Schneider Electric ATV6000 User Manual

A

ltivar Process ATV6000

MFR24213 07/2020

Altivar Process ATV6000

Variable Speed Drives

Modbus SL Manual

07/2020

MFR24213.01

www.schneider-electric.com

The information provided in this documentation contains general descriptions and/or technical characteristics of the performance of the products contained herein. This documentation is not intended as a

substitute for and is not to be used for determining suitability or reliability of these products for specific user

applications. It is the duty of any such user or integrator to perform the appropriate and complete risk

analysis, evaluation and testing of the products with respect to the relevant specific application or use

thereof. Neither Schneider Electric nor any of its affiliates or subsidiaries shall be responsible or liable for

misuse of the information contained herein. If you have any suggestions for improvements or amendments

or have found errors in this publication, please notify us.

You agree not to reproduce, other than for your own personal, noncommercial use, all or part of this

document on any medium whatsoever without permission of Schneider Electric, given in writing. You also

agree not to establish any hypertext links to this document or its content. Schneider Electric does not grant

any right or license for the personal and noncommercial use of the document or its content, except for a

non-exclusive license to consult it on an "as is" basis, at your own risk. All other rights are reserved.

All pertinent state, regional, and local safety regulations must be observed when installing and using this

product. For reasons of safety and to help ensure compliance with documented system data, only the

manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant instructions must

be followed.

Failure to use Schneider Electric software or approved software with our hardware products may result in

injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2020 Schneider Electric. All rights reserved.

2 MFR24213 07/2020

Table of Contents

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 1 Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Hardware Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 Cyber Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Cyber Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3 Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1 Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Definition of a Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional Profiles Supported by the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CIA402 Operating State Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description of Operating States. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cmd Register CMd . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stop Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assigning Control Word Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[CIA402 State Reg] EtA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting Sequence for a Drive Powered by the Power Stage Supply . . . . . . . . . . . . . . . . . .

Starting Sequence for a Drive with Separate Control Stage . . . . . . . . . . . . . . . . . . . . . . . . .

Starting Sequence for a Drive with Mains Contactor Control . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Modbus Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modbus Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supported Modbus Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 Hardware Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Hardware Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Firmware Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Routing Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5 Software Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.1 Basic Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Communication Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Modbus Address] Add . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Modbus baud rate] tbr . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Modbus format] tFO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[ModbusTimeout] tto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Additional Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Local Configuration of the Communication Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Scan.IN1 address] nMA1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Scan.IN2 address] nMA2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Scan.IN3 address] nMA3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Scan.IN4 address] nMA4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Scan.IN5 address] nMA5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Scan.IN6 address] nMA6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Scan.IN7 address] nMA7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Scan.IN8 address] nMA8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Scan.Out1 address] nCA1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Scan.Out2 address] nCA2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14

15

17

20

21

22

23

24

25

27

28

29

30

31

32

33

34

36

37

38

39

46

46

47

49

49

52

53

53

53

54

54

55

56

58

58

59

59

59

60

60

60

61

61

MFR24213 07/2020 3

[Scan.Out3 address] nCA3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Scan.Out4 address] nCA4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Scan.Out5 address] nCA5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Scan.Out6 address] nCA6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Scan.Out7 address] nCA7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Scan.Out8 address] nCA8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Monitoring the Communication Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Com Scan.In1 val.] nM1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Com Scan.In2 val.] nM2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Com Scan.In3 val.] nM3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Com Scan.In4 val.] nM4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Com Scan.In5 val.] nM5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Com Scan.In6 val.] nM6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Com Scan.In7 val.] nM7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Com Scan.In8 val.] nM8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Com Scan.Out1 val.] nC1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Com Scan.Out2 val.] nC2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Com Scan.Out3 val.] nC3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Com Scan.Out4 val.] nC4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Com Scan.Out5 val.] nC5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Com Scan.Out6 val.] nC6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Com Scan.Out7 val.] nC7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[Com Scan.Out8 val.] nC8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 Fieldbus Integration Using Unity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modbus Master Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

61

62

62

62

63

63

64

65

66

66

66

67

67

67

68

68

69

69

69

70

70

70

71

71

72

73

74

75

Chapter 6 Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

6.1 Operating States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Communication Error Response. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Control Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration of the Drive for Operation in I/O Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration of the Drive for Operation with CiA 402 Profile in Combined Mode. . . . . . . . .

Configuration of the Drive for Operation with CiA 402 Profile in Separate Mode. . . . . . . . . .

80

80

81

82

83

84

85

Chapter 7 Diagnostics and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Fieldbus Status LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Monitoring of Communication Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communication Interruption Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

88

90

91

93

95

4 MFR24213 07/2020

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device before

trying to install, operate, service, or maintain it. The following special messages may appear throughout

this documentation or on the equipment to warn of potential hazards or to call attention to information that

clarifies or simplifies a procedure.

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel.

No responsibility is assumed by Schneider Electric for any consequences arising out of the use of this

material.

A qualified person is one who has skills and knowledge related to the construction and operation of

electrical equipment and its installation, and has received safety training to recognize and avoid the

hazards involved.

Qualification Of Personnel

Only appropriately trained persons who are familiar with and understand the contents of this manual and

all other pertinent product documentation are authorized to work on and with this product. In addition, these

persons must have received safety training to recognize and avoid hazards involved. These persons must

have sufficient technical training, knowledge and experience and be able to foresee and detect potential

hazards that may be caused by using the product, by changing the settings and by the mechanical,

electrical and electronic equipment of the entire system in which the product is used. All persons working

on and with the product must be fully familiar with all applicable standards, directives, and accident

prevention regulations when performing such work.

MFR24213 07/2020 5

Intended Use

This product is a drive for three-phase synchronous, asynchronous motors and intended for industrial use

according to this manual.

The product may only be used in compliance with all applicable safety standard and local regulations and

directives, the specified requirements and the technical data. The product must be installed outside the

hazardous ATEX zone. Prior to using the product, you must perform a risk assessment in view of the

planned application. Based on the results, the appropriate safety measures must be implemented. Since

the product is used as a component in an entire system, you must ensure the safety of persons by means

of the design of this entire system (for example, machine design). Any use other than the use explicitly

permitted is prohibited and can result in hazards.

Product Related Information

Read and understand these instructions before performing any procedure with this drive.

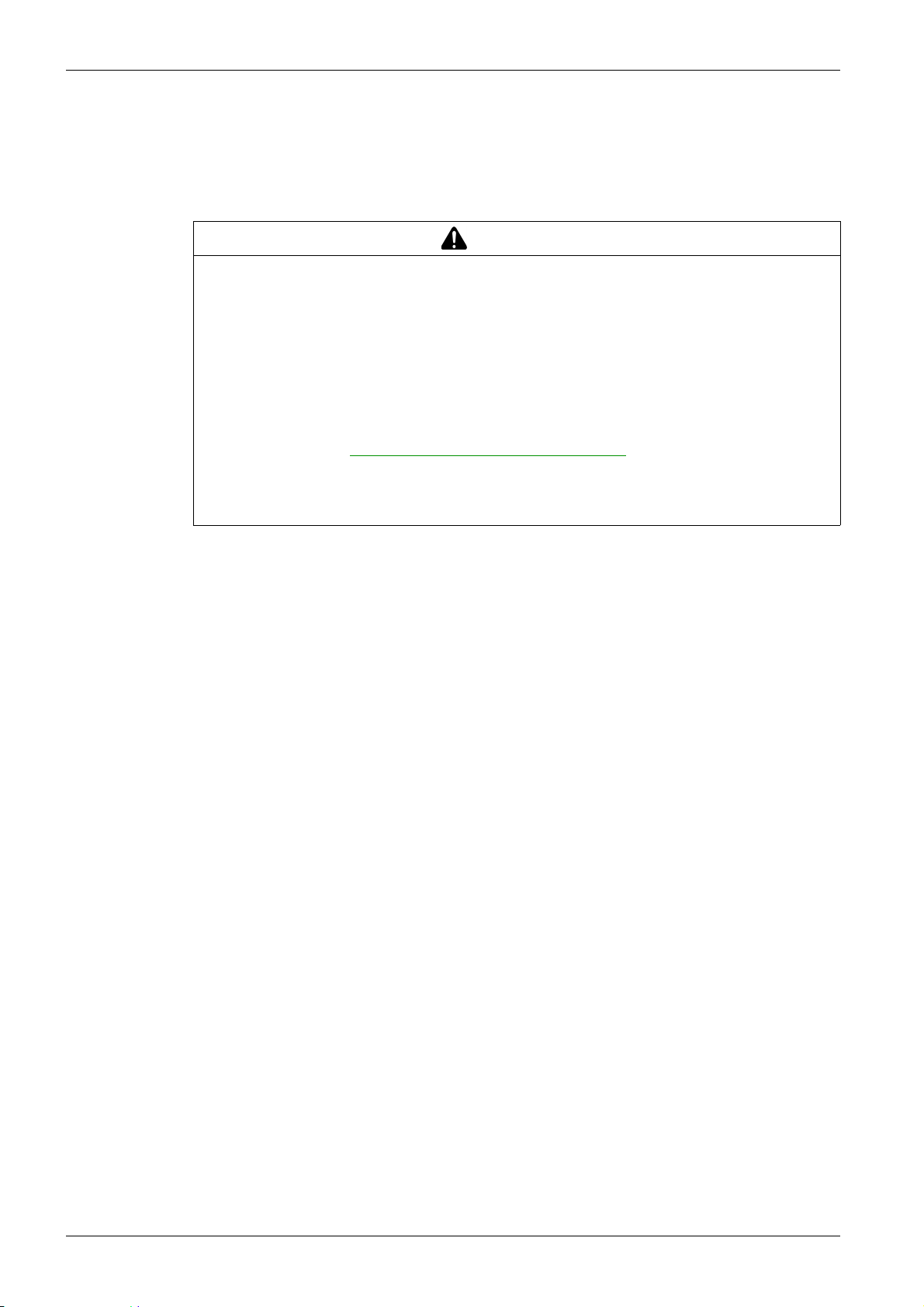

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Only appropriately trained persons who are familiar with and understand the contents of this manual

and all other pertinent product documentation and who have received safety training to recognize and

avoid hazards involved are authorized to work on and with this drive system.

Installation, adjustment, repair and maintenance must be performed by qualified personnel.

Before performing work on the drive system, follow the instructions given in the section ”Complete

drive system power Off procedure” described in the installation manual:

Before applying voltage to the drive system:

Verify that the work has been completed and that the entire installation cannot cause hazards.

Remove the ground and the short circuits on the mains input terminals and the motor output

Verify proper grounding of all equipment.

Verify that all protective equipment such as covers, doors, grids is installed and/or closed.

Failure to follow these instructions will result in death or serious injury.

DANGER

terminals.

Many components of the equipment, including the printed circuit board, operate with mains voltage, or

present transformed high currents, and/or high voltages.

The motor itself generates voltage when the motor shaft is rotated.

AC voltage can couple voltage to unused conductors in the motor cable.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Verify compliance with all safety information, different electrical requirements, and standards that

apply to your machine or process in the use of this equipment.

Verify compliance with all applicable standards and regulations with respect to grounding of all

equipment.

Only use properly rated, electrically insulated tools and measuring equipment.

Do not touch unshielded components or terminals with voltage present.

Prior to performing any type of work on the drive system, block the motor shaft to prevent rotation.

Do not create short circuits across the DC bus terminals or the DC bus capacitors or the braking

resistor terminals, if present.

Failure to follow these instructions will result in death or serious injury.

Damaged products or accessories may cause electric shock or unanticipated equipment operation.

6 MFR24213 07/2020

DANGER

ELECTRIC SHOCK OR UNANTICIPATED EQUIPMENT OPERATION

Do not use damaged products or accessories.

Failure to follow these instructions will result in death or serious injury.

Contact your local Schneider Electric sales office if you detect any damage whatsoever.

This equipment has been designed to operate outside of any hazardous location. Only install this

equipment in zones known to be free of a hazardous atmosphere.

DANGER

POTENTIAL FOR EXPLOSION

Install and use this equipment in non-hazardous locations only.

Failure to follow these instructions will result in death or serious injury.

Your application consists of a whole range of different interrelated mechanical, electrical, and electronic

components, the drive being just one part of the application. The drive by itself is neither intended to nor

capable of providing the entire functionality to meet all safety-related requirements that apply to your

application. Depending on the application and the corresponding risk assessment to be conducted by you,

a whole variety of additional equipment is required such as, but not limited to, external encoders, external

brakes, external monitoring devices, guards, etc.

As a designer/manufacturer of machines, you must be familiar with and observe all standards that apply

to your machine. You must conduct a risk assessment and determine the appropriate Performance Level

(PL) and/or Safety Integrity Level (SIL) and design and build your machine in compliance with all applicable

standards. In doing so, you must consider the interrelation of all components of the machine. In addition,

you must provide instructions for use that enable the user of your machine to perform any type of work on

and with the machine such as operation and maintenance in a safe manner.

The present document assumes that you are fully aware of all normative standards and requirements that

apply to your application. Since the drive cannot provide all safety-related functionality for your entire

application, you must ensure that the required Performance Level and/or Safety Integrity Level is reached

by installing all necessary additional equipment.

WARNING

INSUFFICIENT PERFORMANCE LEVEL/SAFETY INTEGRITY LEVEL AND/OR UNINTENDED

EQUIPMENT OPERATION

Conduct a risk assessment according to EN ISO 12100 and all other standards that apply to your

application.

Use redundant components and/or control paths for all critical control functions identified in your risk

assessment.

If moving loads can result in hazards, for example, slipping or falling loads, operate the drive in closed

loop mode.

Verify that the service life of all individual components used in your application is sufficient for the

intended service life of your overall application.

Perform extensive commissioning tests for all potential error situations to verify the effectiveness of

the safety-related functions and monitoring functions implemented, for example, but not limited to,

speed monitoring by means of encoders, short circuit monitoring for all connected equipment, correct

operation of brakes and guards.

Perform extensive commissioning tests for all potential error situations to verify that the load can be

brought to a safe stop under all conditions.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

MFR24213 07/2020 7

Drive systems may perform unexpected movements because of incorrect wiring, incorrect settings,

incorrect data or other errors.

WARNING

UNANTICIPATED EQUIPMENT OPERATION

Carefully install the wiring in accordance with the EMC requirements.

Do not operate the product with unknown or unsuitable settings or data.

Perform a comprehensive commissioning test.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

WARNING

LOSS OF CONTROL

The designer of any control scheme must consider the potential failure modes of control paths and,

for critical control functions, provide a means to achieve a safe state during and after a path failure.

Examples of critical control functions are emergency stop, overtravel stop, power outage and restart.

Separate or redundant control paths must be provided for critical control functions.

System control paths may include communication links. Consideration must be given to the

implications of unanticipated transmission delays or failures of the link.

Observe all accident prevention regulations and local safety guidelines (1).

Each implementation of the product must be individually and thoroughly tested for proper operation

before being placed into service.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

(1) For USA: Additional information, refer to NEMA ICS 1.1 (latest edition), Safety Guidelines for the

Application, Installation, and Maintenance of Solid State Control and to NEMA ICS 7.1 (latest edition),

Safety Standards for Construction and Guide for Selection, Installation and Operation of Adjustable-Speed

Drive Systems.

Machines, controllers, and related equipment are usually integrated into networks. Unauthorized persons

and malware may gain access to the machine as well as to other devices on the network/fieldbus of the

machine and connected networks via insufficiently secure access to software and networks.

WARNING

UNAUTHORIZED ACCESS TO THE MACHINE VIA SOFTWARE AND NETWORKS

In your hazard and risk analysis, consider all hazards that result from access to and operation on the

network/fieldbus and develop an appropriate cybersecurity concept.

Verify that the hardware infrastructure and the software infrastructure into which the machine is

integrated as well as all organizational measures and rules covering access to this infrastructure

consider the results of the hazard and risk analysis and are implemented according to best practices

and standards covering IT security and cybersecurity, such as:

ISO/IEC 27000 series, ISO/ IEC 15408, IEC 62351, ISA/IEC 62443,

NIST Cybersecurity Framework,

Information Security Forum - Standard of Good Practice for Information Security,

Schneider Electric

Verify the effectiveness of your IT security and cybersecurity systems using appropriate, proven

methods.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Recommended Cybersecurity Best Practices

.

WARNING

LOSS OF CONTROL

Perform a comprehensive commissioning test to verify that communication monitoring properly detects

communication interruptions

Failure to follow these instructions can result in death, serious injury, or equipment damage.

8 MFR24213 07/2020

NOTICE

DESTRUCTION DUE TO INCORRECT MAINS VOLTAGE

Before switching on and configuring the product, verify that it is approved for the mains voltage.

Failure to follow these instructions can result in equipment damage.

MFR24213 07/2020 9

10 MFR24213 07/2020

At a Glance

Document Scope

Validity Note

About the Book

The purpose of this document is to:

Show you how to connect the Modbus fieldbus on your drive.

Show you how to set up the drive to use Modbus for display, monitoring, and control.

Provide examples of setup using Unity

NOTE: Read and understand this document and all related documents (see below) before

installing,operating, or maintaining your drive.

Original instructions and information given in this manual have been written in English (before optional

translation).

This documentation is valid for the Altivar Process ATV6000 drives.

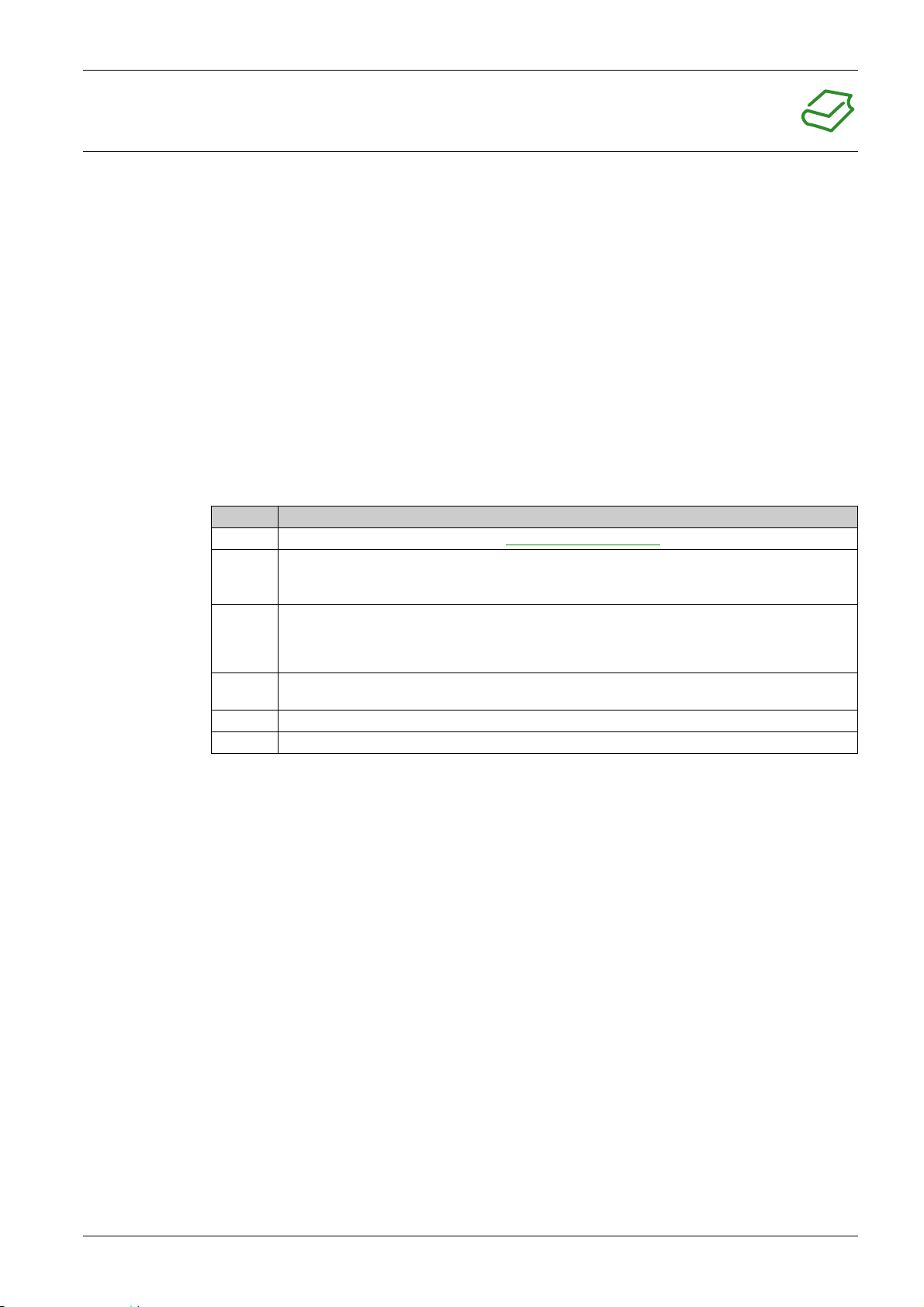

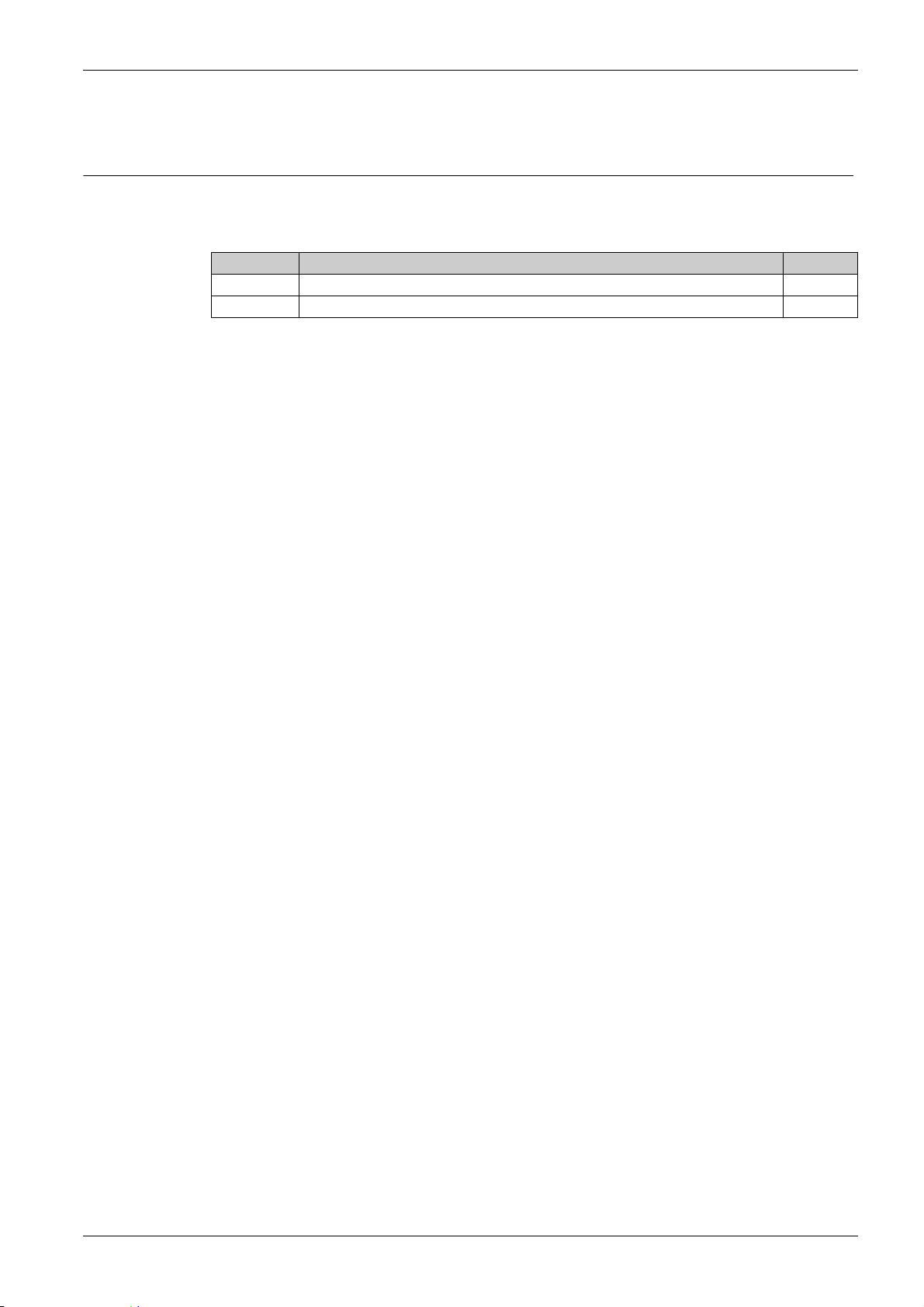

The technical characteristics of the devices described in the present document also appear online. To

access the information online:

Step Action

1 Go to the Schneider Electric home page

2 In the Search box type the reference of a product or the name of a product range.

Do not include blank spaces in the reference or product range.

To get information on grouping similar modules, use asterisks (

3 If you entered a reference, go to the Product Datasheets search results and click on the reference that

interests you.

If you entered the name of a product range, go to the Product Ranges search results and click on the

product range that interests you.

4 If more than one reference appears in the Products search results, click on the reference that interests

you.

5 Depending on the size of your screen, you may need to scroll down to see the datasheet.

6 To save or print a datasheet as a .pdf file, click Download XXX product datasheet.

www.schneider-electric.com

.

*

).

The characteristics that are described in the present document should be the same as those characteristics that appear online. In line with our policy of constant improvement, we may revise content over time

to improve clarity and accuracy. If you see a difference between the document and online information, use

the online information as your reference.

MFR24213 07/2020 11

Related Documents

Use your tablet or your PC to quickly access detailed and comprehensive information on all our products

on www.schneider-electric.com.

The Internet site provides the information you need for products and solutions:

The Handbook for detailed characteristics and selection guides,

The CAD files to help design your installation,

All software and firmware to maintain your installation up to date,

Additional documents for better understanding of drive systems and applications

And finally all the User Guides related to your drive, listed below:

(Other option manuals and Instruction sheets are available on www.schneider-electric.com)

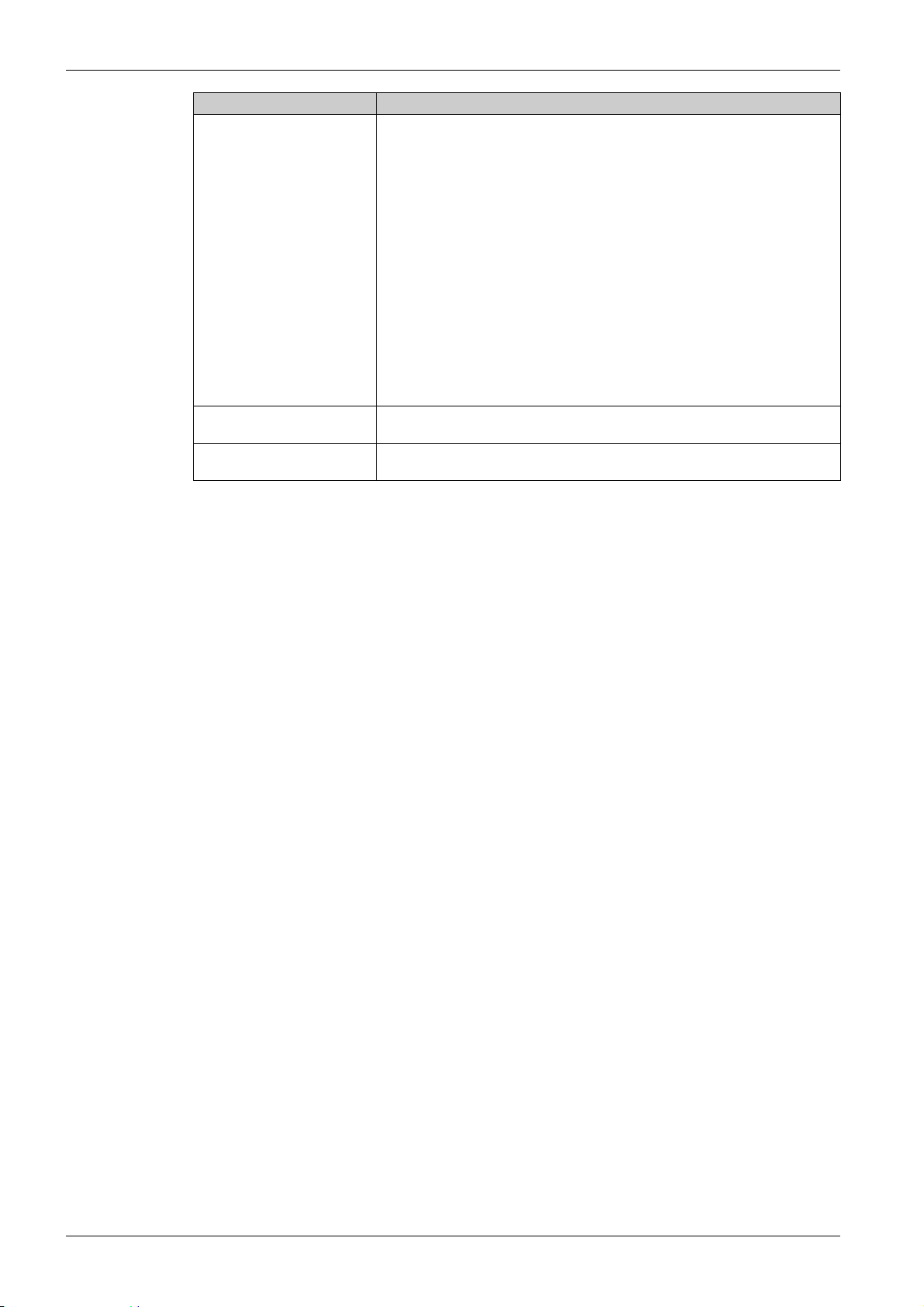

Title of Documentation Catalog Number

Digital Catalog for Industrial Automation

Altivar Process range brochure

ATV6000 Handbook

ATV6000 Installation Manual

ATV6000 Programming Manual for Operator

and Advanced Operator

ATV6000 Embedded Ethernet Manual

ATV6000 Modbus SL Manual

ATV6000 PROFIBUS Manual

ATV6000 DeviceNet Manual

ATV6000 EtherCat Manual

ATV6000 Profinet Manual

ATV6000 CANopen Manual

SoMove: FDT

Altivar Process ATV6000: DTM

Recommended Cybersecurity Best Practices

Digit-Cat

998-20307132

QGH83255

PHA51120

PHA51118

QGH83258

QGH83260

QGH83265

QGH83267

PHA30472

MFR24213

PHA30474

PHA30471

PHA30473

PHA30475

PHA30470

SoMove_FDT

(English)

(English),

(Spanish),

(Chinese).

(English),

(Spanish),

(English),

(Spanish),

(English)

(English)

(English)

(English)

(English)

(English)

(English)

PHA51119

GDE94089

QGH83259

GDE94087

QGH83266

GDE94088

(English, French, German, Spanish, Italian, Chinese)

CS-Best-Practices-2019-340

(French),

(Italian),

(French),

(Italian),

(French),

(Italian)

(English)

PHA51121

PHA51122

QGH83261

QGH83257

QGH83268

(German),

(Russian),

(German),

(Chinese).

(German),

Terminology

Contact Us

You can download these technical publications and other technical information from our website at

www.se.com/en/download

The technical terms, terminology, and the corresponding descriptions in this manual normally use the terms or

definitions in the relevant standards.

In the area of drive systems this includes, but is not limited to, terms such as error, error message, failure, fault,

fault reset, protection, safe state, safety function, warning, warning message, and so on.

Among others, these standards include:

IEC 61800 series: Adjustable speed electrical power drive systems

IEC 61508 Ed.2 series: Functional safety of electrical/electronic/programmable electronic safety-related

EN 954-1 Safety of machinery - safety-related parts of control systems

ISO 13849-1 & 2 Safety of machinery - safety related parts of control systems

IEC 61158 series: Industrial communication networks - Fieldbus specifications

IEC 61784 series: Industrial communication networks - Profiles

IEC 60204-1: Safety of machinery - Electrical equipment of machines – Part 1: General requirements

In addition, the term zone of operation is used in conjunction with the description of specific hazards, and is

defined as it is for a hazard zone or danger zone in the EC Machinery Directive (2006/42/EC) and in ISO 12100-1.

Also see the glossary at the end of this manual.

Select your country on

www.schneider-electric.com/contact

Schneider Electric Industries SAS

Head Office

35, rue Joseph Monier

92500 Rueil-Malmaison

France

12 MFR24213 07/2020

A

ltivar Process ATV6000

Presentation

MFR24213 07/2020

Presentation

Chapter 1

Presentation

What Is in This Chapter?

This chapter contains the following topics:

Hardware Overview 14

Software Overview 15

Topic Page

MFR24213 07/2020 13

Presentation

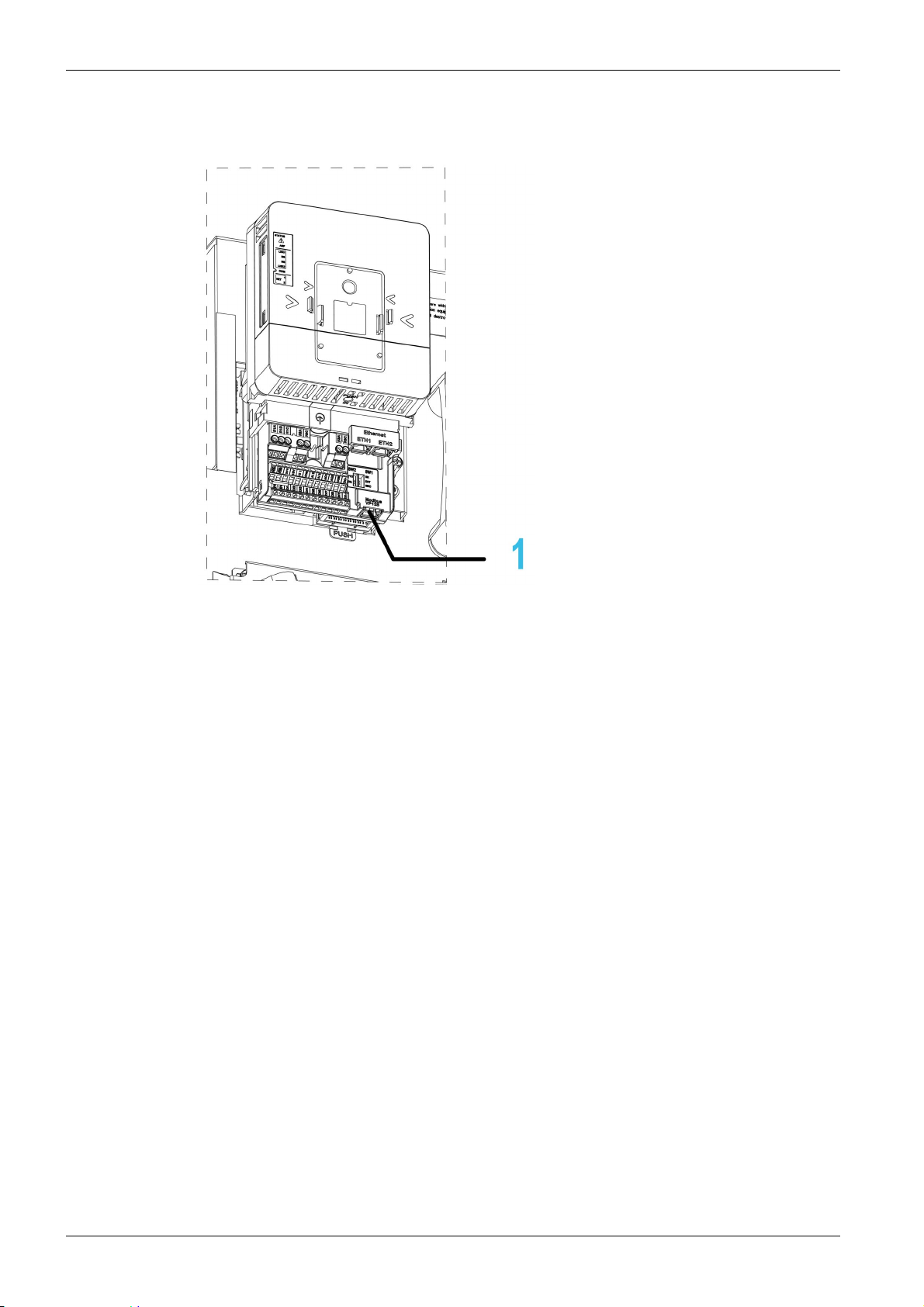

Hardware Overview

General

1 Modbus serial communication port

14

MFR24213 07/2020

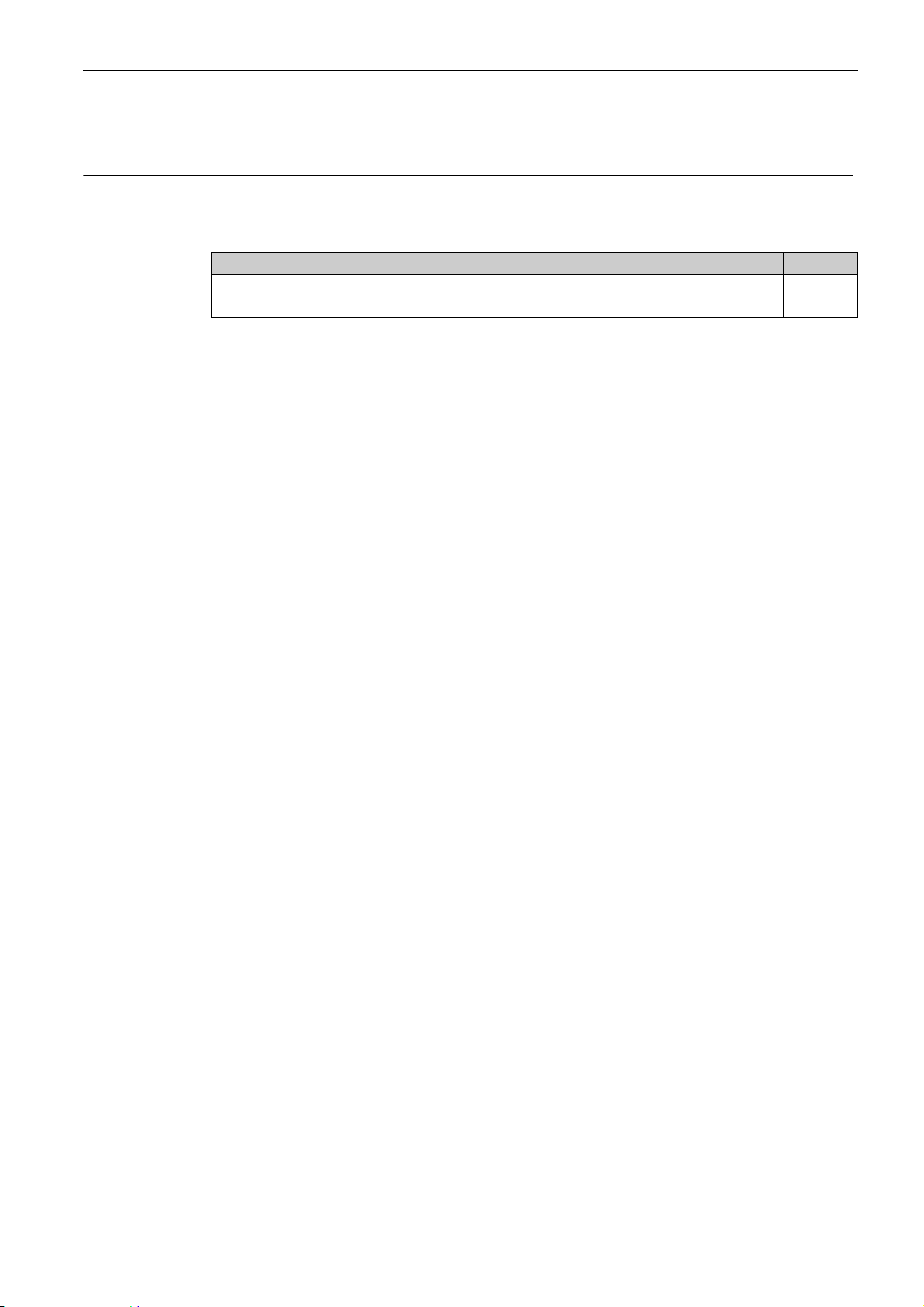

Software Overview

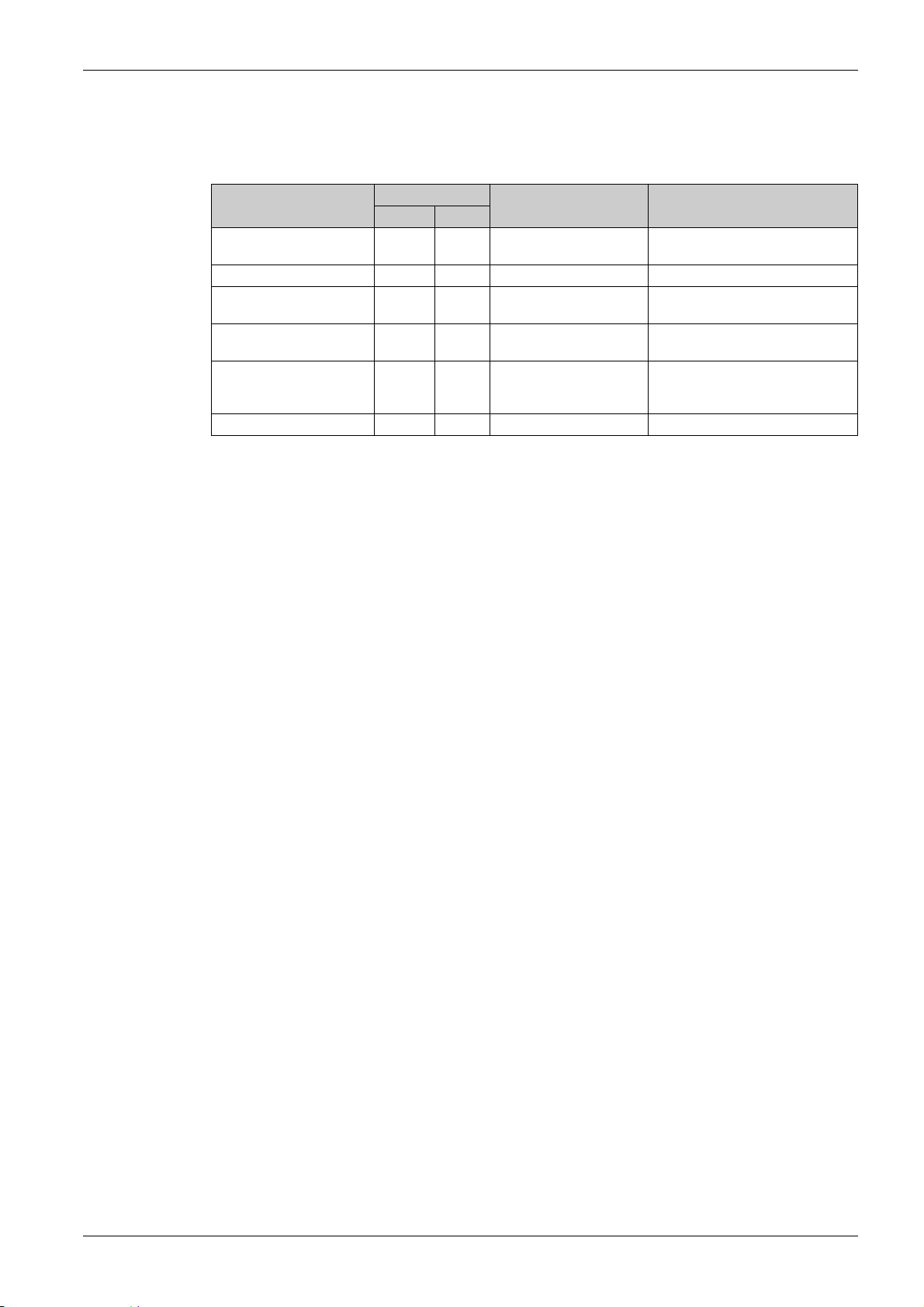

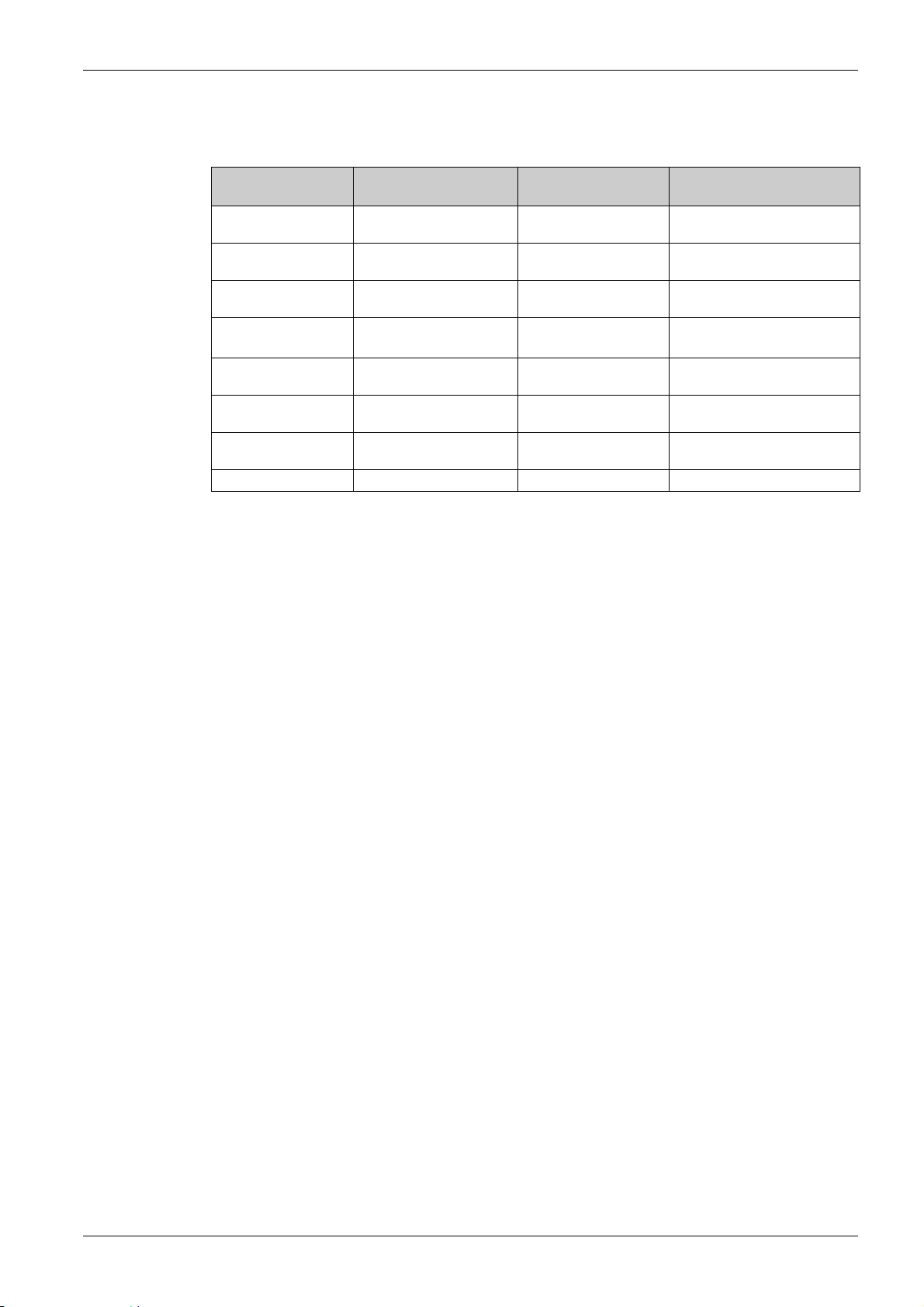

Supported Modbus Functions

The drive supports the following Modbus functions:

Function Name Code Description Remarks

Read Holding

Registers

Write One Output Word

Write Multiple

Registers

Read/write Multiple

Registers

(Subfunction)

Read Device

Identification

Diagnostics

Presentation

Dec. Hex

03 03 hex Read N output words Maximum PDU length: 63 words

06 06 hex Write 1 output word −

16 10 hex Write N output word Maximum PDU length: 61 words

23 17 hex Read/write multiple

registers

43/14 2B hex/

0E hex

08 08 hex Diagnostics −

Encapsulated interface

transport/Read device

identification

Maximum PDU length: 20 words

(W), 20 words (R)

−

MFR24213 07/2020 15

Presentation

16

MFR24213 07/2020

A

Cyber Security

Introduction

ltivar Process ATV6000

Cyber Security

MFR24213 07/2020

Cyber Security

Chapter 2

Cyber Security

Cyber Security is a branch of network administration that addresses attacks on or by computer systems

and through computer networks that can result in accidental or intentional disruptions.

The objective of Cyber Security is to help provide increased levels of protection for information and physical

assets from theft, corruption, misuse, or accidents while maintaining access for their intended users.

No single Cyber Security approach is adequate. Schneider Electric recommends a defense-in-depth

approach. Conceived by the National Security Agency (NSA), this approach layers the network with

security features, appliances, and processes.

The basic components of this approach are:

Risk assessment

A security plan built on the results of the risk assessment

A multi-phase training campaign

Physical separation of the industrial networks from enterprise networks using a demilitarized zone

(DMZ) and the use of firewalls and routing to establish other security zones

System access control

Device hardening

Network monitoring and maintenance

This chapter defines the elements that help you configure a system that is less susceptible to cyber attacks.

For detailed information on the defense-in-depth approach, refer to the TVDA:

Vulnerability to Cyber Attacks in the Control Room (STN V2)

on the Schneider Electric website.

To submit a Cyber Security question, report security issues, or get the latest news from Schneider Electric,

visit the Schneider Electric website.

How Can I Reduce

Password Management

The system is secured thanks to several passwords:

Drive password must contain six characters (blanks are allowed)

Webserver password must contain:

A total of eight characters

At least one upper-case letter

At least one lower-case letter

At least one special character (for example, @, #, $)

No blank character

NOTE: After five unsuccessful login attempts, the access must be reactivated by the administrator.

Schneider Electric recommends to:

Modify the password every 90 days

Use a dedicated password (not related to your personal password)

NOTE: No responsibility is assumed by Schneider Electric for any consequences if anyone hacks your

product password and if you use the same password for personal usage.

Backing-up and Restoring the Software Configuration

To protect your data, Schneider Electric recommends backing-up the device configuration and keeping

your backup file in a safe place. The backup is available in the device DTM, using "load from device" and

"store to device" functions.

MFR24213 07/2020 17

Cyber Security

Remote Access to the Drive

When remote access is used between a device and the drive, ensure your network is secure

(VPN,Firewall…).

Machines, controllers, and related equipment are usually integrated into networks. Unauthorized persons

and malware may gain access to the machine as well as to other devices on the network/fieldbus of the

machine and connected networks via insufficiently secure access to software and networks.

UNAUTHORIZED ACCESS TO THE MACHINE VIA SOFTWARE AND NETWORKS

In your hazard and risk analysis, consider all hazards that result from access to and operation on the

network/fieldbus and develop an appropriate cybersecurity concept.

Verify that the hardware infrastructure and the software infrastructure into which the machine is

integrated as well as all organizational measures and rules covering access to this infrastructure

consider the results of the hazard and risk analysis and are implemented according to best practices

and standards covering IT security and cybersecurity, such as:

ISO/IEC 27000 series, ISO/ IEC 15408, IEC 62351, ISA/IEC 62443,

NIST Cybersecurity Framework,

Information Security Forum - Standard of Good Practice for Information Security,

Schneider Electric

Verify the effectiveness of your IT security and cybersecurity systems using appropriate, proven

methods.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

WARNING

Recommended Cybersecurity Best Practices

.

Data Flow Restriction

To secure the access to the drive and limit the data flow, the use of a firewall device is required.

ConneXium Tofino Firewall Product

The ConneXium TCSEFEA Tofino Firewall is a security appliance that provides levels of protection against

cyber threats for industrial networks, automation systems, SCADA systems, and process control systems.

This Firewall is designed to permit or deny communications between devices connected to the external

network connection of the Firewall and the protected devices connected to the internal network connection.

The Firewall can restrict network traffic based on user defined rules that would permit only authorized

devices, communication types and services.

The Firewall includes built-in security modules and an off-line configuration tool for creating secure zones

within an industrial automation environment.

Control Command Restriction

To prevent unauthorized use of the command of the drive, it is possible to grant access to a limite d number

of IP address using the IP master parameter.

The parameter IP Master defines which device can command with the device. This parameter is available

in the device DTM.

Deactivation of unused functions

To avoid unauthorized access, it is advisable to deactivate unused functions.

Example: WebServer, Fast Device Replacement …

18

MFR24213 07/2020

A

ltivar Process ATV6000

Basics

MFR24213 07/2020

Basics

Chapter 3

Basics

What Is in This Chapter?

This chapter contains the following sections:

Section Topic Page

3.1 Profile 20

3.2 Modbus Functions 37

MFR24213 07/2020 19

Basics

Profile

Section 3.1

Profile

What Is in This Section?

This section contains the following topics:

Definition of a Profile 21

Functional Profiles Supported by the Drive 22

Functional Description 23

CIA402 Operating State Diagram 24

Description of Operating States 25

Summary 27

Cmd Register CMd 28

Stop Commands 29

Assigning Control Word Bits 30

[CIA402 State Reg] EtA 31

Starting Sequence 32

Starting Sequence for a Drive Powered by the Power Stage Supply 33

Starting Sequence for a Drive with Separate Control Stage 34

Starting Sequence for a Drive with Mains Contactor Control 36

Topic Page

20

MFR24213 07/2020

Definition of a Profile

Types of Profiles

There are 3 types of profile:

Communication profiles

Functional profiles

Application profiles

Communication Profile

A communication profile describes the characteristics of a bus or network:

Cables

Connectors

Electrical characteristics

Access protocol

Addressing system

Periodic exchange service

Messaging service

...

A communication profile is unique to a type of fieldbus (such as Modbus, PROFIBUS DP, and so on) and

is used by different types of devices.

Functional Profile

A functional profile describes the behavior of a type of device:

Functions

Parameters (such as name, format, unit, type, and so on.)

Periodic I/O variables

State chart

...

A functional profile is common to all members of a device family (such as variable speed drives, encoders,

I/O modules, displays, and so on).

They can feature common or similar parts. The standardized (IEC 61800-7) functional profiles of variable

speed drives are:

CiA402

PROFIDRIVE

CIP AC Drive

CiA402 device profile for drives and motion control represents the next stage of this standard development

and is now part of the IEC 61800-7 standard.

Basics

Application Profile

Application profile defines the services to be provided by the devices on a machine. For example, CiA DSP

417-2 V 1.01 part 2: CANopen application profile for lift control systems - virtual device definitions.

Interchangeability

The aim of communication and functional profiles is to achieve interchangeability of the devices connected

via the fieldbus.

MFR24213 07/2020 21

Basics

Functional Profiles Supported by the Drive

I/O Profile

Using the I/O profile simplifies PLC programming.

The I/O profile mirrors the use of the terminal strip for control by utilizing 1 bit to control a function.

The I/O profile for the drive can also be used when controlling via a fieldbus.The drive starts up as soon as

the run command is sent.15 bits of the control word (bits 1...15) can be assigned to a specific function.

This profile can be developed for simultaneous control of the drive via:

The terminals

The Modbus control word

The CANopen control word

Ethernet Modbus TCP embedded control word

The fieldbus module control word

The I/O profile is supported by the drive itself and therefore in turn by all the communication ports.

CiA402 Profile

The drive only starts up following a command sequence.

The control word is standardized.

5 bits of the control word (bits 11...15) can be assigned to a function.

The CiA402 profile is supported by the drive itself and therefore by all the communication ports.

The drive supports the velocity mode of CiA402 profile.

In the CiA402 profile, there are two modes that are specific to the drive and characterize commands and

references value management:

Separate [Separate] SEP

Not separate [Not separ.] SIm,

22

MFR24213 07/2020

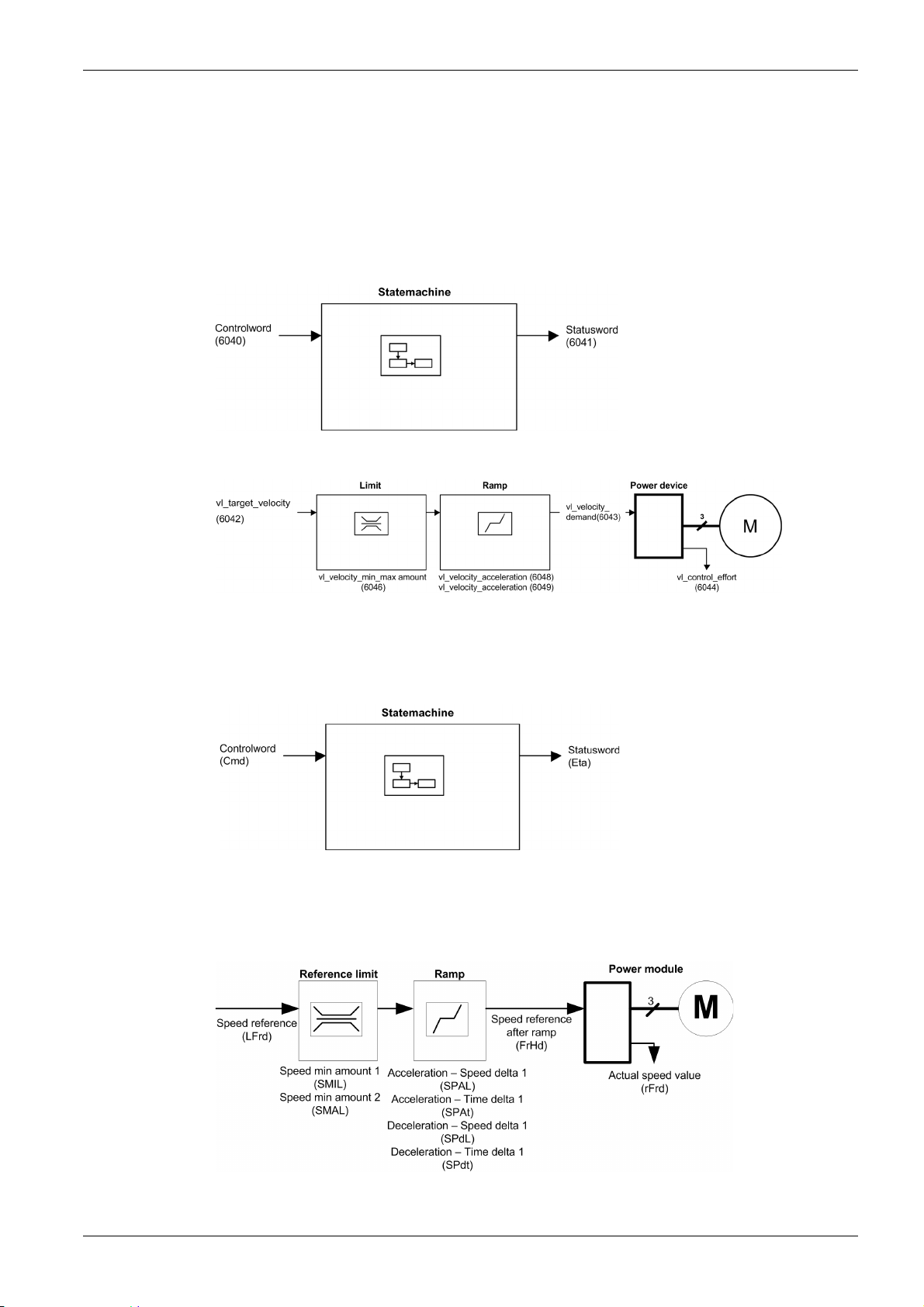

Functional Description

Introduction

Drive operation involves two main functions, which are illustrated in the diagrams below.

CiA402

The main parameters are shown with their CiA402 name and their CiA402/Drivecom index (the values in

brackets are the CANopen addresses of the parameter).

The following figure shows the control diagram for drive operation:

Simplified diagram for speed control in Velocity mode:

Basics

Altivar Drive

These diagrams translate as follows for the Altivar drive.

The following figure shows the control diagram for drive operation:

Simplified diagram for speed control in Velocity mode:

MFR24213 07/2020 23

Basics

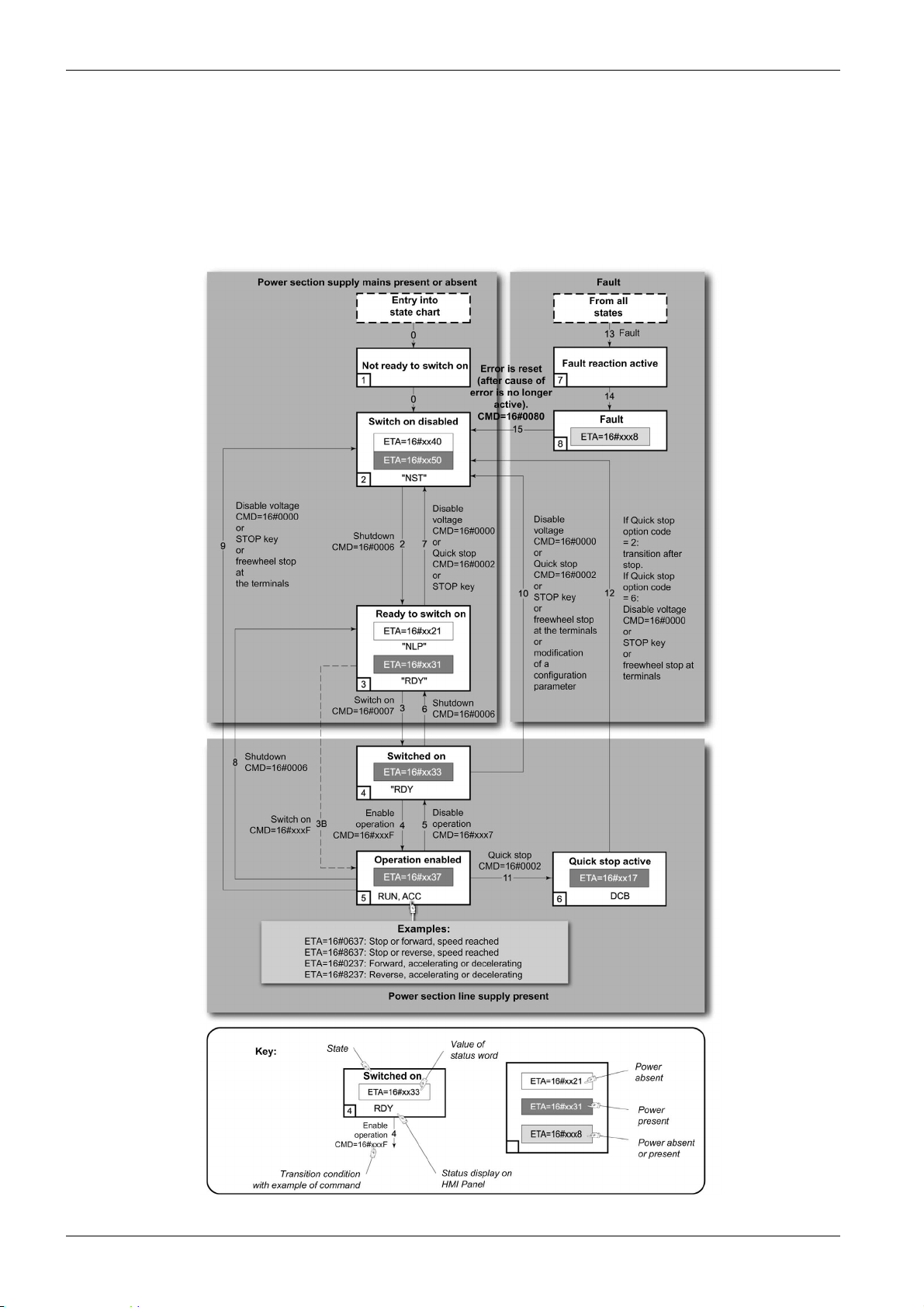

CIA402 Operating State Diagram

State Diagram

After switching on and when an operating mode is started, the product goes through a number of operating

states.

The state diagram (state machine) shows the relationships between the operating states and the state

transitions. The operating states are internally monitored and influenced by monitoring functions.

The following figure shows the CIA402 state diagram:

24

MFR24213 07/2020

Description of Operating States

Drive Operating State

The operating state of the drive changes depending on whether the control word [Cmd Register] CMd, is

sent or an event occurs (an error detection, for example).

The drive operating state can be identified by the value of the status word [CIA402 State Reg] EtA.

Operating State Description

1 - Not ready to switch

on

2 - Switch on disabled

3 - Ready to switch on

4 - Switched on

5 - Operation enabled

Basics

Initialization starts. This is a transient state invisible to the communication network.

The power stage is not ready to switch on.

The drive is locked, no power is supplied to the motor.

For a separate control stage, it is not necessary to supply the power.

For a separate control stage with mains contactor, the contactor is not closed.

The configuration and adjustment parameters can be modified.

The power stage is ready to switch on and awaiting power stage supply mains.

For a separate control stage, it is not necessary to supply the power stage, but the

system expects it in order to change to state 4 - Switched on.

For a separate control stage with mains contactor, the contactor is not closed.

The drive is locked, no power is supplied to the motor.

The configuration and adjustment parameters can be modified.

Power stage is switched on.

For a separate control stage, the power stage must be supplied.

For a separate control stage with mains contactor, the contactor is closed.

The drive is locked, no power is supplied to the motor.

The power stage of the drive is ready to operate, but voltage has not yet been

applied to the output.

The adjustment parameters can be modified.

If a configuration parameter is modified, the drive returns to the state 2 - Switch

on disable .

Power stage is enabled. The drive is in running state

For a separate control stage, the power stage must be supplied.

For a separate control stage with mains contactor, the contactor is closed.

The drive is unlocked, power is supplied to the motor.

The drive functions are activated and voltage is applied to the motor terminals.

If the reference value is zero or the Halt command is applied, no power is supplied

to the motor and no torque is applied. To perform [Auto tuning] tUn, the drive must

be in state 5 - Operation enabled.

The adjustment parameters can be modified.

The configuration parameters cannot be modified.

NOTE: The command 4 - Enable operation must be taken into consideration

only if the channel is valid. In particular, if the channel is involved in the command

and the reference value, transition 4 is possible only after the reference value has

been received once.

The reaction of the drive to a Disable operation command depends on the

value of the [SwitchOnDisable Stp] dOtd parameter:

If the [SwitchOnDisable Stp] dOtd parameter is set to 0, the drive changes to

operating state 4 - Switched on and stops in freewheel stop.

If the [SwitchOnDisable Stp] dOtd parameter is set to 1, the drive stops on

ramp and then changes to operating state 4 - Switched on.

MFR24213 07/2020 25

Basics

Operating State Description

6 - Quick stop active

The drive performs a fast stop and remains locked in the operating state 6-Quick

stop active. Before restarting the motor, it is required to go to the operating state

2-switch on disabled.

During fast stop, the drive is unlocked and power is supplied to the motor.

The configuration parameters cannot be modified.

The condition for transition 12 to state 2 - Switch on disabled depends on the

value of the parameter

[Quick stop Mode] QStd:

If the Quick stop mode parameter has the value FST2, the drive stops

according to the fast stop ramp and then changes to state 2 - Switch on

disabled .

If the Quick stop mode parameter has the value FST6, the drive stops

according to the fast stop ramp and then remains in state 6 - Quick stop

active until:

A Disable voltage command is received or

The STOP key is pressed or

A freewheel stop command via the digital input of the terminal.

7 - Fault reaction

active

8 - Fault

Transient state during which the drive performs an action corresponding to the

selected error response.

Error response terminated. Power stage is disabled.

The drive is locked, no power is supplied to the motor.

26

MFR24213 07/2020

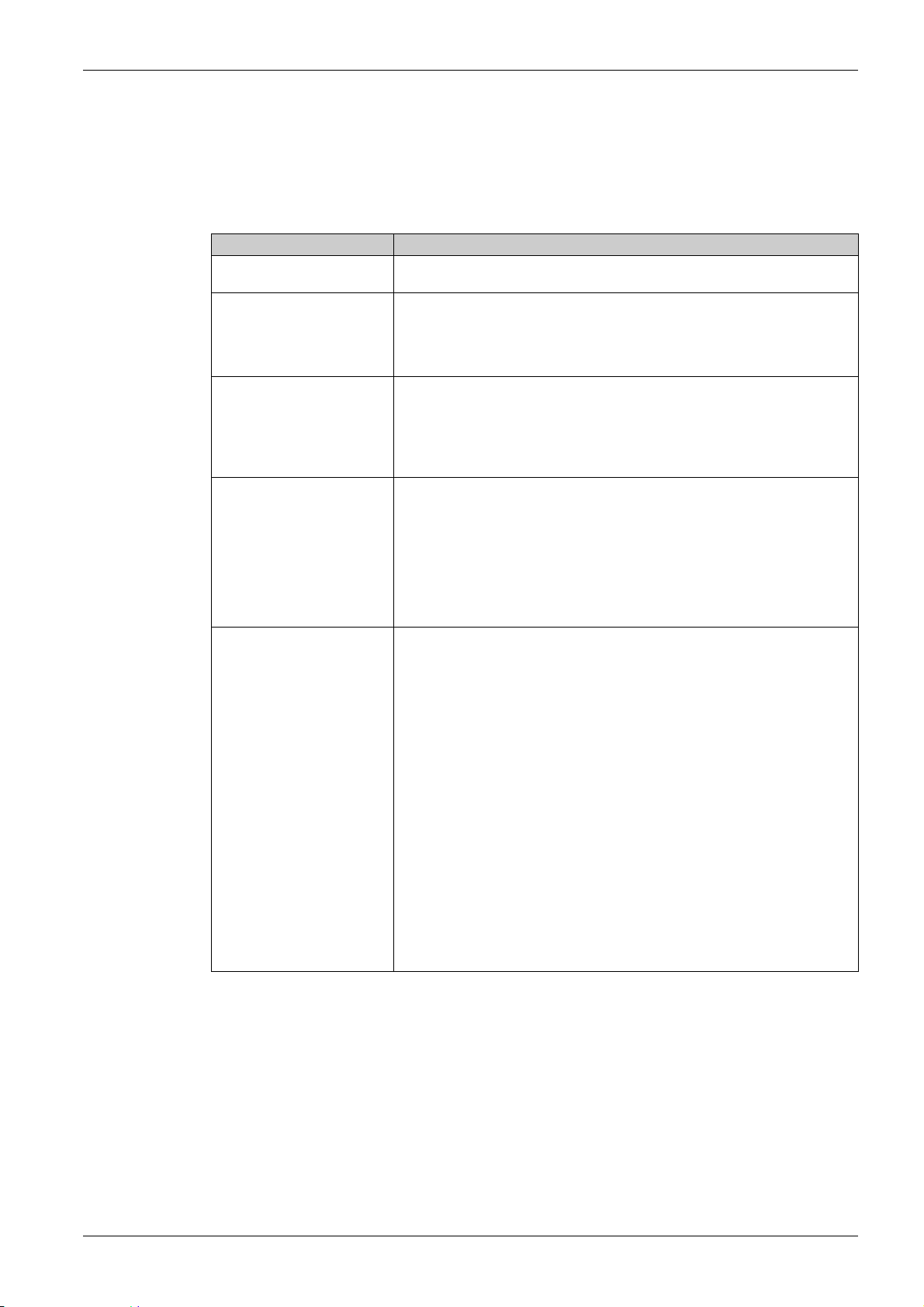

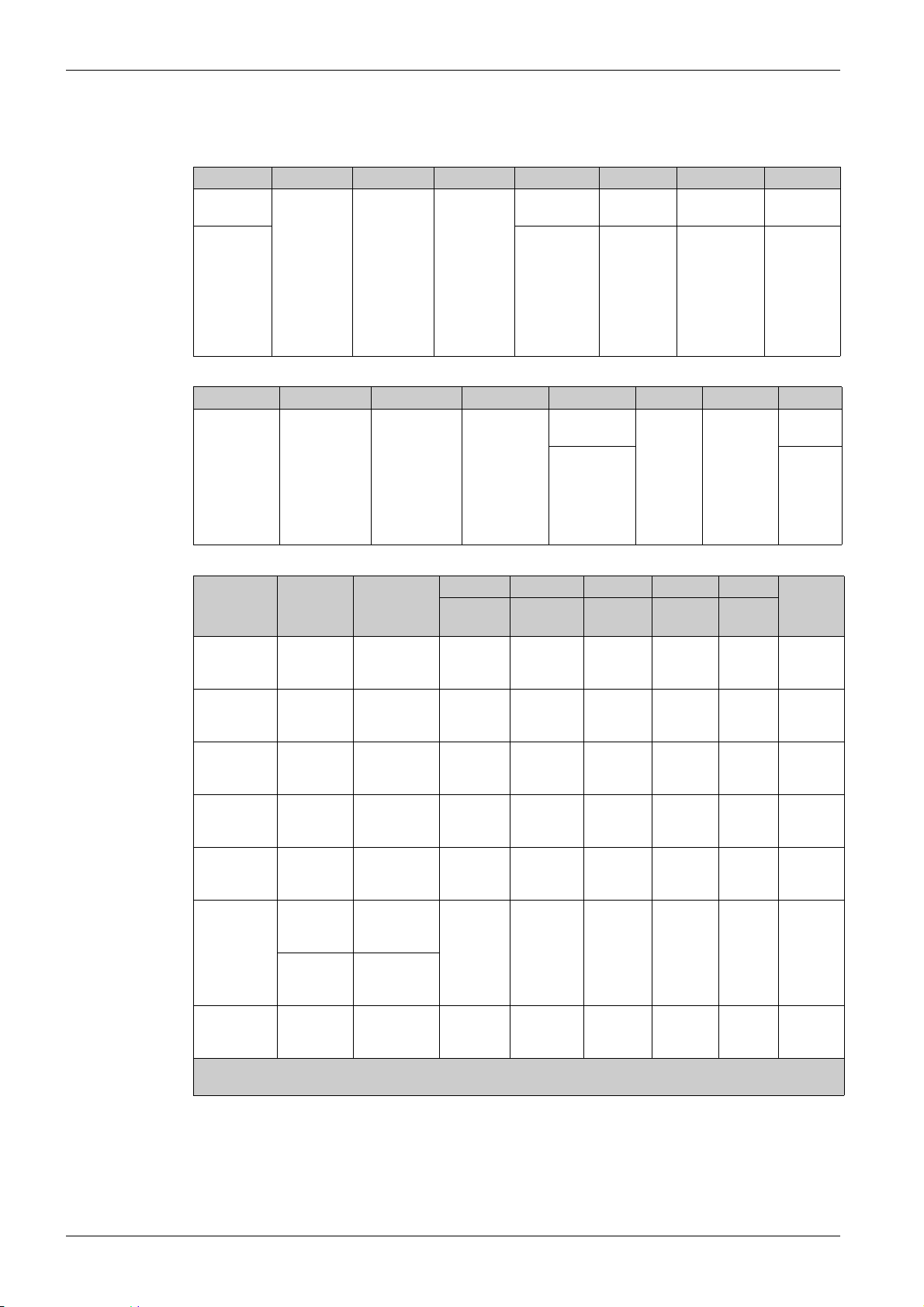

Summary

Device Status Summary

Basics

Operating State Power Stage Supply for

Separate Control Stage

1 - Not ready to

switch on

2 - Switch on

disabled

3 - Ready to

switch on

4 - Switched on

5 - Operation

enabled

6 - Quick stop

active

7 - Fault reaction

active

8 - Fault

Not required No Yes

Not required No Yes

Not required No Yes

Required No Yes, return to 2 - Switch on

Required Yes No

Required Yes, during fast stop No

Depends on error response

configuration

Not required No Yes

Power Supplied to Motor Modification of Configuration

Parameters

disabled operating state

Depends on error

response configuration

−

NOTE:

Configuration parameters are described in communication parameter file as R/WS access type

parameters. Other parameters can be accessed whatever the operating state.

A Setting parameter can be accessed in all operating state of the drive.

MFR24213 07/2020 27

Basics

Cmd Register CMd

Bit Mapping of the Control Word

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Fault reset Reserved

0 to 1

transition =

Error is

reset (after

cause of

error is no

longer

active)

Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8

Manufacturer

specific

assignable

(=0)

Manufacturer

specific

assignable

Reserved

(=0)

Manufacturer

specific

assignable

Reserved

(=0)

Manufacturer

specific

assignable

Enable

operation

1 = Run

command

Manufacturer

specific

0 = Forward

direction

asked

1= Reverse

direction

asked

Quick stop Enable

voltage

0 = Quick

stop active

Authorization

to supply AC

power

Reserved

(=0)

Reserved

(=0)

Switch on

Mains

contactor

control

Halt

0 = run

asked

1 = stop

asked

Command State

Transition

Shutdown

Switch on

Enable

operation

Disable

operation

Disable

voltage

Quick stop

Fault

reset

X: Value is of no significance for this command.

0→1: Command on rising edge.

2, 6, 8

3

4

5

7, 9, 10, 12

11

7, 10

15

Final

Operating

State

3 - Ready

to switch

on

4 Switched

on

5 Operation

enabled

4 Switched

on

2 - Switch

on

disabled

6 - Quick

stop

active

2 - Switch

on

disabled

2 - Switch

on

disabled

Bit 7 Bit 3 Bit 2 Bit 1 Bit 0 Example

Fault

Reset

X X 1 1 0 0006 hex

X X 1 1 1 0007 hex

X 1 1 1 1 000F hex

X 0 1 1 1 0007 hex

X X X 0 X 0000 hex

X X 0 1 X 0002 hex

0 → 1 X X X X 0080 hex

Enable

Operation

Quick

Stop

Enable

Voltage

Switch

On

Value

28

MFR24213 07/2020

Stop Commands

Halt Command

Freewheel Command

Basics

The Halt command enables movement to be interrupted without having to leave the 5 - Operation

enabled state. The stop is performed in accordance with the [Type of stop] Stt parameter.

If the Halt command is active, no power is supplied to the motor and no torque is applied.

Regardless of the assignment of the [Type of stop] Stt parameter [On Ramp] rMP, [Freewheel Stop]

nSt, the drive remains in the 5 - Operation enabled state.

A Freewheel Stop command using a digital input of the terminal or a bit of the control word assigned

to Freewheel Stop causes a change to operating state 2 - Switch on disabled.

MFR24213 07/2020 29

Basics

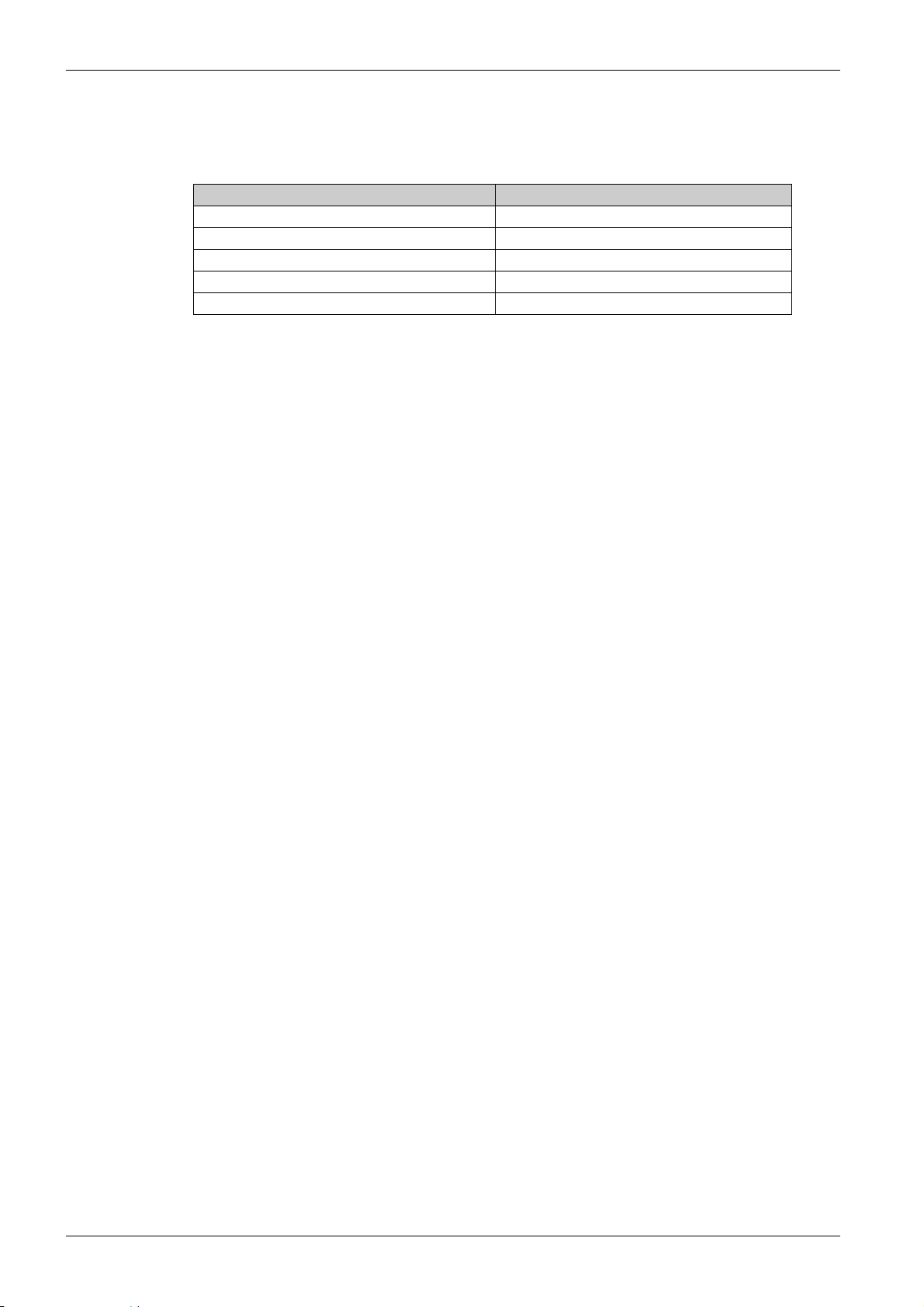

Assigning Control Word Bits

Function Codes

In the CiA402 profile, fixed assignment of a function input is possible using the following codes:

Bit Modbus Serial

Bit 11 C111

Bit 12 C112

Bit 13 C113

Bit 14 C114

Bit 15 C115

For example, to assign the external error to bit 13 of the fieldbus adapter, simply configure the [Ext Error

assign] ETF parameter with the [C113] C113 value.

Bit 11 is assigned by default to the operating direction command [Reverse Assign] rrS.

30

MFR24213 07/2020

Loading...

Loading...