Page 1

03:03 Issue 5.0 en-GB

© Scania CV AB 2016, Sweden

Installation manual

Instrumentation 2.0

Marine engines

DI09, DI13, DI16

344 457

Page 2

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

03:03 Issue 5.0 en-GB 2

System overview ......................................................................................................3

List of abbreviations............................................................................................ 3

System overview ................................................................................................. 3

Positioning of the displays .................................................................................. 5

Connection ...............................................................................................................7

Electrical cables................................................................................................... 7

Junction box, connection..................................................................................... 8

Junction box, components................................................................................. 11

Main display (DCU), junction blocks ............................................................... 12

Auxiliary display (RP), junction blocks............................................................ 19

Safety module (SDU), connection .................................................................... 22

Gateway – overview.......................................................................................... 22

Position of the monitors on the engine.............................................................. 23

Connecting emergency stop .............................................................................. 25

Engine shutdown override in systems with safety device unit (SDU).............. 26

Using the main display ..........................................................................................27

First start............................................................................................................ 27

Navigation ......................................................................................................... 30

Administration in the main display ................................................................... 33

Configuring and upgrading software with USB memory stick.........................37

Configuring the main display with a USB memory stick ................................. 38

Upgrading the main display or auxiliary display software ............................... 39

Copying one configuration file in the main display.......................................... 39

Configuring the main display via a web browser............................................... 40

Connecting a computer to the main display...................................................... 40

General information about the IP address......................................................... 42

Homepage.......................................................................................................... 43

Logging in to the main display.......................................................................... 44

Important system settings: dcu / Miscellaneous / System Type........................ 44

Password: dcu > Password................................................................................ 45

File management: dcu > File ............................................................................ 46

Configuring input signals: dcu > I/O Configuration > Config Inputs .............. 47

Configure output signals: dcu > I/O Configuration / Config Outputs.............. 63

Designing instrument pages: dcu > Interface Design ....................................... 67

Set the sequences for starting, stopping and for lubrication: dcu > Start/Stop/Pre-

lube ................................................................................................................... 69

Settings for the user interface: dcu > User Interface ........................................ 72

Changing the engine designation: dcu > Engine Model................................... 73

Setting the maintenance interval: dcu > Service Interval ................................. 74

Network settings: dcu > Communication ......................................................... 75

Other functions: dcu > Miscellaneous .............................................................. 77

SDU .................................................................................................................. 82

Auxiliary display ................................................................................................... 83

First start ........................................................................................................... 83

Administration in the auxiliary display ............................................................ 85

Examples of connection of sensors and monitors .............................................. 92

Connection of 4-20 mA, e.g. oil pressure sensor for the reverse gear.............. 92

Connection of PT100, e.g. coolant temperature sensor.................................... 94

Connection of switch input, e.g. low engine oil pressure monitor ................... 96

Page 3

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

System overview

03:03 Issue 5.0 en-GB 3

System overview

List of abbreviations

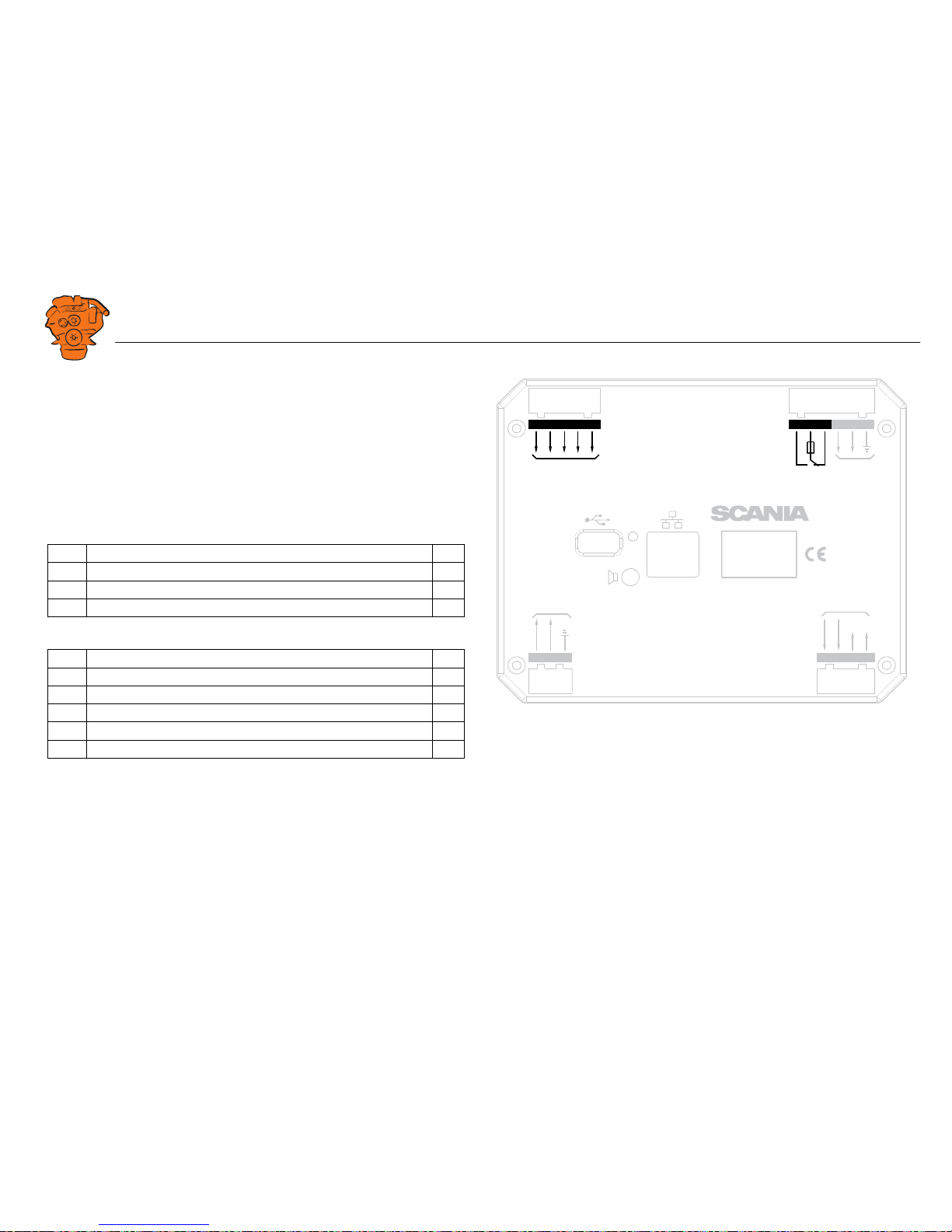

The abbreviations in the list below are used in this manual. DCU, RP och SDU appear in the display interface and in the configuration interface.

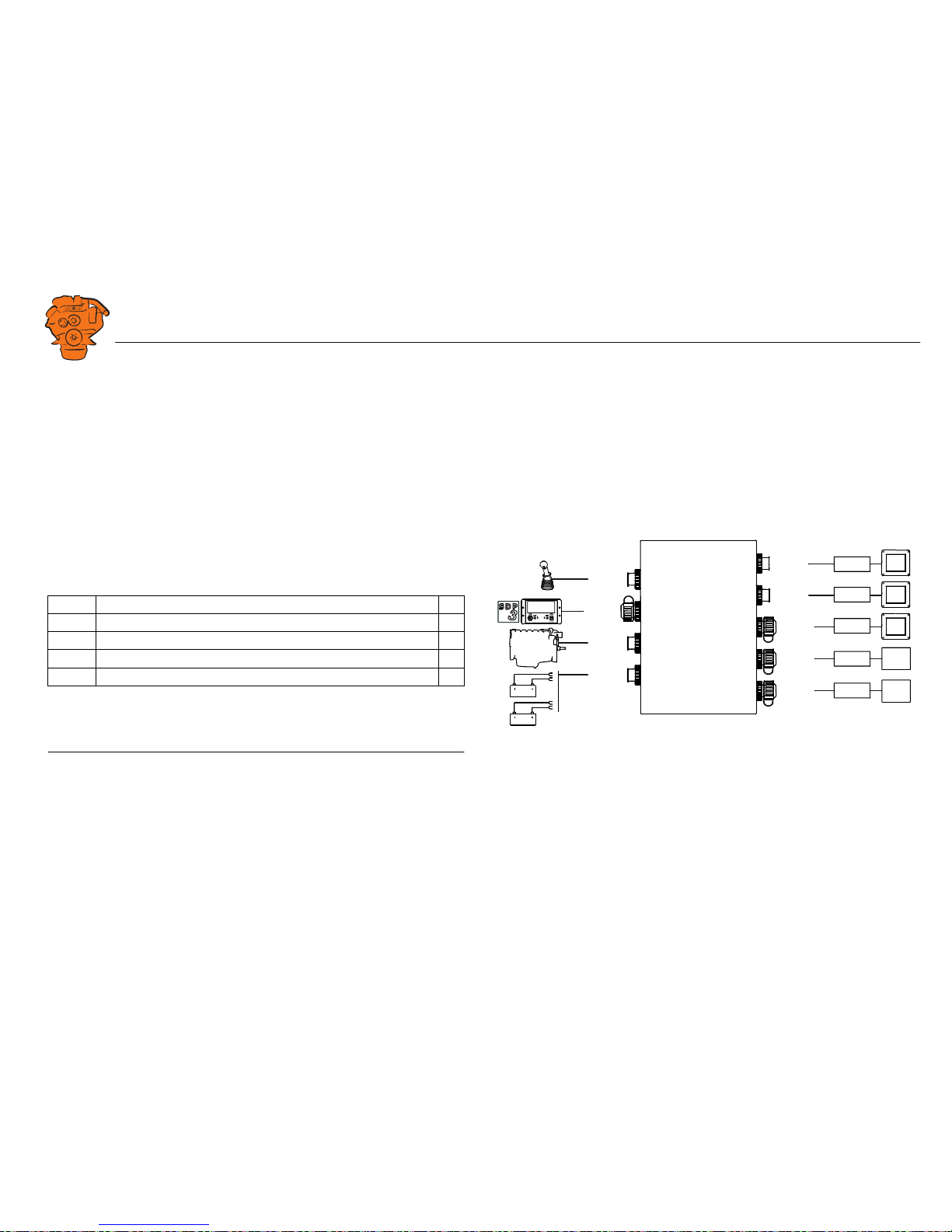

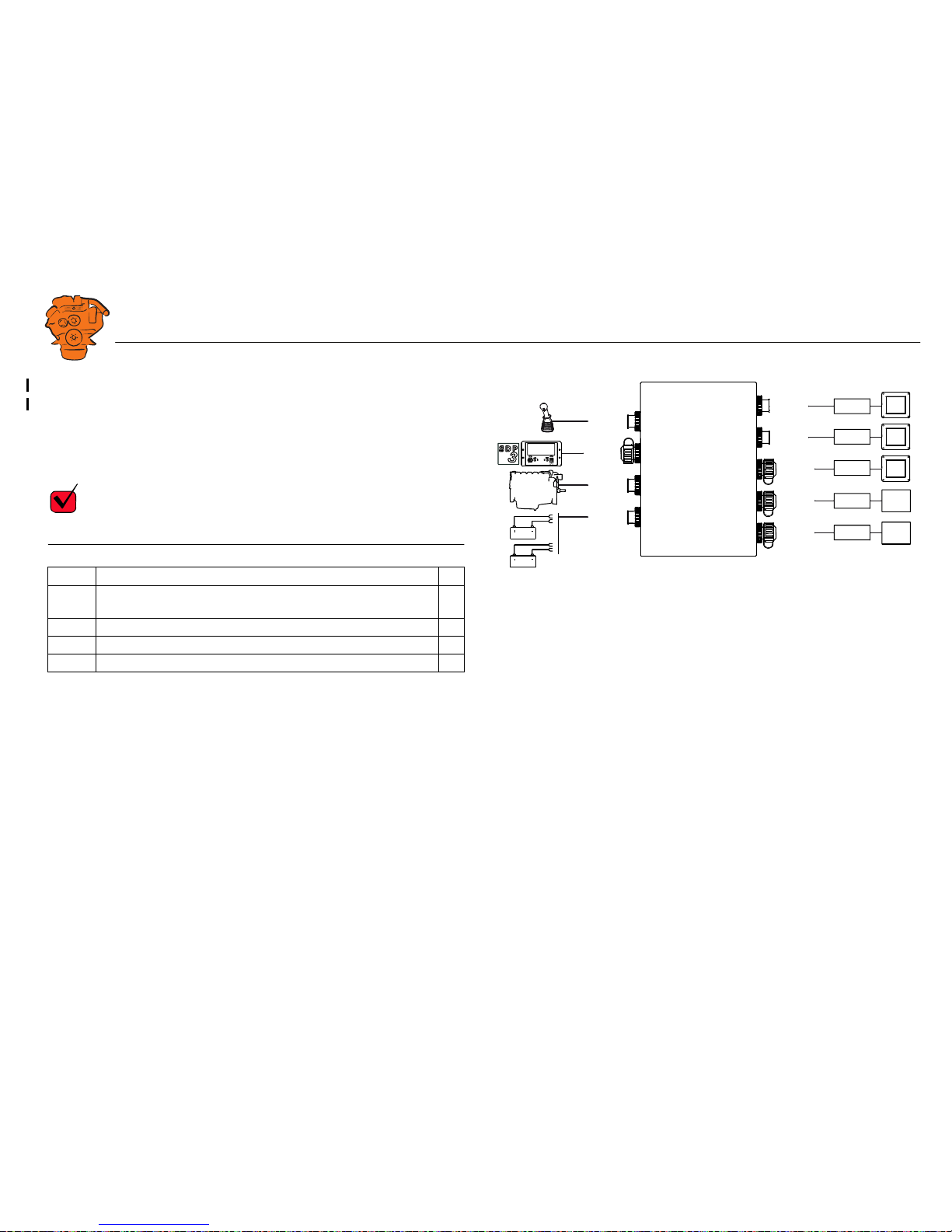

System overview

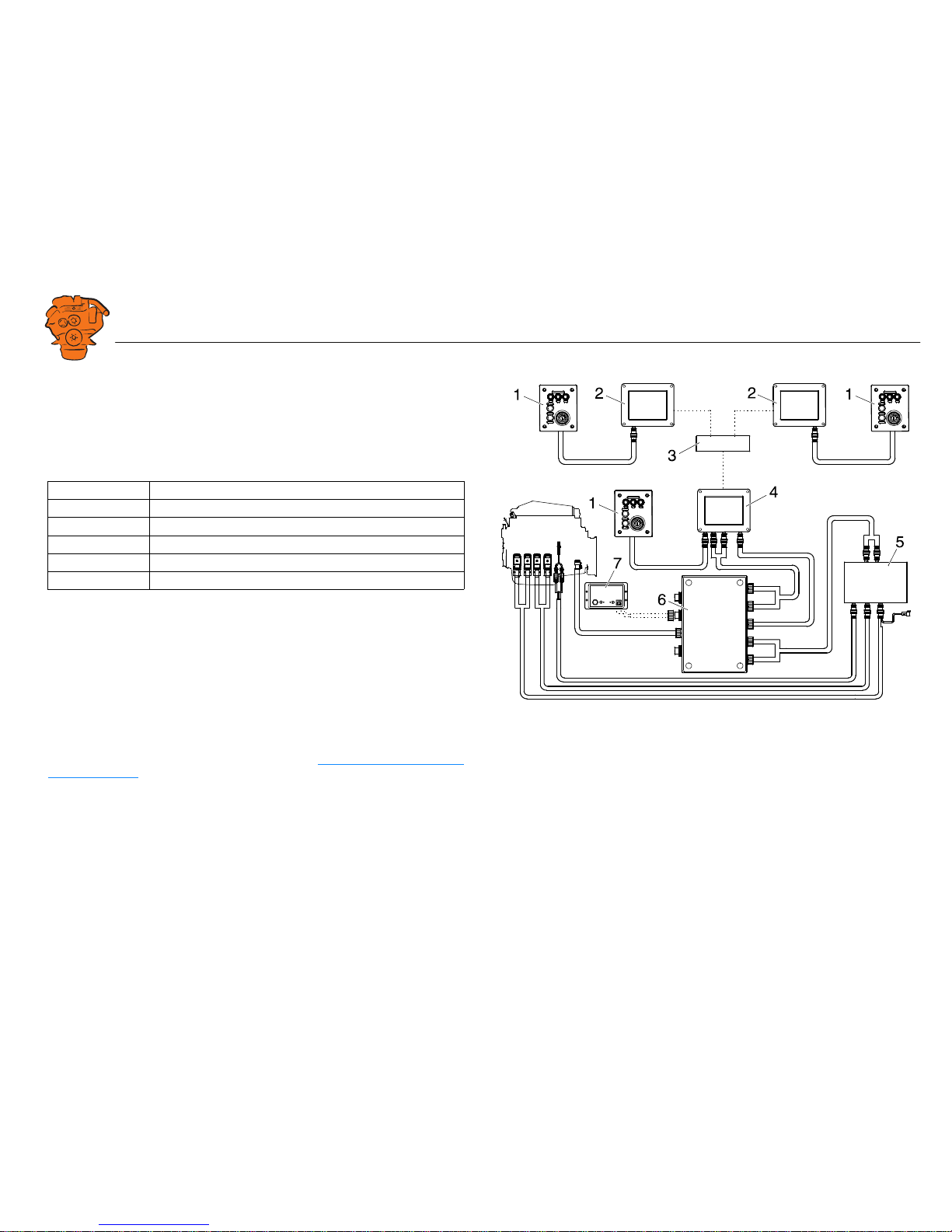

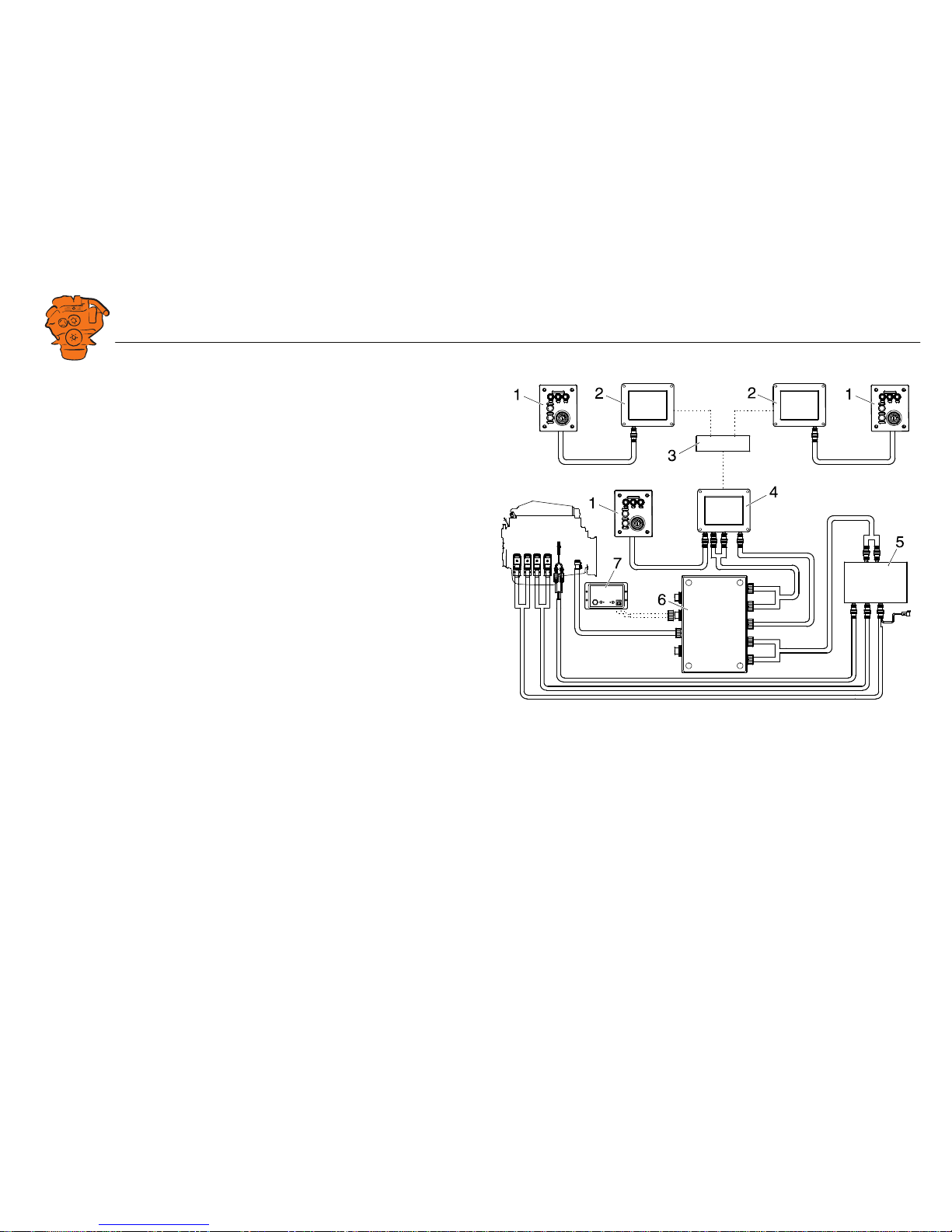

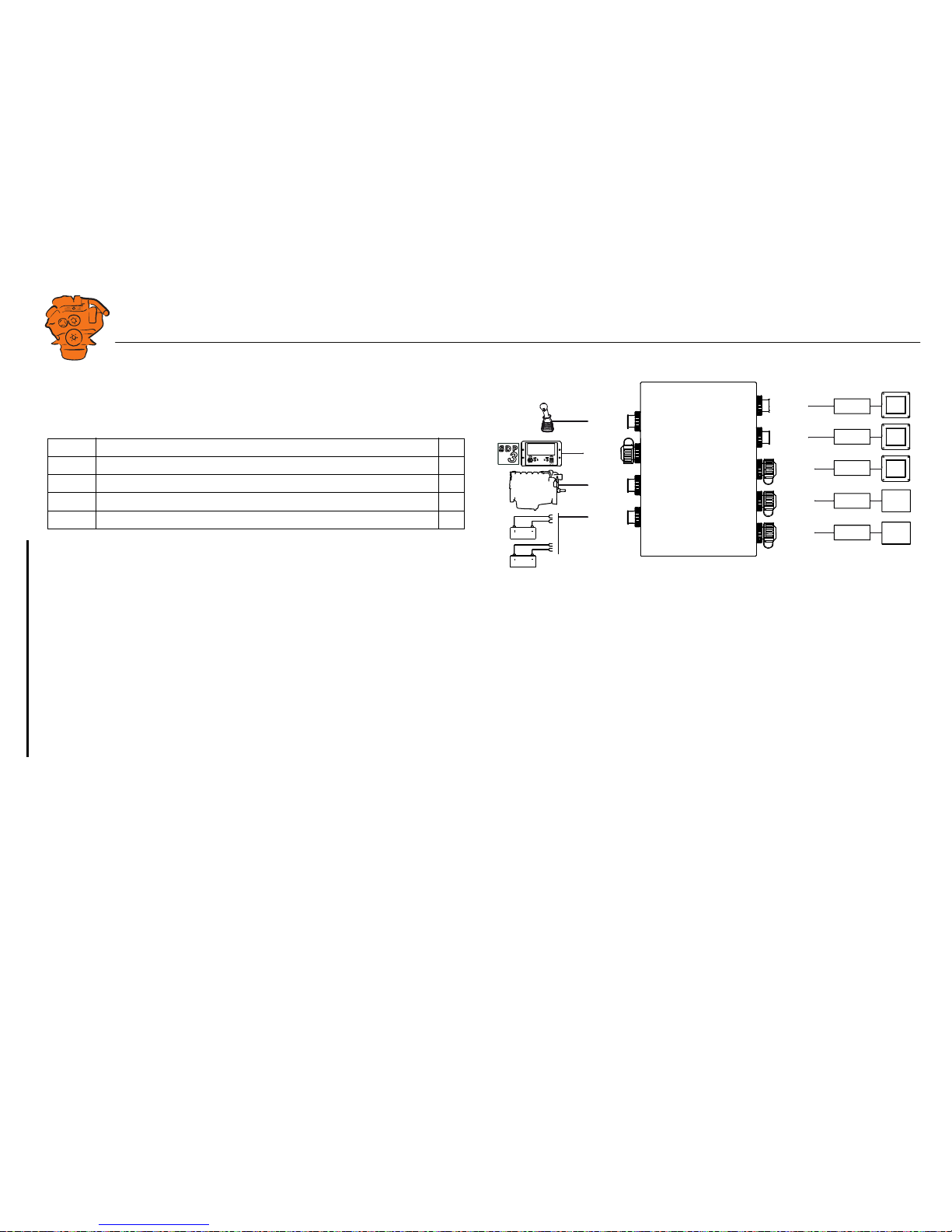

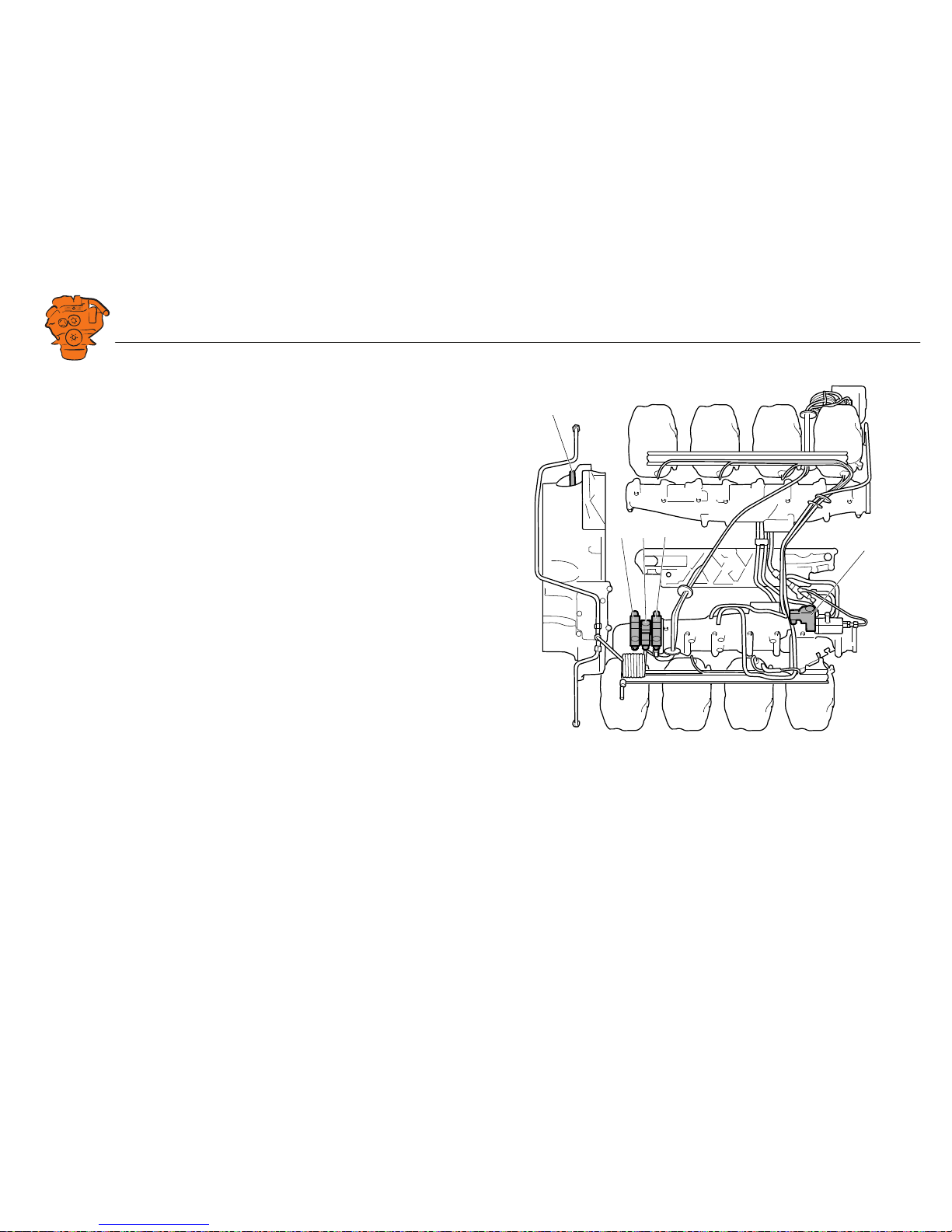

The illustration shows an overview of component parts in a marine engine management system prepared for classification.

Main display (DCU)

The main display is the basic unit of the engine management system. Different sensor

values are displayed on the main display touch screen, and different commands are

also carried out there.

The main display is configured using a computer with a web browser via the built in

web server of the main display. This is described in the Configuring the main display

via a web browser section.

Abbreviation Description

DCU Main display

RP Auxiliary display

SDU Safety device unit

FMI Failure Mode Identifier

SPN Suspect Parameter Number

361 900

Example of the layout of a type approved marine engine management system.

1. Control panel.

2. Auxiliary display (RP).

3. Network switch.

4. Main display (DCU).

5. Safety module (SDU).

6. Junction box.

7. Gateway.

Page 4

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

System overview

03:03 Issue 5.0 en-GB 4

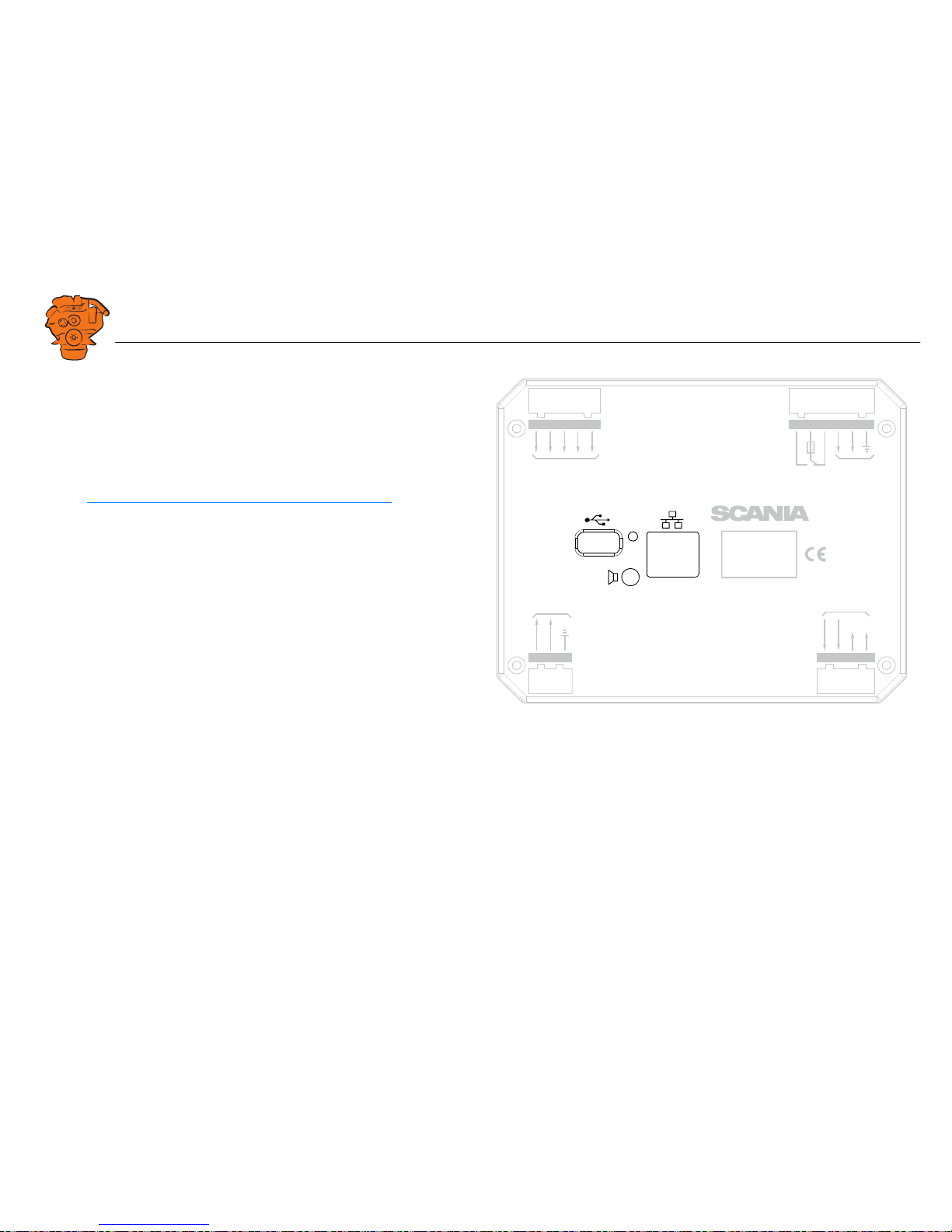

Auxiliary display (RP)

The auxiliary display is an option and has the same user interface as the main display.

The auxiliary display reads the configuration from the main display. This makes it

easy to retrofit.

Control panel

The engine can be started and stopped through the control panel. It can also be used

to activate and adjust engine speed settings 1 or 2. The engine installation can be carried out with or without a control panel.

Network switch

A network switch is only required if more than one auxiliary display is connected to

the engine management system. If the system only contains one auxiliary display, it

is connected directly to the main display via a crossover network cable.

Safety module (SDU)

The safety device unit has monitoring and shutdown functions and is a requirement

for classified engine management systems. It should be easily accessible so that

alarms can be acknowledged in an easy way.

Junction box

The junction box is used to connect all the parts of the engine management system to

the engine. The junction box also contains fuses. It should be easily accessible.

Gateway

The gateway reads specific messages about position and speed via NMEA 2000, so

that the instrumentation can calculate fuel consumption per nautical mile. The gateway cannot process messages other than these. The gateway requires software version 2.11 or later to be installed in the displays.

361 900

Example of the layout of a type approved marine engine management system.

1. Control panel.

2. Auxiliary display (RP).

3. Network switch.

4. Main display (DCU).

5. Safety module (SDU).

6. Junction box.

7. Gateway.

Page 5

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

System overview

03:03 Issue 5.0 en-GB 5

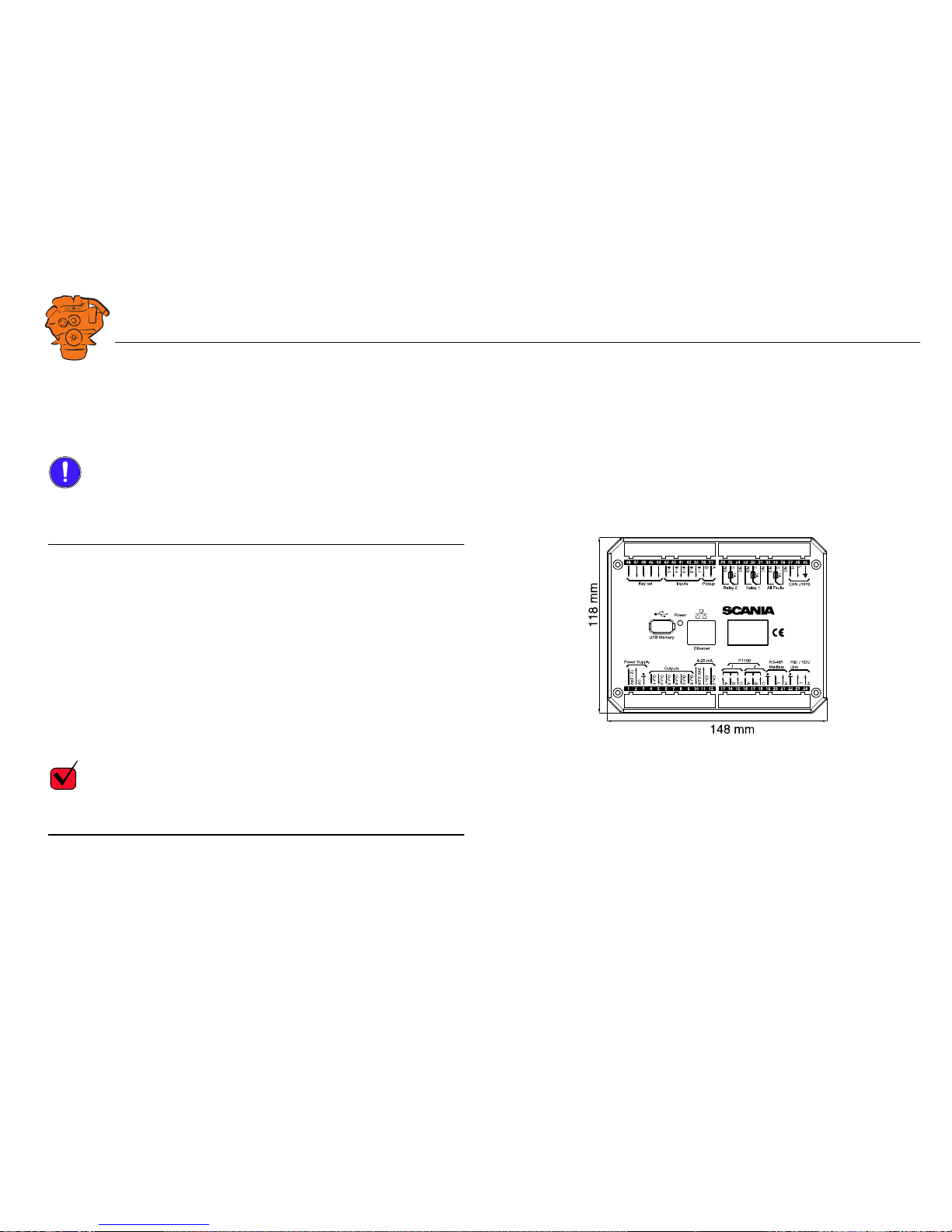

Positioning of the displays

Do not position the displays so that they are exposed to direct sunlight. This impairs

the readability of the displays. The user should have full access to the displays. It

must also be easy to access the connections on the rear of the displays.

IMPORTANT!

The displays must not be fitted on vibrating equipment. They may only be positioned

next to the engine bed if either the engine or the display housing has vibration damping.

Installation dimensions

Provide a 150 x 120 mm rectangle where the display is to be positioned. There must

be at least 70 mm free space behind the display.

Main display

Scania recommends positioning the main display in the engine compartment for the

following reasons:

• To ensure that operation and monitoring are close to the engine.

• To minimise the lengths of the electrical cables between the sensors and main display.

• To reduce the risk of electrical interference caused by long electrical cables.

REQUIREMENT!

On a type approved installation, the main display must be located in the engine compartment.

361 901

Installation dimensions for the main display and auxiliary display.

Page 6

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

System overview

03:03 Issue 5.0 en-GB 6

Auxiliary display

The auxiliary display is normally positioned outside the engine compartment, but can

also be positioned in the engine compartment.

Page 7

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Connection

03:03 Issue 5.0 en-GB 7

Connection

Electrical cables

To protect against electromagnetic interference, Scania recommends that all electrical cables within the system are twisted in pairs with 35-40 turns/m. This only applies

to external signal cables connected to the system.

IMPORTANT!

If a shielded electrical cable is used, the shielding should be connected to ground, not

to 0 V. Only connect the shielding to one end of the electrical cable.

To provide good separation of the electromagnetic interference that can occur, some

of the electrical cables can be routed separately from the others, e.g. the signal cable

from a magnetic pulse sensor.

Electrical cables for electric power supply must have a minimum cross section of

2.5 mm

2

.

Ground

IMPORTANT!

Separate ground and 0 V. In marine installations, ground and 0 V must not be connected. The hull is ground and the battery negative terminal is 0 V.

24 V and 0 V are filtered in the main display in order to reduce electromagnetic interference. If ground and 0 V are connected together, the filters in the main display

will not function.

Page 8

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Connection

03:03 Issue 5.0 en-GB 8

Junction box, connection

Minimum connection

The minimum connection required for the system to function is for the pins on connector C4066 to be connected. If the throttle control is to be controlled via the main

display, then pins 1 and 2 of connector C4068 must also be connected.

Please refer to the electrical system installation manual 03:01 for information on how

to connect the throttle control to the engine control unit. If the throttle control is connected to the engine control unit, secondary throttle control cannot be used.

C4066

Connection of power supply to the engine management system and instrumentation

2.0 (battery).

Note:

If the system has a safety device unit (SDU), 2 separate groups of batteries must be

used.

Pin Description I/O

1 30 voltage, 24 V -

2 Ground (battery negative terminal) -

3 30 voltage, 24 V -

4 Ground (extra battery negative terminal) -

1

2

3

4

DCU

DCU

DCU

SDU

SDU

C4068

C4067

C4052

C4053

C4056

C4058

C4059

C4054

C4055

C4057

C4060

C4061

C4062

C4066

Gateway

C4001

372 773

Connecting the junction box.

Page 9

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Connection

03:03 Issue 5.0 en-GB 9

C4062

Connection to engine connector C4001.

C4067

Diagnostic socket for connecting e.g. SDP3 and CAN communication. Use connector 1 508 055 and hand crimping tool 99 494.

REQUIREMENT!

Any equipment connected to the connector must comply with the CAN specification.

Pin Description I/O

1 15 voltage: 24 V after fuse F4005 and relay in the junction box. Con-

trolled by the system being active.

-

2Ground -

3CAN high -

4CAN low -

1

2

3

4

DCU

DCU

DCU

SDU

SDU

C4068

C4067

C4052

C4053

C4056

C4058

C4059

C4054

C4055

C4057

C4060

C4061

C4062

C4066

Gateway

C4001

372 773

Connecting the junction box.

Page 10

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Connection

03:03 Issue 5.0 en-GB 10

C4068

Connecting the incoming throttle actuation signal. The update frequency is 100 Hz,

with a median filter on 3 readings.

C4052

Connection to main display via C4054.

C4053

Connection to main display via C4055.

C4056

Connection to main display via C4057.

C4058

Connection to safety device unit (SDU) via C4060.

C4059

Connection to safety device unit (SDU) via C4061.

Pin Description I/O

1 24 V (0.2 A), voltage supply to passive throttle control O

2 Input for signal from throttle control, 4-20 mA I

3 Not used -

4 Not used -

1

2

3

4

DCU

DCU

DCU

SDU

SDU

C4068

C4067

C4052

C4053

C4056

C4058

C4059

C4054

C4055

C4057

C4060

C4061

C4062

C4066

Gateway

C4001

372 773

Connecting the junction box.

Page 11

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Connection

03:03 Issue 5.0 en-GB 11

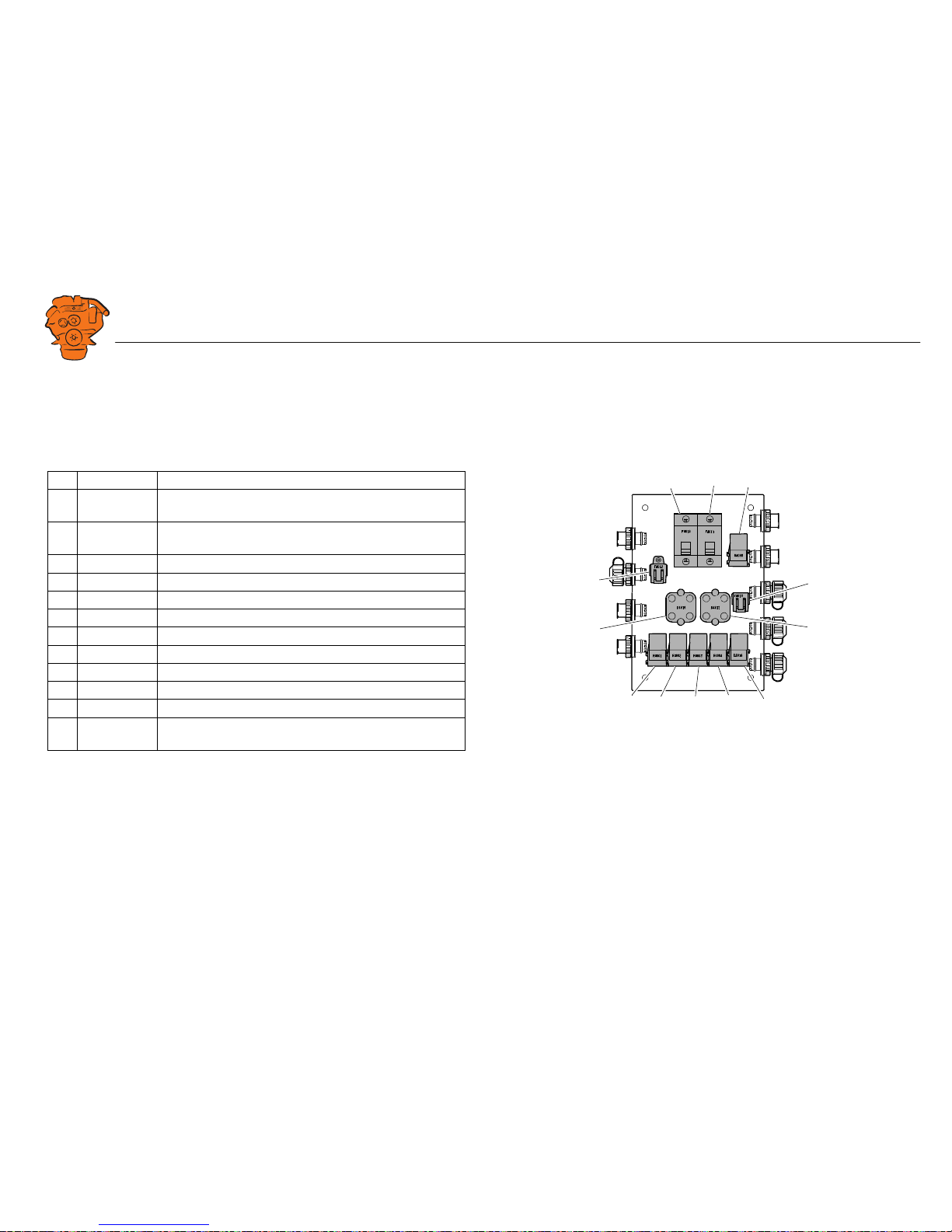

Junction box, components

There are two 20 A miniature circuit breakers in the junction box, one for each battery connection. Depending on the cable length, it may be necessary to fit extra fuses

for the electrical cable. The junction box also has a number of blade fuses, diodes and

relays as described below.

Designation Description

1 F4010 20 A miniature circuit breaker for incoming voltage from bat-

tery group, main supply

2 F4011 20 A miniature circuit breaker for incoming voltage from bat-

tery group, redundant supply

3 R4005 Relay for 15 voltage

4 F4013 2 x 2 A blade fuses for auxiliary socket

5 D4017 Diode to separate the battery groups, ground

6 D4018 Diode to request shutdown/activation of 15 voltage

7 R4004 Relay for engine shutdown (15 voltage)

8 R4003 Relay for engine shutdown (30 voltage)

9 R4002 Relay for detecting loss of redundant battery group

10 R4001 Relay for detecting loss of main battery group

11 D4016 Diode to separate the battery groups (30 voltage)

12 F4012 2 x 20 A blade fuses for engine control unit, 2 x 5 A blade

fuses for internal supply to panels

347 887

123

4

5

10

9876

12

11

Components in the junction box.

Page 12

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Connection

03:03 Issue 5.0 en-GB 12

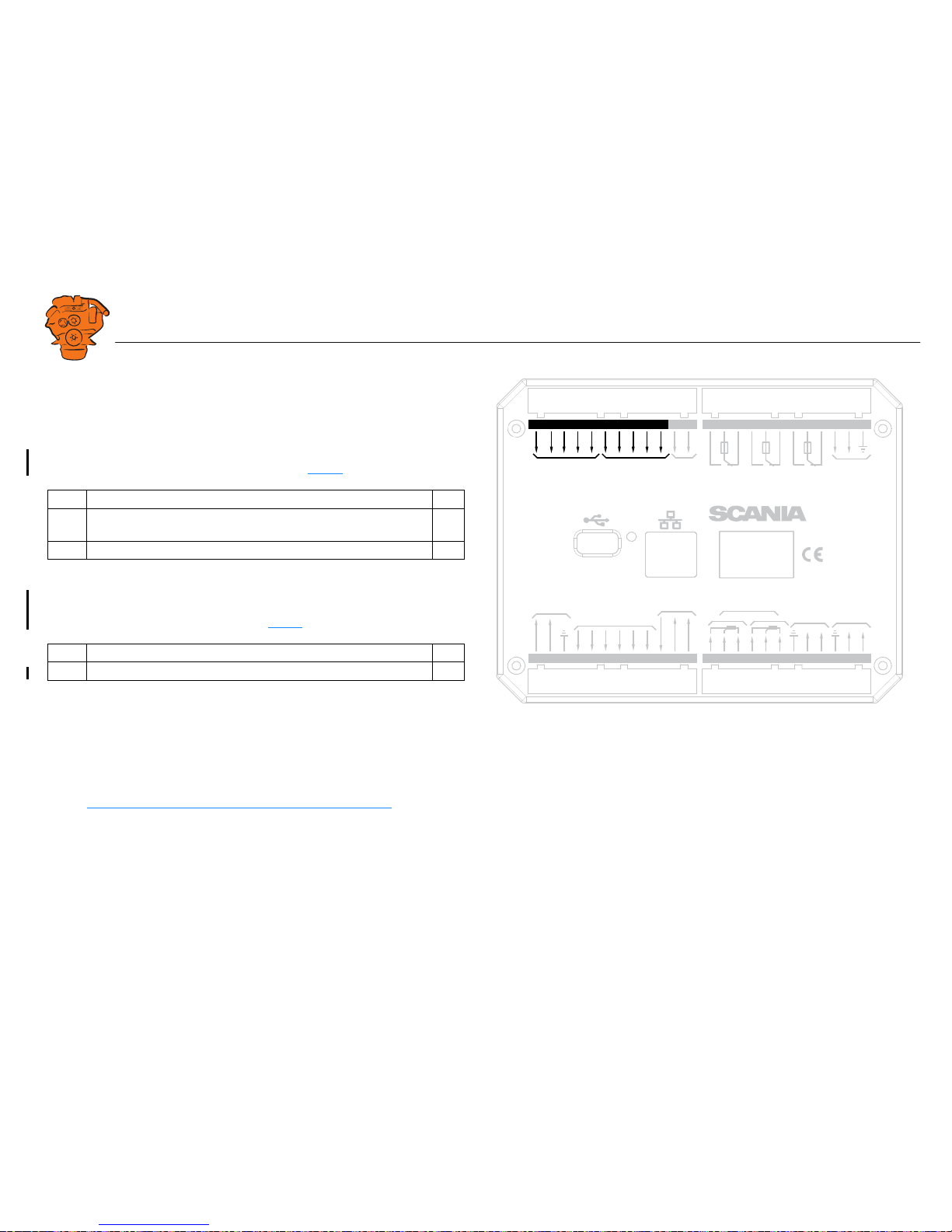

Main display (DCU), junction blocks

The only connection needed for the system to work is for the main display connector

to be connected and the main display to be connected to the junction box via junction

box connectors C4052, C4053 and C4056. See System overview

.

The connections on the main display are listed on the following pages.

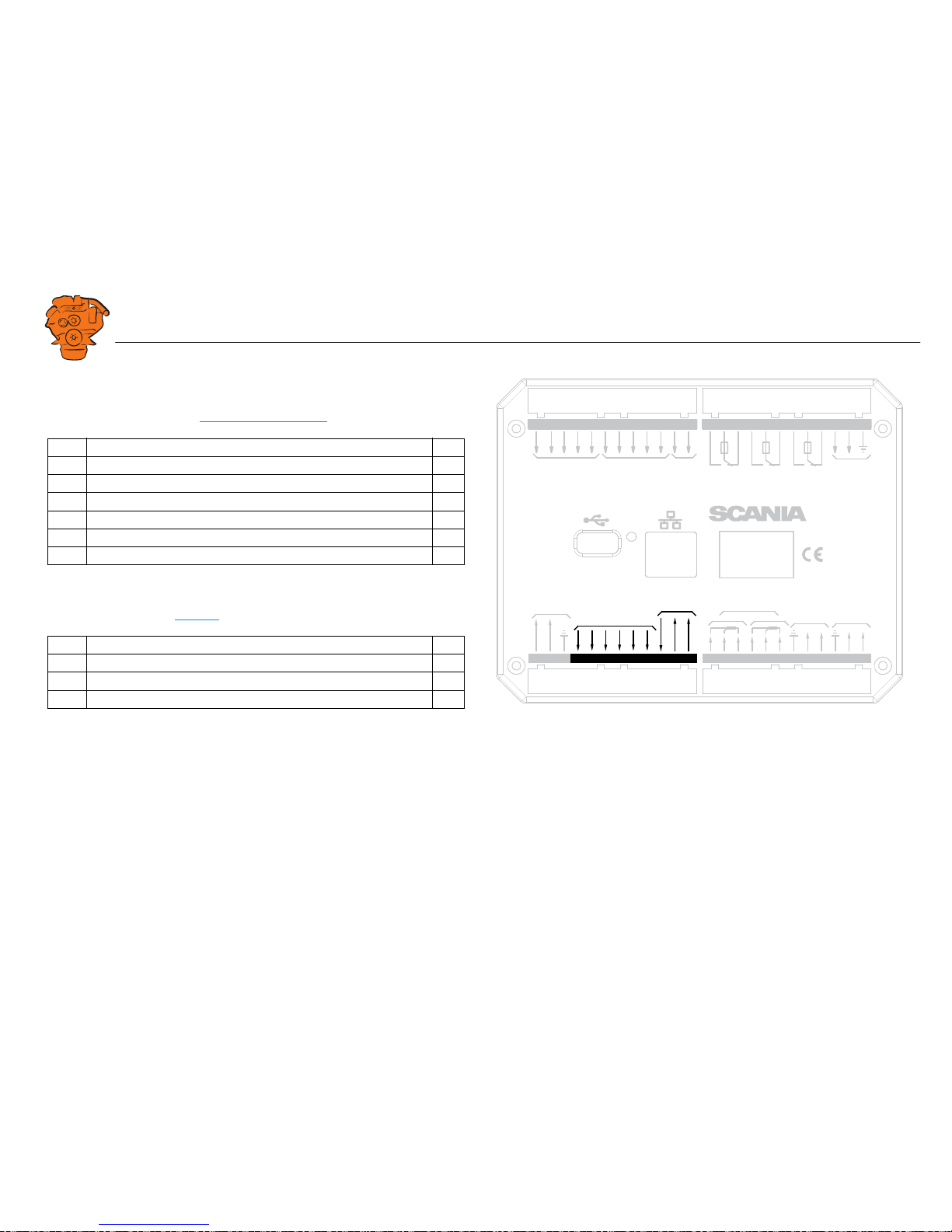

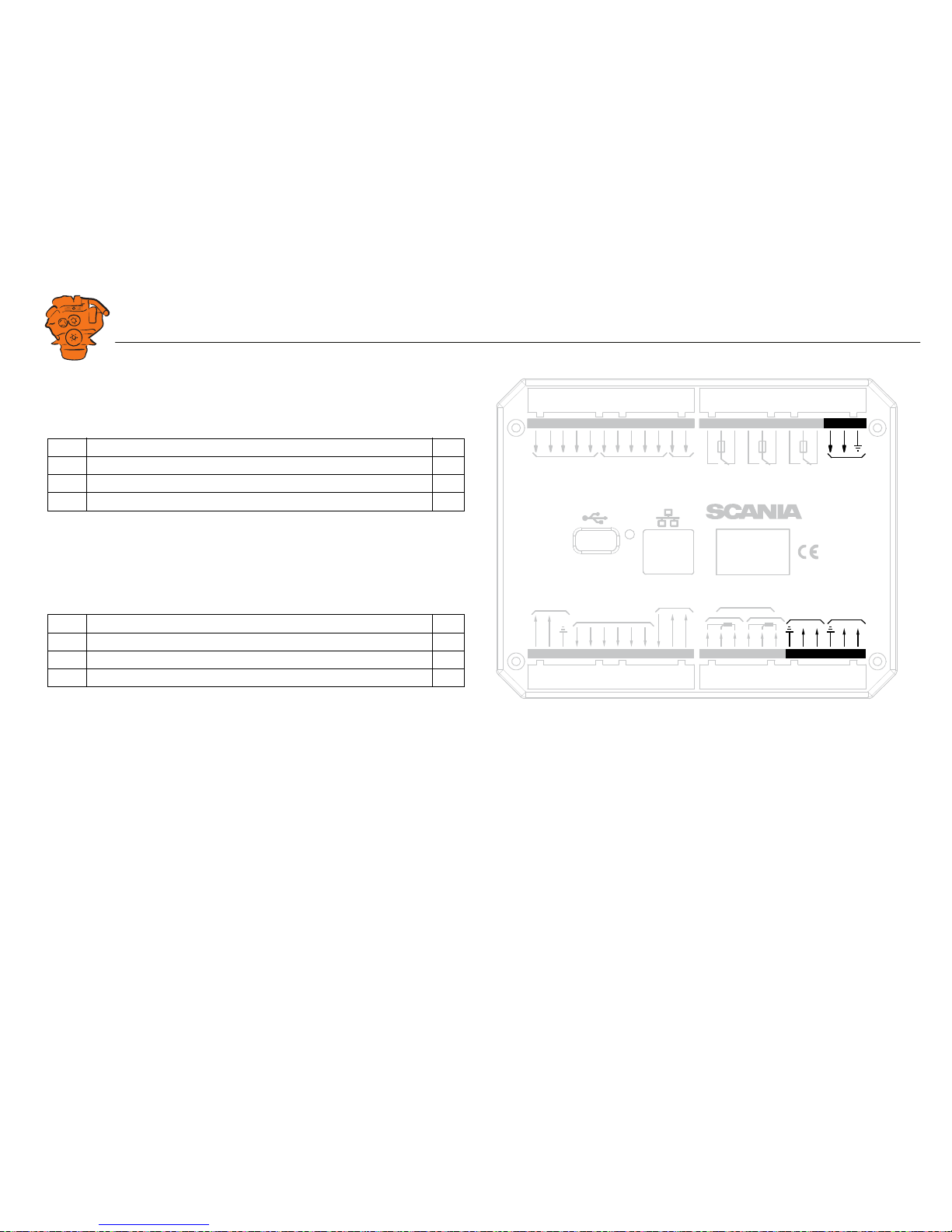

Electric power supply: junction block 1-3

The system is designed for a voltage of 24 V.

REQUIREMENT!

Connect the display directly to the battery and not to the starter motor. Use twisted

pair electrical cables and do not make the electrical cable longer than necessary. The

cable cross-sectional area must be at least 2.5 mm².

Alarm at low voltage

There is a 30 second delay before the alarm or warning is activated.

Description I/O

1 24 V main power supply I

2 0 V main power supply I

3 Ground connection I

Warning < 21 V

Alarm < 18 V

0V

Out 1

12 / 24V

Out 3

Out 4

Out 5

Out 6

L

H

L

H

USB Memor

y

Powe

r

Out 2

Pic

kup

H

L

CAN J1939

All Faults

NO

NC

Rela

y 1

NO

NC

Rela

y 2

NO

NC

In 5

A

B

In 1

In 2

In 3

In 4

Inputs

Outputs

1A

1A

1A

Pow

er Supply

Ether

net

C

C

C

RIO / SDU

Link

RS-485

Modb

us

24V 0.2A

Ch. 1Ch.

2

4-20 mA

A

B

C

1

PT100

2

A

B

C

Key set

123456789

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

36 35 34 33 32 31 30 29 28 2 7 26 2548 47 46 45 44 43 42 41 40 39 38 37

347 812

Junction blocks on the main display.

Page 13

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Connection

03:03 Issue 5.0 en-GB 13

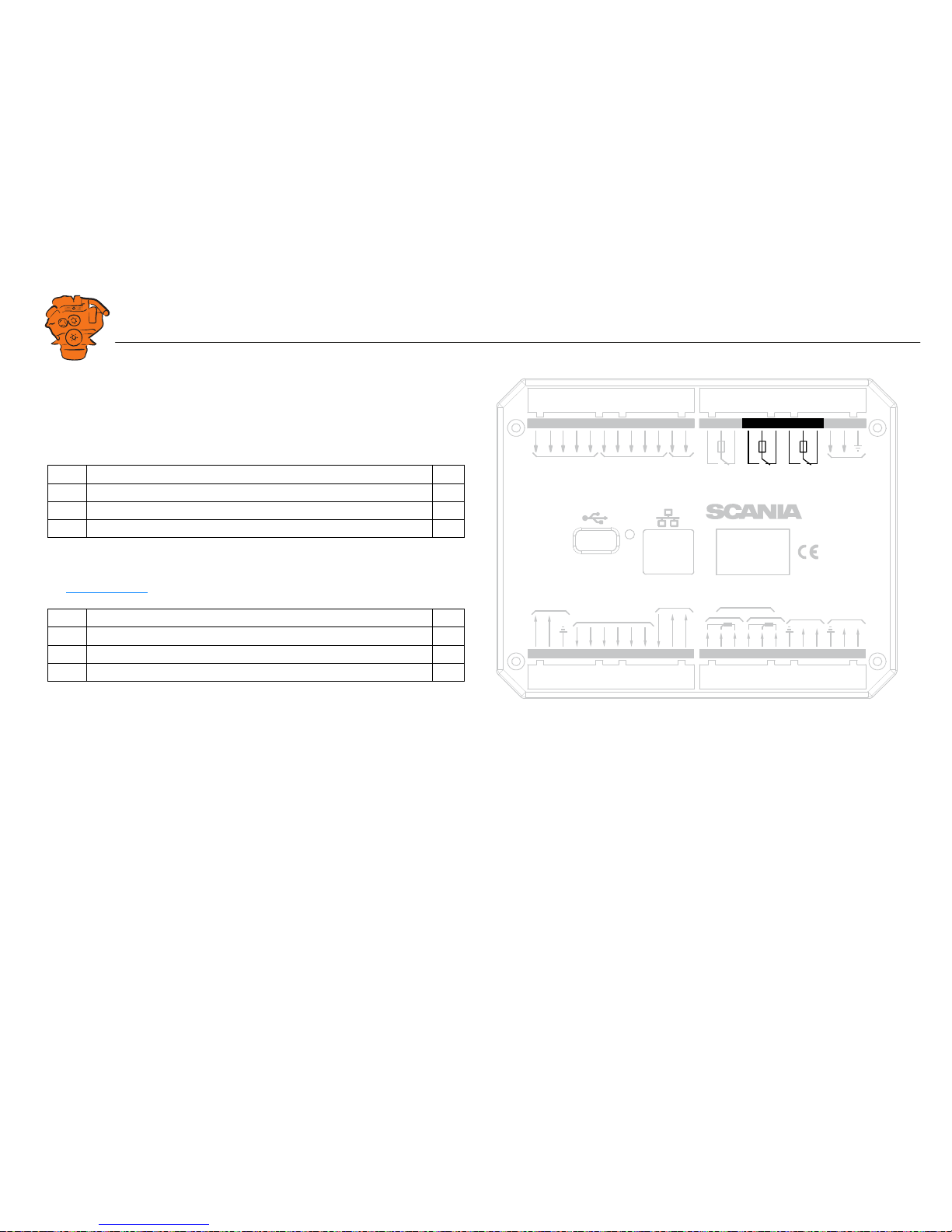

Change-over output: junction block 4-9

The main display has six 24 V outputs that can be configured individually for optional functions or events. See the 12/24V Output Functions

section.

4-20 mA input: junction block 10-12

The main display has two configurable analogue inputs. Information on how to configure the inputs is in the 4-20 mA

section.

If the signal is outside the following limit values, a warning is displayed on the display.

• Less than 2 mA: defective

• Over 24 mA: short circuit

2-4 mA is treated as 4 mA and 20-22 mA is treated as 20 mA. The updating frequency is 2 Hz.

Description I/O

4 24 V output #1 (0.5 A shared with output #2) O

5 24 V output #2 (0.5 A shared with output #1) O

6 24 V output #3 (0.2 A) O

7 24 V output #4 (0.2 A) O

8 24 V output #5 (0.2 A) O

9 24 V output #6 (0.2 A) O

Description I/O

10 24 V supply (0.2 A). The junction block is occupied O

11 4-20 mA input #1 I

12 4-20 mA input #2 I

0V

12 / 24V

L

H

L

H

USB Memor

y

Powe

r

Pic

kup

H

L

CAN J1939

All Faults

NO

NC

Rela

y 1

NO

NC

Rela

y 2

NO

NC

In 5

A

B

In 1

In 2

In 3

In 4

Inputs

1A

1A

1A

Pow

er Supply

Ether

net

C

C

C

RIO / SDU

Link

RS-485

Modb

us

Out 1

Out 3

Out 4

Out 5

Out 6

Out 2

Outputs

24V 0.2A

Ch. 1Ch.

2

4-20 mA

A

B

C

1

PT100

2

A

B

C

Key set

123456789

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

36 35 34 33 32 31 30 29 28 27 26 2548 47 46 45 44 43 42 41 40 39 38 37

347 813

Junction blocks on the main display.

Page 14

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Connection

03:03 Issue 5.0 en-GB 14

PT100 input: junction block 13-18

There are two PT100 inputs in the main display. The inputs are adapted for PT100

sensors with 2 or 3 electrical cables. Connect the electrical cables as follows:

2 wire PT100: Bridge A and B. Connect one wire to AB and the other to C.

3 wire PT100: Connect A to A, B to B and C to C.

4 wire PT100: Connect in the same way as 3 wire PT100, but note that the fourth

wire, D, should not be connected. It should hang loose or, if necessary, be cut off.

Information on how to configure the inputs is in the PT100

section.

If the signal is outside the following limit values, a warning is displayed on the display.

The updating frequency is 2 Hz.

Description I/O

13 PT100 #1 A I

14 PT100 #1 B I

15 PT100 #1 C I

16 PT100 #2 A I

17 PT100 #2 B I

18 PT100 #2 C I

Below 90

ohms

short circuit

Above 390

ohms

defective

0V

12 / 24V

L

H

L

H

USB Memor

y

Powe

r

Pic

kup

H

L

CAN J1939

All Faults

NO

NC

Rela

y 1

NO

NC

Rela

y 2

NO

NC

In 5

A

B

In 1

In 2

In 3

In 4

Inputs

1A

1A

1A

Pow

er Supply

Ether

net

C

C

C

RIO / SDU

Link

RS-485

Modb

us

Out 1

Out 3

Out 4

Out 5

Out 6

Out 2

Outputs

24V 0.2A

Ch. 1Ch.

2

4-20 mA

A

B

C

1

PT100

2

A

B

C

Key set

123456789

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

36 35 34 33 32 31 30 29 28 27 26 2548 47 46 45 44 43 42 41 40 39 38 37

369 835

Junction blocks on the main display.

Page 15

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Connection

03:03 Issue 5.0 en-GB 15

Modbus RTU, RS-485: junction block 19-21

The main display has a built-in ModbusTM interface, on both RS-485 and Ethernet.

The latter can also be designated Modbus TCP.

RIO link: junction block 22-24

Not used.

J1939 CAN interface: junction block 25-27

Connection to engine control unit via CAN. The connection is terminated.

Description I/O

19 Shielded I

20 Low I

21 High I

Description I/O

25 Not used I

26 Low I

27 High I

0V

12 / 24V

L

H

L

H

USB Memor

y

Powe

r

Pic

kup

H

L

CAN J1939

All Faults

NO

NC

Rela

y 1

NO

NC

Rela

y 2

NO

NC

In 5

A

B

In 1

In 2

In 3

In 4

Inputs

1A

1A

1A

Pow

er Supply

Ether

net

C

C

C

RIO / SDU

Link

RS-485

Modb

us

Out 1

Out 3

Out 4

Out 5

Out 6

Out 2

Outputs

24V 0.2A

Ch. 1Ch.

2

4-20 mA

A

B

C

1

PT100

2

A

B

C

Key set

123456789

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

36 35 34 33 32 31 30 29 28 27 26 2548 47 46 45 44 43 42 41 40 39 38 37

369 836

Junction blocks on the main display.

Page 16

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Connection

03:03 Issue 5.0 en-GB 16

Relay for all faults: junction block 28-30

The relay is activated when there are no active faults and is deactivated when a fault

occurs. Every new event is counted as a fault in the alarm list, except diagnostics

messages with a white ranking. The relay can be used to switch on an external lamp

or emit an acoustic signal, for example.

Relay #1: junction block 31-33

The relay can be configured so that it is activated for any of the built in functions. See

the Relay Functions

section.

Description I/O

28 NC (1 A) -

29 C (1 A) -

30 NO (1 A) -

Description I/O

31 NC (1 A) -

32 C (1 A) -

33 NO (1 A) -

0V

12 / 24V

L

H

L

H

USB Memor

y

Powe

r

Pic

kup

H

L

CAN J1939

All Faults

NO

NC

Rela

y 1

NO

NC

Rela

y 2

NO

NC

In 5

A

B

In 1

In 2

In 3

In 4

Inputs

1A

1A

1A

Pow

er Supply

Ether

net

C

C

C

RIO / SDU

Link

RS-485

Modb

us

Out 1

Out 3

Out 4

Out 5

Out 6

Out 2

Outputs

24V 0.2A

Ch. 1Ch.

2

4-20 mA

A

B

C

1

PT100

2

A

B

C

Key set

123456789

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

36 35 34 33 32 31 30 29 28 27 26 2548 47 46 45 44 43 42 41 40 39 38 37

369 838

Junction blocks on the main display.

Page 17

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Connection

03:03 Issue 5.0 en-GB 17

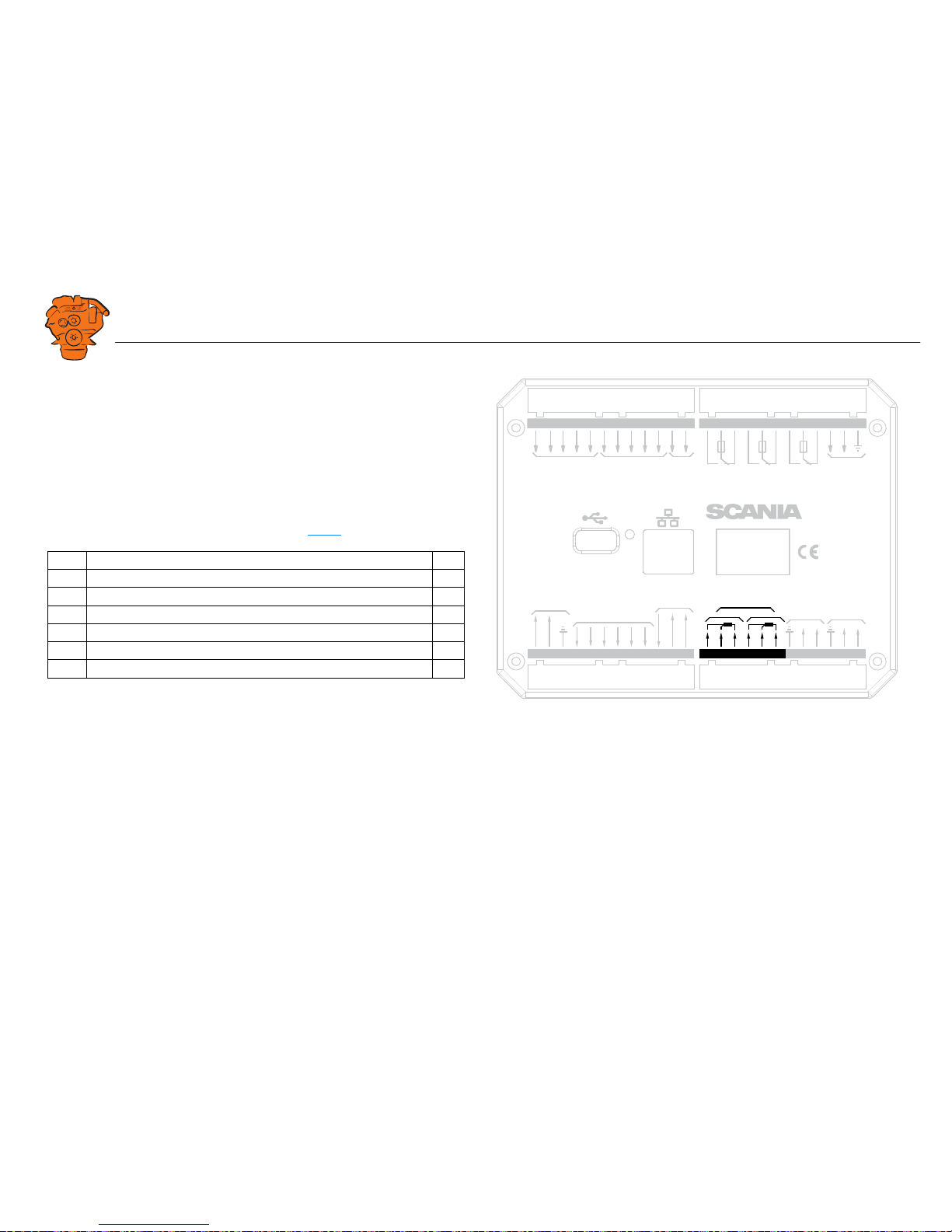

Relay #2: junction block 34-36

The relay can be configured so that it is activated for any of the built in functions. See

the Relay Functions

section.

Input for magnetic pulse sensor: junction block 37-38

An auxiliary rotational speed sensor is connected here. Only shield the electrical cable on the sensor side. Information on configuration is in the Local Pickup

section.

Description I/O

34 NC (1 A) -

35 C (1 A) -

36 NO (1 A) -

Description I/O

37 A I

38 B I

0V

12 / 24V

L

H

USB Memor

y

Powe

r

In 5

In 1

In 2

In 3

In 4

Inputs

Pow

er Supply

Ether

net

Pic

kup

Rela

y 2

NO

NC

A

B

1A

C

H

L

CAN J1939

All Faults

NO

NC

Rela

y 1

NO

NC

1A

1A

C

C

RIO / SDU

Link

Out 1

Out 3

Out 4

Out 5

Out 6

Out 2

Outputs

24V 0.2A

Ch. 1Ch.

2

4-20 mA

L

H

RS-485

Modb

us

A

B

C

1

PT100

2

A

B

C

Key set

123456789

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

36 35 34 33 32 31 30 29 28 27 26 2548 47 46 45 44 43 42 41 40 39 38 37

347 816

Junction blocks on the main display.

Page 18

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Connection

03:03 Issue 5.0 en-GB 18

Change-over input: junction block 39-43

There are five 24 V inputs that can be configured individually for available functions.

For example, a low oil pressure sensor can be connected, or the input can be configured to activate a built in function such as automatic start.

If there is a safety device unit (SDU) in the system, three of the inputs are reserved.

Information on how to configure the inputs is in the Switch

section.

Connection of control panel. junction block 44-48

If there is no control panel in the system, inputs 44-48 can also be configured. However, this only applies if the software version of the display is 2.12 or later. Information on how to configure the inputs is in the Switch

section.

Ethernet (Modbus TCP)

The main display is connected to the LAN or directly to a computer via a standard

CAT-5 network. Connect to port RJ45 via a crossover network cable. The IP address

in the main display or the computer may need to be changed in order to configure the

main display via a web browser.

USB input

See the Configuring and upgrading software with USB memory stick section.

Description I/O

39-41 24 V inputs. The inputs are reserved if there is a safety device unit in

the system.

I

42-43 24 V inputs, configurable. I

Description I/O

44-48 24 V inputs. Reserved in systems with control panel. I

0V

12 / 24V

L

H

USB Memor

y

Powe

r

Inputs

Pow

er Supply

Ether

net

Pic

kup

Rela

y 2

NO

NC

A

B

1A

C

H

L

CAN J1939

All Fau lts

NO

NC

Rela

y 1

NO

NC

1A

1A

C

C

RIO / SDU

Link

Out 1

Out 3

Out 4

Out 5

Out 6

Out 2

Outputs

24V 0.2A

Ch. 1Ch.

2

4-20 mA

L

H

RS-485

Modb

us

A

B

C

1

PT100

2

A

B

C

In 5

In 1

In 2

In 3

In 4

Key set

123456789

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

36 35 34 33 32 31 30 29 28 27 26 2548 47 46 45 44 43 42 41 40 39 38 37

347 817

Junction blocks on the main display.

Page 19

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Connection

03:03 Issue 5.0 en-GB 19

Auxiliary display (RP), junction blocks

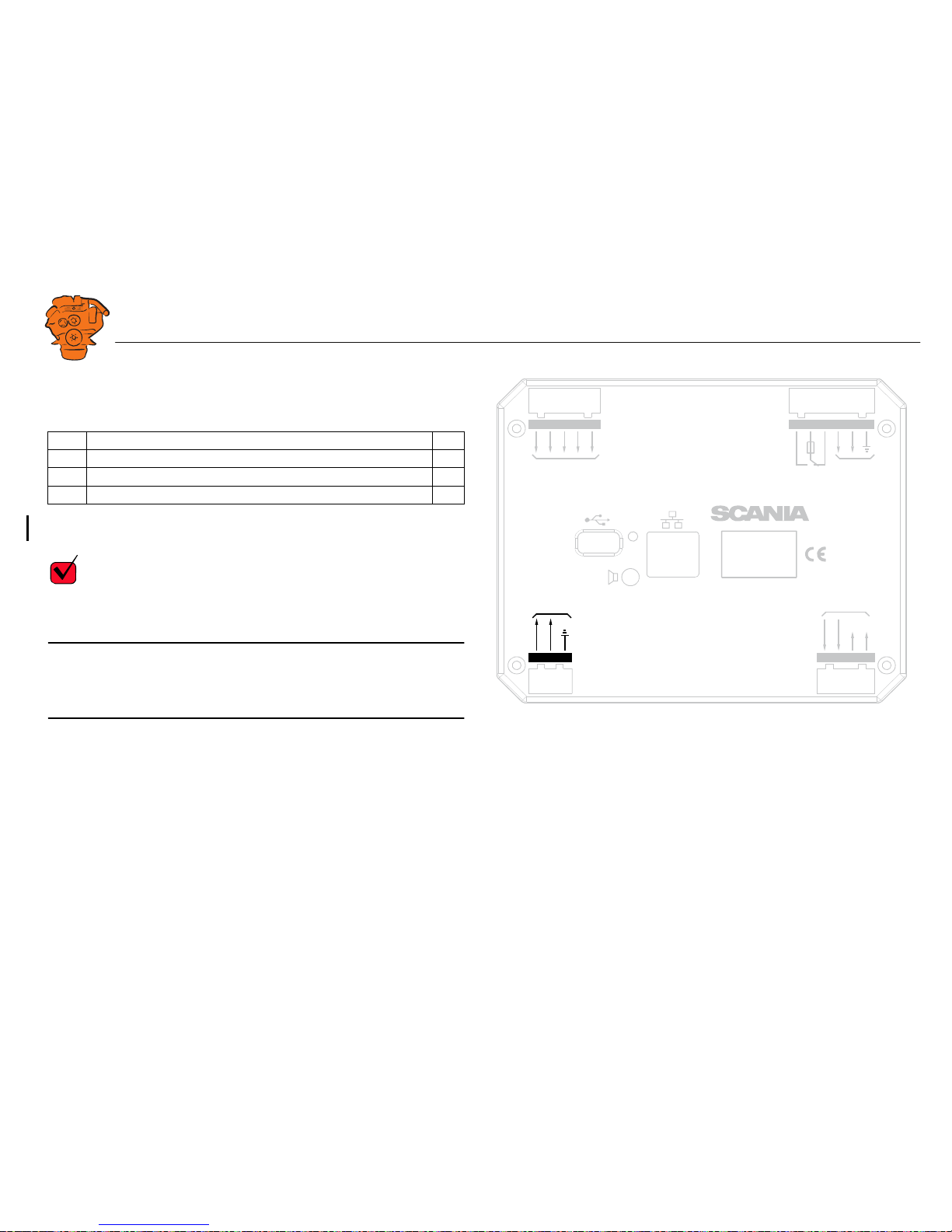

Electric power supply: junction block 1-3

The auxiliary display must have a separate electric power supply. The system is designed for a voltage of 24 V.

REQUIREMENT!

Connect the display directly to the battery and not to the starter motor. Use twisted

pair electrical cables and do not make the electrical cables longer than necessary. The

cable cross-sectional area must be at least 2.5 mm².

Note:

Scania recommends connecting the auxiliary display to the same fuse group as the

main display.

Alarm at low voltage

There is a 30 second delay before an alarm or warning is activated.

Description I/O

1 24 V main power supply I

2 0 V main power supply I

3 Ground connection I

Warning < 21 V

Alarm < 18 V

0V

12 / 24V

123

21 22 23 24

L

H

USB Memor

y

Powe

r

Pow

er Supply

Ether

net

30 29 28 27 26 25

H

L

CAN J1939

All Faults

NO

NC1AC

RIO / SDU Link

0V

12 / 24V

A

udio

Line Out

48 47 46 45 44

Key set

347 825

Junction blocks on the auxiliary display.

Page 20

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Connection

03:03 Issue 5.0 en-GB 20

RIO link: junction block 21-24

Not used.

J1939 CAN interface: junction block 25-27

Not used. The connection is terminated.

Relay for all faults: junction block 28-30

The relay is activated when there are no active faults and is deactivated when a fault

occurs. Every new event is counted as a fault in the alarm list, except diagnostics

messages with a white ranking.

Connection of control panel. junction block 44-48

Description I/O

28 NC -

29 C -

30 NO -

Description I/O

44 24 V input #6. Reserved for the control panel I

45 24 V input #7. Reserved for the control panel I

46 24 V input #8. Reserved for the control panel I

47 24 V input #9. Reserved for the control panel I

48 24 V input #10. Reserved for the control panel I

0V

12 / 24V

123

21 22 23 24

L

H

USB Memor

y

Powe

r

Pow

er Supply

Ether

net

30 29 28 27 26 25

H

L

CAN J1939

All Faults

NO

NC1AC

RIO / SDU Link

0V

12 / 24V

A

udio

Line Out

48 47 46 45 44

Key set

347 823

Junction blocks on the auxiliary display.

Page 21

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Connection

03:03 Issue 5.0 en-GB 21

Ethernet (Modbus TCP)

Connection to the LAN.

USB input

See the Configuring and upgrading software with USB memory stick section.

Loudspeaker output

The auxiliary display has a standard output of 3.5 mm for the connection of regular

computer speakers. The installation will then have more sounds than just the built in

buzzer, and different types of sound can be linked with different events. This is how

to activate external speakers:

• In the auxiliary display, go to Menu > Settings > Sound.

• Activate the Speakers option with the Sound Configuration button.

0V

12 / 24V

123

21 22 23 24

L

H

USB Memor

y

Powe

r

Pow

er Supply

Ether

net

30 29 28 27 26 25

H

L

CAN J1939

All Faults

NO

NC1AC

RIO / SDU Link

0V

12 / 24V

A

udio

Line Out

48 47 46 45 44

Key set

347 824

Junction blocks on the auxiliary display.

Page 22

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Connection

03:03 Issue 5.0 en-GB 22

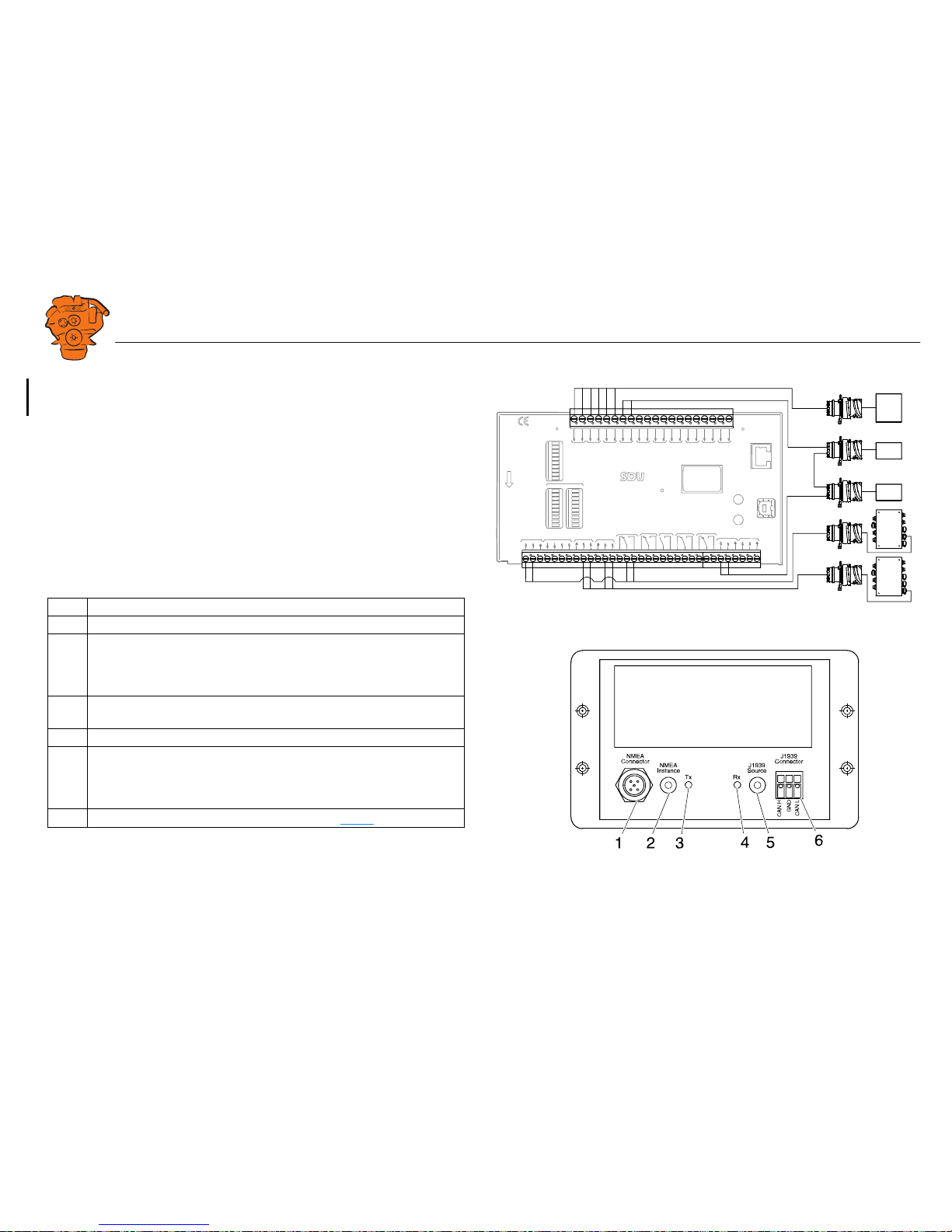

Safety module (SDU), connection

The illustration shows the safety device unit connections.

Gateway – overview

Pos. Description

1 Connection to the ship NMEA 2000 network.

2 "NMEA Instance" rotary control. Set the instance which the gateway trans-

mits to other units. Used if 2 or more gateways are connected to the same

NMEA 2000 network. In such a case, make sure that each gateway has a

unique instance, e.g. "0" and "1".

3 Blue "Tx" LED, indicates that data is being received from NMEA 2000

every 2.5 seconds.

4 Green "Rx" LED, indicates that data is being sent to J1939.

5 "J1939 Source" rotary control. Set the instance for the NMEA 2000 GPS

which the information should be loaded from. If the gateway does not receive any signals from a GPS with the selected instance within 30 seconds,

all valid GPS data is transferred automatically.

6 Connection to connector C4067 junction box. See C4067

.

SWITCH 1

SWITCH 2

SWITCH 3

SWITCH 4

SWITCH 5

SWITCH 6

SWITCH 7

SWITCH 8

SWITCH 1

SWITCH 2

SWITCH 3

SWITCH 4

SWITCH 5

SWITCH 6

SWITCH 7

SWITCH 8

SHUTDOWNFAULT

SWITCH 1 SWITCH 2 SWITCH 3 SWITCH 4 SWITCH 5 SWITCH 6 SWITCH 7 SWITCH 8

STA

TUS

PO

WER

CRANK CUTOFF

R

UNNING

TACHO 1

TACHO 2

SHUTDOWN OVERRIDE

B

UZZER

COM 1

COM 2

COM 3

SHUTDOWN

O

VERRIDE

A

CKNOWLEDGE

COM 3

CONFIGURATION

ETHERNET

shutdown unit

RELEASE

SHUTDOWN

O

VERSPEED

SHUTD

O

WN COIL

SHUTD

O

WN OVERIDE

SHUTDOWN

CRANK

CUTOFFBUZZLERFA

ULT R

UNNING

COM 1

DCU LINK

COM 2

RS 485

MODBUS RTU

ACKNOWLEDGE

OVERSPEED

TEST

COM 4

USB

TACHO 2

TACHO 1

S

H

U

T

D

O

W

N

C

O

I

L

S

U

P

P

L

Y

1 24V

4 24V

6 24V

20V

70V

50V38

34353637383940414243421

422

423

424

425

42650515253

9101112131415161718192021222324252627282930313233

H

L

H

L

C4063

T4003

T4004

C4064

T4006

T4007

T4006

T4007

C4058

C4059

C4074

C4060

C4061

C4065

372 772

361 902

Page 23

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Connection

03:03 Issue 5.0 en-GB 23

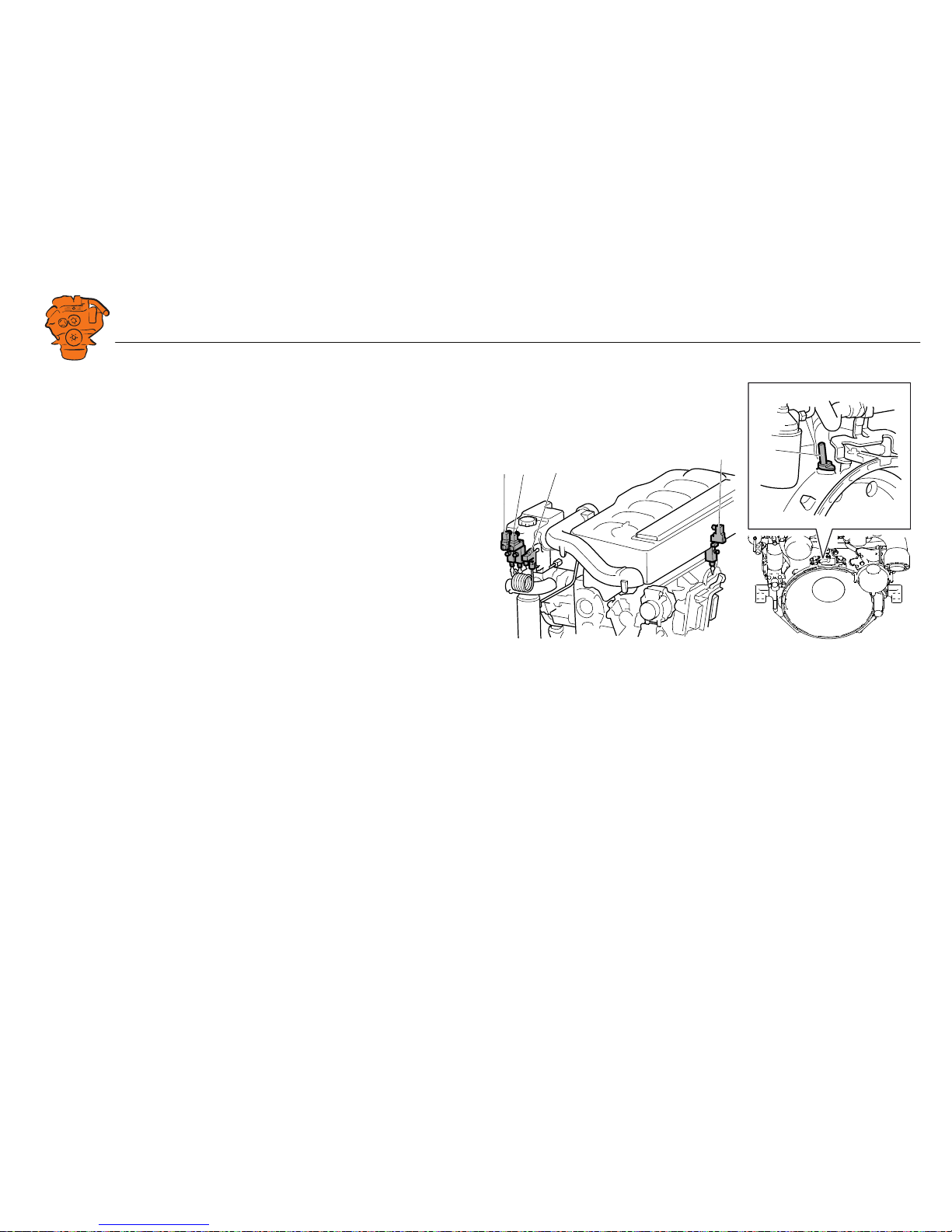

Position of the monitors on the engine

The illustration shows the position of the monitors on DI09 and DI13.

See 02:01 Engine for information on where to connect external monitoring sensors.

1

5

2

4

3

347 830

DI09, DI13.

1. Coolant pressure monitor, T4006.

2. Oil pressure monitor, T4003.

3. Coolant temperature monitor, T4004.

4. Fuel pressure monitor, T4007.

5. Engine speed monitor, T4005.

Page 24

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Connection

03:03 Issue 5.0 en-GB 24

The illustration shows the location of the monitors on DI16.

See 02:01 Engine for information on where to connect external monitoring sensors.

5

2

43

1

347 831

DI16.

1. Engine speed monitor, T4005.

2. Oil pressure monitor, T4003.

3. Coolant temperature monitor, T4004.

4. Coolant pressure monitor, T4006.

5. Fuel pressure monitor, T4007.

Page 25

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Connection

03:03 Issue 5.0 en-GB 25

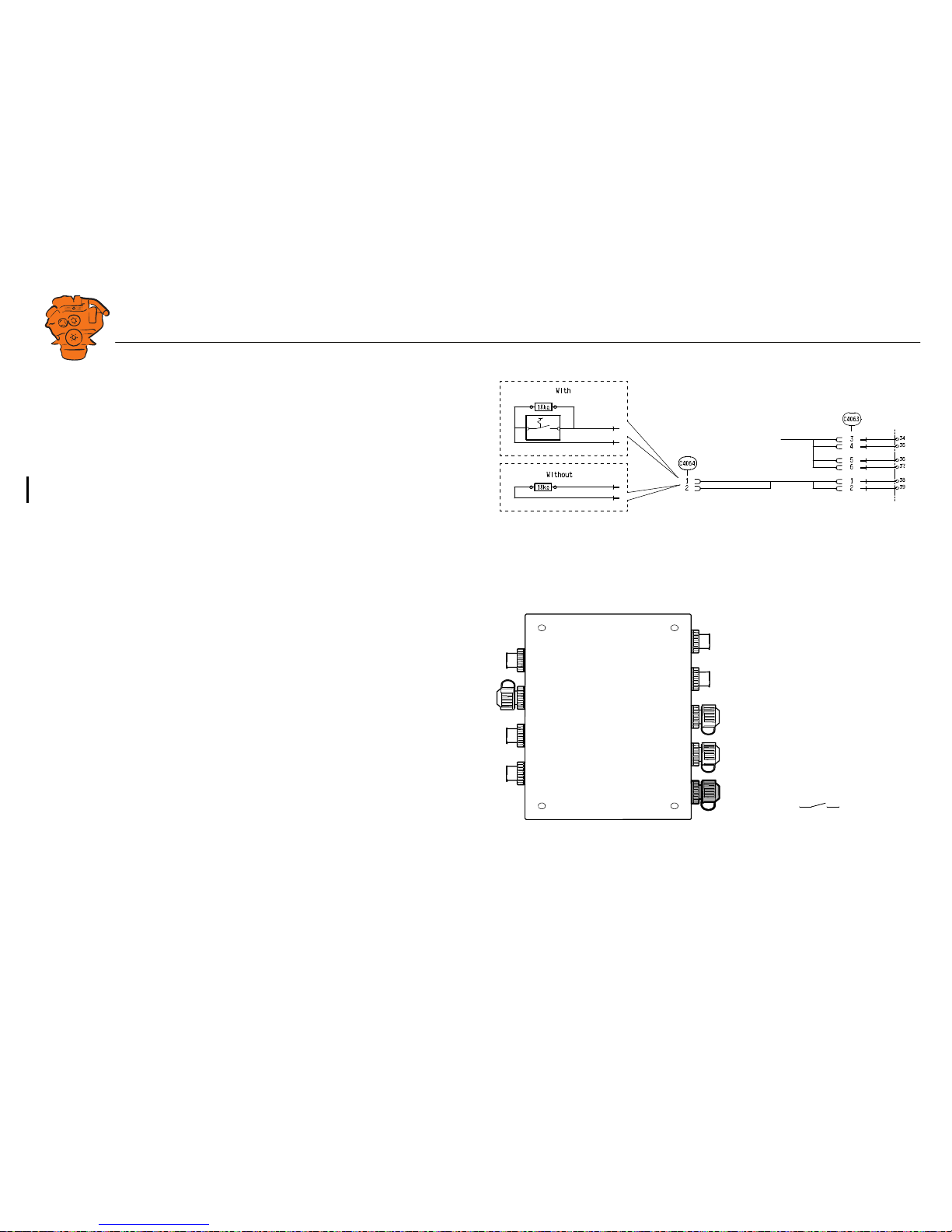

Connecting emergency stop

It is possible to connect an emergency stop which disconnects the voltage to the engine control unit. The connection is made in different ways, depending on whether

the system has a safety device unit (SDU) or not.

System with safety device unit (SDU)

Connect a switch with a 10 kohms resistor to connector C4064 in cable harness connected to the safety device unit.

System without safety device unit (SDU)

Connect a regular open switch to pin 3 in connector C4059 in the junction box. The

switch should be connected to 24 V.

Use connector 2 131 199 and the following tools:

• Hand crimping tool 99 494

• Hand crimping tool 99 491

347 885

SDU

System with safety device unit: connection of emergency stop to C4064.

+24V

C4059-3

347 886

System without safety device unit: connecting an emergency stop to the junction box.

Page 26

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Connection

03:03 Issue 5.0 en-GB 26

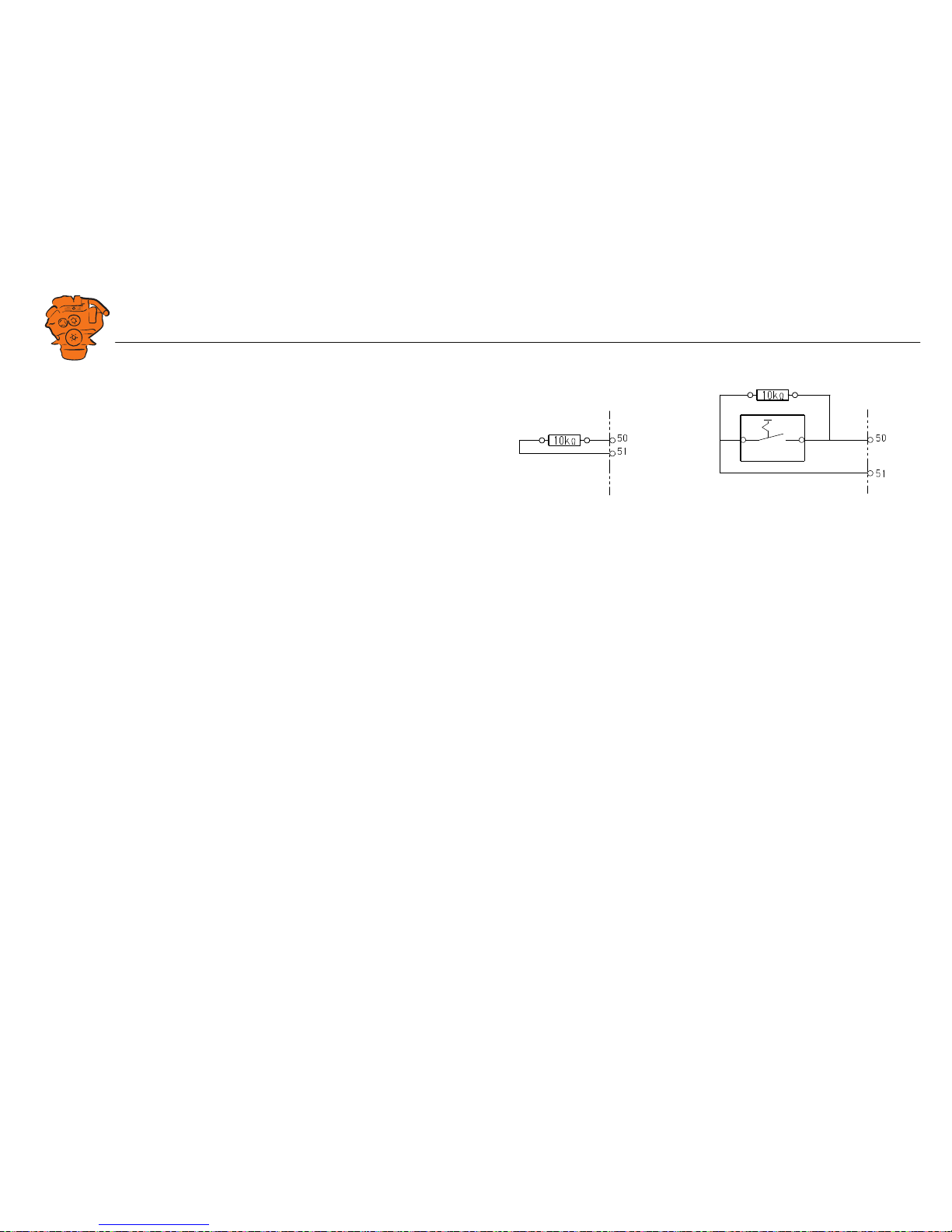

Engine shutdown override in systems with safety

device unit (SDU)

It is possible to override engine shutdown requested by the safety device unit in systems prepared for classification. Proceed as follows:

1. Remove the existing 10 kohms resistor between junction blocks 50 and 51 in the

safety device unit.

2. Connect a switch with a 10 kohms resistor between junction blocks 50 and 51.

SDU

347 888

SDU

12

Overriding engine shutdown requested by the safety device unit.

Page 27

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Using the main display

03:03 Issue 5.0 en-GB 27

Using the main display

First start

When you start the main display for the first time or have performed a factory reset,

a power-on wizard is displayed. All settings made in the wizard can also be made at

a later stage. The first power-on wizard contains the following steps:

1. Calibrate Touch

Calibrate the display by pressing the 5 marks which are displayed one after another.

The calibration must be performed correctly in order to continue with the wizard.

372 511

Main display first power on wizard.

372 512

Page 28

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Using the main display

03:03 Issue 5.0 en-GB 28

2. Select Installation Language

Select the language that should be used during the installation. There are 3 pages of

language options.

Note:

In this installation manual, all buttons and options are in English.

3. Select IP number

Enter an IP address. The IP address in the factory settings is 192.168.0.101.

The last 2 numbers in the main display's IP address are displayed as the engine number in the auxiliary display. Example:

• 192.168.0.101 is displayed in the auxiliary display as Engine #1.

• 192.168.0.104 is displayed in the auxiliary display as Engine #4.

The main display IP address can be changed at a later stage. This is done via Short-

cuts > Menu > Settings > Administration > Network Configuration in the main display.

REQUIREMENT!

The last numeral in the IP address must always be unique to the network.

372 513

372 514

Page 29

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Using the main display

03:03 Issue 5.0 en-GB 29

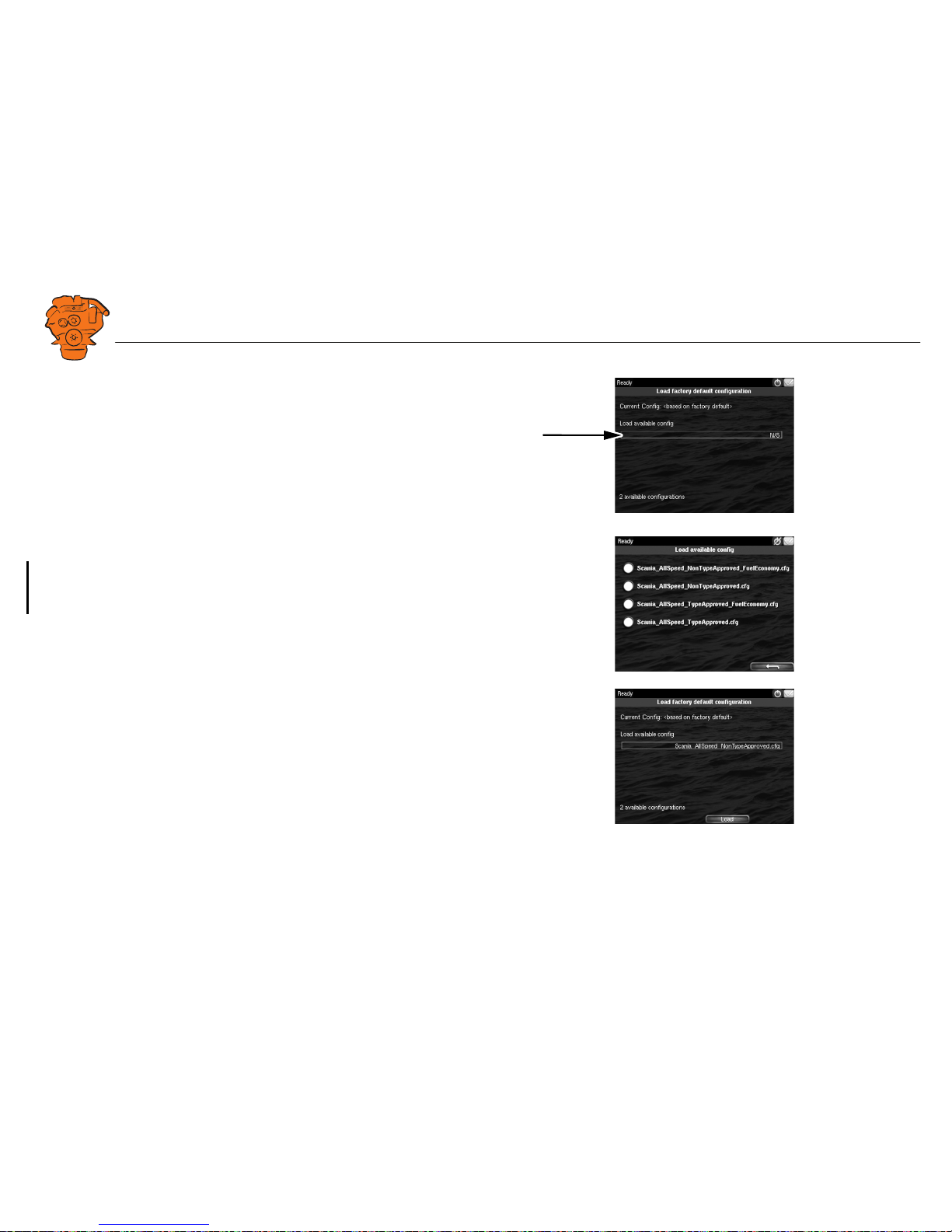

4. Load a configuration

Load a configuration file depending on whether the system is prepared for classification or not.

1. Press the bar. See illustration.

2. Select one of the available configuration files:

– Non-classified system with gateway for calculation of fuel consumption.

– Non-classified system.

– Classified system with gateway for calculation of fuel consumption.

– Classified system.

3. Press the arrow button.

5. Finish – Restart

Exit the first power-on wizard by pressing Load and then Restart.

372 515

372 516

372 517

Page 30

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Using the main display

03:03 Issue 5.0 en-GB 30

Navigation

Both the main display and auxiliary display are touch screens, without any buttons.

All functions are accessed by pressing the display.

The displays have 5 different display modes:

• Instrument pages

• Select Page

• Shortcut Menu

• Alarm List

• Menu

Different touch areas on the display have different functions. For example, if you

touch the left-hand side of the display on an instrument page, you get to the previous

instrument page. How to navigate:

To get to Press

Select Page in the middle of the display

previous instrument page on the left of the display

next instrument page on the right of the display

Shortcut Menu in the top left-hand corner

Alarm List in the top right-hand corner

Menu a long press (1 s) in the middle of the

display

Page 31

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Using the main display

03:03 Issue 5.0 en-GB 31

Instrument pages

The instrument page is the highest level in the main display structure. There are 4

preset instrument pages. It is also possible to configure a further instrument page so

that there will be 5 instrument pages in total.

• You scroll between the instrument pages by pressing on the right- or left-hand

side of the display.

Select Page

In Select Page thumbnails of the instrument pages and the Shortcuts menu are shown.

• You get to Select Page by pressing in the middle of the display.

• Then select one of the instrument pages from the thumbnails by pressing it.

372 518

Example of instrument page.

372 519

Page 32

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Using the main display

03:03 Issue 5.0 en-GB 32

Shortcut Menu

In the Shortcut Menu, buttons Start Engine, Stop Engine, Alarm List and Menu are

available. If the display has software version 2.12, there are also the Ignition Off and

Black Panel Mode buttons.

• Access the Shortcut Menu by pressing the upper left-hand corner of the display,

or by pressing Shortcuts in Select Page.

Alarm List

The Alarm List is described in the Operator's manual.

Menu

Only the administration section under Menu > Settings is described in this manual.

Other sections in the Menu are described in the Operator's manual.

Note:

You can switch off the button beep by going to Menu > Settings and selecting Disabled with the Button Beep button.

372 520

Page 33

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Using the main display

03:03 Issue 5.0 en-GB 33

Administration in the main display

Some settings can be made via the main display administration section. How to open

the administration section:

•Go to Select Page > Shortcuts > Menu > Settings.

• Scroll to page 3 in Settings and press Administration.

• The administration section is password-protected. Enter the password, which is

set at the factory to 1234.

The administration section consists of three pages and contains the buttons below.

The buttons are described in the following section.

372 521

Administration in the main display: pages 1, 2 and 3

Page 34

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Using the main display

03:03 Issue 5.0 en-GB 34

Password Configuration

This is where you can change the password for access to the administration section.

First, you have to enter the existing password.

Configuration Files

This is where you can restore the display to factory settings, load user-configured

files or delete user-configured files.

RIO 425

Not used.

SDU 410/SDU 404

This is where you synchronise the main display to the safety device unit and vice versa, if the system has a safety device unit.

372 522

372 540

Page 35

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Using the main display

03:03 Issue 5.0 en-GB 35

Network Configuration

This is where you change the IP address of the main display.

Note:

The last numeral in the IP address becomes the engine number in the auxiliary display.

System Type

This is where control panel settings are made:

Note:

The default setting is System Without Keyset. If the system has a control panel, you

must change the default setting.

Setting Description

System Without Keyset System without control panel

System With Keyset at This Station Control panel connected to this display

System With Keyset at Another Station Control panel connected to another dis-

play

372 056

372 057

Page 36

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Using the main display

03:03 Issue 5.0 en-GB 36

Adjust Idle Speed

Adjusting low idling. The following conditions must be met in order to adjust low

idling:

• The accelerator control should be at 0% and the engine should be idling.

• The engine coolant temperature should be at least 50°C.

Service Mode

If you activate Service Mode, the system is kept active, so that work on the engine

control unit, for example, can be carried out. The screensaver timer configured in the

Goto Sleep Time setting is bypassed. See Important system settings: dcu / Miscella-

neous / System Type. The button is only available if the display has software version

2.12.

Automatic Buzzer Silence

Activating and deactivating the automatic buzzer switch-off.

CANbus Amber Lamp

Set how Amber Lamp signals that are sent from the engine control unit to the main

display should be handled. Select if a warning (yellow alarm) should be displayed in

the main display or whether the signal should be deactivated.

CANbus Red Lamp

Set how Red Lamp signals that are sent from the engine control unit to the main display should be handled. You can select from the following options:

Disabled Red alarm via CAN bus deactivated

Alarm Red alarm via CAN bus activated

Shutdown Red alarm via CAN bus results in engine shutdown

372 523

Adjust Idle Speed.

372 524

Options for CANbus Red Lamp.

Page 37

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Configuring and upgrading software with USB memory stick

03:03 Issue 5.0 en-GB 37

Lock

Once the administrator password has been entered, the administration section is unlocked for 1 hour. Press Lock to lock the administration section immediately.

Factory Reset

This is where you reset the main display to factory settings.

Configuring and upgrading software with

USB memory stick

The USB inputs on the main display and auxiliary display can be used to

• configure the main display,

• upgrade the main display software or an auxiliary display,

• copy an existing configuration file in the main display in order to save a backup

copy of the configuration file or transfer the configuration to another display, for

example.

Note:

Files to be copied to a display must be saved in the root of the USB memory stick.

Valid characters in the configuration file name are a-z, A-Z, 0-9, _ (underscore) and

- (hyphen). If other characters are used, there is a risk that the display may not be able

to interpret them.

Page 38

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Configuring and upgrading software with USB memory stick

03:03 Issue 5.0 en-GB 38

Configuring the main display with a USB memory

stick

1. Insert the USB memory stick with the configuration files into the display.

2. Enter the administrator password (4 digits).

3. The window USB Storage is opened. Press Configuration Files.

4. The configuration files available on the USB memory stick are listed in the dis-

play.

5. Select the file or files you want to copy to the display and press Copy.

6. Confirm by pressing Yes. The files are not activated, they are only copied to the

display.

7. Select the configuration file you want to use and press Use.

8. Confirm by pressing Yes. The main display will restart.

Different configuration files in the same main display

It is possible to use different configuration files in the same main display. Do this by

first copying the configuration files from the USB memory stick according to the instructions above. Then go to Menu > Settings > Administration > Configuration Files

> Load User File to activate the file you want to use.

372 525

Page 39

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Configuring and upgrading software with USB memory stick

03:03 Issue 5.0 en-GB 39

Upgrading the main display or auxiliary display software

Note:

If the display is new or has factory settings restored, you must first go through the

first power-on wizard before you can upgrade the software.

1. Insert the USB memory stick with the new software version into the display.

2. Enter the administrator password (4 digits).

3. Press DCU Firmware Files and follow the instructions on the display.

Note:

When the software has been upgraded, the display will restart. This may take a few

minutes. Do not turn off the power until you have waited for at least 5 minutes for

the display to restart automatically.

Copying one configuration file in the main display

1. Insert the USB memory stick into the display.

2. Enter the administrator password (4 digits).

3. The window USB Storage is opened. Press Copy Configuration File and confirm

by pressing Yes.

The configuration file is now copied to the USB memory stick.

372 525

Page 40

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Configuring the main display via a web browser

03:03 Issue 5.0 en-GB 40

Configuring the main display via a web

browser

The main part of this section describes how to configure the main display via a web

browser. In the final subsection - SDU - some settings of the safety device unit are

also described, if the system has one.

The main display is configured using a computer with a web browser via the built in

web server of the main display. Therefore, connect a computer to the main display

first.

Connecting a computer to the main display

1. In the main display: Go to Shortcuts > Menu > Help > Version Information. Make

a note of the IP address. The IP address in the factory settings is 192.168.0.101.

2. Go to Shortcuts > Menu > Settings > Connect a PC.

372 526

372 527

Page 41

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Configuring the main display via a web browser

03:03 Issue 5.0 en-GB 41

3. Tick the Enabled box and press Ok.

4. Connect an Ethernet cable between the computer and the main display.

5. Enter the IP address in the address field of the web browser; for example: http://

192.168.0.101, and press Enter.

Approved web browsers:

Other web browsers probably also work but have not been tested.

Web browser Version

Internet Explorer

TM

9 or later

Firefox

TM

8 or later

Chrome

TM

10 or later

372 528

Page 42

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Configuring the main display via a web browser

03:03 Issue 5.0 en-GB 42

General information about the IP address

The main display has a fixed IP address, which is set in the first power-on wizard.

However, the IP address can always be changed later in the main display administration section:

• In the main display, go to Shortcuts > Menu > Settings > Administration > Net-

work Configuration.

Composition of the IP address

Within a network, the first 3 groups of the IP address must always be the same, Example:

192.168.0.X

where X represents another component on the network.

Note:

The last numeral in the IP address must always be unique to the network.

Factory settings for the main display

The factory settings only apply when the main display is started for the first time.

When the settings have been changed, the changes are saved even if factory settings

are restored.

• IP-adress: 192.168.0.101

• Subnet Mask: 255.255.255.0

• Default gateway: 192.168.0.1

Page 43

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Configuring the main display via a web browser

03:03 Issue 5.0 en-GB 43

Homepage

When you have connected a computer to the main display and entered the IP address,

the homepage is displayed. All configurations can be carried out via the built in web

interface.

The following menu options are available on the homepage:

Menu option Description

DCU To configure the main display. This menu option is described

in the following section.

RIO Not used.

SDU Safety device unit. This contains information about the safety

device unit, some settings can be also be made here. However,

as a general rule, no safety device unit settings may be

changed. If the settings are changed, the classification may no

longer be valid.

Upload Wallpaper Upload your own background images to the main display here.

The file format must be .png.

Versions Information on the hardware and software version of the main

display.

Troubleshooting Troubleshooting I/O communication in the main display.

344 457

Page 44

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Configuring the main display via a web browser

03:03 Issue 5.0 en-GB 44

Logging in to the main display

On the homepage: Click DCU and then log in to the main display with the following

details:

• User Name: dcu

• Password: 1234

The different configuration menus under Home > DCU are described in the following

section. The layout of this chapter reflects the menu structure of the web service interface, so that each menu in the illustration on the right has a section of its own. The

settings are saved to the main display and not to the computer.

Important system settings: dcu / Miscellaneous /

System Type

Some important settings regarding system type, screensaver and password are made

in the first step of the configuration. You do not have to change the factory settings,

but you should be aware of them.

Setting Description

System Type Select System Without Keyset for systems without a con-

trol panel.

Select System With Keyset at This Station if there is a control panel connected to this display.

Select System With Keyset at Another Station if a control

panel is connected to another display.

Goto Sleep Time [sec] Set the timeout for shutting down the system when no

control panel is being used (instead of starter key). The

setting applies when the system is in Ready mode, i.e.

once the engine has stopped. The standard setting is

1,000 seconds.

372 774

Page 45

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Configuring the main display via a web browser

03:03 Issue 5.0 en-GB 45

Password: dcu > Password

The configuration of the main display is password-protected. This is where you

change the password for the configuration.

If you have forgotten your password: Click Get encrypted PIN. An encrypted password is sent to you. The encrypted password can be decoded. Contact the Scania

helpdesk for more information.

Pin Code Change the system operator password if no control panel

is being used. The default setting is 0000.

Pin Code On Wakeup Specify whether an operator password should be used

(instead of starter key) if no control panel is being used.

Setting Description

Page 46

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Configuring the main display via a web browser

03:03 Issue 5.0 en-GB 46

File management: dcu > File

This menu is used for file management.

Submenu Description

Load any file Change the configuration of the main display by activat-

ing another configuration file.

Factory Default: Activate a factory-configured file.

User Uploaded: Activate a user-configured file which

has previously been uploaded to the main display via File

> Upload to DCU > Configuration. See Upload to DCU

below. When you activate the new configuration file, the

main display will restart.

Delete configuration file Remove the user-configured files.

Configuration printout Take a screenshot.

Save file as... Save the current main display configuration as a file on

the computer. The file is saved in .cfg format.

Upload to DCU Firmware: Upgrade the software in the main display to

the latest version.

Wallpaper: Upload your own background images to the

main display. The file format must be .png.

Configuration: Upload a new configuration file to the

main display. Note: The file will be uploaded but not activated. See Load any file above.

372 775

Page 47

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Configuring the main display via a web browser

03:03 Issue 5.0 en-GB 47

Configuring input signals: dcu > I/O Configuration >

Config Inputs

This is where you configure input signals to the main display.

Enter your own name for all input signals by clicking the assign custom name link,

at the top of every section.

Note:

Remember to click Submit after every change, otherwise they will not be saved.

Engine Speed

This is where the engine speed sensors are configured and the engine overspeed limit

value is set.

Source

The main display can receive signals for engine speeds from 3 different sources RPM Primary Source, RPM Secondary Source and RPM Third Source.

The engine speed sources have an order of priority. The main display uses the primary source in the first instance. The secondary source is only used if the main display

loses contact with the primary source.

Source Description

J1939 J1939 CAN bus connected to inputs 25-27.

DCU Magnetic detection locally connected to inputs 37 and 38.

SDU Signal from the safety device unit, if the system has one.

372 776

Page 48

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Configuring the main display via a web browser

03:03 Issue 5.0 en-GB 48

Local Pickup

Enter the number of pulses per engine revolution if a magnetic pulse sensor is connected to the main display, or if DCU has been selected from the sources above.

General Configuration

Setting Description

RPM Rounding Rounds off the value displayed in the display to 1, 5 or 10

rpm.

RPM Setpoint States the engine speed at which the starter motor is

switched off and the main display indicates that the engine is running.

RPM Setpoint 2–5 Optional engine speed settings which can be used togeth-

er with other sensors.

RPM Ready To Take

Load

A signal that can be configured to an output. The signal

is activated when the set engine speed is reached. The

signal is deactivated when a stop signal is sent, or when

the engine speed drops by 15% or more below the set value.

RPM Nominal Speed Nominal engine speed. This engine speed is used to cal-

culate the engine overspeed limit value and the engine

overspeed test limit value.

372 776

Page 49

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Configuring the main display via a web browser

03:03 Issue 5.0 en-GB 49

General > Channel Use

Select the display in which the signal should be displayed graphically. This display

is possible on the main display (DCU), auxiliary display (RP) or on both simultaneously (DCU+RP).

Display

Set the way in which the signal will be displayed on the tachometer.

Setting Description

Display Range Min The lowest engine speed displayed on the tachometer,

normally 0.

Display Range Max The highest engine speed displayed on the tachometer.

For an engine with a nominal engine speed of 1,500 rpm,

the maximum engine speed may be 1,800 rpm, for example.

Display Major Divider The larger scale marks on the tachometer, i.e. how often

the tachometer records an rpm value. A common setting

is every 500 rpm.

Display Minor Divider The minor scale marks between the larger scale marks

(Major Divider) on the tachometer. A common setting is

every 100 rpm.

Display Multiplier The multiplication factor displayed on the tachometer,

e.g. x100 rpm.

372 776

Page 50

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Configuring the main display via a web browser

03:03 Issue 5.0 en-GB 50

Overspeed

Individual Speed Sensors

Set the inputs for optional engine speed signals in Individual Speed Sensors. Signals

coming in via these inputs are handled separately from the engine speed signals that

were configured in the previous section.

Engine speed (DCU)

Setting Description

RPM Overspeed The value at which the main display will indicate engine

overspeed.

RPM Overspeed Delay Delay in milliseconds before an alarm or engine shut-

down occurs, normally 100 ms.

RPM Overspeed Shutdown Enabled

How the engine should react to engine overspeed. Select

Yes if the engine should be shut down at engine overspeed, or No if the engine should not be shut down at engine overspeed.

Setting Description

Channel Use Select the display in which the signal should be displayed

on the tachometer. Display is possible on the main display, on the auxiliary display or on both simultaneously.

Sensor Unit Only RPM can be selected here.

Sensor Range Min/ These are fixed values that cannot be changed.

Sensor Range Max

Display Unit Only RPM can be selected.

Display Range Min Select the lower part of the scale.

Display Range Max Select the upper part of the scale.

Display Major Divider Select the larger scale marks, where the rpm value is also

shown.

Page 51

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Configuring the main display via a web browser

03:03 Issue 5.0 en-GB 51

Engine Speed (J1939)/Engine Speed (SDU)

See previous section.

Engine Load

Select an engine load source in the Engine Load Source drop-down list. You can now

select engine load as a setting when configuring the alarm.

Transmission

This menu is used to display the gear engaged or to inhibit engine start if a gear is

engaged.

Display Minor Divider Select the number of scale marks that should be displayed

between the larger scale marks (Major Divider).

Display Multiplier Select the multiplication factor to be displayed on the dis-

play: 1, 10, 100 or 1,000.

Event Determine how the engine should react to different

events for this input.

Setting Description

Page 52

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Configuring the main display via a web browser

03:03 Issue 5.0 en-GB 52

Switch

In systems with a control panel, the main display has five configurable inputs. If there

is no control panel and the software version of the display is 2.12, the five inputs 4448 are also configurable.

The inputs can be configured so that they are compatible with a regular switch or sensor. They can also be configured to perform a function, e.g. automatic starting. The

inputs are activated by applying 24 V to each input.

Note:

Inputs 1-3 (39-41) are reserved in systems with a safety device unit.

Select one of the inputs and configure it according to the instructions below.

Use as

Set the input function. The functions written in bold are the most common. Some of

the functions are only available if the software version of the display is 2.12.

Setting Description

None The input is used as an input for a regular engine sen-

sor.

Local Mode Sets the display into local mode, i.e. all external com-

mands are blocked.

Remote Mode External commands are accepted.

0V

12 / 24V

USB Memory

Pow

er

Inputs

Pow

er Supply

Eth

Out 1

Out 3

Out 4

Out 5

Out 6

Out 2

Outputs

24V 0.2A

4

In 5

In 1

In 2

In 3

In 4

Key set

123456789

10

48 47 46 45 44 43 42 41 40 39

372 778

Page 53

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Configuring the main display via a web browser

03:03 Issue 5.0 en-GB 53

Setting Description

Backlight 100 Percent Forces the background lighting to light at 100 per cent.

Prelube Override Not used.

Prelube Complete Not used.

Start Disabled Engine start deactivated.

Automatic Mode The display accepts automatic start and stop signals.

Automatic Start The display initiates the start sequence. Automatic

Mode must be activated.

Automatic Stop The display initiates the shutdown sequence. Automat-

ic Mode must be activated.

Remote Start Same as starter button. The display must be in Remote

mode.

Remote Stop Same as stop button. The display must be in Remote

mode.

Local Start Same as starter button. The display must be in Local

mode.

Local Stop Same as stop button. The display must be in Local

mode.

0V

12 / 24V

USB Memory

Pow

er

Inputs

Pow

er Supply

Eth

Out 1

Out 3

Out 4

Out 5

Out 6

Out 2

Outputs

24V 0.2A

4

In 5

In 1

In 2

In 3

In 4

Key set

123456789

10

48 47 46 45 44 43 42 41 40 39

372 778

Page 54

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Configuring the main display via a web browser

03:03 Issue 5.0 en-GB 54

Setting Description

Local Acknowledge Acknowledge all events in the alarm list. The display

must be in Local mode.

Local/Remote Acknowledge

Acknowledge all events in the alarm list.

Remote Acknowledge Acknowledge all events in the alarm list. The display

must be in Remote mode.

Shutdown Override Allows all configured engine shutdown inputs to be-

come alarm inputs. The engine is then not shut down

automatically. Engine shutdown during engine overspeed is however always active.

In Gear Signal from the gearbox that engine start is not possible

due to a gear being engaged. Applies only if the engine

drives a propeller. The function can only be configured

as Normally open or Normally closed if the software

version of the display is 2.12.

0V

12 / 24V

USB Memory

Pow

er

Inputs

Pow

er Supply

Eth

Out 1

Out 3

Out 4

Out 5

Out 6

Out 2

Outputs

24V 0.2A

4

In 5

In 1

In 2

In 3

In 4

Key set

123456789

10

48 47 46 45 44 43 42 41 40 39

372 778

Page 55

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Configuring the main display via a web browser

03:03 Issue 5.0 en-GB 55

Setting Description

In Gear (Ahead) Signal from the gearbox that engine start is not possible

due to a forward gear being engaged. Applies only if

the engine drives a propeller.

In Gear (Astern) Signal from the gearbox that engine start is not possible

due to reverse gear being engaged. Applies only if the

engine drives a propeller.

Toggle Crank Mode Switch between running the engine normally and with

the starter motor only.

Torque Limitation Curve

1-3

Activate torque limitation curve 1-3.

Speed Mode 1-2 Activate engine speed setting 1-2.

Speed Mode Off Deactivate engine speed setting.

Ignition Voltage on.

Start Start the engine.

0V

12 / 24V

USB Memory

Pow

er

Inputs

Pow

er Supply

Eth

Out 1

Out 3

Out 4

Out 5

Out 6

Out 2

Outputs

24V 0.2A

4

In 5

In 1

In 2

In 3

In 4

Key set

123456789

10

48 47 46 45 44 43 42 41 40 39

372 778

Page 56

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Configuring the main display via a web browser

03:03 Issue 5.0 en-GB 56

Channel Use

Set the input should be used.

Event = Warning, alarm or, torque limitation or engine shutdown.

Note:

Select normally DCU+RP+Event. Then the signal is displayed on both the main display and the auxiliary display. If the signal only needs to be displayed on the main

display, select DCU+Event.

Setting Description

Not in use The input must not be used.

Event The signal will activate an event.

DCU The signal will only be displayed in the main display.

DCU+Event The signal will activate an event that is only displayed

in the main display.

RP The signal will only be displayed in the auxiliary dis-

play.

RP+Event The signal will activate an event that is only displayed

in the auxiliary display.

DCU+RP The signal will be displayed in both the main display

and auxiliary display.

DCU+RP+Event The signal will activate an event which is displayed in

both the main display and auxiliary display.

Silent Event The input will be active, but the signal will not trigger

any event which is displayed in the display. The signal

is only used for communication.

0V

12 / 24V

USB Memory

Pow

er

Inputs

Pow

er Supply

Eth

Out 1

Out 3

Out 4

Out 5

Out 6

Out 2

Outputs

24V 0.2A

4

In 5

In 1

In 2

In 3

In 4

Key set

123456789

10

48 47 46 45 44 43 42 41 40 39

372 778

Page 57

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Configuring the main display via a web browser

03:03 Issue 5.0 en-GB 57

Event

If you have chosen a type of event (Event or Silent Event) under Channel Use, you

should select the type of event here, i.e. warning, alarm or engine shutdown.

If None is selected then the input is active but no events are triggered.

Input State

Delay Before Event

If you have selected an event under Event, here you enter the desired delay in seconds

before the event is triggered.

Delayed Shutdown

If you have selected engine shutdown under Event, here you enter the desired delay

in seconds before engine shutdown.

Requires Running Engine

Normally, select Yes for a pressure sensor and No for all other sensors. Select a different value in order to activate the input at another engine speed.

Setting Description

Normally Closed, Event

on open

The switch must be open in order for an event to be

triggered.

Normally Open, Event on

Closed

The switch must be closed in order for an event to be

triggered.

0V

12 / 24V

USB Memory

Pow

er

Inputs

Pow

er Supply

Eth

Out 1

Out 3

Out 4

Out 5

Out 6

Out 2

Outputs

24V 0.2A

4

In 5

In 1

In 2

In 3

In 4

Key set

123456789

10

48 47 46 45 44 43 42 41 40 39

372 778

Page 58

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Configuring the main display via a web browser

03:03 Issue 5.0 en-GB 58

Requires In Gear

Select Yes if an engaged gear is required for an event to be triggered.

Requires Engine Load

Select Yes if engine load is required for an event to be triggered.

Initial Delay

Set the delay in seconds before which the input should be activated. This setting can

only be made if Requires Running Engine is activated.

Use As Additional Run

If the main display only has one engine running indicator, Scania recommends adding the oil pressure sensor as an additional engine running indicator.

IMPORTANT!

Use no other pressure sensor signals or other signals as engine running indicator.

• If the main display has two active engine running indicators

1

: Select No.

• If the main display only has one active engine running indicator: Select Yes and

use the oil pressure sensor as a further engine running indicator.

1. An engine running signal can be a magnetic sensor or an SAE J1939 CAN bus signal connected to

the main display.

0V

12 / 24V

USB Memory

Pow

er

Inputs

Pow

er Supply

Eth

Out 1

Out 3

Out 4

Out 5

Out 6

Out 2

Outputs

24V 0.2A

4

In 5

In 1

In 2

In 3

In 4

Key set

123456789

10

48 47 46 45 44 43 42 41 40 39

372 778

Page 59

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Configuring the main display via a web browser

03:03 Issue 5.0 en-GB 59

4-20 mA

First select one of the 4-20 mA inputs. Then configure the input according to the instructions below.

Channel Use

See Channel Use

in the Switch section.

Sensor

Display

Setting Description

Sensor Unit Select the unit indicated on the sensor. An oil pressure

sensor can, for example, have bar or psi as units.

Sensor Range Min/Sensor Range Max

Select the sensor measuring range, i.e. the highest and

lowest values recorded by the sensor.

Setting Description

Display Unit Select the unit in US and Metric to be shown in the sensor

display.

Display Range Min/Display Range Max

Select the highest and lowest value in US and Metric that

should be displayed on the display for the sensor.

Display Major Divider/

Display Minor Divider