Page 1

IMPORTANT INFORMATION

When working on the engine. e.g. adjusting drive belts, changing oil or adjusting the clutch,

!

it is important not to start the engine. There is a risk of damaging the engine but, more

importantly, there is a

SERIOUS DANGER OF INJURY

For this reason, always secure the starter device or detach a battery lead before working

on the engine.

This is especially important if the engine has a remote starter or automatic start.

This warning symbol and text is reproduced beside those maintenance points where it is

especially important to consider t he risk of injury.

START-UP REPORT- WARRANTY

When the start-up report has been fi lled i n and sent to Scania, you have a 1 yea r warran ty from the d ate of star tup. Also fill in the information below as this can make things easier if you need to contact a service workshop

or the like.

Engine number

Start-up date

User’s name and address

Engine type

Variant

Engine type and variant are indicated on the engine type plate

Operator’s Manual

DI14 69 (750 hp)

DI14 82 (800 hp)

Marine engine

opm96-750 en 1 588 538

2001-05:1

Industrial & Marine Engines

Page 2

FOREWORD

This instruction manual describes the operation and maintenance of Scania

marine engine DI14 69 (750 hp) and DI14 82 (800 hp). The instr uctions apply

to this engine type in program 96 with effect fr om e ngi ne n umber 5 564 900.

The engines are direct- injection, l iquid-coole d, four-stroke, V8 di esel engines

with 2 turbochargers. This engine has 2 charge air coolers connected to the

internal cooling system and a charge air cooler cooled by seawater, see also

page 10.

The engines feature an internal cooling system with a heat exchanger cooled

by seawater.

The engine type has el ectronic control of the injection system’s governor to

optimize engine performance and such important operating factors as fuel

consumption and exhaust emissions. Called DEC2 (Digital Electronic Control), the electronic control system is described in greater detail on page 12.

A common application is as the propulsion unit in larger leisure boats.

The normal output setting of the engine (performance code) is indicated on

the type plate, see page 10.

Note Only stand ard compon ents are described in the instruction

manual. For special equipment we would refer you to the appropriate manufacturer’s instructions.

In order to obtain the best value and service life from your engine, there are

several points to bear in mind:

- Read through the Instruction Manual before starting to use your engine.

Even those experienced with Scania engines may find new information

in this manual.

- Follow the mainten ance i nstruct ions. Ma intenance carrie d out accordin g

to these inst ructions fo rms the basis of reliable operation and a long

service life.

- Pay special attention to the safety information beginning on page 6.

- Get to know your engine so that you know what it can do and how it

works.

- When necessary, always turn to an authorised Scania workshop. These

have special tools, genuine parts and staff with training and practical

experience of Scania engines.

Note Always use genuine Scania parts i n servi ce and re pair to keep t he

engine operating correctly.

The particulars in this manual were ap plicable at th e time it was printed. We

reserve the right to introduce changes without prior notice.

During the warranty period,

only use genuine Scania parts in

service and repair for the

warranty to be valid.

Scania CV AB

Industrial and Marine engines

S-151 87 Södertälje

2 © Scania Industrial & Marine Engines 2001-05:1

Page 3

LIST OF CONTENTS

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . 2

LIST OF CONTENTS . . . . . . . . . . . . . . . . . 3

ENVIRONMENTAL RESPONSIBILITY . . . . . .4

CERTIFIED ENGINES . . . . . . . . . . . . . . . . . . . .5

SAFETY DETAILS . . . . . . . . . . . . . . . . . . . . . . .6

Safety precautions for operation . . . . . . . . . . . . 7

Safety precautions for handling ma terials . . . . .8

Safety pre cautions for care and maintenance . .8

TYPE DESIGNATIONS . . . . . . . . . . . . . . . 10

DEC2 CONTROL SYSTEM . . . . . . . . . . . . 12

STARTING AND RUNNING . . . . . . . . . . . 18

AT FIRST START . . . . . . . . . . . . . . . . . . . . . . .18

CHECKS BEFORE RUNNING . . . . . . . . . . . . .19

STARTING THE ENGINE . . . . . . . . . . . . . . . .19

At temperatures below 0 °C: . . . . . . . . . . . . . .20

RUNNING . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Engine speed . . . . . . . . . . . . . . . . . . . . . . . . . .21

Coolant temperature . . . . . . . . . . . . . . . . . . . .21

Oil pressure . . . . . . . . . . . . . . . . . . . . . . . . . . .22

STOPPING THE ENGINE . . . . . . . . . . . . . . . . .22

CHECKS AFTER RUNNING . . . . . . . . . . . . . .23

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . 24

ENGINES WITH FEW HOURS OF

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . .24

MAINTENANCE SCHEDULE . . . . . . . . . . . . .25

LUBRICATION OIL SYSTEM . . . . . . . . . 26

OIL GRADE . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Oil analysis . . . . . . . . . . . . . . . . . . . . . . . . . . .26

CHECKING OIL LEVEL . . . . . . . . . . . . . . . . . .27

OIL CHANGE . . . . . . . . . . . . . . . . . . . . . . . . . .27

Maximum oil sump angles of inclination

when in operation . . . . . . . . . . . . . . . . . . . . . .27

CLEANING THE OIL CLEANER . . . . . . . . . .28

CHANGING THE TURBO FILTER . . . . . . . . .30

COOLING SYSTEM . . . . . . . . . . . . . . . . . . 30

CHECKING COOLANT LEVEL . . . . . . . . . . .30

CHECKING CORROSION PROTECTION

RODS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

CHECKING SEAWATER PUMP IMPELLER .31

CHECKING COOLANT . . . . . . . . . . . . . . . . . .32

Checking glycol content . . . . . . . . . . . . . . . . .32

Checking Protection against corrosion . . . . . .34

Changing the coolant . . . . . . . . . . . . . . . . . . .34

CLEANING THE COOLING SYSTEM . . . . . .35

External cleaning . . . . . . . . . . . . . . . . . . . . . .35

Internal cleaning . . . . . . . . . . . . . . . . . . . . . . .38

Preventive replacement of coolant pump gear 38

AIR CLEANER . . . . . . . . . . . . . . . . . . . . . . . 39

TEST READING

LOW PRESSURE INDICATOR . . . . . . . . . . . .39

CLEANING OR CHANGING THE

FILTER INSERT . . . . . . . . . . . . . . . . . . . . . . . .39

FUEL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . 41

CHECKING THE FUEL LEVEL . . . . . . . . . . . .41

CHANGING THE FUEL FILTER . . . . . . . . . . .41

CHECKING INJECTORS . . . . . . . . . . . . . . . . .42

ELECTRICAL SYSTEM . . . . . . . . . . . . . . . 43

CHECKING THE ELECTROLYTE LEVEL IN

BATTERIES . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

CHECKING THE CHARGE STATE

OF THE BATTERIES . . . . . . . . . . . . . . . . . . . .43

CLEANING BATTERIES . . . . . . . . . . . . . . . . .43

CHECKING THE COOLANT LEVEL MONITOR

44

MISCELLANEOUS . . . . . . . . . . . . . . . . . . . 45

CHECK/TENSION

V-BELTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

LOOK FOR LEAKS,

REMEDY AS NECESSARY . . . . . . . . . . . . . .46

CHECKING/ADJUSTING

VALVE CLEARANCE . . . . . . . . . . . . . . . . . . .47

CHANGING (

FOR CLOSED CRANKCASE VENTILATION 48

OR CLEANING) VALVES

LONG-TERM STORAGE . . . . . . . . . . . . . . 49

Preservative fuel . . . . . . . . . . . . . . . . . . . . . . .49

Preservative oil . . . . . . . . . . . . . . . . . . . . . . . .50

Preparations for storage . . . . . . . . . . . . . . . . .50

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Taking out of storage . . . . . . . . . . . . . . . . . . .51

TECHNICAL DATA . . . . . . . . . . . . . . . . . . 52

FUEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

ALPHABETICAL INDEX . . . . . . . . . . . . . . 55

2001-05:1 © Scania Industrial & Marine Engines 3

Page 4

ENVIRONMENTAL RESPONSIBILITY

Scania has always been at the f ore front in the deve lopment and produc tion of

environmentally safe engines.

We have made great progress in reducing harmful exhaust emissions to be

able to meet the stringent emission standards that are mandatory for almost

all markets.

We have done this without compromising the high quality of Scania

industrial and marine engines in terms of performance and cost effective

operation.

To maintain these superior properties throughout the life of the engine it is

important that the operator/owner follows the instructions of this manual as

regards operation, maintenance and choice of fuel and lubricants.

To further contribute to protecting the environment in service, maintenance

and repair , ensure that harmful was te (oil, fuel, coolant, filt ers, batteries etc.)

is disposed of and destroyed according to applicable local regulations.

This operator’s manual contains highlighted text urging you to protect the

environment in different service and maintenance operat ions.

Refer to exam ple

Always use suitable containers

to avoid spillage when bleeding

systems or renewing

components.

4 © Scania Industrial & Marine Engines 2001-05:1

Page 5

CERTIFIED ENGINES

An emission certified engine has been approved according to a specific

certification standard. The certified engines delivered by Scania meet the

most compelling emissi on sta nda rds i n the Europe an (EU) and no n-Europ ean

(USA) markets.

Scania guarantees that a ll engin es of a cert ified e ngine typ e that a re deli vered,

correspond to the engine approved for certification.

The engine is fitted with a certification plate, stating according to which

certification rules (standard) the engine has been approved. Refer to page 10.

The following is required for the engine to meet the emission standards after

being commissioned:

- Service and maintenance must be performed according to this

Operator’s Manual.

- Only genuine Scania parts must be used.

- Service work on the injection equipment must be performed by an

authorized Scania workshop.

- The engine must not be modified with equipment not approved by

Scania.

- Seals and setting data may only be broken/modified after approval by

Scania, Södertälje. Changes should only be made by qualified

personnel.

- Changes affecting the exhaust s ystem and intake system must be

approved by Scania.

Otherwise, follow the instructions in this manual for operation, care and

maintenance of the engine. Also observe the safety precautions described in

the following four pages.

Important! If service and maintenance are not performed as stated

above, Scania cannot guarantee that the engine corresponds

to the certifie d co nfiguration and will not assume liability for

any damage occurring.

2001-05:1 © Scania Industrial & Marine Engines 5

Page 6

SAFETY DETAILS

General

This Operator’s Manual c ont ai ns safety information that must be observed i n

order to avoid persona l in jur ie s and damage to the product or property. Refer

to page 1.

The text boxes to th e right on the pages provide informati on tha t i s i m por tant

for the proper operation of the engine and to avoid damage to the engine.

Failure to follow these i nstructions may void the w arranty.

Refer to example.

Corresponding texts may also appe ar in the text co lumn, hea ded Caution! or

Important

The warning text in text boxes to the right on the pages provided with a

warning triangle and headed WARNING is extremely important and warns

of serious defects to the engine or improper handling that may lead to

personal injury.

Refer to example

The safety precautions that must b e observed in the operati on and

maintenance of Scania engines are compiled on the following three pages.

The corresponding text is also often stated next to the maintenance step

concerned, shown with different degrees of significance as described above.

Only use Scania genuine fuel

filter.

Immobilise the starting device

when working on the engine.

If the engine starts out of

control, there is a

SERIOUS RISK

OF INJURY.

All items are marked with a

item in the section.

! to highlight the importance of reading each

A general safety rule is that no smoking is allowed:

• Near the engine and the engine bay

• When refuelling and near the filling station

• When work is performed on the fuel system

• Near flammable or explosive materials (fuel, oils, batteries, chemicals

etc.)

6 © Scania Industrial & Marine Engines 2001-05:1

Page 7

Safety precautions for operation

Daily inspection

Always perform visual inspect ion of the engin e

and engine bay before the engine is started and

when the engine has been stopped after operation.

This will make it easy to detect any leakage of

fuel, oil or coolant o r any other abnormal con dition that may require remedial action.

Refuelling

When refuelling, there is a risk o f fire and explosion. The engine must be stopped and smoking

is not allowed.

Do not overfill the tank, since the fuel may expand, and close the fuel filler cap properly.

Only use fuel recommended in the service

literature. Fuel of an incorrect grade may cause

malfunctions or stoppage by i nterfering with the

operation of the fuel injection pump and the injectors.

This could cause engine damage an d poss ibly

personal injury.

Starter lock

If the control panel is not fitted with a key

switch, the engine bay should be fit ted with a

lock to prevent unauthorized starting of the engine.

Alternatively, a lockable main switch or battery

master switch may be used.

Starting spray

Never use starting spray or si milar as a starting

aid. An explosion may occu r in the i ntake pipe,

which could cause personal injury.

Operation

The engine should not be operated in environments with surrounding explosive materials

since electrical or mechanical components of

the engine may emit sparks.

It is always a safety hazard to be near an engine that is running. Body parts o r clothing, or a

dropped tool may get stuck in rotating parts,

such as the fan, causing bodily injury.

Harmful gases

Only start the engine in a properly venti lated area. The exhaust emissions contain carbon

monoxide and nitrogen oxides that are toxic.

When operating the engine in an enclosed area, an effective extraction device for exhaust

gases and crankcase gases must be used.

Always cover rotating parts and hot surfaces as

much as possible to ensure personal safety.

2001-05:1 © Scania Industrial & Marine Engines 7

Page 8

Safety precautions for handling

materials

Safety precautions for care and

maintenance

Fuel and lubrication oil

All fuels and lubricants as well as ma ny chemicals are flammable. Always follow the instruc tions stated on the container.

All work on the fuel system must be performed

when the engine is cold. Fuel leakage and spill age on hot surfaces may cause fire.

Store drenched rags and other flammable materials in a safe way to avoid spontaneous combustion.

Batteries

Batteries, particularly when being recharged,

emit highly flammable fumes that c an explode.

Do not smoke or let open f lame or sparks come

near the batteries or the battery compartment.

Incorrect connection of a batte ry cable or jump

start cable may cause a spark, which in tun may

cause the battery to explode.

Stop the engine

Always stop the engine before any maintenance and service work unless otherwise

stated.

Prevent unauthorized starting by removi ng the

starter key and turning off the power by the

main switch or the battery disconnect switch,

locking it in the of f p ositi on. Al so atta ch a warning tag, stating that work on the engine is in

progress, at a suitable locati on.

It is always a safety hazard to work on an engine that is running. Parts of your body or clothing, or a dropped tool may get stuck in rotating

parts, causing bodily injury.

Hot surfaces and fluids

A hot engine always presents a risk of scaldin g.

Always take care not to touch the exhaust

manifold, turbocharger , oil pan, hot coolant and

oil in pipes and hoses.

Chemicals

Most chemicals, such as glycol, corrosion inhibitors, preservation oil s, degreasers etc. are

hazardous. Always follow the safety precautions stated on the container.

Some chemicals, e.g. preservative oil, are

flammable.

Always store chemicals and other hazardous

materials in approved and distinctly marked

containers and out of reach of unauthorized

persons. Always dispose of superfluous or

used chemicals through an authorized waste

disposal contractor.

Lifting the engine

Use the engine lifting eyes when lifting the

engine. First check that the li fting equipment i s

in proper condition and has suff icient l ift capacity rating.

Auxiliary equipment fitted to the engine may

cause the centre of gravity to be displaced.

Thus, additional lift devices may be r equired in

order to provide proper balance and a safe lift.

Never work below a suspended engine!

Batteries

Batteries contain a highly corrosive elec trolyte

(sulphuric acid). Always take care to protect

your eyes, skin and clothing when charging and

handling batteries. W ear pr otective g loves and

goggles.

If electrolyte splashes on the skin, wash the

affected part of the body with soap and plenty

of water. If electrolyte splashes into the eyes,

rinse eyes immediately with pl enty of water and

seek medical attention.

Dispose of used batteries through an authorized waste disposal contractor.

8 © Scania Industrial & Marine Engines 2001-05:1

Page 9

Electrical system

Cooling system

Before work is performed on the electrical system, turn off the power by the main switch or the

battery disconnect switch.

Also disconnect any external power supply to

auxiliary equipment on the engine.

Arc Welding

Before welding near or on the engine, remove

the battery and alternator cables. Als o remove

the control unit connector.

Connect the weld clamp to the component to be

welded, close to the weld location. Never connect it to the engine or in such a way that the

current can pass through a bearing.

After the welding is completed, connect the cables to the alternator and t he control unit before

connecting the batteries.

Lubrication system

Hot oil may cause scalding and skin irritation.

Avoid skin contact with hot oil.

Never open the coolant filler cap while the engine is hot. Steam and hot coolant can come

out forcefully and cause scalding.

If the cooling system must still opened or disassembled while the engine is hot , ope n the fi ller

cap very cautiously and slowly to release the

pressure before the cap is removed. Use

gloves since the coolant is still very hot.

Dispose of used coolant through an authorized

waste disposal contractor.

Fuel system

Always use gloves when checking for leaks in

or performing other wor k on the fuel syst em. Always wear eye protection when testing injectors.

Fuel escaping under high pressure can penetrate body tissue and cause serious injury.

Never use non-genuine parts in the fuel system

and the electrical system. Genuine part s are

designed and manufactured to minimize fire

and explosion hazard.

Make sure that the pressure in the lubrication

system is relieved before work is carrie d out.

Never start or operate the engine with the oil fil ler cap removed since oil will be ejected forcefully.

Dispose of used oil through an authorized

waste disposal contractor.

Before starting

Install any guards that have been removed before the engine is started. Check to ensure that

no tools or other objects have been left on the

engine.

Never start the engine unless the air filter is installed. Otherwise there is a risk of objects entering the compressor wheel or a risk of

personal injury from contact with it.

2001-05:1 © Scania Industrial & Marine Engines 9

Page 10

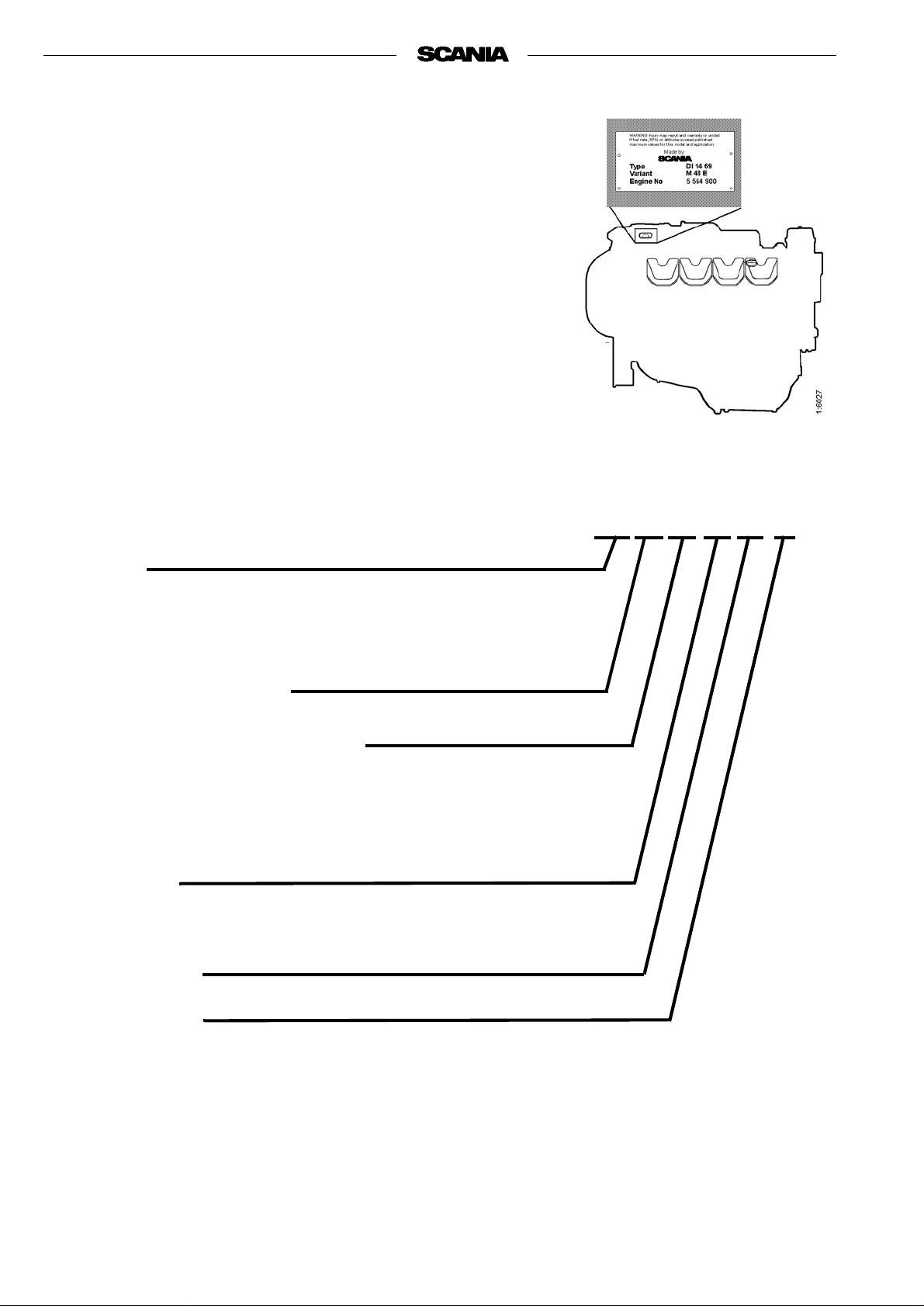

TYPE DESIGNATIONS

The engine designatio n indicates, in the form of a code, t he type of engi ne, its

size and intended use, etc.

The type designation and engine serial number are indicated on a type plate

affixed to the right- hand side of the en gine. The serial number is also punc hed

in the engine block, adj acent to the first cylinder head. Refer to the

illustration.

Engines that are cert ifie d r egardi ng smoke a nd emissi ons ar e fit ted wit h a cer tification plate specifying the documents they conform to. The plate is fitted

to rocker cover number four from the front on the right hand side.

DI 14 69 M 48 E

Type

DI Supercharged diesel engine with liquid-cooled charge air cooler

Swept volume in whole dm

3

Performance and certification code

Indicates, together with the application code, the normal gross engine

output.

The actual output setting of the engine is indicated on the engine card.

Application

M For marine use

Variant 01-99

Type of governor

E Electronically controlled governor (DEC2)

10 © Scania Industr ial & Marine Engines 2001-05:1

Page 11

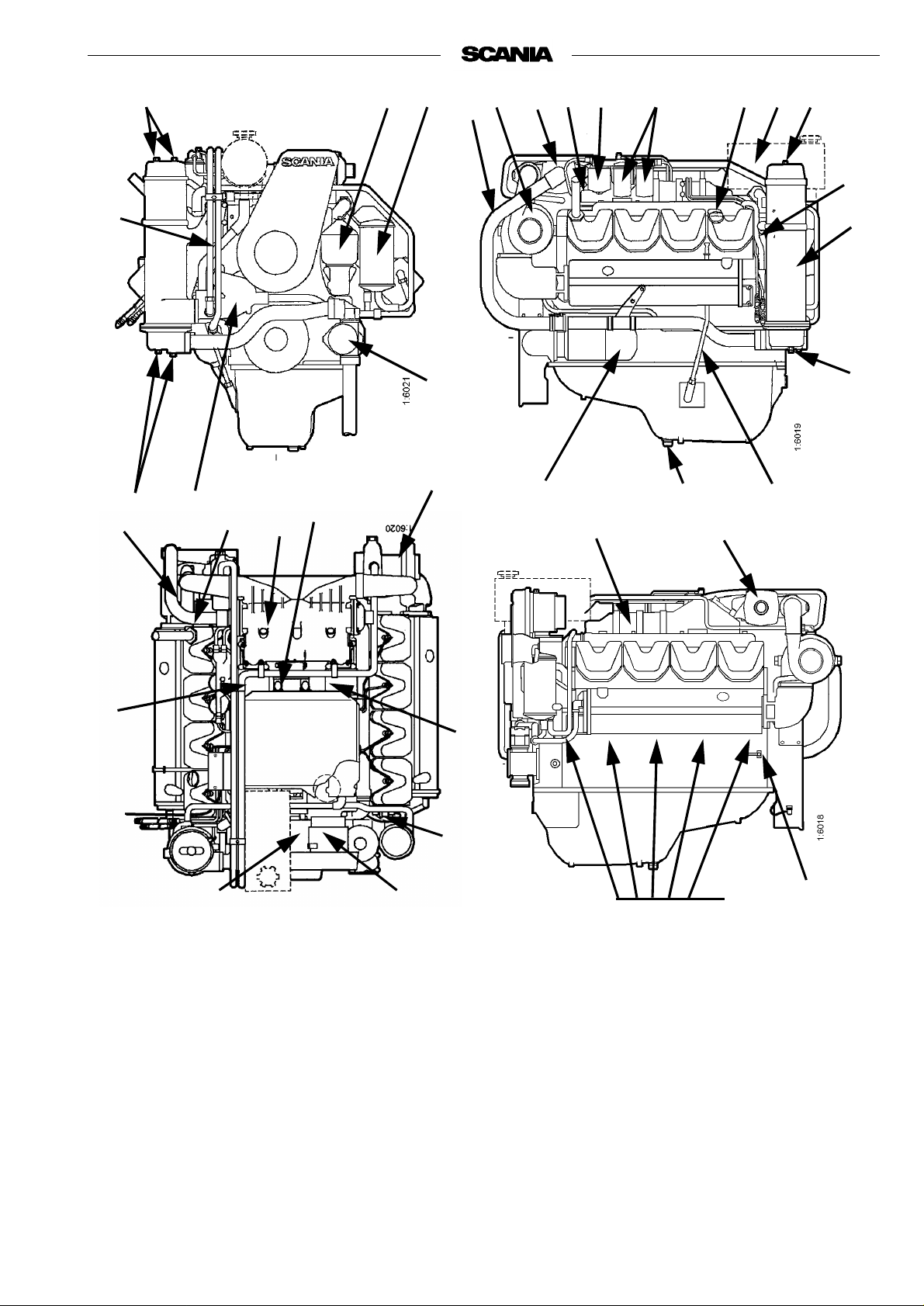

31612192322

51022

25

26

2

16

22 8

10

26

25

11

20

10

21

22

713

9

25

4

9

15

The illustrations show a typical DI14 69 engine configuration.

Your engine may have different equipment from the one shown.

1. Type plate

2. Engine serial number,

punched in engine block

3. Oil cooler

4. Oil dipstick

5. Oil cleaner

6. Oil filter, turbo

7. Drain plug, engine oil

8. Coolant pump

9. Charge air cooler (engine

coolant-cooled)

9

24

14

10. Turbocharger

11. Injection pump

12. Fuel filter

13. Starter motor

14. Alternator

15. Fan belt, adjuster

16. Coolant pipes to turbo

17. Inspection holes, engine

block

18. Drain cock, coolant

19. Oil filler cap

17

18

20. Seawater pump

21. Heat exchanger

22. Sacrificial anodes

23. Expansion tank with pres-

sure cap

24. Oil pressure monitor

25. Charge air cooler (seawa-

ter-cooled)

26. Seawater pipe to charge air

cooler

2001-05:1 © Scania Industrial & Marine Engines 11

Page 12

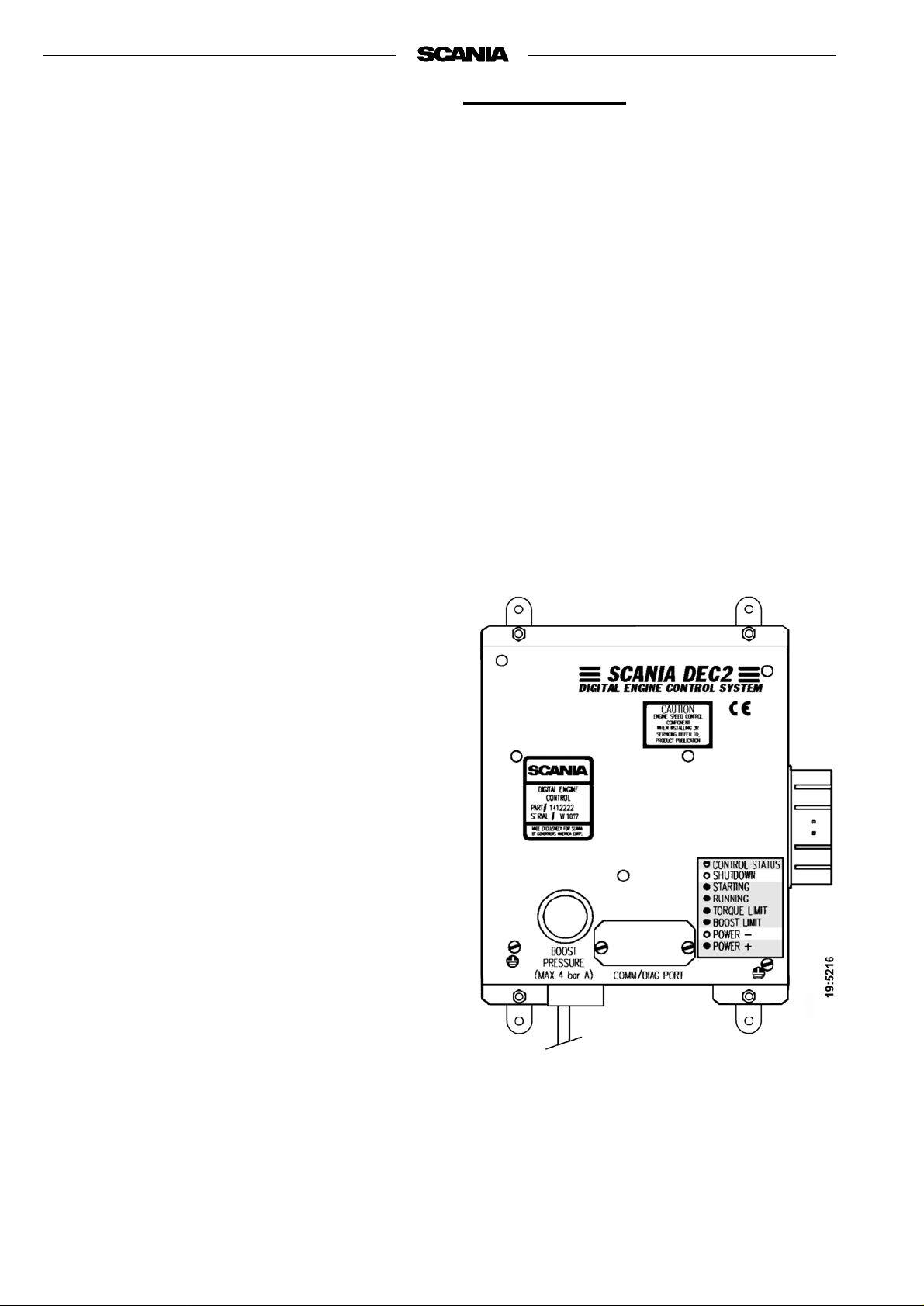

DEC2 CONTROL SYSTEM

This engine has an injection pump with an electromagnetic actuator which

adjusts the control rack to give the correct amount of fuel.

The system which controls the pump is called DEC2 (Digital Engine Control,

generation 2).

The control unit (DEC2) continuously receives signals from sensors for

engine speed, charge air temperature and pressure, coolant temperature, oil

pressure, throttl e positi on and cont rol rac k travel in the injecti on pump. Usin g

this input data and a control program, the correct amount of fuel for the

current operating conditions can be calculated.

The system’s sensors may be used only for DEC2, not for other instruments

or other monitoring purposes.

The control unit contains monitoring functions to protect the engine in the

event of a fault which would otherwise damage it. Faults and the more

important monitoring functions are indicated on the control unit in the form

of light emitting diodes. See illustration on page 14 for a description.

In case of a fault, the Power - or Shutdown indicator on the DEC2 control

unit as well as the main indicator lamp on the main supply box and the

instrument panel will illuminate.

If a fault has been indicated on the main indicator lamp the operator can

determine the cause of th e fault with the help of the LEDs on the control unit

and the troubleshooting schedule on page 17, and carry out the required

investigation and remedy.

Depending on the nature of the fault, the control system will take different

actions to protect the engine such as reducing the power output, keeping the

engine running at a constant low speed or, in case of a function impairing

fault, shutting down the engine (Shutdown).

To enable readout of LED fault codes there is a lamp test/fault code switch

located in the main supply box near the control unit.

A PC based program is also available to help service personnel to detect and

rectify fau lts and to adjust certain parameters in th e operating p rogram.

Diagnostics and changes to programs must only be performed by

authorized personnel.

The locations of the sensors and moni tors tha t send signal s to the cont rol unit

are shown in the illustrations on pages 13.

There is a description of the functions of the LEDs during normal operation

on page 14.

On page 15 there is a description of the functions of the LEDs in case of a

fault and actions in case of Power- and Shutdown indication.

Troubleshooting and fault code reading are described on pages 16 and 17.

12 © Scania Industr ial & Marine Engines 2001-05:1

Page 13

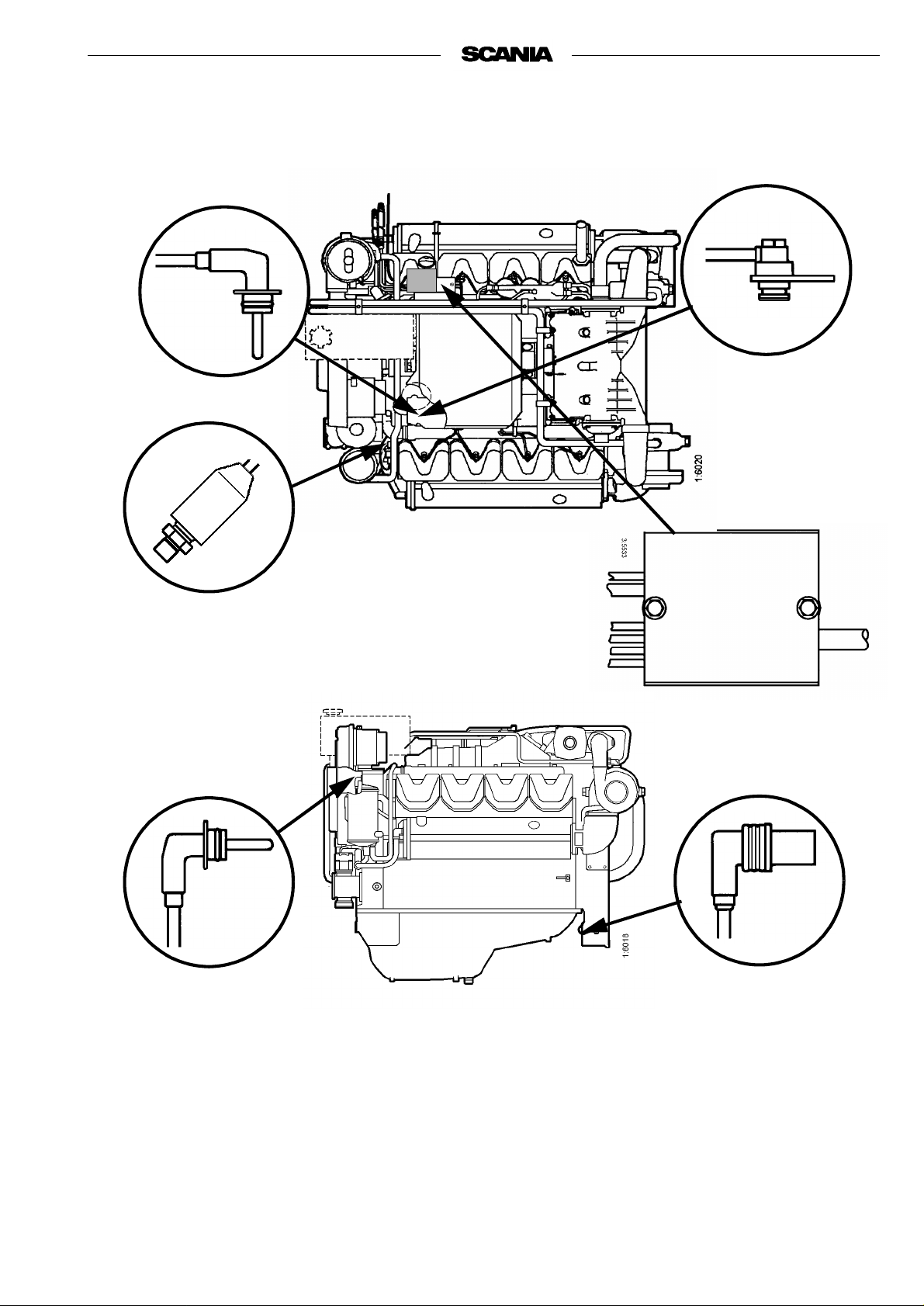

Location of sensors for DEC2

2

1

5

6

3

4

1. Connection of lead to charge air

temperature sensor

2. Charge air temperature sensor

3. Coolant temperature sensor

4. Engine speed sensors

5. Oil pressure monitor

6. Connector panel

2001-05:1 © Scania Industrial & Marine Engines 13

Page 14

LED functions during normal operation

Note: The lamp test/fault code switch should no t be

depressed. All LEDs come on briefly when

the control unit is powered up.

CONTROL STATUS

✹ The LED flashes continuousl y when the cont rol

unit is supplied with current, regardless of

whether the engine is running or not.

SHUTDOWN

❍ The LED is out.

STARTING

✹ The LED lights up as soon as the engine turns

over on cranking and follows the programmed

starting sequence until it has been completed

and then goes out.

RUNNING

✹ The LED comes on when the engine has started

and the "Starting" LED goes out. It remains on

until the engine is stopped.

POWER-

❍ The LED remains out during normal operation

as long as no fault is detected by the control

unit. See next page for the procedure to be

adopted in the event of a fault.

POWER+

✹ If the control unit is programmed to allow the

engine to be operated according to more than

one power/torque curve (map), the following

applies.

The LED comes on when the engine is run at

more than 100% power output ( MAP 2). It goes

out when the engine returns to the 100% power

output curve (MAP 1) or when the power output

required is less than 100%.

TORQUE LIMIT

✹ The LED comes on when the control unit

detects th at the engine h as received the

maximum permissible quantity of injected fu el

according to its power curve. This means 100%

power output at the curr ent rpm. If the load

increases, engine rpm will decrease.

BOOST LIMIT

✹ The LED comes on when the control unit smoke

limiter restricts the maxi mum f uel quantity.

Operation of the smoke limiter is dependent on

the charge air pressure.

14 © Scania Industrial & Marine Engines 2001-05:1

Page 15

Action in case of a fault

LED indications in case of a fault

Note The main indicator lamp in the main supply

box and at the instrument panel has

indicated a fault. The lamp test/fault code

switch should not be depressed.

CONTROL STATUS

✹ The LED will continue to flash even in case of a

fault as long as volt age is suppli ed to t he con trol

unit.

POWER -

✹ If the LED comes on, the control unit has

detected a defect that c ould cau se da mage to th e

engine if operation continues.

The control unit automatically reduces engine

power output to a predefined level if the

corresponding function has been selected.

Action: Reduce engine speed to idle if possible

and conduct troubleshooting according to

instructions on page 16 and the chart on page 17

SHUTDOWN

✹ The LED comes on and the engine is switched

off automatically in case of a severe fault that

could cause damage to the engine if operation

continues.

Action: Conduct troubleshooting according to

instructions on page 16 and the chart on page 17

If the engine has not stopped, reduce engine

speed to idle and conduct troubleshooting.

2001-05:1 © Scania Industrial & Marine Engines 15

Page 16

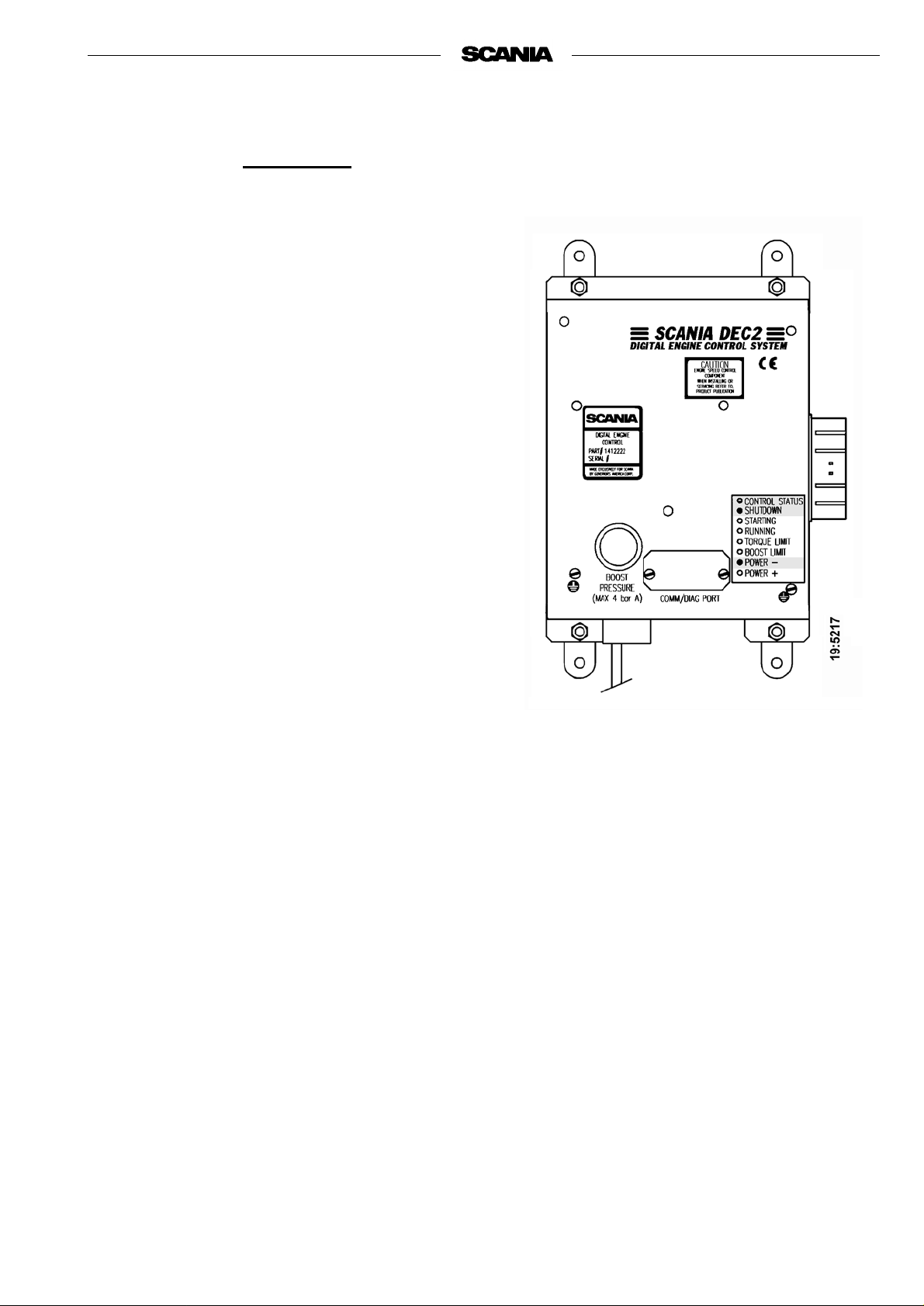

Changing functions using the DIP

switches in the control unit

There are 8 DIP switches in the control unit under the

round black rubber cover.

These switches shall be in the ON position to obtain

normal functions according to the operating program.

However, for single-speed engines, the normal

position of DIP switches 6, 7, and 8 may also be OFF

Shutdown at threshold values for low oil pressure and

high coolant temperature can be selected by setting

DIP switch 4 to OFF

With DIP switch 4 in position ON, Power- indication

is obtained for these thr eshold value s. Engine output

reduction (LOP) can be selected to prevent damage to

the engine. Changes to the program must only be

performed by authorized personnel.

Note Do not operate the engine with a Power-

indication except for in emergencies.

Readout of fault codes

Note If the engine has stopped or lost power but

the main indicator lamp is out and neither

POWER- nor SHUTDOWN are on, the

fault is outside the control unit detection

range. Probable causes: fuel shortage,

temporary overload, mechanical fault.

- Activate the lamp test/fault code switch. In

Scania electrical equipment the main indicator

lamp is located in this switch on the main supply

box.

- All LEDs will then come on for 2 seconds to

indicate that they are intact and in working order.

This also applies to the main indicat or lamp in the

main supply box and the instrument panel

a note of any LED that is defective.

- All LEDs will then be out for approximately 4

seconds.

- Following this, a fault code will be indicated on

one of the LEDs for 2 seconds. Note which LED

it is.

. Make

- The control unit then r esumes the operating mode

automatically.

- After having made a note of the fault code, reset

the lamp test/fault code switch and reset the

control unit by turning off its power supply

momentarily.

- The most probable cause of the fault can then be

found in the tr ouble shoot ing sched ule on the next

page.

- When the fault or faults have been rectified the

engine can be restarted.

- If the cont rol system continues to indicate a fault

by way of the main indicator lamp, further faults

may have been recorded. The fault code readout

must then be repeated as per above since the

system can only display one fault code at a time.

- The fault(s) will be stored in a specia l memory in

the control unit al ong with information about the

operating time when it(they) occurred. Stored

faults can be accessed and erased by authorised

service personnel.

The DIP switches are showed in ON position

16 © Scania Industrial & Marine Engines 2001-05:1

Page 17

READOUT OF FAULT CODES

Send in the control unit for repair as soon as

possible.

Check the cooling system. Check the temperature

sensor a nd cable routing.

Check the wiring and connector.

Renew the engine speed sensor.

Check the intake system. Check the temperature

sensor a nd cable routing.

Check the charge air pressure hose. Send in the

control unit for repair if the connection is damaged.

Check the cable routing, connectors and cables.

Check oil level, connector and cable.

Renew the oil pressure monitor.

Probable cause Action

DEC2 has detected an internal fault in the control unit.

The engine temperature has reached the threshold level

or the temperature sensor is inoperative.

The engine has reached the overrevving limit or the

engine speed sensor is inoperative.

Control rack position sensor inoperative. Check connectors and cables to governor.

The intake air temperature has reached the threshold

level or the charge air temperature sensor is inoperative.

DEC2 detects no charge air pressure.

The charge air pressure sensor is inoperative.

Engine speed potentiometer or the idling safety switch

is inoperative.

The oil pressure has dropped to the threshold level or

the oil pressure m onitor is inoperative.

POWER +

✹

LED INDICATION WHEN THE LAMP TEST/FAULT CODE SWITCH IS ACTIVATED

2001-05:1

POWER -

BOOST LIMIT

TORQUE LIMIT

RUNNING

✹

STARTING

✹

SHUTDOWN

✹

CONTROL STATUS

✹

© Scania Industrial & Marine Engines

✹

✹

✹

✹=LED on

17

Page 18

STARTING AND RUNNING

AT FIRST START

When the engine is starte d for the first time, the maintenance points listed

under ”First start” in the maintenance schedule should be followed, see

page 25.

Since these points are important for the engine to work satisfactorily right

from the start, they are a lso listed below.

1. Checking oil level (see page 27).

8. Checking coolant (see page 32).

The coolant should contain anti-corrosive to protect the cooling system

from corrosion.

If there is a danger of freezing:

- Only glycol anti-freeze should be used in the coolant as protection

against corrosion. We recommend only nitrite-free glycol anti-freeze

with the following supplier designations:

BASF G48 or BASF D542

- The concentration of glycol should be 30 - 50% by volume depending

on ambient temperature. 30% by volume offers protection down to

-18 °C. See page 32.

- Never top up with water only or glycol only. Lost fluid should always

be replaced with pre-mixe d coolan t with the same gl ycol cont ent as the

coolant in the engine. If the concentration of glycol drops, both antifreeze and corrosion protection will suffer.

Coolant composition:

If there is a danger of freezing:

minimum 30% glycol by volume

maximum 60 % glycol by volume

If there is no danger of freezing:

7-12% by volume

Scania Anti-corrosive

(no glycol)

Ethylene glycol and corrosion

inhibitor, if swallowed can be

fatal.

Avoid contact with the skin.

Note: A glycol concentration below 30% by volume wi ll no t provi de suf -

ficient protection against corrosion. A glycol concentration

greater than 50% will not increase anti-freeze protection and

reduces engine cooling capacity.

If there is no danger of freezing:

- Only Scania Anti-corrosive should be used in the coolant to protect

against corrosion. The correct level of anti-corrosive is 7-12% by volume and this must never drop below 7% by volume. The inhibitor in

Scania Anti-corrosive is nitrite-free.

- First fill: Fill with Scania Anti-corrosive as indicated on the packaging.

- Never top up with water only or anti-corrosive only. Lost fluid should

always be replaced with pre-mixed coolant:

water + 10% Scania Anti-corrosive by volume.

Coolant filter

Only coolant filter without inhibitor may be used. The use of a coolant filter

increases the life of the coolant and reduces the risk of deposit corrosion.

The recommended glycol must

not be mixed with glycol having

nitrite-based anti-corrosive.

The use of too much Scania

Anti-corrosive as mixed with

glycol may cause deposits.

If a coolant filter has been fitted

it must not contain inhibitor.

18 © Scania Industrial & Marine Engines 2001-05:1

Page 19

12. Checking fuel level (see page 41).

15. Checking electrolyte level in batteries (see page 43).

16. Checking battery charge (see page 43).

18. Checking coolant level monitor (see page 44).

19. Checking V-belt tension (see page 45).

CHECKS BEFORE RUNNING

Before running, ”Daily maintenance” as described in the maintenance schedule should be carried out, see page 25.

Immobilise the starting device

when working on the engine.

If the engine starts out of

control, there is a

SERIOUS RISK

OF INJURY.

STARTING THE ENGINE

If the fuel tank has been run dry or if the engine has not been used for a long

time, bleed the fuel system, see page 41.

Out of consideration for our common environment, your new Scania engine

has been designed to s tart using a smaller amount of fue l. Unnecess arily l arge

amounts of fuel used for starting the engine always result in the discharge of

unburnt fuel.

- Open the seawater system’s intake v alve (if fitted).

- Open the fuel cock (if fitted).

- Disengage the engine.

- Engines with battery master switch: Switch on the power using the battery master switch.

- DEC2: If the main indicator lamp come s on or flashes when th e power is

turned on, this indicates the presence of a fault in the control system or

engine which must be found and rectified before the engine is started.

See page 16.

- Start the engine by means of the starter button or ignition key.

Starting at low temperatures

Local environmental requirements should be complied with. Start aids,

engine heater and/or flame start should be used to avoid starting problems

and white smoke.

Only start the engine in a

properly ventilated area.

When operating the engine in

an enclosed area, an effective

extraction device for exhaust

gases and crankcase gases

must be used.

Never use starting spray or

similar as a starting aid.

An explosion may occur in the

intake pipe, which could cause

personal injury.

To limit white smoke, the engine should be run at low speed and under moderate load. Avoid running it longer than necessary at idling speed.

2001-05:1 © Scania Industrial & Marine Engines 19

Page 20

At temperatures below 0 °C:

Note: Use only start aids recommended by Scania.

- The starter motor may only be used for 30 seconds, after which it must

rest for 2 minutes.

If the engine has flame start:

- Operating flame start without timer relay: Press the control button

which also acts as a pre-glow button (max. 20 s). The glow plug continues to glow as long as the bu tton i s held down aft er th e en gine i s star ted.

Max. time is 5 minutes.

- Operating flame start with timer relay: Press the pre-glow button (max.

20 s). Release the pre-glow button after the engine starts. The timer

relay keeps the glow plug working for 5 minutes. If a shorter on-tim e is

required, press the release button. The key must be set to 0 if the start

attempt fails.

Note: If the engine is equipped with an INTERLOCK switch, this

switch should be depressed and held down until the oil pressure

has reached a sufficiently high level.

- Run the engine until warm with a light load. A light load on a cold

engine gives better c ombus tion a nd faster heati ng tha n warming u p wit h

no load.

Maximum starter engagement

time is 30 seconds. Risk of

overheating. Allow starter to

cool for 2 minutes after a

starting attempt before

cranking again.

20 © Scania Industrial & Marine Engines 2001-05:1

Page 21

RUNNING

Check instruments and warning lamps at regular intervals.

Engine speed

The Scania tachometer is divided into different coloured sectors as follows.

0-500 rpm red area: prohibited engine speed,

passed when stopping and

starting.

500-700 rpm yellow area: low idle.

700-2200 rpm green area: normal operati ng speed.

The engine’s operating

speed range is controlled by

the DEC2 control system.

2200-2600 rpm yellow/green

striped:

2600-3000 rpm red area: prohibited engine speed

unsuitable operating speed.

May occur when switching

off

Cruising speed

Important: To achieve good operating economy and long engine life,

cruising speed should be about 200 rpm below maximum

engine speed.

Coolant temperature

Normal coolant temperatur e when the en gine is run ning sho uld be 70 - 90 °C.

DEC2: If the temperature is too high, 98 °C or above, the control system will

reduce engine power (Power -) in order to lower the temperature.

If the temperature continues to rise, the engine will be stopped automatically

(Shutdown) at 103 °C.

Excessively high cool ant temperature can damage the engine.

If run for extended periods under an extremely light load, the engine may

have difficulty in maintaining normal operating temperature. However, the

temperature will rise to a normal lev el again when the load on the engine is

increased.

2001-05:1 © Scania Industrial & Marine Engines 21

Page 22

Oil pressure

Max. oil pressure:

warm engine at speed above 800 rpm 6 bar

Normal oil pressure:

warm engine at operating speed 3 - 6 bar

Min. oil pres sure:

warm engine at 800 rpm 0.7 bar

At speeds below 800 rpm, the gauge may show low oi l pressur e without there

being a fault.

Oil pressure below 0.7 bar at speeds above 800 rpm will cause engine damage. The engine must be stopped immediately.

Charge warning lamp

If the lamp lights during operation:

Check/adjust the alternator drive belts as described under maintenance point

See page 45. If the charge warning lamp is still lit, there may be a fault in the

alternator or in the electrical system.

High lubrication oil pressure

(above 6 bar) is normal when

starting a cold engine.

STOPPING THE ENGINE

1. Allow the engine to run without load for a few minutes if it has been run

with a high continuous load.

2. Stop the engine with the stop button. Keep the stop button depressed

until the engine is completely stationary.

3. DEC2: Before switching off, check that the control system’s m ain indi-

cator lamp is not on or flashing. See page 9 for trouble shooting.

4. Engines with batt ery maste r switch: t urn o ff the cur rent usi ng the ba ttery

master switch.

5. Set the control switch to ”0”.

There is danger of turbo damage

and post boiling if the engine is

stopped without cooling.

The power must not be switched

off before the engine has

stopped.

22 © Scania Industrial & Marine Engines 2001-05:1

Page 23

CHECKS AFTER RUNNING

- Check that the power is cut with the battery master switch and that the

control switch is set to ”0”.

- Fill the fuel tank. Make s ure that the ca p and the area around the filler

opening are clean to avoid contamination of the fuel.

- If there is a risk of freezing, the cooling system must be drained if it

does not contain sufficient anti-freeze, see page 32.

- Close inta ke valve for seawater (if fitted).

- If there is a danger of freezing, the seawater must also be drained .

- At temperatures below 0 °C: Pre par e for the n ext st art by conne cting the

engine heater (if fitte d).

Immobilise the starting device

when working on the engine.

If the engine starts out of

control, there is a

SERIOUS RISK

OF INJURY.

Top up engine coolant when the

engine has been stopped after

being started for the first time.

2001-05:1 © Scania Industrial & Marine Engines 23

Page 24

MAINTENANCE

The maintenance programme covers 22 points, divided into the following

main groups:

Lubrication oil system . . . . . . . . . . . . . . . . .page 26

Cooling system. . . . . . . . . . . . . . . . . . . . . . .page 30

Air cleaner . . . . . . . . . . . . . . . . . . . . . . . . . .page 39

Fuel system. . . . . . . . . . . . . . . . . . . . . . . . . .page 41

Electrical system, monitors, batteries, etc.. . page 43

Miscellaneous. . . . . . . . . . . . . . . . . . . . . . . .page 45

The maintenance points are divided into intervals as foll ows:

Daily maintenance

Maintenance before first start

Maintenance after the first 400 hours of operation

Periodic maintenance every 200 hours of operation (carried out after

200, 400, 600, 800, etc. hours)

Periodic maintenance after every 400 hours of operation (carried out after

400, 800, 1,200, 1,600, etc. hours)

Periodic maintenance after every 1,200 hours of operation (carried out after

1,200, 2,400, 3,600, etc. hours)

Immobilise the starting device

when working on the engine.

If the engine starts out of

control, there is a

SERIOUS RISK

OF INJURY

Maintenance every year

Maintenance every 3rd year

ENGINES WITH FEW HOURS OF

OPERATION

The engine is run to operating temperat ure and t he main tenanc e points below

should be carried out:

1. Checking oil level.

5. Checking coolant level.

10. Checking low pressure indicator.

12. Checking fuel level.

15. Checking electrolyte level in batteries.

16. Checking battery charge.

17. Cleaning batteries.

20. Look for leaks. Remedy as necessary

For engines with few

operating hours which do not

receive periodic maintenance

according to the maintenance

schedule on page 25,

maintenance should be

carried out according to the

schedules for:

“Every year”

24 © Scania Industrial & Marine Engines 2001-05:1

Page 25

MAINTENANCE SCHEDULE

LUBRICATION OIL SYSTEM, page 26

1. Checking oil level

2. Oil change

3. Cleaning the lubrication oil cleaner

4. Changing the turbo filter

COOLING SYSTEM, page 30

5. Checking coolant level

6. Checking corrosion protection rods 4)

7. Checking seawater pump impeller 4)

8. Chec king coolant

9. Cleaning cooling system

AIR CLEANER, page 39

10. Test reading low pressure indicator

11. Cleaning or ch anging filter insert

FUEL SYSTEM, page 41

12. Checking fuel level

13. Changing main filter

14. Checking injectors

ELECTRICAL SYSTEM, page 43

15. Checking electrolyte level in batteries

16. Checking charge state of batteries

17. Cleaning batteries

18. Checking level monitor

MISCELLANEOUS, page 45

19. Checking V-belts

20. Look for leaks. Remedy as necessary

21. Checking/adjusti ng val v e cle ara nce

22. Changing (or cleaning) valve for closed crankcase

ventilation

First time

Interval

at

Daily

At first start

400 h

200 h

400 h

l l

l1 l

l1 l

l1 l

l

l4 l

l4 l

ll5 l5

l

l l

l l2 l

l l2 l

l2 l

l l l

l l l

l

l l

At least

1200 h

Every yea r

Every 3rd year

l1 l

l3 l

l1 l

ll

l

1. More often if required

2. For engines with few operating hours, see page 24.

3. Earlier if lo w pressure i ndicator sho ws red.

4. Guiding value. Varies according to composition of seawater.

5. If inhibitor has not been topped up for three years, the coolant should be changed.

2001-05:1 © Scania Industrial & Marine Engines 25

Page 26

LUBRICATION OIL SYSTEM

OIL GRADE

The engine oil should at least meet the requirements for one of t he following

oil classifications:

-Service CE or CF as per API

-CCMC - D5

-Acea E3-96

- Check with your oil supplier that the oil meets these requirements.

- Specified oil change interv als appl y unde r the prov ision that the sulp hur

content of the fuel does not exceed 0.3% by weight.

- Viscosities as illustrated.

- At very low outside temperatures: Consult your nearest Scania representative to avoid starting difficulties.

Oil analysis

Some oil companies can offer analysis of the engine oil. This analysis measures the oil’s total base number (TBN), total acid number (TAN), fuel dilution, water content, viscosi ty and the con tent of wear partic le s and soot in the

oil.

The result of a series of anal ys es forms the basis of establishing a suitable oi l

change interval.

If the conditions are changed, a new oil analysis programme must be undertaken to es tablish a new change inter val.

Additives must not be used.

The oil should be suitable for all

temperature variations until the

next oil change.

-40 -30 -20 -10 0 10 20 30 40

SAE 20W-30

SAE 30

SAE 40

SAE 50

SAE 15W-40

°C

26 © Scania Industrial & Marine Engines 2001-05:1

Page 27

1. Daily:

CHECKING OIL LEVEL

Before checking oil level: Let the engine remain stationary for at

least 1 minute.

- The correct level is between the marks on the dipstick. Top up when the

level is at the lower mark.

- Correct type, see ”Oil grade”, page 26.

2. Every 200 hours:

OIL CHANGE

If the engine is used in particularly demanding operating

conditions, in an especially dusty environment or if the deposits in

the centrifugal cleaner are thicker than 20 mm: Change the oil

more often.

- Pump out the oil using the oil bilge pump when the engine is warm.

Max. 30 dm

Min. 25 dm

3

3

- Fill with n ew oil.

- Check the level on the dipstick.

Note: Observe the applicable environment protection regulations when

disposing of the old oil.

WARNING

The oil may be hot.

Wear protective gloves and

goggles

Maximum oil sump angles of inclination when in

operation

Maximum permissible angles for operation vary according to the type of oil

sump, see figure.

Note: Given angles may only be used intermittently.

Max. 26 dm

Min. 20 dm

Always use a suitable container

to avoid spillage when

changing oil.

Dispose of used oil through an

authorized waste disposal

contractor.

3

3

15°

45° 35°

2001-05:1 © Scania Industrial & Marine Engines 27

18°

30°

30°

Page 28

3. Every 200 hours:

CLEANING THE OIL CLEANER

(at same time as oil change)

- Unscrew the nut and remove the cover.

Open the cap carefully. The

oil may be hot.

- Lift out the rotor and slacken the nut for the rotor cover three turns.

- If the nut is stuck:

Clamp the nut, absolutely no t the ro tor, in a vice and turn the rotor three

turns by hand or using a screwdriver.

- Gently tap the nut using your hand or a plastic hammer so that the rotor

bowl becomes detached from the bottom plate.

- Undo the nut and remove the rotor bowl.

- Carefully prise the strainer loose from the bott om plate.

- Scrape away deposits from the inside of the rotor bowl. If there are no

deposits, this shows that the cleaner is not working.

- If the deposits are thicker than 20 mm: Clean more often.

28 © Scania Industrial & Marine Engines 2001-05:1

Page 29

- Clean all the parts in diesel fuel oil.

- Place the O-ring in position in the rotor bowl. This must not be damaged.

Change if necessary.

- Assemble the rotor

- Tighten the rotor nut hard by hand

- Refit the rotor.

- Check that it turns easily.

- Check that the O-ring in the bowl is not damaged.

A hardened or damaged O-ring should be replaced.

- Screw down the bowl hard by hand.

If the nut is tightened using a tool, the rotor shaft, nut or bowl may be

damaged.

Operational test

The rotor turns very quickly and should continue to rotate when the engine

has stopped.

- Stop the engine when it is warm.

- Listen for the whirring from the rotor or feel whether the cleaner housing is vibrating.

The rotor normally rotates for 30 - 60 seconds after the engine has stopped.

If not: Dismantle and check.

2001-05:1 © Scania Industrial & Marine Engines 29

Page 30

4. Every 200 hours:

CHANGING THE TURBO FILTER

(at the same time as the oil change)

- Remove the old filter and discard it according to environmental requirements.

- Oil the rubber gasket and fit a new genuine Scania filter.

- Tighten the filter by hand.

Never use tools as the filter may sustain damage, interfering with

circulation.

- Start the engine and check for leaks.

If the deposits in the centrifugal cleaner exceed 20 mm, the turbo filter

must be changed more often, at the same time as cleaning the centrifugal

filter and changing the oil.

Always collect oil in a suitable

container to avoid spillage when

renewing the oil filter.

Dispose of used filters through

an authorized waste disposal

contractor.

COOLING SYSTEM

5. Daily:

CHECKING COOLANT LEVEL

- Open the expansion tank cap and check the coolant level.

- Correct level: (Scania expansion tank)

- Cold engine: The coolant should reach up to the bottom of

the filler pipe.

- Warm engine: The coolant should be 10 - 20 mm above the bottom

of the filler pipe.

- Other types of expansion tank according to the installer’s instructions.

- Top up coolant as necessary, see point 6.

Note: When filling large amounts of coolant:

Never pour cold coolant into a warm engine.

This could crack the cylinder block and head.

Carefully open the cap.

Hot water and steam

may blow out.

Always top up with ready mixed

coolant.

30 © Scania Industrial & Marine Engines 2001-05:1

Page 31

6. Every 400 hours:

CHECKING CORROSION

PROTECTION RODS

- Drain the seawater circuit and check the corrosion protection rods

(sacrificial anodes). Location as per drawing on page 11.

- Scrape away all loose material from the anode.

- Change if less than half the rod remains.

New rods are 55 mm long, diameter 17 mm.

If the corrosion protect ion rods ar e highl y eroded, they should be c hecked

more often, e.g. every 200 hours.

7. Every 400 hours:

CHECKING SEAWATER PUMP

IMPELLER

- Close the bottom valve if the seawater pump is below the water li ne.

- Drain the seawater circuit.

- Remove the cover from the seawater pump.

- Check that the impeller vanes are not worn or damaged.

If the impeller often requires changing, it is necessary to improve

the purity of the seawater.

Changing the impeller

- Extract the impeller using extractor 98 482 (Scania special tool).

- Fit a new impeller and the cov er. Che ck that the cover seal is not

hard or damaged.

Note: A spare impeller should be carried on board.

- The impeller can bec ome deformed after long p eriods of standstill.

Change before starting or remove the impeller before long periods of

disuse. Also see “Mothballing”.

2001-05:1 © Scania Industrial & Marine Engines 31

Page 32

8. Every 400 hours:

CHECKING COOLANT

Coolant should be checked as follows:

a) Check the appearance of the coolant.

b) Coolant with glycol: Check the glycol content.

c) Coolant with Scania Anti-corrosive:

Check the corrosion protection.

The composition of the coolant is also described under

“Starting and running”.

a)

Checking the appearance of the coolant

- Take a little coolant in a vessel and check that it is clean and clear.

- If the coolant is contaminated or cloudy: Consider changing the coolant

- The water for the coolant should be free of dirt.

- Use drinking water with a pH of 6 - 9.

b)

Checking glycol content

Coolant composition:

If there is a danger of freezing:

at least 30% glycol by volume

max. 50% glycol by volume

If there is no danger of

freezing:

7-12% by volume

Scania Anti-corrosive

If there is a dan ger of f reezing, use only glycol a s protec tion aga inst corrosio n

in the coolant.

- Cooling systems with glycol must contain at least 30% glycol by volume to offer sufficient protection ag ainst corrosion.

- 30% glycol by volume provides anti-freeze protection down to -16 °C.

If more protection is required, see the table on the next page for calculating the necessary amount of glycol.

We recommend only nitrite-free glycol anti-freeze with the following sup-

plier designations:

BASF G48 or BASF D542

- Top up with glycol if the glycol content is less than 30% by volume. A

glycol content greater than 50% by volume will not provide more antifreeze protection.

- The table shows the temperature at which ice (slush) starts to form. The

engine freezes and brea ks at significa ntly lower temp eratures, see graph.

- Ice forming in the coolant often causes malfunction without any risk of

damage. The engine must not be loaded hard when ice is forming.

Note: The coolant should be changed when the cooling system is

cleaned: every 1,200 hours or at least every 3rd year.

Important: If a coolant filter is u sed in the cooling syste m, it must not

contain an inhibitor.

Ethylene glycol is highly

dangerous if ingested and can

prove fatal.

Avoid skin contact with glycol.

The coolant should be ready

mixed when it is poured into the

cooling system.

Never top up with only water or

only glycol.

The recommended glycol must

not be mixed with glycol having

nitrite-based anti-corrosive.

Risk for build up of sludge and

reduced cooling capacity.

32 © Scania Industrial & Marine Engines 2001-05:1

Page 33

Properties of glycol at low temperatures:

- Example with 30% glycol by volume

- Ice slus h starts to form at -16°C.

- There is risk for malfunctions at -30°C

No risk of damage by freezing with a minimum

content of 30% glycol by volume

A

% glycol by volume

Curve A: Ice build up starts (slush)

Curve B: Temperature at which damage due to

freezing can occur

1. Safe range

2. Malfunctions may occur (ice slush)

3.

Risk of damage by freezing

% glycol by

volume

Ice slush starts

to form at °C

Glycol dm

3

(litres)

15 20 25 30 35 40 45 50 60

Cooling

system

-6 -9 -12 -16-22-27-36-46-55

capacity, dm

5 6 8 9 1112141518 30

6 8 10 12 14 16 18 20 24 40

8 10 13 15 18 20 23 25 30 50

9 12 15 18 21 24 27 30 36 60

11 14 18 21 25 28 32 35 42 70

12 16 20 24 28 32 36 40 48 80

14 18 23 27 32 36 41 45 54 90

15 20 25 30 35 40 45 50 60 100

17 22 28 33 39 44 50 55 66 110

18 24 30 36 42 48 54 60 72 120

20 26 33 39 46 52 59 65 78 130

21 28 35 42 49 56 63 70 84 140

23 30 38 45 53 60 68 75 90 150

3

24 32 40 48 56 64 72 80 96 160

26 34 43 51 60 68 77 85 102 170

27 36 45 54 63 72 81 90 108 180

29 38 48 57 67 76 86 95 114 190

30 40 50 60 70 80 90 100 120 200

A = Range to be avoided. Only for calculation of glycol mix.

Freezing point of coolant when ice slush starts to form at different glycol mixes

2001-05:1 © Scania Industrial & Marine Engines 33

Page 34

b)

Checking Protection against corrosion

There must always be sufficient anti-corrosive (inhibitor) in the coolant to

protect the cooling system against corrosion.

If there is no danger of freezing use only Scania Anti-corrosive.

The inhibitor in Scania Anti-co rrosive is nitrite-free.

The correct level of anti-corrosive is 7- 12% by volume.

- Fill with Scania Anti-corrosive as indicated on the packaging.

- Topping up with 1.0% by volume of Scania Anti-corrosive should be

done after every 400 operating hours.

- Never top up with water only or anti-corrosive only. Lost fluid should

always be replaced with pre-mixed coolant:

water + 10% Scania Anti-corrosive by volume.

Note: The coolant should be changed when the cooling system is cleaned:

every 1,200 hours or at least every 3rd year.

Corrosion inhibitor, if

swallowed can be fatal.

Avoid contact with the skin.

Mixing corrosion inhibitor with

glycol or adding too much

corrosion inhibitor may cause

deposits and reduced cooling

capacity.

If a coolant filter has been fitted

it must not

contain inhibitor.

Changing the coolant

1. Remove the filler cap from the expa nsion tank.

2. The coolant is drained at two points:

- the ”lowest point” of the engine block, see drawing

- the ”lowest point” of the cooling system.

3. Close the drain cocks.

4. Fill coolant through the expansion tank filler hole.

Mix coolant as described on page 32.

Always collect fluid in a suitable

container to avoid spillage when

changing coolant.

Dispose of used coolant through

an authorized waste disposal

contractor.

34 © Scania Industrial & Marine Engines 2001-05:1

Page 35

9. Every 1200 hours:

CLEANING THE COOLING SYSTEM

Note: If n ecessary, the cooling system should be cleaned more often.

External cleaning

Heat exchanger

Drain the coolant from the engine, see “Changing coolant”.

1.

2. Close the bottom valve or valves and drain the seawater circuit.

3. Disconnect the heat exchanger’s seawater pipe connections and the con-

nections to the charge air coolers, oil cooler and block.

4. Remove the heat exchanger assembly and dismantle it as illustrated.

5. Clean the outside of the element. Use a paraffin-based engine cleaner.

6. Remove any deposit on the inside of the pipes using a round file.

7. Assemble the heat exchanger. Change damaged and hardened O-rings.

8. Make sure that the thermostats are in place and fit the heat exchanger

back in place on the engine. Reconnect the pipes to the charge air coolers and oil cooler and also the return line from the block.

9. Fill the sy stem with coo lant as described in the specifications on

page 32.

The cooling system must never

be cleaned with caustic soda.

There is a risk of damage to

aluminium parts.

There are springs and retainers

in the heat exchanger, between

the housing and th e ele m en t ,

which are not illustrated.

1. Housing

2. Spiral pin

3. Element

4. O-ring

5. Gasket

6. Gasket

7. Cover

8. Bolt

9. Washer

10. Cover

11. Bolt

12. O-ring

13. Plug

14. Sacrificial anode

2001-05:1 © Scania Industrial & Marine Engines 35

15. Gasket

16. O-ring

17. Bolt

18. Gasket

19. Flange pipe

20. Gasket

21. Bolt

22. Bolt

23. Plug

24. Washer

25. Washer

26. Bolt

27. Bolt

Page 36

Seawater-cooled charge air cooler

1. Disconnect the connecting pipes for air and seawater and remove the

charge air cooler assembly.

2. Dismantle the charge air cooler as illustrated.

3. Clean the outside of the element. Use a paraffin-based engine cleaner.

4. Remove any deposit on the inside of the pipes using a round file.

5. Assembly the charge air cooler . Change any dama ged and hard O-rings .

6. Refit the charg e air cool er as semb ly af ter the seawa ter-c ooled charg e air

coolers have been cleaned and assembled.

Tighten bolt 8 to 9±2 Nm.

Note: On assembly, silicone (816 064) should be applied t o bot h si des of

new gaskets 13.

7. Refit the pipe connections for air and seawater.

1. Housing

1. Housing

2. Element

2. Element

3. Spiral pin

3. Spiral pin

4. Spacer

4. Spacer

5. O-ring

5. O-ring

6. Cover

6. Cover

7. Bolt

8. Bolt

8. Bolt

9. Washer

9. Washer

10. Bolt

10. Bolt

11. Bolt

11. Bolt

12. Washer

12. Washer

13. Gasket (2)

7. Bolt

36 © Scania Industrial & Marine Engines 2001-05:1

Page 37

Coolant-cooled charge air cooler

1. Drain the coolant from the engine, see “Changing the coolant”, and

drain the seawater circuit if this has not been done when cleaning the

heat exchanger.

2. Remove the catwalk, delivery pipes, fuel filter and water pipes to the

turbo unit.

3. Remove the rear, transverse charge air cooler (seawater-cooled).

4. Undo the charge air cooler’s inlet and outlet pipe connections.

5. Dismantle the charge a i r cooler as illustrated.

Exercise care - do not damage the element’s water connections.

6. Clean the outside of the element. U se a paraffin-based engi ne cleaner.

7. Clean and degrease the sealing surfaces on the core and the air intake

manifold upper and lowe r parts with a spirit based cleaner.

8. Apply sealant (silicone 816 064) in a uniform bead, approximately

2-3 mm, on both sealing surfaces of the element.

9. Fit new V-ring seals on the connections of the element.

10. Assemble the charge air cooler within 15 minutes of applying the sea-

lant. Torque tighten the bolts to 50 Nm.

11. Reconnect the inlet and outlet pipe connections and refit the delivery

pipe, fuel filter and other parts that have been removed.

12. Refit the transver se charge a ir cooler and its pipe c onnecti ons for ai r and

seawater.

Note: On reassembly, apply silicone to the sealing surfaces against the

seawater-cooled char ge air cooler and its gaskets.

13. Fill up with coolant as per the specifications on page 32.

Important Allow the sealant to cure for minimum

24 hours before the engine is used.

The cooling system must never

be cleaned with caustic soda.

There is a risk of damage to

aluminium parts.

1. Intake manifold,

lower part

2. Radiator element

3. Intake manifold,

upper part

4. V-ring seal

5. Sealant 816 064

2001-05:1 © Scania Industrial & Marine Engines 37

Page 38

Internal cleaning

Removing oils and greases

- If possible, run the engine until it is warm and then drain the cooling

system.

- Remove the thermostats. This will necessitate removal of the heat

exchanger assembly. It is therefore advisable to do this in connection

with cleaning the heat exchanger.

- Fill the system with clean, hot water mixed with liquid dishwasher

detergent designed for household machines. Mix 1% (0.1/10 l).

- Warm up the engine for about 20 or 30 minutes. Do not forget the cab

heating system, if any.

- Drain the cooling system.

- Fill the system again using cl ean, hot water and r un the engi ne for ab out

20-30 minutes.

- Drain the water from the system.

- Refit the thermostats.

- Fill the system with coolant as described in the specifications on

page 32.

Removing deposits

- If possible, run the engine until it is warm and then drain the cooling

system.

- Remove the thermostats. This will necessitate removal of the heat

exchanger assembly. It is therefore advisable to do this in connection

with cleaning the heat exchanger.

- Fill the s ystem with clean, hot water mixed with one of the com mercially available radiator cleaners based on sulphamic acid and containing dispersing agents. Follow the manufacturer’s instructions for mix

ratios and cleaning times.

Handling cleaning agents for

the cooling system:

Read the warning label on the

container.

Always collect fluid in a suitable

container to avoid spillage when

draining coolant.

Dispose of used coolant through

an authorized waste disposal

contractor.

- Run the engine for the specified time and then drain the cooling system.

- Fill the system again with hot water and run the engine for about 20 or

30 minutes.

- Drain the water from the system.

- Refit the thermostats.

- Fill the system with coolant as described in the specifications on

page 32.

Preventive replacement of coolant pump gear

Note: To be carried out in connection with cleaning of the cooling

system.

- Remove the coolant pump.

- Remove the drive gear.

- Fit a new gear and tighten the nut to 200 Nm.

Note: D o not apply the tightening to rque to the gea r itself.

- Refit the coolant pump, using new gaskets for the timing gear cover.

38 © Scania Industrial & Marine Engines 2001-05:1

Page 39

AIR CLEANER

10. Daily:

TEST READING

LOW PRESSURE INDICATOR

If the indicator’s red plunger is fully visible, change or clean the air cleaner

filter insert, point 11.

11. Every 1,200 hours:

CLEANING OR CHANGING THE

FILTER INSERT

Note: Earlier if low pressure indicator shows red.

Dismantling

1. Remove air cleaner’s side cover.

2. Change or clean the insert.

Note: Cleaning the insert always entails a risk of damage. The insert

may be cleaned no more than four times. A fter cleaning, it has a

lower dust capacity than a new insert.

3. Mark the filter when it has been cleaned.

Cleaning insert

- Careful ly blow the filter insert clean using dry compressed air from the

inside.

Note: This insert must not be washed using water.

1

Only use Scania genuine air

filter. Change the filter element

if it is damaged.

Danger of engine damage if the

filter element is damaged.

Never start the engine unless

the air filter is installed.

Danger of personal injury or

engine damage.

2

3

1. Cover

2. Filter insert

3. Filter housing

2001-05:1 © Scania Industrial & Marine Engines 39

Page 40

Checking

- Insert a flashlamp into the insert and check from the outside that there

are no holes or cracks in the filter paper.

- Change the filter insert if there is any damage at all. Danger of engine

damage.

Assembly

1. Assemble the air cleaner in reverse order.

2. Reset the red plunger in the low pressure indicator by pressing in the

button.

Filter with non-replaceable insert (unit cleaner)

Cleaning

- The filter must be clean ed no mor e th an 3 times. Make a mark on it each

time it is cleaned.

- Use a washing solution consisting of water mixed with about 1% mild

detergent.

1. Pour the washing s o lu ti on into the filter outlet while t urning the filter so

that the solution runs out of it opposite to the direction of air flow.

2. Leave the filter in the washing solution for 5 minutes and then lift it to

drain off the solution.

3. Rinse the filter with about 30 litres of clean water at 30 - 40 °C. Pour the

rinse water into the filter in the same way as the washing solution.

4. Lift the filt er and allow t he rinse water to drain.

5. Repeat this procedure until the rinse water runs clear.

6. Leave the filter to dry in a warm place for a day or so.

Note: The filter must not be blown dry using compressed air.

40 © Scania Industrial & Marine Engines 2001-05:1

Page 41

FUEL SYSTEM

12. Daily:

CHECKING THE FUEL LEVEL

- Top up fuel if necessary.

- If the tank is run dry, bleed the fuel system, see point 13.

13. Every 1200 hours:

CHANGING THE FUEL FILTER

Fuel tanks

- Drain any water from the fuel tanks.

Filter

The filter consists of two filter units connected in parallel.

- Wash the outside of the filters and unscrew them. Dispose of the filters

according to environmental regulations.

Be extremely careful with

cleanliness when working on

the fuel system.

Malfunctions

can easily arise and the

injection equipment

can be damaged.

- Tighten the new filters by hand.

Never use tools. The filters may be damaged, inhibiting circulation.

- Bleed the fuel system as described below.

- Start the engine and check for leaks.

Bleeding the fuel system

- Open bleed screw 1 on the main filt er.

- Pump hand pump 2 until air-free fuel flows out at the main bleed screw.

- Close the bleed screw. Pump a few times using the hand pump.

If the engine is difficult to start after bleeding . . . . .

- Slacken injection pump overflow valve 3 half a turn

and make a fresh attempt to start.

If the engine still won’t start . . . . . . .

- Pump the hand pump until bubble-free fuel flows from the overflow

valve.

Tighten the overflow valve when the engine has started.

Only use Scania genuine fuel

filter.

Always collect fuel in a suitable

container to avoid spillage when

bleeding system or renewing

components.

2

3

2001-05:1 © Scania Industrial & Marine Engines 41

Page 42

14. Every 1,200 hours:

CHECKING INJECTORS

Injectors should be inspected by trained personnel with access to the required

equipment, at least once every year or every 2,400 hours.

Removal

1. Clean around the injectors and connections including clamps and

brackets.

2. Undo the leak-off pipes and bunch of delivery pipes. Be careful to

avoid bending any of the delivery pipes.

3. Unscrew the injector.

4. Place protective plugs on the injector and delivery pipe.

5. Lift the seal from the bottom of the injector seat if it does not come out

together with the injector.

6. Place a seal plug in the injector seat in the cylinder head.

7. Clean the injectors and check/adjust in an injector tester.

Correct opening pressure, see Technical data, page 52.

Fitting

1. Check that there is no old seal in place and fit a new seal in the bottom

of the injector seat.

2. Fit a new O-ring in the socket nut and a new seal under it.

3. Fit the injector.

4. Tighten the socket nut to 70 Nm (7.0 kgfm).

5. Fit the delivery pipe and tighten the cap nuts to 20 Nm (2.0 kgfm).

Fit clamps and brackets.

Take care to fit the delivery pipe without tension and make sure that

the con e on the deliv ery pipe is correctly positioned in the connection.

1. Socket nut

2. O-ring

3. O-ring

4. Stop ring

5. Guide pin

6. Seal

The delivery pipes must

not be bent.

All clamps must be refitted.

Always wear gloves and eye

protection when testing

injectors.

Fuel escaping under high

pressure can penetrate body

tissue and cause serious injury.

6. Fit the leak-off fuel line. Tighten the bolts to 11 Nm (1.1 kgfm).

1. Delivery pipes

2. Cap nut

3. Washer

4. Cone