Page 1

00:45-52

Issue 1

Dismantling information

Bus

FKN series

en

©

Scania CV AB 2010, Sweden

Page 2

Work description

General information

This information is aimed at all people dealing

with reconditioning and scrapping of Scania

vehicles. The information applies to workshops

as well as dismantling and recycling companies.

The information is applicable to all Scania

models. However, not all parts are covered by

this information booklet. The information is

incomplete.

Drainage and removal describes how

environmentally hazardous waste should be

removed from the vehicle (pre-treatment).

The purpose of identification of materials is to

facilitate identification and sorting of materials

for recycling.

Page 3

Drainage and removal

Fluids and materials that are harmful to the environment

The following list is a guide of lubricants, fluids

and parts that are recovered from the bus during

pre-treatment. The volumes are approximate.

IMPORTANT! Avoid spillage and use a

collecting vessel when handling hazardous

fluids.

Engine: Specification Quantity

9 litre engine

12 litre engine

13 litre engine

Oil filter Oil 2 l

Fuel filter Diesel/Ethanol -

Compressor Oil 0.4 l

Fuel tank Diesel/Ethanol -

Catalytic converter - -

Cooling system: Specification Quantity

9 litre engine

12 litre engine

13 litre engine

Hydraulic cooling fan Oil 15 l

Power train: Specification Quantity

Clutch Brake fluid 0.5-1.0 l

Manual gearbox Oil 9-11 l

Automatic gearbox ATF oil 30-50 l

Oil 29-35 l

22 l

40 l

Coolant 40 l

50 l

50 l

Opticruise Oil 0.3 l

Scania Retarder Oil 7.5 l

Rear axle gear Oil 10-18 l

Rear axle, oil filter Oil filter 0.5 l

Rear steering tag axles ATF oil 3.9-4.6 l

Compressed air tanks - -

Steering: Specification Quantity

Power steering ATF oil 6-9 l

Hydraulic unit for articulated buses ATF oil 2.8 l

Page 4

AC: Specification Quantity

Climate control system Refrigerant R134a 8-15.5 kg

Electrics: Specification Quantity

Starter battery - -

Wheels: Specification Quantity

Balancing weights Lead -

Page 5

!

WARNING!

Isocyanates are found in some paints,

putties, adhesives and plastic foams,

etc., that are used in motor vehicles.

Inhaling isocyanates in the form of

vapour, dust or aerosols may cause

irritation of mucous membranes causing

asthmatic symptoms from the

respiratory passages and an impaired

function of the lungs. Even brief

exposure to high concentrations can

cause problems of permanent

hypersensitivity.

When products containing isocyanates

in combined form are heated to

temperatures above 150°C, isocyanates

are set free. This results in a high degree

of exposure.

This applies for example to grinding,

welding and cutting products to which a

top coat of paint containing isocyanates

has been applied. For this reason, make

sure that there is adequate ventilation in

the areas where the work is carried out.

Personnel carrying out such work

should use protection, such as

respiratory masks with air supply.

Do not take any risks when working with

heated materials that might contain

isocyanates; always presume that the

material contains isocyanates and take

necessary safety precautions.

Page 6

!

WARNING!

Where a vehicle is involved in a fire, a

number of substances that are

hazardous to health and the

environment are formed. Smoke and

water carry these substances and they

remain in the vehicle to a certain extent

(ashes).

When dismantling a vehicle that has

been involved in a fire, the following

should be taken into consideration:

Use protective equipment such as

respiratory protection and gloves when

working on vehicles which have been

involved in a fire. Avoid skin contact

with ashes.

The vehicle may be weakened, which

can have a negative affect on lifting

points. This should also be taken into

consideration when tilting cabs.

Gas dampers that have not been

punctured represent an explosion risk,

as the material they are made of may be

weakened and/or damaged.

Wash the vehicle before starting

dismantling.

Keep the following in mind:

Do not start dismantling before the

cause of the fire has been fully

investigated.

Power should be disconnected on

vehicles which have been involved in a

fire as soon as possible, by

disconnecting the battery cables. This is

to prevent short circuits, which can

result in a new fire.

Corrosion is accelerated on vehicles

which have been involved in a fire, for

example due to moisture in combination

with ashes and some extinguishing

medium. The vehicle should be

processed as soon as possible, to

minimise the risk of undesirable leakage

of environmentally hazardous fluids and

substances.

Page 7

Burnt vehicles should be washed in a

!

WARNING!

!

WARNING!

!

WARNING!

!

WARNING!

way that allows the washing water to be

disposed of in an environmentally

responsible way, as it contains

environmentally hazardous

contaminants.

When carrying out any type of work

which involves heating products, the

relevant safety regulations for this type

of work should be followed.

Cut the power to the vehicle before

starting work.

The system must be depressurised

when working with air bellows.

Risks in connection with ethanol

• Ethanol fuel is extremely flammable

and must be handled with great care.

Like petrol, ethanol is classified with

a flammability class.

• Ethanol fuel is hazardous to health. If

ethanol has come into contact with

eyes or skin, flush with water.

• Ventilate properly when handling

ethanol.

Page 8

• Ethanol fumes can form an ignitable

!

WARNING!

mixture with air at approximately

9°C, both in closed and open

containers.

• The fumes are heavier than air and

therefore spread along the ground

and can catch fire a long way from

the source.

• Avoid free-falling jets; otherwise

there is a risk of static electricity,

which would cause sparks.

• Prevent sparking through

equipotential bonding (grounding).

• Ethanol burns with a barely visible

flame and no smoke. Burning

ethanol is therefore hard to detect in

daylight.

Safety precautions and equipment in

connection with ethanol

• Comply with local regulations when

handling ethanol fuel.

• Establish ethanol decontamination

routines for workshop work. There

must be sand or Absol for

decontamination.

• Store ethanol spillage in a marked,

closed collecting vessel specially

designed for ethanol fuel and in a

manner that ensures it is not

confused with diesel.

• Wear protective gloves and goggles

resistant to ethanol when handling

the fuel. Cotton clothes are

recommended.

• Powder is the best extinguishing

medium for putting out ethanol fires.

Page 9

Engine

!

WARNING!

!

WARNING!

Beware of hot oil after driving. Wear

protective goggles and gloves.

Ethanol fuel is extremely flammable and

must be handled with great care. Like

petrol, ethanol is classified with a

flammability class.

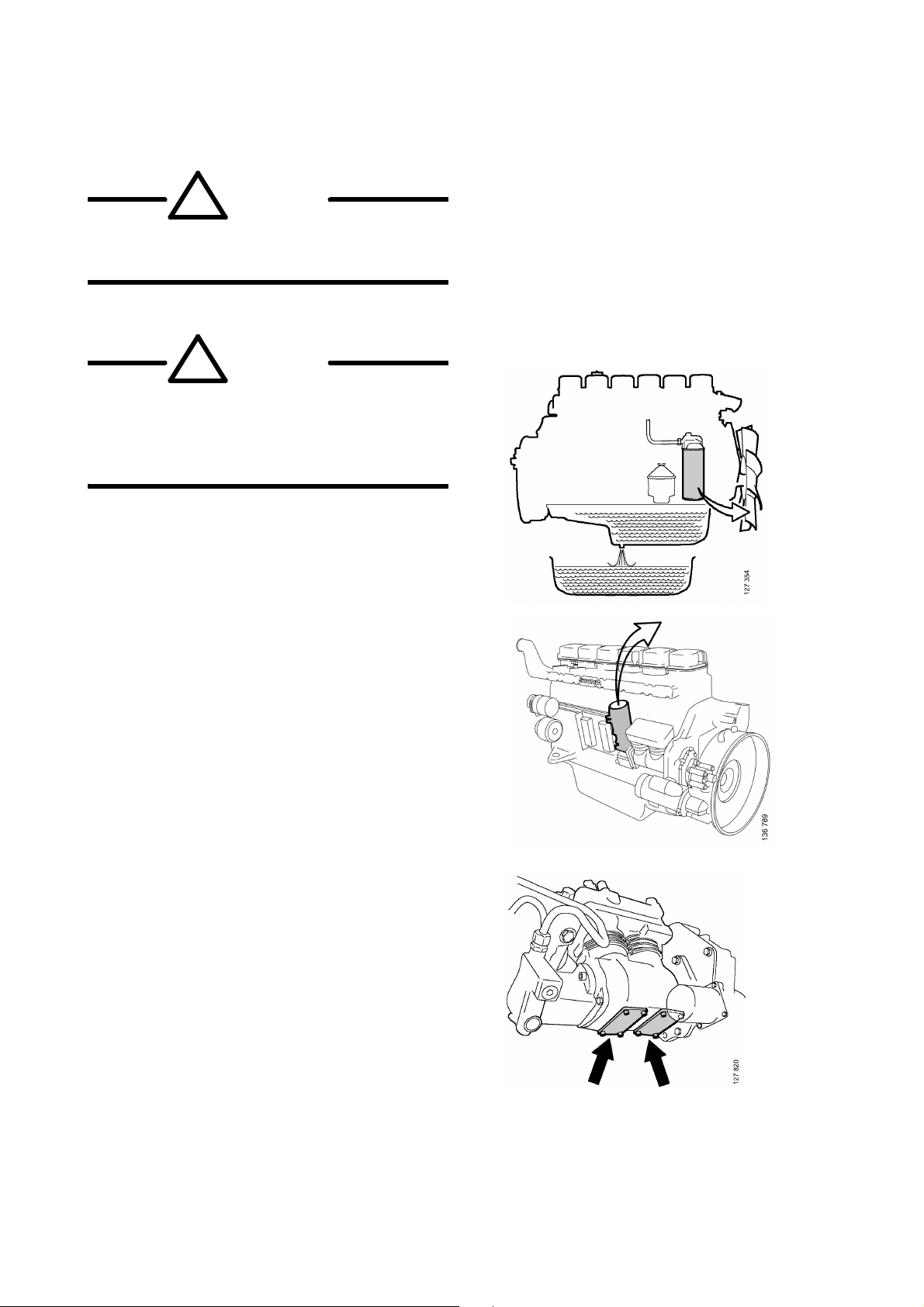

1 Drain the engine oil.

2 Remove the oil filter. Also drain the oil

from the centrifugal oil cleaner reservoir.

3 Remove the fuel filter element. Use suction

on the filter housing if necessary.

Note: The fuel system may be pressurised.

Release the pressure before dismantling.

4 Drain the oil from the compressor by

unscrewing the blanking pieces.

Page 10

Fuel tank

!

WARNING!

Diesel

1 Check or estimate how much fuel is in the

fuel tanks. Make sure that there is enough

room for the fuel in the collecting vessel.

2 Drain the tank by unscrewing the drain plug.

Note: Some tank variants do not have a drain

plug. Some bus bodybuilders have their own

tanks. Check their instructions.

Ethanol

Ethanol fuel is extremely flammable and

must be handled with great care. Both

ethanol and petrol are classified as

flammability class 1.

Note: Before the vehicle is taken into the

workshop, check whether the fuel system is

leaking ethanol. The recommended method is to

leak test the fuel system using measuring

instrument 588 875. Check that the measuring

instrument has been calibrated as described in

the instrument documentation before it is used.

1 Check or estimate how much fuel is in the

fuel tanks. Make sure that there is enough

room for the fuel in the collecting vessel.

2 Connect the fuel tank to be drained with the

pump and the collecting vessel via a ground

connection.

3 Pump away as much ethanol as possible

through the filler pipe. Make sure that the

pump hose reaches the bottom of the

collecting vessel to prevent the formation of

static electricity. Repeat for all fuel tanks

with a filler pipe.

Page 11

4 Check that there are no ethanol fumes

151 973

around the vehicle by checking for leaks

using, for example, measuring instrument

588 875.

5 Jack up the vehicle.

6 Check the location of each fuel tank drain

plug.

Note: Some tank variants do not have a drain

plug. Some bus bodybuilders have their own

tanks. Check their instructions.

7 Carry out the following for all tanks:

• Connect a ground connection between the

fuel tank and the collecting vessel.

• Suspend a funnel under the drain plug.

Make sure the funnel is large enough for the

fuel that runs down when the drain plug is

undone. Try to keep free fall as short as

possible as free fall causes static electricity.

If possible, connect a hose that reaches the

bottom of the collecting vessel to the funnel.

• Undo the drain plug.

• Drain the remaining fuel.

8 Check that there are no ethanol fumes by

checking for leaks using, for example,

measuring instrument 588

875.

Page 12

Catalytic converter

The SCR catalytic converter contains vanadium.

Vanadium can constitute a health hazard.

The SCR catalytic converter is fitted in the

silencer and does not constitute a health hazard

during normal use and handling.

When carrying out work on the SCR catalytic

converter which may result in exposure to dust,

safety precautions must be taken. Such work

includes, for example, opening the silencer,

machining and scrapping the catalytic converter.

Safety precautions when working on the

SCR system

• Inhalation: If dust is inhaled, the person

should be provided with fresh air

immediately. If a significant amount of dust

is inhaled, seek medical attention.

• Eye contact: Rinse eyes with water

immediately. If irritation persists, seek

medical attention.

• Skin contact: Wash with soap and water.

Remove contaminated clothes.

• Ingestion: If large amounts have been

ingested, drink plenty of water and induce

vomiting. Seek medical attention.

Health hazards

• Inhalation of dust from the SCR catalytic

converter can constitute a health hazard as it

may cause irritation of the respiratory

system.

• Eye contact may cause eye irritation.

• Skin contact may irritate the skin.

• Ingestion can cause irritation in the mouth

and throat and produce discomfort. The

ingestion of large quantities may cause

disorders in the gastric and intestinal canals.

• There is a possible risk of permanent health

damage. There is also a risk of foetal

damage.

Environmental hazards

• Vanadium pentoxide is toxic to water

organisms and can cause detrimental longterm effects to the water environment.

Page 13

Environmental protection measures

!

WARNING!

• Any dust or spillages should be collected in

a container for recycling or disposal in

compliance with local regulations. It should

not be drained into watercourses or into the

general treatment system.

• A scrapped SCR catalytic converter should

be disposed of in compliance with the

relevant EU, national or local regulations.

The constituent parts are classified as

harmful to the environment by the EU.

Use protective goggles and gloves if

there is any risk of splashing or

spraying of reductant or coolant.

When the engine is running, the exhaust

system parts can reach such high

temperatures that there is a risk of

personal injury. Make sure that the

exhaust system temperature has fallen

to a suitable level before starting work.

The SCR system is heated by water from

the engine cooling system. The cooling

system runs at overpressure and when

the engine is hot the coolant is hot. Do

not open any hoses without first

stopping the coolant flow in the hose.

A P3 type respiratory protection/filter

mask, protective goggles and gloves

should be used for any work where

there is a risk of exposure to dust from

the SCR catalytic converter.

You should not eat, drink or smoke while

working.

Any dust from the SCR catalytic

converter should be removed using a

vacuum cleaner with microfilter to

minimise exposure.

Make sure you clean your hands after

working with a SCR catalytic converter

to avoid ingestion.

Page 14

Remove filter

1

3

5

2

6

4

309 113

1 Undo the exhaust pipe V-clamp 1.

2 Undo the exhaust pipe V-clamp 2.

3 Remove the exhaust gas temperature

sensor 3.

4 Undo the reductant doser fastening bolts 4

to facilitate injection nozzle pipe removal.

5 Remove the injection nozzle pipe 5.

6 Remove the silencer 6.

Remove the reductant tank

1 Clamp the hose 1 using pliers to stop the

coolant flow. Warning! The hose contains

coolant from the engine. Open the coolant

filler cap first to relieve any pressure.

2 Detach the retaining straps 2.

1

4

3

3 Remove the electrical connection 3.

4 Remove the hoses 4 from the combined tank

unit.

5 Remove the reductant pick-up unit.

Note: Only use containers and collecting vessels

manufactured from material recommended for

use with reductant.

2

309 112

Page 15

Coolant

!

WARNING!

The coolant system operates with

overpressure. There is a risk that hot

coolant may be emitted if the system is

opened while hot.

Hot coolant can cause burns.

Avoid skin contact with coolant. Skin

contact may cause irritation.

Always wear protective goggles and

rubber gloves when handling coolant.

Scania corrosion inhibitor, ethylene

glycol and other coolant additives can

be fatal if swallowed.

Page 16

Special tools

142 231

Number Denomination Illustration Tool board

99 301 Quick release coupling -

587 129 Complete coolant draining unit -

Note: Check bus bodybuilder’s instructions for

draining.

1 Open the heat outlet and heat return valves.

2 Carefully open the expansion tank cap. The

cooling system may be exposed to

overpressure.

3 Connect adapter 99 301 to the cooling

system drain and filler nipple and use

coolant tank 587 129 to drain and collect the

coolant. The nipple is located at the lower

coolant hose.

Note: The coolant volume increases when

components are connected to the cooling

system:

• Retarder + 20 litres

• Oil cooler and hose

• Auxiliary heater Webasto

Page 17

Hydraulic cooling fan

!

WARNING!

Beware of hot oil after driving. Wear

protective goggles and gloves.

1 Remove the oil connection between the oil

cooler and hydraulic motor.

Clutch

1 Connect a suitable collecting vessel to the

bleed nipple at the clutch housing.

2 Detach the hose from the connection, and

pump out the brake fluid using the clutch

pedal.

3 Drain the clutch fluid reservoir which is

located at the front of the bus.

Bleed nipple

Page 18

Manual gearbox

!

WARNING!

Beware of hot oil after driving. Wear

protective goggles and gloves.

1 Remove the drain plug and level plug.

Allow the oil to drain.

2 Remove the filter.

1 Level plug

2 Drain plug

3 Filter

Page 19

Automatic gearbox

!

WARNING!

Beware of hot oil after driving. Wear

protective goggles and gloves.

1 Put the drive mode selector in position N.

2 Remove the drain plug. Allow the oil to

drain.

3 Remove the oil filter cover and remove the

filter.

1 Drain plug

2 Oil filter cover

Page 20

4 Drill through the torque converter housing

and then through the torque converter.

Allow the oil to drain.

5 Drill through the underside of the angle gear

housing. Allow the oil to drain.

6 Remove the oil pipes on the gearbox oil

cooler. Allow the oil to drain.

Page 21

Opticruise

308 302

1 Remove the longitudinal stroke cylinder and

drain it from oil through the rectangular

opening.

Longitudinal stroke cylinder,

GZ gearbox

Longitudinal stroke cylinder,

TP gearbox

315 199

Page 22

Scania Retarder

!

WARNING!

142 231

587 129

99 301

307 398

Beware of hot oil after driving. Wear

protective goggles and gloves.

Make sure the compressed air tanks are

empty before starting work. Oil under

pressure or blows from loose parts can

cause personal injury.

Retarder, type 1

Special tools

Number Denomination Illustration Tool board

99 301 Quick release coupling -

587 129 Complete coolant draining unit -

1 Drain the coolant by connecting quick

release coupling 99 301 to the bottom of the

radiator. Remove the radiator cap to make

the coolant drain faster.

2 Put the retarder lever in position 5 and

switch on the ignition. This empties out

most of the oil volume from the

accumulator so that all the oil ends up in the

retarder sump.

Page 23

3 Undo the drain plug 1 under the planetary

2

1

308 304

308 305

3

4

gear and drain the oil.

4 Detach the hoses from the retarder.

5 Remove the oil filter 2.

6 Detach the hose 3 from the oil accumulator.

7 Blow out the remaining oil with compressed

air at the connection 4.

Retarder, type 2

1 Remove the plug 1 and drain the oil.

2 Drain the oil accumulator by turning the key

to the drive position (compressed air system

filled to working pressure) and move the

retarder lever between the 0 position and

maximum position several times, waiting

for 5 seconds at each end position.

3 Remove the oil filter 2.

R4

M1

2

1

311 976

Page 24

Rear axle gear

!

WARNING!

Beware of hot oil after driving. Wear

protective goggles and gloves.

1 Remove the drain plug and level plug.

Allow the oil to drain.

2 Remove the oil filter.

1 Oil filter with protective casing

2 Level plug

3 Drain plug

Portal axle

1 Drain plug

Page 25

Rear steering tag axles

!

WARNING!

Before starting work on the hydraulic

system, the pressure must first be

relieved in a controlled manner. The

system has an overpressure of 14 bar,

which means that the oil will be forced

out if a union is opened without relieving

the system. This means there is a risk of

eye injuries, etc. Wear protective

goggles.

The accumulator tank is filled with

nitrogen gas at an overpressure of

approx. 8.5 bar. This means that the

accumulator tank is pressurised even if

there is no oil in the system.

Hydraulic oil is aggressive; avoid skin

contact at all times. Wear protective

gloves.

IMPORTANT! Handle empty accumulator

tanks in compliance with local regulations.

Relieving the pressure

1 Close the return valve. Unscrew the

pressure limiting valve.

Filling equipment 99 355

1 Pressure connection P

2 Return connection T

3 Pressure limiting valve

4 Return valve

Page 26

2 Connect the return hose from the filling

equipment return connection to the union

marked Y/Z or L3/L4 on the accumulator as

illustrated.

3 Open the return valve on the filling

equipment. The oil will now be returned to

the filling equipment tank.

4 Oil can be drained from the pipe using

compressed air. The connections on the

master cylinder and centering cylinder must

then be undone.

New marking Previous marking

Y/Z L3/L4

5 Remove the protective cap on the gas side

of the accumulator tank.

6 Undo the plug on the gas side max 2 turns

and allow the gas to seep out.

7 Remove the plug completely.

Compressed air tanks

IMPORTANT! Handle empty compressed air

tanks in compliance with local regulations.

1 Pull the drain valves to depressurise the

tanks.

1 Protective cap

2 Plug

Page 27

Power steering

1 Undo the fluid reservoir return hose.

2 Plug the return hose outlet on the reservoir.

3 Connect a light overpressure to the

reservoir.

4 Let the oil run out of the return hose open

end.

5 Turn the pinion on the power steering gear

to both end positions to drain the oil.

Page 28

Climate control system

!

WARNING!

114 045

Refrigerant R134a

Number Denomination Illustration Tool board

588 431 Recycling station

Wear protective gloves and goggles.

Welding, smoking or heating are not

allowed if there is refrigerant present in

the air. The refrigerant generates a very

toxic gas when heated.

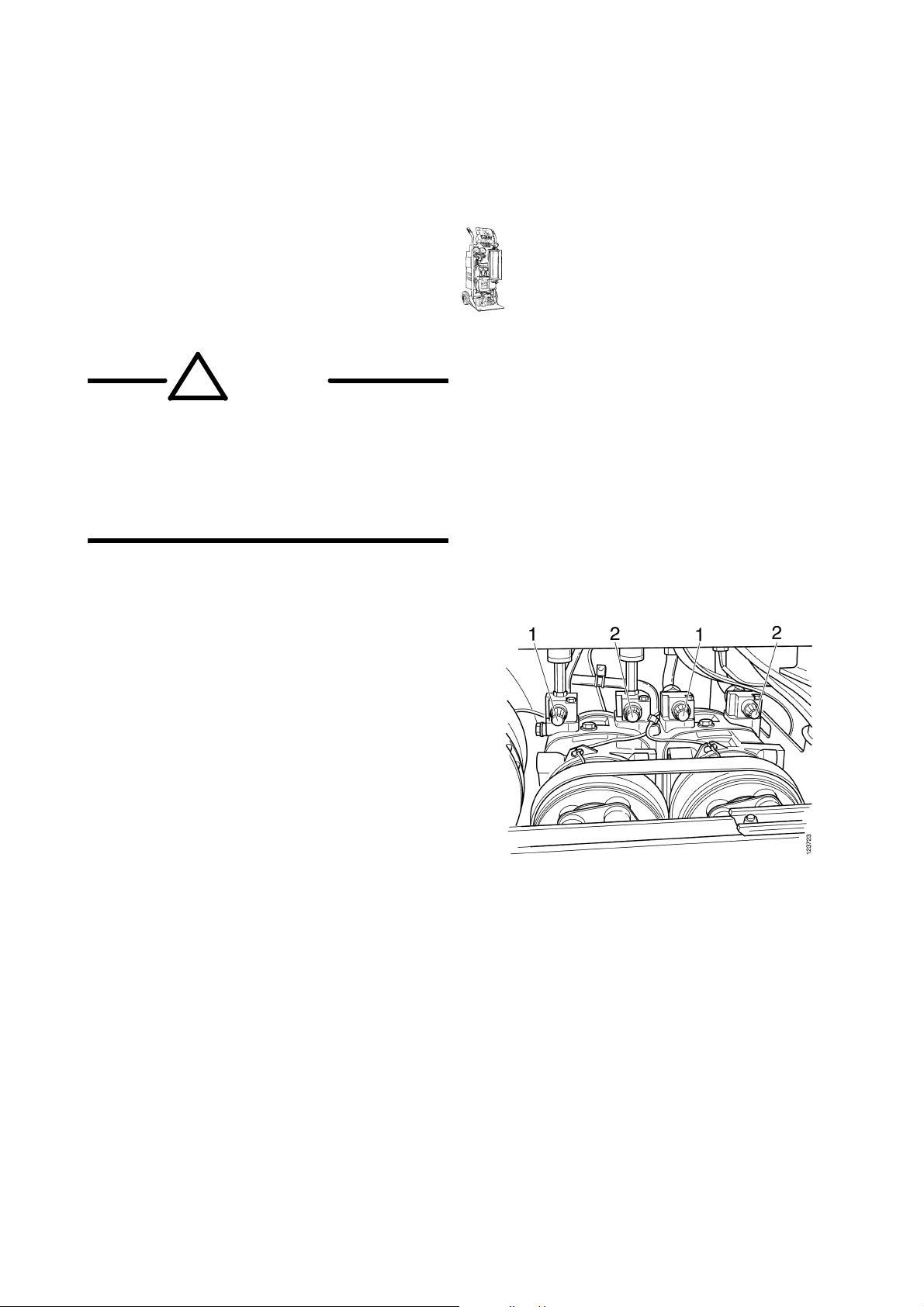

1 Remove the protective caps from the

maintenance valves and connect recycling

station 588 431 to the high-pressure and

low-pressure sides. The maintenance valves

are of different dimensions and thus

different size quick release couplings must

be used.

2 Drain the refrigerant (R134a) slowly. The

refrigerant must not be released into the

atmosphere but must be recycled according

to local regulations.

Note: The compressors can have different

locations and can be 1, 2 or 3 unit systems.

1 Maintenance valves, high pressure

2 Maintenance valves, low pressure

Page 29

Starter battery

!

WARNING!

−

+

−

+

100964

Wear protective gloves and goggles.

Batteries contain diluted sulphuric acid.

If acid gets into your eyes or onto your

skin or clothes, rinse them immediately

with water. Always seek medical

attention if you get acid in your eyes.

Vehicle batteries contain lead. Lead is

harmful to humans and the environment.

The batteries must therefore be handled

in accordance with national regulations

on environmentally hazardous

substances.

IMPORTANT! Batteries must be handled and

stored in compliance with local regulations.

Manufacturer responsibility applies to batteries

within the EU. This means that all Scania

workshops are obligated to take care of batteries

and ensure that they are recycled.

314 619

1 Detach the ground connection (negative

terminal) first and then the other

connections.

Balancing weights

1 Remove the lead balancing weights on all

wheels.

IMPORTANT! Lead balancing weights should

be disposed of in accordance with local

regulations.

Loading...

Loading...