Page 1

Scania EMS

Instrumentation

1 588 955

1588955

©

Scania CV AB 2008-03:1 1

Page 2

2

©

Scania CV AB 2008-03:1 1588955

Page 3

Contents

Scania EMS Instrumentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Instrument Panel (analogue). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Troubleshooting using flash codes for the EMS control unit . . . . . .8

Overview of flashing codes for EMS control unit . . . . . . . . . . . . . .9

Troubleshooting using flash codes for the EMS coordinator . . . . .10

Overview of flash codes for EMS coordinator . . . . . . . . . . . . . . . .11

Scania Control Panel (SCP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Remote Control Box (RCB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Scania EMS Display (SED) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Favourite screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Information (4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Fault codes (5). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Settings (6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Alarm and fault code generation. . . . . . . . . . . . . . . . . . . . . . . . . . .34

1588955

©

Scania CV AB 2008-03:1 3

Page 4

Scania EMS Instrumentation

General

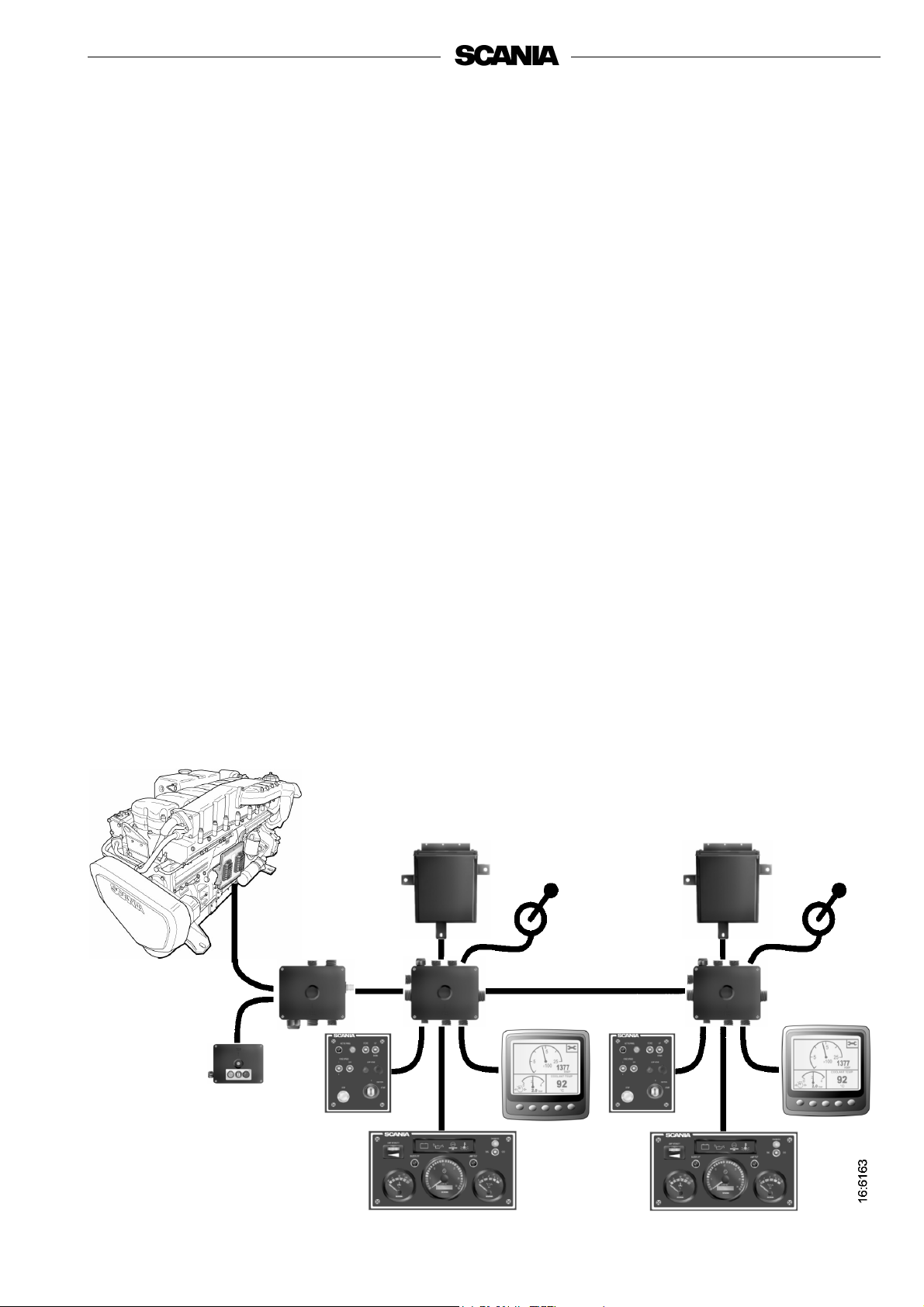

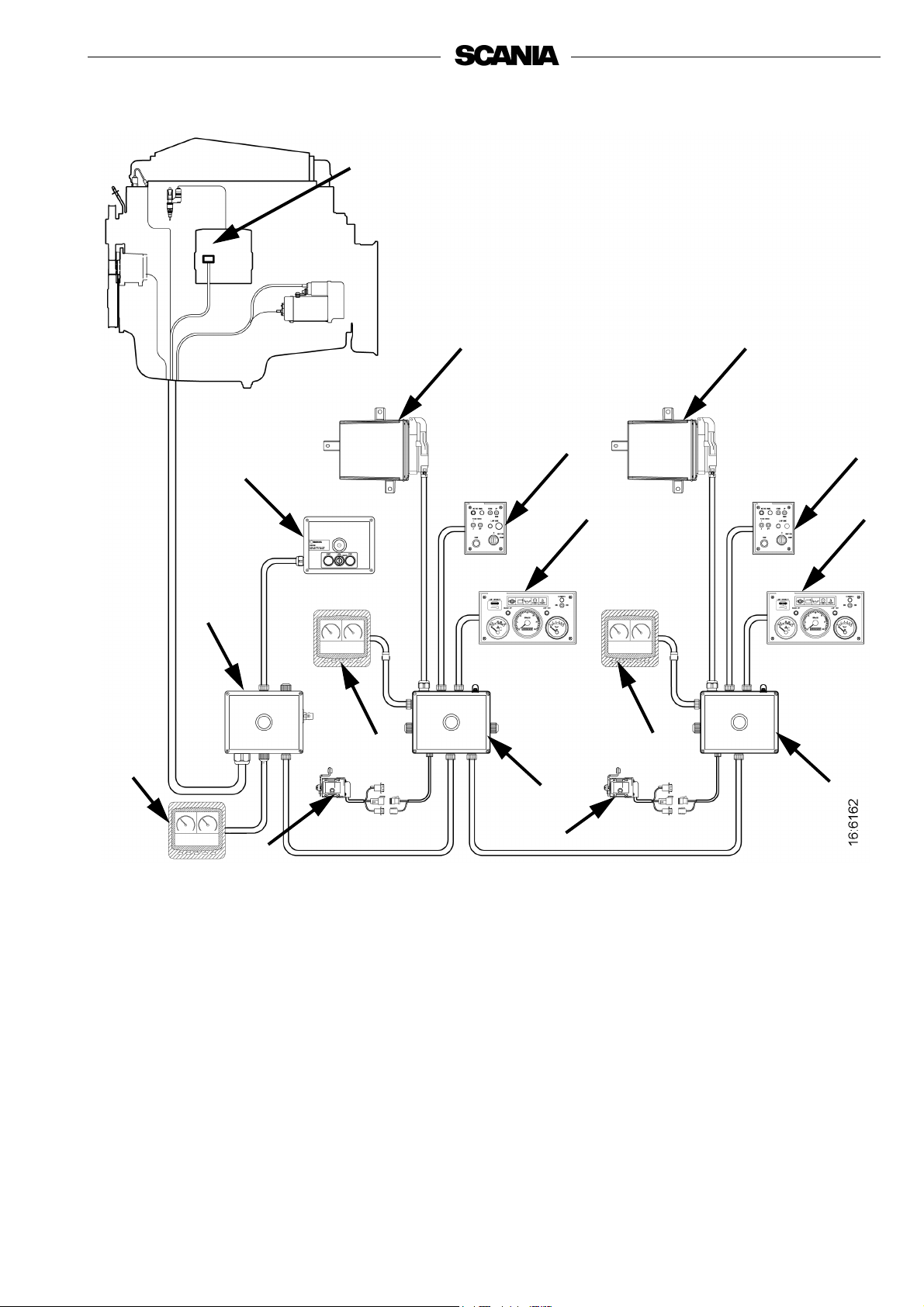

The base system comprises of the main supply box (MSB), the

junction box for the coordinator (CBC) and the coordinator (COO).

The main supply box is connected directly to the S6 control unit.

For this base system there are several different options for connection

to the system:

- Scania EMS digital display together with a control panel with

ignition key.

- A remote control box which enables controlling the engine from the

engine room.

- An analogue instrument panel instead of the digital display or

together with it.

- A Scania APS sensor (accelerator pedal sensor).

- In addition, the system can be doubled if there are two control

pulpits.

The whole system for instrumentation is Plug and Play which makes it

very simple to install.

See illustration of dual system on the next page.

In this Operator's manual, only the analogue instrument panel 9,

Scania EMS display 10 and Control Panel, 8 and 9, are described.

4

©

Scania CV AB 2008-03:1 1588955

Page 5

1

10

3

7

4

8

12

9

9

2

10

5

10

6

1588955

11

11

1. Control Unit S6

2. Main Supply Box

3. Coordinator

4. Coordinator

5. Connection Box Coordinator (master)

6. Connection Box Coordinator (slave)

7. Control Panel (master)

8. Control Panel (slave)

9. Instrument Panel

10. Scania EMS Display

11. Accelerator Position Sensor

12. Remote Control Box

Scania instrumentation, dual system

©

Scania CV AB 2008-03:1 5

Page 6

Instrument Panel (analogue)

General

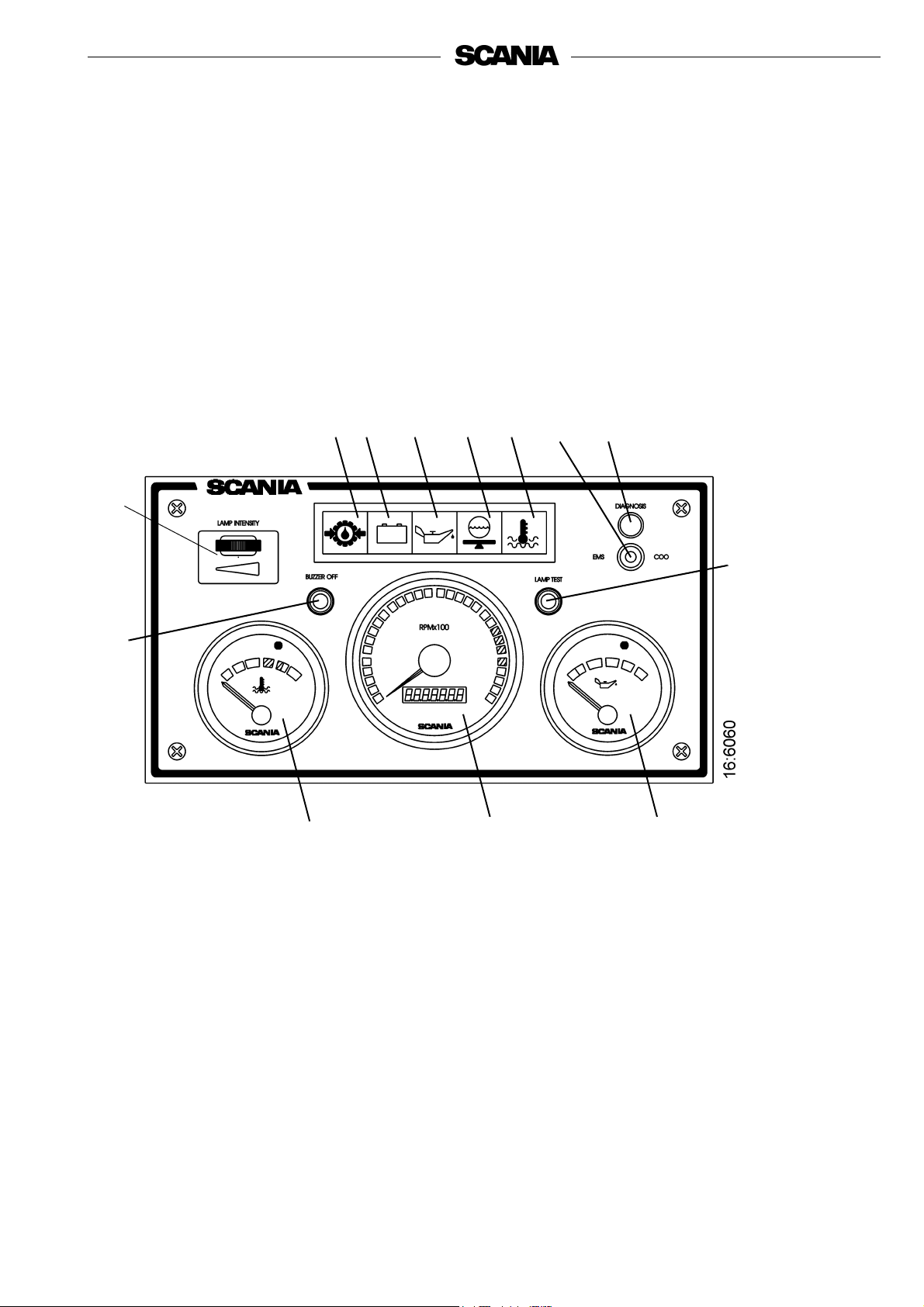

The analogue instrument panel has instruments for reading rotation

speed with hour counter, coolant temperature and oil pressure as well

as switches and lamps for diagnosis and alarm.

The analogue instrument panel has the following functions:

Also see illustration on next page.

Lamp intensity (S54)

The intensity of the gauges can be regulated with this roller control.

Buzzer off (S51)

This button deactivates the buzzer sound on any existing alarm. The

warning lamp for the current alarm trigger will continue to illuminate

until the fault is rectified.

Lamp test (S52)

With this button it is possible to check that the system lamps are intact

and functioning. When the button is activated the coordinator will

activate all lamps on the panel and the buzzer will sound. The lamps

illuminate and the buzzer sounds as long as the button is depressed.

When the key in the control panel is turned to the Ignition position an

automatic lamp test takes place for 2 seconds and the buzzer sounds for

1 second.

Diagnosis EMS/COO (W21 and S53)

This is a 3-position switch which belongs to diagnostic lamp W21. The

diagnostic lamp remains lit for as long as the system has an active fault

code.

When the switch is activated in the direction of the COO for at least 1

second, the coordinator will send out any fault codes as flash codes on

the diagnostic lamp (W21).

When the switch is activated in the direction of the EMS for at least 1

second, the coordinator will send out any fault codes for the EMS the

control unit as flash codes on the diagnostic lamp (W21).

6

©

Scania CV AB 2008-03:1 1588955

Page 7

In order to read flash codes with dual instrumentation it is necessary to

demand diagnosis from the instrument panel where the coordinator in

question is connected.

For further information on reading and deleting flash codes, see

Troubleshooting using flash codes.

Warning lamps (W1, W4, W5, W6, W7)

On the warning lamp panel there are warning lamps for alternator

charging, oil pressure, coolant temperature and coolant level. Warning

lamp for hydraulic pressure is not used.

S54

S51

W6

W1

O2

O1 Tachometer with hour counter

O2 Coolant temperature gauge

O3 Oil pressure gauge

S51 Deactivation of buzzer

S52 Lamp test switch

S53 Diagnostic switch

S54 Rheostat for instrument lighting

W1 Charge warning lamp

W4 Warning lamp, coolant temperature

W5 Warning lamp, oil pressure

W6 Warning lamp, hydraulic pressure

W7 Warning lamp, coolant level

W21 Diagnostic lamp

W5

W7

O1

W4

S53

W21

S52

O3

1588955

Scania analogue instrument panel

©

Scania CV AB 2008-03:1 7

Page 8

Troubleshooting using flash codes for the EMS control unit

1. Switch on the ignition. If the diagnostic lamp is on after 2 seconds

there is an active fault.

2. Activate the diagnostic switch (S53) to the left to see the flash

codes for the control unit (EMS).

3. A fault code will then flash on the diagnostic lamp (W21). This

flash code consists of long flashes (approximately 1 second long)

and short flashes (0.3 seconds long). Long flashes are equivalent

to tens and short flashes to units.

Example: long - short - short = fault code 12.

4. Repeat this procedure until the first flash code is repeated. This

means that the entire fault code memory has been flashed out. If

the fault code memory is empty, only one long flash

approximately 4 seconds long will be given.

5. See the flash code table on the next page for a description and

localisation of the fault.

6. In order to obtain further information on the fault code, the

PC-based diagnostics tool or Scania EMS Display must be used.

Contact an authorised Scania workshop.

7. The diagnostic lamp will stay on for as long as a fault is active.

Even if the lamp has gone off and the fault is no longer active, the

code can generally be read off in accordance with the instruction

above.

8. When a fault has been rectified the fault code can be erased as

described below.

Erasing fault codes (flash codes)

1. Turn the ignition off. If there is dual instrumentation the ignition

must be switched off on both panels.

2. Activate the diagnostic switch in the direction of the flash codes,

i.e. to the left for EMS.

3. Turn the ignition on at the same time as holding the diagnostic

switch activated to the left (EMS) for 3 seconds.

4. This will erase passive fault codes which can be read off via flash

code for the relevant system. The rest of the fault code will remain

in the EEPROM and can only be deleted using the PC tool.

8

©

Scania CV AB 2008-03:1 1588955

Page 9

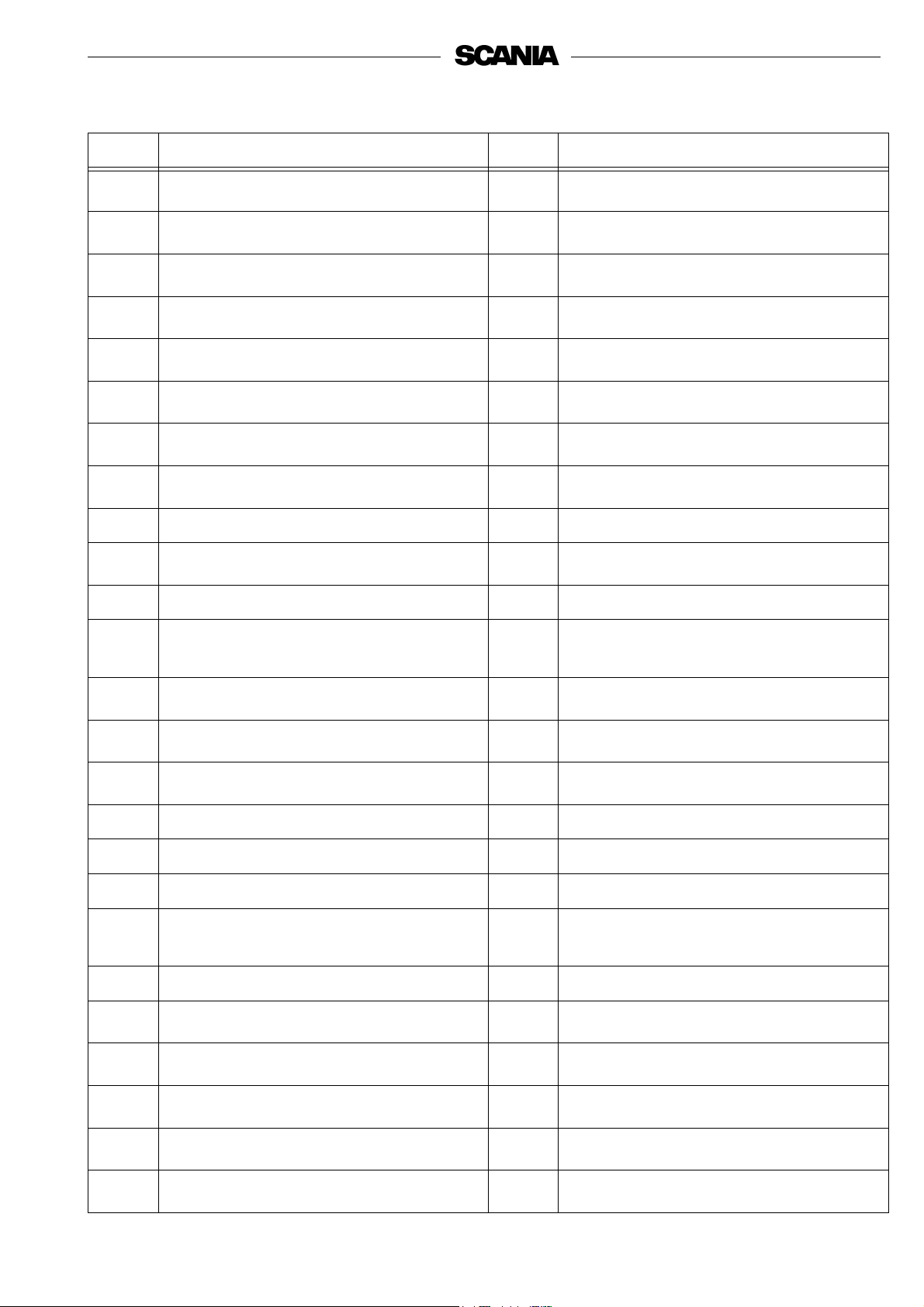

Overview of flashing codes for EMS control unit

Code Description

No fault detected.

0

11

12

13

14

15

16

17

18

20

Overspeed. One or both rotation speed

sensors are indicating values above 3000 rpm.

Rotation speed sensor 1 faulty, or incorrect

signal.

Rotation speed sensor 2 faulty, or incorrect

signal.

Coolant temperature sensor faulty, or incorrect

signal.

Charge air temperature sensor faulty, or

incorrect signal.

Charge air pressure sensor faulty, or incorrect

signal.

Oil temperature sensor faulty, or incorrect

signal.

Oil pressure sensor faulty, or incorrect signal.

Coolant level sensor faulty.

Code

53

54

55

56

57

58

59

61

66

69

Description

PDE in cylinder 3: The solenoid valve does not

work correctly.

PDE in cylinder 4: The solenoid valve does not

work correctly.

PDE in cylinder 5: The solenoid valve does not

work correctly.

PDE in cylinder 6: The solenoid valve does not

work correctly.

PDE in cylinder 7: The solenoid valve does not

work correctly.

PDE in cylinder 8: The solenoid valve does not

work correctly.

Incorrect signal in extra analogue input.

Incorrect control unit shutdown.

Shutdown due to coolant level

Starter motor function interrupted or not

activated.

23

24

25

27

28

31

32

33

37

43

47

Fault code internally in the coordinator.

Accelerator pedal / brake. If the accelerator

and brake pedals have been operated

simultaneously.

Accelerator pedal sensor / idling switch

Accelerator pedal sensor / kick-down switch

Engine shutdown bypassed.

Shutdown due to oil pressure

Torque limitation due to oil pressure

Incorrect parameters for limp home function.

Battery voltage incorrect or no signal.

Emergency shutdown switch activated in

accordance with CAN message from

coordinator.

CAN circuit faulty in the control unit.

Immobiliser function. Ignition key code

incorrect.

82

83

84

85

86

87

88

89

93

94

96

Rotation speed above ref.speed at start

Fault in memory circuit (EEPROM) in control

unit.

Data transfer to the control unit memory

(EEPROM) has been interrupted.

Incorrect temperature internally in the control

unit.

Internal fault in the control unit: Fault in

hardware control.

Fault in control unit RAM.

Internal control unit fault: Memory fault

Incorrect seal: Prohibited changes in software.

Rotation speed sensors faulty or not

connected.

Shutdown due to high coolant temperature.

Torque limitation due to high coolant

temperature.

48

49

51

52

1588955

CAN message from the coordinator incorrect

or missing.

Incorrect CAN version in control unit or

coordinator.

PDE in cylinder 1: The solenoid valve does not

work correctly.

PDE in cylinder 2: The solenoid valve does not

work correctly.

©

Scania CV AB 2008-03:1 9

98

99

Incorrect voltage supply to one of the sensors.

Internal hardware fault in the processor (TPU).

Page 10

Troubleshooting using flash codes for the EMS coordinator

1. Switch on the ignition. If the diagnostic lamp is on after 2 seconds

there is an active fault.

Important! The diagnostic lamp only indicates faults for the

coordinator connected to the instrument panel from which the

flash codes are read.

2. Activate the diagnostic switch (S53) to the right to see the flash

codes for the coordinator (COO).

3. A fault code will then flash on the diagnostic lamp (W21). This

flash code consists of long flashes (approximately 1 second long)

and short flashes (0.3 seconds long). Long flashes are equivalent

to tens and short flashes to units.

Example: long - short - short = fault code 12.

4. Repeat this procedure until the first flash code is repeated. This

means that the entire fault code memory has been flashed out. If

the fault code memory is empty, only one long flash

approximately 4 seconds long will be given.

5. See the flash code table on the next page for a description and

localisation of the fault.

6. In order to obtain further information on the fault code, the

PC-based diagnostics tool or Scania EMS Display must be used.

Contact an authorised Scania workshop.

7. The diagnostic lamp will stay on for as long as a fault is active.

Even if the lamp has gone off and the fault is no longer active, the

code can generally be read off in accordance with the instruction

above.

Erasing fault codes (flash codes)

1. Turn the ignition off. If there is dual instrumentation the ignition

must be switched off on both panels.

2. Activate the diagnostic switch in the direction of the flash codes,

i.e. to the right for the coordinator COO.

3. Turn the ignition on at the same time as holding the diagnostic

switch activated to the right (COO), for 3 seconds.

4. Any fault code that can be read by a flash code for the system in

question will be deleted. The rest of the fault code will remain in

the EEPROM and can only be deleted using the PC tool.

Important! It is only possible to delete fault codes for the

coordinator that is connected to the instrument panel from

which deletion is carried out.

10

©

Scania CV AB 2008-03:1 1588955

Page 11

Overview of flash codes for EMS coordinator

Flashing

Fault description

code

1)

11

11

12

12

2)

1)

2)

Incorrect signal from the nominal rotation speed signal fine adjustment.

Incorrect analogue signals from the accelerator pedal sensor.

Incorrect analogue signal from the resistor module for governor setting.

Incorrect analogue signal from the resistor module for idling and fixed speed

setting.

13 No communication (EMS) with the engine.

14 Short-circuit in the tachometer signal cable.

15 Faulty atmospheric pressure sensor.

17 Short-circuit in the coolant temperature gauge signal cable.

18 Short-circuit in the oil pressure gauge signal cable.

19 Short-circuit in the oil pressure lamp signal cable.

21

Different versions of the communications protocol between the coordinator and

EMS.

22 Faulty start switch or short circuit.

23 The supply voltage is too high.

24 The supply voltage is too low.

25 Check value from end of line (EOL) is incorrect.

26 Road speed sensor signal missing or incorrect.

27 The signals from the RCB (Remote Control Box) switches are implausible.

28 Incorrect signals from the droop-setting switches.

29 Faulty remote start switch or short circuit.

31 No communication from the slave coordinator or the master coordinator.

32 Short circuit in the signal cable to the coolant temperature warning lamp.

33 Short circuit in the signal cable to the charge indicator lamp.

34 Incorrect signal from the Fixed speed switches.

35 Fault in CAN communication.

1) Single speed engine

2) All-speed engine

1588955

©

Scania CV AB 2008-03:1 11

Page 12

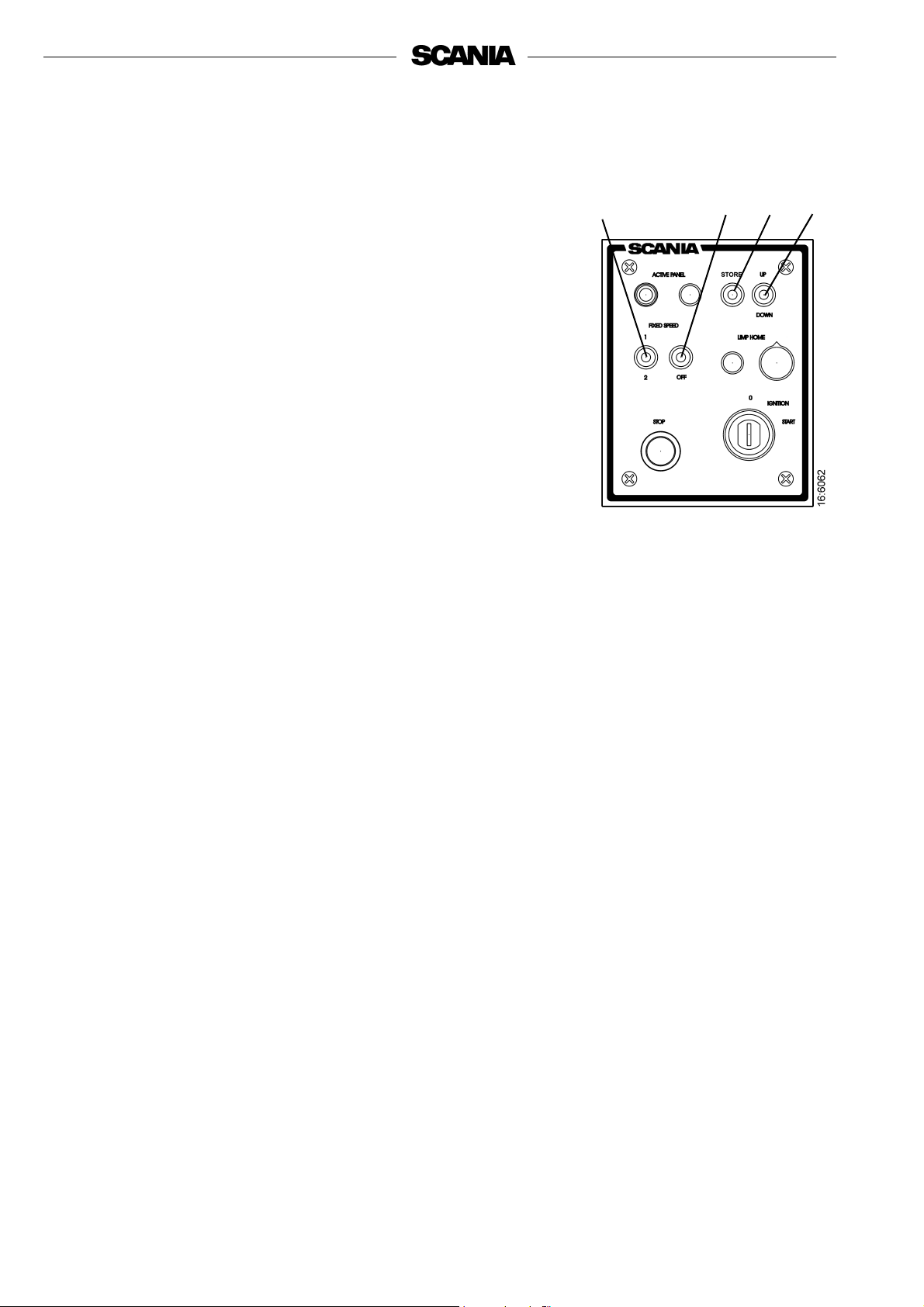

Scania Control Panel (SCP)

Start and stop the engine from the Scania Control Panel which has a

starter key and a stop button together with functions for Fixed Speed

and Limp Home.

S42 W19

S49

S43

S46

S45

S47

W20

S1

S50

W20

12

1. Master panel

2. Slave panel

W19 Lamp for Active Panel

W20 Lamp for Limp Home Throttle

S1 Ignition key

S42 Switch for Active Panel function

S43 Switch for activating and switching between Fixed Speed 1 and 2

S45 Switch for storing

S46 Stop button

S47 Switch for adjusting Fixed Speed / idle speed up or down

S49 Switch for deactivating Fixed Speed function

S50 Potentiometer for Limp Home Throttle

12

Scania Control Panel with ignition key

©

Scania CV AB 2008-03:1 1588955

Page 13

Following functions are available in Scania Control Panel:

Active Panel

Activate the panel by depressing pushbutton S42. The coordinator

registers that this control position is active and switches on lamp W19.

The panel from which the engine is started is automatically active and

it is then possible to make adjustments and requesting throttle

actuation.

In order to change active panel (changing throttle position) both

throttle controls must be at 0% throttle. Switch off the active panel so

that neither panel is active. Then it is possible to change control

position.

With single instrumentation, the panel is activated when the key is

turned to the ignition position.

If the throttle control fails, the Active Panel lamp is still illuminated

and the Limp Home lamp comes on which means that the limp home

throttle (emergency throttle) is engaged.

If CAN communication fails, the Limp Home lamp comes on and the

Limp Home throttle is engaged.

See also under Limp Home Throttle.

S42

W19

1588955

©

Scania CV AB 2008-03:1 13

Page 14

Fixed Speed 1 and 2

These two functions are activated via a 3-position switch, S43. With

Fixed Speed 1 it is possible to set an isochronous speed between high

and low idle speed. With Fixed Speed 2 it is possible to set an

isochronous speed between 450 and 2000 rpm. In both modes, it is

possible to set torque limitation via diagnostic tool or the digital

display.

When activating, the engine goes up or down to the last saved value for

the mode.

It is a prerequisite for activating these modes that the engine is running,

that the panel is active and that the throttle is at 0%.

Change the speed for either modes in the following way:

- Activate the mode to be changed by activating switch S43 to 1 or 2.

- Adjust the speed up or down using switch S47.

- Press Store switch S45 for 3 seconds to save the new values. If you

exit the mode without saving, the engine will resume the latest

speed value that was stored for that mode.

- With dual instrumentation, it is only possible to make adjustments

from the panel that is active.

S43

S49

S45

S47

- In order to deactivate the function, press switch S49 to Off, touch

the accelerator pedal, change panel when using dual

instrumentation, or switch off the engine.

14

©

Scania CV AB 2008-03:1 1588955

Page 15

Idle speed adjustment

Adjust the engine idle speed as follows:

1. Activate Store switch S45 for 3 seconds in order to go to

adjustment mode.

2. Adjust the idle speed up or down (+ or -) using switch S47.

3. Save the set value by activating the Store switch for

3 seconds.

- It is also possible to set the engine idle speed using the diagnostic

tool or Scania digital display.

- In order to adjust the idle speed, the coolant temperature must be

higher than 50°C and the engine running at idle.

- The idle speed can be set to between 500 and 1,050 rpm.

Stop

The function stop the engine is available in several places in the

system.

S45

S47

With single instrumentation, the stop button can be located in 2 places:

- In the Remote Control Box (RCB).

- In the Control Panel (S46).

With dual instrumentation, the stop button can be located in 3 places:

- In the Remote Control Box (RCB).

- In both Control Panels (S46).

When one of these buttons is activated COO sends a message to S6 to

stop the engine.

It is also possible to stop the engine by turning the key to O. With dual

instrumentation it is possible that both Control Panels are in ignition

position and both keys must then be turned to O.

Therefore we recommend that the engine is stopped with a stop

button.

S46

1588955

©

Scania CV AB 2008-03:1 15

Page 16

Limp Home Throttle

Limp Home Throttle is an emergency function that is activated if the

master coordinator fails or if the master throttle control fails while the

master control panel is active, or if the slave throttle control, slave

coordinator fail while the slave control panel is active or CAN traffic is

not working.

If this happens Limp Home lamp W20 will come on and Limp Home

Throttle will be engaged.

Limp Home Throttle, S50, consists of a potentiometer on the master

Control Panel with which it is possible to drive in limp home mode.

The potentiometer value goes directly to switch A2 on the S6 control

unit.

In order to use Limp Home Throttle the potentiometer must first be

turned to the 0 position before it is activated. The potentiometer is only

on the Master Control Panel. There is a Limp Home lamp on both

panels. If CAN fails, both lamps will come on and Limp Home Throttle

is activated.

The potentiometer is only on the master panel but Limp Home lamp

W20 is on both panels.

W20

S50

If the master control fails when the master panel is active, the lamps on

both panels will come on. If you then change to the slave panel, both

lamps will go off and it is possible to control the engine throttle via the

slave panel.

The same will also apply the other way round.

Start Key

Start the engine by using key S1 on Scania Control Panel. The key

gives U15 signal in the Ignition position and U50 signal in the Start

position.

When the coordinator receives a signal from the key to start, the

coordinator sends a CAN message to the S6 control unit, which in turn

sends a signal to the starter relay that supplies the starter motor with

power and the engine starts.

- If one panel is active, it is only possible to start from that panel.

- If no panel is active, the panel that you use to start the engine will

automatically become active.

The engine stops when the key is turned to the 0 position. In dual

systems, this only applies if the other key is not turned on.

S1

16

©

Scania CV AB 2008-03:1 1588955

Page 17

Remote Control Box (RCB)

Remote Control Box is connected on switch C57 on Main Supply Box

(MSB). With RCB it is possible to lock the engine so that it is not

possible to operate it from another position than where the RCB is

located.

Note: This can only be done when the boat is moored, i.e.

when there is no risk that the boat will drift out of

control. There is a sign on the RCB with this warning

text.

- There are two positions for key switch S26: Local and Remote.

- Local: The engine cannot be operated from any other location

than from the RCB box.

- Remote: Normal position, the engine can be operated from the

other throttle control positions.

- When the Local position is activated the green lamp 2 is

illuminated. At the same time the Active Panel lamps on the Scania

Control Panel (Slave and Master) starts to flash, which indicates

that neither of these panels can be activated.

- When the engine is started from the RCB using S27 it only runs on

idle as long as the Local position is activated and no other throttle

control can be used.

- If the key switch is reset from Local to Remote when the engine is

running, the green lamp 2 will go out and the engine will continue to

run on idle, but it will then be possible to operate throttle control

from other control positions if the Slave or Master panel is active.

- If key switch S26 is reset from Remote to Local while driving,

nothing will happen, except that this will be regarded as an

unintentional action.

- If CAN communication fails when the engine has been started from

the RCB the engine will stop but the Limp Home function will not

be engaged.

1588955

©

Scania CV AB 2008-03:1 17

Page 18

- In order to start the engine again, it is necessary to carry out the

following procedure:

- Connect pin 50 on the starter relay with the plus pin on the

starter motor. The engine starts but it is only possible to control

the throttle using the Limp Home potentiometer

- In order to stop the engine you must switch off the power to EMS

S6 by turning the starter key to 0 or via switch C122 in the MSB.

1

S27

S26 S28

1 Green indicator lamp

S26 Rotary switch for activating the Local function

S27 Starter button

S28 Stop button

Scania Remote Control Box (RCB)

18

©

Scania CV AB 2008-03:1 1588955

Page 19

Scania EMS Display (SED)

General

Scania EMS Display is a graphic display which represents engine data,

diagnostics which enables settings of certain parameters in the engine

control unit EMS. Scania EMS Display can only be used together with

EMS and the new electrical system adapted for marine use.

Communication to and from the display is carried out via CAN bus,

protocol J1939.

Function

The information content can be found in different screens according to

a tree structure. On the upper level there are six different screens, three

Favourites, Information, Diagnostics and Settings.

The buttons are configured to function differently depending on which

screen is currently active. To scroll between different screens on the

upper level, use button 1 and 5 depending on whether you want to

move forwards or backwards in the structure.

When one of the favourite screens is active, the information about each

button's function is hidden. The reason for this is to make as big an area

as possible available for presentation. As soon as a button is depressed,

the description for the button is displayed for approx 5 s.

Each window (except the favourites) has a number in the upper left

corner. The numbers indicate the current screen and level.

Favourite screen

The screen Favourites is used to display engine data during operation,

more or less equivalent to Scania analogue instrument panel. The

favourite screen can have three different appearances, all on the

highest level.

1588955

©

Scania CV AB 2008-03:1 19

Page 20

If you want to change from one Favourite to another Favourite, press

button 1 or 5 depending on which is currently displayed.

On this screen, the buttons have the following functions:

1 Scroll to the left in the upper level

2

3

4 Go down one level in the structure

5 Scroll to the right in the upper level

Change the appearance of a Favourite by pressing button 4.

The button screen shown on the right, will then be displayed.

By pressing button 2 the appearance of the screen changes according to

the order on page 19.

When an appearance has been selected, it is possible to change the

contents of the selected window.

Press button 4 to display the button bar according to the table below.

- In order to select the contents for a partial window, it must be

active.

- Activate the partial window by pressing button 2. The window will

then be greyed out.

1 Changing between digital and analogue signal

2 Changing between greyed active partial screen

3 Changing of signal in greyed active partial screen

4

5 Go up one level in the structure

20

©

Scania CV AB 2008-03:1 1588955

Page 21

- Change the active partial window by pressing button 2.

- The contents of the partial window is changed with button 3 and 1

according to the following table:

The information of the different partial windows can be displayed in

digital or analogue format. Some signals can only be displayed in one

format, see the table.

- Press button 1 to change between analogue and digital display (1).

- Press button 3 to change the content of the active partial window

(2).

Signal

Engine speed Yes Yes

Oil pressure Yes Yes

Coolant temperature Yes Yes

Charge air pressure Yes Yes

System voltage Yes Yes

Fuel consumption Yes No

Load at current speed Yes No

Engine hours Yes No

Throttle Yes No

Digital

display

Analogue

display

Symbol

RPM

1

2

1

1588955

2

©

Scania CV AB 2008-03:1 21

Page 22

Information (4)

Carry out the following in order to go to this screen from the basic

screen (favourite):

- Press any button to display the button bar.

- Press button 5 one to three times (depending on which favourite that

is active) to go to screen 4 INFORMATION.

- The button bar will now stay on the screen.

- Buttons 2 and 3 are used to move up or down in this screen.

- Press button 4 to go down one step in the structure to STATISTICS

TRIP (4.1).

- Here is some information according to the screen.

- Press button 1 (Reset) in order to zero the reading.

- In order to go back to screen 4, press button 5.

- Maximum time for a registered reading is 999 h, then Reset will be

automatic.

x1-3

- Go down one step with button 2 to PERFORMANCE.

- Press button 4 to go down one step in the structure to

4.2 PERFORMANCE.

- The information displayed here is the current performance at that

time, i.e. the displayed values are real-time. Corresponding values

can also be read in the Favourite window, but this is a quicker way

to get a summary of the performance related parameters.

22

©

Scania CV AB 2008-03:1 1588955

Page 23

- In order to go back to screen 4, press button 5

- Go down one step with button 2 to SYSTEM DATA.

- Press button 4 to go down one step in the structure to

4.3 SYSTEM DATA.

- Here it is possible to select information about the four different

system control units.

- If you select EMS and press 4, information about the engine, engine

number and engine type and the EMS control unit part number will

be displayed.

- If you select DISPLAY the following information about Scania EMS

Display is displayed:

- Part number (complete)

- Hardware number

- Software number

- Version number

- The corresponding information is retrieved for the coordinators if

the COO MASTER or COO SLAVE is selected.

1588955

©

Scania CV AB 2008-03:1 23

Page 24

Fault codes (5)

- Return to screen 4 INFORMATION by pressing twice on 5. If you

press button 5 again, screen 5 FAULT CODES. is displayed.

- The upper symbol to the right indicates that there is at least one

active fault code.

- The button bar has a different appearance and it will be displayed

the whole time. Refer to the table below.

1 Scroll to the left in the upper level

2 Go down to the next line in the list

3 Short press: Up to the next line in the list

Long press (3 s): Update the list

4 Short press: Information about the highlighted fault code

Long press (3 s): Clear fault codes

5 Scroll to the right in the upper level

- In the example, the Coolant temp sensor and Oil pressure sensor

marked by a ! which means that they are active fault codes.

Information about the highlighted fault code

In the example, Coolant temp sensor is black. By a short press on

button 4 the information screen about the fault code is displayed.

Information type Description

Affected control unit The control unit where the fault originated,

e.g. EMS

Name of fault Fault code name, e.g. Coolant temp sensor

System behaviour How the system is behaving when the fault

is active, for example Problems starting

Code The number of the selected fault code, e.g.

2001

Status If the fault is active

Hex code Gives more information than just status,

e.g. 20

or passive

Times How many times that the fault has occurred,

e.g. 3

24

©

Scania CV AB 2008-03:1 1588955

Page 25

To erase fault codes

- Press button 4 for three seconds.

- A screen asking if you want to erase all fault codes is displayed.

- Press button 1 to erase all fault codes.

- Then press button 3, OK, to confirm.

3 s

Update the fault code list

- Update the fault code list by pressing button 3 for three seconds.

- Confirm by pressing button 3, OK.

3 s

1588955

©

Scania CV AB 2008-03:1 25

Page 26

Settings (6)

- Press button 1 or 5 from the Favourite screen to go to screen 6

SETTINGS.

- In order to quickly go to the setting mode, irregardless of where you

are: Press buttons 2 and 4 simultaneously.

CONTRAST / BRIGHTNESS (6.1)

- Using buttons 2 and 3 to go up or down in the list.

- Press button 4 to go to the adjustment screen for

CONTRAST / BRIGHTNESS.

- Here it is possible to adjust the brightness and contrast to the current

operating conditions.

- In order to reset to the original setting, press buttons 2, 3 and 4 at the

same time for three seconds.

BUTTON BLEEP (6.2)

- Press button 2 to go to BUTTON BLEEP.

- Press button 4 to go to the adjustment screen.

- Press button 3 to change between BUTTON BLEEP OFF or

BUTTON BLEEP ON

- Press button 5 to return to the selection screen.

- The setting BUTTON BLEEP OFF does not affect the alarm signal.

26

©

Scania CV AB 2008-03:1 1588955

Page 27

LANGUAGE (6.3)

Information on Scania EMS Display can be displayed in seven

different languages:

Swedish English German French Spanish

Italian Portuguese

The default language is English

- Press button 2 or 3 to go to LANGUAGE.

- Press button 4 to go to the selection screen.

- Press button 2 or 3 to select language.

- Press 4 to confirm the change. The box to the right about selecting

language will then be marked, which means that the change has

taken place.

- Press button 5 to return.

UNITS (6.4)

It is possible to select between two different sets of units for different

parameters according to the table:

METRIC

US IMPERIAL

Parameter Metric US Imperial

Pressure Bar Psi

Voltage V V

Engine speed Rpm Rpm

Temperature °C °F

Fuel consumption L/h, L Gal/h, Gal*

*) US Gallon = 3.79 l

- Press button 2 or 3 to go to UNITS.

- Press button 4 to go to the selection screen.

- Press button 2 or 3 to select unit system.

1588955

©

Scania CV AB 2008-03:1 27

Page 28

- Press button 4 to confirm the change. The box to the right will then

be marked, which means that the change has taken place.

- If you press button 1, information according to the table above is

displayed.

- Press button 5 to return.

ENGINE (6.5)

From this screen it is possible to change the basic settings of the engine

when it was delivered.

Note: Changing basic settings may affect safety-critical

functions.

- Press button 2 or 3 to go to ENGINE.

- Press button 4 to confirm the selection.

- To prevent unintentional changes, this function is passwordprotected. The password has a default setting of "2 2 2 2" but can be

changed by the end-customer, see 6.5.9.

Enter the password and press button 4 to proceed.

- A screen with a warning is displayed. Press button 3 OK, to proceed

to the parameters that can be set.

On the first screen, 6 parameters are displayed and by pressing button

2, you can access the two last parameters.

There is a short description below about the engine settings that can be

made from this screen:

IDLE SPEED (6.5.1)

Low idling on a warm engine can be set between

500 and 1,050 rpm. It is not possible to reset the idle speed value if the

coolant temperature is below 50°C. If the engine is running on a raised

idle speed for any reason, the idle speed cannot be reset either

28

©

Scania CV AB 2008-03:1 1588955

Page 29

LOW TEMP LIMIT (6.5.2)

The lower temperature limit, which has the basic setting 95°C (203°F),

is the level for the alarm and torque reduction if this has been selected.

See page 33 for an example.

It is possible to set this level between 85°C (185°F) and 105°C

(221°F). The lower limit cannot be set above the upper temperature

limit.

HIGH TEMP LIMIT (6.5.3)

The upper temperature limit, which has the basic setting 105°C

(221°F), also makes it possible (in addition to the alarm function) to

stop the engine automatically.

It is possible to set this level between 95°C (203°F) and 105°C

(221°F). The upper limit cannot be set below the lower temperature

limit.

FIXED SPEED 1 (6.5.4)

Setting of upper torque limit:

This is an isochronous idle speed which can be set and activated from

Scania Control Panel. See page 14.

On Scania EMS Display it is then possible to set an upper torque limit

for FIXED SPEED 1. This setting only applies when FIXED SPEED 1

is activated.

FIXED SPEED 2 (6.5.5)

Setting of upper torque limit:

This is an isochronous idle speed which can be set and activated from

Scania Control Panel. See page 14.

On Scania EMS Display it is then possible to set an upper torque limit

for FIXED SPEED 2. This setting only applies when FIXED SPEED 2

is activated.

SAFETY SWITCH (6.5.6)

The safety switch (idle switch) is a safety function in Scania's electrical

system which checks that the accelerator pedal is functioning correctly.

The component is a closing switch that is activated when the

accelerator pedal position is greater than zero.

The function can be disengaged.

Note: A safety function is then disconnected.

FUEL DENSITY (6.5.7)

Fuel density affects the calculation of the engine power and it can be

noted here. Default is 840 kg/m3 and the setting range is

700-1,000 kg/m3.

1588955

©

Scania CV AB 2008-03:1 29

Page 30

ALARM REACTION (CMOL) (6.5.8)

The engine behaviour may vary depending on how EMS is

programmed.

Signal Line EMS behaviour

1 Only alarm with fault

Low oil

pressure

High coolant

temperature

Low coolant

level

2 Alarm and torque reduction

3 Alarm and engine stop

4 Engine stop and override

1 Only alarm with fault

2 Torque reduction

3 Engine stop

4 Torque reduction at the lower temperature limit

Engine stop at the upper temperature limit

5 Engine stop and override

6 Torque reduction at the lower temperature limit

Engine stop at the upper temperature limit and

override

1 Only alarm with fault

2 Alarm and torque reduction

3 Alarm and engine stop

4 Engine stop and override

- Press button 2 to go to ALARM REACTION.

- Press button 4 to go down one level.

- Select signal type using button 2 or 3 and go down to the EMS

function using button 4.

+

30

©

Scania CV AB 2008-03:1 1588955

Page 31

- Select the EMS function using button 2 or 3. On the displayed

screen: ONLY ALARM.

- Press 4 to confirm the selection. The box to the right will then be

marked, which means that the change has taken place.

- Press button 1 to get a more detailed description of the selected

EMS function.

- Press button 5 to return.

1588955

©

Scania CV AB 2008-03:1 31

Page 32

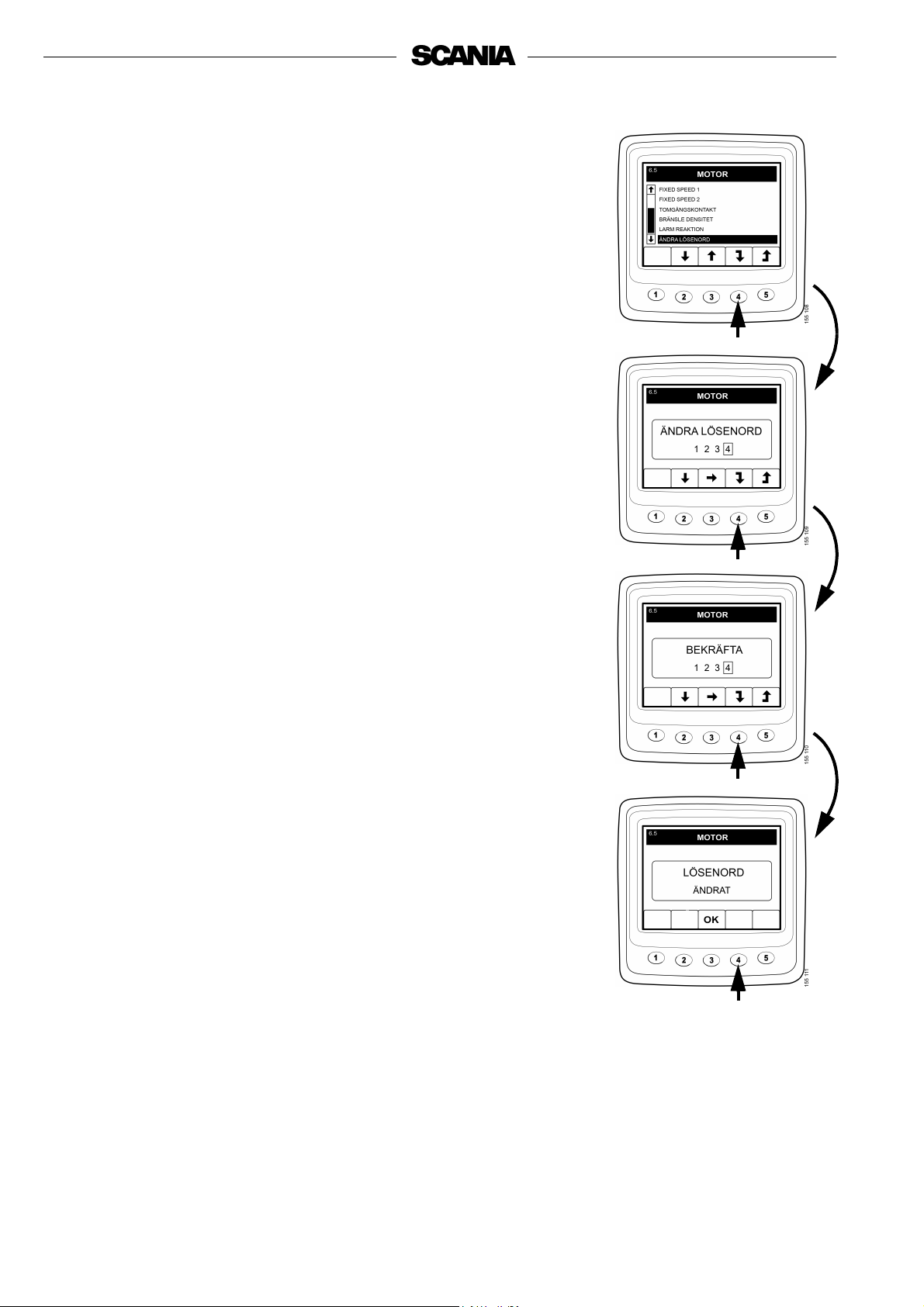

CHANGE PASSWORD (6.5.9)

A new password can be set, the valid values are 0001 - 9999.

- Press button 4 to change the password.

- Enter the desired password and press button 4

- Press button 4 to confirm the password.

- Press button 4 to return.

Note: If you have forgotten the password, contact your

nearest Scania representative.

32

©

Scania CV AB 2008-03:1 1588955

Page 33

Example

Setting of LOW TEMP LIMIT (6.5.2)

- Press button 4 to proceed.

- Enter the password and press button 3

A warning is displayed.

- Press button 3 OK, to confirm the warning and proceed to the

parameters that can be set.

- Press button 2 or 3 to move up or down in the selection screen.

- Press button 4 when for example LOW TEMP LIMIT has been

selected.

- Press button 4 again to display the setting screen.

- Press button 2 or 4 to increase or decrease the setting value.

- Press + or - and automatic deletion of old values and the new value

is entered.

- Press button 5 to return.

The same settings can be made for the other parameters.

1588955

©

Scania CV AB 2008-03:1 33

Page 34

BASE SYSTEM (6.6)

Here it is possible to configure Scania EMS Display for the electrical

system to be used. The alternatives are NO, SINGLE or DOUBLE.

- Press button 2 or 3 to go to BASE SYSTEM.

- Press button 4 to go to the selection screen.

- Press button 2 or 3 to select base system.

- Press button 4 to confirm the change. The box to the right will then

be marked, which means that the change has taken place.

- Press button 5 to return.

Alarm and fault code generation

Both new alarms and fault codes create dialogue boxes (so-called popup boxes).

The dialogue box for alarm has the highest priority for all functions in

Scania EMS Display.

Alarm

There are four different alarms available in the system:

Alarm Icon Remarks

Low oil pressure

High coolant temperature

Low coolant level

Alternator does not charge System voltage

displayed

34

©

Scania CV AB 2008-03:1 1588955

Page 35

Function

When an alarm is created it is displayed as a warning on the basic

screen together with the alarm icon. The alarm signal sounds at the

same time both on the instrument panel and on Scania EMS Display.

Alarm signal on Scania EMS Display is confirmed by pressing button

3, OK. If there are more alarms (icons), one alarm has to be confirmed

at a time. Screen 1.

Each confirmed alarm is then displayed as an icon in the upper right

corner of the screen as long as a fault is active, irregardless of which

screen is active.

Note: All alarms must be confirmed before the next screen will be

displayed.

The screen in illustration 2 always has the same content.

If you press button 3, OK when in screen 2, you will return to the

screen displayed before the first alarm was generated. Screen 3.

1.

2.

External alarm signal

Output for external alarm

As soon as an alarm is present, pin 11 on the 12-pin display connector

is activated. The output can be used to activate a warning lamp or

suchlike. Pin 11 must be connected to earth a lamp or a relay connected

to +24V.

Maximum current 200mA.

3.

1588955

©

Scania CV AB 2008-03:1 35

Page 36

Fault code generation

There are several fault codes in the electrical system to help when a

system fault or engine fault occurs.

When a new active fault code is registered in the system, it will be

displayed on the screen as in illustration 1.

Confirm all active fault codes by pressing button 3, OK. In the next

screen, a spanner icon is displayed in the upper right corner. Screen 2.

This is displayed when at least one fault code is active.

It is not possible to view the number of active fault codes from these

screens. To view active fault codes, go to the description of Fault

codes on page 20.

When starting the system a dialogue box as in illustration 1 is

displayed if there is at least one active fault code.

1.

2.

36

©

Scania CV AB 2008-03:1 1588955

Loading...

Loading...