Page 1

A

ltivar Process ATV6000 UL

GDE99019 09/2020

Altivar Process ATV6000 UL

Variable Speed Drives

Installation Manual

09/2020

GDE99019-02

www.schneider-electric.com

Page 2

The information provided in this documentation contains general descriptions and/or technical characteristics of the performance of the products contained herein. This documentation is not intended as a

substitute for and is not to be used for determining suitability or reliability of these products for specific user

applications. It is the duty of any such user or integrator to perform the appropriate and complete risk

analysis, evaluation and testing of the products with respect to the relevant specific application or use

thereof. Neither Schneider Electric nor any of its affiliates or subsidiaries shall be responsible or liable for

misuse of the information contained herein. If you have any suggestions for improvements or amendments

or have found errors in this publication, please notify us.

You agree not to reproduce, other than for your own personal, noncommercial use, all or part of this

document on any medium whatsoever without permission of Schneider Electric, given in writing. You also

agree not to establish any hypertext links to this document or its content. Schneider Electric does not grant

any right or license for the personal and noncommercial use of the document or its content, except for a

non-exclusive license to consult it on an "as is" basis, at your own risk. All other rights are reserved.

All pertinent state, regional, and local safety regulations must be observed when installing and using this

product. For reasons of safety and to help ensure compliance with documented system data, only the

manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant instructions must

be followed.

Failure to use Schneider Electric software or approved software with our hardware products may result in

injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2020 Schneider Electric. All rights reserved.

2 GDE99019 09/2020

Page 3

Table of Contents

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 1 Technical Data and Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Technical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Type designation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Nameplate Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selection and ordering data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Key Interlock System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 Steps for Setting Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3 Transportation, Storage and Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Transport and Storage Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage and Handling Instructions for Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

End of Life / Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lifting and Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

General Notes on Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabinet Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabinet Combination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Cell Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cooling Fan Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fan Shutter Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5 Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Overview of Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Grounding Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

External Power cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Auxiliary Power cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control cabling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Terminals Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6 Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Service and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spares and repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Visual Inspection and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Grounding Cable for Maintenance (Option). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning and Replacement of Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scheduled Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 7 ATV6000 UL Drive System I/O Interface Diagram (standard configuration) 79

I/O Interface Diagram (Standard Configuration) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 8 Operating Environment Maintenance of VSD. . . . . . . . . . . . . . . . . . . . . . . 81

Operating Environment Maintenance of Variable Speed Drive (VSD) . . . . . . . . . . . . . . . . .

14

16

19

21

22

23

26

30

32

33

34

34

35

40

43

45

47

50

52

58

59

60

63

65

67

70

72

72

73

73

73

74

76

79

81

GDE99019 09/2020 3

Page 4

4 GDE99019 09/2020

Page 5

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device before

trying to install, operate, service, or maintain it. The following special messages may appear throughout

this documentation or on the equipment to warn of potential hazards or to call attention to information that

clarifies or simplifies a procedure.

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel.

No responsibility is assumed by Schneider Electric for any consequences arising out of the use of this

material.

A qualified person is one who has skills and knowledge related to the construction and operation of

electrical equipment and its installation, and has received safety training to recognize and avoid the

hazards involved.

Qualification Of Personnel

Only appropriately trained persons who are familiar with and understand the contents of this manual and

all other pertinent product documentation are authorized to work on and with this product. In addition, these

persons must have received safety training to recognize and avoid hazards involved. These persons must

have sufficient technical training, knowledge and experience and be able to foresee and detect potential

hazards that may be caused by using the product, by changing the settings and by the mechanical,

electrical and electronic equipment of the entire system in which the product is used. All persons working

on and with the product must be fully familiar with all applicable standards, directives, and accident

prevention regulations when performing such work.

GDE99019 09/2020 5

Page 6

Intended Use

This product is a drive for three-phase synchronous, asynchronous motors and intended for industrial use

according to this manual.

The product may only be used in compliance with all applicable safety standard and local regulations and

directives, the specified requirements and the technical data. The product must be installed outside the

hazardous ATEX zone. Prior to using the product, you must perform a risk assessment in view of the

planned application. Based on the results, the appropriate safety measures must be implemented. Since

the product is used as a component in an entire system, you must ensure the safety of persons by means

of the design of this entire system (for example, machine design). Any use other than the use explicitly

permitted is prohibited and can result in hazards.

Product Related Information

Read and understand these instructions before performing any procedure with this drive.

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Only appropriately trained persons who are familiar with and understand the contents of this manual

and all other pertinent product documentation and who have received safety training to recognize and

avoid hazards involved are authorized to work on and with this drive system.

Installation, adjustment, repair and maintenance must be performed by qualified personnel.

Before performing work on the drive system, follow the instructions given in the section ”Complete

drive system power Off procedure”

Before applying voltage to the drive system:

Verify that the work has been completed and that the entire installation cannot cause hazards.

Remove the ground and the short circuits on the mains input terminals and the motor output

Verify proper grounding of all equipment.

Verify that all protective equipment such as covers, doors, grids is installed and/or closed.

Failure to follow these instructions will result in death or serious injury.

terminals.

DANGER

(see page 9)

:

Many components of the equipment, including the printed circuit board, operate with mains voltage, or

present transformed high currents, and/or high voltages.

The motor itself generates voltage when the motor shaft is rotated.

AC voltage can couple voltage to unused conductors in the motor cable.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Verify compliance with all safety information, different electrical requirements, and standards that

apply to your machine or process in the use of this equipment.

Verify compliance with all applicable standards and regulations with respect to grounding of all

equipment.

Only use properly rated, electrically insulated tools and measuring equipment.

Do not touch unshielded components or terminals with voltage present.

Prior to performing any type of work on the drive system, block the motor shaft to prevent rotation.

Do not create short circuits across the DC bus terminals or the DC bus capacitors or the braking

resistor terminals, if present.

Failure to follow these instructions will result in death or serious injury.

6 GDE99019 09/2020

Page 7

Damaged products or accessories may cause electric shock or unanticipated equipment operation.

DANGER

ELECTRIC SHOCK OR UNANTICIPATED EQUIPMENT OPERATION

Do not use damaged products or accessories.

Failure to follow these instructions will result in death or serious injury.

Contact your local Schneider Electric sales office if you detect any damage whatsoever.

This equipment has been designed to operate outside of any hazardous location. Only install this

equipment in zones known to be free of a hazardous atmosphere.

DANGER

POTENTIAL FOR EXPLOSION

Install and use this equipment in non-hazardous locations only.

Failure to follow these instructions will result in death or serious injury.

Your application consists of a whole range of different interrelated mechanical, electrical, and electronic

components, the drive being just one part of the application. The drive by itself is neither intended to nor

capable of providing the entire functionality to meet all safety-related requirements that apply to your

application. Depending on the application and the corresponding risk assessment to be conducted by you,

a whole variety of additional equipment is required such as, but not limited to, external encoders, external

brakes, external monitoring devices, guards, etc.

As a designer/manufacturer of machines, you must be familiar with and observe all standards that apply

to your machine. You must conduct a risk assessment and determine the appropriate Performance Level

(PL) and/or Safety Integrity Level (SIL) and design and build your machine in compliance with all applicable

standards. In doing so, you must consider the interrelation of all components of the machine. In addition,

you must provide instructions for use that enable the user of your machine to perform any type of work on

and with the machine such as operation and maintenance in a safe manner.

The present document assumes that you are fully aware of all normative standards and requirements that

apply to your application. Since the drive cannot provide all safety-related functionality for your entire

application, you must ensure that the required Performance Level and/or Safety Integrity Level is reached

by installing all necessary additional equipment.

WARNING

INSUFFICIENT PERFORMANCE LEVEL/SAFETY INTEGRITY LEVEL AND/OR UNINTENDED

EQUIPMENT OPERATION

Conduct a risk assessment according to EN ISO 12100 and all other standards that apply to your

application.

Use redundant components and/or control paths for all critical control functions identified in your risk

assessment.

If moving loads can result in hazards, for example, slipping or falling loads, operate the drive in closed

loop mode.

Verify that the service life of all individual components used in your application is sufficient for the

intended service life of your overall application.

Perform extensive commissioning tests for all potential error situations to verify the effectiveness of

the safety-related functions and monitoring functions implemented, for example, but not limited to,

speed monitoring by means of encoders, short circuit monitoring for all connected equipment, correct

operation of brakes and guards.

Perform extensive commissioning tests for all potential error situations to verify that the load can be

brought to a safe stop under all conditions.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

GDE99019 09/2020 7

Page 8

Drive systems may perform unexpected movements because of incorrect wiring, incorrect settings,

incorrect data or other errors.

WARNING

UNANTICIPATED EQUIPMENT OPERATION

Carefully install the wiring in accordance with the EMC requirements.

Do not operate the product with unknown or unsuitable settings or data.

Perform a comprehensive commissioning test.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

WARNING

LOSS OF CONTROL

The designer of any control scheme must consider the potential failure modes of control paths and,

for critical control functions, provide a means to achieve a safe state during and after a path failure.

Examples of critical control functions are emergency stop, overtravel stop, power outage and restart.

Separate or redundant control paths must be provided for critical control functions.

System control paths may include communication links. Consideration must be given to the

implications of unanticipated transmission delays or failures of the link.

Observe all accident prevention regulations and local safety guidelines (1).

Each implementation of the product must be individually and thoroughly tested for proper operation

before being placed into service.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

(1) For USA: Additional information, refer to NEMA ICS 1.1 (latest edition), Safety Guidelines for the

Application, Installation, and Maintenance of Solid State Control and to NEMA ICS 7.1 (latest edition),

Safety Standards for Construction and Guide for Selection, Installation and Operation of Adjustable-Speed

Drive Systems.

WARNING

LOSS OF CONTROL

Perform a comprehensive commissioning test to verify that communication monitoring properly detects

communication interruptions

Failure to follow these instructions can result in death, serious injury, or equipment damage.

NOTICE

DESTRUCTION DUE TO INCORRECT MAINS VOLTAGE

Before switching on and configuring the product, verify that it is approved for the mains voltage.

Failure to follow these instructions can result in equipment damage.

8 GDE99019 09/2020

Page 9

Complete Drive System Power Off Procedure

Perform the following actions to verify the absence of voltage

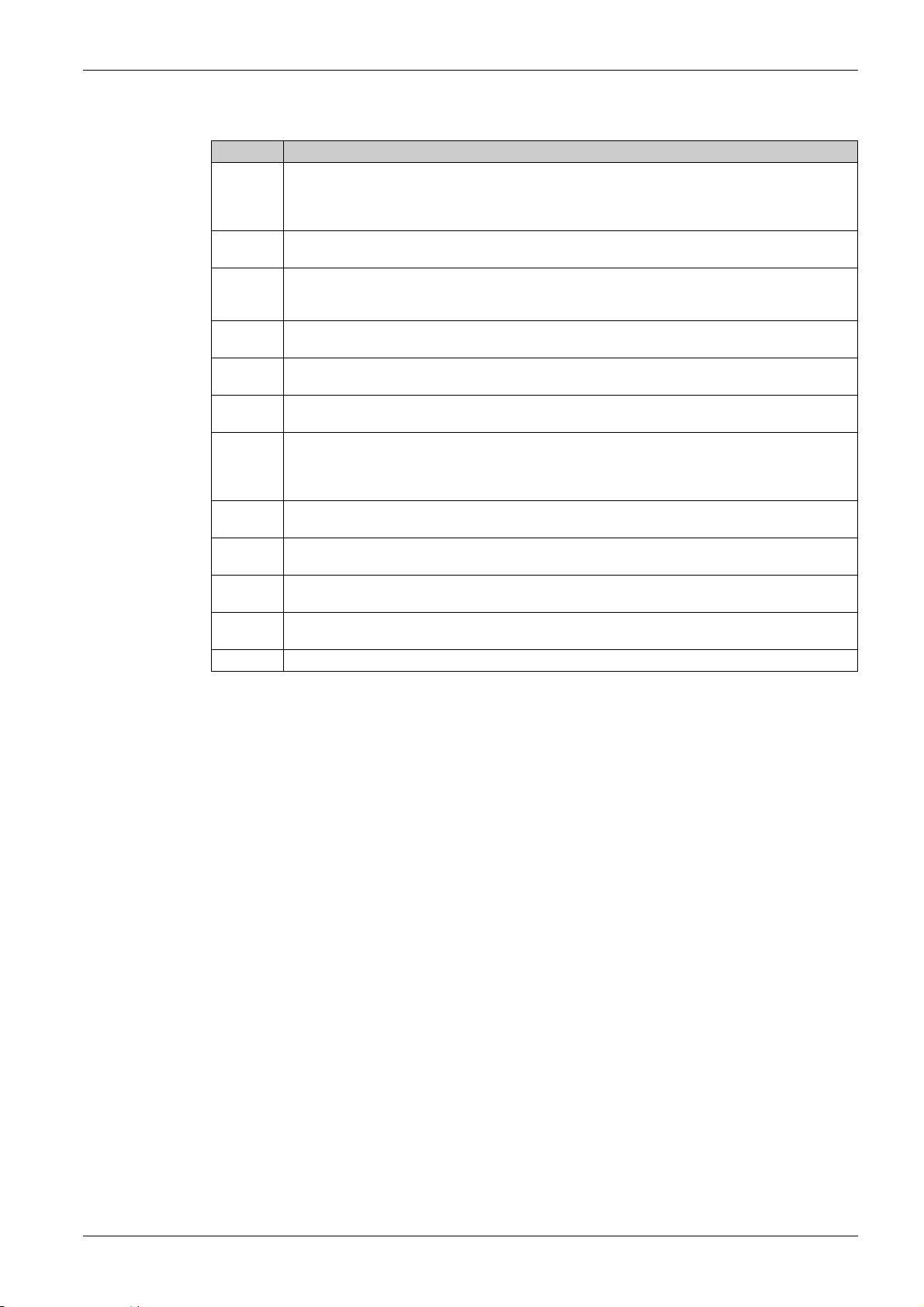

Step Description

1 Only appropriately trained persons who are familiar with and understand the contents of this manual and

2 Wear appropriate personal protective equipment (PPE).

3 Before disconnecting mains voltage, verify that the red LEDs of all power cells are ON by checking the

4 Switch OFF all main power supply and ground the mains breaker.

5 Lock the grounding switch of the mains breaker with your personal lock and place a "Do Not Turn On"

6 Wait 20 minutes to allow the DC bus capacitors to discharge.

7 Verify that the red LEDs on all power cells are OFF.

8 Remove free key K0 from the medium voltage circuit breaker of the drive system and release the keys

9 Open the transformer cabinet doors and verify the absence of voltage with a properly rated voltage

10 If there is no voltage detected on the mains terminals, short circuit the input terminals to ground using a

11 If there is no voltage detected on the motor terminals, short circuit the terminal to ground using a properly

12 Verify that no other voltage is present in the drive system.

all other pertinent product documentation and who have received safety training to recognize and avoid

hazards involved are authorized to work on and with this drive system. Installation, adjustment, repair,

and maintenance must be performed by qualified personnel.

e.g. Arc flash protection, helmet & visor, Insulation gloves.

LED state via the openings in the cabinet doors. If one or more of the red LEDs of the power cells are

OFF, do not perform any further work, but contact your local Schneider Electric representative.

Switch OFF all external auxiliary power supply (230V / 400V / ...) and lock them in off position.

label on the medium voltage circuit breaker.

The DC bus LEDs located on each power cell are not an indicator of the absence of DC bus voltage.

If one or more of the red LEDs of the power cells remain ON for 20 minutes after the mains voltage has

been disconnected, do not perform any further work, but contact your local Schneider Electric

representative

to open the cabinet doors.

sensing device on the mains terminals and motor terminals.

properly rated grounding equipment.

rated grounding equipment.

GDE99019 09/2020 9

Page 10

10 GDE99019 09/2020

Page 11

At a Glance

Document Scope

Validity Note

About the Book

The purpose of this document is to:

give you mechanical and electrical information related to the ATV6000 drive.

show you how to install and wire this drive.

Original instructions and information given in this manual have been written in English (before optional

translation).

This documentation is valid for the Altivar Process ATV6000 Medium Voltage Drives.

The asterisks (*) available to this document is linked to the following information: Based on previous data.

This is not a guarantee of future performance or performance in your particular circumstances.

The technical characteristics of the devices described in the present document also appear online. To

access the information online:

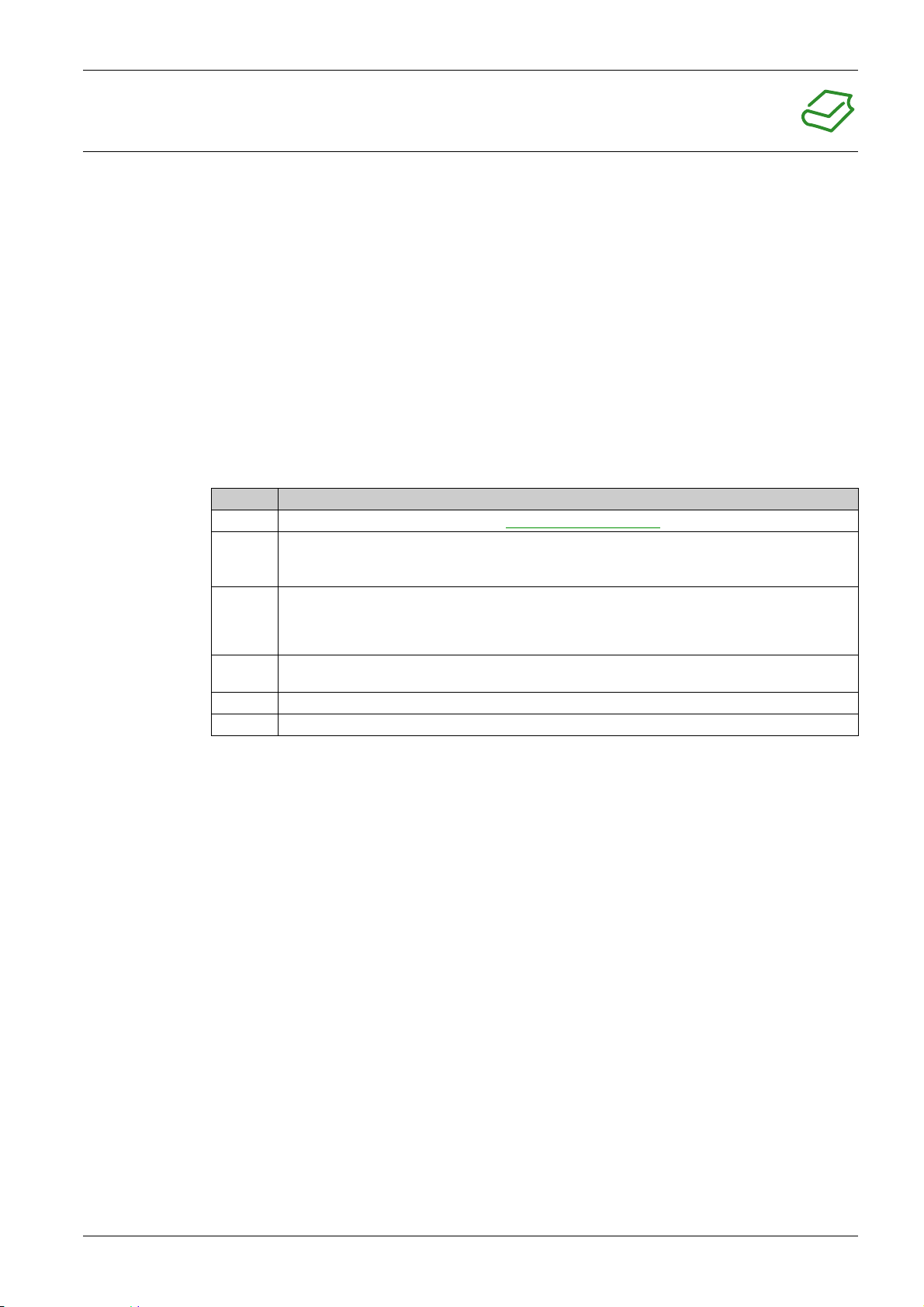

Step Action

1 Go to the Schneider Electric home page

2 In the Search box type the reference of a product or the name of a product range.

Do not include blank spaces in the reference or product range.

To get information on grouping similar modules, use asterisks (

3 If you entered a reference, go to the Product Datasheets search results and click on the reference that

interests you.

If you entered the name of a product range, go to the Product Ranges search results and click on the

product range that interests you.

4 If more than one reference appears in the Products search results, click on the reference that interests

you.

5 Depending on the size of your screen, you may need to scroll down to see the datasheet.

6 To save or print a datasheet as a .pdf file, click Download XXX product datasheet.

www.schneider-electric.com

.

*

).

The characteristics that are described in the present document should be the same as those characteristics that appear online. In line with our policy of constant improvement, we may revise content over time

to improve clarity and accuracy. If you see a difference between the document and online information, use

the online information as your reference.

GDE99019 09/2020 11

Page 12

Related Documents

Use your tablet or your PC to quickly access detailed and comprehensive information on all our products

on www.schneider-electric.com.

The Internet site provides the information you need for products and solutions:

The Handbook for detailed characteristics and selection guides,

The CAD files to help design your installation,

All software and firmware to maintain your installation up to date,

Additional documents for better understanding of drive systems and applications

And finally all the User Guides related to your drive, listed below:

(Other option manuals and Instruction sheets are available on www.schneider-electric.com)

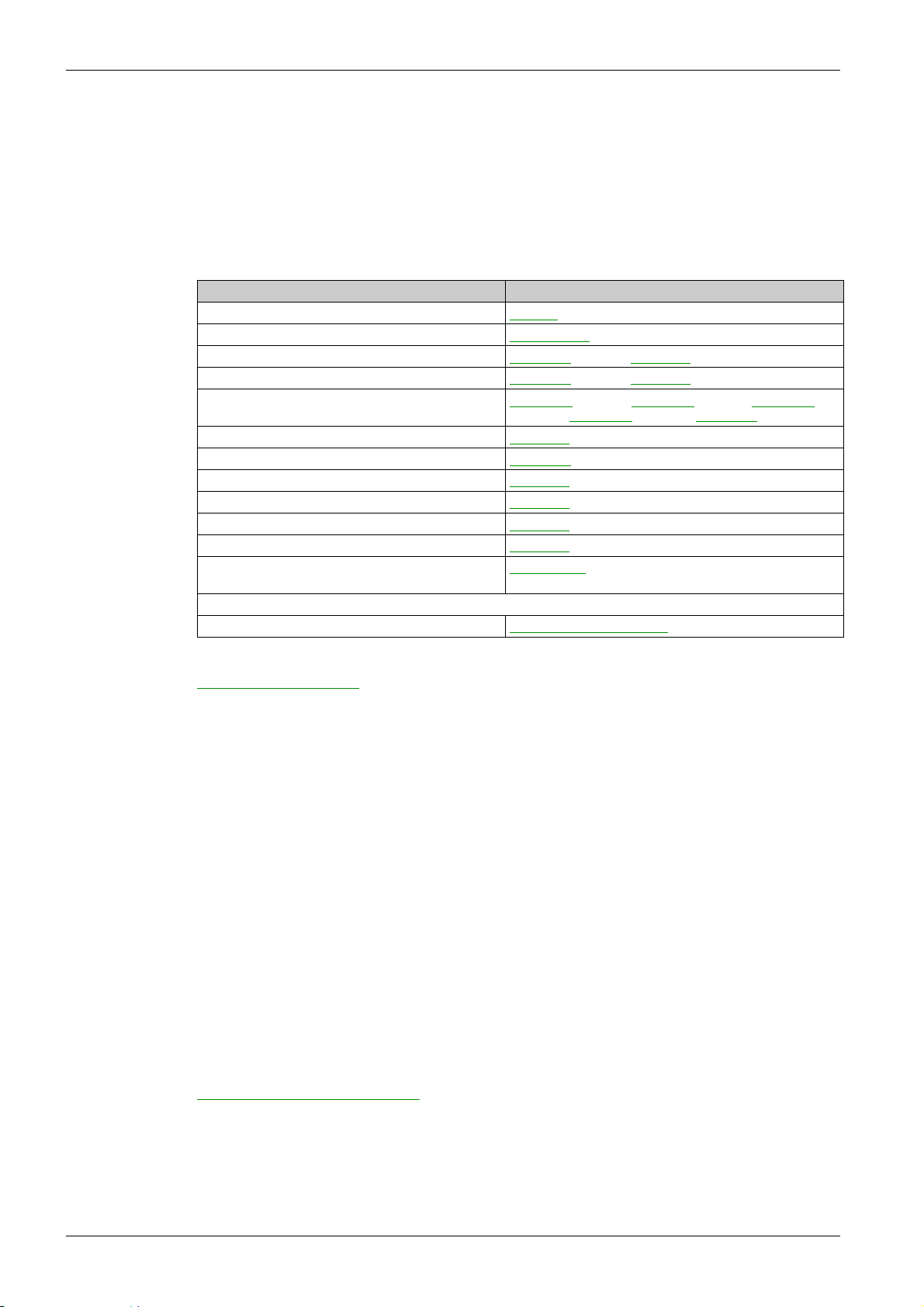

Title of Documentation Catalog Number

Digital Catalog for Industrial Automation

Altivar Process range brochure

ATV6000 UL Handbook

ATV6000 UL Installation Manual

ATV6000 Programming Manual for Operator and

Advanced Operator

ATV6000 Embedded Ethernet Manual

ATV6000 Modbus SL Manual

ATV6000 PROFIBUS Manual

ATV6000 DeviceNet Manual

ATV6000 EtherCat Manual

ATV6000 Profinet Manual

SoMove: FDT

Altivar Process ATV6000: DTM

Recommended Cybersecurity Best Practices

Digit-Cat

998-20307132

GDE99017

GDE99019

QGH83265

(German),

PHA30472

MFR24213

PHA30474

PHA30471

PHA30473

PHA30475

SoMove_FDT

Chinese)

(English)

(English),

(English),

(English),

QGH83267

(English)

(English)

(English)

(English)

(English)

(English)

NNZ67544

NNZ67545

QGH83266

(Spanish),

(English, French, German, Spanish, Italian,

CS-Best-Practices-2019-340

(Spanish)

(Spanish)

(French),

GDE94088

(English)

QGH83268

(Italian)

Terminology

Contact Us

You can download these technical publications and other technical information from our website at

www.se.com/en/download

The technical terms, terminology, and the corresponding descriptions in this manual normally use the

terms or definitions in the relevant standards.

In the area of drive systems this includes, but is not limited to, terms such as error, error message, failure,

fault, fault reset, protection, safe state, safety function, warning, warning message, and so on.

Among others, these standards include:

IEC 61800 series: Adjustable speed electrical power drive systems

IEC 61508 Ed.2 series: Functional safety of electrical/electronic/programmable electronic safety-related

EN 954-1 Safety of machinery - safety-related parts of control systems

ISO 13849-1 & 2 Safety of machinery - safety related parts of control systems

IEC 61158 series: Industrial communication networks - Fieldbus specifications

IEC 61784 series: Industrial communication networks - Profiles

IEC 60204-1: Safety of machinery - Electrical equipment of machines – Part 1: General requirements

In addition, the term zone of operation is used in conjunction with the description of specific hazards, and

is defined as it is for a hazard zone or danger zone in the EC Machinery Directive (2006/42/EC) and in ISO

12100-1.

Select your country on:

www.schneider-electric.com/contact

Schneider Electric Industries SAS

Head Office

35, rue Joseph Monier

92500 Rueil-Malmaison

France

12 GDE99019 09/2020

Page 13

A

ltivar Process ATV6000 UL

Technical Data and Features

GDE99019 09/2020

Technical Data and Features

Chapter 1

Technical Data and Features

What Is in This Chapter?

This chapter contains the following topics:

Presentation 14

Benefits 16

General Technical Data 19

Type designation 21

Nameplate Example 22

Selection and ordering data 23

Key Interlock System 26

Topic Page

GDE99019 09/2020 13

Page 14

Technical Data and Features

Presentation

Control and Transformer Cabinet

Clever and modular arrangement of control section in front of transformer.This section with independent access allows

the integration of additional components according to your personal needs.

Benefits

Space optimized dimensions without squeezing

components in small compartments, granting you a

nominal service life avoiding hot spot inside the

system.

The integrated transformer and multilevel structure

helps to avoid bearing currents in existing motors. This

results in a capability to run your old motor on a new

MV drive, leading to a drastic reduction of energy

costs where your damper controlled fan or throttle

controlled pump is concerned.

Fig. Control and transformer cabinet

14

GDE99019 09/2020

Page 15

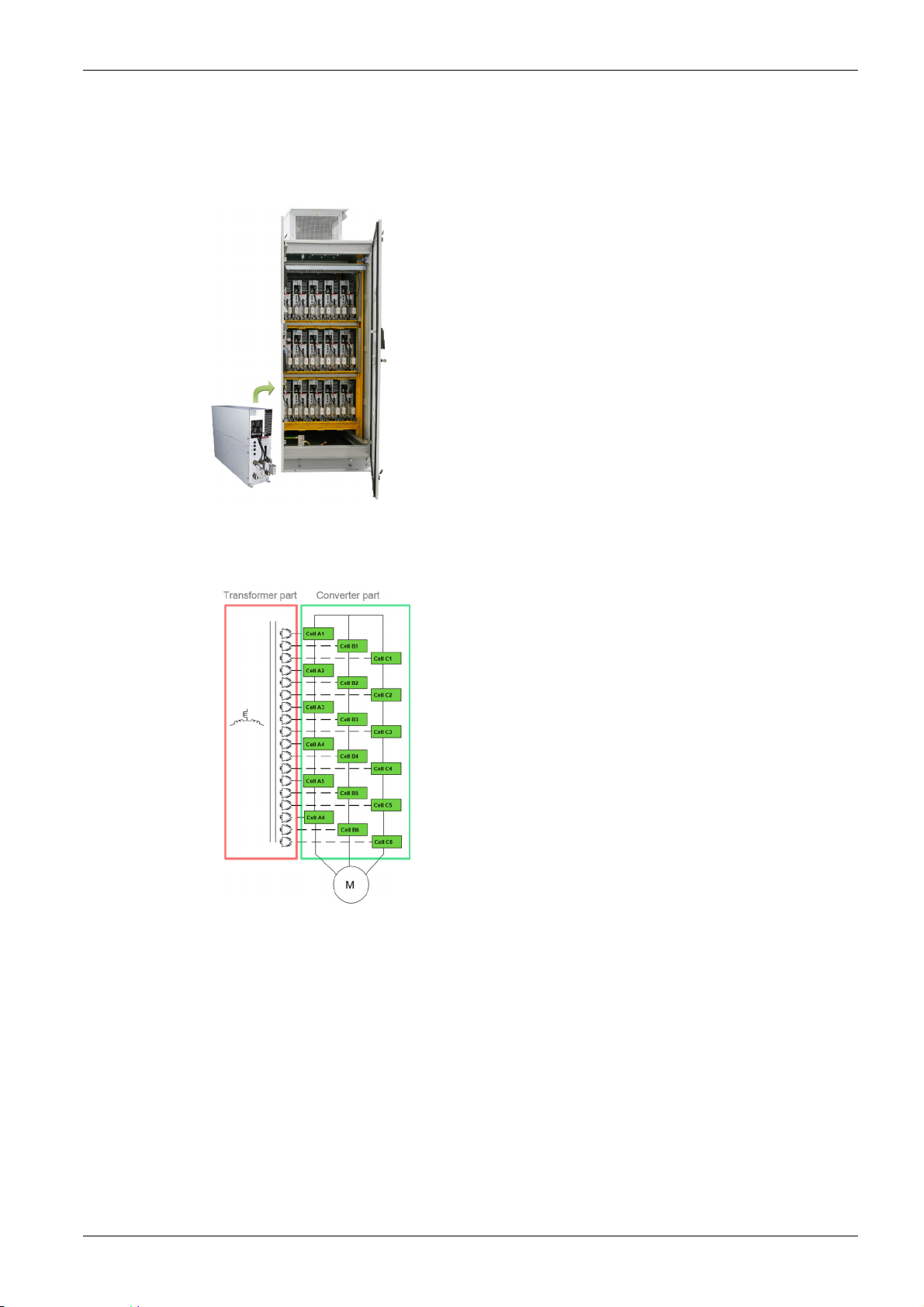

Power cells Cabinet

Technical Data and Features

The power cells cabinet contains the inverter function of the ATV6000. It is a modular cabinet that can be used with

the transformer cabinet according to the implementation requirements. The power cells are placed onto a fast-track

system providing a convenient access to it.

Benefits

Clear arrangement of components helping your team

in maintenance and service

Compact and low weight cell design saving

maintenance shutdown time

Easier installation to save time

Drive Topology

Fig. Power cells cabinet and Power cell

Fig. ATV6000 multilevel architecture

Its simple two level power cell design takes away the complexity of multilevel architecture and makes it into

a clear and easy understandable technology. This saves your maintenance cost because the crew will

easily understand Altivar 6000.

One of the core component of ATV6000 is the “Power cell”. This “Power cell” is a single phase, two level

output switching device, supplied by a 700/720 V low voltage winding of a transformer.

The big advantage of this is, that the switching elements are state-of-the-art LV components. By putting

this AC - supplies in series, higher voltages are achieved. The number of “Power cells” determines the

output voltage. Every cell provides a small step of motor supply, resulting in a smooth waveform. Phase

shifting can be done on the secondary windings of transformer, allowing an elimination of harmonics of

input.

The drive regulation system and control system are installed at front of the drive to provide an optimized

footprint. The transformer and cell section can be separated for easy installation.

As an option the adequate cooling fans on top of the cabinet can be supplied by an additional secondary

windings of the integrated transformer to avoids additional 3phase supplies for the drive

Schneider Electric offers this transformer in a standard efficiency as well as in increased high efficiency.

GDE99019 09/2020 15

Page 16

Technical Data and Features

Benefits

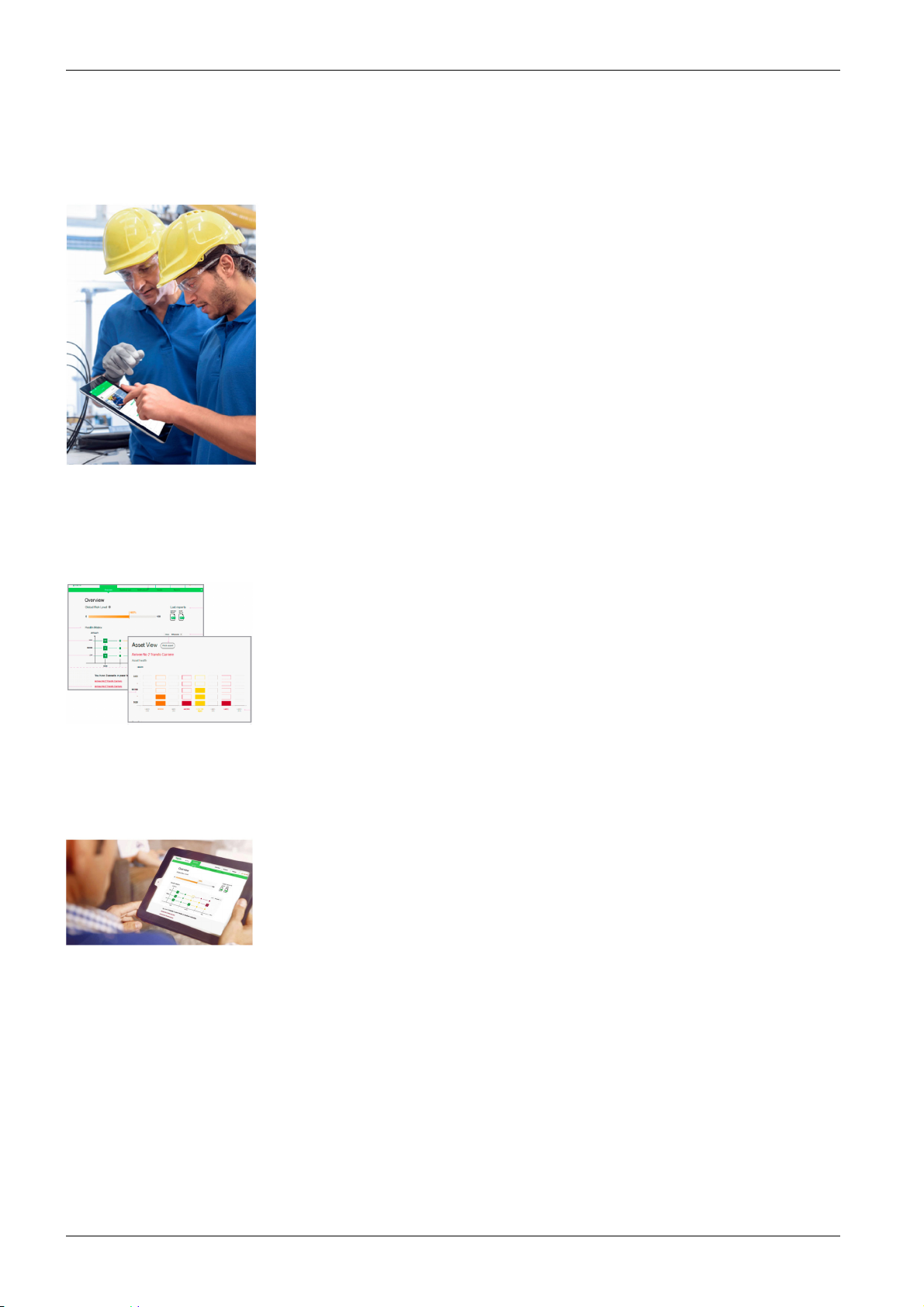

Services-oriented drives

Increase availability and reduce Downtime for service continuity by 20%*

Improved operator efficiency

Generation of robust, actionable, and relevant information

Advanced communication and predictive maintenance capabilities

Functionalities for remote intervention and online support

Easy troubleshooting with QR code

Comfortable usability with the connected 10" Magelis HMI screen

Key performance indicators

Fast and easy on-site maintenance operation

Quicker intervention

Optimized management of spare parts stock with modular architecture

Easy front access design

Digital services

More uptime & shorter recovery time with predictive maintenance and reduce TCO by 20%*

EcoStruxure Asset Advisor

Preventive analytics to increase operational performance of your drives systems

Predictive maintenance, including continuous monitoring, risk assessment, and

mitigation plan, with EcoStruxure

Identification of energy saving potential

Optimized maintenance budgeting

360° diagnostics, with report and analysis

Records of your crucial assets

Access to 24/7 Schneider Electric service assistance

™

Asset Advisor

ATV6000 UL provides a unique solution to optimize the operation and maintenance

of your installation. It allows you to manage maintenance tasks on your assets with

preventive and predictive management based on real-time assessments and

predictive analytics. All thanks to the combination of smart connected device

technologies and powerful cloud-based risk prediction capabilities.

The ATV6000 UL with EcoStruxure Asset Advisor transforms data into insight to

help run your operations more efficiently and safer, with more availability, and

increased profits.

Continuous health monitoring

The operator gets a complete health monitoring view of its assets and conditions of usage (drive, transformer, MCB, motor) and the assets

are seen as super-sensors providing relevant data and KPIs.

Risk evaluation

The operator knows in real-time where and what risks are on the installation. Predictive analytics constantly evaluates the level and criticality

of risk by looking at an asset, the process duty cycle, and the condition of usage. This enables the ability to predict, in advance, a potential

failure or dysfunction of the installation.

Risk mitigation

The operator receives notification of the necessary maintenance task required at the right time to secure the asset and production at minimal

cost, mitigating the risks of downtime.

16

GDE99019 09/2020

Page 17

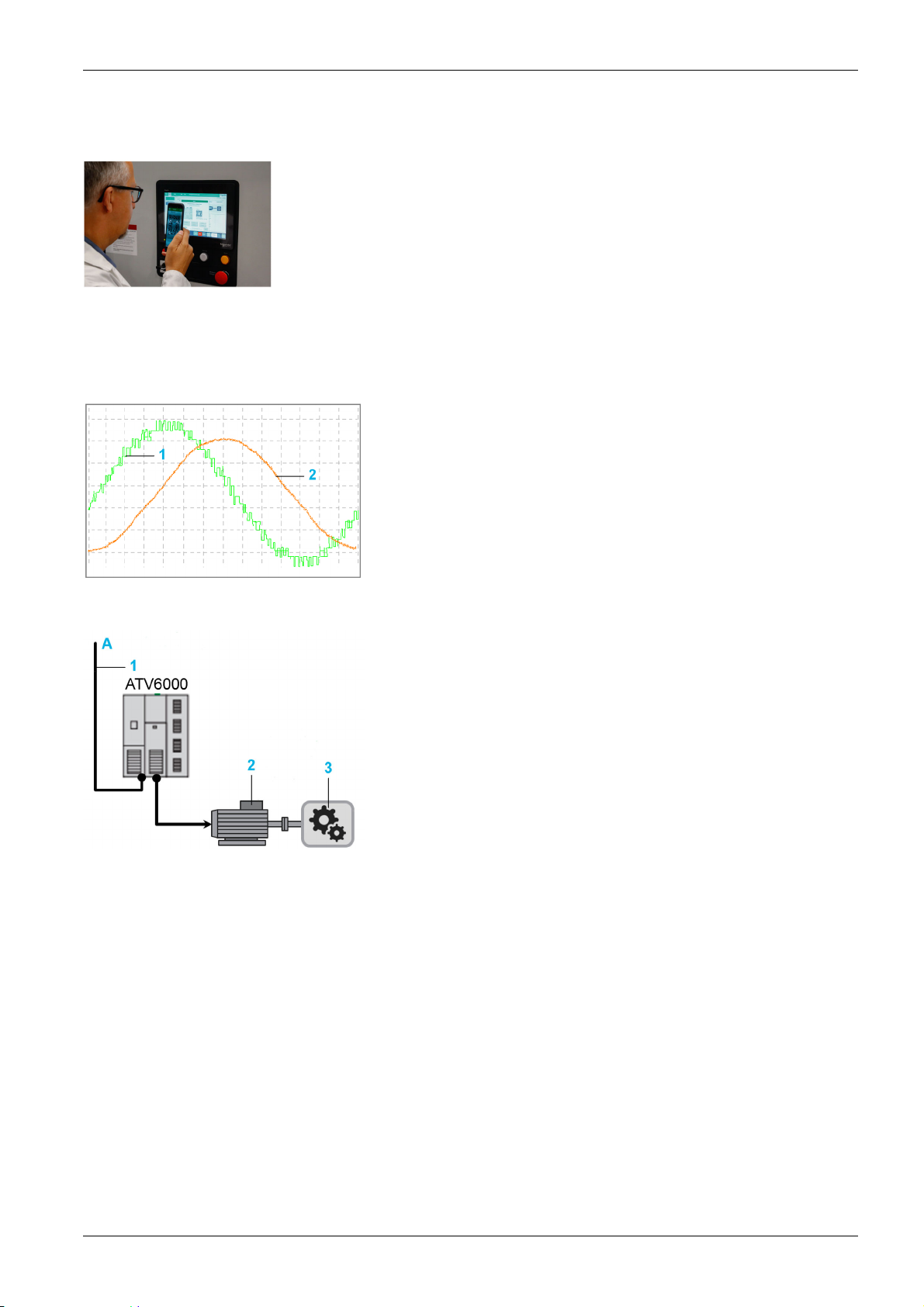

QR code interface

Energy management

Technical Data and Features

Empowered operator to improve efficiency

The ATV6000 UL provides a smart and easy to use QR-code interface to provide

the operator with relevant drive information. With just one scan of the QR-code with

a mobile device (as tablet or smartphone) on the name plate or the HMI screen you

get easy access to technical documentation or technical online support for easy

error management.

Optimize usage of energy and reduce consumption by up to 30%*

Better usage of energy

Embedded power management with < 5% measurement error

Key performance indicators and service life monitoring on energy usage

Smart data collection and access to real-time information

1 Voltage on motor side

2 Current on motor side

A Mains

1 Drive input voltage, Drive input current, Drive input

power

2 Motor current, Motor voltage, Motor speed, Motor

winding & bearing temperature, Consumption kWH

3 Over-/Underload, Stall, Cavitation, Flow, Pressure,

BEP

Use of clean power

Designed for seamless integration into installation

No need to add harmonic mitigation on mains side

Minimized energy waste

Reduced motor losses, vibrations, and torque pulses with advanced harmonic-

free technology

GDE99019 09/2020 17

Page 18

Technical Data and Features

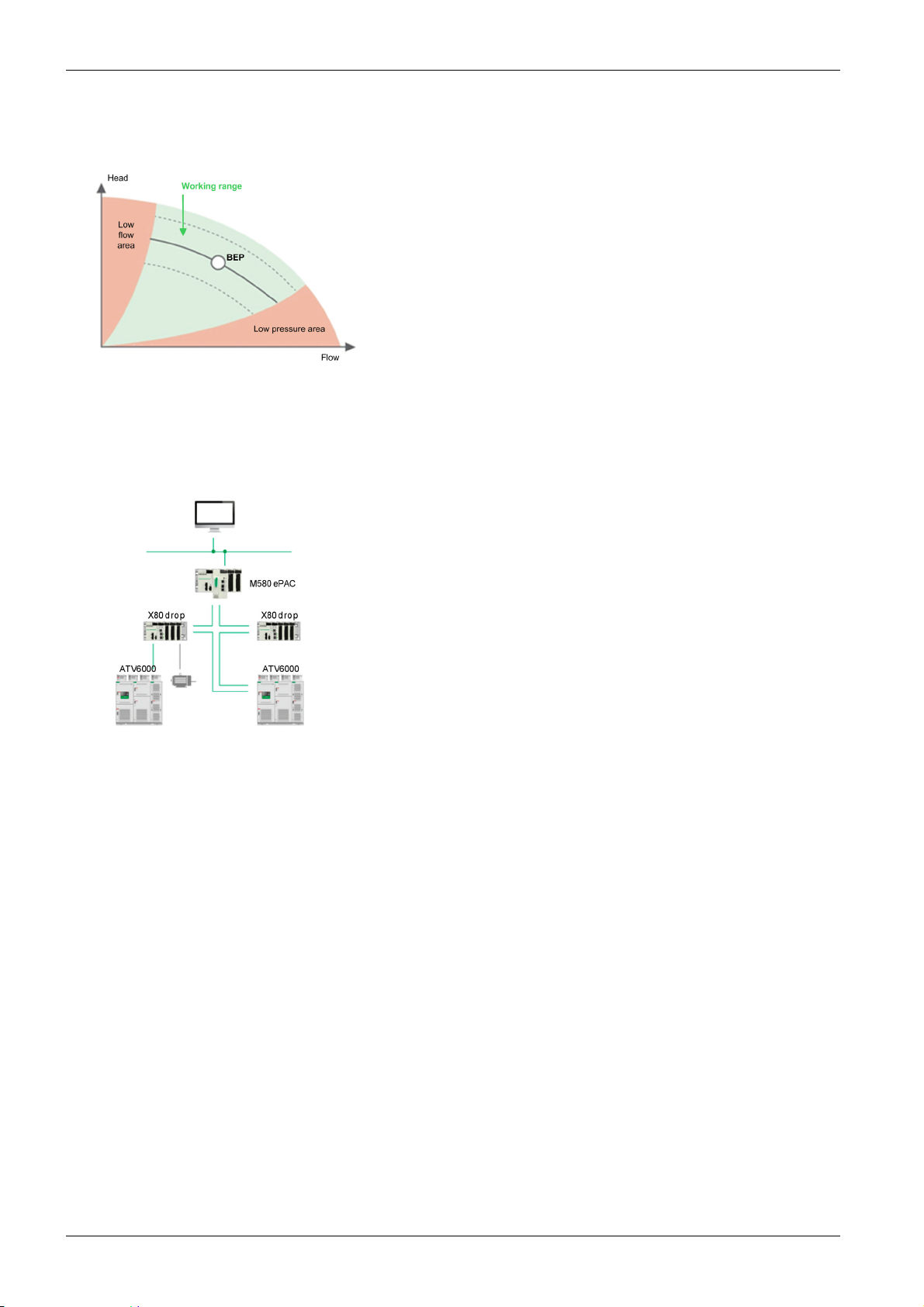

Process optimization

Improve productivity and availability by up to 20%*

BEP Best Efficiency Point Function

Error tolerant operations

Equipped with level inverter bypass features, ATV6000 UL help to reduce process

interruption.

Proactive maintenance approach

With improved warning functions in case of unusual conditions, and sophisticated

measures to help protect equipment against damage. The ATV6000 UL is also

highly modular, enabling fast maintenance operation.

Maximized performance and production output

Ensuring sustainable operation efficiency through making necessary adjustment in

case of best efficiency point (BEP) deviation.

Our IIoT-enabled EcoStruxure solution

Provides compatibility with Process Expert System (PES) architectures, Modicon

M580 controllers, and Foxboro EVO DCS systems.

The ATV6000's smart drive capabilities offer innovative features based on IIoT,

mobility, detecting, analysing, and recommending solutions to boost your operation

and maintenance activities.

The drive is EcoStruxure-ready, providing a complete integrated solution for overall

equipment effectiveness.

It allows you to save time and exploit the full range of capabilities of your equipment

on a single platform.

EcoStruxure PES and Modicon

™

M580-compatible, enabling use of dedicated

libraries for quicker product implementation and commissioning

DTM library and application function blocks provide full programming and

diagnostic functions

EcoStruxure Asset Advisor uses the drive as a super sensor for predictive

maintenance

Tailored solutions

Deliver solutions to optimize your operation efficiency and investment (time & expenditure)

Delivers a highly versatile platform to meet demanding customer requirements beyond those of

standard drives

Provides a high level of customization to fit specific purposes

Offers flexibility with electrical or mechanical modifications and extensions easily delivered

Utilizes a simplified design process and shortened system implementation time

18

GDE99019 09/2020

Page 19

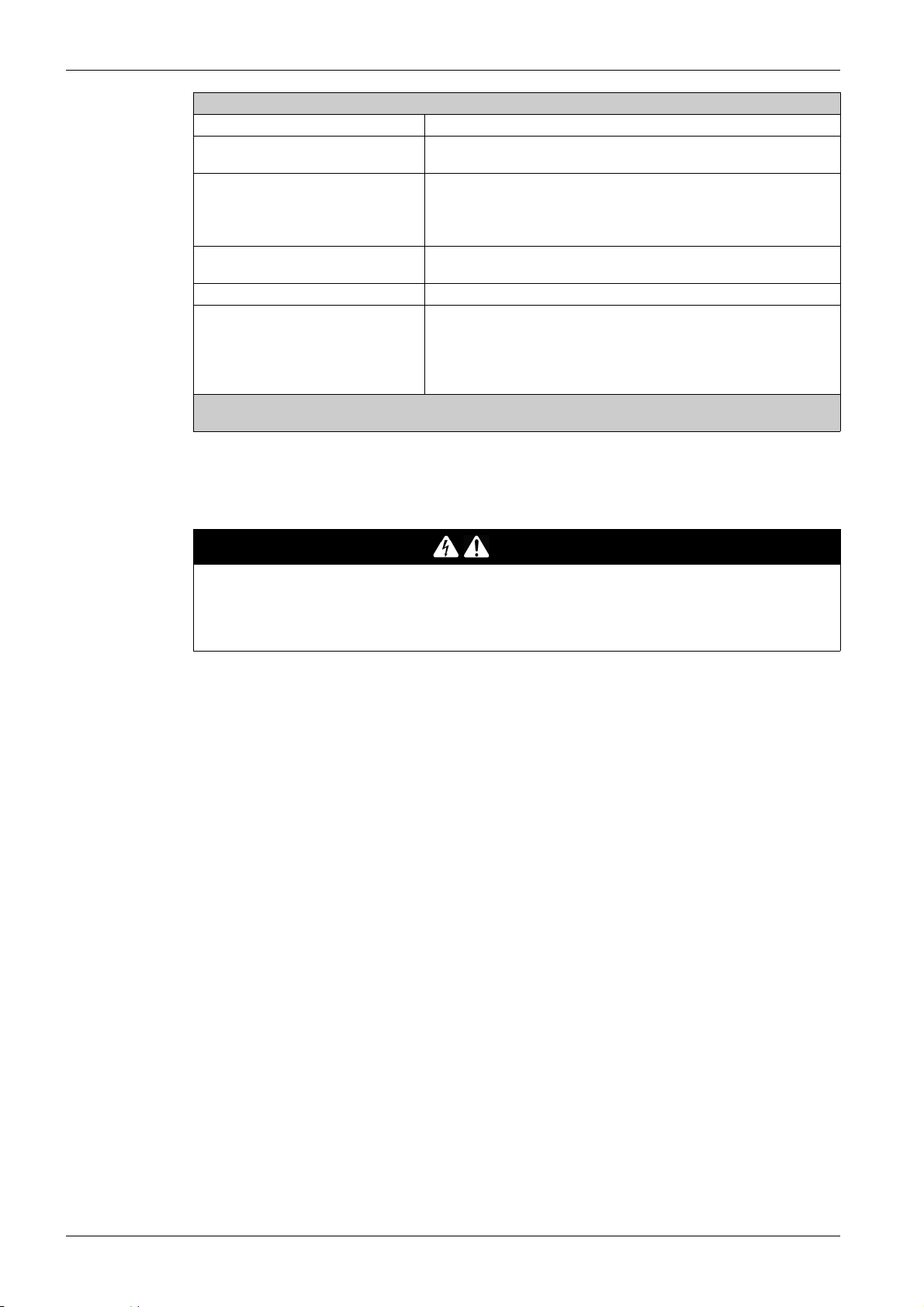

General Technical Data

Input 18-66 pulse diode rectifier bridge

Output Multilevel PWM with 2 level low-voltage IGBT inverter cells

Input voltage

Allowable voltage fluctuation The drive is subject to derating operation when the voltage drop of power

Input frequency 50/60 Hz ± 5 %

Incoming short circuit withstand 31.5 kA for 150 ms

Overload capability

Total harmonics THD(i) Comply with the requirements of power quality standard of IEEE519-2014

Input power factor ≥0.96 from 20 % to 100 % of load

Cable entry Bottom (on request for others)

Frequency resolution 0.01 Hz

Power cells command signals

transmission

Efficiency at rated power Inverter efficiency is 98.5 %. Drive efficiency including input transformer is

Type of motor Asynchronous motor, synchronous motor, permanent magnet motor

Three-phase output voltage for motor

connection

Output frequency 0.1 to 120 Hz

Input transformer Indoor type integrated in the frequency variable device, the dry phase-

Control power supply 100...240 Vac ± 10 % (47...63 Hz), 1 kVA capacity.

Auxiliary power supply 120 Vac +/- 10%, single phase, 60 Hz, 1kVA capacity for standard

Cooling fan power supply 480 VAC ± 10 %, 3-phase, 60Hz, actual capacity depending on drive

Communication protocols Modbus TCP, EtherNet/IP, Modbus serial

HMI 10 inch, color graphic, touch screen, multi-languages

Control interface 8 DI, 3AI, 2AO,3 relay output (more on request)

Protection class UL type 1

Paint RAL 7035

Cooling Forced air ventilation

EMC EN/IEC 61800-3 environment 2 category C4 for power, C3 for control

Reference standard IEC EN 61800-3, IEC EN 61800-4, IEC EN 61800-5-1, IEC EN 60529,

Product certification CE, EAC, cULus

Technical Data and Features

2.4 kV, 4.16 kV, 6.6 kV

Variation: standard ± 10 %

supply is within -25 %.

Normal duty: 120 % 60 s/10 min and 150 % 3 s/10 min

Heavy duty: 150 % 60 s/10 min, 185 % 3 s/10 min

Fiber optic transmission

96 % to 96.5 % depending on product.

(Surface / Interior magnet).

0 to respective output voltage.

shifting transformer can be supplied for 18-66 pulse rectifier

Power supply must be secured (uninterrupted) or UPS to be selected.

Other AC and DC voltage on request.

configuration, actual capacity depending on auxiliary options used.

reference.

Other voltage on request

IEEE 519 and other optional ones

Environment features

Storage temperature 0 °C to 50 °C

Transportation temperature -25 °C to 70 °C

Working temperature

0 to 40 °C, up to 50°C possible with derating

(1)

.

Relative humidity Up to 90% (without condensation)

Optional: maximum up to 95% (without condensation)

Altitude

≤1000 m, up to 2000m possible with derating

(1)

.

(1): Derating must be applied on the drive system and the value of the derating is defined by Schneider Services

depending on the customer application and the local environment conditions

GDE99019 09/2020 19

Page 20

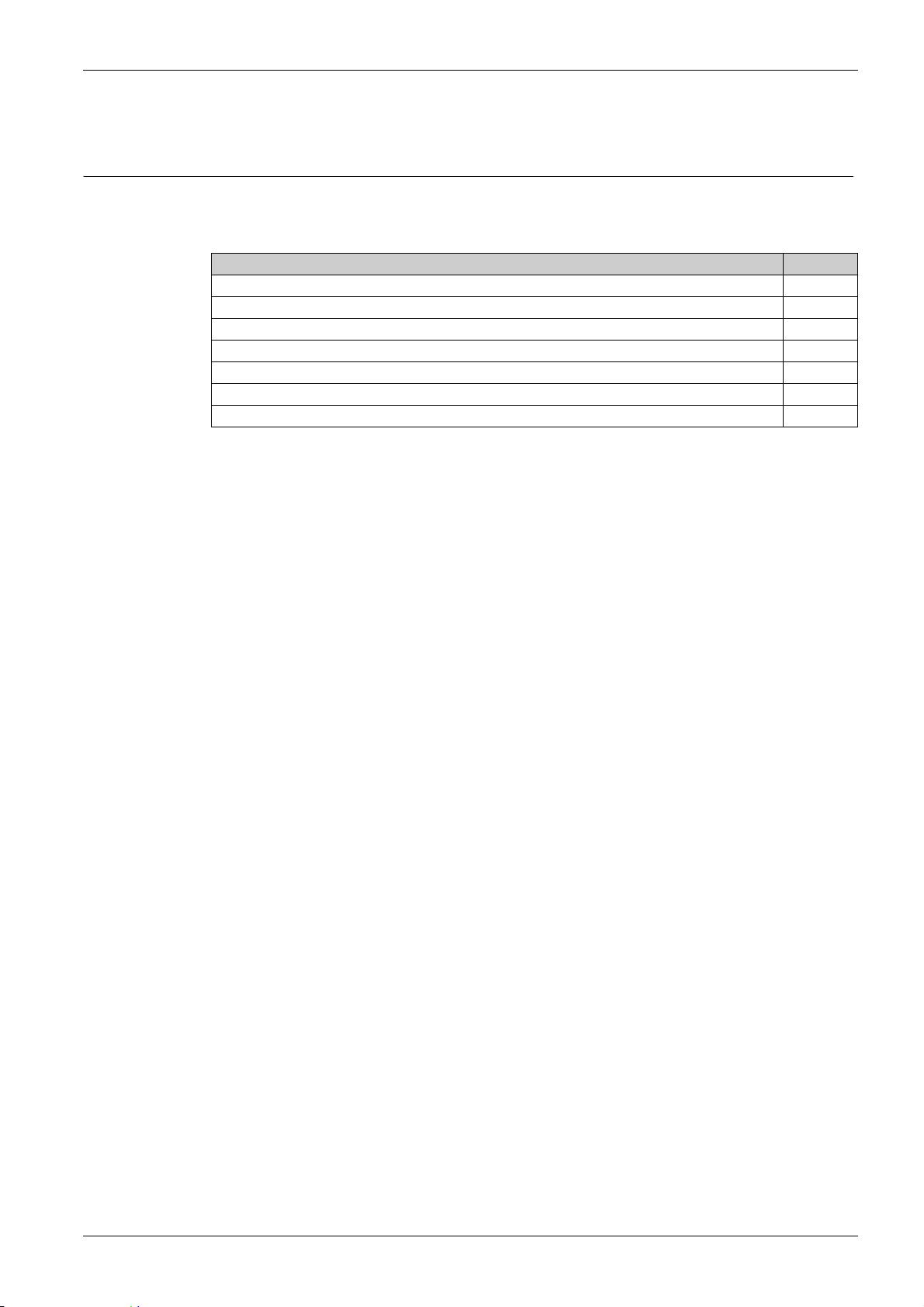

Technical Data and Features

Environment features

Noise level 80/83/85 dB (A)

Over Voltage Category IEC61800 (Adjustable speed electrical power drive systems - Part 5-1:

Drive line side

Drive motor side

Secures Control power supply

Auxiliary and fan power supply

Pollution in accordance with IEC 618005-1

Environmental parameters (operation) Refer to IEC60721-3-3

Climatic conditions

Mechanical conditions

Biological conditions

Chemical conditions

Mechanically active substances

(1): Derating must be applied on the drive system and the value of the derating is defined by Schneider Services

depending on the customer application and the local environment conditions

Ambient conditions for operation such as temperature, relative humidity, air contamination, shock, and

vibration must be in compliance with the maximum permissible levels.

Safety requirements - Electrical, thermal and energy)

Category III

Category II

Category II

Category III

Pollution degree 2

3K3

3M1

3B1

3C2

3S1

DANGER

HAZARD OF EXPLOSION AND ARC FLASH

The product must never be operated in explosive atmospheres and where vibrations and inductive bursts

occur.

Failure to follow these instructions will result in death or serious injury.

Contact Schneider Electric if the condition of the installation site is not within the specifications.

20

GDE99019 09/2020

Page 21

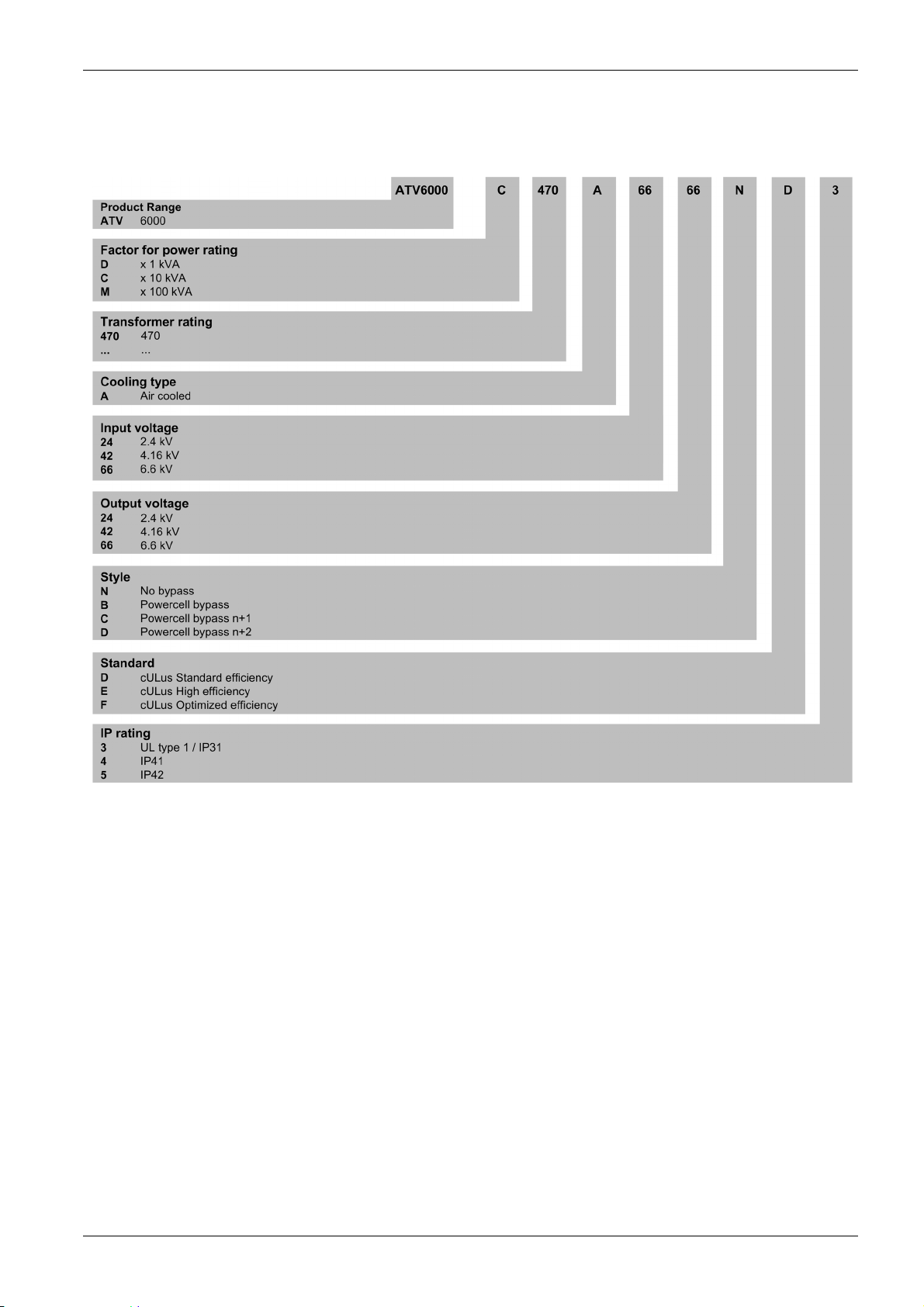

Type designation

Technical Data and Features

The product designation of the ATV6000 consists of several points of reference (characters and figures).

The meaning of each point is illustrated in the following example.

For ATV6000 UL

GDE99019 09/2020 21

Page 22

Technical Data and Features

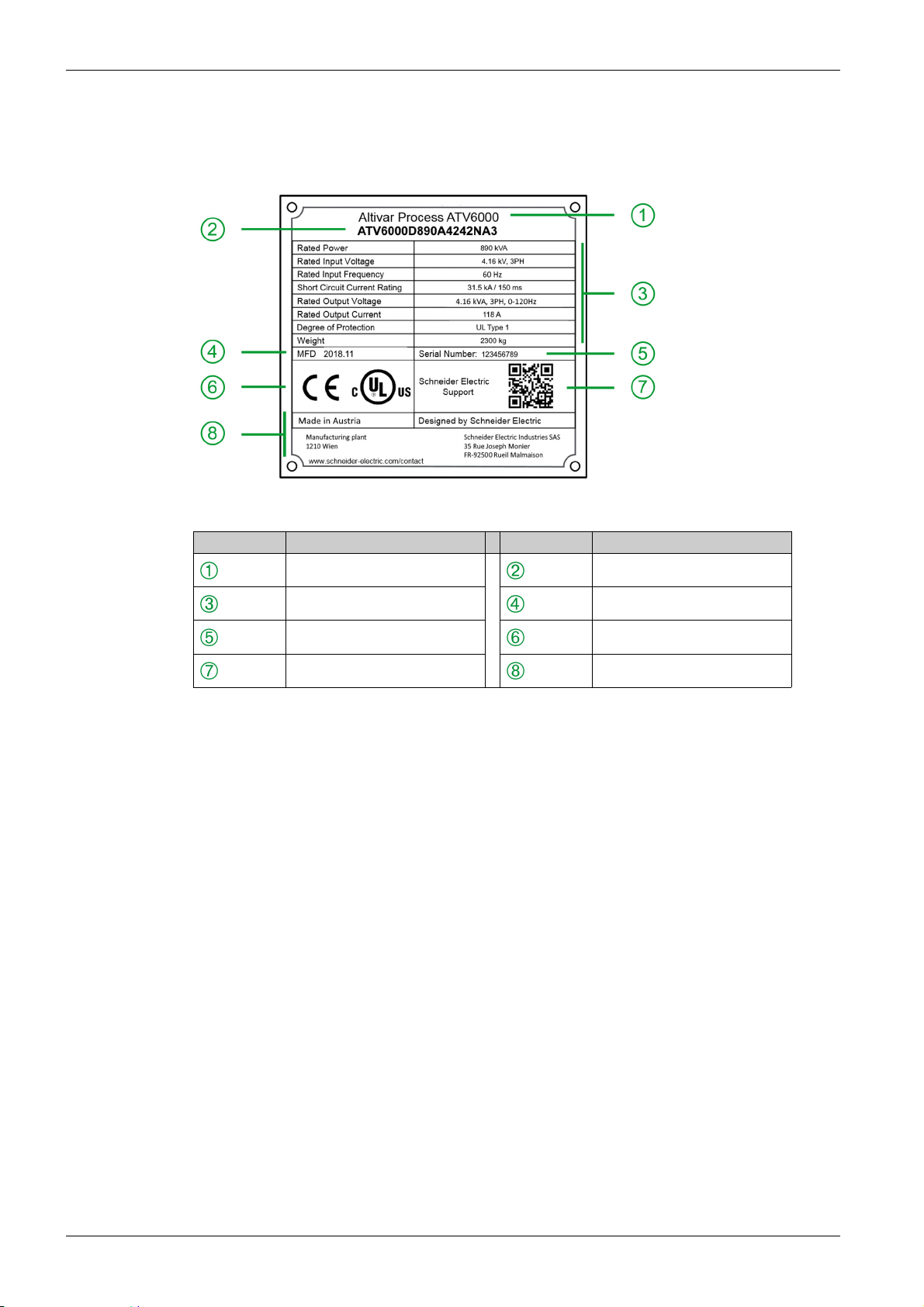

Nameplate Example

For ATV6000 UL

The nameplate contains the following data:

Legend

Marking Description Marking Description

Product Type Part number

Technical data Manufacturing date

Serial number Certifications

QR code Legal information

NOTE: Use the nameplate to validate that the product characteristics are compatible with your local

installation.

22

GDE99019 09/2020

Page 23

Technical Data and Features

Selection and ordering data

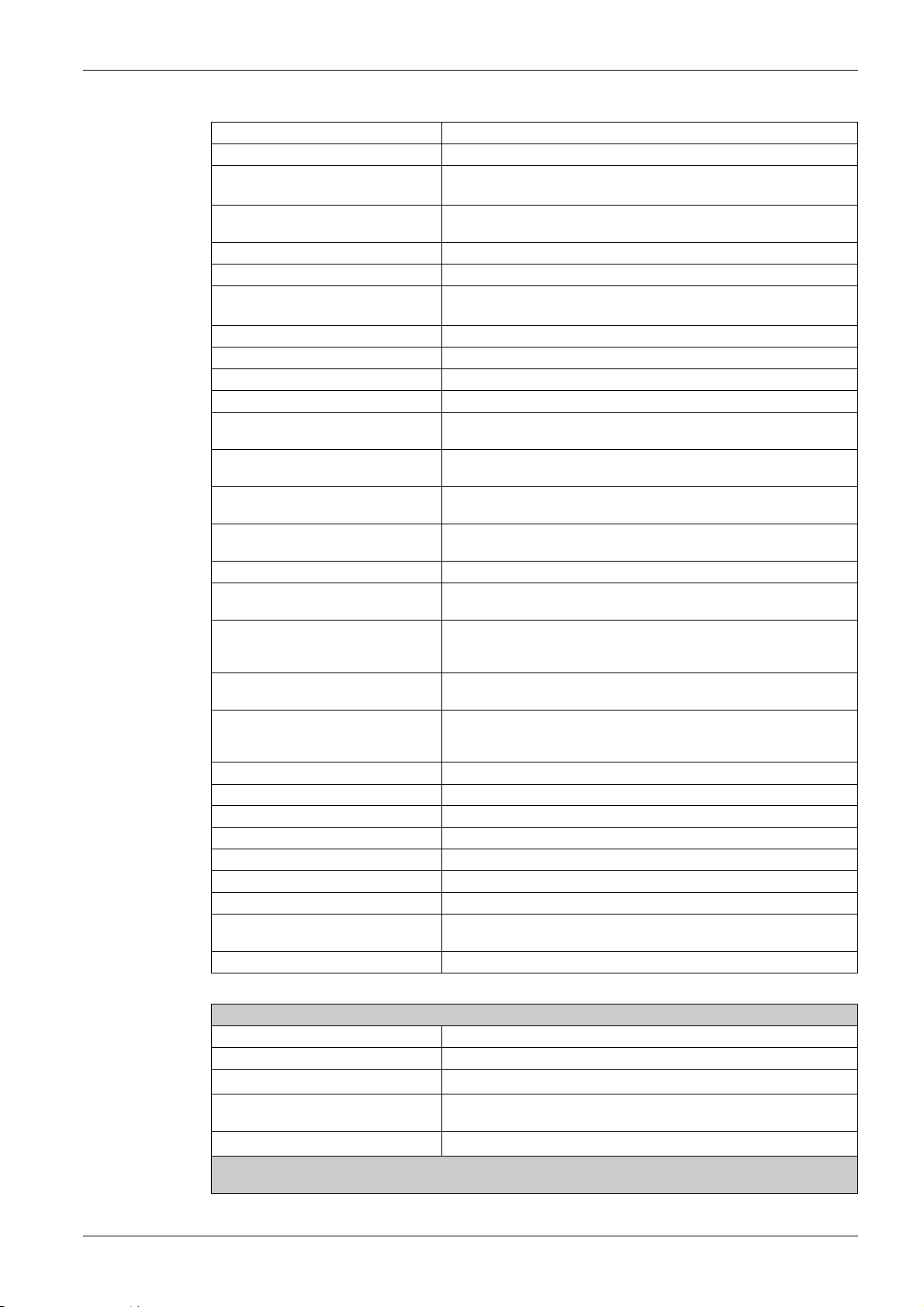

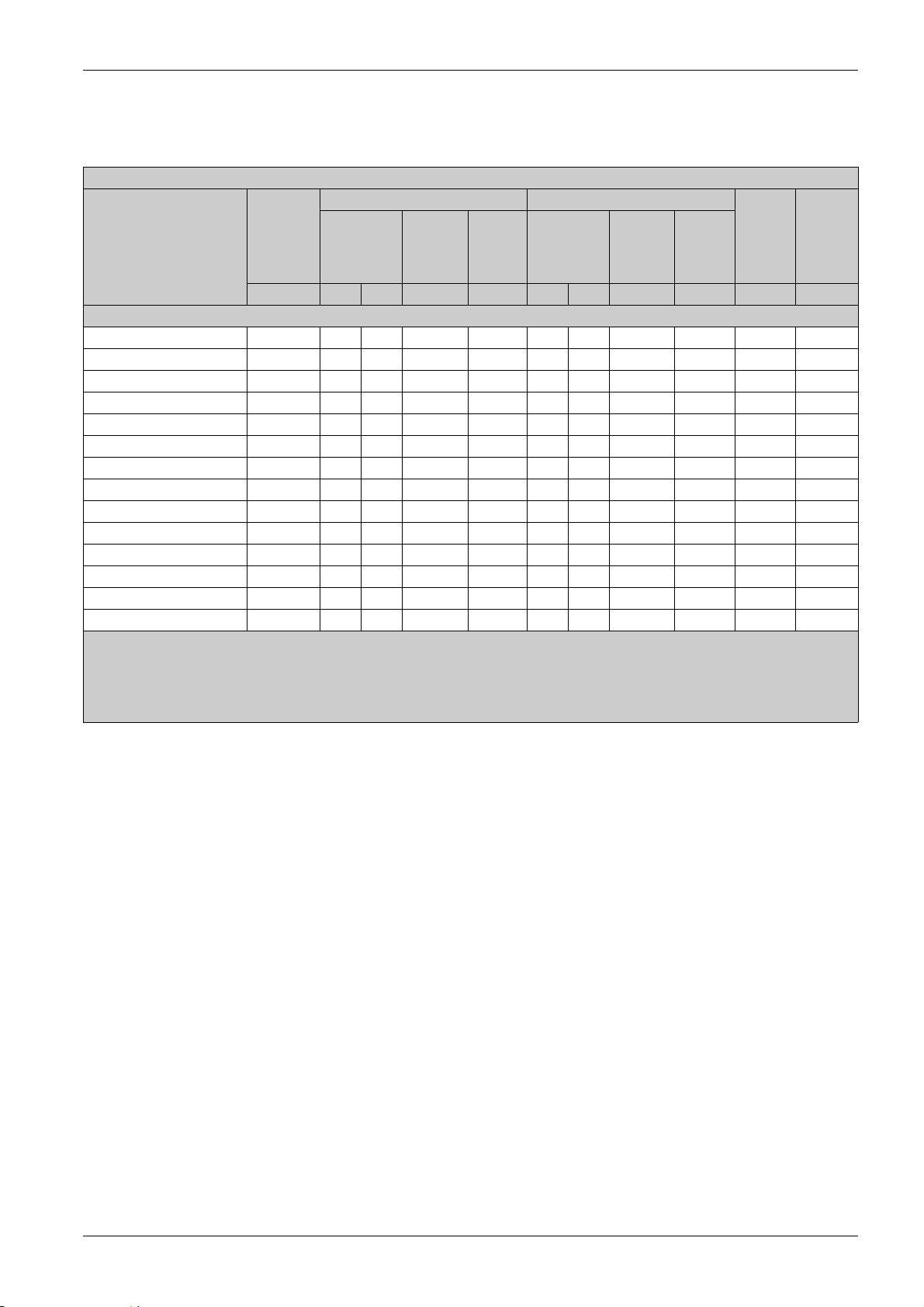

Voltage class 2.4 kV

Power specifications for output voltage 2.4 kV, 9 power cells, 18 input pulses

Model Transformer

rating (1)

kVA kW HP A A kW HP A A A A

ATV6000D200A2424●●● 200 160 214 46 55.2 150 201 44 66 65 97.5

ATV6000D280A2424●●● 280 220 295 65 78 180 241 52 78 65 97.5

ATV6000D350A2424●●● 350 280 375 80.6 96.7 260 348 77 116 100 150

ATV6000D430A2424●●● 430 340 455 100 120 270 362 80 120 100 150

ATV6000D570A2424●●● 570 450 603 130 155 410 549 120 180 150 225

ATV6000D650A2424●●● 650 520 697 150 180 410 549 120 180 150 225

ATV6000D790A2424●●● 790 630 844 181 218 550 737 160 240 200 300

ATV6000D950A2424●●● 950 760 1019 220 264 610 818 176 264 220 330

ATV6000C122A2424●●● 1220 970 1300 280 336 770 1032 224 336 280 420

ATV6000C139A2424●●● 1390 1100 1475 320 384 880 1180 256 384 320 480

ATV6000C163A2424●●● 1630 1300 1743 374 449 1130 1515 328 492 410 615

ATV6000C178A2424●●● 1780 1420 1904 410 492 1130 1515 328 492 410 615

ATV6000C200A2424●●● 2000 1600 2145 460 552 1360 1823 392 588 490 735

ATV6000C213A2424●●● 2130 1700 2279 490 588 1360 1823 392 588 490 735

(1) For higher drive power please contact Schneider Electric.

(2) Values valid for synchronous motor and asynchronous motor. The specifications for the maximum motor shaft power is based on a motor

efficiency of 95%, and power factor 0.88.

(3) Please contact Schneider Electric for other combinations of input and output voltage.

Maximum

motor shaft

power (2)

NOTE: For dimensions and outline drawings please refer to chapter Technical data.

Normal duty Heavy duty Individual

Nominal

continuous

current

Voltage class: 2.4 kV (3)

120%

overload

1 min/10

mins

Maximum

motor shaft

power (2)

Nominal

continuous

current

150%

overload

1 min/10

power cell

rating

mins

Max

overload

3 sec/10

mins

GDE99019 09/2020 23

Page 24

Technical Data and Features

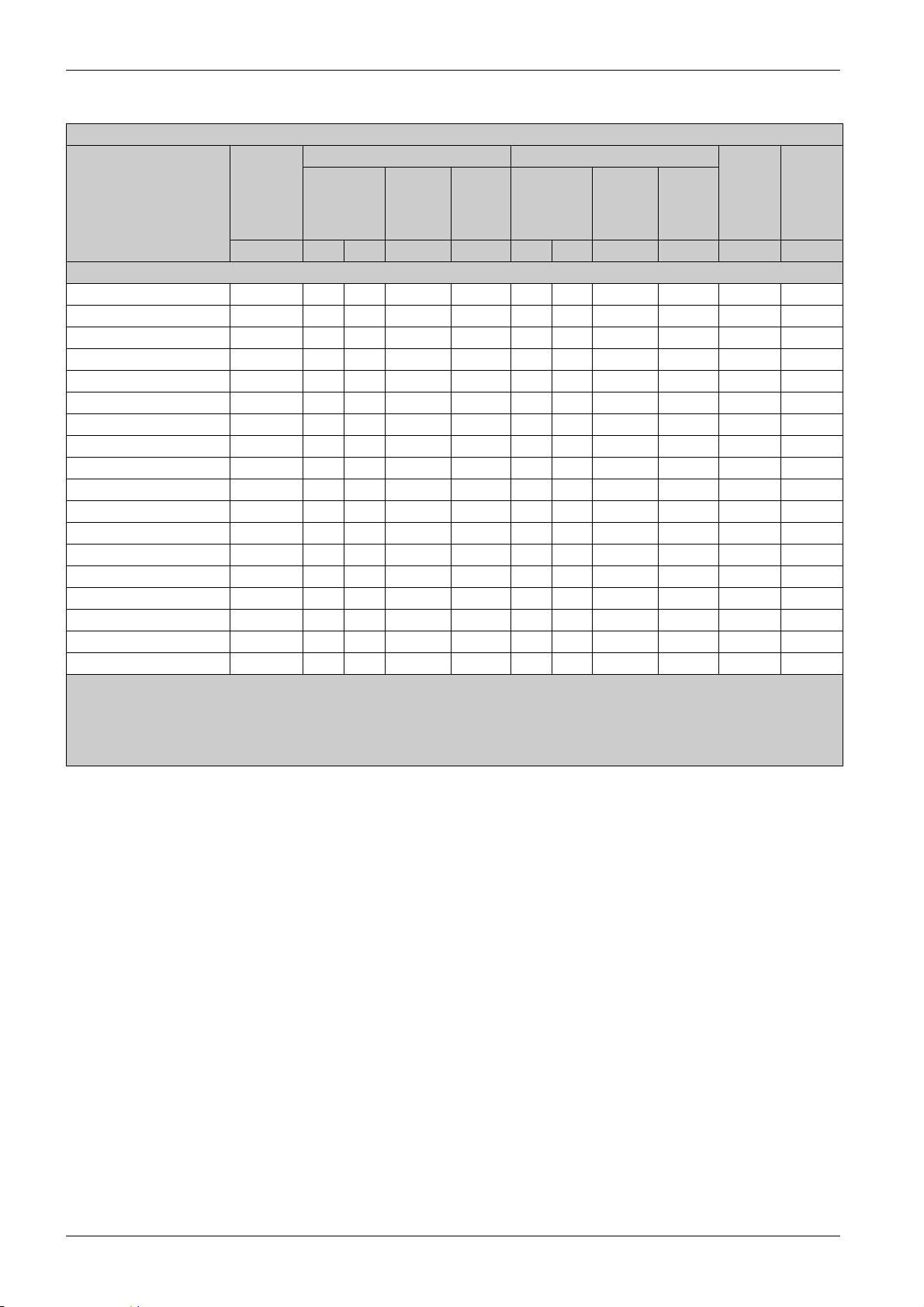

Voltage class 4.16 kV

Power specifications for output voltage 4.16 kV, 12 power cells, 24 input pulses

Model Transformer

rating (1)

kVA kW HP A A kW HP A A A A

ATV6000D350A4242●●● 350 280 375 46.5 55.8 260 348 44 66 65 97.5

ATV6000D490A4242●●● 490 390 522 65 78 310 415 52 78 65 97.5

ATV6000D570A4242●●● 570 450 603 74.7 89.6 420 563 71 107 100 150

ATV6000D630A4242●●● 630 500 670 83 99.6 470 630 79 119 100 150

ATV6000D750A4242●●● 750 600 804 100 120 480 643 80 120 100 150

ATV6000D890A4242●●● 890 710 952 118 141 680 911 113 170 150 225

ATV6000C100A4242●●● 1000 800 1072 133 159 720 965 120 180 150 225

ATV6000C113A4242●●● 1130 900 1206 150 180 720 965 120 180 150 225

ATV6000C125A4242●●● 1250 1000 1341 166 199 950 1273 159 239 200 300

ATV6000C150A4242●●● 1500 1200 1609 199 239 960 1287 160 240 200 300

ATV6000C165A4242●●● 1650 1320 1770 220 264 1060 1421 176 264 220 330

ATV6000C188A4242●●● 1880 1500 2011 249 299 1340 1796 224 336 280 420

ATV6000C210A4242●●● 2100 1680 2252 280 336 1340 1796 224 336 280 420

ATV6000C240A4242●●● 2400 1920 2574 320 384 1540 2065 256 384 320 480

ATV6000C275A4242●●● 2750 2200 2950 365 438 1970 2641 328 492 410 615

ATV6000C308A4242●●● 3080 2460 3298 410 492 1970 2641 328 492 410 615

ATV6000C338A4242●●● 3380 2700 3620 448 538 2360 3164 392 588 490 735

ATV6000C369A4242●●● 3690 2950 3956 490 588 2360 3164 392 588 490 735

(2) Values valid for synchronous motor and asynchronous motor. The specifications for the maximum motor shaft power is based on a motor

(3) Please contact Schneider Electric for other combinations of input and output voltage.

Maximum

motor shaft

power (2)

(1) For higher drive power please contact Schneider Electric.

Normal duty Heavy duty Individual

Nominal

continuous

current

Voltage class: 4.16 kV (3)

efficiency of 95%, and power factor 0.88.

120%

overload

1 min/10

mins

Maximum

motor shaft

power (2)

Nominal

continuous

current

150%

overload

1 min/10

mins

power cell

rating

Max

overload

3 sec/10

mins

NOTE: For dimensions and outline drawings please refer to chapter Technical data.

24

GDE99019 09/2020

Page 25

Technical Data and Features

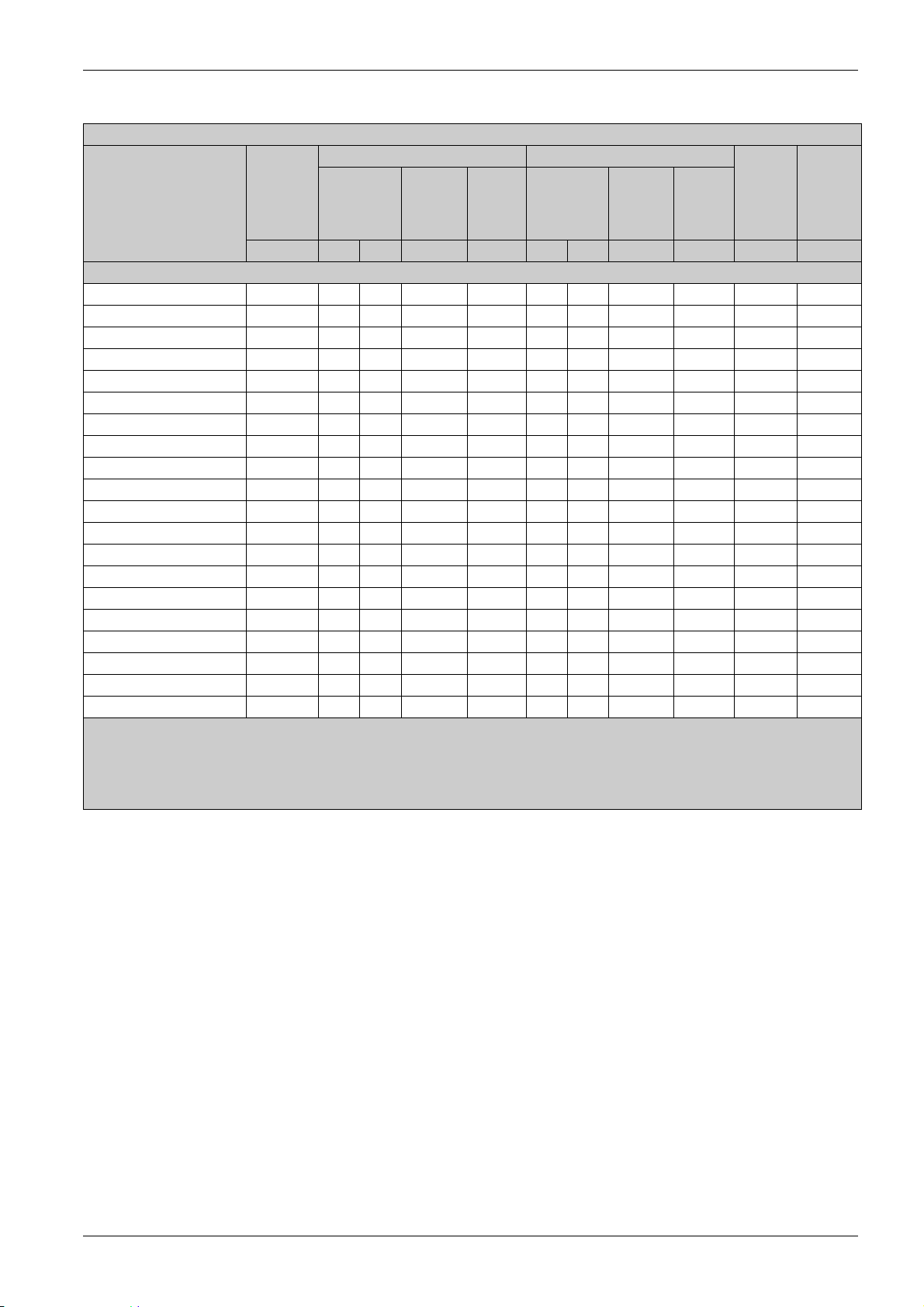

Voltage class 6.6 kV

Power specifications for output voltage 6.6 kV, 15 (18) power cells, 30 (36) input pulses

Model Transforme

r rating (1)

kVA kW HP A A kW HP A A A A

ATV6000D450A6666●●● 450 355 476 37.1 44.5 330 442 35 52.5 65 97.5

ATV6000D570A6666●●● 570 450 603 47.1 56.5 430 576 45 67.5 65 97.5

ATV6000D630A6666●●● 630 500 670 52.3 62.7 470 630 50 75 65 97.5

ATV6000D780A6666●●● 780 620 831 65 78 590 791 62 93 100 150

ATV6000D890A6666●●● 890 710 952 74.3 89.1 670 898 71 107 100 150

ATV6000C100A6666●●● 1000 800 1072 83.7 100 760 1019 80 120 100 150

ATV6000C119A6666●●● 1190 950 1273 100 120 760 1019 80 120 100 150

ATV6000C138A6666●●● 1380 1100 1475 115 138 1050 1408 110 165 150 225

ATV6000C163A6666●●● 1630 1300 1743 136 163 1140 1528 120 180 150 225

ATV6000C179A6666●●● 1790 1430 1917 150 180 1140 1528 120 180 150 225

ATV6000C200A6666●●● 2000 1600 2145 167 201 1520 2038 160 240 200 300

ATV6000C225A6666●●● 2250 1800 2413 188 226 1520 2038 160 240 200 300

ATV6000C263A6666●●● 2630 2100 2816 220 264 2010 2695 211 317 280 420

ATV6000C288A6666●●● 2880 2300 3084 241 289 2140 2869 224 336 280 420

ATV6000C334A6666●●● 3340 2670 3580 280 336 2140 2869 224 336 280 420

ATV6000C382A6666●●● 3820 3050 4090 320 384 2930 3929 307 461 410 615

ATV6000C425A6666●●● 4250 3400 4559 356 427 3130 4197 328 492 410 615

ATV6000C489A6666●●● 4890 3910 5243 410 492 3740 5015 392 588 490 735

ATV6000C538A6666●●● 5380 4300 5766 450 540 3740 5015 392 588 490 735

ATV6000C585A6666●●● 5850 4680 6275 490 588 3740 5015 392 588 490 735

(1) For higher drive power please contact Schneider Electric.

(2) Values valid for synchronous motor and asynchronous motor. The specifications for the maximum motor shaft power is based on a motor

efficiency of 95%, and power factor 0.88.

(3) Please contact Schneider Electric for other combinations of input and output voltage.

Maximum

motor shaft

power (2)

Normal duty Heavy duty Individual

Nominal

continuous

current

Voltage class: 6.6 kV (3)

120%

overload

1 min/10

mins

Maximum

motor shaft

power (2)

Nominal

continuous

current

150%

overload

1 min/10

power cell

rating

mins

Max

overload

3 sec/10

mins

NOTE: For dimensions and outline drawings please refer to chapter Technical data.

GDE99019 09/2020 25

Page 26

Technical Data and Features

Key Interlock System

Main Features

Key interlock system is used to help to prevent opening a door when the mains supply is present and also

helps to prevent powering on the drive system when a door is still unlocked. (Only the control cabinet is

unlocked when the mains supply is applied).

Key box is used to mechanically lock electrical installations. The basic functionalities are:

The lock only can work with special key.

The lock must self- lock (i.e. cannot rotate) without special key.

The key can not be pulled out when it is rotated to locked position.

The lock can not popup the key automatically. Hereafter, a 4 key product example.

Description

26

Figure 1-8

NOTE: the keys for interlock system are located in a file box inside the control cabinet.

Free Key Captive Key

Figure 1-9

GDE99019 09/2020

Page 27

Power on Procedure

Technical Data and Features

Step Action

1 Once installation is completed, close all the doors and take the captive key out of each door.

Closed door:

Figure 1-10

The free key

2 Put the keys from all the doors into the key box then turn to captive position (control compartment is not part

of the interlock system).

3 Take the free key out after all the captive keys are in the captive position.

4 Switch off the grounded switch of the main circuit breaker, interlock the free key with main circuit breaker.

5 Get authorization from the person(s) in charge to work on and with this equipment to Power On.

Power off Procedure (for Maintenance)

Step Action

1 Switch the main circuit breaker off then switch on its grounding switch.

2 Take the free key out the main circuit breaker.

3 Put the free key into the key box and turn to captive position.

4 Turn the captive keys to free position and then take them out to open the corresponding door for maintenance.

Opened door:

Figure 1-11

The

1,2,3,4

NOTE: If the free key K0 we provide cannot be used as the Key for the mains circuit breaker cabinet, it's

mandatory to attach the both keys together on a permanent manner (Free Key k0 and Circuit Breaker Key)

to forbid to use them separately.

0

only can be released when the captive keys

keys may be released when the free key 0 has been turned to the captive position.

1,2,3,4

have been turned to captive position.

An interlock compatible box can be provided as an option.

The standard brand of mechanical locks provided for the ATV6000 UL is Ro nis. I n case the ke y of th e MCB

[Main circuit breaker] and the key K0 of the VSD cannot be attached together, it is possible to supply an

MCB compatible box if brands such as Fortress or others are used on site. The interlock compatible box

has a dual cylinder lock system: one cylinder for the MCB's brand and the other is a "Free key" lock, from

the brand Ronis.

Once the MCB's brand and key identification code of lock cylinder is provided, an MCB interlock

compatible box such as the picture can be provided.

The MCB’s key can only be released when the "Free key" (K0) is inserted into the compatible box and

turned to the captive position.

Switch off the grounded switch of the MCB; lock the MCB with the MCB’s key.

Figure 1-12

GDE99019 09/2020 27

Page 28

Technical Data and Features

Dash Blocks (out of supply scope)

Figure 1-13

Interlock with Main Circuit Breaker

The main circuit breaker can be switched on only if the free key “K0” is taken out from the key box and

interlocked with the main circuit breaker. Once the main circuit breaker is powered on, the free key is

trapped and cannot be taken out, so that the doors cannot be opened.

To open the doors for maintenance purposes, the free key can be removed from the main circuit breaker

only if the main circuit breaker is grounded. If any door is opened, the main circuit breaker cannot be

powered on.

28

GDE99019 09/2020

Page 29

A

ltivar Process ATV6000 UL

GDE99019 09/2020

Steps for Setting Up

Chapter 2

Steps for Setting Up

GDE99019 09/2020 29

Page 30

Procedure

30 GDE99019 09/2020

Page 31

A

ltivar Process ATV6000 UL

Transportation, Storage and Disposal

GDE99019 09/2020

Transportation, Storage and Disposal

Chapter 3

Transportation, Storage and Disposal

What Is in This Chapter?

This chapter contains the following topics:

Transport and Storage Conditions 32

Storage and Handling Instructions for Spare Parts 33

Unpacking and Inspection 34

End of Life / Disposal 34

Lifting and Transport 35

Topic Page

GDE99019 09/2020 31

Page 32

Transportation, Storage and Disposal

Transport and Storage Conditions

The product should be protected from rain and excessive sun exposure. The room where the drive is stored

should be well dry and ventilated, ensure that there is no corrosive gas in the storage room.

The following temperature range is permissible during transportation and storage:

Transportation temperature: -25°C to 70°C (-13°F to 158°F)

Storage temperature: 0°C to 50°C(32°F to 122°F)

The following relative humidity is permissible during transportation and storage:

Relative humidity: up to 90%(without condensate)

If the product is stored for more than six months, the oxidation and aging of cabinets and components of

ATV6000 UL must be inspected completely.

Long Time Storage for the Drive or Power Cell (as spare parts)

If the drive or the power cell (as spare parts) were not connected to mains for an extended period of time,

the capacitors must be restored to their full performance before the motor is started.

REDUCED CAPACITOR PERFORMANCE

Apply mains voltage to the drive for one hour before starting the motor if the drive has not been

connected to mains for 12 months.

Verify that no Run command can be applied before the period of one hour has elapsed.

Failure to follow these instructions can result in equipment damage.

NOTICE

If the specified procedure cannot be performed without a Run command because of internal mains

contactor control, perform this procedure with the power stage enabled, but the motor being at standstill

so that there is no appreciable mains current in the capacitors.

Long Time Storage for the Optional Internal UPS

If UPS does not work for a long time, it must be charged and discharged completely once every 6 months

to help ensure the service life of the battery.

32

GDE99019 09/2020

Page 33

Storage and Handling Instructions for Spare Parts

RISK OF COMPONENT DAMAGE DUE TO INCORRECT HANDLING AND STORAGE

Apply static-free precautions when handling these components.

Do not touch components without wearing a wrist grounding strap.

Put the component on a grounded working surface to help protect against electrostatic discharges.

Take components only at their edges.

The storage conditions and the packaging must be checked regularly.

Any damage that occurs during the storage period must be repaired immediately.

Follow the “storage place requirements” described below.

Failure to follow these instructions can result in equipment damage.

Storage place requirements:

Protected against vibration and shocks.

Free from dust, sand, vermin, and insects.

Free from corrosive gases, salt mist, and others that could damage electronic equipment.

Keep dry; relative air humidity up to 90% without condensation.

Keep spare parts in their original packaging.

Store printed circuit board assembly in anti-static bags or boxes.

Storage temperature range: 0°C to 50°C(32°F to 122°F).

Transportation, Storage and Disposal

NOTICE

Damaged products or accessories may cause electric shock or unanticipated equipment operation.

DANGER

ELECTRIC SHOCK OR UNANTICIPATED EQUIPMENT OPERATION

Do not use damaged products or accessories.

Failure to follow these instructions will result in death or serious injury.

Contact your local Schneider Electric sales office if you detect any damage whatsoever.

GDE99019 09/2020 33

Page 34

Transportation, Storage and Disposal

Unpacking and Inspection

Proceed as follows:

Step Action

1 Remove all packaging material carefully. Do not use sharp tools.

2 Check if drive and spare parts are not damaged.

3 Check if deliveries are consistent with the purchase order and the packing list.

4 Contact your local Schneider Electric sales office if you detect any damage whatsoever.

The user must record any damage in detail, obtain a confirmation signature from the carrier, take photos.

5 Reserve the package of spare parts that can be recycled for transportation in case of repair is required.

INCORRECT UNPACKING

Do not use sharp tools to open the packaging.

Failure to follow these instructions can result in injury or equipment damage.

End of Life / Disposal

The components of the product consist of different materials which can be recycled and which must be

disposed of separately.

Dispose of the packaging in compliance with all applicable regulations.

Dispose of the components of the product in compliance with all applicable regulations.

CAUTION

34

GDE99019 09/2020

Page 35

Lifting and Transport

Verify the size and weight of ATV6000 UL to choose proper lifting equipment. It is required to have the

general layout drawing which contains relevant dimensions and weight information of the product before it

is transported.

INCORRECT LIFTING AND HANDLING

Lifting and handling must be performed by qualified personnel in accordance with the requirements of

Use lifting and handling equipment appropriate for the load and take all necessary measures to avoid

Verify that there are no persons or obstructions in the area of operation of the lifting and handling

Use a cross spreader to lift and handle the product.

Only lift and handle the product with the lifting lugs provided with the product.

To prevent possible damage to the frame of equipment from excessive compressive forces by lifting

During lifting and handling, do not exceed an acceleration of 0.1 m/s and a speed of 6m/min.

Load swinging must be less than 6 °.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Transportation, Storage and Disposal

WARNING

the site and in compliance with all pertinent regulations.

swinging, inclination, toppling and any other potentially hazardous conditions.

equipment.

belts, ensure the angle is not less than 30°, additional spreader beams need be equipped if necessary.

Cabinet Lifting

Lifting equipment and lifting belts are not part of the delivery and must be provided by the customer.

Mounting steps Key points Illustration

Unscrew the M8 screw, pull out the clevis

pin.

4 lifting lugs is packed in drive

package.

NOTE: There are two sizes of lifting

lugs : ≤10t and ≥10t.

1 Lifting lugs

2 M8 screw

3 Clevis pin

Insert the clevis pin within the lifting belt,

secure the clevis pin with the M8 screw

and nuts. Refer to the torque setting table

1 Lifting belt

GDE99019 09/2020 35

Page 36

Transportation, Storage and Disposal

Mounting steps Key points Illustration

Remove the screws from base frame,

assemble the lifting lugs on the base

frame them tighten the screws.Refer to

M16 bolt for the drive which weight

less than 10 tons, M20 for the drive

which weight more than 10 tons.

the torque setting table

Use 4 lifting belts to lift the cabinet to the

final position.

Remove the lifting lugs and take out the

lifting belts, then reassemble the screws

on the base frame.

The load bearing of each lifting must

not be less than 20 tons of load

capacity.

α: angle ≥ 30°

1: lifting equipment

36

GDE99019 09/2020

Page 37

Cooling Fan Lifting

Mounting steps Key points Illustration

Move the assembled cooling fan on the

forklift.

The distance must be 3 cm±10%

between each outer side of forklift

arm and the side edge of the fan.

Transportation, Storage and Disposal

Transport the cooling fan to the cabinet using

the forklift, forklift arms facing the front of the

cabinet.

Lift the forklift arms to the same height as the

cabinet top; stop the forklift, and then the

worker on the cabinet top may move the

cooling fan to the top of the cabinet.

NOTE: Take appropriate measure to secure

the position of the worker in compliance with

your national and local safety regulations.

Keep the forklift front ends at least

10 cm from the cabinet.

1. The lifting height of the forklift

arms shall be at the same level of

the cabinet top.

2. The worker can move the cooling

fan only after the forklift has

stopped.

See cooling fan installation procedure

GDE99019 09/2020 37

Page 38

Transportation, Storage and Disposal

38

GDE99019 09/2020

Page 39

A

ltivar Process ATV6000 UL

Mechanical Installation

GDE99019 09/2020

Mechanical Installation

Chapter 4

Mechanical Installation

What Is in This Chapter?

This chapter contains the following topics:

General Notes on Installation 40

Cabinet Installation 43

Cabinet Combination 45

Power Cell Installation 47

Cooling Fan Installation 50

Fan Shutter Installation 52

Topic Page

GDE99019 09/2020 39

Page 40

Mechanical Installation

General Notes on Installation

Overview of Installation

Conductive foreign objects, dust or liquids or damaged parts may cause parasitic voltage.

ELECTRIC SHOCK CAUSED BY FOREIGN OBJECTS OR DAMAGE

Do not use damaged products.

Keep foreign objects such as chips, screws or wire clippings from getting into the product.

Verify correct seat of seals and cable entries in order to avoid deposits and humidity.

Failure to follow these instructions will result in death or serious injury.

Dimensions

Refer to the general layout drawing shipped with the drive for information on:

Cabinet dimensions

Maintenance space

Foundation plan

DANGER

40

GDE99019 09/2020

Page 41

Foundation Requirements

Before installation, the foundation for ATV6000 UL positioning must be prepared by the user. The floor

must be made of non-flammable material, with smooth and non-abrasive surface, protected against

humidity diffusion, level, and able to support the cabinet.

The suggestions for the foundation depend on your ATV6000 UL configuration.

NOTE: Cable trench has to be prepared for bottom-in cable connection.

Front access:

Mechanical Installation

1 The embedded channel steel must be 5 mm higher than the ground. In order to increase the stress area, the

length of the embedded channel steel must be 400 mm longer than the base of the ATV6000 UL (200 mm

longer for left and right sides respectively), the quality of the embedded channel steel installation must be

guaranteed.

Figures 4-1 Foundation plan

2 Cable ducts should be of non-flammable material and of a non-abrasive surface. All cable entries and exits

should be protected against dust, humidity, and animals entering into the drive. Suitable fire protection

measures should be applied to prevent fire from the drive.

3 Cable trench considerations

Standard design of ATV6000 UL is for cable entry from bottom (cable entry from top is available as option).

Therefore a corresponding cable trench has to be prepared for appropriate cable connection.

A) The depth of cable trench is depending on the required bending radius of the used cable type and cross

section.

GDE99019 09/2020 41

Page 42

Mechanical Installation

Front & Rear access:

1 Depending on the model, the drive may require a 600 mm rear access for maintenance.

The embedded channel steel must be 5 mm higher than the ground. In order to increase the stress area, the

length of the embedded channel steel must be 400 mm longer than the base of the ATV6000 UL (200 mm

longer for left and right sides respectively), the quality of the embedded channel steel installation must be

guaranteed.

Figures 4-2 Foundation plan

2 Cable ducts should be of non-flammable material and of a non-abrasive surface. All cable entries and exits

should be protected against dust, humidity, and animals entering into the drive. Suitable fire protection

measures should be applied to prevent fire from the drive.

3 Cable trench considerations

Standard design of ATV6000 UL is for cable entry from bottom (cable entry from top is available as option).

Therefore a corresponding cable trench has to be prepared for appropriate cable connection.

Cabinet Top

Cabinets Fixed

42

A) The depth of cable trench is depending on the required bending radius of the used cable type and cross

section.

It is not allowed to install any foreign device on the top of the cabinet.

Verify the drive cabinets are reliably fixed, one of the two methods below must be followed.

The base of ATV6000 UL must be connected to the embedded channel steel by spot - welding.

Match the cabinet base with specially designed fixing holes by which VSD cabinet is fixed on the ground.

Floor fixings are not supplied. Anchor bolts or screws and nuts of size M14 are recommended.

NOTE: For fixing holes, refer to the Foundation Plan, also available in the Handbook Manual

GDE99017

(English).

GDE99019 09/2020

Page 43

Cabinet Installation

Typical ATV6000 UL consists of two cases:

Front access drive with transformer and control cabinet + power cell cabinet

Front & Rear access drive with transformer cabinet + control cabinet + power cell cabinet

The ATV6000 UL is disassembled into different parts according to cabinets:

Mechanical Installation

Figure 4-3 Front view of ATV6000

1. Transformer and control cabinet

2. Power cell cabinet

GDE99019 09/2020 43

Page 44

Mechanical Installation

Note of Integrated Transportation

ATV6000 UL is designed as integrated transportation for the 145, 245, 335 types of power cells. Power cell

is fastened on its rail by front and back screws for easy and quick installation.

Figure 4-4 Back view of power cell cabinet

1. Power cell

2. Bearing beam

3. Fastening screws

For front access before mounting against a wall, the fastening screws at the rear of the power cell cabinet

must be removed (the fastening screws must be kept for future transportation of the cabinet.).

Procedure:

Step Action

1 Open the doors on the back side of the power cell cabinet;

2 Remove the fastening screws, refer to the following illustration (Rear view A or B);

Rear view A (1 fixation screw for each power cell)

1. Power cell

2. Bearing beam

3. fastening screws

3 Close the back side doors after confirming that the product is well-grounded.

Rear view B (2 fastening screws for each power cell)

44

GDE99019 09/2020

Page 45

Cabinet Combination

Before fixing the cabinets on the base by anchor bolts, the cabinets need to be combined.

ELECTRIC SHOCK CAUSED BY INSUFFICIENT GROUNDING

Join all cabinets by means of the bolts provided with the drive system as shown in the figures below.

Fasten the bolts with the tightening torques specified in this document.

Failure to follow these instructions will result in death or serious injury.

The connection between transformer cabinet and power cell cabinet must be precisely adjacent to help

ensuring that the doors can easily be opened and closed:

Between transformer cabinet and power cell cabinet:

Mechanical Installation

DANGER

4 M6 bolts are fixed on the front of the cabinet, according to the tightening torque given in the table 5-1

(see page 58)

GDE99019 09/2020 45

.

Page 46

Mechanical Installation

Between two power cell cabinets:

8 M6 bolts are fixed to the cabinet (4 M6 bolts at the front of cabinet, 4 M6 bolts at the back of cabinet),

according to the tightening torque given in the table 5-1

Units must be bolted or welded to the channel steel embedded in the concrete.

Verify that the electrical resistance of the channel steel embedded in the concrete is equal to or less

than 1 Ohm.

Instructions for Cabinet Combination

Figure 4-6

1 Screw

2 Cabinet cover plate

(see page 58)

.

46

Step Action

1 Place the cabinet cover plate on top of the cabinet to cover the gap.

2 Use the M6*16 screws (contained in spare parts box) to fasten the cabinet cover plate, according to the

tightening torque given in the table 5-1

(see page 58)

.

GDE99019 09/2020

Page 47

Power Cell Installation

Power Cell Inspection (Before Installing):

Conduct a careful inspection before installing power cells:

Step Action

1 Confirm that the technical label of power cell is consistent with the nameplate of the drive.

2 Confirm that each power cell is referring to the same drawing number.

Markings Specification

IMPROPER CONNECTION AND LAYOUT

The head of the optical fiber and its socket must be clean and fixed, never pull or bend it, bending radius

no less than 50 mm.

The Color of the optical fiber heads and sockets must be the same.

Failure to follow these instructions can result in equipment damage.

Step Action

1 Each power cell is marked with a part reference, for example:APVa1, APVa2..., APVb1, APVb2..., APVc1,

APVc2..., which indicates the location of the cell in the system: e.g. APVa1 is the marking of the first cell of L1/A

phase.

2 Each power cell has 2 fuses, 2 optical fiber sockets (J1, J2) and 3 input terminals. Each terminal is marked with

L1-LV, L2-LV, L3-LV, which indicates the input terminals of each phase.

Mechanical Installation

NOTICE

Power Cell Installation

DANGER

HAZARD OF FIRE OR ELECTRIC SHOCK

Tightening torques must comply with the specifications provided in the table 5-1

Failure to follow these instructions will result in death or serious injury.

For drives using power cells type 510 and 710, the power cells are delivered separately and must be

installed on site.

Step Action

1 Install power cells (510 or 710 type, if the current is above 490 A) by sliding them into the cabinet channels,

verify that the power cells are correctly positioned.

2 Input power wiring connection: Connect the input terminals (L1-LV, L2-LV…) and input fuses, according to the

tightening torque given in the table 5-1

3 Connection between the power cells: Connect the terminal V with terminal U between two adjacent power cells

using a copper bar, according to the tightening torque given in the table 5-1

same phase are connected in series. See the drawing in step 4 below.

(see page 58)

. See the drawing in step 4 below.

NOTE: For details refer to the drawing delivered in the drive package.

(see page 58)

(see page 58)

. The cells of the

GDE99019 09/2020 47

Page 48

Mechanical Installation

Step Action

4 Communication wirings connection used to connect the power cell and master controller: Insert the optical fiber

cables.

Figure 4-7 configuration drawing of installed power cells.

5 Connection between the neutral points: The output terminal V of each cell at the end of every phase is

connected at neutral point using cables or a copper bar, according to the tightening torque given in the table

5-1

(see page 58)

. See the drawing as below step 6.

NOTE: For details refer to the drawing delivered in the drive package.

48

GDE99019 09/2020

Page 49

Mechanical Installation

Step Action

6 Connection of output cables: Connect the terminal U of the cells which is the first one in each phase with output

cables, the hall sensor should be mounted with a cable/copper bar passing through it. See the drawing as

below.

NOTE: Plug the connectors of hall sensor to the Master controller terminal.

NOTE: For details refer to the drawing delivered in the drive package.

GDE99019 09/2020 49

Page 50

Mechanical Installation

Cooling Fan Installation

Cooling Fan Installation

For convenience during transportation, cooling fans are packed individually. Carefully distinguish power

cell cabinet cooling fans and transformer cabinet cooling fans according to drawings and labels before

installing cooling fans.

1 Mount the fan and fan housing on the top of cabinet. The face with yellow arrow should be faced

towards front side of cabinet.

Use 5 M8 bolts (contained in the spare parts box) to fasten the fan housing, according to the

tightening torque given in the table 5-1

(see page 58)

.

1. The yellow arrow represents direction of fan rotation

2. Fan and fan housing.

3. Front dust filter.

4. 3 M8 bolts (2 M8 for rear side)

2 Remove the front dust filter (6 M4 bolts) from fan housing and keep it.

1. 3 M4 bolts.

2. 3 M4 bolts.

50

GDE99019 09/2020

Page 51

Mechanical Installation

3 Connect fan wire with terminal and power wire with terminal through PG gland (the wirings according

to the drawings in the drive package).

1. Fan wire.

2. Power wire.

3. PG gland.

NOTE: The red power fan cable is inside the cabinet (on the top).

4 Install the front dust filter with 6 M4 bolts.

5 Mount the fan cover for each fan if provided. (Option for air duct)

Fan Type Size (mm) Weight in kg (lb)

400 580*745*330 15 (33.1)

450 580*745*394 11 (24.2)

500 620*803*408 22 (48.5)

560 750*933*435 31 (68.3)

NOTE: the service life of cooling fan will be reduced if the working temperature is more than 40°C (104°F).

This information can be provided by Schneider Services depending on the local environment conditions.

GDE99019 09/2020 51

Page 52

Mechanical Installation

Fan Shutter Installation

Procedure

For convenience during transportation, fan shutter are packed individually.

Step Action

1 Assemble the fan and fan shutter, (5 M8 bolts) according to the tightening torque given in the table

5-1

(see page 58)

.

1. 3 M8 bolts for front side

2. 2 M8 bolts for rear side

2 Remove the front cover of fan, and front cover of fan shutter.

1: 6 M4 nuts for fan cover

2: 6 M5 bolts for fan shutter cover

52

GDE99019 09/2020

Page 53