC

application.

However, in response to a function 43 identification request (16 #2B) the drive will ident ify itself as an Altivar 61, not an Altivar 38.

Scenario 2 Using the built-in port when replacing the ATV38 terminal port

Configuring the drive

This example is implemented in the PowerSuite software workshop and consequently all the settin gs linked to the configuration p arameters

(address, baud rate, parity) will be assigned automatically, identical to the Altivar 38.

Configuring communication monitoring

Since the Altivar 38’s communication monitoring time out is th e same as the default value of the Al tivar 61’s [Modbus time out] (ttO)

field (10 s), there is no point in modifying the value of thi s field.

Modification of these parameters will only take effect on the next power-up.

PLC configuration and application

The fact of opening the Altivar 61’s "ATV38 compatibility" memory zone (SE8 mode) means that no changes need to be made in the PLC

application.

However, in response to a function 43 identification request (16 #2B) the drive will ident ify itself as an Altivar 61, not an Altivar 38.

41

Page 42

3. Implementation of the communication option cards

3. 3. Communication via Unitelway/Modbus network and VW3 A3 303 option card

3. 3. 1. Reminder of possible connection methods

ATV38 ATV 61

3 = D(A)

4 = 0 V

7 = D(B)

If the chosen communication interface is the VW3 A3 303 option card (Modbus RTU/Jbus/Ascii, Unitelway) both the address and the

protocol format must be configured manually.

3. 3. 2. Configuring the drive address on the Modbus/Unitelway network

Transfer the Altivar 38 address to the Altivar 61:

An Altivar 38 was identified on the bus by its address, coded between 0 and 31.

The address corresponds to the number represented by the binary value 1 or 0 of the 8 card switches

(in fact only micro-switches 3 to 7 are used).

The least significant bits are on the right.

Transfer the Altivar 38 address to the Altivar 61 using the 8 switches on the right of the card; the value 0 being the OFF position,

the value 1 the ON position.

The least significant bits are on the right.

3 = D(A)

4 = 0 V

7 = D(B)

On the Altivar 38, the binary value 1 of a switch is in the up position, on the Altivar 61 this position is reversed, and the value 1 is effective

in the down position.

Example

ATV38 ATV 61

Address 11 = 2#0001011

Address ATV38 switches ATV61 switches Address ATV38 switches ATV61 switches

12345678 12345678 12345678 12345678

0 0000 0000 0000 0000 16 0010 0000 0001 0000

1 0000 0010 0000 0001 17 0010 0010 0001 0001

2 0000 0100 0000 0010 18 0010 0100 0001 0010

3 0000 0110 0000 0011 19 0010 0110 0001 0011

4 0000 1000 0000 0100 20 0010 1000 0001 0100

5 0000 1010 0000 0101 21 0010 1010 0001 0101

6 0000 1100 0000 0110 22 0010 1100 0001 0110

7 0000 1110 0000 0111 23 0010 1110 0001 0111

8 0001 0000 0000 1000 24 0011 0000 0001 1000

9 0001 0010 0000 1001 25 0011 0010 0001 1001

10 0001 0100 0000 1010 26 0011 0100 0001 1010

11 0001 0110 0000 1011 27 0011 0110 0001 1011

12 0001 1000 0000 1100 28 0011 1000 0001 1100

13 0001 1010 0000 1101 29 0011 1010 0001 1101

14 0001 1100 0000 1110 30 0011 1100 0001 1110

15 0001 1110 0000 1111 31 0011 1110 0001 1111

Address 11 = 2#0001011

Use of address 0 is not recommended on a Modbus/Unitelway network as this address has the effect of deactivating the option card.

42

Page 43

3. Implementation of the communication option cards

3. 3. 3. Configuring polarity on the drive RS 485 bus

The card is equipped with 2 line polarity configuration switches but the orientation is not the same for the Altivar 38 and the Altivar 61.

Configure the polarity according to the following method.

ATV38 ATV 61

Unitelway protocol

Modbus/Jbus protocol

Configuring the drive control mode

Check and configure as necessary the control mode applied to the drive in the [1.6 - COMMAND] (CtL-) menu on the graphic display

terminal, the integrated display terminal or the PowerSuite software workshop.

[Profile] (CHCF) = [8 serie] (SE8)

3. 3. 4. PLC configuration and application

The fact of opening the Altivar 61’s "ATV38 compatibility" memory zone (SE8 mode) performed by the PowerSuite software workshop

means that no changes need to be made in the PLC application.

However, in response to a function 43 identification reque st (16#2B) the drive will identify itself as an Altivar 61, not an Altivar 38.

3. 4. Communication via CANopen network

3. 4. 1. Reminder of possible connection methods

ATV38 ATV 61

1 = CAN_GND

2 = CAN_L

4 = CAN_H

The ATV61 CANopen adapter must be used when connecting the Altivar 61 to a CANopen network.

ATV61

CANopen

adapter

E.g., ATV61HU22M3

2 = CAN_L

3 = CAN_GND

7 = CAN_H

3. 4. 2. Matching the line termination resistor

The VW3 CAN KCDF 180T connector for connecting to the CANopen bus incorporates a line termination resistor. You should ensure this

has been activated when the drive is at the end of the trunk cable.

43

Page 44

3. Implementation of the communication option cards

3. 4. 3. Configuring the drive

On the Altivar 38’s CANopen communication option card, both addresses and the bus speed could be set via switches.

The PowerSuite software workshop is not capable of configuring the Al tivar 61 automaticall y since these parameters we re not stored in t he

Altivar 38 but in the option card.

The Altivar 61 parameters should, therefore, be set via the programming terminal, and where the product is bei ng migrated, the PowerSuite

software workshop is responsible for configuring the drive so that it is identical to the configuration that existed on the Altivar 38.

3. 4. 4. Address and Baud rate

Configuration of the Altivar 61’s CANopen communication functions is accessed via the [CANopen] (CnO-) submenu in the [1.9 -

COMMUNICATION]

The configuration can only be modified when the motor is s topped and the drive locked (no run command present).

In order for modifications to take effect, the drive must be shut down then restarted.

[CANopen address] (AdCO) 0 to 127 [0] (0) to [127] (127) 0

[CANopen bit rate] (bdCO) 50 kbps [50 kbps] (50)

(COM-) menu on the graphic di splay te rminal, i ntegrated disp lay termina l or the PowerSuite software work shop.

Parameter Possible values Terminal display Default value

125 kbps

250 kbps

500 kbps

1000 kbps

[125 kbps] (125) 125 kbps

[250 kbps] (250)

[500 kbps] (500)

[1 Mbps] (1M)

3. 4. 5. PLC configuration and application

The fact of opening the Altivar 61’s "ATV38 compatibility" memory zone (SE8 mode) performed by the PowerSuite software workshop

means that no changes need to be made in the PLC application.

In fact, the PDO used by default in the Altivar 61 in 8 serie mode is PDO1 type and is, therefore, compatible with that in the Altivar 38.

Configuring the drive control mode

Check and configure the control mode applied to t he drive in the [1.6 - COMMAND] (CtL-) menu on the graphic display terminal, the

integrated display terminal or the PowerSuite software workshop.

[Profile] (CHCF) = [8 serie] (SE8)

44

Page 45

3. Implementation of the communication option cards

3. 5. Communication via Profibus DP network

3. 5. 1. Reminder of the possible connection methods: Same as existing

3 = Rx/Tx5 = GND

3. 5. 2. Configuring the drive address on the Profibus DP network

With the Altivar 38’s VW3-A58307 Profibus DP option card, the drive address was co ded via the programming terminal. You need, therefore,

to use this terminal to find this address before turning off the drive and replacing it.

Transfer the Altivar 38 address to the Altivar 61 using the 7 swit ches on the ri ght of t he card; th e val ue 0 bei ng the OFF posi ti on, th e value

1 the ON position.

Example

Address 23

Address Switches Address Switches Address Switches Address Switches

1234 5678 1234 5678 1234 5678 1234 5678

6 = VP

8 = Rx/Tx+

Address 89

0 1000 0000 32 1010 0000 64 1100 0000 96 1110 0000

1 1000 0001 33 1010 0001 65 1100 0001 97 1110 0001

2 1000 0010 34 1010 0010 66 1100 0010 98 1110 0010

3 1000 0011 35 1010 0011 67 1100 0011 99 1110 0011

4 1000 0100 36 1010 0100 68 1100 0100 100 1110 0100

5 1000 0101 37 1010 0101 69 1100 0101 101 1110 0101

6 1000 0110 38 1010 0110 70 1100 0110 102 1110 0110

7 1000 0111 39 1010 0111 71 1100 0111 103 1110 0111

8 1000 1000 40 1010 1000 72 1100 1000 104 1110 1000

9 1000 1001 41 1010 1001 73 1100 1001 105 1110 1001

10 1000 1010 42 1010 1010 74 1100 1010 106 1110 1010

11 1000 1011 43 1010 1011 75 1100 1011 107 1110 1011

12 1000 1100 44 1010 1100 76 1100 1100 108 1110 1100

13 1000 1101 45 1010 1101 77 1100 1101 109 1110 1101

14 1000 1110 46 1010 1110 78 1100 1110 110 1110 1110

15 1000 1111 47 1010 1111 79 1100 1111 111 1110 1111

16 1001 0000 48 1011 0000 80 1101 0000 112 1111 0000

17 1001 0001 49 1011 0001 81 1101 0001 113 1111 0001

18 1001 0010 50 1011 0010 82 1101 0010 114 1111 0010

19 1001 0011 51 1011 0011 83 1101 0011 115 1111 0011

20 1001 0100 52 1011 0100 84 1101 0100 116 1111 0100

21 1001 0101 53 1011 0101 85 1101 0101 117 1111 0101

22 1001 0110 54 1011 0110 86 1101 0110 118 1111 0110

23 1001 0111 55 1011 0111 87 1101 0111 119 1111 0111

24 1001 1000 56 1011 1000 88 1101 1000 120 1111 1000

25 1001 1001 57 1011 1001 89 1101 1001 121 1111 1001

26 1001 1010 58 1011 1010 90 1101 1010 122 1111 1010

27 1001 1011 59 1011 1011 91 1101 1011 123 1111 1011

28 1001 1100 60 1011 1100 92 1101 1100 124 1111 1100

29 1001 1101 61 1011 1101 93 1101 1101 125 1111 1101

30 1001 1110 62 1011 1110 94 1101 1110

31 1001 1111 63 1011 1111 95 1101 1111

126 0111 1110

If the PLC module was configured using the Sycon < v2.8 configurati on t ool, it was po ssib le to use ad dress 1 26 for a s ubscri ber

(Altivar or other).

This address is reserved and, therefore, its use is prohibited from version v2.8 onward s in accordance with the recommendatio ns

of the Profibus consortium.

45

Page 46

3. Implementation of the communication option cards

3. 5. 3. Configuring the drive in "ATV38 Interchangeability" mode

The Profibus protocol operates according to the principle of exchanging periodic data.

In order to use the output data and input data from Altivar 38 cyclic exchanges, rather than those from Altivar 61, you need to set switch 1